Reinforced spiral pipe and reinforced spiral pipe suction barrel foundation and using method thereof

A technology of suction barrel and spiral tube, which is applied in infrastructure engineering, construction, etc., can solve the problems of lack of grout diffusion orientation in grouting around the barrel, bearing ring increases the resistance of the barrel end, and the suction barrel cannot be recycled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

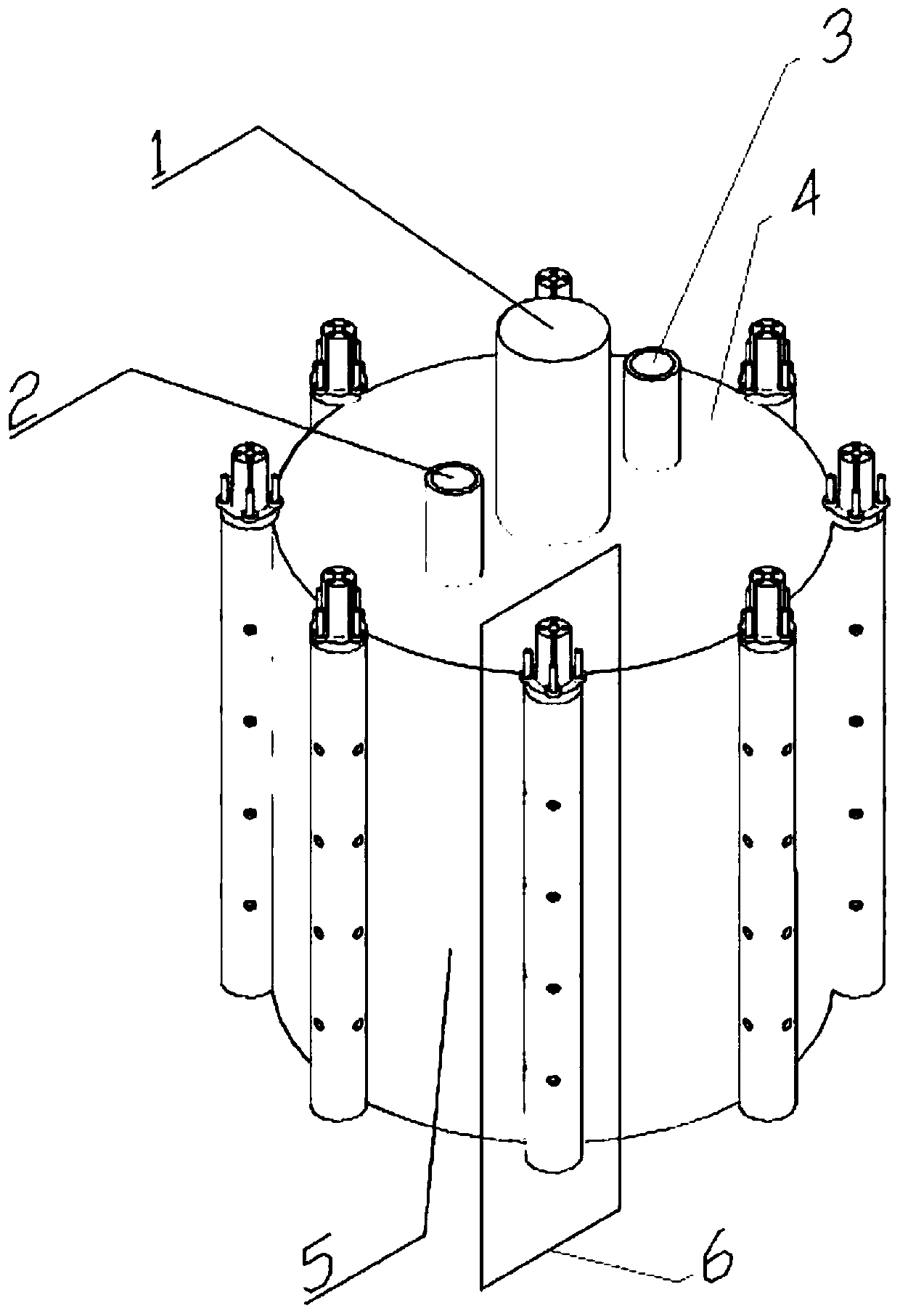

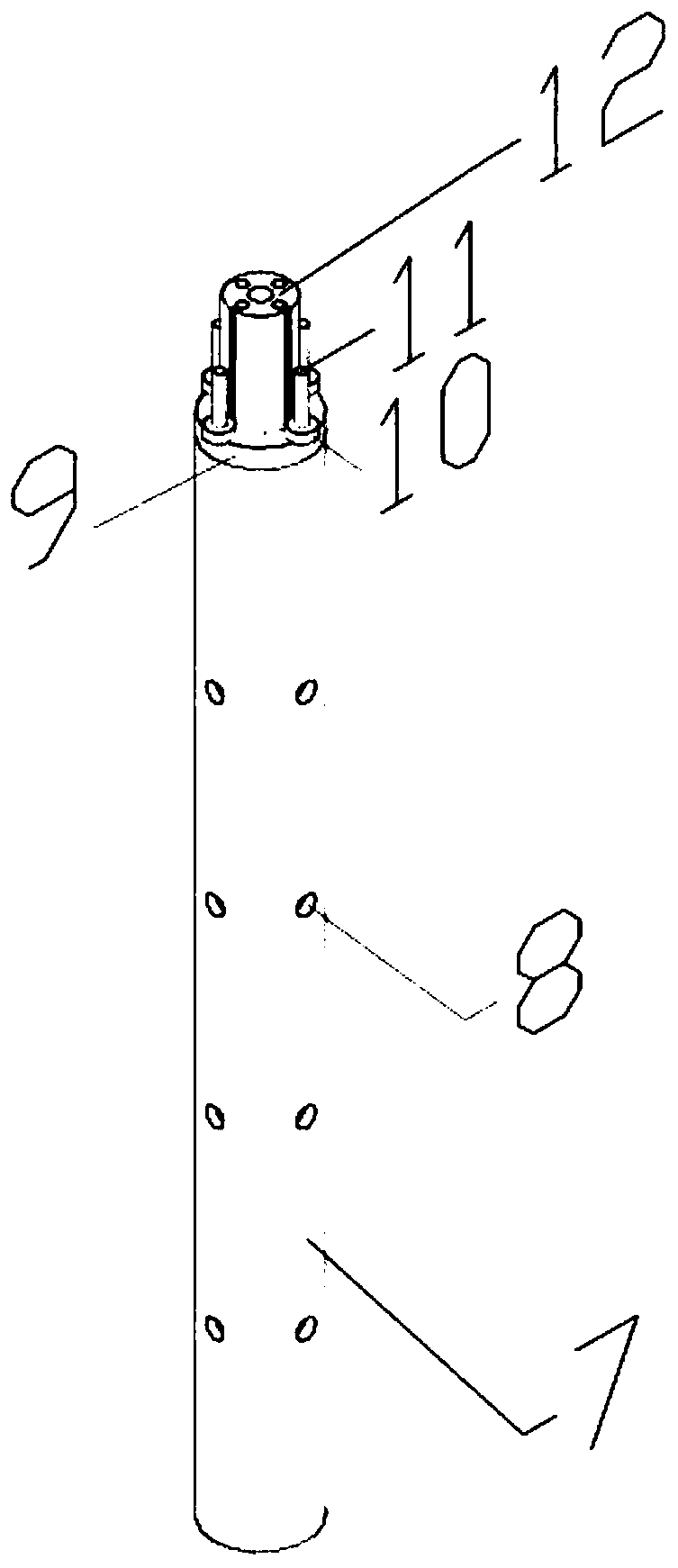

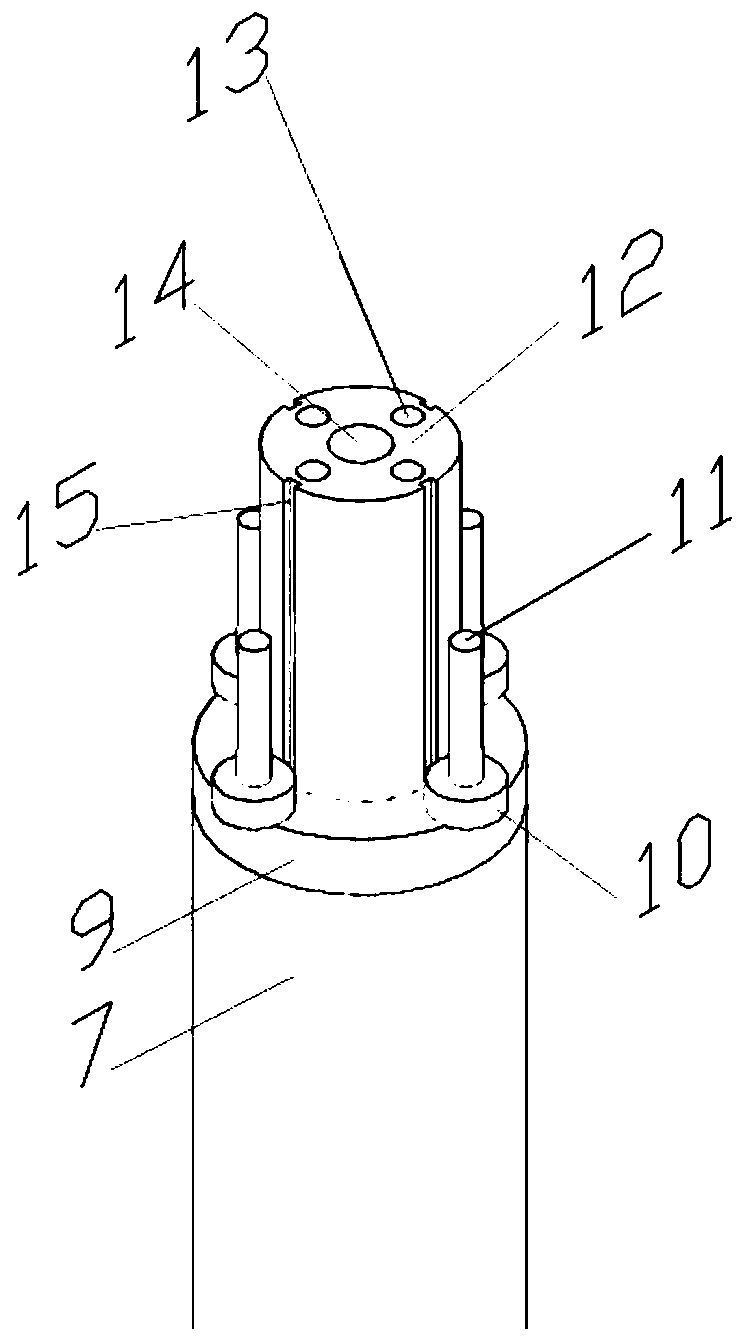

[0051] figure 1 is a three-dimensional schematic diagram of the suction bucket foundation, figure 2 In order to strengthen the three-dimensional schematic diagram of the spiral tube, image 3 In order to strengthen the three-dimensional schematic diagram of the upper part of the spiral tube, Figure 4 is a three-dimensional schematic diagram of the outer casing, Figure 5 is a three-dimensional schematic diagram of the internal screw, Figure 6 It is a schematic diagram of the upper part of the internal screw, Figure 7 It is a schematic cross-sectional view of the horizontal plane where the center of the infusion hole at the bottom of the plug inner ring is located, Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com