Weighting water-based fracturing drag reducer

A technology for water-based fracturing and base fluid, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of limited weighting ability of sodium and potassium salts and affect liquid properties, etc., and achieves low cost and fast dispersion speed. , reduce the effect of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

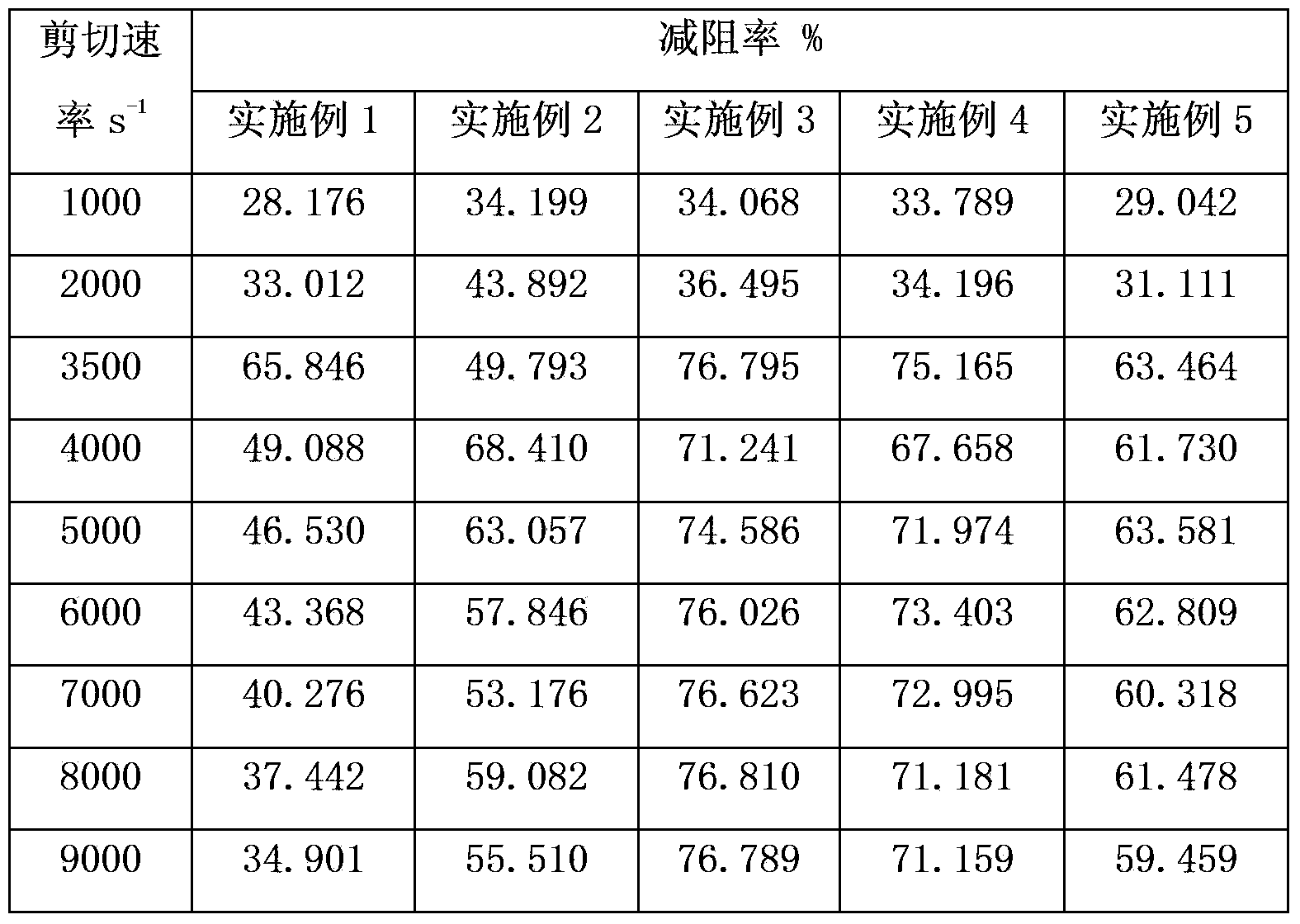

Examples

Embodiment 1

[0030] Preparation of drag reducer (the following substances are all parts by weight): After dissolving 25 parts of dimethylaminoethyl methacrylate chloroalkyl quaternary ammonium salt and 12 parts of acrylamide monomer in 25 parts of water, slowly add it dropwise to 34.9 parts In a mixed solution of white oil and 3 parts of span80, under the trigger of 0.1 part of azobisisobutyronitrile, stir at 50° C. for 10 h.

[0031] Slowly add 0.02 g of the drag reducer emulsion prepared in the previous step into 99.48 g of water, stir vigorously to completely disperse the emulsion, then add 0.5 g of 3% by weight Intechem-06 methanol solution, and finally add 10 g of CuCl 2 , and vigorously stirred for 30 minutes to obtain the weighted drag reducing fluid of the present invention with a density of 1.12g / cm 3 .

Embodiment 2

[0033] Slowly add 0.05 g of the drag reducer emulsion prepared in Example 1 dropwise to 99.25 g of water, stir vigorously to completely disperse the emulsion, then add 0.7 g of 3% by weight of FS-300 methanol solution, and finally add 50 g of ZnCl 2 , and vigorously stirred for 30 minutes to obtain the weighted drag reducing fluid of the present invention with a density of 1.46g / cm 3 .

Embodiment 3

[0035] Slowly add 0.1 g of the drag reducer emulsion prepared in Example 1 dropwise to 98.9 g of water, stir vigorously to completely disperse the emulsion, then add 1 g of Intechem-06 methanol solution of 3% by weight, and finally add 80 g of Cu(NO 3 ) 2 , and vigorously stirred for 30 minutes to obtain the weighted drag reducing fluid of the present invention with a density of 1.73g / cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com