Patents

Literature

87results about How to "Reduce construction pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

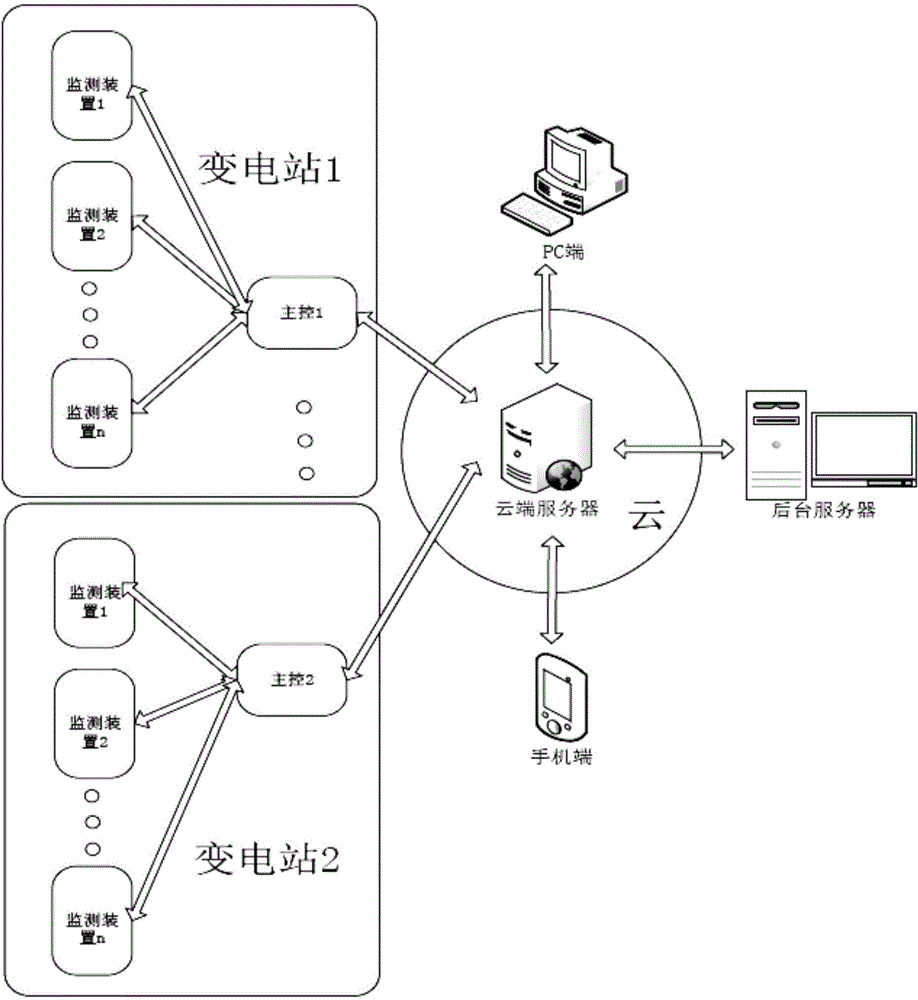

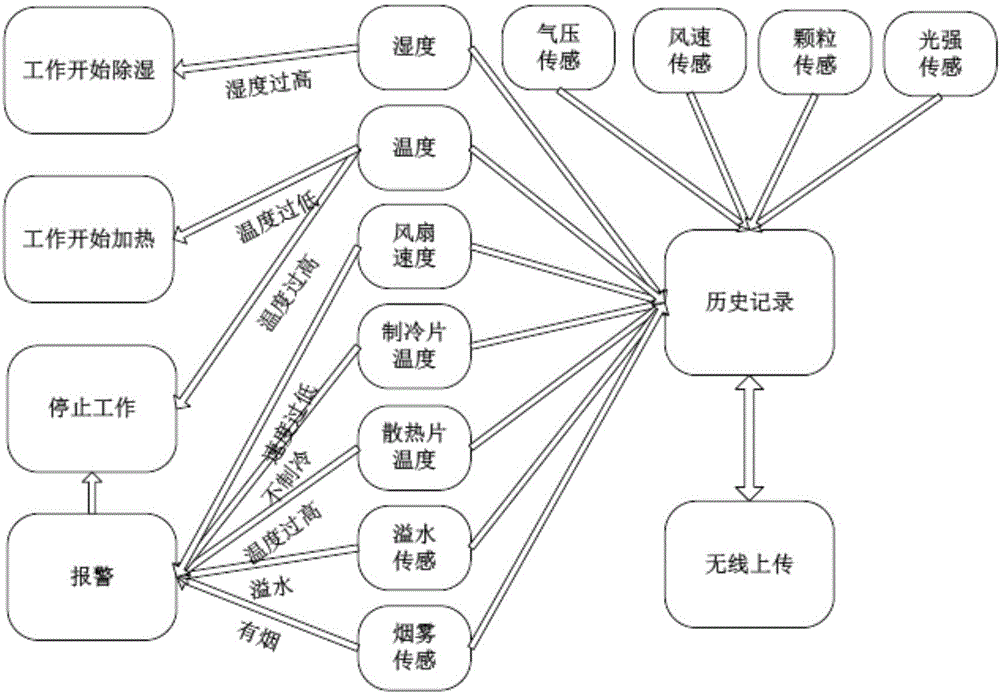

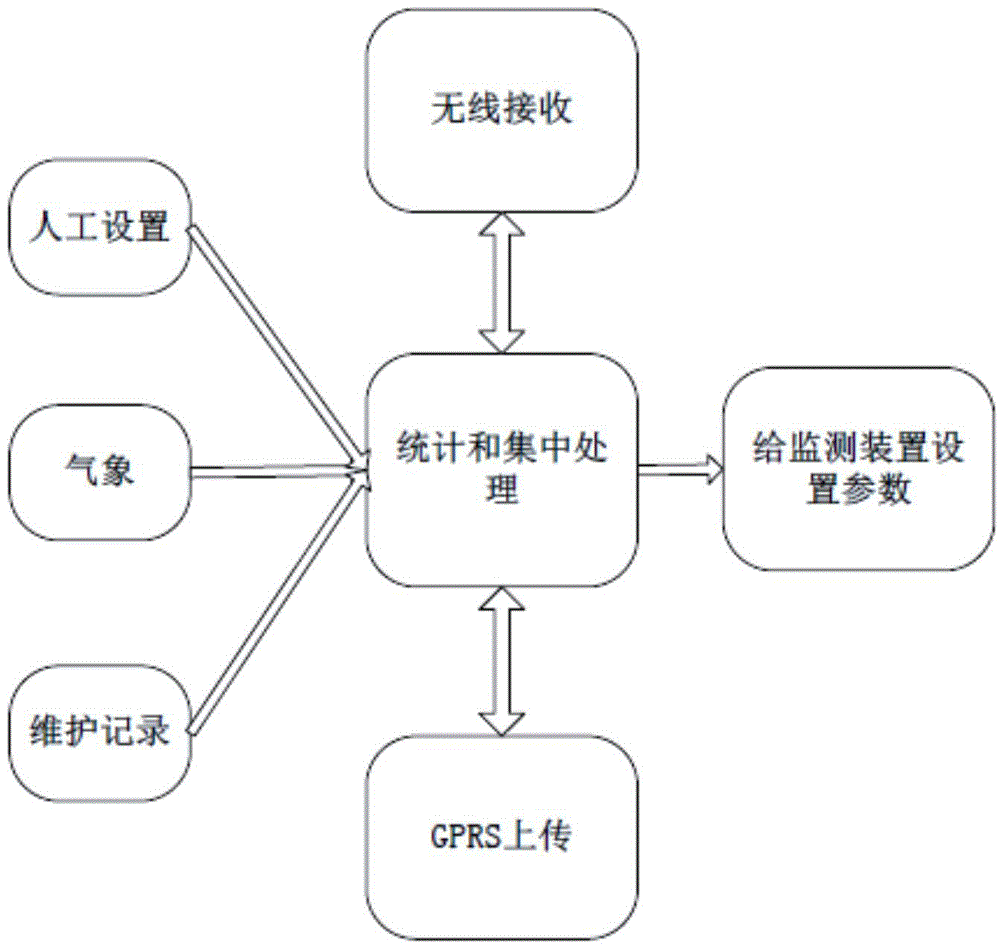

Intelligent electrical equipment environment monitoring system based on cloud computing and big data analysis

InactiveCN104950769AImprove scalabilityReduce construction pressureProgramme controlComputer controlReal-time dataMonitoring system

The invention discloses an intelligent electrical equipment environment monitoring system based on cloud computing and big data analysis. The system comprises a cloud server, an intelligent master control device, monitoring devices and communication equipment communicating with the cloud server, wherein the monitoring devices are used for acquiring related data of an electrical equipment environment and transmitting the data to the intelligent master control device; the intelligent master control device is used for controlling the monitoring devices and transmitting the data received from the monitoring devices to the cloud server; the cloud server is used for receiving and storing the related data of the electrical equipment environment; a user accesses the cloud server through a mobile phone or a computer and then controls the master control device and the monitoring devices remotely. The system depends on cloud computing to perform big data analysis on online meteorological information, real-time data and historical data, intelligently monitors the monitoring devices of all nodes, evaluates the monitoring effectiveness, analyzes potential risks effectively and solves problems by which people are puzzled for many years about outdoor electrical equipment microenvironments, online micrometeorology monitoring, real-time intelligent control and the like.

Owner:JIANGSU LIDE INTELLIGENT MONITORING TECH CO LTD

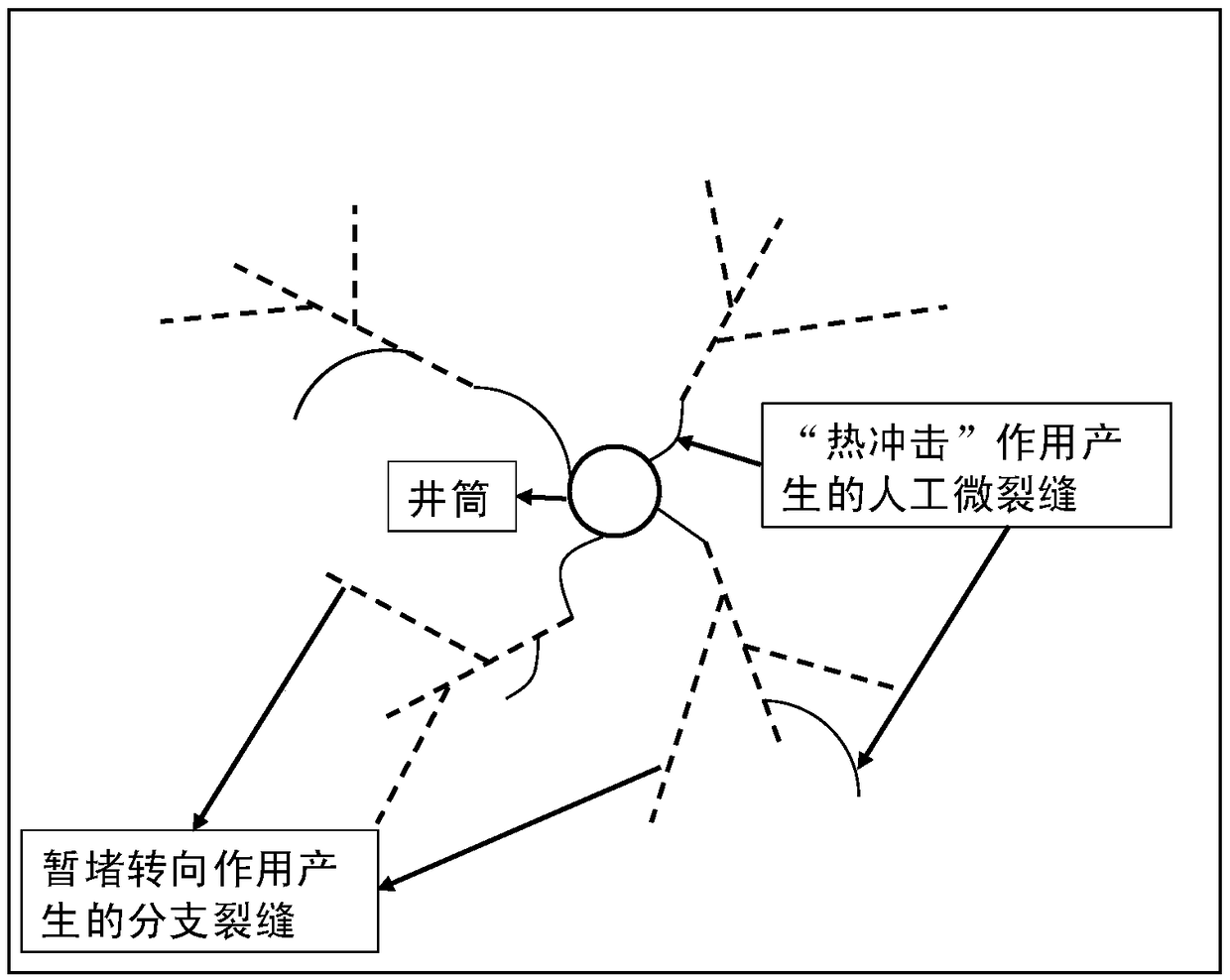

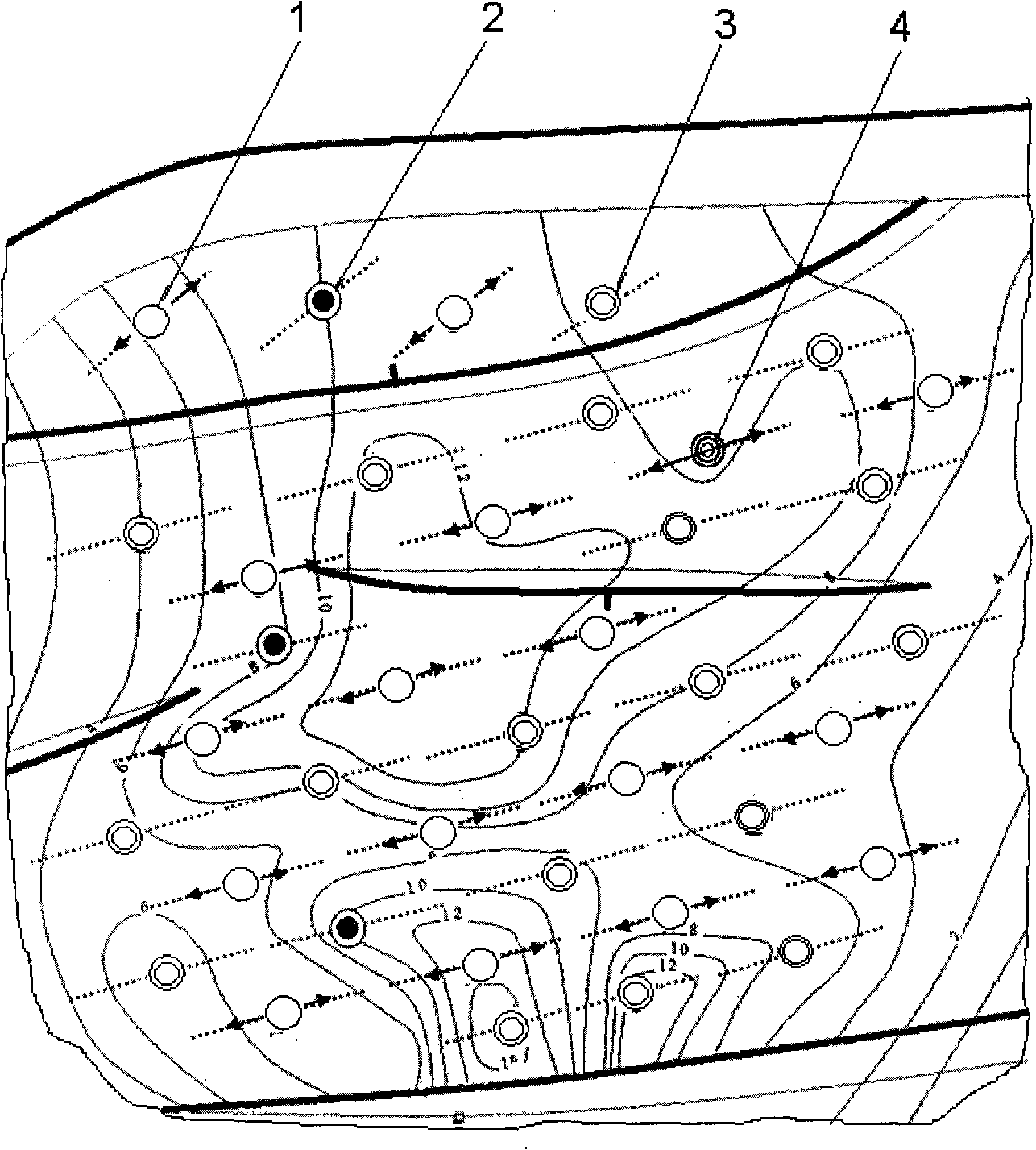

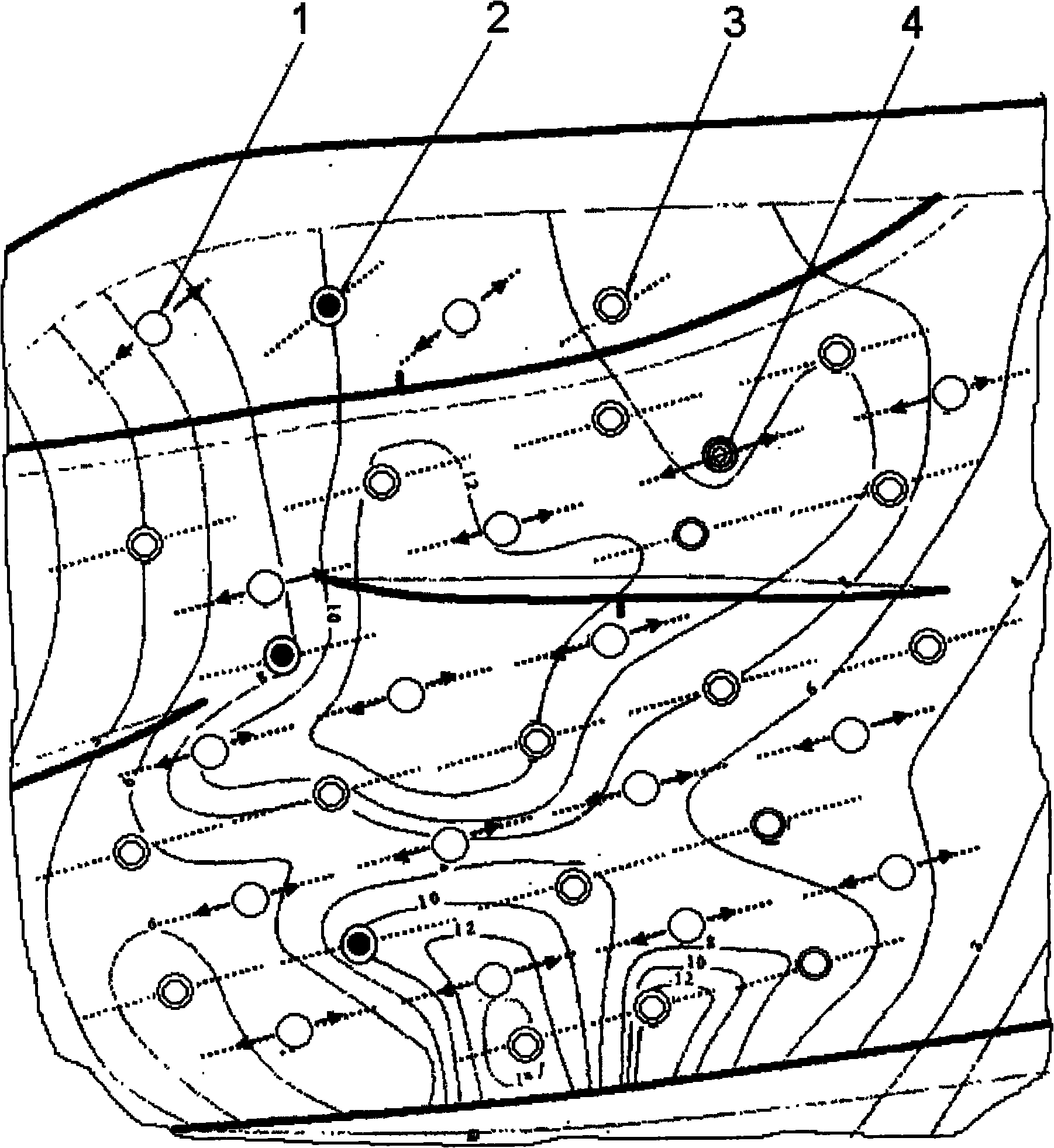

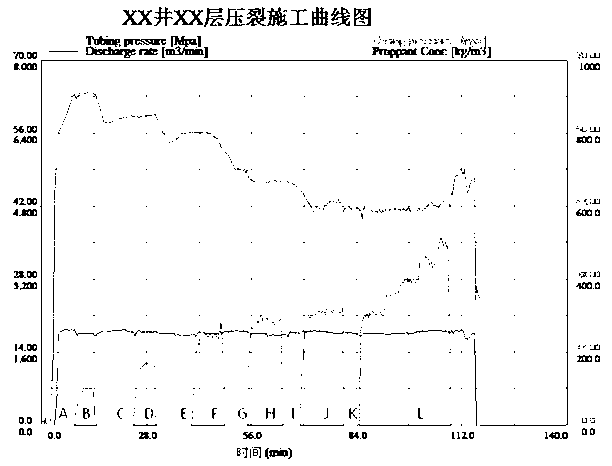

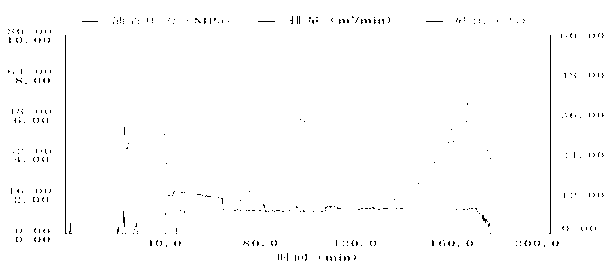

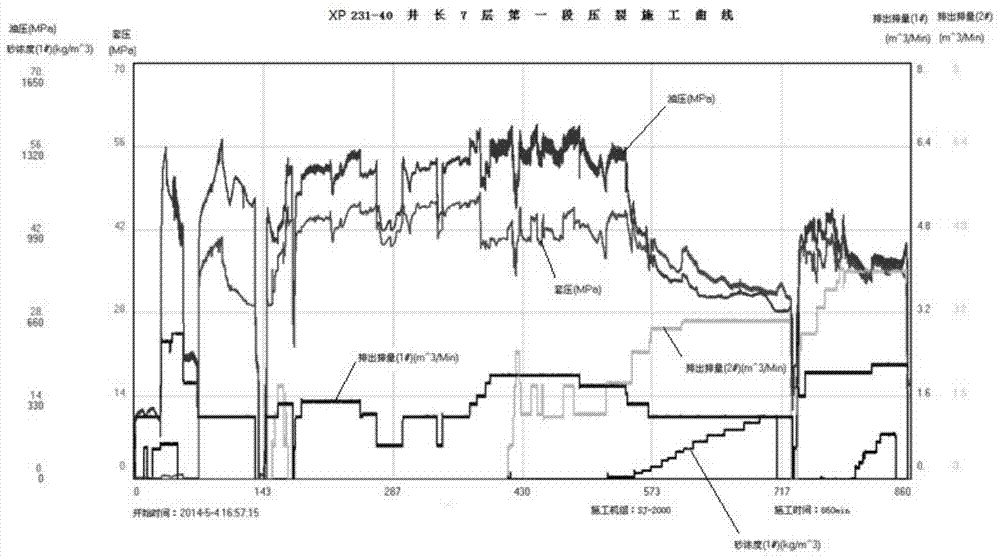

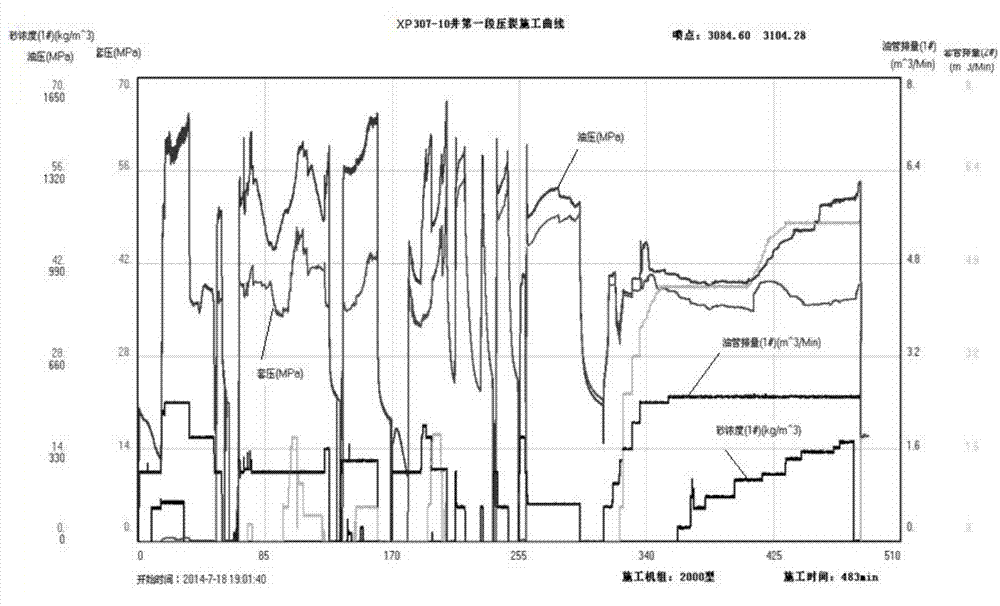

Fracturing method for increasing complexity of high-temperature stratum artificial crack net

ActiveCN108661617AReduce construction pressureIncrease the complexity of artificial fracturesFluid removalHorizontal wellsFracturing fluid

The invention discloses a fracturing method for increasing the complexity of a high-temperature stratum artificial crack net and belongs to the technical field of petroleum and natural gas engineeringexploitation. The method comprises the following steps that low-temperature work liquid is injected into a high-temperature stratum, a strong cold-hot stress impacting effect is generated through thehigh-temperature difference between the low-temperature work liquid and the high-temperature stratum, rock around a well is induced to generate micro cracks, then fracturing liquid is injected to enable the micro cracks to continue to expand forwards, finally temporary plugging steering liquid is injected to conduct bridge plugging on the artificial cracks to force the cracks to steer to form multi-branch cracks, and the steps are executed at least once. Through the fracturing method, the multiple artificial cracks can be formed, the seepage area is enlarged, the single-well yield and economic benefits are increased, the bursting pressure can be lowered, the fracturing construction risk caused by high temporary plugging steering pressure in the high-temperature stratum is avoided, and safe construction is ensured. The fracturing method is suitable for the high-temperature strata such as hot dry rock, deep-layer shale gas and deep-layer compact oil gas, can be used for vertical well fracturing construction and can also be applied to fracturing construction of horizontal wells, oblique wells and the like.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Shale gas reservoir pre-fracture composite acid solution, preparation method and application thereof

InactiveCN105086989APrevent collapseCore dissolution rate maintenanceDrilling compositionAcetic acidHydrofluoric acid

The invention belongs to the field of petroleum engineering and relates to a shale gas reservoir pre-fracture composite acid solution and its preparation method and application. The composite acid solution comprises the following components: Component a) at least one component of hydrochloric acid, hydrofluoric acid, fluorboric acid, phosphoric acid, formic acid and acetic acid; and Component b) a corrosion inhibitor, a discharge aiding agent, a ferric iron stabilizer and a clay stabilizer. The composite acid solution containing different acids is selected for different reservoirs. Rock core corrosion ratio is 25-30%. A certain rock core corrosion ratio is maintained, and borehole wall collapse caused by too high corrosion ratio is also prevented. The corrosion inhibitor, the discharge aiding agent, the ferric iron stabilizer and the clay stabilizer which are used as additives have good compatibility with acid. The composite acid solution provided by the invention has advantages of fast dissolving speed, uniform mixing, high corrosion inhibition efficiency, high surface activity, good clay stabilizing effect and wide range. Applicable temperature of the composite acid solution is 20-180 DEG C. by the use of the composite acid solution, normal construction of large-scale fracturing of long horizontal-section shale gas wells can be guaranteed under the condition of existing equipment capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

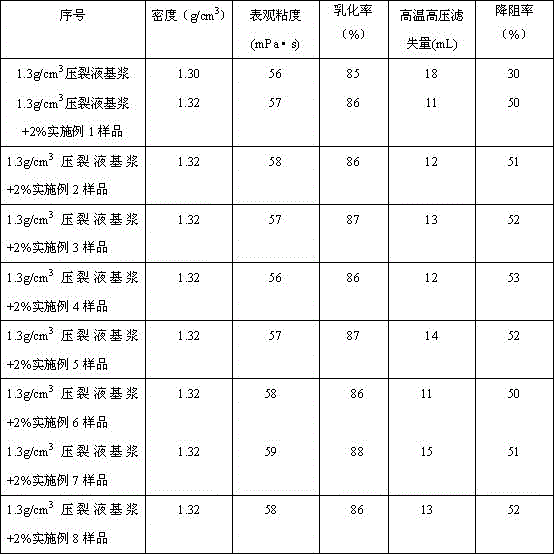

High density fracturing liquid

The invention offers high density fracturing fluid formula used inorganic salt to improve water-base fracturing fluid density. Its feature is that its weight ratio is as follows: weight additive 4-50%, vegetable gum thickener 0.3-1.0%, cross linking agent 0.1-2.0%, pH value regulator 0.5-1.0%, cracking agent 0.002-0.3%, cleanup additive 0.05-0.5%, fungicide 0.03-0.2%, and water 30-73%. The density of the high density fracturing fluid is adjustable and can exceed 1.51g / cm3. It has good high temperature resistant, shearing resistant, and so on. Thus it can supply reliable assurance for abnormal high pressure and ultra-deep well exploration test oil and exploitation.

Owner:PETROCHINA CO LTD

Multi-crack fracturing control method for medium-depth coal beds

ActiveCN103244097AJoin smoothlyOvercoming poor sand-carrying abilityFluid removalFracturing fluidHigh pressure

The invention relates to an oil extraction process for oil fields, in particular to a multi-crack fracturing control method for medium-depth coal beds. The method comprises six steps of 1) preparation of a filtrate reduction fracturing fluid; 2) utilization of a high-pressure pump set; 3) utilization of a high-pressure pump set; 4) utilization of a high-pressure pump set; 5) phased utilization of a prepad liquid; and 6) ending of work. According to the multi-crack fracturing control method, prior conventional active-water sand fracturing method is changed through theoretical analysis and on-site verification, and the filtrate reduction fracturing fluid, the prepad liquid variable displacement technology, a multi-stage particle size slug technology, a reasonable mortar-sand ratio raising technology and the like are used, accordingly, difficulties such as large filter losses, poor sand carrying capabilities and excess leak-off of the fracturing liquid and high construction pressure during opening of natural cracks are overcome. Multi-crack is effectively prevented and treated through the means of the filtrate reduction fracturing fluid, and the prepad liquid variable displacement technology and the multi-stage particle size slug technology, so that the construction pressure is reduced, smooth adding of a propping agent is guaranteed, and the fracturing construction success rate is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

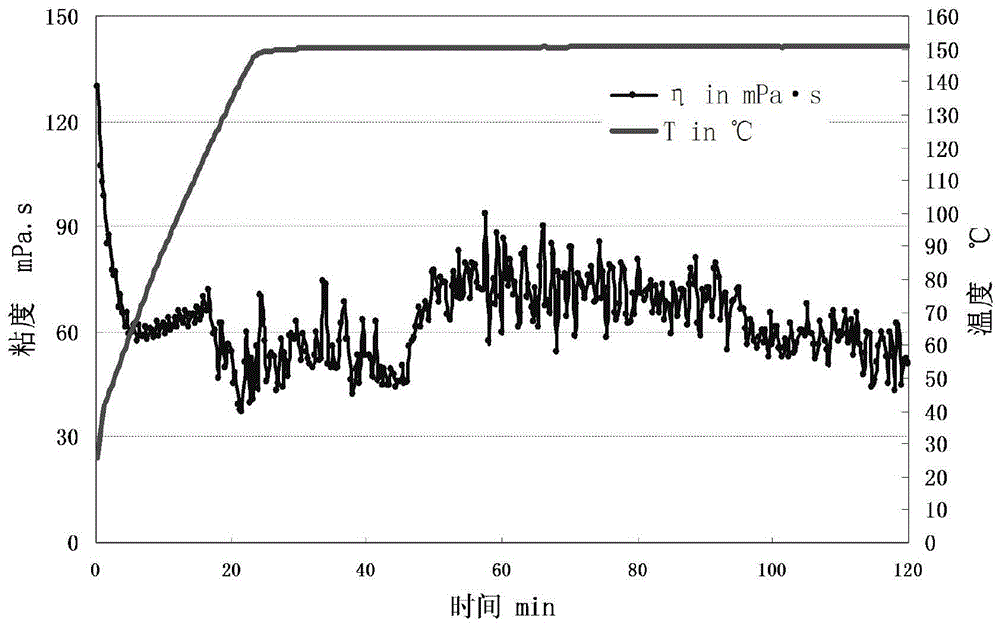

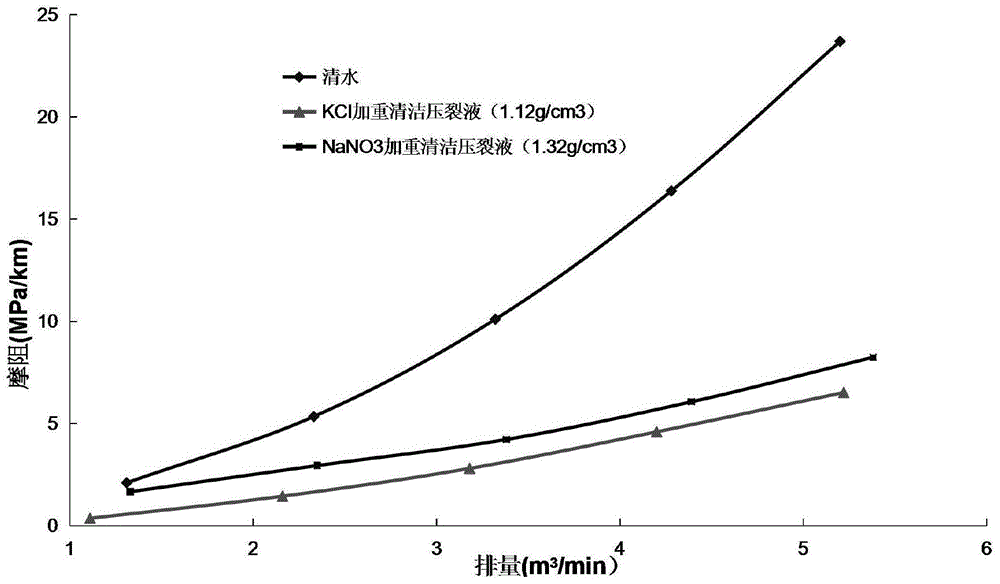

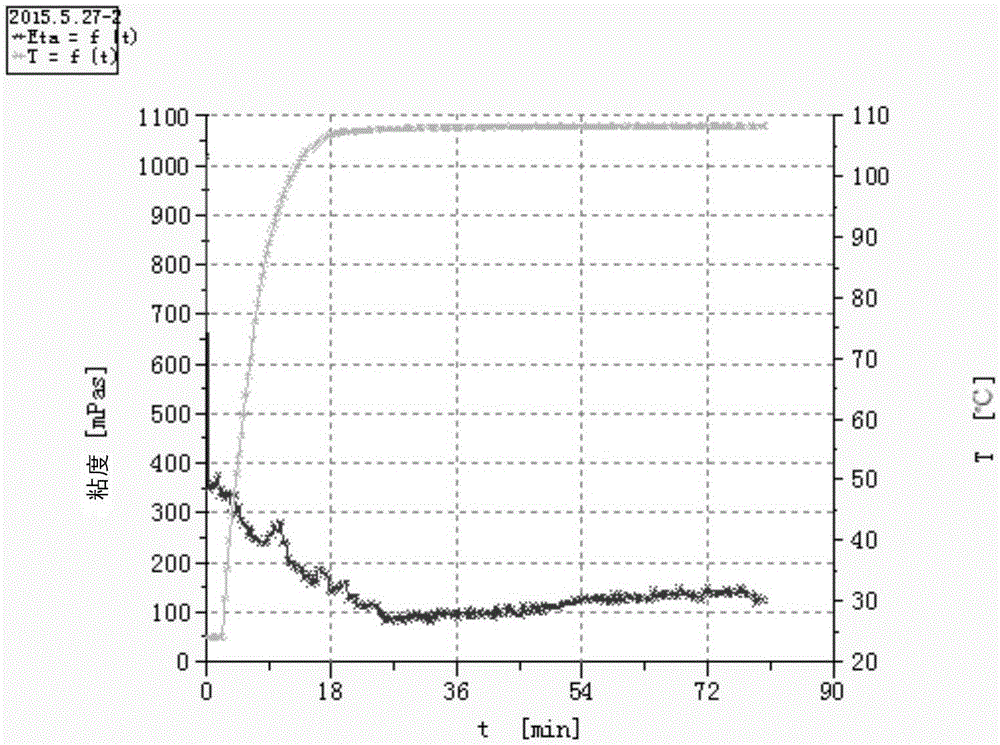

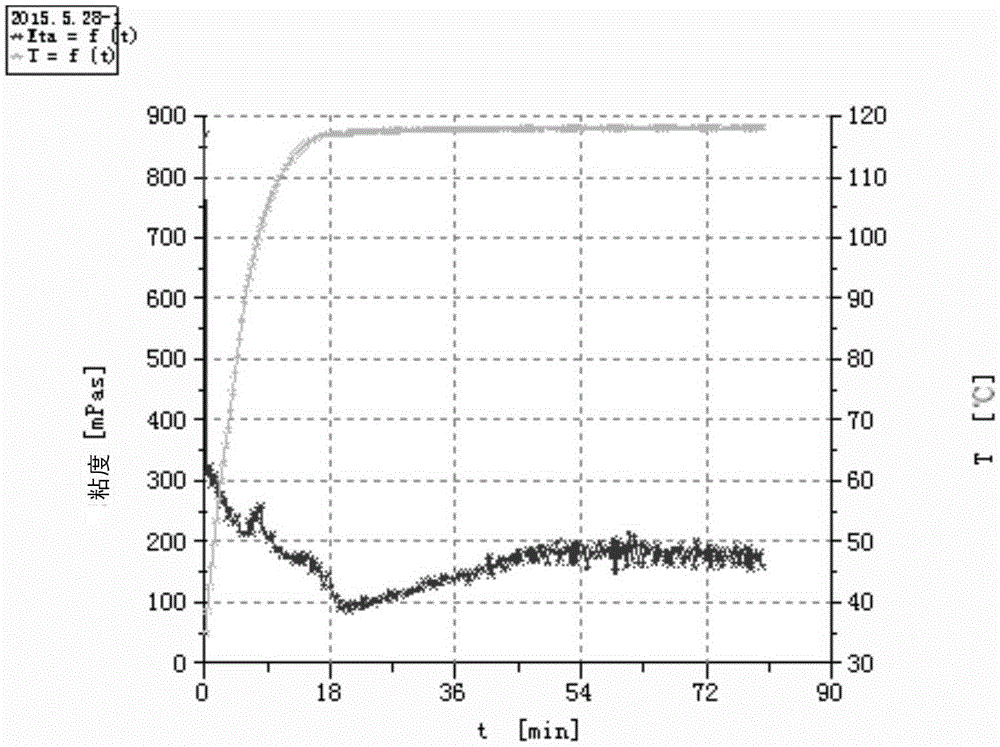

High-temperature-resistance low-friction weighted clean fracturing fluid and preparation method thereof

ActiveCN105733547APromote swellingEnhanced associationDrilling compositionReduction rateHigh pressure

The invention discloses a high-temperature-resistance low-friction weighted clean fracturing fluid which is suitable for high-temperature and high-pressure reservoir reconstruction at 170 DEG C and a preparation method thereof.The fracturing fluid is prepared from, by weight, 0.2%-0.8% of high-temperature-resistance thickening agent, 0.1%-0.8% of system synergist, 0.1%-0.3% of high temperature stabilizer, 0%-42% of weighting agent and the balance fresh water.The high-temperature-resistance low-friction weighted clean fracturing fluid has the following functions and advantages that the weighting agent can be adopted for weighting, and the density is adjustable between 0 and 1.32 g / cm<3>; good temperature-resistance and anti-shearing properties are achieved, and the requirement of high-temperature deep well fracturing construction at 170 DEG C can be met by adjusting a formula; a good resistance reduction property is achieved, pipeline friction resistance can be effectively reduced, and the resistance reduction rate can reach 70%; the fracturing fluid is a fluid with a reversible structure, and the structure damage after high shearing is small; the residue content of the fracturing fluid is decreased to below 10 mg / L, damage to a reservoir and supporting cracks is reduced, the fracturing effect is improved, and the reservoir productivity is increased.

Owner:CHENGDU BAICHUN PETROLEUM TECH +1

Low permeable oil deposit virtual horizontal well development method

The invention relates to a low permeable oil deposit virtual horizontal well development method, comprising the following process technologies: deploying a developed well pattern, early flooding under nearly high pressure condition, optimizing a perforation well section and a perforation way, designing and deploying the development technology and producing a long slot by ultra large scale fracturing. When the developed well pattern is deployed, the well pattern is designed and deployed in a region with the thickness of an oil layer being higher than a 4m line, the well pattern is a five-spot square one with the distance between an oil well row and a water well row being 490-520m and the distance between an injection well row and an extraction well row being 170-200m, wherein the directionof the oil well row and the water well row is consistent with the direction of the main geostatic stress; the early flooding is carried out under the nearly high pressure condition that the strata pressure coefficient is kept to be 0.9-1.0; at the middle part of the oil layer is perforated for only 2-4 meters, and the perforating is carried out by adopting a multiphase optimized perforation way; the development technology is designed and oil-water wells and capacities of the oil-water wells are deployed in a block; and the slot is produced by adopting the ultra large scale fracturing while monitoring is carried out, wherein average length of half slot is 190-250m, and high delivery volume construction at the speed of high quality fracturing fluid being 5-6m<3> / min is adopted in the whole course. The invention is applied to a low permeable oil deposit development process.

Owner:胜利油田鲁明油气勘探开发有限公司

Carbonate rock multi-slug injection type fracturing method

InactiveCN103244094AReduce bending resistanceEfficient fillingFluid removalFracturing fluidLow density

The invention relates to the technology of oil field fracturing construction, in particular to a carbonate rock multi-slug injection type fracturing method which is characterized by including the following steps: determining fracturing liquid dosage and fracturing scale, determining propping agent slug and adding quantity of isolation liquid, adding small-particle propping agent in the prepad fluid section stage, adding low-density high-strength propping agent in the main fracturing stage, increasing sand ratio and utilizing a wedging mode to add sand. In the carbonate rock multi-slug injection type fracturing method, a multi-slug mode is adopted for injection under the condition that sand adding of a carbonate reservoir is difficult to achieve fracturing construction of the carbonate reservoir.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

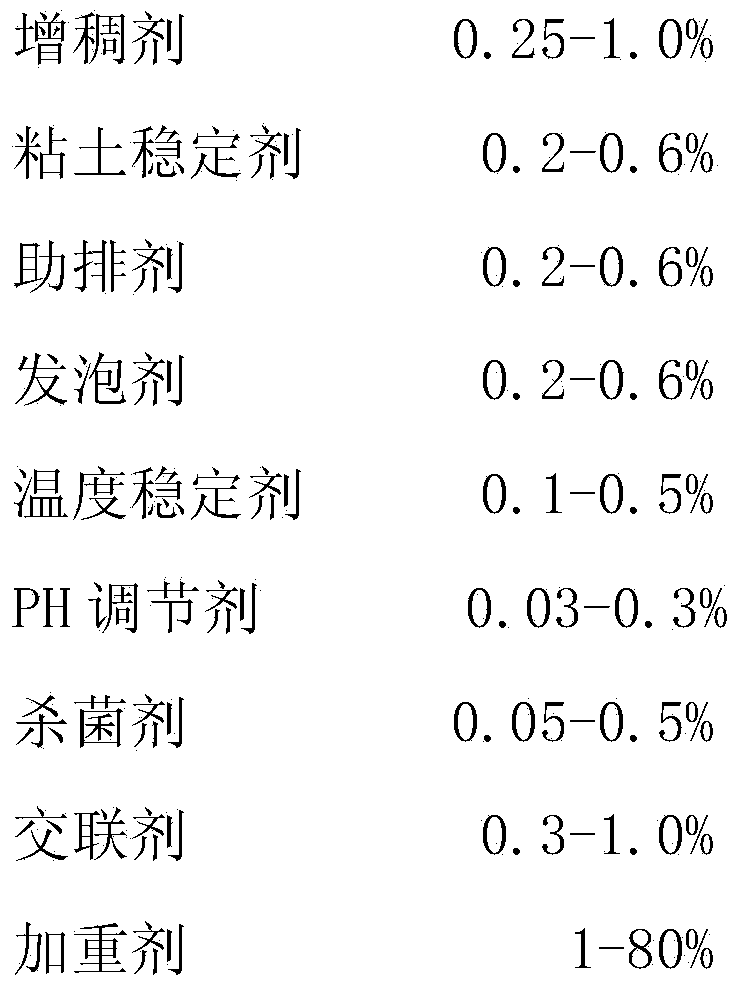

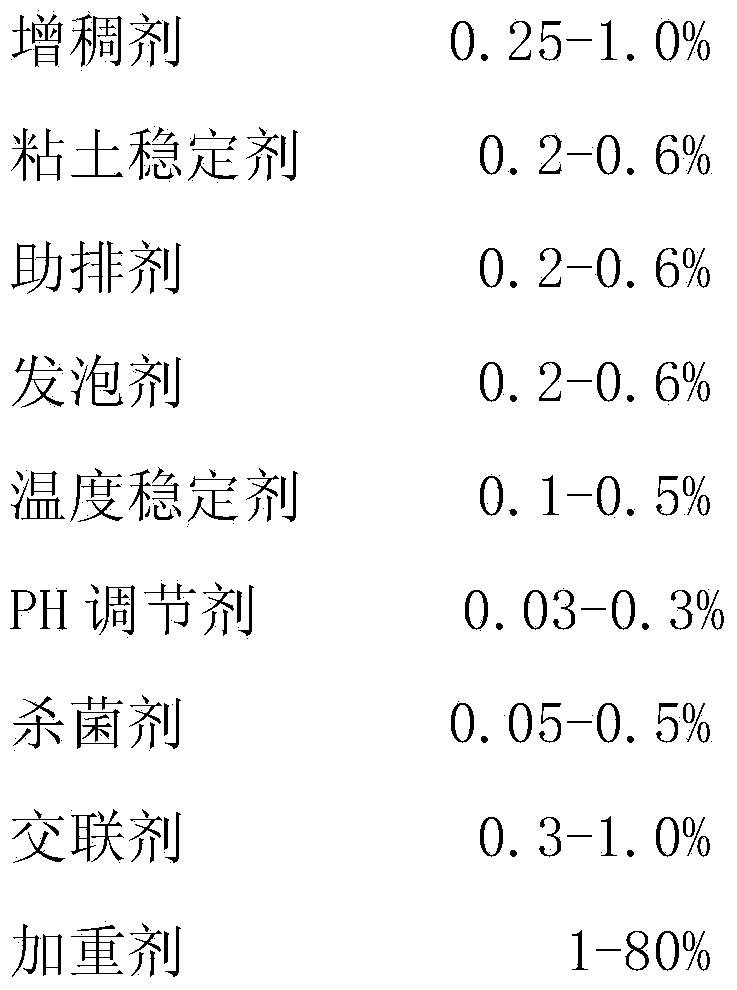

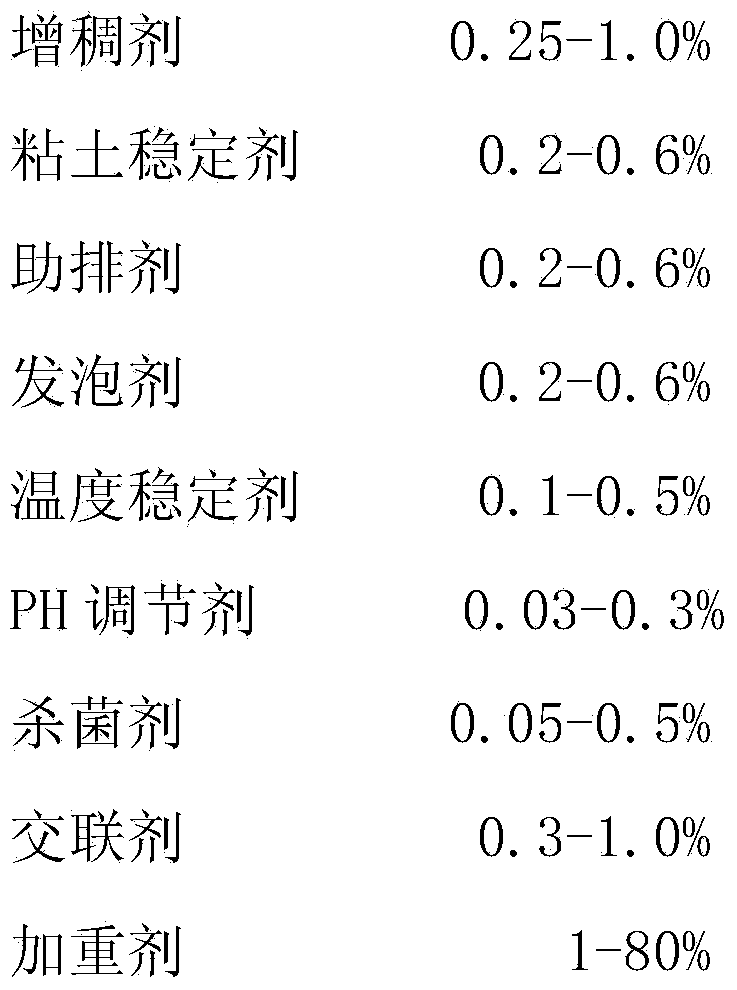

Density adjustable type composite weighted fracturing fluid

The invention discloses density adjustable type composite weighted fracturing fluid. The density adjustable type composite weighted fracturing fluid is prepared from the following components in percentage by mass: 0.25-1.0% of thickening agent, 0.2-0.6% of clay stabilizer, 0.2-0.6% of cleanup agent, 0.2-0.6% of foaming agent, 0.1-0.5% of temperature stabilizer, 0.03-0.3% of PH regulator, 0.05-0.5% of sterilizing agent, 0.3-1.0% of crosslinking agent, 1-80% of weighting agent and the balance of water, wherein the weighting agent is one of or a mixture of two of sodium chloride, potassium chloride, sodium bromide and potassium bromide. The density adjustable type composite weighted fracturing fluid disclosed by the invention can be applied to the fracturing construction of deep well compact oil and gas reservoirs and is capable of effectively achieving the purposes of reducing construction pressure, thus a ground pressure-bearing manifold can be protected.

Owner:CNPC BOHAI DRILLING ENG

Shale gas horizontal well bridge plug separation and ball throwing segmented fracturing process

InactiveCN104989358AGood flow channelReasonable designFluid removalSealing/packingShale gasMaterial Perforation

The invention discloses a shale gas horizontal well bridge plug separation and ball throwing segmented fracturing process, which concretely comprises the following steps of: 1, draining, exploring and washing a well tube; 2, performing clustering perforation on a first segment; 3, performing fracturing construction on a first cluster; 4, throwing balls for sealing the first cluster; 5, repeatedly performing the fracturing construction, ball throwing and sealing steps in the third step and the fourth step on a second cluster, a third cluster to an N-th cluster; 6, sealing the first segment by a lower bridge plug, and performing clustering perforation on a second segment; 7, sequentially and repeatedly performing fracturing construction, ball throwing, sealing and lower bridge plug sealing steps in the third, fourth, fifth and sixth steps on the second segment to the N-th segment; and 8, performing sweeping grinding. The process method has the advantages that the design is reasonable; the construction cost is low; the optimum flowing passage of shale gas can be realized by adopting the process method; high economic return is obtained at high speed and high yield; and the fractures can be limited to the most economic positions.

Owner:中国石油化工股份有限公司华东分公司采油厂

Fracturing method of coal bed gas in smashed pea coal

The invention provides a fracturing method of coal bed gas in smashed pea coal. Perforation parameters are optimized, and a liquid inlet channel is established in a stable coal seam section; in the whole fracturing process, the using proportion of pre-liquid volume is increased, and the pre-liquid volume is increased to 45-55% of total fracturing fluid; firstly, pure fracturing fluid accounting for 20-25% of the total fracturing fluid is pumped; then prepad fluid is pumped and a sand slug is added; sand-carrying fluid and the added sand slug support fractures and prevent sand blocking; and at last, displacing liquid is pumped. According to the fracturing method of the coal bed gas in the smashed pea coal, fracturing modification of the coal bed gas in the smashed pea coal can be effectively guided through the methods of optimizing the perforation parameters, optimizing the pumping procedure and the like.

Owner:重庆矿产资源开发有限公司

Heavy cracking-fluid formula

An emphasized fracturing liquid formula consists of water 500 proportion, emphasizing agent 180-483 proportion, gelatinizer hydroxypropyl guar gum 2-3 proportion, pH value adjuster sodium carbonate 0.8-1 proportion, pH value adjuster sodium hydrate 0.15-0.27 proportion, auxiliary 3.0-3.3 proportion, and emphasized fracturing liquid density is between 1.25-1.5g / cm3. It can be used to increase liquid column pressure in well and decrease construction pressure on well opening and finish oil-well fracture of deep well, super-deep well, abnormal high-pressure well and realize storage-layer transformation.

Owner:PETROCHINA CO LTD

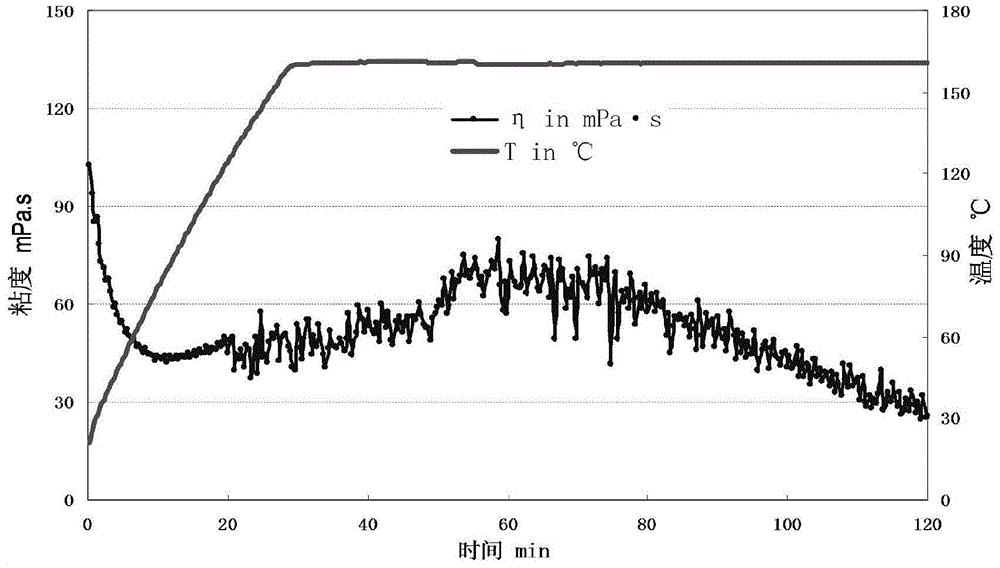

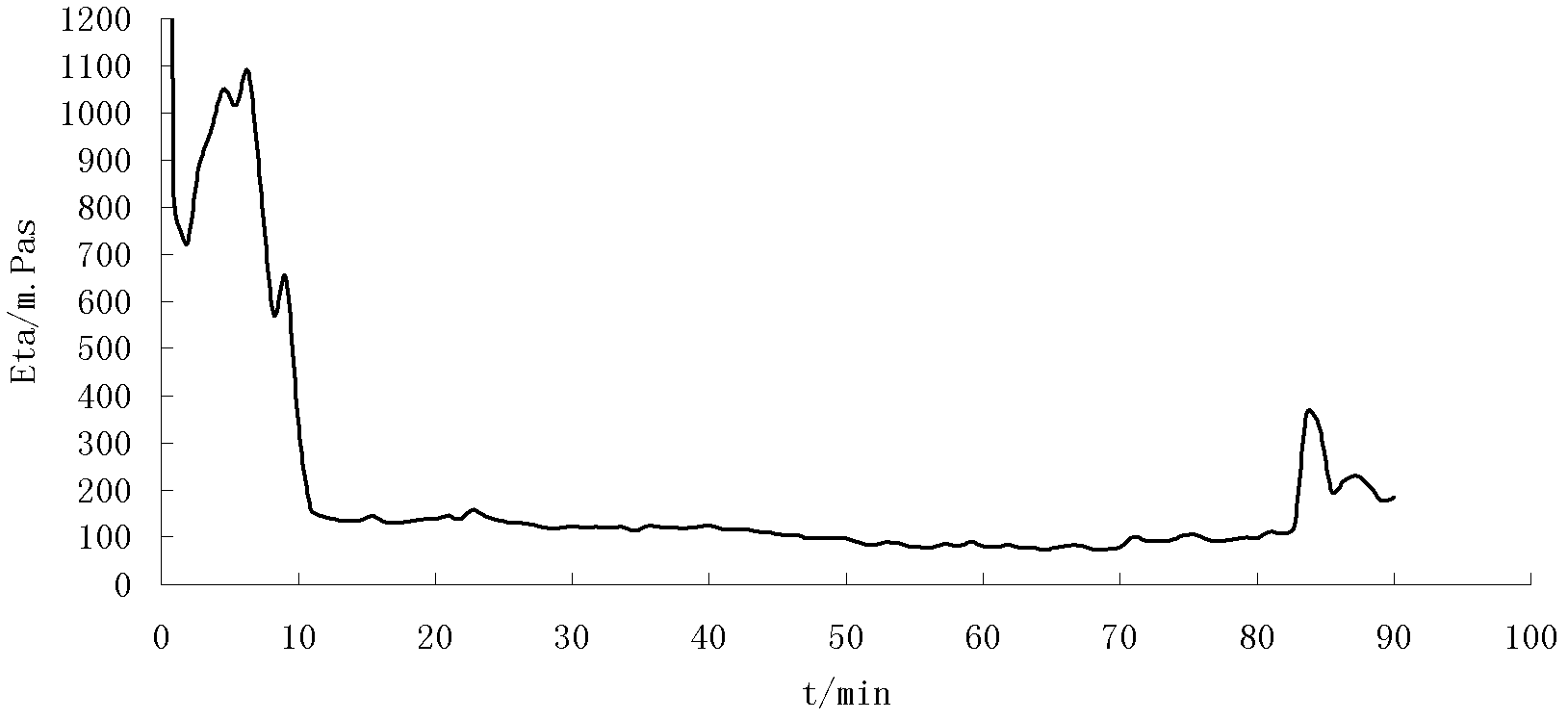

High-density fracturing fluid capable of slowing crosslinking and resisting high temperature

ActiveCN103254885AGood temperature and shear resistanceIncrease pressureDrilling compositionCross-linkPolymer science

The invention relates to a high-density fracturing fluid capable of slowing crosslinking and resisting high temperature. The fracturing fluid is composed of a stock solution and a crosslinking liquid with a volume ratio of 10 : 1, wherein the stock solution comprises, by weight percent, 0.5-0.65 % of hydroxypropyl guar gum, 8-45 % of a weighting agent A, 6-30 % of a weighting agent B, 0.5-2 % of a ZJ-07 cleanup additive, 0.01-0.04 % of a pH-value conditioning agent A, and the balance being water; the crosslinking liquid comprises, by weight percent, 0.5-3 % of a cross-linking agent YGB, 1-2 % of a cross-linking agent HT, 0.1-0.4 % of a pH-value conditioning agent B, 0-0.35 % of a gel breaker and the balance being water. The fracturing fluid is good in temperature-resistance and shearing-resistance performances, wherein the temperature-resistance performance is up to 145 DEG C, and a viscosity is still more than 120 Pa*S after the liquid is sheared for 90 minutes under 145 DEG C and 170 S<-1>.

Owner:PETROCHINA CO LTD

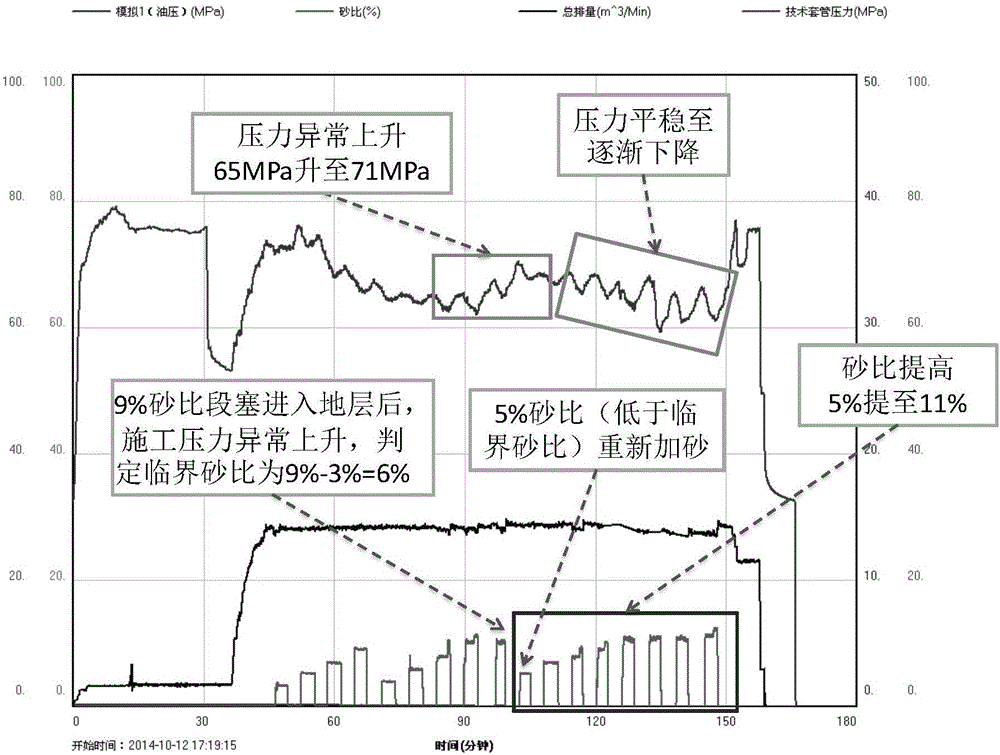

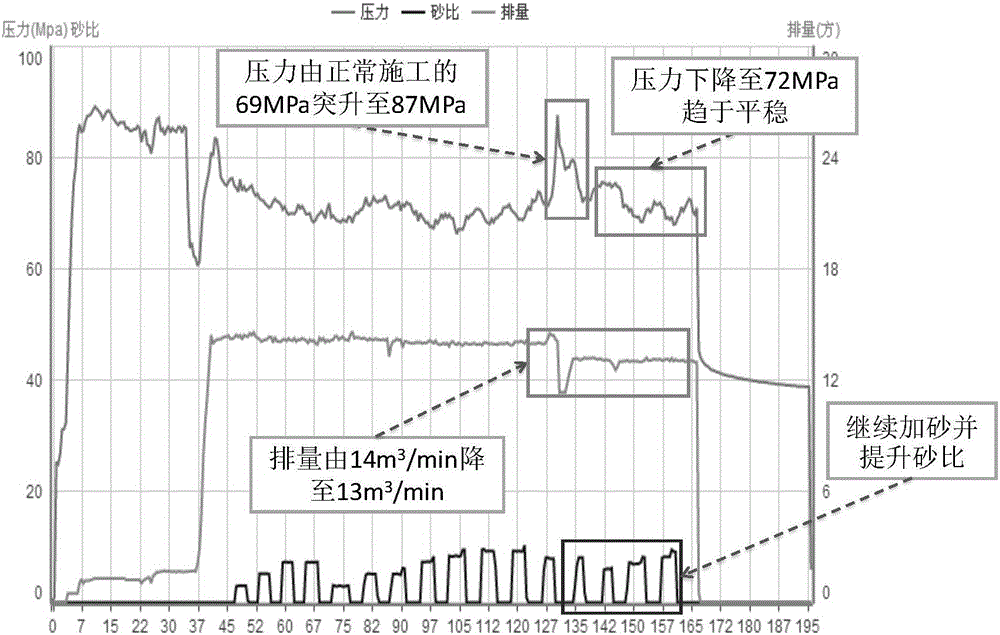

Processing method for controlling abnormal pressure rise in shale fracturing process

InactiveCN106761644ASlow down the rate of formationEfficient pluggingFluid removalPressure riseFracturing fluid

The invention discloses a processing method for controlling abnormal pressure rise in the shale fracturing process. The processing method comprises the following steps that in the middle and later periods of fracturing, a critical sand ratio method is adopted for construction when abnormal pressure rise occurs and comprises the specific steps that 1, the critical sand ratio is determined, wherein a critical sand ratio range is determined as the sand ratio subtracted by 2%-5% at the moment when pressure rises at the slope greater than 1 / 2 in the sand adding process, sand adding is stopped immediately, fracturing fluid injection continues, the injection amount is 1-1.5 times of shaft volume, sand adding is stopped but fluid injection is not stopped; 2, abnormal pressure rise is processed, wherein the point not exceeding the critical sand ratio serves as a starting point to perform pressurized fracturing again after the injection of a fracturing fluid 1-1.5 times of shaft volume is completed, and a sand ratio value in fracturing sand is gradually increased till designed sand adding amount is completed. By adopting the critical sand ratio method, a sandy dyke formation speed can be reduced, the rapid rise situation of construction pressure is effectively controlled, and the method has the advantages that operation is simple and convenient, an existing fracturing process is not changed, the fracturing construction quality can be improved, and a reconstruction effect is ensured.

Owner:PETROLEUM ENG TECH RES INST OF JIANGHAN OILFIELD BRANCH OF

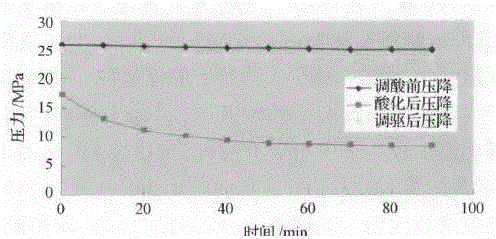

Modified oilfield acid regulation integrated technique

InactiveCN105298436AAdjustable intensityReach \"blockingFluid removalSealing/packingThermodynamicsOil field

The invention discloses a modified oilfield acid regulation integrated technique and aims to provide an oilfield deep profile controlling and flooding technique which allows continuous construction, fewer moving string steps, simple process, low risk and low cost. The acid regulation integrated technique is continuously carried out for construction according to a sequence of temporary plugging process, acid regulation process and profile regulation process. The technique also comprises a cleaner injection process. The technique is suitable for water injection wells, having great inter-reservoir differences, non-uniform inter-reservoir suction profiles, low water injection pressure with high water injection quantity, and severe injected water rush in high permeable layers.

Owner:天津立坤石油技术服务有限公司

Downward layering horizontal drift high-sublevel filling mining method

ActiveCN110905516AExtended service lifeIncrease segment heightUnderground miningSurface miningMining engineeringGeotechnical engineering

The invention discloses a downward layering horizontal drift high-sublevel filling mining method. The downward layering horizontal drift high-sublevel filling mining method particularly comprises thesteps of division of ore blocks, stope preparation cutting, stoping, stope ventilation and stope filling and so on, and a whole sublevel mine can be mined. The sublevel height is increased, the stoping layer number is increased, the sublevel stoping mine amount is increased, the panel service life can be prolonged, panel mining disorder can be solved, after middle level stope preparation engineering arranging optimization, six sublevels are arranged in the 150 m middle level, the sublevel construction is reduced, the middle level stope preparation engineering amount is reduced by about 3500m / 72000m<3>, the mine engineering construction investment is greatly saved, after the sublevel height is increased, the sublevel service life is prolonged, the sublevel digging disorder contradiction isrelieved, and the sublevel engineering construction pressure is reduced.

Owner:JINCHUAN GROUP LIMITED

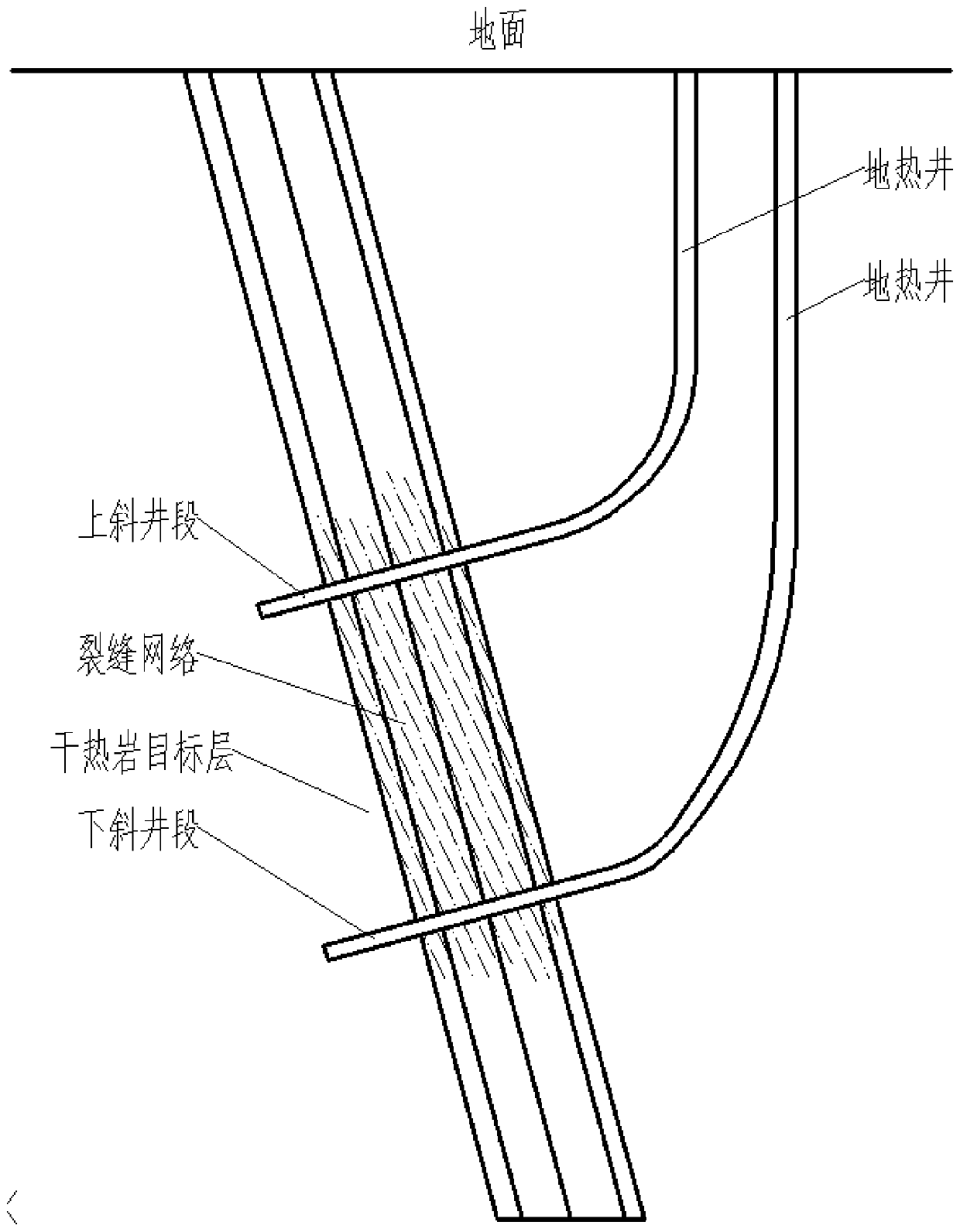

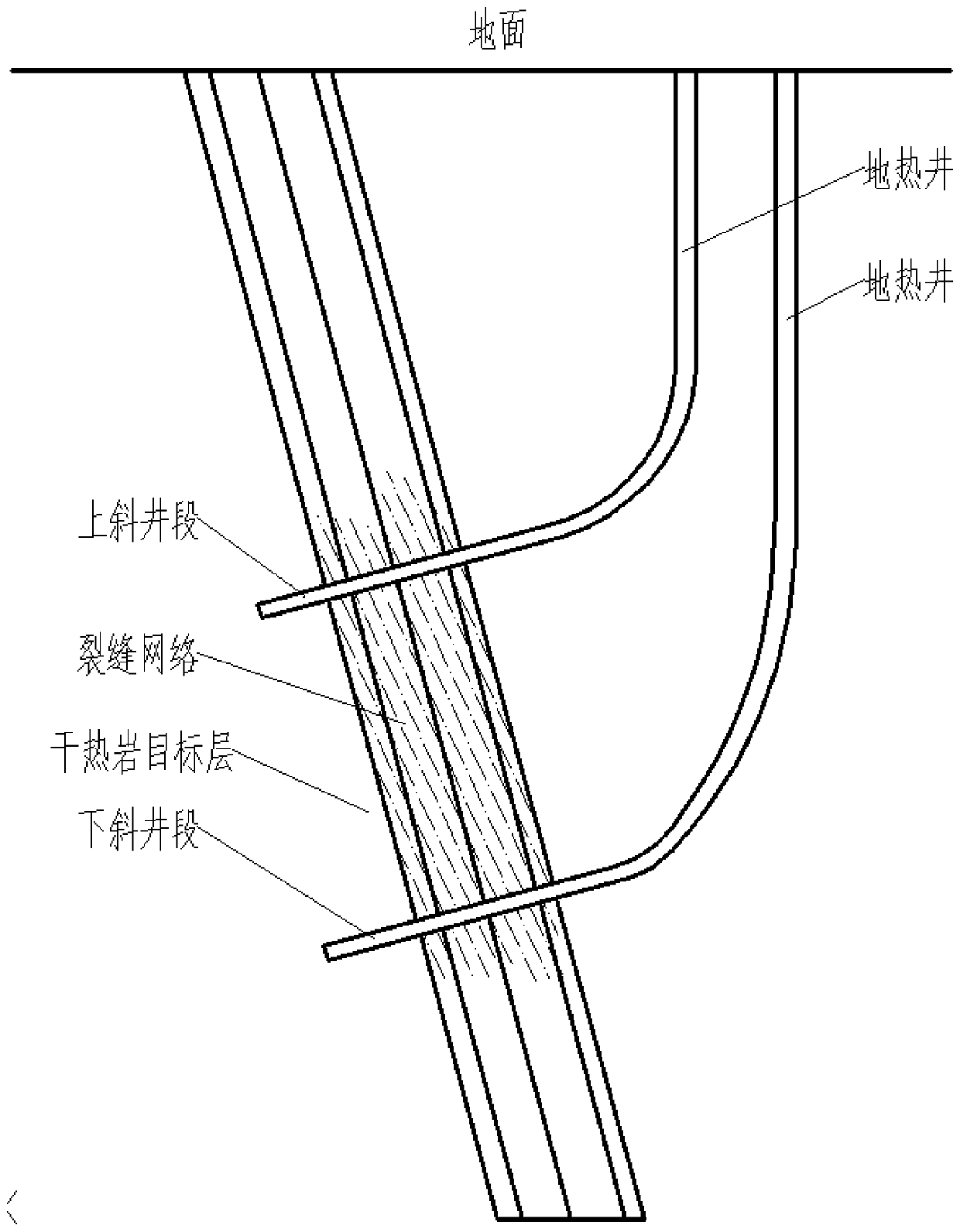

Dry hot rock geothermal exploitation method

ActiveCN110006185ALow costReduce difficultyGeothermal energy generationFluid removalGeomorphologyGeothermal desalination

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

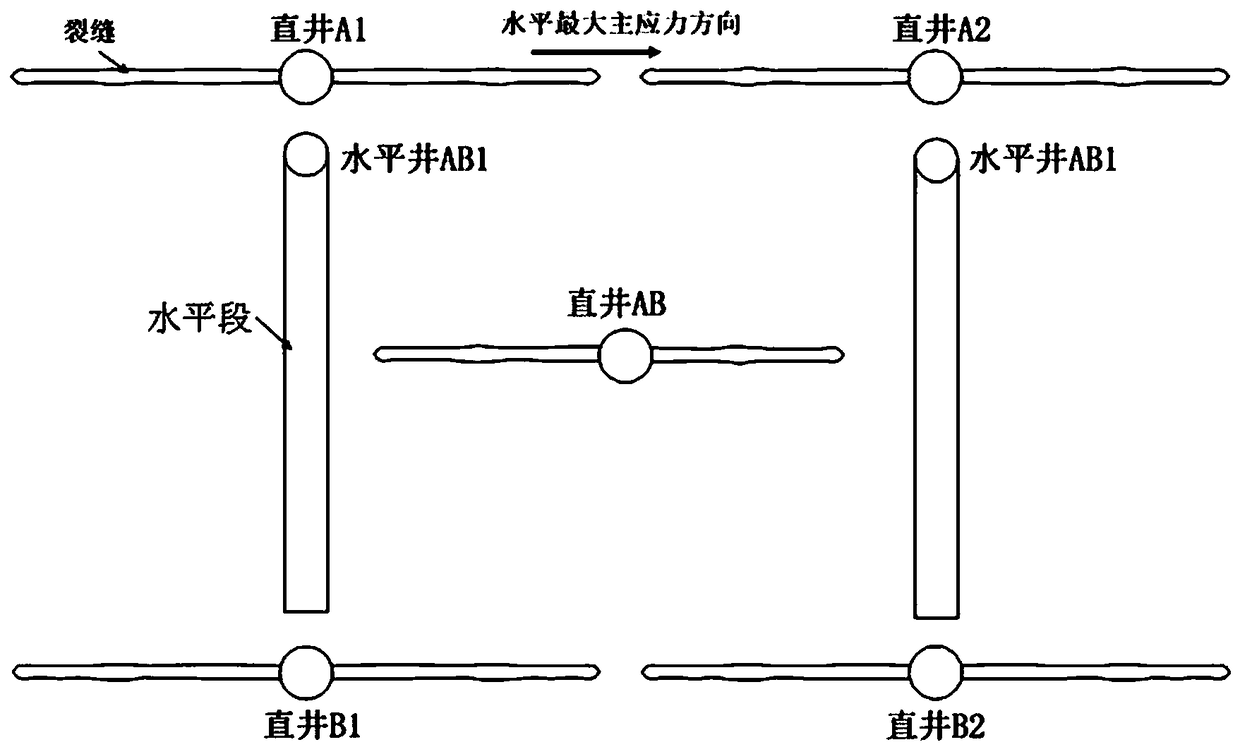

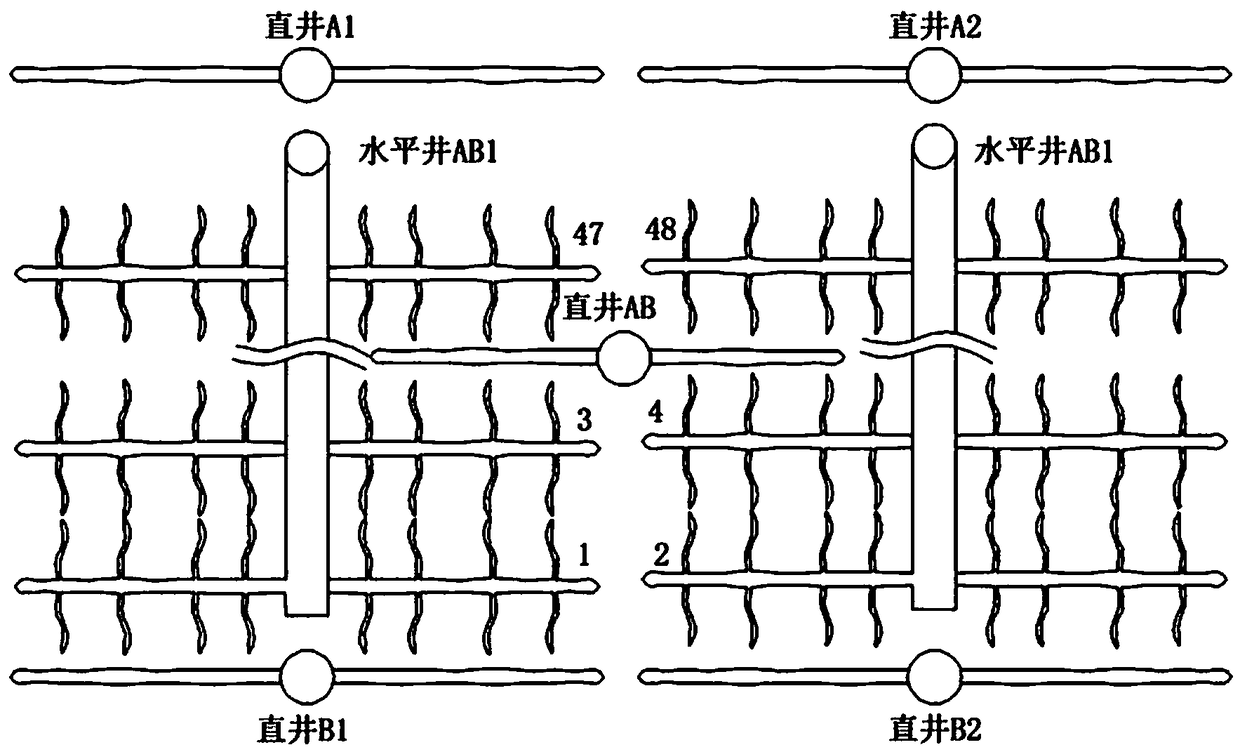

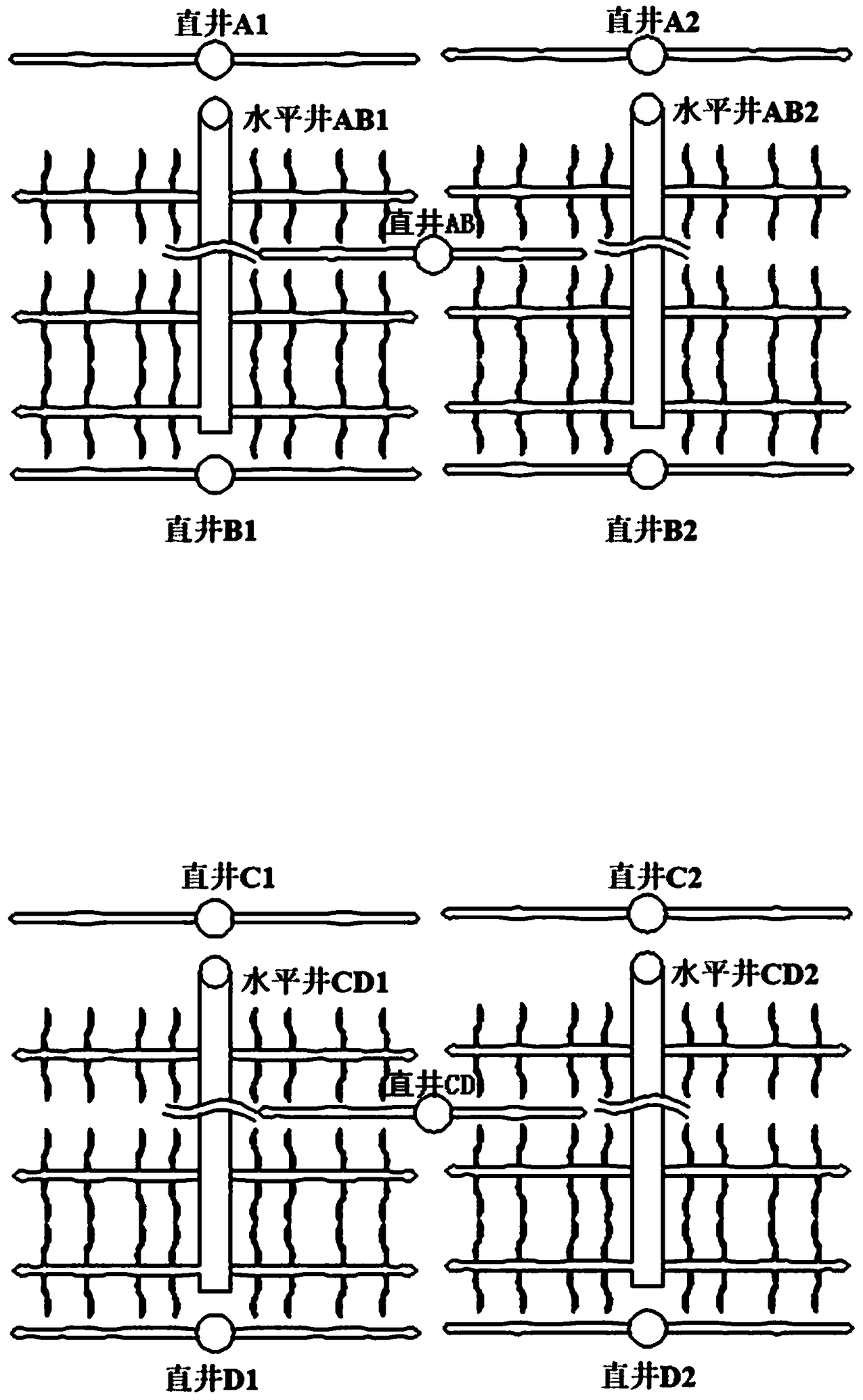

Fracturing production increasing method for deep shale gas

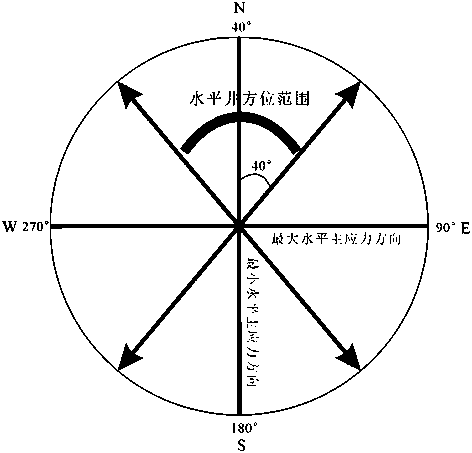

ActiveCN109488274AMinimize the horizontal stress differenceEasily brokenFluid removalComplex networkShale gas

The invention provides a fracturing production increasing method for deep shale gas, which divides a deep shale gas exploitation area into at least three fracturing units, wherein each fracturing unitcomprises five straight wells and two horizontal wells; the fracturing production increasing method for the deep shale gas comprises the following steps: fracturing the two fracturing units positioned on the two sides; S11, performing hydraulic fracturing operation on the straight wells to generate cracks with single shape in the same direction as the horizontal maximum principal stress; S12, performing pumping bridge plug fracturing operation in staggered sequence on horizontal wells to generate network fractures in a reservoir, and the fracturing fluid adopted by the pumping bridge plug fracturing operation is liquid nitrogen carrying proppant; S2, fracturing the horizontal wells of the middle fracturing unit and a straight well positioned between the horizontal wells to generate network cracks. According to the fracturing production increasing method, complex network fractures interwoven with artificial fractures and branch fractures can be generated, the volume and the seepage area of the reformed reservoir can be increased, and the purpose of improving the recovery ratio of the shale gas reservoir can be achieved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

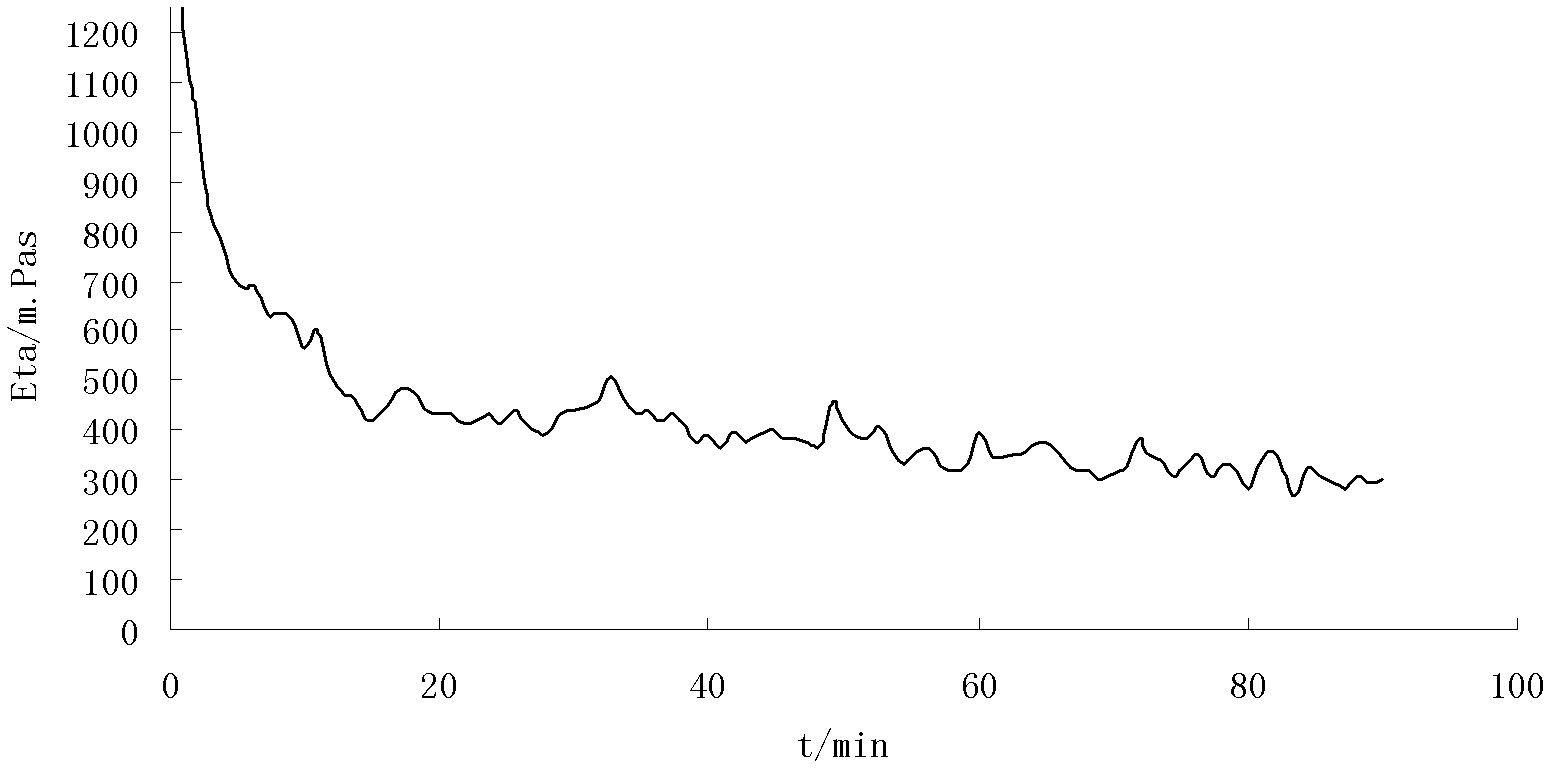

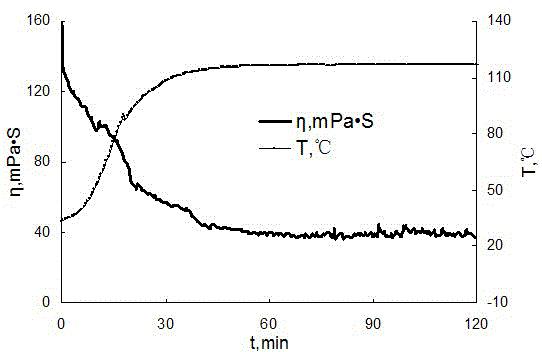

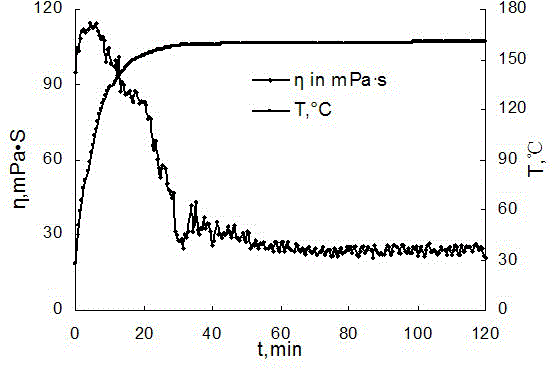

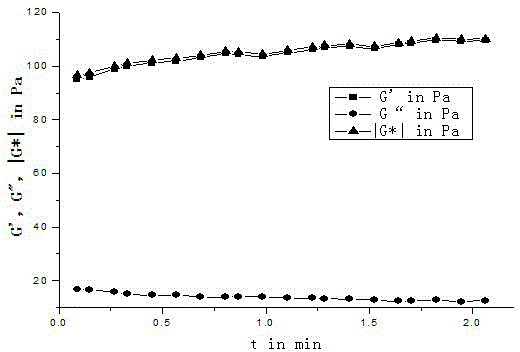

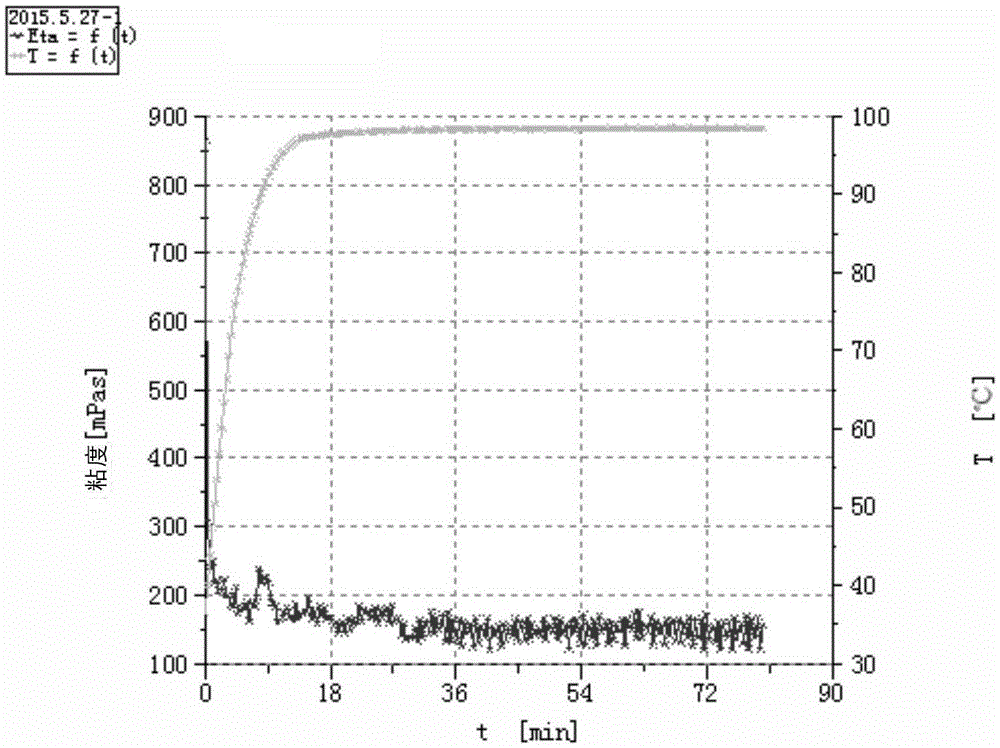

Association type high-temperature resistant fracturing fluid suitable for volcanic rock fracture

The invention provides an association type high-temperature resistant fracturing fluid suitable for volcanic rock fracture. The fracturing fluid comprises two parts, namely a base liquid and construction additives. The base liquid comprises following components by weight: 0.5-0.9% of a thickening agent and 0.2-0.3% of a flow promoter, with the balance being water. The construction additives comprise a thickening auxiliary agent and a gel breaker. The thickening auxiliary agent is 0.25-0.45% by weight of the base liquid. The gel breaker is 0.02-0.05% by weight of the base liquid. The fracturing fluid belongs to supramolecular structure fluids, and has good viscoelasticity, thus achieving viscoelastic sand carrying. The fracturing fluid has characteristics of capability of being clean and free of residue, good temperature resistance, shearing resistance, shearing dilutability, and the like. During fracturing construction, the fracturing liquid can reduce friction so as to reduce the construction pressure, and the fracturing liquid is low in harm to a reservoir stratum, thus increasing the success rate of fracturing construction, improving fracturing effects, and increasing the productivity of the reservoir stratum. The fracturing liquid is suitable for fracturing transformation of a volcanic rock reservoir stratum.

Owner:CHINA PETROLEUM & CHEM CORP +2

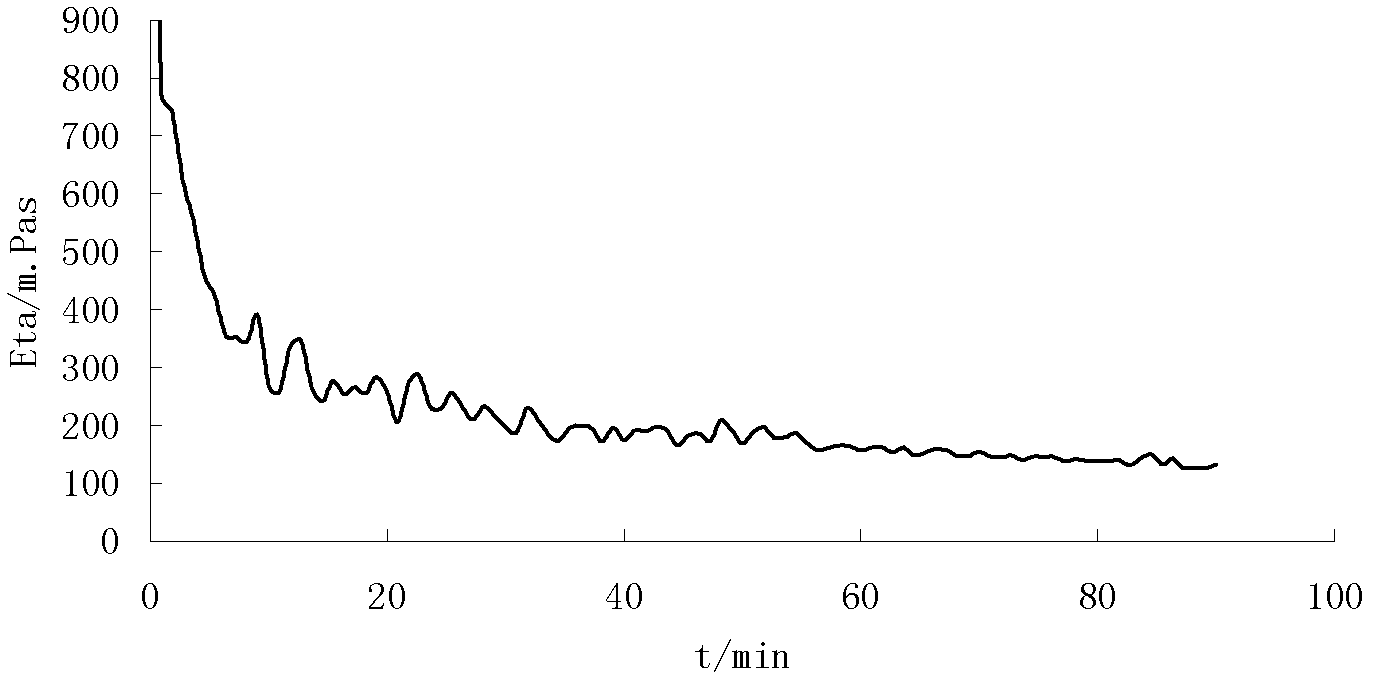

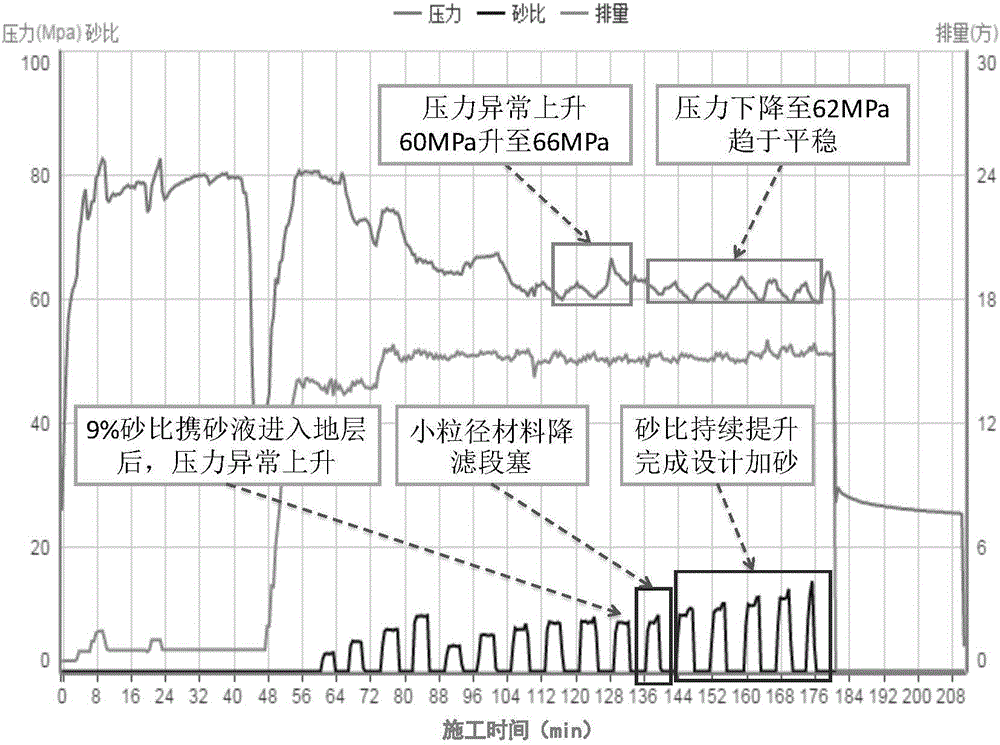

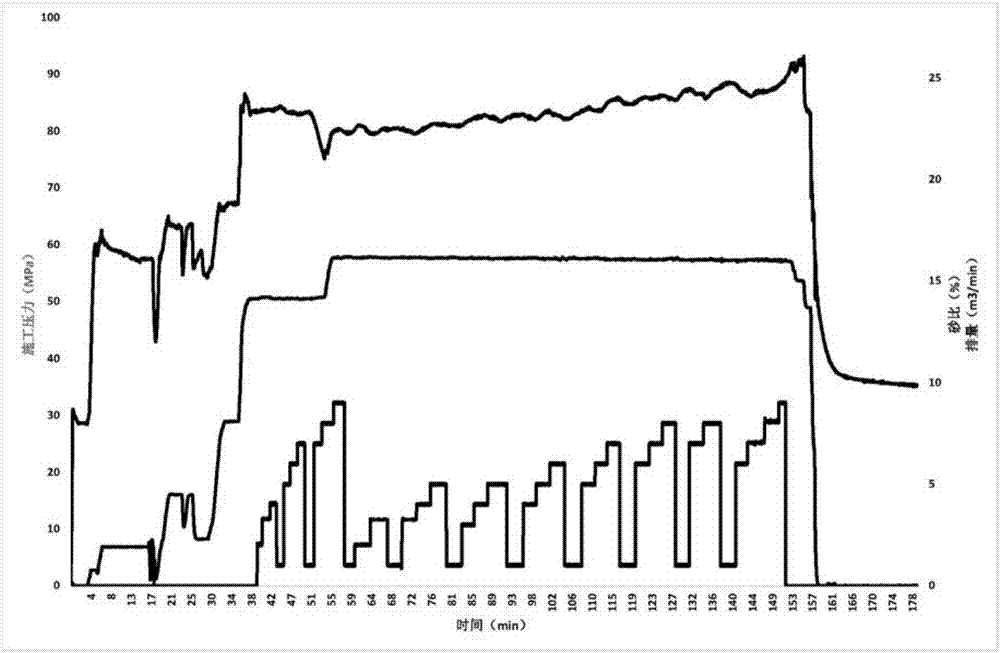

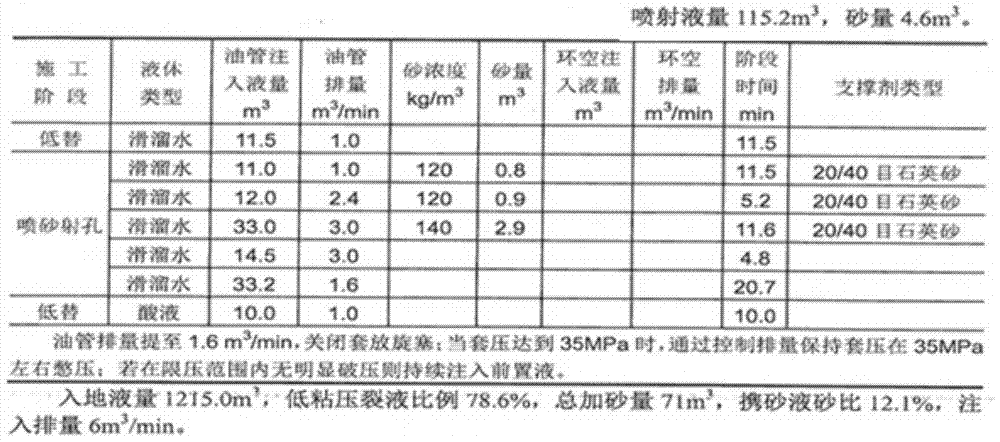

Shale gas pool hydraulic fracturing sand-adding technology

InactiveCN107023285AEliminates clogging effectsReduce construction pressureFluid removalSoil scienceVolumetric Mass Density

The invention discloses a shale gas pool hydraulic fracturing sand-adding technology, and belongs to the field of hydraulic fracturing. The shale gas pool hydraulic fracturing sand-adding technology comprises the following steps that (1) acid-pickling is conducted, and acid-pickling is conducted to an perforating area and a near-wellbore zone to remove blockages on perforations and the periphery of the near-wellbore zone; (2) silt is fractured, and sand-carrying fluid carries the silt to form fissure; (3) medium sand is fractured, and the sand-carrying fluid carries the medium sand to form the fissure; (4) coarse sand is fractured, and the sand-carrying fluid carries the coarse sand to fill the fissure of the near-wellbore zone; (5) the sand-carrying fluid is replaced, and ground high pressure pipe joints and the sand-carrying fluid in the wellbore are replaced into stratum to clear out the remaining sand in the wellbore; and (6) ending operation is conducted, a pressure dropping test is conducted, and the construction comes to an end. According to the shale gas pool hydraulic fracturing sand-adding technology, the whole sand-adding amount is improved, the construction pressure is smoother and steadier, the density of sand-paving is evener, and the fissure flow conductivity is effectively improved.

Owner:华美孚泰油气增产技术服务有限责任公司

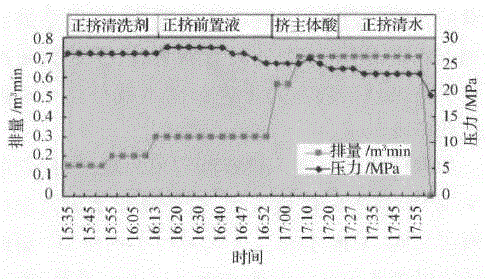

Method for improving highly argillaceous sandstone layer

InactiveCN104747158AReduce construction pressureImprove the transformation effectFluid removalDrilling compositionEmulsionCitric acid

The invention relates to a method for improving a highly argillaceous sandstone layer. Firstly, an acid solution is used for preprocessing a reservoir stratum, then prepad fluid and sand-carrying fluid are injected, and sand plugging processing is carried out, wherein the acid solution comprises, by mass, 10-12% of HCL, 3.0-6.0% of HF, 0.5% of emulsion breaker, 0.3% of clay stabilizer, 0.1% of citric acid, 1.0% of corrosion inhibitor, and the balance water. The acid solution is used for preprocessing the reservoir stratum before the prepad fluid is injected, the construction pressure is effectively reduced, the fracturing success rate of the highly argillaceous sandstone and the reservoir stratum improvement effect are improved, the method has an obvious effect for improving the reservoir stratum of poor physical performance, and the yield of a single well is improved.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

Pad-acid solution and acid pretreatment method for horizontal well fracturing of deep shale gas

ActiveCN107446566AReduce construction pressureEnhance acid rock reactionCleaning apparatusFluid removalPretreatment methodFront edge

The invention provides a pad-acid solution and acid pretreatment method for horizontal well fracturing of deep shale gas. The pad-acid solution comprises, by volume, 10 to 20 parts of mud acid and 1 to 10 parts of an additive, wherein the additive is at least one selected from the group consisting of a viscoelastic surfactant, a corrosion inhibitor, an anti-swelling agent, a stabilizer and a cleanup additive. The acid pretreatment method comprises a step of injecting the above pad-acid solution, wherein before the front edge of the pad-acid solution enters a perforation blast hole, normal pump casting is carried out on the pad-acid solution, and after the front edge of the pad-acid solution reaches the blast hole, the output volume of the pad-acid is reduced. The pad-acid solution and acid pretreatment method provided by the invention can effectively reduce construction pressure, strengthen acid-rock reaction, control the form of crack propagation and improve the effect of multi-stage fracturing.

Owner:CHINA PETROLEUM & CHEM CORP +1

Graphene resistance-reducing agent for fracturing fluid

InactiveCN106085385AReduce frictionGood resistance reduction effectDrilling compositionPhosphateFiltration

The invention discloses a graphene resistance-reducing agent for a fracturing fluid. The graphene resistance-reducing agent comprises the following raw materials by weight: 1 to 50 parts of graphene, 5 to 60 parts of a surfactant and 1 to 60 parts of a wetting agent, wherein the surfactant is a nonionic surfactant or anionic surfactant and is one or more selected from a group consisting of alkylphenol polyoxyethylene ether, stearyl alcohol polyoxyethylene polyoxypropylene ether, polyether phosphate, dodecylbenzene sulfonic acid and fatty alcohol ether sodium sulfate-AES. The graphene resistance-reducing agent has the advantages of good resistance-reducing performance, few components, small filtration loss, high viscosity, environment friendliness and good compatibility; through addition of graphene or modified graphene, a lubrication coefficient can be effectively decreased, frictional resistance between the fracturing fluid and a crack wall is lowered and filtration loss is reduced; thus, construction pressure in the process of fracture is reduced, and the graphene resistance-reducing agent is applicable to large-scale large-discharge volume fracture technology. The graphene or modified graphene resistance-reducing agent has good compatibility with a reservoir in the process of fracture and acidification, does not contain mineral oil and poses no pollution to the reservoir and environment.

Owner:CARBORN TIME TECH CO LTD

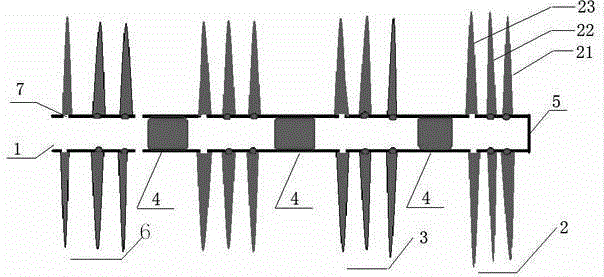

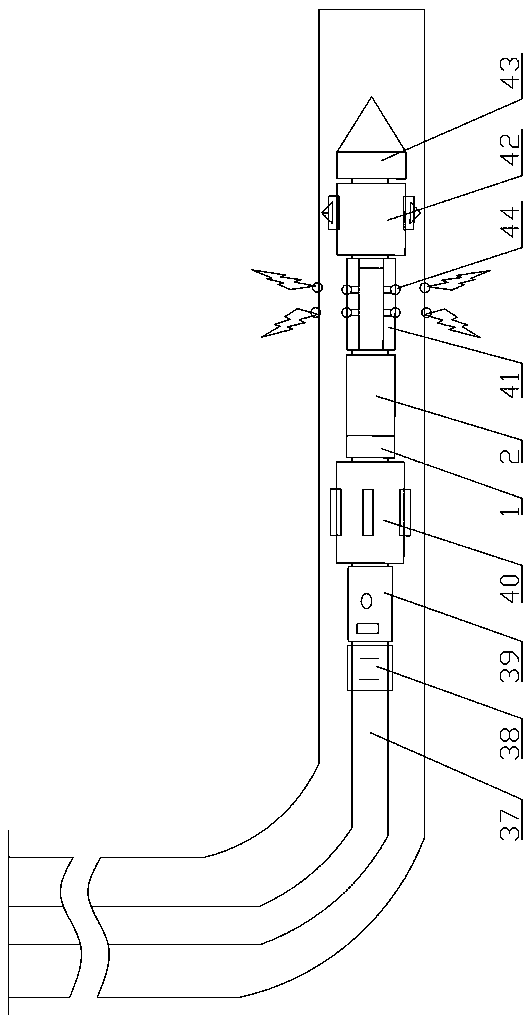

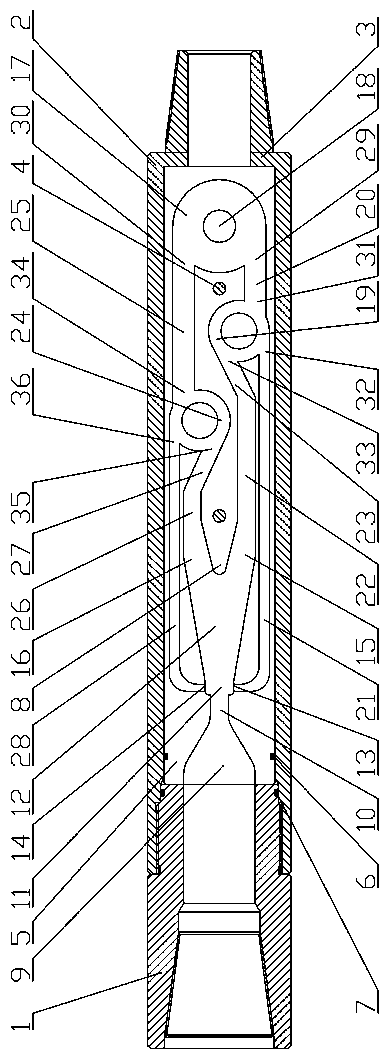

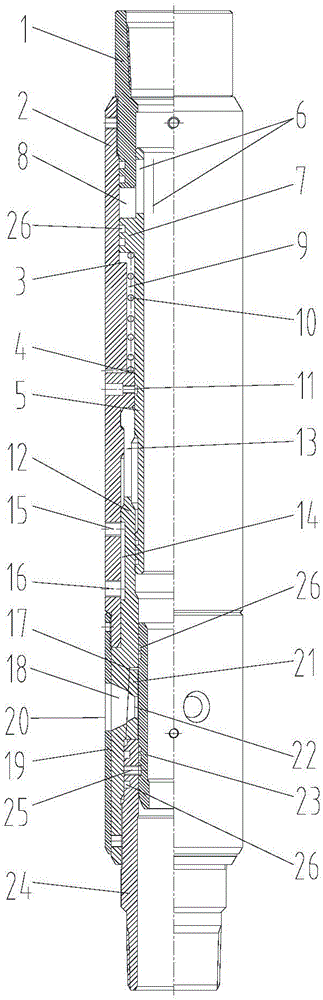

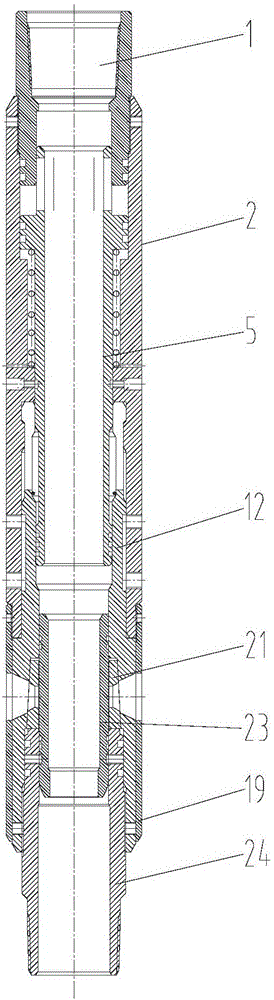

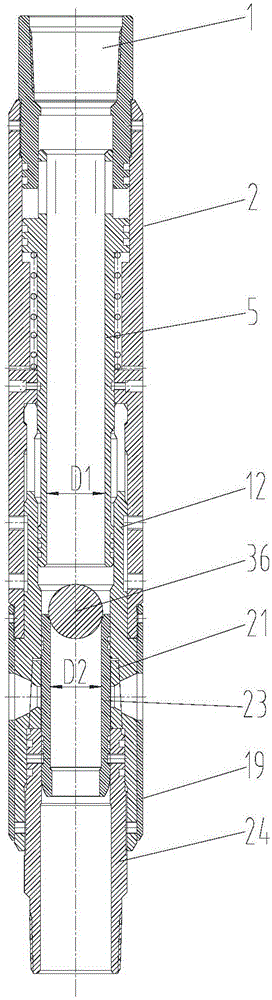

Pulse horizontal well volume fracturing device and horizontal well volume fracturing method

ActiveCN111577234ARapid crackingEnergizeGeothermal energy generationFluid removalHorizontal wellsCoiled tubing

The invention relates to the technical field of oil and gas field exploitation, and provides a pulse horizontal well volume fracturing device and a horizontal well volume fracturing method. The devicecomprises a coiled tubing, a horizontal section of the coiled tubing is sequentially connected with a connector, a motor head assembly, a centralizer, a pulse tool, an ejector, a positioner and a guide shoe, and the pulse tool, the ejector, the positioner and the guide shoe can generate a high-pressure fluid body. The method comprises the following step of (1) drilling down and determining a perforation position. According to the device and the method, the structure is reasonable and compact, the use is facilitated, through the arrangement, the disassembled and assembled can be quickly achieved, the construction cost can be reduced, a pulse fluid body can be generated by the pulse tool, the pulse fluid body can improve the perforation efficiency during volume fracturing through a nozzle,the generation of micro-cracks in a perforation hole eyelet can be increased, the energy increasing in the perforation hole eyelet is realized, cracks is quickly formed on stratum, the construction pressure is reduced, and the device and the method solve the problem that a traditional volume fracturing reforming technology is relatively limited in a method of reforming a target layer section whenformation fracture pressure is high.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Acid polymer weighted fracture fluid and preparation method thereof

InactiveCN105295885AAdjustable densityAdjustable crosslinking timeDrilling compositionPolymer scienceFracturing fluid

The invention discloses an acid polymer weighted fracture fluid and a preparation method thereof, wherein the acid polymer weighted fracture fluid comprises a base fluid and a crosslinked fluid, the base fluid comprises components with percentage by quality: weighting agents 20%-50%, polymer thickening agent 0.8%-1.20% and discharge aiding agent 0.2%-0.5%, and the allowance is water. The crosslinked fluid comprises an acid polymer delayed crosslinked agent and an acid polymer crosslinked agent, wherein the weight radio of the acid polymer delayed crosslinked agent and the acid polymer crosslinked agent is (1.5-2.5): (3.5-5), and the quality of the crosslinked fluid is 0.6%-0.8% of the quality of the base fluid. The acid polymer weighted fracture fluid achieves to adjust density in 1.10g / cm3-1.50g / cm3, meets the density demands for the scene, improves pressure of fluid columns in shafts, reduces construction pressure of wellheads, and is suitable to remould fracture reservoirs of deep wells, superdeep wells, abnormal high pressure wells and dense wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

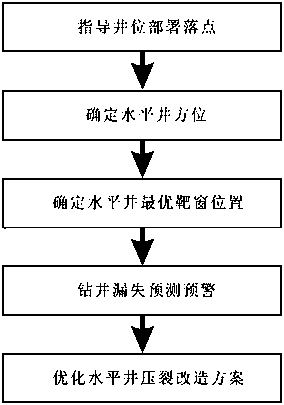

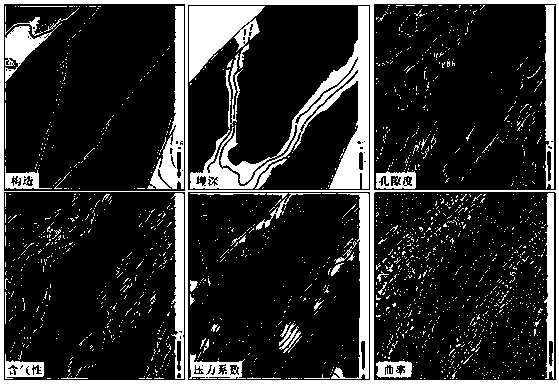

Basin edge complex tectonic zone normal-pressure shale gas horizontal well integrated design method

InactiveCN110295882AHigh Efficiency DrillingEnsure drilling safetyFluid removalPorosityGeomorphology

The invention relates to a basin edge complex tectonic zone normal-pressure shale gas horizontal well integrated design method. In the design process, for the characteristics that such as the Southeast Chongqing basin edge transition zone is strong in tectonic deformation, and the geological condition is complex, through superposition evaluation of a structural figure, a burial depth figure, a porosity figure, a gas content figure, a pressure coefficient figure and a curvature figure, geology and engineering optimal dessert areas are optimized, well sites are deployed, the seismic attribute isused for predicting stratum seam hole development situation, interval intvl losing is avoided, the well drilling aging is improved, and through target window and horizontal well orientation optimization and curvature prediction, the reservoir stratum fracturing effect is improved, the reservoir stratum capacity is sufficiently released, the single well economic benefits are improved, the technical support is provided for efficient exploration and development of the basin edge transition zone shale gas, operation is high, and the application prospect is wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-erosion and no sand card fracturing sliding bush

The invention provides an anti-erosion and no sand card fracturing sliding bush which can be connected with an oil pipe and arranged inside a bushing. The anti-erosion and no sand card fracturing sliding bush compromises a shell body. The upper end of the shell body is connected with an upper contact, and the lower end of the shell body is connected with a closed outer cylinder. A plurality of open holes is arranged on the circumferential direction of the closed outer cylinder. The outer shell is provided with a movable piston cylinder. The anti-erosion and no sand card fracturing sliding bush also compromises a sand blasting body. The upper end of the sand blasting body is stuck between the shell body and the piston cylinder. The upper end of the sand blasting body is connected with a lower contact. A nozzle is embedded inside the sand blasting body. The nozzle is provided with a plurality of bell shaped spray holes along the circumferential direction. The spray holes can be communicated with the open holes. The inside of the sand blasting is provided with sliding bush which is used for sealing the spray holes, and the sliding bush is connected with the lower contact detachably. The anti-erosion and no sand card fracturing sliding bush has the advantages of being capable of reducing casing damage during fracturing, and avoiding the sand card when lifting the pope, being thorough in back flushing, and high efficient in fracturing.

Owner:华鼎鸿基石油工程技术(北京)有限公司

Low-friction cleaning fracturing fluid for coal-bed gas

InactiveCN105670595AImprove the transformation effectReduce frictionDrilling compositionFracturing fluidPotassium

The invention provides a low-friction clean fracturing fluid for coalbed methane, comprising the following components: by mass percentage, 0.1-0.5% octadecyl glyceryl dimethyl ammonium chloride, 0.1-0.2 % sodium dibutylnaphthalene sulfonate, 0.2-0.3% potassium chloride and 90.0-96.0% water. The fracturing fluid has a simple preparation method, low viscosity, low friction, no gel breaking, and can be reused, which reduces construction operation costs, low friction, and reduces construction pressure. It is a clean and environmentally friendly fracturing fluid that can be used Achieve large displacement (10m 3 / min) above volume fracturing construction to improve the effect of coal seam stimulation.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

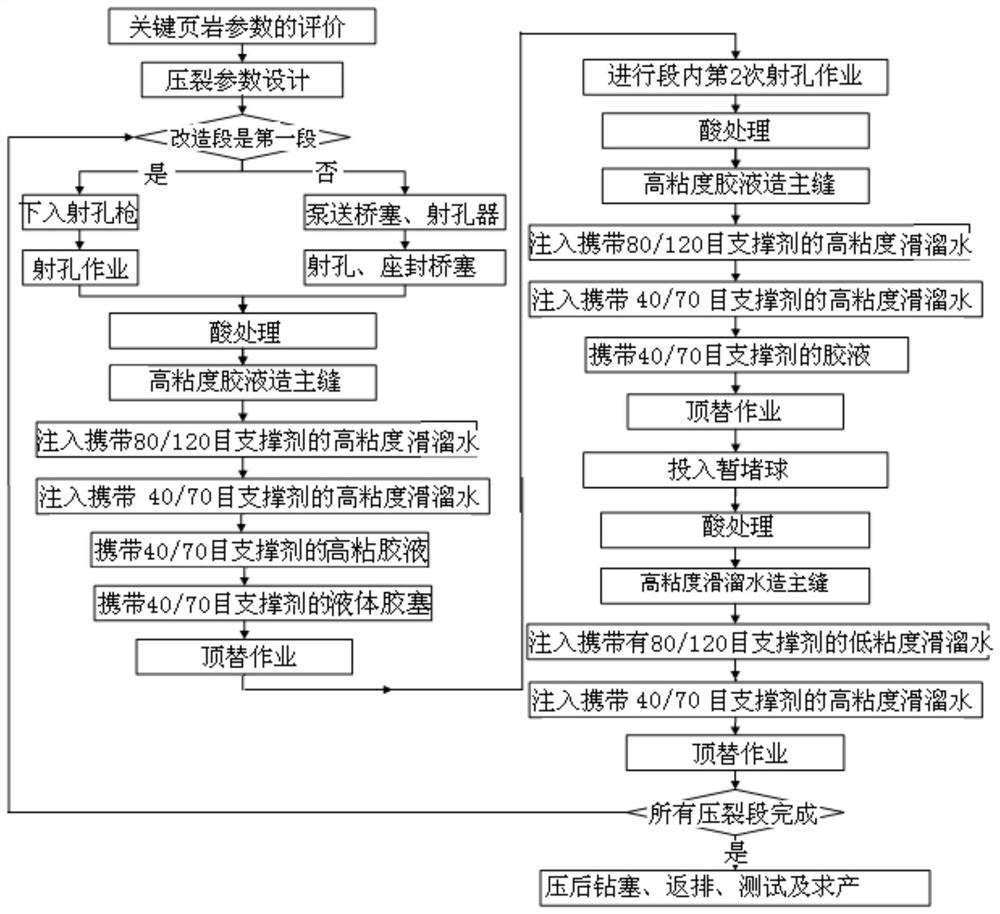

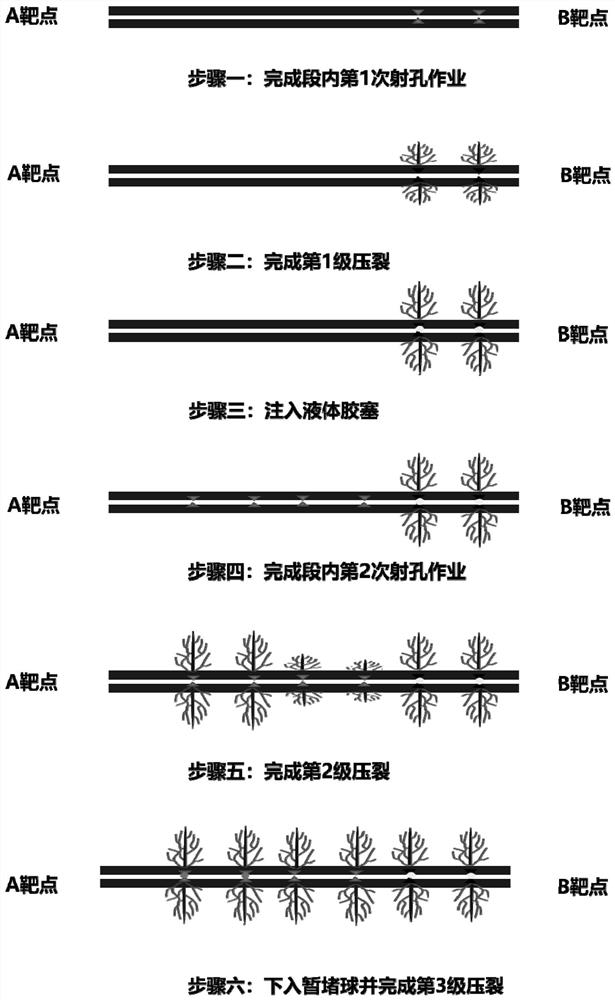

Close cutting fracturing method

ActiveCN112177583AIncrease the amount of liquidRealize centralized liquid intakeFluid removalThermodynamicsSingle stage

The invention relates to a close cutting fracturing method. The method comprises the steps that shale parameters are evaluated, and fracture parameters and fracturing construction parameters are optimized; perforation operation of the first time is carried out; fracturing treatment is carried out, and a liquid rubber plug carrying a propping agent is injected after fracturing treatment is finished; displacement operation is carried out; perforation operation of the second time is carried out; fracturing treatment and displacement operation are carried out; ball throwing temporary plugging is carried out on transformed perforation clusters; fracturing treatment is carried out on perforation clusters which are not transformed; displacement operation is carried out; a bridge plug is tripped in, and the above steps are repeated until construction of all sections is completed; and plug drilling after pressing, flowback, testing and production are carried out. 5-8 clusters of high-difficultyoperation are converted into 3-stage fracturing operation through two times of perforation operation and ball throwing temporary plugging in a single section, and therefore conventional 3-6 clustersof the single section are reduced into 1-2 clusters of the single stage fracturing operation, the liquid inlet amount of a single cluster is increased, the requirement of fracturing construction for displacement is reduced, and a construction pressure window is enlarged; and meanwhile, the horizontal principal stress difference is reduced through the stress shadow effect, the fracture complexity is improved, and the transformation size of a deep shale gas well is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

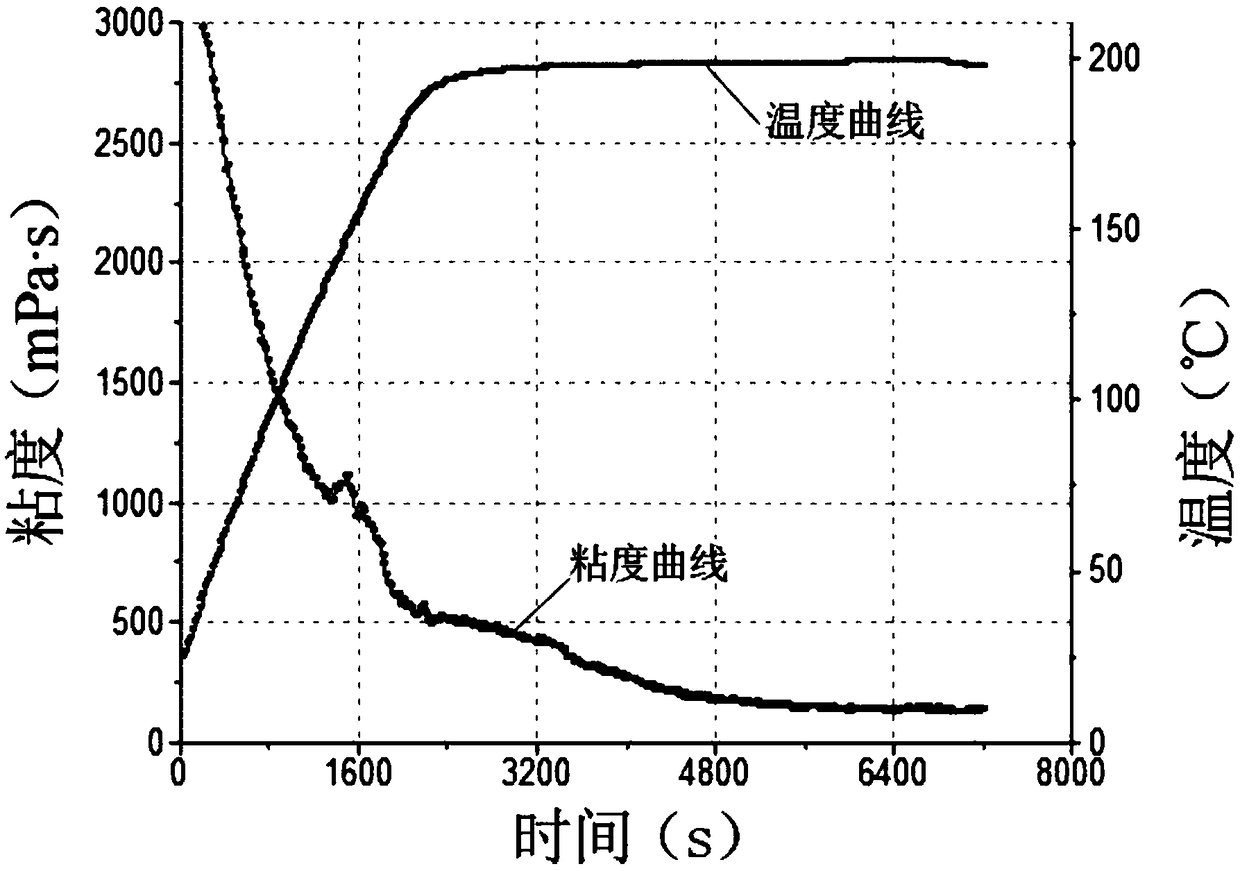

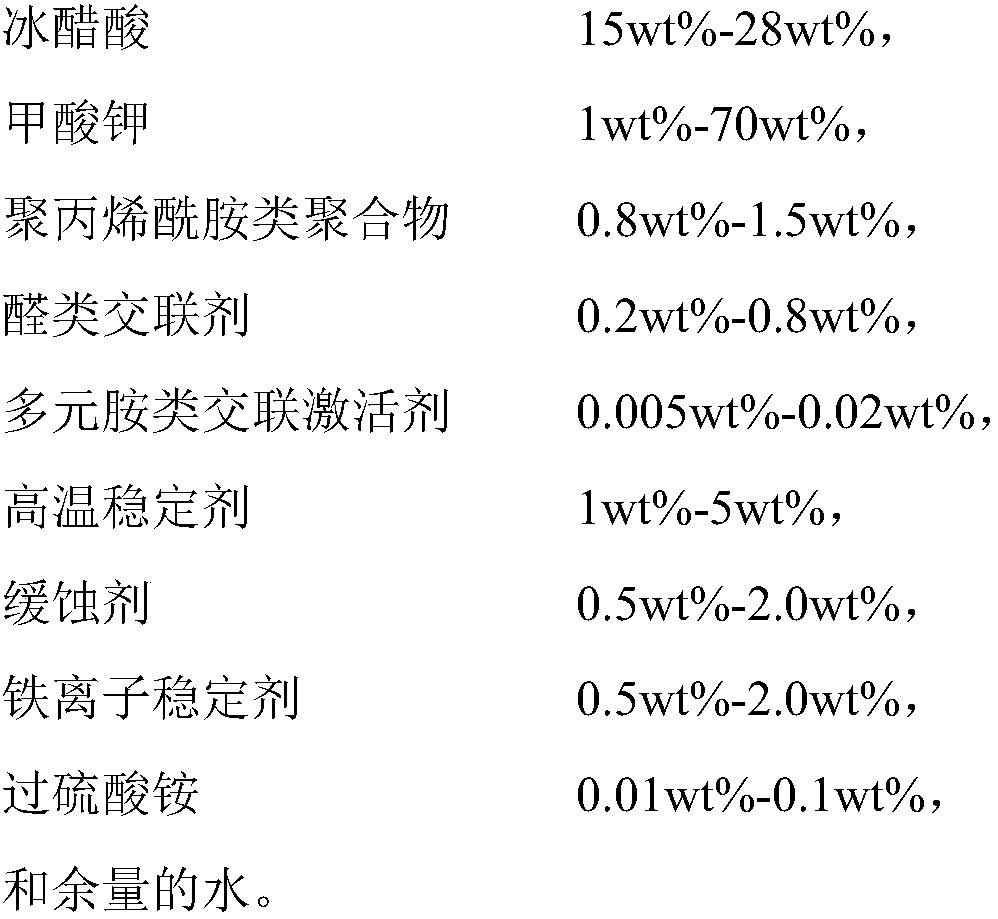

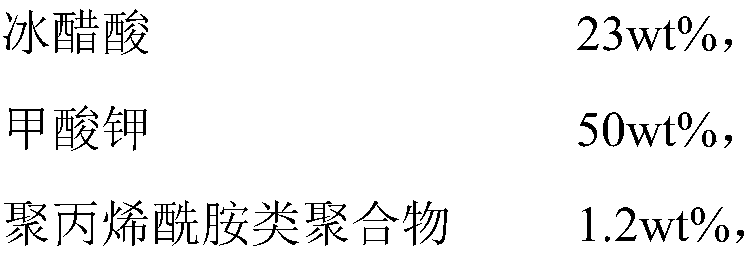

Glacial acetic acid crosslinked weighted fracturing fluid as well as preparation method and application thereof

ActiveCN109439308ALower the activation energy of the reactionGood temperature resistance and shear resistanceFluid removalDrilling compositionHigh concentrationPotassium

The invention provides a glacial acetic acid crosslinked weighted fracturing fluid as well as a preparation method and an application thereof. The weighted fracturing fluid is prepared from the following components in percent by weight (based on 100%): 15-28 wt% of glacial acetic acid, 1-70 wt% of potassium formate, 0.8-1.5 wt% of a polyacrylamide polymer, 0.2-0.8 wt% of an aldehyde crosslinking agent, 0.005-0.02 wt% of a polyamine crosslinking activator, 1-5 wt% of a high-temperature stabilizer, 0.5-2.0 wt% of a corrosion inhibitor, 0.5-2.0 wt% of an iron ion stabilizer, 0.01-0.1 wt% of ammonium persulfate and the balance water. According to the weighted fracturing fluid, the crosslinking agent, the crosslinking agent activator and the polyacrylamide polymer can be crosslinked quickly andefficiently in the presence of high concentration glacial acetic acid and potassium formate at normal temperature (25 DEG C) or at a lower temperature. In addition, a superhigh temperature glacial acetic acid crosslinked weighted fracturing fluid system is suitable for a deep high temperature carbonate reservoir.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com