Fracturing production increasing method for deep shale gas

A technology for shale gas and shale gas exploitation, which is applied in earthwork drilling, extraction fluid, wellbore/well components, etc., can solve problems such as the difficulty of artificial fractures, reduce horizontal stress difference, reduce friction, and ground The effect of construction pressure reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details. In other instances, well-known structures and devices are shown in block diagram form in order to facilitate describing one or more embodiments.

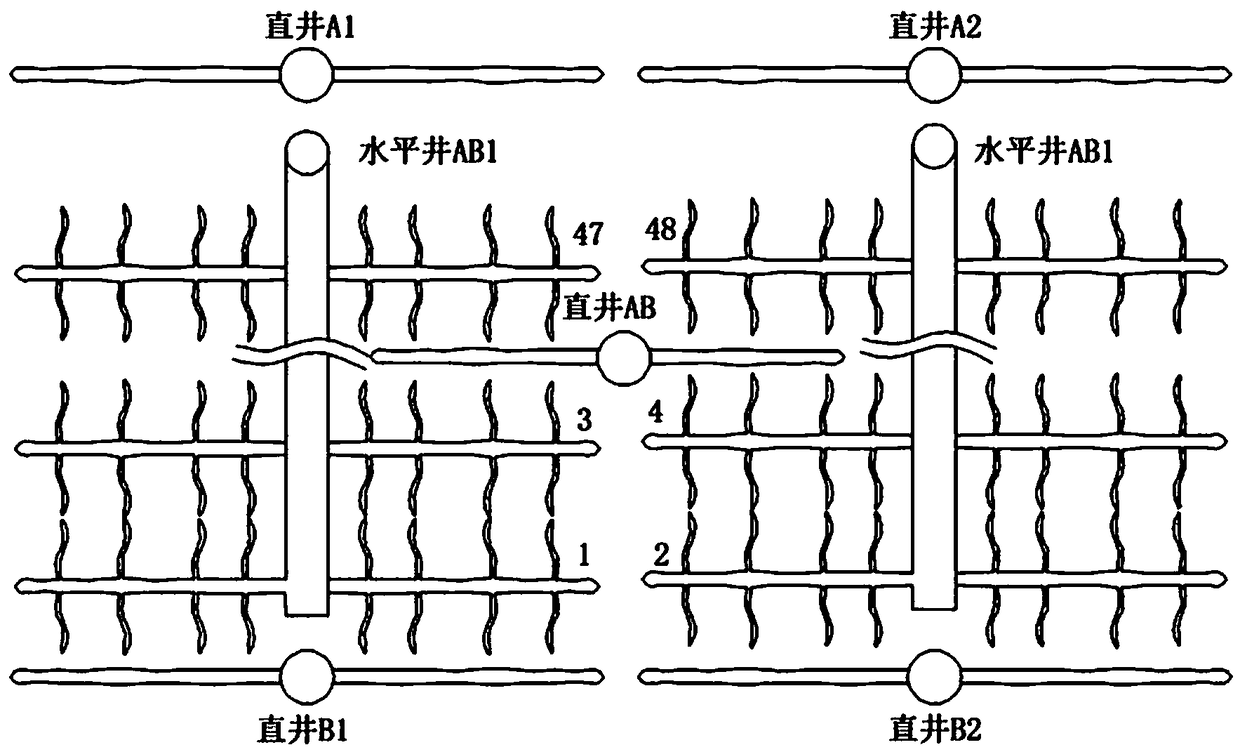

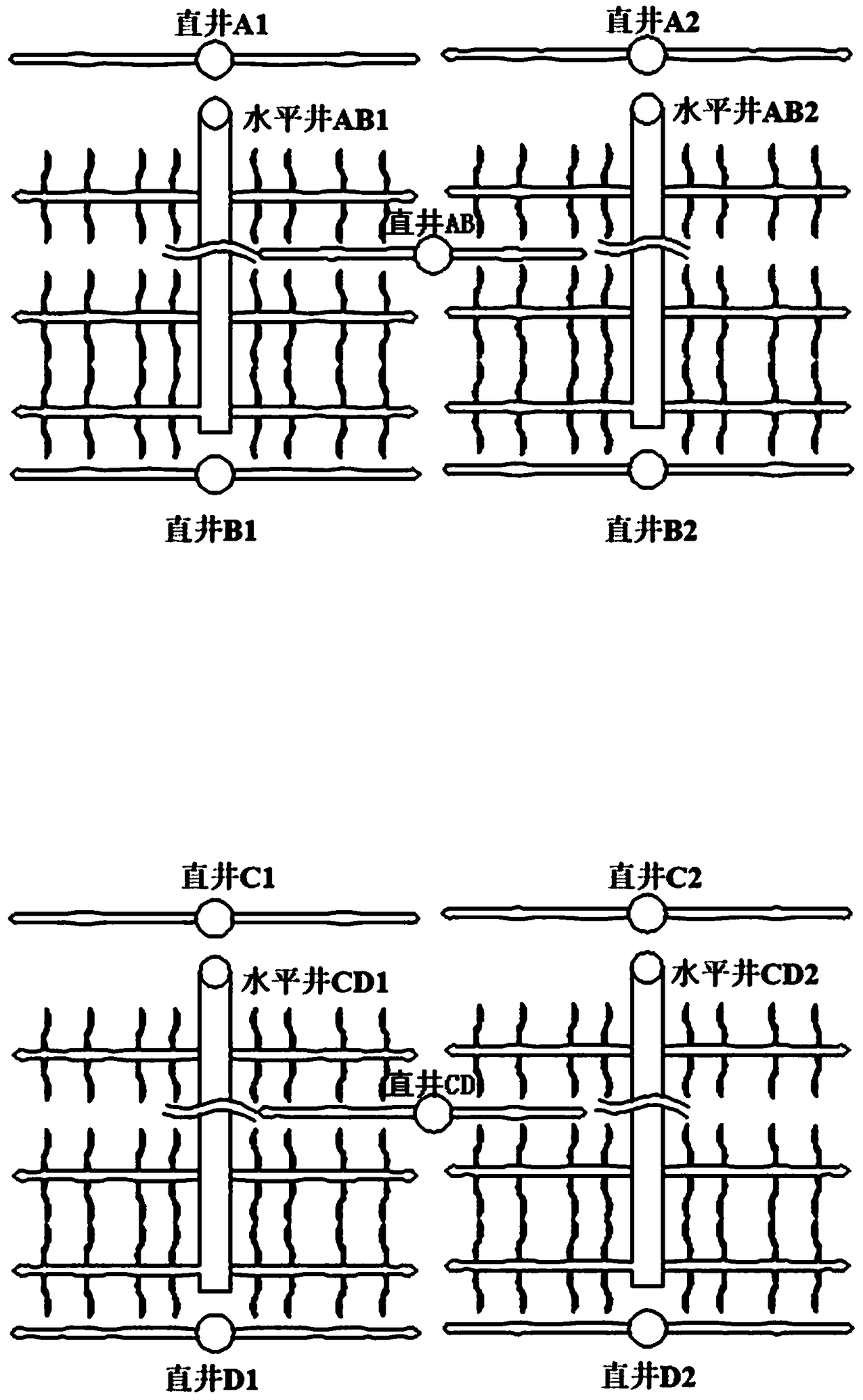

[0030] The shale in a deep shale gas development operation area is located 3900m underground, the thickness of the rock formation is 210m, and the temperature in the middle of the rock formation is 120°C. Below, three fracturing units are taken as examples to illustrate the fracturing stimulation method for deep shale gas provided by the present invention:

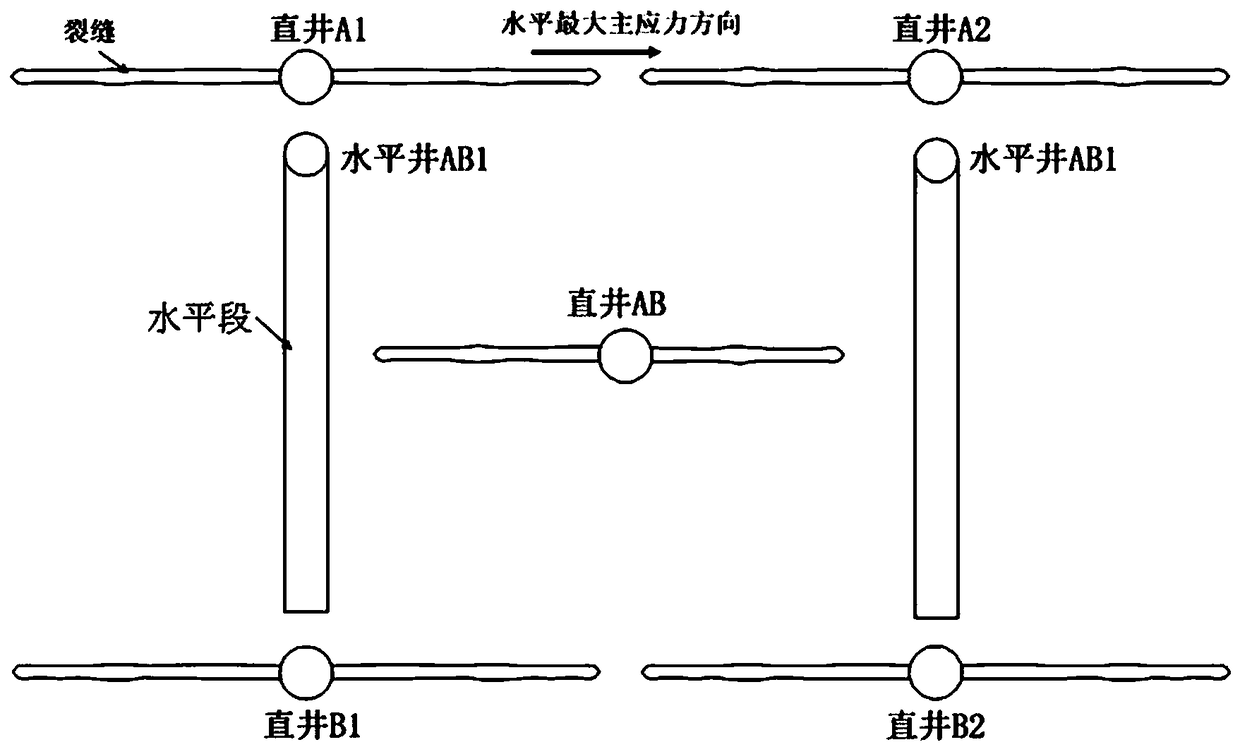

[0031] Step S1: The direction of the horizontal maximum principal stress is measured to be 90° northeast, and vertical wells A1 and A2 are drilled sequentially along this direction. The distance between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com