Patents

Literature

44results about How to "High Efficiency Drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot pressing high phosphorus iron base diamond drilling bit and preparation method thereof

The invention relates to a hot compression high phosphorus iron-base diamond bit and the preparation method. The content of the diamond is 75 percent to 95 percent, the matrix materials have the component and the content that Fe powder is 35 percent to 50 percent; P is 3 percent to 6 percent; B is 1 percent to 2 percent; Ni is powder 5 percent to 10 percent; Co powder is 5 percent to 7 percent; 663-Cu powder is 25 percent to 32 percent; Mn powder is 2percent to 3 percent; Ti powder is 1 percent to 2 percent; rare earth La is 1.5 percent to 2 percent, and rare earth Ce is 1.0 percent to 1.5 percent. The preparation method comprises the procedures of material preparation, material packing and material mixture, die filling, hot-pressed sintering. The invention has the advantages that the matrix materials are widely used, and the cost is low; the sintering temperature is decreased; the hot etching of the iron to the diamond under high temperature is reduced; and the service life of the drill bit are improved; the drill bit has a broad spectrum; and the application scope is wide.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

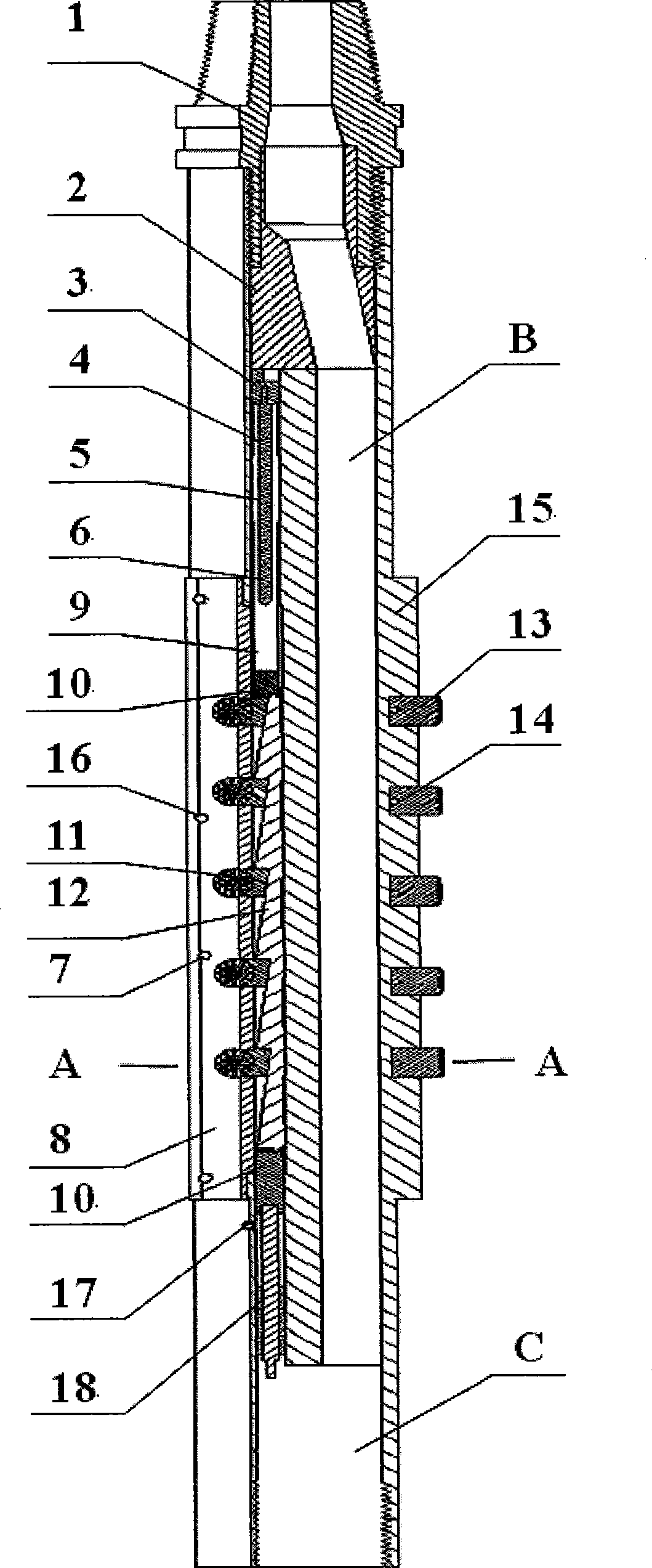

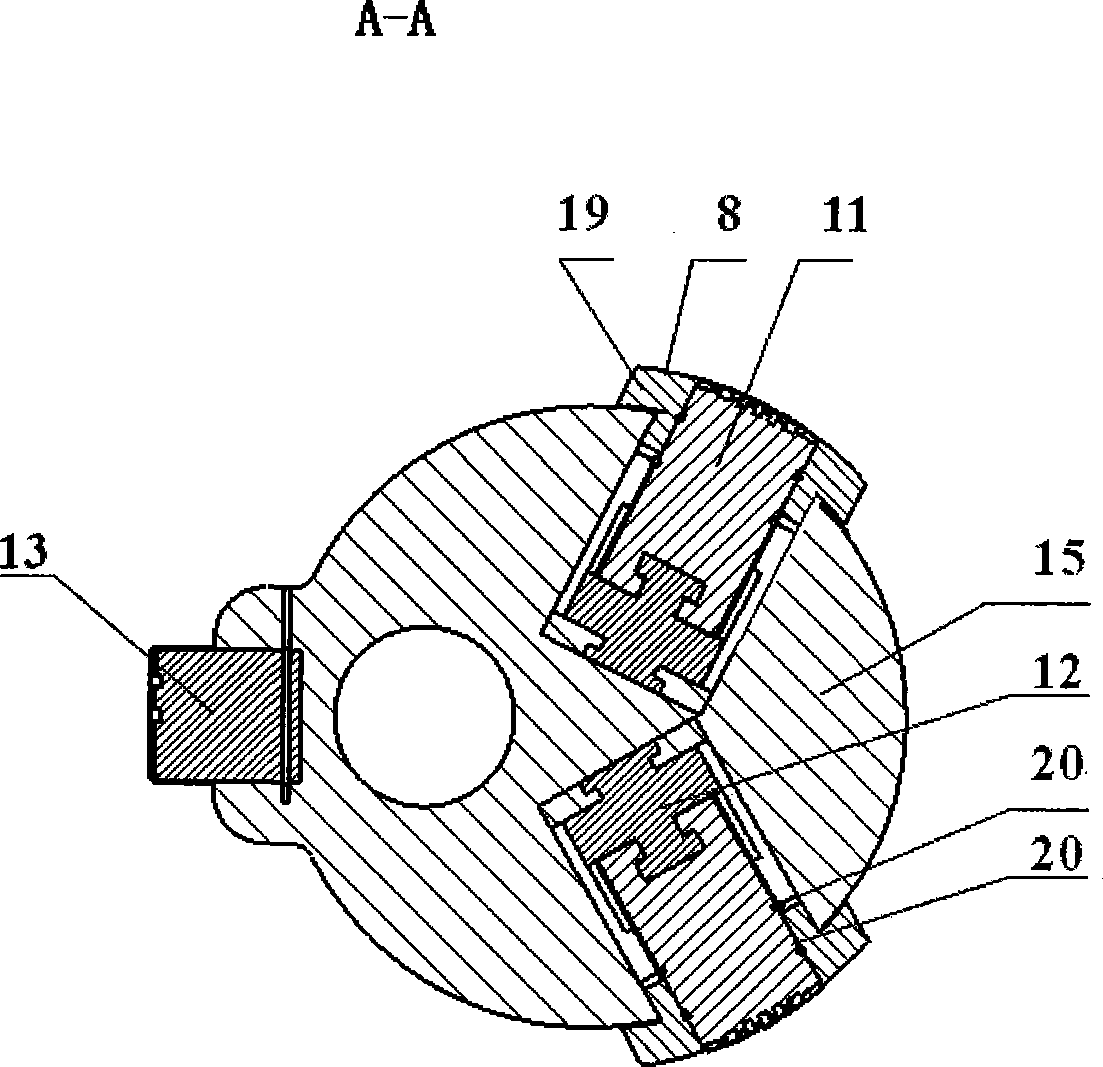

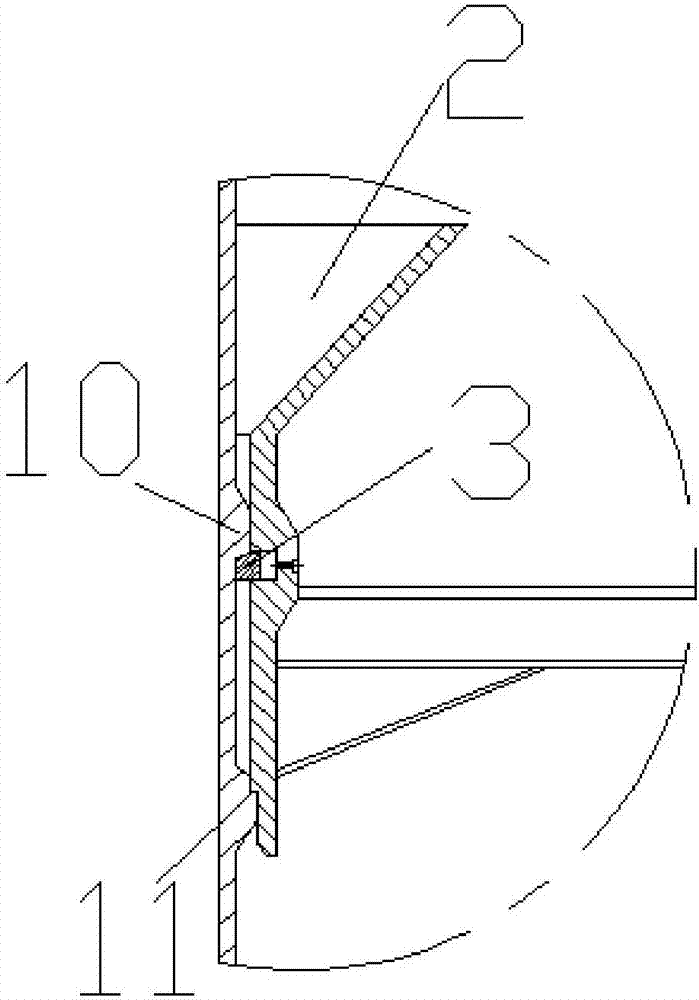

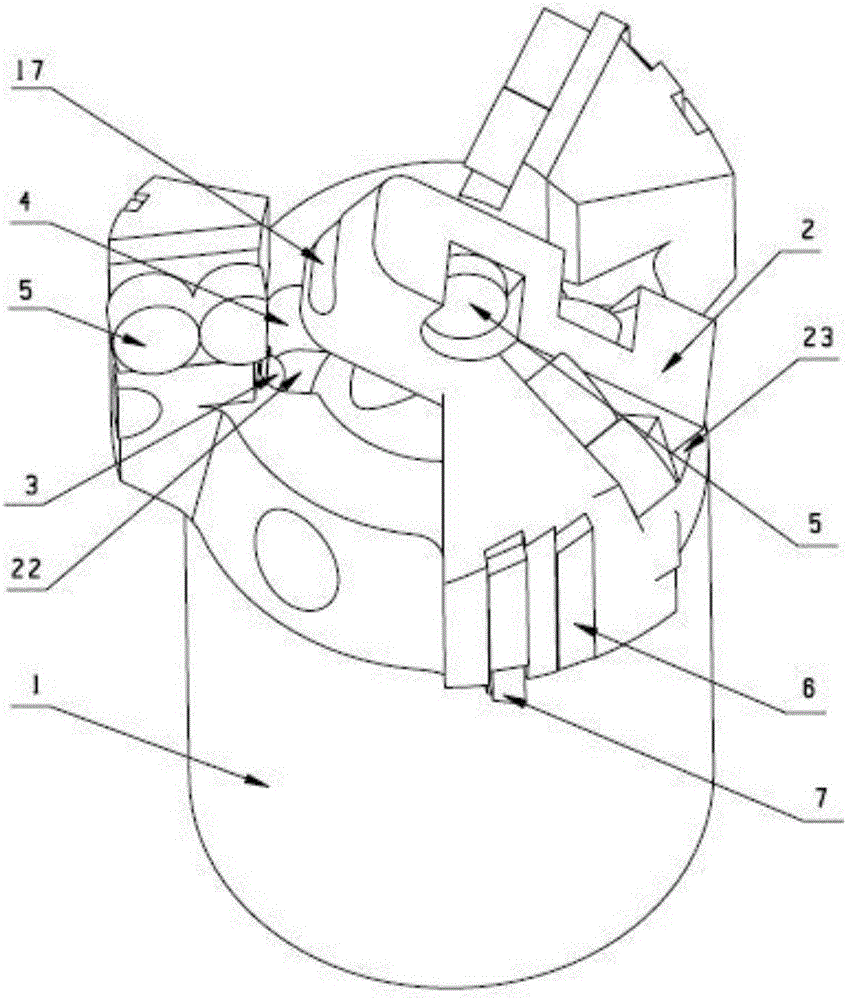

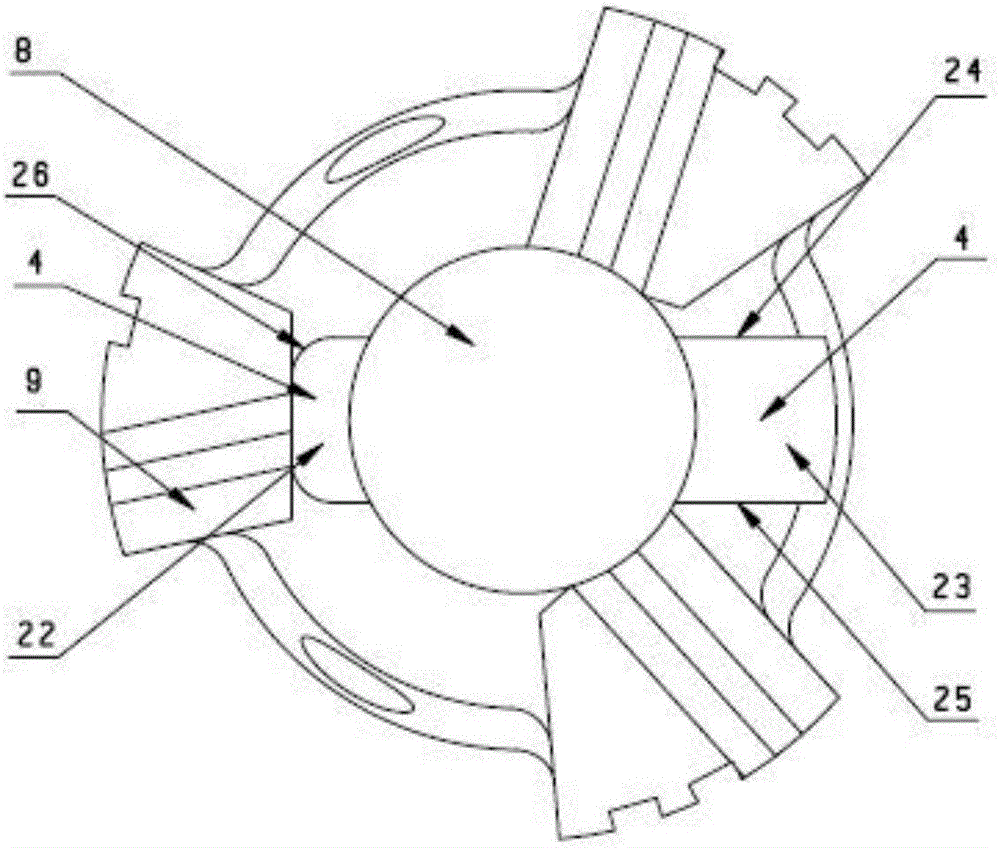

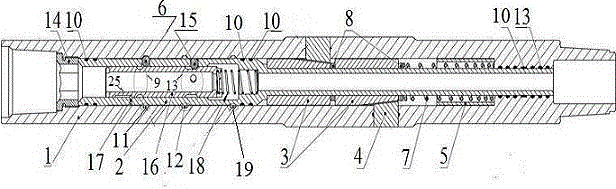

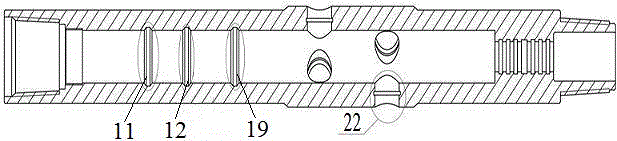

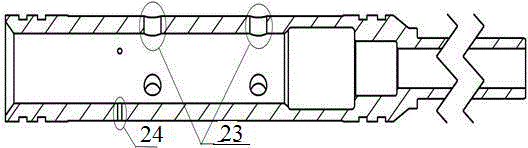

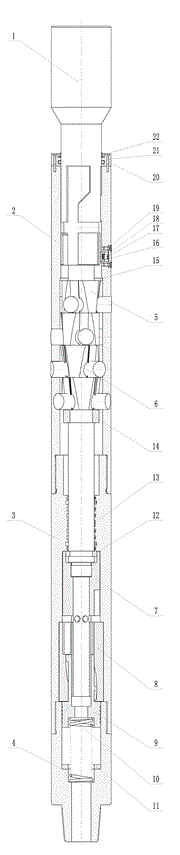

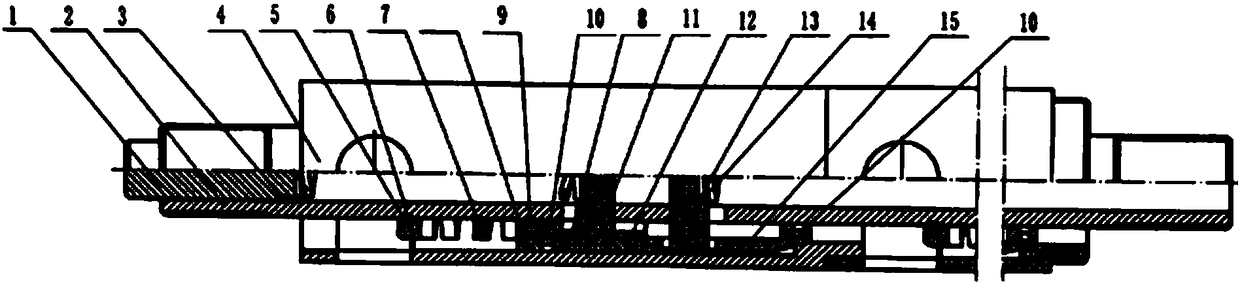

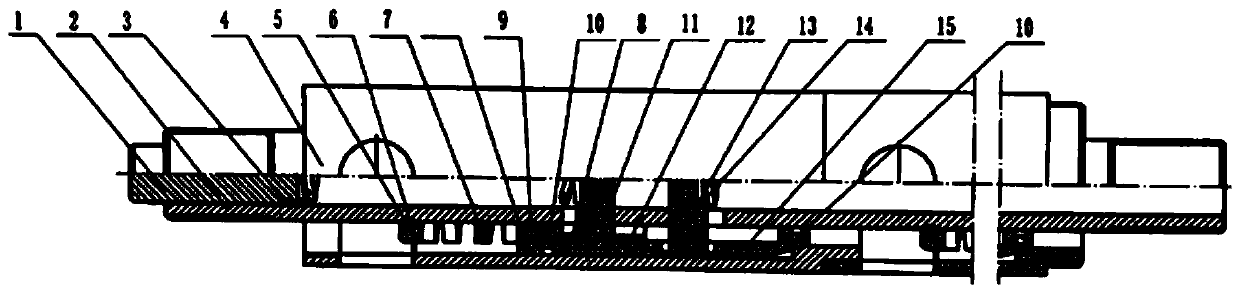

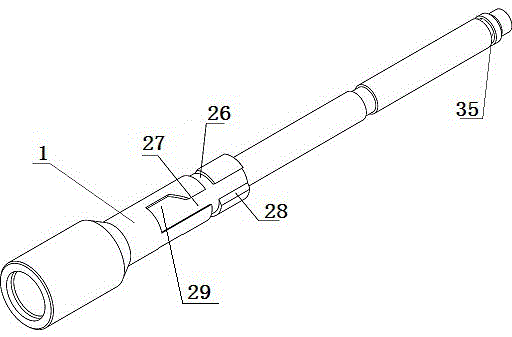

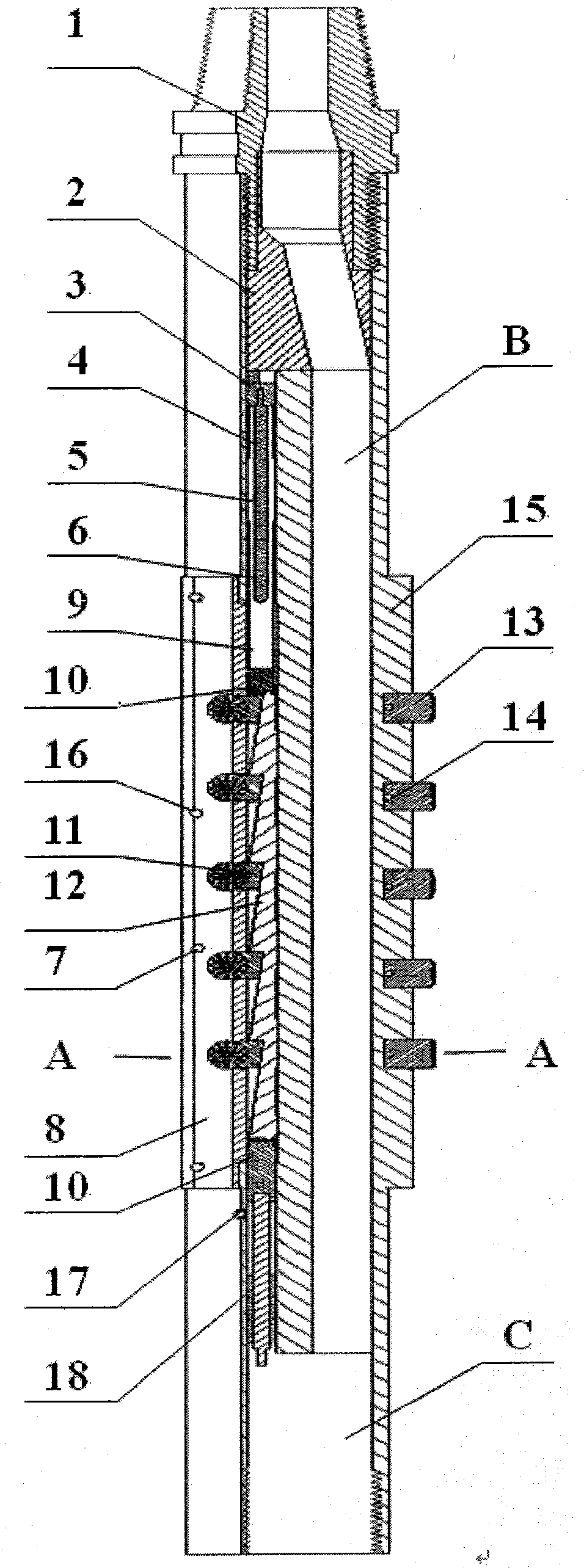

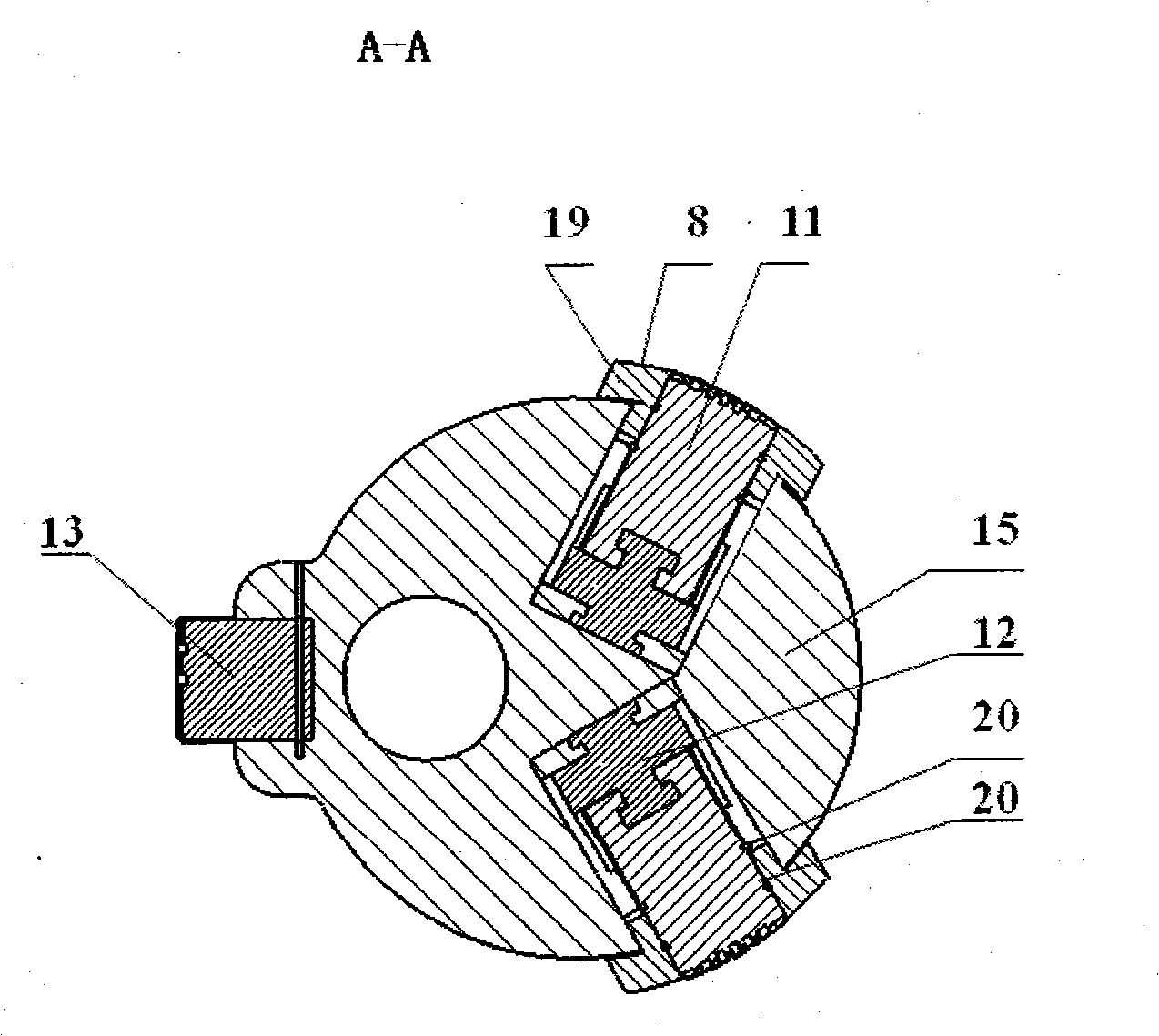

Eccentric center-adjustable reducing stabilizer

ActiveCN101463712AEasy to controlHigh strengthDrilling rodsDirectional drillingDirectional wellPiston

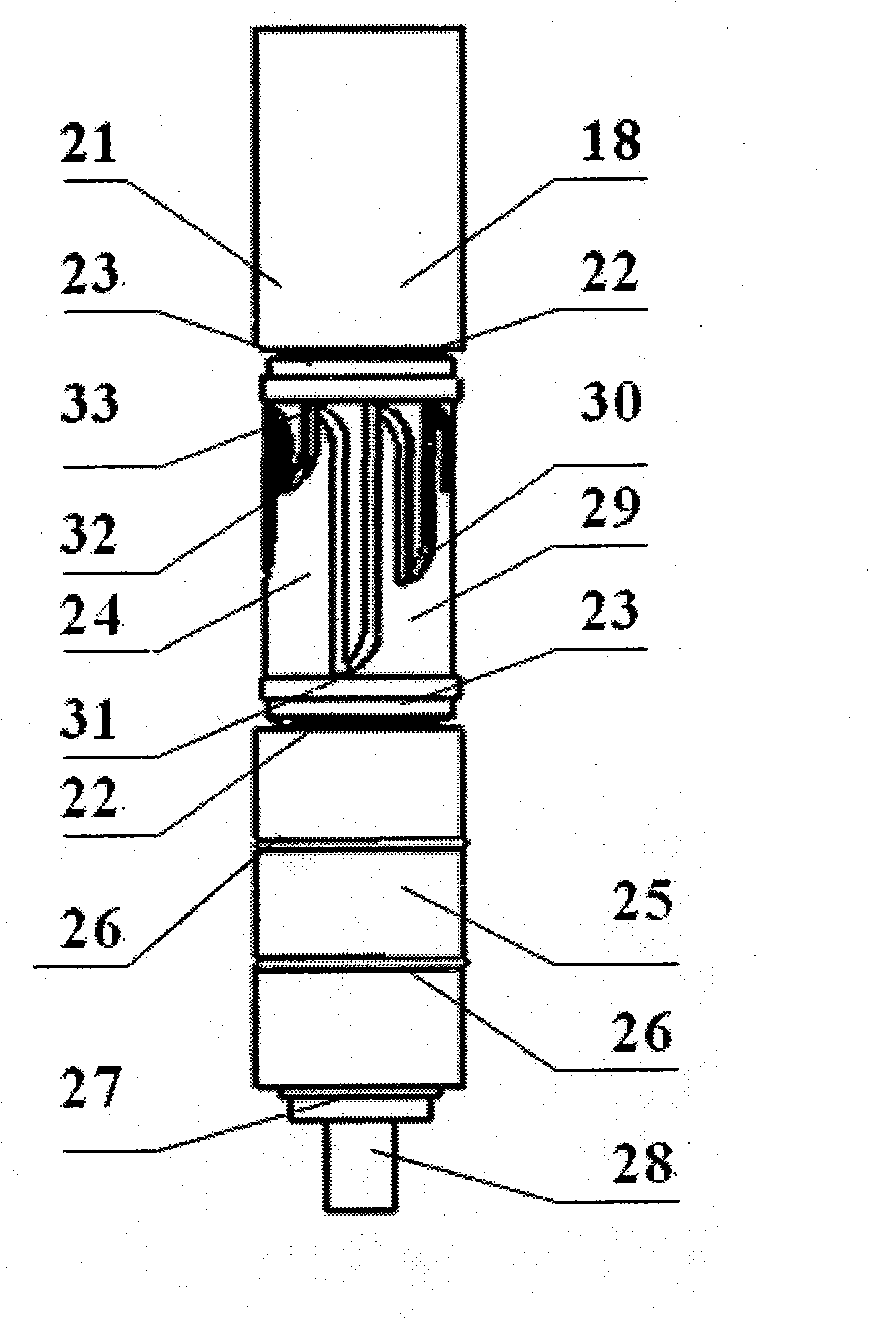

The invention relates to an eccentric adjustable stabilizer with a variable diameter, which is used for being combined with an underground directional or anti-tip drilling tool, can be used in match with a rotary directional drilling system, and can realize the automatic underground diameter variation and the eccentric adjustment, improve the level of the drilling technique and increase the economic benefit. The technical scheme is as follows: a compression sleeve barrel, a cross joint, a diameter variation mechanism, a cross joint, a gear shifting piston and a gear shifting mechanism are sequentially installed on the inner cavity of a housing from the top to bottom; five fixed cylindrical bodies are installed on a protruded arris of the outer part of the housing in an axial direction, five moveable hard alloy cylinders are respectively installed in the inner cavities of the other two protruded arrises in an axial direction, the front end of a gear shifting dowel pin in the gear shifting mechanism is inserted in the gear shifting slot of a gear shifting cam body, and gear shifting slots with special traces are arranged on the outer periphery of the gear shifting cam body. The gear shifting cam body can be moved up and down, can be rotated, can automatically realize the diameter variation and the eccentricity underground, and can realize step gear shifting and stepless gear shifting. The eccentric adjustable stabilizer with the variable diameter has the advantages of high intensity, favorable leak-proofness and long service life, and can be used for the drilling construction of directional wells and straight wells, thereby improving the overall drilling technical and the economic benefits.

Owner:SOUTHWEST PETROLEUM UNIV

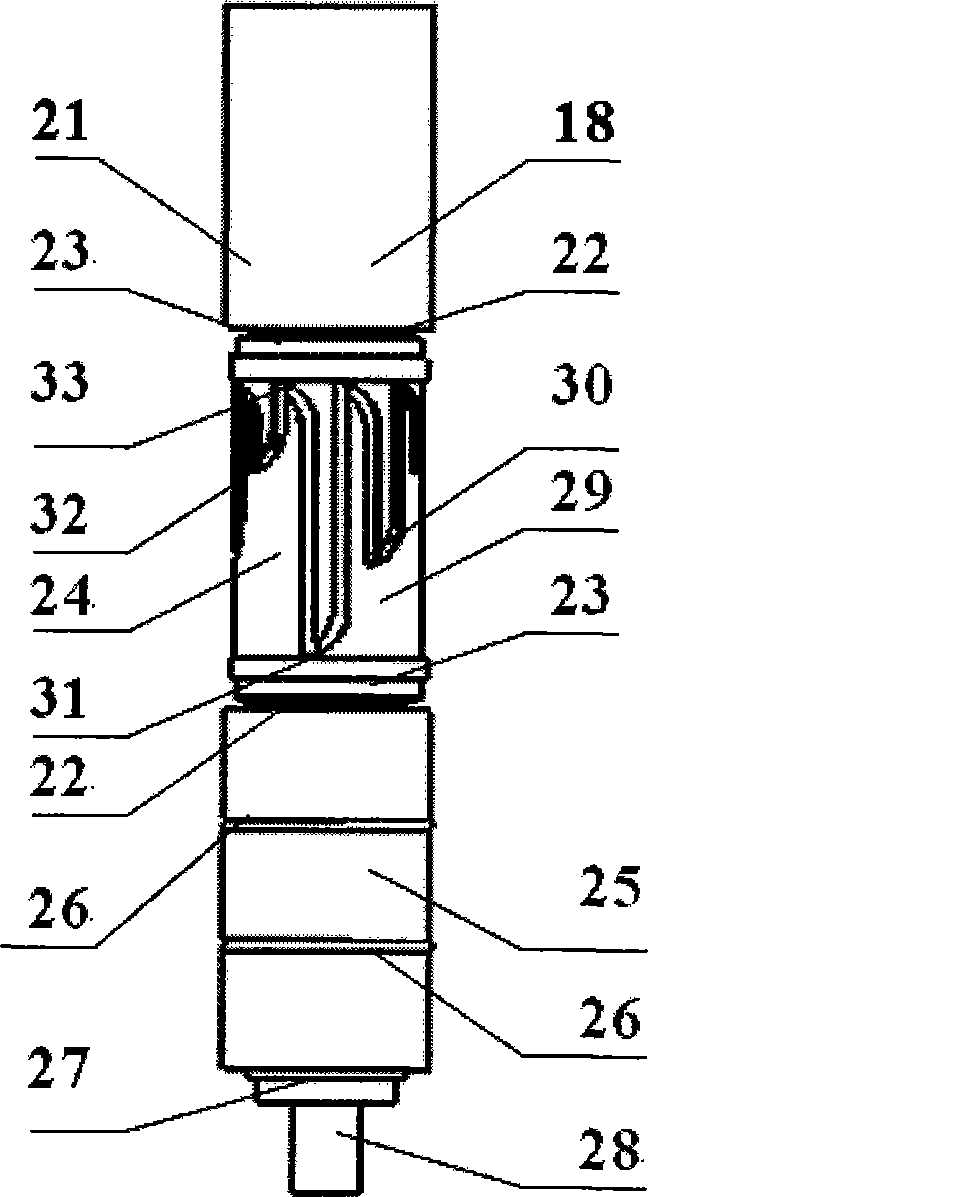

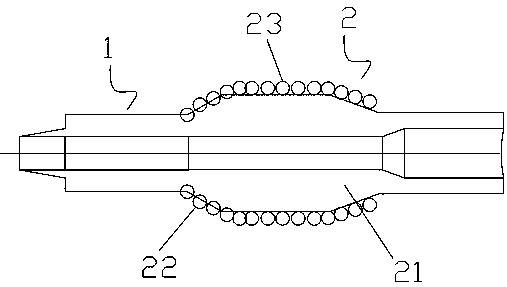

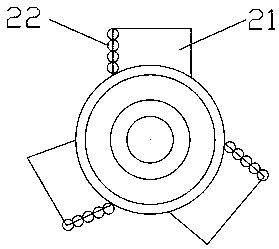

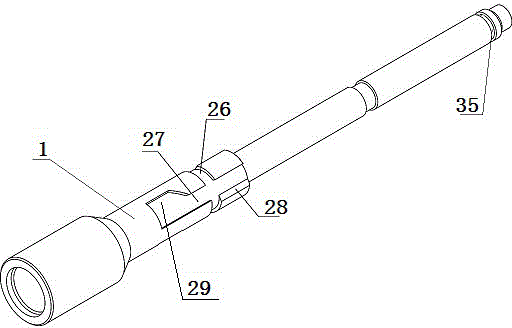

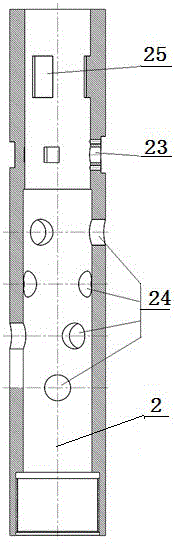

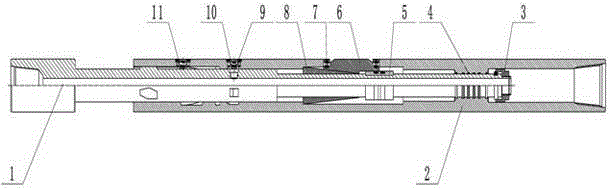

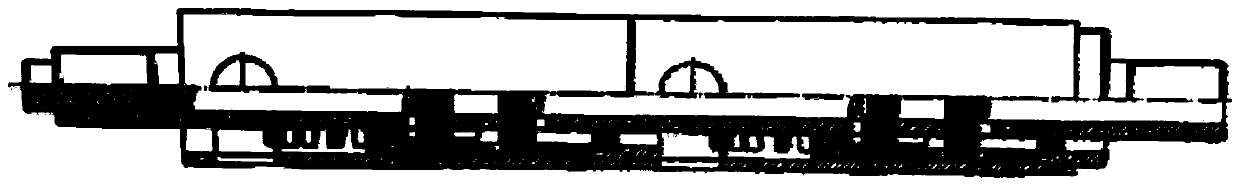

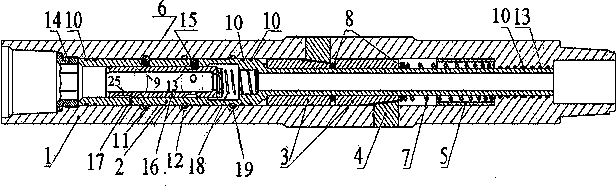

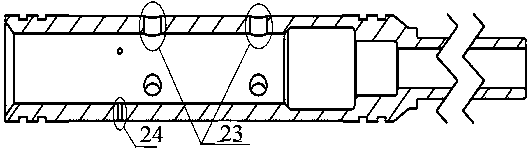

Axial vibrator

ActiveCN103742076ASolve the pressure problemHigh Efficiency DrillingVibration drillingHorizontal wellsEngineering

The axial vibrator belongs to the field of drilling tools, in particular to an axial vibrator. The axial vibrator can produce an axial vibrating through adopting pressure pulses produced by a circumferential vibrator or a pulser to effectively solve the pulling problem of drill string of high angle extended-reach wells and horizontal wells. The axial vibrator is simple in structure and reliable in vibrating. The pulser can be replaced and pressure oscillation of slurry can be changed; therefore, the vibration power can be adjusted and the adjustability is strong.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

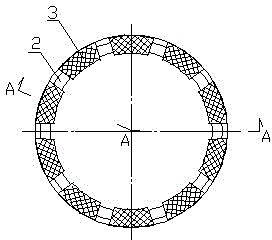

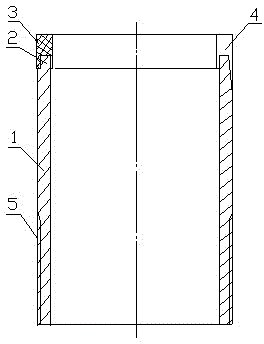

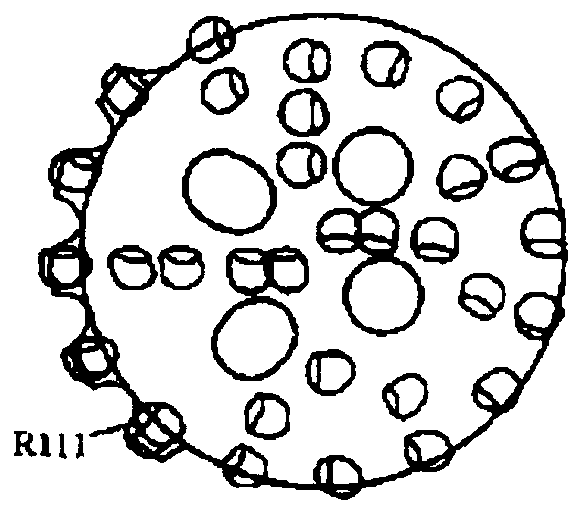

Manufacturing method of electroformed diamond geological drill bit with honeycomb structure

InactiveCN103952730AReduce consumptionReduced total diesel consumptionElectroforming processesManganeseAlloy

The invention discloses a manufacturing method of an electroformed diamond geological drill bit with a honeycomb structure. The manufacturing method comprises the following steps: adding the following components: 220-250g / L of nickel sulfate, 10-15g / L of cobalt sulfate, 5-10g / L of manganese sulfate, 30-45g / L of nickel chloride, 30-40g / L of boric acid, 0.5-1.0g / L of saccharin, 0.05-0.1g / L of sodium dodecyl sulfate, 5-10g / L of ammonium chloride, and 0.2-0.5g / L of cerium oxide into per liter deionized water, and stirring and mixing to prepare an electroforming solution; putting the processed drill bit into a compound mold, then putting the compound mold into an electroplating bath, carrying out strike plating in the electroplating solution with the temperature of 20-30 DEG C through a current with the current density of 1.0-2.0A / dm<2>, then performing vacuum plating with a current with the current density of 1.5-2.0A / dm<2> to form a plated layer, and then repeatedly spreading diamond powder on a tool bit at intervals to form a diamond alloy plating layer, thus manufacturing the electroformed diamond drill bit with the honeycomb structure. The electroforming production period is shortened by at least three days; the usage amount of nickel can be reduced by 10%-20%; the drilling aging can be improved by more than 50%.

Owner:JIANGXI SHANGPIN DIAMOND TOOL TECH CO LTD

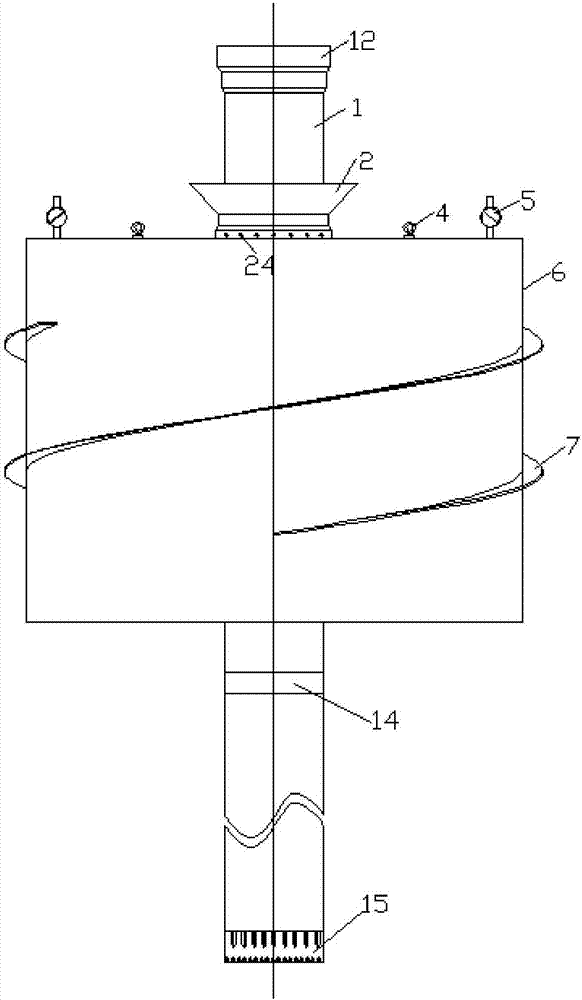

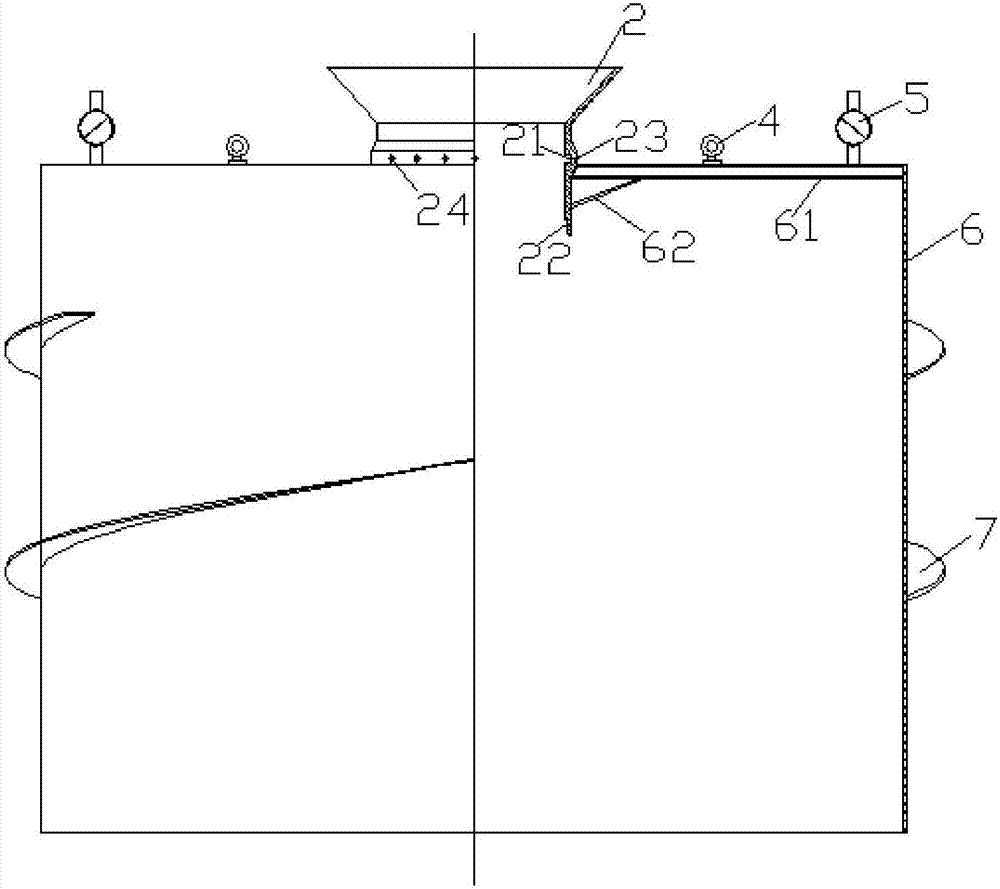

Seabed mud face anchoring type deepwater guide pipe structure and underwater installing method thereof

InactiveCN107227746AShorten run length"Waiting time savesArtificial islandsLiquid/gas jet drillingWater dischargeWell drilling

The invention discloses a seabed mud face anchoring type deepwater guide pipe structure and an underwater installing method thereof. The structure comprises a guide pipe column and a barrel-shaped base, a well opening head is arranged at the upper end of the guide pipe column, a guide pipe shoe is arranged at the lower end of the guide pipe column, the barrel-shaped base is wholly a hollow barrel, the barrel is provided with a top wall and a side wall surrounding the top wall, and the top wall is provided with a hole where the guide pipe column penetrates; a spiral wing plate is arranged on the side wall, and the barrel is further provided with a water discharge valve and a suspension piece, wherein the water discharge valve is communicated with the interior of the barrel, and water in the barrel can be discharged out; and a limiting mechanism used for limiting axial movement and circumferential rotation of the guide pipe column relative to the barrel-shaped base is arranged between the guide pipe column and the barrel-shaped base. By means of the seabed mud face anchoring type deepwater guide pipe structure and the underwater installing method of the seabed mud face anchoring type deepwater guide pipe structure, the well drilling ageing can be improved, and smooth driving can be achieved as for firm-soil deepwater seabeds.

Owner:PETROCHINA CO LTD

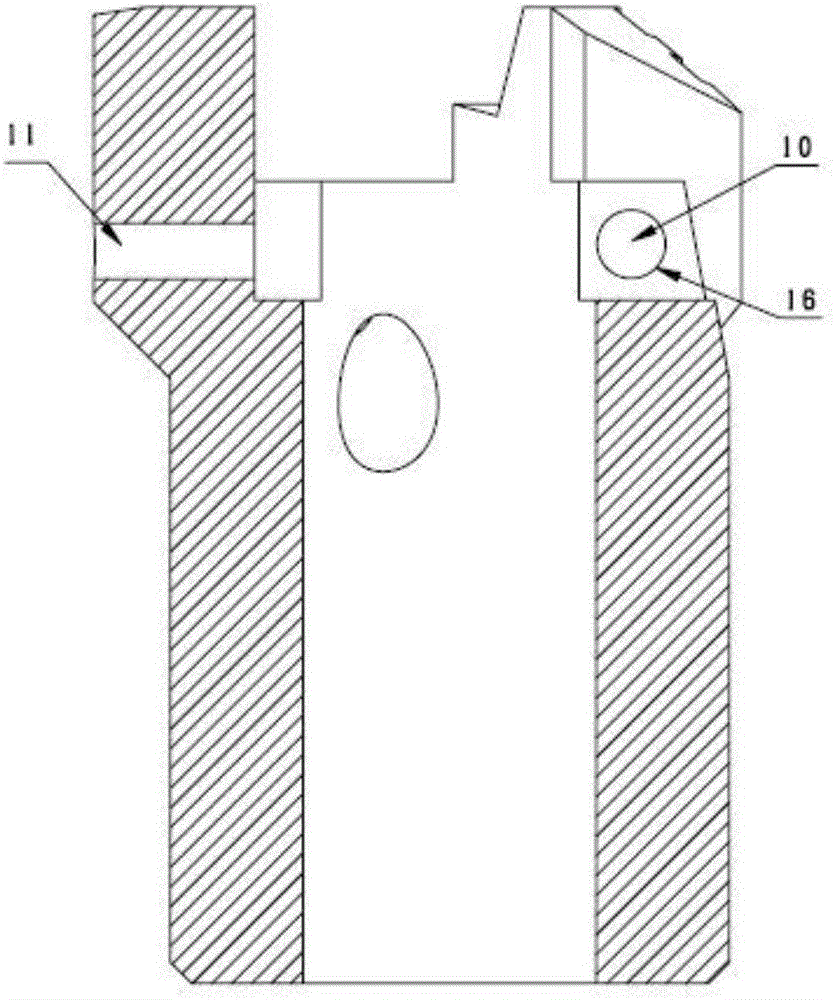

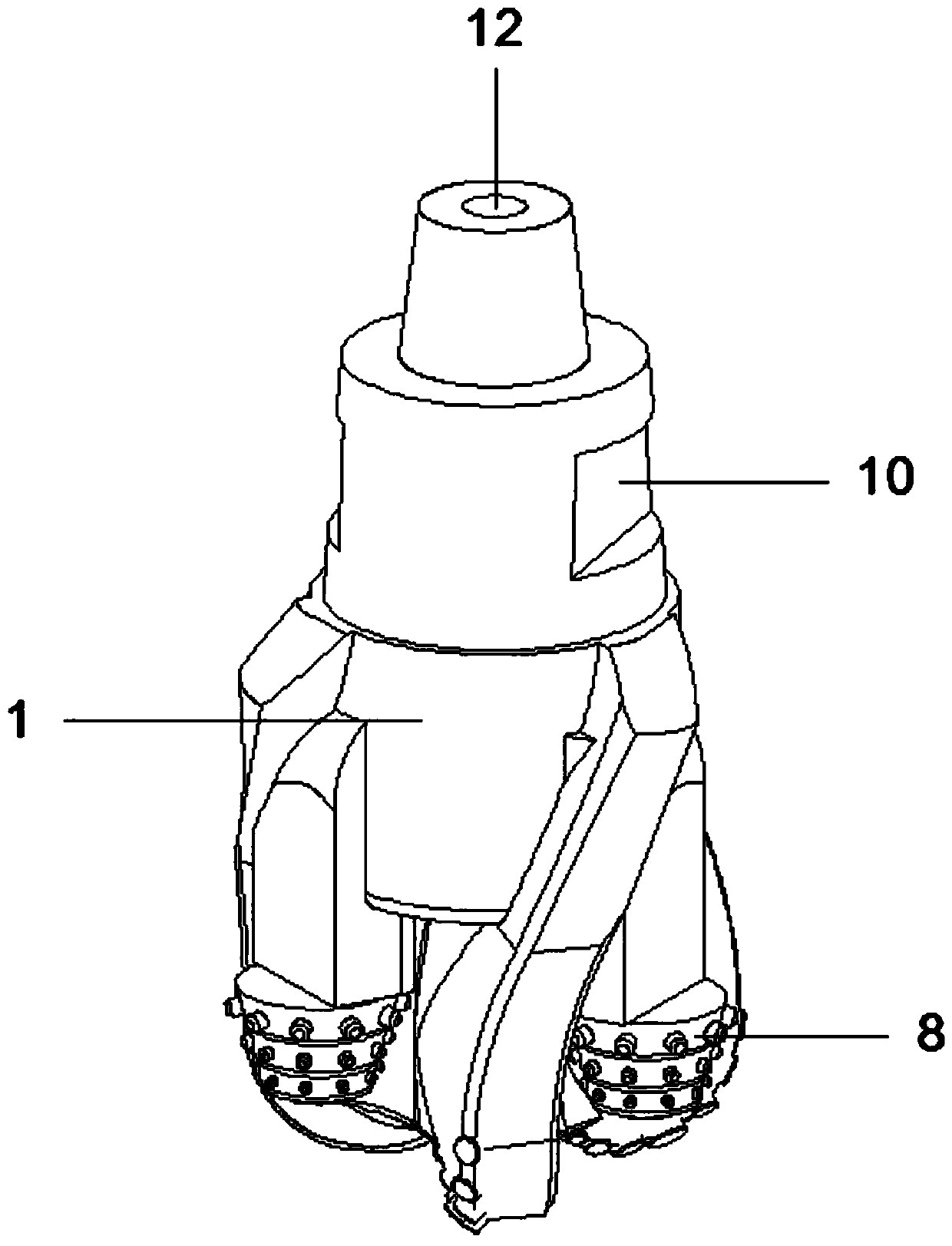

Openable-closeable drill bit

ActiveCN106703703AGuaranteed integritySolve technical problems that are easily deformedConstructionsCore drillDrill bit

An openable-closed drill bit comprises a hollow drill bit body and a central moving wing hinged to the hollow drill bit body. The hollow drill bit body is provided with at least three knife wings, each knife wing is provided with a cutting tooth at least, the central moving wing is provided with at least one cutting tooth and positioned to the hollow drill bit body through a spring positioning pin, a groove for mounting the central moving wing is formed in the hollow drill bit body, one end of the central moving wing is connected in the groove of the hollow drill bit body through a hinging structure while the other end of the same is provided with a positioning groove, the positioning groove allows the spring positioning pin to be clamped therein for positioning when the central moving wing is closed, the groove is of a half-open groove structure, and the hinging structure is positioned at one open end of the groove. Therefore, the openable-closeable drill bit is simple in structure and convenient to mount and demount and is used for solving the technical problem that the central wing of the drill bit cannot be normally opened caused by the fact that the drill bit body is highly stressed and is prone to deforming when the drill bit comes across hard rock during drilling of a lower sieve pipe in a drill column.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Redressing-while-drilling machine for drilling engineering and redressing method

InactiveCN108533180AApplicable to a wide range of formationsImprove impact resistanceDrill bitsConstructionsCarrying capacityWell drilling

The invention discloses a redressing-while-drilling machine for drilling engineering. The redressing-while-drilling machine for drilling engineering comprises a cylinder body and three spiral-shaped blade wings, the three blade wings are evenly fixed to the cylinder body. The blade wings comprise blade wing bodies, PDC clad sheet cutting teeth and gauge protection flat teeth. Every blade wing bodies is evenly provided with 13-17 PDC clad sheet cutting teeth, and the gauge protection portions of the blade wing bodies are evenly provided with the gauge protection flat teeth. The redressing-while-drilling machine for drilling engineering is simple in structure, redressing while drilling is performed by using the redressing-while-drilling machine, the well wall can be cleaned and scraped whiledrilling, so that the well wall can be corrected, the redressing effect is improved, hole shrinkage is eliminated and a mould bed is cleaned, and the size of a hole diameter is ensured. The redressing machine can change the flow field of drilling fluid in a well, rotational flow upwards going of the drilling fluid and rock debris is facilitated, and the sand-carrying capacity of the drilling fluid is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

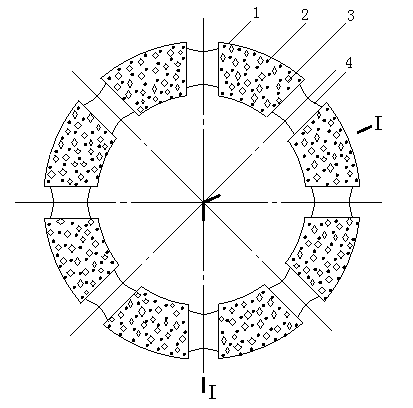

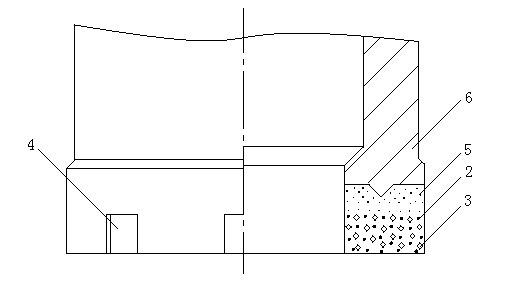

Fabrication method for hot pressing diamond bit with added aluminium oxide hollow balls

InactiveCN103015903AManufacturing Method AdvantagesEnhance the edge effectDrill bitsAdhesiveGraphite

The invention relates to a fabrication method for a hot pressing diamond bit with added aluminium oxide hollow balls. The method comprises the following processes: allowing the aluminium oxide hollow balls and the diamonds to be subjected to pelletization and film applying; uniformly mixing the film applied aluminium oxide hollow balls, the diamonds and bit matrix powder subjected to ball milling and an adhesive; weighing the mixture and filling into a graphite die according to the required amount of each of drill bits in various specifications; pressing a drill bit steel basal body on the graphite die which is then delivered into an mid-frequency electric furnace and pressing machine all-in-one machine for sintering, wherein the hot pressing pressure is 15-16 MPa, the boiler temperature is 950-960 DEG C, the heat-insulating time is 4-5 min, and the discharging temperature is 815-830 DEG C; and after discharging, slowly cooling to the ambient temperature under the heat-insulating condition, and carrying out demoulding so as to fabricate the drill bit provided by the invention. According to the invention, the diamond volume concentration of the diamonds in a fan-shaped cutting operating block of the drill bit is 11-13 percent, and the volume concentration of the aluminium oxide hollow balls is 12-18 percent. The drill bit is used for drilling objects that are as hard as that of hard and compact rocks; and average drilling effectiveness is improved by 95 percent, and the service life is improved by 80 percent as compared with a general diamond bit.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

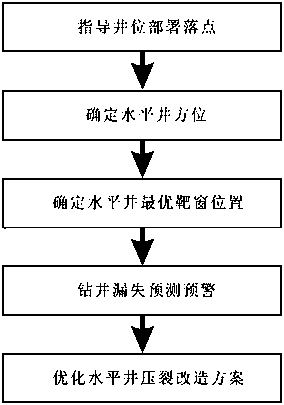

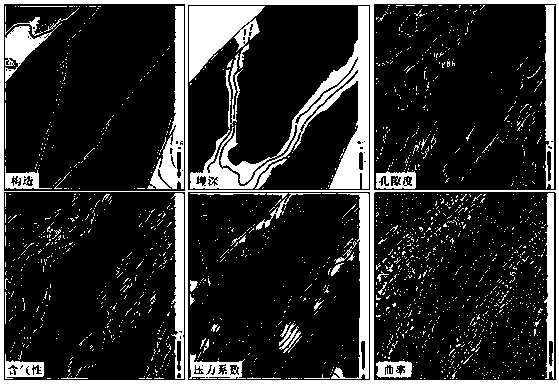

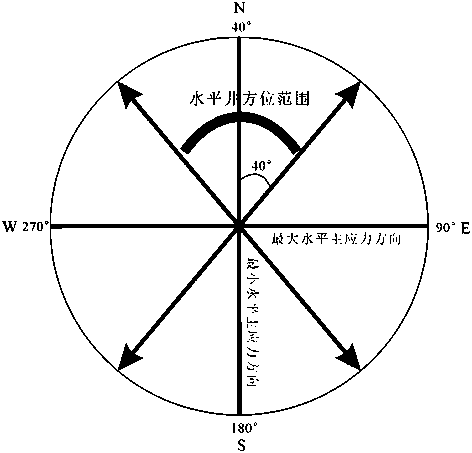

Basin edge complex tectonic zone normal-pressure shale gas horizontal well integrated design method

InactiveCN110295882AHigh Efficiency DrillingEnsure drilling safetyFluid removalPorosityGeomorphology

The invention relates to a basin edge complex tectonic zone normal-pressure shale gas horizontal well integrated design method. In the design process, for the characteristics that such as the Southeast Chongqing basin edge transition zone is strong in tectonic deformation, and the geological condition is complex, through superposition evaluation of a structural figure, a burial depth figure, a porosity figure, a gas content figure, a pressure coefficient figure and a curvature figure, geology and engineering optimal dessert areas are optimized, well sites are deployed, the seismic attribute isused for predicting stratum seam hole development situation, interval intvl losing is avoided, the well drilling aging is improved, and through target window and horizontal well orientation optimization and curvature prediction, the reservoir stratum fracturing effect is improved, the reservoir stratum capacity is sufficiently released, the single well economic benefits are improved, the technical support is provided for efficient exploration and development of the basin edge transition zone shale gas, operation is high, and the application prospect is wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

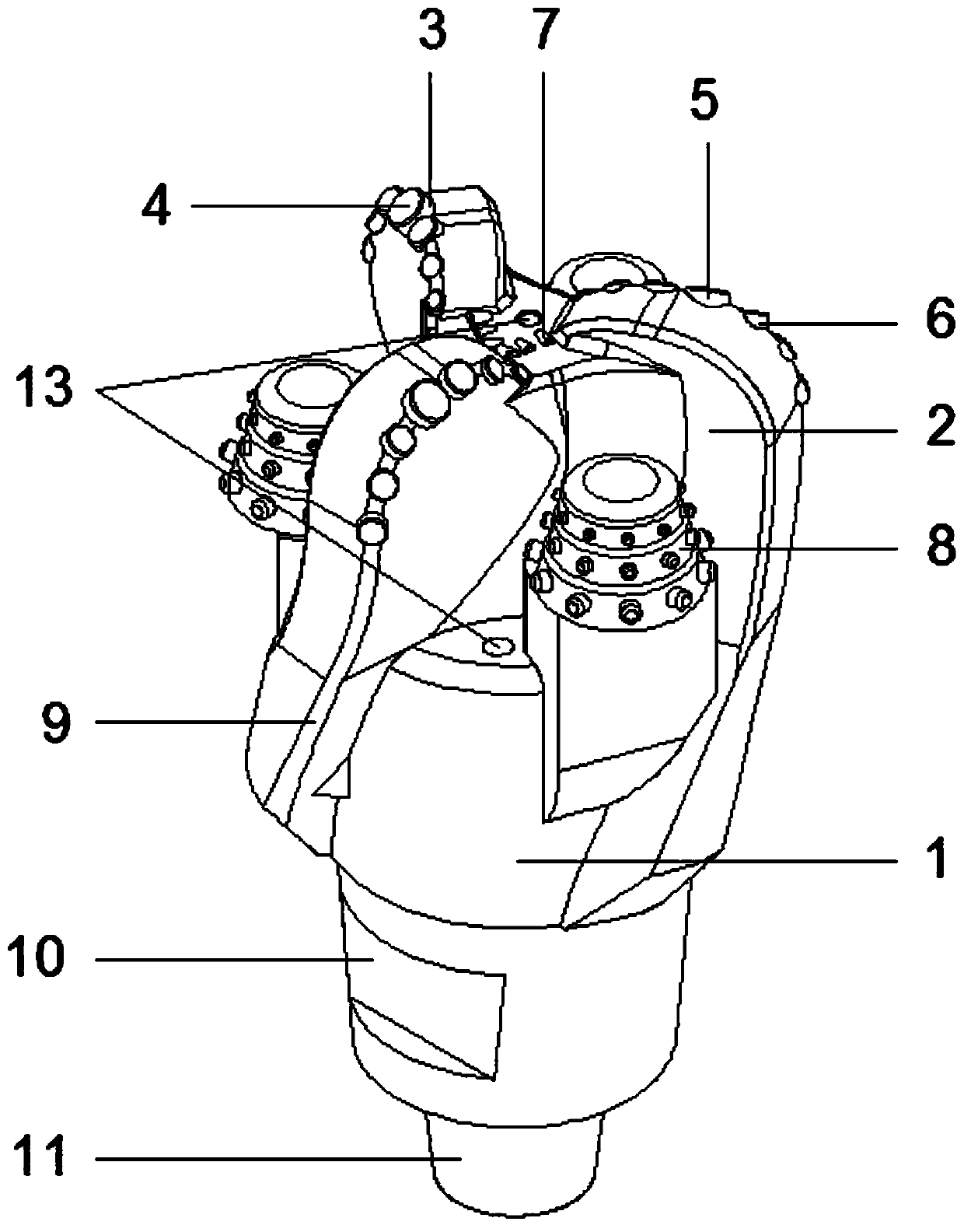

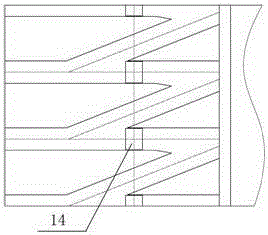

Secondary rock breaking drill bit for assisting pressurizing flow back through spiral blade

InactiveCN109898998AExtended service lifeReduce vibration amplitudeDrill bitsConstructionsWell drillingSpiral blade

The invention provides a secondary rock breaking drill bit for assisting pressurizing flow back through a spiral blade. The secondary rock breaking drill bit comprises a drill bit body, the blade anda cone; the blade is arranged at the top end of the drill bit body, and the blade and the drill bit body are of an integrated structure; and a gauge protection part is arranged on the outer wall of the blade. Through improvement for the rock breaking drill bit, primary cutting is conducted at the bottom of the drill bit to form primary rock debris, the rock debris returns to the cone under carrying flow back of a well-drilling fluid, the cone can conduct secondary breaking, the spiral blade slides in the longitudinal direction to be in surface contact with the well wall, a surface contact modeof the spiral blade is far greater than a line contact mode of a traditional straight blade, longitudinal vibration in the well-drilling process can be reduced, the rock debris generated by cutting of the drill bit flows back upwards under the action of vertical component force of the spiral face, fluid carrying the rock debris generates reactive force on the spiral blade surface, the drill bit can be pressurized, and thus the problems and deficiencies proposed in the background technology are effectively solved and overcome.

Owner:LANZHOU CITY UNIV

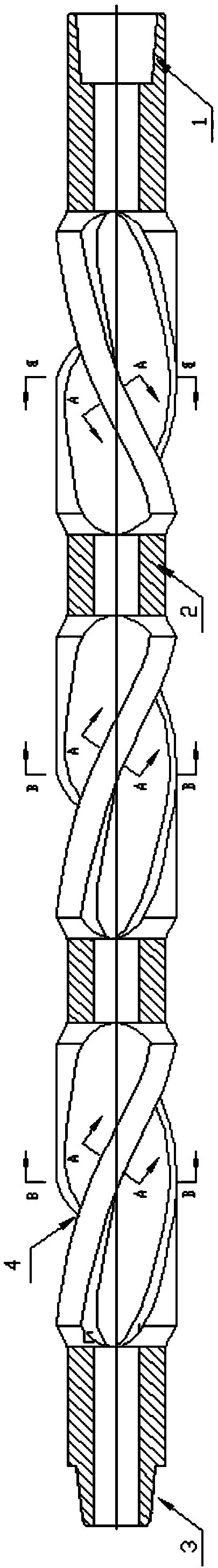

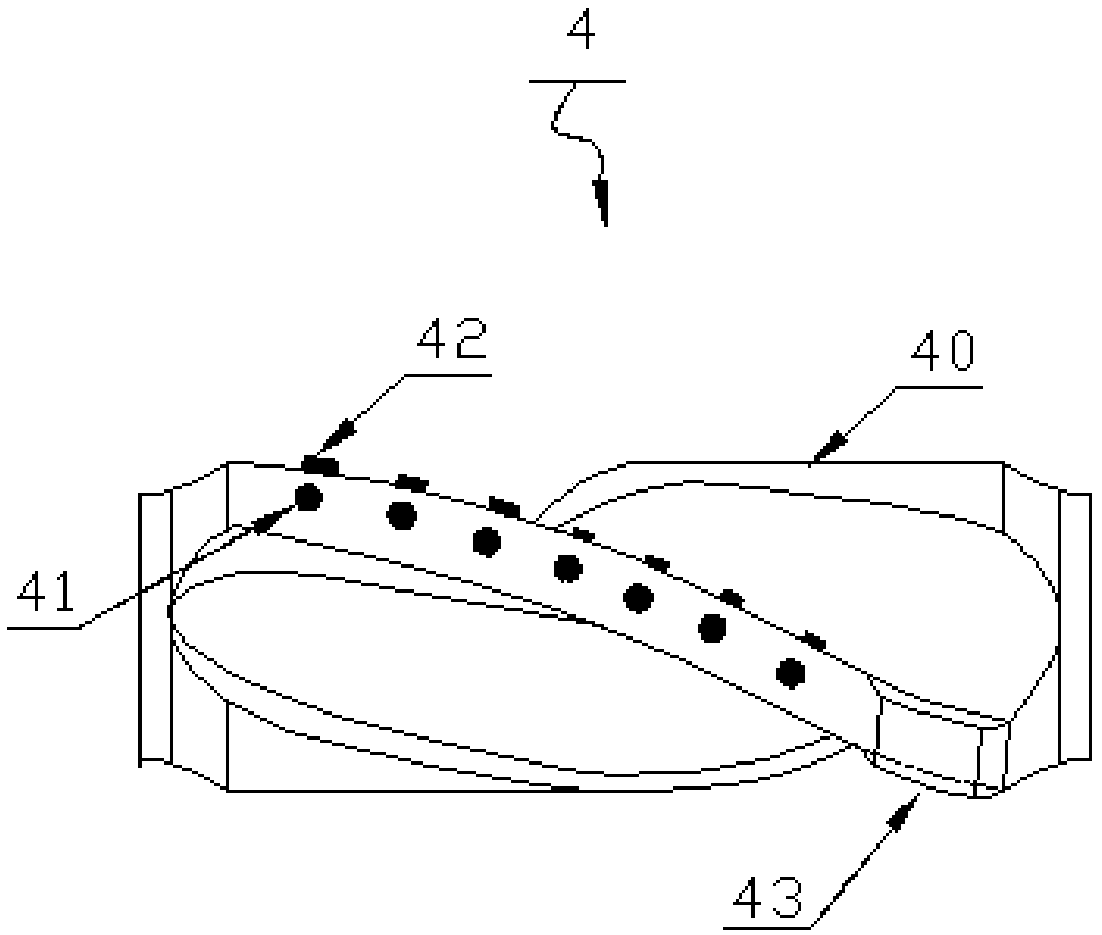

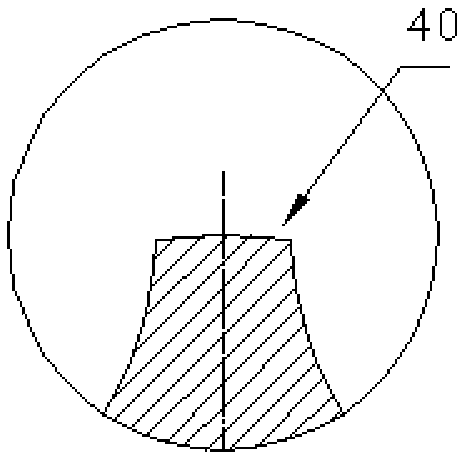

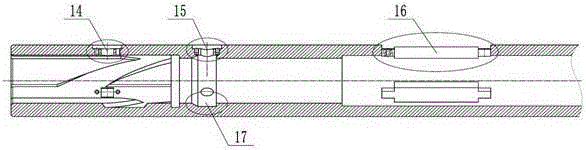

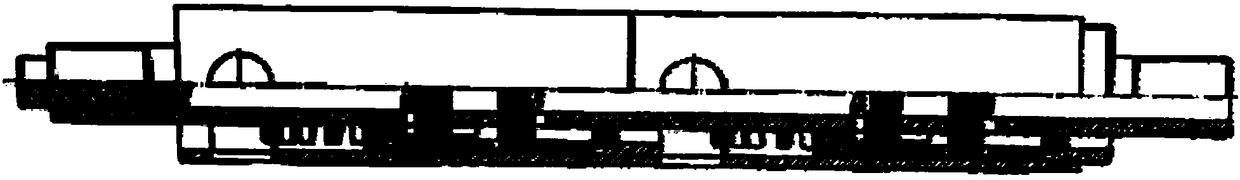

Bidirectional screw-type while-drilling well wall shaper

ActiveCN109403885ANo increase in drilling operation timeReduce wearDrill bitsDrilling rodsSpiral bladeWell drilling

The invention discloses a bidirectional screw-type while-drilling well wall shaper. The bidirectional screw-type while-drilling well wall shaper comprises a shaper body and further comprises a femalethread and a male thread which are arranged at the two ends of the shaper body correspondingly, at least three sets of spiral bodies are arranged on the shaper body at intervals, spiral structureson the positions, close to the two ends of the shaper body correspondingly, of the two sets of spiral bodiesin the at least three sets of spiral bodies are arranged in reverse, each set of spiral bodies is composed of at least three spiral bladeswhich are distributed in parallel and have spiral angles of 10 to 45 degrees with the center line of the shaper body, the outer diameters of one of the spiralblades on the corresponding set of the spiral bodies are larger than those of other spiral blades on the corresponding set of the spiral bodies to show the eccentric structures, and diameter retaining teeth and cutting teeth are arranged at the centers of the tops of the spiral blades and the edges of the tops of one sides of the spiral blades, at the eccentric positions, on the spiral bodies atintervals correspondingly. According to the bidirectional screw-type while-drilling well wall shaper, while-drilling downwards can be achieved, a well wall is shaped while drilling operation is conducted, the drilling operation time is not increased, and the well wall can be shaped once again when back reaming is conducted.

Owner:深圳越海工程技术有限公司

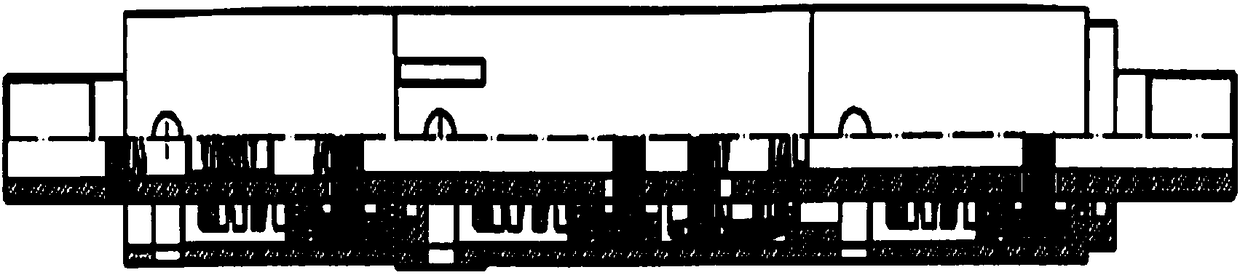

Variable-diameter stabilizer

ActiveCN106761470AShorten the soaking timeReduced risk of collapseDrilling rodsDrilling casingsSingle supportEngineering

The invention provides a variable-diameter stabilizer which comprises a shell, a piston, a slide sleeve, a cone sleeve and a righting column. The cone sleeve is arranged on the lower portion of the piston, the righting column is arranged on the shell, and the cone sleeve and the righting column are matched with each other, so that the diameter can vary. The variable-diameter stabilizer has the advantages that the variable-diameter stabilizer can be controlled from the ground, so that the purpose of varying the diameter can be achieved; balls are cast to wellheads repeatedly, and accordingly the drafting purposes can be achieved by the aid of different drilling tool combinations without tripping out when the corresponding stabilizer is in rolling-out states; only drilling strings need to be tripped out to casing legs when double-support or triple-support drafting needs to be carried out, the balls can be cast, the righting column of the double-support (or triple-support) drafting variable-diameter stabilizer can stretch out under the control, and single-support, double-support and triple-support drafting can be carried out; the trip-out time can be saved when the stabilizer is used, the well wall soaking time can be shortened, downhole collapse risks can be reduced, and the drafting efficiency can be improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

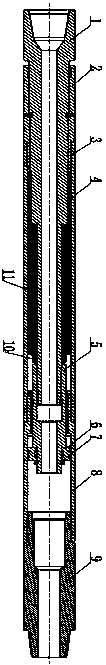

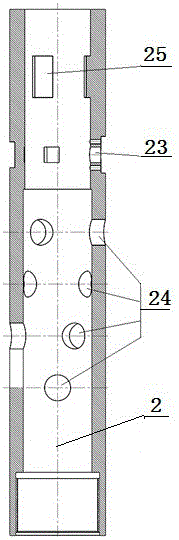

Variable-diameter stabilizer capable of being controlled on ground

ActiveCN104594824AEasy to operateImprove reliabilityDrilling rodsDrilling casingsWell drillingEngineering

The invention belongs to the technical field of a downhole tool and particularly relates to a variable-diameter stabilizer capable of being controlled on the ground. The variable-diameter stabilizer comprises a pipe-shaped shell, wherein a central shaft is arranged in the shell; a self-locking groove is formed in the upper part of the central shaft; a tapered sleeve sleeves the middle part of the central shaft; a locking block square hole is formed in the upper part of the shell; a self-locking device is arranged in the locking block square hole; the inner end of the self-locking device corresponds to the self-locking groove in the central shaft; a plurality of cylindrical holes are uniformly formed in the shell along the peripheral direction and the axial direction; stabilization columns are arranged in the cylindrical holes; the inner ends of the stabilization columns are located on the outer wall of the tapered sleeve. According to the variable-diameter stabilizer capable of being controlled on the ground, the aim that the stabilizers with different outer diameter sizes are utilized in different well sections is realized. Meanwhile, the outer diameter conversion is realized by different ground operations and a control unit does not need to be specially and additionally arranged; the link that an existing non-electric-control variable-diameter stabilizer needs to control pump pressure or count the times of switching on and off a pump is overcome; the operation is simplified, the structure is simple, the operation is convenient and the well drilling timeliness is improved.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

Drilling circulating fluid conversion preflush and preparation method thereof

ActiveCN101948681AProduct performance is stableWell wall stabilization effect is goodDrilling compositionFormate EstersPlasticizer

The invention discloses drilling circulating fluid conversion preflush and a preparation method thereof. The drilling circulating fluid conversion preflush consists of an organic ester, a plasticizer, oil, an emulsifier and a plugging agent, wherein the organic ester is phthalate esters or polyol benzoates; the plasticizer is one of polyethylene or vinyl chloride resin; the oil is mineral oil or vegetable oil; the emulsifier is one or more of OP-10, OP-30, tween-80, SP-80, oleic acid, P-30 and P-20; and the plugging agent is one of asphalt or modified asphalt products. The drilling circulating fluid conversion preflush has the advantages of: nontoxic or harmless production process, wider appropriate temperature range (-30 to 200 DEG C) than the appropriate temperature range (-5 to 160 DEGC) of conventional oil-in-water circulating fluid conversion preflush, stable product performance, good effect on keeping borehole wall stability, and capacity of shortening over 2 / 3 of complex processing time after conversing a drilling circulating fluid, improves drilling prescription, and saves drilling cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

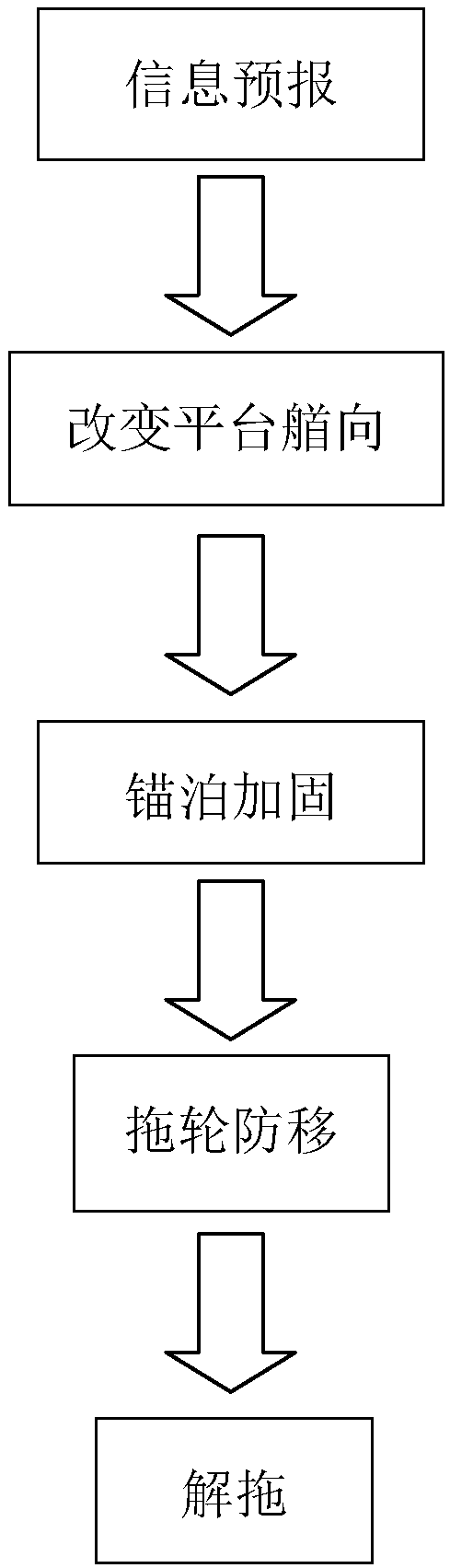

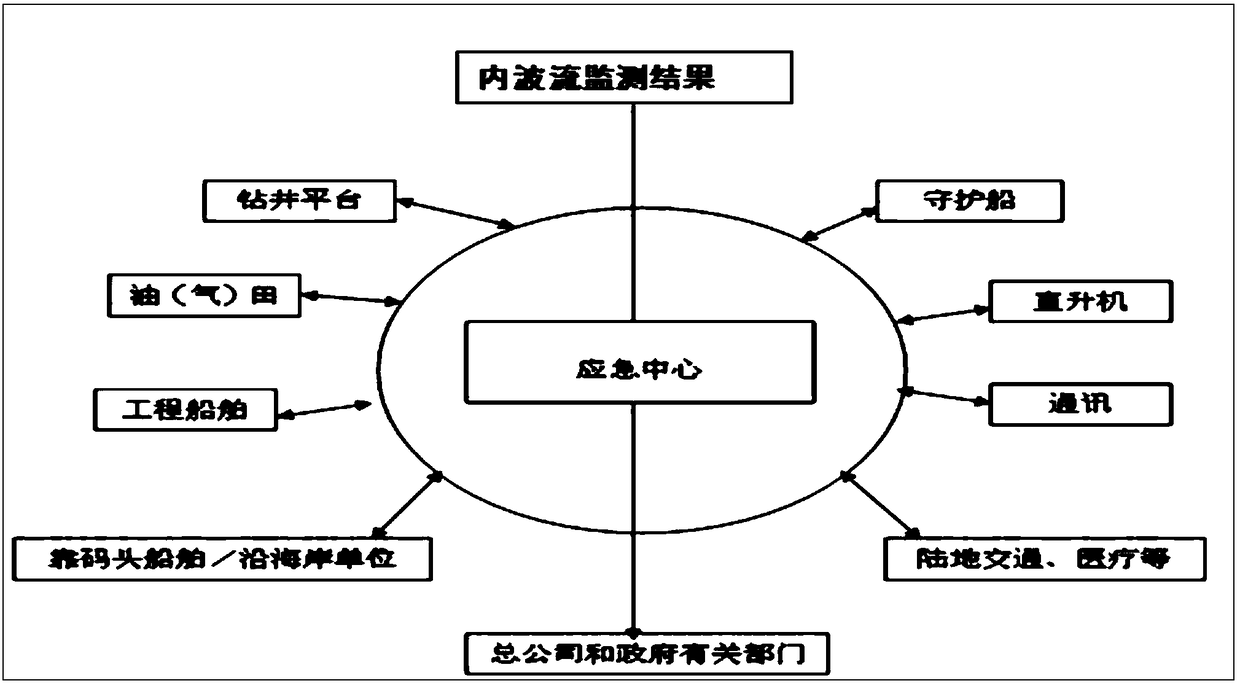

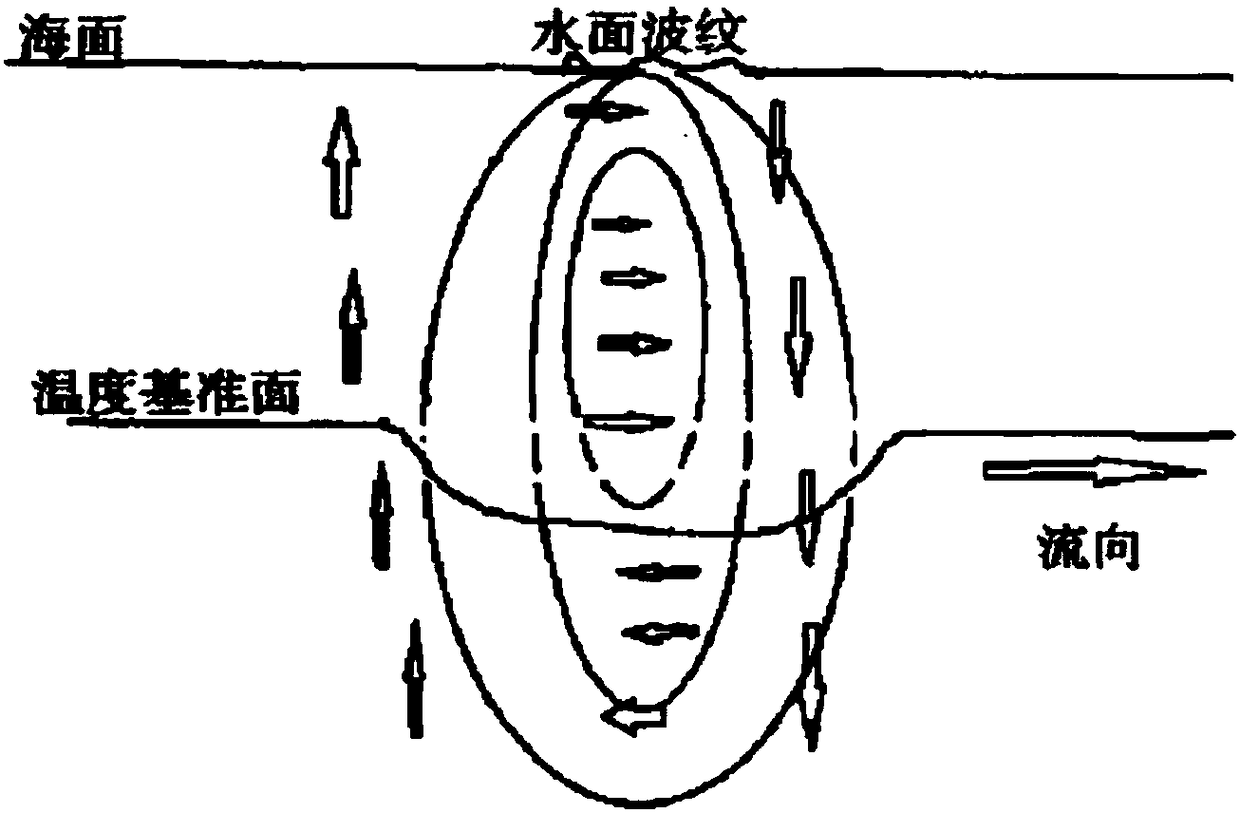

Method of dealing with deep-water internal wave flow for deep-water semi-submersible platform

InactiveCN108068999AReduce offsetEnsure job safetyShip vibration reductionMovement controllersMarine engineeringWell drilling

The invention discloses a method of dealing with deep-water internal wave flow for a deep-water semi-submersible platform. The method includes the following steps of 1, forecasting information, wherein conducting monitoring and early warning on the deep-wave internal wave flow, and predicting the information of the deep-water internal wave flow in advance; 2, changing platform orientation, whereinwhen the deep-water internal wave flow is monitored, the platform orientation is changed to a direction facing the deep-water internal water flow; 3, anchoring and reinforcing; 4, dragging wheels andpreventing deviation, wherein when the deep-water internal wave flow reaches the platform, the power and tension of a main tub are gradually increased, and the deviation amount of the platform is reduced; 5, removing the tug, wherein after the deep-water internal water flow disappears, the tug is removed, and a next operation is conducted. The method for conducting prediction in advance, changingthe orientation, conducting dragging on the wheels and preventing deviation is adopted to deal with the deep-water internal flow wave encountered in deep-water drilling, reduce the impact of the deep-water internal wave flow on the deep-water semi-submersible platform and ensure the operation, control and safe operation of the platform and is conducive to improvement of drilling time efficiency.The method is simple and convenient to operate and can be widely applied in the field of deep-water oil drilling.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Automatic grouting-type float-collar float-shoe device

InactiveCN107829693AImprove efficiencyRealization of automatic groutingDrilling rodsWell/borehole valve arrangementsEngineeringCheck valve

Owner:潜江市联瑞石油机械有限公司

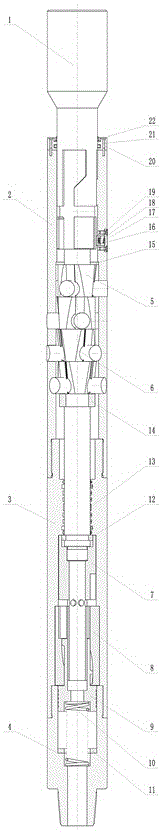

A variable diameter stabilizer

ActiveCN103742084BEasy to operateImprove reliabilityDrilling rodsDrilling casingsAxial displacementWell drilling

The invention relates to a variable gauge stabilizer. The variable gauge stabilizer comprises a shell, wherein a central tube is arranged in the shell; a conical sleeve is sleeved on the outer diameter of a central tube; a baffle ring which is arranged on the central tube and is used for pushing the conical sleeve upwards when the central tube moves upwards is arranged below the conical sleeve; a stabilizing block is arranged on the shell; reset springs are arranged at the two ends of the stabilizing block; the stabilizing block is contacted with the conical sleeve; lugs are uniformly distributed on the outer diameter of the central tube along the radial direction; piston holes are uniformly distributed in the central tube along the radial direction; pistons are arranged in the piston holes; a screw cap for adjusting the axial displacement of the central tube and carrying the weight of a lower drill column is arranged at the bottom end of the central tube. By adopting the variable gauge stabilizer, the aim of varying the outer diameter of the stabilizer through ground operation is fulfilled. The stabilizer can be kept in different working states by changing the sequences of pump starting and bit weight increasing rotation, thereby fulfilling the aim of using stabilizers of different outer diameters in different well sections. Meanwhile, in trip-out operation, the stabilizer is kept in a contraction state. The variable gauge stabilizer is simple in structure, and the well drilling efficiency is increased.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

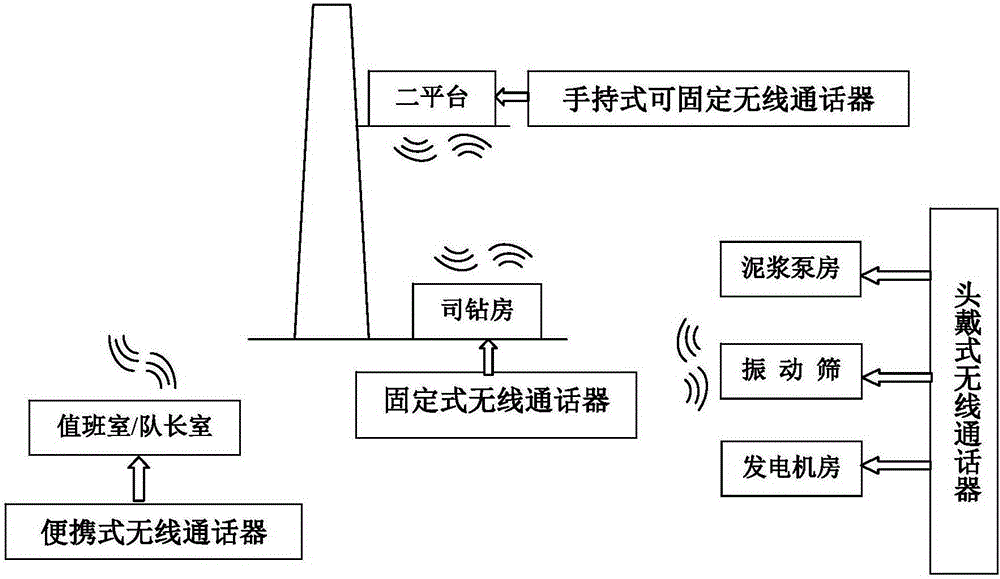

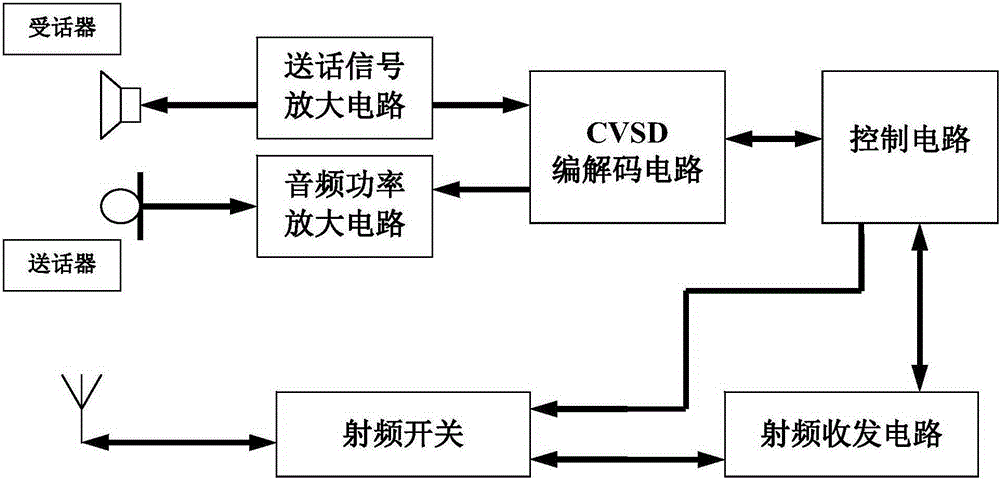

Portable wireless communication system applied to oilfield drilling operation

ActiveCN105306649ASolve communication problemsUnlimited quantityTransmissionTelephone set constructionsCommunications systemInterference resistance

The invention relates to a portable wireless communication system applied to an oilfield drilling operation. The portable wireless communication system comprises handheld fixable wireless interphones arranged on two platforms for the oilfield drilling operation, a portable wireless interphone arranged on a duty room or a header room for the oilfield drilling operation, head-wearing wireless interphones arranged in a mud pump room, a generator room and a vibrating screen for the oilfield drilling operation, and a fixed wireless interphone arranged in a driller room for the oilfield drilling operation, wherein communication circuit boards are arranged inside the handheld fixable wireless interphones, the portable wireless interphone, the head-wearing wireless interphones and the fixed wireless interphone. The portable wireless communication system is small in size, and has high interference resistance. The security of engineering operations is ensured; the drilling timeliness is enhanced; and the drilling cost is saved. When the portable wireless communication system is applied to a drilling high-noise place, calls are clear. Under 140-decibel noises, over 85 percent of noises can be filtered. Under 120-decibel noises, calls are clear and smooth, and murmurs are avoided.

Owner:张效瑛

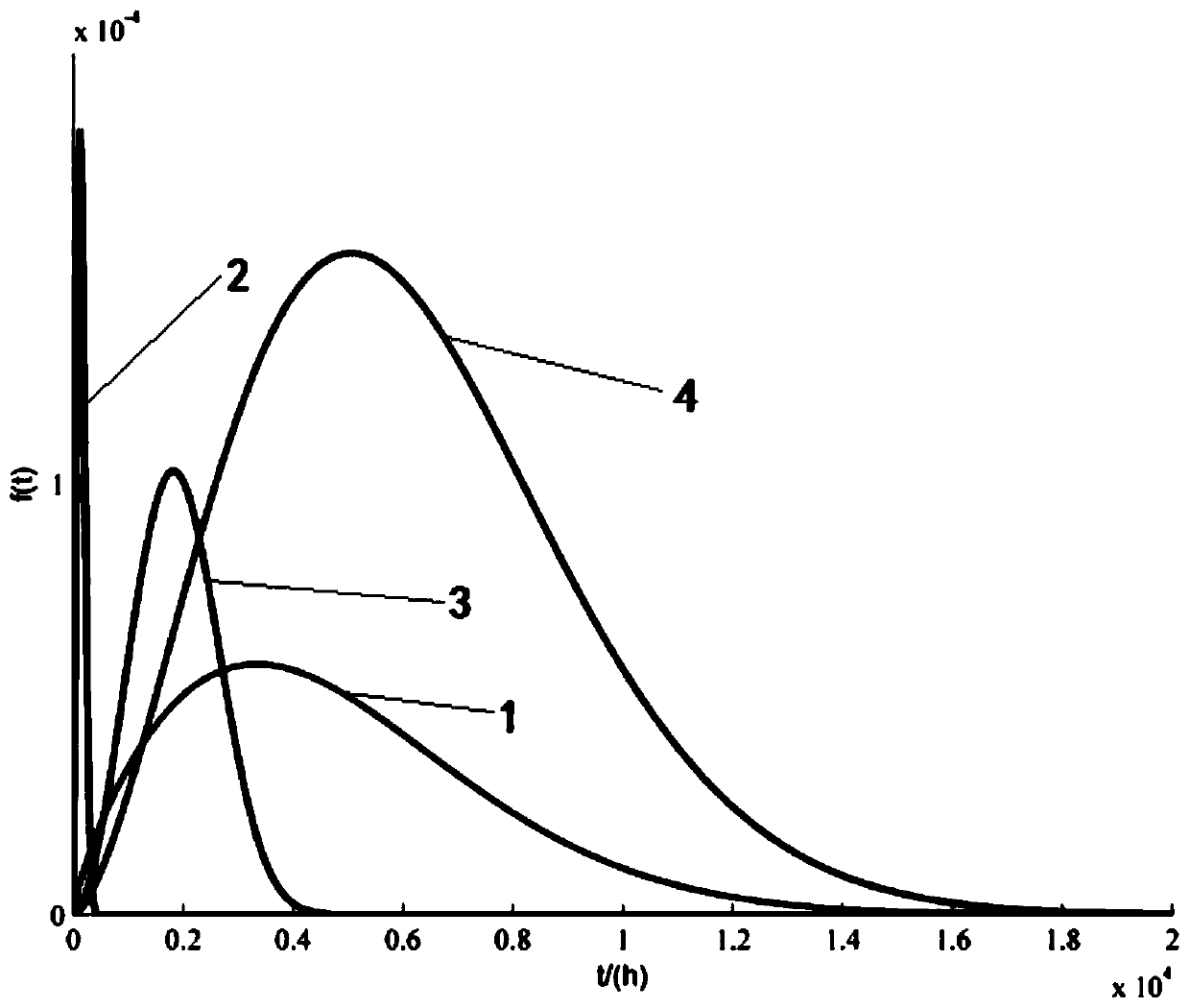

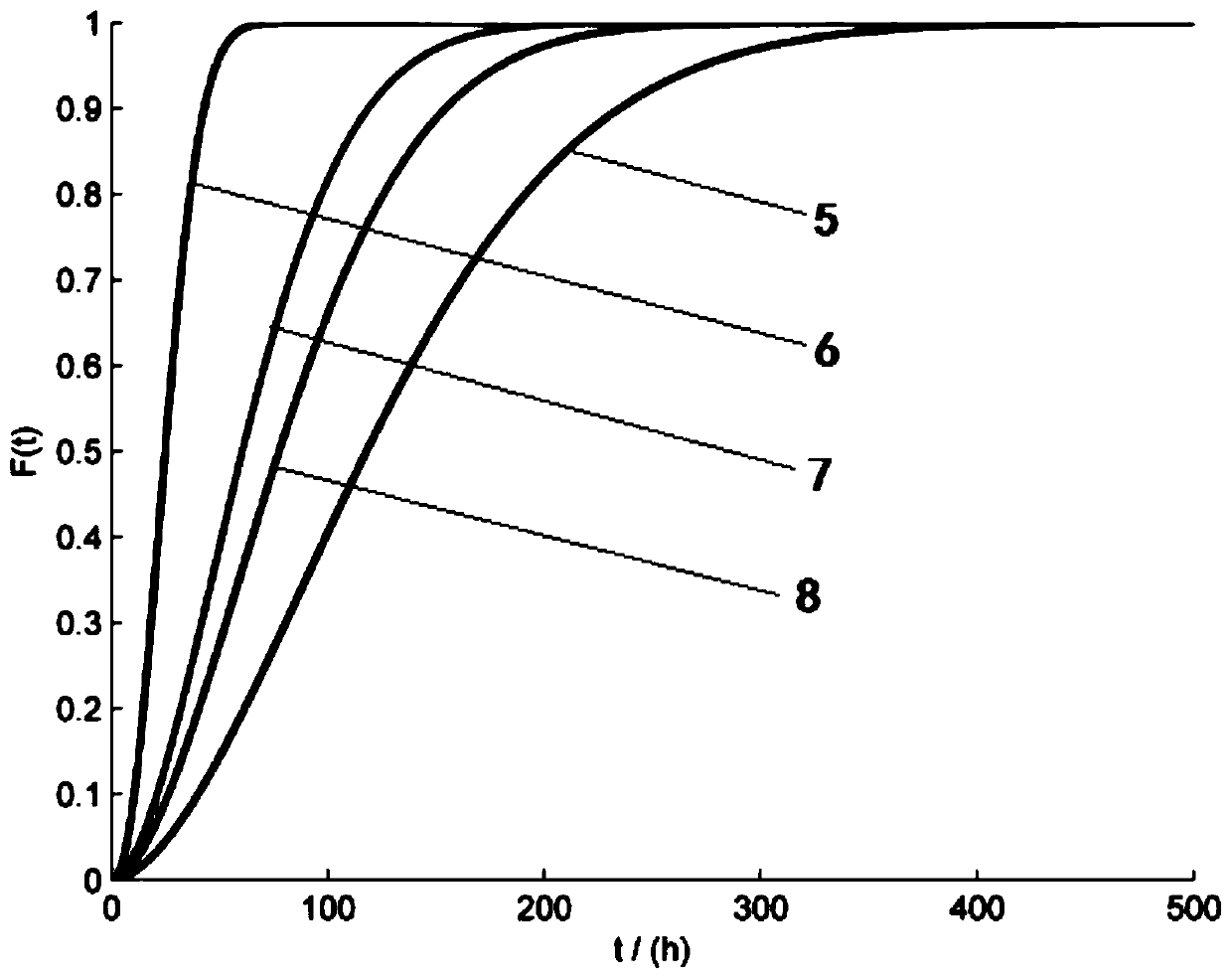

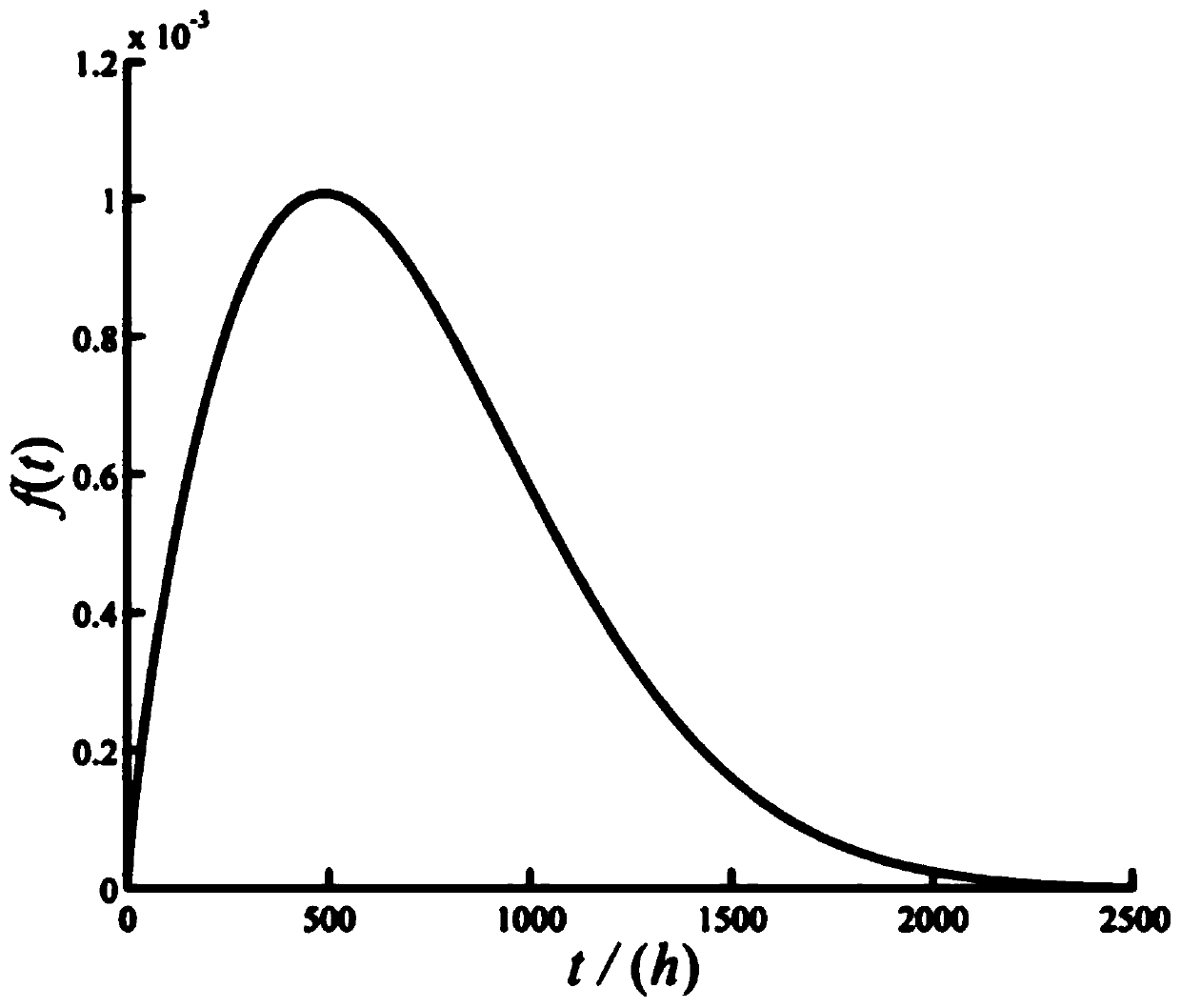

Logging instrument reliability evaluation method

InactiveCN111414674AAccurate analysisHigh Efficiency DrillingDesign optimisation/simulationSystem failureComputer engineering

The invention provides a logging instrument reliability evaluation method. The logging instrument reliability evaluation method comprises the following steps: carrying failure mode analysis and failure mechanism analysis on an antenna system of a logging instrument by utilizing the reliability experiment method; establishing a logging instrument antenna system fault analysis model based on a Weibull distribution model, and performing reliability life analysis on the antenna system of the logging instrument; performing goodness-of-fit test on the logging instrument antenna system fault analysismodel based on the Weibull distribution model by using a Kolmogorov-Smirnov test method; and evaluating the reliability of the logging instrument by utilizing the model which is inspected to be qualified by the Kolmogorov-Smirnov inspection method.

Owner:CHANGZHOU INST OF TECH

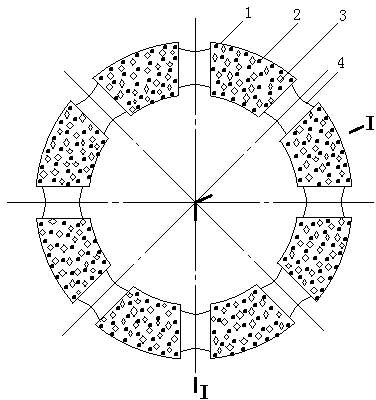

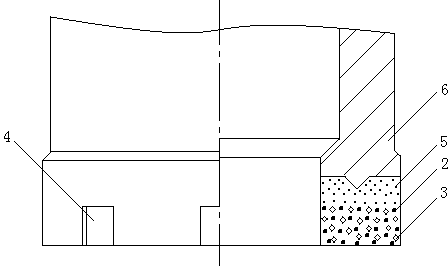

Fabrication method for hot pressing diamond bit with added aluminium oxide hollow balls

The invention relates to a fabrication method for a hot pressing diamond bit with added aluminium oxide hollow balls. The method comprises the following processes: allowing the aluminium oxide hollow balls and the diamonds to be subjected to pelletization and film applying; uniformly mixing the film applied aluminium oxide hollow balls, the diamonds and bit matrix powder subjected to ball milling and an adhesive; weighing the mixture and filling into a graphite die according to the required amount of each of drill bits in various specifications; pressing a drill bit steel basal body on the graphite die which is then delivered into an mid-frequency electric furnace and pressing machine all-in-one machine for sintering, wherein the hot pressing pressure is 15-16 MPa, the boiler temperature is 950-960 DEG C, the heat-insulating time is 4-5 min, and the discharging temperature is 815-830 DEG C; and after discharging, slowly cooling to the ambient temperature under the heat-insulating condition, and carrying out demoulding so as to fabricate the drill bit provided by the invention. According to the invention, the diamond volume concentration of the diamonds in a fan-shaped cutting operating block of the drill bit is 11-13 percent, and the volume concentration of the aluminium oxide hollow balls is 12-18 percent. The drill bit is used for drilling objects that are as hard as that of hard and compact rocks; and average drilling effectiveness is improved by 95 percent, and the service life is improved by 80 percent as compared with a general diamond bit.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

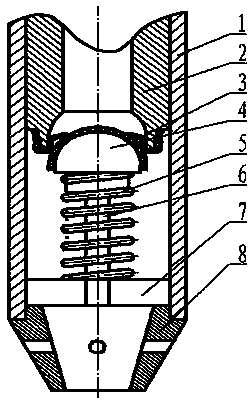

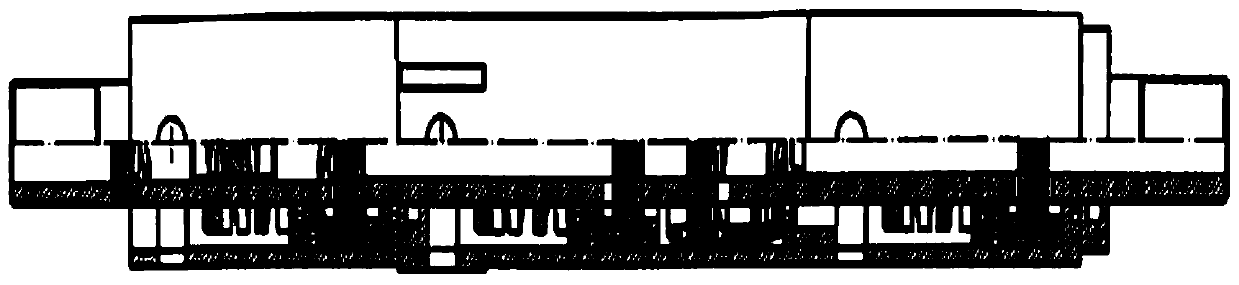

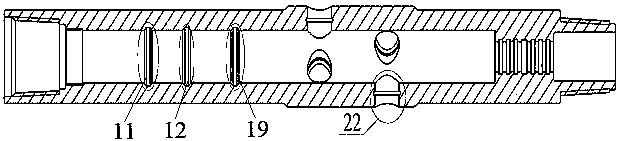

Pulse shock frequency generator

ActiveCN108252671AIncreased crushing impactImprove permeabilityVibration devicesShock waveWell drilling

The invention relates to a pulse shock frequency generator. The pulse shock frequency generator comprises a liquid cylinder, a connecting rod, a piston and a pressure relief valve. The connecting rodis arranged in the liquid cylinder. The piston and the pressure relief valve are arranged on the connecting rod in a sleeving mode. The connecting rod is provided with a piston guide hole and a pressure relief valve guide hole. The pressure relief valve is arranged at the pressure relief valve guide hole in a hung mode and used for controlling opening and closing of a pressure relief opening of the liquid cylinder. The piston is arranged at the piston guide hole in a hung mode. The connecting rod is provided with a liquid inlet hole. According to the pulse shock frequency generator, mechanicalpulse shock waves can be produced through up-down reciprocating movement of the connecting rod; meanwhile, liquid of the liquid cylinder also produces pulse waves to be sprayed out of the liquid cylinder; therefore, the pulse shock frequency generator is widely used in various practical production areas such as mine mining, piling, equipment breaking-demolition and vibration tests, especially thepulse shock frequency generator plays an important role and application in oil exploitation, the difficulty of oil production is reduced, and the permeability of stratum rock is increased; breaking of the stratum rock is accelerated, the drilling speed of a drill bit is increased, and drilling aging is improved; and the salvage lifting load is reduced, and the salvage and unfreezing efficiency isimproved.

Owner:程显达 +1

Impregnated diamond bit matrix material with high wear resistance and method for manufacturing diamond bit by using same

ActiveCN111822715ATimely edgeRight amount of edgeDrill bitsHigh wear resistanceHot isostatic pressing

The invention provides an impregnated diamond bit matrix material with high wear resistance and a method for manufacturing a diamond bit by using the same. The matrix material comprises the followingcomponents of, by weight, 42%-56% of FAM-1020(Fe80Ni18Co2), 16%-22% of FAM-3010(Fe81Ni7Mn12), 28%-36% of FAM-2120(Fe85Ni6Cu6Sn3) and inevitable impurities. The manufacturing method comprises the following steps of heating the matrix material; carrying out low-pressure sintering treatment on the matrix material; cooling the matrix material to room temperature; carrying out hot isostatic pressing treatment on an impregnated diamond bit blank; and cooling to room temperature. By reasonably designing the components of the impregnated diamond bit matrix material and adopting the special low-pressure sintering heating isostatic pressing manufacturing method matched with the components, the wear resistance and the comprehensive mechanical property of the impregnated diamond bit matrix are effectively improved, and the drilling target with high efficiency and long service life can be achieved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

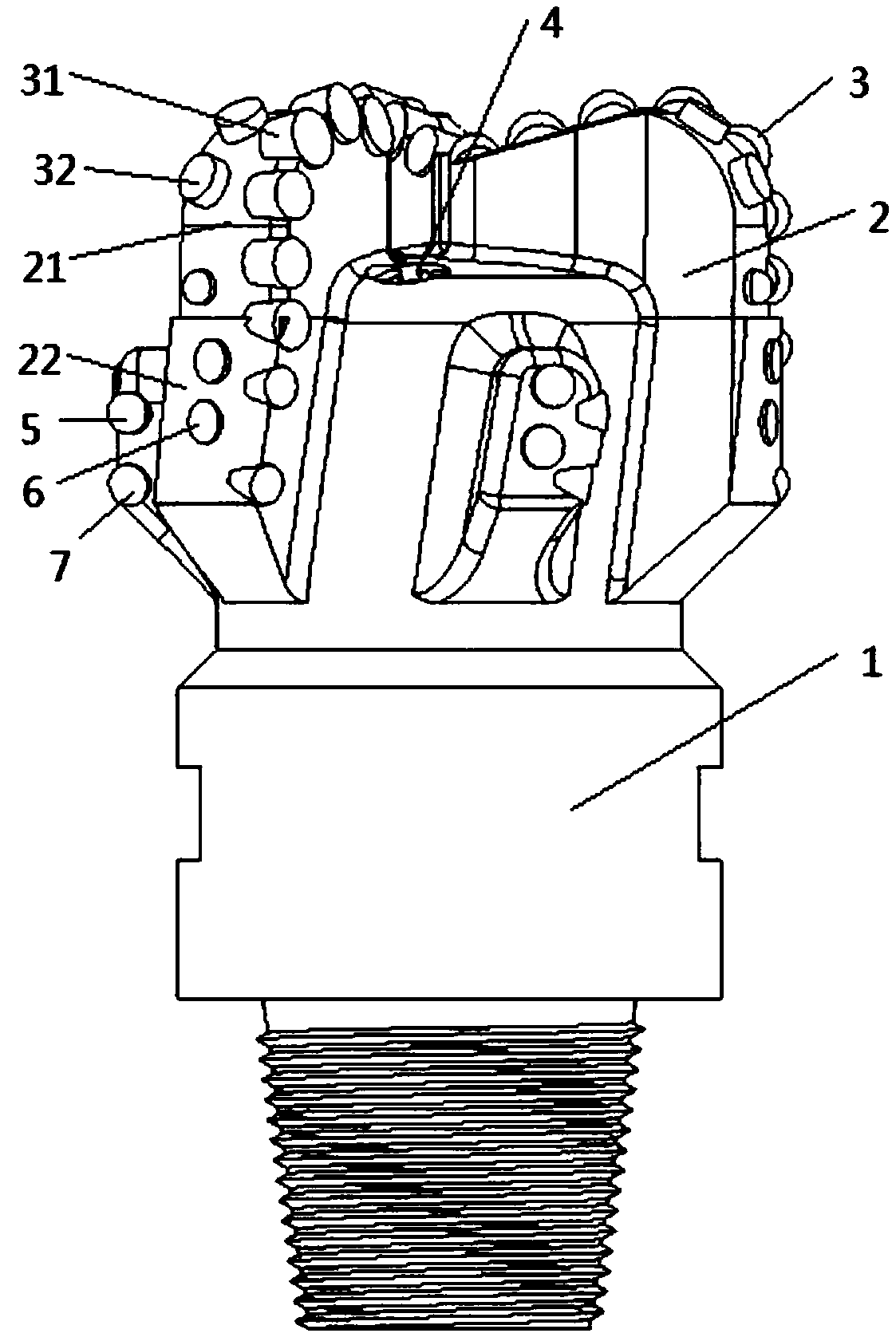

PDC drill bit suitable for middle-shallow formation directional well drilling

InactiveCN108019153AGood orientationIncrease the number ofDrill bitsDirectional drillingDirectional wellEngineering

The invention discloses a PDC drill bit suitable for middle-shallow formation directional well drilling. The PDC drill bit comprises a drill bit body and further comprises blades, a cutting teeth anda water hole. The blades are arranged at the crown of the drill bit body, and each blade is provided with a gauge protection area. Parts of the blades are provided with cutting areas, and the positions, above the planes where the upper end faces of the drill bit body is located, of the blades are the cutting areas. The portions below the panels are the gauge protection areas. The number of the cutting areas is smaller than that of the blades, and the number of the gauge protection area is equal to that of the blades. According to the PDC drill bit suitable for soft formation directional drilling, through separation-type structural design of the cutting areas and the gauge protection areas, the number of the cutting areas and the gauge protection areas can be independently adjusted according to the formation characteristics and the directional drilling needs, and thus the directional well drilling capacity of the PDC drill bit in a middle-shallow formation can be greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP

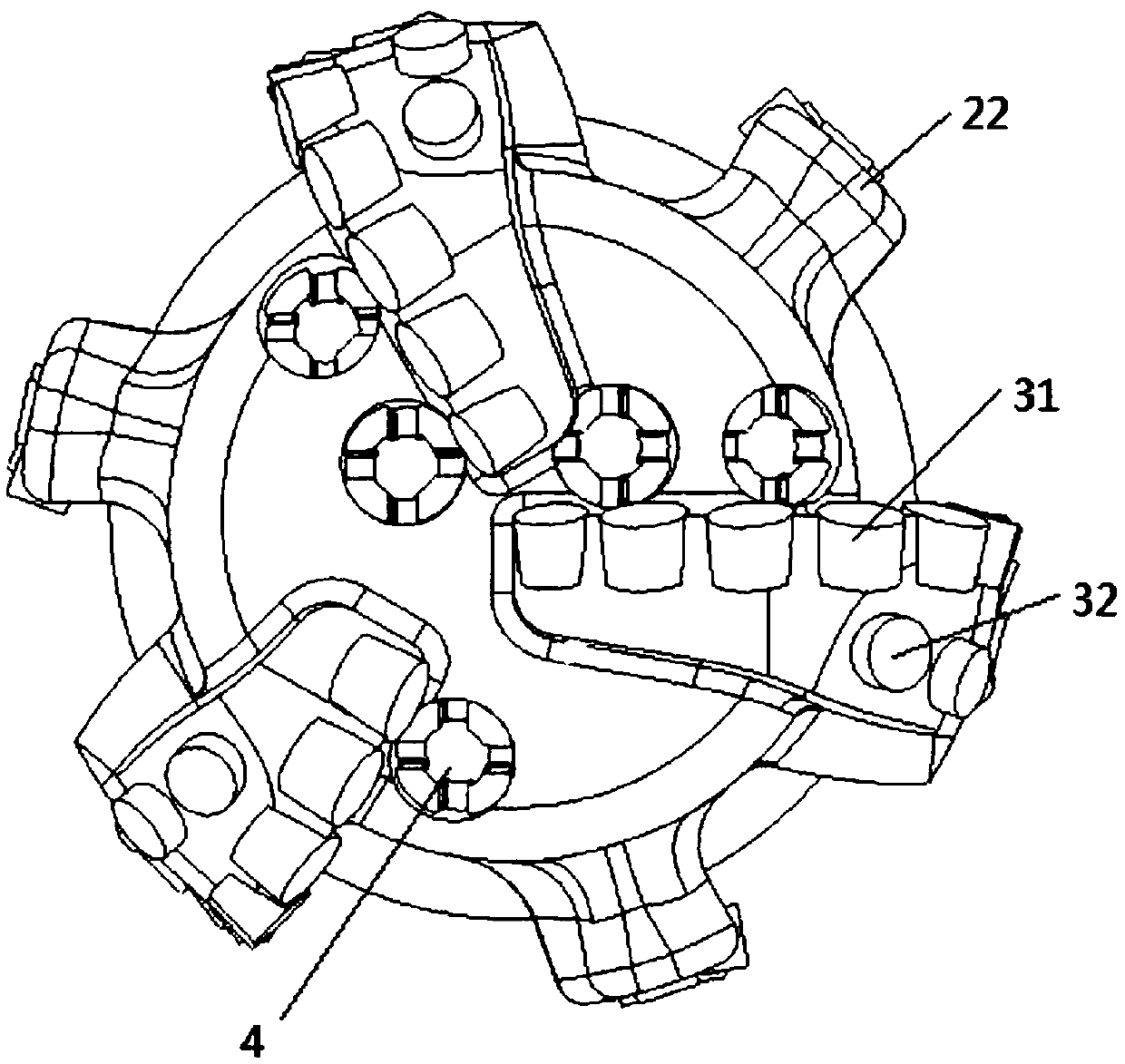

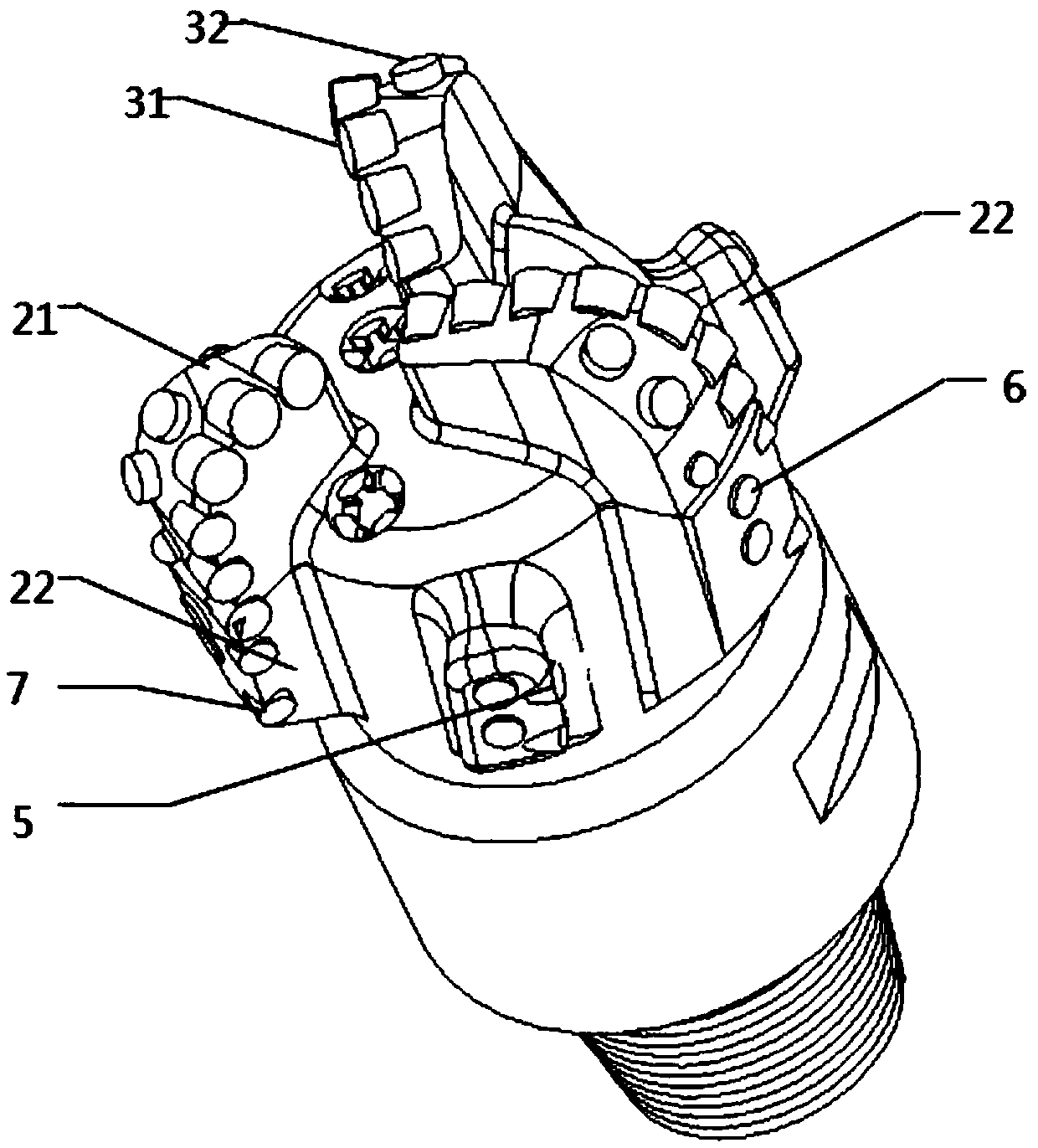

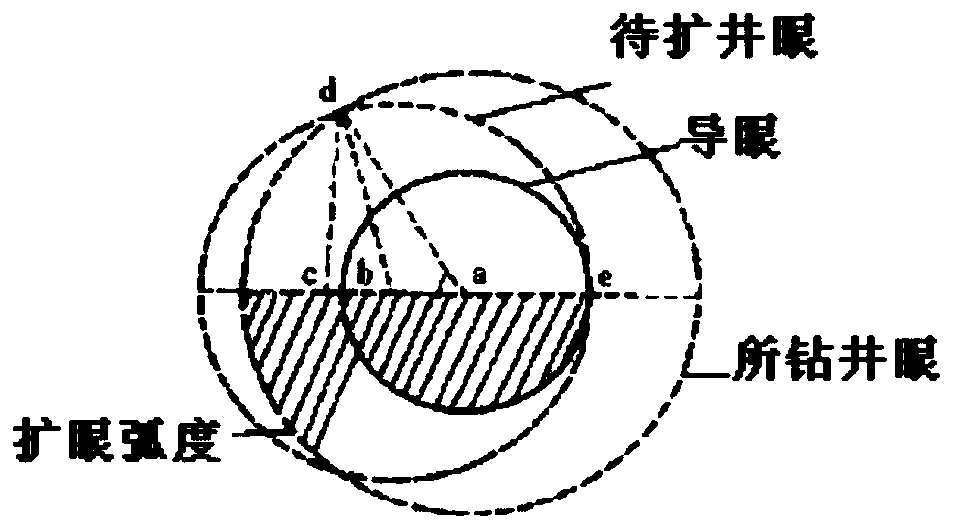

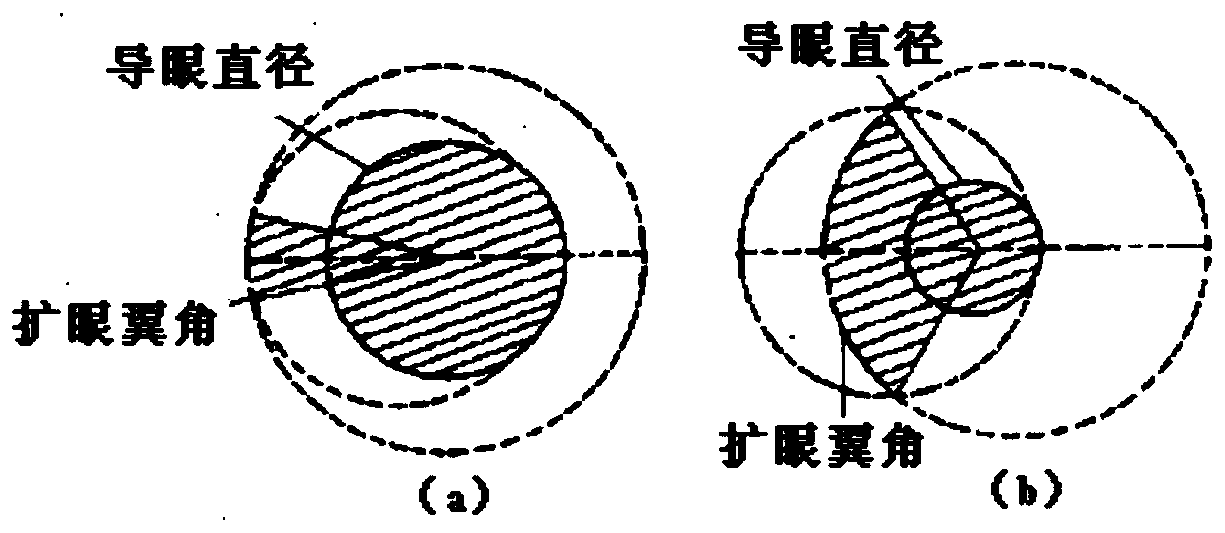

Eccentric split type PDC bit

InactiveCN110295851AImprove cementing qualityReduce labor intensityDrill bitsConstructionsNominal sizeEngineering

The invention provides an eccentric split type PDC bit. The geometrical shape of the eccentric split type PDC bit is determined by four parameters including the drilled well hole diameter D being 2Lad, the to-be-drilled well hole diameter N being equal to 2Lbd and 2Lbc, the guide eye diameter P being equal to 2Lav and the half angle corresponding to the reaming curvature, and the half angle is thehalf angle phi of a wing angle, wherein the Lad represents the drilled well hole radius, the Lbd represents the to-be-drilled well hole radius, the Lbc represents another form of the to-be-drilled well hole radius, and the Lav represents the guide hole radius; and the eccentric split type PDC bit adopts a double-core structure, the drill has two central axes including the reaming central axis andthe to-be-reamed central axis, and the distance between the two centers is the eccentricity. According to the design method of the double-core bit, the relevant dimensions are characterized in that the nominal size of the bit is phi215. 9, and the deviation value between the rotation axis of the bit and the axis of a drill column is 4 mm; a cutting part of the eccentric split PDC bit is made intotwo concentric unequal-radius sections, the small radius is 105.9 mm, the large radius is 110 mm, and when the bit rotates, the unequal-radius sections can form a well hole larger than phi220 in thebit rotating process.

Owner:河北锐石钻头制造有限公司

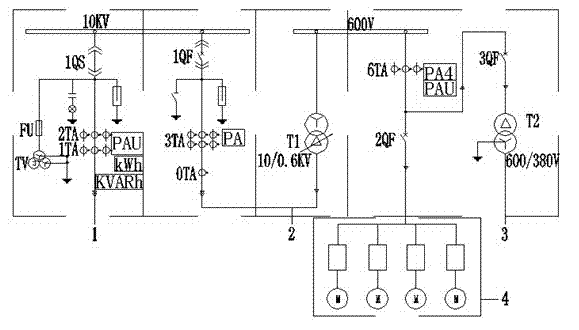

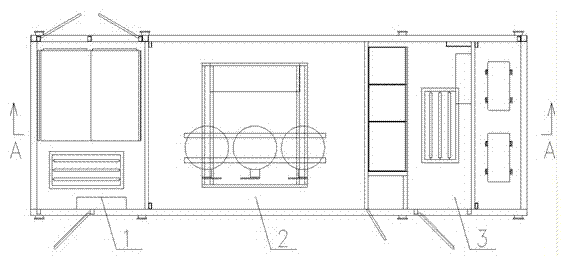

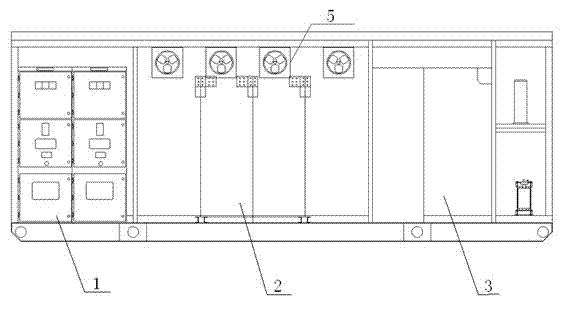

Power supply system for drilling machine grid electricity

InactiveCN102969660AImprove stabilityImprove reliabilityBus-bar/wiring layoutsBoards/switchyards circuit arrangementsElectricityGeneration process

The invention relates to a power supply system for drilling machine grid electricity. The power supply system at least comprises a high-voltage part, a transformer part and a low-voltage part and is characterized in that a high-voltage incoming wire metering cabinet of the high-voltage part is connected with an external industrial power grid, the output end of a high-voltage wire outgoing cabinet of the high-voltage part is connected with the input end of a transformer, the output end of the transformer is connected with the low-voltage part, and output ports are distributed in the low-voltage part. According to the invention, the problems of low energy efficiency, high loss and pollution caused in a fuel oil power generation process are solved, and the power supply system ensures that well drilling work is safer, more efficient and more environmentally-friendly, and is beneficial to increase of economic benefits.

Owner:海尔海斯(西安)控制技术有限公司

A pulse shock frequency generator

ActiveCN108252671BIncreased crushing impactImprove permeabilityVibration devicesShock wavePiston Guide

The invention relates to a pulse shock frequency generator. The pulse shock frequency generator comprises a liquid cylinder, a connecting rod, a piston and a pressure relief valve. The connecting rodis arranged in the liquid cylinder. The piston and the pressure relief valve are arranged on the connecting rod in a sleeving mode. The connecting rod is provided with a piston guide hole and a pressure relief valve guide hole. The pressure relief valve is arranged at the pressure relief valve guide hole in a hung mode and used for controlling opening and closing of a pressure relief opening of the liquid cylinder. The piston is arranged at the piston guide hole in a hung mode. The connecting rod is provided with a liquid inlet hole. According to the pulse shock frequency generator, mechanicalpulse shock waves can be produced through up-down reciprocating movement of the connecting rod; meanwhile, liquid of the liquid cylinder also produces pulse waves to be sprayed out of the liquid cylinder; therefore, the pulse shock frequency generator is widely used in various practical production areas such as mine mining, piling, equipment breaking-demolition and vibration tests, especially thepulse shock frequency generator plays an important role and application in oil exploitation, the difficulty of oil production is reduced, and the permeability of stratum rock is increased; breaking of the stratum rock is accelerated, the drilling speed of a drill bit is increased, and drilling aging is improved; and the salvage lifting load is reduced, and the salvage and unfreezing efficiency isimproved.

Owner:程显达 +1

A variable-diameter stabilizer that can be controlled on the ground

ActiveCN104594824BEasy to operateImprove reliabilityDrilling rodsDrilling casingsWell drillingEngineering

The invention belongs to the technical field of a downhole tool and particularly relates to a variable-diameter stabilizer capable of being controlled on the ground. The variable-diameter stabilizer comprises a pipe-shaped shell, wherein a central shaft is arranged in the shell; a self-locking groove is formed in the upper part of the central shaft; a tapered sleeve sleeves the middle part of the central shaft; a locking block square hole is formed in the upper part of the shell; a self-locking device is arranged in the locking block square hole; the inner end of the self-locking device corresponds to the self-locking groove in the central shaft; a plurality of cylindrical holes are uniformly formed in the shell along the peripheral direction and the axial direction; stabilization columns are arranged in the cylindrical holes; the inner ends of the stabilization columns are located on the outer wall of the tapered sleeve. According to the variable-diameter stabilizer capable of being controlled on the ground, the aim that the stabilizers with different outer diameter sizes are utilized in different well sections is realized. Meanwhile, the outer diameter conversion is realized by different ground operations and a control unit does not need to be specially and additionally arranged; the link that an existing non-electric-control variable-diameter stabilizer needs to control pump pressure or count the times of switching on and off a pump is overcome; the operation is simplified, the structure is simple, the operation is convenient and the well drilling timeliness is improved.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

Eccentric center-adjustable reducing stabilizer

ActiveCN101463712BReduce wearExtended service lifeDrilling rodsDirectional drillingDirectional wellWell drilling

The invention relates to an eccentric adjustable stabilizer with a variable diameter, which is used for being combined with an underground directional or anti-tip drilling tool, can be used in match with a rotary directional drilling system, and can realize the automatic underground diameter variation and the eccentric adjustment, improve the level of the drilling technique and increase the economic benefit. The technical scheme is as follows: a compression sleeve barrel, a cross joint, a diameter variation mechanism, a cross joint, a gear shifting piston and a gear shifting mechanism are sequentially installed on the inner cavity of a housing from the top to bottom; five fixed cylindrical bodies are installed on a protruded arris of the outer part of the housing in an axial direction, five moveable hard alloy cylinders are respectively installed in the inner cavities of the other two protruded arrises in an axial direction, the front end of a gear shifting dowel pin in the gear shifting mechanism is inserted in the gear shifting slot of a gear shifting cam body, and gear shifting slots with special traces are arranged on the outer periphery of the gear shifting cam body. The gearshifting cam body can be moved up and down, can be rotated, can automatically realize the diameter variation and the eccentricity underground, and can realize step gear shifting and stepless gear shifting. The eccentric adjustable stabilizer with the variable diameter has the advantages of high intensity, favorable leak-proofness and long service life, and can be used for the drilling construction of directional wells and straight wells, thereby improving the overall drilling technical and the economic benefits.

Owner:SOUTHWEST PETROLEUM UNIV

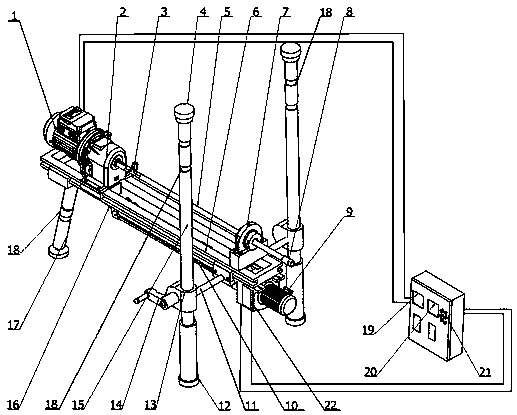

An all-electric coal mine tunnel drilling rig

InactiveCN106050126BSimple structureReduce weightConstructionsDerricks/mastsControl systemClosed loop

The invention discloses an all-electric coal mine underground drill rig which comprises a rotating mechanism, a feeding mechanism, a lifting and angle change mechanism and a control system. The height and direction of a main engine are adjusted through cooperation of a gear-rack lifter and screw telescoping mechanisms on a supporting leg and stand columns. The rotating speed and rotating direction of a rotary motor are controlled through the control system to adjust the rotating direction and rotating speed of the drill rig, and constant-rotating-speed drilling is achieved. The rotating direction and rotating speed of a feeding motor are controlled through the control system to achieve feeding and lifting at different speeds, the rotating speed of a control motor is fed back in a closed loop through the pressure of a feeding mechanism closed hydraulic system, and constant-drilling-pressure feeding of the feeding mechanism is achieved. The drill rig is simple in structure, low in weight and lower in power consumption, and labor is saved during operation.

Owner:JILIN UNIV

A variable diameter stabilizer

ActiveCN106761470BShorten the soaking timeReduced risk of collapseDrilling rodsDrilling casingsSingle supportEngineering

The invention provides a variable-diameter stabilizer which comprises a shell, a piston, a slide sleeve, a cone sleeve and a righting column. The cone sleeve is arranged on the lower portion of the piston, the righting column is arranged on the shell, and the cone sleeve and the righting column are matched with each other, so that the diameter can vary. The variable-diameter stabilizer has the advantages that the variable-diameter stabilizer can be controlled from the ground, so that the purpose of varying the diameter can be achieved; balls are cast to wellheads repeatedly, and accordingly the drafting purposes can be achieved by the aid of different drilling tool combinations without tripping out when the corresponding stabilizer is in rolling-out states; only drilling strings need to be tripped out to casing legs when double-support or triple-support drafting needs to be carried out, the balls can be cast, the righting column of the double-support (or triple-support) drafting variable-diameter stabilizer can stretch out under the control, and single-support, double-support and triple-support drafting can be carried out; the trip-out time can be saved when the stabilizer is used, the well wall soaking time can be shortened, downhole collapse risks can be reduced, and the drafting efficiency can be improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com