Fabrication method for hot pressing diamond bit with added aluminium oxide hollow balls

An alumina hollow ball and diamond drill bit technology is applied in drill bits, drilling equipment, earth-moving drilling and other directions to achieve the effects of increasing the drilling pressure, improving the effect of cutting edge and improving the coefficient of friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Take the manufacturing method of the hot-pressed diamond drill bit adding aluminum oxide hollow balls of the present invention as an example to manufacture the φ77 / 48mm specification drill bit, and the specific process steps are:

[0027] (1) Prepare the material for alumina hollow sphere granulation and film coating: select alumina hollow spheres with a diameter of 1 to 3mm, and the film coating material is copper-iron-graphite mixed powder, and the copper-iron-graphite mixed powder is based on mass The ratio is: copper 45%, iron 35%, graphite 20%; the adhesive is triethanolamine.

[0028] (2) The granulation film coating machine adopts the self-developed stepless speed regulation granulator. The barrel of the granulation film coating machine is drum-shaped, the maximum diameter of the barrel is 350mm, and the height is 200mm. The central axis of the barrel and the horizontal angle Adjust to 45°, and adjust the speed of the granulator to 60r / min.

[0029...

Embodiment 2

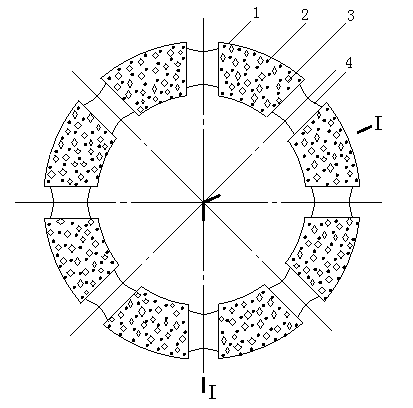

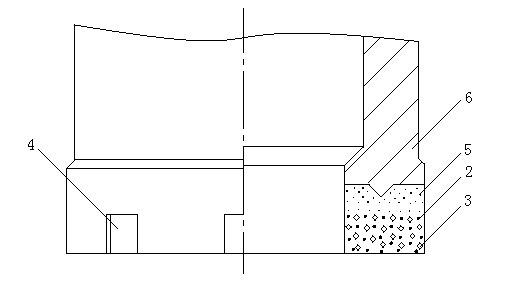

[0035]Embodiment 2: Adopt the manufacturing method of the hot-pressed diamond drill bit that adds aluminum oxide hollow ball of the present invention to manufacture φ95 / 68 specification drill bit, each step of specific process is basically the same as embodiment 1, difference is: fan-shaped cutting working block 1, nozzle 4 There are 10 pieces, the height of the fan-shaped cutting work block 1 is 12mm, and the height of the gauge layer 5 of the drill bit is 9mm. As the specifications of the drill bits are different and the caliber becomes larger, the amount of the matrix material of the drill bit is different accordingly, so step (5) and step (6) must be different.

[0036] Step (5) Take the matrix powder of the drill bit. The matrix powder of the drill bit is: iron 36%, nickel powder 12%, YG8 powder 8%, cobalt 3%, copper alloy powder 41%. Mill in a ball mill for 8 hours to ensure that all kinds of powders are mixed and ground evenly. φ95 / 68 specification drill bits require 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com