Patents

Literature

341results about How to "Improve drilling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

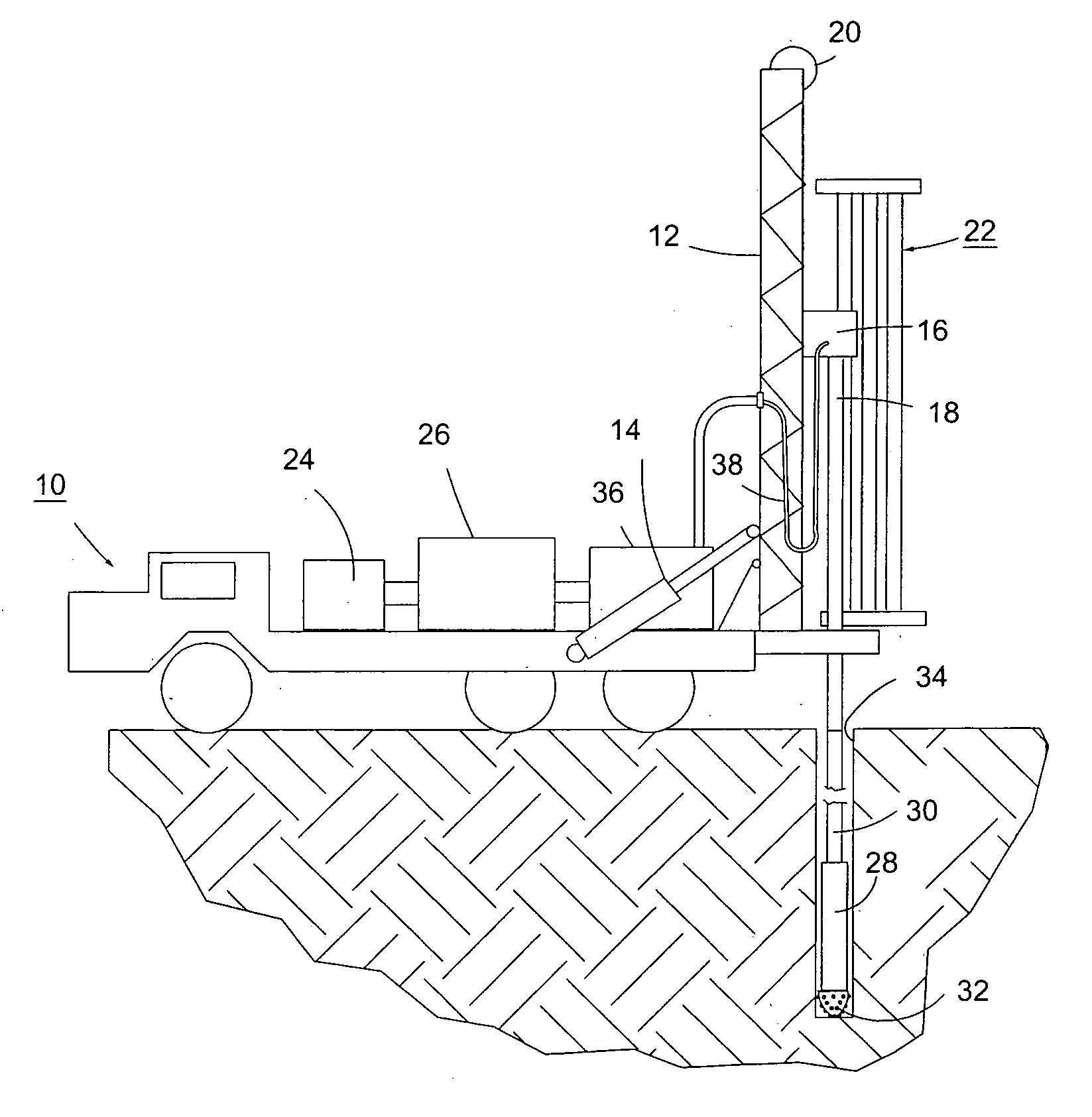

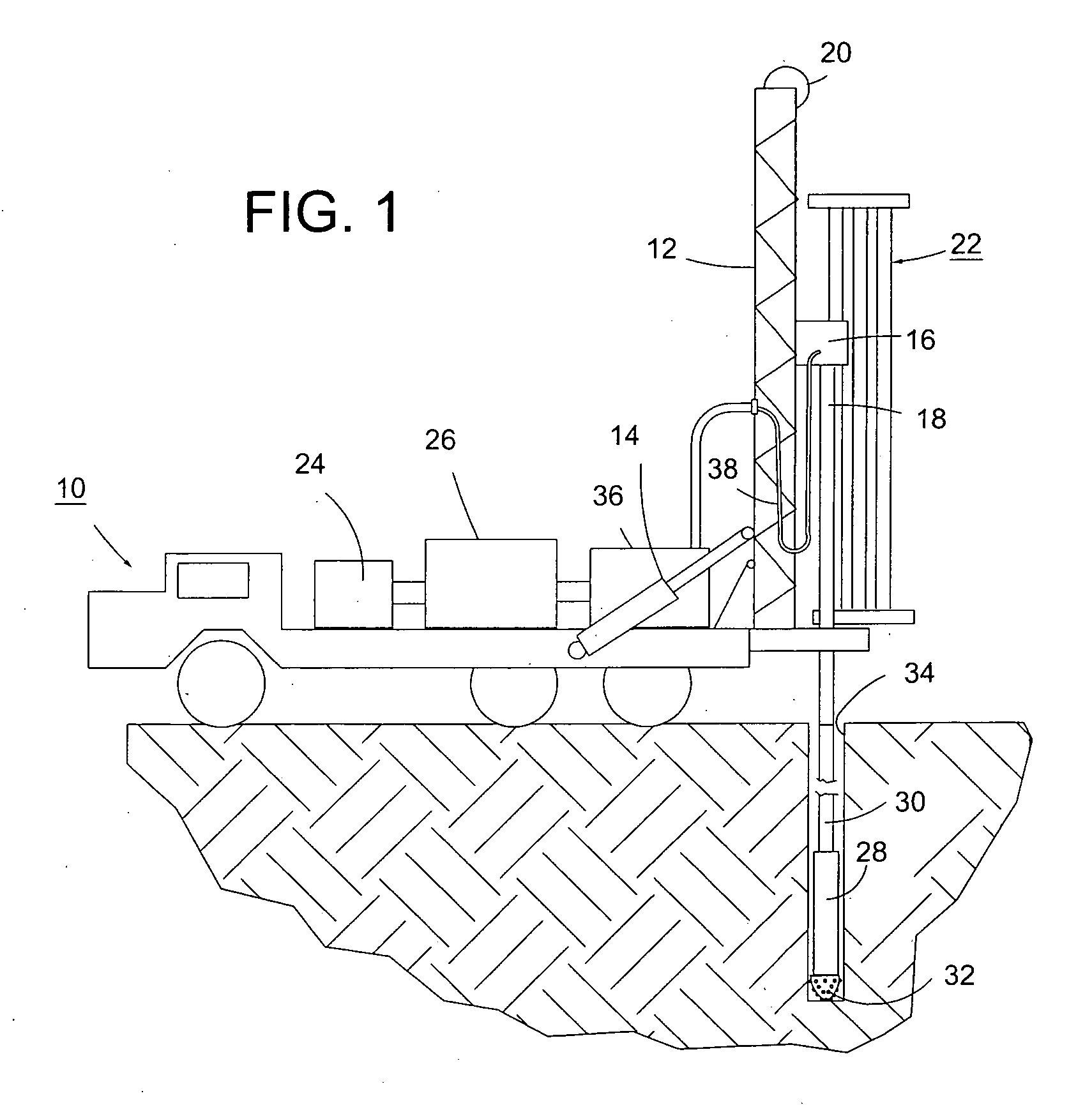

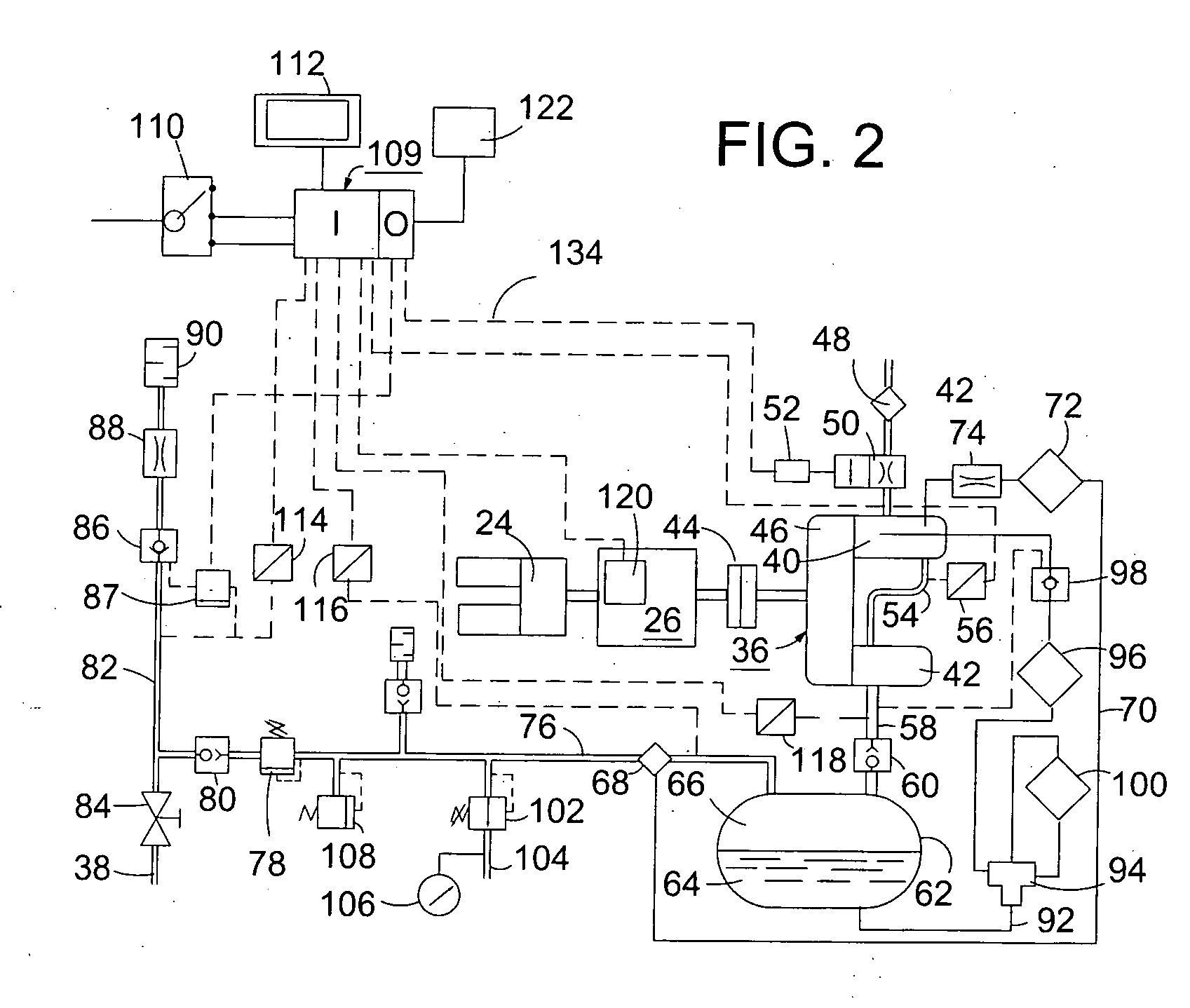

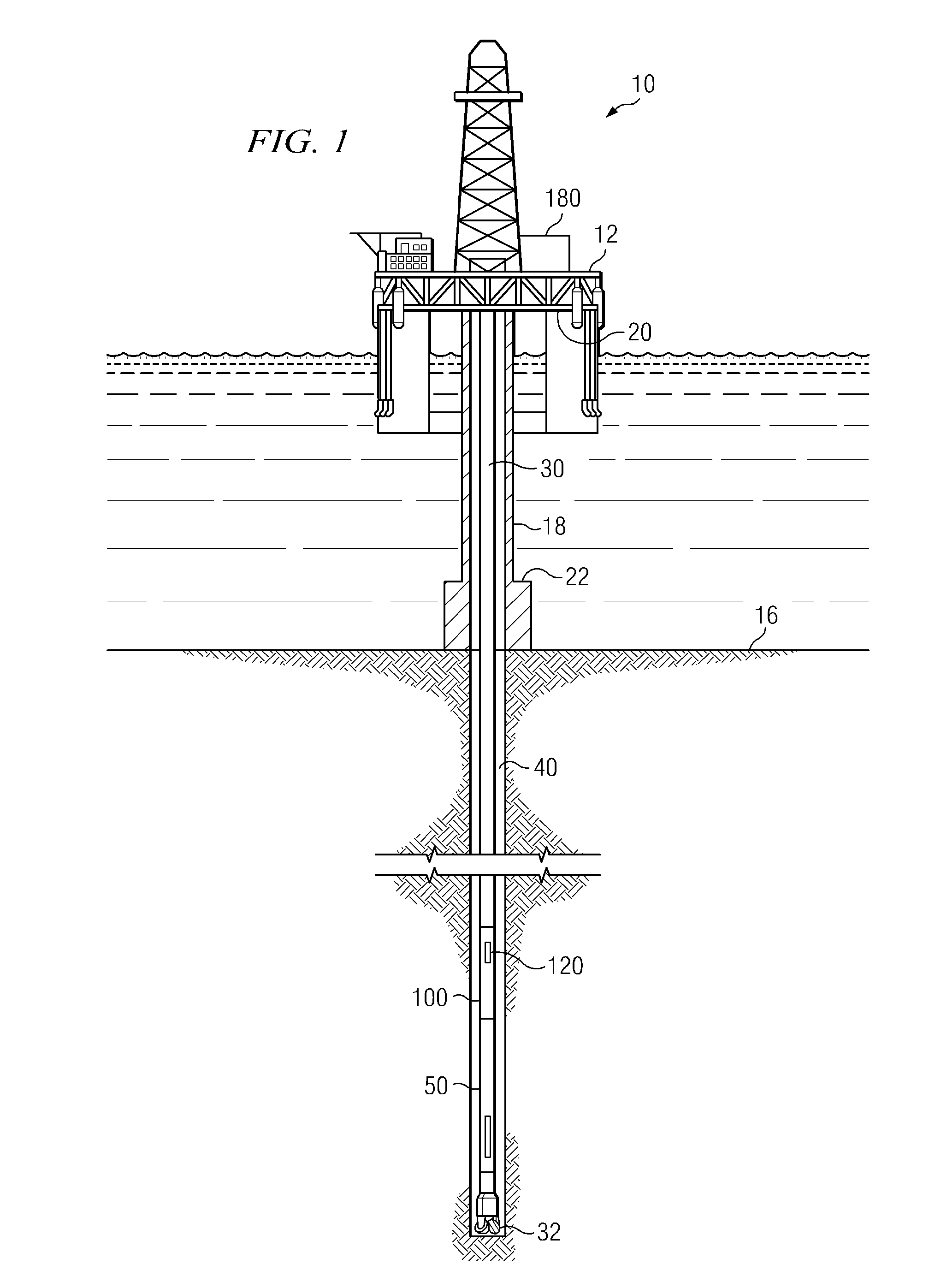

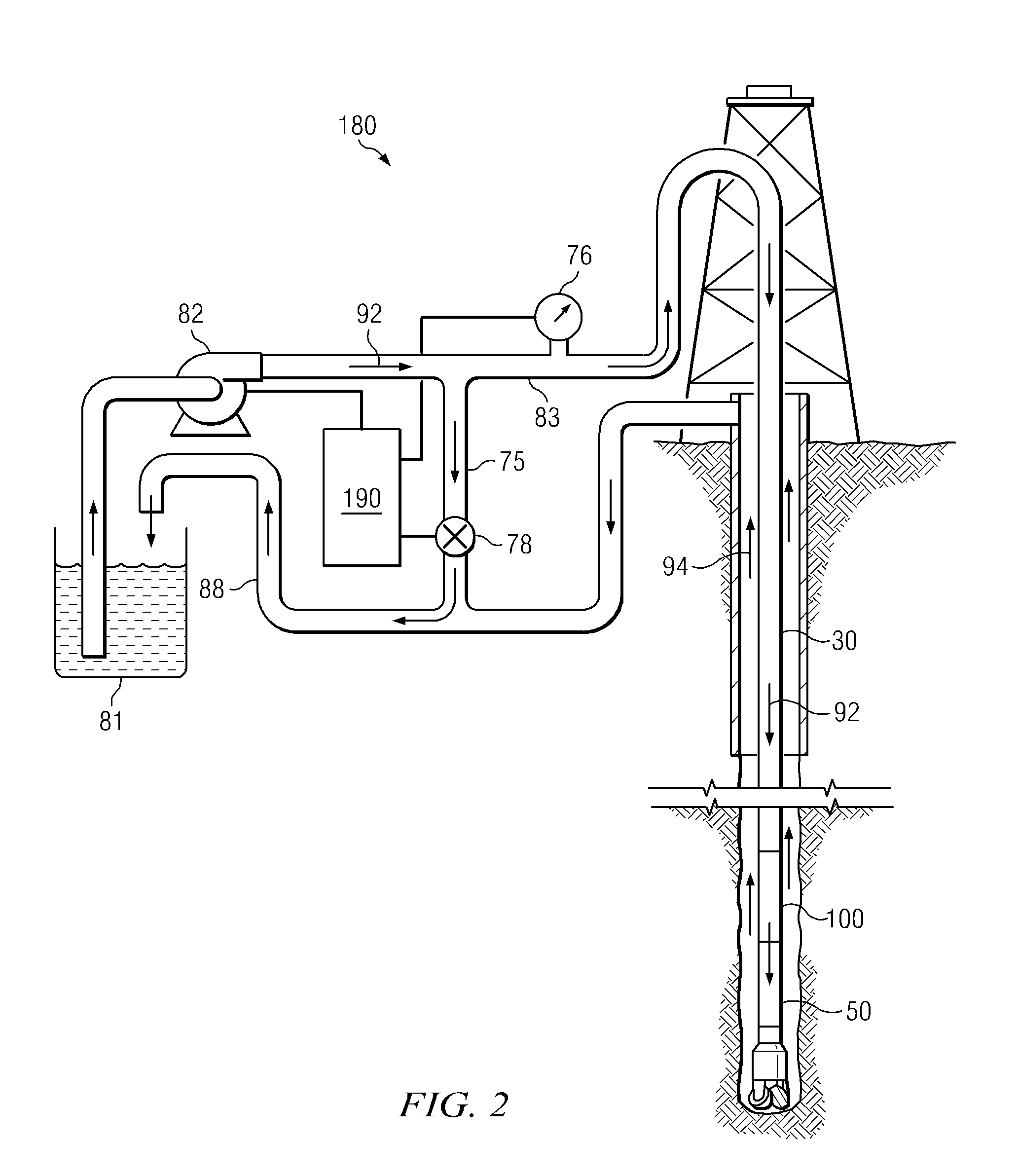

Earth drilling rig having electronically controlled air compressor

InactiveUS20070246262A1Reduce generationImprove drilling qualityDrilling rodsConstructionsCritical levelElectronic controller

In an earth drilling rig in which an air compressor and one or more hydraulic pumps are driven by the same engine, the intake throttle of the compressor is controlled by an electronic controller having a proportional integral derivative control. The controller minimizes unloading of the compressor, allowing the engine to operate more efficiently, the hydraulic system to provide more consistent power to drilling functions and the volume and pressure of compressed air to be optimized for the drilling conditions encountered. The electronic controller also operates a blowdown valve at the discharge side of an air receiver, and effects various overrides of the control system, for example when air discharge temperature approaches a critical level, or when an overpressure condition is detected.

Owner:SCHRAMM INC

Copper foil excellent in laser beam drilling performance and production method therefor

InactiveUS6638642B2Improve drilling effectFine surfaceRadiation applicationsExtrusion containersIndiumCopper foil

Owner:JX NIPPON MINING & METALS CORP

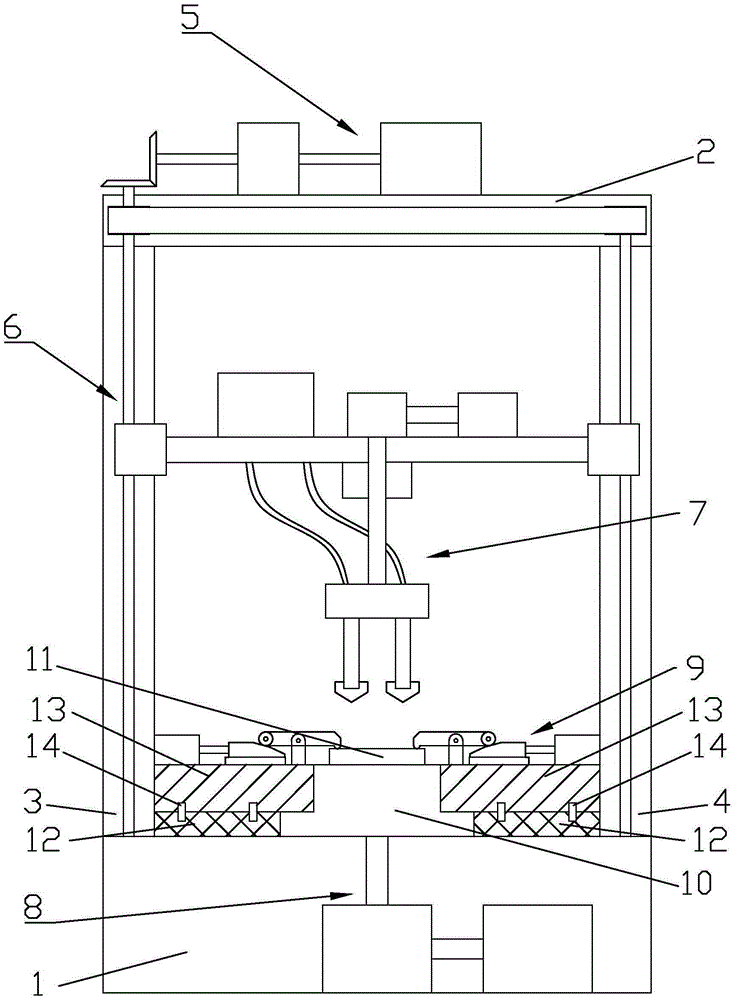

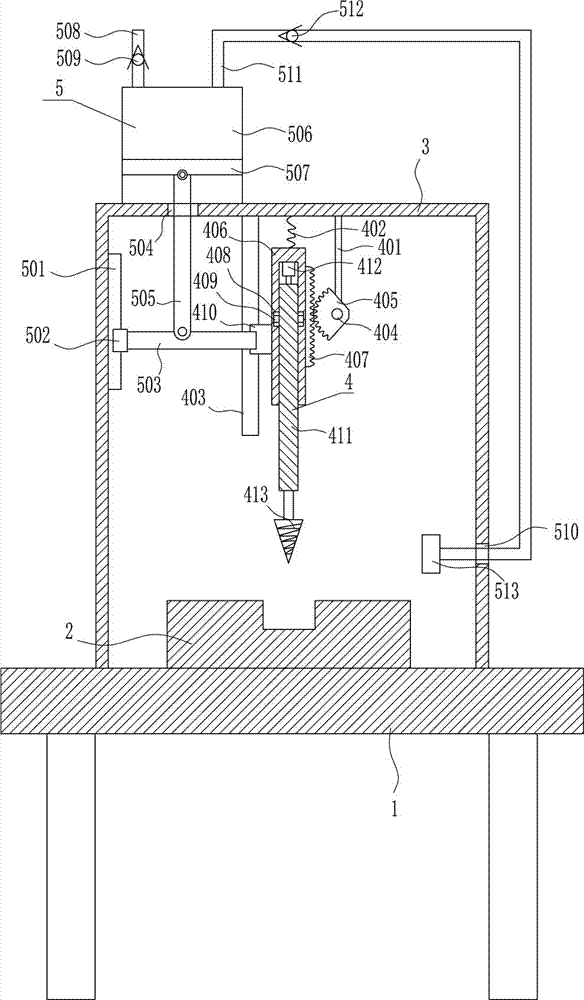

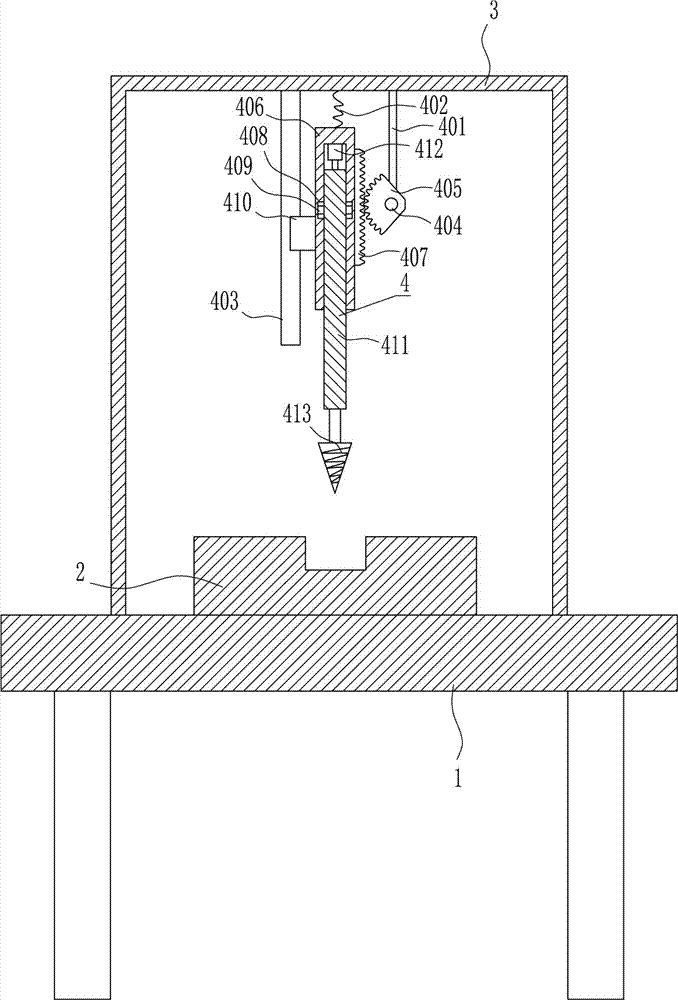

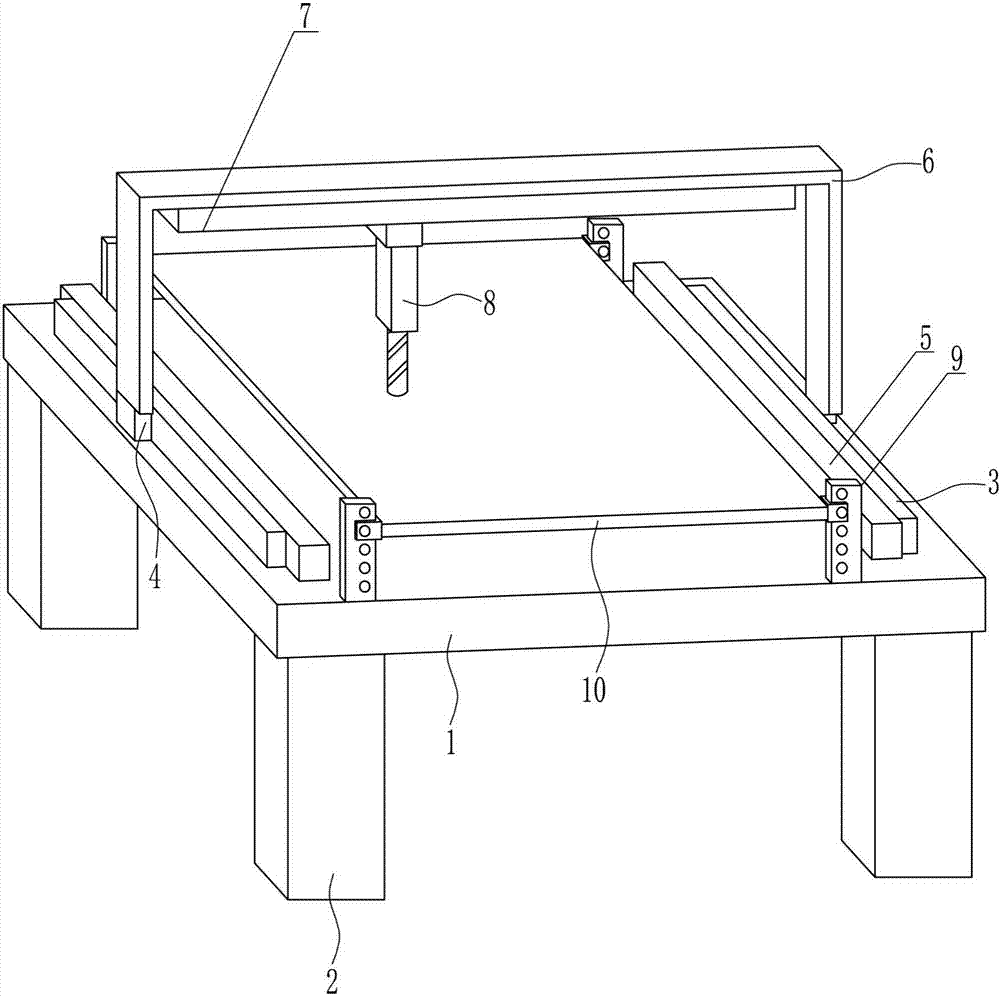

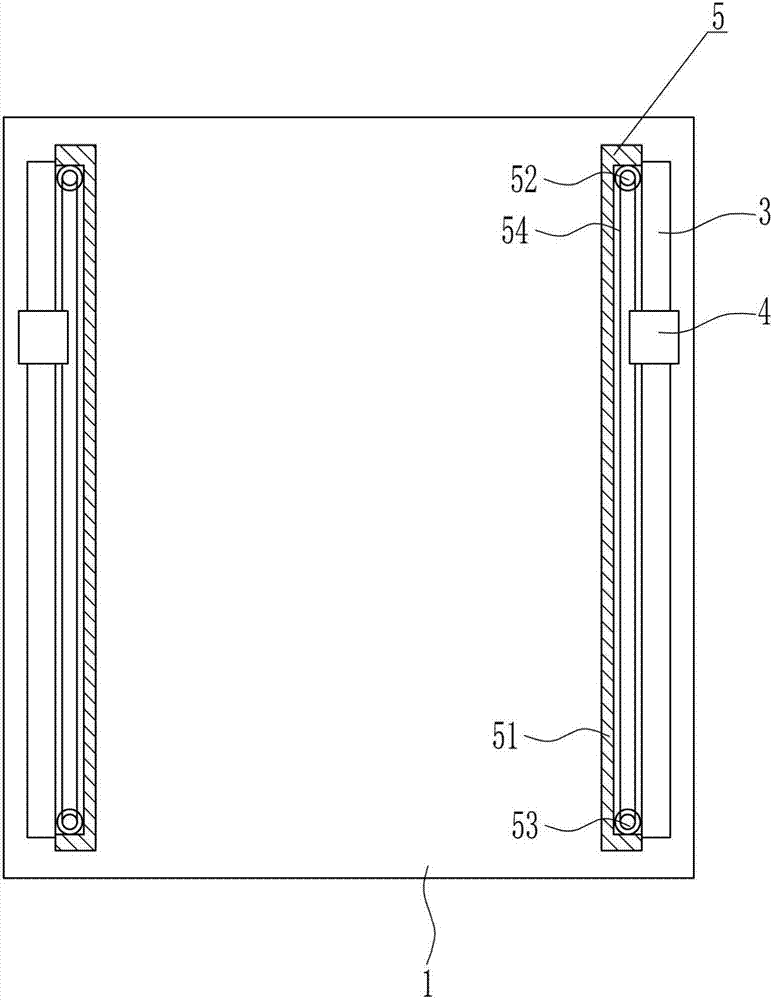

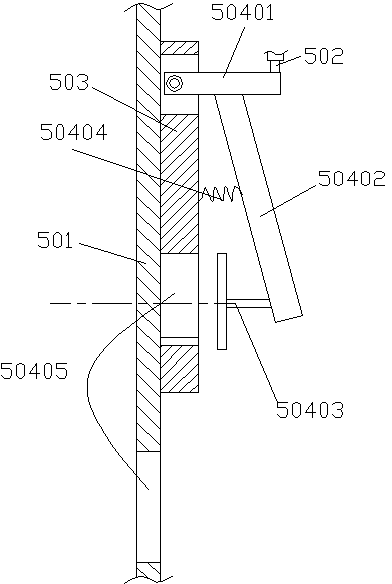

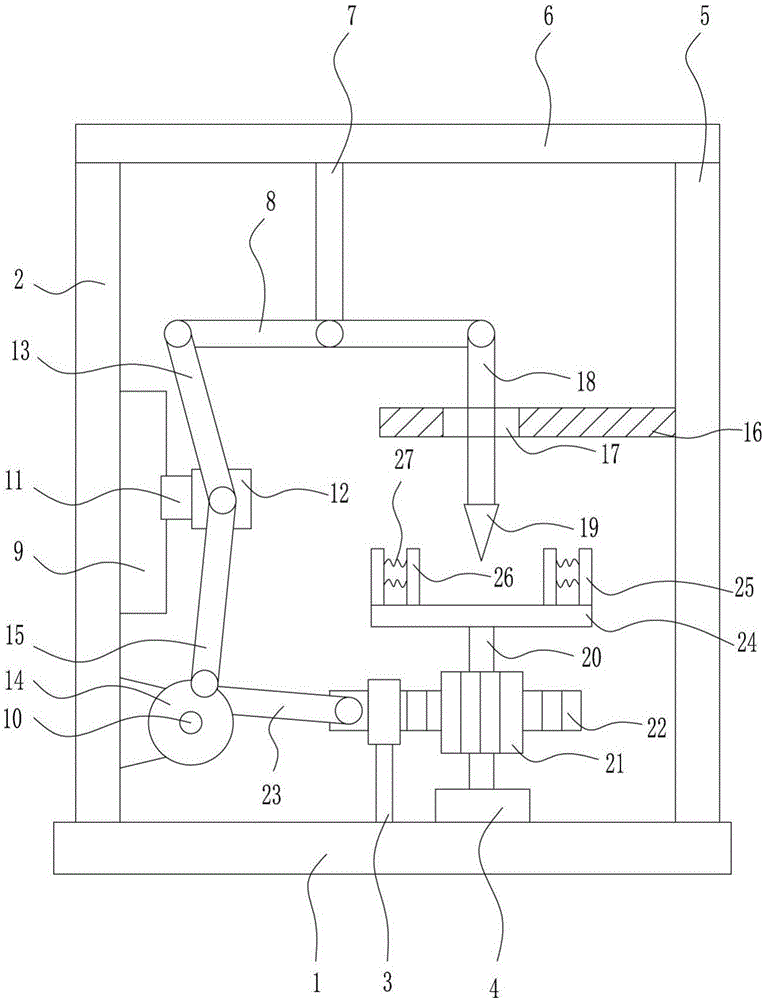

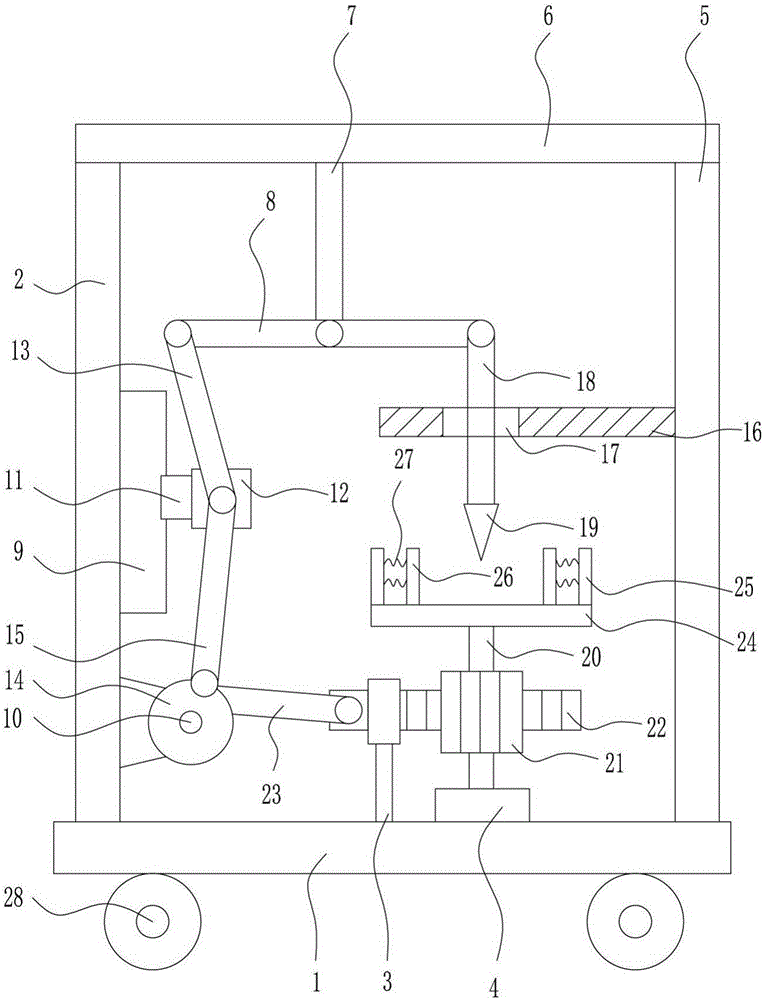

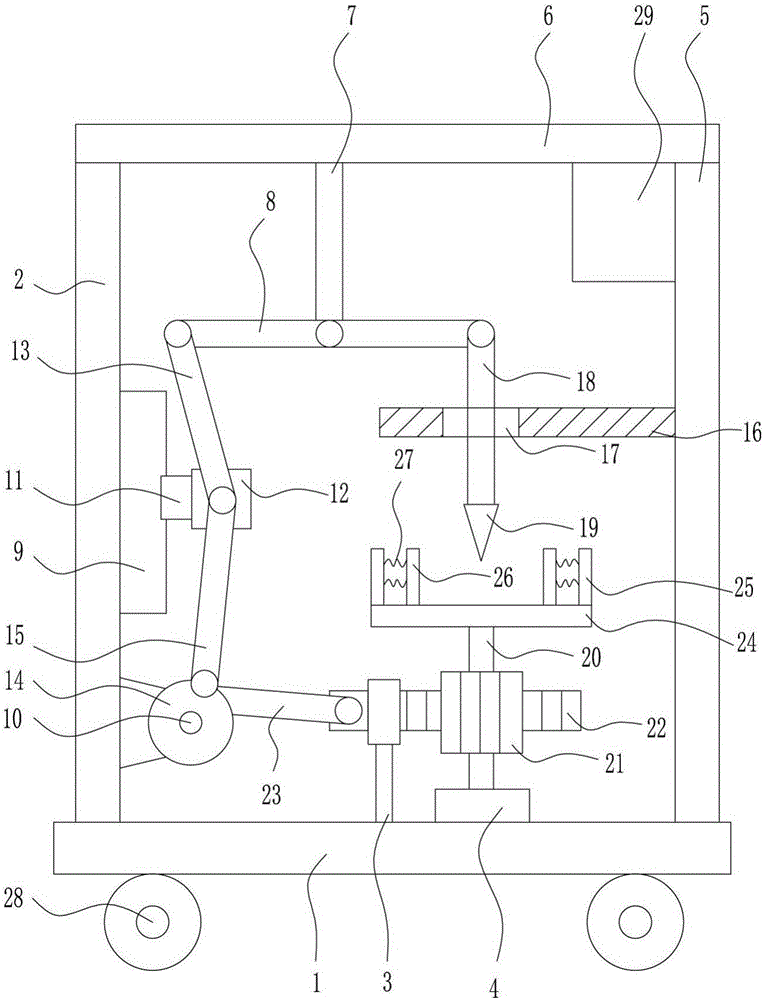

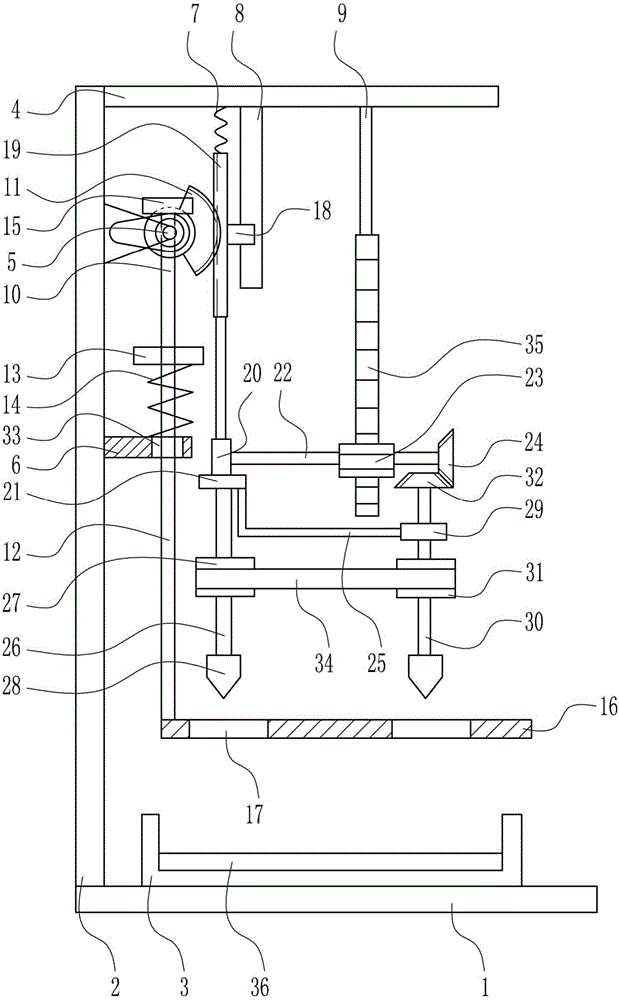

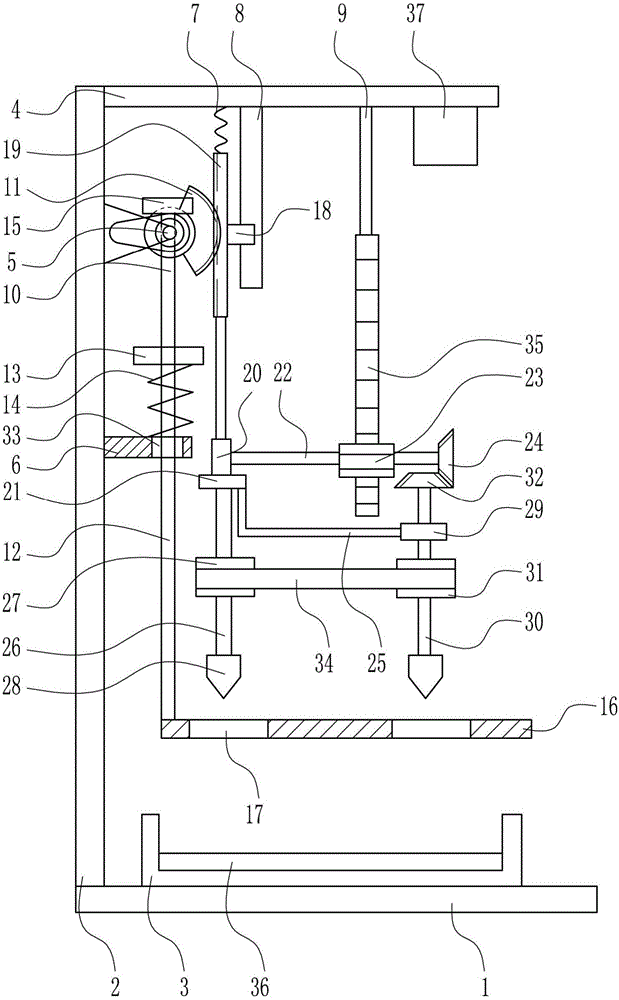

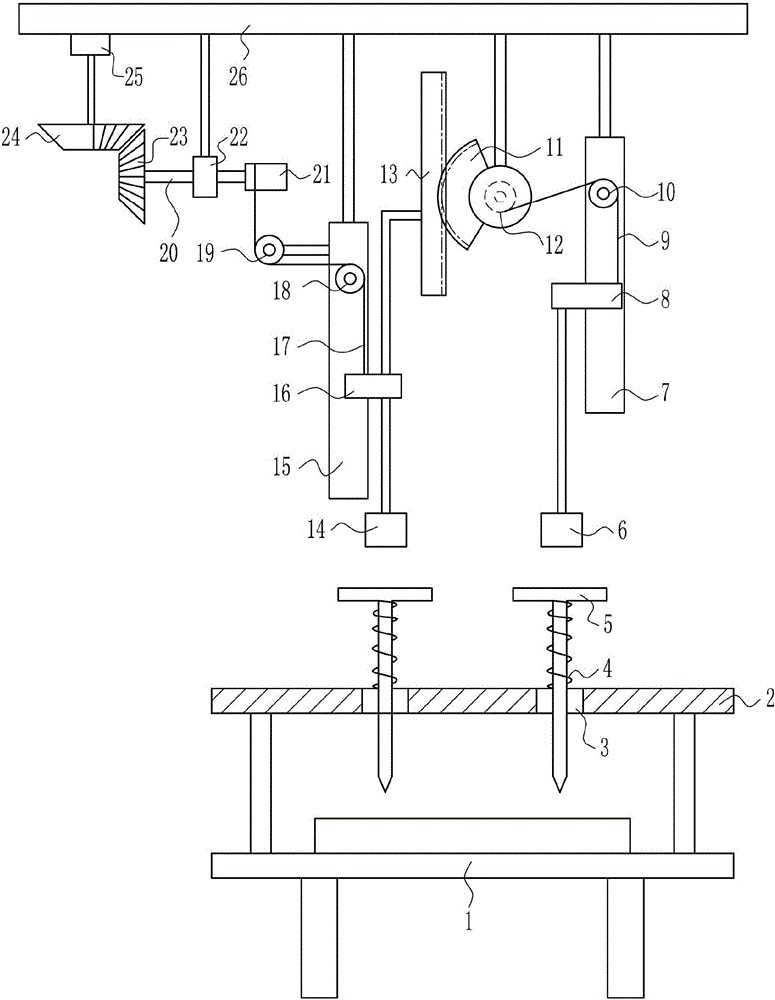

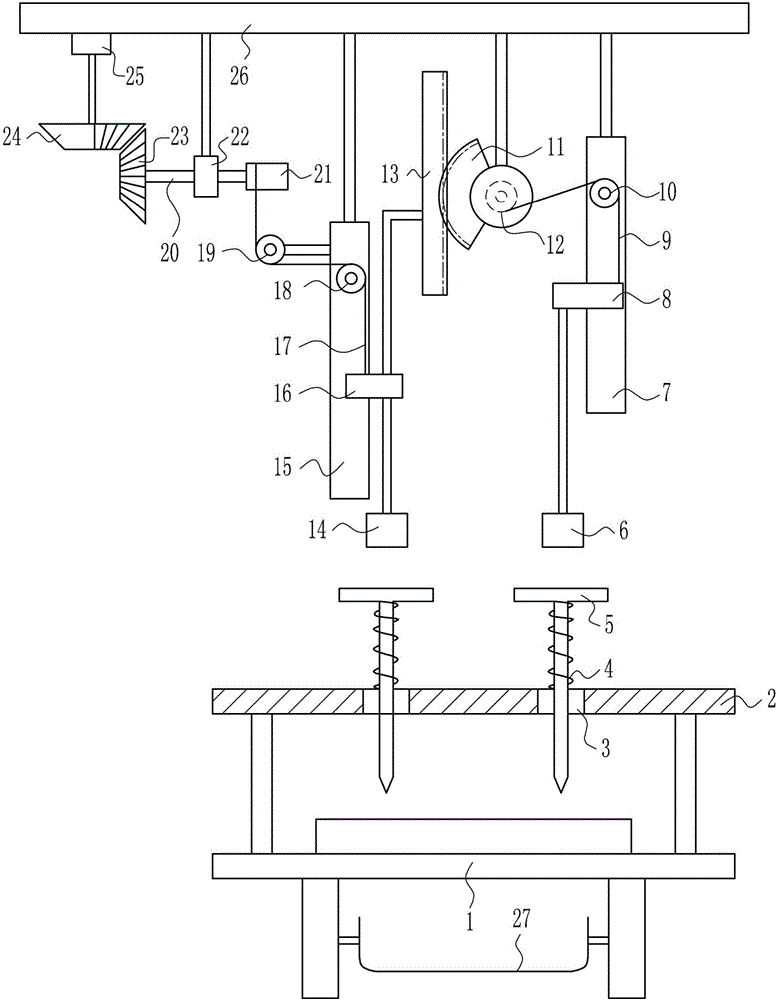

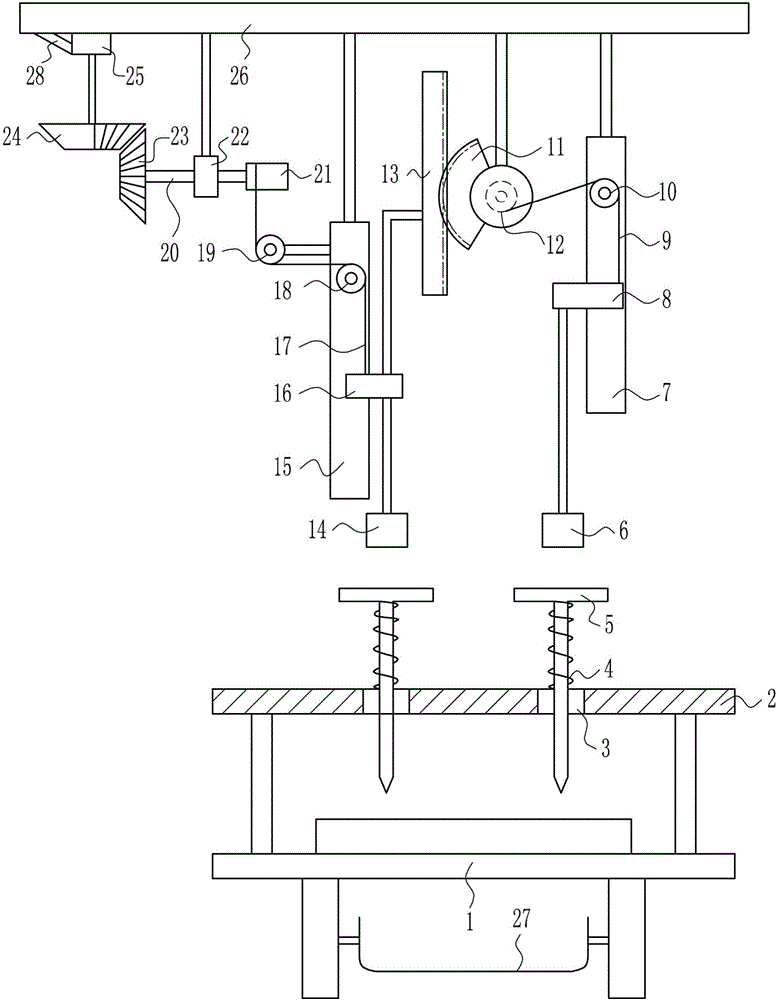

Drilling device applied to graphite mold production

InactiveCN105414599ASolving Drilling ProblemsStrong targetingWorkpiecesTurning toolsElectric machineryReducer

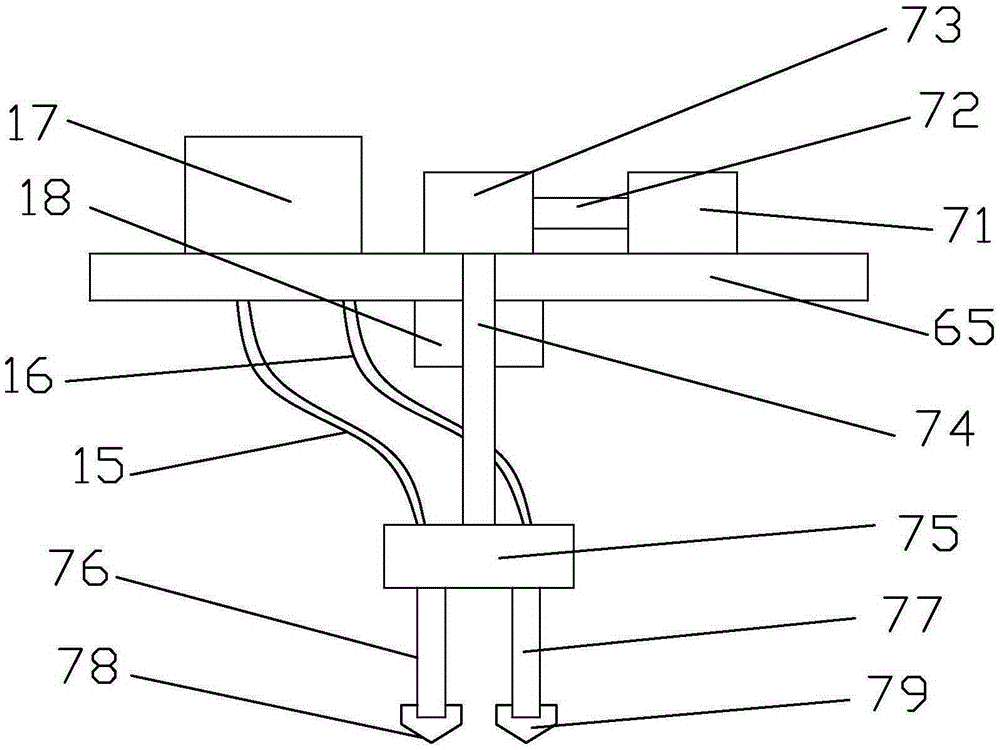

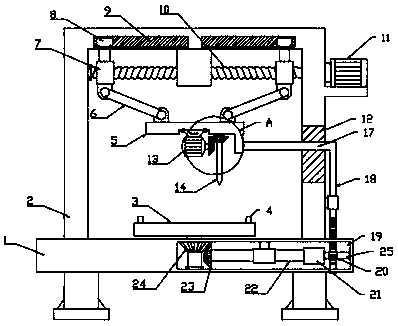

The invention discloses a drilling device applied to graphite mold production. The drilling device comprises a frame and a drilling table; drilling longitudinal frames and a drilling transverse frame are arranged on the frame; the drilling longitudinal frames are positioned at the two sides of the frame; the drilling transverse frame is positioned between the drilling longitudinal frames, and is provided with a lifting driving mechanism and a lifting mechanism; the lifting mechanism includes lifting platforms and lifting lead screws; the lifting lead screws are mounted in the drilling longitudinal frames, and are connected with lifting lead screw connecting bases; the lifting lead screw connecting bases are connected with the lifting platforms; drilling mechanisms are arranged on the lifting platforms, and include drilling motors and drilling lead screws; the drilling motors are connected with drilling motor output shafts; the drilling motor output shafts are connected with drilling speed reducers; the drilling speed reducers are connected with the drilling lead screws; the drilling lead screws are connected with drilling bases; and the drilling bases are connected with drill rods. The machine is simple in structure, strong in pertinency, precise in positioning and excellent in drilling effect, and preferably solves the drilling problem in the graphite mold production.

Owner:SHENGZHOU SIGMA TECH

Hot pressing high phosphorus iron base diamond drilling bit and preparation method thereof

The invention relates to a hot compression high phosphorus iron-base diamond bit and the preparation method. The content of the diamond is 75 percent to 95 percent, the matrix materials have the component and the content that Fe powder is 35 percent to 50 percent; P is 3 percent to 6 percent; B is 1 percent to 2 percent; Ni is powder 5 percent to 10 percent; Co powder is 5 percent to 7 percent; 663-Cu powder is 25 percent to 32 percent; Mn powder is 2percent to 3 percent; Ti powder is 1 percent to 2 percent; rare earth La is 1.5 percent to 2 percent, and rare earth Ce is 1.0 percent to 1.5 percent. The preparation method comprises the procedures of material preparation, material packing and material mixture, die filling, hot-pressed sintering. The invention has the advantages that the matrix materials are widely used, and the cost is low; the sintering temperature is decreased; the hot etching of the iron to the diamond under high temperature is reduced; and the service life of the drill bit are improved; the drill bit has a broad spectrum; and the application scope is wide.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

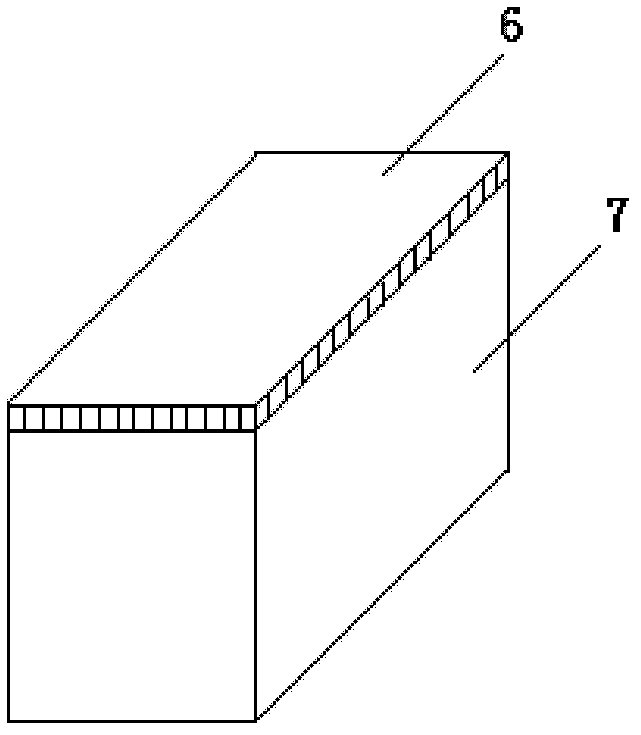

Automatic punching device for processing parts

InactiveCN109570548AHigh degree of automationImprove drilling accuracyFeeding apparatusPositioning apparatusAutomationThreaded rod

The invention discloses an automatic punching device for processing parts. The automatic punching device comprises a bottom plate, a bracket, a placing table, a bidirectional threaded rod and a transmission cavity; the right end of a working table is provided with a transmission cavity, a bevel gear D is arranged on the inner side of the transmission cavity, a rotating shaft of the bevel gear D penetrates through the transmission cavity to reach the upper end of the working table and to be fixedly connected with the lower end of the placing table, and the upper end of the placing table is provided with a fixing mechanism. The automatic punching device is novel in design, when a push plate moves downwards, a rack plate is driven by a connecting rod to move downwards, when the rack plate moves downwards, an annular gear on a third rotating rod drives ratchet teeth to rotate, the ratchet teeth cannot drive a second rotating rod to rotate under the effect of pawls, after punching is completed, a positive and negative rotation motor rotates reversely, at the time, the push plate moves upwards, rotation of the second rotating rod is achieved, the placing table is driven to be rotated under the effects of a bevel gear C and the bevel gear D, rotation of part plates is achieved, automatic transposition and punching are achieved, and the automation degree is high.

Owner:泰州市津专知识产权服务有限公司

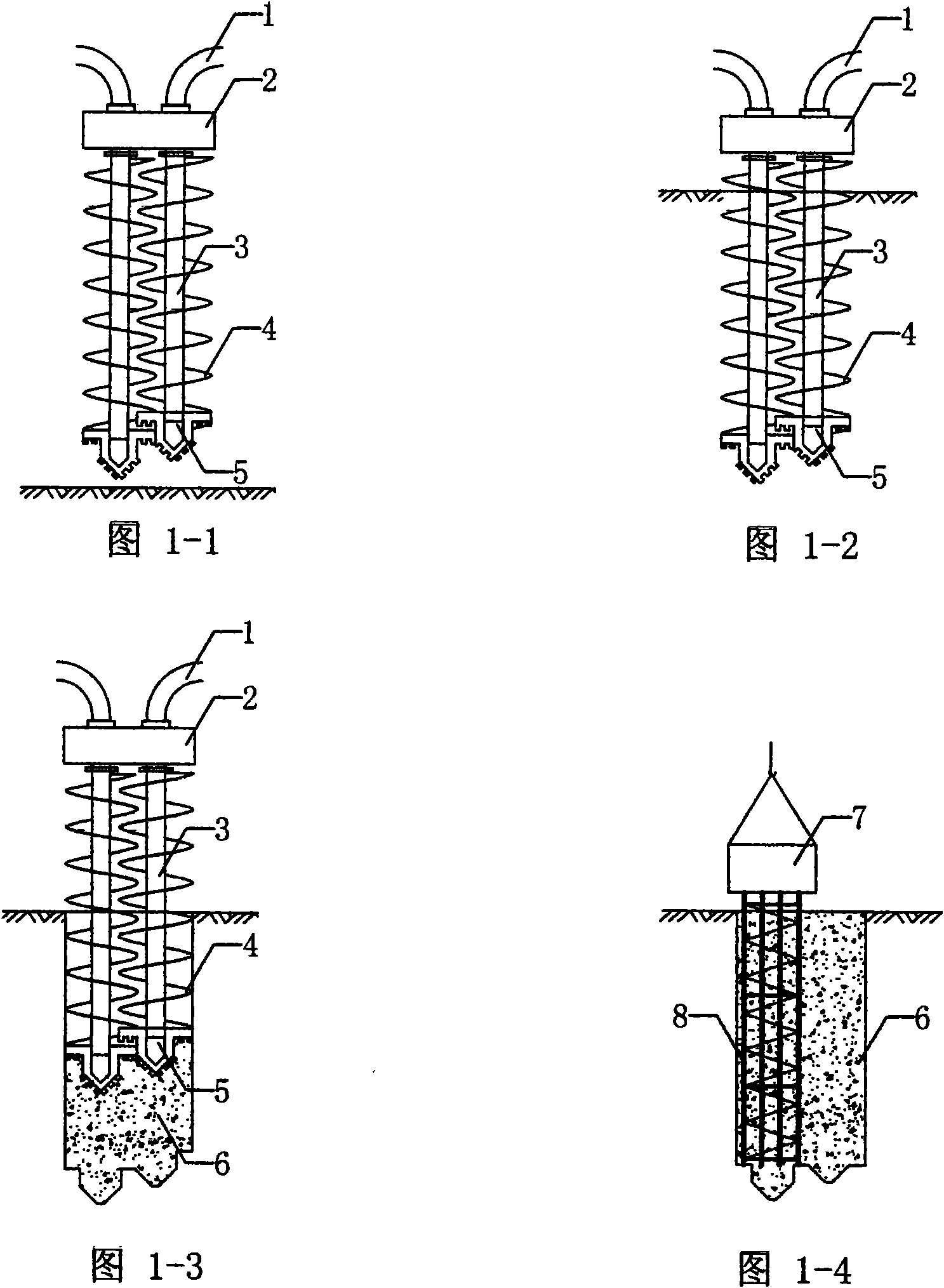

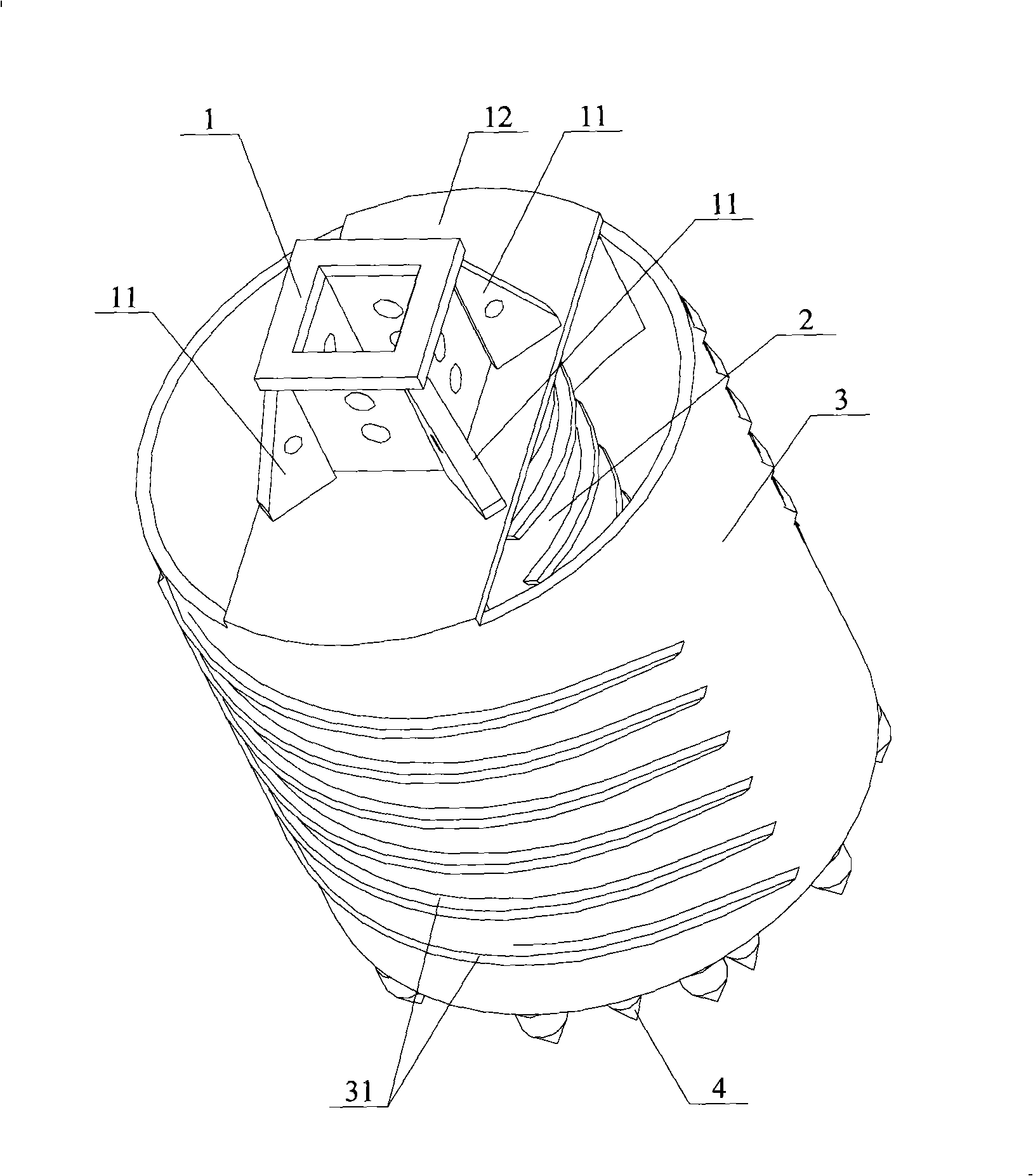

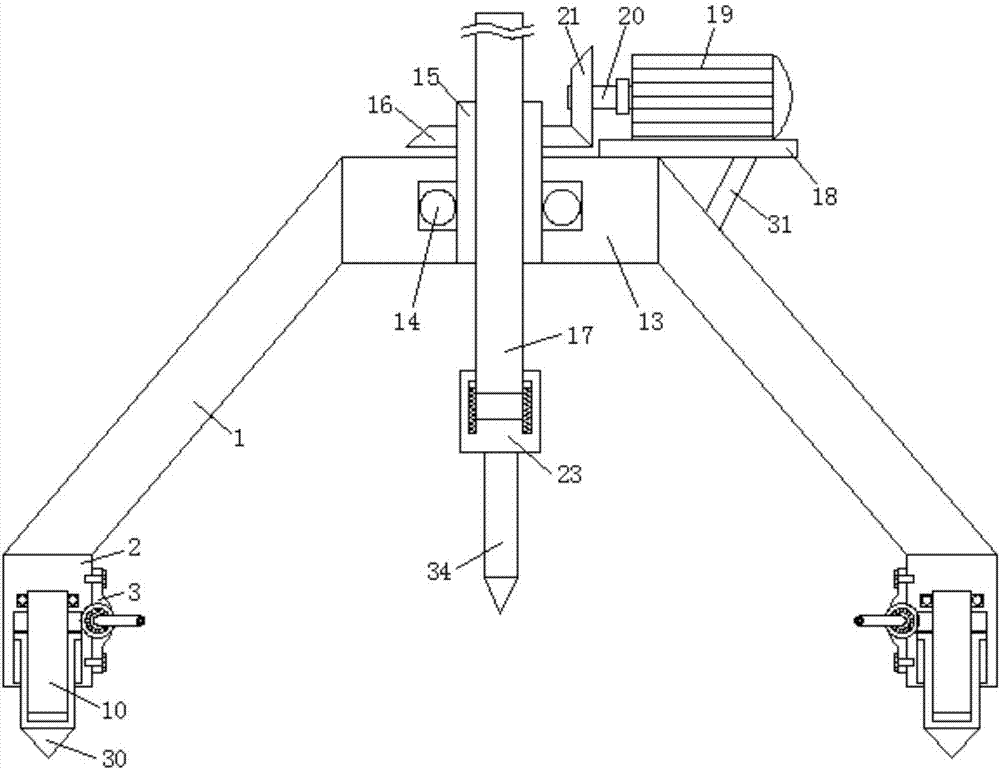

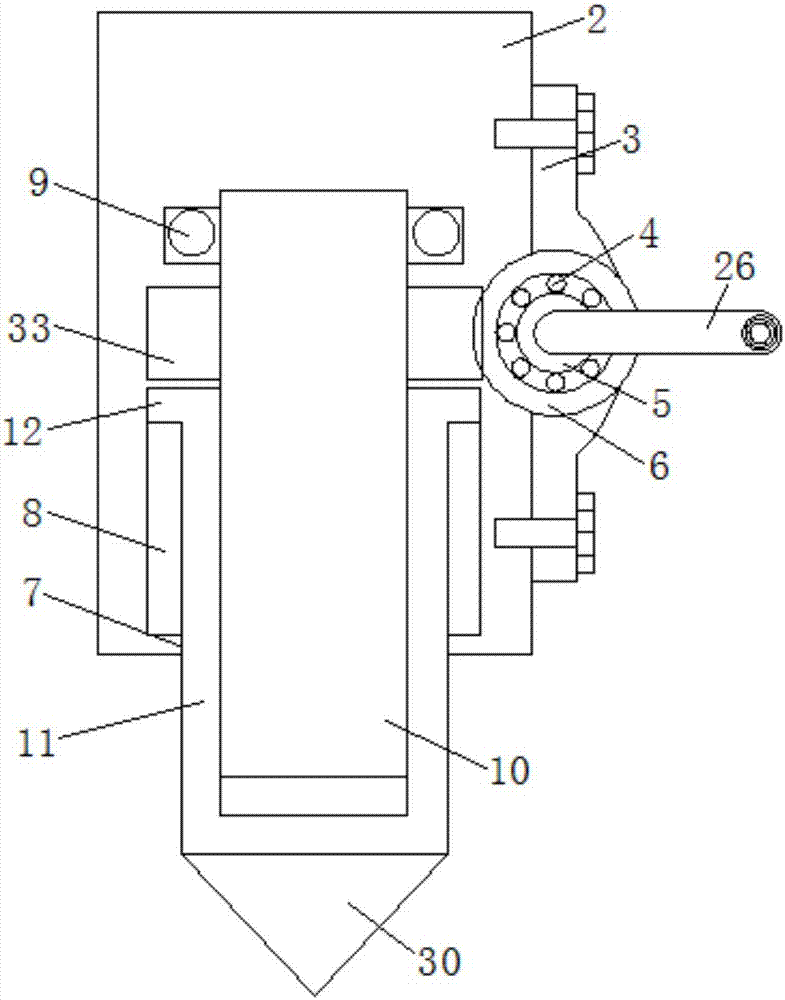

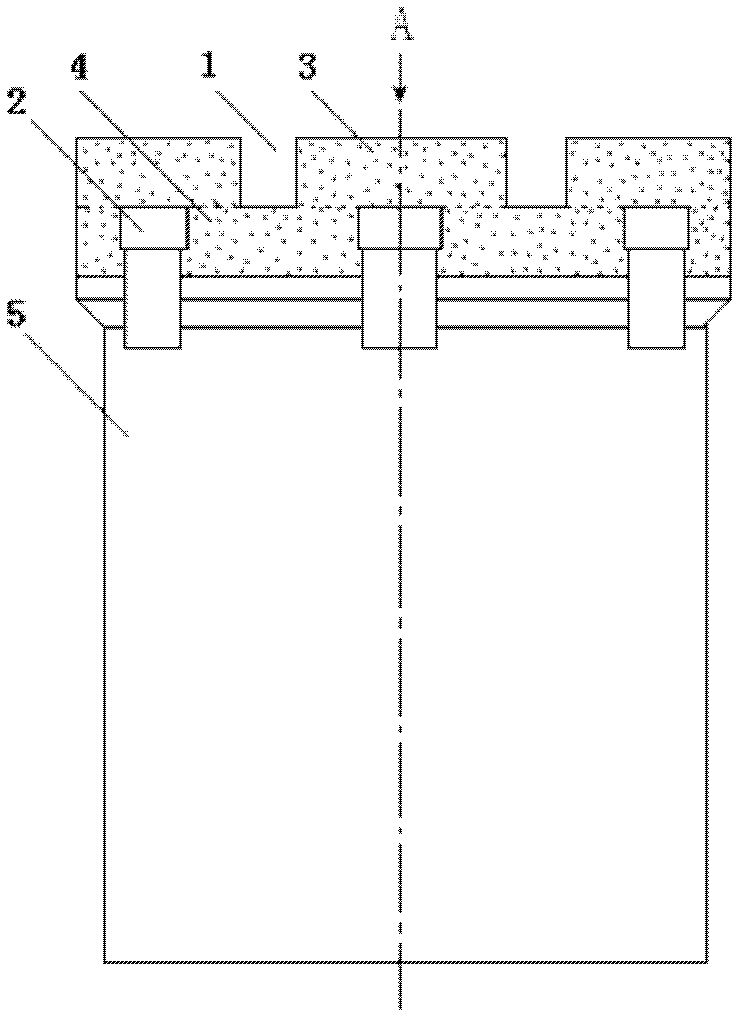

Underground continuous wall construction technique of multi-spindle long spiral drill pipe occluding pile

InactiveCN101560765AIncreased drilling capacityAccelerateArtificial islandsUnderwater structuresDry soilDrill pipe

The invention relates to an underground continuous wall construction technique of multi-spindle long spiral drill pipe occluding pile, which belongs to deep foundation and underground continuous wall construction technique and is suitable for construction of deep foundation maintenance walls in civil engineering and deep foundation of buildings. In the construction technique, a plurality of long spiral drill pipes (3) are adopted, wherein continuously spiral blades are arranged along the whole length of the outer walls of the drill pipes, and the drill pipe cores are hollow. During work, a drive set (2) drives the long spiral drill pipes (3) to carry out drilling operation simultaneously in such a way that two adjacent drill pipes rotate in opposite directions, so that large-caliber and large-depth construction is realized; and the spiral blades of adjacent long spiral drill pipes rotate in opposite directions so that the spiral blades can occlude each other in the whole length all the time to effectively ensure the constructing quality of the buildings. The invention can reduce the use level of steel products, effectively reduces the cost of the engineering and only discharges dry soil during the construction so as to be beneficial to the spot management of the construction and achieve environmental-friendly construction.

Owner:万勇 +7

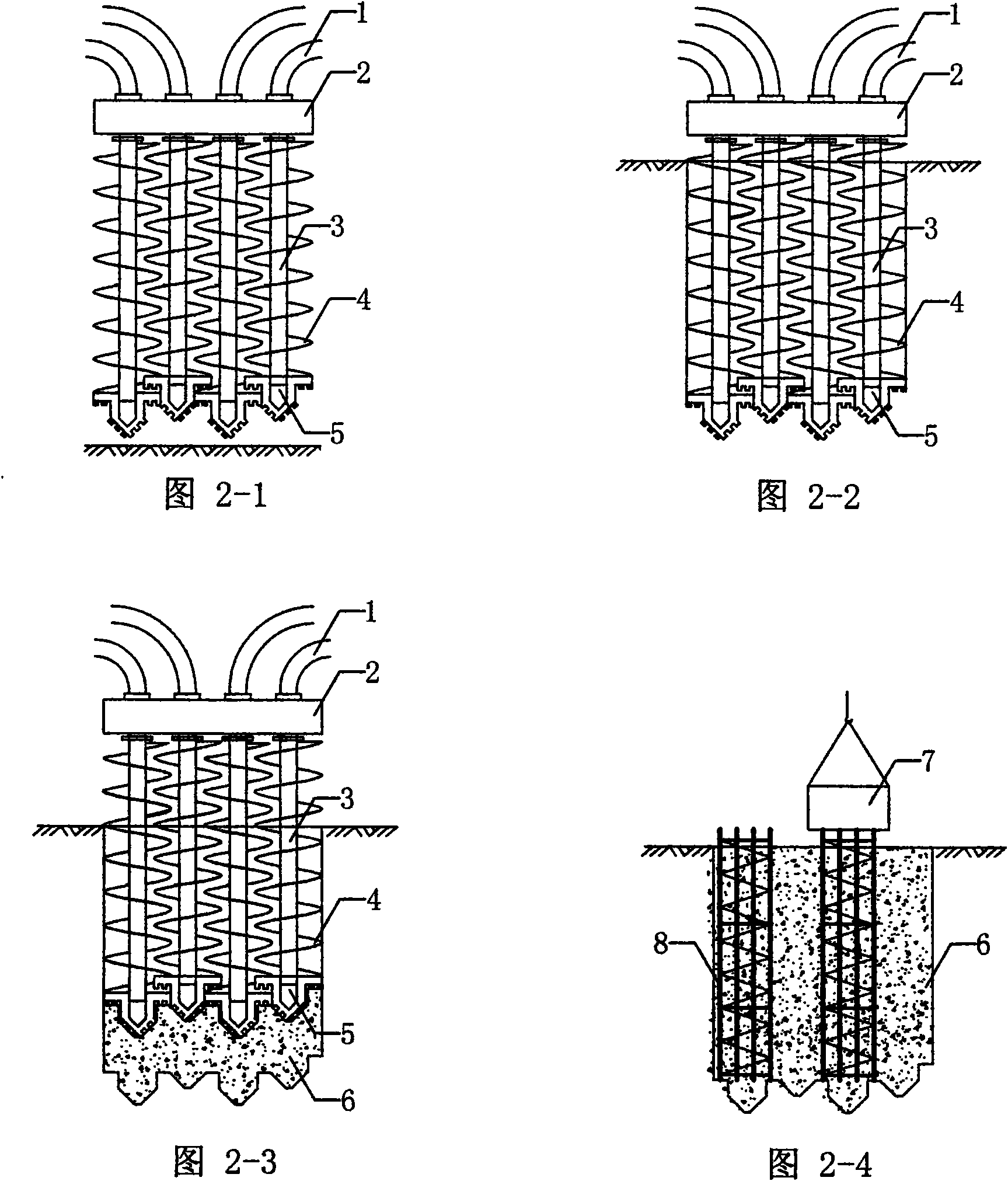

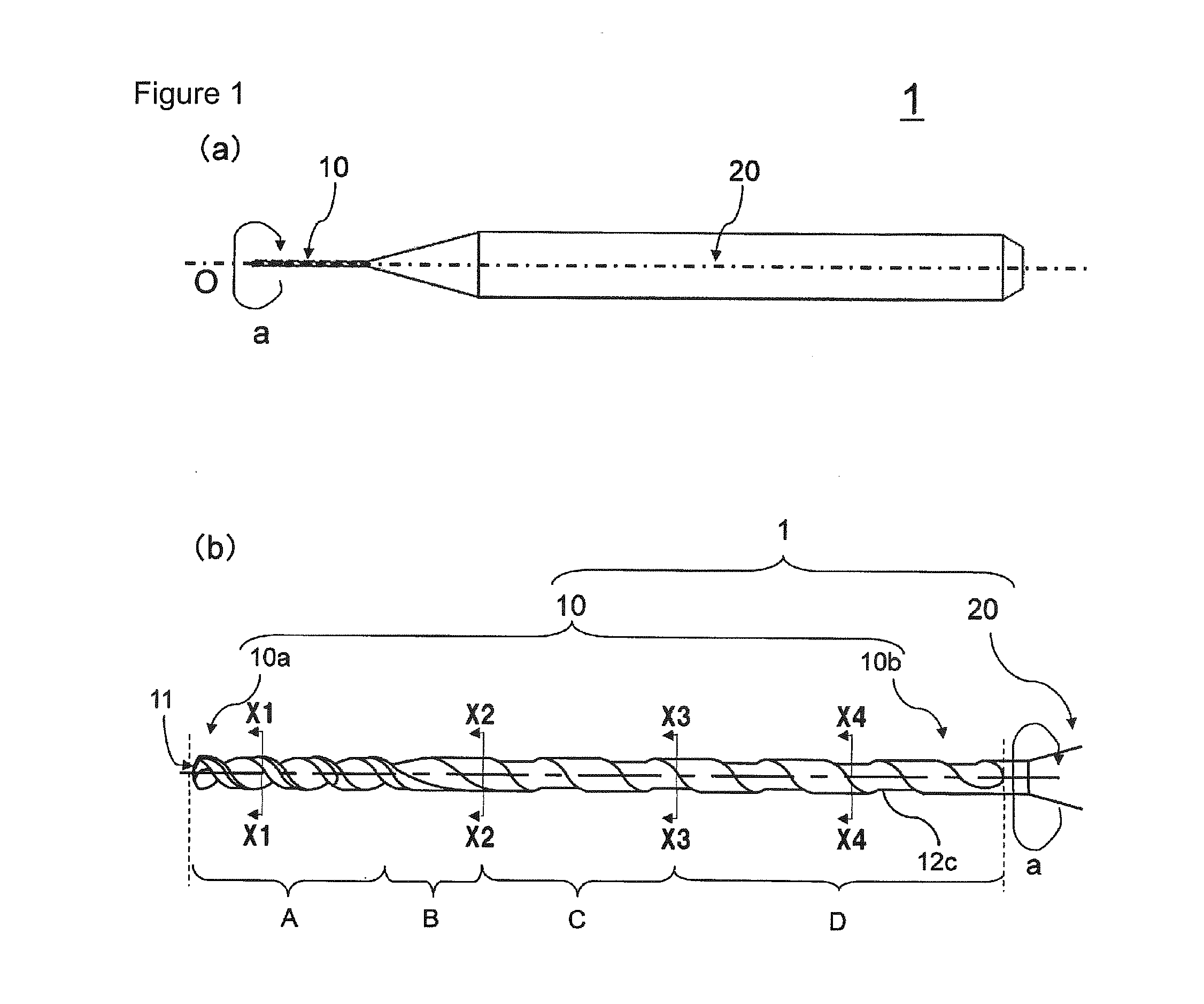

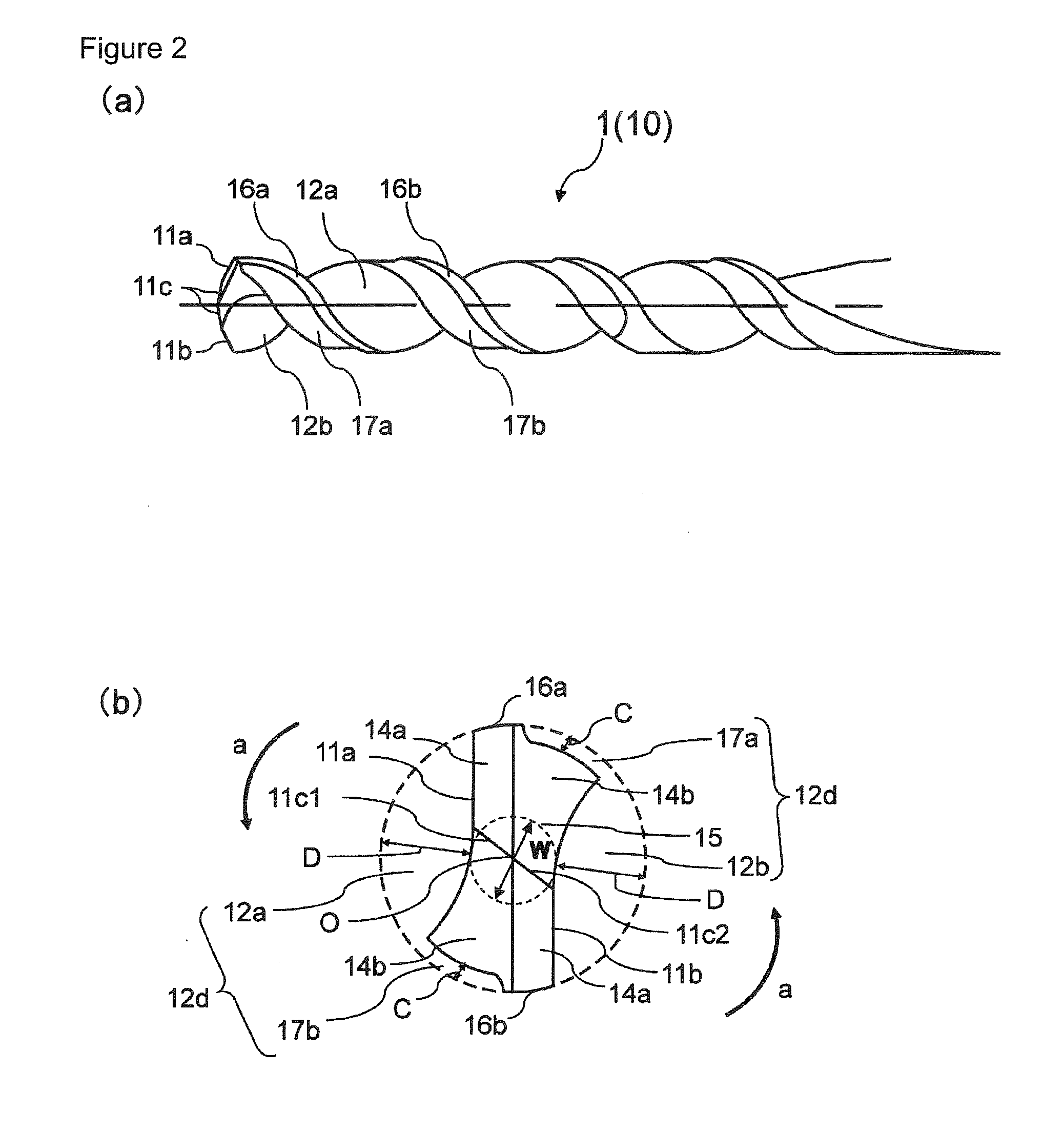

Drill and method of manufacturing machined product using the same

InactiveUS20130170920A1Reduce situationLarge core thicknessWood turning toolsTransportation and packagingFluteDrill bit

A drill according to an embodiment of the present invention includes a body part and a cutting part with a cylinder-like shape. The cutting part includes two cutting edges located separately from each other at a front end portion of the cutting part, two flutes which are continuous with each of the two cutting edges and extend spirally toward a rear end portion of the cutting part, and a clearance which extends spirally from a side of the front end portion to a side of the rear end portion, and is recessed inward in reference to a periphery of the cutting part in a sectional view. The cutting part includes a first joining flute including at least one of the two flutes and the clearance being joined together. The first joining flute includes a bottom surface being outwardly protruding curve-like line in a sectional view. A method of manufacturing a machined product using the drill is also provided.

Owner:KYOCERA CORP

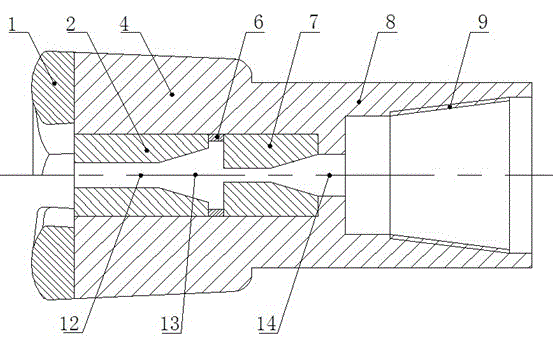

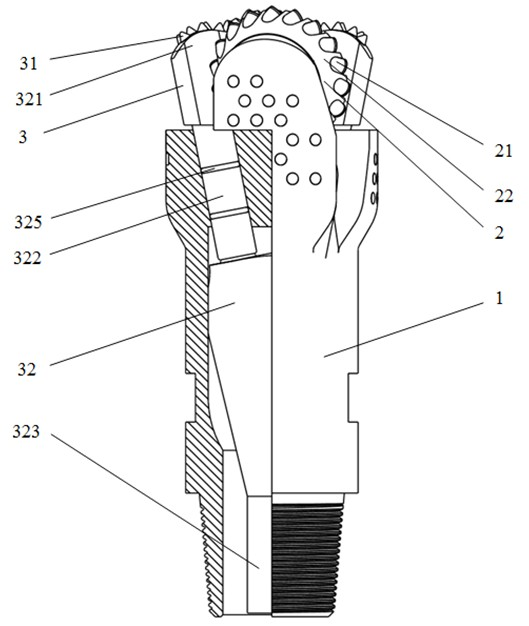

Coal mine underground self-suction abrasive jet flow drill bit and drilling method

ActiveCN103556947ARealize continuous additionSimple structureDrill bitsLiquid/gas jet drillingHole drilling methodCoal

The invention discloses a coal mine underground self-suction abrasive jet flow drill bit which can utilize the combination of abrasive jet flow guiding smash and mechanical smash to increase the drilling speed during the coal mine underground drilling operation. The self-suction abrasive jet flow drill bit comprises an abrasive jet flow nozzle, a self-suction device and a main smashing structure, wherein the self-suction device comprises a cavity, a filter screen, a support ring positioned inside the cavity and an inlet nozzle positioned at the rear end of the cavity. According to the invention, coal debris generated in the drilling process can be sifted by the filter screen, then enters the inside of the cavity of the self-suction device, and is fully mixed with a water jet flow to form an abrasive jet flow, the abrasive jet flow is jetted from the abrasive jet flow nozzle to perform guiding smash on coal and rock mass; the main smashing structure of the drill bit comprises three cutting pieces and three main smashing teeth, and a finished drill-hole can be formed under the mechanical smash action of the main smashing structure. The invention further relates to a method for utilizing the drill bit to drill in an underground coal mine. The drill bit has high drilling speed and little abrasion, and can be widely applied to coal mine underground drilling operation.

Owner:CHONGQING UNIV

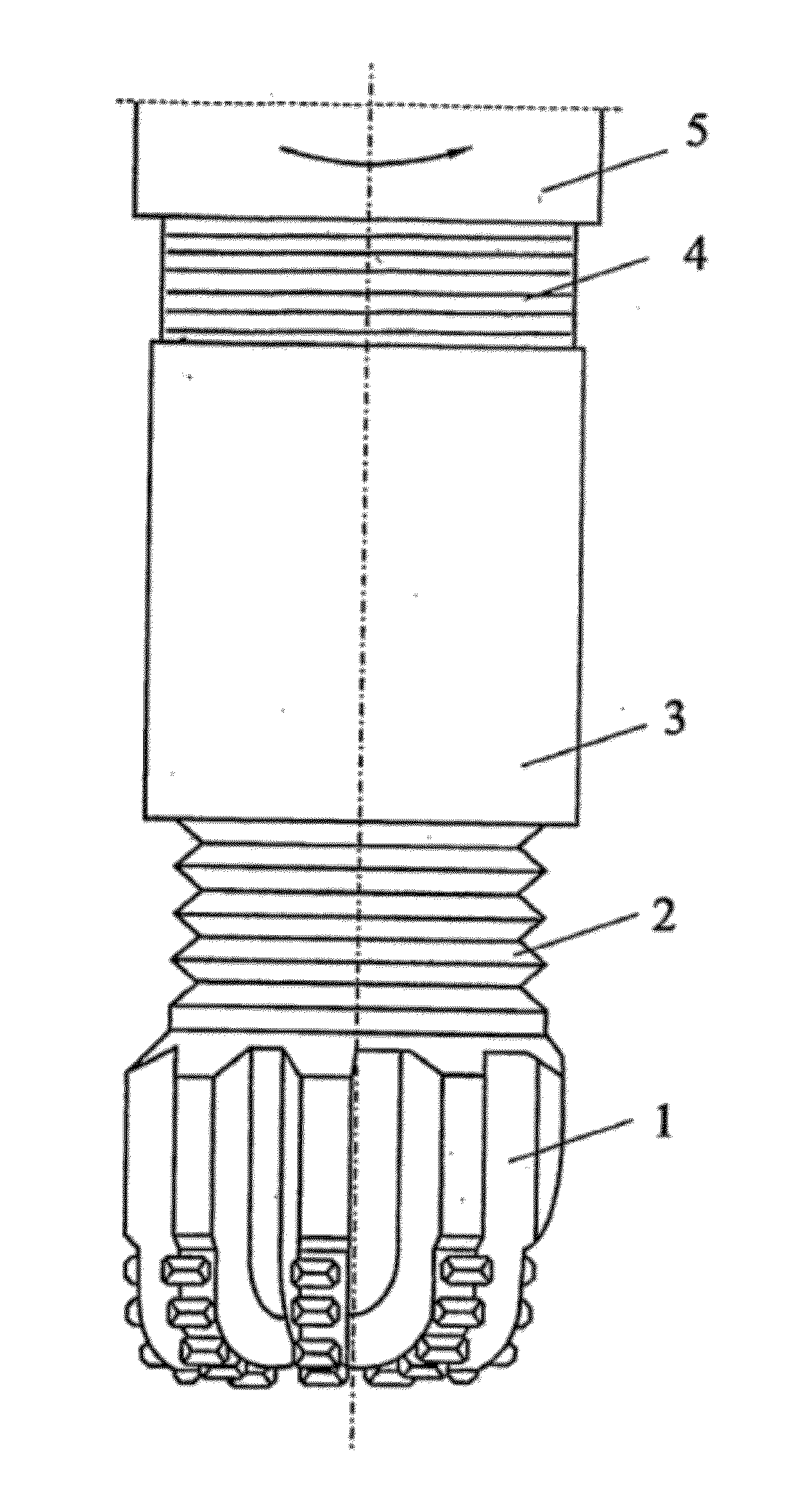

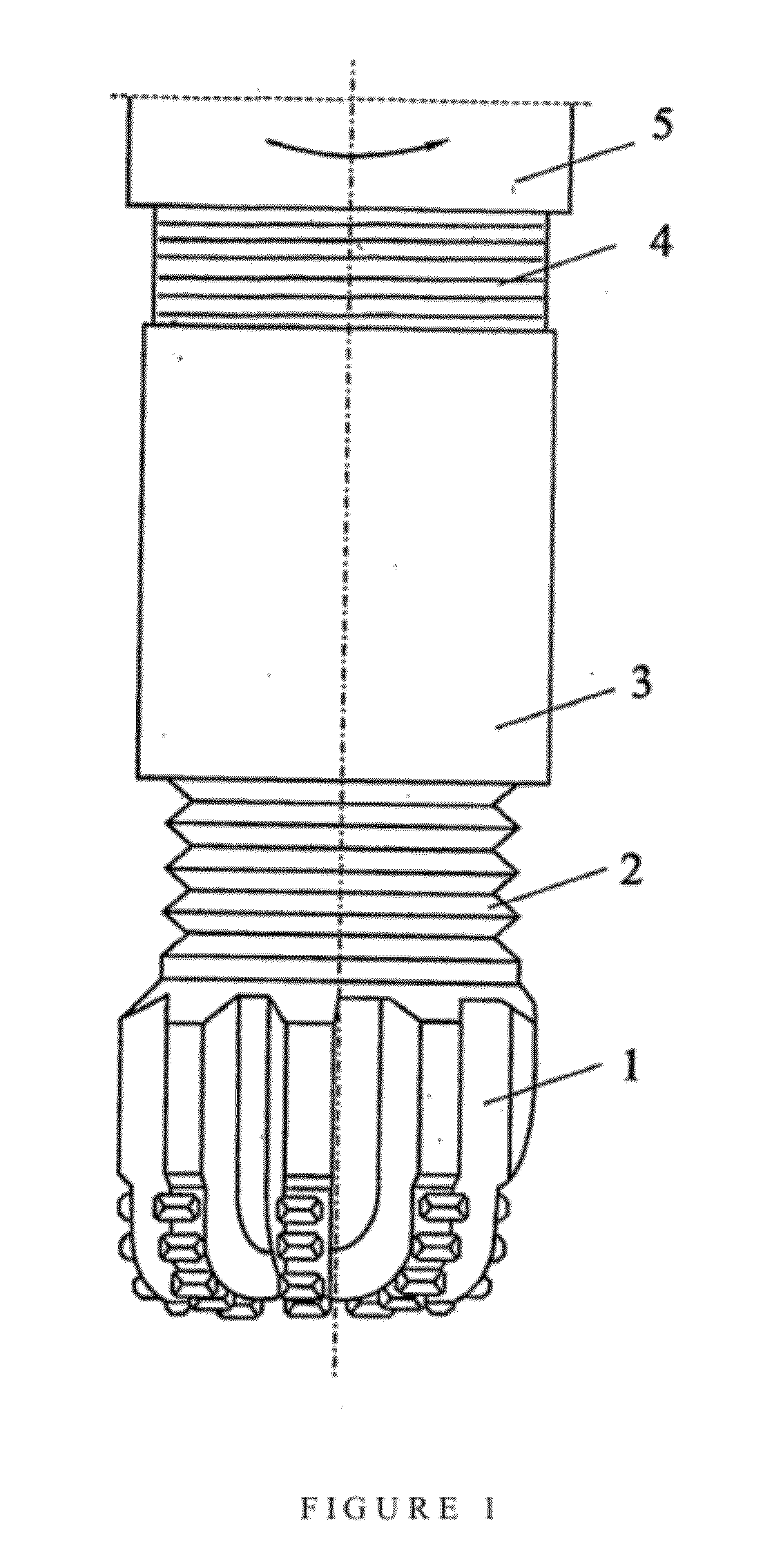

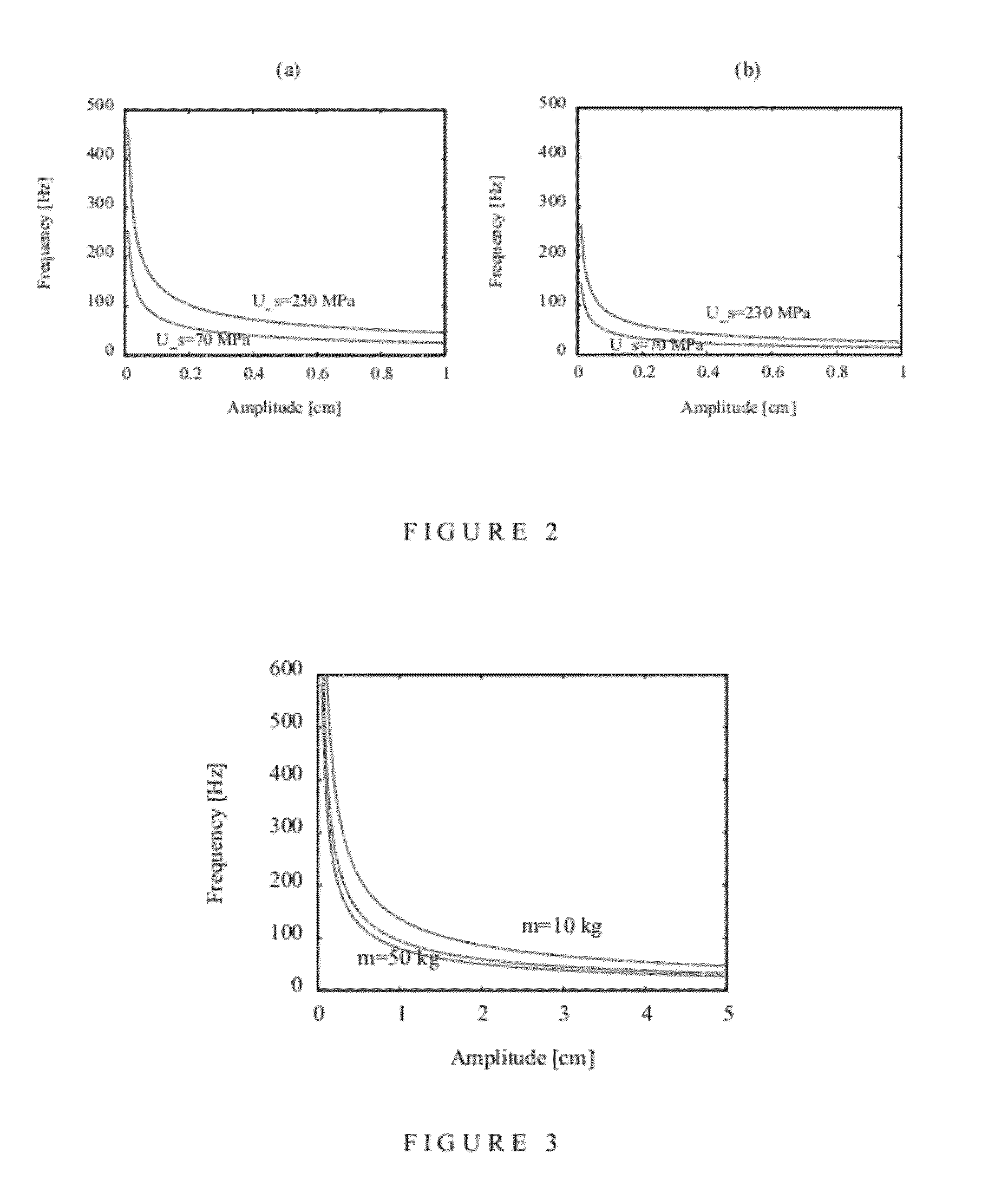

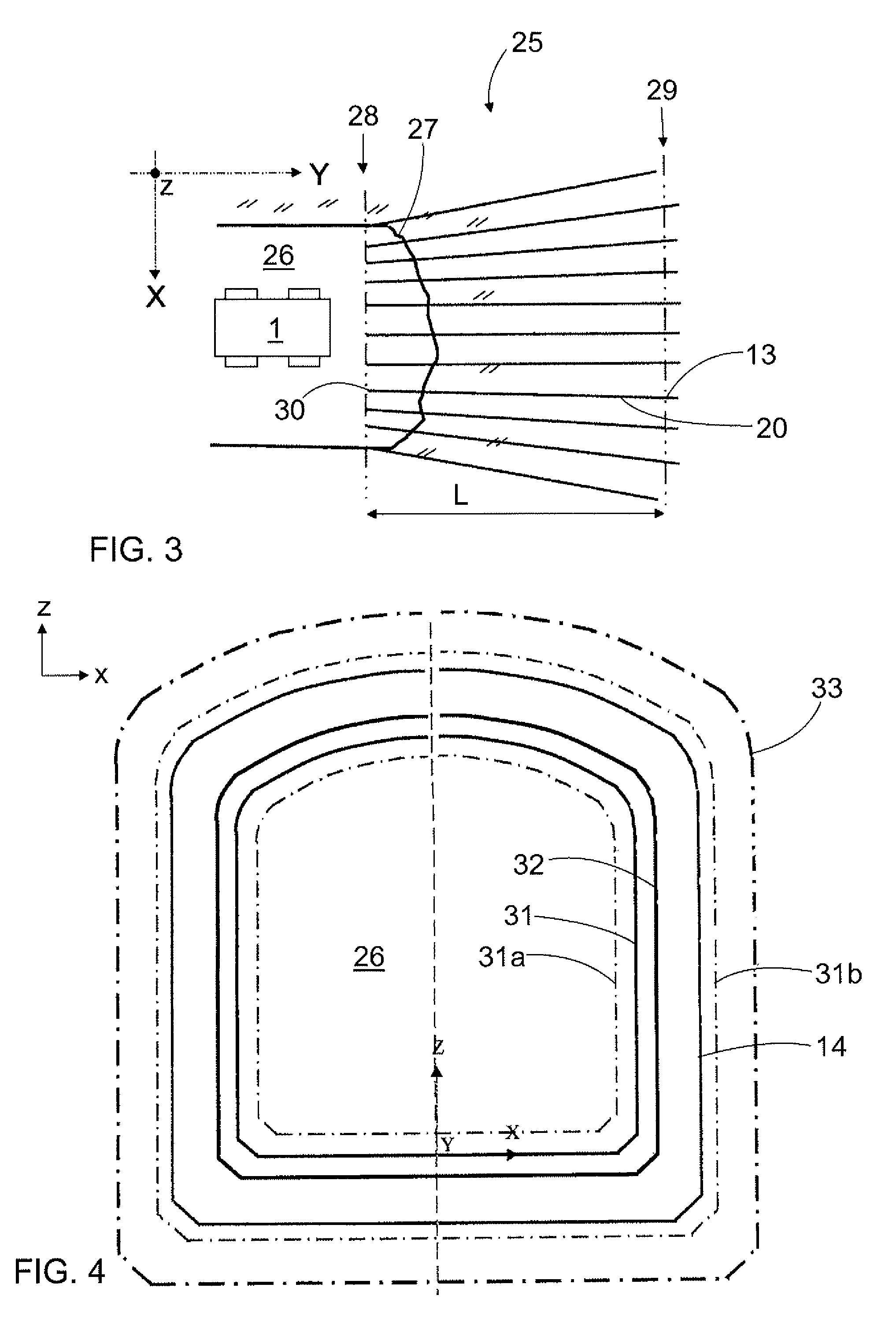

Resonance enhanced rotary drilling

ActiveUS20120241219A1Improve high performanceHigh drilling performanceDirectional drillingVibration devicesEffective diameterDrill bit

A method for controlling a resonance enhanced rotary drill comprising a rotary drill bit and an oscillator for applying axial oscillatory loading to the rotary drill bit, the method comprising:controlling frequency (f) of the oscillator in the resonance enhanced rotary drill whereby the frequency (f) is maintained in the range(D2 Us / (8000 πAm))1 / 2≦f≦Sf(D2 Us / (8000 πAm))1 / 2 where D is diameter of the rotary drill bit, Us is compressive strength of material being drilled, A is amplitude of vibration, m is vibrating mass, and Sf is a scaling factor greater than 1; andcontrolling dynamic force (Fd) of the oscillator in the resonance enhanced rotary drill whereby the dynamic force (Fd) is maintained in the range[(π / 4)D2effUs]≦Fd≦SFd[(π / 4)D2effUs]where Deff is an effective diameter of the rotary drill bit, Us is a compressive strength of material being drilled, and SFd is a scaling factor greater than 1,wherein the frequency (f) and the dynamic force (Fd) of the oscillator are controlled by monitoring signals representing the compressive strength (Us) of the material being drilled and adjusting the frequency (f) and the dynamic force (Fd) of the oscillator using a closed loop real-time feedback mechanism according to changes in the compressive strength (Us) of the material being drilled.

Owner:ITI SCOTLAND

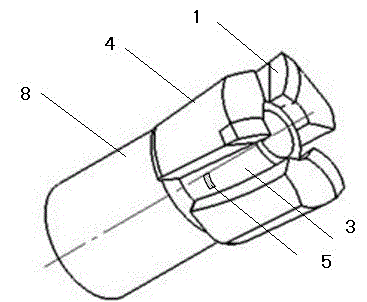

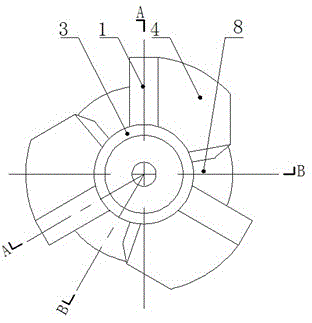

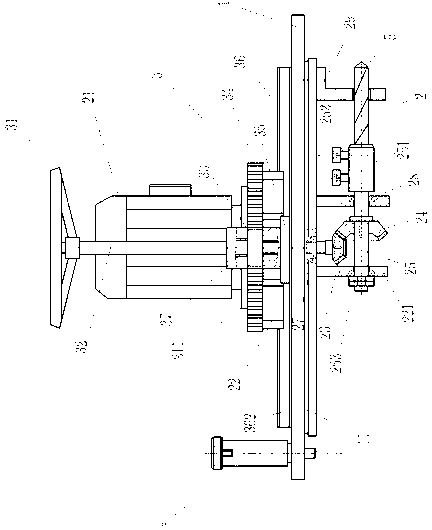

Multi-functional end effector

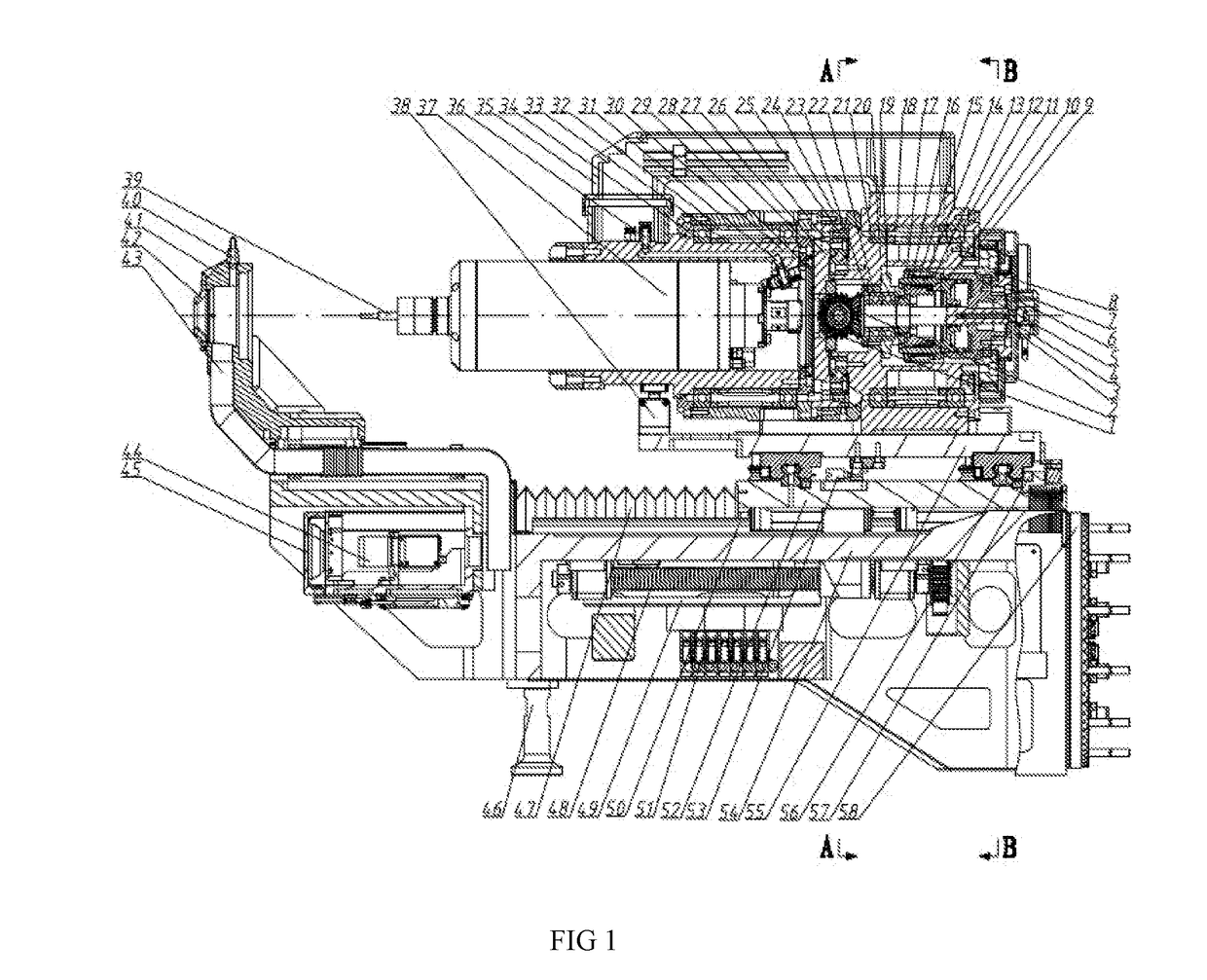

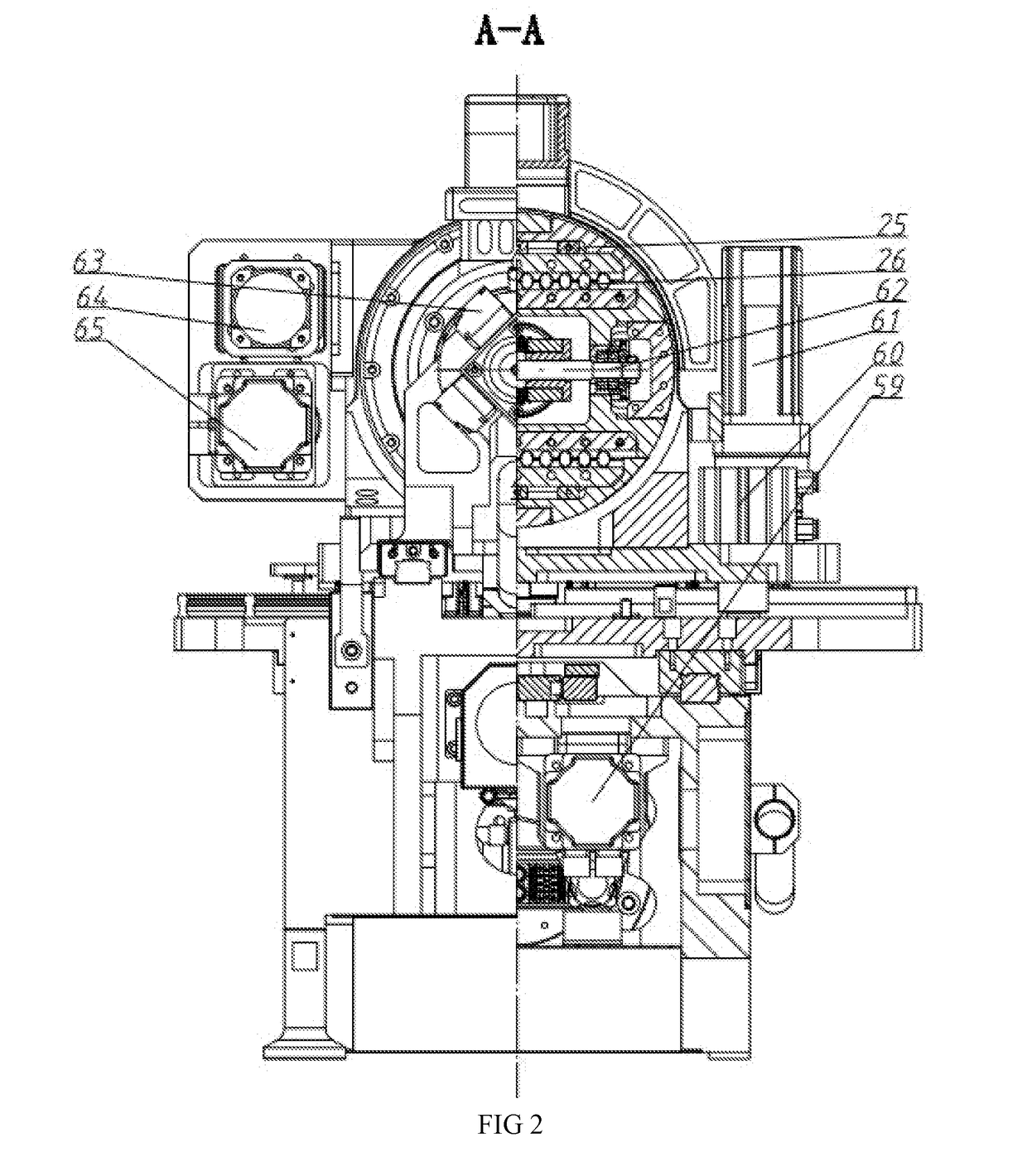

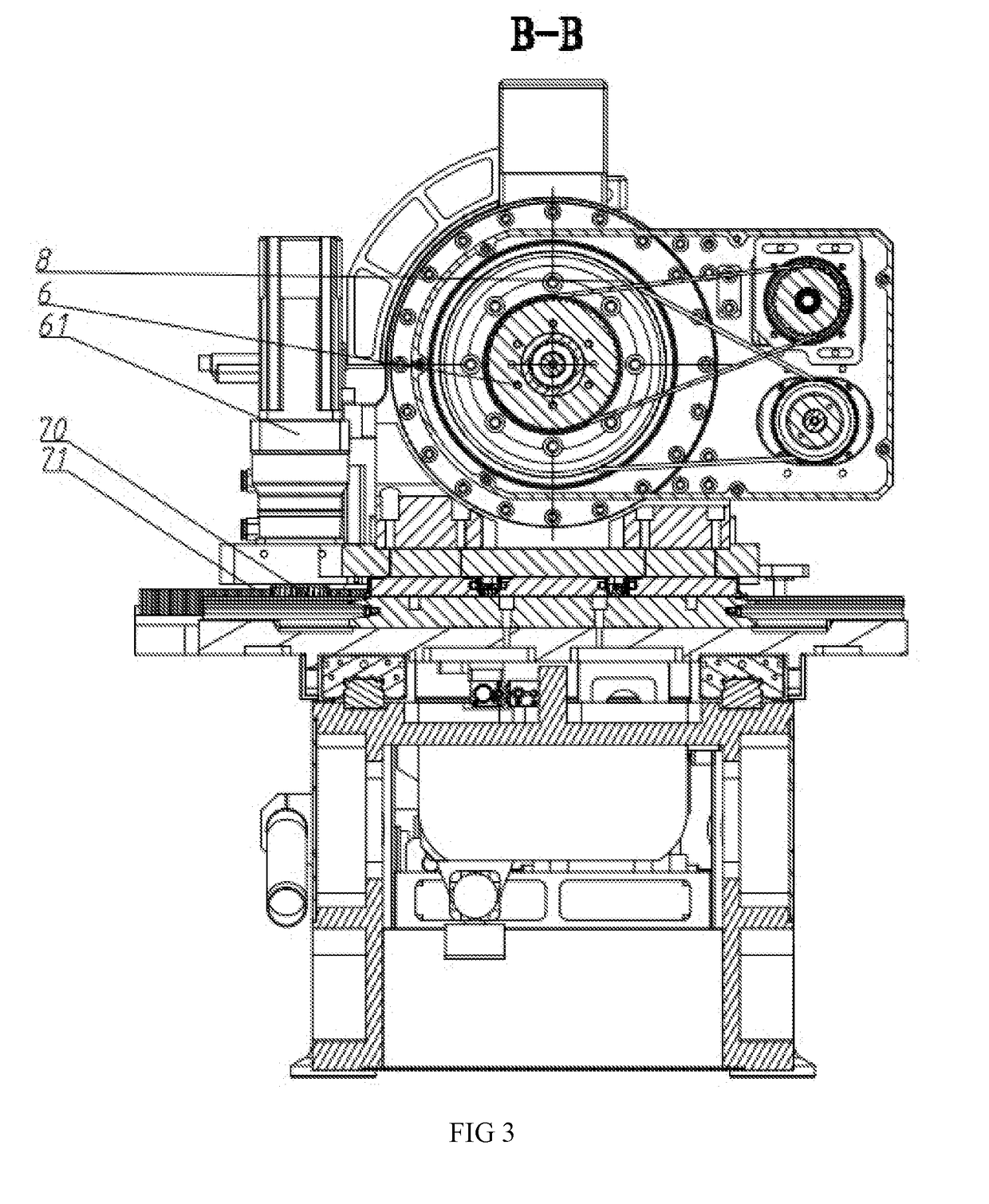

ActiveUS20190061019A1High precisionImprove efficiencyMilling machinesAircraft assemblyFeed driveEngineering

The present invention discloses a multifunctional end effector, comprising a base (54) and a cutting tool (39); a feed slide (52) on the base (54) and a feed driving mechanism used to drive feed slide (52) to feed cutting tool (39); a swing slide (55) on the feed slide (52) and a swing driving mechanism used to drive swing slide (55) to realize circular arc swing of cutting tool (39); a mounting base (12) on the swing slider (55); a revolving rotation shaft (20) and a rotation shaft driving mechanism used to drive revolving rotation shaft (20) to make the cutting tool rotate in the mounting base (12); an eccentric slide (27) fixed to the end of revolving rotation shaft (20); cutting tool (39) is connected to the end of eccentric slide (27) via the electric spindle (37) and an eccentric regulating mechanism used to regulate eccentric slide (27) and control radial bias of cutting tool (39). Use feed driving mechanism to realize feed of cutting tool or feed of cutting tool along the swing trail through combination with swing driving mechanism; use eccentric regulating mechanism to realize radial bias of cutting tool; make use of rotation shaft driving mechanism to realize feed of cutting tool along the helical trail; it can realize such functions as drilling, boring, reaming, helical milling and reaming of elliptical recess.

Owner:ZHEJIANG UNIV

Reusable high performance water based

ActiveUS20150096808A1Reduce environmental impactMinimize dilutionFlushingDrilling compositionWater basedPotassium

Compositions emulate oil based fluids include an aqueous phase and an organic internal phase, which creates an osmotic membrane within the aqueous continuous phase. The osmotic membrane allows hydration-dehydration mechanisms to be in place and control interactions between formation and fluid, where the non-aqueous phase is composed of glycerols, polyglycerols, poly hydroxyl alcohols, monosaccharide derivatives, polysaccharide derivatives, or mixtures and combinations thereof, while the aqueous phase contains additives that impart different inhibiting mechanisms to the overall composition, where the additives include, without limitation, amphoteric polymers, potassium and / or sodium salts up to saturation and / or acrylamides.

Owner:WEATHERFORD TECH HLDG LLC

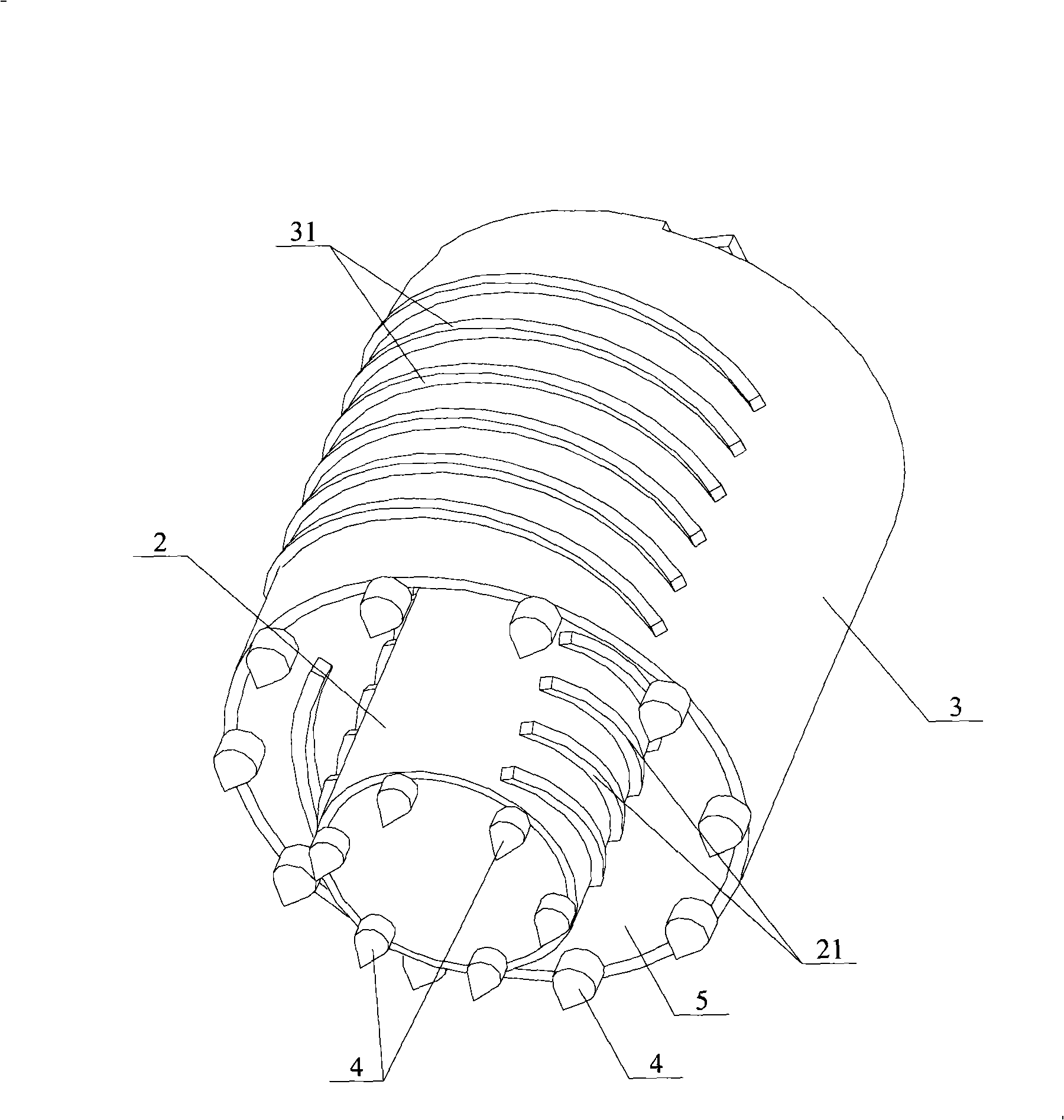

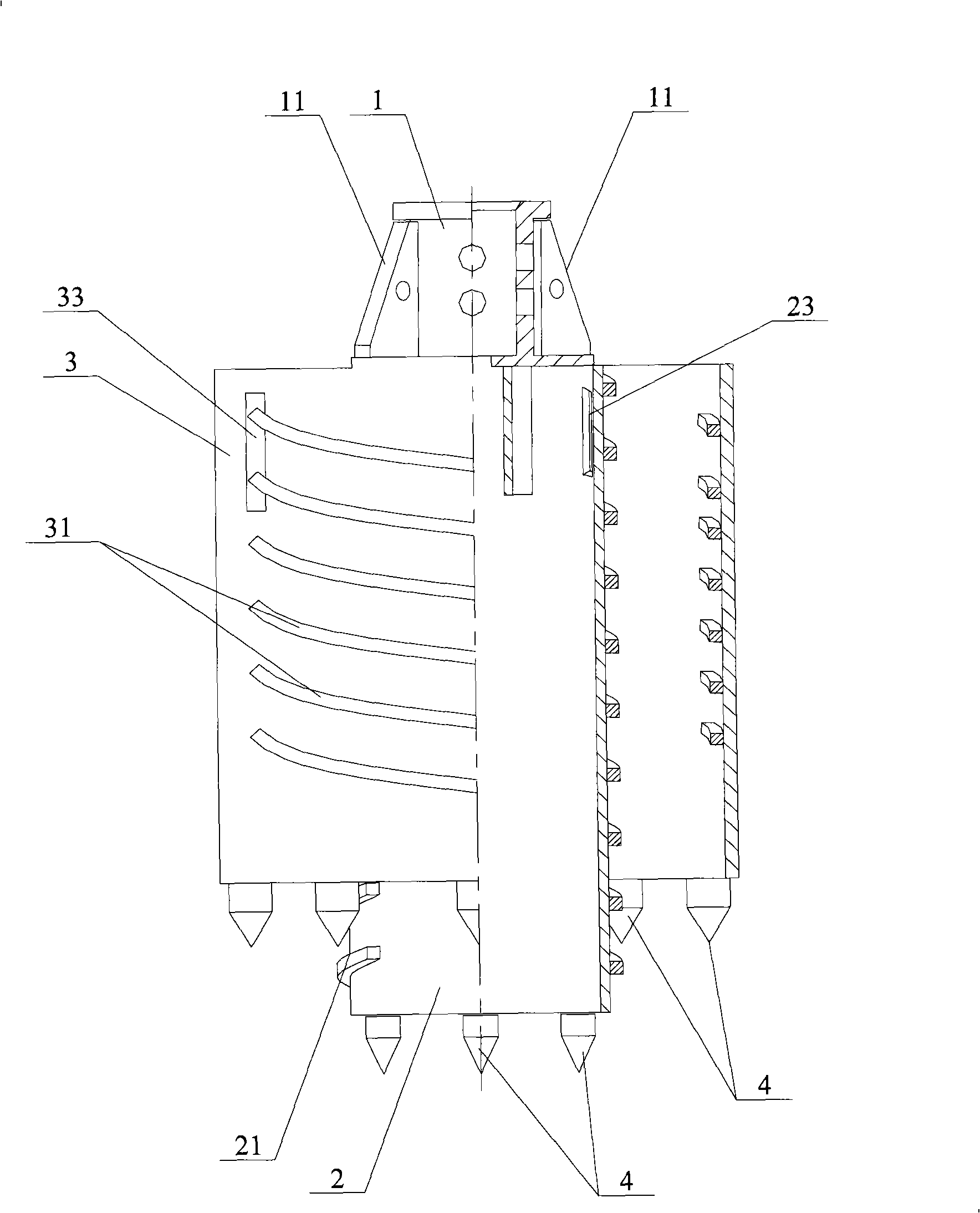

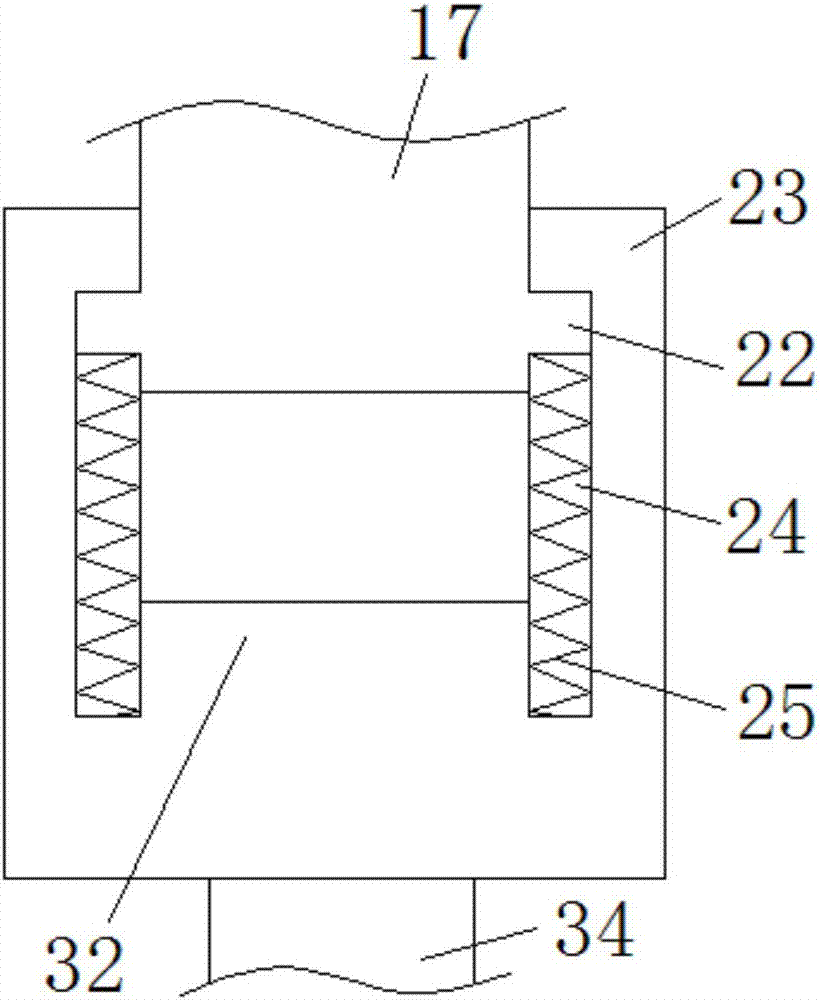

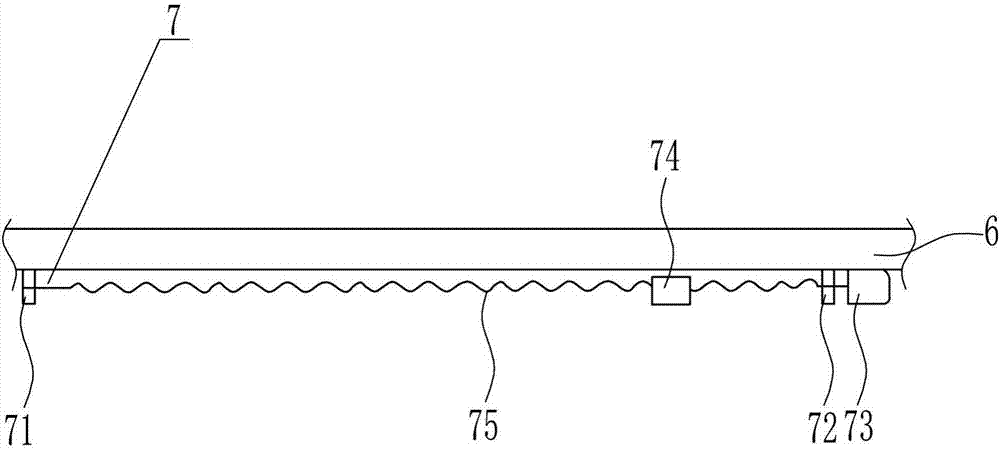

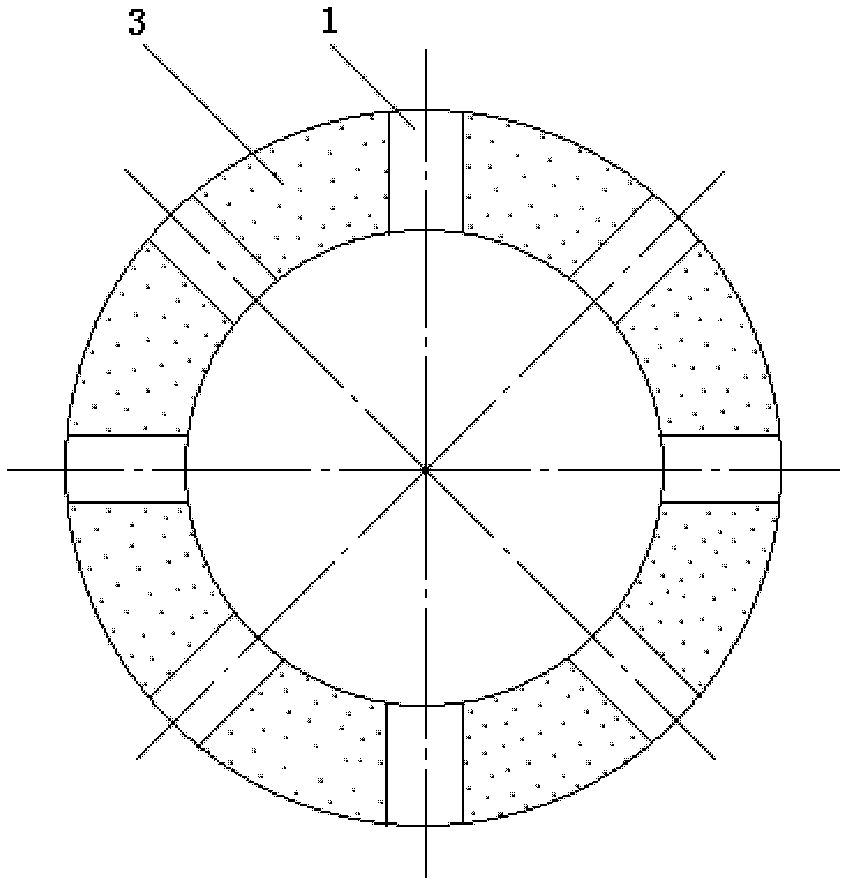

Double-layer barrel type drilling tool

InactiveCN101343982AImprove drilling efficiencyImprove slag carrying capacityDrill bitsEngineeringDrill pipe

The invention discloses a double-layer cylindrical drilling tool, which comprises a connecting part, an inner cylinder body, an outer cylinder body and a plurality of cutting tools. The upper end part of the inner cylinder body is fixedly connected with the connecting part; the outer cylinder body is nested at the outer side of the inner cylinder body, and an annular cavity is formed between the inner cylindrical surface of the outer cylinder body and the outer cylindrical surface of the inner cylinder body; the upper end part of the outer cylinder body is fixedly connected with the connecting part; the plurality of cutting tools are respectively fixedly arranged on the lower edges of the inner cylinder body and the outer cylinder body; and a plurality of guiding strips which present spiral elevating status along the cylindrical surface of the cylinder body are respectively arranged on the inner cylinder body and the outer cylinder body. The space used for carrying boring mud in the double-layer cylindrical drilling tool is divided into two parts, namely the inner cavity of the inner cylinder body and an annular space formed between the inner cylinder body and the outer cylinder body, thereby being favorable for carrying hard boring mud particles, greatly enhancing the mud carrying capability of the drilling tool, further effectively avoiding the accidents of drill pipe sticking and the like and enhancing the drilling efficiency and the hole forming speed.

Owner:BEIJING SANY HEAVY MASCH CO LTD

Construction engineering underwater drilling device easy to fix

InactiveCN106869793AEasy to fixSmooth rotationDerricks/mastsDrilling machines and methodsThreaded pipeArchitectural engineering

The invention discloses a conveniently fixed underwater drilling device for construction engineering, which includes a support leg, the bottom end of the support leg is fixedly connected with a fixed base, the surface of the fixed base is fixedly connected with a bearing seat through bolts, and the inside of the bearing seat The first bearing is fixedly connected, the inner ring of the first bearing is fixedly connected with the first rotating shaft, one end of the first rotating shaft is fixedly connected with the worm, and the inside of the fixed base is respectively provided with a lifting chamber and a chute. The easy-to-fix underwater drilling device for construction workers achieves the effect of telescopically adjusting the first threaded pipe, thereby facilitating the fixed base to be fixed and stable, achieving the effect of facilitating the rotation of the first threaded rod, and at the same time preventing the first threaded rod from The problem of the self-rotation of the rod after adjustment occurs, which can make the two-threaded rod connected by the second threaded pipe screw up and down more stable, and enhance the drilling effect of the drill bit, thus effectively solving the problem of insufficient stability of ordinary underwater drilling equipment question.

Owner:陈海永

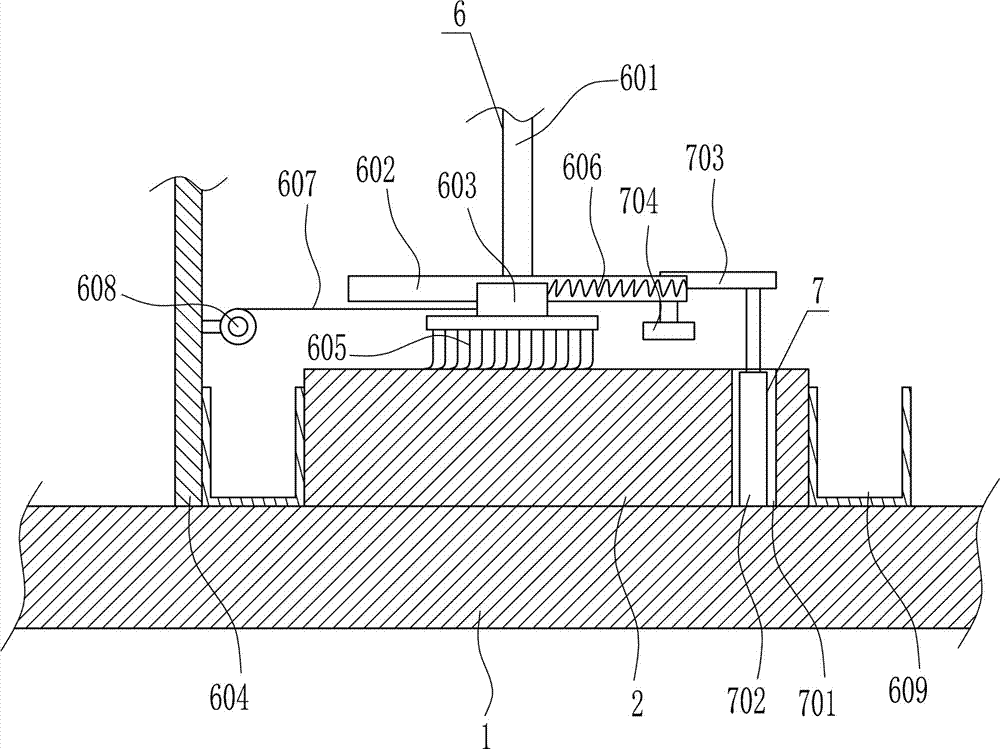

Rapid drilling device for hardware production

InactiveCN106956015AReach drilling efficiencyIncrease drilling speedWork clamping meansFeeding apparatusEngineeringDrill bit

The invention relates to a drilling device, in particular to a rapid drilling device for hardware production. The rapid drilling device for hardware production aims to achieve the technical effects of being good in drilling effect, capable of fixing hardware, preventing the hardware from shaking, improving the quality of the hardware and capable of clearing fragments on a workbench. The rapid drilling device for hardware production comprises the workbench and the like. An n-shaped plate and a U-shaped holding block are welded to the top of the workbench. The U-shaped holding block is located inside the n-shaped plate. A drilling device body is arranged on the top inside the n-shaped plate. According to the rapid drilling device for hardware production, the hardware is drilled through a drill bit, the hardware is fixed through a fixing device and prevented from shaking during drilling, and the workbench is cleaned through brushes.

Owner:珠海市江辉机械科技有限公司

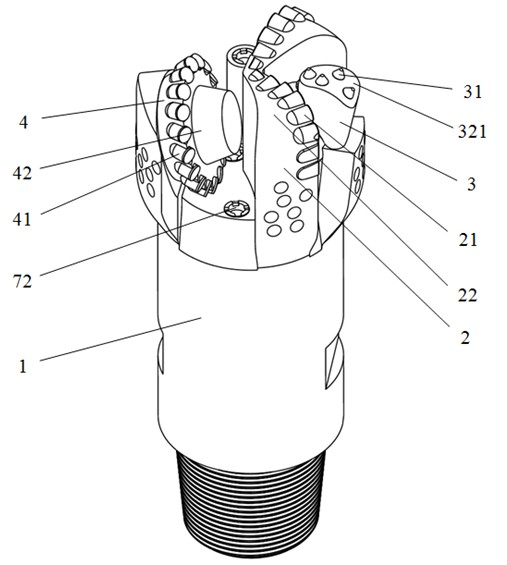

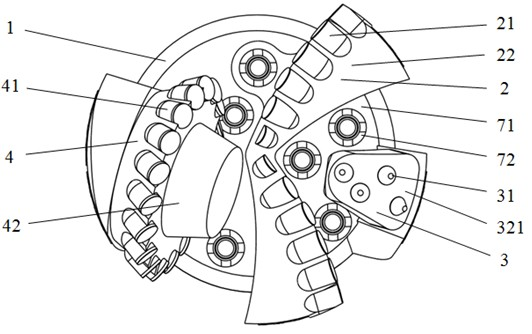

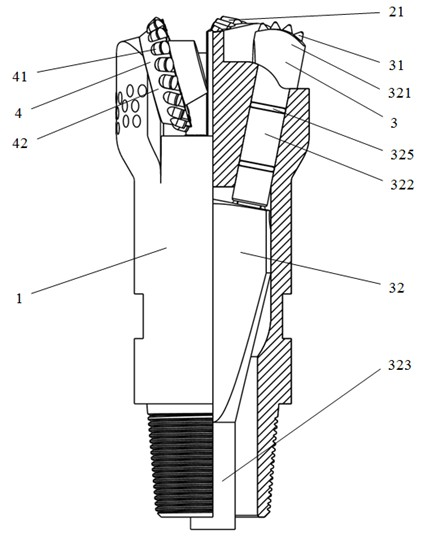

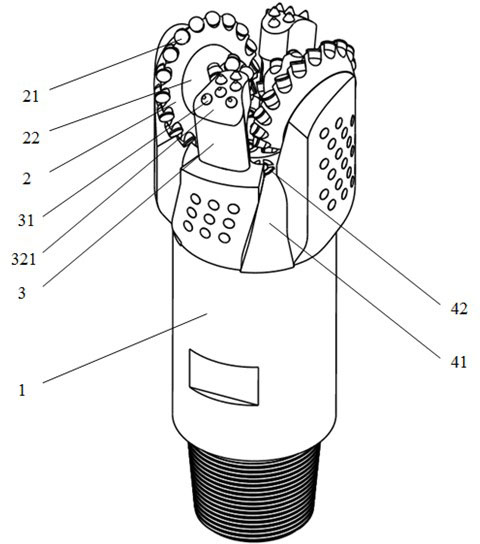

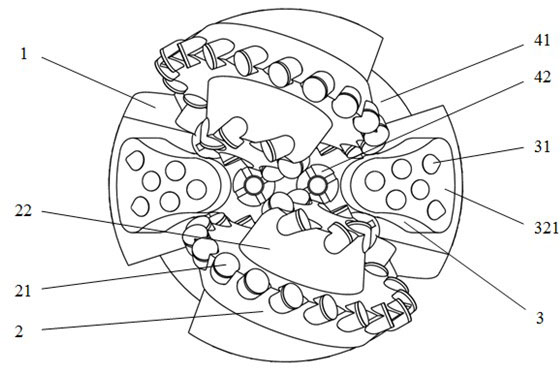

Crossed scraping-impacting composite drill bit

ActiveCN102678053AReduce difficultyReduce rock breaking energy consumptionDrill bitsConstructionsMining engineeringHydraulic structure

The invention discloses a crossed scraping-impacting composite drill bit belonging to the field of rock blasting tools for drilling equipment for oil and gas, mine engineering and building foundation engineering construction, geology, hydrology and the like. The crossed scraping-impacting composite drill bit comprises a drill bit body, a fixed cutting structure, a disc cutter cutting structure and a hydraulic structure, wherein the fixed cutting structure, the disc cutter cutting structure and the hydraulic structure are arranged on the drill bit body; the drill bit body is also provided with an impact cutting structure; and the impact cutting structure comprises a force transferring mechanism for transferring impact forces and impact cutting teeth, wherein the impact cutting teeth are solidified on a punch arranged at the tail end of the force transferring mechanism, and the punch can slide or slidingly impact relative to the drill bit body in the impact force transferring direction. Compared with a drill bit for blasting a rock in a cutting way, the crossed scraping-impacting composite drill bit is not only beneficial to the drilling of the cutting teeth of the drill bit to stratums and the increment of the rock blasting efficiency, but also beneficial to the retardance of the wear rate of the cutting teeth and particularly has remarkable technical advantages for higher-strength and stronger-abrasiveness stratums which are difficult to drill.

Owner:SOUTHWEST PETROLEUM UNIV

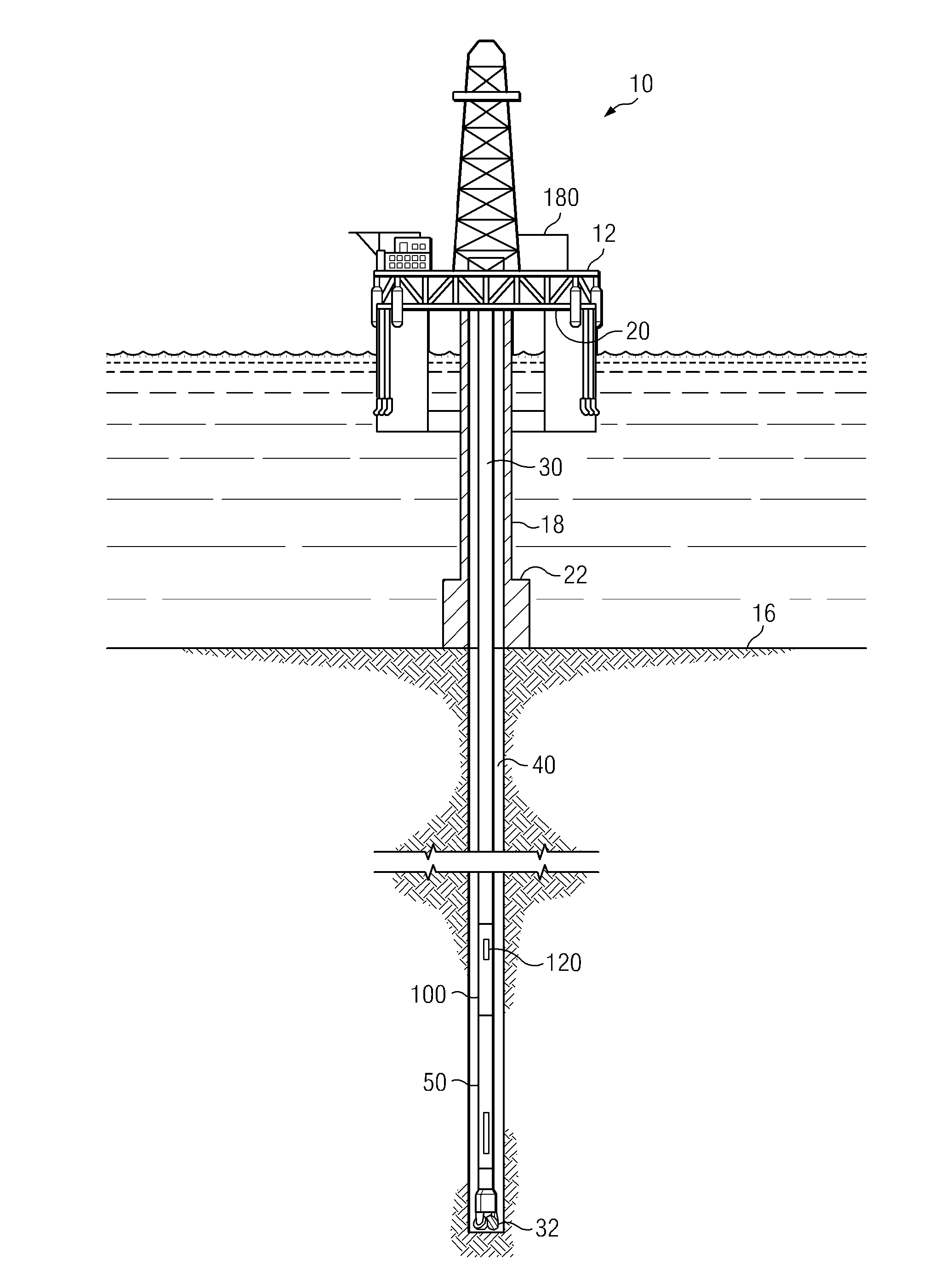

Downlinking Communication System and Method

ActiveUS20110286308A1Improve signal-to-noise ratioAdd depthSurveyConstructionsCommunications systemEngineering

A downlinking signal is transmitted downhole from the surface using drilling fluid as the communications medium. The downlinking signal includes at least a synchronization phase and a command phase. Attributes of the synchronization phase are used upon reception of the signal to determine corresponding attributes of the command phase. Commands may be transmitted downhole while drilling and simultaneously while using mud-pulse telemetry uplinking techniques.

Owner:SCHLUMBERGER TECH CORP

Hardware drilling equipment

InactiveCN106944640AEasy to adjustEasy clampingPositioning apparatusMetal-working holdersMoving partsDrilling machines

The invention belongs to the technical field of hardware and particularly relates to hardware drilling equipment. The hardware drilling equipment is easy to operate, stable in drilling, good in drilling effect and high in working efficiency, and comprises a base, supporting legs, first sliding rails, a first sliding block, front-back moving devices, an n-shaped support and the like, wherein the supporting legs are arranged at the bottom of the base; the first sliding rails are symmetrically arranged on the left side and the right side of the top of the base; the first sliding block is sliably arranged on the first sliding rails; the front-back moving devices are symmetrically arranged on the left side and the right side of the portion, between the two first sliding rails, of the top of the base; and moving components of the front-back moving devices are connected with the first sliding block. By means of the front-back moving devices and left-right moving devices, a drilling machine can be adjusted to any position, drilling is convenient, and hardware can be well clamped by a clamping device.

Owner:叶宝义

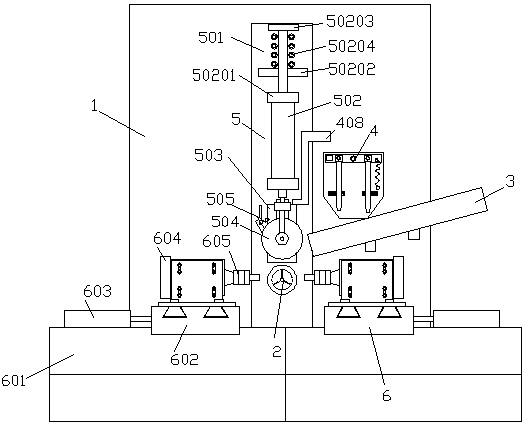

Drilling equipment for bearing

ActiveCN103801727AImprove work efficiencyAccelerateBearing componentsMetal working apparatusDrill holeEngineering

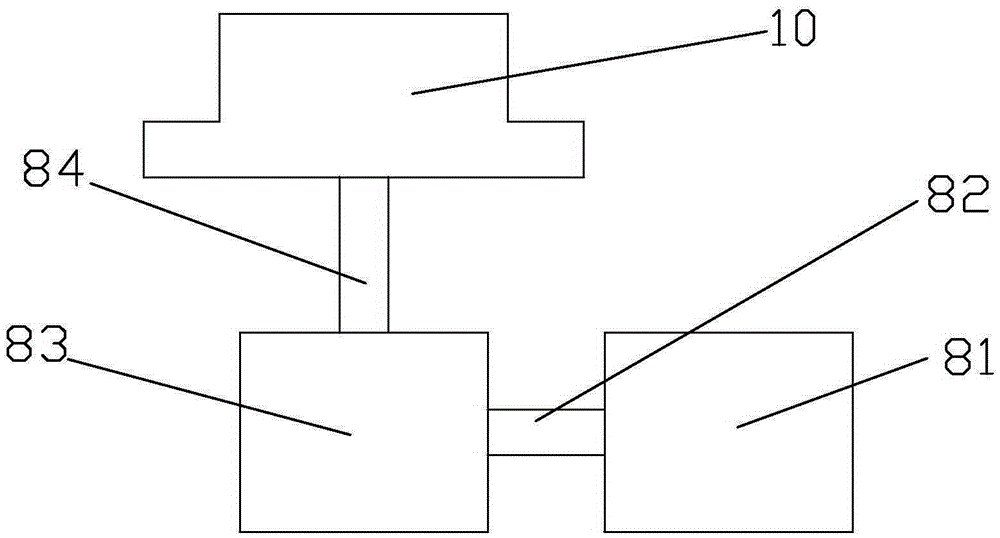

The invention discloses drilling equipment for a bearing. The drilling equipment for the bearing comprises a machine tool body and an expanding main shaft mounted on the machine tool body, and further comprises a feeding device, a material putting device, a conveying and press-in device, a drilling device and a discharging device. The feeding device is used for containing and conveying a plurality of rings to be drilled. The material putting device is located above the feeding device and used for putting one ring on the feeding device into the conveying and press-in device at a time. The conveying and press-in device is used for conveying the rings put by the material putting device to the position of the expanding main shaft, the rings are mounted on the expanding main shaft in a sleeved mode, and the rings are fixed through the expanding main shaft. The drilling device is used for carrying out drilling on the rings fixed on the expanding main shaft. The discharging device is used for at least separating the rings with drilling finished from the expanding main shaft. The drilling equipment for the bearing is simple in structure, easy to manufacture, high in working efficiency and good in drilling effect.

Owner:ZHEJIANG LIZU MACHINERY

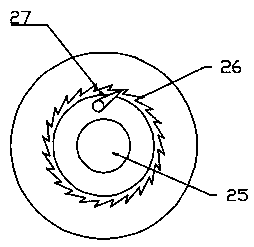

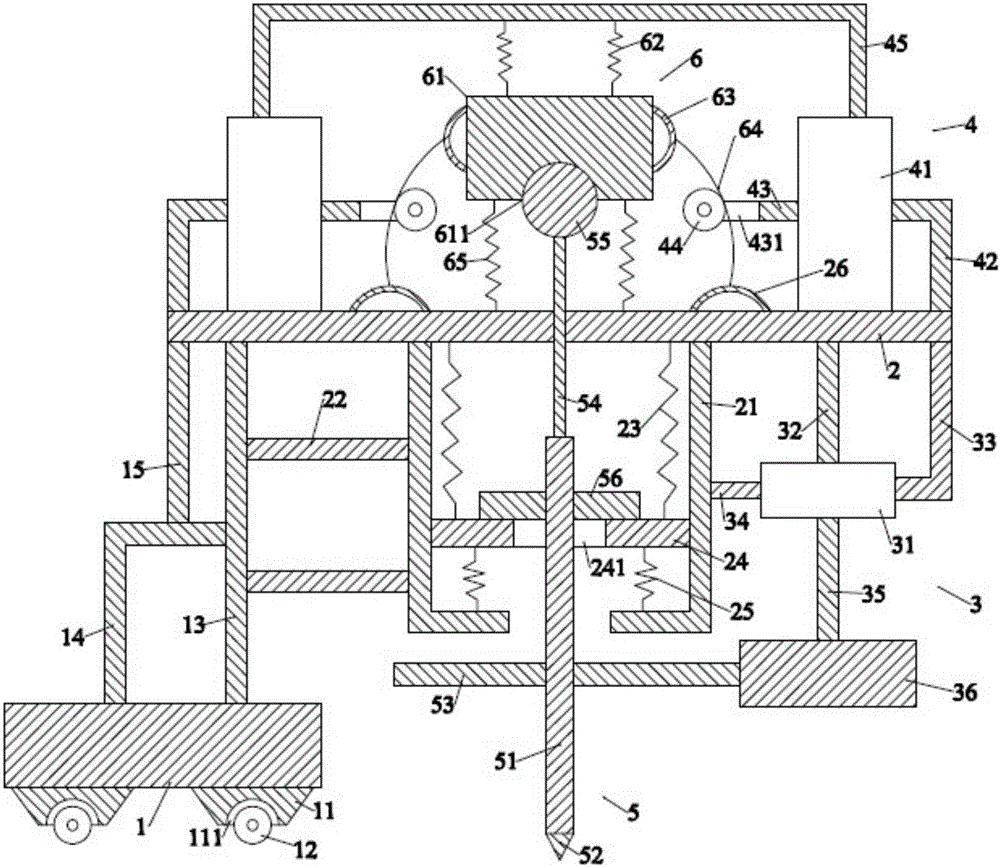

Shoe sole punching device for shoe production and processing

The invention relates to a shoe sole punching device, in particular to a shoe sole punching device for shoe production and processing. The technical problem to be solved in the invention is to provide the shoe sole punching device for shoe production and processing with the advantages of excellent punching effect, high punching speed and ideal punching. In order to solve the technical problem, the shoe sole punching device for shoe production and processing provided by the invention comprises a bottom plate, a left side plate, a guide sleeve, a bearing block, a right side plate, a top plate, a supporting rod, a swing rod, a sliding rail, a motor, a slide block, a connecting block, a first connecting rod, a disc, a second connecting rod, a guide plate, a connecting rod, a drill bit, a rotating shaft, a gear, a rack, a third connecting rod, a placement plate, a fixed baffle, a movable plate and a spring, wherein the left side plate, the guide sleeve, the bearing block and the right side plate are sequentially arranged on the bottom plate from the left to right; the top plate is arranged on the top between the left side plate and the right side plate. The device disclosed by the invention achieves the effects of excellent punching effect, high punching speed and ideal punching.

Owner:张浩杰

Vertical height-adjustable drilling equipment

Vertical height-adjustable drilling equipment comprises a base plate, a transverse plate, a motor device, air cylinder devices, a supporting device and a drilling structure; first supporting blocks, first idler wheels, a first supporting rod, a first supporting frame and a second supporting rod are disposed on the base plate; second supporting frames, a first transverse rod, first springs, a supporting block, second springs and fixing rings are disposed on the transverse plate; the motor device comprises a motor, a third supporting rod, a third supporting frame, a second transverse rod, a first spindle and a gear; each air cylinder device comprises an air cylinder, a fourth supporting frame, a pushing rod, a second idler wheel and a fifth supporting frame; the drilling structure comprises a drilling rod, a drilling head, a ring gear, a first vertical rod, a bulb and a fixing ring; the supporting device comprises a fixed block, third springs positioned upon the fixed block, supporting rings positioned on both sides of the fixed block, bracing wires and fourth springs positioned under the fixed block. The drilling equipment disclosed by the invention can drill bores on demanded positions automatically, and reduces the labor intensity of manual work greatly.

Owner:江门市新会区绚丽五金电器有限公司

Manufacturing method for long life electroplated diamond bit

ActiveCN102586843AExtended service lifeImprove flexural strengthDrill bitsElectrolytic coatingsEngineeringCoring

The invention discloses a manufacturing method for a long life electroplated diamond bit. A working layer is designed into upper and lower double working layers which are separated by upper and lower waterways. The manufacturing method adopts a secondary feeding groove secondary forming electroplating process and comprises the following steps: electroplating the upper working layer of the electroplated bit by adopting conductive water gap plug 'bridging', adding a common water gap plug in the middle of the working layer and continuously electroplating the lower working layer; and entering inner and outer gauge protection layers of a secondary feeding groove electroplated bit after the operation of electroplating the working layers meets the requirement. The electroplating process comprises the steps of discharging the bit with the electroplated working layers out of the groove, cleaning completely, soaking and preplating in activating preplating liquid, electroplating inner and outer diameters of the electroplating bit in a normal electroplating groove and finishing manufacturing of the bit. The method is unique. According to the method, the effective working layers of the bit are high, the gauge protection effect of the bit can be effectively improved and the adaptability of the bit to the rock stratum is improved, so that the drilling effect of the bit can be obviously improved and the requirements of deep exploration and wire line coring drilling can be met well.

Owner:WUHAN WAN BANG LASER DIAMOND TOOLS

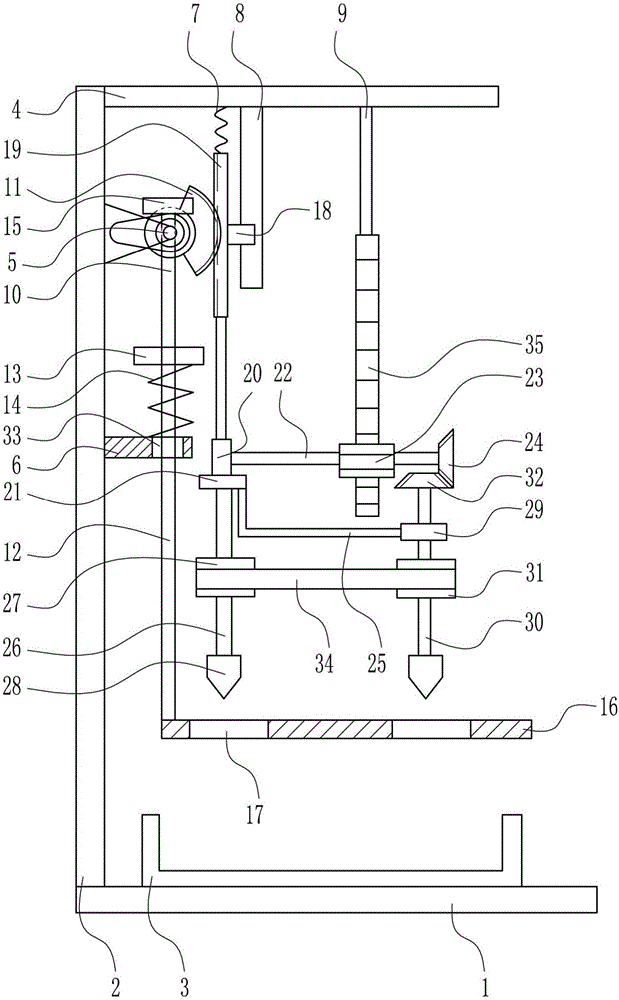

Efficient flip-flop drilling device for producing shoes

The invention relates to a flip-flop drilling device, in particular to an efficient flip-flop drilling device for producing shoes. The efficient flip-flop drilling device for producing the shoes is good in drilling effect, high in drilling efficiency and easy to operate. According to the technical scheme, the efficient flip-flop drilling device for producing the shoes comprises a bottom plate, a left side plate, a collecting frame, a top plate, a motor, a guiding rod, a spring, a sliding rail, a connecting rod, a cam, a sector gear, a lifting rod, a fixing stopping block, an elastic piece, a contact plate, a placing plate, a sliding block, a first bearing base, a first rotating shaft, a first gear, a first bevel gear, an L-shaped rod, a second rotating shaft, a first belt wheel, drills, a flat belt, a first rack and the like. According to the efficient flip-flop drilling device for producing the shoes, the lifting rod drives the placing plate to move upwards while the drillers move downwards and rotate, and operating steps are small.

Owner:嘉兴磊佳电子科技有限公司

Epoxide-resin glue liquid, laminated board for printed circuit board manufactured by using the same and manufacturing method thereof

ActiveCN101376734AImprove drilling effectDoes not affect electrical performanceLamination ancillary operationsSynthetic resin layered productsEpoxyEngineering

The invention relates to an epoxy resin glue liquid, a laminate used for a printing circuit board manufactured by adopting the glue liquid as well as a manufacture method thereof. In the epoxy resin glue liquid, every 100 portions of epoxy resins are added with 2.5 to 20 portions of talcum powder; besides, the talcum powder meets a molecular formula of 3MgO.4SiO2.H2O; simultaneously the largest size of the talcum powder is required to be less than 40microns. The laminate manufactured by using the glue liquid is simply manufactured, has excellent drilling performance and is conveniently drilled. The laminate also has an excellent electric performance; the heat expansion coefficient of the epoxy resin on the Z direction is lower and the circuit failure rate is low, thus being suitable for the printing circuit board; besides, the manufacture cost of the laminate is lower when the talcum powder is used as inorganic fittings.

Owner:VENTEC ELECTRONICS SUZHOU

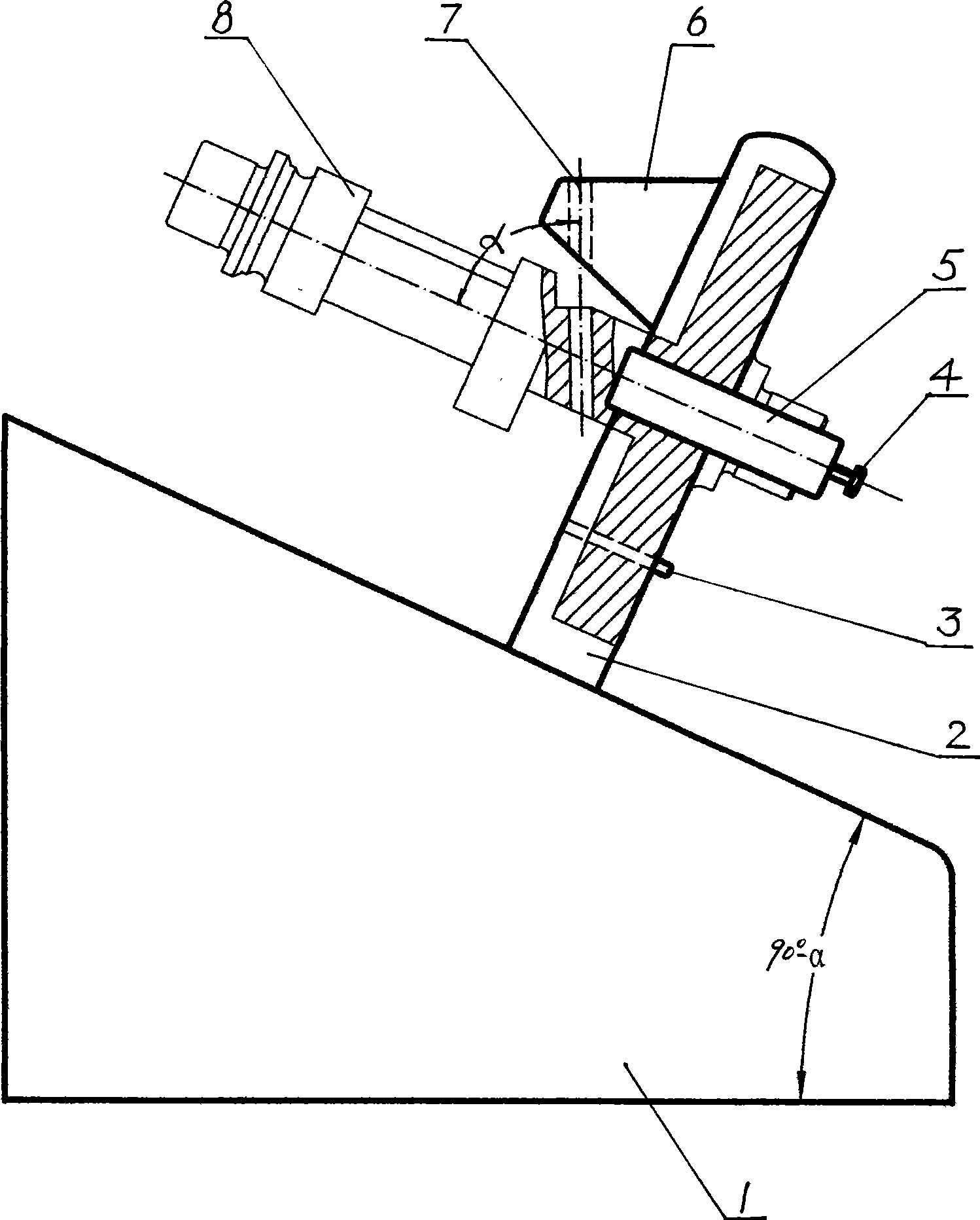

Camshaft flank hole processing clamp

InactiveCN101396795AReduce mistakesPrecise positioningPositioning apparatusBoring/drilling componentsProcessing accuracyBatch production

The invention discloses a camshaft side surface hole processing clamp; a positioning plate which forms an oblique angle Alpha with the bottom surface of a base is arranged above the base; the middle position of the positioning plate is provided with a positioning hole vertical to the positioning plate and a positioning pin which is arranged below the positioning hole; one side of the positioning plate is provided with a movable pressing plate and a pressing screw. Further improvement of the camshaft side surface hole processing clamp is characterized in that the movable pressing plate is a hook-shaped sliding pressing plate which is sheathed on the positioning plate; the positioning plate is provided with a drill sleeve which is arranged above the positioning hole. The camshaft side surface hole processing clamp is used for processing the side surface hole on the camshaft in a gasoline engine, has convenient assembly and disassembly and small positioning error, can improve the processing efficiency and processing precision and is suitable for batch production.

Owner:TAIZHOU HONGXIANG POWER MACHINERY

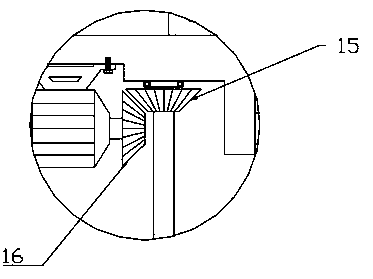

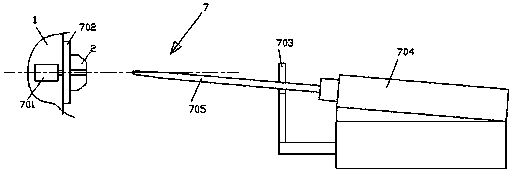

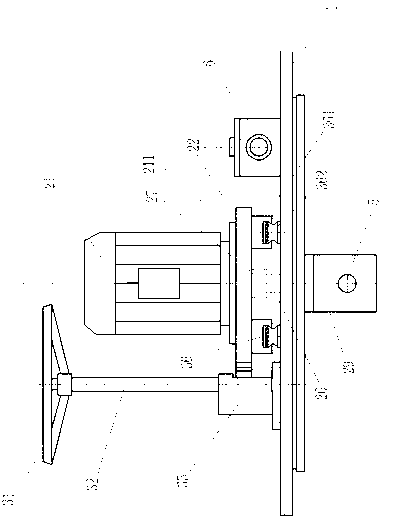

Horizontal hole drill for cooling water passages of diesel engine cylinder liner-mounting holes

ActiveCN103008718AImprove processing qualityImprove drilling effectBoring/drilling componentsBoring/drilling machinesCooling effectEngineering

The invention discloses a horizontal hole drill for cooling water passages of diesel engine cylinder liner-mounting holes, which comprises a positioning plate, a drilling mechanism and a feed mechanism, and the positioning plate is embedded into a diesel engine cylinder liner-mounting hole through a positioning disk on the lower side of the positioning plate. The drilling mechanism comprises a motor, a motor base, a pair of engaged small cone gears, a big cone gear and a horizontal spindle, and the feed mechanism comprises an operating handwheel, an operating handwheel shaft, an engaged gear-rack pair, a gear base and a pair of linear rolling guide rails. By adopting the pair of engaged spiral bevel gears to change power direction, the horizontal hole drill can accurately drill horizontal holes in the radial narrow space of the diesel engine cylinder liner-mounting hole and improve the cooling effect of a housing. By adopting the linear rolling guide rails as the horizontal feed base of the feed mechanism, the horizontal hole drill can guarantee the linearity of a fed drill bit, and because the feed mechanism with the gear-rack pair can be smoothly operated, the feed precision is increased.

Owner:CSSC MARINE POWER

Inorganic filler and electric material containing the same

InactiveUS20130105209A1Improve drilling effectGood high-frequency transmission functionPigmenting treatmentSynthetic resin layered productsTransmission functionComposite material

An inorganic filler containing (1) from 50 to 60 parts by weight of SiO2; (2) from 5 to 20 parts by weight of Al2O3; (3) from 0 to 10 parts by weight of CaO; (4) from 15 to 30 parts by weight of B2O3; (5) from 0 to 5 parts by weight of MgO; (6) from 0 to 1 parts by weight of Na2O, K2O or a combination of both; and (7) from 0 to 5 parts by weight of TiO2; based on a total weight of the filler, and having a maximum particle diameter below 100 μm is introduced. A resin composition containing the inorganic filler and application in printed circuit boards are also introduced. A laminate prepared by the inorganic filler provides a good drilling function, a good dielectric performance and a good high frequency transmission function in high frequency transmission printed circuit board.

Owner:ELITE ELECTRONICS MATERIAL KUNSHAN

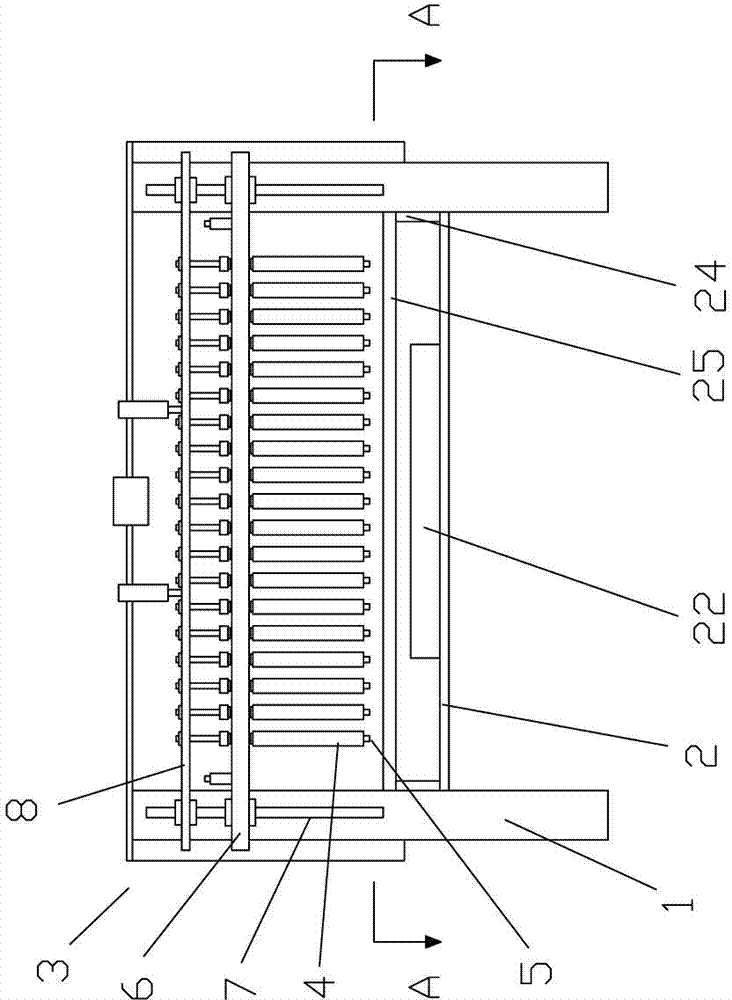

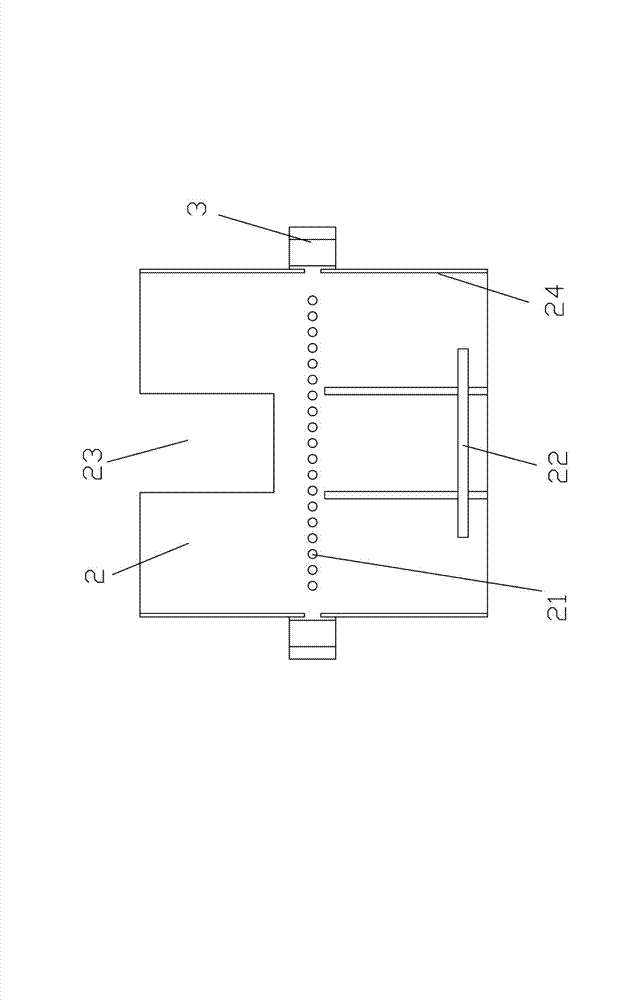

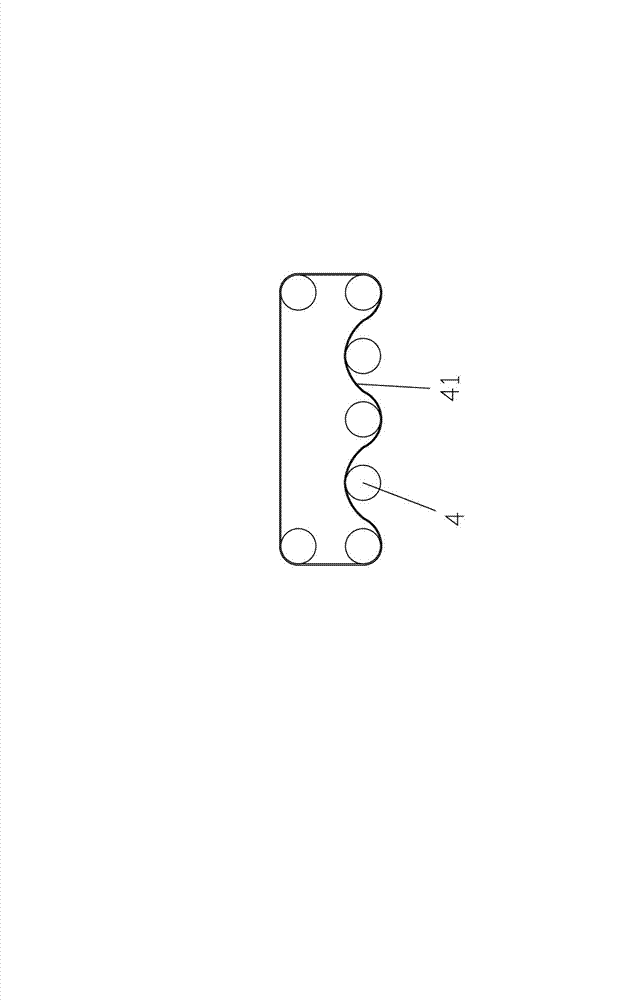

Furniture sponge drilling machine

InactiveCN102729291AImprove work efficiencyAvoid deformationMetal working apparatusDrill bitEngineering

The invention discloses a furniture sponge drilling machine which is good in drilling effect, convenient to use and high in working efficiency. The furniture sponge drilling machine comprises a rack, wherein the rack is provided with a workbench for placing furniture sponge, a gantry support is arranged in the middle of the workbench, a plurality of hollow drilling bits which can vertically move are horizontally arranged on the gantry support, the rotation directions of two adjacent hollow drilling bits are opposite, and a push rod which can vertically move is arranged in each hollow drilling bit. In the furniture sponge drilling machine, the plurality of hollow drilling bits which can vertically move are arranged above the workbench so as to drill a plurality of holes on the furniture sponge once, so that the working efficiency is high; and the rotation directions of two adjacent hollow drilling bits are opposite, so that the stress directions of the contact surfaces between the two adjacent hollow drilling bits and the furniture sponge are opposite, and the stress of the whole furniture sponge is in a balanced state so as to avoid deformation of the furniture sponge and ensure the drilling effect.

Owner:李钊怀

Vamp perforating device for shoe making

InactiveCN106174890AImprove aestheticsIncrease drilling speedShoemaking devicesDesign improvementEngineering

The invention relates to a perforating device, in particular to a vamp perforating device for shoe making. The technical problem to be solved by the invention is to provide the vamp perforating device for shoe making, with the advantages of high perforating speed, good perforating effect and long service life. In order to solve the technical problems, the invention provides such vamp perforating device for shoe making. The vamp perforating device for shoe making comprises a perforating worktable, a guiding plate, springs, perforating rods, a first pressing block, a first sliding rail, a first slide block, a first pull rope, a first roller, a sector gear, a first wire reeling wheel, a rack, a second pressing block, a second sliding rail, a second slide block, a second pull rope, a second roller, a third roller, a rotating rod, a second wire reeling wheel, a bearing base, a first bevel wheel, a nicked bevel wheel and a rotating motor. The vamp perforating device for shoe making achieves the effects of high perforating speed, good perforating effect and long service life; through design improvements, the perforating speed of the vamp perforating device for shoe making becomes very high, but the perforating effect is not changed thereby.

Owner:温州市日翔鞋业有限公司

Disc cutter composite drill bit

InactiveCN102678052AReduce difficultyReduce rock breaking energy consumptionDrill bitsConstructionsMining engineeringTransfer mechanism

The invention discloses a disc cutter composite drill bit belonging to the field of rock blasting tools for drilling equipment for oil and gas, mine engineering and building foundation engineering construction, geology, hydrology and the like. The disc cutter composite drill bit comprises a drill bit body and a disc cutter cutting structure arranged on the drill bit body; the drill bit body is also provided with an impact cutting structure; and the impact cutting structure comprises a force transferring mechanism for transferring impact force and impact cutting teeth, wherein the impact cutting teeth are solidified on a punch arranged at the tail end of the force transferring mechanism, and the punch can slide or slidingly impact relative to the drill bit body in the impact force transferring direction. Compared with a drill bit (also named as wheel type drill bit) with the disc cutter cutting structure, the disc cutter composite drill bit is not only beneficial to the drilling of the cutting teeth of the drill bit to stratums and the increment of the rock blasting efficiency, but also beneficial to the retardance of the wear rate of the cutting teeth and particularly has remarkable technical advantages for higher-strength and stronger-abrasiveness stratums which are difficult to drill.

Owner:SOUTHWEST PETROLEUM UNIV

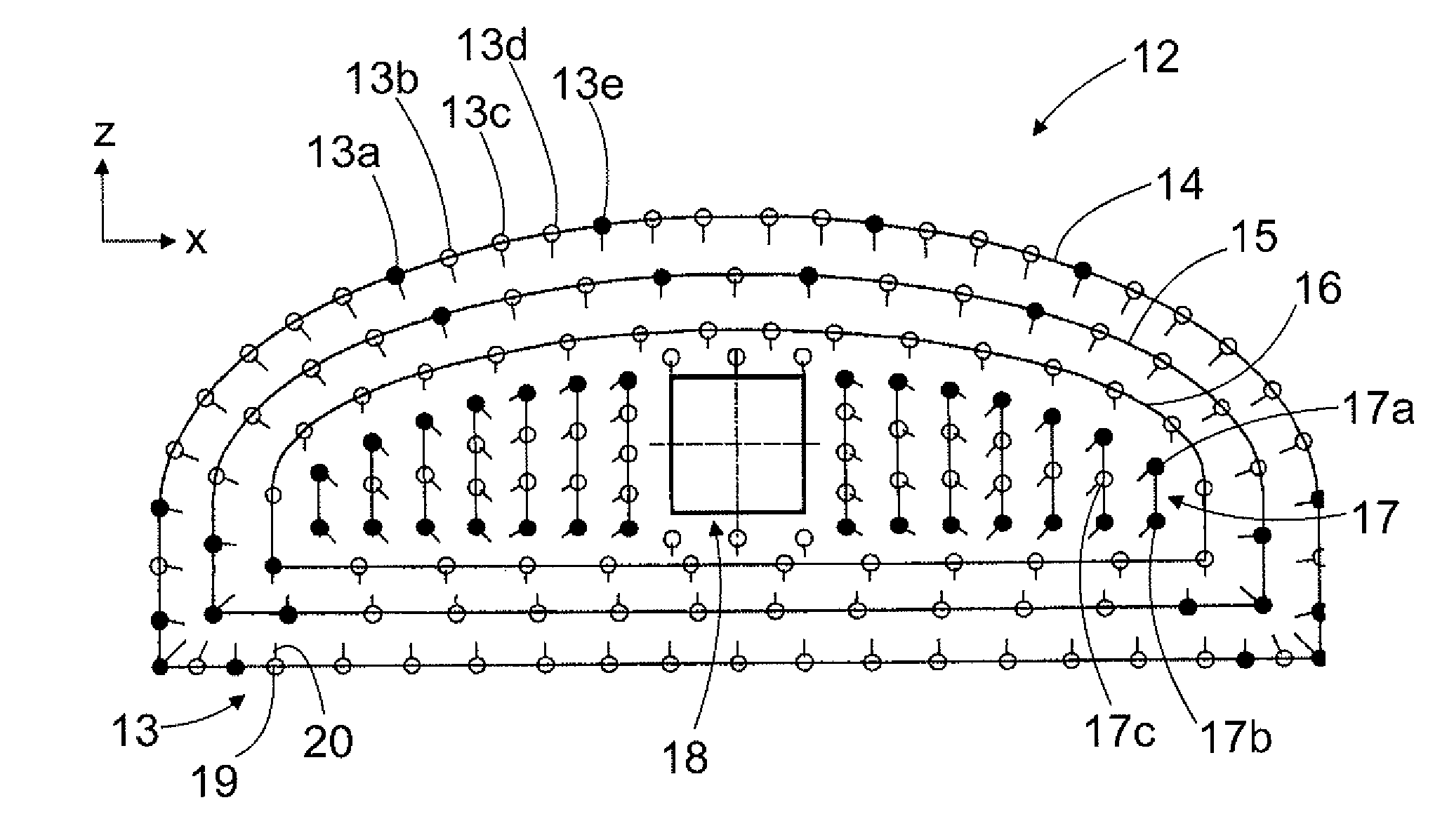

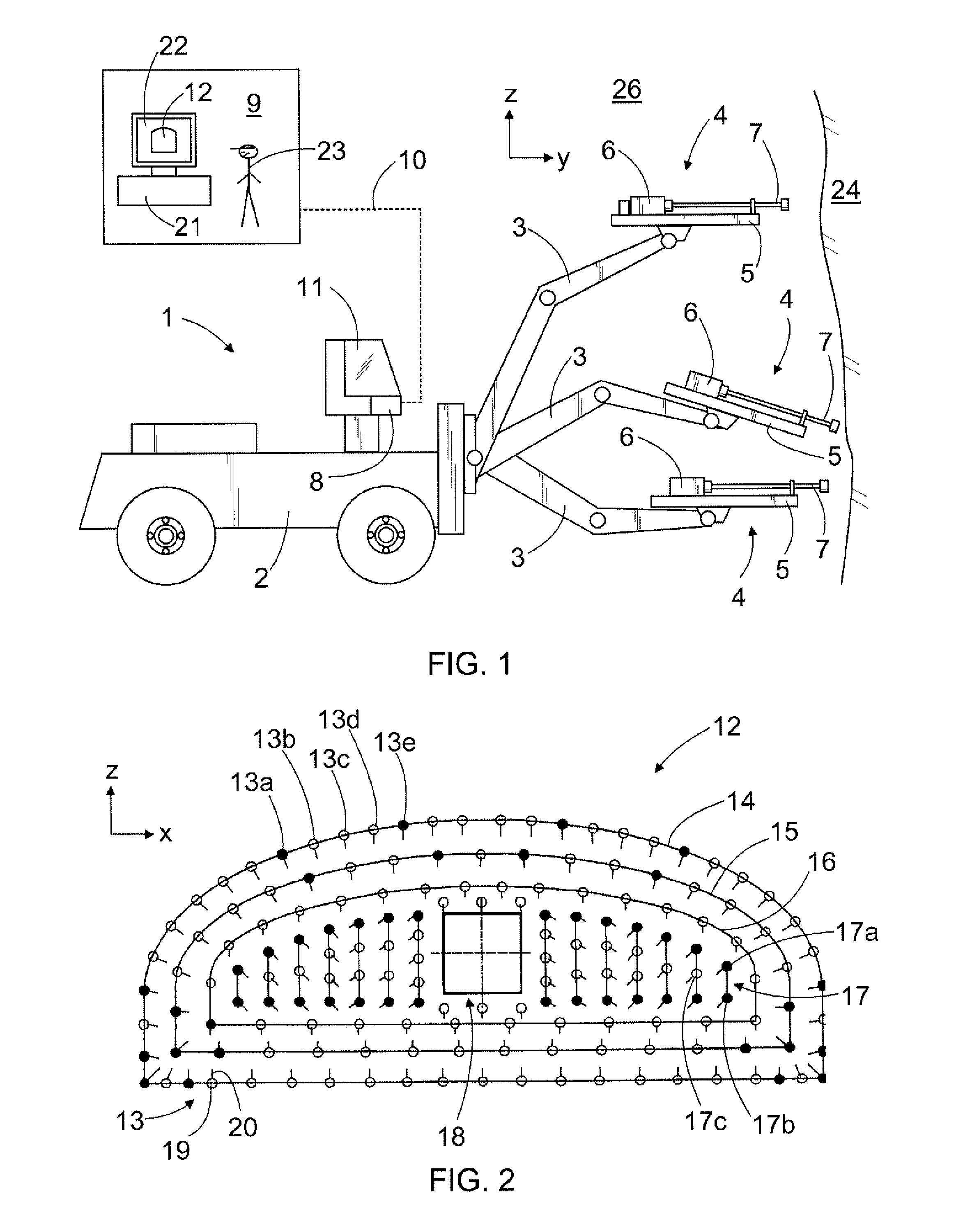

Designing drilling pattern for excavating rock cavern

InactiveUS8392014B2Easy and faster to designEasy and fast to editComputer controlBlasting cartridgesControl unitSoftware

A method and a storage device including a software product for designing a drilling pattern, and further a rock drilling rig, in the control unit of which a software product may be executed for designing the drilling pattern. For a group of holes of the drilling pattern, at least one master hole can be determined which comprises at least one dominating factor. The properties of at least one other drill hole are determined on the basis of the dominating properties of the master hole. A master hole may be a hole location master, hole depth master or hole direction master.

Owner:SANDVIK MINING & CONSTR OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com