Manufacturing method for long life electroplated diamond bit

A technology of electroplating diamonds and manufacturing methods, which is applied to drill bits, electrolytic coatings, earthwork drilling and mining, etc. It can solve the problems that the diameter protection effect of drill bits cannot meet the requirements, the height of the electroplating working layer of drill bits is limited, and the service life of drill bits is reduced. Good performance, easy operation, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

[0029] Two-time electroplating forming process technology of drill bit:

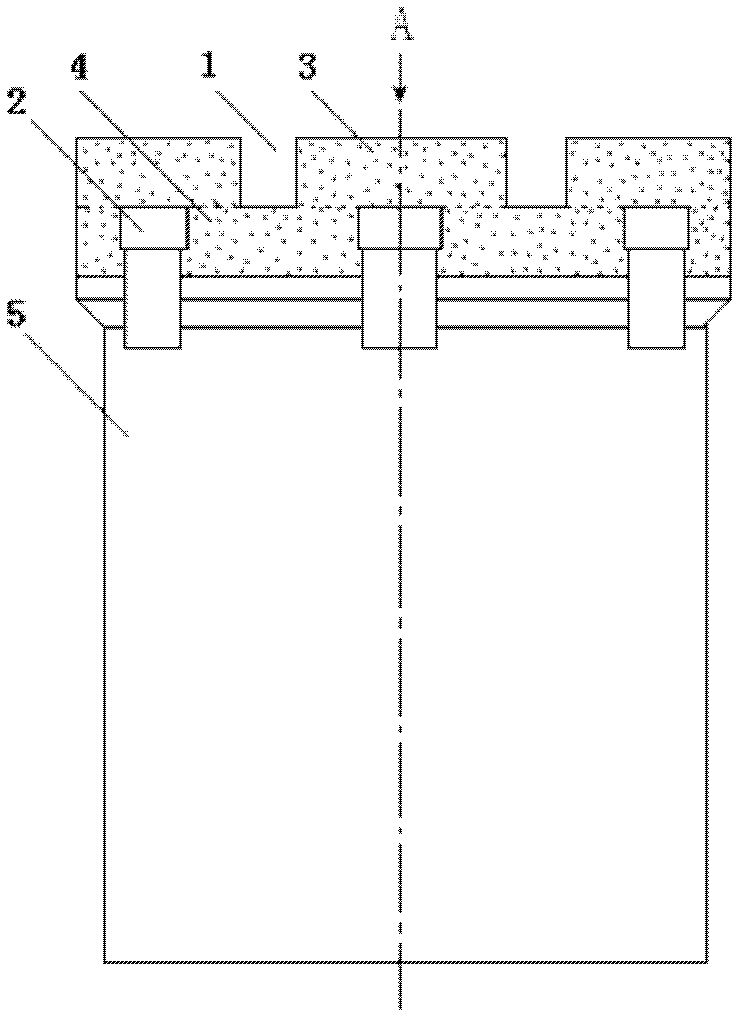

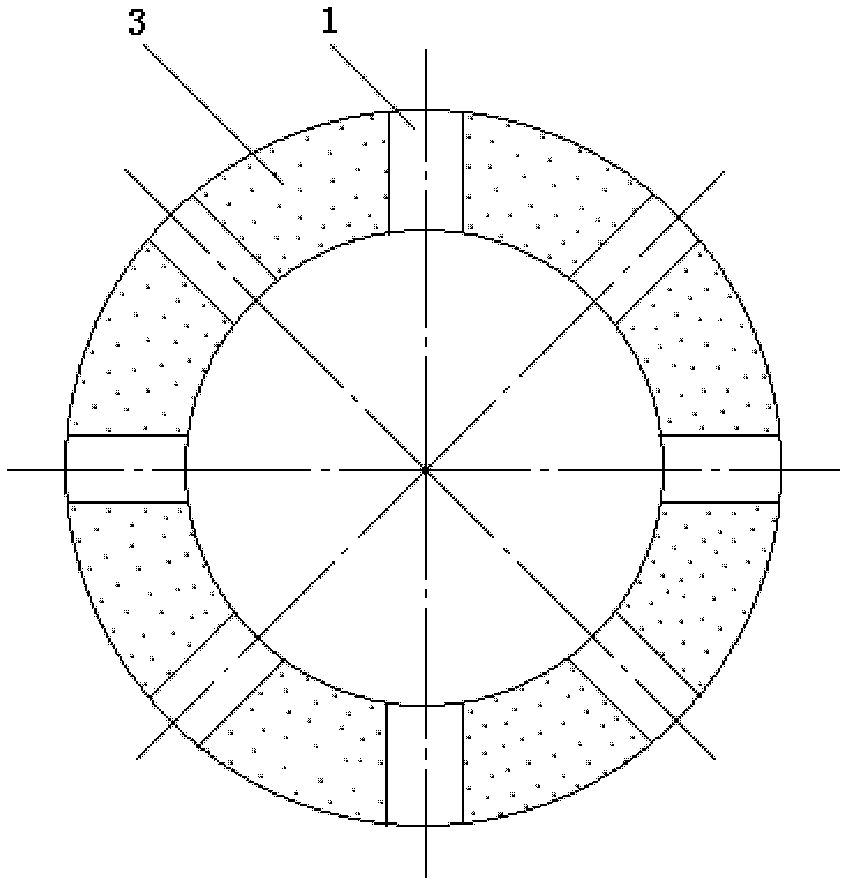

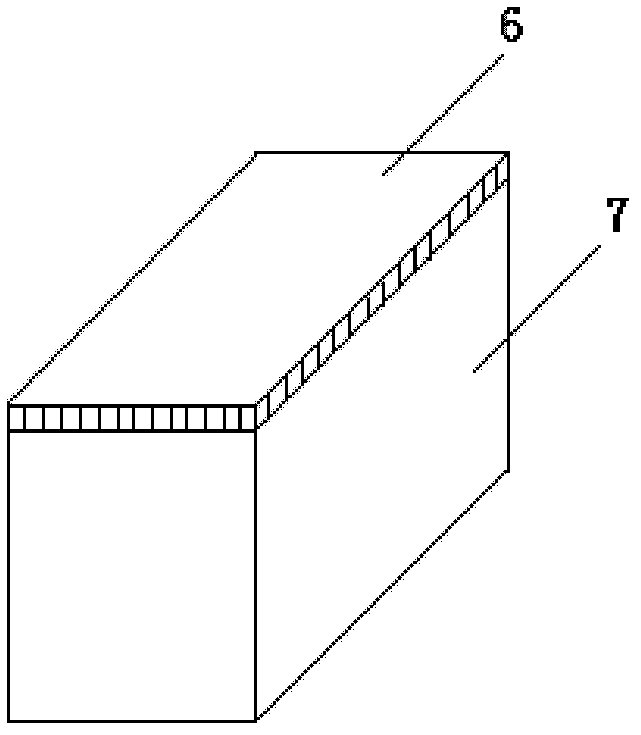

[0030] The drill bit steel substrate 5 that has been treated before plating is electroplated in the tank. After 25 minutes of electroplating, put on the inner and outer diameter molds, and add diamond composite plating on the bottom lip of the drill bit. After the coating height of the upper working layer 4 reaches the requirement of 5mm, use the conductive nozzle Plug ( image 3 ) to replace the ordinary nozzle plug "bridge", and place an ordinary nozzle plug in the middle of the upper working layer 4 at the same time; continue to add diamond composite plating to the lower working layer 3 of the drill bit until the lower working layer 3 of the drill bit reaches the design height of 8mm.

[0031] After the upper and lower working layers of the electroplated diamond drill bit are all com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com