Horizontal hole drill for cooling water passages of diesel engine cylinder liner-mounting holes

A technology of cooling water channel and drilling device, applied in boring/drilling, drilling/drilling equipment, components of boring machine/drilling machine, etc. Frame cooling effect and other issues, to achieve the effect of improving processing quality, improving cooling effect, and improving drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

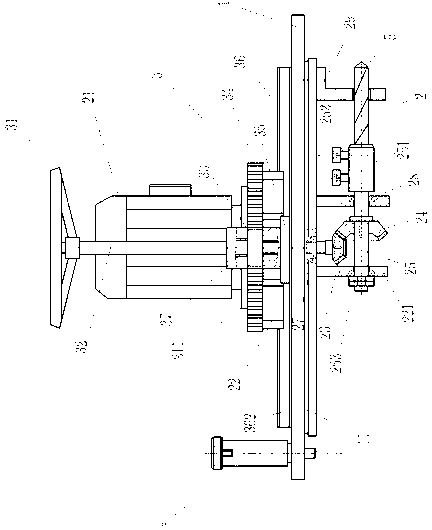

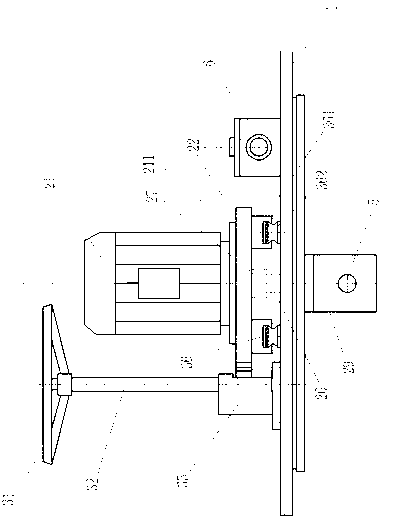

[0016] Such as Figure 1 ~ Figure 2 As shown, the present invention includes a positioning plate 1, a drilling mechanism 2 arranged under the positioning plate 1, and a feed mechanism 3 on the positioning plate. The positioning plate 1 is embedded in the cylinder liner mounting hole of the diesel engine through the positioning disc 11 on the lower side, and the positioning Disk 11 serves as the plane and radial installation positioning datum of the present invention. The elastic positioning pin 4 is vertically arranged on one end of the positioning plate 1, and the positioning plate 1 is positioned on the installation hole of the cylinder liner of the diesel engine through the elastic positioning pin 4. The elastic positioning pin 4 can be used as a positioning reference for the drilling angle of the horizontal hole of the cylinder liner installation hole of the diesel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com