Patents

Literature

515results about How to "High feed accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

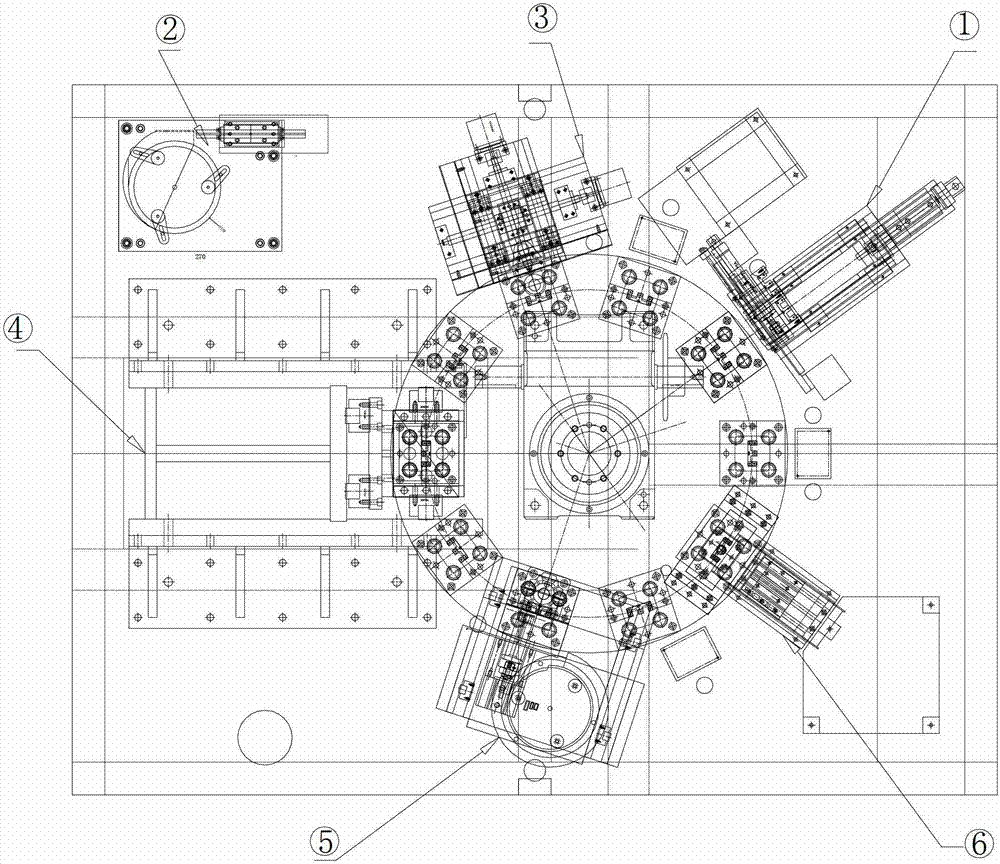

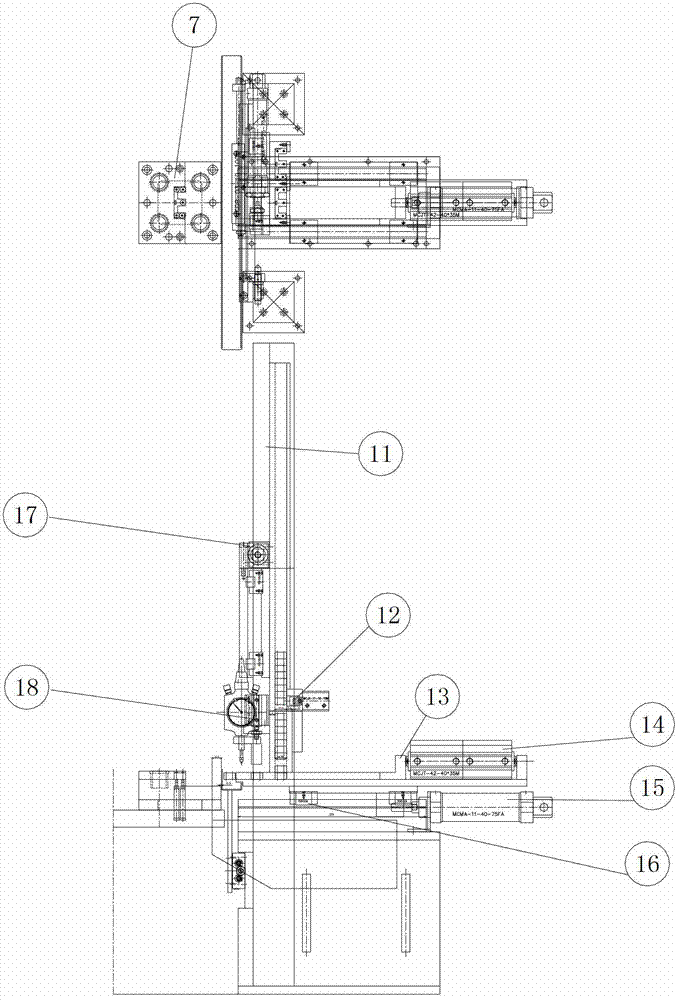

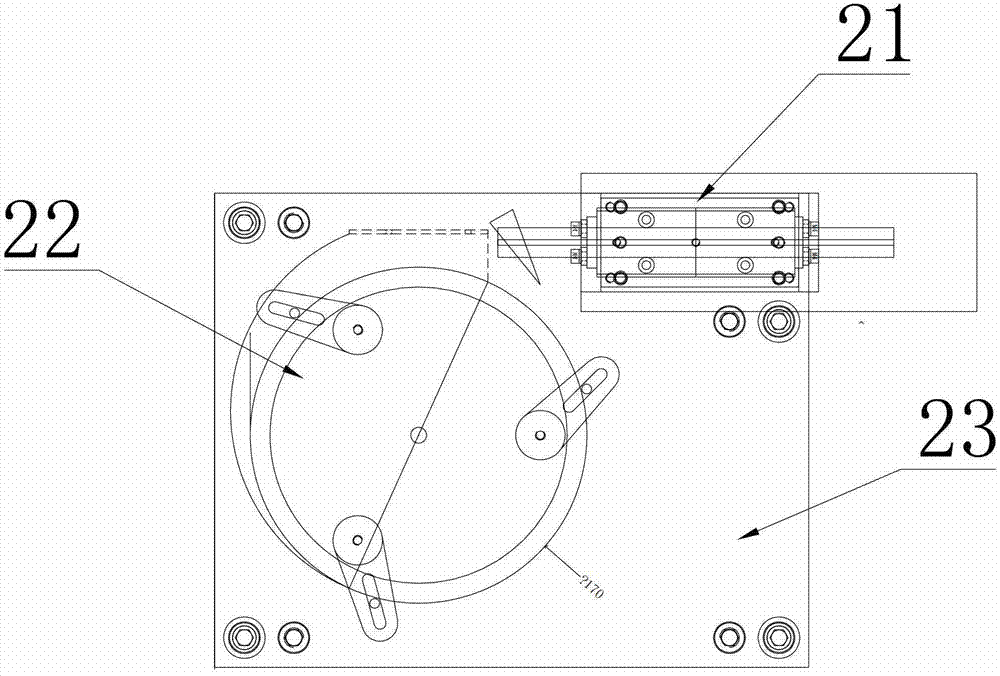

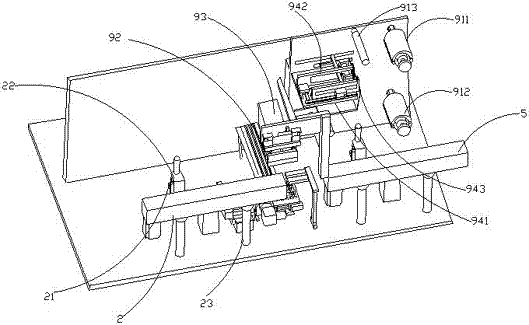

Automatic film sticking machine

ActiveCN106428746AFast and effective film applicationImprove the efficiency of automatic film applicationPackagingEngineeringElectrical and Electronics engineering

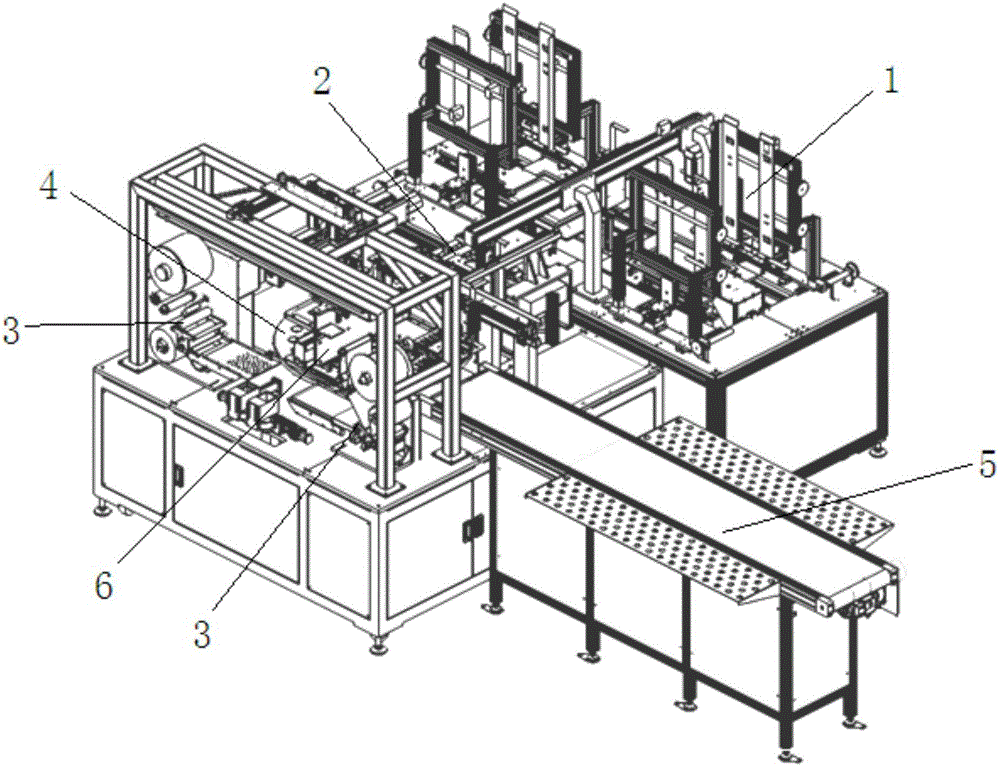

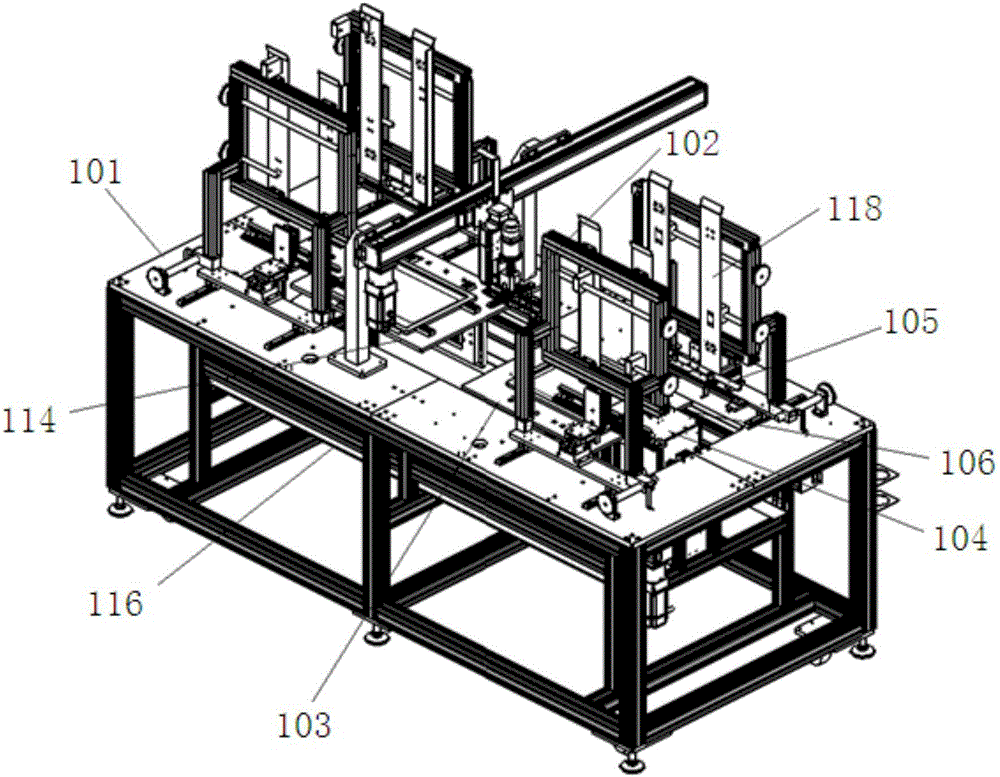

The invention discloses an automatic film sticking machine. The machine comprises an automatic feeding mechanism, a pre-positioning mechanism, a film sticking automatic stripping mechanism, a film sticking station conversion mechanism, an automatic film sticking mechanism and a finished product output mechanism; according to the automatic feeding mechanism, an element to be subject to film sticking is taken out and conveyed to the pre-positioning mechanism, the pre-positioning mechanism carries out position pre-adjustment on the element to be subject to film sticking, the element to be subject to film sticking and position pre-adjustment is placed on the film sticking station conversion mechanism, the automatic film sticking mechanism enables a sticking film stripped from the film sticking automatic stripping mechanism to be pasted and covered on the element to be subject to film sticking on the film sticking station conversion mechanism, and the element subject to film sticking is output through the finished product output mechanism for quality inspection. The automatic film sticking machine can be suitable for single-layer or multi-layer rapid effective film sticking, full-automatic feeding, cleaning, sticking film stripping, sticking film absorbing and film sticking are achieved, time and labor are saved, the automatic film sticking efficiency is improved, the film sticking yield is high, and the good application prospect is achieved.

Owner:JIANGSU BVM INTELLIGENT TECH

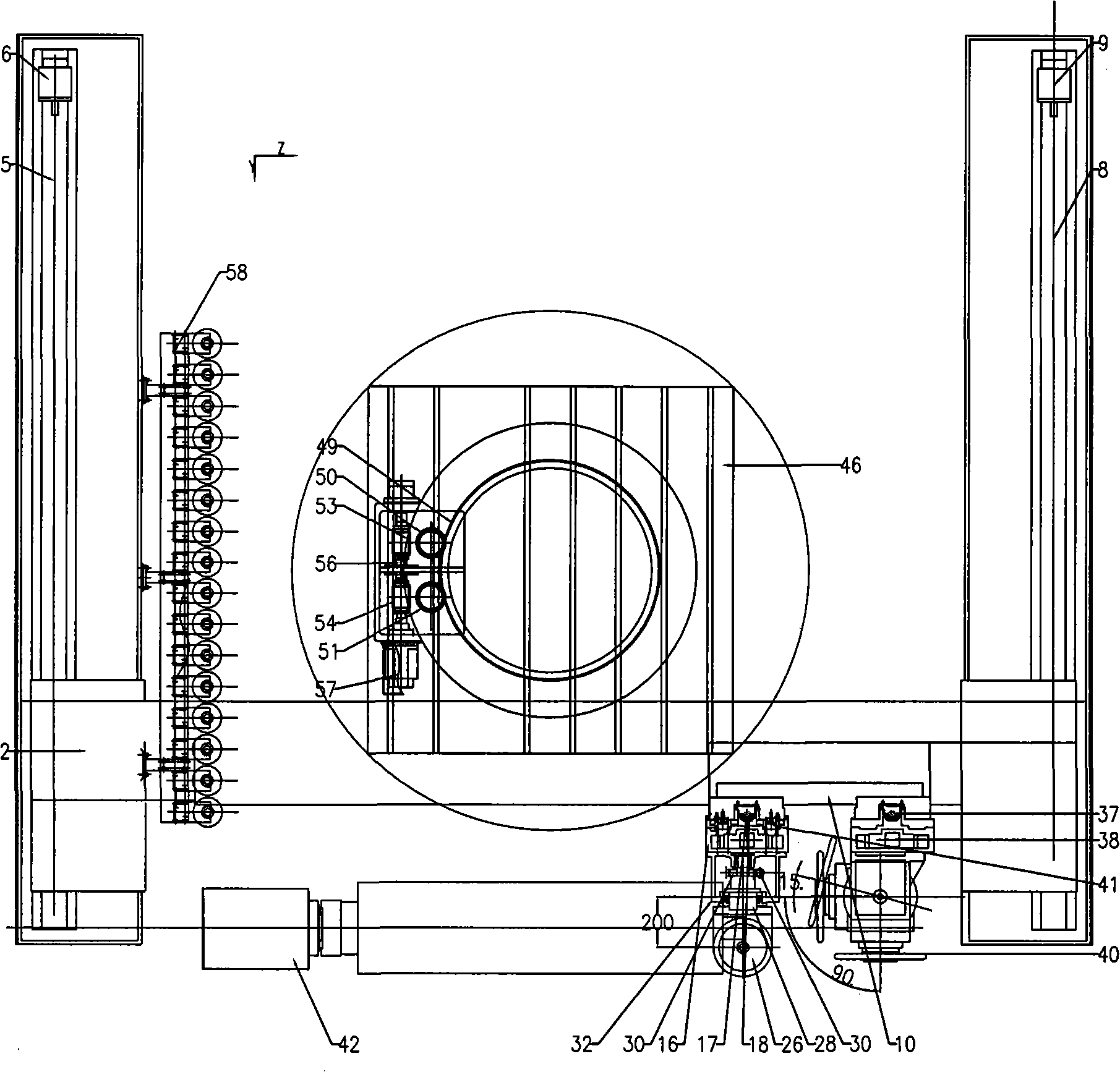

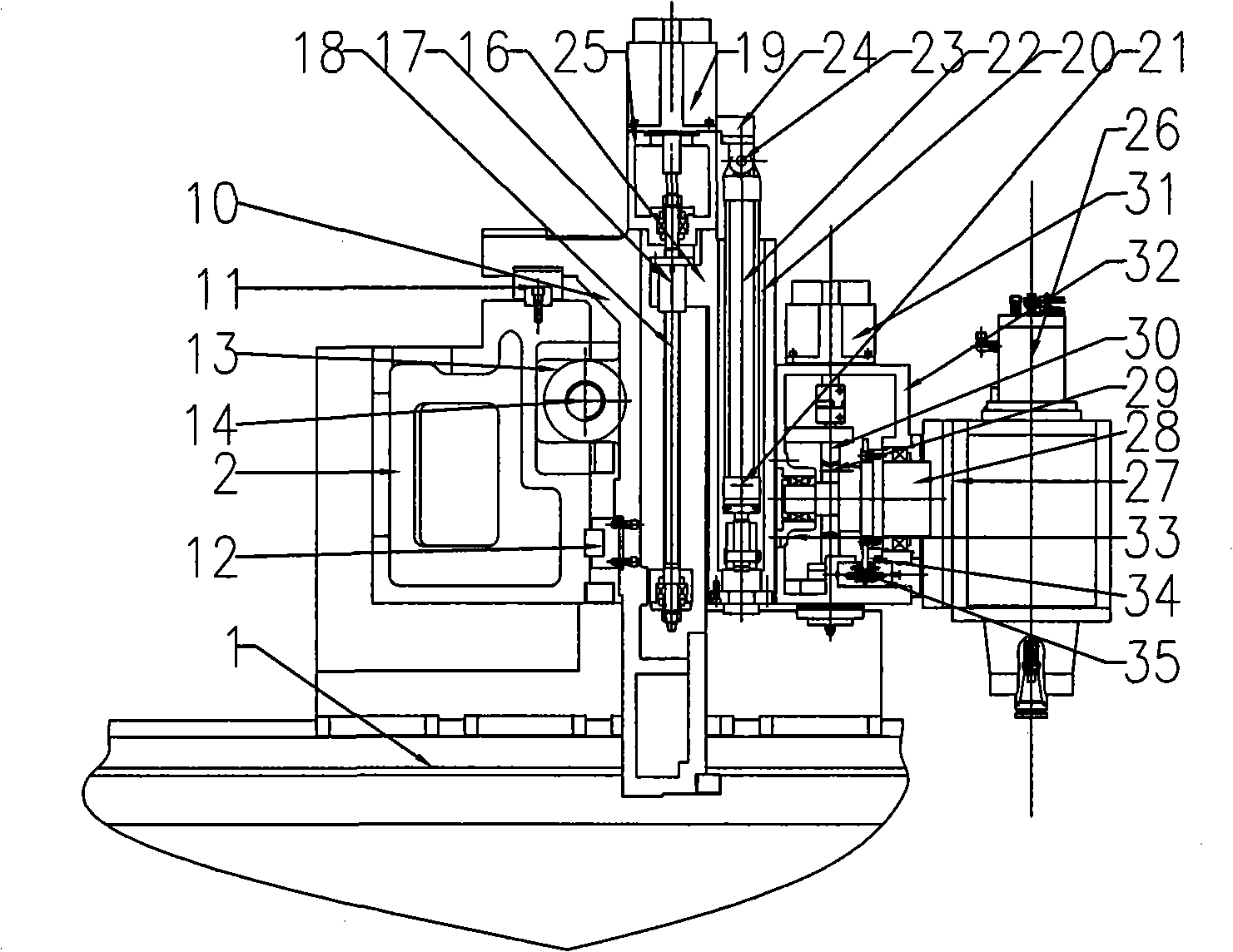

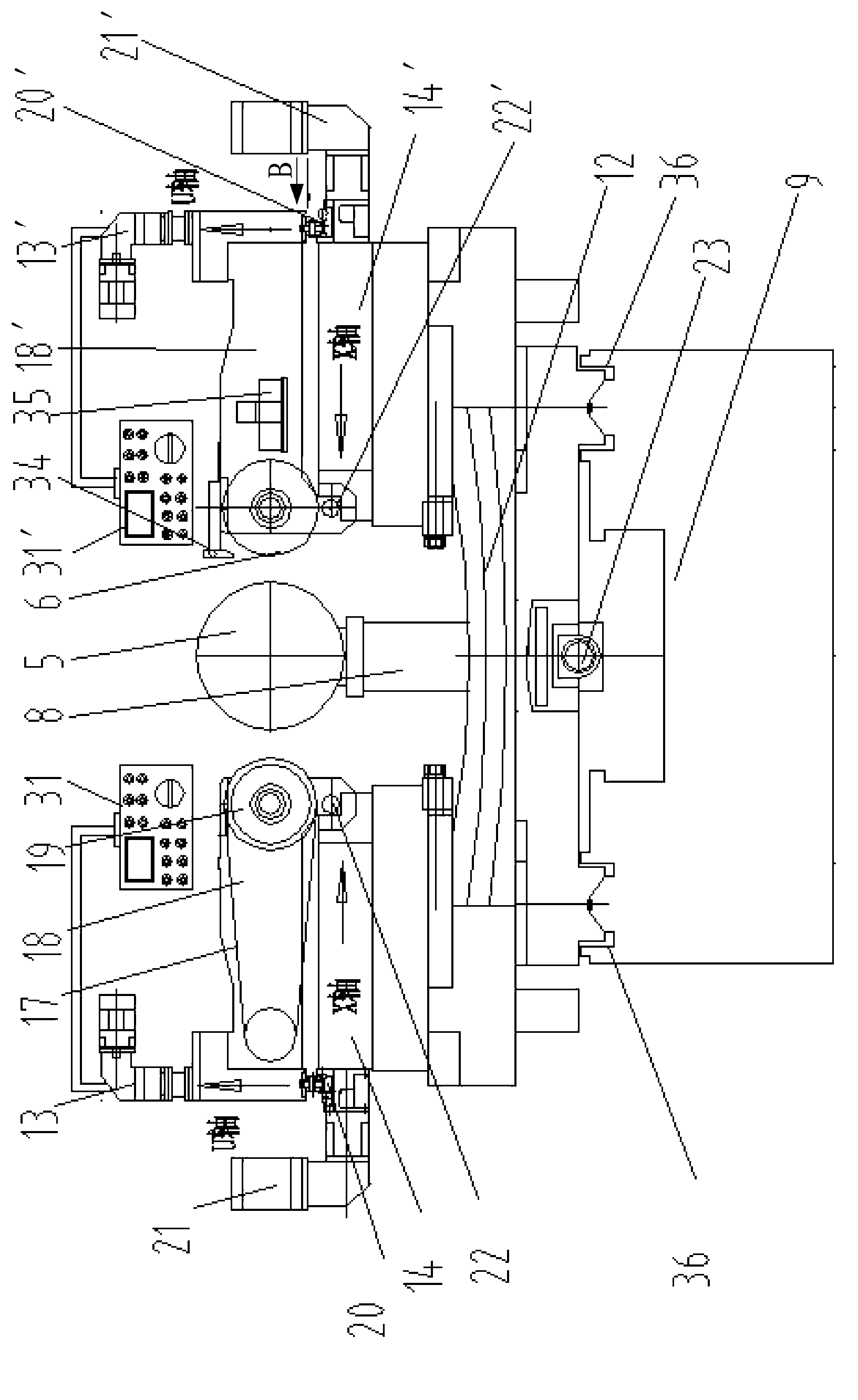

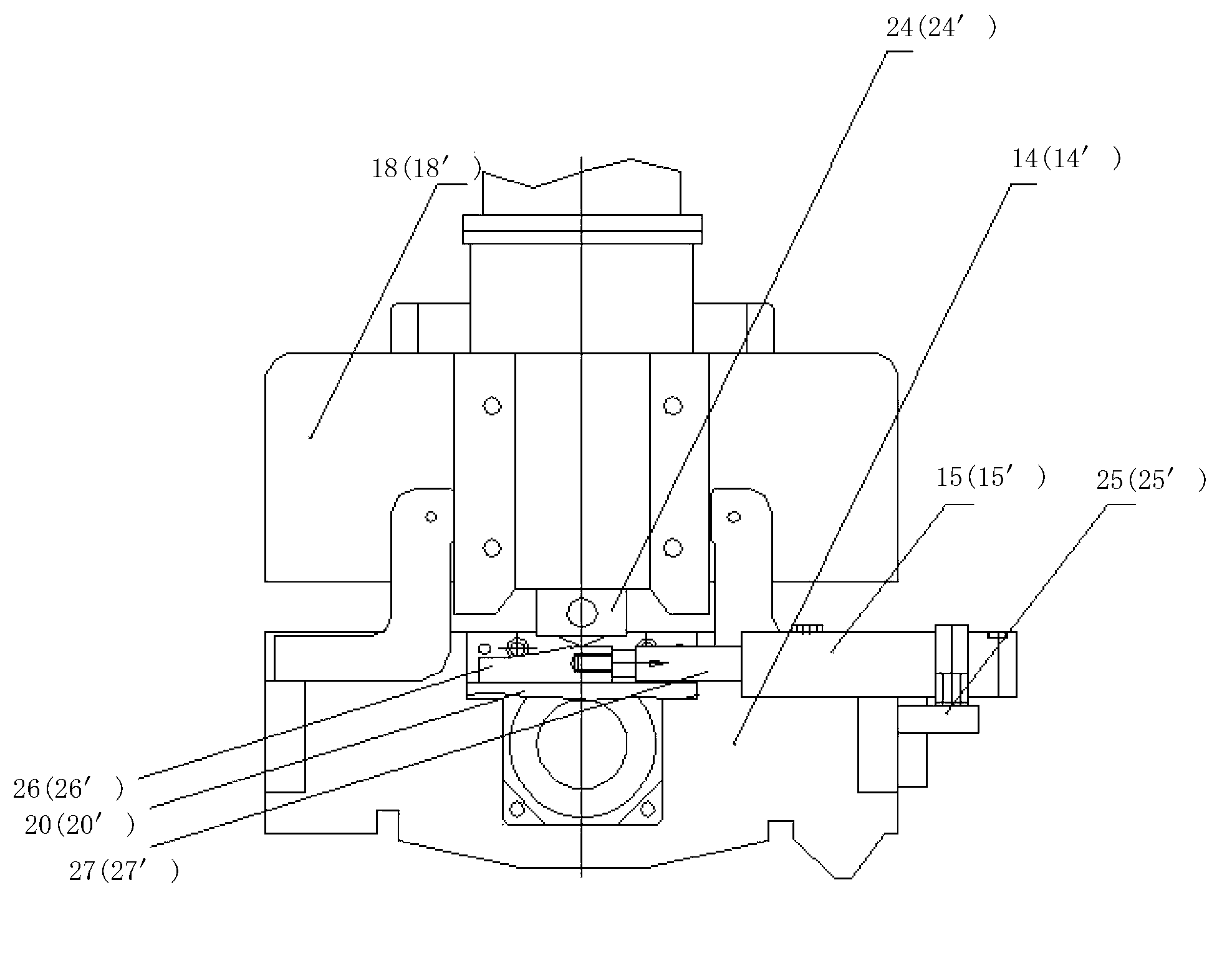

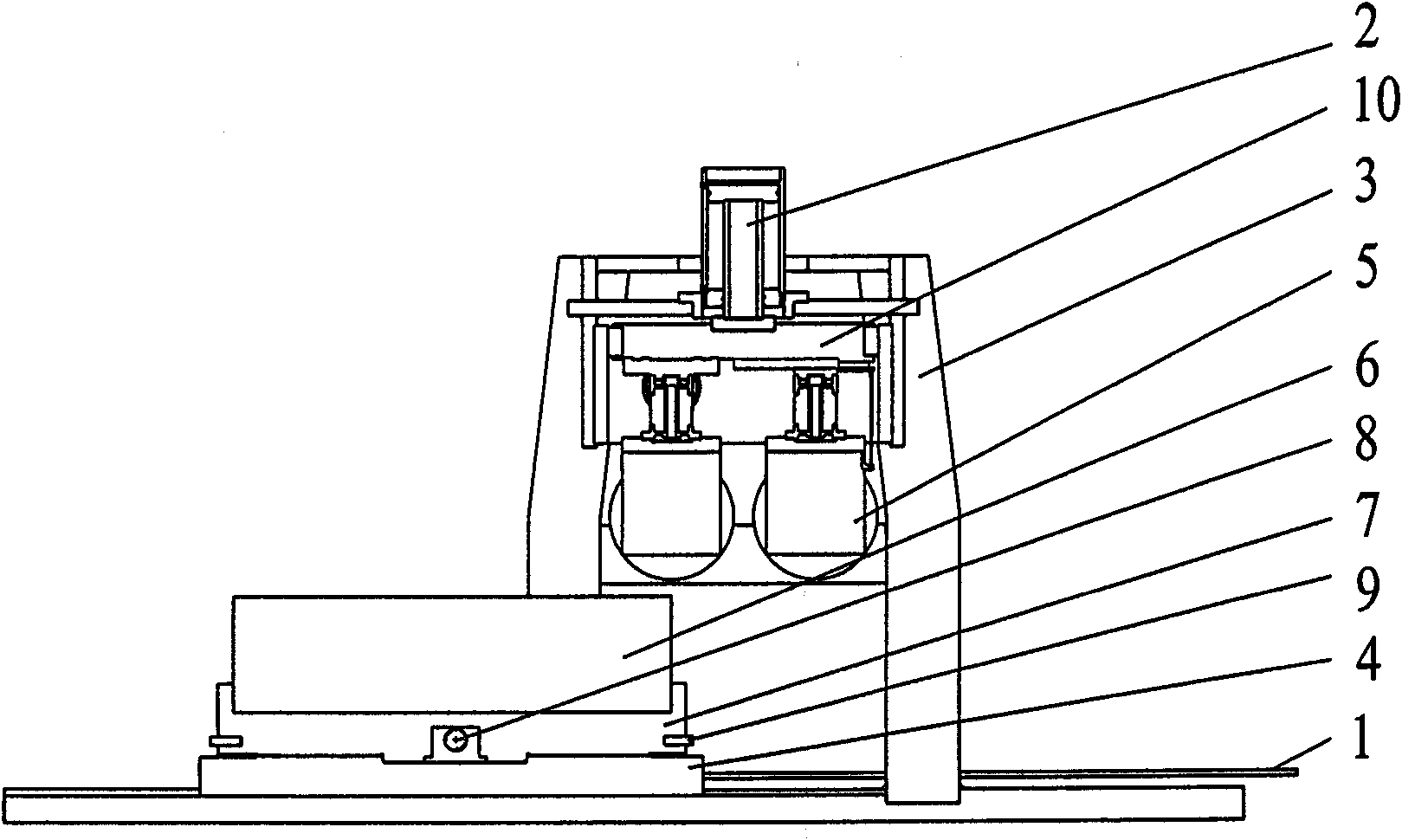

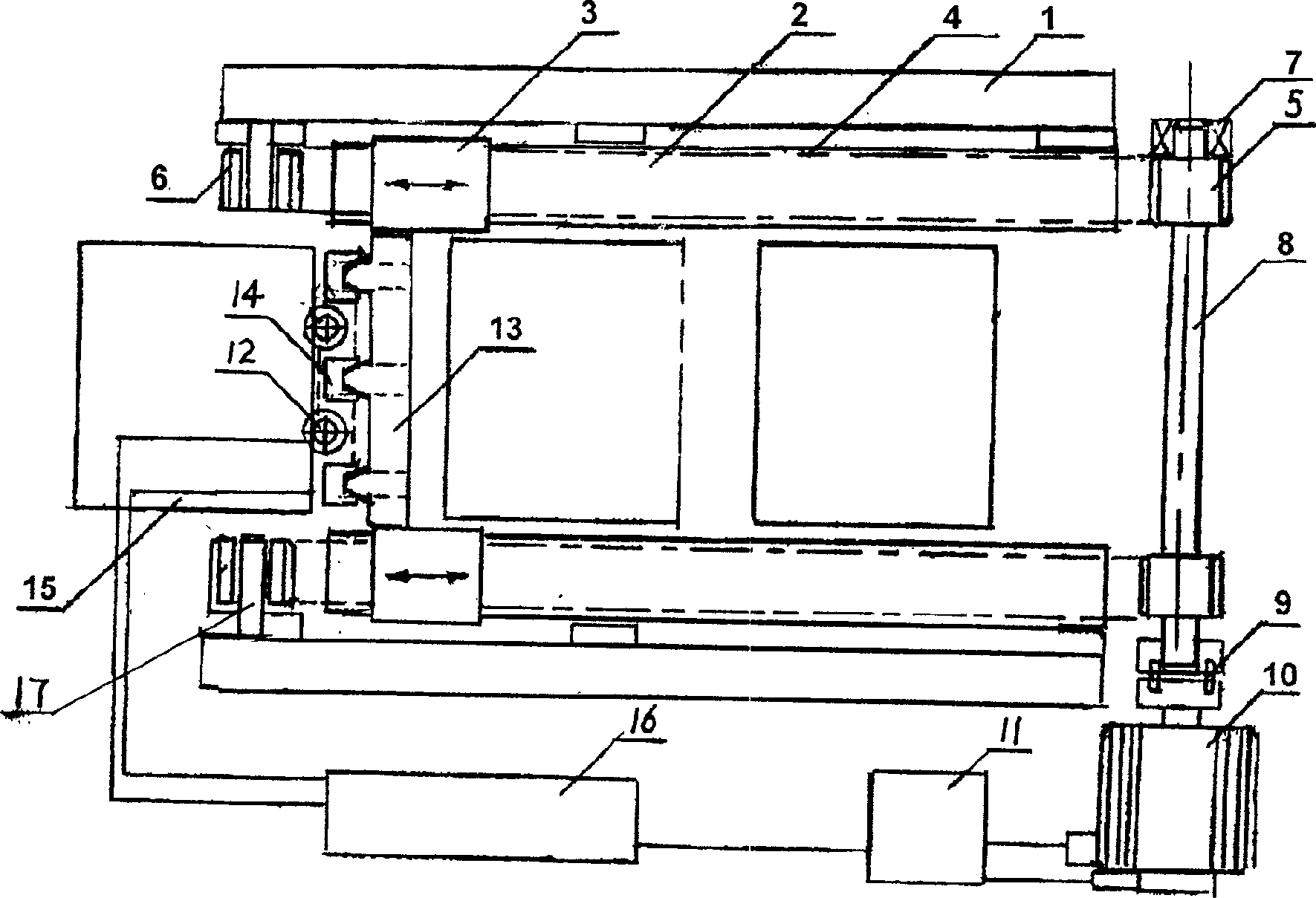

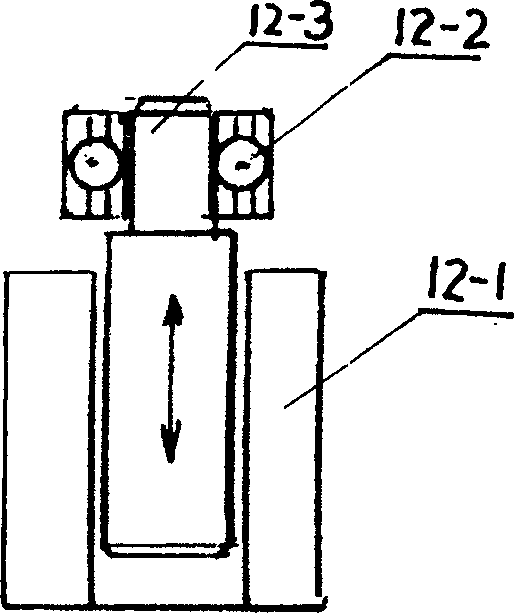

Irregular stone multifunctional composite processing center with double five-axle linkage system

ActiveCN101357490AEngraving and milling realizationAchieve turningGrinding machinesStone-like material working toolsEngineeringMechanical engineering

The invention relates to a special shaped stone high-speed high-efficiency combined machining center with the functions of double five-axis linkage and synchronous cutting by double working heads, and relates to a device for processing stones. Active gantry structure is adopted in the machining center, the double-motor synchronous driving technology is adopted on the gantry beam, and synchronous high-speed driving is realized by the screw bar pair at the two sides; a milling working head component and a turning working head component are respectively arranged on the saddle of the beam, the vertical feeding mechanism thereof is formed by a suit of screw bar pair and a hydraulic pressure auxiliary mechanism; wherein, the milling working head can carry out rotation and scales division around the axis B, and the turning working head facilitates the same servo motor to realize rotation and scale division of axis A and cutting movement; the turning working head and the milling working head are arranged alternately, and both the turning process and the grinding processing can be carried out on stone articles at the same time. The machining center is provided with a numerical control system with the function of double five-axis linkage, and horizontal five-axis linkage machining and vertical five-axis linkage machining can be realized.

Owner:SHENYANG JIANZHU UNIVERSITY

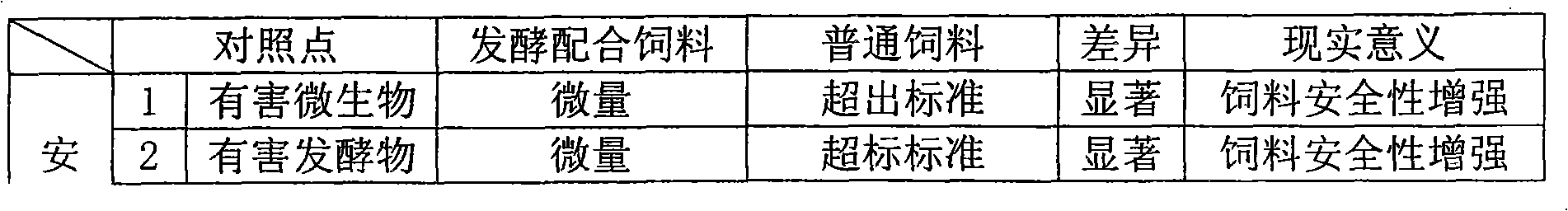

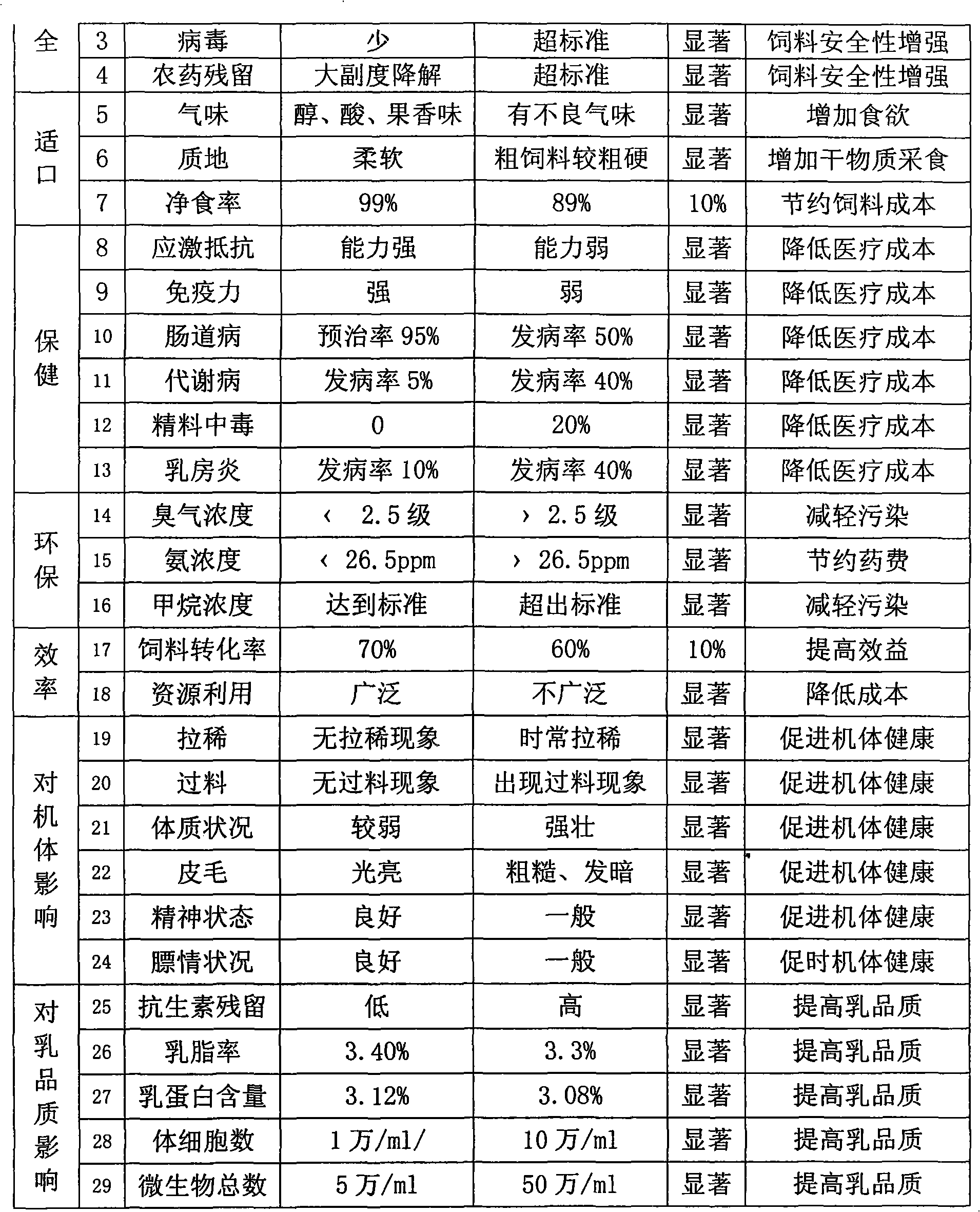

Fermentation compound feed products and its preparation method

ActiveCN101283732AImprove securityPrevent diseaseFood processingAnimal feeding stuffResource utilizationAdditive ingredient

The invention discloses a fermented compound feed and a production method thereof. In a TMR mixer, premixed fine and coarse feed materials and other nutritional ingredients are pulverized, kneaded and mixed until the particle size, uniformity and water content are desired. Further, microbial fermentation starters are added and water is added during the mixing process to allow the water content of the compound feed to meet the standard. The raw material mixture is compacted and sealed with films by using industrial equipment or directly packed in a sealed container and then subjected to directional and timed fermentation in a predetermined environment, to produce the final fermented compound feed. The product has rich and balanced nutrition, good palatability, high safety, environmental friendliness and convenient transport and use. The invention realizes industrial production and commoditization of feeds for dairy cows as well as resource utilization.

Owner:单德章

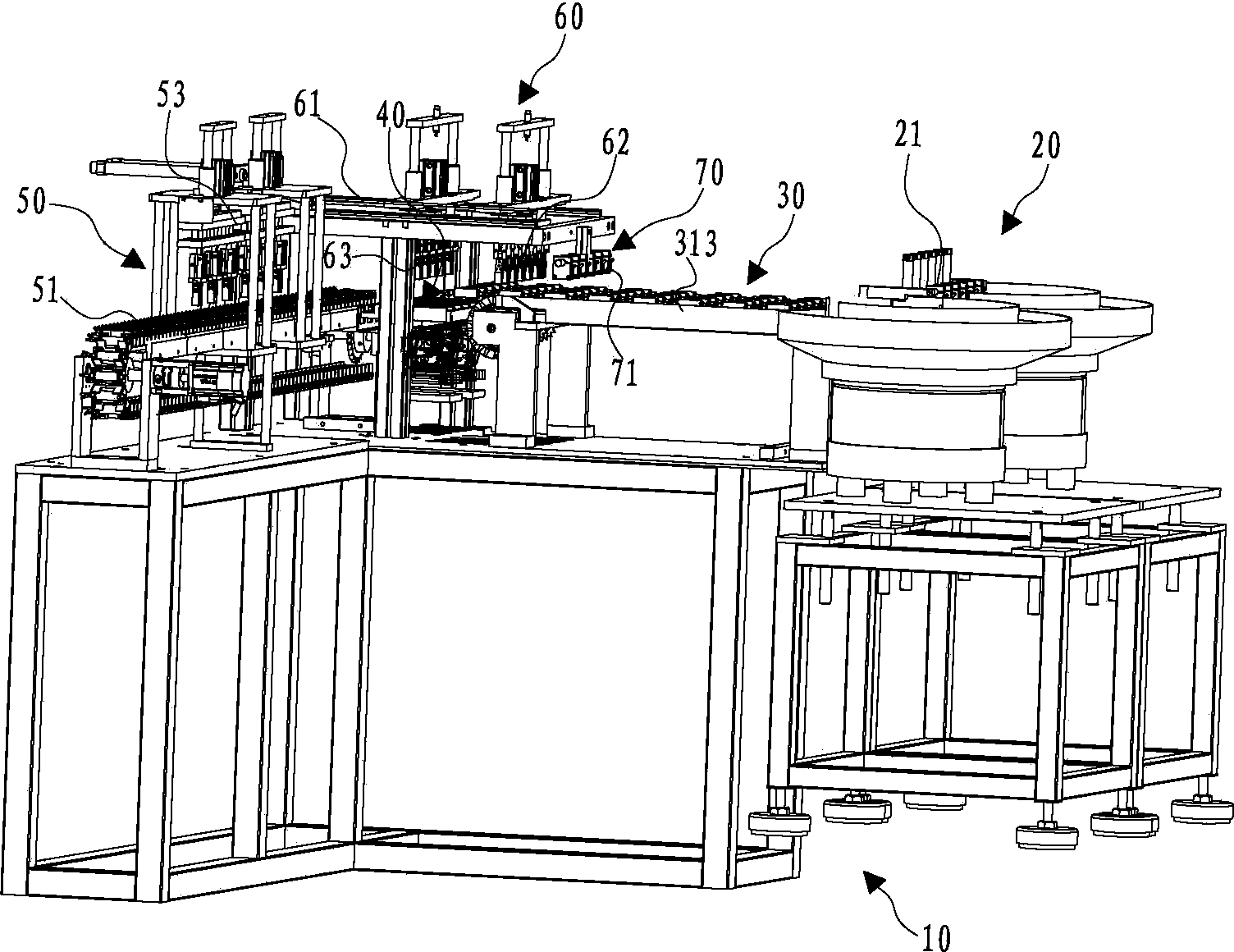

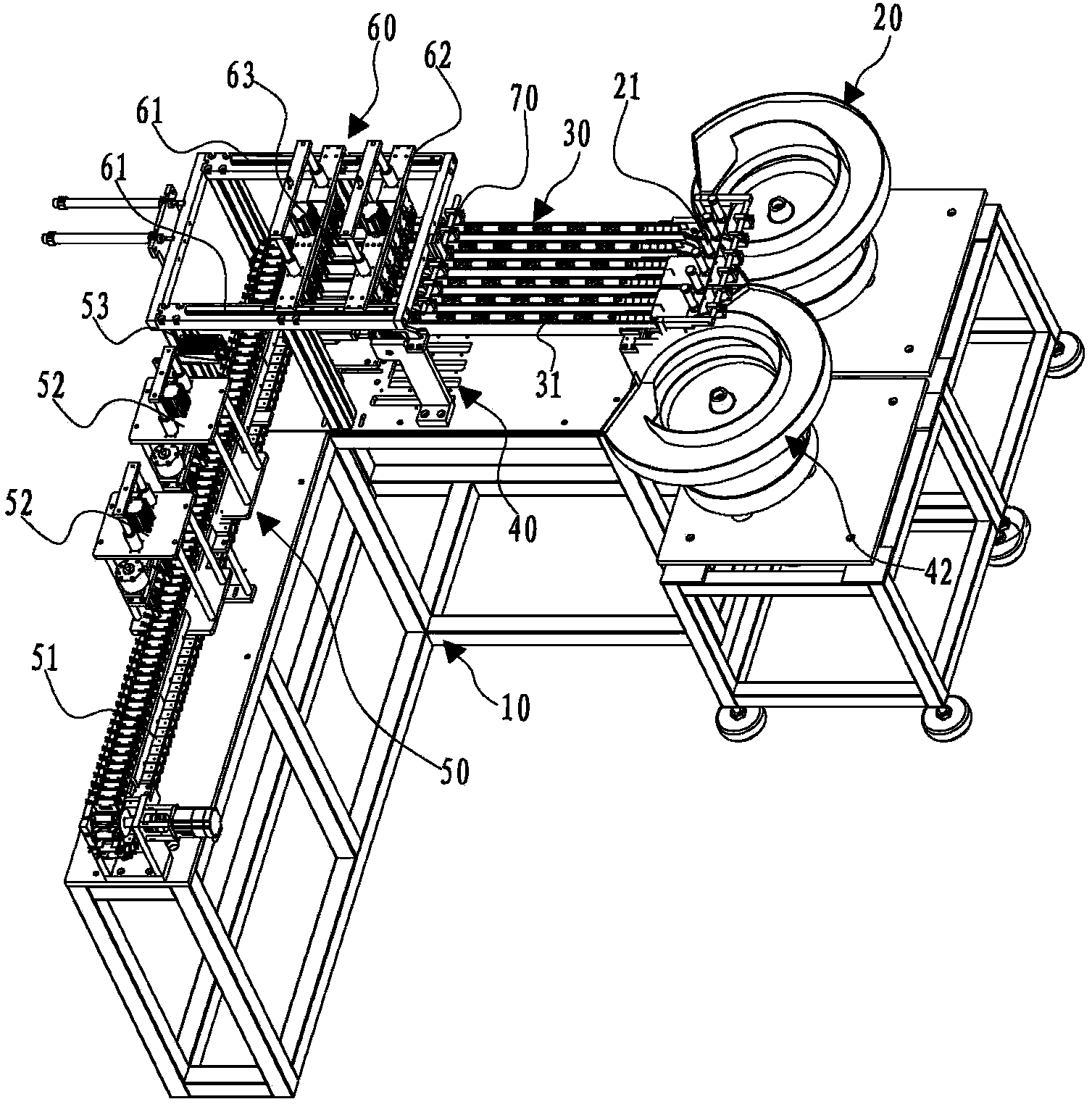

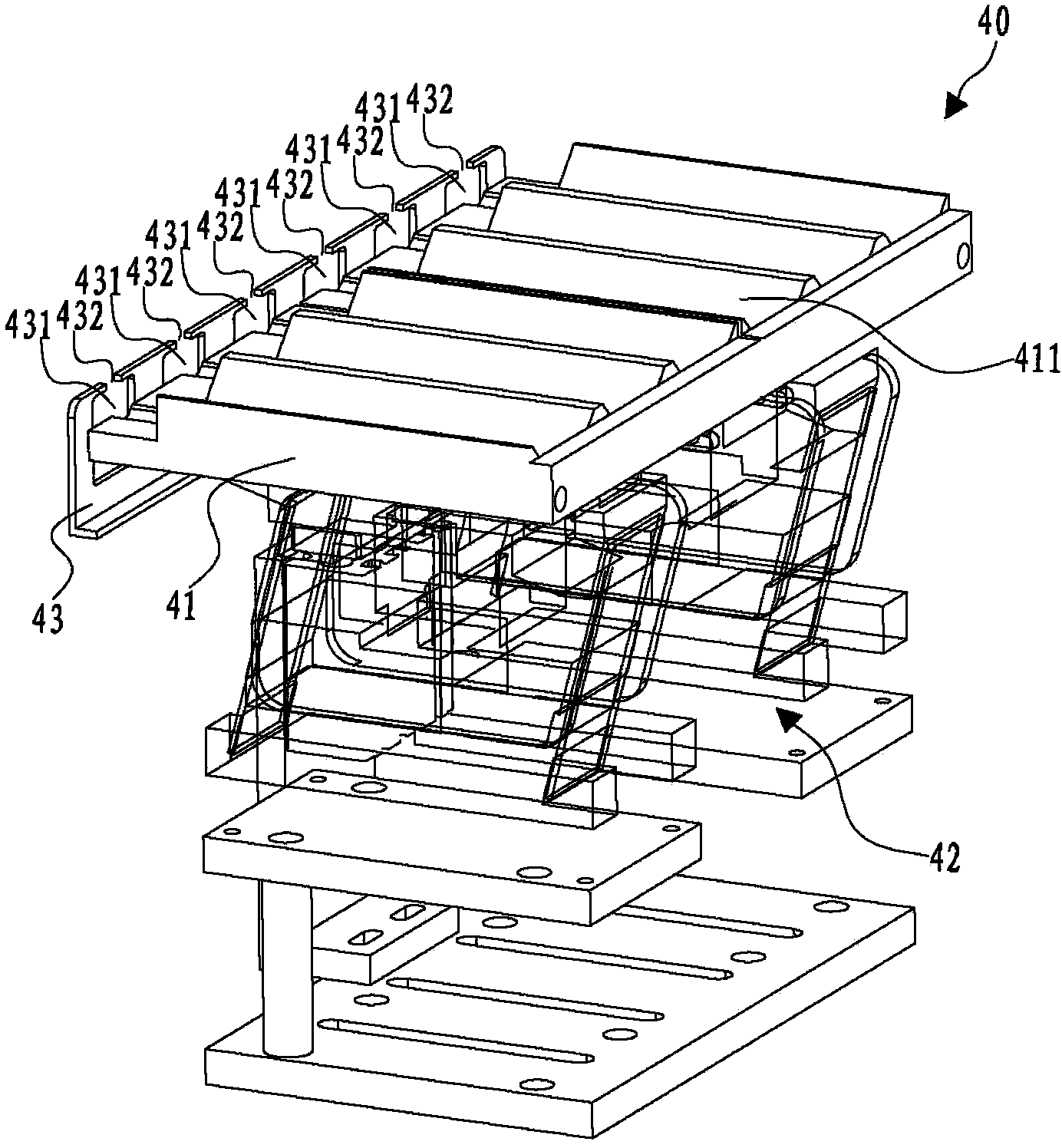

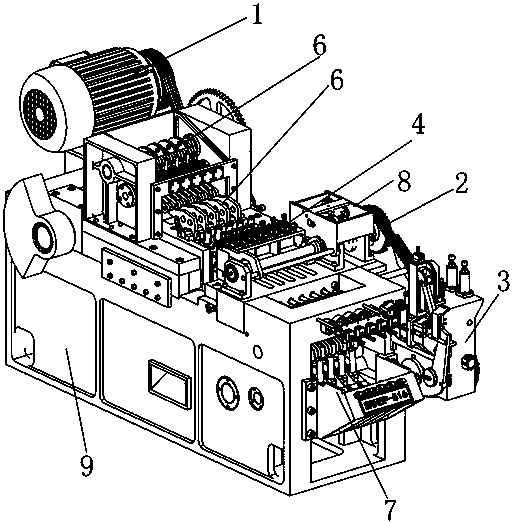

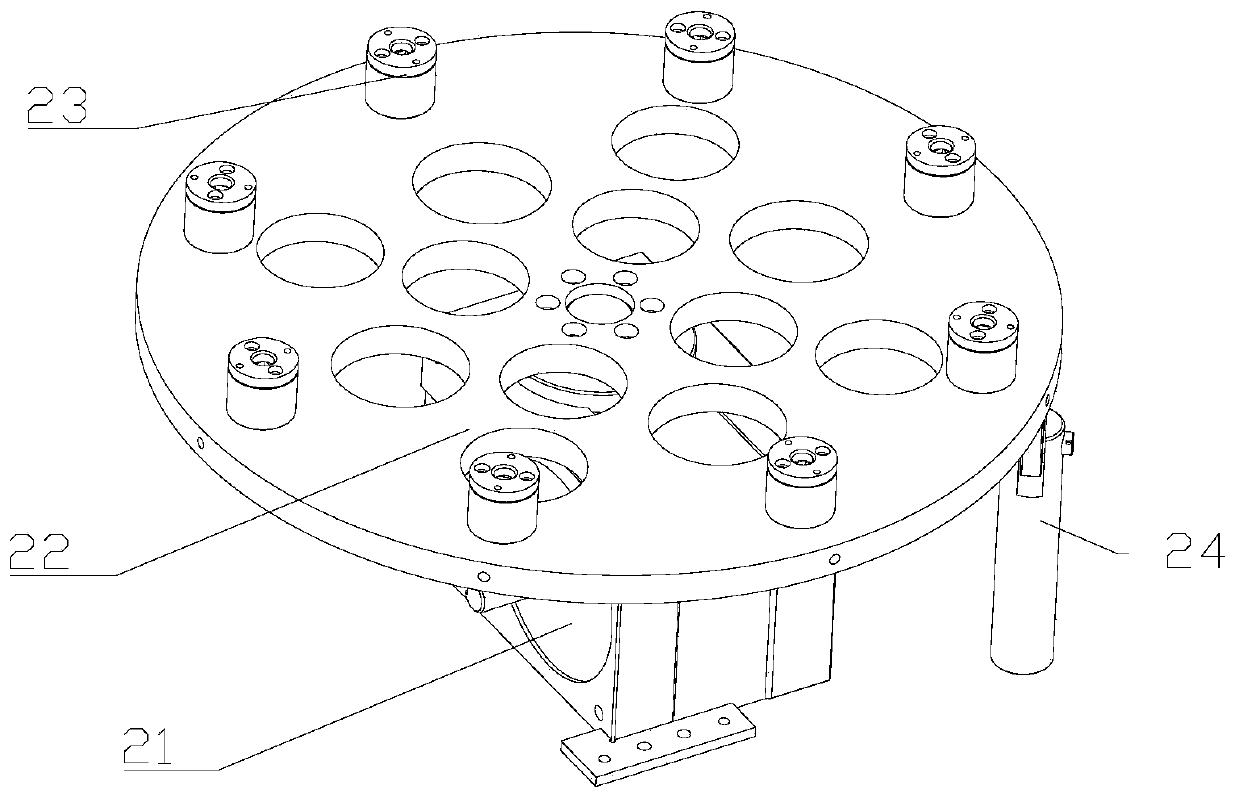

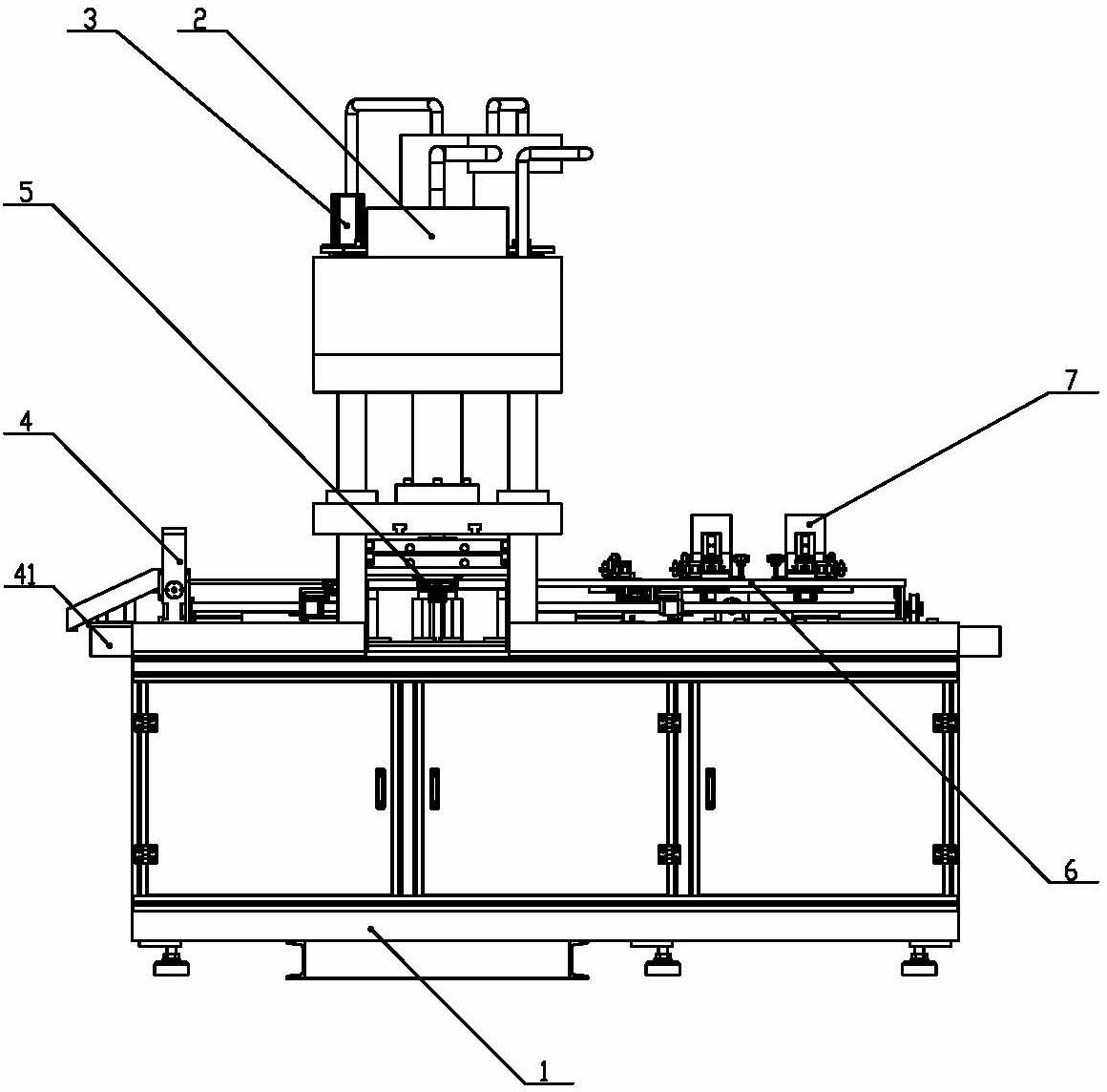

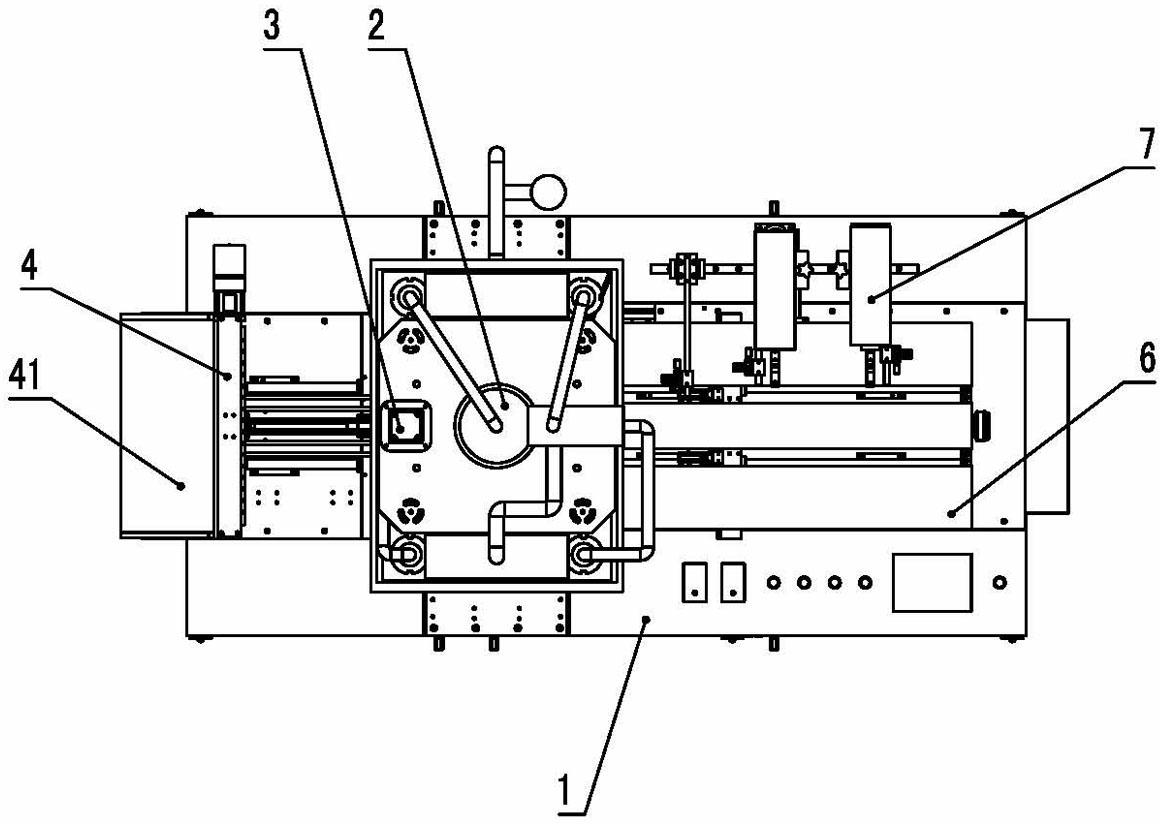

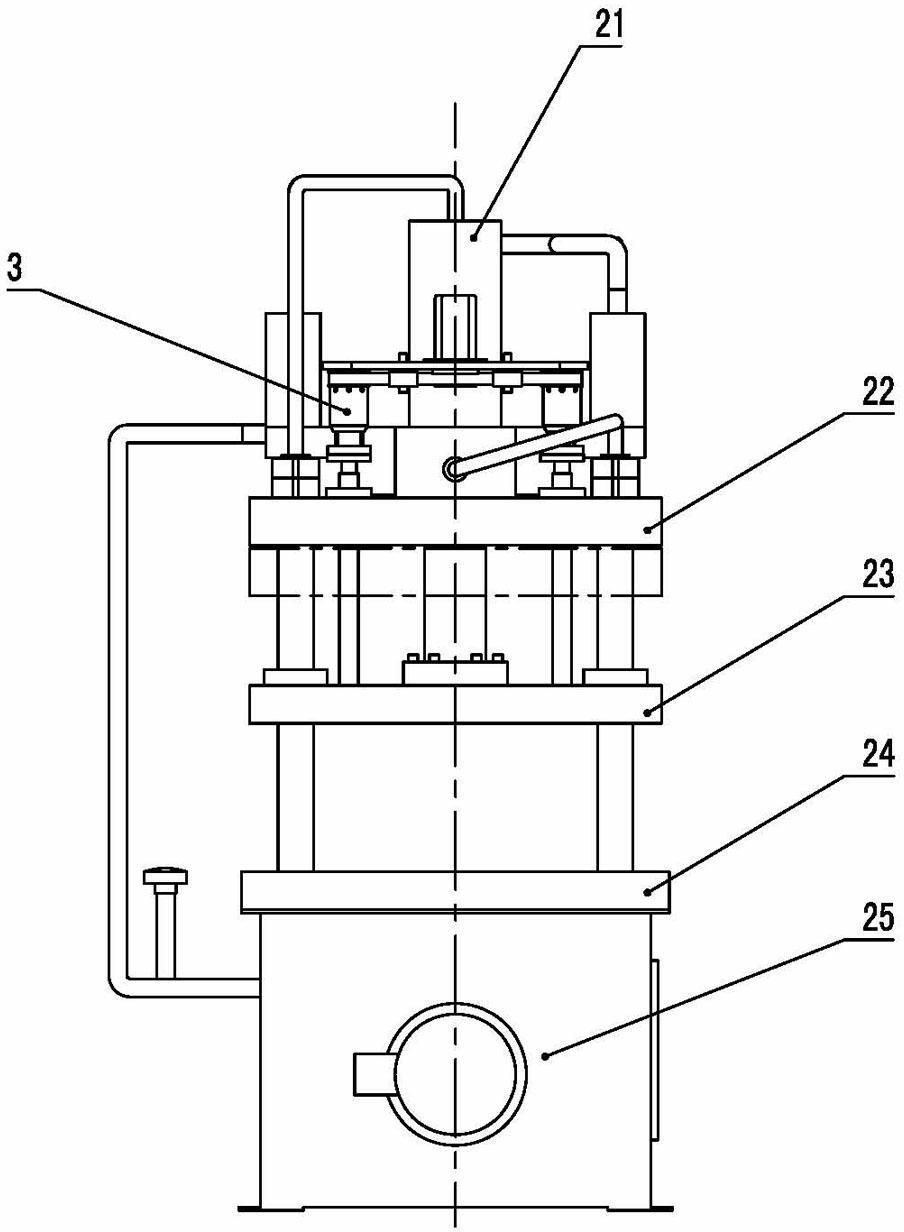

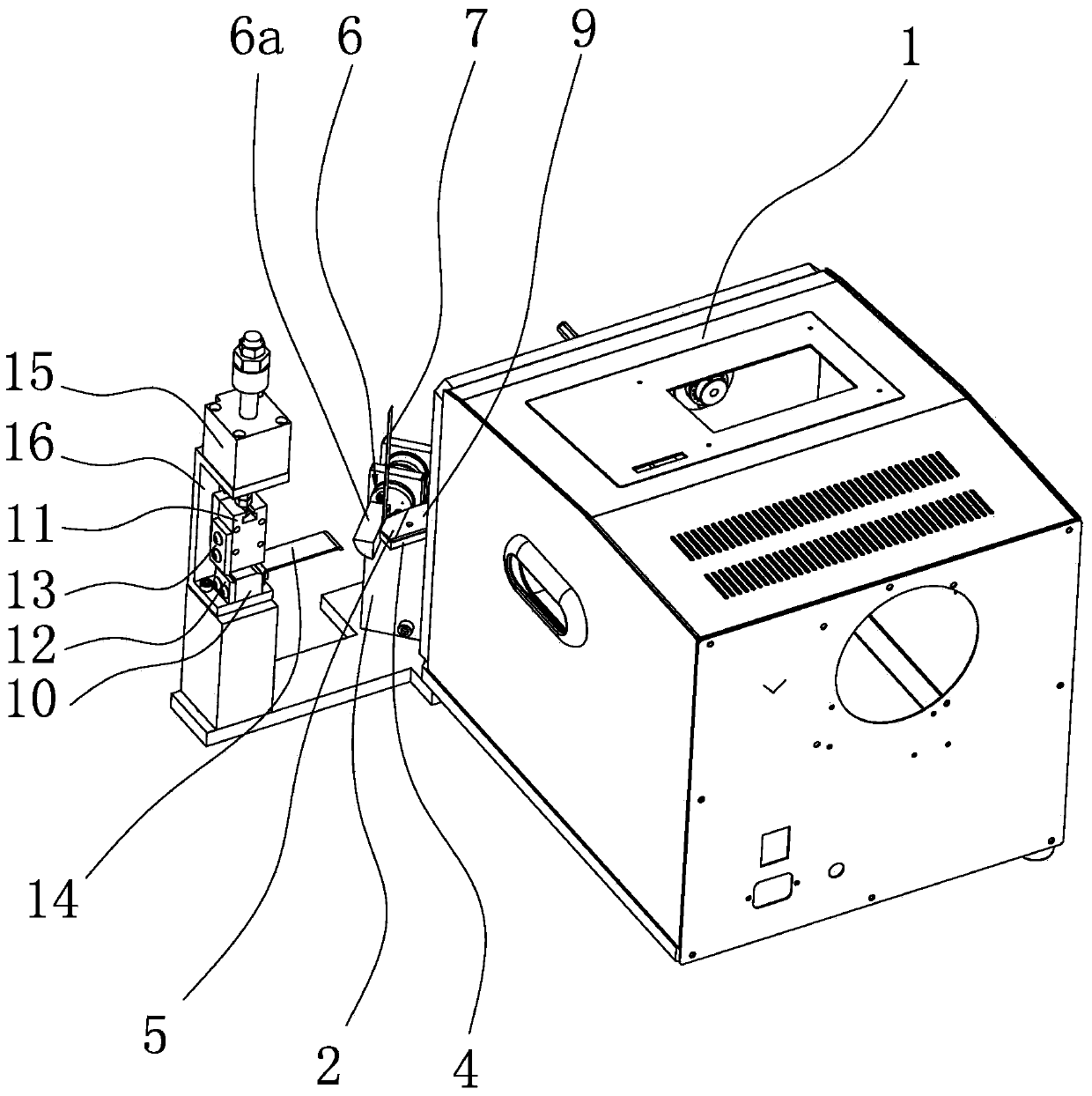

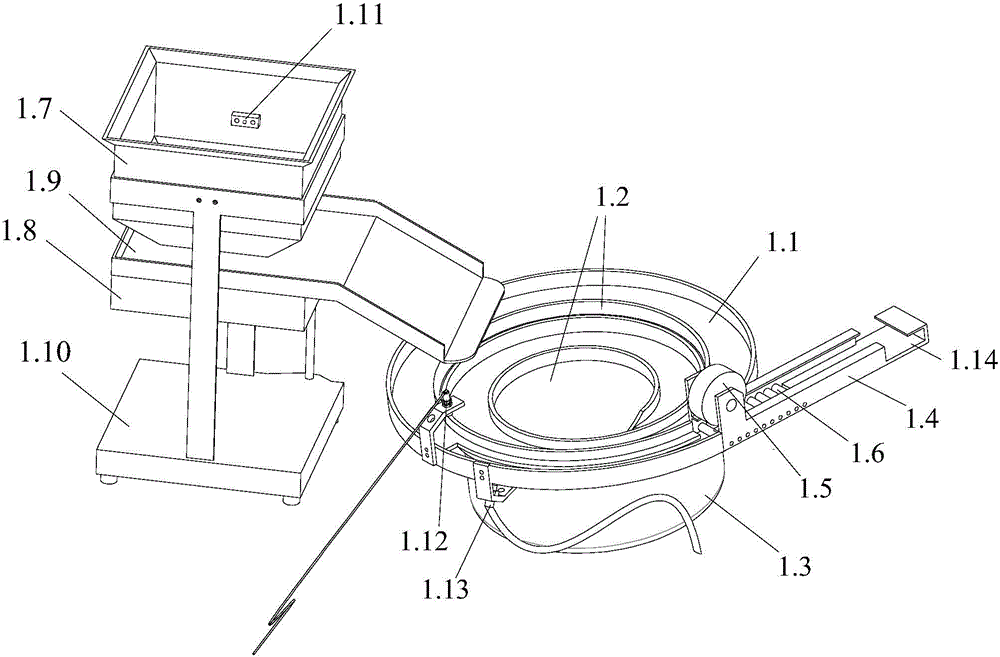

Automatic feeding machine for medical drip chambers

The invention discloses an automatic feeding machine for medical drip chambers. The automatic feeding machine for the medical drip chambers is characterized in that the automatic feeding machine comprises a frame body, a vibrating disc, a discharging conveying device, a leveling device and an assembling conveying device, wherein the vibrating disc, the discharging conveying device, the leveling device and the assembling conveying device are arranged on the frame body. The output end of the vibrating disc is connected with the input end of the discharging conveying device, the leveling device is arranged at the output end of the discharging conveying device, the assembling conveying device is arranged at the output end of the leveling device, a material fetching and feeding device is arranged above the output end of the discharging conveying device, the leveling device and the input end of the assembling conveying device in an erected mode, and a sensing device is arranged above the output end of the discharging conveying device. According to the automatic feeding machine for the medical drip chambers, independent material belt conveying mechanisms are adopted, each material belt conveying mechanism only allows a single material to pass, and each material belt conveying mechanism is correspondingly provided with an independent sensor and an independent motor, the material feeding and fetching processes are more efficient and accurate, the conveying efficiency and the accuracy of the material are improved greatly, the subsequent assembling of the products is facilitated, and the assembling accuracy and assembling efficiency are improved.

Owner:东莞市倍加自动化设备有限公司

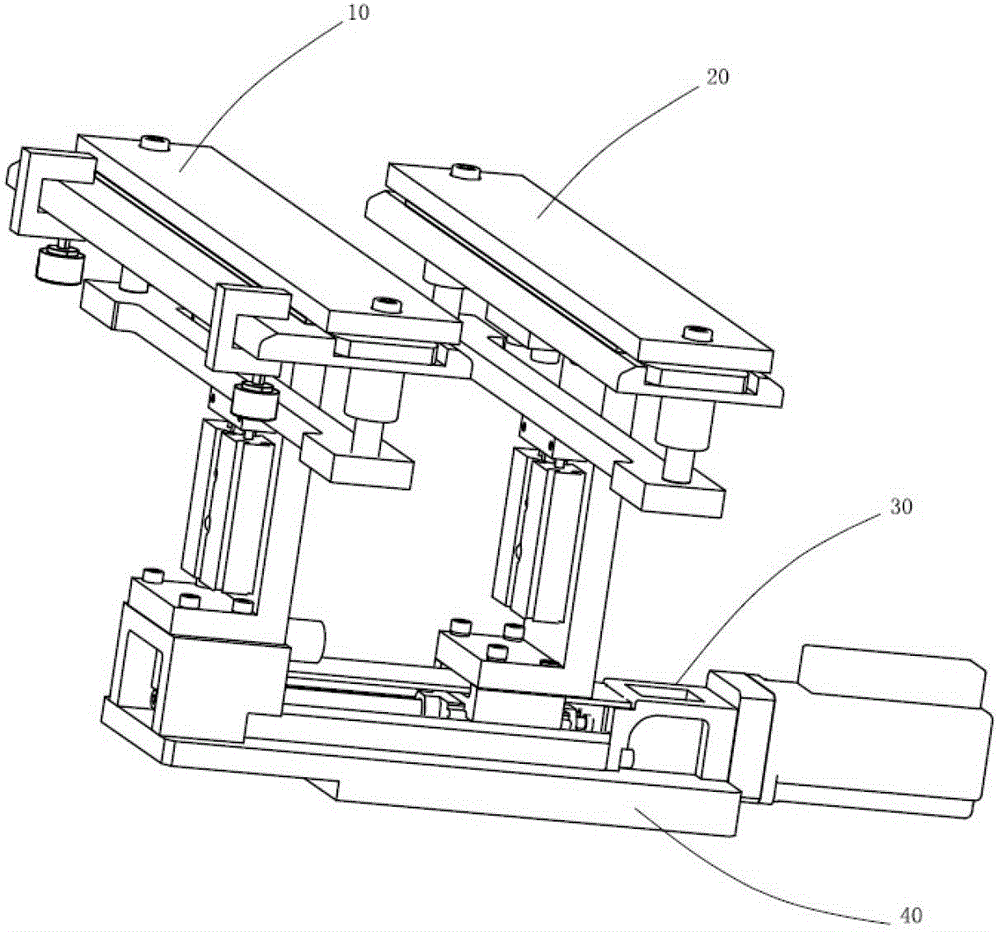

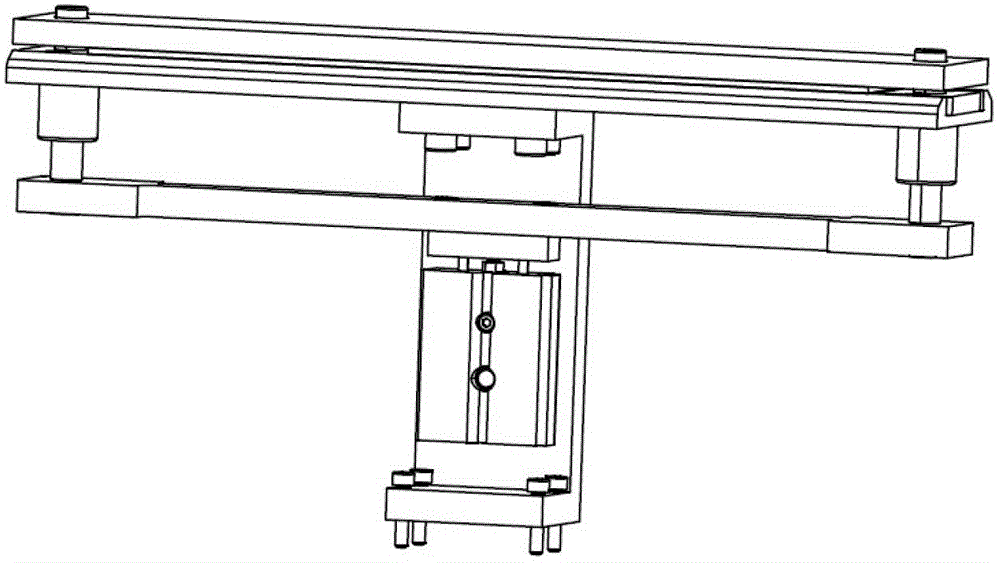

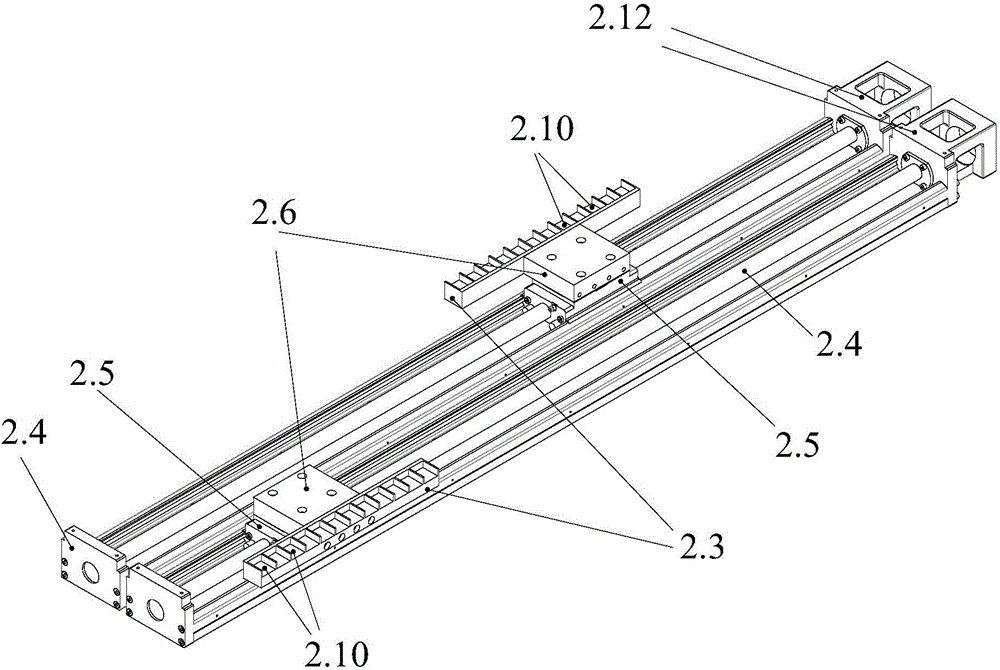

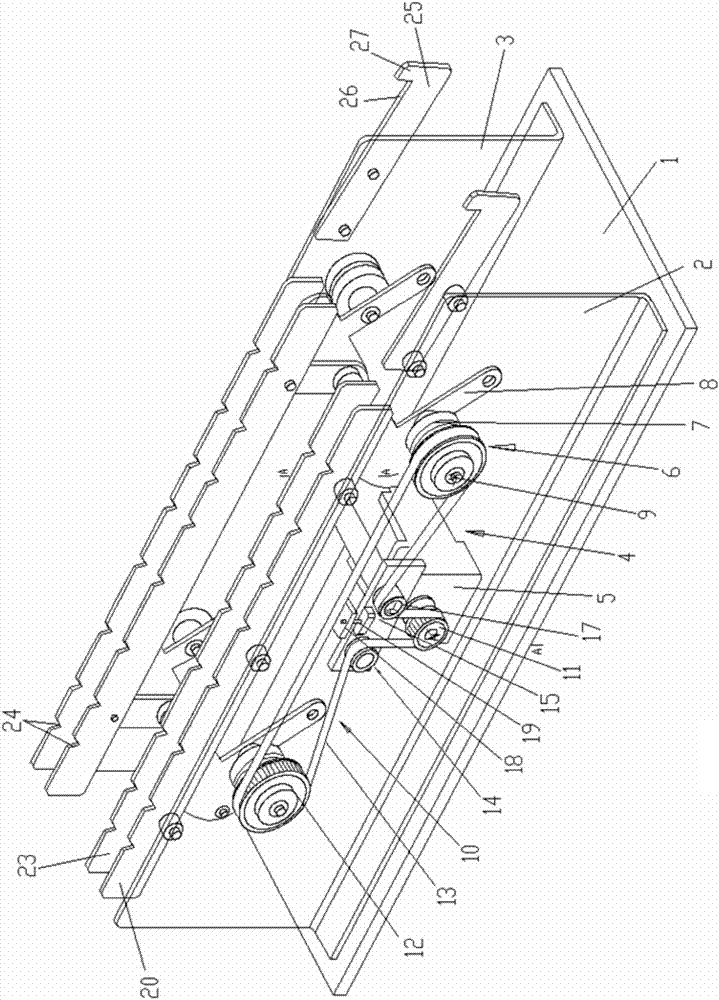

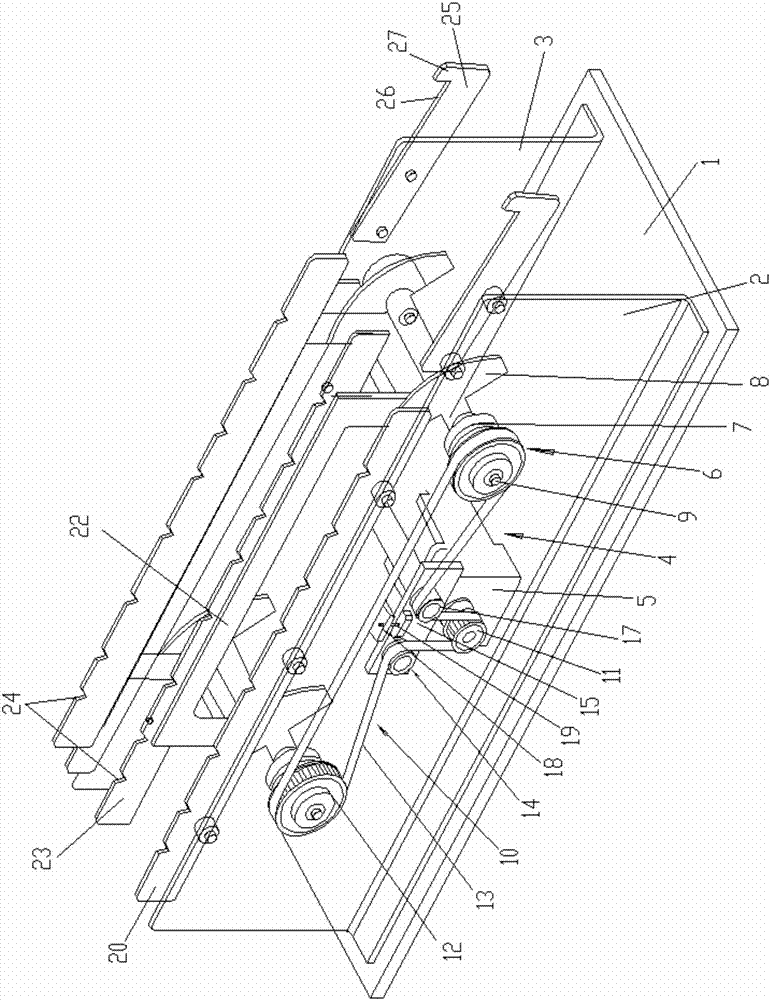

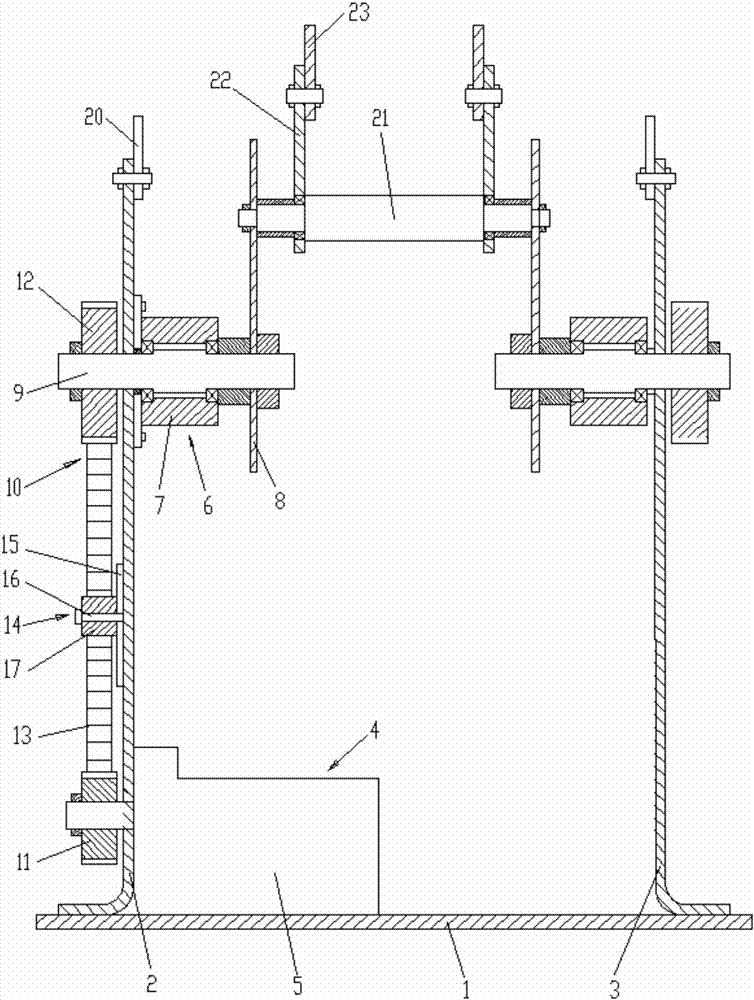

Alternated plate feeding device

InactiveCN102745459ARealize clamping and conveyingCompact structureConveyorsReciprocating motionEngineering

The invention discloses an alternated plate feeding device, which comprises a conveyor belt, at least two plate clamping mechanisms and a slide rail, wherein the conveyor belt comprises a plurality of working sections arranged in parallel, and at least two of all the working sections have opposite conveying directions; the plate clamping mechanisms are fixedly connected to different working sections; and the slide rail is used for bearing reciprocating motion of the plate clamping mechanisms. The alternated plate feeding device does not slip during clamping; and the feeding distance can be conveniently calculated through the conveying distance of the conveyor belt, so that the feeding precision is greatly promoted. In the optimal technical scheme, a first plate clamping mechanism and a second plate clamping mechanism are adopted, so that idle travel is avoided in the feeding process, uninterrupted feeding is realized, and the feeding efficiency is greatly improved; and only one clamping part is required in one feeding stroke, so that the surface of a material is scratched little. The device has the advantages of convenience in control, high feeding precision, little surface scratch, high feeding efficiency and the like.

Owner:ZHEJIANG UNIV

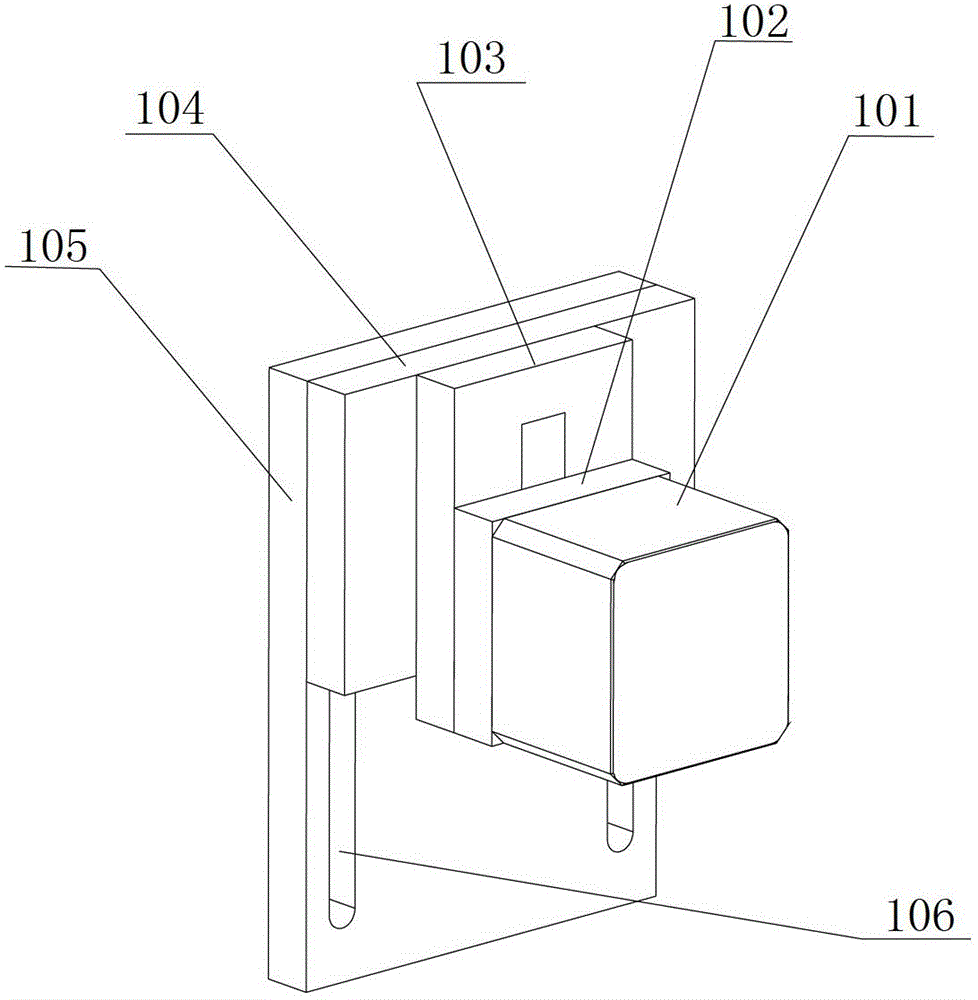

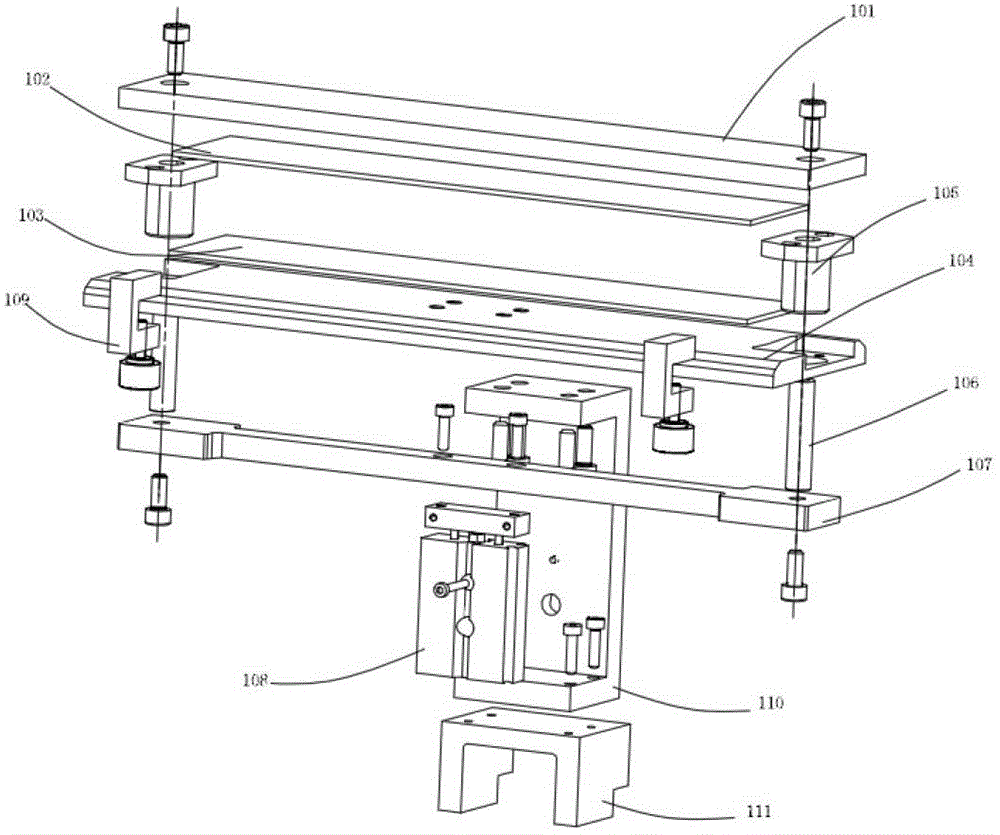

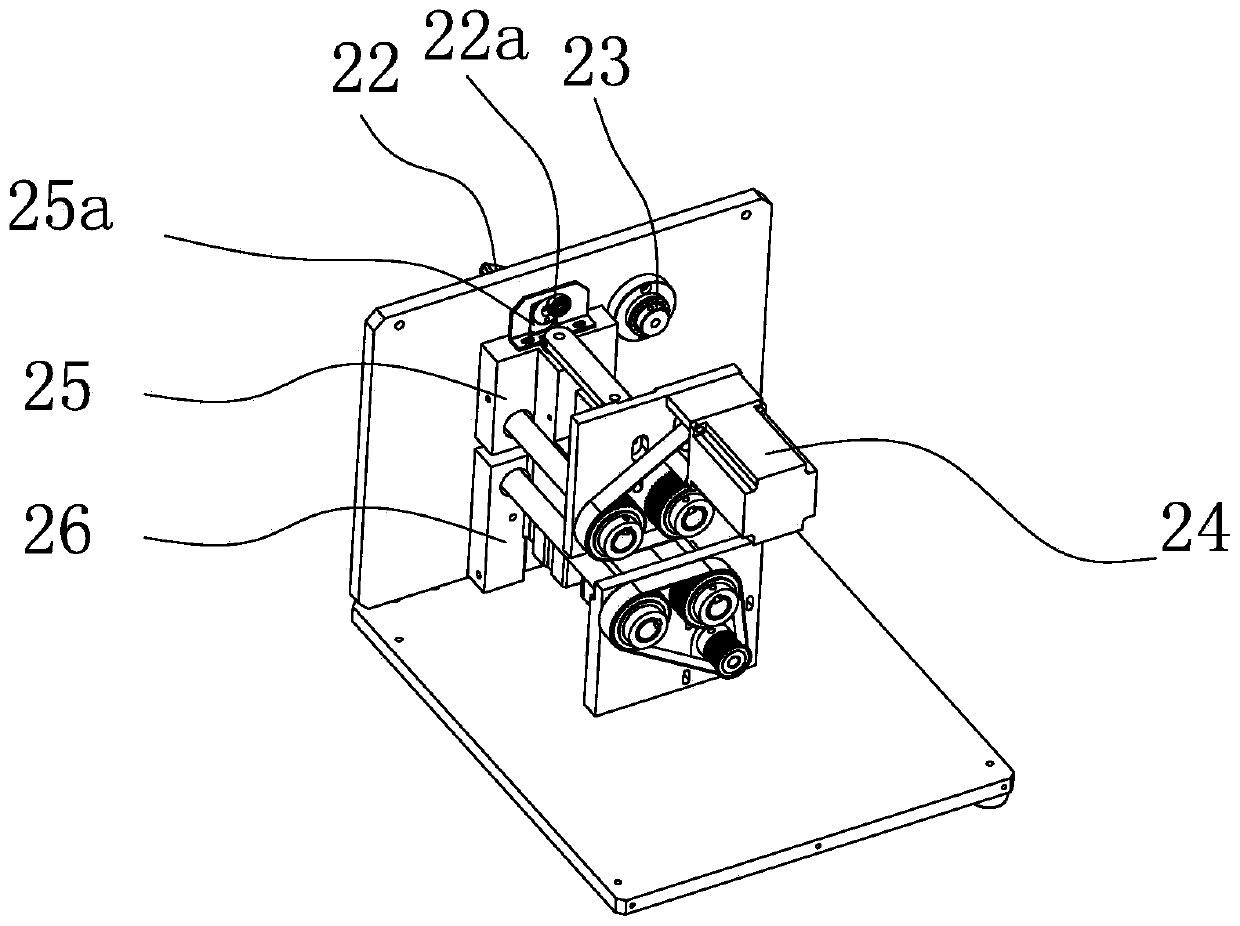

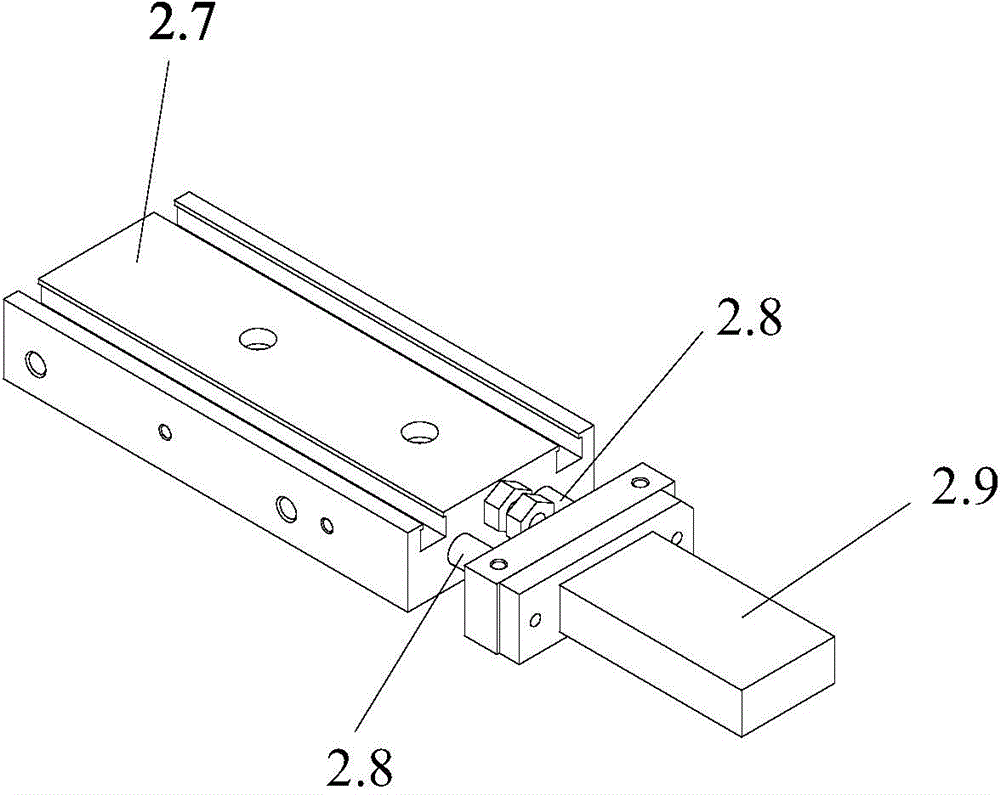

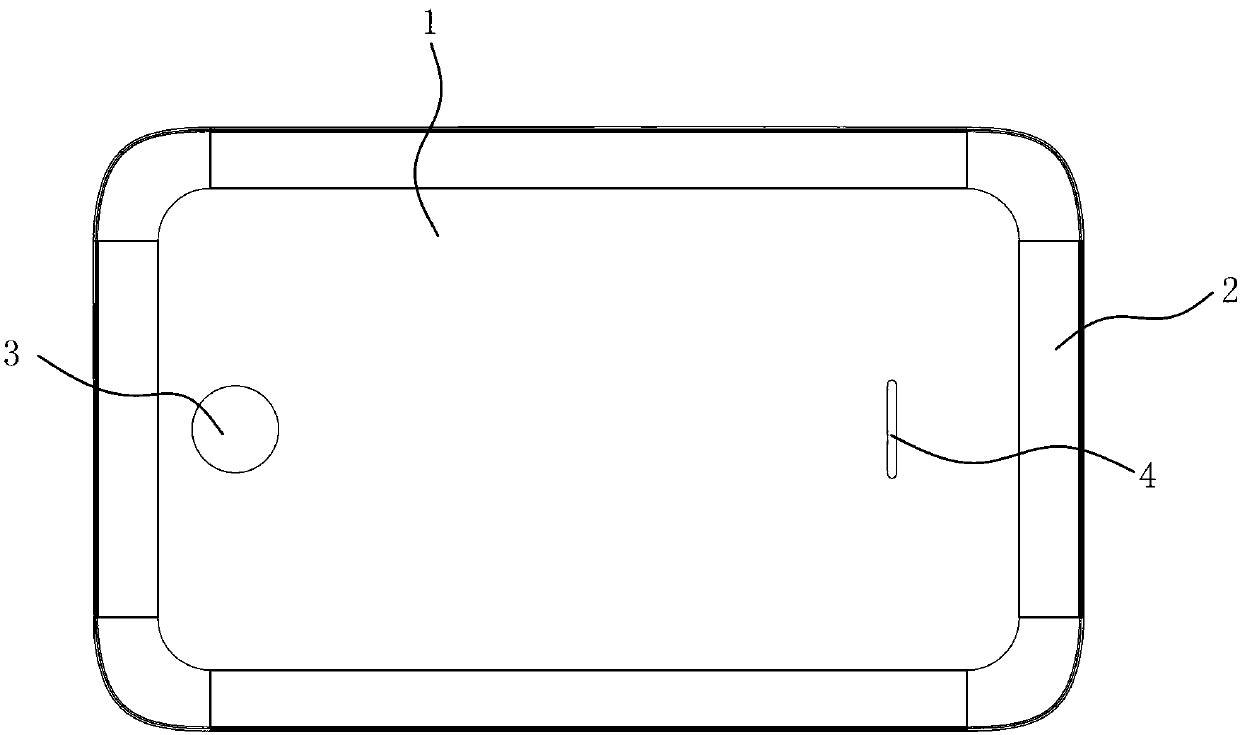

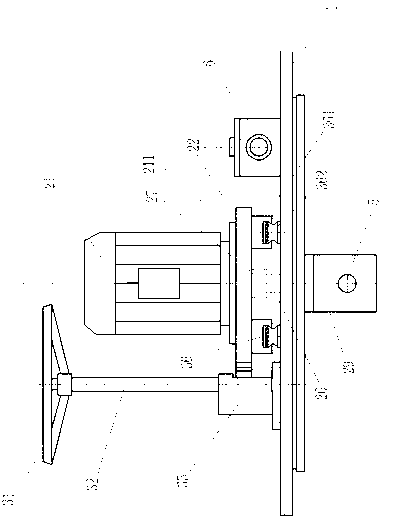

Clamping device for intermittently feeding films

The invention discloses a clamping device for intermittently feeding films. The clamping device comprises a supporting base, a driving component, a fixed clamping piece and a movable clamping piece; the fixed clamping piece is fixedly arranged on the driving component; the movable clamping piece is movably arranged on the driving component; the structure of the fixed clamping piece is similar to that of the movable clamping piece; and each of the fixed clamping piece and the movable clamping piece comprises a base, a single driving cylinder, a horizontal supporting plate, an upper clamping plate, a lower clamping plate and a pair of linear bearings, the single driving cylinder is arranged along a vertical direction, the horizontal supporting plate is fixedly connected with a piston of the driving cylinder, the upper clamping plate is connected with the supporting plate through a pair of vertical guide shafts, the upper clamping plate and the supporting plate jointly form a frame structure, the lower clamping plate is positioned between the upper clamping plate and the supporting plate, and the linear bearings are respectively used for accommodating and installing the vertical guide shafts and are fixed at two ends of the lower clamping plate. By the clamping device for intermittently feeding films, the phenomenon of jamming or uneven pressure caused by double-cylinder drive can be avoided, damage of elements such as the cylinders is avoided by the linear bearings and corresponding structures, feeding accuracy and clamping stability are improved, and accordingly the films can be ensured to be accurately clamped and conveyed.

Owner:HUAZHONG UNIV OF SCI & TECH

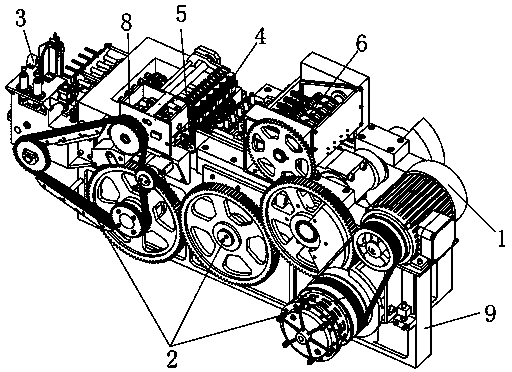

Cold heading machine

ActiveCN104174802AMeet sporting requirementsNot easy to move at high speedUpsetting pressesSwagging pressesMotor driveBack support

The invention discloses a cold heading machine. The cold heading machine comprises a machine body, wherein a main motor, a drive system, a linear feeding device, a rotary clamp, a cutter system, an adjustable male die ejecting mechanism and a closed back support are arranged on the machine body; the main motor is arranged at a first end of the machine body, and the drive system is arranged at an output end of the main motor; the linear feeding device is arranged at a second end of the machine body, and the closed back support is arranged on one side of the feeding device; the rotary clamp and the male die ejecting mechanism are arranged in the middle of the machine body; and the cutter system is arranged below the rotary clamp. After the main motor of the machine is started, the main motor drives the linear feeding device, the rotary clamp, cutters, the male die ejecting mechanism and the like through the drive system to finish processing steps of feeding, cutting, upsetting, finished product ejecting and the like. The cold heading machine has the advantages that the drive efficiency can be improved, the high-speed driving is realized, the working efficiency and precision of the cold heading machine are improved, and the like.

Owner:HUANGSHAN SHENGRUI HEAVY IND MACHINERY

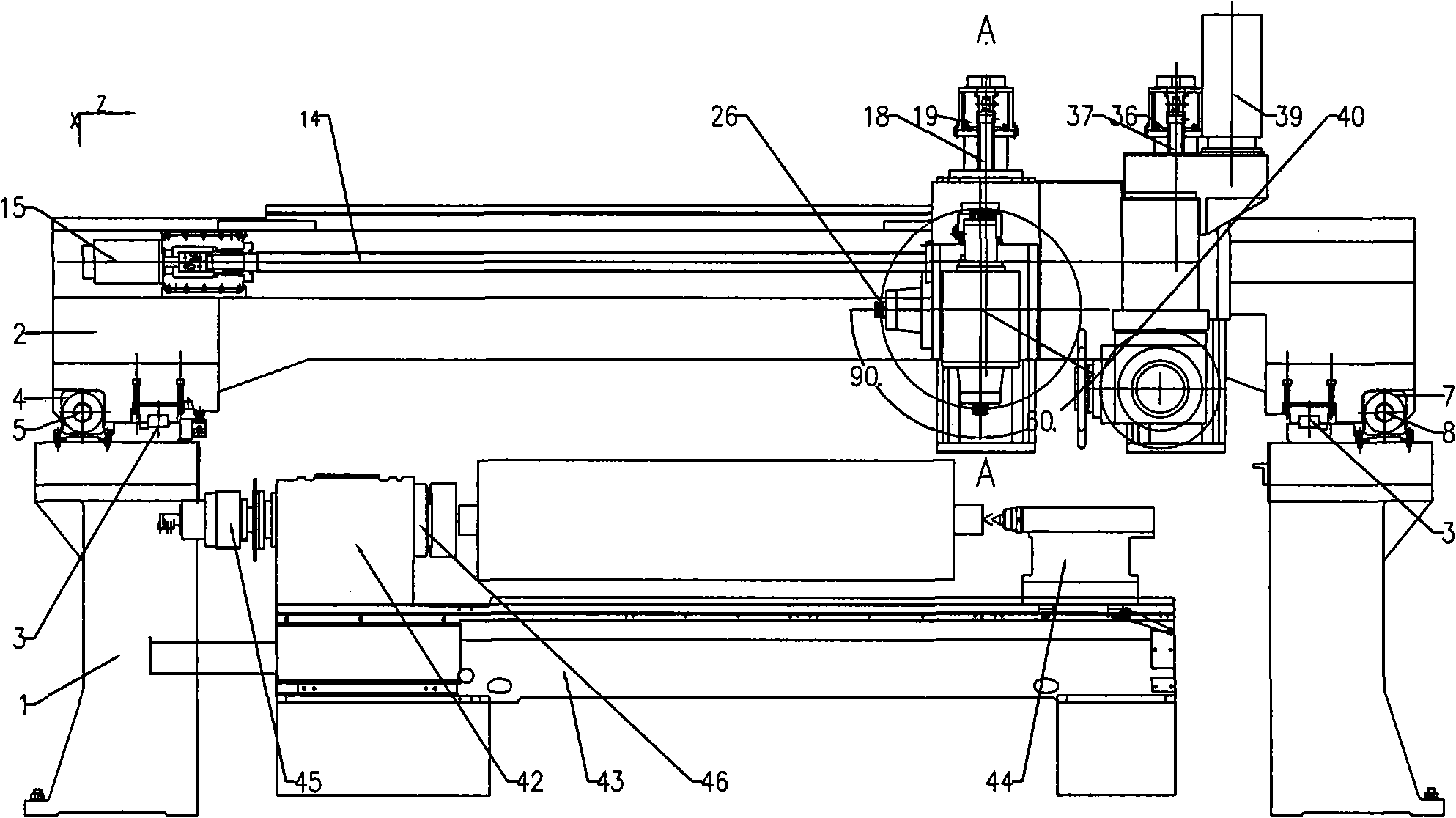

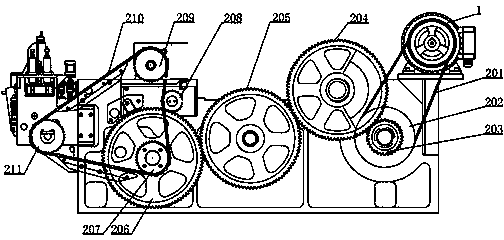

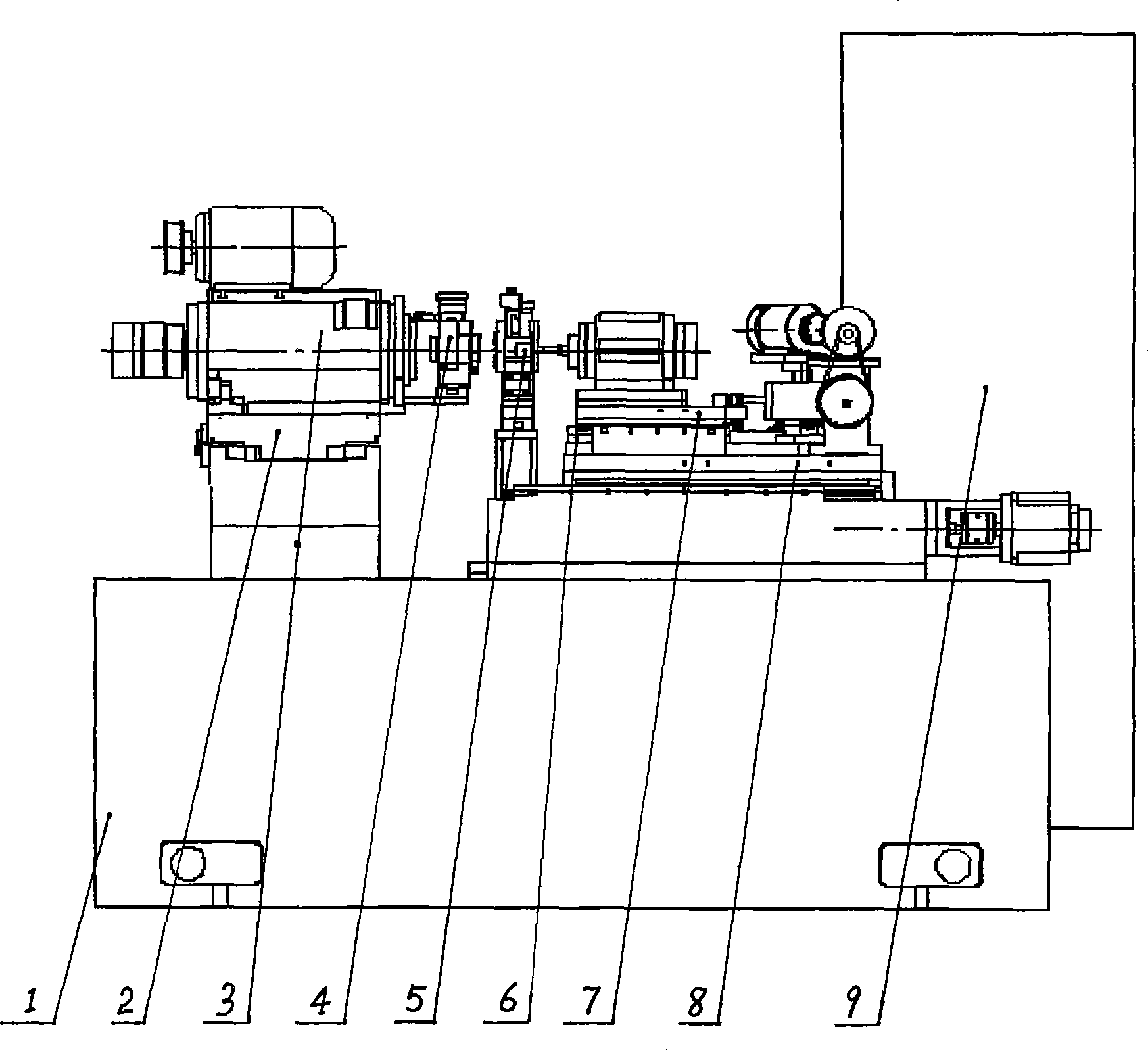

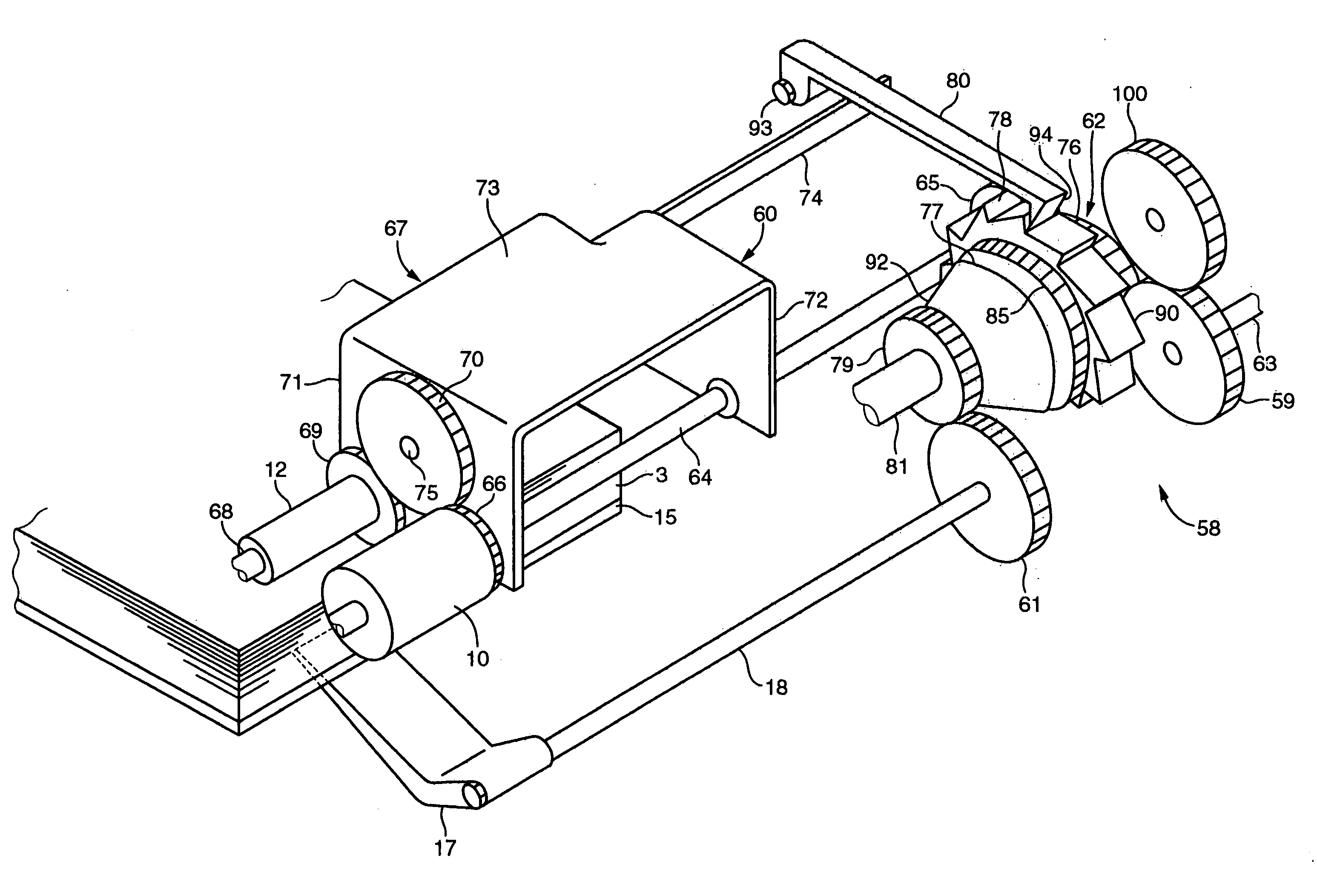

Two-wheeled numerical control roll grinder and numerical control method thereof

ActiveCN103009200ALow costSave energyRevolution surface grinding machinesBelt grinding machinesNumerical controlEngineering

The invention discloses a two-wheeled numerical control roll grinder and a numerical control method thereof. A small sliding frame of the double-wheeled numerical control roll grinder is provided with a U-axis micro-feeding mechanism, a main mechanical transmission case is lubricated by adopting an active lubricating loop, a cooling water purifying device is arranged on a grinder body, a large sliding frame guide rail is connected with a Z-axis guide rail hydraulic station through a lubricating oil tube, the Z-axis guide rail hydraulic station is subjected to dynamic pressure lubrication, a grinding wheel and an abrasive belt wheel are respectively connected with a shared mainshaft hydraulic station, a hybrid bearing and a capillary tube adjuster are respectively arranged at the front and the back of a main shaft of the grinding wheel and a main shaft of the abrasive belt wheel, and the mainshaft of the grinding wheel and the mainshaft of the abrasive belt wheel are subjected to dynamic and static pressure lubrication. According to the invention, due to adoption of a numerical-control setting manner, a roll curve is easy to change, ground workpieces are higher in quality and are easy to automatically control, the manual misoperation probability is lowered, a very excellent repeatable machining purpose is achieved and the quality of batch production can be ensured.

Owner:武汉宝德机电股份有限公司

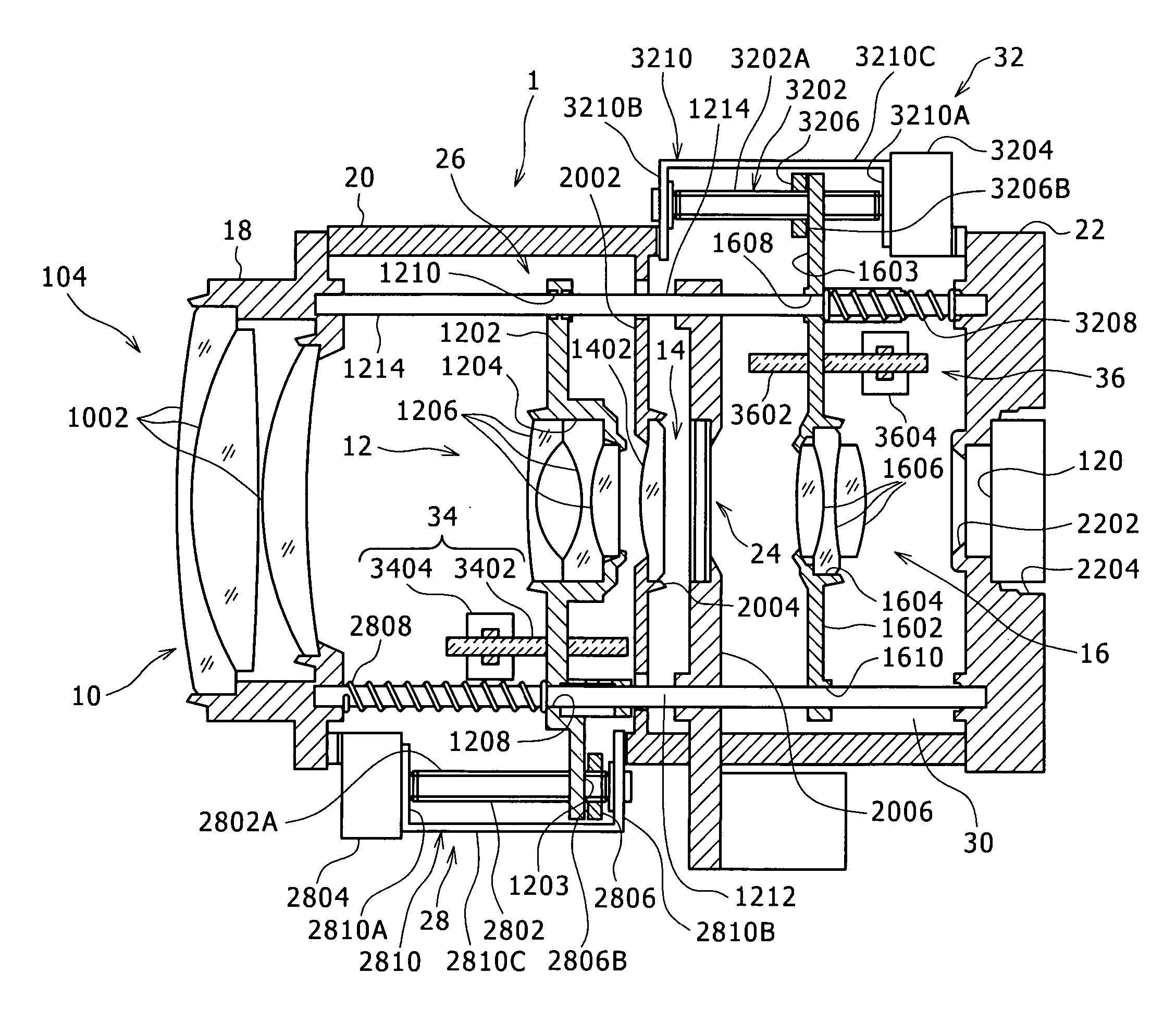

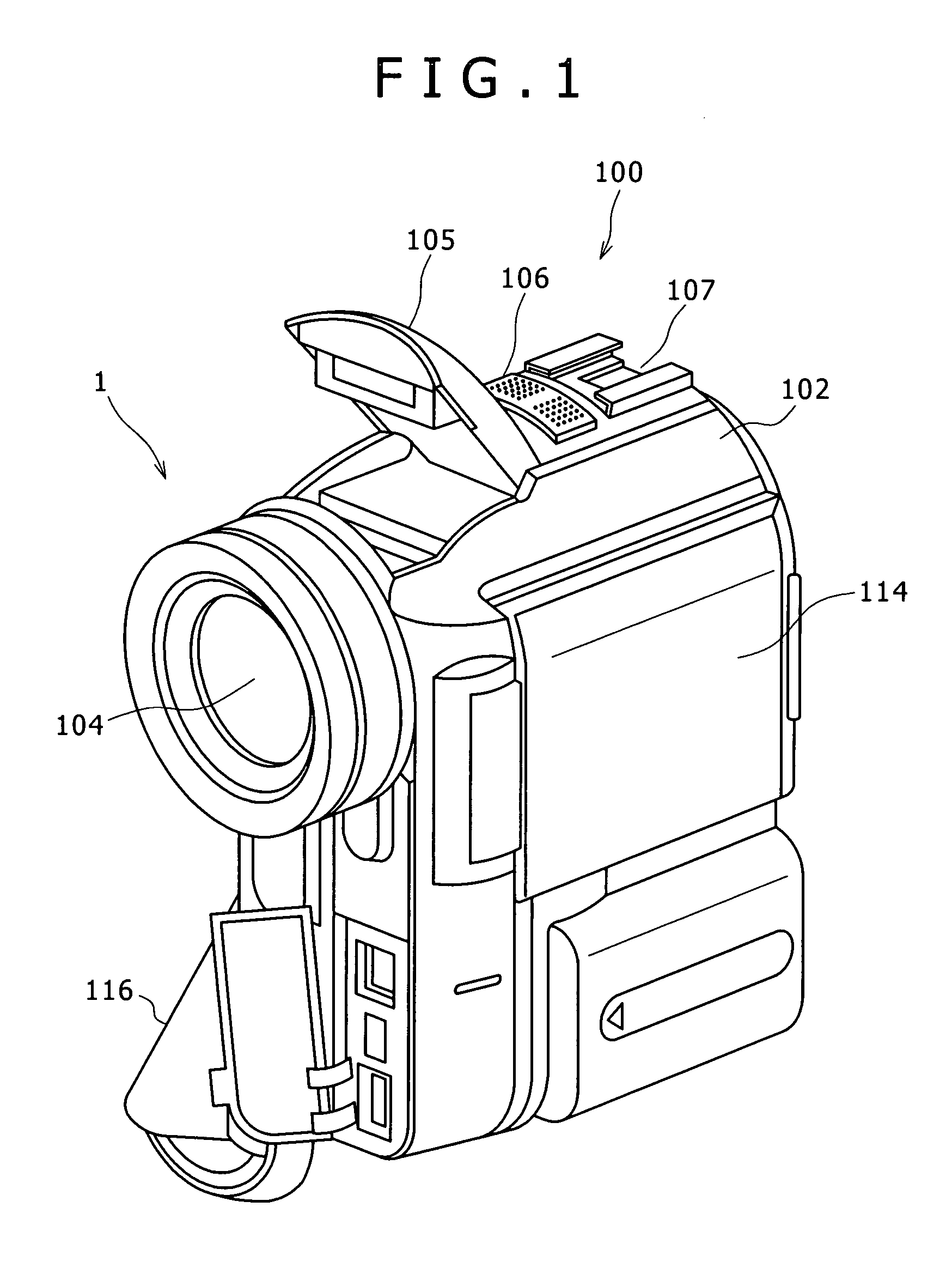

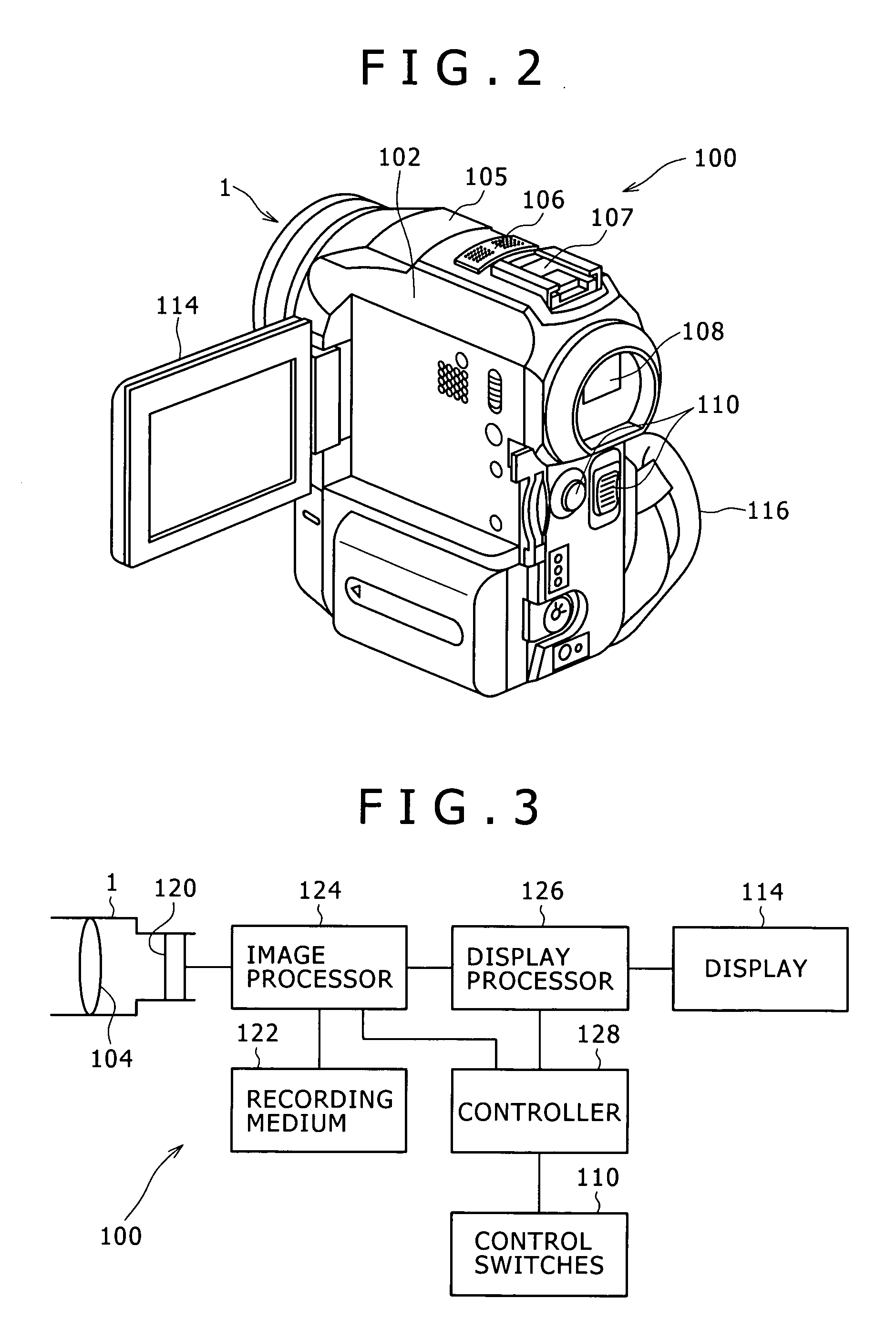

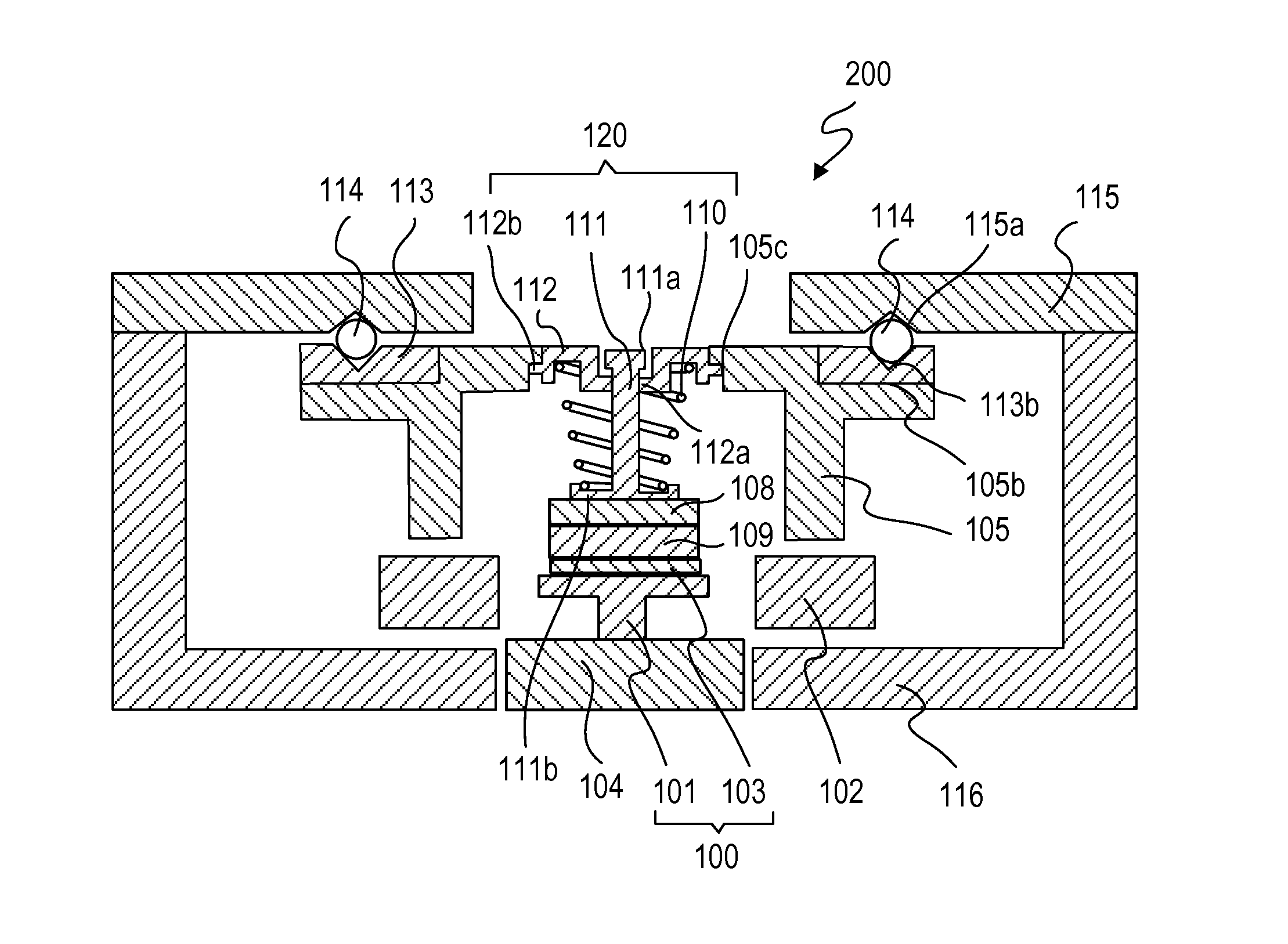

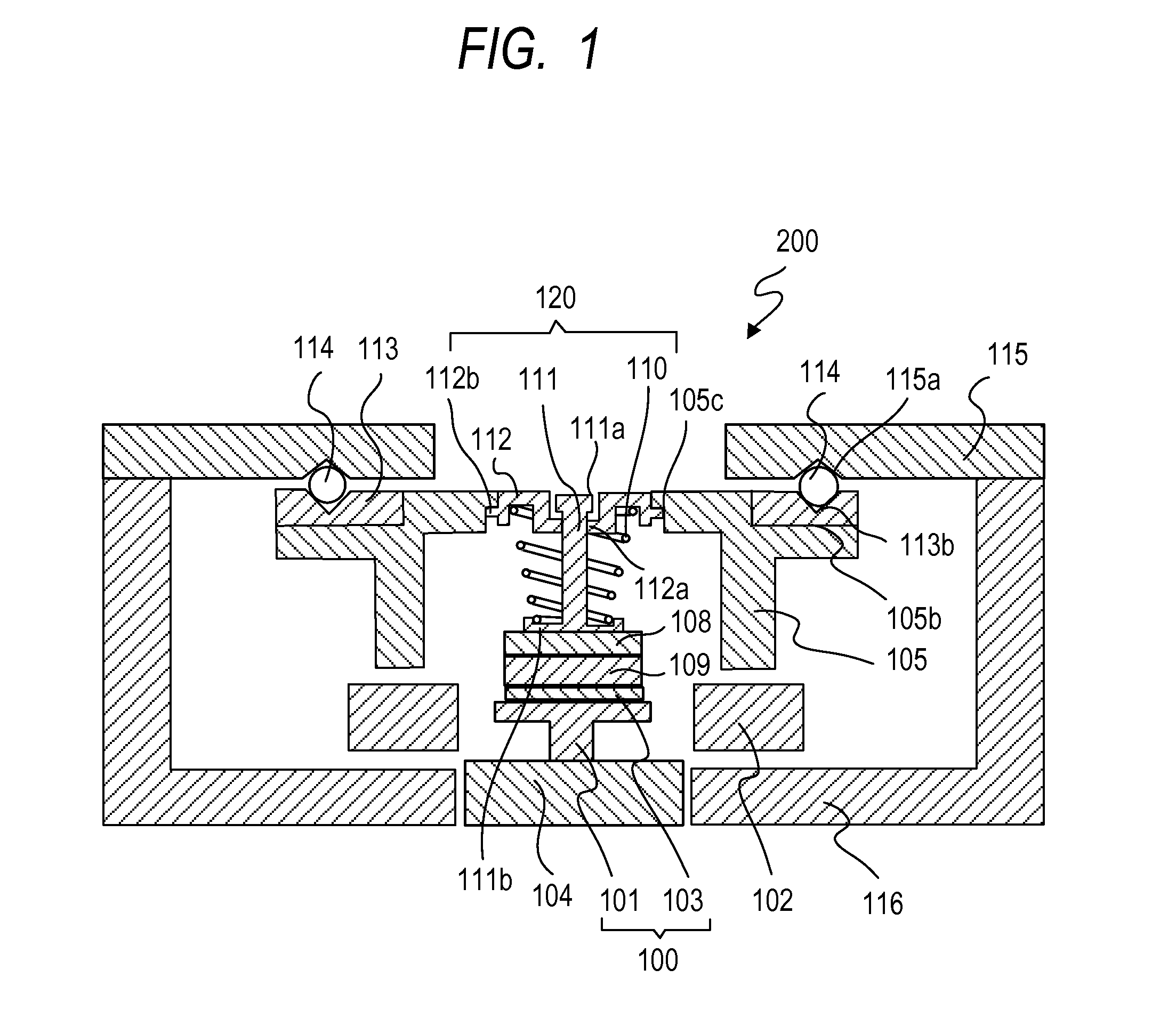

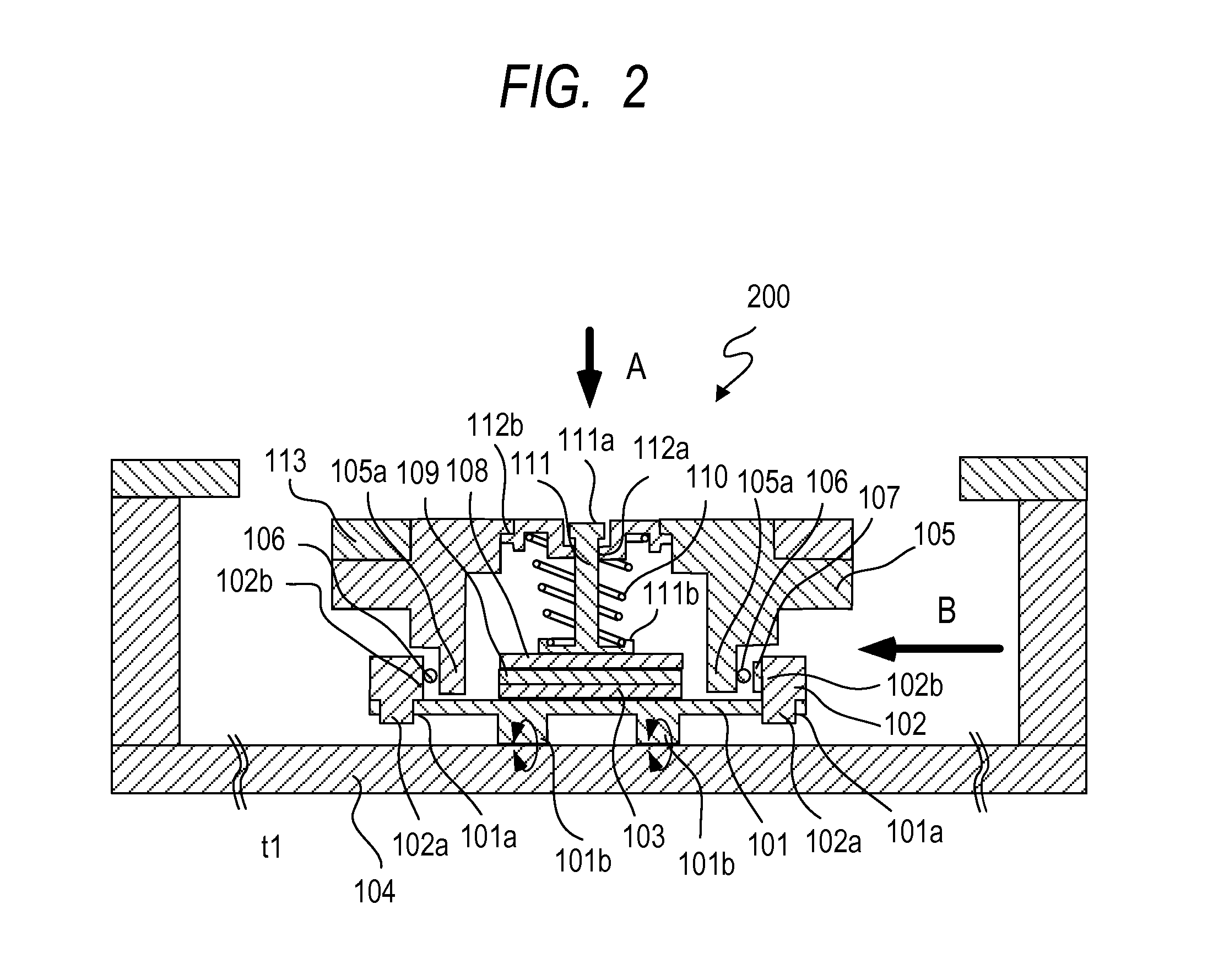

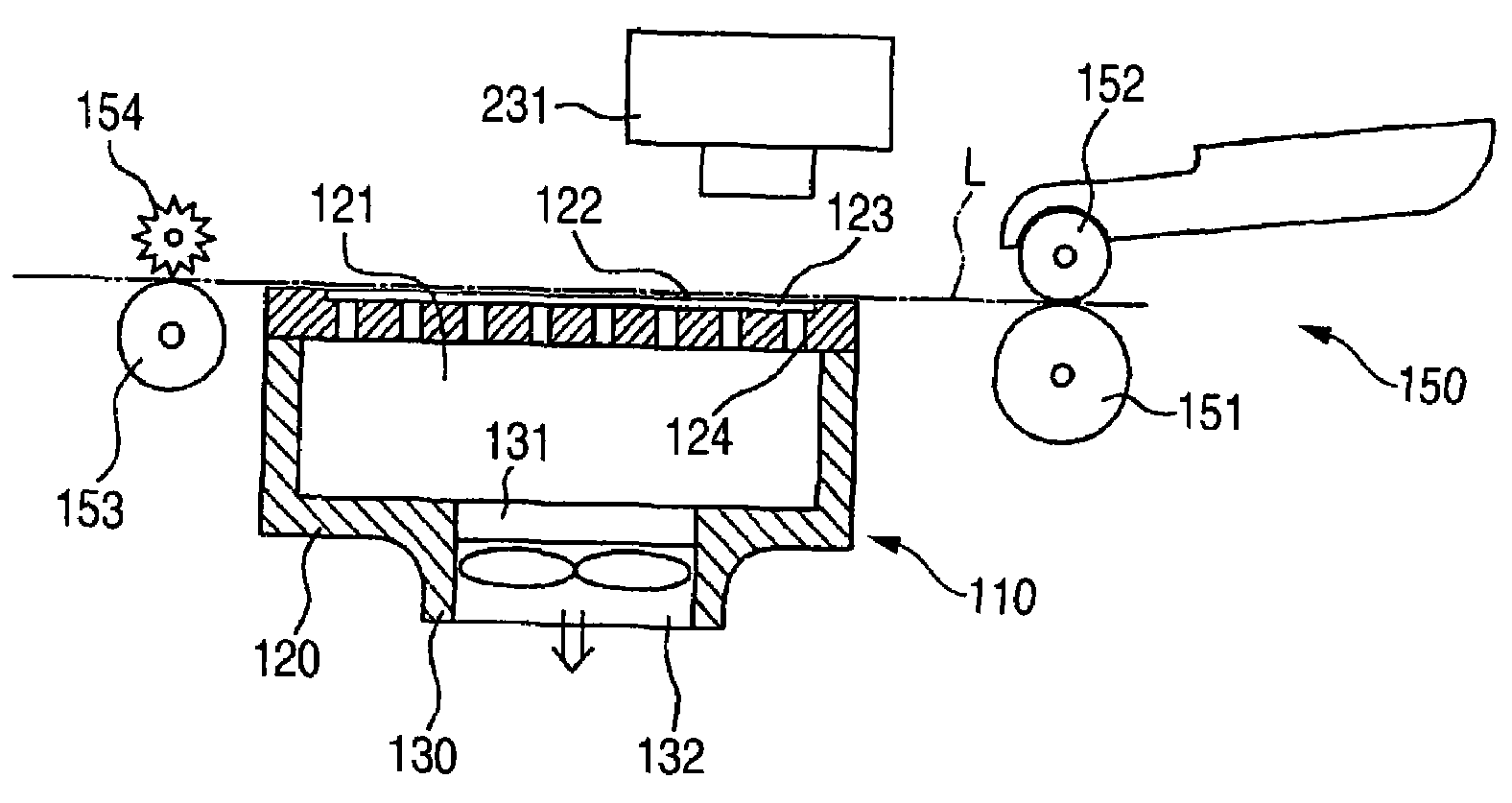

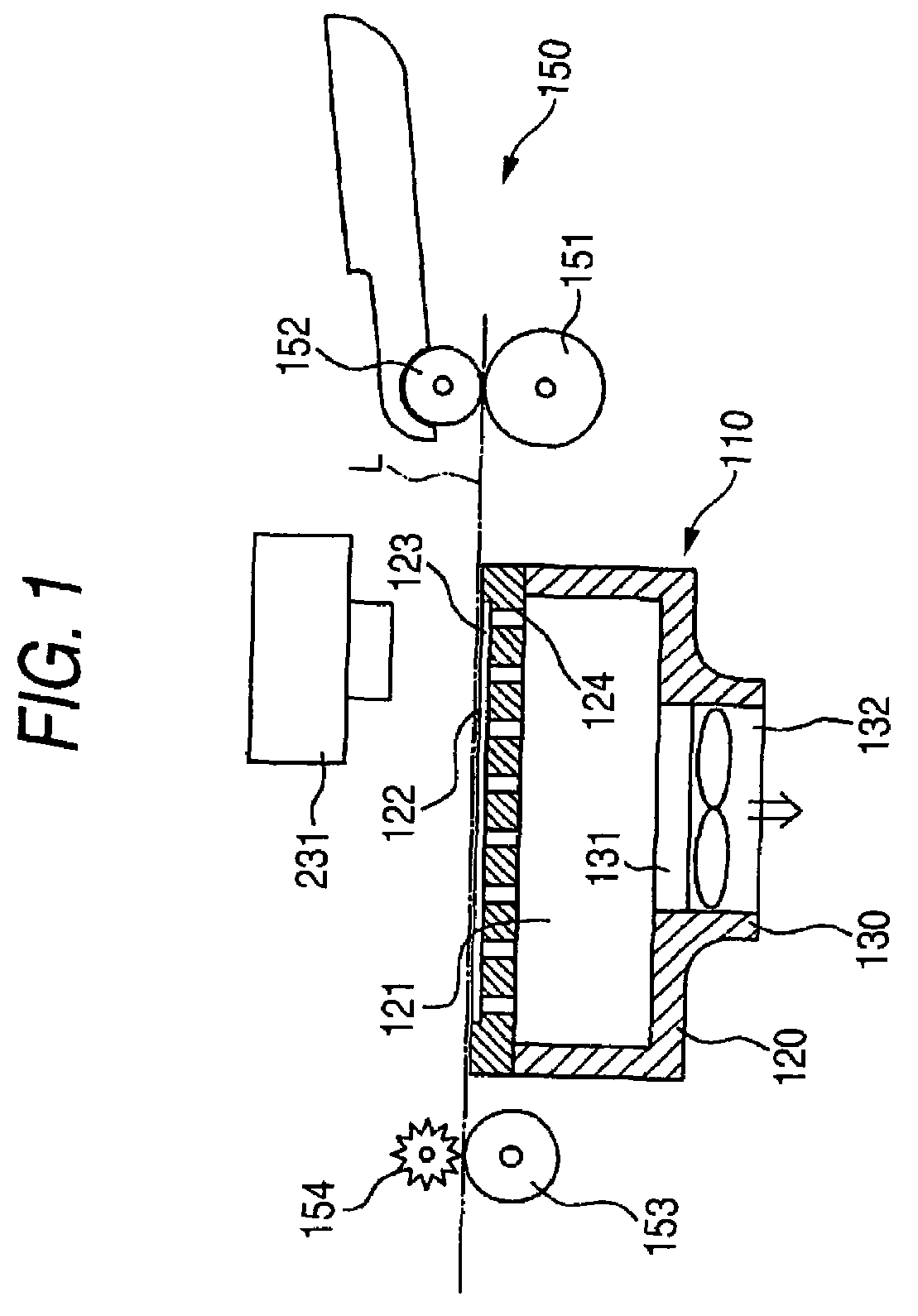

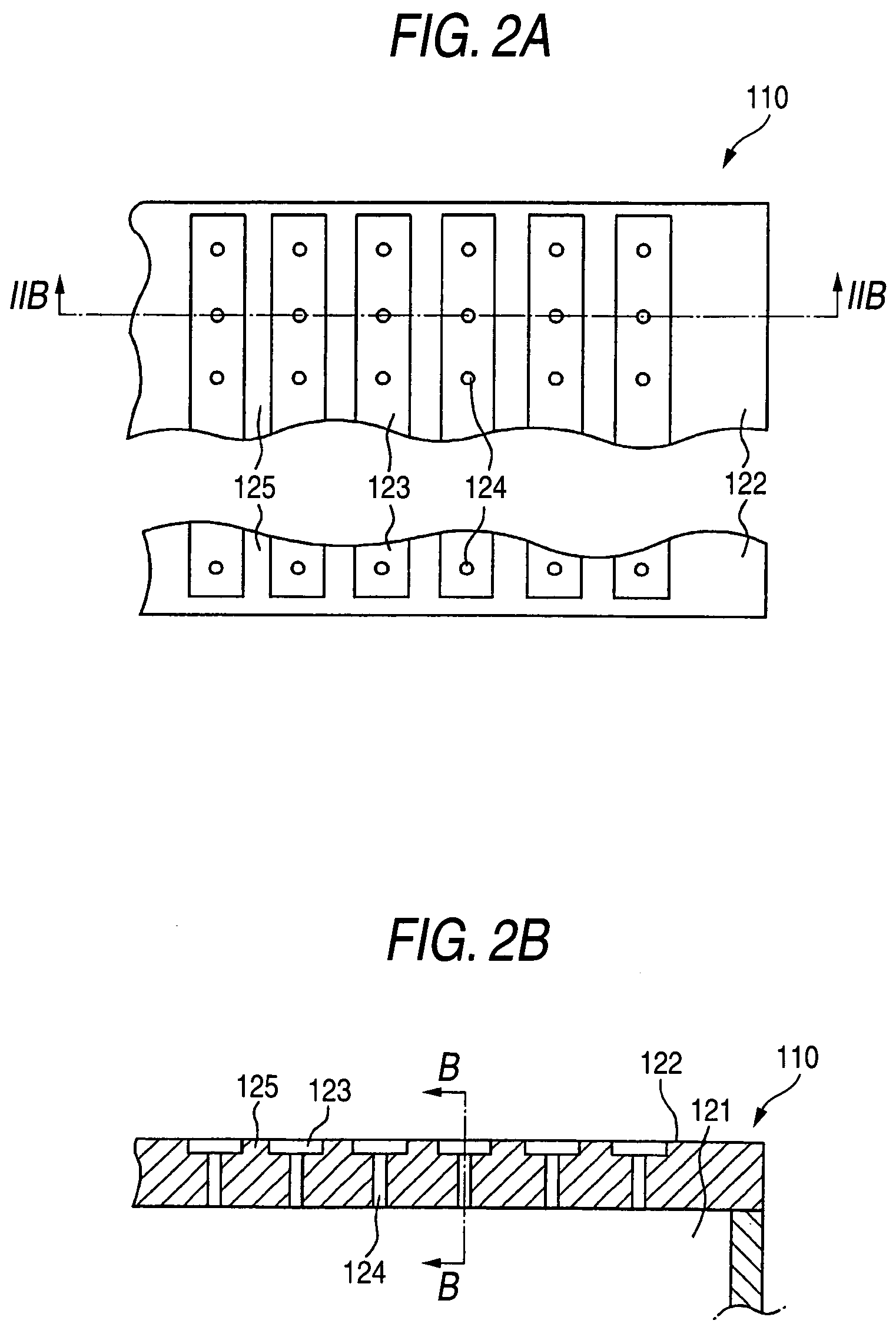

Lens barrel assembly and image capturing apparatus

InactiveUS20070177046A1Improve feeding accuracyReduce sizeTelevision system detailsColor television detailsPhysicsImage capture

There are provided a lens barrel assembly and an image capturing apparatus which are advantageous to increase the feeding accuracy for a movable lens and to reduce the size of a lens barrel. Second group position detecting means 34 is provided for generating positional data corresponding to the position of a second group lens 12. The angular displacement of a second group motor 2804 is controlled in order to equalize the position of the second group lens 12 along the optical axis to a target position based on the positional data supplied from the second group position detecting means 34. If the positional data remains unchanged for a certain period of time while the second group motor 2804 is in rotation, then it is judged that the second group lens 12 is forcibly stopped against movement and the second group motor 2804 is immediately de-energized.

Owner:SONY CORP

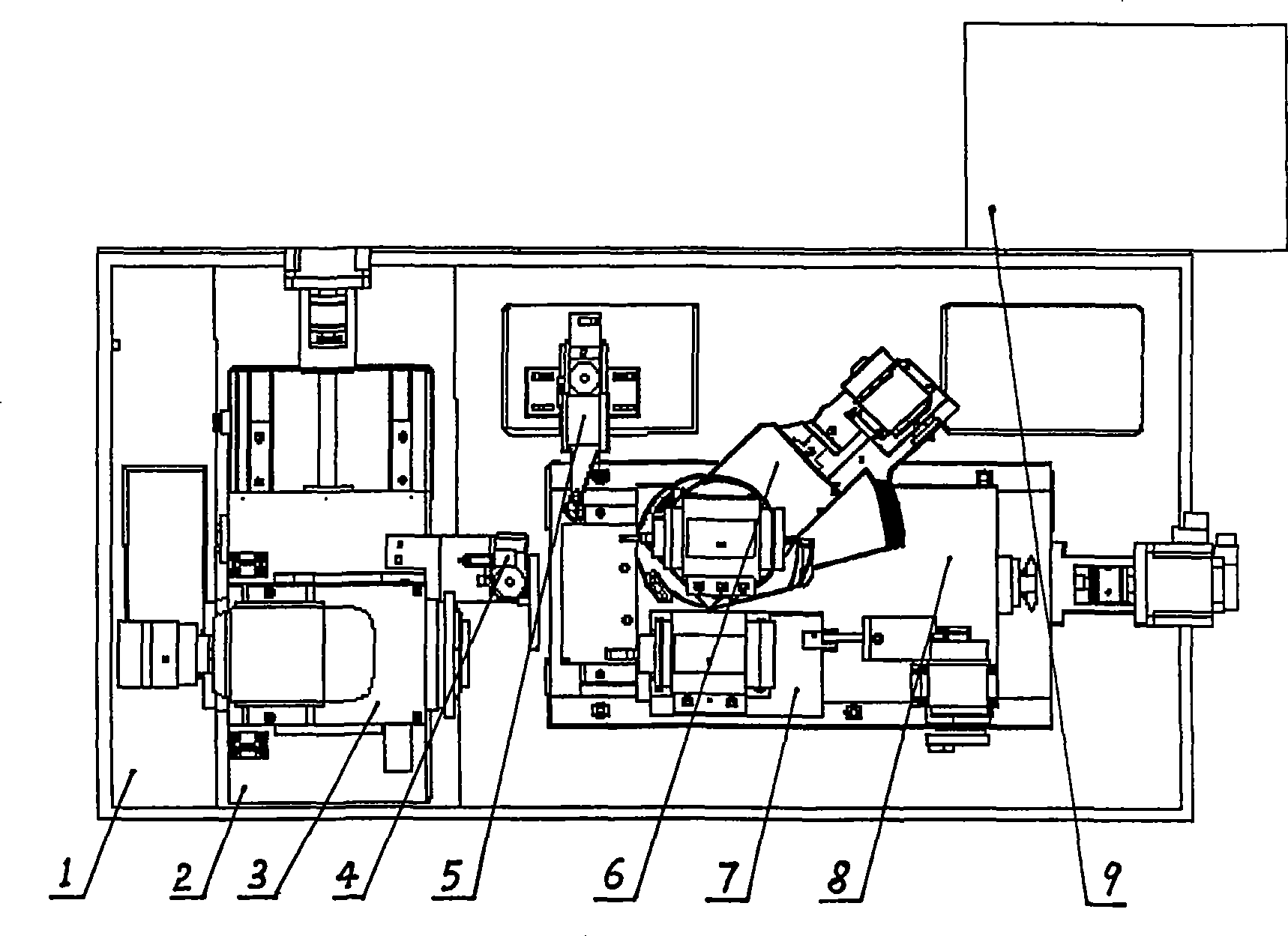

Precise numerical control internal grinder and processing control method thereof

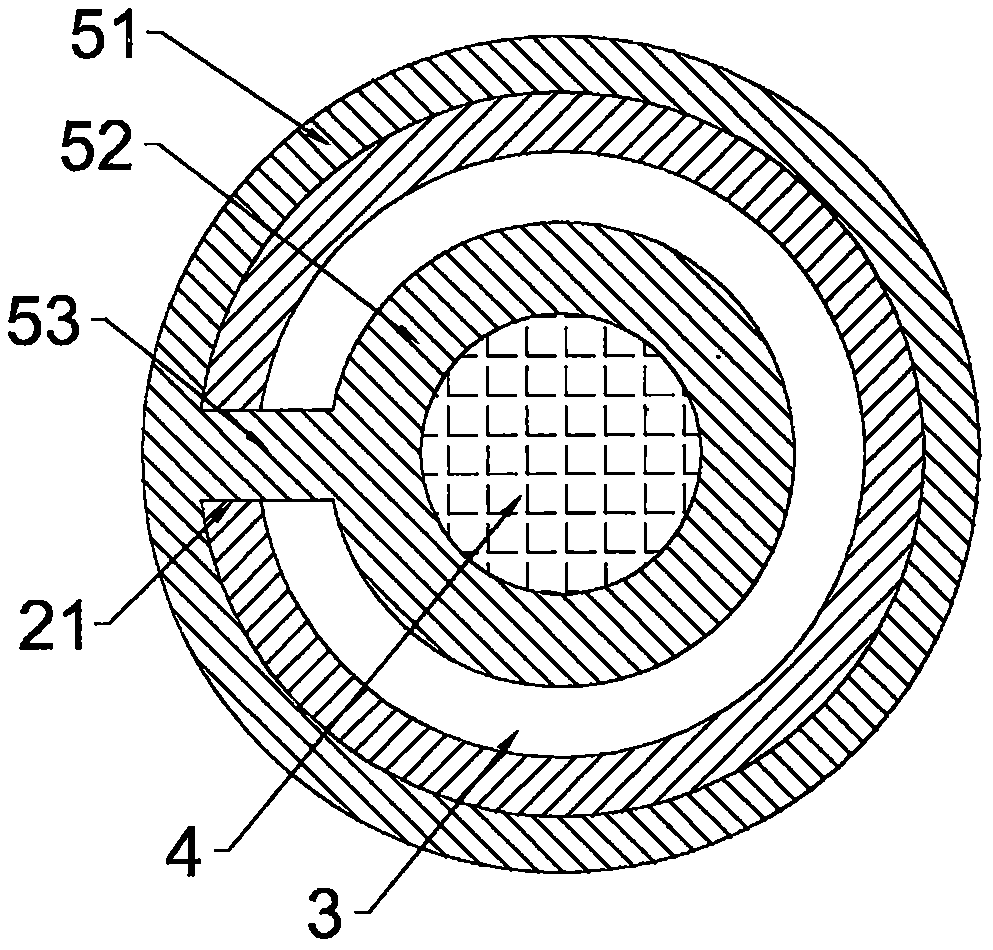

InactiveCN101530978AHigh feed accuracyImprove feeding efficiencyRevolution surface grinding machinesAbrasive surface conditioning devicesNumerical controlBall screw

The invention discloses a precise numerical control internal grinder and processing control method thereof. The grinder comprises a grinder body, a grinder head, a grinding module and an electric control gear. The grinder also comprises a transverse slide mechanism and a longitudinal slide mechanism, wherein, each set of slide mechanism is driven by a servo motor and adopts a ball screw for transmission. The grinder head is arranged on a sliding plate of the transverse slide mechanism. The grinding module also comprises an inner hole grinding module and a conical surface grinding module, wherein, each set of grinding module is respectively arranged on the sliding plate of the longitudinal slide mechanism by a set of independent grinding sliding plate mechanism, and each set of grinding module all comprises a set of independent reciprocating driving mechanism, a grinding tool and a grinding tool rotation drive mechanism. The method refines the processing process and sets proper processing parameter according to best grinding technical curve. A programmable controller finishes accurate grinding processing according to reliable parameter. The invention can improves the processing efficiency and precision of an internal grinder and is particularly fit for parts with inner holes and the conical surfaces which are required to be ground accurately.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

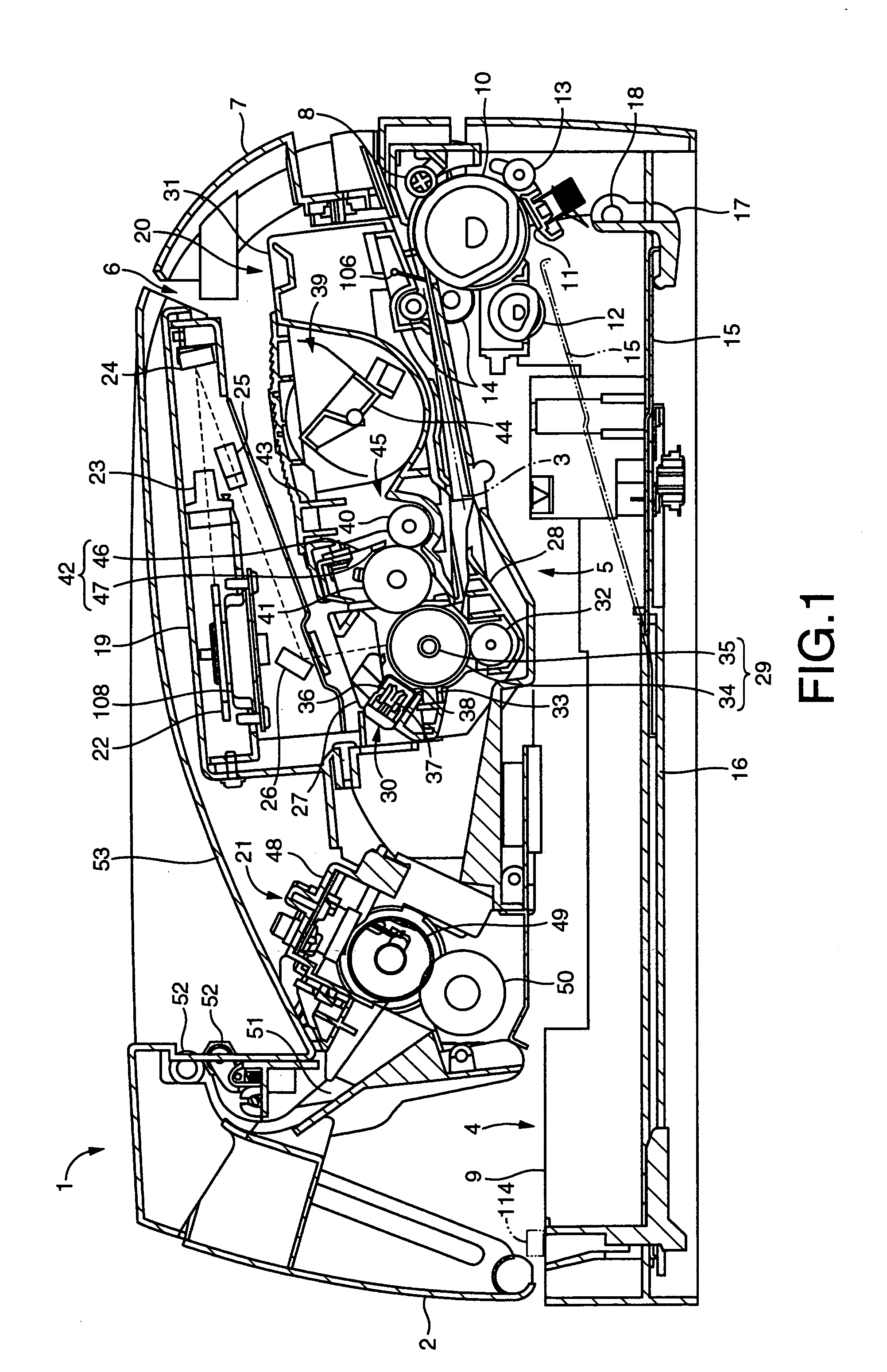

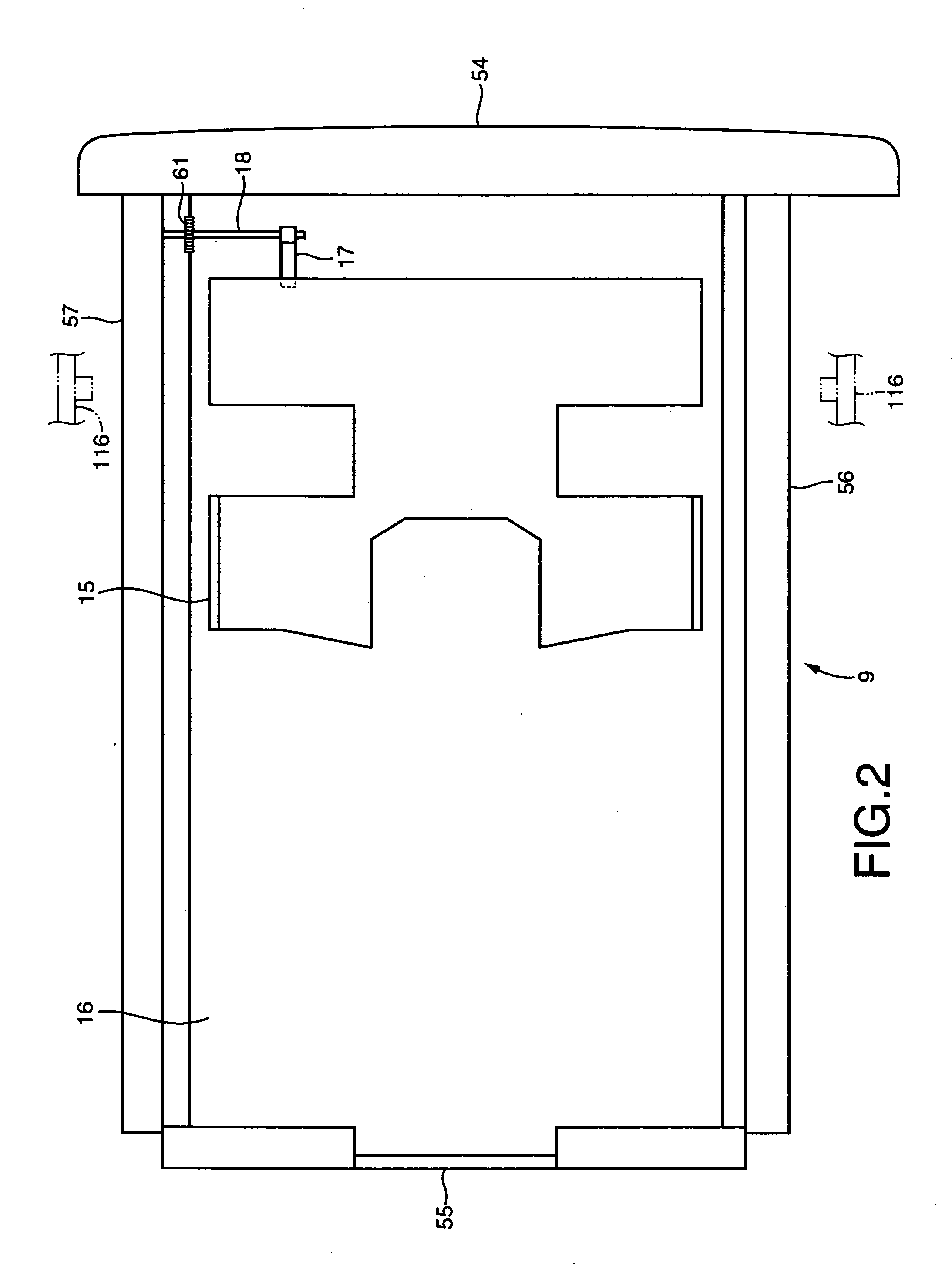

Image forming apparatus with recording medium support member adjustable in position for desired position of uppermost recording medium on support member

ActiveUS20050218584A1Increase manufacturing costImprove recording accuracyElectrographic process apparatusArticle separationMechanical engineeringRecording media

Owner:BROTHER KOGYO KK

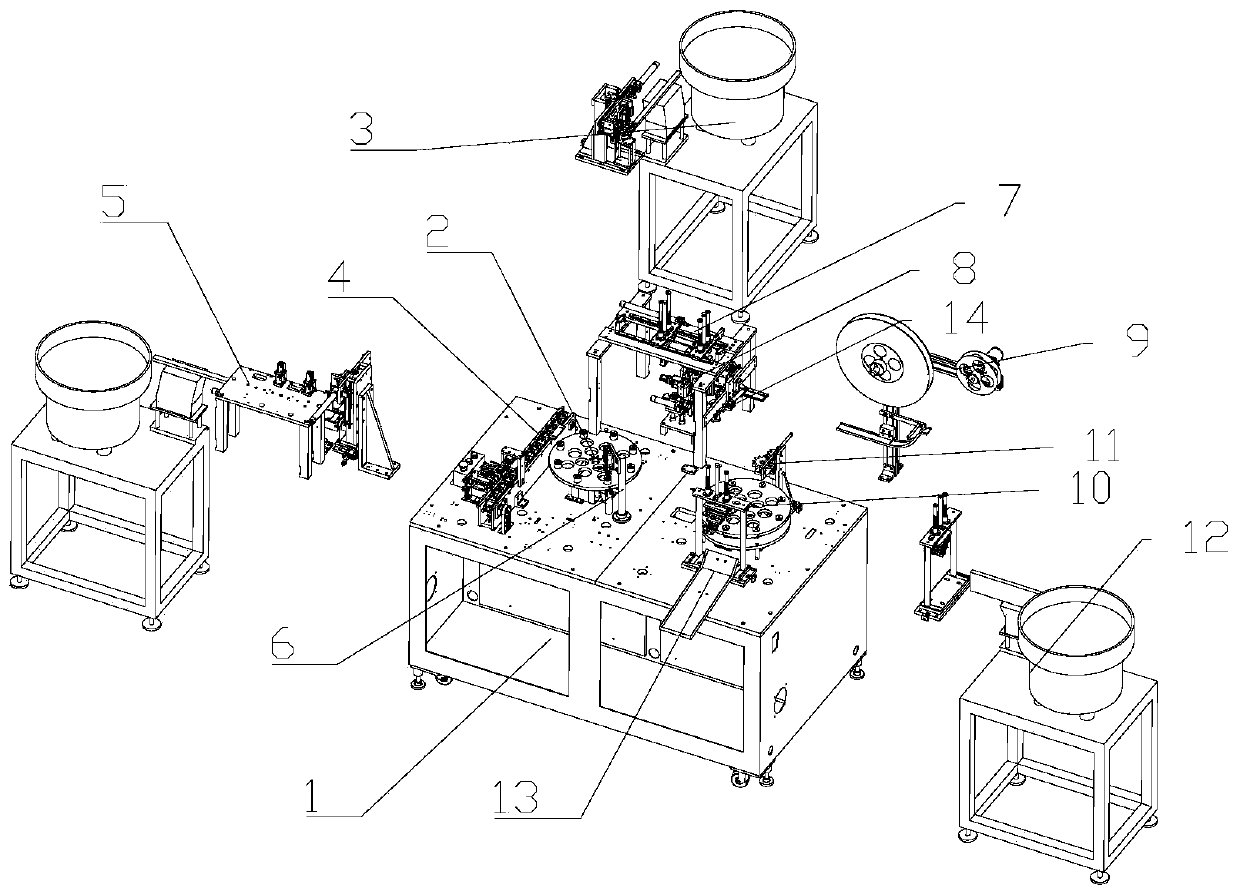

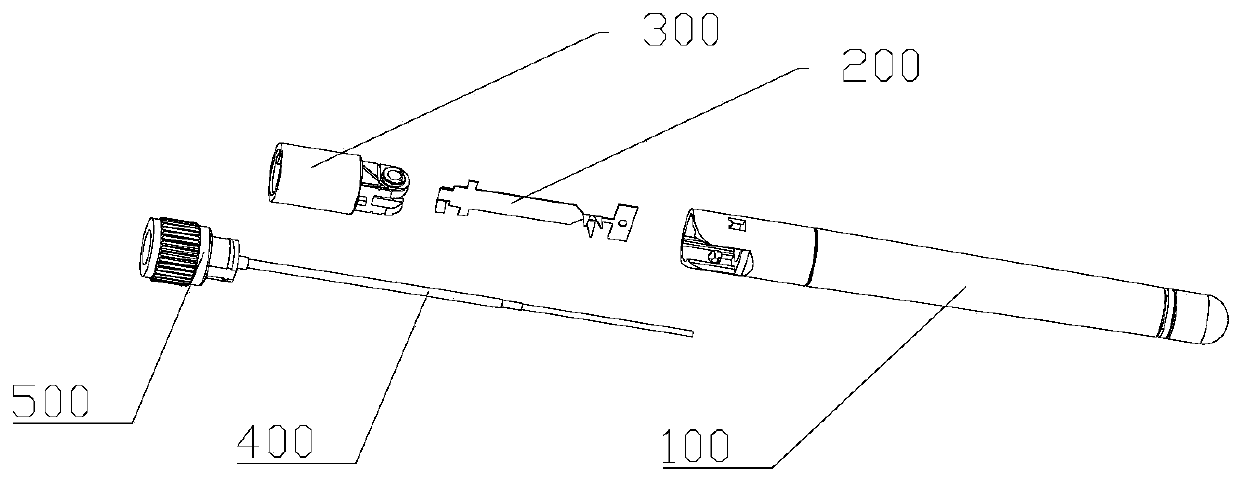

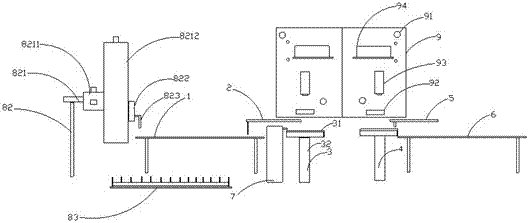

Electronic antenna and full automatic assembling method and production system thereof

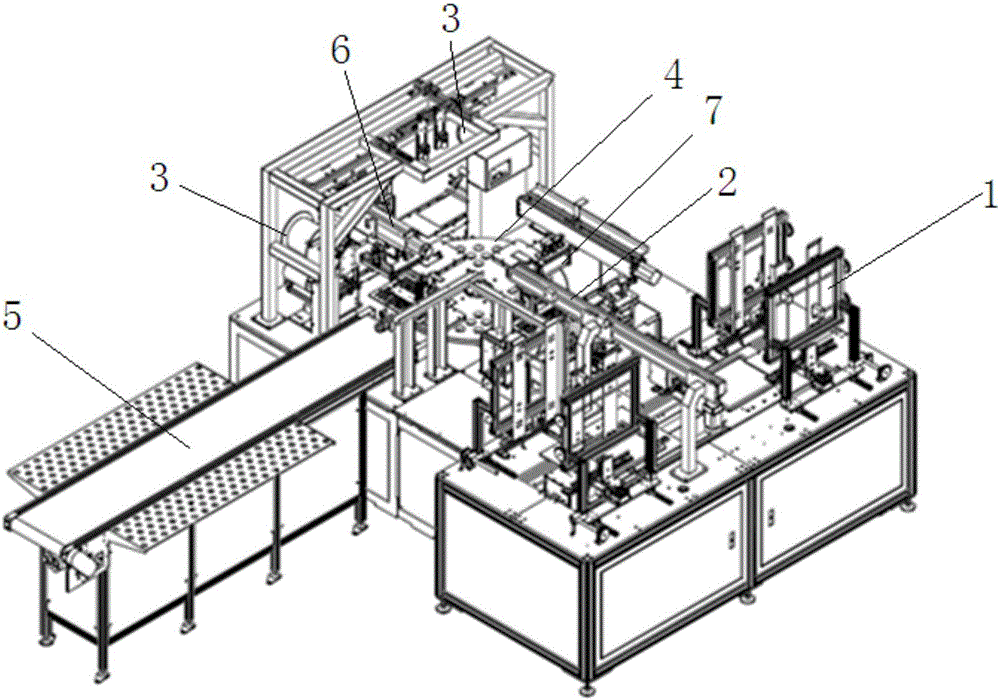

The invention relates to the field of communication equipment manufacturing. An electronic antenna full automatic assembling method sequentially comprises the following steps that rotation piece feeding is conducted, specifically, a rotation piece is fed to a first rotary disc device through a rotation piece feeding device; an antenna core and an sma connector are assembled into a core body, specifically, the antenna core and the sma connector are fed and assembled through an antenna core feeding transferring device and an sma connector feeding assembling device, the connector is fixed, and the antenna core is inserted into the connector; the rotation piece and the core body are pressed, specifically, pressing is conducted through a pressing device; copper sheet assembling is conducted, specifically, a carrying device carries a product into a copper sheet pressing device to be assembled; and protection bar assembling is conducted, specifically, a protection bar is fed by an antenna protection bar feeding device, and then, final product assembling is conducted through a protection bar assembling device. An electronic antenna full automatic assembling production system adopted the technical scheme is high in automation degree, working efficiency and finished product percent of pass.

Owner:王朝火

Fully automatic iron core riveting machine

The invention discloses a fully automatic iron core riveting machine which comprises a working table surface and a riveting jig table. The fully automatic iron core riveting machine is characterized by comprising a silicon steel sheet material separation mechanism, an iron rivet vibrating disk mechanism, an iron rivet material delivery mechanism, an oil pressure riveting mechanism, a short circuit ring riveting mechanism and a material returning mechanism, wherein the silicon steel sheet material separation mechanism delivers silicon steel sheets to the riveting jig table, the iron rivet vibrating disk mechanism and the iron rivet material deliver mechanism deliver rivets to the position of the silicon steel sheets in the riveting jig table, the oil pressure riveting mechanism rivets the silicon steel sheets and the rivets, the short circuit ring riveting mechanism put a short circuit ring into the riveted silicon steel sheets and assemblage parts of the rivets to be rivet again, and the material returning mechanism returns the riveted work pieces. The fully automatic iron core riveting machine has the advantage of being convenient to operate, high in precision rate of material delivery, good in consistency of products, and capable of greatly improving production efficiency comparing with the prior art.

Owner:建宏金属材料(苏州)有限公司

Ultrasonic motor

ActiveUS20150183001A1High feed accuracyPiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationCouplingEngineering

There is disclosed an ultrasonic motor having a vibrator that vibrates by a high frequency drive voltage applied thereto, a sliding member that comes in contact frictionally with the vibrator, pressurizing means for pressurizing the vibrator to the sliding member, a base to which the vibrator is fixed, a vibrator support member holding the base, and coupling means for coupling the vibrator with the vibrator support member, the vibrator and the sliding member being relatively moved by the vibration, wherein the coupling means includes the base, the rolling member that freely moves the base to the vibrator support member in a pressurizing direction of the pressurizing means, and an urging member that urges the rolling member in a direction perpendicular to the pressurizing direction of the pressurizing means.

Owner:CANON KK

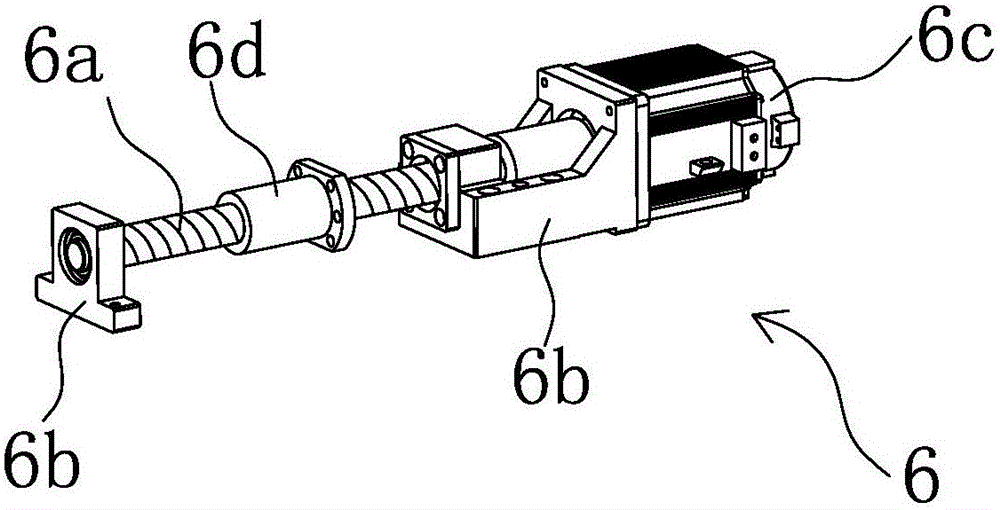

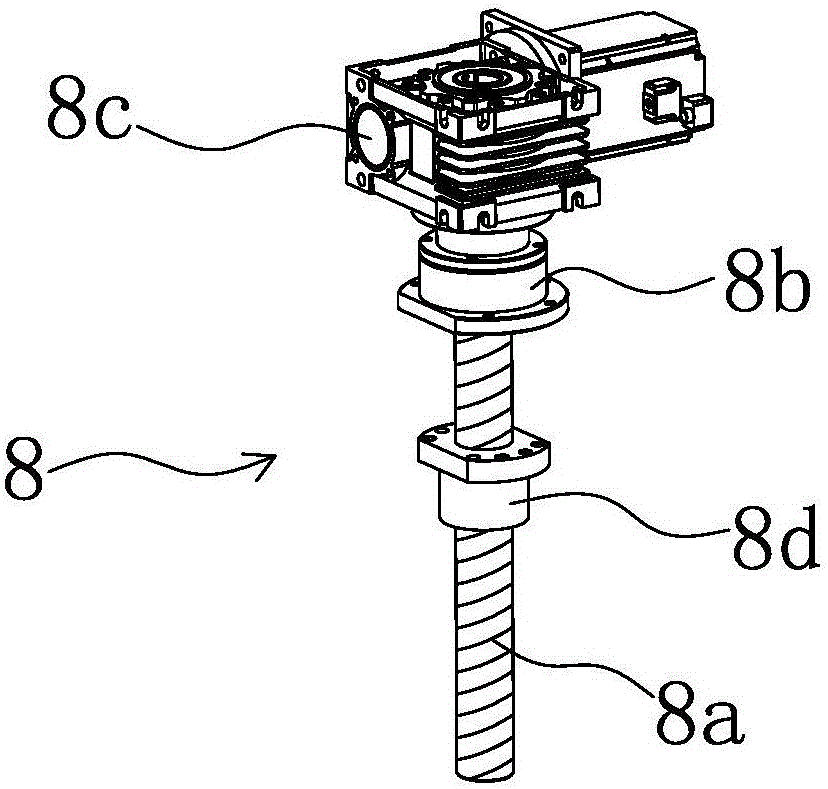

Sheet die-cutting machine

ActiveCN102581878AQuality improvementHigh feed accuracyMetal working apparatusElectric machineryEngineering

The invention relates to a sheet die-cutting machine, which comprises a base. A servo slide feeding mechanism for feeding, an automatic sheet correction mechanism, a hydraulic die-cutting mechanism and a limit depth adjusting mechanism are disposed on the base, wherein the automatic sheet correction mechanism is used for correcting X-axial position and Y-axial position of a sheet on the servo slide feeding mechanism, the hydraulic die-cutting mechanism is used for die cutting, and the limit depth adjusting mechanism is used for adjusting die-cutting depth of the hydraulic die-cutting mechanism. The servo slide feeding mechanism comprises a feeding slide, a first X-axial screw pair and a first servo motor, wherein the first X-axial screw pair is connected with the feeding slide, and the first servo motor is connected with the first X-axial screw pair. The sheet die-cutting machine has the advantages that the automatic sheet correction mechanism can be used for adjusting the X-axial position and the Y-axial position of the sheet on the feeding slide, and accordingly feeding precision can be improved and die-cutting quality can be improved; and the limit depth adjusting mechanism can be used for automatically finely adjusting a moving pressure plate in the hydraulic die-cutting mechanism so as to adjust the die-cutting depth, and the die-cutting depth can be adjusted accurately.

Owner:SHENZHEN HOCHUEN TECH

Corrugated pipe cutting device

ActiveCN106270740AEasy to adjustEffective clampingTube shearing machinesShearing machine accessoriesEngineeringReducer

The invention discloses a corrugated pipe cutting device. The corrugated pipe cutting device comprises a baseplate, a main support rod, a slide sleeve, a cavity, a screw rod, a bevel gear assembly, a speed reducer, a motor, a connecting support rod, a cutting wheel blade, a hydraulic adjusting rod, a clamping device, a control device, a power supply connecting port, a support column and a support baseplate; the slide sleeve includes an outer sleeve, an inner sleeve and a connecting block; the main support rod is provided with a slide hole matched with the connecting block; and the clamping device includes a transverse plate, a support frame, a clamping cylinder, a first connecting rod and a second connecting rod. The corrugated pipe cutting device is simple and reasonable in structure and convenient to use, can conveniently adjust the height of the cutting wheel blade through the motor and the speed reducer, is high in feeding precision, can effectively clamp a corrugated pipe to be cut, is convenient and fast in clamping, is stable in clamping, is high in automation degree, and is longer in service life.

Owner:ZHEJIANG QIAI TUBING IND

Medium transporting device and recording apparatus

ActiveUS7390085B2Avoid curlInhibition effectRigid pipesOther printing apparatusEngineeringMechanical engineering

On a medium transporting surface, a dimple extending continuously from a transportation upstream end of a medium to a transportation downstream end are formed. Hereby, a leading end of the medium, after pulled into the dimples once, is transported in the pulled state. Therefore, it is prevented that the leading end of the medium is curled up by a conventional partition wall provided in the direction perpendicular to the medium transporting direction, so that it is possible to prevent a stain on the medium caused by contact with a recording head.

Owner:SEIKO EPSON CORP

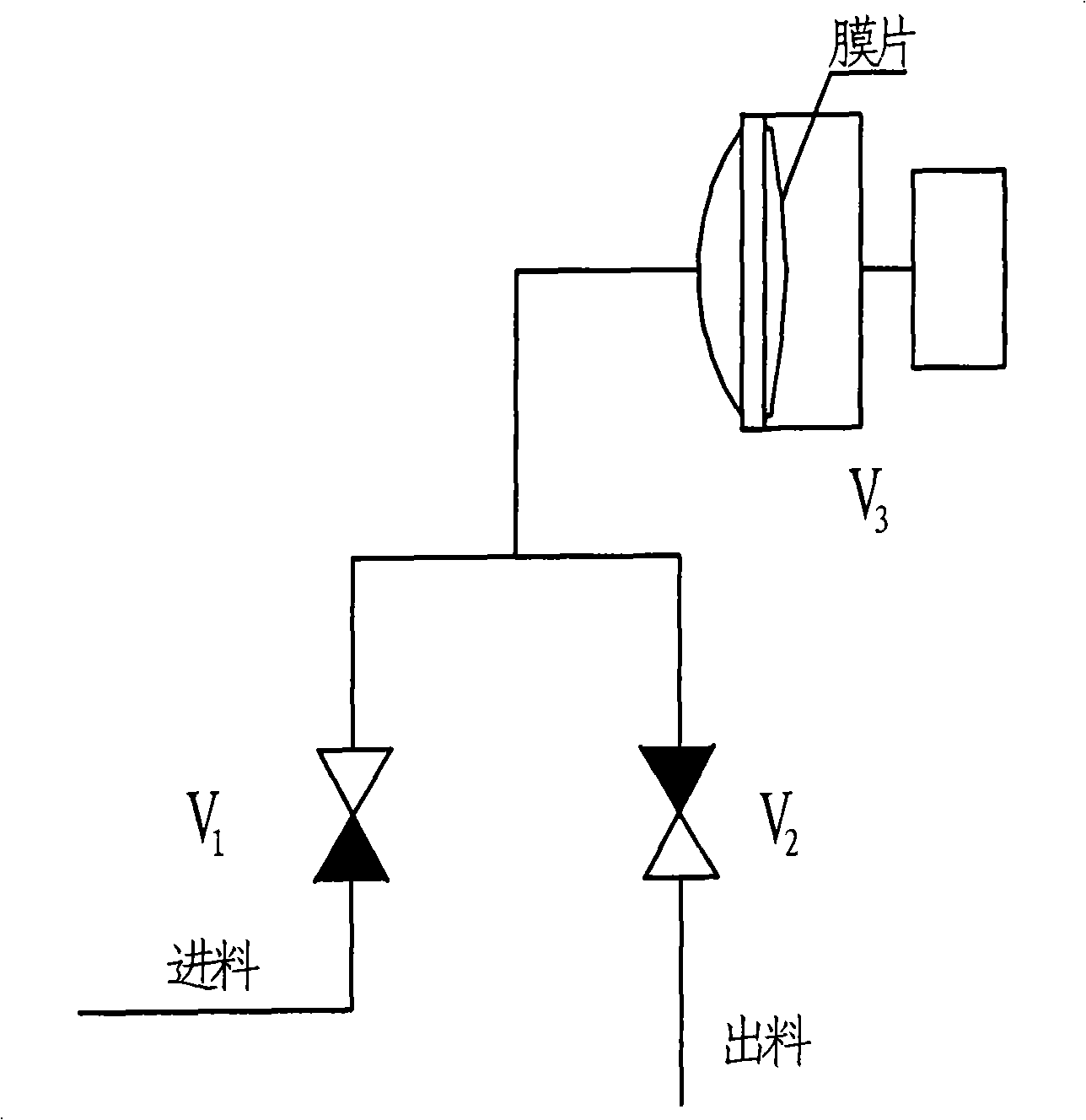

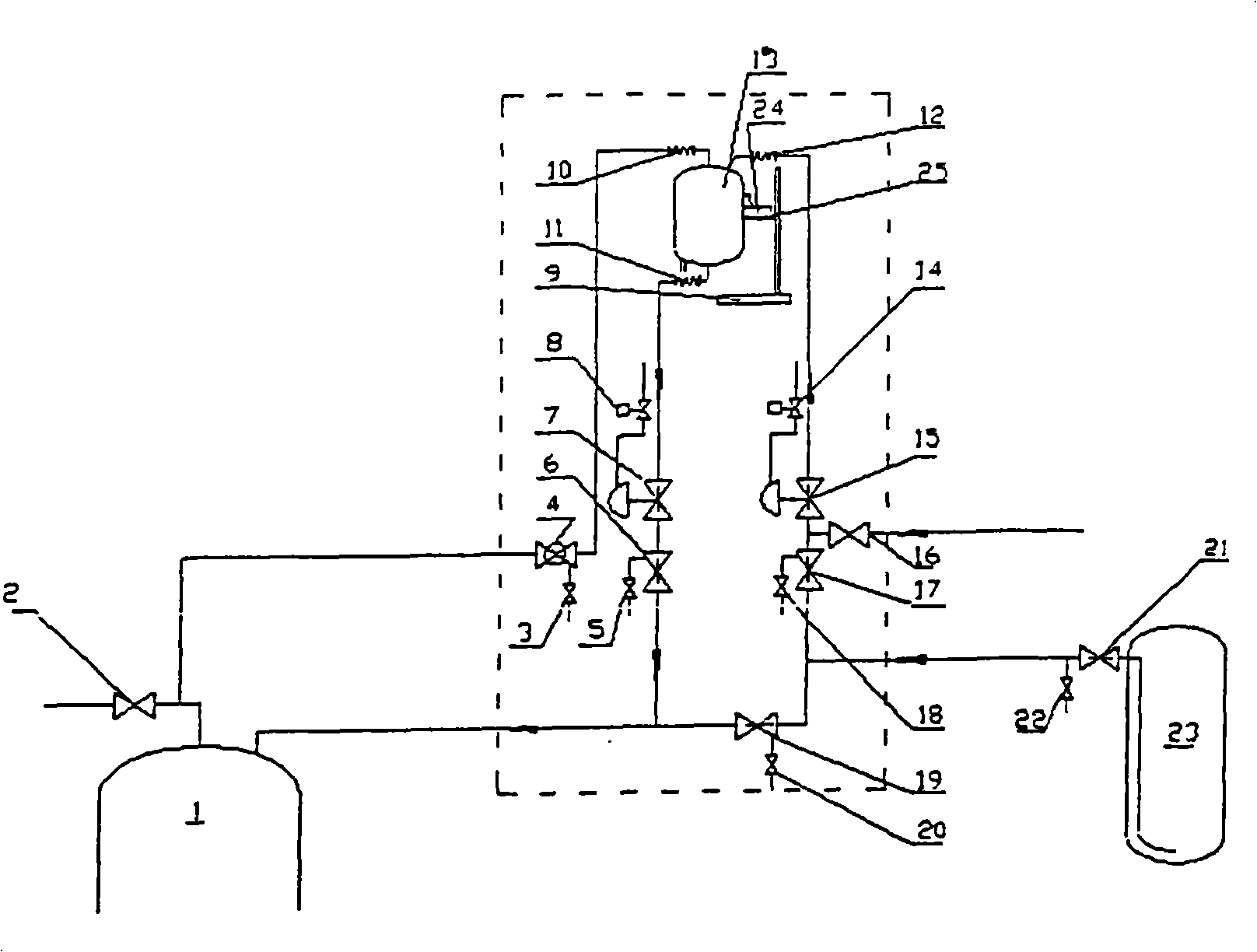

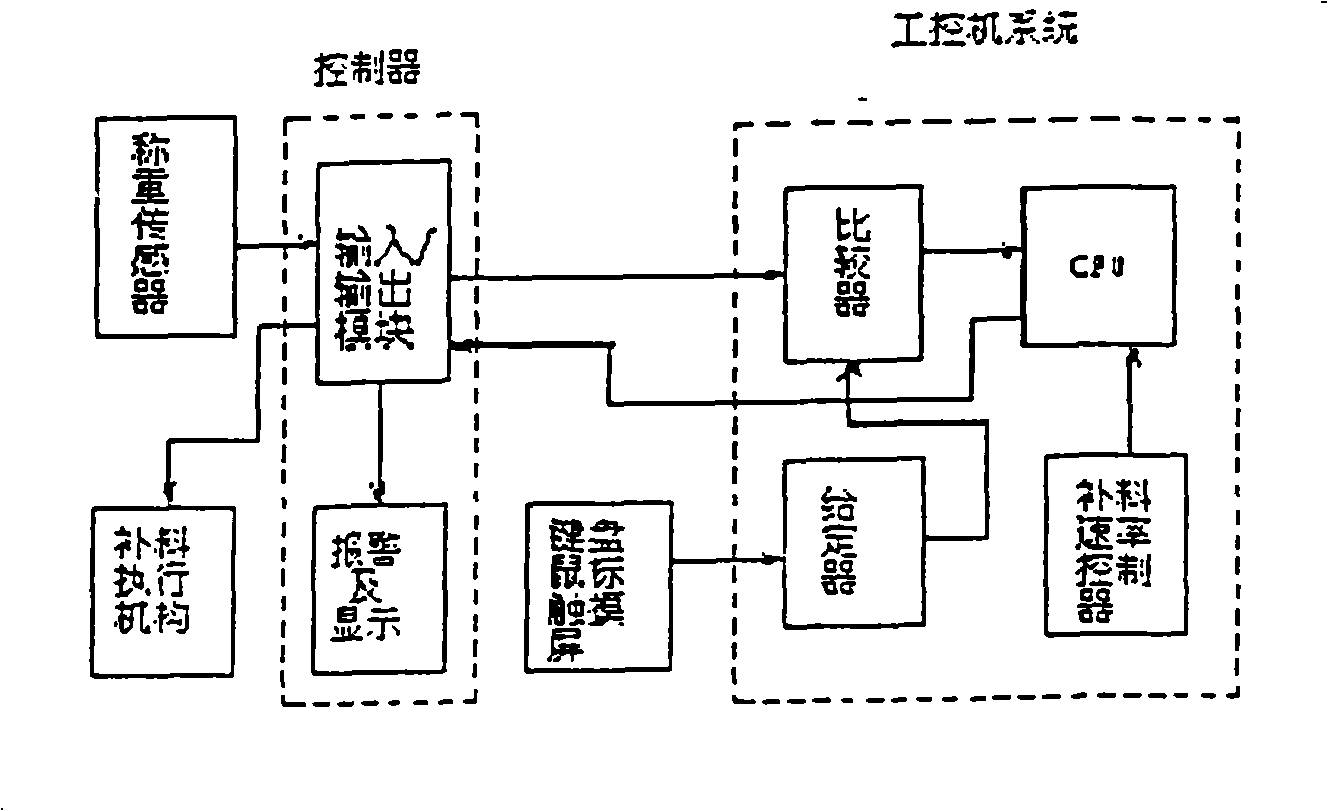

Supplementary food weighing and metering control device

ActiveCN101514918AHigh feeding accuracyHigh feed accuracyWeighing apparatus with automatic feed/dischargeIndustrial fermentationMonitoring system

The invention discloses a fluid supplementary food weighing and metering control device, which comprises a supplementary food cup, a valve system, a fermentation tank and a supplementary food tank, and is characterized by also comprising a weighing system and an electronic monitoring system, wherein the weighing system comprises a weighting sensor, a suspension arm, a fixed bracket and a weighing cup, the supplementary food cup is connected with the weighting sensor to weigh the supplementary food in the supplementary food cup, the electronic monitoring system comprises an A / D conversion module, an alarming and display module, a keyboard, a mouse, a touch screen, a comparator, a setter, a CPU and a food supplementation speed controller. As the supplementary food is metered by the weighing device, the device has the advantages of up to 0.5 percent high food supplementation accuracy and providing a reliable guarantee for the optimization and amplification of an industrial fermentation process.

Owner:SHANGHAI GUOQIANG BIOCHEMICAL ENG EQUIP CO LTD

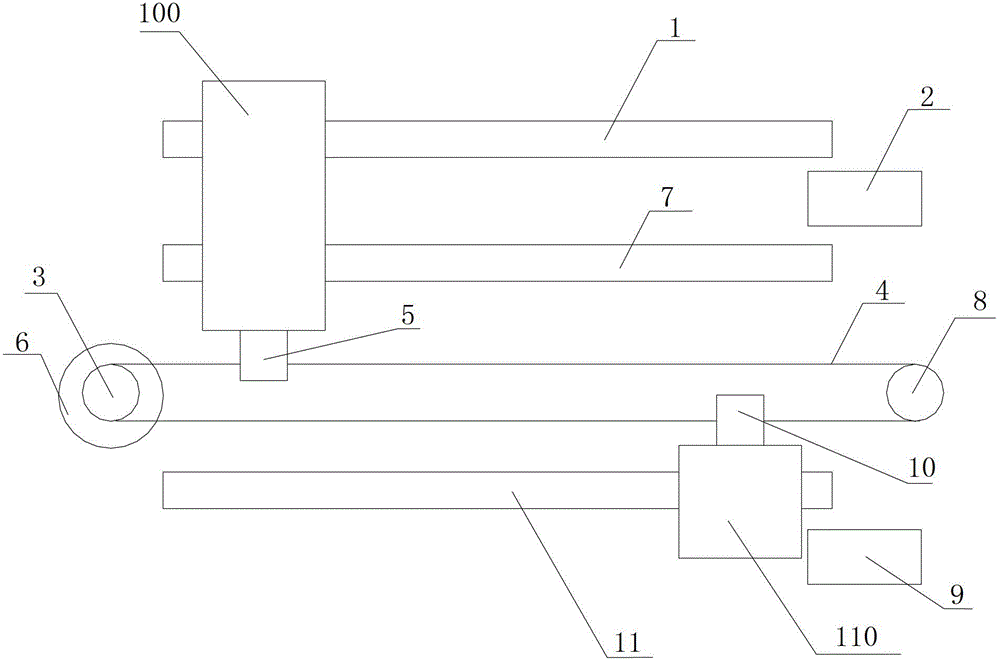

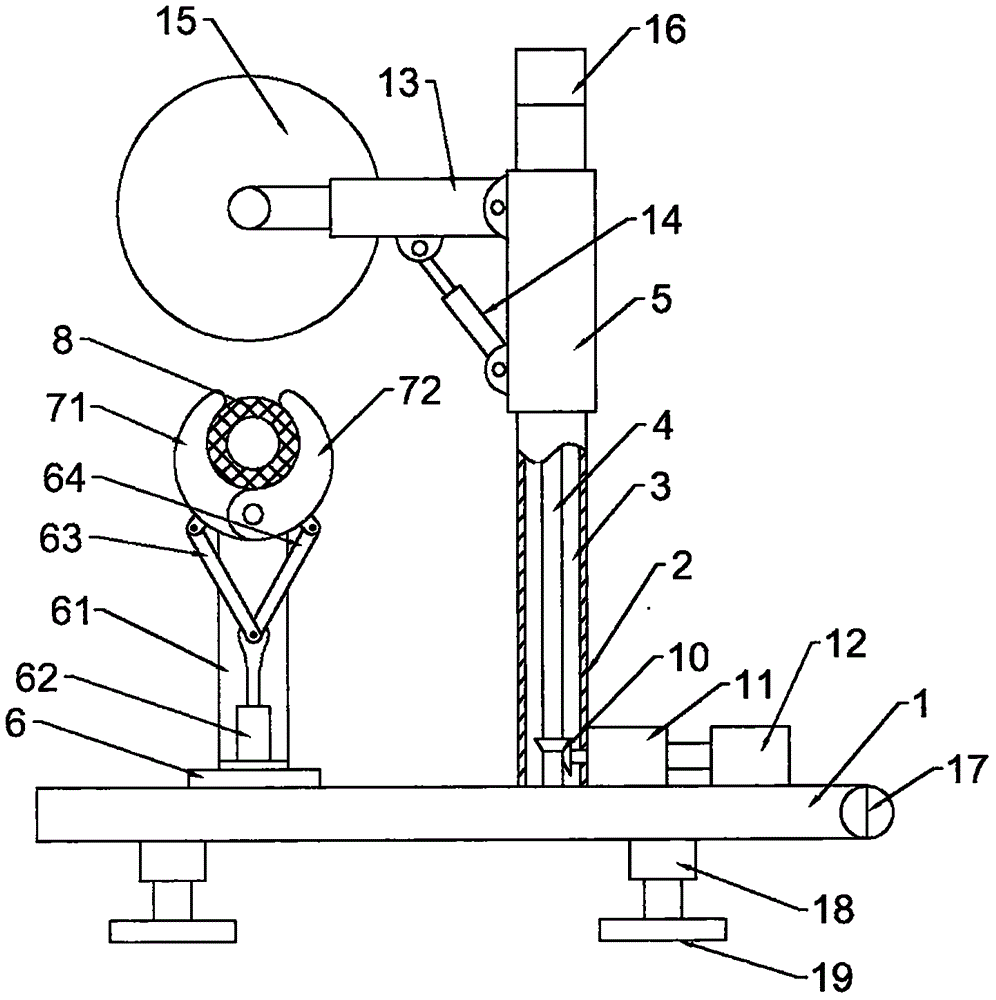

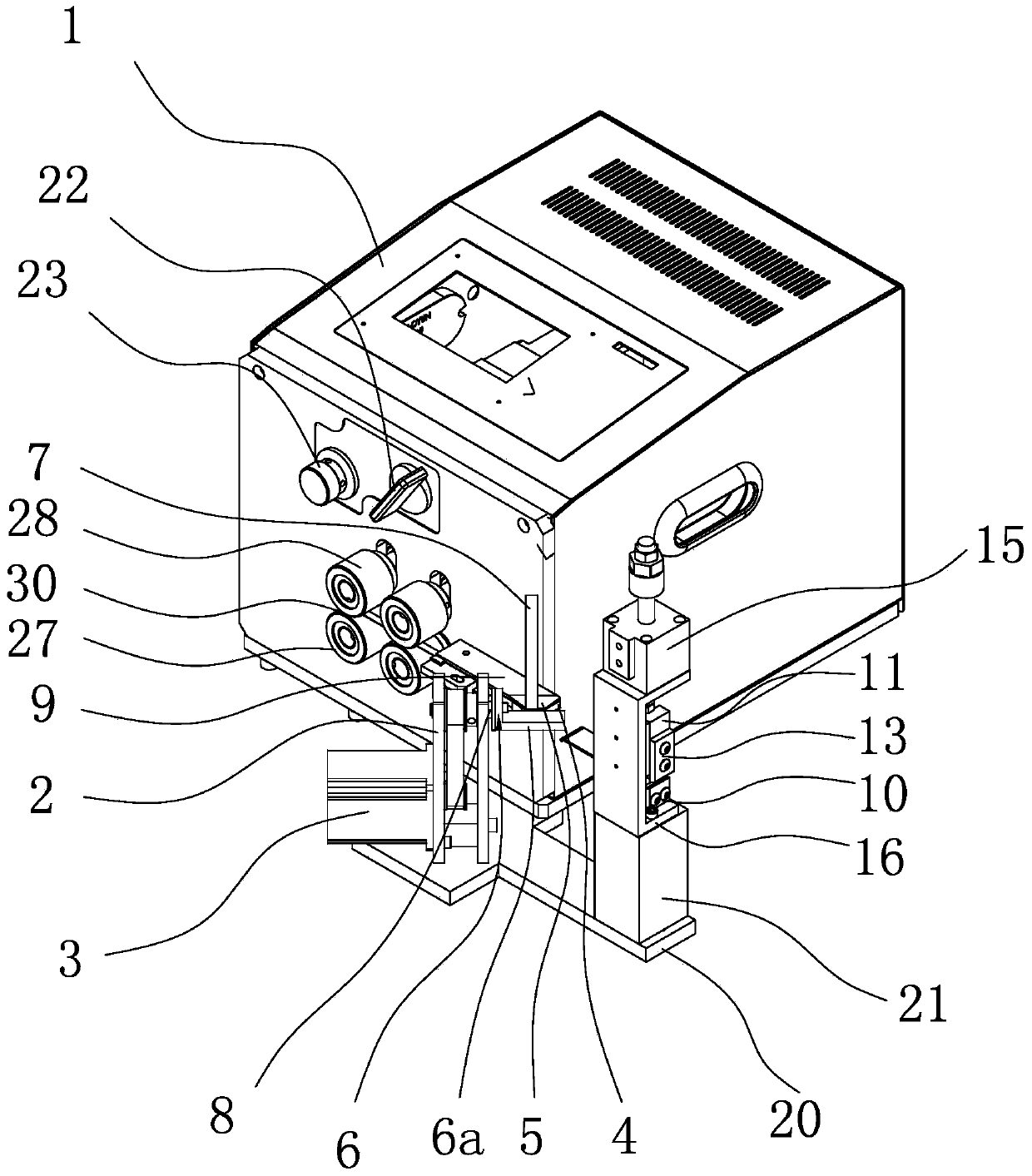

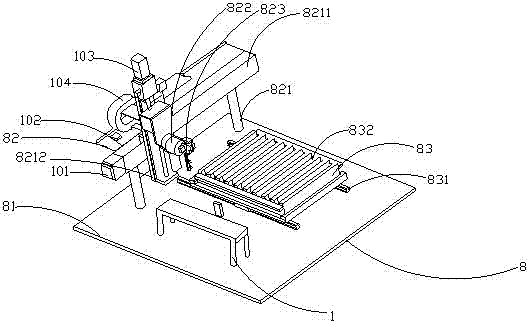

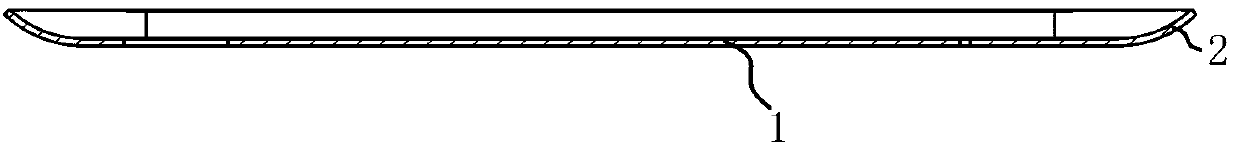

Solar component solder strip bending, shaping and blanking integrated machine

InactiveCN104201246AAchieve initial compactionEnsure consistencyMetal-working feeding devicesFinal product manufactureEngineeringSolar module

The invention provides a solar component solder strip bending, shaping and blanking integrated machine and belongs to the technical field of machinery, solving the problems of low work efficiency and poor evenness of bending portions caused by manual bending of solar solder strips. The solar component solder strip bending, shaping and blanking integrated machine comprises a case, a feeding mechanism, a bending mechanism and a shaping and cutting mechanism. The bending mechanism comprises a bending base, a bending motor, a bending base plate, a bending press plate and a bending block; the bending motor, the bending base plate, the bending press plate and the bending block are arranged on the bending base; a gap for a solar strip to penetrate is formed between the bending press plate and the bending base plate; the bending block is cylindrical, with the axis inclining to a feeding direction of the solder strip; and the bending block is connected with the bending motor and capable of bending the solder strip to the bending press plate under driving of the bending motor. During bending, the solder strip can be bent to the bending press plate through the bending block, and the bending portion of the solder strip can be flattened under pressing force which is applied continuously during bending.

Owner:TAIZHOU HAORAN MACHINERY MFG

Automatic single-color mosaic-particle lay-up device and lay-up method thereof

ActiveCN104085241AImprove laying efficiencyHigh speedOrnamental structuresConveyor partsEngineeringAutomatic testing

The invention provides an automatic single-color mosaic-particle lay-up device and a lay-up method of the automatic single-color mosaic-particle lay-up device. The automatic single-color mosaic-particle lay-up device comprises a stander, a mosaic forming die which is arranged on the stander, at least one automatic mosaic-particle single-track lay-up unit, a loading device and a controller, wherein each automatic mosaic-particle single-track lay-up unit is used for gradually collecting mosaic particles one by one after transporting the mosaic particles one by one, arranging the mosaic particles into rows / columns according to a preset rule and then driving the entire row / column of mosaic particles to enter a loading procedure; the loading device is connected with the stander and used for sequentially transporting and loading the well-arranged entire row / column of mosaic particles in each automatic mosaic-particle single-track lay-up unit into the mosaic forming die; the controller is respectively connected with each automatic mosaic-particle single-track lay-up unit and the feeding device by signals. The automatic single-color mosaic-particle lay-up device is high in lay-up stability, high in lay-up speed and capable of effectively improving the lay-up efficiency and lay-up accuracy of the mosaic particles. The automatic lay-up method is used for substituting the traditional manual lay-up process, so that the problems that the current mosaic industry is low in automation degree and low in production efficiency can be solved.

Owner:FOSHAN UNIVERSITY

Full-automatic LCD glass surface mounting machine

The invention relates to a surface mounting machine, and discloses a full-automatic LCD glass surface mounting machine. The full-automatic LCD glass surface mounting machine is provided with a servo motor and a PLC and successively comprises a loading device, a first transmission belt, a glass feeding device, a first surface mounting platform, a first surface mounting machine, a second surface mounting platform, a second surface mounting machine, a transport adsorption device and a second transmission belt according to a passing-through sequence of glass chips; the particular running process of full-automatic LCD glass surface mounting machine includes the steps that the loading device transports the glass chips to the first transmission belt, the glass feeding device transports the glass chips to the first surface mounting platform, the first surface mounting platform completes the surface mounting and transports the glass chips to the second surface mounting platform, and the second surface mounting platform completes the surface mounting and transports the glass chips to the second transmission belt through the transport adsorption device. According to the full-automatic LCD glass surface mounting machine, the PLC is adopted to take control, and the accurate and rapid attachment between base chips and substrates is achieved through the servo motor, ball screws, a linear guide rail, an auxiliary pneumatic system, a vision sensor and a mechanical positioning device; the full-automatic LCD glass surface mounting machine is safe and reliable in running, convenient to operate, accurate in positioning and high in attachment accuracy, and the production efficiency is greatly improved.

Owner:株洲晶彩电子科技有限公司

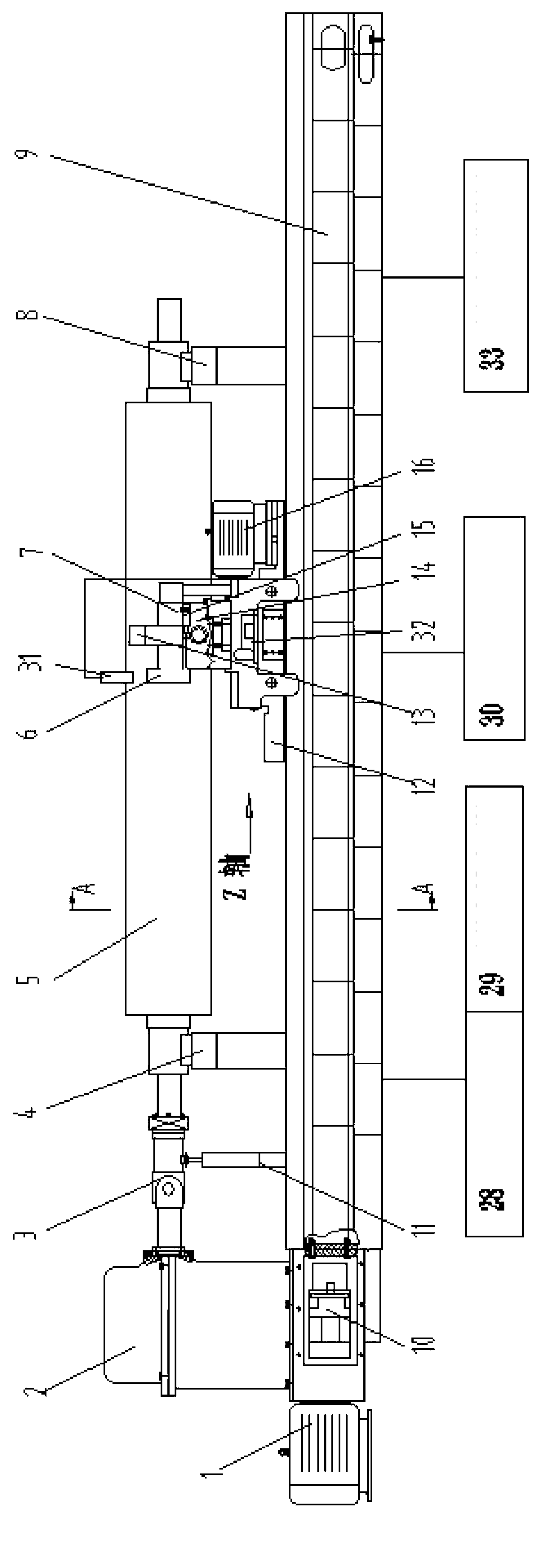

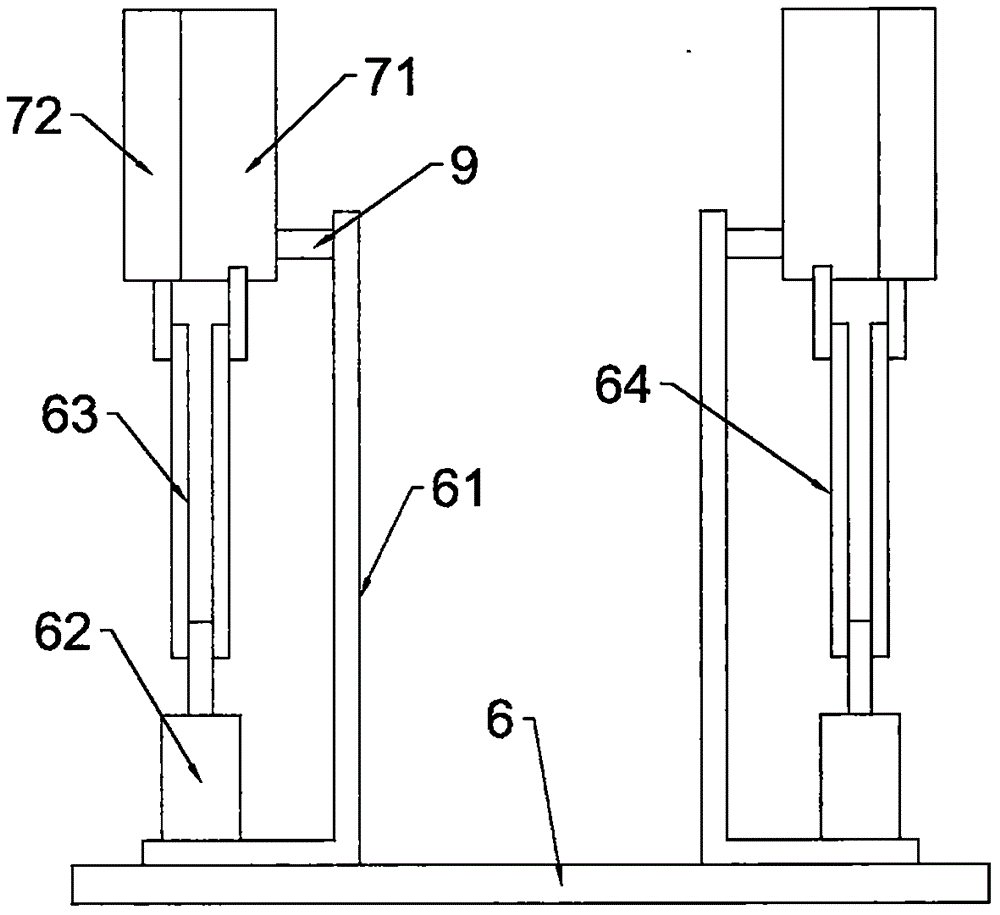

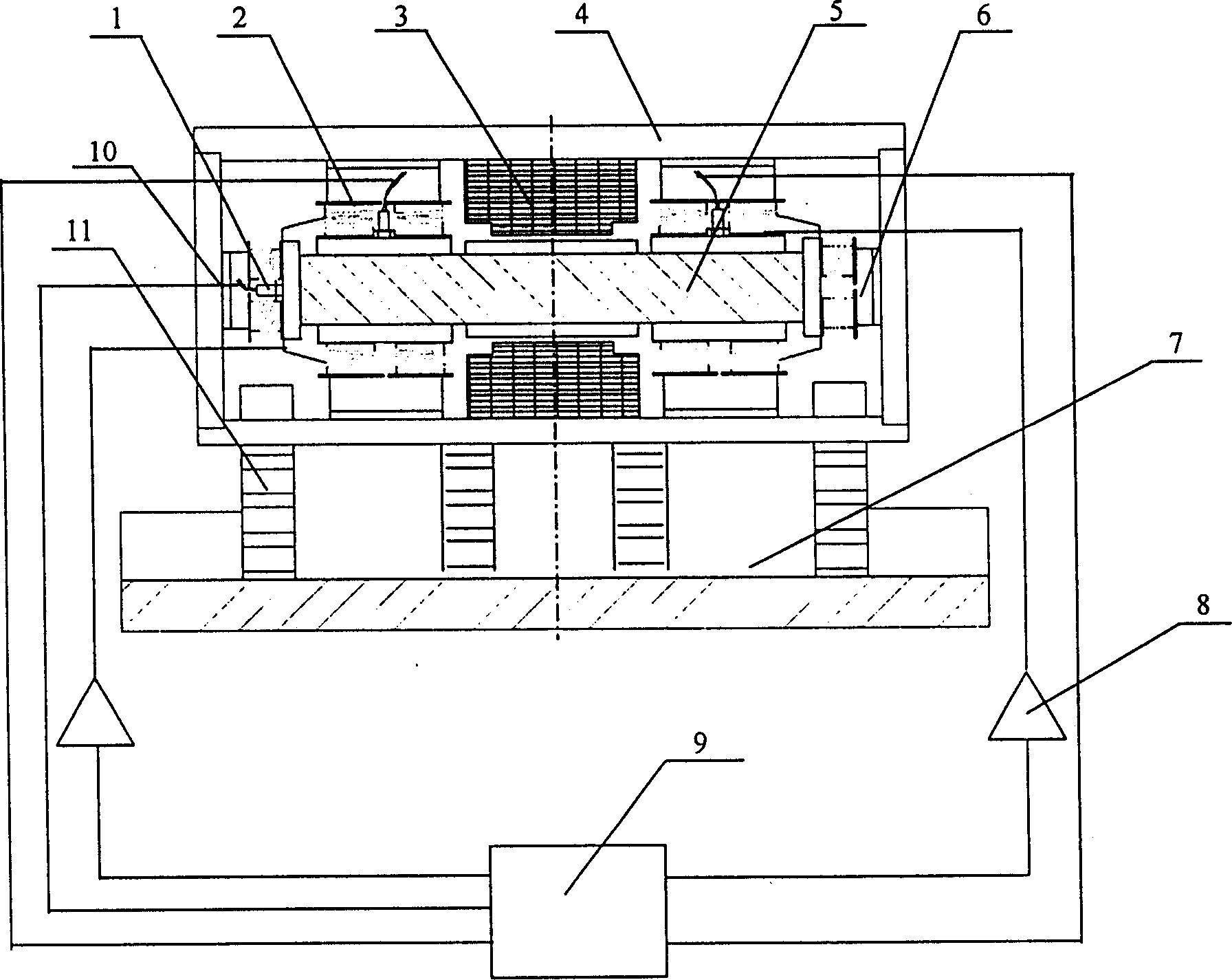

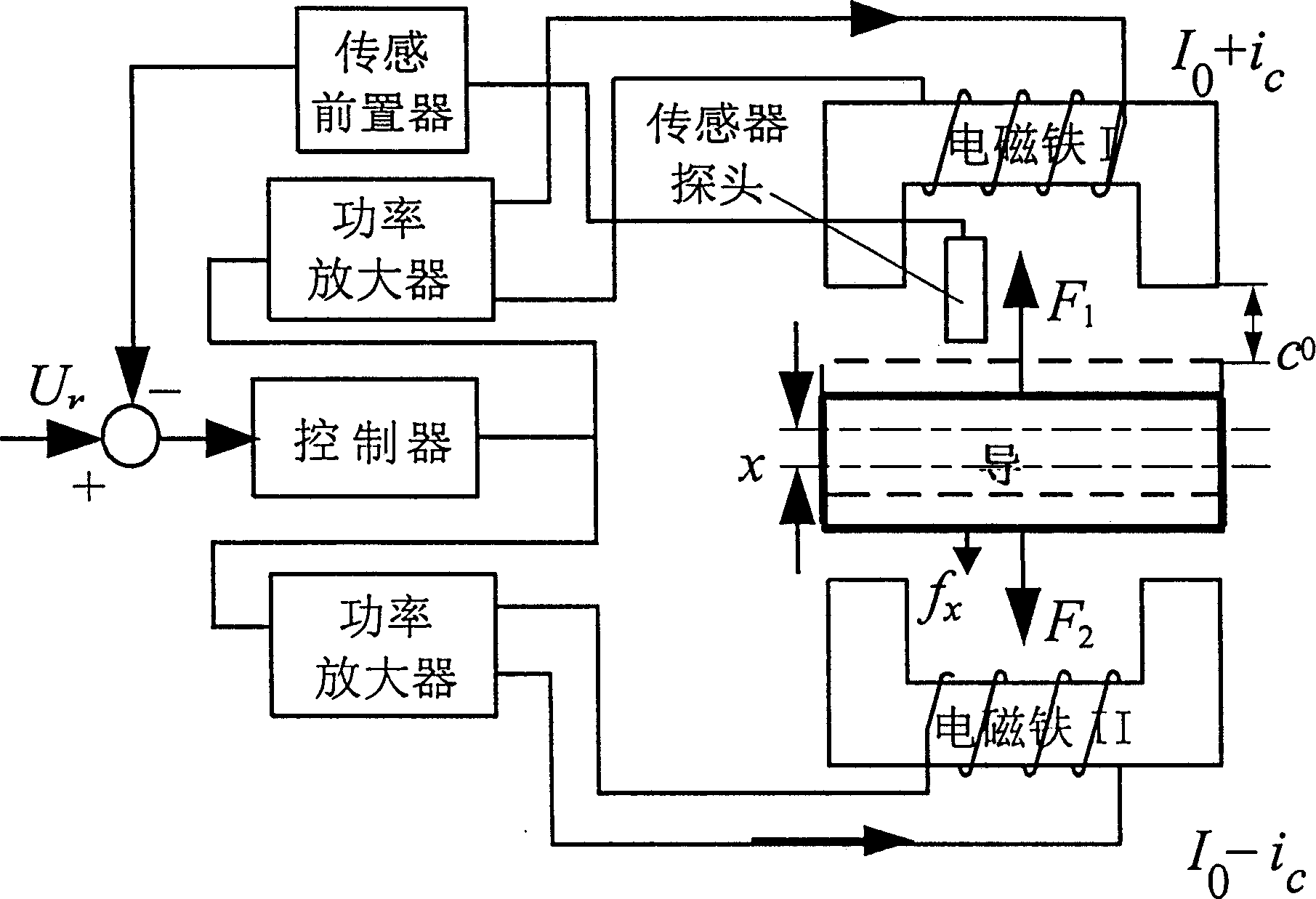

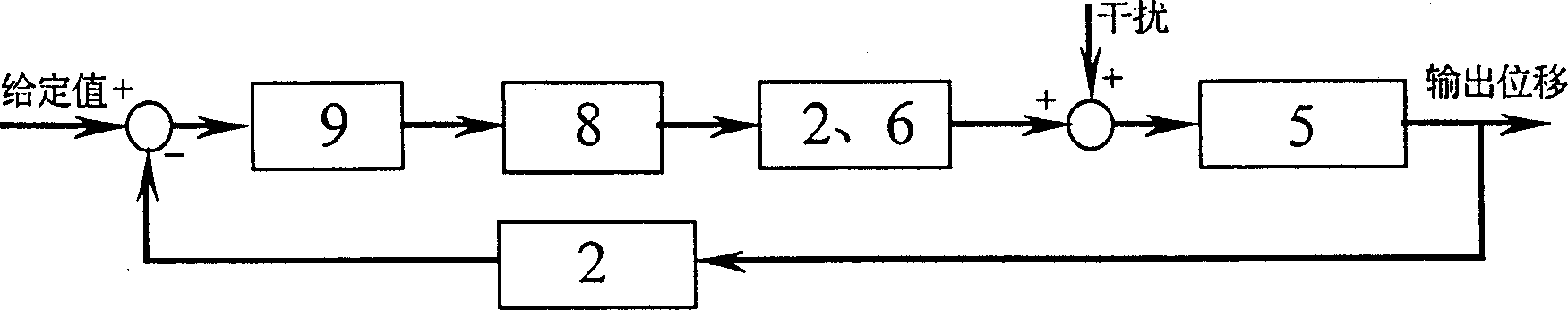

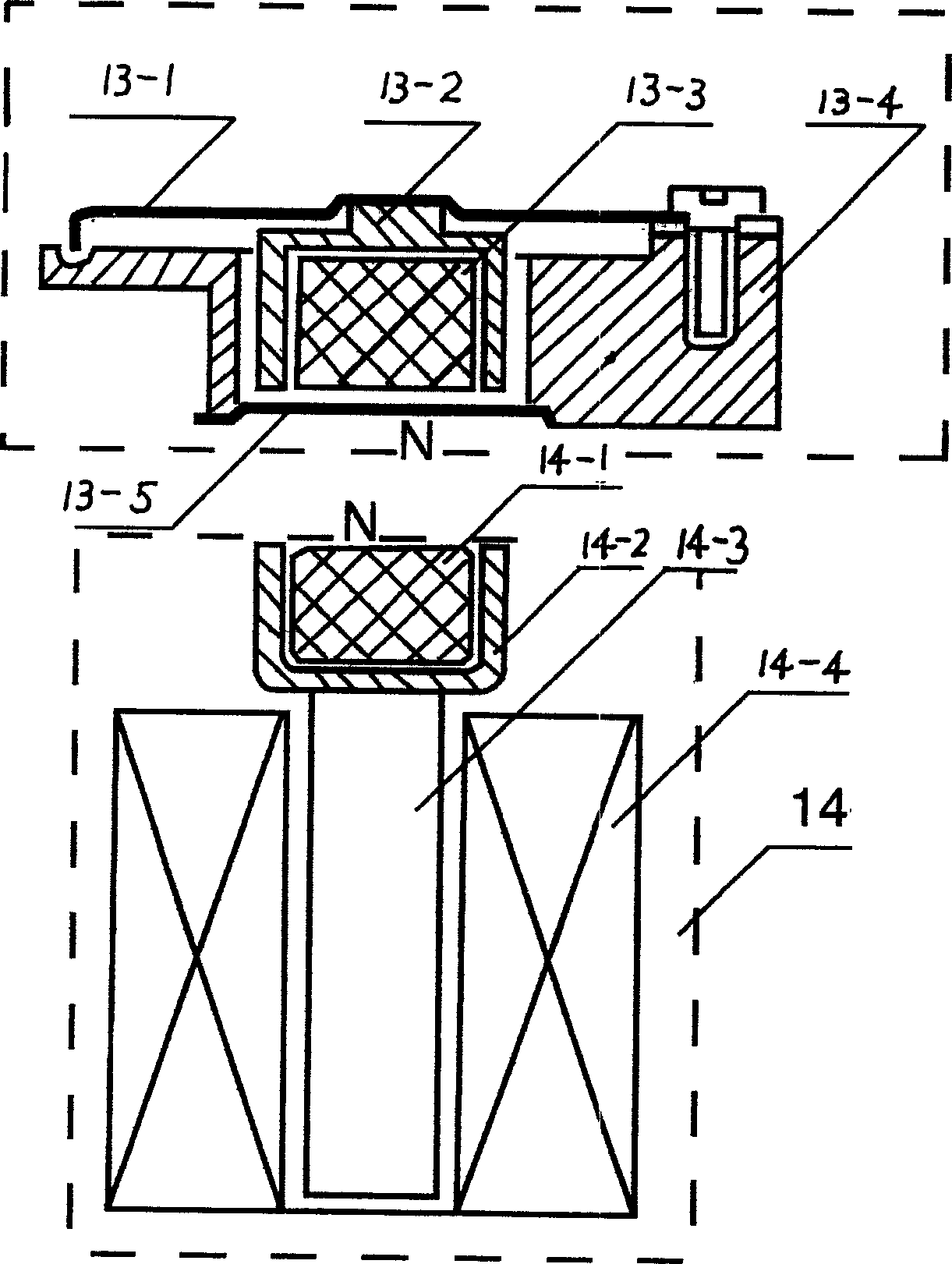

Industrial-application type active magnetic suspension machine tool guide linear motor feeding platform

InactiveCN1244432CIncrease feed rateHigh feed accuracyFeeding apparatusLarge fixed membersElectric machineLinear motor

The invention relates to an industrial applied guide-way linear-electric machine feed platform of driving magnetic suspension machine tool, containing guide way stationarily supported on the machine base, moving platform and linear electric machine, where the electric machine is in the center line of the guide way, and the top and bottom surfaces of the guide way are set with bearing electromagnet, two side surfaces of the guide way are set with guiding electromagnet, the bearing and guiding electromagnets are stationarily linked with the moving platform, both set with displacement sensors and linked with a control system of the moving platform. It largely heightens the platform feed speed and precision, and has adjustable support rigid damping, no friction, etc.

Owner:SHANGHAI UNIV

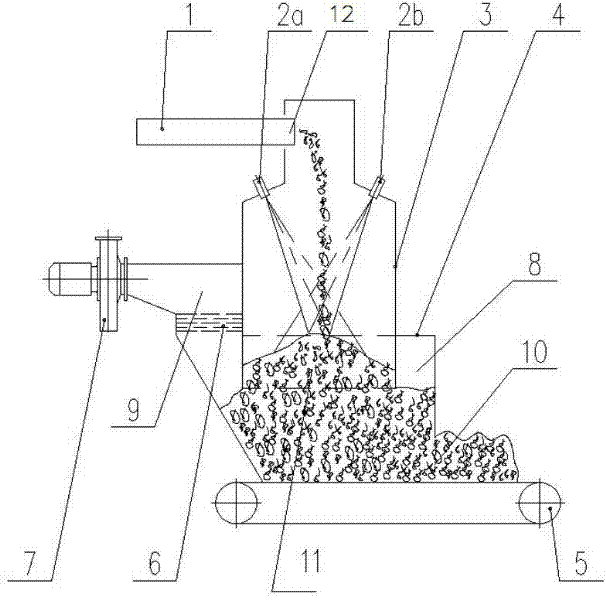

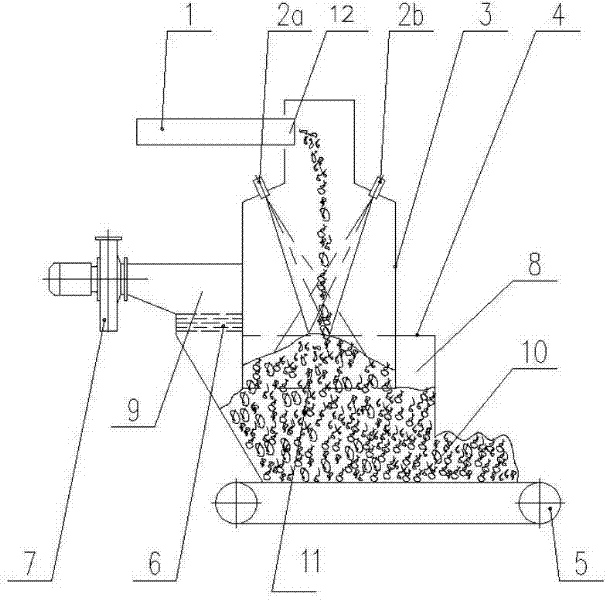

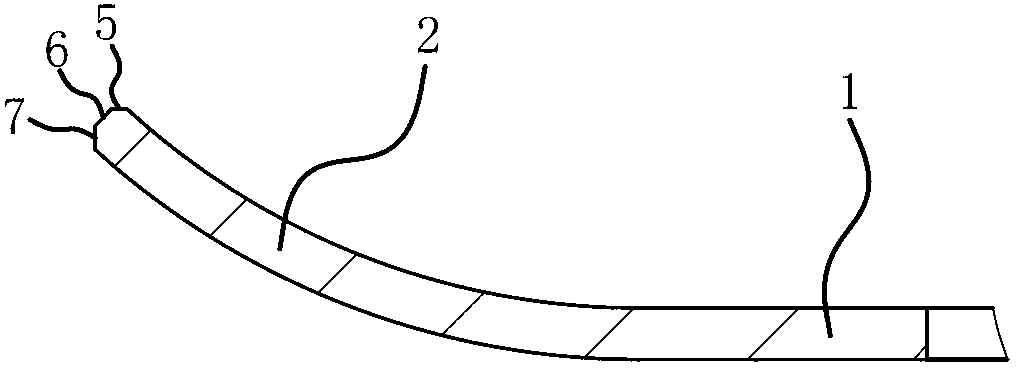

Material and flavor adding method and device capable of reducing liquid loss

The invention relates to a material and flavor adding method and a device capable of reducing liquid losses. Atomized liquid is sprayed to materials in a mixing chamber (3). Negative-pressure air is applied to suck atomized liquid particles which do not adhere to the materials and are suspended above a material layer to enable the atomized liquid particles to penetrate through the material layer, to be filtered and to be absorbed. The device comprises the mixing chamber (3) which is used for applying the liquid to the materials, a feeding device (1) which is arranged at the upper end of the mixing chamber (3) and leads to a feed inlet (12), and a discharge hopper (4) which is arranged below the mixing chamber (3). The lower end with a bottom outlet of the mixing chamber (3) partially stretches into the discharge hopper (4) to form a negative-pressure cavity (8). The negative-pressure cavity (8) is communicated with a negative-pressure device (7) through an air duct (9). A spray nozzle (2a) is arranged at the upper part of the mixing chamber (3) at a position above the feed inlet (12). A discharge outlet (10) is arranged at the bottom of the discharge hopper (4). By adopting the material and flavor adding method and the device capable of reducing liquid losses, the content of residual liquid in waste gas exhausted from the mixing chamber can be reduced to the utmost extent. The material and flavor adding method and the device capable of reducing liquid losses have the characteristics of low liquid losses, good added material evenness, high material adding accuracy and the like.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

Interval feeding device with eccentric lifting transferring structure

The invention provides an interval feeding device with an eccentric lifting transferring structure. The interval feeding device comprises a base, a left standing plate and a right standing plate are symmetrically arranged on the upper end face of the base, fixed bearing plates are fixedly arranged on the upper portions of the left standing plate and the right standing plate, a power device is arranged on the middle portion of the base, and eccentric rotating devices are arranged at the front and back portions of the left standing plate and the right standing plate; the power device is connected with one end of the eccentric rotating devices on the front and back portions of the left standing plate through belt wheel transmission devices and drives the eccentric rotating devices to rotate, and tensioning devices for adjusting the tensioning degree of the belt wheel transmission devices are arranged on the left standing plate; the eccentric rotating devices on the front portions of the left standing plate and the right standing plate are fixedly connected through a rotating shaft II, and the eccentric rotating devices on the back portions of the left standing plate and the right standing plate are fixedly connected through a rotating shaft II; and pushing bearing plates are rotationally supported to the ends of the same sides of the two rotating shafts II. By means of the interval feeding device, interval feeding motion of a cylinder bar material can be better achieved, the structure is simple, the defects that cylinder bar material production line operation and conveying operation are difficult, and the manpower is large are overcome, and the working efficiency is improved.

Owner:BAOJI YINKANG MACHINERY EQUIP

Three-dimensional (3D) glass machining method and cutting tool of numerical control machine

ActiveCN103342460AImprove yieldIncrease productivityGlass severing apparatusPlane surface grinding machinesNumerical controlEngineering

The invention provides a three-dimensional (3D) glass machining method and a cutting tool of a numerical control machine, and belongs to the technical field of machinery. According to the method and the tool, the problems of frangibility and low yield of glass in an existing 3D glass machining method are solved. The 3D glass machining method comprises the following steps of: pretreatment: knowing a margin between a 3D glass blank 8 and a 3D glass finished product; cutting: if the margin is greater than a set margin, performing rough cutting until the margin is smaller than the set margin, and performing fine cutting until the 3D glass finished product meets a product design requirement; if the margin is smaller than the set margin, directly performing fine cutting until the 3D glass finished product meets the product design requirement. The cutting tool of the numerical control machine comprises a cylindrical body, wherein an annular concave shoulder is arranged at one end of the body; the surface of the annular concave shoulder is a tool machining surface; a part matched with the target shape of a product is arranged on the surface of the annular concave shoulder; carborundum is coated on the surface of one end of the body. 3D glass processed by using the 3D glass machining method has the advantages of high yield and high production efficiency.

Owner:ZHEJIANG XINGXING TECH CO LTD

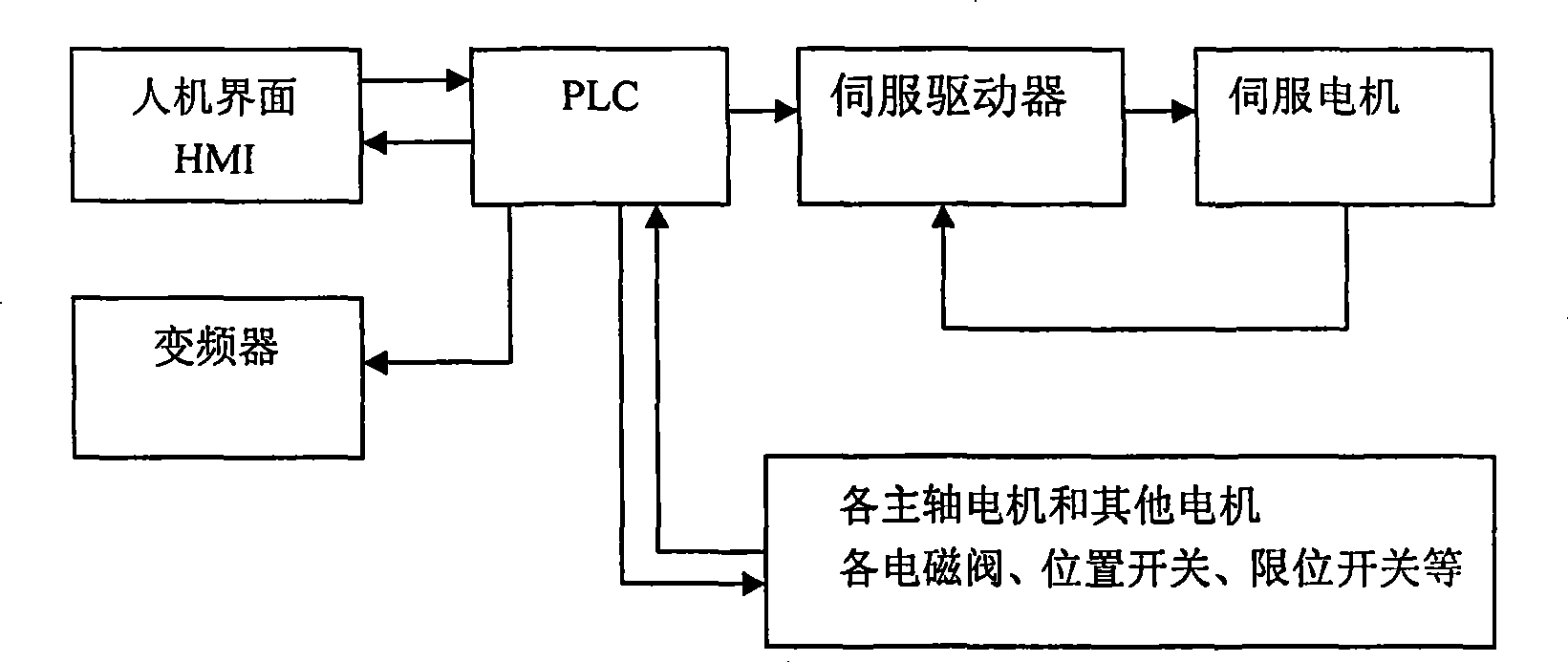

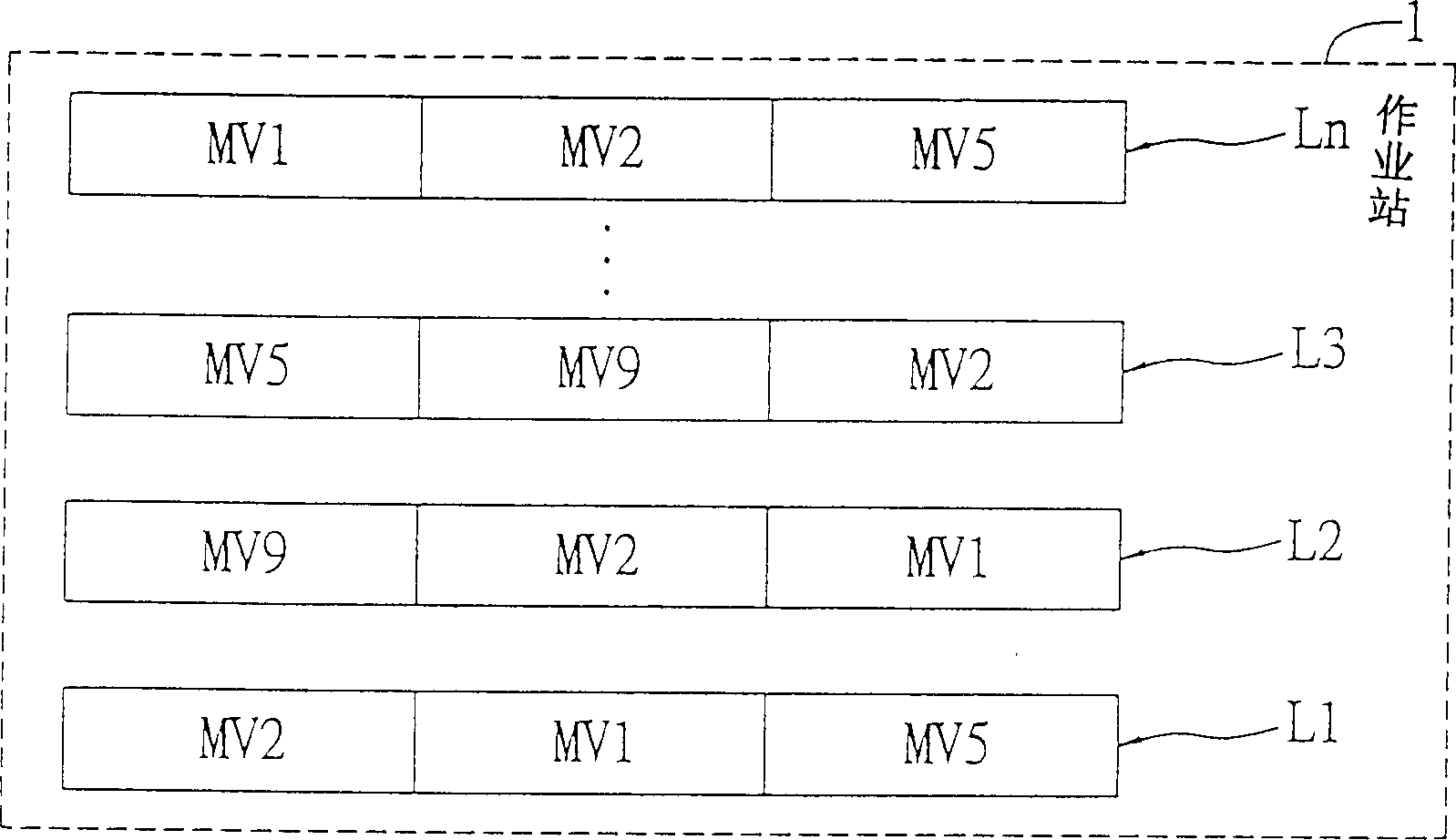

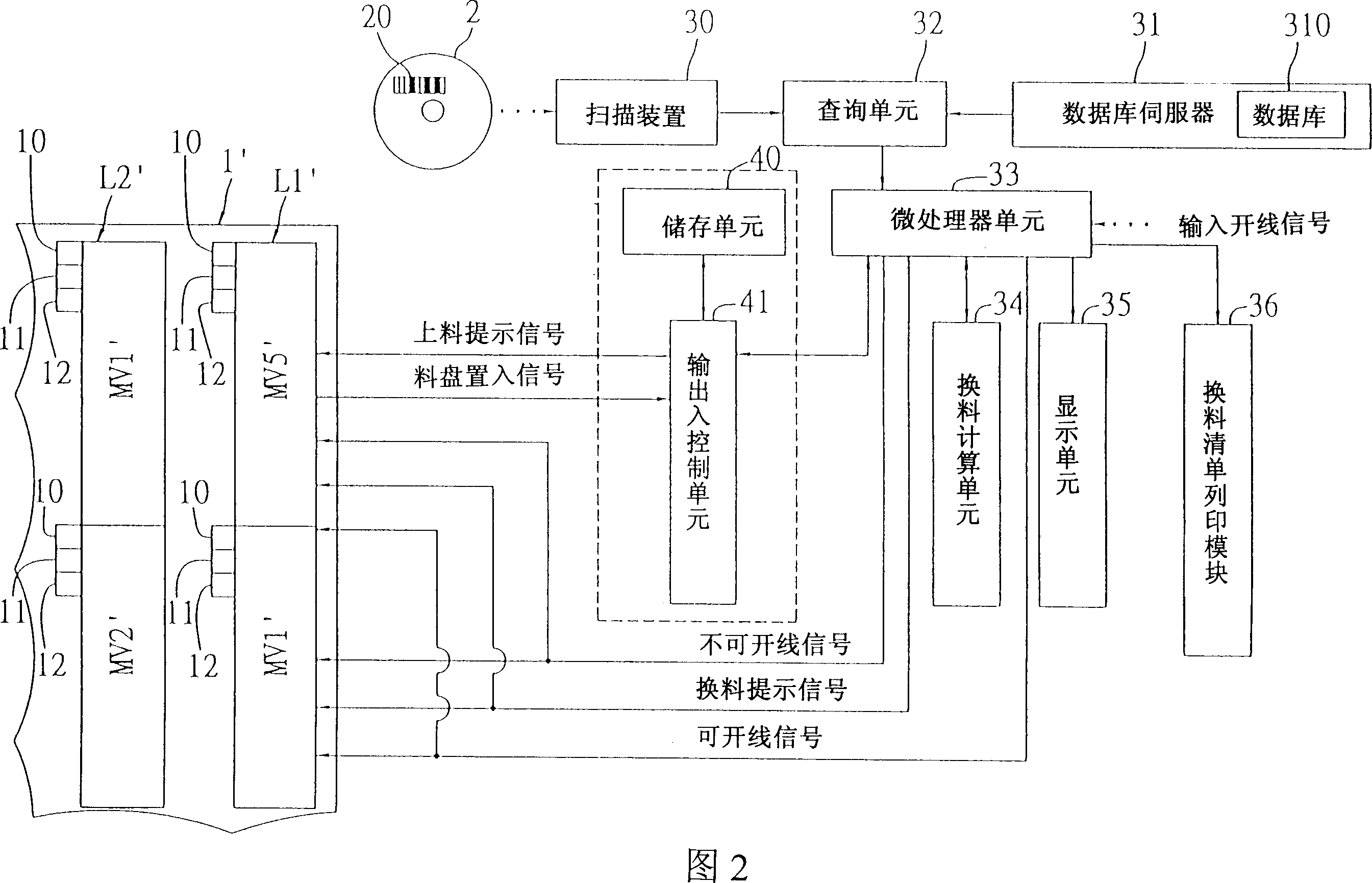

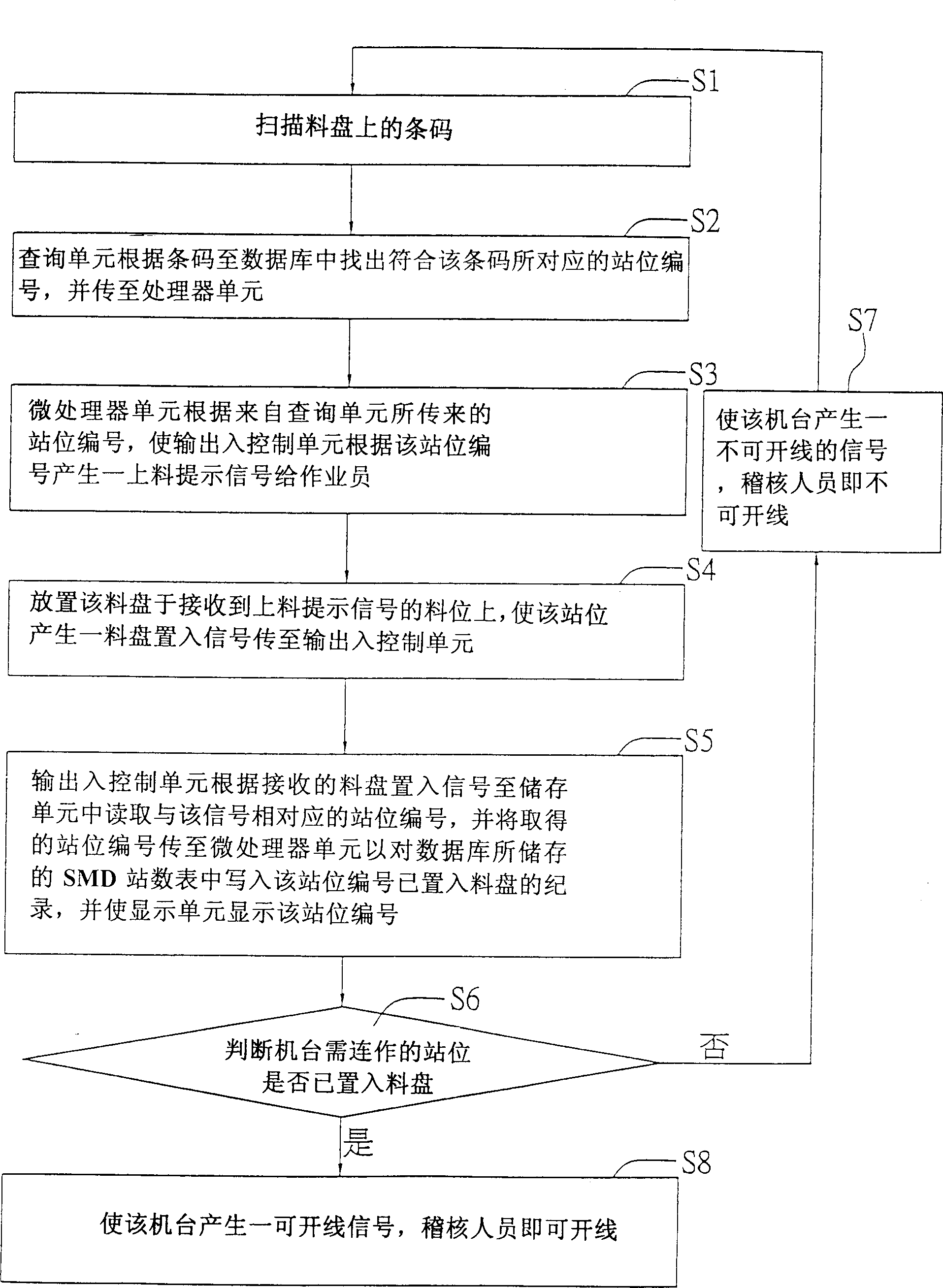

Feeding control system and its method

InactiveCN1400542AAvoid negligenceReduce downtime for refuelingSensing record carriersSpecial data processing applicationsBarcodeMaterial supply

Charging control system and its method applies to charging control in SMD work station, the corresponding bar code is pasted on the material plate in advance, the bar code has information of materialnumber, quantity of material supply and the numbers of bar code, and the bar code corresponds to SMD station number, it stores the bar code and SMD station number table into data bank, it sets up station number corresponding table with the material plate putting sign of charging control system in every station, it numbers the material plate putting sign corresponding to station, and it stores thestation number corresponding table into store unit. At first it scans the bar code of material plate; when the material plate is set in the station, it generates the putting sign.

Owner:INVENTEC CORP

Horizontal hole drill for cooling water passages of diesel engine cylinder liner-mounting holes

ActiveCN103008718AImprove processing qualityImprove drilling effectBoring/drilling componentsBoring/drilling machinesCooling effectEngineering

The invention discloses a horizontal hole drill for cooling water passages of diesel engine cylinder liner-mounting holes, which comprises a positioning plate, a drilling mechanism and a feed mechanism, and the positioning plate is embedded into a diesel engine cylinder liner-mounting hole through a positioning disk on the lower side of the positioning plate. The drilling mechanism comprises a motor, a motor base, a pair of engaged small cone gears, a big cone gear and a horizontal spindle, and the feed mechanism comprises an operating handwheel, an operating handwheel shaft, an engaged gear-rack pair, a gear base and a pair of linear rolling guide rails. By adopting the pair of engaged spiral bevel gears to change power direction, the horizontal hole drill can accurately drill horizontal holes in the radial narrow space of the diesel engine cylinder liner-mounting hole and improve the cooling effect of a housing. By adopting the linear rolling guide rails as the horizontal feed base of the feed mechanism, the horizontal hole drill can guarantee the linearity of a fed drill bit, and because the feed mechanism with the gear-rack pair can be smoothly operated, the feed precision is increased.

Owner:CSSC MARINE POWER

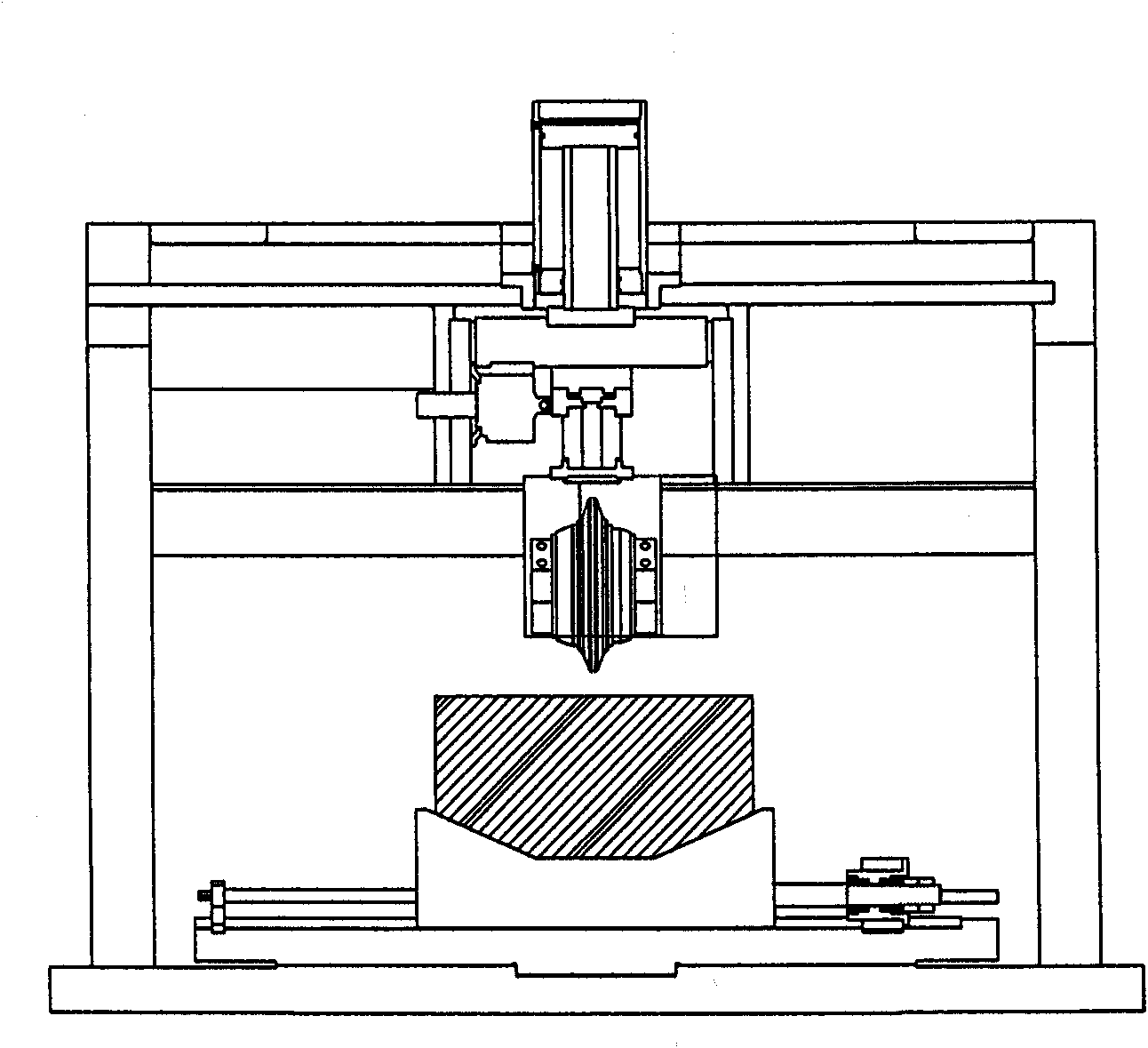

Double hobbing cutter rock hobbing comprehensive test bed

InactiveCN101782490AReasonable structural designSimple structural designInvestigating machinabilityHobbingControl system

The invention relates to a double hobbing cutter rock hobbing comprehensive test bed, which relates to rock tunnel boring machine hobbing cutter experimental equipment. The double hobbing cutter rock hobbing comprehensive test bed comprises a hydraulic system, a worktable, cutters, cutter holders, guide rails, a test system, a control system and the like. The worktable is pulled by a hydraulic system to move quickly and a test piece drives the hobbing cutters to hob rocks, the position of the test bed in the direction vertical to the motion direction of the worktable is adjusted by a screw, and the pressure plates at two ends of the worktable lock the test piece. The cutter holders are connected with cutter hydraulic push / pull rods through connecting discs; seven steel-embedding sliding blocks on four sides are matched with the steel-embedding guide rails on a test bed body to absorb the impact exerted by lateral loads on the hydraulic push rods; the hydraulic system drives the entire cutter holders to enter penetration regulation and keep a hobbing pressure. The test bed is reasonable, simple and safe in structural design and high in bearing capacity and impact strength.

Owner:SHENYANG JIANZHU UNIVERSITY

Digital linear reciprocal paper sheet feeding mechanism of automatic flat pressing cutter

InactiveCN1583405AReduce maintenance workloadExtended service lifePlaten pressesMechanical wearEngineering

A digitalized linear reciprocating paper-feeding mechanism of automatic paper cutter features that only one group of paper-driving tooth gange is used to do linear reciprocating movement for feeding paper, the teeth can be precisely opened and closed without contact under the action of permanent magnet and the control of digital instructions, and the action of front track is directly controlled by digital signal. Its mechanical parts can be saved by 80%.

Owner:徐景芳

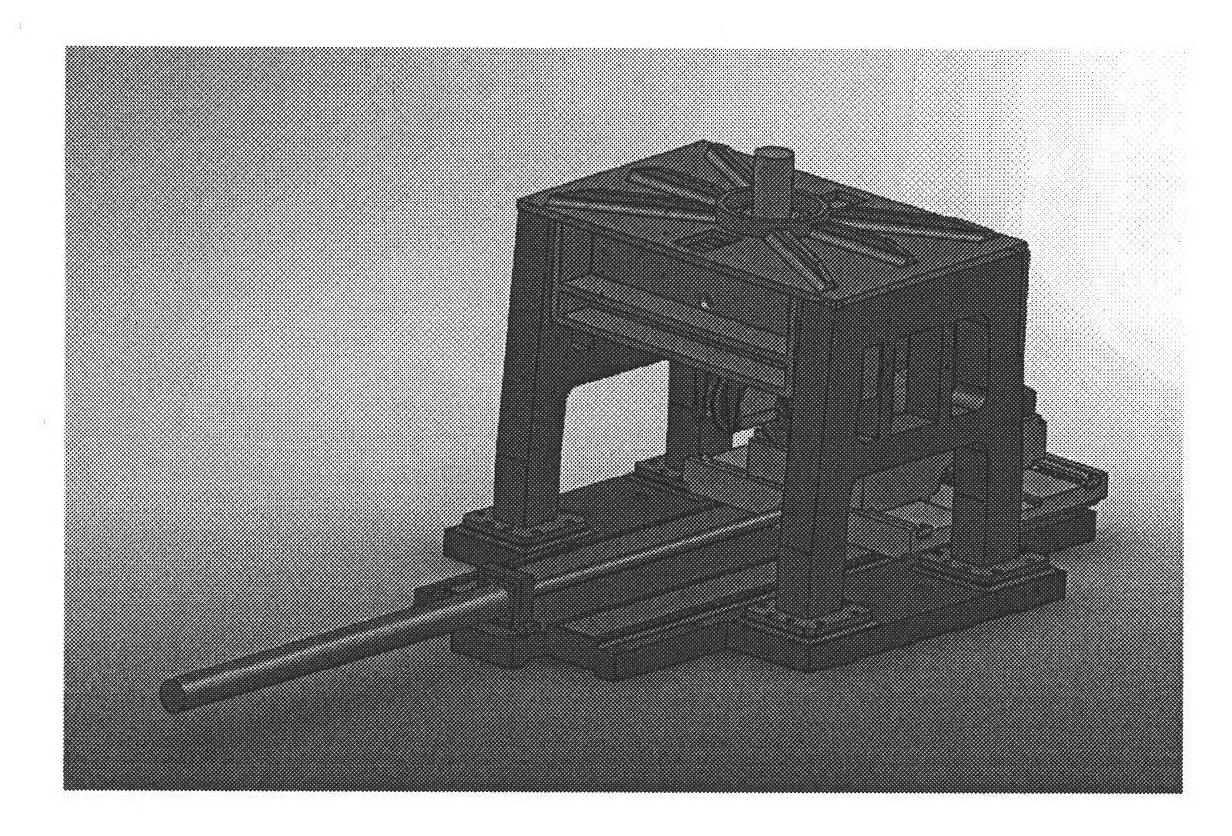

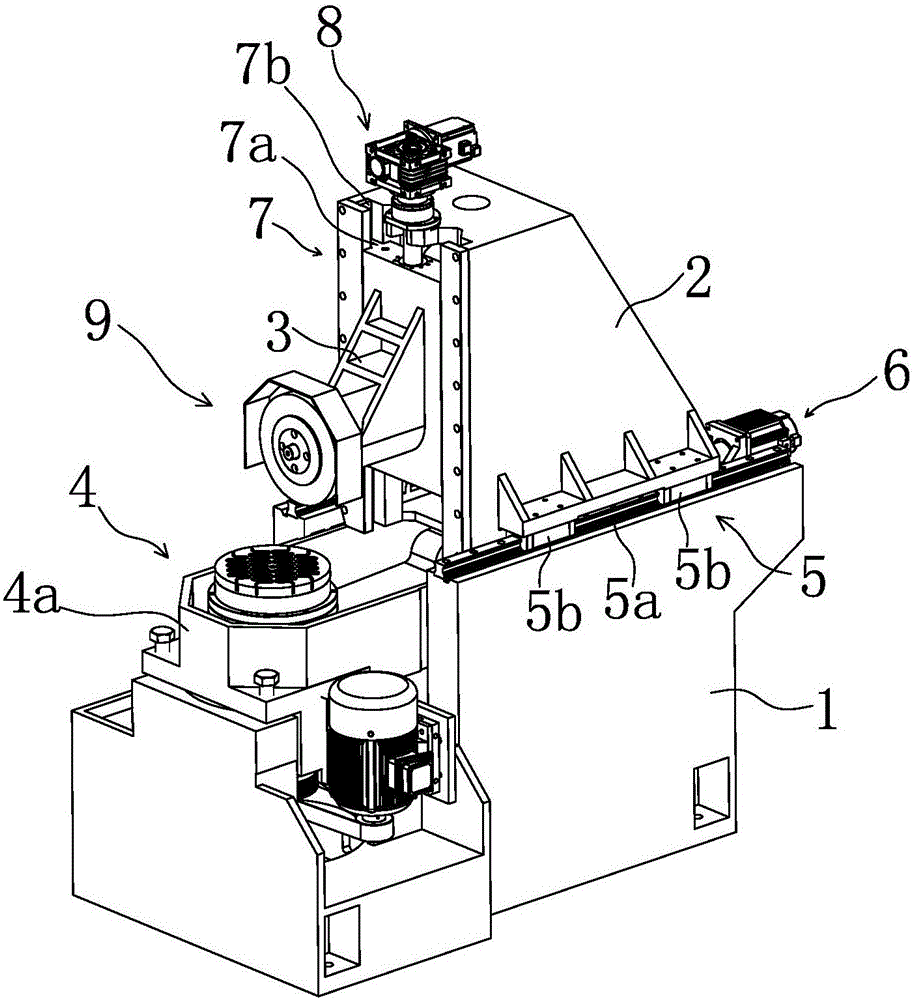

Grinding head movable type horizontal shaft circular truncated cone plane grinding machine

ActiveCN106425718AHigh feed accuracyCompact structureGrinding carriagesGrinding drivesMovable typeGrinding wheel

The invention belongs to the technical field of grinding machines, and particularly relates to a grinding head movable type horizontal shaft circular truncated cone plane grinding machine. The technical problem that the design is unreasonable and other technical problems in the prior art are solved. The grinding head movable type horizontal shaft circular truncated cone plane grinding machine comprises a fixed frame, a rotatable working platform which can fix a workpiece and enable the workpiece to rotate in the circumferential direction is arranged on one side of the fixed frame, a horizontally-moving frame is arranged on the other side of the fixed frame, a horizontally-moving drive mechanism which can drive the horizontally-moving frame to horizontally move back and forth is arranged on the fixed frame, a lifting frame is arranged on the horizontally-moving frame, a lifting drive mechanism which can drive the lifting frame to ascend and descend is arranged on the horizontally-moving frame, and a grinding assembly which can grind the workpiece is arranged on the lifting frame. The grinding head movable type horizontal shaft circular truncated cone plane grinding machine has the beneficial effects that the structure is compact, the size is reduced, and operation is more convenient; a high-speed rotating plane is adopted, and the machining precision is higher; and a cast hard rail is adopted and can absorb shaking produced during running of equipment, and the grinding wheel feeding precision is improved.

Owner:德清勤龙磨床制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com