Patents

Literature

74results about How to "No crossover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

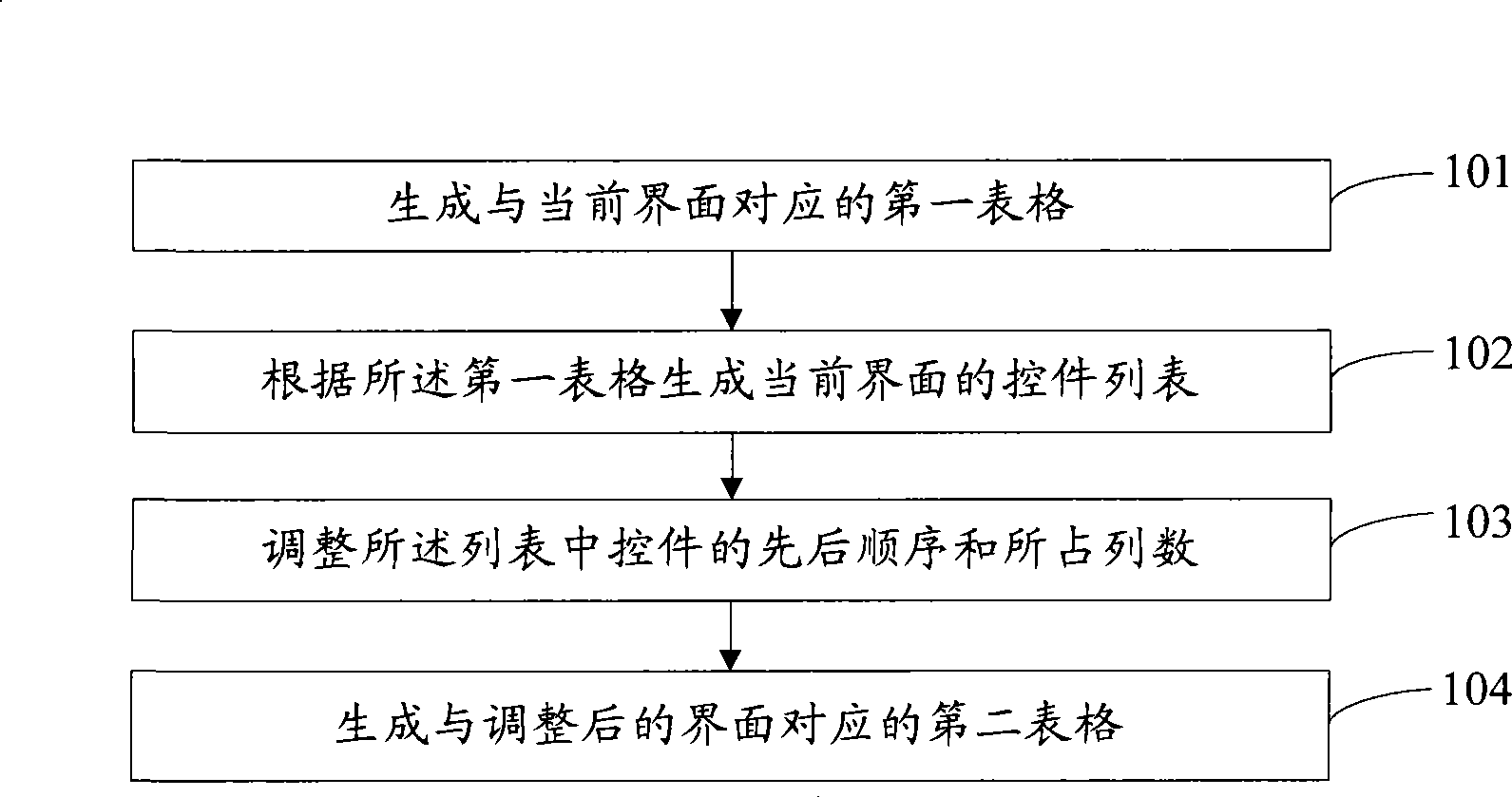

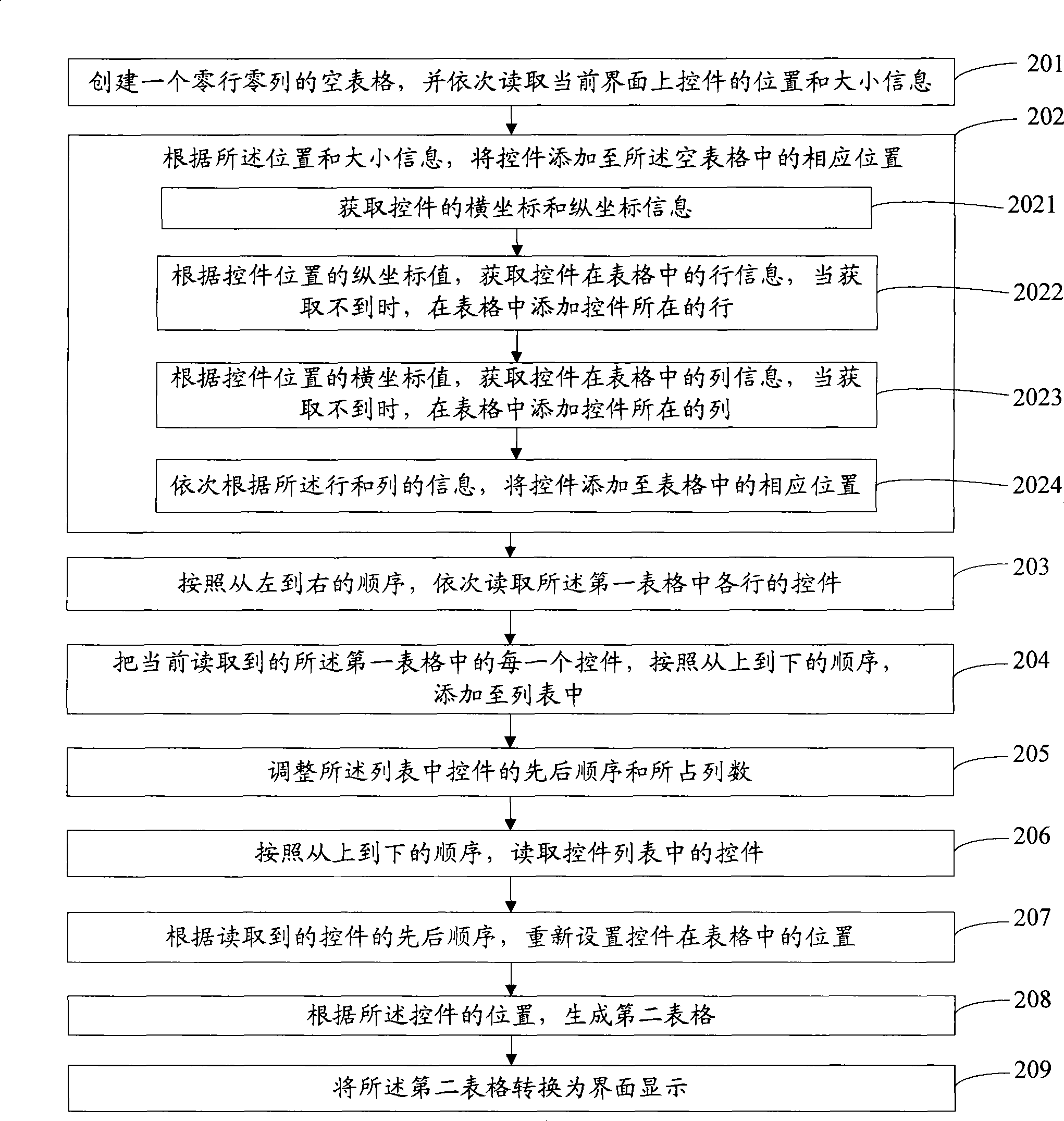

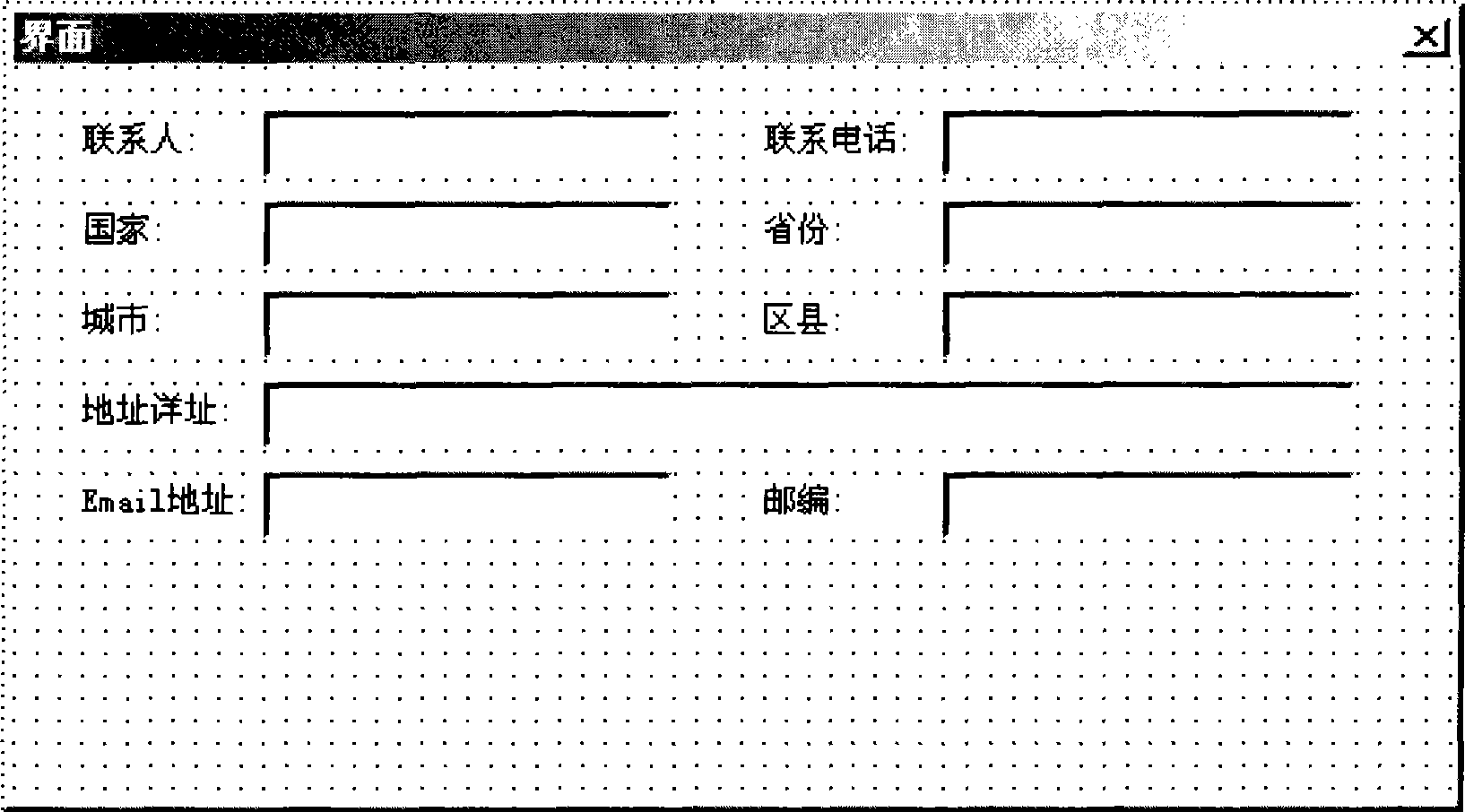

Method and apparatus for regulating interface layout

InactiveCN101382887ANo overlapNo crossoverSpecific program execution arrangementsSoftware engineeringForm generation

The invention provides a method for regulating interface layout, and a device thereof; the method comprises the steps that: a first table corresponding to a current interface is generated; a control element list of the current interface is generated according to the first table; then, the order and the occupied column number of control elements in the control element list is regulated; and a second table corresponding to the regulated control element list is generated. By the adoption of the method, the current interface can be converted to the control element list which shows the control elements according to the order that the control elements are read from the left to the right line by line. Therefore, by regulating the order of the control elements in the control element list and the occupied column number, a user can regulate the layout of the current interface, as each column of the control element list is corresponding to each grid of the second table, the control elements are not overlapped or transected. Moreover, the order of the control elements can be regulated according to the demands of users or the importance levels of the control elements, thus being more capable of meeting different demands of users in practice.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

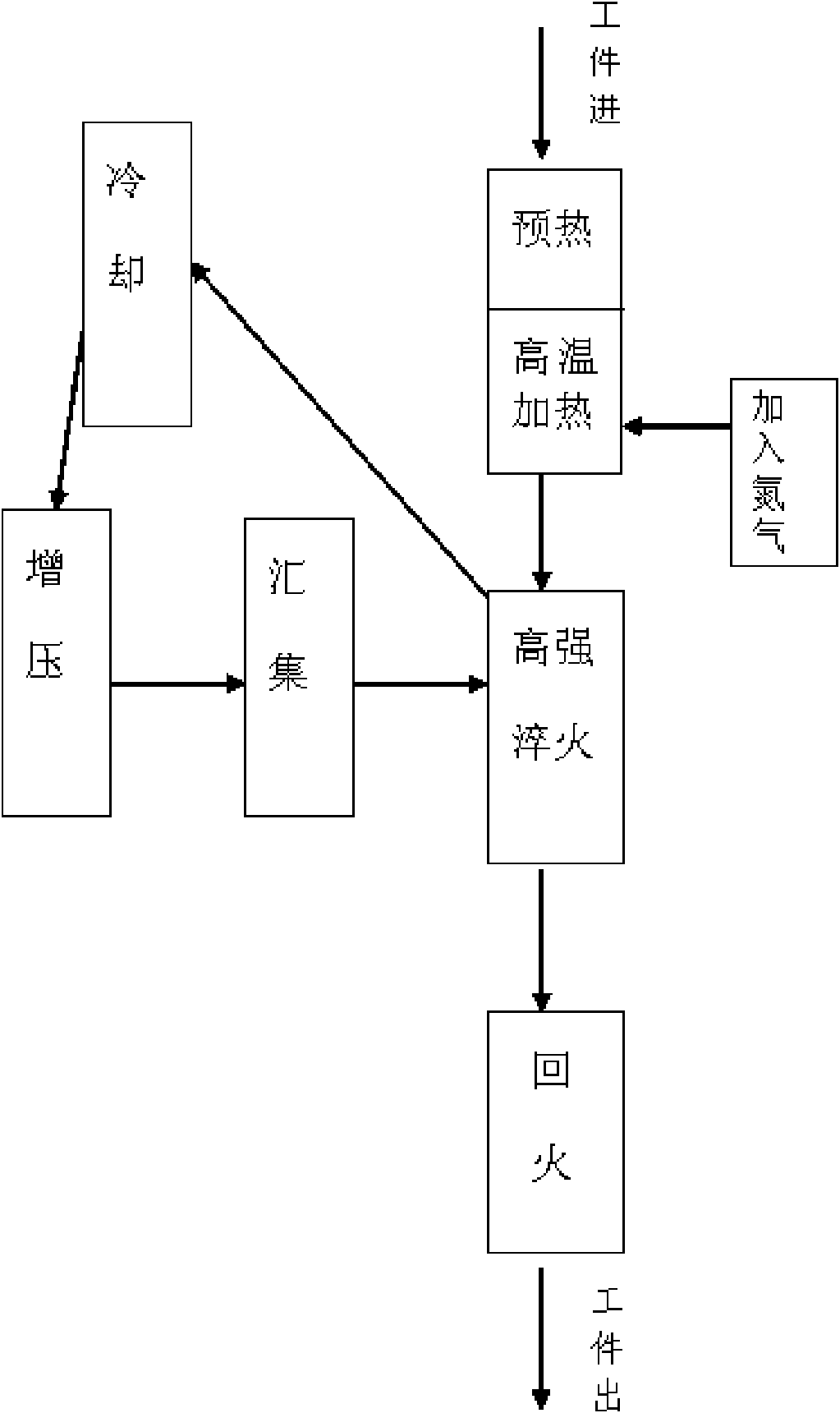

Heating processing technology for wear-resistant cutting board

ActiveCN101570819AHigh strengthIncrease productivityFurnace typesQuenching agentsQuenchingWear resistant

The invention relates to a heating processing technology of a wear-resistant cutting board, in which a shaped wear-resistant cutting board workpiece is preheated, heated under high temperature, and then is subjected to high-strength quenching and tempering. The technology comprises the following steps: A. preheating: the preheating temperature is 450-550 DEG C, and the preheating time is 0.5-1.125min / mm; B. high temperature heating: the temperature is 870-890 DEG C, and the holding time is 0.5-1.125min / mm; C. high-strength quenching: whole spray water time of high-strength quenching is 70-700 seconds, and time in intensified spray is 15-20 seconds; D. tempering: low temperature tempering is carried out, followed by air cooling to room temperature; high pressure cooling water used in the invention is recyclable. The invention has the advantages of making full use of reasonable heating processing technology under the premise of ensuring fine property of the wear-resistant cutting board, improving production efficiency and saving energy consumption, thus lowering production cost of the wear-resistant cutting board.

Owner:LIUZHOU JINMAO MACHINERY

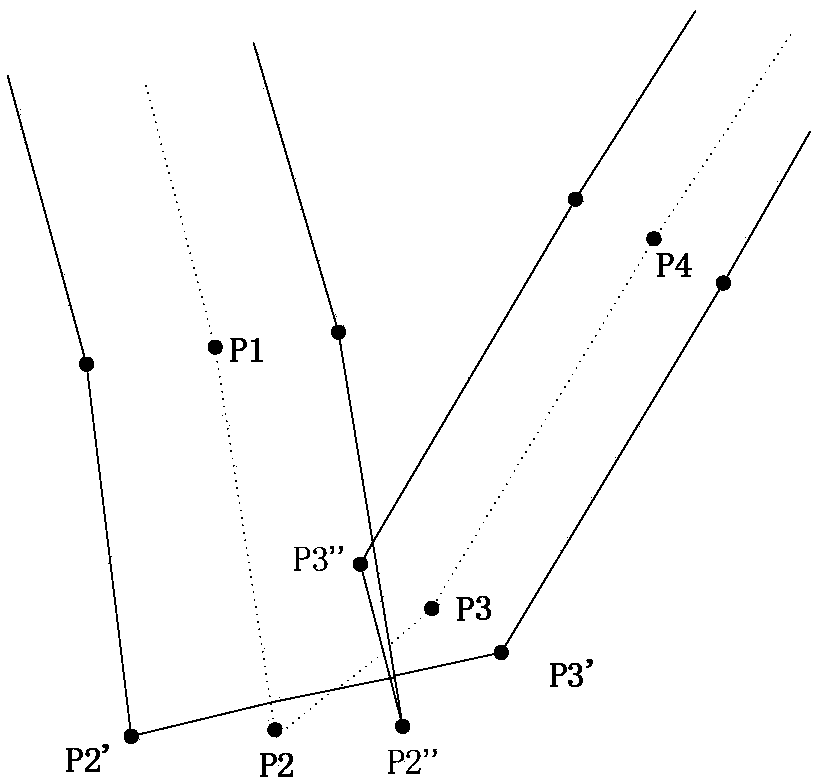

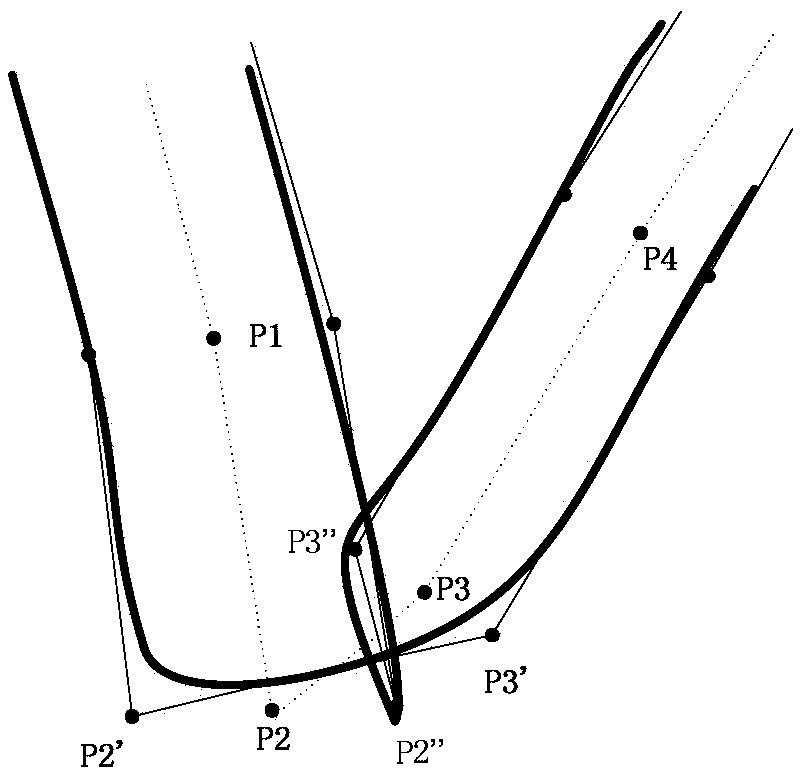

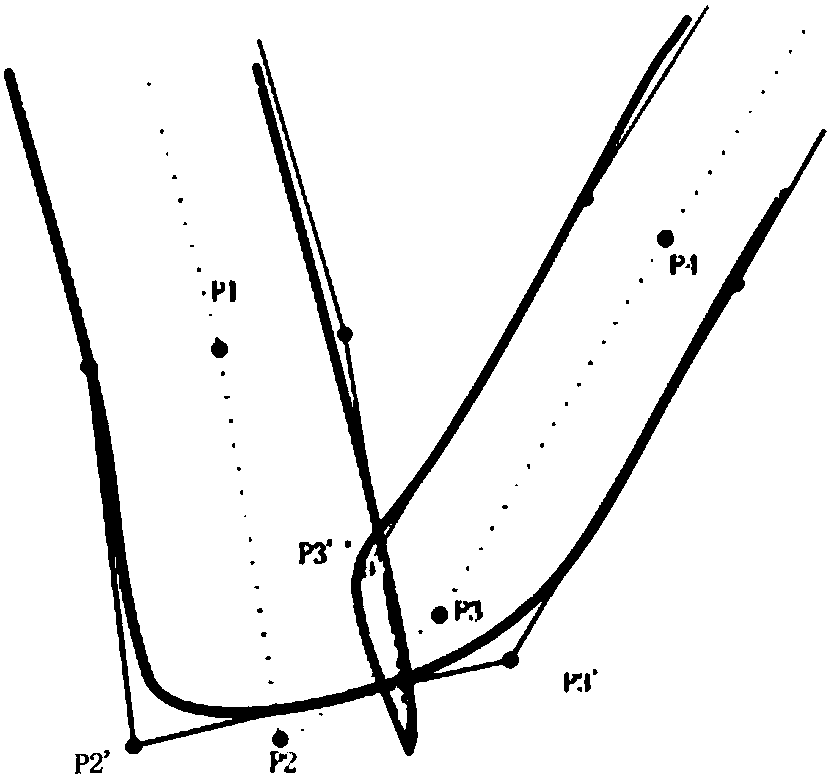

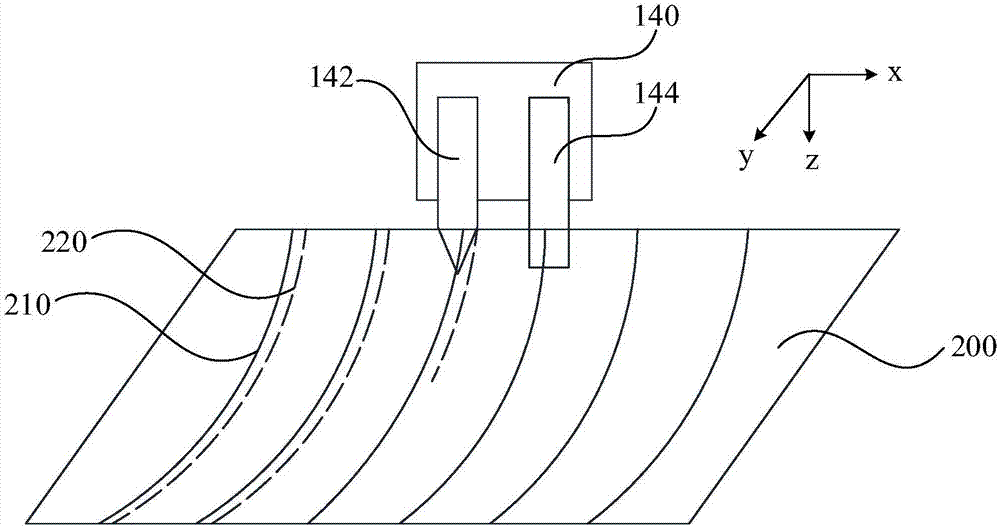

Touch control inflection point correction method and device and touch screen

ActiveCN108228057AAvoid crossover situationsNo crossoverInput/output processes for data processingCorrection methodComputer science

The invention provides a touch control inflection point correction method and device and a touch screen. The touch control inflection point correction method and device and the touch screen have the advantages that a target touch control point, located at an inflection point, in various touch control points is determined, a correction point is determined according to the position coordinates of the target touch control point, a previous touch control point and a following touch control point, the position coordinates of inner contour points corresponding to the target touch control point are corrected to the inner side of a touch control inflection point according to the position coordinates of the correction point, and outer contour points corresponding to the target touch control point are further corrected; due to the fact that the inner contour points are located on the inner side of the inflection point and the out contour points are located on the outer side of the inflection point, intersection of the inner contour points and the outer contour points can be avoided during inner contour point connection and outer contour point connection, inner contour point intersection or outer contour point intersection can be avoided at the same time, and accordingly a small angle phenomenon, which does not conform to a touch control trajectory, at the inflection point is avoided, andreal touch control writing is achieved.

Owner:HISENSE VISUAL TECH CO LTD

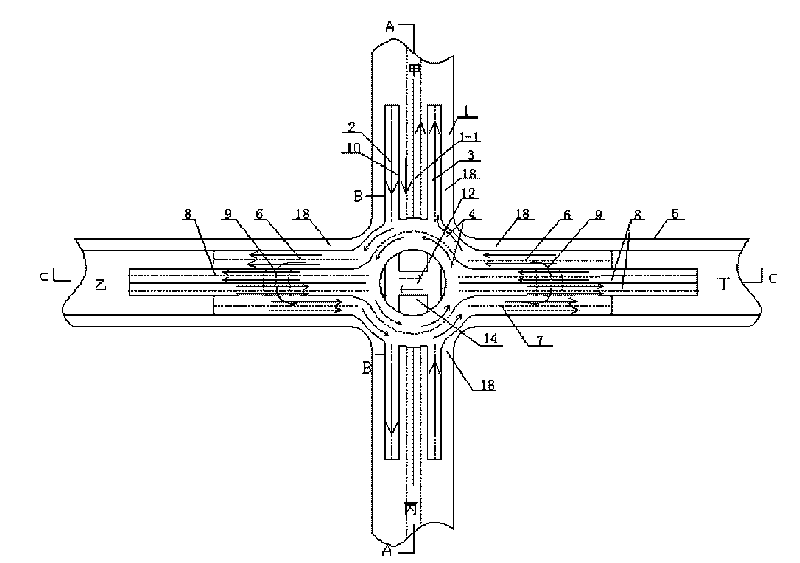

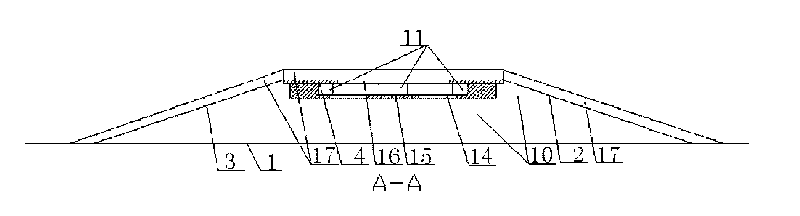

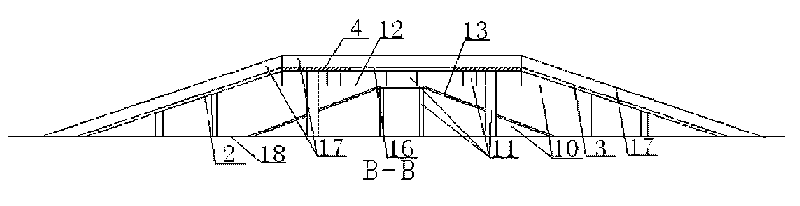

Unblocked cloverleaf intersection at traffic crossroad

The invention relates to an unblocked cloverleaf intersection at a traffic crossroad. Two layers or more than two layers of roadways are built at the crossroad, wherein the first layer of pavements are distributed on the most bottom surface of the crossroads in a cross manner; the middle of a road in a straight direction is provided with a pavement A at the first layer for vehicles to go straight; are pavements A1 and A2 at the second layer are arranged at the left side and the right side of the pavement A at the first layer; the center of the crossroads is provided with a ring-shaped viaduct; a pavement B at the first layer is arranged at the most bottom layer in the vertical direction of the pavement A at first layer; the middle of the pavement B at the first layer is provided with a pavement at the third layer; pavements B1 and B2 at the second layer are arranged at the left side and the right side of the pavement at the third layer; and a curved rod communicating the pavements B1 and B2 at the second layer is arranged between the pavements B1 and B2 at the second layer. The invention enables the vehicles to run on own roads, so the condition of cross running can not happen, thereby increasing the traffic flow of the current roads and reducing and even avoiding fuel air pollution created by the vehicles due to waiting for pass.

Owner:郑勤民

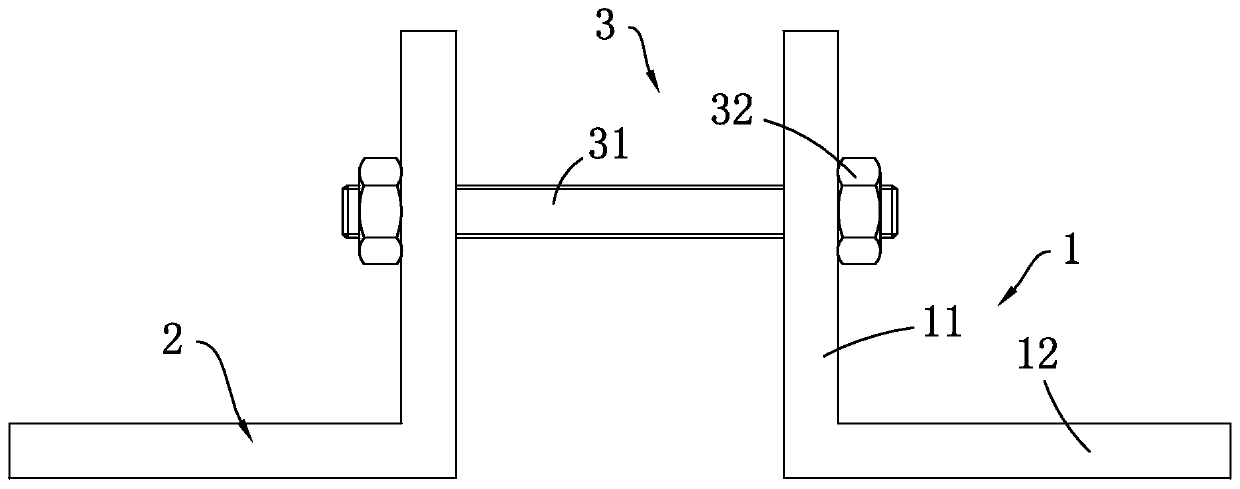

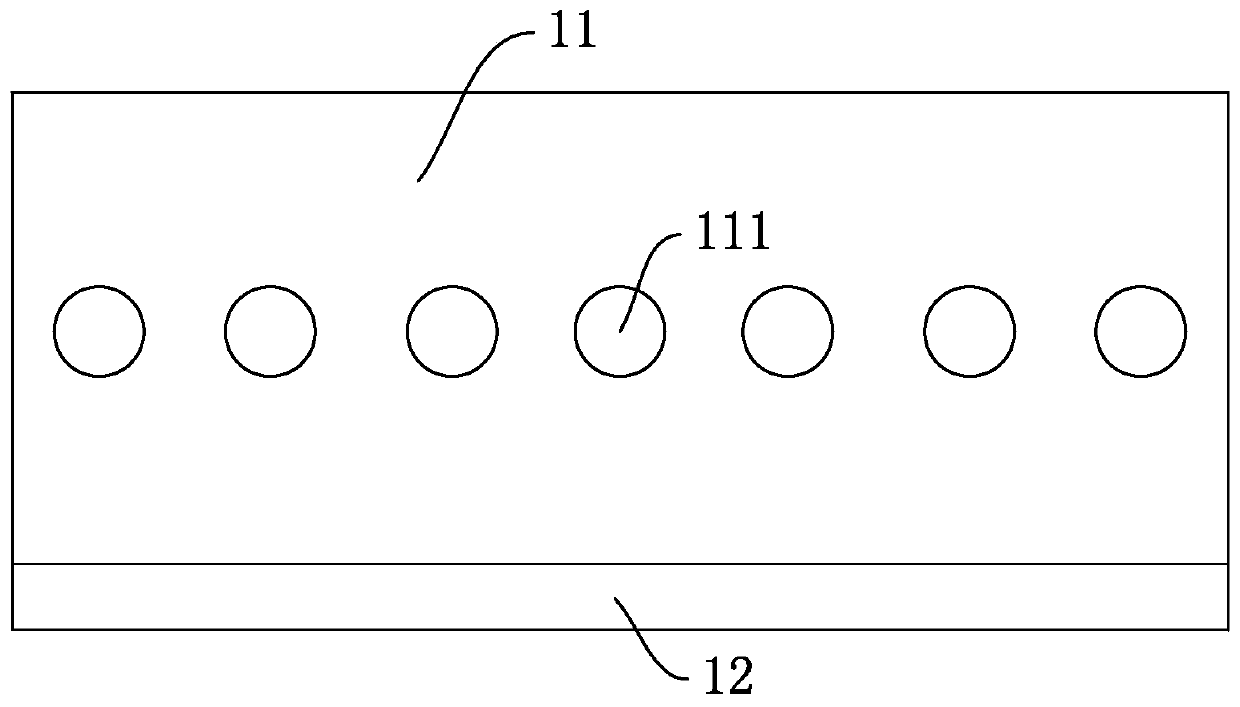

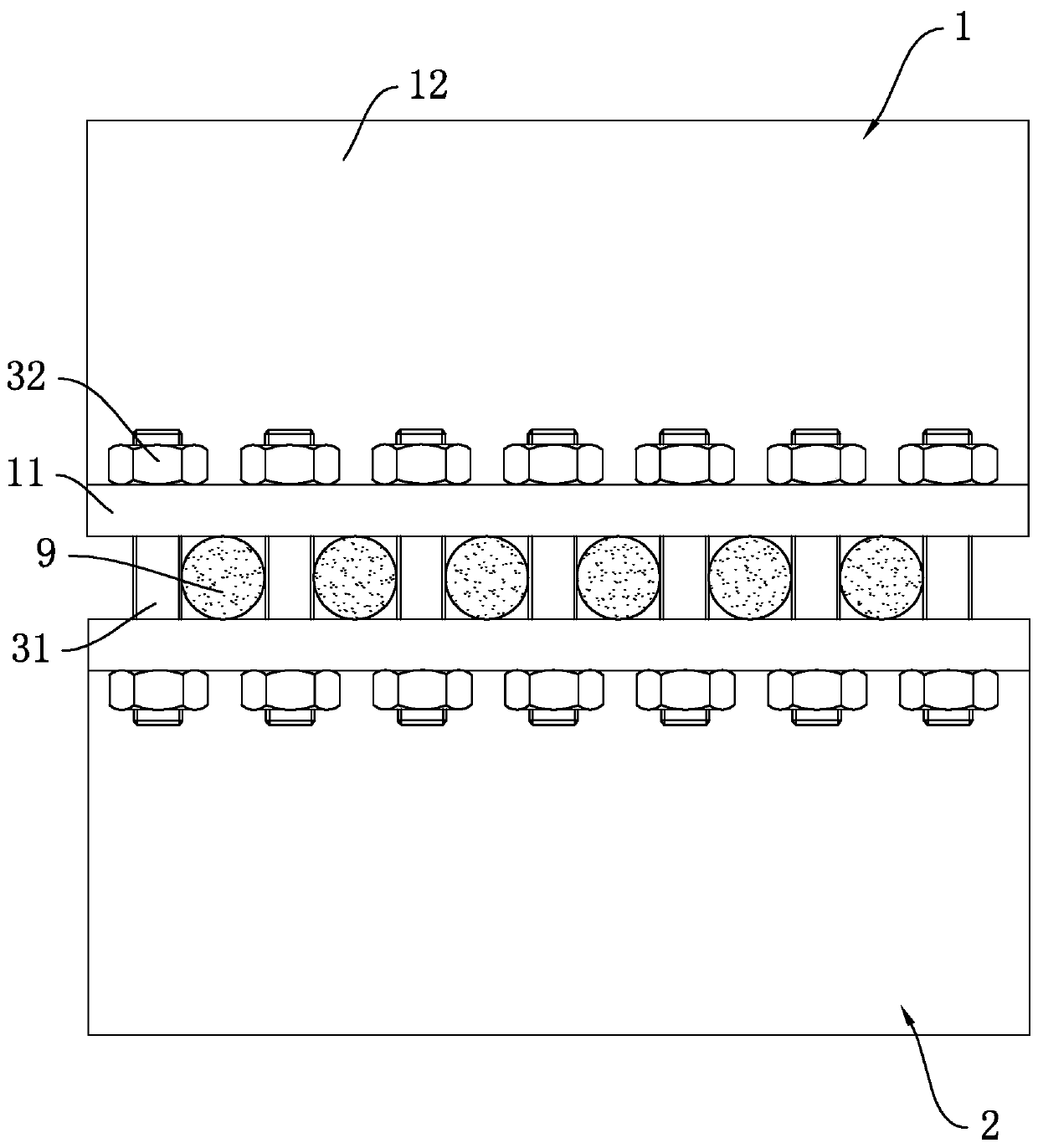

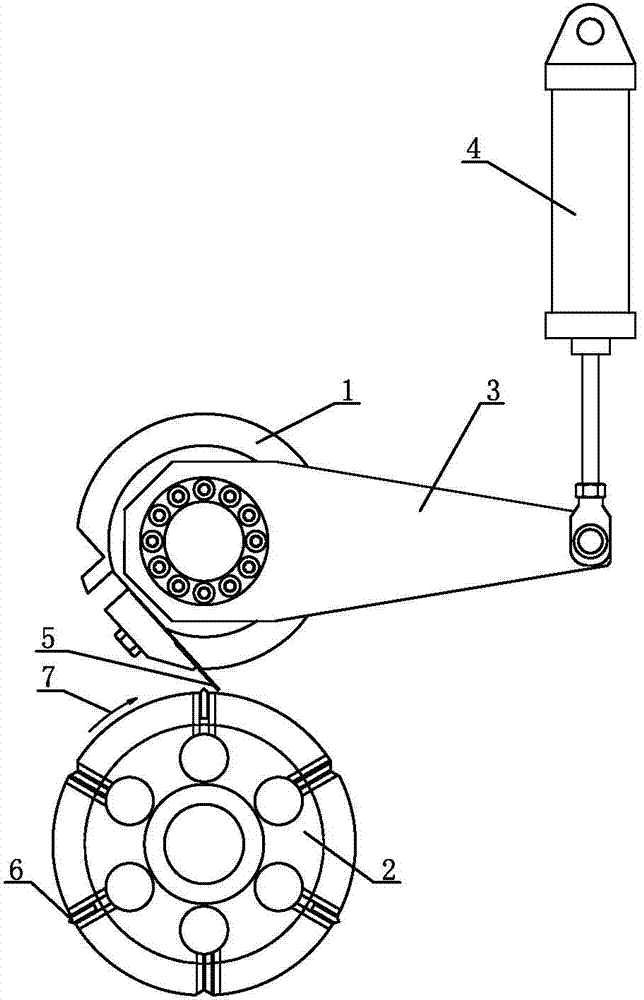

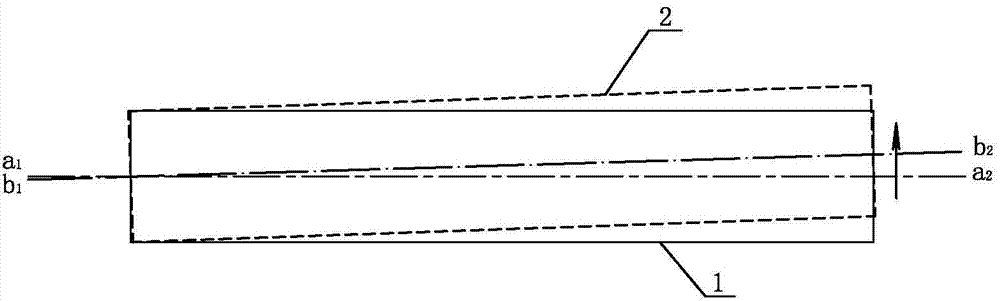

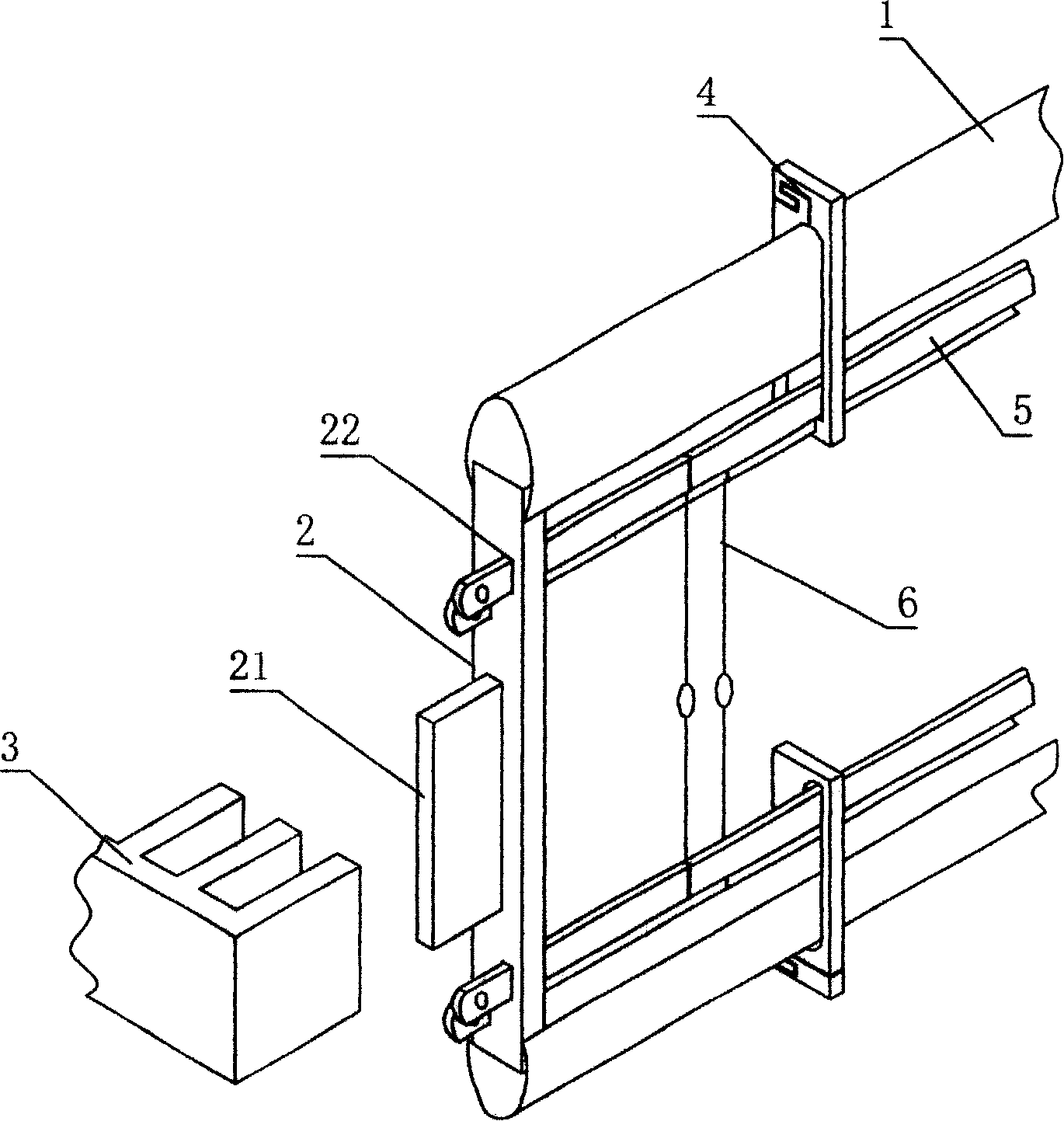

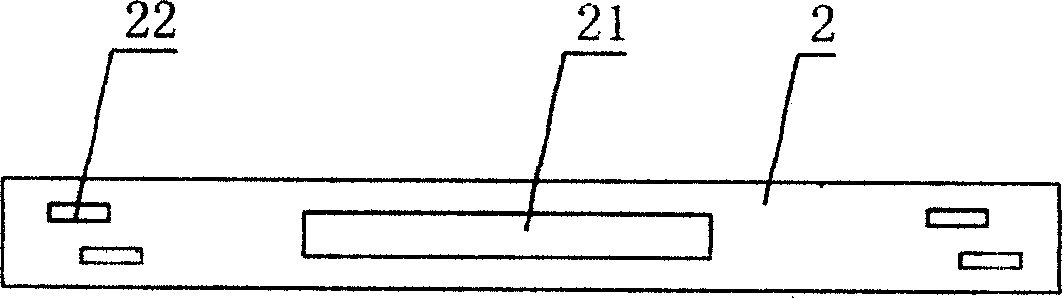

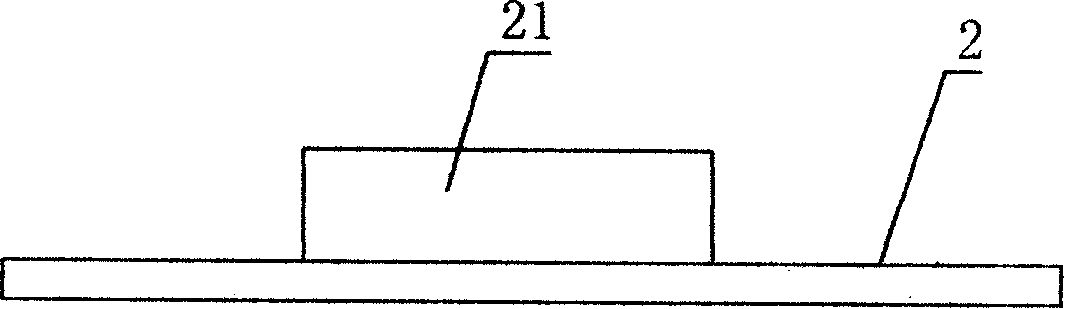

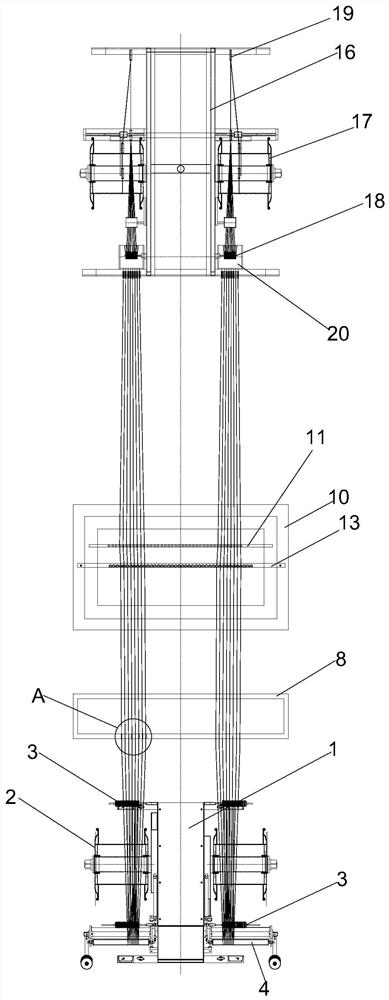

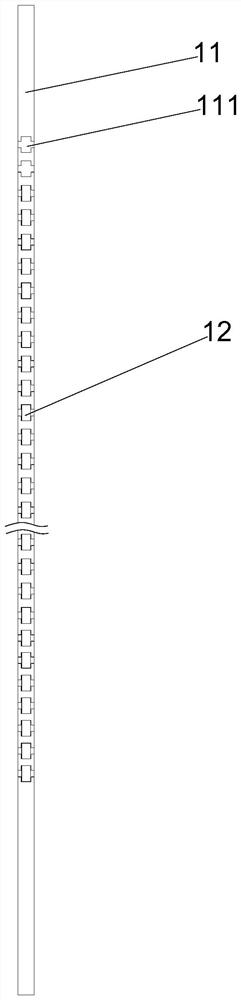

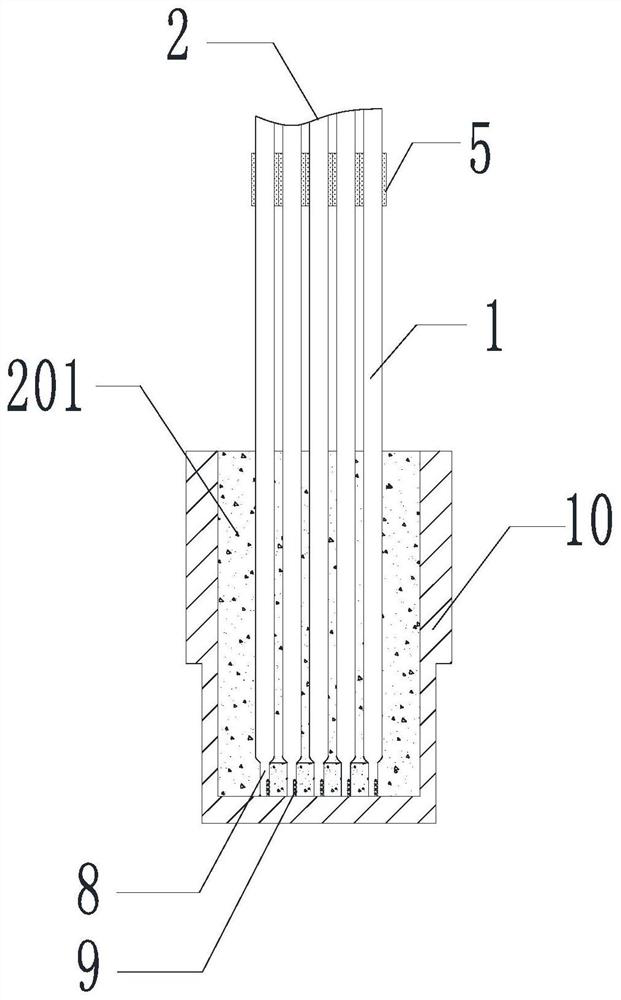

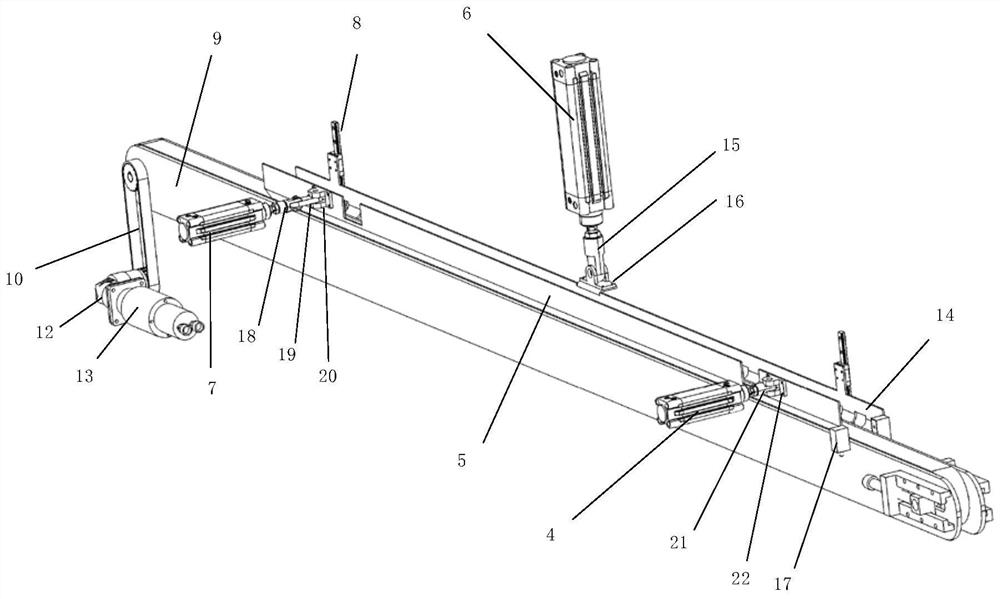

Elevator traction rope clamping device and rope cutting method applying same

The invention relates to an elevator traction rope clamping device and a rope cutting method applying the rope clamping device, and relates to the technical field of elevator detection and maintenance. According to the technical scheme, the rope clamping device comprises a first clamping plate, a second clamping plate and a plurality of connecting assemblies, wherein the first clamping plate and the second clamping plate are arranged oppositely, the connecting assemblies are used for connecting the first clamping plate and the second clamping plate, a plurality of mounting intervals corresponding to the traction steel wire ropes in one-to-one correspondence and used for allowing the traction steel wire ropes to pass through are formed between the first clamping plate and the second clamping plate through the connecting assemblies, and the plurality of traction steel wire ropes are clamped between the first clamping plate and the second clamping plate through the connecting assemblies.According to the rope clamping device and the rope cutting method applying the rope clamping device, the plurality of traction steel wire ropes are fixed, so that the traction steel wire ropes can beprevented from being crossed and scattered during rope cutting and mounting, and the maintenance work efficiency of rope cutting is improved.

Owner:北京汇沣联合电梯科技有限公司

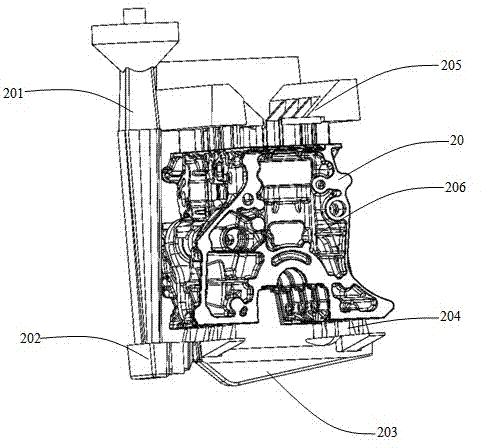

Production technology for manufacturing automobile cylinder by aid of crankcase core module

The invention discloses production technology for manufacturing an automobile cylinder by the aid of a crankcase core module. Molten iron is filled from bottom to top, and air in a cavity is 'squeezed' out of the cavity by the molten iron from bottom to top and exhausted from a strain relief. As a molten iron filling direction is consistent with an air exhausting direction, intersection is avoided, less secondary slag is generated, and forming quality can be improved. Moreover, as intersection is avoided, the molten iron can be completely filled in the whole cavity, dead space is avoided, andstable wall thickness can be kept.

Owner:华东泰克西汽车铸造有限公司

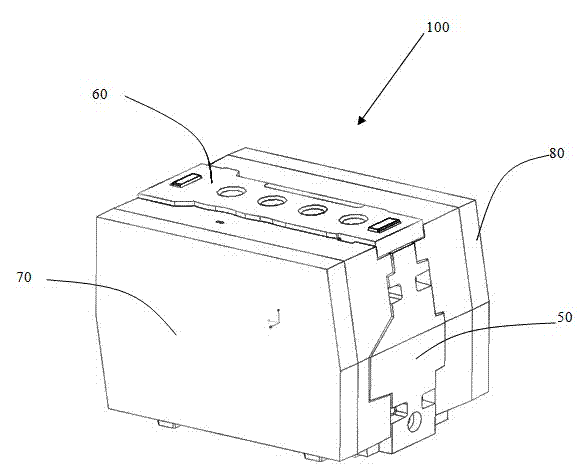

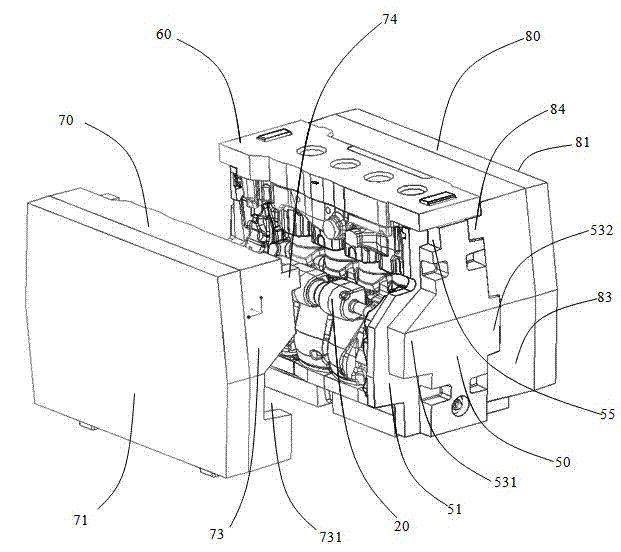

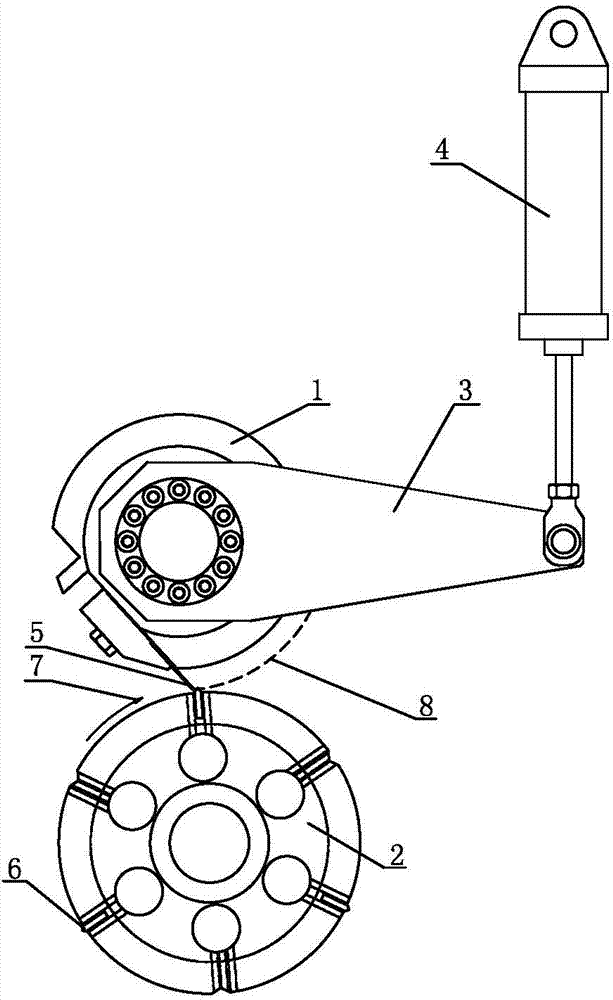

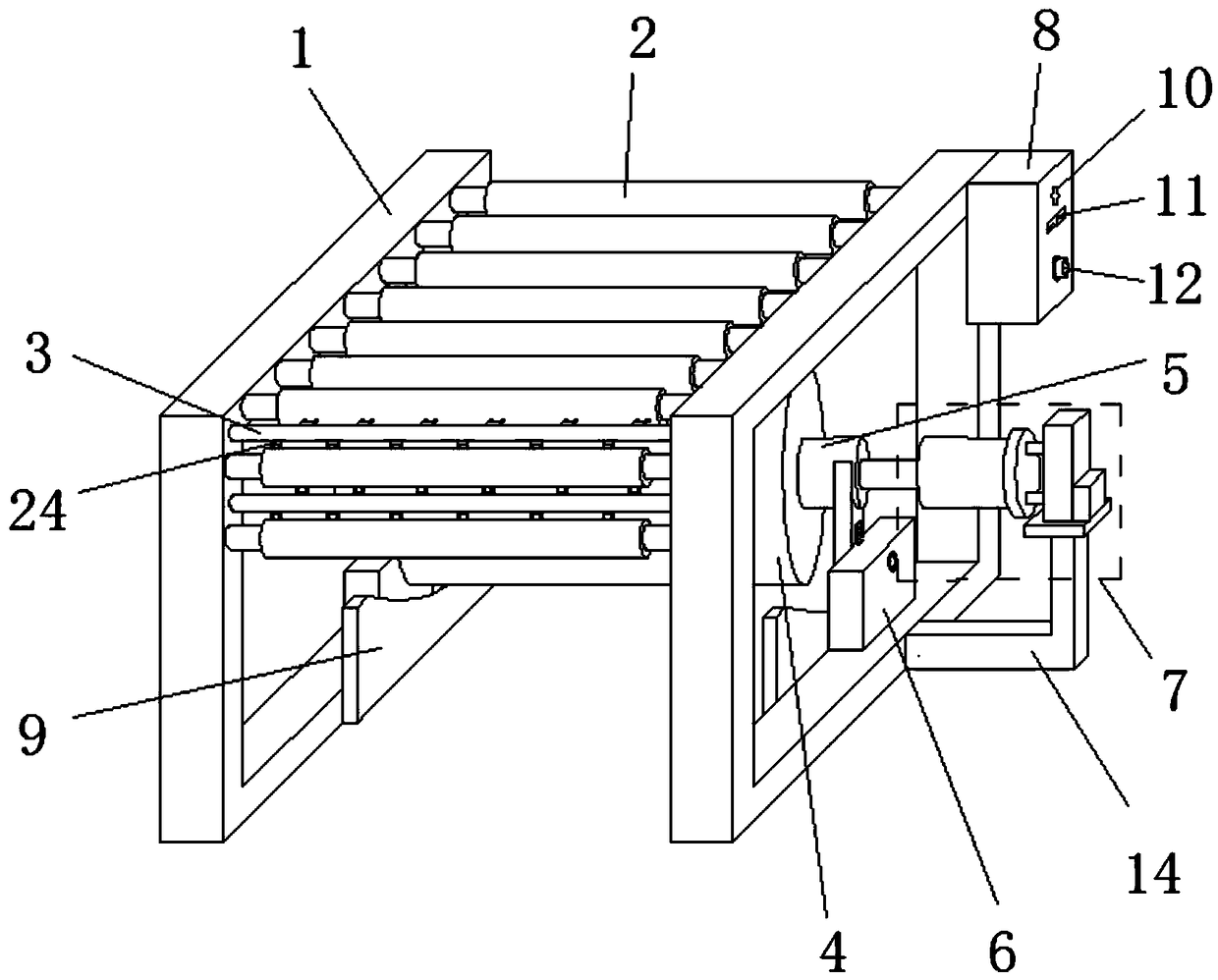

Paper cutting device

The invention discloses a paper cutting device. The paper cutting device comprises a frame, a cutting upper knife roller, a vacuum folding roller, a swinging arm and a driving device, wherein the vacuum folding roller is supported by the frame; projections of central axis of the cutting upper knife roller and the vacuum folding roller on the horizontal plane have an intersecting point; the driving device is mounted on the frame; one end of the swinging arm is connected with the end part of the cutting upper knife roller, and the other end is mounted on the frame; and one end, connected with the cutting upper knife roller, of the swinging arm is in fit connection with the driving device. The process of avoiding a cutting upper knife is to vertically move the cutting upper knife roller, so that the paper cutting device can prevent the interference with the vacuum folding roller, and the cutting upper knife and a cutting lower knife can cut by a larger cutting included angle so as to realize reliable cutting of large-breadth papers. Therefore, the device cutting device is suitable for cutting papers with various breadths; and the adjustment of the cutting knives is not limited by the swinging of the cutting upper knife roller, so that the operation difficulty is reduced, and the production efficiency is improved.

Owner:郭超毅

Fly-shuttle loom harness frame position limiter

InactiveCN101173414AGood for up and down movementReduce distanceAuxillary apparatusHealdsYarnFlying shuttle

The invention discloses a heald frame limit device for shuttle loom, comprising a plurality of heald frames, which is characterized in that: two heald transverse heads are respectively arranged at two ends of a heald frame; an upper row and a lower row of location perforations are arranged on the heald transverse heads of the heald frame for a heald bar to pass through; a plurality of heald yarns pass through the heald bar; the heald bar is fixed on the heald frame via a heald clip; a slider is arranged on each heald transverse head of the heald frame; a limited block is arranged at each end of the heald frame, and a lifting track corresponding to the slider and capability of controlling the sliding of the slider is arranged on the limited block. The invention has the advantages that the shaking of the heald frames in the weaving process is effectively solved and the distance between heald frames is greatly reduced, so that friction between warp and heald yarn or other loom elements in the weaving process is avoided and the end breaking is reduced.

Owner:丁宏利

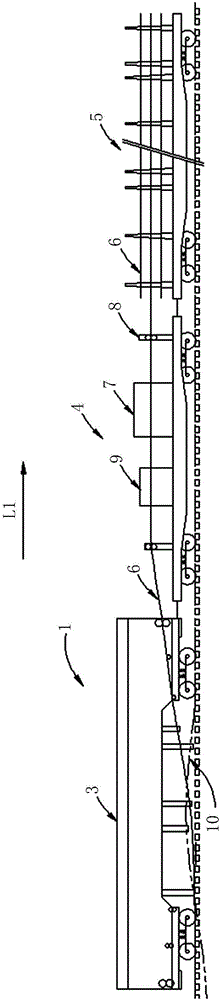

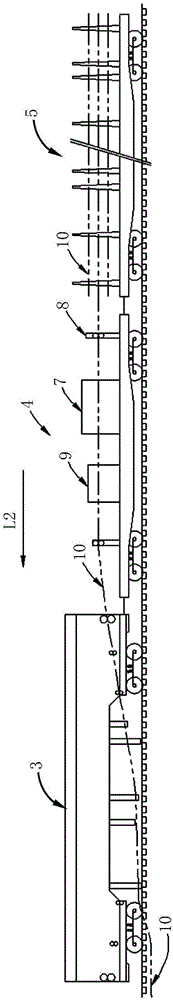

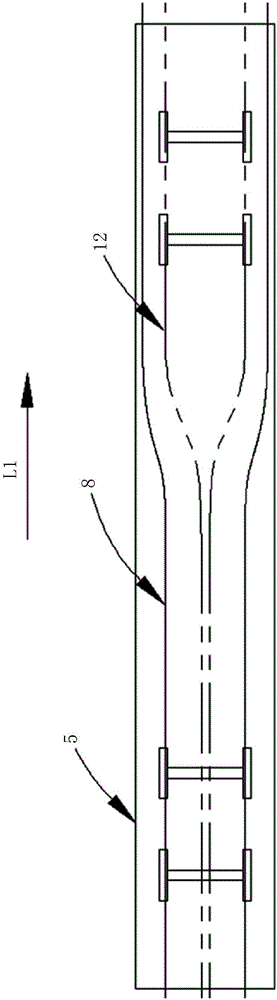

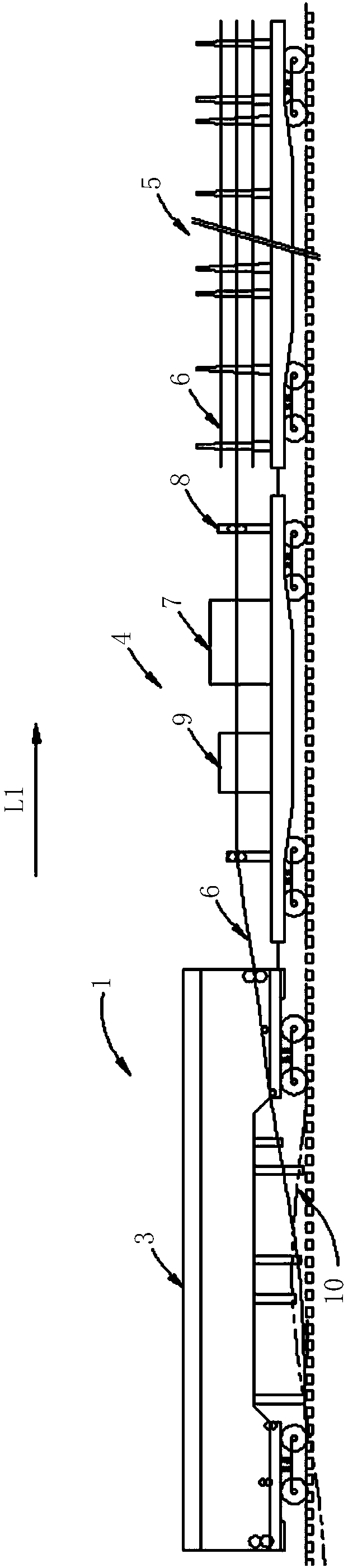

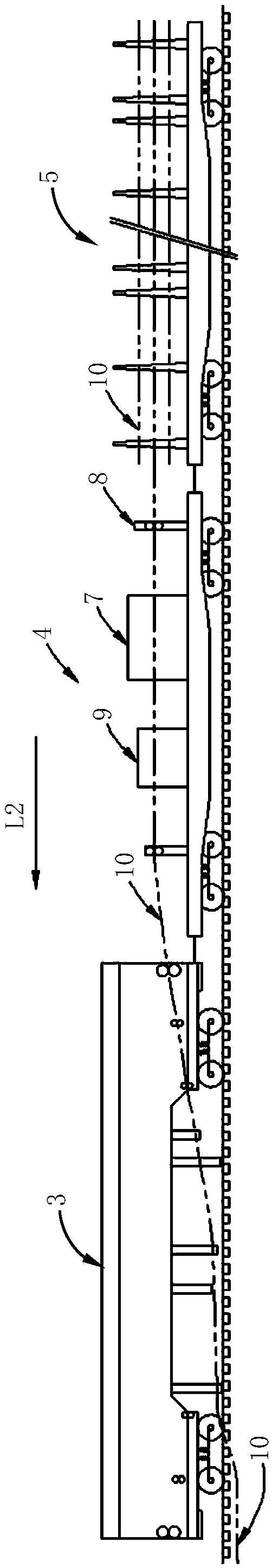

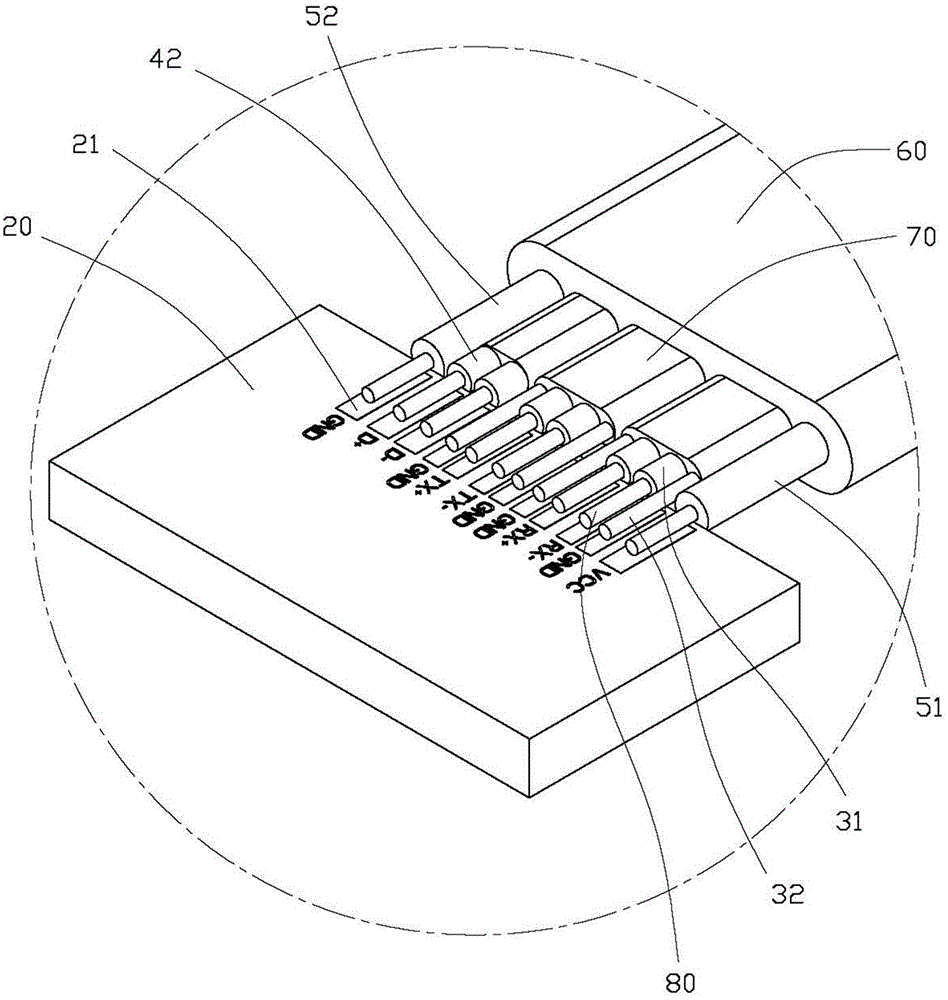

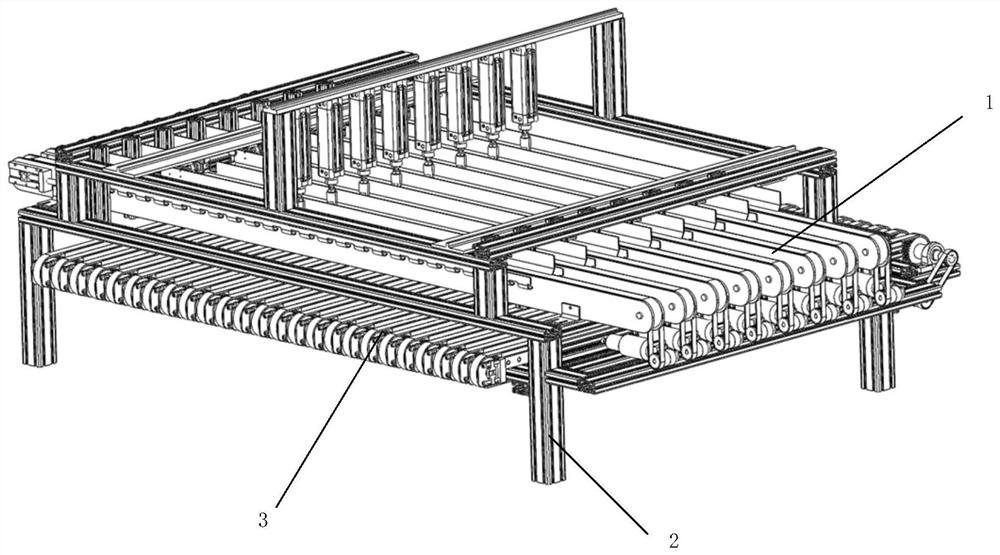

Operating method of rail exchanging train

ActiveCN106283996ASave time when unloading new railsReduce downtimeTrack superstructureRailway track constructionEngineeringFastener

The invention discloses an operating method of a rail exchanging train. The operating method comprises the following steps: after release of rail fasteners, the rail exchanging trains arrives at a construction starting point within the skylight time, and new rails are loaded and transported through a transport module; a rail conveying device arranged on a loading module conveys the new rails to an exchanging module; a rail dividing device arranged on the loading module adjusts the new rails to be at an appropriate space; the exchanging module carries old rails away from rail sinking slots of sleepers; the rail exchanging train runs in a rail exchanging direction, and the exchanging module unloads the new rails into the rail sinking slots of the sleepers; the rail exchanging train runs in a rail collecting direction, and the old rails are driven by the exchanging module and collected to the transport module according to steps opposite to those of rail unloading and exchanging. The operating method of the rail exchanging train can finish rail unloading, exchanging and collecting within a skylight point, so that the new rail unloading time in a traditional rail exchanging construction mode is saved, and potential safety hazards in the rail exchanging construction operation are effectively avoided.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

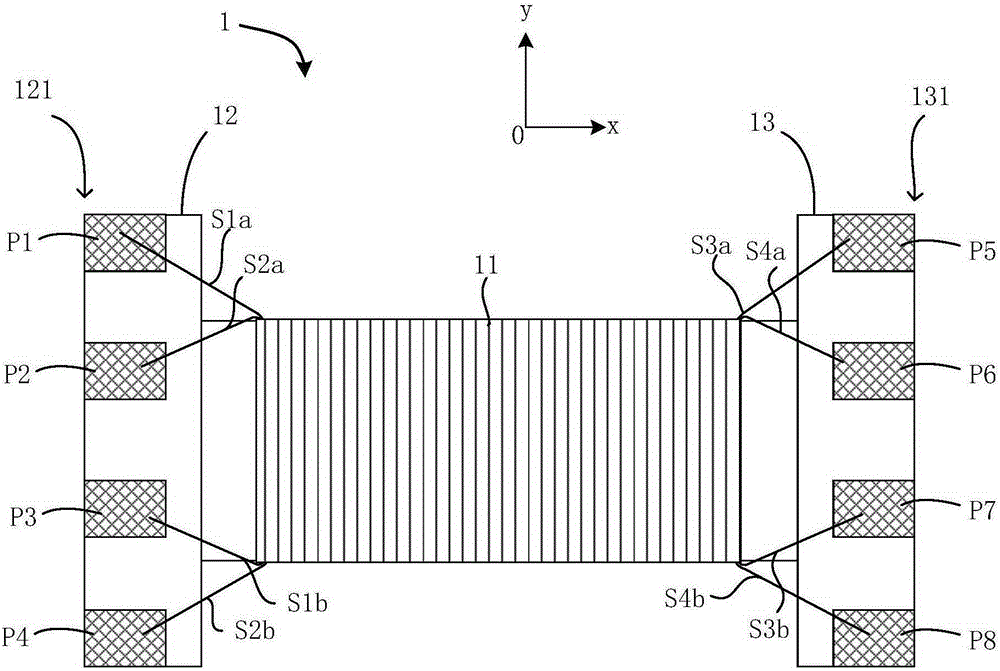

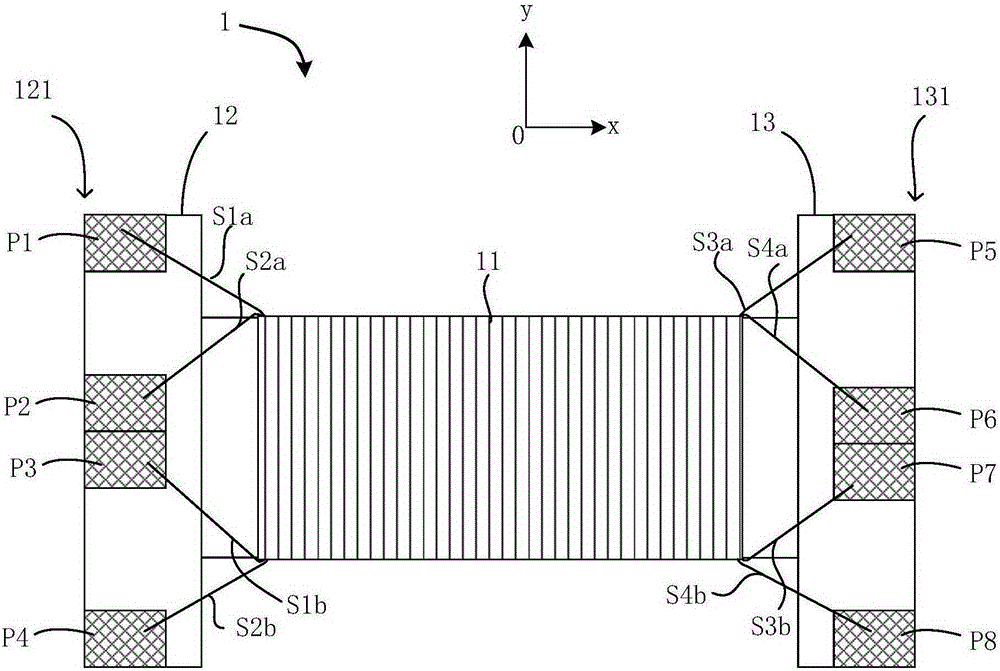

Pulse transformer

ActiveCN105304266ALower requirementNo crossoverTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresPhysicsPulse transformer

The invention provides a pulse transformer, comprising a magnetic core composed of a first magnetic core body and a second magnetic core body, wherein winding wires are wound on the first magnetic core body in advance to form a corresponding winding coil, and then the first magnetic core body is mounted on the second magnetic core body so that the first magnetic core body and the second magnetic core body form a closed magnetic circuit, the winding coil comprises a first winding and a second winding, the first winding comprises two first winding wires, the first ends of the two first winding wires are respectively connected with a first electrode and a second electrode, the second ends of the two first winding wires are respectively connected with a third electrode and a fourth electrode, the second winding comprises two second winding wires, the first ends of the two second winding wires are respectively connected with fifth and sixth electrodes, the second ends of the two second winding wires are respectively connected with seventh and eighth electrodes. The start and tail ends of the two windings are both arranged on the same side of the first magnetic core body, and thus the insulation capability of primary and secondary windings can be improved and the requirement on magnetic core material can be reduced further.

Owner:深圳市普扬技术有限公司

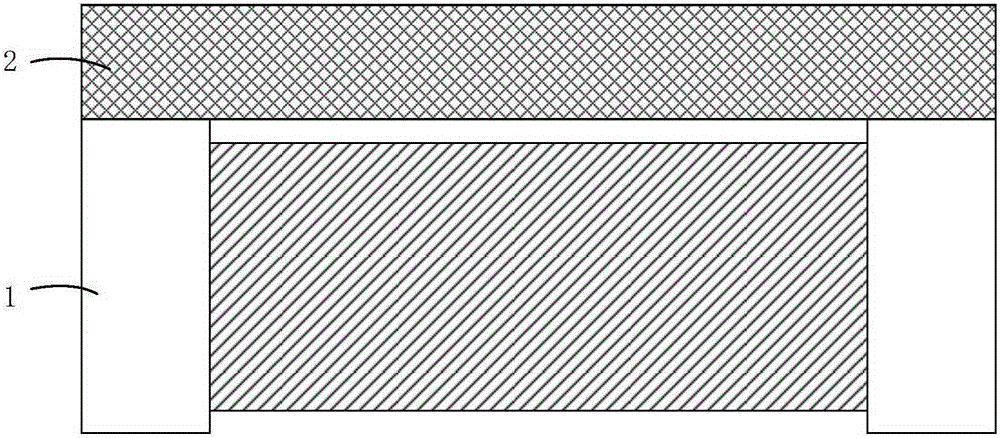

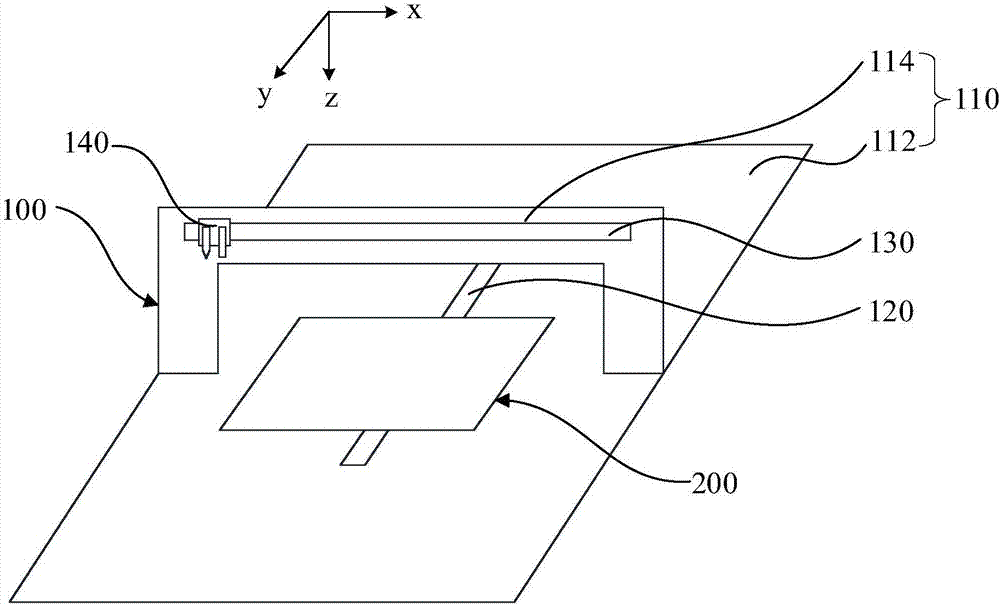

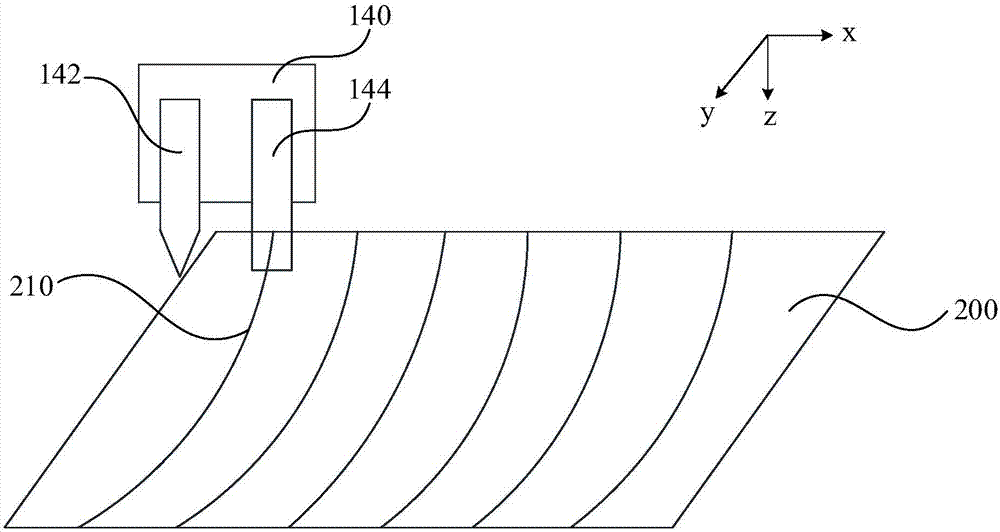

Thin film solar cell scribing device and method

ActiveCN106876518AGuaranteed yieldReduce areaFinal product manufactureFine working devicesElectrical batteryEngineering

The present invention relates to a thin film solar cell scribing device and method. The device comprises a work bench, a first guide rail which is arranged on the work bench and used to move a thin film solar cell, a second guide rail which is arranged on the work bench and positioned above the first guide rail, wherein the extension direction of the second guide rail is orthogonal with the extension direction of the first guide rail and is parallel to the extension directions of multiple pre-scribing lines, a scribing assembly which is slidably arranged on the second guide rail and comprises a scribing head and a pick-up head arranged at an interval, wherein the scribing head scribes the thin film solar cell and the pick-up head can collect image information of the multiple pre-scribing lines, a processing module which is in communication connection with the scribing assembly and obtains the paths of the multiple pre-scribing lines according to the image information of the multiple pre-scribing lines to obtain the paths of the multiple scribing lines corresponding to the thin film solar cell and to control the scribing head to scribe the thin film solar cell. The device can improve the overall conversion efficiency of the thin film solar module.

Owner:西安中易建科技集团有限公司

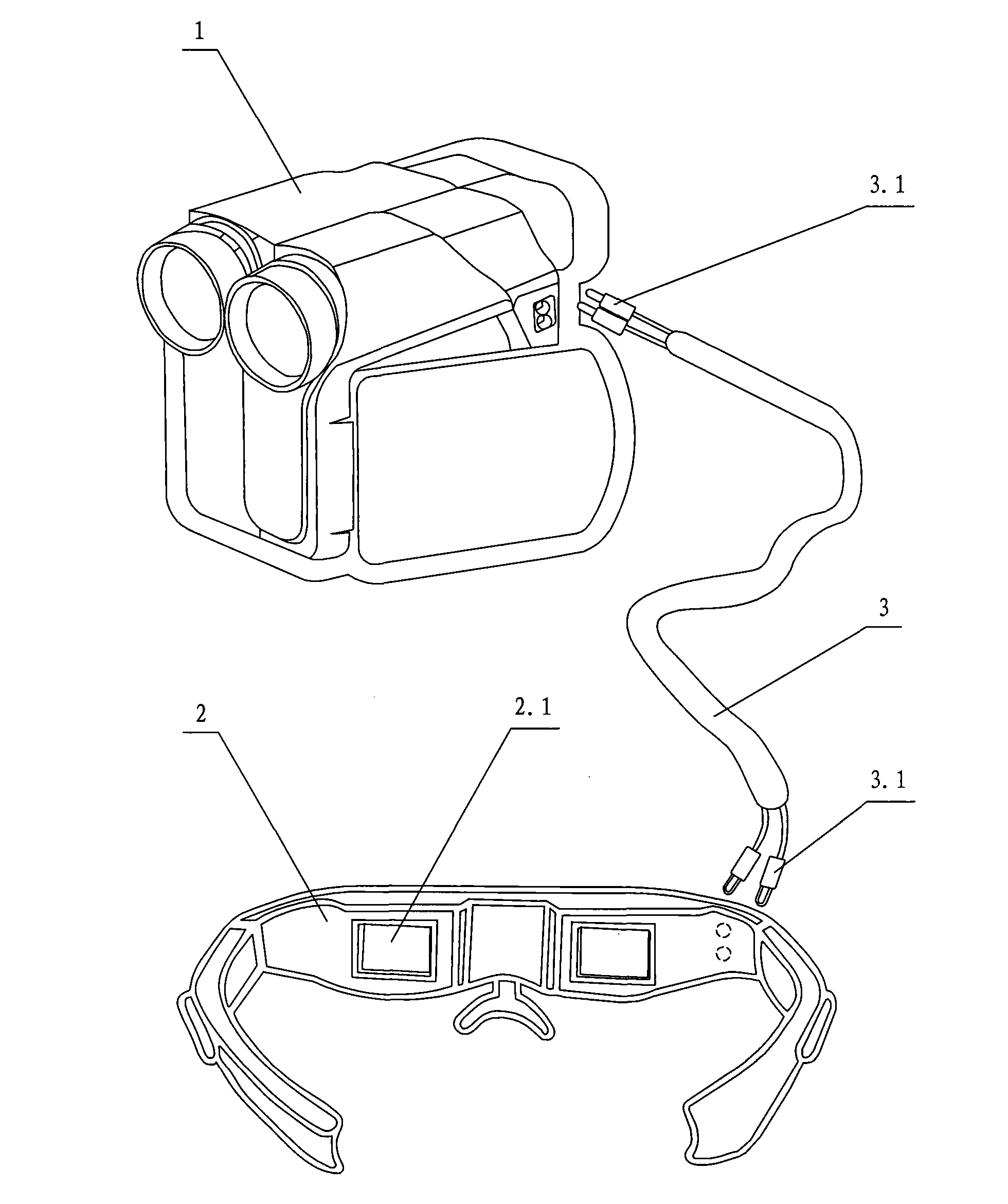

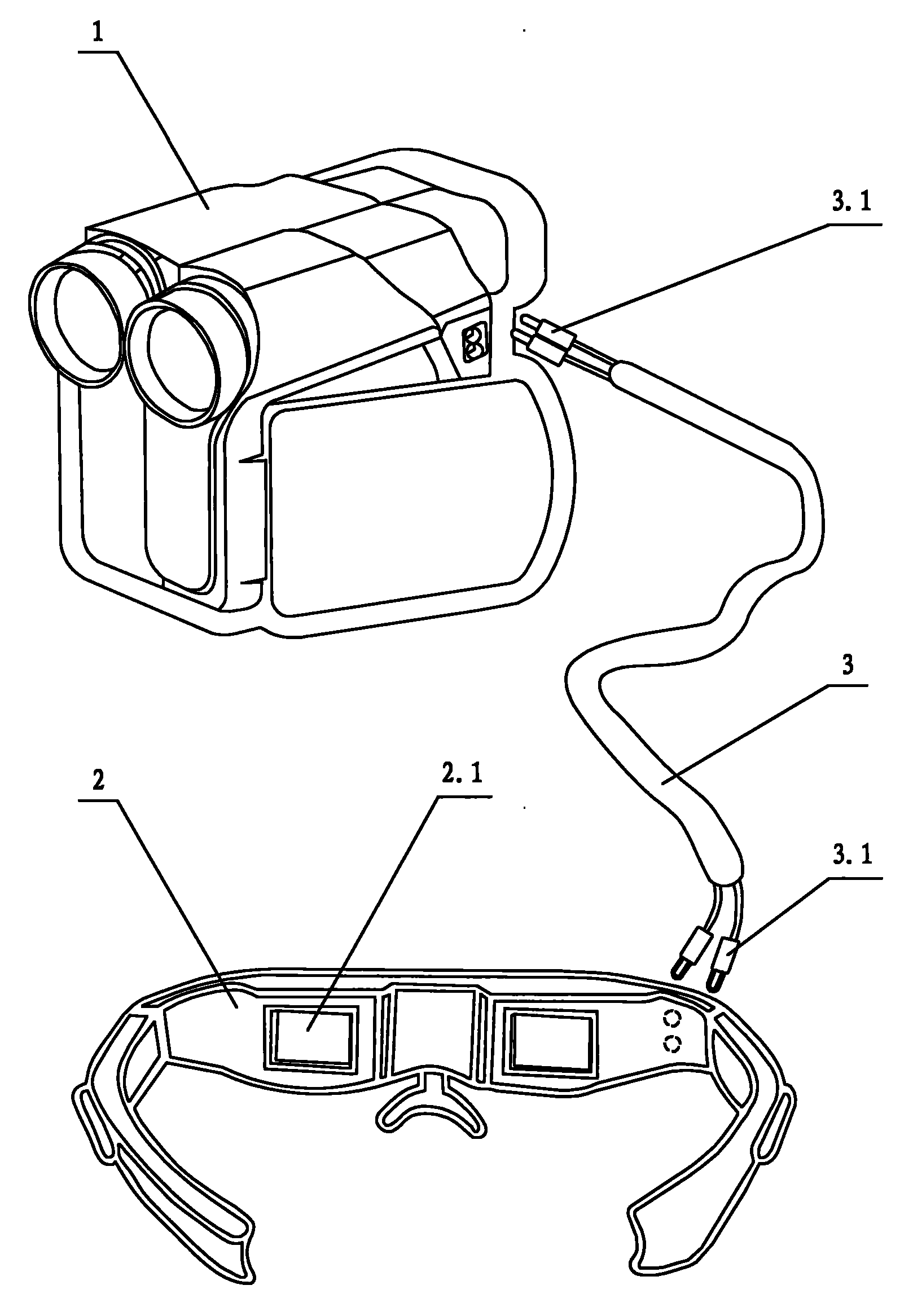

Three-dimensional photographing and viewing device and control method thereof

InactiveCN101778304AEasy to watchReduce manufacturing costSteroscopic systemsCamera lensGlasses type

The invention relates to a three-dimensional photographing and viewing device and a control method thereof. The three-dimensional photographing and viewing device comprises a digital camera and a viewer which are separated and a synchronous controller, wherein the digital camera has double lenses, and two independent image processors and two independent followers are arranged on the double-lens digital camera; the viewer is in a glass type, and two independent display screens and two independent receivers are arranged on the glass-type viewer; the double-lens digital camera is connected with the glass-type viewer through wires; and the synchronous controller controls the two lenses of the double-lens digital camera to synchronously photograph respectively and controls the two display screens of the glass-type viewer to synchronously image respectively. The wires comprise two parallel video connecting lines, and both ends of each video connecting line are respectively provided with a connector. The three-dimensional photographing and viewing device has the characteristics of flexible operation, portability, good three-dimensional reproducibility and is particularly suitable for household three-dimensional photographing and viewing.

Owner:邹华

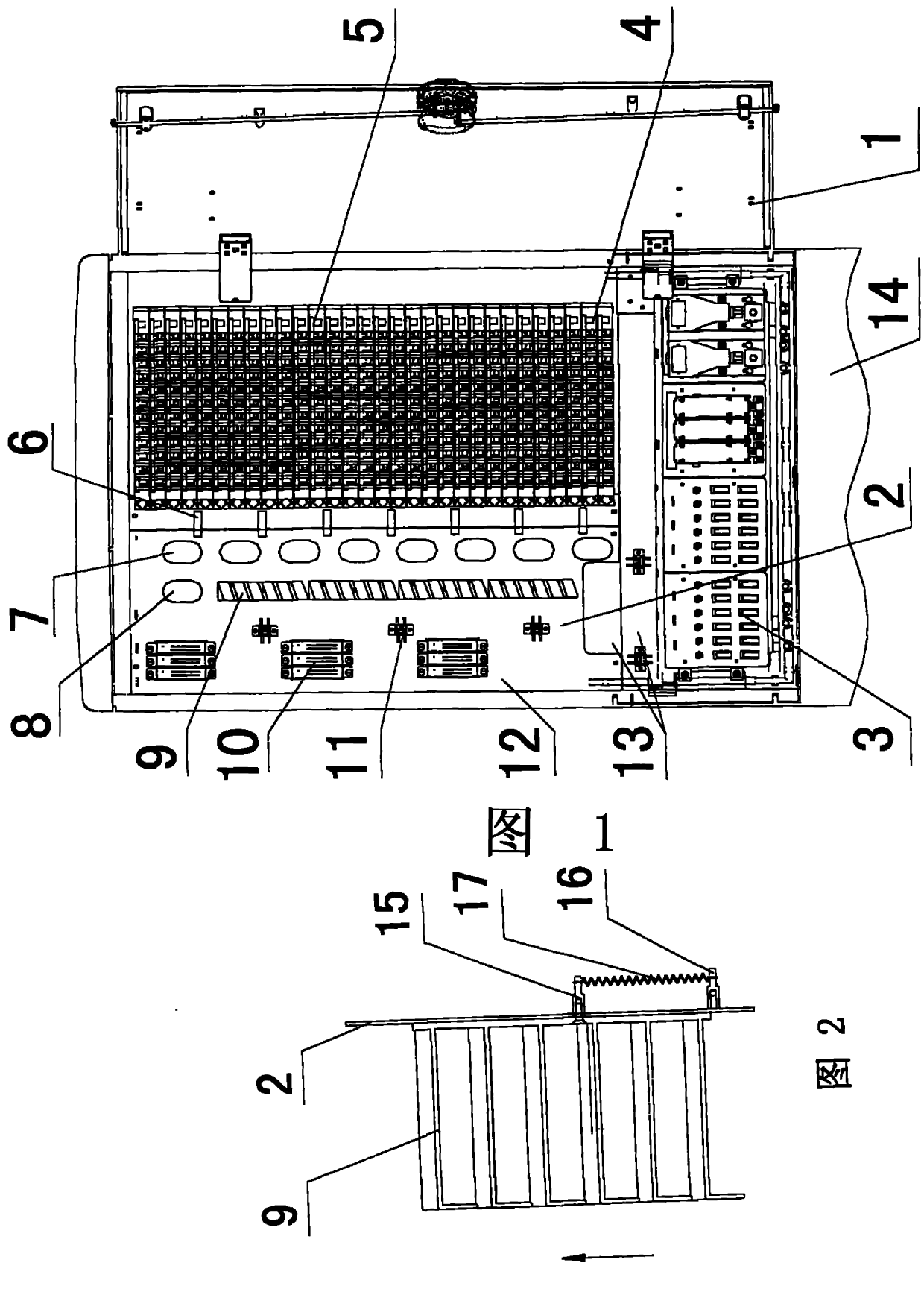

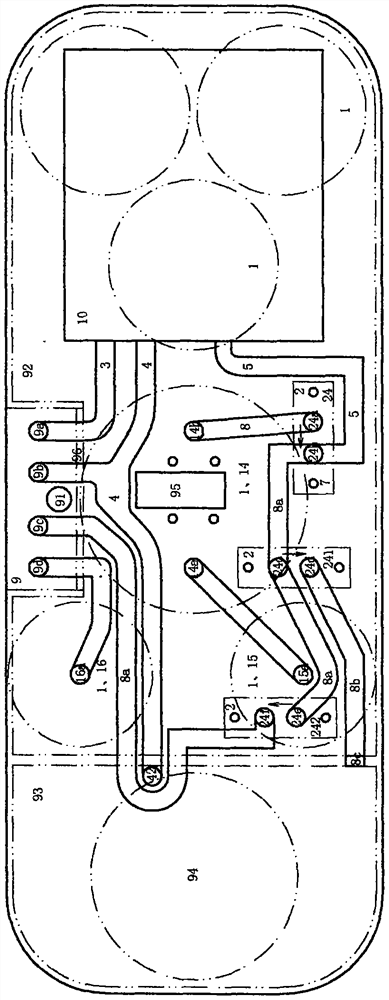

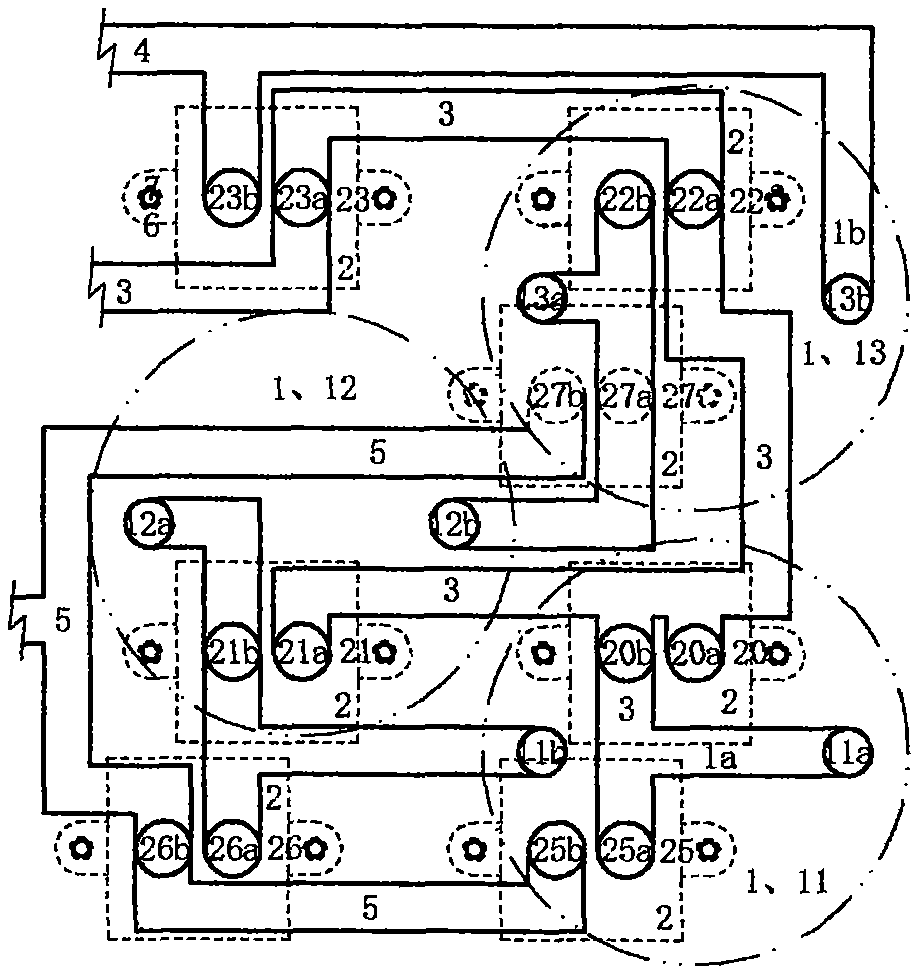

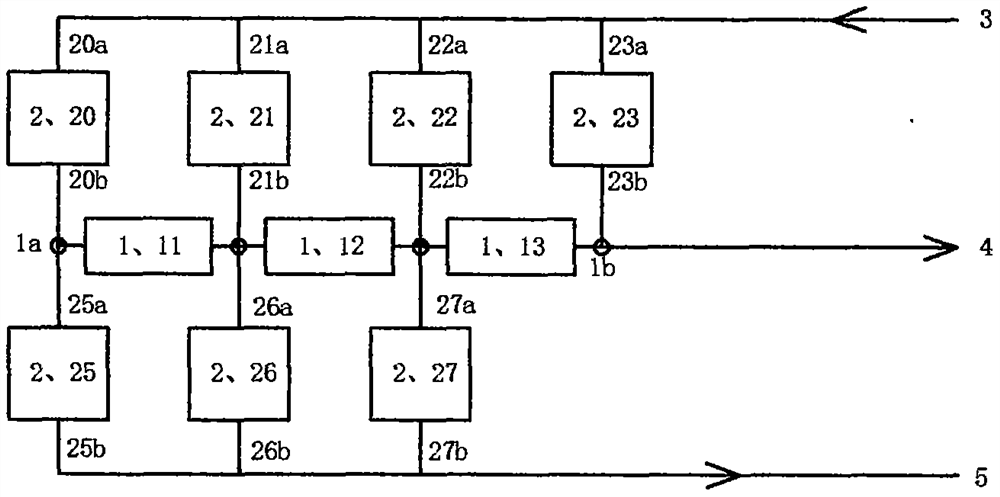

Tow path management system used for optical cable distribution box in optical fiber access network

The invention relates to a tow path management system used for an optical cable distribution box in an optical fiber access network, which is characterized in that a wire hook group, a tow coiling column group, a transition tow coiling column, a floating wire loop group, optical branching device groups and left-side wire loop groups are all installed on a wire loop fixed plate; and the left side in the optical cable distribution box is provided with a main tow of an optical branching device, which is connected with an integrative tray of a trunk, an optical cable introduction group is arranged on the wire loop fixed plate, a distance exists among the wire hook group, the tow coiling column group, the floating wire loop group and the left-side wire loop groups, the tow coiling column group is arranged between the wire hook group and the transition tow coiling column, the left-side wire loop groups are arranged above a tow storage box, an integrative tray of a wiring or trunk optical cable is arranged on an integrative tray of a trunk or wiring optical cable, and each optical branching device is correspondingly arranged at the left upper side of each left-side wire loop group. The invention has the advantages that the management of a gradient jumper (tail) tow is carried out by adopting a combined structure, the entire management of the jumper (tail) tow is orderly, a tow path is definite and does not generate an intersection phenomenon, the maintenance is convenient, the utilization rate of the optical cable distribution box is enhanced, and the time is saved.

Owner:NANJING PUTIAN CHANGLE COMM EQUIP

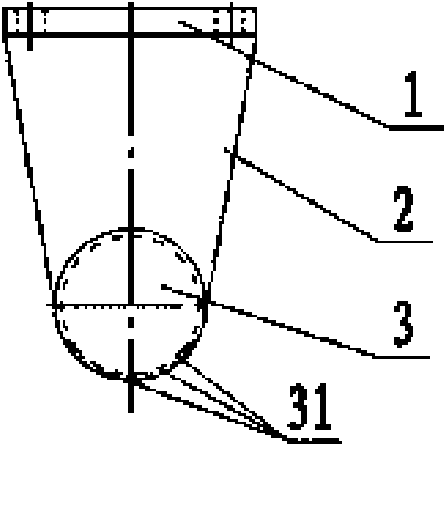

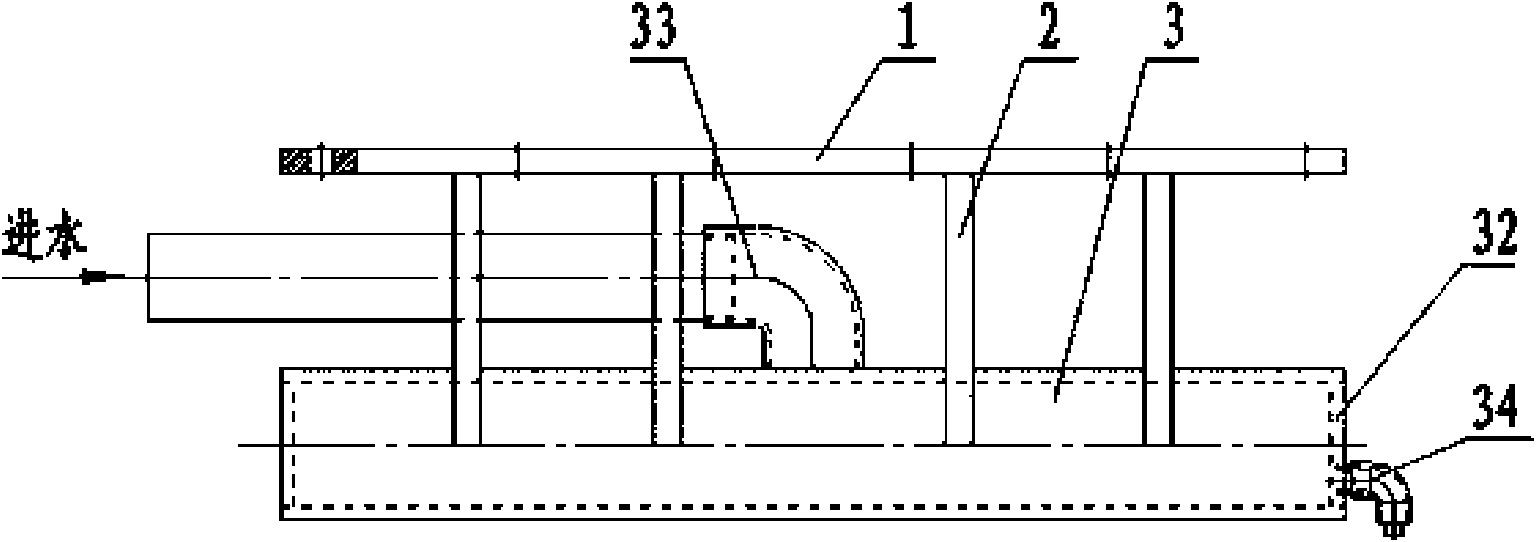

Double-layer rigid pipeline structure of water purifier provided with upper module and lower filter container bin

PendingCN112390390ARigid piping is simplifiedOptimize layoutTreatment involving filtrationMultistage water/sewage treatmentWater pipeWater purification filter

The invention relates to the water treatment industry, in particular to deep filtration and purification of drinking water. The invention discloses a double-layer rigid pipeline structure of a water purifier provided with an upper module and a lower filter container bin. A vertical side concave structure is arranged at the middle portion of the rear side wall of the lower filter container bin equipped with a facility cavity and a filter container cavity; the upper module is provided with a downward external water inlet and another two external water outlets above the vertical side concave structure according to distances from the facility cavity; a front water inlet pipeline and a front water outlet pipeline are arranged above a front inner filter container far away from the facility cavity, and the front inner filter container is connected with the external water inlet through the front water inlet pipeline; the front water outlet pipeline passes through the rear parts of two ports inbutt joint with a concentrated water outlet and a pure water outlet and then approaches the facility cavity, and is communicated with the water inlet end of a booster pump in the lower filter container bin; the water outlet end of the booster pump is connected with the water inlet of a reverse osmosis membrane filter container; a pure water pipeline in butt joint with the pure water port is connected with a subsequent functional filter container and an external pure water port; and a concentrated water discharge pipeline connected with the concentrated water discharge port bypasses the pure water pipeline and the front water outlet pipeline and then is connected with an external discharge port.

Owner:杜宁峻

Textile machinery special textile line integration machine

InactiveCN108914308AQuality assuranceNo crossoverTextiles and paperFailure rateAgricultural engineering

The invention discloses a textile machinery special textile line integration machine. The structure comprises a support, wire passing rollers, carding bars, an integrating roller, a support shaft, support devices, a drive unit, a controller and curved slide-out boards; wire passing rollers are uniformly arranged on an upper side of the support; carding bars are arranged between two adjacent wirepassing rollers; the integrating roller is arranged under the wire passing rollers; the support shaft is arranged in the middle of the integrating roller in a penetrating mode; the support devices aresymmetrically arranged under the two ends of the support shafts; the drive unit is connected to the right side of the support shaft; the drive unit is fixedly arranged on a connecting board; a connecting frame is connected to a lower side of the connecting board; a lower end of the connecting frame is connected to the support; the curved slide-out boards are symmetrically arranged inside the lower end of the support. The invention has simple structure, convenient installation and disassembly of the integrating roller, easy maintenance and repair, can ensure the quality of the wire harness after winding, avoids the failure rate in the disassembly process, facilitates driving of the integrating roller, and has high work efficiency.

Owner:FOSHAN SANCHUANG KNITTING CO LTD

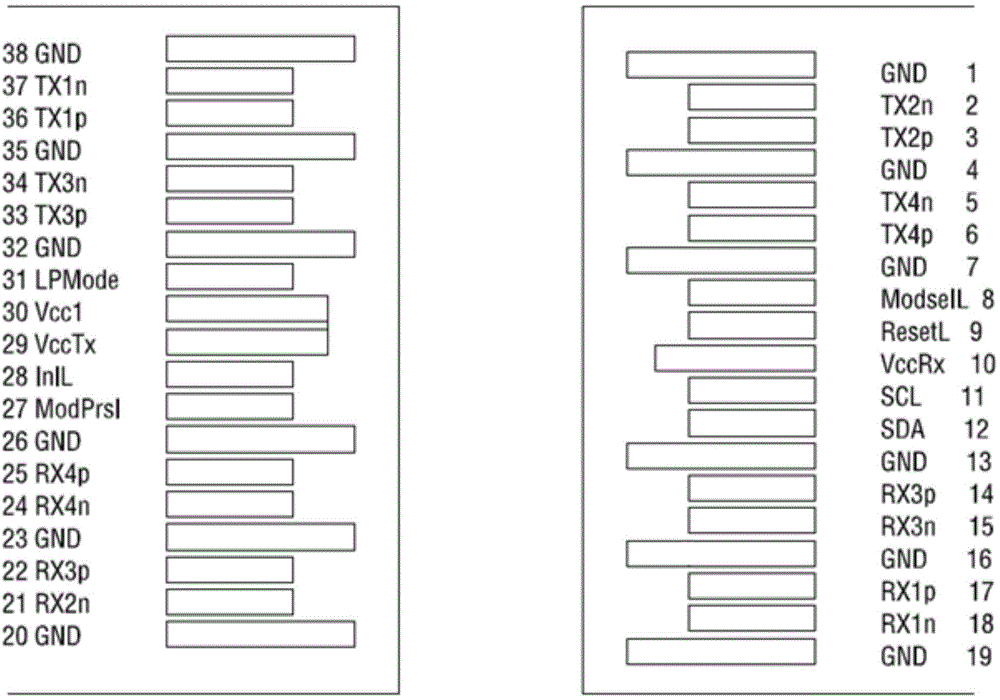

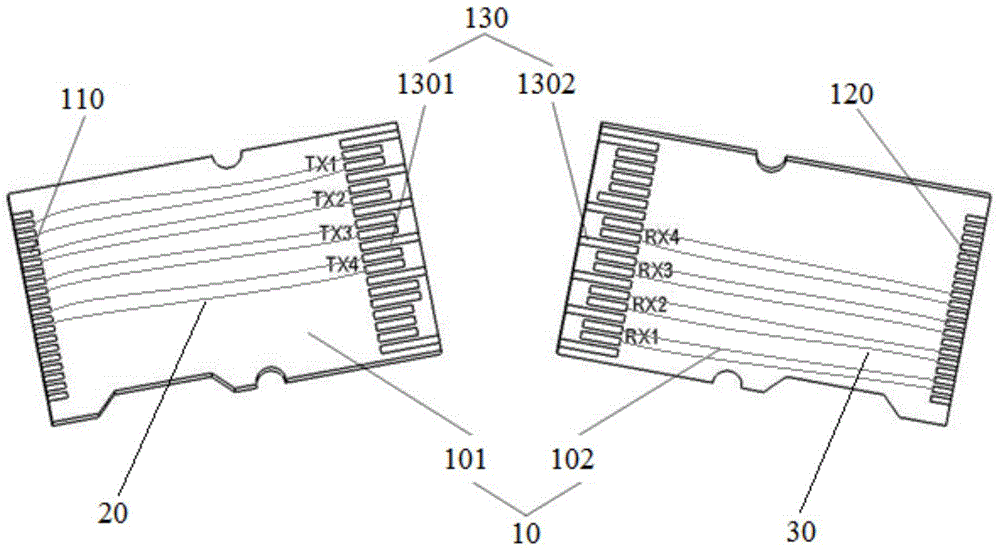

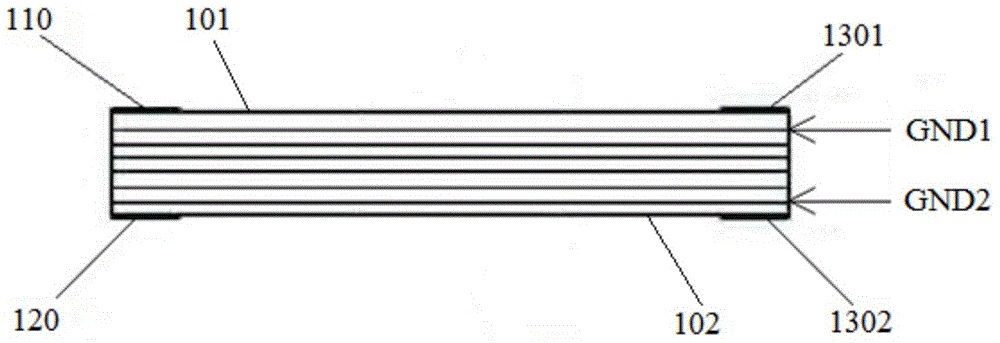

Printed circuit board for optical module

ActiveCN104540319AReduce the overall heightReduce the numberPrinted circuit non-printed electric components associationOptical ModuleData transmission

The invention provides a printed circuit board for an optical module. The printed circuit board for the optical module comprises a base plate, transmitting terminal light component interfaces, receiving terminal light component interfaces, electrical interfaces, first circuit board wiring and second circuit board wiring; the electrical interfaces comprise transmitting terminal data interfaces and receiving terminal data interfaces, the base plate comprises a first surface and a second surface opposite to the first surface, the transmitting terminal light component interfaces and the transmitting terminal data interfaces are arranged on the first surface and connected with each other through the first circuit board wiring to form a transmitting terminal data transmission path, and the receiving terminal light component interfaces and the receiving terminal data interfaces are arranged on the second surface and connected with each other through the second circuit board wiring to form a receiving terminal data transmission path. By means of the printed circuit board for the optical module, the signal crosstalk between the transmitting terminal data transmission path and the receiving terminal data transmission path can be effectively reduced or even basically eliminated, and the integrity of the signals can be greatly improved.

Owner:旭创科技有限公司

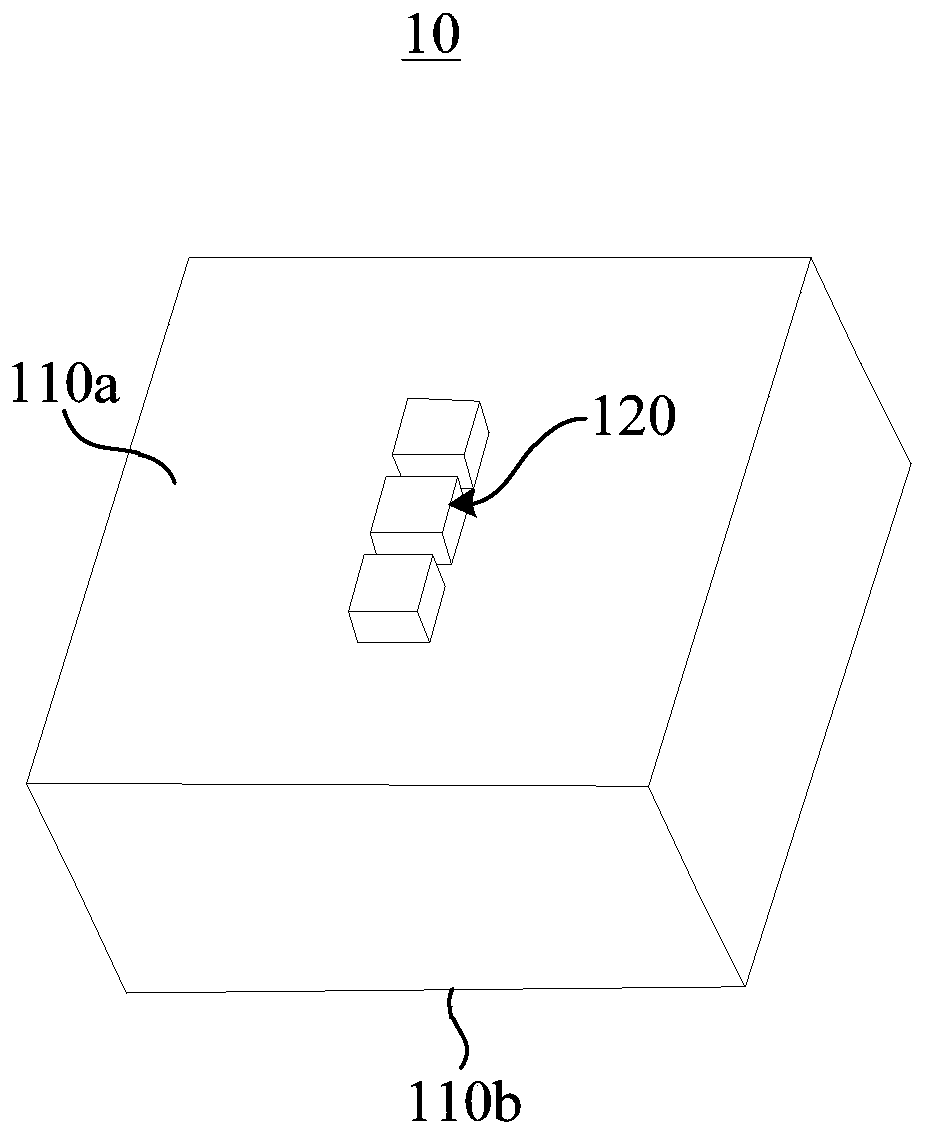

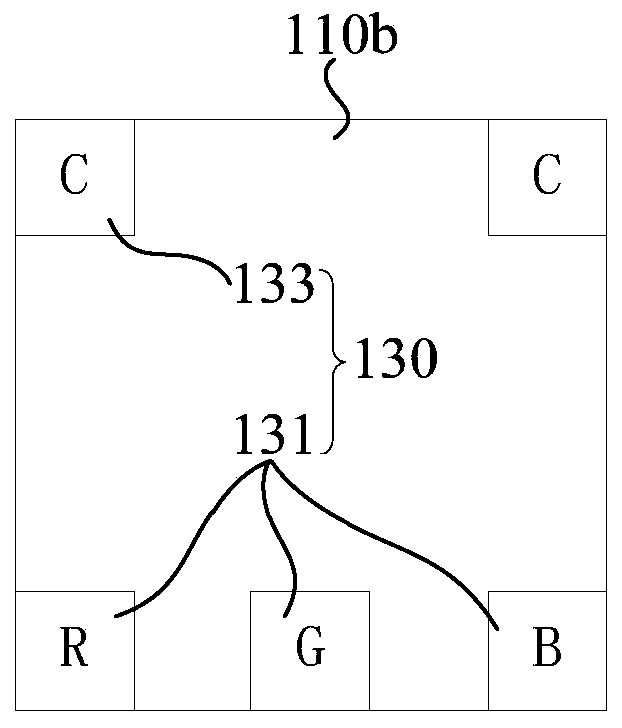

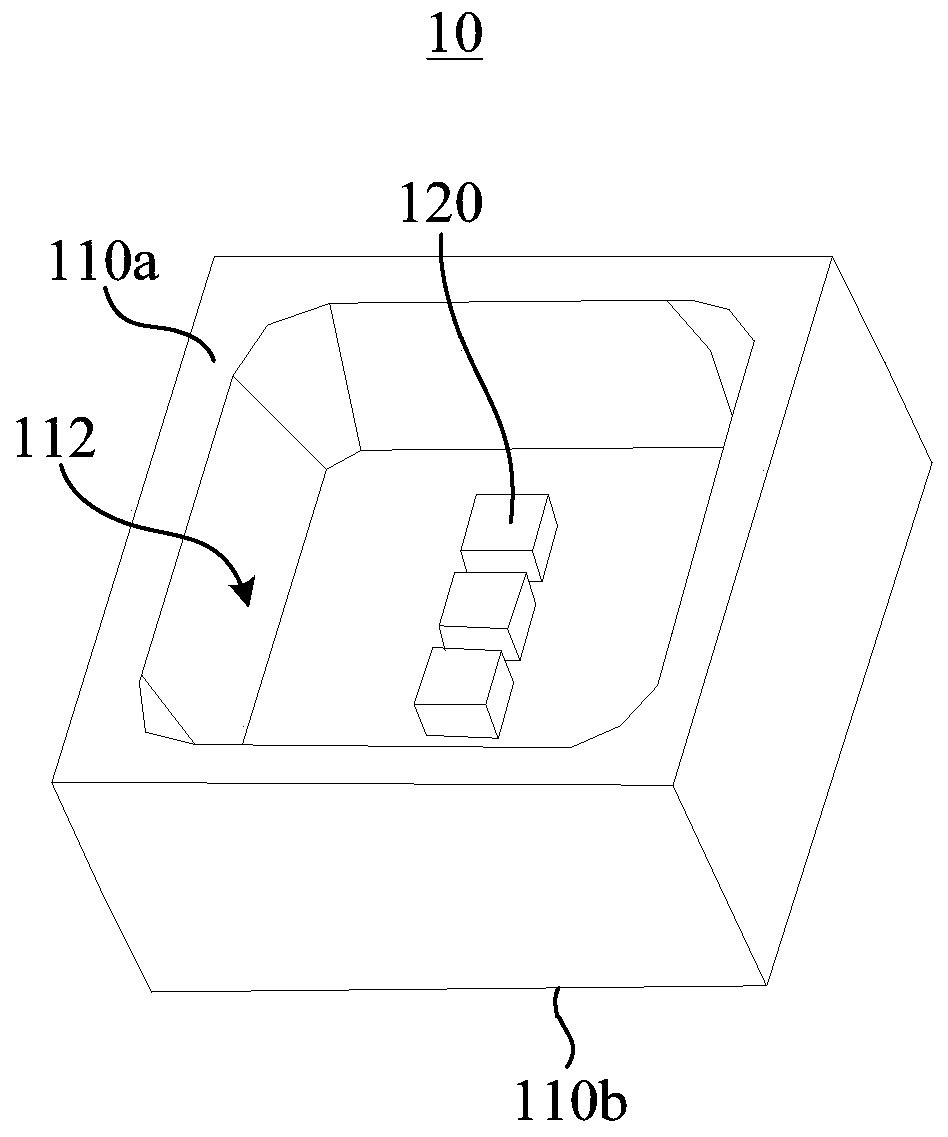

LED lamp bead and LED display structure

InactiveCN111462643AReduce wiring difficultyReduce manufacturing costSolid-state devicesPrinted circuit non-printed electric components associationLED displayLED lamp

The invention relates to an LED lamp bead and an LED display structure. The LED lamp bead comprises a lamp body, a light-emitting chip set and pins, wherein the light-emitting chip set is arranged onthe first end face of the lamp body, the pins are arranged on the second end face of the lamp body, the light-emitting chip set comprises at least one light-emitting chip, the pins comprise color signal pins and row signal pins, the number of the row signal pins is at least two, every two row signal pins of the same LED lamp bead are paired, one pair of row signal pins is electrically connected with each other through a circuit in the lamp body, one of the pair of row signal pins which are electrically connected with each other is directly connected with the electrode of the light-emitting chip, the other row signal pin is a redundant row signal pin, and the LED lamp beads are attached to PCB to form an LED display structure. By providing the redundant row signal pins, the color signal circuit and the row signal circuit can be arranged on the same layer of the PCB, so that the wiring difficulty and the manufacturing cost of the PCB are reduced.

Owner:SHENZHEN AOTO ELECTRONICS

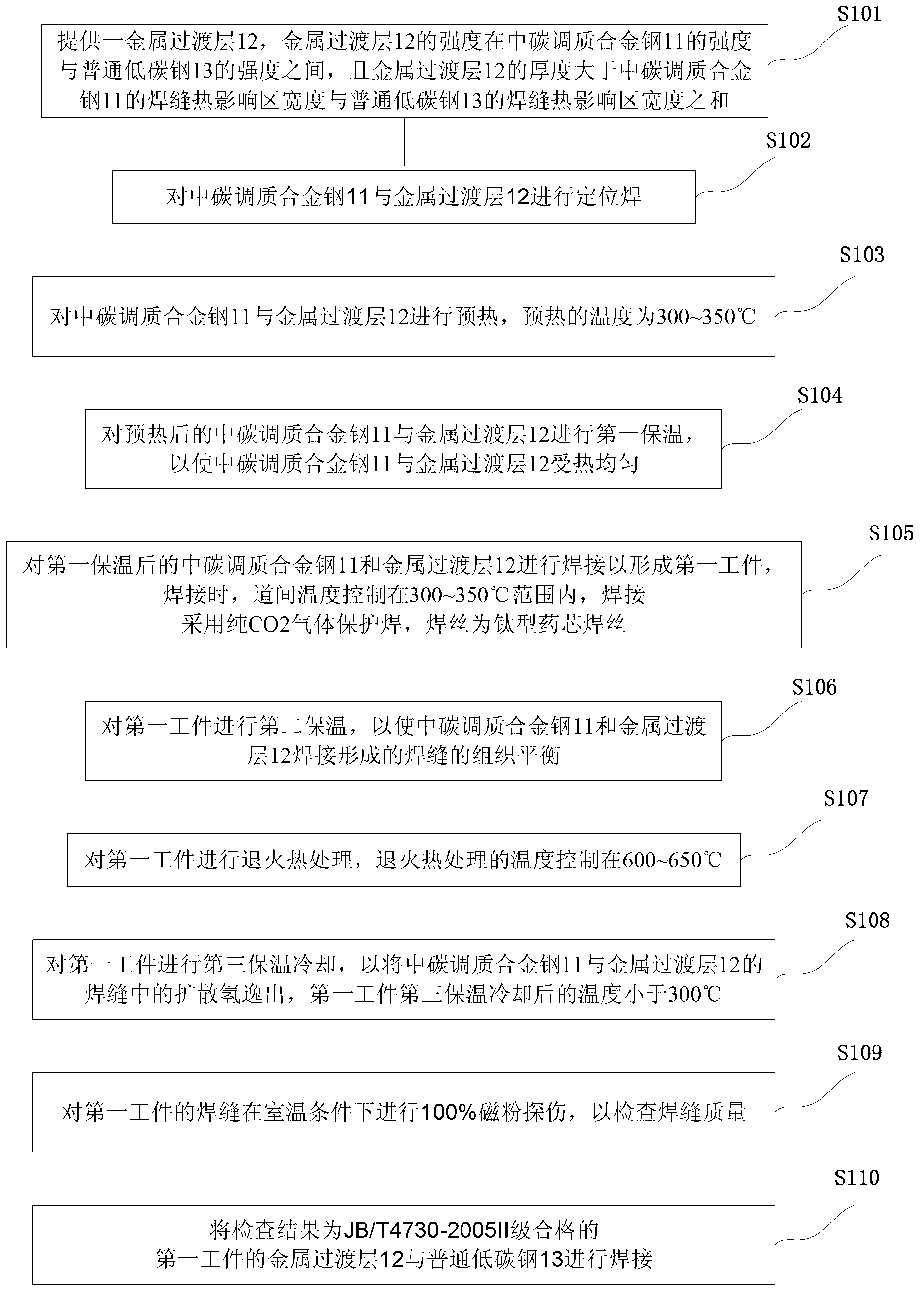

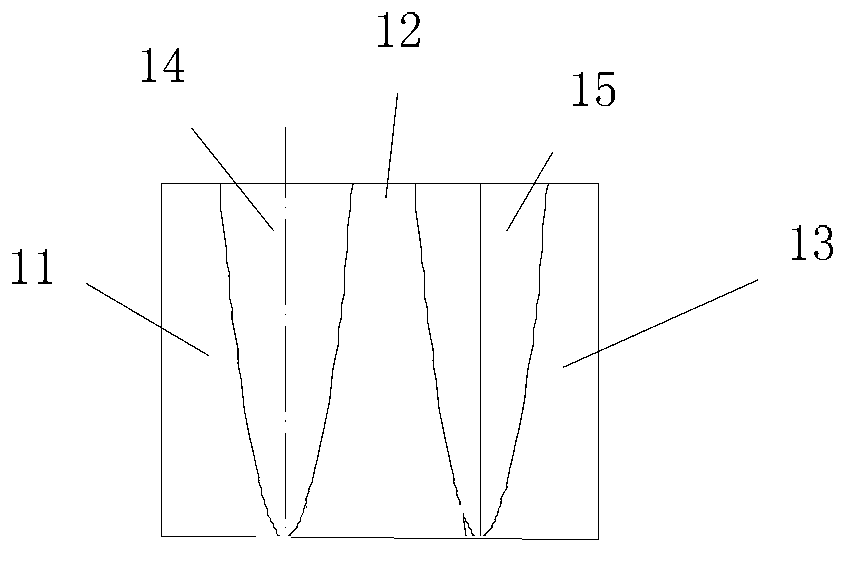

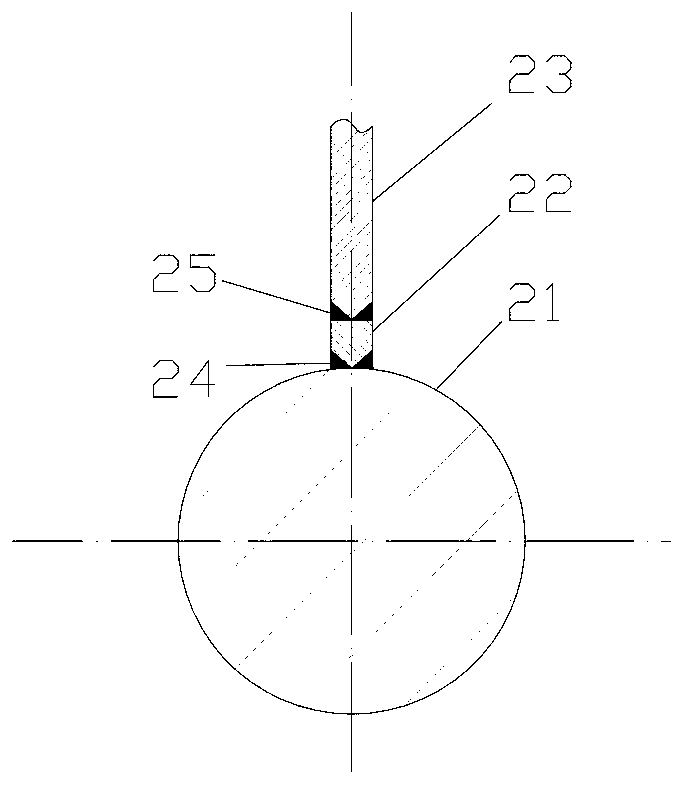

Method for welding medium-carbon quenched and tempered alloy steel and ordinary low-carbon steel

ActiveCN103286464AReduce crackingImprove toughnessArc welding apparatusHeat-affected zoneUltimate tensile strength

The invention discloses a method for welding medium-carbon quenched and tempered alloy steel and ordinary low-carbon steel, and belongs to the technical field of welding. The method includes providing one metal transition layer with strength ranging between that of the medium-carbon quenched and tempered alloy steel and the ordinary low-carbon steel and thickness being larger than sum of width of welding joint heat-affected zones of the medium-carbon quenched and tempered alloy steel and the ordinary low-carbon steel; welding the medium-carbon quenched and tempered alloy steel and the metal transition layer to form a first workpiece; welding the metal transition layer of the first workpiece with the ordinary low-carbon steel. According to above technical scheme, the two welding joint heat-affected zones formed by the metal transition layer and the medium-carbon quenched and tempered alloy steel and the ordinary low-carbon steel cannot be overlapped, welding cracks are less prone to being caused in the welding joint heat-affected zone close to one side of the medium-carbon quenched and tempered alloy steel after being welded, so that a welded joint is high in toughness and good in reliability.

Owner:WUHAN MARINE MACHINERY PLANT

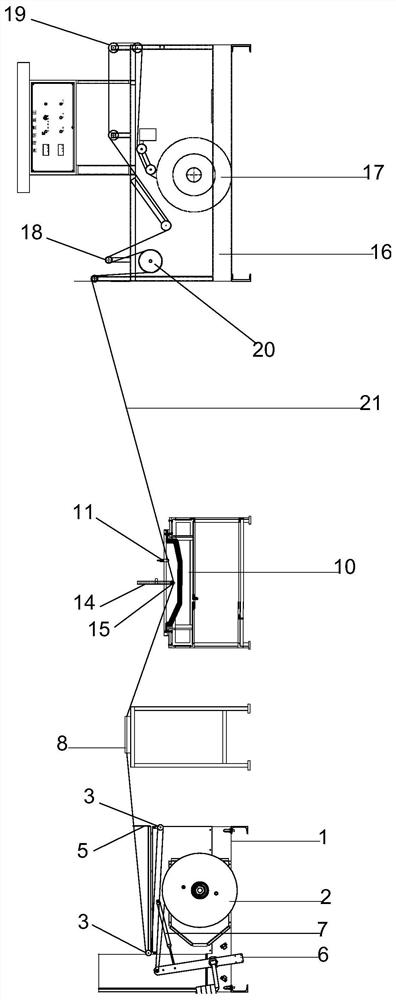

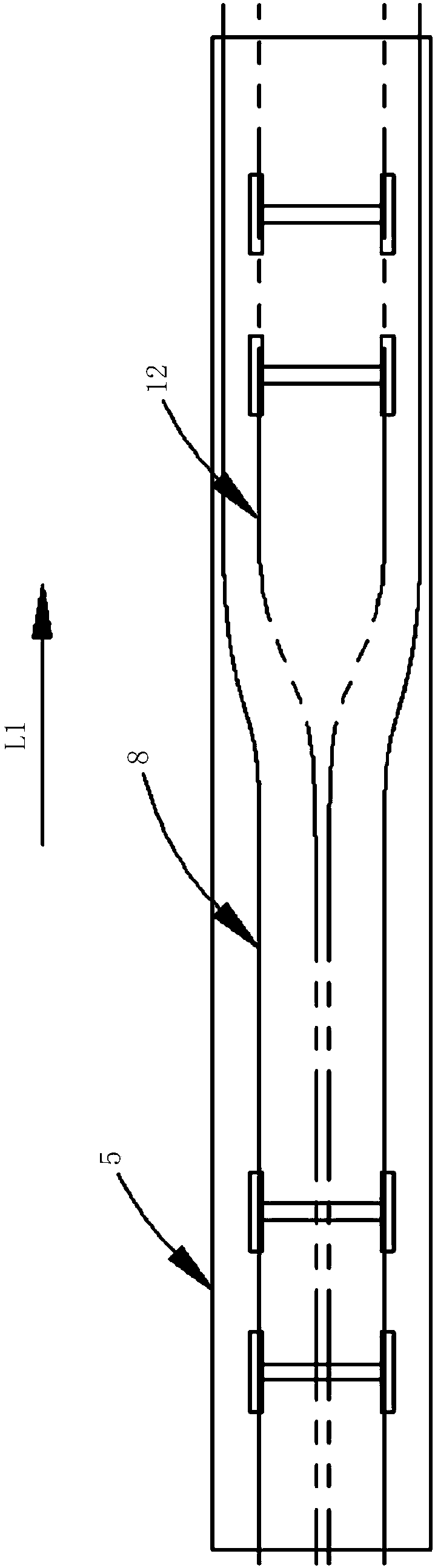

Hot tinning device for copper doubled wires

PendingCN112853246ARealize simultaneous payoutAvoid crossoverHot-dipping/immersion processesInsulating conductors/cablesTinningProduction line

The invention discloses a hot tinning device for copper doubled wires. The hot tinning device comprises a pay-off mechanism, a cleaning mechanism, a tinning mechanism and a take-up mechanism which are sequentially arranged from back to front, wherein the pay-off mechanism comprises a pay-off rack, pay-off guide wheels, tensioning rollers and wire distributing plates, and the pay-off rack is provided with pay-off reels wound with the bare copper doubled wires; the bare copper doubled wires bypass the tensioning rollers and are guided to the wire distributing plates through the paying-off guide wheels; the cleaning mechanism comprises a cleaning tank and cleaning felt arranged in the cleaning tank; copper single wires make contact with the surface of the cleaning felt; the tinning mechanism comprises a tinning furnace, and a tinning mold for the copper single wires to penetrate through is mounted on the tinning furnace; and the take-up mechanism comprises a take-up rack, take-up guide wheels and doubling guide wheels, the take-up rack is provided with take-up reels, and the copper single wires are guided by the take-up guide wheels and then wound on the take-up reels after passing through the doubling guide wheels. According to the hot tinning device, the technological process of simultaneous paying-off and wire distributing, simultaneous tinning, simultaneous taking-up and doubling of a plurality of the copper single wires is realized, so that the copper wire tinning technological process is relatively short, the occupied space of a production line is saved, and the tinning efficiency is improved.

Owner:JIANGSU HENGTONG PRECISION METAL MATERIALCO LTD

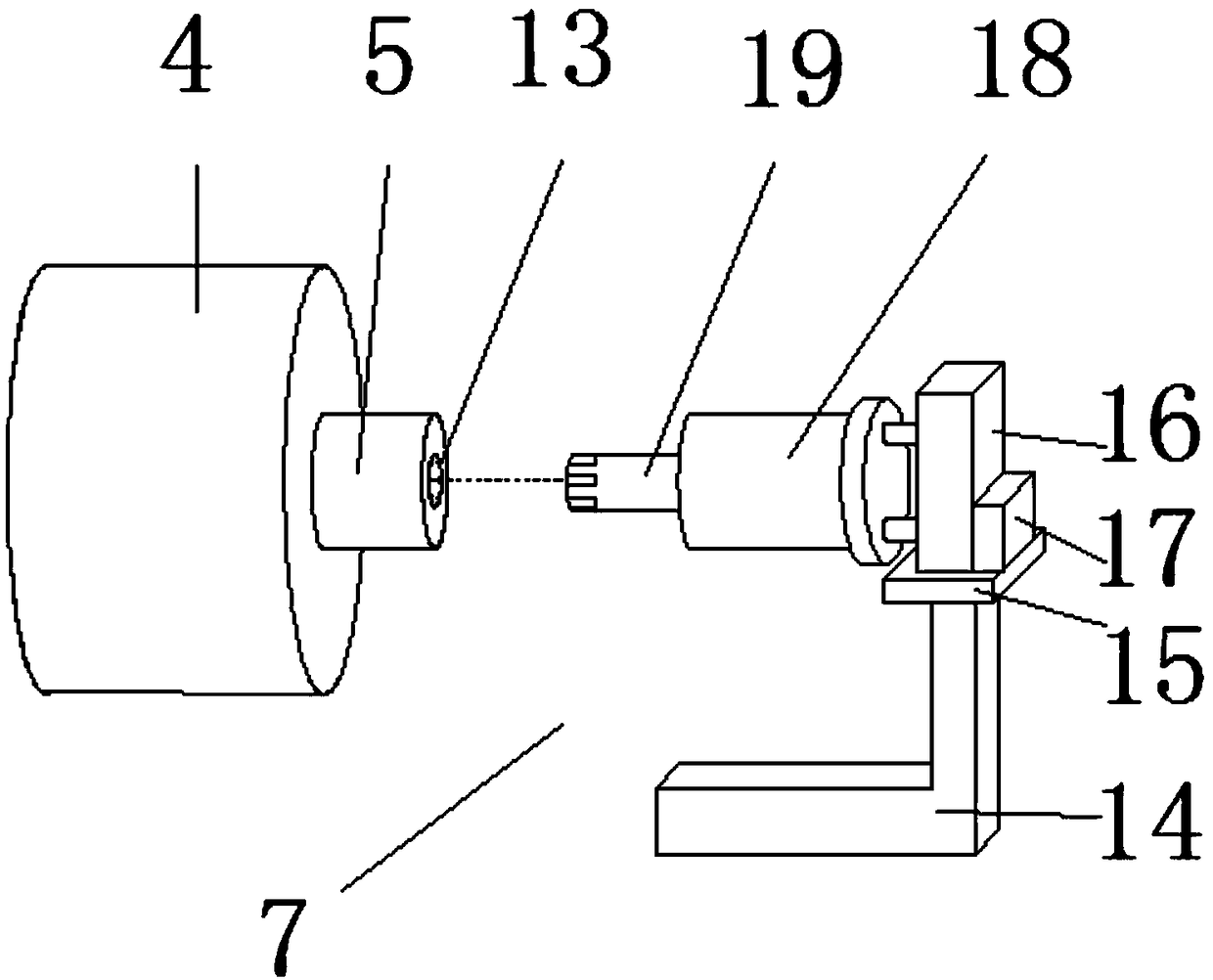

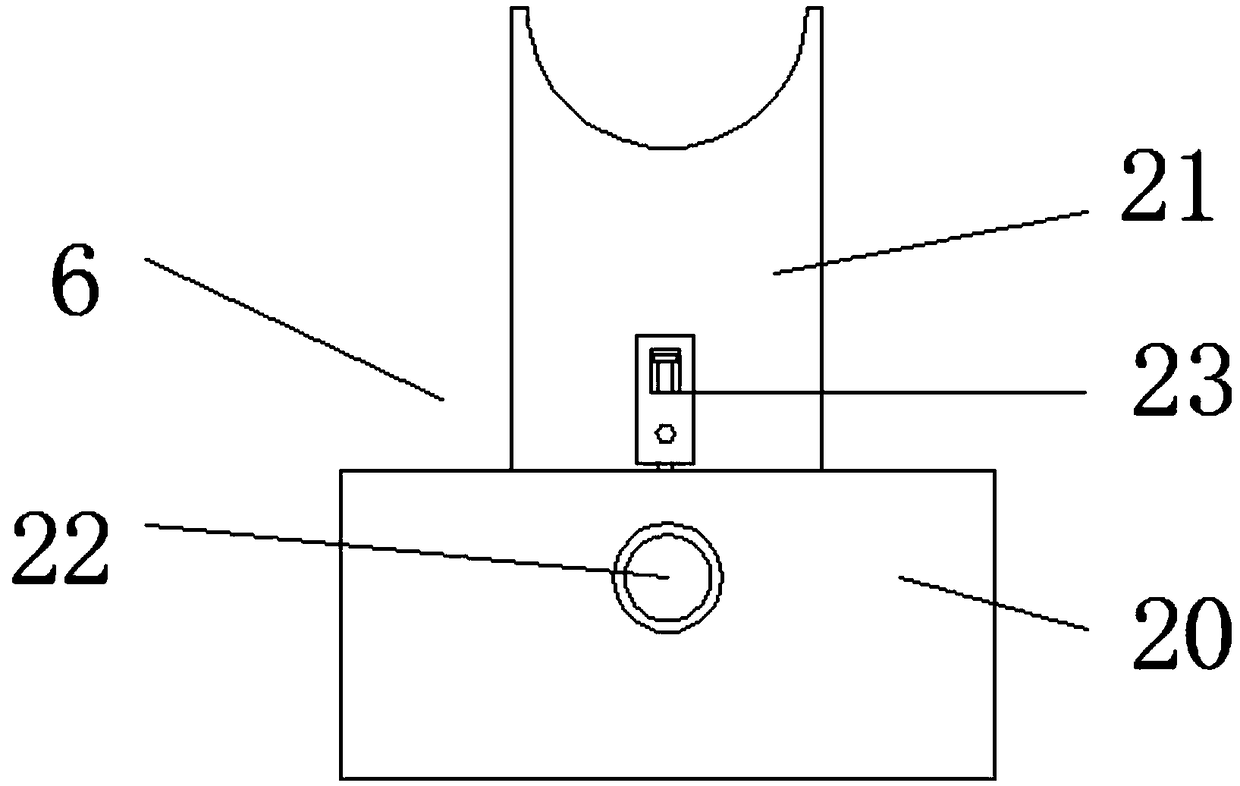

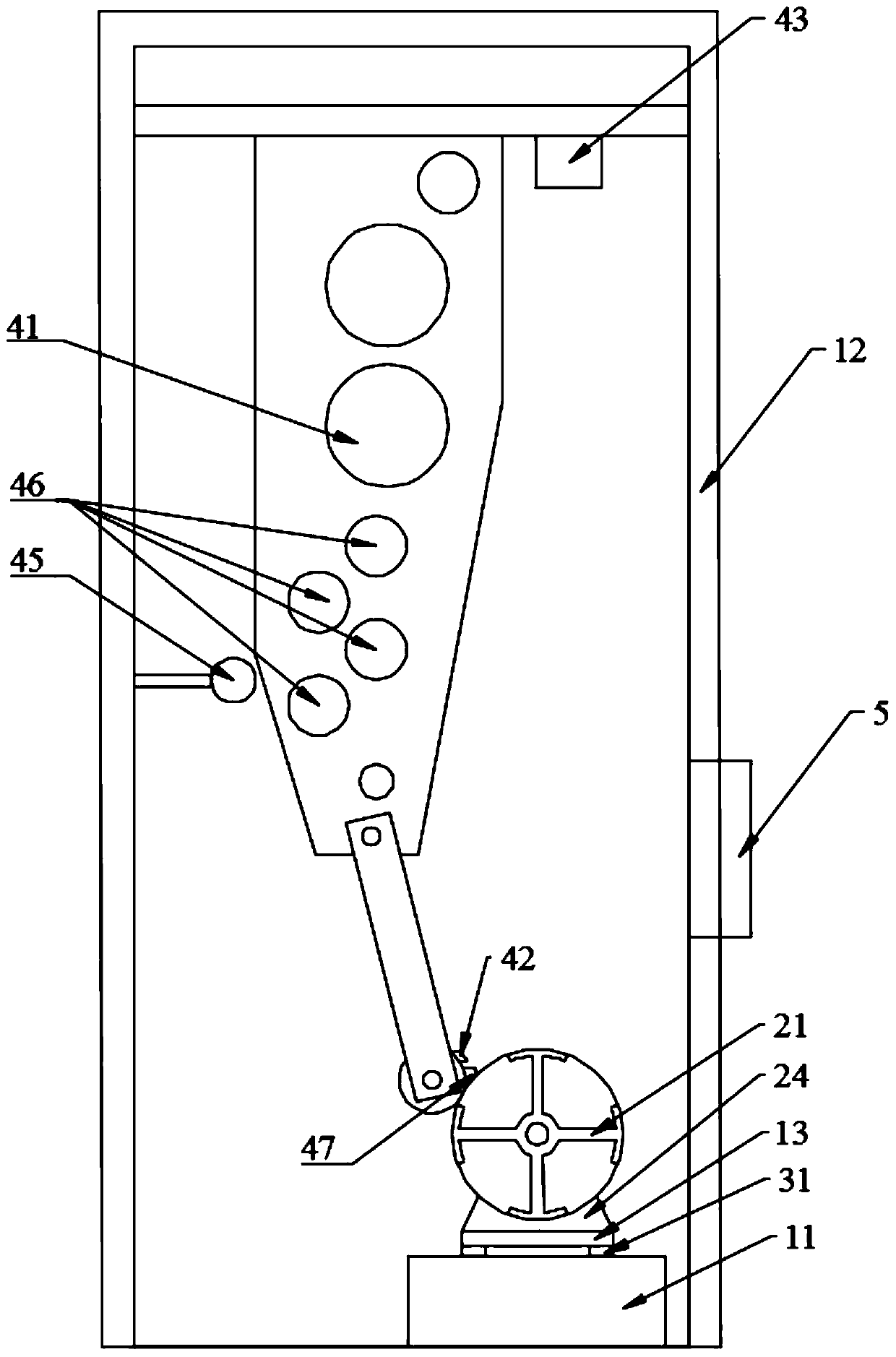

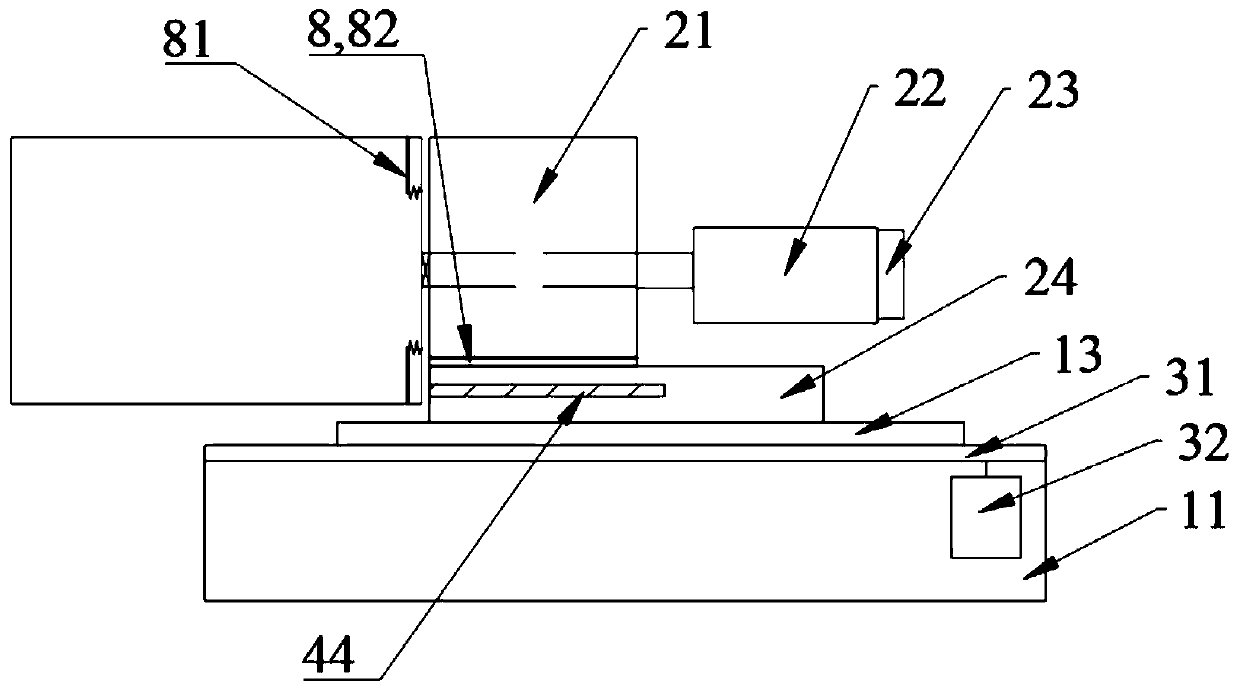

Binding tape reciprocating type coiling machine and using method thereof

The invention relates to a binding tape reciprocating type coiling machine and a using method thereof. The binding tape reciprocating type coiling machine comprises a machine base and a rack, whereina horizontal coiling wheel is arranged on the machine base, the coiling wheel is driven by a driving motor for driving the coiling wheel to rotate to rotate, and the rotating direction of the drivingmotor is controlled by an encoder. One end of the coiling wheel is arranged on a coiling wheel case, and the coiling wheel case is fixed to a bottom plate. The bottom plate is provided with a screw rod which can axially and horizontally move, and the screw rod is fixedly arranged on the machine base. The screw rod is controlled by a servo motor for controlling the screw rod to axially move, the rack is provided with a guide mechanism, and the guide mechanism is composed of reels with different diameters. The binding tape reciprocating type coiling machine further comprises an electrical equipment control box containing a logical program, and the electrical equipment control box is electrically connected with the encoder and the servo motor. The horizontal movable binding tape reciprocatingtype coiling machine is high in coiling precision, continuous automatic production can be achieved, the coiling edge of a binding tape is neat, and the tightness is moderate.

Owner:JIANGSU JU HONG BUNDLE BRING MFG

A kind of rail-changing train operation method

ActiveCN106283996BSave time when unloading new railsReduce downtimeTrack superstructureRailway track constructionFastenerBuilding construction

The invention discloses an operating method of a rail exchanging train. The operating method comprises the following steps: after release of rail fasteners, the rail exchanging trains arrives at a construction starting point within the skylight time, and new rails are loaded and transported through a transport module; a rail conveying device arranged on a loading module conveys the new rails to an exchanging module; a rail dividing device arranged on the loading module adjusts the new rails to be at an appropriate space; the exchanging module carries old rails away from rail sinking slots of sleepers; the rail exchanging train runs in a rail exchanging direction, and the exchanging module unloads the new rails into the rail sinking slots of the sleepers; the rail exchanging train runs in a rail collecting direction, and the old rails are driven by the exchanging module and collected to the transport module according to steps opposite to those of rail unloading and exchanging. The operating method of the rail exchanging train can finish rail unloading, exchanging and collecting within a skylight point, so that the new rail unloading time in a traditional rail exchanging construction mode is saved, and potential safety hazards in the rail exchanging construction operation are effectively avoided.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

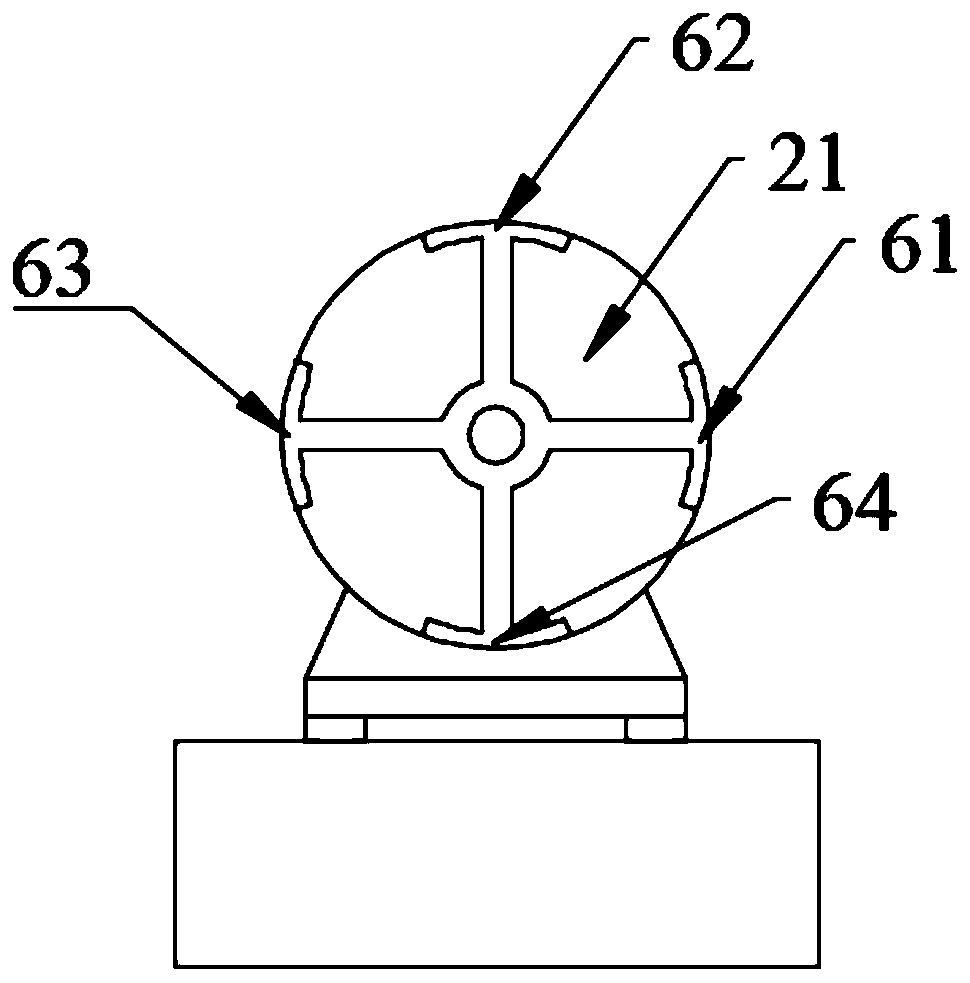

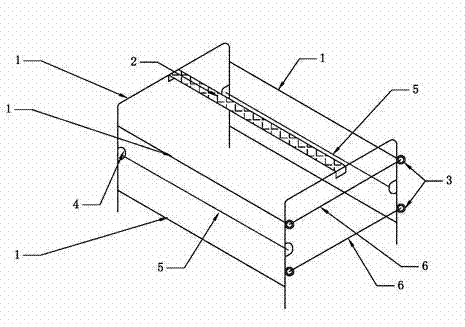

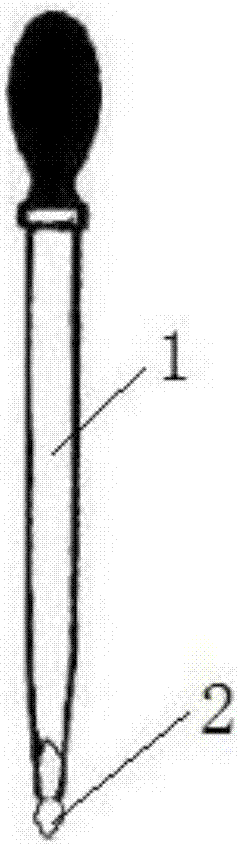

Spiral stirrup fixing device

The invention discloses a spiral stirrup fixing device, and relates to the field of building construction. The spiral stirrup fixing device comprises a main device frame (1), wherein the main device frame (1) has a U-shaped groove structure; and the spiral stirrup fixing device also comprises a stirrup clamping device, wherein the stirrup clamping device comprises a stirrup fixing insertion pipe (4) fixed on the main device frame (1) and a clamping plate (5) capable of passing through the stirrup fixing insertion pipe (4). Through the spiral stirrup fixing device, spiral stirrups can be normally and regularly bound together; and in the transport and distribution process, the spiral stirrups are not crossed or disordered, so that manpower is saved, the production efficiency is improved, and the production cost is greatly reduced.

Owner:DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

Thin-layer sample application method for preparing thin-layer chromatography

InactiveCN107085069AEasy to operateGood effectComponent separationThin-layer chromatographyChemistry

The invention discloses a thin-layer sampling method for preparing thin-layer chromatography. The invention belongs to the technical field of thin-layer chromatography analysis and preparation. The method of the invention mainly includes the following steps: preparation of thin layer plate, preparation of sample pointing device, sample pointing, sample development and sample enrichment. The method of the invention has the advantages of simple equipment, easy operation, quickness, convenience, low cost and good separation effect after sample unfolding.

Owner:LIAONING UNIVERSITY

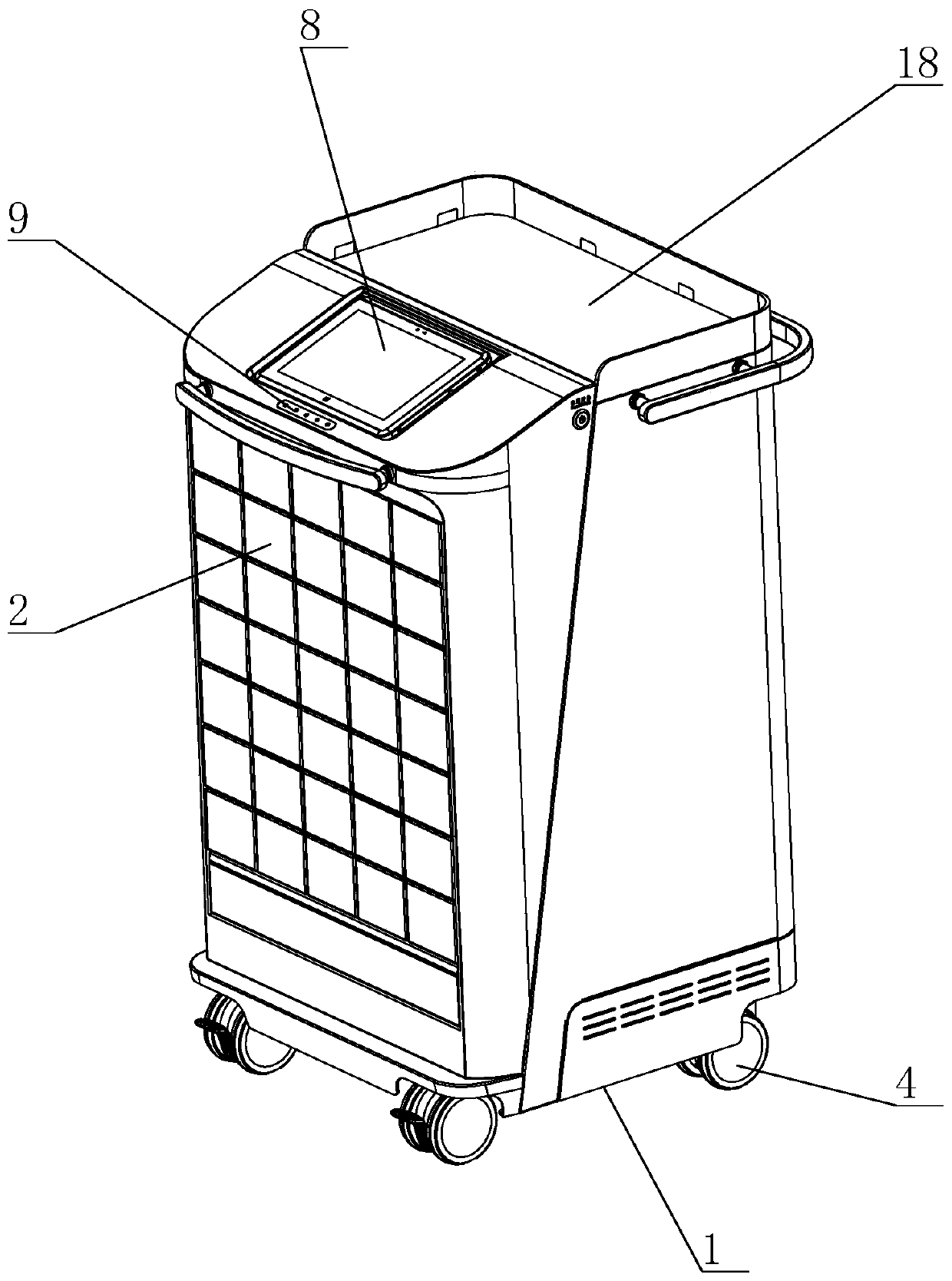

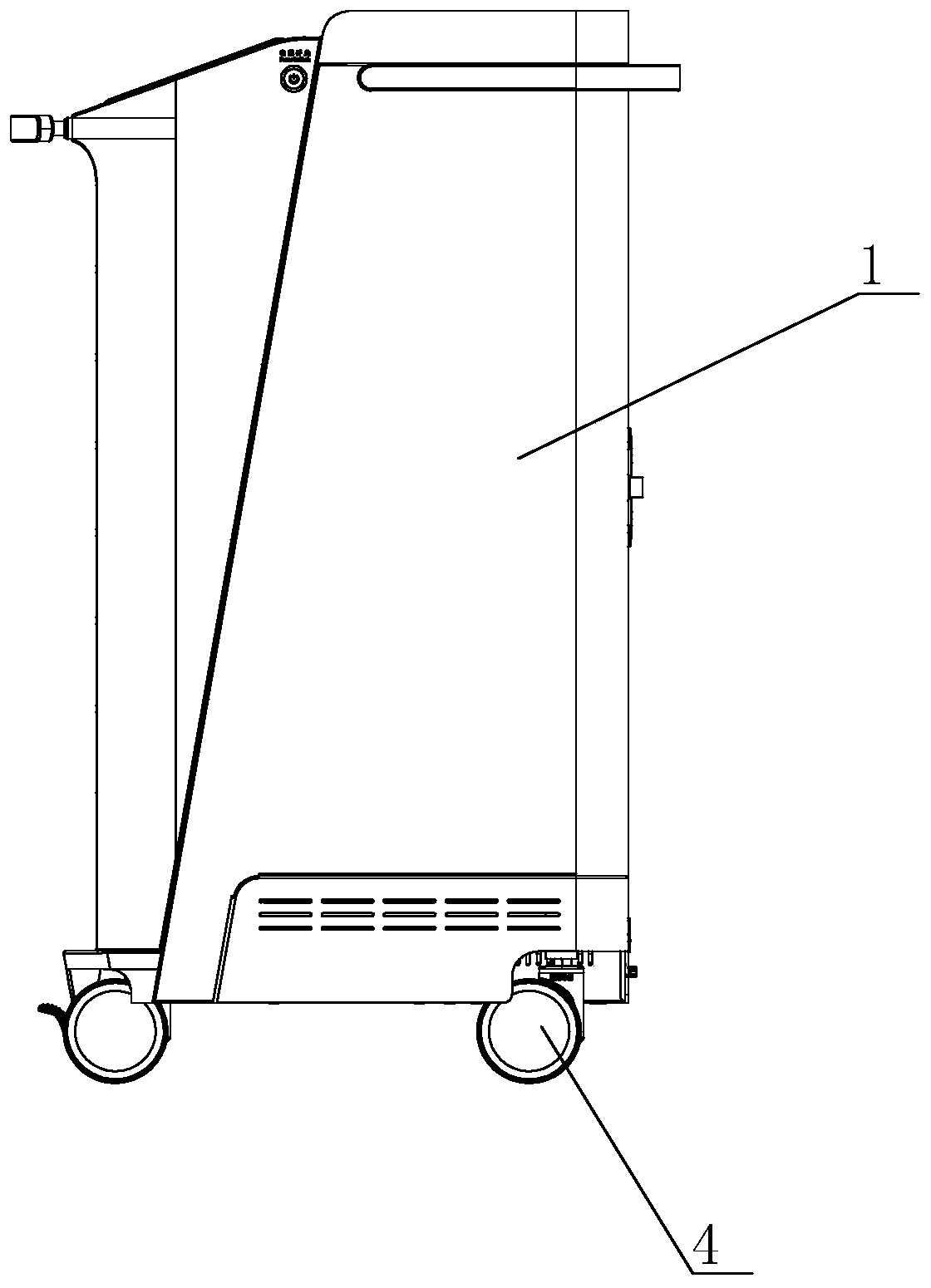

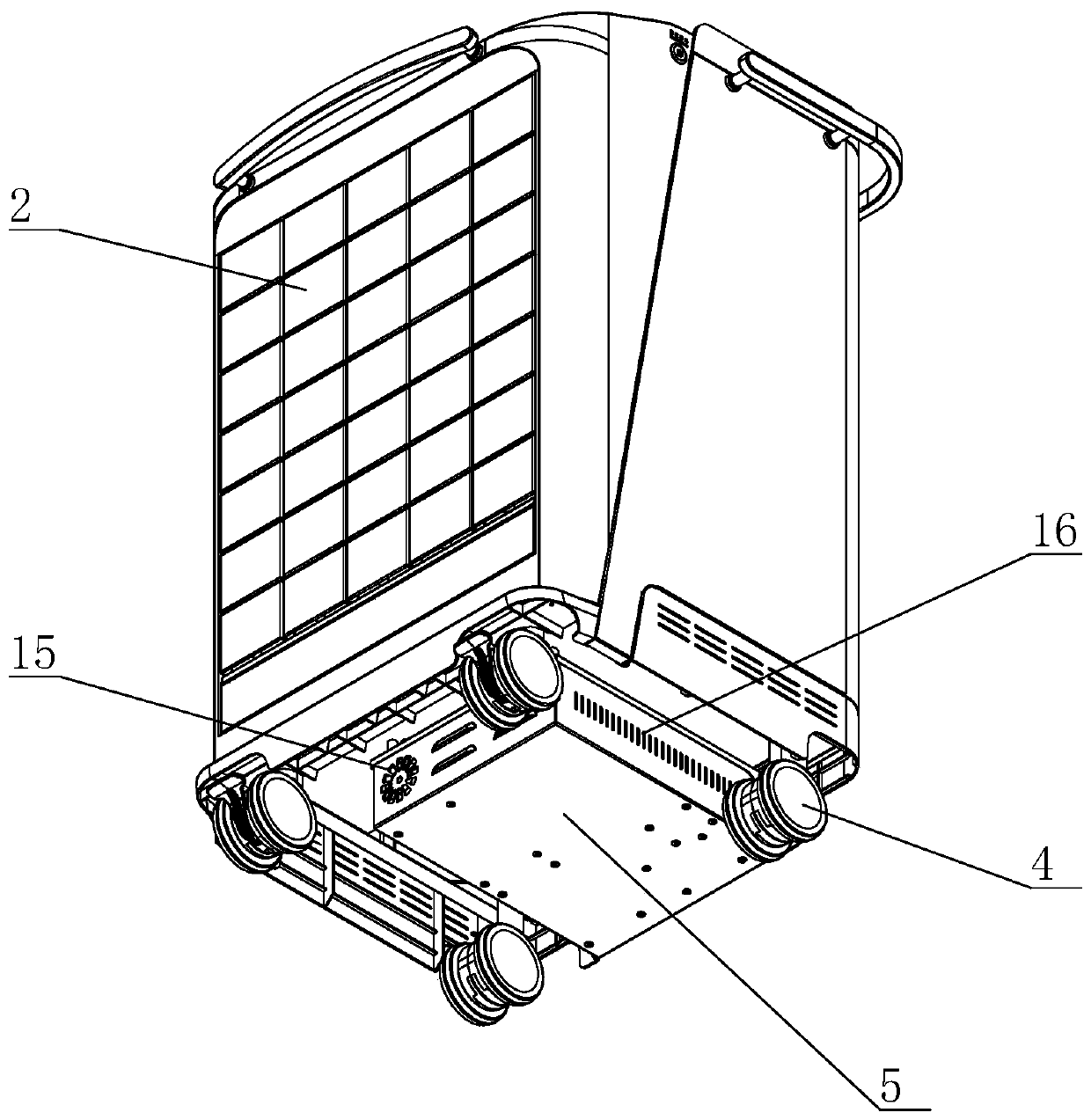

Expandable dressing change vehicle

InactiveCN110215369AReduce difficultyIntelligent NursingNursing accommodationDressing changeEngineering

The invention discloses an expandable dressing change vehicle, and mainly relates to a drug vehicle. The vehicle includes a vehicle body, several drug boxes are arranged on the vehicle body, each drugbox is provided with an intelligent lock, and the top of the vehicle body is provided with an intelligent control system; the drug boxes are arranged on the side, near a front plate, in the vehicle body in a pull-push mode like a drawer, and one intelligent lock corresponds one drug box; the intelligent control system includes a control box, a display screen and a control key, the display screen,the control key and the intelligent locks are connected with a control panel in the control box, and a power supply box is used for supplying power for the intelligent locks and the control panel. The expandable dressing change vehicle has the advantages that drugs required by each patient can be stored intensively, drug overlap does not occur, and medical personnel do not need to take much timeand labor to find the drugs. Moreover, intelligent nursing can be achieved, the pressure and errors of intern nurses can be reduced, and the difficulty of nursing work is greatly reduced.

Owner:LAIWU VOCATIONAL & TECHNICAL COLLEGE

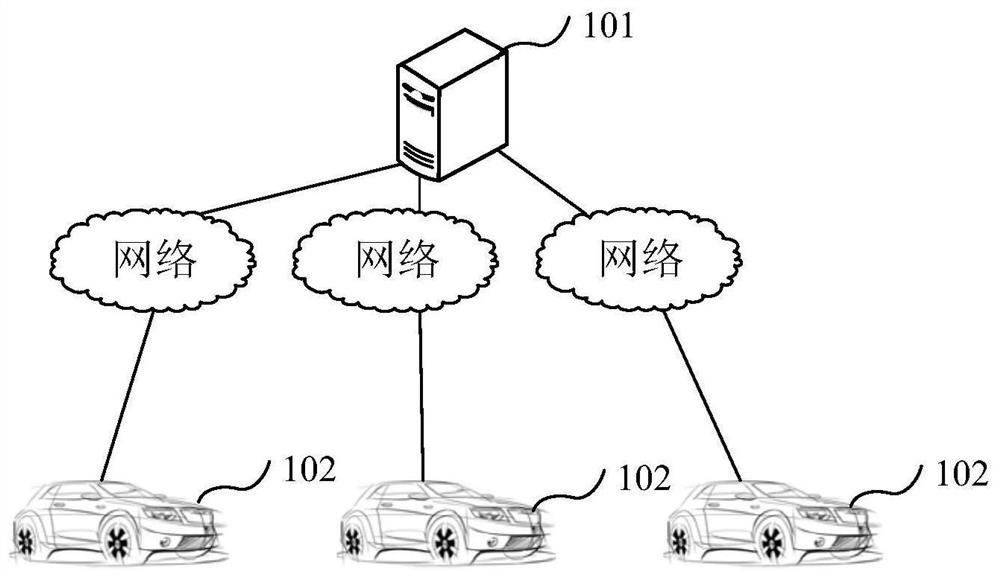

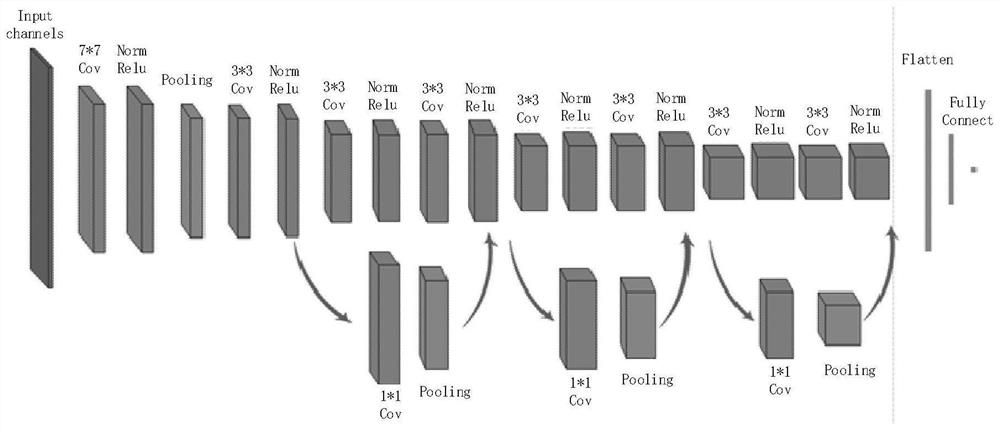

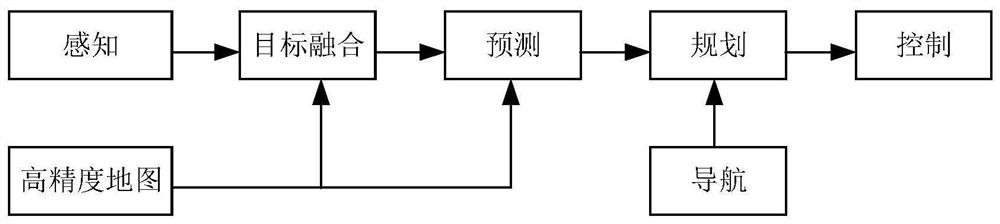

Vehicle intention prediction method and related device

ActiveCN114283576AAvoid overlappingEasy to learnDetection of traffic movementAnti-collision systemsSimulationComputer vision

The embodiment of the invention provides a vehicle intention prediction method and a related device, and the method comprises the steps: obtaining an intention prediction model which is used for predicting the driving intention of a vehicle in all directions of an intersection; performing rasterization coding on the target driving data to obtain a target image sample, wherein different types of data in the target driving data and data corresponding to different exit directions are respectively coded into different data channels in one image sample; and inputting the target image sample into the intention prediction model to obtain the intention probability of driving of the second vehicle in each direction of the intersection. According to the embodiment of the invention, the intention prediction accuracy of the vehicle in a complex road condition can be improved.

Owner:HUAWEI TECH CO LTD

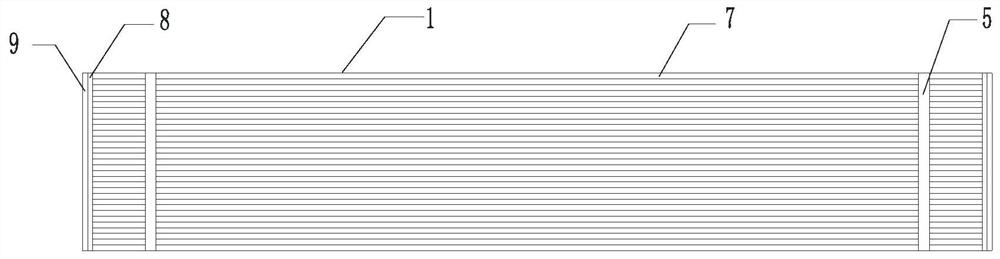

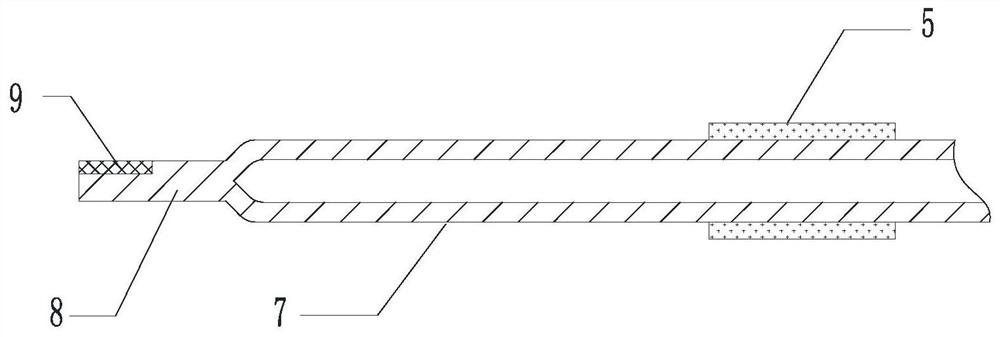

Hollow fiber curtain type membrane, membrane element and manufacturing method thereof

ActiveCN112337311AImprove water production efficiencyReduce wasteSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWater productionAdhesive glue

The invention discloses a hollow fiber curtain type membrane, a membrane element and a manufacturing method thereof. The membrane element comprises a membrane fixing frame and a membrane set arrangedin the membrane fixing frame and composed of a plurality of membranes arranged in a stacked mode, and each membrane is formed by compounding a plurality of hollow fiber membrane filaments with openings in the two ends in parallel; the membrane fixing frame comprises an upper water collecting tank and a lower water collecting tank which are arranged on the outer sides of the two ends of the membrane set in a sleeving mode correspondingly, and two communicating pipes arranged on the two sides of the membrane set and used for communicating the two ends of the two water collecting tanks. The manufacturing method comprises the following steps of manufacturing the membrane, assembling a membrane, manufacturing a membrane set, namely putting the sealing connecting part of the assembled membrane into the sealing glue inner groove, pouring glue into the sealing glue inner groove, and cutting off the bottom of the sealing glue inner groove from the upper part of the sealing connecting part afterthe glue is cured, so as to obtain the membrane set, and mounting the membrane set. In the manufacturing process, waste of membrane filaments is reduced, and the production efficiency is improved; meanwhile, during use, the membrane filaments are not crossed and wound with one another, so that the water production efficiency is improved.

Owner:NINGBO SHUIYI FILM TECH DEV CO LTD

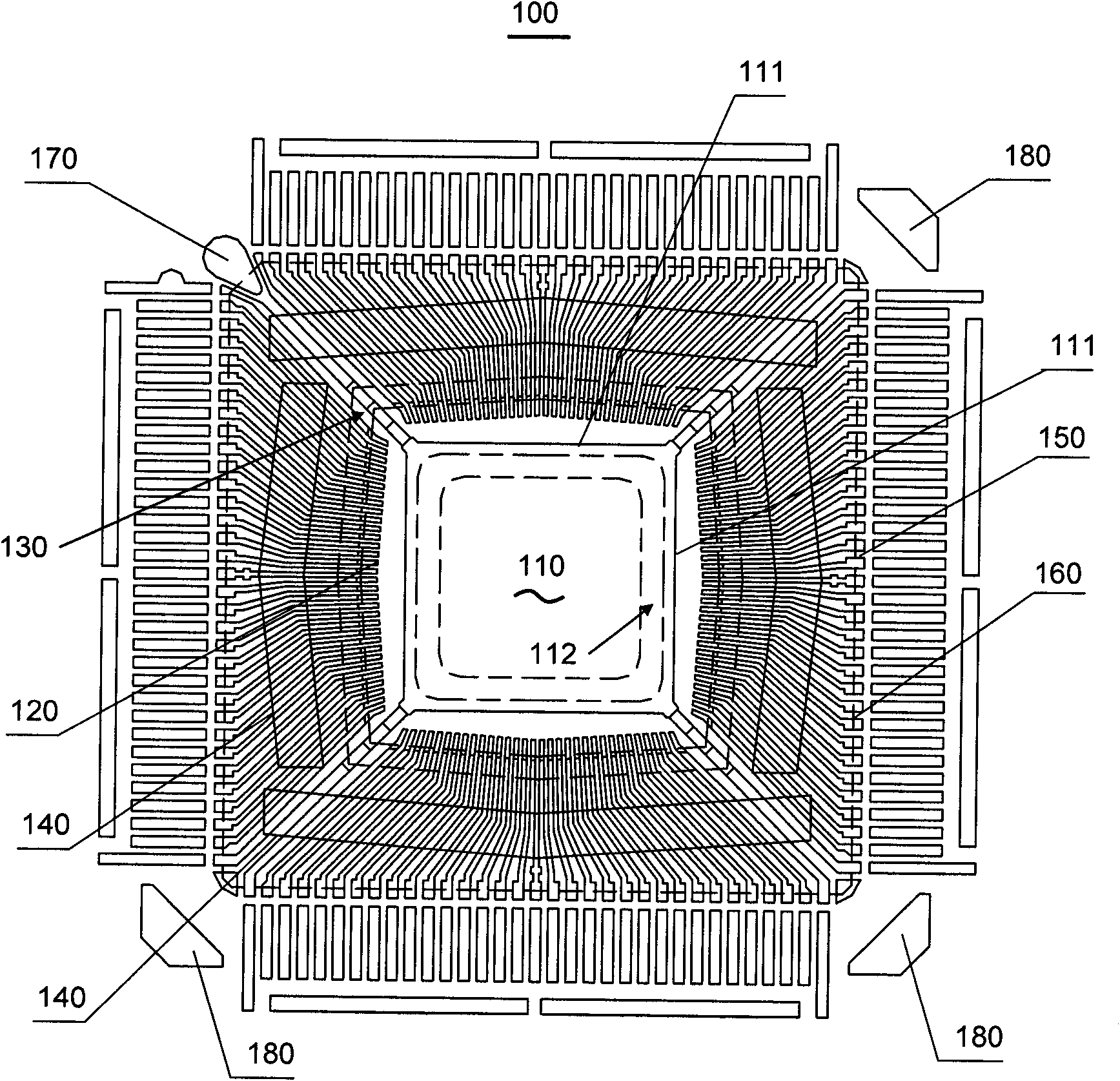

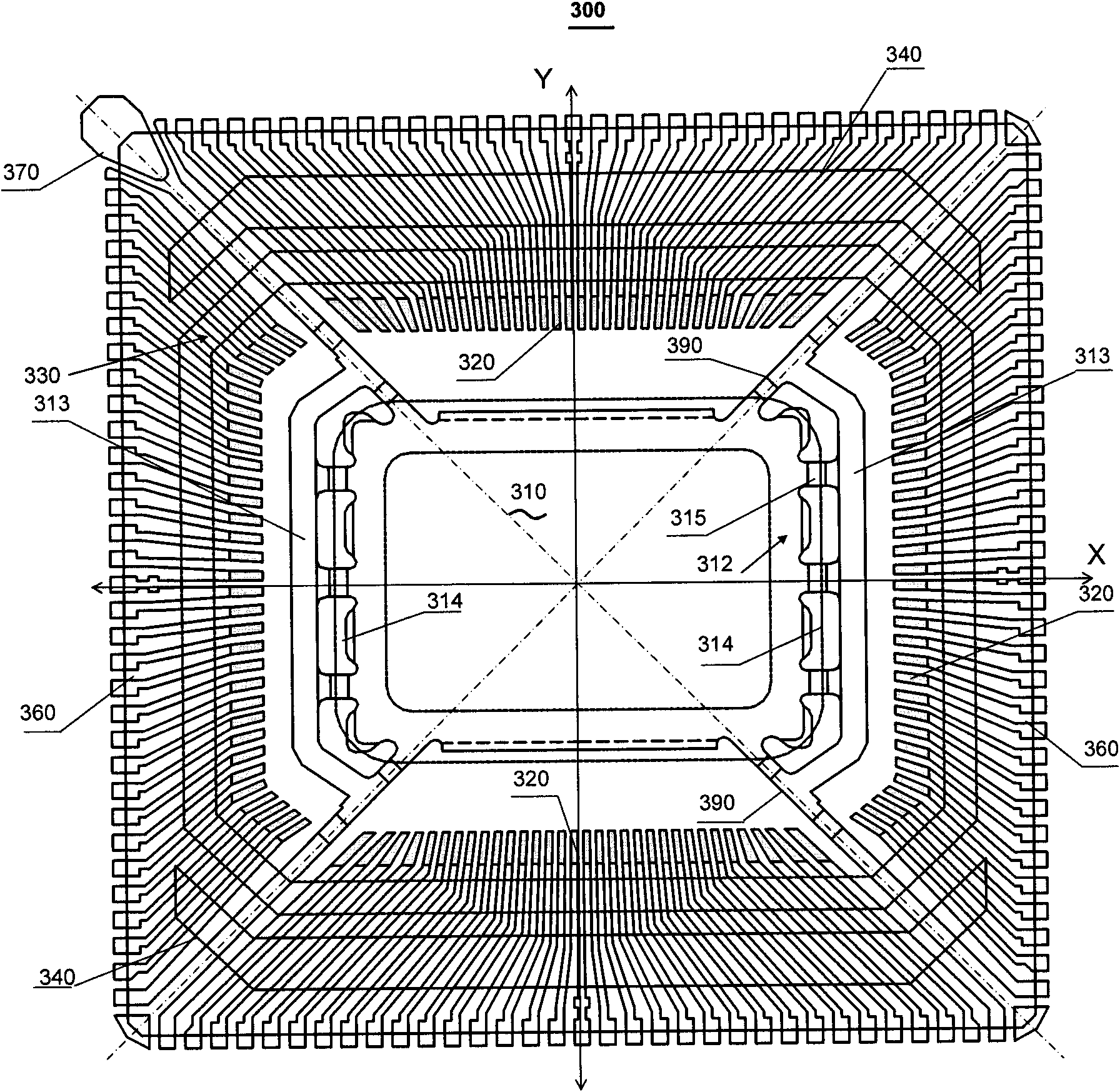

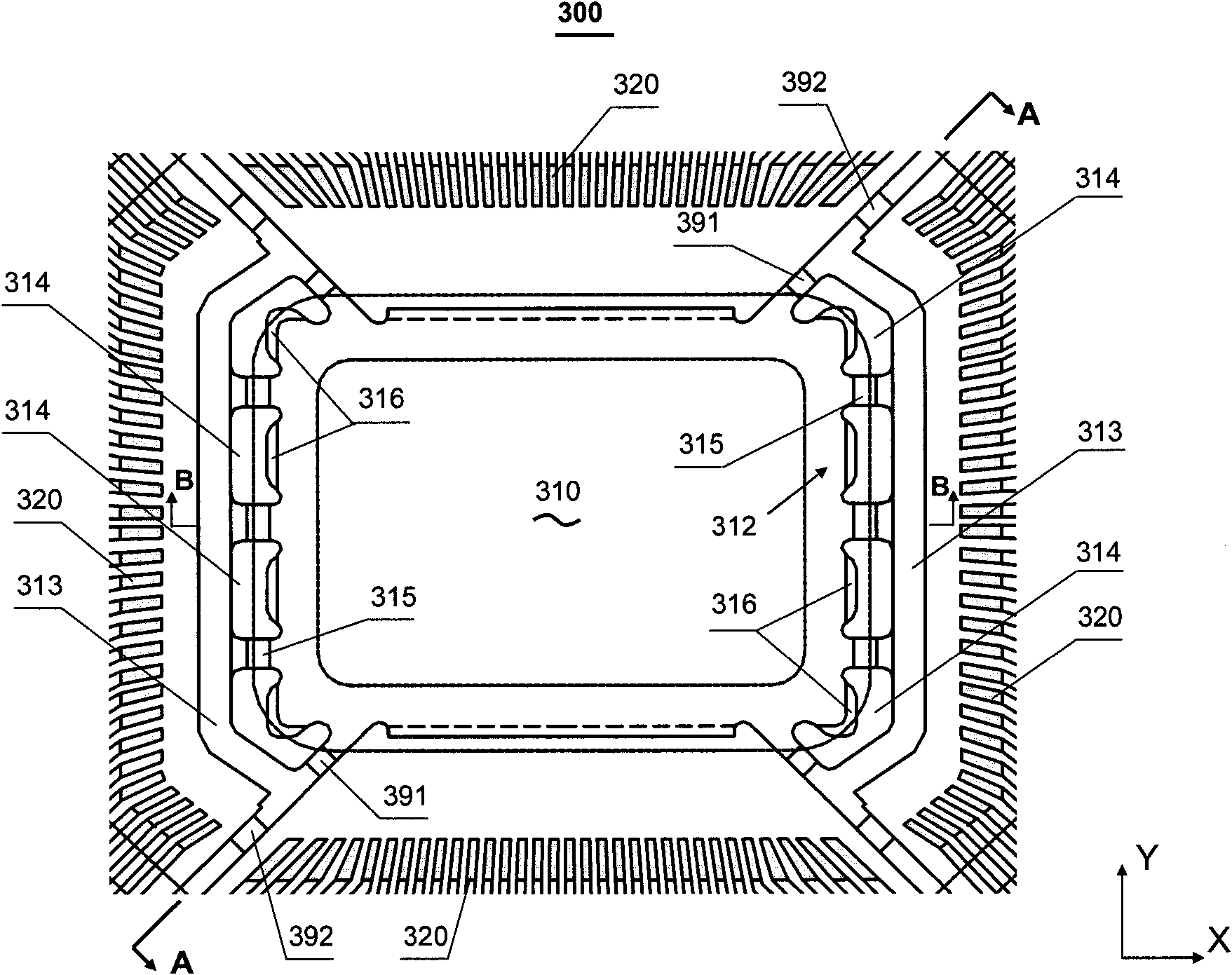

High-alignment-packaging-type lead frame and packaging structure thereof

ActiveCN102332441BNo crossoverAvoid asymmetric deformationSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

Owner:WUXI CHINA RESOURCE MICRO ASSEMBLY TECH

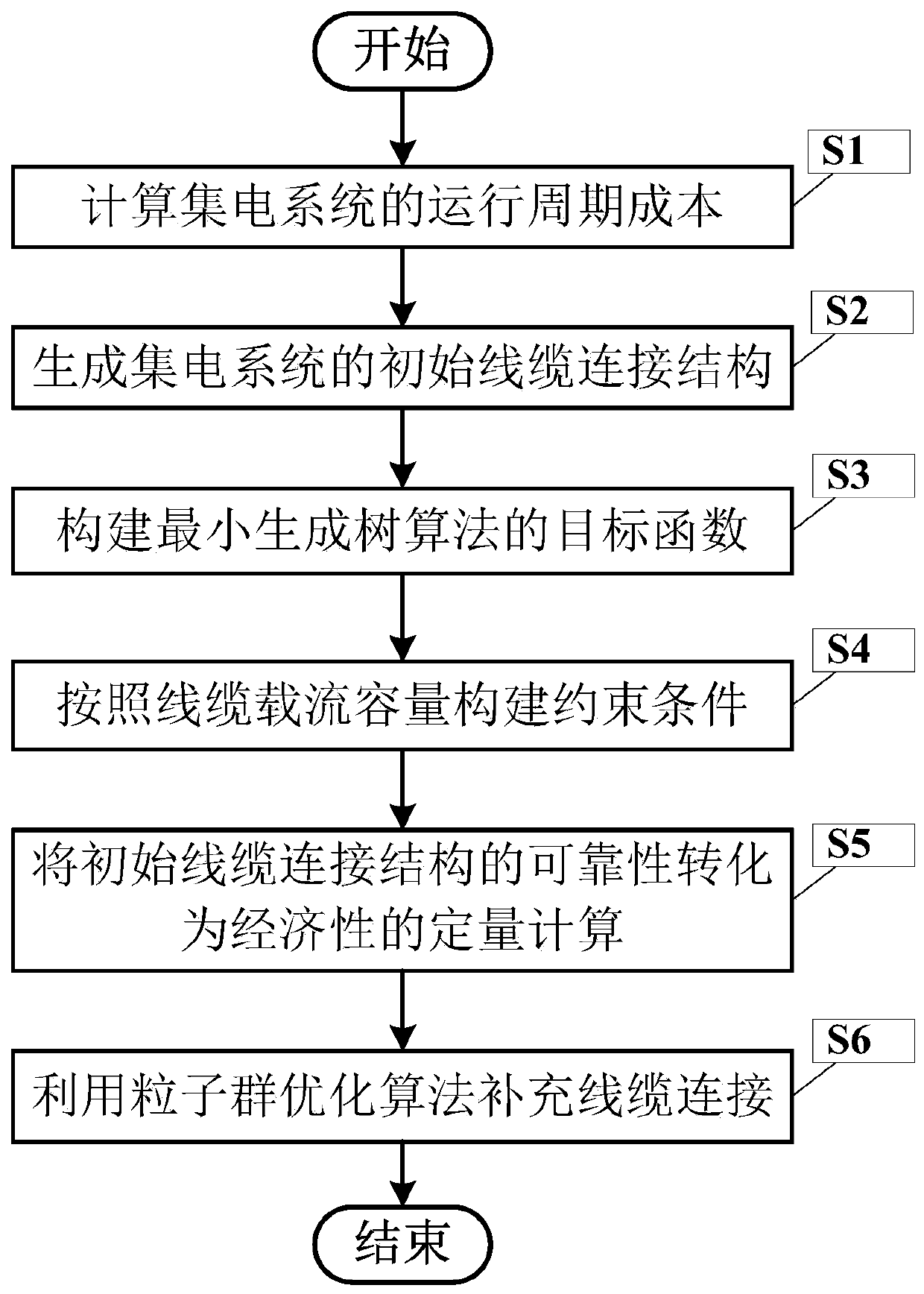

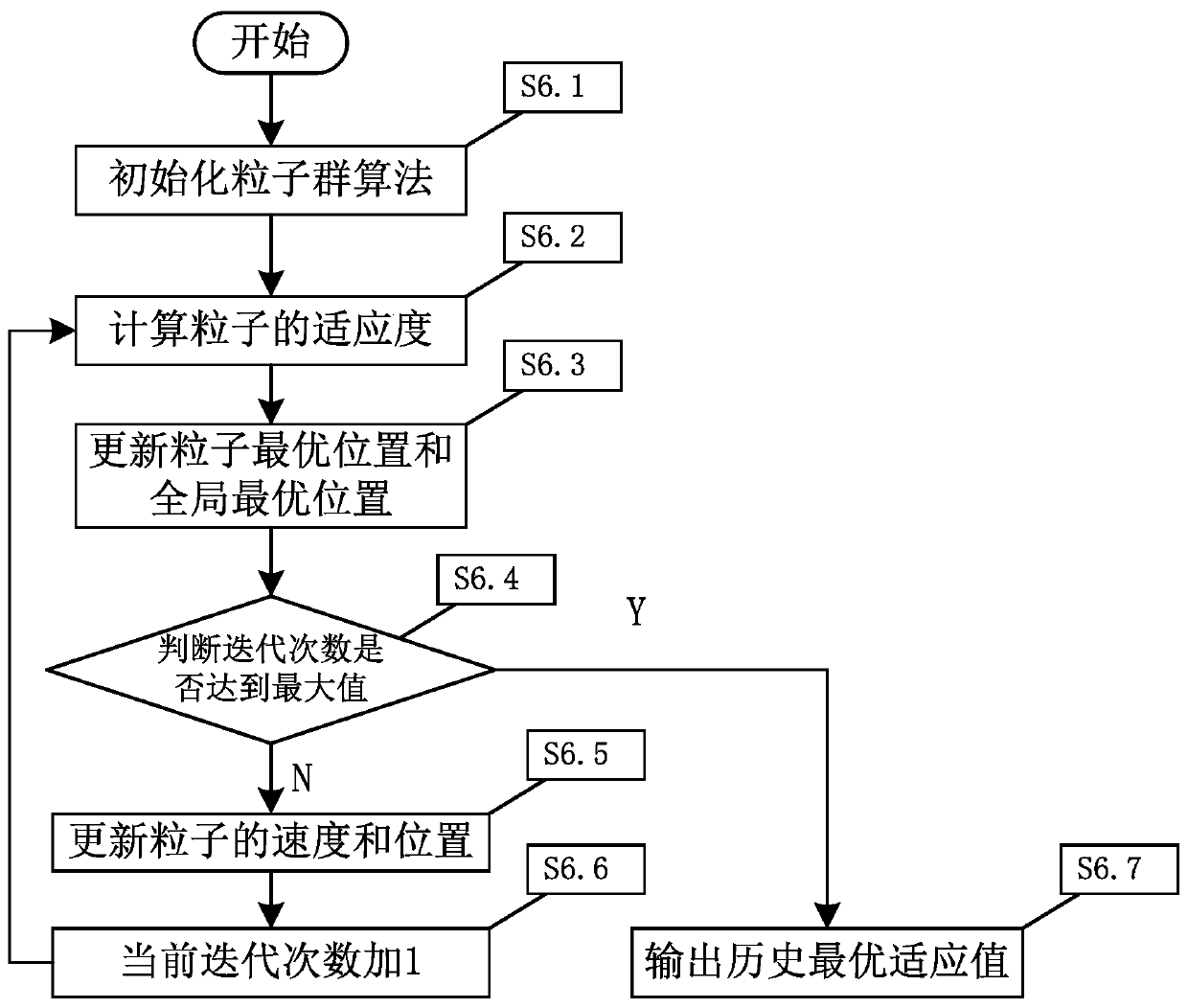

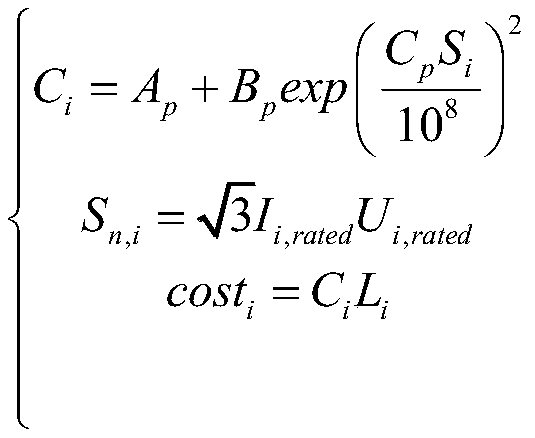

Hybrid cable connection method considering reliable wind power plant current collection system

ActiveCN110705813AReasonable planningLow costArtificial lifeWind energy generationCollection systemParticle swarm algorithm

The invention discloses a hybrid cable connection method considering the reliability of a wind power plant current collection system, and the method comprises the steps: taking an economic index and areliability index as optimization objectives, considering the power generation cost of a wind power plant in the whole operation period, analyzing the reliability of an initial cable connection structure, and carrying out the conversion of reliability and the quantitative calculation of economy; and on the basis of economic calculation and constraint conditions, adopting a particle swarm algorithm to find a proper cable and add the cable into the initial cable layout, so that a final cable layout can be formed.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

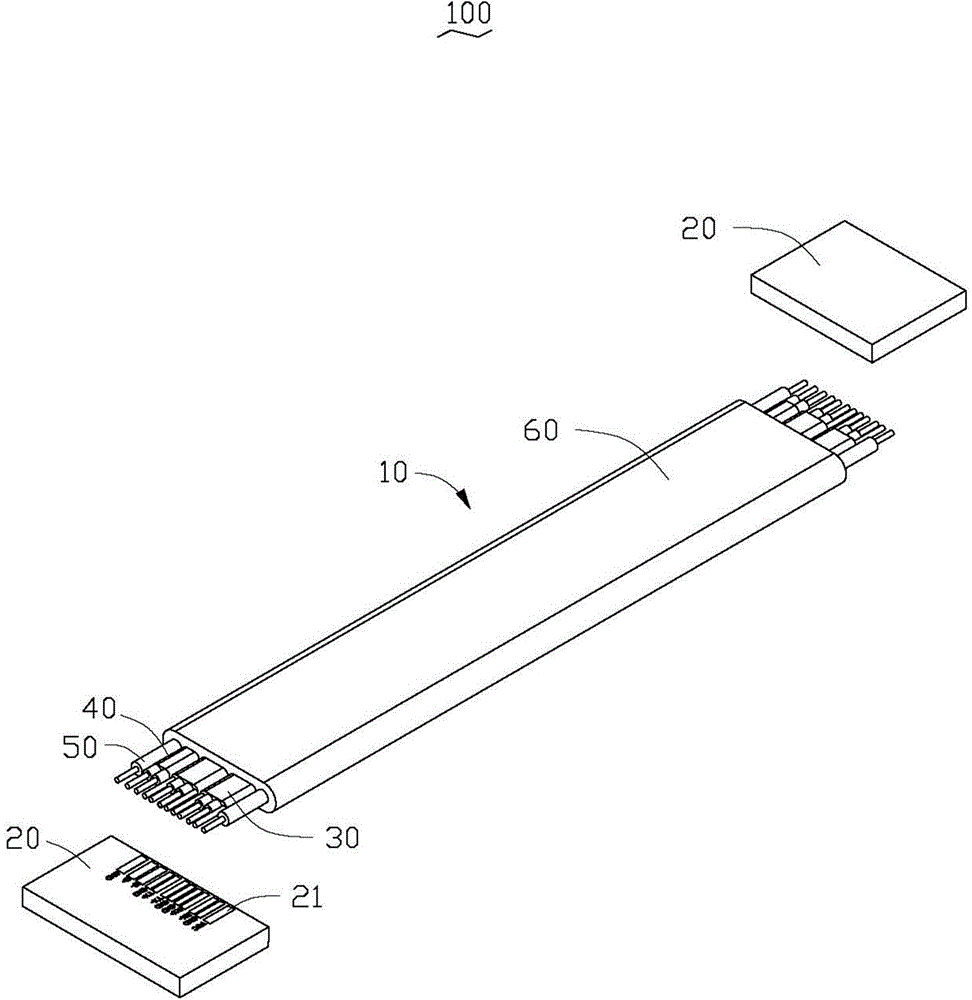

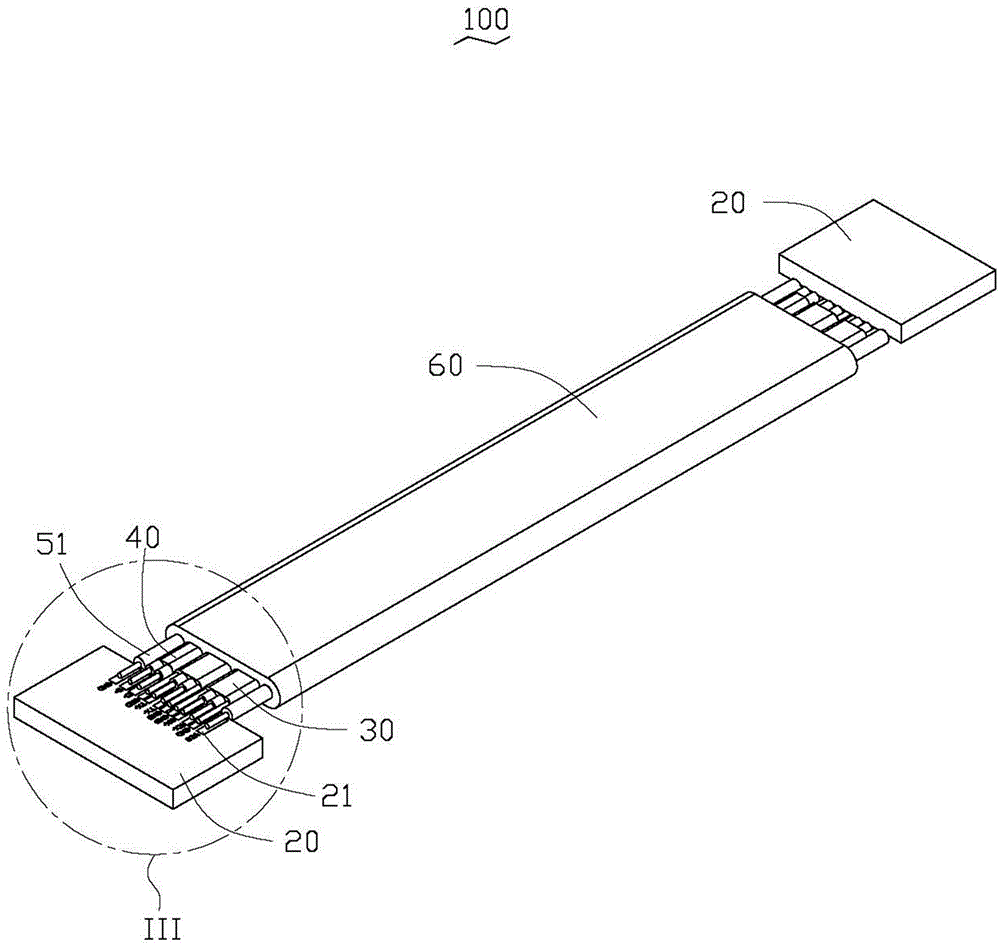

USB connector

InactiveCN104868267AReduce distractionsImprove product performanceCoupling device detailsInsulated cablesSignal linesUSB

A USB connector comprises a plug-in joint and a cable. The plug-in joint is provided with a switching board. The switching board is provided with a plurality of welding strips. The cable comprises a plurality of signal line modules. The signal line modules are parallel to each other and approximately arranged in one plane. Each signal line module can be fixed to the welding strip corresponding to the switching board.

Owner:HONG FU JIN PRECISION IND WUHAN CO LTD +1

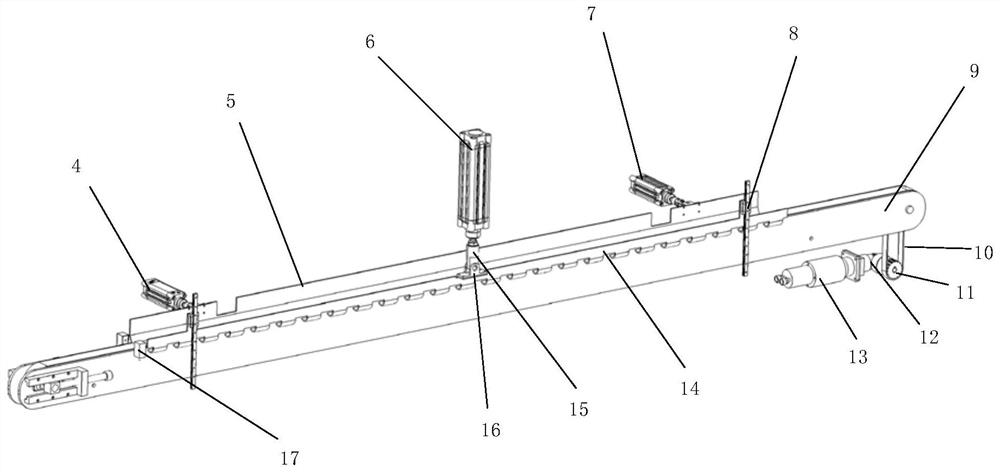

Arrangement device for strip-shaped materials with asynchronous feeding speeds after cutting off

ActiveCN112919103AAvoid destructionReduce frictional resistanceConveyorsConveyor partsControl systemEngineering

The invention belongs to the field of machining, and particularly relates to an arrangement device for strip-shaped materials with asynchronous feeding speeds after cutting off. The arrangement device comprises a power system, a control system, a material pushing plate mechanism, a material supporting plate mechanism, a material arranging conveying belt and a material conveying belt; and the material arranging conveying belt comprises a plurality of material arranging units, through coordination and cooperation of material pushing plates and material supporting plates in the material arranging units, the operation conditions are judged through the control system, and therefore after the slender materials are cut off, ordered placement in the multiple channels at different feeding speeds is completed. One-to-one independent conveying is carried out on a single material arranging unit and a single material, and the material pushing plate mechanism is matched with the material supporting plate mechanism, so that the slender materials which are cut into a certain length can be tidily placed on the material conveying belt to be conveyed to the next working procedure, the material arranging effect is good, the arrangement device can adapt to the conditions that the material discharging speed fluctuates within a certain range and the advancing speeds of multiple materials are inconsistent, the damage degree to the materials is small, and manual intervention is not needed.

Owner:NANJING UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com