Hollow fiber curtain type membrane, membrane element and manufacturing method thereof

A fiber membrane and curtain membrane technology, which is applied in the field of membrane element production, can solve the problems of high production cost, waste of membrane filaments, and large consumption of human resources, and achieve the effects of improving service life, reducing fatigue fracture, and improving water production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

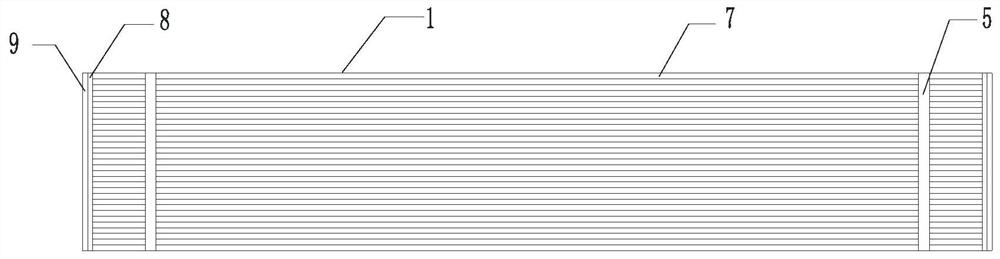

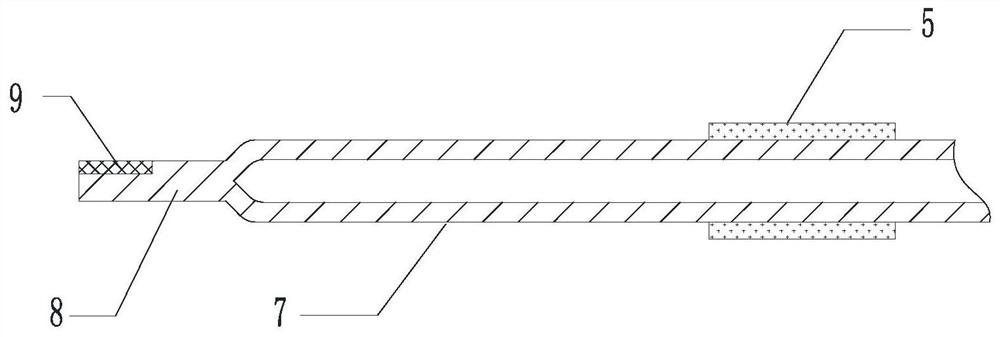

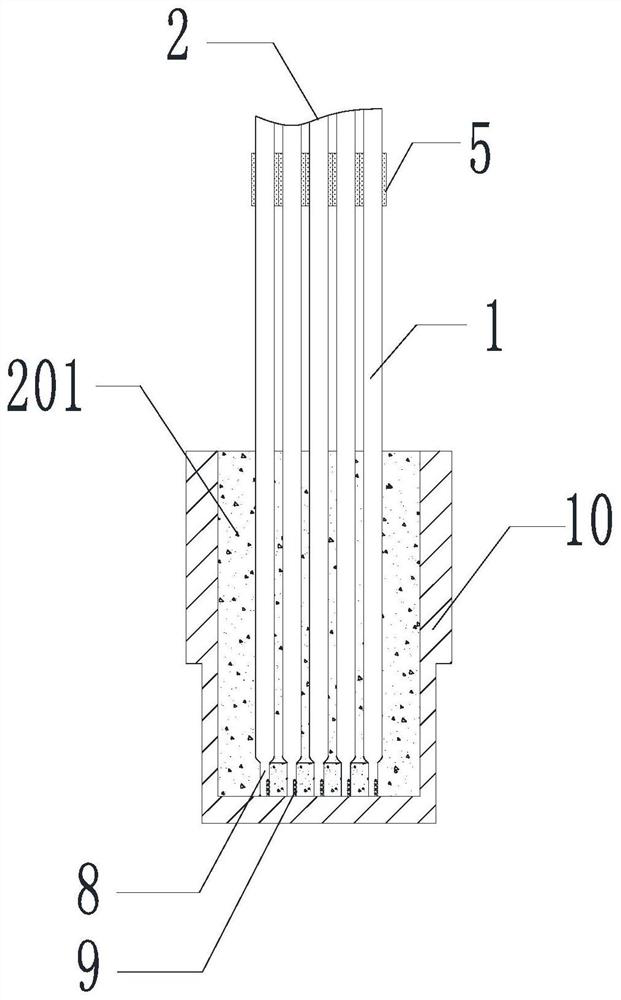

[0066]In the hollow fiber curtain membrane element in Example 1, the diaphragm group is formed by stacking 16 groups of diaphragms. The outer diameter of the hollow fiber membrane filaments of each membrane is 2.05mm, the number of membrane filaments is 120, and the length of the membrane It is 2200mm.

Embodiment 2

[0068]In the hollow fiber curtain membrane element in Example 2, the diaphragm group is formed by stacking 16 groups of diaphragms, the outer diameter of the hollow fiber membrane filaments of each membrane is 2.3mm, the number of membrane filaments is 40, and the length of the membrane Is 900mm.

Embodiment 3

[0070]In the hollow fiber curtain membrane element in Example 3, the diaphragm group is formed by stacking 16 groups of diaphragms, the outer diameter of the hollow fiber membrane filaments of each membrane is 2.05mm, the number of membrane filaments is 100, and the length of the membrane 1300mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com