Patents

Literature

3754results about How to "Stable flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reaction chamber

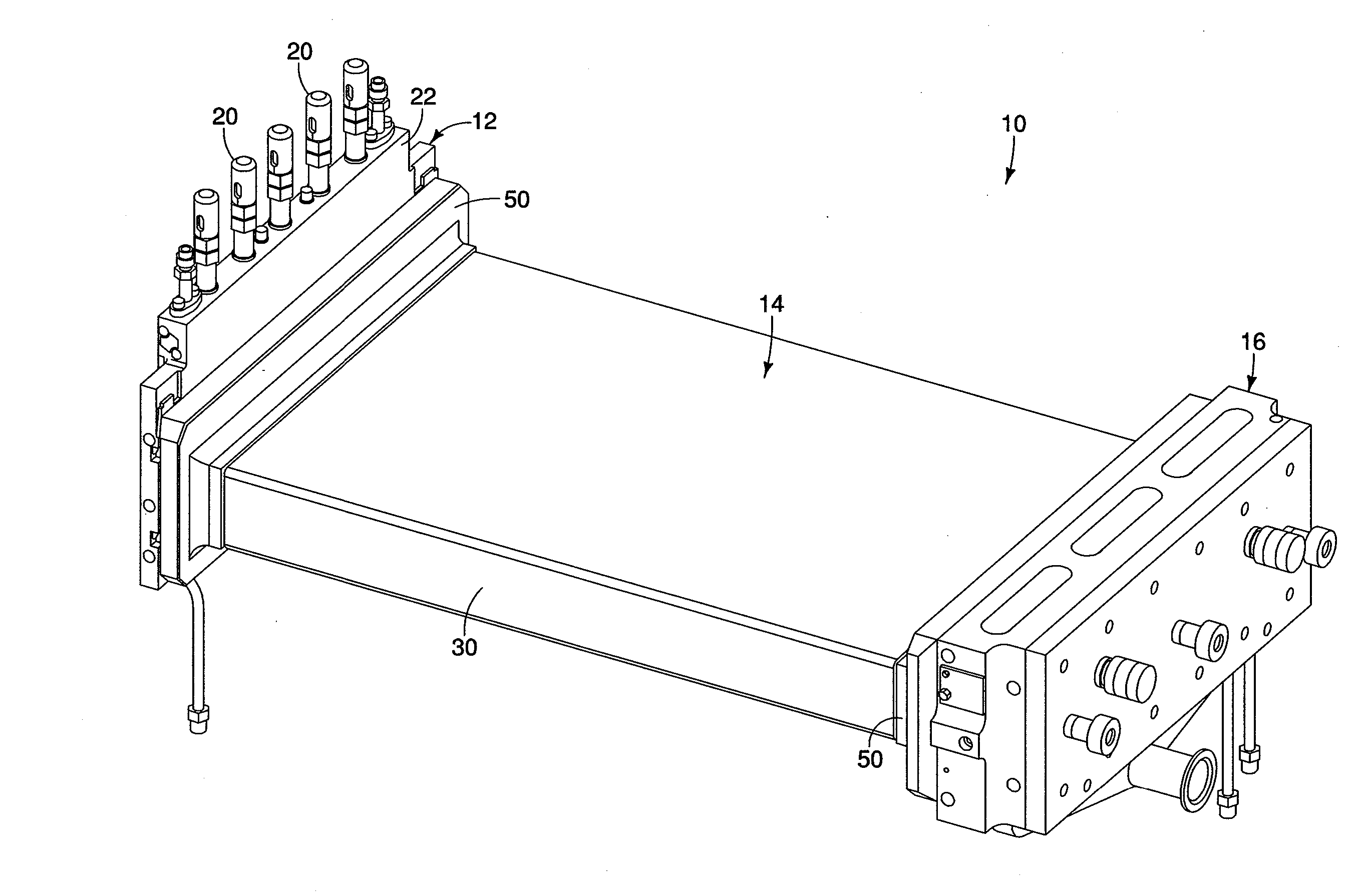

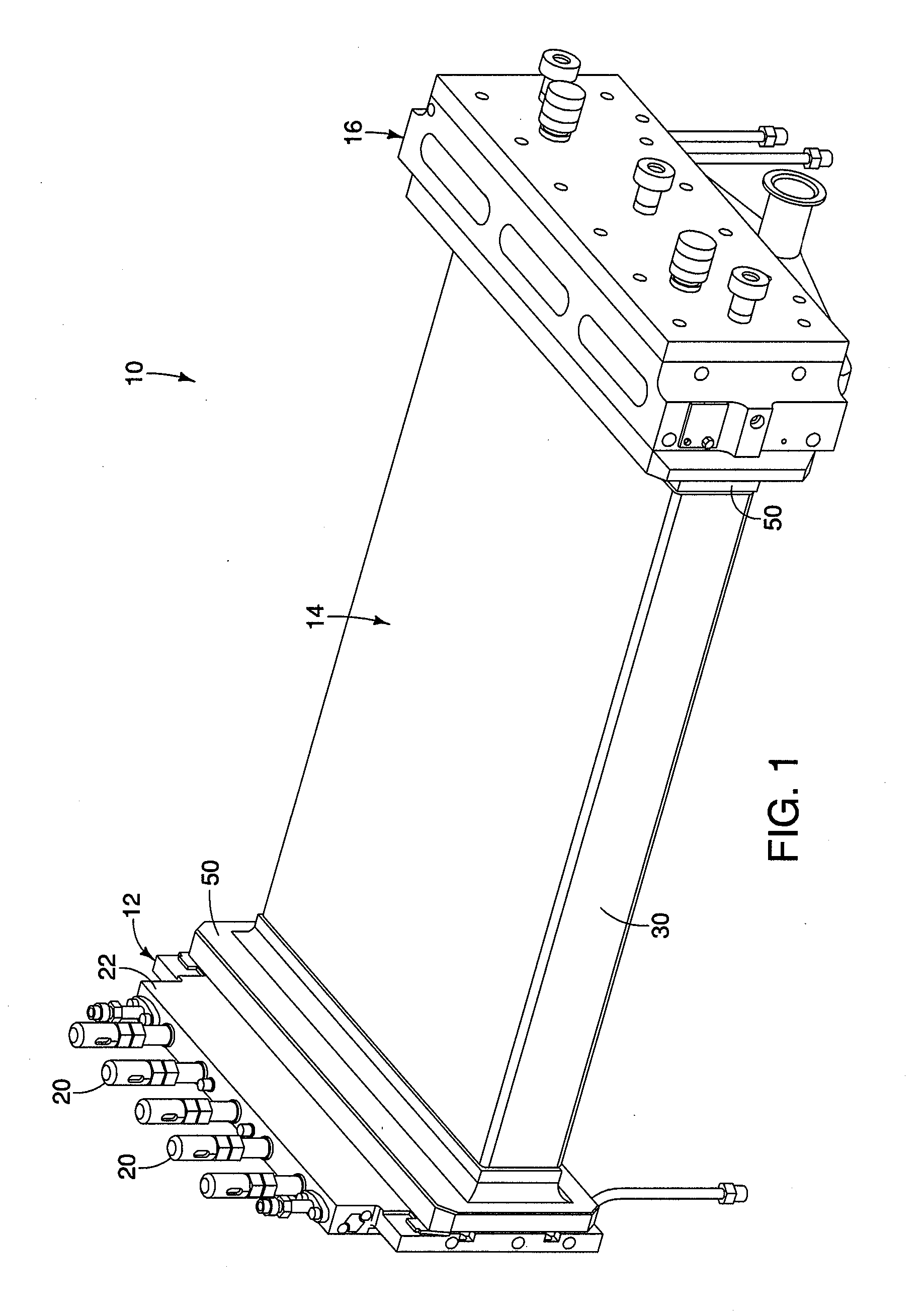

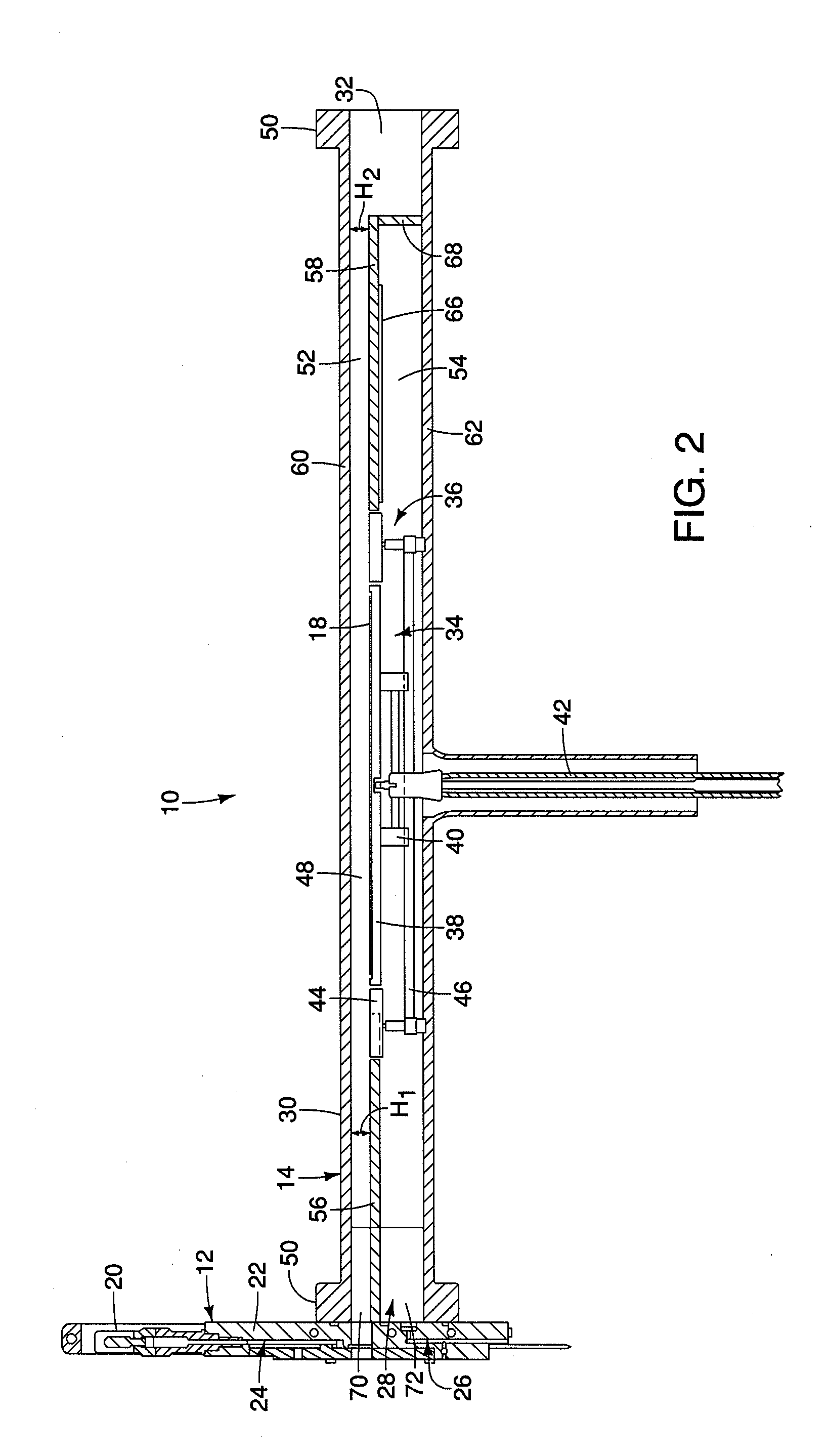

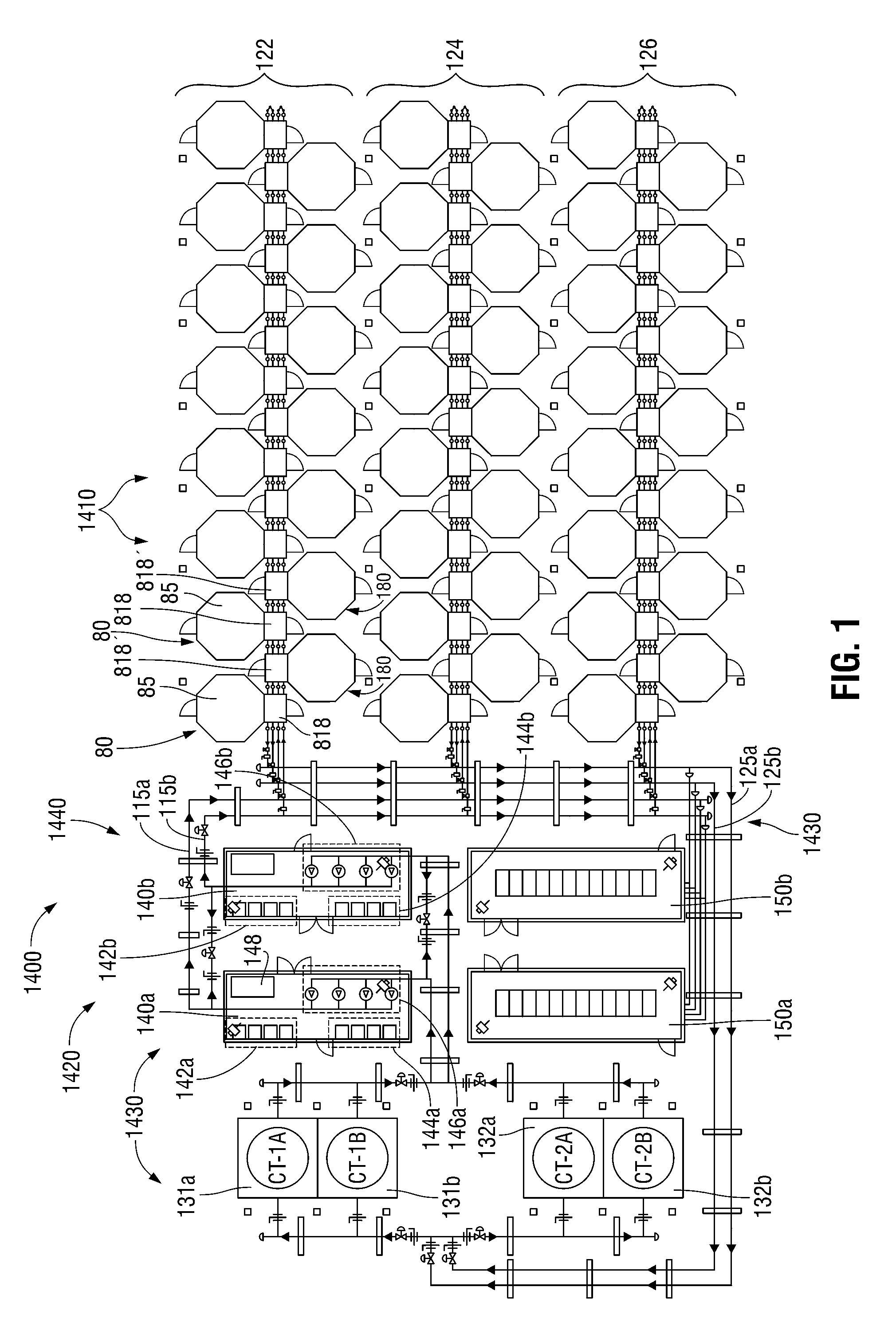

InactiveUS20100116207A1Stable flowSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPhotochemistryReaction chamber

A reaction chamber having a reaction spaced defined therein, wherein the reaction space is tunable to produce substantially stable and laminar flow of gases through the reaction space. The substantially stable and laminar flow is configured to improve the uniformity of deposition on substrates being processed within the reaction chamber to provide a predictable deposition profile.

Owner:ASM AMERICA INC

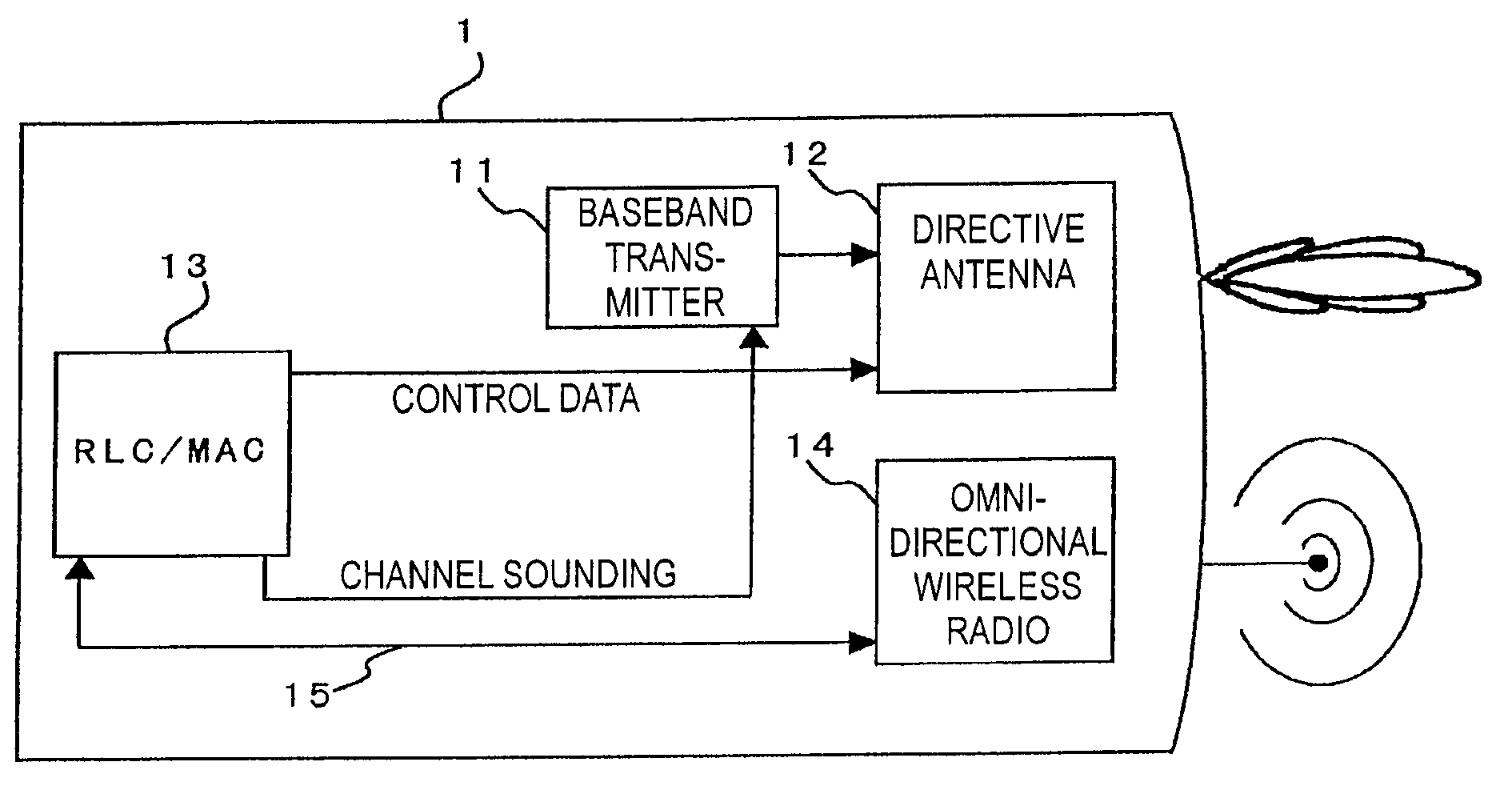

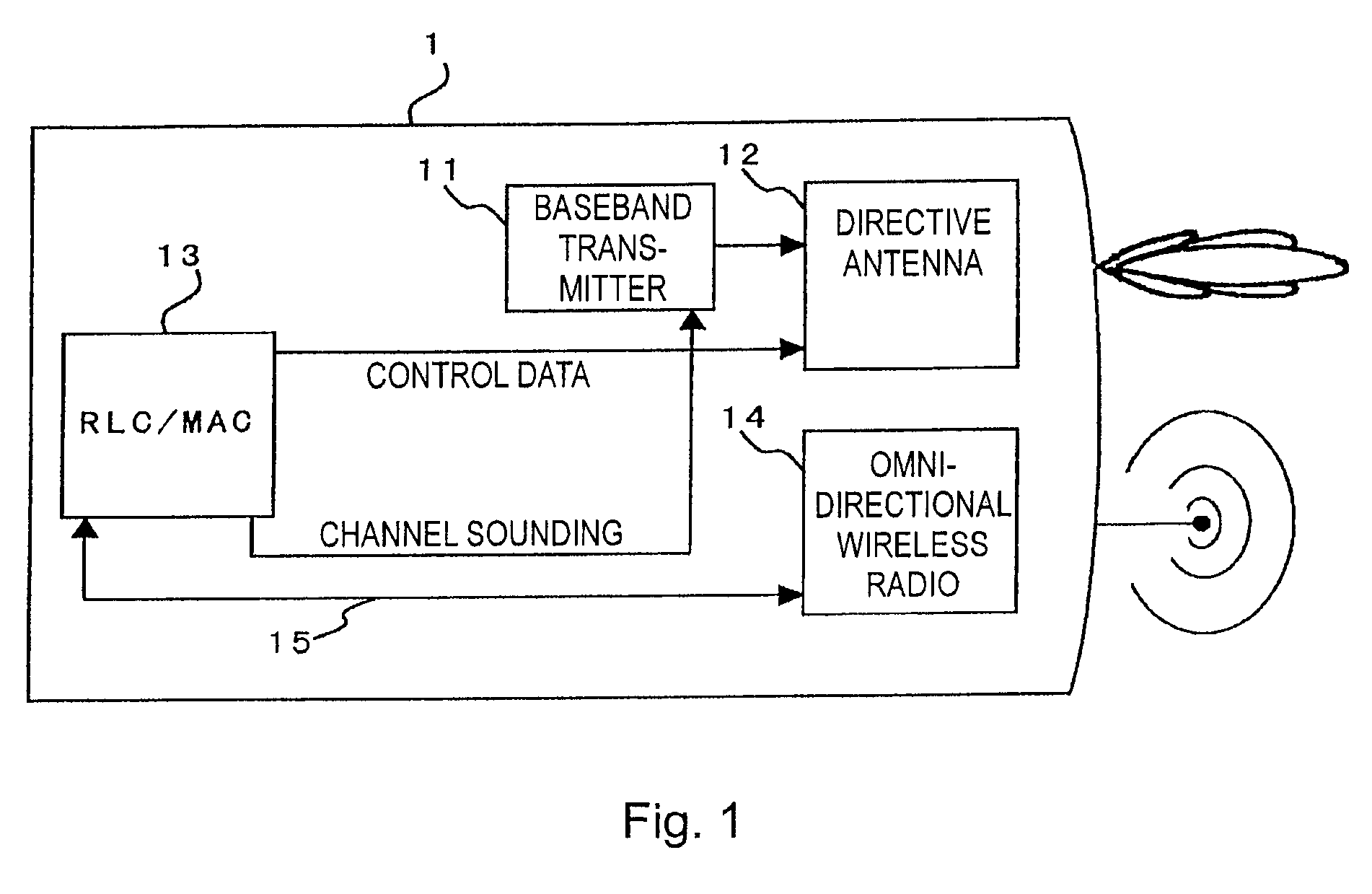

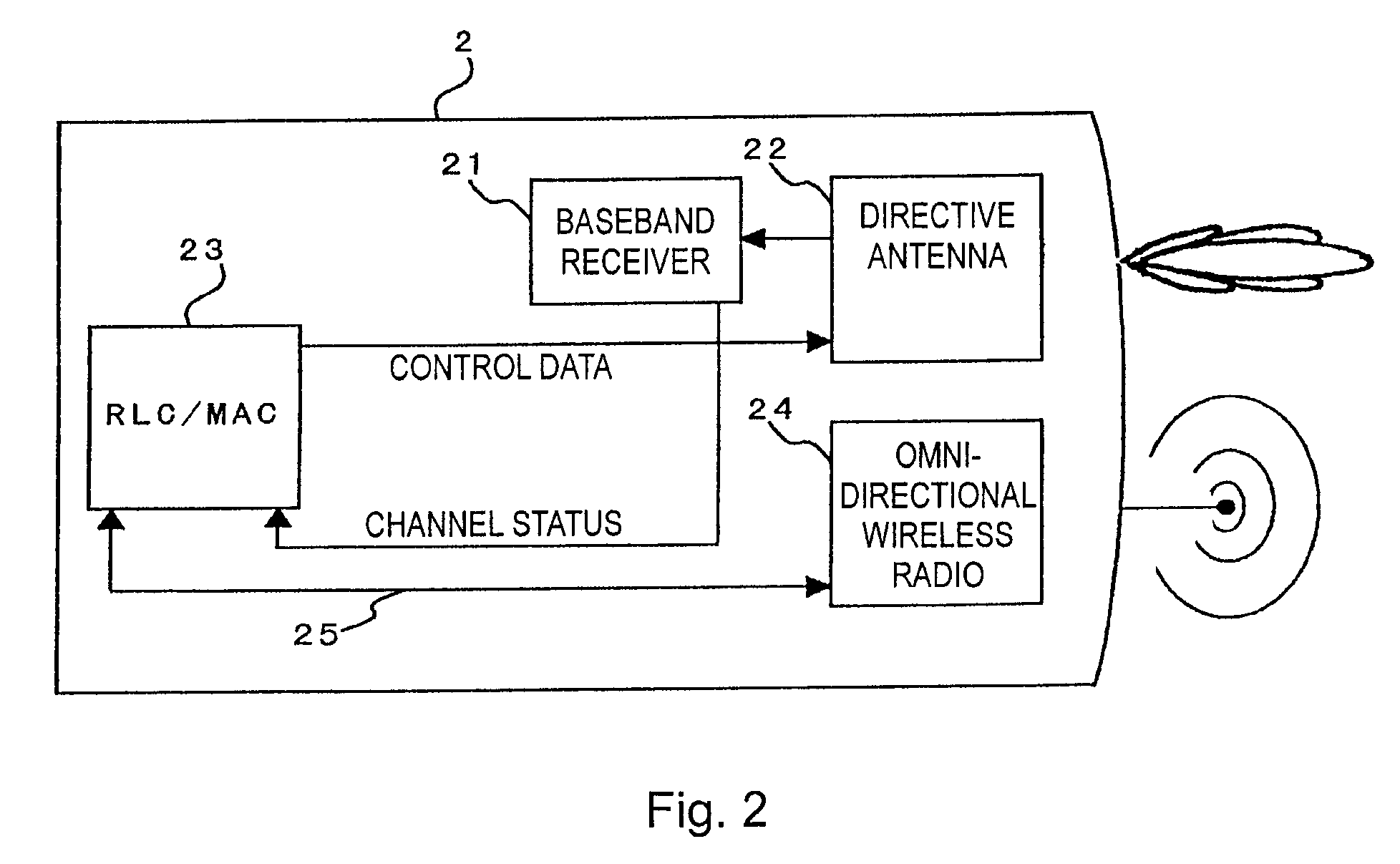

Out-of-band radio link protocol and network architecture for a wireless network composed of wireless terminals with millimetre wave frequency range radio units

ActiveUS20110053498A1Optimization rangeStable flowRadio relay systemsWireless communicationNetwork architectureDirectional antenna

The present invention relates to a wireless transmitter comprising a transmitter radio unit working a wireless transmitter comprising a transmitter radio unit working in the millimeter wave frequency band using a directional antenna and a bidirectional radio unit working in a frequency range different from said transmitter radio unit and using an omnidirectional antenna. The invention further relates to a wireless receiver and a wireless relay.

Owner:SONY CORP

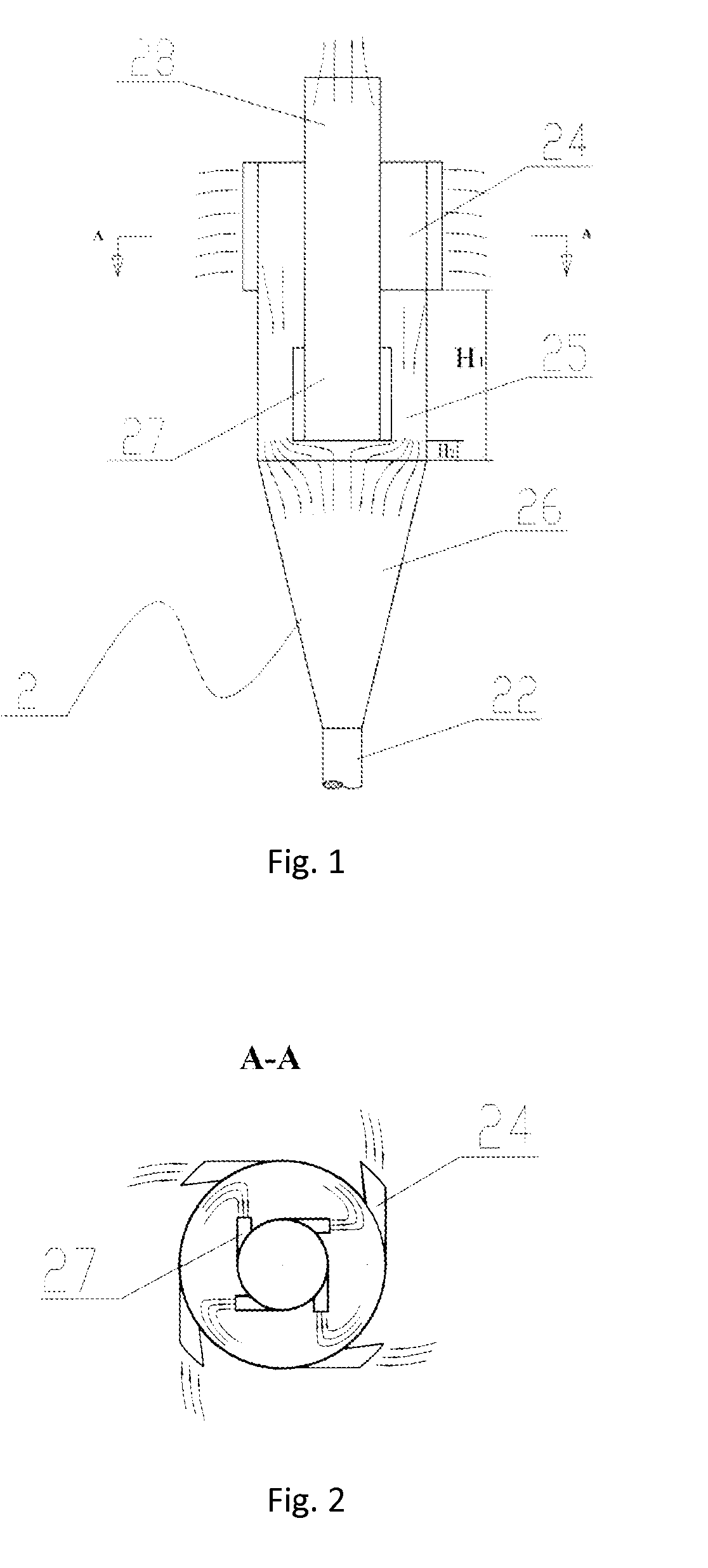

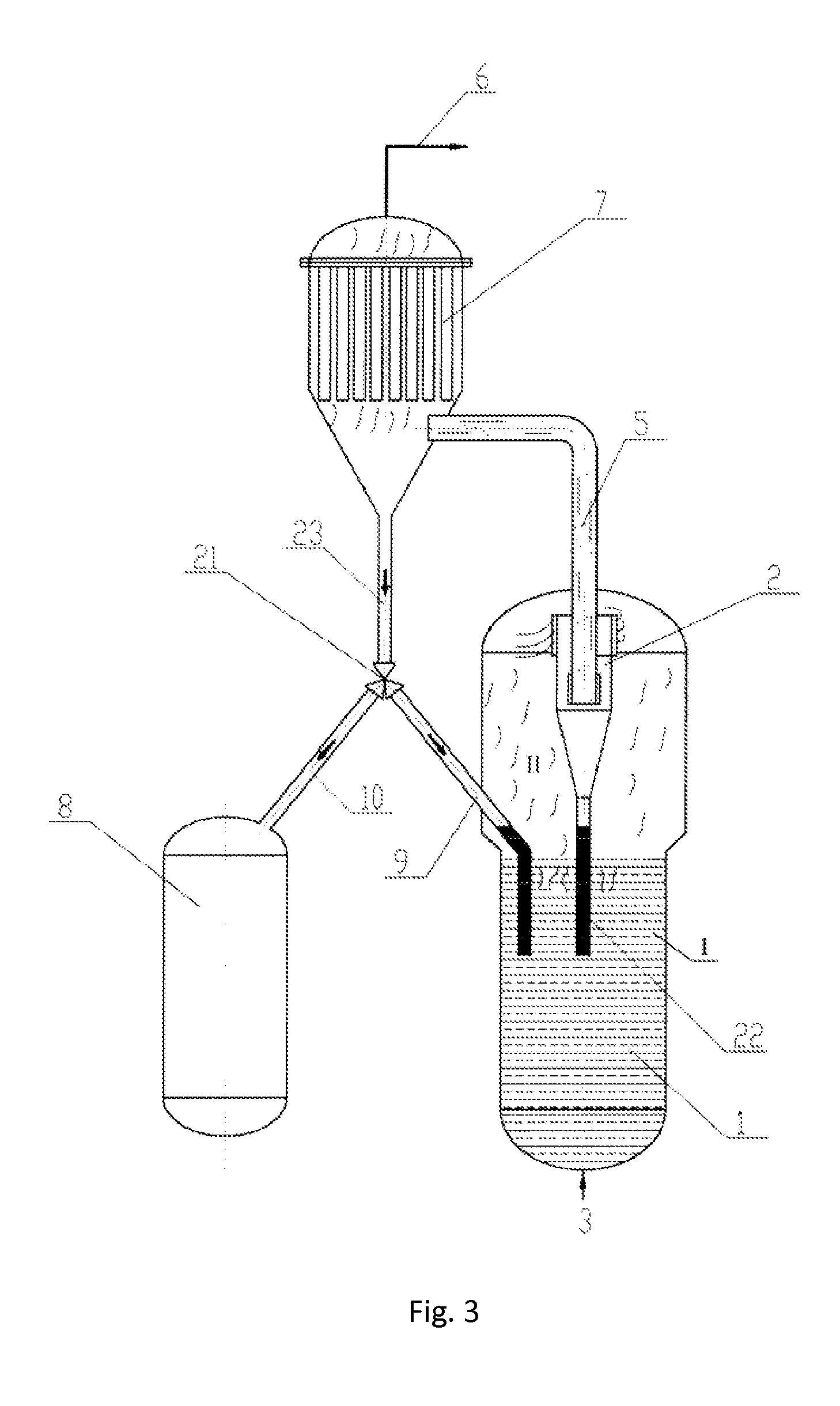

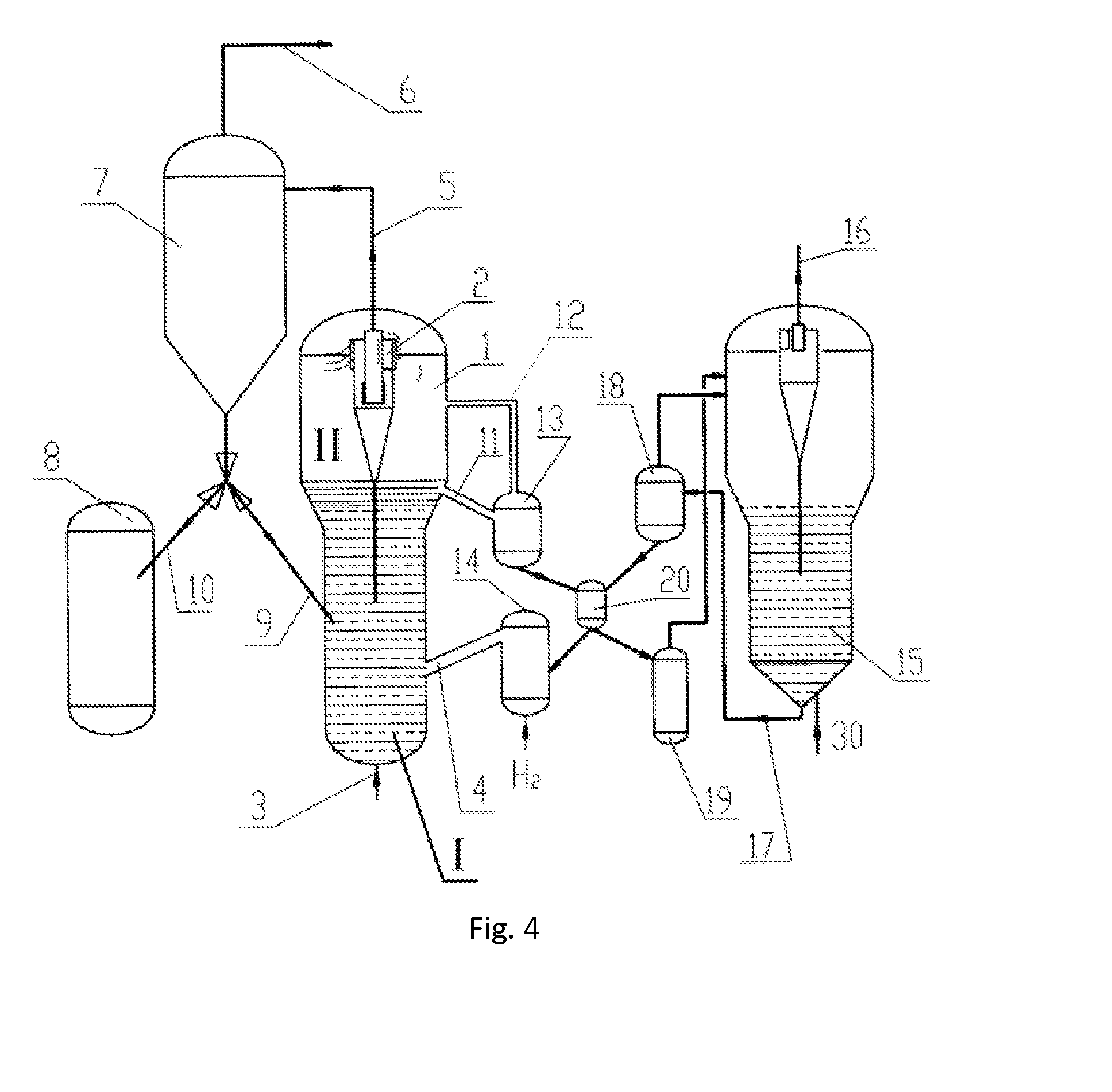

Adsorption Desulfurization Process for Hydrocarbons and a Reaction Apparatus Therefor

ActiveUS20140121438A1Efficient removalReduce flow rateReversed direction vortexHydrocarbonsFluidized bedStraight tube

The present invention relates to an airflow particle sorter, comprising: a top-sealed sorter main body, a discharge port, an outtake tube and at least one directing-intake port; the inner space of the sorter main body, from the above to the bottom, includes, a straight tube zone and a cone zone, the conical bottom of the cone zone is connected to the straight tube zone; the discharge port is located at the bottom of the cone zone; the directing-intake port is installed in the upper part of the straight tube zone in a tangential direction of the straight tube zone, and is communicated with the inner space of the sorter main body; the outtake tube is hermetically inserted into the top of the sorter main body, and extends downwardly to the lower part of the straight tube zone, and the outtake tube has a sealed bottom end; the lower part of the outtake tube is installed with at least one directing-outtake port, which communicates the outtake tube with the inner space of the sorter main body, the directing-outtake port is installed in a tangential direction of the outtake tube. The present invention further relates to a fluidized bed reactor and an adsorption desulfurization reaction apparatus as well as an adsorption desulfurization process.

Owner:CHINA PETROCHEMICAL CORP +1

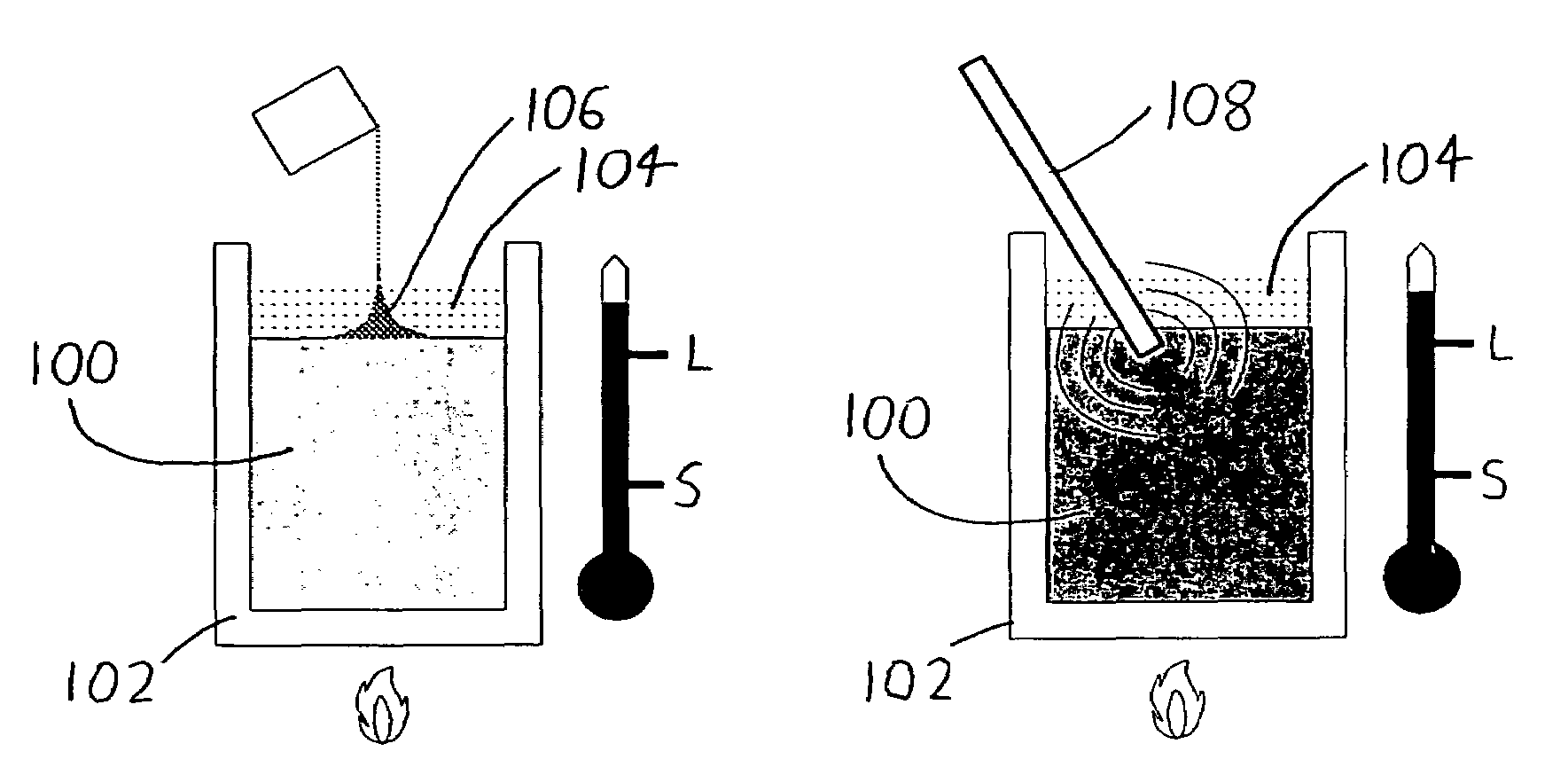

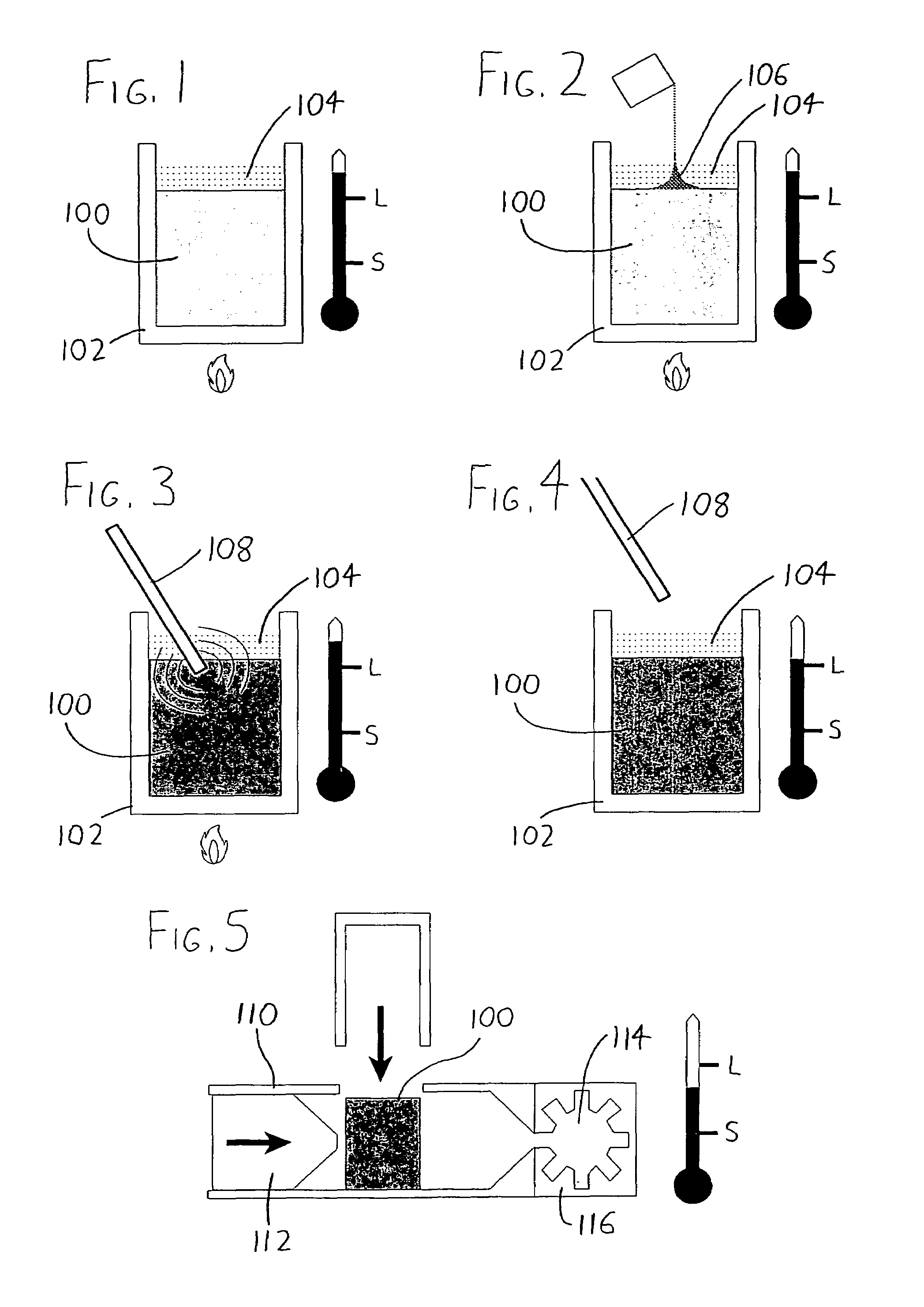

Semi-solid forming of metal-matrix nanocomposites

ActiveUS7509993B1Reduce problemPromote solidification and build-upMaterial nanotechnologyMetal foundingNanometreLiquidus

A metal matrix nanocomposite is formed by heating a metal above its liquidus temperature, adding nanoparticles, and then agitating the mixture with high-frequency (and preferably ultrasonic) vibration. The mixture can then be cooled below the liquidus of the metal to a semisolid state, and placed in a mold to form it into some desired shape. The formed mixture can then be quenched or otherwise allowed to cool to provide an article in finished (or nearly so) form.

Owner:WISCONSIN ALUMNI RES FOUND

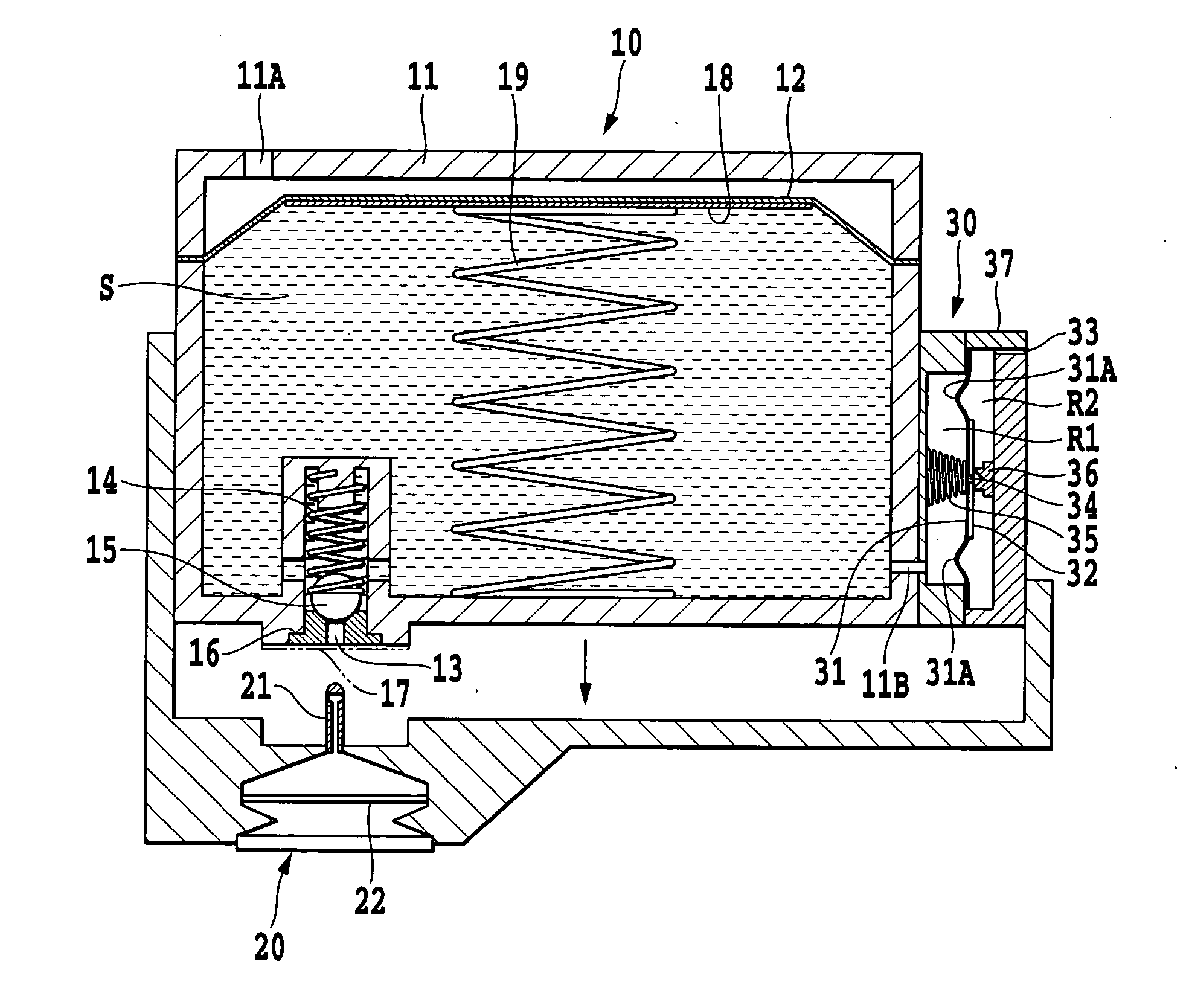

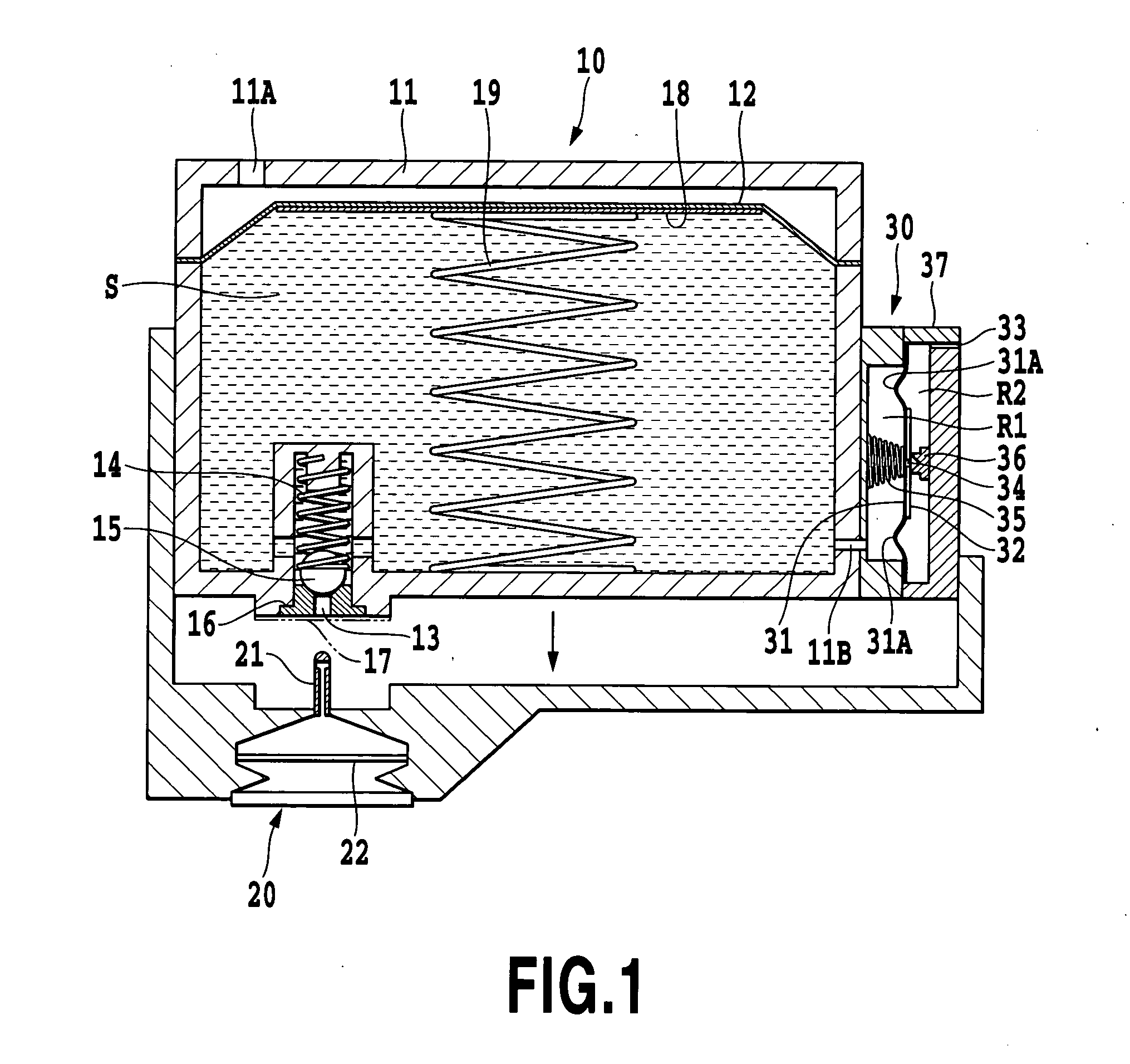

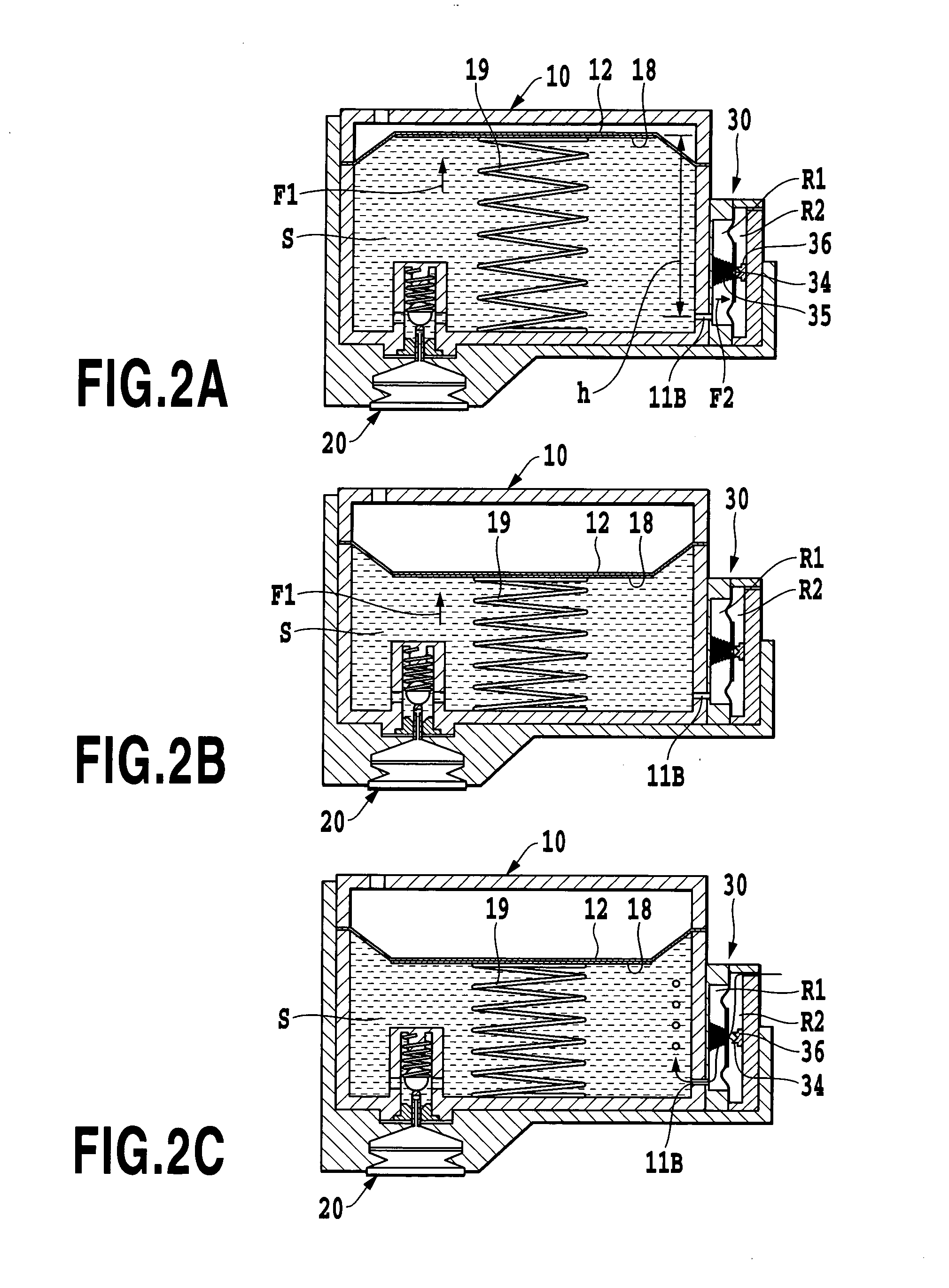

Liquid container, liquid using device, printing apparatus, and method of manufacturing liquid container

InactiveUS20040196341A1Relieve stressStable flow rateDispensing apparatusPrintingEngineeringVALVE PORT

Owner:CANON KK

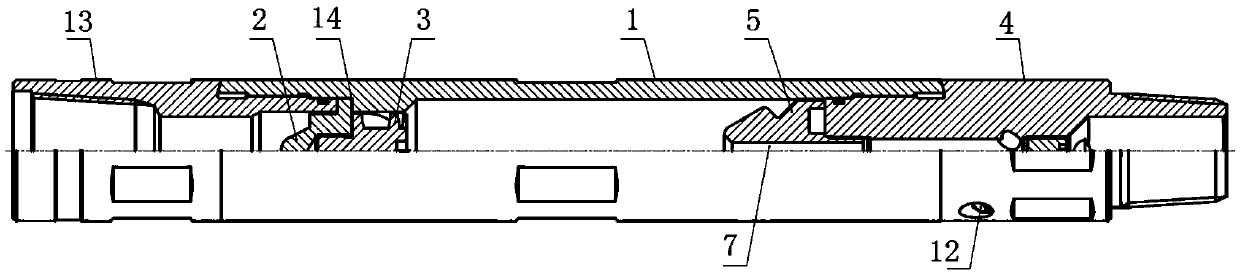

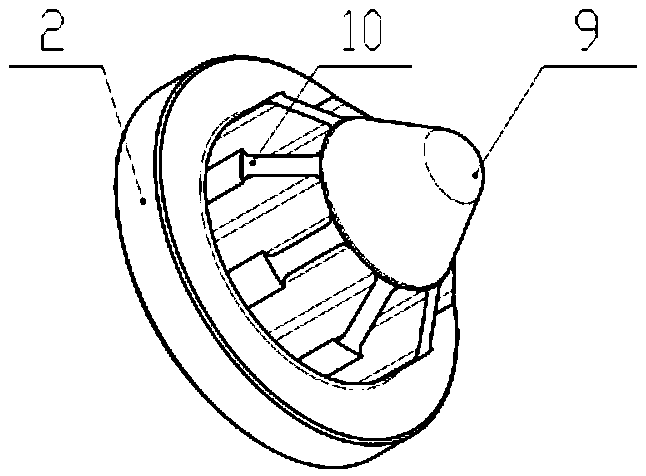

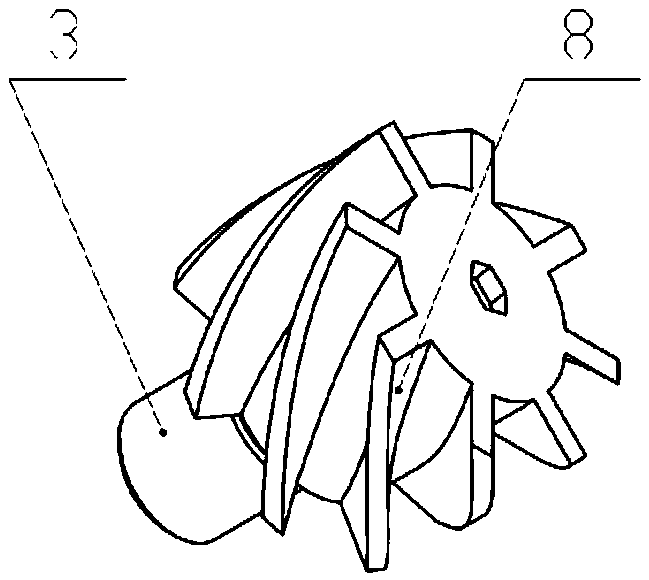

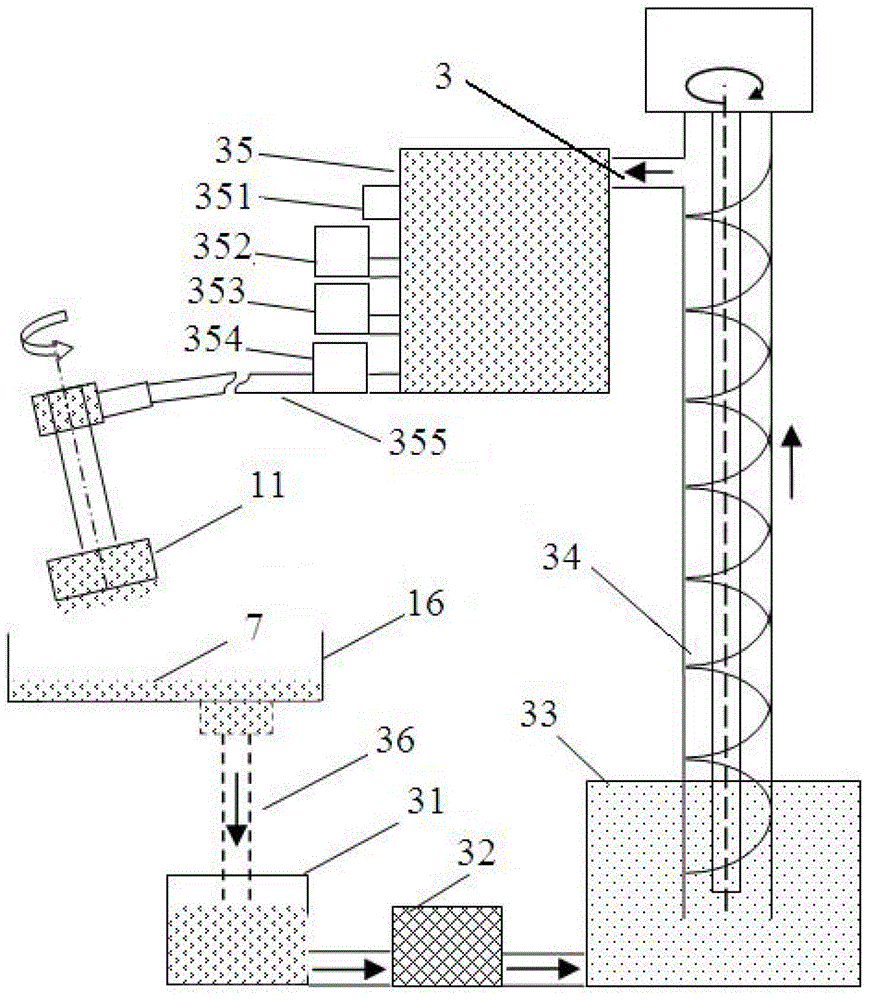

Downhole gas-liquid separation device and working method thereof

ActiveCN105536299AReduce in quantitySimple structureLiquid degasificationSeparation devicesEngineeringProduct gas

A downhole gas-liquid separation device comprises a barrel-shaped body, and a positioning wheel is fixedly installed in the body. A rotatable swirling wheel is installed on the positioning wheel and provided with spiral wheel blades, and the positioning wheel is provided with fluid channels. A lower connector is connected to the body, a diverting joint is arranged at the inner end, located in an inner cavity of the body, of the lower connector, a gas outlet channel is formed in the center of the diverting joint in a coaxial mode, and the outer side of the diverting joint is provided with liquid drainage channels. An interval is formed between the swirling wheel and the diverting joint. The downhole gas-liquid separation device is small in part number, simple in structure and lower in cost; the swirling wheel is driven to rotate when liquid passes through the swirling wheel to enable the liquid to generate centrifugal force and swirlingly flow in the inner cavity in the mode of being attached to the wall, the liquid in gas is gathered to the center, and then the liquid and the gas flow out through the liquid drainage channels formed in the outer side and the gas outlet channel formed in the center respectively, so that gas and liquid separation is achieved; accordingly, the liquid sent to a motor does not contain the gas, damage to the motor is avoided, and the service life of the motor is prolonged.

Owner:JEREH ENERGY SERVICES

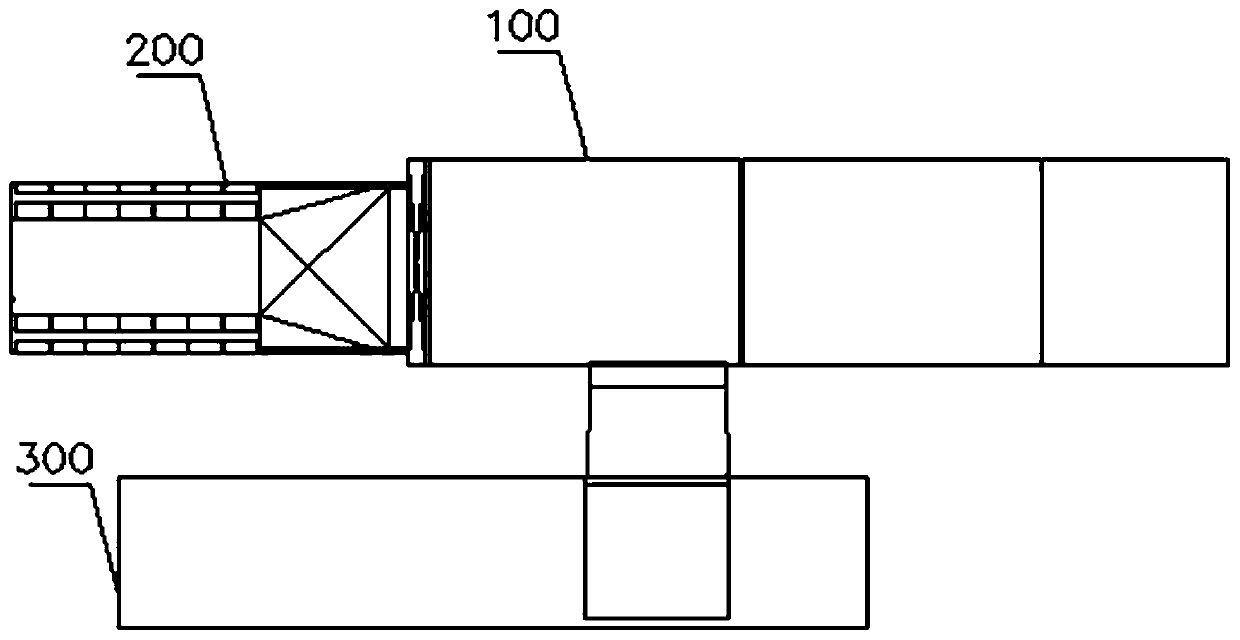

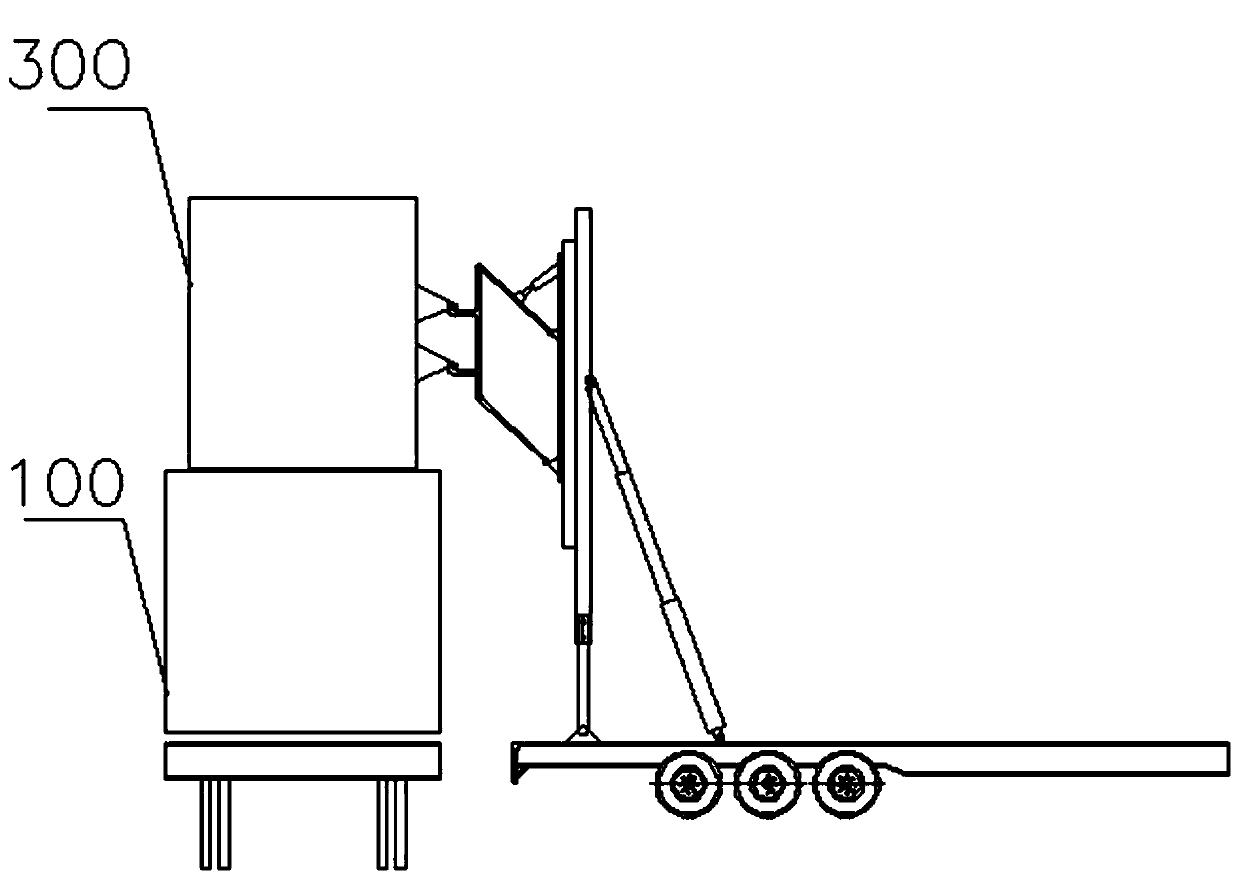

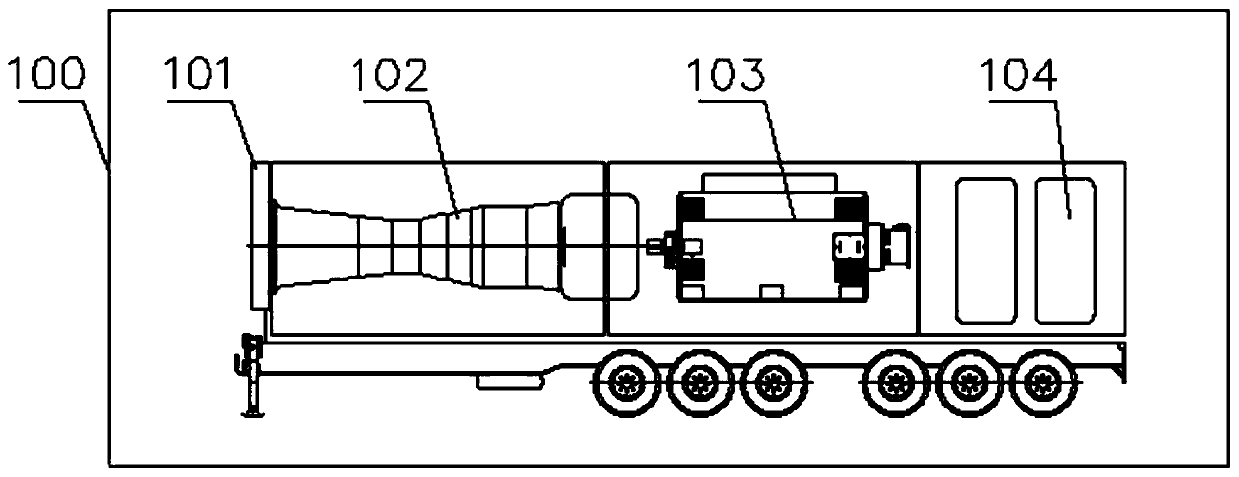

System for providing mobile electric power

PendingCN110848028AReduce in quantityLow costEngine fuctionsGas turbine plantsInlet pressureControl theory

The invention discloses a system for providing mobile electric power. Equipment needed by mobile electric power is integrated on three transportation tools, so that one overall transportation can be combined, the connecting time needed by field operation is greatly shortened, and combination flexibility and high adaptability are achieved. An exhaust system can perform side connection and also canperform top connection, so the connection mode is flexible; and a gas inlet system is axially connected with a gas turbine engine and an electric generator, so that unnecessary bends are avoided, theloss of gas inlet pressure is small and the flowing direction is stable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

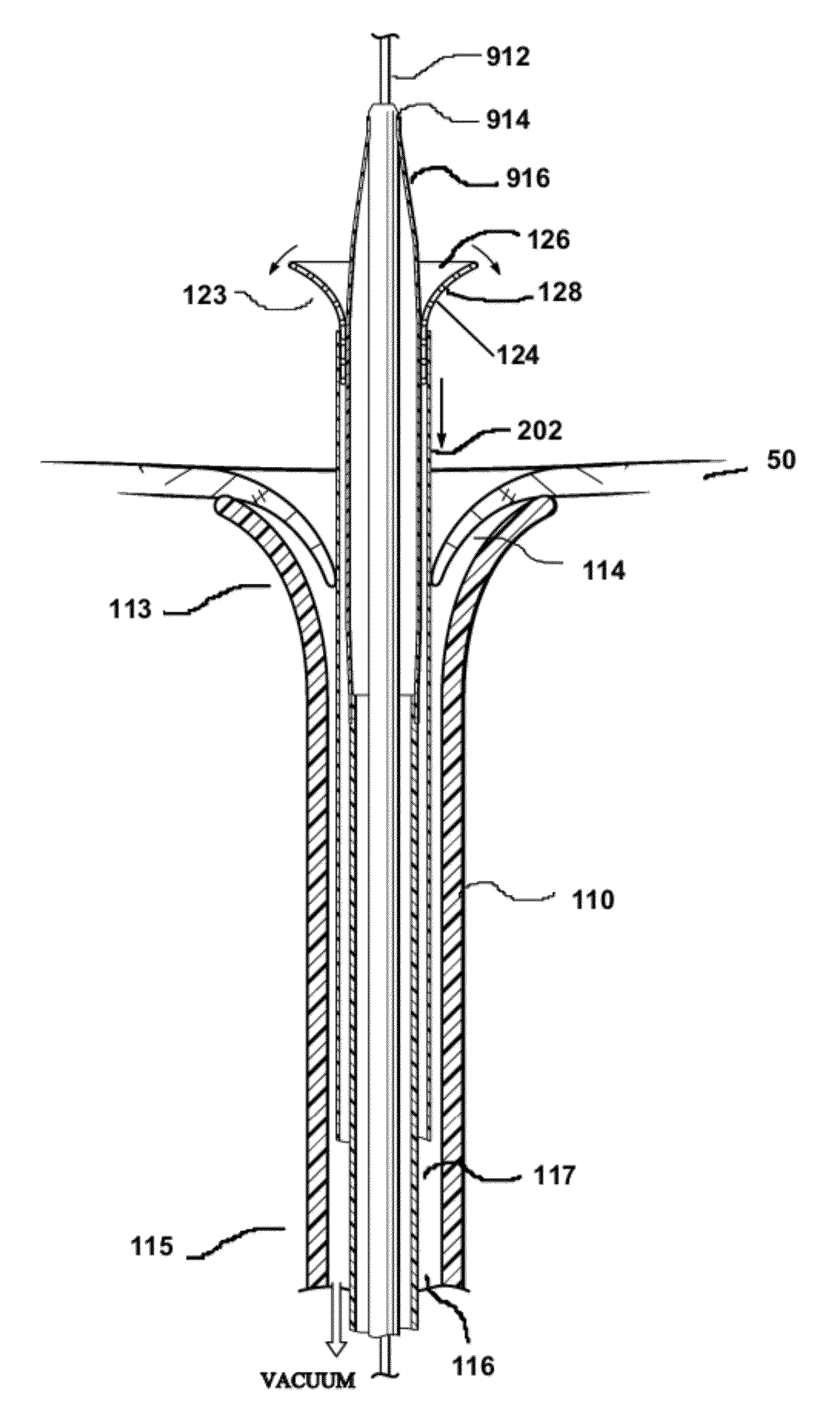

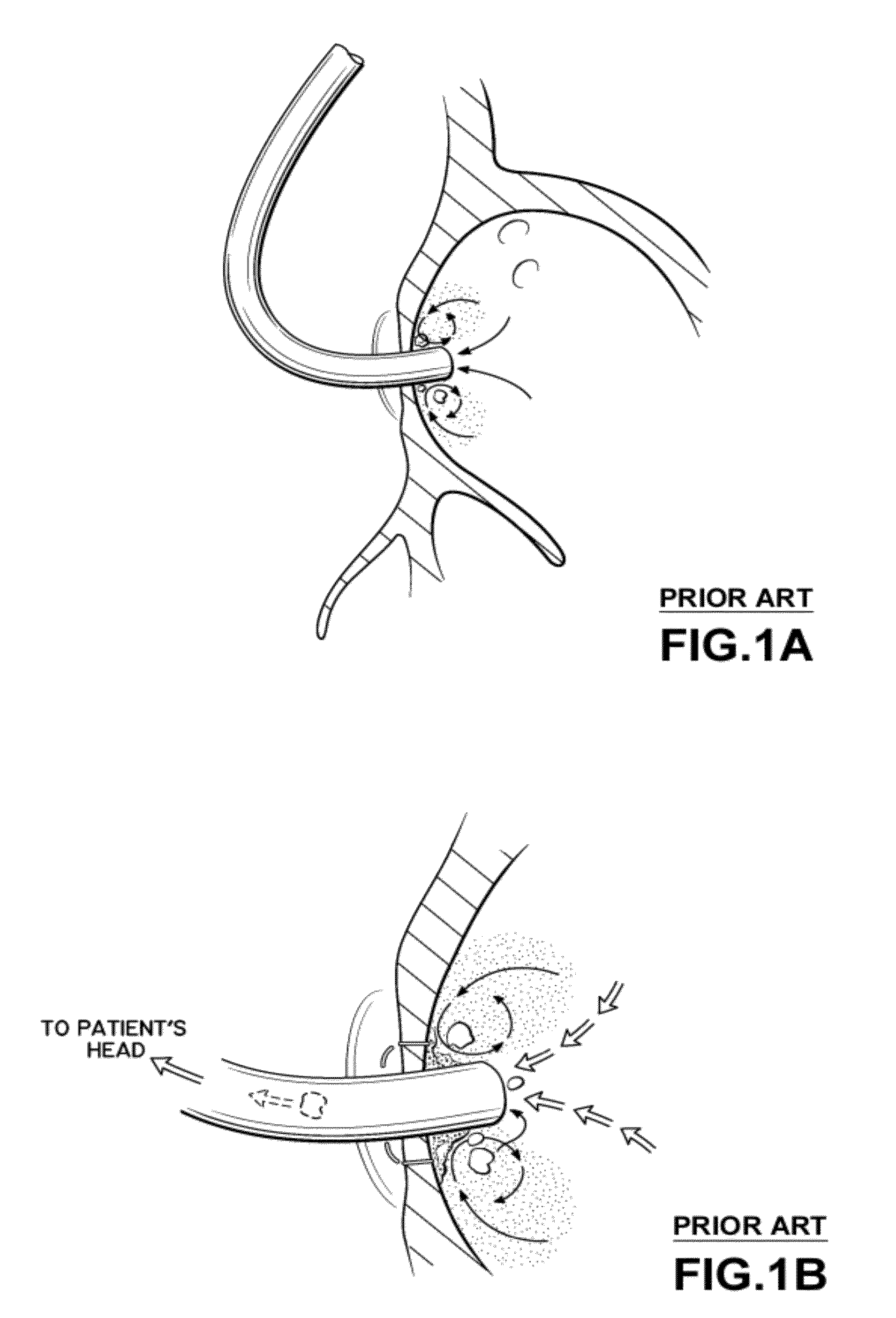

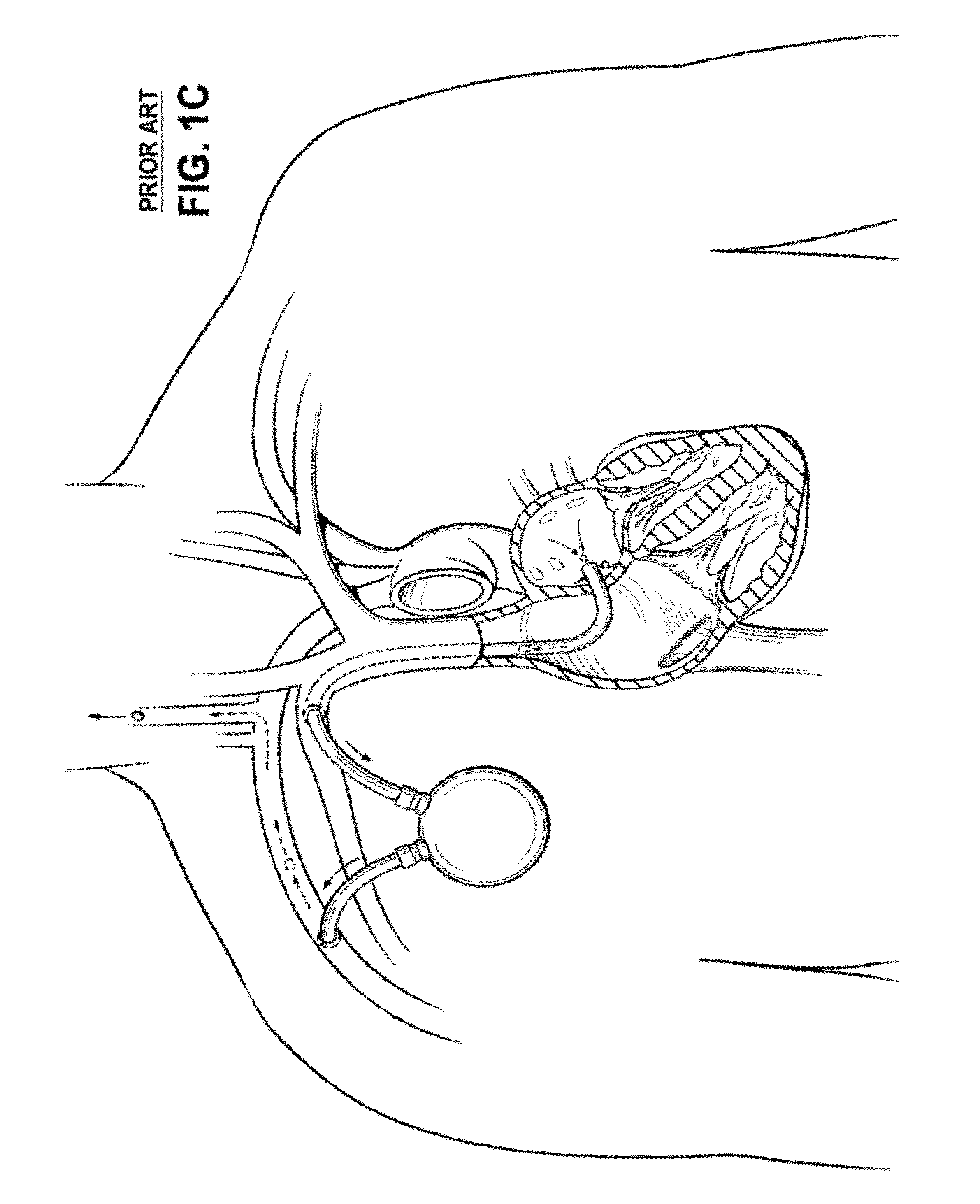

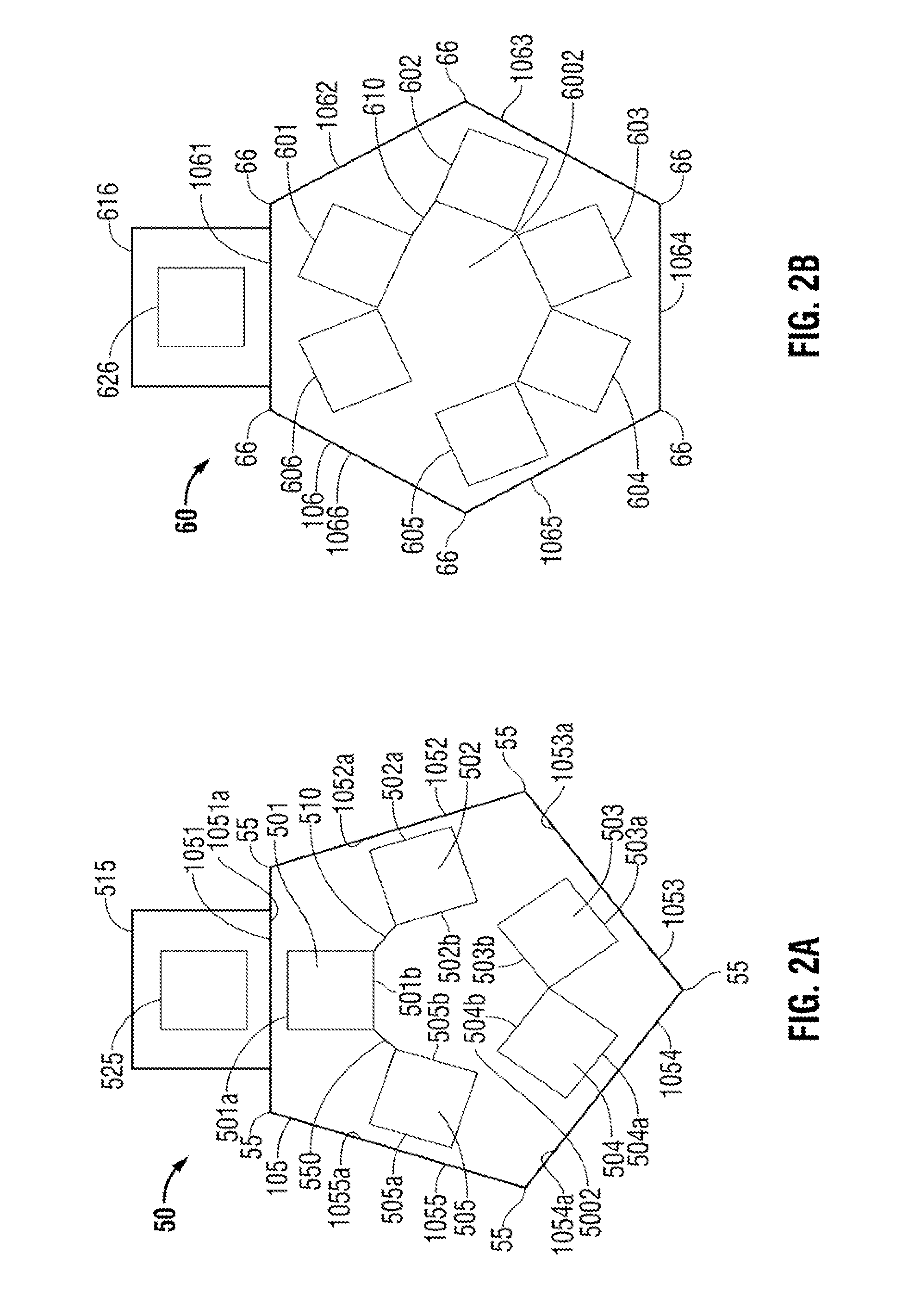

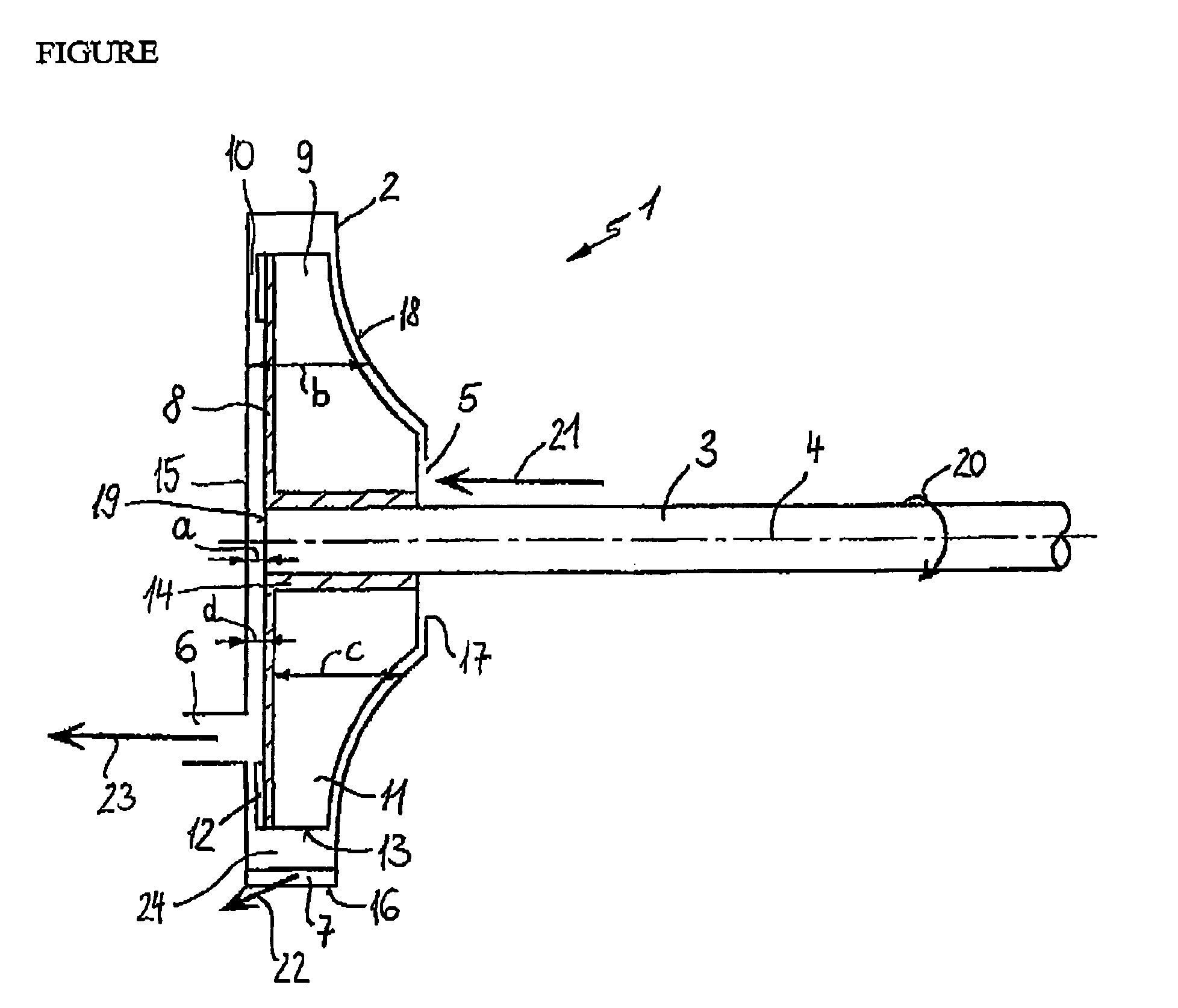

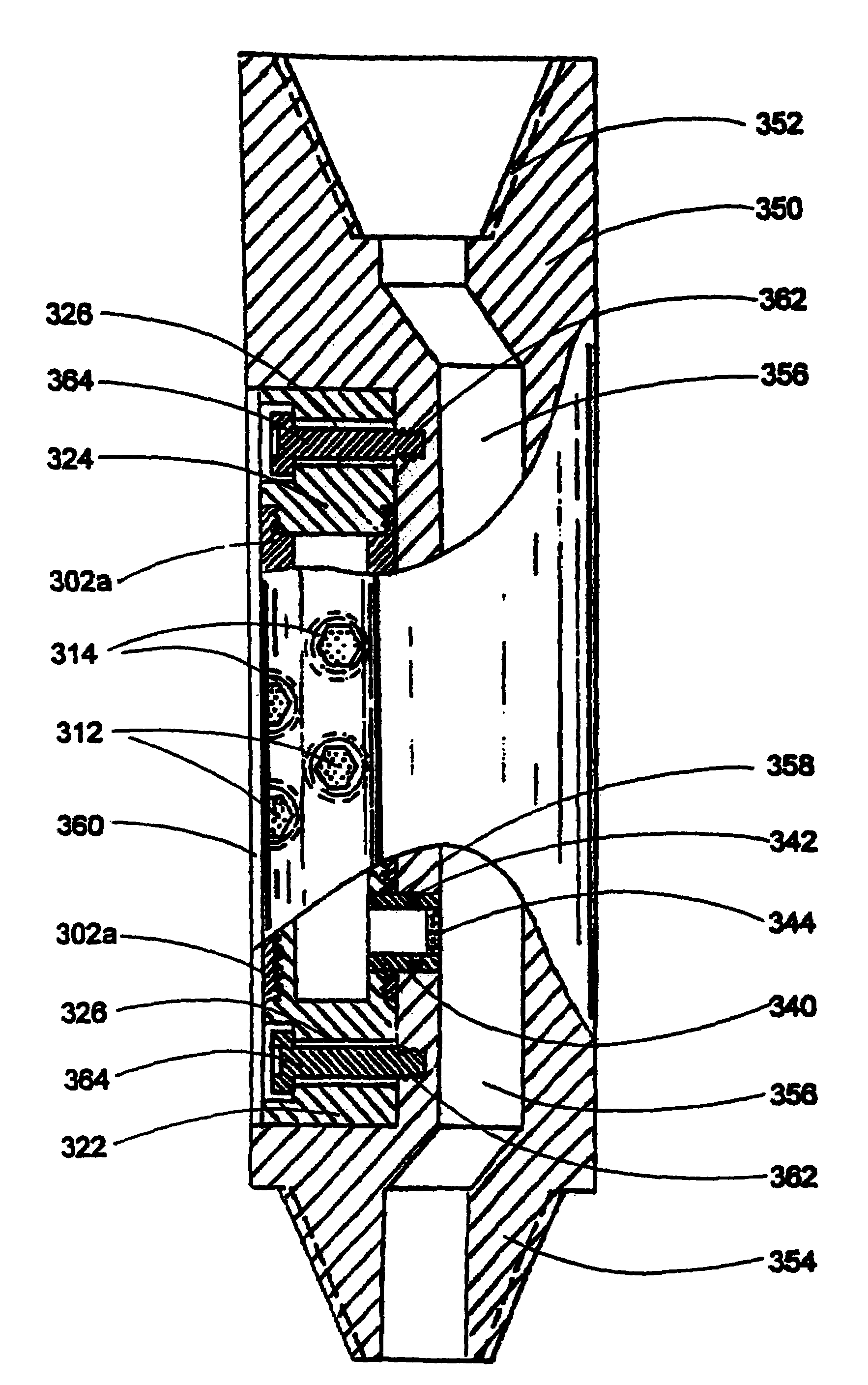

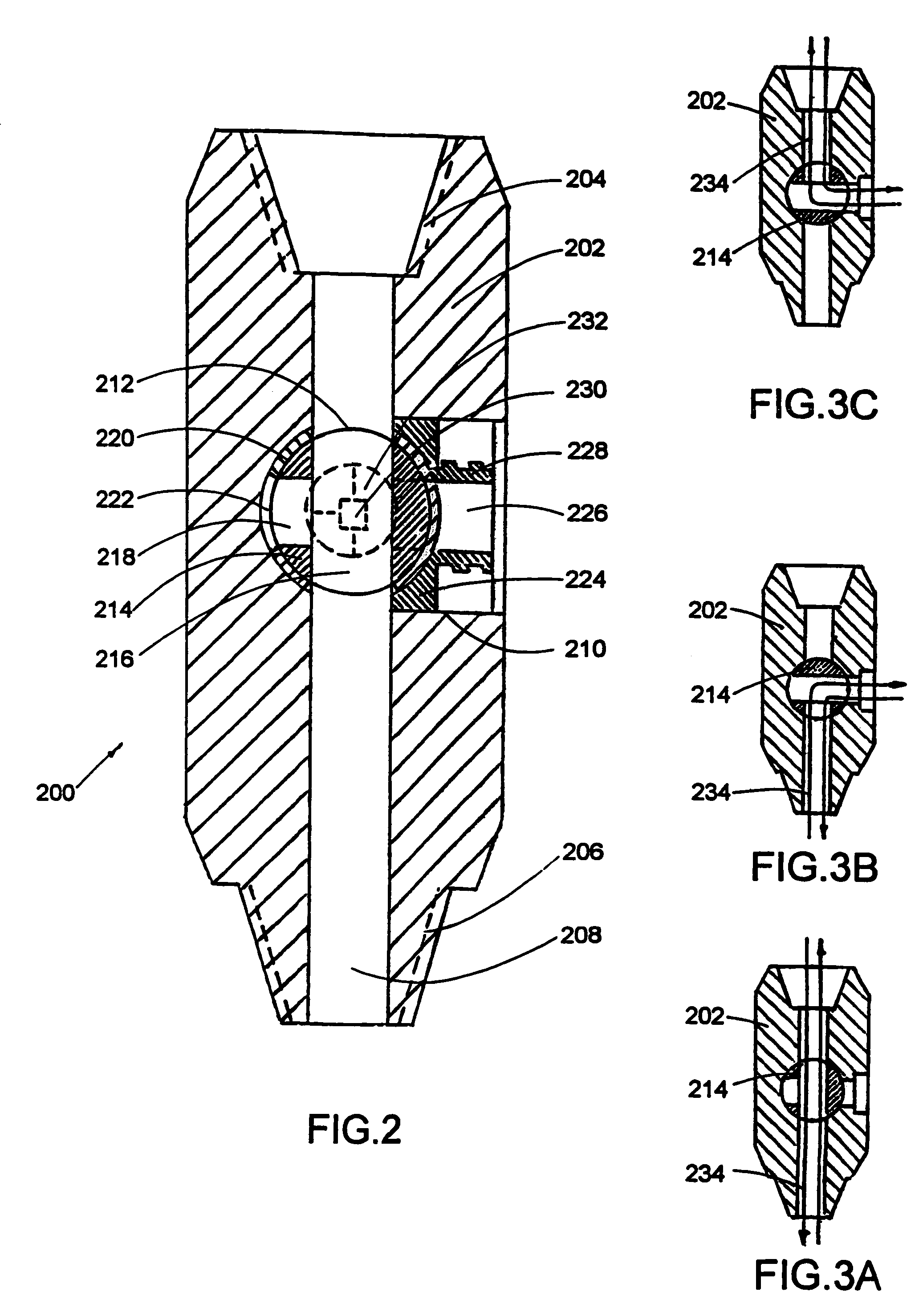

Cannula Systems and Methods

Disclosed herein is a cannula assembly for directing the flow of material from an organ chamber, e.g., blood from the left chamber of the heart, and methods of placing the cannula assembly in fluidic communication with the chamber. The cannula assembly includes an elongate tubular member and a coupling assembly disposed at the distal end of elongate tubular member. The elongate tubular member includes a lumen extending from a distal opening at the distal end to a proximal opening at the proximal end. The coupling assembly includes a retaining element and a retention member configured to cooperate with each other and with the portion of the organ wall surrounding the opening in the wall to couple or anchor cannula system to the wall and to provide fluidic communication between the distal opening of the elongate tubular member and the organ chamber.

Owner:SPENCE PAUL A

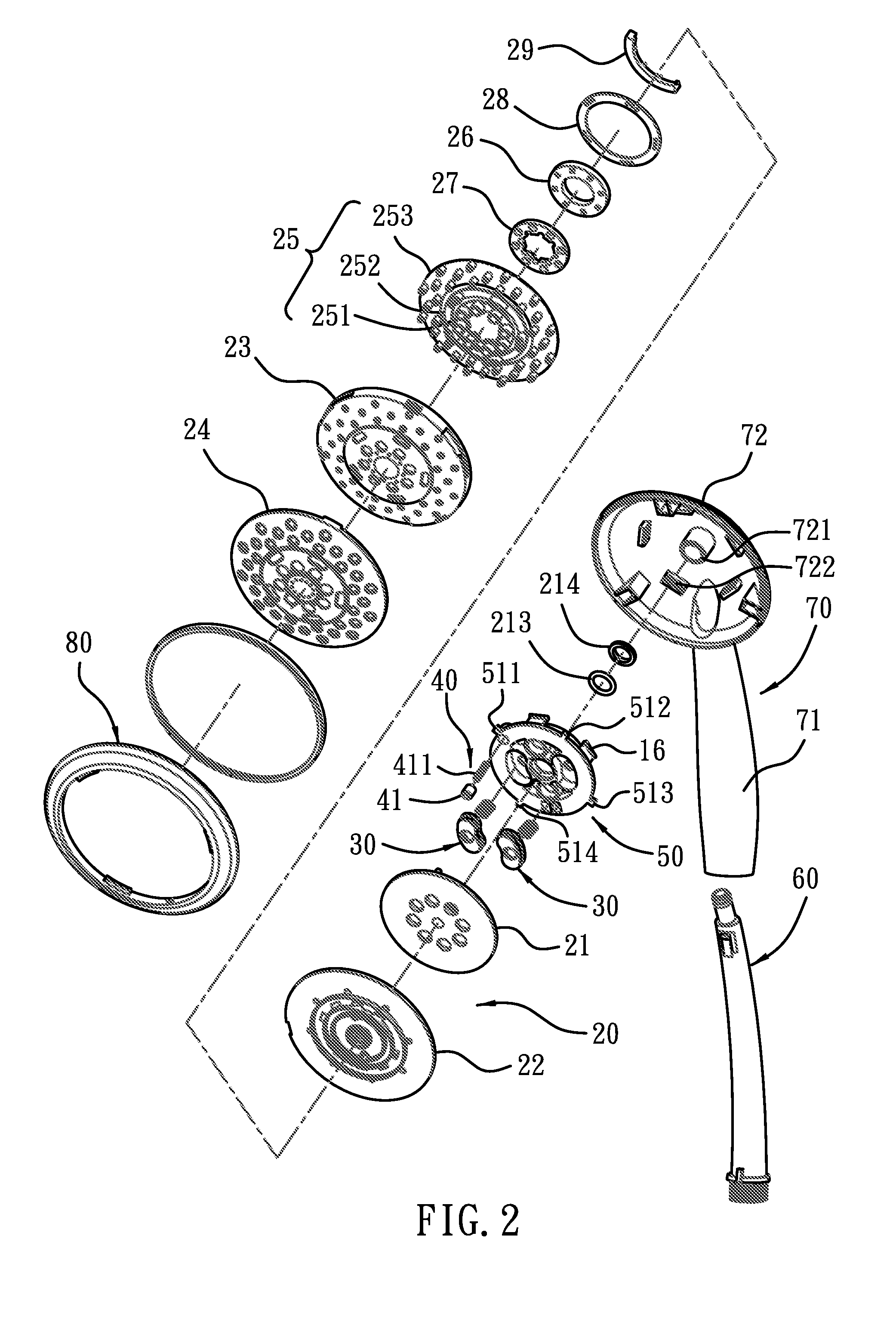

Adjustable module spray head and adjusting method thereof

An adjustable module spray head and adjusting method thereof comprises a module core unit having a holder, a distributing set rotating relative to the holder, two plugs, and a rotable positioning structure between the holder and the distributing set; the module core unit is used to assembled with various spray heads with different watering levels to meet different demands by selecting an installing position of a levering pin of the rotable positioning structure and by removing at least one stator or a rotor of the adjustable levering assembly.

Owner:GLOBE UNION INDAL

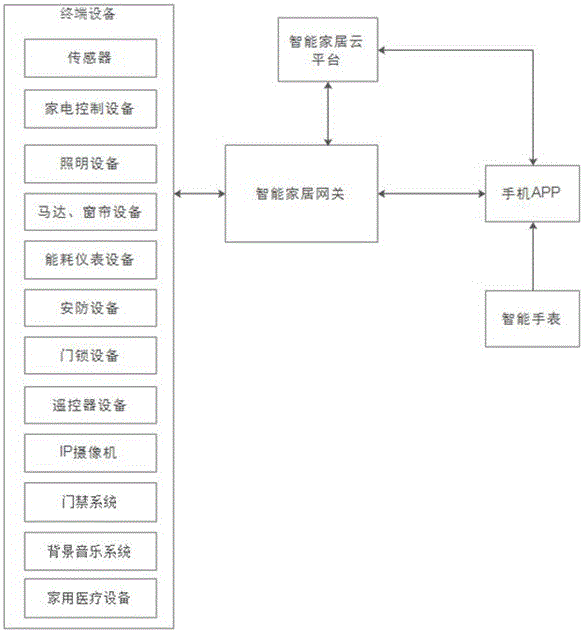

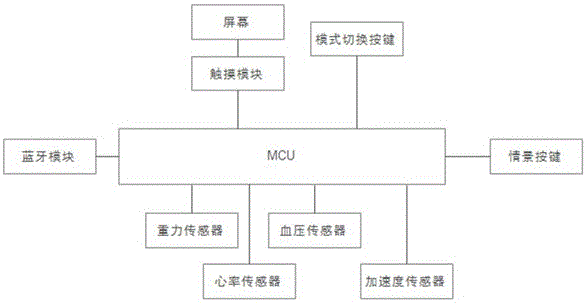

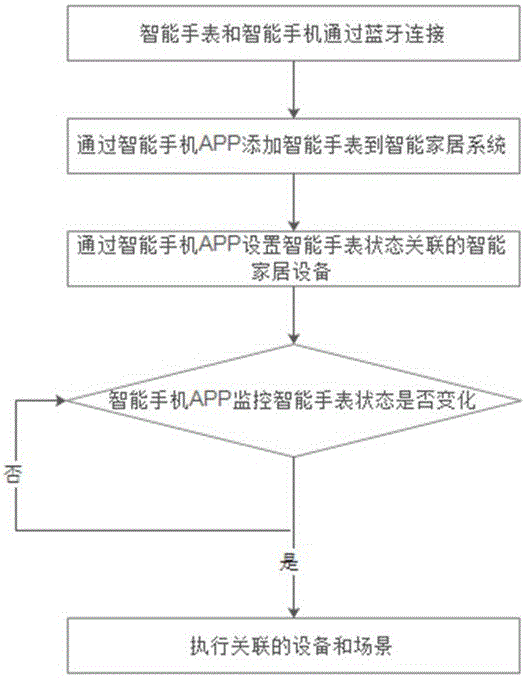

Intelligent household system controlled by wearable intelligent watch

InactiveCN106094534AGood serviceEasy to controlComputer controlProgramme total factory controlUser needsMedical device

The invention discloses an intelligent household system controlled by a wearable intelligent watch. Fast control of the intelligent household is achieved by monitoring the sensor state, screen slide and button of the wearable intelligent watch. Compared with the traditional intelligent household system that the user controls intelligent household equipment only by cellphone APP, the user needs to open a cellphone and then to open the APP if the user wants to control a switch, and then the user needs to find corresponding equipment for controlling the switch, the system provided by the invention enables to the user to fast control a switch only by sliding the screen of the intelligent watch or pressing down a corresponding button of the intelligent watch. Combination of the wearable intelligent watch and intelligent household techniques not only achieves fast control of the intelligent household, but also monitors human body features such as human body blood pressure and heart rate, and achieves automatic associated control with household or medical equipment. The convenience and the intelligentization experience of the user for the intelligent household system are greatly improved.

Owner:HANK ELECTRONICS

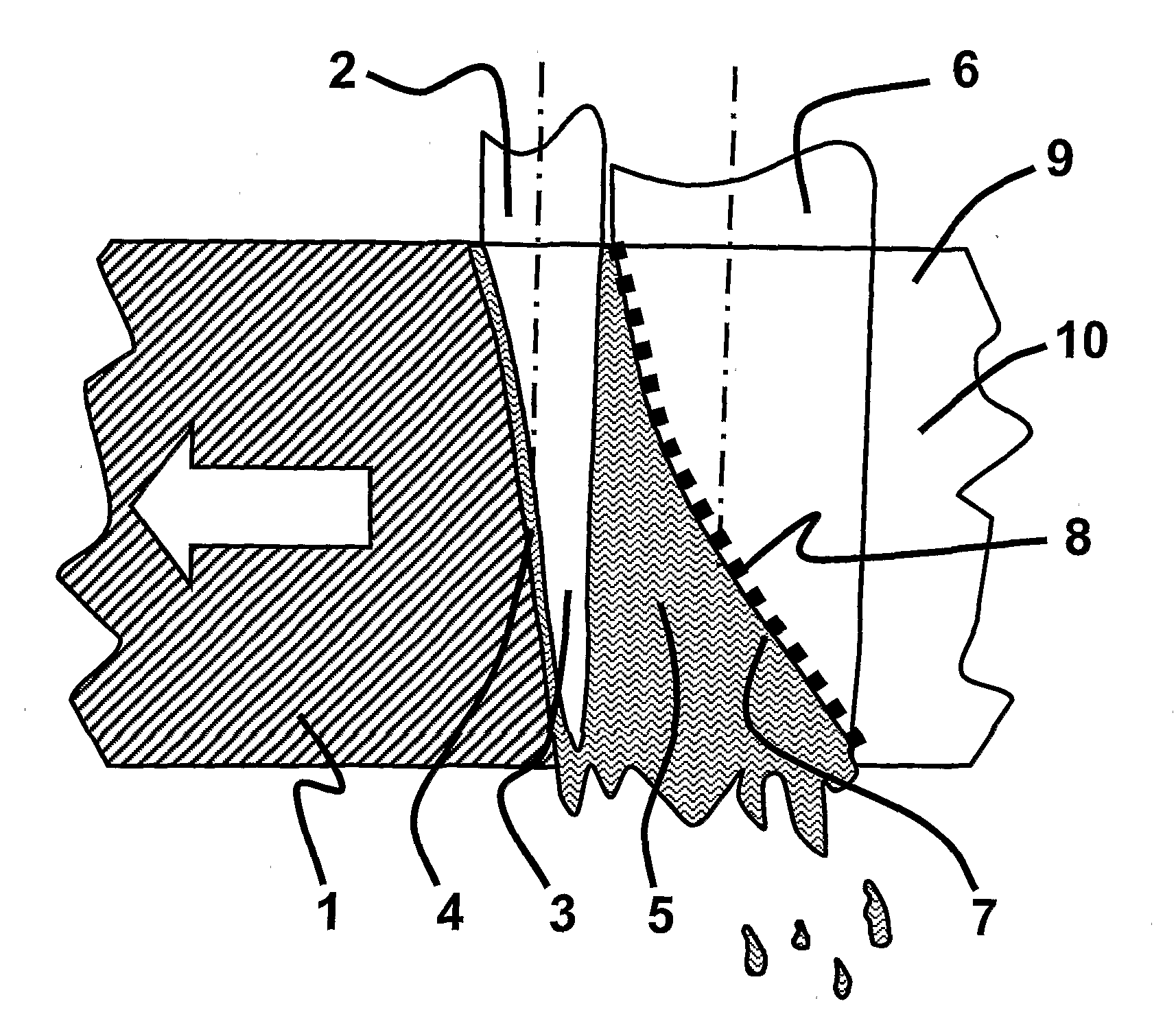

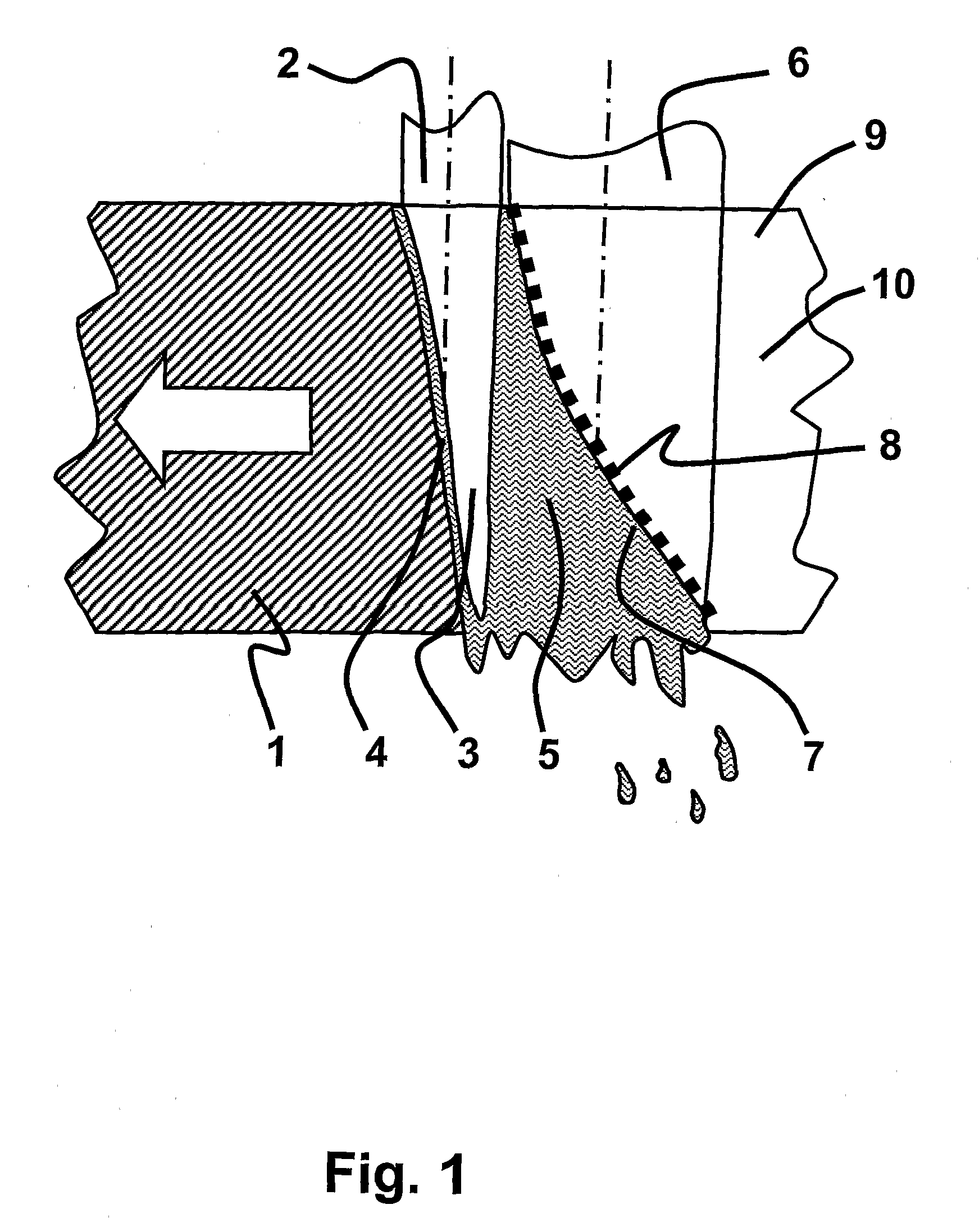

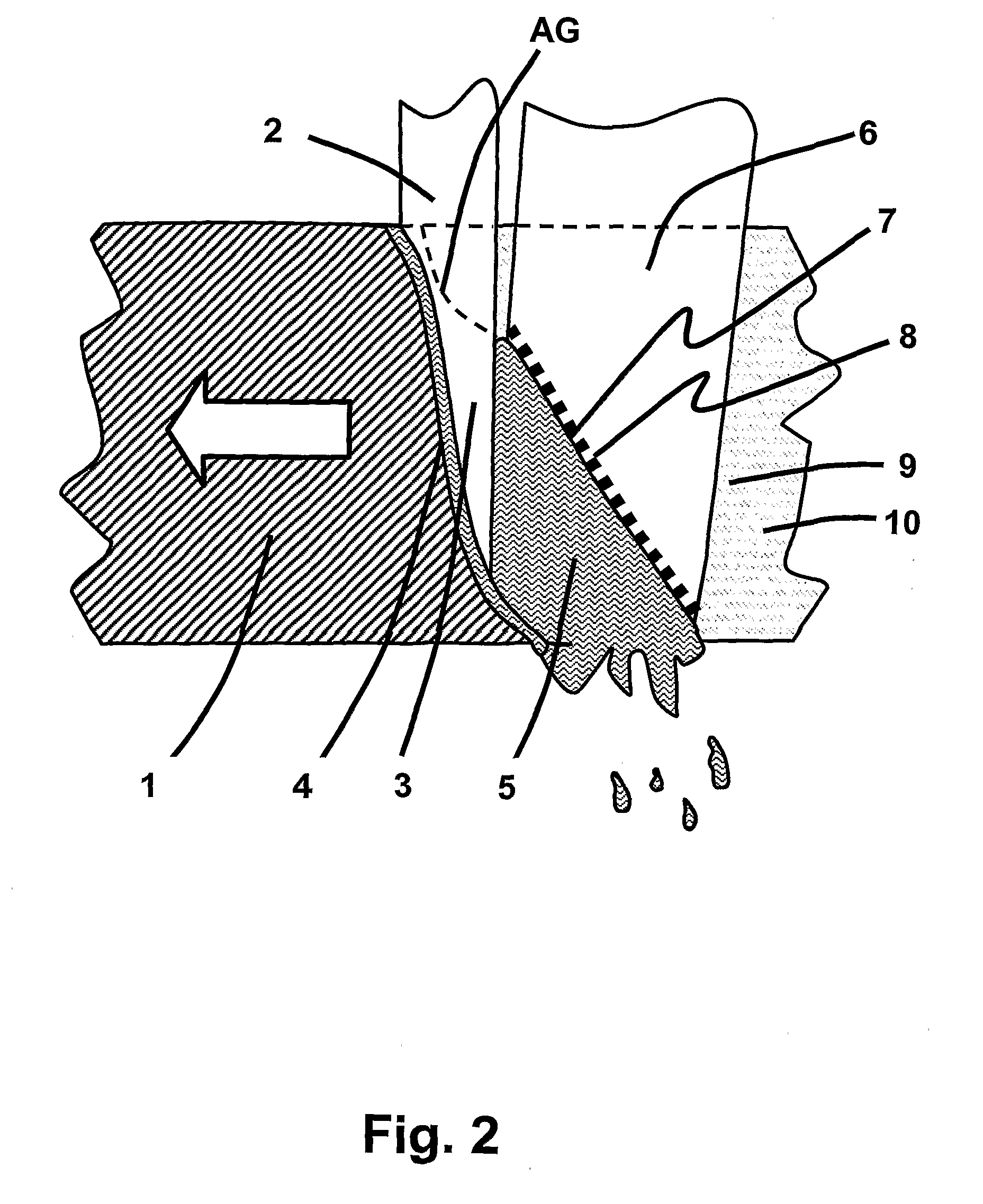

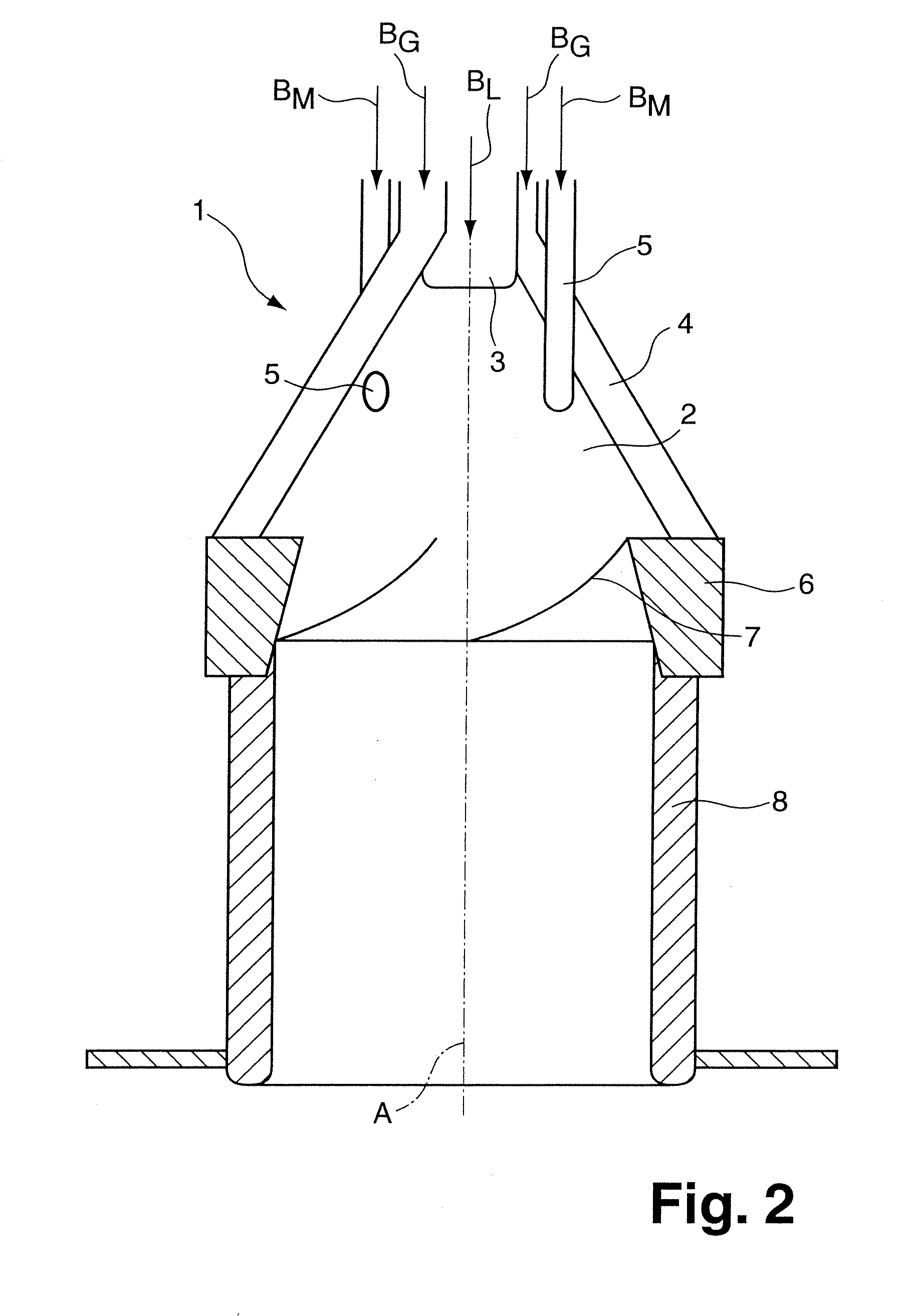

Method and system for laser processing

InactiveUS20100044353A1Increase pressureStable flowLaser beam welding apparatusLaser processingHigh power lasers

The invention relates to laser cutting, using multiple laser beams directed to a processing region. At least one first laser beam (2) is coupled into the work piece (1) material to generate a melt (5) and to form a keyhole (3). At least one second beam (6) is guided onto selected surface regions (7) of the melt (5). The laser energy is provided to the processing region as individual beams that may be conditioned independently. The invention has the advantage that arbitrary energy distributions can be arranged in the processing region as determined according to the requirements of the laser cutting process, rather than being limited by an inappropriate beam shape of a single high power laser beam.

Owner:OLSEN FLEMMING OVE

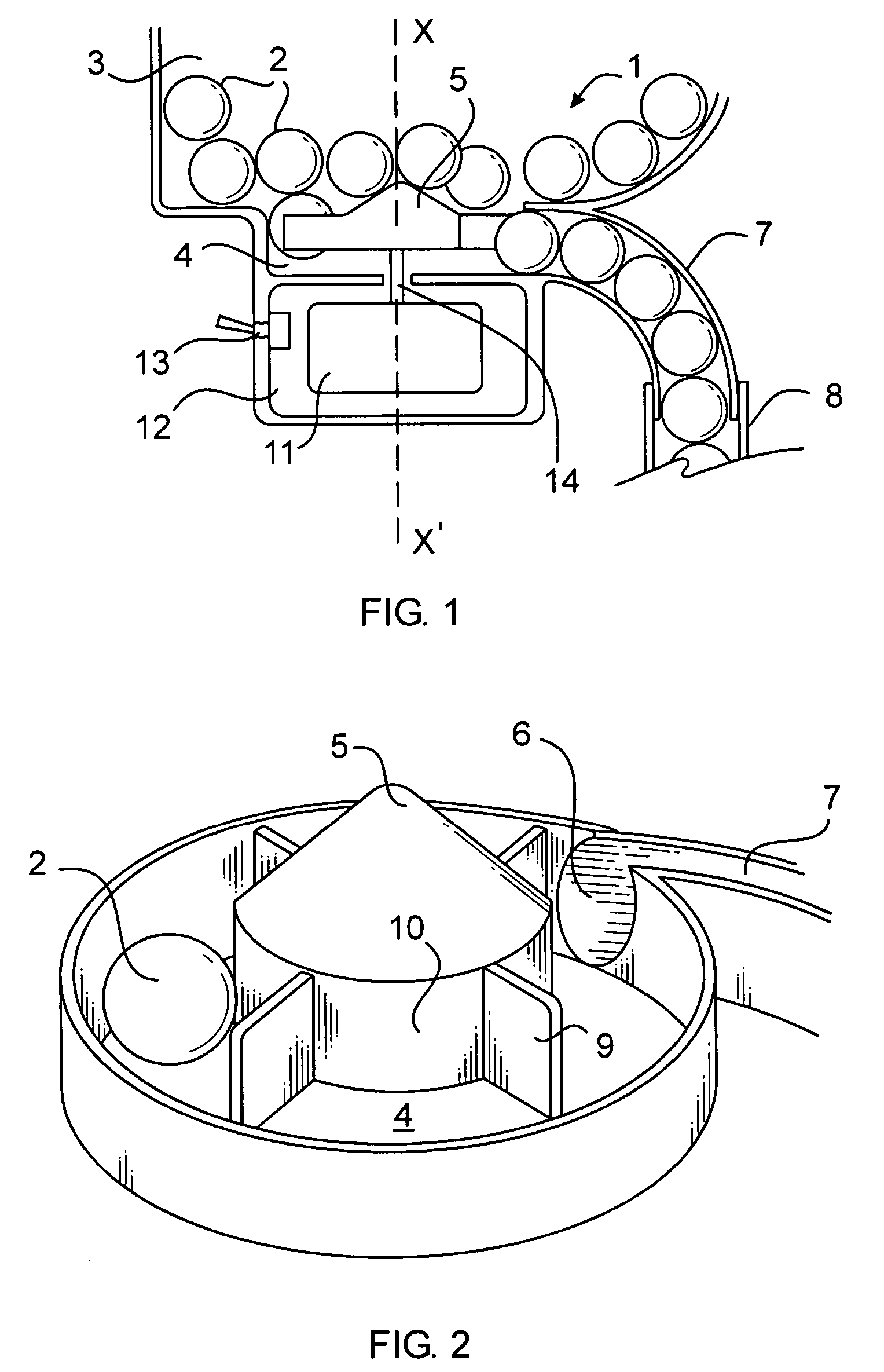

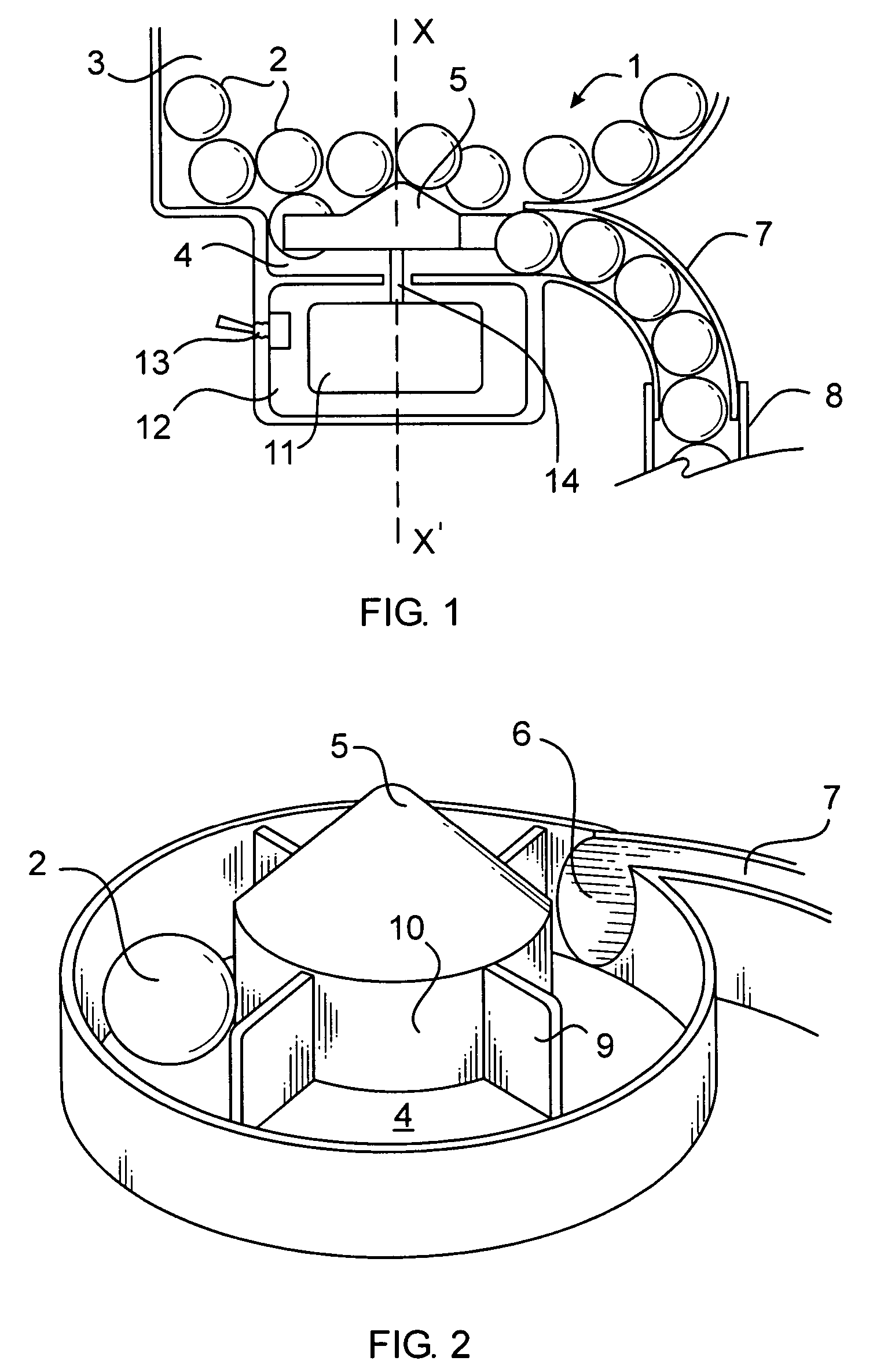

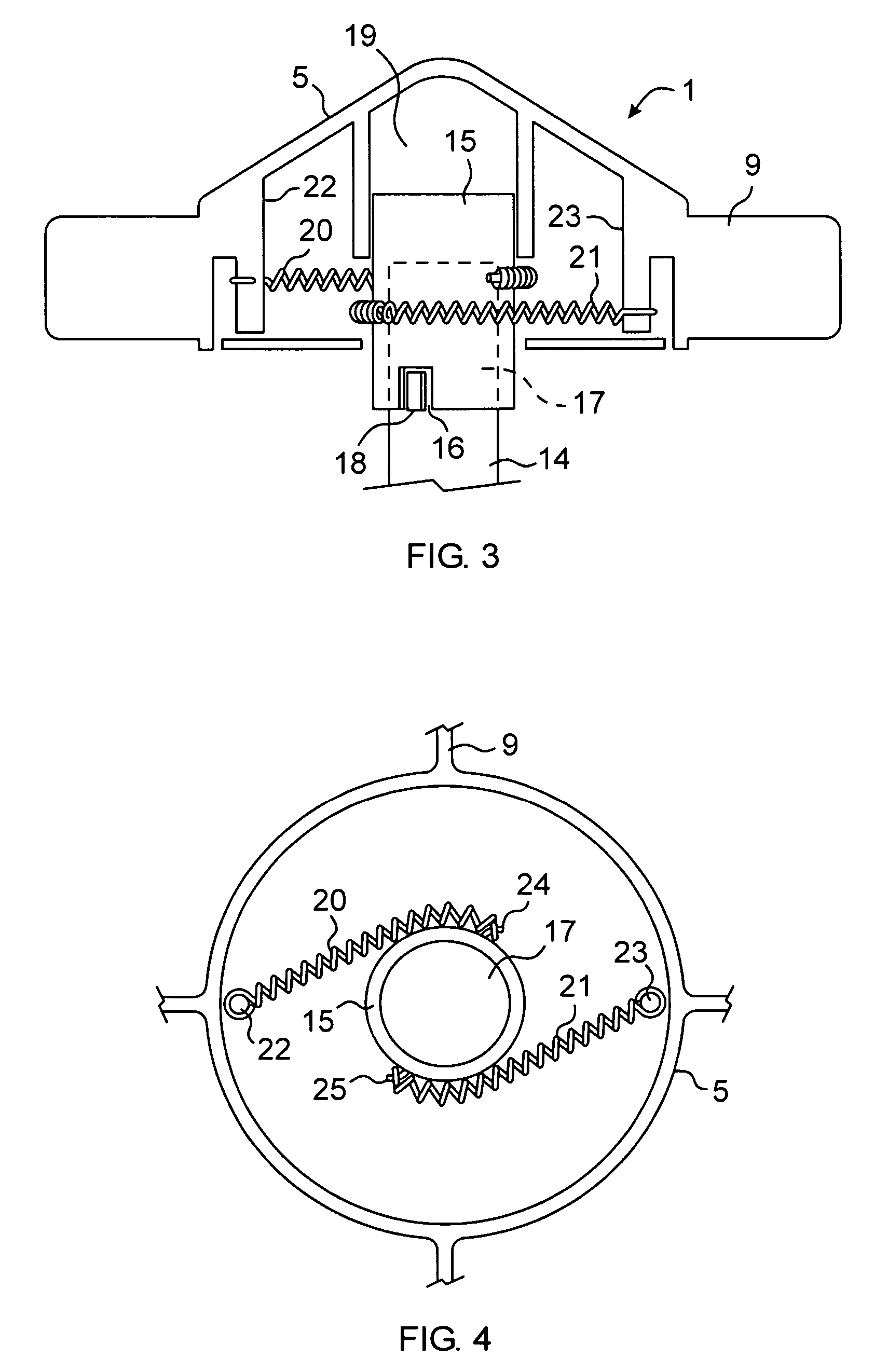

Spring-assisted paintball loader

InactiveUS20060249131A1Stable flowReduce gapAmmunition loadingCompressed gas gunsCoil springEngineering

A mechanism for feeding uniformly-sized spherical projectiles such as paintballs into a gun adapted to shoot said projectiles is positioned in a lower region of a paintball-holding magazine, and includes a spinning body in the form of a spool from the peripheral side of which project radial arms shaped and dimensioned to urge projectiles toward a duct leading to the ammunition intake port of the gun. The spool is driven by a switchable electrical motor. In order to avoid gaps into the row of paintballs that are urged toward the ammunition intake port when the motor is not running which could result in dry firing, a resiliently variable linkage between the propelling arms is provided by a spiral spring or a pair of stretchable coil springs.

Owner:KEE ACTION SPORTS I

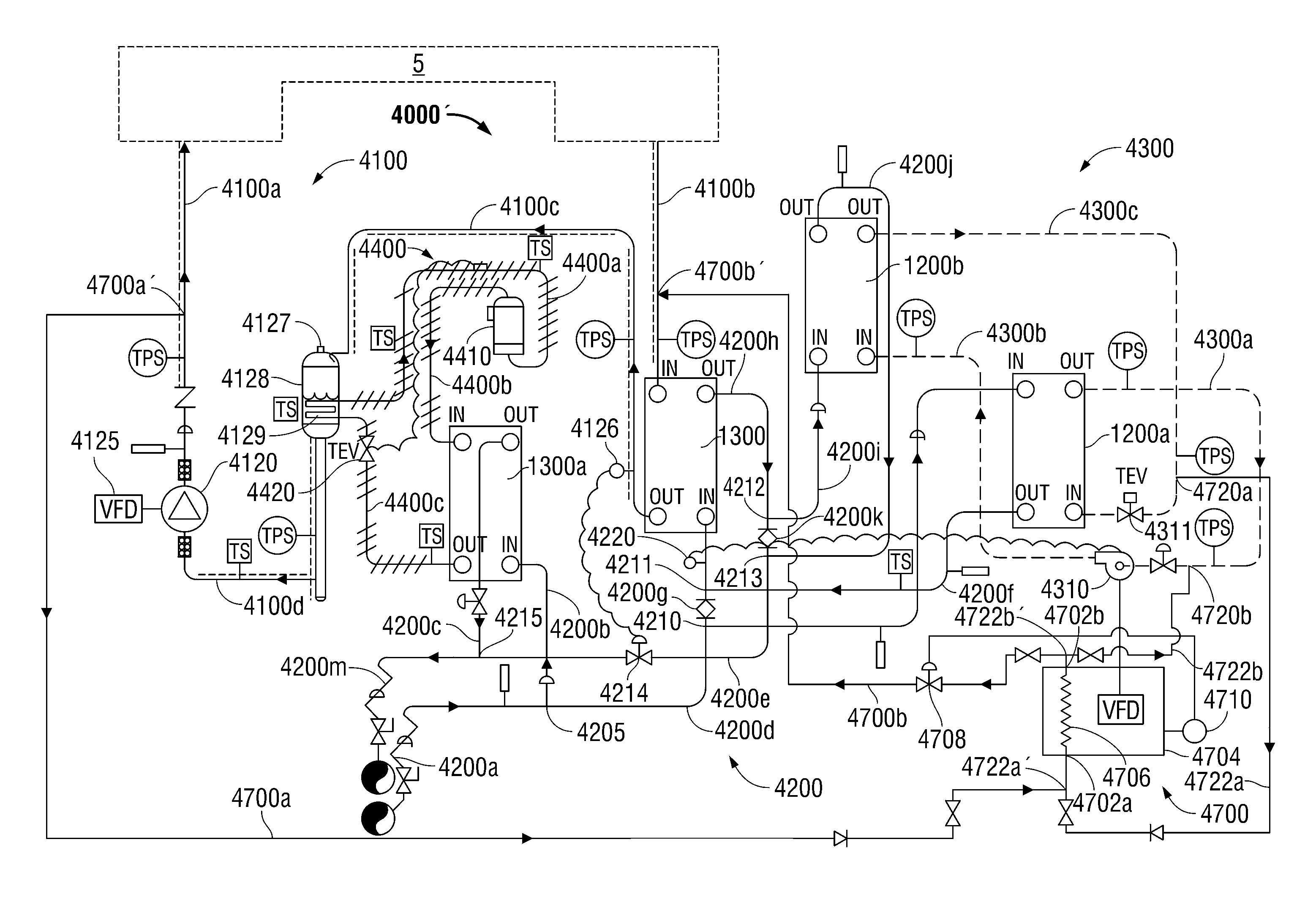

System and methods for cooling electronic equipment

ActiveUS9119326B2Stable toleranceImprove securityCompressorEfficient regulation technologiesAtmospheric airWet-bulb temperature

Systems and methods for cooling an inverter of a variable frequency drive that drives a compressor in a cooling system for electronic equipment are disclosed. The system includes a first fluid circuit that cools electronic equipment using a first fluid flowing therethrough and a second fluid circuit that free cools a second fluid flowing therethrough. The second fluid circuit cools the first fluid using the free-cooled second fluid. The system further includes a third fluid circuit that mechanically cools the second fluid using a third fluid flowing therethrough as a function of the wet bulb temperature of atmospheric air. The third fluid circuit includes at least one compressor compresses the third fluid and is driven by a motor coupled to the variable frequency drive. At least a portion of the first fluid flowing through the third fluid circuit is diverted to cool the inverter of the variable frequency drive.

Owner:INERTECH IP

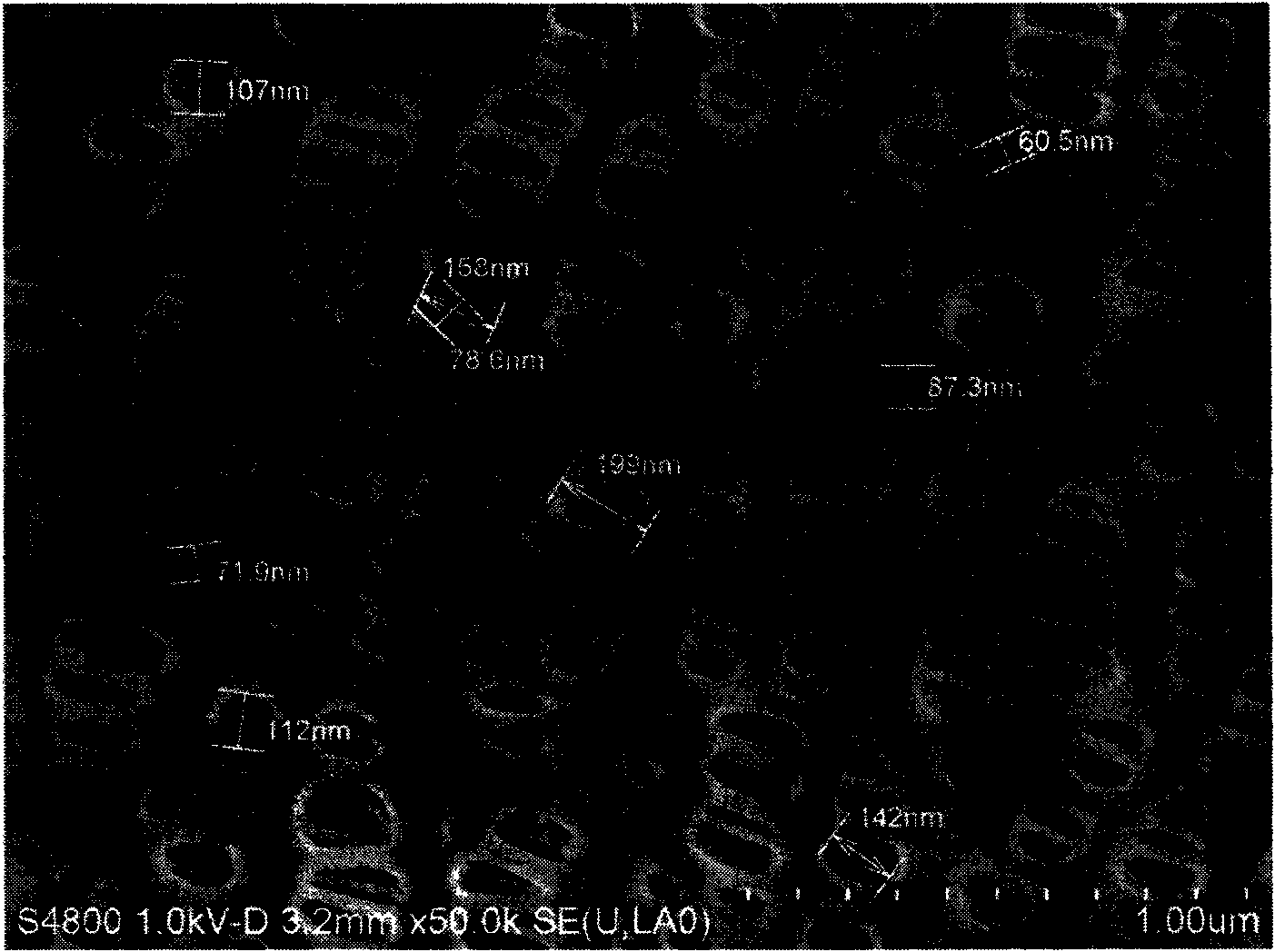

High-liquid absorbing rate micro-nano structure polymer electrolyte membrane and preparation method thereof

InactiveCN101626097AHigh liquid absorptionPromote absorptionSecondary cellsMicro nanoPolymer science

The invention discloses a preparation method of a high-liquid absorbing rate micro-nano structure polymer electrolyte membrane, wherein the membrane is prepared by polymer material being packed on a support frame. The method comprises the following steps of: by being processed, the polymer membrane has a micro-nano structure, forms holes with micron level and nanometer level, and forms a netty distribution hole structure with the nanometer holes of the support frame; and the polymer which is crossly linked layer by layer is packed on the special support frame to form a special netty micro-nano structure polymer electrolyte membrane. The polymer membrane of the micro-nano structure can absorb large numbers of electrolyte, greatly increase liquid-absorption rate, and improve the affinity of diaphragm to the electrolyte; the netty micro-nano structure leads the electrolyte to be kept in the membrane well, leads lithium ion in the polymer electrolyte membrane to be evenly distributed, leads the concentration to be to balanced, and lead the current density in the battery to be evenly when discharging electricity; and the special support frame guarantees the mechanical capability of the membrane. The preparation technology of the polymer electrolyte membrane has simple route and easily obtained raw material, can be operated under a normal condition, and does not need harsh production environment. The polymer lithium ion battery prepared by the membrane has good electrochemistry capability.

Owner:CHANGSHA HIGH TECH INDAL DEV ZONE CAISHENG NEW ENERGY TECH

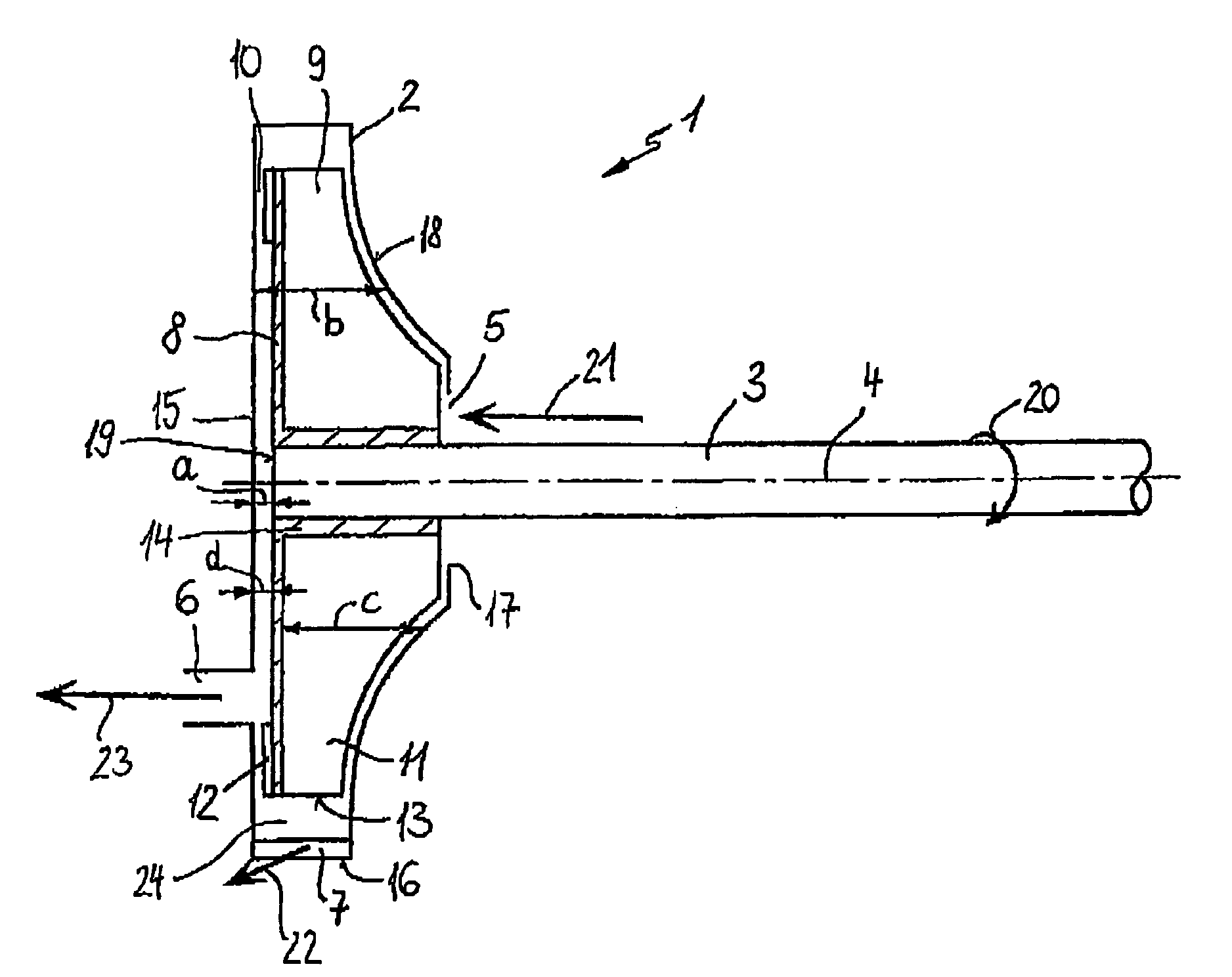

Centrifugal separator

InactiveUS7033410B2Simple constructionSimple to manufactureCombination devicesLiquid degasificationImpellerAirflow

A centrifugal separator for separating oil from a gas stream, particularly for venting the crankcase of an internal combustion engine, having a housing (2) in which the flow guiding means are arranged. The flow guiding means are connected to a drive shaft (3). A gas inlet (5) opens into the housing (2), and a gas outlet (6) and an oil outlet (7) lead out of the housing (2). An easily produced and functionally reliable arrangement is obtained if the housing (2) is non-rotatably mounted and an impeller (14) with blades (11) that produce a centrifugal flow is disposed in the housing (2) such that it is rotatable about the longitudinal axis (4) of the drive shaft (3).

Owner:MANN HUMMEL GMBH

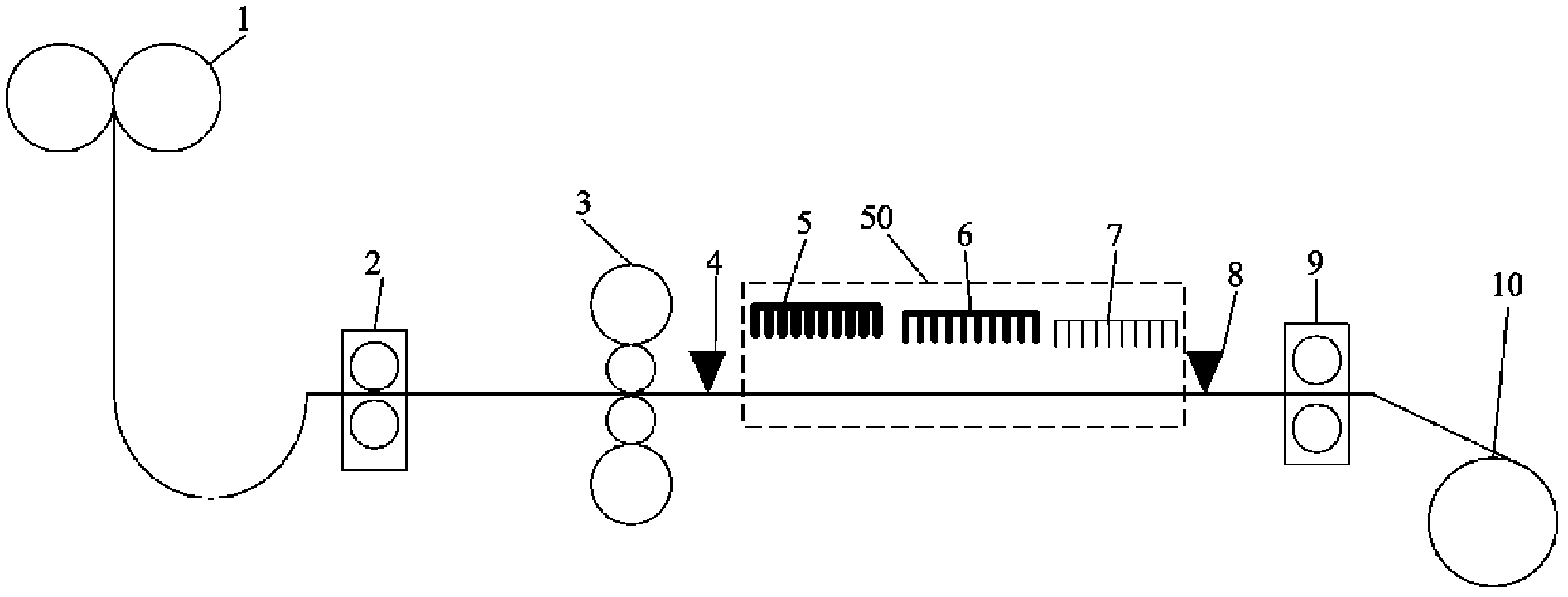

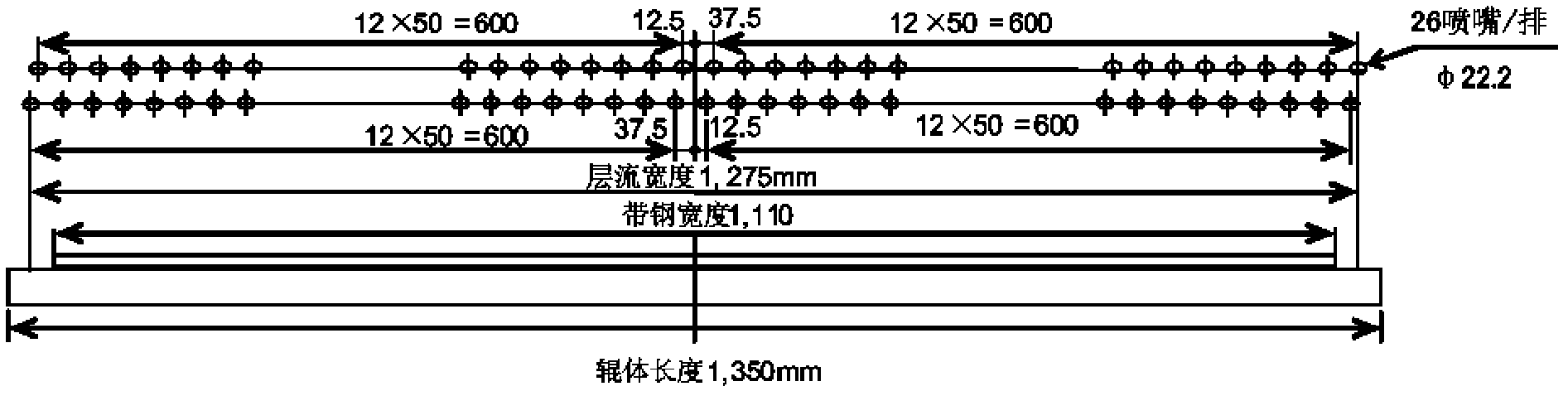

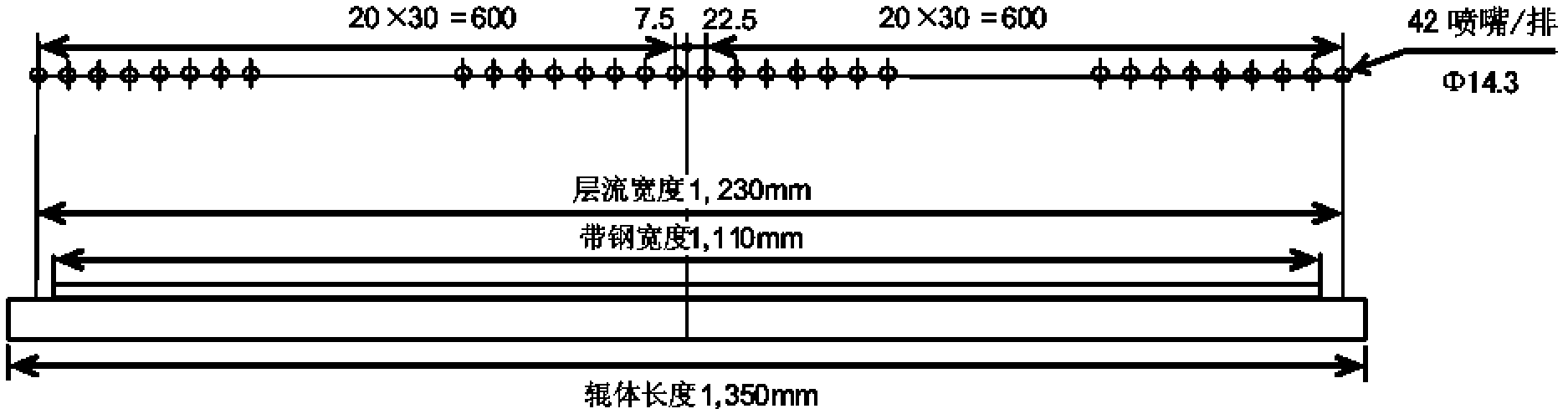

Cooling system for rolled stripe continuously-casting production line and control method thereof

ActiveCN102553950AMeet the temperature dropFulfil requirementsTemperature control deviceWork treatment devicesAdaptive learningLow speed

The invention relates to control devices or methods specially for metal rolling machines and manufacturing products of the metal rolling machines and discloses a cooling system for a rolled stripe continuously-casting production line and a control method of the cooling system. The system comprises a segmented laminar flow cooling device and a cooling control system which are arranged behind an online hot rolling machine, wherein the segmented laminar flow cooling device comprises at least two segmented laminar flow cooling collecting pipe areas, wherein one of the at least two segmented laminar flow cooling pipe collecting areas adopts a nozzle cooling collecting pipe with small pipe diameter, the cooling control system is an online double-closed-loop control system and comprises a double-closed-loop control circuit, the double-closed-loop control circuit comprises a feedforward control module, a precomputation module, a feedback control module, a coiling-ahead temperature measuring module and a self-adaption learning module, the double-closed-loop control circuit selects at least one collecting pipe area of the segmented laminar flow cooling device, the number of open collecting pipes in the selected collecting pipe area can be adjusted by a group of control valves, and the requirements on the accuracy of coiling temperature of steel stripes rolled at a low speed during the variation of speed and thickness in a limited cooling area can be met by the nozzle cooling collecting pipe with the small pipe diameter and the online double-closed-loop control system.

Owner:BAOSHAN IRON & STEEL CO LTD

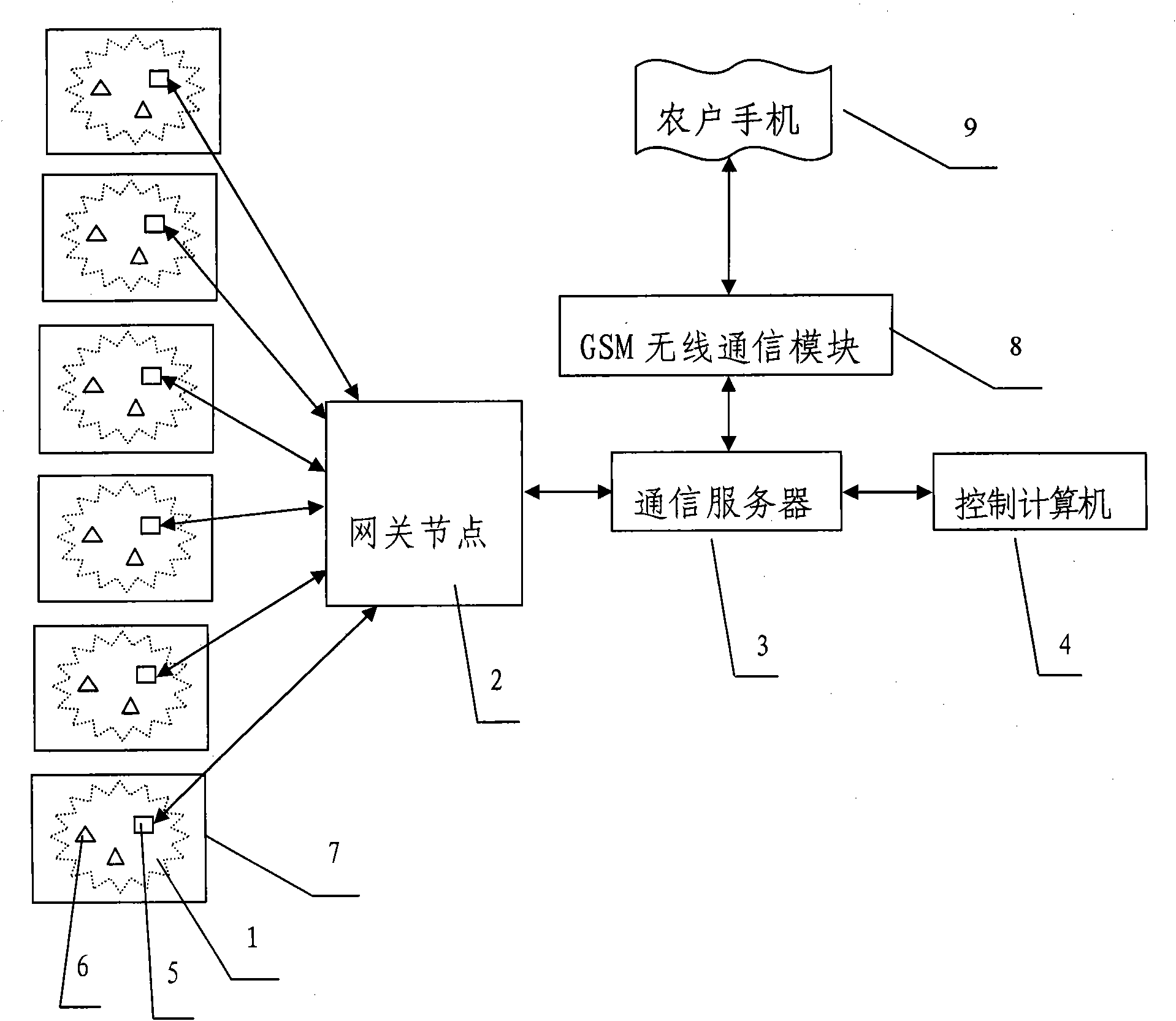

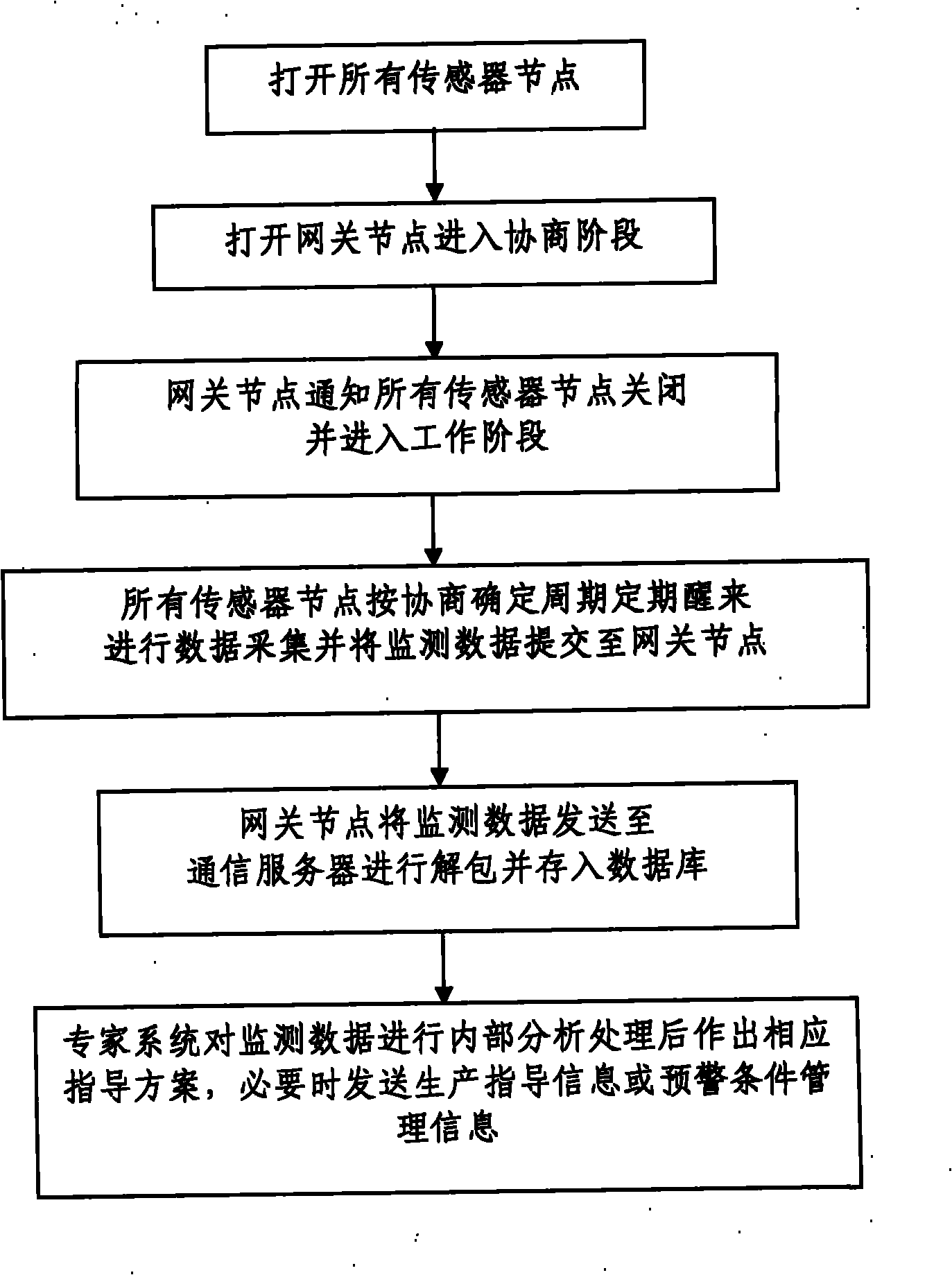

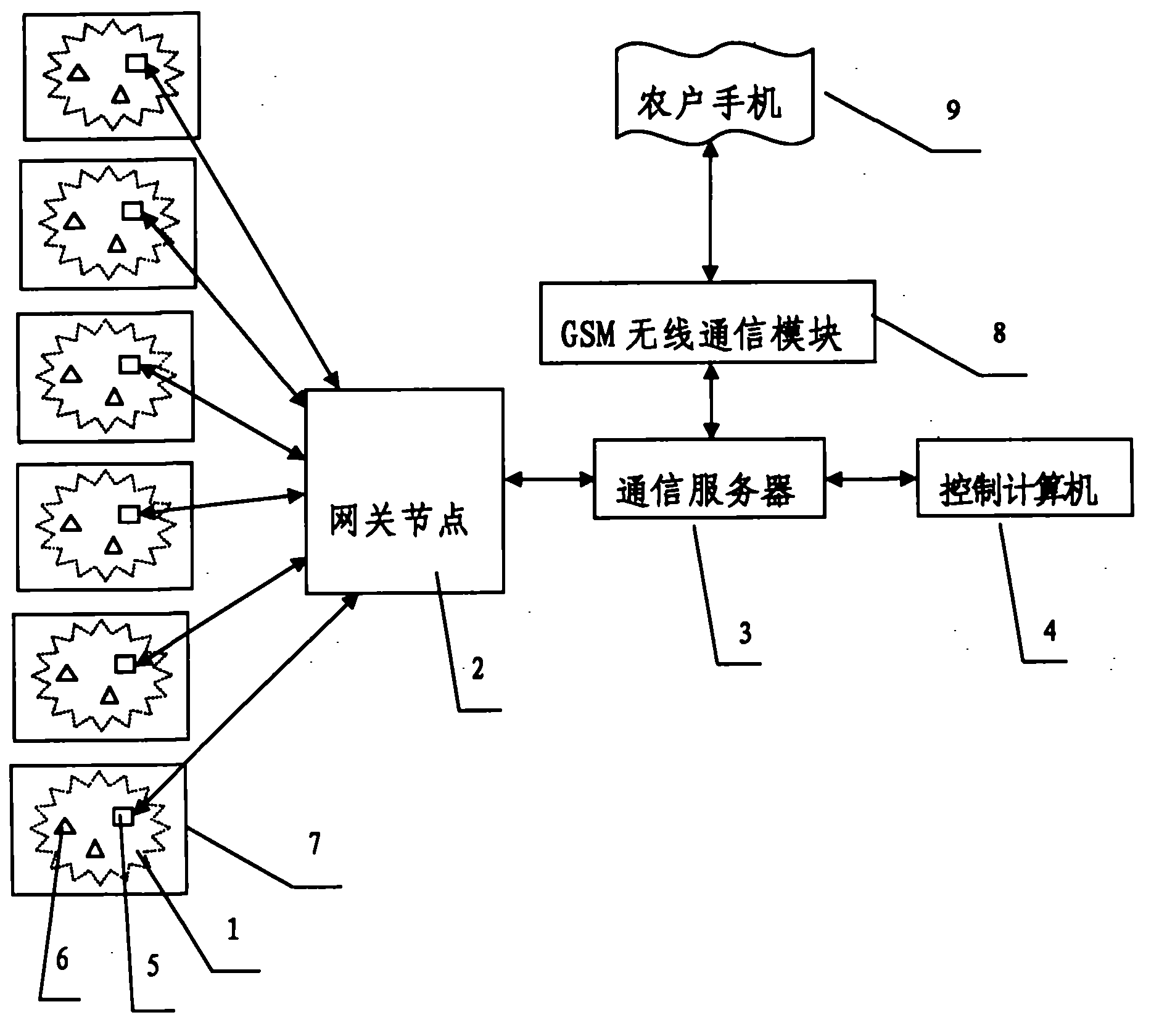

Wireless sensor network-based greenhouse group control system and control method thereof

InactiveCN101969613AStable flowGet it in timeMeasurement devicesNetwork topologiesLine sensorWireless mesh network

The invention discloses a wireless sensor network-based greenhouse group control system and a control method thereof. Each greenhouse is provided with a plurality of wireless sensor nodes and a cluster head node for acquiring environmental factors of the greenhouses according to needs, wherein the wireless sensor nodes and the cluster head nodes autonomously form wireless sensor networks by wireless communication; the wireless sensor nodes transmit monitoring data to the corresponding cluster head nodes in a multi-hop way; the cluster head nodes transmit the data to a gateway node which uploads the data to a communication server; the communication server performs two-way communication with a control computer; and the control computer makes corresponding guidance schemes according to the data monitored by the wireless sensor networks in real time, and synchronously transmits control instructions to the wireless sensor networks according to the guidance schemes. In the system and the method, the real-time data monitored by each sensor node in the greenhouses can be timely and accurately acquired, and the control instructions can be fast transmitted to the sensor nodes after specific production guidance is made or early-warning setting is performed according to the monitoring data.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

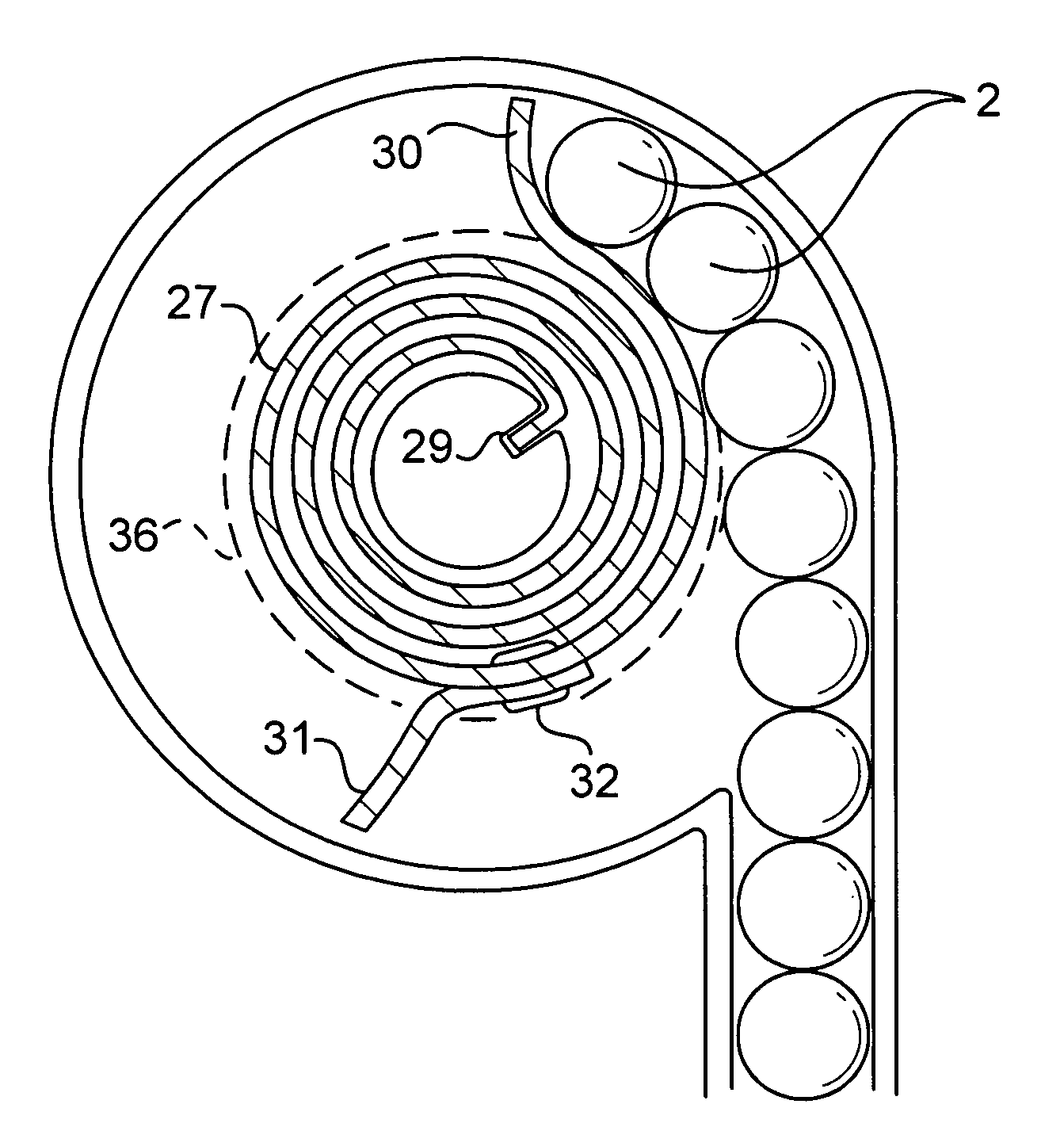

Spring-assisted paintball loader

InactiveUS7357130B2Stable flowReduce gapAmmunition loadingCompressed gas gunsElectric machineryCoil spring

A mechanism for feeding uniformly-sized spherical projectiles such as paintballs into a gun adapted to shoot said projectiles is positioned in a lower region of a paintball-holding magazine, and includes a spinning body in the form of a spool from the peripheral side of which project radial arms shaped and dimensioned to urge projectiles toward a duct leading to the ammunition intake port of the gun. The spool is driven by a switchable electrical motor. In order to avoid gaps into the row of paintballs that are urged toward the ammunition intake port when the motor is not running which could result in dry firing, a resiliently variable linkage between the propelling arms is provided by a spiral spring or a pair of stretchable coil springs.

Owner:KEE ACTION SPORTS I

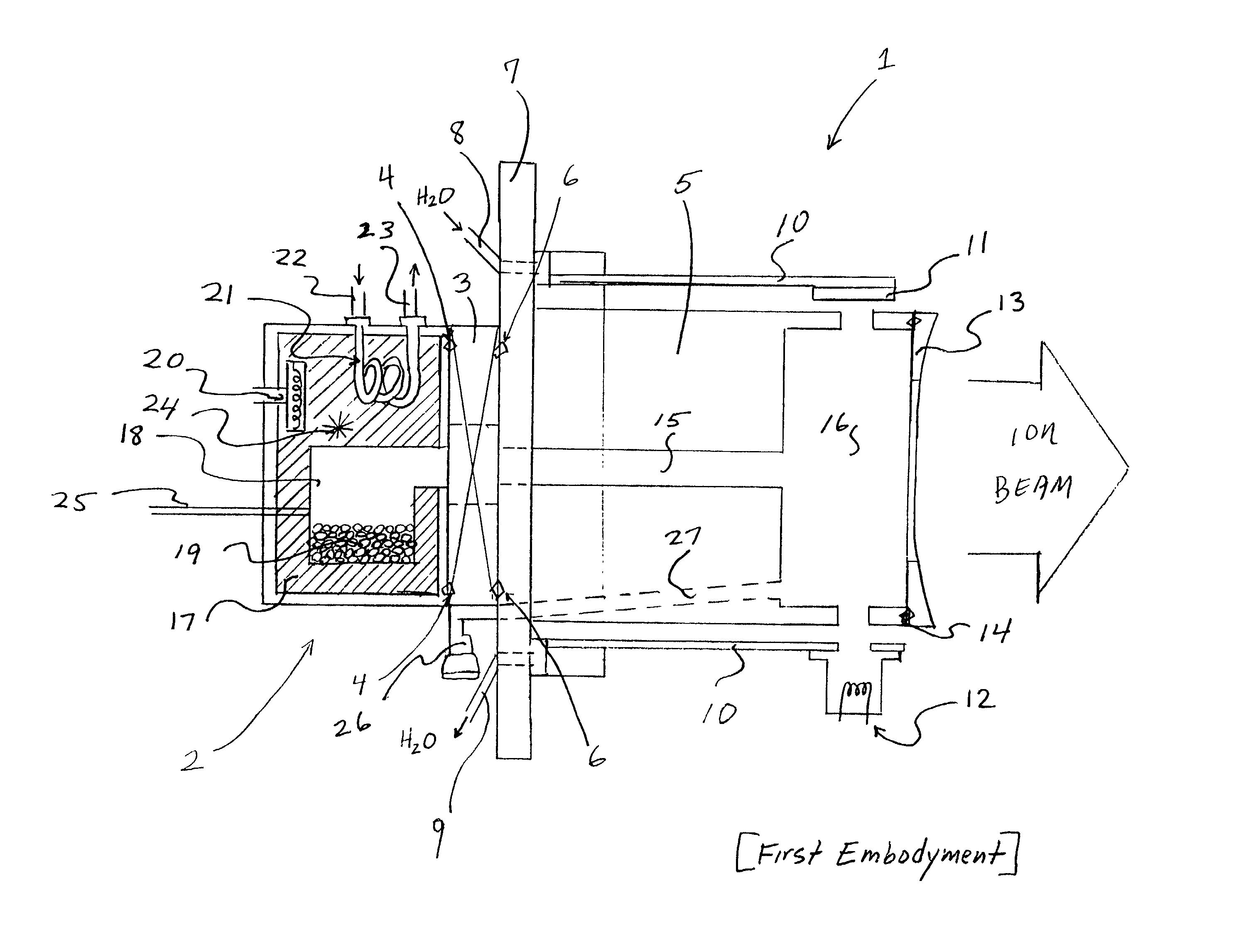

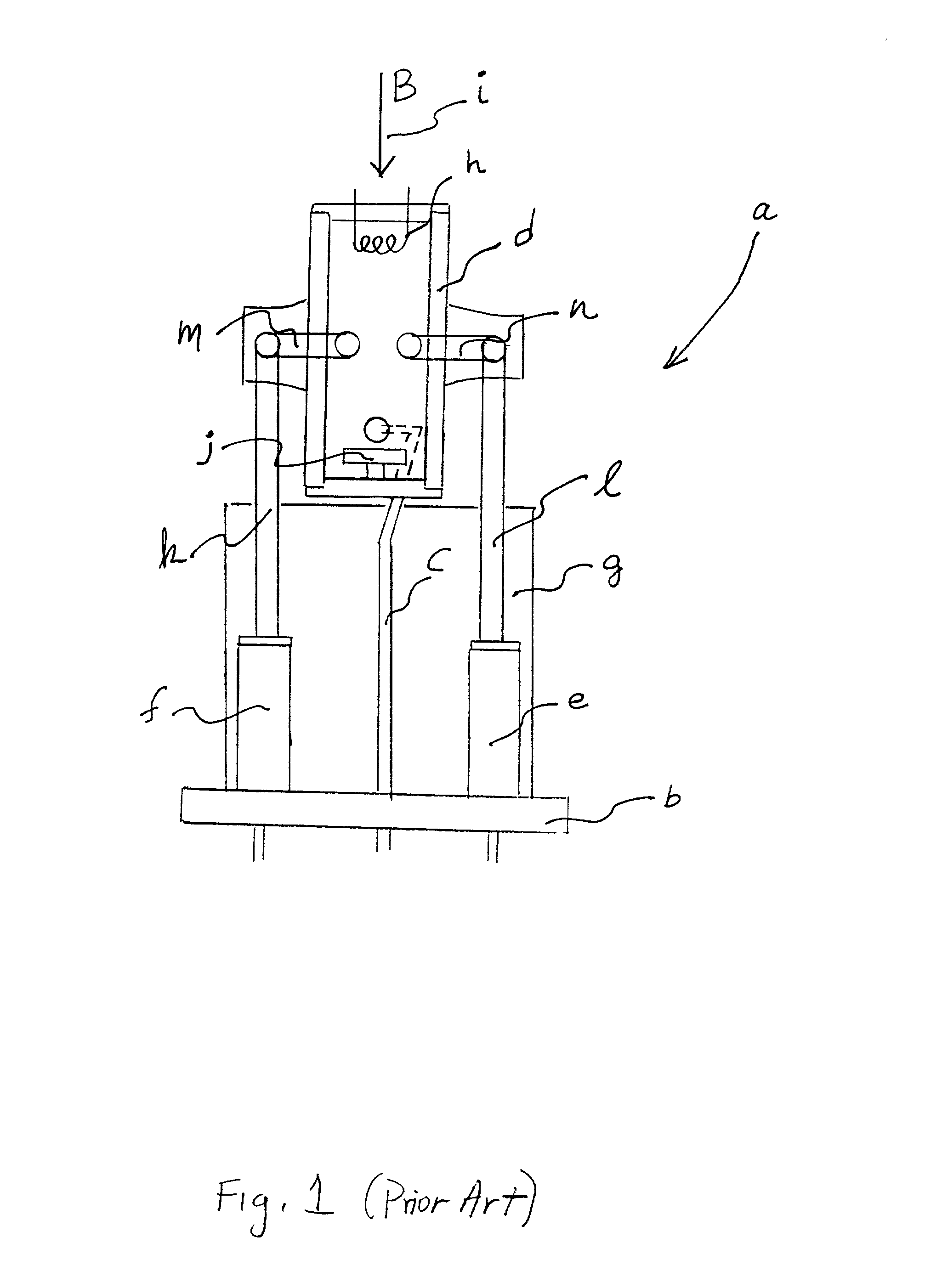

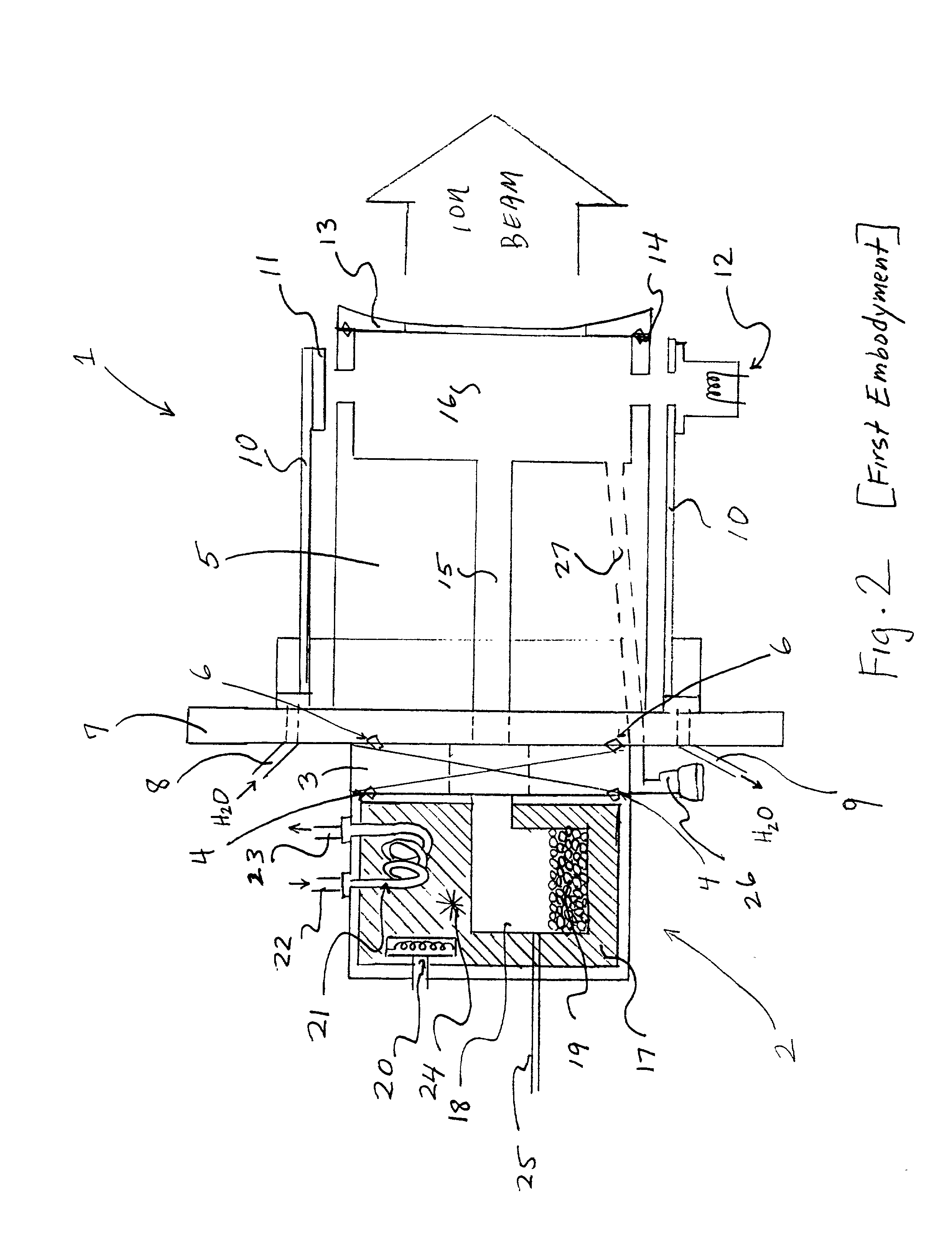

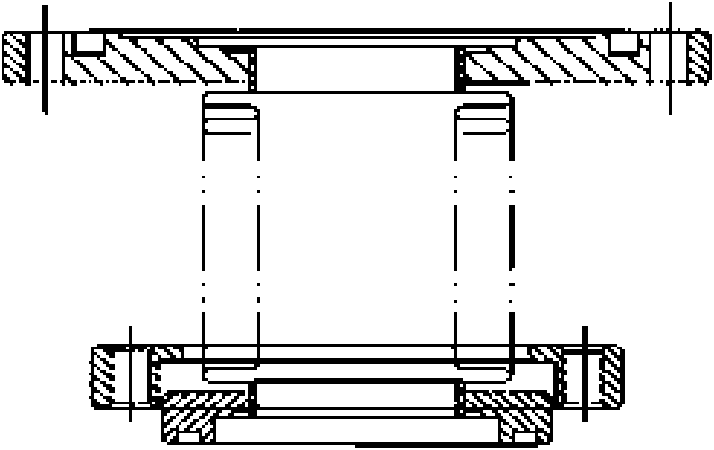

Electron beam ion source with integral low-temperature vaporizer

InactiveUS20020070672A1Maximizes conductanceMinimizes conductanceElectric discharge tubesSemiconductor/solid-state device manufacturingHigh energy beamIon implantation

An ion source for ion implantation system and a method of ion implantation employs a controlled broad, directional electron beam to ionize process gas or vapor, such as decaborane, within an ionization volume by primary electron impact, in CMOS manufacturing and the like. Isolation of the electron gun for producing the energetic electron beam and of the beam dump to which the energetic beam is directed, as well as use of the thermally conductive members for cooling the ionization chamber and the vaporizer, enable use with large molecular species such as decaborane, and other materials which are unstable with temperature. Electron optics systems, facilitate focusing of electrons from an emitting surface to effectively ionize a desired volume of the gas or vapor that is located adjacent the extraction aperture. The components enable retrofit into ion implanters that have used other types of ion sources. Demountable vaporizers, and numerous other important features, realize economies in construction and operation. Achievement of production-worthy operation in respect of very shallow implants is realized.

Owner:SEMEQUIP

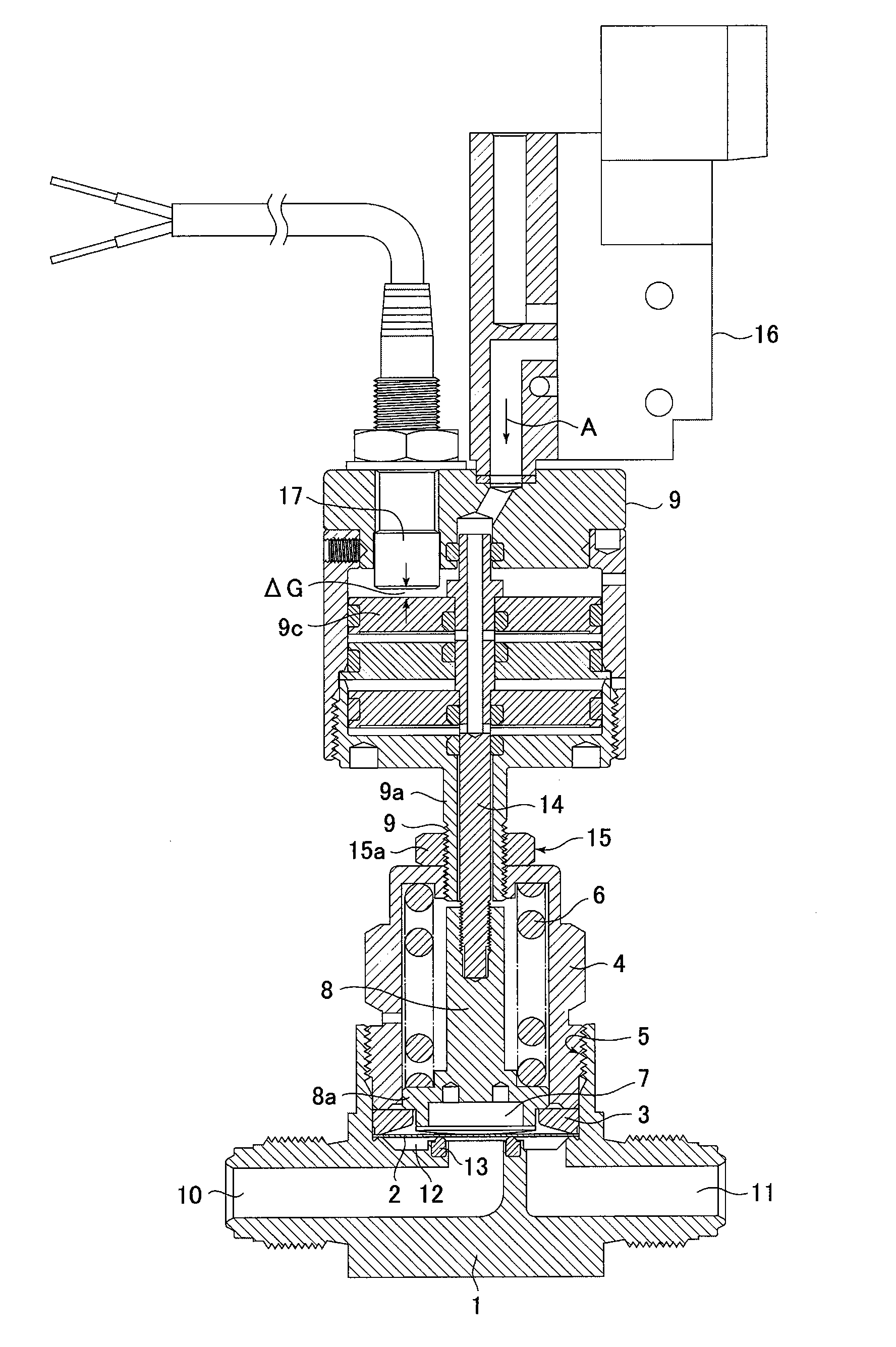

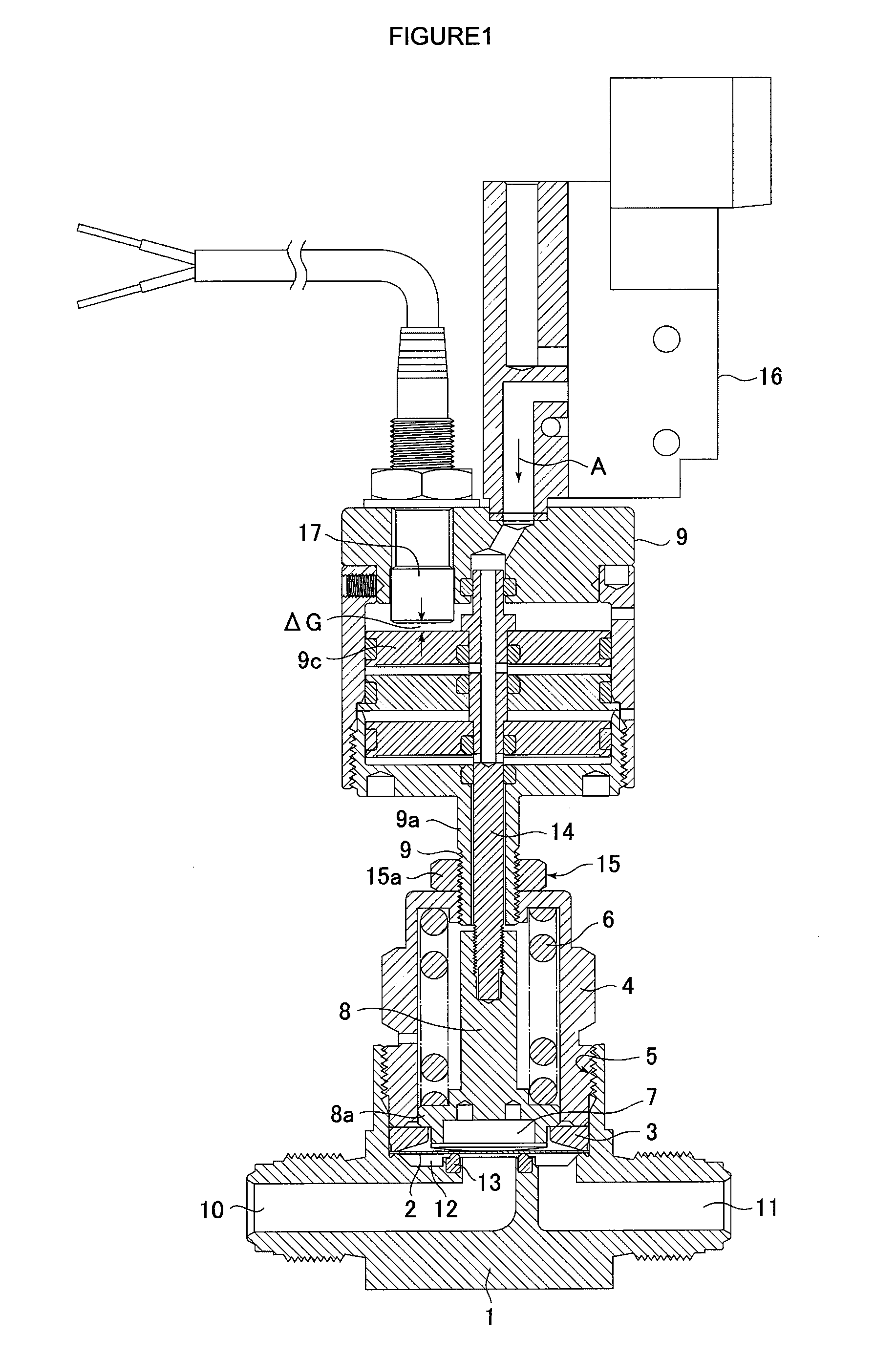

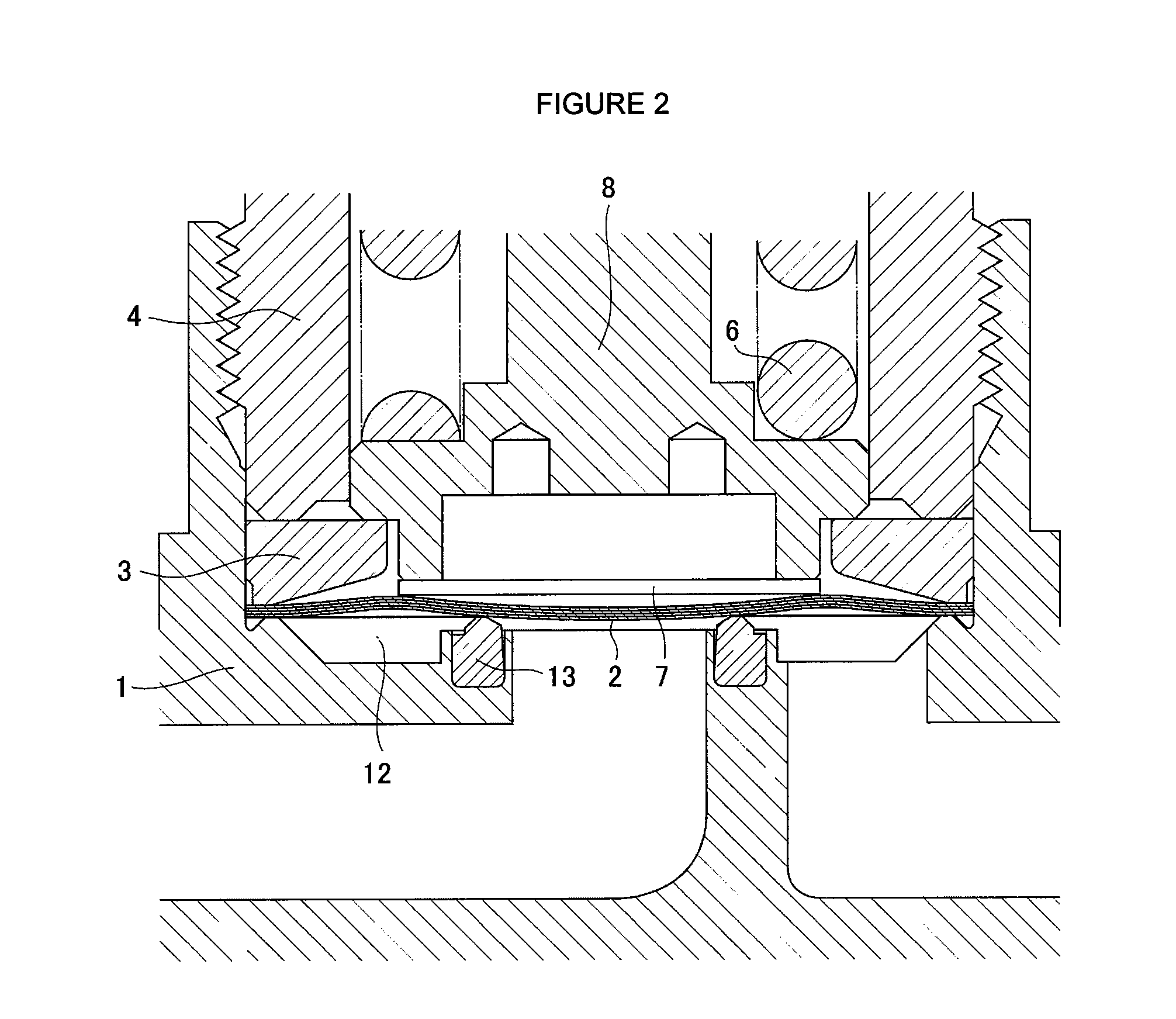

Direct touch type metal diaphragm valve

ActiveUS20100090151A1Reduce replacement timeAchieve stabilityDiaphragm valvesOperating means/releasing devices for valvesDirect touchEngineering

A direct touch type metal diaphragm valve, wherein durability of the valve, that is to say, the ensured number of continuous open / close operations of the valve, is substantially increased under conditions that an appropriate flow rate coefficient Cv is maintained, and changes of the afore-mentioned Cv value over time are mitigated by means of restricting the deformation of the valve seat over time. The afore-mentioned metal diaphragm is formed in a round, reverse-dish shape by laminating a plural number of thin stainless steel plates and a thin Nickel.Cobalt alloy plate, and its center part is bulged upward, and the maximum valve stroke of the valve is regulated to be 55% to 70% of the distance of the maximum bulge height Δh of the afore-mentioned metal diaphragm.

Owner:FUJIKIN INC

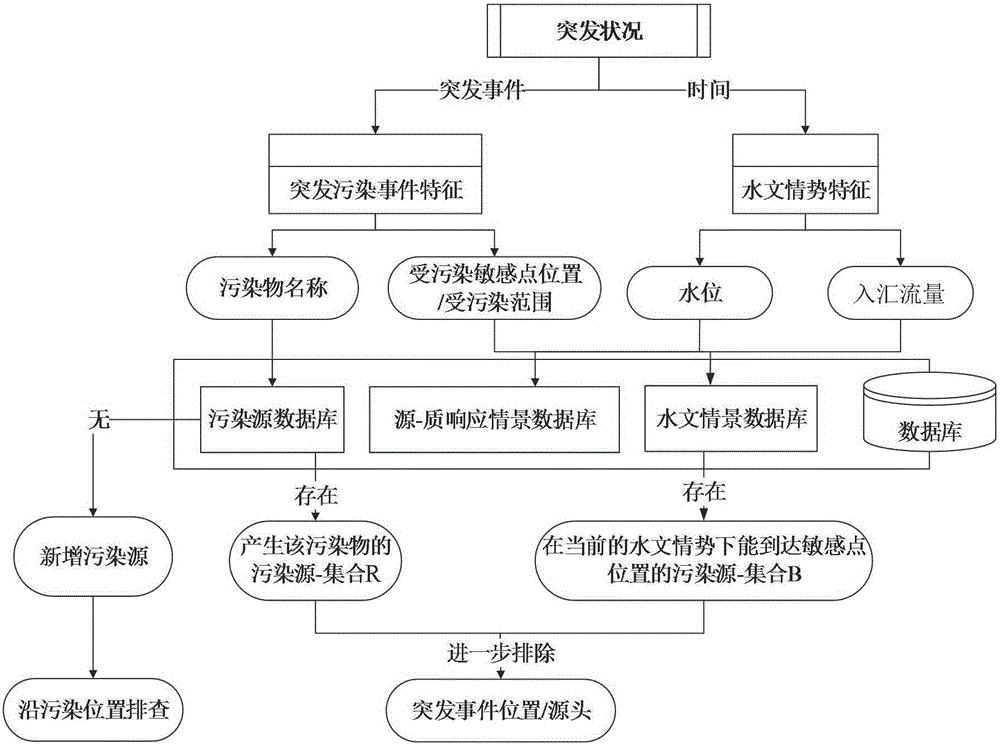

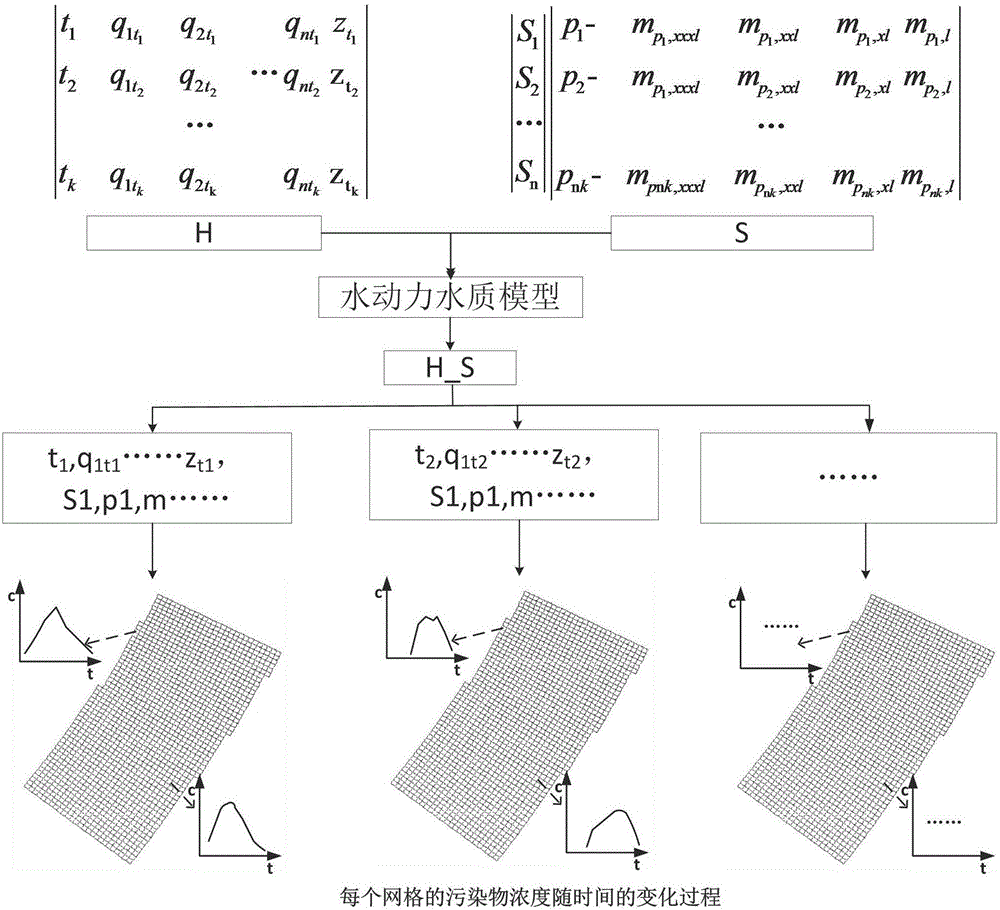

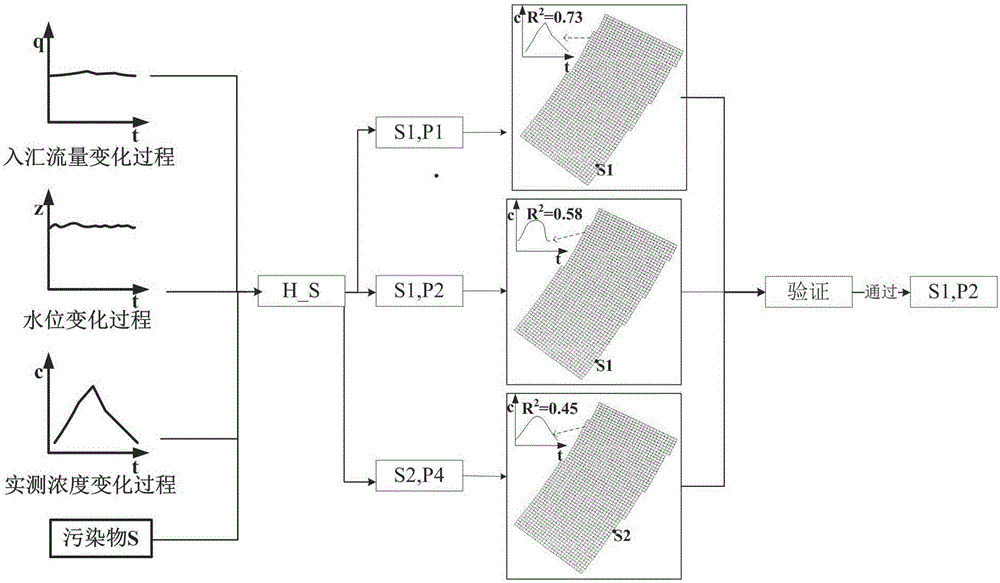

Method for tracing pollution source in emergency events

ActiveCN106228007AQuick traceability resultsEfficient searchGeneral water supply conservationInformaticsUnexpected eventsPollutant emissions

The invention provides a method for tracing pollution sources in emergency events. The method is characterized by comprising steps of 1, constructing source-quality response scene databases, to be more specific, creating fixed and mobile pollution source databases in certain ranges of river basins and hydrological scene databases of river basins where projects are located, simulating pollution statues of the project river basins due to pollutants of each pollution source under the conditions of different hydrological scenes and different emission amounts and creating the source-quality response scene databases in project regions; 2, carrying out source tracing analysis and computation, to be more specific, investigating and screening the pollution sources in the source-quality response scene databases according to feature information of the pollutants and hydrological regime information, finding out possible pollution sources which meet requirements of screening targets, constructing target libraries, analyzing pollution procedure fitting degrees of the target libraries, sorting the target libraries according to the fitting degrees, determining risk sources which possibly cause the emergency pollution accidents, and further conforming the risk sources by means of verification. The method has the advantage that the locations and the pollutant emission amounts of the pollution sources can be quickly determined by the aid of the method.

Owner:WUHAN UNIV

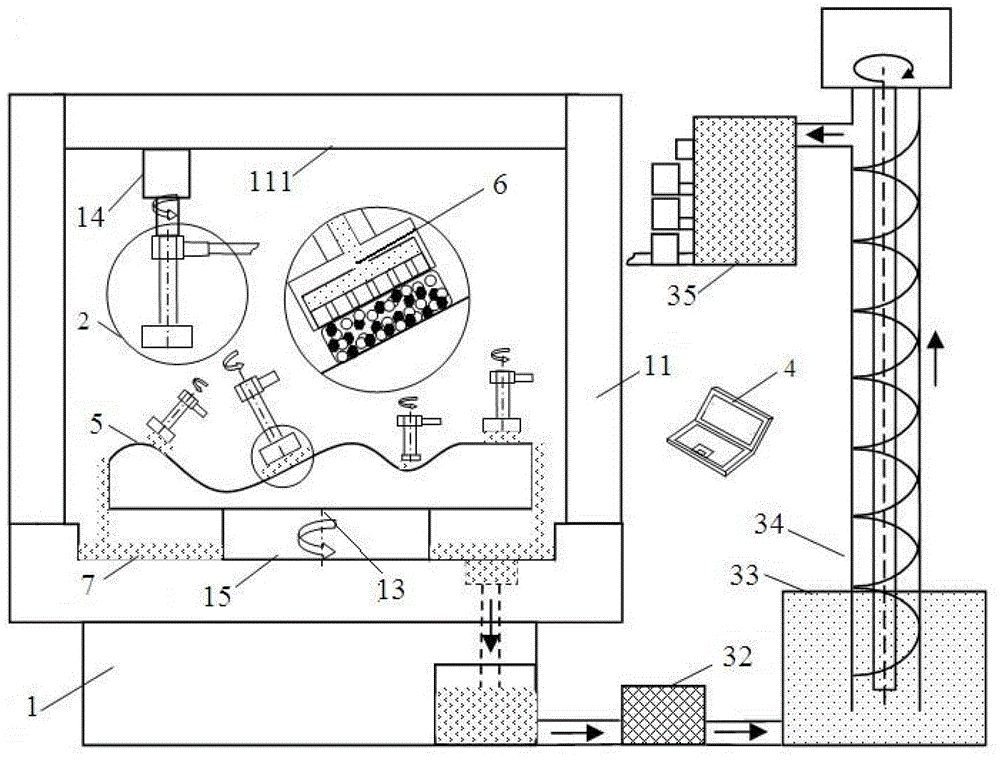

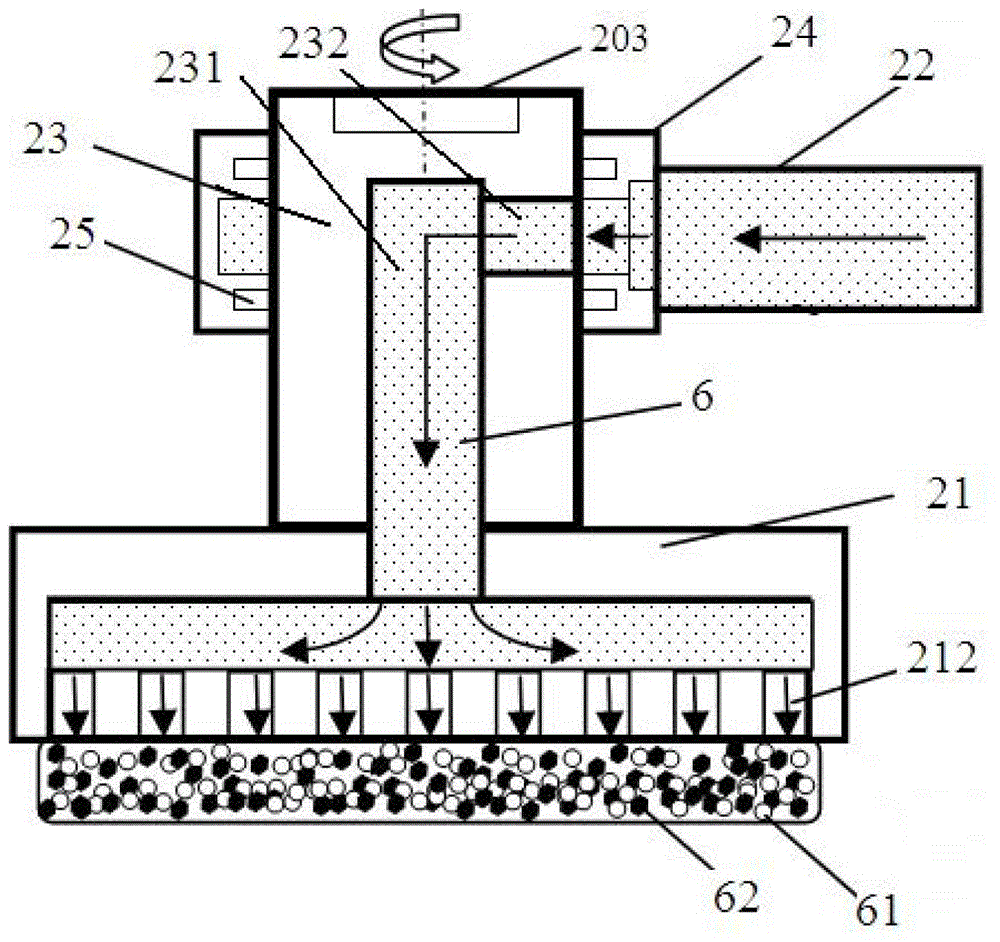

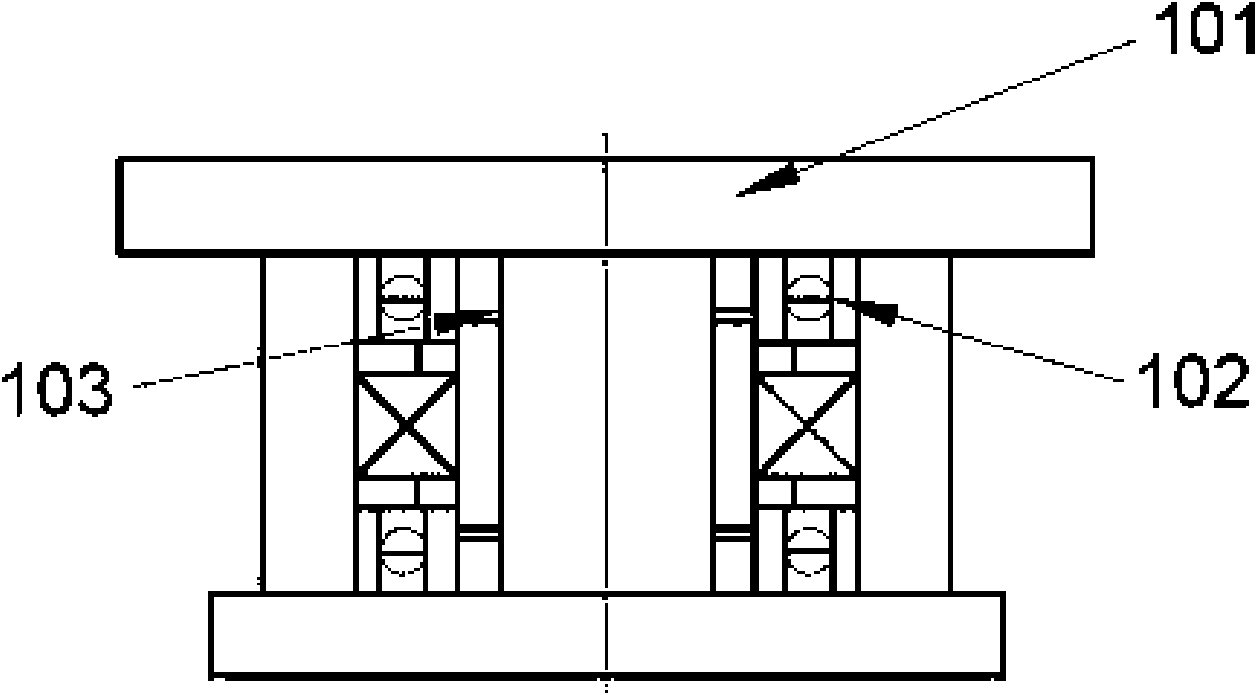

Machining device based on non-Newtonian fluid shear thickening mechanism polishing method

ActiveCN103331685ARealize multi-pose transformationRemovablePolishing machinesEngineeringPortal frame

A machining device based on a non-Newtonian fluid shear thickening mechanism polishing method comprises a workbench, a polishing tool system, an abrasive fluid circulation device and a computer control module, wherein the polishing tool system is installed on a portal frame of the workbench, an inlet of the abrasive fluid circulation device is communicated with an abrasive backflow opening in the workbench, and the workbench, the polishing tool system and the abrasive fluid circulation device are respectively connected with the computer control module. The machining device has the advantages that the application range is wide, the size of machined workpieces is not limited, the structure of the device is simple, the device is controlled easily, a computer controls the operation track of the device, the polishing process of non-Newtonian fluid abrasive fluid and the surfaces of the workpieces can be controlled effectively, a non-Newtonian fluid abrasive fluid circulation system is adopted, and the functions of removing abrasive dust, purifying, recycling, transporting and storing the abrasive fluid, and adjusting performance are achieved.

Owner:ZHEJIANG UNIV OF TECH

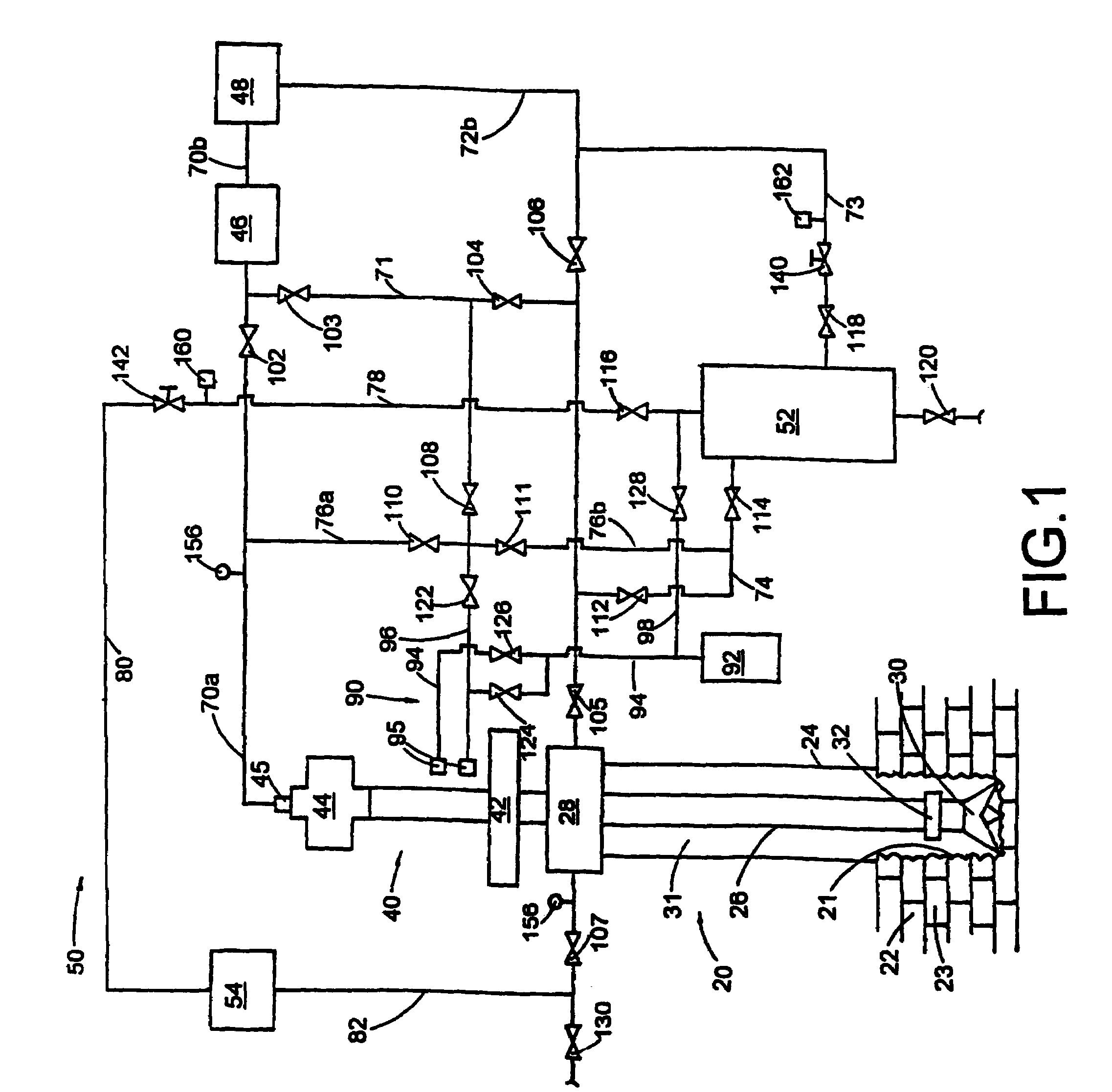

Underbalanced drilling method and apparatus

InactiveUS7308952B2Eliminate the problemAvoid excessive volumeConstructionsFluid removalGas liftMechanics

A method of drilling well bore (20) through and below permeable formation (22) bearing such fluids as gas, oil, water wherein drill cuttings may be evacuated by formation fluid (23) being produced through the drill string (26) either by decreasing well head back pressure or by gas lift. Production rate is kept substantially stable by operating choke valves (140) and (142) placed after separator (52). Formation fluid being produced while drilling may be pumped into well bore (20) through annulus (31) or utilized. The unique injector included in the drill string provides for possibility to pump simultaneously into annulus (31) lifting gas and produced liquid and may be operated from the surface. A method and system (90) comprising a plurality of special 3-way valves included in drill string (26), are provided for making connections without interrupting flushing the well bore.

Owner:STRAZHGORODSKIY SEMEN IOSIPHOVICH

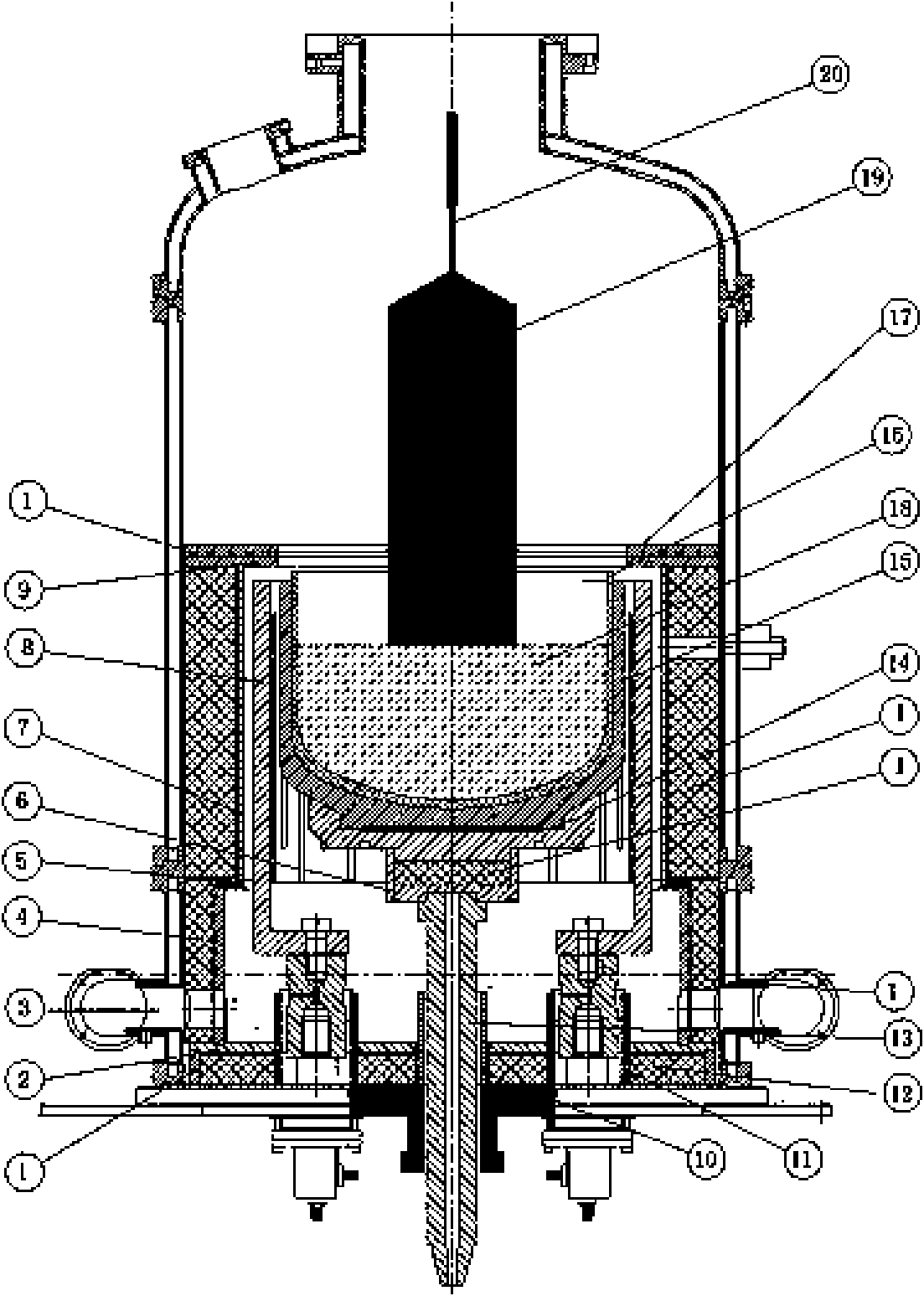

Process for growing phi 8'' solar-grade Czochralski silicon by using 18-inch thermal field

ActiveCN101798704AOptimize parameter conditionsImprove insulation effectBy pulling from meltSlagEvaporation

The invention discloses a process for growing phi 8'' solar-grade Czochralski silicon monocrystalline by using an 18-inch thermal field. By adopting the 18-inch thermal-shielding thermal field and an upper-shaft magnetic fluid sealing device with a cooling system and combining the optimized parameter conditions of crystal-pulling processes, the invention enables the thermal field to have good heat preservation and obviously reduced energy consumption, enables gas to smoothly flow to be beneficial for the exhaustion of volatile matter, stabilizes crystallization, prolongs the service life of equipment and reduces the production cost; and in addition, the invention reduces magnet demagnetization and the evaporation of a magnetic fluid to avoid the air leakage and the slag dropping of the sealing of the magnetic fluid affecting the growth of the Czochralski silicon monocrystalline, improves the sealing performance and prolongs the service life, thereby ensuring the crystal-pulling processes of crystal leading, diameter equalization, shoulder rotation and the like to be stable and improving production efficiency and yield.

Owner:峨嵋半导体材料研究所

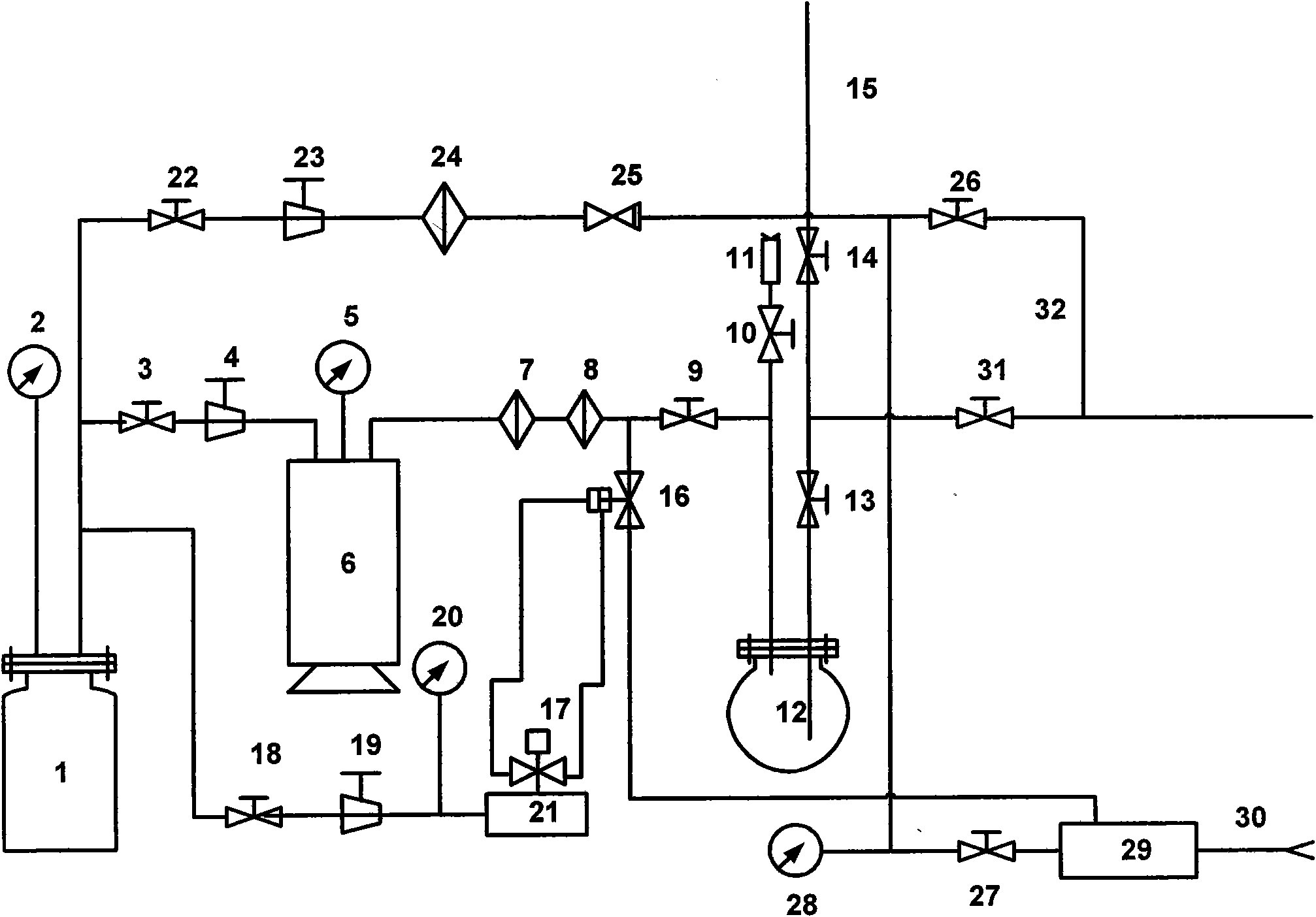

Pressure stability control device supplied with constant voltage by propellant

InactiveCN101539069AStable flowImprove working conditionsRocket engine plantsBuffer tankHigh pressure

The invention provides a pressure stability control device supplied with constant voltage by a propellant, in particular comprising a high-pressure air supply device, a supercharging device, a control gas device, a blowing device and a liquid propellant supplying device. The high-pressure air supply device supplies high-pressure air. The supercharging device supercharges a propellant storage tank to extrude the propellant to enter a feeding pipeline, and a supercharging buffer tank can stabilize the pressure of pressurized gas. The blowing device is in charge of filling the clearing of pipeline propellant. The control gas device provides control gas for the system. The pressure of pressurized gas can be always kept constant by the pressure stability control device supplied with constant voltage by the propellant, thereby continuously supplying liquid propellant in testing, and satisfying the principle of slow supercharging and preventing collapse of the feeding pipeline due to too fast pressurizing in pressurization.

Owner:BEIHANG UNIV

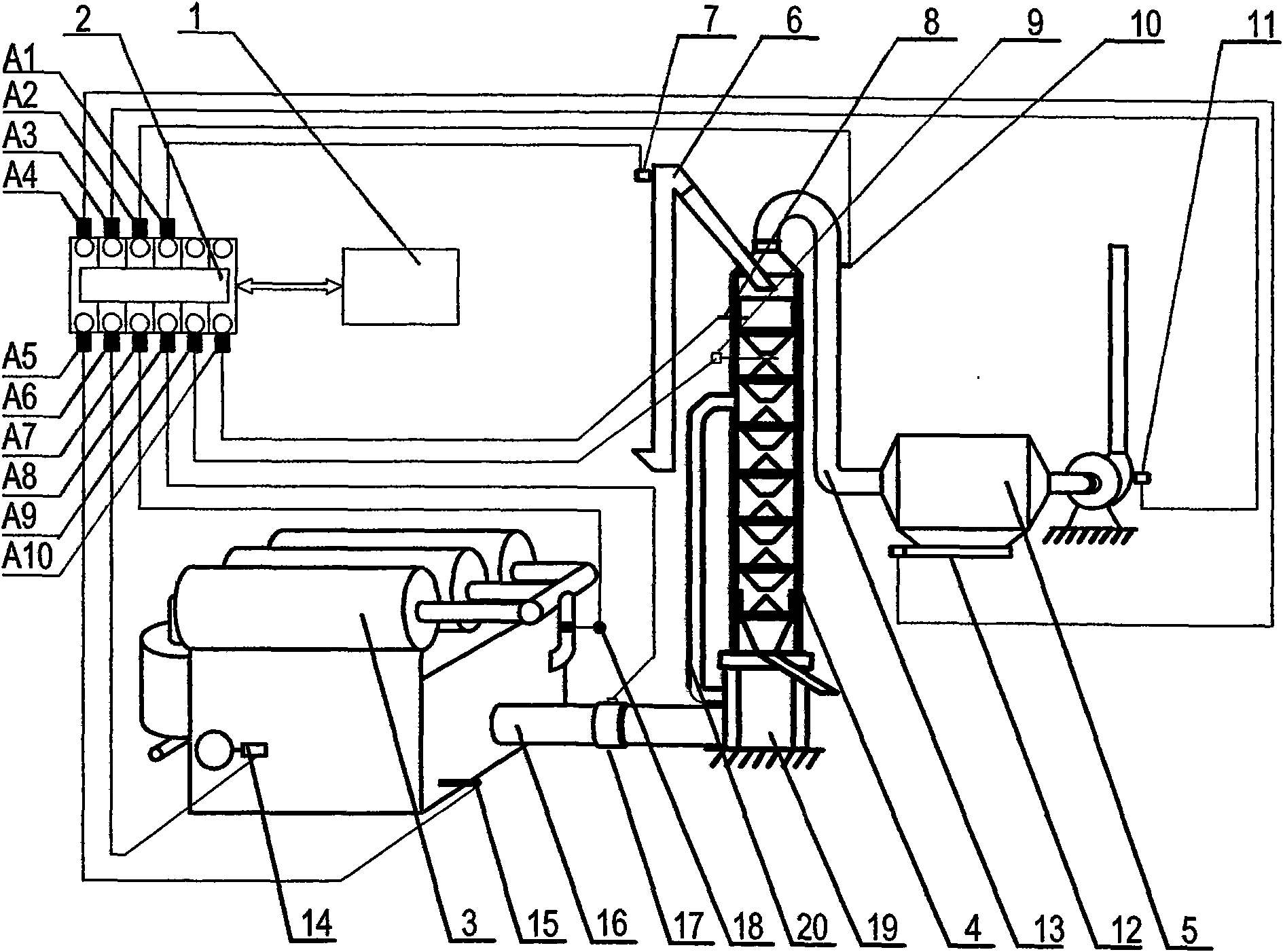

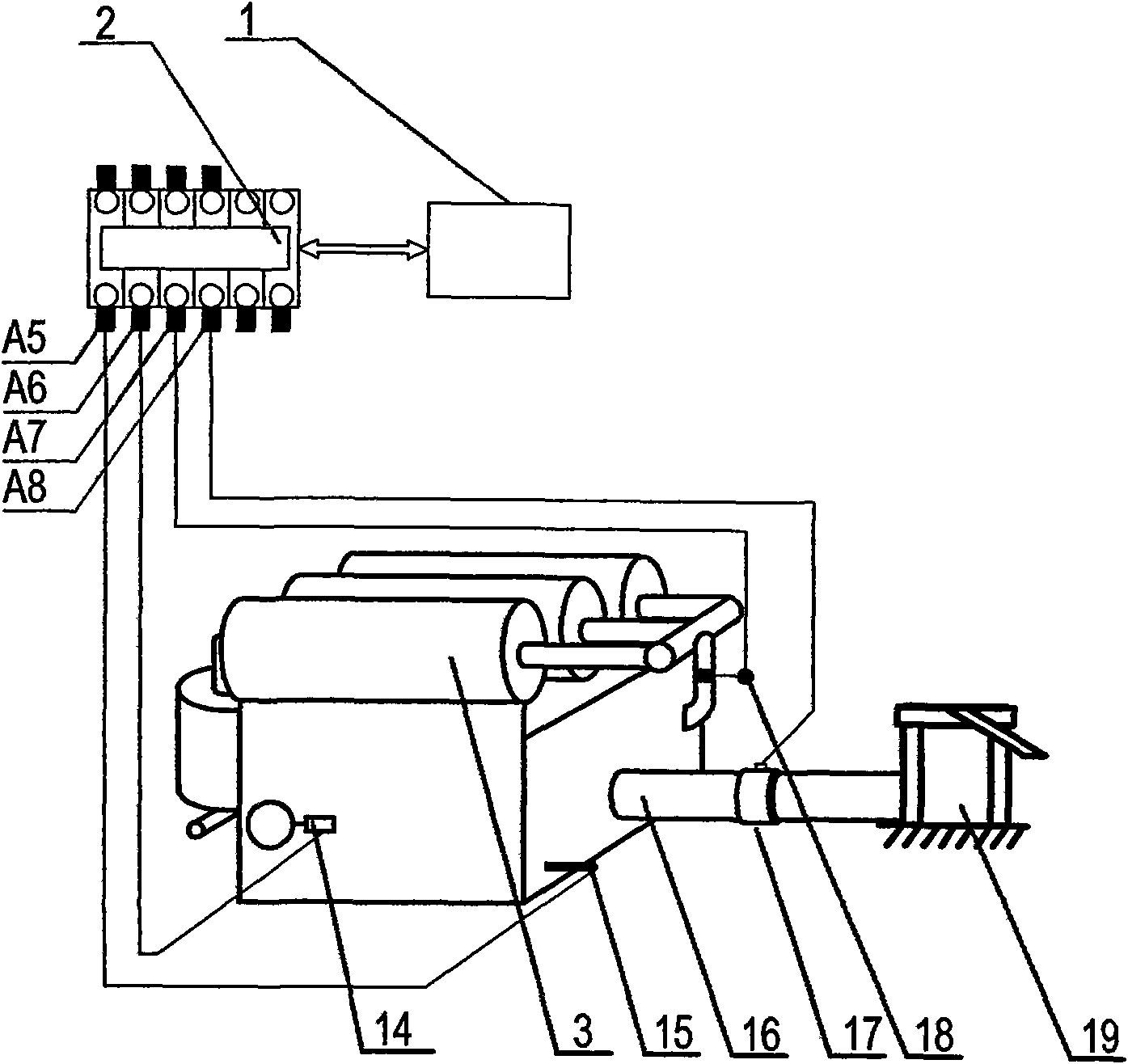

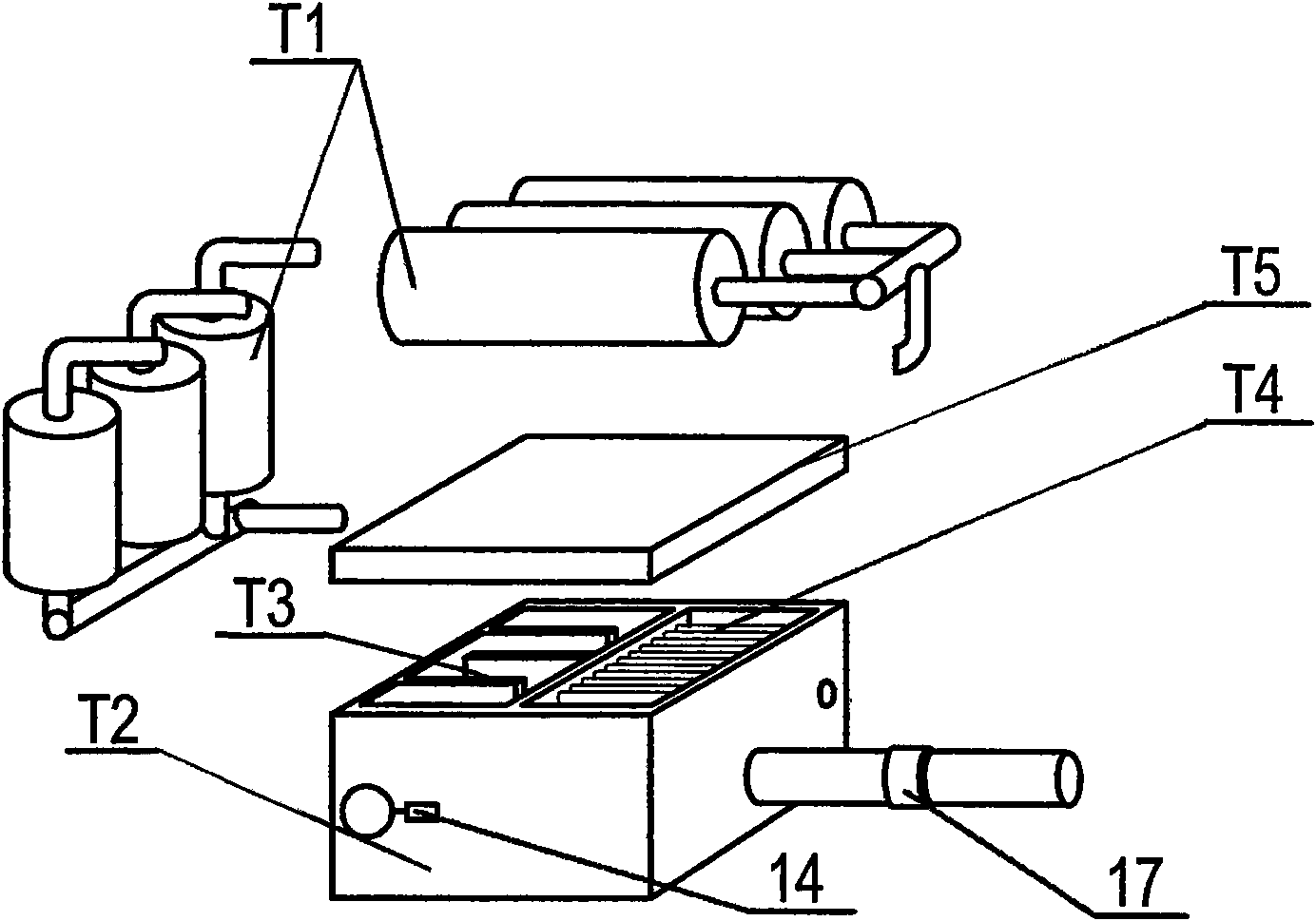

Automatic constant temperature drying and automatic regulation material flow control device of light energy vertical dryer

InactiveCN101886874AIncrease the level of automationStable flowSolar heating energyDrying solid materials with heatAutomatic controlLight energy

The invention discloses an automatic constant temperature drying and automatic regulation material flow control device of a light energy vertical dryer, aiming to solve the problems of environmental pollution caused by a great deal of harmful gas and dusts generated by drying the materials by the traditional vertical dryer through adopting a coal extracted heat in the production process and poor system automation degree in the control system of the traditional vertical dryer. The automatic constant temperature drying and automatic regulation material flow control device comprises a standard control device, an industrial control computer, a solar heat exchanger, a vertical dryer, an automatic constant temperature drying control device and a vertical dryer control device, wherein the standard control device is connected with the industrial control computer through a standard serial communication interface and is respectively connected with the solar heat exchanger and the vertical dryer, and the solar heat exchanger is connected with the vertical dryer. The invention has the advantages of simpleness, smooth flow and high automation degree, carries out automatic control by the industrial control computer, replaces fuel coals to dry the materials, improves the production efficiency and achieves the purposes of energy saving and emission reduction.

Owner:GANSU JINSHI CHEM

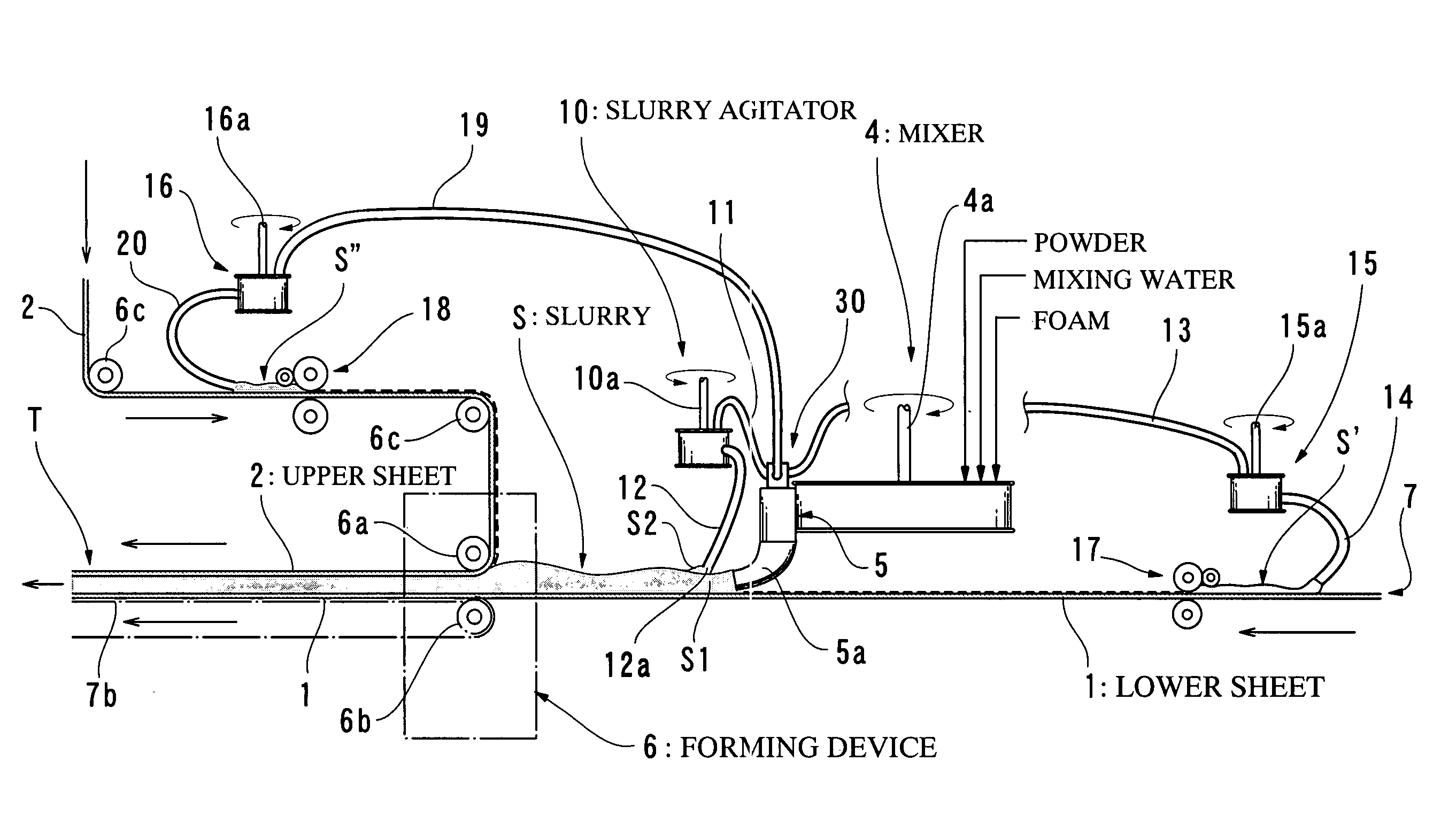

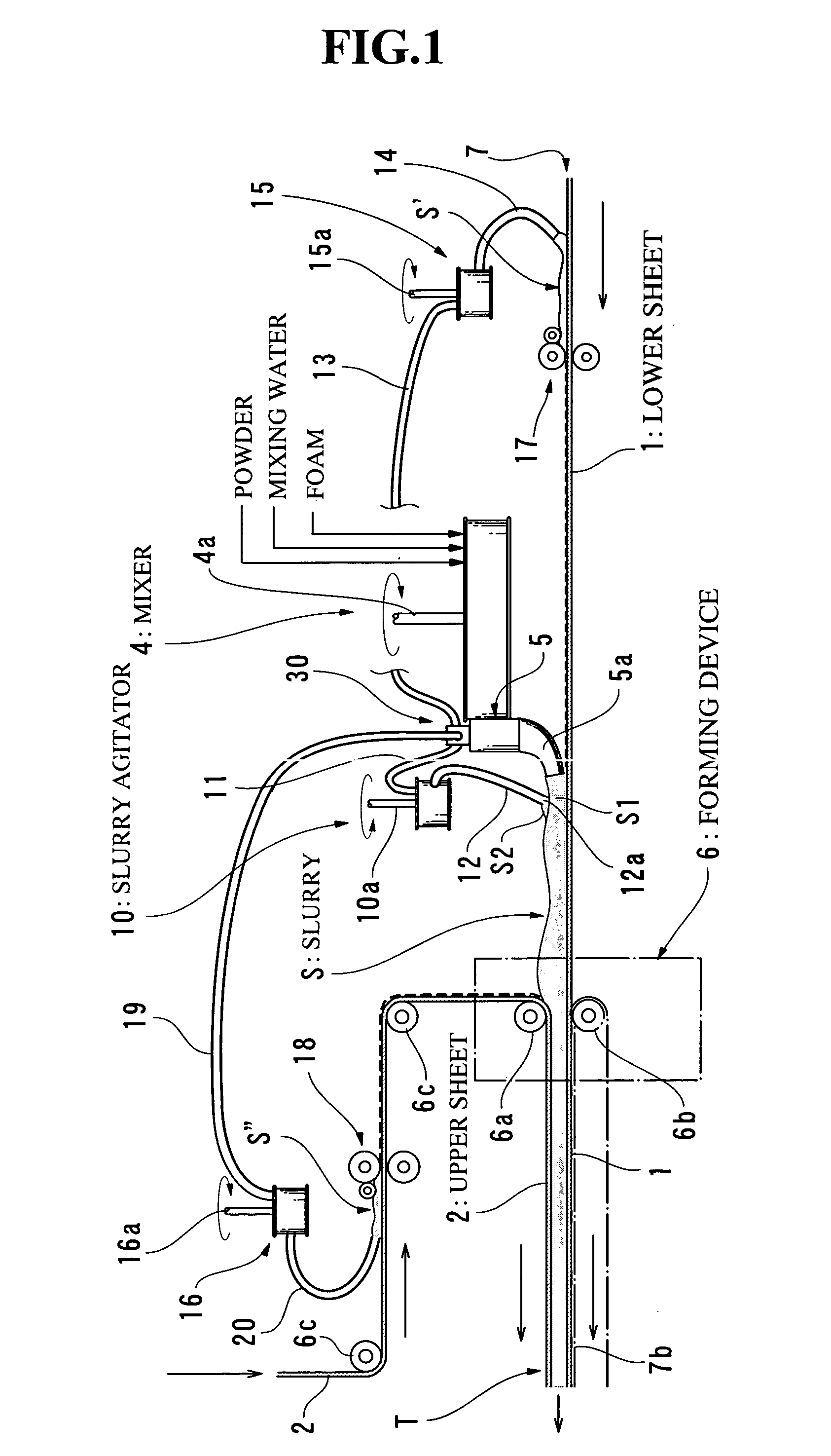

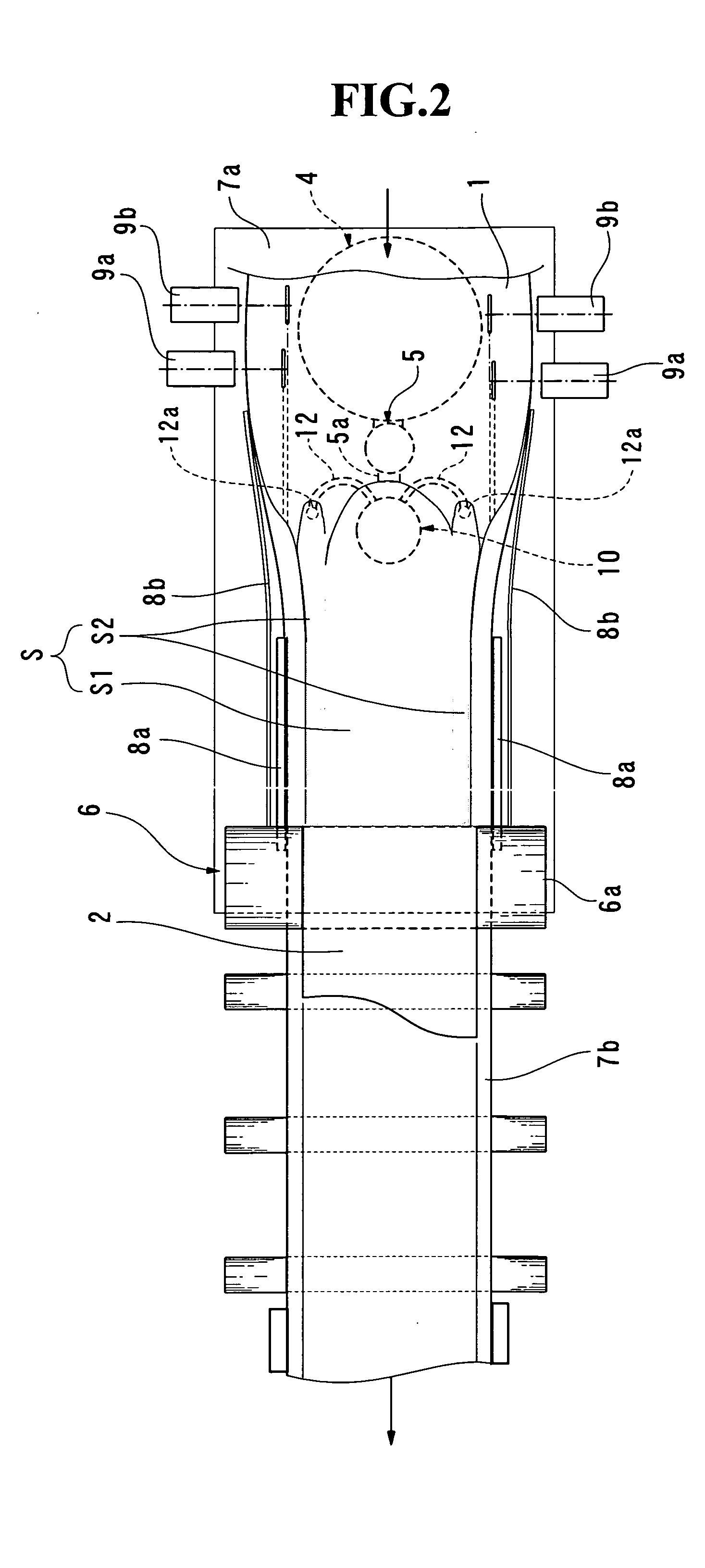

Apparatus and method for fractionating slurry and method of producing plaster-board

ActiveUS20060045975A1High densityStable pressurePretreated surfacesLaminationFoaming agentFractionation

The present invention provides an apparatus and a method for fractionating gypsum slurry which can surely control the density of the gypsum slurry fractionated from the mixer (fractionated slurry), which can restrict change of the flow rate of the fractionated slurry, and which can reduce the consumption of foam or foaming agent. The fractionation apparatus (30) fractionates the gypsum slurry from a mixer (4) for mixing calcined gypsum and water. The mixer has a hollow connector section (50), which allows the gypsum slurry to flow from a mixing area inside of the mixer into a chute section (5), and the chute section (5) discharging the inflow of gypsum slurry through its slurry discharge port onto a gypsum board liner paper. The fractionation apparatus has a slurry fractionation port (33) opening to the chute section or the hollow connector section, and causes a part of the gypsum slurry in the chute or hollow connector section to be delivered to a slurry delivery conduit (11,13,19).

Owner:YOSHINO GYPSUM CO LTD

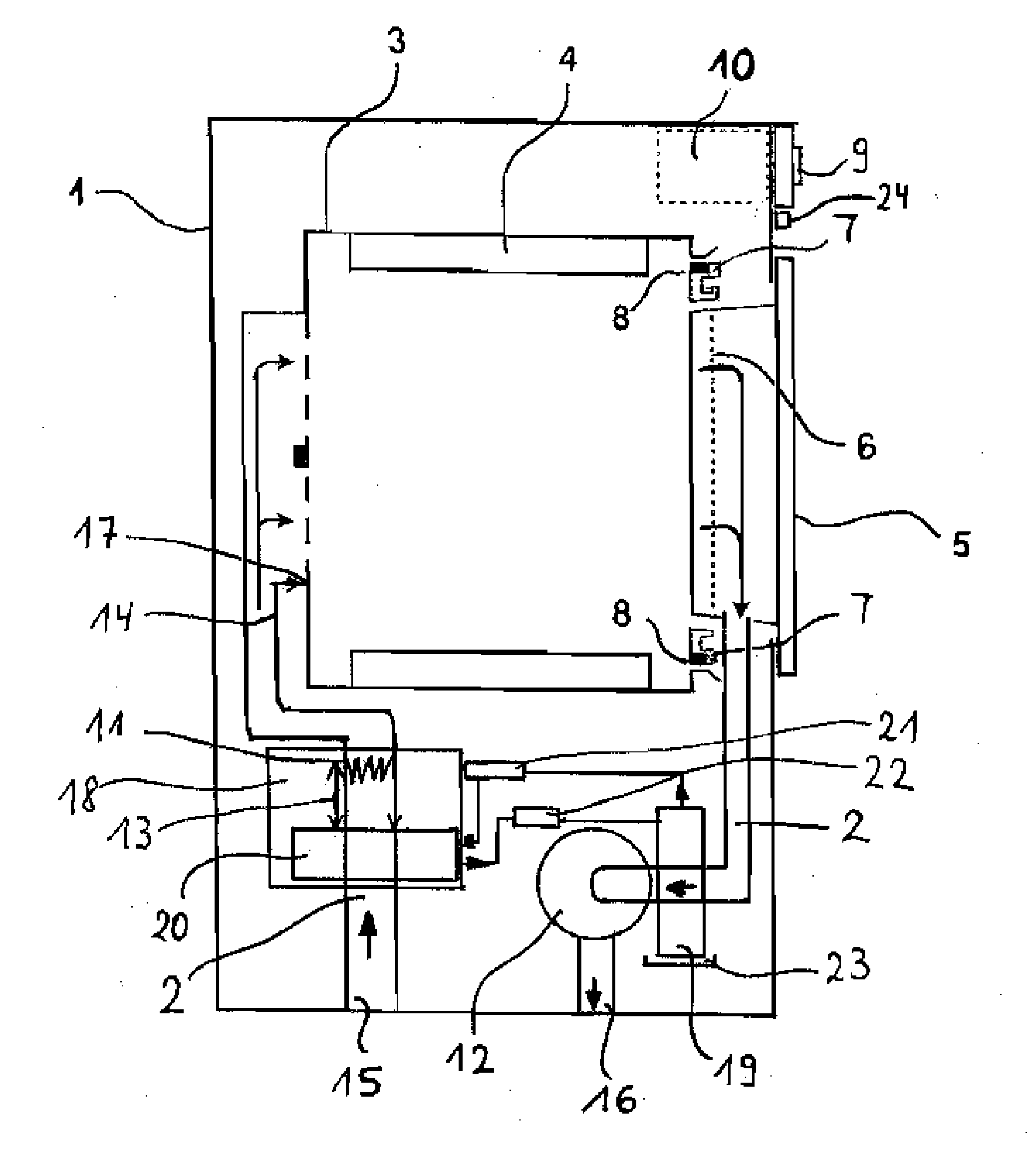

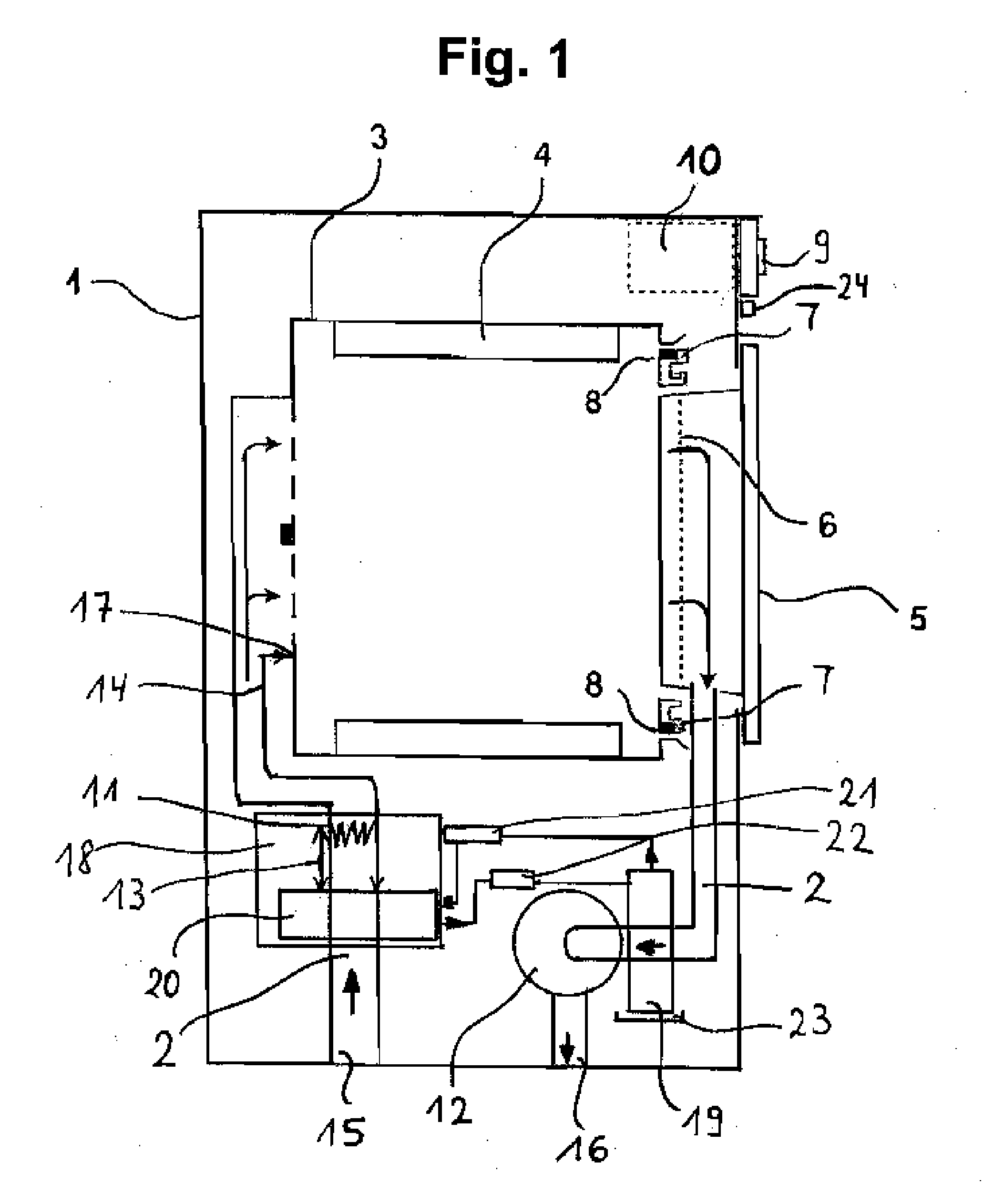

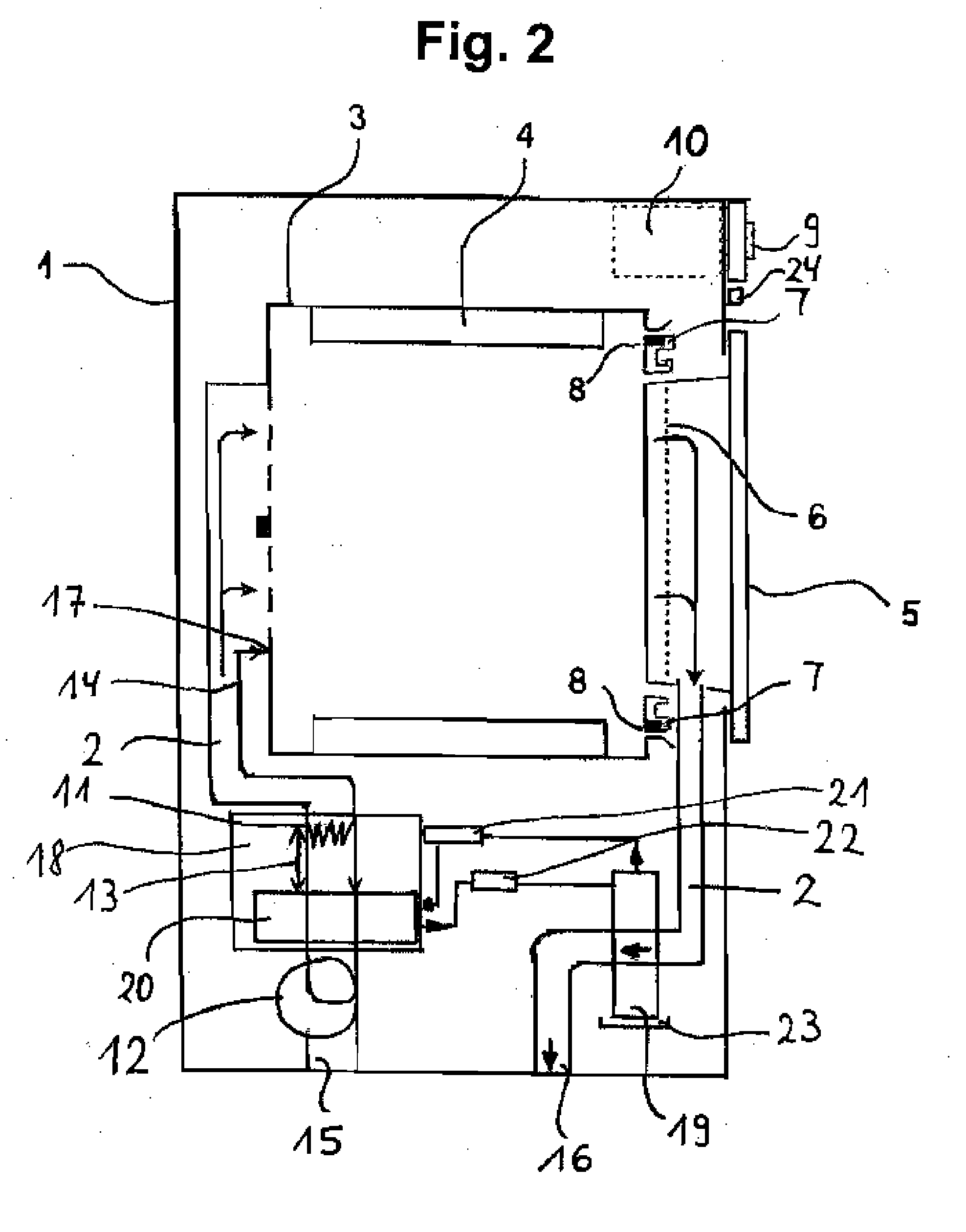

Dryer with a heat pump and an electrical heating element and also a method for its operation

InactiveUS20100132216A1Secure ability to regulateReduce the temperatureDrying solid materials with heatDrying chambers/containersElectricityProcess engineering

The invention relates to a dryer with a drying chamber for the items to be dried, a process air duct, a fan in the process air duct, a heat pump with a heat sink and a heat source thermally coupled to the process air duct, and also an electrical heating element. The electrical heating element is arranged in the direct vicinity of the heat source, with a first distance between the electrical heating element and the heat source being smaller than a second distance between the electrical heating element and an entry for the process air into the drying chamber. The invention also relates to a method for operating this dryer.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

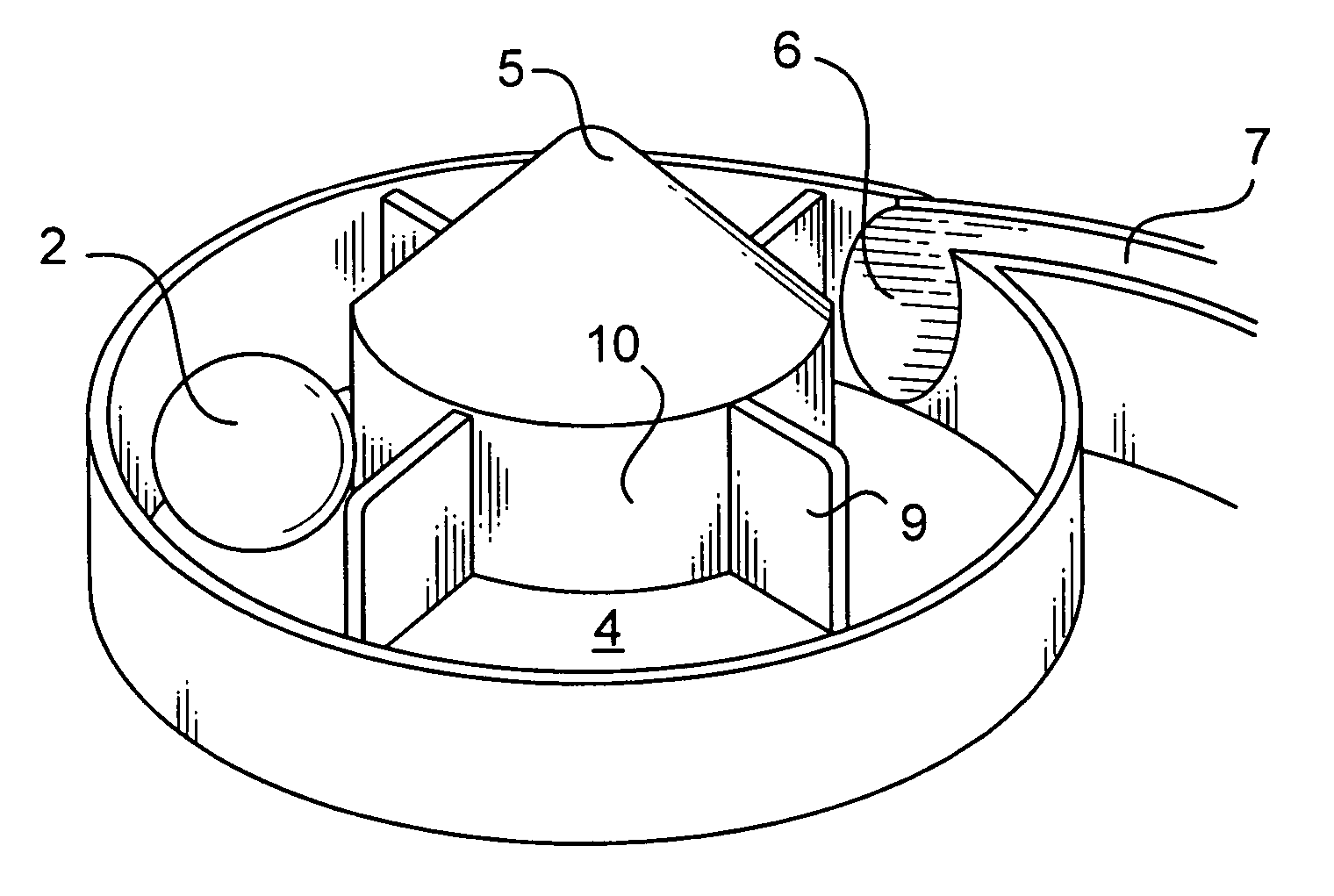

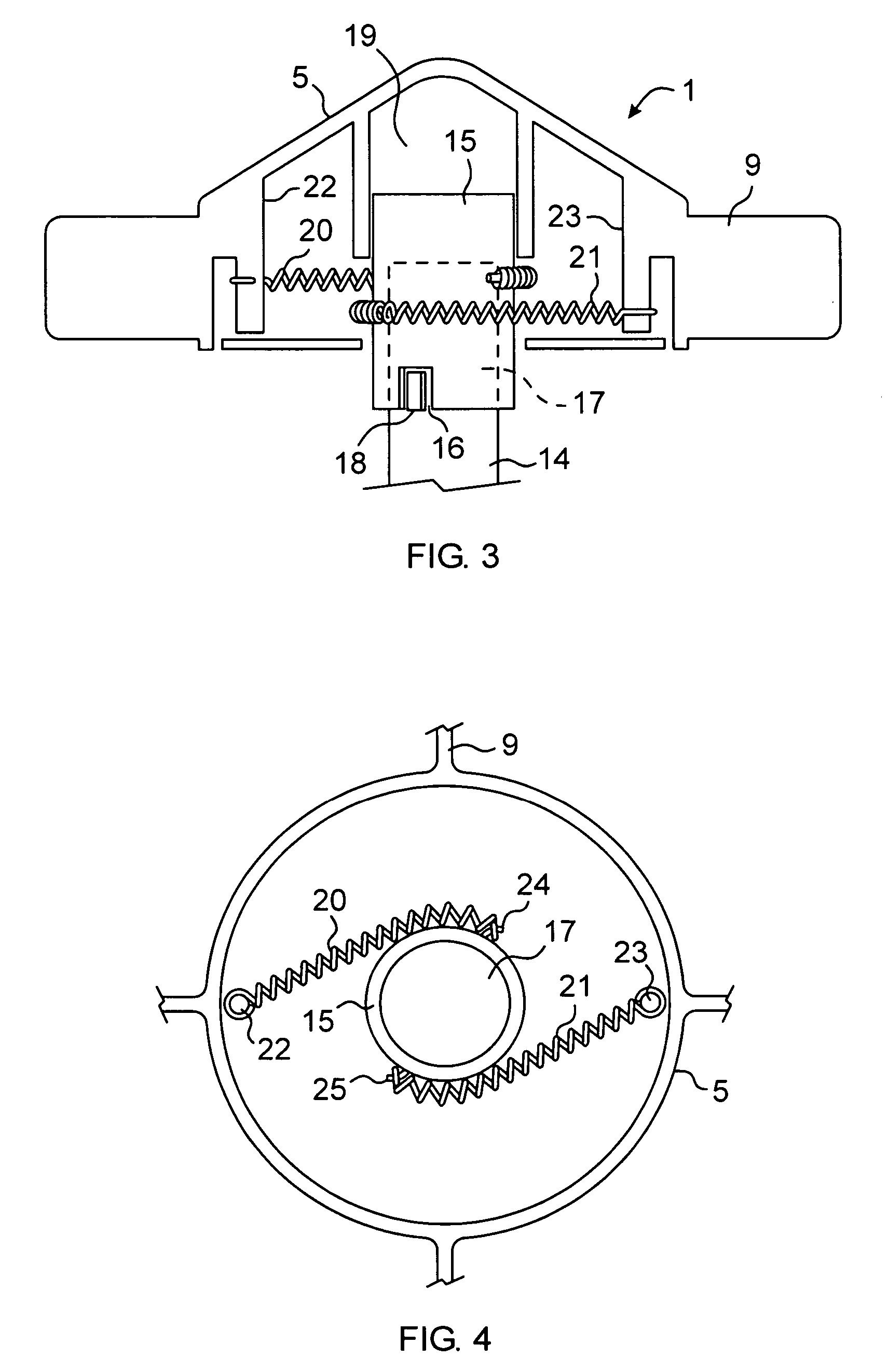

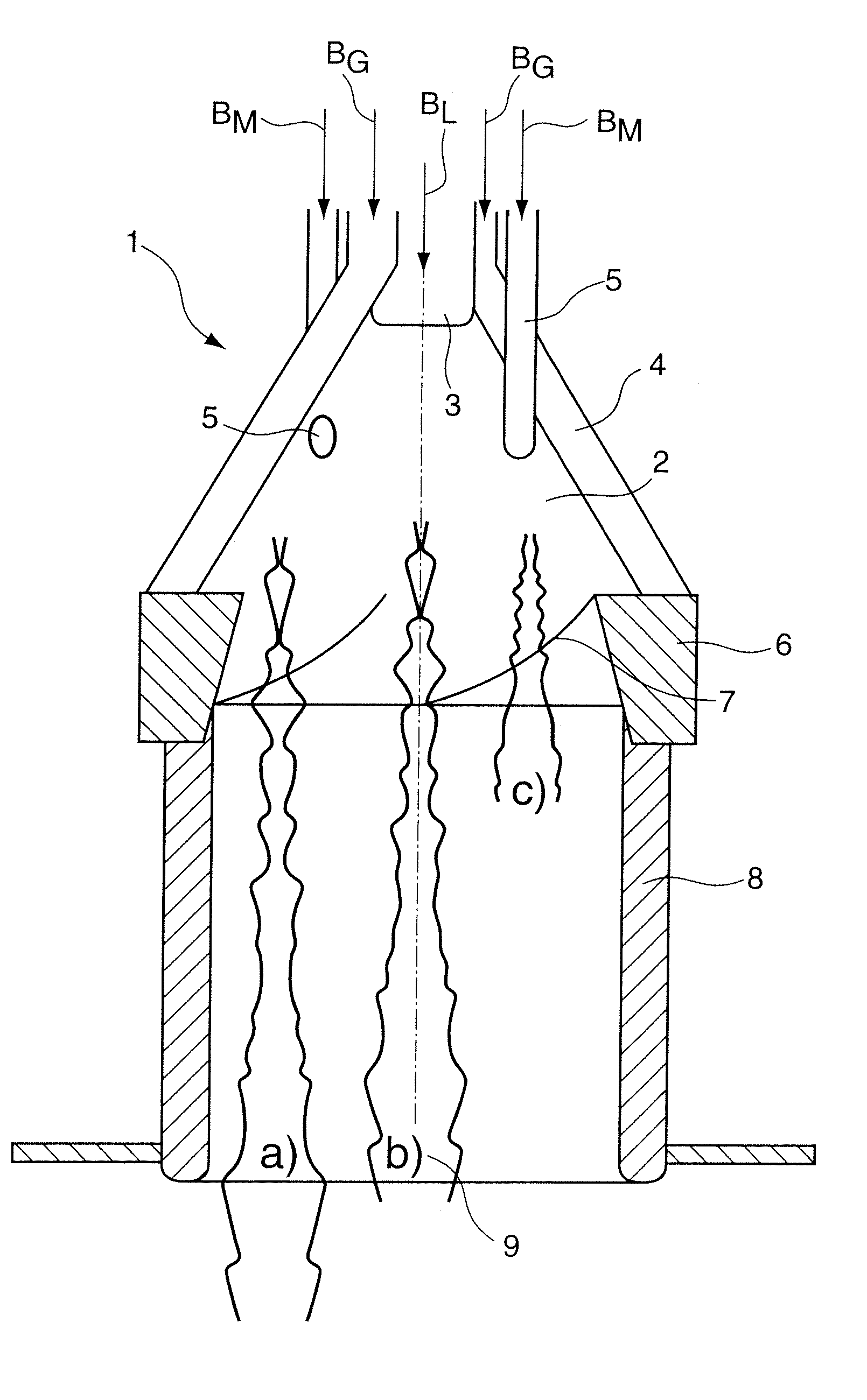

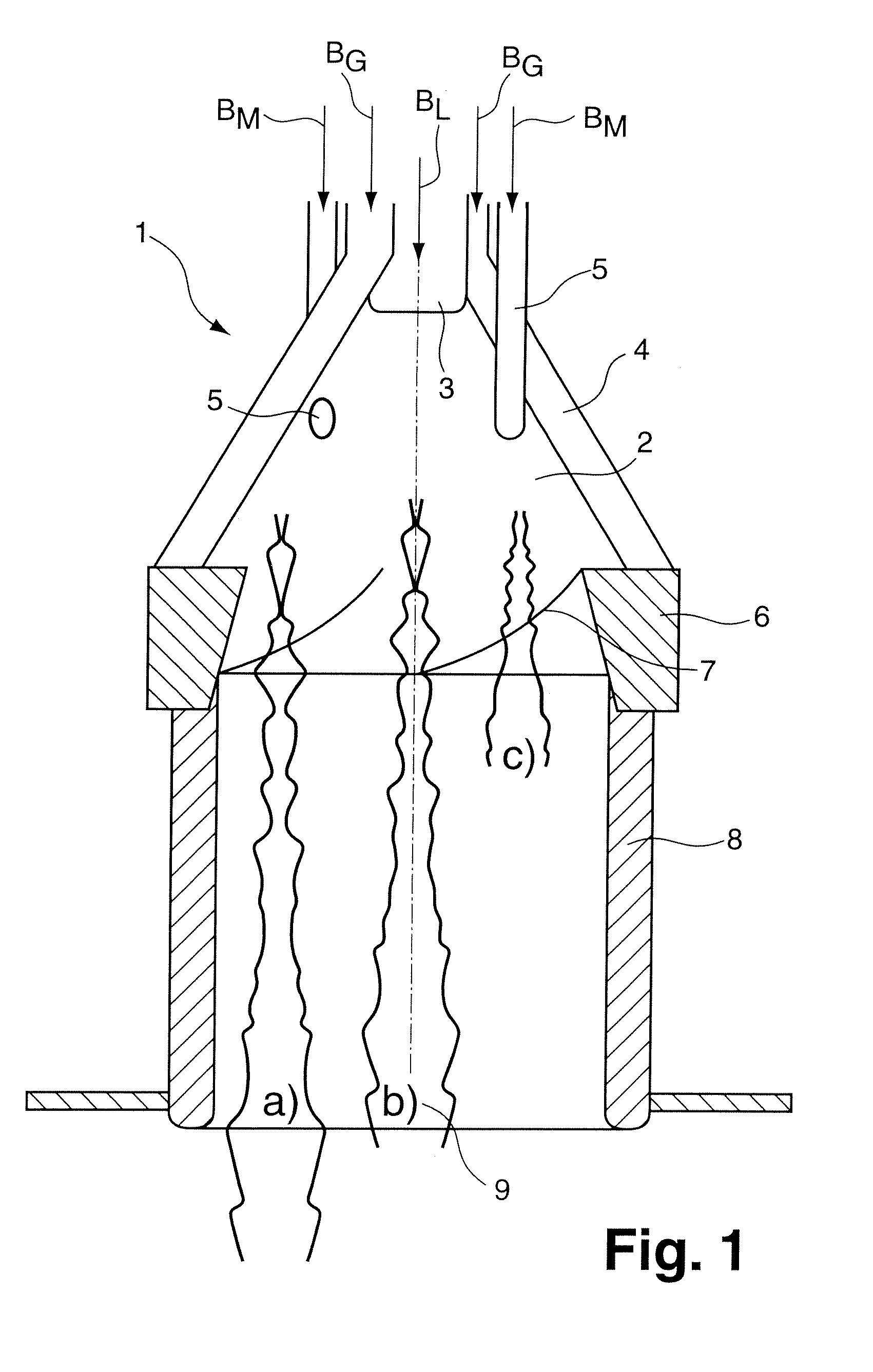

Method and Device for Burning Hydrogen in a Premix Burner

ActiveUS20080280239A1Stable flow conditionWell mixedCombustion using gaseous and pulverulent fuelPulsating combustionCombustorHydrogen

A method and a device for combusting gaseous fuel which contains hydrogen or consists of hydrogen, includes a burner which provides a swirl generator (1) into which liquid fuel is feedable centrally along a burner axis (A), forming a liquid fuel column which is conically formed and which is enveloped by, and mixed through with, a rotating combustion air flow which flows tangentially into the swirl generator (1). The gaseous fuel is fed inside the swirl generator (1) largely axially and / or coaxially to the burner axis (A), forming a fuel flow with a largely spatially defined flow pattern (9) which is maintained inside the burner and bursts open in the region of the burner outlet.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com