Automatic constant temperature drying and automatic regulation material flow control device of light energy vertical dryer

A flow control device and technology of the control device, applied in dryers, drying of solid materials, drying and other directions, can solve the problems of low degree of automation and low level of environmental pollution caused by harmful gases and dust, and achieve a high degree of automation, energy saving, Smooth process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples can enable those skilled in the art to more fully understand the technical characteristics and control process of the automatic constant temperature drying control device and automatic adjustment of material flow of the light energy vertical dryer.

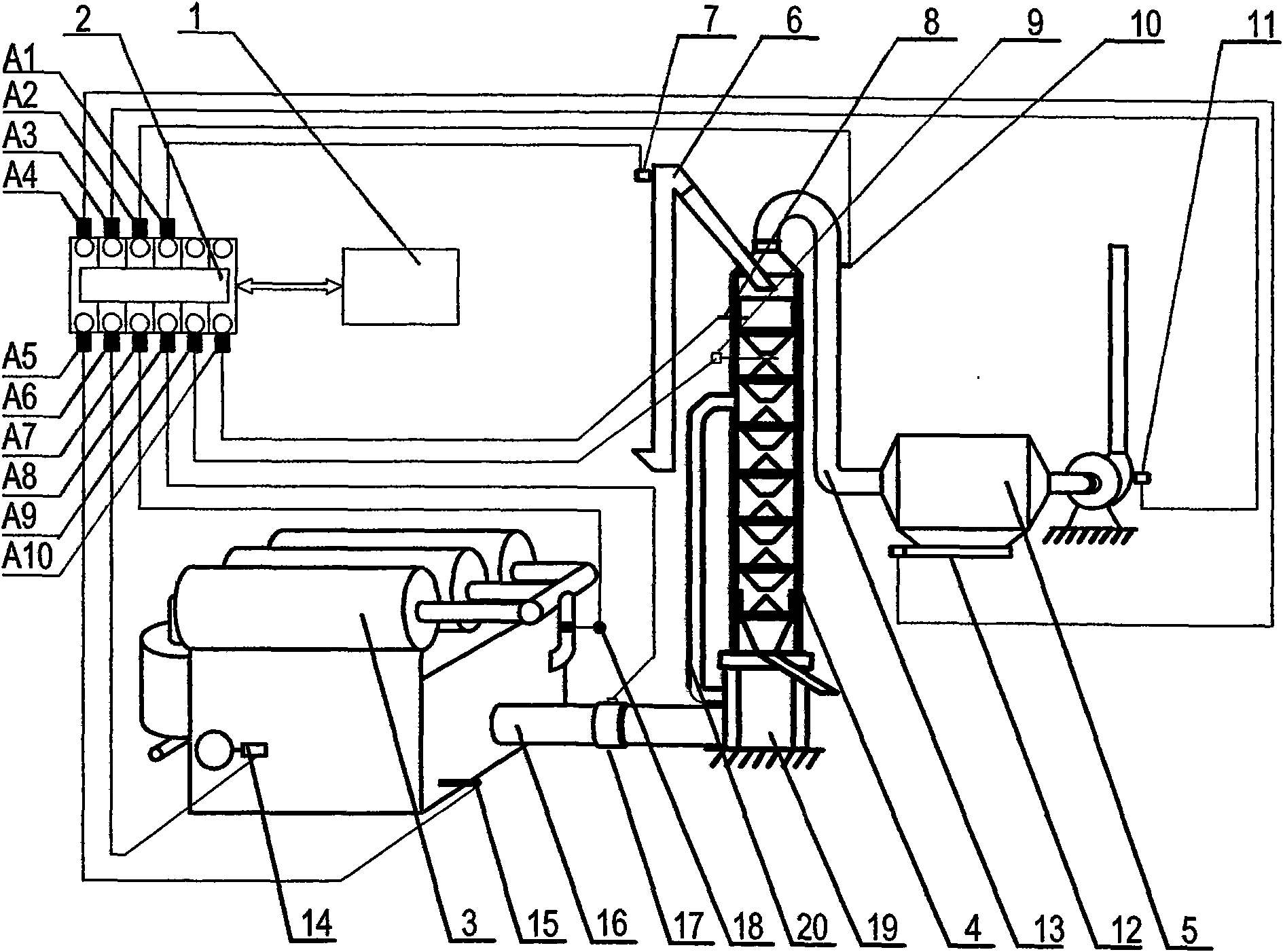

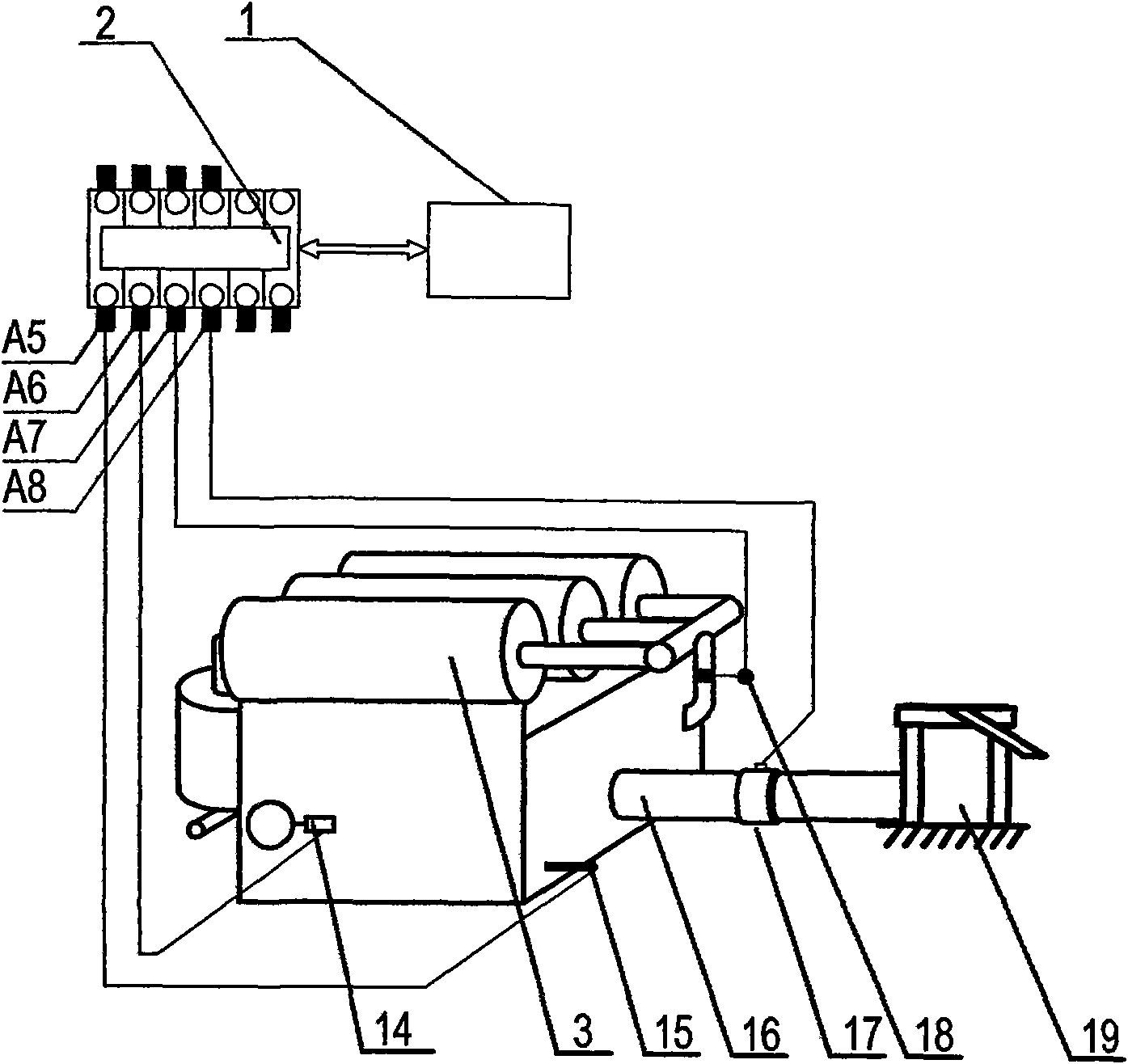

[0029] The present invention includes a standard control device 2, an industrial computer 1, a solar heat exchanger 3, a vertical dryer 4, an automatic constant temperature drying control device, and a vertical dryer control device. The standard control device 2 passes through a standard serial communication interface It is connected with the industrial computer 1, the standard control device 2 is connected with the solar heat exchanger 3 and the vertical dryer 4 respectively, and the solar heat exchanger 3 is connected with the vertical dryer 4.

[0030] figure 2 A schematic diagram of the control flow of the inventive cylindrical solar heat exchanger is shown.

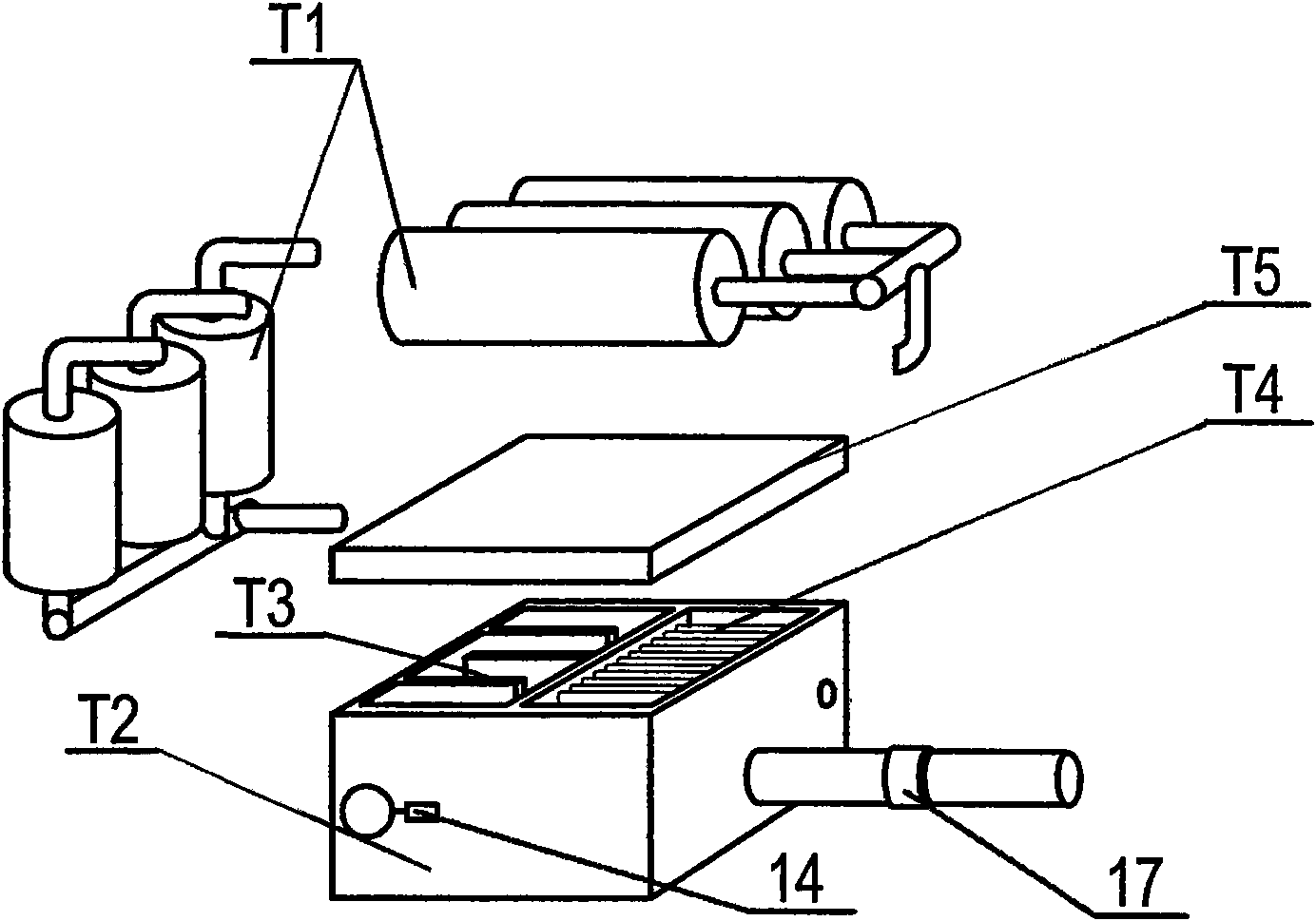

[0031]A No. 1 temperature sensor 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com