High-liquid absorbing rate micro-nano structure polymer electrolyte membrane and preparation method thereof

A technology of electrolyte membrane and micro-nano structure, which is applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems of battery electrochemical performance degradation, high-performance advantages of batteries that cannot be realized, and limitations of industrial applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

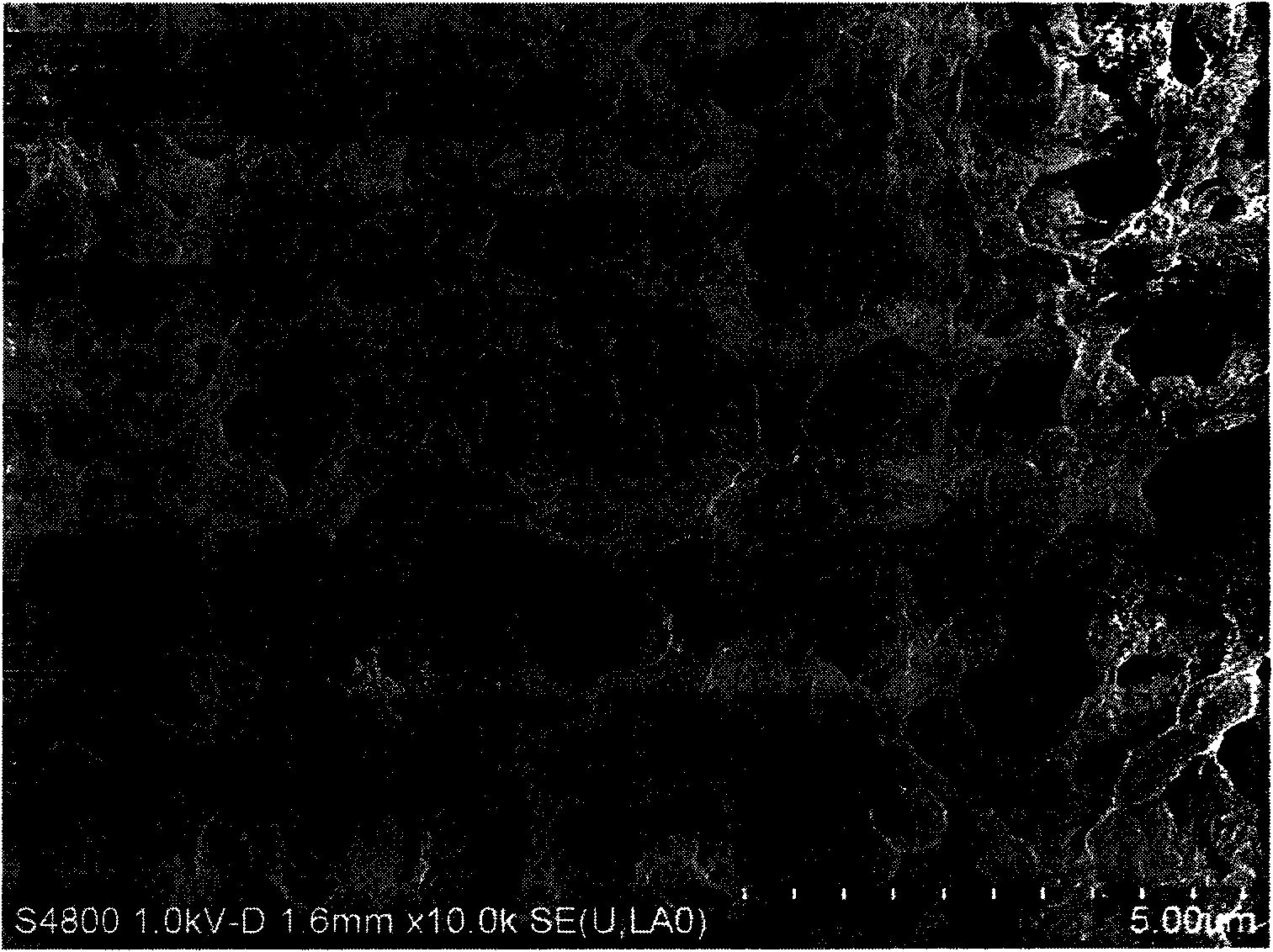

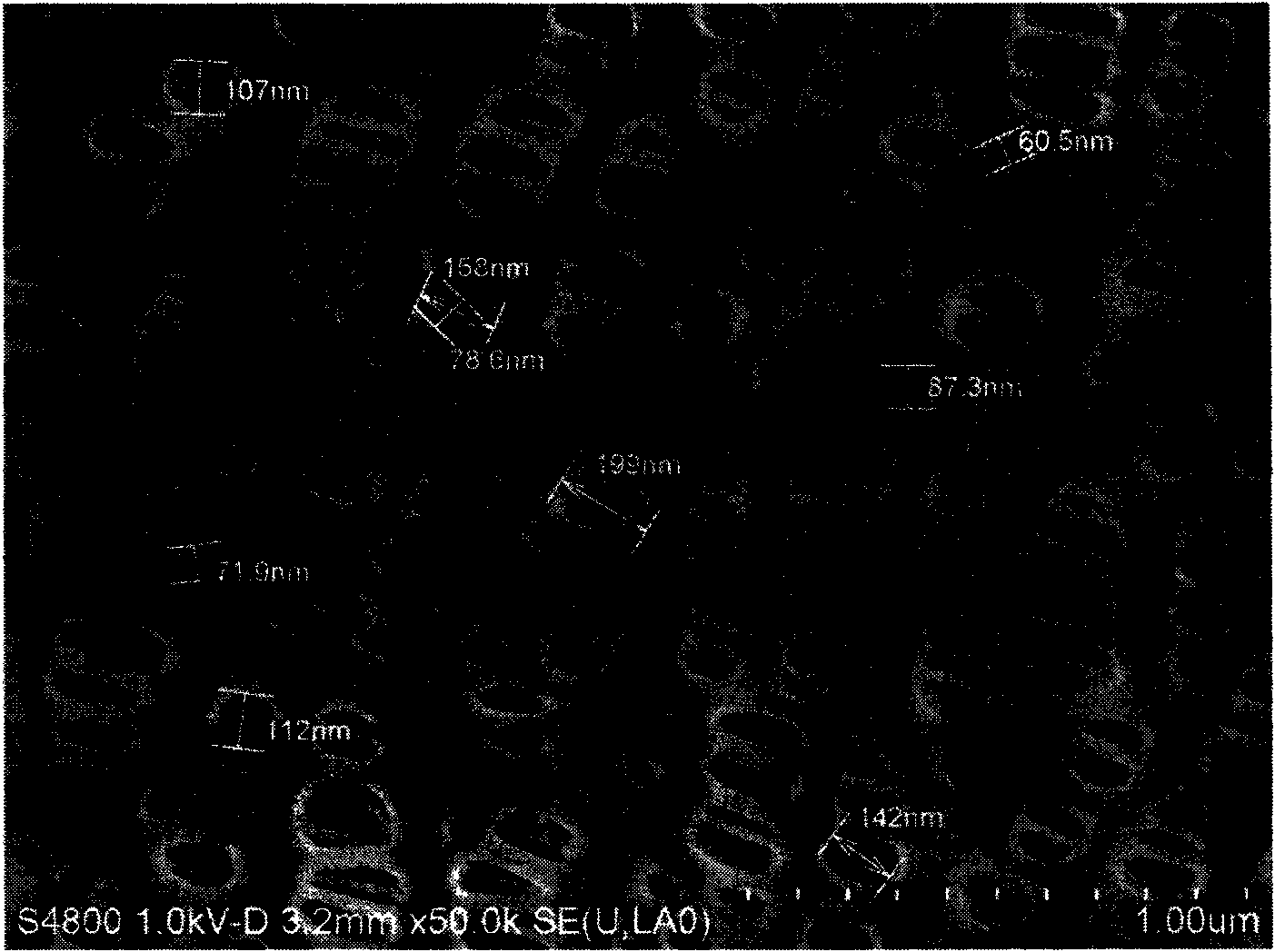

[0088] Add 3g of polyvinylidene fluoride (PVDF) powder into 50g of acetone solution, and stir magnetically in a constant temperature water bath at 50°C for 1.5 hours to completely dissolve the polymer. Slowly add 3g of dioctyl adipate (DOA) solvent dropwise with a syringe, continue to stir the solution for 1 hour, transfer the solution into a special glass vessel, cut out a PP film of a certain size, immerse it in the solution, and seal it. Place the glassware in a vacuum oven at 60°C. After 5 minutes, when the membrane is completely infiltrated, open the vessel and lift the membrane vertically with tweezers, let the excess solution on the surface of the membrane flow down naturally under the action of gravity, volatilize the acetone, and dry it in the air. Polymer Electrolyte Membrane Primary Membrane. Soak the primary membrane in ether for 1 hour. After aerothermal treatment with a wind speed of 3m / s and a temperature of 50°C, a polymer electrolyte membrane with a micro-nan...

Embodiment 2

[0091] Add 3 g of polyvinylidene fluoride (PVDF) powder into 60 g of acetone solution, and stir magnetically in a constant temperature water bath at 50° C. for 1.5 hours to completely dissolve the polymer. Slowly add 3g of dioctyl adipate (DOA) solvent dropwise with a syringe, continue to stir the solution for 1 hour, transfer the solution into a special glass vessel, cut out a PP film of a certain size, immerse it in the solution, and seal it. Place the glassware in a vacuum oven at 60°C. After 5 minutes, when the membrane is completely infiltrated, open the vessel and lift the membrane vertically with tweezers, let the excess solution on the surface of the membrane flow down naturally under the action of gravity, volatilize the acetone, and dry it in the air. Polymer polymer electrolyte membrane primary membrane. Soak the primary membrane in ether for 1 hour. After aerothermal treatment with a wind speed of 3m / s and a temperature of 50°C, a polymer electrolyte membrane with...

Embodiment 3

[0094] Add 3 g of polyethylene glycol (PEG) powder into 70 g of acetone solution, and magnetically stir in a constant temperature water bath at 50° C. for 1.5 hours to completely dissolve the polymer. Slowly add 3g of dioctyl adipate (DOA) solvent dropwise with a syringe, continue to stir the solution for 1 hour, transfer the solution into a special glass vessel, cut out a PP film of a certain size, immerse it in the solution, and seal it. Place the glassware in a vacuum oven at 60°C. After 5 minutes, when the membrane is completely infiltrated, open the vessel and lift the membrane vertically with tweezers, let the excess solution on the surface of the membrane flow down naturally under the action of gravity, volatilize the acetone, and dry it in the air. Polymer polymer electrolyte membrane primary membrane. Soak the primary membrane in ether for 1 hour. After aerothermal treatment with a wind speed of 3m / s and a temperature of 50°C, a polymer electrolyte membrane with a mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com