Preparation method of coating membrane containing PVDF and copolymer thereof

A technology of copolymer and diaphragm, which is applied in the field of preparation of diaphragm containing PVDF and its copolymer coating, which can solve the problems that the binder cannot act as a bonding layer, is prone to agglomeration, and the specific surface area of ceramic particles and whiskers is large. , to achieve the effect of improving structural stability and safety, avoiding heat shrinkage, and not easy to disperse and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

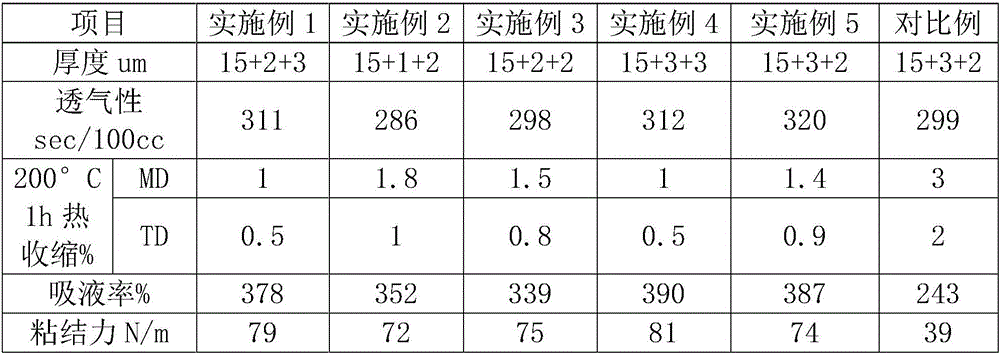

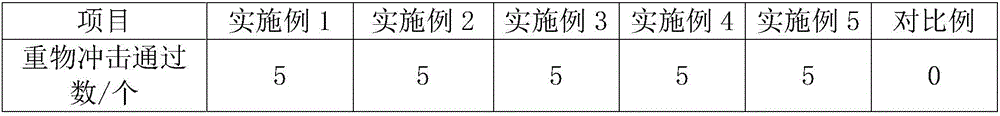

Examples

Embodiment 1

[0023] A preparation method containing PVDF and its copolymer coating diaphragm, comprises the following steps:

[0024] 1) Preparation of modified polypropylene microporous membrane: Soak a polypropylene microporous membrane with a thickness of 16 μm in the initiating solution formed by mixing 10 g of benzoyl peroxide and 500 g of acetone solution, and react for 1 h at a temperature of 100 ° C , and then evaporated to dryness at room temperature, and then soaked the evaporated polypropylene microporous membrane in a modified solution formed by mixing 10 parts of acrylic acid and 90 parts of water, and reacted at a temperature of 80 ° C for 5 hours. After ultrasonic rinsing and vacuum drying, the modified polypropylene microporous membrane was obtained;

[0025] 2) Preparation of modified alumina: Stir 300g of alumina powder and 500g of deionized water evenly, then add 30g of acrylic acid and 10g of benzoyl peroxide, react at a temperature of 80°C for 5h, then filter and dry ...

Embodiment 2

[0030] A preparation method containing PVDF and its copolymer coating diaphragm, comprises the following steps:

[0031] 1) Preparation of modified polypropylene microporous membrane: Soak a polypropylene microporous membrane with a thickness of 15 μm in an initiating solution formed by mixing 10 g of benzoyl peroxide and 500 g of acetone solution, and react for 2 hours at a temperature of 90° C. , and then evaporated to dryness at room temperature, then soak the evaporated polypropylene microporous membrane in a modified solution formed by mixing 10 parts of methacrylic acid and 90 parts of water, and react for 2 hours at a temperature of 100 ° C. , the modified polypropylene microporous membrane was obtained after ultrasonic rinsing and vacuum drying;

[0032] 2) Preparation of modified magnesium oxide: Stir 300g of magnesium oxide powder and 500g of deionized water evenly, then add 30g of methacrylic acid and 10g of benzoyl peroxide, react at a temperature of 80°C for 3h, t...

Embodiment 3

[0037] A preparation method containing PVDF and its copolymer coating diaphragm, comprises the following steps:

[0038] 1) Preparation of modified polypropylene microporous membrane: Soak a polypropylene microporous membrane with a thickness of 3 μm in a solution that is uniformly mixed with 20 g of benzoyl peroxide and 500 g of acetone to form an initiating solution at a temperature of 80° C. React for 3 hours, then evaporate to dryness at room temperature, and then soak the evaporated polypropylene microporous membrane in a modification solution formed by mixing 10 parts of methyl acrylate and 90 parts of water, at a temperature of 80 ° C After reacting for 3 hours, the modified polypropylene microporous membrane was obtained after ultrasonic rinsing and vacuum drying;

[0039] 2) Preparation of modified silica: Stir 300g of silica powder and 500g of deionized water evenly, then add 30g of methyl acrylate and 10g of benzoyl peroxide, react at a temperature of 80°C for 3 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com