Patents

Literature

1422 results about "Hexafluoropropylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexafluoropropylene is a compound with the formula C₃F₆. It is a fluorocarbon alkene in which all of the hydrogen atoms in propylene are replaced by fluorine atoms. It is used as a chemical intermediate.

Hydrophobic membrane materials for filter venting applications

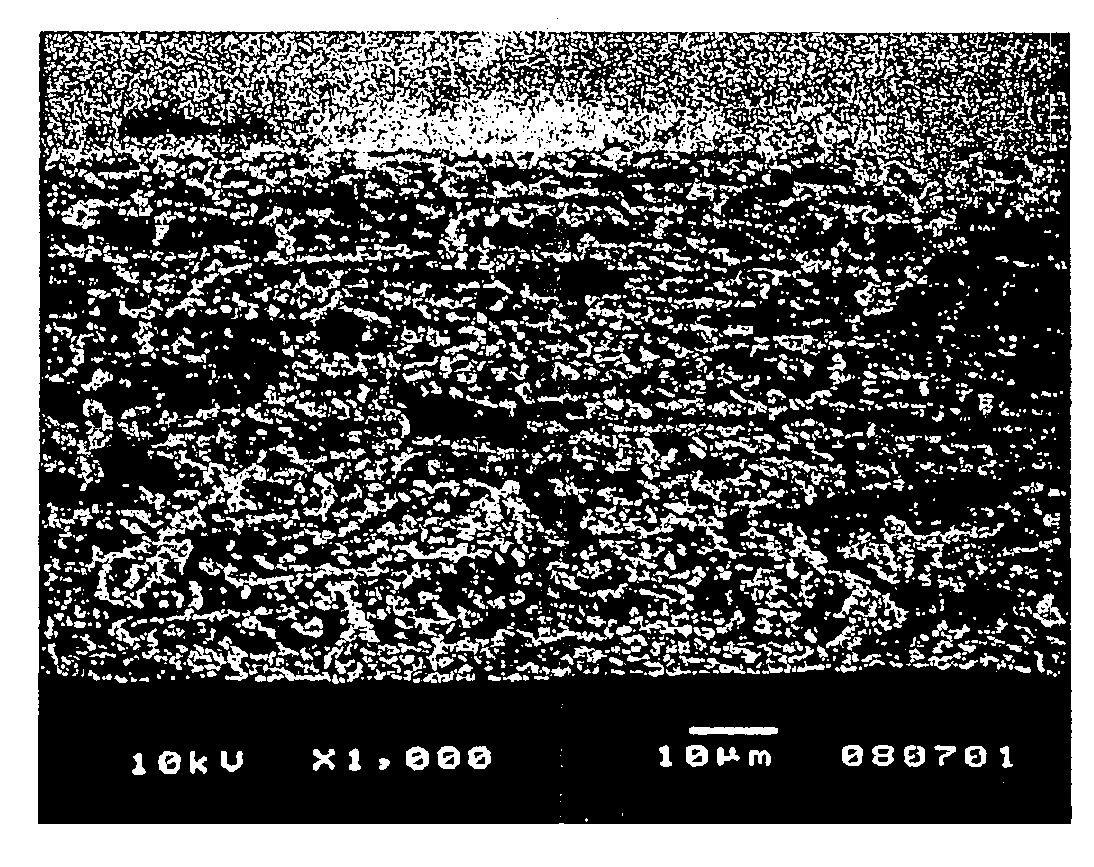

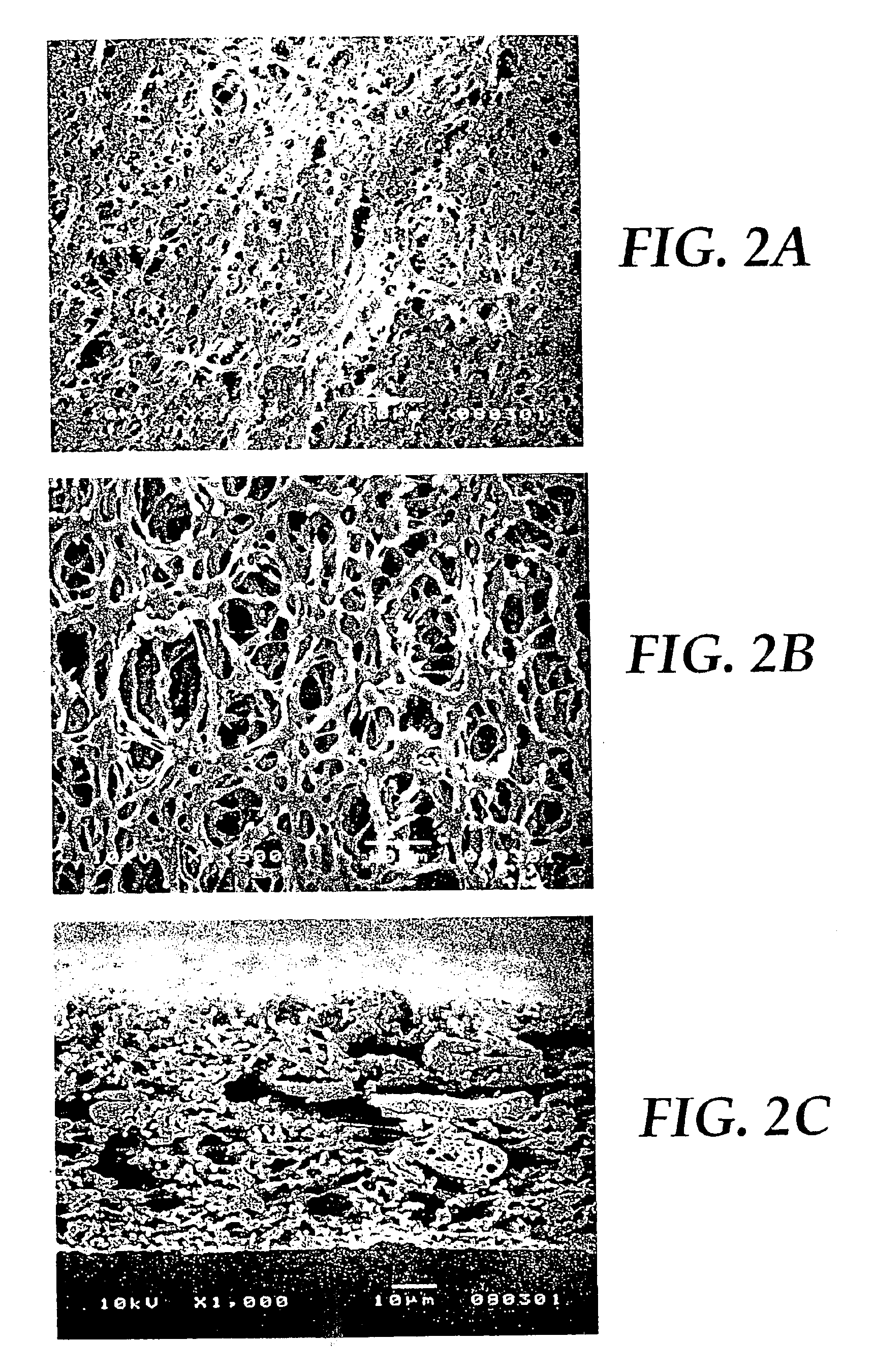

The present invention relates to filtration media having both hydrophobic (water-repellent) properties. The filtration media are produced using a fluorothermoplastic material, such as a terpolymer of tetrafluoroethylene, vinylidene fluoride, and hexafluoropropylene. The invention also relates to methods of preparing such filtration media using casting solution phase inversion.

Owner:PALL CORP

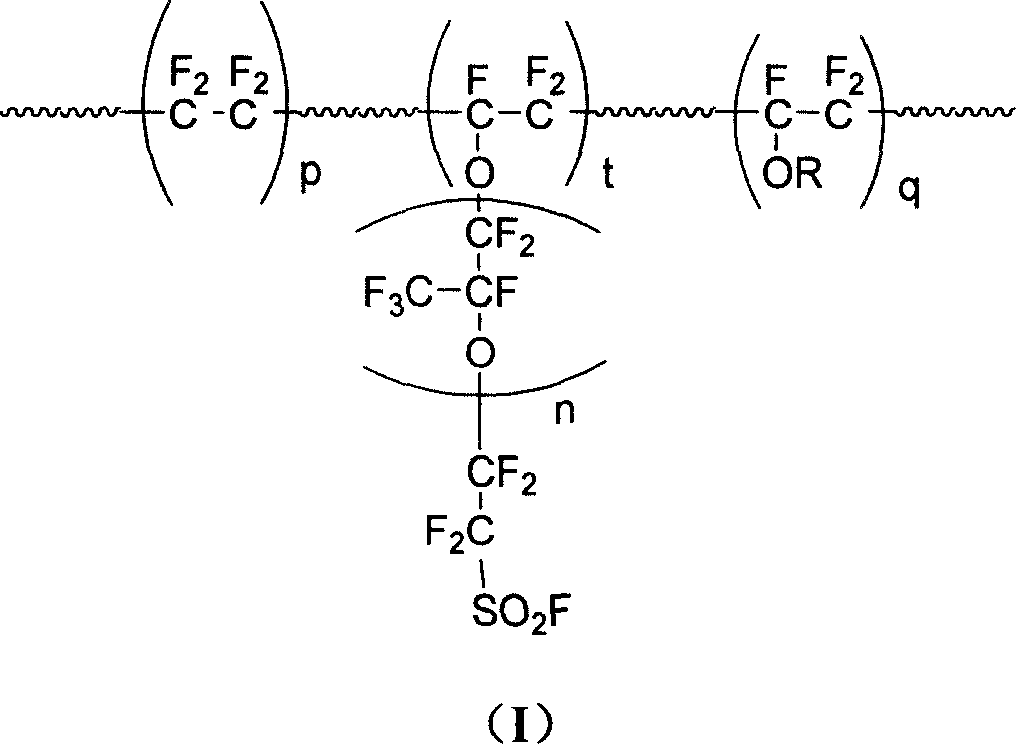

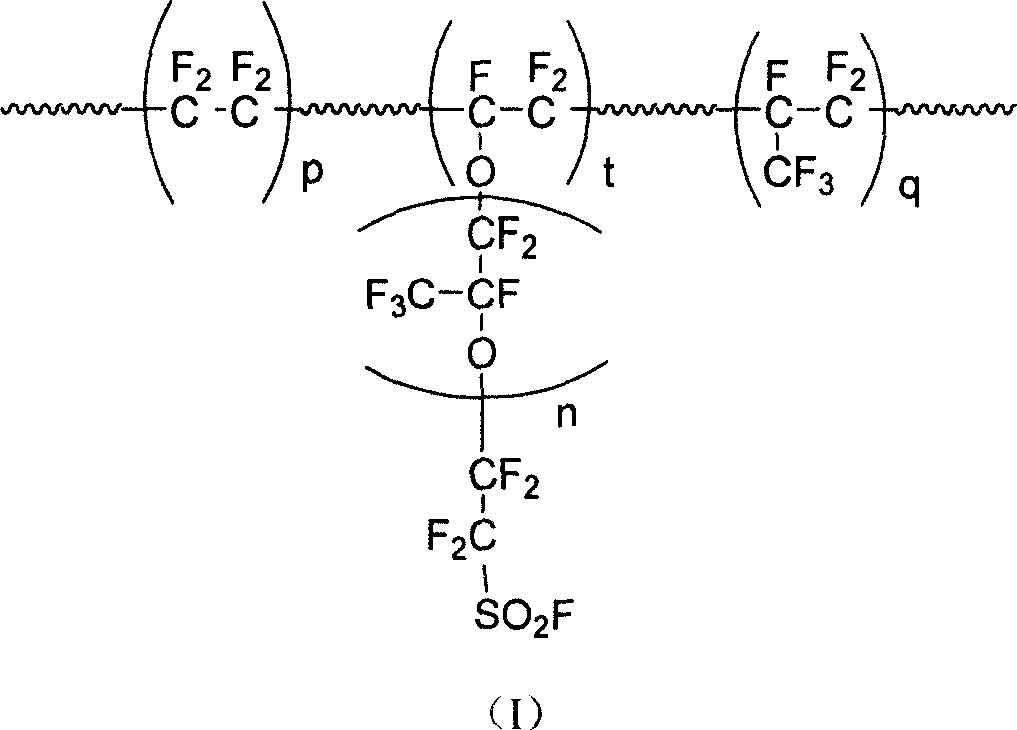

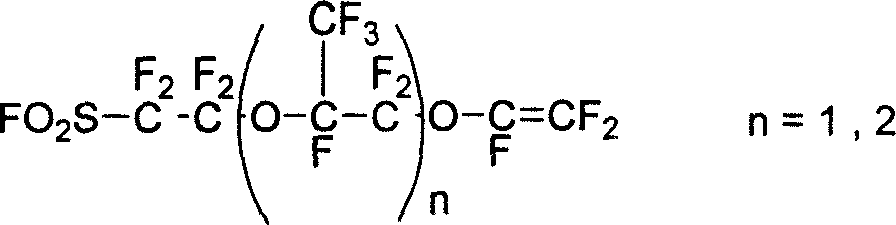

Polymer of containing fluorin, and application as material of ion exchange fiber

InactiveCN101003588AIncrease the effective areaLower resistanceMelt spinning methodsVinyl etherAlkali ions

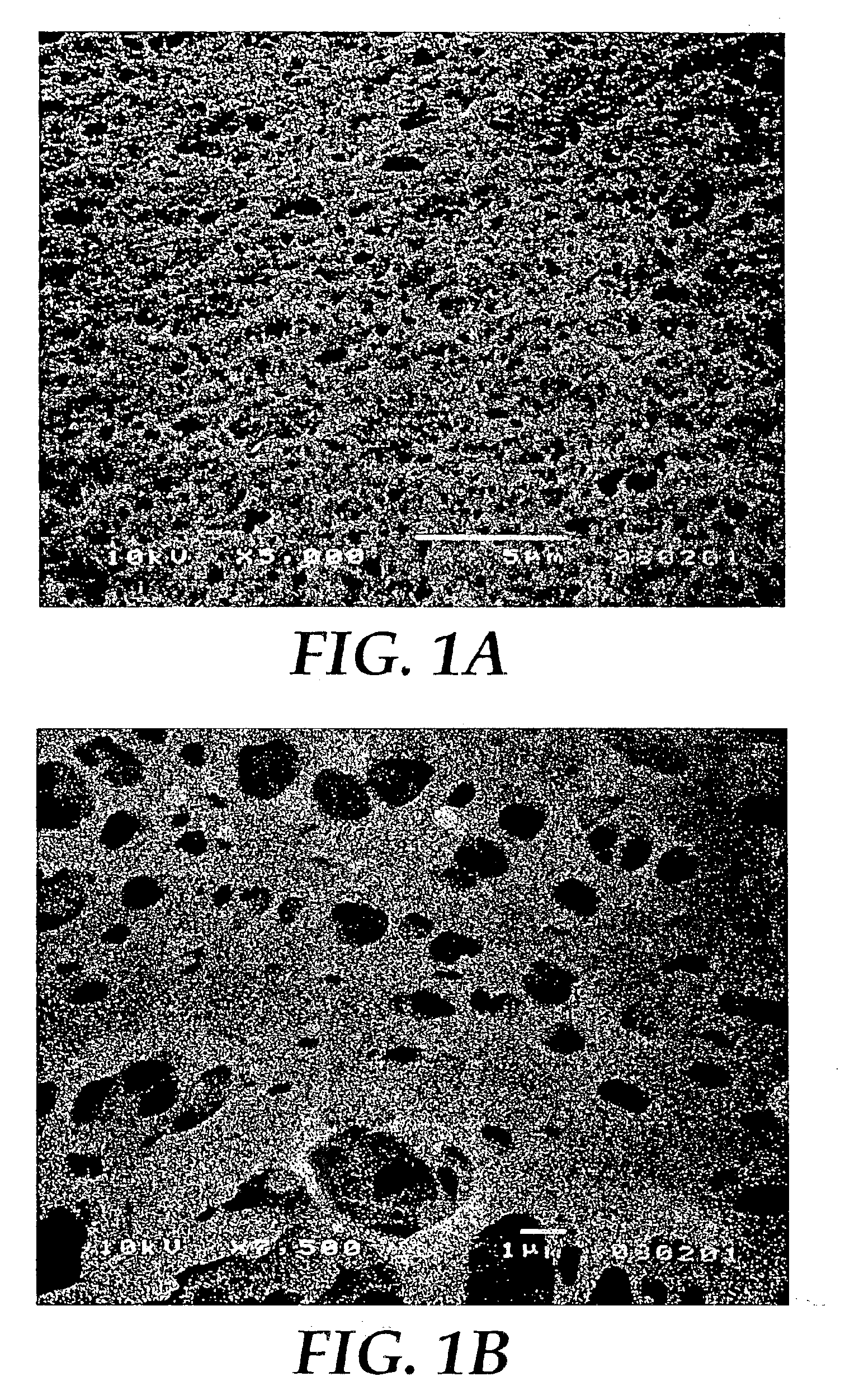

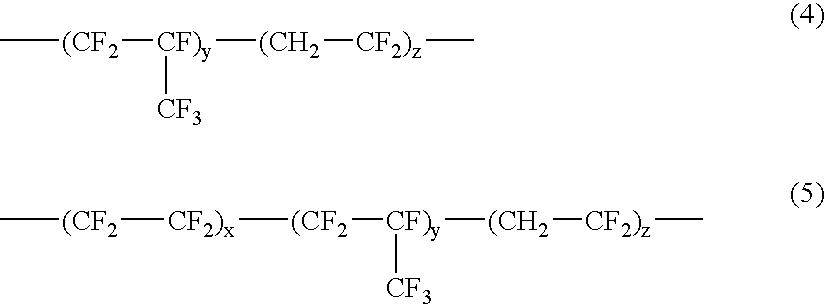

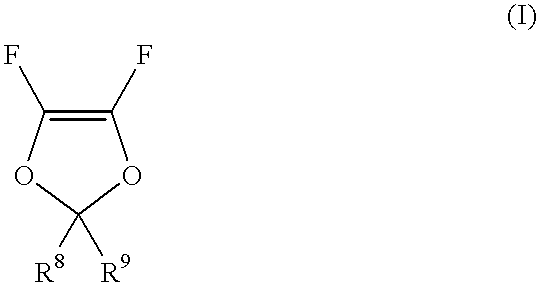

This invention discloses a fluorine-containing polymer and its application as ion exchange fiber material. The fluorine-containing polymer is a perfluoro resin containing sulfonylfluoride groups, and is shown in formula 1. The fluorine-containing polymer has ion exchange function, and is prepared by free radical copolymerization of perfluorosulfonyl vinyl ether, tetrafluoroethylene and hexafluoropropylene in the presence of dispersant, solvent and initiator. The dispersant / solvent is mixed solution of melamine derivative containing linear perfluoro hydrocarbon and water. The fluorine-containing polymer can be melt-spun into polymer fibers, which can be woven into fiber network that can be used as the reinforcing network material for ion exchange membranes and chlor-alkali ion membrane to reinforce and improve the ion exchange ability.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Highly-stable polymeric electrolyte and use thereof in electrochemical systems

ActiveUS20050234177A1Hybrid capacitor electrolytesHybrid capacitor electrodesPolymer electrolytesElectrolysis

Polymer electrolyte for an electrochemical generator based on at least a four branched polymer, at least a poly(vinylyldienefluoride), a poly(vinyldiene fluoro-co-hexafluoropropene copolymer), a poly(tetrafluoroethylene), a poly(ethylene-co-propylene-co-5-methylene-2-norbornene) or an ethylene propylene-diene copolymer, a polyol, a poly(methylmethacrylate, a poly(acrylonitrile), SiO2Al2O3, or nano TiO2 non coated or coated with an organic material. This electrolyte allows to prepare electrolytic compositions that can be used in high performance electrochemical devices.

Owner:HYDRO QUEBEC CORP

Membrane polymer compositions

InactiveUS7226541B2Good chemical stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsHexafluoropropylenePolyvinylidene difluoride

Owner:EVOQUA WATER TECH LLC

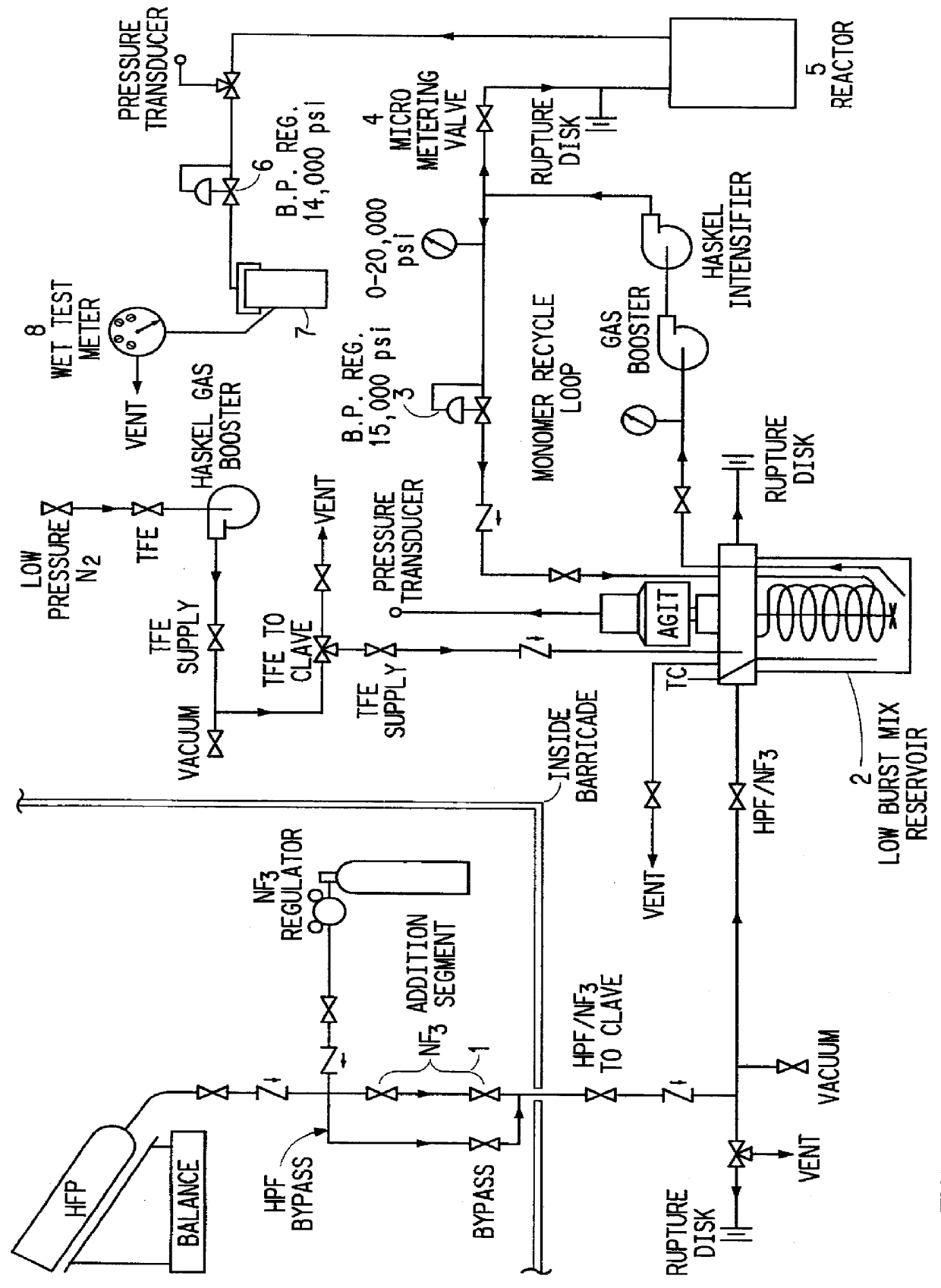

Amorphous tetrafluoroethylene-hexafluoropropylene copolymers

InactiveUS6133389AThin coatingIncrease coating thicknessOrganic chemistryCoatingsPolymer scienceHexafluoropropylene

Disclosed herein are novel amorphous tetrafluoroethylene-hexafluoropropylene (TFE-HFP) dipolymers, and other copolymers containing TFE, HFP and a third monomer, many of which are more random than previous amorphous TFE-HFP copolymers, as well as a novel high productivity continuous process for making these polymers. The polymers are particularly useful in the form of coatings, films and encapsulants.

Owner:THE CHEMOURS CO FC LLC

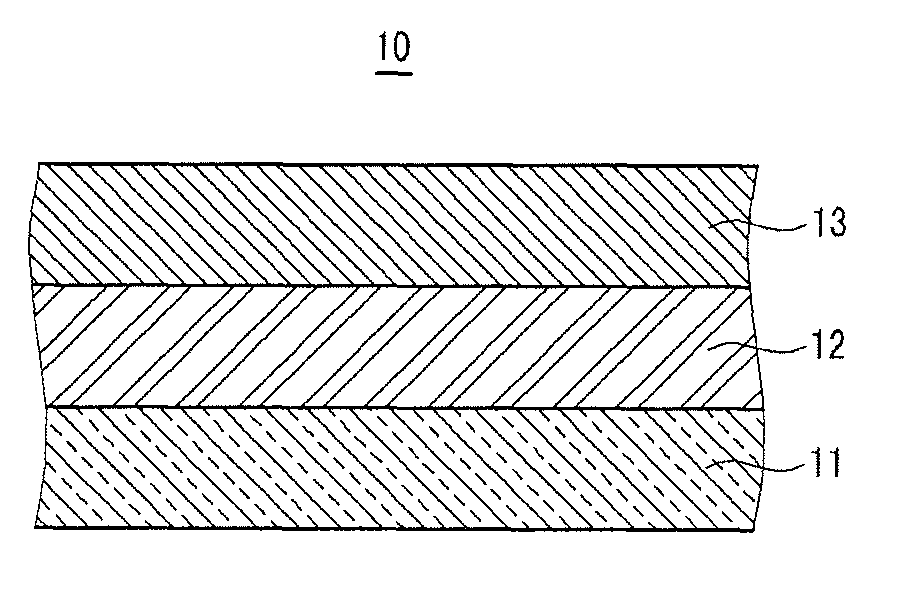

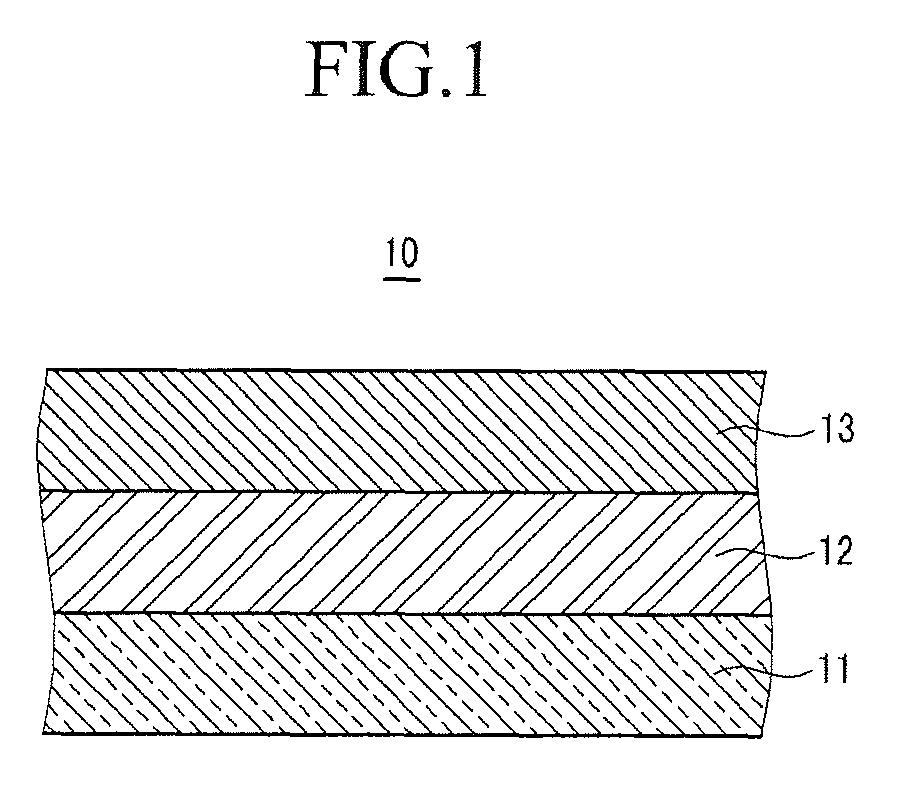

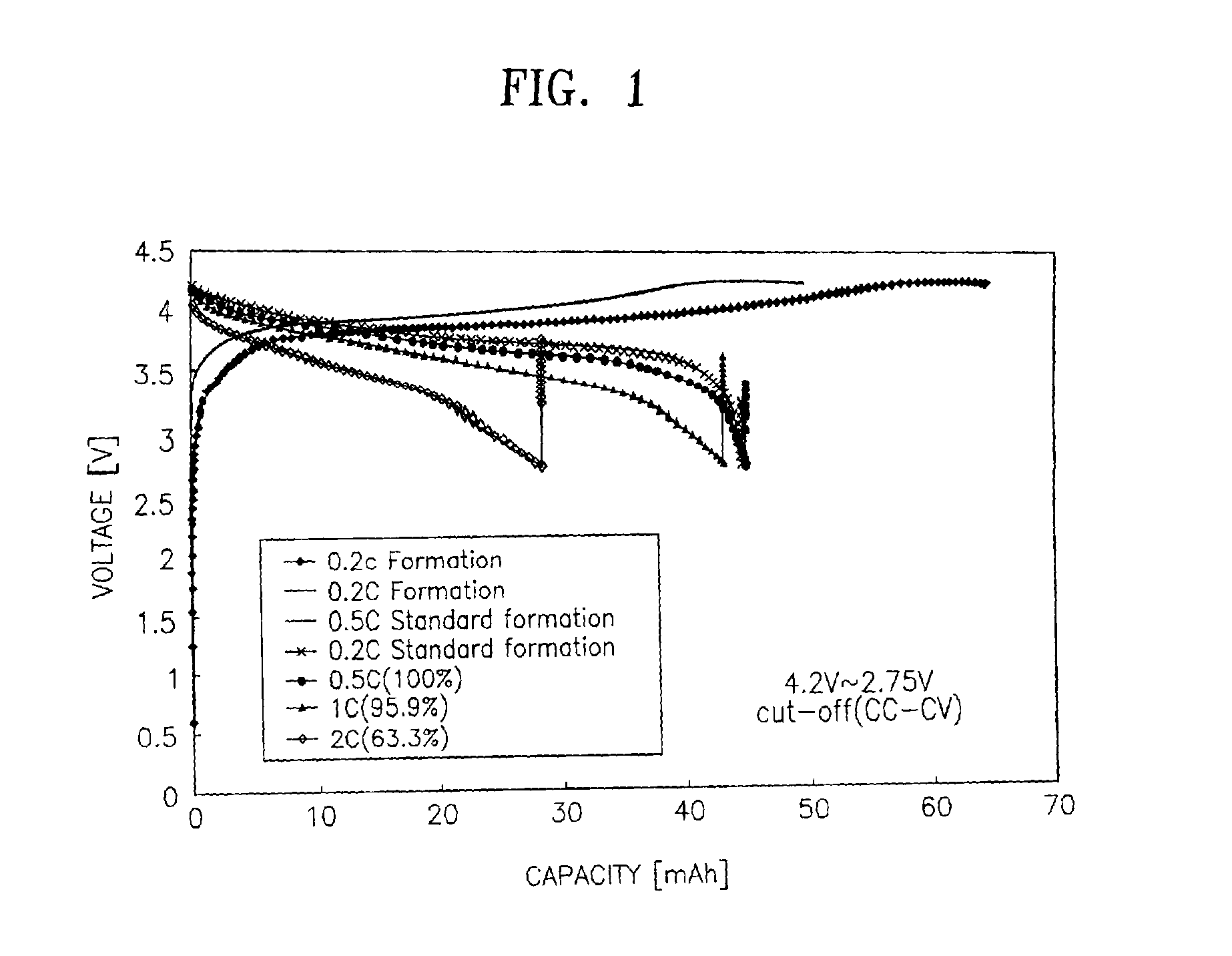

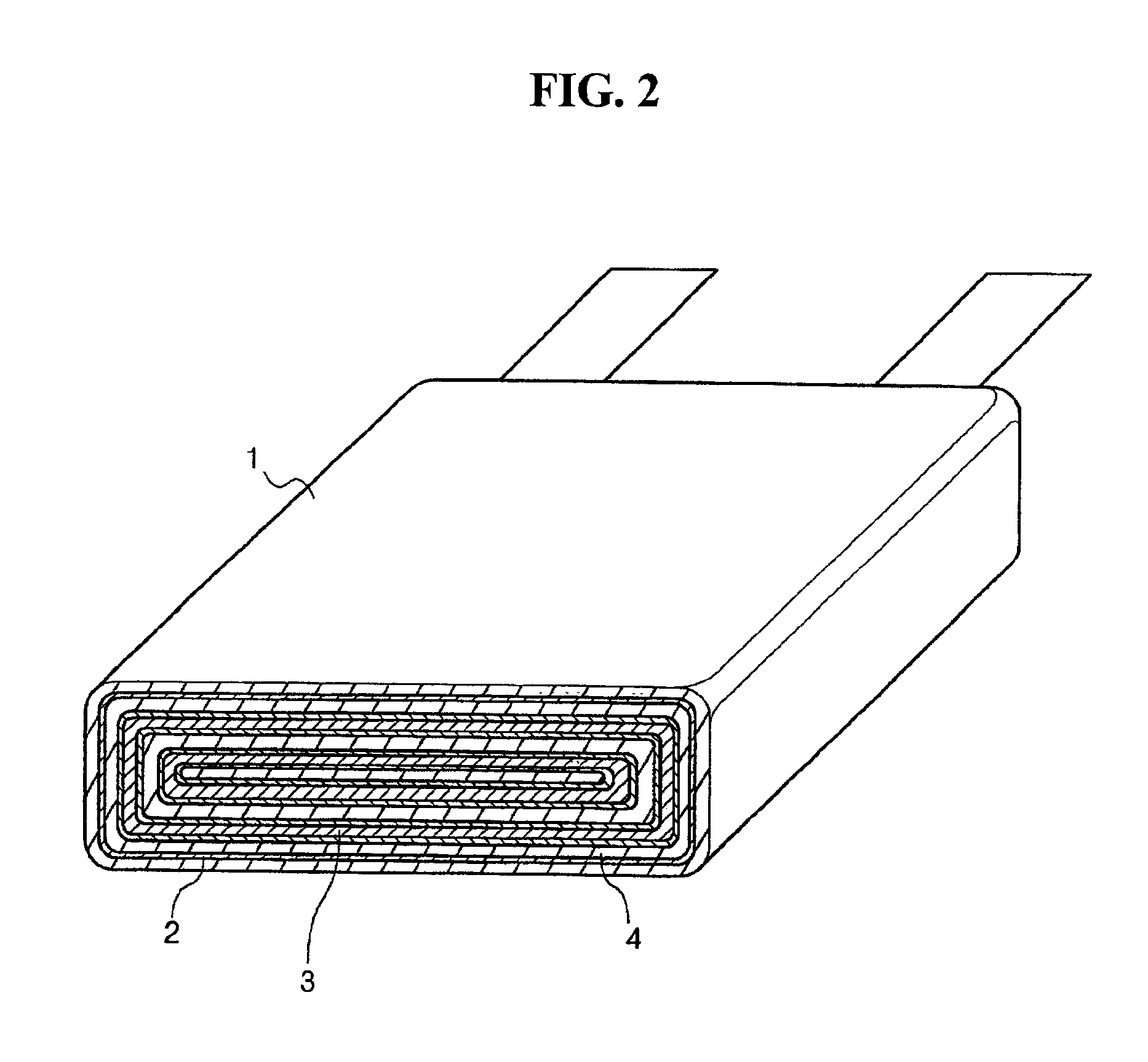

Positive electrode for rechargeable lithium battery and rechargeable lithium battery including same

ActiveUS7923149B2Inhibit side effectsImprove stability and reliabilitySilver accumulatorsElectrode carriers/collectorsHexafluoropropyleneCopolymer

A positive electrode including a current collector; a positive active material layer disposed on the current collector; and a coating layer disposed on the positive active material layer. The coating layer includes a binder and a inorganic additive. The binder is a poly(vinylidenefluoride-hexafluoropropylene) copolymer comprising 2 to 16 mole % of hexafluoropropylene. The positive electrode for a rechargeable lithium battery suppresses side-reactions between a positive electrode and an electrolyte, at a high voltage.

Owner:SAMSUNG SDI CO LTD

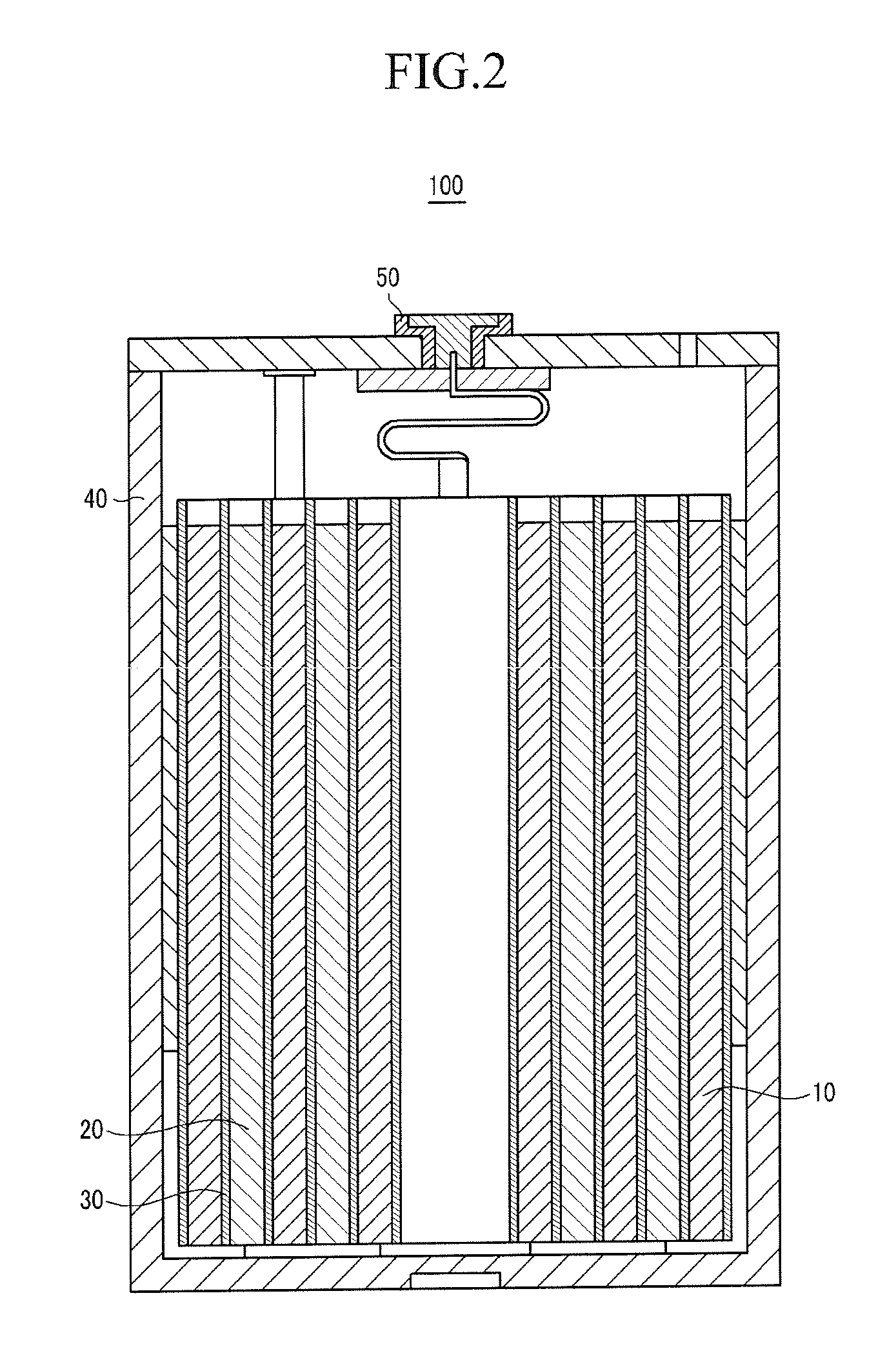

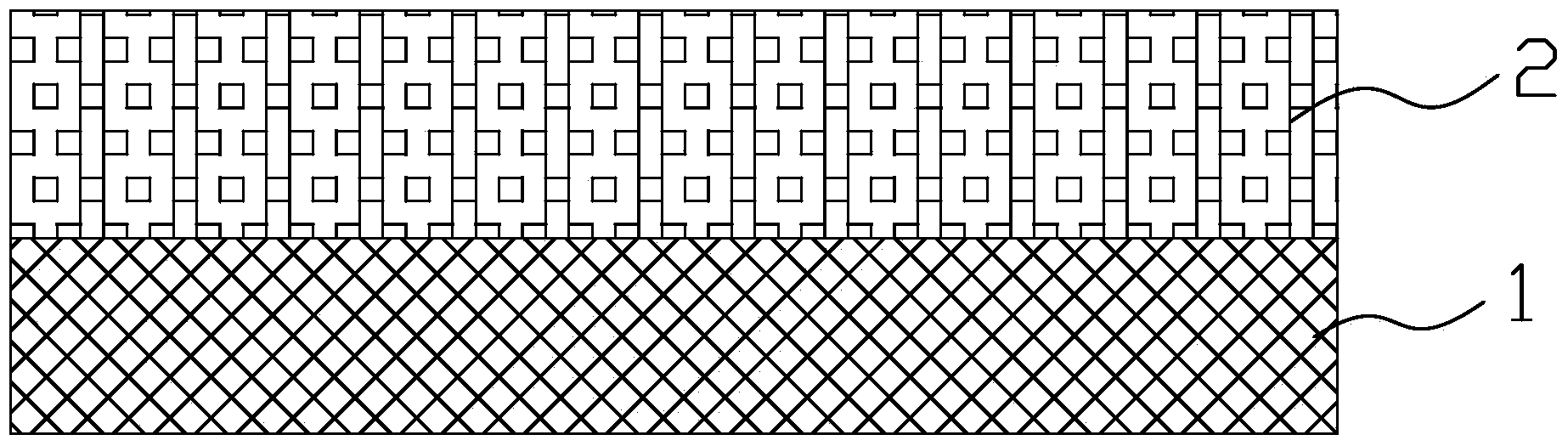

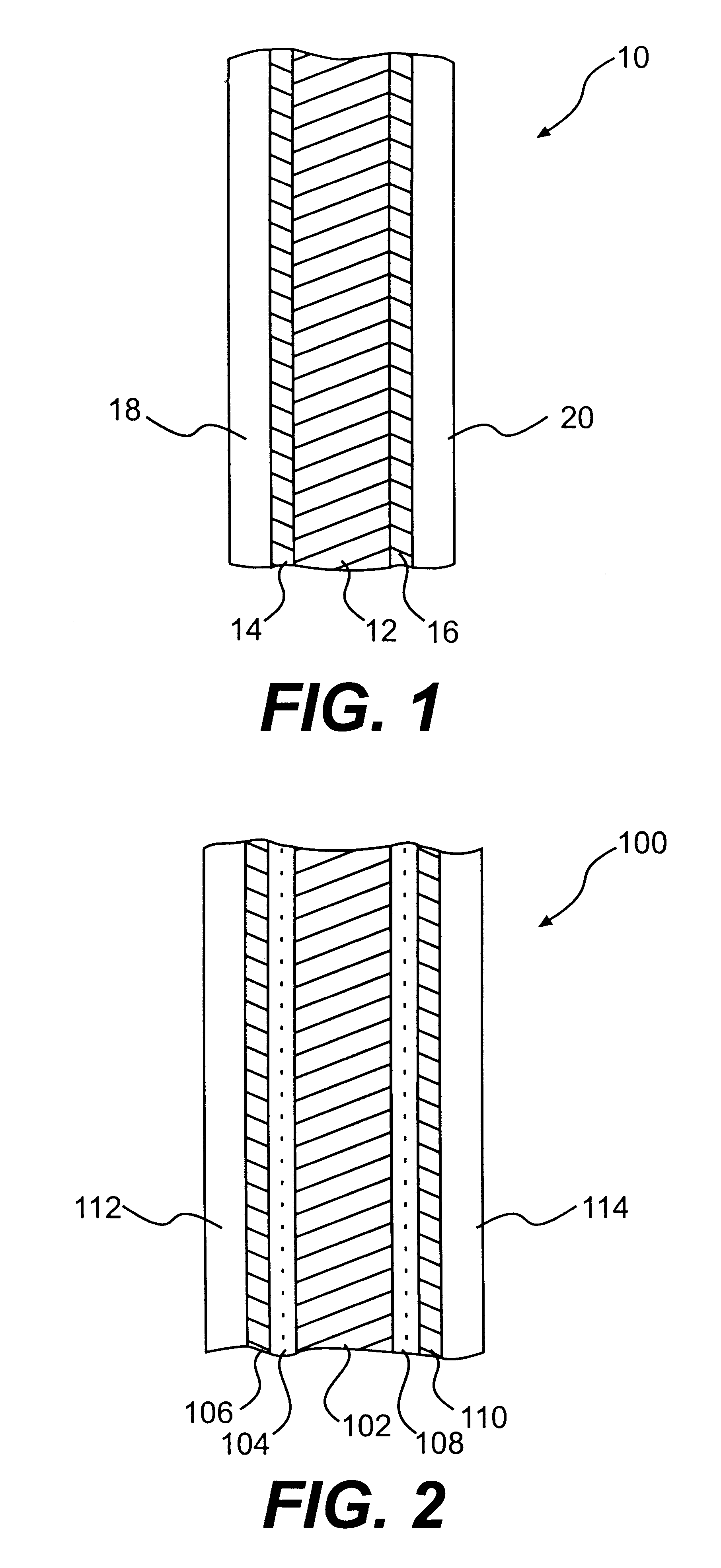

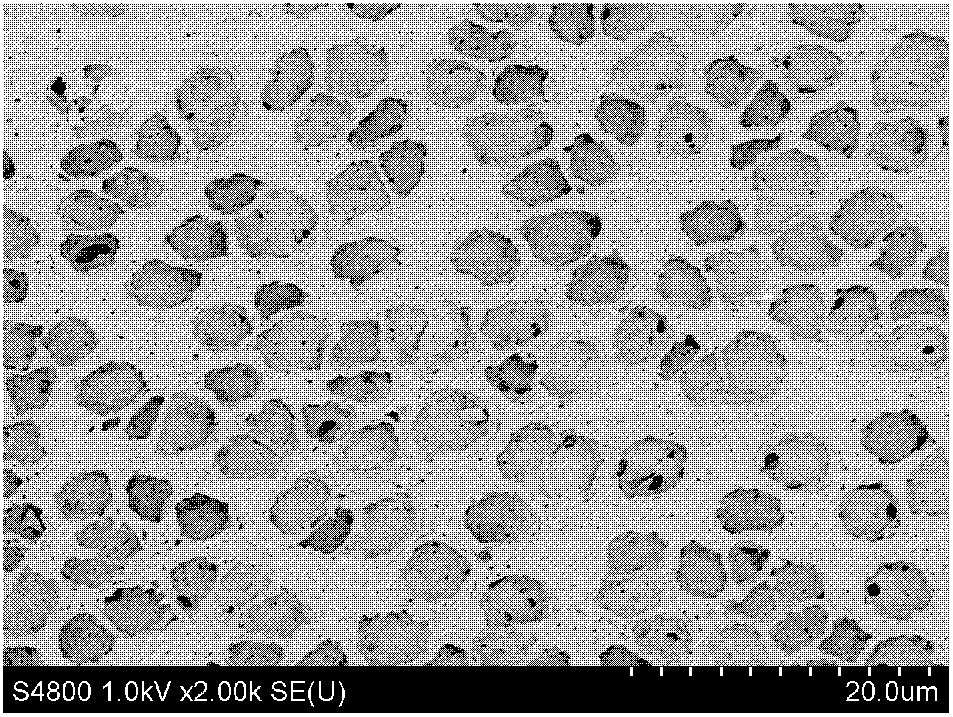

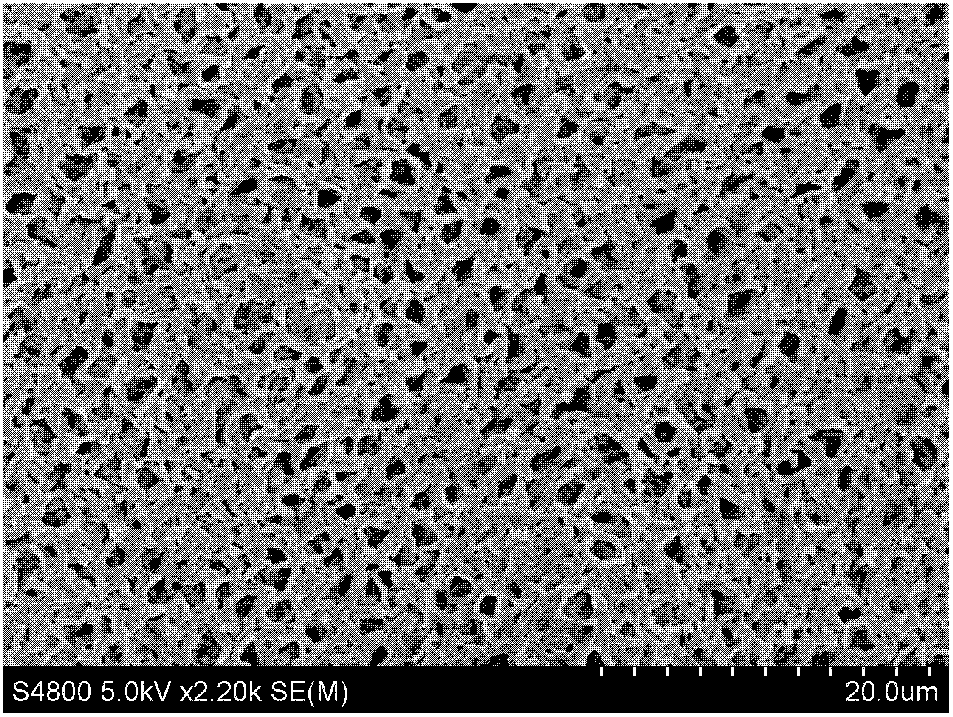

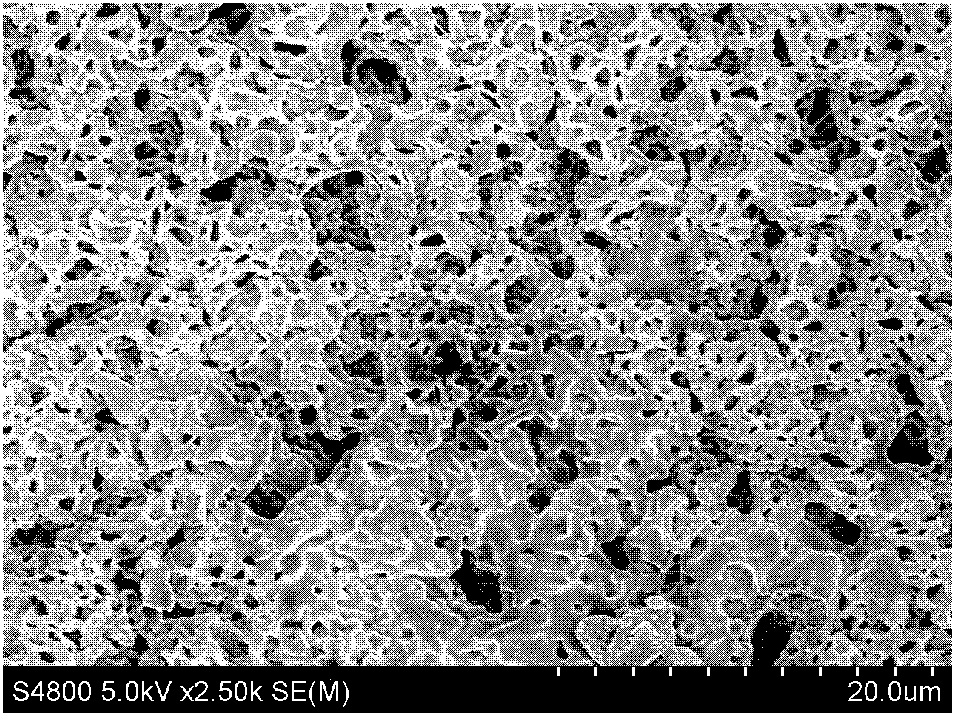

Composite diaphragm and method for preparing same

ActiveCN103515564AImprove thermal safetyImprove wettabilityCell seperators/membranes/diaphragms/spacersPorosityAdhesive

The invention discloses a composite diaphragm which comprises a supporting layer and an organic / inorganic particle blended coating layer, laminated; the coating layer comprises a polymer particle and an inorganic particle, uniformly mixed in an adhesive; micropore structures are arranged on the surface and at the inner part of the coating layer; the porosity is 20%-80%; the aperture average is 0.01 to 10 micrometers; the polymer particle comprises one or more of polytetrafluoroethylene, polyvinylidene fluoride, polyvinylidene fluoride-hexafluoropropylene copolymer, polyimide, polyacrylonitrile and aramid fiber resin; the particle size of the polymer particle is 0.01-10 micrometers; the inorganic particle comprises any one or more of SiO2, Al2O3, CaO, TiO2, MgO, ZnO, SnO2 and ZrO2; the particle size of the inorganic particle is 0.01-10 micrometers; the mass ratio of the polymer particle to the inorganic particle is (1:10) to (10:1). The invention further discloses a method for preparing the composite diaphragm. The composite diaphragm and the method have good thermal safety and strong in electrolyte absorption stiffness value, and meanwhile, and can achieve the advantages of low cost and low pollution.

Owner:SHENZHEN SENIOR TECH MATERIAL

Postive electrode for rechargeable lithium battery and rechargeable lithium battery including same

ActiveUS20080118836A1Inhibit side effectsImprove reliabilitySilver accumulatorsElectrode carriers/collectorsHexafluoropropyleneCopolymer

A positive electrode including a current collector; a positive active material layer disposed on the current collector; and a coating layer disposed on the positive active material layer. The coating layer includes a binder and a inorganic additive. The binder is a poly(vinylidenefluoride-hexafluoropropylene) copolymer comprising 2 to 16 mole % of hexafluoropropylene. The positive electrode for a rechargeable lithium battery suppresses side-reactions between a positive electrode and an electrolyte, at a high voltage.

Owner:SAMSUNG SDI CO LTD

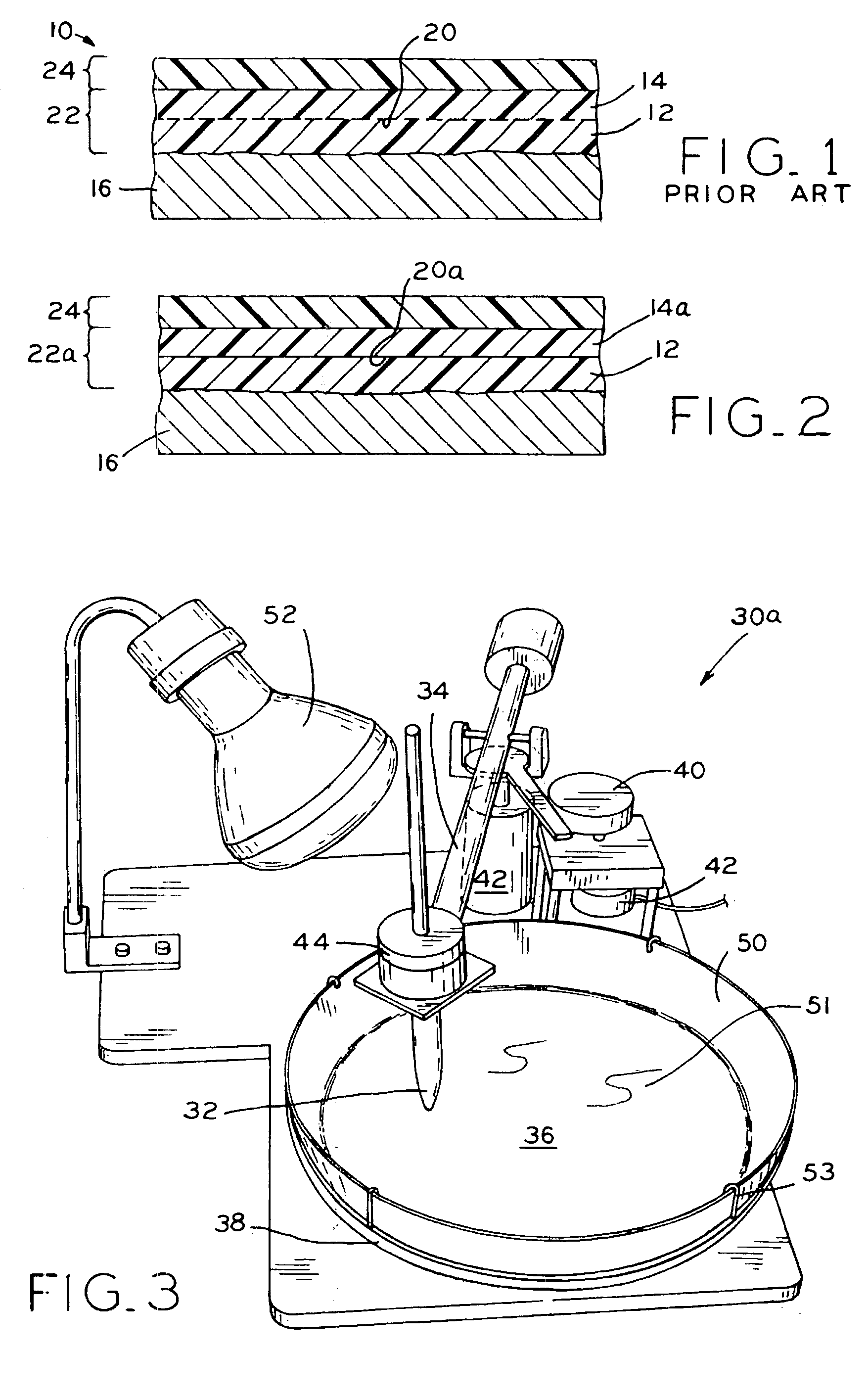

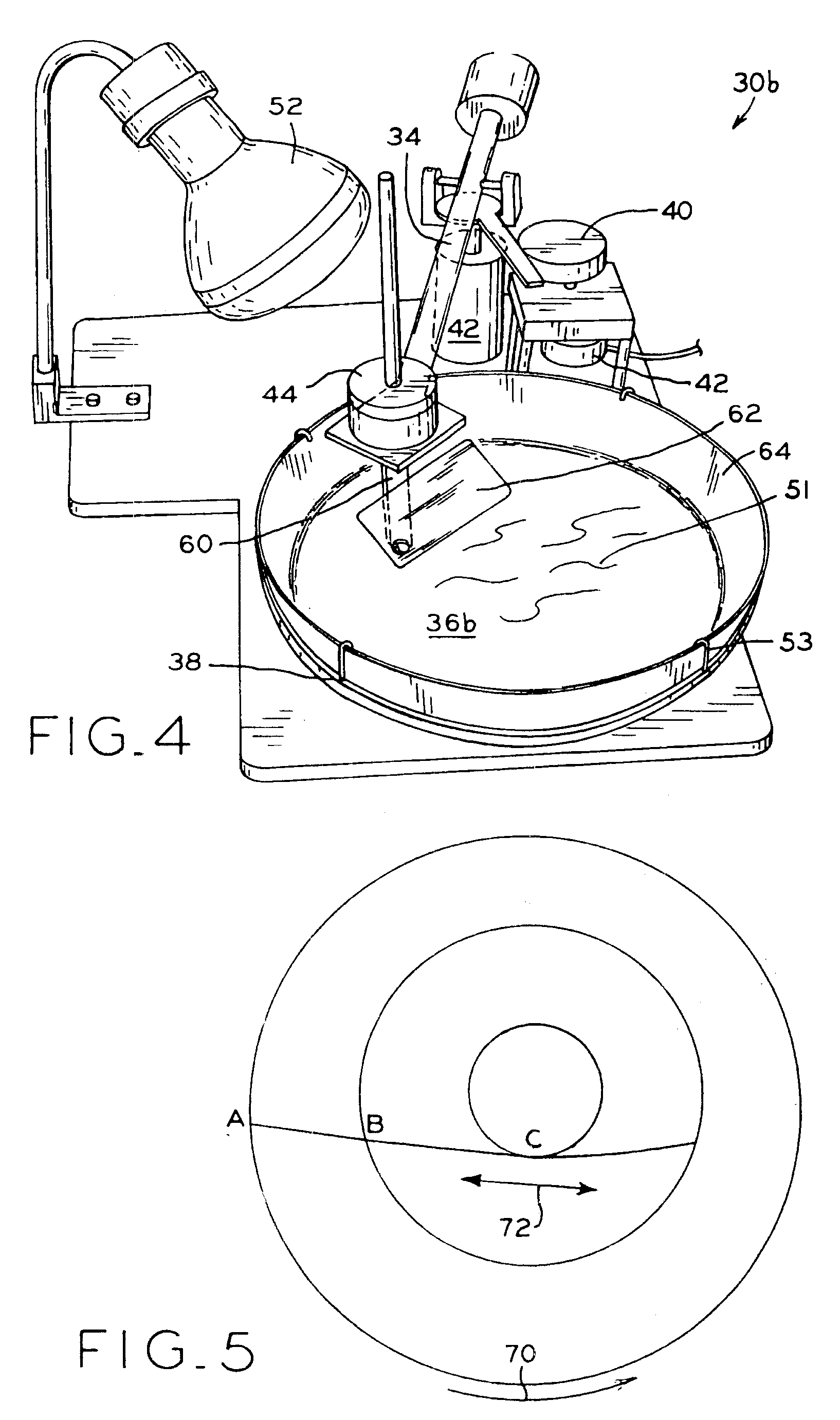

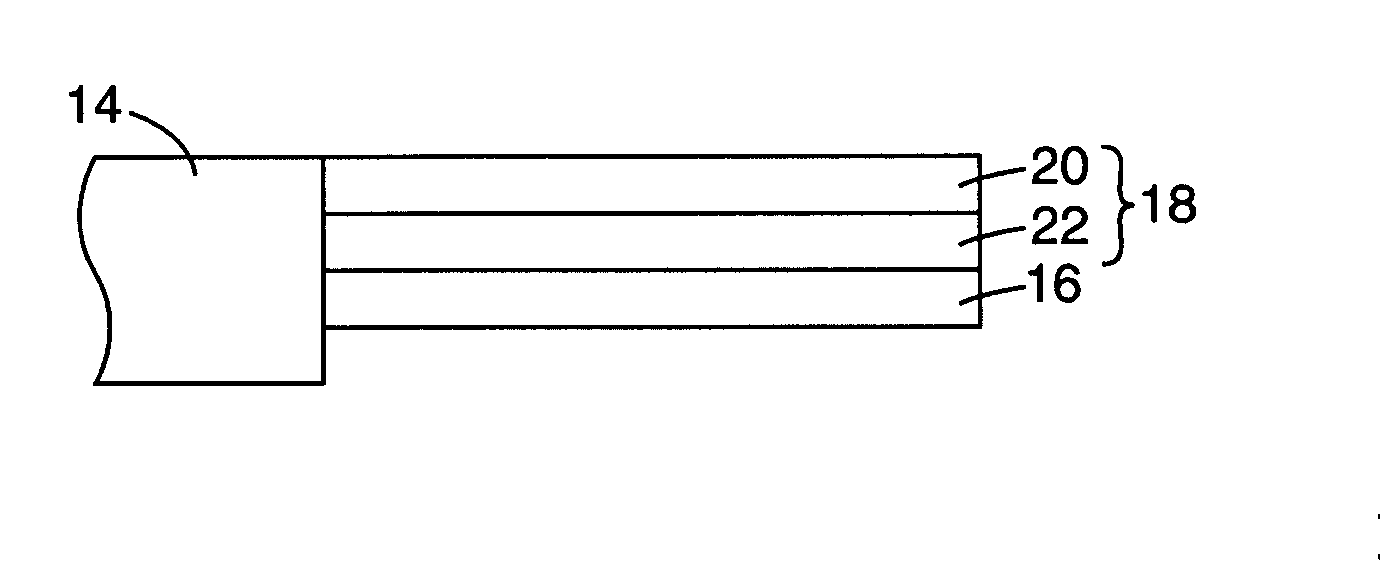

Single coat non-stick coating system and articles coated with same

InactiveUS7026036B2Enhanced release propertiesGood substrate adhesionSynthetic resin layered productsPolyether coatingsPolymer scienceHexafluoropropylene

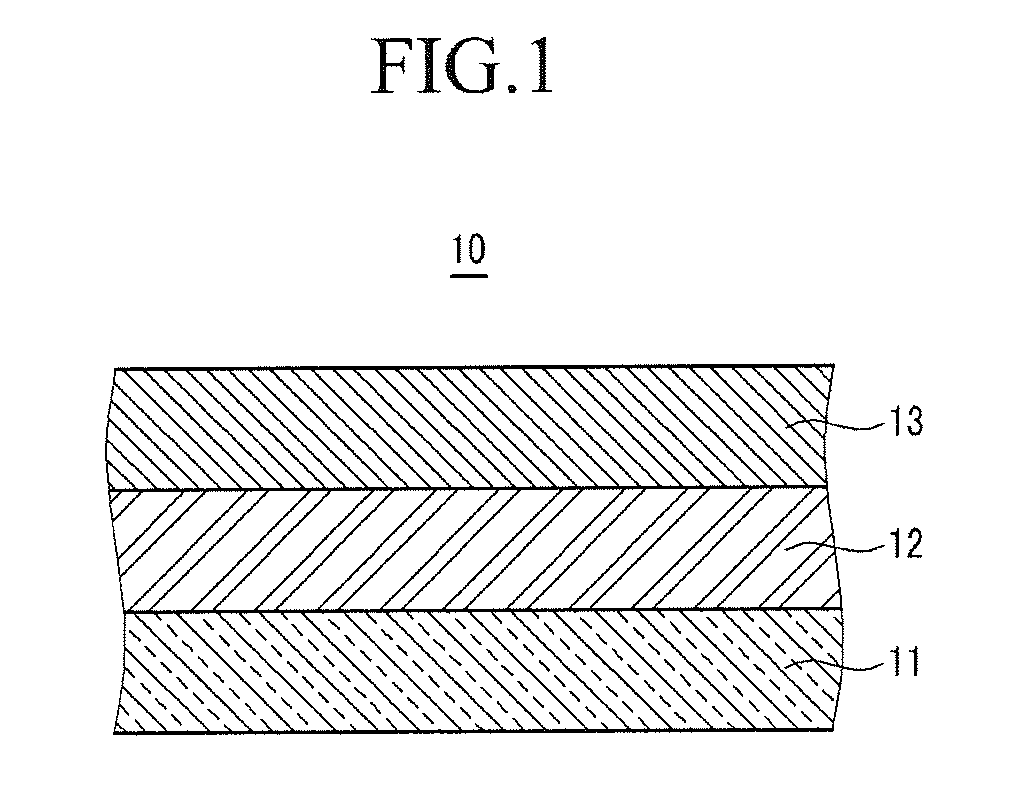

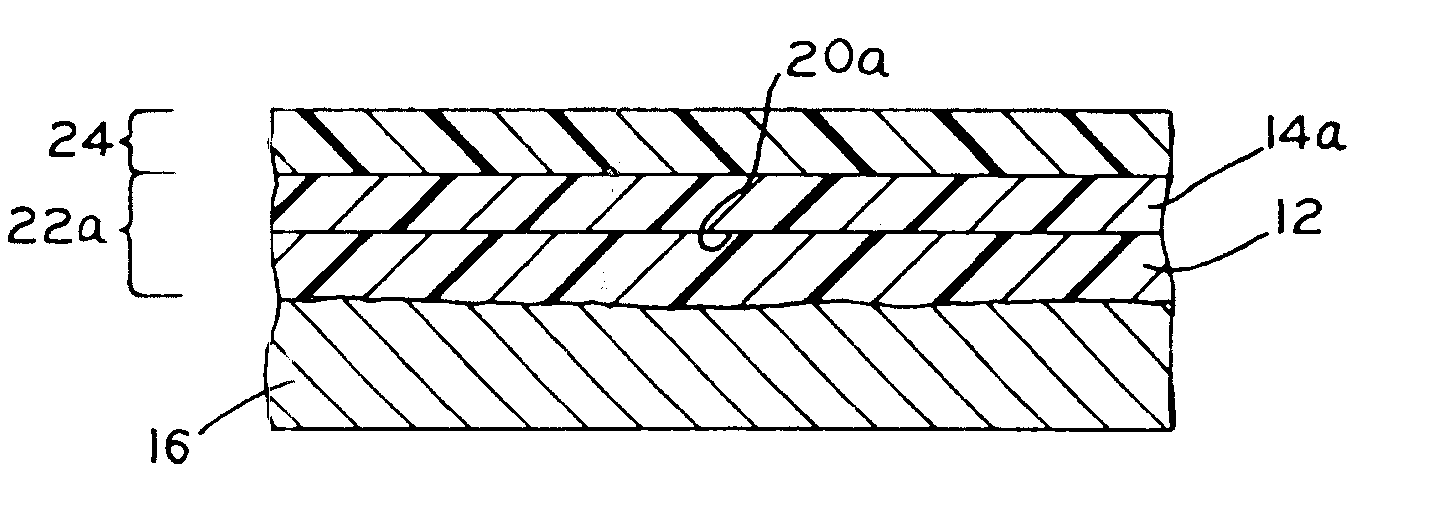

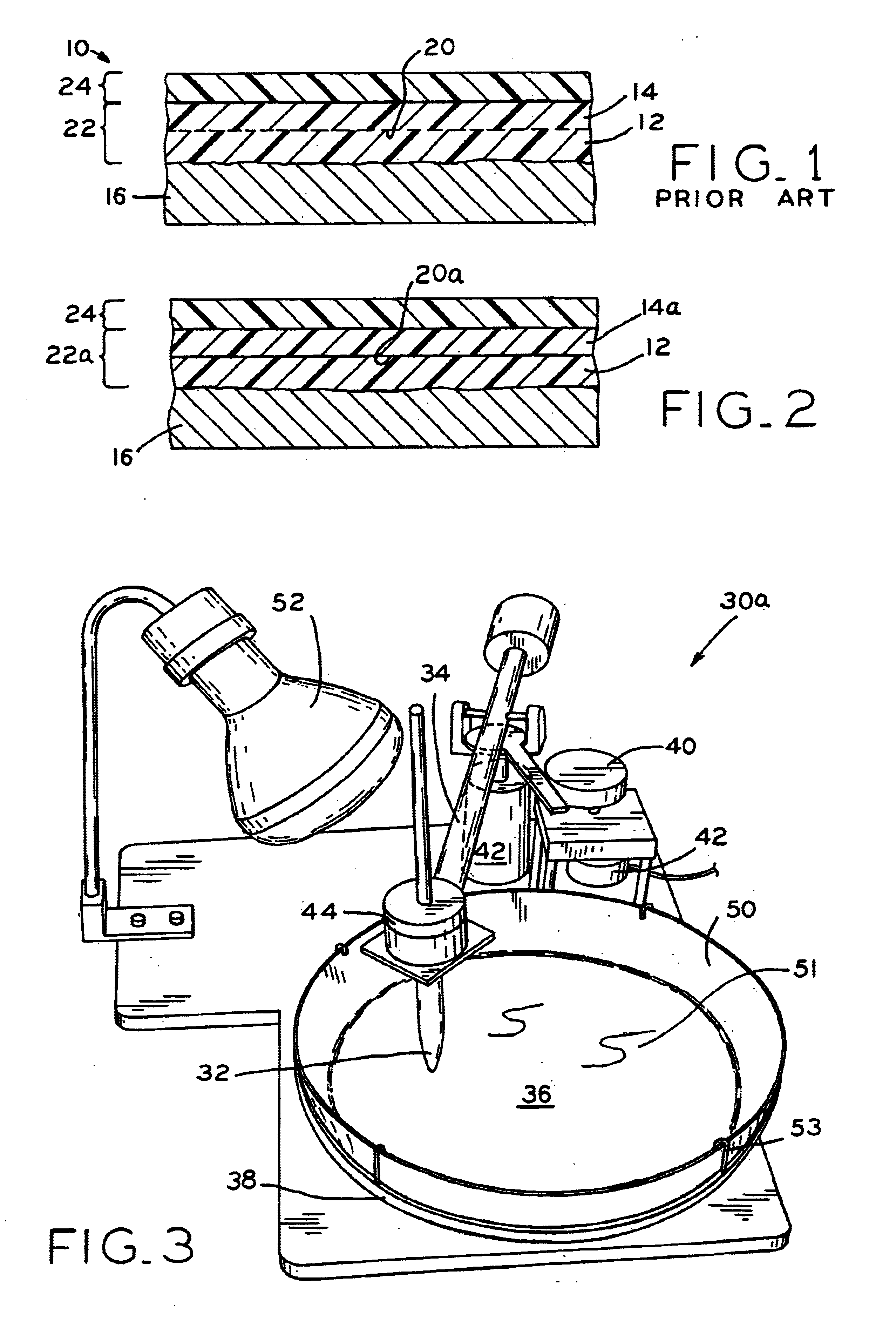

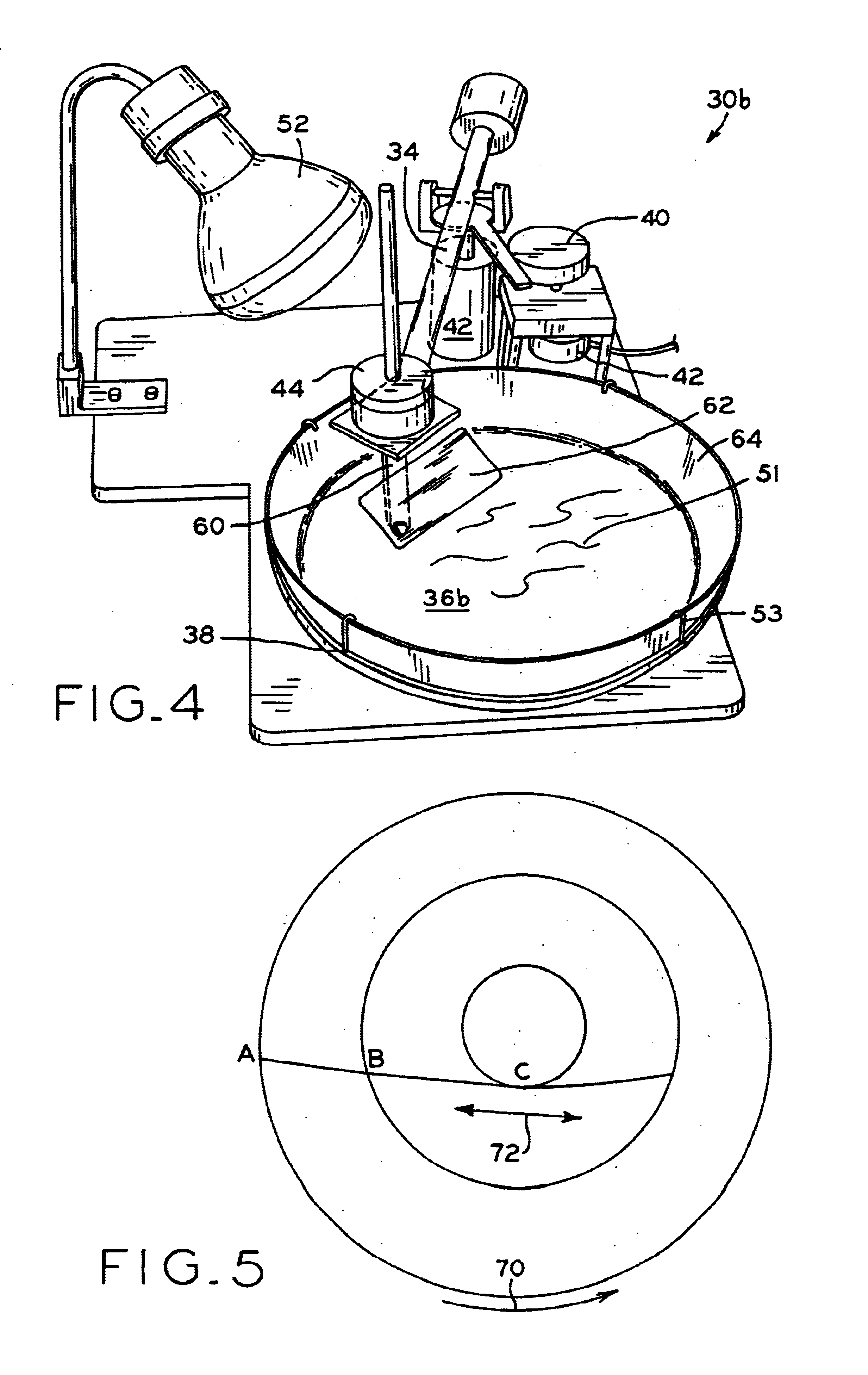

Single coat coating systems (22), as well as articles coated with such non-stick coating systems, are provided. The single coat system includes a fluoropolymer copolymer (14a), such as fluoropolymer terpolymer including tetrafluoroethylene, hexafluoropropylene, and vinylidene fluoride monomers, with fluoropolymer copolymers are referred to collectively as THV. The single coat system exhibits excellent substrates adhesion and release properties, is resistant to separation failure at the interface between the binder (12) and fluoropolymer components (14a), and exhibits adhesion to smooth substrates (16). The single coat system may also include a high level of fillers to provide increased damage resistance without compromising the above benefits.

Owner:WHITFORD

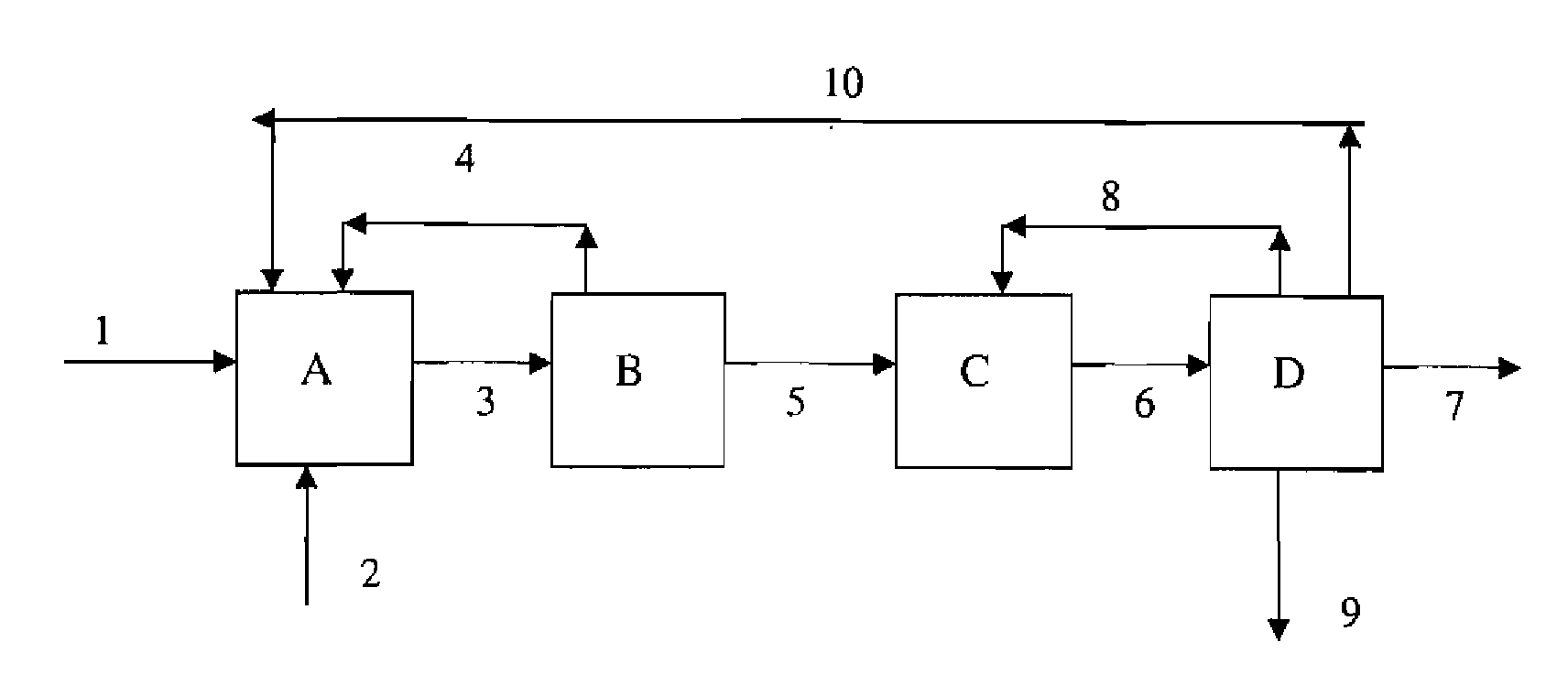

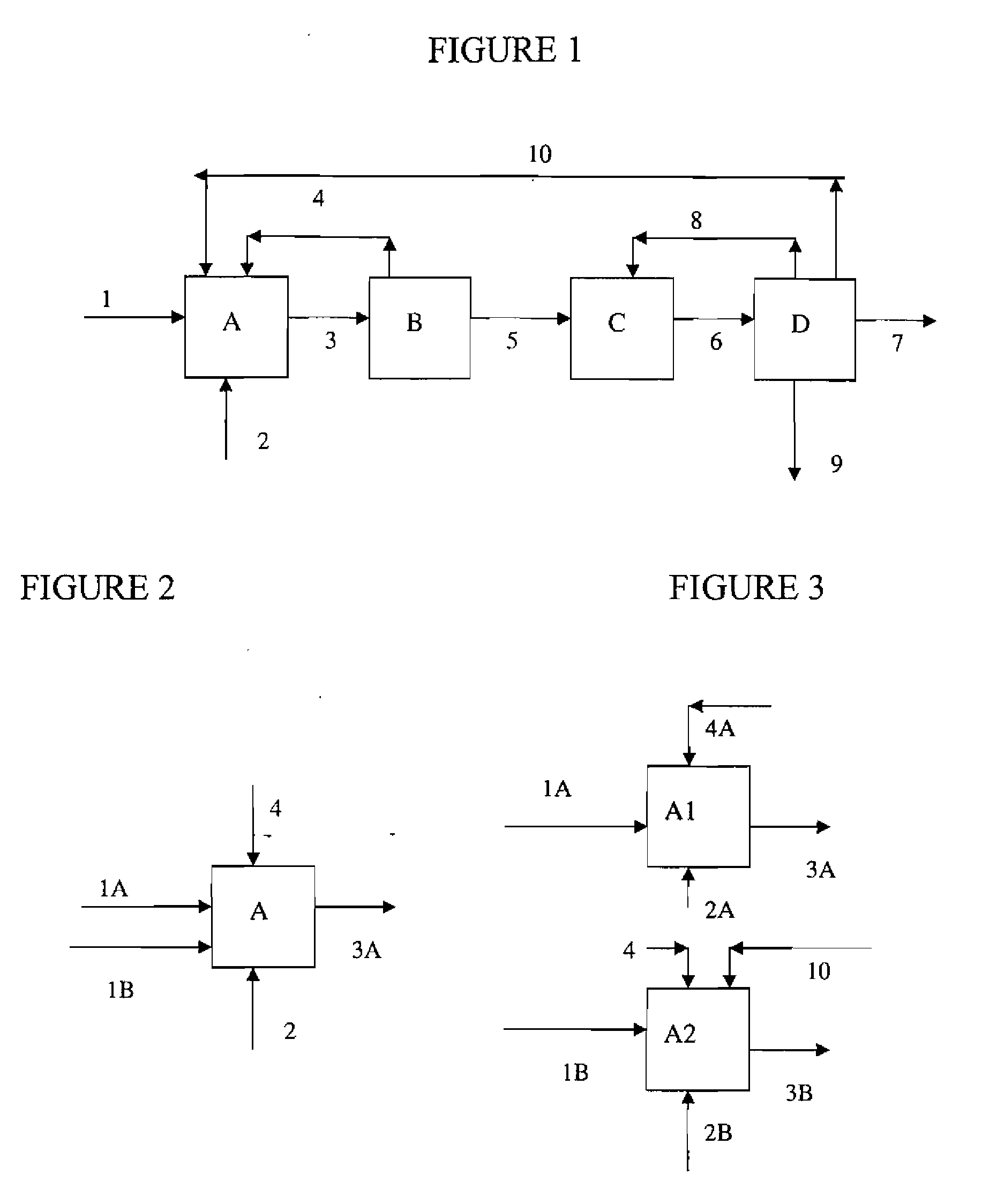

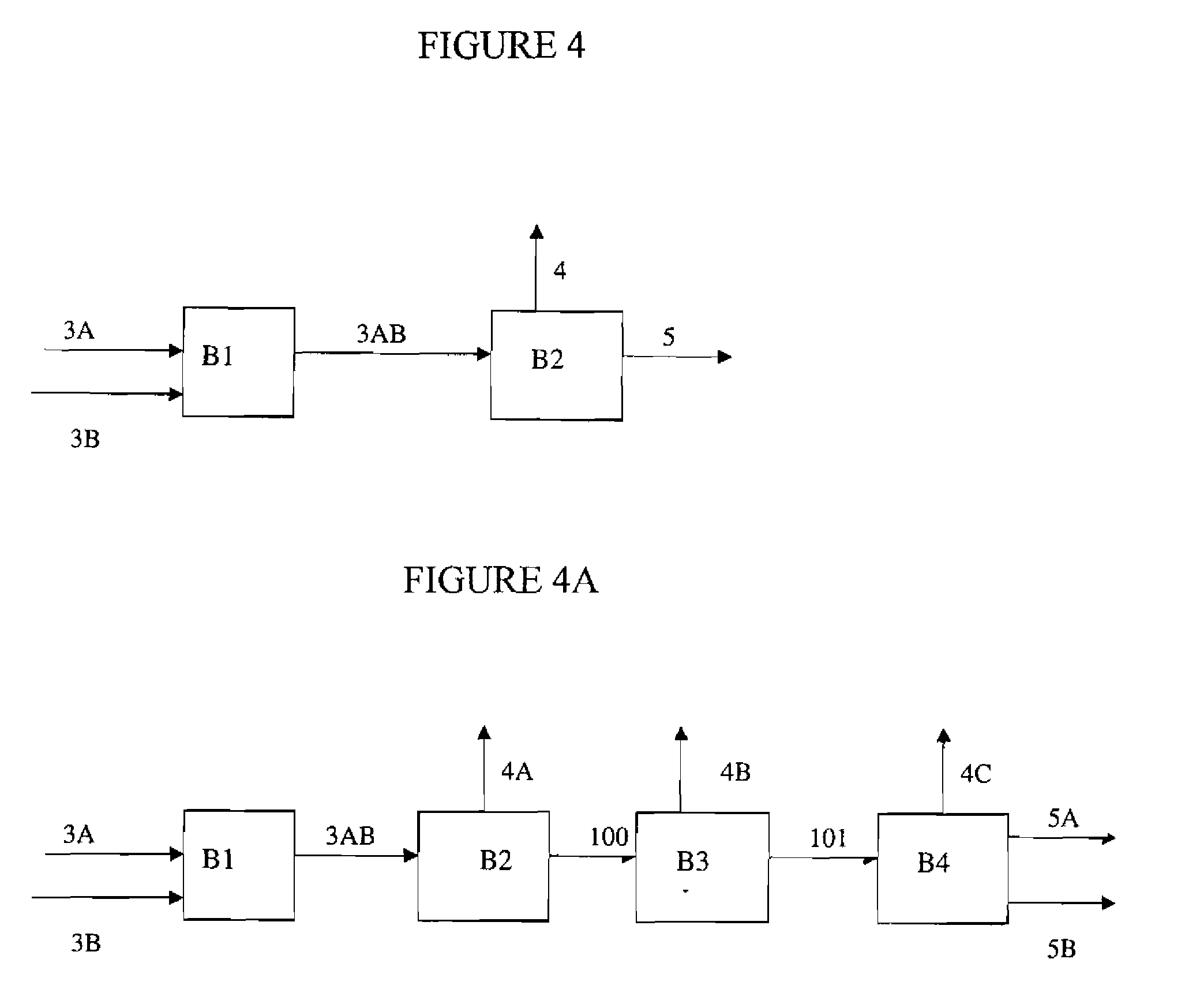

Process for the manufacture of fluorinated olefins

ActiveUS20090234165A1Good economic advantagePreparation by dehalogenationSequential/parallel process reactionsHexafluoropropylenePentafluoropropane

A method for producing 1,1,1,2-tetrafluoropropene and / or 1,1,1,2,3 -pentafluoropropene using a single set of four unit operations, the unit operations being (1) hydrogenation of a starting material comprising hexafluoropropene and optionally recycled 1,1,1,2,3-pentafluoropropene; (2) separation of the desired intermediate hydrofluoroalkane, such as 1,1,1,2,3,3-hexafluoropropane and / or 1,1,1,2,3-pentafluoropropane; (3) dehydrofluorination of the intermediate hydrofluoroalkane to produce the desired 1,1,1,2-tetrafluoropropene and / or 1,1,1,2,3-pentafluoropropene, followed by another separation to isolate the desired product and, optionally, recycle of the 1,1,1,2,3-pentafluoropropene.

Owner:HONEYWELL INT INC

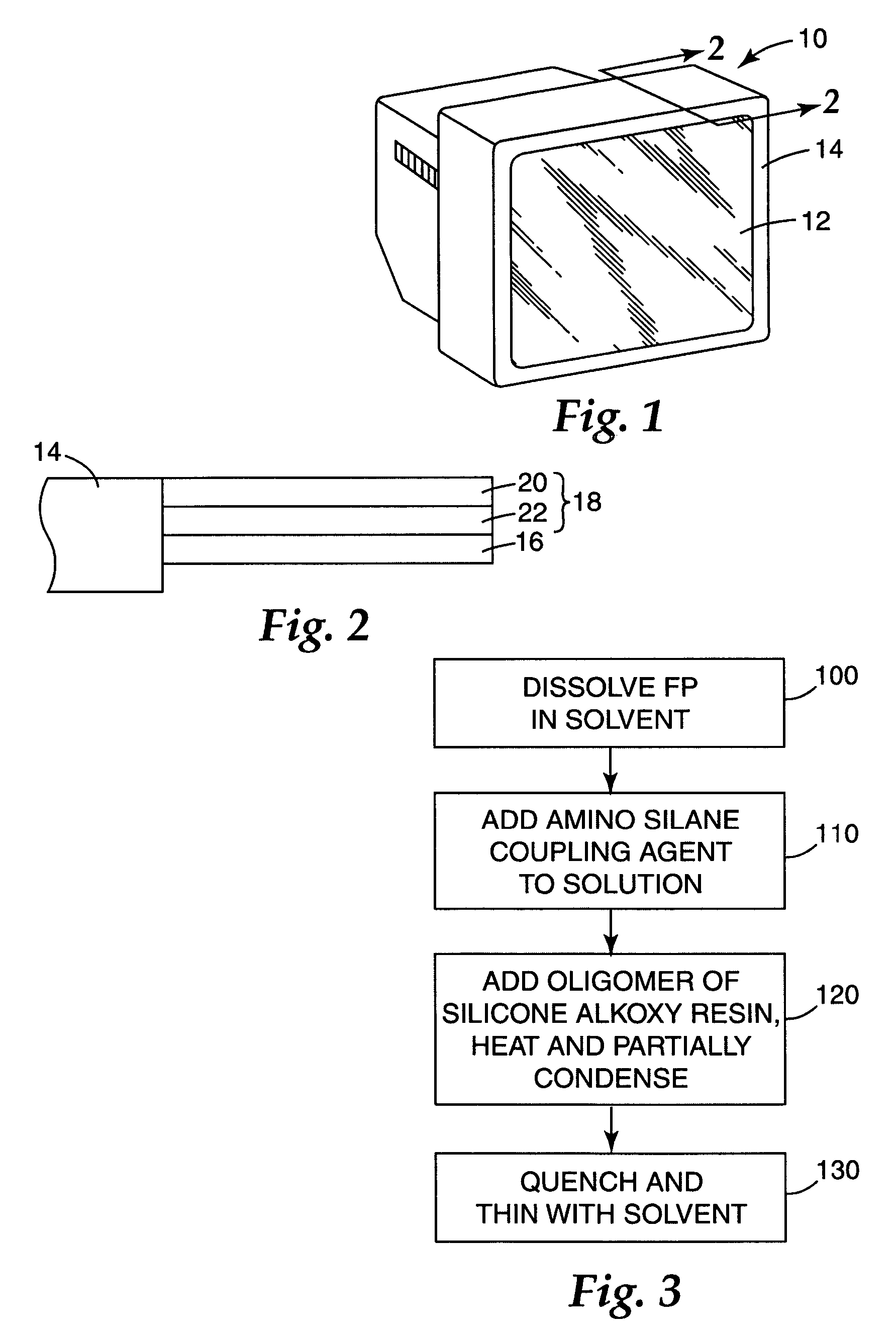

Low refractive index coating composition for use in antireflection polymer film coatings and manufacturing method

InactiveUS7374812B2Easy to manufactureImprove wettabilitySynthetic resin layered productsThin material handlingPolymer scienceSilanes

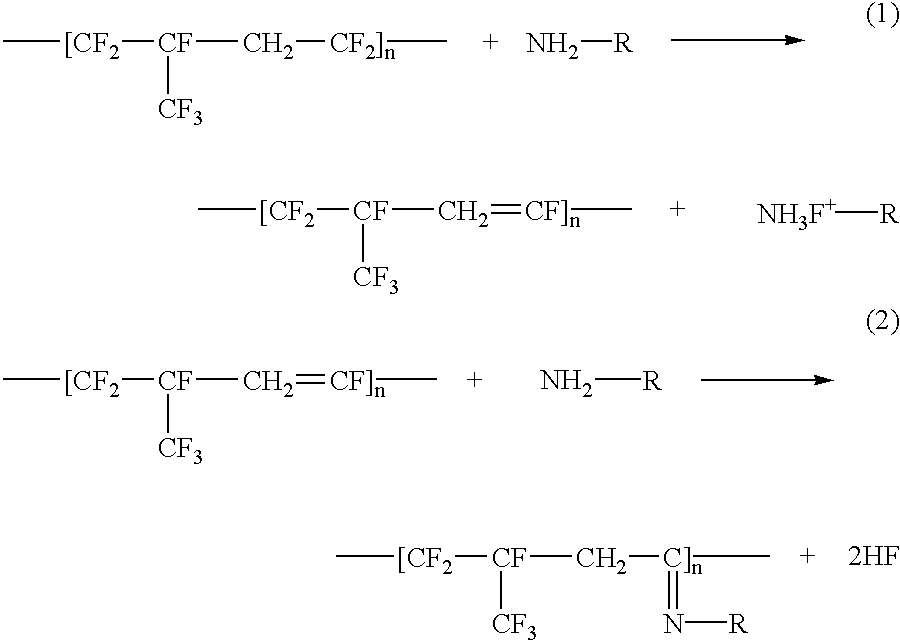

A silicone-modified fluoropolymer is formed by first dissolving a fluoropolymer in an organic solvent, the fluoropolymer having at least one monomer of vinylidene fluoride coupled to a hexafluoropropylene monomer unit, and subsequently reacting the mixture with an amino silane coupling agent to form an aminosilane-modified fluoropolymer. The aminosilane fluoropolymer is subsequently heated and partially condensed with an oligomer of a silane compound including alkoxy silane. The resultant composition is suitable for use as a low refractive index layer in an antireflection coating on an optical substrate.

Owner:3M INNOVATIVE PROPERTIES CO

Multiple coat non-stick coating system and articles coated with same

InactiveUS6846570B2Improve adhesionImprove the level ofCooking-vessel materialsOther chemical processesPolymer scienceCoating system

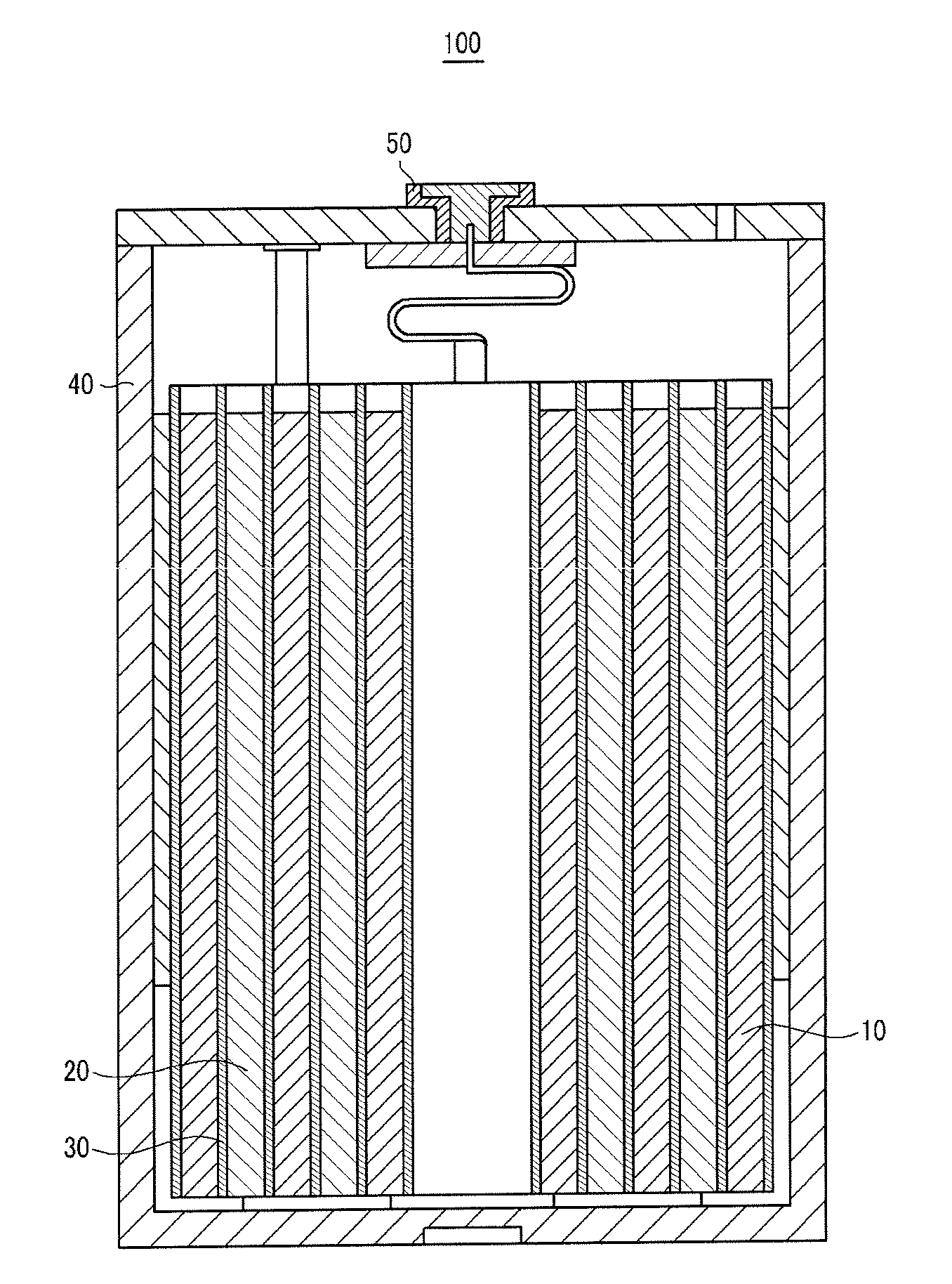

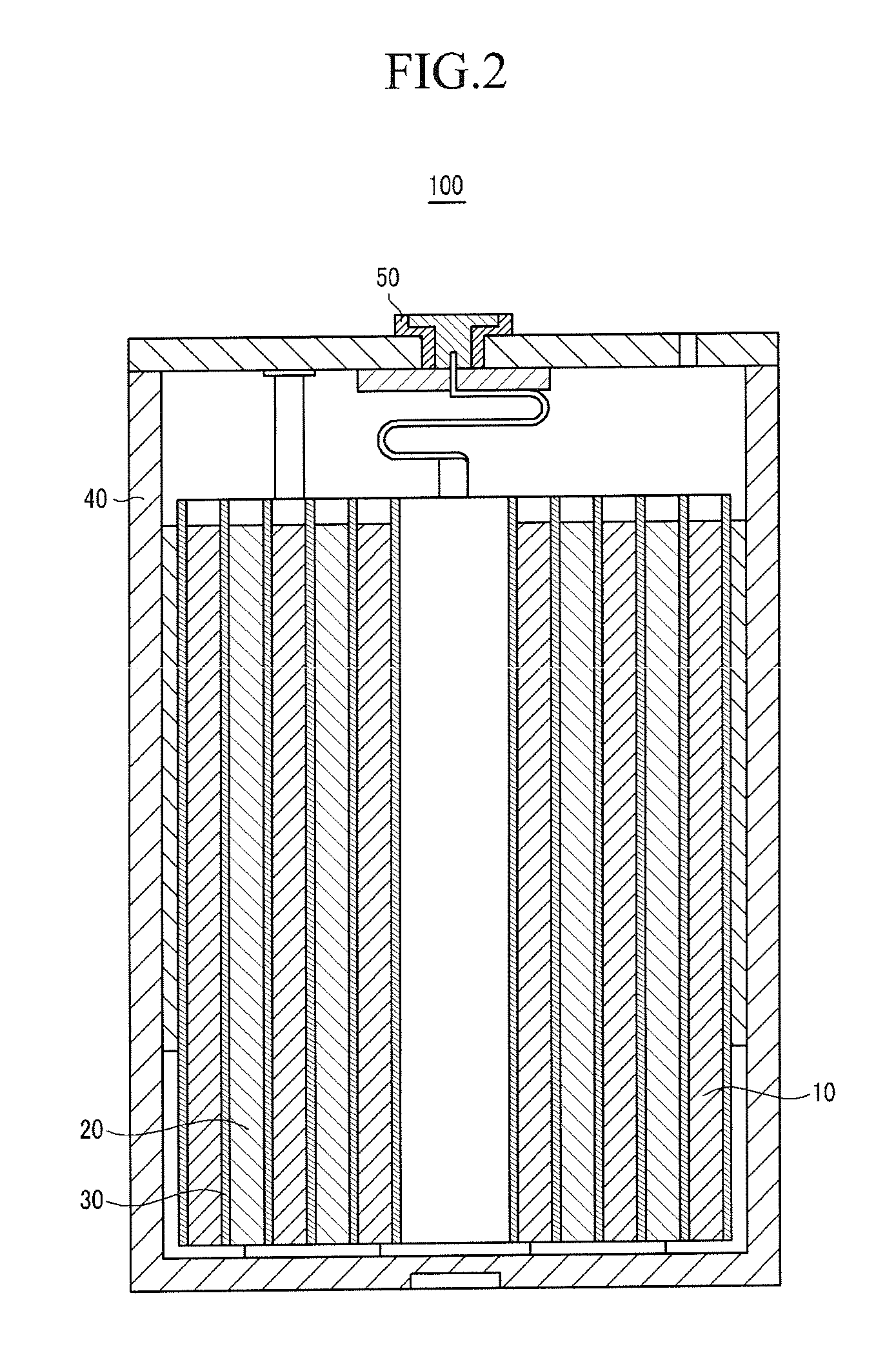

Multiple coat non-stick coating systems, as well as articles coated with such non-stick coating systems, are provided. The primer (22a) of the multiple coat system includes a fluoropolymer (14a) copolymer, such as a fluoropolymer terpolymer including tetrafluoroethylene, hexafluoropropylene, and vinylidene fluoride monomers, which fluoropolymer copolymers are referred to collectively as THV. The multiple coat system exhibits excellent substrate adhesion and release properties, and the primer exhibits excellent primer-substrate adhesion and primer-topcoat adhesion. The multiple coat system is additionally resistant to separation failure at the interface between the binder (12) and fluoropolymer components of the primer, exhibits excellent adhesion to smooth substrates (16), and may also include a high level of fillers to provide increased damage resistance without compromising the above benefits.

Owner:PPG IND OHIO INC

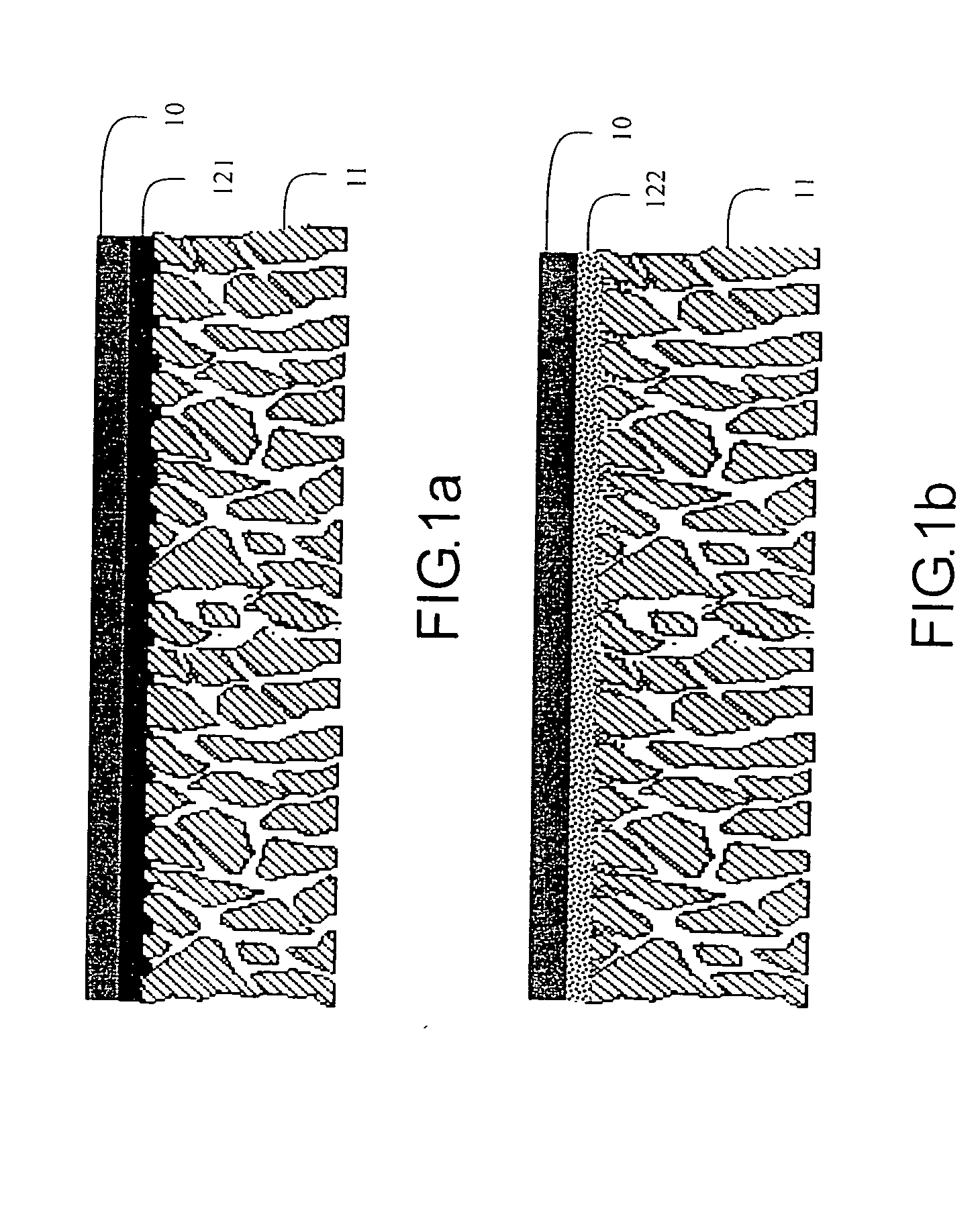

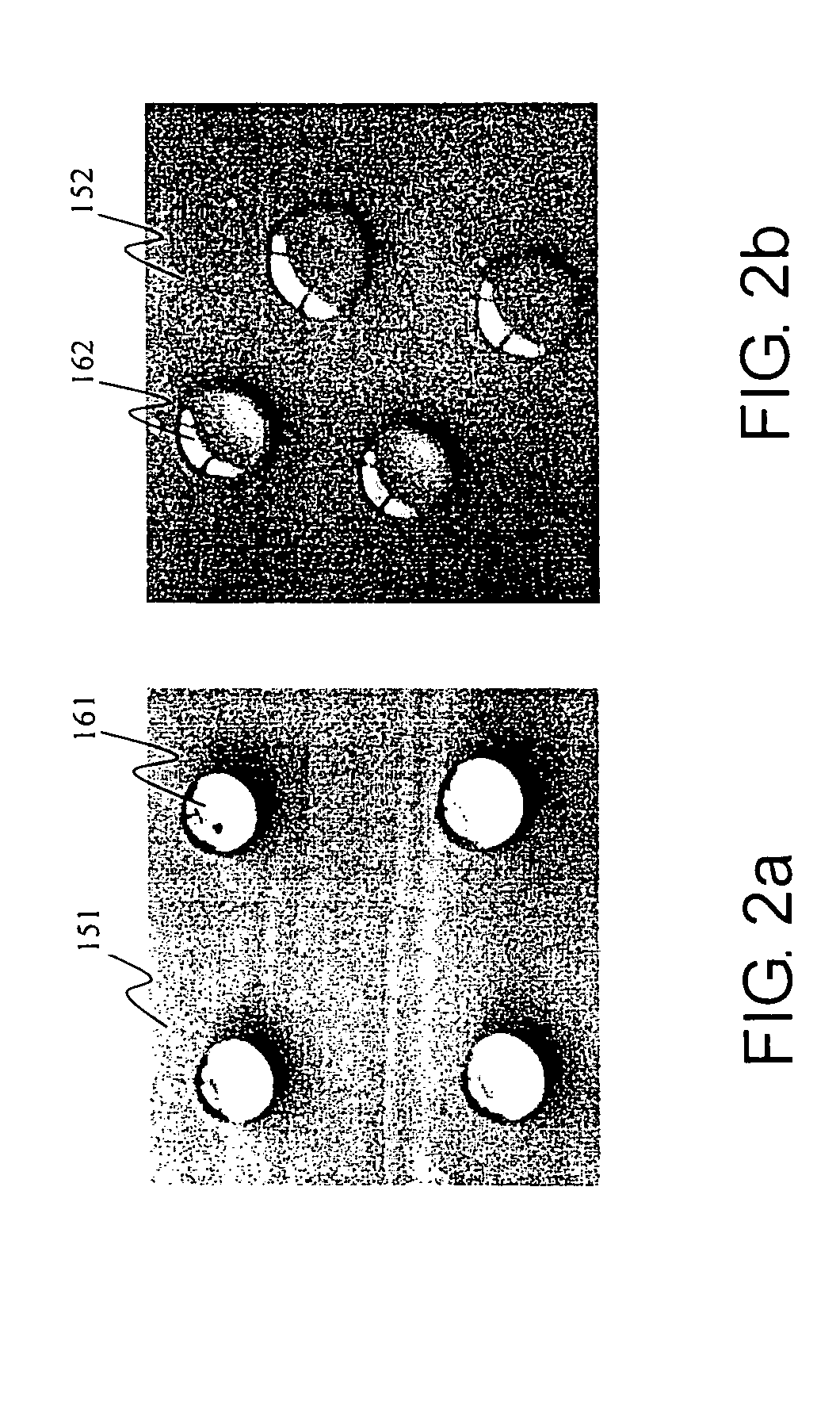

Coated separators for lithium batteries and related methods

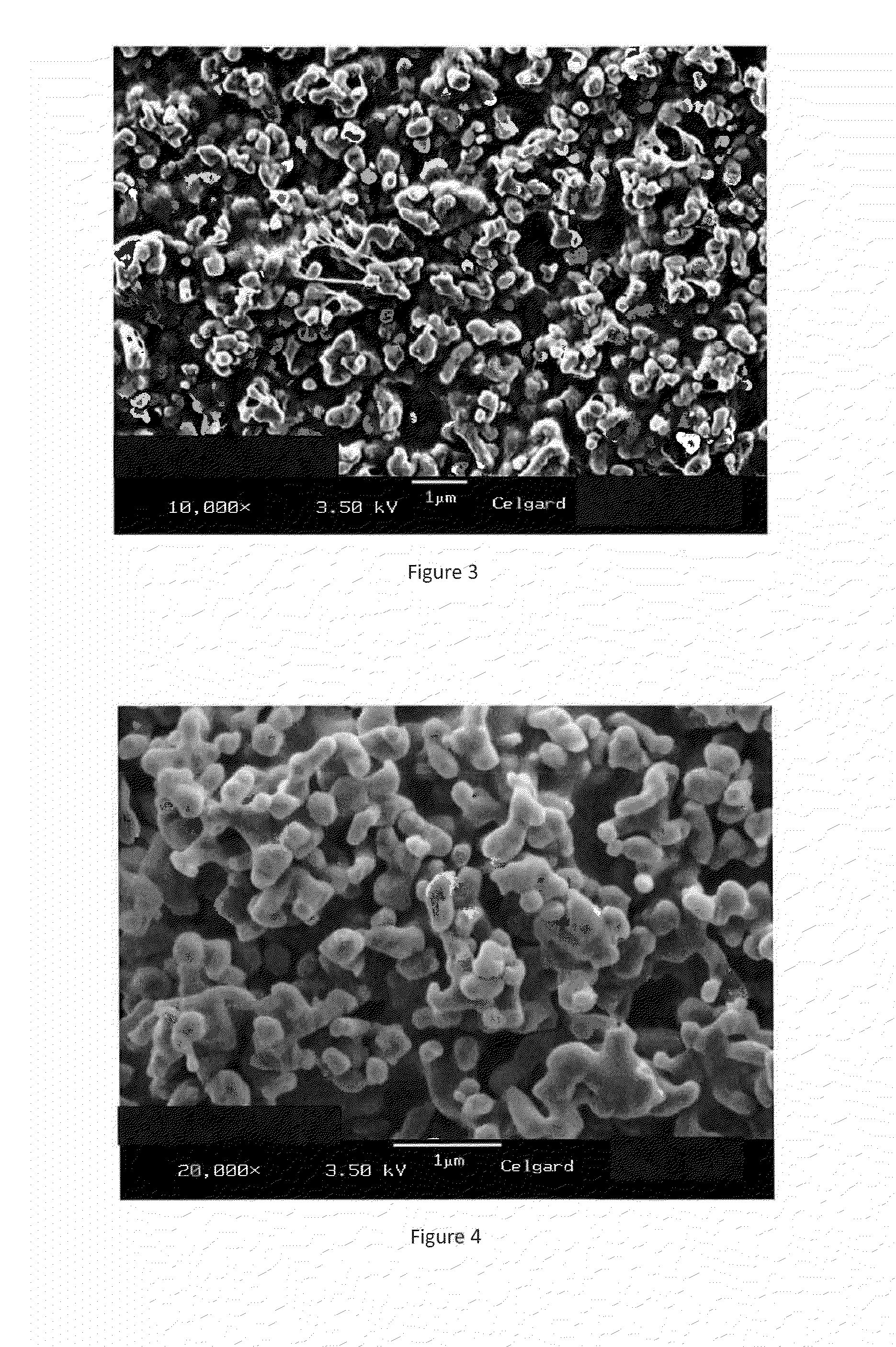

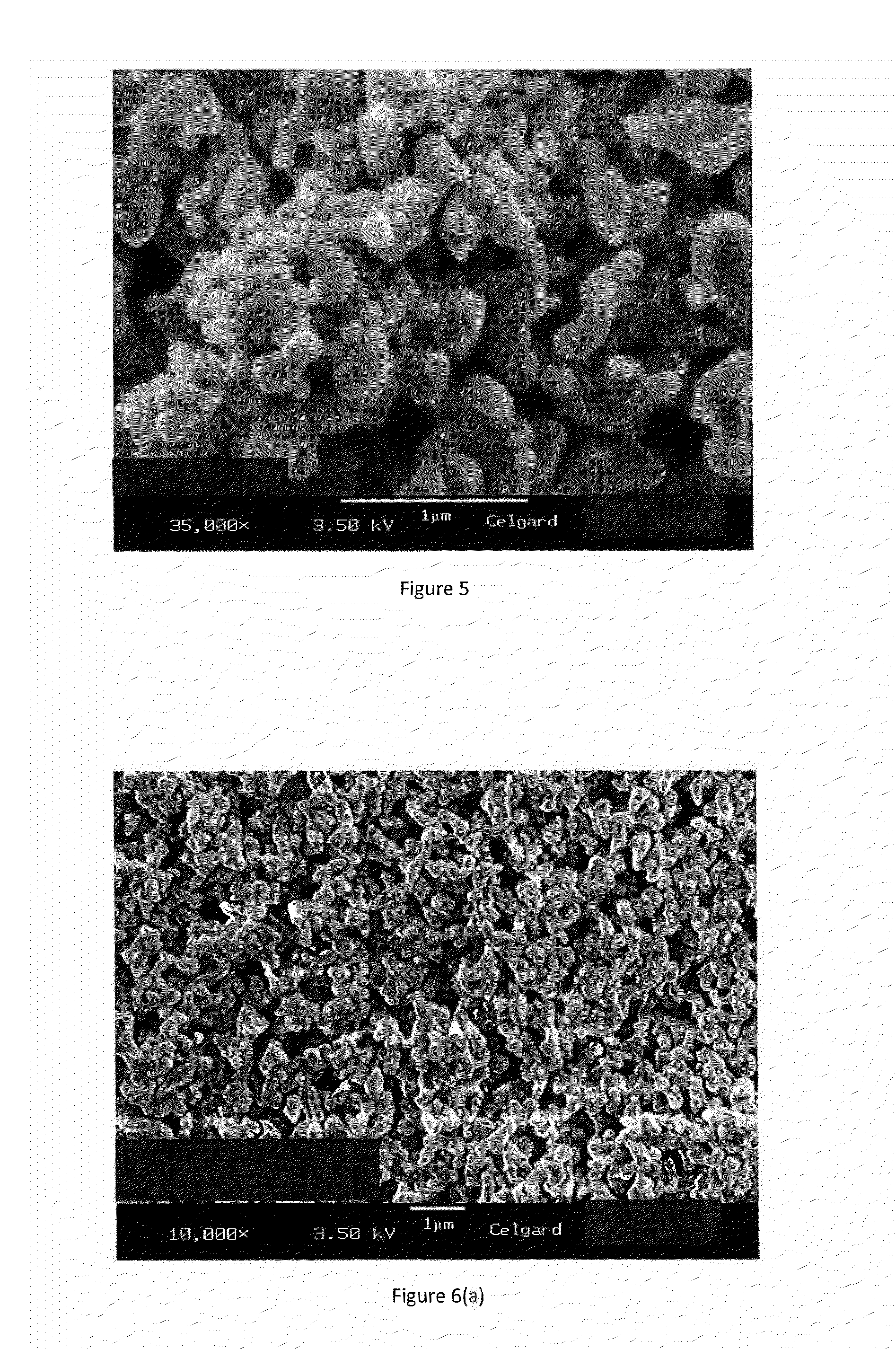

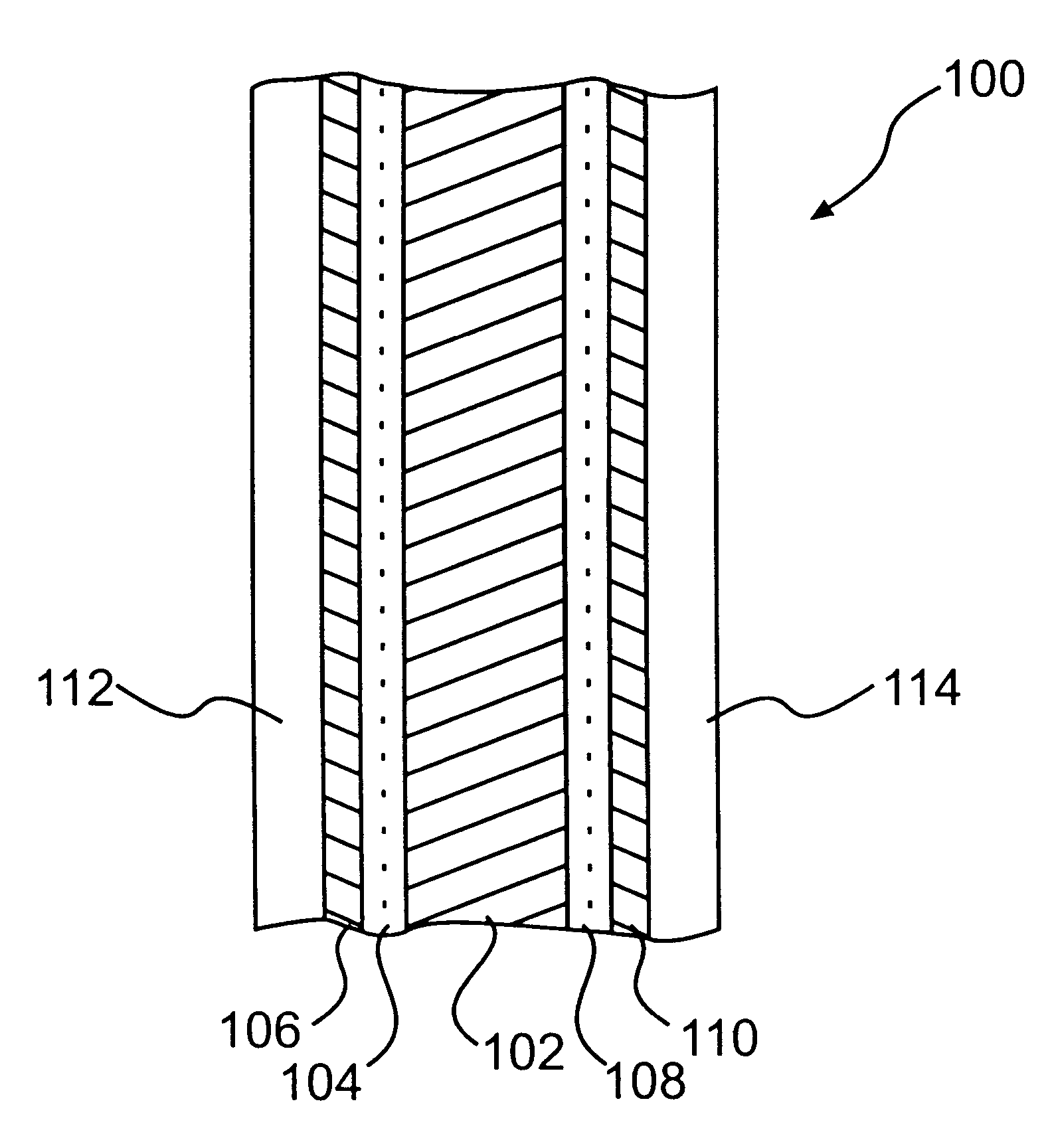

PendingUS20160164060A1Desirable level of porosityImprove thermal stabilityCell seperators/membranes/diaphragms/spacersFinal product manufacturePolymer scienceHexafluoropropylene

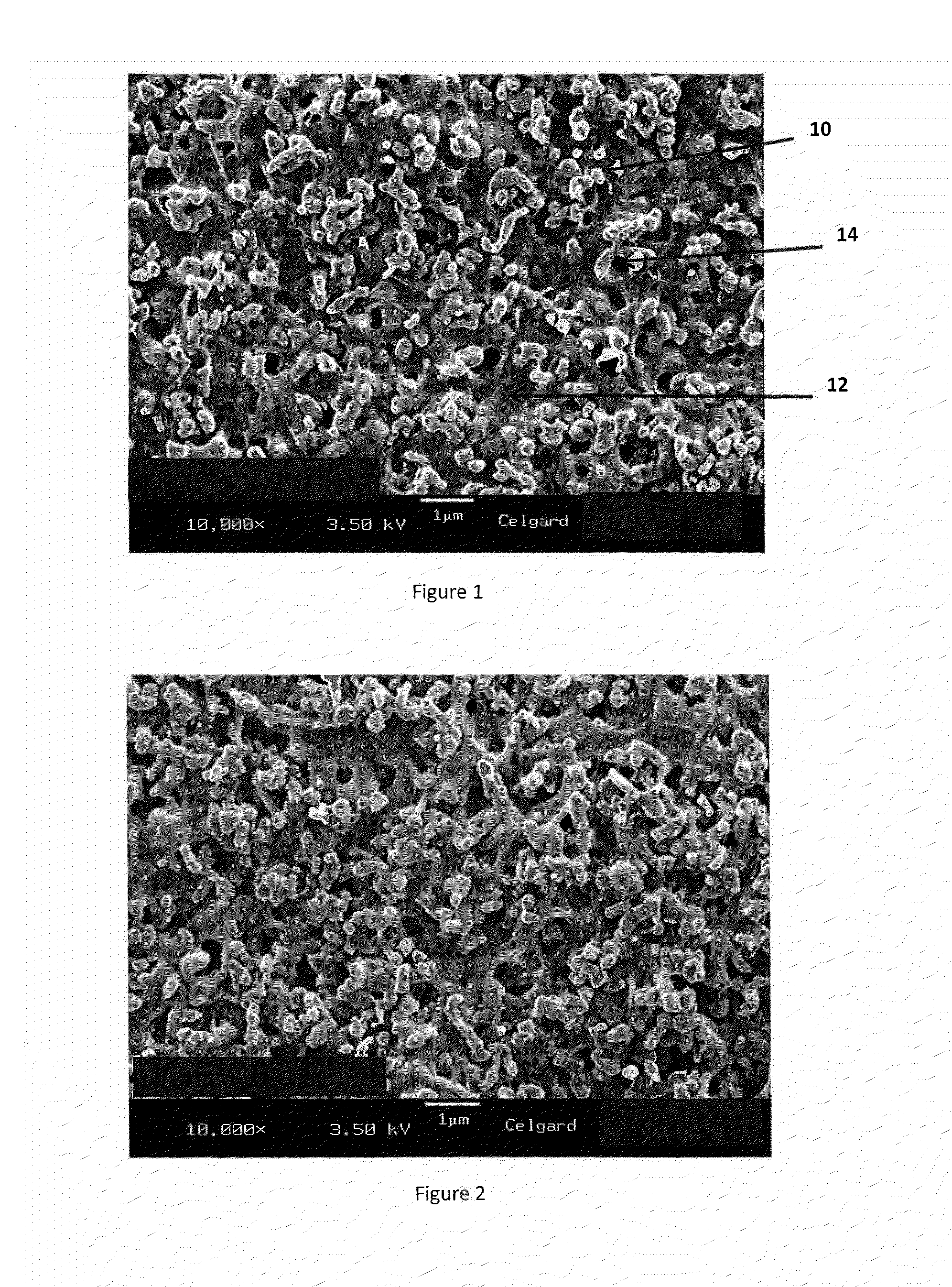

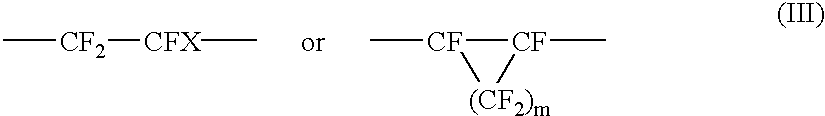

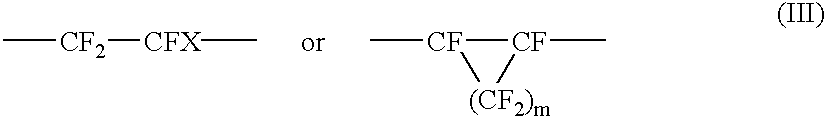

In accordance with at least selected embodiments, new or improved ceramic coated separators, membranes, films, or the like for use in lithium batteries, new or improved batteries including such ceramic coated separators, membranes, films, or the like, and methods of making or using such ceramic coated separators, membranes, films or the like are disclosed. In accordance with at least certain embodiments, new or improved aqueous or water-based polymeric coated separators, membranes, films, or the like are disclosed. In accordance with at least particular embodiments, new or improved aqueous or water-based polyvinylidene fluoride (PVDF) or polyvinylidene difluoride (PVDF) homopolymer or co-polymers of PVDF with hexafluoropropylene (HFP or [—CF(CF3)—CF2—]), chlorotrifluoroethylene (CTFE), vinylidene fluoride (VF2.HFP), tetrafluoroethylene (TFE), and / or the like, blends and / or mixtures thereof, coated separators, membranes, films or the like, new or improved porous separators for use in lithium batteries, new or improved coating or application methods for applying a coating or ceramic coating to a separator for use in a lithium battery, new or improved PVDF or PVDF:HFP films or membranes, and / or the like are disclosed.

Owner:CELGARD LLC

Copolymers of maleic anhydride or acid and fluorinated olefins

Novel copolymers of fluorinated olefins and maleic anhydride, maleic acid, dichloromaleic anhydride or dichloromaleic acid may be made by using as solvents for the maleic anhydride or acid a perfluorinated alkyl carboxylic acid, or liquid or supercritical hexafluoropropylene or carbon dioxide. The resulting polymers are useful as adhesives or compatibilizing agents for fluoropolymers, and in coatings.

Owner:THE CHEMOURS CO FC LLC

High melt flow fluoropolymer

ActiveUS7122609B2Quality improvementLong extrusion runPlastic/resin/waxes insulatorsInsulated cablesVinyl etherPolymer science

The present invention relates to a partially-crystalline copolymer comprising tetrafluoroethylene, hexafluoropropylene in an amount corresponding to a hexafluoropropylene index (HFPI) of from about 2.8 to 5.3, and preferably from about 0.2% to 3% by weight of perfluoro(alkyl vinyl ether), said copolymer being polymerized and isolated in the absence of added alkali metal salts, having a melt flow rate of within the range of about 30±3 g / 10 min, and having no more than about 50 unstable endgroups / 106 carbon atoms can be extruded at high speed onto conductor over a broad polymer melt temperature range to give insulated wire of high quality.

Owner:THE CHEMOURS CO FC LLC

Narrow composition distribution polyvinylidene fluoride RECLT films, processes, articles of manufacture and compositions

InactiveUS6620342B1Liquid crystal compositionsLiquid surface applicatorsSolubilityOptical transparency

The disclosure relates to a reversible, electrically controllable light transmission (RECLT) film, article of manufacture composition, process and product produced by the process, comprising a conductive narrow composition distribution polyvinylidene fluoride copolymer in combination with an electrolyte and an RECLT material. The narrow composition distribution polyvinylidene fluoride copolymer has low solubility, high thermal stability and strength, and very high optical clarity. The polyvinylidene fluoride copolymer comprises a nonporous or porous copolymer of vinylidene fluoride preferably with either hexafluoropropylene or tetrafluoroethylene or chlorotrifluoroethylene, or vinyl acetate, or combinations thereof. The RECLT material includes organic or inorganic compounds known in the art. Typical RECLT materials include electrochromic materials, reversible metal electrodeposition materials, liquid crystal materials and dispersed particle materials.

Owner:ARKEMA INC

Copolymers of maleic anhydride or acid and fluorinated olefins

Novel copolymers of fluorinated olefins and maleic anhydride, maleic acid, dichloromaleic anhydride or dichloromaleic acid may be made by using as solvents for the maleic anhydride or acid a perfluorinated alkyl carboxylic acid, or liquid or supercritical hexafluoropropylene or carbon dioxide. The resulting polymers are useful as adhesives or compatibilizing agents for fluoropolymers, and in coatings.

Owner:THE CHEMOURS CO FC LLC

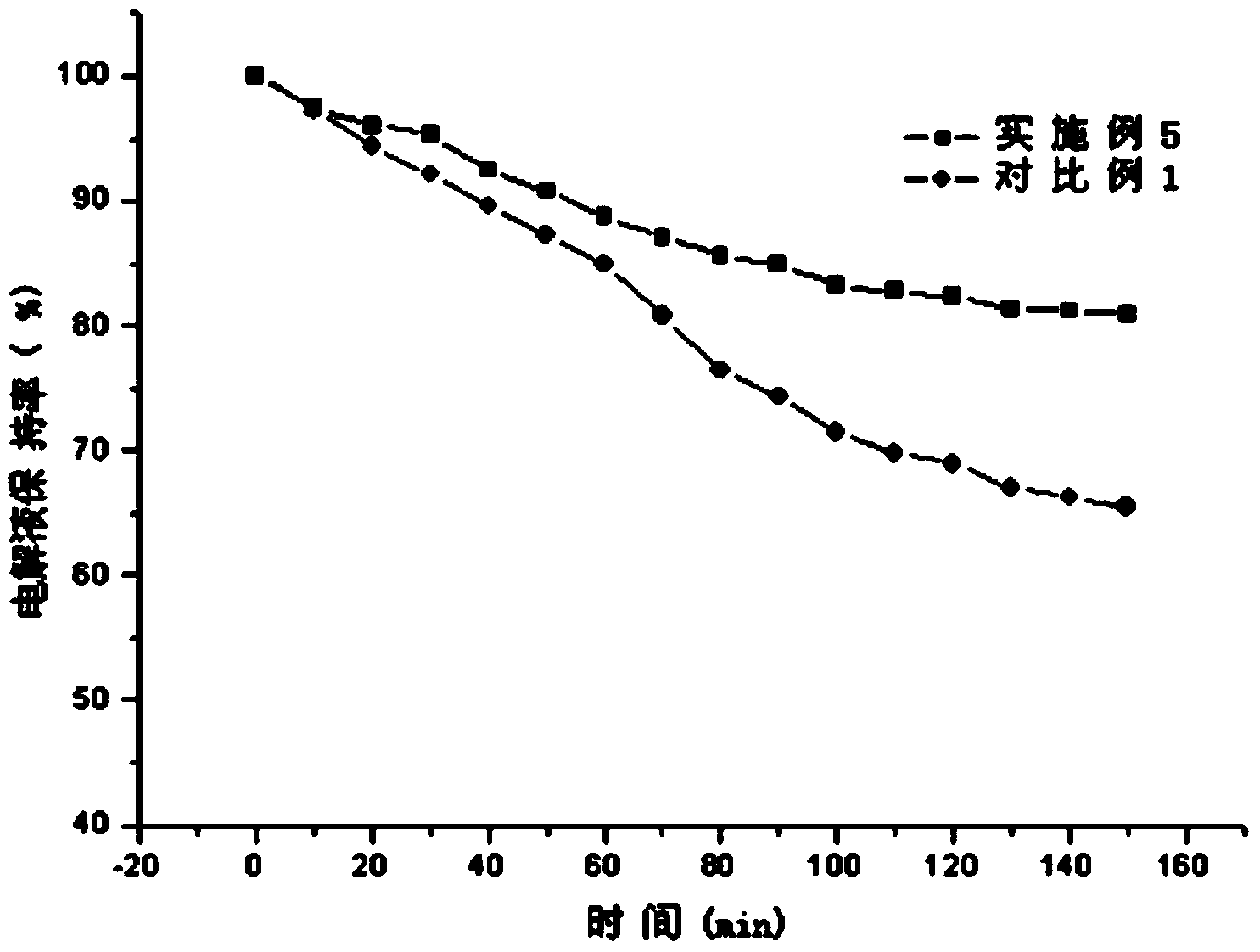

Inorganic/organic composite porous lithium battery diaphragm and preparation method thereof

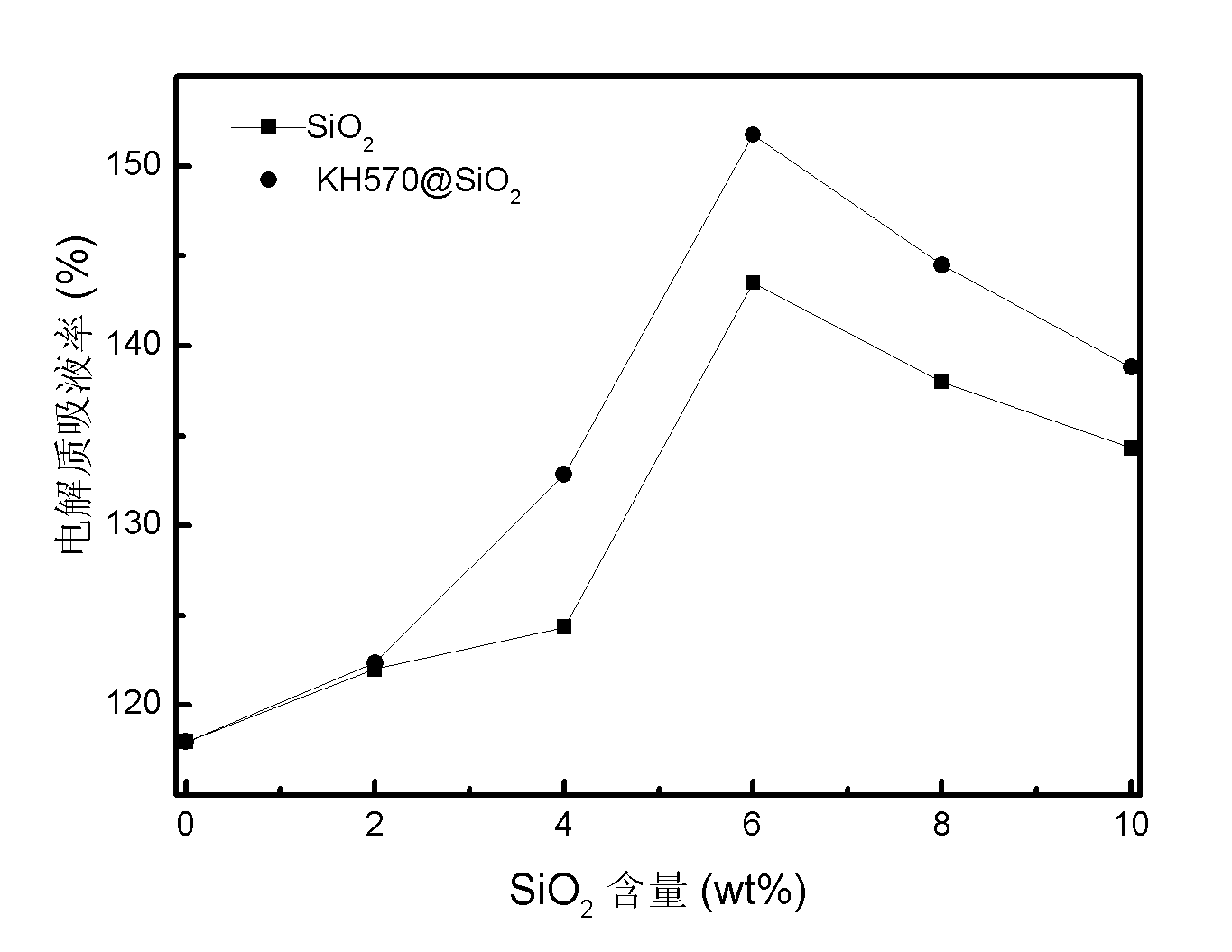

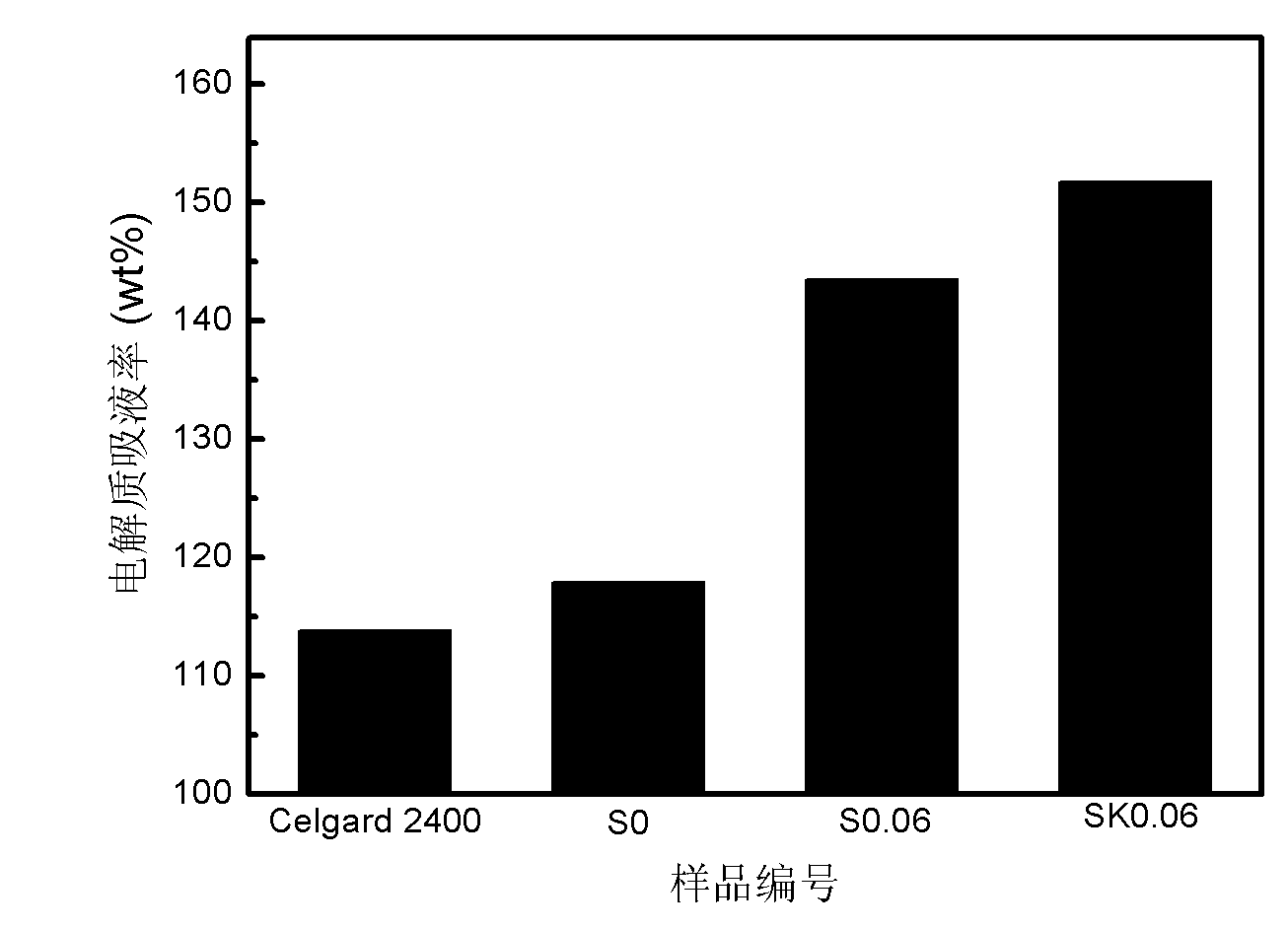

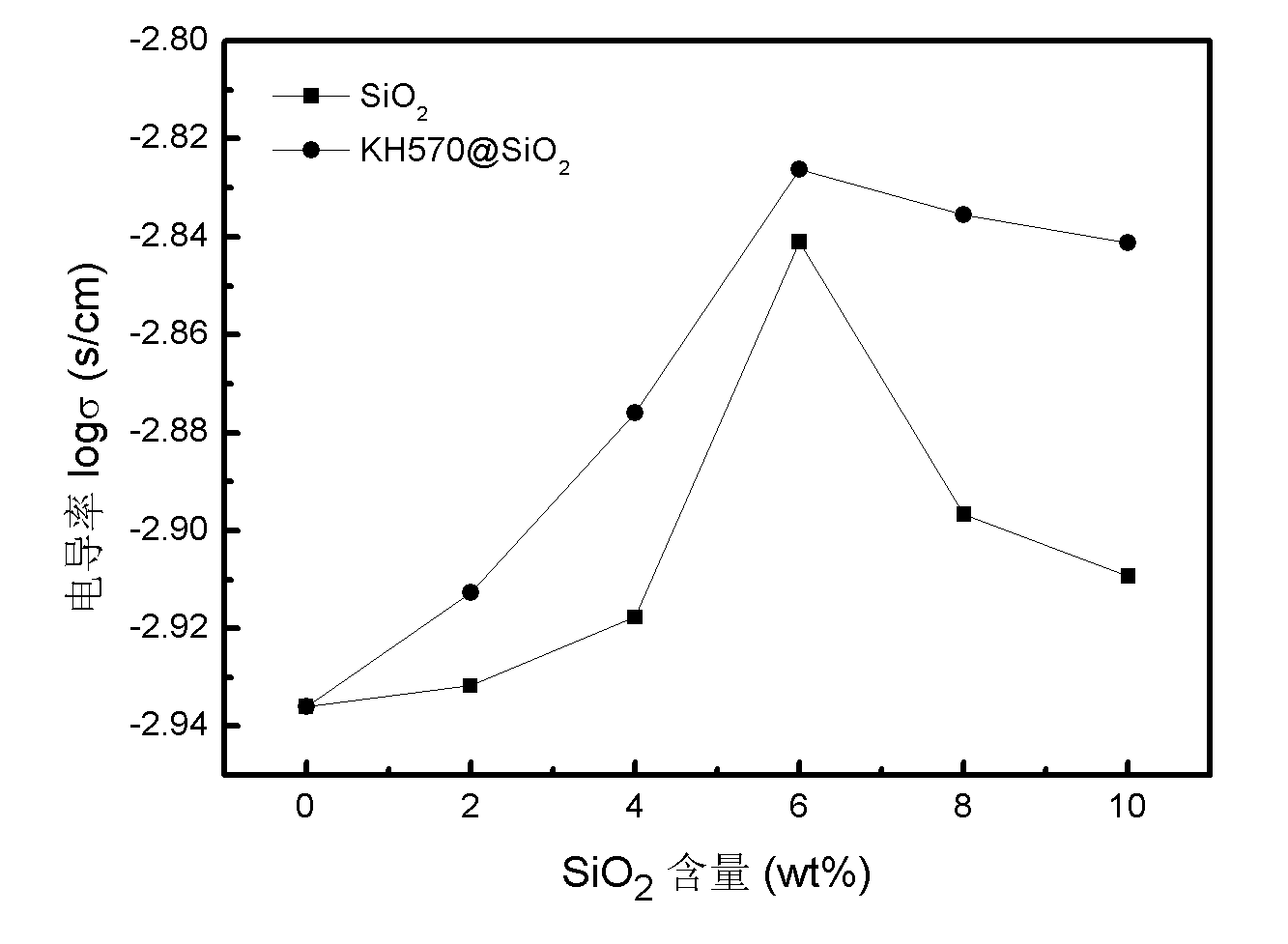

ActiveCN102529247AHigh liquid absorptionImprove ionic conductivitySynthetic resin layered productsCell component detailsSilica nanoparticlesHexafluoropropylene

The invention belongs to the field of lithium batteries, and relates to an inorganic / organic composite porous lithium battery diaphragm and a preparation method thereof. The inorganic / organic composite porous lithium battery diaphragm comprises a base material layer and an inorganic / organic composite porous diaphragm layer arranged on the surface of the base material layer, wherein the base material layer adopts polypropylene non-woven fabrics; the inorganic / organic composite porous diaphragm layer adopts a polyvinylidene fluoride- hexafluoropropylene multipolymer containing inorganic nano grains and hydrophilizing agents; and the inorganic nano grains are silicon dioxide nano grains or coupling agent improved silicon dioxide nano grains. The inorganic / organic composite porous lithium battery diaphragm provided by the invention has the advantages that the production cost of the lithium battery diaphragm is lowered while high ion-conductivity, excellent electrochemical performance, high mechanical strength and low thermal shrinking percentage are ensured.

Owner:SUZHOU UNIV

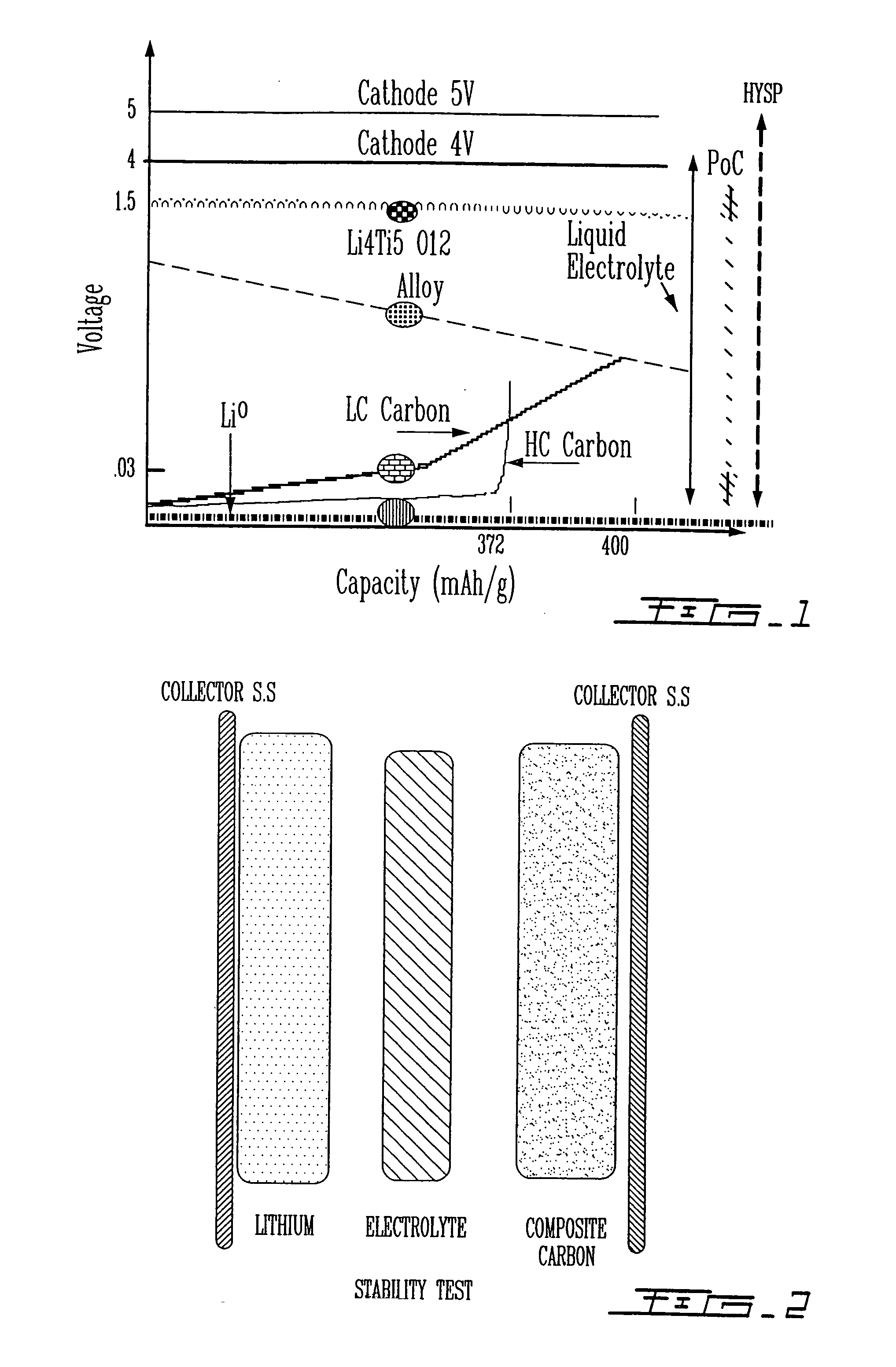

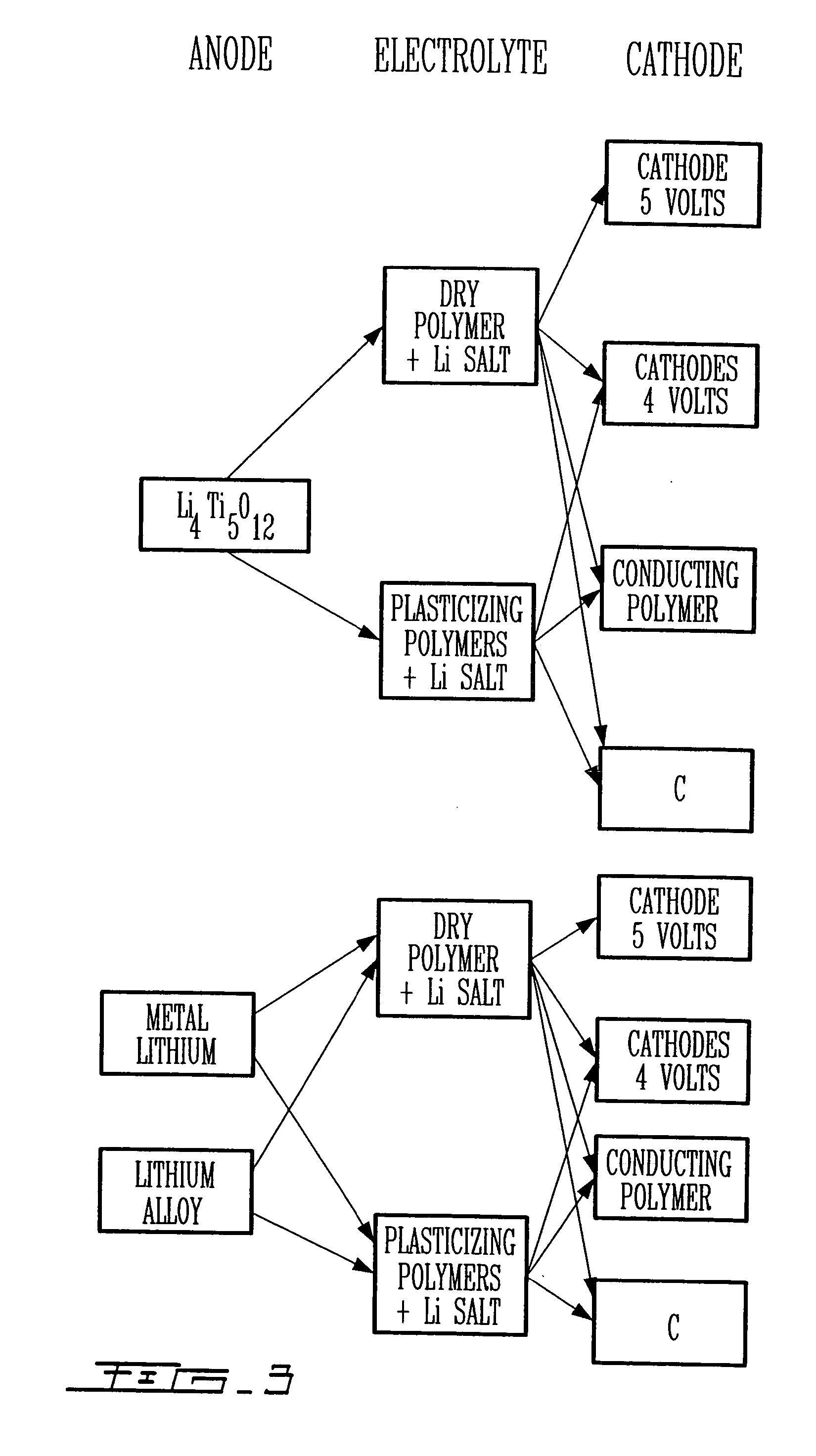

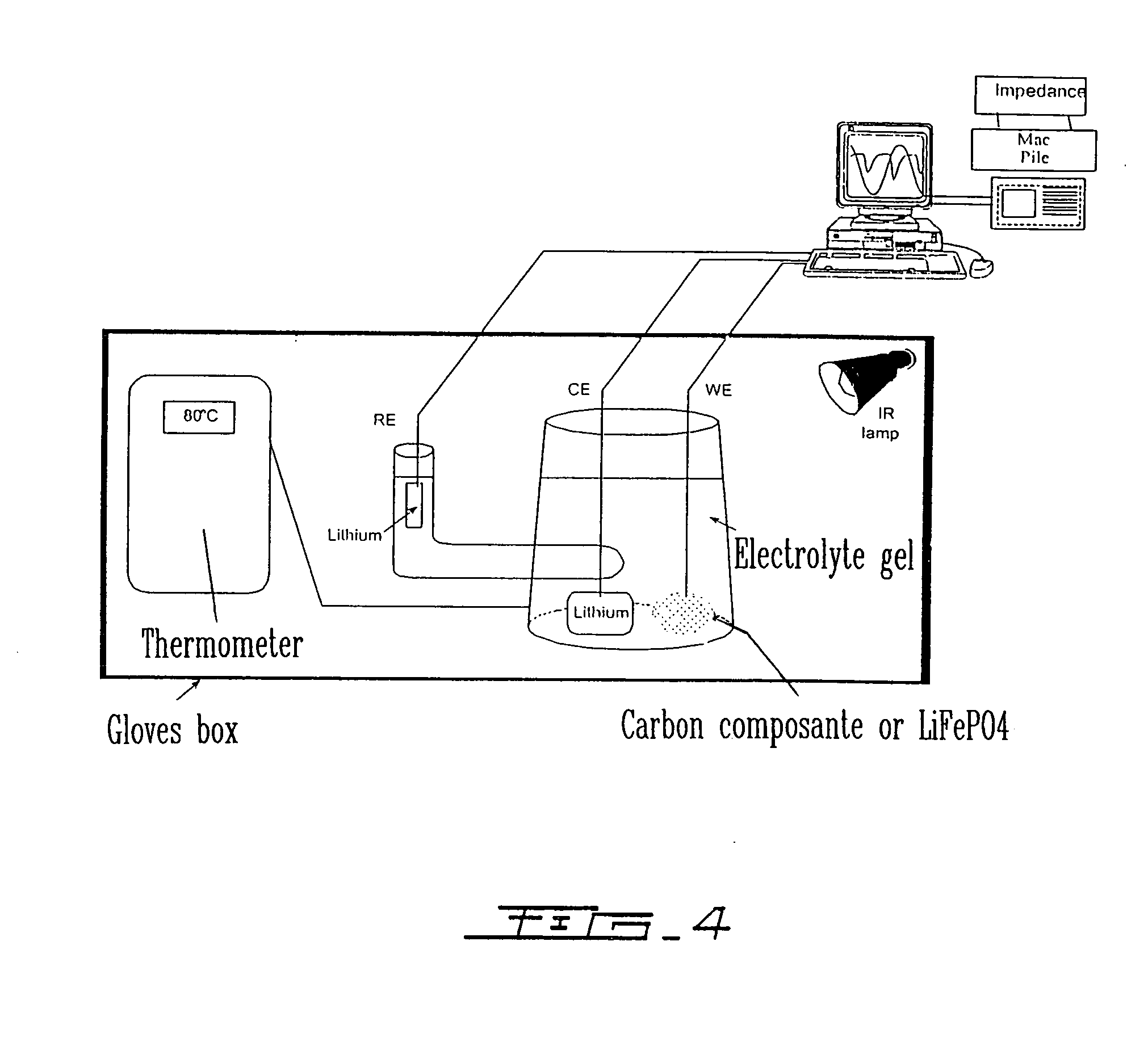

Method of making polymer electrolyte electrochemical cells

InactiveUS6852138B1Reduce contentEasy temperatureElectrode carriers/collectorsOrganic electrolyte cellsPolymer electrolytesHexafluoropropylene

The invention relates to a method for the preparation of a polymer electrolyte electrochemical cell using an electrolyte precursor, said precursor comprising one or more solvents, one or more salts and a polymer which dissolves in the solvent at a first temperature (Tdissol) and which is capable of forming a gel on subsequent cooling following heating to a second temperature (Tgel). Tdissol being lower than Tgel, which method comprises: (a) heating the electrolyte precursor to Tdissol; (b) optionally cooling the electrolyte precursor, (c) incorporating the electrolyte precursor into the electrochemical cell; (d) heating the electrochemical cell to Tgel; (e) cooling the polymer electrochemical cell to ambient temperature to bring about gelling of the polymer electrolyte. Preferably the polymer is a homopolymer or copolymer from the group of monomers of vinyl fluoride, vinylidenefluoride, trifluoroethylene, tetrafluoroethylene and hexafluoropropylene.

Owner:DANIONICS ASIA

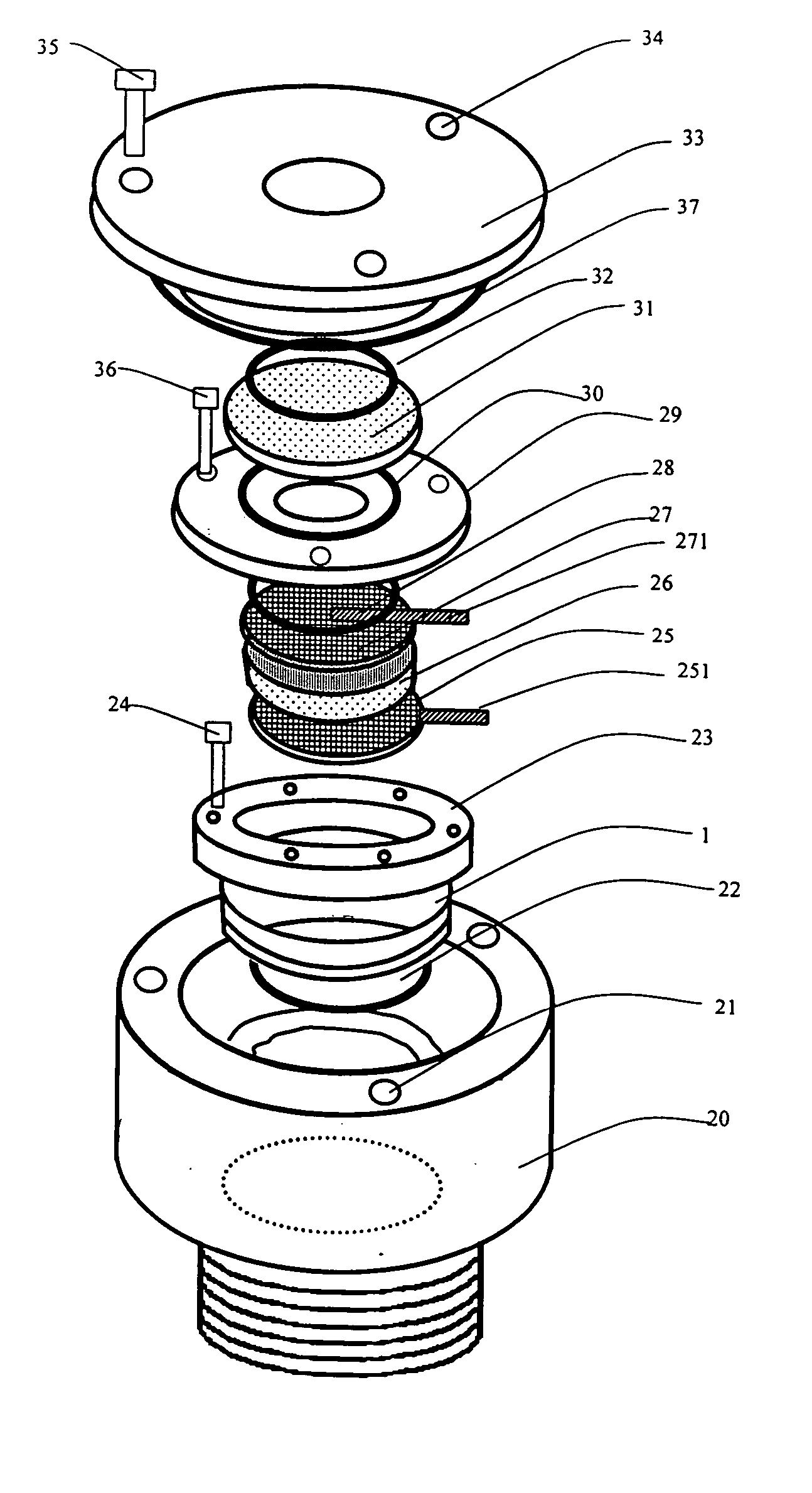

Oil/gas separation membrane, its use in gas sensor and process for producing the same

InactiveUS20050086998A1Losing mechanical propertyLosing permeation efficiencyPreparing sample for investigationFuel testingAdhesiveHexafluoropropylene

An oil gas separation membrane combines a gas permeable yet oil and temperature resistant bulk polymer membrane such as poly(tetrafluoroethylene) and poly(tetrafluoroethylene-co-hexafluoropropylene); a porous metal support such as sintered metal frit disk made with stainless steel, bronze or nickel; and an highly gas permeable adhesive that bonds firmly the bulk polymer membrane and the metal frit surface together. The adhesive is either a homogenous polymer that has desirable gas permeability, or a coalescent porous polymer particulates network. A gas sensor employing the oil gas separation membrane for detecting and monitoring fault gases of oil filled electrical equipment requires no mechanical wearing or moving part such as pump and valve and the gas sensor is operated normally under various temperature and pressure conditions.

Owner:ASENSOR TECH

Polyvinylidene fluoride and vinylidene fluoride-hexafluoropropylene copolymer blended nanofibre polymer electrolyte membrane and preparation method thereof

InactiveCN101805454AHigh liquid absorptionHigh porosityFilament/thread formingSecondary cellsFiberPorosity

The invention relates to a polyvinylidene fluoride and vinylidene fluoride-hexafluoropropylene copolymer blended nanofibre polymer electrolyte membrane prepared by electrospinning and a preparation method thereof. The blended nanofibre polymer electrolyte membrane is a blended nanofibre membrane containing electrolyte and is made of a polyvinylidene fluoride and vinylidene fluoride-hexafluoropropylene copolymer blended nanofibre material; the polyvinylidene fluoride accounts for 50 to 90 percent of the mass of the blended nanfibre membrane, and the vinylidene fluoride-hexafluoropropylene copolymer accounts for 10 to 50 percent of the mass of the blended nanfibre membrane; and the porosity between polyvinylidene fluoride and vinylidene fluoride-hexafluoropropylene copolymer blended nanofibres in the blended nanfibre membrane is 45 to 80 percent. The liquid absorption rate of the membrane of the invention is 210 to 360 percent; and the room-temperature conductivity of the membrane of the invention can reach 3.04*10<-3>S / cm.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Electrolyte membrane, process for its production and polymer electrolyte fuel cell

InactiveUS20050186461A1Excellent characteristicsIncreased durabilityIon-exchanger regenerationFinal product manufactureVinyl etherFuel cells

An electrolyte membrane characterized by comprising a porous body formed from a melt-moldable fluororesin and having interconnected pores and an ion exchange resin with which the interconnected pores are filled, is provided. Specifically, the porous body is formed, for example, from an ethylene / tetrafluoroethylene copolymer, a tetrafluoroethylene / perfluoro(alkyl vinyl ether) copolymer, a tetrafluoroethylene / hexafluoropropylene copolymer, a tetrafluoroethylene / [CF2═CF—(OCF2CFY)a—Oc—(CF2)b—SO3H] copolymer (wherein Y is a fluorine atom or a trifluoromethyl group, a is an integer of 0 to 3, b is an integer of from 0 to 12, and c is 0 or 1, provided that when b=0, C=0), or the like. An electrolyte membrane reinforced by such a porous body has high mechanical strength even if it is thin, and is excellent in dimensional stability when hydrated, and a polymer electrolyte fuel cell with a membrane-electrode assembly having the electrolyte membrane provides a high output and is excellent in durability.

Owner:ASAHI GLASS CO LTD

Separators for winding-type lithium secondary batteries having gel-type polymer electrolytes and manufacturing method for the same

InactiveUS6924065B2Improve ionic conductivityHigh mechanical strengthFinal product manufactureLi-accumulatorsLithiumPolymer science

A porous separator for a winding-type lithium secondary battery having a gel-type polymer electrolyte includes a matrix made of polyvinyl chloride, or a matrix made of mixtures of polyvinylchloride and at least one polymer selected from the group consisting of polyvinylidenefluoride, a vinylidenefluoride / hexafluoropropylene copolymer, polymethacrylate, polyacrylonitrileand polyethyleneoxide.

Owner:SAMSUNG SDI CO LTD

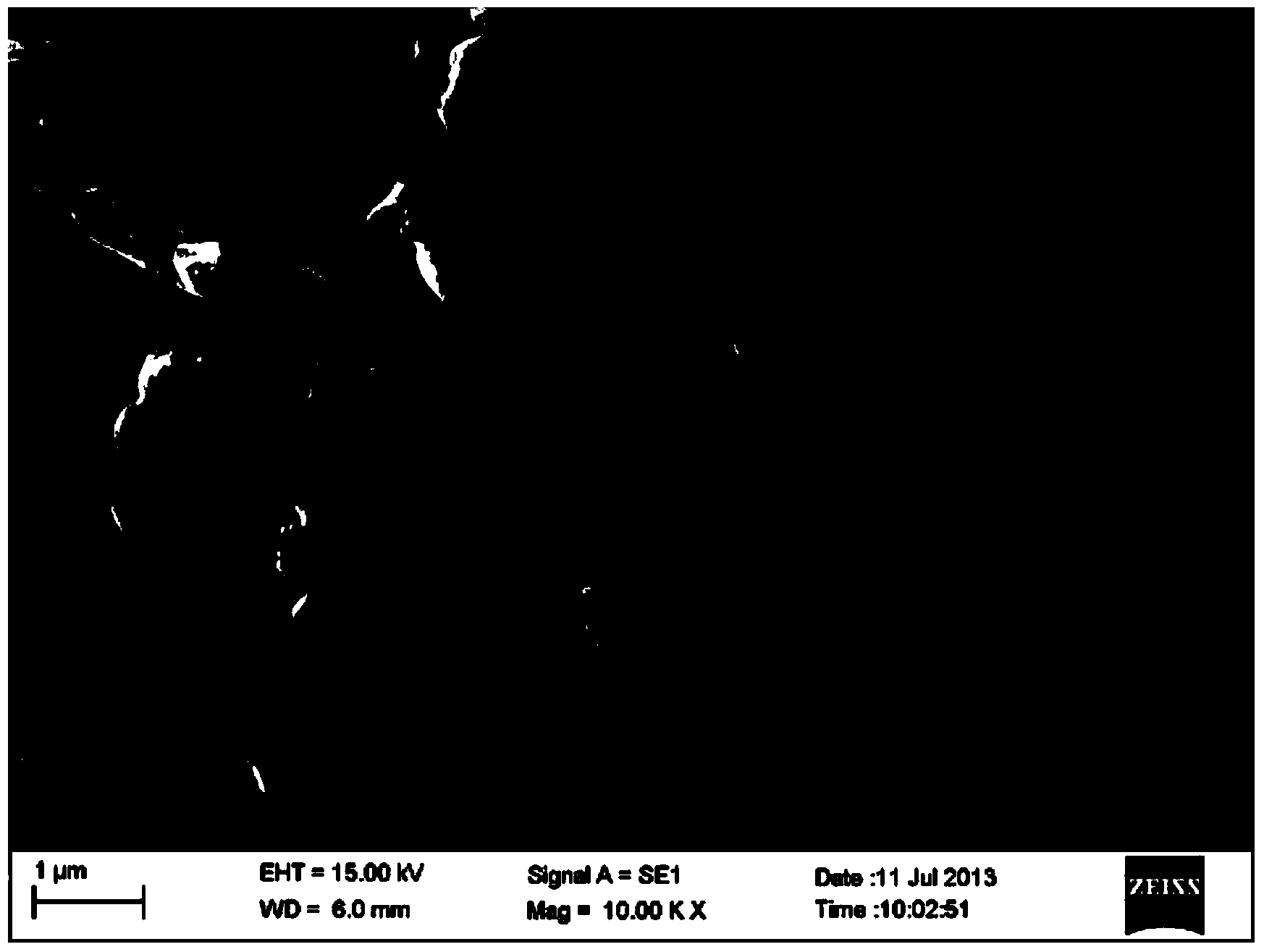

Carbon material modified porous polymer electrolyte membrane and preparation method thereof

InactiveCN102585280ASmall apertureEvenly distributedCell component detailsPolymer scienceHexafluoropropylene

The invention discloses a carbon material modified porous polymer electrolyte membrane and a preparation method thereof, and relates to the polymer electrolyte membrane and the preparation method thereof. The invention aims at solving the problems of low ionic conductivity, small lithium ion transference number and poor electrochemical stability of the conventional porous polymer electrolyte membrane. The carbon material modified porous polymer electrolyte membrane is prepared by soaking the porous polymer membrane in an electrolyte of a lithium ion battery for 1h-4h; and the porous polymer membrane is prepared from PVDF-HFP (polyvinylidene fluoride-hexafluoropropylene), a solvent, a plasticizer and a modified carbon material. The method comprises the following steps of: (1) preparing theporous polymer membrane; and (2) performing soaking treatment to get the carbon material modified porous polymer electrolyte membrane. The carbon material modified porous polymer electrolyte membranehas the advantages that the ionic conductivity achieves 10-3S / cm order of magnitude, the lithium ion transference number is 0.80-0.95, and an electrochemical stability window is 5.5V-6.0V. The preparation method disclosed by the invention is mainly used for preparing the carbon material modified porous polymer electrolyte membrane.

Owner:DAQING BRANCH OF HEILONGJIANG ACAD OF SCI

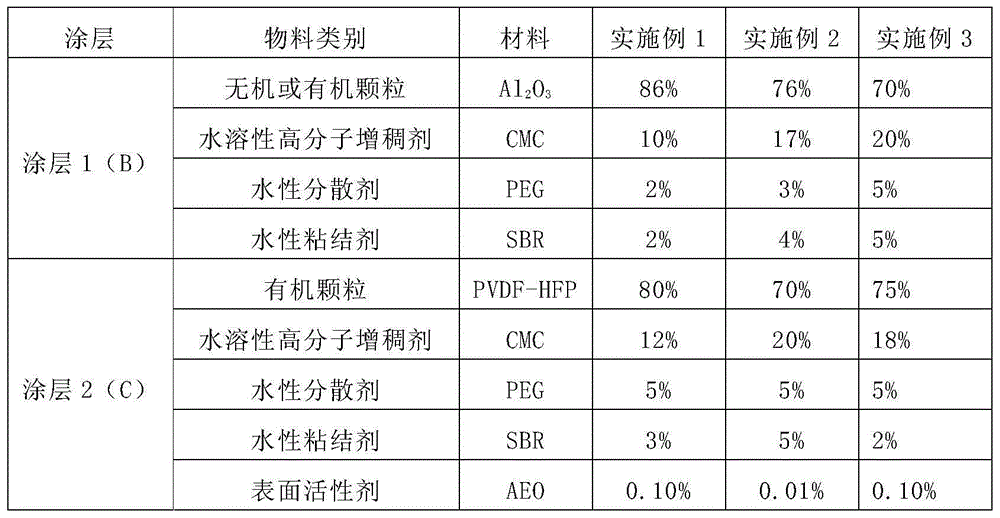

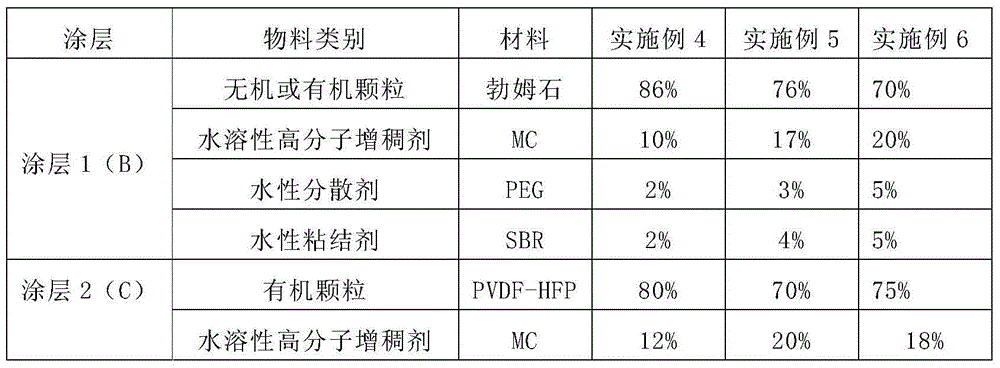

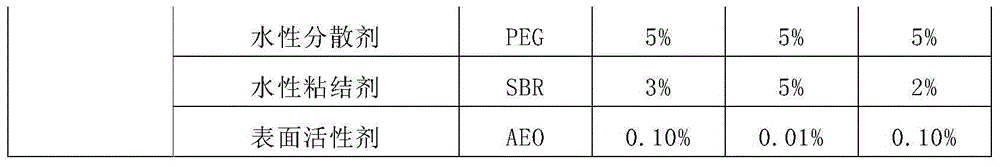

Water-based multi-layer membrane for lithium ion battery

InactiveCN104868081ACell seperators/membranes/diaphragms/spacersSecondary cellsWater basedElectrical battery

The invention provides a water-based multi-layer membrane for a lithium ion battery. The water-based multi-layer membrane comprises a polymer membrane substrate (A), an inorganic or organic particle coating (B) coating one or two sides of the polymer membrane substrate (A), and an organic particle coating (C) coating the inorganic or organic particle coating (B), wherein the inorganic or organic particle coating (B) is formed by a composition which comprises 15-70wt% of inorganic or organic particles and 30-85wt% of water; the inorganic or organic particles are selected from aluminum oxide, silica, barium sulfate, boehmite or polyimide; the organic particle coating (C) is formed by a composition which comprises 5-30wt% of organic particles and 70-95wt% of water; and the organic particles are selected from polyvinylidene fluoride-hexafluoropropylene, polyacrylonitrile, polyoxyethylene or polymethyl methacrylate.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

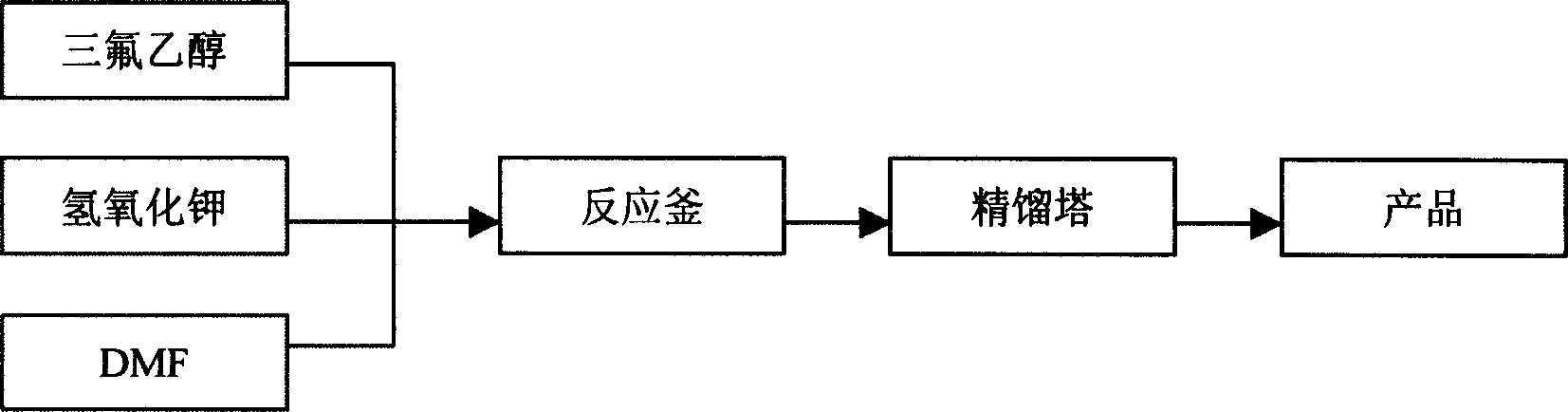

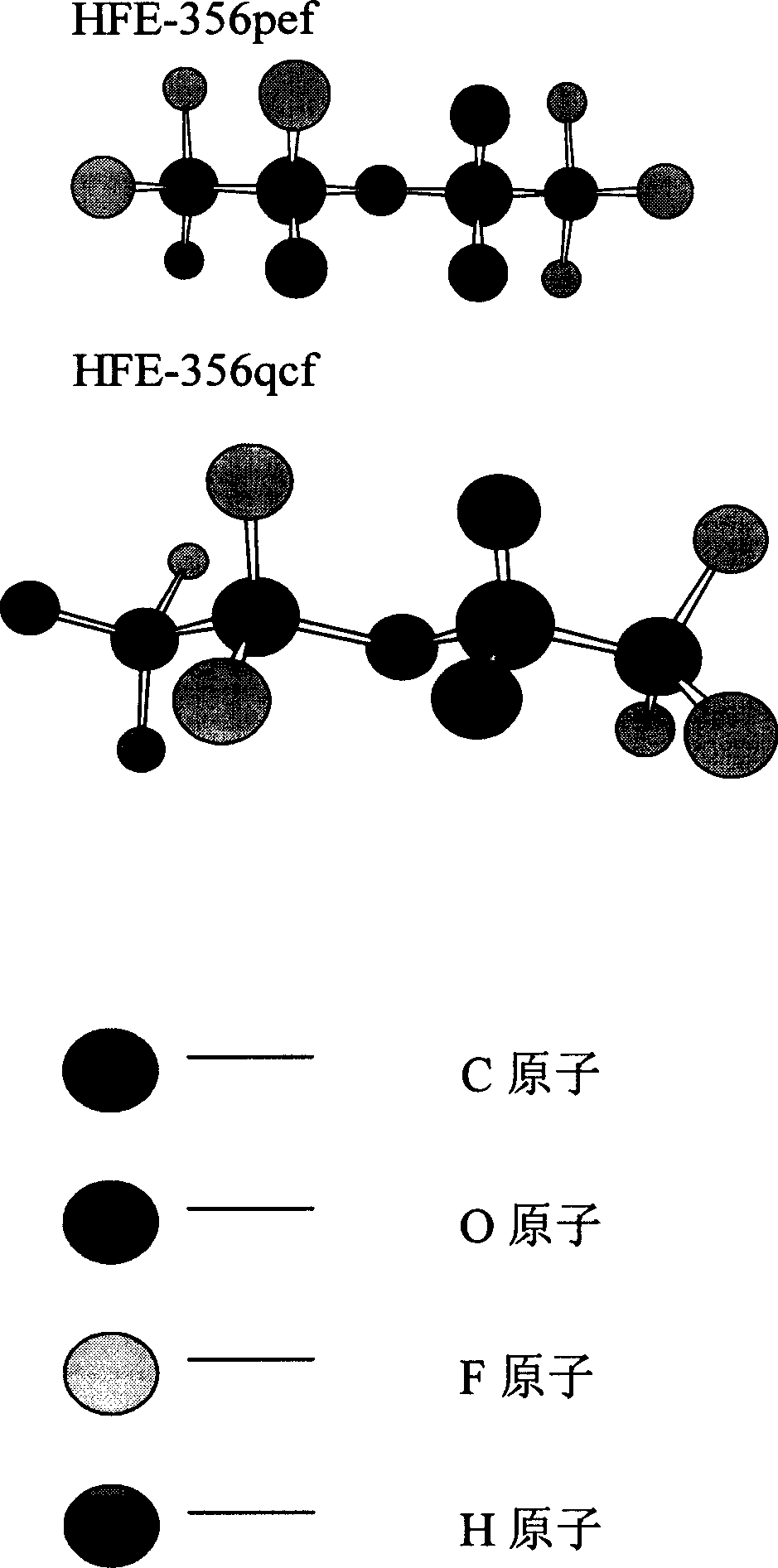

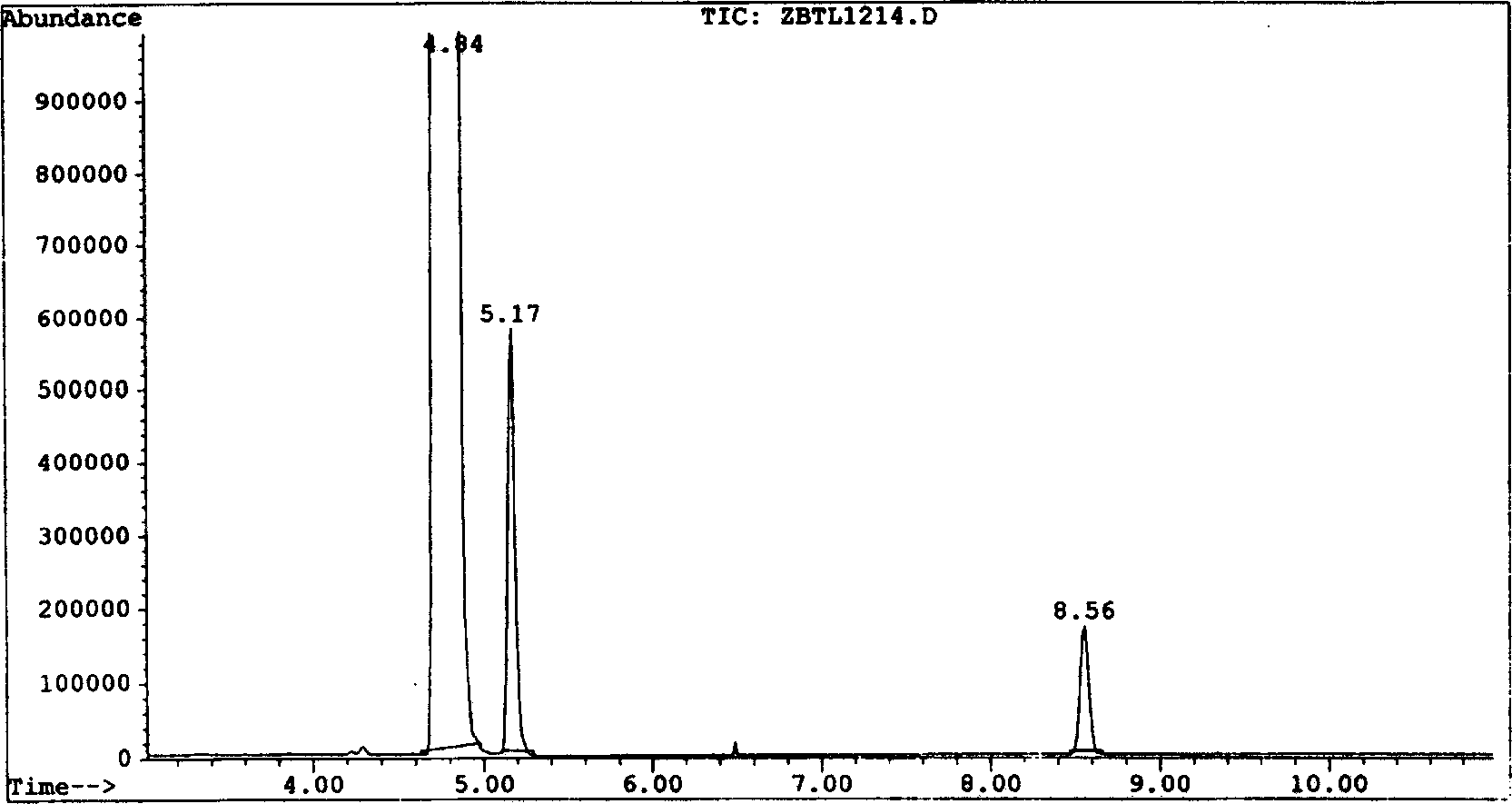

New hydrofluoro ether and its preparation method

InactiveCN1651378AHigh yieldEasy to separate and purifyEther preparationFoaming agentOrganic solvent

A process for preparing hydrofluoroether features the reaction between one of trifluoroethene, tetrafluoroethene, hexafluoro propene, etc and one of trifluoroethanol, trifluoropropanol, metanol, etc in organic solvent (DMF or DMSO). Its advantages are high output rate and easy purifying and separating.

Owner:大连振邦氟涂料股份有限公司

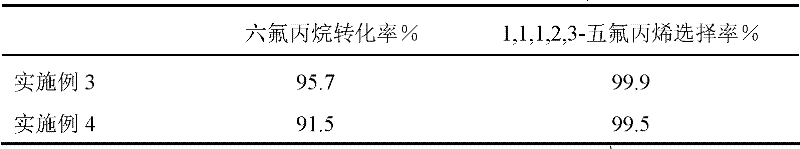

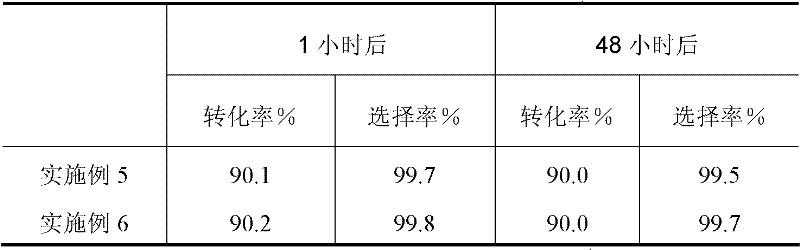

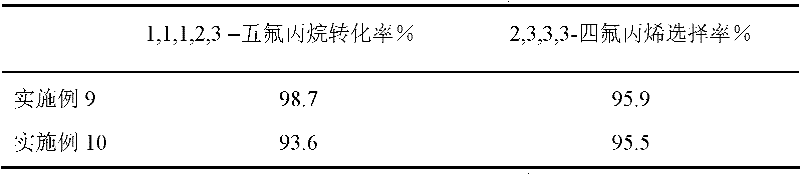

The synthetic method of 2,3,3,3-tetrafluoropropene

InactiveCN102267869AHigh yieldPreparation by hydrogen halide split-offHexafluoropropyleneOzone depletion potential

The present invention provides a method for synthesizing 2,3,3,3-tetrafluoropropene, which uses hexafluoropropene as a starting material, and undergoes multi-step hydrogenation reduction, HF removal and other steps to obtain high-purity target product 2,3 , 3,3-Tetrafluoropropene. The raw material hexafluoropropylene of the method is easy to obtain, and can be prepared by existing methods in the art, and can also be purchased commercially. The prepared 2,3,3,3-tetrafluoropropene is an excellent refrigerant substitute and has the advantages of zero ozone depletion potential (ODP) and low greenhouse effect potential (GWP value of 4).

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Amorphous tetrafluoroethylene-hexafluoropropylene copolymers

InactiveUS6486280B1Lack of crystallinityLower surface energyOrganic chemistryCoatingsPolymer scienceHexafluoropropylene

Disclosed herein are novel amorphous tetrafluoroethylene-hexafluoropropylene (TFE-HFP) dipolymers, and other copolymers containing TFE, HFP and a third monomer, many of which are more random than previous amorphous TFE-HFP copolymers, as well as a novel high productivity continuous process for making these polymers. The polymers are particularly useful in the form of coatings, films and encapsulants.

Owner:EI DU PONT DE NEMOURS & CO

High melt flow fluoropolymer

ActiveUS7126056B2Long extrusion runInsulated cablesInsulated conductorsVinyl etherElectrical conductor

The present invention relates to a partially-crystalline copolymer comprising tetrafluoroethylene, hexafluoropropylene in an amount corresponding to HFPI of from about 2.8 to 5.3, and preferably from about 0.2% to 3% by weight of perfluoro(alkyl vinyl ether), said copolymer being polymerized and isolated in the absence of added alkali metal salts, having a melt flow rate of within the range of about 30±3 g / 10 min, and having no more than about 50 unstable endgroups / 106 carbon atoms can be extruded at high speed onto conductor over a broad polymer melt temperature range to give insulated wire of high quality.

Owner:THE CHEMOURS CO FC LLC

Novel fluorinated polymer

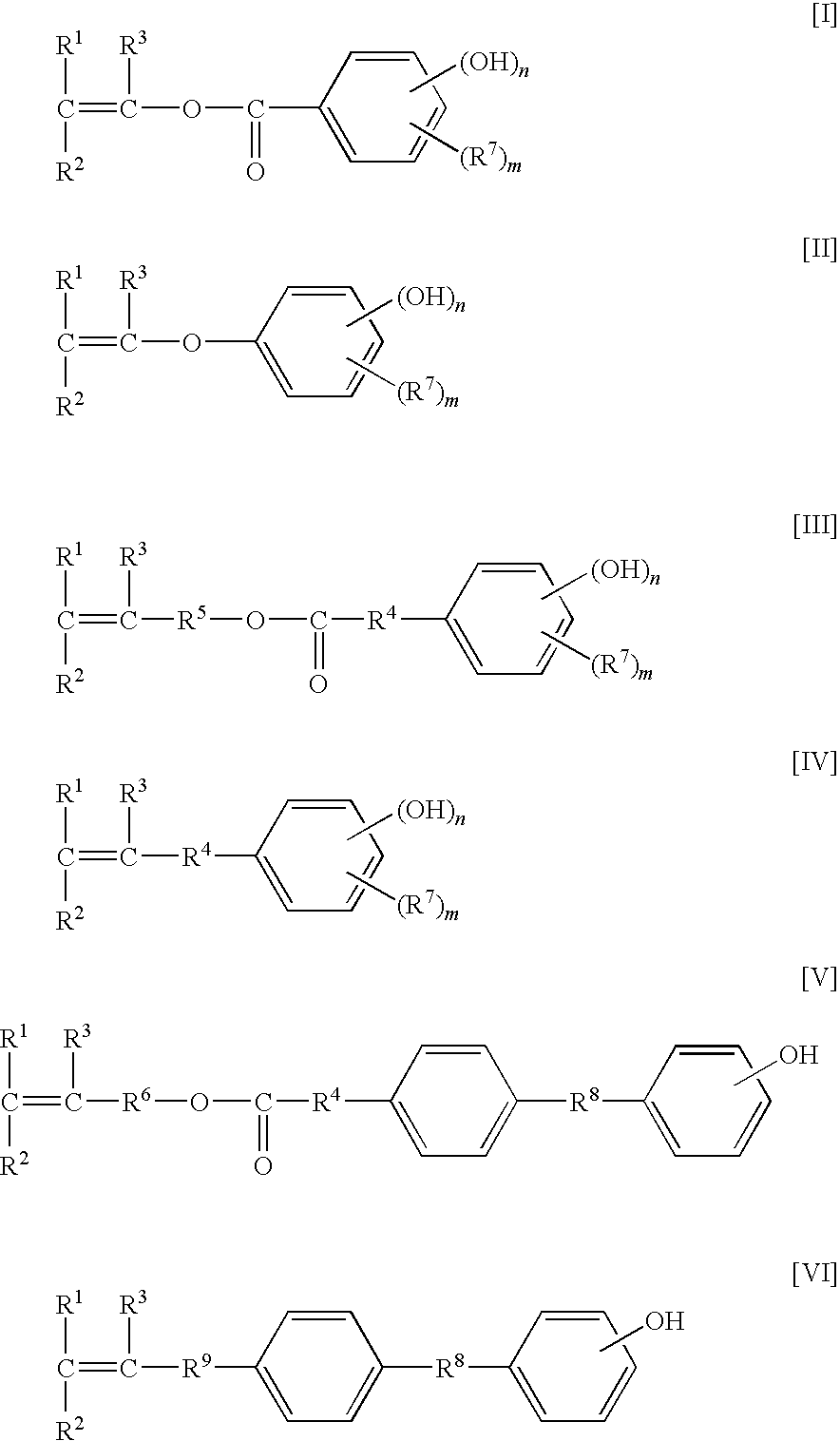

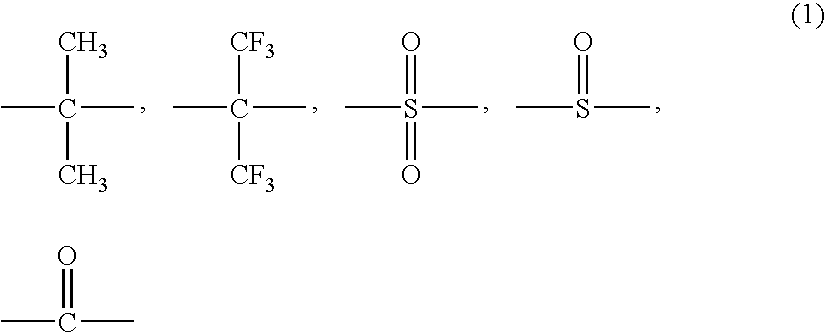

InactiveUS20090186986A1Excellent cross-linking reactivityMaintain good propertiesPolymer scienceHexafluoropropylene

The present invention provides a fluorinated polymer excellent in the crosslinking reactivity, crosslinked rubber physical properties and chemical resistance, and its crosslinked rubber.A fluorinated polymer comprising repeating units (a) based on at least one monomer selected from the group consisting of ethylenic unsaturated compounds each having a hydroxyphenyl group, repeating units (b) based on at least one fluoromonomer selected from the group consisting of tetrafluoroethylene, hexafluoropropylene, vinylidene fluoride, 3,3,3-trifluoropropene, 1,3,3,3-tetrafluoropropene, 1,1,2-trifluoroethylene, vinyl fluoride, 1,2-difluoroethylene and CF2═CF—O—Rf (wherein Rf is a C1-8 saturated perfluoroalkyl group or a perfluoro(alkoxyalkyl) group) and, if necessary, repeating units (c) based on at least one hydrocarbon monomer selected from the group consisting of ethylene, propylene and CH2═CH—O—R1.

Owner:ASAHI GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com