Polyvinylidene fluoride and vinylidene fluoride-hexafluoropropylene copolymer blended nanofibre polymer electrolyte membrane and preparation method thereof

A polyvinylidene fluoride, nanofiber membrane technology, applied in the direction of conjugated synthetic polymer rayon, fiber processing, circuits, etc., can solve the problems of unsafe batteries, low absorption rate, low conductivity, etc., and achieve bonding The effect of firmness, high liquid absorption and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

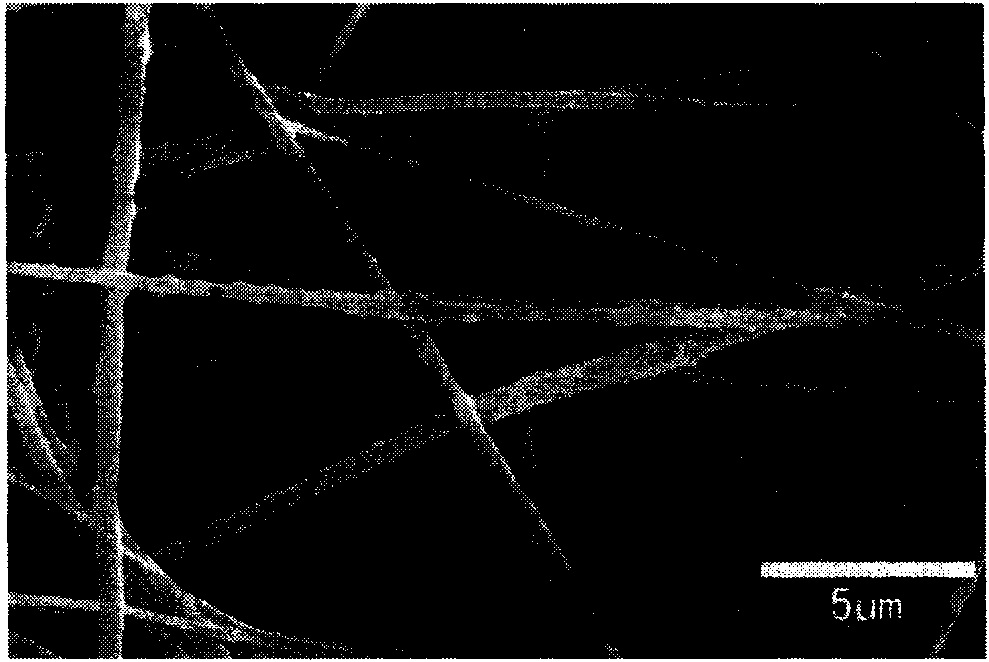

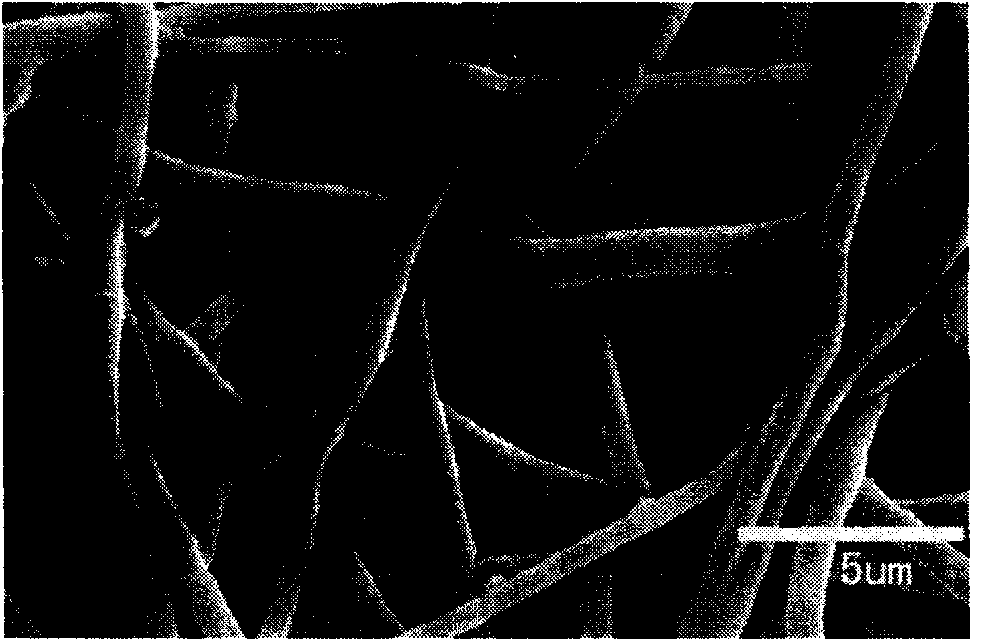

[0054] 5.6g polyvinylidene fluoride and 2.4g vinylidene fluoride-hexafluoropropylene copolymer are dissolved in 64.4gN, in N-dimethylformamide and 27.6g acetone, the total concentration of solution is 8wt%, polyvinylidene fluoride and The mass ratio of vinylidene fluoride-hexafluoropropylene copolymer is 7:3, and the mass ratio of N,N-dimethylformamide to acetone in the solvent is 7:3. After magnetic stirring at 50°C for 48 hours, a clear and transparent The spinning solution was filtered and left to defoam. The polyvinylidene fluoride / vinylidene fluoride-hexafluoropropylene copolymer blended spinning solution is placed in the syringe of the electrospinning equipment, and the distance between the spinneret connected to the syringe and the drum receiver is adjusted to be 13 cm, and the temperature is When the temperature is 20±2°C and the humidity is 80%, the spinning solution is injected into the spinneret at a constant flow rate of 1ml / h under the action of the syringe pump, ...

Embodiment 2

[0057] 7.2g polyvinylidene fluoride and 0.8g vinylidene fluoride-hexafluoropropylene copolymer are dissolved in 64.4gN, in N-dimethylformamide and 27.6g acetone, the total concentration of solution is 8wt%, polyvinylidene fluoride and The mass ratio of vinylidene fluoride-hexafluoropropylene copolymer is 9:1, and the mass ratio of N,N-dimethylformamide to acetone in the solvent is 7:3. After magnetic stirring at 50°C for 48 hours, a clear and transparent The spinning solution was filtered and left to defoam. The polyvinylidene fluoride / vinylidene fluoride-hexafluoropropylene copolymer blended spinning solution is placed in the syringe of the electrospinning equipment, and the distance between the spinneret connected to the syringe and the drum receiver is adjusted to be 13 cm, and the temperature is When the temperature is 20±2°C and the humidity is 55%, the spinning solution is injected into the spinneret at a constant flow rate of 1ml / h under the action of the syringe pump, ...

Embodiment 3

[0061]4.0g polyvinylidene fluoride and 4.0g vinylidene fluoride-hexafluoropropylene copolymer are dissolved in 64.4gN, in N-dimethylformamide and 27.6g acetone, the total concentration of solution is 8wt%, polyvinylidene fluoride and The mass ratio of vinylidene fluoride-hexafluoropropylene copolymer is 1:1, and the mass ratio of N,N-dimethylformamide to acetone in the solvent is 7:3. After magnetic stirring at 50°C for 48 hours, a clear and transparent The spinning solution, after filtering, let it stand for defoaming. The polyvinylidene fluoride / vinylidene fluoride-hexafluoropropylene copolymer blended spinning solution is placed in the syringe of the electrospinning equipment, and the distance between the spinneret connected to the syringe and the drum receiver is adjusted to be 13 cm, and the temperature is When the temperature is 20±2°C and the humidity is 55%, the spinning solution is injected into the spinneret at a constant flow rate of 1ml / h under the action of the sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity at room temperature | aaaaa | aaaaa |

| Conductivity at room temperature | aaaaa | aaaaa |

| Conductivity at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com