Patents

Literature

91results about How to "Easy to clean and remove" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cooperative pretreatment method for biological catalysis and controlled oxidation of cotton and cotton-type fabrics

InactiveCN102191692AReduce dosageReduce wasted waterBiochemical fibre treatmentDry-cleaning apparatus for textilesElectricityChemical oxygen demand

The invention relates to a cooperative pretreatment method for biological catalysis and controlled oxidation of cotton and cotton-type fabrics, comprising the following steps: (1) preparing a biological compound enzyme preparation, a biological enzyme synergist and a non-ionic surfactant into an enzyme working solution, wherein the pH of a processing bath is 6-7.5; padding the fabrics into the working solution; carrying out heat preservation; (2) washing the processed fabrics with cold water; padding the fabrics into a hydrogen peroxide bleaching solution containing the controlled decomposition additive of hydrogen peroxide; and steaming, washing with water and drying to obtain the finished products. In the method, high-density strong base is not required to serve as a scouring agent, thepH value of pretreatment waste water is 7-8, the chromaticity is low, the COD (Chemical Oxygen Demand) value is lowered by 30% compared with that of the traditional alkali kiering pretreatment technology, the water is saved by 10-30%, and the steam and electricity can be saved by 20%. The indexes (whiteness, capillary effect, water absorption, cotton seed hull strainaway rate, desizing rate, strong force and the like) of the processed cotton and cotton-type fabric all reach the quality indexes of a semi-product, cotton seed hulls can be completely removed, and the fabrics have vivid color andgood levelling property after being dyed.

Owner:DONGHUA UNIV

Method for preparing organic solvent adsorbing material

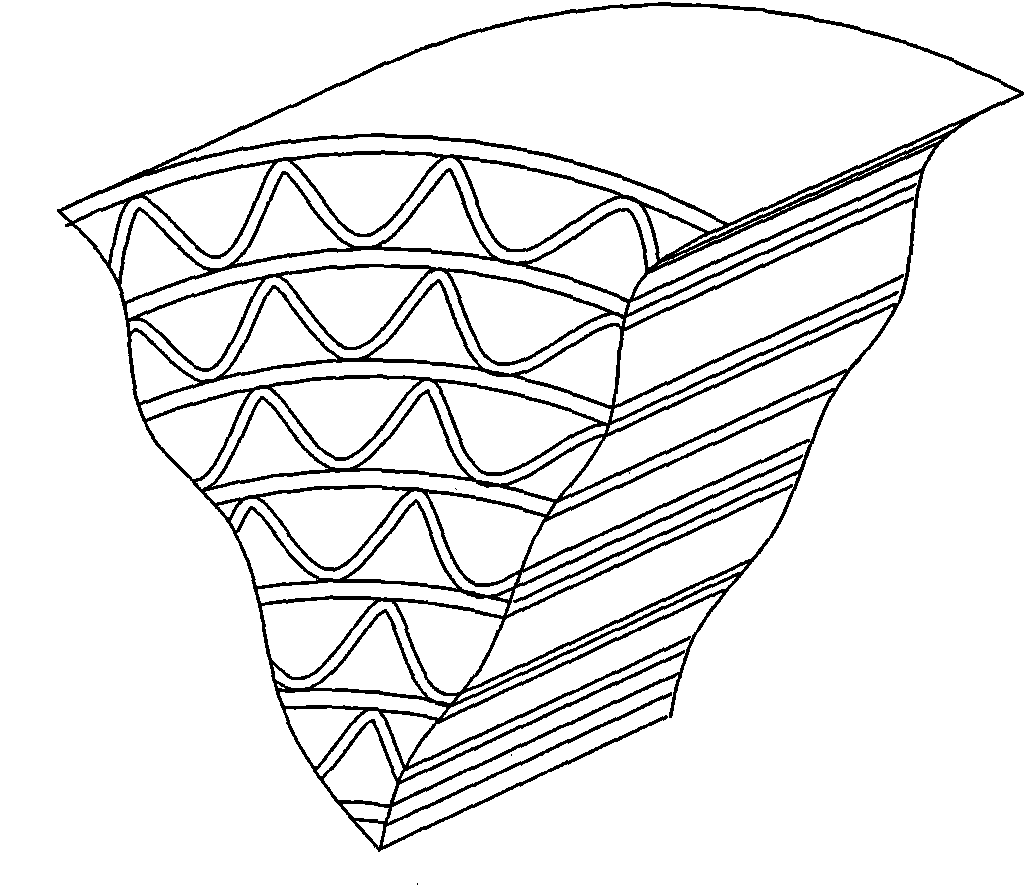

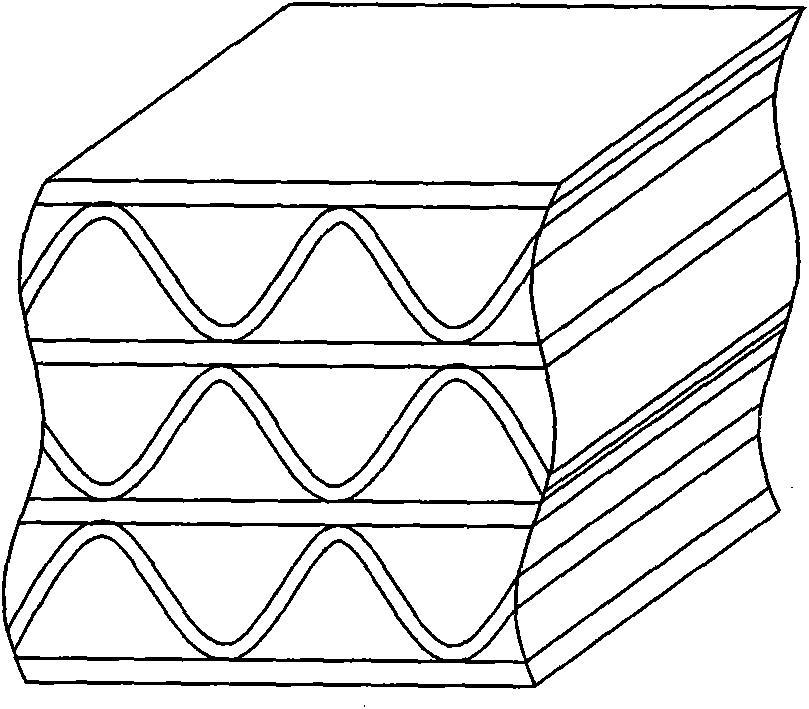

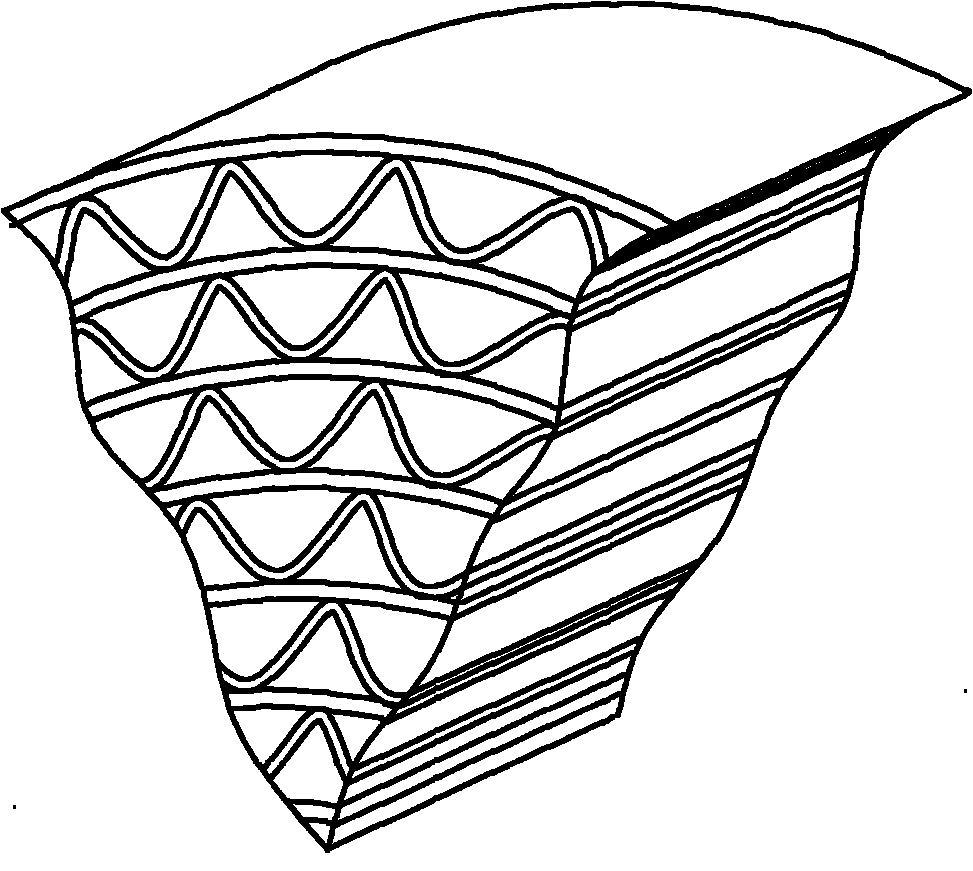

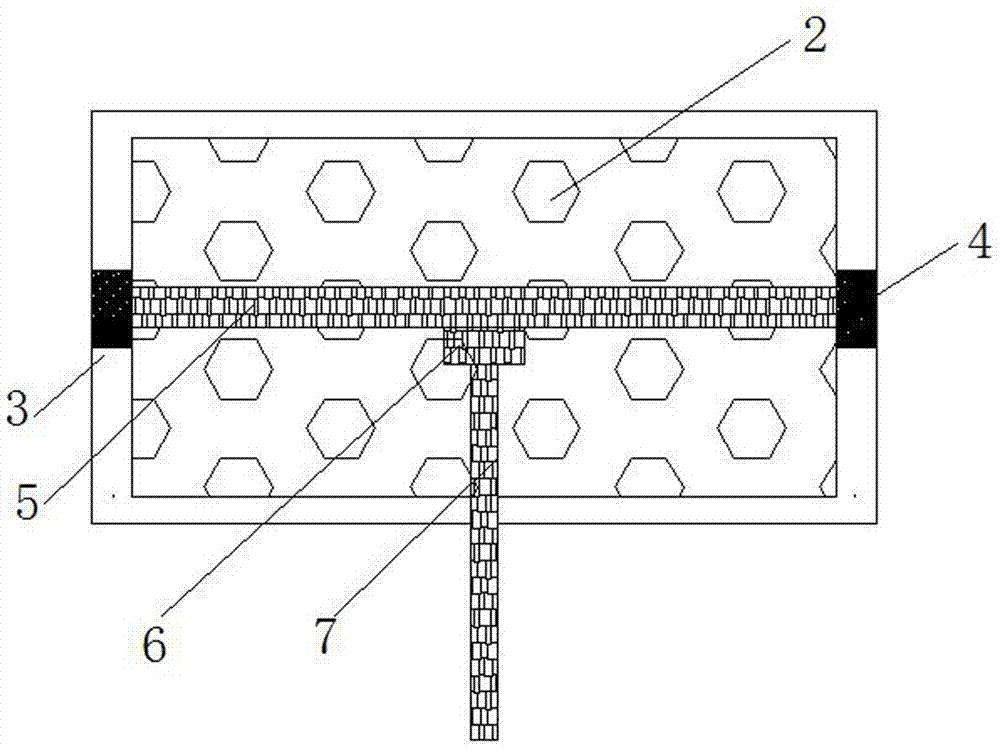

ActiveCN101850239AThorough and even reactionSi-Al Ratio UniformOther chemical processesAluminium silicatesMolecular sieveHoneycomb

The invention discloses a method for preparing an organic solvent adsorbing material. The method comprises the following steps of: manufacturing molecular sieve paper; thermally pressing the molecular sieve paper into corrugated molecular sieve paper; preparing the molecular sieve paper into a honeycomb; performing a chemical reaction on the molecular sieve honeycomb and a mixed gas of nitrogen and SiCl4 gas or water vapor in an airtight container; exhausting residual reaction gas; repeatedly cleaning the molecular sieve honeycomb to remove a solid reaction product on the molecular sieve honeycomb and washing the molecular sieve honeycomb with acid; and continuing to perform a chemical reaction on the molecular sieve honeycomb and the mixed gas of nitrogen and SiCl4 gas or water vapor in the airtight container. The adsorbing material prepared by the method has a high and uniform ratio of silicate to aluminum, so the adsorbing material has excellent organic solvent adsorbing performance and can be widely used for adsorbing and separating an organic solvent from the air or adsorbing and separating the organic solvent in water which contains the organic solvent.

Owner:马军

Medical polyvinyl alcohol sponge and preparation method

ActiveCN106916333AEasy to clean and removeGood biocompatibilityAbsorbent padsBandagesPolyvinyl alcohol spongeCross-link

The invention provides a medical polyvinyl alcohol sponge and a preparation method. The preparation method comprises the following steps: adding polyvinyl alcohol and starch into distilled water carrying out dissolving at 50 to 95 DEG C under stirring so as to obtain a mixed solution; adding a cross-linking agent, an emulsifier and a foam stabilizer into the mixed solution and carrying out stirring at 20 to 60 DEG C for 2 to 8 h so as to obtain a second mixed solution; adding an acidic catalyst into the second mixed solution and carrying out an acetalation cross-linking reaction at a constant temperature of 20 to 90 DEG C for 30 to 180 min so as to obtain emulsion-like liquid; and completion of the reaction, pouring the emulsion-like liquid into a mold, carrying out heating at 50 to 95 DEG C for curing, carrying out demoulding and washing after cooling, and then carrying out cutting and sterilization so as to obtain the medical polyvinyl alcohol sponge. The medical polyvinyl alcohol sponge prepared in the invention has a through hole structure, uniform pore diameter, good biocompatibility, excellent affinity, high porosity and fast liquid absorption rate, and is applicable to the field of surgical sciences, especially as a sponge consumable for vacuum sealing drainage.

Owner:WUHAN DRAGONBIO ORTHOPEDIC PROD

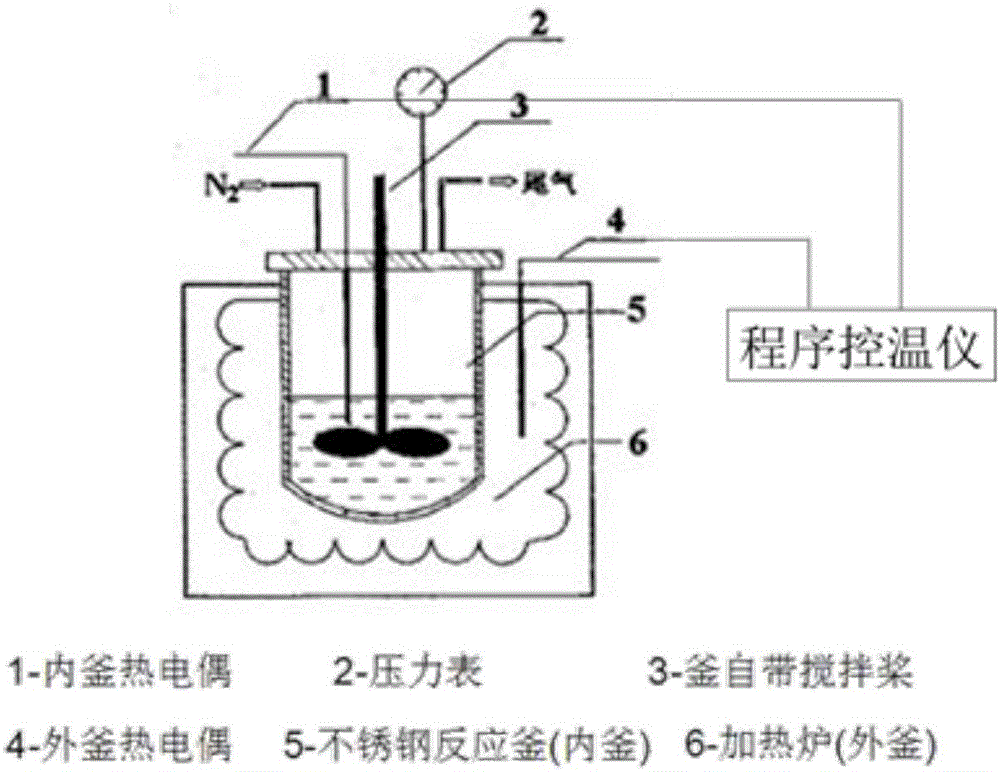

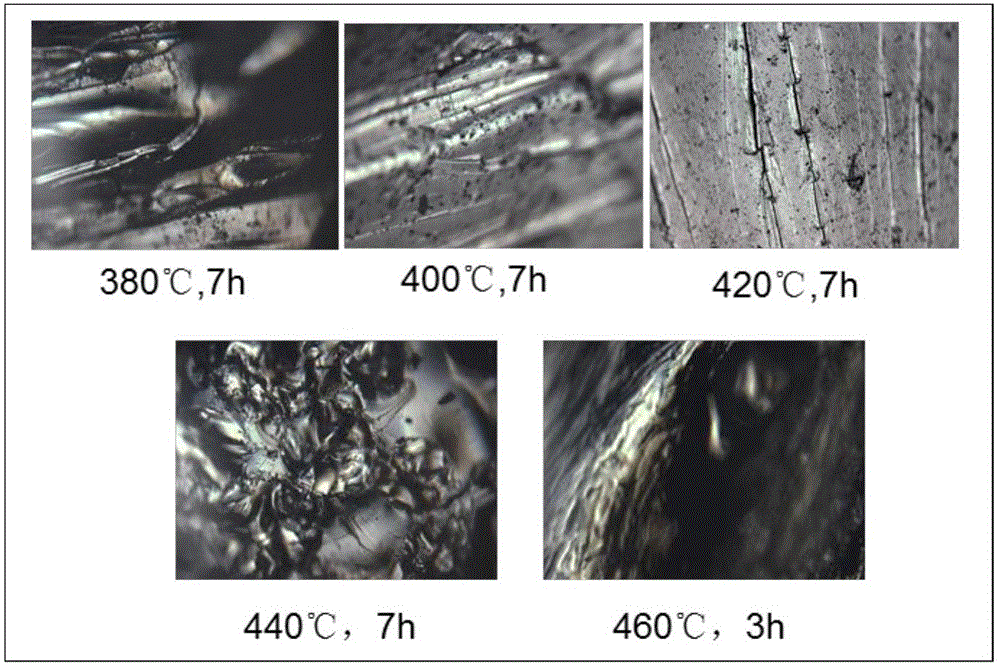

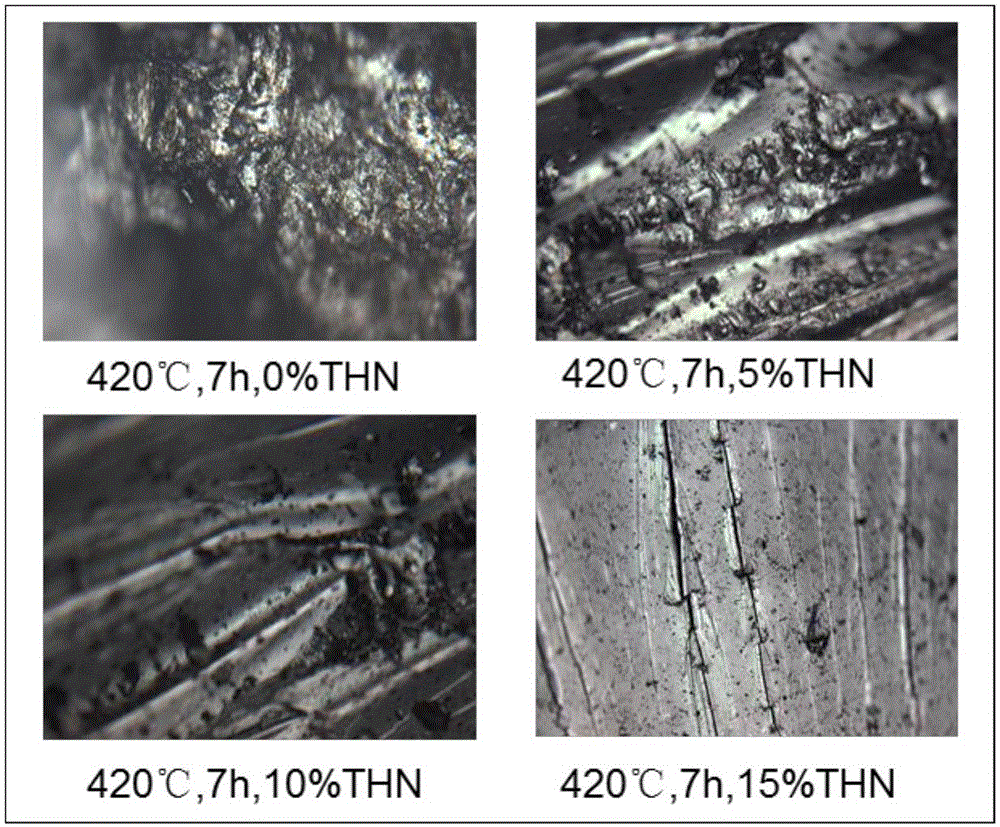

Preparation method of low-ash mesophase pitch

InactiveCN106367093AGood flexibilityOrderly stackingWorking-up pitch/asphalt/bitumen by chemical meansTar working-up by water removalFiberCarbon fibers

The invention provides a preparation method of low-ash high-property mesophase pitch. The method comprises the steps that the raw material coal tar is purified, a fraction is put into a reaction kettle, temperature programming and heat preservation are conducted in sequence, and purified coal tar pitch is obtained. The purified coal tar pitch and a co-carbonization agent are mixed, the mixture is added into a high pressure reactor, under certain pressure condition, the temperature is increased to a certain temperature, then heat preservation is conducted, and the mesophase pitch is obtained. According to the method, a series of physical methods such as gravity settlement centrifugation and circulating filtration are adopted to purify the coal tar, the very good effect of removing ash impurities is achieved, quinoline insoluble matter formed by mesophase is especially hindered, the content of the mesophase pitch ash is lower than 50 ppm, the content of mesophase reaches up to 100%, and carbon fibers with excellent properties can be prepared continuously; meanwhile, by mixing the pitch with the co-carbonization agent, the rheological property of the mesophase pitch is improved. Compared with a coal tar pitch purification process, the coal tar purification technology is simple, the cost is low, and the high-purity purified coal tar pitch can be obtained through preparation, so that the low-ash high-property mesophase pitch is obtained.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

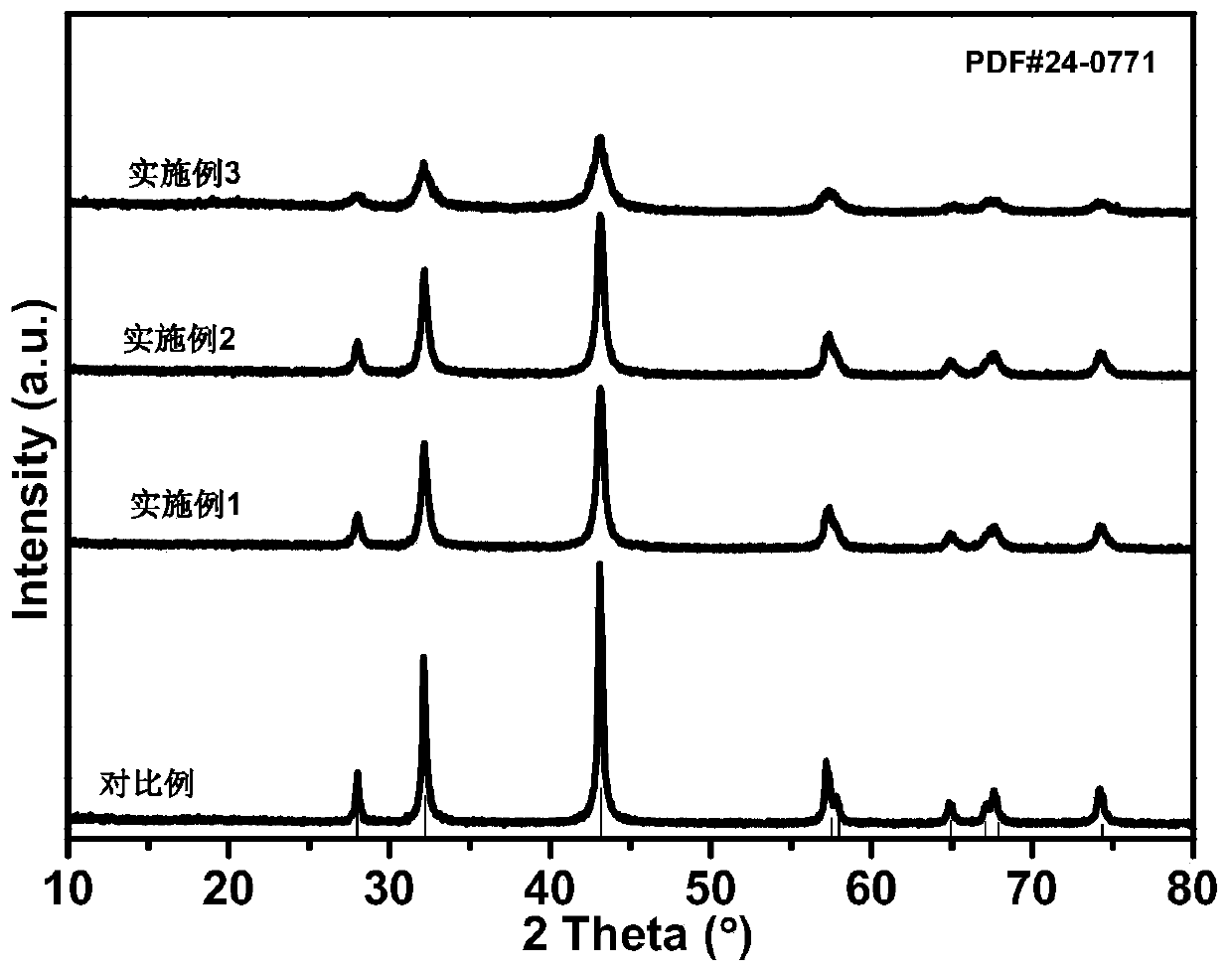

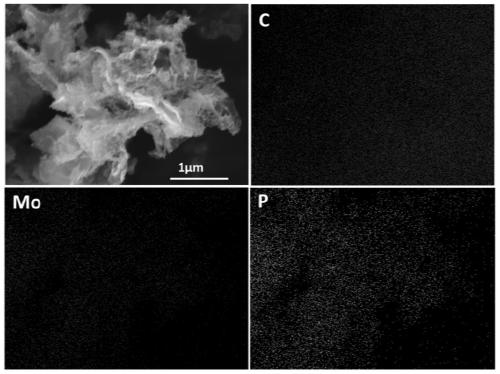

Porous flaky molybdenum phosphide/carbon composite material and preparation method thereof

InactiveCN110479332AHigh puritySmall particle sizeCatalyst activation/preparationElectrodesCarbon compositesPlatinum

The invention belongs to the technical field of material processing, and particularly relates to a porous flaky molybdenum phosphide / carbon composite material and a preparation method thereof. The preparation method comprises the following steps of providing a molybdenum source, a phosphorus source, a carbon source and sodium chloride; dissolving the molybdenum source, the phosphorus source, the carbon source and sodium chloride in a water solvent to obtain a mixed solution; drying the mixed solution to obtain precursor powder; calcining the precursor powder, and then cleaning to obtain the porous flaky molybdenum phosphide / carbon composite material. According to the preparation method disclosed by the invention, the high-purity two-dimensional flaky molybdenum phosphide / carbon composite material can be obtained, the whole preparation process is safe and reliable, the process conditions are simple and easy to control, the production cost is low, and the preparation method is suitable for industrial large-scale production; the obtained porous flaky molybdenum phosphide / carbon composite material has the characteristics of small molybdenum phosphide particle size, high purity and large effective specific surface area, shows good catalytic activity similar to platinum, and can be widely applied to the field of catalysis.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Processing method of wash-and-wear shirt containing bast fiber or regenerated cellulose fiber

ActiveCN109577004ADoes not affect hydrophilicityEasy to clean and removeMercerising of indefinite length fabricsLiquid/gas/vapor removalEmulsionRegenerated cellulose

The invention discloses a processing method of a wash-and-wear shirt containing bast fiber or regenerated cellulose fiber. The processing method comprises the steps of fabric processing and garment making, wherein fabric processing comprises yarn preparation, yarn dyeing, yarn softening, drying, spooling, warping, slashing, weaving, cloth preparation, singeing, desizing, mercerizing, sizing and preshrinking; the garment making comprises cloth preparation, piece tailoring, sewing, pre-washing, drying, spraying, pre-drying, pressing, baking, moisture regaining, washing, drying, button cuffing, ironing and packaging; yarn softening involves that a polyethylene wax emulsion is used for treating fabric after yarn dyeing, the use concentration of the polyethylene wax emulsion is 2-4 g / L, and thebath ratio is 1:5-10. The processing method of the wash-and-wear shirt containing the bast fiber or the regenerated cellulose fiber has the advantages that the polyethylene wax emulsion is taken as asoftening agent of the yarn softening process, the softening agent is easy to clean off in the subsequent dyeing and finishing process, the hydrophilia of the fabric and the combination of resin andfiber in the non-iron finishing stage of ready-made garment are not affected, so that the processed wash-and-wear shirt has excellent appearance flatness and good dimensional stability after washing.

Owner:雅戈尔服装控股有限公司 +1

Airplane engine heat exchanger guiding-tube bend filling and technique

InactiveCN101058708AImprove bending qualityStable performance of filling processOther chemical processesHollow article cleaningSodium bicarbonateJet aeroplane

The invention discloses a bending filler and technique of heat exchanger conduit of airplane motor in the machine making domain, which comprises the following steps: allocating raw material proportionally; putting disodium phosphate and sodium bicarbonate in the autoclave; blending 2h; adding stablizier and reinforcer; packing the allocated fill; sealing to reserve. The filling technique of conduit product comprises the following steps: weighing the filler; controlling the temperature after the filler is fused; entering into the working condition; filling the conduit. The cleaning technique is characterized by the following: placing the moulded conduit into cleaning groove; injecting the tap water to heat and stir; controlling the water temperature between 80 and 90 deg. c for 20-30 min; fetching the conduit; draining the solution; repeating 5 times; fetching the conduit to dry; finishing the cleaning process.

Owner:沈阳华铁异型材有限公司 +1

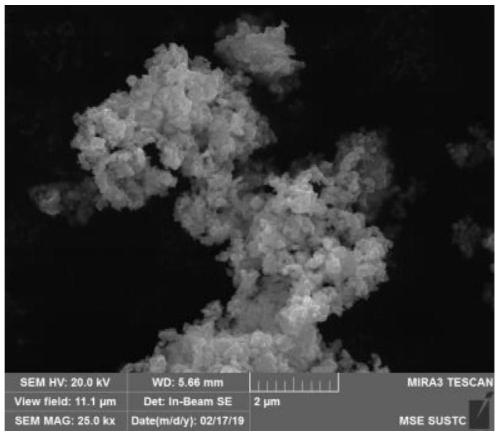

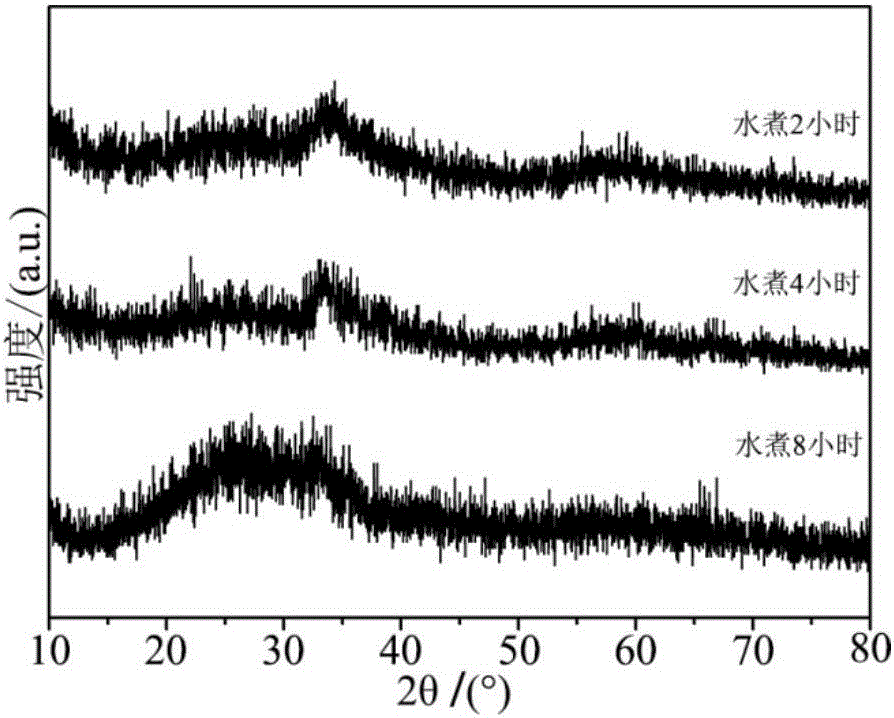

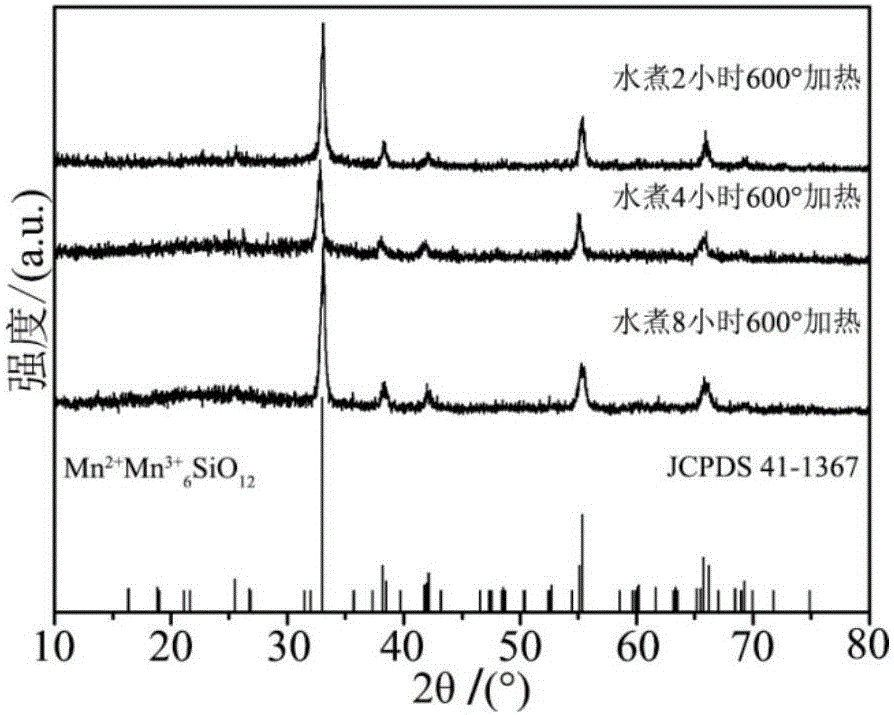

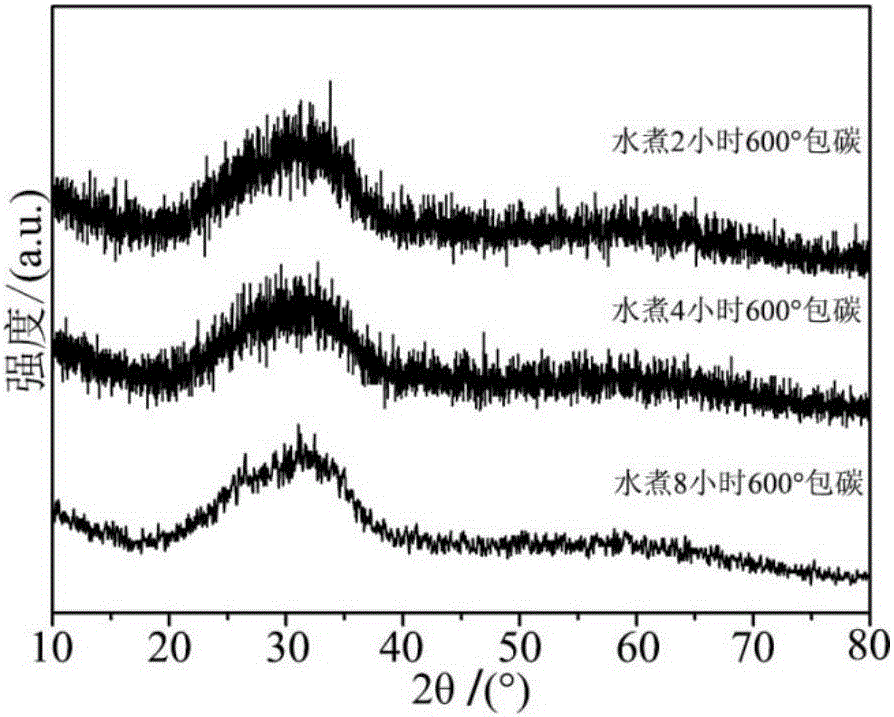

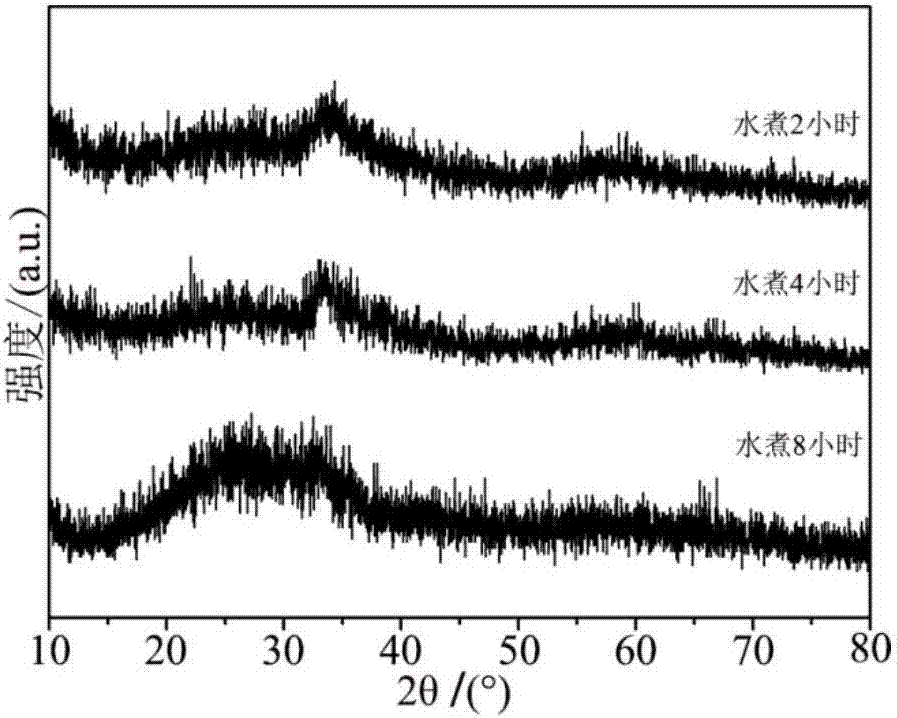

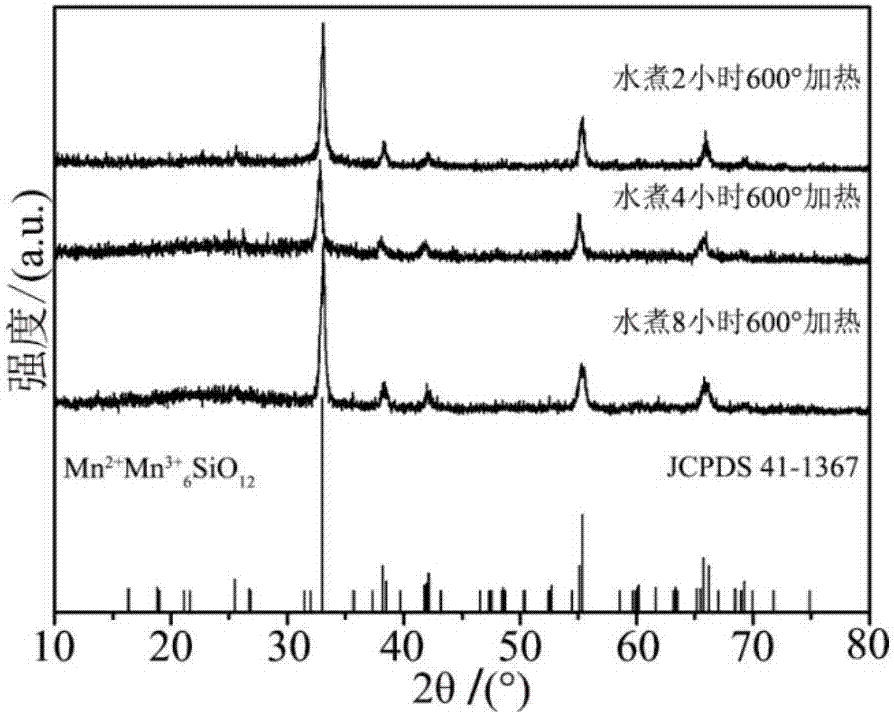

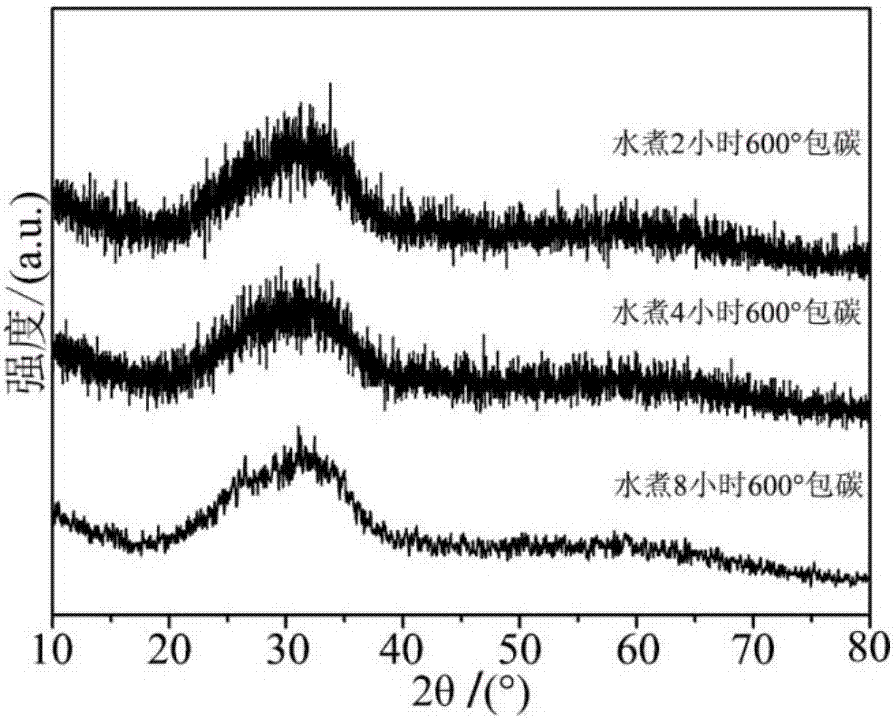

Preparation method of high-stability amorphous manganous silicate

ActiveCN105680045AEasy to clean and removeImprove responseCell electrodesSilicon compoundsPhysical chemistryManganous chloride

The invention discloses a preparation method of high-stability amorphous manganous silicate. The method comprises the steps that sodium silicate and manganese chloride are used as raw materials, and amorphous manganous silicate powder is obtained through boiling water processing; the amorphous manganous silicate powder and glucose are mixed to be subjected to a reaction under the temperature of 600-700 DEG C. According to the preparation method of the amorphous manganous silicate, the reaction time is short, the reaction temperature is low, the production efficiency is high, and the method is suitable for mass production. The obtained amorphous manganous silicate is high in purity and amorphous structural stability.

Owner:SHANDONG UNIV

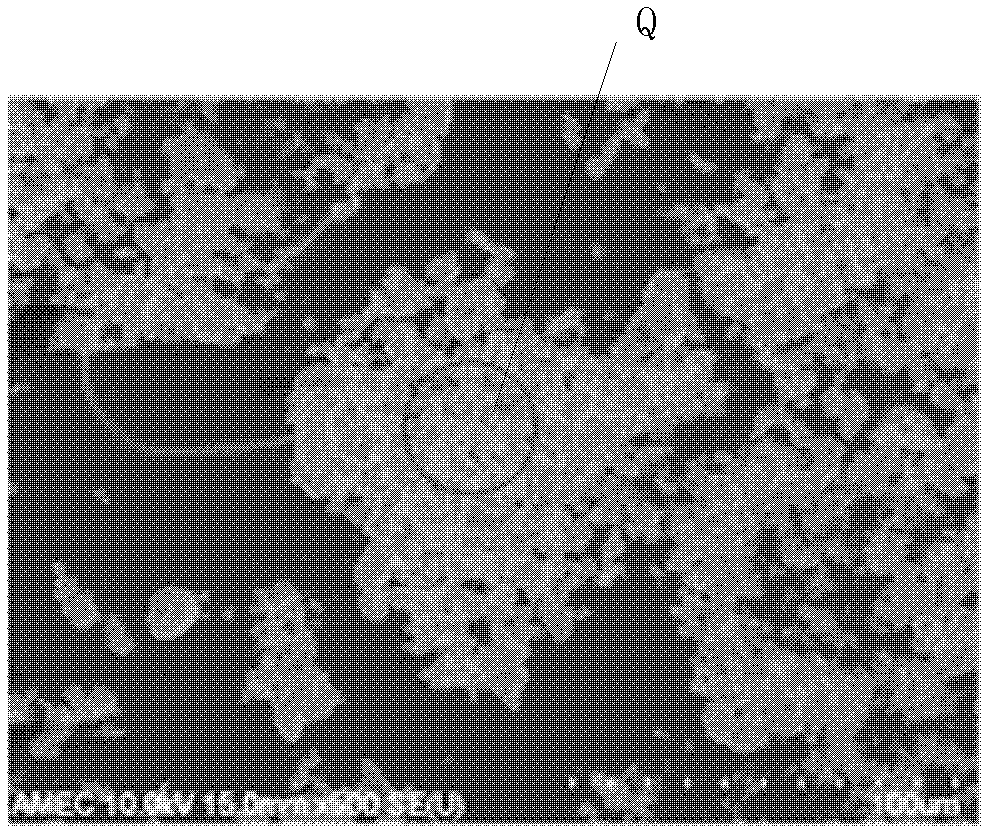

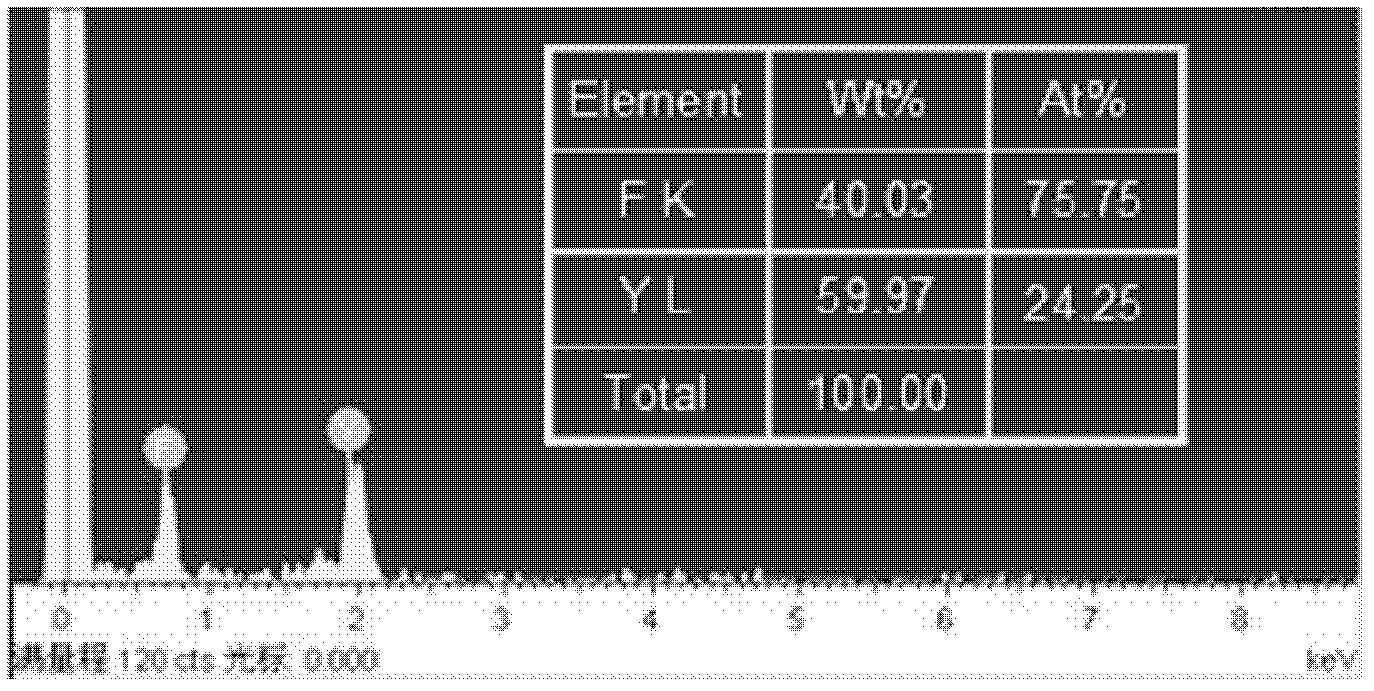

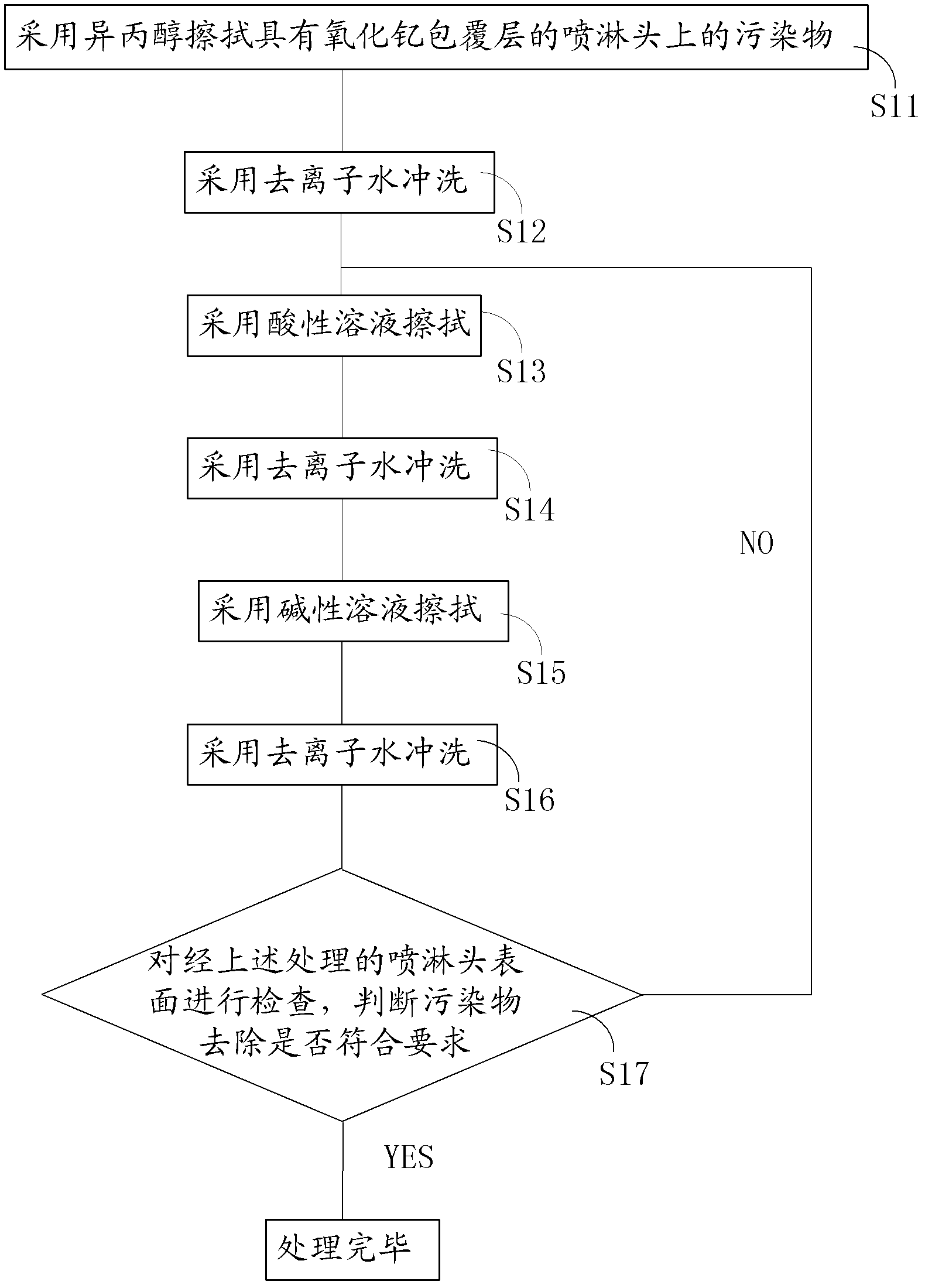

Method for treating pollutant of workpiece provided with yttrium oxide coating layer

ActiveCN102513314AImprove wettabilityEasy to clean and removeCleaning using liquidsOxide coatingYttrium

The invention relates to a method for treating the pollutant of a workpiece which is provided with an yttrium oxide coating layer and is used for etching plasma, which comprises the steps of: at least adopting acid solution to wipe the workpiece, and then adopting deionized water to flush the workpiece. The treatment method can be used for leading the polluted workpiece such as a spray head, a focusing ring and the like to be used again.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Airplane engine fuel oil total pipe bend filling and technique

InactiveCN101054506AStable performance of filling processImprove bending qualityOther chemical processesHollow article cleaningJet aeroplaneSodium bicarbonate

An airplane engine fuel manager bending filling and its craft in machinery manufacturing field are provided. The product preparing craft is correctly weighing material weight by proportion, adding the disodium hydrogen phosphate, trisodium phosphate, sodium bicarbonate by proportion into the material preparing vessel, fully mixing for two hours, adding stabiliser, seal preserving the prepared filling packing. The filling craft of the conduit product is weighing the fillings, enterring the working state after the filling melting achieves the controlling temperature, performing the conduit filling craft. The cleaning craft of the bending conduit product is putting the moulded conduit into the cleaning groove, emitting tap water, heating and stirring, controlling water temperature of 80-90 DEG C for 20-30 minutes, taking out conduit, discharging the water solution, repeating 5 times, taking out conduit and drying. The product and the craft is scientific and novel and has a low cost, a stability to the alloy conduit material non-erosion, alloy conduit bending filling easily being cleaned, and alloy conduit bending filling packing craft.

Owner:沈阳华铁异型材有限公司 +1

Method for removing magnesium in manganese sulfate solution through double salt crystallization process

ActiveCN109680300AWon't hurtShort processing cyclePhotography auxillary processesElectrolysis componentsElectrolysisSulfate

The invention discloses a method for removing magnesium in a manganese sulfate solution through a double salt crystallization process. According to the method, a crystallization device is additionallyarranged in an electrolytic manganese production system, and the concentration of ammonia sulfate in the manganese sulfate solution is controlled to be 80-140 g / L; the magnesium ion concentration is10-30 g / L; then, the pressure is controlled to be 3-20 Mpa, the initial temperature is 50-90 DEG C, ammonia sulfate magnesium crystals are added, the temperature is reduced to 30-70 DEG C within 45-180 min, the ammonia sulfate magnesium crystals are obtained, the crystals are taken out, and accordingly magnesium removal can be achieved. The method has the advantages that the method is economical and feasible, and no pollution is caused to an electrolytic manganese system.

Owner:GUIZHOU UNIV

Acidic ink digital printing anti-bleeding size for woolen fabric

The invention discloses acidic ink digital printing anti-bleeding size for a woolen fabric. The anti-bleeding size is prepared from 0.5%-3% of modified starch, 2%-5% of a cosolvent, 1%-3% of glycerin, 1%-2% of anhydrous sodium sulphate, 1.5%-2.5% of ammonium sulfate, 0.2%-1.4% of a thickening agent, an acidity pH value regulator and the balance water, wherein the pH value of the anti-bleeding size is 4-5, and the thickening agent is selected from at least one of konjac glucomannan, xanthan gum, guar gum and carrageenan. According to the acidic ink digital printing anti-bleeding size for the woolen fabric, chitosan in the prior art is replaced with the water-soluble thickening agent, the characteristics of being hydrophilic, capable of forming a film and high in stability of konjac glucomannan, xanthan gum, guar gum, carrageenan and the like are utilized, paste materials in the fabric which is pretreated by the pretreating size, subjected to digital printing and steamed are easy to wash and remove, and the fabric free of residual paste materials is soft in handfeel.

Owner:JIANGSU SUNSHINE GRP CO LTD

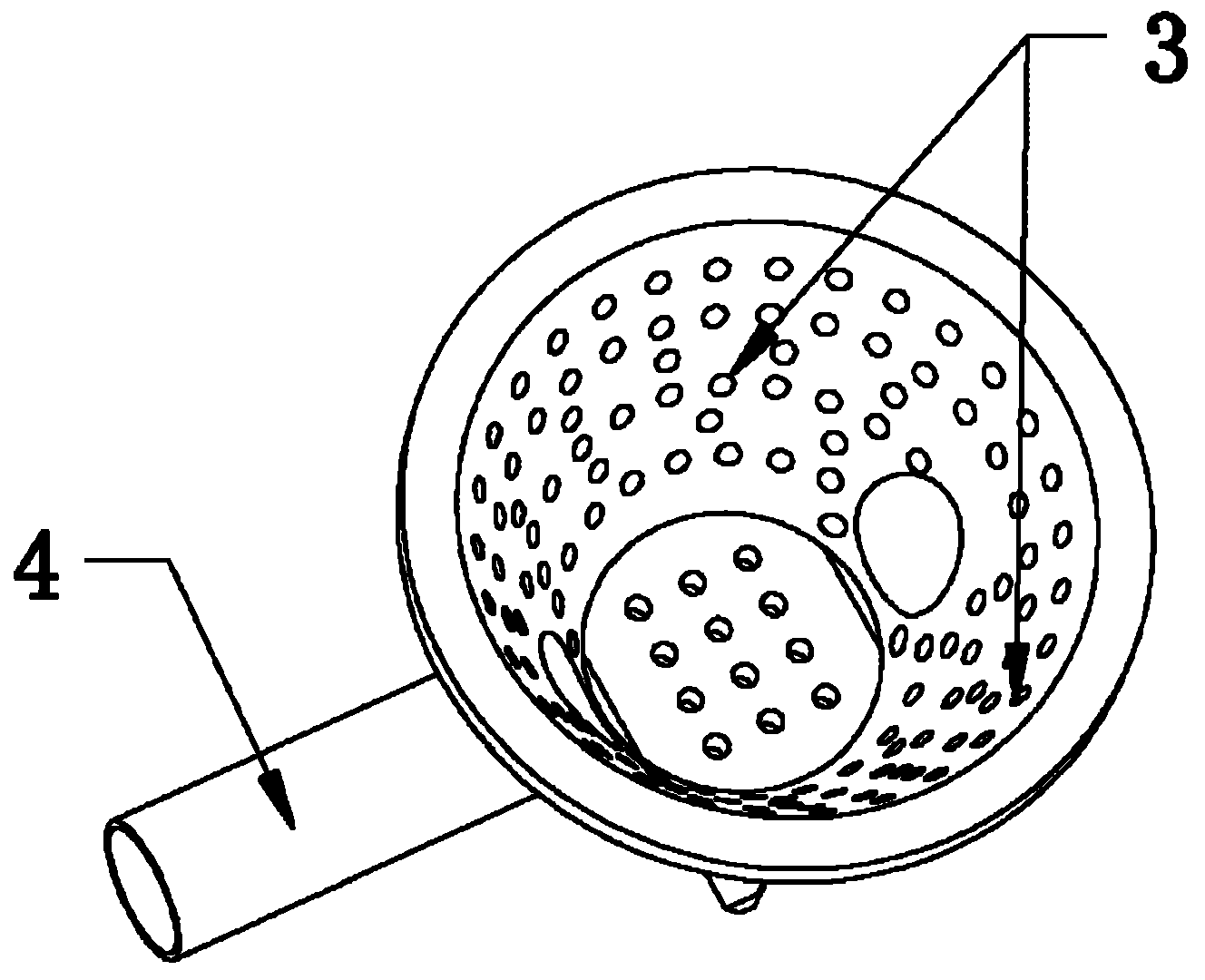

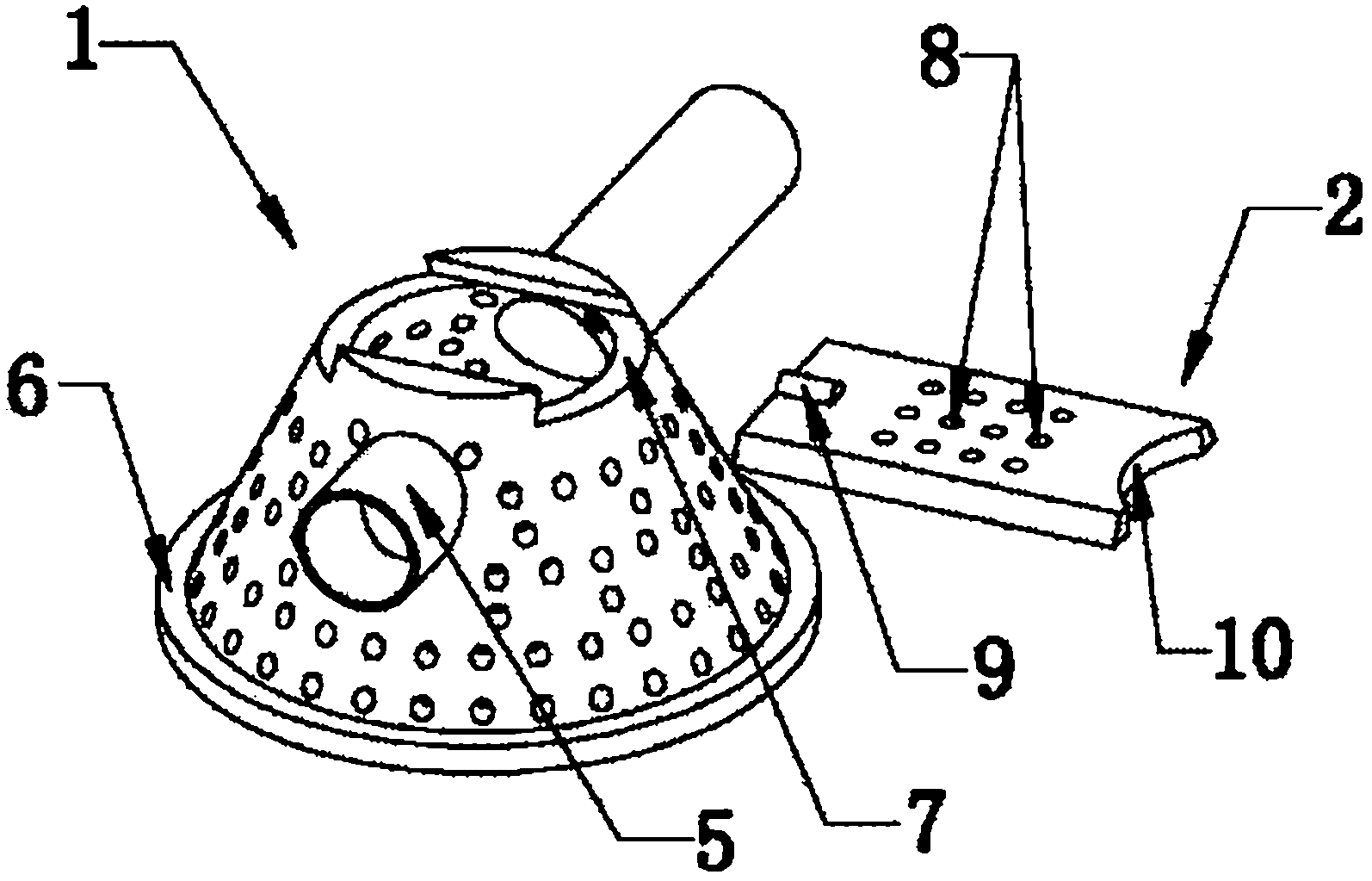

Grate for biomass particle environment-friendly boiler

The invention discloses a grate for a biomass particle environment-friendly boiler, which comprises a grate and a valve, wherein the grate body is movably connected with the valve; the grate body is in a taper shape and a plurality of vent holes A are uniformly distributed on the grate; one end of a side wall of the grate is provided with a long pipe for ignition and the other end of the side wall is symmetrically provided with a short pipe for ventilation; and a large orifice end of the grate body is circularly provided with a support block, a small orifice end is provided with a cavity of which the shape and the size are matched with the shape and the size of the valve, and a plurality of vent holes B are uniformly arranged on the valve. The problems that biomass particles in the prior art are hard to ignite and cannot burn fully, black smoke is easy to generate and fuel residue is inconvenient to remove and wash are effectively solved through the grate for the biomass particle environment-friendly boiler.

Owner:田和东

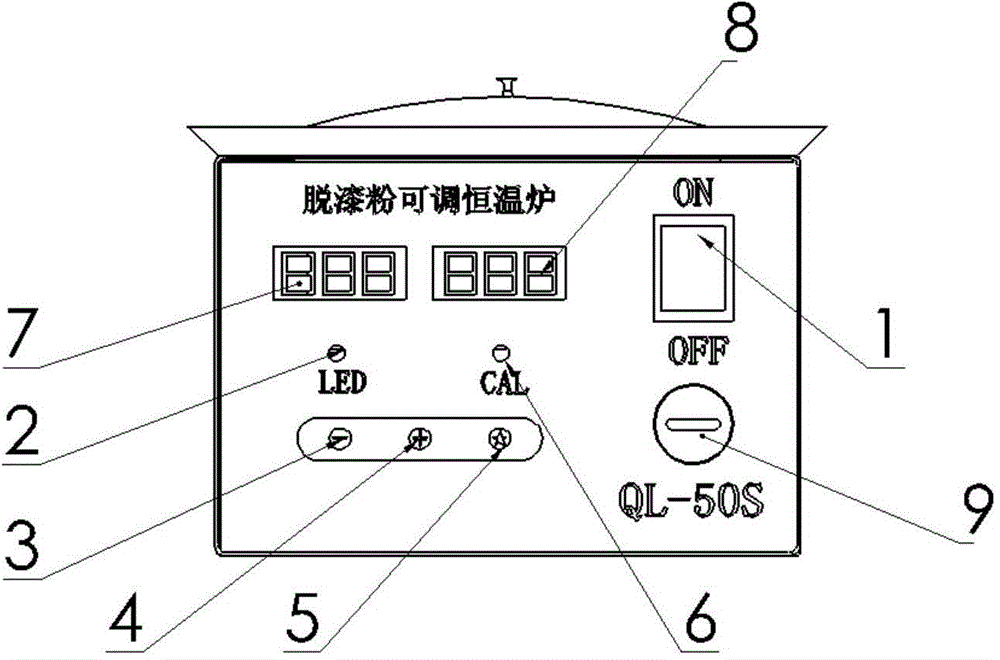

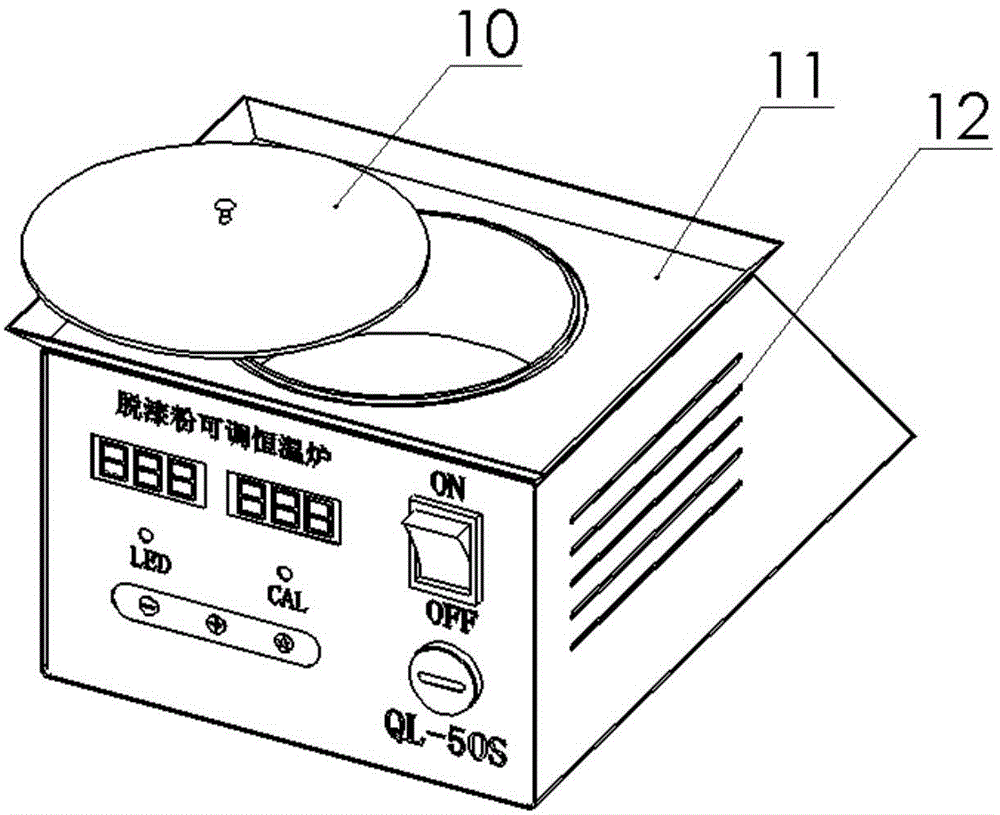

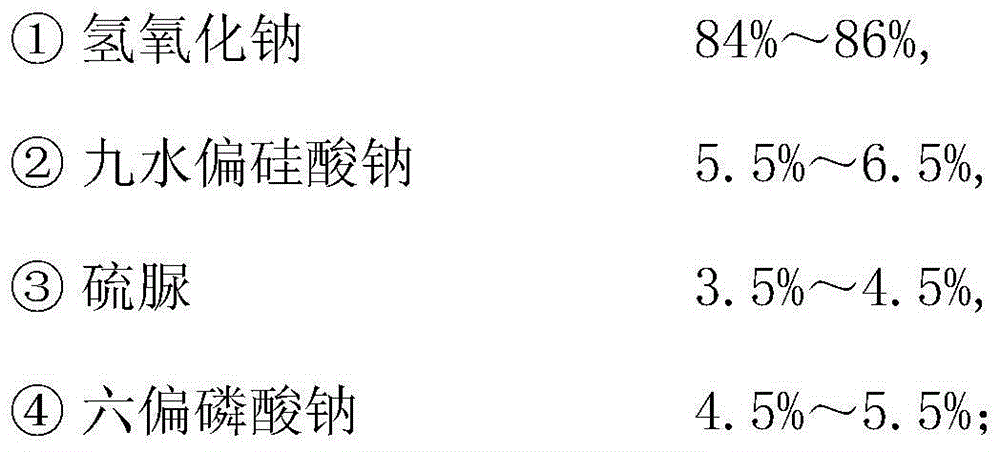

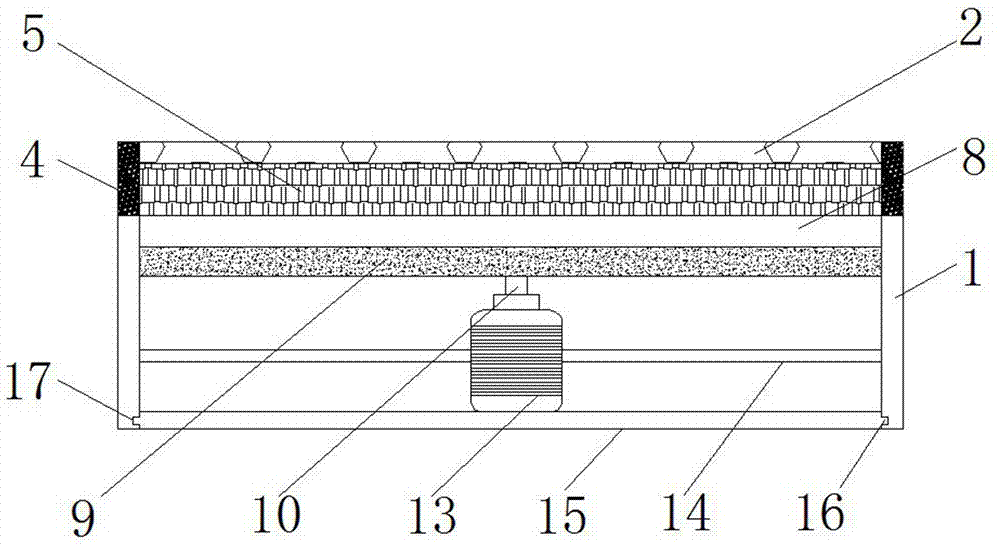

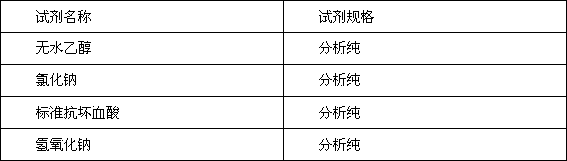

Enameled wire polyimide insulating layer nondestructive depainting powder and depainting method

ActiveCN104312257ADoes not affect solderabilityEasy to clean and removeLine/current collector detailsChemical paints/ink removersCopperSodium hydroxide

The invention relates to an enameled wire polyimide insulating layer nondestructive depainting powder and depainting method. The depainting powder is prepared by adopting the following raw materials by weight percent: 84 to 86 percent of sodium hydroxide, 5.5 to 6.5 percent of sodium metasilicate nonahydrate, 3.5 to 4.5 percent of thiourea and 4.5 to 5.5 percent of sodium hexametaphosphate. The depainting method comprises the following steps: heating the depainting powder in a special depainting furnace to form liquid, soaking an enameled wire head needing depainting into the molten liquid to be subjected to depainting, then taking out the enameled wire head, washing, rinsing and dehydrating the enameled wire head, so that a purpose for completing the quick nondestructive depainting of a lead-out end of the enameled wire can be achieved. The depainting powder formula is environmental friendly and safe, not only can the enameled wire copper material be prevented from being corroded, oxidized and decolored, but also is easy to wash and remove, and the soldability of the enameled wire copper material is not affected. By adopting the method, the traditional method for depainting the lead-out end of the enameled wire by virtue of a piece of abrasive paper can be changed, and the breaking potential safety hazard of a coil can be greatly eliminated.

Owner:SHAANXI QUNLI ELECTRIC

Grading dust removal device of electronic electric appliance

InactiveCN107377432AExtended service lifeNormal work will not affectDirt cleaningCleaning using toolsEngineeringElectron

The invention relates to the technical field of electric appliance dust prevention, and discloses a grading dust removal device of an electronic electric appliance. The grading dust removal device comprises a dust removal outer cover, wherein an electric appliance heat dissipation port is fixedly installed at the top of the dust removal outer cover, sliding rails are fixedly installed at the two ends of the lower surface of the electric appliance heat dissipation port, a sliding block is movably connected to the inner portion of each sliding rail, a dustproof brush is connected to one end of each sliding block, a connecting block is fixedly installed at the axis of the dustproof brush, a handle is fixedly installed at the bottom of the connecting block, an air inlet is arranged below the dustproof brush, a fan is arranged below the air inlet, a connecting shaft is fixedly connected to the top of the fan, and blades are fixedly installed at the top of the connecting shaft. According to the grading dust removal device of the electronic electric appliance, the sliding rails, the sliding blocks and the dustproof brush are arranged, and the purpose of clearing dust accumulated at the heat dissipation port is achieved by moving the handle up and down; and the fan is arranged, the fan reversely rotates to form a reverse airflow to suck the dust raised by the dustproof brush into the dust removal outer cover, so that the purpose of secondary dust collection and dust removal is achieved.

Owner:合肥杰代机电科技有限公司

Special anti-oxidation lubricating coating for hot stamping, and preparation method and application thereof

InactiveCN109021630AReduce generationAvoid damageFireproof paintsHot stampingHexagonal boron nitride

The invention concretely relates to a special anti-oxidation lubricating coating for hot stamping, and a preparation method and an application thereof. The coating comprises hexagonal boron nitride, athickener, a dispersant, an antifoaming agent, a rust inhibitor and a solvent. The preparation method is characterized in that all above components are thoroughly uniformly mixed to prepare the coating. The application comprises the following steps: spraying the coating on a plate, carrying out drying and heat insulation on the sprayed plate, carrying out hot stamping molding, and removing the special anti-oxidation lubricating coating for hot stamping. Compared with coatings in the prior art, the coating has the advantages of realization of oxidation prevention by isolating oxygen, maintaining of a good lubricity and a good thermal conductivity at a high temperature, improvement of the surface quality of parts, and easiness in later removal.

Owner:SUZHOU PRESSLER ADVANCED FORMING TECHNOLOGIES CO LTD

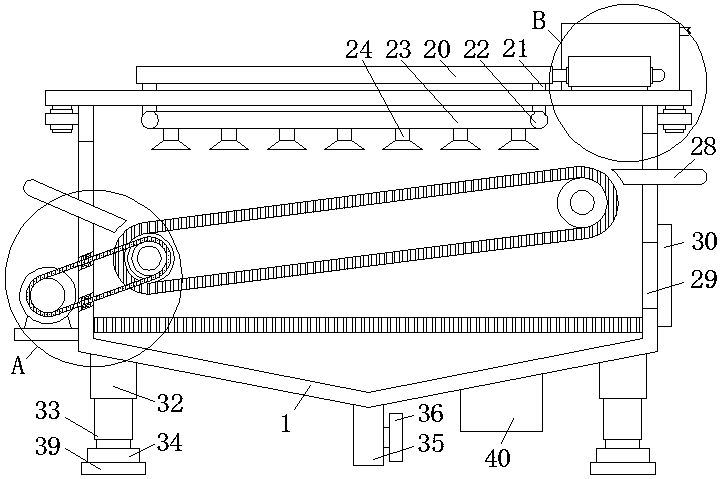

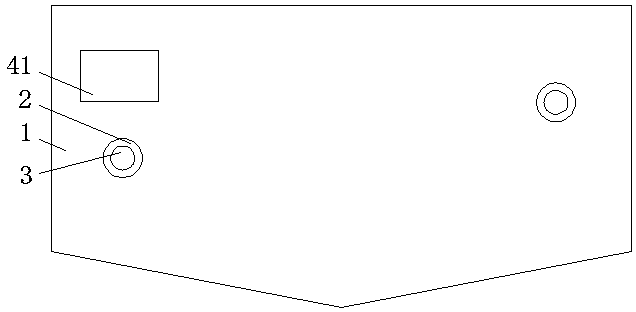

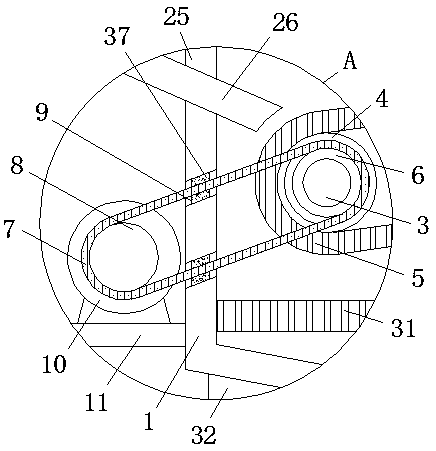

Etching device for machining

The invention discloses an etching device for machining. The device includes a shell. Two bearings are engaged on the front and the back of the casing respectively, and the four bearings are respectively located on the left and right sides of the front and the back of the shell. The left two bearings and the right two bearings sleeve two rotating shafts respectively. The surfaces of the rotating shafts are fixedly connected to idler wheels. The two idler wheels are in transmission connection through a conveyer mesh belt. A position, of the surface of the left rotating shaft, in the front sideof the corresponding idler wheel is fixedly connected to a driven wheel. Through arrangement of the conveyer mesh belt, a belt, a motor, a cover plate, a liquid conveying pump, nozzles and electric push rods in the device, the nozzles can be replaced conveniently, fragment impurities on a filtration plate in the shell can be conveniently removed through a decontamination port and the height of theshell can be adjusted, and therefore, material placement by operators is not influenced, and the production and machining efficiency can be increased.

Owner:ZHENGZHOU YUNQI IND EQUIP TECH CO LTD

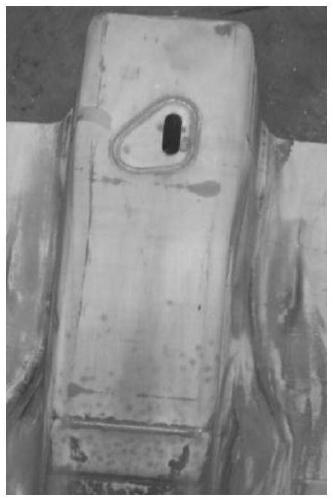

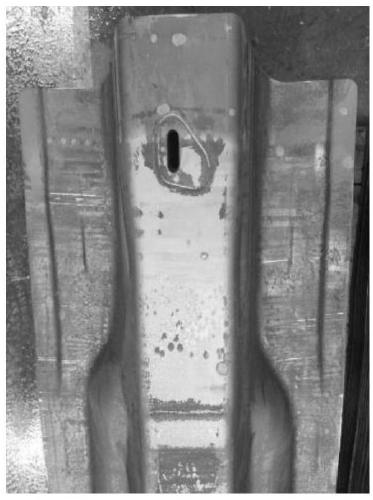

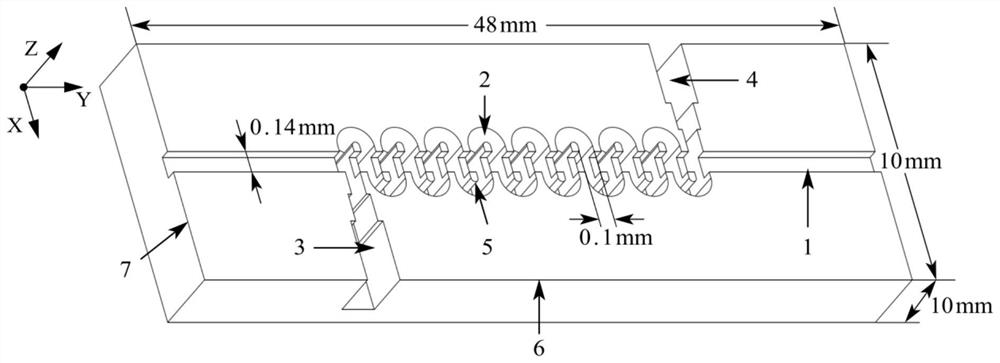

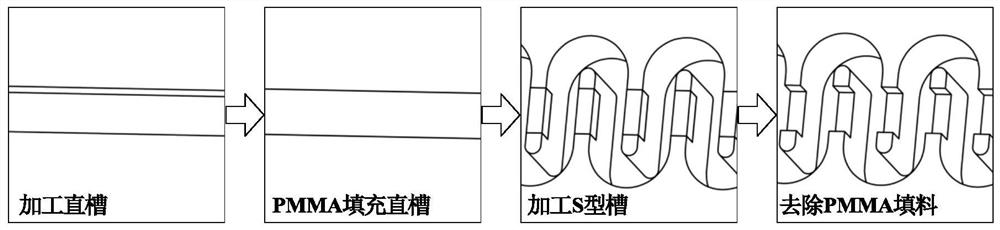

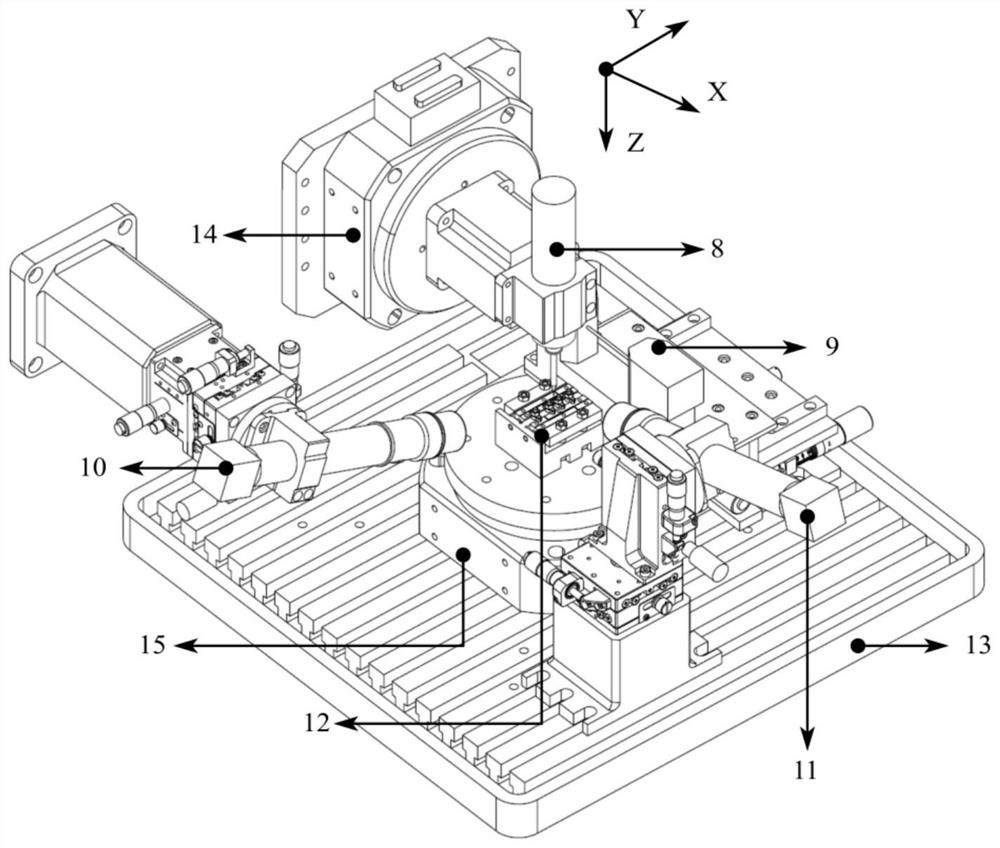

Micro-milling burr inhibition method applied to folded waveguide slow wave structure

InactiveCN112276176AMeet the requirements of high machined surface qualityRemove inhibitionMeasurement/indication equipmentsMilling equipment detailsWave structurePolymer science

The invention relates to a micro-milling burr inhibition method applied to a folded waveguide slow wave structure. The method comprises the steps that after a straight groove in the slow wave structure is generated through micro-milling machining, a cavity of the straight groove is filled with PMMA colloid; after the PMMA colloid is cured, micro-milling machining of an S-shaped groove in the slowwave structure is carried out; and after a workpiece is machined, the workpiece is placed in an organic solvent to dissolve a PMMA curing layer, and cleaning and drying are carried out, wherein the PMMA colloid is prepared by uniformly mixing polymethyl methacrylate and an acrylic curing agent according to the mass ratio of (1-1.4): 1. According to the micro-milling burr inhibition method appliedto the folded waveguide slow wave structure, the machined cavity of the straight groove is filled with the PMMA colloid in a coated mode to serve as an auxiliary supporting material, the PMMA colloidis used for enhancing the plastic deformation resistance of the boundary of a dispersed oxygen-free copper material in the cutting process, and then formation of burrs at the groove top, the groove shoulder and the island root is inhibited.

Owner:HARBIN INST OF TECH

Antibacterial fresh-keeping agent for keeping vegetables fresh as well as preparation method and application thereof

InactiveCN108208137AGood biocompatibilityImprove securityNatural extract food ingredientsMeat/fish preservation using chemicalsAdditive ingredientGlycerol

The invention provides an antibacterial fresh-keeping agent for keeping vegetables fresh. The fresh-keeping agent is prepared from the following raw materials in parts by weight: 12 to 16 parts of a shaddock peel fermentation solution, 0.5 to 1 part of sodium diacetate, 0.4 to 0.7 part of glycerol and 7 to 12 parts of a plant extracting solution, wherein the plant extracting solution is prepared by mixing cortex eucommiae, herba lysimachiae, flos chrysanthemi indici, herba houttuyniae and herba seu radix cirsii japonici according to the weight ratio of (1 to 1.5) to (2 to 3) to (0.5 to 1) to (1 to 3) to (1 to 2) and extracting. The compound vegetable antibacterial fresh-keeping agent, which takes natural plant components as the raw materials, has the advantages of natural components, no toxicity and relatively good insect-repelling, bacterium-inhibiting and fresh-keeping effects; the compound vegetable antibacterial fresh-keeping agent can be used for effectively prolonging the fresh-keeping, storage and shelf life of the vegetables and the healthy safety is high.

Owner:河南健特生物科技集团有限公司

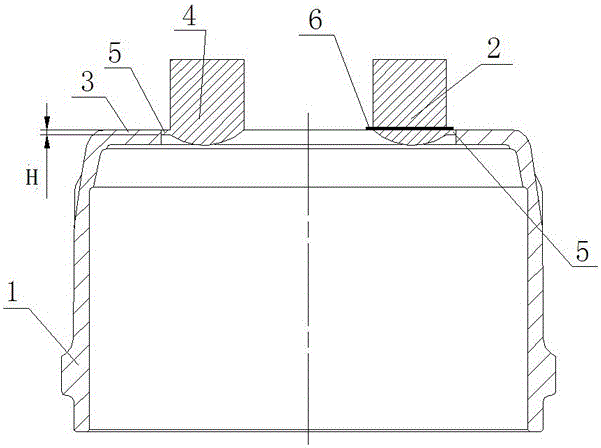

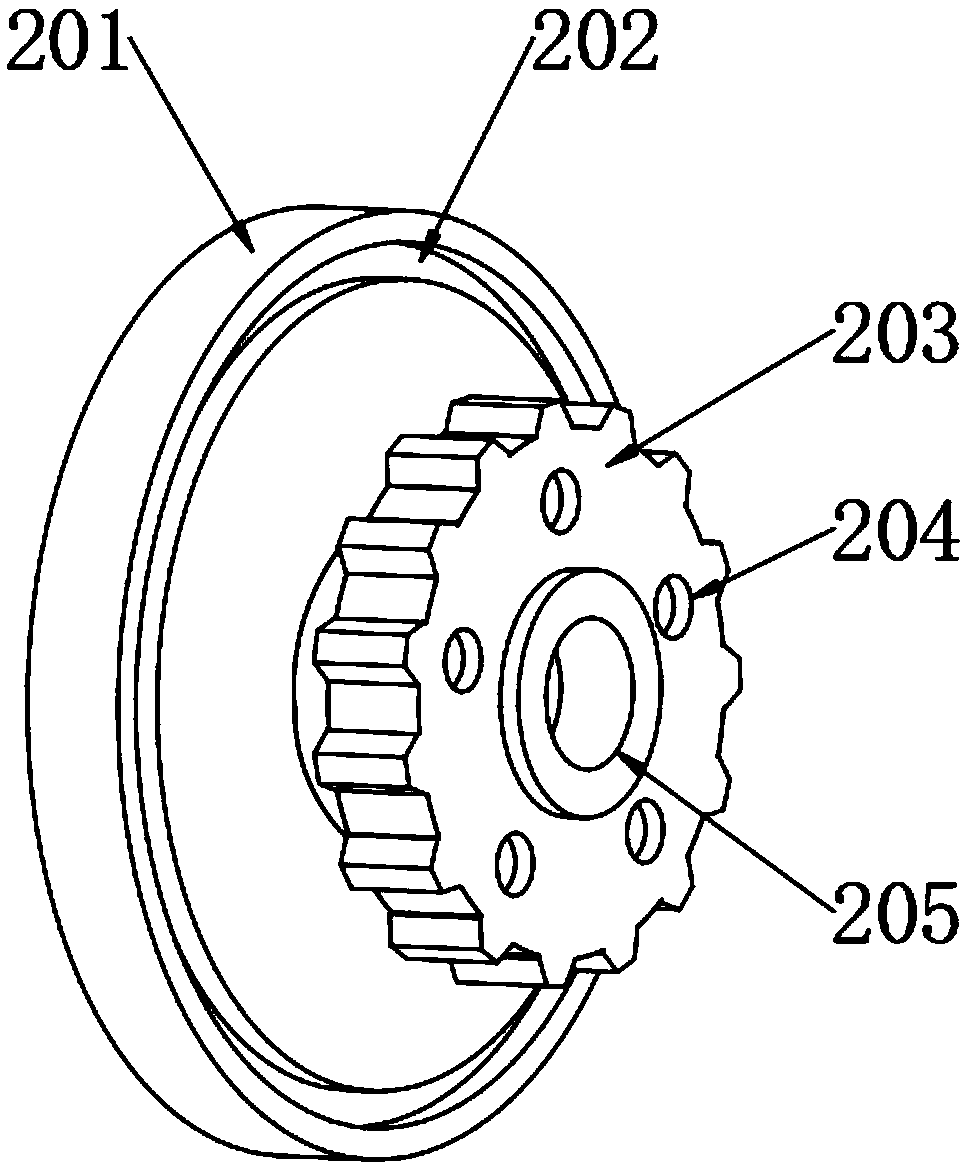

Pouring system device and pouring method for iron based sand coated cast brake drums

InactiveCN105750502ASmooth dischargeGood for pouring and fillingFoundry mouldsFoundry coresIron basedCasting

The invention relates to a pouring system device and a pouring method for iron based sand coated cast brake drums, and belongs to the field of machinery.The pouring system device comprises an overflow riser, an exhaust overflow groove, a sprue and an ingate.The sprue and the ingate are connected with each other, the overflow riser is arranged at an end of an inner circle of the upper end of a brake drum casting, and the exhaust overflow groove is formed in a side of the overflow riser.The pouring system device and the pouring method have the advantages that the pouring system device is reasonable in structure and low in cost, exhausting and cleaning can be facilitated, pouring can be facilitated by the pouring method, and the casting is high in quality.

Owner:浙江省机电设计研究院有限公司

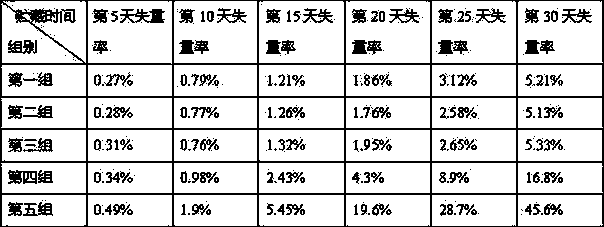

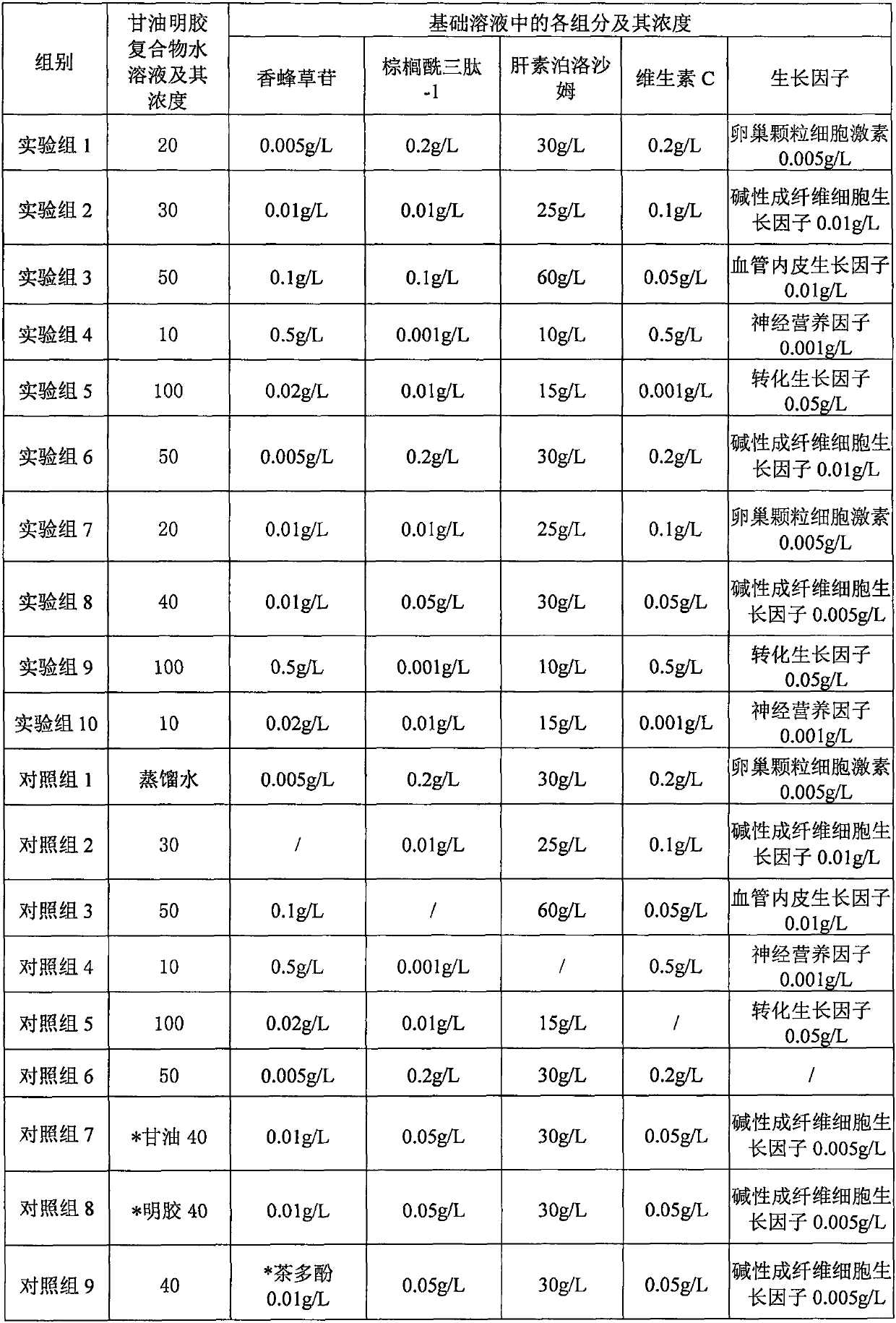

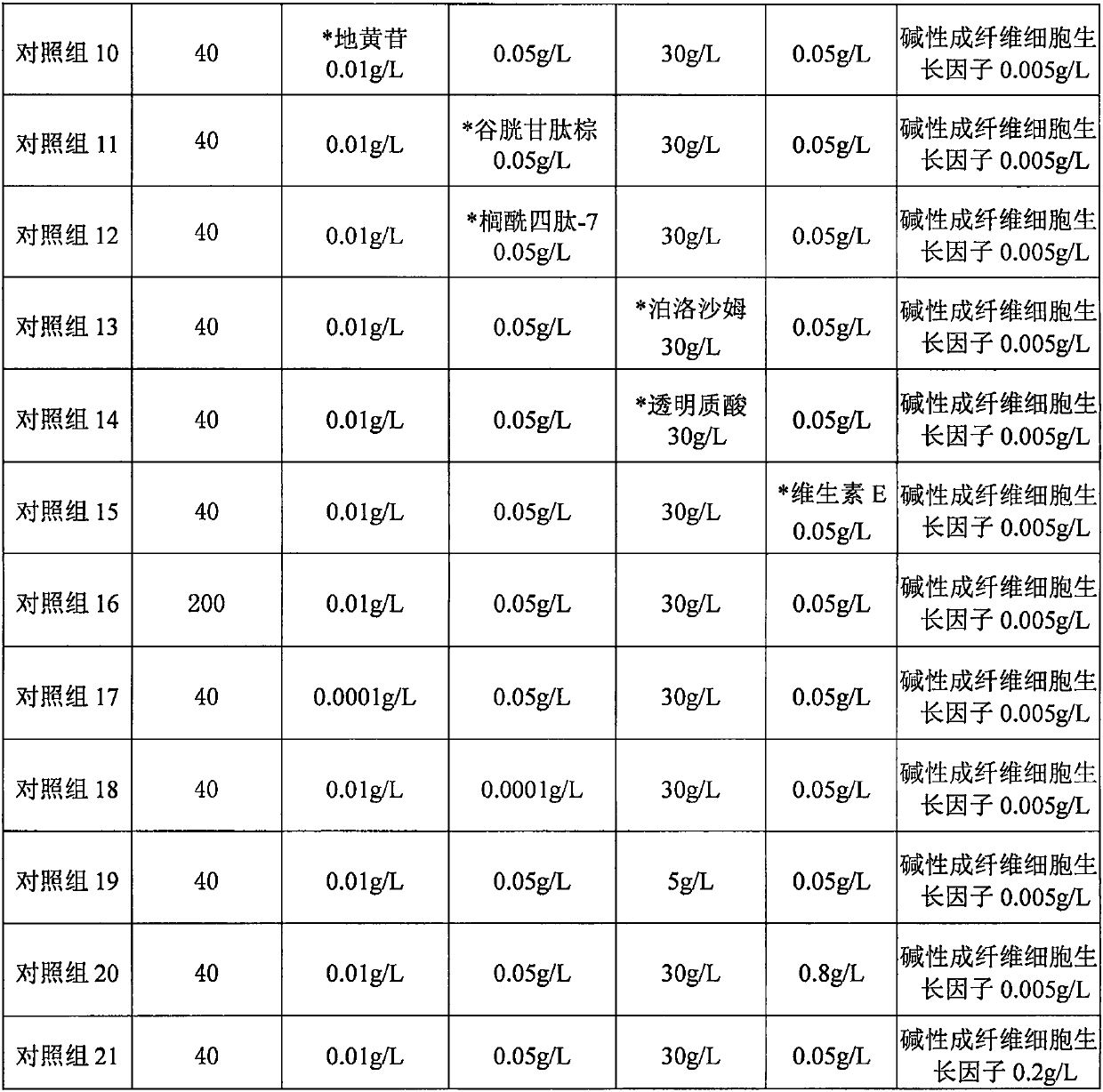

Cryopreservation resuscitation solution system capable of preserving ovary activity

The invention relates to a cryopreservation resuscitation solution system capable of preserving ovary activity. A glycerin and gelatin compound water solution with the concentration of 10-100 g / L is taken as a basic solution, the mass ratio of glycerin to gelatin in the glycerin and gelatin compound is 10:1, didymin, a growth factor, palmitoyl tripeptide-1, heparin poloxamer and vitamin C are added to the basic solution, an ovary is put in the solution system for cryopreservation, and the biological activity after cryopreserved ovary is resuscitated can be improved.

Owner:WENZHOU MEDICAL UNIV

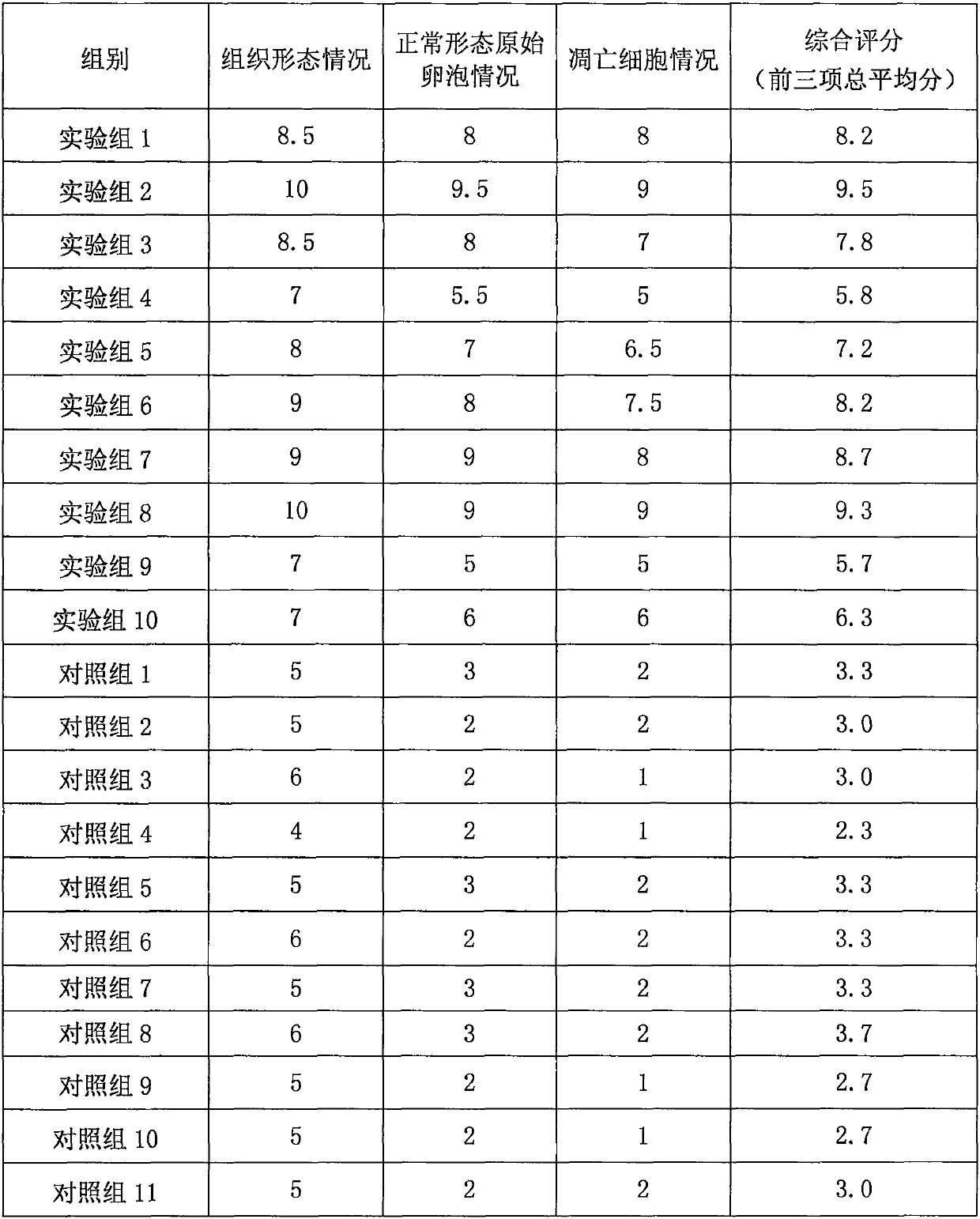

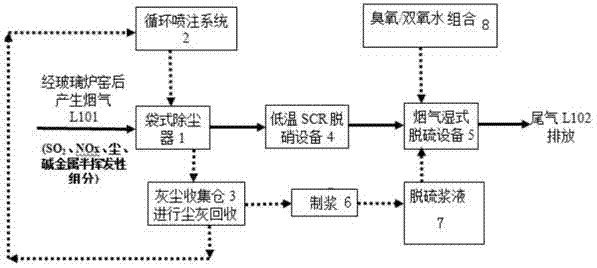

Comprehensive treatment process for deep dust removal, desulfurization and denitrification of flue gas from glass kiln

ActiveCN105435545BImprove propertiesImprove capture efficiencyDispersed particle filtrationLow nitrogenJet injection

The invention discloses a comprehensive treatment process for deep dust removal, desulfurization and denitrification of flue gas from a glass kiln. The invention relates to the field of glass furnace flue gas treatment. The raw material flue gas is discharged into the dust removal flue, where magnesium-containing powder and part of the collected dust are injected to mix it with the raw material flue gas to obtain a mixed flue gas; the resulting mixed flue gas is passed into the bag filter for Filtration to obtain low-dust flue gas and dust; the dust is divided into two parts, and magnesium-containing powder is added to one part, which is reinjected into the dust removal flue with an air jet device, and mixed with the raw material flue gas; the other part is added water to make desulfurization slurry; the obtained low-dust flue gas is passed into a low-temperature SCR denitrification device for denitrification to obtain low-nitrogen and low-dust flue gas; the low-nitrogen and low-dust flue gas is passed into a wet desulfurization device, and the desulfurization The slurry is desulfurized, and the tail gas is discharged into the atmosphere. Compared with the prior art, the present invention has good dust removal effect, can improve the efficiency of denitrification, realizes recycling of wastes, and realizes the purpose of deep emission reduction of flue gas pollutants.

Owner:SHANGHAI JIAOTONG UNIV

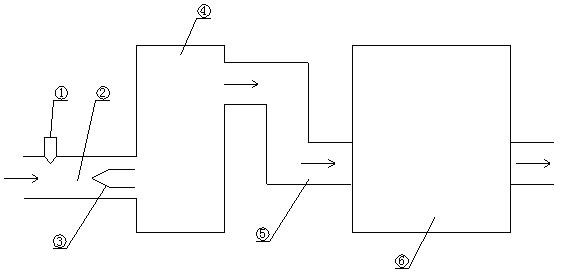

Device and method for efficient adsorption and agglomeration removal of ultrafine particles and heavy metal mercury

PendingCN112023623AAbundant specific surface areaImprove adsorption capacityGas treatmentDispersed particle separationFuel oilDust abatement

The invention relates to a device and a method for efficient adsorption and agglomeration removal of ultrafine particles and heavy metal mercury. By adopting physicochemical and catalytic adsorption,turbulence enhanced agglomeration and other mechanisms, pollutants such as ultrafine particles and heavy metals, including PM2.5 and aerosol, discharged by industrial flue gas are efficiently adsorbed, agglomerated and removed. By adopting the structural form that a modified fly ash spraying device, an airflow distribution device, a turbulence enhanced agglomeration device and a dust removal device are sequentially arranged in the airflow direction, the invention provides the device and method for efficient adsorption and agglomeration removal of pollutants in industrial flue gas of fire coal,fuel oil, waste incineration and the like, wherein the device and method are high in removal efficiency, low in operation cost, and convenient to overhaul, operate and maintain.

Owner:BEIJING LONDIAN HONGTAI ENVIRONMENTAL TECH

A kind of preparation method of high stability amorphous manganese silicate

ActiveCN105680045BEasy to clean and removeImprove responseCell electrodesSilicon compoundsReaction temperatureWater processing

Owner:SHANDONG UNIV

Stone treatment agent

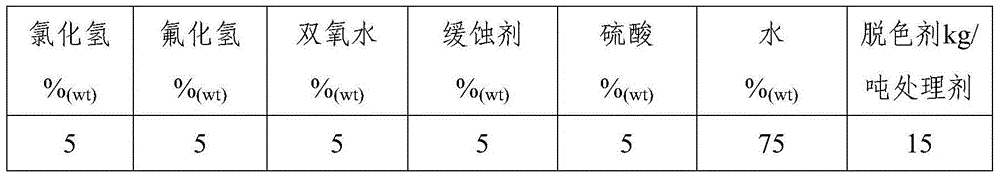

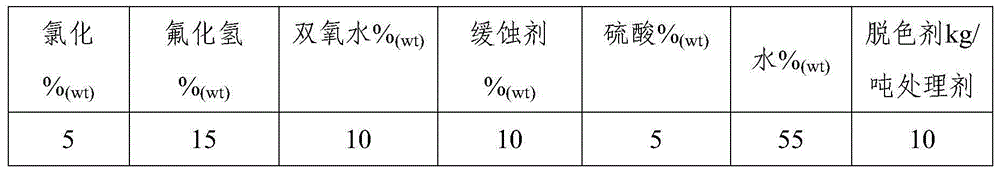

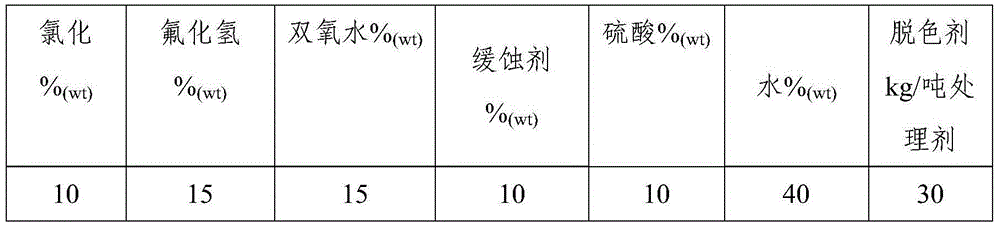

The invention provides a stone treatment agent which consists of hydrogen chloride, hydrogen fluoride, hydrogen peroxide, sulfuric acid, water, a corrosion inhibitor and water. The preparation method comprises the following steps: treating the liquid containing the components by using a decolorizing agent, thereby obtaining the stone treatment agent product, wherein the hydrogen chloride accounts for 5-20 mass percent, the hydrogen fluoride accounts for 10-20 mass percent, the hydrogen peroxide accounts for 10-30 mass percent, the corrosion inhibitor accounts for 5-15 mass percent, the sulfuric acid accounts for 1-10 mass percent, and the rest is water; and the use amount of the decolorizing agent is 10-30Kg / ton of the liquid. According to the stone treatment agent provided by the invention, the treatment operations in aspects of removing impurities on the stone surface, removing stains and impurities on the cutting surface and the polishing surface, flattening the surface, engraving the stones can be effectively realized, a phenomenon that a layer of colored oxides is attached to the surface of the stone is avoided, the oxides are easy to clean and remove, and the subsequent treatment difficulty is reduced.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

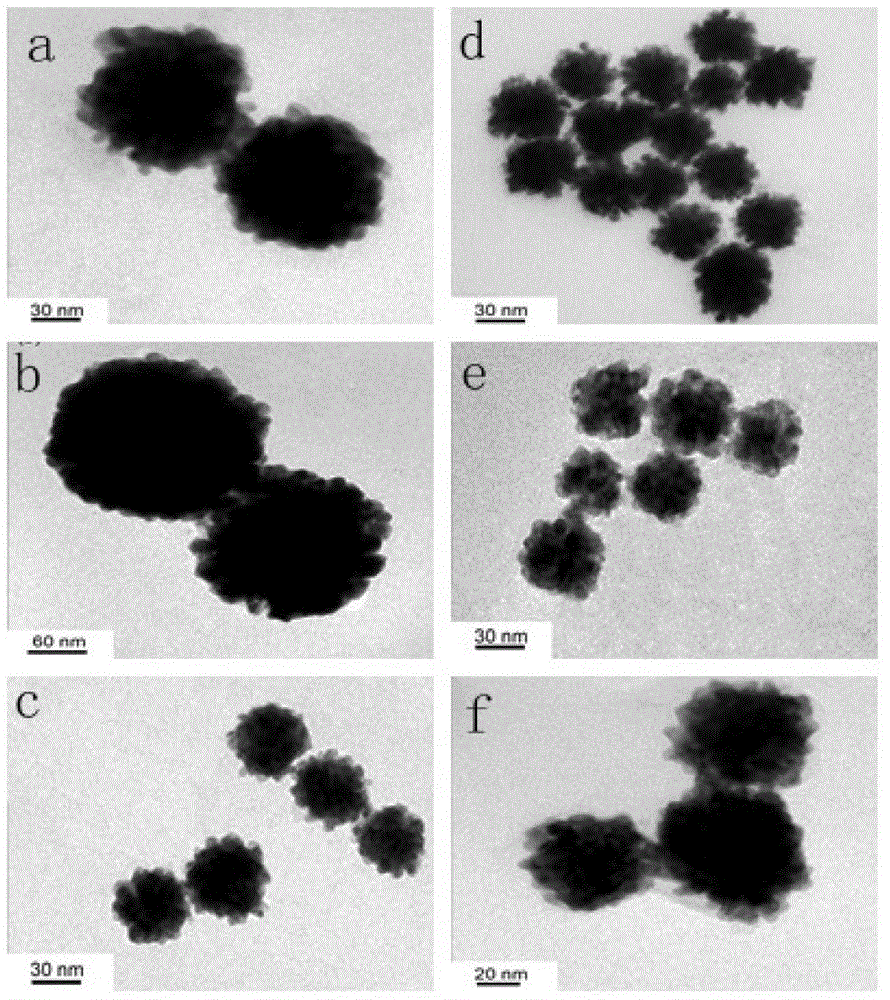

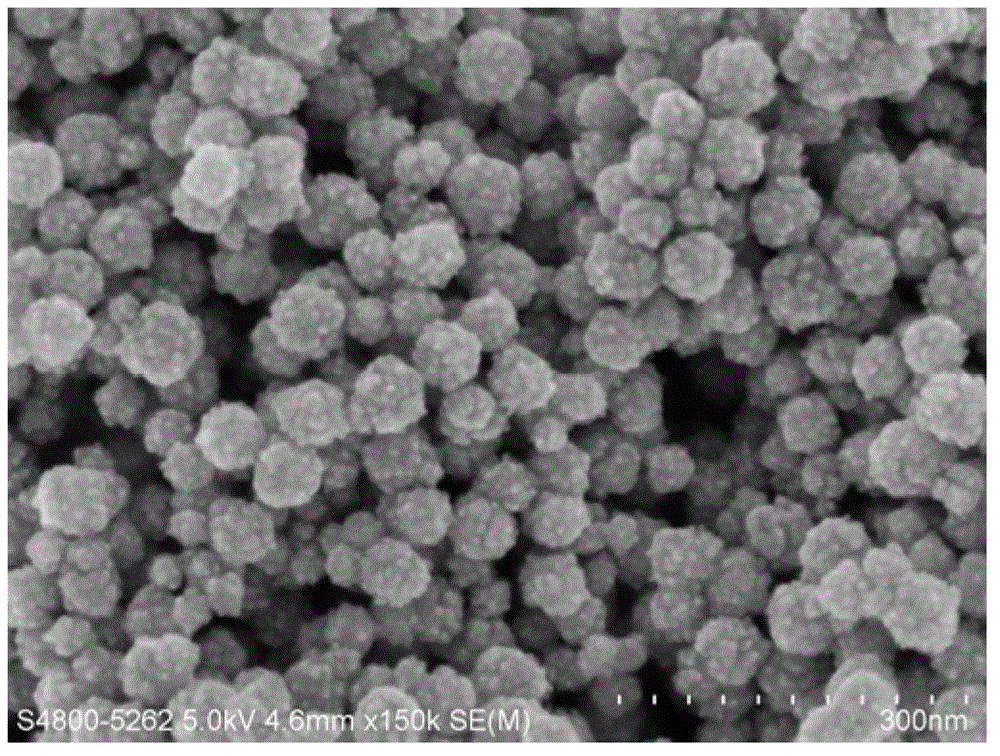

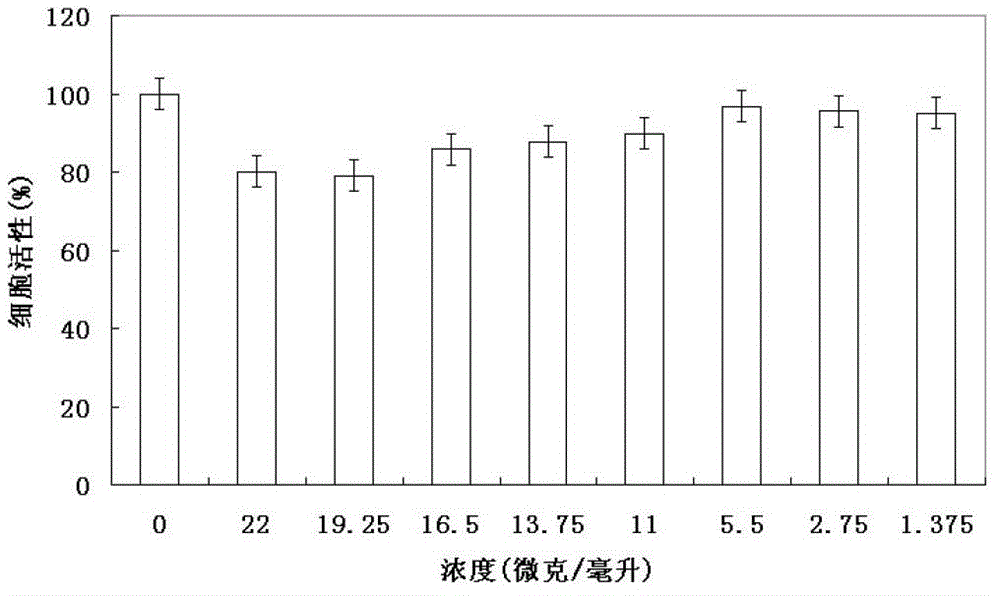

Gold nanoflower preparing method and application of gold nanoflowers

InactiveCN103273079BWide variety of sourcesCheap sourceInorganic non-active ingredientsRaman scatteringLuminol chemiluminescenceBiocompatibility Testing

The invention relates to a gold nanoflower preparing method and the application of gold nanoflowers. The preparing method comprises the following steps that 1) under room temperature, polyphenol is added to water solution with the pH value of 7-12 to obtain mixed solution; 2) chloroauric acid and hydrogen peroxide are then added in sequence, shaking up is carried out to obtain reaction solution; 3) the reaction solution is centrifuged, supernatant is abandoned, and the gold nanoflowers are obtained after washing. The particle diameters of the gold nanoflowers obtained under different pH values are 50-200nm, stability is good, the gold nanoflowers can be used in a biological body as a medicine carrier and have good biocompatibility, the gold nanoflowers can be used in chemiluminescence analysis, the signal intensity of a luminal chemiluminescence system can be obviously enhanced, the gold nanoflowers can be used in surface-enhanced Raman scattering (SERS) analysis, and the sensitivity is better than that of spherical gold nanoparticles. The gold nanoflower preparing method has the advantages that raw materials are easy to get, reaction conditions are mild, efficiency is high, speed is high, and batch preparing and producing are benefited.

Owner:ANHUI MEDICAL UNIV

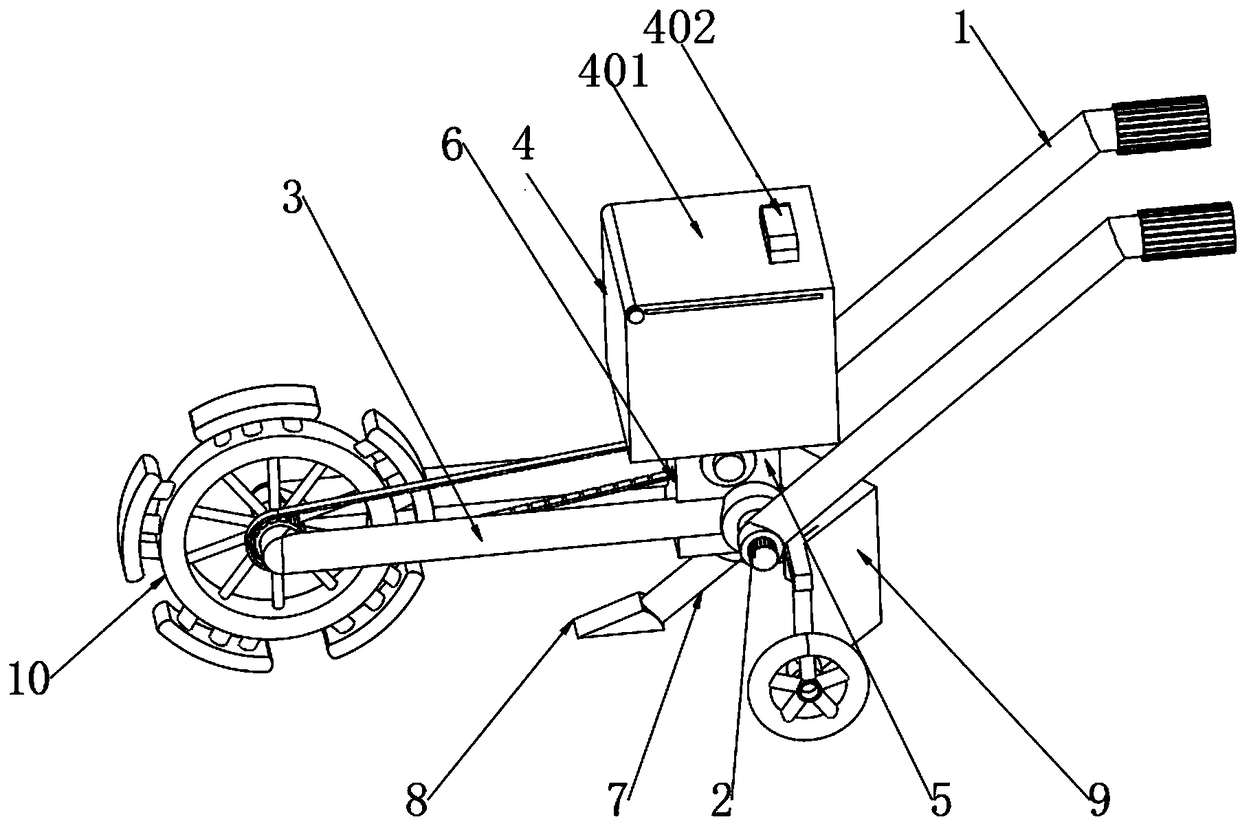

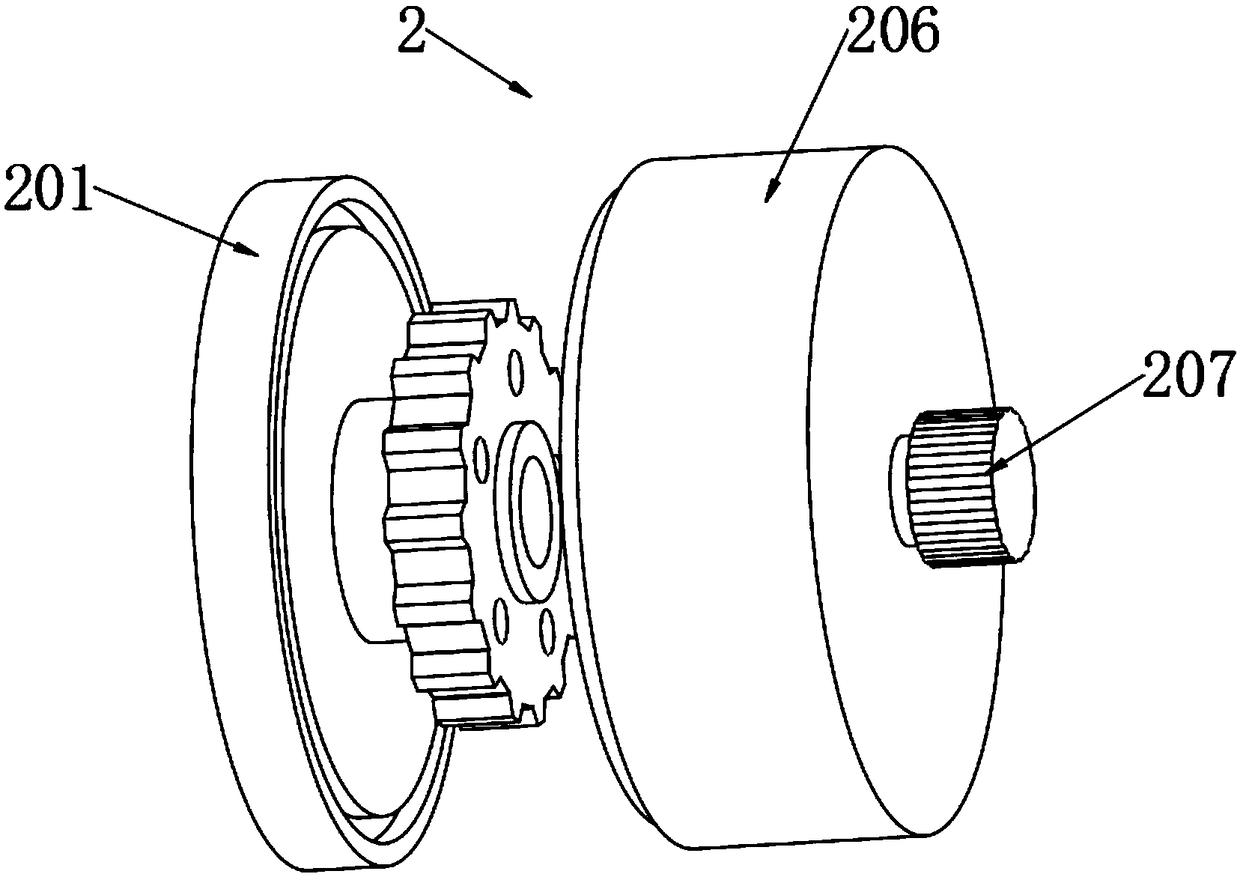

Device for agricultural sowing

ActiveCN109168468AContinuous sowingAutomatic seedingPlantingSeed depositing seeder partsEngineeringOpto electronic

The invention discloses a device for agricultural sowing. The device comprises a push rod, a support frame is mounted at one side of the push rod, an adjustment assembly is mounted between the push rod and the support frame, a seed storage box is mounted at the upper end of the support frame, and the seed storage box is connected with a residual amount detecting assembly; the residual amount detecting assembly comprises a photoelectric sensor arranged in the seed storage box and used for detecting the seed residual amount in the box in real time, a single-chip microcomputer connected with thephotoelectric sensor, a power source connected with the single-chip microcomputer and an alarm, the single-chip microcomputer, the power source and the alarm device are arranged in a control box, andthe control box is fixed on the seed storage box. A worker can continuously and automatically sow seeds by using the device, so the sowing efficiency is effectively improved; and the device is also provided with the residual amount detecting assembly, and the photoelectric sensor is specifically used for detecting the condition of remaining seeds in the seed storage box, so an alarm is issued whenthe amount of seeds is insufficient in order to avoid the phenomenon of blank sowing.

Owner:奉节县唯丞农业开发有限公司

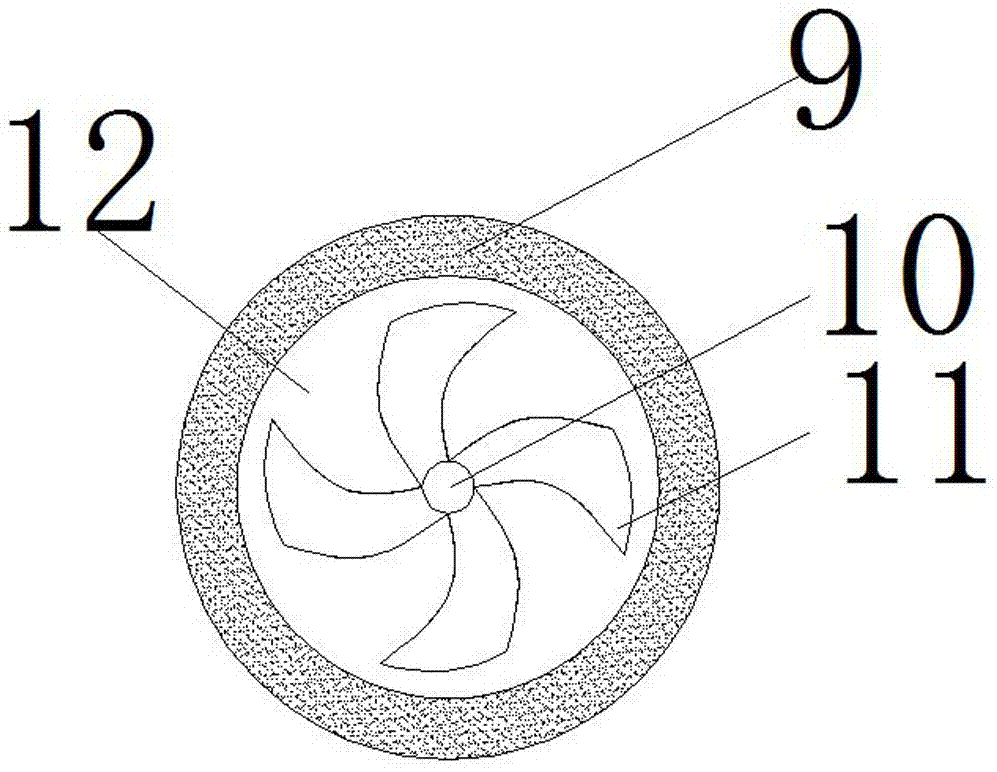

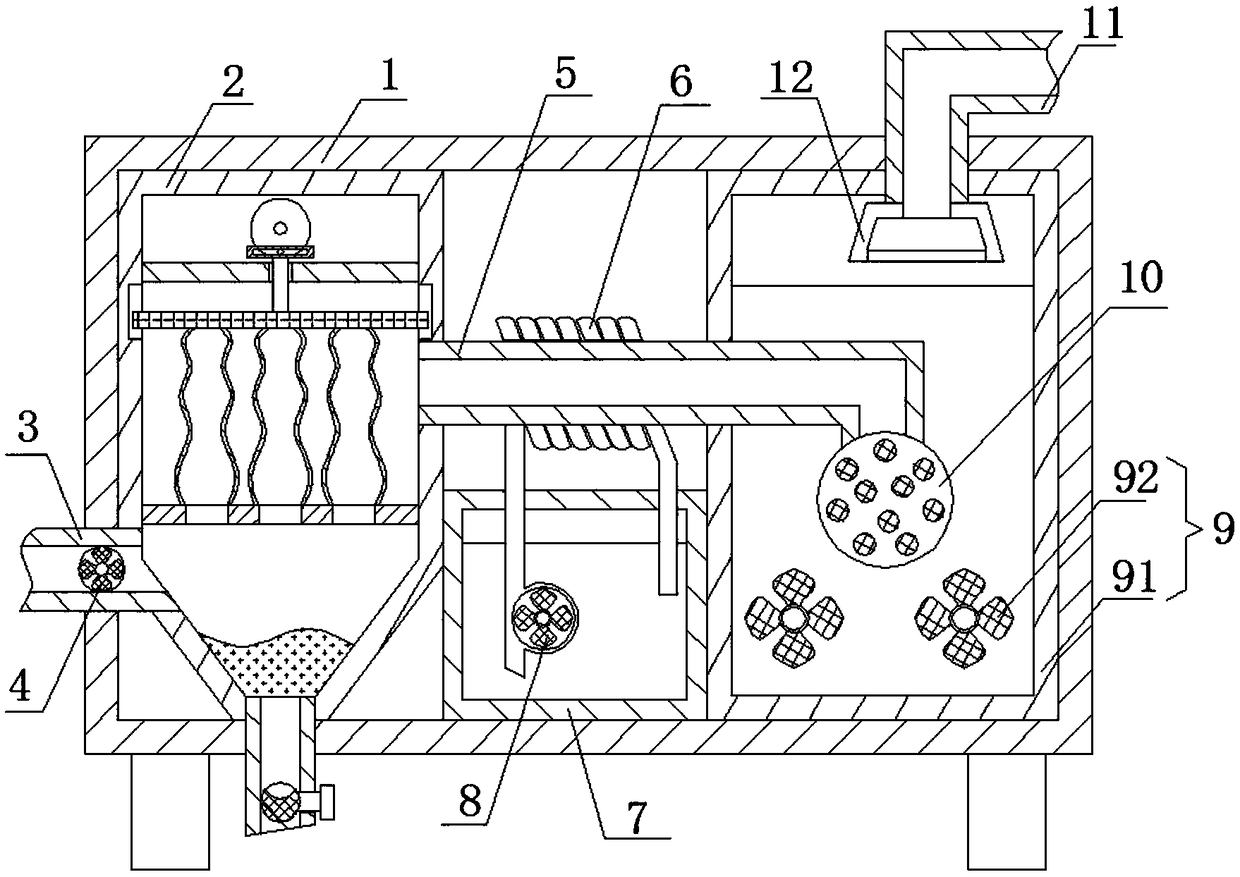

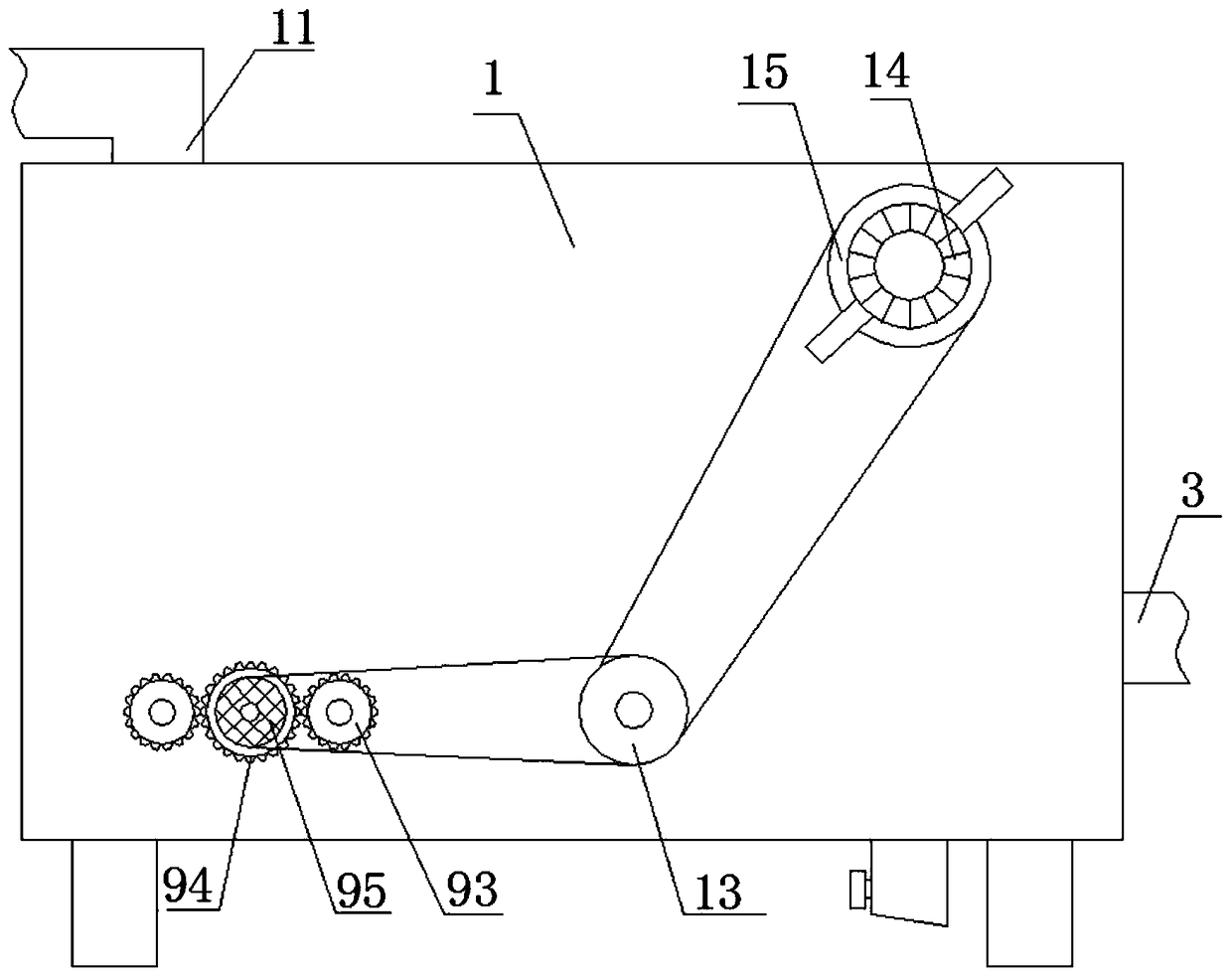

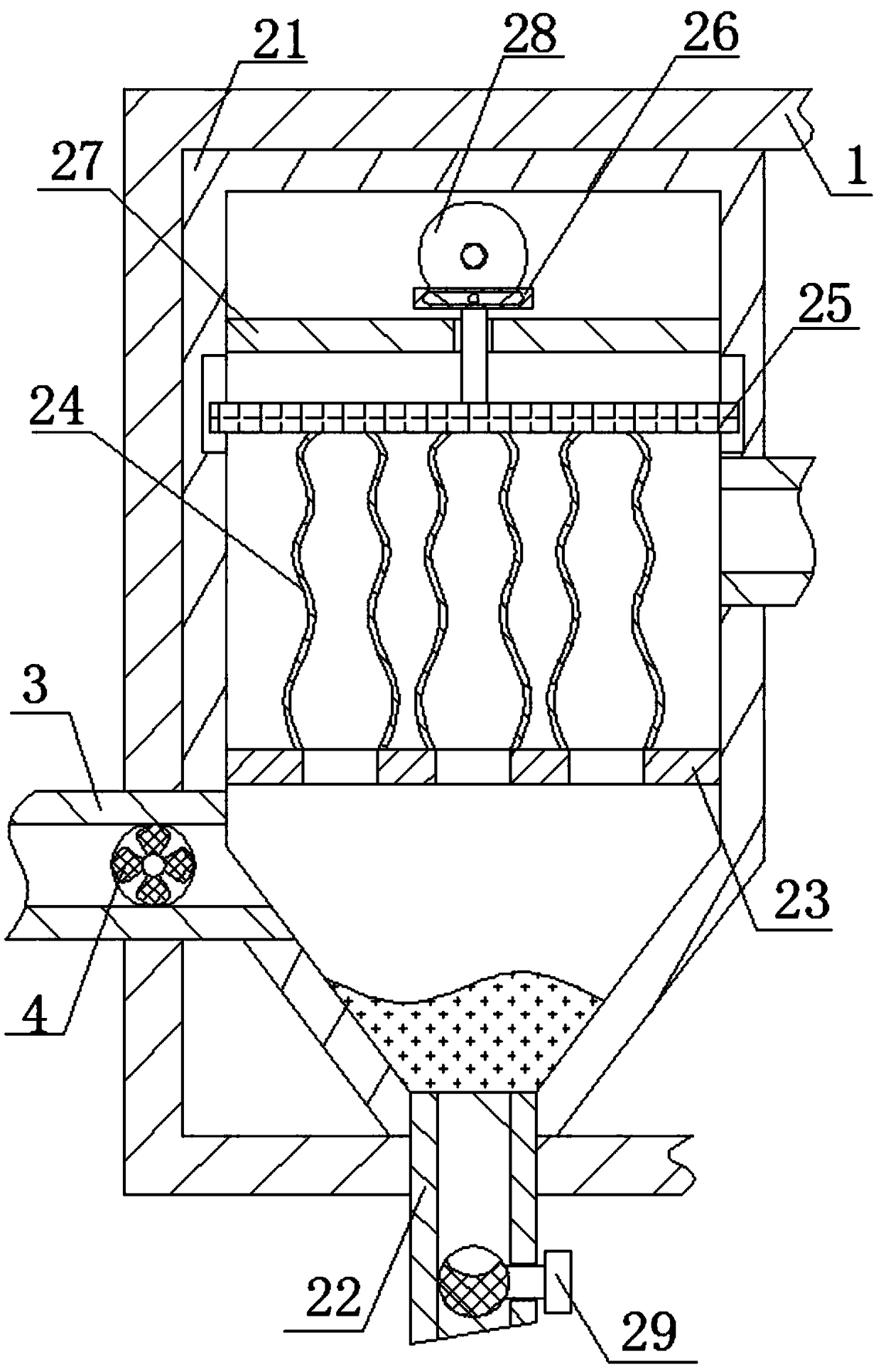

Fuel gas purification plant for pneumatic power generation by biomass in the countryside

InactiveCN108774550AHigh-efficiency filtration and purificationEfficient purificationCombination devicesGas purification by non-gaseous materials condensationTarSpray nozzle

The invention provides a fuel gas purification plant for pneumatic power generation by biomass in the countryside comprising a shell, a main purification device, an inlet pipe and a fan, wherein, theshell is fixedly connected with the main purification device in the inner walls, the air inlet is in through connection with the lower end of walls of one side of the main purification device at one end, penetrates side walls of the shell to hit the external cavity of the shell at the other end and provided with the fan, a connecting pipe is in through connection with walls of the other side of the main purification device at one end, hits the internal cavity of a purification-aided device and is in through connection with a spherical exhaust nozzle at the other end. The fuel gas purificationplant for pneumatic power generation by biomass in the countryside overcomes defects of the prior art, has reasonable design and compact structure, efficiently extracts and collects products with highadditional value, effectively cools high-temperature fuel gas to reduce damage of high temperature on gas turbines, and effectively clears remaining vinegar and tar by single washing to facilitate extraction by staff.

Owner:安徽省建辉生物质能发展有限公司

A kind of polyvinyl alcohol medical sponge and preparation method thereof

ActiveCN106916333BEasy to clean and removeGood biocompatibilityAbsorbent padsBandagesCross-linkPolyvinyl alcohol sponge

The invention provides a medical polyvinyl alcohol sponge and a preparation method. The preparation method comprises the following steps: adding polyvinyl alcohol and starch into distilled water carrying out dissolving at 50 to 95 DEG C under stirring so as to obtain a mixed solution; adding a cross-linking agent, an emulsifier and a foam stabilizer into the mixed solution and carrying out stirring at 20 to 60 DEG C for 2 to 8 h so as to obtain a second mixed solution; adding an acidic catalyst into the second mixed solution and carrying out an acetalation cross-linking reaction at a constant temperature of 20 to 90 DEG C for 30 to 180 min so as to obtain emulsion-like liquid; and completion of the reaction, pouring the emulsion-like liquid into a mold, carrying out heating at 50 to 95 DEG C for curing, carrying out demoulding and washing after cooling, and then carrying out cutting and sterilization so as to obtain the medical polyvinyl alcohol sponge. The medical polyvinyl alcohol sponge prepared in the invention has a through hole structure, uniform pore diameter, good biocompatibility, excellent affinity, high porosity and fast liquid absorption rate, and is applicable to the field of surgical sciences, especially as a sponge consumable for vacuum sealing drainage.

Owner:WUHAN DRAGONBIO ORTHOPEDIC PROD

Comprehensive processing technology for conducting deep dust removal, denitration and desulphurization on glass kiln smoke

ActiveCN105435545AImprove capture efficiencyCapable of trapping sulfur trioxideDispersed particle filtrationLow nitrogenSlurry

The invention discloses a comprehensive processing technology for conducting deep dust removal, denitration and desulphurization on glass kiln smoke, and relates to the field of glass kiln smoke processing. Raw material smoke is discharged into a smoke removal flue, magnesium-containing powder and partly-collected dust are injected into the raw material smoke and mixed with the raw material smoke, and mixed smoke is obtained; the obtained mixed smoke is injected into a bag type dust remover to be filtered, and low-dust smoke and dust are obtained; dust is divided into two parts; magnesium-containing powder is added to one part, the part is injected back into the dust removal flue through a gas flow jetting device to be mixed with the raw material smoke; water is added to the other part, and desulphurization slurry is prepared; the obtained low-dust smoke is injected into a low-temperature SCR denitration device to be subjected to denitration, and low-nitrogen and low-dust smoke is obtained; the low-nitrogen and low-dust smoke is injected into a wet type desulphurization device, the prepared desulphurization slurry is added for desulphurization, and waste gas is discharged into the atmosphere. Compared with the prior art, the comprehensive processing technology has the advantages that dust removal effect is good, denitration efficiency can be improved, recycle of waste is achieved, and smoke pollutant deep emission reduction is achieved.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com