Pouring system device and pouring method for iron based sand coated cast brake drums

A technology of iron mold sand-covered casting and pouring system, which is applied to casting molding equipment, molds, cores, etc., can solve the problems of defective castings, inconvenient cleaning, shrinkage and other problems, and achieves large static pressure head, cleaning and removal. Convenient, low air pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0026] Example.

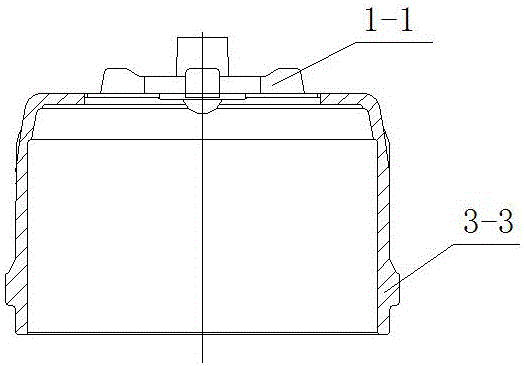

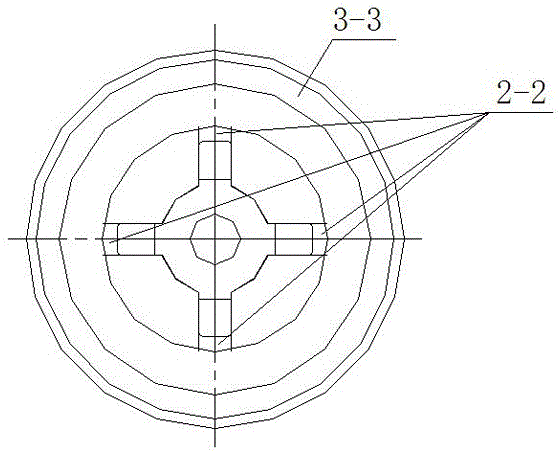

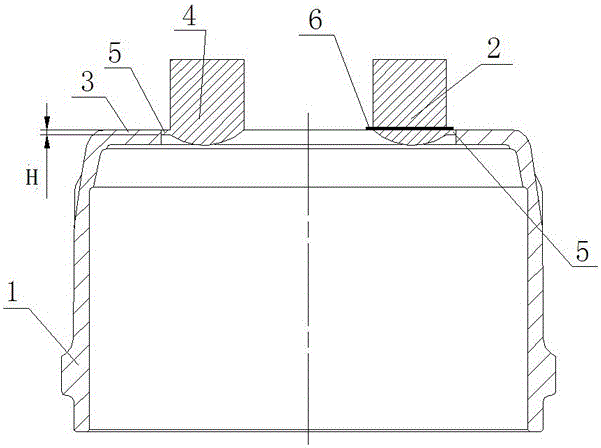

[0027] see Figure 3 to Figure 7 The sprue 2 and the inrunner 3 in the gating system device of the iron-type sand-covered casting brake drum are connected to each other. The overflow riser 4 is arranged at the other end of the inner circle of the upper end of the brake drum casting 1, and the exhaust overflow The groove 5 is arranged on one side of the overflow riser 4 .

[0028] The filter screen 6 in this embodiment is arranged under the sprue 2 , and the wedge is arranged at the overflow edge of the overflow riser 4 close to the inner circle of the brake drum casting 1 .

[0029] The height H of the inrunner 3 in this embodiment is 3-5 mm, the width is 80 mm, the diameter of the overflow riser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com