Device and method for efficient adsorption and agglomeration removal of ultrafine particles and heavy metal mercury

A technology for ultra-fine particles and heavy metals, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation. It can solve the problems of high operation and maintenance costs, poor operation stability, large equipment investment, etc. The effect of convenient operation and maintenance and low operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

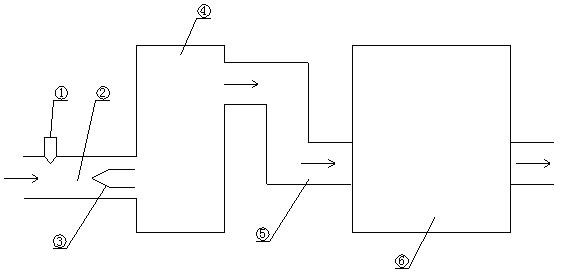

[0019] figure 1 Among them, along the direction of flue gas flow, a modified fly ash injection device (1) is installed in the front section of the inlet flue (2), an air flow distribution device (3) is installed in the rear section of the inlet flue (2), and the inlet flue (2) It is connected with the turbulence enhanced agglomeration device (4), and the turbulent flow enhanced agglomeration device (4) is connected with the dust removal device (6) through the outlet flue (5).

[0020] When the device and method of the present invention are in working condition, the modified fly ash injection device (1) installed in the front section of the inlet flue (2) injects modified fly ash into the flue gas according to the designed injection amount, and the modified fly ash is modified. After the non-toxic fly ash is sprayed into the inlet flue, its rich ultrafine micropores, carbon adsorption sites, metal oxide catalytic sites, etc. have a strong impact on the ultrafine particles and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com