High-sulfur-content carbon-sulfur material and preparation method thereof

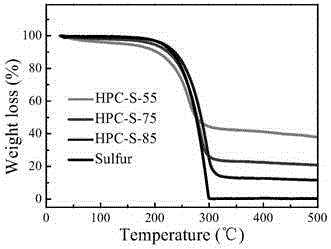

A content, carbon and sulfur technology, applied in the direction of electrical components, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of insufficient capacity, sulfur agglomeration, etc., to improve cycle performance and rate performance, enrich the specific surface area, and facilitate Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In the first step, 1.8 g of sodium sulfate, 1.5 g of glucose and 15 g of deionized water were mixed to obtain a mixed solution.

[0023] In the second step, the melamine foam was immersed in the mixed solution, squeezed and infiltrated repeatedly, and then freeze-dried at -50°C for 12 hours to obtain a precursor.

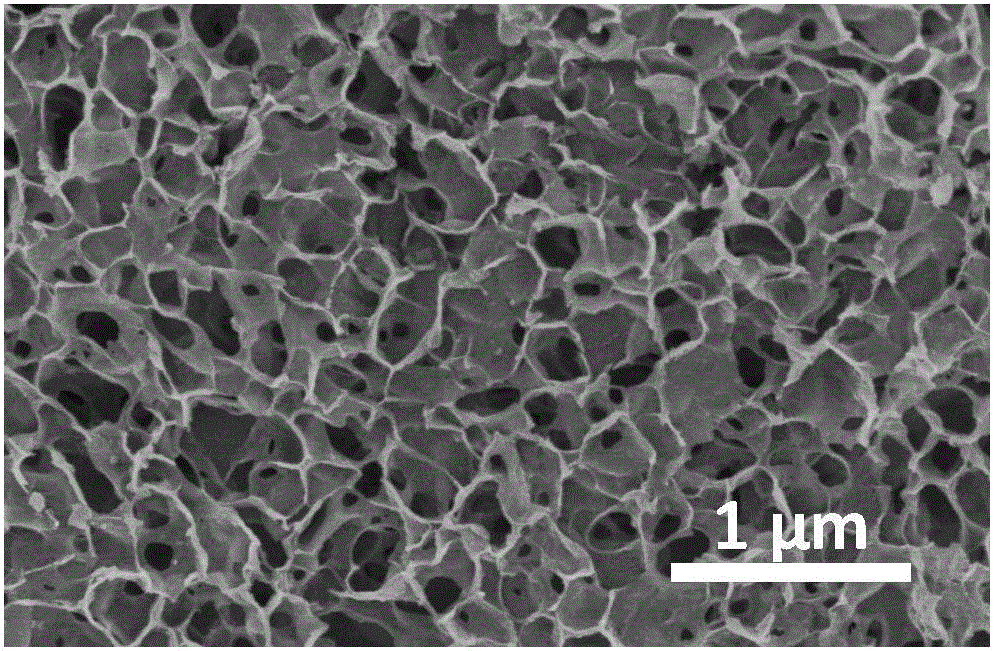

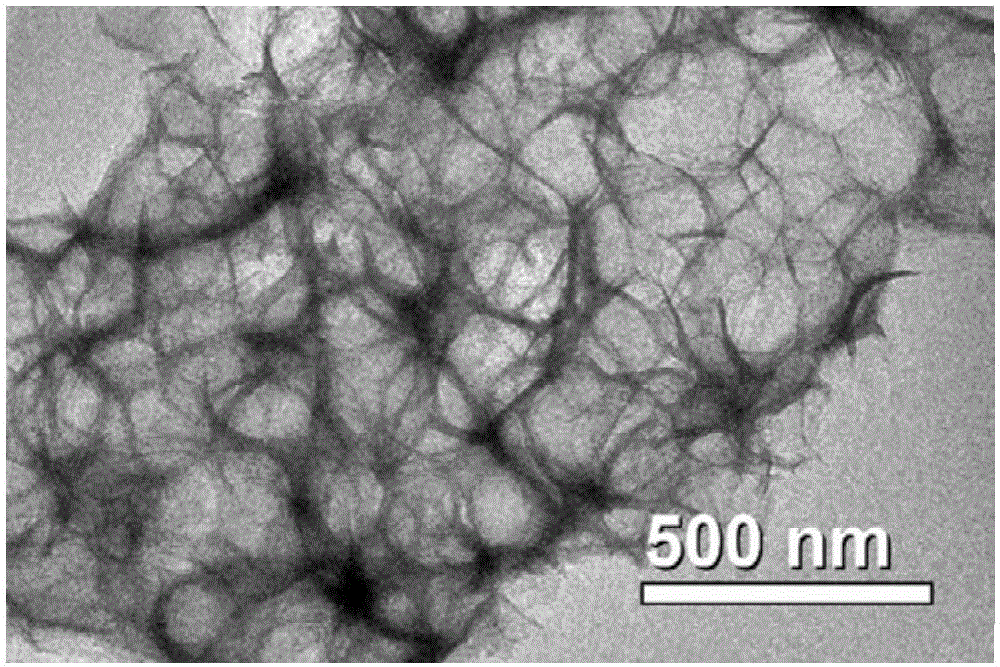

[0024] The third step is to put the precursor in a nitrogen-protected tube furnace, heat treatment reaction at 900°C, the heating rate is 5°C / min, and the holding time is 2 hours. After natural cooling, the intermediate product is obtained.

[0025] In the fourth step, the intermediate product was added into 60ml of 8g ferric chloride solution, and reacted for 6 hours under stirring to obtain the initial reaction product.

[0026] In the fifth step, the initial reaction product is vacuum filtered, washed with water three times, and then dried in an oven at 60°C to obtain the final product, which is a carbon-sulfur material with high sulfur content.

[0027] ...

Embodiment 2

[0031] The difference from Example 1 is that lithium sulfate is used as a template and a sulfur source: 1.8 g of lithium sulfate, 1.5 g of glucose and 15 g of deionized water are mixed to obtain a mixed solution, and melamine foam is immersed in the mixed solution, and repeatedly extruded and infiltrated Afterwards, freeze-dry for 12 hours to obtain the precursor. The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0033] The difference from Example 1 is that magnesium sulfate is used as a template and a sulfur source: 1.8 g of magnesium sulfate, 1.5 g of glucose and 15 g of deionized water are mixed to obtain a mixed solution, and the melamine foam is immersed in the mixed solution, and repeatedly extruded and infiltrated Afterwards, freeze-dry for 12 hours to obtain the precursor. The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com