Micro-fluidic apparatus integrated with PDMS film, manufacturing method and application thereof

A microfluidic and microfluidic chip technology, which is applied to laboratory containers, chemical instruments and methods, and photoplate-making processes on patterned surfaces. It can solve the problems of complex preparation steps, high cost, and harsh experimental conditions. , to achieve the effect of simple production steps, good air permeability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

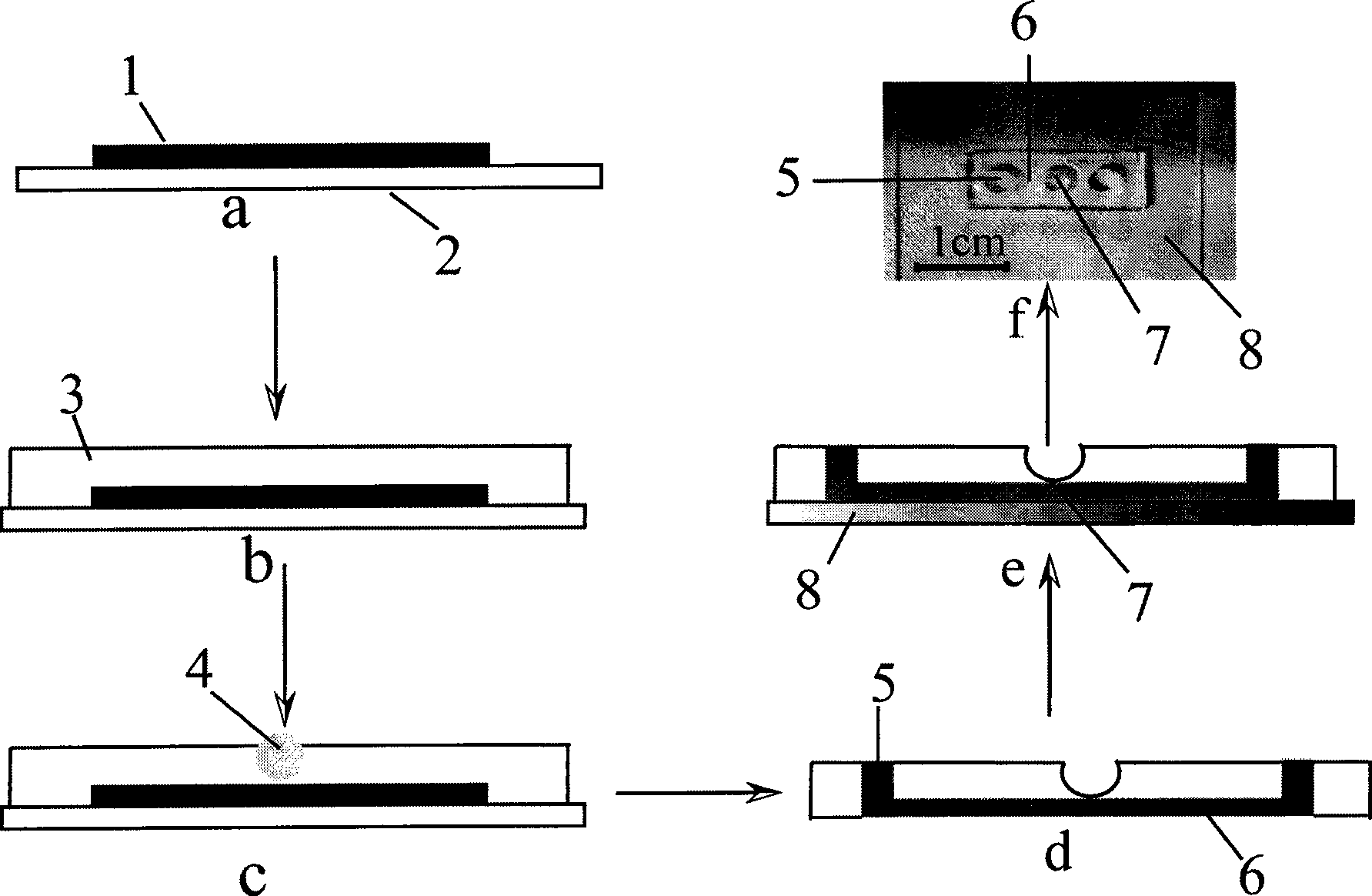

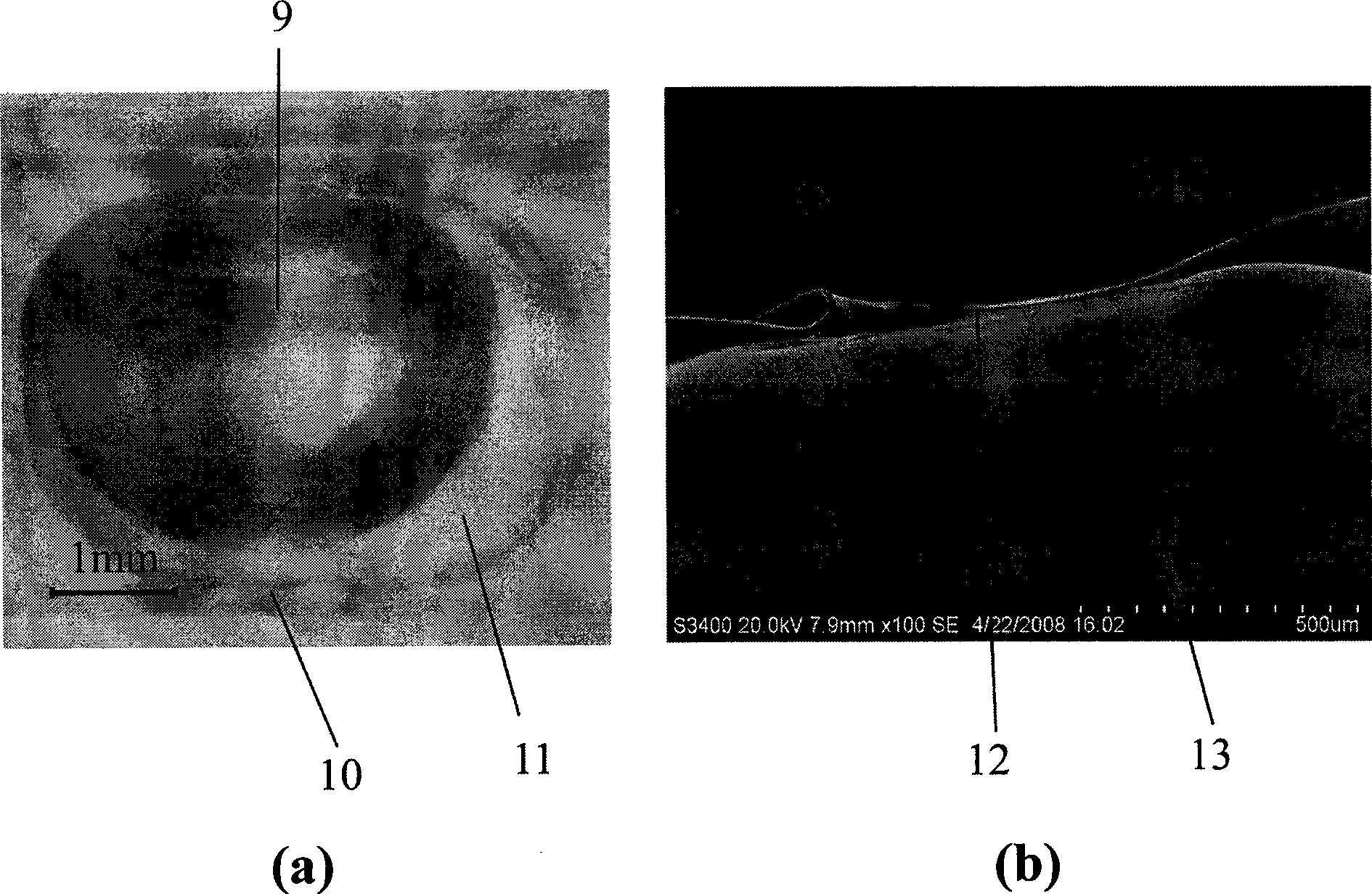

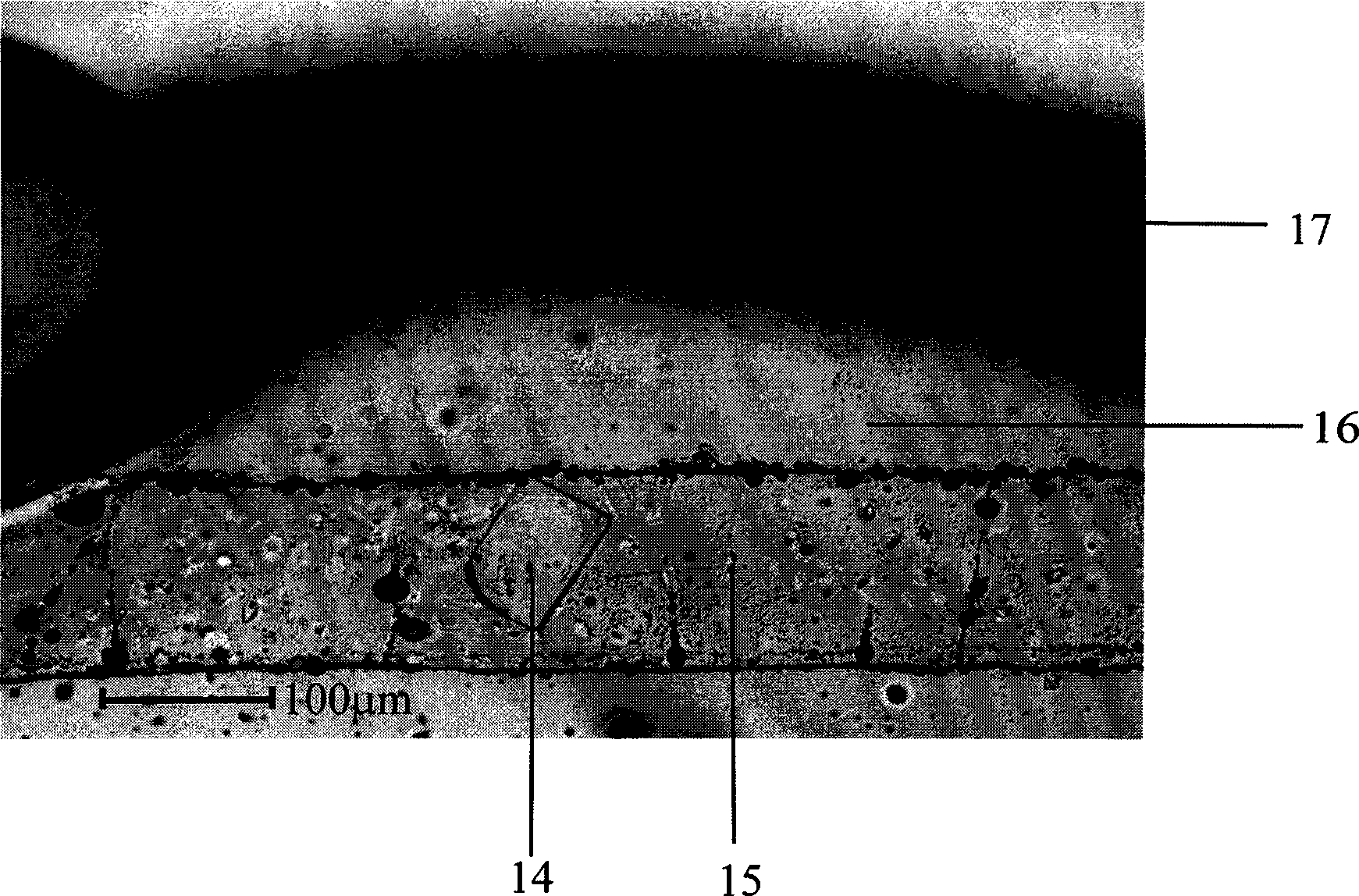

[0023] Such as figure 1 As shown in (a), cut a piece of 2.5 cm x 4 cm PET film (2: PET hydrophobic substrate), print a 1.5 cm long x 150 micron wide toner pipe as a male mold (1: print pipe male mold), and The surrounding area is piled up with PDMS strips less than 0.4 cm wide and 0.4 cm high to form a pool. (b) Pour the PDMS prepolymer prepared by the PDMS body (Dow Corning Corporation, Midland-Michigan, USA) and its cross-linking agent (Dow Corning Corporation, Midland-Michigan, USA) at a mass ratio of 10:1 into the pool , so that the PDMS liquid level is about 0.4 cm (3: PDMS prepolymer). (c) 20 microliters of water droplets (4: water droplets) were dropped into the PDMS prepolymer, and after the water droplets settled to the bottom, they were put into an oven and cured at 60 degrees Celsius for 30 minutes. (d) After the PDMS is completely solidified, take it out from the oven, remove the remaining droplets, uncover the PDMS cured layer, that is, separate from the PET sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com