Method for removing magnesium in manganese sulfate solution through double salt crystallization process

A technology of manganese sulfate solution and crystallization method, which is applied in the direction of photographic process, instrument, photographic auxiliary process, etc., can solve the problems of lower product quality, low production efficiency, loss of active ingredients, etc., and meet the requirements of process production, manpower and material resources , easy to realize the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, double salt crystallization method removes the method for magnesium in the manganese sulfate solution, and the steps are as follows:

[0039] The crystallization device is added to the leaching link of the electrolytic manganese production system. Specifically, it can be added between the leached liquid and the low tank, between the low tank and the high tank, between the high tank and the electrolytic tank, or between the anolyte and the leaching tank in the leaching process. Among them, the crystallization device is a commonly used device, which includes the functions of pressurization and temperature control. In this embodiment, the crystallization device is added between the upper tank and the lower slag, and then part of the manganese sulfate solution is drawn out, and the concentration of ammonium sulfate in the manganese sulfate solution is first controlled to be 80g / L; the concentration of magnesium ions is 10g / L; then the pressure is controlled to be...

Embodiment 2

[0040] Embodiment 2, double salt crystallization method removes the method for magnesium in the manganese sulfate solution, and the steps are as follows:

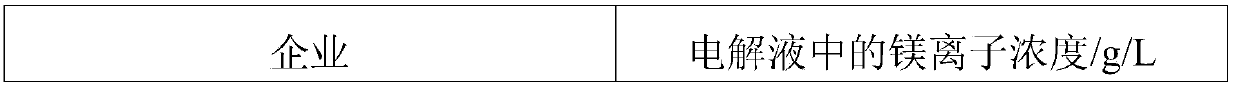

[0041] Add the crystallization device between the high-level tank and the low-level slag, and then lead out part of the manganese sulfate solution. First, control the concentration of ammonium sulfate in the manganese sulfate solution to 140g / L; the concentration of magnesium ions to 30g / L; and then control the pressure to 20Mpa. The initial temperature is 90°C, add magnesium ammonium sulfate to crystallize, and reduce the temperature to 70°C in 180 minutes. The amount of seed crystals added is 200g / L, and the reaction time is 72h to obtain magnesium ammonium sulfate crystals. Take out the crystals to realize magnesium removal. .

Embodiment 3

[0042] Embodiment 3, double salt crystallization method removes the method for magnesium in the manganese sulfate solution, and the steps are as follows:

[0043] Add the crystallization device between the anolyte and the leaching tank, and then draw out part of the manganese sulfate solution. First, control the concentration of ammonium sulfate in the manganese sulfate solution to be 100g / L; the concentration of magnesium ions to be 15g / L; and then control the pressure to 8Mpa. The initial temperature is 60°C, add magnesium ammonium sulfate to crystallize, and reduce the temperature to 40°C in 60 minutes. The amount of seed crystals added is 40g / L, and the reaction time is 22h. Magnesium ammonium sulfate crystals are obtained, and the crystals are taken out to realize magnesium removal. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com