Cutting method for laminated body and cutting knife used therein

A laminated body and cutter technology, applied in metal processing and other directions, can solve problems such as damage to the surface of brittle material substrates, and achieve the effect of prolonging the service life and preventing rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

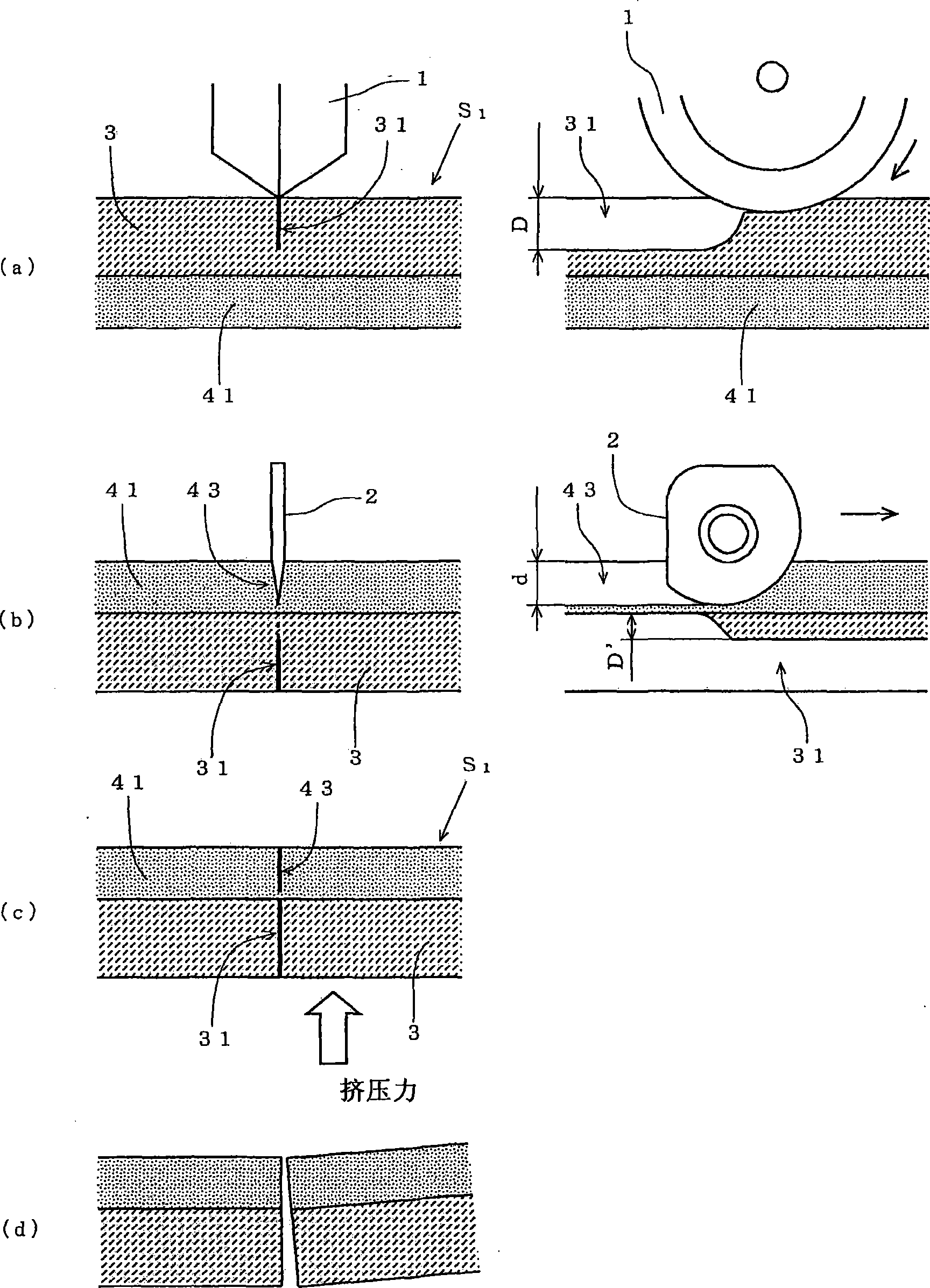

Embodiment 1

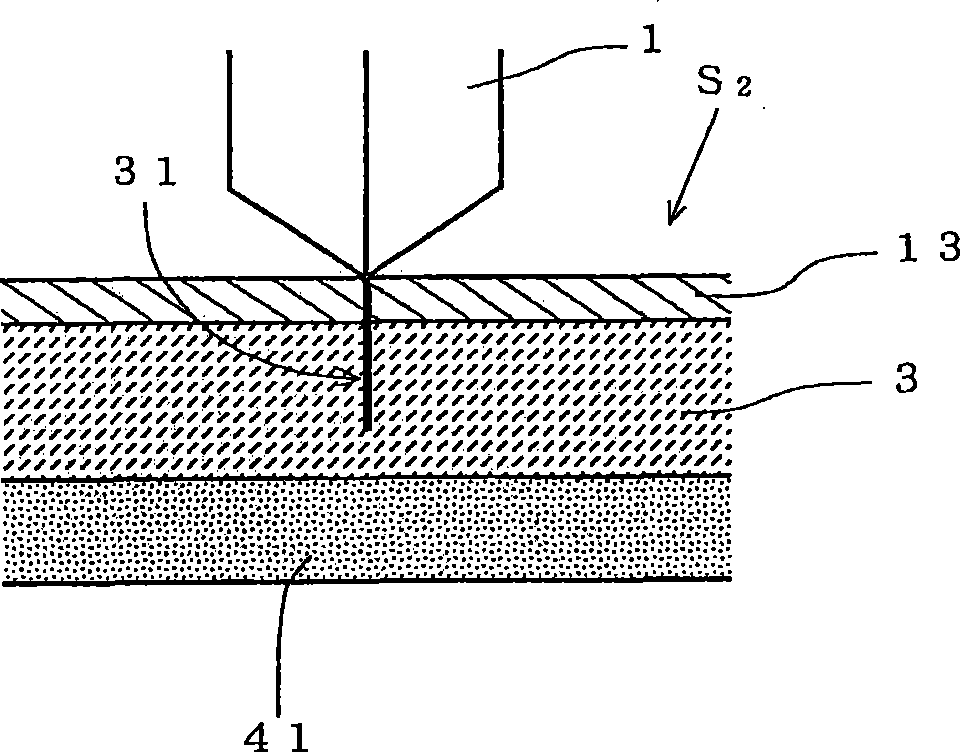

[0076] On one side of a glass substrate made of soda lime glass (soda lime) with a thickness of 1.1 mm, a first PET (polyethylene terephthalate) film with a thickness of 0.2 mm is sequentially laminated from the glass substrate. The second PET film constitutes a laminated body. For such a laminated body, firstly, the cutting wheel is applied with a load of 0.14 MPa and pressed against the glass substrate, and moves relative to the glass substrate at a cutting speed of 300mm / sec to form on the glass substrate. Cutting line. The depth of the vertical crack formed at this time was 50% of the thickness of the glass substrate. In addition, the specifications of the cut-off wheel used are as follows.

[0077] Cutting Wheel Specifications:

[0078] Outer diameter: 2mm

[0079] Thickness: 0.65mm

[0080] Inner diameter: 0.8mm

[0081] Blade angle: 115°

[0082] Groove depth: 25μm

[0083] Ridgeline length between grooves: 25μm

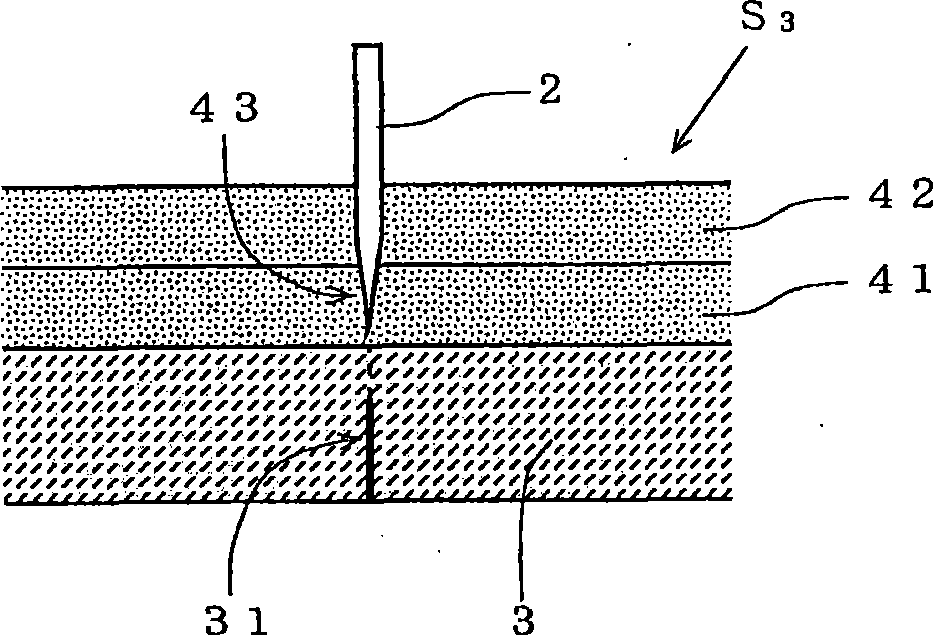

[0084] Next, a cutter with a blade angle of 45° ...

Embodiment 2

[0087] For a laminate having the same structure as in Example 1 except that the thickness of the glass substrate is 0.55 mm, the thickness of the first PET film is 0.2 mm, and the thickness of the second PET film is 0.05 mm, the following specifications are cut The wheel applies a load of 0.1MPa and presses against the glass substrate, moves relative to the glass substrate at a cutting speed of 300mm / sec, and forms a cutting line on the glass substrate. The depth of the vertical crack formed at this time was 10% of the thickness of the glass substrate.

[0088] Cutting Wheel Specifications:

[0089] Outer diameter: 3mm

[0090] Thickness: 0.65mm

[0091] Inner diameter: 0.8mm

[0092] Blade angle: 130°

[0093] Groove depth: 3μm

[0094] Ridge length between grooves: 15μm

[0095] Next, a cutter with a blade angle of 30° was pressed against the second PET film with a load of 0.4 MPa, and the cutter was moved relative to the laminate to completely cut the second PET film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com