Method for producing synthesis gas by using coal powder as raw material

A technology for synthesis gas and pulverized coal, which is applied in the gasification of granular/powdered fuel, chemical instruments and methods, and the manufacture of combustible gases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125] Embodiment 1: According to the inventive method, take pulverized coal as raw material to produce synthesis gas

[0126] The method of the present invention is implemented using Shaanxi Shenfu coal as a raw material. The raw material calorific value: 27070J / g, the main element analysis results are listed in the following table 1:

[0127] Table 1: Analytical results of major elements of Shaanxi Shenfu coal

[0128]

[0129] The implementation steps are as follows:

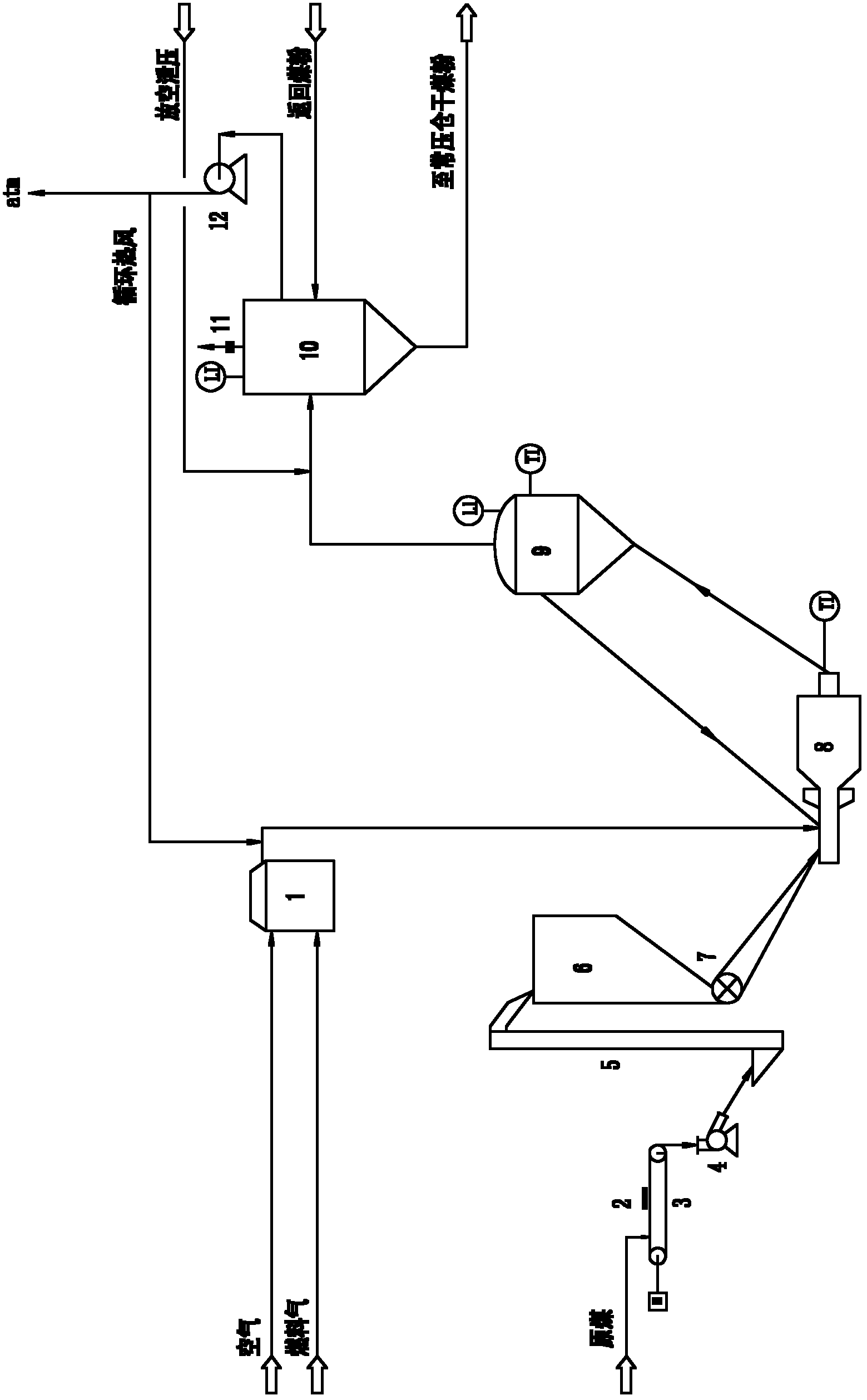

[0130] A. Preparation of dry coal powder: After removing iron that may exist in Shaanxi Shenfu coal with a magnet, use an impact crusher produced by Shanghai Yuanhua Machinery Manufacturing Co., Ltd. to crush coal particles with a particle size of less than 30mm, and then let this The coal particles are lifted to the silo 6 through the bucket elevator 5 . The coal particles in the silo are quantitatively sent to the mill 8 by the feeder 7, and the mill grinds the coal particles into coal powder, and a...

Embodiment 2

[0145] Example 1 The method of the present invention is implemented using Shaanxi Shenfu coal as a raw material, which is long-flame coal with low ash content and low ash melting point with a relatively shallow metamorphism. In this embodiment, Huainan lean coal with high ash content, high ash melting point and deep deterioration degree is used as raw material. The calorific value of the raw material: 22590J / g, the main element analysis results are as follows:

[0146]

[0147] The implementation steps are as follows:

[0148] A. Preparation of dry coal powder: After the Huainan coal is removed with a magnet to remove possible iron, it is crushed with an impact crusher until the particle size is less than 30 mm, and then the coal particles are lifted to the silo 6 through the bucket elevator 5 . The coal particles in the silo are quantitatively sent to the mill 8 by the feeder 7, and the mill grinds the coal particles, and at the same time fully exchanges heat with the hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com