Patents

Literature

5732results about How to "Improve delivery efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

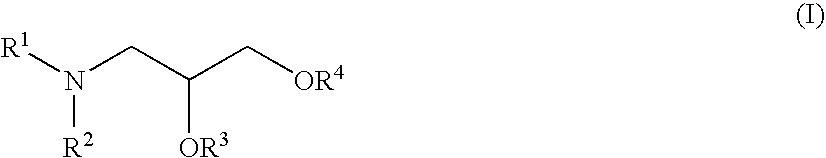

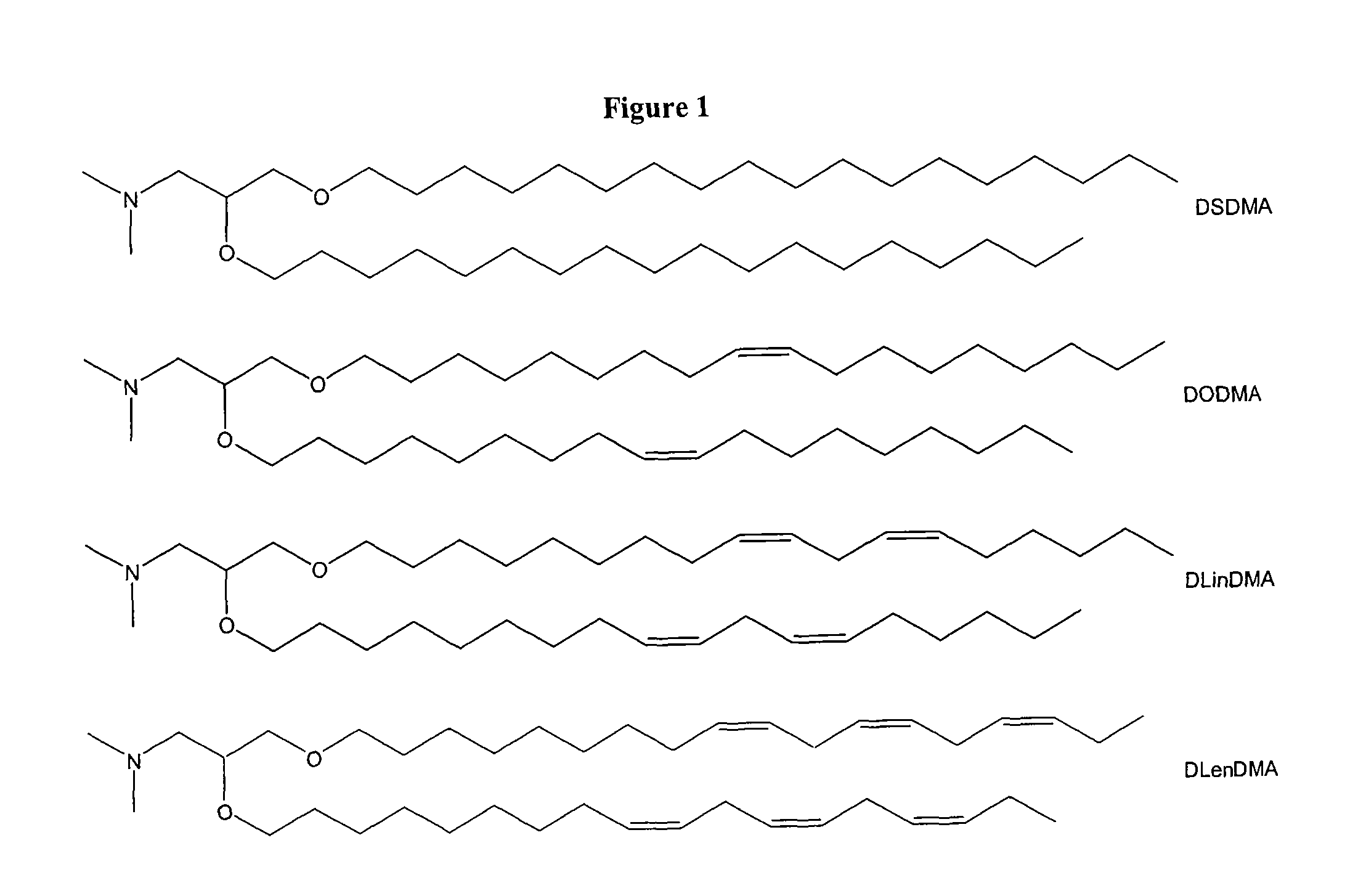

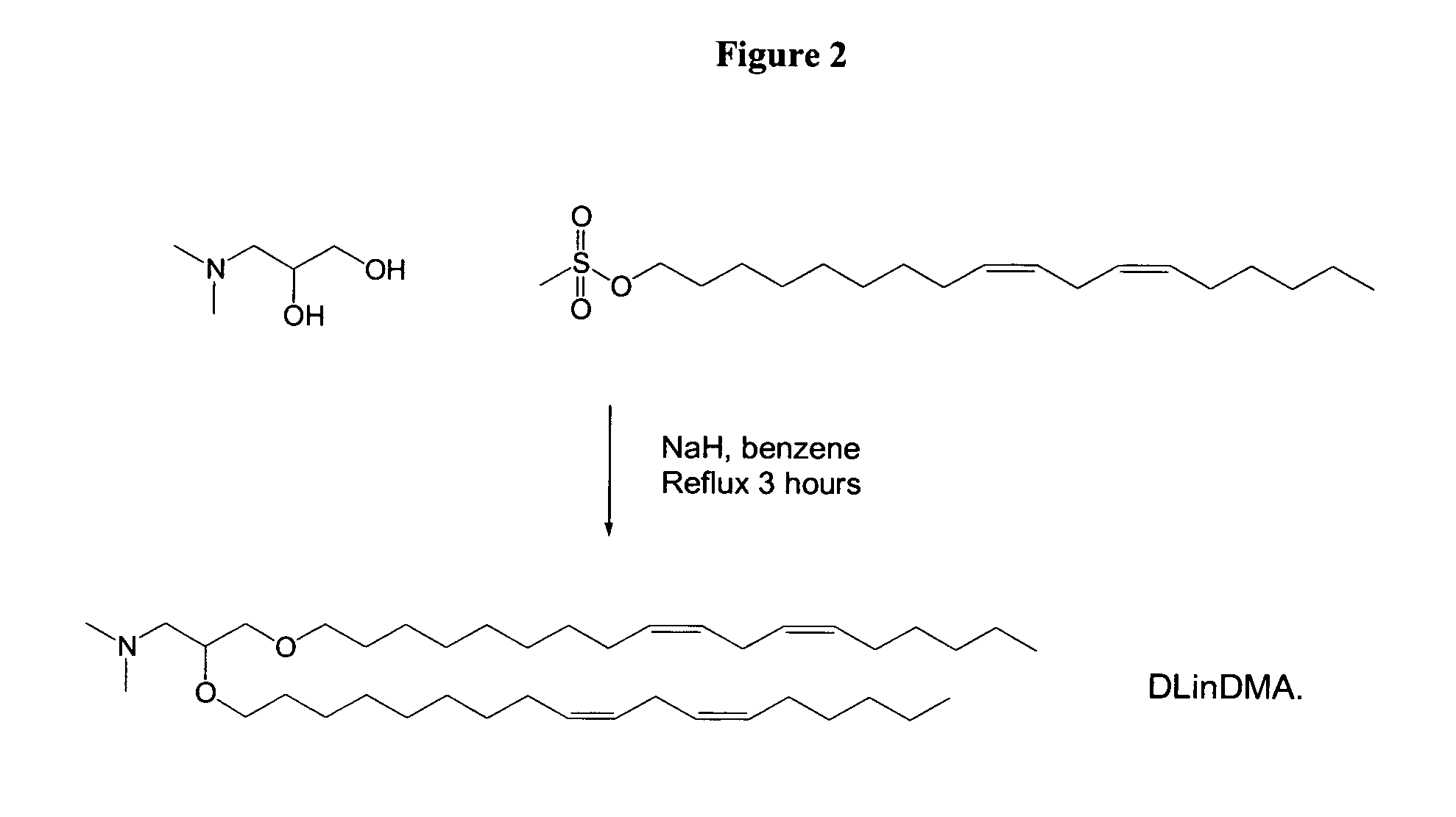

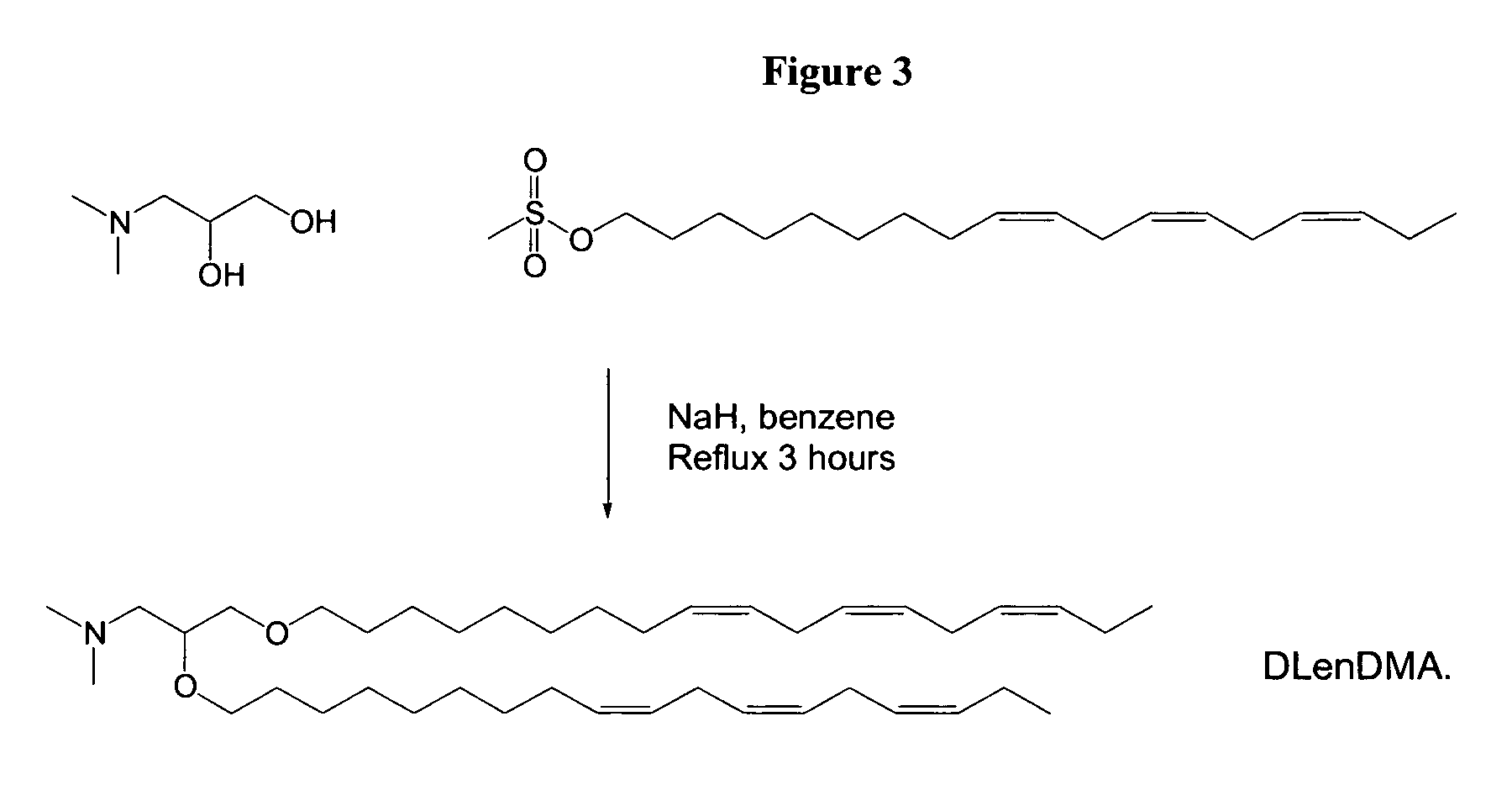

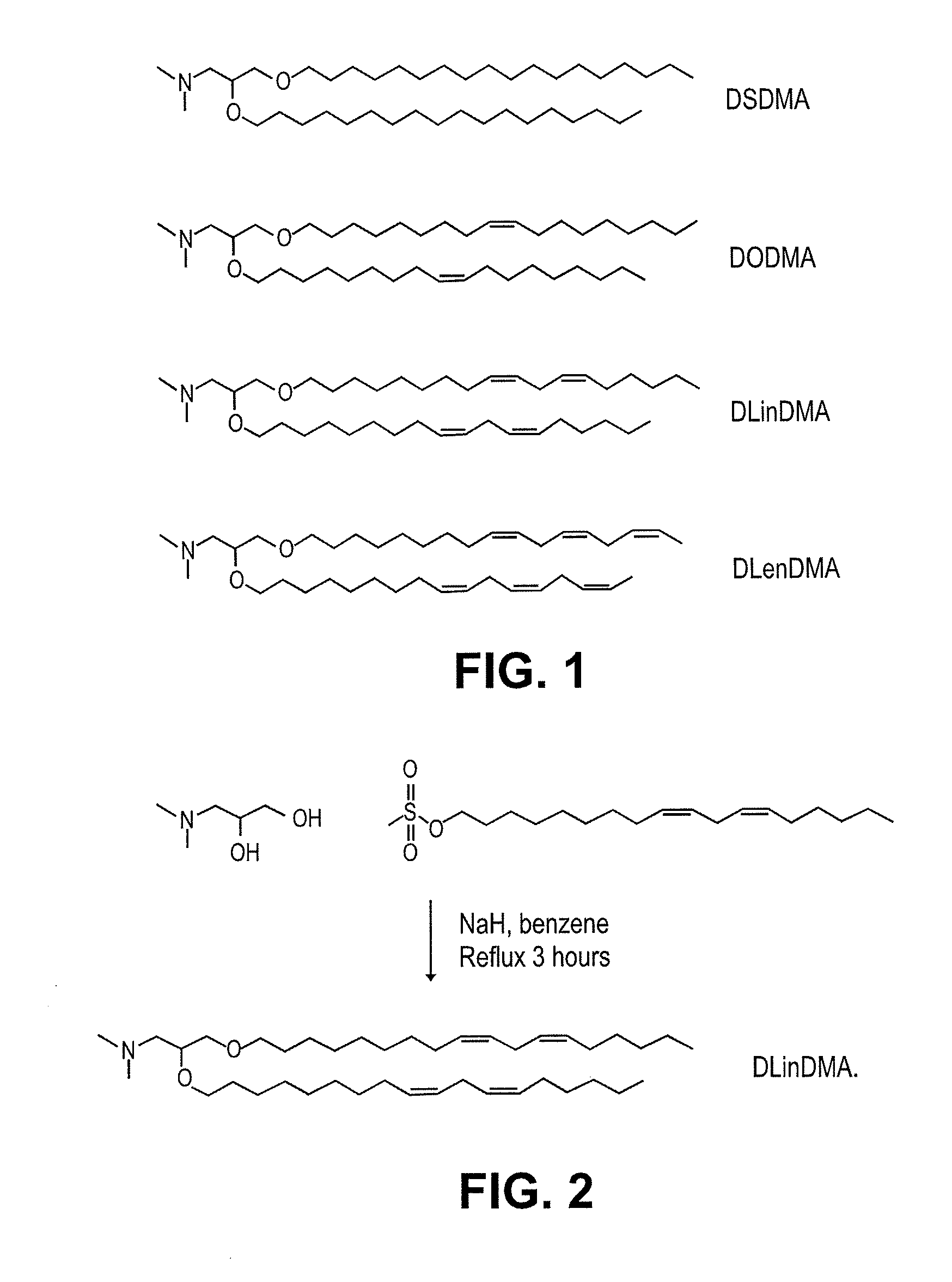

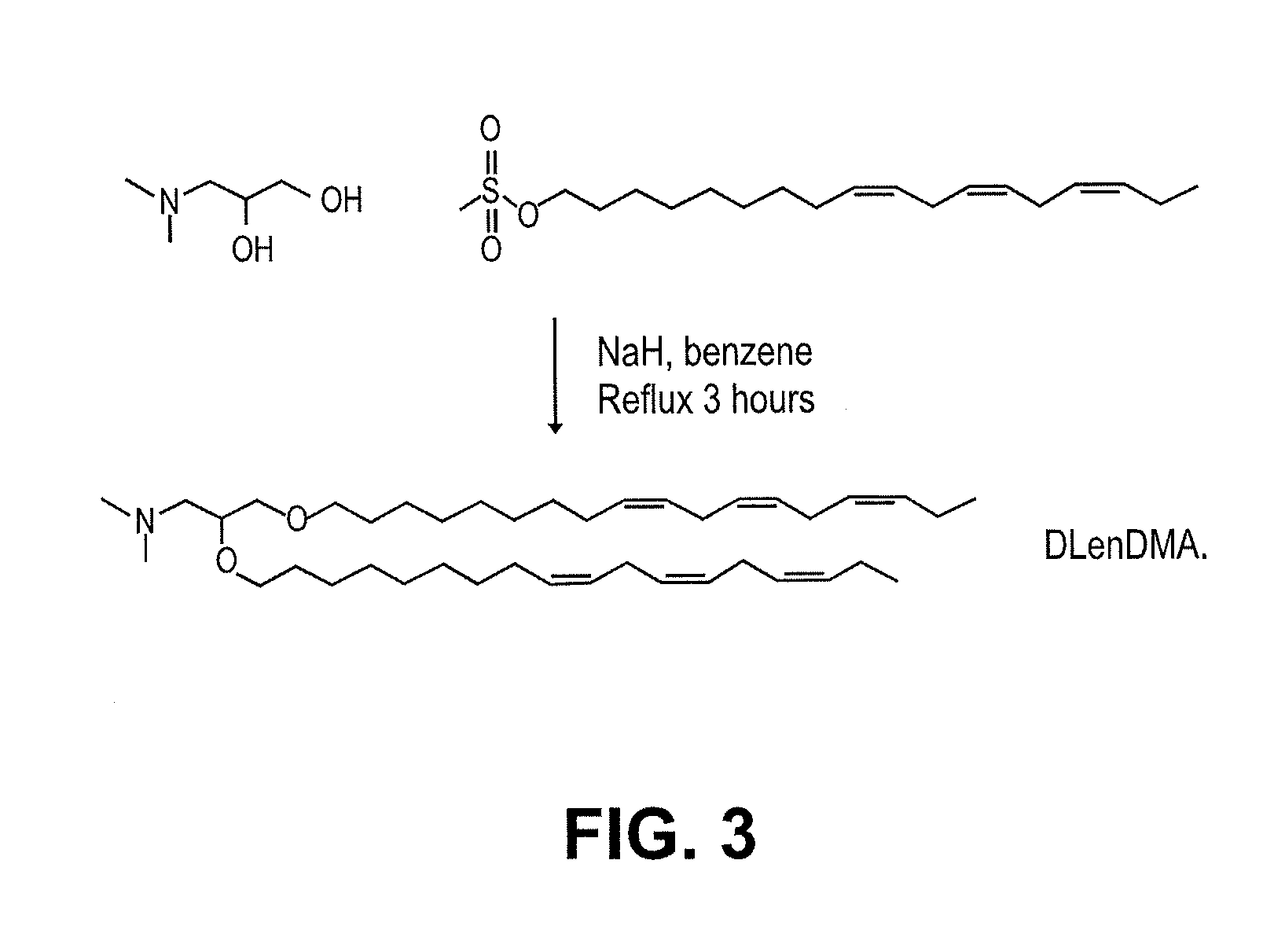

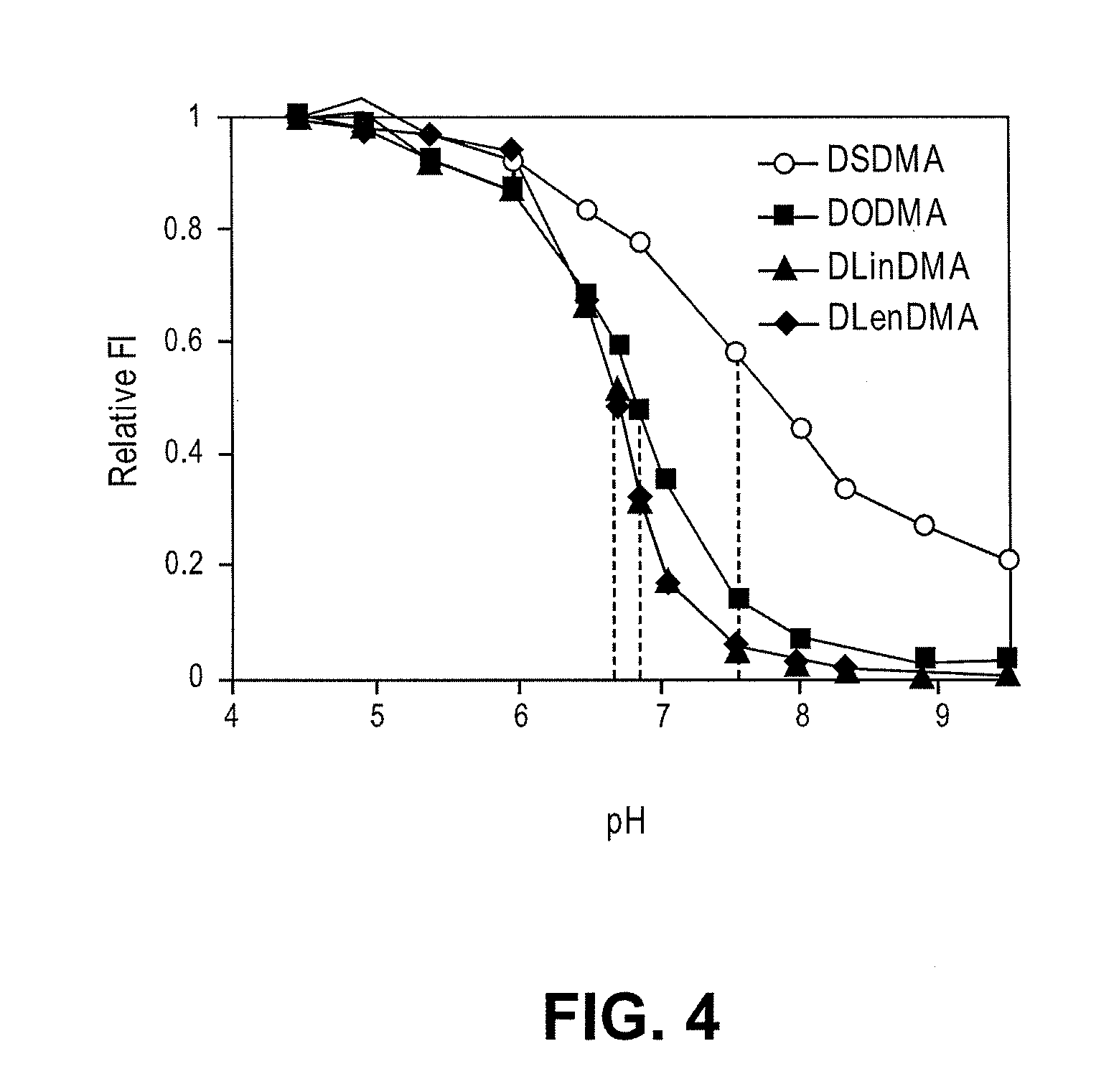

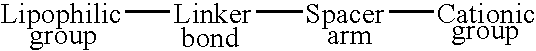

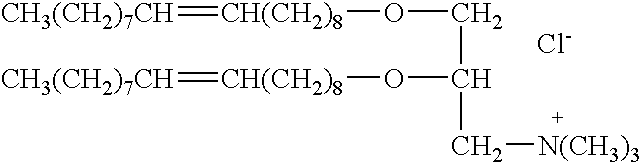

Cationic lipids and methods of use

ActiveUS20060083780A1Increase flexibilityImprove propertiesUltrasonic/sonic/infrasonic diagnosticsNervous disorderLipid formationLipid particle

The present invention provides compositions comprising cationic lipids, liposomes and nucleic acid-lipid particles comprising the cationic lipids, and methods of using such compositions, liposomes, and nucleic acid-lipid particles.

Owner:ARBUTUS BIOPHARMA CORPORAT ION

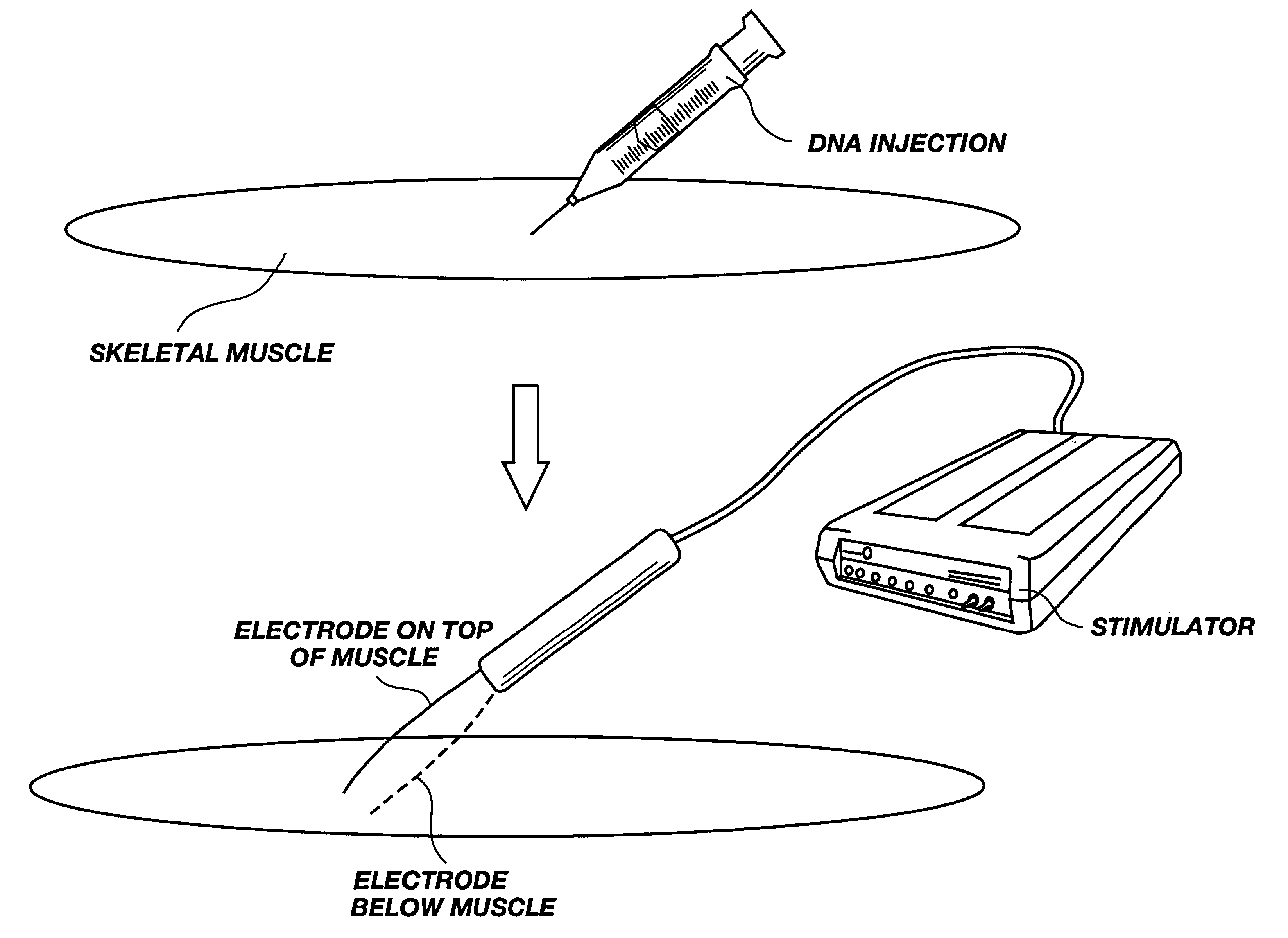

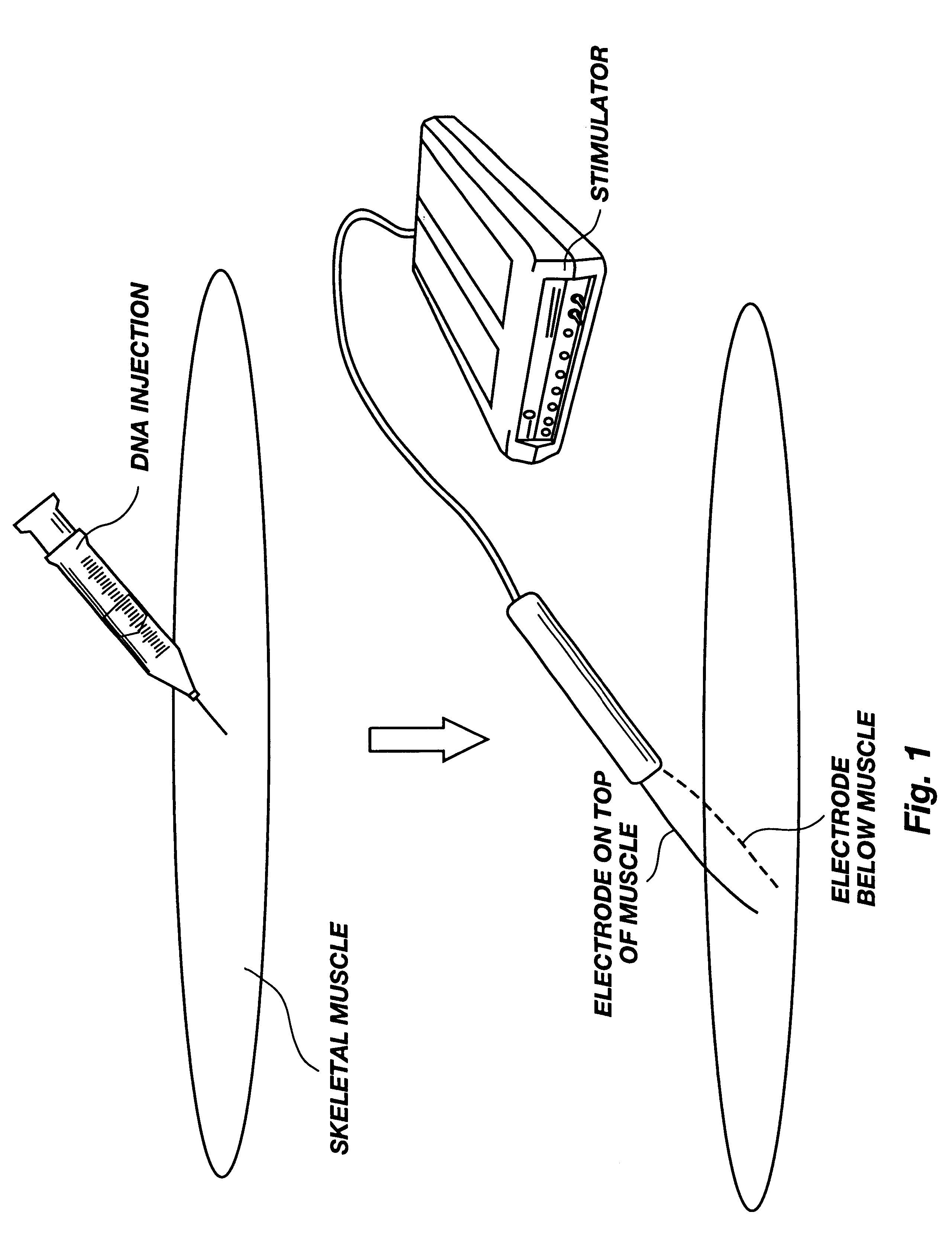

Method for genetic immunization and introduction of molecules into skeletal muscle and immune cells

InactiveUS6261281B1High transfection efficiencyGreat luciferace activityBacterial antigen ingredientsElectrotherapyVaccinationWhole body

A method is disclosed for enhanced vaccination and genetic vaccination of mammals. The vaccination is accomplished by delivering molecules such as proteins and nucleic acids into skeletal muscle and other cells residing in the skeletal muscle in vivo. The protein or nucleic acid is first injected into the muscle at one or multiple sites. Immediately or shortly after injection, electrodes are placed flanking the injection site and a specific amount of electrical current is passed through the muscle. The electrical current makes the muscle permeable, thus allowing the pharmaceutical drug or nucleic acid to enter the cell. The efficiency of transfer permits robust immune responses using DNA vaccines and produces sufficient secreted proteins for systemic biological activity to be observed.

Owner:INOVIO

Cationic lipids and methods of use

ActiveUS7745651B2Increase flexibilityGood fluidityUltrasonic/sonic/infrasonic diagnosticsBiocideLipid particleLiposome

The present invention provides compositions comprising cationic lipids, liposomes and nucleic acid-lipid particles comprising the cationic lipids, and methods of using such compositions, liposomes, and nucleic acid-lipid particles.

Owner:ARBUTUS BIOPHARMA CORPORAT ION

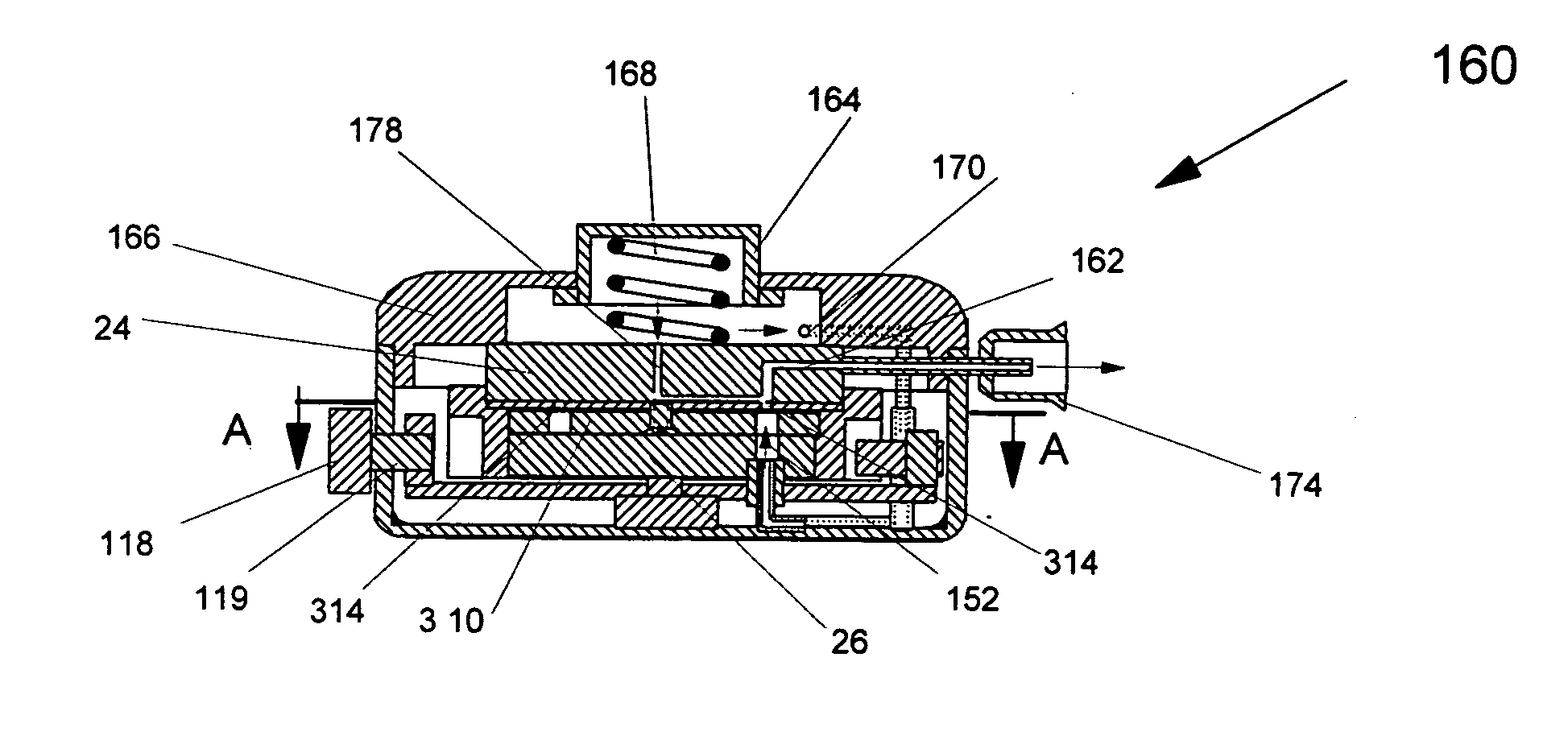

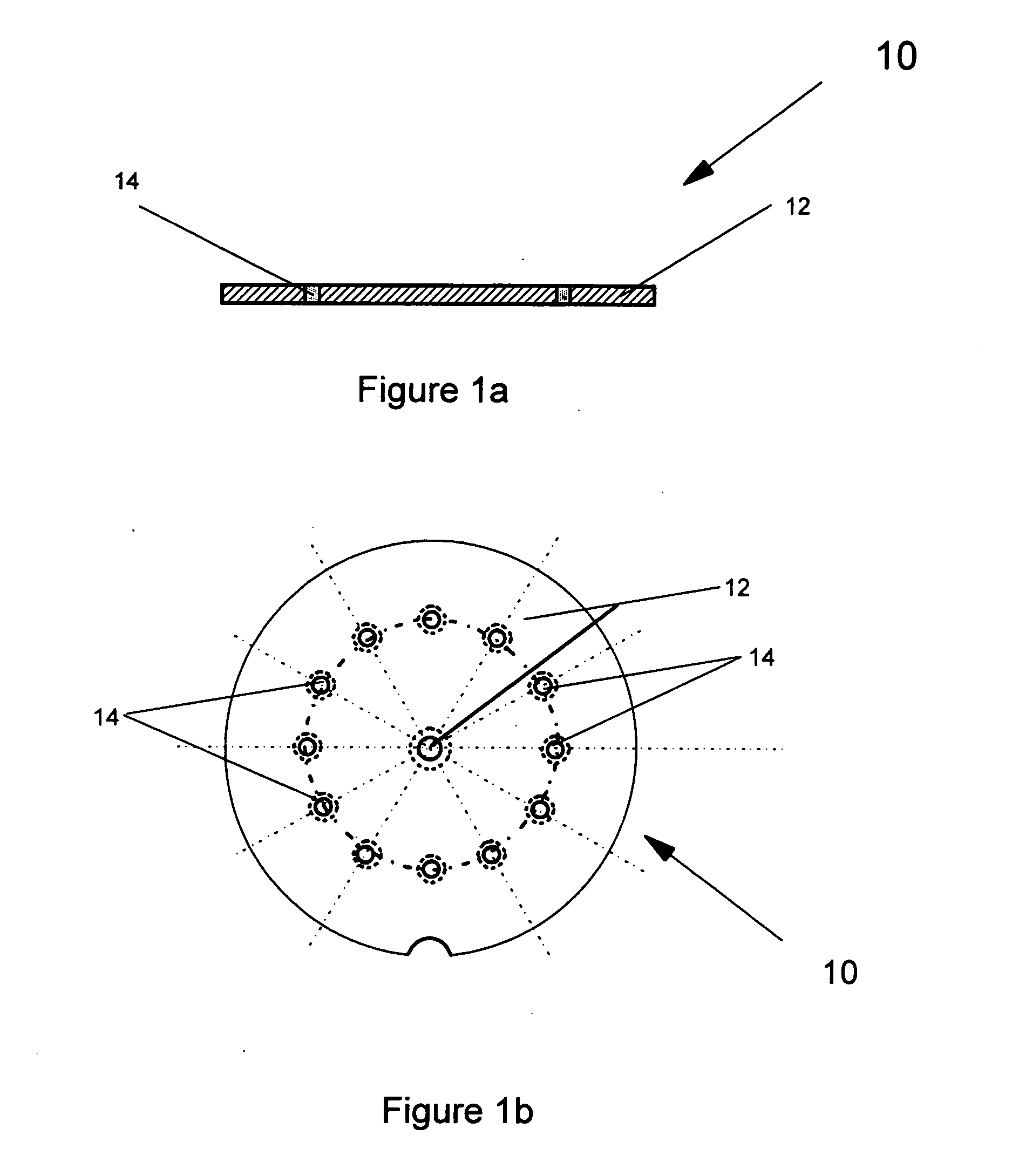

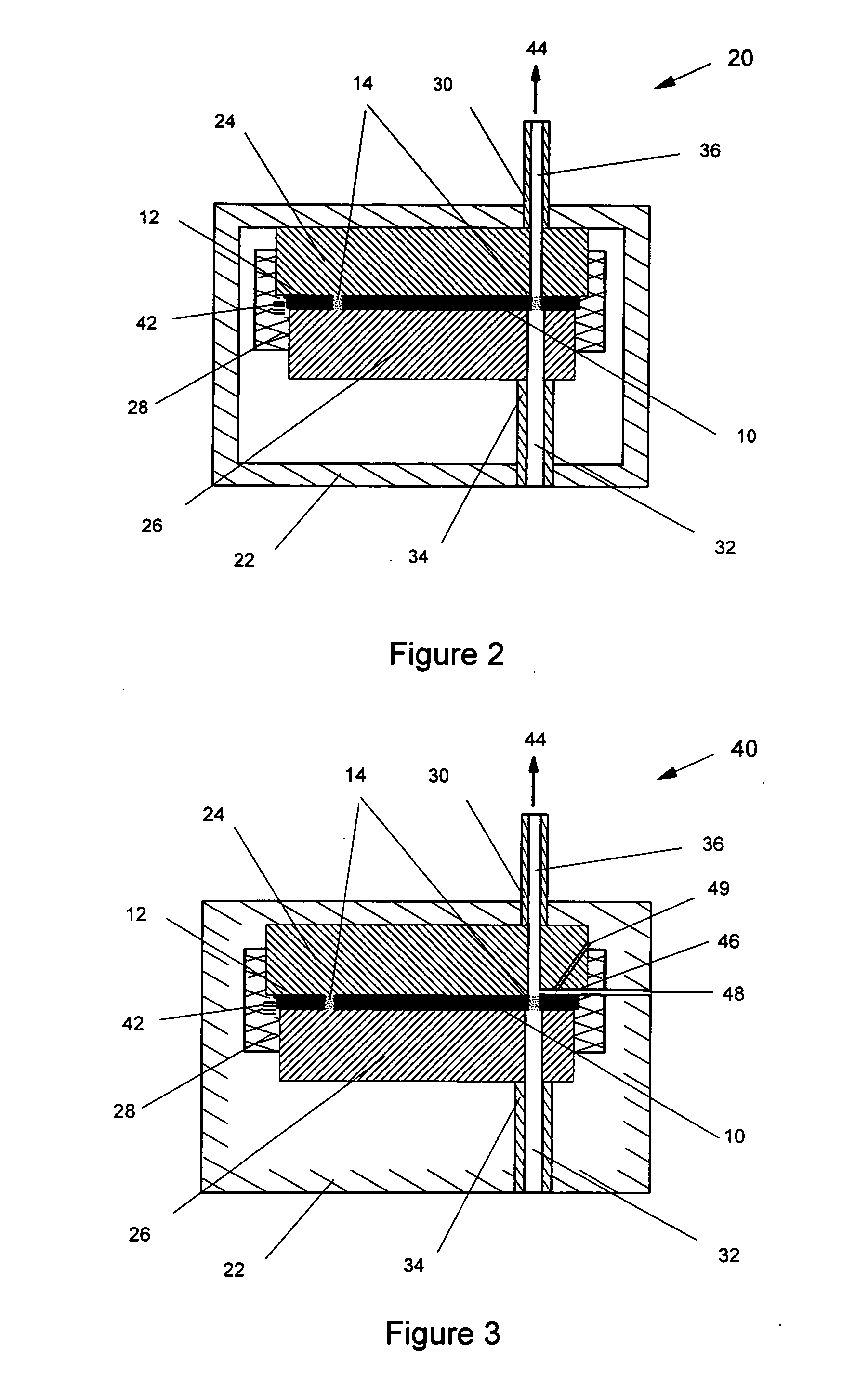

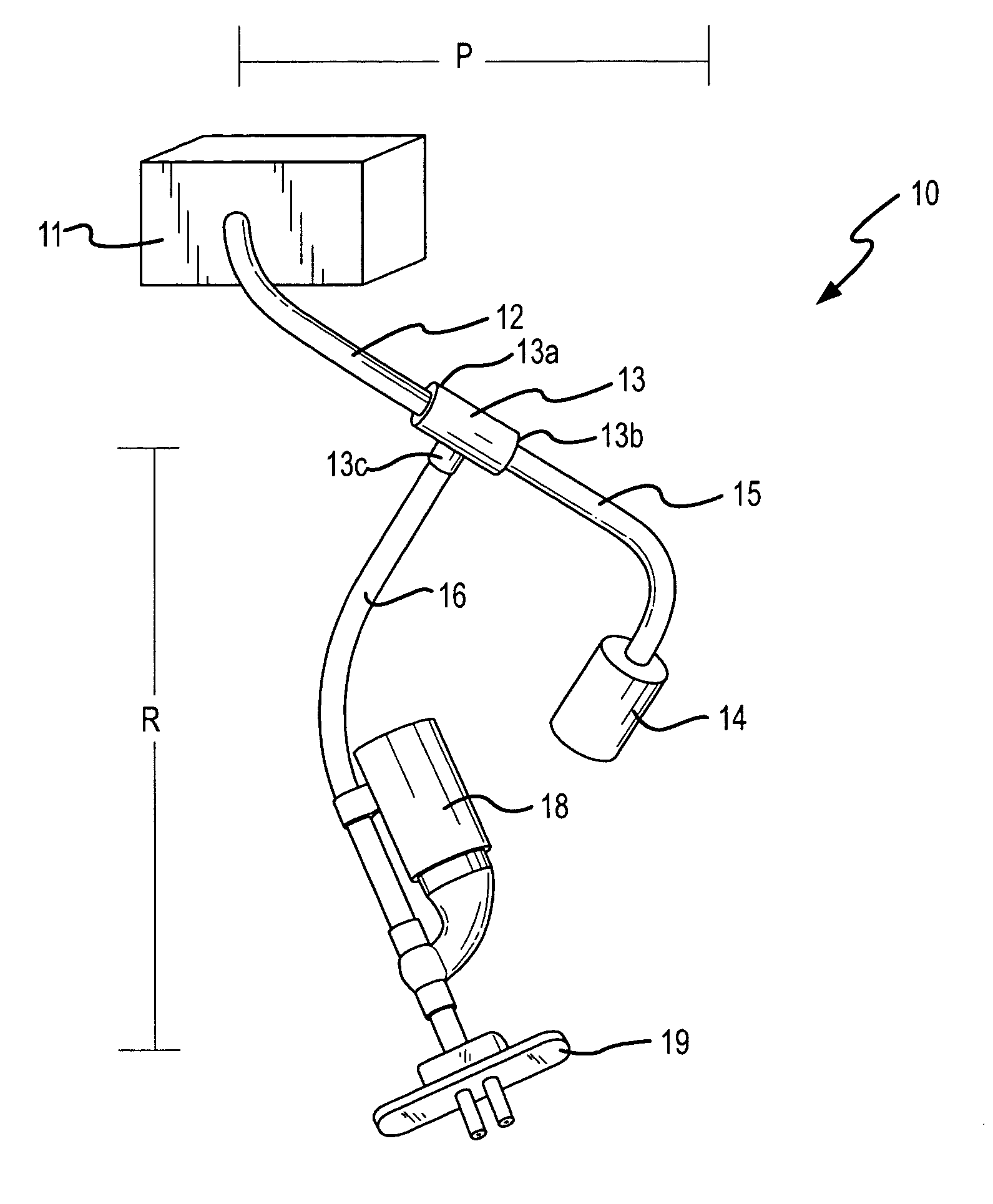

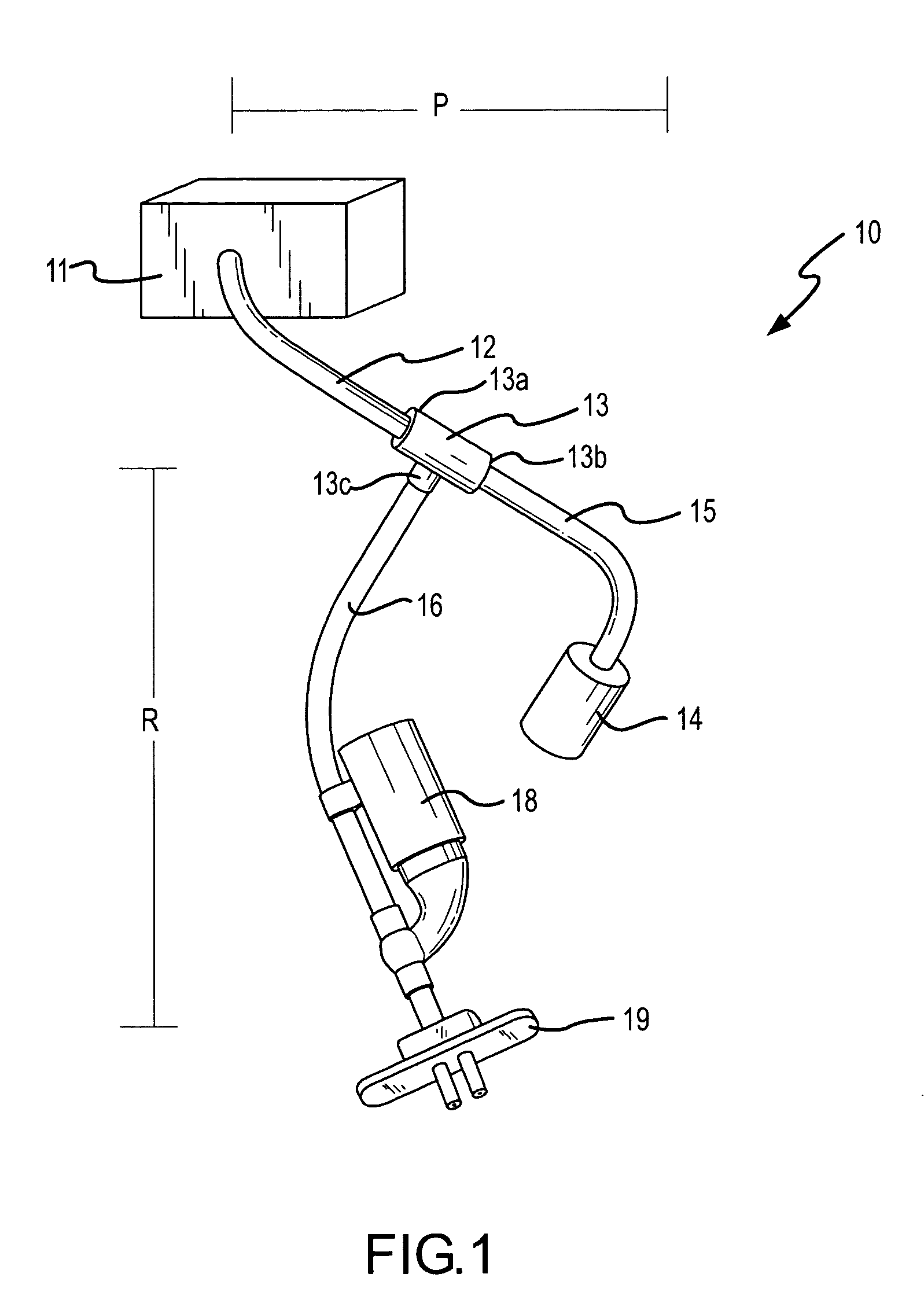

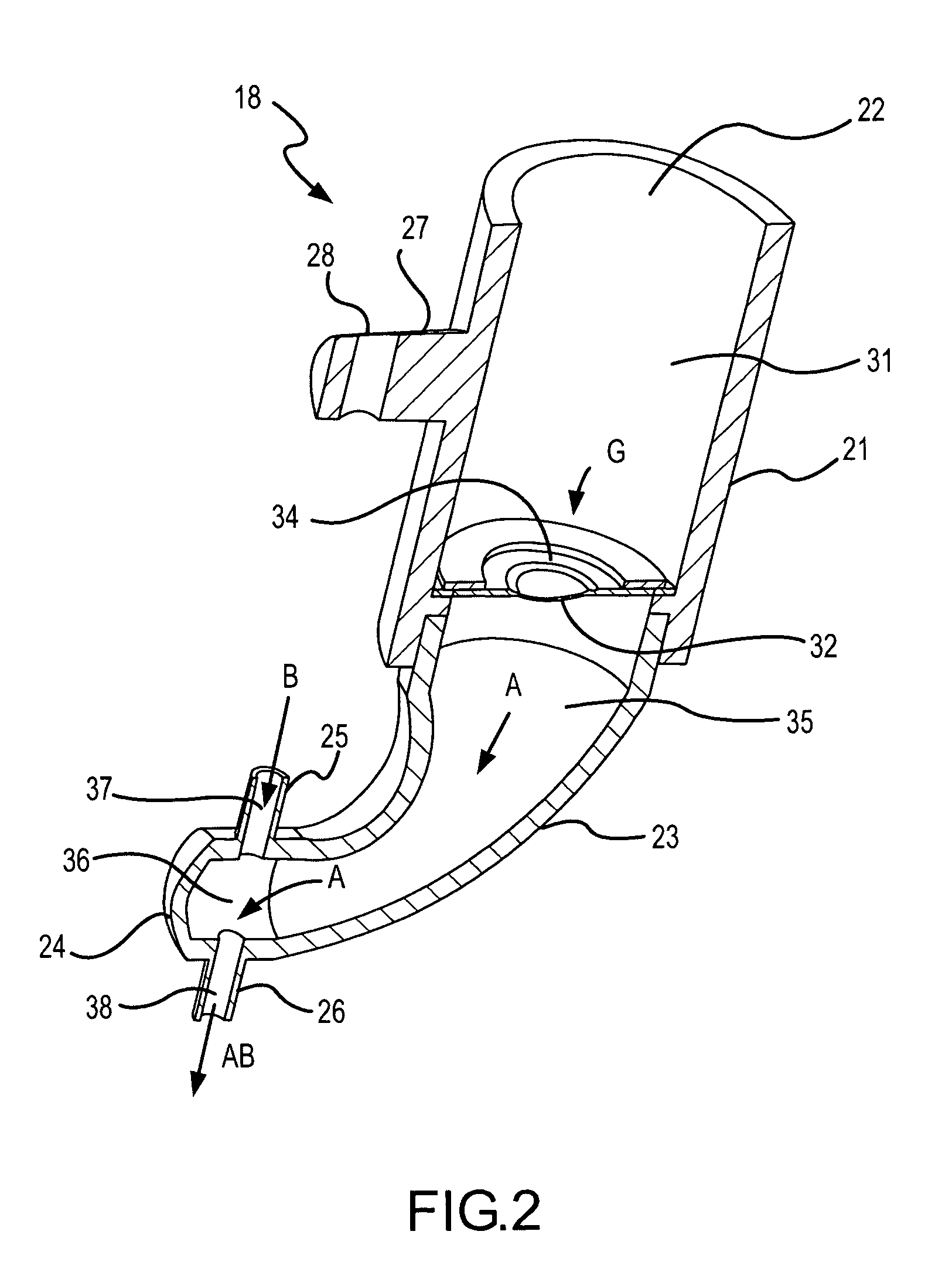

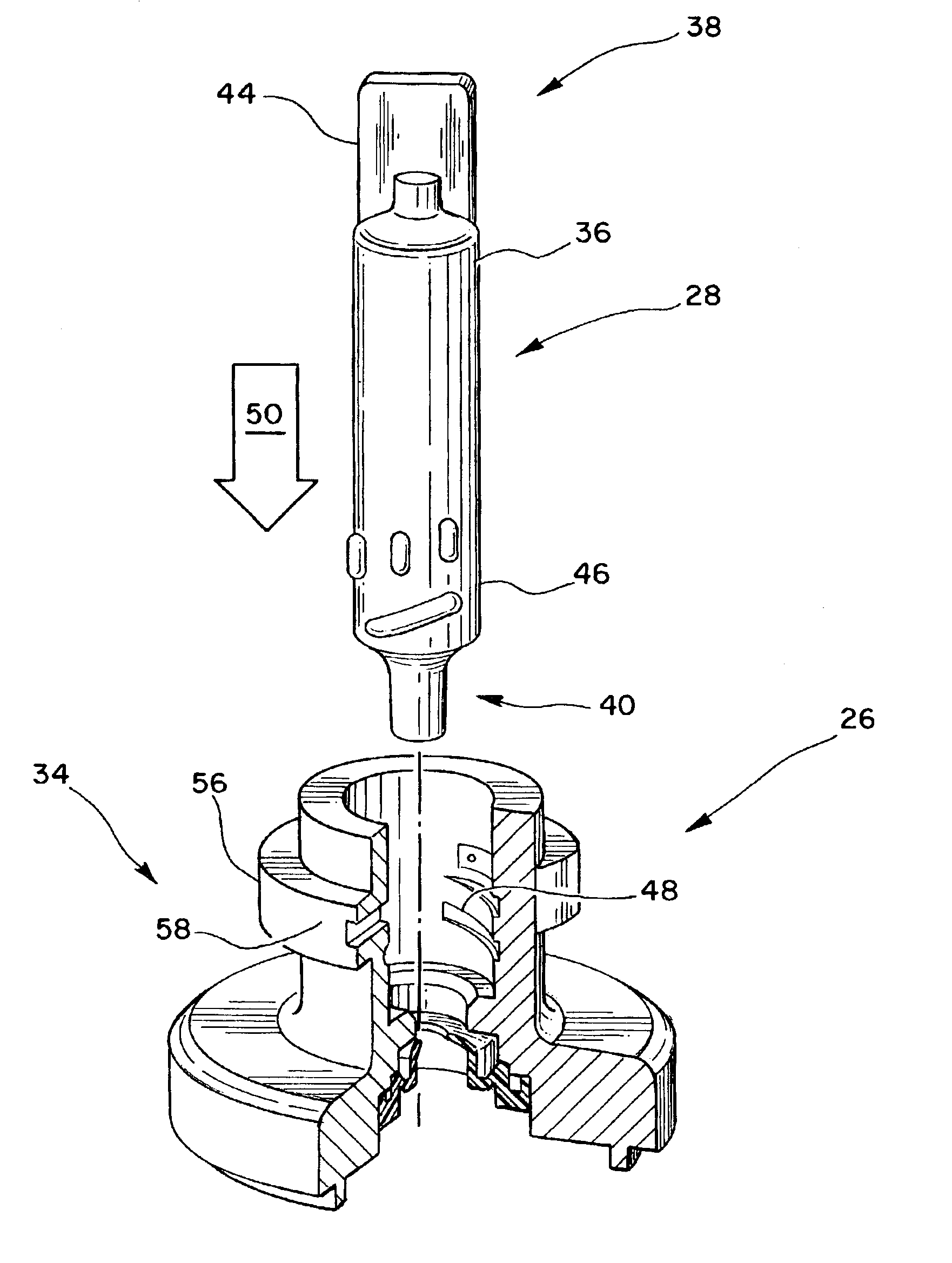

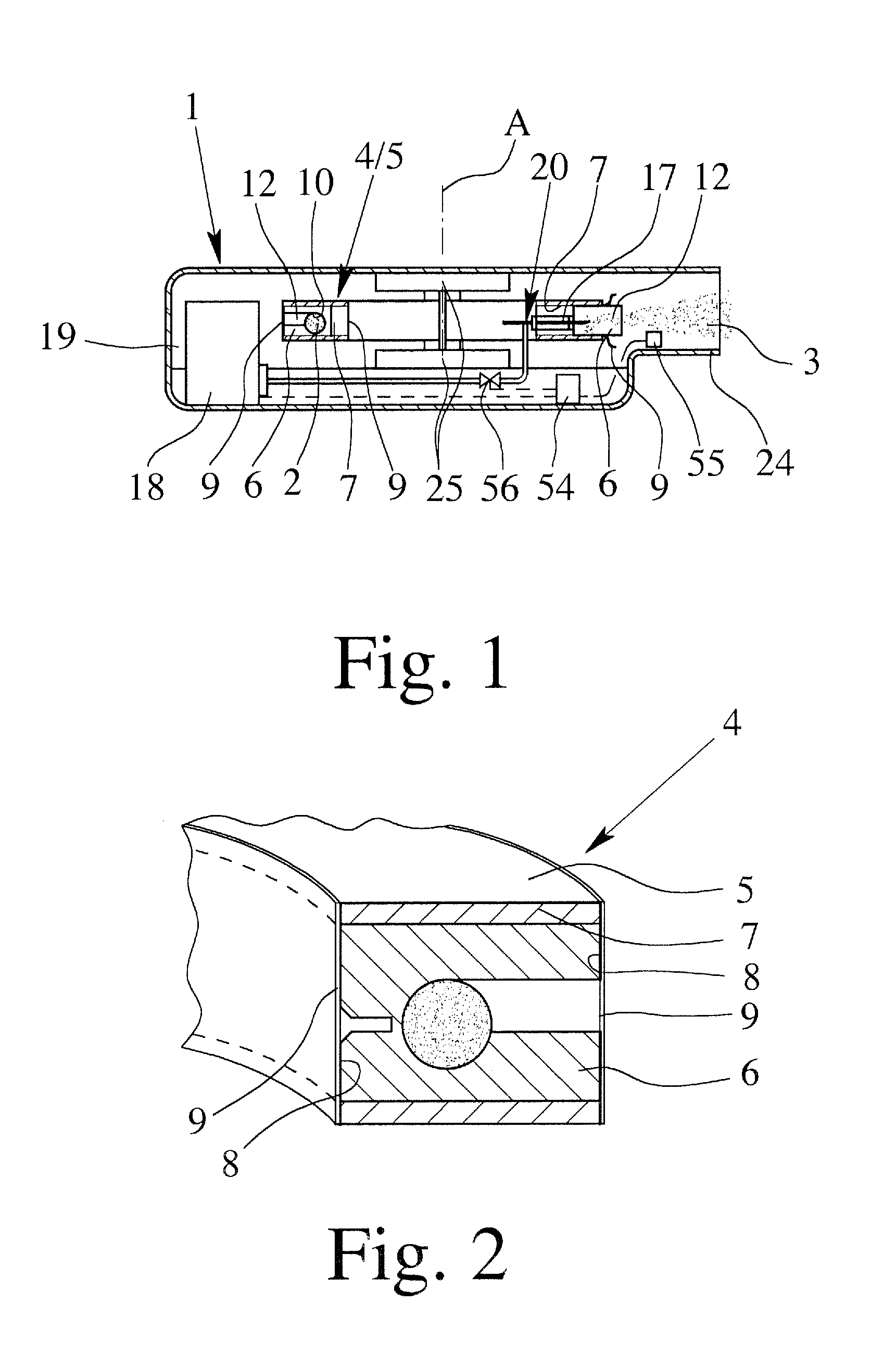

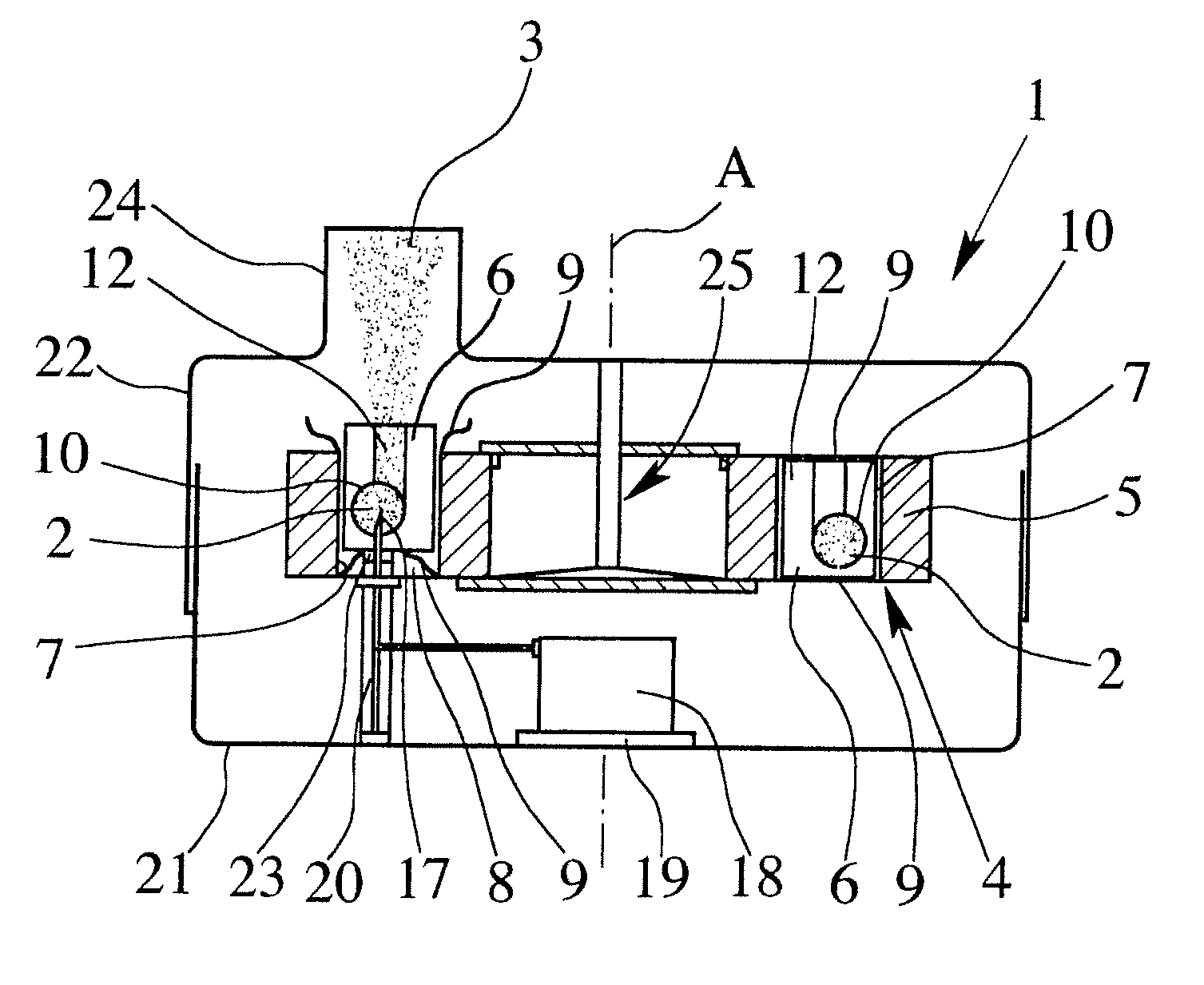

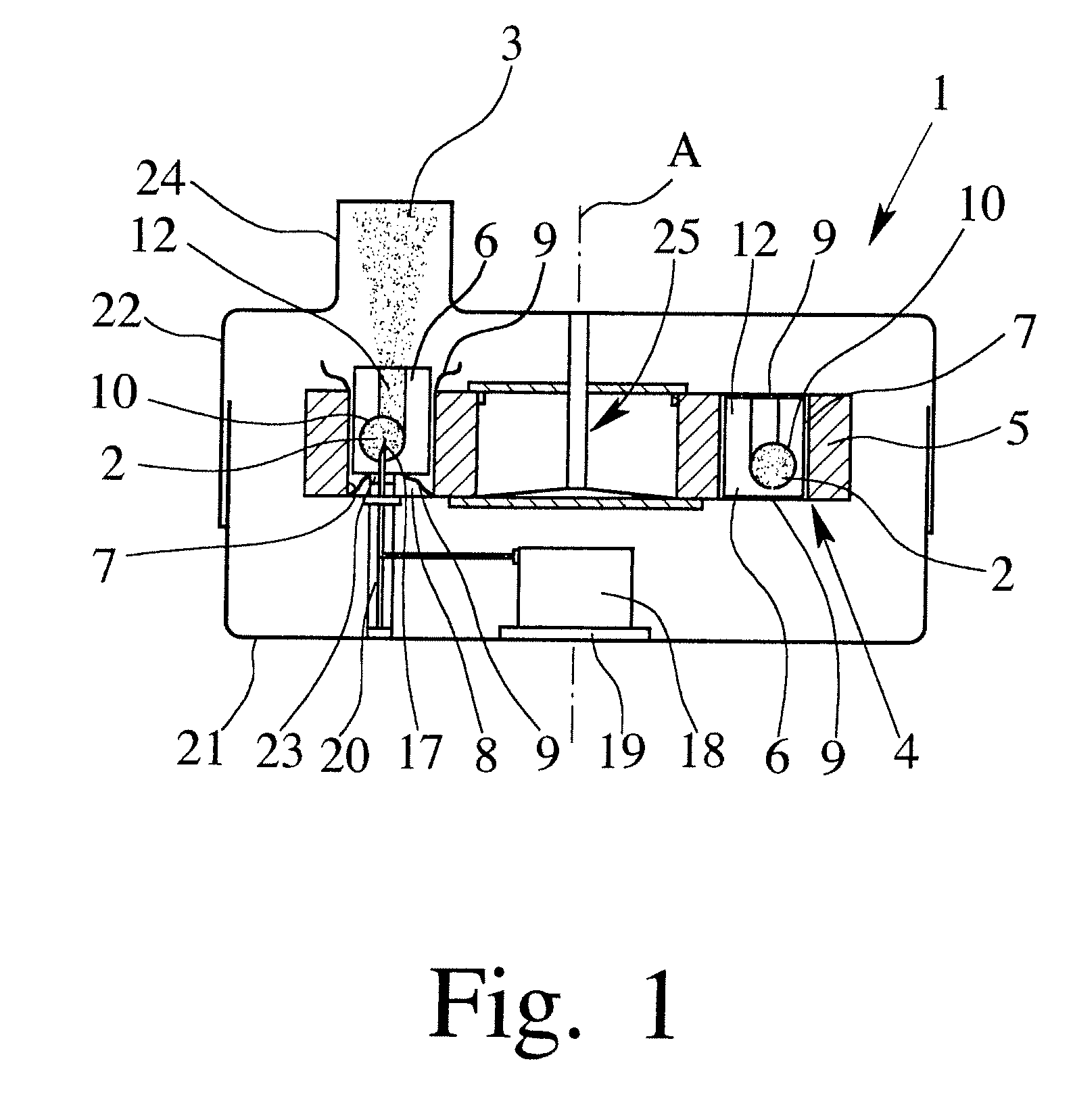

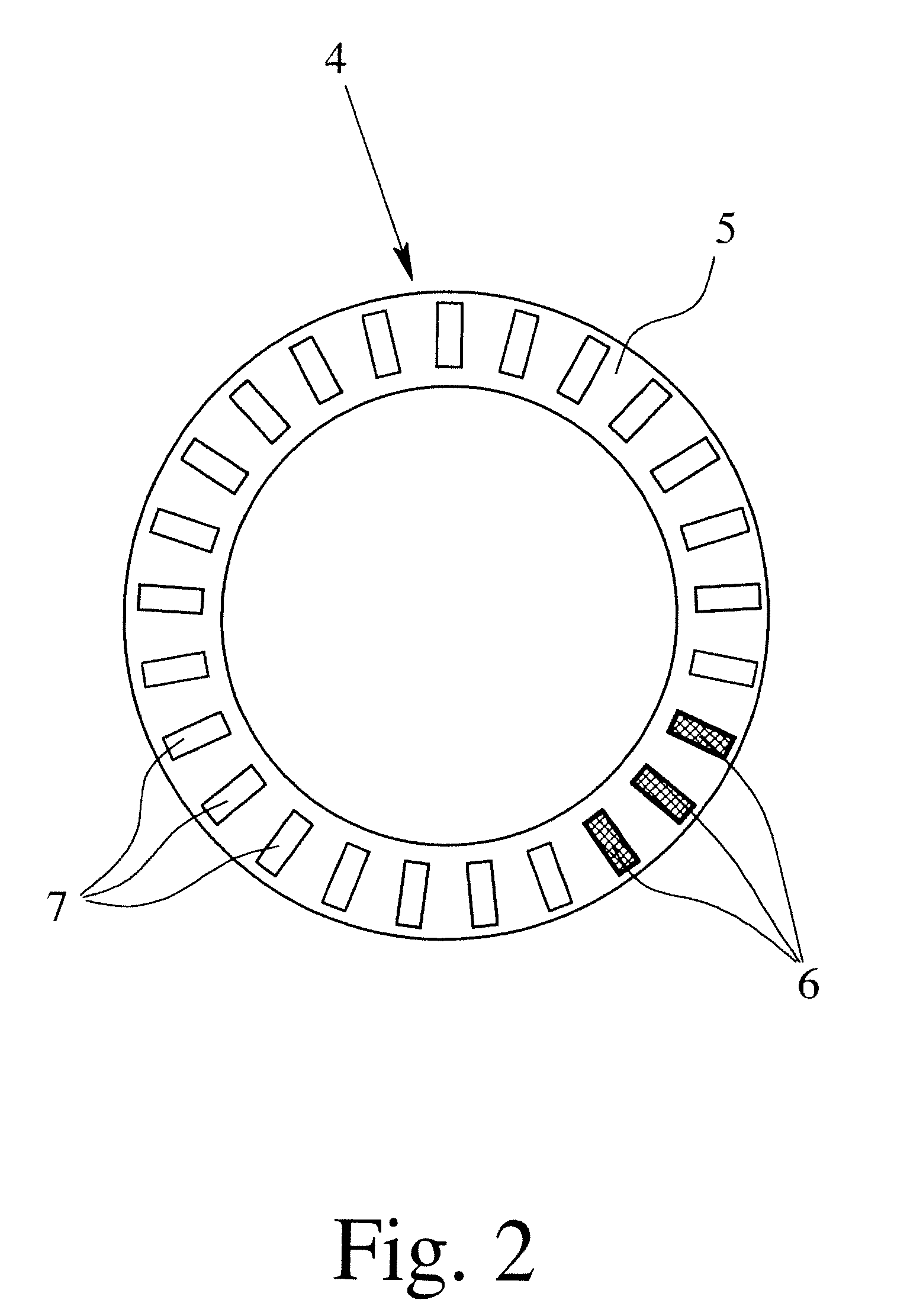

Dry powder inhaler

ActiveUS20070235029A1Small accurate volumePrecise deliveryRespiratorsLiquid surface applicatorsMicroDoseAerosolize

A new dry powder inhaler is developed as a pulmonary medicine delivery device for dispersing precise tiny dosages (10 μg-50 mg) of pure carrier-free ultra-fine powdered medicament (<5 μm aerodynamics particle size) into a patient's lung. The powder is drawn from the blister cell and dispersed through an outlet tube assisted by two air streams. The first air stream goes through a the blister cell from its upstream side, to significantly fluidize the medicament in the dose to flow upward. The second one extracts the fluidized powder from downstream of the blister cell for further deagglomeration and dispersion of the medicament powder by shear force. The rotating multi-dose blister can hold up to 60 doses, which are pre-metered with pure ultra-fine powdered medicament. So that it has higher drug loading capability in small volumes, compared to most current dry powder inhalers, which usually use some excipient. The inhaler efficiently disperse the aerosolized medicament in the air stream to the deep interior of patient's lung. The fine particle fraction (<4.7 μm) is reported to reach as high as 80% using this inhaler.

Owner:NINGBO INHAL PHARMA CO LTD

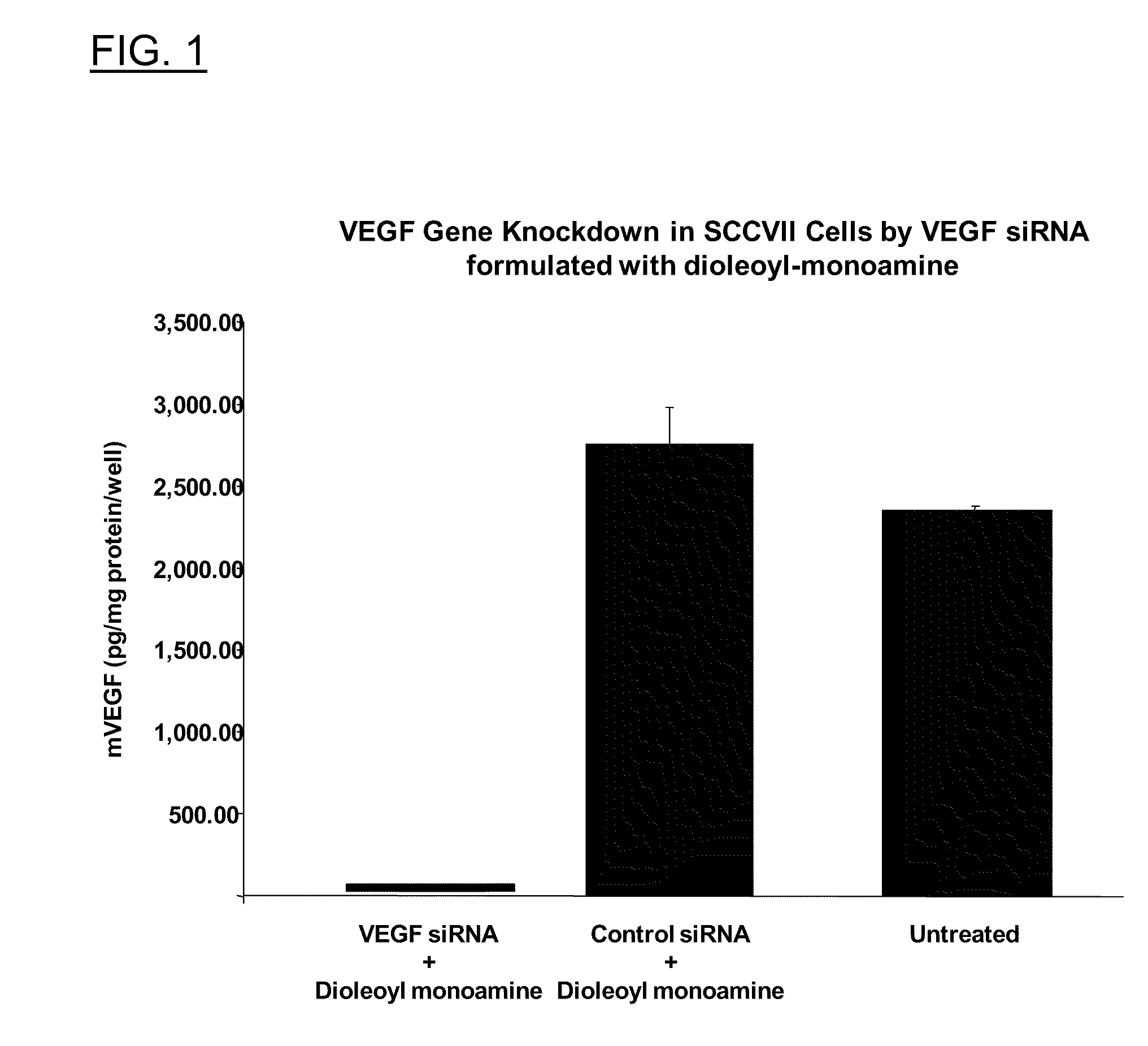

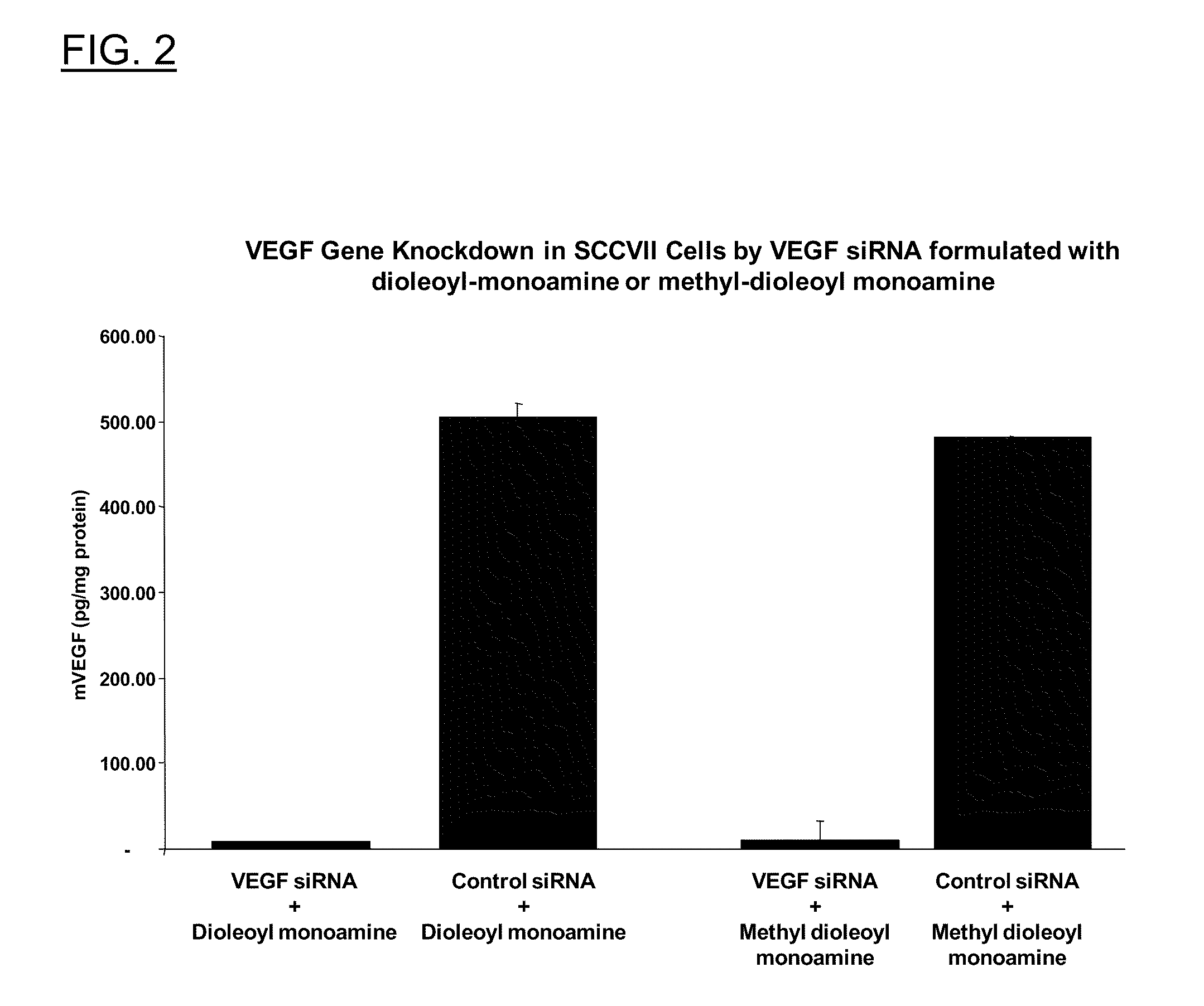

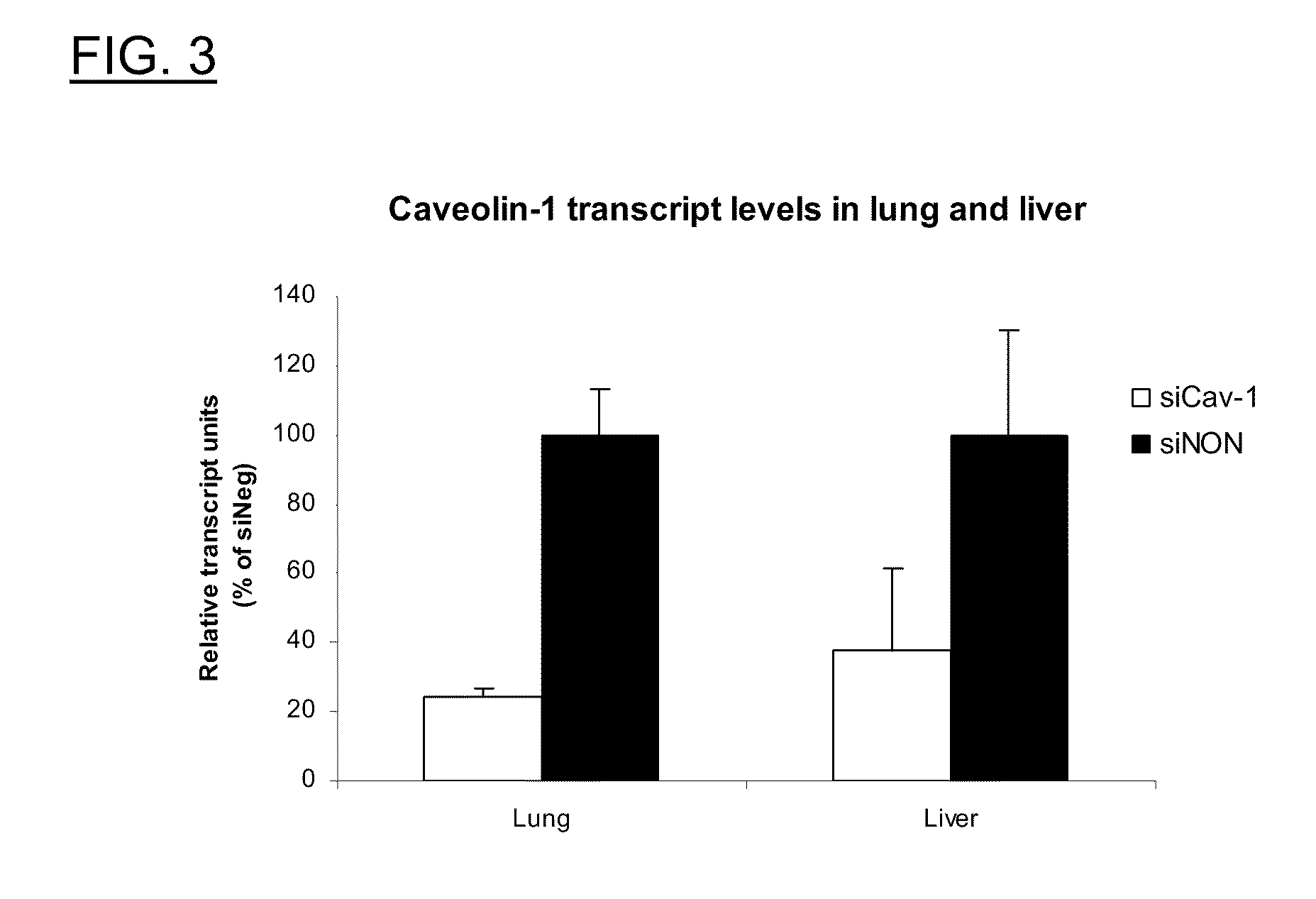

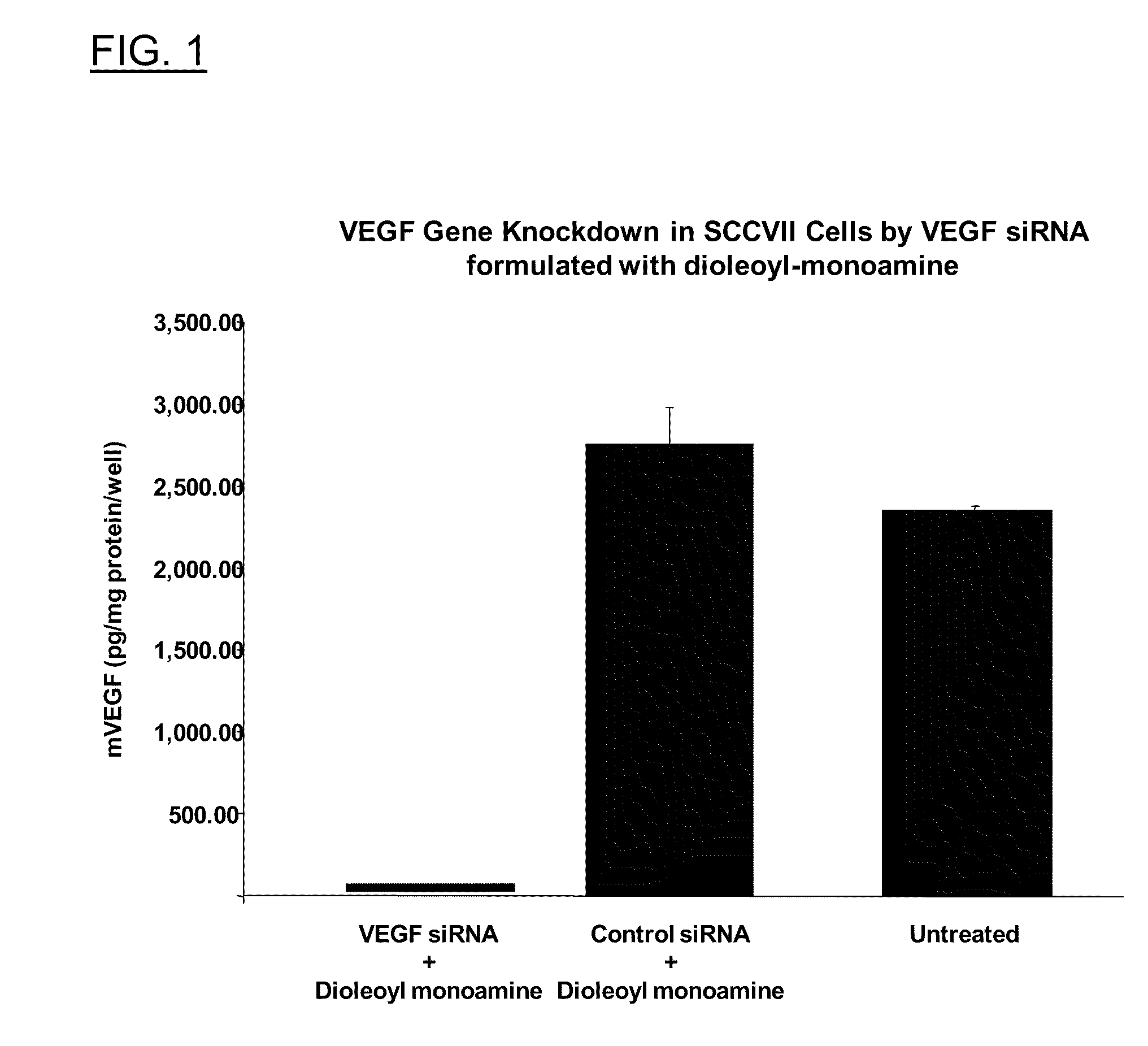

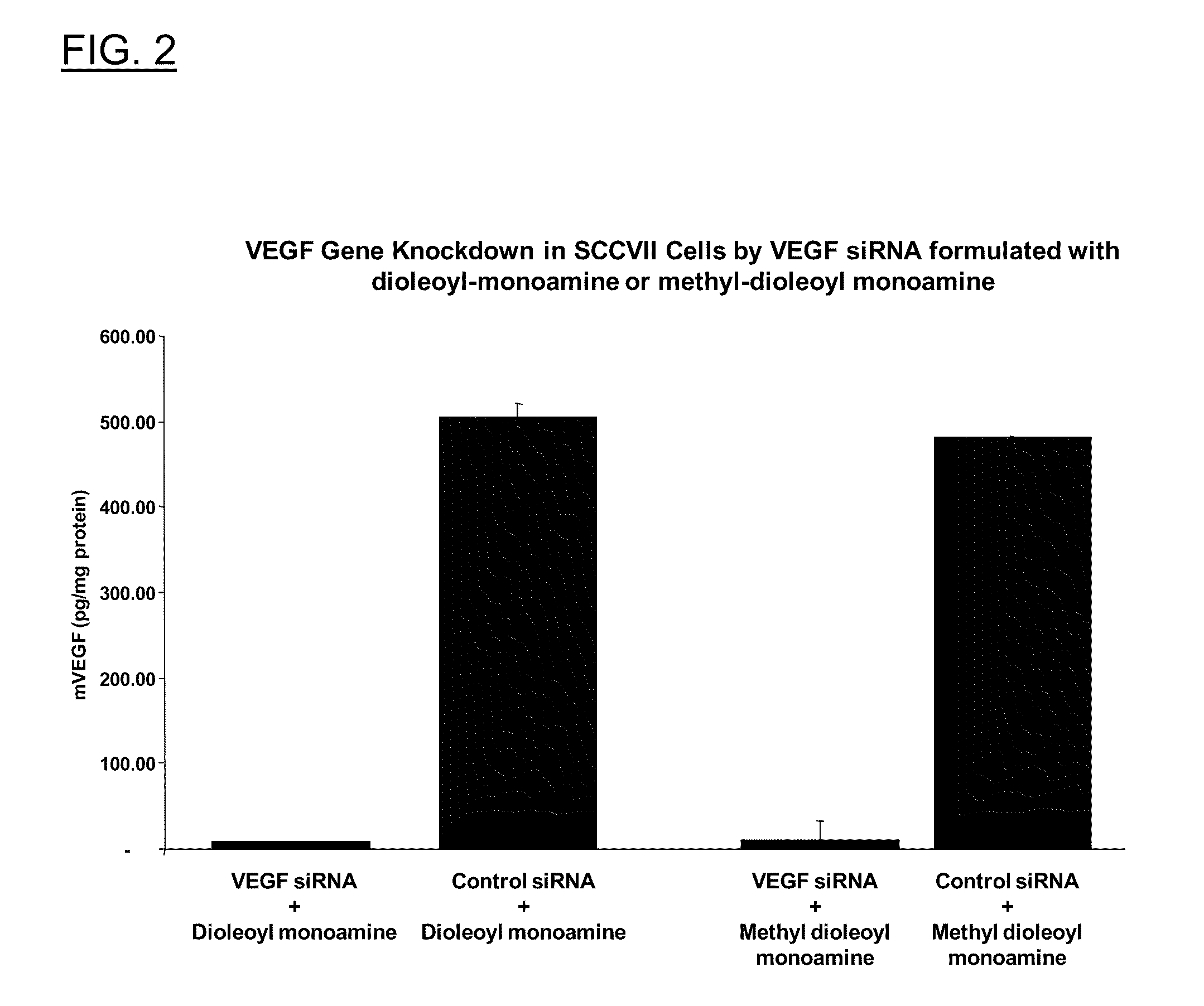

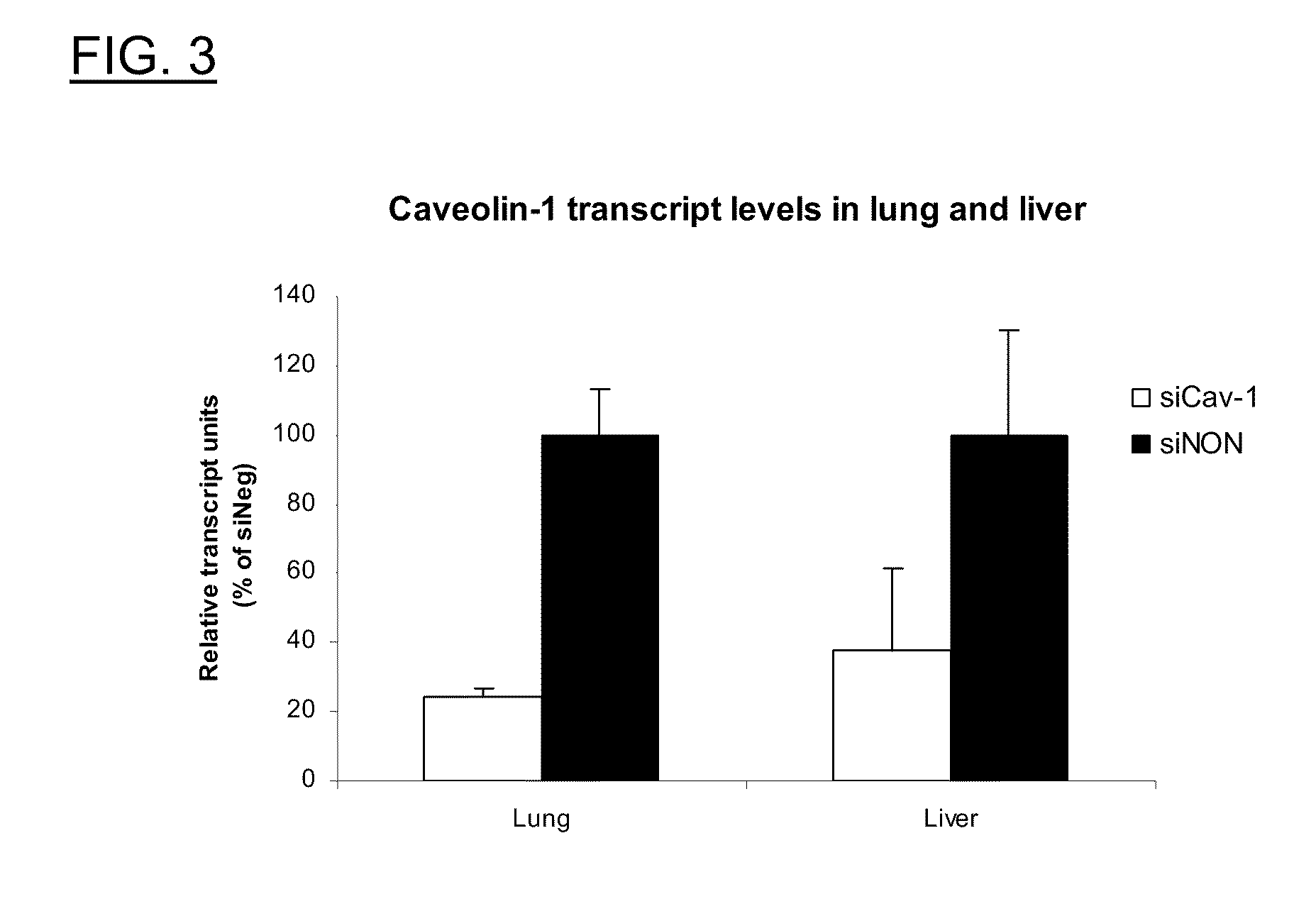

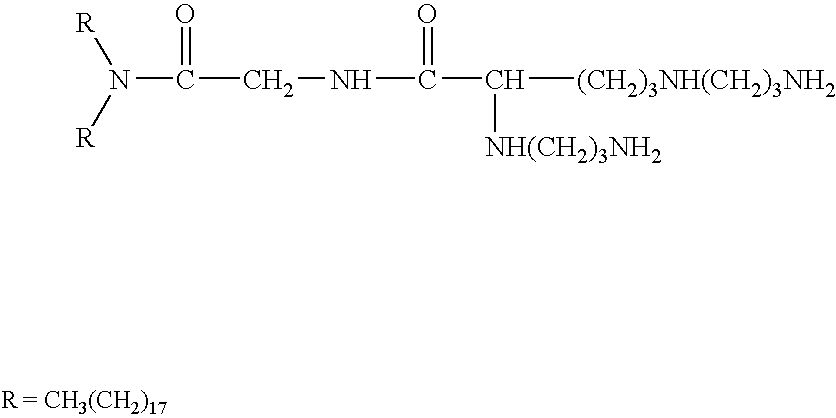

Polyamine Derivatives

ActiveUS20100260817A1Improve efficiencyImproving of local deliveryOrganic active ingredientsSenses disorderWhole bodyMedicinal chemistry

Owner:CLSN LAB

Polyamine derivatives

ActiveUS8460696B2Reduce deliveryImprove efficiencyOrganic active ingredientsSenses disorderMedicinal chemistryPolyamine

Owner:CLSN LAB

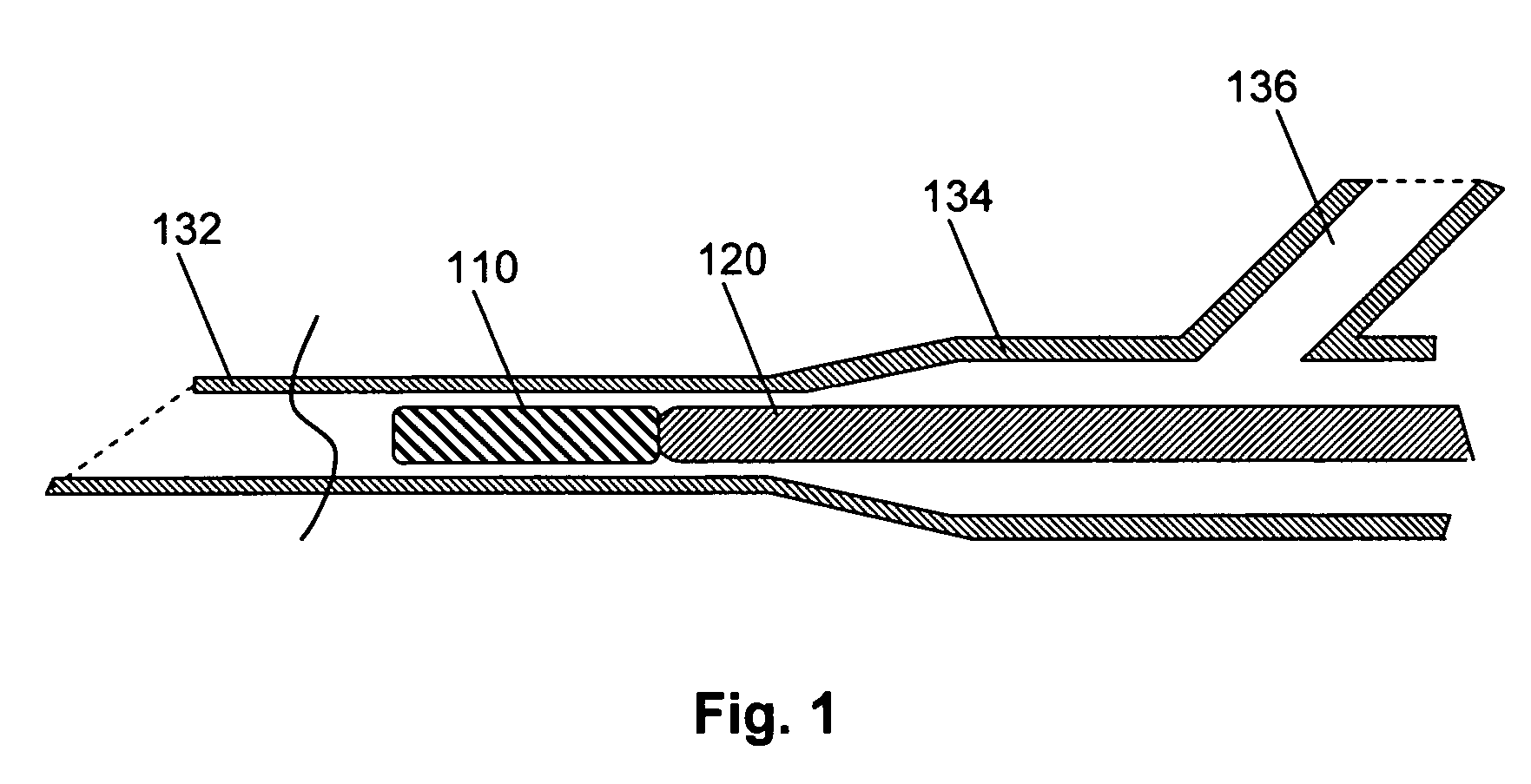

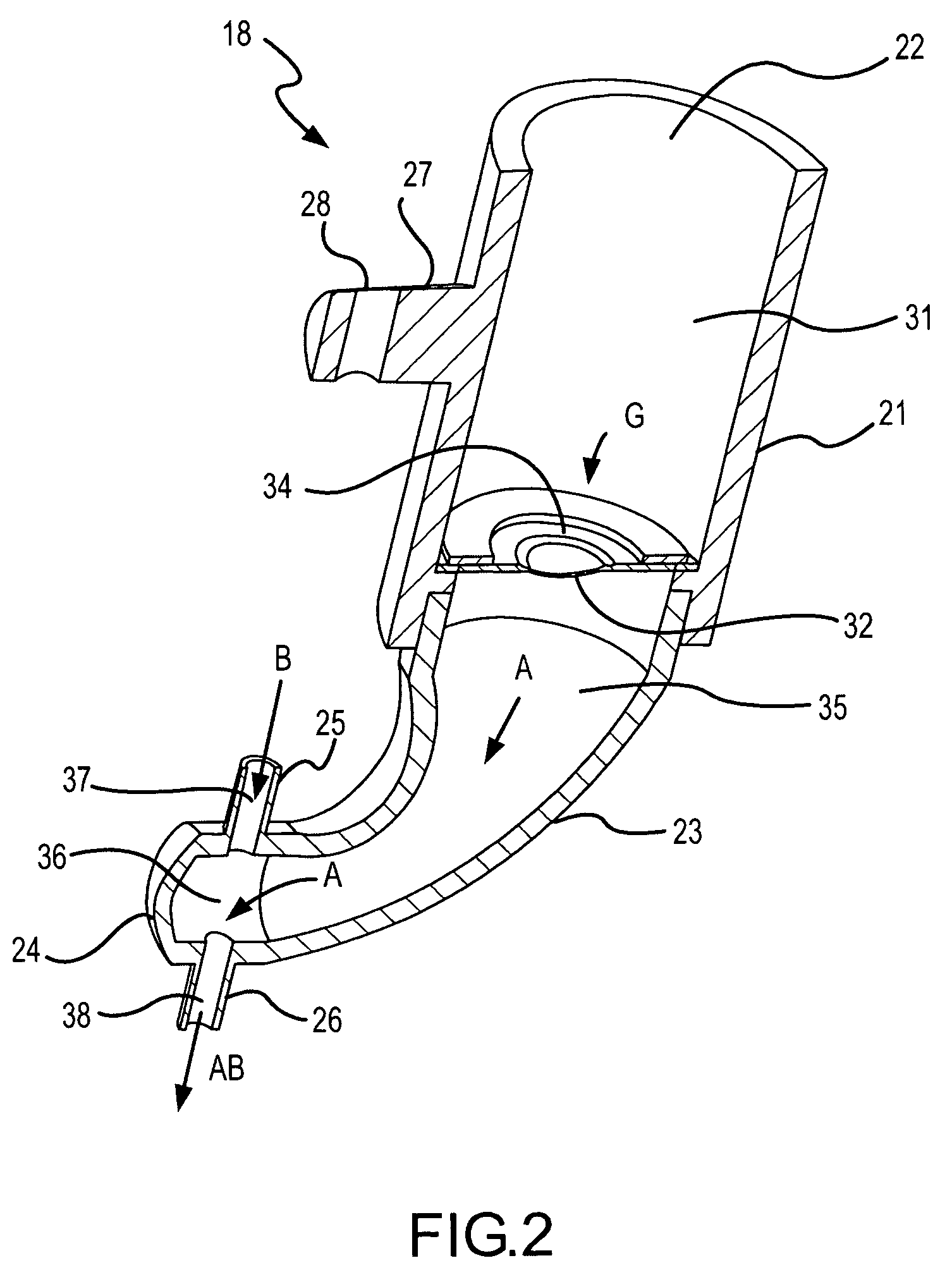

Method and composition for the treatment of lung surfactant deficiency or dysfunction

ActiveUS20050229926A1Quantity minimizationReduce the amount requiredRespiratorsMedical devicesSurfactant deficiencyAssisted breathing

A method of treating a disease involving surfactant deficiency or dysfunction in a patient's lungs is disclosed comprising the steps of providing a liquid lung surfactant composition; aerosolizing the lung surfactant composition with a vibrating aperture-type aerosol generator to form a surfactant aerosol; and introducing the surfactant aerosol into the gas flow within a circuit of a pressure-assisted breathing system coupled to the patient's respiratory system, whereby a therapeutically effective amount of said surfactant is delivered to the patient's lungs. Apparatus is also disclosed that increases the efficiency of delivery of aerosolized medicaments such as aerosolized lung surfactant.

Owner:NOVARTIS AG

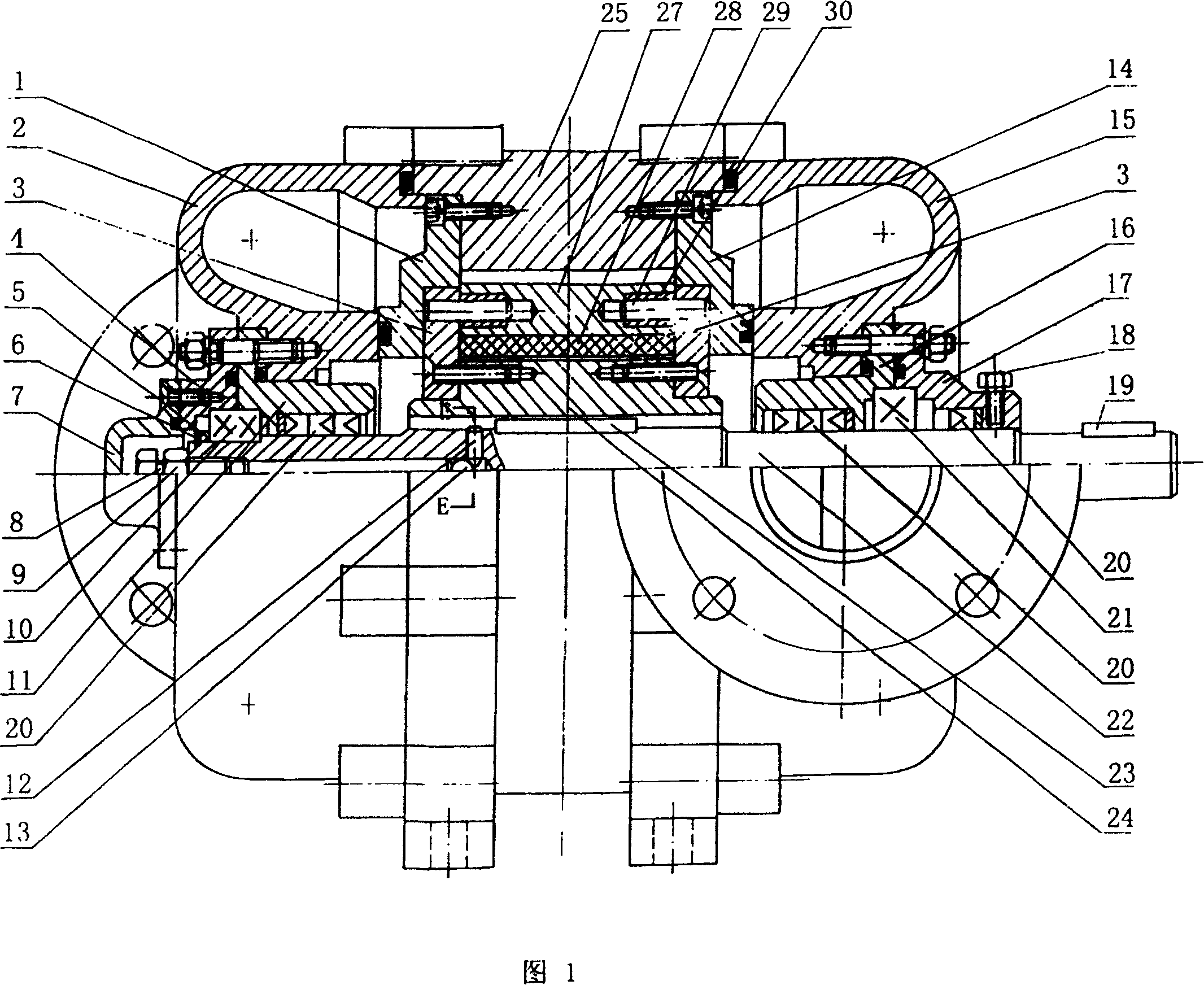

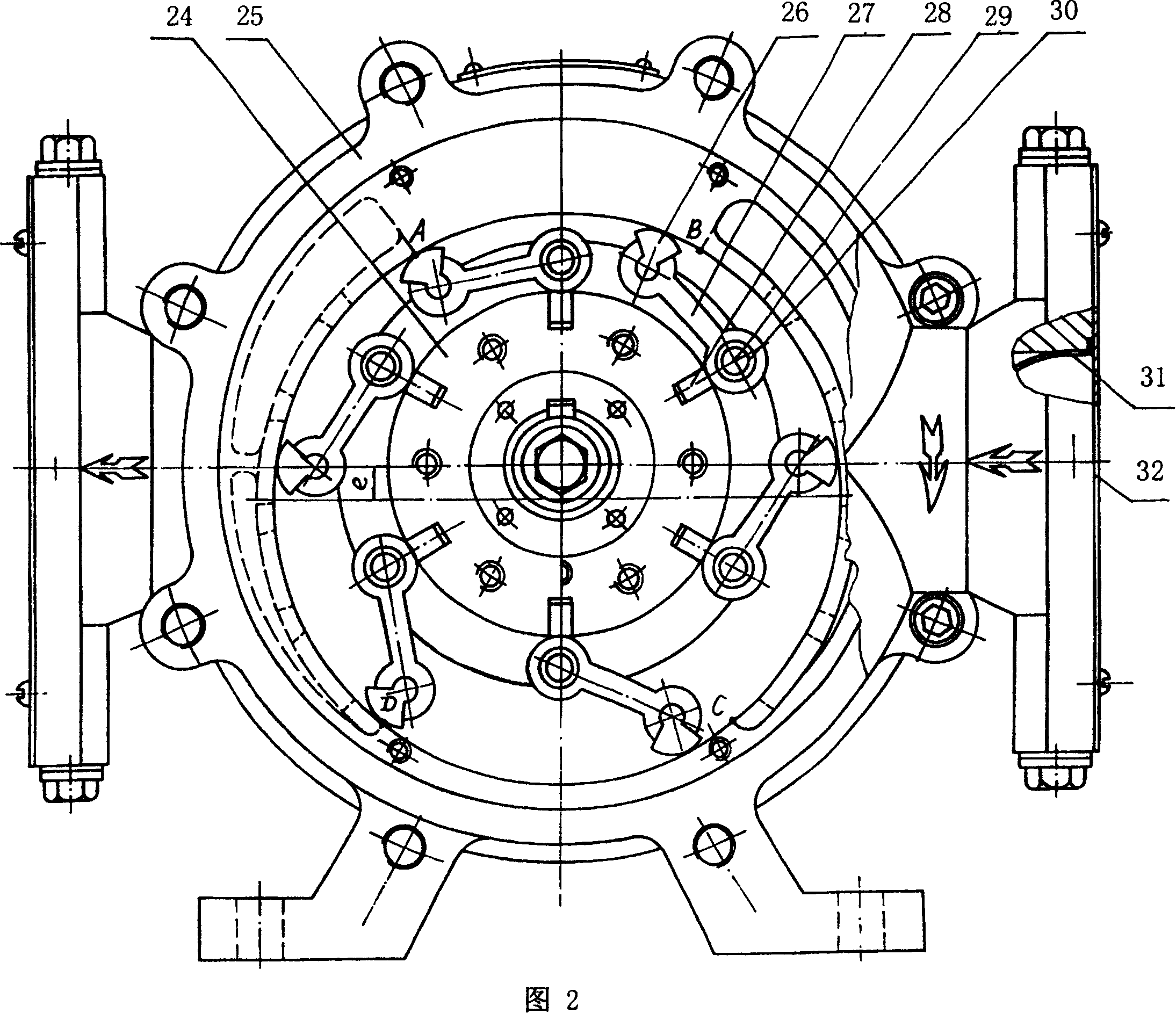

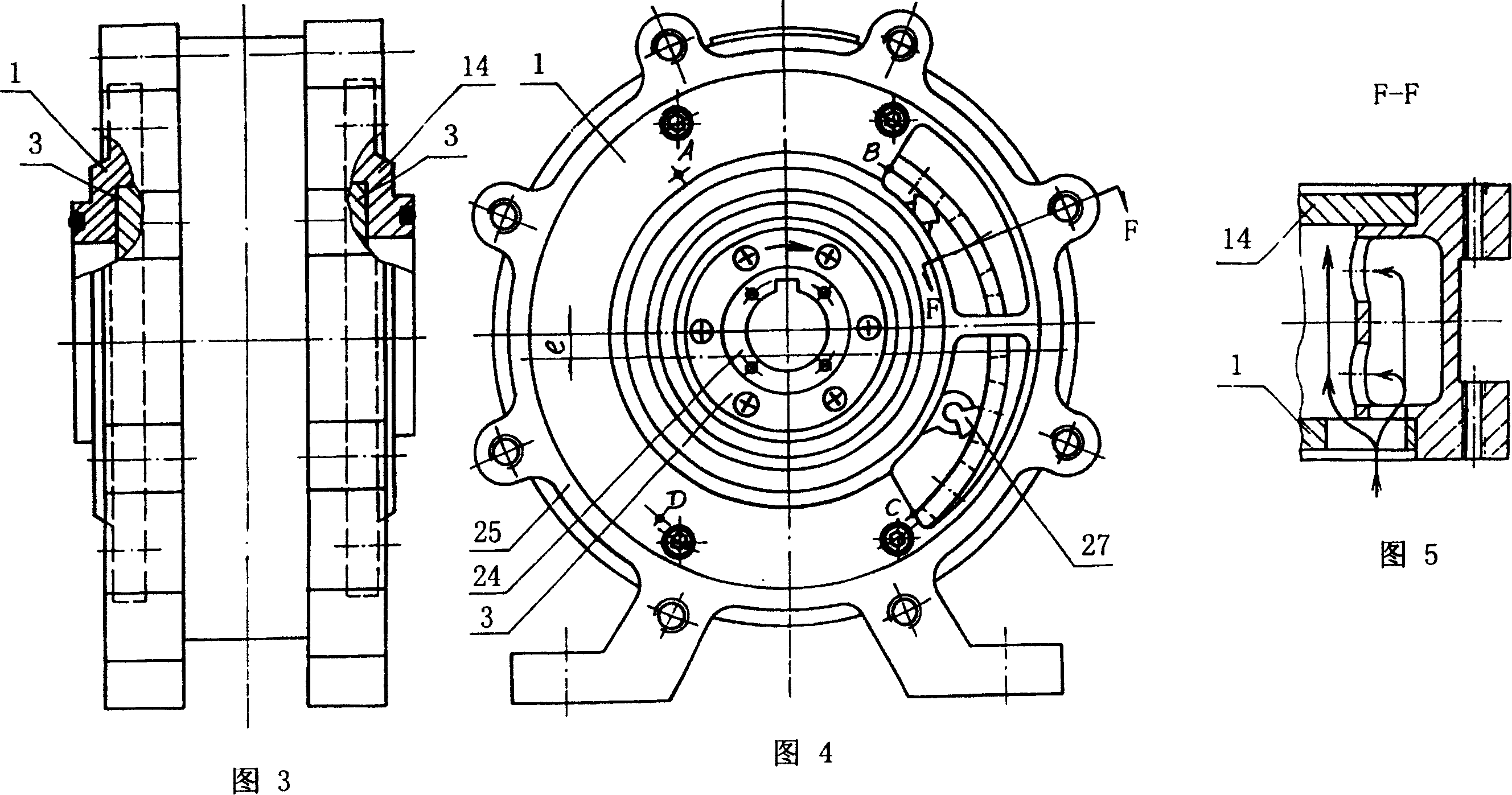

Rotary blade pump

InactiveCN100374725CReduce line speedEliminate cavitationRotary piston pumpsRotary piston liquid enginesClassical mechanicsEngineering

In the invention, an inlet-outlet oil flow plate is fixed at two ends of a pump case stator. A radial inlet-outlet runner is built-up on the pump case stator to realize axial and radial inlet and outlet oil at the same time. A rotor is mounted in the internal cavity of the pump case stator and there is an offsetting e between the rotor and the ID of the pump case stator. Rotary vanes are mounted on a rotating board fixed on the two end faces of the rotor. The rotor is mounted on the pump spindle via a rotor key. A rotor locking device is assembled on the front part of the pump spindle. The inlet-outlet oil pump covers are fixed at two ends of the pump stator separately. A ring inlet-outlet oil passageway is disposed in inlet-outlet oil pump. A bearing support and sealing device is assembled on the central of the inlet-outlet oil pump cover.

Owner:王振忠 +1

Method for treatment of uterine fibroid tumors

InactiveUS20060251581A1Improve delivery efficiencyMinimize adverse effectsUltrasonic/sonic/infrasonic diagnosticsPowder deliverySemi solidViscosity

Various injectable or insertable uterine fibroid treatment formulations are provided, which comprise a uterine fibroid treatment agent in an amount effective to cause shrinkage or elimination of uterine fibroids. The injectable or insertable formulations are typically solids, semi-solids or high-viscosity fluids. Other aspects of the invention are directed to systems and methods for treatment of uterine fibroids.

Owner:SCI MED LIFE SYST

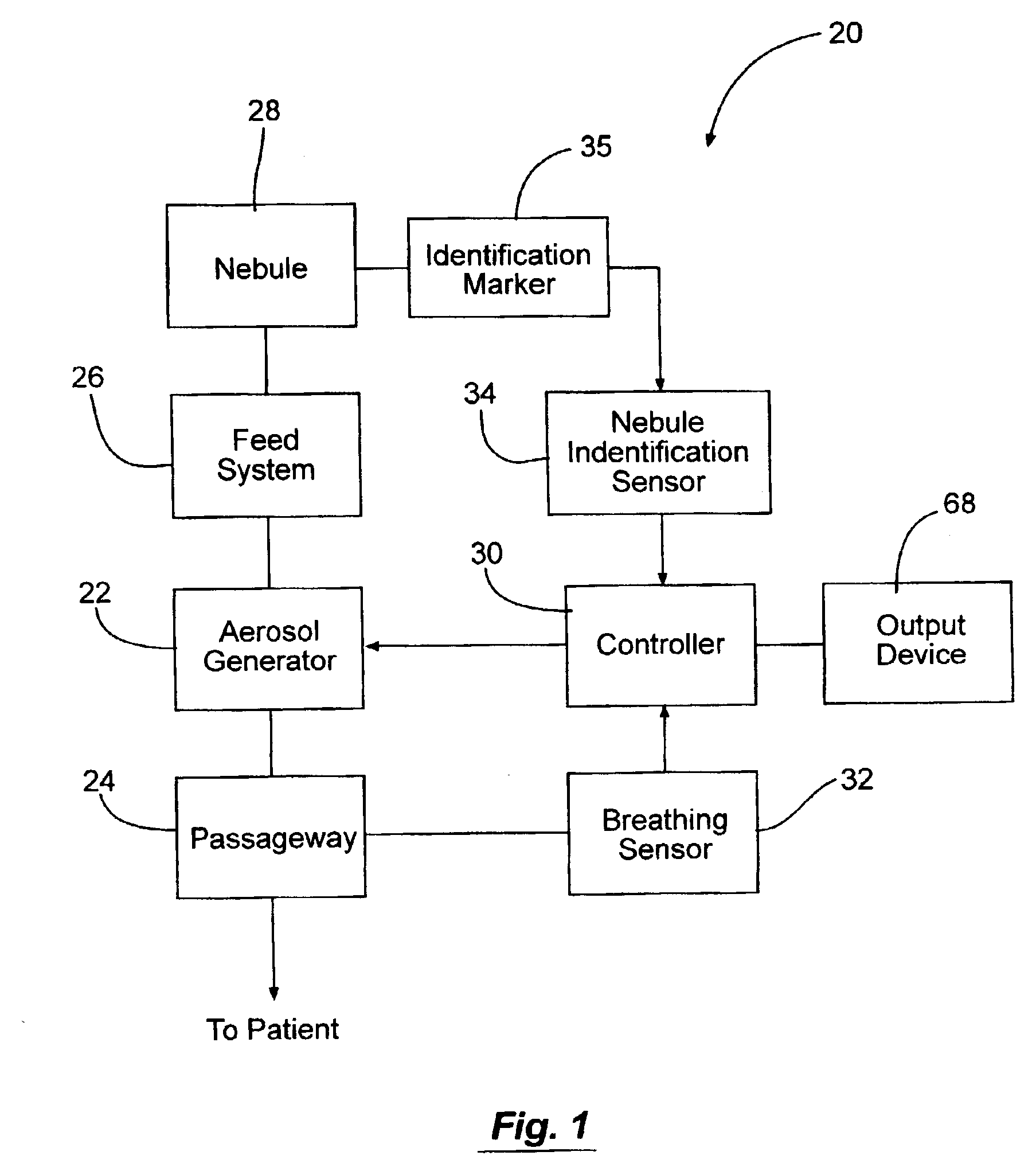

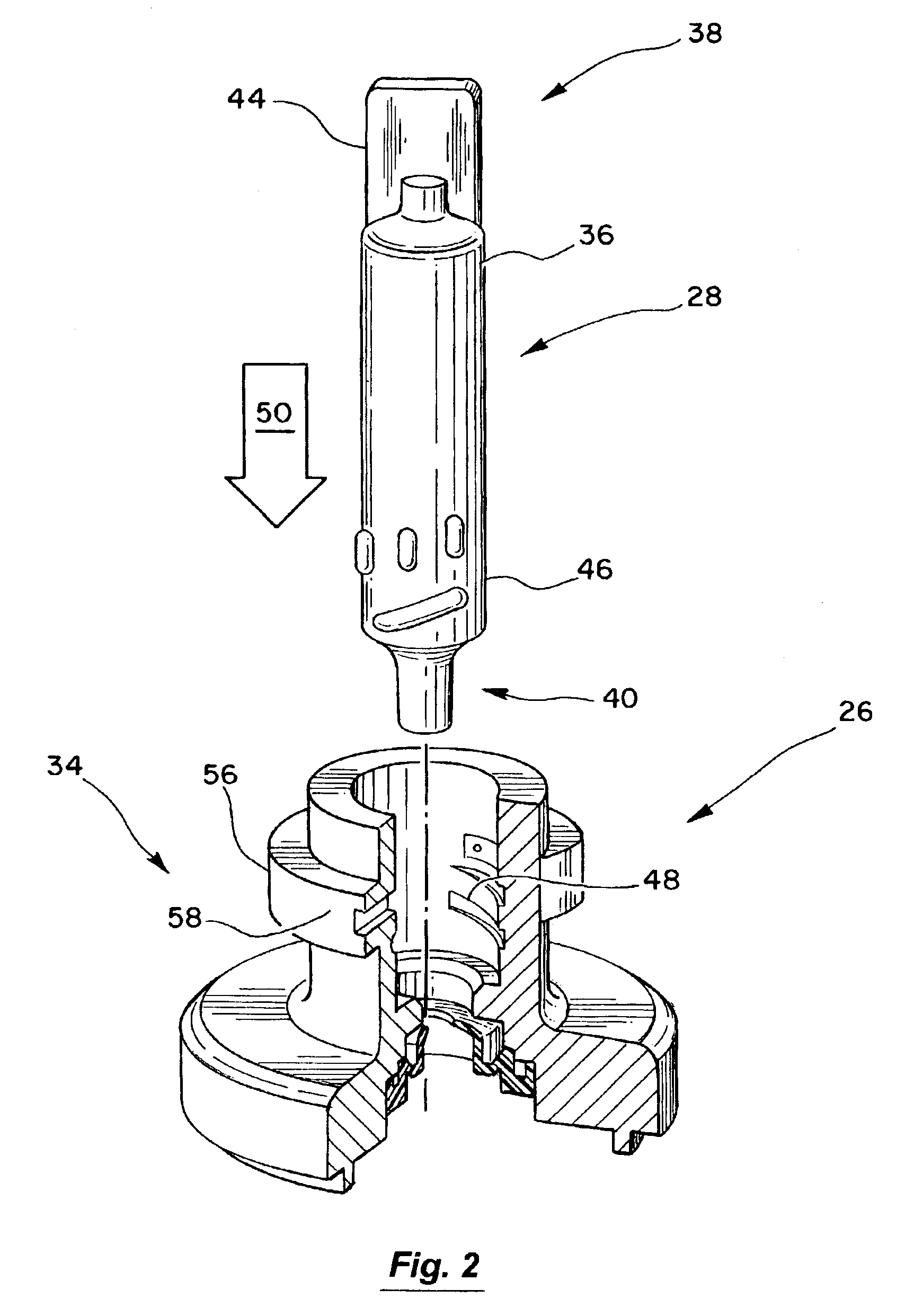

Methods and systems for operating an aerosol generator

InactiveUS6968840B2Improve security levelImprove delivery efficiencyLiquid surface applicatorsPowdered material dispensingControl theoryAerosol generator

Owner:NOVARTIS FARMA

Cationic lipids and methods of use

InactiveUS20110262527A1Increase flexibilityGood fluidityOrganic active ingredientsNervous disorderLipid particleLiposome

The present invention provides compositions comprising cationic lipids, liposomes and nucleic acid-lipid particles comprising the cationic lipids, and methods of using such compositions, liposomes, and nucleic acid-lipid particles.

Owner:ARBUTUS BIOPHARMA CORPORAT ION

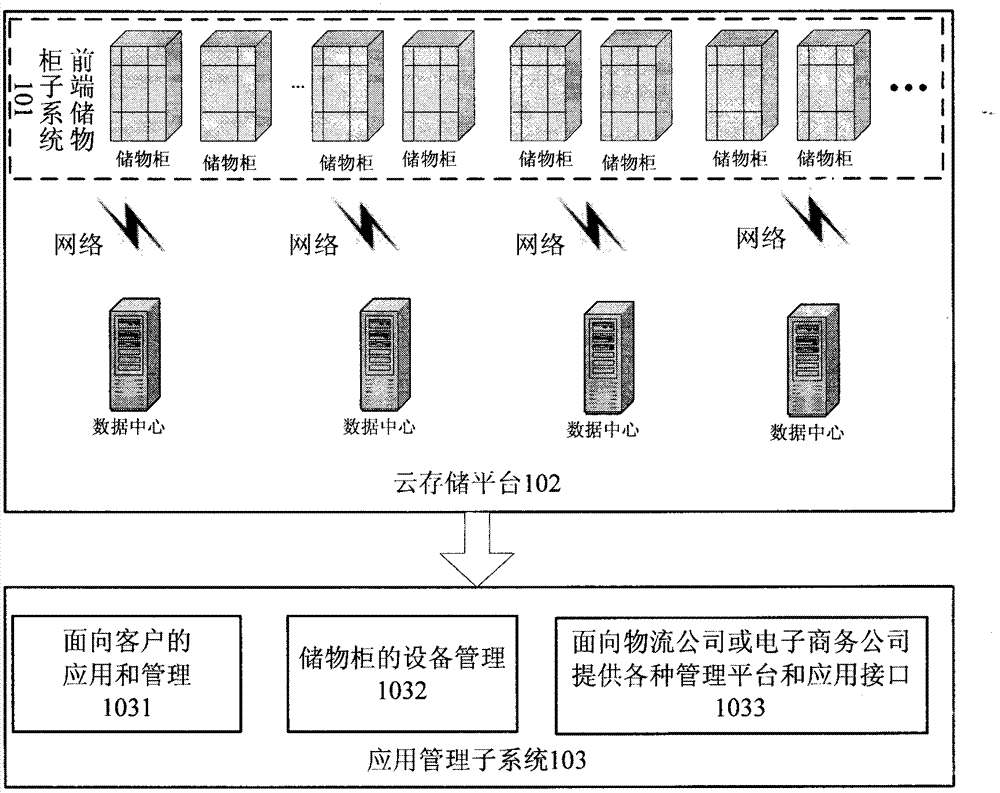

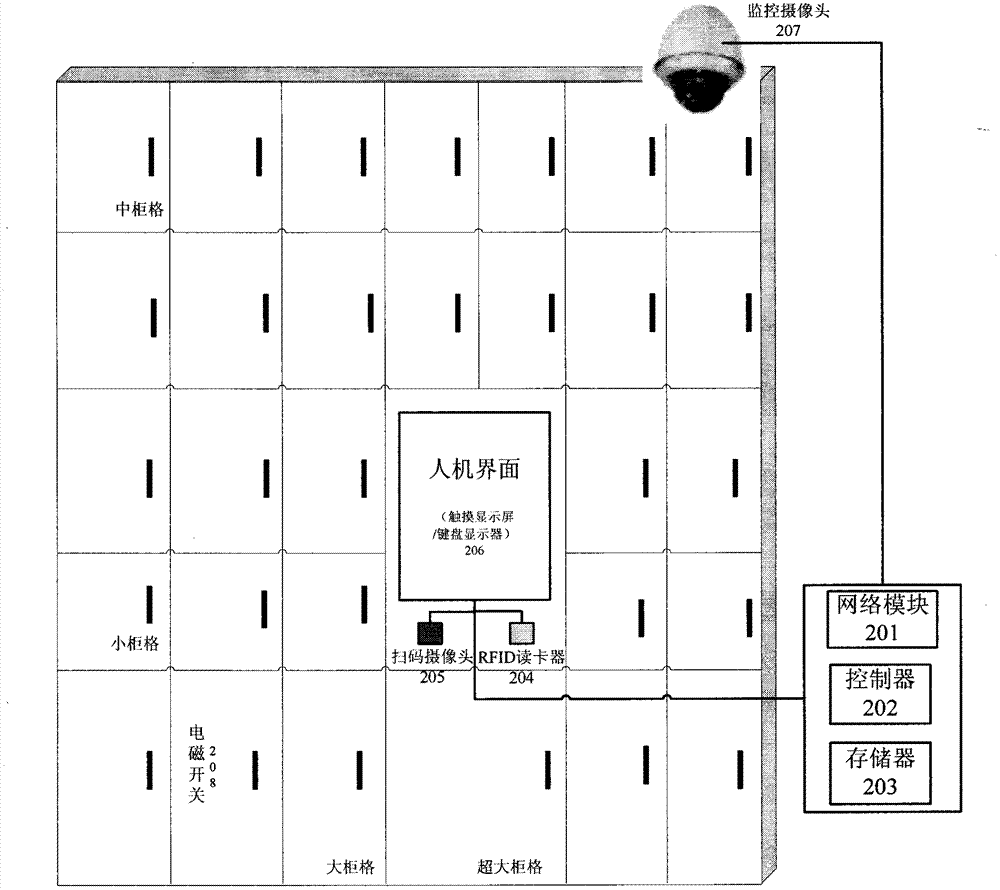

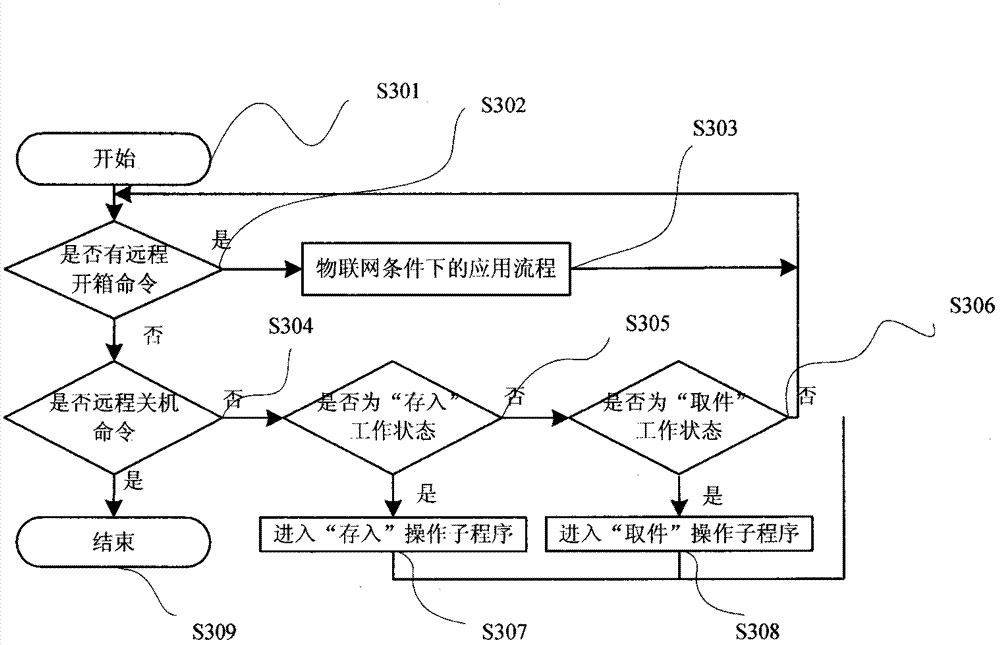

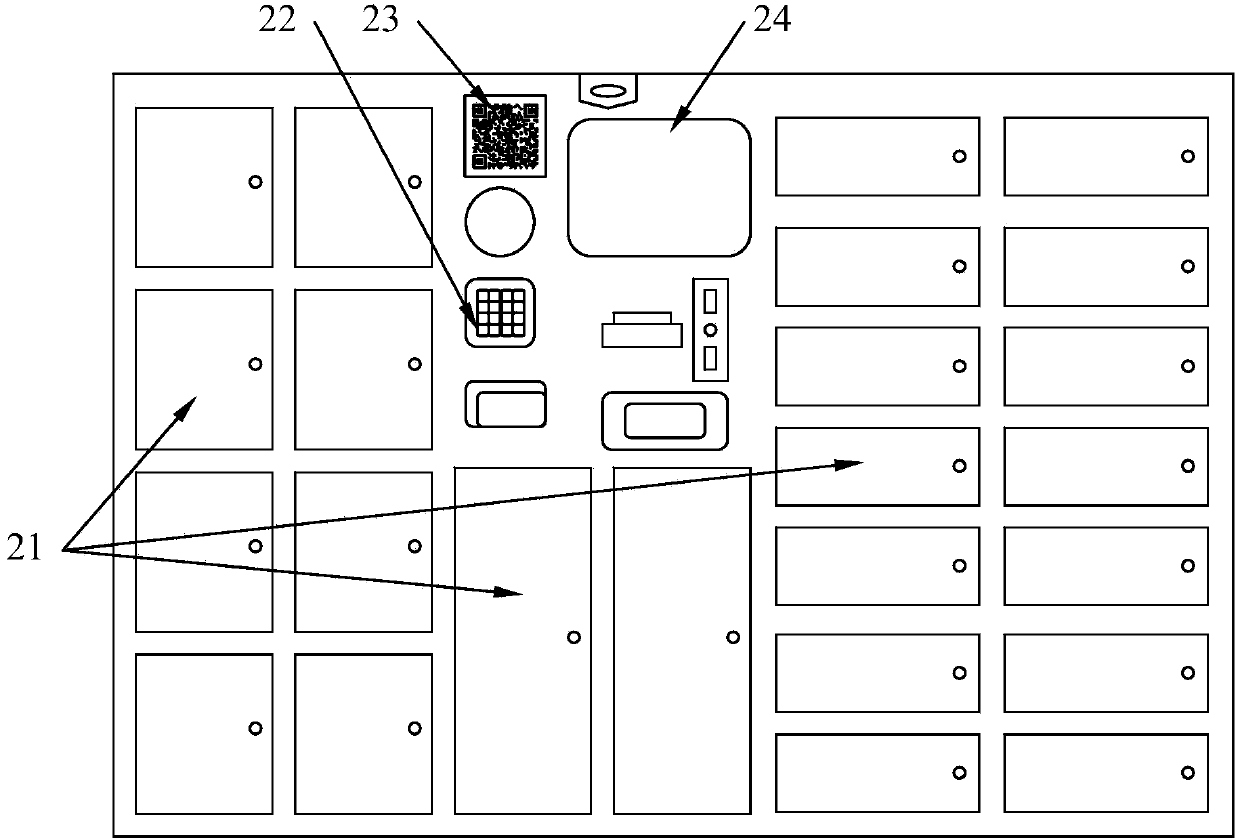

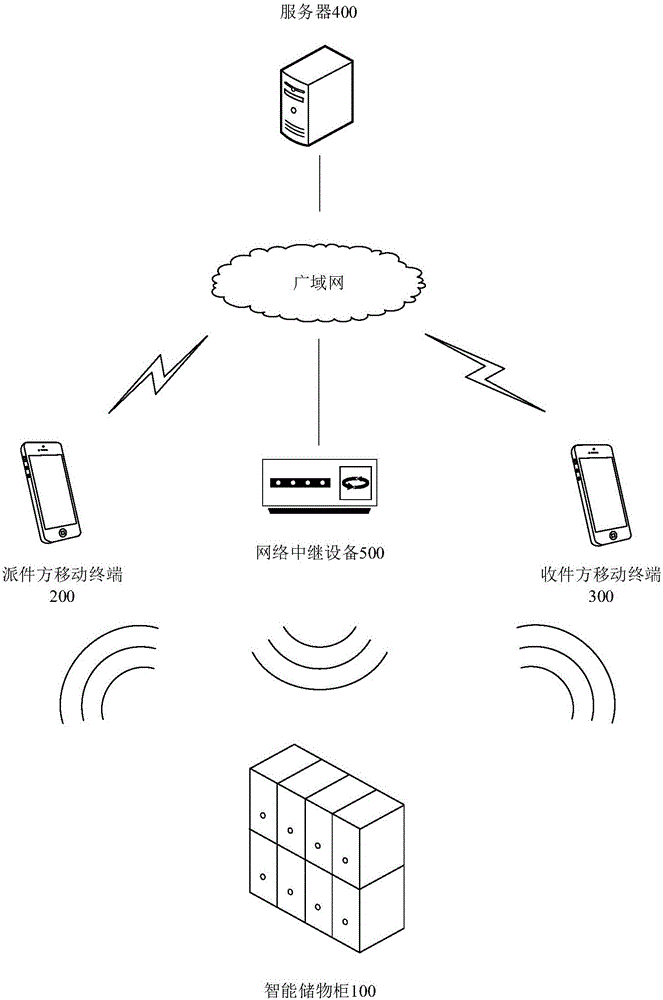

Intelligent cloud storage system based on dynamic binding of customer information and storage cabinet position

InactiveCN103208153AImprove satisfactionDelivery work is simple and easyApparatus for meter-controlled dispensingTransmissionComputer terminalCustomer information

The invention relates to an intelligent storage system (cloud storage cabinet system) for storing customer information and a cabinet position to a cloud platform and dynamically binding the customer information and the cabinet position under the condition of networking a storage cabinet. The intelligent storage system mainly comprises a front-end storage cabinet subsystem, a cloud storage platform and an application management subsystem, and a terminal storage cabinet subsystem comprises three portions. By the aid of the front-end storage cabinet subsystem, a dispatcher stores dispatch goods in a centralized manner, and a user picks up the dispatch goods in a self-service manner. The cloud storage platform mainly offers distributed data storage and centralized request receiving service, and the application management subsystem is used for managing the storage cabinet under the condition of leaving the cabinet, and realizing user-oriented application related to remote cabinet opening. By the aid of the intelligent storage system, dispatches are conveniently stored and taken out, and flexibility, diversity and convenience of storage and fetch modes of the user are improved.

Owner:重庆云创科技有限公司

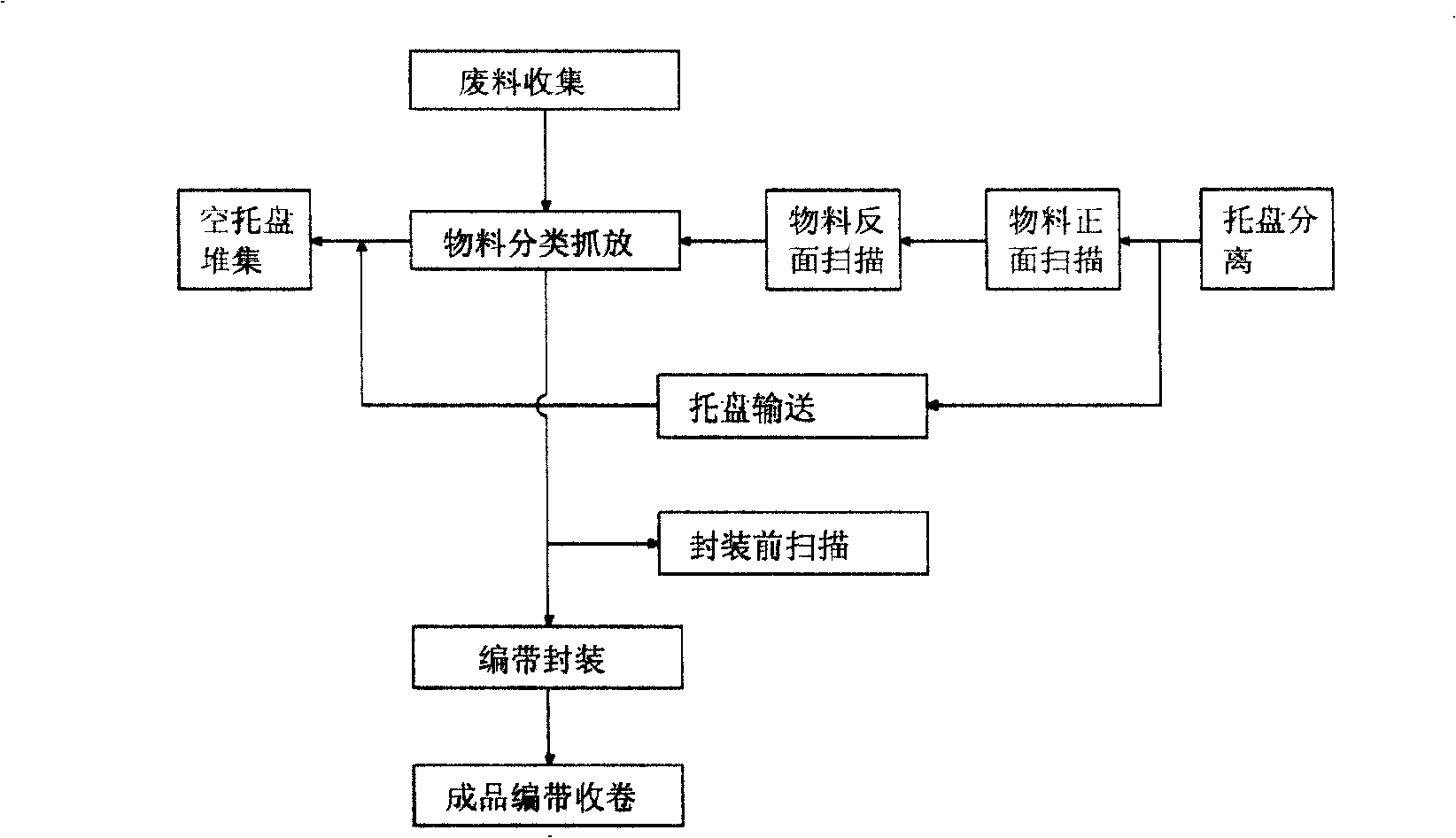

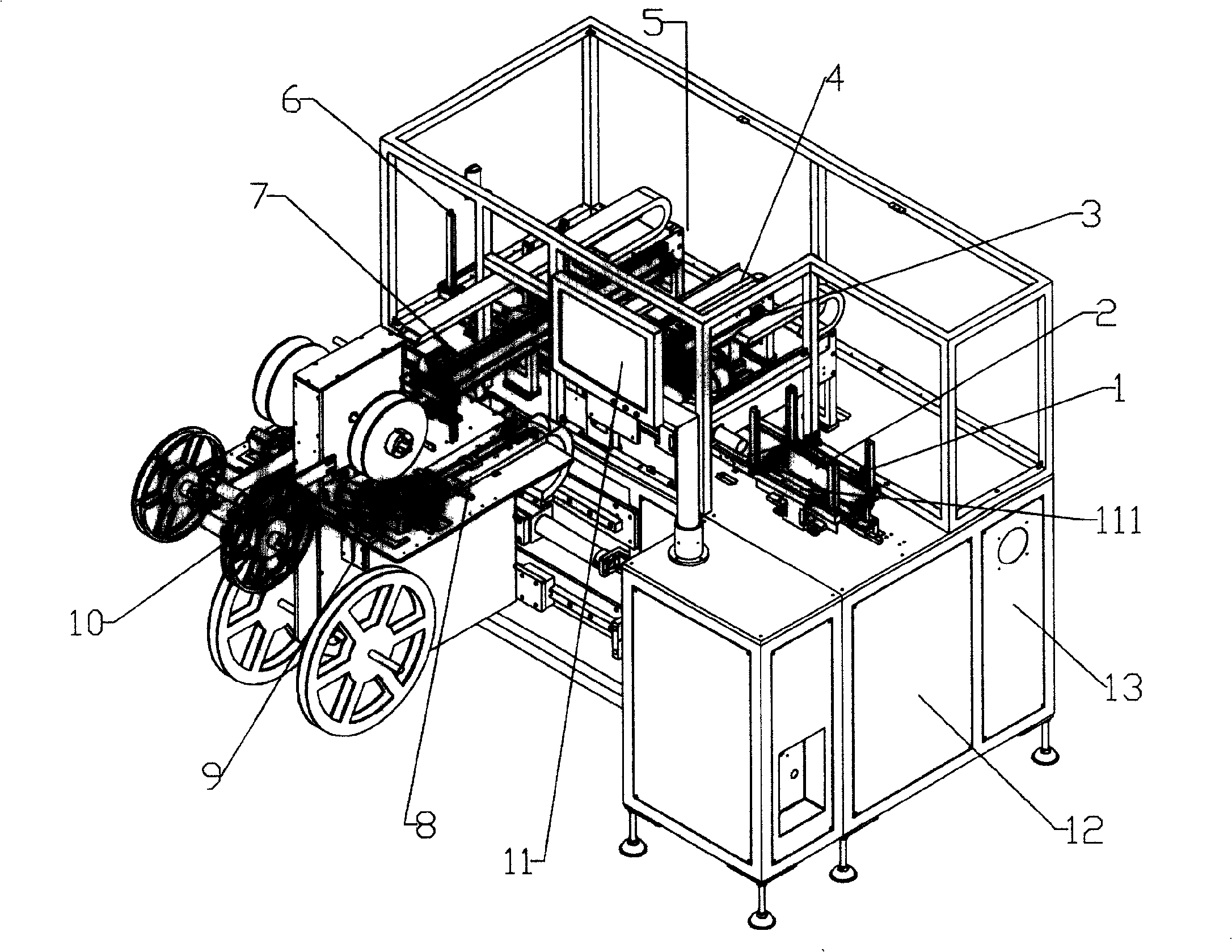

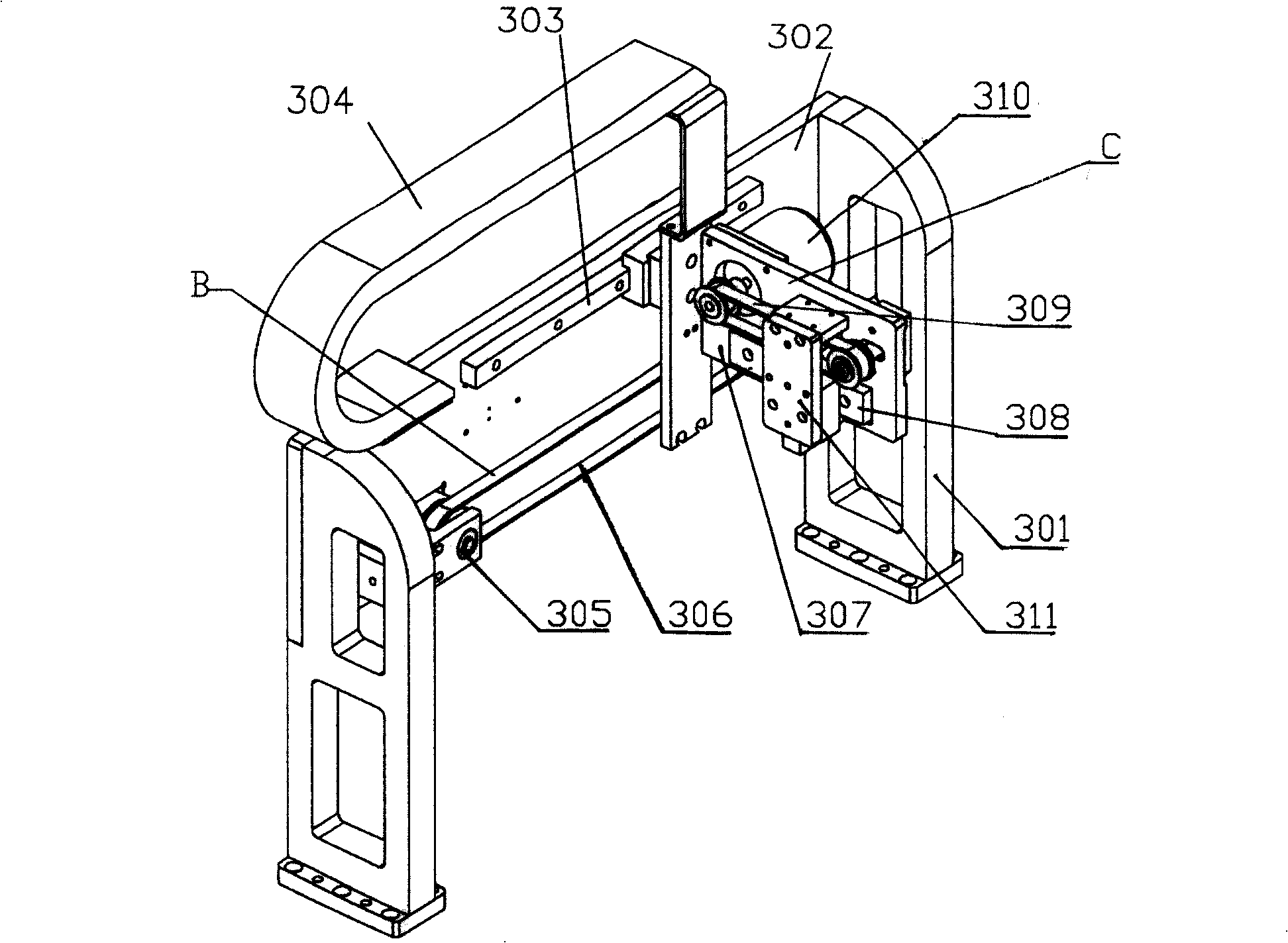

IC full-automatic method for testing brede and full-automatic holding tray type machine for testing brede

InactiveCN101244767AQuality assuranceAvoid lostSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationElectricityControl system

The invention discloses an IC automatic detecting braiding method and an automatic pallet type detecting braiding machine, comprising a pallet-transport device, a braiding packing device, a waste materials collecting device. A PC control system and an electrical control system as well as a pallet-separate device are arranged on the front end of the pallet transport device and an empty pallet-collect device is arranged on the back end. The braiding lead direction of the braiding packing device is vertical to the pallet-transport direction of the pallet-transport device. A face side scan device and a back side device for detecting IC as well as a catch-and-put device for catching IC from the pallet are orderly arranged in the transportation range of the pallet-transport device. The catch-and-put device is electrically connected with the PC control system and the electrical control system and is a classification catch-and-put device which can classify the ICs according to the detecting results of the face side scan device and the back side device and then send the eligible ICs to the braiding packing device and the unqualified ICs to the waste materials collecting device. The braiding machine has the advantages of good accuracy and reliability for scanning and detecting, rapid speed for braiding and packing, low composite cost and high production efficiency.

Owner:GRAND TECH SHENZHEN

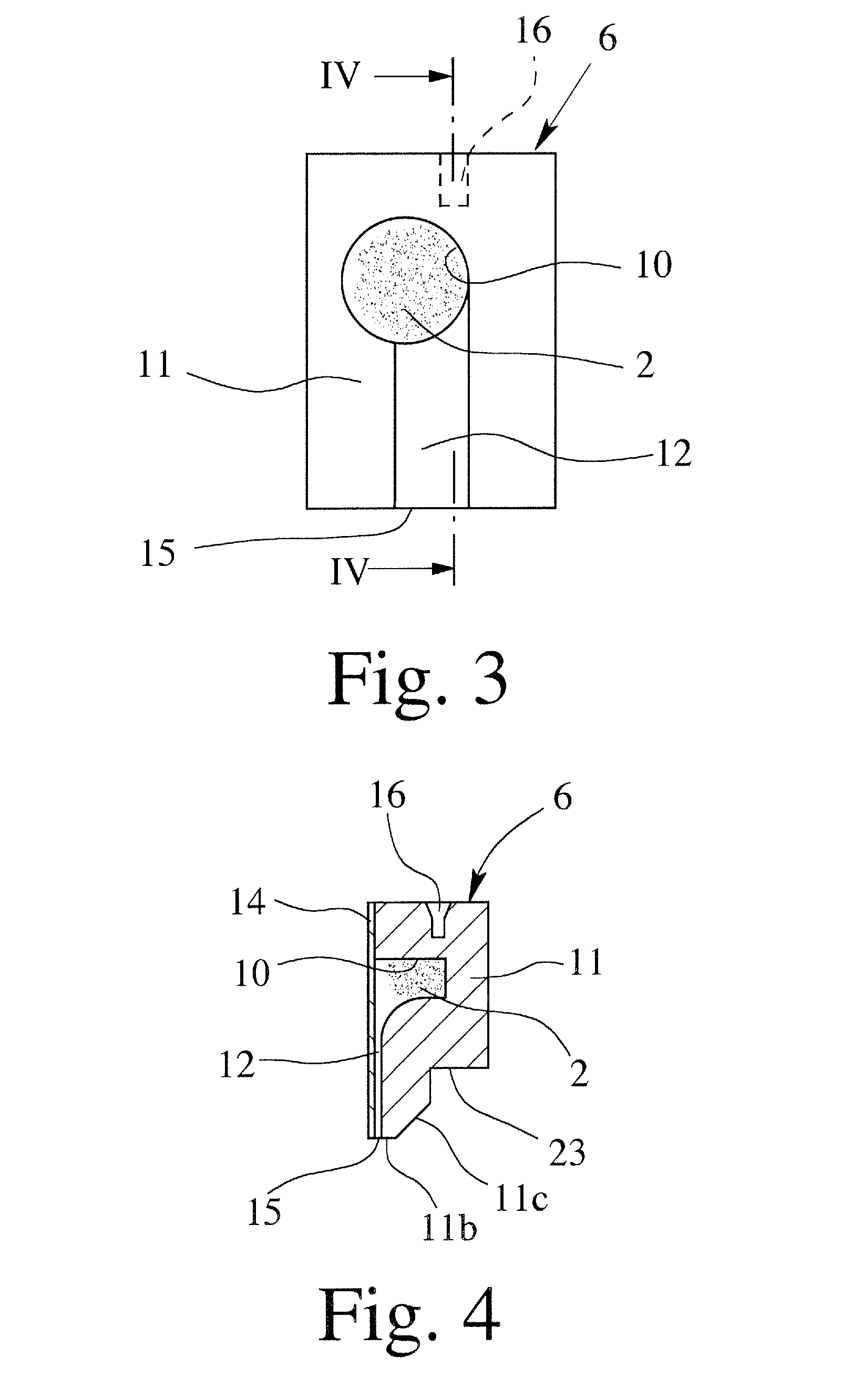

Dispensing device

InactiveUS20080295833A1Easy to handleEasy to operateRespiratorsLiquid surface applicatorsBiomedical engineering

A dispensing device has a storage device and an air pump for dispensing a medical formulation has multiple inserts, each insert containing a single dose of the formulation. Each insert is located in a separate sealed cavity. The cavities can be individually opened for dispensing the respective dose from the respective insert. A connecting element that is moveable relative to the cavities is provided for individually opening and supplying pressurized gas thereto for dispensing a respective dose of formulation, and the storage device has an empty, hollow or dummy receptacle into which the connecting element is engaged in a state prior to first use of the dispensing device.

Owner:BOEHRINGER INGELHEIM INT GMBH

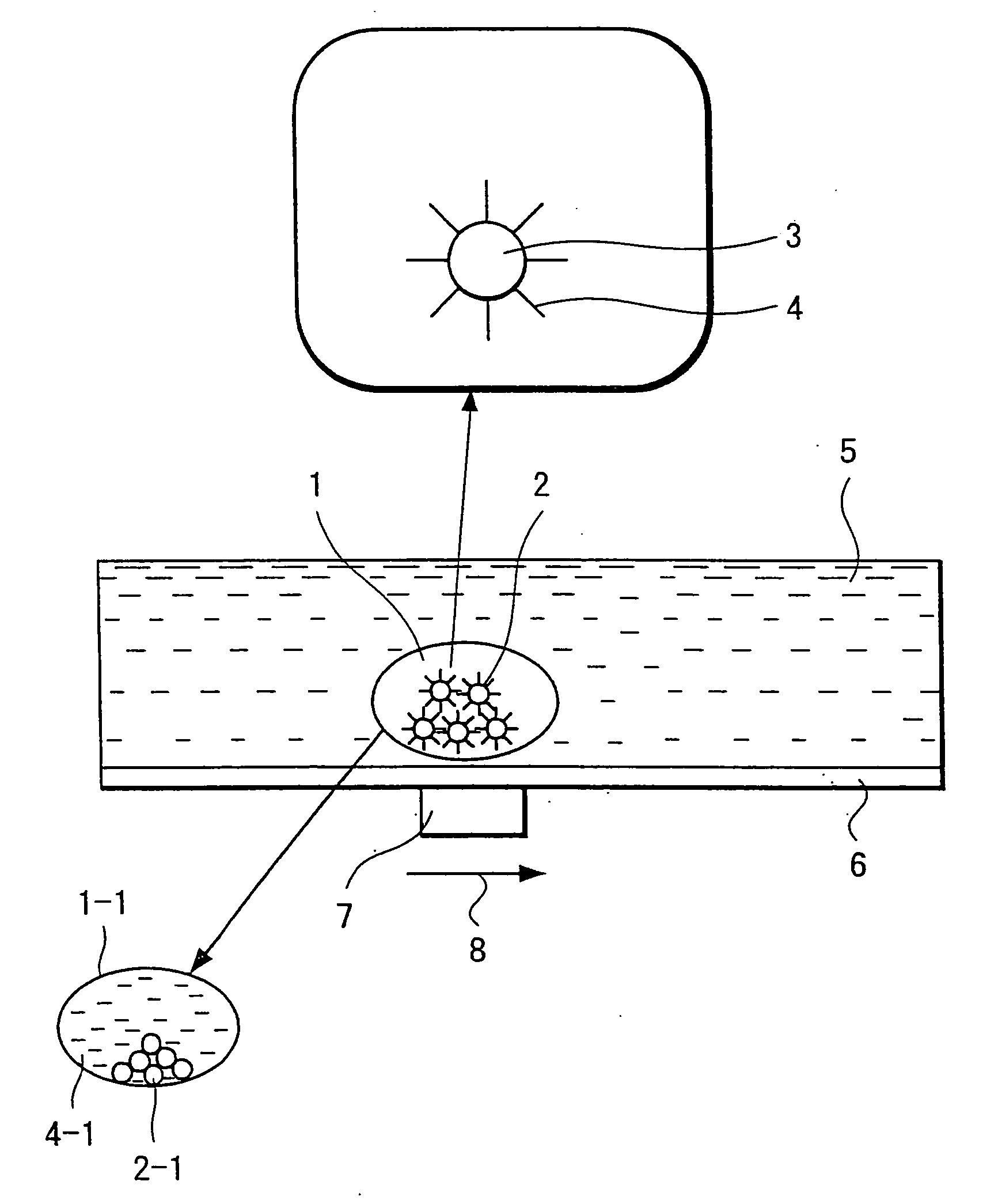

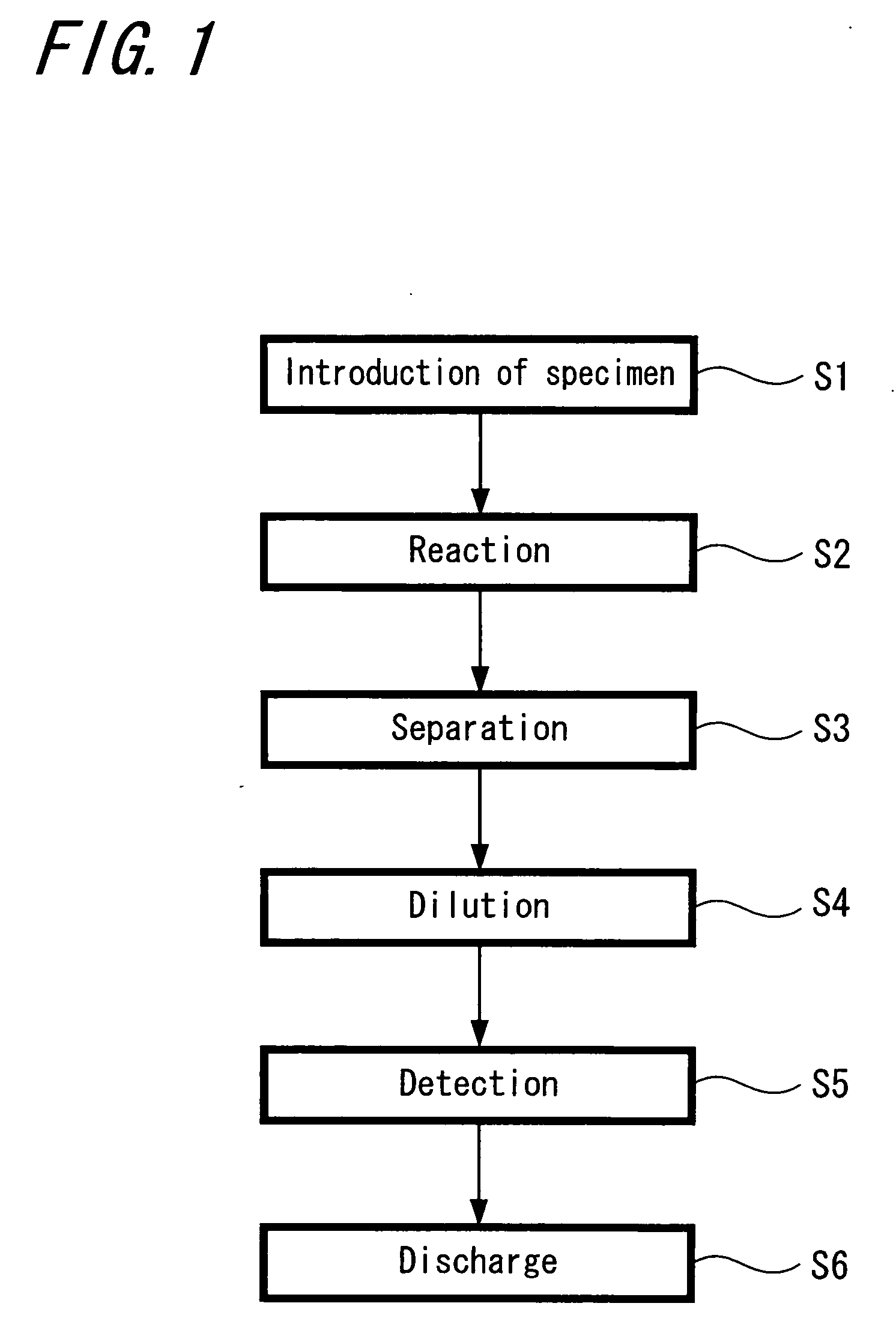

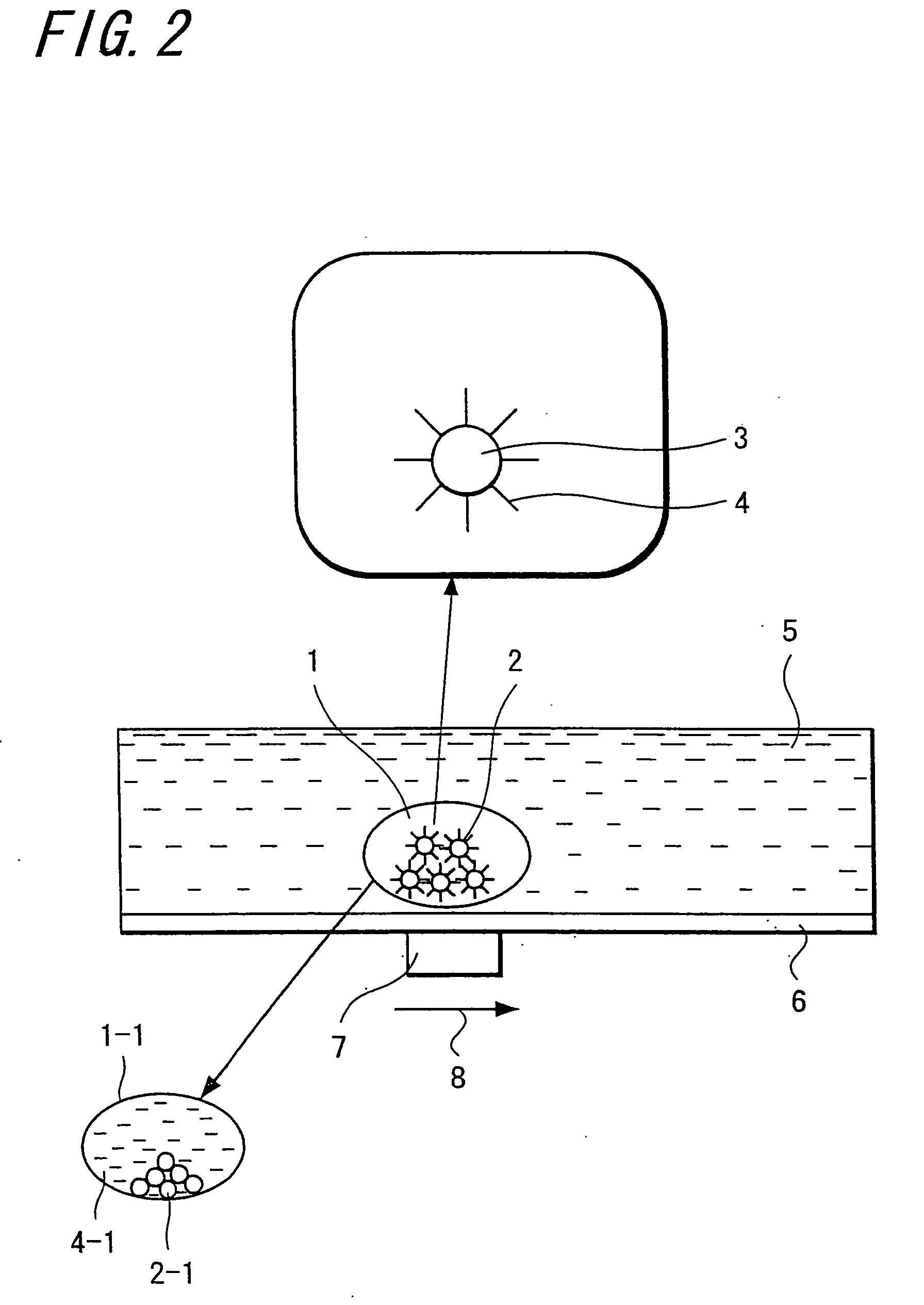

Chemical Analytic Apparatus and Chemical Analytic Method

InactiveUS20080226500A1Improve magnetic efficiencyImprove accuracyLaboratory glasswaresBiological testingCompound (substance)Miniaturization

A chemical analytic apparatus of the present invention is the one which proposes that a miniaturization, a making low-cost and portability are possible and also the operation of each process of separation, concentration and dilution of specimen is possible, and which includes: an introduction means (S1) that introduces a droplet to which magnetic ultrafine particles are mixed into another liquid that differs from the droplet while maintaining a single droplet; a conveyance means by which the droplet that includes the magnetic particles is conveyed in another liquid of the introduction means by applying magnetic field externally to the magnetic ultrafine particles; and processing means (S2 to S6) by which operations for processing of chemical analysis are performed one by one in the process in which the droplet to which the magnetic ultrafine particles are mixed is conveyed by the conveyance means

Owner:JAPAN SCI & TECH CORP

Method and composition for the treatment of lung surfactant deficiency or dysfunction

ActiveUS7201167B2Improve delivery efficiencyQuantity minimizationRespiratorsMedical devicesDiseaseSurfactant deficiency

A method of treating a disease involving surfactant deficiency or dysfunction in a patient's lungs is disclosed comprising the steps of providing a liquid lung surfactant composition; aerosolizing the lung surfactant composition with a vibrating aperture-type aerosol generator to form a surfactant aerosol; and introducing the surfactant aerosol into the gas flow within a circuit of a pressure-assisted breathing system coupled to the patient's respiratory system, whereby a therapeutically effective amount of said surfactant is delivered to the patient's lungs. Apparatus is also disclosed that increases the efficiency of delivery of aerosolized medicaments such as aerosolized lung surfactant.

Owner:NOVARTIS AG

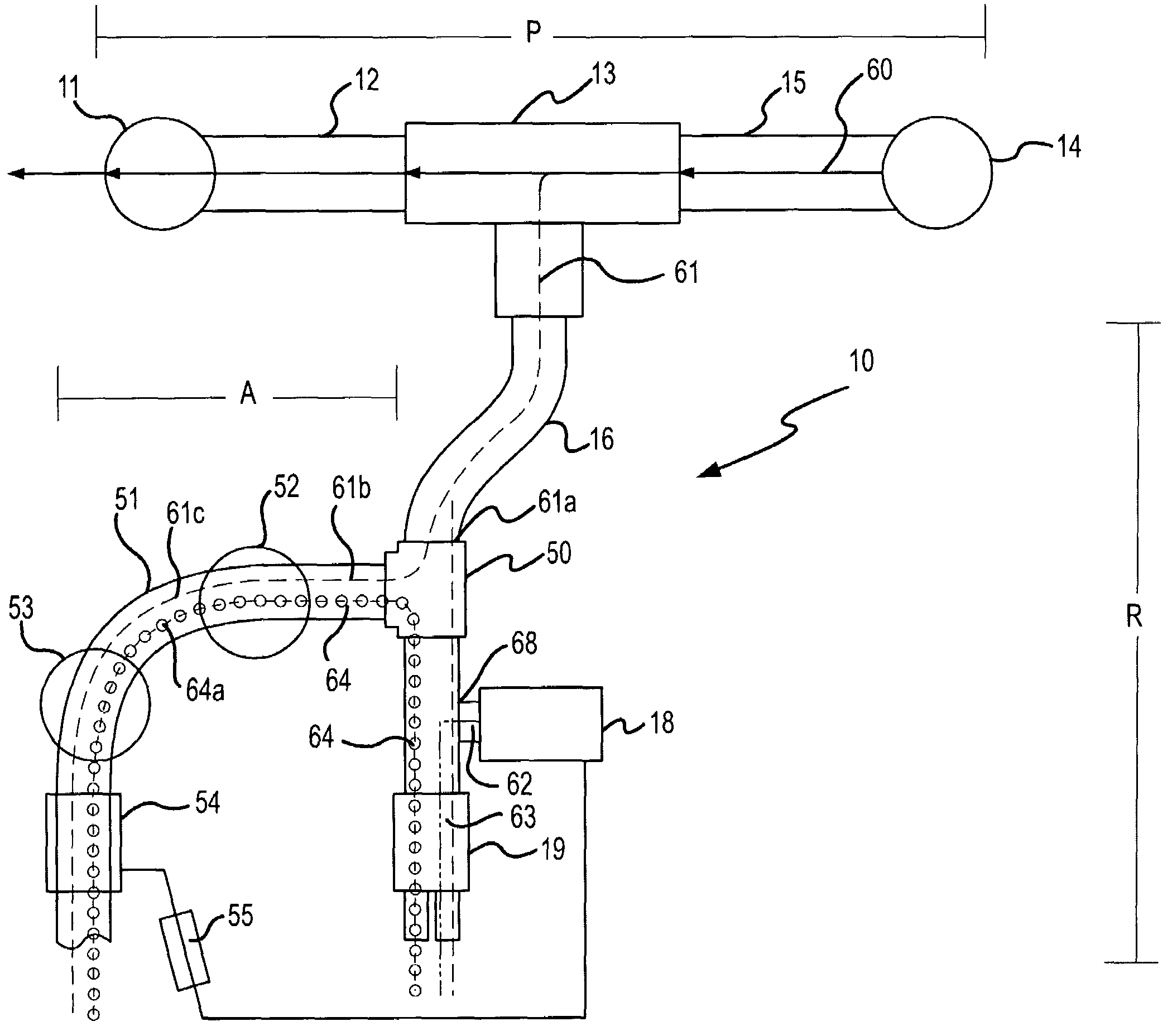

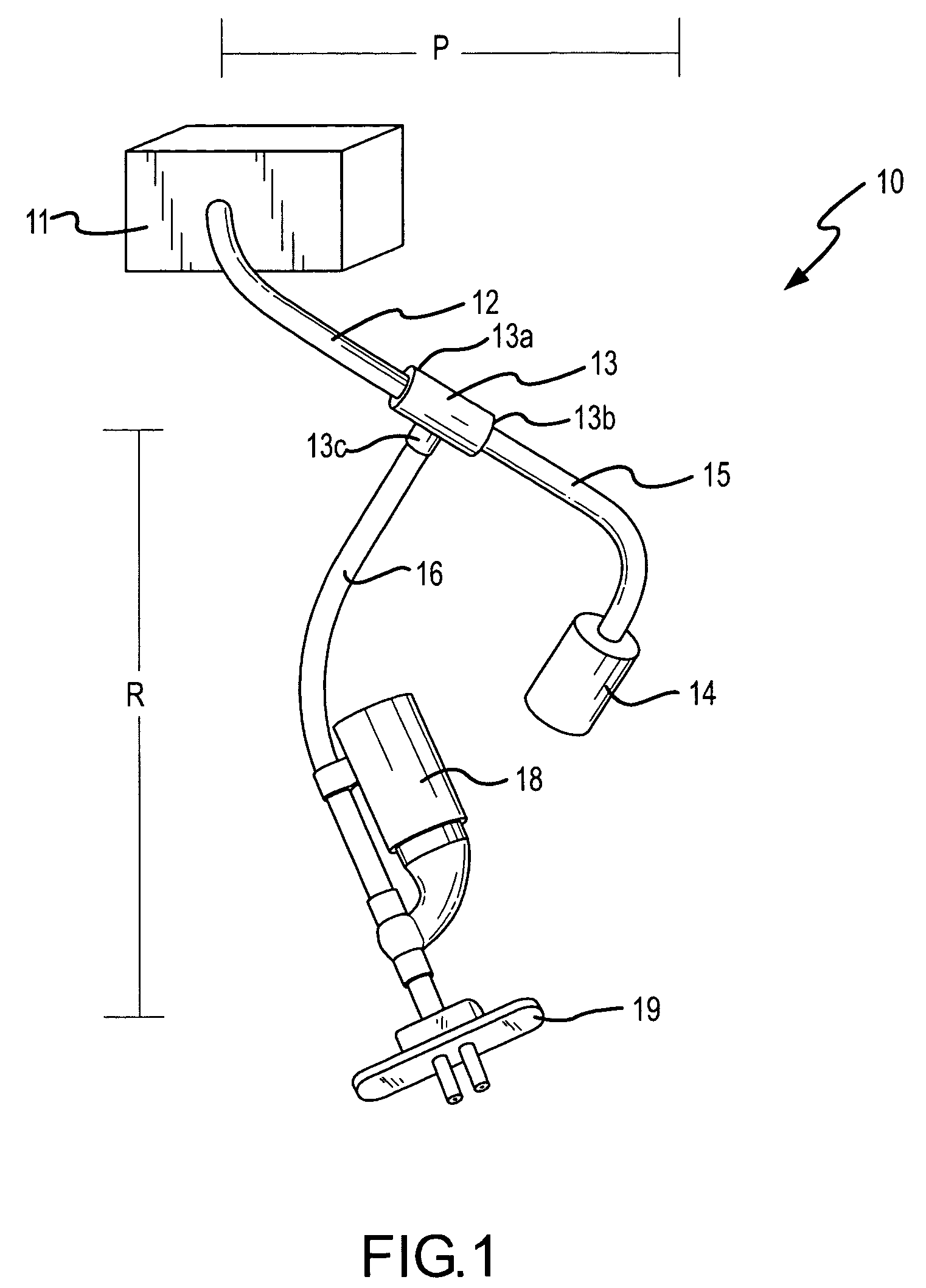

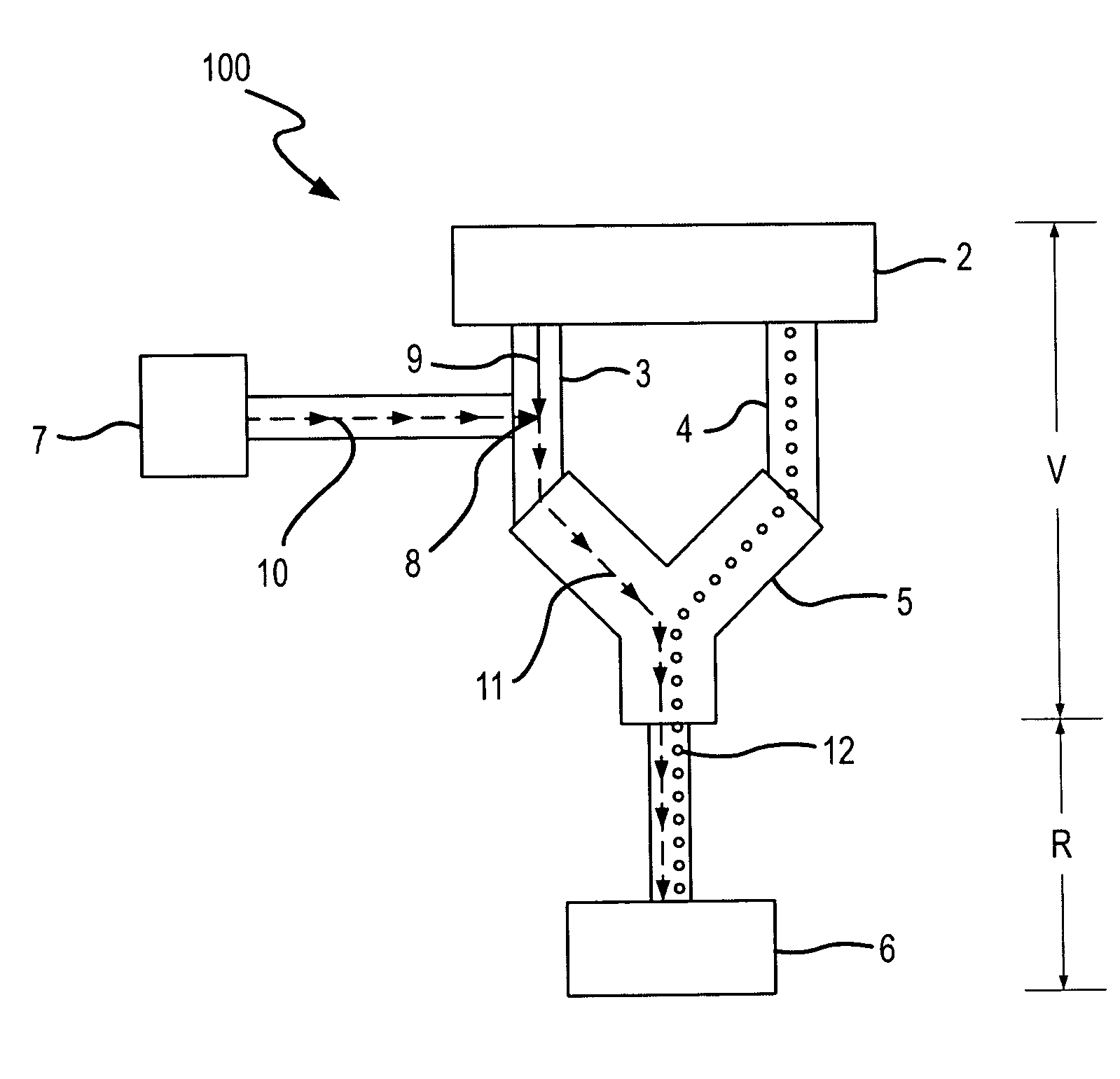

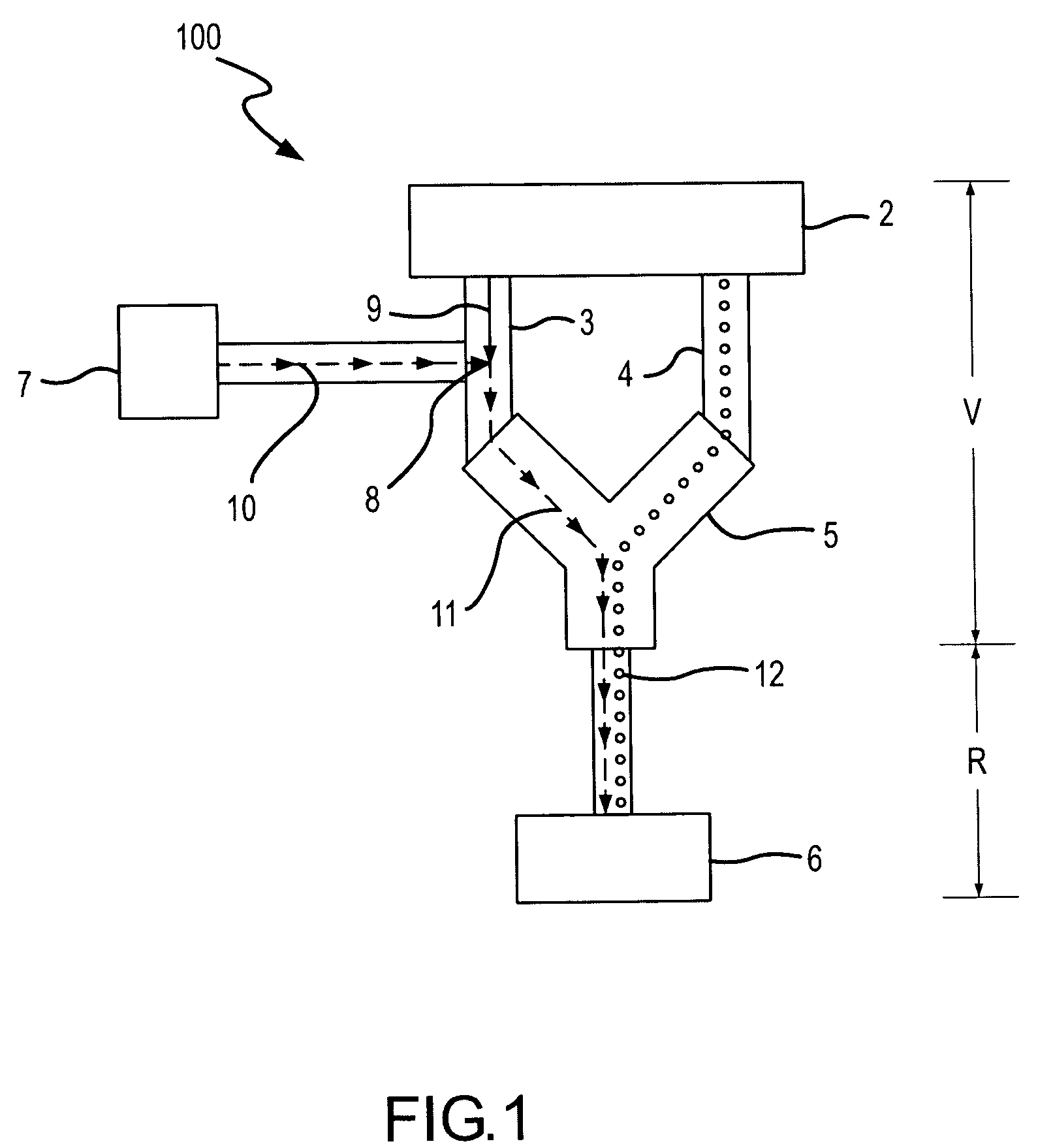

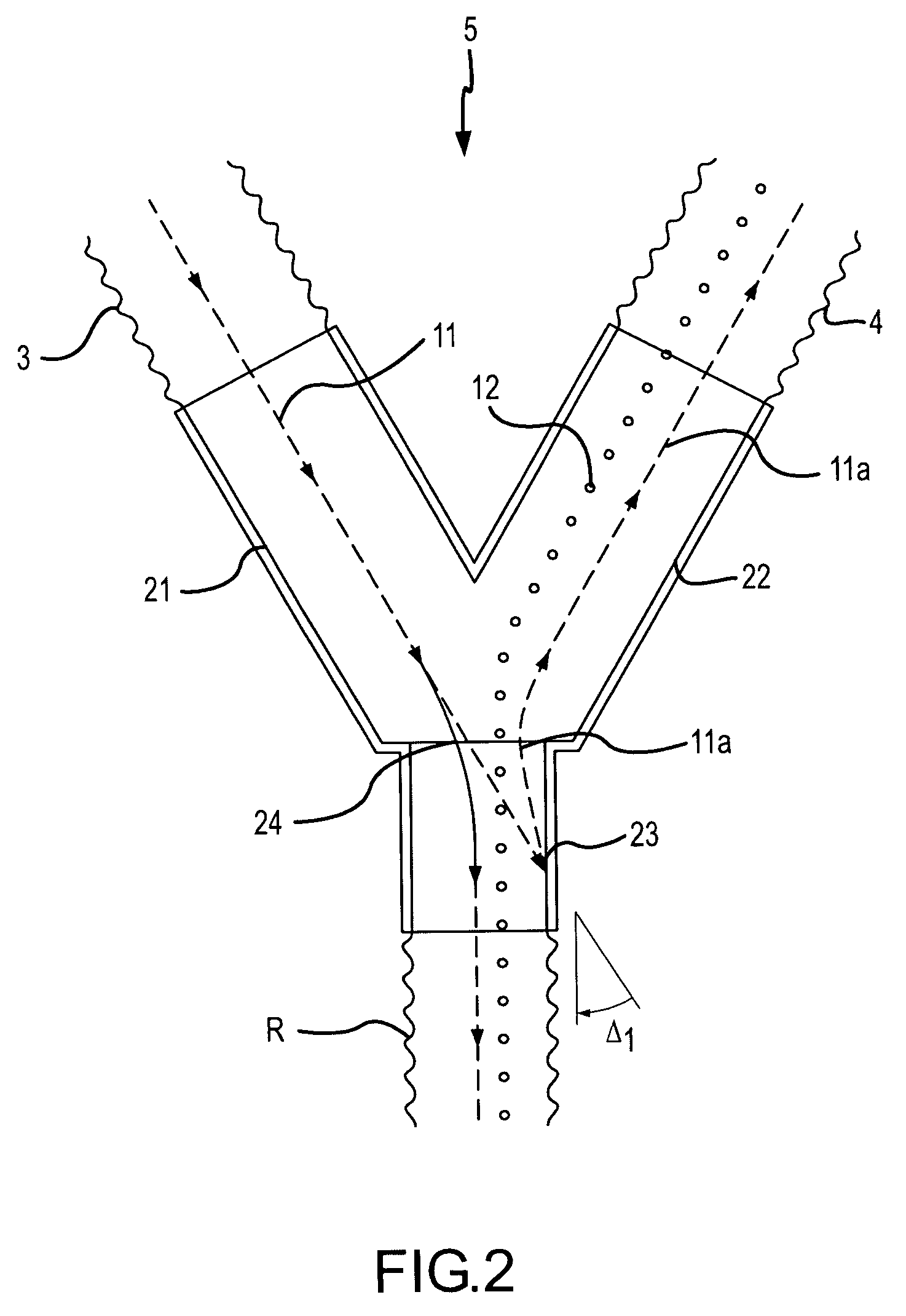

Aerosol delivery apparatus and method for pressure-assisted breathing systems

ActiveUS7290541B2Improve delivery efficiencyImprove efficiencyRespiratorsMedical atomisersAerosol deliveryAssisted breathing

A pressure-assisted breathing system comprises a flow generator, a circuit connecting the flow generator to a patient's respiratory system and an aerosol generator for emitting aerosol particles into the circuit, wherein the circuit defines a path for the emitted aerosol particles having a change in angle no greater than 15°.

Owner:NOVARTIS FARMA

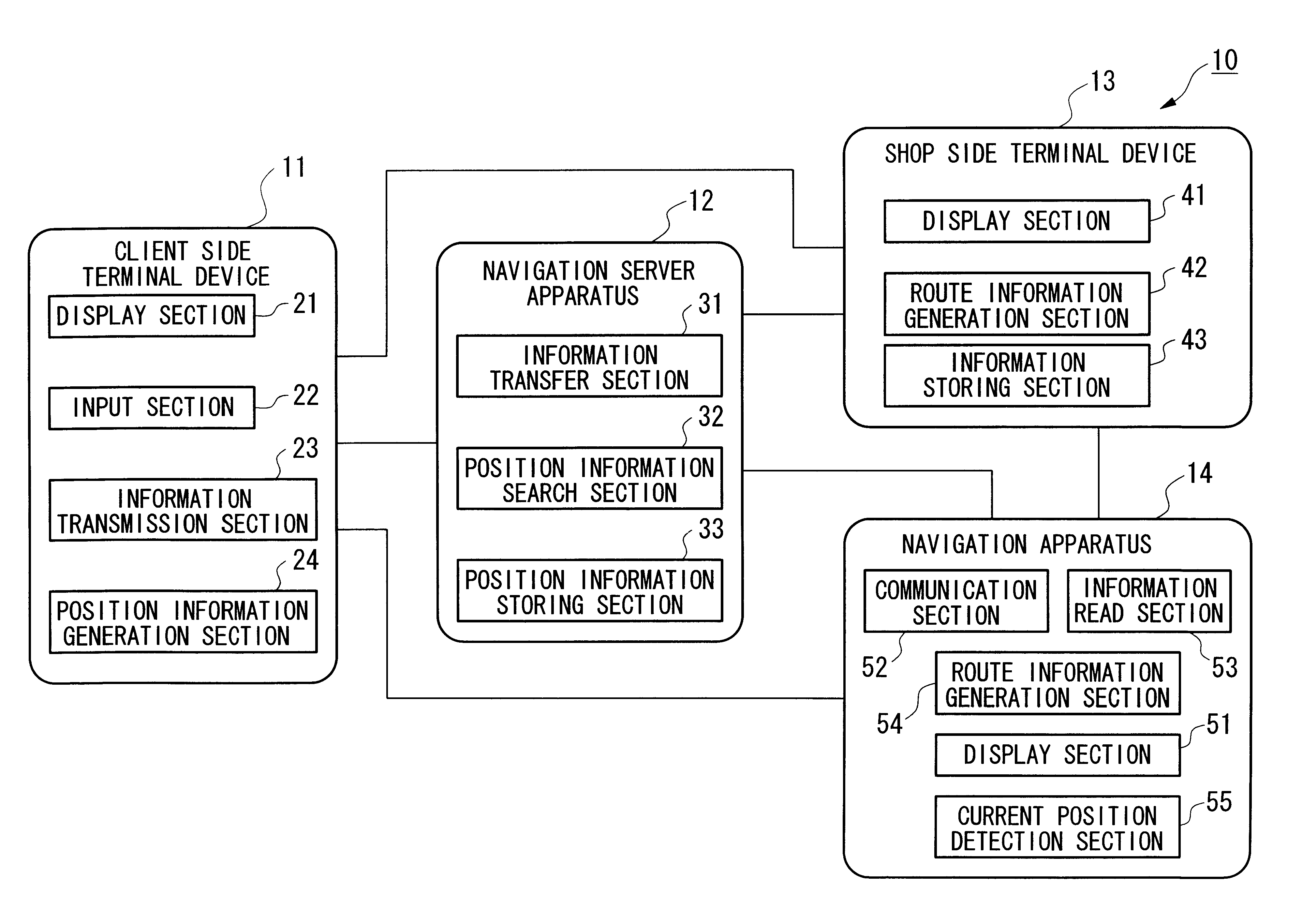

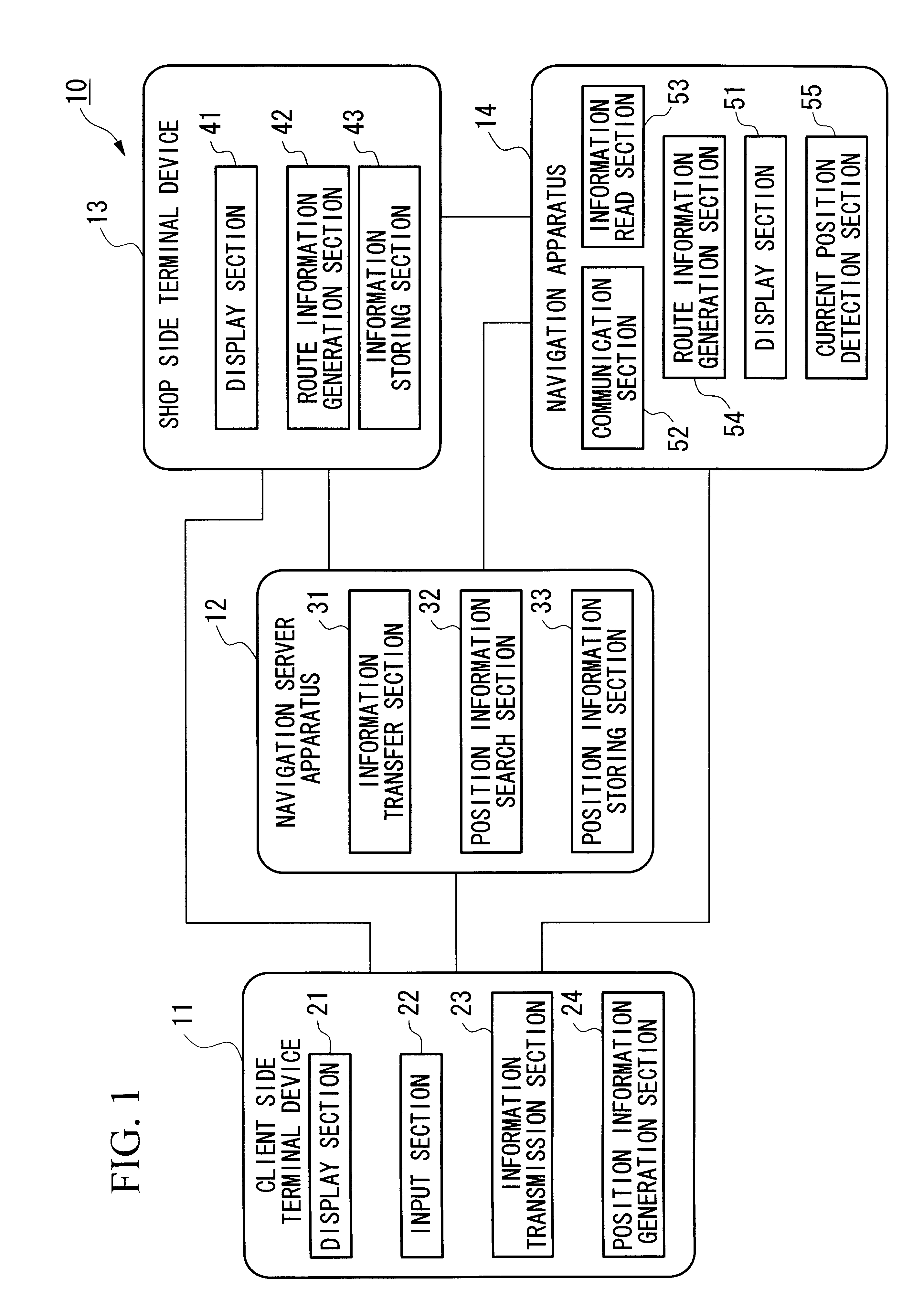

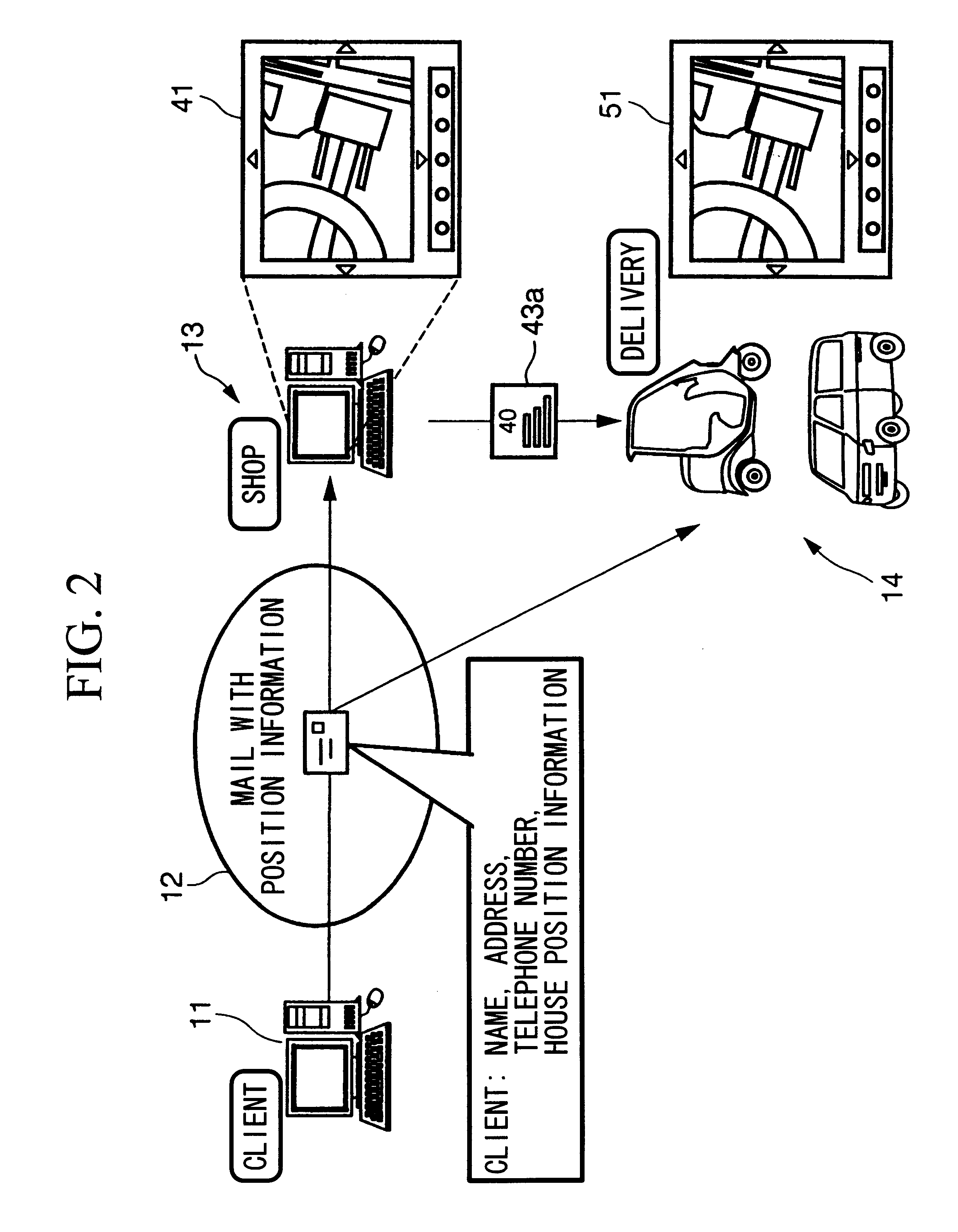

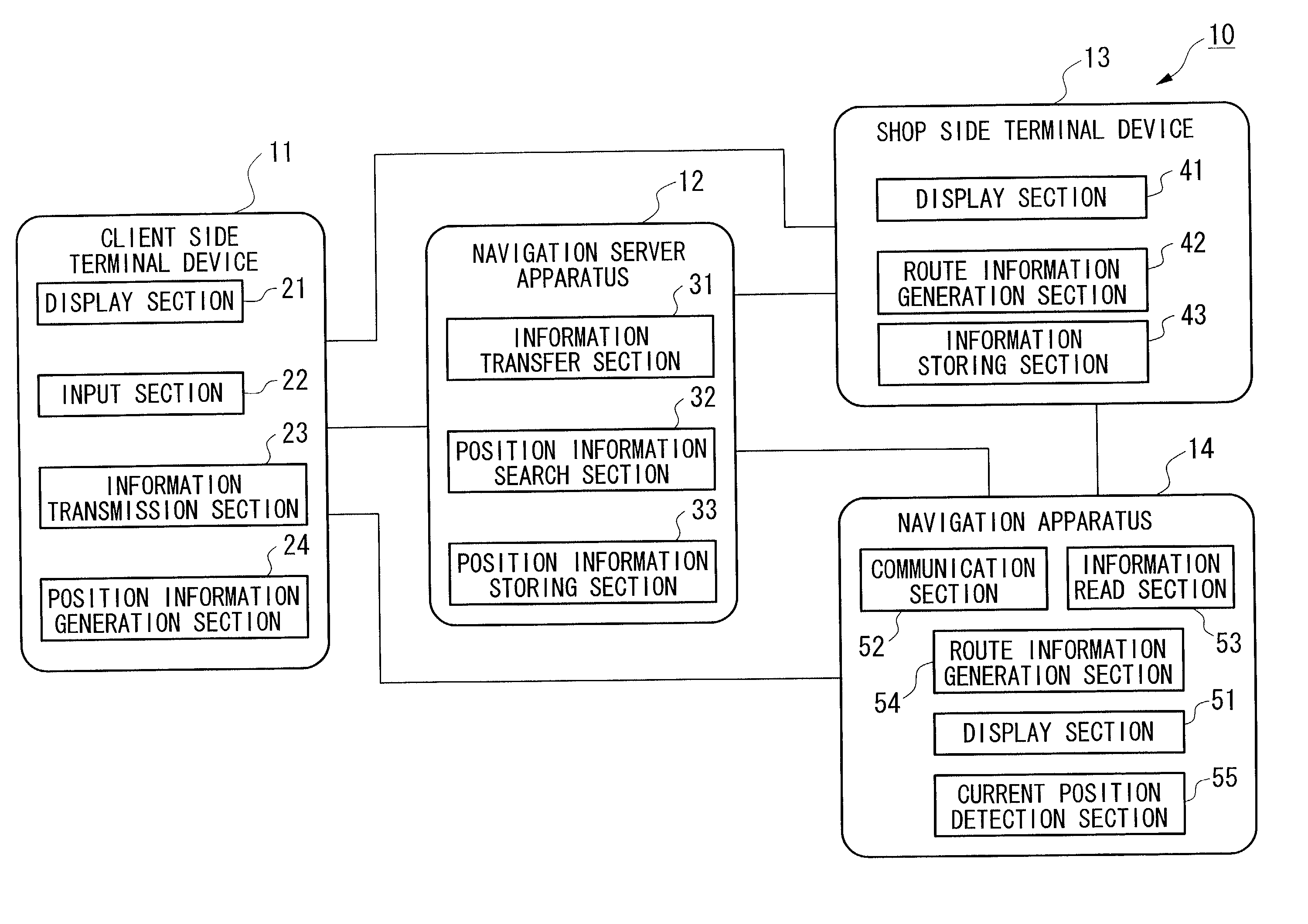

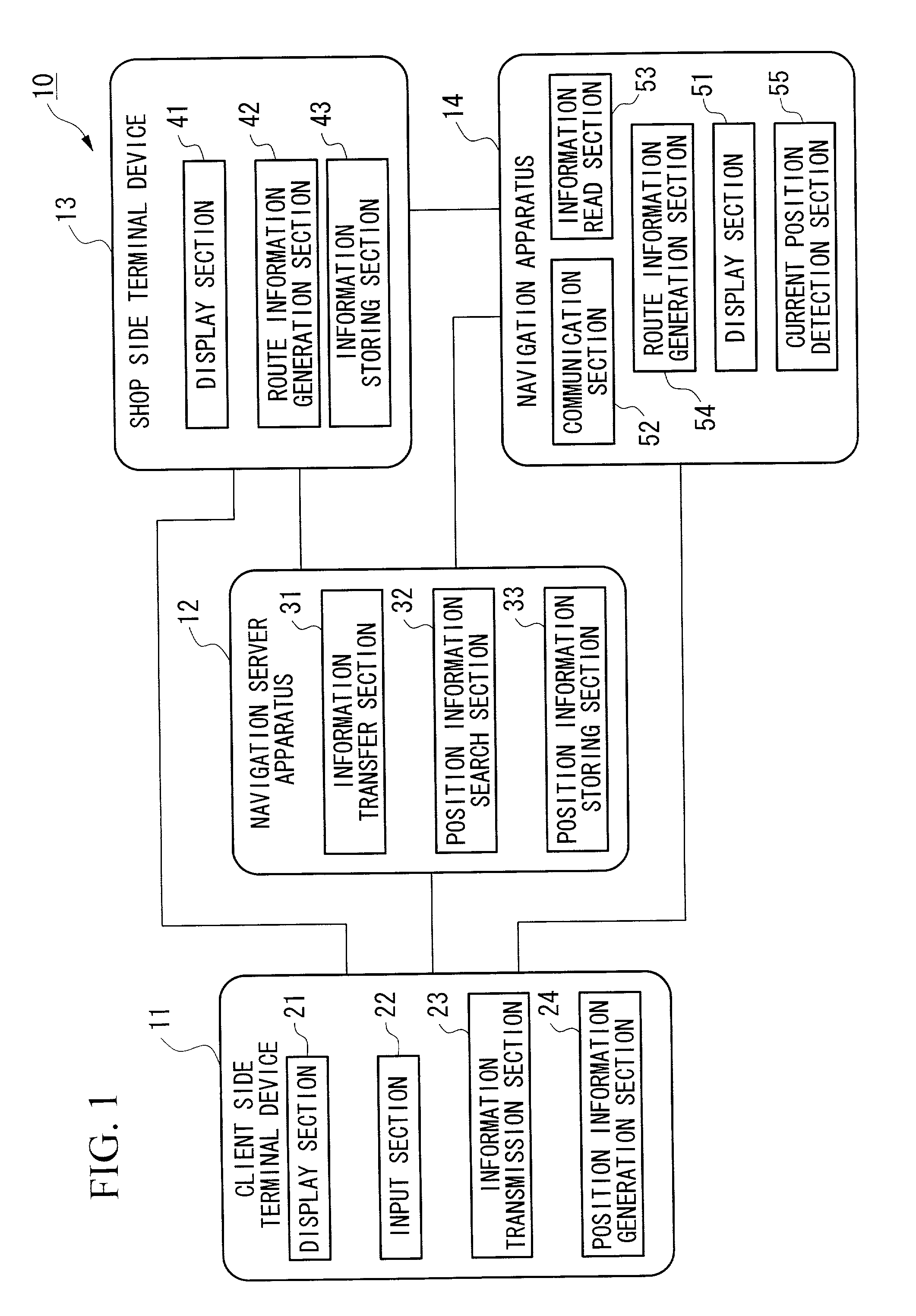

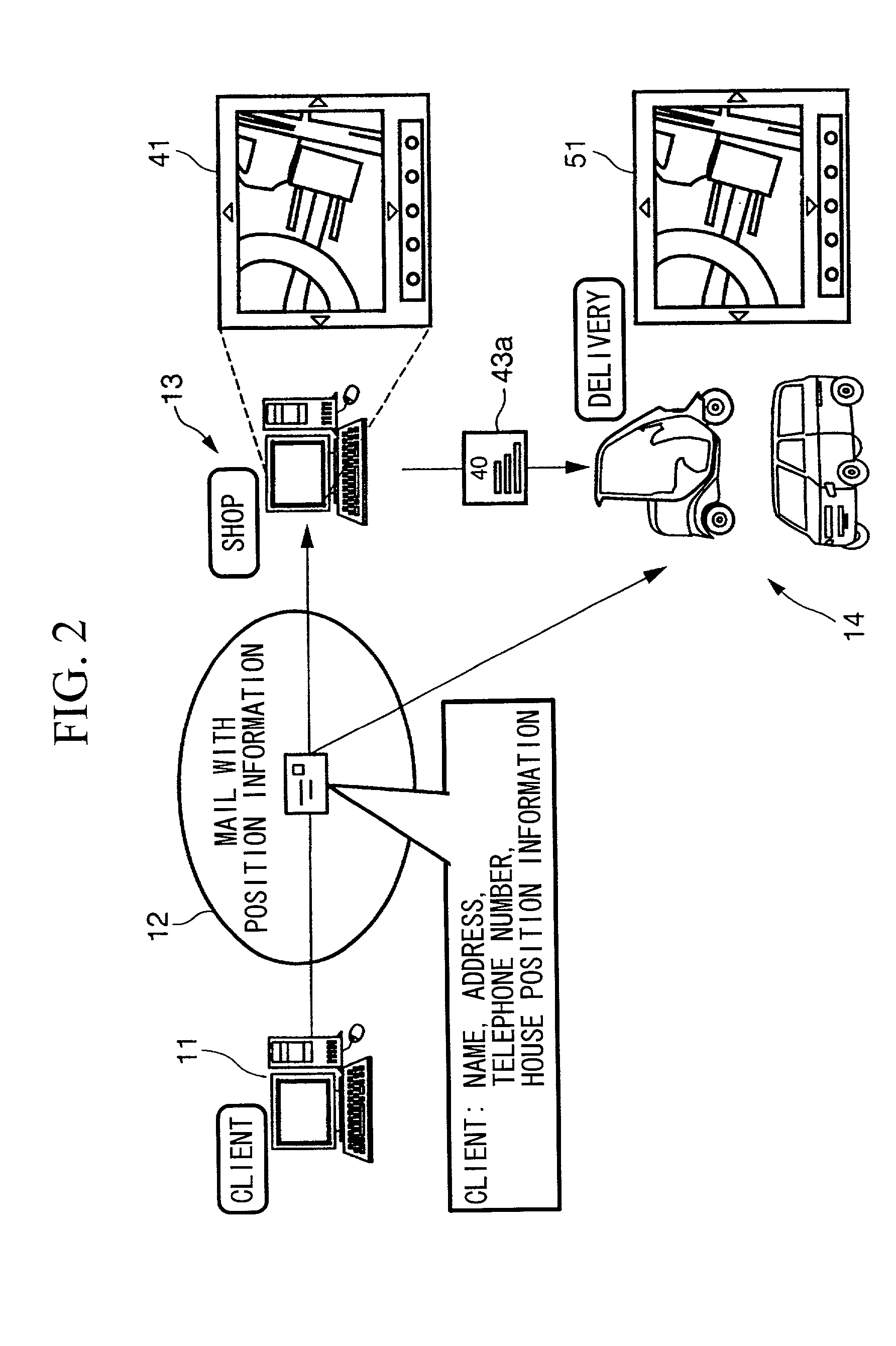

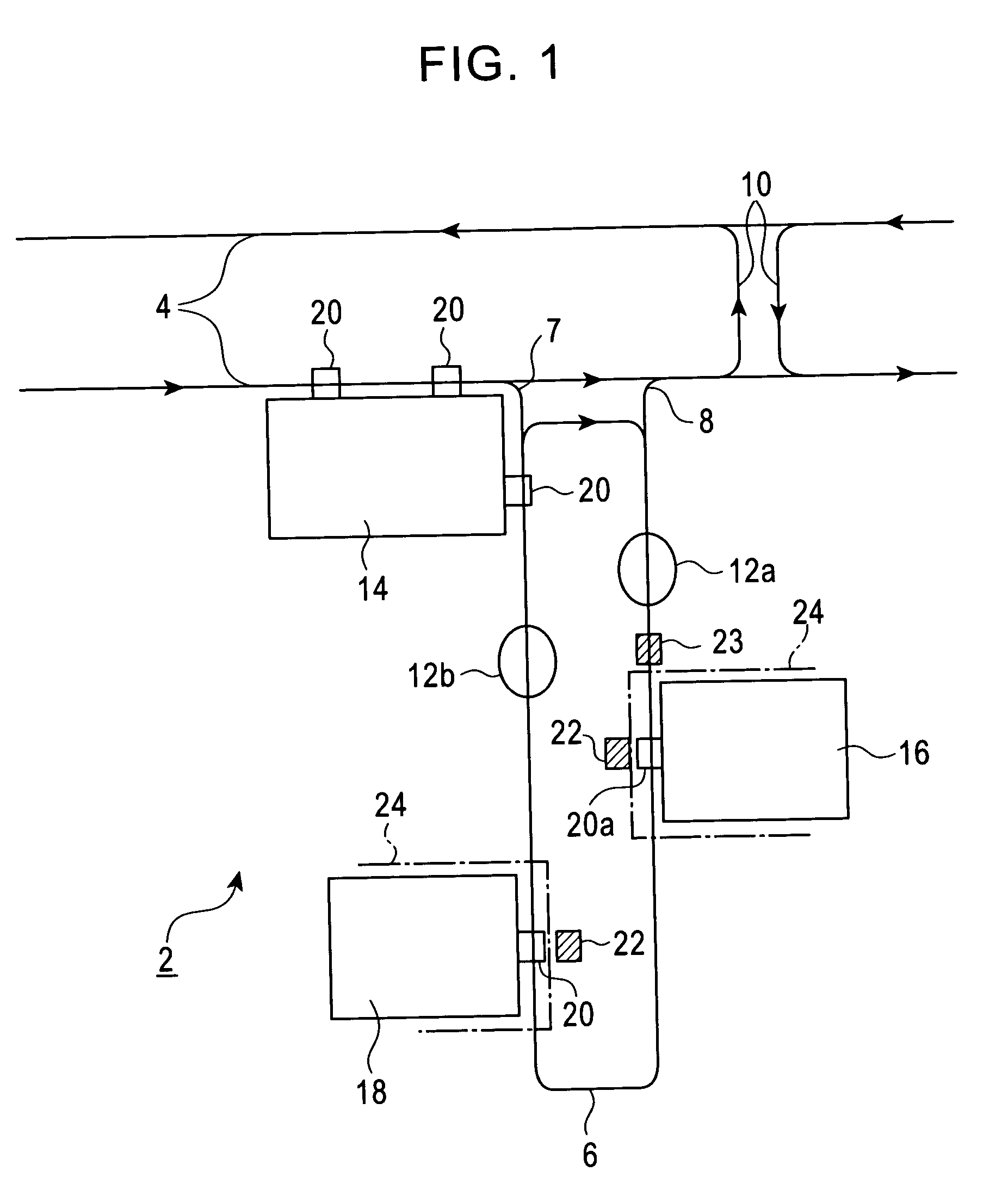

Service delivery system

InactiveUS6408243B1Improve service efficiencyEasy to processInstruments for road network navigationRoad vehicles traffic controlInformation transmissionService provision

The invention is a service delivery system comprising: a client side terminal for ordering delivery of various services to a delivery destination, and a shop side terminal for receiving the order information and instructing delivery of the service to the delivery destination. The client side terminal comprises a client side display device for displaying map information and product information on a screen, and an order information transmission device for attaching position information for the delivery destination to the order information and transmitting this combined information. The shop side terminal comprises a shop side display device for displaying map information and product information on a screen and a route information generation device for generating route information for a route to the delivery destination based on the position information.

Owner:HONDA MOTOR CO LTD

Service delivery system

InactiveUS20020052688A1Improve service efficiencyEasy to processInstruments for road network navigationRoad vehicles traffic controlClient-sideService provision

The invention is a service delivery system comprising: a client side terminal for ordering delivery of various services to a delivery destination, and a shop side terminal for receiving the order information and instructing delivery of the service to the delivery destination. The client side terminal comprises a client side display device for displaying map information and product information on a screen, and an order information transmission device for attaching position information for the delivery destination to the order information and transmitting this combined information. The shop side terminal comprises a shop side display device for displaying map information and product information on a screen and a route information generation device for generating route information for a route to the delivery destination based on the position information.

Owner:HONDA MOTOR CO LTD

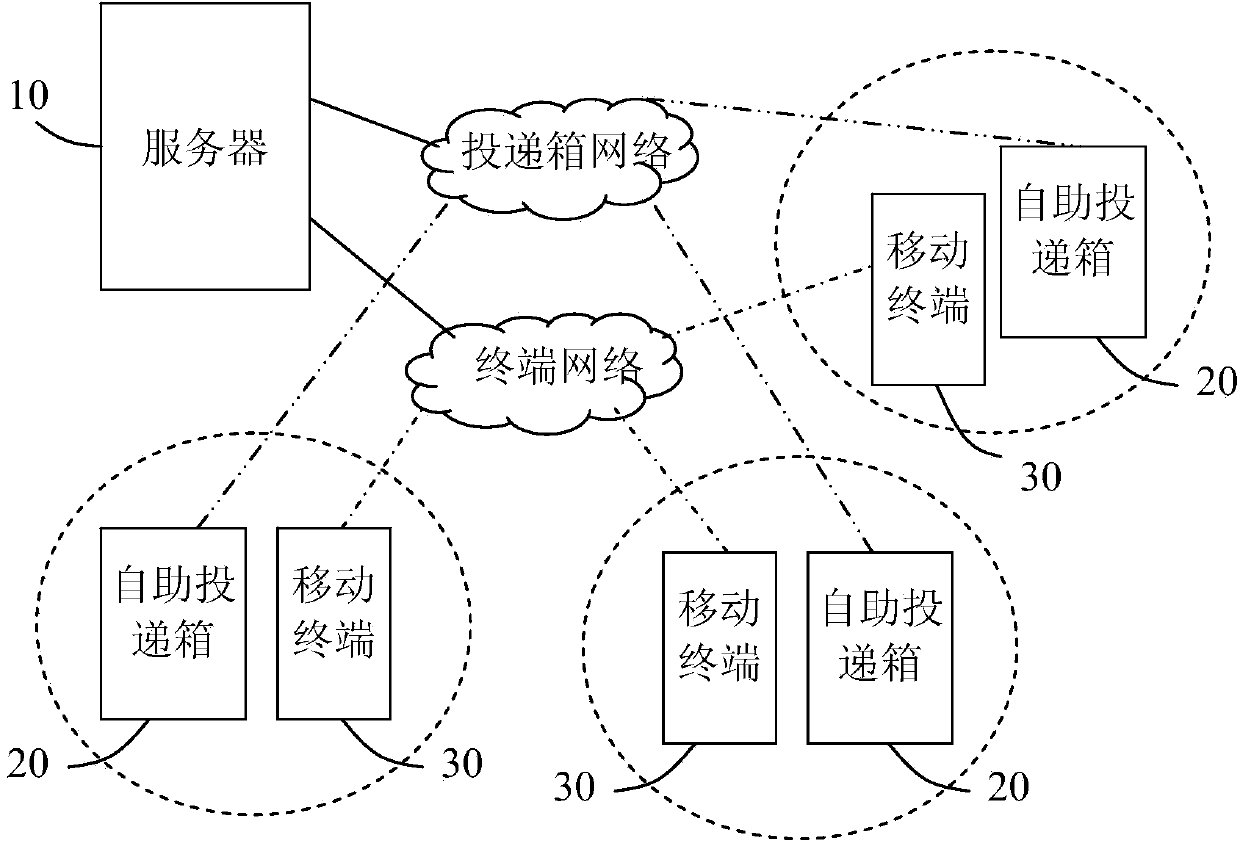

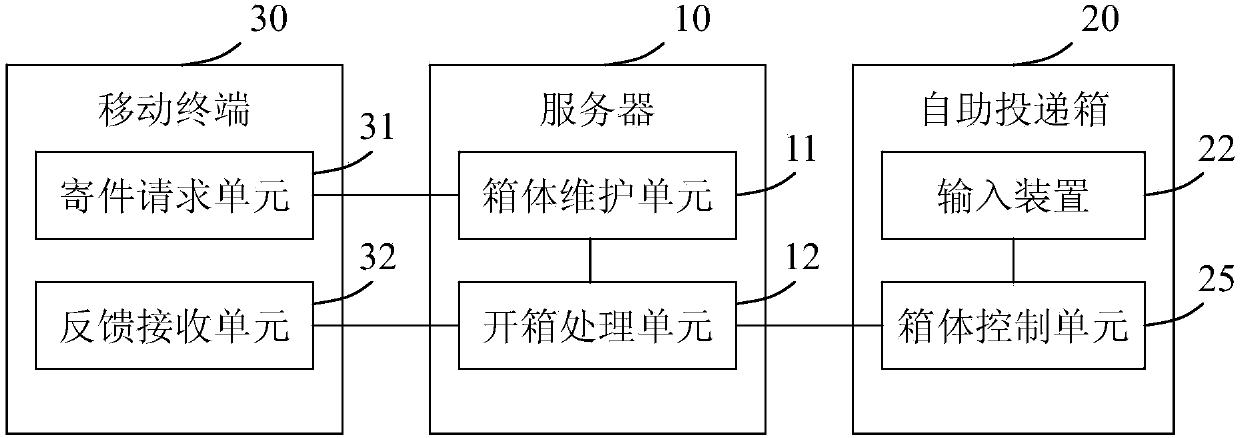

Self-service type article transmitting and receiving system and method and mobile terminal

InactiveCN103729749ASimplify delivery proceduresImprove delivery efficiencyApparatus for meter-controlled dispensingTransmissionComputer terminalDelivery Procedure

The invention provides a self-service type article transmitting and receiving system which comprises a server, a mobile terminal and self-service deliver boxes. The server comprises a box body maintaining unit and a box opening processing unit, the mobile terminal comprises an article sending request unit and a feedback receiving unit, each self-service deliver box comprises only one identification, a plurality of box bodies of different types, an input device and a box body control unit, and the box bodies are used for storing articles. The invention further provides a self-service type article transmitting and receiving method and the mobile terminal. The mobile terminal launches the request to the server, the server controls the self-service deliver boxes to deliver articles, self-service delivery can be carried out through the popularized mobile terminal and the self-service deliver boxes, delivery procedures are simplified, and delivery efficiency is improved.

Owner:马建国

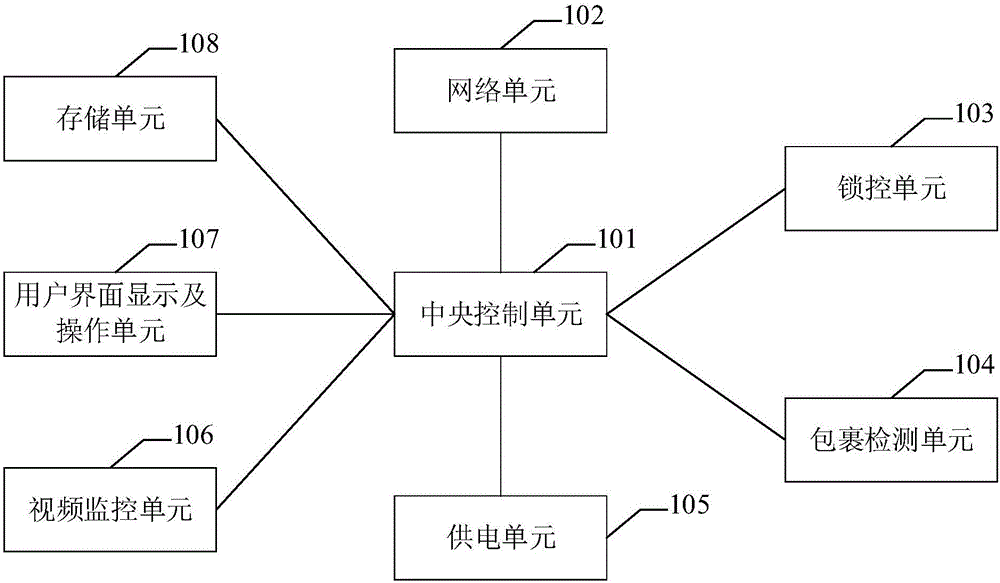

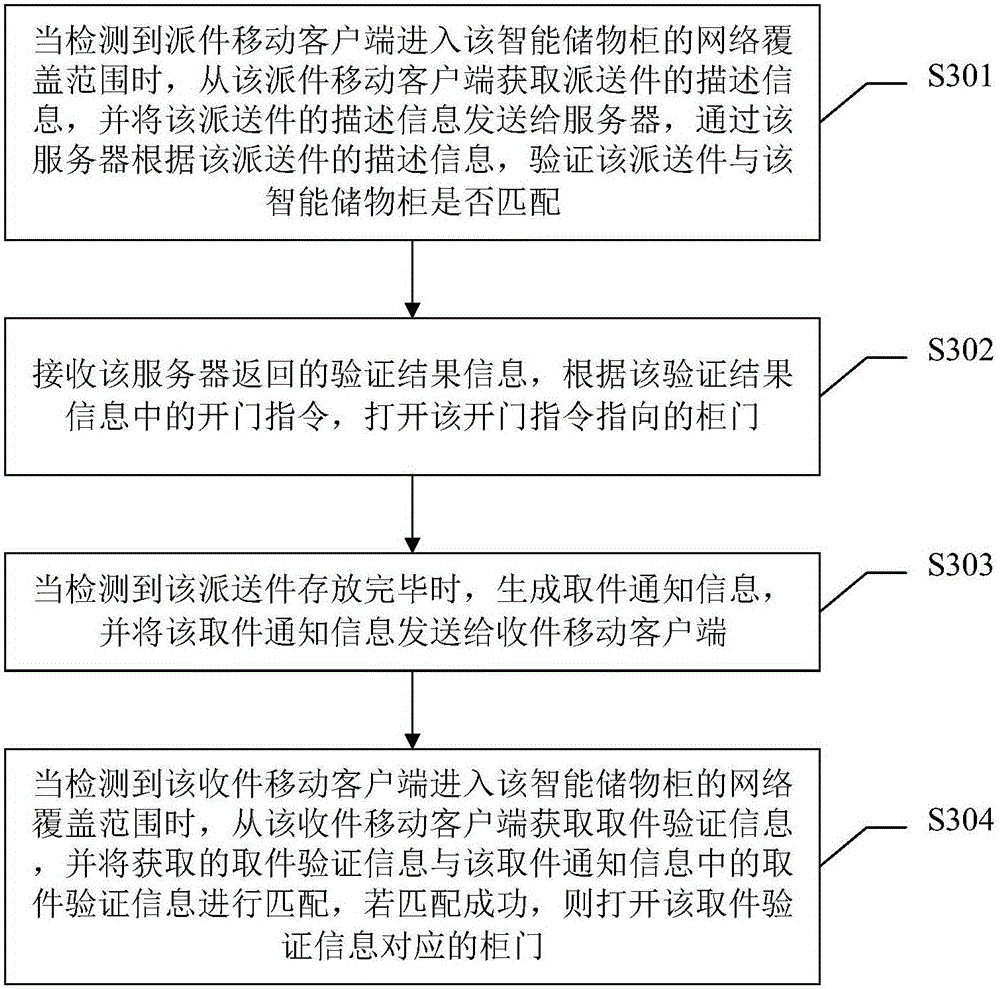

Intelligent logistics delivery method, apparatus, and system

ActiveCN105117882ASolve the docking delivery problemSimplify the sending and receiving processLogisticsLogistics managementClient-side

The invention discloses an intelligent logistics delivery method, an apparatus, and a system. The method includes: when it is detected that a delivery mobile client enters a network coverage of intelligent lockers, description information of a delivered item is obtained from the delivery mobile client and sent to a server in order to verify whether the delivered item is matched with the intelligent locker; a door of the locker is opened according to a door-opening instruction in verification result information returned by the server; when it is detected that the storage of the delivered item is accomplished, pick-up notification information is generated, and the pick-up notification information is sent to a reception mobile client; and when it is detected that the reception mobile client enters the network coverage of the intelligent lockers, pick-up verification information is obtained from the reception mobile client, the match between the obtained pick-up verification information and the pick-up verification information in the pick-up notification information is performed, and the door of the locker is opened if the matching is successful. According to the method, the apparatus, and the system, compared with the prior art, the delivery process can be simplified, and the delivery efficiency is improved.

Owner:SHENZHEN WINEXT TECH

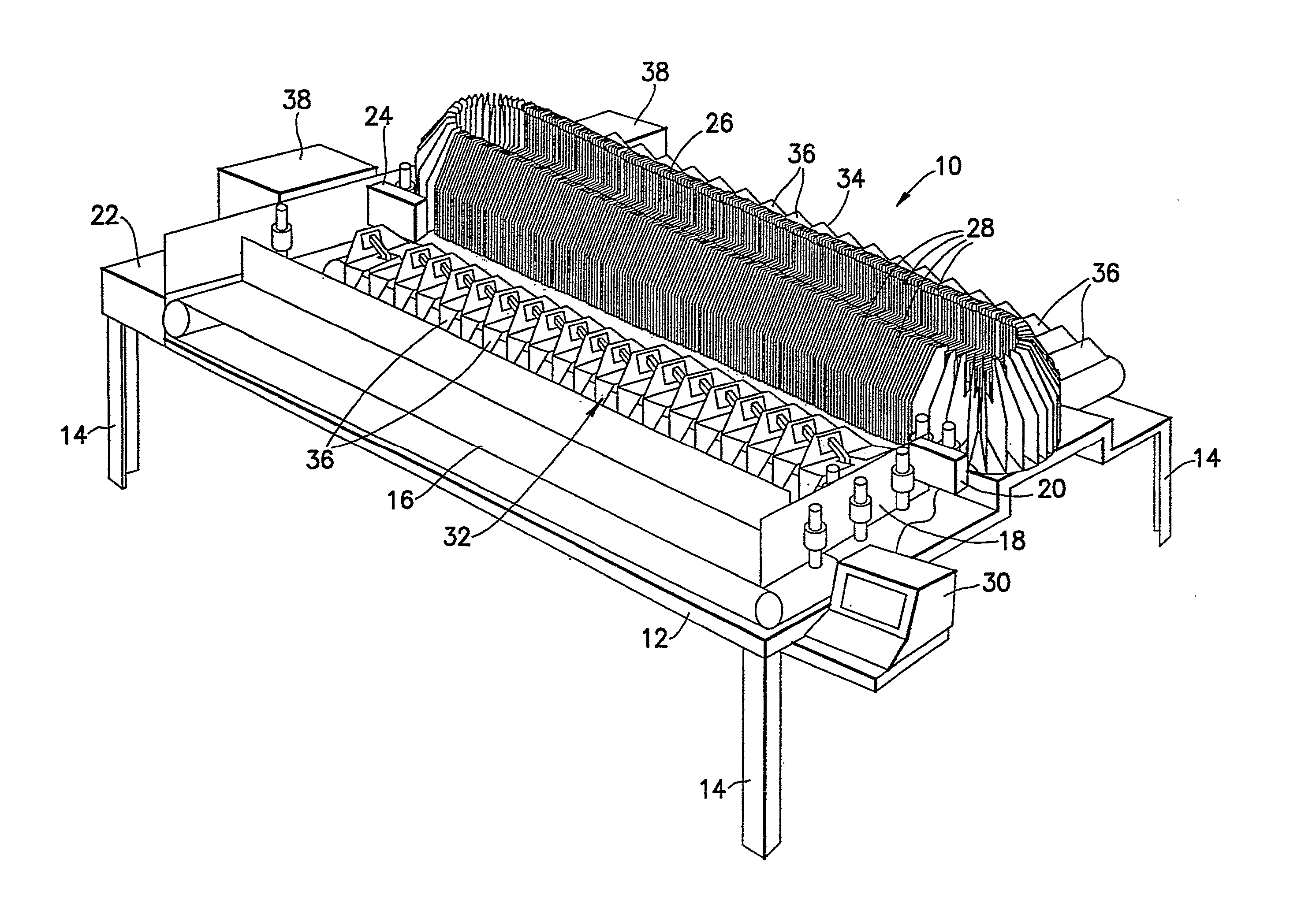

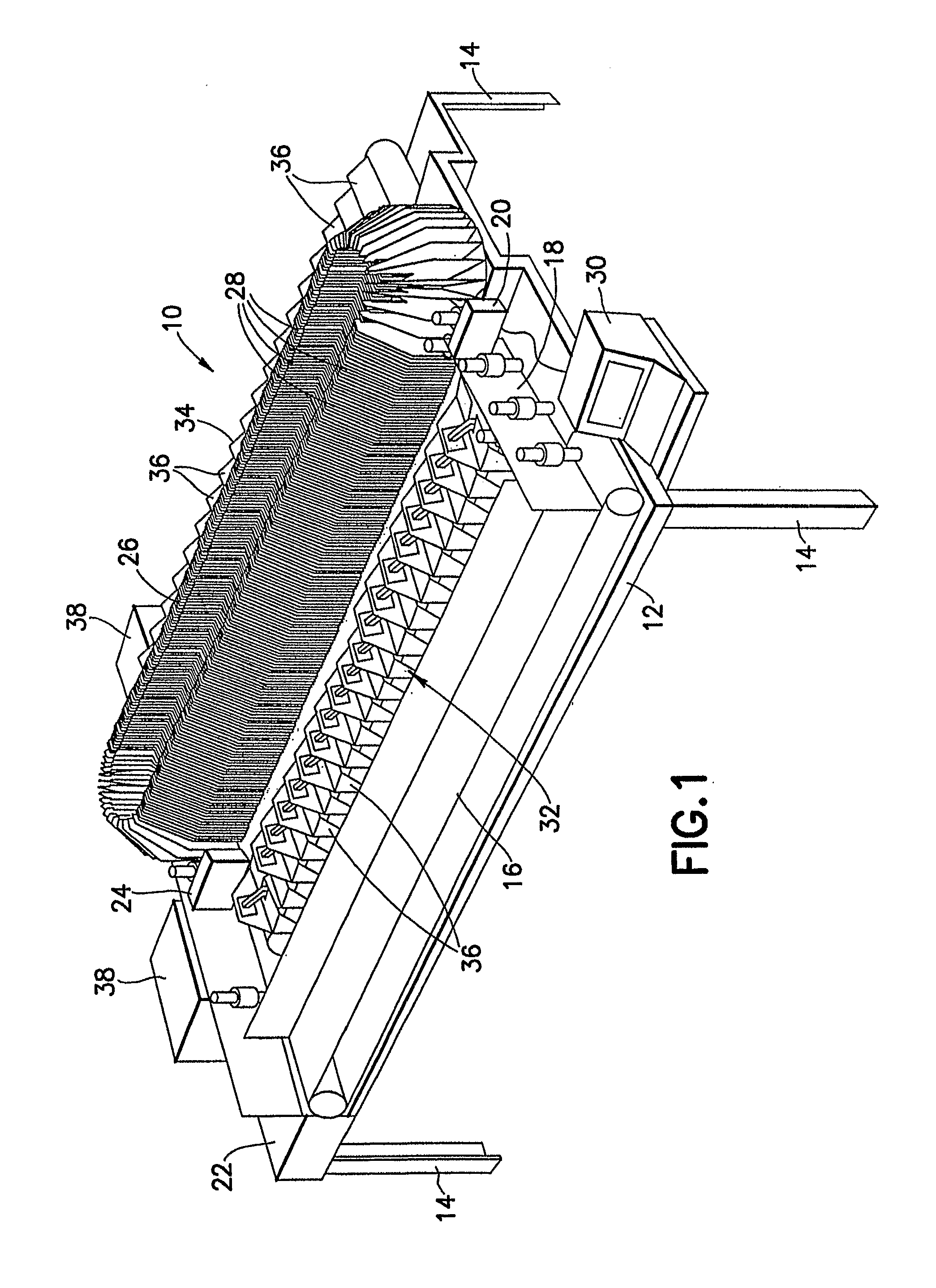

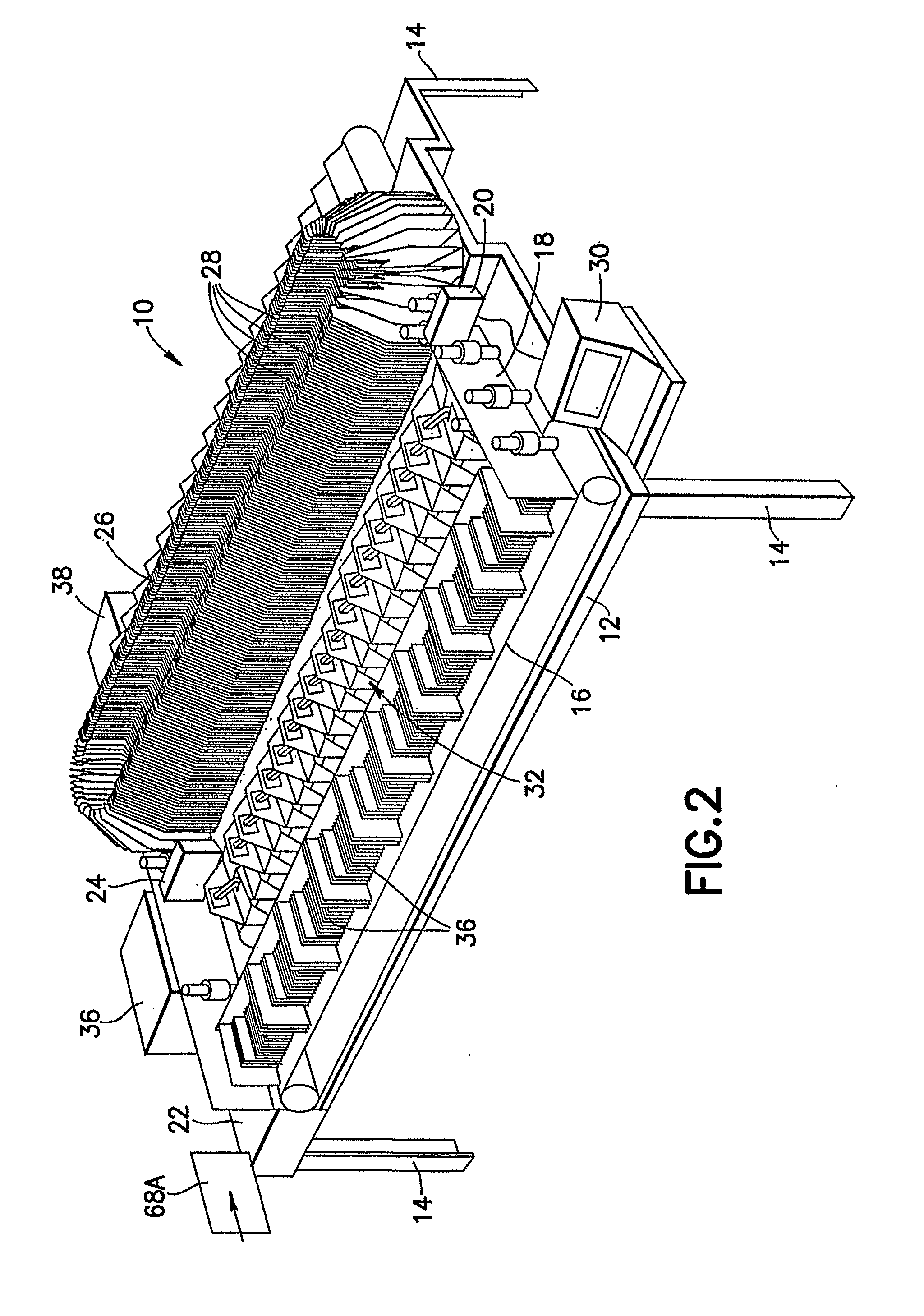

Carrier Delivery Sequence System And Process Adapted For Upstream Insertion Of Exceptional Mail Pieces

InactiveUS20080093273A1Long lastingEasy to makeDigital data processing detailsSeparation devicesEngineering

Owner:LOCKHEED MARTIN CORP

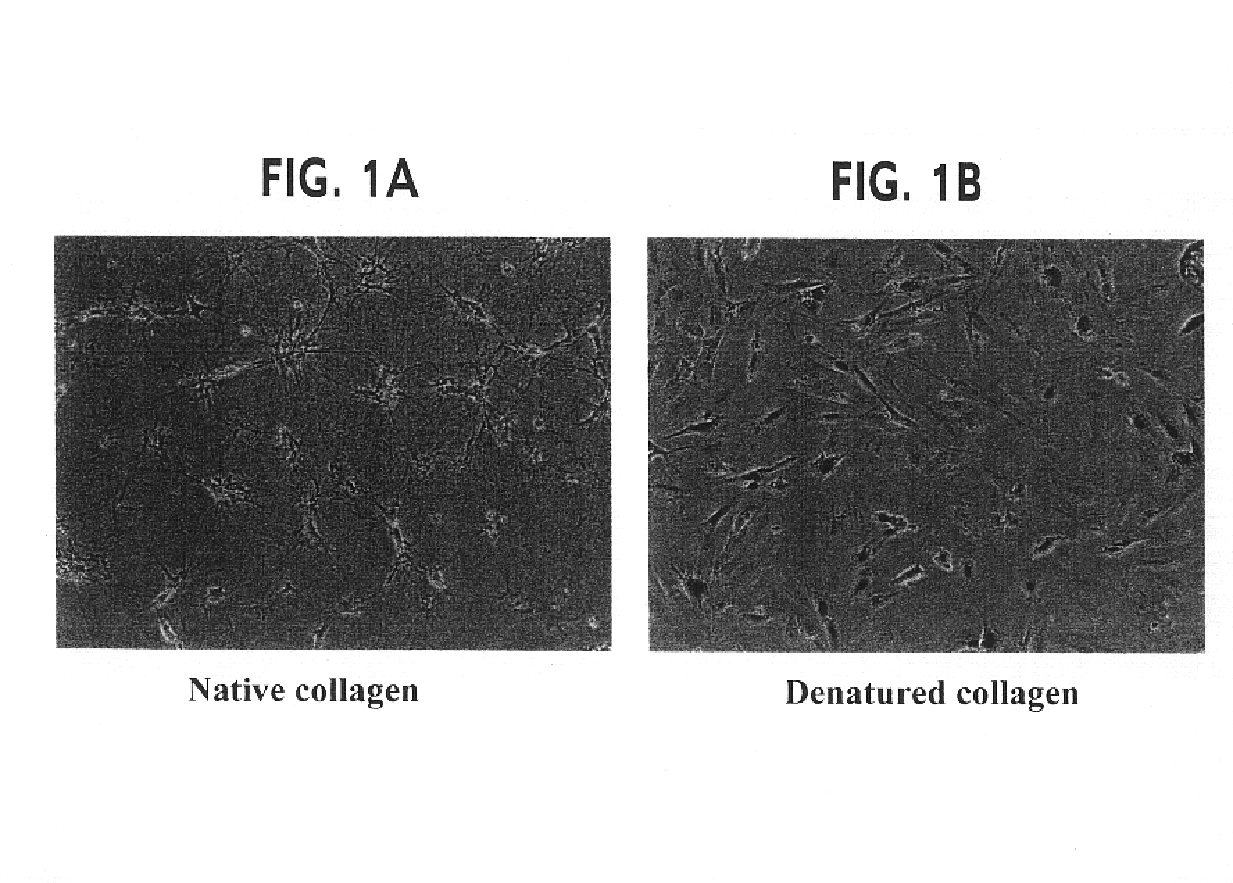

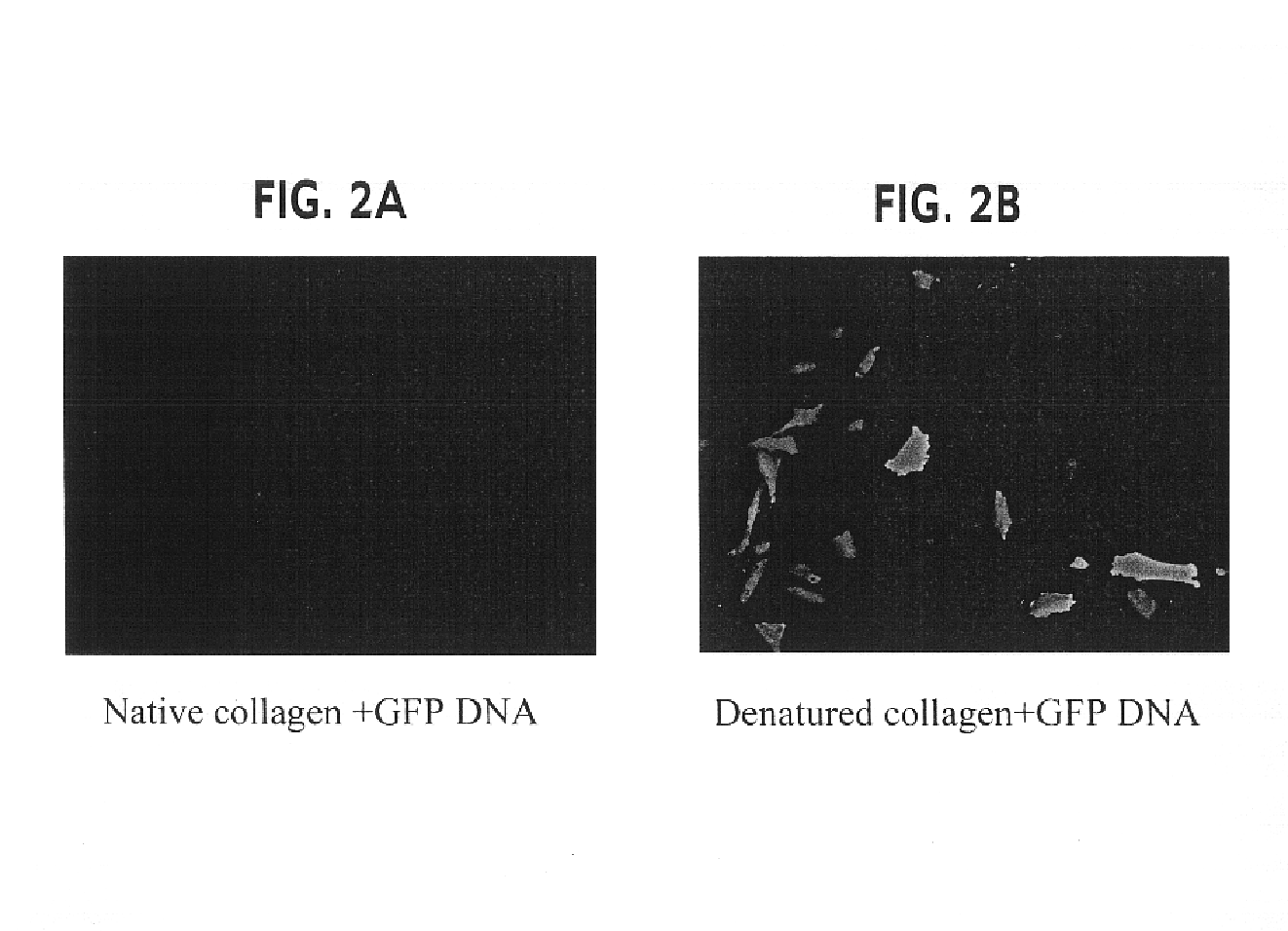

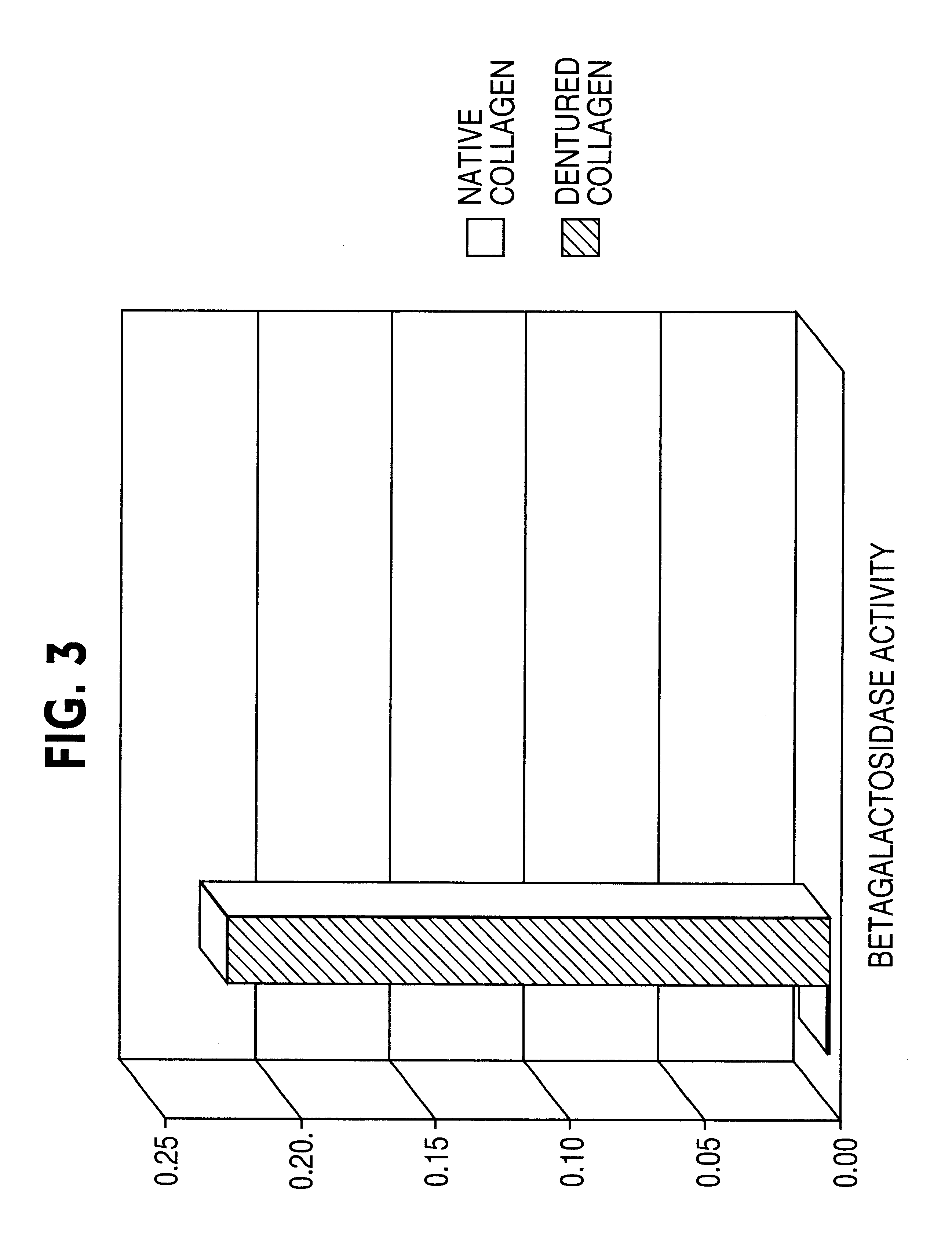

Methods and compositions for enhancing the delivery of a nucleic acid to a cell

InactiveUS6919208B2Improve efficiencyEnhancing the cytoskeletal permissiveness of the cellOrganic active ingredientsMicroencapsulation basedCytoskeletonMammalian cell

Owner:THE CHILDRENS HOSPITAL OF PHILADELPHIA

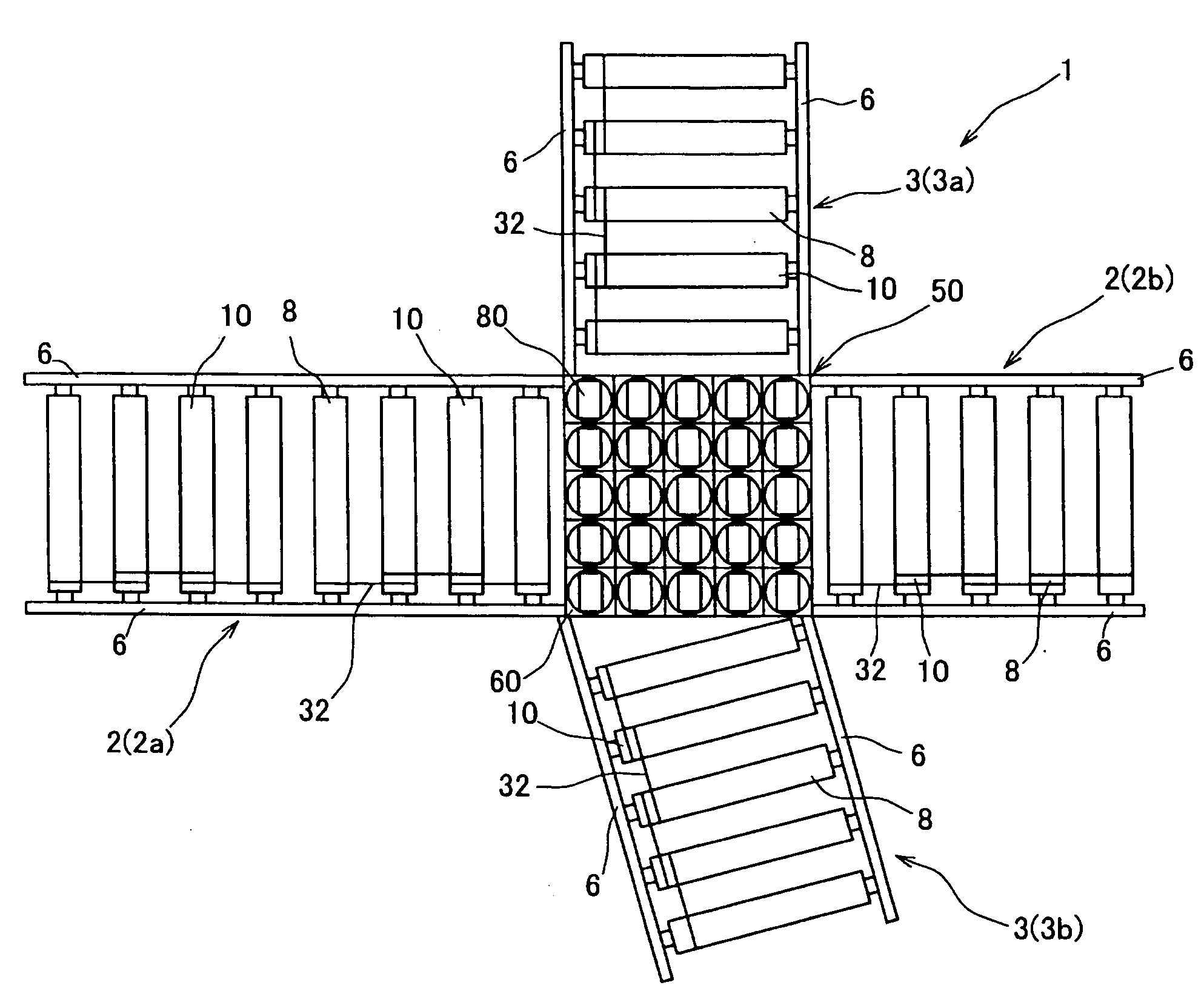

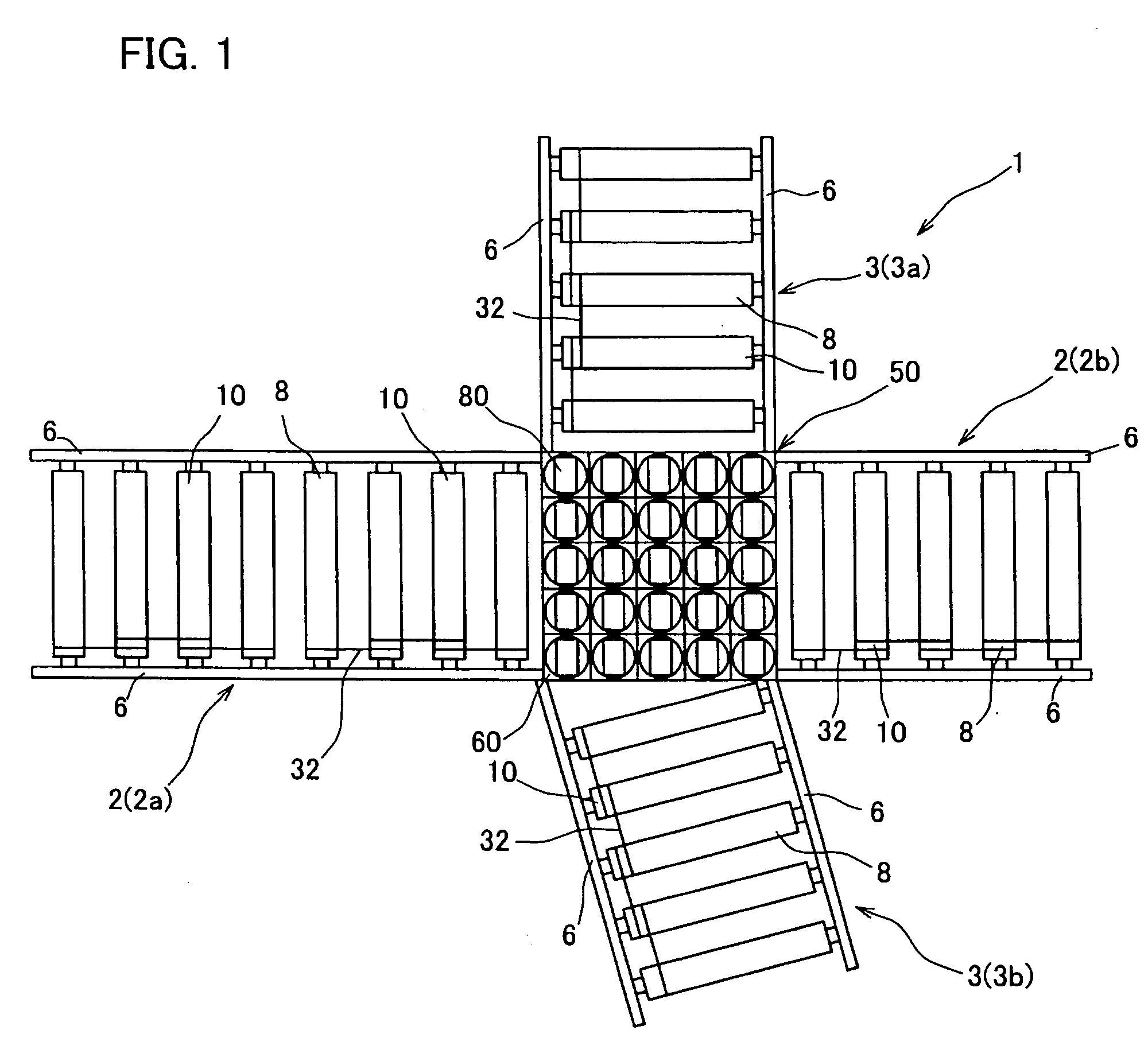

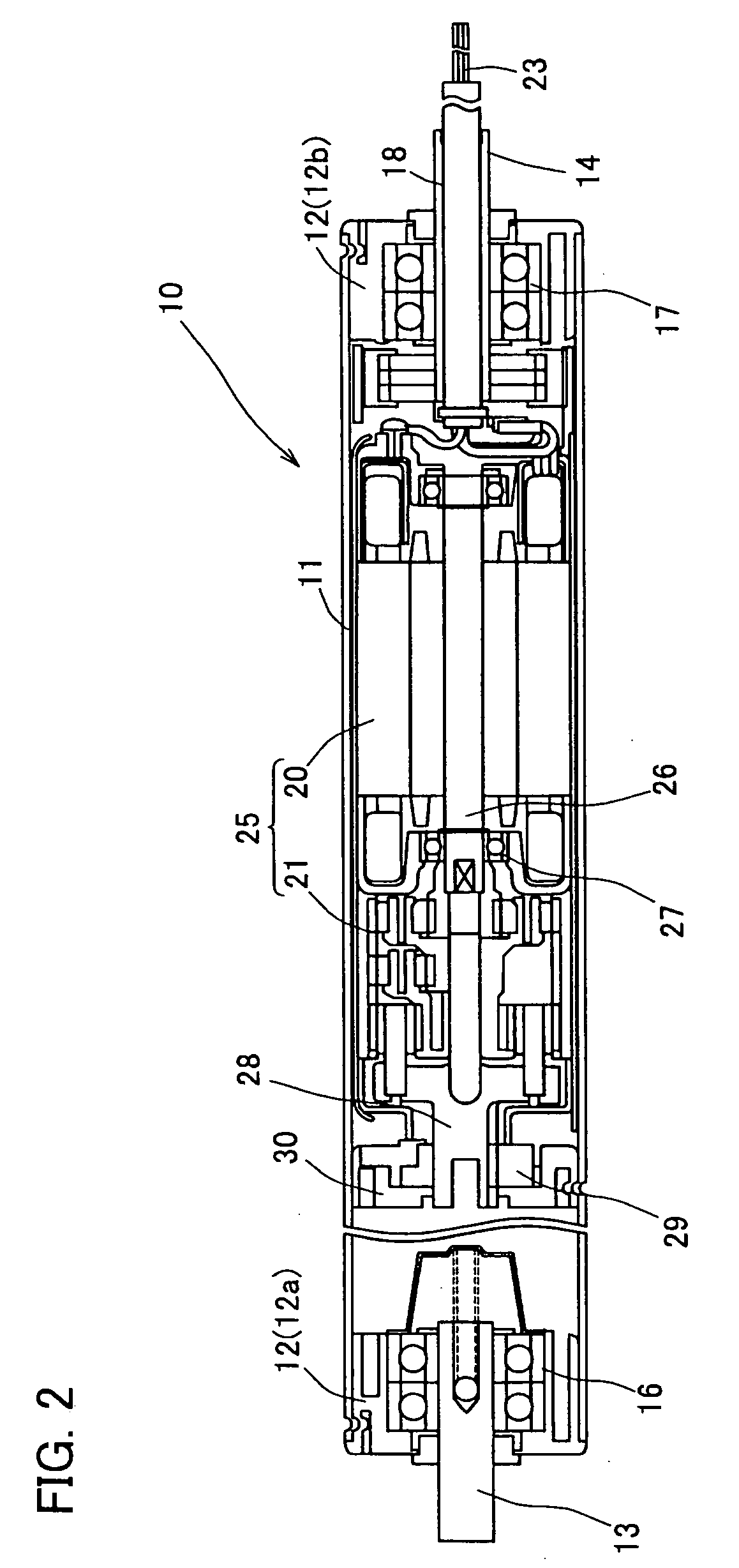

Sorter and roller-conveying system incorporating the sorter

InactiveUS20080169171A1Improve delivery efficiencySwiftly and securely sortConveyor partsRoller-waysRotational axisEngineering

A roller-conveying system includes a sorter for sorting the articles from one passage to others as desired, the sorter including a plurality of cells arranged on substantially the same level as the conveying surfaces of the passages; and at least some of the cells including a motorized roller rotatably carried in a shell, and a shifter for changing the direction of the motorized roller; wherein the shifter includes a revolving shaft vertical to the conveying surface, the revolving shaft connected to the motorized roller, so as to revolve the motorized roller so as to cause it to direct toward a desired conveying passage.

Owner:ITO DENKI KK

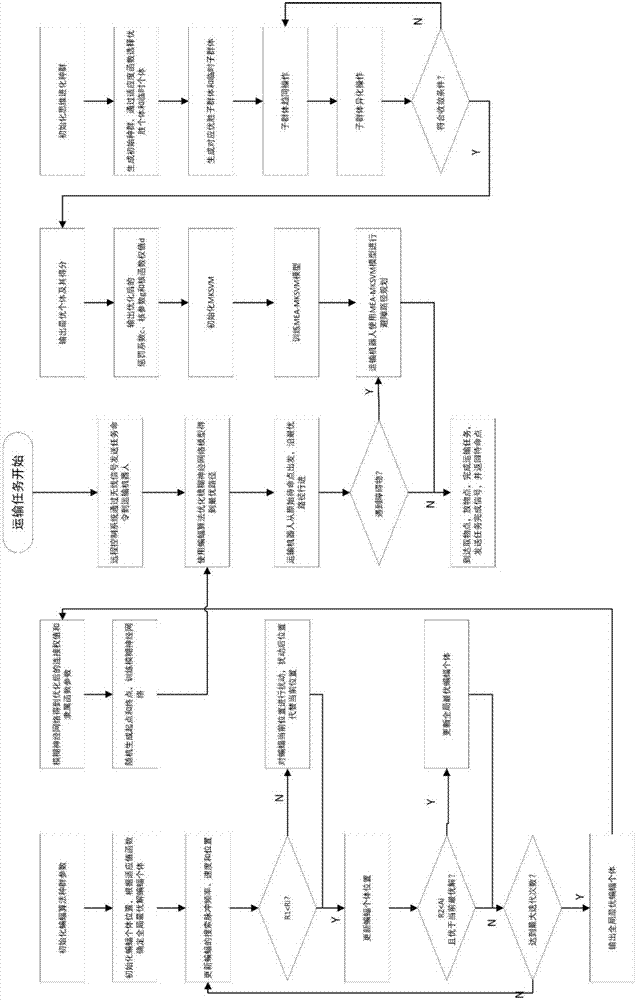

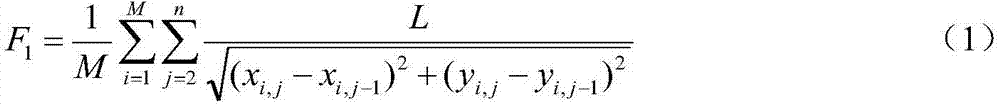

Multi-neural network control planning method for robot path in intelligent environment

ActiveCN107272705AEasy to implementImprove delivery efficiencyPosition/course control in two dimensionsVehiclesIntelligent environmentSimulation

The invention provides a multi-neural network control planning method for a robot path in an intelligent environment. The method comprises the steps that 1 a global map three-dimensional coordinate system is constructed for the carrying area of a carrier robot to acquire a walkable area coordinate in the global map three-dimensional coordinate system; 2 a training sample set is acquired; 3 the global static path planning model of the carrier robot is constructed; and 4 starting and ending coordinates in a transportation task are input into the global static path planning model based on a fuzzy neural network to acquire the corresponding optimal planning path for the carrier robot. According to the invention, the global static path planning model and a local dynamic obstacle avoidance planning model are separately established; the nonlinear fitting property of the neural network is used to find the global optimal solution quickly; and the problem of falling into a local optimum in common path planning is avoided.

Owner:CENT SOUTH UNIV

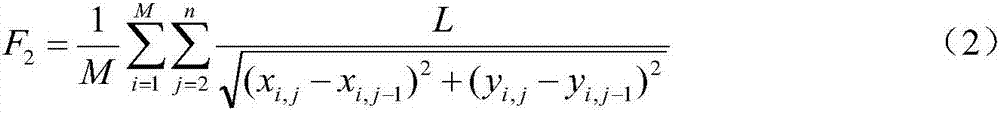

Energy-saving heat supply system with function of reducing temperature of heat supply return water

InactiveCN106705185AIncrease profitReduce circulating water flowLighting and heating apparatusSteam useCooling towerTemperature difference

The invention discloses an energy-saving heat supply system with a function of reducing the temperature of heat supply return water, and belongs to the field of improvement of energy utilization efficiency. Heat exchange can be repeatedly carried out on heat sources by multistage heat exchangers, multistage absorption heat exchange units, multistage compression heat pumps and an ice making type refrigerator, accordingly, the heat supply areas can be enlarged, and the energy utilization efficiency can be improved. The energy-saving heat supply system has the advantages that the temperature of the return water of heat supply primary pipe networks can be reduced and reach 0 DEG C, the return water contains 10% of ice particles, accordingly, route heat loss of the return water of the heat supply primary pipe networks can be reduced, the temperature difference of the return water of the heat supply primary pipe networks can be increased and reaches 118 DEG C from the original 60 DEG C, the flow rate of circulating water of the heat supply primary pipe networks can be lowered, energy consumption of circulating pumps can be reduced, heat supply flow rates of a user side can be greatly increased, the delivery efficiency of the pipe networks can be improved, the heat supply scale can be expanded, waste heat of a cooling tower can be recycled, and the like.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

Novel reagents for intracellular delivery of macromolecules

InactiveUS20050260757A1Great efficiency of deliveryEnhance rangeSugar derivativesMicroencapsulation basedLiposomeCompound (substance)

The present invention provides certain cationic lipids containing stigmasterol, ergosterol and cholic acid groups. Compounds of the invention are useful, either alone or in combination with other lipid aggregate-forming components (e.g., DOPE, DOSPA, DOTMA or cholesterol) for formulation into liposomes or other lipid aggregates. Such aggregates are cationic, and able to form stable complexes with anionic macromolecules, such as nucleic acids. The cationic lipids of the invention are useful in methods of transfecting cells, particularly to introduce nucleic acids into cells. The invention also related to kits for the preparation of lipid aggregates and to lipid aggregates and compositions for transfection of cells.

Owner:LIFE TECH CORP

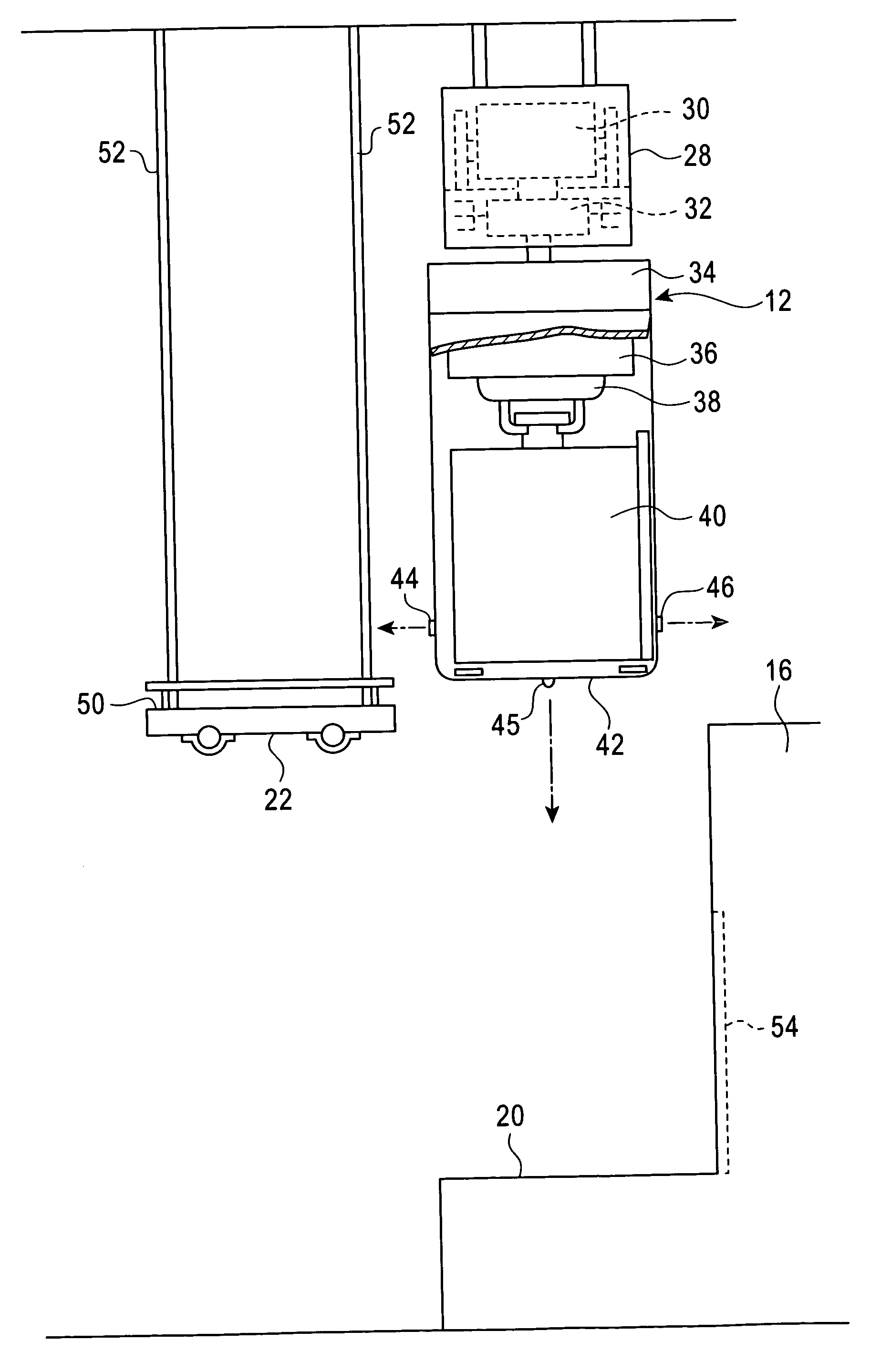

Dispensing device, storage device and method for dispensing a formulation

ActiveUS20070163574A1Improve delivery efficiencyImprove sealingRespiratorsLiquid surface applicatorsBiomedical engineeringMedical treatment

A dispensing device, a storage device and a method for dispensing a medical formulation are proposed. Multiple doses of the formulation are stored in a carrier having multiple inserts, each insert containing a single dose. Preferably, each insert has at least one duct or nozzle for dispensing the respective dose. Each insert is located in a separate and sealed cavity in the carrier. The cavities can be individually opened for dispensing the respective dose from the respective insert.

Owner:BOEHRINGER INGELHEIM INT GMBH

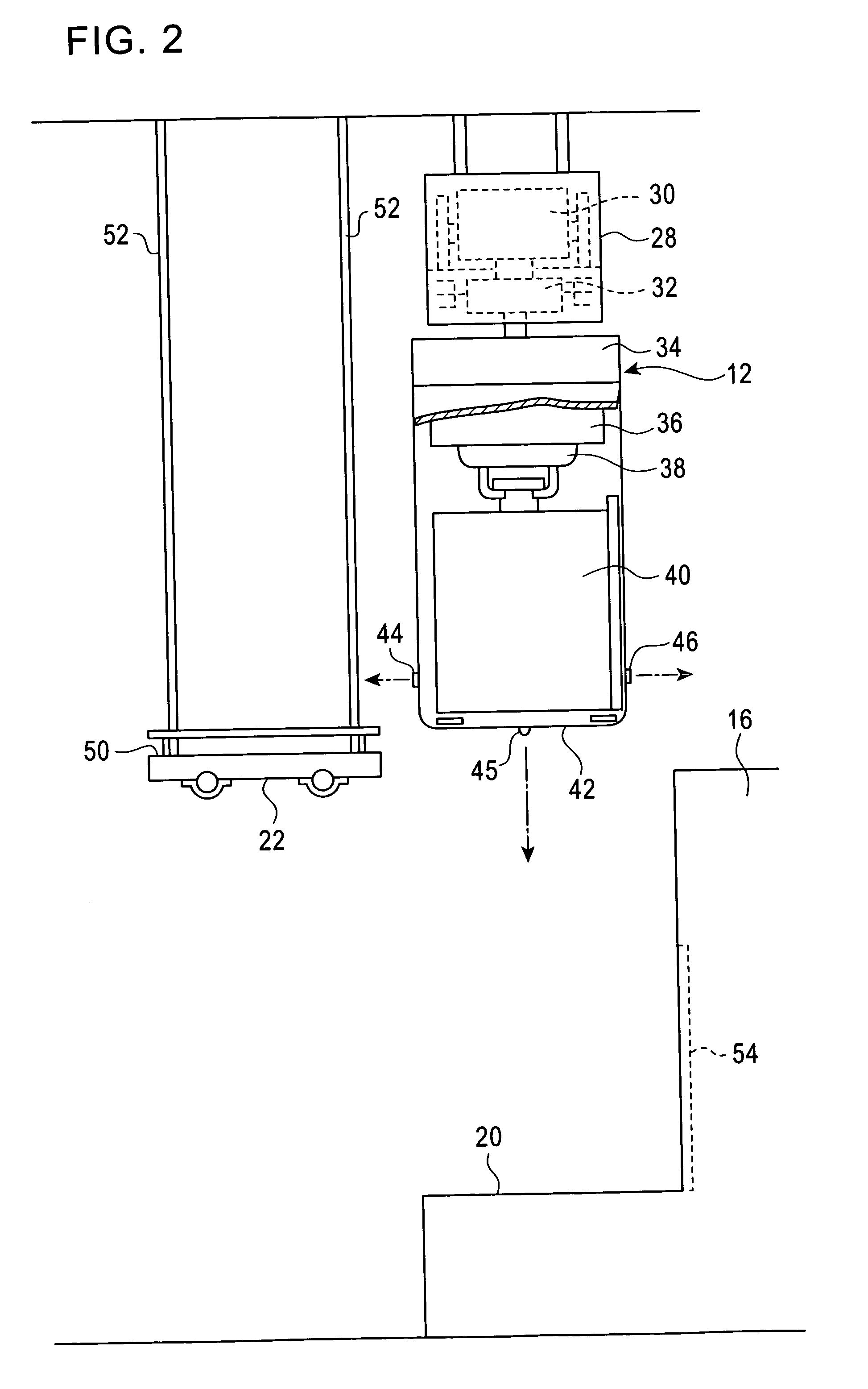

Carrying system

InactiveUS20060051192A1Improve efficiencyFacilitate assignmentRailway componentsConveyor partsEngineering

Conveyance of an article from a processing device 16 is assigned to an overhead running carriage 12a. Conveyance of an article to the processing device 16 is assigned to an overhead running carriage 12b. When the overhead running carriage 12b reaches the processing device 16 earlier, it unloads the conveyed article onto a buffer shelf 22 facing a load port 20. The article originally present at the load port 20 is loaded on the overhead running carriage 12b and then transferred. The overhead running carriage 12a, reaching the processing device 16 later, transfers the article from the buffer shelf 22 to the load port 20. Conveyance instructions can be assigned without the consciousness of the state of load port. As a result, articles can be efficiently transferred.

Owner:MURATA MASCH LTD

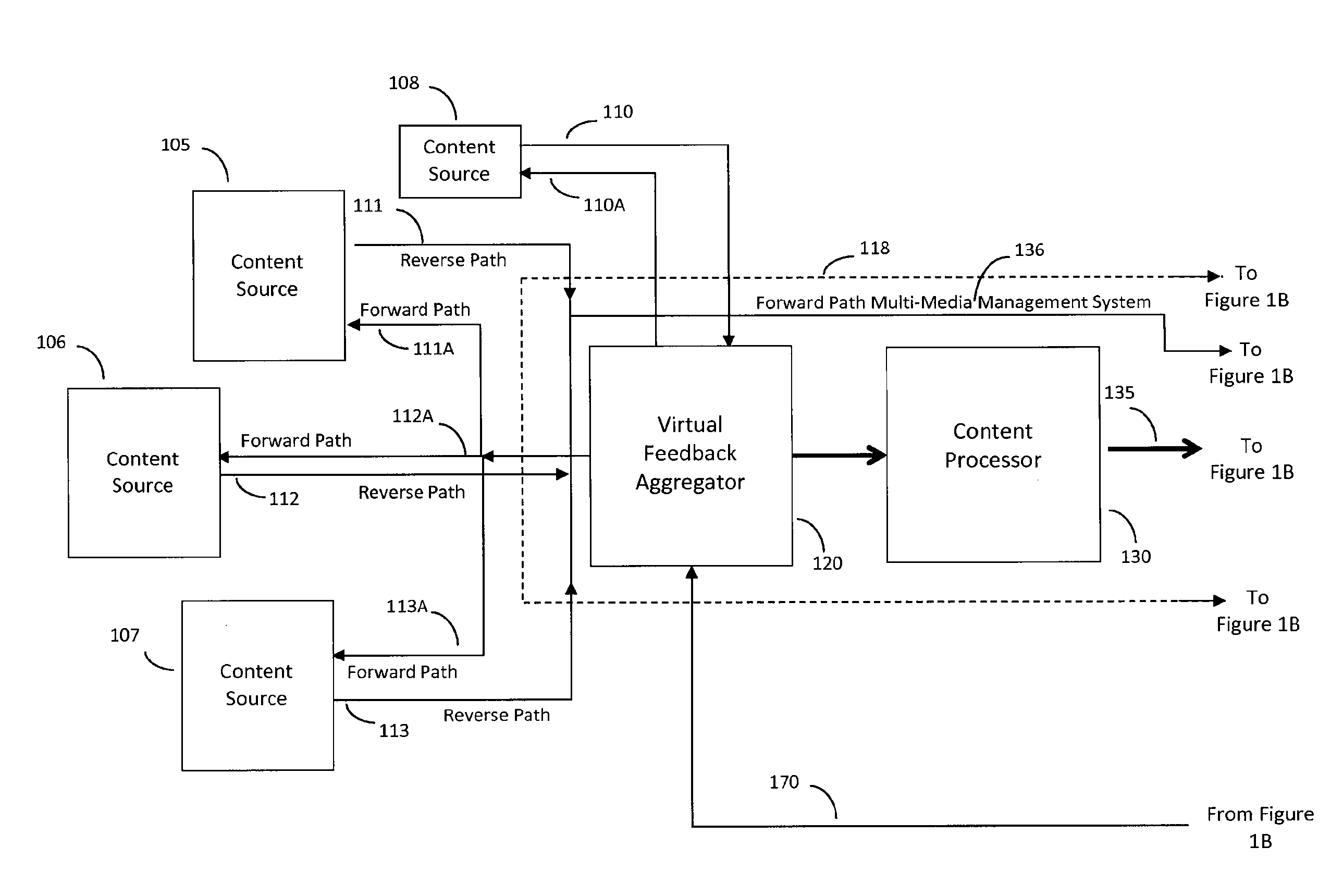

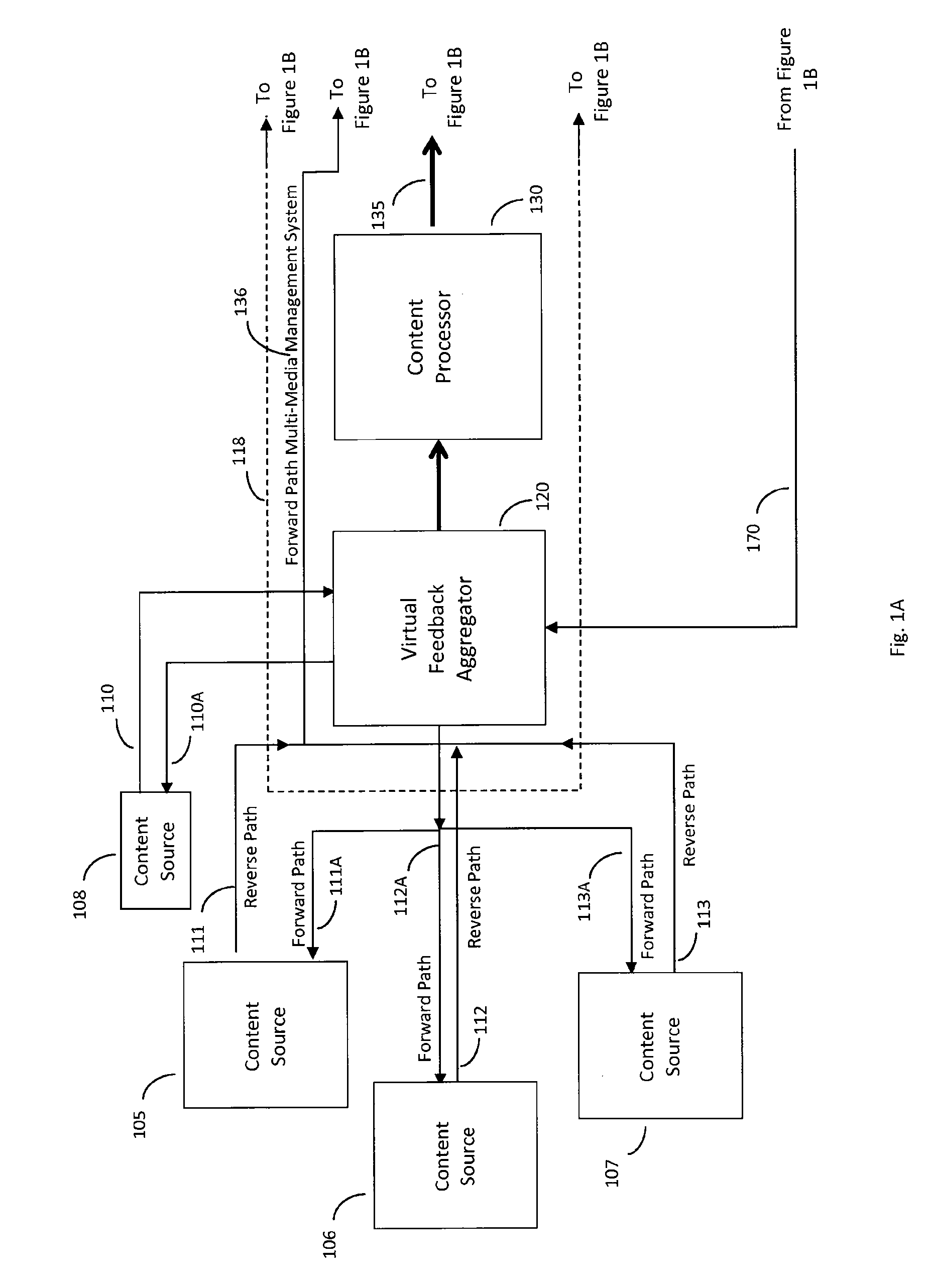

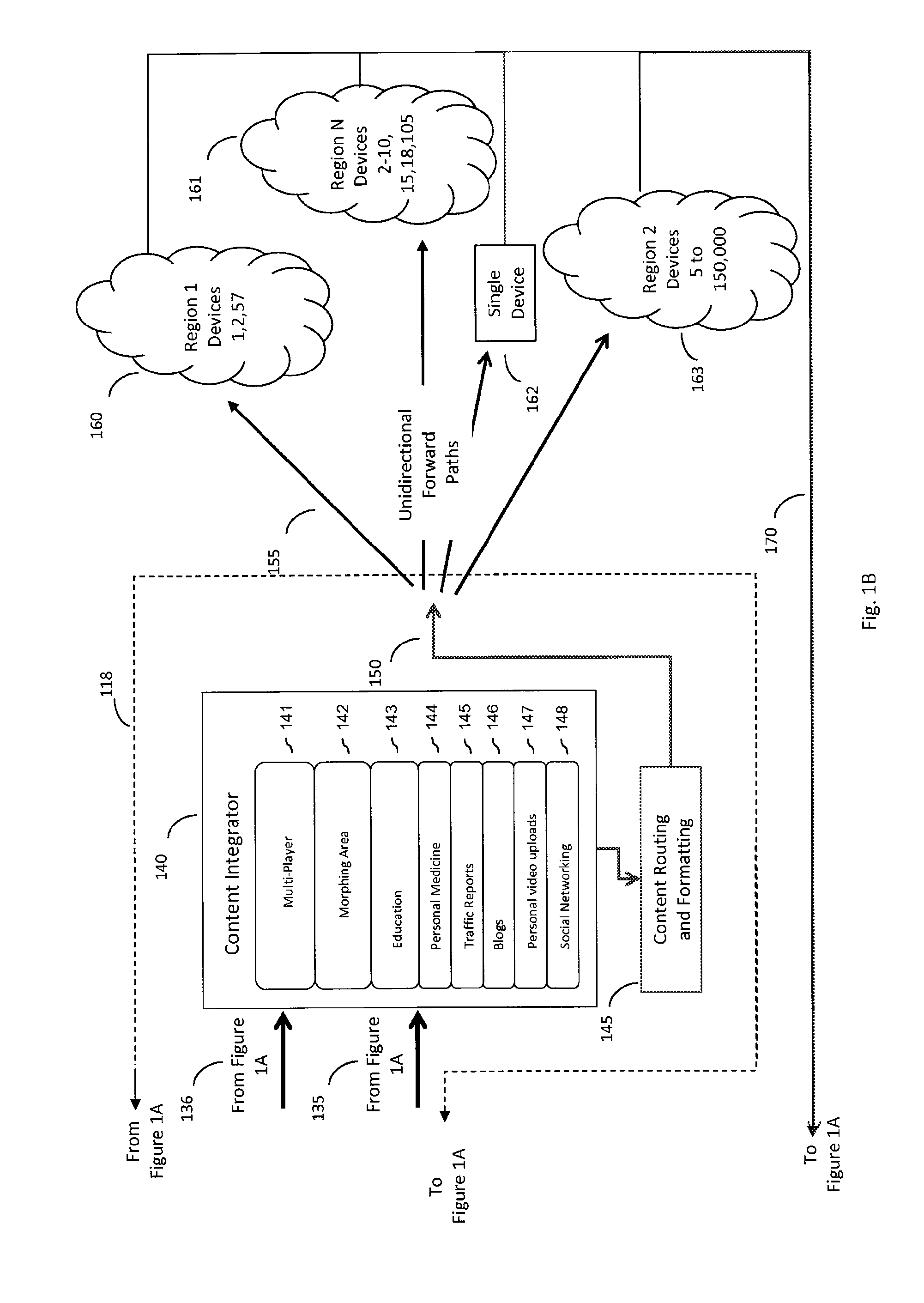

Forward path multi-media management system with end user feedback to central content sources

ActiveUS20110188415A1Improve efficiencyImproves takenTelevision systemsBilling/invoicingClosed loopMulticast communication

The Forward Path Multi-Media Management System architecture enables end user devices to share a common wireless forward path of a multicast communication architecture in which the forward path delivered content is dynamically changed or modified based on a real-time, near-real-time, or delay-time basis via aggregated reverse path feedback from at least one of a plurality of end user devices. The Forward Path Multi-Media Management System periodically or continuously aggregates the feedback input received via the reverse path (having wired and / or wireless connectivity), modifies the forward path multi-media content, and delivers this dynamically modified multi-media content to the then connected population of end user devices via a wireless forward path multicast in a repetitive closed loop fashion.

Owner:LAVA TWO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com