Patents

Literature

97 results about "Particle fraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pharmaceutical formulations for dry powder inhalers in the form of hard-pellets

InactiveUS20030180227A1Reduce intensityEfficient deliveryPowder deliveryDispersion deliveryPrillInhalation

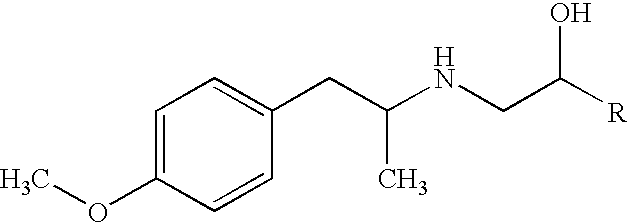

The invention provides a formulation to be administered as dry powder for inhalation suitable for efficacious delivery of active ingredients into the low respiratory tract of patients suffering of pulmonary diseases such as asthma. In particular, the invention provides a formulation to be administered as dry powder for inhalation freely flowable, which can be produced in a simple way, physically and chemically stable and able of delivering either accurate doses and high fine particle fraction of low strength active ingredients by using a high- or medium resistance device.

Owner:CHIESI FARM SPA

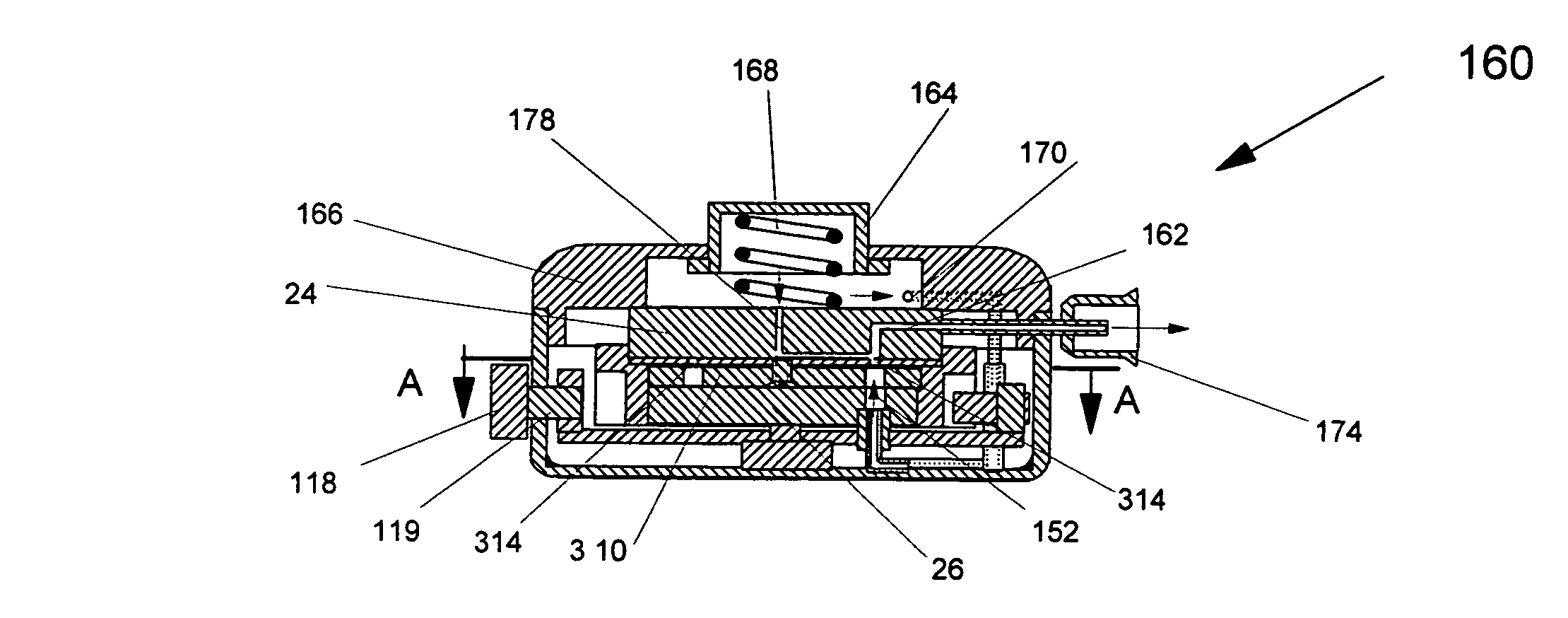

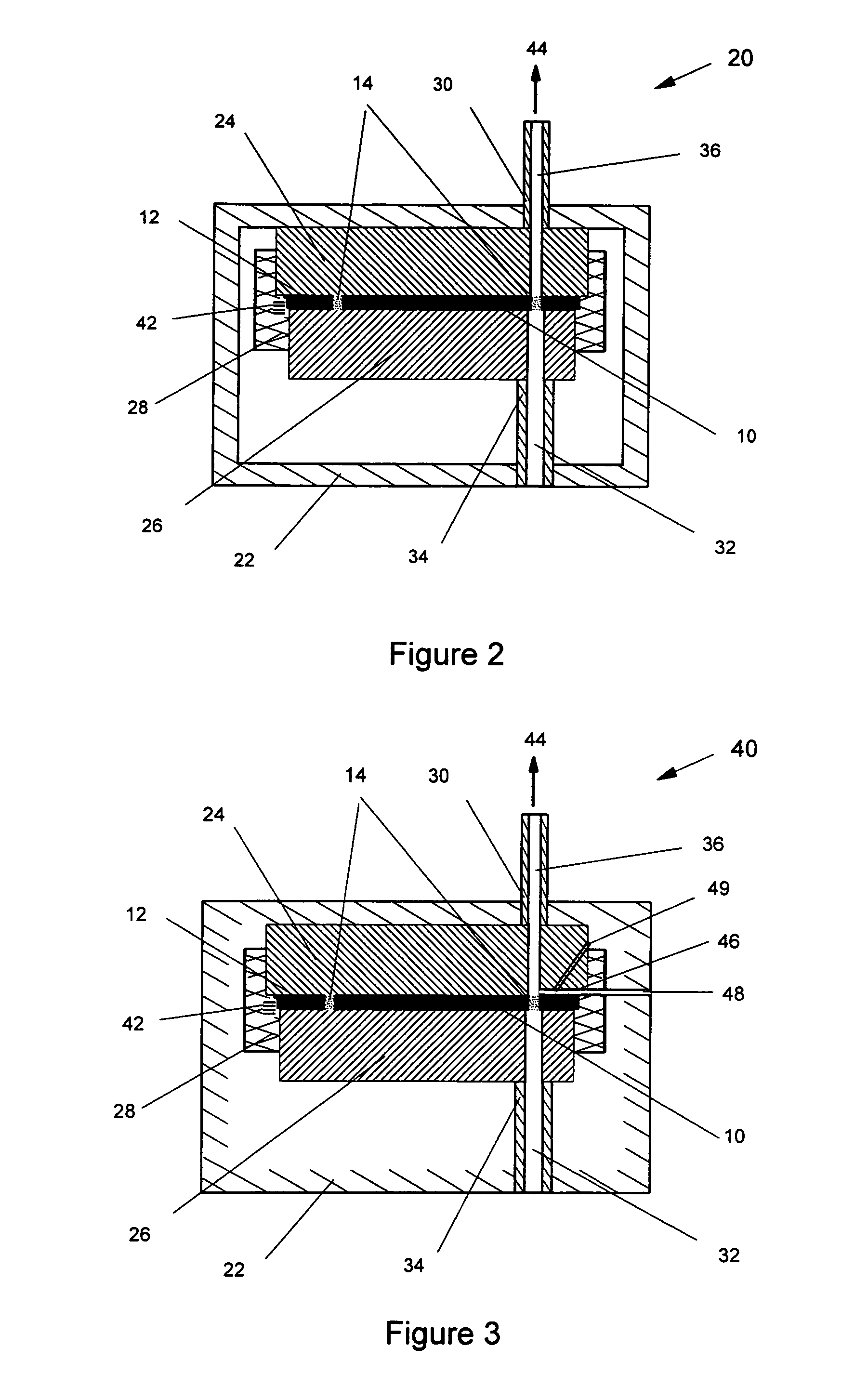

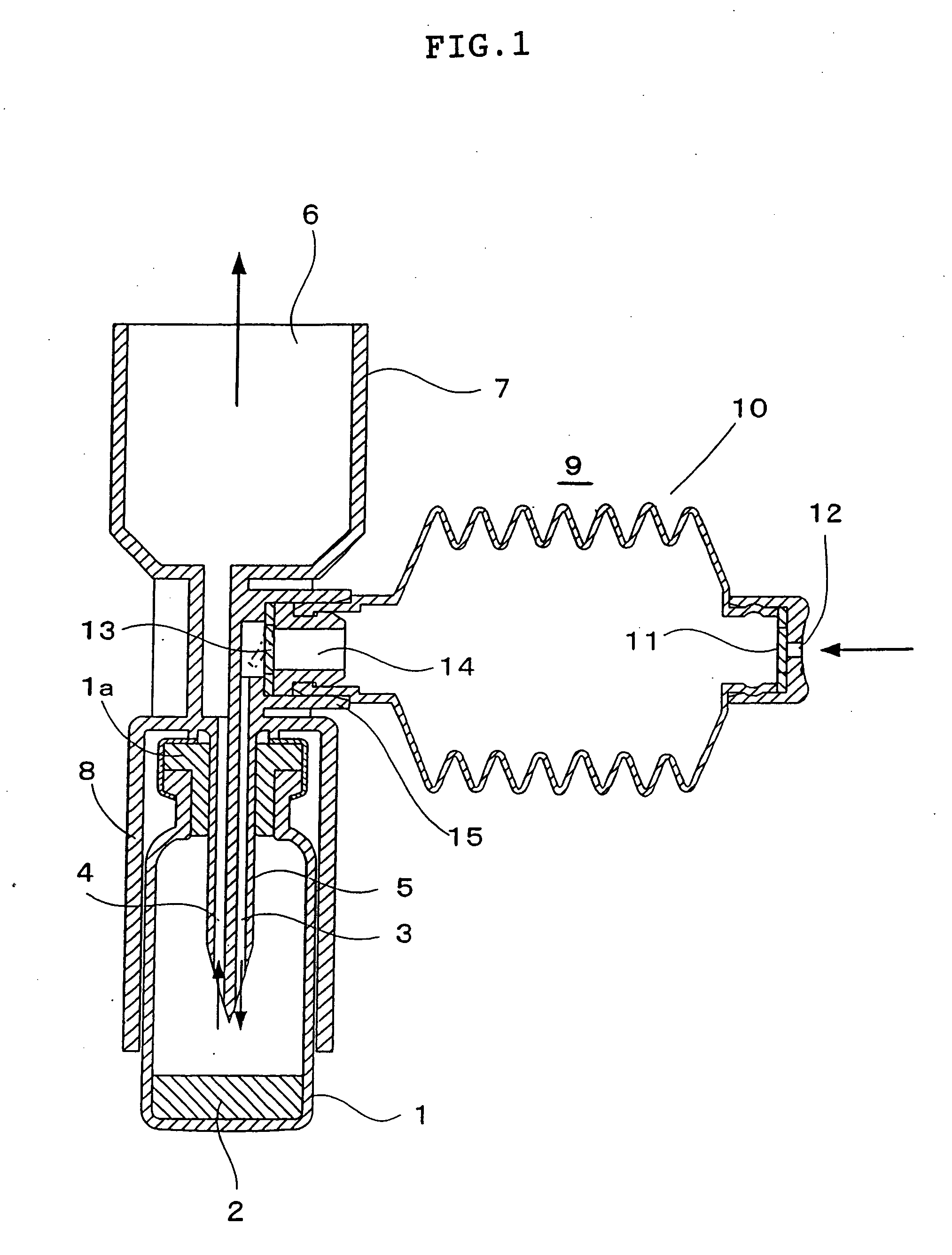

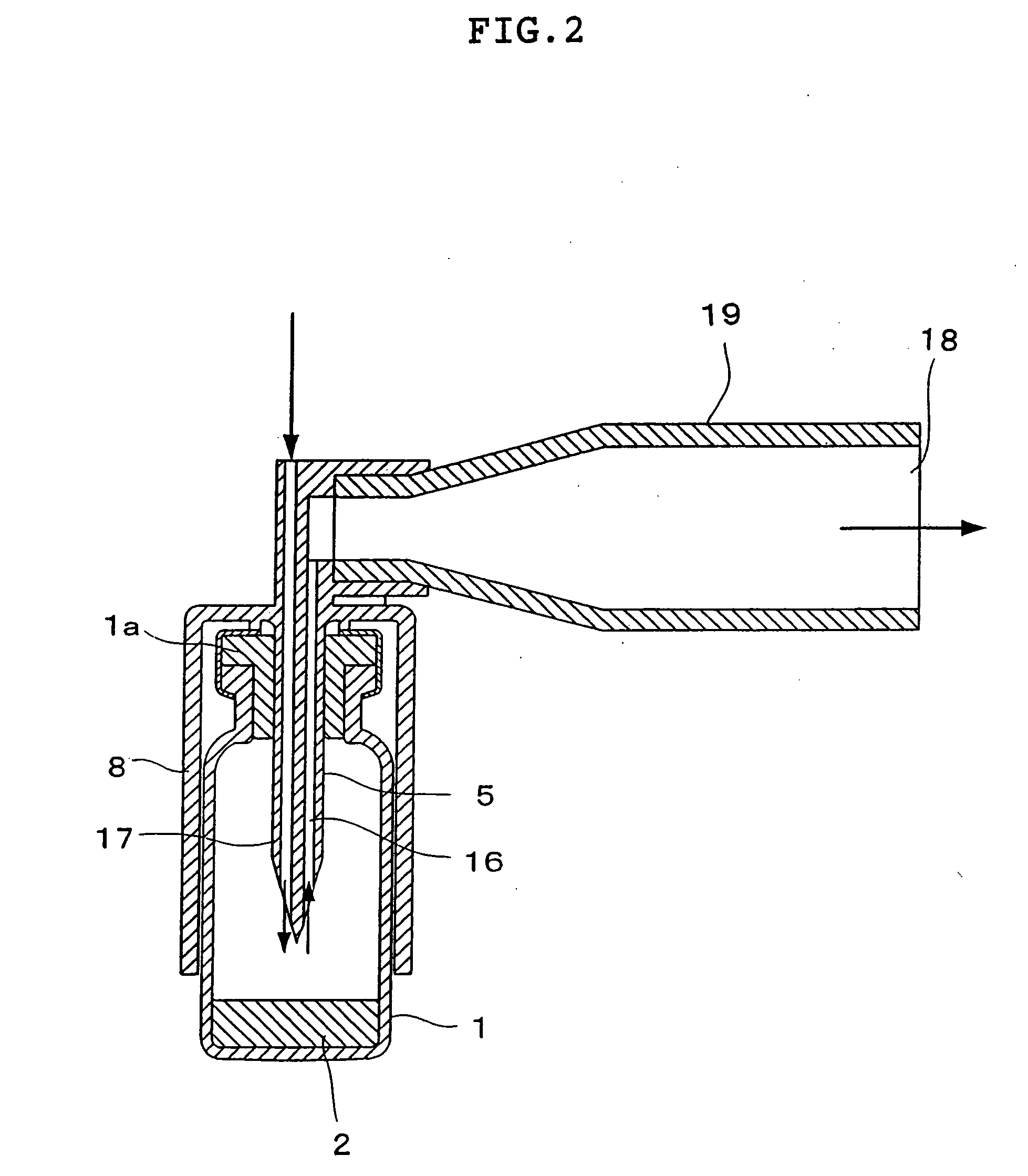

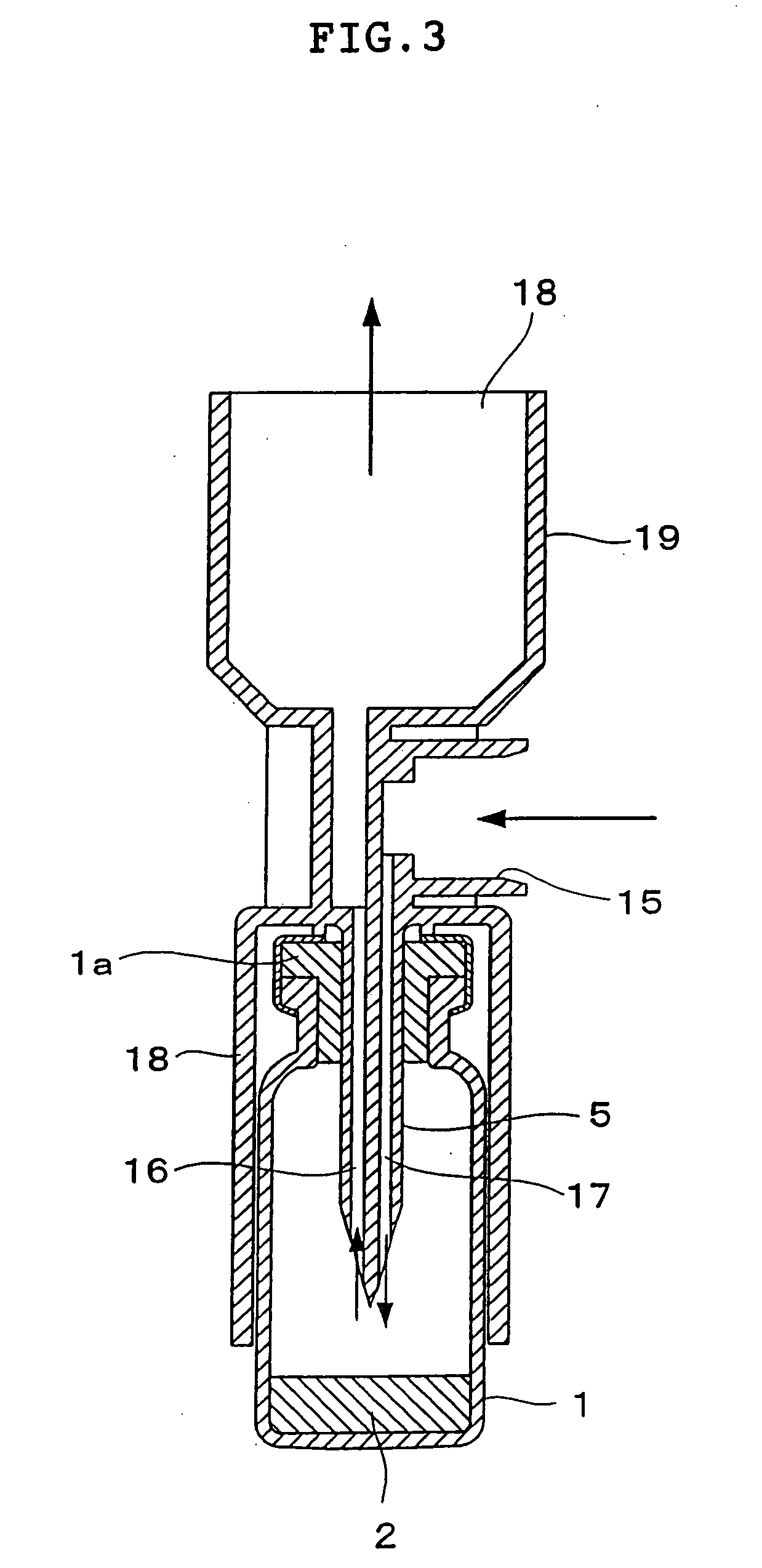

Dry powder inhaler

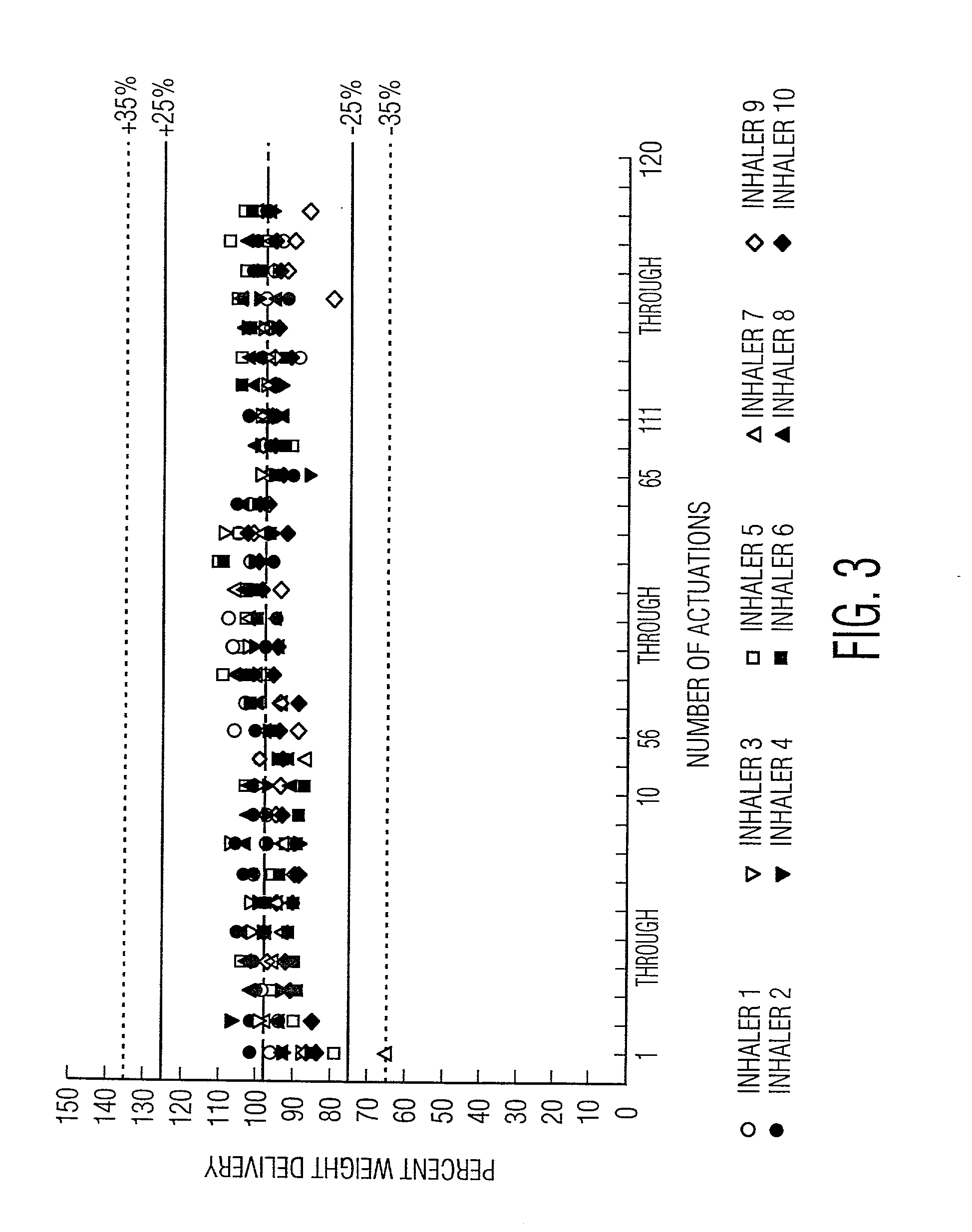

ActiveUS8037880B2Small accurate volumePrecise deliveryRespiratorsLiquid surface applicatorsUltra fineExcipient

A new dry powder inhaler is developed as a pulmonary medicine delivery device for dispersing precise tiny dosages (10 μg-50 mg) of pure carrier-free ultra-fine powdered medicament (<5 μm aerodynamics particle size) into a patient's lung. The powder is drawn from the blister cell and dispersed through an outlet tube assisted by two air streams. The first air stream goes through a the blister cell from its upstream side, to significantly fluidize the medicament in the dose to flow upward. The second one extracts the fluidized powder from downstream of the blister cell for further deagglomeration and dispersion of the medicament powder by shear force. The rotating multi-dose blister can hold up to 60 doses, which are pre-metered with pure ultra-fine powdered medicament. So that it has higher drug loading capability in small volumes, compared to most current dry powder inhalers, which usually use some excipient. The inhaler efficiently disperse the aerosolized medicament in the air stream to the deep interior of patient's lung. The fine particle fraction (<4.7 μm) is reported to reach as high as 80% using this inhaler.

Owner:NINGBO INHAL PHARMA CO LTD

Pharmaceutical formulations for dry powder inhalers

InactiveUS7541022B2Powder deliveryOrganic active ingredientsBULK ACTIVE INGREDIENTPharmaceutical formulation

A powder for use in a dry powder inhaler comprises: i) a fraction n of fine particle size constituted by a mixture of physiologically acceptable excipient and an additive; ii) a fraction of coarse particles; and iii) at least one active ingredient. The powder is suitable for efficacious delivery of active ingredients into the low respiratory tract of patients suffering from pulmonary diseases such as asthma. In particular, the invention provides a formulation to be administered as dry powder for inhalation which is freely flowable, can be produced in a simple way, is physically and chemically stable and capable of delivering accurate doses and / or high fine particle fraction of low strength active ingredients by using a high- or medium resistance device.

Owner:VECTURA LTD

Pharmaceutical formulations for dry powder inhalers

InactiveUS20030185764A1Powder deliveryOrganic active ingredientsBULK ACTIVE INGREDIENTPharmaceutical formulation

A powder for use in a dry powder inhaler comprises: i) a fraction of fine particle size constituted by a mixture of physiologically acceptable excipient and an additive; ii) a fraction of coarse particles; and iii) at least one active ingredient. The powder is suitable for efficacious delivery of active ingredients into the low respiratory tract of patients suffering from pulmonary diseases such as asthma. In particular, the invention provides a formulation to be administered as dry powder for inhalation which is freely flowable, can be produced in a simple way, is physically and chemically stable and capable of delivering accurate doses and / or high fine particle fraction of low strength active ingredients by using a high- or medium resistance device.

Owner:VECTURA LTD

Dry powder for inhalation

InactiveUS7186401B2Reduce sensitivityMinimize impactBiocidePowder deliveryInhalable particlesInhalation

The aim of the invention is to improve the moisture resistance of dry powder formulations for inhalation which contain a pharmaceutically ineffective carrier of not-inhalable particle size and a finely divided pharmaceutically active compound of inhalable particle size and to also improve the storage stability of said formulations. To this end, magnesium stearate is used in said formulations. One of the features of the inventive dry powder is that a high fine particle dosage or fine particle fraction can be maintained also under relatively extreme temperature and humidity conditions.

Owner:JAGOTEC AG

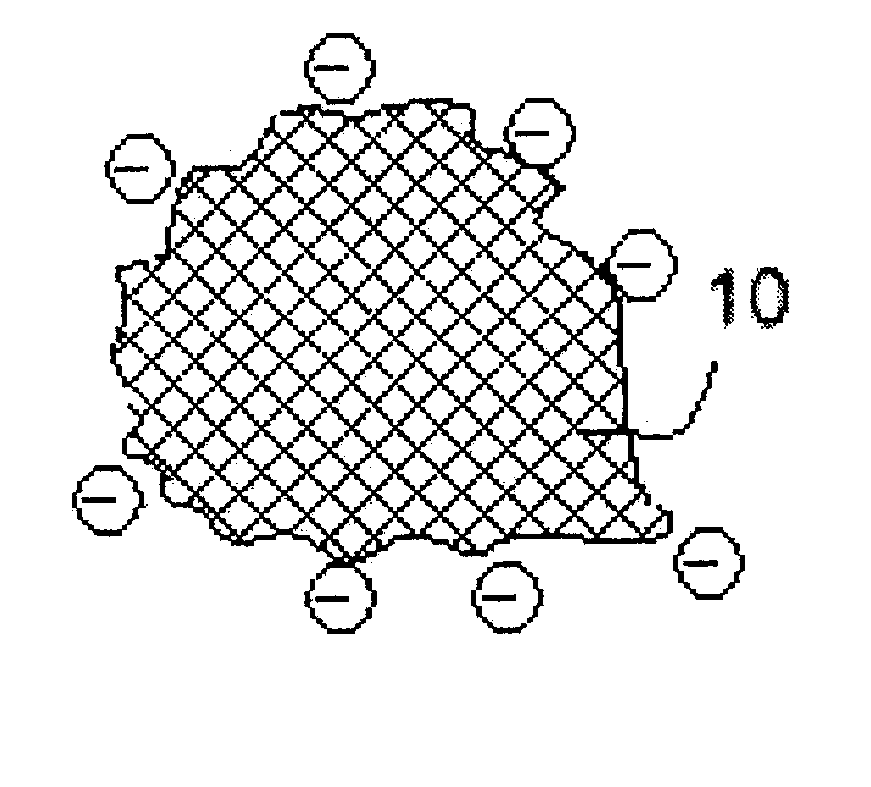

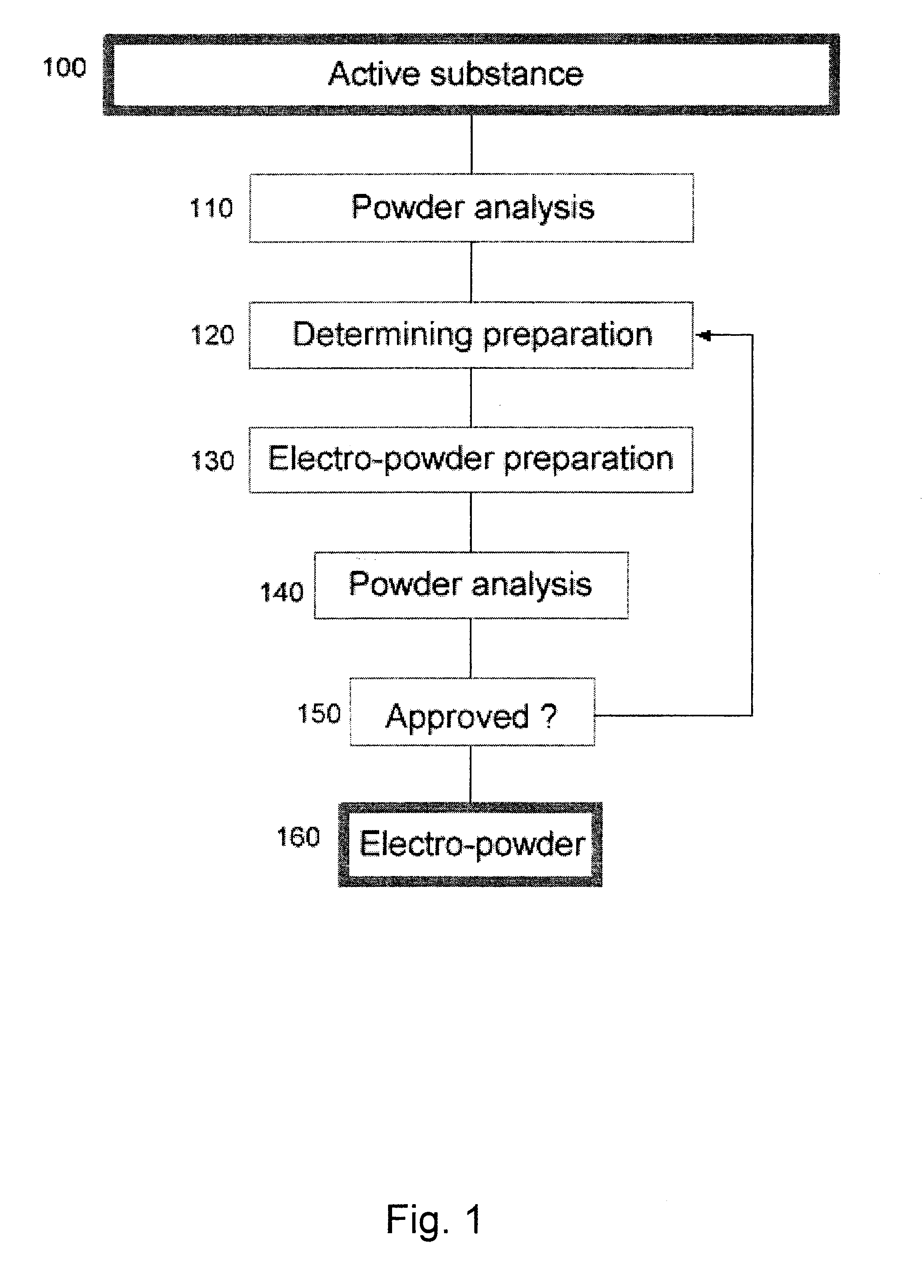

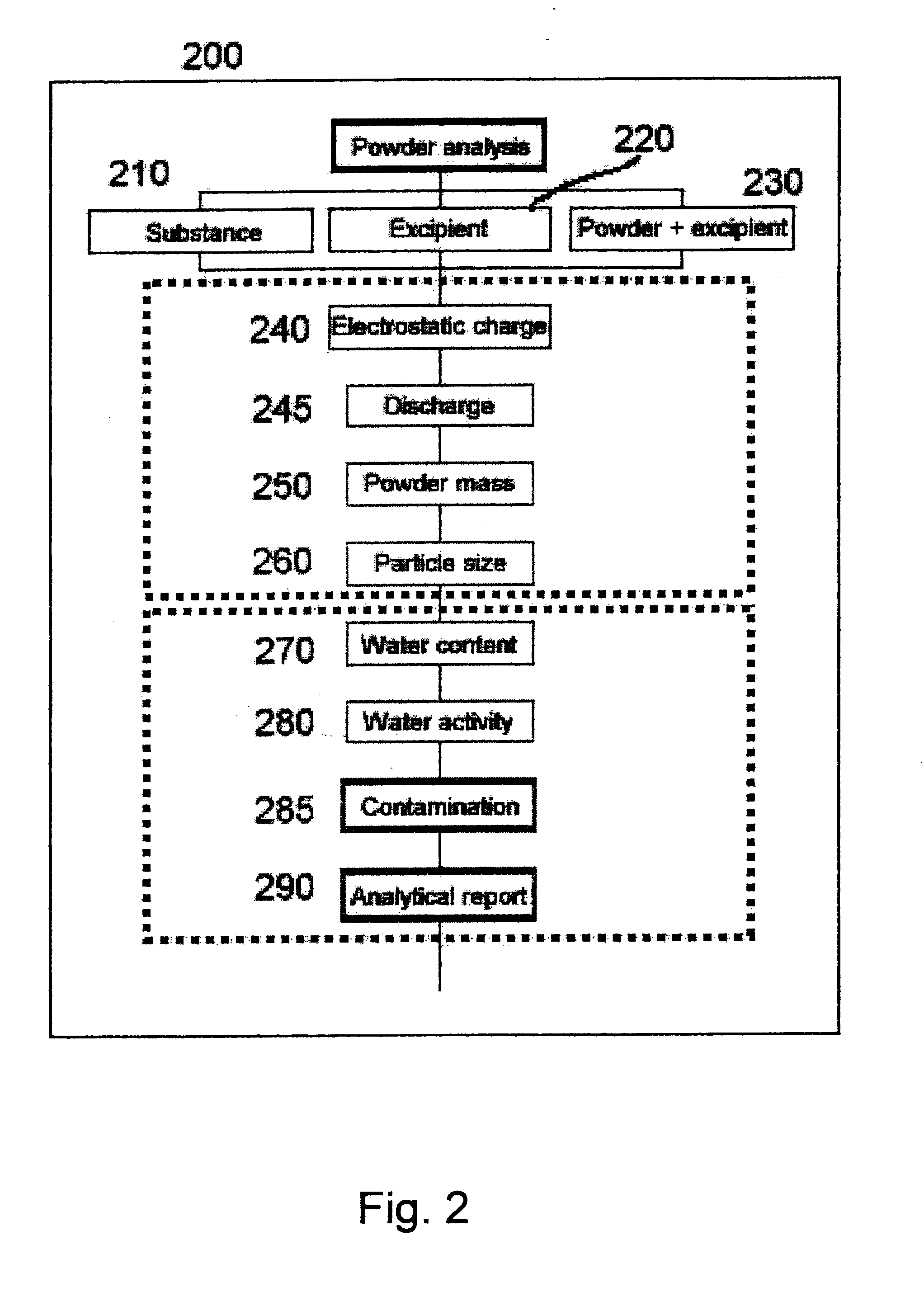

Electro-powder

A method and a process are disclosed for preparation of medical electro-powders. The electro-powder results from preparations of chemical and biological substances to form electro-powders suitable for electrostatic charging and dosing for functionality in a dry powder inhaler device. The electro-powder resulting from the method and process forms an active powder substance or a dry powder medical formulation with a fine particle fraction representing of the order 50% or more of the content having a size ranging between 0.5-5 mum and provides electrostatic properties with an absolute specific charge per mass after charging of the order 0.1x10<-6 >to 25x10<-6 >C / g and presenting a charge decay rate constant Q50>0.1 sec with a tap density of less than 0.8 g / ml and a water activity aw of less than 0.5. In the processing the active substance is a generally pharmaceutical active chemical or biological substance, for instance a polyeptide or any other corresponding substance selected alone or mixed or blended together with one or more excipients being a compound to improve electrostatic properties of the medical dry powder substance or dry powder medical formulation. Further the electro-powder may even be formed as a micro-encapsulation by coating micronized powder with the excipient in such a way that the active substance is capsulated, whereby the powder electrostatic properties mainly comes from the excipient.

Owner:MEDERIO AG

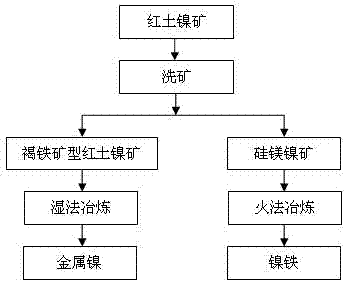

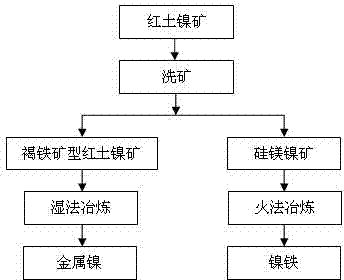

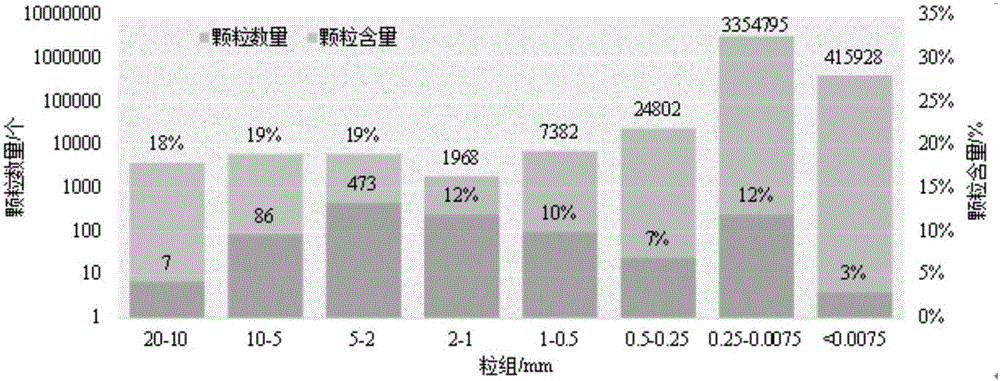

Method for processing laterite-nickel ore

InactiveCN102226232AHigh recovery rateReduce energy consumptionProcess efficiency improvementLateriteMaceral

The invention discloses a method for processing laterite-nickel ore. The method provided by the invention is characterized in that laterite-nickel ore undergoes an ore-washing treatment; noumeite and limonite-type laterite-nickel ore are separated; separated noumeite is melted by the pyrometallurgical process to generate ferronickel; and metallic nickel is extracted from the separated limonite-type laterite-nickel ore by the wet process. According to the method provided by the invention, based on the different mineral compositions of different laterite-nickel ore particle fractions, limonite-type laterite-nickel ore containing high content of iron and low content of magnesium is melted by the wet process to extract metallic nickel, thus leading to low acid consumption; noumeite containing low content of iron and high content of magnesium is melted by the pyrometallurgical process to extract ferronickel, thus leading to high quality of the produced ferronickel, high recovery rate of nickel, low energy consumption and simultaneous recovery of iron.

Owner:广西银亿新材料有限公司

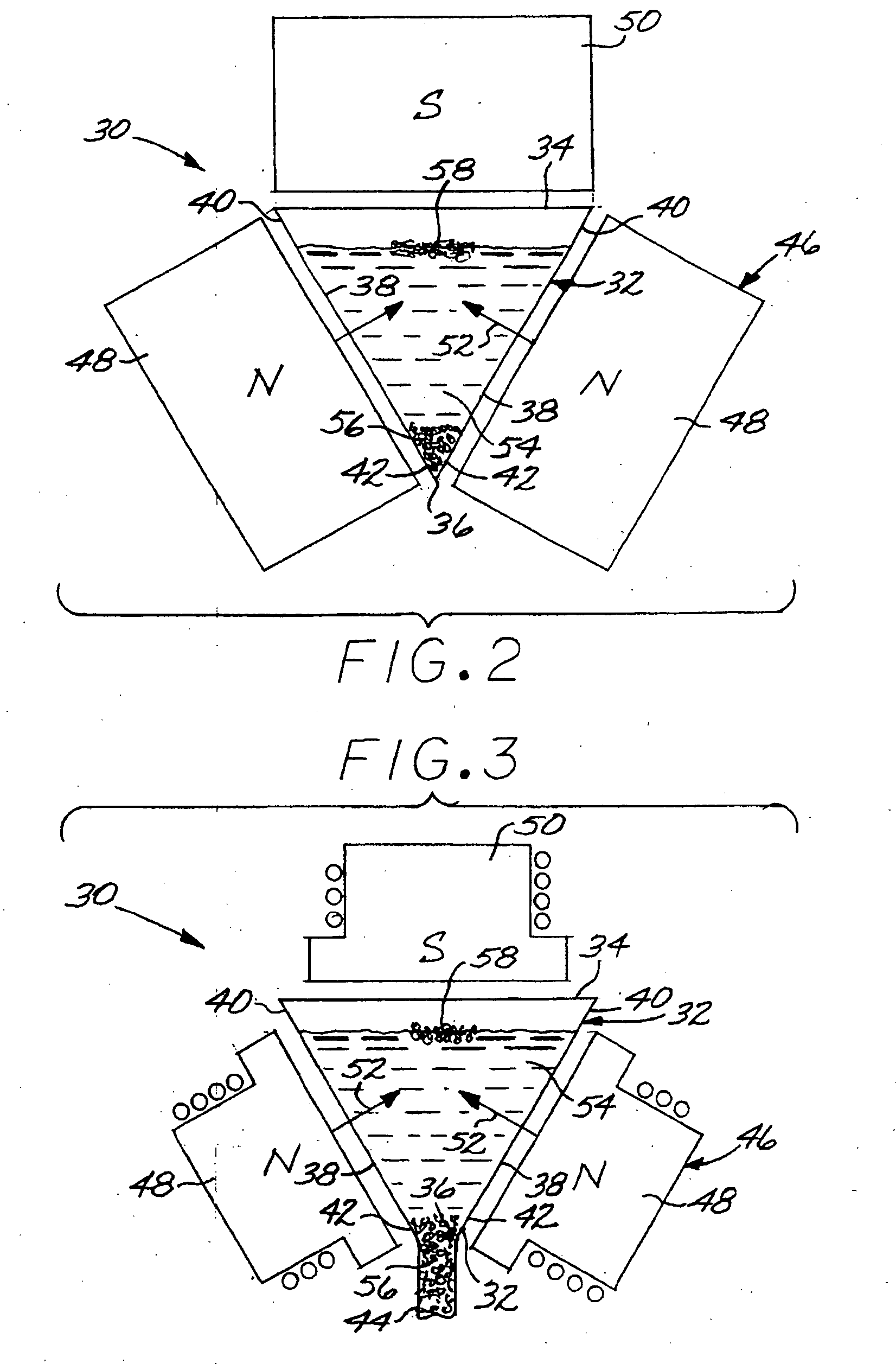

Semipermeable membrane system for magnetic particle fractions

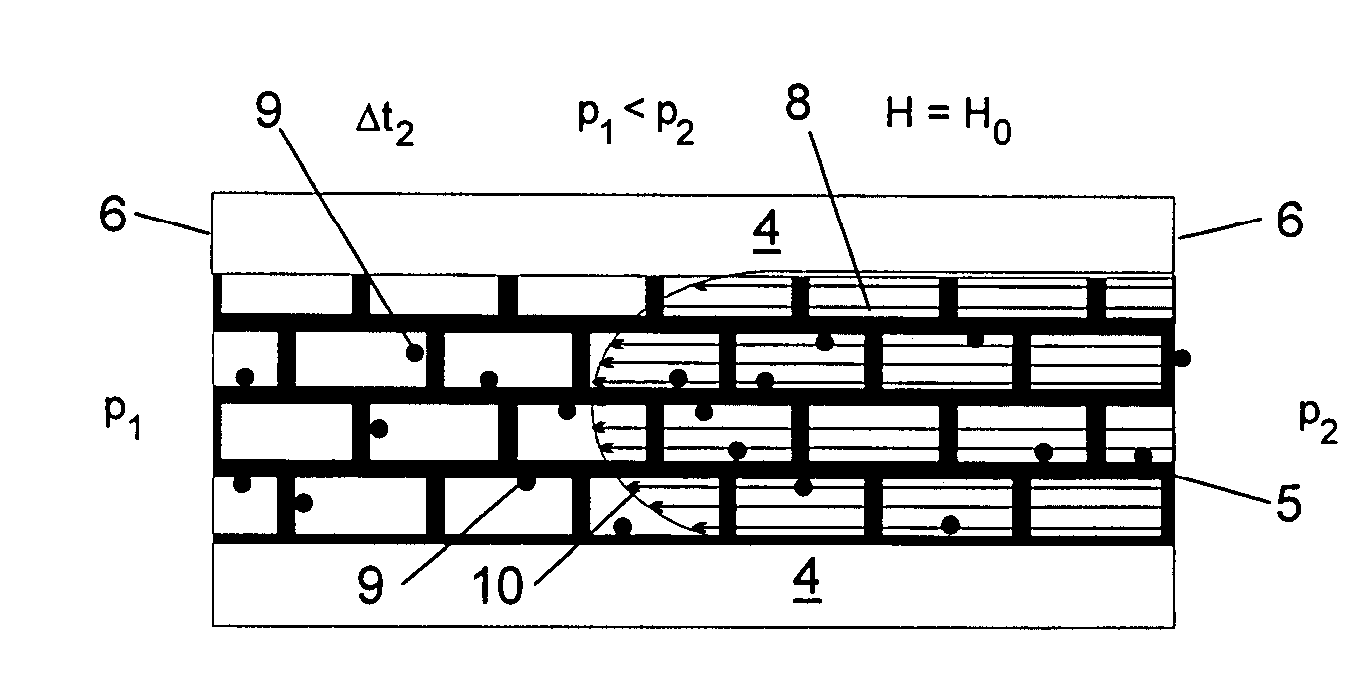

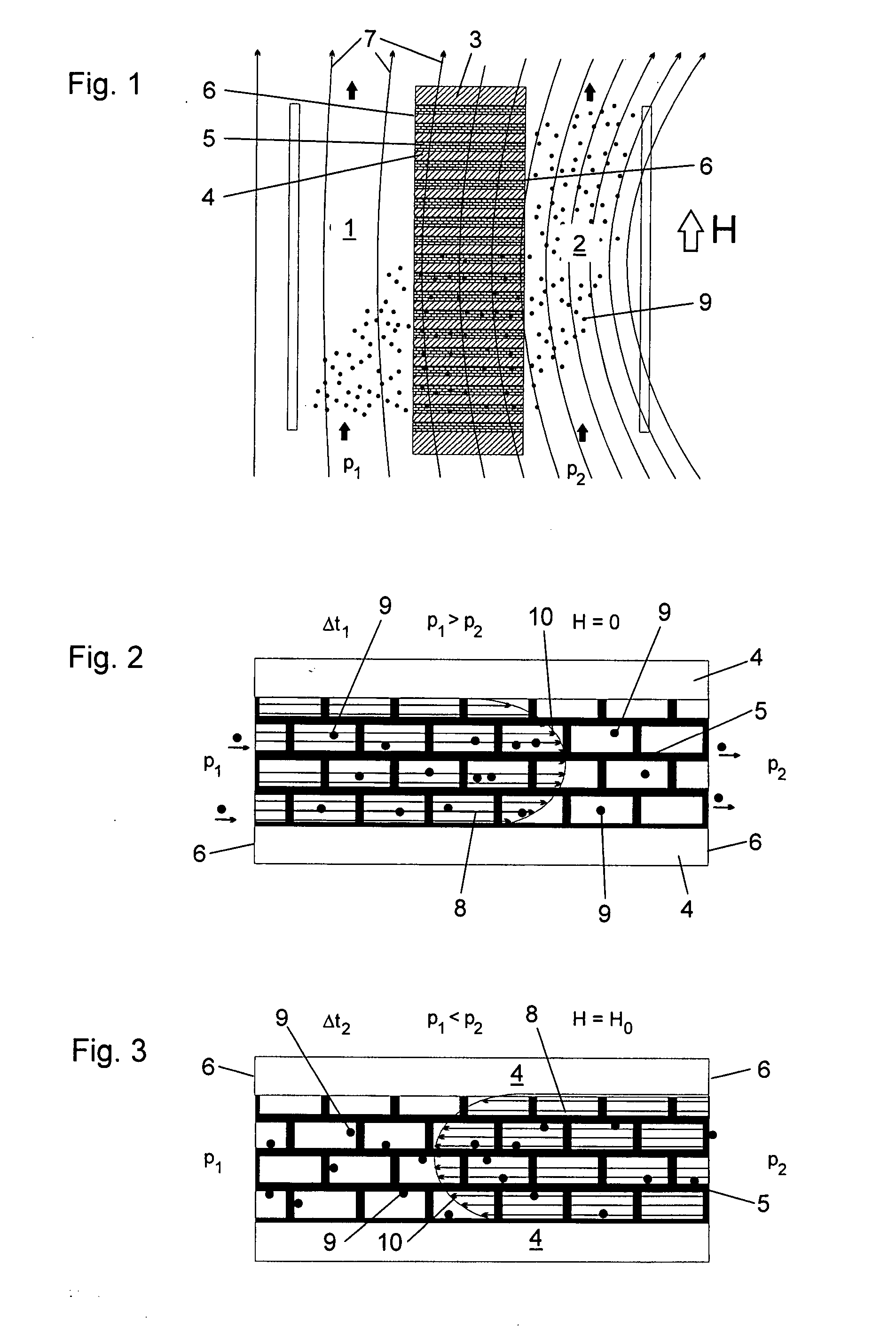

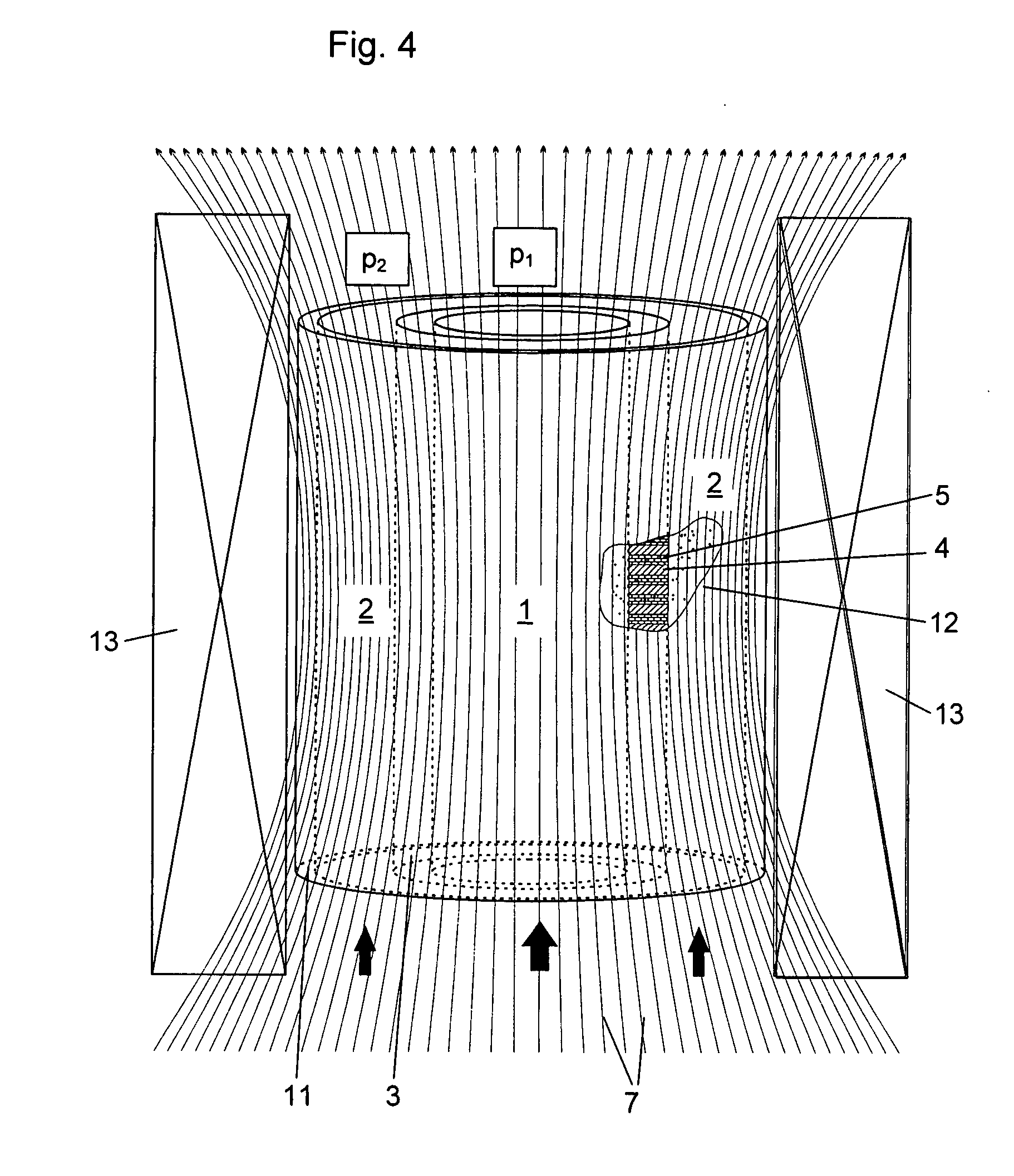

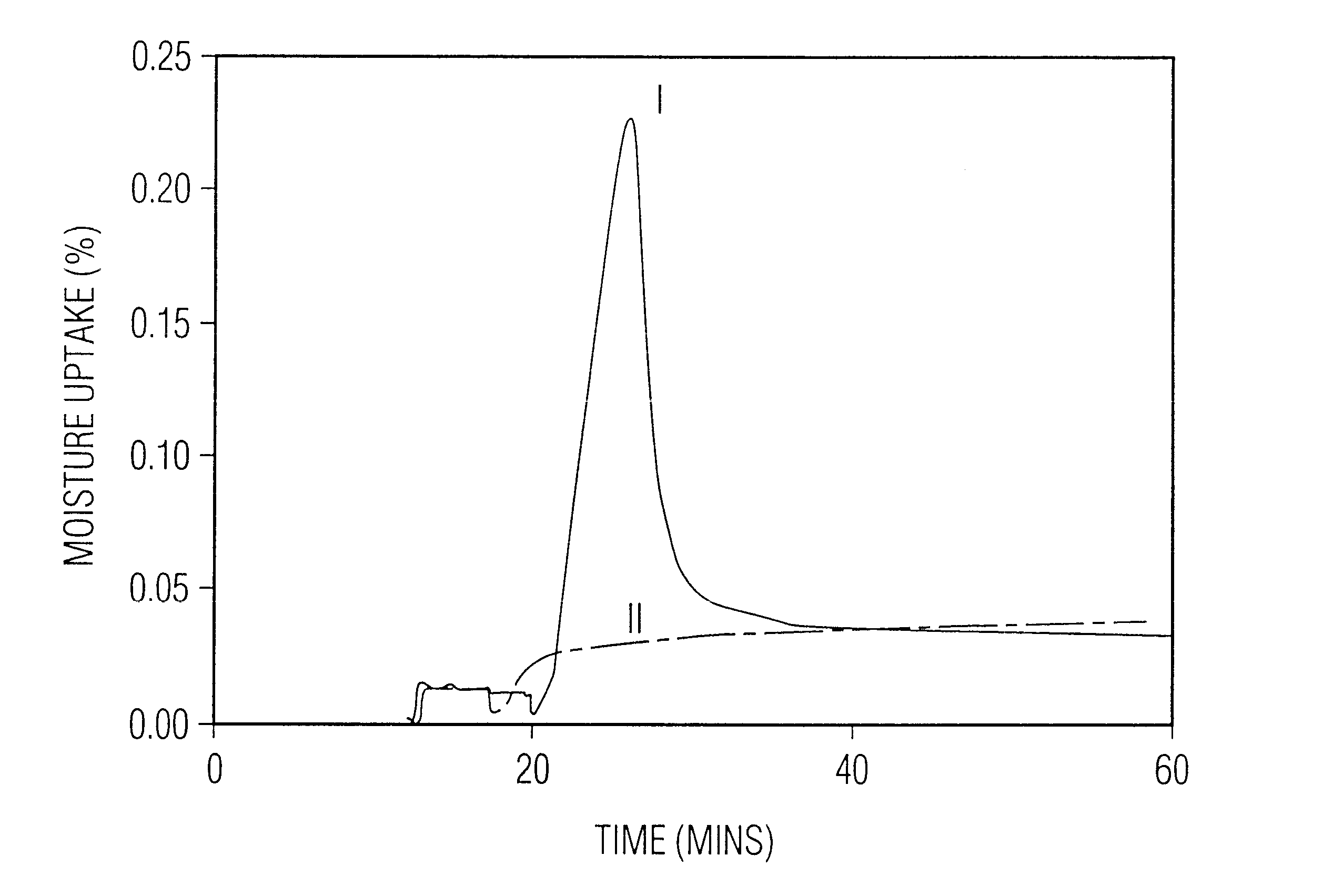

InactiveUS20080035541A1Increases force effectiveImprove concentrationSemi-permeable membranesWater/sewage treatment by magnetic/electric fieldsMembrane surfaceSemipermeable membrane

In a semi-permeable membrane system for separating magnetic particle fractions from a mixture contained in a first fluid, comprising a membrane with opposite membrane surfaces between which passages extend and which separates the first fluid from a second fluid each of which is in contact with one of the membrane surfaces, means are provided for generating a reversible pressure differential between the two fluids across the membrane and means for generating and eliminating a magnetic field in the membrane for alternately causing a fluid flow through the membrane in opposite directions wherein, during the fluid flow in one direction, the magnetic field is switched on to hold the magnetic particles in place in the membrane and, during fluid flow in the opposite flow direction, the magnetic field is switched off to permit the magnetic particles to be moved through the membrane in the other direction.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

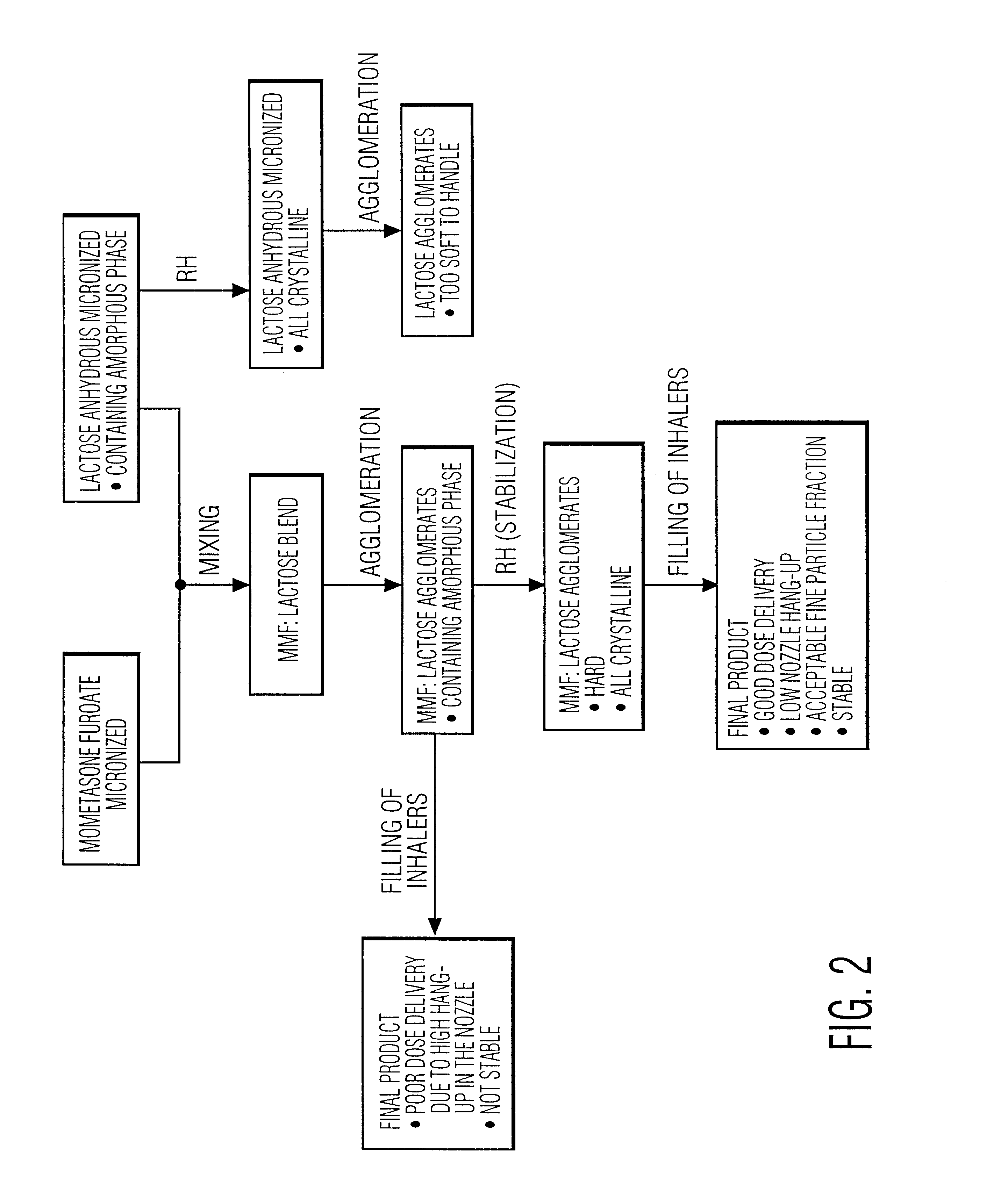

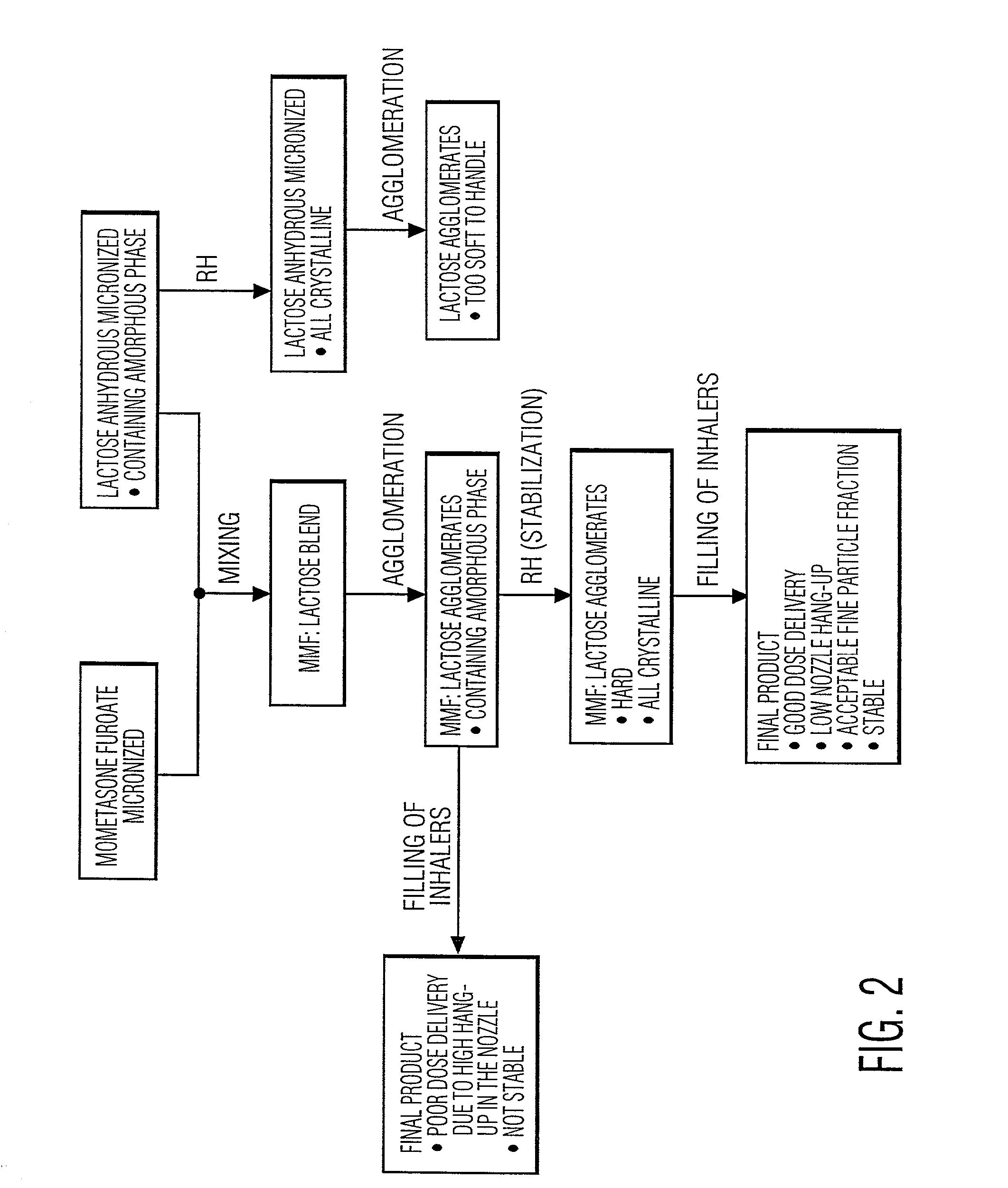

Preparation of powder agglomerates

The invention relates to a method of producing an agglomerate of drug and solid binder. The process involves producing individual agglomerate particles and then converting the convertible amorphous content of same, following agglomeration, by the application of, for example, moisture. Agglomerates capable of conversion as well as the finished agglomerates and oral and nasal dosing systems including same are also contemplated. The process produces agglomerates which are rugged but which will produce an acceptable fine particle fraction during dosing.

Owner:MERCK SHARP & DOHME CORP

Preparation of powder agglomerates

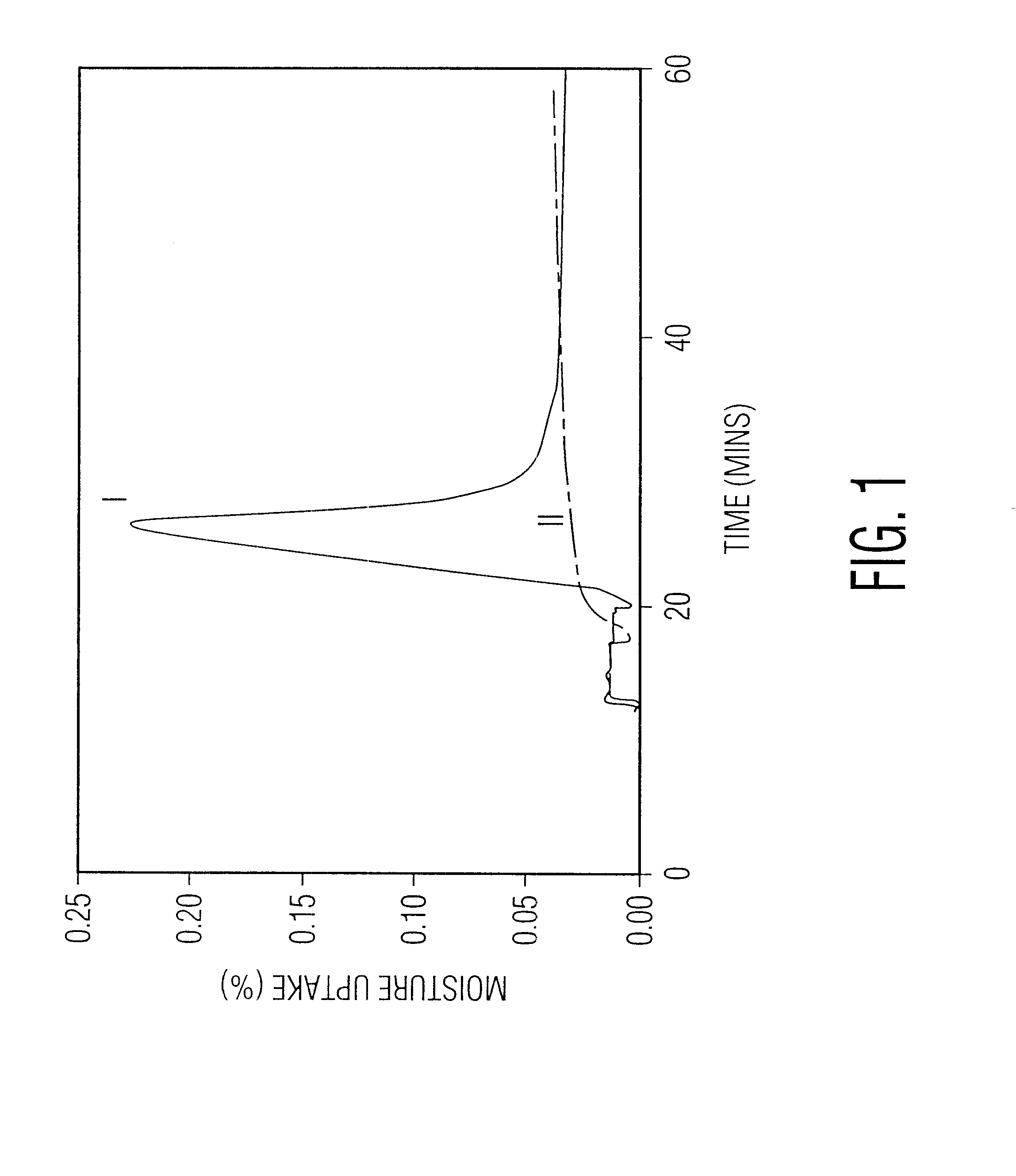

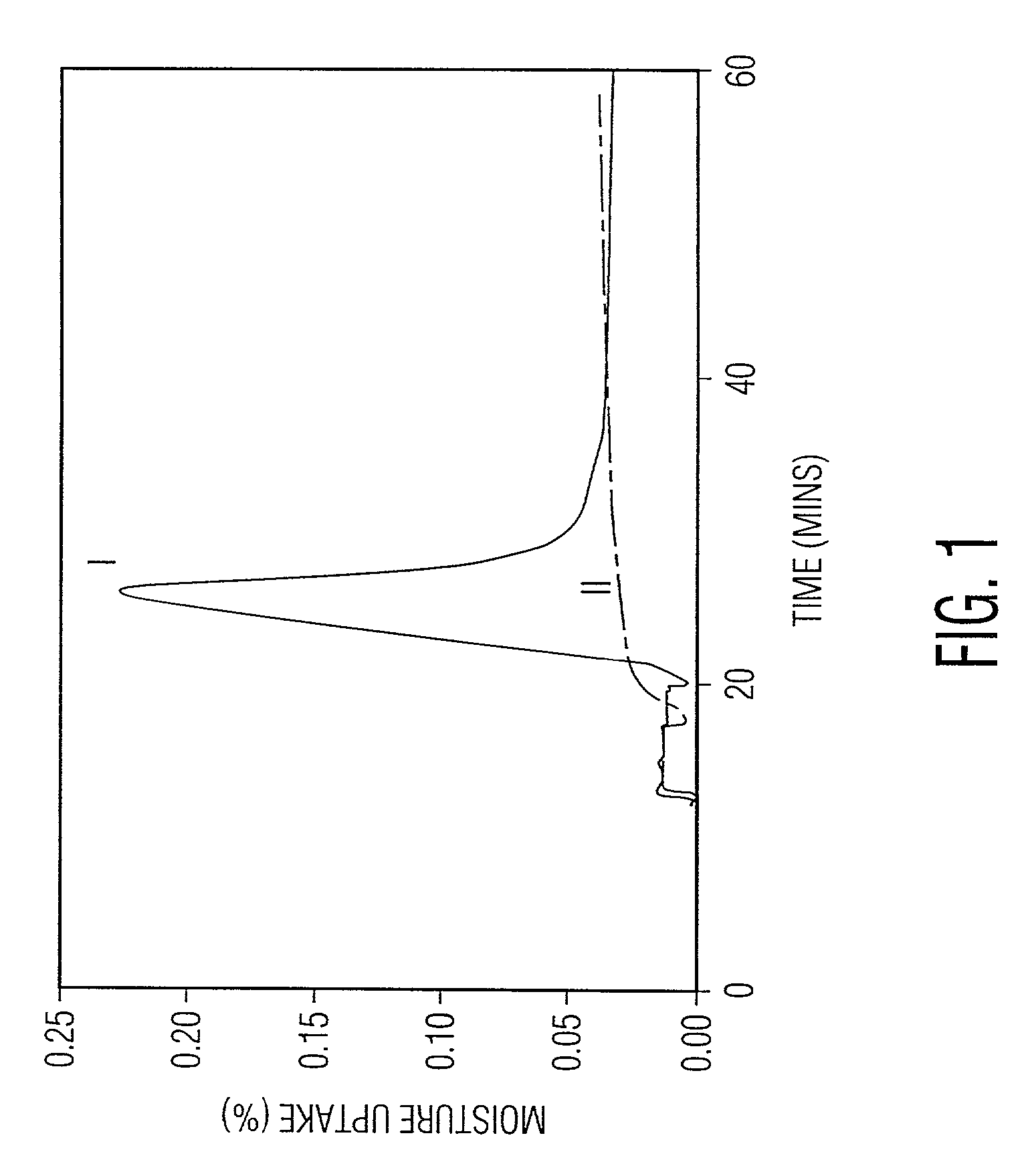

InactiveUS20010024641A1Reduce the amount requiredPowder deliveryOrganic active ingredientsPrillMedicine

The invention relates to a method of producing an agglomerate of drug and solid binder. The process involves producing individual agglomerate particles and then converting the convertible amorphous content of same, following agglomeration, by the application of, for example, moisture. Agglomerates capable of conversion as well as the finished agglomerates and oral and nasal dosing systems including same are also contemplated. The process produces agglomerates which are rugged but which will produce an acceptable fine particle fraction during dosing.

Owner:MERCK SHARP & DOHME CORP

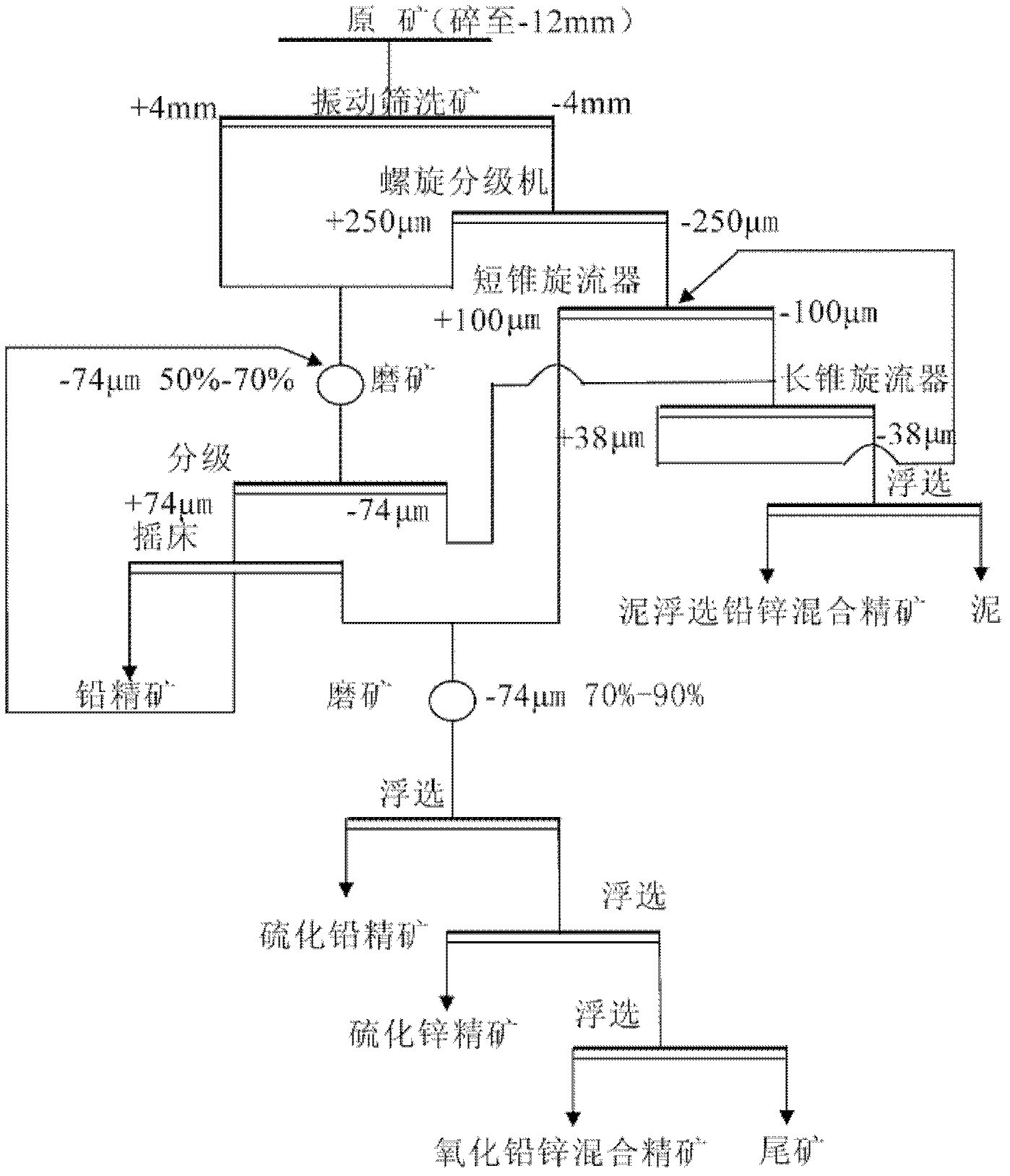

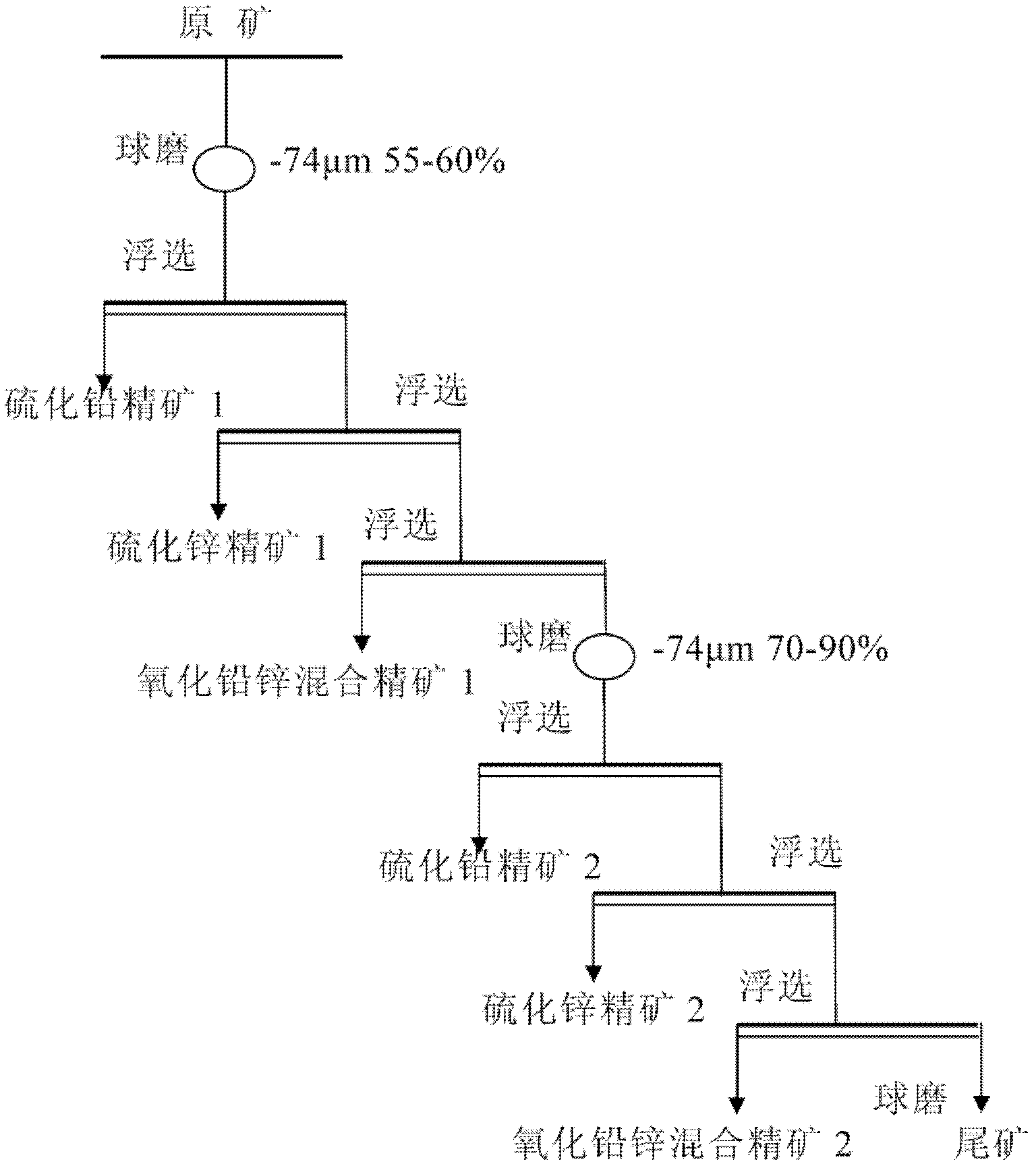

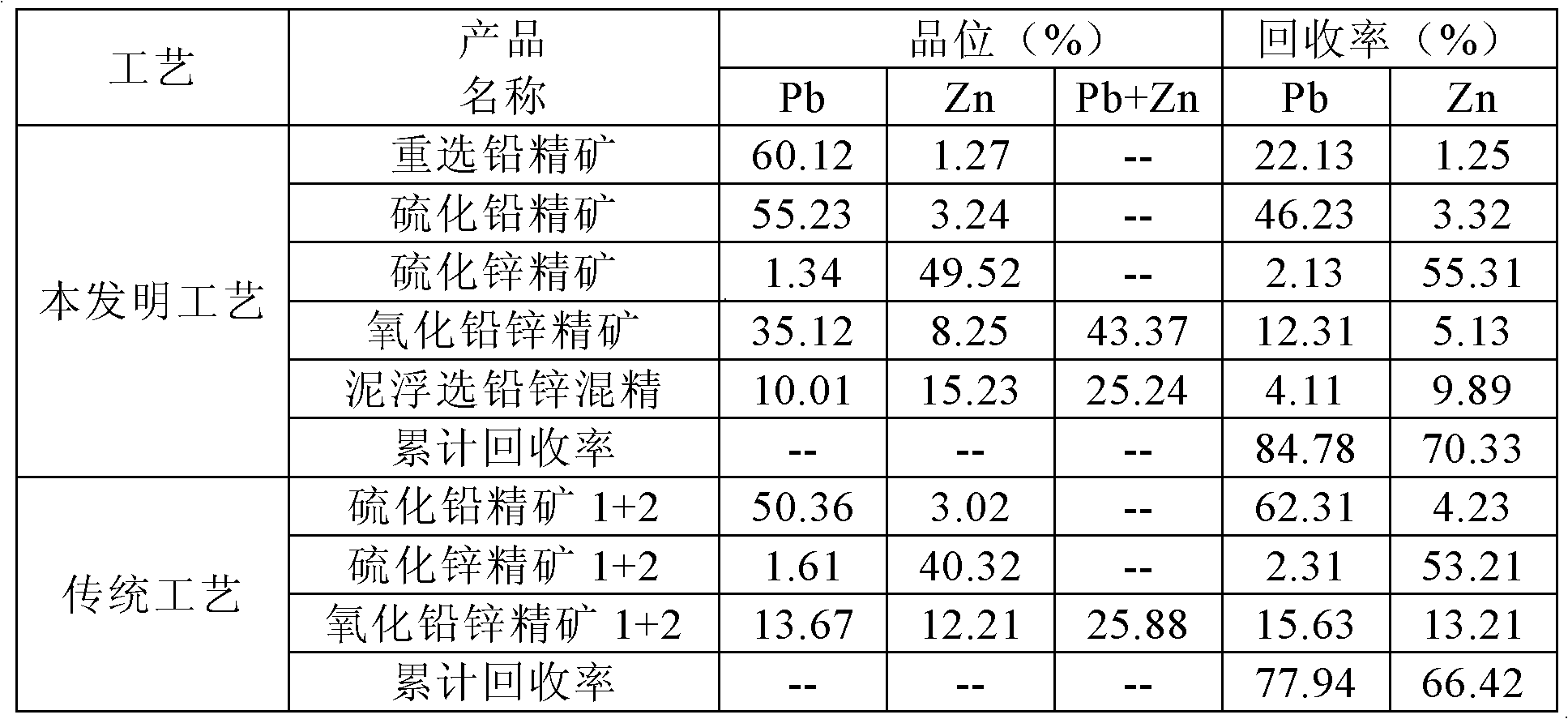

Ore dressing combination process for processing high-slime lead-zinc oxide and sulfide mixed ore

ActiveCN103182344AEasy to operateImprove technical indicatorsFlotationWet separationOxygenLead sulfide

The invention relates to an ore dressing combination process for processing a high-slime lead-zinc oxide and sulfide mixed ore. The ore dressing combination process comprises the steps as follows: crushing a raw ore and washing by a vibration sieve; carrying out primary classification on parts under the sieve and desliming fine particle fractions after primary classification through a two-stage one-closed-circuit process; combining parts over the sieve with rough particle fractions after primary classification, carrying out primary grinding, carrying out secondary classification on ground products, carrying out table-shaking gravity separation on rough particle fractions after secondary classification, and enabling fine particle fractions after secondary classification to enter a long conical cyclone for desliming; obtaining concentrate, namely lead concentrate by gravity separation, carrying out primary grinding on middlings obtained by gravity separation, combining tailings obtained by gravity separation with settled sand obtained by desliming in a short conical cyclone, carrying out ore grinding, and carrying out floatation separation to obtain lead sulfide concentrate, zinc sulfide concentrate and lead-zinc oxide bulk concentrate in sequence; and carrying out floatation separation on slime to obtain lead-zinc oxide and sulfide bulk concentrate. The ore dressing combination process is stable in operation, has very good technical indexes, and can bring very good economic benefits to enterprises.

Owner:有研资源环境技术研究院(北京)有限公司

Dry powder for inhalation

InactiveUS20070212422A1Reduce sensitivityMinimize impactPowder deliveryOrganic active ingredientsMagnesium stearateExtreme temperature

The aim of the invention is to improve the moisture resistance of dry powder formulations for inhalation which contain a pharmaceutically ineffective carrier of not-inhalable particle size and a finely divided pharmaceutically active compound of inhalable particle size and to also improve the storage stability of said formulations. To this end, magnesium stearate is used in said formulations. On of the features of the inventive dry powder is that a high fine particle dosage or fine particle fraction can be maintained also under relatively extreme temperature and humidity conditions.

Owner:KELLER MANFRED +1

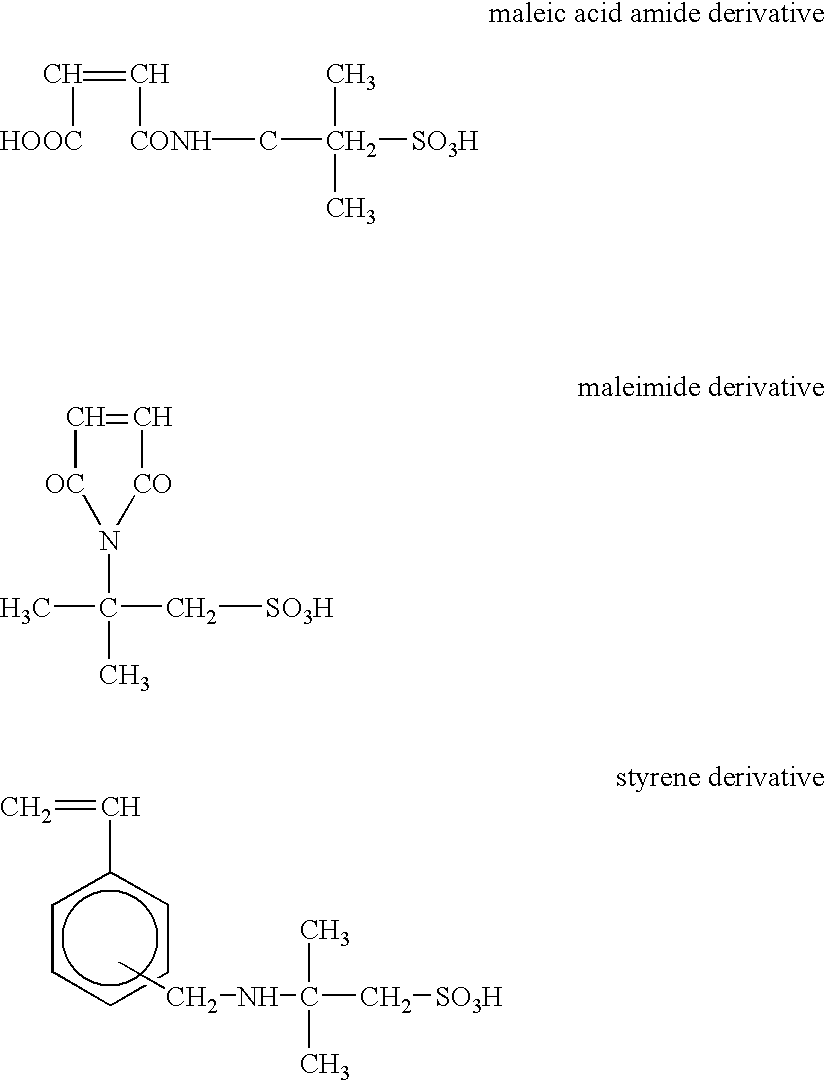

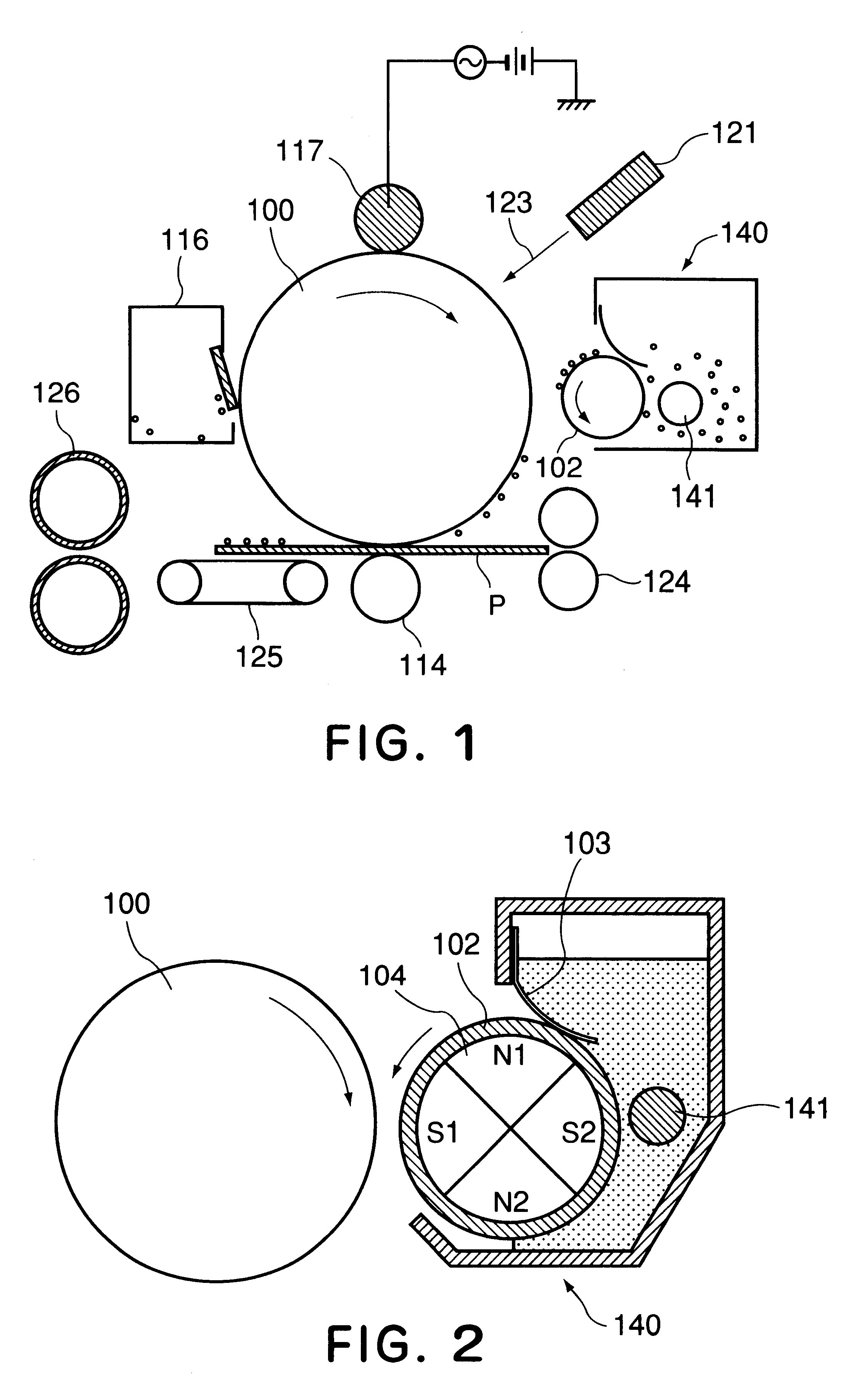

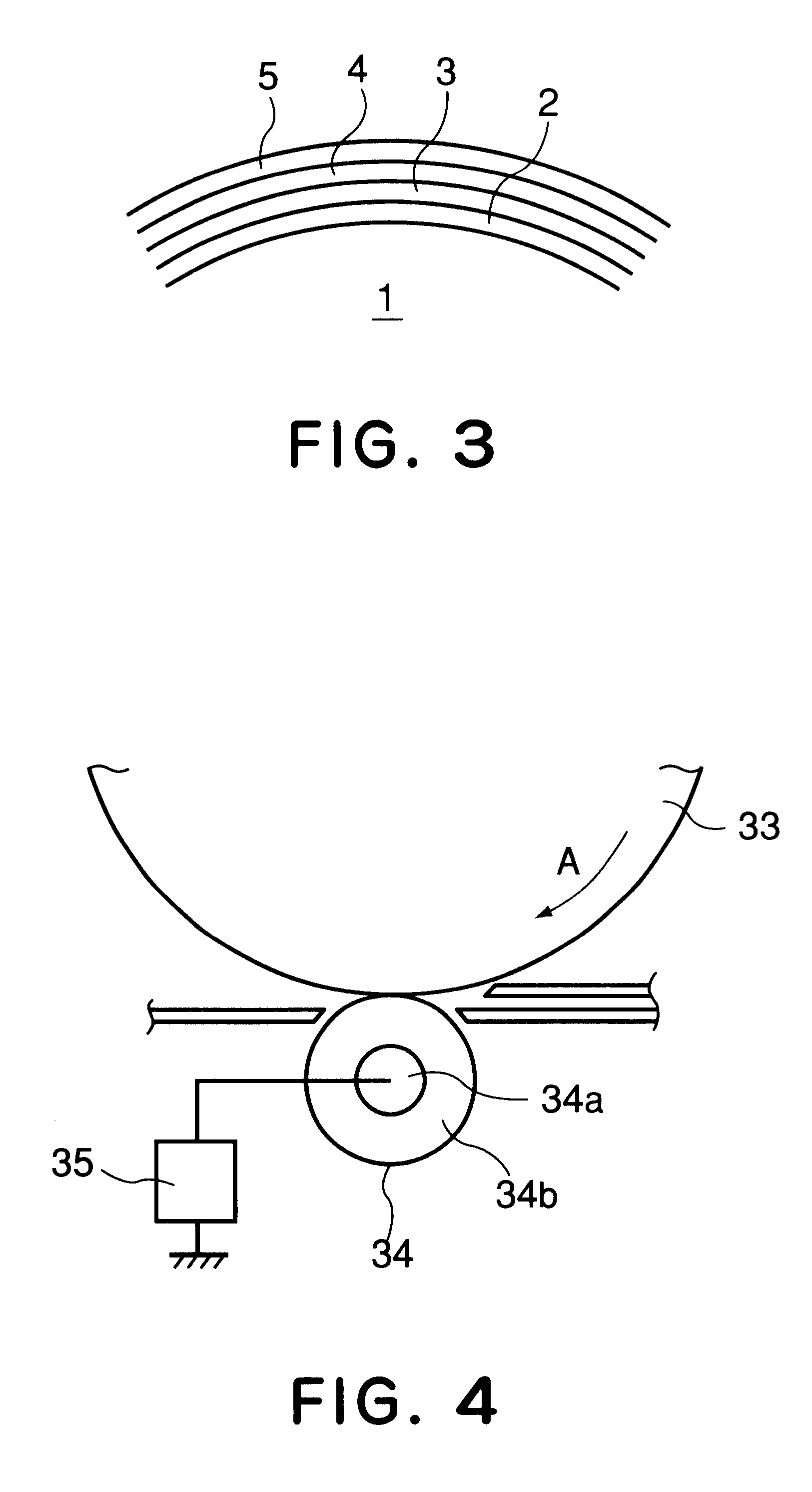

Magnetic toner

A magnetic toner exhibiting stable performances under various environmental conditions is formed of toner particles each comprising at least a binder resin and iron oxide dispersed therein. Relative to the dry specific gravity (A) of the magnetic toner, the magnetic toner is characterized by a specific gravity distribution of toner particle fractions obtainable through wet sedimentation and including: at most 15 wt. % of a fraction having a specific gravity of above (A)x1.000 and at most (A)x1.025, 0.1-20 wt. % of a fraction having a specific gravity of above (A)x0.975 and at most (A)x1.000, at least 30 wt. % of a fraction having a specific gravity of above (A)x0.950 and at most (A)x0.975, 0.1-20 wt. % of a fraction having a specific gravity of above (A)x0.925 and at most (A)x0.950, and at most 15 wt. % of a fraction having a specific gravity of above (A)x0.900 and at most (A)x0.925.

Owner:CANON KK

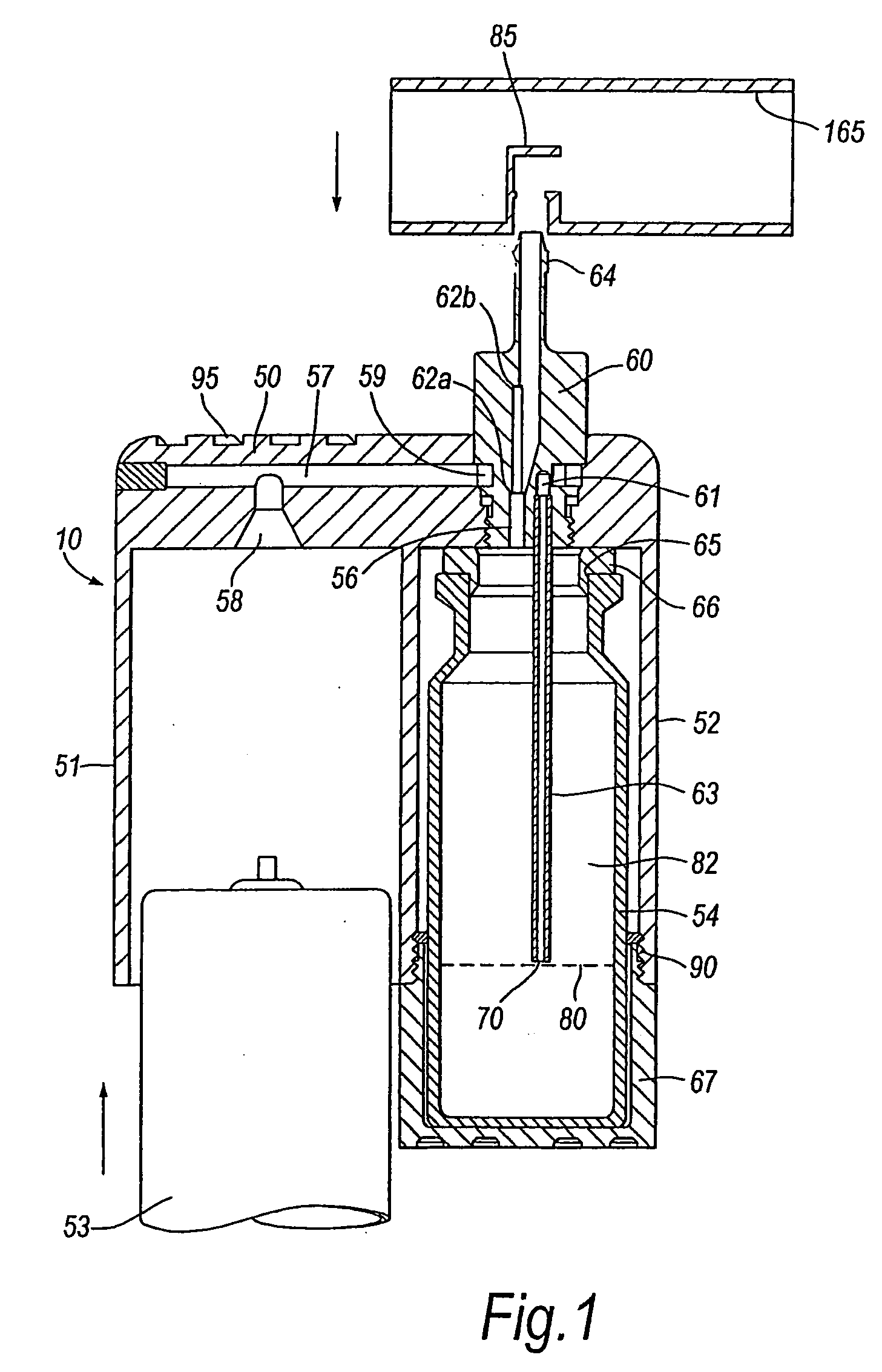

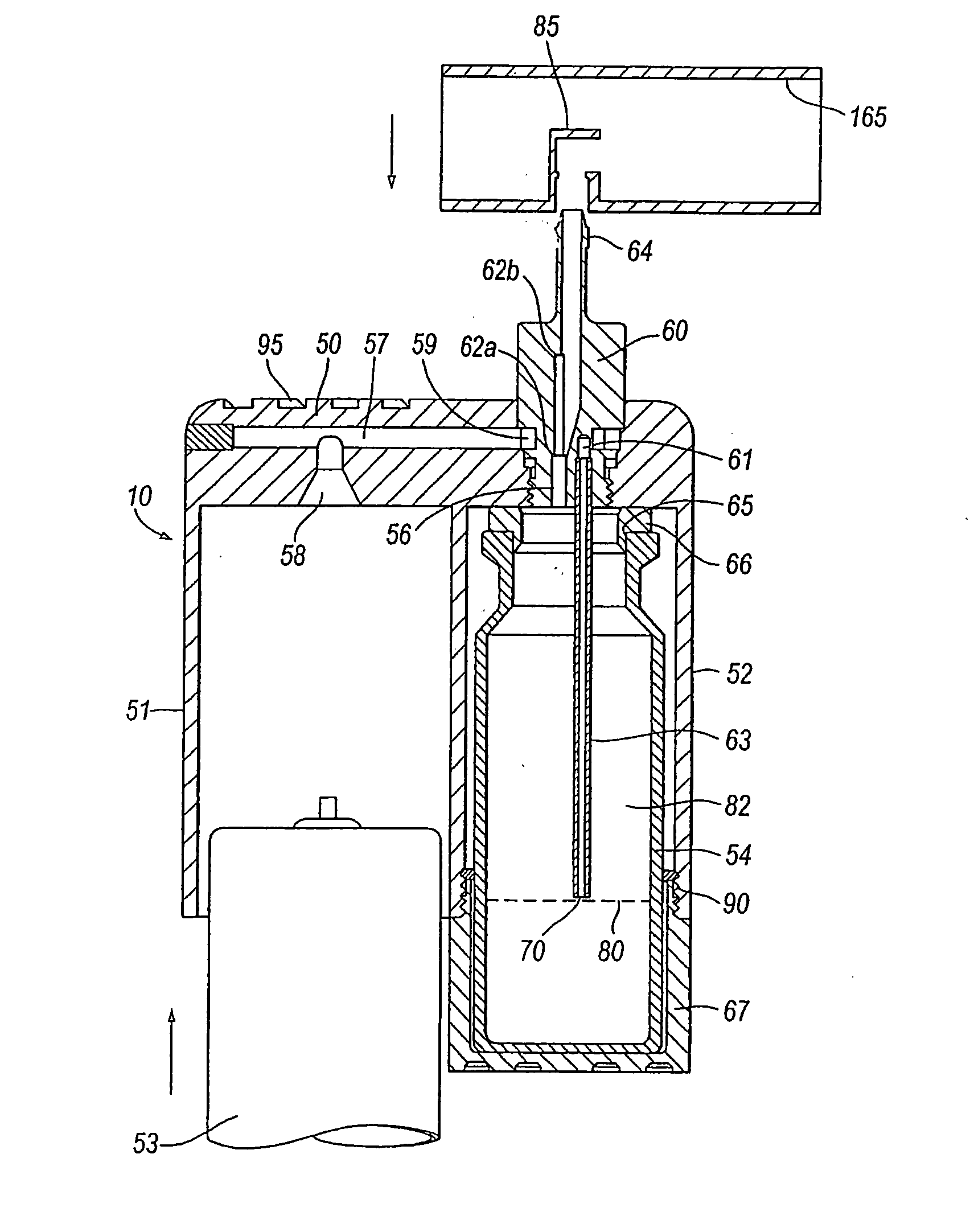

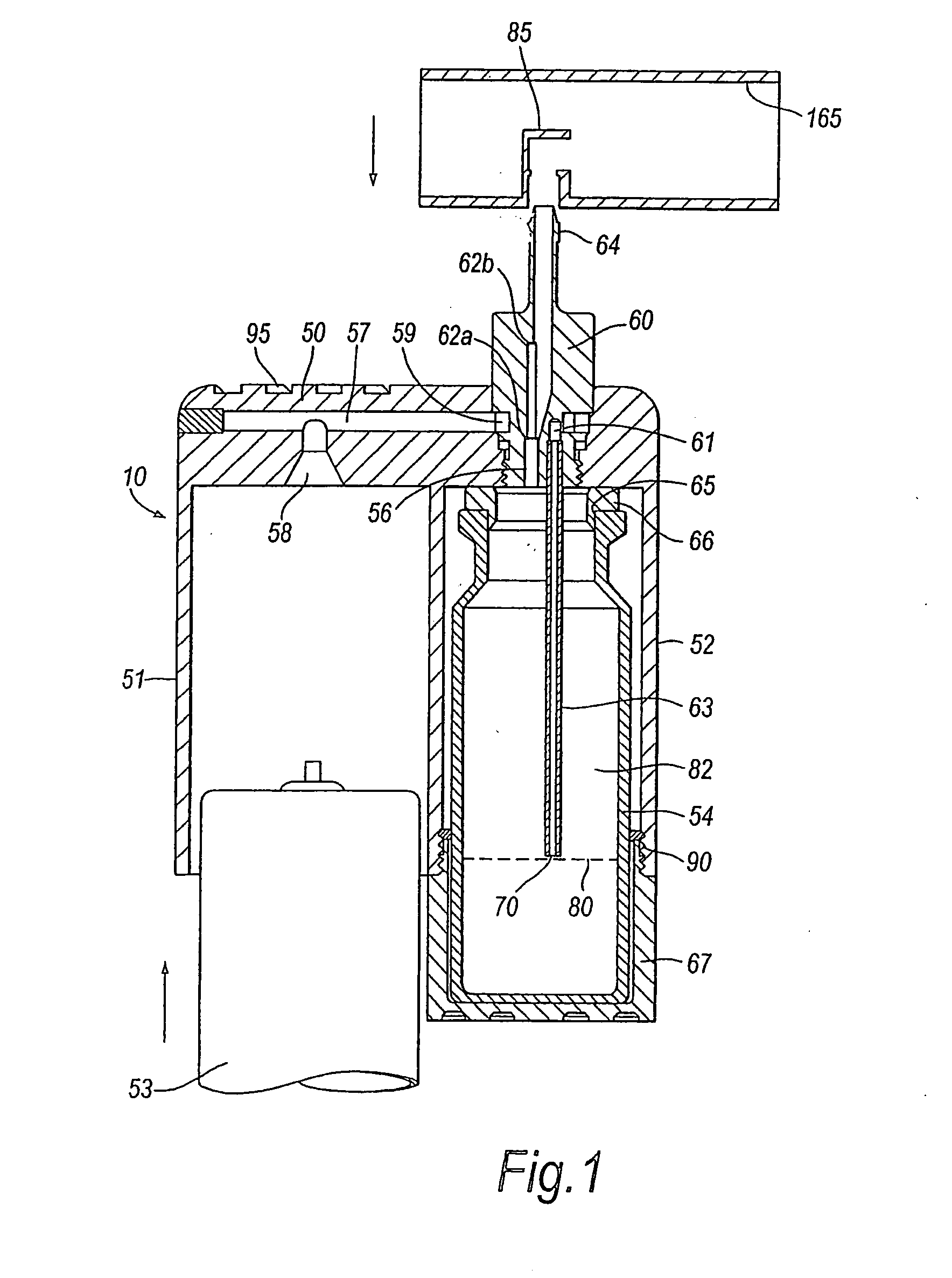

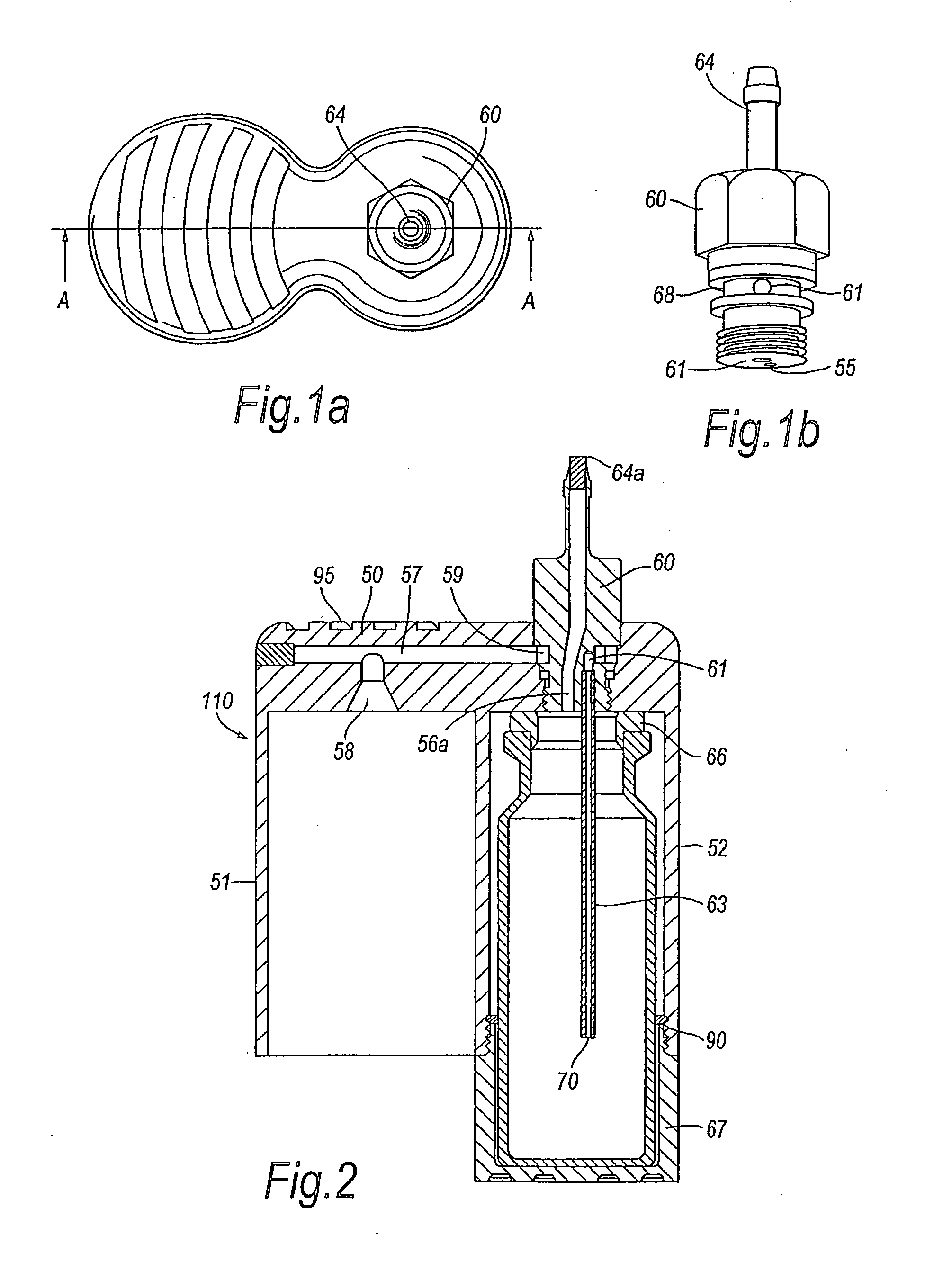

Delivery device for a powder aerosol

InactiveUS20060213514A1Highly effectiveImprove energy transferRespiratorsLiquid surface applicatorsPowder AerosolAerosolization

A delivery device for a medicament including: a housing, a receptacle holding a medicament in the form of a power; and a source of propellant, wherein the housing provides an inlet and an outlet for the receptacle, wherein the inlet is in fluid communication with the source of propellant and is directed against the medicament and the outlet is spaced from the medicament to allow aerosolization of the medicament; the device provides improved delivery efficiency, particularly a delivered fine particle fraction of greater than 20% by weight.

Owner:AIRPHARMA

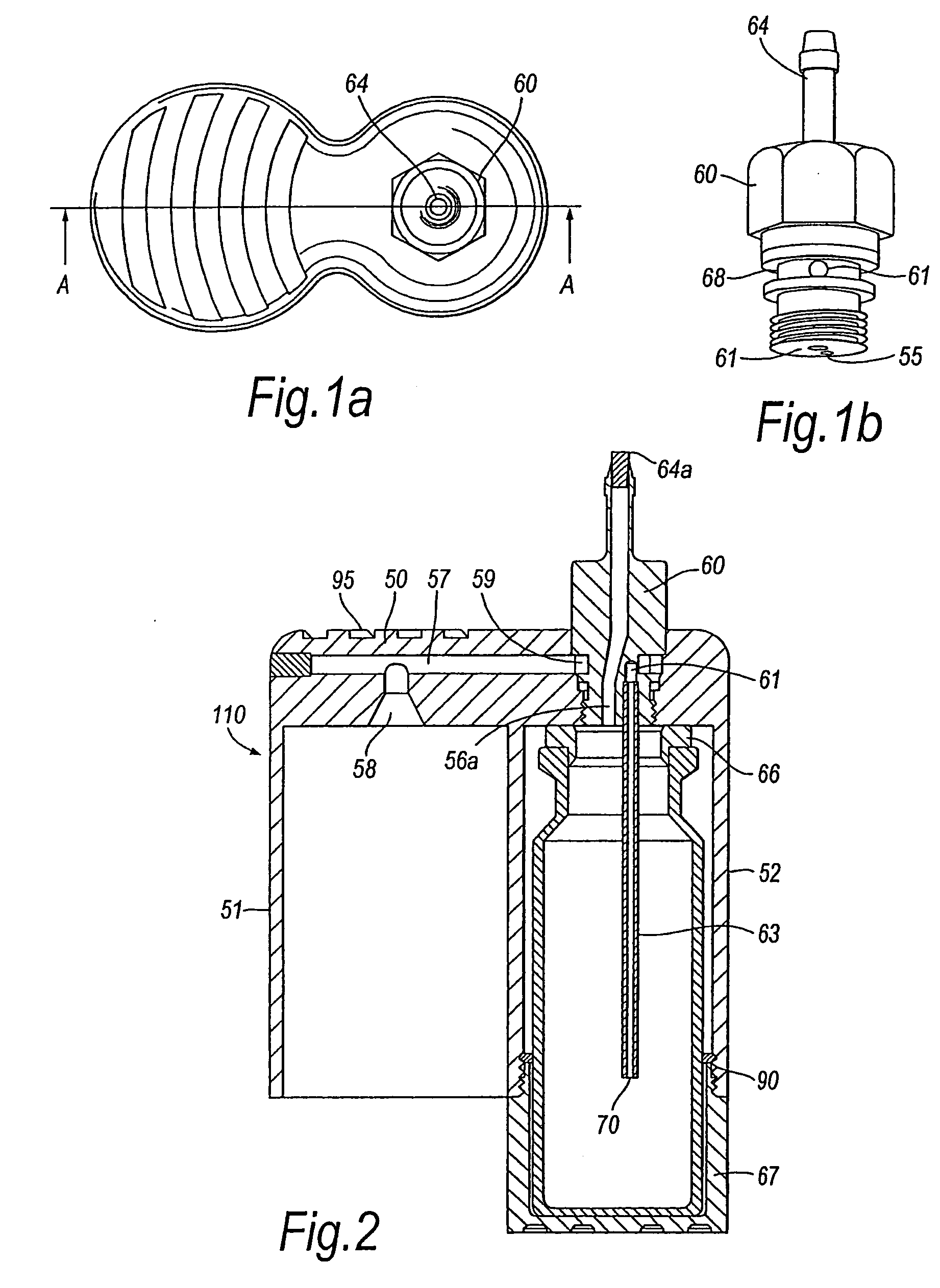

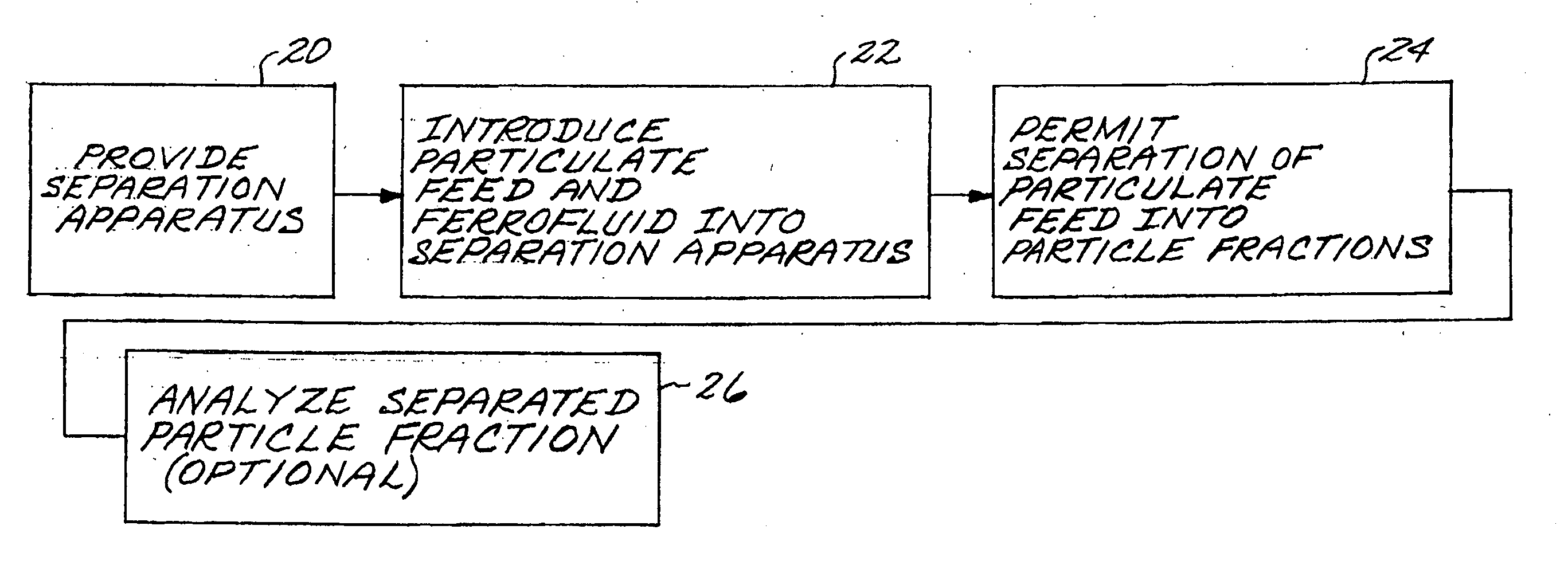

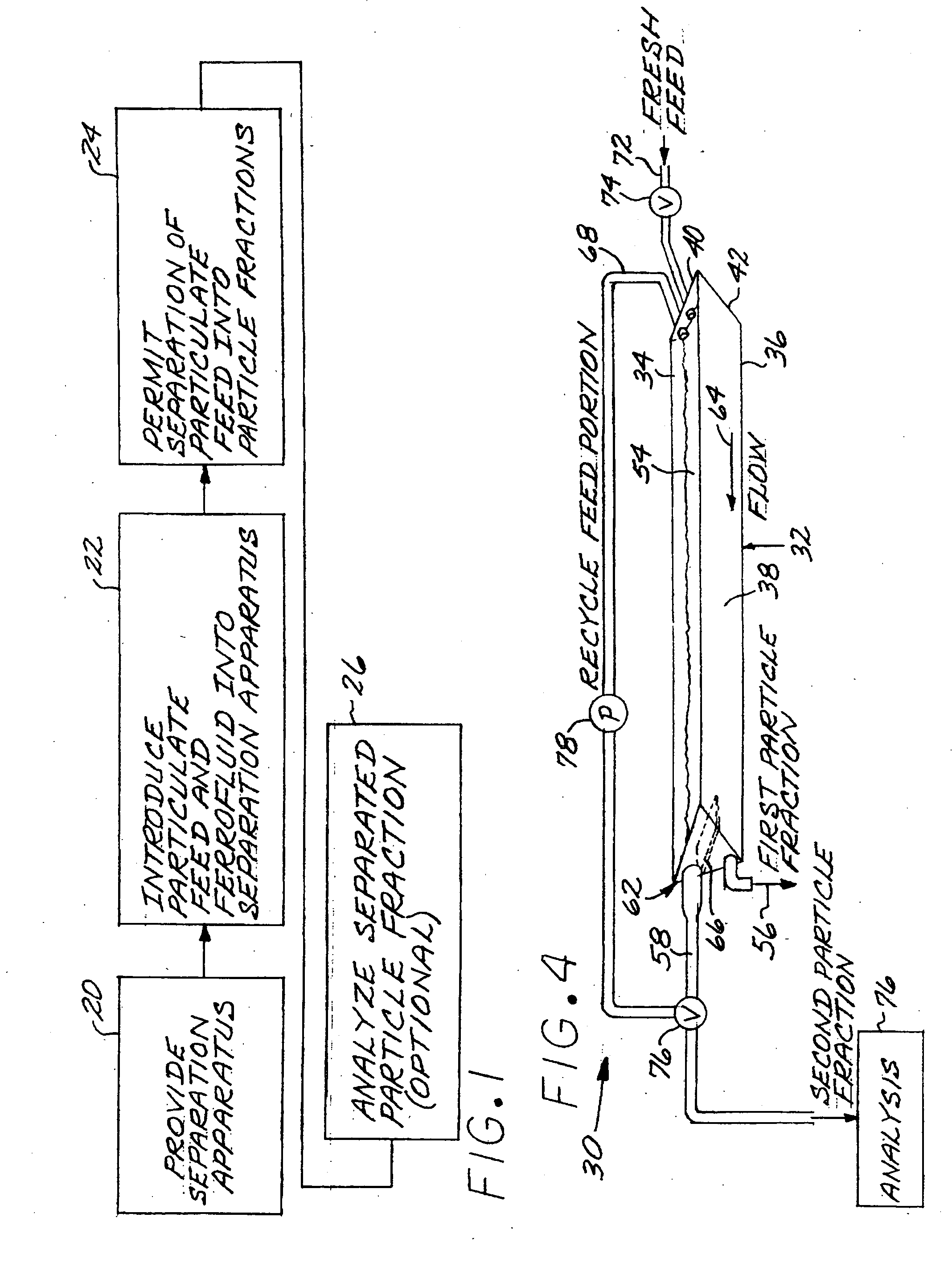

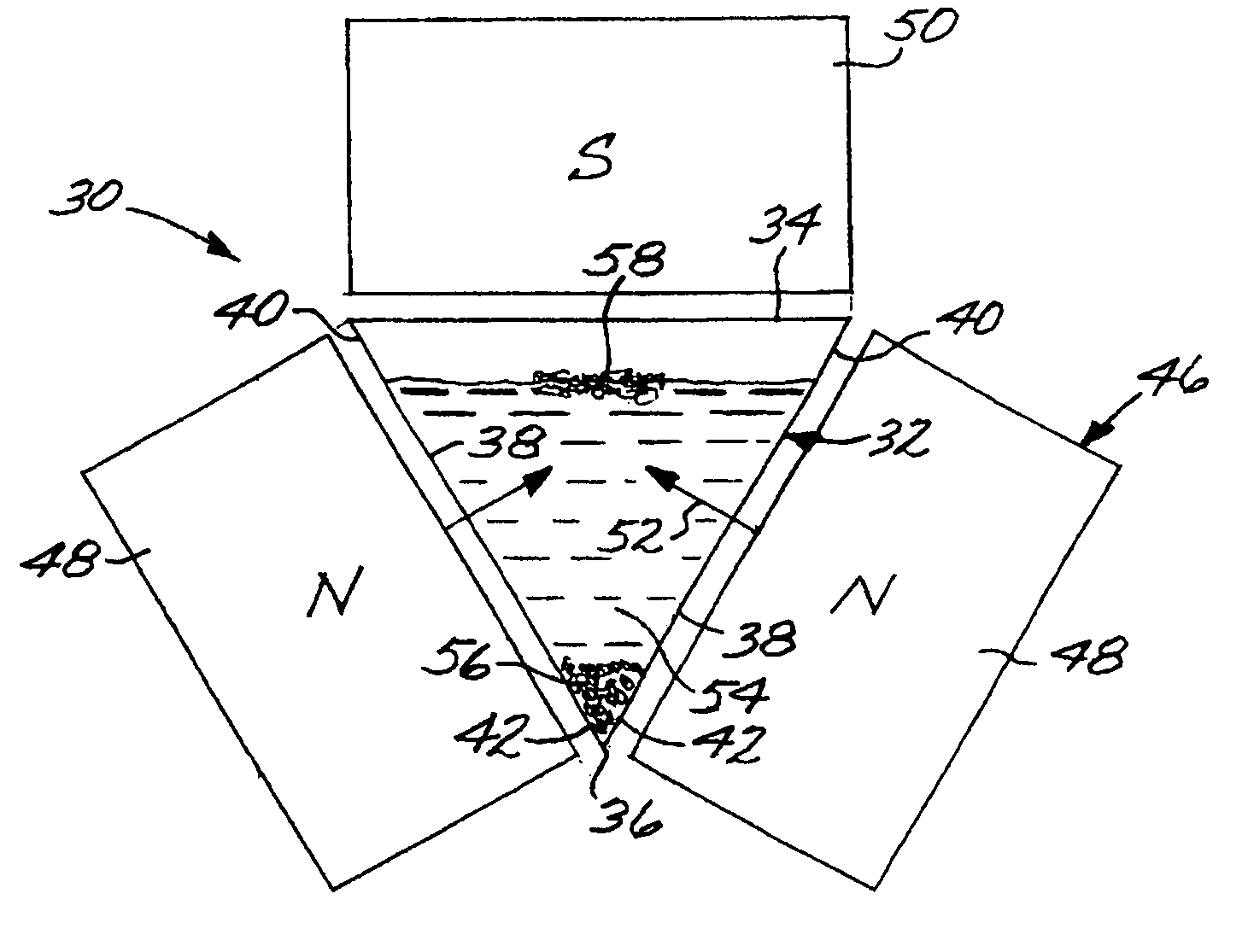

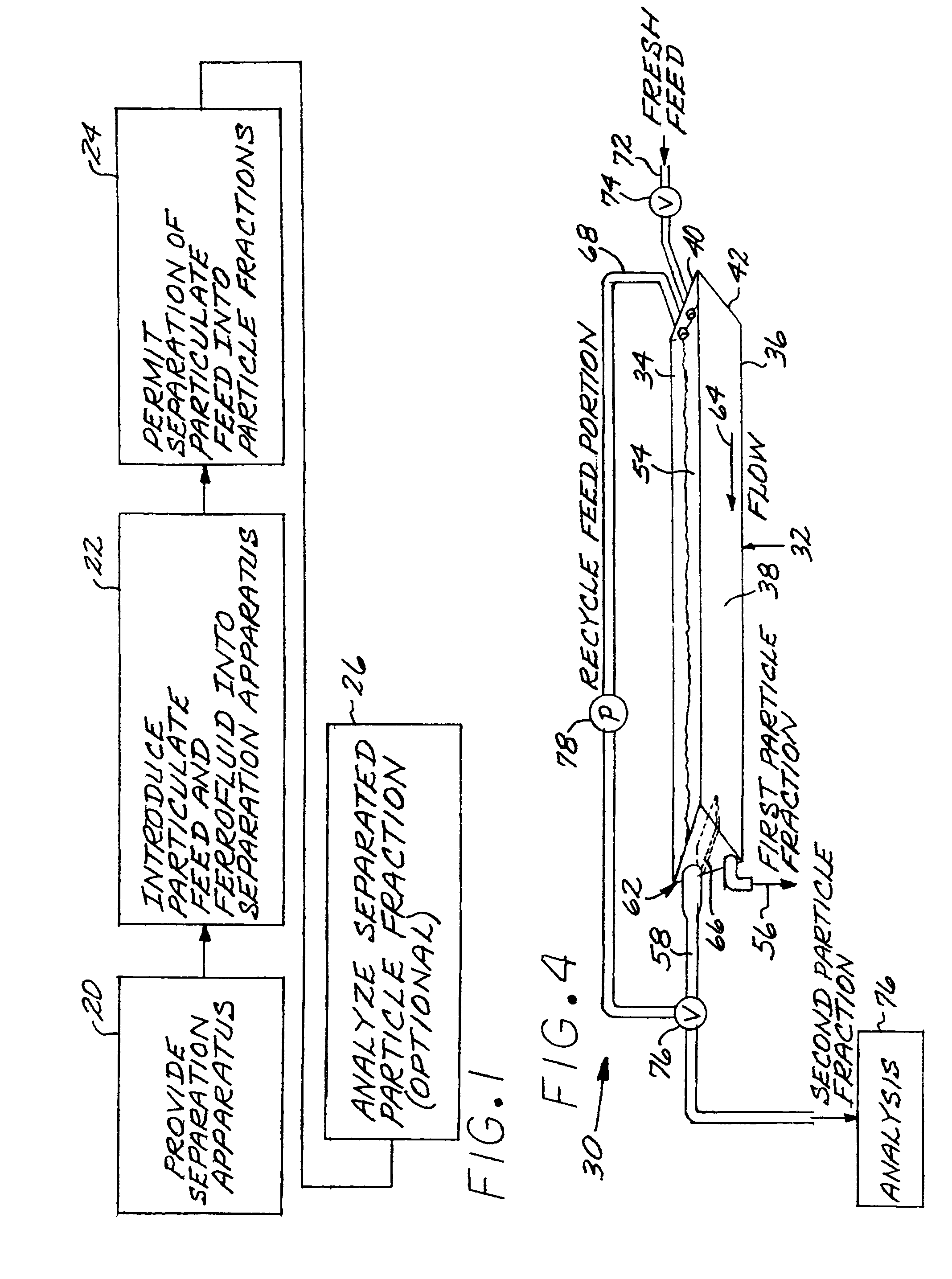

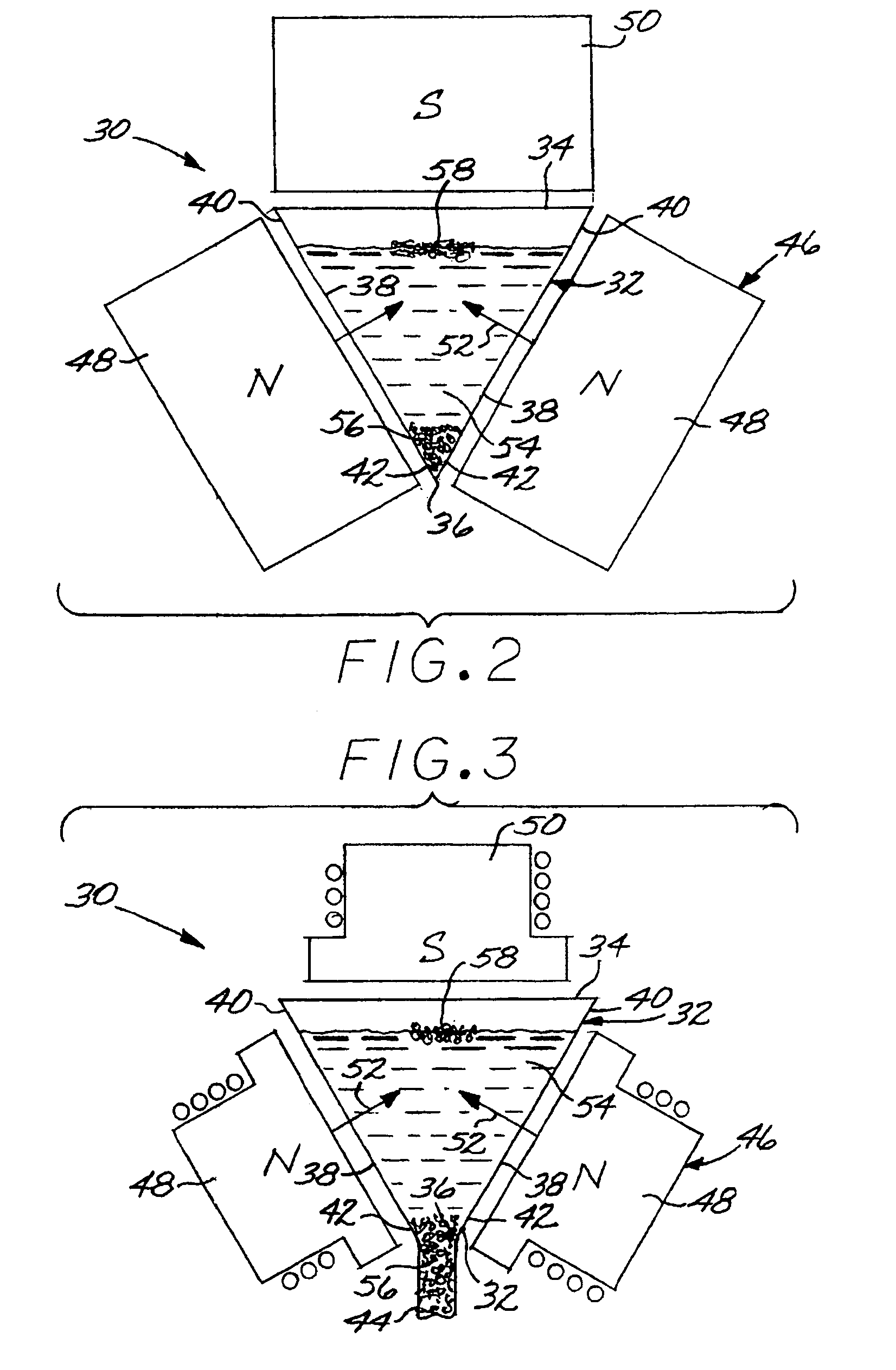

Method for magnetic/ferrofluid separation of particle fractions

InactiveUS20050178701A1Easy to collectEasy to cleanElectrostatic separationHigh gradient magnetic separatorsParticulatesChemical physics

A particulate feed comprising a first particle type and a second particle type is separated by providing a separation apparatus having a separation vessel having a top and a bottom, and wherein the separation vessel includes inwardly sloping side walls. A magnet structure has a first pole positioned exterior of and adjacent to each of the side walls of the separation vessel, and a second pole positioned above the separation vessel. A mixture of the particulate feed and a ferrofluid is introduced into the separation vessel, and the particulate feed is separated into a first particle fraction comprising a majority of the first particle type, which sinks in the separation vessel, and a second particle fraction comprising a majority of the second particle type which floats in the separation vessel.

Owner:GENERAL ELECTRIC CO

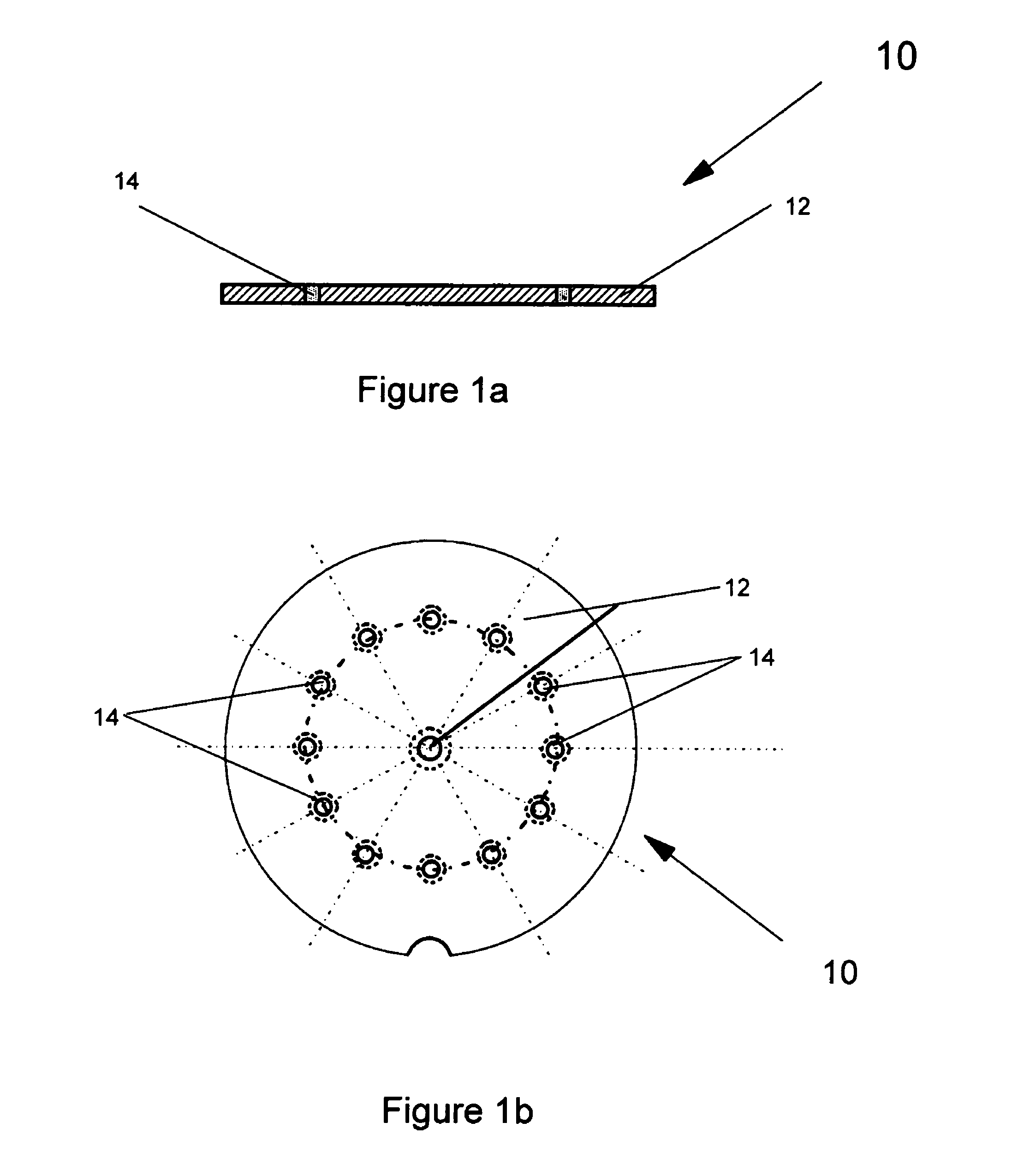

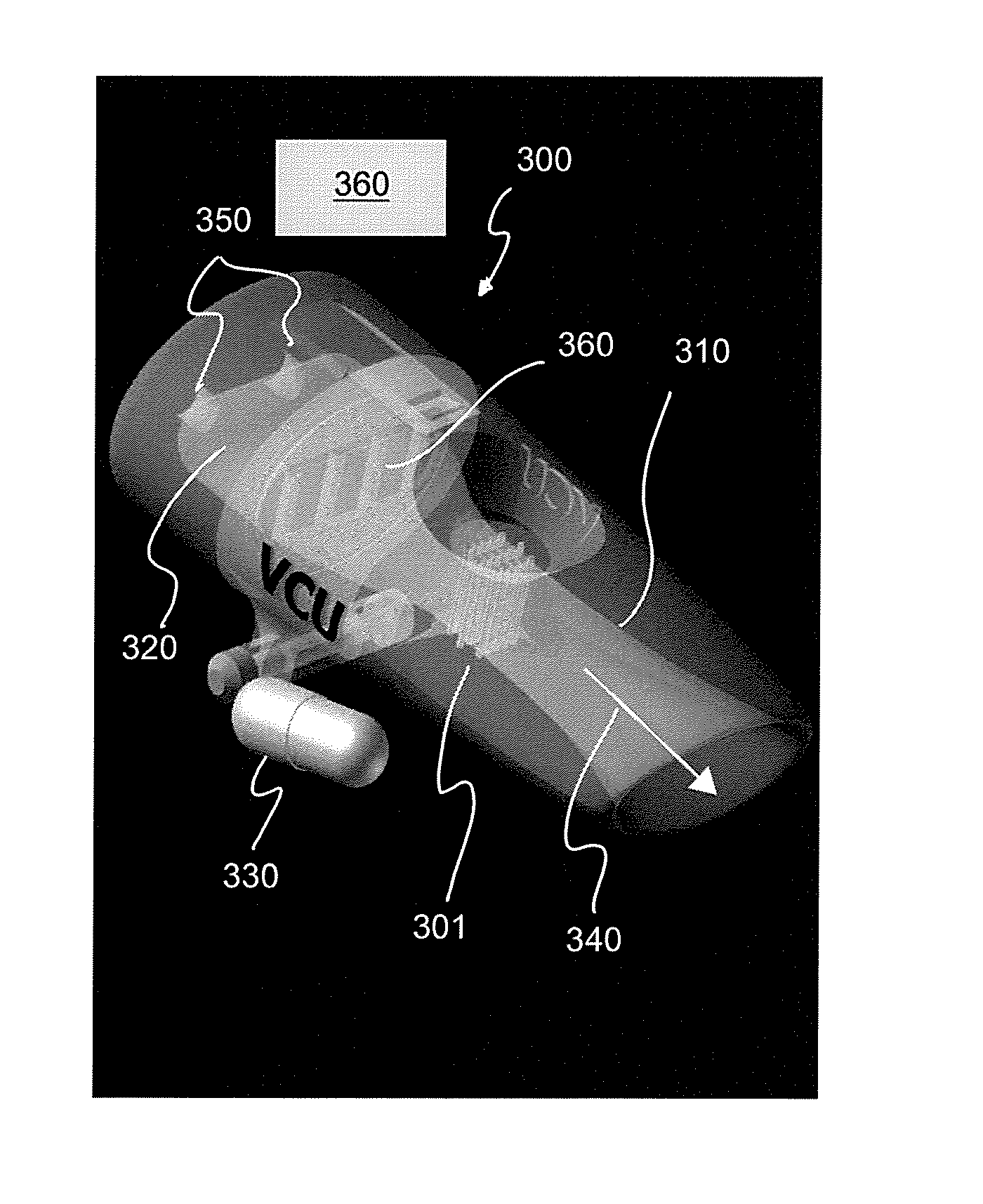

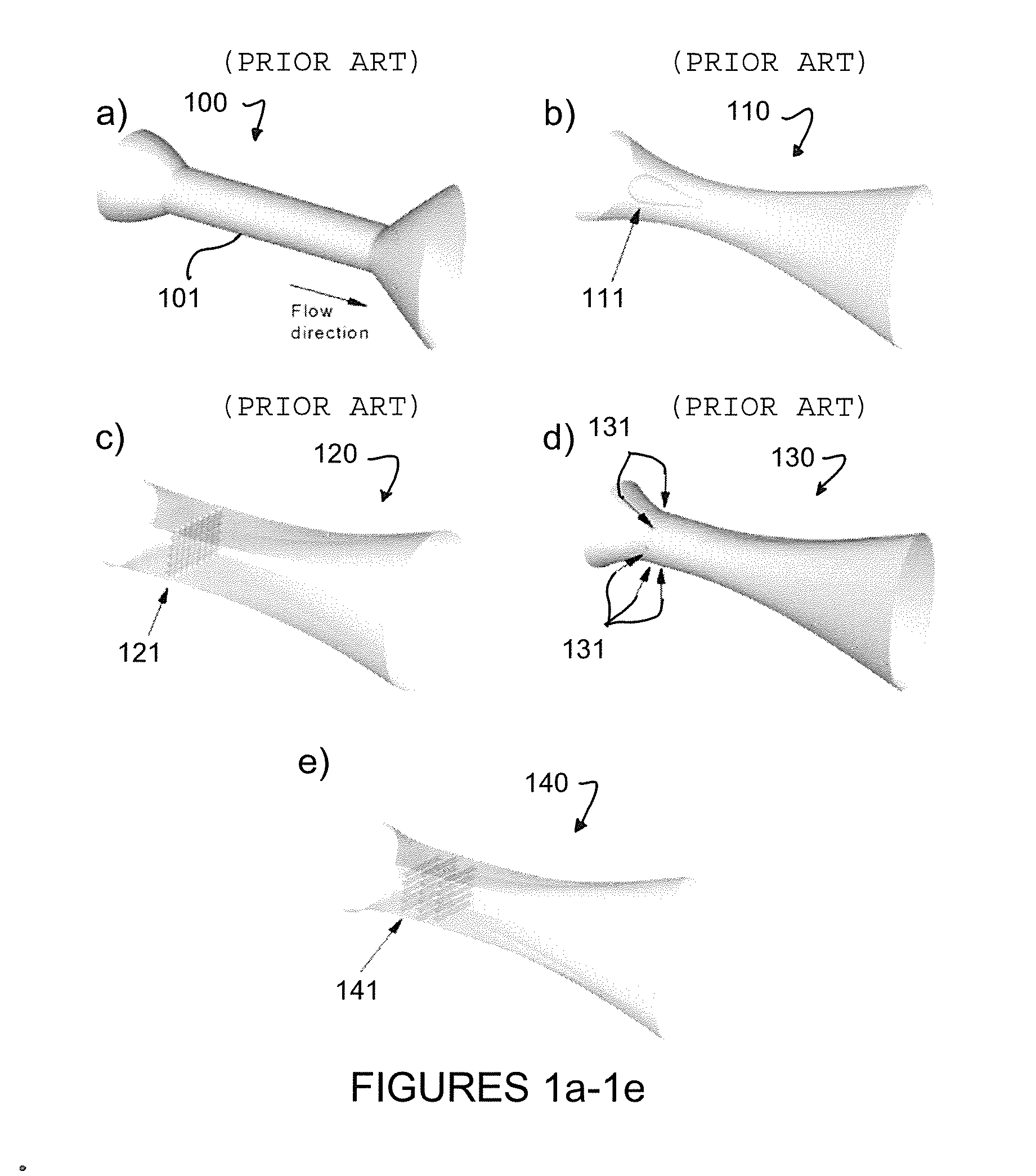

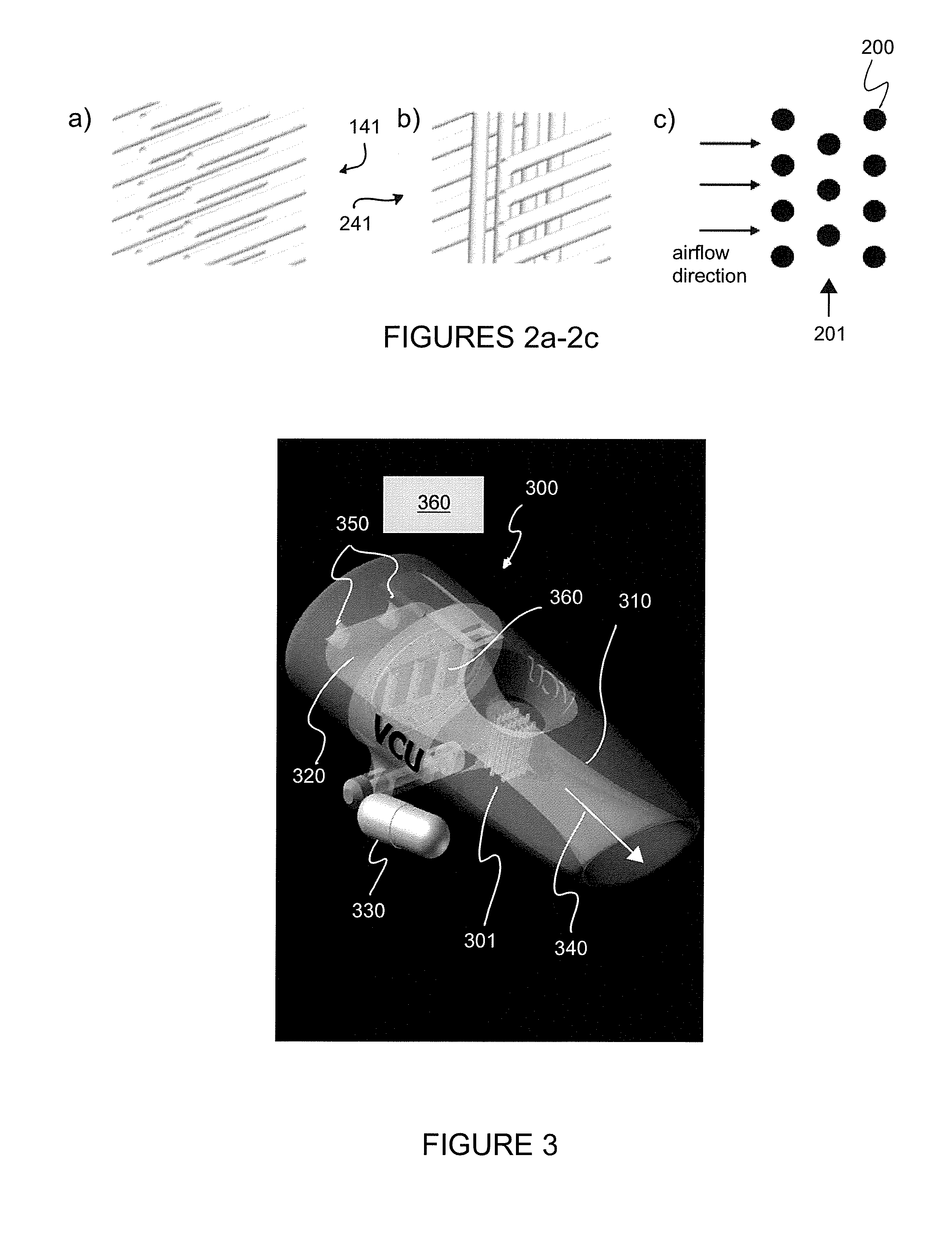

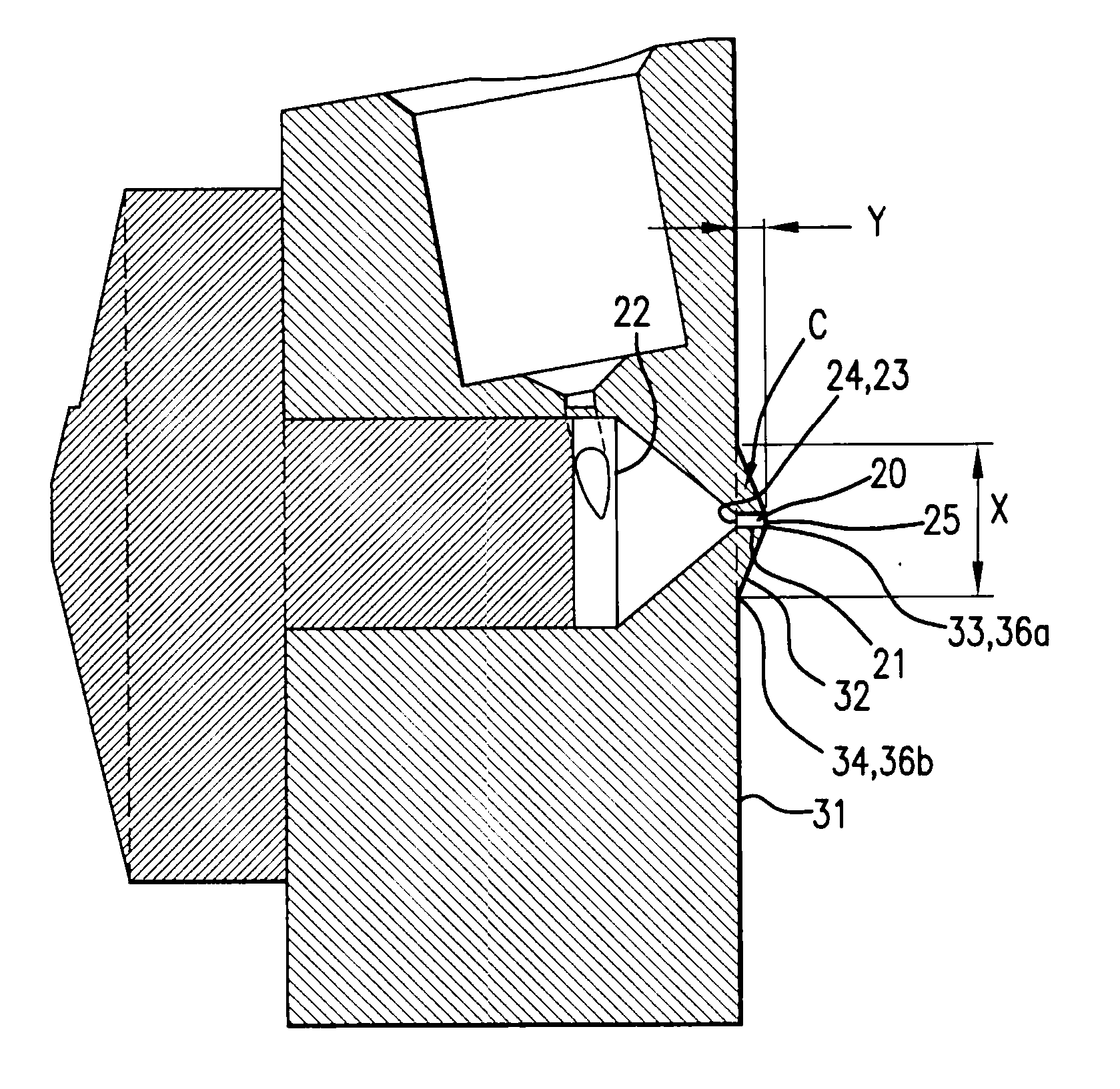

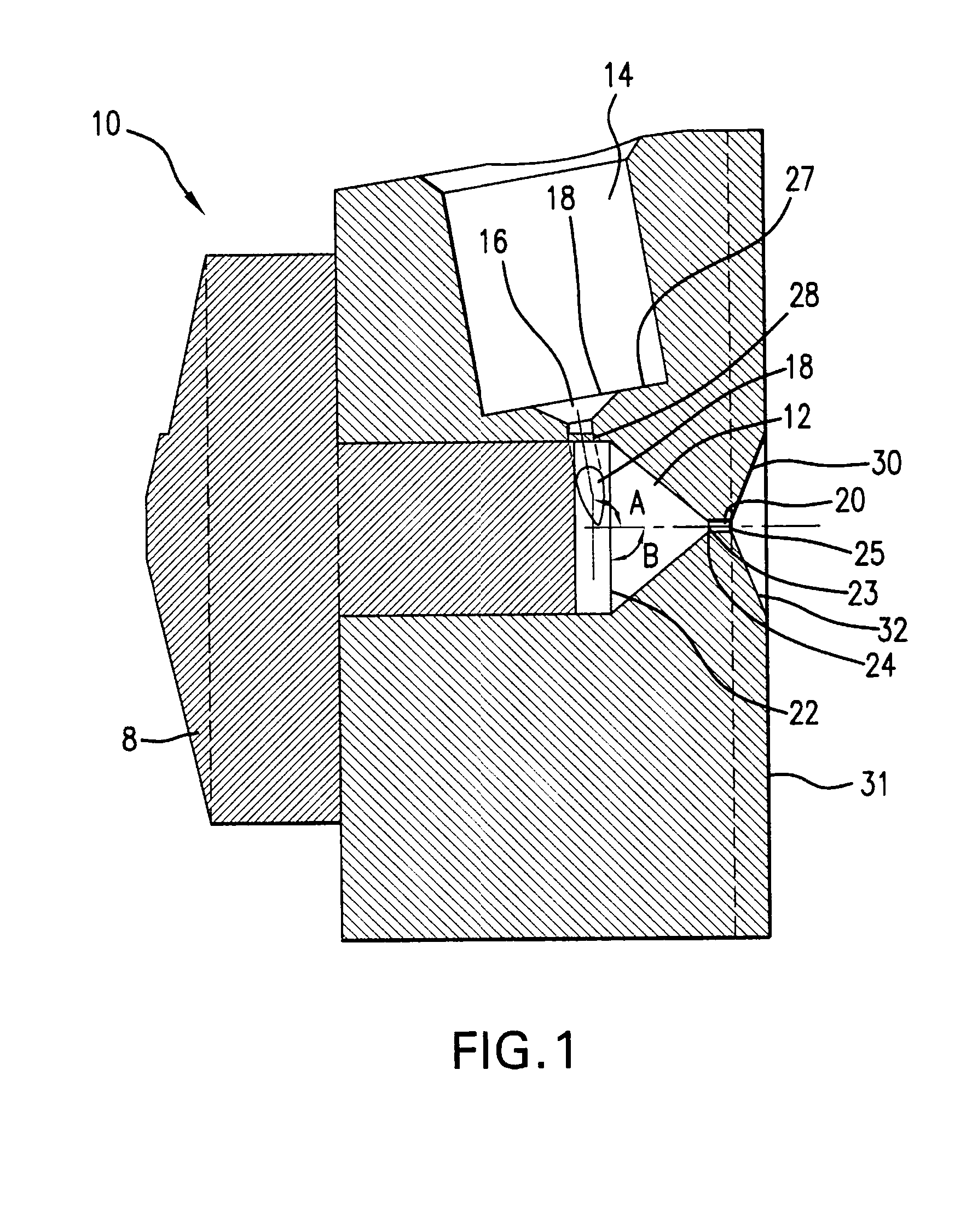

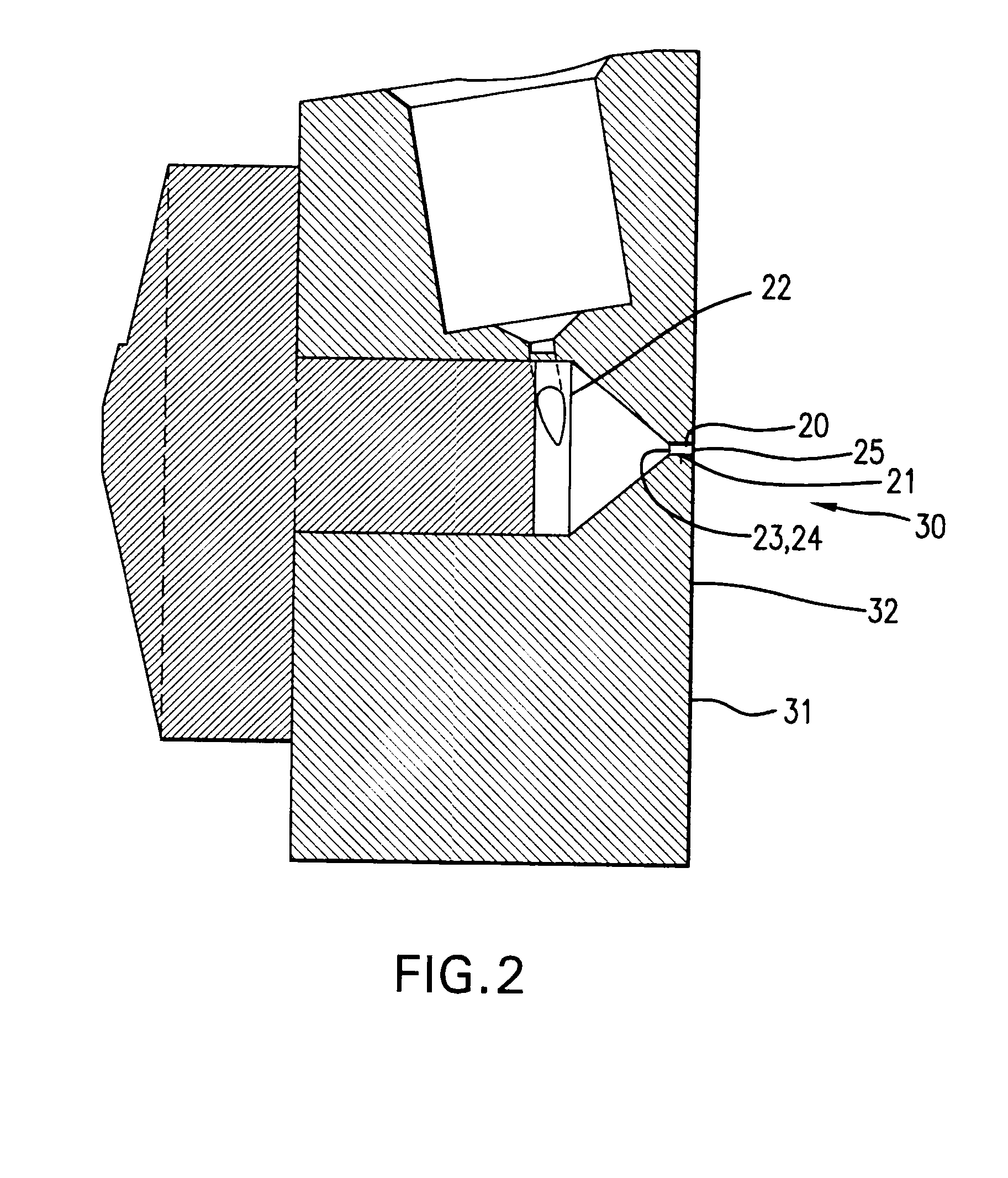

Dry powder inhaler (DPI) designs for producing aerosols with high fine particle fractions

ActiveUS20150107589A1Better placementGood dispersionOrganic active ingredientsBiocideMedicineInhalation

A dry powder inhaler (DPI) device has a flow passage with a three-dimensional (3D) rod array. The rod array includes multiple rows each having multiple unidirectional rods. The rows are spaced apart along a primary direction of air flow and are staggered. A viewing window to the capsule chamber allows viewing of the capsule's position within the chamber which provides visual feedback of inhalation flow rate to the user during inhalation. The capsule chamber may orient the capsule parallel to a primary direction of air flow or perpendicular to a primary direction of air flow and provide capsule motion in a plane which is perpendicular to the primary direction of air flow.

Owner:VIRGINIA COMMONWEALTH UNIV

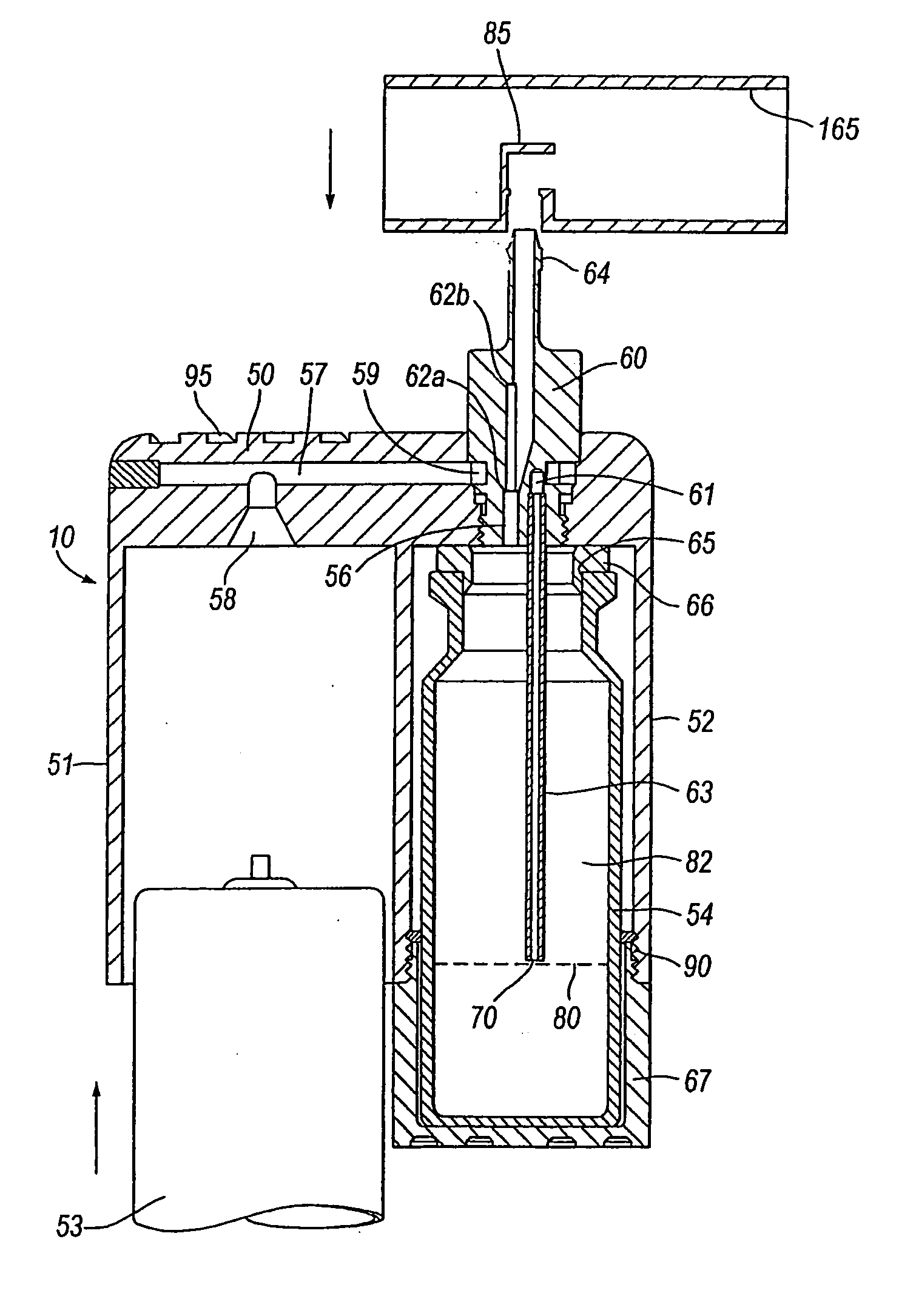

Novel dry powder inhalation system for transpulmonary administration

InactiveUS20060073105A1Reduce manufacturing costHigh fine particle fractionPowder deliverySpray deliveryFreeze-dryingMedicine

The present invention provides a novel dry powder inhalation system suitable for transpulmonary administration. The dry powder inhalation system of the present invention characterized by using a combination of: (1) a vessel housing a freeze-dried composition prepared by freeze-drying a composition liquid containing ingredients in a non-dissolved form, and has: (i) a non-powder cake-like form, (ii) a disintegration index of 0.05 or more, and (iii) a property of becoming fine particles having a mean particle diameter (mass median aerodynamic diameter) of 10 microns or less or a fine particle fraction of 10% or more upon receipt of an air impact having an air speed of at least 1 m / sec and an air flow rate of at least 17 ml / sec; and (2) a device comprising a member capable of applying said air impact to the freeze-dried composition in said vessel, and a member for discharging the powder-form freeze-dried composition that has been made into fine particles.

Owner:OTSUKA PHARM CO LTD

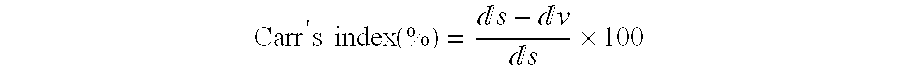

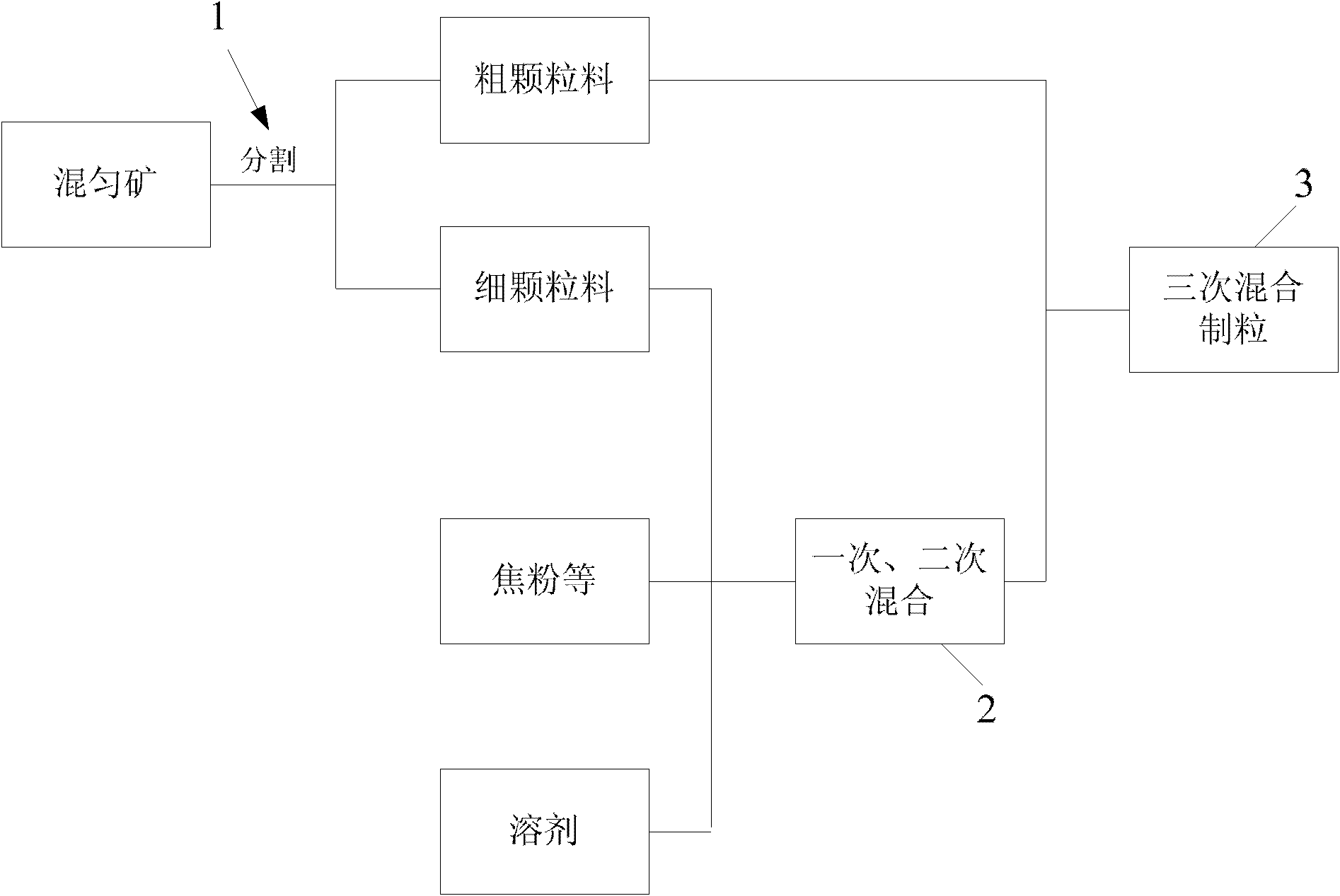

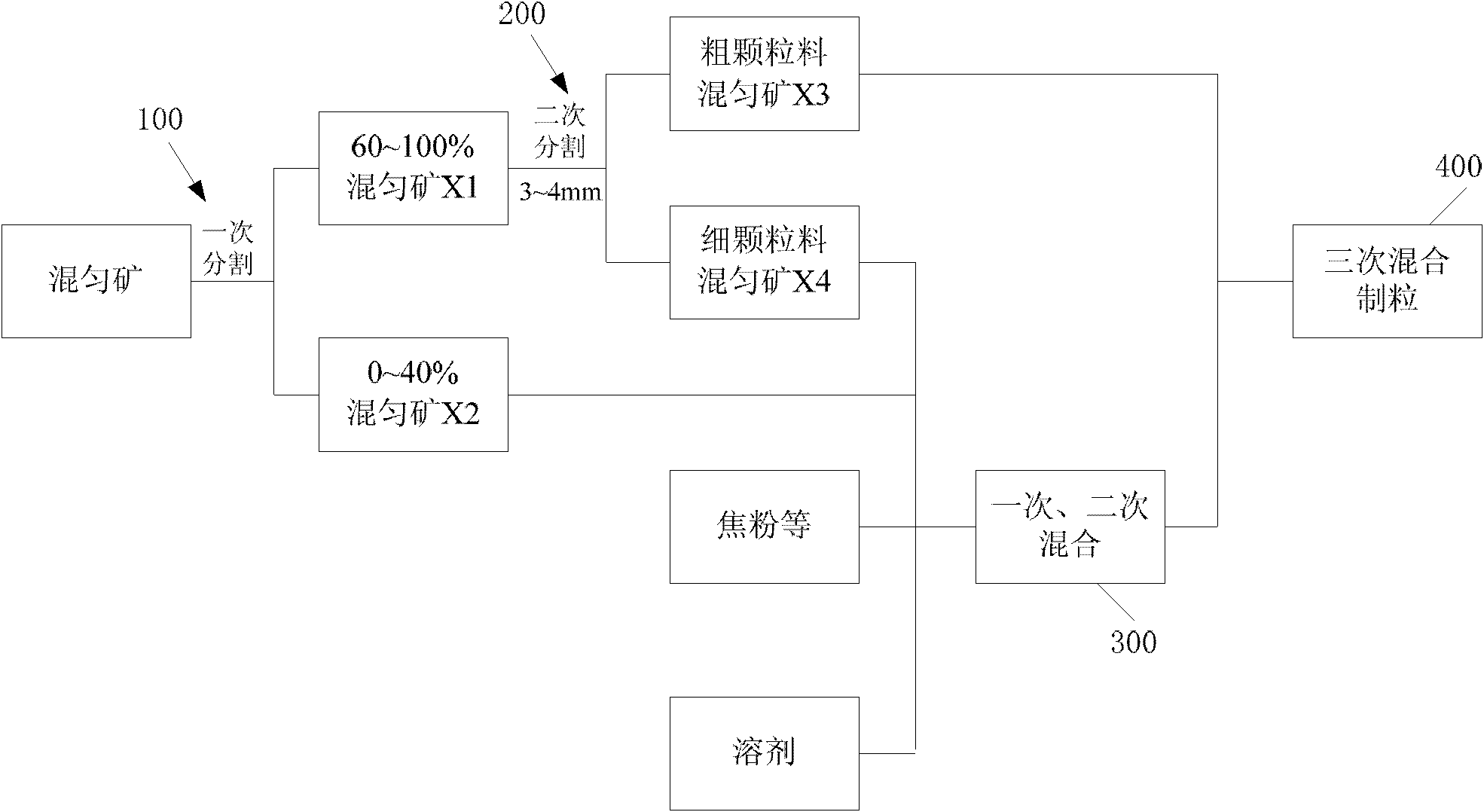

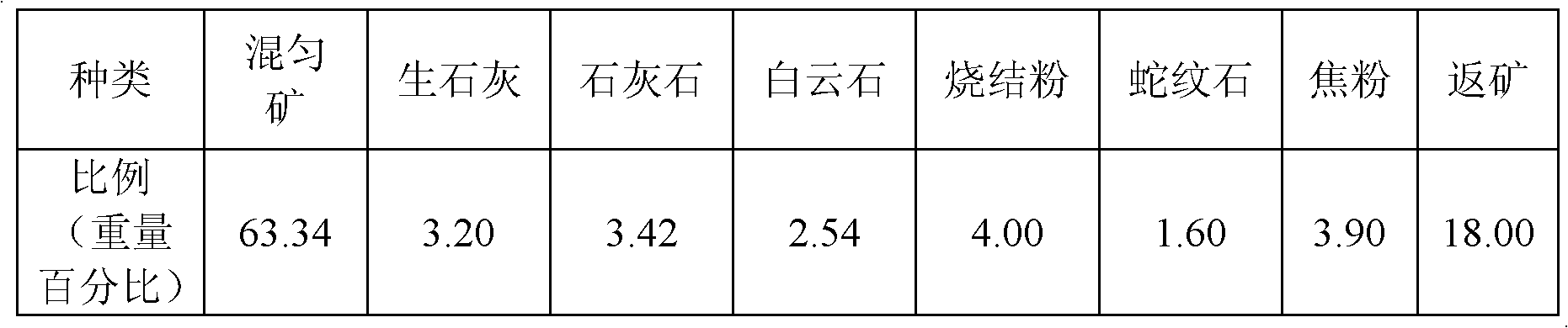

Sinter mixture granulating method

InactiveCN102719659AIncreased chances of granulationImprove granulation effectMetallurgyParticle fraction

A sinter mixture granulating method comprises following steps: 1) a blending ore is applied as a granulating raw material; 2) the blending ore is segmented into two parts according to a particle fraction of 3.0-4.0 mm. The blending ore whose particle fraction is less than 3.0-4.0 mm is subjected to a primary and a secondary mixing granulation with other conventional ingredients of preparing a sinter mixture. 3) the particles obtained from the secondary mixing granulation are added into the blending ore having the particle fraction greater than 3.0-4.0 mm obtained by the segmentation before, and subjected to a tertiary mixing granulation. The method can improve granulating effects for the sinter mixture, improve permeability of a material layer in a sintering process, optimize a sintering state and reach an ideal producing technique index finally.

Owner:BAOSHAN IRON & STEEL CO LTD

Delivery device for a powder aerosol

InactiveUS20070056586A1Improve efficiencyPromote activationRespiratorsLiquid surface applicatorsMedicinePowder Aerosol

A delivery device for a medicament including: a housing, a receptacle holding a medicament in the form of a power; and a source of propellant, wherein the housing provides an inlet and an outlet for the receptacle, wherein the inlet is in fluid communication with the source of propellant and is directed against the medicament and the outlet is spaced from the medicament to allow aerosolization of the medicament; the device provides improved delivery efficiency, particularly a delivered fine particle fraction of greater than 20% by weight.

Owner:AIRPHARMA

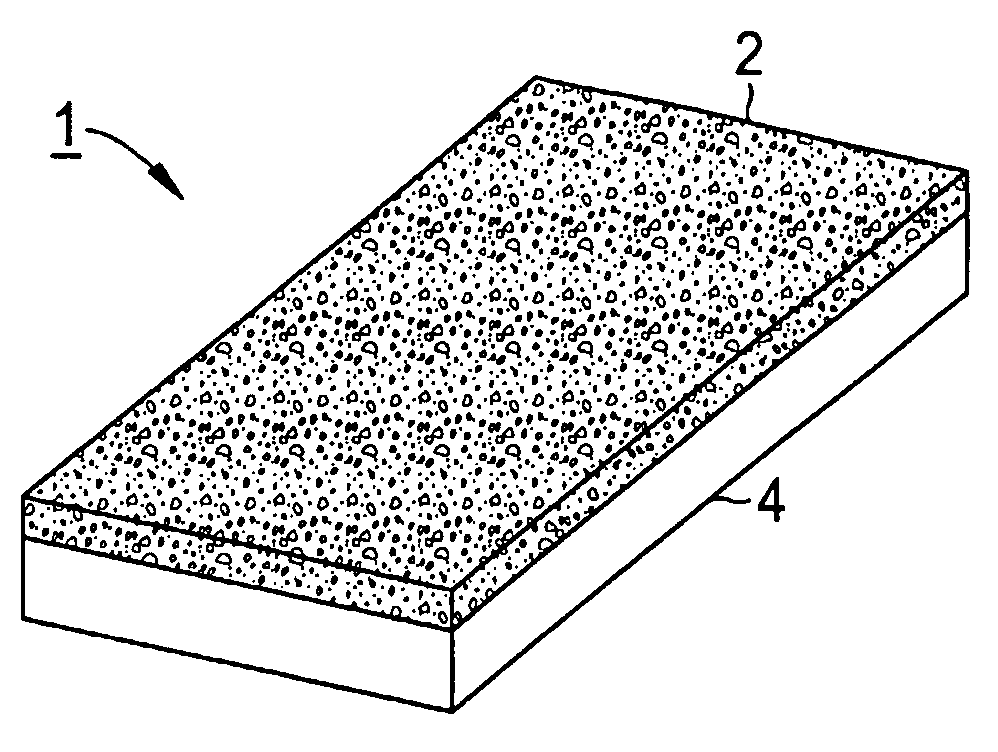

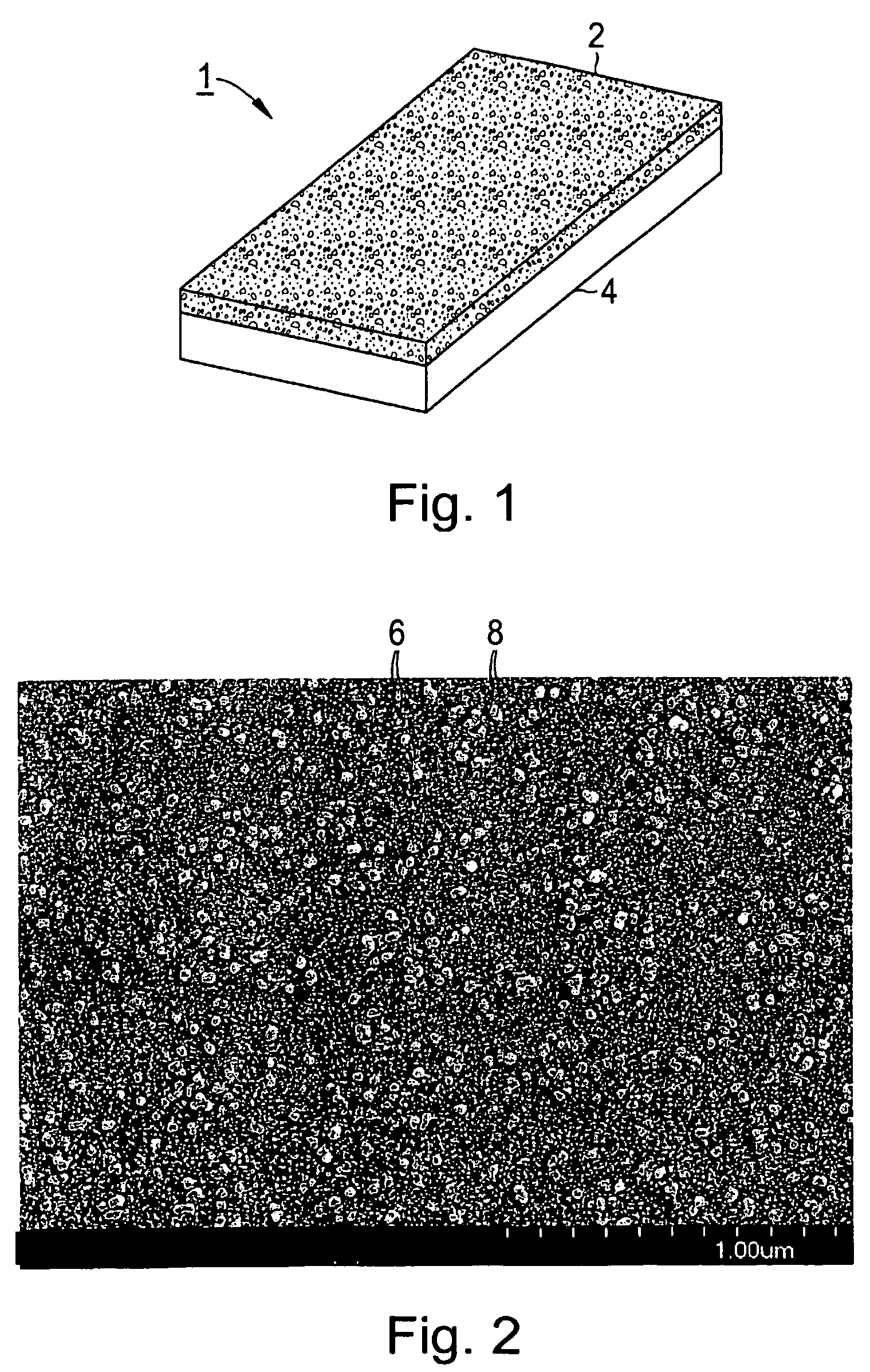

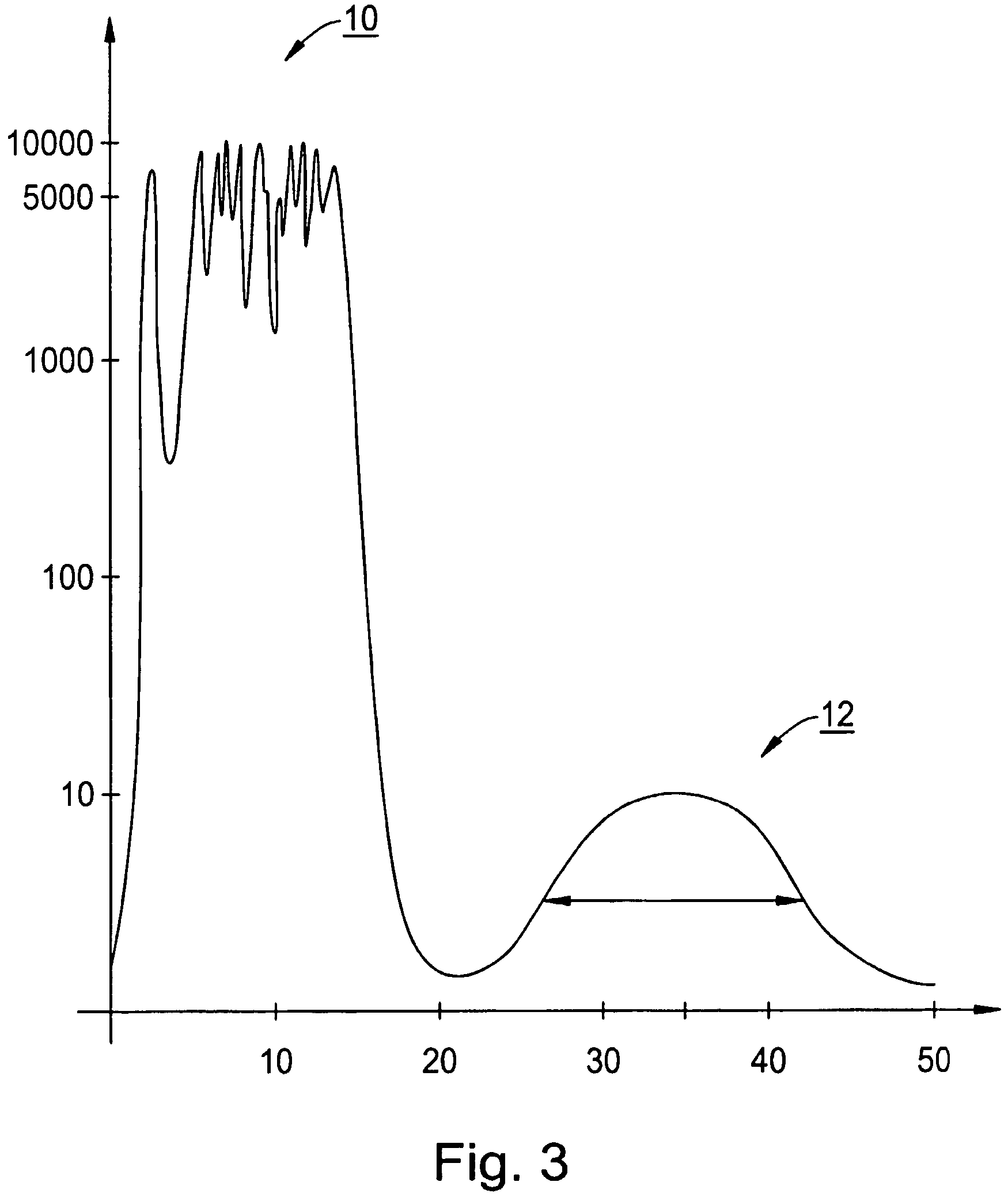

Glass having a porous anti-reflection surface coating and method for producing such glass

InactiveUS7575809B2High-quality optical propertyImprove mechanical propertiesSolar heat devicesSolar ray transmission and prevent heat radiationMetallurgyParticle fraction

A coated glass product includes a glass substrate and a porous antireflection surface coating including SiO2-based particles having a first particle fraction including a first characteristic particle size range and a second particle fraction having a second characteristic particle size range that is different from the first characteristic particle size range. In addition, a method for producing the coated glass product is provided.

Owner:DUCATT NV +1

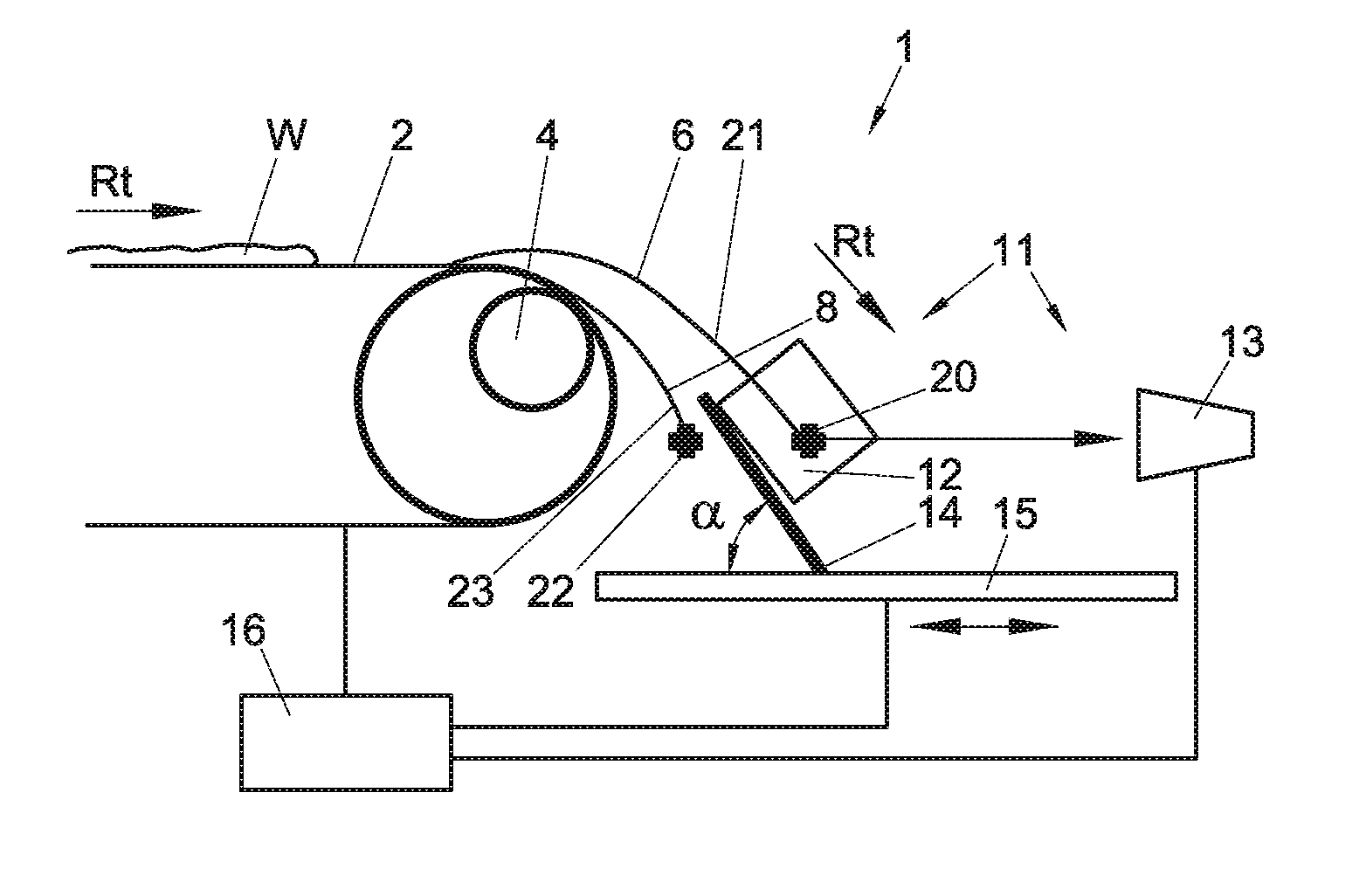

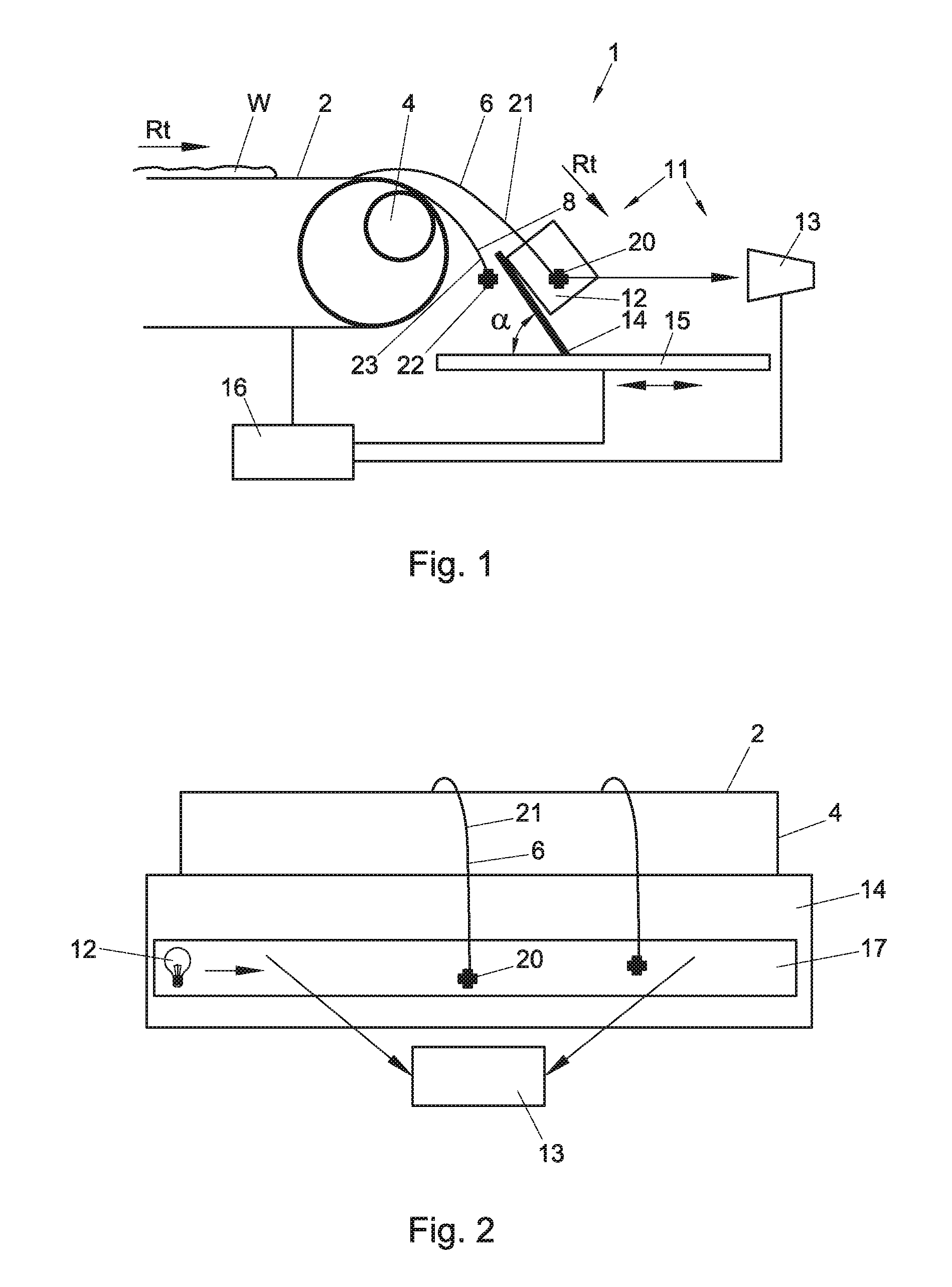

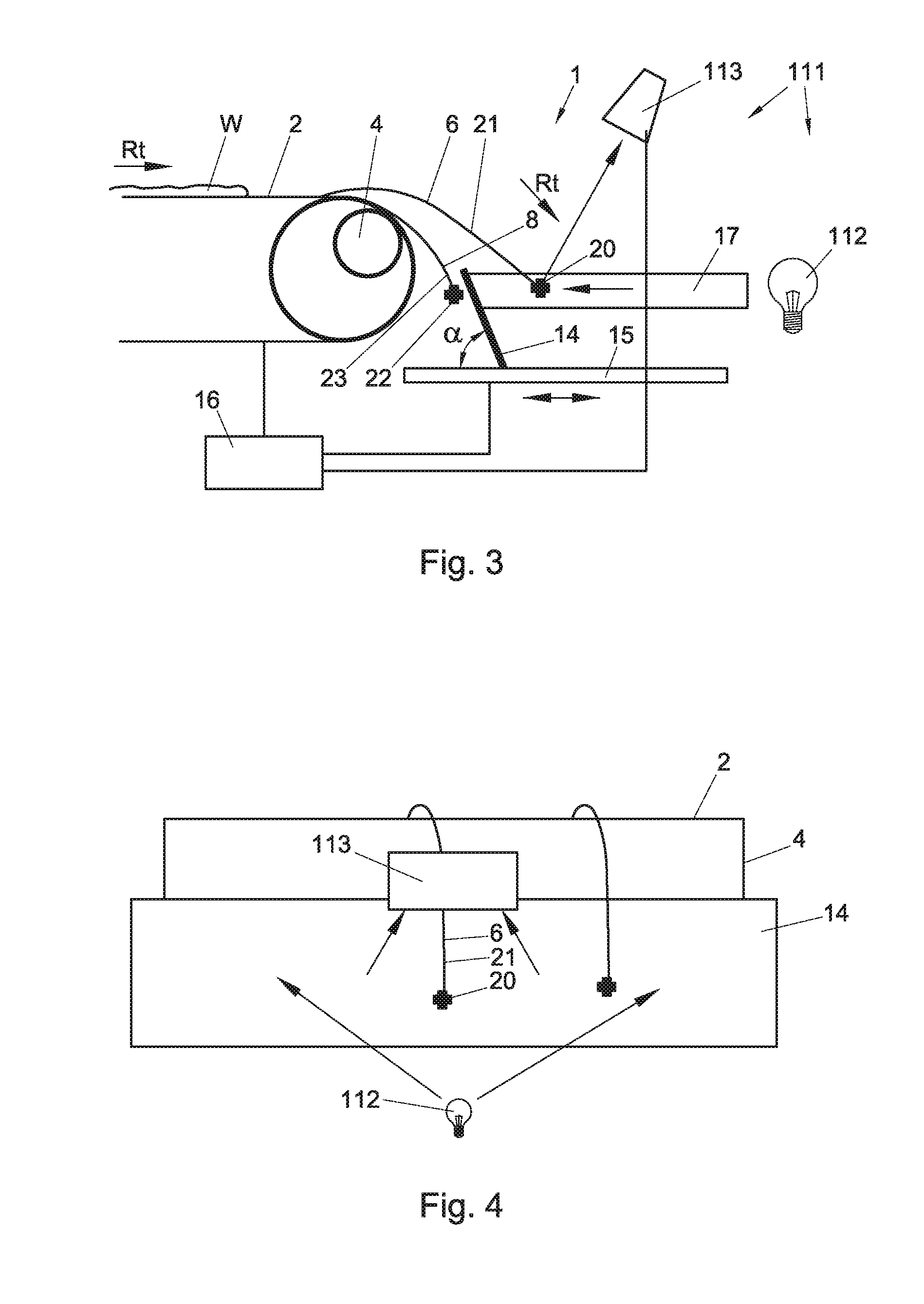

Eddy current separation apparatus, separation module, separation method and method for adjusting an eddy current separation apparatus

InactiveUS20150108047A1Easy to adjustHigh purityElectrostatic separationMagnetic separationEngineeringEddy current

Eddy current separation apparatus (1) for separating particles (20) from a particle stream (w), wherein the apparatus (1) comprises a separator drum (4) adapted to create a first particle fraction (21) and a second particle fraction (23), a feeding device (2) upstream of the separator drum (4) for supplying particles (20) to said separator drum (4), and a splitter element (14) provided downstream of the separator drum (4) for splitting the respective fractions (21,23), wherein the apparatus (1) further comprises a sensor device (11,111,211) arranged for detecting particles (20), at least a number and / or material properties thereof, from at least part of one of the particle fractions (21), wherein the separation apparatus (1) is configured to adjust, in use, a position and / or orientation of the splitter element (14) with respect to the separator drum (4) and / or a transporting velocity of the feeding device (2) in dependence of a signal from the sensor device (11,111,211) based on the number and / or material properties of the detected particles (20).

Owner:ADR TECH

Method for the production of magnet cores, magnet core and inductive component with a magnet core

InactiveUS8287664B2Freeze fastReduce field strengthInorganic material magnetismTransformers/inductances detailsInductorNanocrystal

A magnet core is required to be particularly dense, made of alloys produced in a rapid solidification process and have a minimal coercitive field strength. To achieve these aims, a coarse-grain powder fraction is first produced from an amorphous strip of a soft magnetic alloy. In addition, at least one fine-grain powder fraction is produced from a nanocrystalline strip of a soft magnetic alloy. The particle fractions are then mixed to produce a multi-modal powder, wherein the particles of the coarse-grain particle fraction have an amorphous structure and the particles of the fine-grain powder fraction have a nanocrystalline structure. The multi-modal powder is then pressed to produce a magnet core.

Owner:VACUUMSCHMELZE GMBH & CO KG

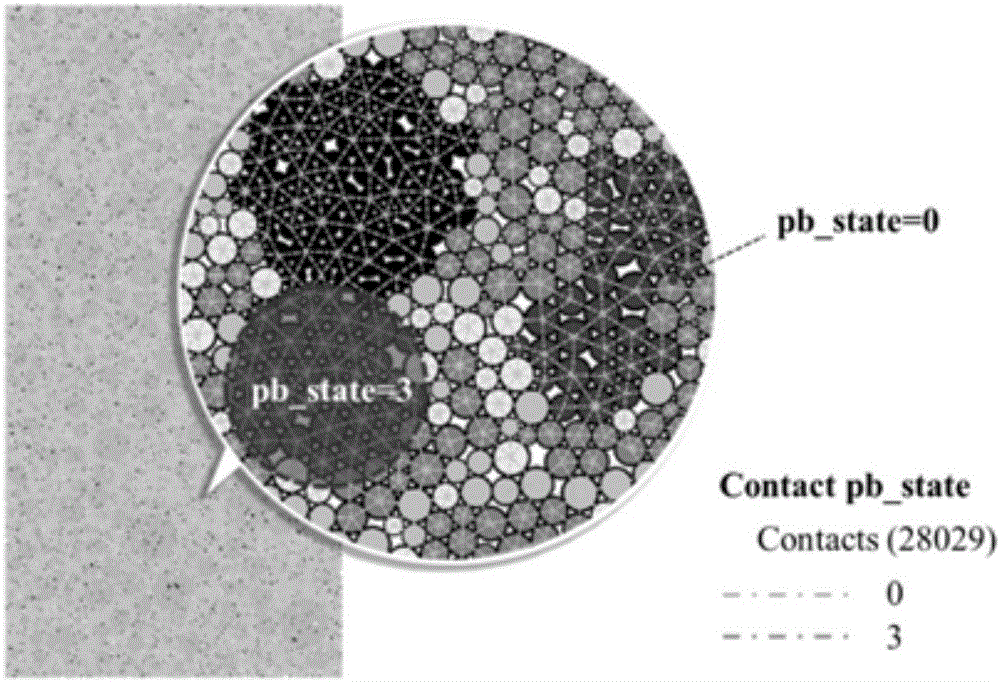

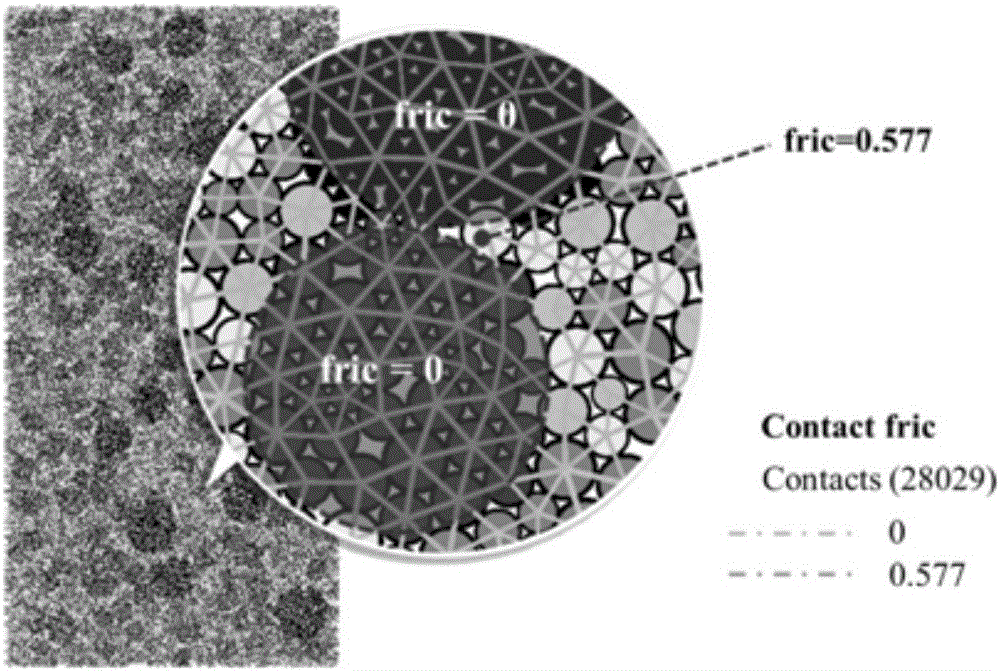

Construction method for two-dimensional discrete element model of mother rock and particle material thereof

ActiveCN105740532AGood simulation performanceImprove performanceSpecial data processing applicationsCAD numerical modellingPorosityElement modeling

The invention discloses a construction method for a two-dimensional discrete element model of a mother rock and a particle material thereof. The construction method comprises three steps of grading curve correction, mother rock test discrete element modeling and particle material discrete element modeling. The step of grading curve correction comprises the sub-step of redistributing the mass of a smallest particle fraction to the remaining particle fractions according to the quality ratio of particles of particle fractions except the particle fraction of a finest stage in a grading curve to obtain a correction simulation curve in a computer operation simulation range and a particle diameter range of basic particle units. The particle material discrete element modeling comprises the sub-step of: firstly, randomly generating a rock area outline; secondly, forming a rock unit from the basic particle units; thirdly, assigning contact attributes in rocks; finally, assigning the contact attributes between the rocks. In rock aggregation generated according to the construction method, good randomness and diversity are available for the particle number and the form of composed rocks and the actual outline of the rocks; the rock size is generated according to a certain grading condition and satisfies the requirement of certain porosities.

Owner:重庆山渝道科技有限公司

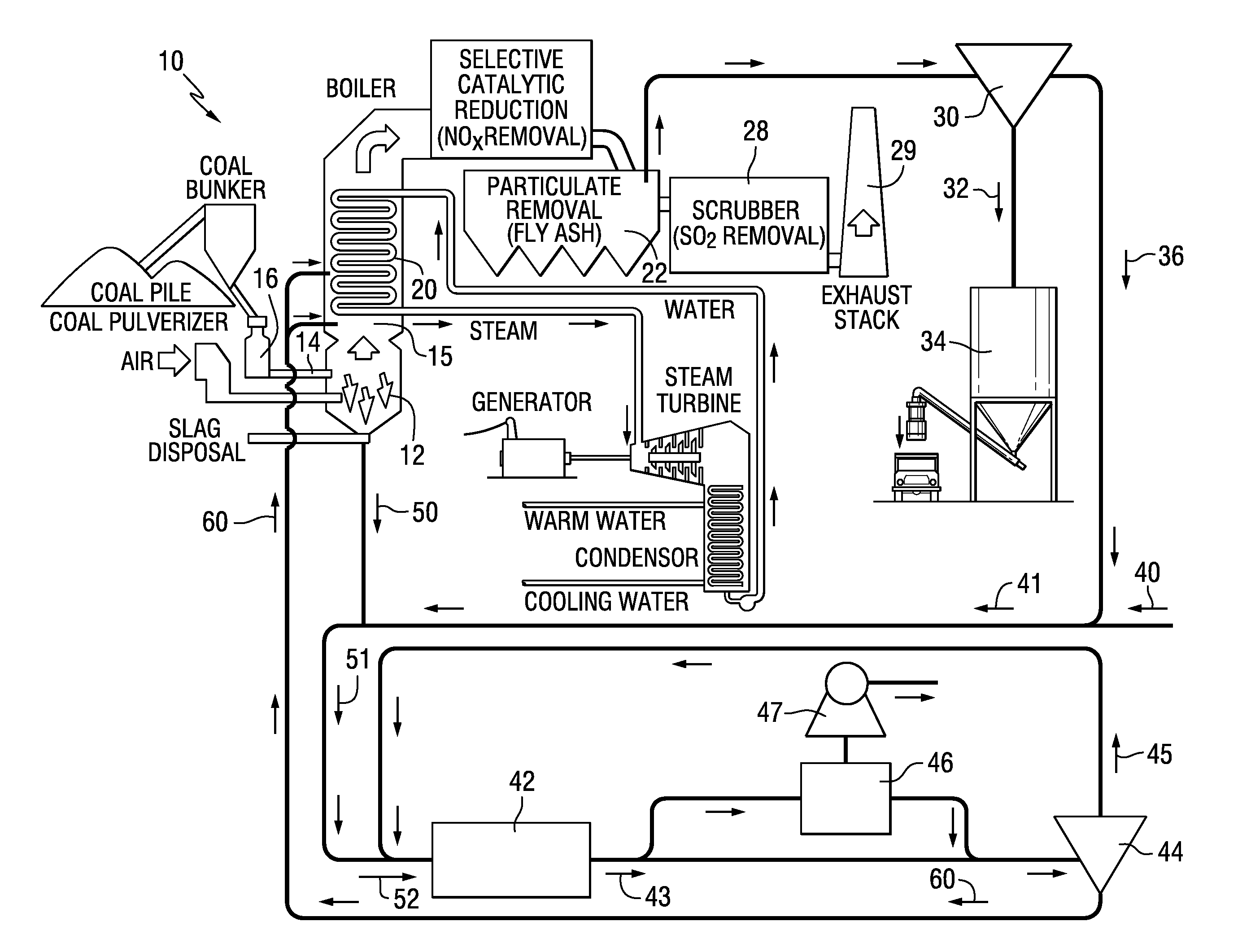

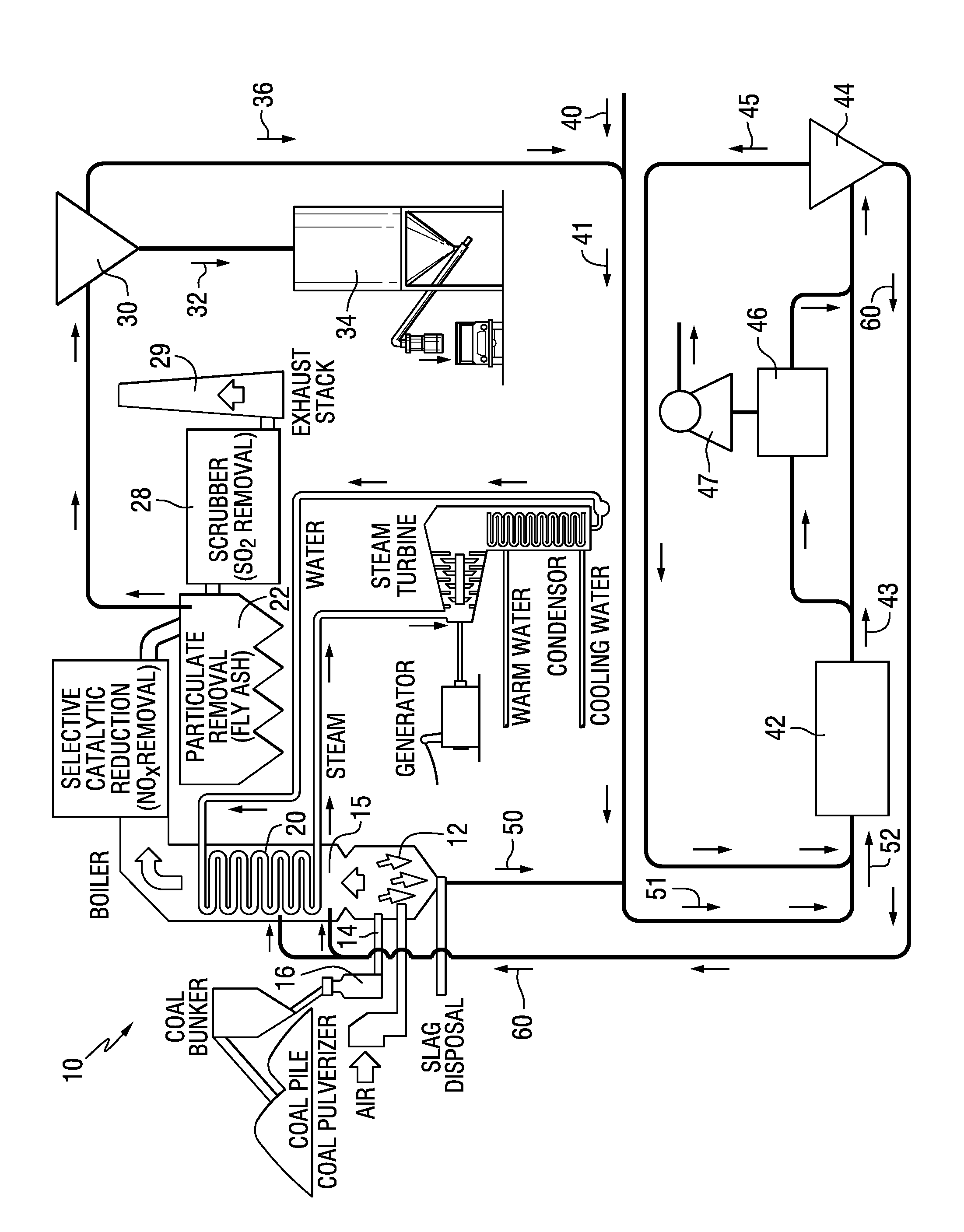

Systems and methods for comminuting and recirculating coal combustion products

InactiveUS20130125799A1Reduce contentSpeed up developmentSolid waste managementCocoaProcess engineeringComminution

A method and system for reducing the un-burned carbon content in coal combustion products are disclosed. A coal combustion product is separated into a coarse particle fraction and a fine particle fraction, and the coarse particles are comminuted by milling, grinding or the like. Additives may be added of the coarse particles prior to comminution. The comminuted particles are then co-combusted with coal to burn at least a portion of the un-burned carbon contained in the original coal combustion product.

Owner:ASH IMPROVEMENT TECH

Nozzle-based atomization system

InactiveUS20080203193A1High fine particle fractionModest throat depositionMovable spraying apparatusMedical devicesParticle fractionAerosol

An improved atomization system for aerosolizing liquids including a vortexing nozzle and a flat or protruding face on the nozzle exit orifice. The system can also include a diverging mouthpiece insert. The present invention can produce a high fine particle fraction and modest throat deposition in conjunction with reduced aerosol plume velocity and impact force.

Owner:ABBOTT LAB INC

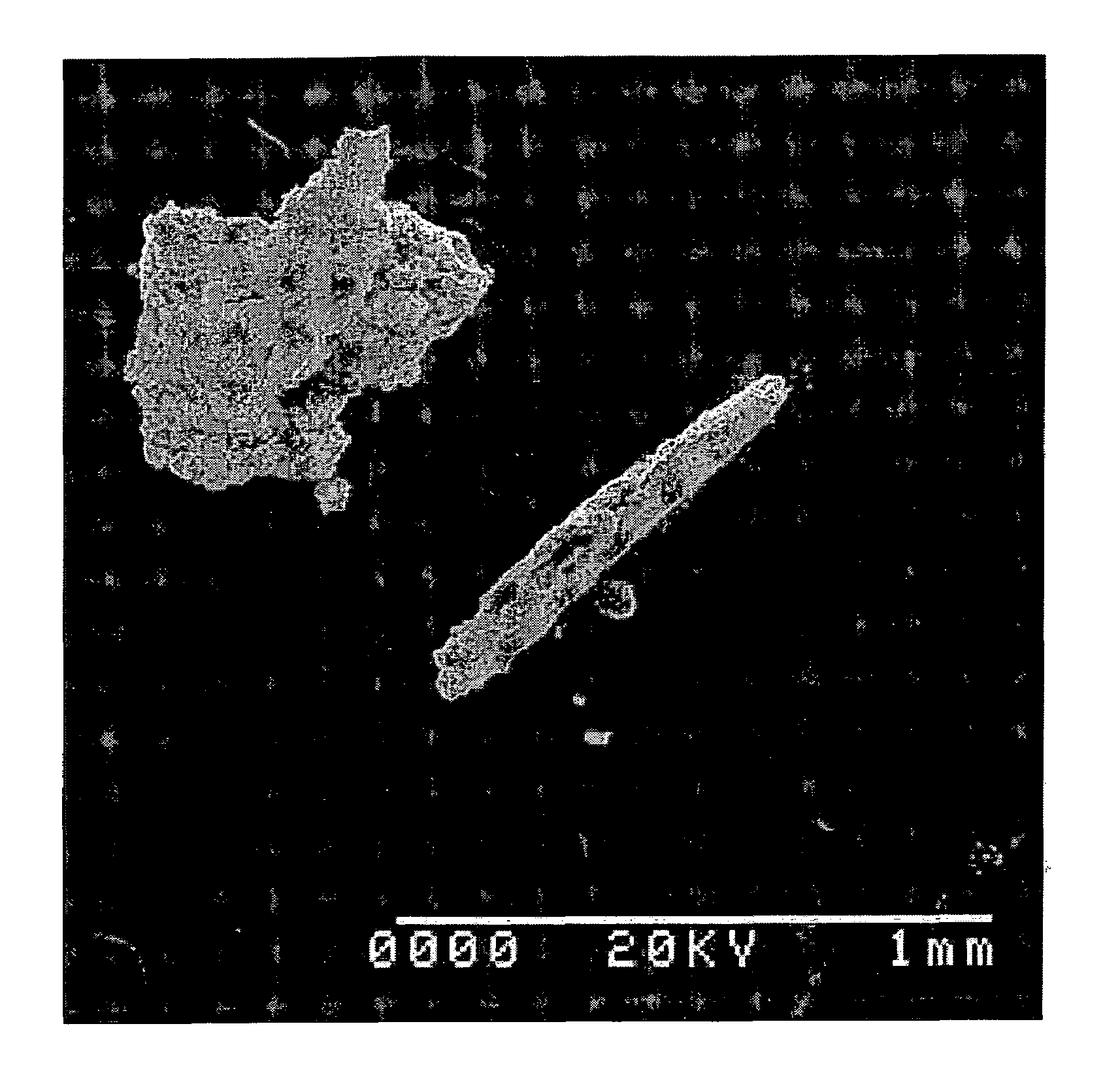

In-situ BWR and PWR CRUD flake analysis method and tool

InactiveUS7304301B1Material analysis using wave/particle radiationNuclear energy generationScanning electron microscopeEngineering

The invention provides a method and tool to perform an analysis of CRUD on a nuclear fuel rod. The method recites providing a nuclear fuel rod with a layer of CRUD on an exterior of the fuel rod, scraping the CRUD from the fuel rod with a CRUD scraping tool and collecting CRUD flakes from the CRUD scraping tool. The method also provides for sorting the CRUD flakes into particle fractions, and analyzing the CRUD with a scanning electron microscope, wherein the scraping tool has a blade with a rigidity that is matched to an anticipated CRUD deposit shear strength.

Owner:FRAMATOME ANP RICHLAND

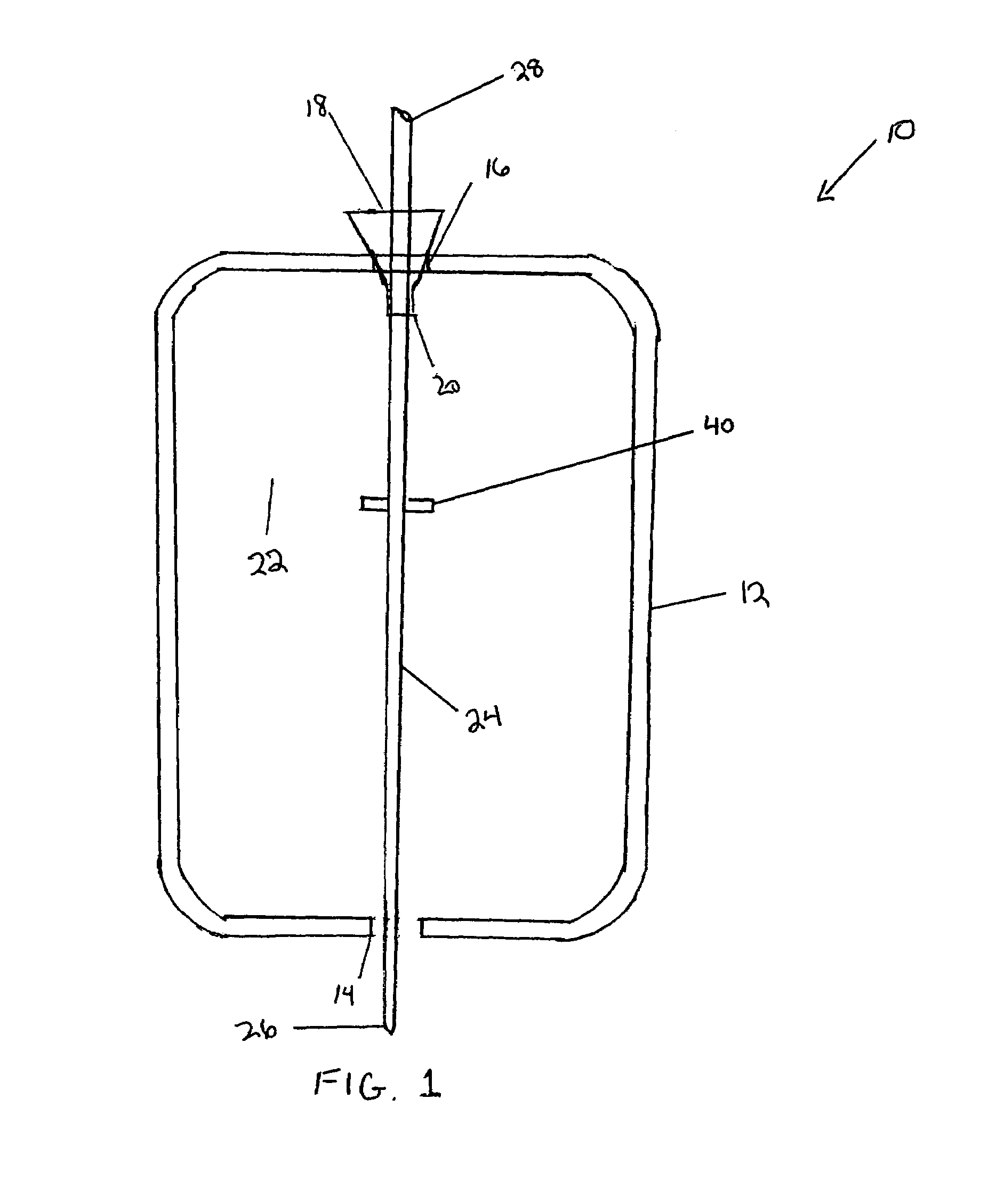

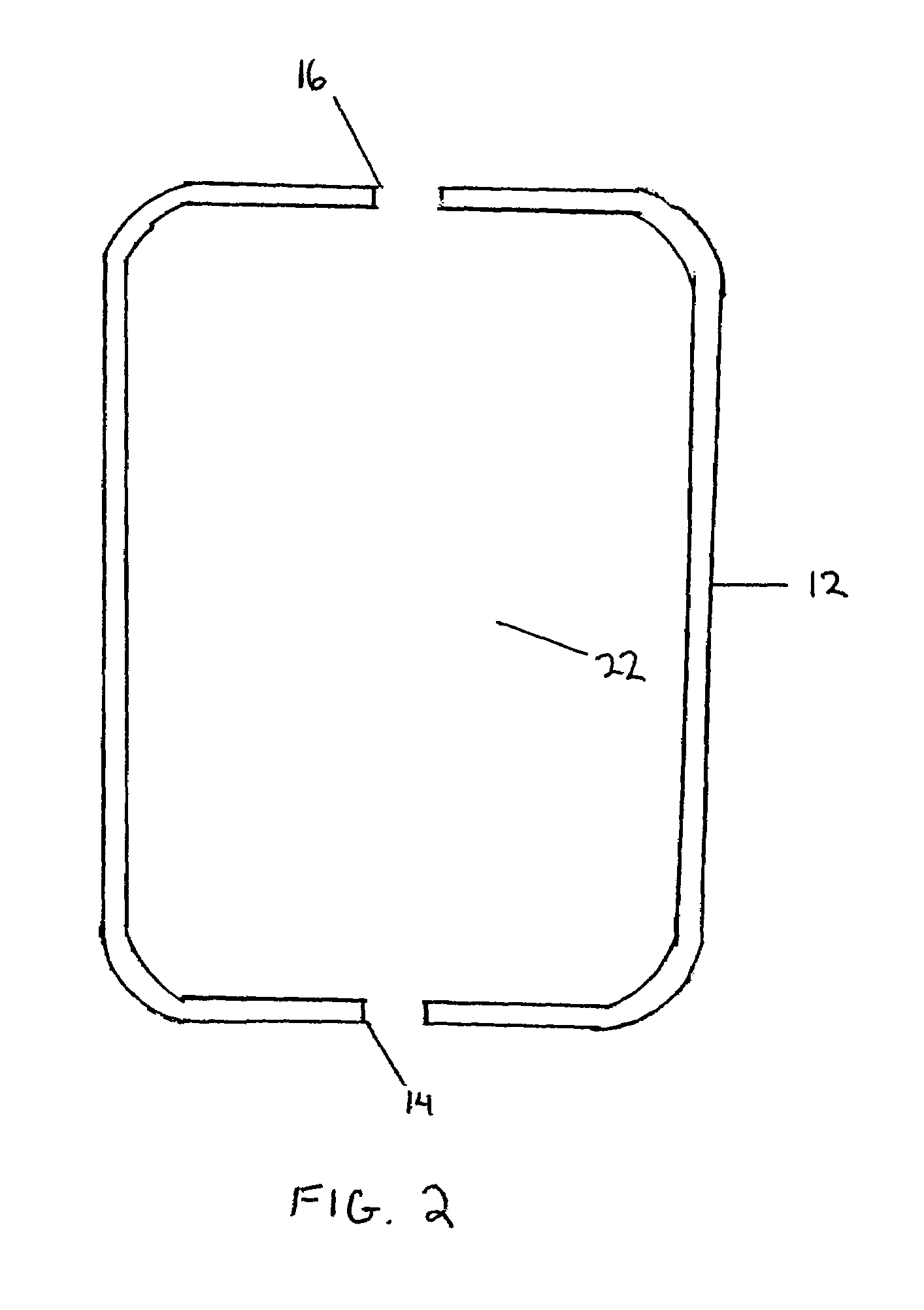

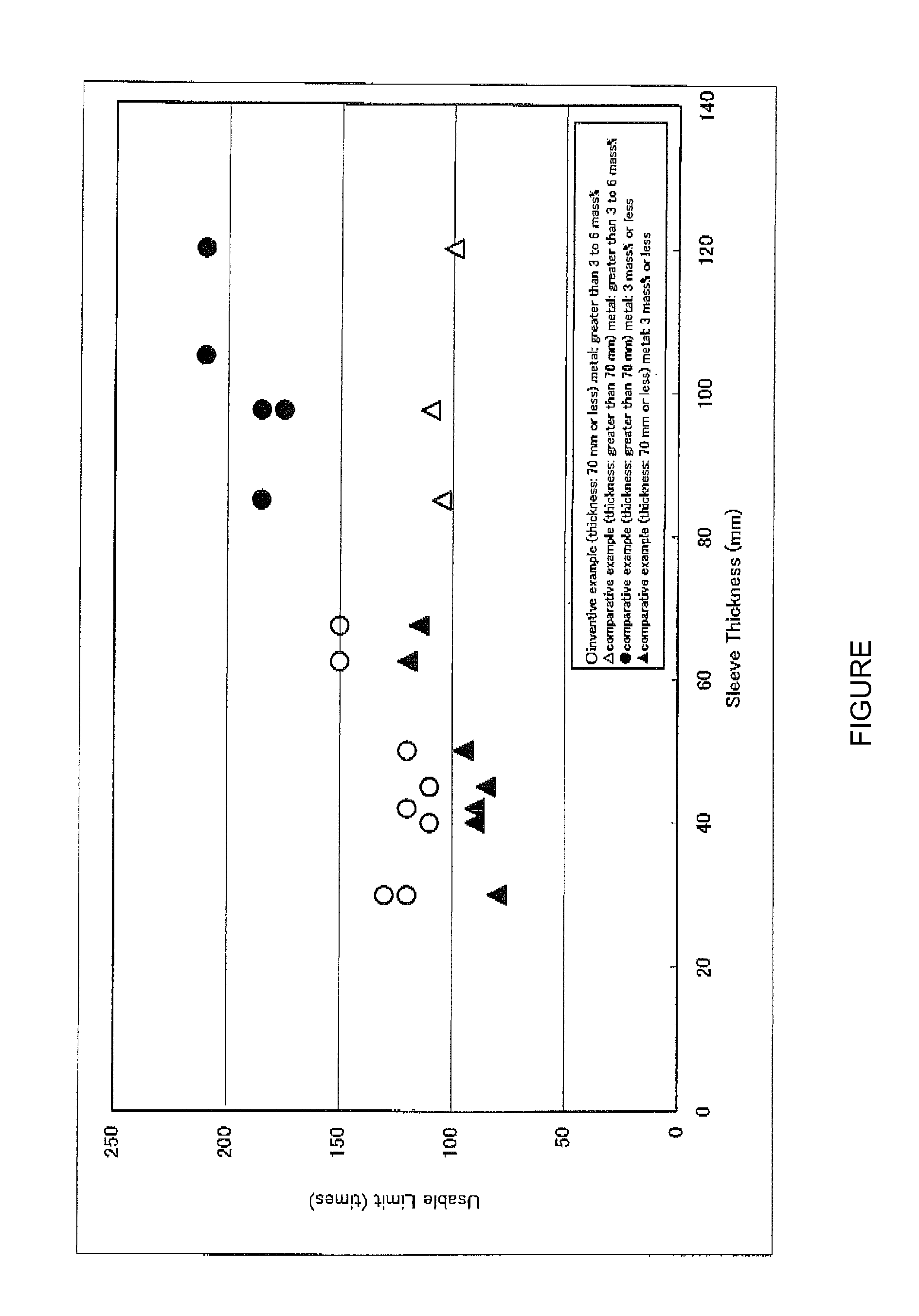

High-durability sleeve bricks

ActiveUS8093169B2Increased durabilityReduce frequencyTransportation and packagingBlast furnace componentsSteelmakingBrick

Disclosed is a magnesia-carbon based sleeve brick for steelmaking converters, which is obtained by adding, to a refractory raw material mix containing 60 to 95 mass % of a magnesia raw material and 5 to 20 mass % of graphite, a metal powder of one or more selected from the group consisting of Al, Si, Mg, Ca, Cr and an alloy thereof, in an amount of greater than 3 to 6 mass %, and an organic binder, in addition to 100 mass % of the refractory raw material mix, and subjecting the resulting mixture to kneading, forming and heat treatment, wherein the sleeve brick is used under a condition that a thickness thereof is set at 70 mm or less. This makes it possible to prevent cracking which would otherwise occur in the sleeve brick itself, to allow the sleeve brick to have enhanced durability. One or more selected from the group consisting of B, B4C, MgB2, CaB6, and CrB may be further added in an amount of 0.1 to 3 mass %, in addition to 100 mass % of the refractory raw material mix, to enhance strength and oxidation resistance and further enhance the durability. The magnesia raw material may comprise a first particle fraction having a particle diameter of greater than 10 to 500 μm and occupying 20 to 50 mass % in the refractory raw material mix, and a second particle fraction having a particle diameter of 10 μm or less and occupying 5 mass % or less in the refractory raw material mix, to additionally enhance corrosion resistance and thermal shock resistance.

Owner:KROSAKI HARIMA CORP

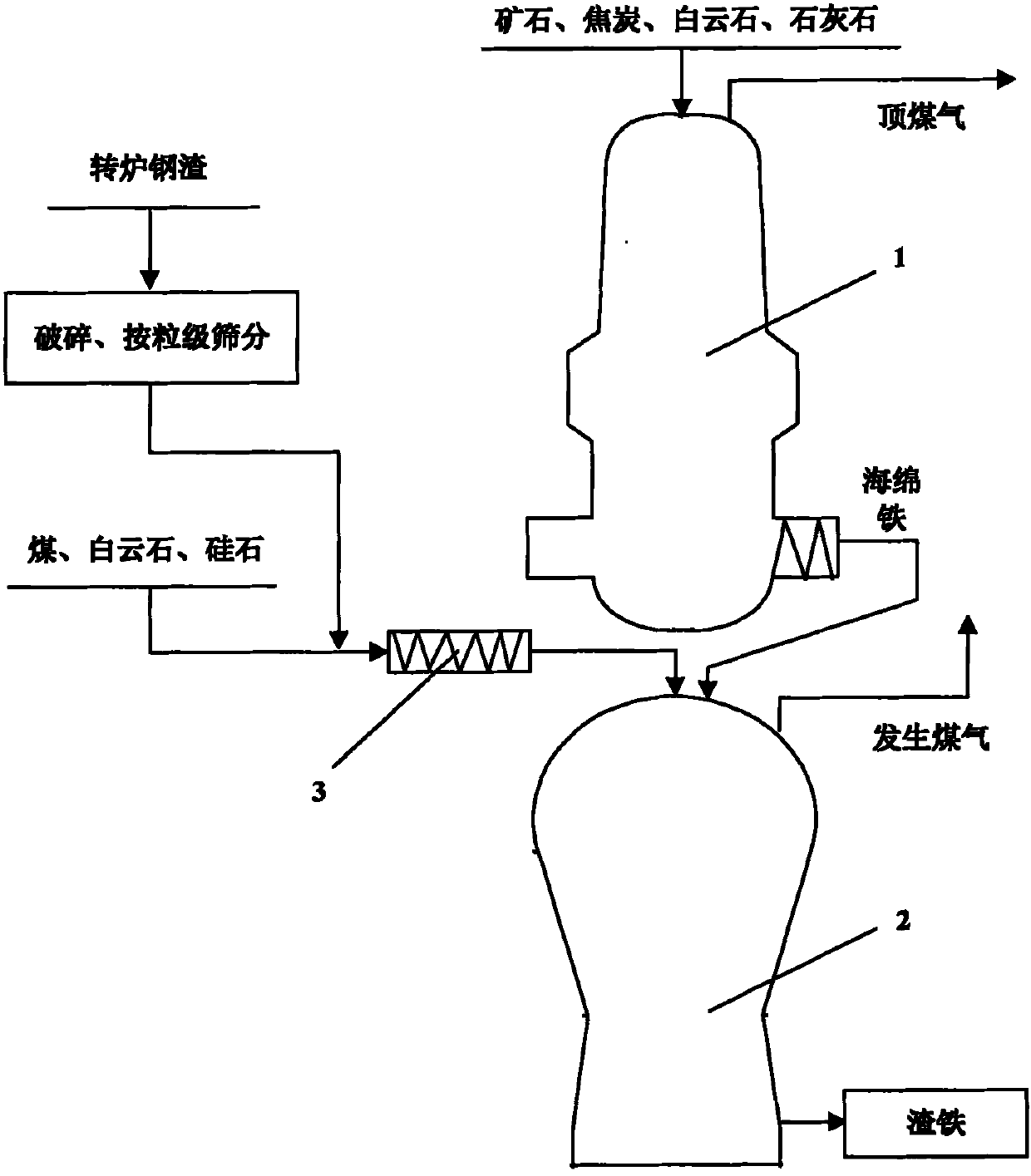

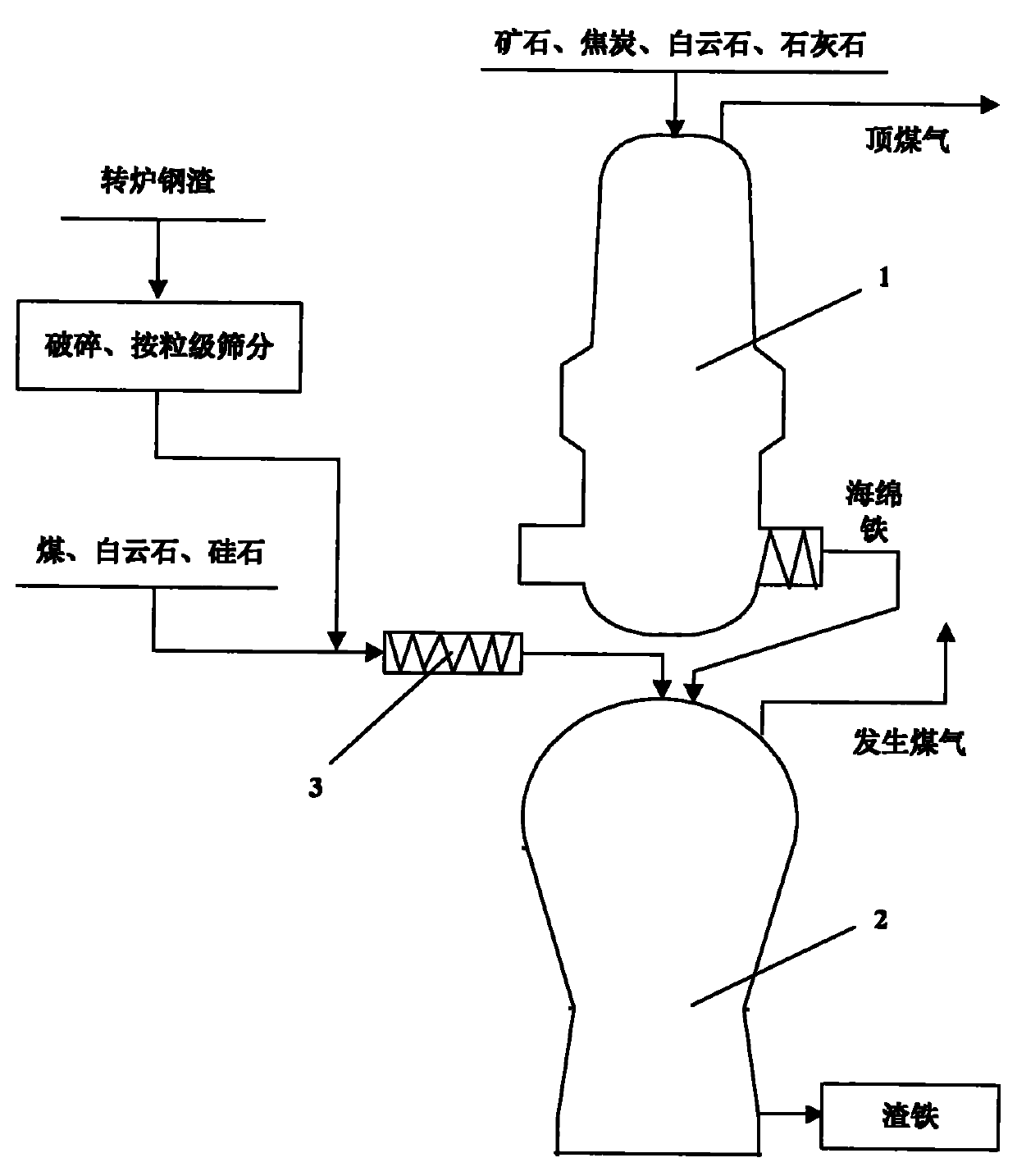

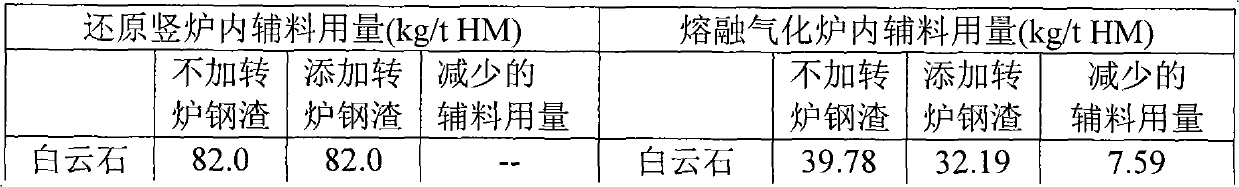

Method for recycling converter slags

ActiveCN102199677AReduce usageEnable recyclingRecycling and recovery technologiesProcess efficiency improvementSlagCrusher

The invention discloses a method for recycling converter slags, comprising the following steps: first, separating remainder iron blocks and shot iron from converter slags by magnetic separation, crushing remaining converter slags to particles with particle size of 0.01-25mm by a crusher, then, screening crushed converter slags according to different particle fractions, selecting converter slags with particle size of 8-25mm to mix with coal, dolomite and silica uniformly, transmitting the mixture into a COREX melter-gasifier via a belt conveyer for feed mixture. The crushed converter slags comprise 10-25wt% TFe, 30-60 wt% CaO, 4-15wt% MgO, 5-25wt% SiO2 and 0-2wt% P. According to the invention, the use of limestone, dolomite and silica in COREX process is reduced, the ironmaking cost is reduced, and discharge capacity of CO2 is also reduced. The method has the advantages of simple technology, low cost, and efficient utilization of industrial waste residues.

Owner:XINJIANG BAYI IRON & STEEL

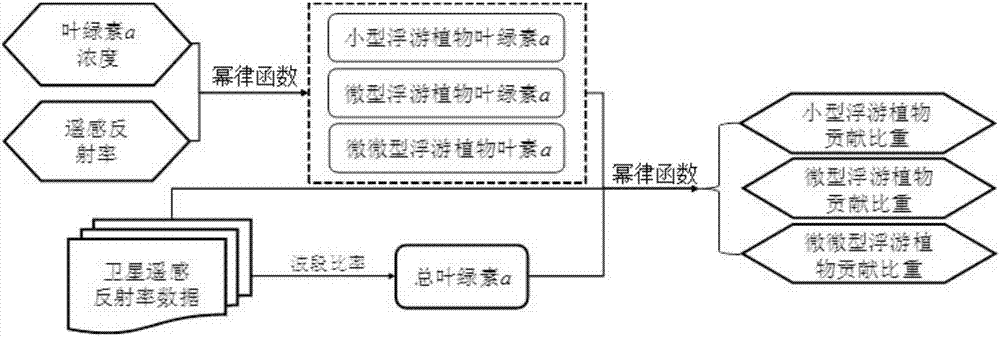

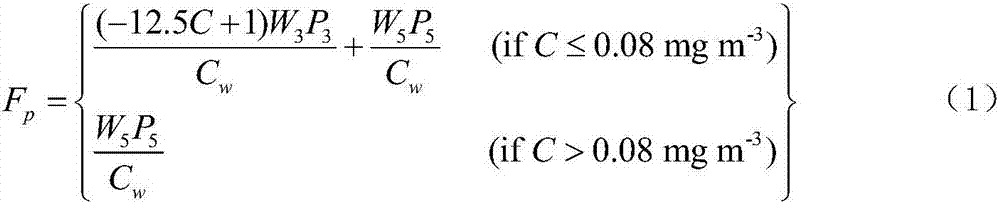

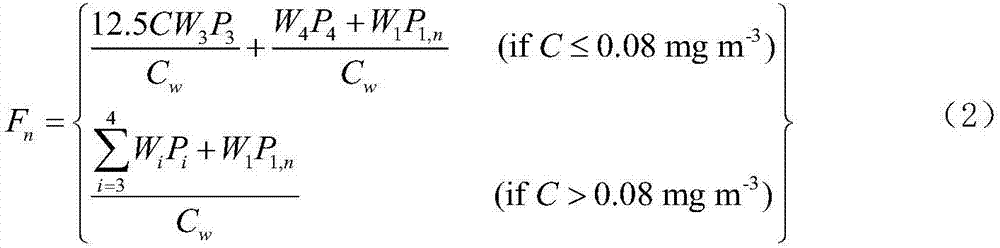

Remote sensing method for estimating particle fraction structure of offshore water body phytoplankton

The invention discloses a remote sensing method for estimating a particle fraction structure of offshore water body phytoplankton. The method comprises the steps of performing diagnostic pigment analysis (DPA) on HPLC data which are obtained through voyage, and obtaining a Chla concentration value which corresponds with each particle diameter; performing derivation based on a power exponent relation according to field measured remote sensing reflectivity data for obtaining a localized parameter; and finally applying an established model to a satellite, thereby obtaining PSC time-space distribution information which is inversed by the satellite. The remote sensing method has advantages of settling a problem of offshore water body phytoplankton particle fraction structure inversion, algorithm shortage in China, expanding application of water color remote sensing satellite data, and improving acquiring capability for an essential parameter of phytoplankton particle fraction structure.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Method for magnetic/ferrofluid separation of particle fractions

InactiveUS6994219B2Easy to collectReadily cleaned and preparedElectrostatic separationHigh gradient magnetic separatorsParticulatesChemical physics

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com