Patents

Literature

340results about How to "Improve granulation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

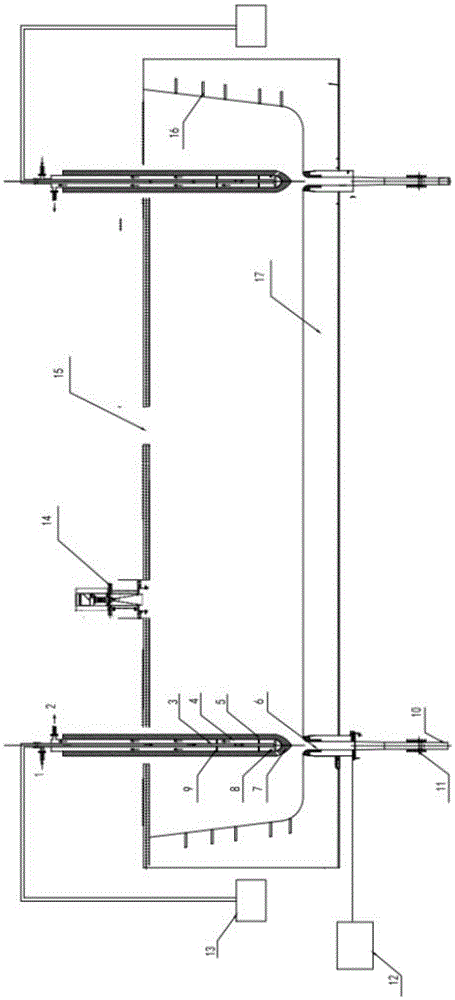

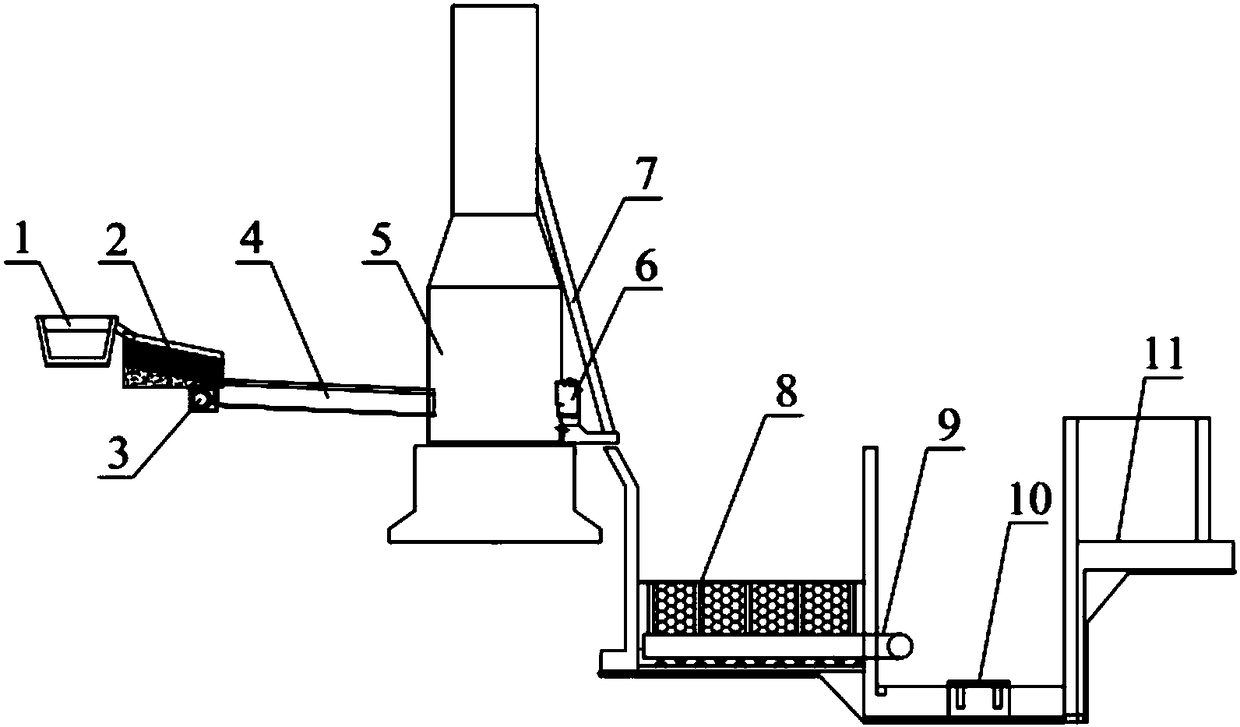

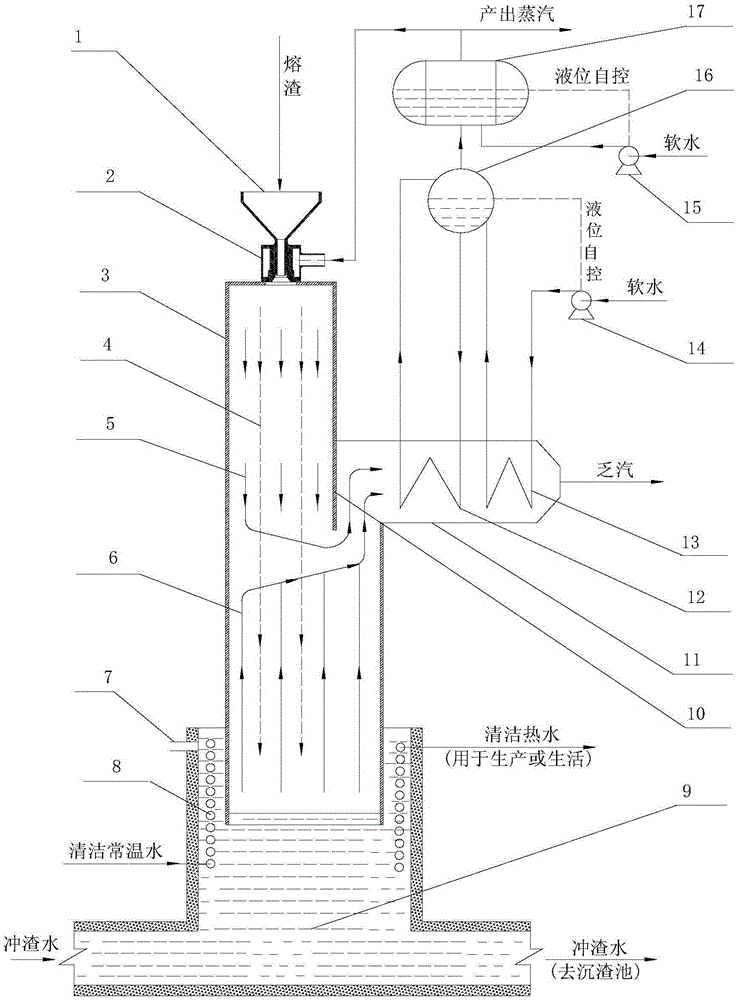

Method and system for recovering high-temperature sensible heat of molten blast furnace slag

ActiveCN102162016ADoes not affect activityImprove waste heat qualityIncreasing energy efficiencyDischarge devicesSlagSlow cooling

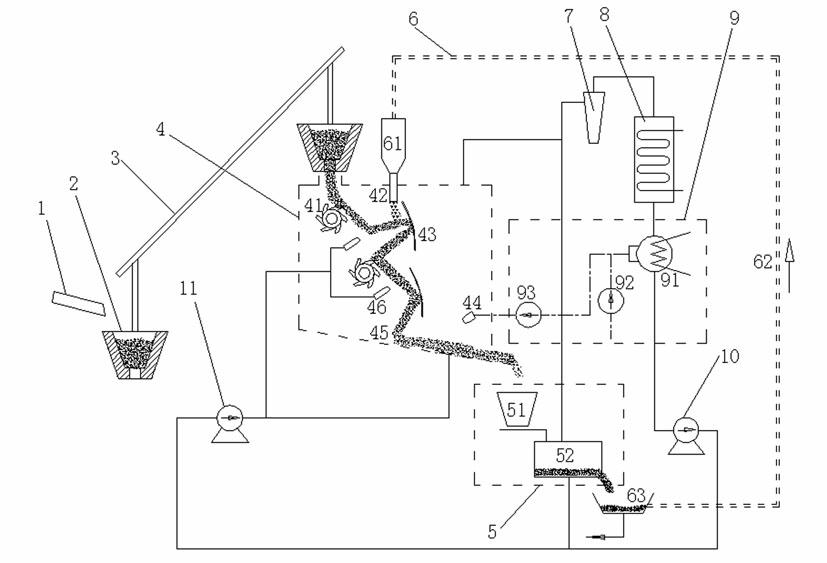

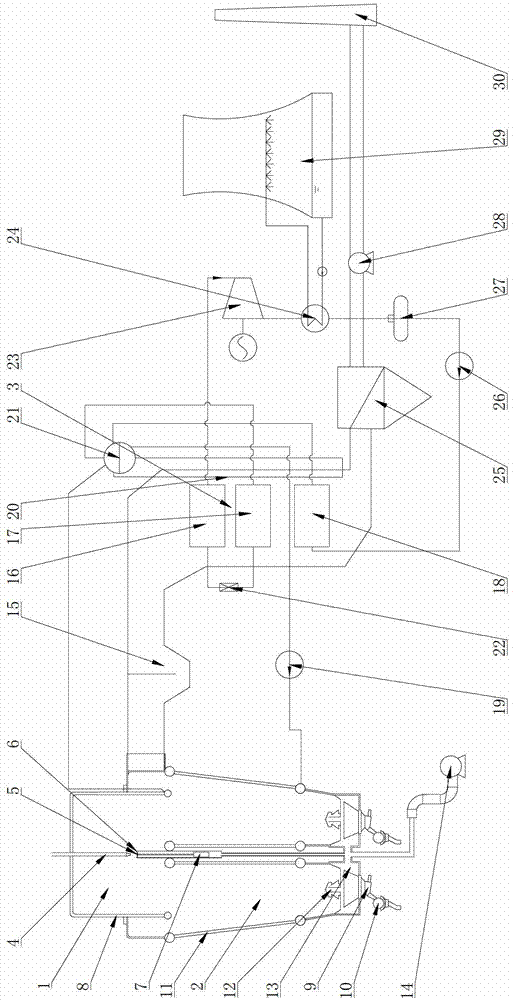

The invention discloses a method and a system for recovering high-temperature sensible heat of molten blast furnace slag. The system comprises a blast furnace slag runner, a slag hopper, a slag hopper lifting mechanism, a quenching unit, a slow cooling unit, a cold slag particle circulation unit, a cyclone dust collector, a waste heat boiler, a condensing unit, a circulating fan, and a booster fan. The method for recovering waste heat comprises the following steps of: crushing and quickly cooling the molten blast furnace slag in the quenching unit in a composite way of a rotary crushing wheel, high-pressure cold air, a slag trap, cold slag particles and cooling water, and fully exchanging heat with solidified blast furnace slag in the slow cooling unit by using cooling air; and allowing high-temperature air which comes out of the quenching unit and the slow cooling unit to enter the waste heat boiler and performing heat exchange, transforming into steam or electric power and then outputting. The subsequent utilization of blast furnace slag and the waste heat recovery efficiency are synchronously considered, condensed water is recycled, finished slag does not contain water or only contains a small amount of water, the granulation effect of the slag is better, and the contradiction between intermittent slagging and continuous heat production of blast-furnace ironmaking is resolved.

Owner:HANGZHOU BOILER GRP CO LTD

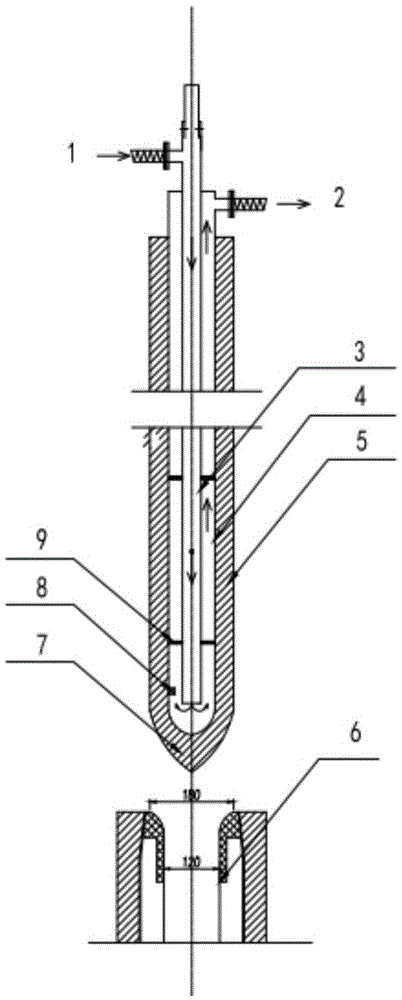

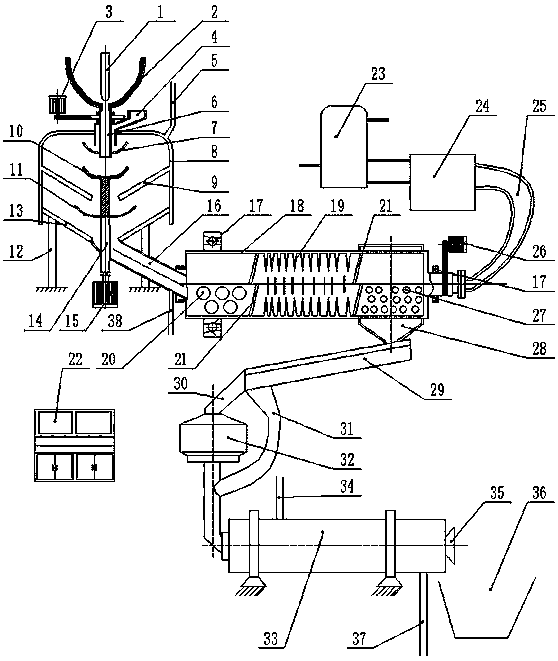

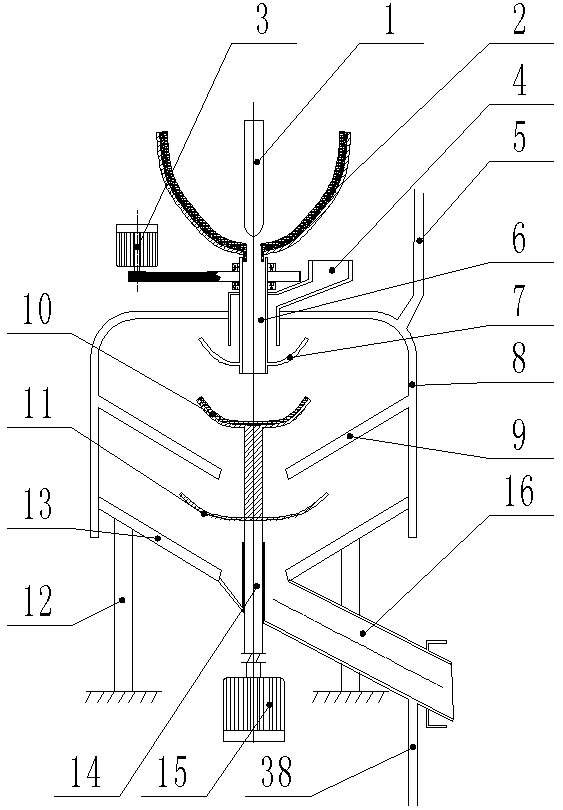

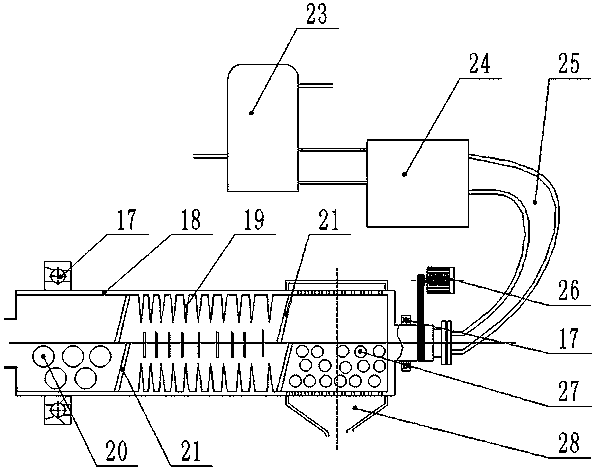

Blast furnace slag granulation and waste heat utilization process technology and equipment

ActiveCN102268495ASmall and uniformSmall sizeProcess efficiency improvementSteam generation using hot heat carriersMolten slagBlast furnace

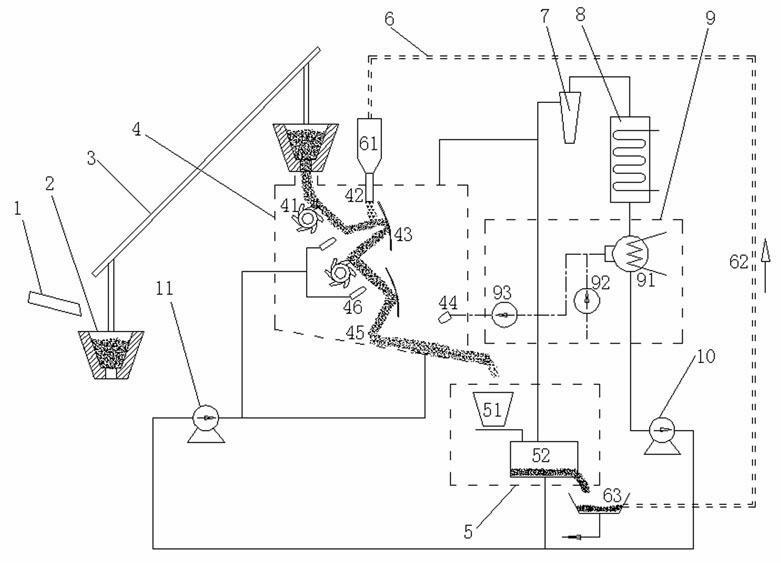

The invention provides a process technology for granulating blast-furnace slag and utilizing waste heat. The process technology is characterized by comprising the following steps of: performing primary cooling and triple granulation on high-temperature molten slag from a blast furnace in a slag primary cooling device to form fine granules with diameter of less than 3mm and temperature of about 800-1,000 DEG C; discharging the fine granules through a high-temperature slag discharge valve; entering a slag basket and conveying to the upper part of a slag secondary cooling device; falling to the lower part of the slag secondary cooling device along a plurality of layers of baffle heat exchange components which are arranged in the slag secondary cooling device; and cooling to about 200 DEG C and discharging through a low-temperature slag discharging valve, wherein waste heat of normal pressure steam of 200 DEG C can be recovered by the slag primary cooling device; and waste heat of hot circulating air of over 600 DEG C can be recovered by the slag secondary cooling device. The invention provides equipment for granulating blast-furnace slag and utilizing waste heat. The equipment mainlycomprises the slag primary cooling device, the slag secondary cooling device, a waste heat boiler and the like. The process technology and the equipment have the advantages of good granulation effectof the molten slag, small and uniform size of slag granules, almost zero new water consumption and low environmental pollution.

Owner:北京中冶设备研究设计总院有限公司

Afterheat recovery system and method of dry granulating liquid slag

ActiveCN102827969AEasy to diluteImprove granulation effectIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodLiquid slag

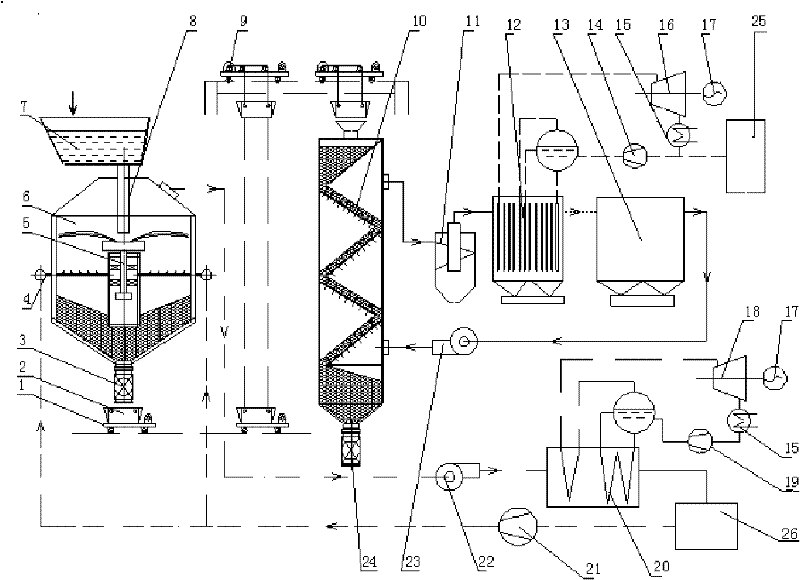

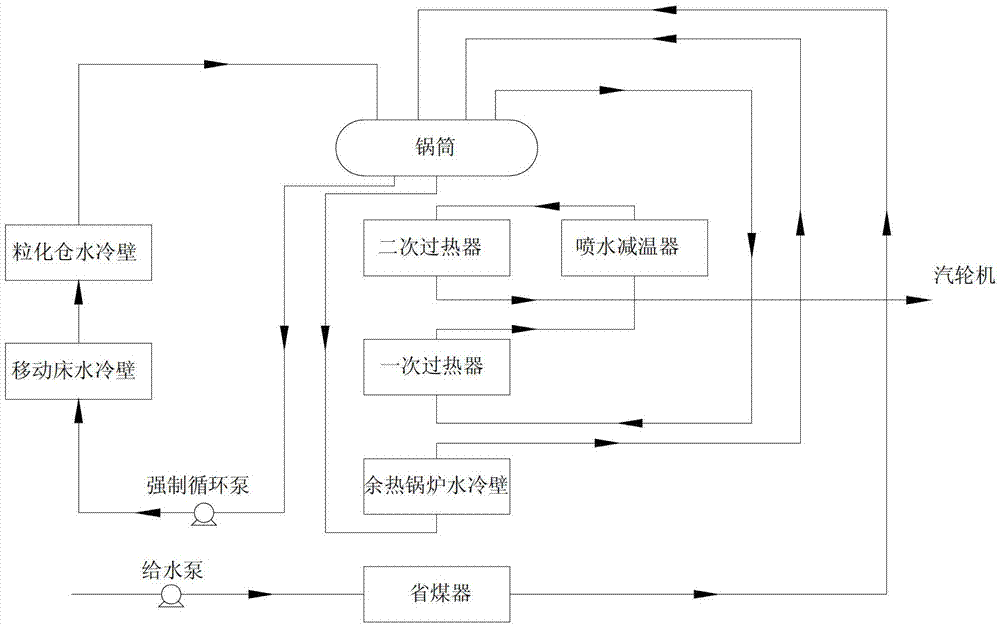

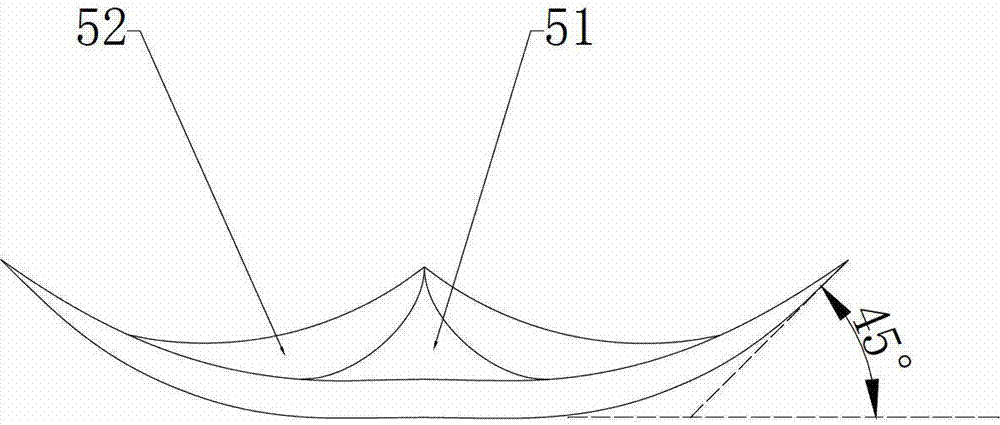

The invention discloses an afterheat recovery system and an afterheat recovery method of dry granulating liquid slag. The system comprises a granulating cabin, a moving bed and an afterheat recovery system, the inner surface of the granulating cabin is provided with a granulating cabin water cooling wall, the center of the top of the granulating cabin is provided with a slag pipe, the slag pipe extends into the granulating cabin, the lower part of the tail end of the slag pipe is provided with a centrifugal granulator, the centrifugal granulator is connected with a motor arranged at the lower part of the centrifugal granulator, the lateral side of the centrifugal granulator is provided with an air supply pipeline, an annular air opening is formed between the centrifugal granulator and the air supply pipeline, the lower part of the granulating cabin is provided with the moving bed, the inner surface of the moving bed is provided with a moving bed water cooling wall, the top of the moving bed is provided with an air outlet, the bottom of the moving bed is provided with a slag discharge device, an air inlet device is arranged above the slag discharge device, the afterheat recovery system comprises a primary dust remover, an afterheat boiler, a secondary dust remover, an exhaust fan and a chimney which are connected in sequence, and the primary dust remover is connected with the air outlet arranged at the top of the moving bed. The system and the method effectively solve the problems of heat recovery and furnace slag granulation of equipment such as a blast furnace.

Owner:XI AN JIAOTONG UNIV +1

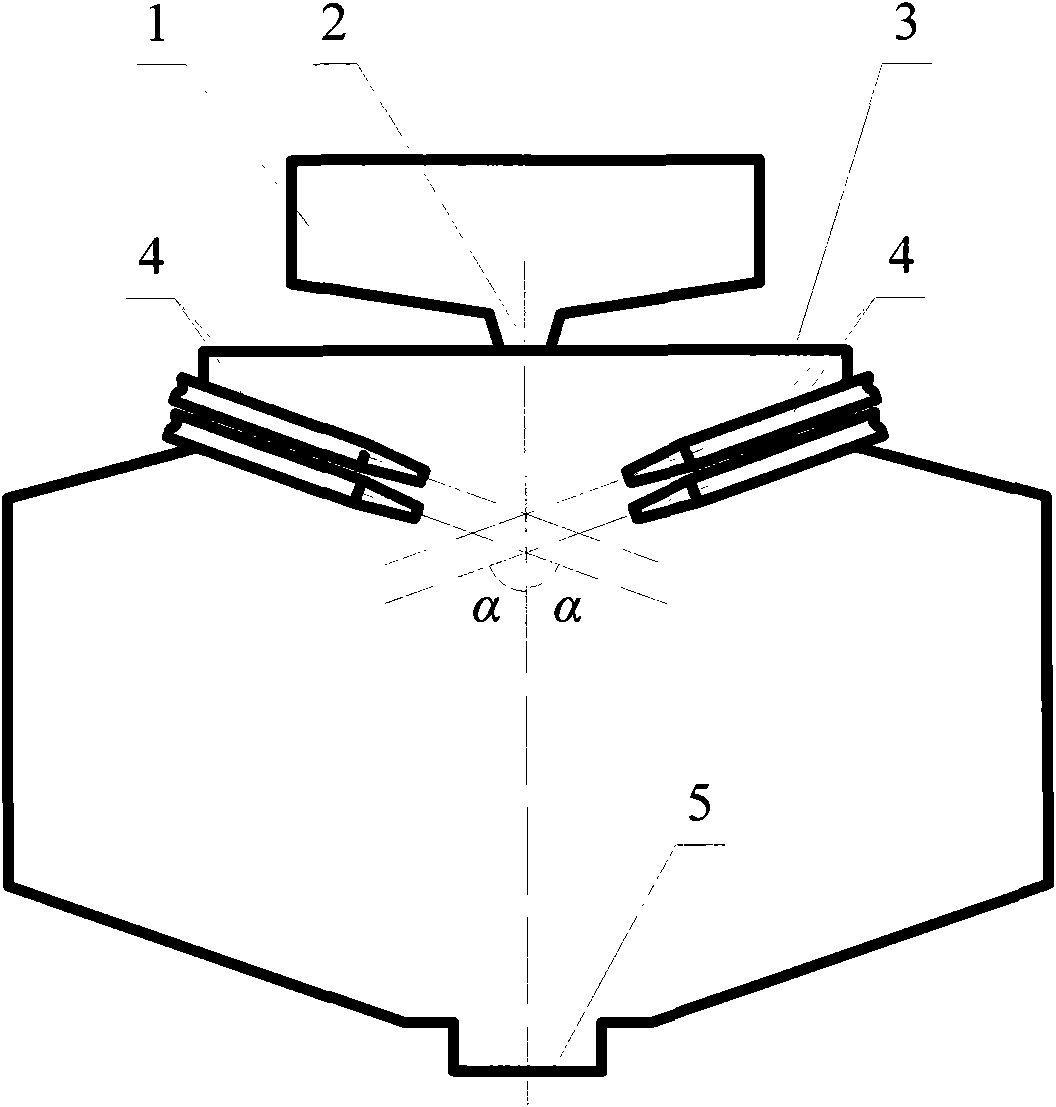

Liquid blast furnace slag granulation method and device thereof

InactiveCN101665845AIncrease impactImprove the effectRecycling and recovery technologiesSlagSolid phases

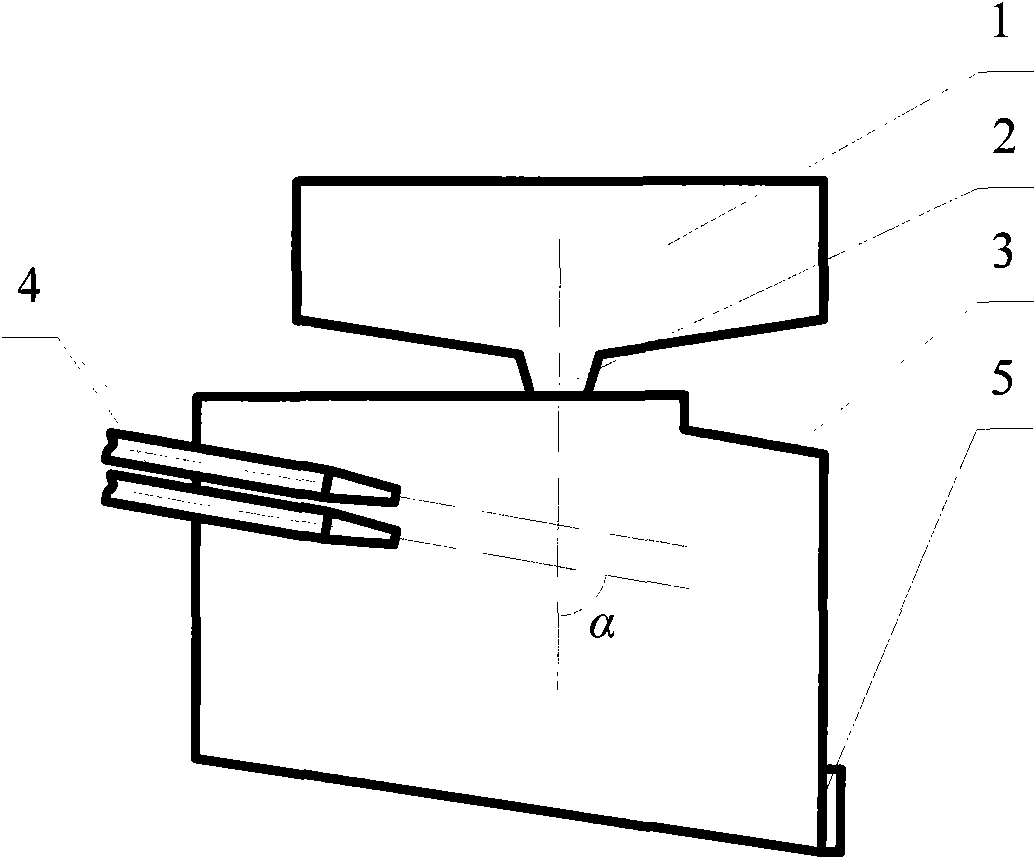

The invention relates to liquid blast furnace slag granulation method and device thereof, belonging to the technical field of blast furnace utilization in the metallurgy industry. The device comprisesa diversion trench, a slag dropping hole, a granulation device, two or more granulation nozzles and a slag discharging hole. The invention realizes dry process quenching granulation adopting high-speed gas and solid phases carrying solid granules as granulation media, impacting liquid blast furnace slag to crushing, and quenching and solidifying into small granules. In the granulation device, thediversion trench is built by refractory materials and is arranged at the top of the granulation device, the lowest point of the diversion trench is provided with the slag dropping hole which is communicated with the granulation device, the upper part of the granulation device is provided with the granulation nozzles, and an included angle between the outlet axes and the vertical direction of thegranulation nozzles is more than 0 degree and is less than or equal to 90 degrees. The granulation nozzles can be arranged at one side or are symmetrically arranged or circularly arranged by using a center perpendicular line of the slag dropping hole as the center of a circle. The invention strengthens the granulation effect and lowers the power consumption and the equipment investment of the granulation device by utilizing the capacity of crushing the liquid blast furnace slag by a gas-solid two-phase strong jet flow.

Owner:TSINGHUA UNIV +1

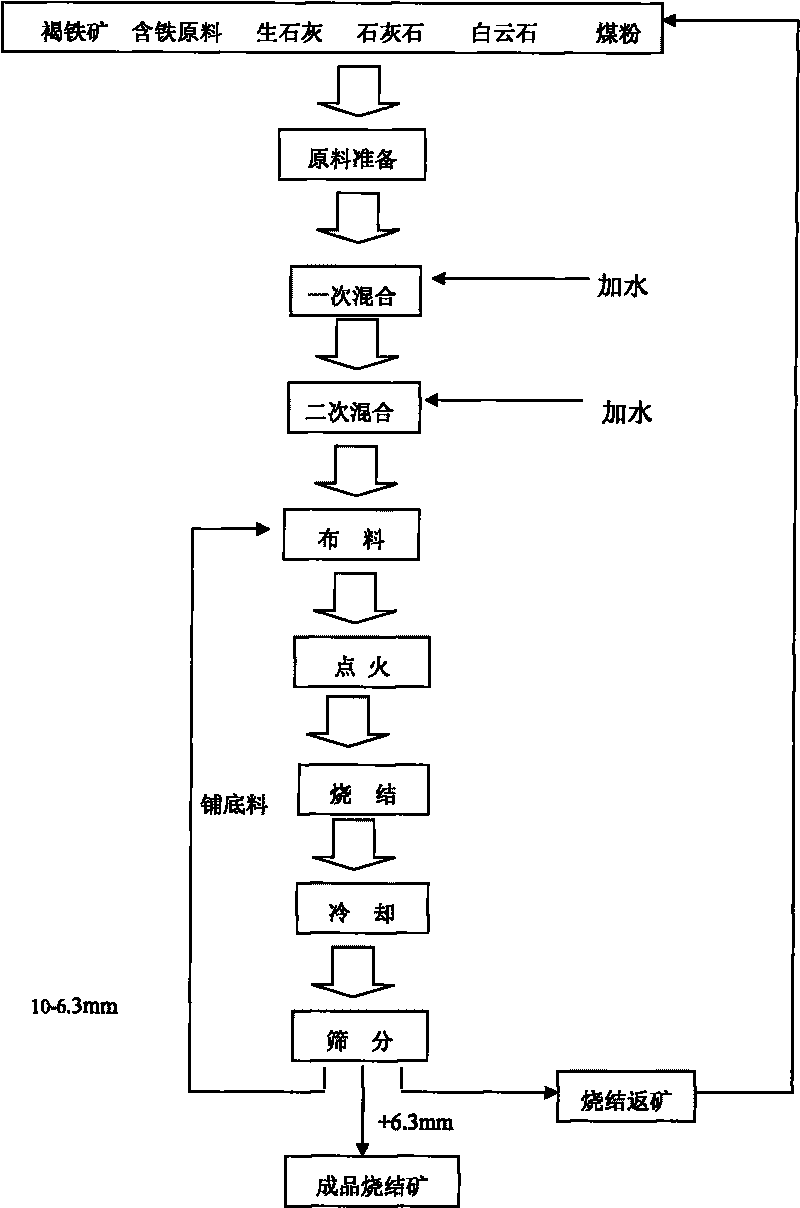

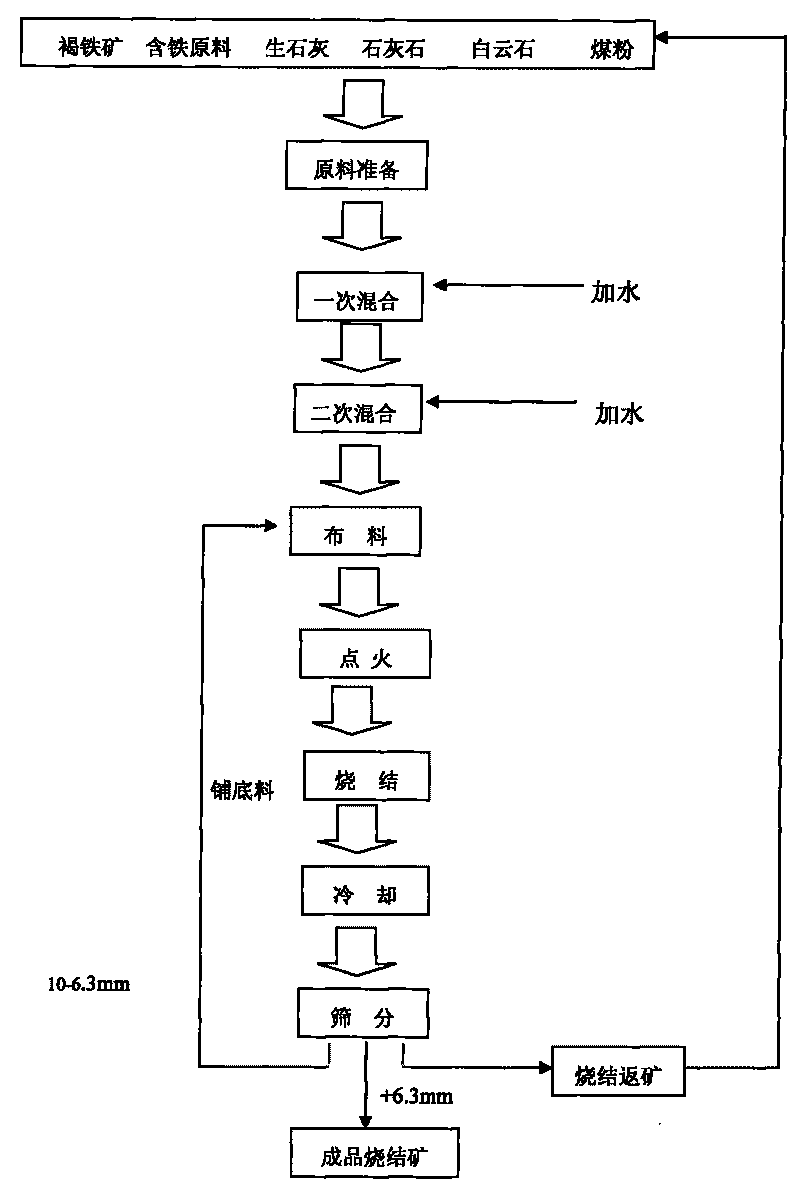

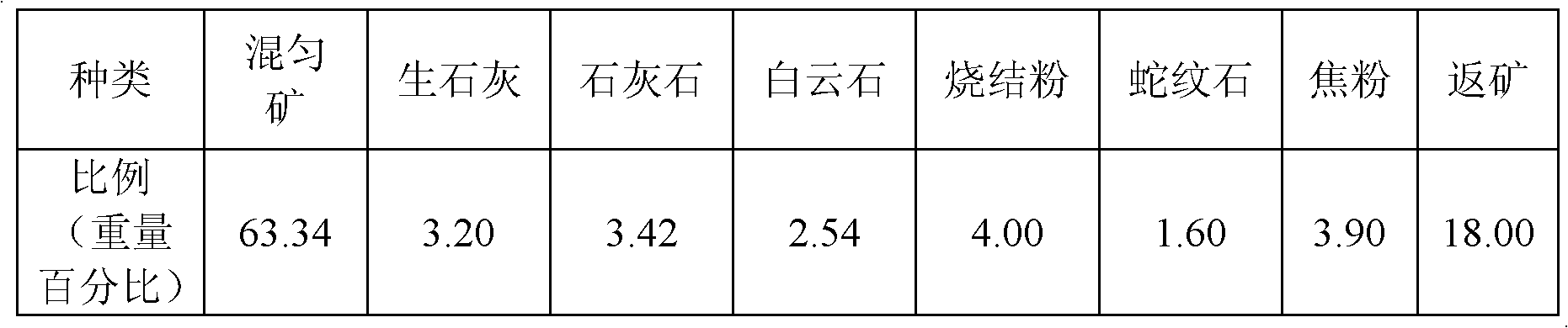

High-ore-matching-ratio brown iron ore sintering technology

The invention relates to a high-ore-matching-ratio brown iron ore sintering technology. The weight ratio of brown iron ore and powdered iron in raw material proportion is (5-19):1, the moisture content of the first mixing is controlled to be 7%-8%, the mixing time lasts for 2-3minutes, and the temperature of the mixture is 50-62 DEG C; the moisture content of second mixing pelletizing is controlled to be 7-9%, the pelletizing time lasts for 2-3.5minutes, and the temperature of materials is 52-65 DEG C; the thickness of grate-layer materials in distribution is 20mm, and a sintering material layer is 780-900mm thick; the ignition temperature for sintering is1050-1150 DEG C, and the ignition time lasts for 1.8-2.2minutes; and the negative pressure for sintering is 12-15kpa, the machine speed is 0.9-1.2m / min, the vertical sintering speed is 29-34mm / min, the air leakage rate is no more than 40%, the cooling negative pressure is 11-14kpa, the temperature of a cooling section of a sintering machine is reduced to 250 DEG C below. By using the high-ore-matching-ratio brown iron ore sintering technology, energy is saved, consumption is reduced, cost is decreased and benefit is increased.

Owner:唐山瑞丰钢铁(集团)有限公司

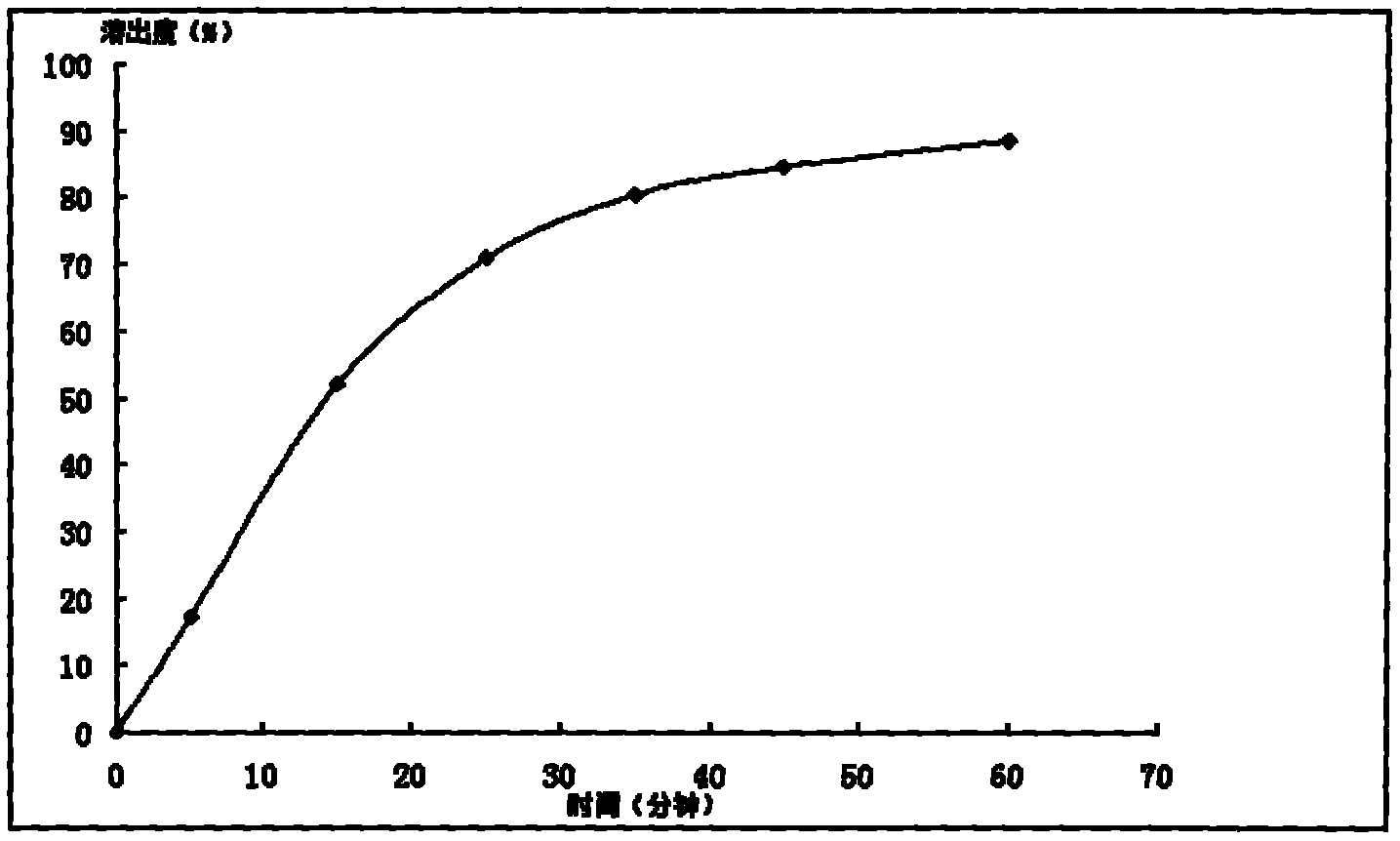

Method for intensifying limonite sintering

InactiveCN101701289APromote sinteringImprove granulation effectBlast furnace detailsSucrose solutionMoisture

A method for intensifying limonite sintering has the advantage of changing the property of the moisture of the mixture by adding sucrose solution with weight concentration being 4-10%. The solution has certain viscosity which is reduced with the increase of the temperature. In the processes of mixing and granulating, the mineral powder with fine grains is well adhered to the surfaces of pellets, thus intensifying limonite granulating, improving the intensity of the pellets of the mixture and achieving the aims of intensifying limonite sintering, improving the quality of sintered minerals and reducing solid fuel consumption. The method has better effects especially on the limonite with finer grain sizes. The sucrose has the greatest characteristic of totally reacting in the process of sintering and leaving no residues in the sinter, thus having no impact on the quality of the sinter.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Sintering method for high-chromic vanadium-titanium ferroferrite

The invention discloses a sintering method of high-chromine typed V-Ti-bearing iron ore, which comprises the following steps: 1) allocating limestone and fined ferric ore to make grain; 2) adding water to wet; 3) putting wet and grained materials into sintering material in the mixer to ball; adding B2O3 in the composite material; 4) adding MgO in the composite material; 5) loading the composite material into sintering cup or sintering machine to sinter over 50 deg.c; increasing the content of calcium ferrite in the sintering ore by 5% and production by 4.2-5.0%.

Owner:PANZHIHUA IRON AND STEEL

Slag buffering system with flow control function

InactiveCN105624346ARealize continuous long-term operationGuaranteed physical properties of slagRecycling and recovery technologiesSlagStreamflow

The invention discloses a slag buffering system with a flow control function. The slag buffering system comprises a slag ladle shell, stopper rods, stopper rod control mechanisms and slag falling pipes. A slag inlet is formed in the upper portion of the slag ladle shell, and a plurality of water openings are formed in the bottom of the slag ladle shell. The slag falling pipes with flow meters are arranged at the lower portions of the water openings. Each water opening is correspondingly provided with a stopper rod. The stopper rods are arranged over the corresponding water openings. The stopper rod control mechanisms are used for controlling the circulation area between the stopper rods and the water openings. Slag flows into a slag ladle from a slag inlet above the slag ladle and is stored in the slag ladle, and the slag flows out of the slag falling pipes from the water openings in the bottom of the slag ladle. The flow of the slag is controlled by controlling the circulation area through cooperation of the stopper rods and the water openings. The flow meters are arranged on the slag falling pipes to detect the flow of the slag, and detection signals are fed back to the stopper rod control mechanisms. According to the slag buffering system, the temporary slag storage function and the flow control function are achieved, the following pelletization process can be continuously and stably conducted on the slag, and the slag buffering system can be widely applied to a slag pelletization waste heat recycling system.

Owner:XI AN JIAOTONG UNIV +1

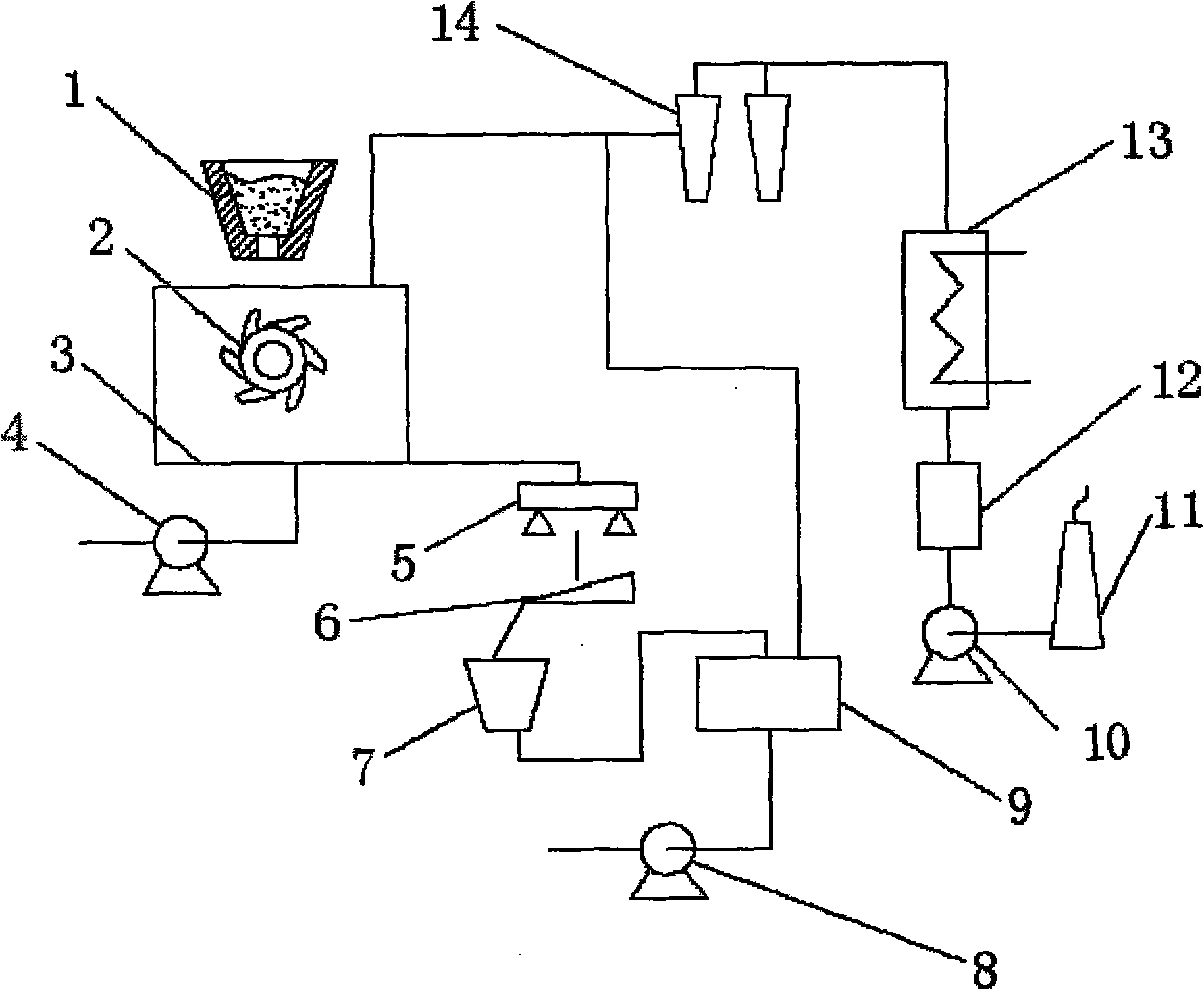

Recovery method of steel slag residual heat and system thereof

ActiveCN101551199AReduce consumptionEliminate pollutionProcess efficiency improvementWaste heat treatmentRecovery methodFluidized bed

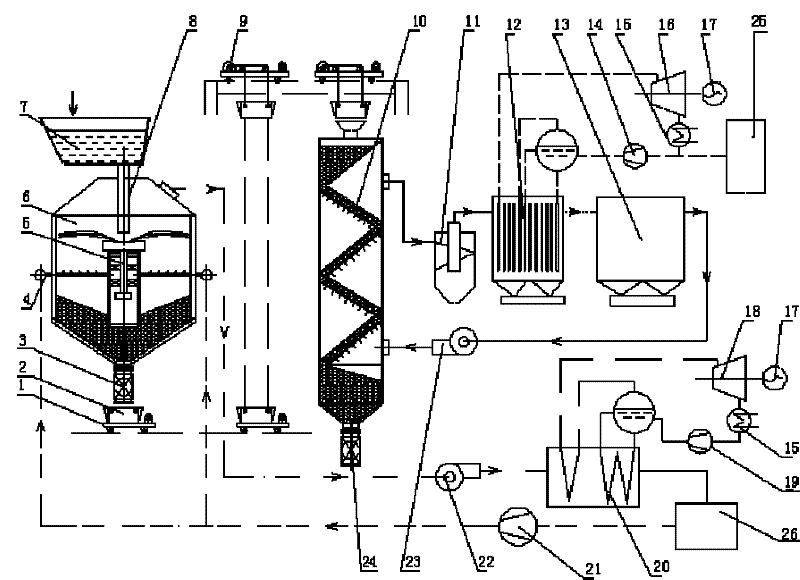

The invention discloses a recovery method of steel slag residual heat and system thereof. The system is composed of a steel slag flow distributor, a water-cooling granulation wheel, a first fluidized bed, a weigher, a vibration sieve, a hot slag particles bunker, a second fluidized bed, a dedusting device, a blower and a residual heat boiler in sequence. The method is that, pouring high-temperature liquid slag into the steel slag flow distributor, the steel slag flown out of the steel slag flow distributor falling onto the water-cooling granulation wheel and being crushed and throwing out to fall into the first fluidized bed for exchanging heat with air, hot slag particles discharged from the first fluidized bed is stored in the hot slag particles bunker after going through the weigher and the vibration sieve, and discharging when the temperature is cooled to 350 DEG by a heat exchanger of the second fluidized bed. High-temperature air discharged from the first fluidized bed and the second fluidized bed enters the residual heat boiler for exchanging heat after dedusting. The invention can reduce energy consumption in steel production, graining effect of the steel slag is good, which is benefit for following degradation of free CaO and magnetic separation of wasted steel.

Owner:HANGZHOU BOILER GRP CO LTD

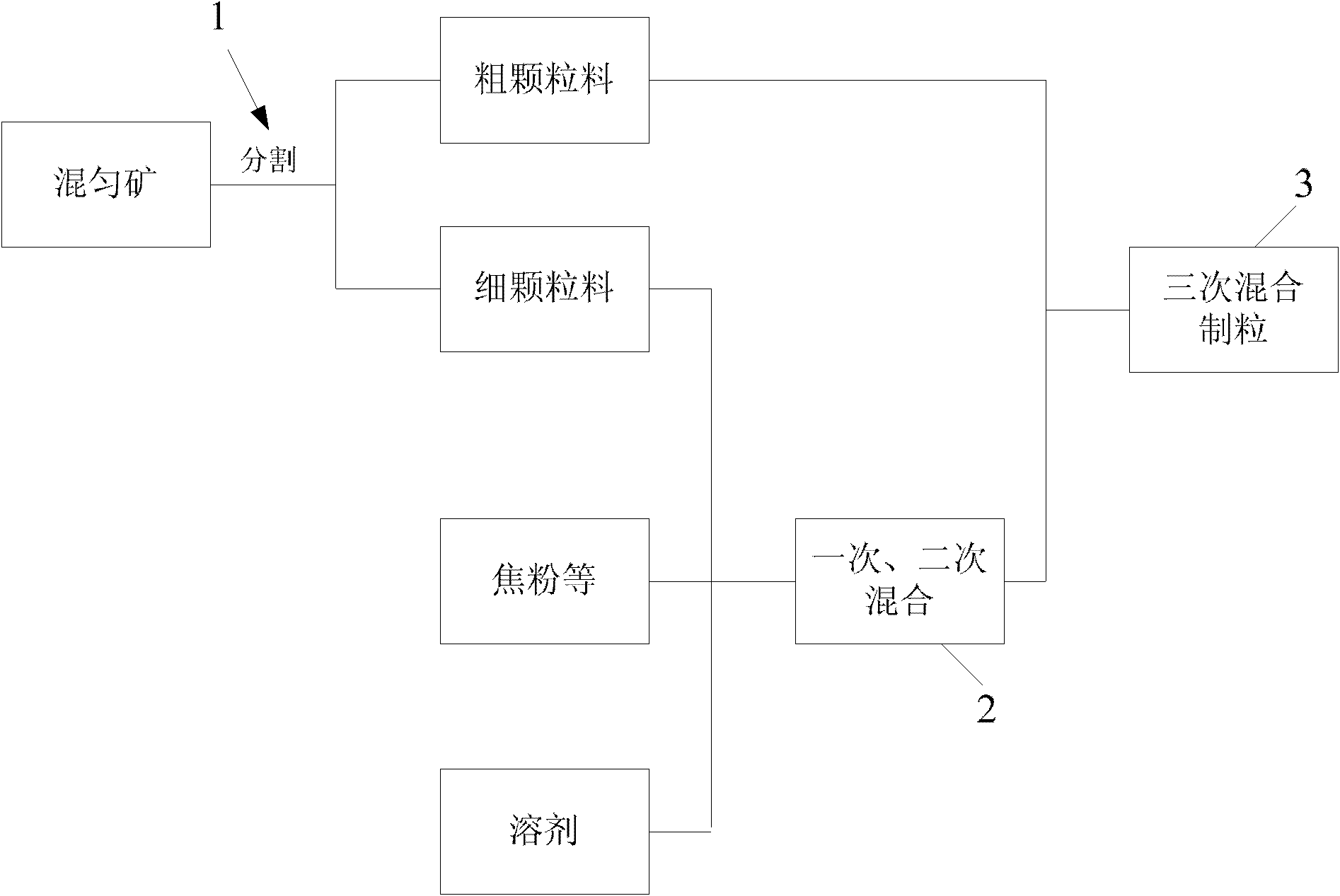

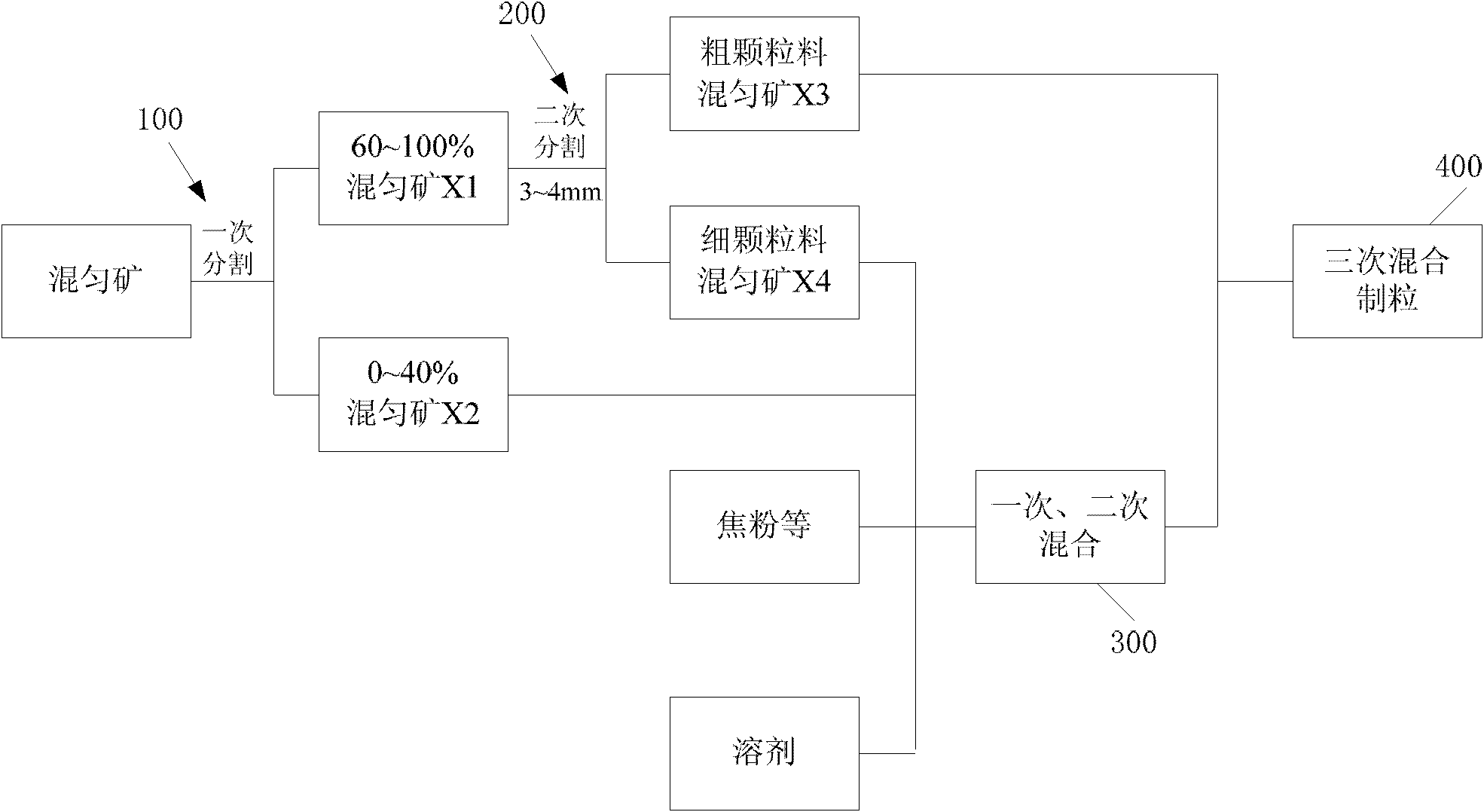

Sinter mixture granulating method

InactiveCN102719659AIncreased chances of granulationImprove granulation effectMetallurgyParticle fraction

A sinter mixture granulating method comprises following steps: 1) a blending ore is applied as a granulating raw material; 2) the blending ore is segmented into two parts according to a particle fraction of 3.0-4.0 mm. The blending ore whose particle fraction is less than 3.0-4.0 mm is subjected to a primary and a secondary mixing granulation with other conventional ingredients of preparing a sinter mixture. 3) the particles obtained from the secondary mixing granulation are added into the blending ore having the particle fraction greater than 3.0-4.0 mm obtained by the segmentation before, and subjected to a tertiary mixing granulation. The method can improve granulating effects for the sinter mixture, improve permeability of a material layer in a sintering process, optimize a sintering state and reach an ideal producing technique index finally.

Owner:BAOSHAN IRON & STEEL CO LTD

Hot disintegration method for converter steel slag

InactiveCN101280346AImprove granulation effectImprove performanceRecycling and recovery technologiesSlagIsolation layer

The invention relates to the steel slag recovery and reclamation processing technology. The invention provides a disruption method of converter steel slag, which is characterized in that the steel slag is poured into a dross box in a hot slag splashing workshop under the temperature of 1050 to 1150 DEG C, little water is sprayed to reduce the temperature, after an isolation layer is formed, the slag is poured and water is sprayed continuously time and again, and then the broken steel slag is obtained after warming up stuffily. The steel slag processed through the method of the invention has the advantages of good graining effect and performance, and the method and the process are advanced, the investment on the system is low, the operating cost is low, and the economic effect is obvious.

Owner:冀更新

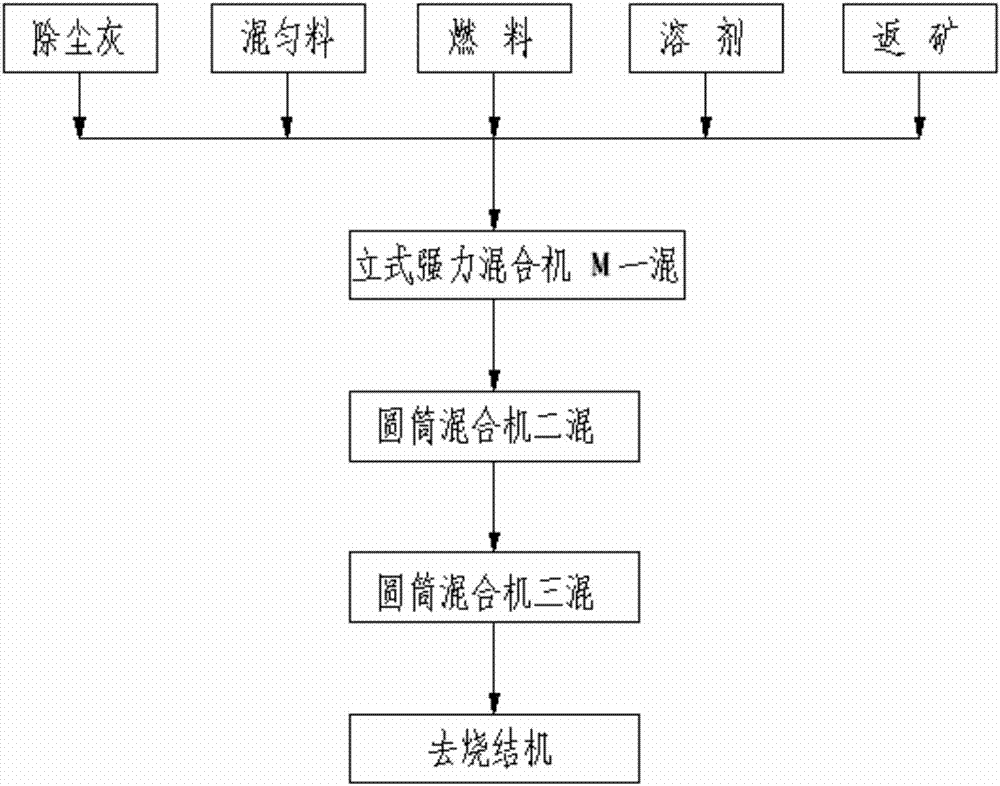

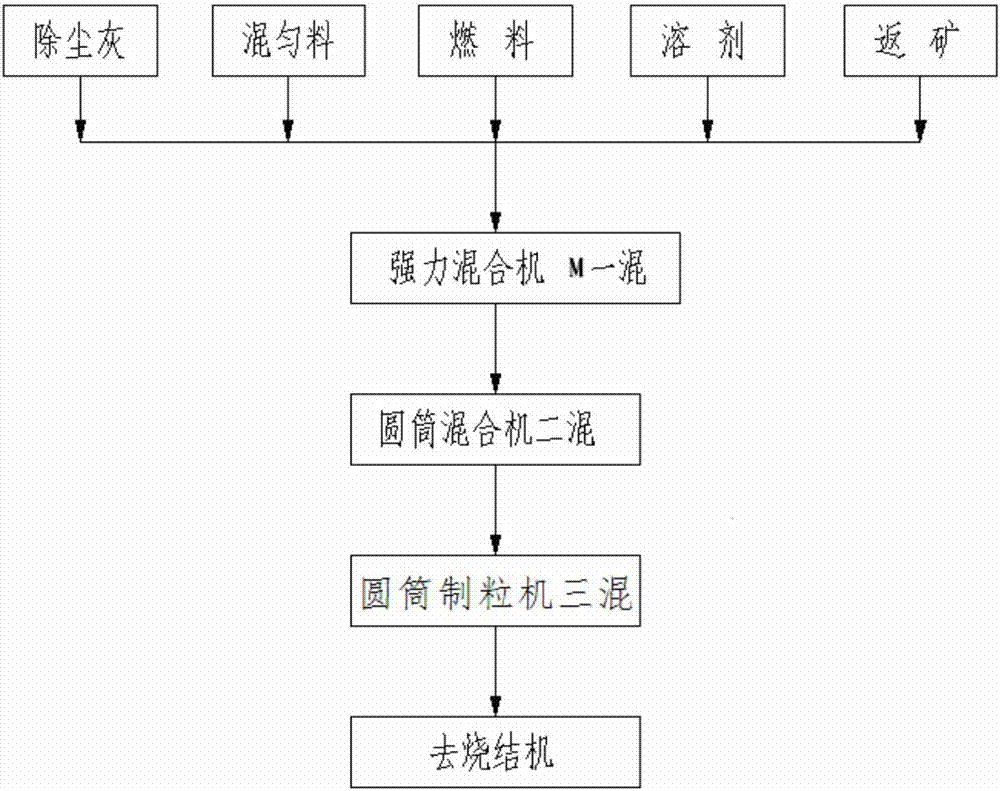

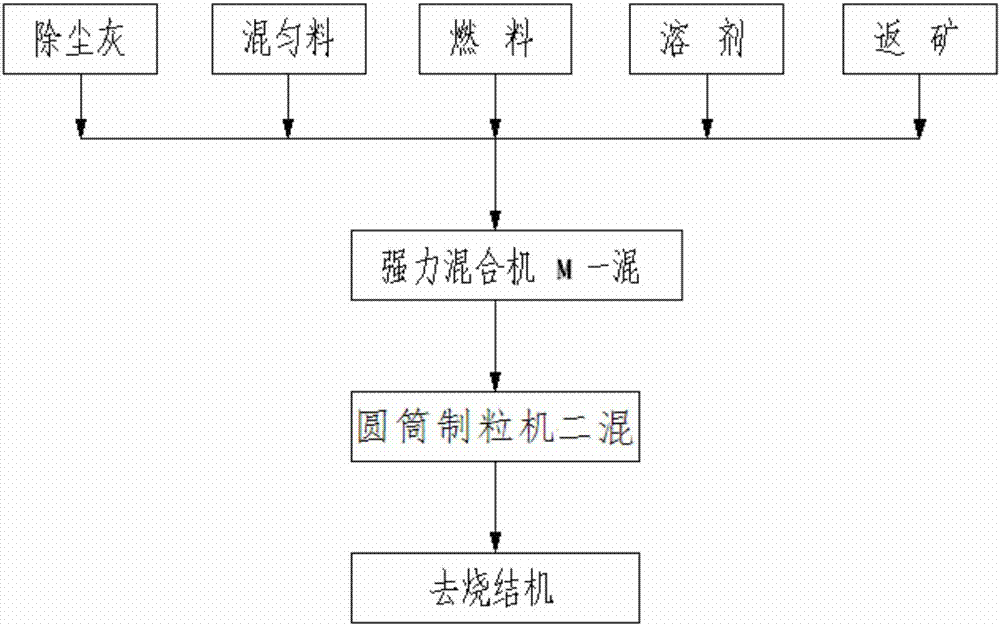

Strong mixing technology for sintering production and device thereof

ActiveCN107304461AIncrease profitSmall footprintTransportation and packagingMixersMixed materialsSolvent

The invention provides a mixing method for sintering production. The mixing method comprises the following steps that 1, iron ore powder, solvent and fuel are conveyed into a strong mixing machine, water is added, and mixing of the first stage is carried out; 2, the material obtained after mixing of the first stage is conveyed into a first cylinder mixing machine, water is added, and mixing of the second stage is carried out; 3, the material obtained after mixing of the second stage is conveyed into a second cylinder mixing machine or a cylinder pelletizer, water is added, mixing of the third stage is carried out, and a mixed material is obtained. By the adoption of the vertical strong mixing machine, the occupied area can be reduced, moreover, the sintering strength of sintered ore can be improved, the yield of the sintered ore is increased, energy is saved, emission is reduced, and multiple advantages are brought to increase of profits of sintering factories.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Formula and production process of dairy cow protein particle feed

InactiveCN101731485AImprove utilization efficiencyIncrease expansionAnimal feeding stuffFiberAntioxidant

The invention relates to a formula of dairy cow protein particle feed which comprises the following components by weigh percent: 15-40 percent of energy feed, 40-80 percent of protein feed, 0-9 percent of oil and fat, 0-18 percent of amino acid, 0-2.3 percent of vitamin, 1.6-2 percent of calcium carbonate, 0-1 percent of adhesive, 0-0.1 percent of antioxidant and 0-0.3 percent of antimold agent. The production process of the dairy cow protein particle feed comprises the following steps: a, weighting the components according to the weight percent thereof; b, grinding the components; c, mixing the ground components; d, tempering the mixture; e, granulating the mixture; f, post-curing the granules; g, drying the granules; and h making the granules into the dairy cow protein particle feed which has the diameter of less than 4 mm and the length of 1 to 2 times of the diameter and contains the dry matter of more than 88 percent. The dry matter contains the crude protein of more than 20 percent and the crude fiber of less than 18 percent. The dairy cow protein particle feed can be kept stable in water for more than 5 min and has the dispersion rate of less than 12 percent in water. The protein in the dairy cow protein particle feed is less degraded by the rumen microorganisms, the rumen bypass efficiency of the protein is improved, the need of the essential amino acids in the nutrient of protein in the dairy cow body is balanced, the efficiency of using the dairy cow protein particle feed by the dairy cow is increased, the health status of the dairy cow body is improved and the pollution of the nitrogen in the excrement of the dairy cow to the environment is reduced.

Owner:ZHEJIANG KESHENG FEED CO LTD

Method for improving quality of high-chromium vanadium and titanium sinter

The invention provides a method for improving the quality of high-chromium vanadium and titanium sinter and belongs to the technical field of ferrous metallurgy. The method mainly comprises the steps that sintering return mines, high-chromium vanadium and titanium concentrate fines, ordinary iron ore concentrate powder, boron iron ore concentrate, metallurgical lime, magnesite, coke powder and other sintering raw materials are subjected to secondary atomization injection and blowing blending, wetting and pelletizing at a certain proportion; then distribution, ignition and sintering are conducted; and finally grain settlement and screening are conducted to obtain the high-chromium vanadium and titanium sinter good in metallurgical performance. The method has the characteristics of being simple in process, high in raw material adaptability, high in production efficiency, low in cost and the like. The quality of the high-chromium vanadium and titanium sinter and the sintering production efficiency can be improved remarkably; the method has important realistic significance for development and utilization of the high-chromium vanadium and titanium sinter and has wide application prospects.

Owner:NORTHEASTERN UNIV

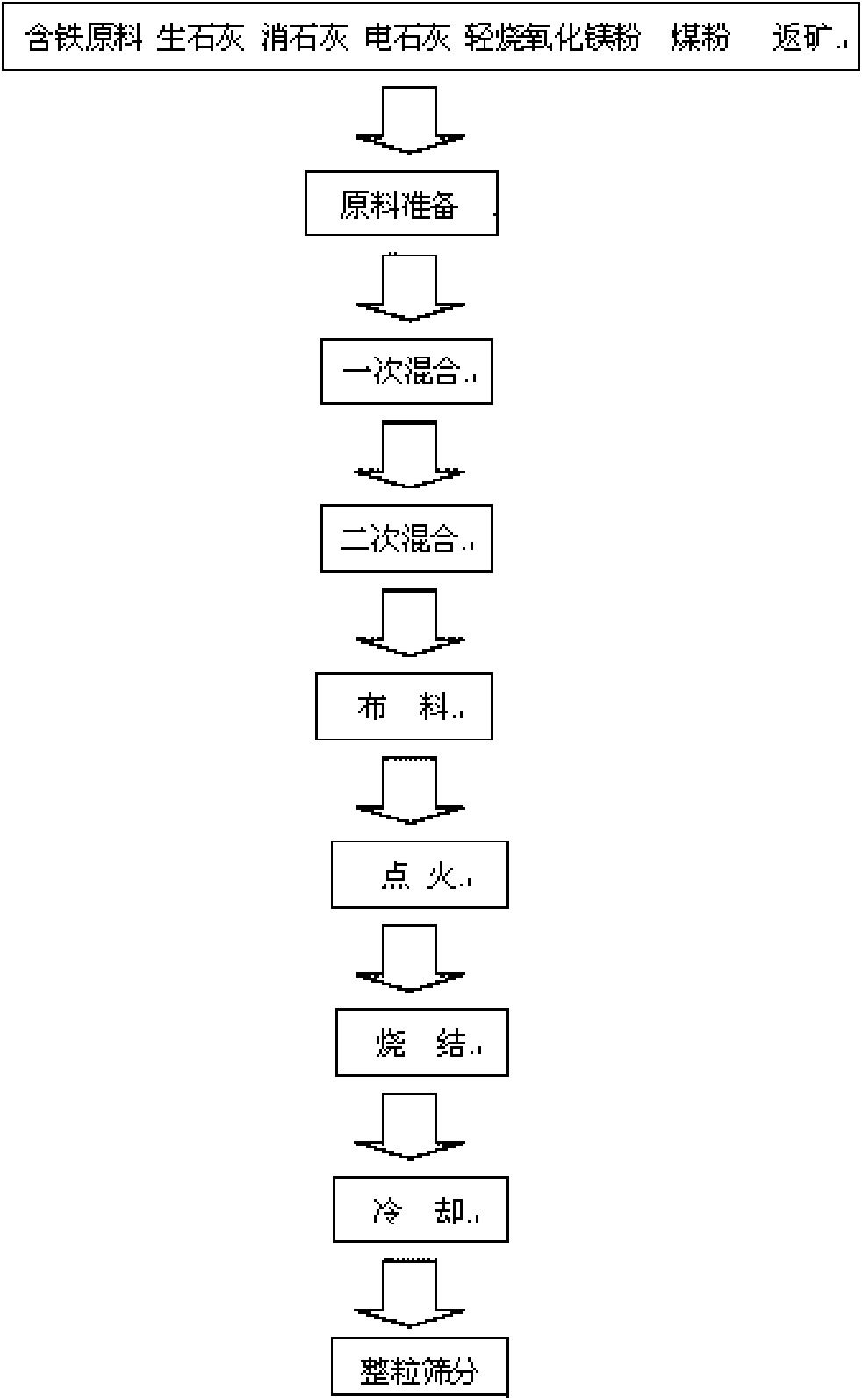

Process for producing sintered ore for ironmaking through blast furnace from high-aluminum limonite

The invention discloses a process for producing sintered ore for ironmaking through a blast furnace from high-aluminum limonite. The high-aluminum limonite accounts for 60%-70% of the weight of iron-containing raw material, and fine particle magnetite concentrate accounting for 25%-35% of the weight of the iron-containing raw material is mixed into the iron-containing raw material. The process comprises the following steps of: performing blending, mixing and pelletizing treatment on the iron-containing raw material, a solvent and coke powder; performing sintering, material distribution, ignition, sintering, cooling and particle adjustment on a pelletized mixture to get a finished product of the sintered ore, determining the alkalinity of a sintered mixture according to the requirement of smelting of the blast furnace on the alkalinity, wherein the ordinary range of the alkalinity is 1.7-2.1; and mixing limestone, dolomite and quicklime into the mixture for regulating the alkalinity, wherein the mixing weight of the quicklime is 1-4%. The adding of the fine particle magnetite concentrate can effectively improve the pelletizing effect of the high-aluminum limonite, significantly improve the sintering air permeability, greatly reduce the using quantity of the coke powder, improve the metallogenic conditions during the sintering process of the high-aluminum limonite, effectively improve the quality indexes of the sintered ore and realize the application of the high-aluminum limonite in sintering production.

Owner:CENT SOUTH UNIV

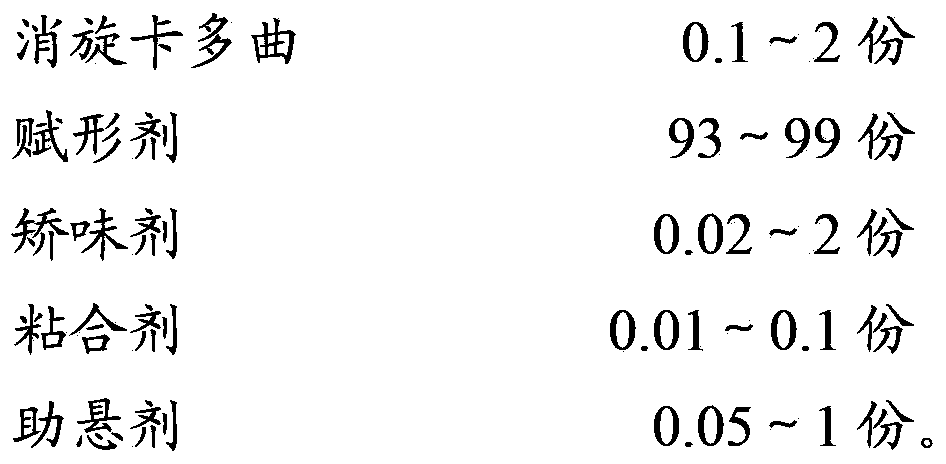

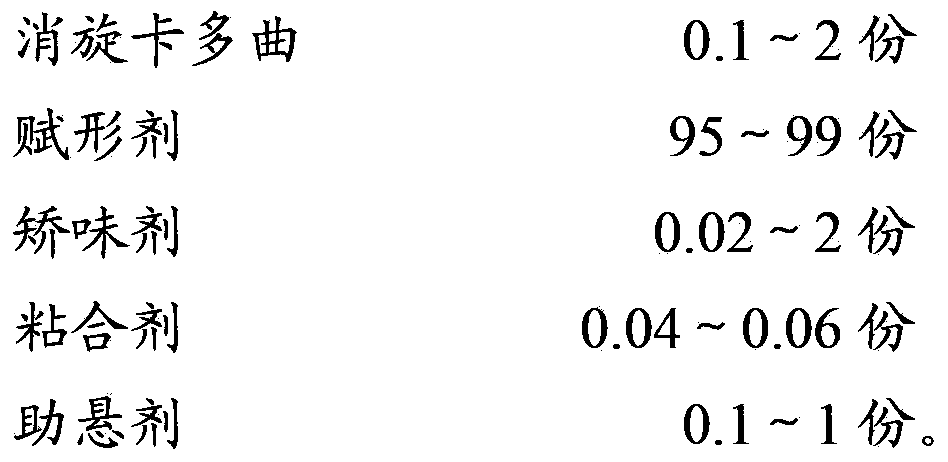

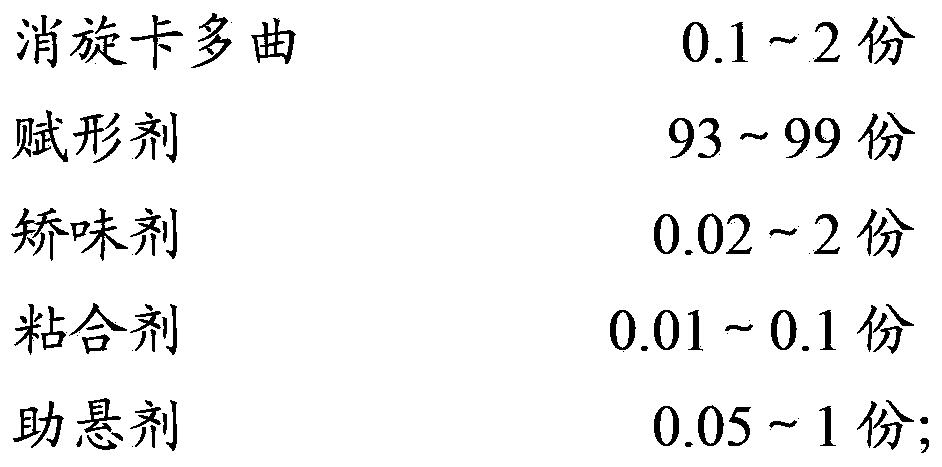

Racecadotril granules and preparation technology thereof

InactiveCN104224724AImprove granulation effectMask bitternessOrganic active ingredientsDigestive systemRacecadotrilSucrose

The invention relates to the field of medicinal preparations, and particularly relates to racecadotril granules and a preparation method thereof. The racecadotril granules are prepared from the following raw materials by weight: 0.1-2 parts of racecadotril, 93-99 parts of an excipient, 0.02-2 parts of a corrigent, 0.01-0.1 part of an adhesive and 0.05-1 part of a suspending agent. The racecadotril granules are prepared by suspending racecadotril in the adhesive and dissolving partial sucrose in the adhesive, so that bitter taste of a drug can be covered. The prepared racecadotril granules have relatively good granulation effect, and increase compliance of children.

Owner:BEIJING HANMI PHARMA CO LTD

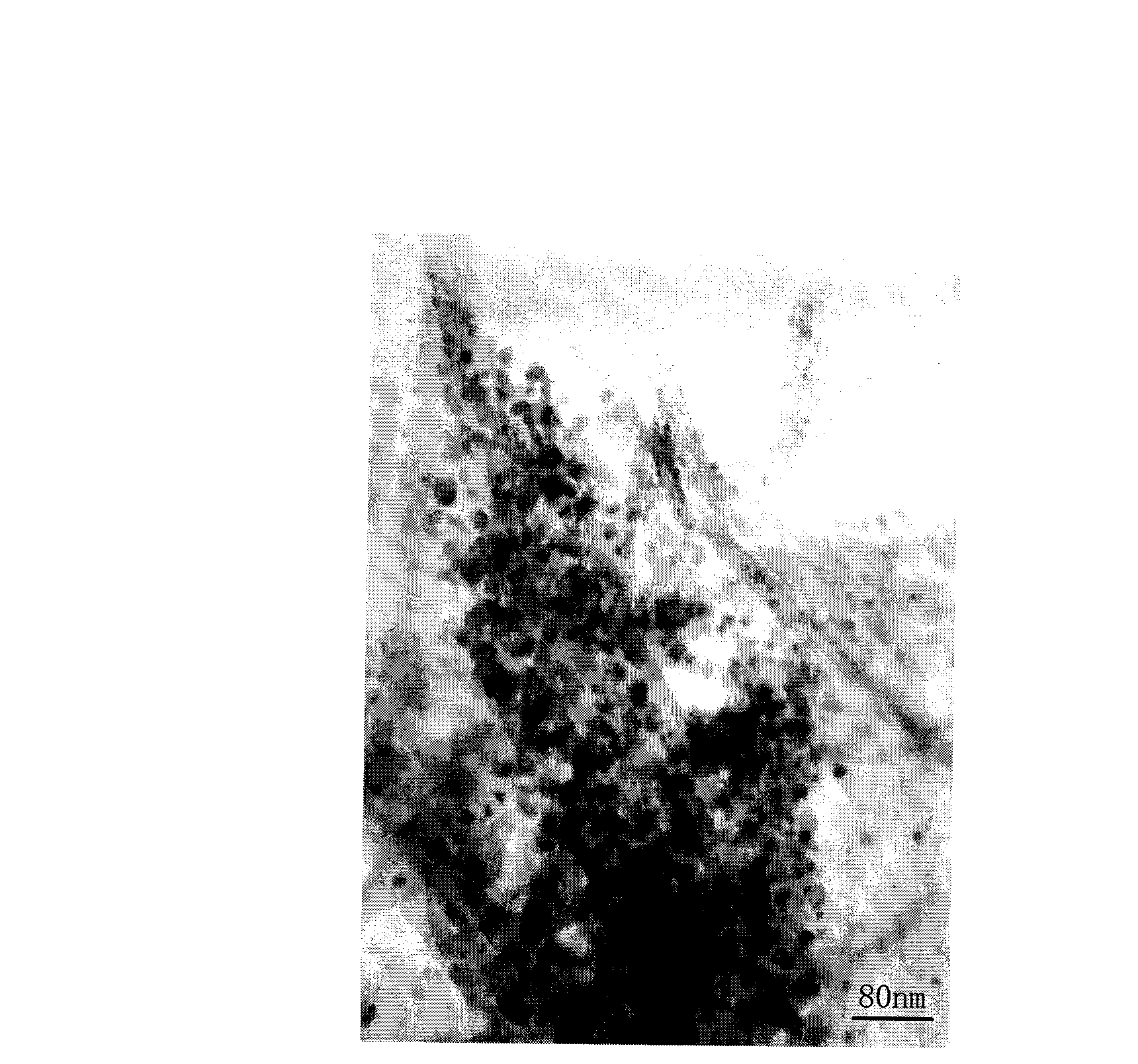

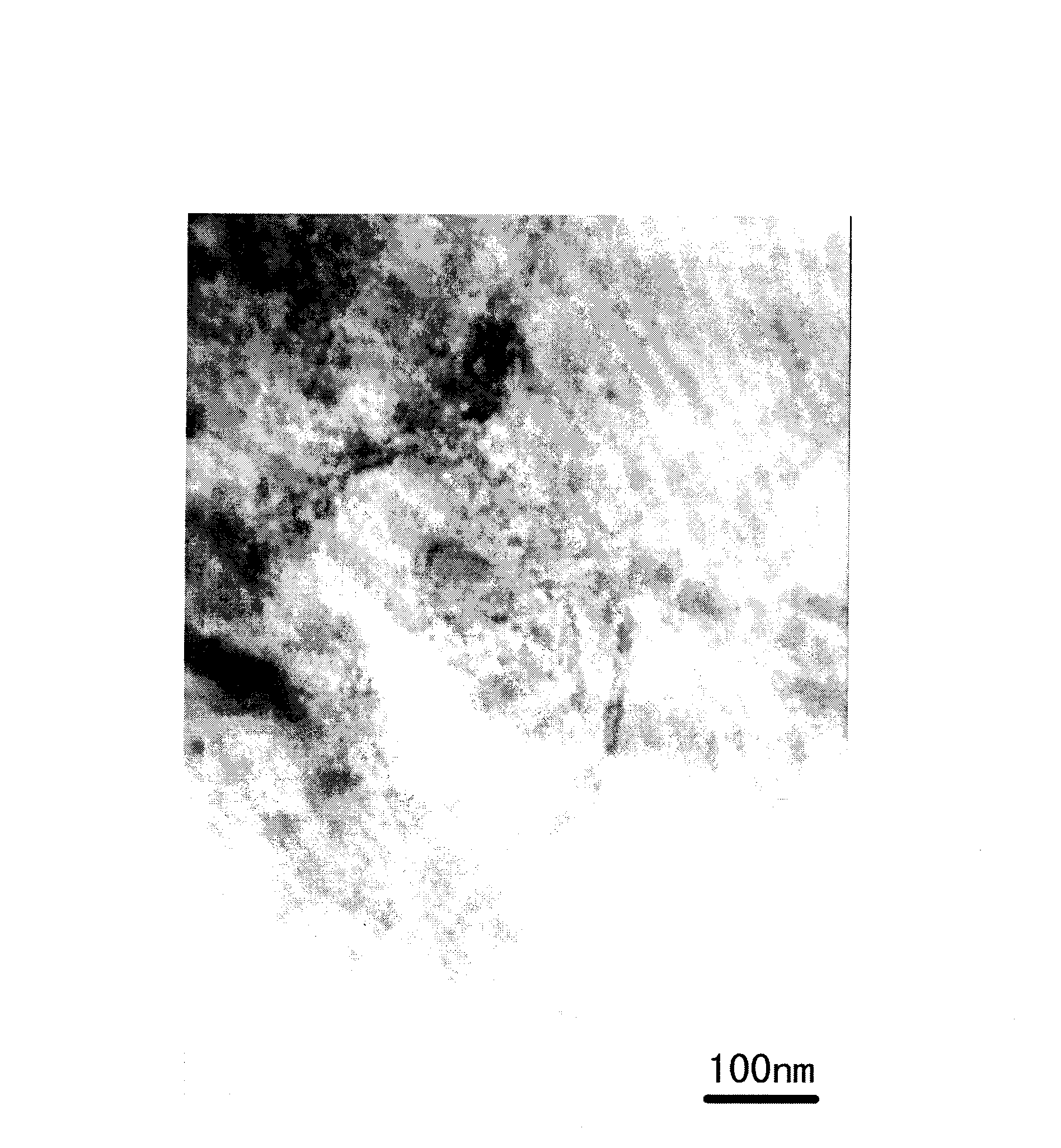

Attapulgite clay-Ni/Fe nano composite material, preparation method and applications thereof

InactiveCN101537356APromote depolymerizationGood dispersionCatalytic crackingOther chemical processesCatalytic pyrolysisNickel salt

An attapulgite clay-Ni / Fe nano composite material, a preparation method and applications thereof are characterized in that the attapulgite clay is taken as the raw material; metallic nickel and / or metallic iron particles with the diameter less than 20nm are loaded on the surface of attapulgite rhabdolith with the diameter between 40 and 50nm; the preparation method is that the attapulgite clay is prepared into suspension liquid, then the suspension liquid is hydrolyzed with iron salt and nickel salt and loaded on the surface of attapulgite crystal in the precipitation form of hydroxide, and finally the composite material is prepared through washing, dehydration, forming, drying and hydrogen reduction and calcination. With a nano structure, the composite material has low activation energy, high catalytic activity and strong resistance to carbon deposit, and can be applied to catalytic pyrolysis and purification of thermal gas and tar of a biomass gasification furnace and the catalytic pyrolysis of other various organisms.

Owner:HEFEI UNIV OF TECH

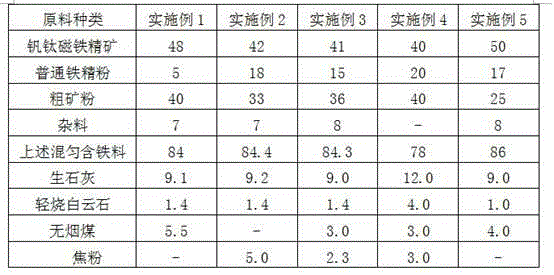

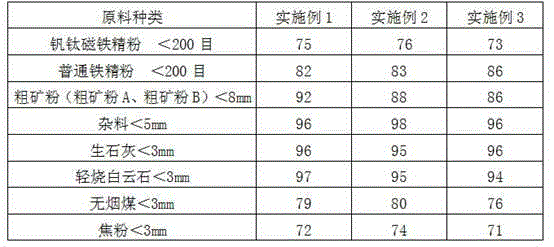

Medium-titanium high-strength sintered ore and preparation method thereof

The invention discloses a medium-titanium high-strength sintered ore which is formed by sintering the following ingredients by weight percentage: 78-86% of iron-bearing material, 9-12% of quicklime, 1-4% of lightly fired dolomite and 4-6% of fuel, wherein the iron-bearing material comprises the following components by weight percentage: 40-50% of vanadium titanium magnetite concentrate, 5-20% of common fine iron powder, 25-40% of coarse ore powder and 0-8% of miscellaneous material. The sintered ore is produced by taking a vanadium titanium magnetite and the vanadium titanium magnetite concentrate as main raw materials; the pelletizing performance of a mixture is improved by reasonably preparing and adding other iron ore powder and fluxes; component and phase composition of the sintered ore is controlled; an influence of higher TiO2 content in the sintered ore on the quality of the sintered ore is reduced; a tumbler index of the sintered ore reaches above 77% when the medium-titanium sintered ore is produced; the sintered ore is high in cold strength and low in return rate; and the sintered ore is smelted via a blast furnace, so that a fuel ratio is reduced and a utilization coefficient is increased.

Owner:HEBEI IRON AND STEEL

Organic-inorganic compound fertilizer capable of improving soil environment

InactiveCN106431780AImprove water absorptionFacilitated DiffusionDi-calcium phosphate fertilisersAnimal corpse fertilisersMonopotassium phosphateCarbonate

The invention discloses organic-inorganic compound fertilizer capable of improving a soil environment. The fertilizer is prepared from raw materials in parts by weight as follows: 20-40 parts of urea, 5-15 parts of calcium ammonium nitrate, 10-20 parts of precipitated phosphate fertilizer, 6-16 parts of monopotassium phosphate, 10-20 parts of potassium sulfate, 40-60 parts of fermented chicken manure, 5-15 parts of fermented pig manure, 2-6 parts of bamboo powder, 2-8 parts of shell powder, 10-20 parts of tapioca flour, 5-15 parts of corncobs, 4-8 parts of modified fly ash, 5-12 parts of oil shale powder, 2-4 parts of montmorillonite powder, 2-6 parts of borax, 1-2 parts of sodium silicate, 0.5-1.5 parts of ammonium molybdate, 0.4-0.9 parts of zinc carbonate, 0.1-0.8 parts of magnesium sulfate and 0.5-2 parts of sodium naphthalene acetate. The fertilizer contains very rich nutrients and can decrease the release speed of organic nutrients, effectively enhance soil fertility, effectively improve the soil structure and make hardened soil loose.

Owner:定远县文凡米业有限公司

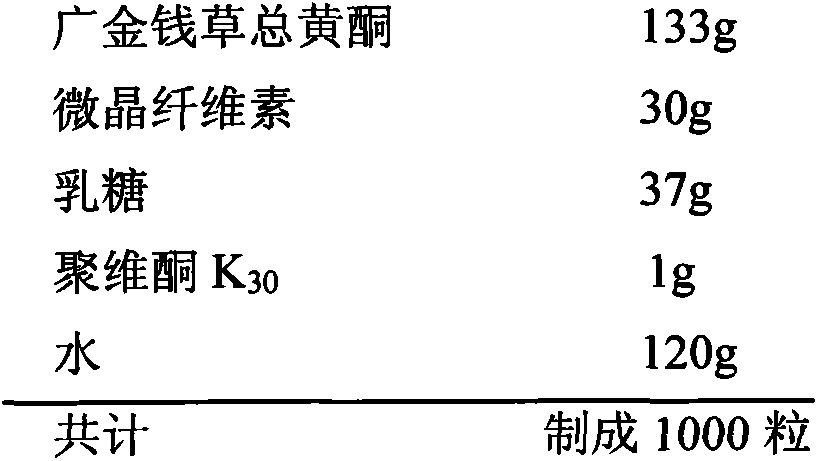

General flavanone capsule of desmodium styracifolium and preparation method and application thereof

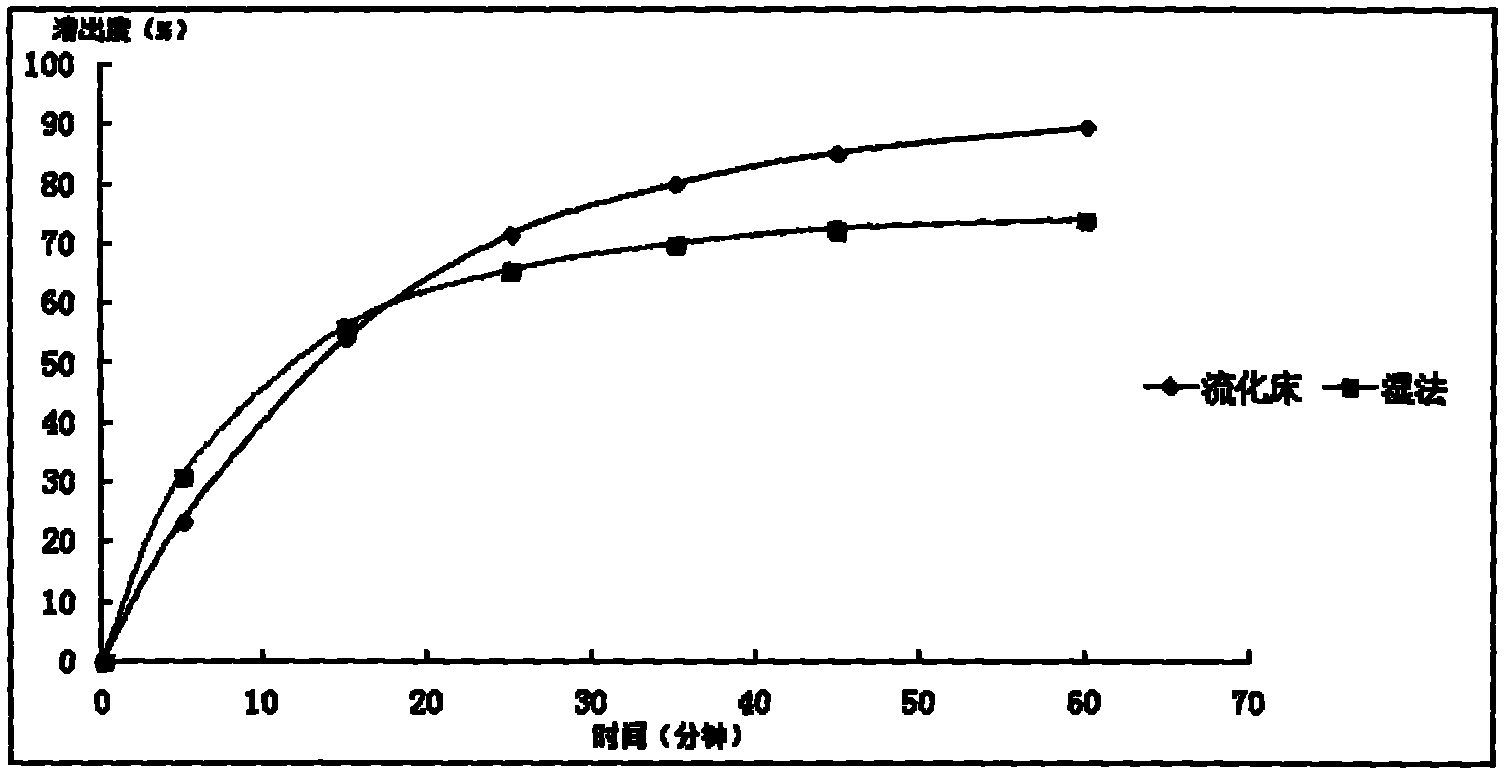

InactiveCN103893246AHigh dissolution rateGood quality and stabilityUrinary disorderGranular deliveryAlcoholMedicine

The invention provides a general flavanone capsule of desmodium styracifolium and a preparation method and application thereof, wherein the general flavanone capsule of the desmodium styracifolium comprises total flavanone of the desmodium styracifolium, which is an alcohol extract of the desmodium styracifolium, and pharmaceutically acceptable medicinal excipients. The general flavanone capsule of the desmodium styracifolium disclosed by the invention has the characteristics of being explicit in effective material basis, controllable in quality standard, good in drug dissolution degree, good in quality stability, significant in pharmacology and drug efficacy, less in dosage, safe and convenient to take, and completely applicable to industrial massive production.

Owner:HUMANWELL HEALTHCARE GRP +1

Method for increasing grade of sinter

The invention discloses a method for increasing grade of sinter, belonging to the metallurgy industry field. The method is used in the production technology of the sinter as follows: in a primary mixing step, roasted flux is used for replacing the existing raw flux in raw materials which comprises the following components according to weight percentage: 70-85% of iron-bearing raw material, 4-6% ofcalcined lime with 75-81% of CaO, 2.5-4.5% of calcium carbide with 65-70% of CaO, 6-8% of slaked lime with 52-54% of CaO, 1-1.5% of light burning magnesium oxide powder with 80-95% of MgO and 3-5% ofSiO2, 5-7% of pulverized coal or coke powder and 30-32% of return fines. The method can effectively increase the grade of sinter and reduce the production cost.

Owner:武钢集团有限公司

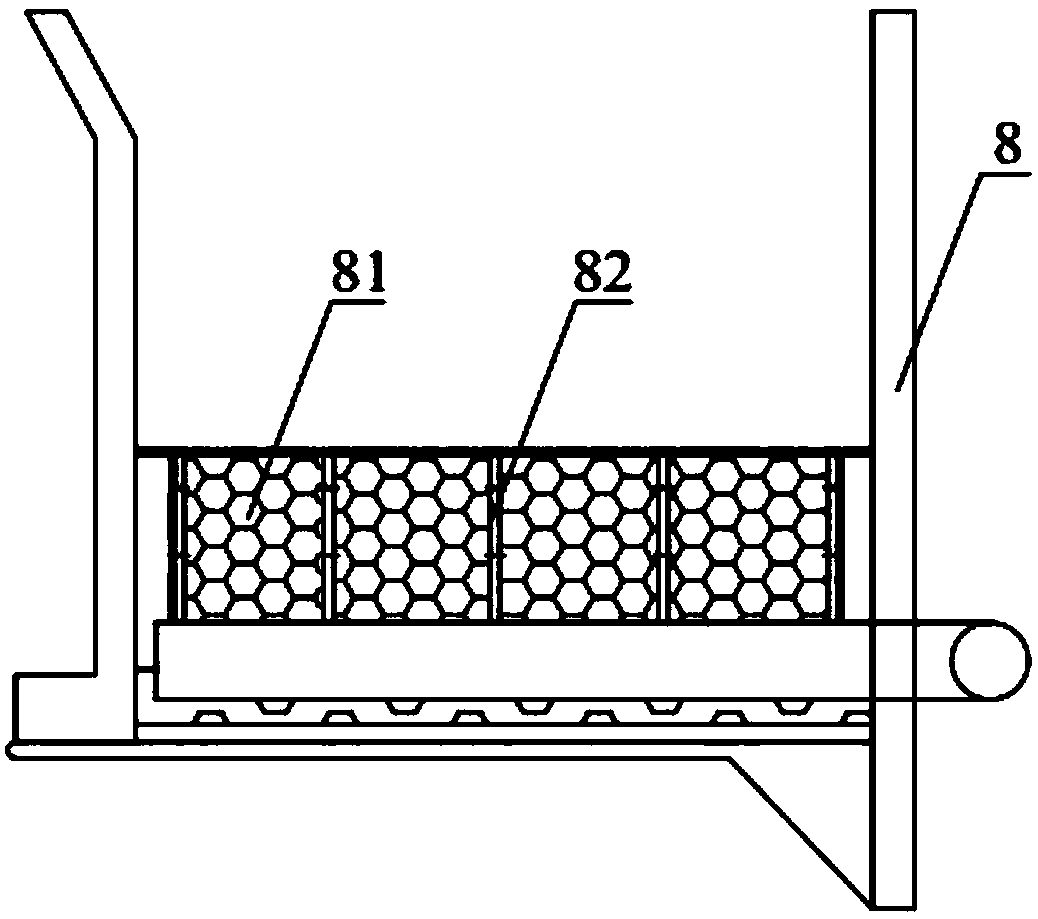

Bottom-filtration-process slag treatment method for ferroalloy submerged arc furnace

ActiveCN108220511AImprove granulation effectReduce generationRecycling and recovery technologiesPunchingFiltration

The invention discloses a bottom-filtration-process slag treatment method for a ferroalloy submerged arc furnace and belongs to the technical field of ferroalloy submerged arc furnace. The method comprises the following steps of making molten slag overflow into a molten slag ditch via a slag tank; performing crushing, water quenching and pelletizing on the slag which flows from the molten slag ditch into a waste slag ditch by high-speed water flow sprayed out of a punching box; making a slag and water mixture flow from the water granulated slag ditch into a buffer tower and continuing to coolthe slag and water mixture; making the slag and water mixture inside the buffer tower directly flow into a filter tank via an outlet device; filtering the water inside the filter tank by using a filter pipe, and conveying the water to a slag treatment water pool by using a water pump; conveying the water inside the water pool to the punching box in order to realize slag punching and cyclic utilization; and grabbing out the water granulated slag from the filter tank by using a water granulated slag grabbing hopper. The method disclosed by the invention is simple in process and reasonable in procedures, commendably guarantees the granulation degree of the slag, realizes more complete slag and water separation, greatly reduces emission of steam, reduces environmental pollution and realizes simple industrial implementation.

Owner:马钢集团设计研究院有限责任公司

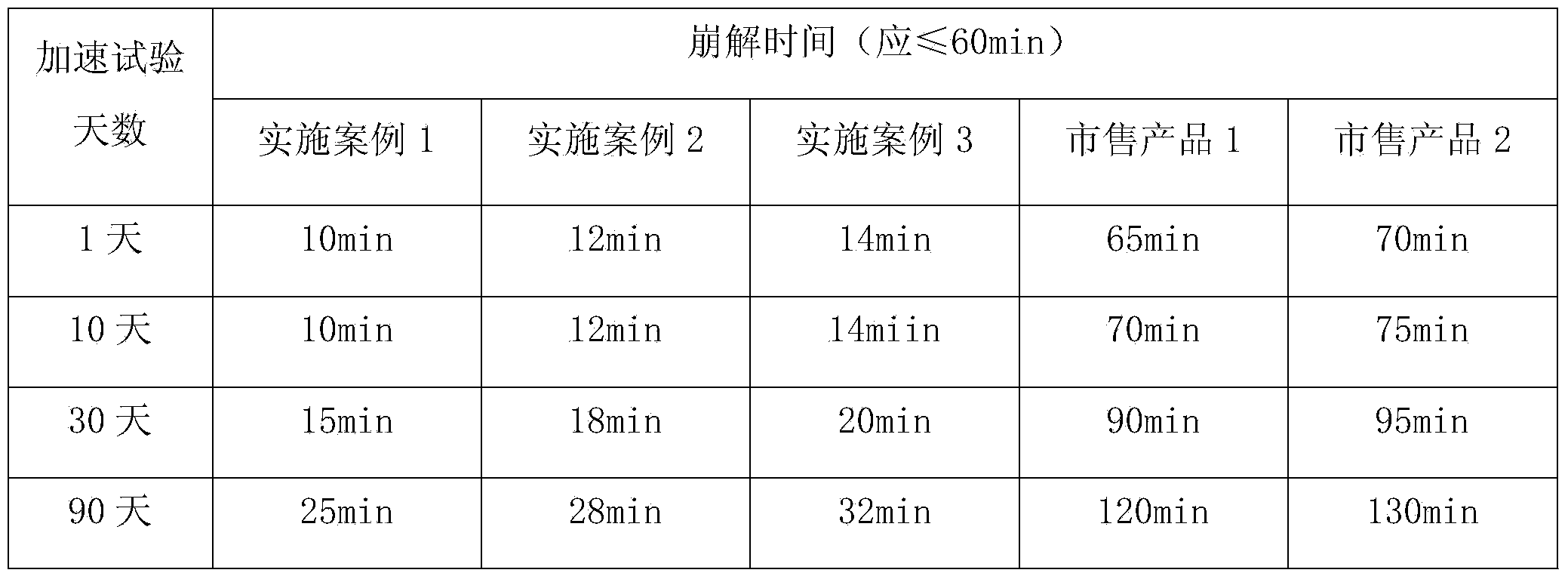

Spirulina tablet, and preparation method thereof

ActiveCN103655639AShort disintegration timePromote absorptionAlgae medical ingredientsPharmaceutical non-active ingredientsCarboxymethyl starchAdditive ingredient

The invention belongs to the field of medicine, and discloses a spirulina tablet. The spirulina tablet comprises following ingredients, by weight, 75 to 88% of spirulina powder, 4 to 10% of xylooligosaccharide, 4 to 10% of isomaltulose, 0.5 to 2% of hydroxypropyl methyl cellulose, 0.5 to 1% of polyethylene glycol 6000, 2 to 5% of carboxy methyl starch, and 0.2 to 1% of magnesium stearate. According to the spirulina tablet, hydrophilia of xylooligosaccharide, isomaltulose and polyethylene glycol 6000 are used; a preparation method is optimized; a common problem of existing spirulina tablet products that disintegration parameters are not qualified is taken as a key point, and is solved. In addition, the spirulina tablet is smooth in surfaces, is stable in quality, is convenient for carrying and taking, and is capable of improving immunity.

Owner:杭州海王生物工程有限公司

Device and method for waste heat recovery of high-temperature molten slag by means of two-step method

ActiveCN105277004AReduce energy consumptionReduce spacingEnergy industryIncreasing energy efficiencySuperheated steamQuenching

The invention provides a device for waste heat recovery of high-temperature molten slag by means of a two-step method. The device comprises a jet pelletizer, a pelletizing barrel and a granulating pit. The lower end of the pelletizing barrel is inserted in the granulating pit, and a liquid level difference is formed due to the difference of inner pressure and outer pressure of the lower end of the pelletizing barrel. The upper end of the pelletizing barrel is connected with a discharging opening of the jet pelletizer. The pelletizing barrel is communicated with a heat exchanger flue, an evaporator is arranged in the heat exchanger flue and connected with a steam bag through a condensation liquid descending pipe and a steam ascending pipe. Waste heat recovery is achieved by means of the two-step method, saturated steam jet pelletizing are firstly carried out on the high-temperature molten slag to form slag particles, superheated steam is generated, and high-grade waste heat is recovered; and water quenching is carried out before the slag particles are solidified, water granulated slag with the high glass phase content is obtained, and low-grade waste heat is recovered. The process is simple, the molten slag waste heat recovery rate is high, energy consumption is reduced, a few of devices are needed, and the size is small. The device can be widely applied to waste heat recovery of blast furnace slag, phosphorus slag and other high-temperature molten slag.

Owner:NANJING SHENGNUO HEAT PIPE

Centrifugal slag granulation and waste heat recovery system

InactiveCN108193006AAvoid stickingImprove granulation effectIncreasing energy efficiencyRecycling and recovery technologiesSlagWater resources

The invention discloses a centrifugal slag granulation and waste heat recovery system. A 'dry-type' treatment method is adopted for slag, and a large quantity of water resources can be saved. According to the centrifugal slag granulation and waste heat recovery system, high-temperature slag is subjected to segmented heat recovery, and the first segment is primarily cooled in a water-cooled wall mode at first; and meanwhile the high-temperature slag is subjected to slag throwing treatment with a slag throwing structure, cold slag and hot slag can be mixed in the slag throwing process, adhesionof the hot slag is prevented and meanwhile agglomeration can be facilitated. By means of the centrifugal slag granulation and waste heat recovery system, after the high-temperature slag is subjected to the first segment of slag throwing agglomeration and heat recovery, the second segment of ball-milling tank heat recovery and crushing procedure is conducted; and meanwhile the absorbed heat is conveyed to a steam boiler and used for generating steam. By adoption of the centrifugal slag granulation and waste heat recovery system, the heat recovery efficiency of the slag is improved, and the pelletization effect of the slag is effectively improved. The first segment of heat recovery and the third segment of heat recovery are series-connection low-temperature heat recovery, and the heat recovery efficiency is effectively improved through segmented recovery of the heat.

Owner:秦皇岛点知汇科技有限公司 +1

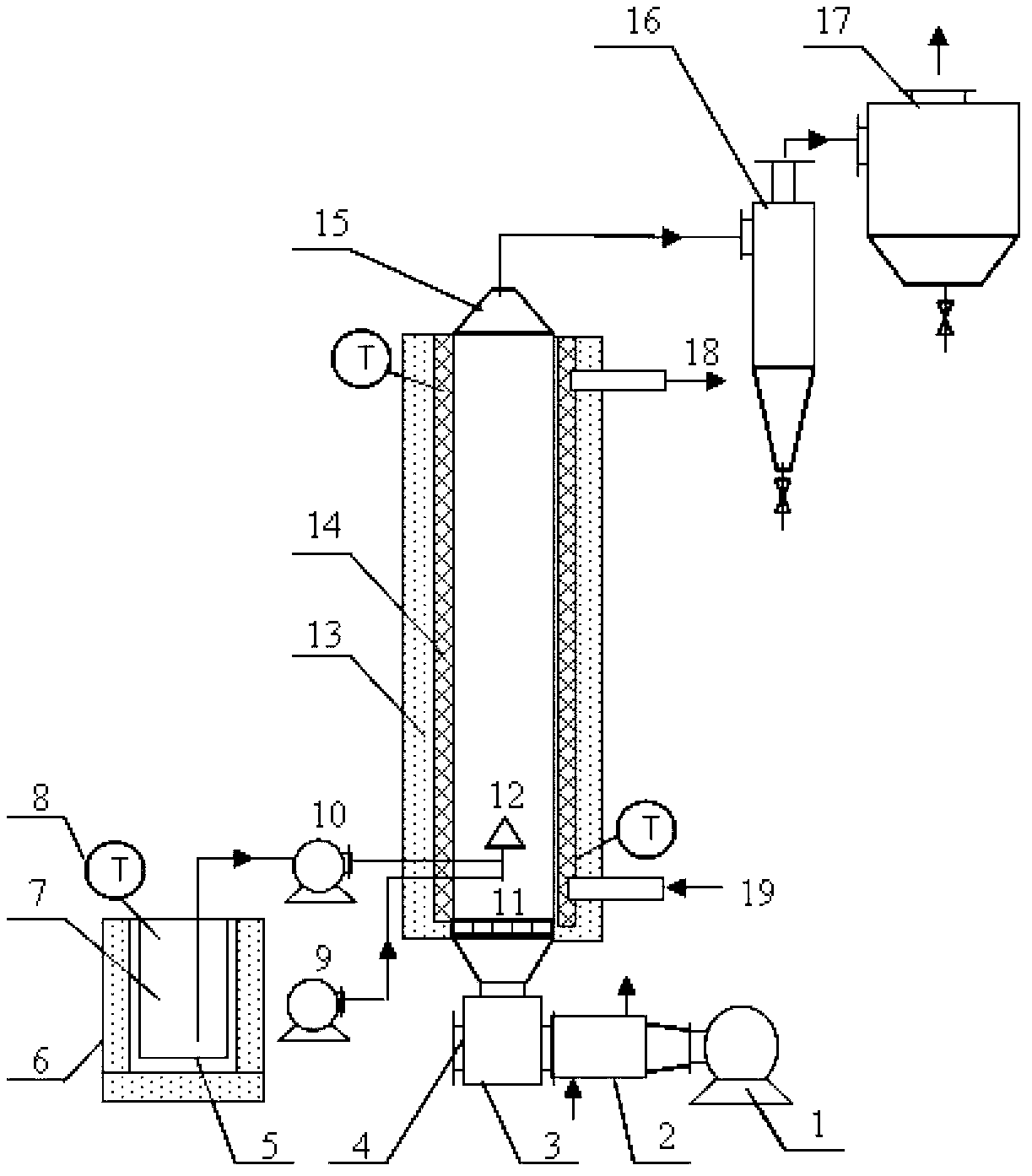

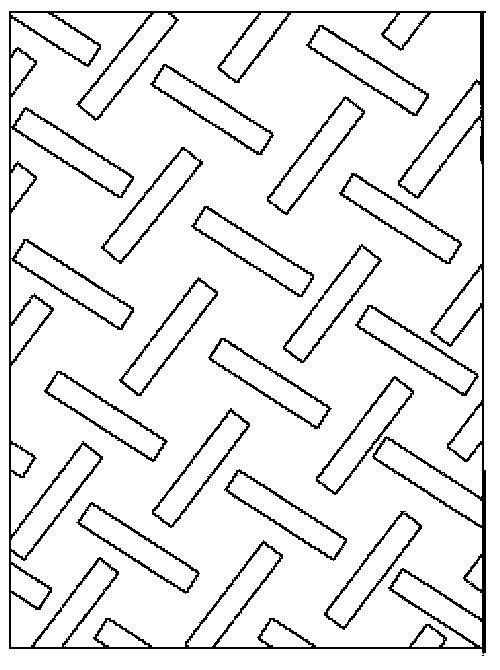

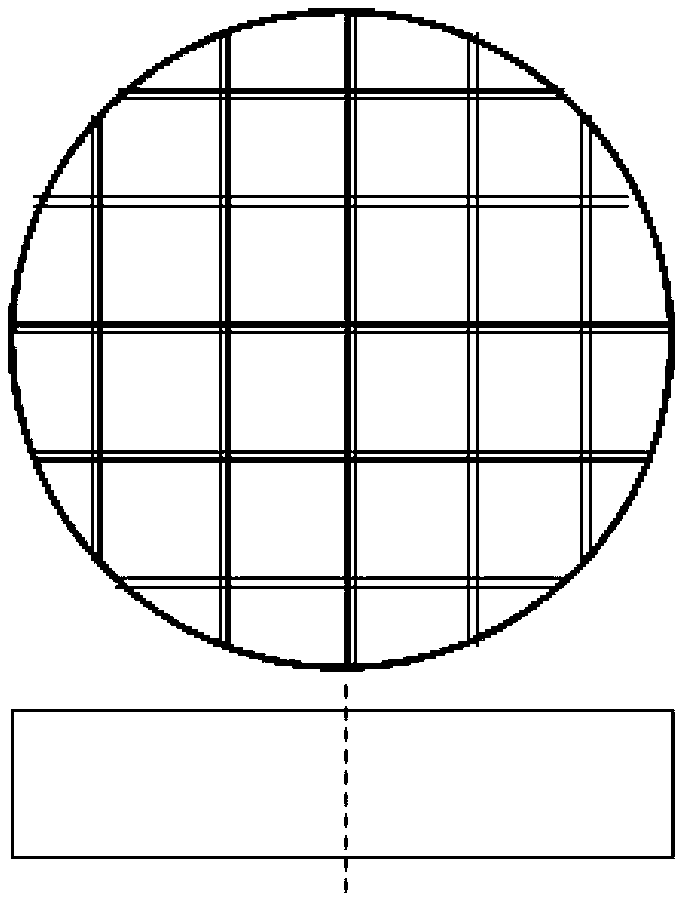

Preparation method of polyethylene wax micropowder and spray granulation system

ActiveCN103275335AEasy to operate, safe and reliableImprove granulation effectGranulation by liquid drop formationPOLYETHYLENE WAXEngineering

The invention discloses a preparation method of polyethylene wax micropowder. The preparation method comprises the following steps of: (1) melting and conveying raw materials, i.e., polyethylene wax feed liquid is prepared by adopting a heating device, the polyethylene wax feed liquid is conveyed to an atomizer inside a spray granulation tower by using a heat-insulation gear pump through a pipeline, and the pipeline and other parts of the atomizer, except a spray hole, need to be subjected to integral heat insulation; (2) compressing and atomizing air, i.e., compressed air provided by an air compressor is conveyed into the atomizer through another pipeline and is matched with the polyethylene wax feed liquid with the pressure, the polyethylene wax feed liquid is sufficiently atomized, and the atomized fogdrops are cooled and solidified into micropowder in the granulation tower; and (3) collecting a product, i.e., the cooled and solidified micropowder is collected by using a collecting device to obtain the product. The invention further discloses a spray granulation system which is used for preparing the polyethylene wax micropowder. The preparation method disclosed by the invention is low in energy consumption, simple and convenient to operate and safe and reliable; and the prepared product has small granularity.

Owner:淮南市德瑞环保科技有限公司

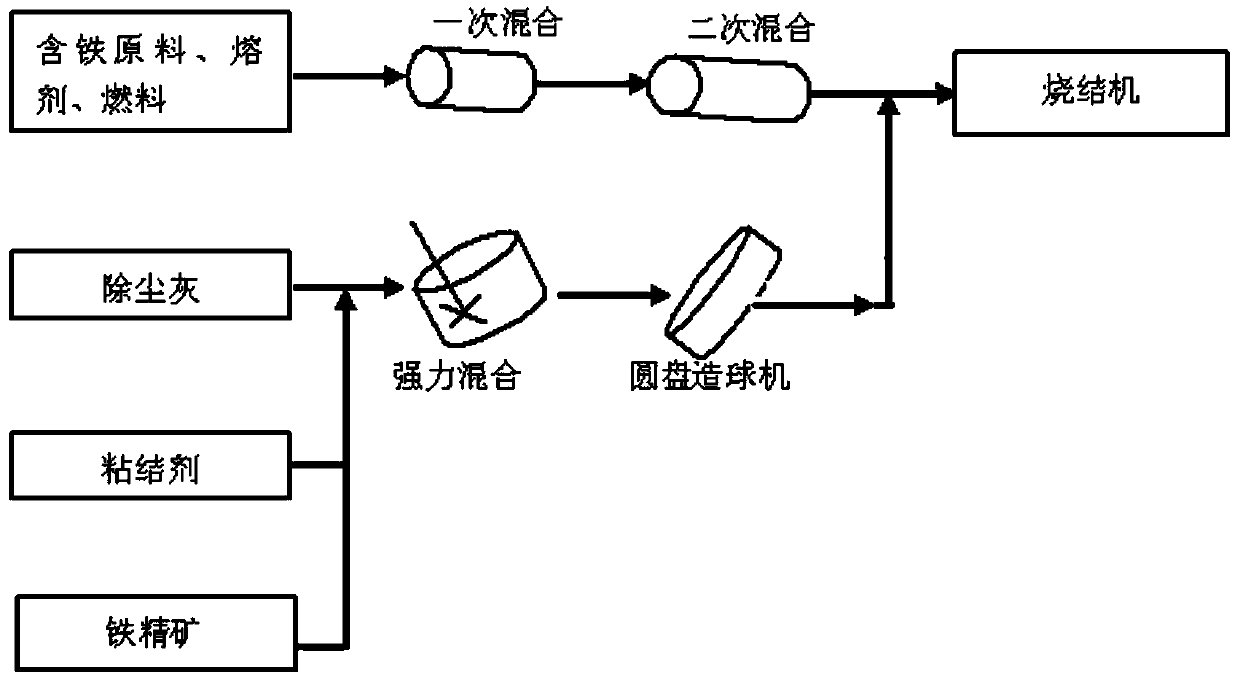

Sintering method utilizing dust removal ash

The invention relates to a sintering method utilizing dust removal ash. The method comprises the following steps of 1, calculating the proportion of a mixed ore to a solvent to a fuel to a return ore participating in material preparation according to a conventional sintering process, and carrying out primary mixing and secondary mixing according to a conventional process for granulation; 2, preparing the dust removal ash, iron ore concentrate and a binding agent according to the ratio of 1 to 2-4 to 0.04-0.06, and feeding a mixture into a strong mixing machine for mixing; 3, feeding materials mixed by the strong mixing machine into a disc pelletizer for pelletizing; and 4, mixing a small pellet prepared by the disc pelletizer with the mixture on a belt conveyor behind a secondary mixing machine, wherein the mixture is granulated through a primary mixing machine and the secondary mixing machine according to the step 1, and the mixture and the small pellet enter a sintering machine together for distribution, ignition and sintering. The method overcomes the defect that the dust removal ash is fine in particle size, the surface hydrophobicity is strong after the dust removal ash is polarized by the electric field, the surface energy is very low, so granulation is difficult to realize if sintering is directly applied, the granulation effect of the sintered mixture is improved, the sintering production can be stabilized, and the good quality of the sintered ore is ensured.

Owner:武汉钢铁有限公司

Biotype seedling strengthening agent

InactiveCN101468932AReduce pollutionImprove efficacyExcrement fertilisersAmmonium salt fertilisersPotassiumBiology

The invention provides a biotype seedling vitalizing agent. The prior conventional seedling vitalizing agent consists of a soil disinfection part, a soil acid regulation part and a nutrition part containing nitrogen, phosphorus and potassium and medium-trace elements, wherein germicides for soil disinfection are all prepared from chemical pesticide which is high in toxicity and not easy to decompose in soil, pollutes environment, and is not easy to operate, poor in safety and easy to cause seedbeds diseases and phytotoxicity, as well as serious loss. The soil acid regulation part of the conventional seedling vitalizing agent adopts zeolite, fly ash and other inorganic raw materials to adsorb acid. The composition of the biotype seedling vitalizing agent comprises biological germicides, chemical germicides, nutritional agents, acid and substances for controlling growth, wherein the weight portion of the biological germicides is 0.5 to 3.3; the weight portion of the chemical germicides is 0.35 to 1.2; the weight portion of the nutritional agents is 66 to 90; the weight portion of the acid is 7 to 30; and the weight portion of the substances for controlling growth is 0.012 to 0.06. The biotype seedling vitalizing agent is applied as an agricultural fertilizer.

Owner:韩庆岭

Iron ore sinter additive

InactiveCN101240374AImprovement effectSintering mineralization rate and strength increaseWater contentCalcium carbonate

The invention relates to a new additive for iron ore sinter, which can greatly improve sintering granulating effect, increase sintering mineralization rate and strength, lower production cost, and improve production efficiency. The invention is characterized in that the new additive for iron ore sinter is composed of 60% of calcium oxide, 2% of silicon dioxide, 2% of Al2O3, 4% of magnesia, 1% of ferric oxide, 1% of calcium chloride and 30% of calcium carbonate. The above materials are uniformly mixed, and then free moisture is dried by a vapor dryer, the water content is 49%, finally, the materials fine grinded by a globe mill to form the new additive for iron ore sinter. The invention can improve the production of sintering granulating 3mm to 5mm granulation pellet from 24% to 36.7%, the fine granulation is reduced obviously, the sintering granulating effect is improved significantly, the sintering mineralization rate and strength are increased notably, thereby lowering production cost and improving production efficiency.

Owner:鞍山市佳良能源技术开发有限公司

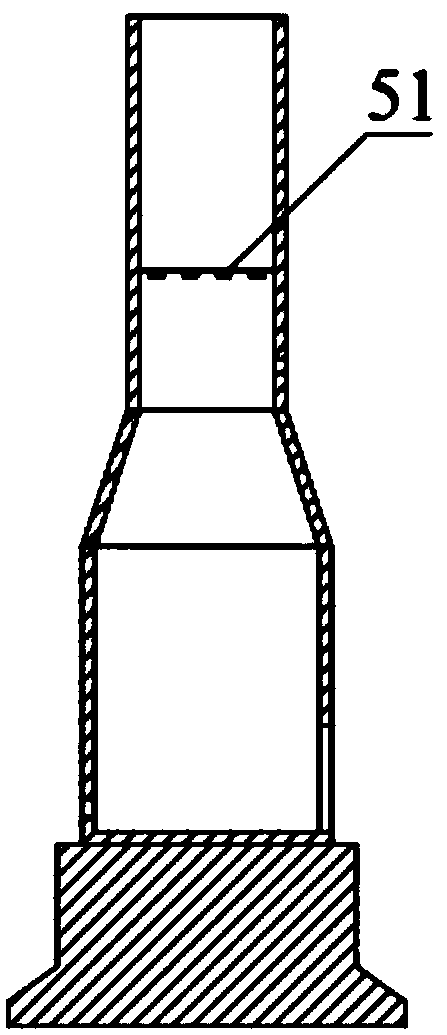

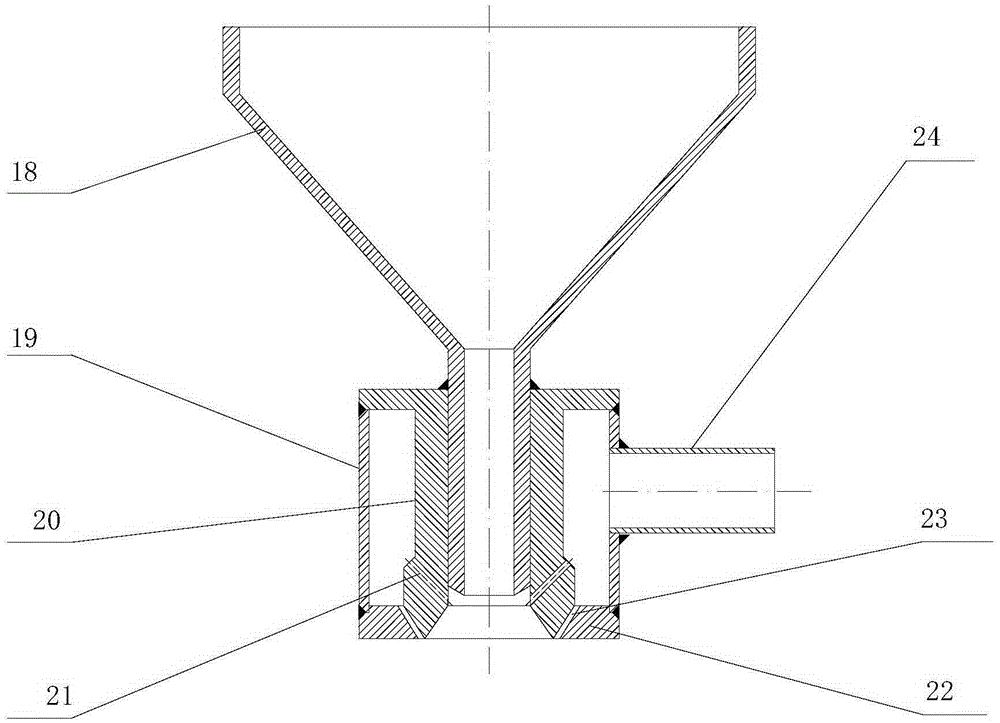

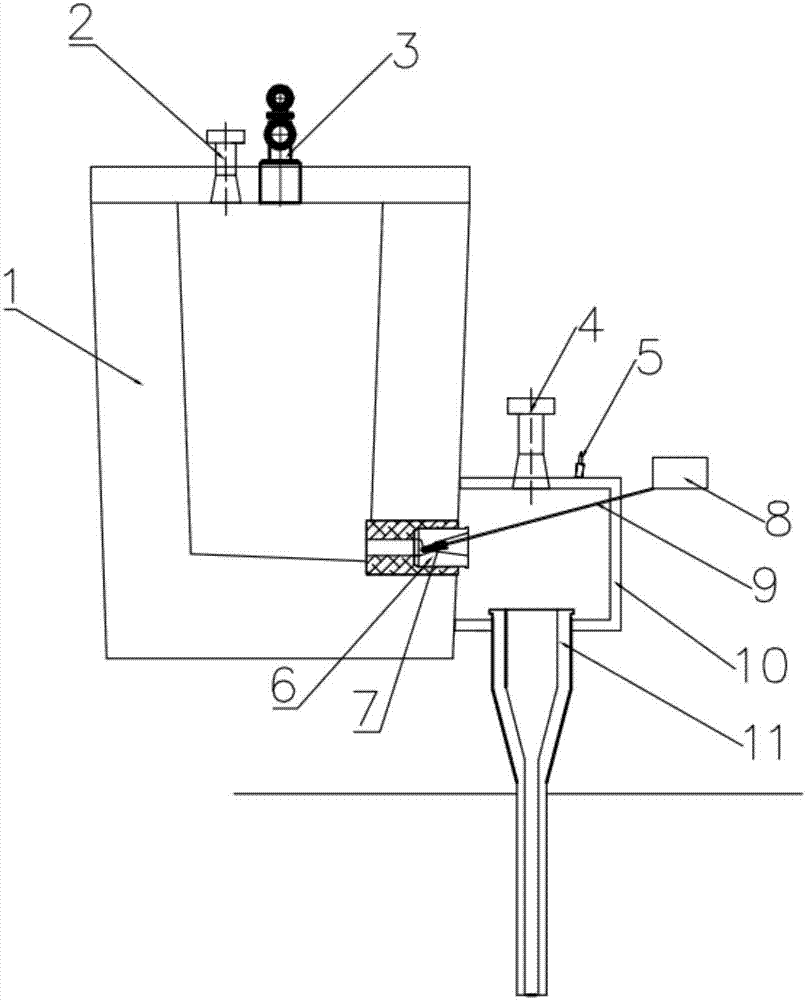

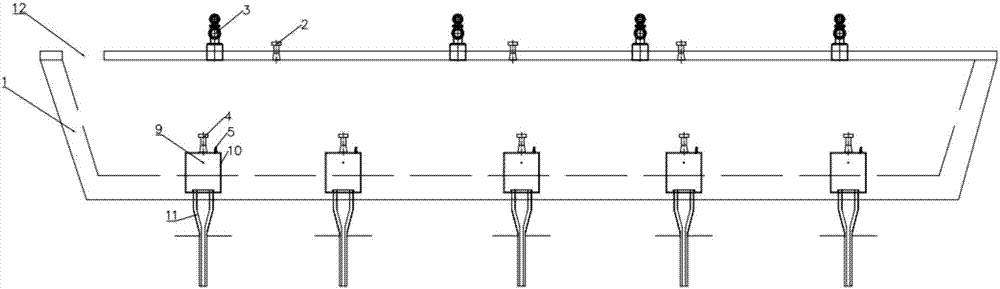

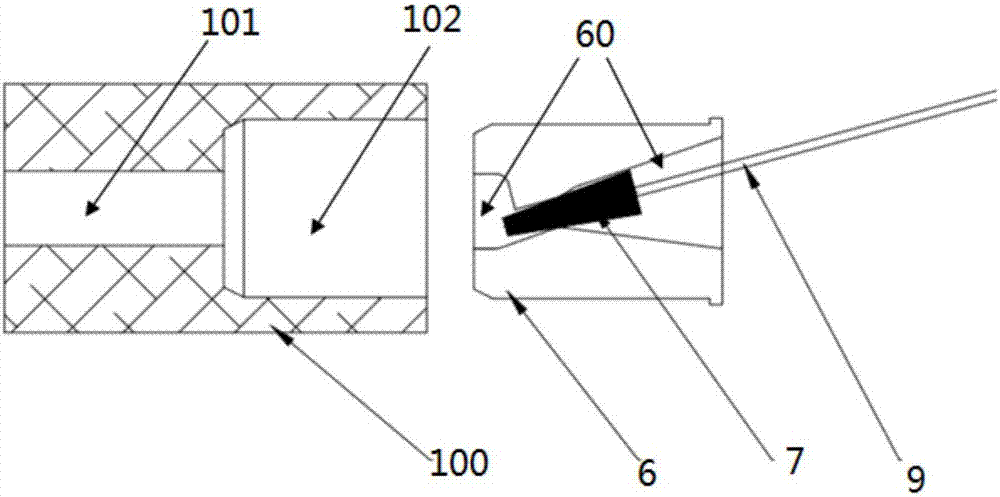

Secondary liquid slag temporary storage system with flow temperature monitoring and controlling functions

ActiveCN106940140AMaintain physical propertiesRealize the industrialization of granulationCharge manipulationControl devices for furnacesBrickLiquid slag

The invention discloses a secondary liquid slag temporary storage system with flow temperature monitoring and controlling functions. A slag inlet is formed in the upper portion of a slag ladle shell. A plurality of slag outlets are formed in the side face of the bottom of the slag ladle shell. Each slag outlet is composed of a brick cup and a fixed-diameter nozzle. A stopper is arranged in each slag outlet, and each stopper comprises a stopper head, a stopper rod and a stopper control device. Each brick cup is provided with a brick cup runner and a fixed-diameter nozzle containing cavity communicating with the brick cup runner. Each fixed-diameter nozzle is installed in the corresponding fixed-diameter nozzle containing cavity. Each brick cup runner communicates with the slag ladle shell and an inlet of a fixed-diameter nozzle inner runner of the corresponding fixed-diameter nozzle. Each stopper rod is connected with the corresponding stopper head and the corresponding stopper control device. Each stopper control device is used for controlling the flow passage area between the corresponding stopper head and the corresponding fixed-diameter water nozzle. A sealing cover is arranged outside each fixed-diameter nozzle, and the bottom of the sealing cover is provided with a slag falling pipe. According to the secondary liquid slag temporary storage system, the liquid slag temporary storage function and the flow temperature monitoring and controlling functions can be achieved, the liquid slag is subjected to subsequent pelletizing process continuously and stably, and the secondary liquid slag temporary storage system can be widely applied to liquid slag pelletizing waste heat recycling systems.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com