Method for increasing grade of sinter

A technology of sinter and grade, applied in the field of metallurgical industry, can solve the problem of unrecorded calcium-containing and magnesium-containing smelting flux, etc., and achieve the effects of improving original permeability, reducing production cost, and increasing use value and promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

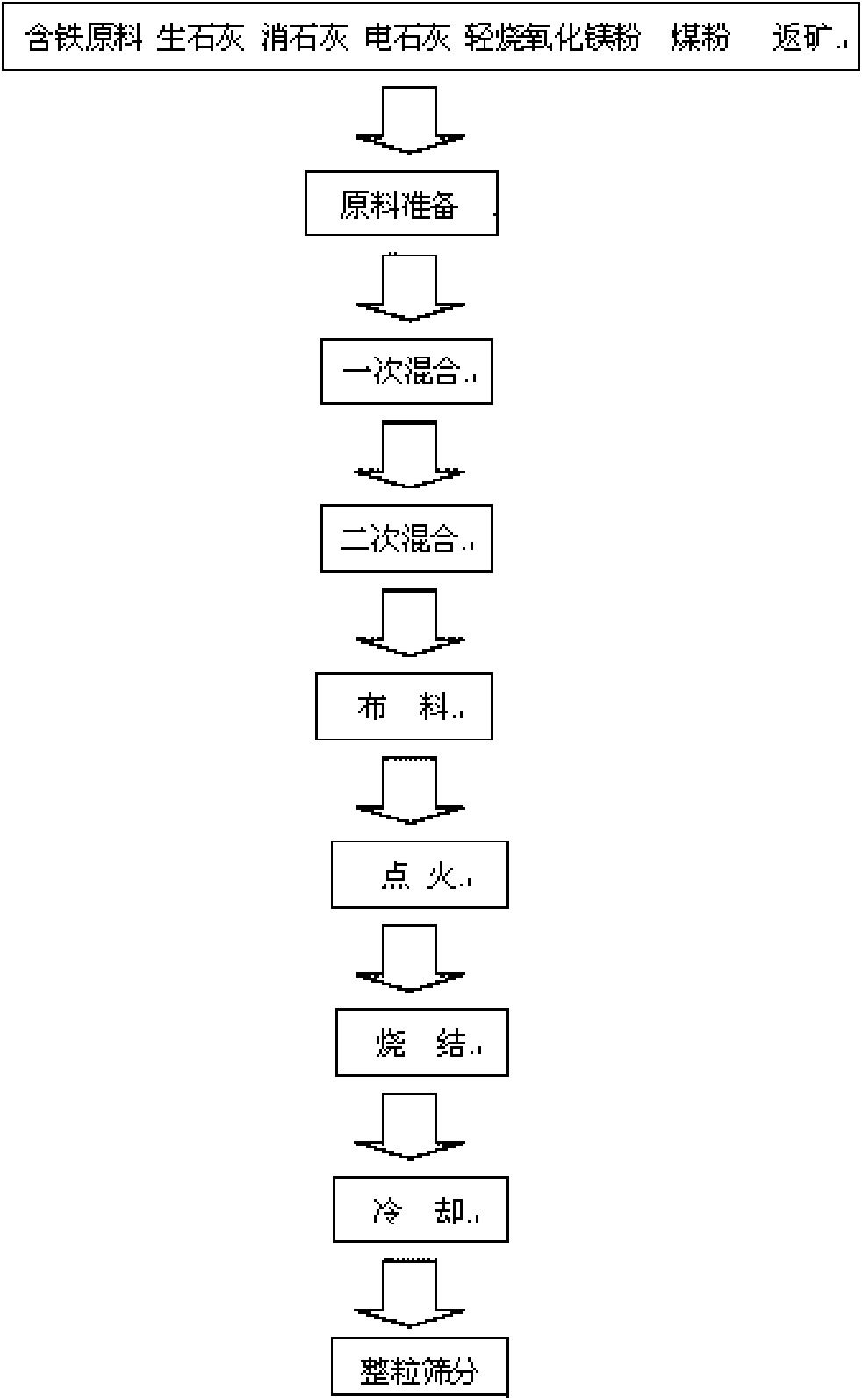

Image

Examples

Embodiment 1

[0035] Sintering basicity CaO / SiO2=1.85, the content of TFe is 57%, the index of MgO content is 2.5%, the weight percent of various components in the raw material sees S-1 in Table 1, contains in the various components of raw material See Table 2 for chemical composition percentages.

[0036] Among the raw materials, the particle size of iron-containing raw materials in the range of 0-10mm and 8-10mm is 14%, and the moisture content is 12%. The burning loss rate of quicklime is 18%, and that of the particle size within the range of 0-3mm is 92%. The moisture content of calcium carbide is 25%, and the particle size is 86% within the range of 0-3mm. The moisture content of slaked lime is 27%, and the particle size is 92% within the range of 0-3mm. The burning loss rate of light-burned magnesium oxide powder is 2.44%, and the particle size is 91% in the range of 0-3mm. The particle size of pulverized coal is 80% within the range of 0-3mm, and the moisture content is 12%.

[0...

Embodiment 2

[0047] Sintering basicity CaO / SiO2=1.80, the content of TFe is 57%, the index of MgO content is 2.6%, the weight percentage of various components in the raw material is shown in S-2 in Table 1, contains in the various components of raw material See Table 2 for chemical composition percentages.

[0048] Among the raw materials, the particle size of iron-containing raw materials in the range of 0-10mm, 8-10mm is 10%, and the water content is less than 13%. The burning loss rate of quicklime is 21%, and that of the particle size within the range of 0-3mm is 95%. The moisture content of calcium carbide is 26%, and the particle size is 88% within the range of 0-3mm. The moisture content of slaked lime is 29%, and the particle size is 95% within the range of 0-3mm. The burning loss rate of light-burned magnesium oxide powder is 3%, and the particle size is 94% in the range of 0-3mm. The particle size of pulverized coal is 77% within the range of 0-3mm, and the moisture content is...

Embodiment 3

[0059] Sintering basicity CaO / SiO2=1.85, the content of TFe is 58%, the index of MgO content is 2.0%, the weight percent of various components in the raw material sees S-3 in Table 1, contains in the various components of raw material See Table 2 for chemical composition percentages.

[0060] Among the raw materials, the particle size of iron-containing raw materials in the range of 0-10mm and 8-10mm is 10%, and the water content is 12%. The burning loss rate of quicklime is 20%, and that of the particle size within the range of 0-3mm is 95%. The moisture content of calcium carbide is 28%, and the particle size is 82% within the range of 0-3mm. The moisture content of slaked lime is 28%, and the particle size is 96% within the range of 0-3mm. The burning loss rate of light-burned magnesium oxide powder is 2%, and the particle size is 95% within the range of 0-3mm. The particle size of pulverized coal is 77% within the range of 0-3mm, and the moisture content is 10%.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com