Secondary liquid slag temporary storage system with flow temperature monitoring and controlling functions

A liquid slag and control function technology, applied in the direction of furnace control devices, lighting and heating equipment, furnace components, etc., can solve the problems affecting the continuous and stable progress of the subsequent granulation process, achieve continuous long-term operation, improve safety, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

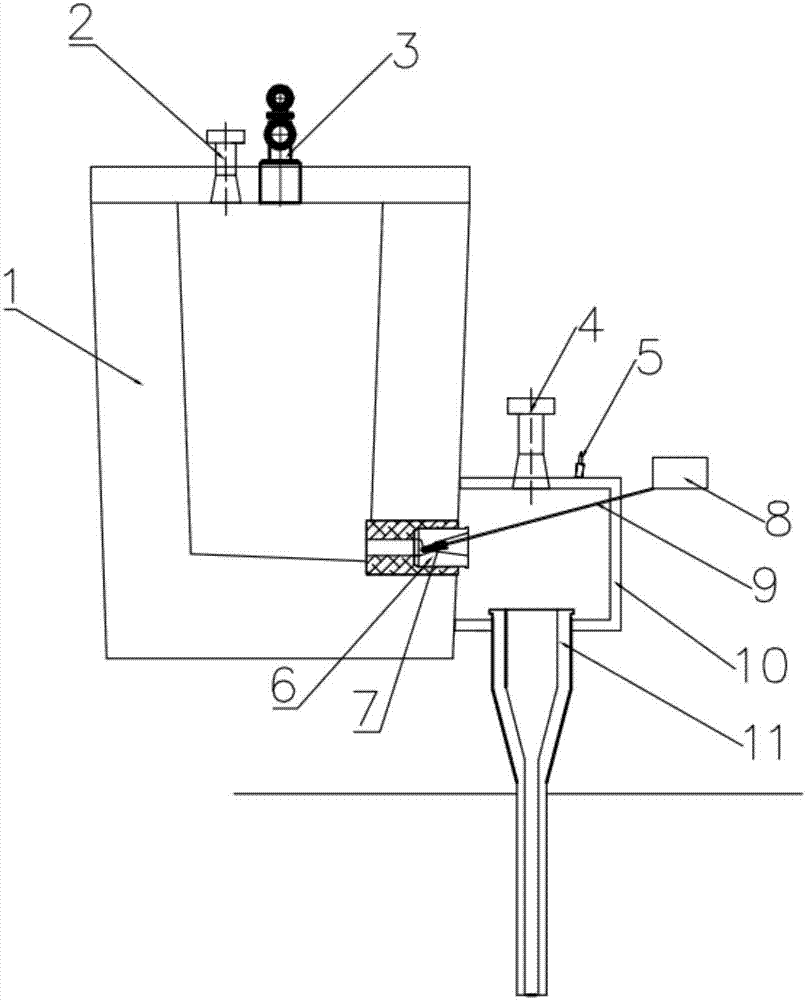

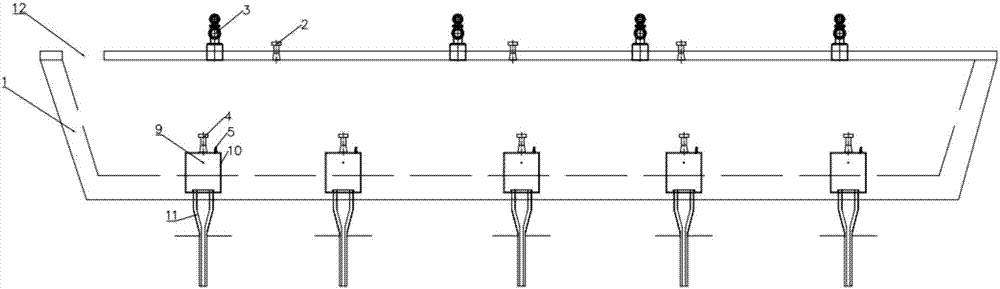

[0029] see Figure 1 to Figure 3 As shown, the present invention is a secondary liquid slag caching system with flow temperature monitoring and control functions, including a slag ladle shell 1, a sizing nozzle 6, a stopper head 7, a stopper control mechanism 8, and a slag drop pipe 11 And sealing cover 10.

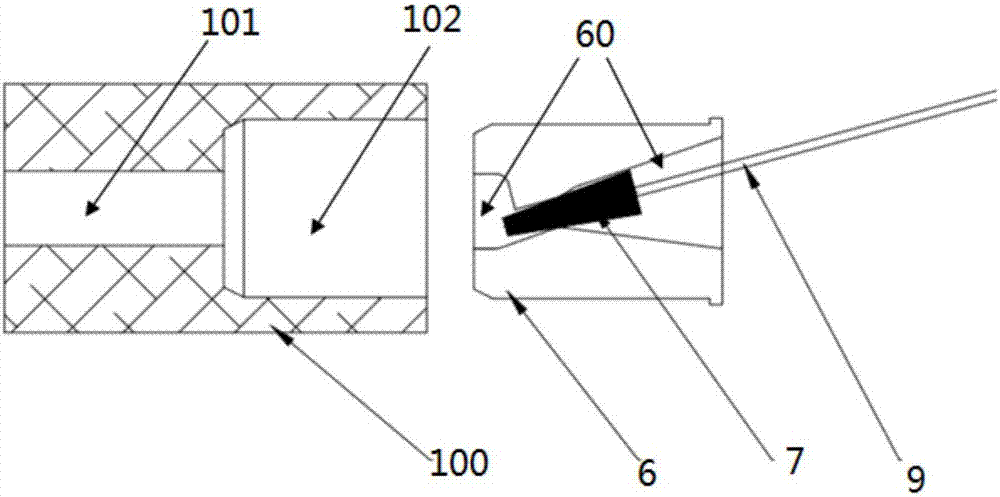

[0030] There is a slag inlet 12 on the upper part of the slag bag shell 1, and one or more slag outlets on the bottom. The slag outlet is composed of a block block 100 and a sizing nozzle 6; a slag outlet is correspondingly provided with a stopper rod, which includes a stopper The head 7, the stopper rod 9 and the stopper control device 8, the seat brick are provided with a block flow channel 101 and a sizing nozzle accommodation chamber 102 which communicate with each other, and the sizing nozzle is installed in the sizing nozzle accommodation chamber; One end of the brick flow channel is connected to the inner cavity of the slag ladle housing for slag, and the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com