Patents

Literature

4573results about How to "Avoid erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

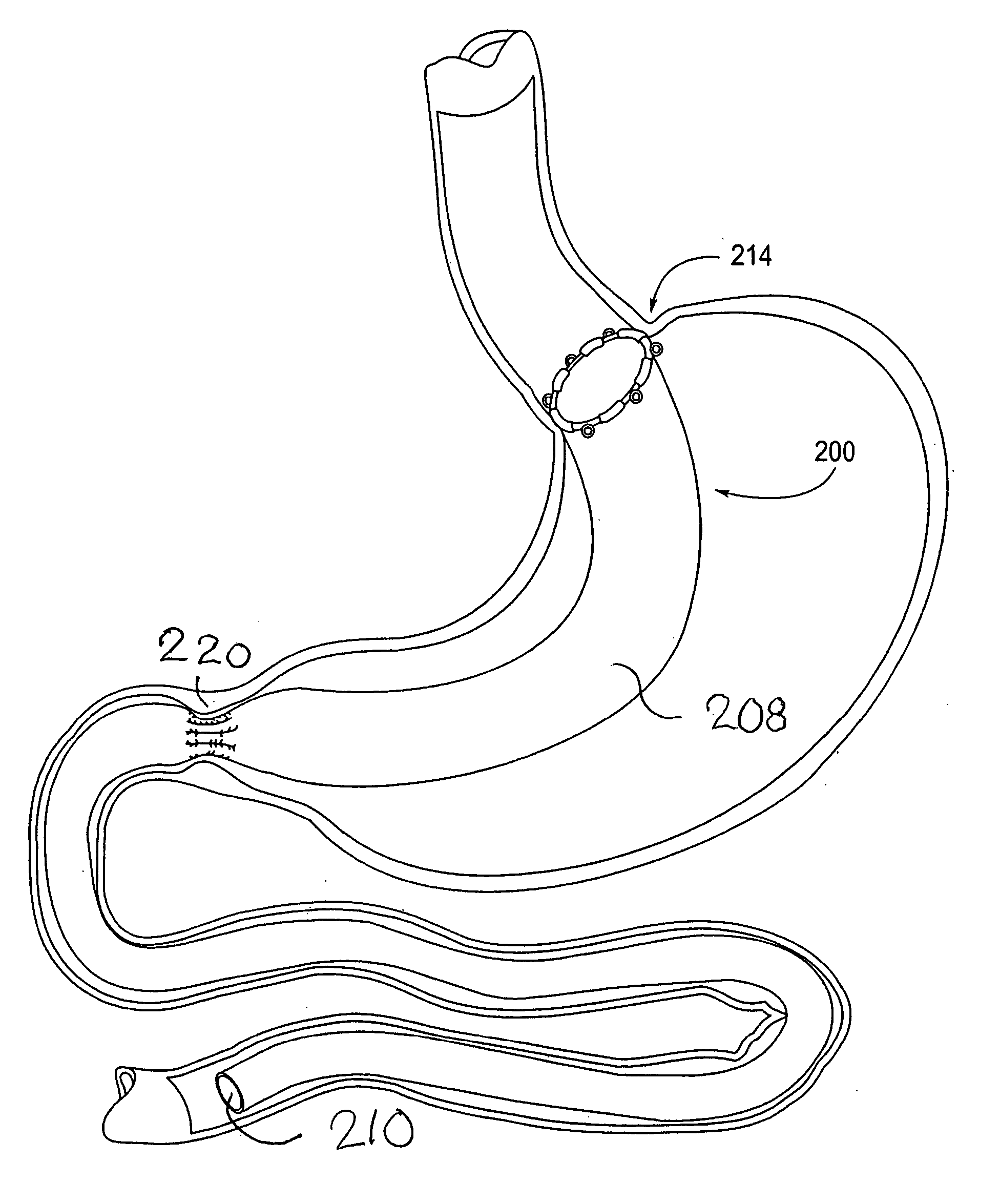

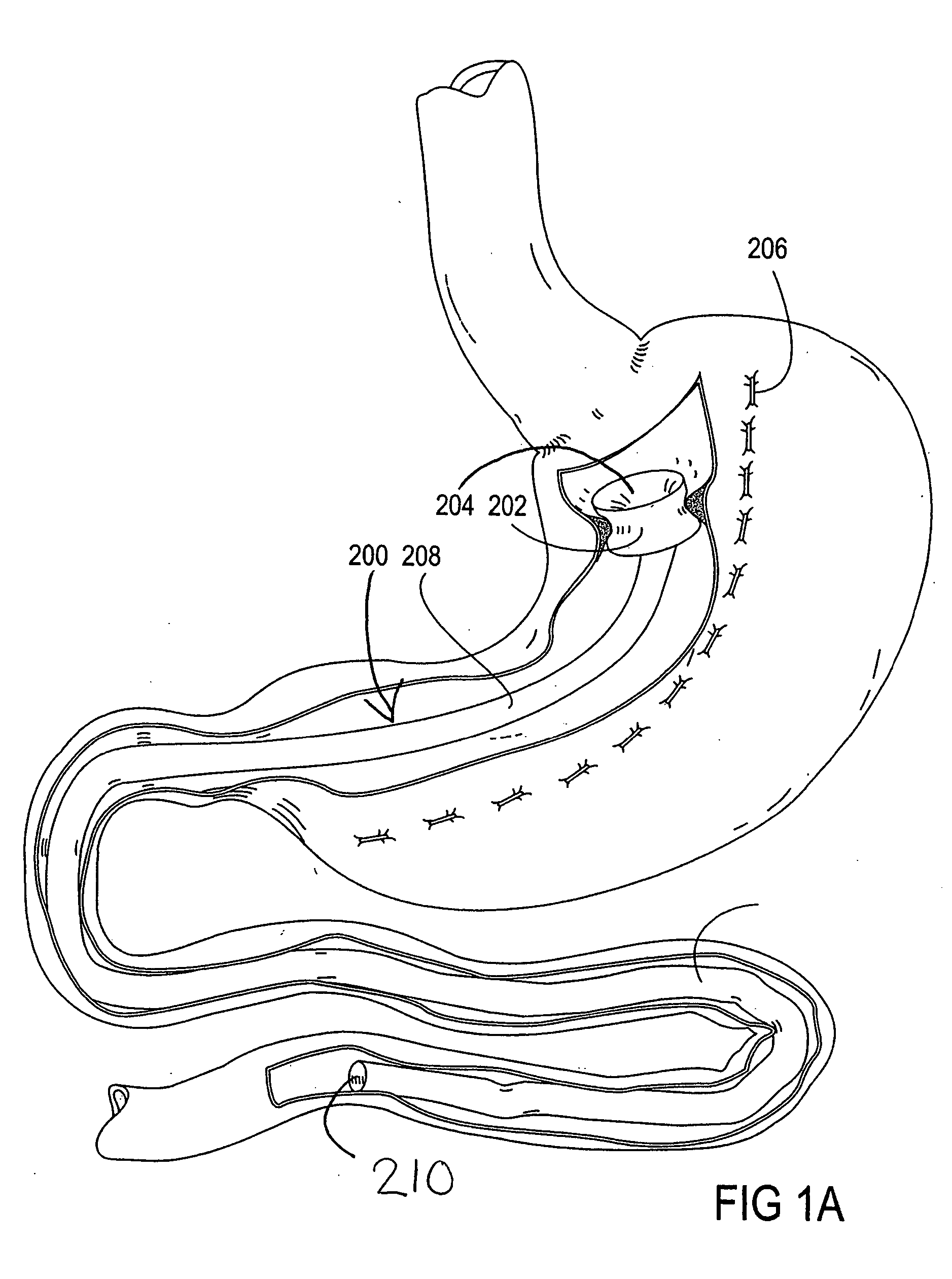

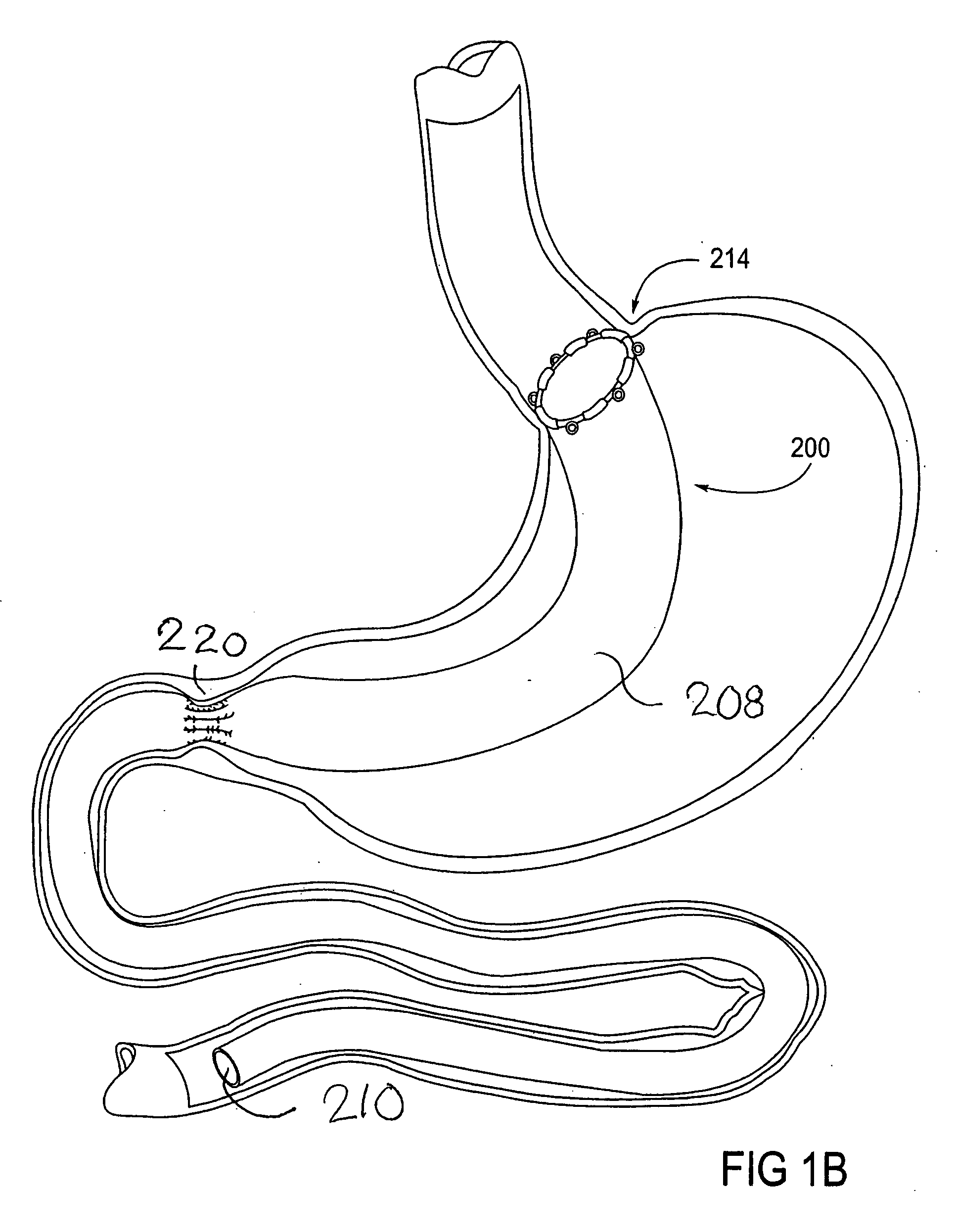

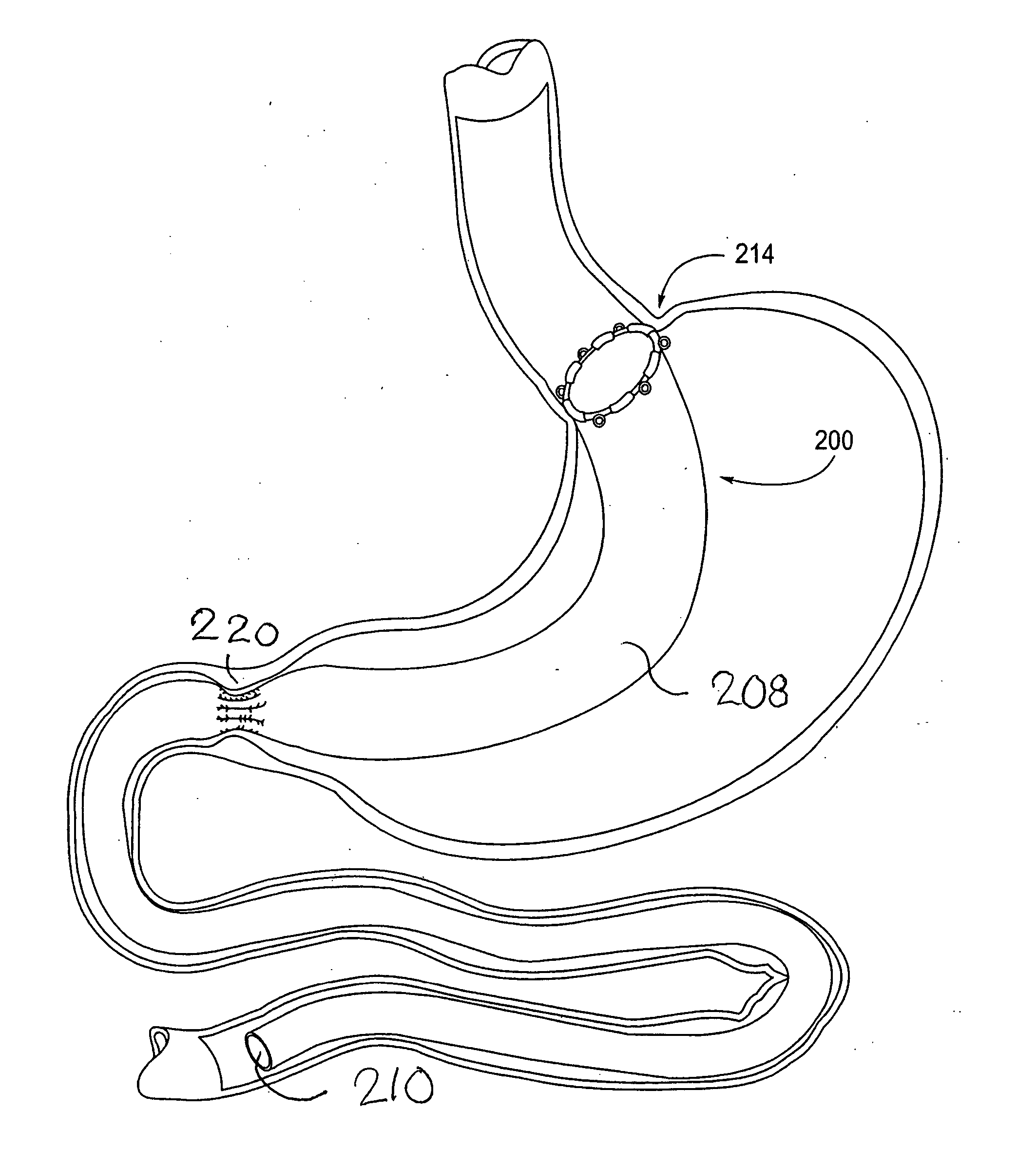

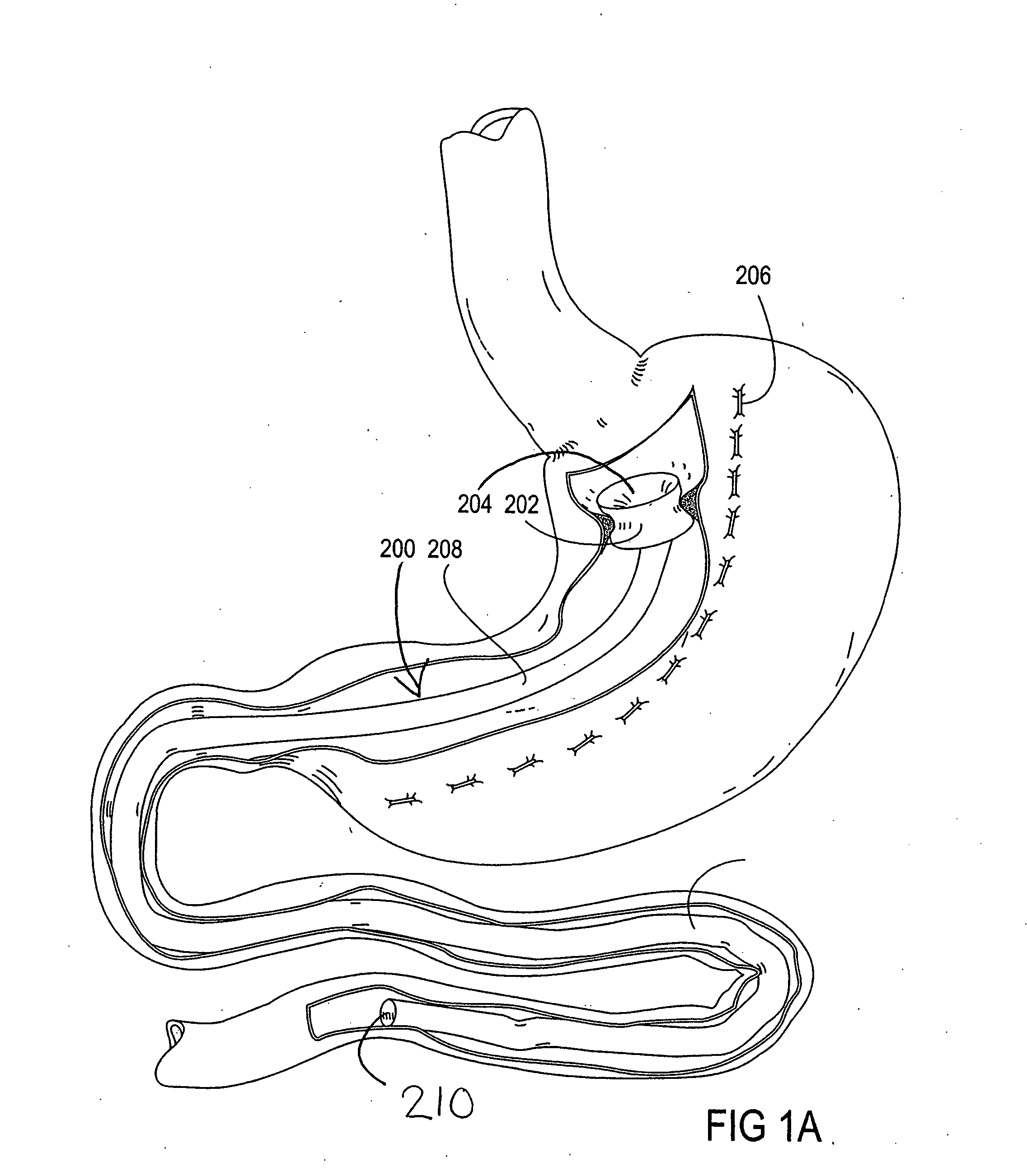

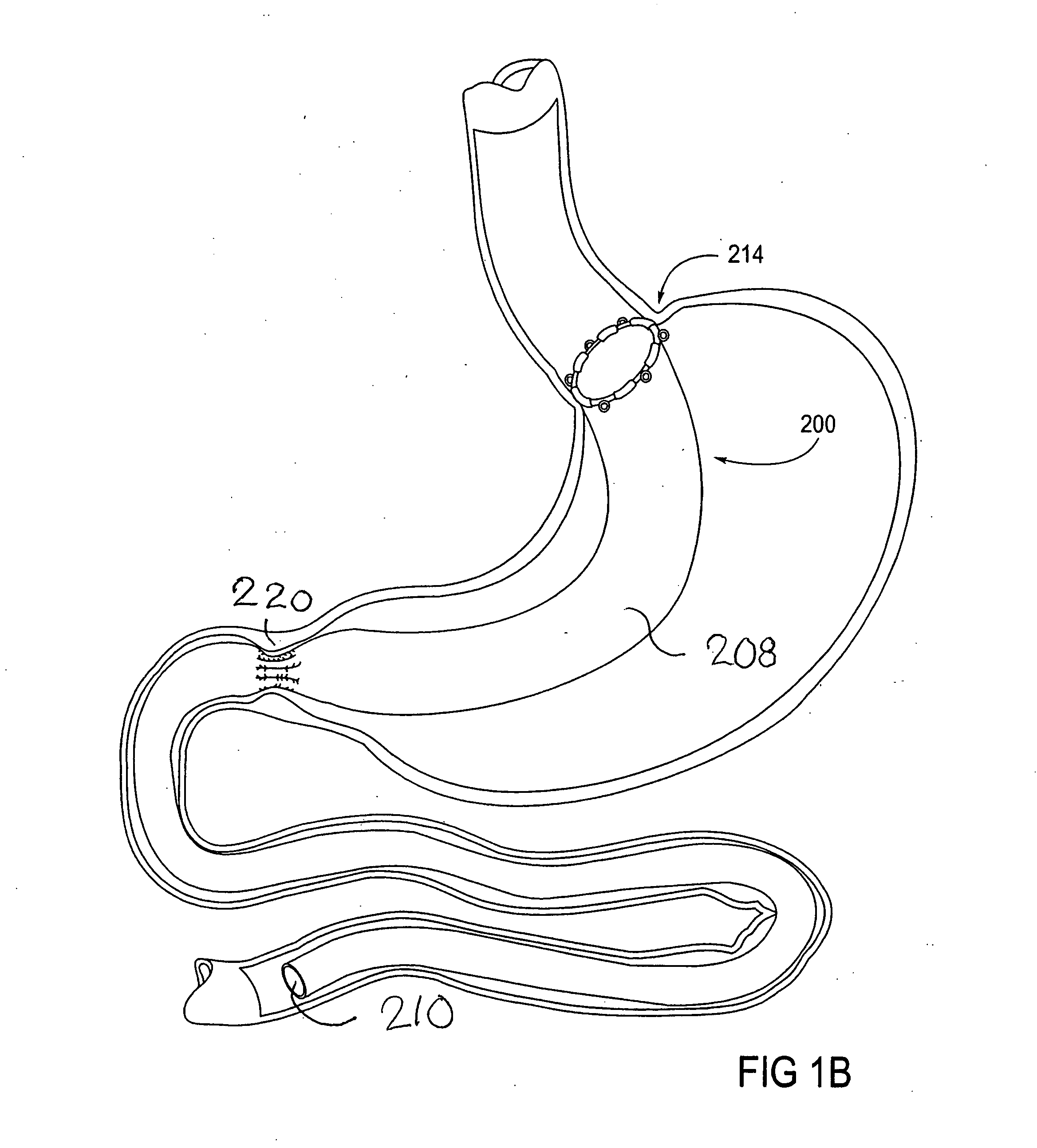

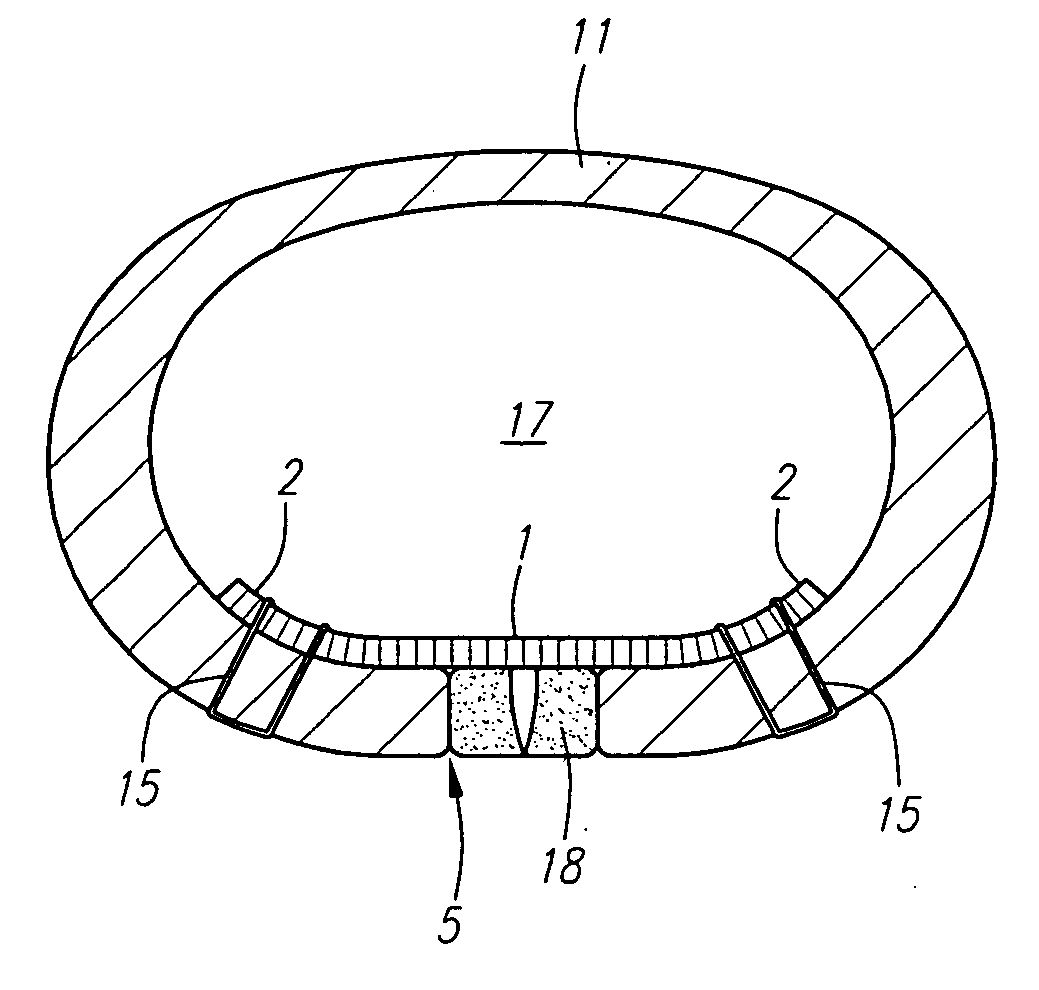

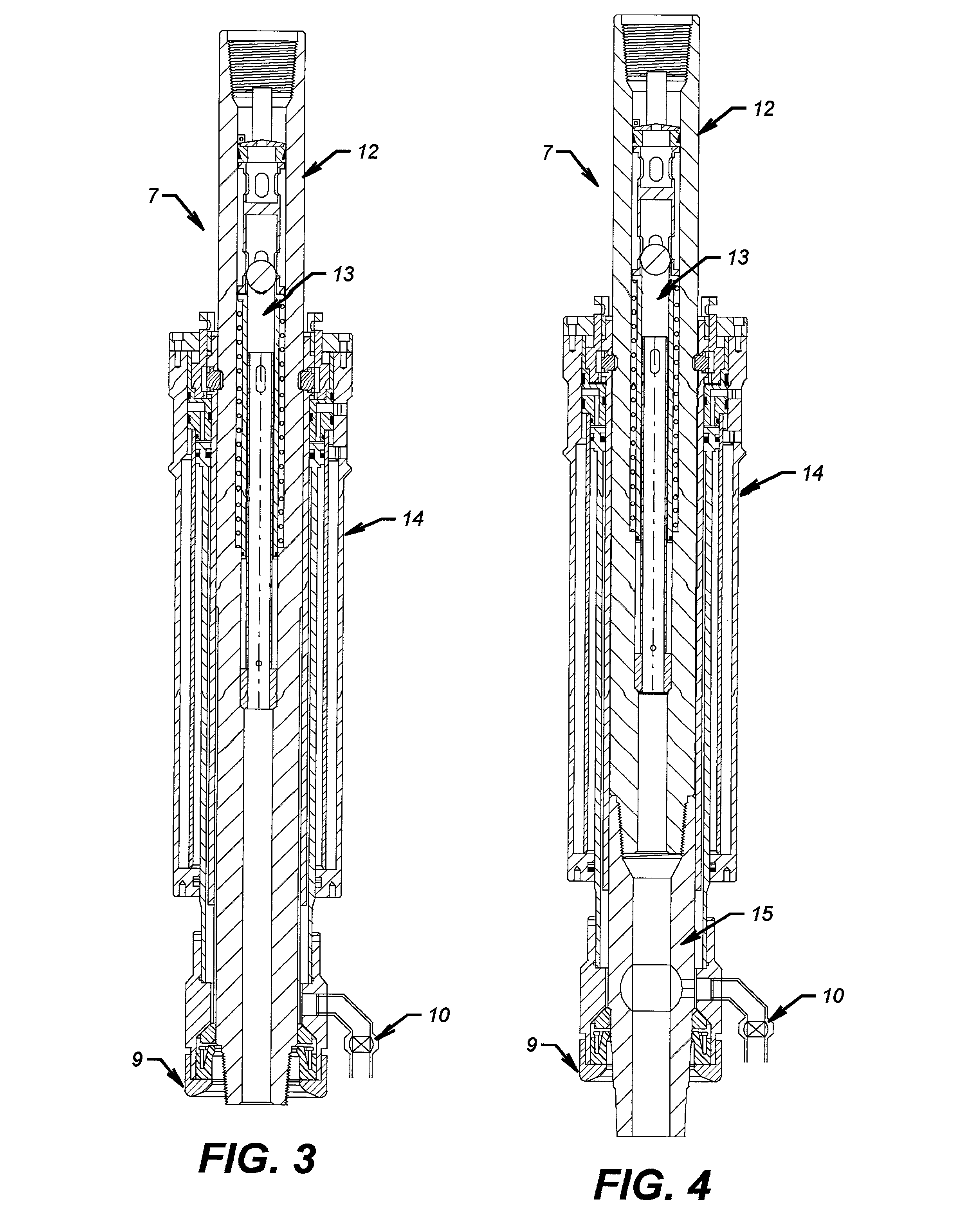

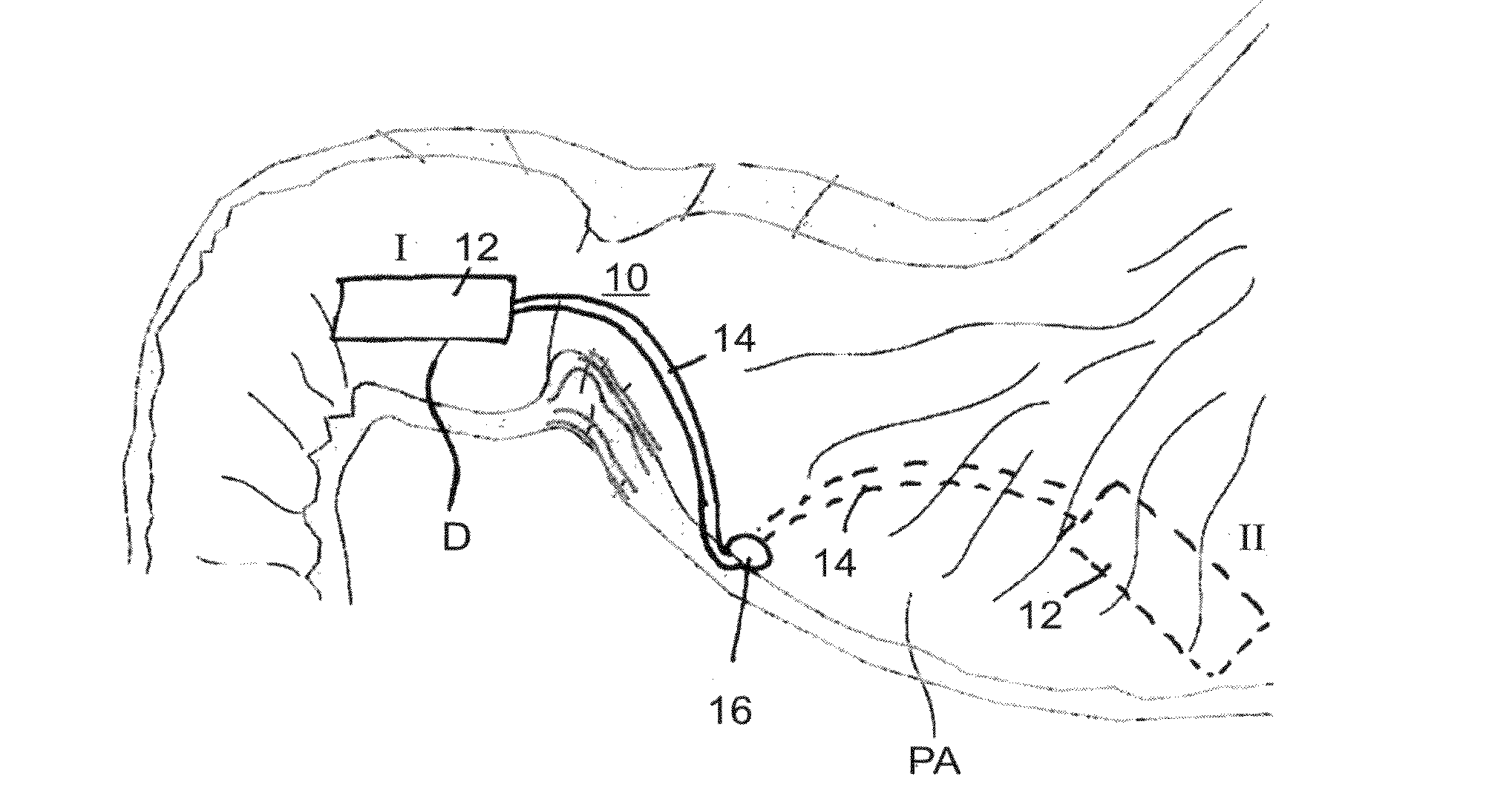

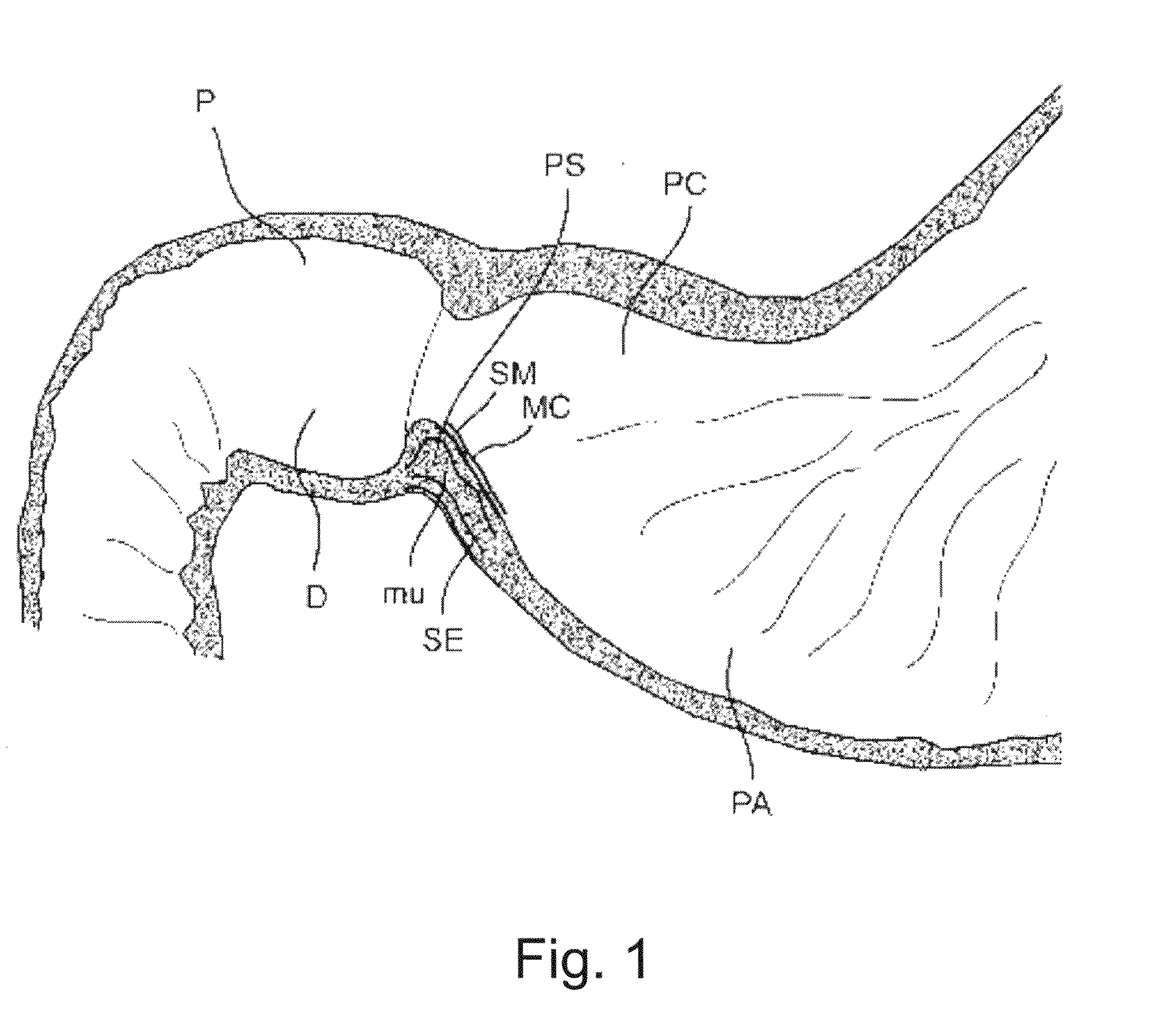

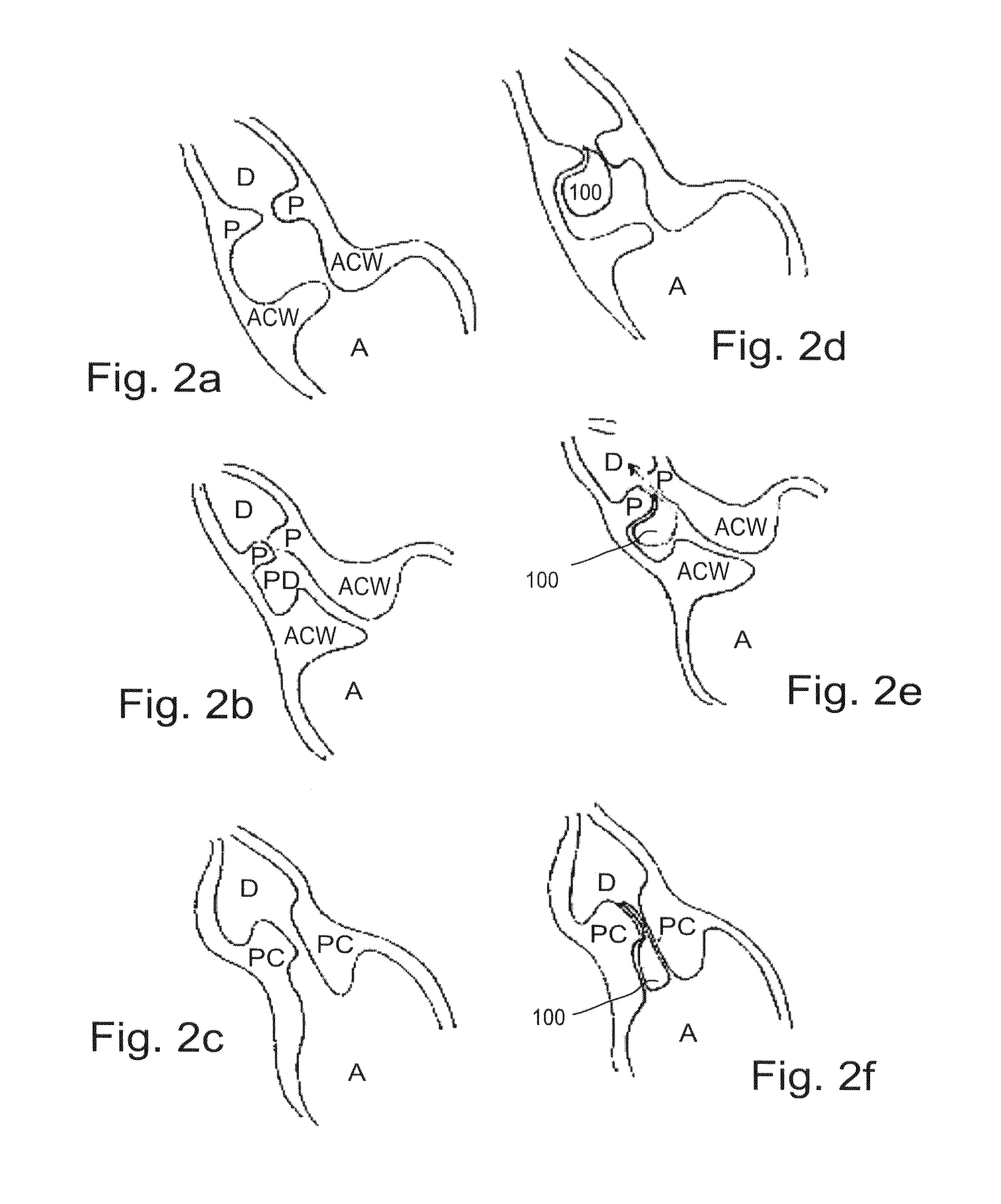

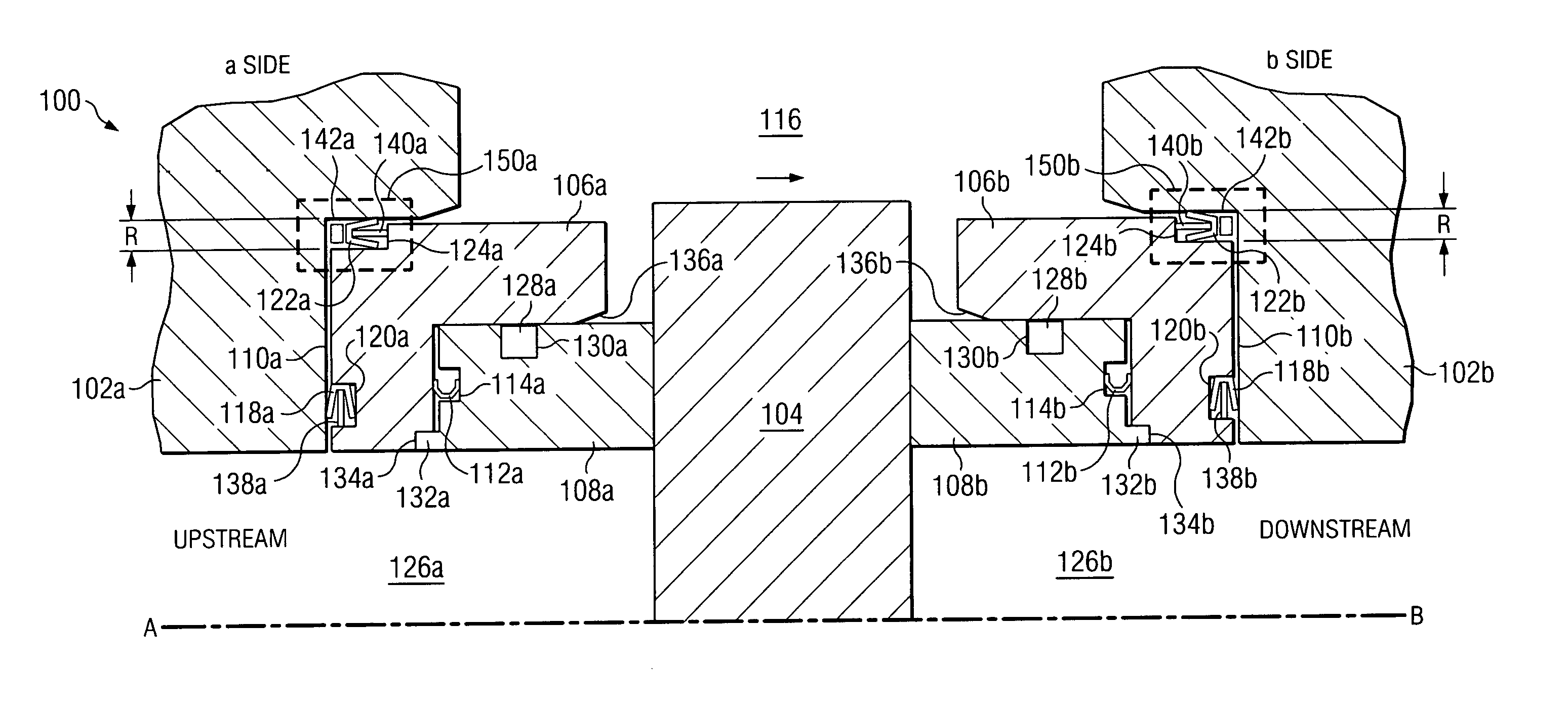

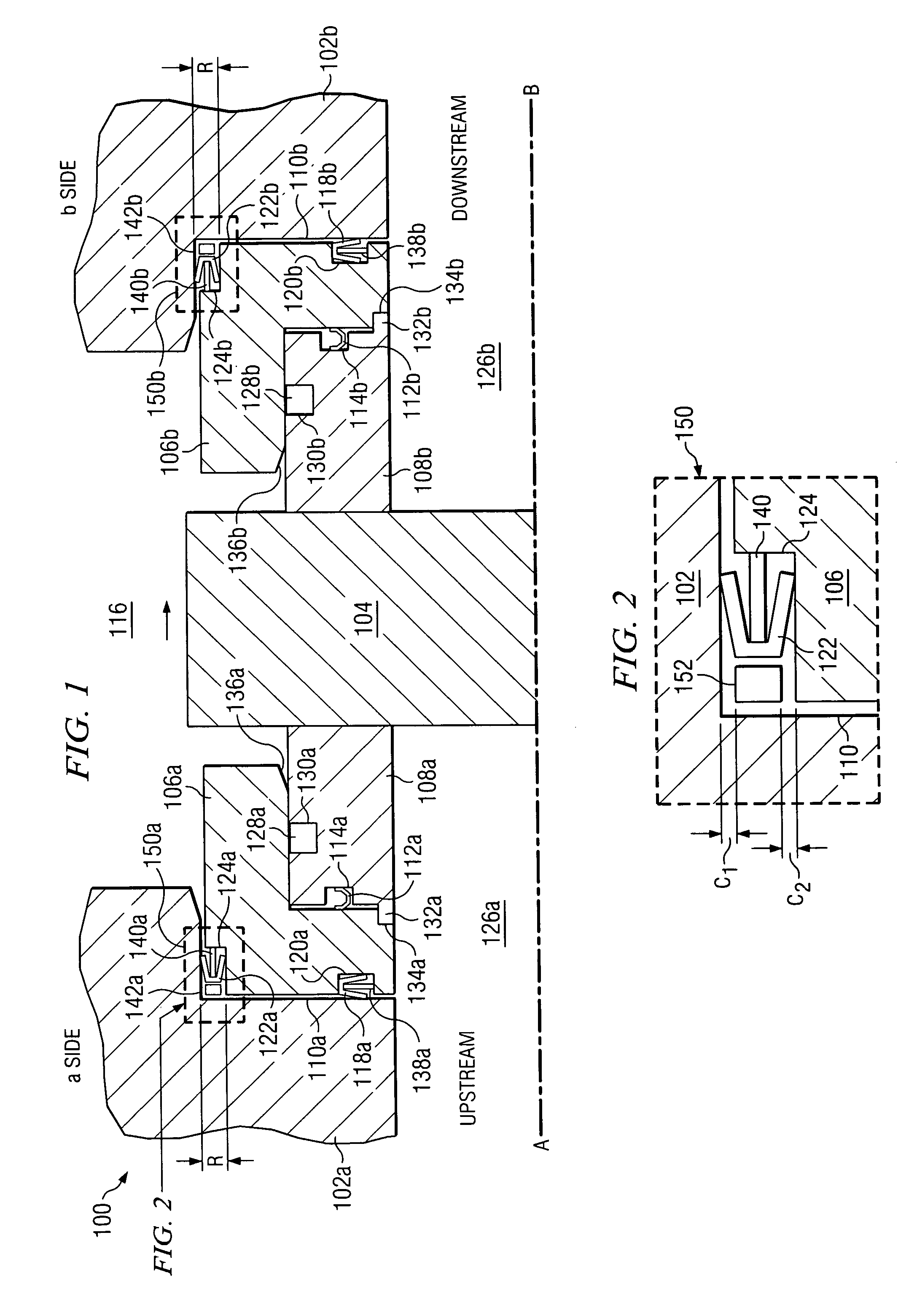

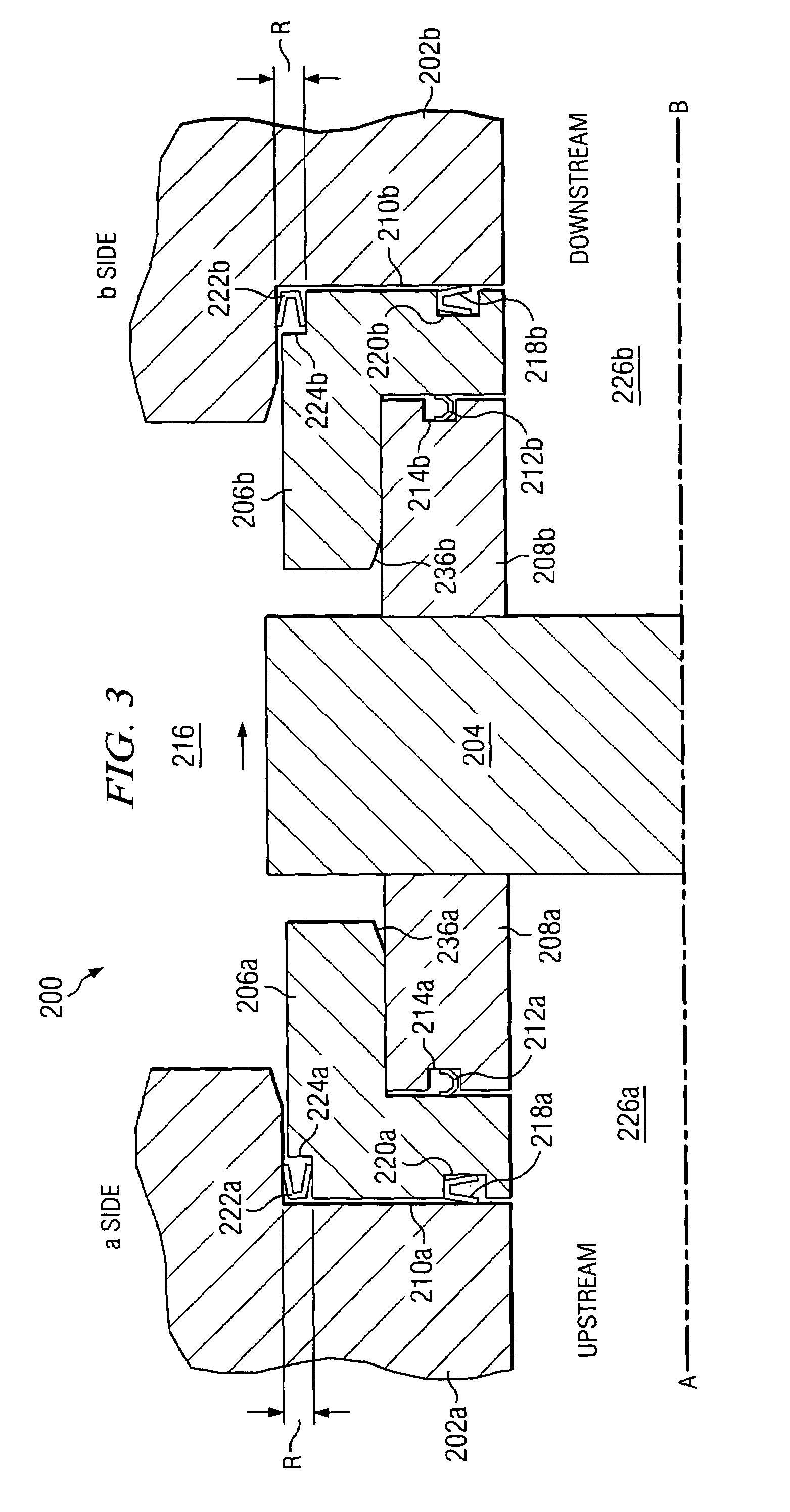

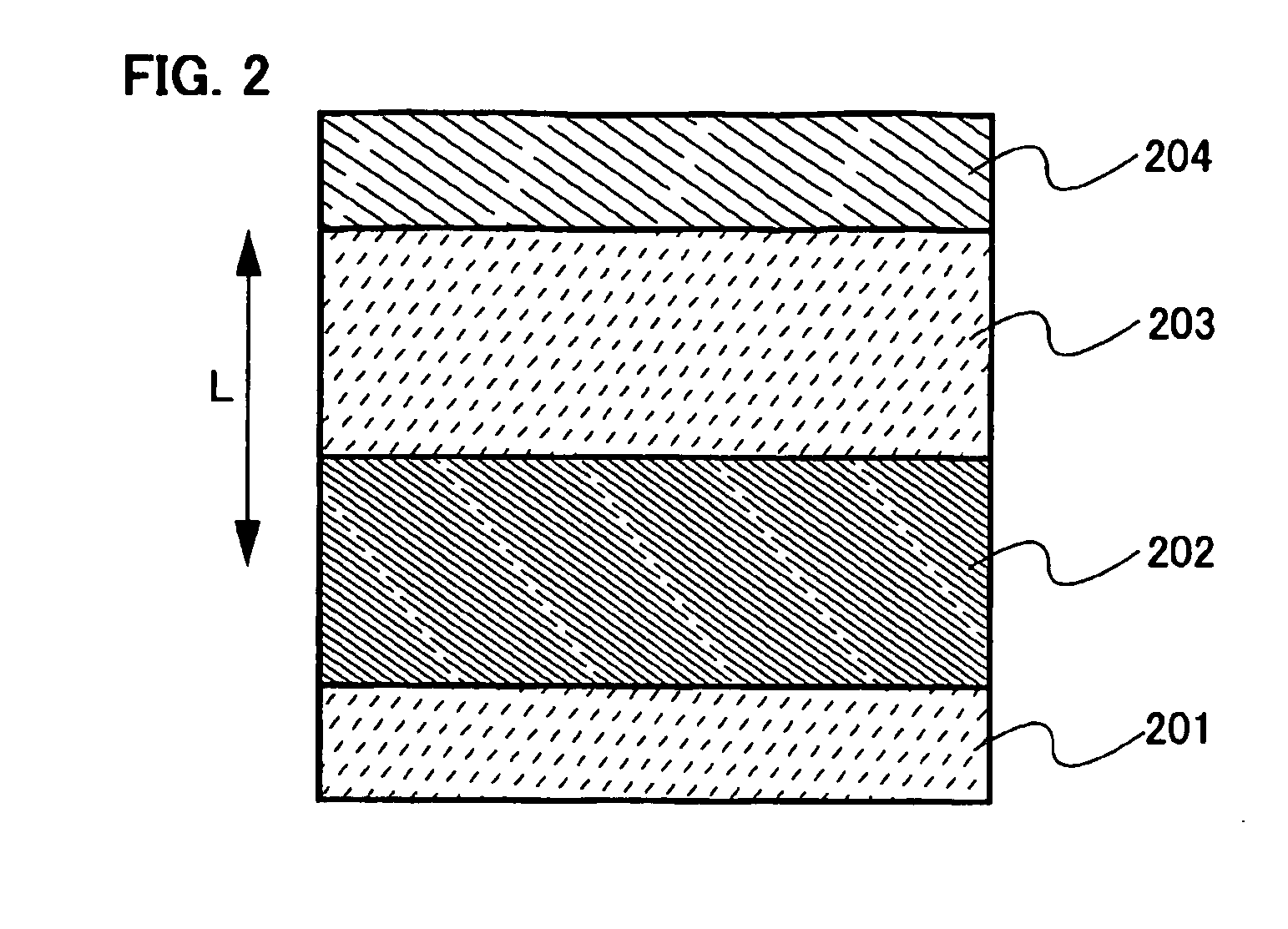

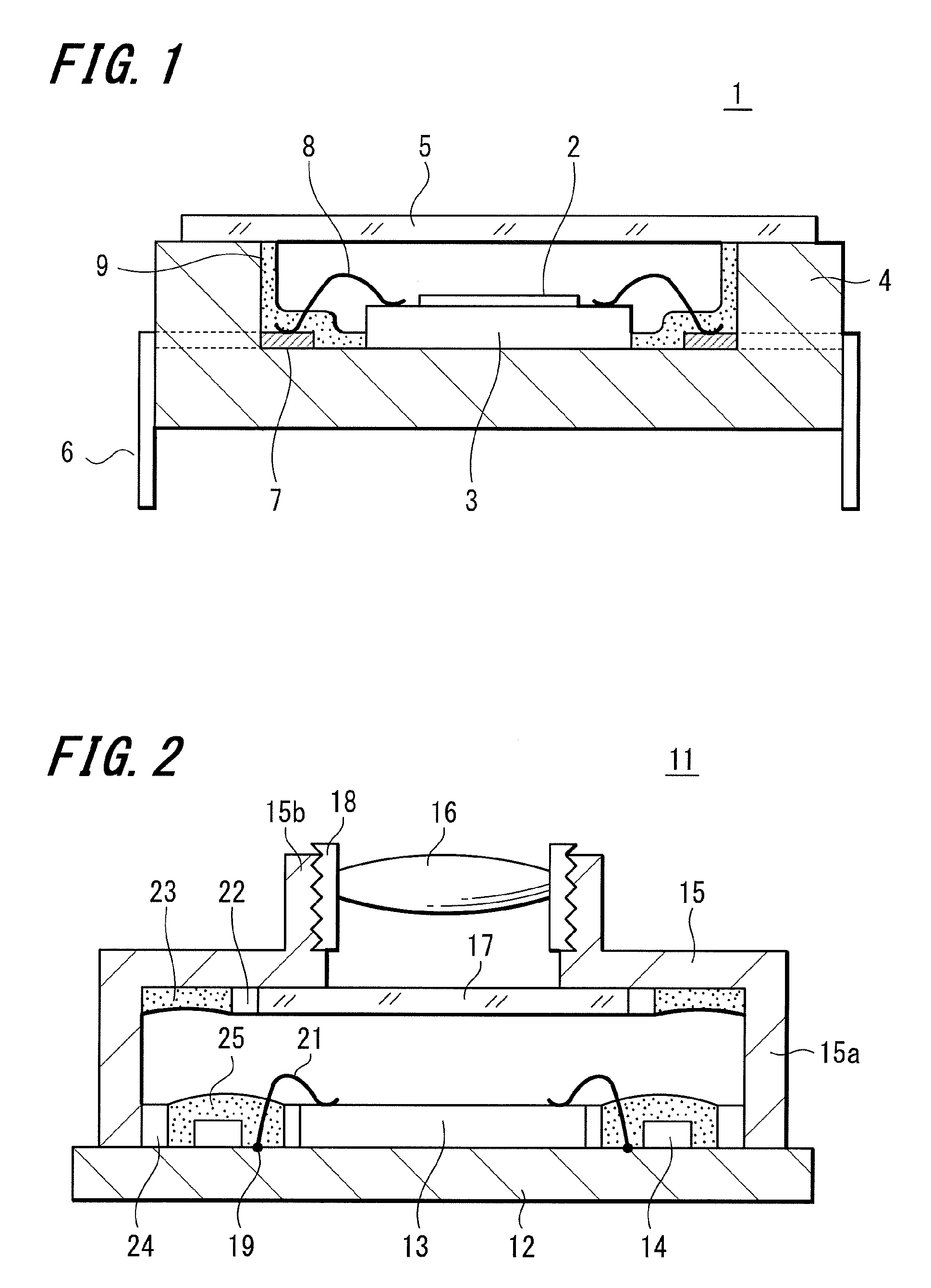

Devices and methods for treating morbid obesity

The present invention provides devices and methods for attachment of an implanted device, such as an artificial stoma device, a gastrointestinal sleeve device or an attachment cuff, within a patient's digestive tract for treatment of obesity. Special surgical fasteners provide a lasting and durable attachment to the gastrointestinal tissue without causing excessive pressure that could result in tissue erosion and detachment of the implanted device. Fastener delivery devices that facilitate peroral placement and deployment of fasteners and secondary devices are also provided. Also described are implantable devices and attachment means that avoid causing excessive pressure within the tissue by having compliance that is compatible with the gastrointestinal tissues where it is attached.

Owner:VALENTX

Devices and methods for treating morbid obesity

The present invention provides devices and methods for attachment of an implanted device, such as an artificial stoma device, a gastrointestinal sleeve device or an attachment cuff, within a patient's digestive tract for treatment of obesity. Special surgical fasteners provide a lasting and durable attachment to the gastrointestinal tissue without causing excessive pressure that could result in tissue erosion and detachment of the implanted device. Fastener delivery devices that facilitate peroral placement and deployment of fasteners and secondary devices are also provided. Also described are implantable devices and attachment means that avoid causing excessive pressure within the tissue by having compliance that is compatible with the gastrointestinal tissues where it is attached.

Owner:VALENTX

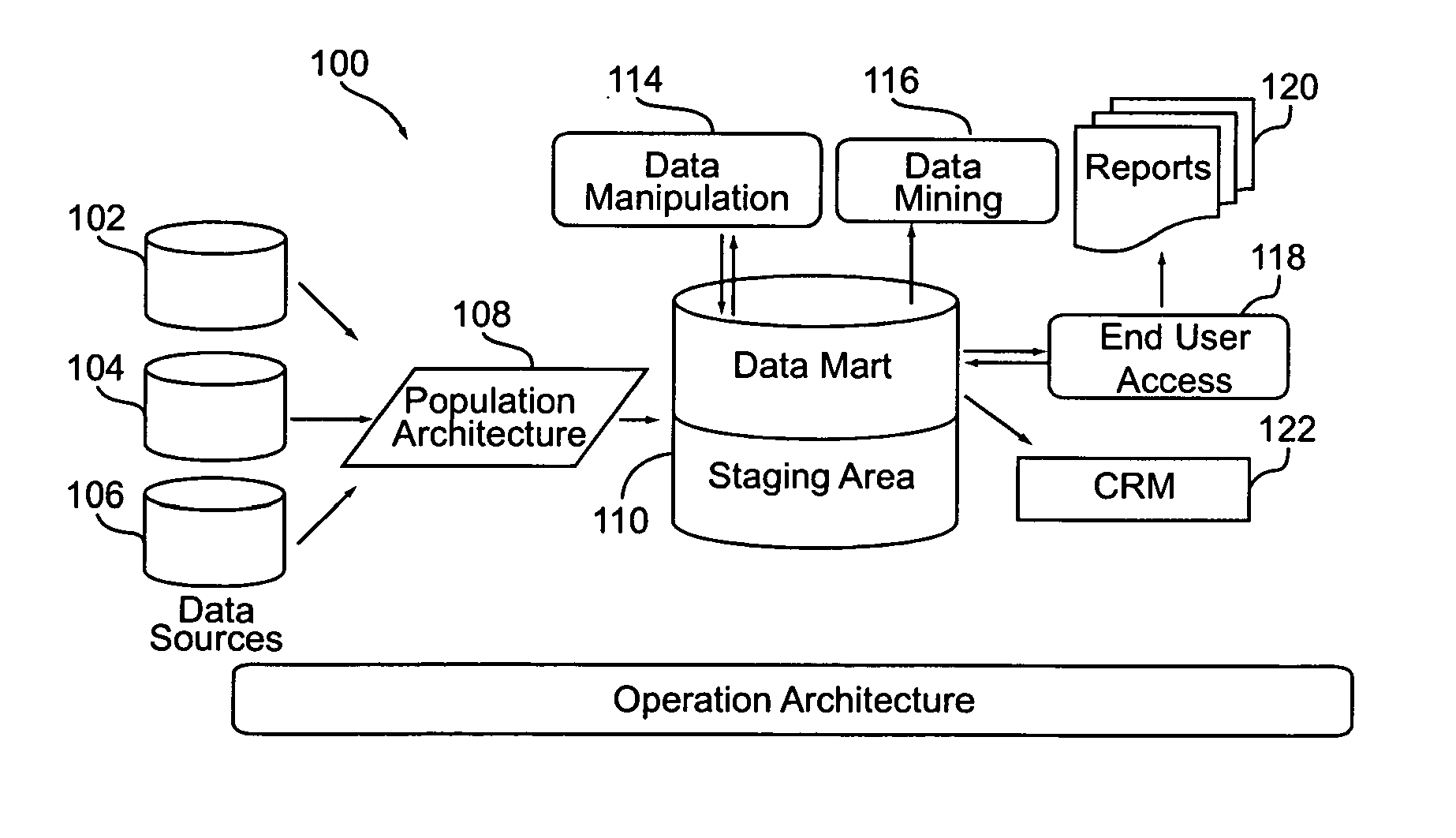

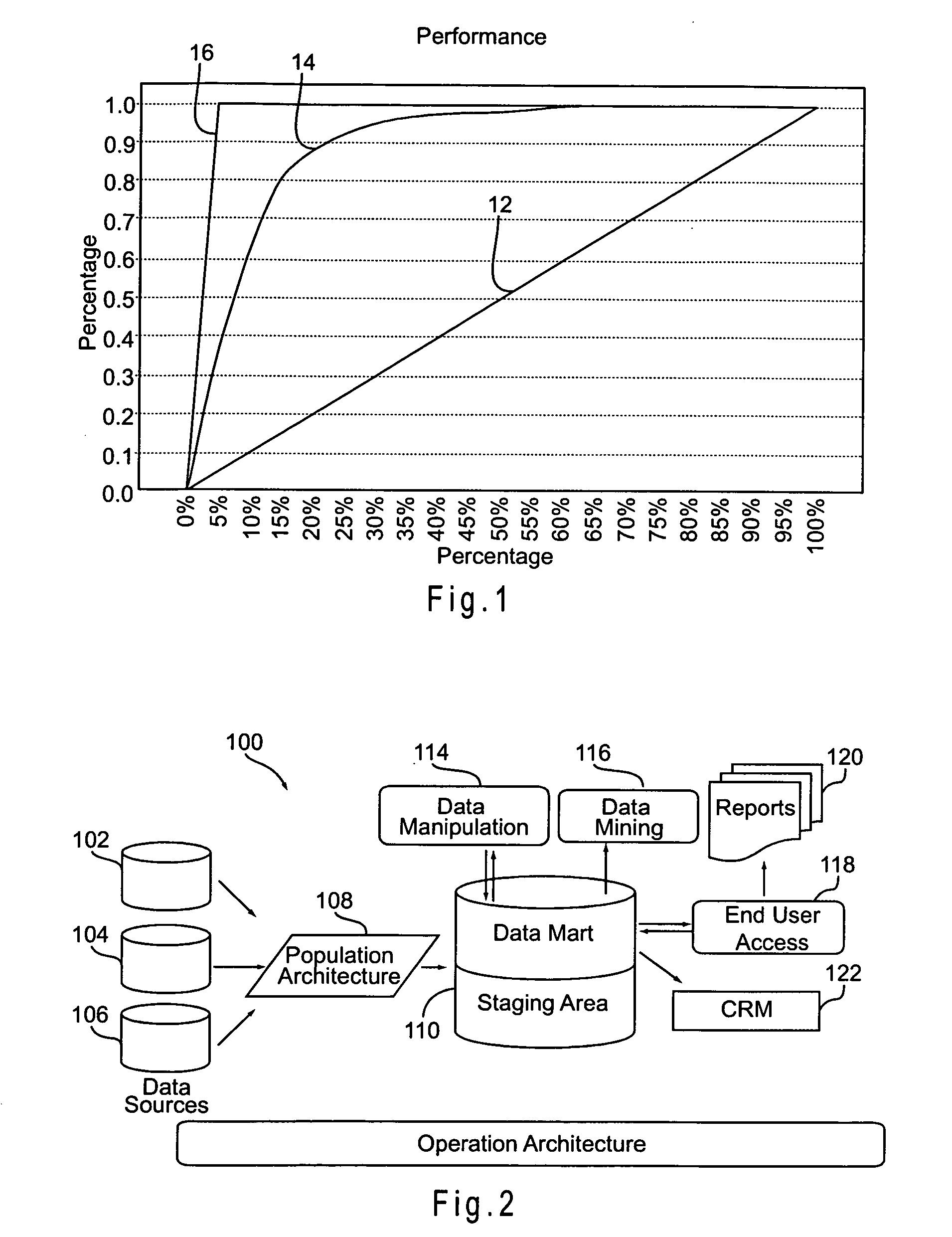

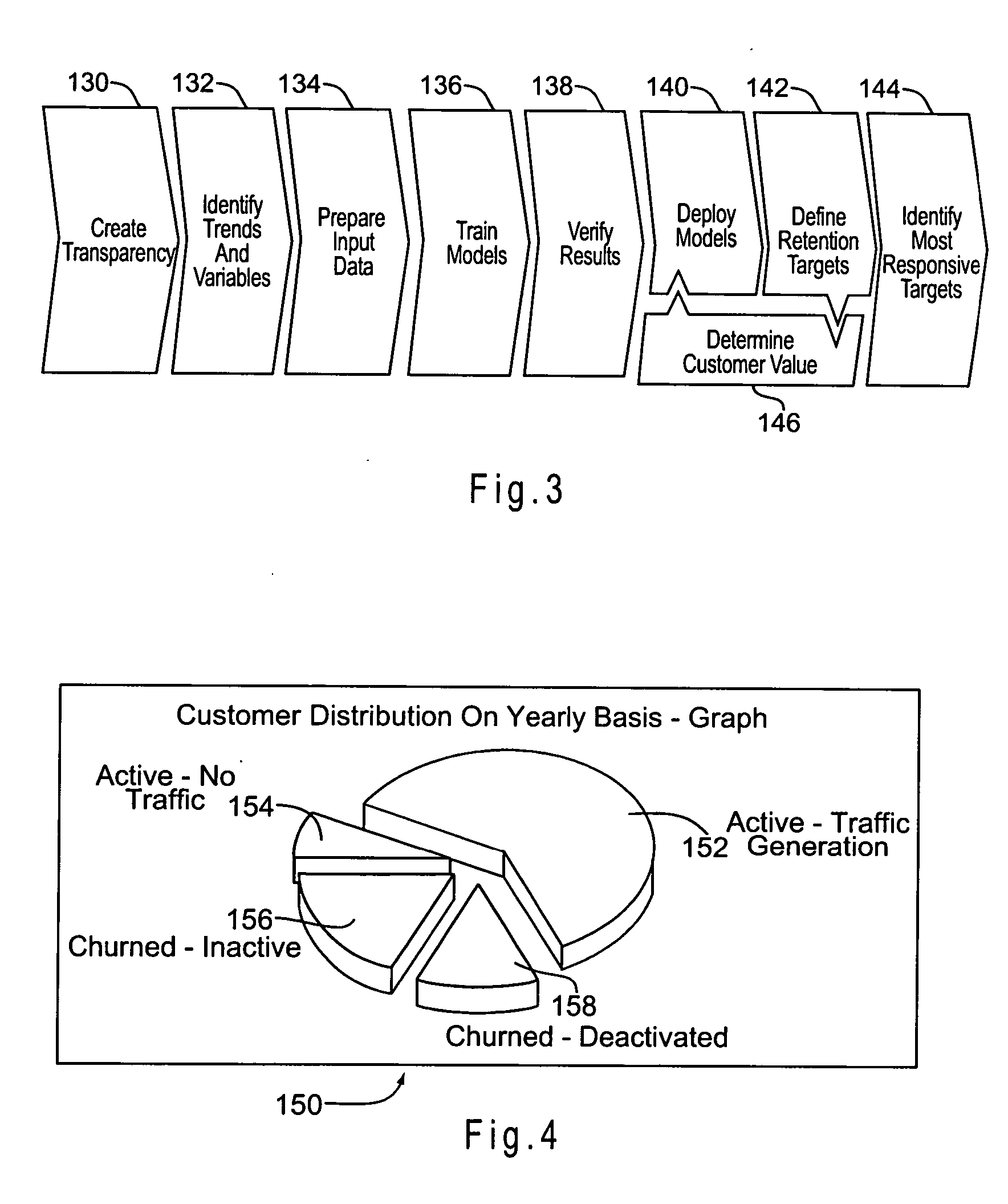

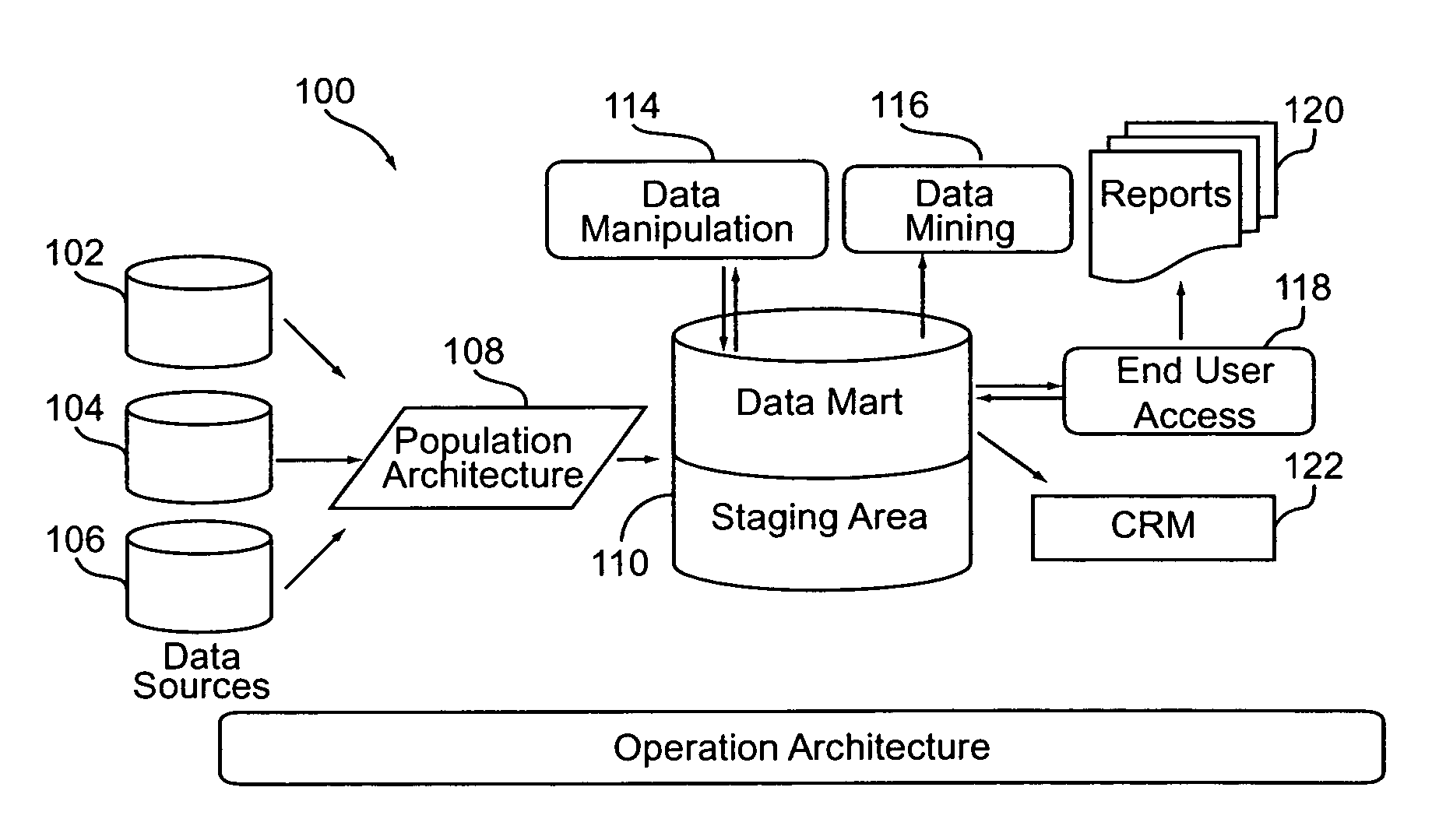

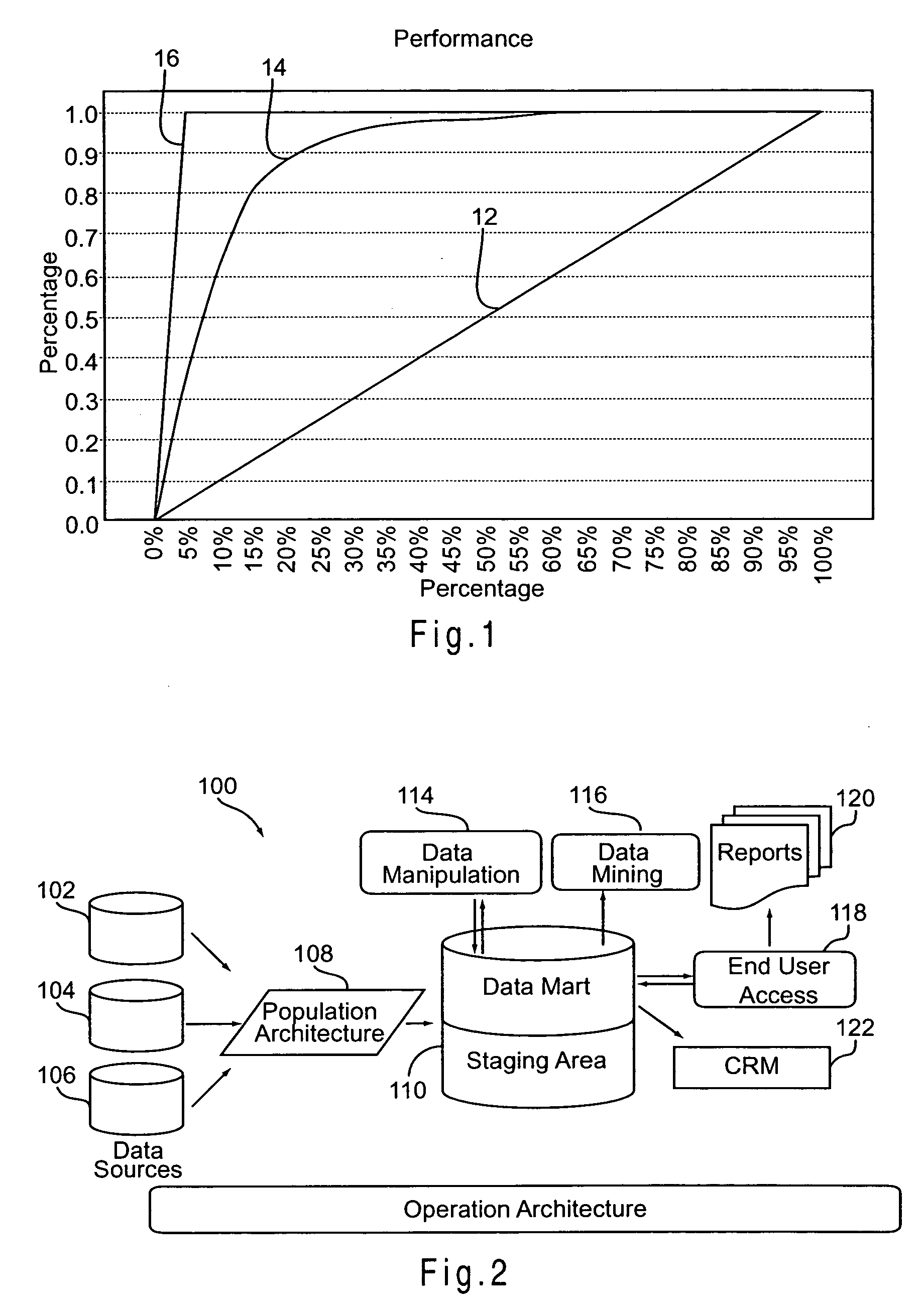

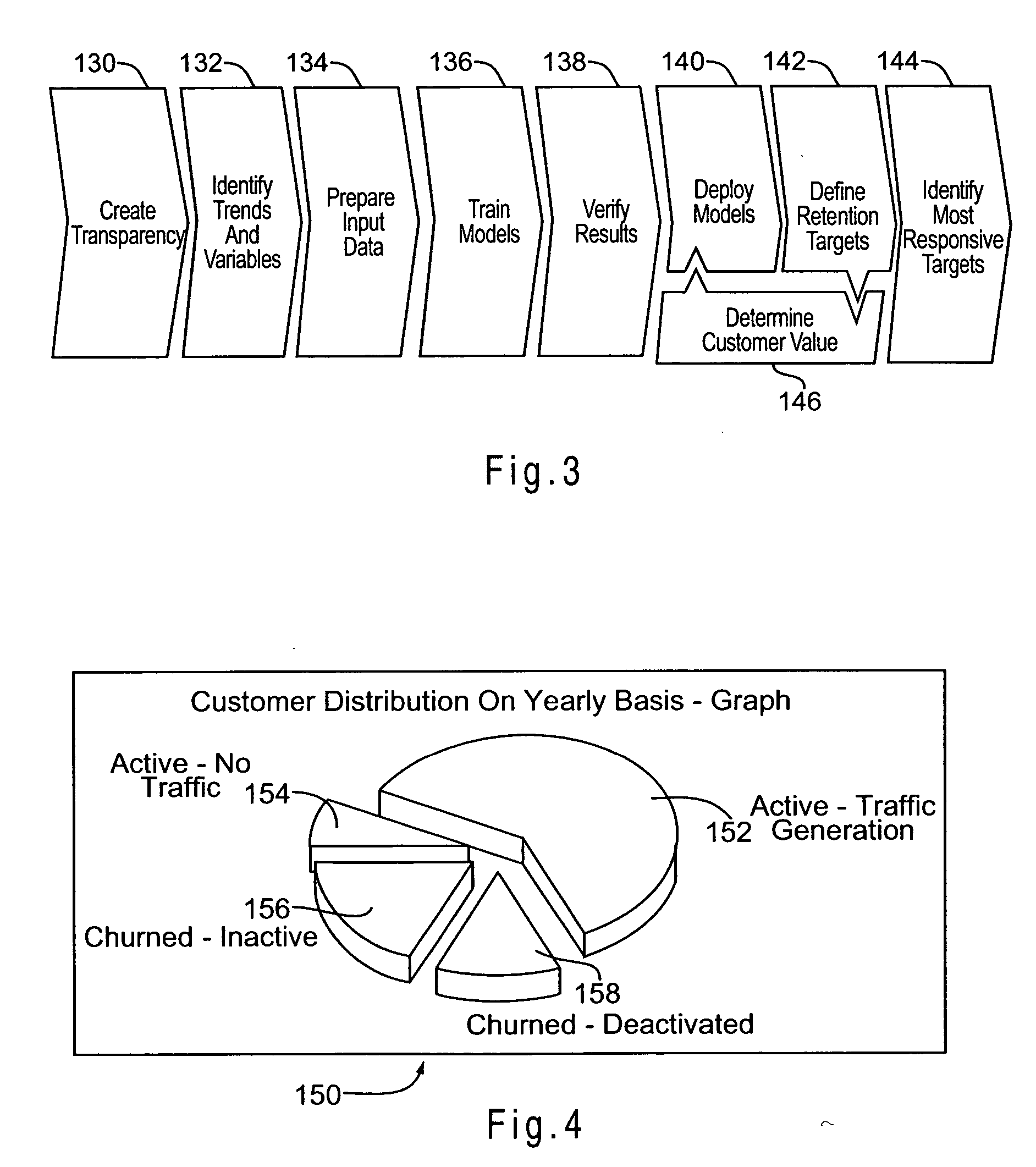

Churn prediction and management system

ActiveUS20070156673A1Avoid erosionFacilitates efforts to retain high profitability customersSpecial data processing applicationsMarketingCustomer attritionData operations

A system and method for managing churn among the customers of a business is provided. The system and method provide for an analysis of the causes of customer churn and identifies customers who are most likely to churn in the future. Identifying likely churners allows appropriate steps to be taken to prevent customers who are likely to churn from actually churning. The system included a dedicated data mart, a population architecture, a data manipulation module, a data mining tool and an end user access module for accessing results and preparing preconfigured reports. The method includes adopting an appropriate definition of churn, analyzing historical customer to identify significant trends and variables, preparing data for data mining, training a prediction model, verifying the results, deploying the model, defining retention targets, and identifying the most responsive targets.

Owner:ACCENTURE GLOBAL SERVICES LTD

Statistical modeling methods for determining customer distribution by churn probability within a customer population

InactiveUS20070185867A1Avoid erosionFacilitates efforts to retain high profitability customersDatabase queryingMarketingData dredgingCustomer attrition

A system and method for managing churn among the customers of a business is provided. The system and method provide for an analysis of the causes of customer churn and identifies customers who are most likely to churn in the future. Identifying likely churners allows appropriate steps to be taken to prevent customers who are likely to chum from actually churning. The system included a dedicated data mart, a population architecture, a data manipulation module, a data mining tool and an end user access module for accessing results and preparing preconfigured reports. The method includes adopting an appropriate definition of churn, analyzing historical customer to identify significant trends and variables, preparing data for data mining, training a prediction model, verifying the results, deploying the model, defining retention targets, and identifying the most responsive targets.

Owner:ACCENTURE GLOBAL SERVICES LTD

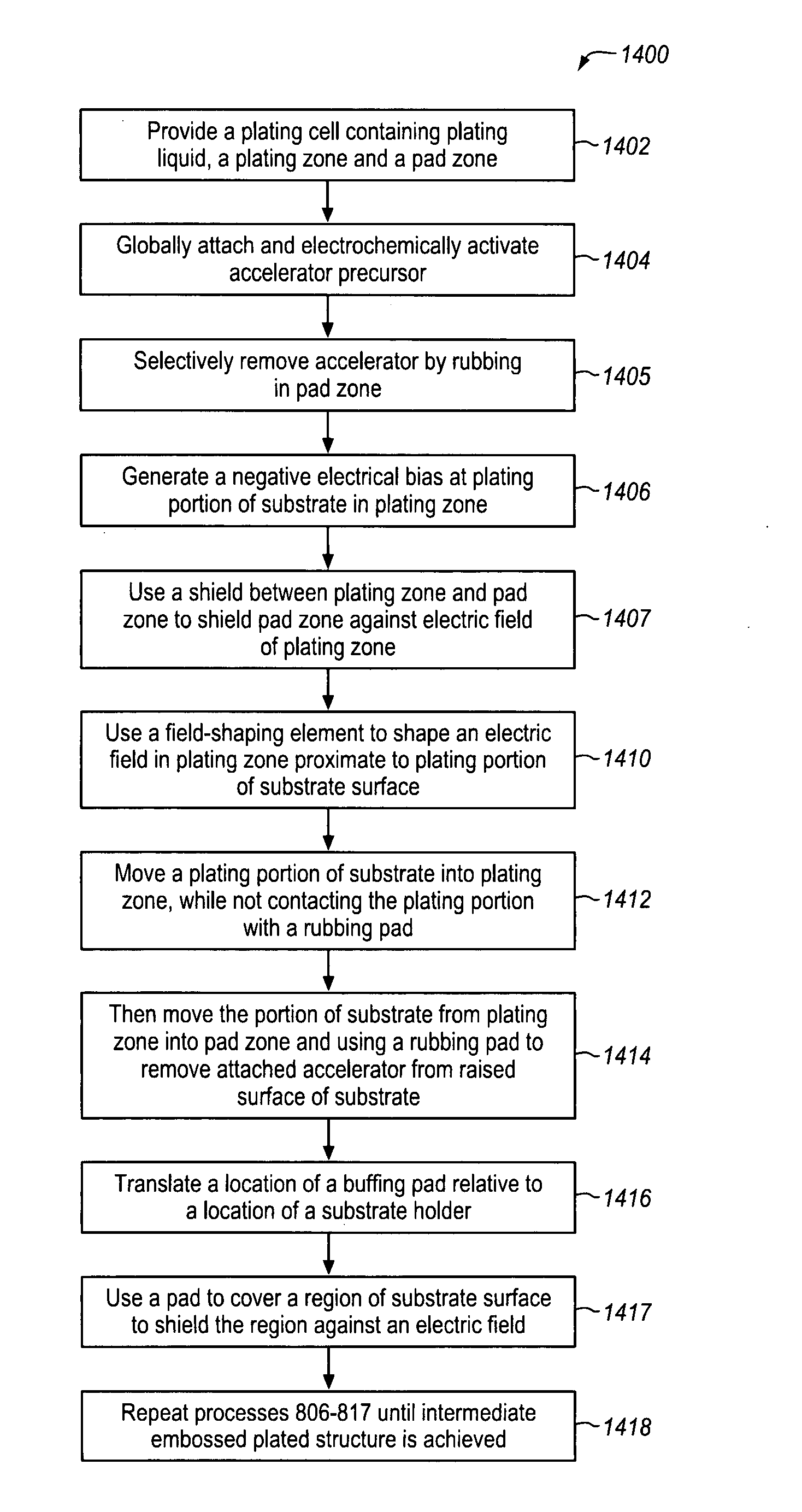

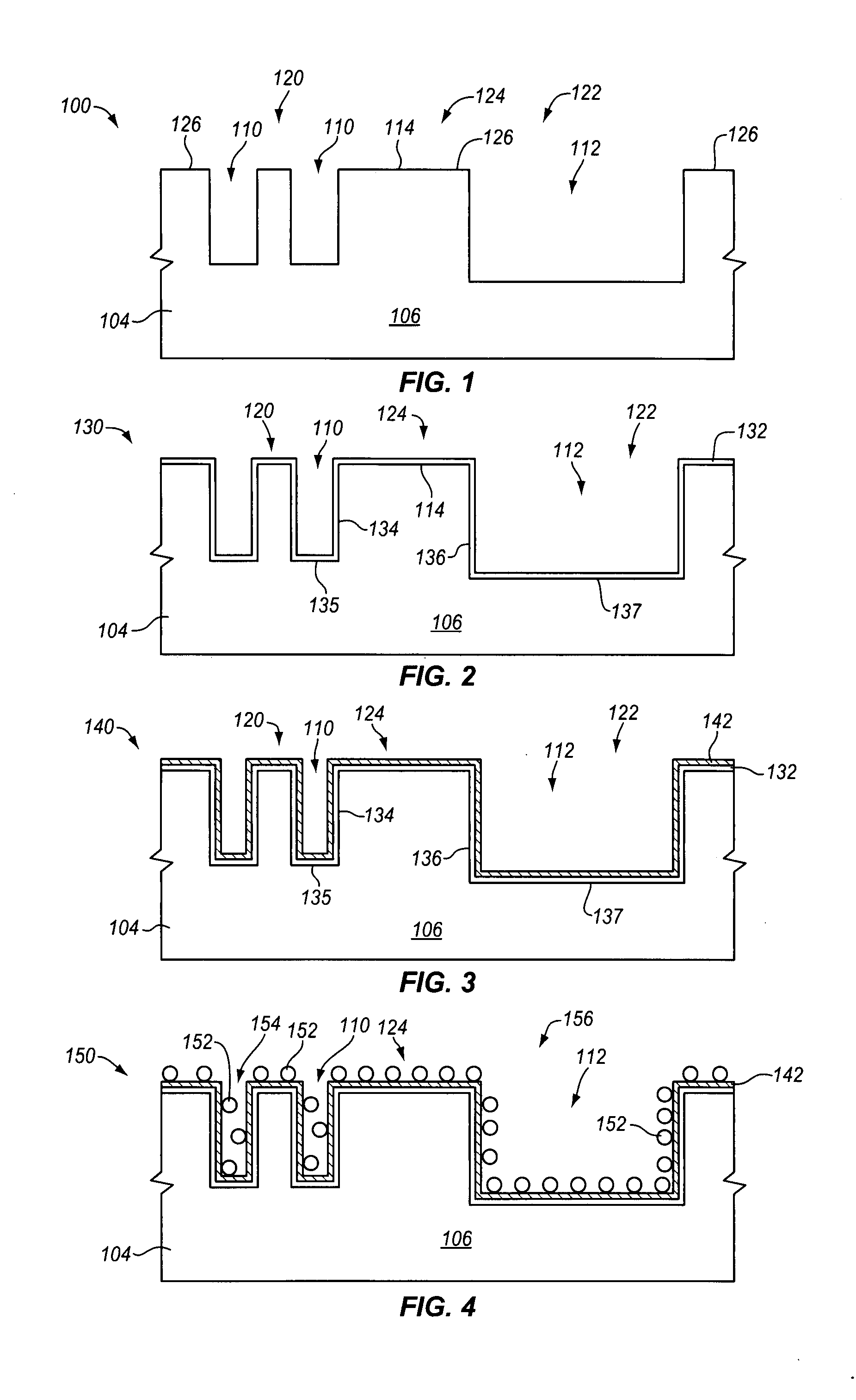

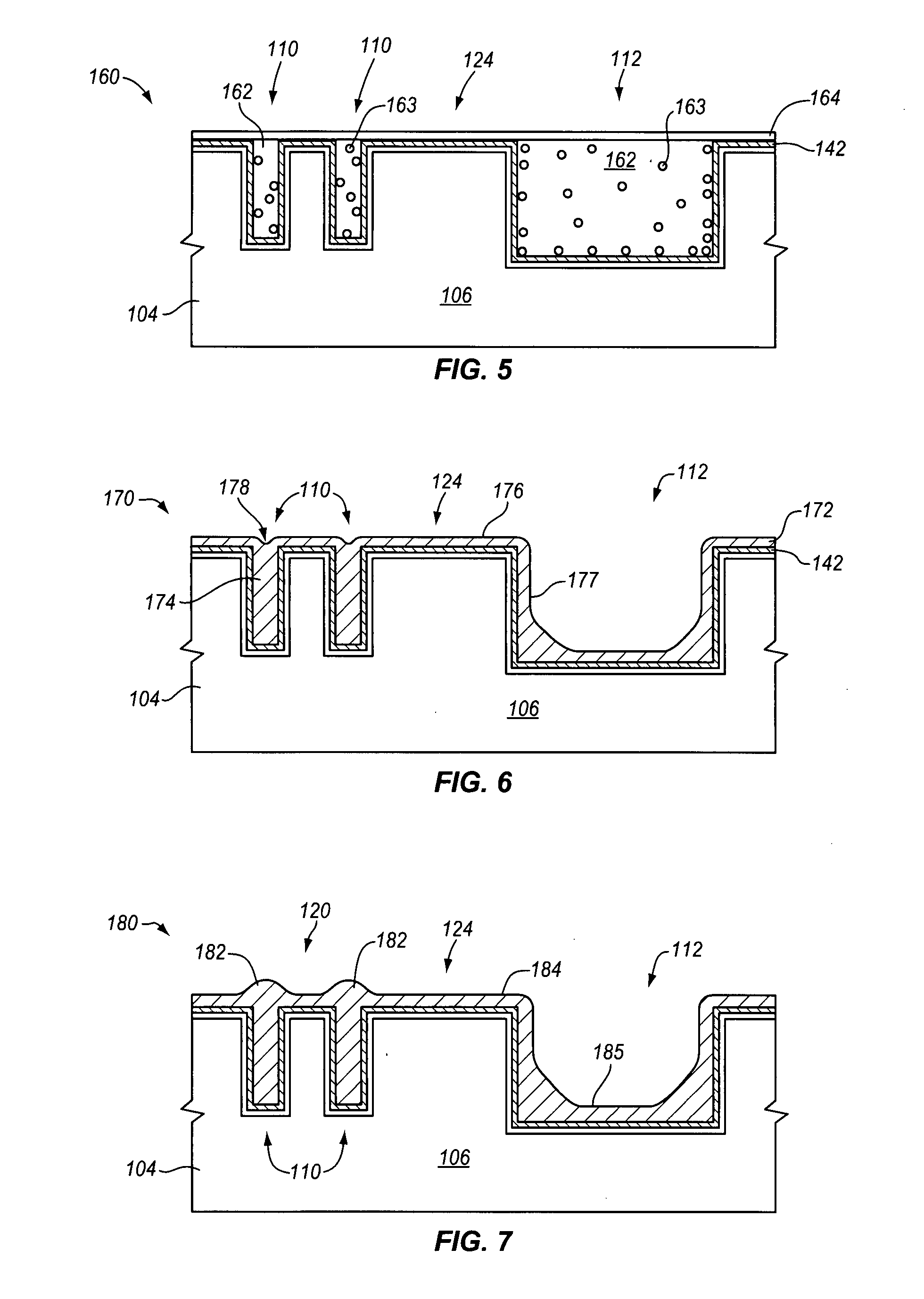

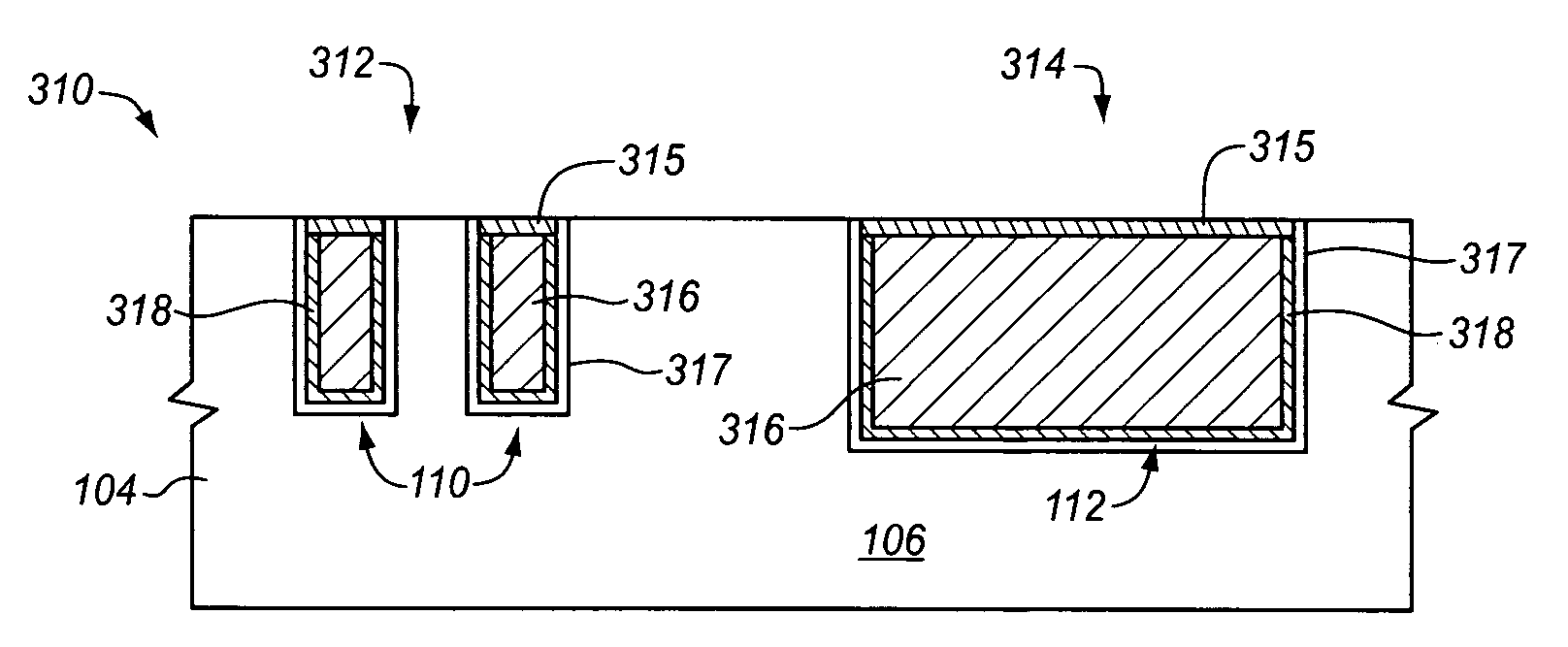

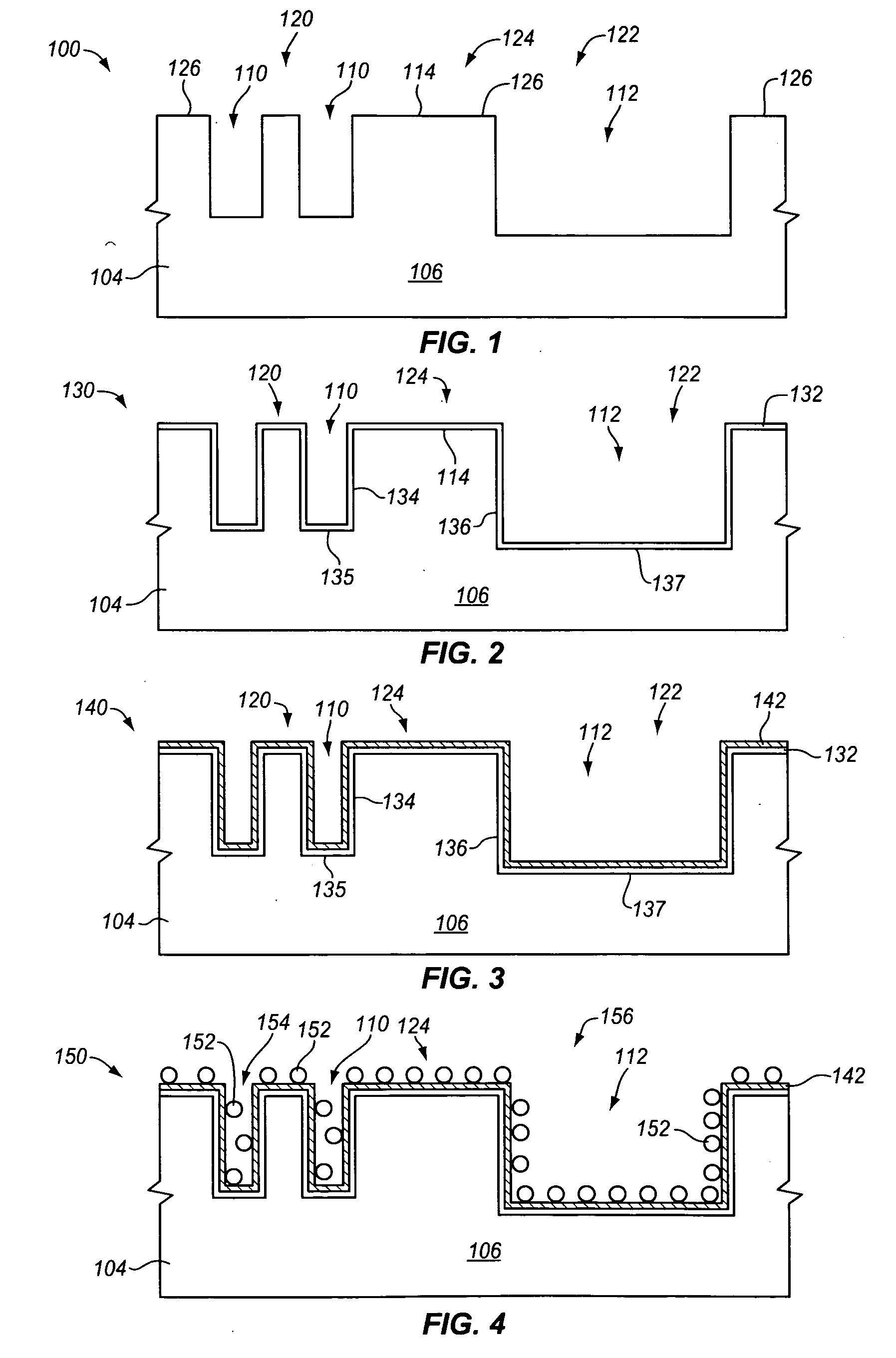

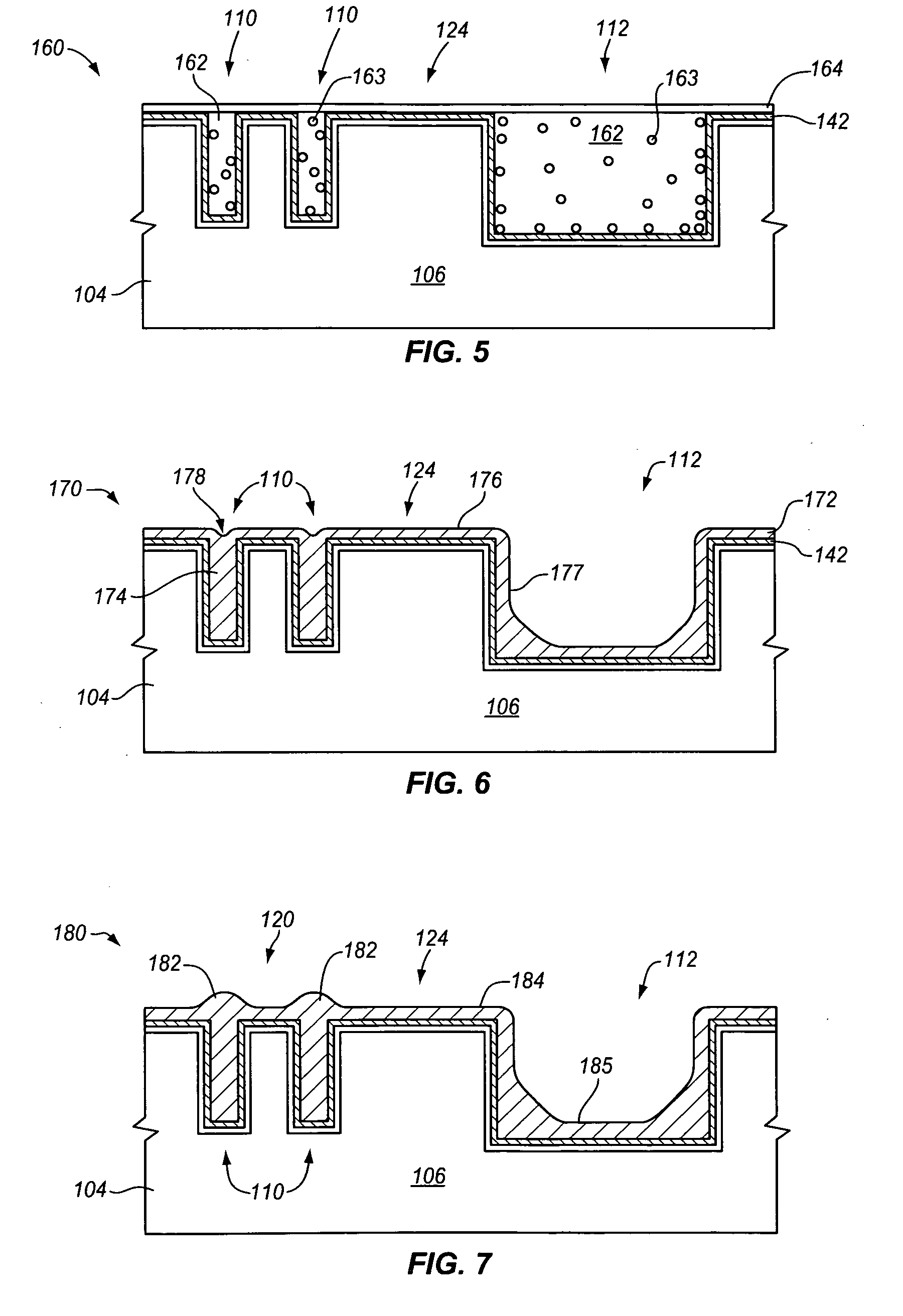

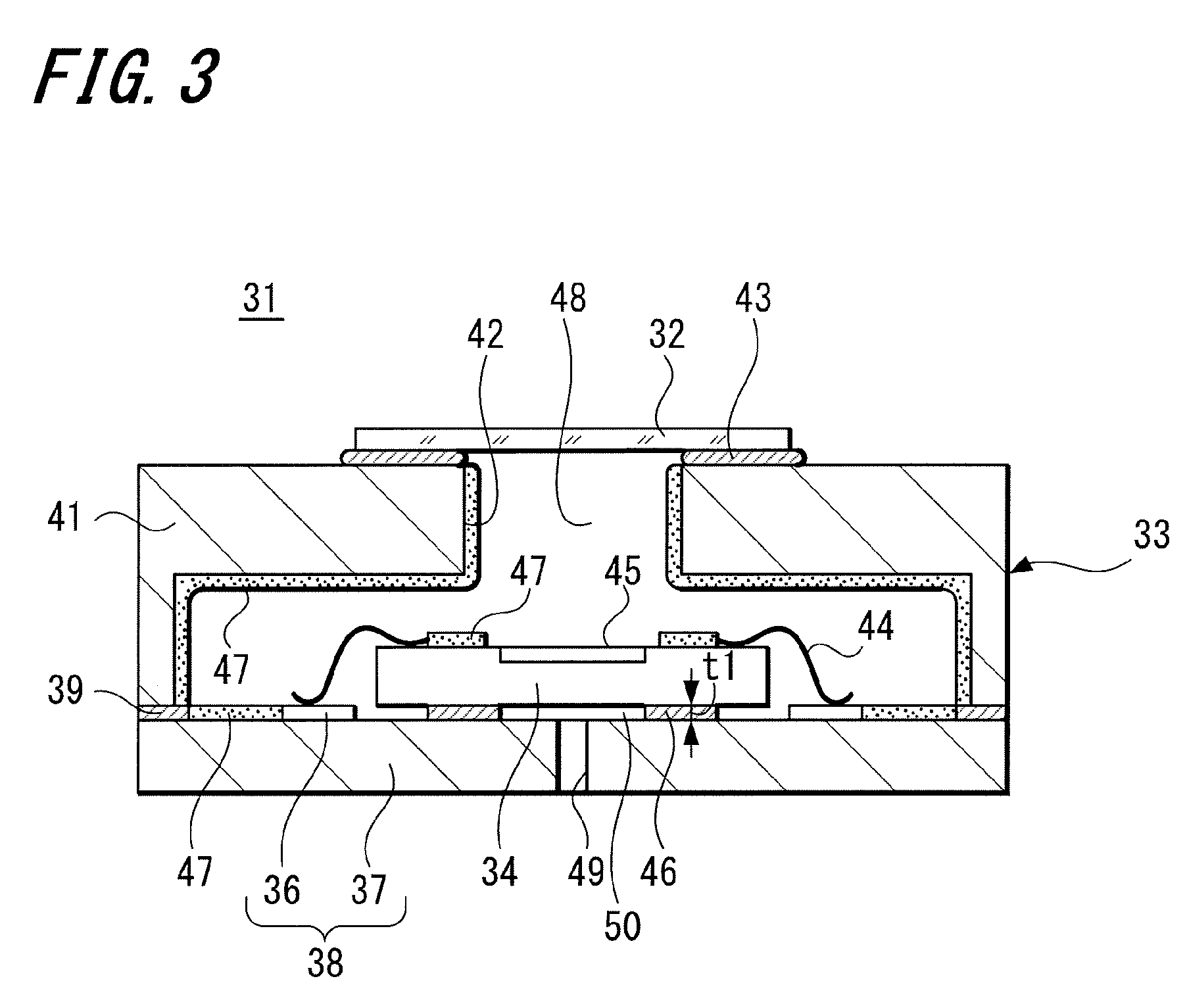

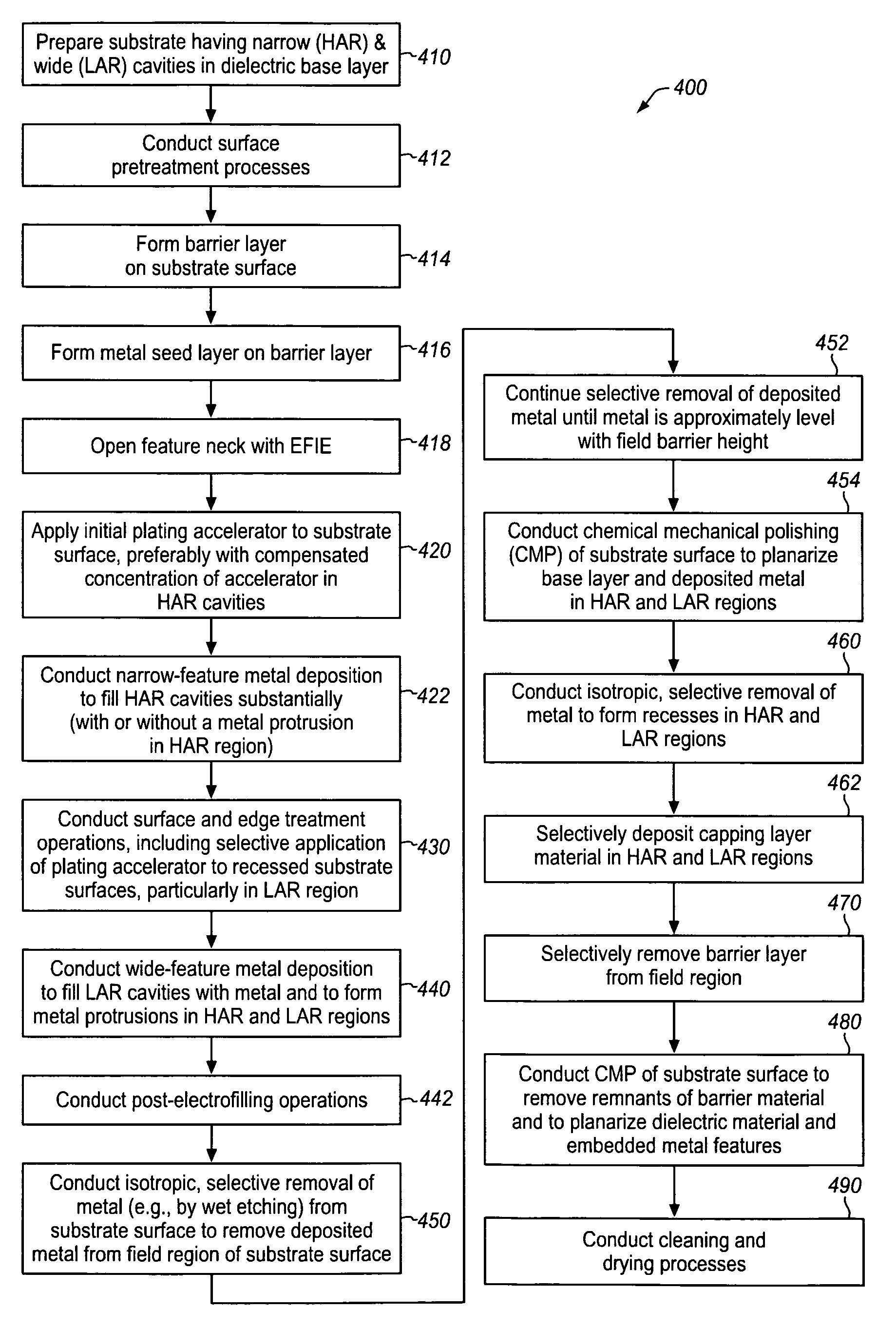

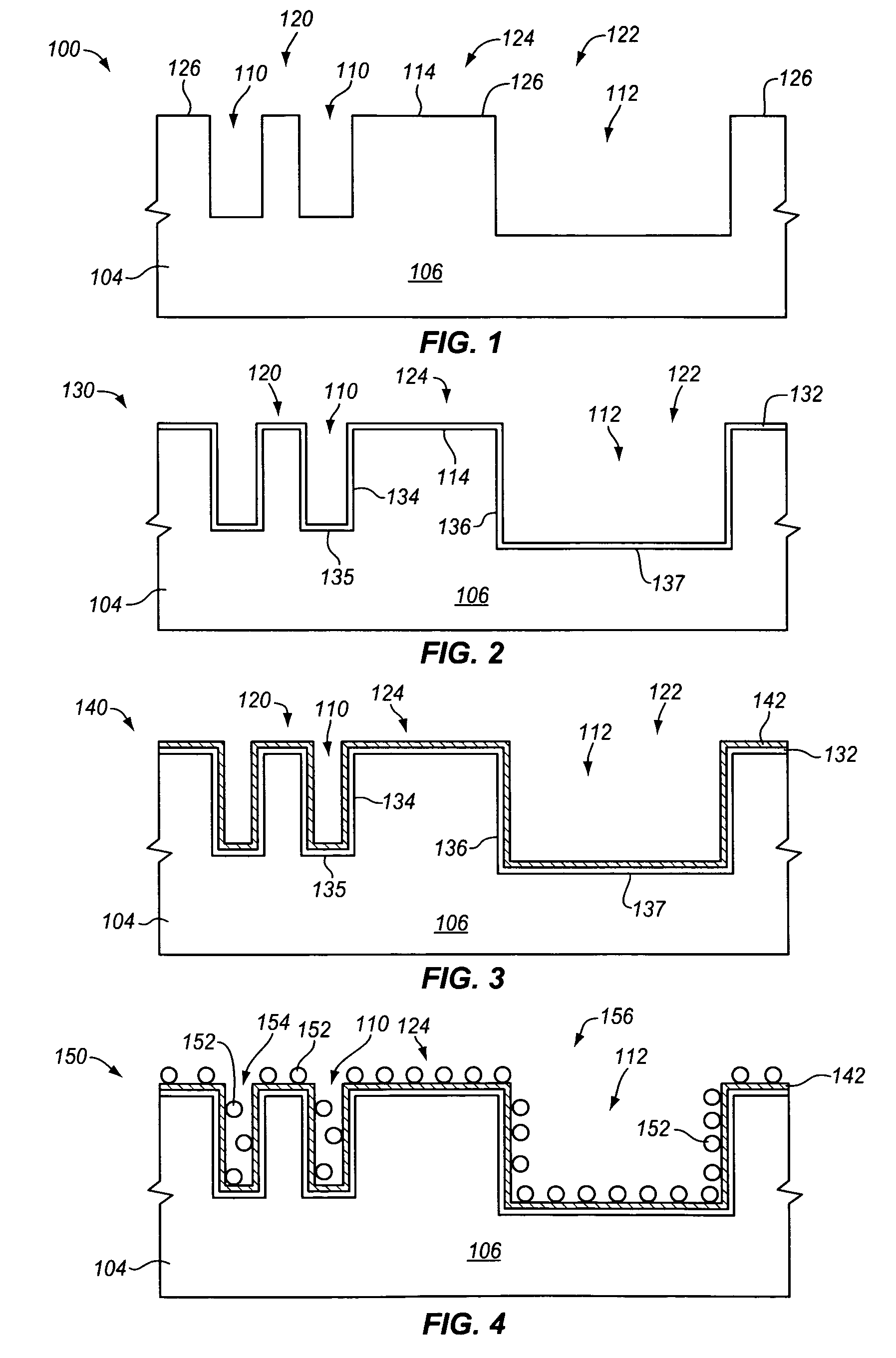

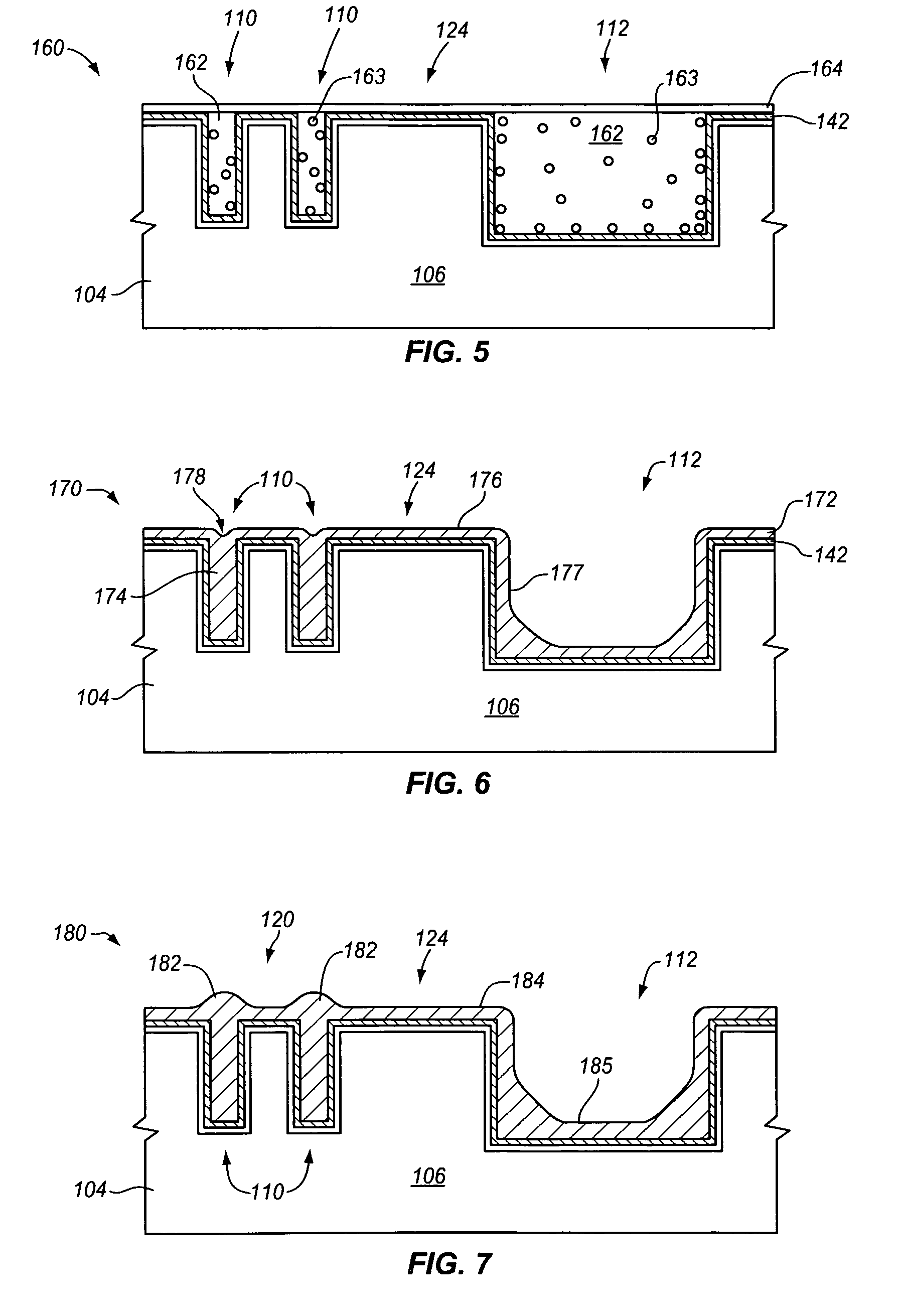

Topography reduction and control by selective accelerator removal

ActiveUS20090280649A1Improve throughputLow costCellsDecorative surface effectsMetal interconnectEtching

Plating accelerator is applied selectively to a substantially-unfilled wide (e.g., low-aspect-ratio feature cavity. Then, plating of metal is conducted to fill the wide feature cavity and to form an embossed structure in which the height of a wide-feature metal protrusion over the metal-filled wide-feature cavity is higher than the height of metal over field regions. Most of the overburden metal is removed using non-contact techniques, such as chemical wet etching. Metal above the wide feature cavity protects the metal-filled wide-feature interconnect against dishing, and improved planarization techniques avoid erosion of the metal interconnect and dielectric insulating layer. In some embodiments, plating of metal onto a substrate is conducted to fill narrow (e.g., high-aspect-ratio feature cavities) in the dielectric layer before selective application of plating accelerator and filling of the wide feature cavity.

Owner:NOVELLUS SYSTEMS

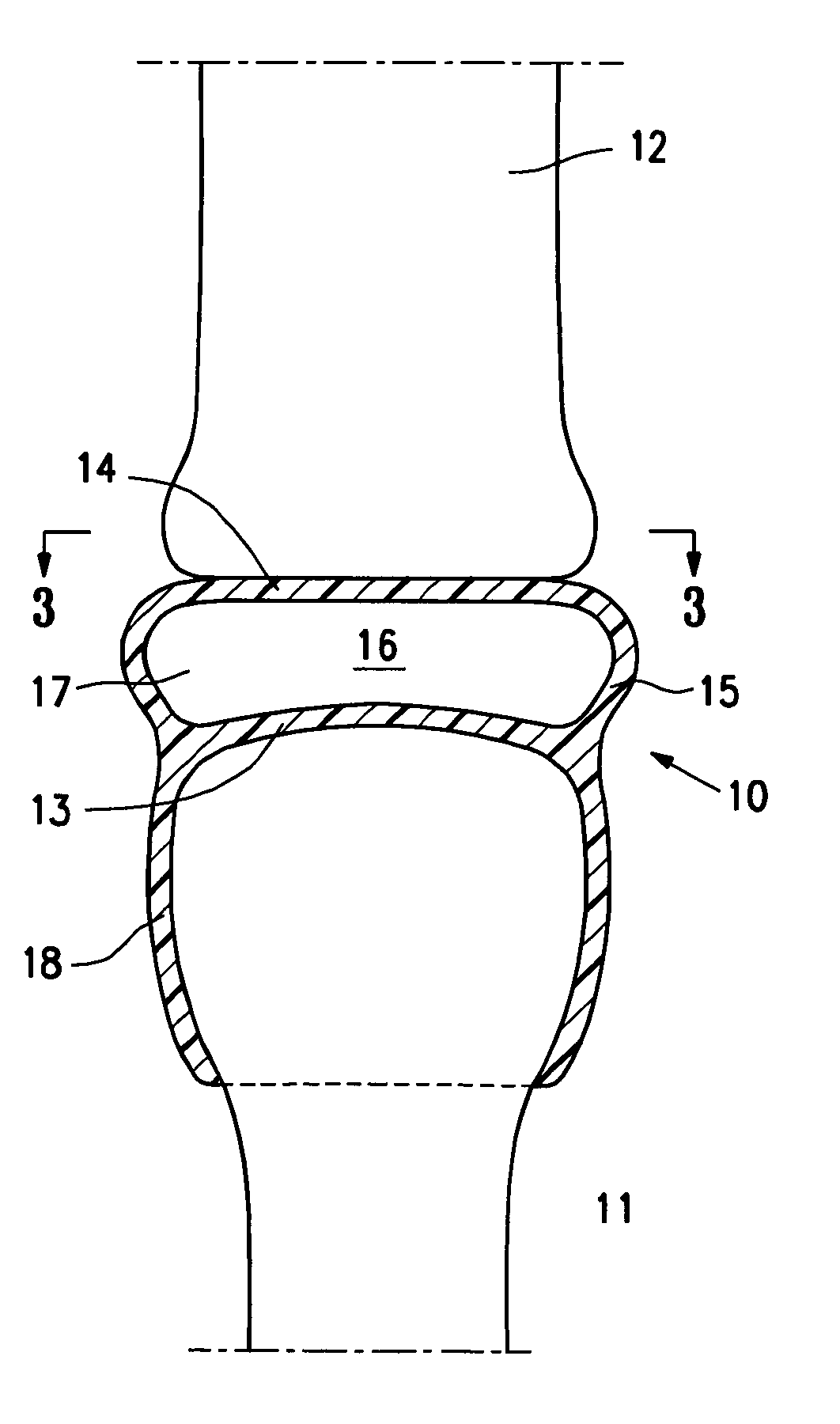

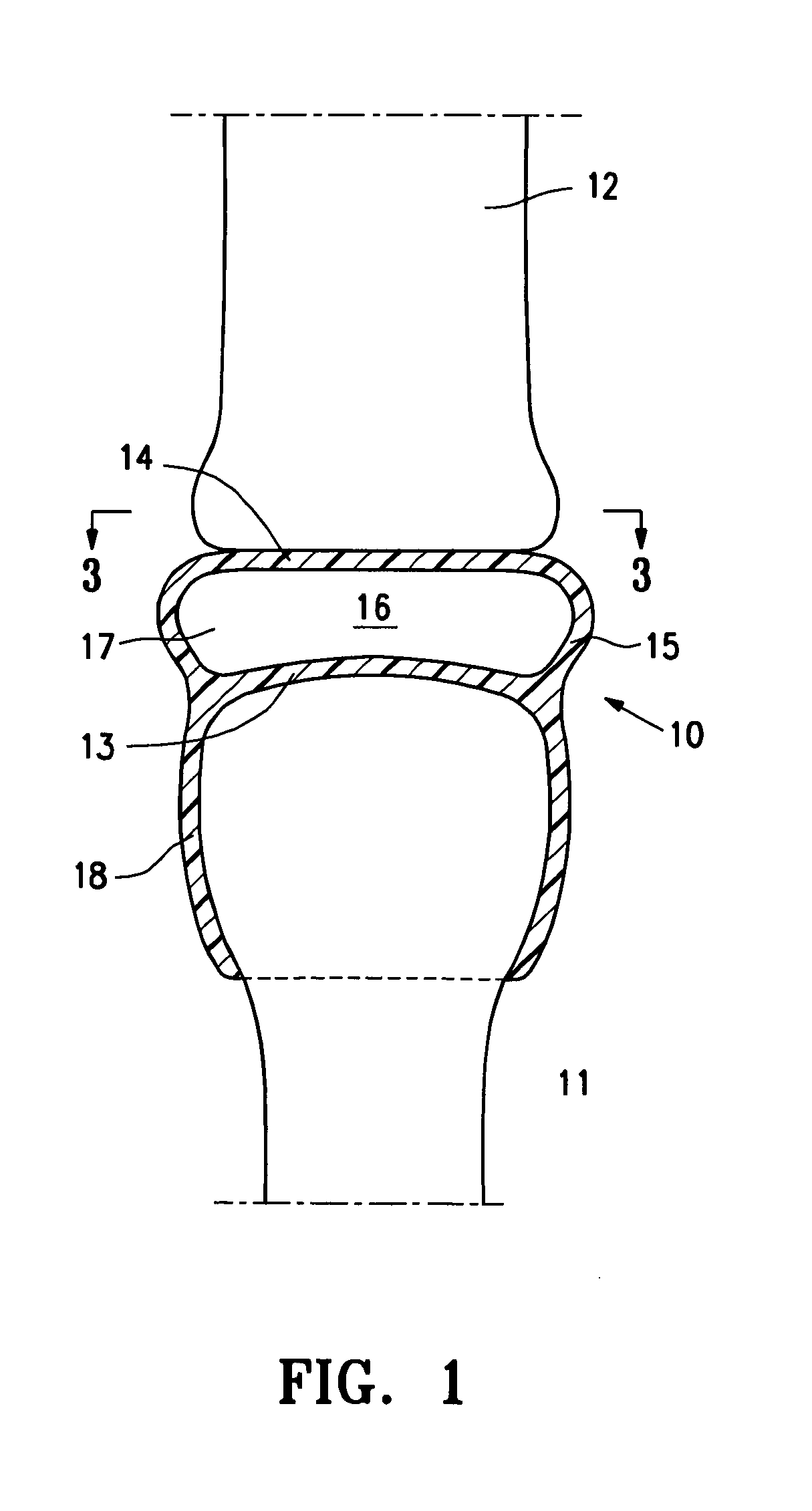

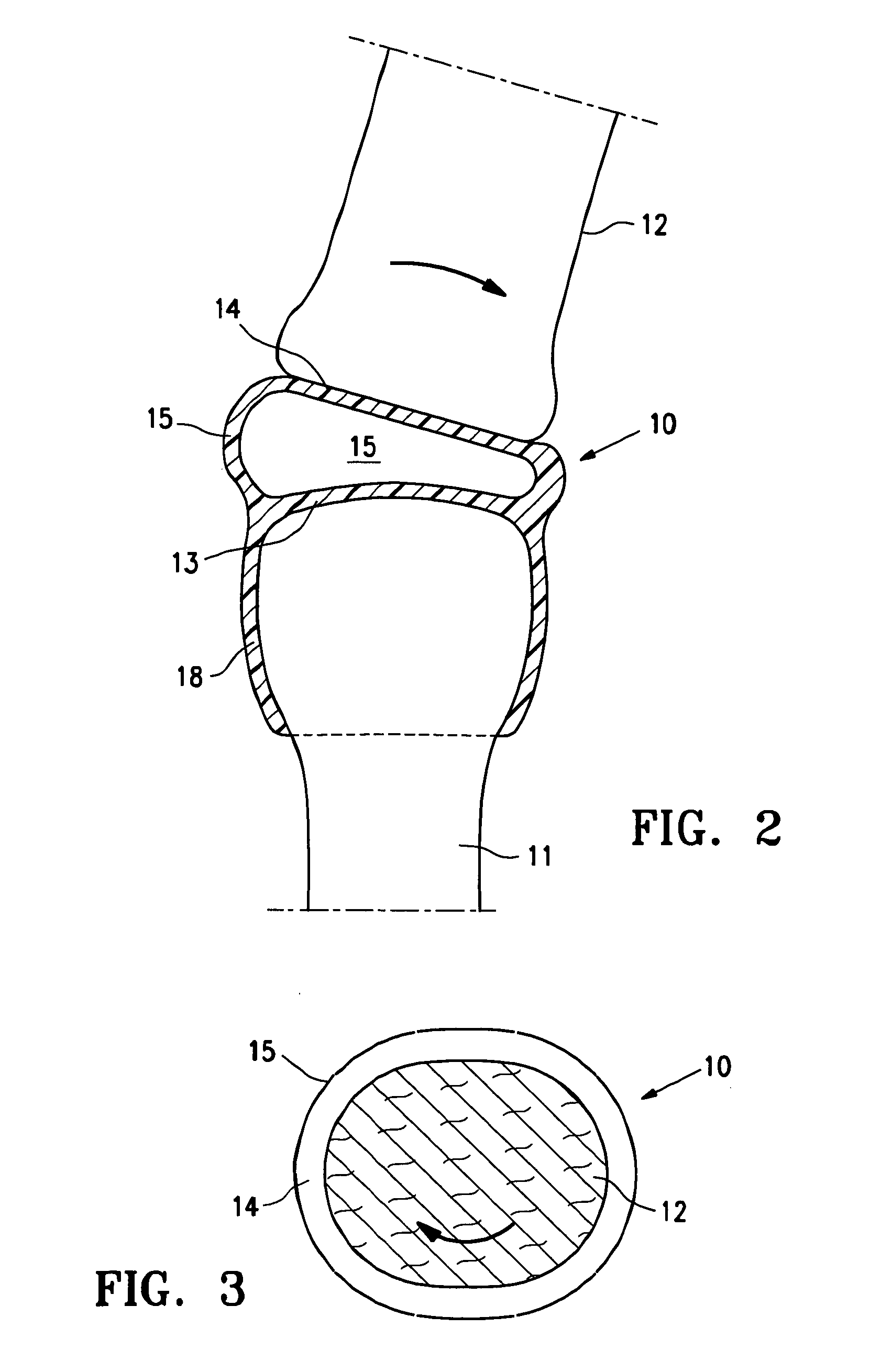

Resilient arthroplasty device

ActiveUS20100023126A1Preserve joint motionFree from painAnkle jointsSurgeryDiseaseArticular surfaces

The disclosure is directed to a resilient implant for implantation into human or animal joints to act as a cushion allowing for renewed joint motion. The implant endures variable joint forces and cyclic loads while reducing pain and improving function after injury or disease to repair, reconstruct, and regenerate joint integrity. The implant is deployed in a prepared debrided joint space, secured to at least one of the joint bones and expanded in the space, molding to surrounding structures with sufficient stability to avoid extrusion or dislocation. The implant has opposing walls that move in varied directions, and an inner space filled with suitable filler to accommodate motions which mimic or approximate normal joint motion. The implant pads the damaged joint surfaces, restores cushioning immediately and may be employed to restore cartilage to normal by delivering regenerative cells.

Owner:IORTHOPEDICS INC

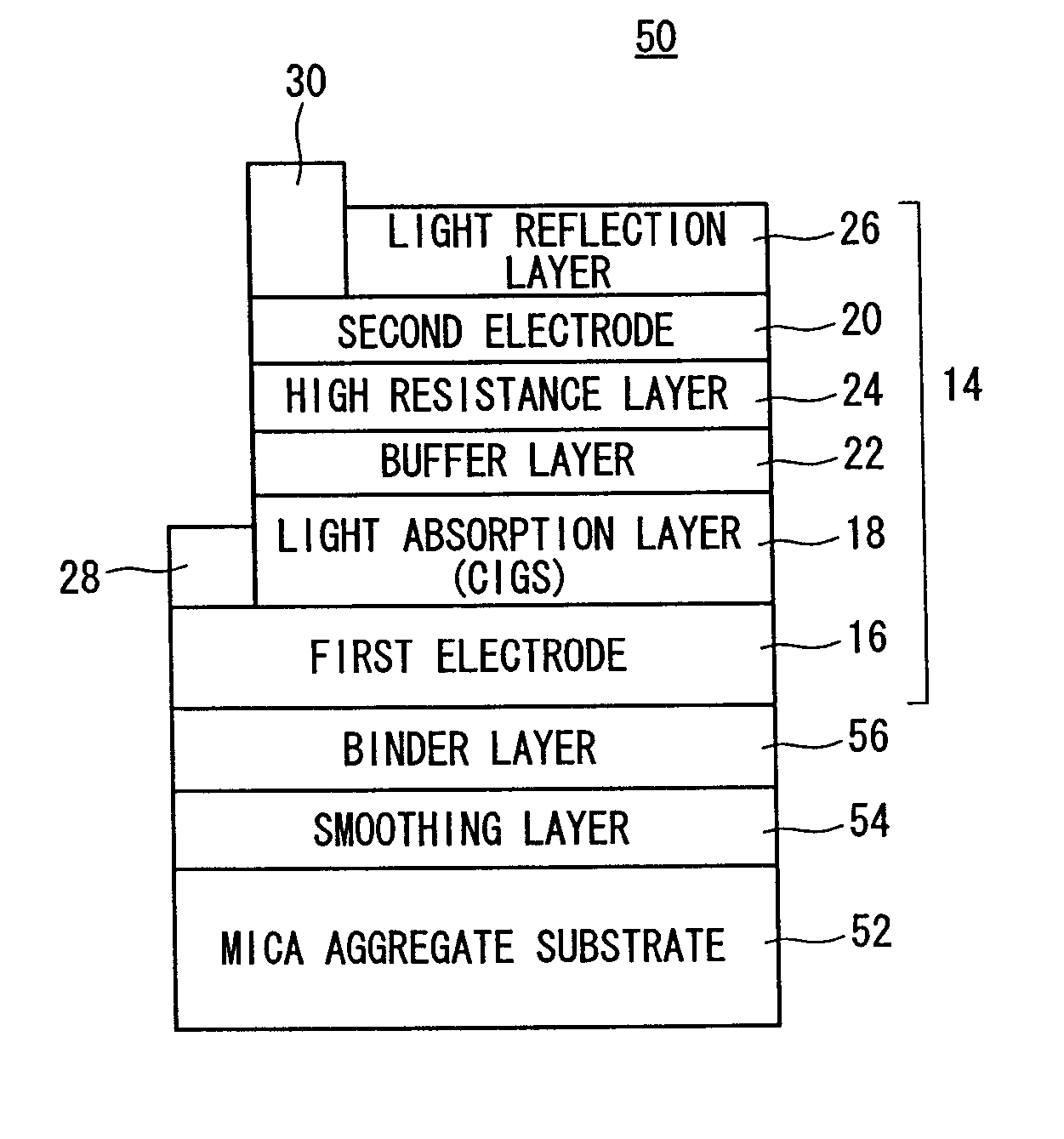

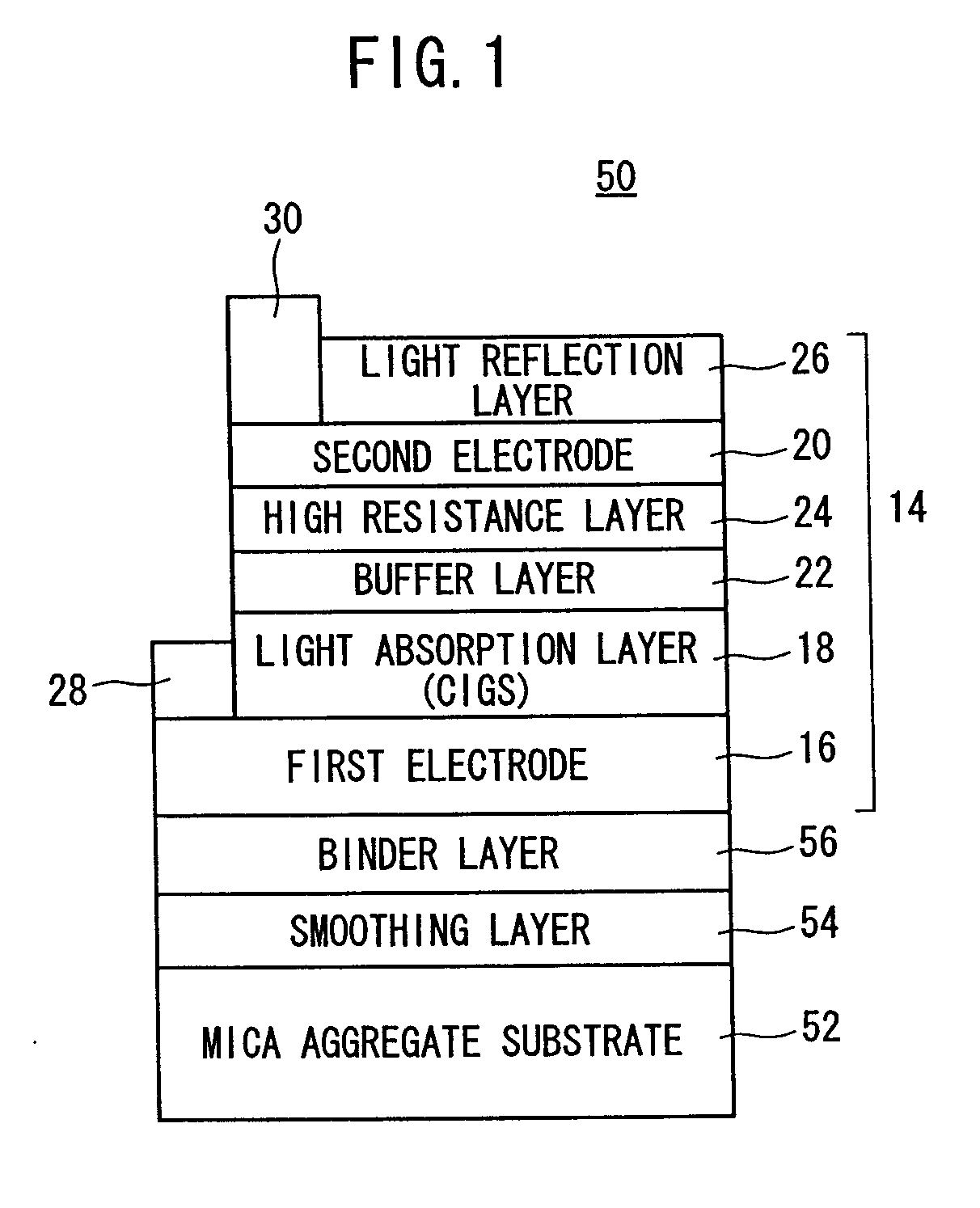

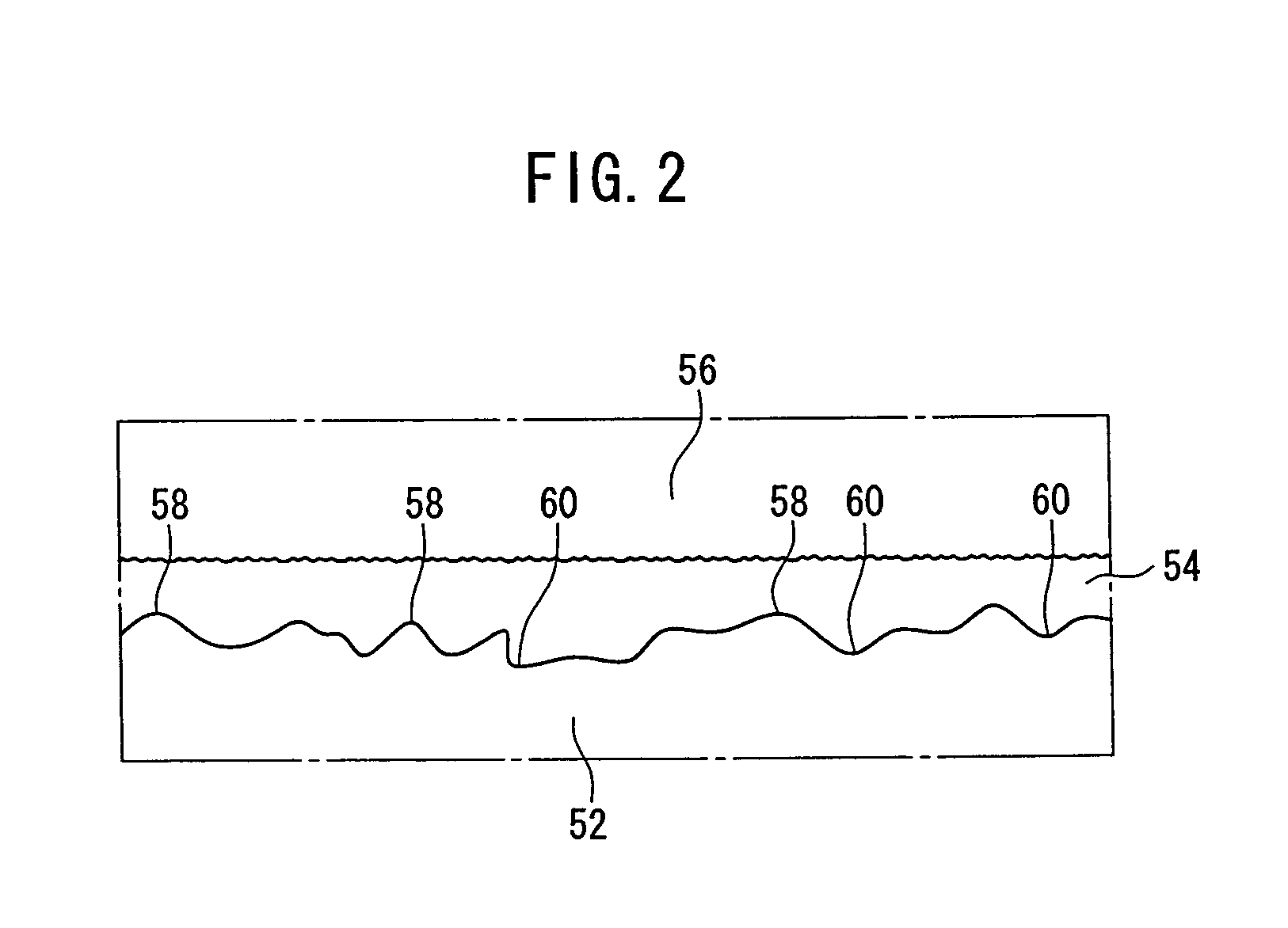

Chalcopyrite Type Solar Cell

InactiveUS20070209700A1Increase the open circuit voltageAvoid violationsFinal product manufacturePhotovoltaic energy generationParticulatesSolar cell

A chalcopyrite type solar cell has a mica aggregate substrate formed by binding mica particulates with a resin. A multilayer body consisting of a first electrode, a light absorption layer and a second electrode is formed on the mica aggregate substrate with a smoothing layer and a binder layer interposed between the substrate and the body. The smoothing layer is preferably made of SiN or SiO2, and the binder layer is made of TiN or TaN.

Owner:HONDA MOTOR CO LTD

Topography reduction and control by selective accelerator removal

ActiveUS20090277867A1Improve throughputLow costDecorative surface effectsSemiconductor/solid-state device manufacturingMetal interconnectEtching

Plating accelerator is applied selectively to a substantially-unfilled wide (e.g., low-aspect-ratio feature cavity. Then, plating of metal is conducted to fill the wide feature cavity and to form an embossed structure in which the height of a wide-feature metal protrusion over the metal-filled wide-feature cavity is higher than the height of metal over field regions. Most of the overburden metal is removed using non-contact techniques, such as chemical wet etching. Metal above the wide feature cavity protects the metal-filled wide-feature interconnect against dishing, and improved planarization techniques avoid erosion of the metal interconnect and dielectric insulating layer. In some embodiments, plating of metal onto a substrate is conducted to fill narrow (e.g., high-aspect-ratio feature cavities) in the dielectric layer before selective application of plating accelerator and filling of the wide feature cavity.

Owner:NOVELLUS SYSTEMS

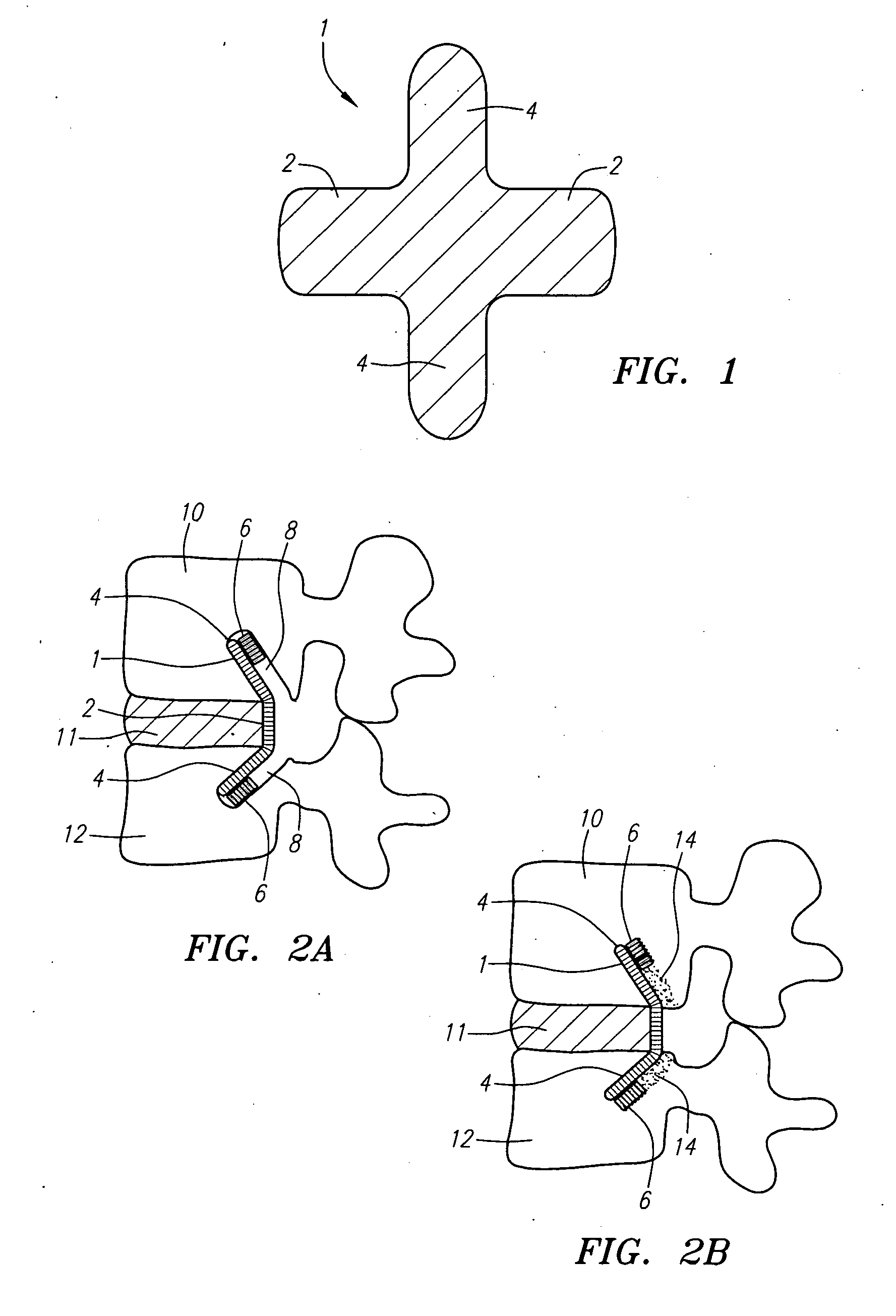

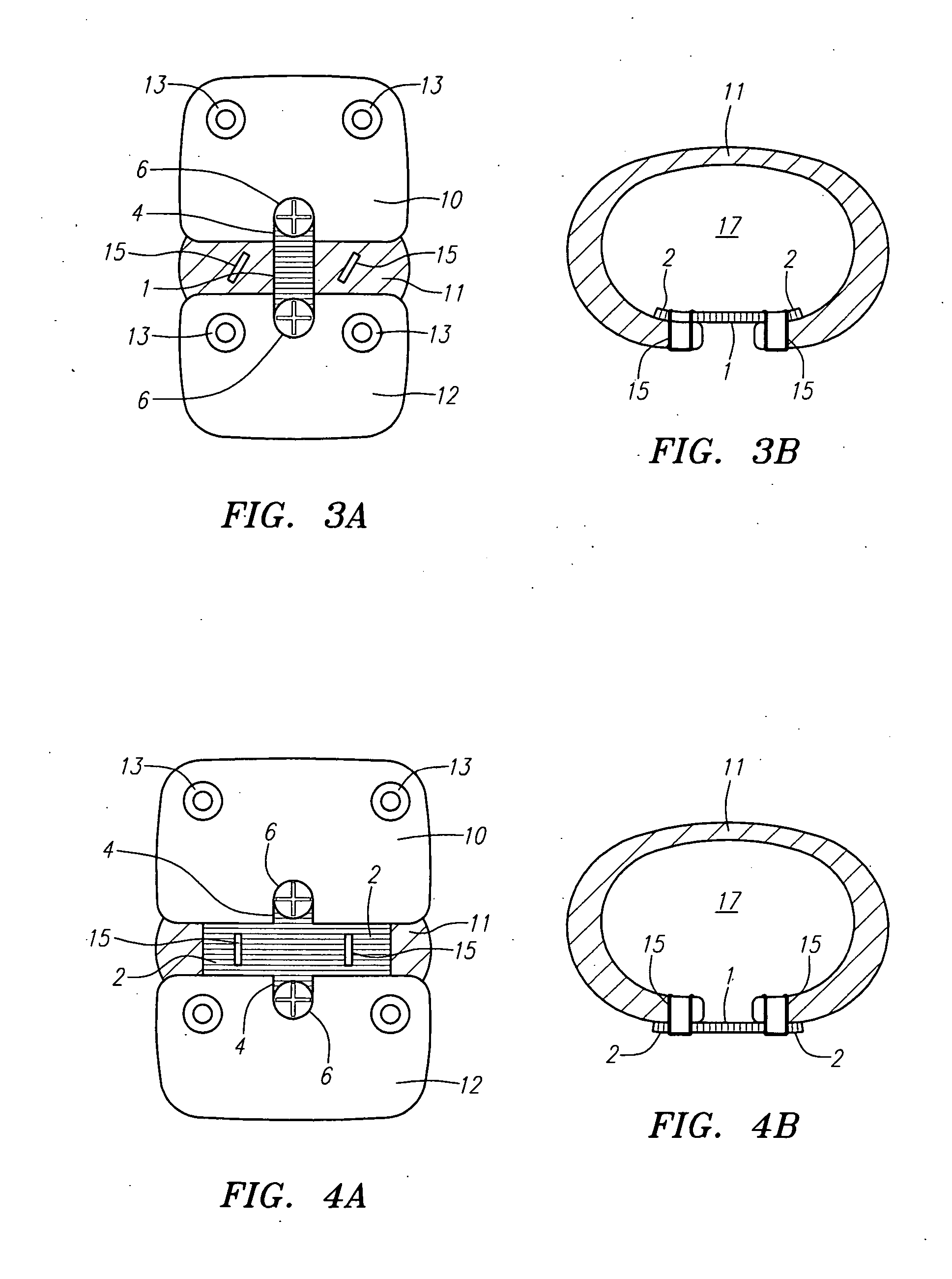

Methods and apparatus for reconstructing the anulus fibrosus

InactiveUS20070067040A1Facilitates reconstructionPrevents herniationSuture equipmentsInternal osteosythesisVertebraEngineering

Methods and devices for fixing a defect in the anulus fibrosus of a patient. The devices include first and second vertical components extending from the middle region of the horizontal component, each of the first and second vertical components having a width and an end. The middle region of the horizontal component of the device blocks the defect in the anulus fibrosus. The first vertical component is attached to the upper vertebra and the second vertical component is attached to the lower vertebra. The horizontal component can be positioned beneath a layer of the posterior longitudinal ligament.

Owner:ANOVA

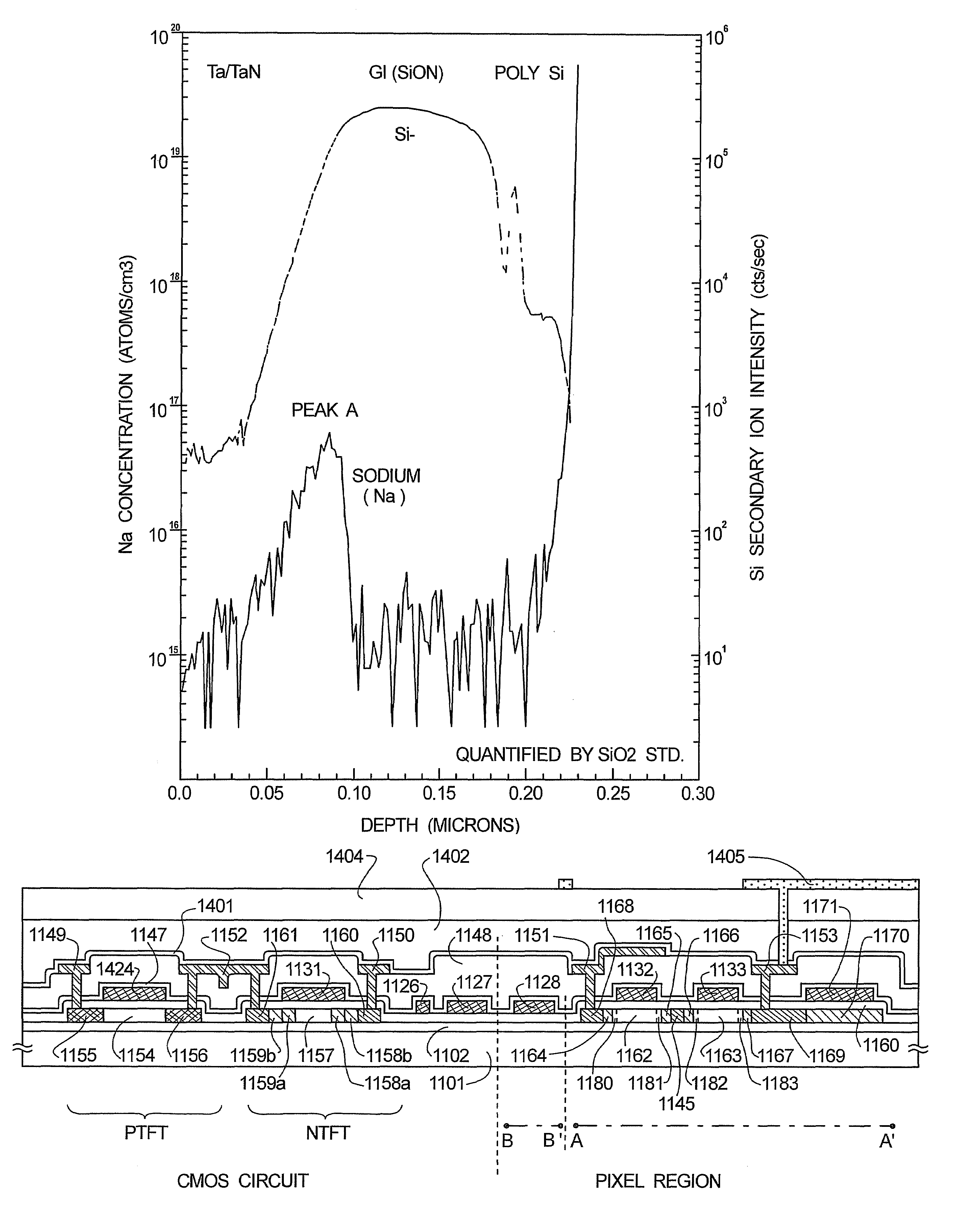

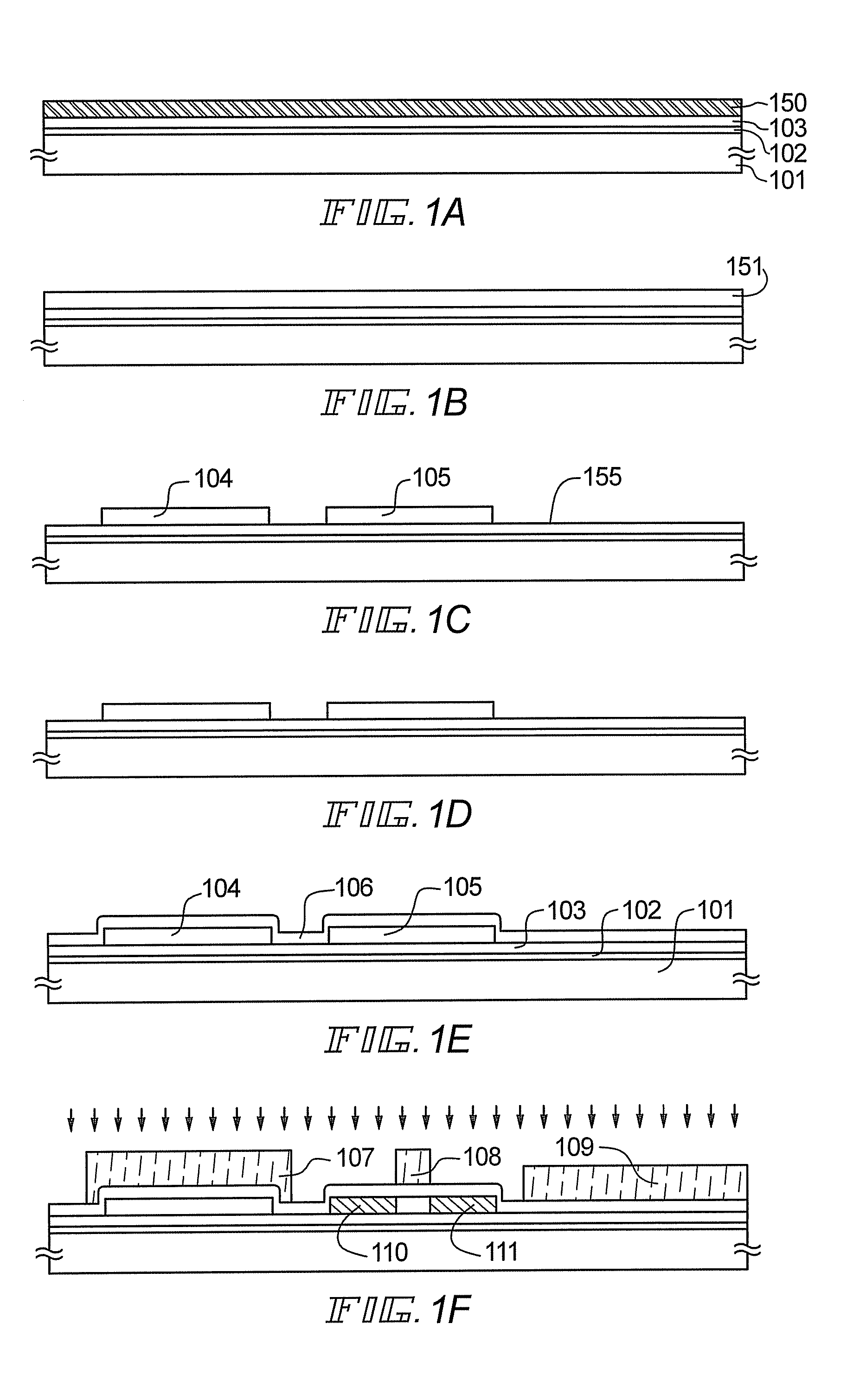

Method of manufacturing a semiconductor device

InactiveUS7402467B1Avoid erosionRemove pollutantsSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A reduction in contaminating impurities in a TFT, and a TFT which is reliable, is obtained in a semiconductor device which uses the TFT. By removing contaminating impurities residing in a film interface of the TFT using a solution containing fluorine, a reliable TFT can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

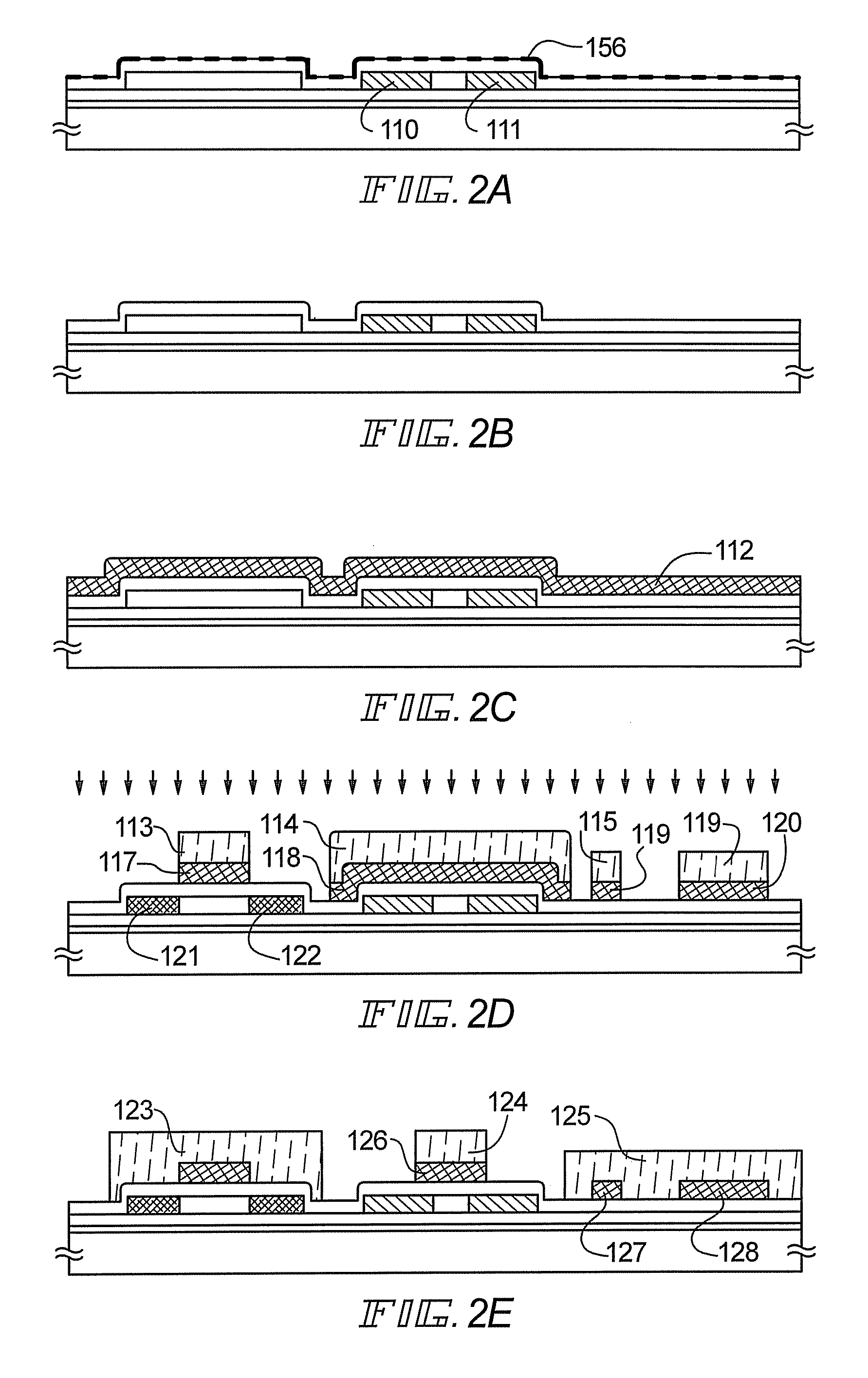

Ecological protection method for high steep side slope

The invention relates to an ecological protection method for a high steep side slope. The method mainly comprises the steps of slope surface treatment, concrete shotcrete and rock bolt support, vegetating hole arrangement, net spreading, spray material preparation, granule spray sowing, maintenance, management, and the like. In the method, guest soil materials such as humus loam rich in organic matters and clay are utilized to undergo a granule reaction after mixed with a granule agent at the moment of spray sowing so as to form a greening template which has the same high order granule structure as natural soil and strong erosion resistance and can suppress water and soil loss. After a diversified mature plant community which is in harmony with surrounding vegetation environment is formed, the slope surface can be protected, which can effectively resist diseases and insect pests and maintain the ecological balance. Post maintenance management and expenses can be saved. All used materials can be naturally degraded, have no pollution to the environment and can purify air and beautify the environment. Equipment of the method does not need to be hung on the slope surface for construction, and spray sowing operations are carried out only below the slope surface, thus the method has high construction speed and safety. The method is suitable for slope surfaces which are difficult to green, and the like, such as various high steep and unstable slope surfaces, bare slope surfaces having high greening expected values, and the like.

Owner:河南国网宝泉抽水蓄能有限公司

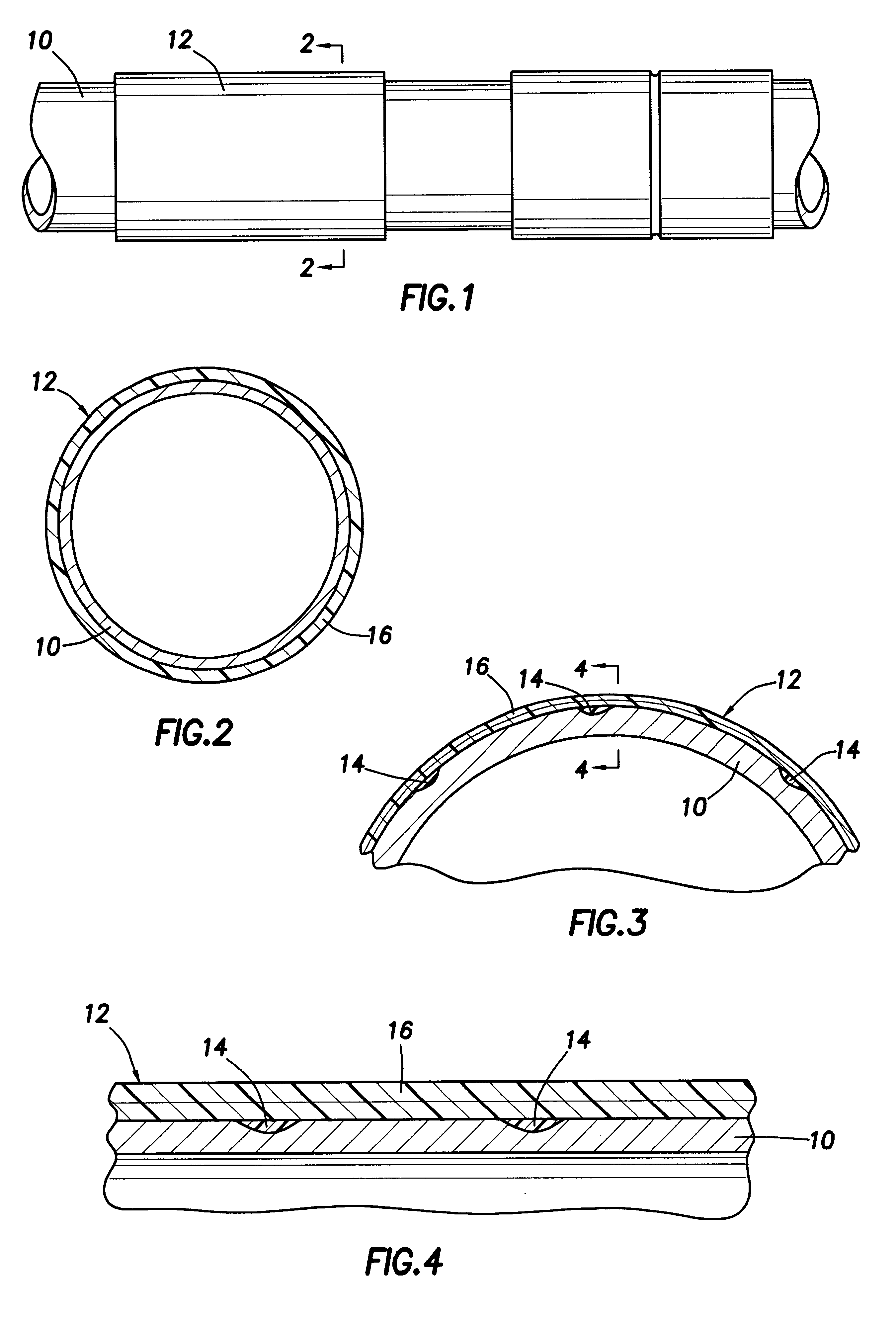

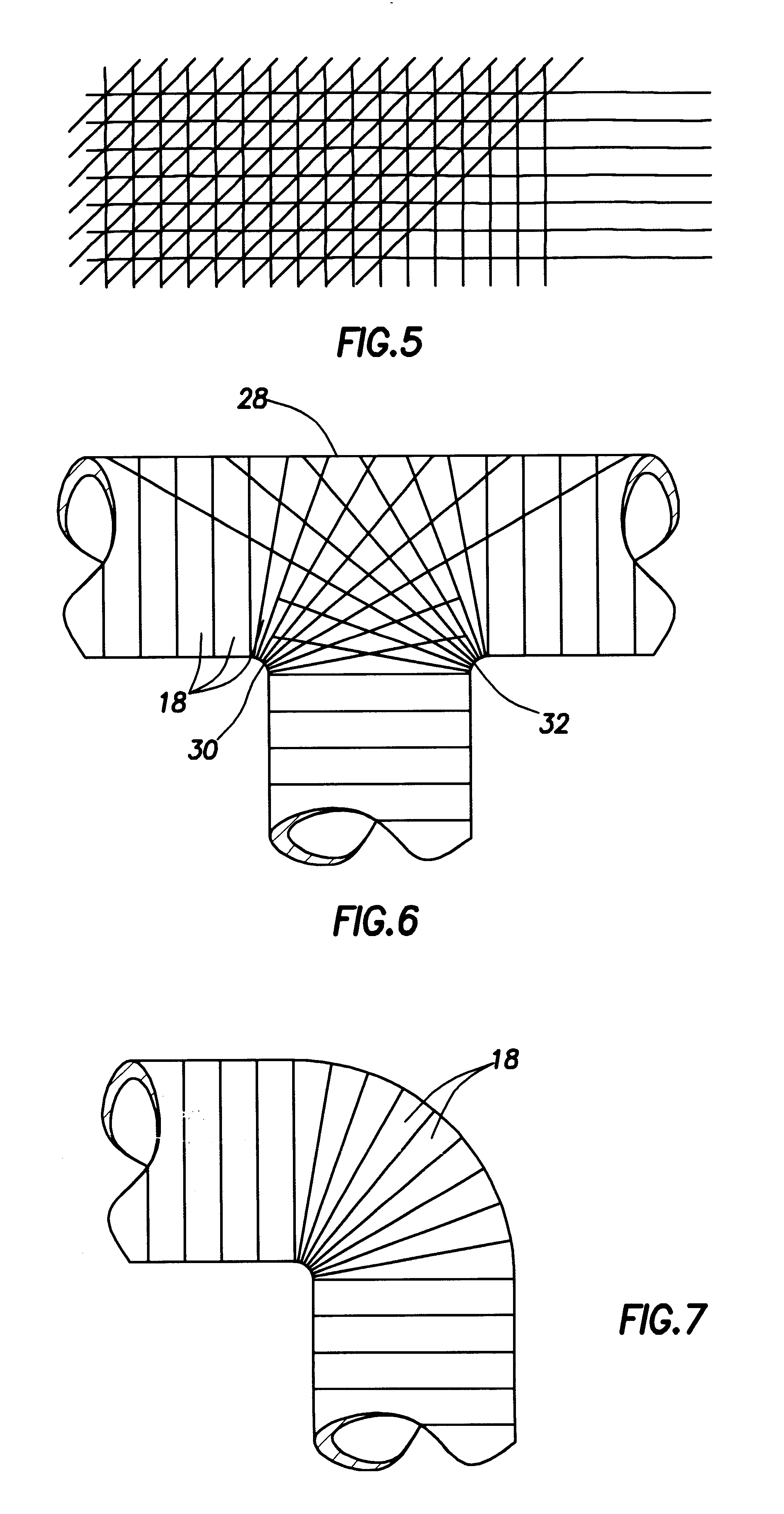

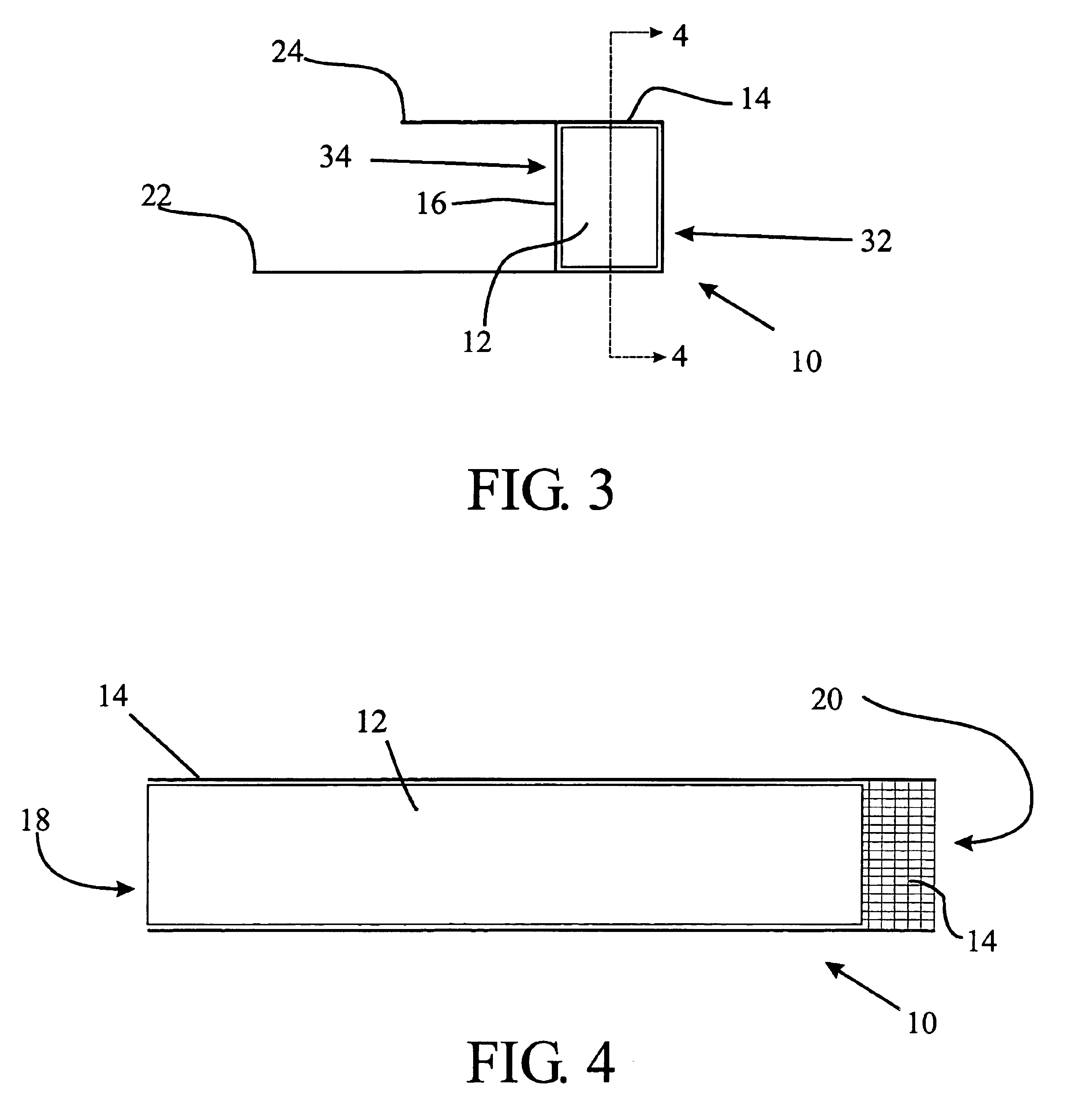

High temperature composite pipe wrapping system

InactiveUS6276401B1Improve stress resistanceMinimize dimensional changeLayered productsLaminationUnderlaySolvent

A method and apparatus for providing metal or non-metal vessels, including straight and curved pipes and various pipe connections, such as T's, elbows, swages, etc., and pressure containing vessels such as tanks, with an external composite lining of a webbing of biaxial or triaxial weave preferably composed of fiberglass which is pre-impregnated with a high temperature heat curable polymer composition capable of being heat cured at a temperature range of from about 275° F. to about 375° F. The vessel is prepared for bonding by abrasive cleaning and by solvent cleaning. Metal imperfections are then filled with an epoxy. A small amount a quick setting epoxy is employed to attach one end of the web to the external surface of the vessel in oriented position for wrapping of the web in intimate surface-to-surface contact with the vessel. During wrapping only enough tension is applied to the pre-impregnated webbing to eliminate any wrinkles. The number of layers of the impregnated webbing will be determined by the safe pressure containing capability of the pipe or vessel and its composite lining. An external heating element is then placed about the wrapping of pre-impregnated webbing material so as to be in substantially intimate relation therewith and is energized to apply sufficient heat for a sufficient period of time to completely cure the epoxy surface filler and to cure the polymer resin components of the pre-impregnated woven wrappings of webbing.

Owner:WILSON FRED D

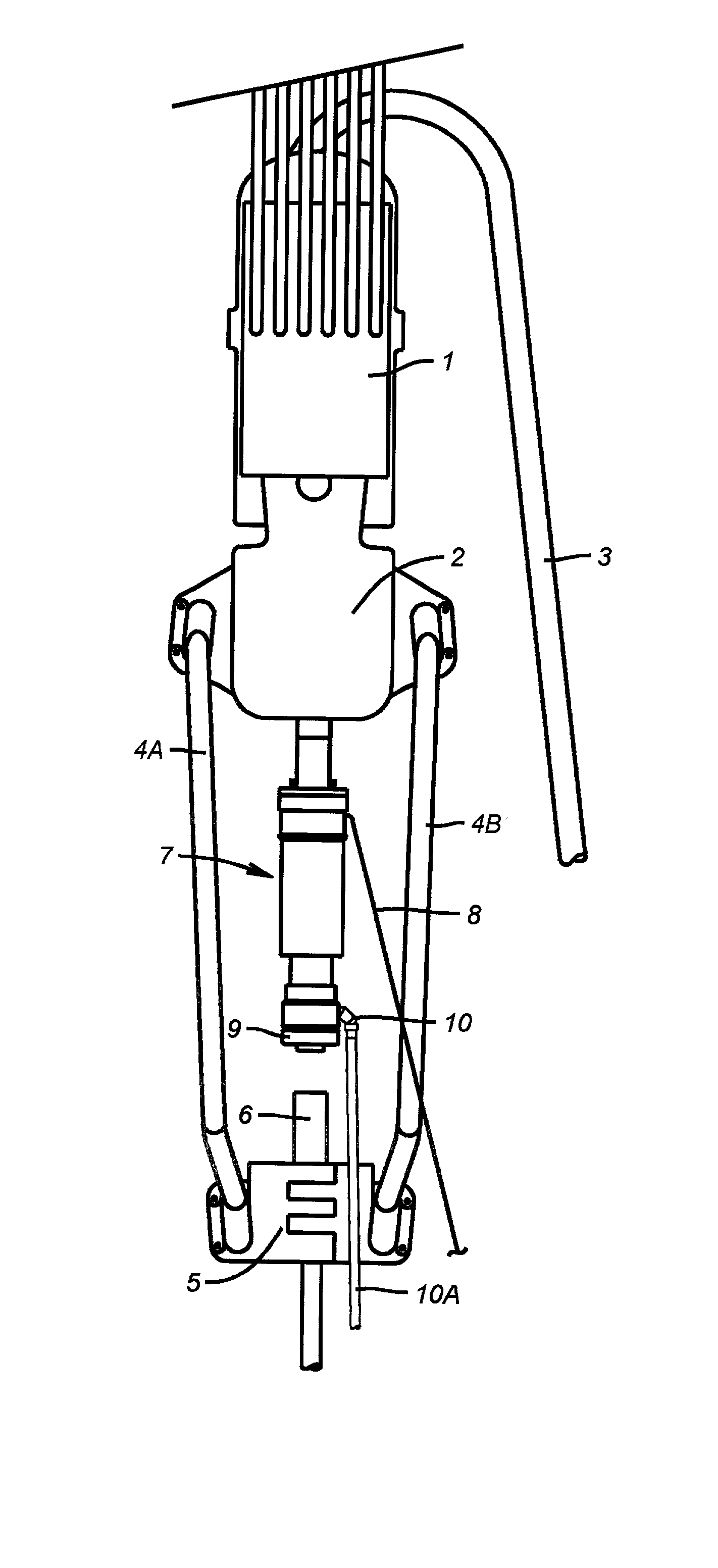

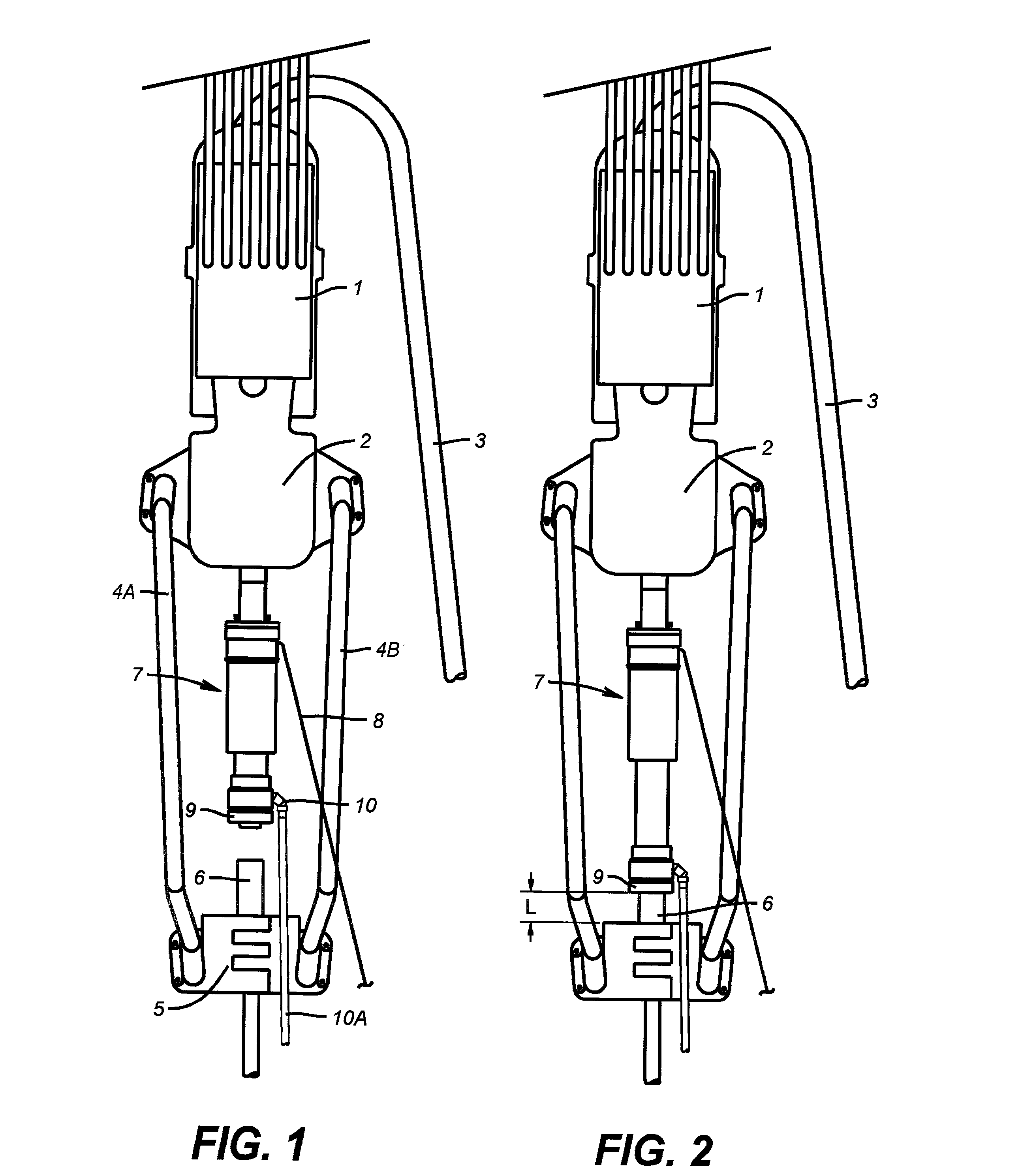

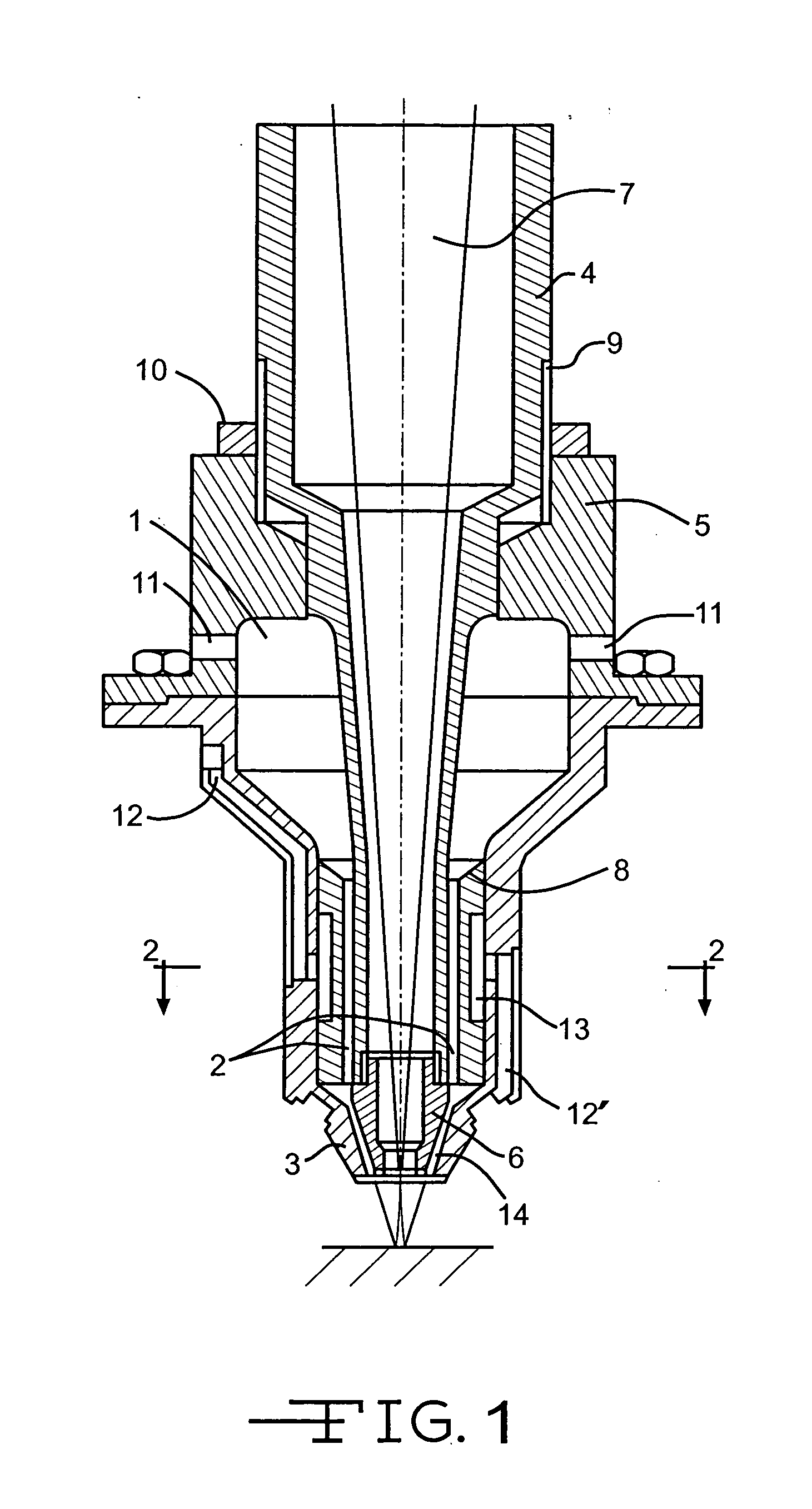

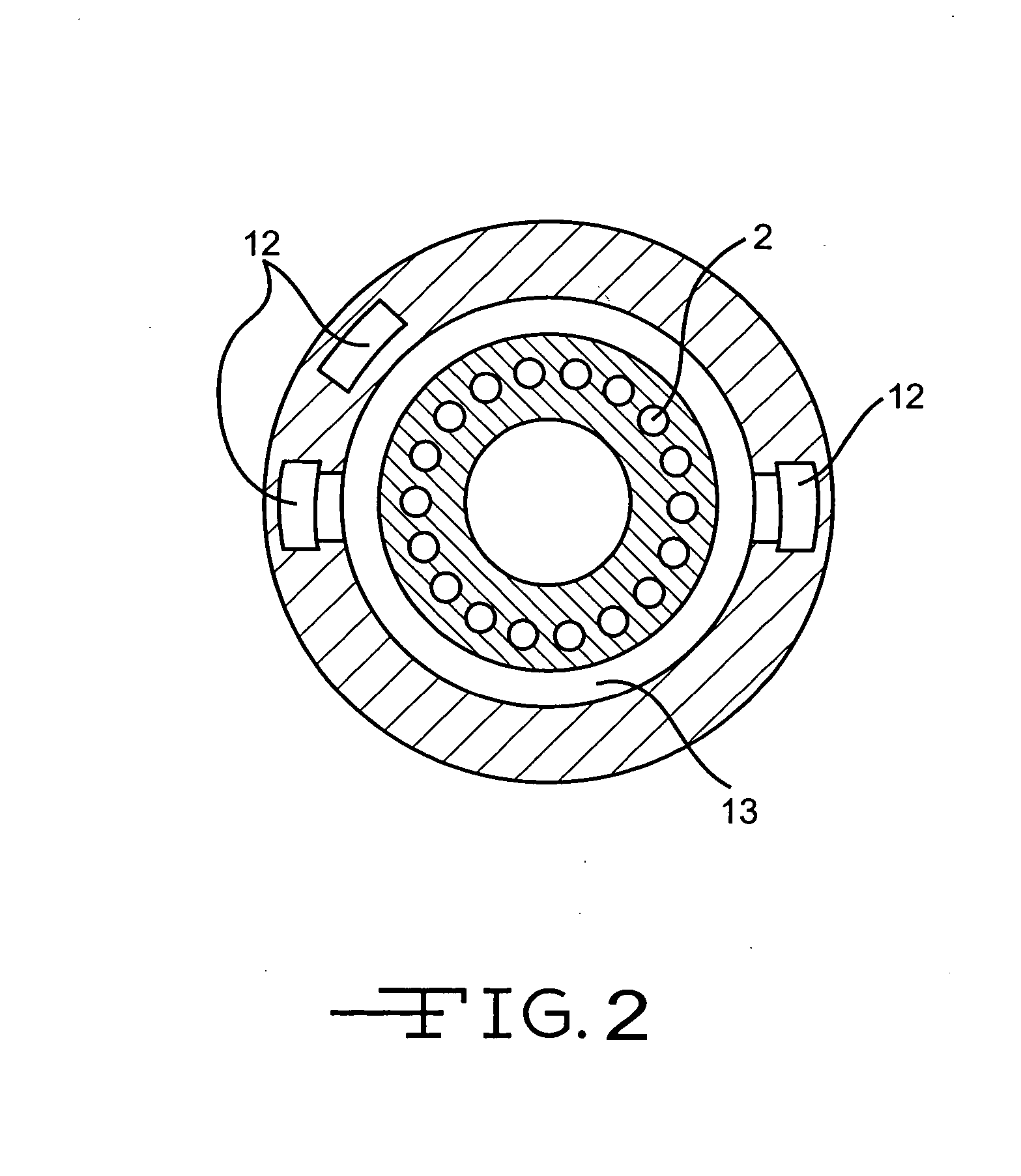

Tubular filling system

InactiveUS20020129934A1Quick connectionQuick releaseDrilling rodsConstructionsInternal pressureSingular control

A system for capturing displaced fluid or pumping fluid through tubulars being run into or out of the wellbore is described. Embodiments are supported by a traveling block and top drive unit with telescoping features to rapidly seal over a tubular to connect the tubular to a mud system. Alternative sealing arrangements for sealing inside the tubular connection are also disclosed. These alternate sealing arrangements also provide flow areas larger than the tubular body since no portion of these arrangements enter the tubular body. All of the sealing arrangements provide a biased area whereby any internal pressure in the invention forces the seals into more intimate contact with their mating seal surfaces. A mudsaver valve having a large flow capacity is described to keep fluid from spilling when the apparatus is removed from the tubular. This mudsaver valve also provides for pumping of fluid into the tubular or flow of fluid from the tubular to the mud system prior to removing the apparatus from the tubular. In these embodiments, the apparatus can be placed in threaded sealing contact with the tubular and can incorporate a safety valve that can be manually closed in the event of a well kick. In another embodiment, a singular control input accomplishes operation of the apparatus to extend or retract the telescoping feature. Also illustrated is a drain valve that provides a method of completely removing all fluid pressure from within the apparatus prior to removing the apparatus from the tubular. The drain system also provides a means of disposing of the excess fluid away from the rig floor where spillage is a danger to the personnel or environment. The drain system can also be connected to a scavenger system that is intended as a vacuum system for removal of spillage. Connection to this system eliminates all possible spillage and completely removes fluids from the tubular handling area.

Owner:OFFSHORE ENERGY SERVICES

Devices and methods for altering eating behavior

InactiveUS20090247992A1Avoid erosionEffectively alterSuture equipmentsHeart valvesGerontologyFeeding behavior

A device for modifying an eating behavior of a subject is provided. The device includes a device body which is attachable to GI tract tissue of a subject and functions in altering an eating behavior thereof.

Owner:SVIP 2

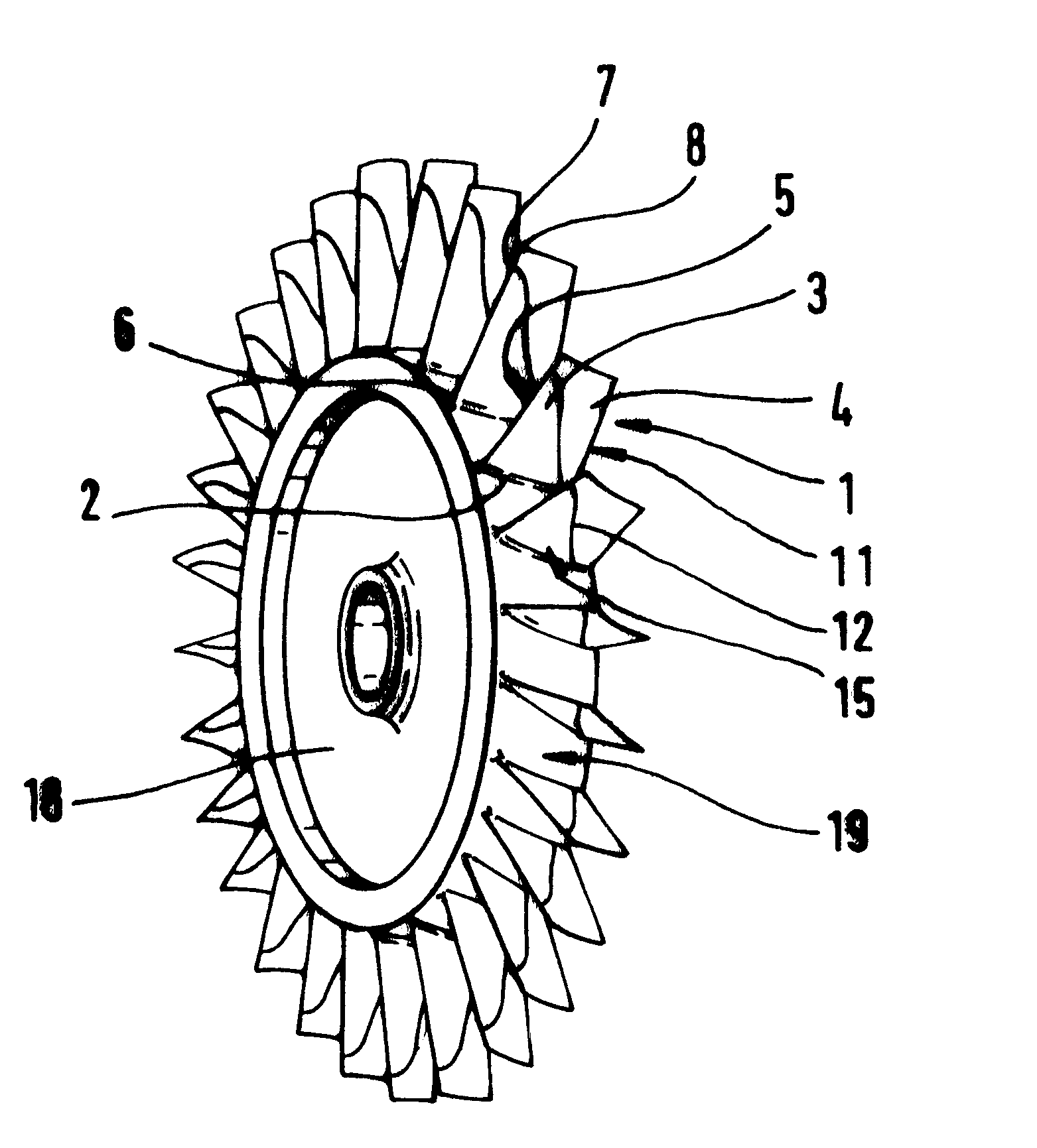

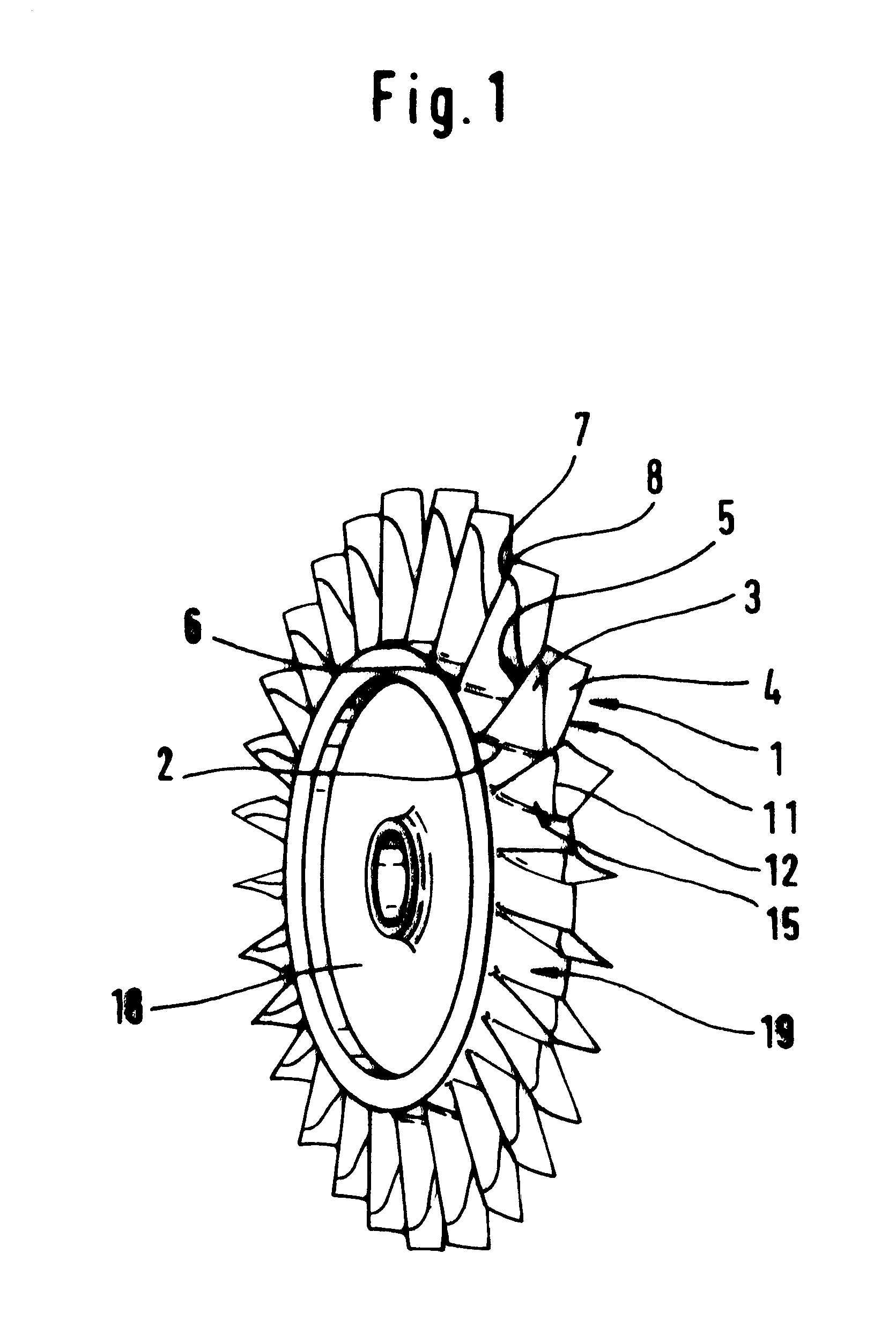

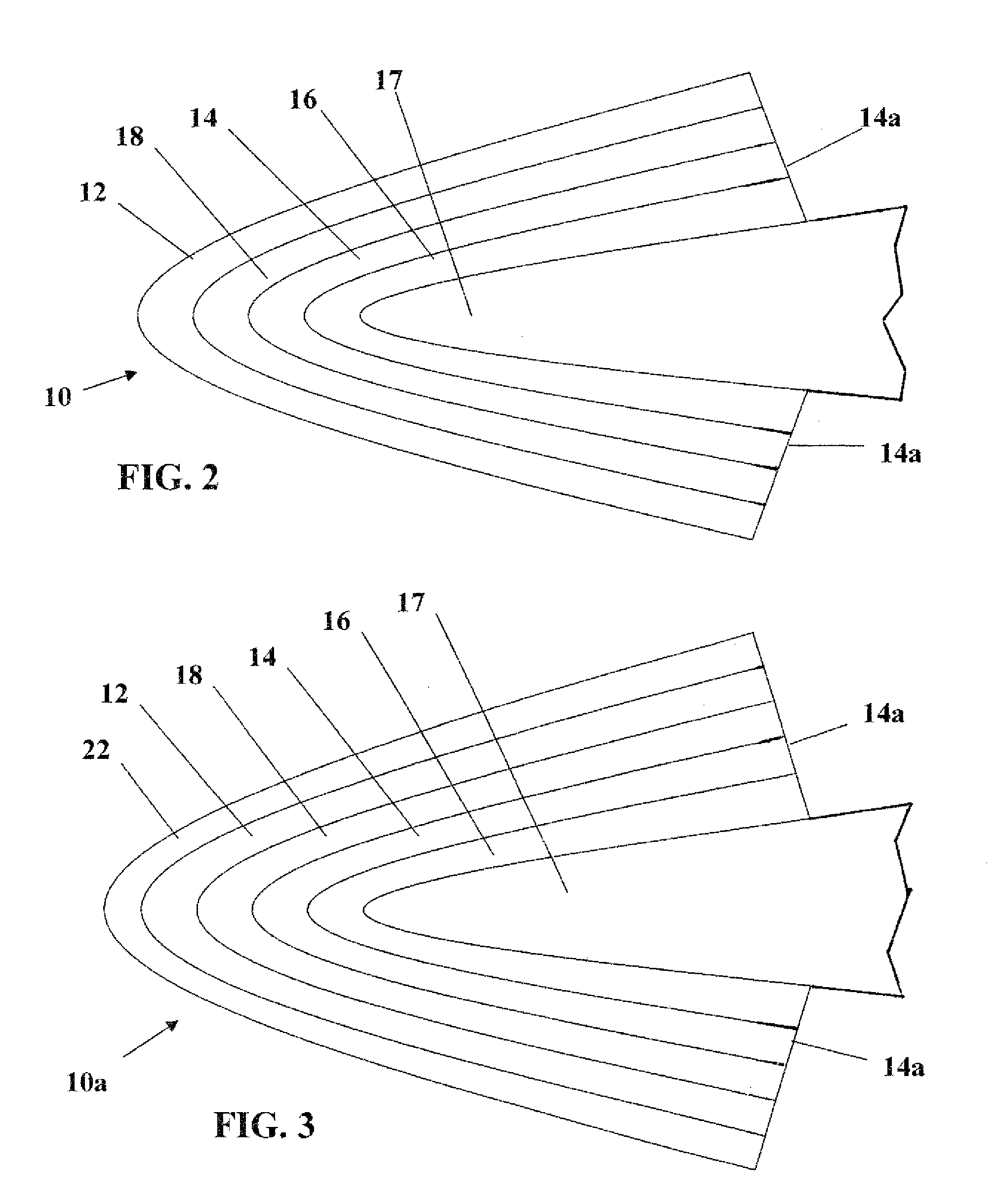

Rotor with integrated blading

InactiveUS6471485B1Improve ductilityGood vibration attenuationPropellersPump componentsLeading edgeFiber

A rotor for a propulsion plant has hybrid rotor blades arranged circumferentially around and extending essentially radially from a rotor. To reduce vibrations, the rotor blade has a metallic blade root and each blade has a metallic blade section that forms at least a portion of the blade leading edge and the area of the blade surface adjacent to the blade leading edge, and a blade section made of fiber-reinforced synthetic material or composite material. The blade sections (3, 4) of each blade (1) are so correlated to each other that damage or loss of the composite material blade section (4) still enables the propulsion plant to deliver a required emergency power.

Owner:MTU AERO ENGINES GMBH

Method for improving alkaline resistance of anode oxide film on surface of aluminum or aluminum alloy material

InactiveCN104233428AGood alkali resistanceImprove corrosion resistanceAnodisationOrganic acidSilanes

The invention discloses a method for improving the alkaline resistance of an anode oxide film on the surface of an aluminum or aluminum alloy material. The method comprises the following steps: performing polishing pretreatment on the aluminum or aluminum alloy material, performing anodic oxidation treatment in electrolytic liquid containing organic acid, inorganic acid and soluble oxysalt, performing closing treatment on an oxide film obtained after the anodic oxidation treatment, and forming a silane film layer on the surface of the aluminum or aluminum alloy material subjected to the closing treatment. The method for surface treatment of the aluminum or aluminum alloy material is easy to perform, economic, environment-friendly and capable of effectively improving the alkaline resistance of the anode oxide film on the surface of the aluminum or aluminum alloy material.

Owner:HUNAN UNIV

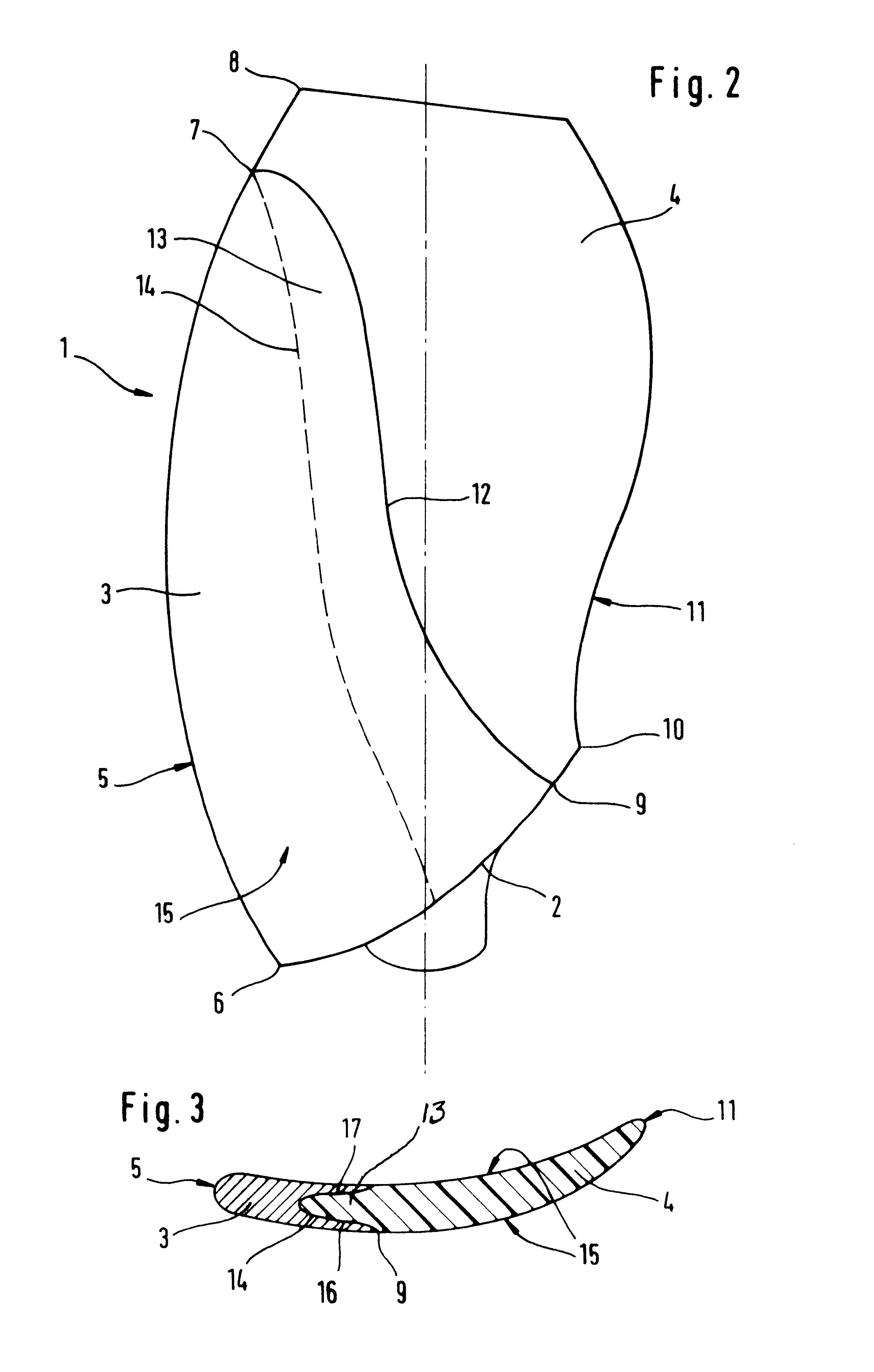

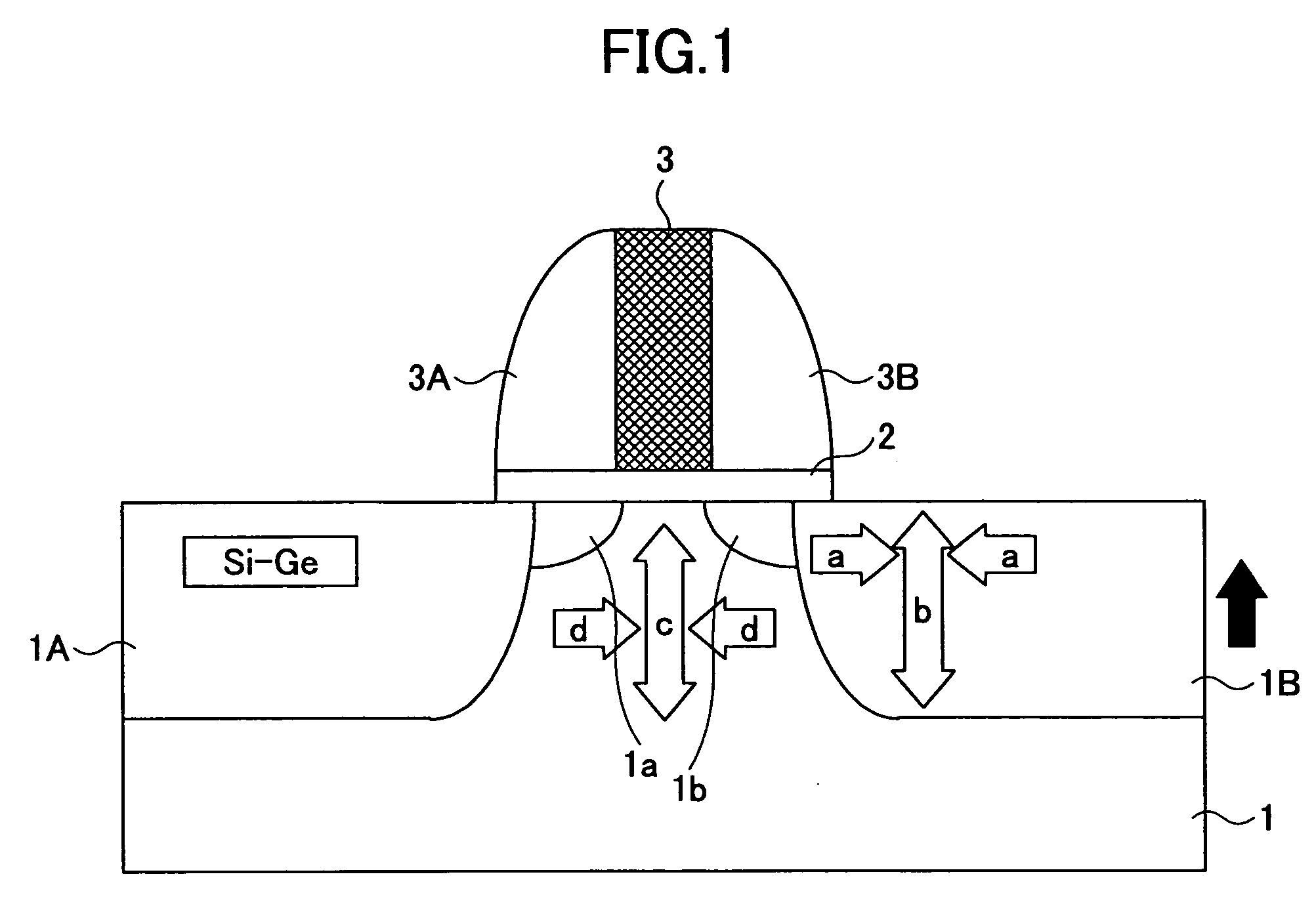

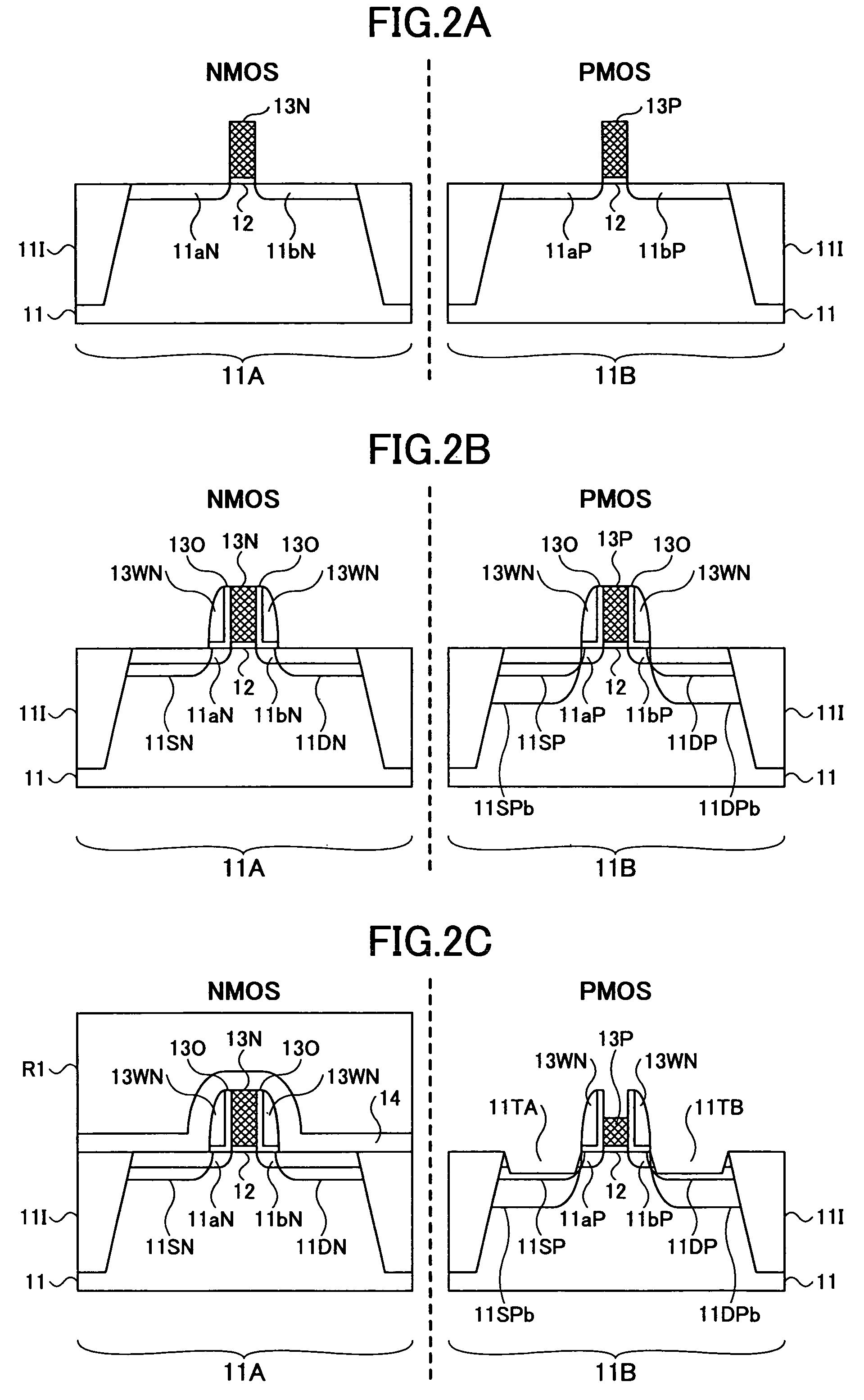

Semiconductor integrated circuit and fabrication process thereof

ActiveUS20060151776A1Suppress leakage currentSufficient distanceSemiconductor/solid-state device manufacturingSemiconductor devicesManufacturing technologyEngineering

A semiconductor integrated circuit device includes an n-channel MOS transistor formed on a first device region of a silicon substrate and a p-channel MOS transistor formed on a second device region of the silicon substrate, wherein the n-channel MOS transistor includes a first gate electrode carrying a pair of first sidewall insulation films formed on respective sidewall surfaces thereof, the p-channel MOS transistor includes a second gate electrode carrying a pair of second sidewall insulation films formed on respective sidewall surfaces thereof, first and second SiGe mixed crystal regions being formed in the second device region epitaxially so as to fill first and second trenches formed at respective, outer sides of the second sidewall insulation films so as to be included in source and drain diffusions of the p-channel MOS transistor, a distance between n-type source and drain diffusion region in the first device region being larger than a distance between the p-type source and drain diffusion regions in the second device region.

Owner:FUJITSU LTD

Erosion-resistant silicone coatings for protection of fluid-handling parts

ActiveUS7033673B2Improve adhesionEconomy in coatingPretreated surfacesLiquid/solution decomposition chemical coatingSilanesSilanol

Owner:SS IND TECH LLC

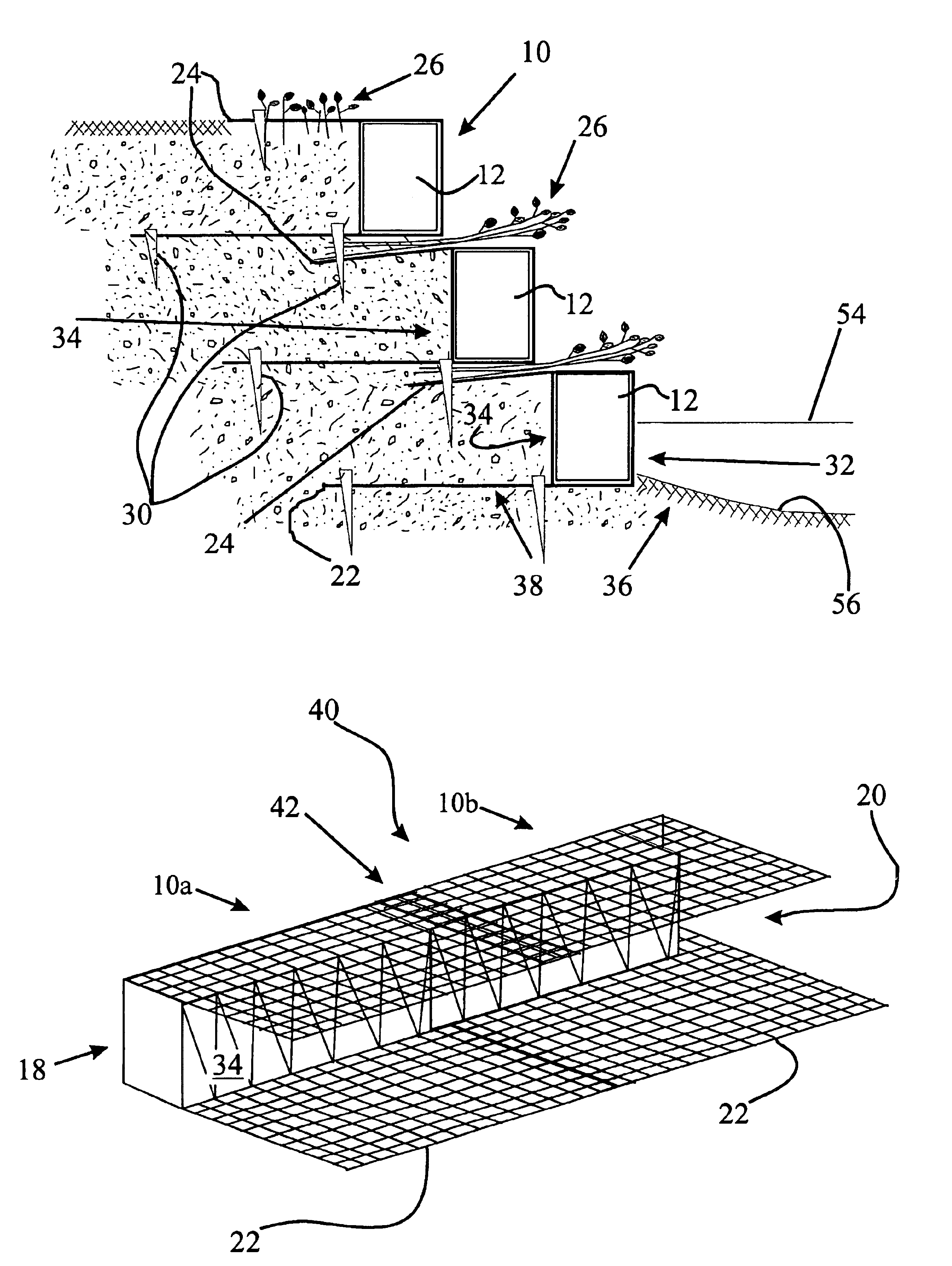

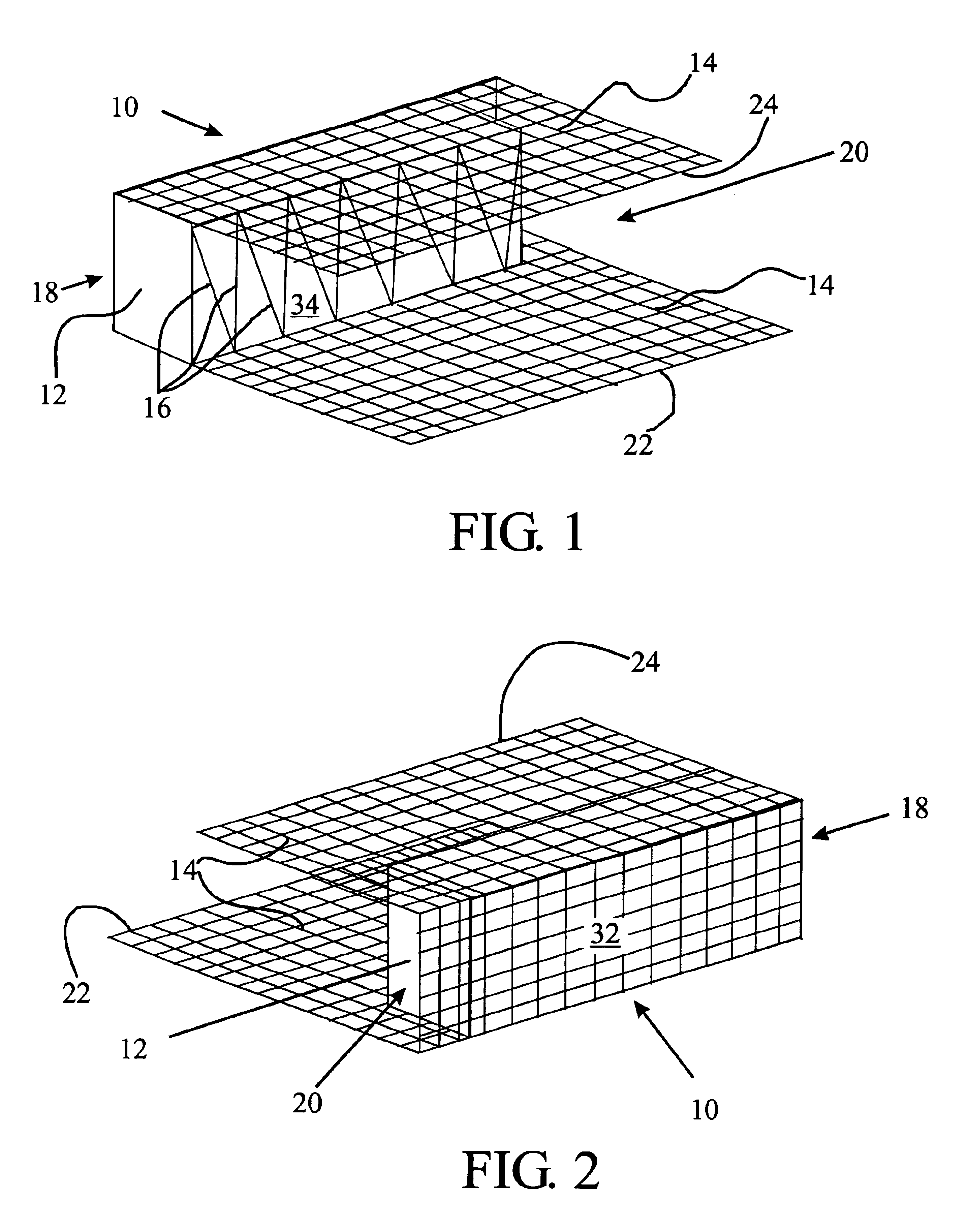

Self-anchoring fiber block system

InactiveUS6893193B2Promote vegetation growthEasy to installArtificial islandsClimate change adaptationFiberEngineering

A fiber block segment suitable for controlling erosion and stabilizing soil is described that comprises an elongated fiber block formed of a densely packed elongated thick fibrous material. The fiber block is wrapped with a fabric around three sides so that the fabric defines a top anchor portion and a bottom anchor portions extending from the block. The fiber block is securely attached to the wrapped fabric by another fabric or twine spanning the fourth side of the block. Additionally, the fabric is wrapped only up to the edges defining one end (a male end) and beyond the edges defining the opposite end (the female end) to define a pouch-like structure at the female end. The fiber block is made of coconut fibers (coir). The fabric is woven from coir twine, and coir twine secures the fabric to the fiber block.

Owner:SANTHA B LANKA

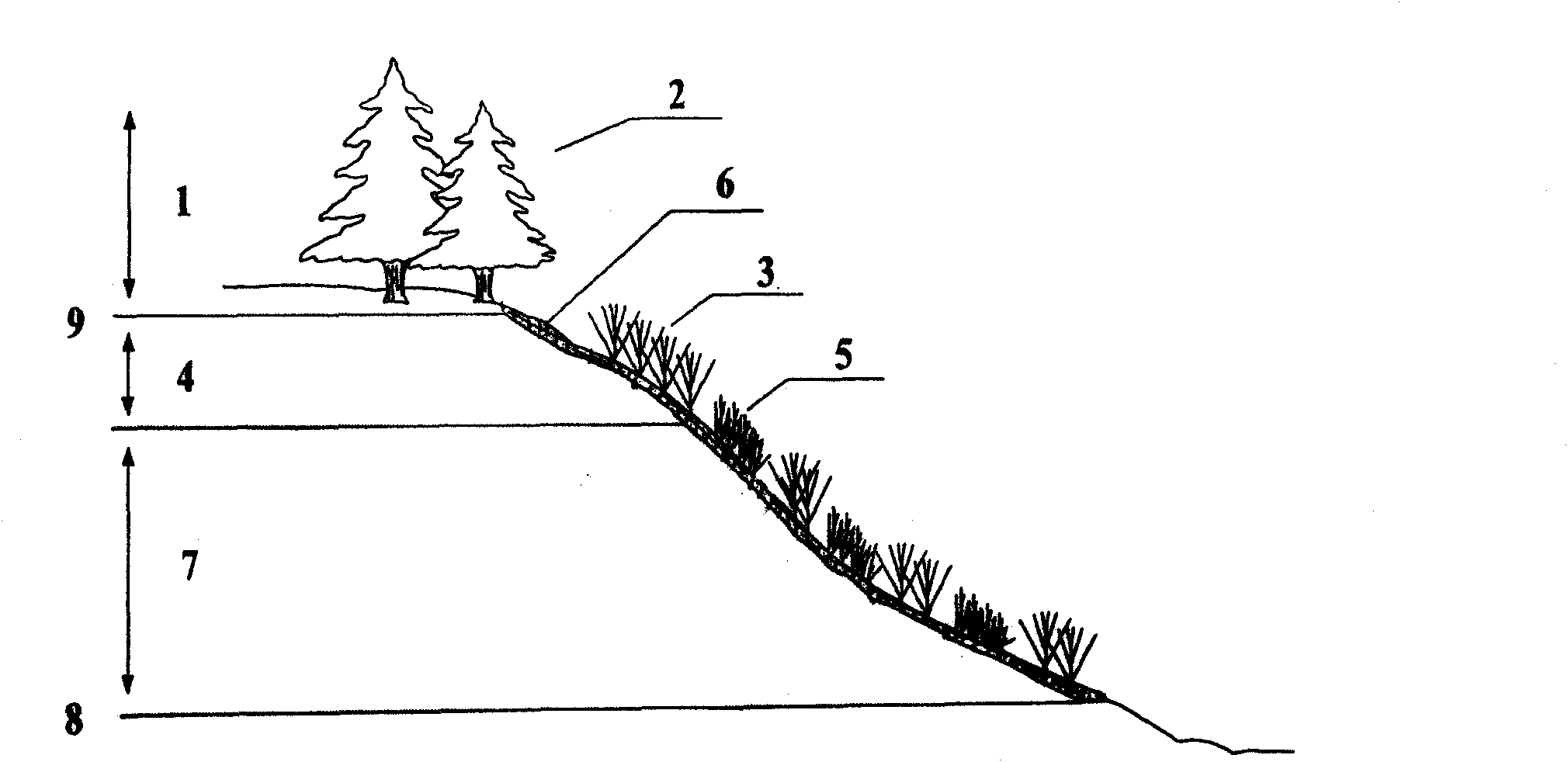

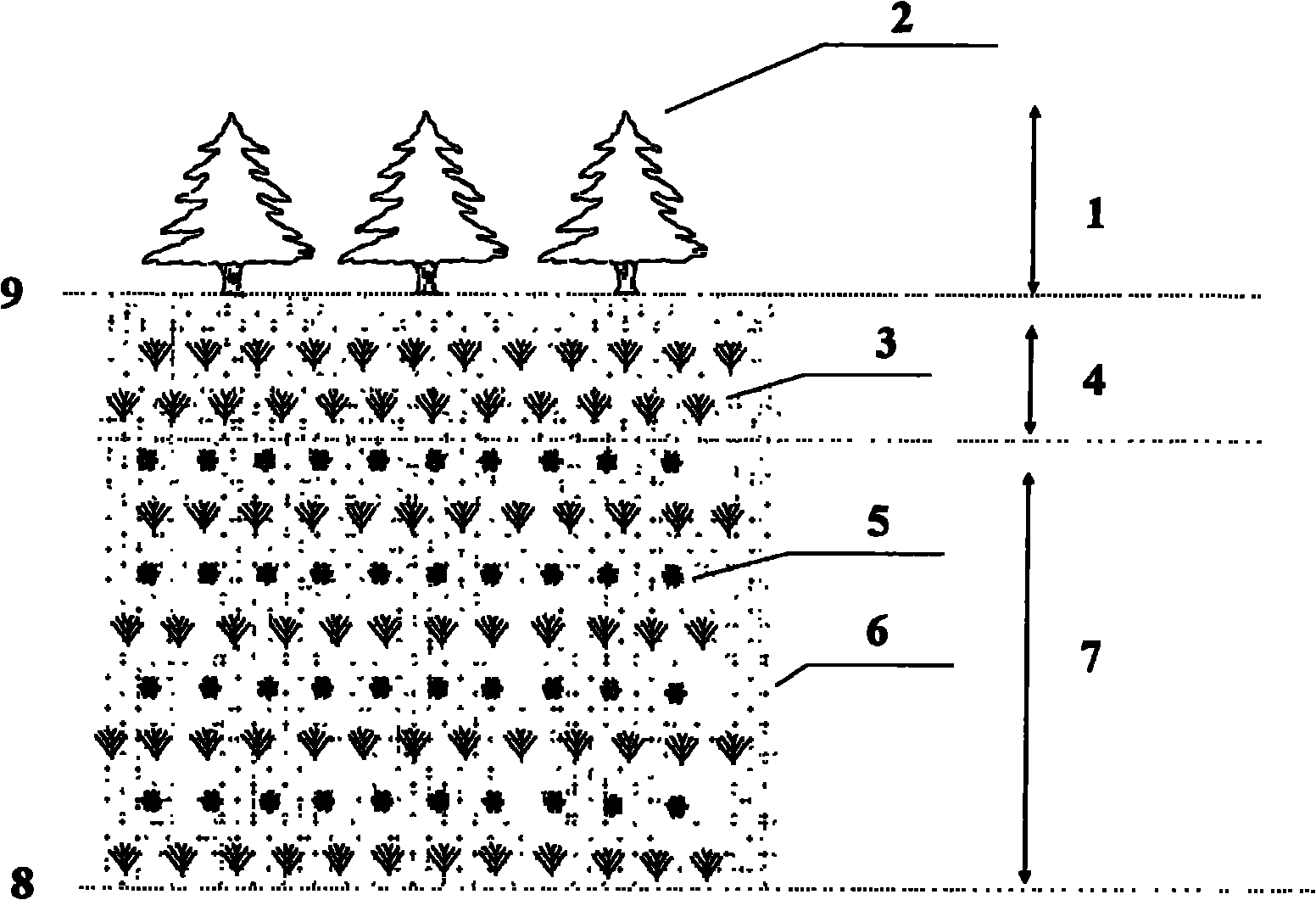

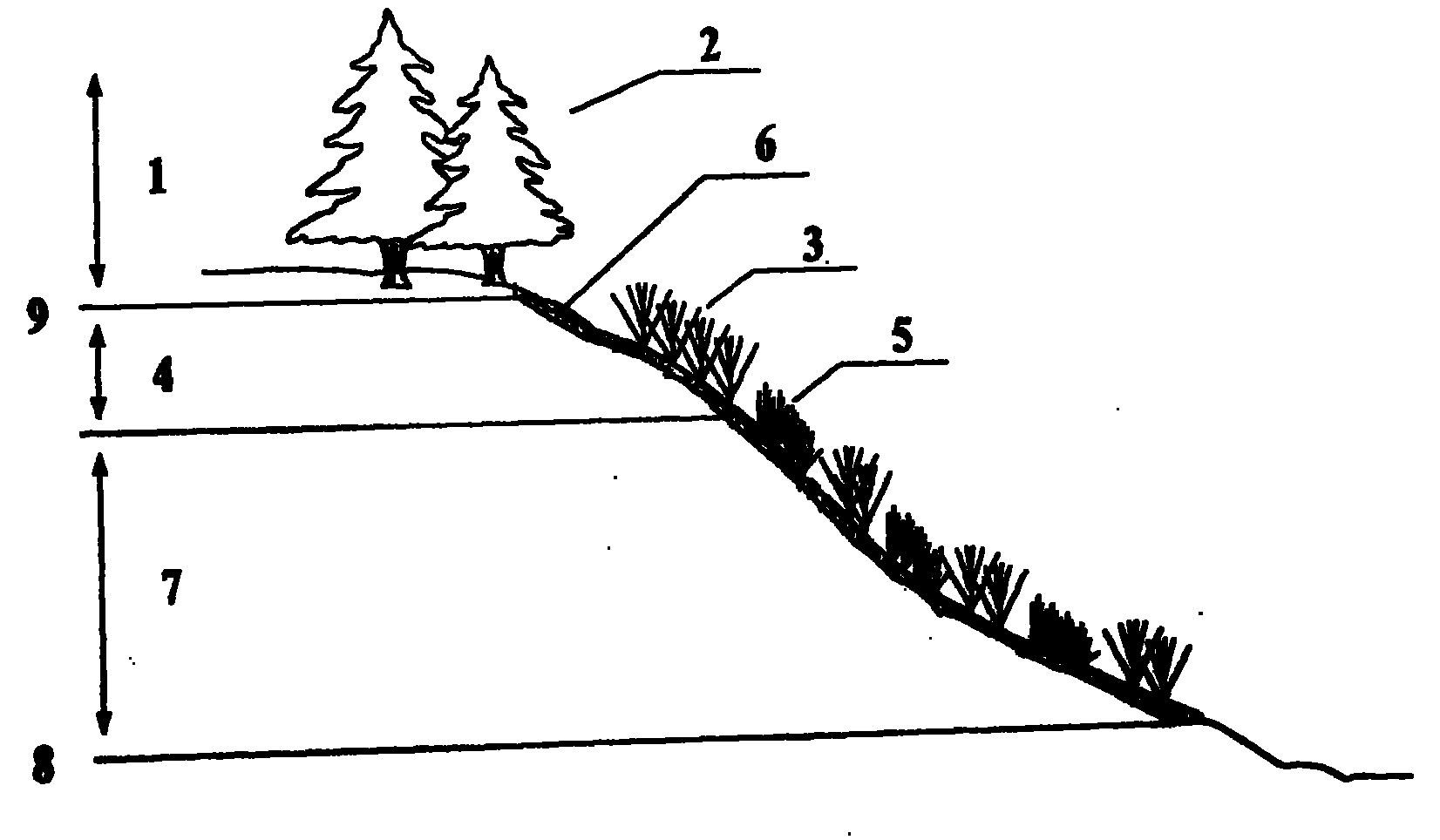

Restoration method for damaged ecosystem in steep-slope area in water-level-fluctuating zone of reservoir

InactiveCN101790931AAvoid erosionStable growth environmentAgriculture gas emission reductionHorticultureTerrainRestoration method

The invention relates to a restoration method for a damaged ecosystem in a steep-slope area in a water-level-fluctuating zone of a reservoir. The method comprises the following steps:when the impounded water level is at the lowest point, cleaning the upstream slope in the water-level-fluctuating zone, and manually tamping; digging planting holes at the top of the slope, and planting Chinese red pines and the like to form a multifunctional protective forest belt; digging planting grooves and planting holes within the range of the water-level-fluctuating zone, laying jute geotextile, planting vetiver within the range with the water-level-fluctuating depth of 2m to form a hedgerow; and mixedly planting vetiver and wire grass within the range with the water-level-fluctuating depth of 2-10m to form a combined vegetation slope restoration belt. The protective forest belt, the hedgerow and the combined vegetation slope restoration belt form a three-dimensional restoration space together, thereby ensuring that plants can take roots and restore in the steep-slope area in the water-level-fluctuating zone. By restoring the vegetation in large area, the invention effectively reduces the overland flow and the soil erosion, and improves the fertility and the properties of the soil, thereby restoring the damaged ecosystem. The invention has the advantages of convenient construction and less investment, can not be easily damaged by water, and is applicable to the water-level-fluctuating zone of a reservoir with large water-level-fluctuating range and precipitous topography.

Owner:HUAZHONG AGRI UNIV

Valve seal assemblies and methods

A method of sealing a valve engaging member to a valve body about a borehole and structure thereof. Two seal members disposed on either side of the valve engaging member include a seat member adjacent the valve engaging member and a pocket insert adjacent the seat member. The pocket inserts fit within first and second pockets of the valve body. A C-shaped seal ring is disposed between the seat member and pocket insert, and two U-shaped seal rings are disposed between the pocket insert and the valve body. One of the U-shaped seal rings between the pocket insert and the valve body functions both as a radial seal ring and a retaining ring.

Owner:HP&T PROD

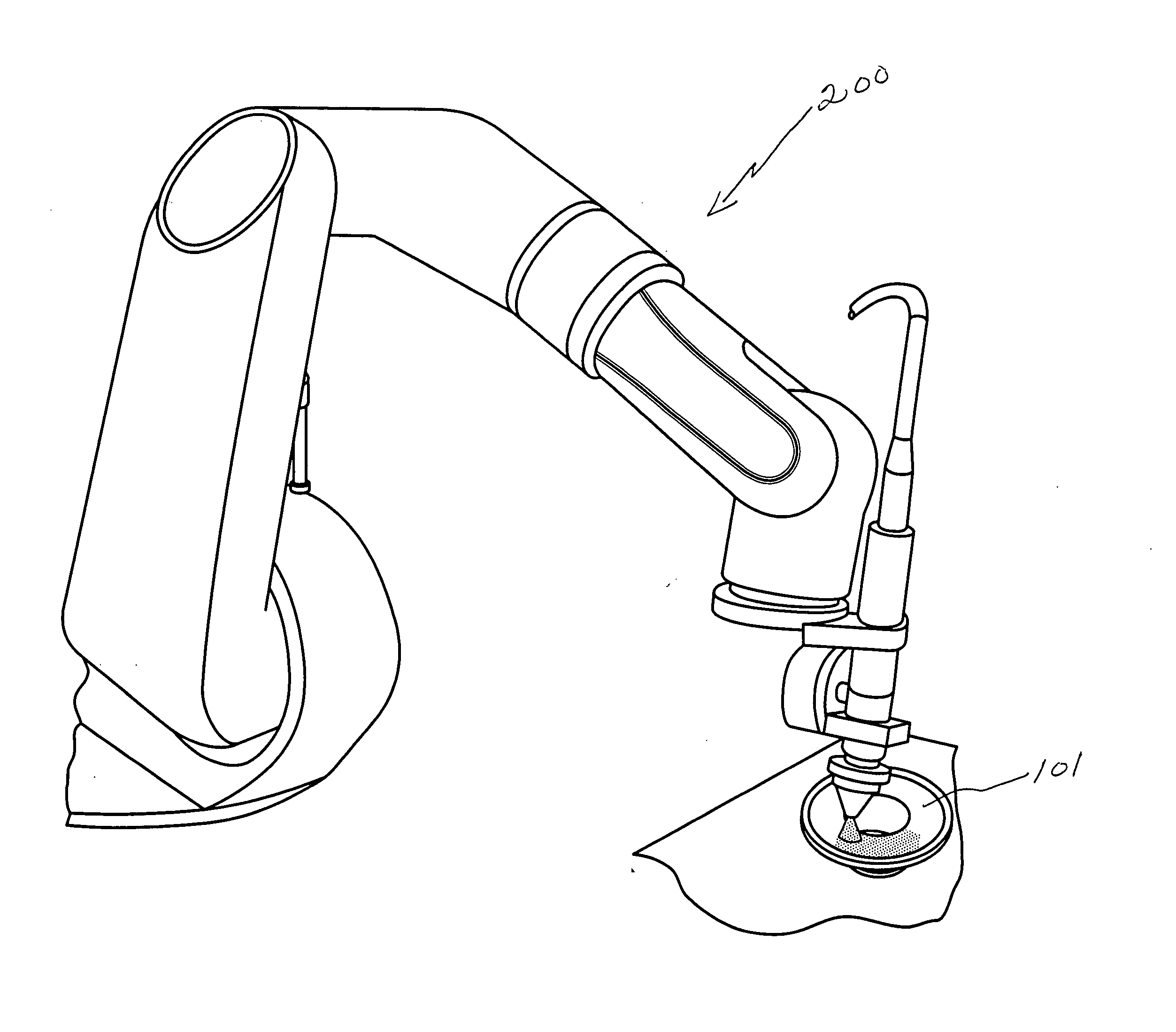

Diamond hard coating of ferrous substrates

The present invention relates to hard coating of ferrous metal substrates using a laser beam with diamond particles in a metal matrix produced from precursor powders of metals which bond to the diamond particles and to the ferrous substrate. The hard coating is particularly useful for white iron castings for pumps ( 200 ) used in piping tar sand and water mixtures.

Owner:FRAUNHOFER USA

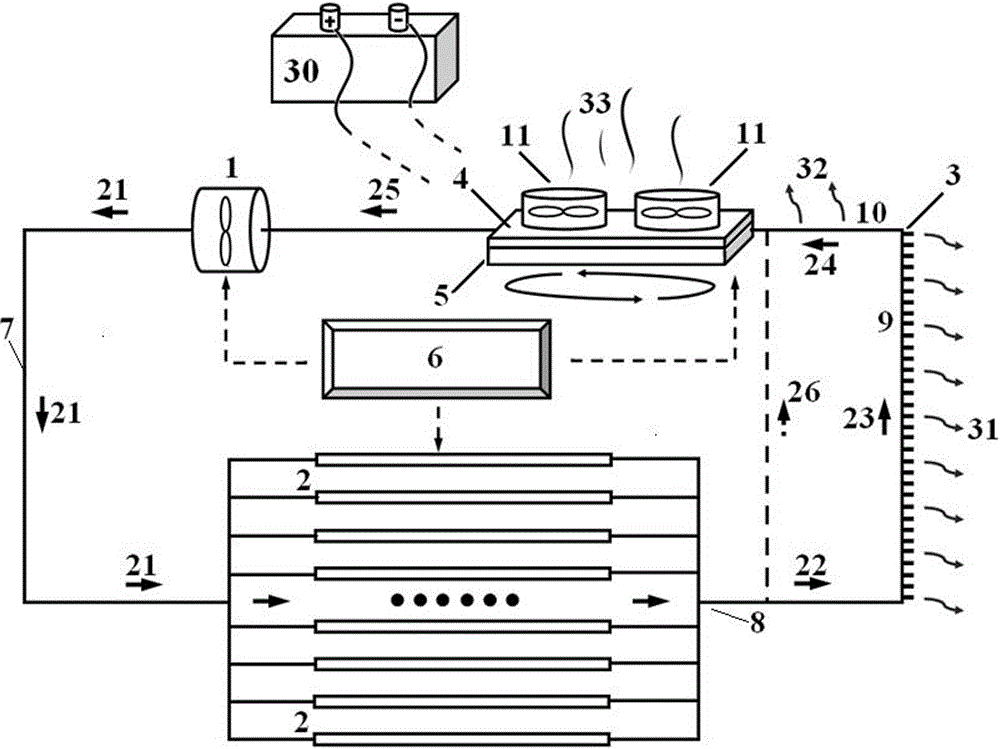

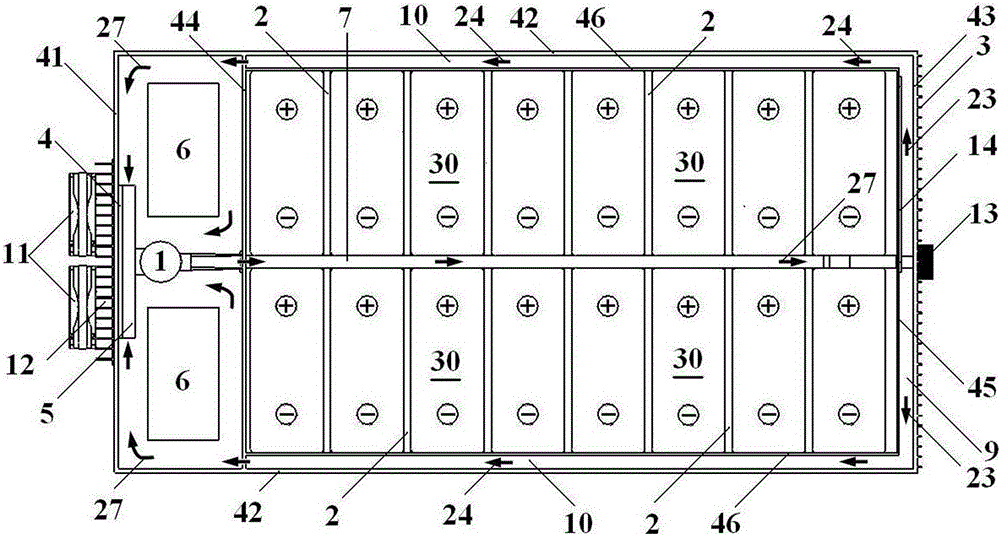

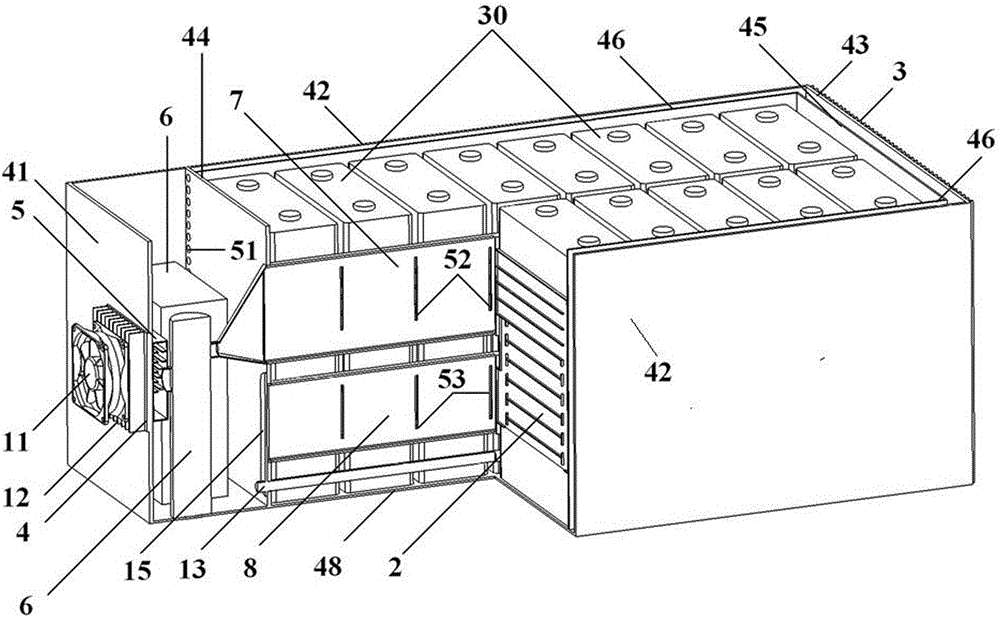

Thermal management system for lithium-ion batteries

ActiveCN105742752AAvoid dust erosionAvoid erosionSecondary cellsCell component detailsInternal cavityCorrosion

The invention discloses a thermal management system for lithium-ion batteries. The system comprises a battery box body and a battery pack, wherein the battery box body comprises a sealed inner cavity; the battery pack comprises at least one group of battery cells; the battery cells are arranged at intervals along the forward-backward direction and are located in the inner cavity; an air pump is arranged at the front part of the inner cavity; an air intake duct which is communicated with the air pump is formed in one side, in the left-right direction, of one group of battery cells and an air return duct is formed in the other side; a radiator for emitting heat in the air intake duct to the outside is arranged on the battery box body; the radiated air in the air intake duct flows to the space in which the air pump is located through the air return duct; and the air intake duct and the air return duct are located in the sealed battery box body and are not communicated with the outside of the battery box body, so that corrosion of dust to the inside of the lithium-ion battery box can be avoided.

Owner:HENAN UNIV OF SCI & TECH

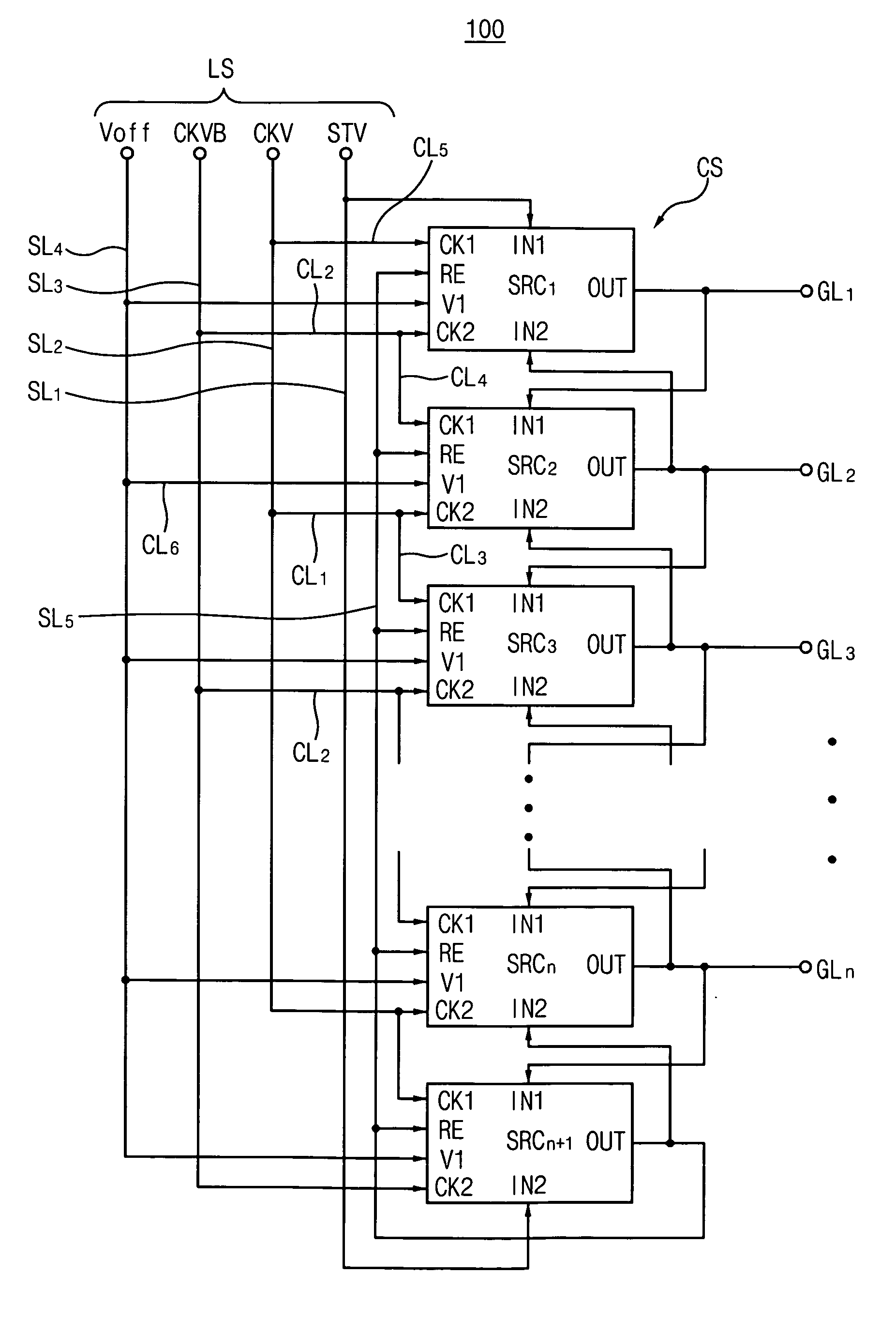

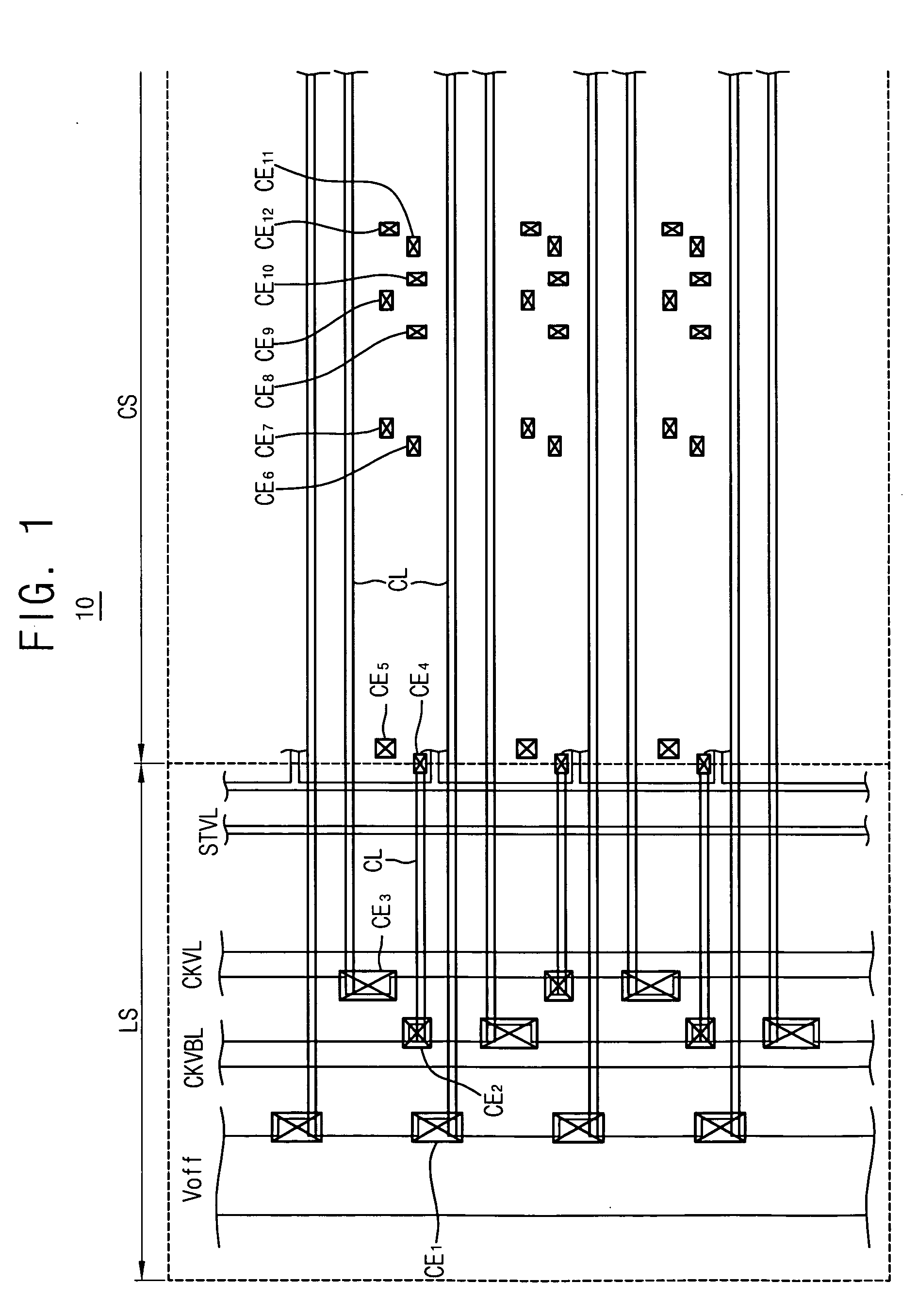

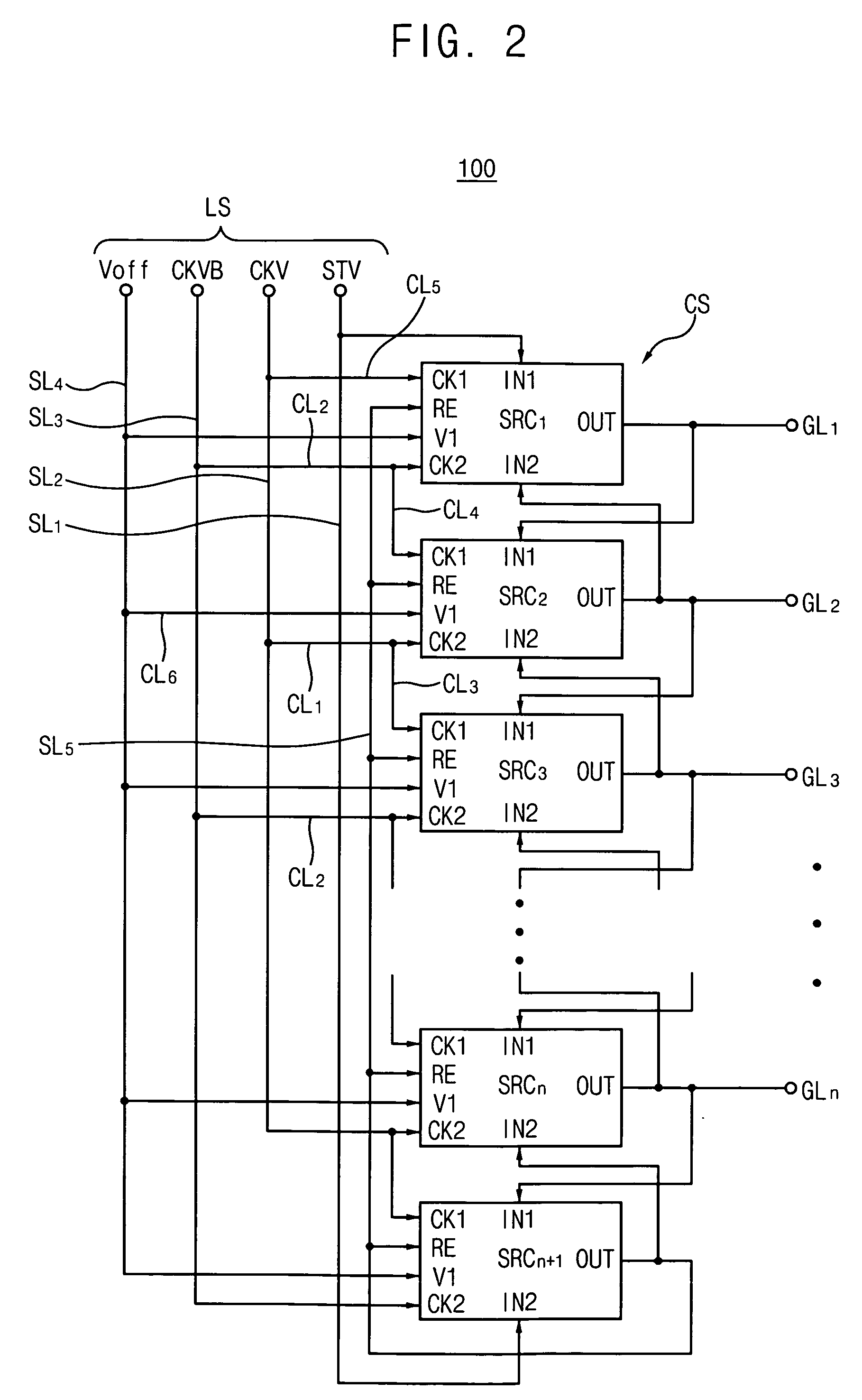

Gate driving unit and display device having the same

ActiveUS20060061562A1Avoid erosionAvoid failureCathode-ray tube indicatorsDigital storageGate driverMultiple stages

A gate driver includes multiple stages. Each stage has a circuit portion and a wiring portion. The wiring portion delivers first and second clock signals to the circuit portion. Further, the wiring portion includes first and second clock wirings receiving the first and second clock signal, respectively, first connecting wirings electrically connecting the first clock wiring with a first every other stage, and second connecting wirings electrically connecting the second clock wiring with the odd-numbered stages. Further, the wiring portion includes third connecting wirings electrically connecting the first connecting wiring with a second every other stage and fourth connecting wirings electrically connecting the second connecting wiring with the even-numbered stages. This configuration may prevent the gate driver from operating erroneously and reduce power consumed by the gate driver.

Owner:SAMSUNG DISPLAY CO LTD

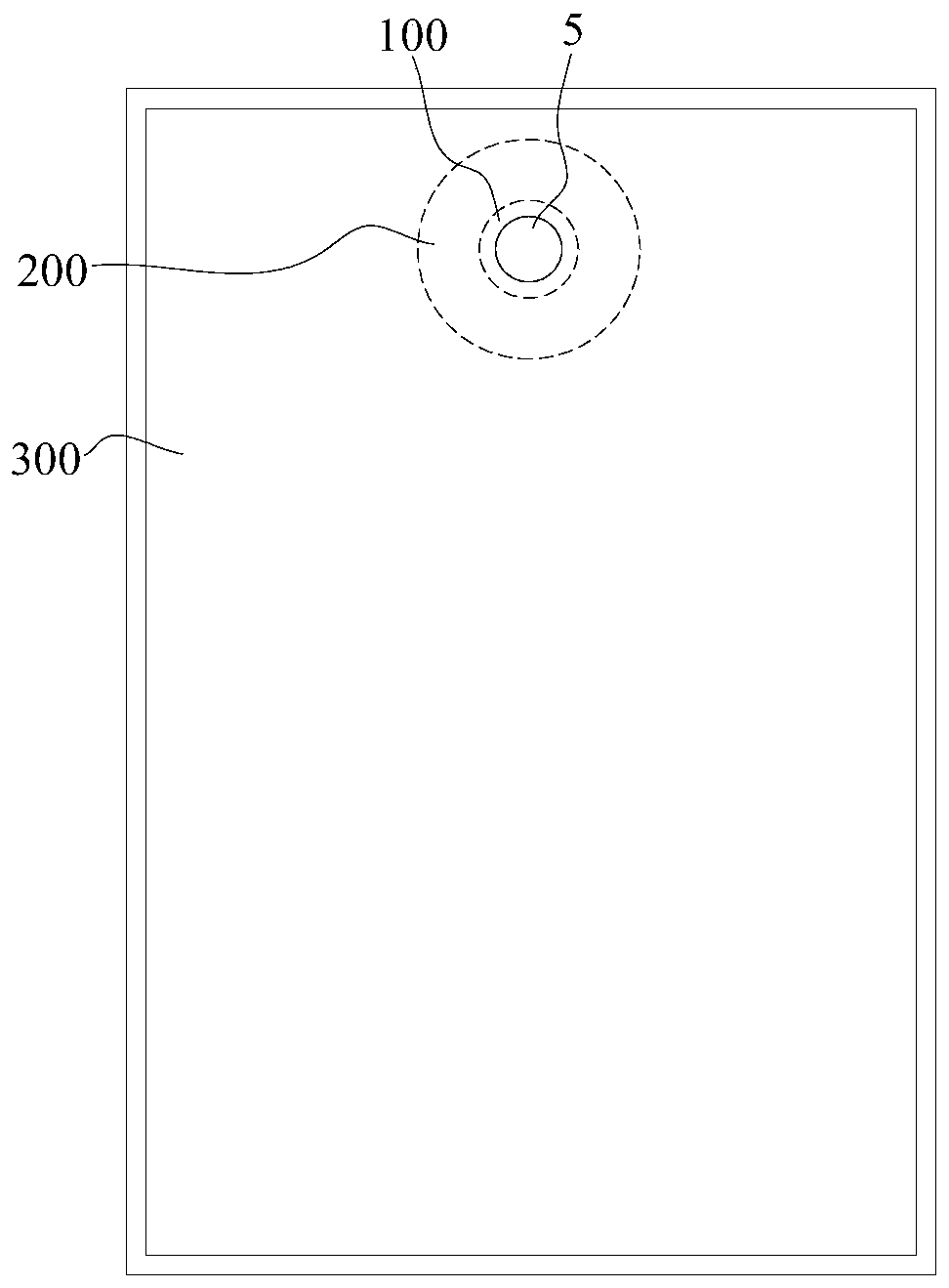

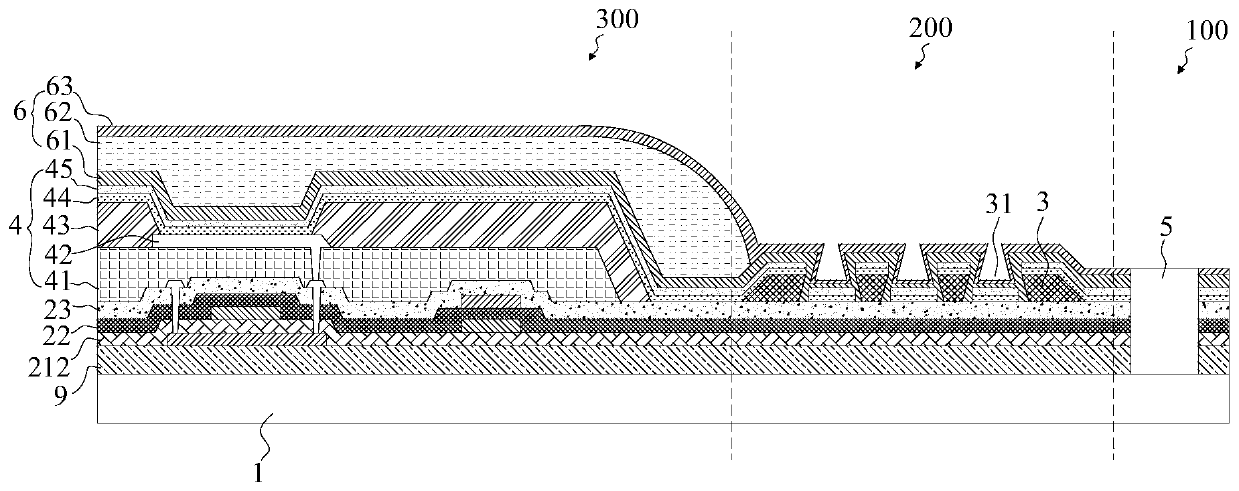

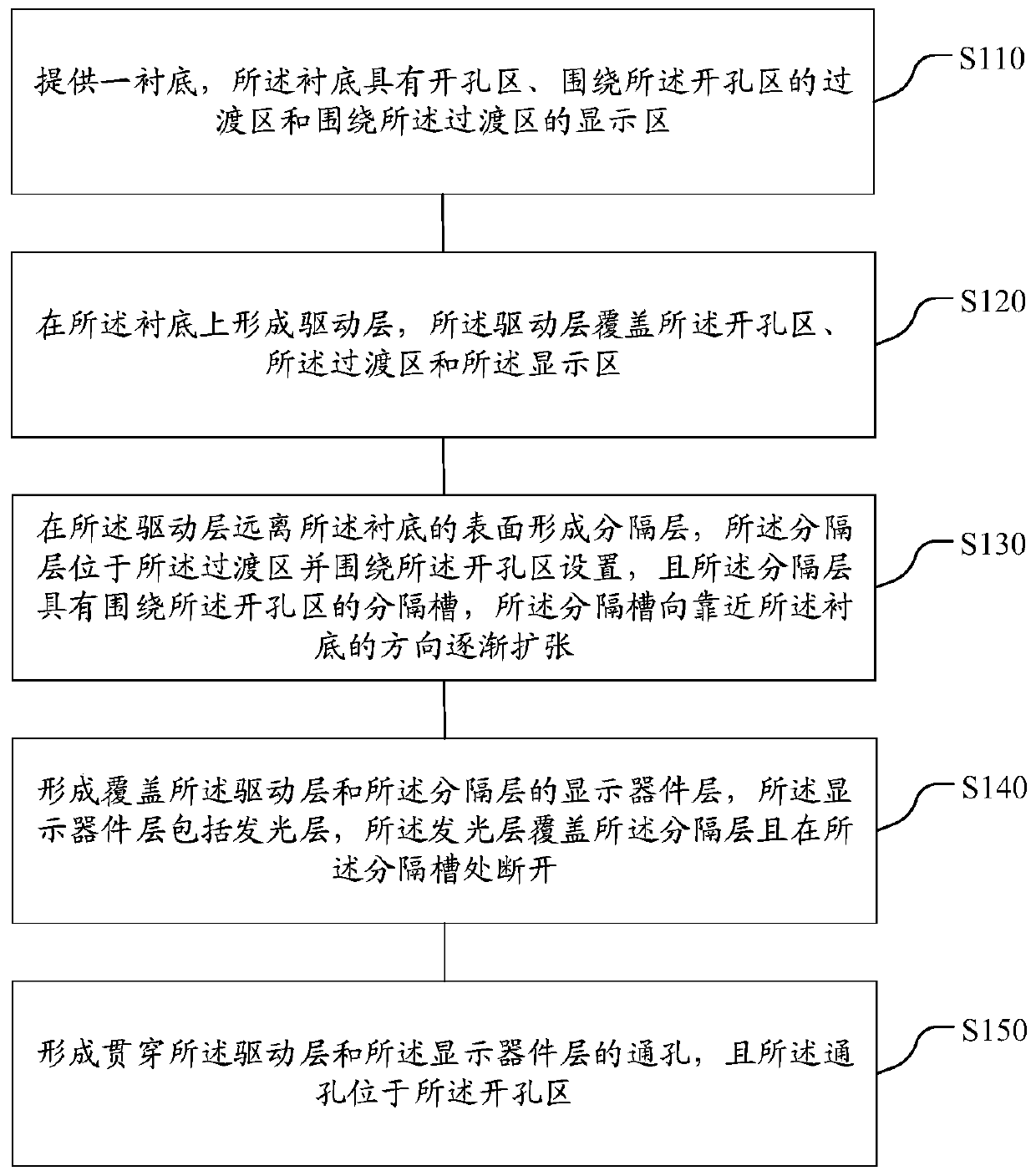

Display device, display panel and manufacturing method thereof

InactiveCN109801956AAvoid erosionGuaranteed display effectSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDisplay device

The invention provides a display device, a display panel and a manufacturing method thereof, and relates to the technical field of display. The display panel comprises a substrate, a driving layer, aseparation layer, a display device layer and a through hole. The substrate has an opening region, a transition region surrounding the opening region, and a display region surrounding the transition region. The driving layer is arranged at one side of the substrate and covers the opening area, the transition area and the display area. The separation layer is arranged on the surface, away from the substrate, of the driving layer and located in the transition area, and the separation layer is arranged around the opening region and provided with a separation groove surrounding the opening region.The separation groove gradually expands in the direction close to the substrate. The display device layer covers the driving layer and the separation layer, and the display device layer comprises a light-emitting layer, wherein the light-emitting layer covers the separation layer and is disconnected at the separation groove. The through hole passes through the driving layer and the display devicelayer and is located in the opening region. According to the display panel, water and oxygen can be prevented from entering the display area, and a display device is prevented from being eroded.

Owner:BOE TECH GRP CO LTD

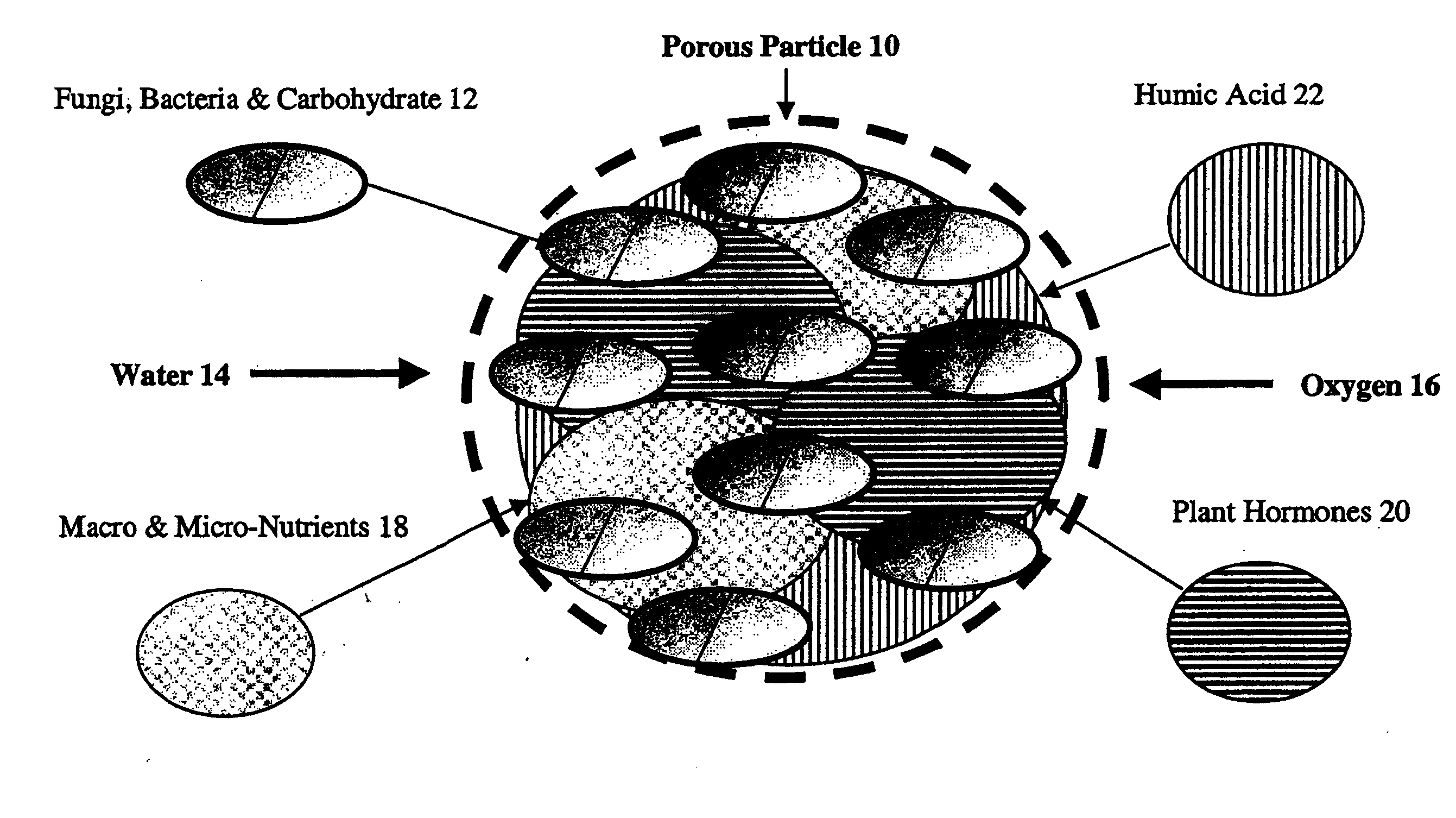

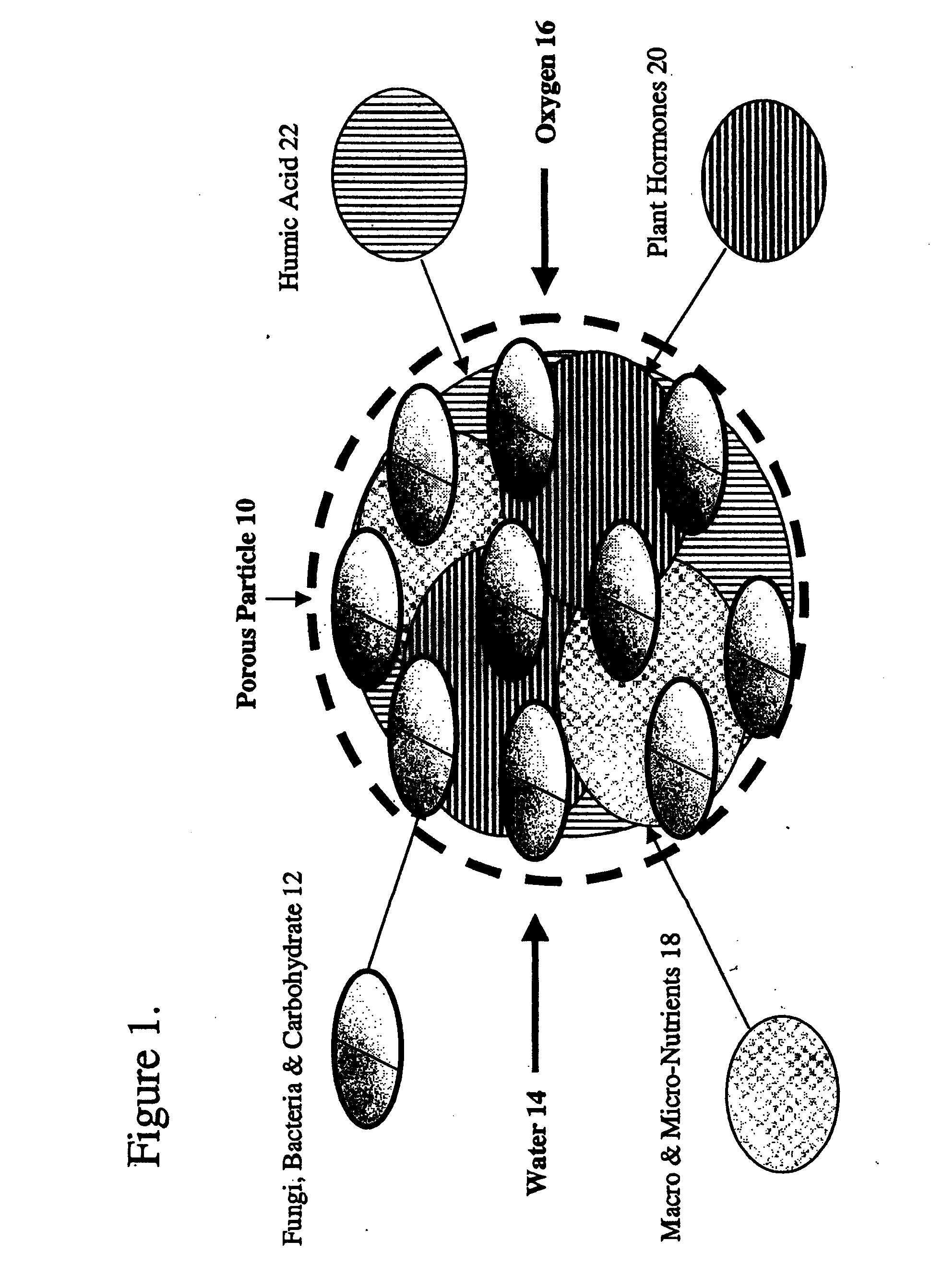

Biological soil nutrient system

ActiveUS20110003693A1Facilitate food and water usageSuccessful soil treatmentBiocideAnimal repellantsGrowth promotingBiology

A biological soil nutrient system that combines beneficial soil fungi and bacteria in a growth promoting nutrient medium, embedded in an inorganic porous ceramic particle for direct delivery during soil aerification to the rhizosphere of adventitious plants, including sports turf, landscape and agricultural applications.

Owner:PROFILE PRODS LLC

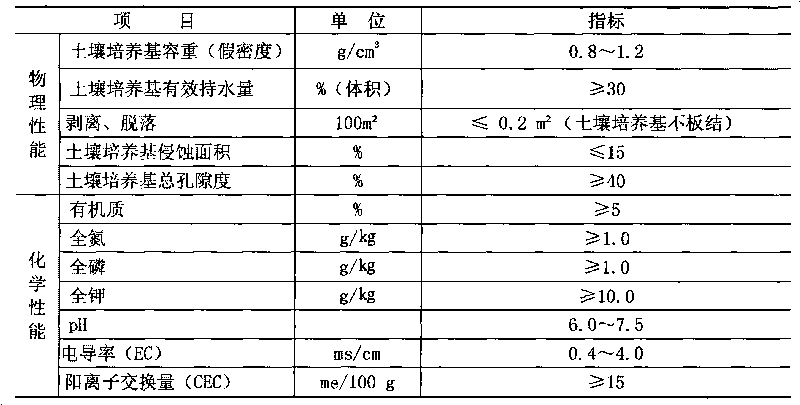

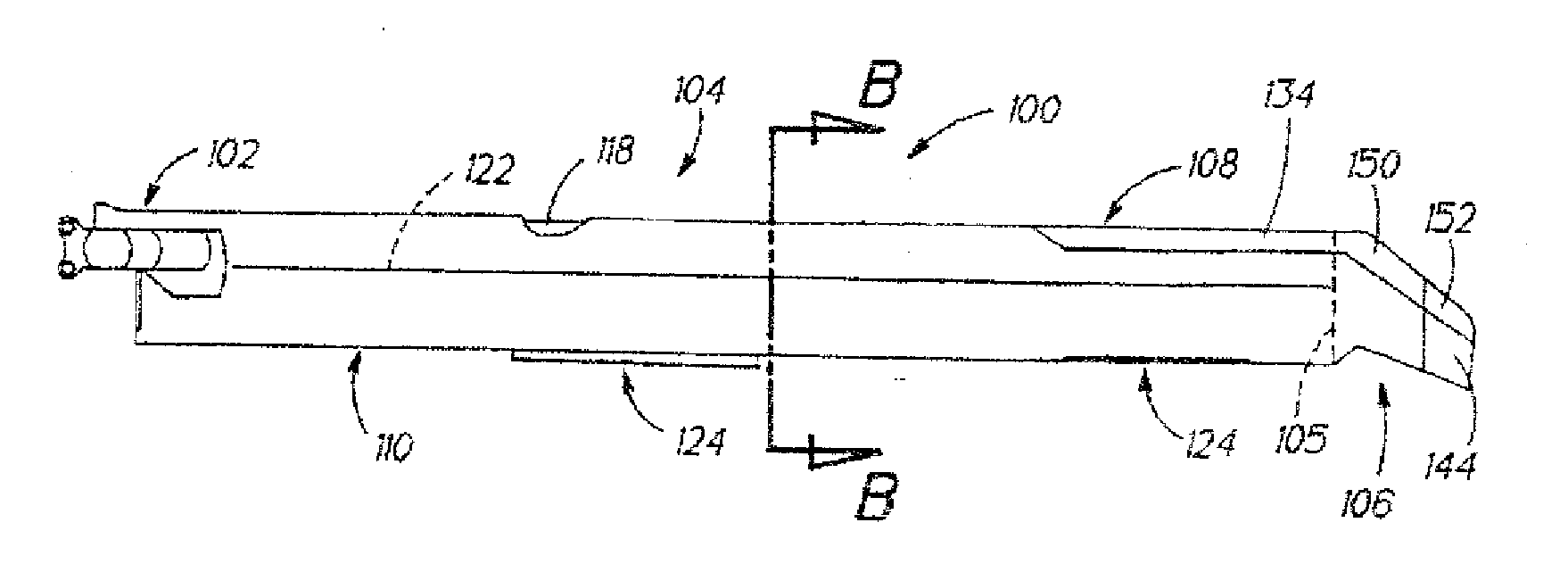

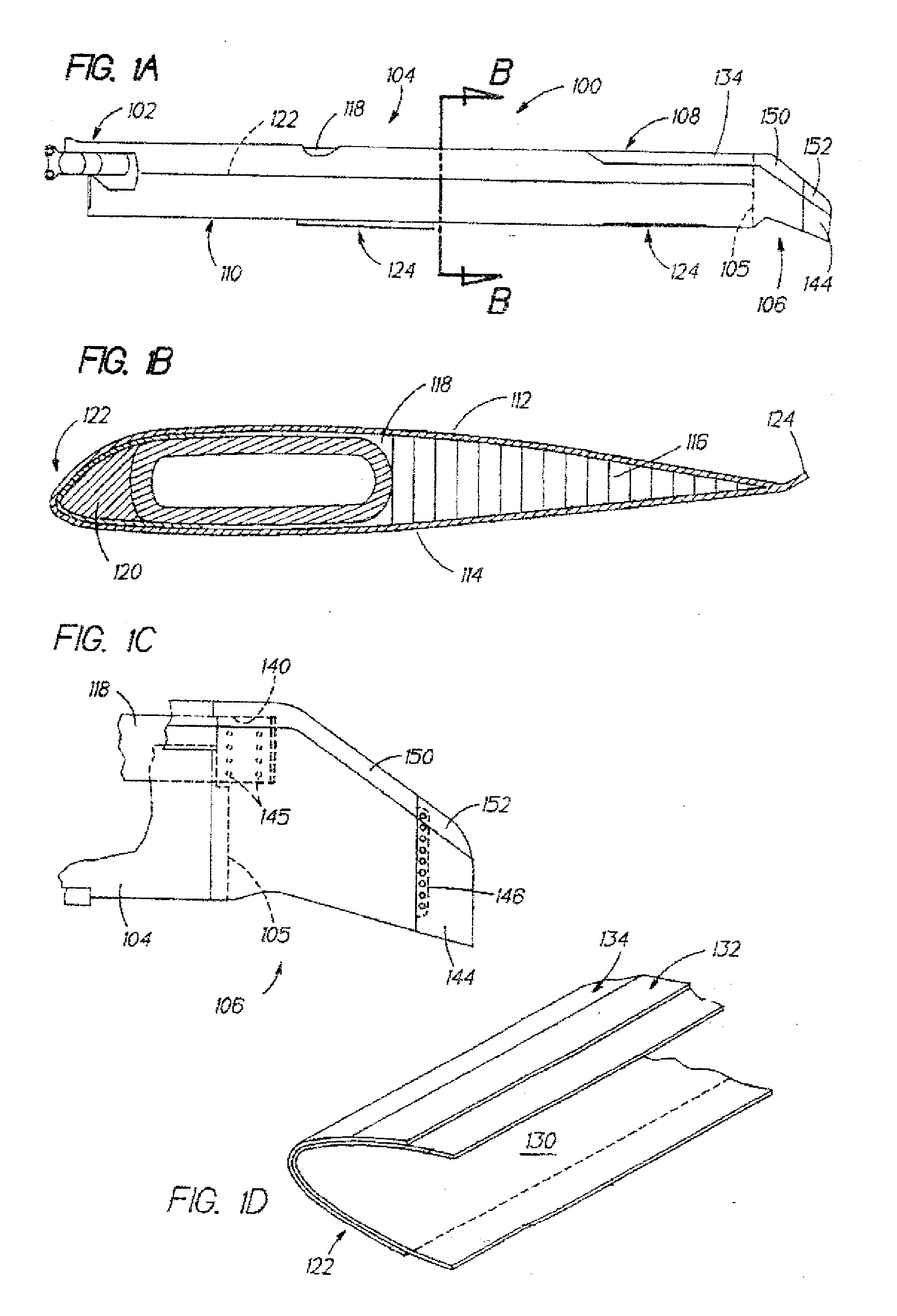

Protector for a leading edge of an airfoil

InactiveUS20100008788A1Reduce resistanceAvoid serious impactBlade accessoriesEfficient propulsion technologiesLeading edgeParticulates

A protector for the leading edge of a rotor blade to provide enhanced erosion protection thereof. In an embodiment, the protector includes an energy absorption member attached to the rotor blade by a first adhesive bond layer and an erosion resistant member attached to the energy absorption member by a second adhesive bond layer. The erosion resistant member is operative to protect the leading edge of the rotor blade from erosion due to impacts from particulate matter, such as sand and rain. The energy absorption member is operative to absorb and disburse energy from impacts to the erosion protection member so that forces from the impacts are diminished or not transferred to the rotor blade. In another embodiment, the erosion resistant member is coated with a diamond film. As the diamond film is harder than sand, excellent resistance to wear from particulate matter and impacts rain is obtained. Other advantages provided by use of the diamond film include: 1) an ultra-smooth surface that reduces drag on the rotor blade whereby flight performance may be improved, and 2) by being ultra-smooth and chemically inert de-icing equipment may not be needed.

Owner:UNITED PROTECTIVE TECH

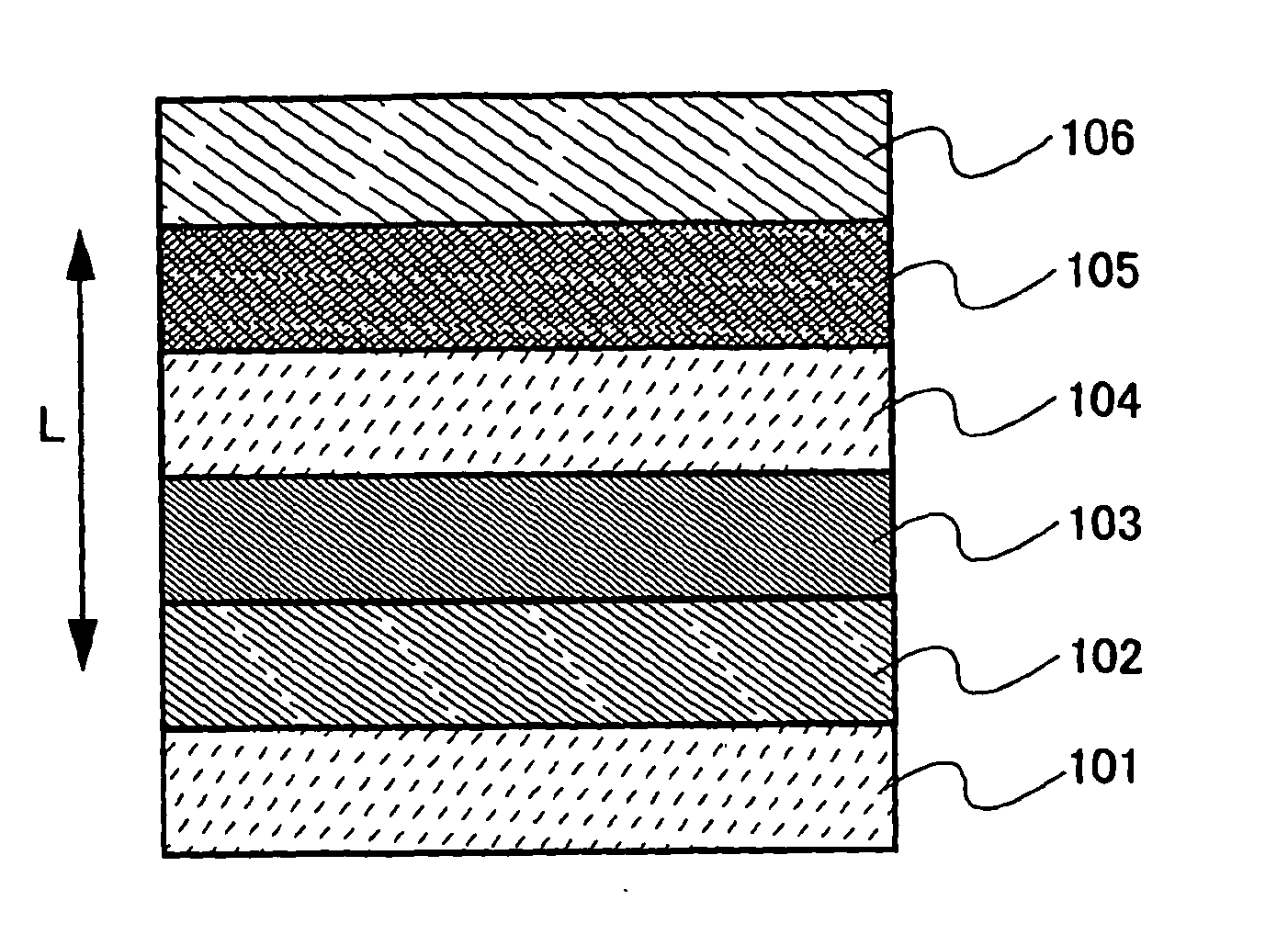

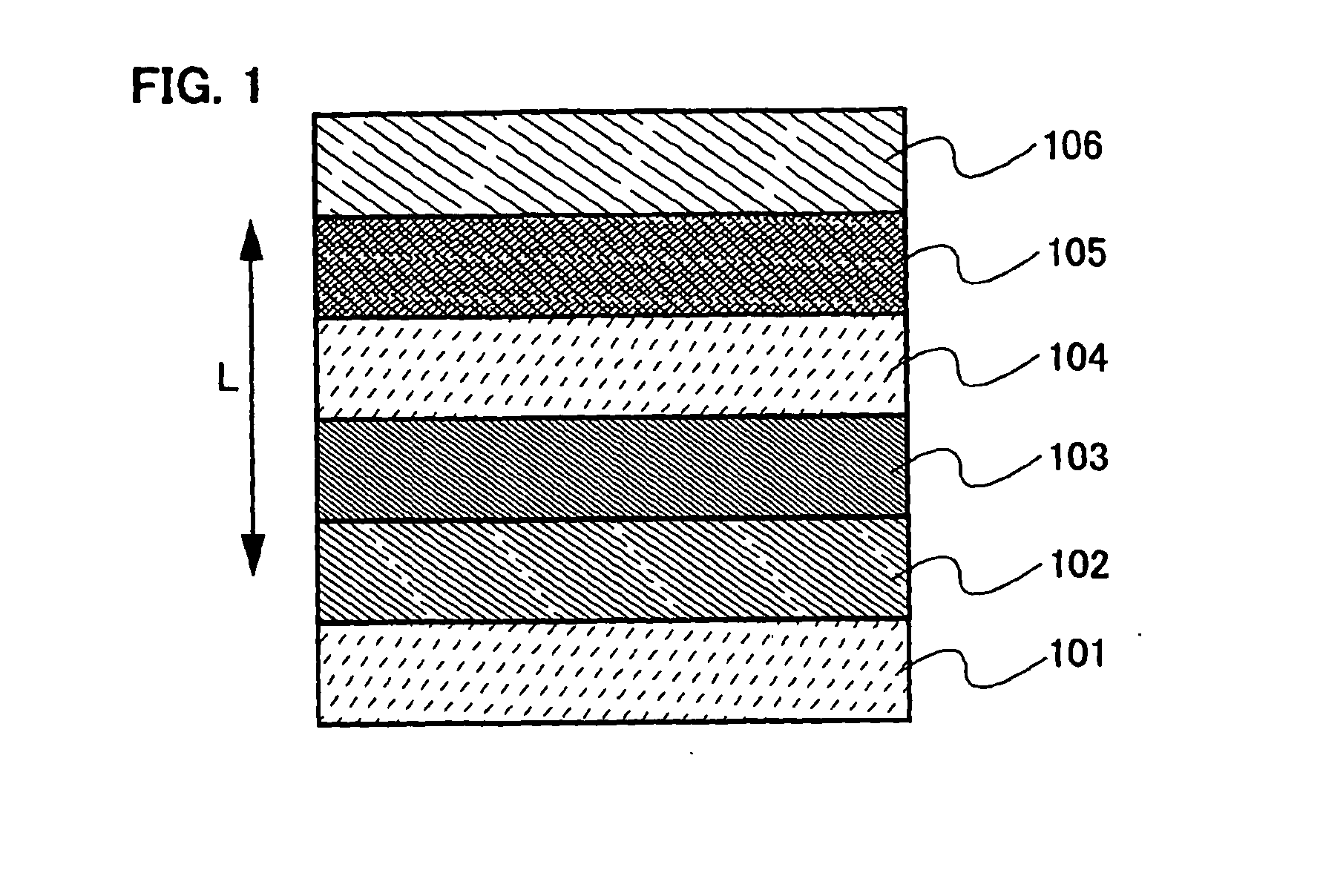

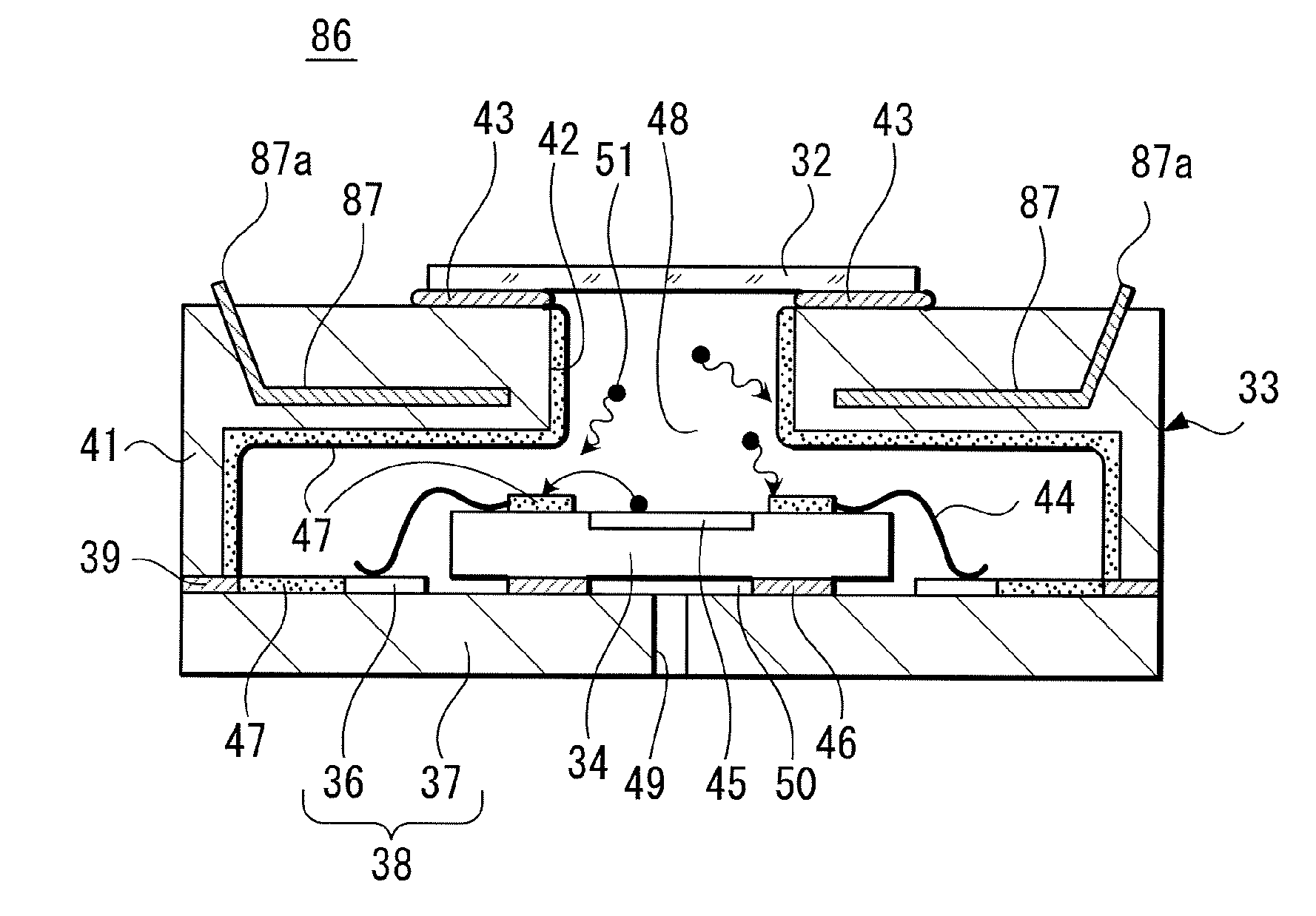

Light-emitting element and light-emitting device

InactiveUS20070090376A1Avoid erosionSolid-state devicesSemiconductor devicesTransport mediumTransparent conducting film

It is an object of the present invention to provide a light-emitting element having, between a pair of electrodes, a layer containing a light-emitting material and a transparent conductive film, wherein the electric erosion of the transparent conductive film and reflective metal can be prevented and to provide a light-emitting device using the light-emitting element. According to the present invention, a first layer 102 containing a light-emitting material, a second layer 103 containing an N-type semiconductor, a third layer 104 including a transparent conductive film, and a fourth layer 105 containing a hole-transporting medium are provided between an anode 101 and a cathode 106, wherein the first layer 102, the second layer 103, the third layer 104, the fourth layer 105, and the cathode 106 are provided in order, and wherein the cathode has a layer containing reflective metal.

Owner:SEMICON ENERGY LAB CO LTD

Solid-state imaging apparatus

InactiveUS20080237768A1Increased durabilityAvoid it happening againTelevision system detailsSemiconductor/solid-state device detailsEngineeringSolid-state

A solid-state imaging apparatus is provided. A solid-state imaging device chip is enclosed in a package having an optically transparent member. An adhesive layer is formed on an internal surface of the package, and a penetration hole is formed in a bottom part of the package to communicate with an open space in the package.

Owner:SONY CORP

Topography reduction and control by selective accelerator removal

ActiveUS8158532B2Avoid dishingAvoid erosionDecorative surface effectsSemiconductor/solid-state device manufacturingMetal interconnectEtching

Plating accelerator is applied selectively to a substantially-unfilled wide (e.g., low-aspect-ratio feature cavity. Then, plating of metal is conducted to fill the wide feature cavity and to form an embossed structure in which the height of a wide-feature metal protrusion over the metal-filled wide-feature cavity is higher than the height of metal over field regions. Most of the overburden metal is removed using non-contact techniques, such as chemical wet etching. Metal above the wide feature cavity protects the metal-filled wide-feature interconnect against dishing, and improved planarization techniques avoid erosion of the metal interconnect and dielectric insulating layer. In some embodiments, plating of metal onto a substrate is conducted to fill narrow (e.g., high-aspect-ratio feature cavities) in the dielectric layer before selective application of plating accelerator and filling of the wide feature cavity.

Owner:NOVELLUS SYSTEMS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com