Patents

Literature

1834results about How to "Increase the open circuit voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar cell

InactiveUS20070169808A1Low costEasy to usePhotovoltaic energy generationSemiconductor devicesHeterojunctionManufacturing technology

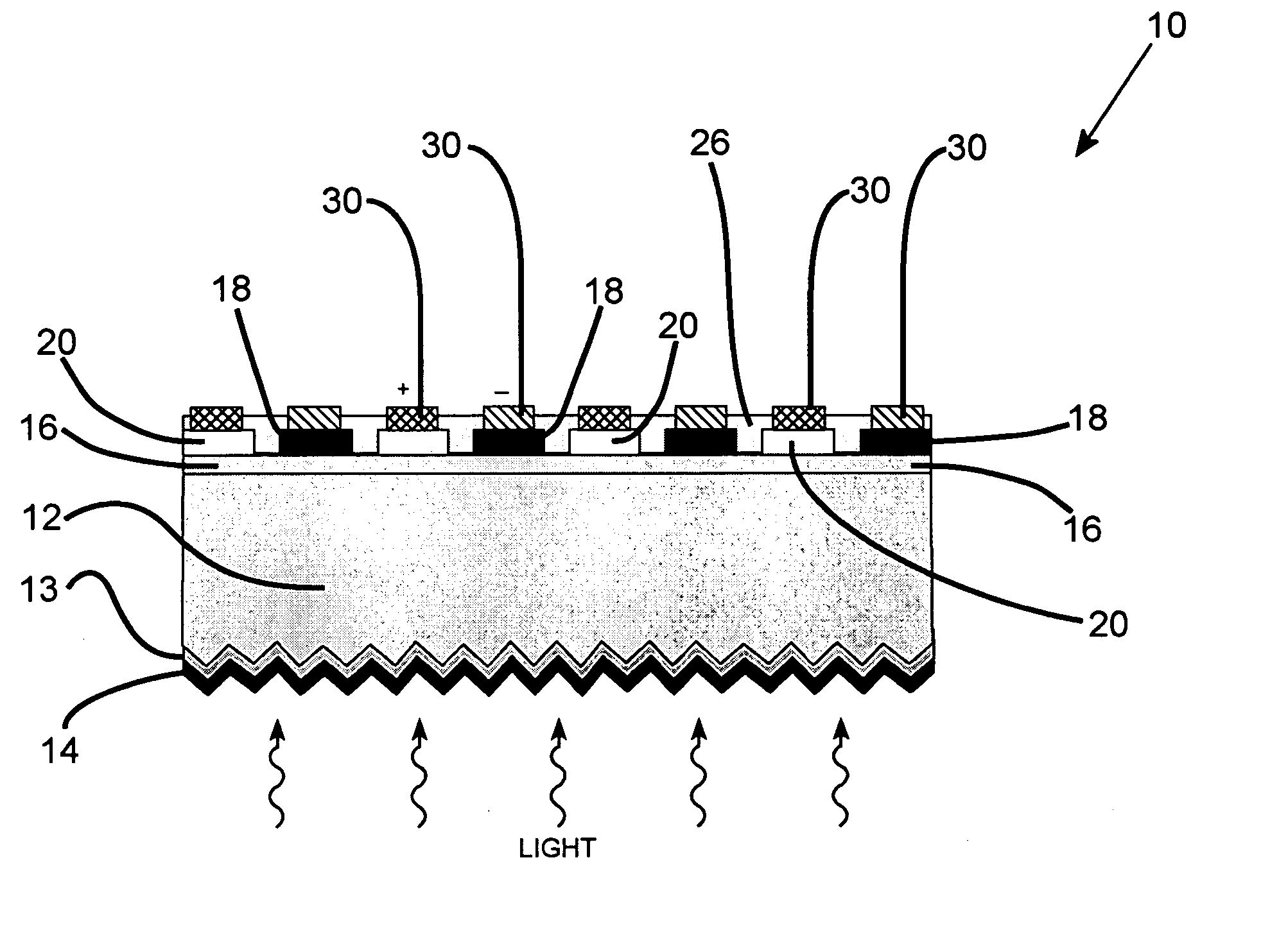

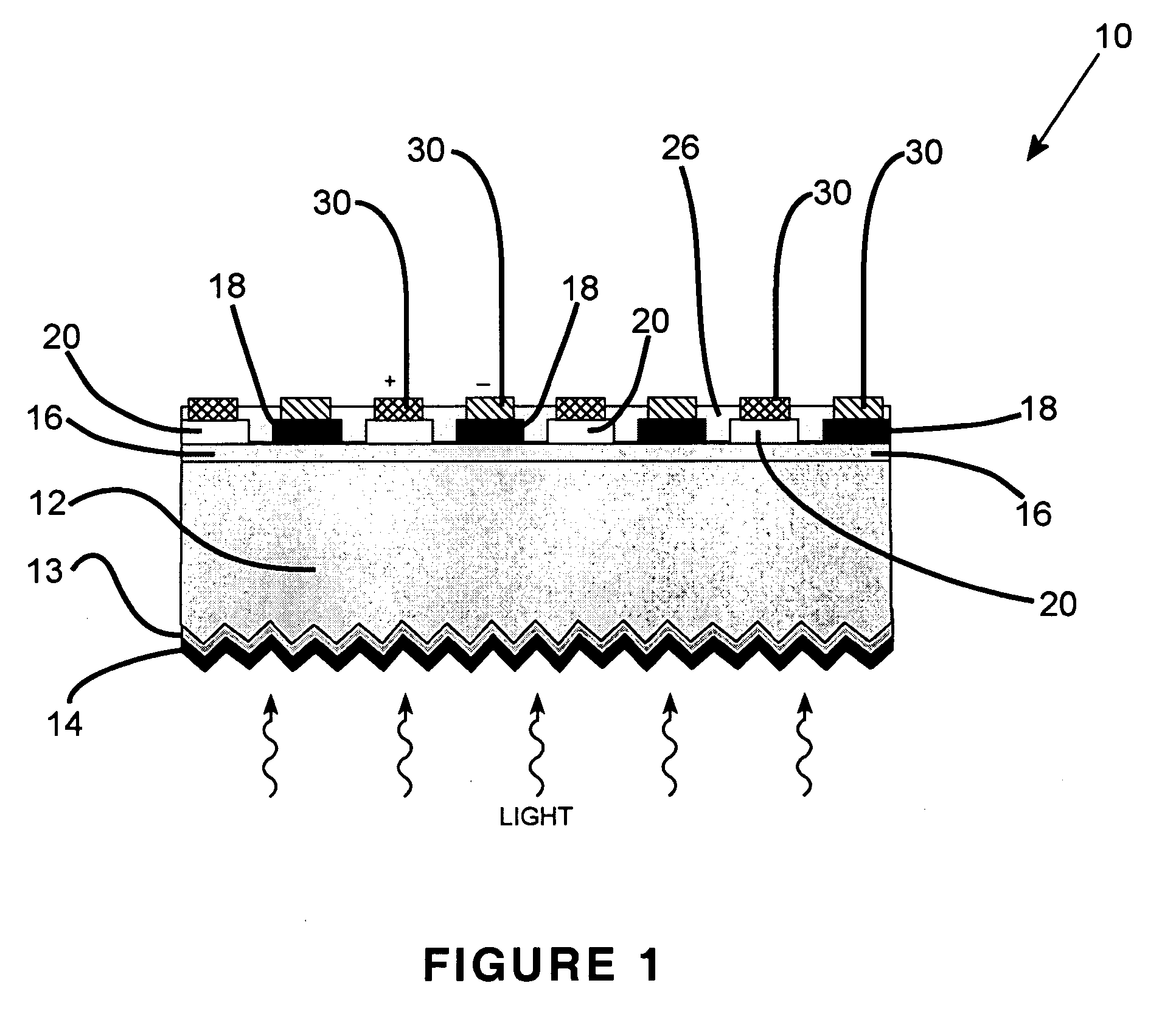

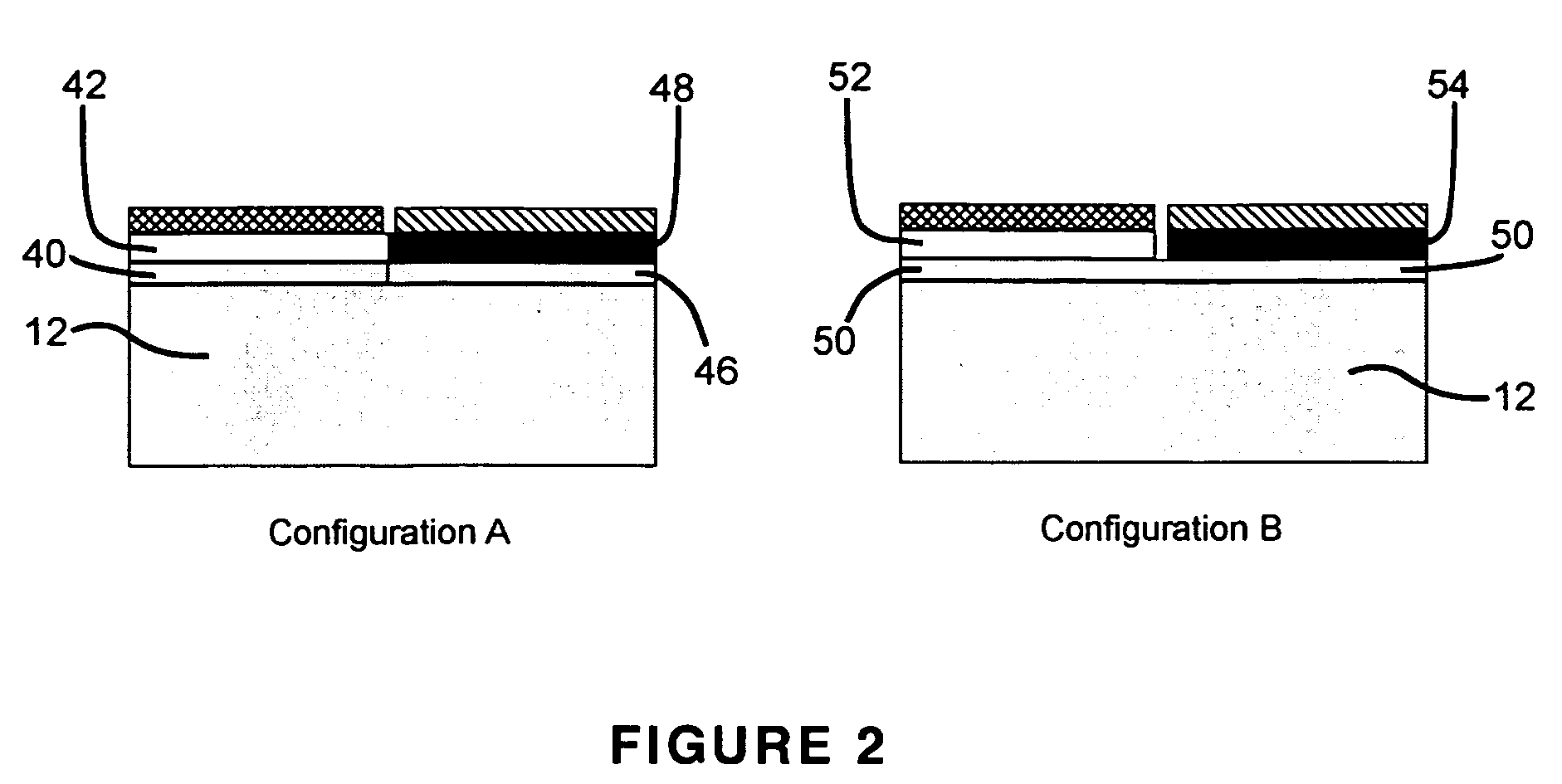

The present invention provides a thin film amorphous silicon-crystalline silicon back heterojunction and back surface field device configuration for a heterojunction solar cell. The configuration is attained by the formation of heterojunctions on the back surface of crystalline silicon at low temperatures. Low temperature fabrication allows for the application of low resolution lithography and / or shadow masking processes to produce the structures. The heterojunctions and interface passivation can be formed through a variety of material compositions and deposition processes, including appropriate surface restructing techniques. The configuration achieves separation of optimization requirements for light absorption and carrier generation at the front surface on which the light is incident, and in the bulk, and charge carrier collection at the back of the device. The shadowing losses are eliminated by positioning the electrical contacts at the back thereby removing them from the path of the incident light. Back contacts need optimization only for maximum charge carrier collection without bothering about shading losses. A range of elements / alloys may be used to effect band-bending. All of the above features result in a very high efficiency solar cell. The open circuit voltage of the back heterojunction device is higher than that of an all-crystalline device. The solar cell configurations are equally amenable to crystalline silicon wafer absorber as well as thin silicon layers formed by using a variety of fabrication processes. The configurations can be used for radiovoltaic and electron-voltaic energy conversion devices.

Owner:KHERANI NAZIR P +1

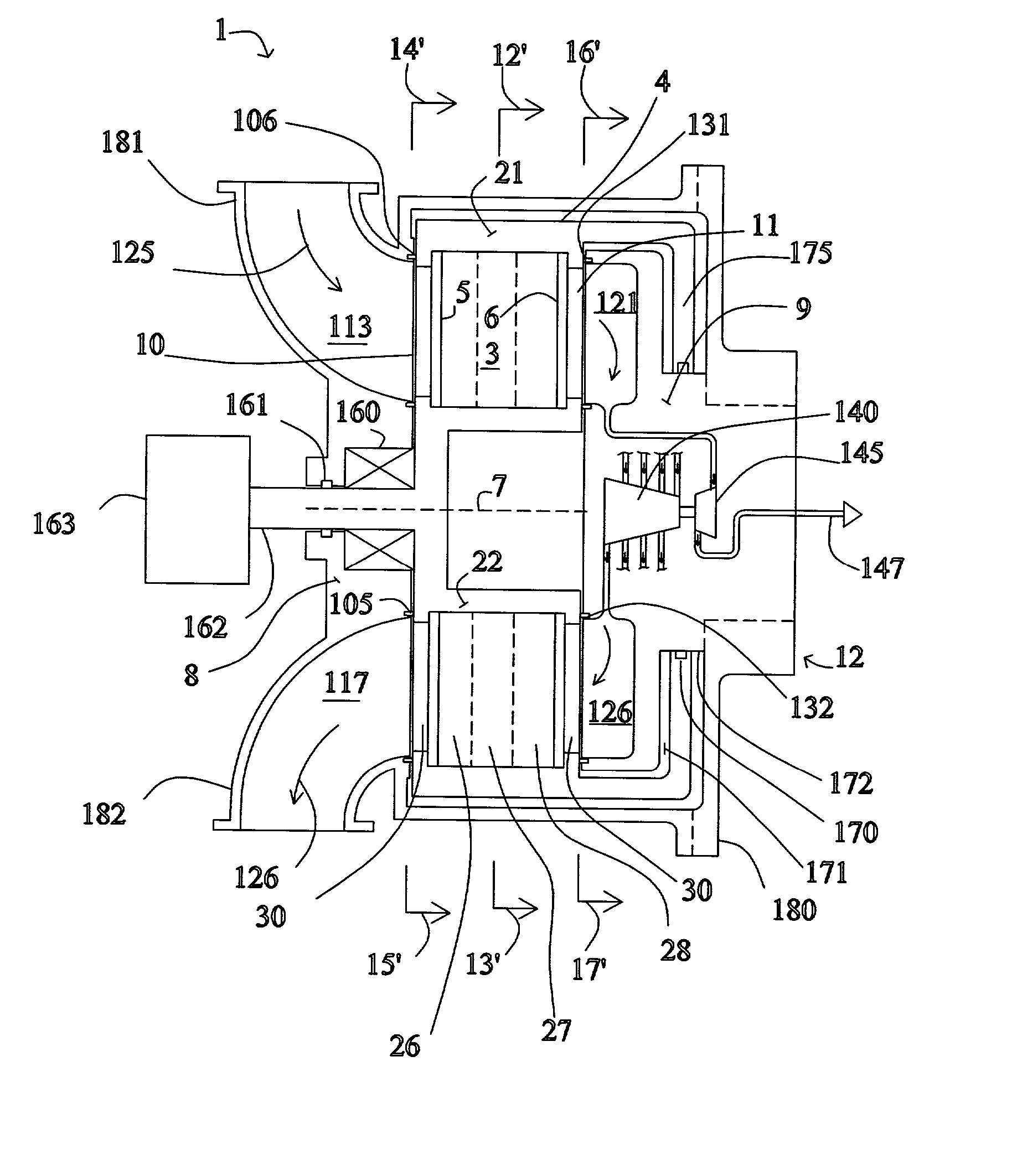

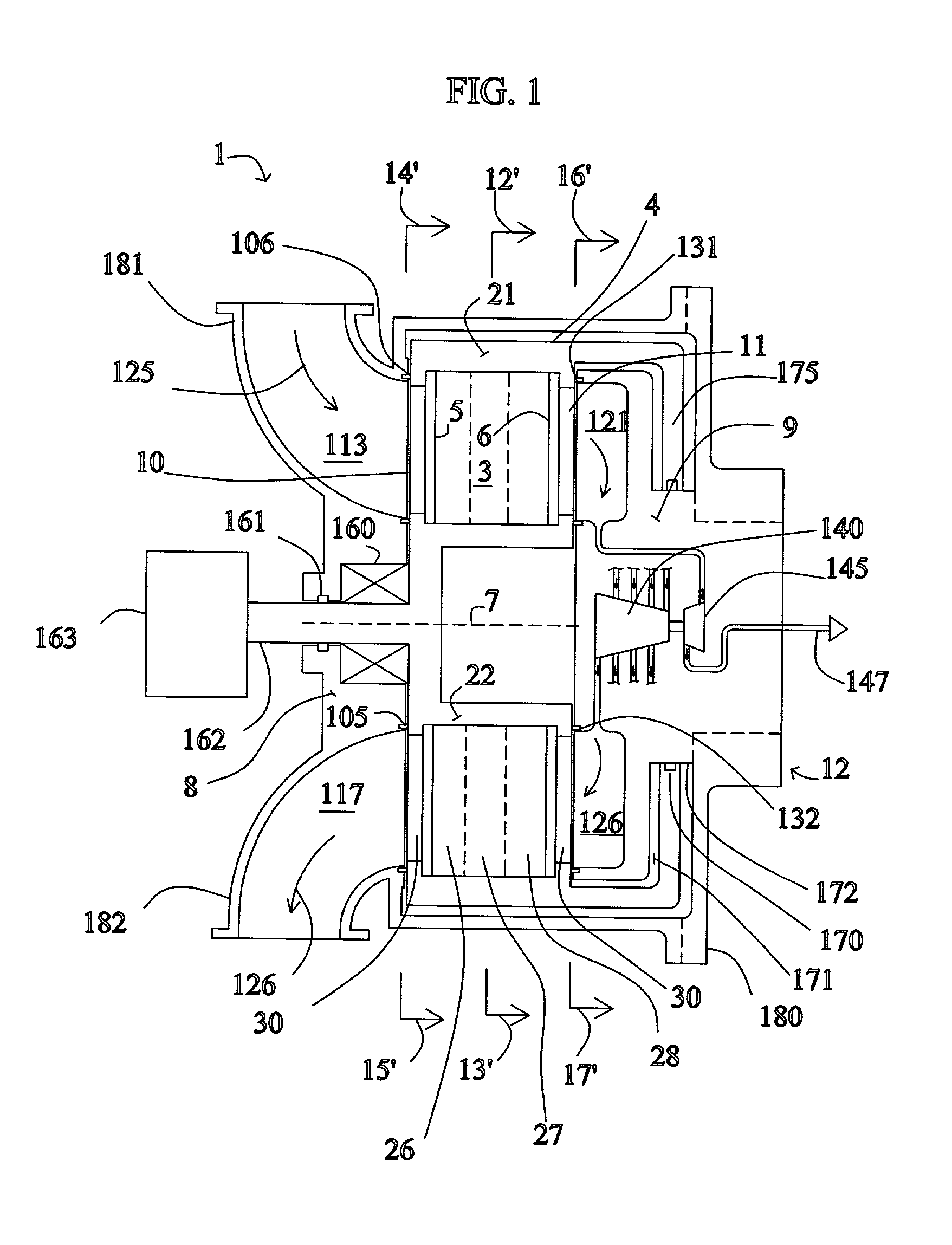

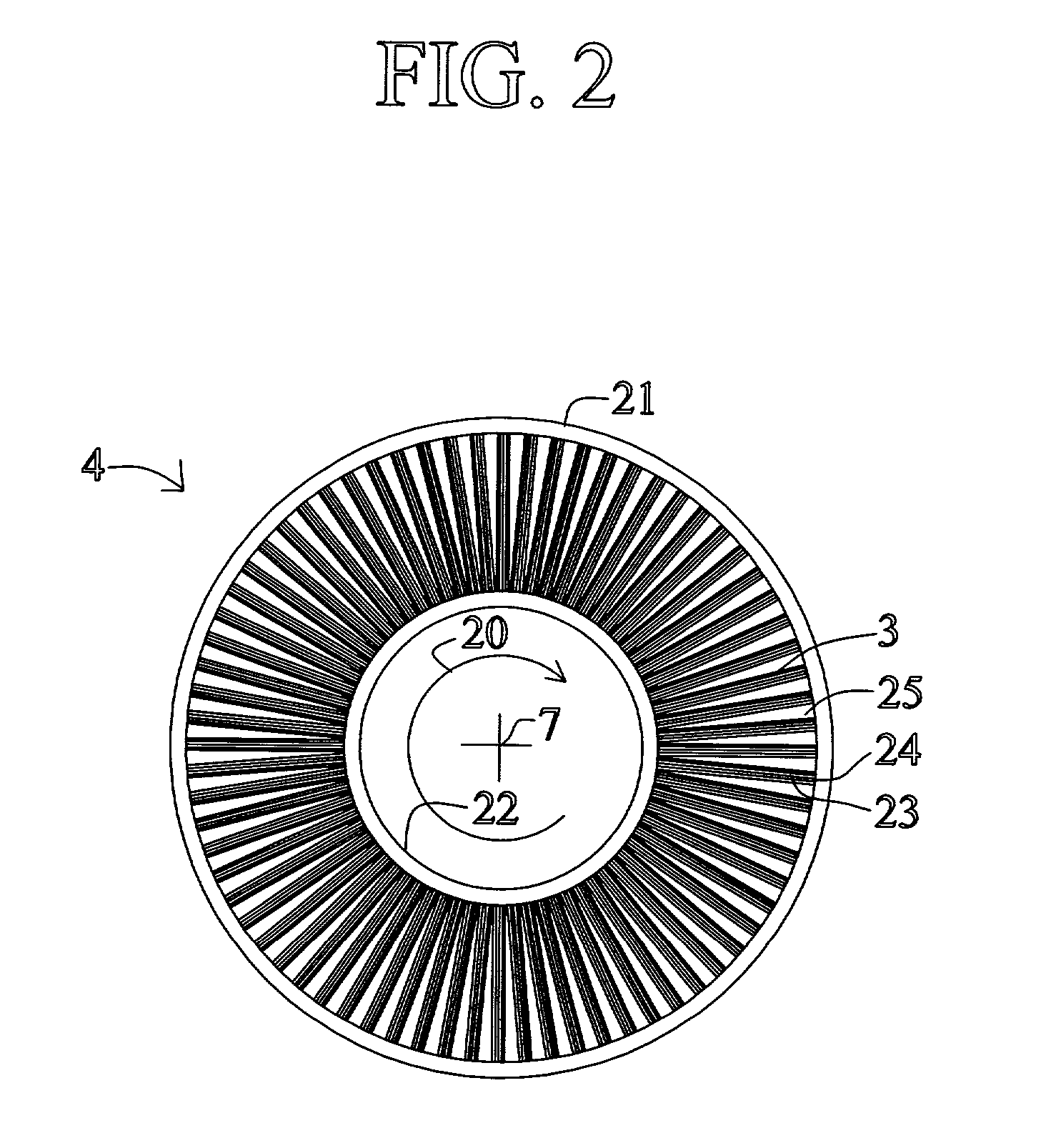

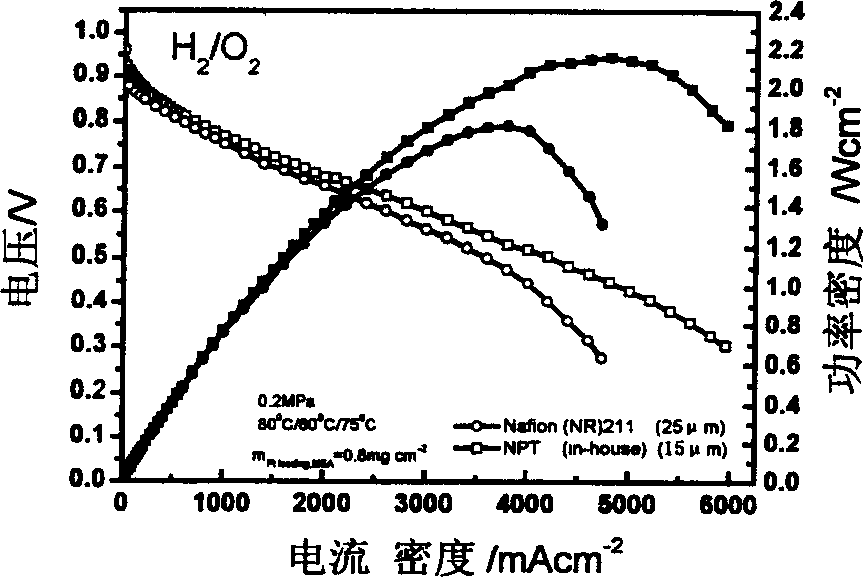

Energy efficient gas separation for fuel cells

InactiveUS20020142208A1Improve efficiencyReduce the ratioFuel cell heat exchangeFused electrolyte fuel cellsEngineeringDelivery system

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

Solar cell and fabrication method thereof

InactiveUS20100243040A1Light trapping capabilityIncrease contact resistanceFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSilicon solar cell

Disclosed are a metal wrap through solar cell including a metal wrap through (MWT) structure as a back contact silicon solar cell and a fabrication method thereof.

Owner:LG ELECTRONICS INC

Aluminum pulp composition of crystal silicon solar cell and preparation method thereof

InactiveCN101728439AEasy to printImprove adhesionFinal product manufactureNon-conductive material with dispersed conductive materialAdhesion forceAdhesive

The invention discloses an aluminum pulp composition of a crystal silicon solar cell and a preparation method thereof, wherein an aluminum pulp is prepared by the following compositions in percentage by weight: 50-85 percent of spherical aluminum powder, 2-15 percent of lead-free glass adhesive, 10-35 percent of organic carrier and 0.5-6 percent of metal / nonmetal power additive. The prepared aluminum pulp is used for a single crystal silicon solar cell, can enable warpage of a silicon wafer to be small, and aluminum films are dense and uniform, have no aluminum pills, do not bulb and have strong adhesion force and high photoelectric conversion efficiency.

Owner:LUOYANG SHENJIA ELECTRONICS CERAMICS

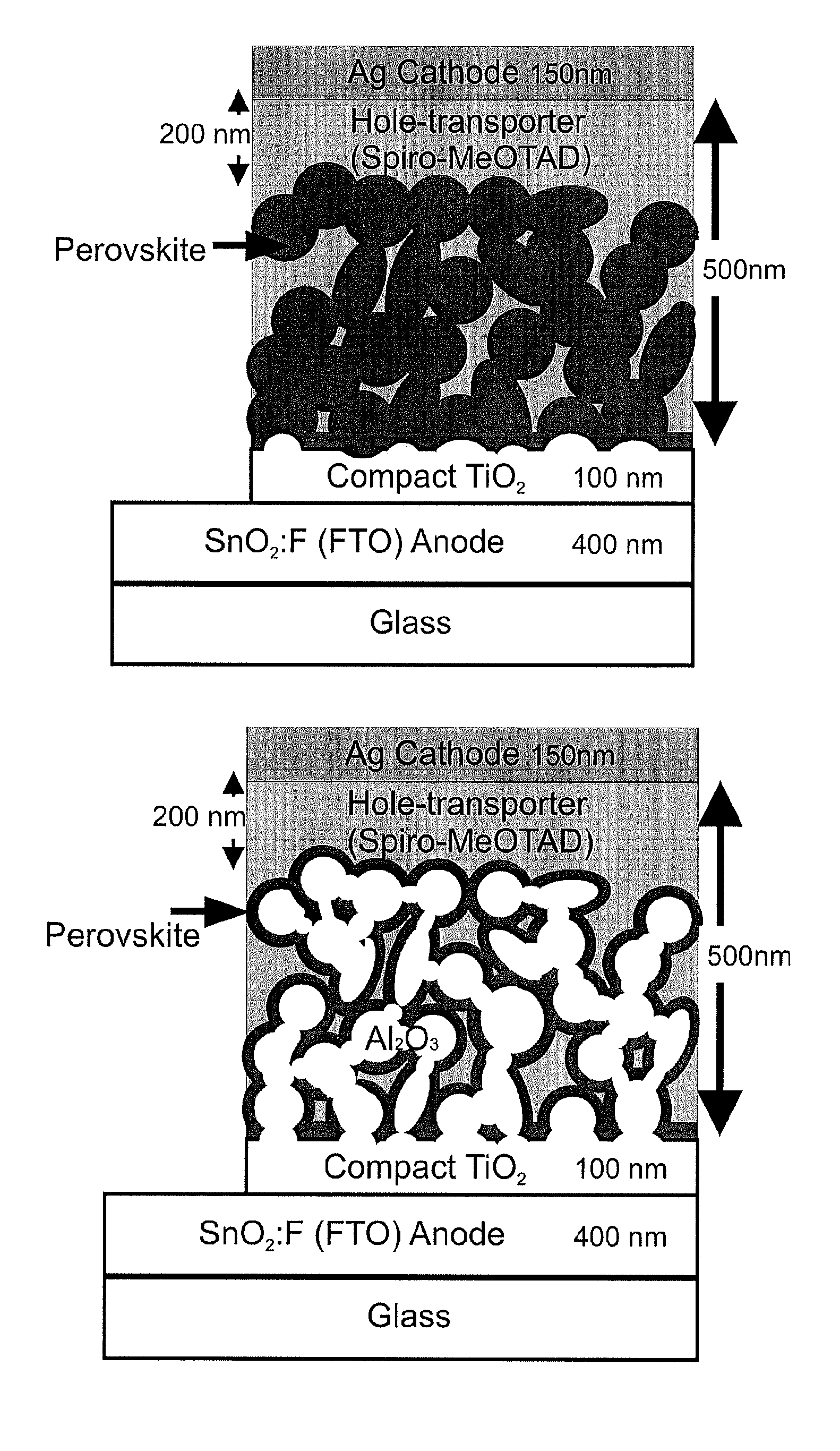

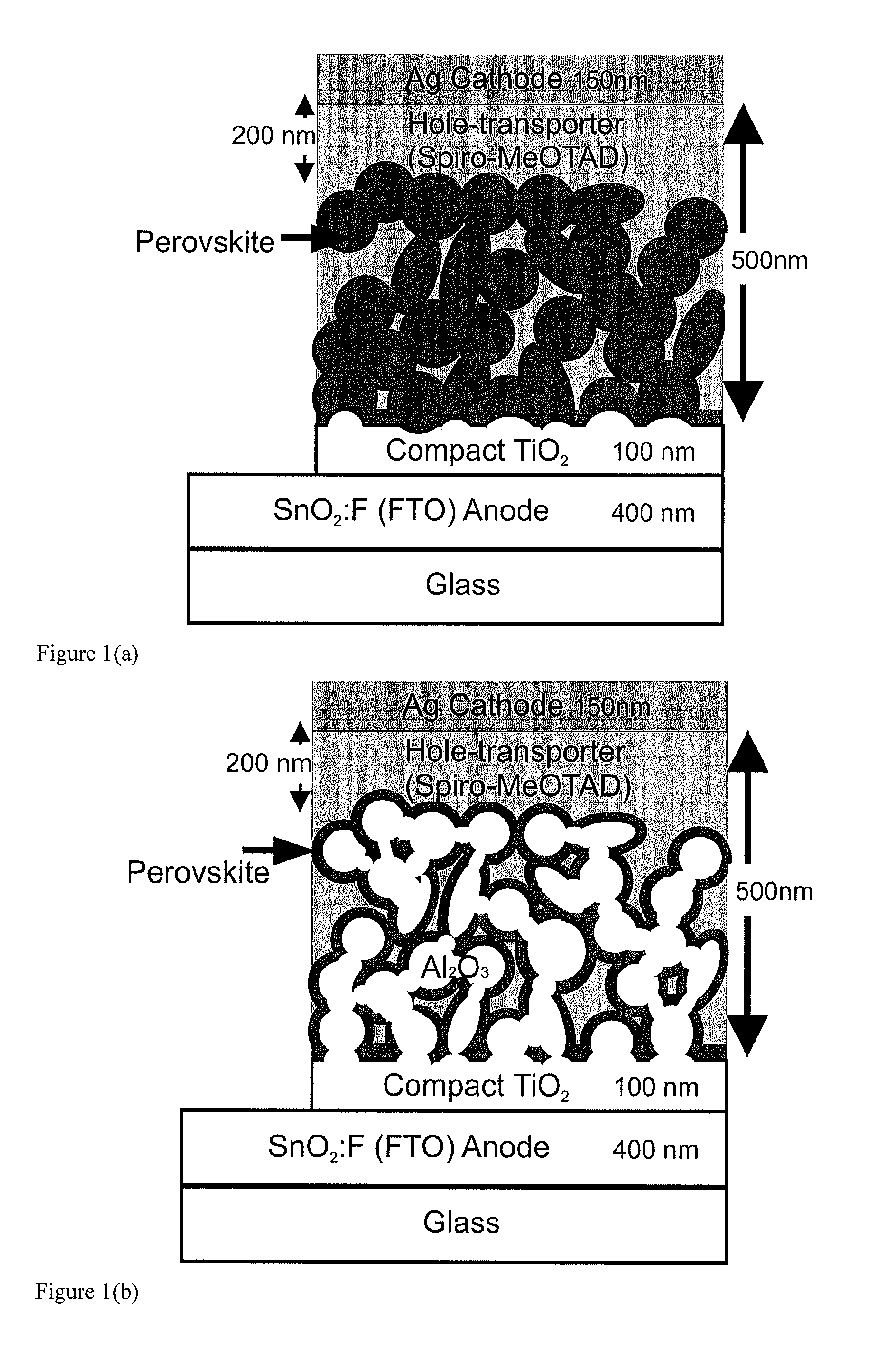

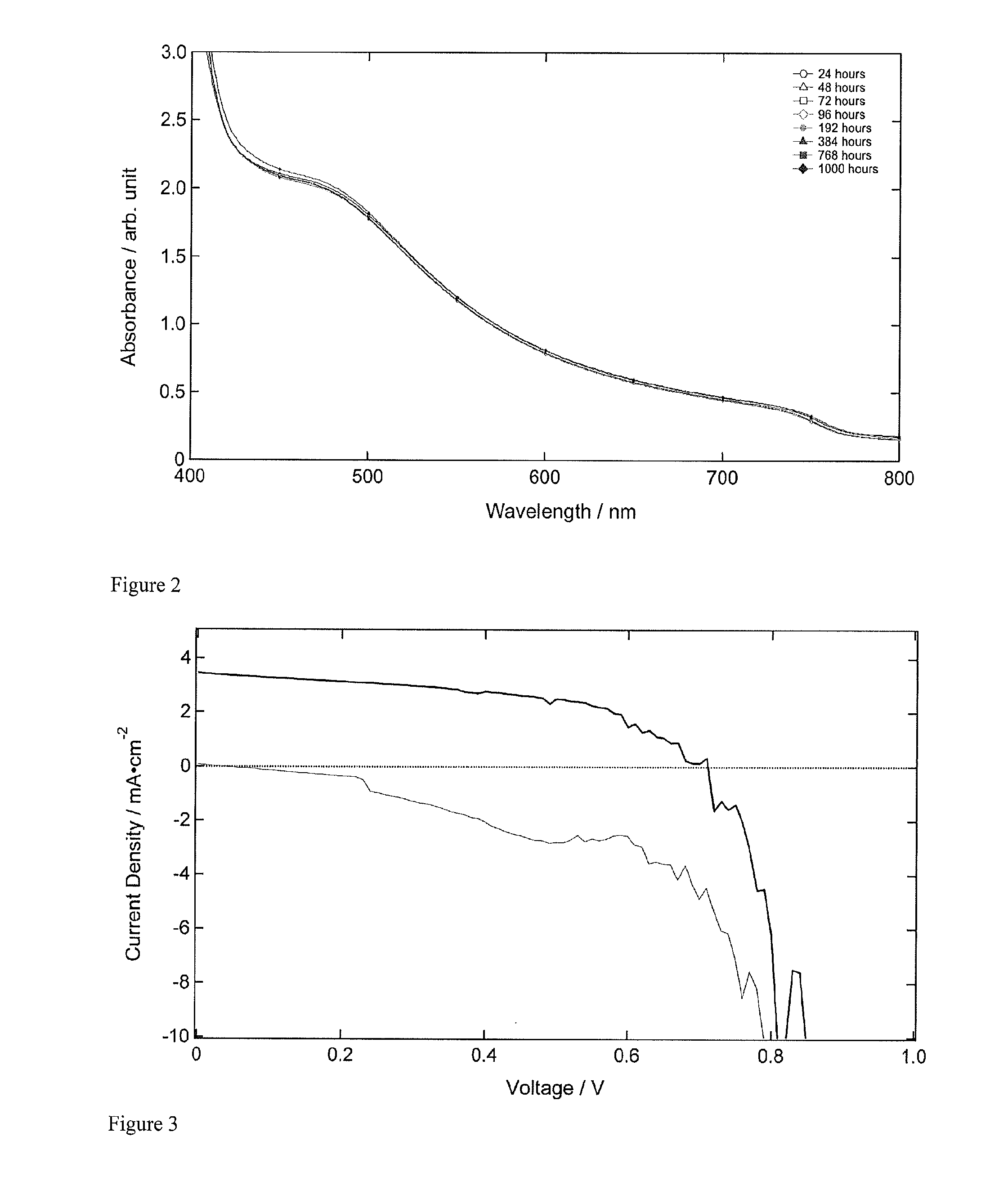

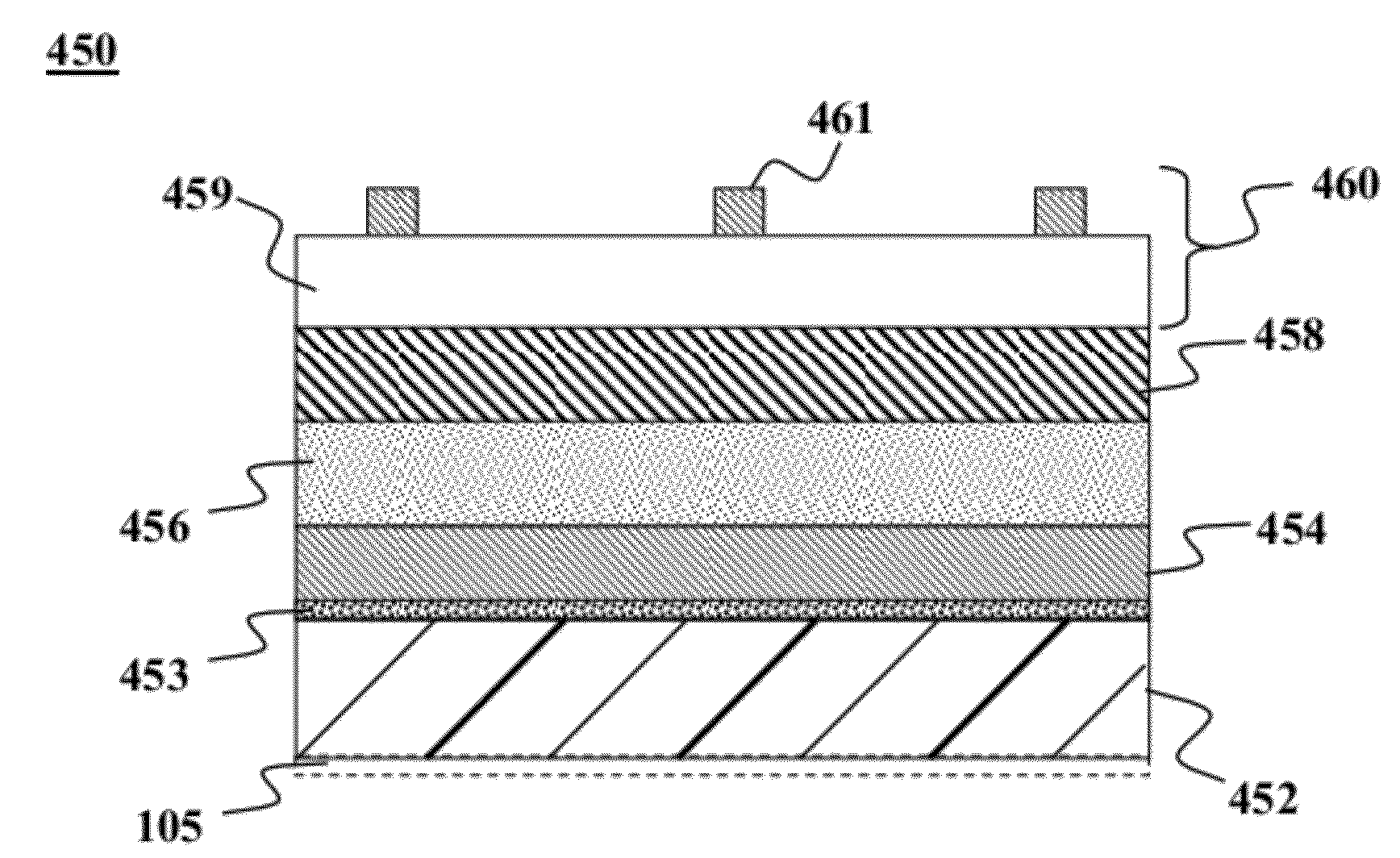

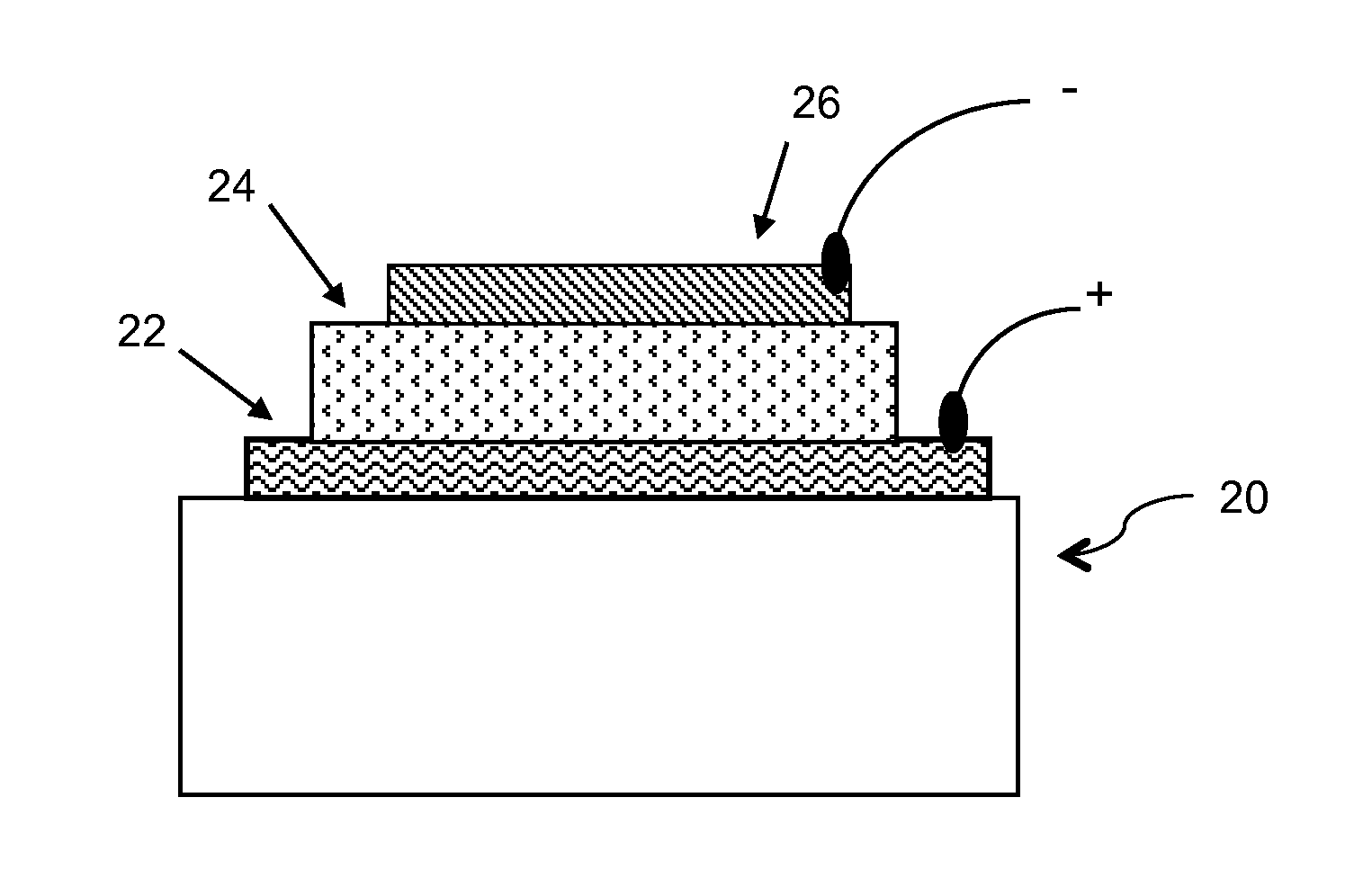

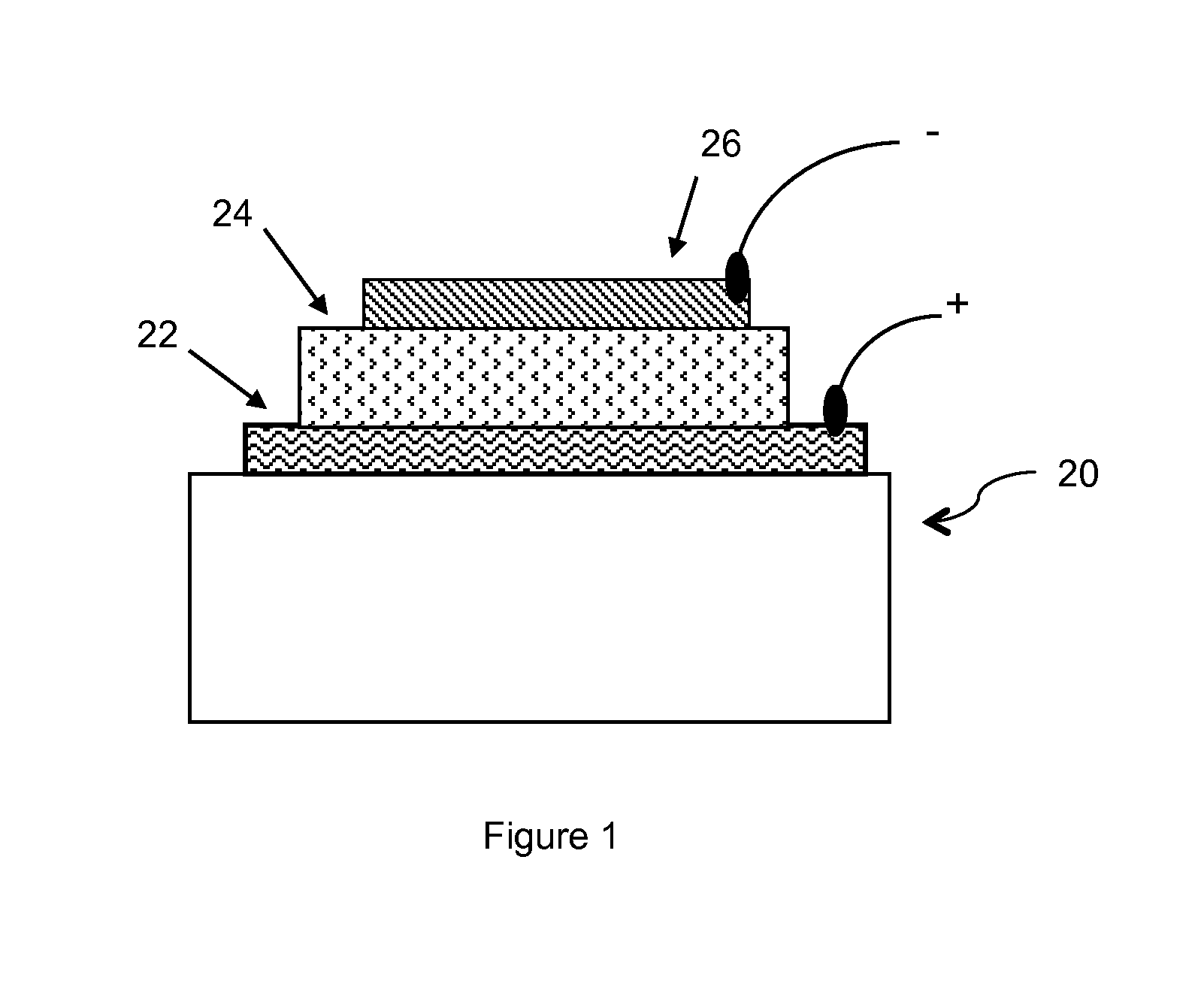

Optoelectronic device comprising perovskites

ActiveUS20150129034A1Excellent propertyHigh device efficiencyLight-sensitive devicesFinal product manufactureElectrical conductorSemiconductor

The invention provides an optoelectronic device comprising a porous material, which porous material comprises a semiconductor comprising a perovskite. The porous material may comprise a porous perovskite. Thus, the porous material may be a perovskite material which is itself porous. Additionally or alternatively, the porous material may comprise a porous dielectric scaffold material, such as alumina, and a coating disposed on a surface thereof, which coating comprises the semiconductor comprising the perovskite. Thus, in some embodiments the porosity arises from the dielectric scaffold rather than from the perovskite itself. The porous material is usually infiltrated by a charge transporting material such as a hole conductor, a liquid electrolyte, or an electron conductor. The invention further provides the use of the porous material as a semiconductor in an optoelectronic device. Further provided is the use of the porous material as a photosensitizing, semiconducting material in an optoelectronic device. The invention additionally provides the use of a layer comprising the porous material as a photoactive layer in an optoelectronic device. Further provided is a photoactive layer for an optoelectronic device, which photoactive layer comprises the porous material.

Owner:OXFORD UNIV INNOVATION LTD

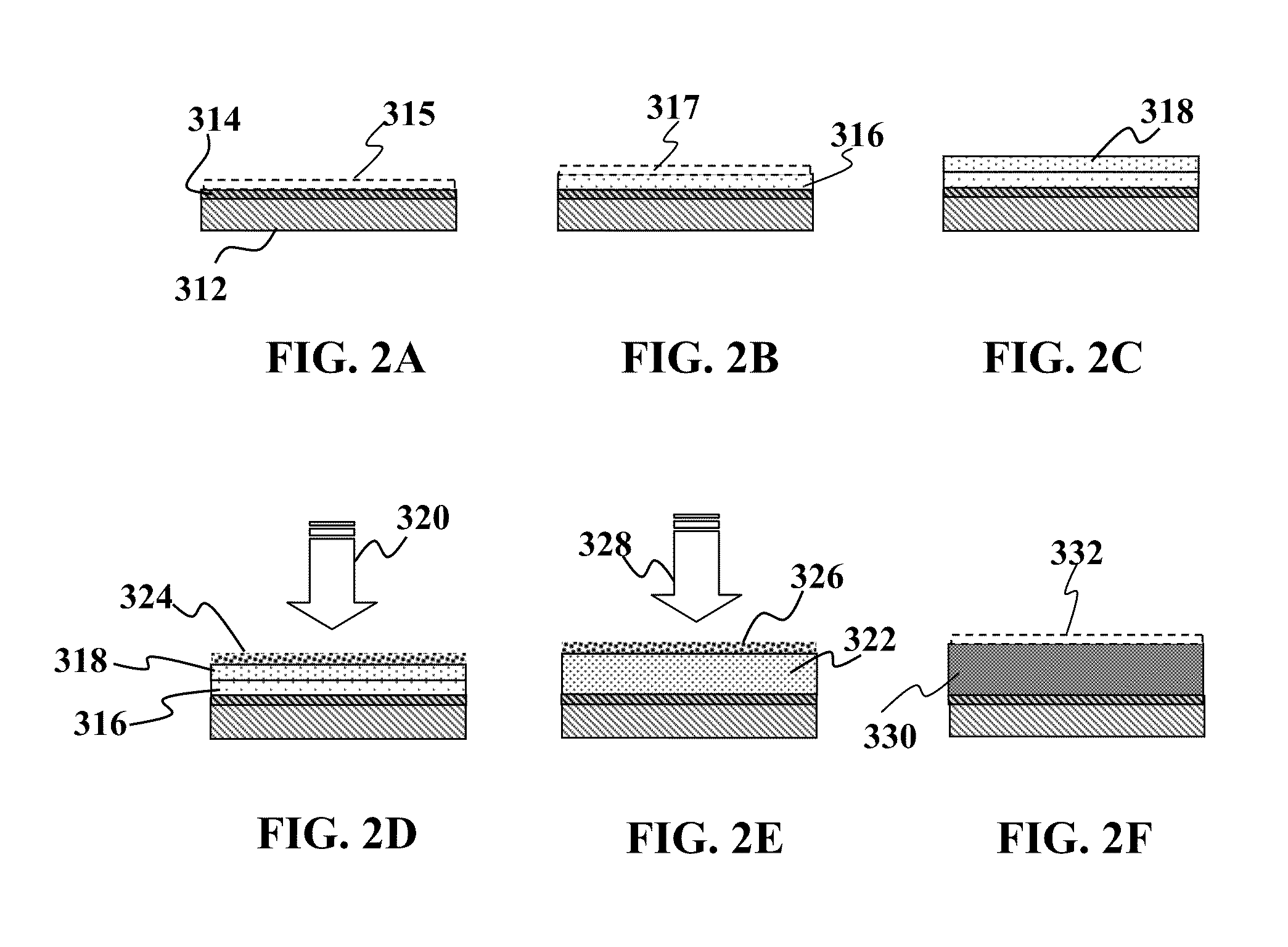

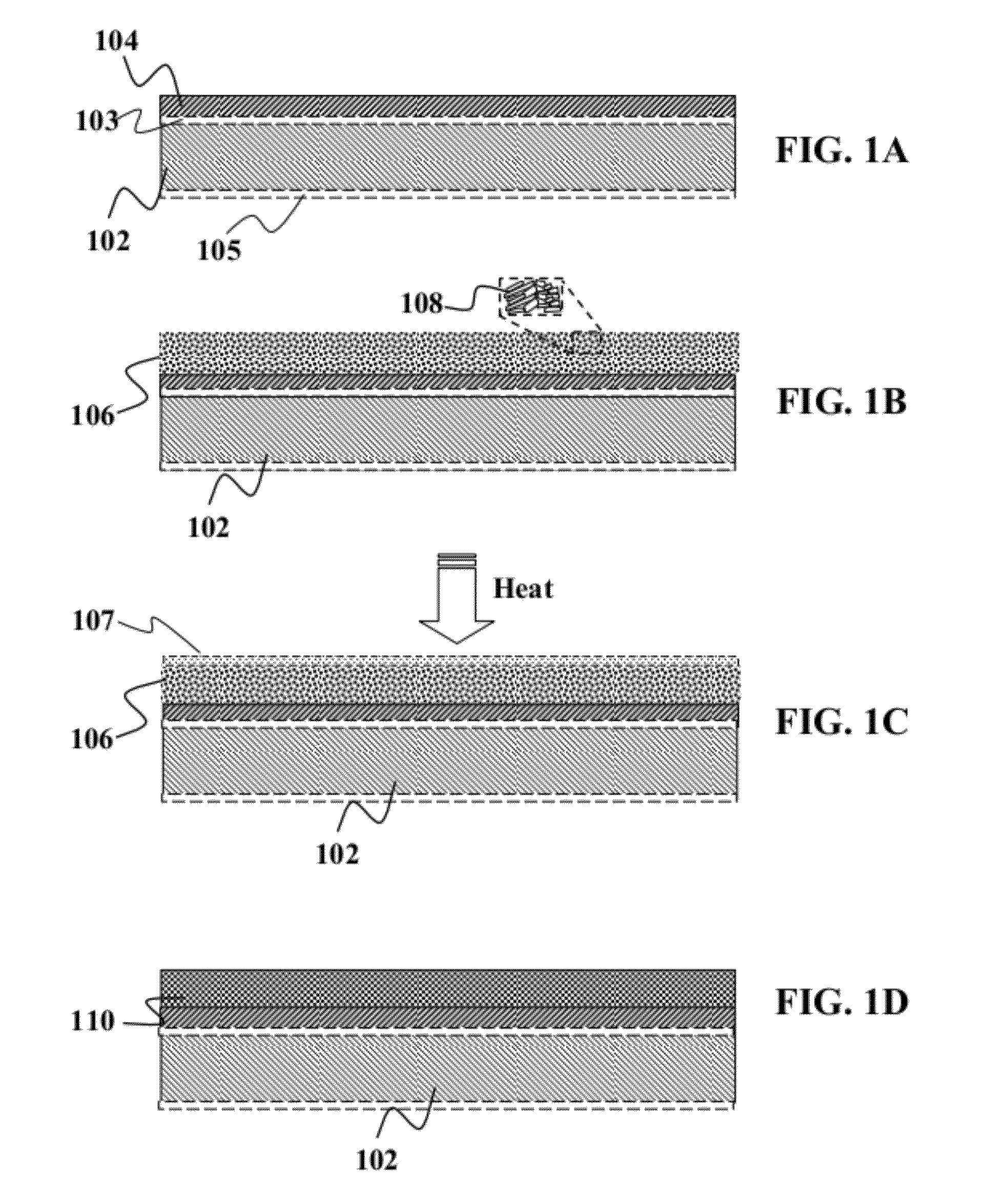

Low cost solar cells formed using a chalcogenization rate modifier

InactiveUS20110294254A1Speed up gallium processingIncrease exposureFinal product manufactureSemiconductor/solid-state device manufacturingAlloySolar cell

Methods and devices are provided for forming an absorber layer. In one embodiment, a method is provided comprising of depositing a precursor material onto a substrate, wherein the precursor material may include or may be used with an additive to minimize concentration of group IIIA material such as Ga in the back portion of the final semiconductor layer. The additive may be a non-copper Group IB additive in elemental or alloy form.

Owner:AERIS CAPITAL SUSTAINABLE IP

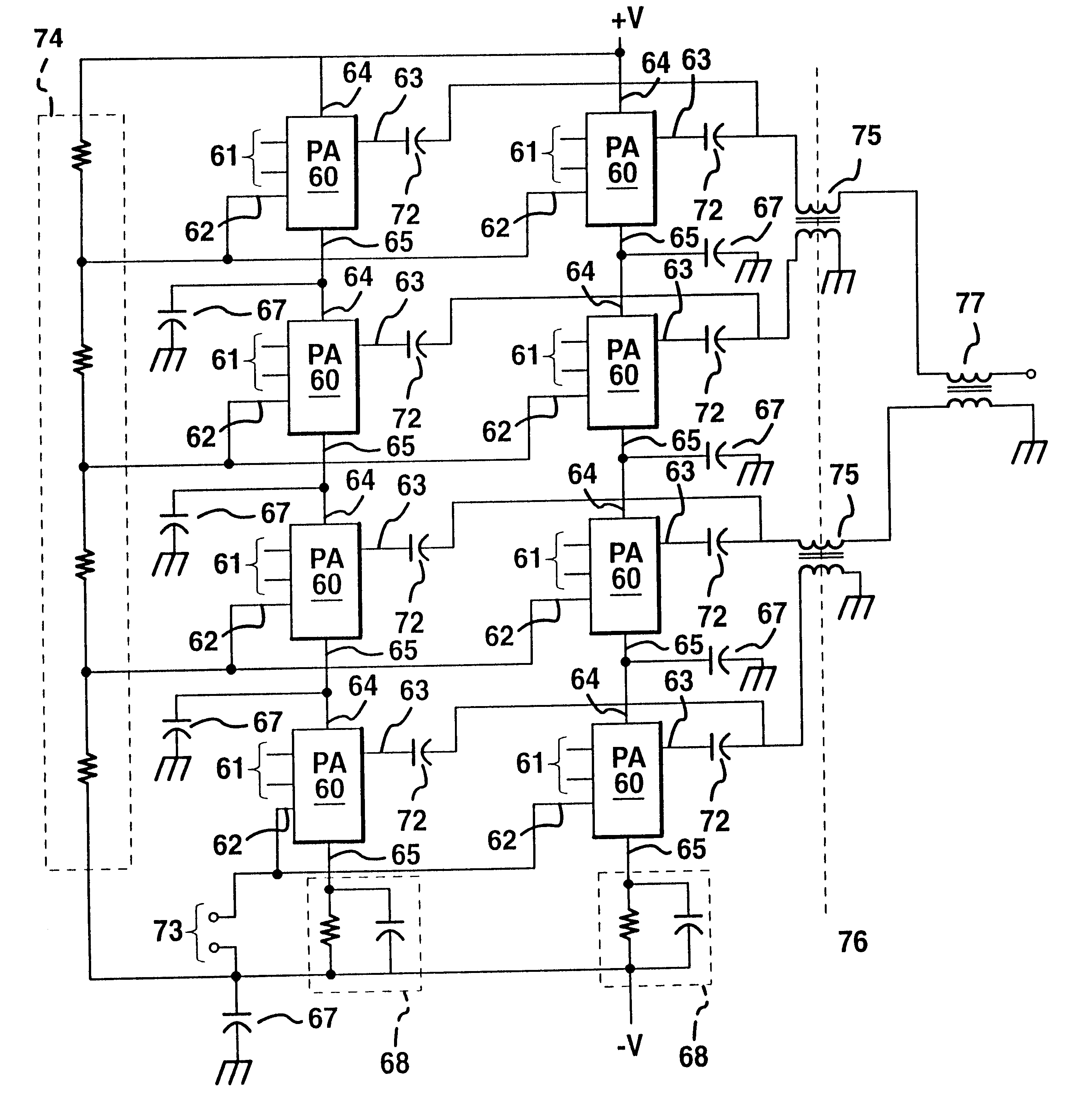

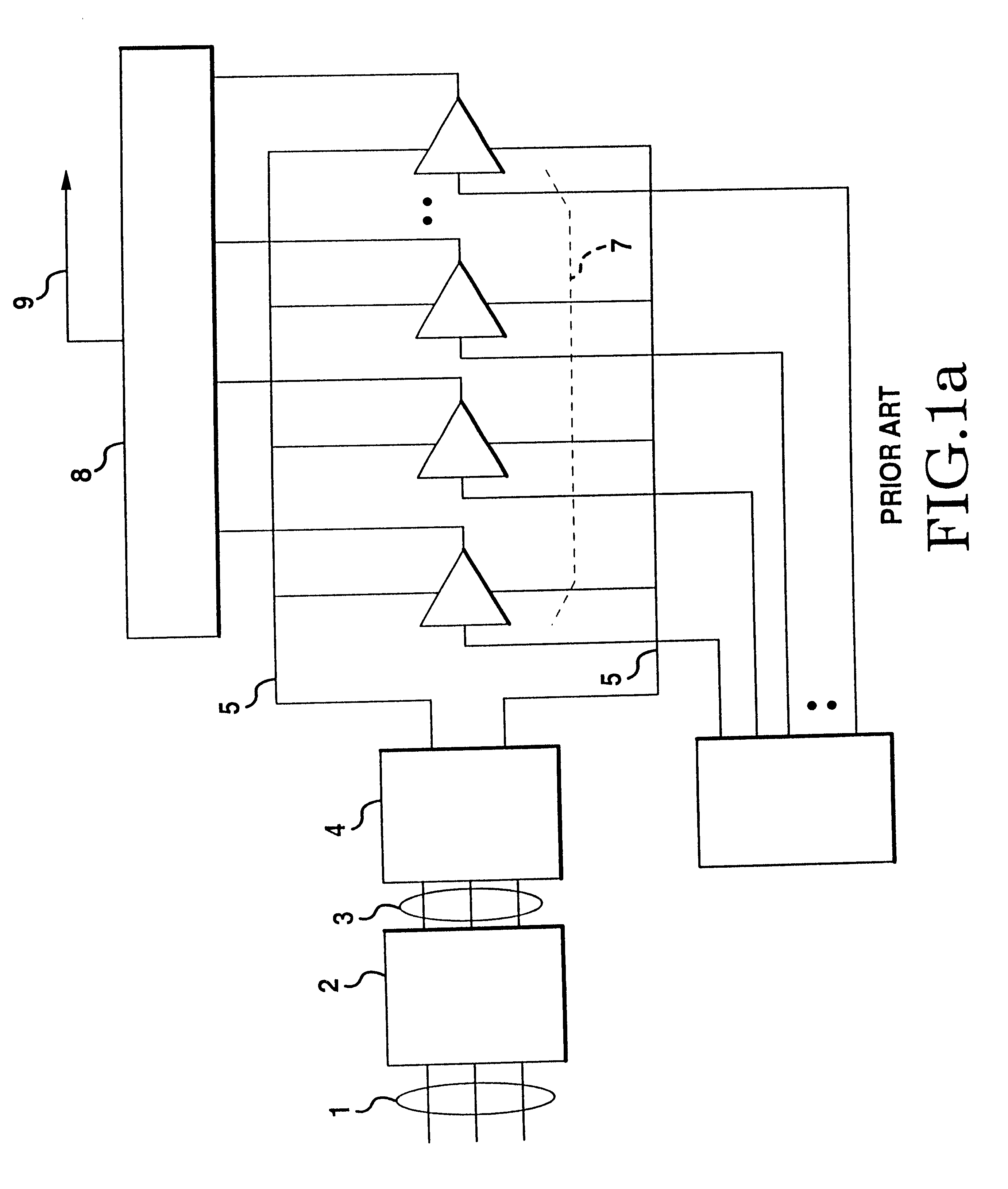

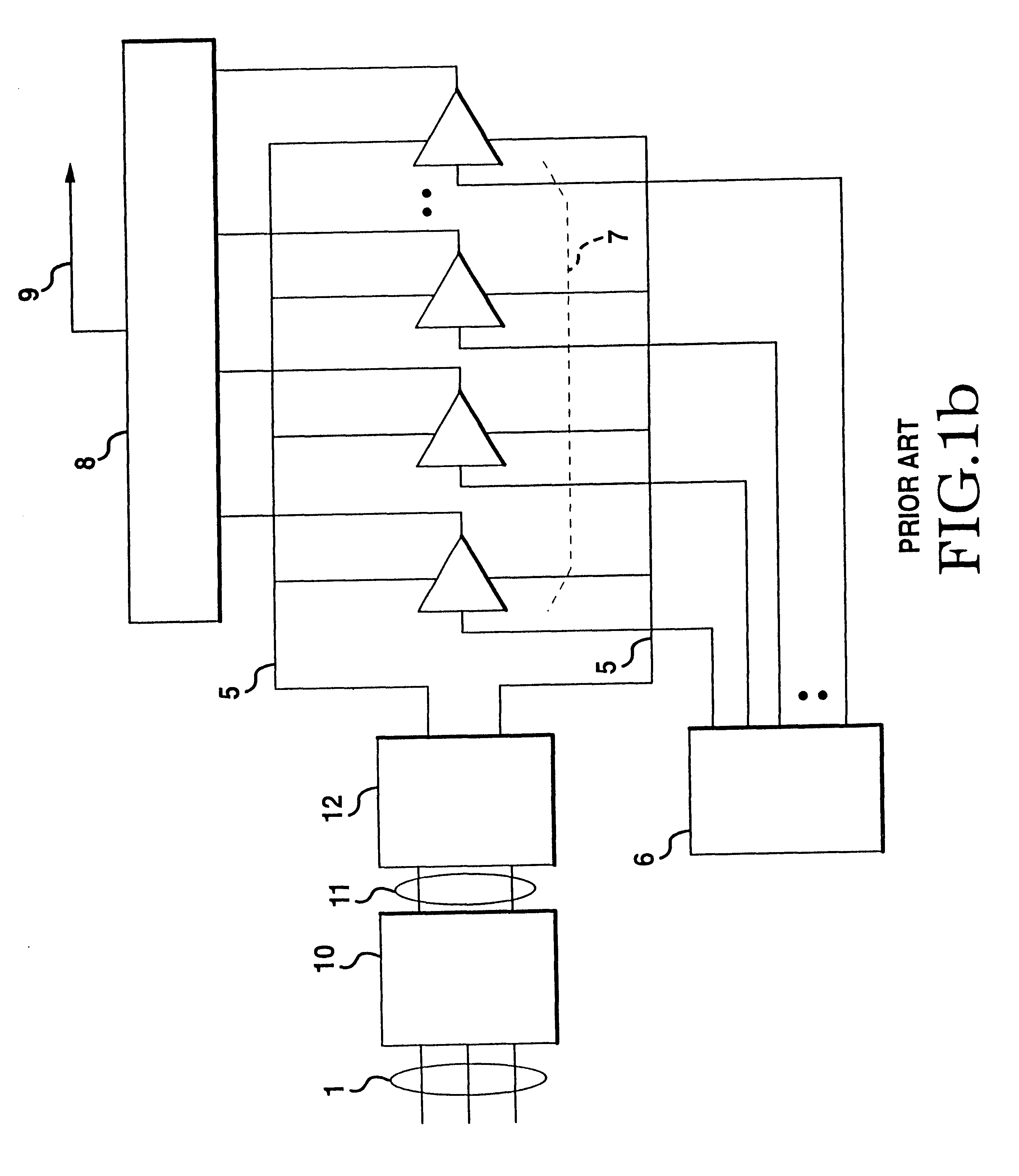

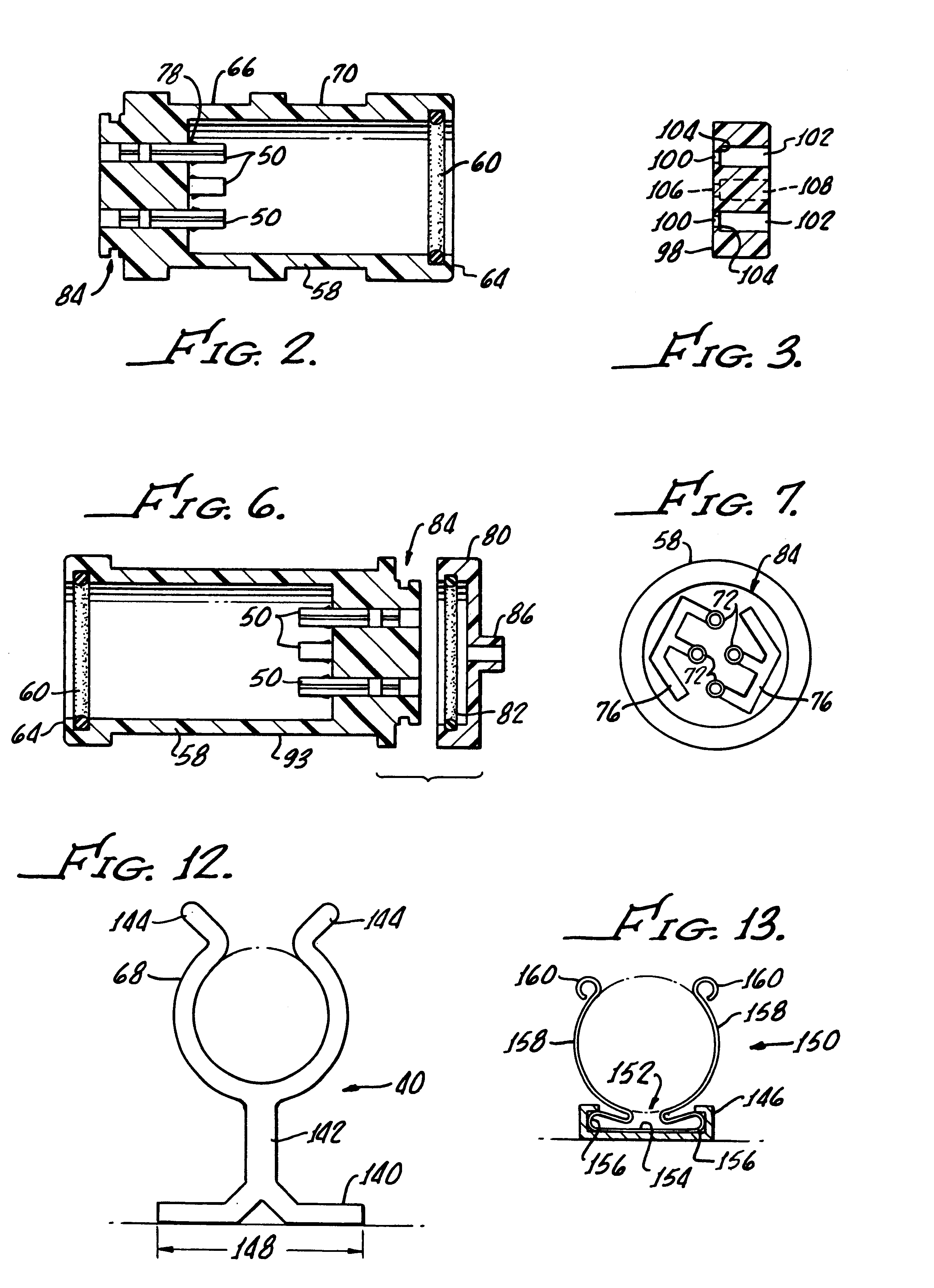

System for high power RF plasma processing

InactiveUS6384540B1Cost effectiveSimple designNegative-feedback-circuit arrangementsElectric discharge tubesAudio power amplifierSystems design

A high power radio frequency power method of amplifications described in which a variety of amplifiers (60 & 86) may be used to reduce the stress any one amplifier experiences. The power leads (64 & 65) may be arranged in a series to power each amplifier at potentials which are lower than the total potential. Outputs (63) may then be connected in a parallel fashion to combine the power output by the system. A variety of unique stabilization, drive, division, combination, and supply configurations are presented as well as the possibility of utilization and adaptation of the designs for a plasma processing system. An aspect of tiered combining is included such as may be especially appropriate for larger numbers of devices which may include switchmode amplifiers and the like.

Owner:ADVANCED ENERGY IND INC

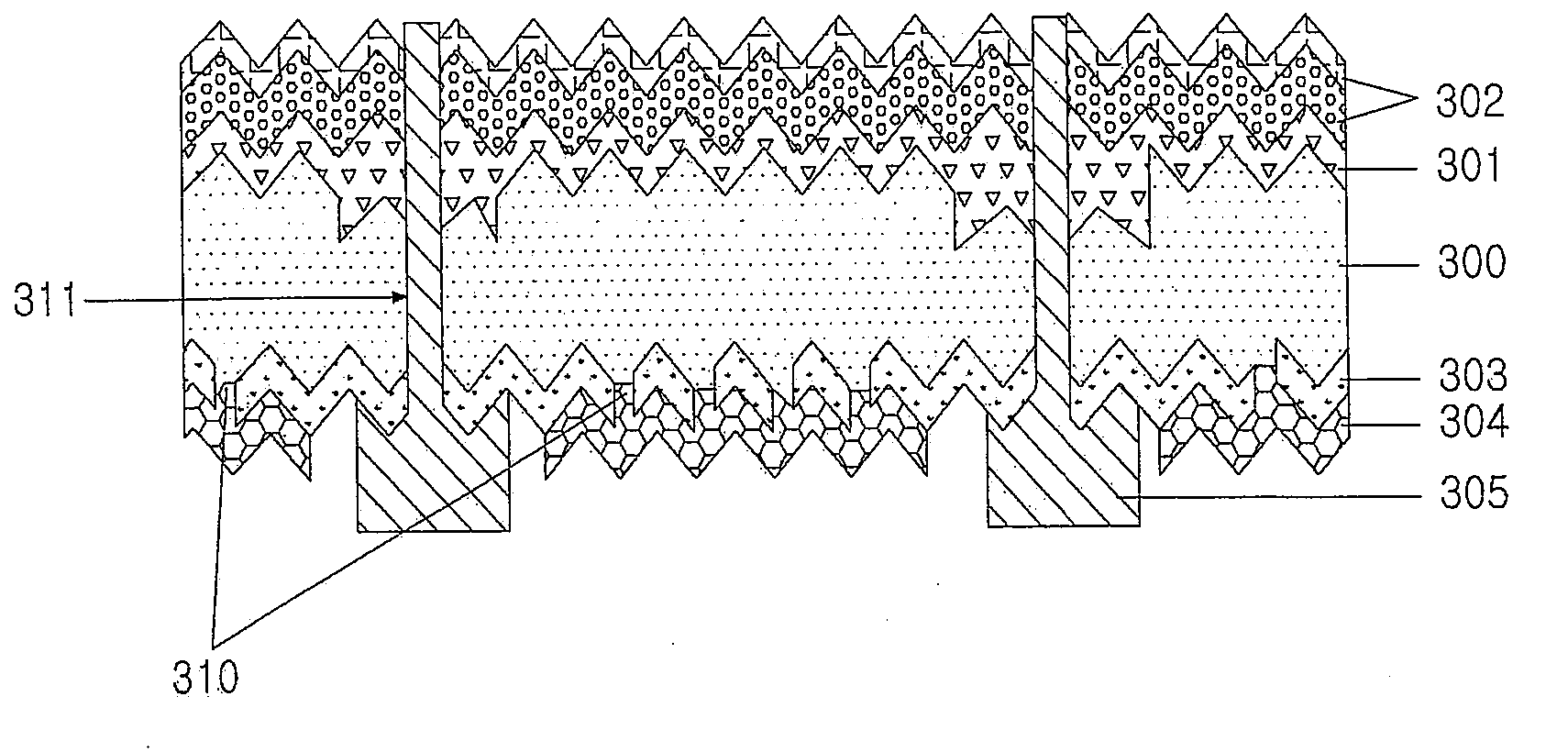

Photovoltaic device and manufacturing method thereof

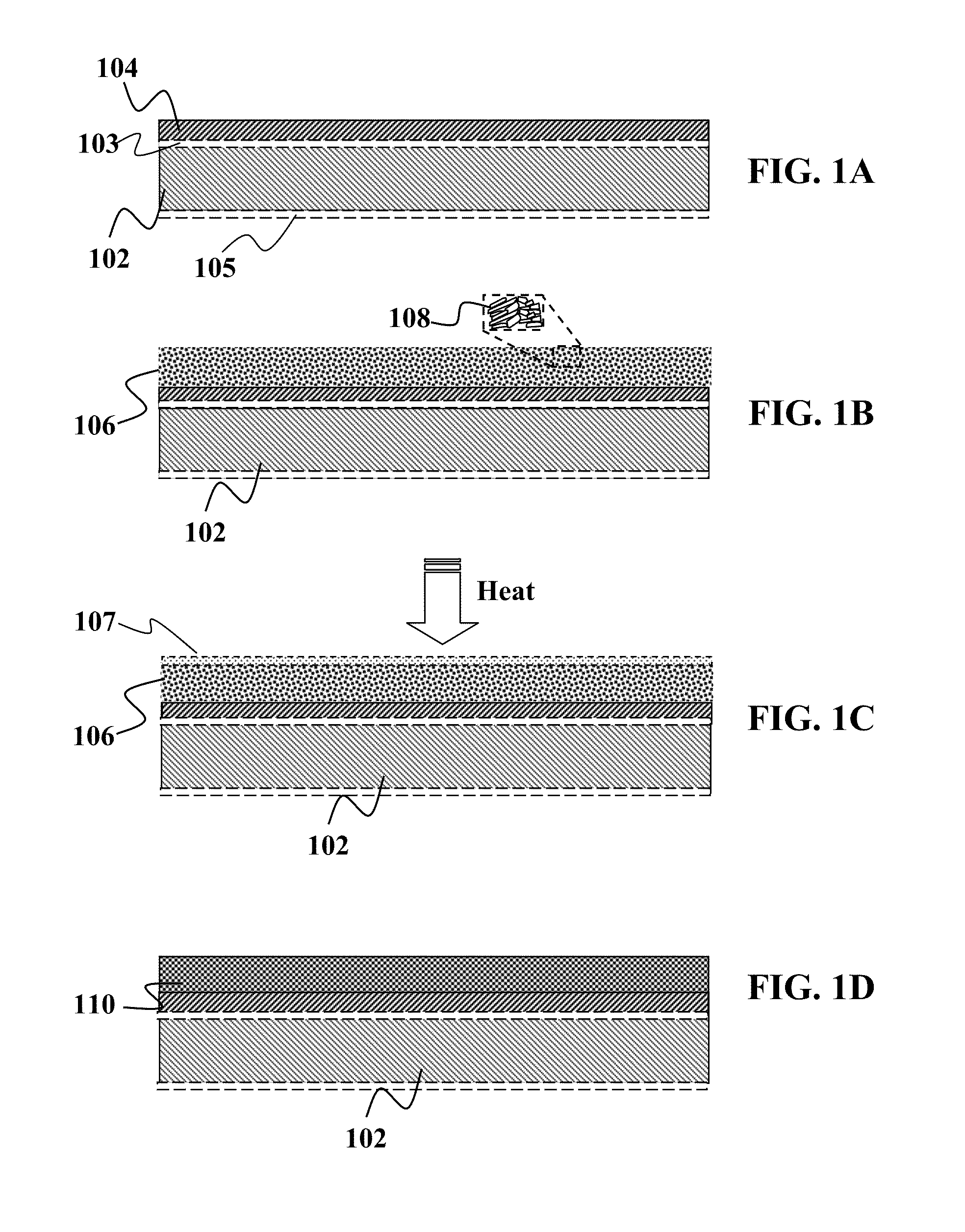

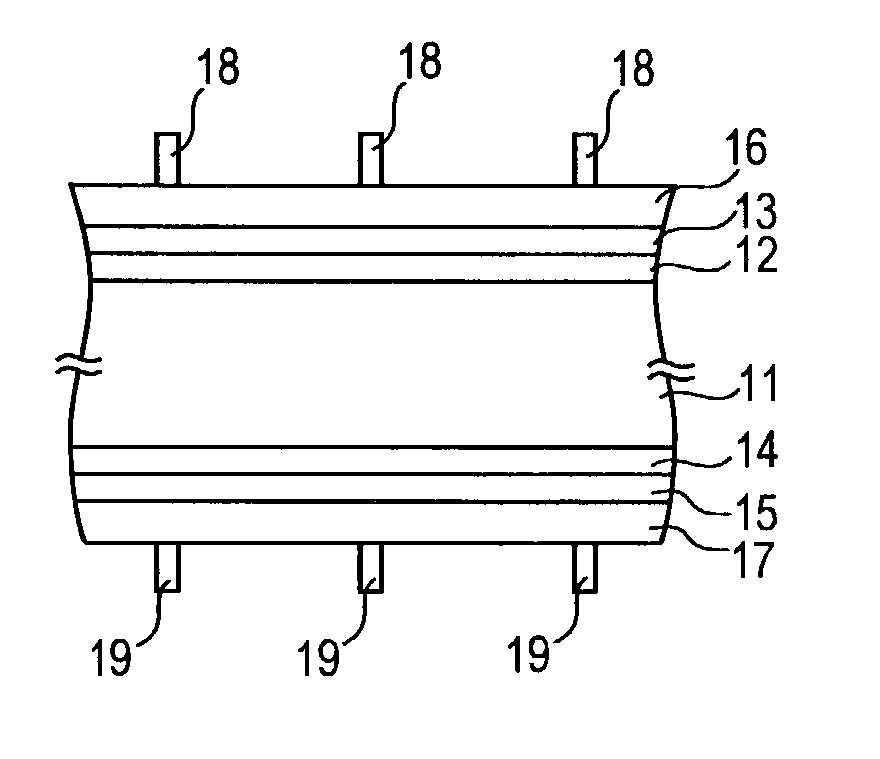

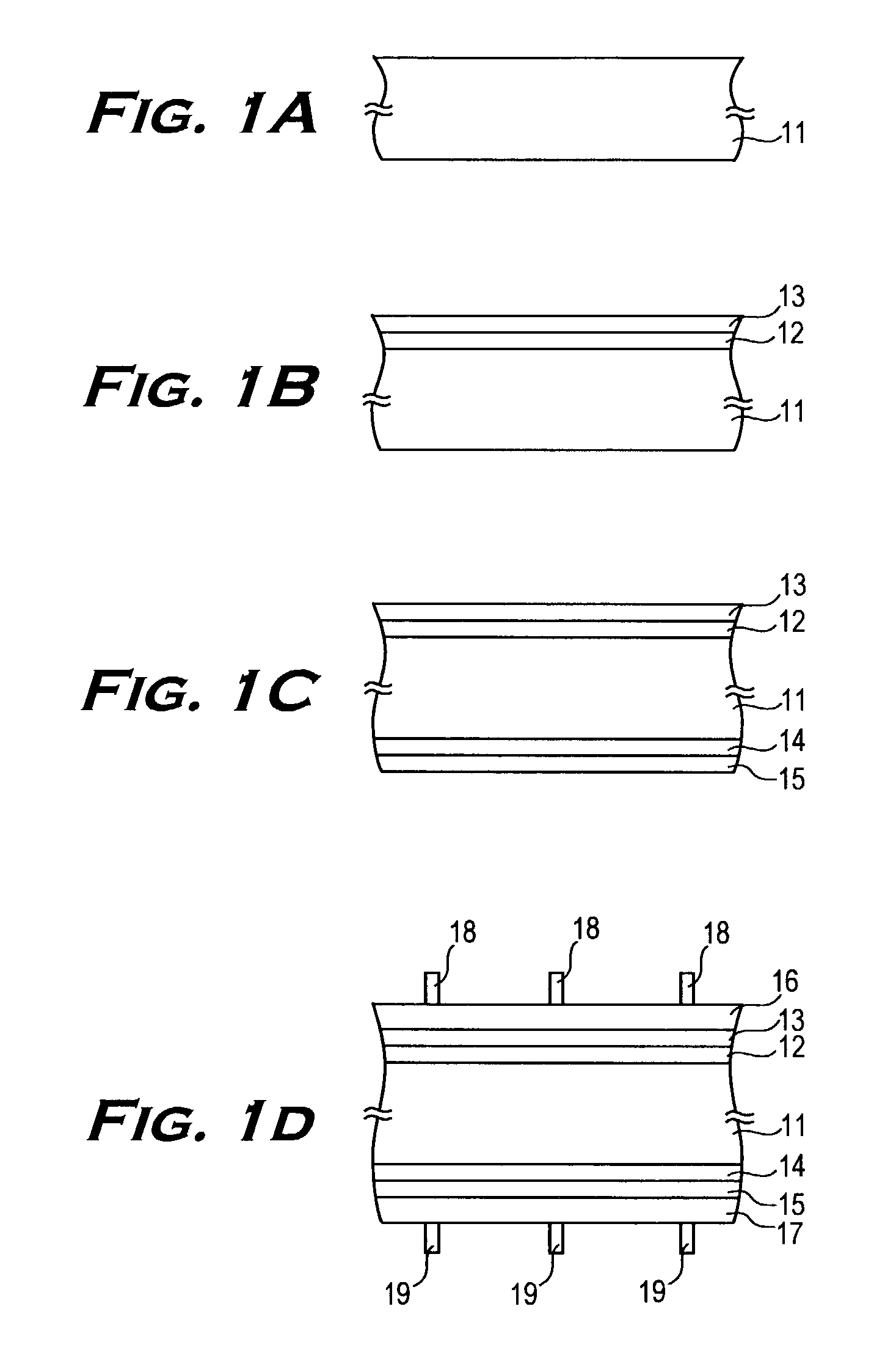

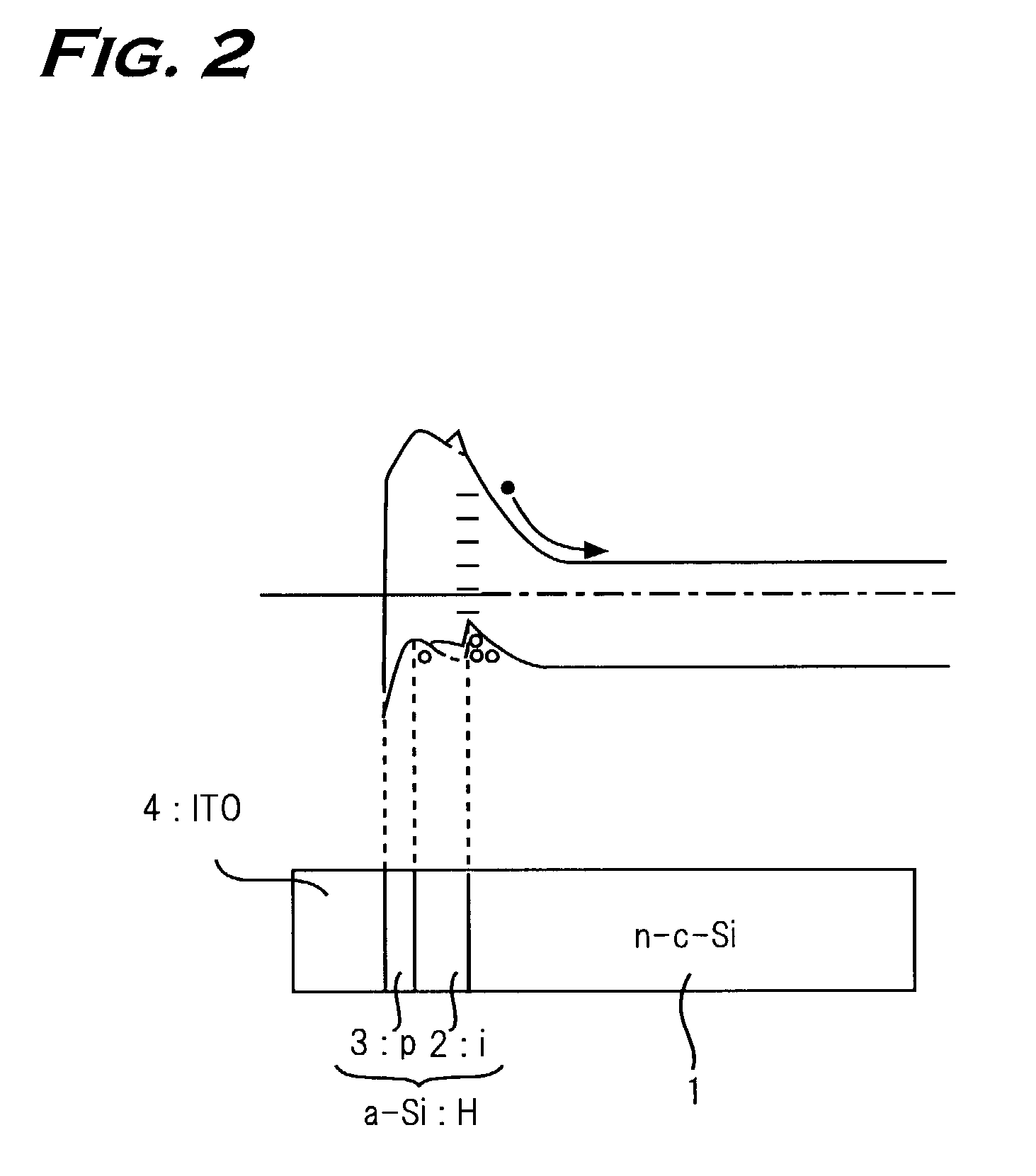

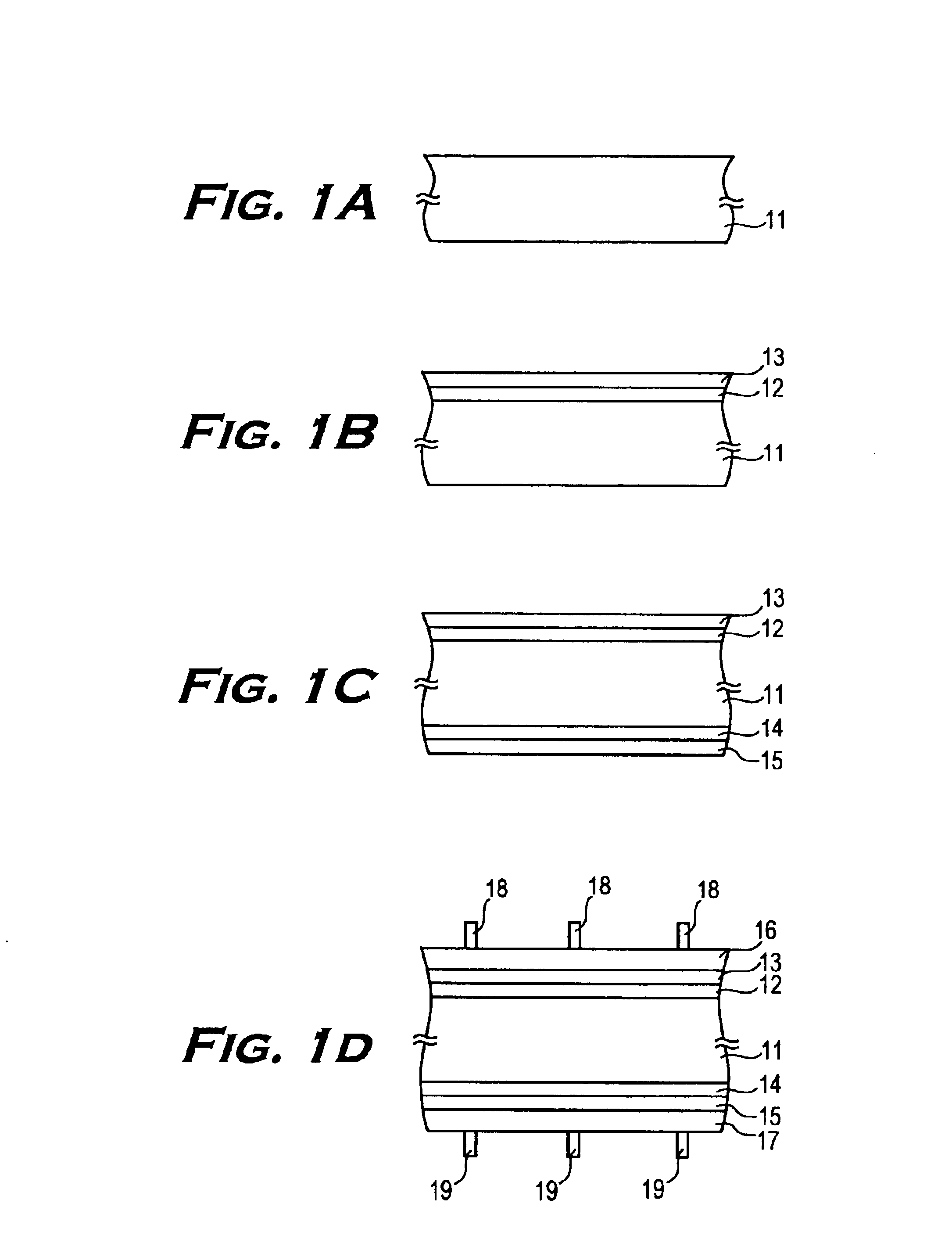

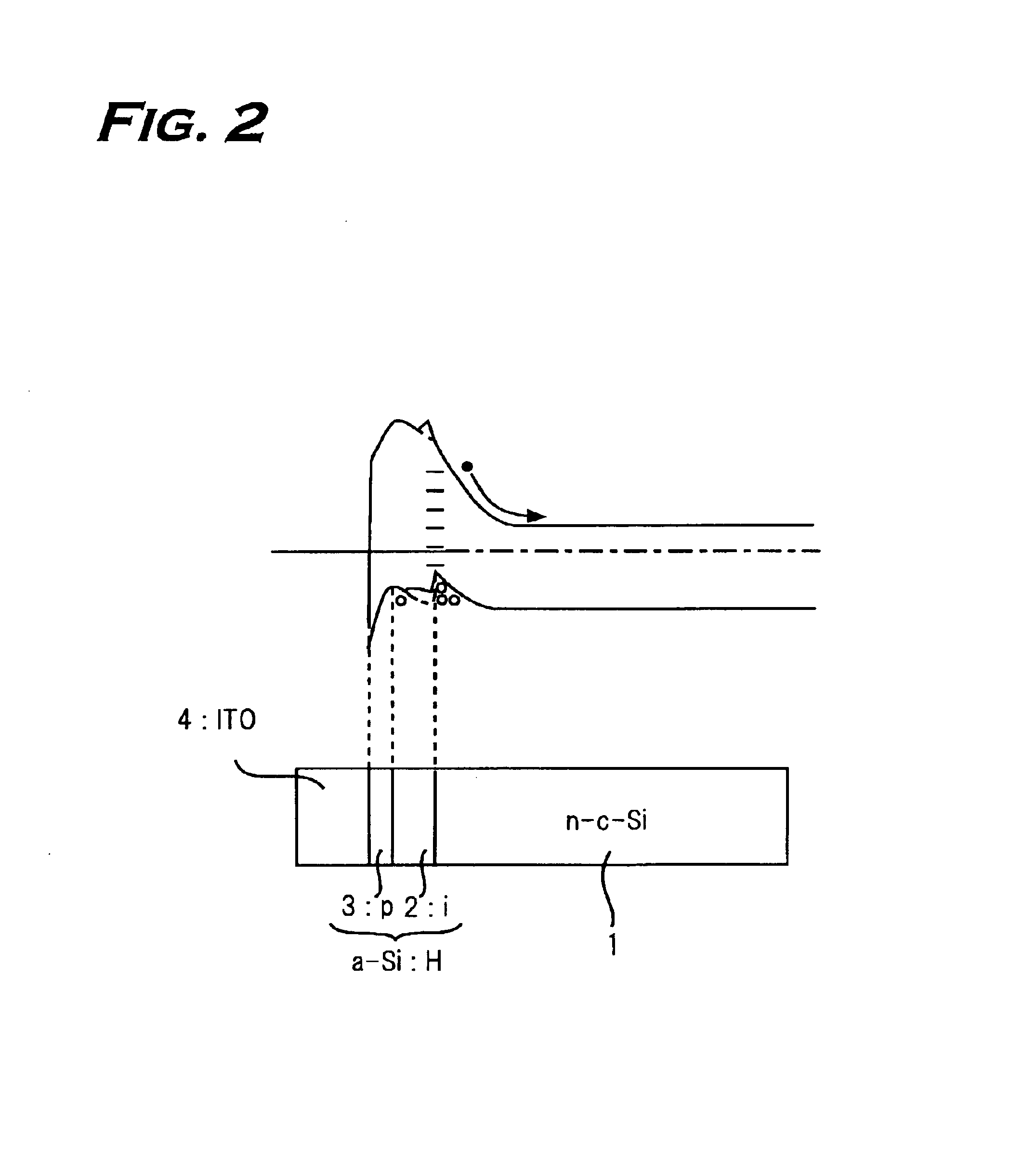

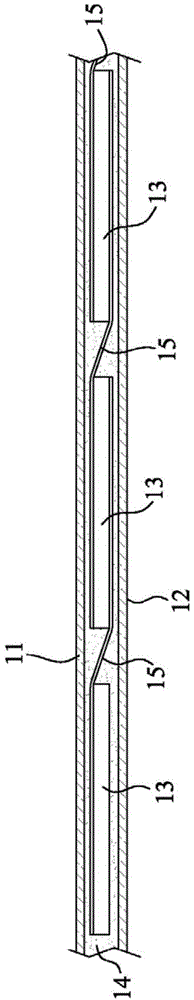

InactiveUS20030168578A1Electron flowIncrease the open circuit voltageFinal product manufactureMaterial analysis by optical meansHydrogenThin layer

The present invention was made to improve interface characteristics between a crystalline semiconductor and an amorphous semiconductor thin film so that junction characteristics can be upgraded. A manufacturing method of a photovoltaic device comprising an i-type amorphous silicon thin film (12) and a p-type amorphous silicon thin layer (13) laminated in this order on a front surface of an n-type single crystalline silicon substrate (11), and an i-type amorphous silicon layer (14) and an n-type amorphous silicon layer (15) laminated in this order on a rear surface of the single crystalline silicon substrate, wherein an i-type amorphous silicon layer (12) is formed after the front surface of the single crystalline silicon substrate (11) is exposed to a plasma discharge using mixed gas of hydrogen gas and a gas containing boron so that atoms of boron may be interposed on an interface between the single crystalline silicon substrate (11) and the i-type amorphous silicon layer (12).

Owner:SANYO ELECTRIC CO LTD

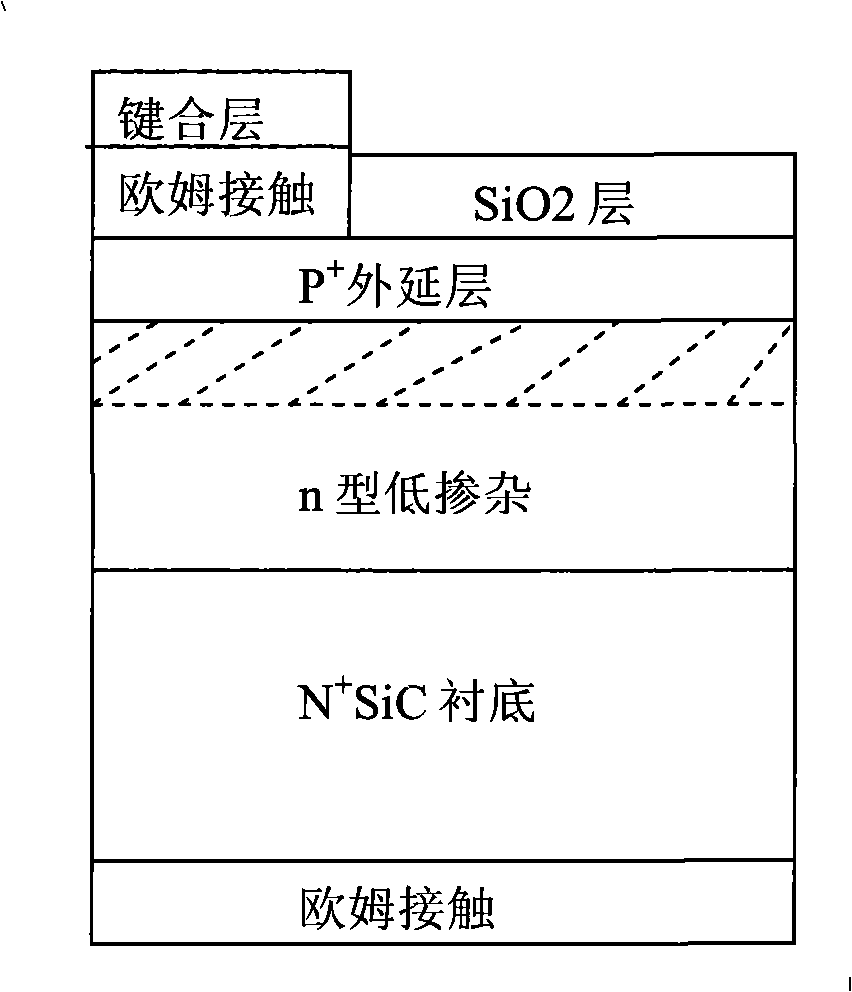

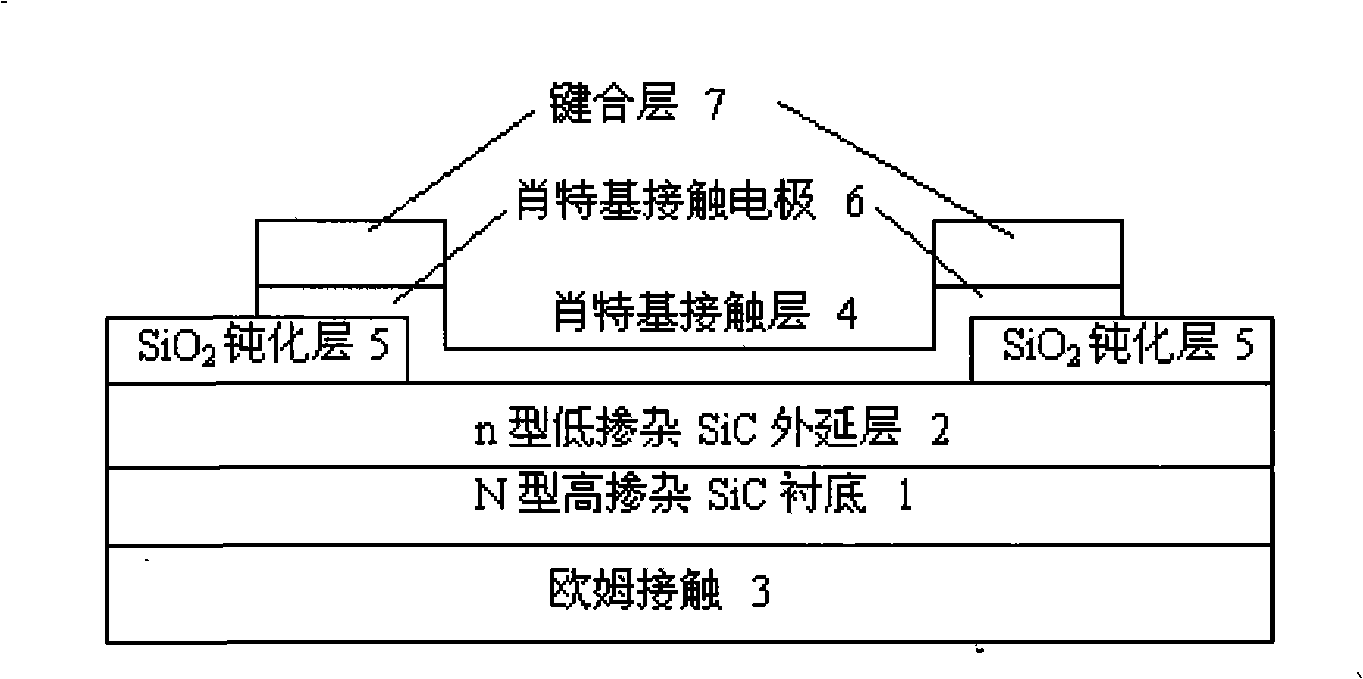

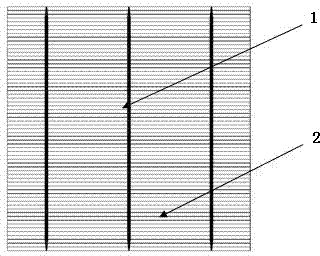

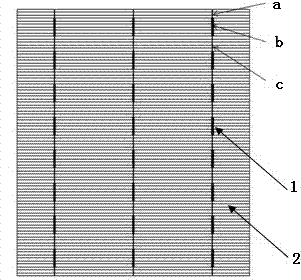

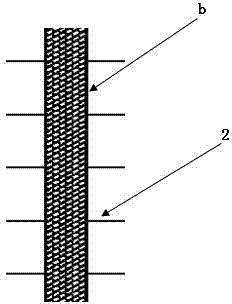

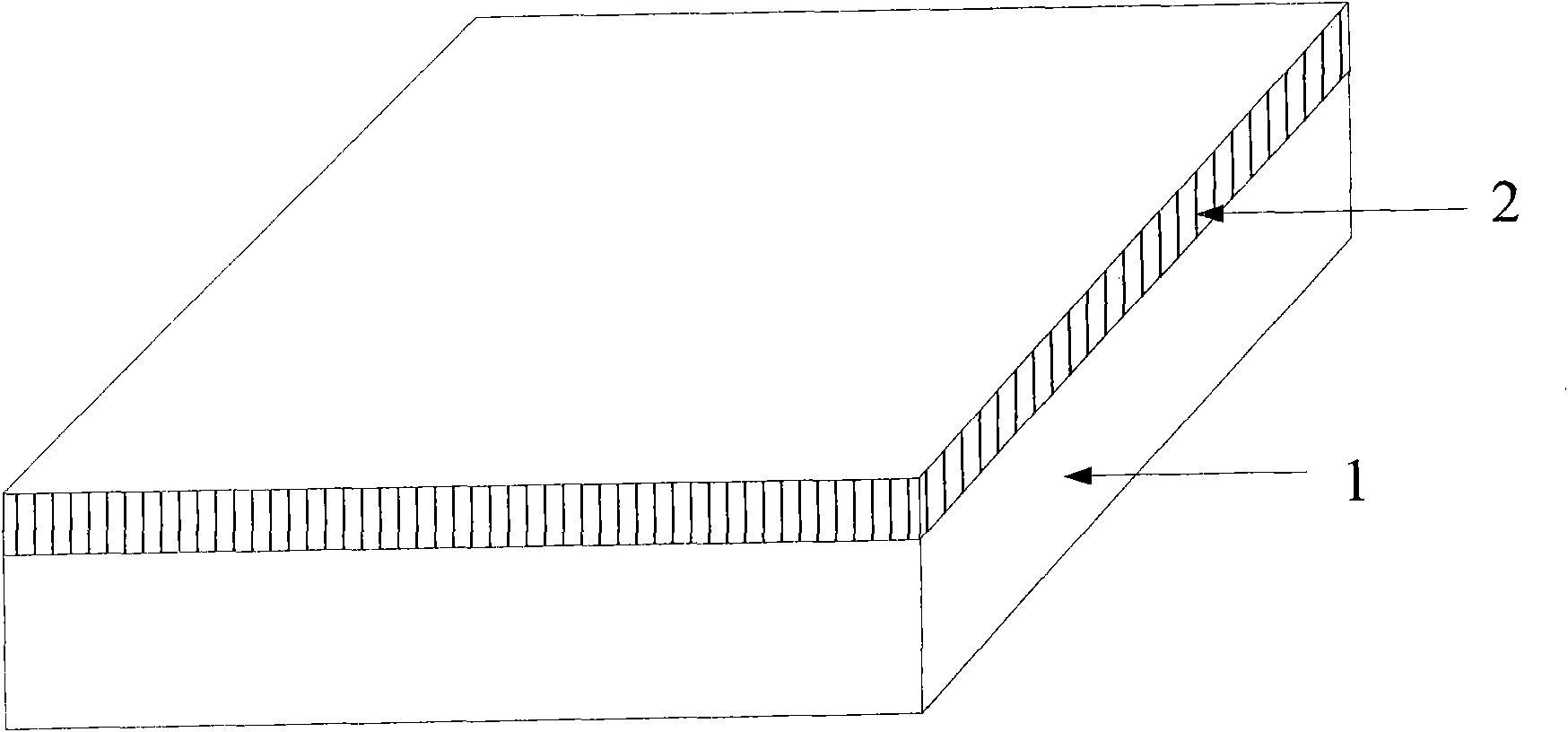

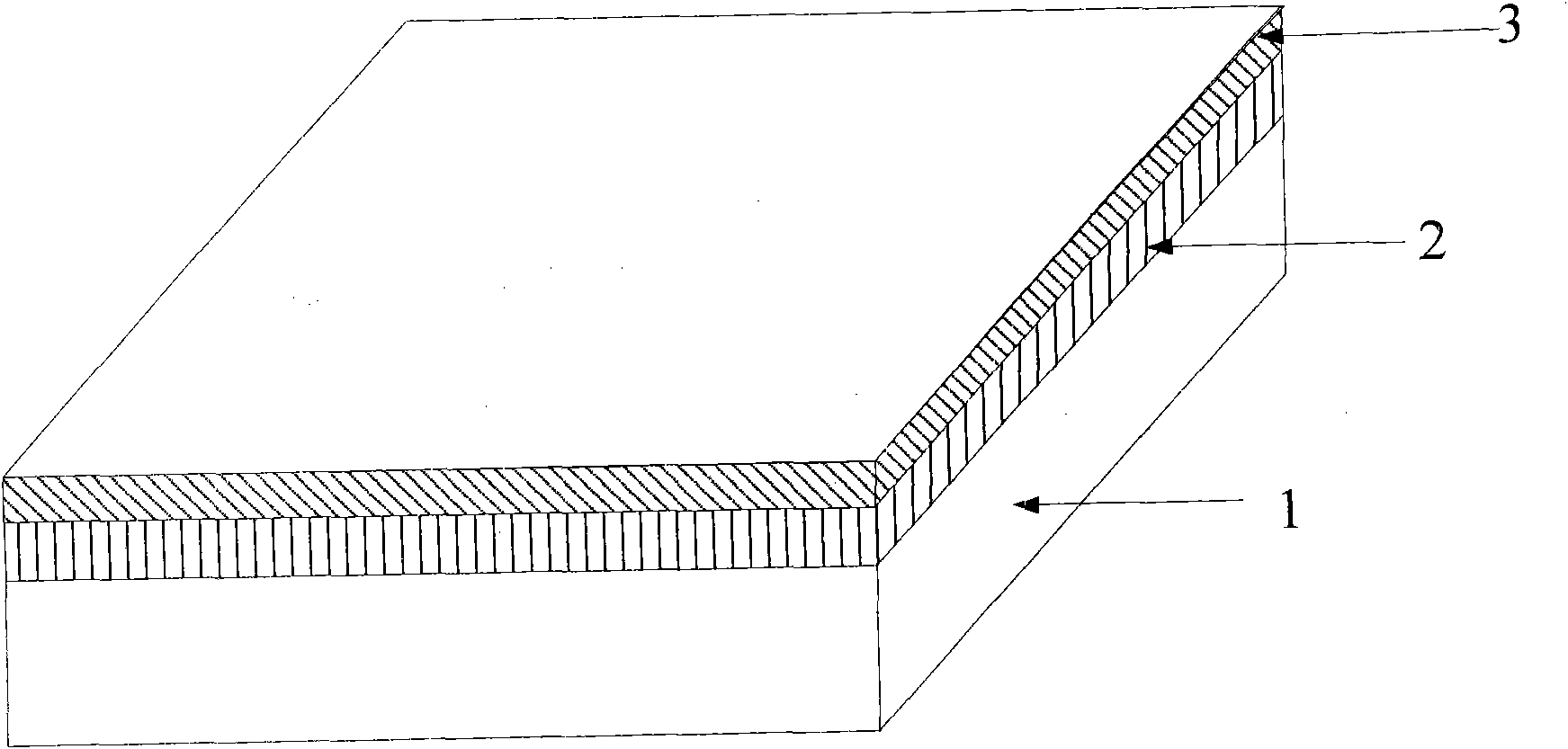

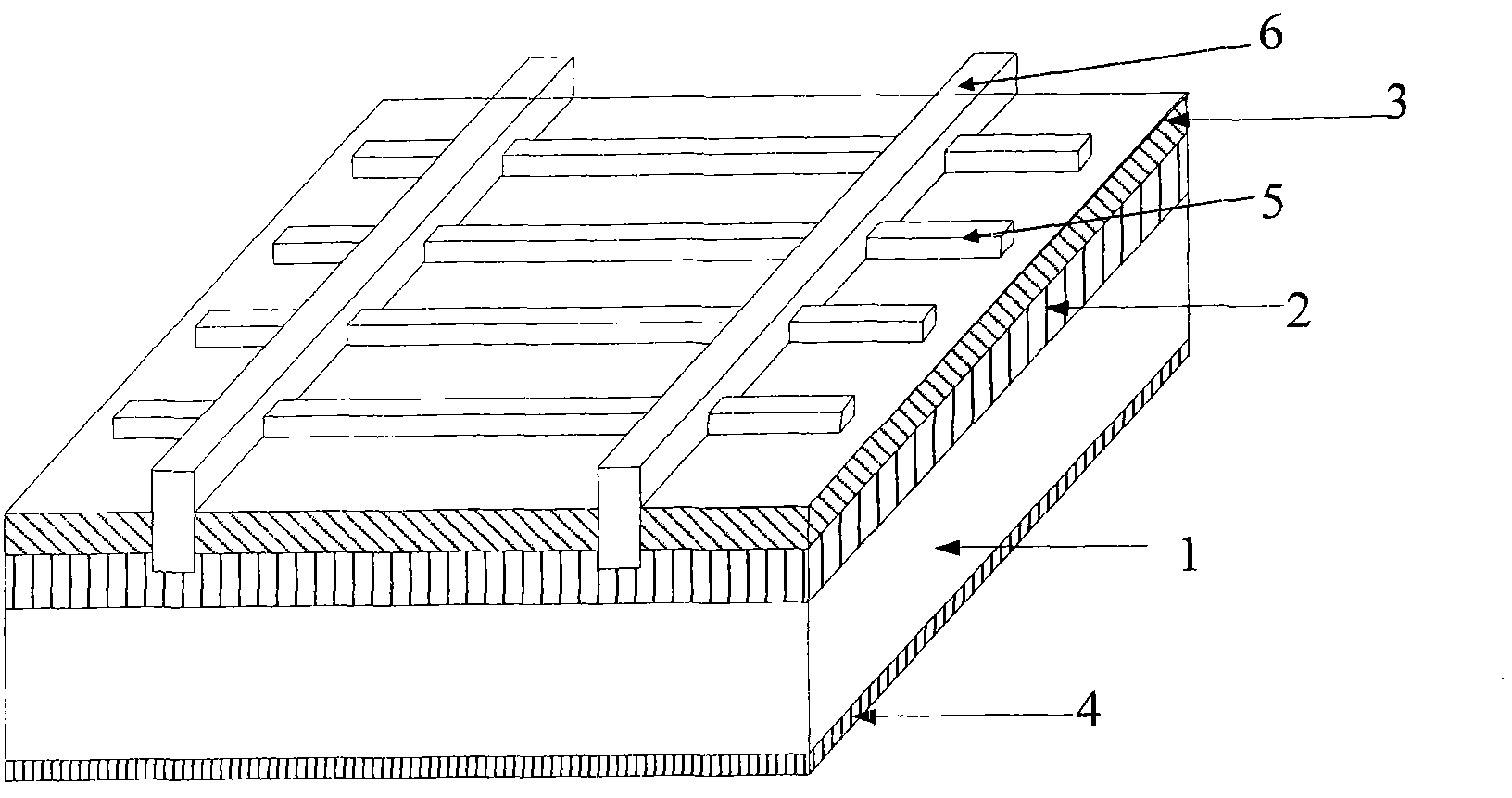

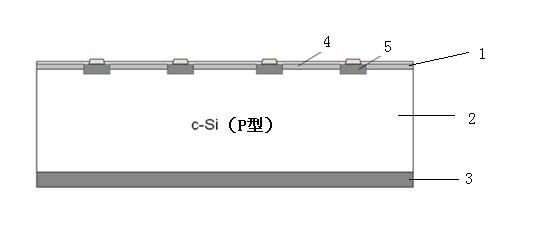

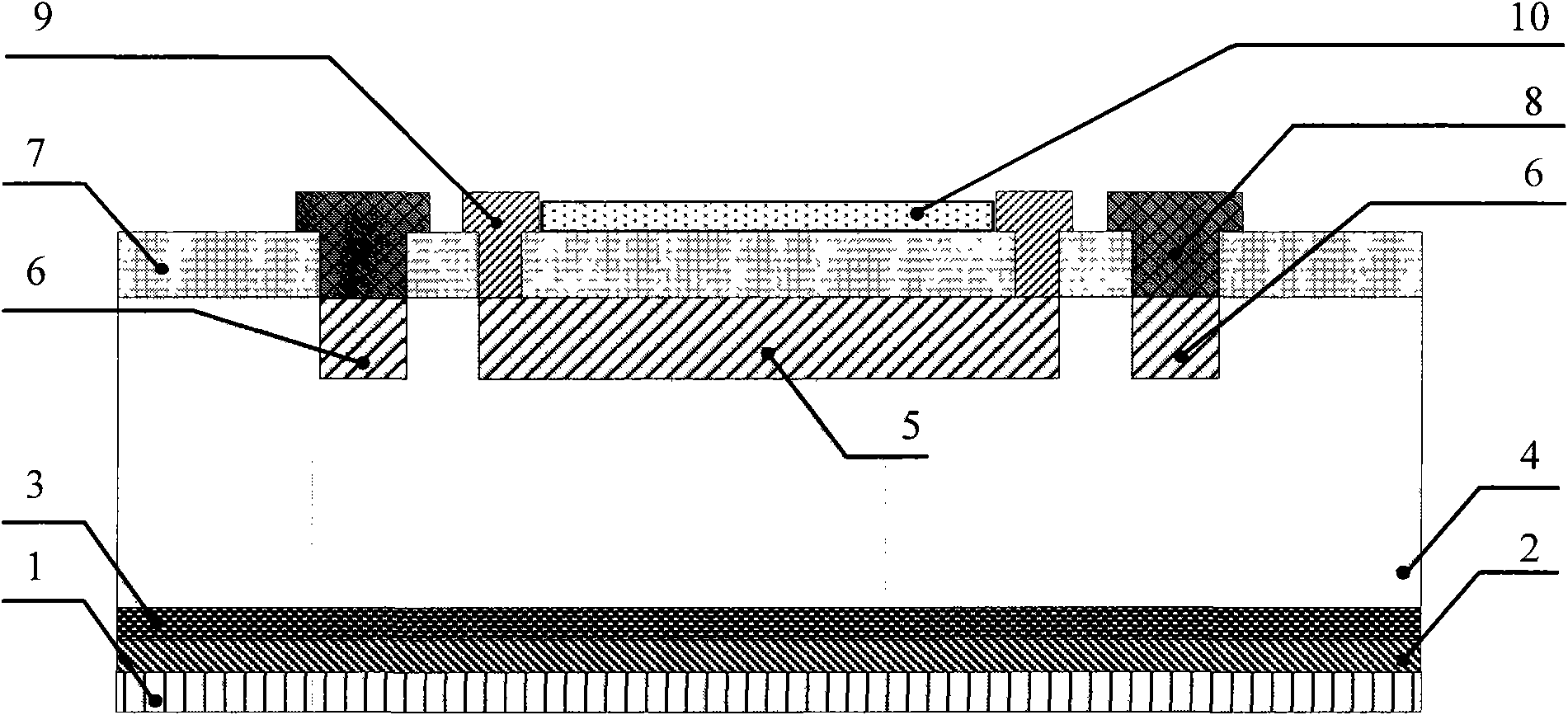

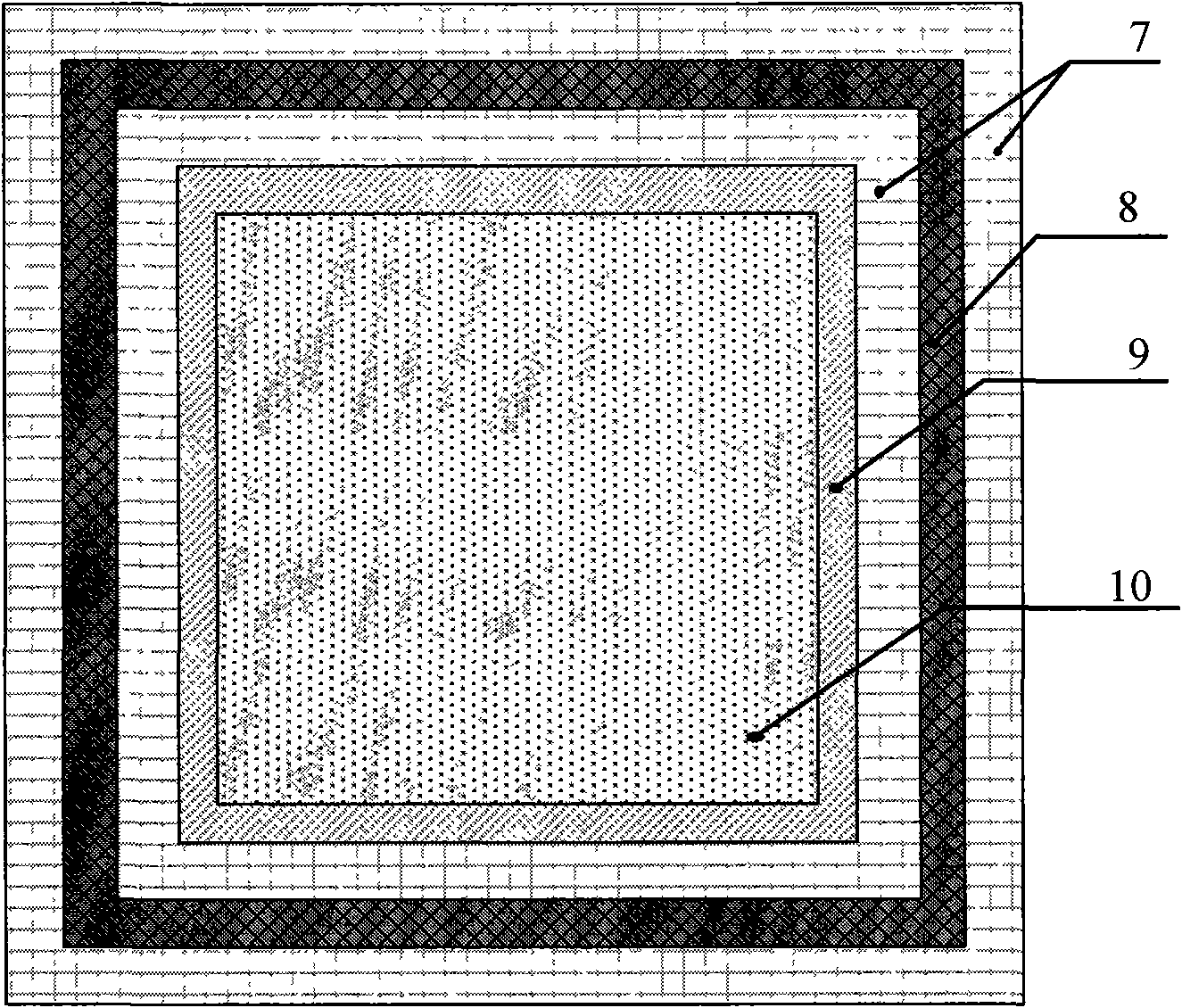

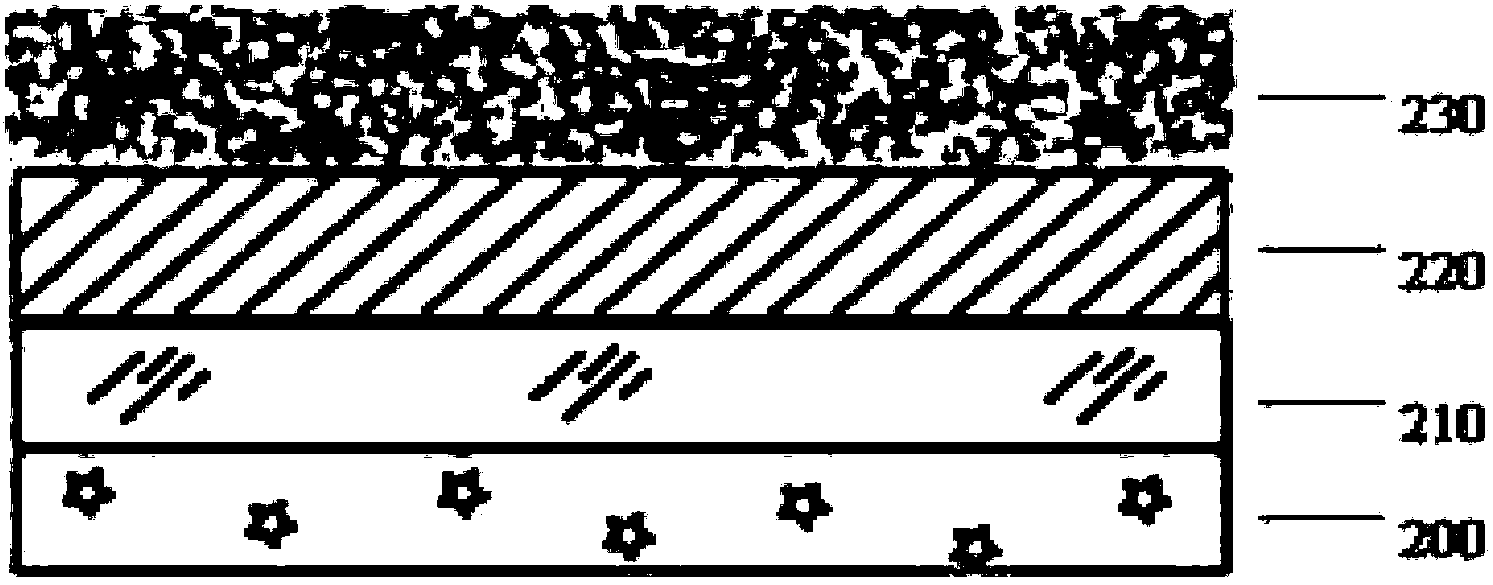

Minisize nuclear battery

InactiveCN101325093AReduce blockingIncrease the open circuit voltageRadiation electrical energyOhmic contactContact layer

The invention discloses a minitype nuclear battery, which mainly solves the problem that the nuclear battery manufacturing is easier than the SiC technology realization. A low doping epitaxial layer (2) and an ohmic contact electrode (3) are respectively arranged at the upper part and the lower part of an N-type high doping SiC substrate (1), wherein, a circular schottky contact layer (4) is deposited on the upper surface of the low doping epitaxial layer (2), and a SiO2 passivating layer (5) and a bonding layer (7) are arranged on the circumference at the outer edge of the schottky contact layer. The schottky contact layer (4) and a schottky contact electrode (6) are formed by adopting an identical technology, that is, a schottky contact hole is etched by adopting wet process in the center position of the SiO2 passivating layer (5), and Ni, Pt or Au with the thickness being 5 to 20 nm deposited on the SiO2 passivating layer on the hole or at the periphery of the hole, and the schottky contact layer (4) and the schottky contact electrode (6) are respectively formed after the SiO2 passivating layer is peeled off. The minitype nuclear battery has the advantages of simple technology and high conversion efficiency, and is applicable in directly converting the nuclear energy radiated by isotopes into the electric energy.

Owner:XIDIAN UNIV

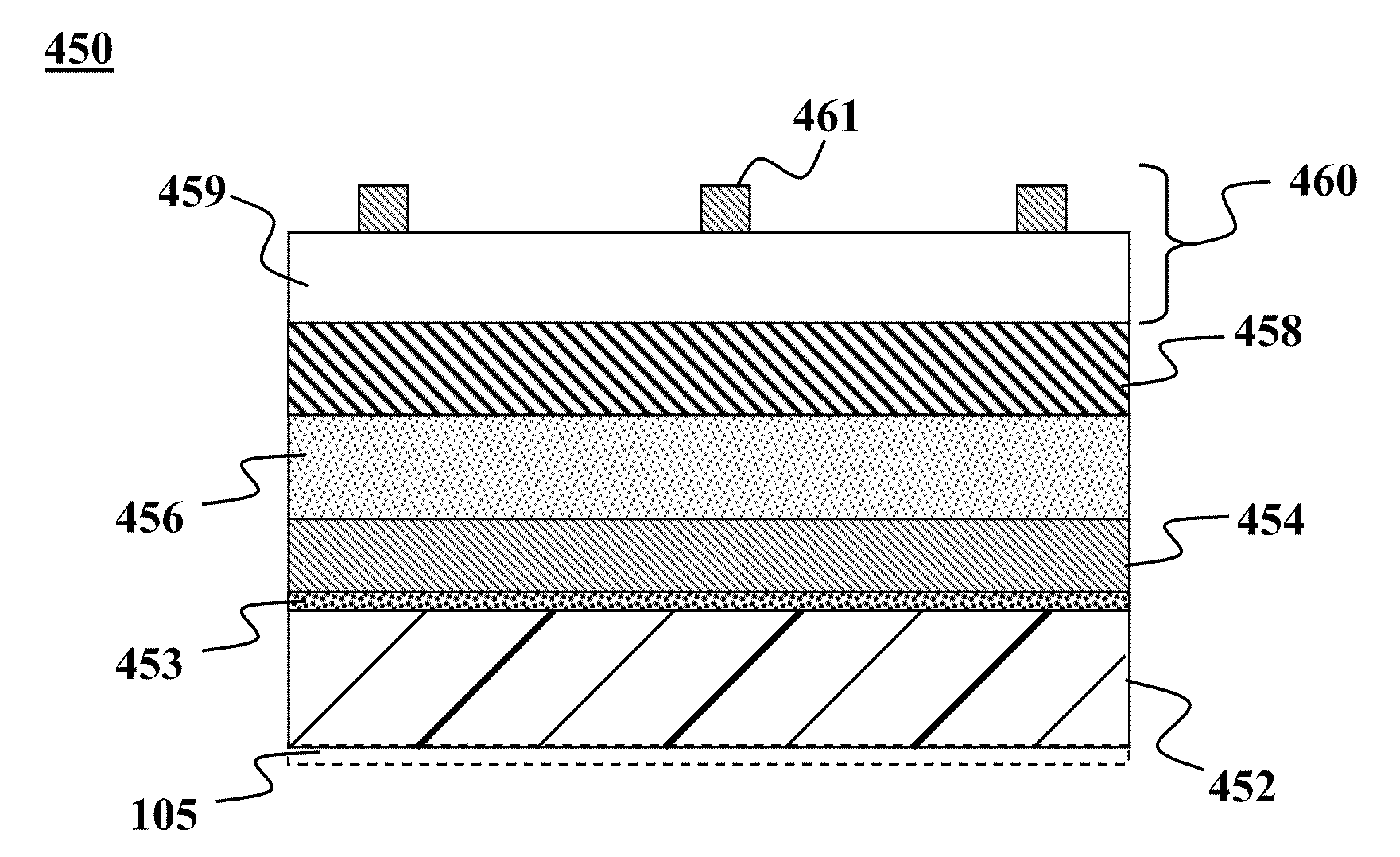

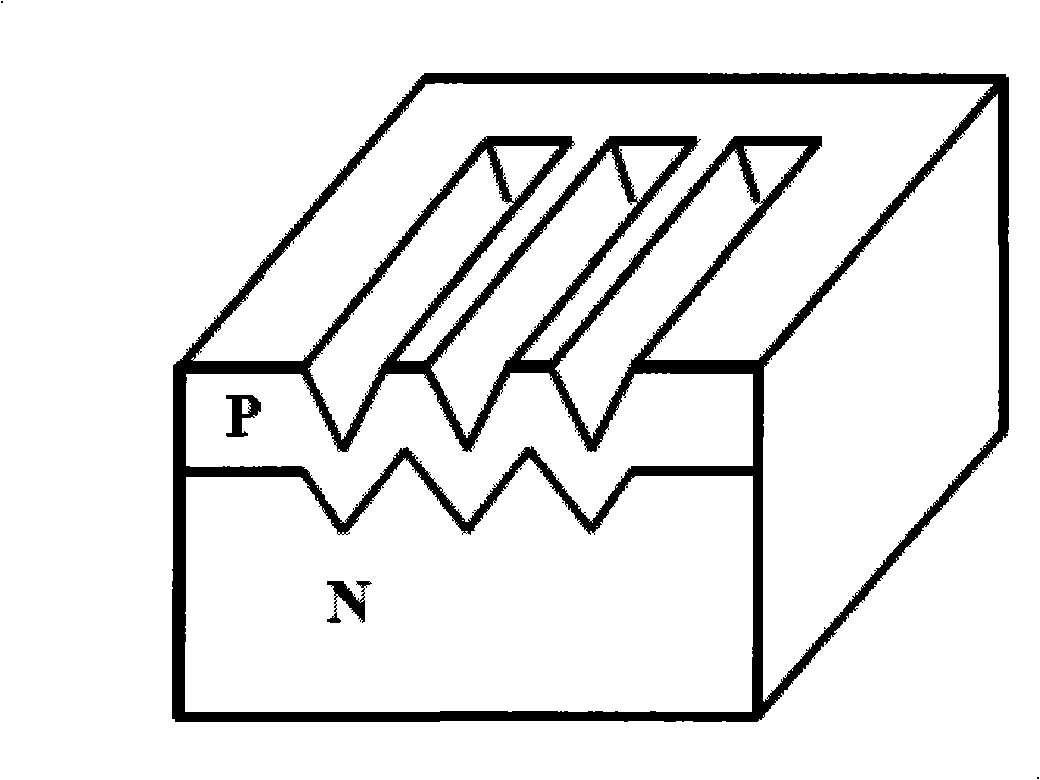

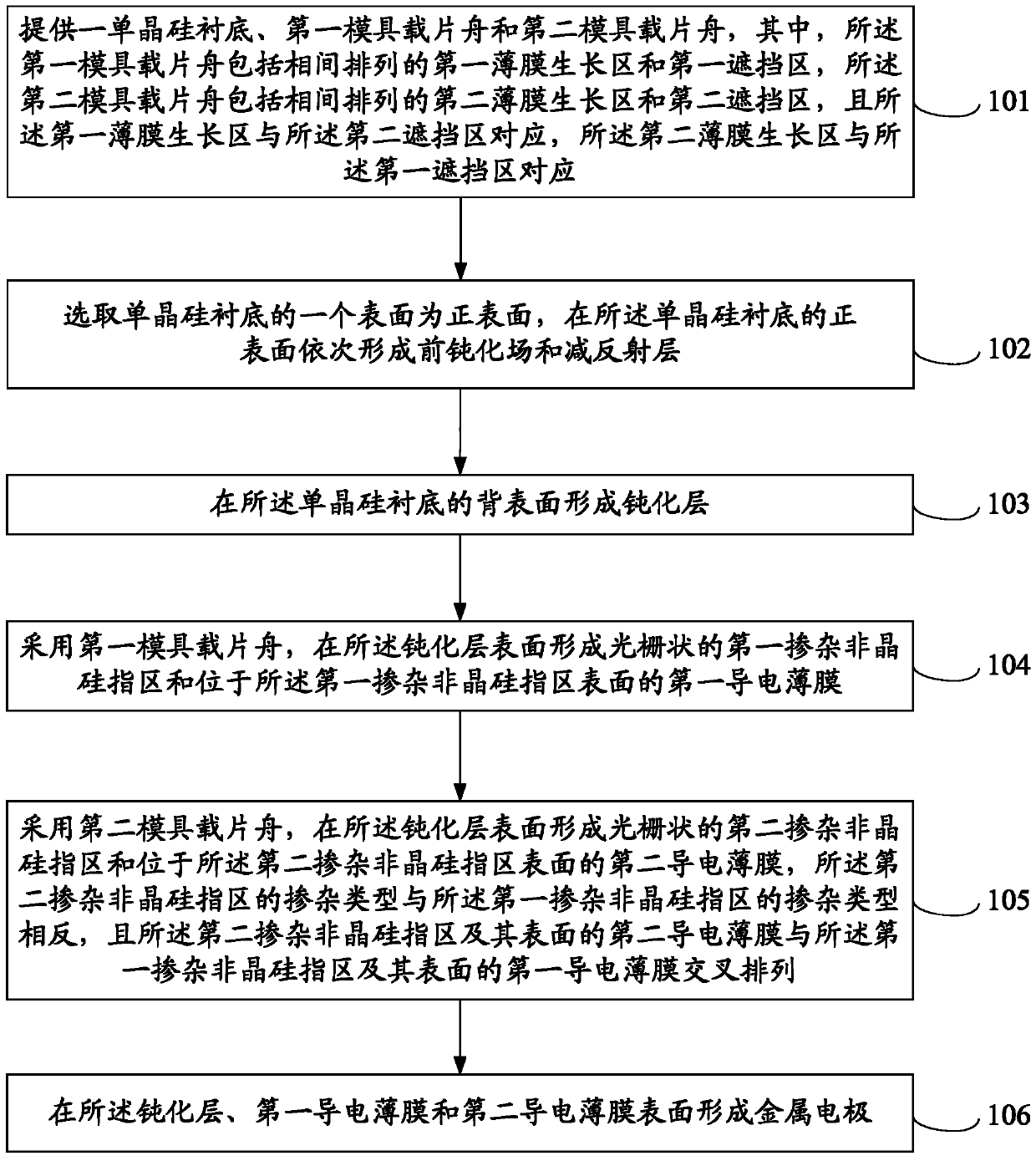

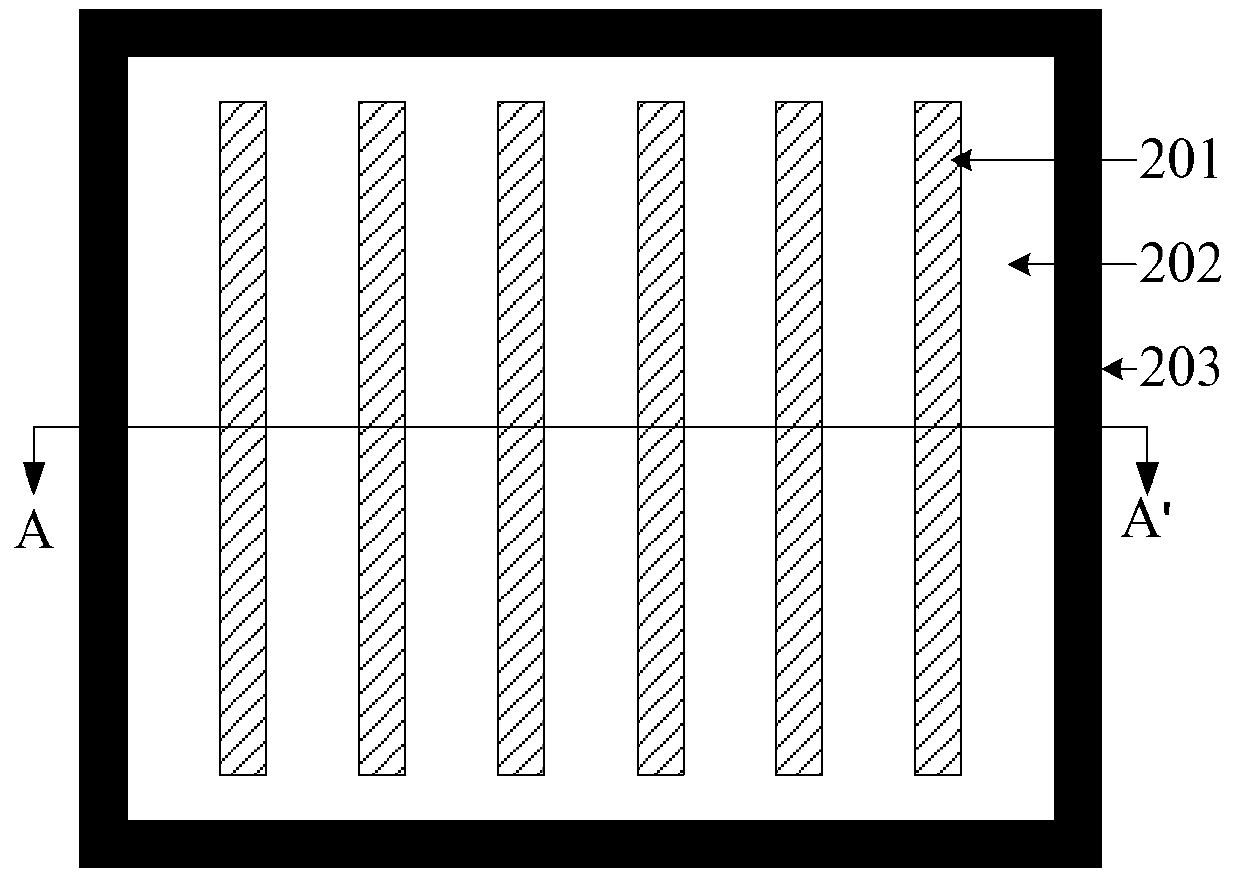

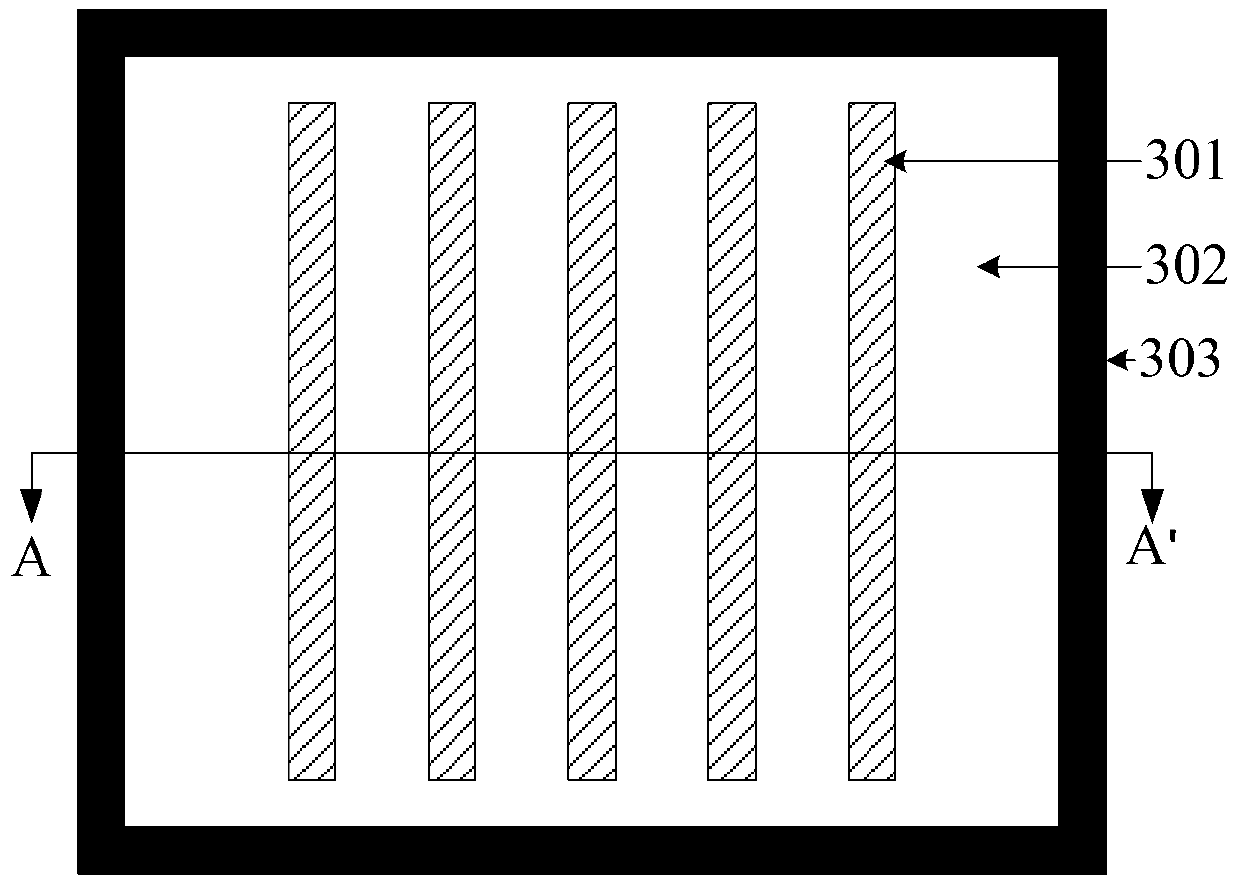

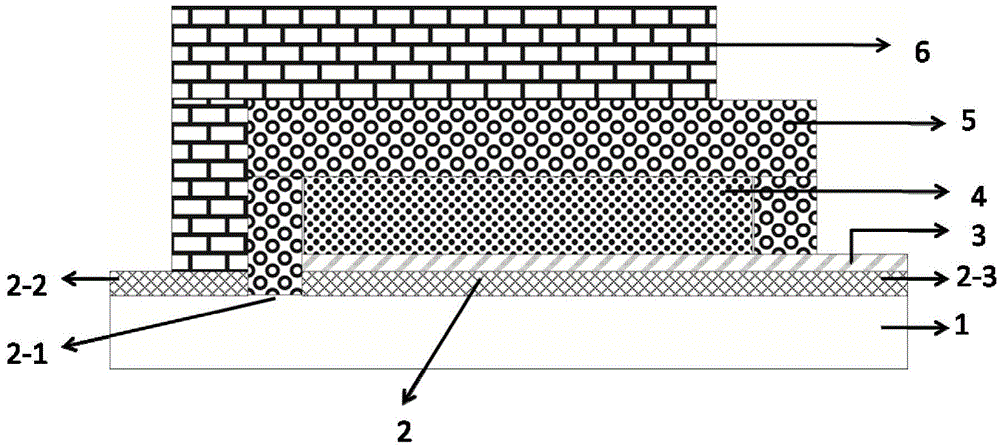

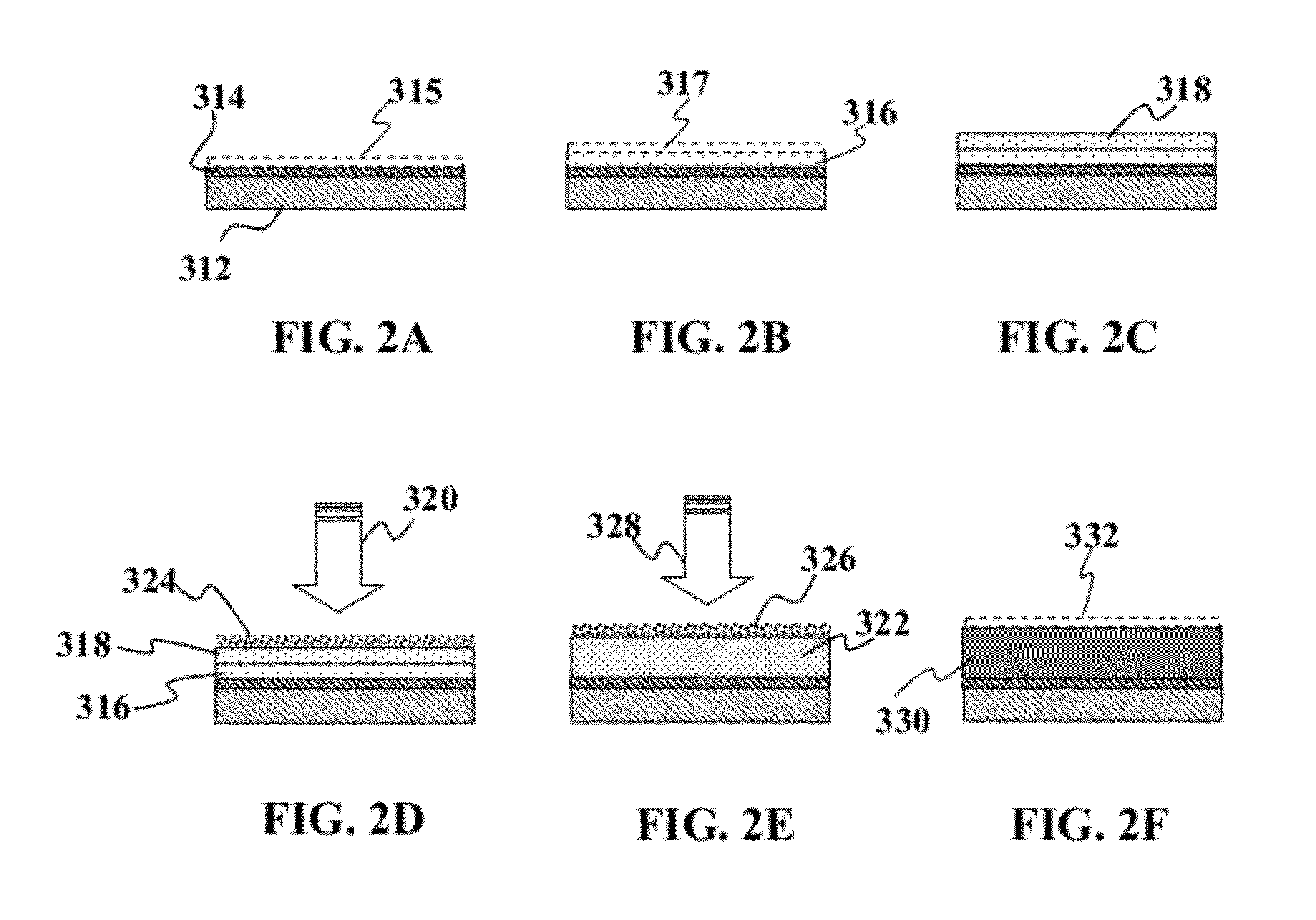

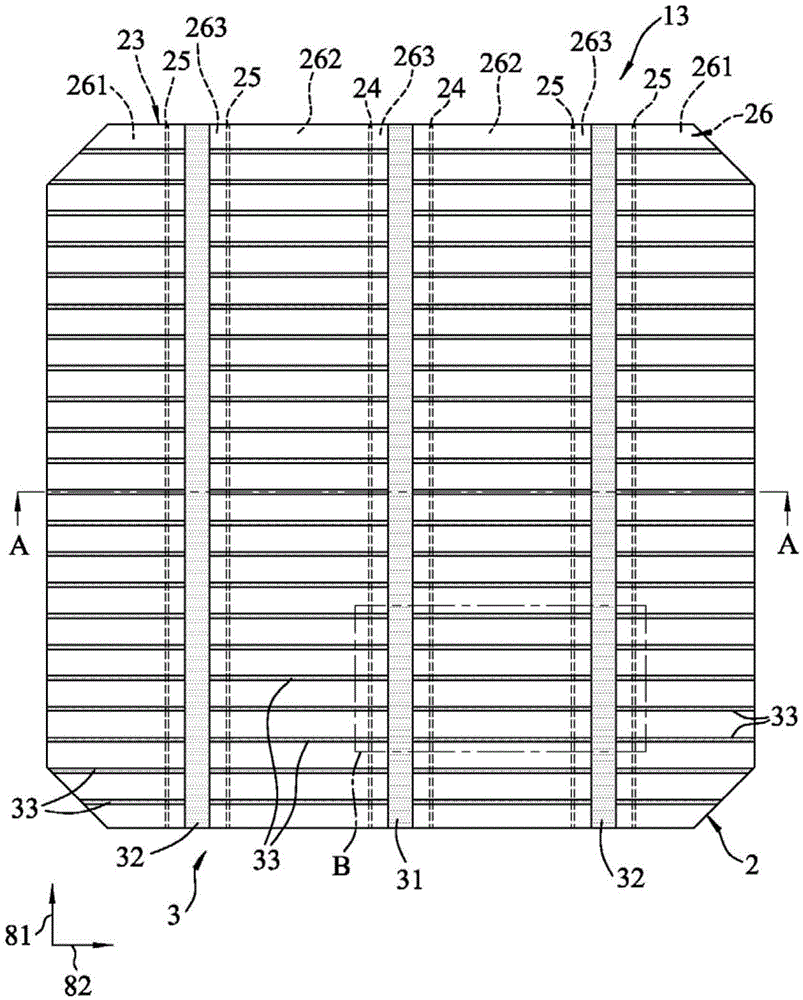

Back contact solar battery and preparing method thereof

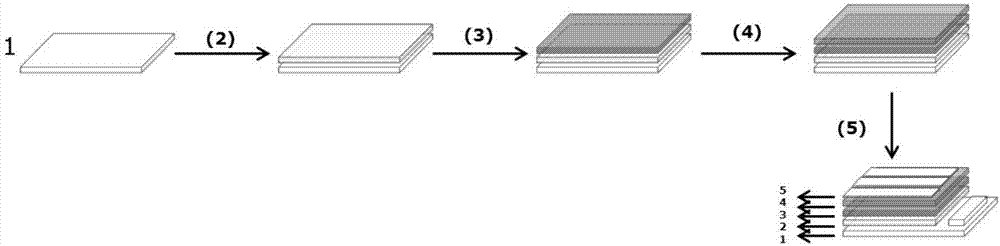

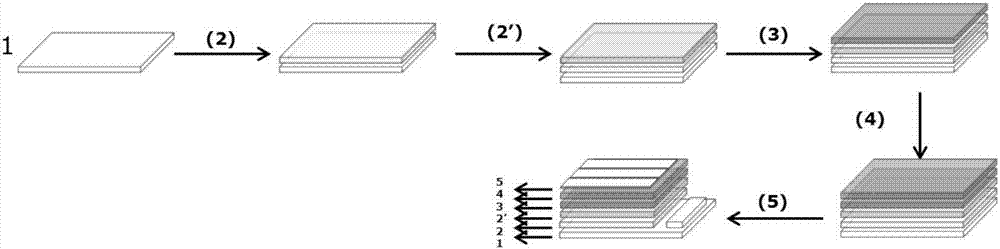

ActiveCN103346211ASimple manufacturing methodImprove electrical performancePhotovoltaic energy generationSemiconductor devicesAmorphous siliconEngineering

The invention provides a back contact solar battery and a preparing method of the back contact solar battery. The preparing method of the back contact solar battery includes the steps of providing a first mould slide boat and a second mould slide boat, wherein the first mould slide boat comprises first film growing areas and first shielding areas which are distributed alternatively, and the second mould slide boat comprises second film growing areas and second shielding areas which are distributed alternatively, the first film growing areas correspond to the second shielding areas, and the second film growing areas correspond to the first shielding areas. First doped amorphous silicon indication areas and second doped amorphous silicon indication areas are formed on the surfaces, with passivated layers, of monocrystalline silicon substrates through the mould slide boats, wherein the first doped amorphous silicon indication areas and the second doped amorphous silicon indication areas are opposite in doping type and crossed in distribution. By means of the preparing method, a fork structure of a back field of the back contact solar battery is achieved simply at low cost, additional manufacturing process of forming the passivated layers is needless, and the preparing method of the back contact solar battery is simplified.

Owner:YINGLI GRP +2

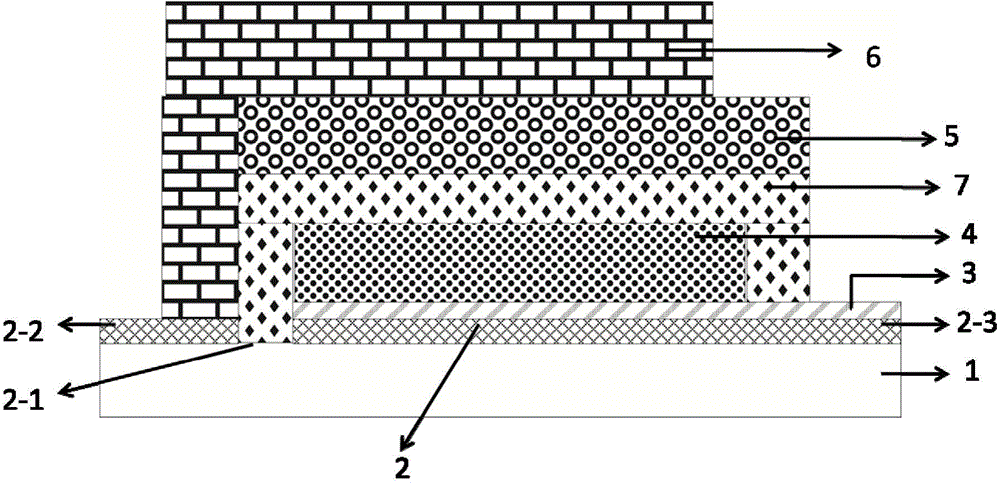

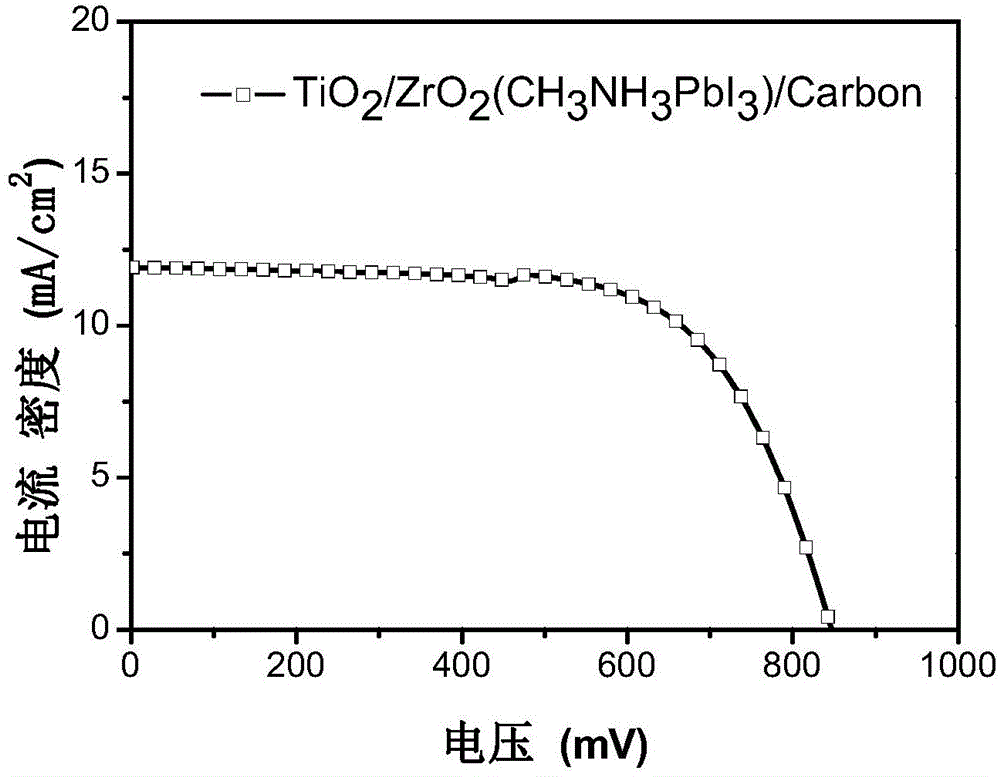

Semi-conductor perovskite solar cell and preparing method thereof

InactiveCN104091889AIncrease the open circuit voltageImprove fill factorSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellFill factor

The invention provides a semi-conductor perovskite solar cell and a preparing method thereof and belongs to the field of solar cells. The semi-conductor perovskite solar cell solves the problems that materials of an existing perovskite solar cell are high in price, and the process is complex, and meanwhile keeps the high photoelectric conversion efficiency. The semi-conductor perovskite solar cell sequentially comprises a substrate, a conducting layer, a hole barrier layer, a mesoporous electron collecting layer, a mesoporous hole collecting layer and a mesoporous back electrode layer from bottom to top. The preparing method of the semi-conductor perovskite solar cell comprises the steps of preparing an electrode region, the hole barrier layer, the mesoporous electron collecting layer, the mesoporous hole collecting layer, the mesoporous back electrode layer and light-absorbing materials filled with perovskite. According to the semi-conductor perovskite solar cell, a mesoporous insulating layer is additionally arranged, and the step of preparing the mesoporous insulating layer is added to the preparing method. The semi-conductor perovskite solar cell solves the problems that the materials of the existing perovskite solar cell are high in price, and the process is complex, and open-circuit voltage, short-circuit current and fill factors of the cell are increased.

Owner:HUAZHONG UNIV OF SCI & TECH

Multi-nary group ib and via based semiconductor

InactiveUS20120168910A1Increase the open circuit voltageLow costFinal product manufactureSemiconductor/solid-state device manufacturingSulfurSemiconductor alloys

Methods and devices are provided for forming multi-nary semiconductor. In one embodiment, a method is provided comprising of depositing a precursor material onto a substrate, wherein the precursor material may include or may be used with an additive to minimize concentration of group IIIA material such as Ga in the back portion of the final semiconductor layer. The additive may be a non-copper Group IB additive in elemental or alloy form. Some embodiments may use both selenium and sulfur, forming a senary or higher semiconductor alloy.

Owner:AERIS CAPITAL SUSTAINABLE IP

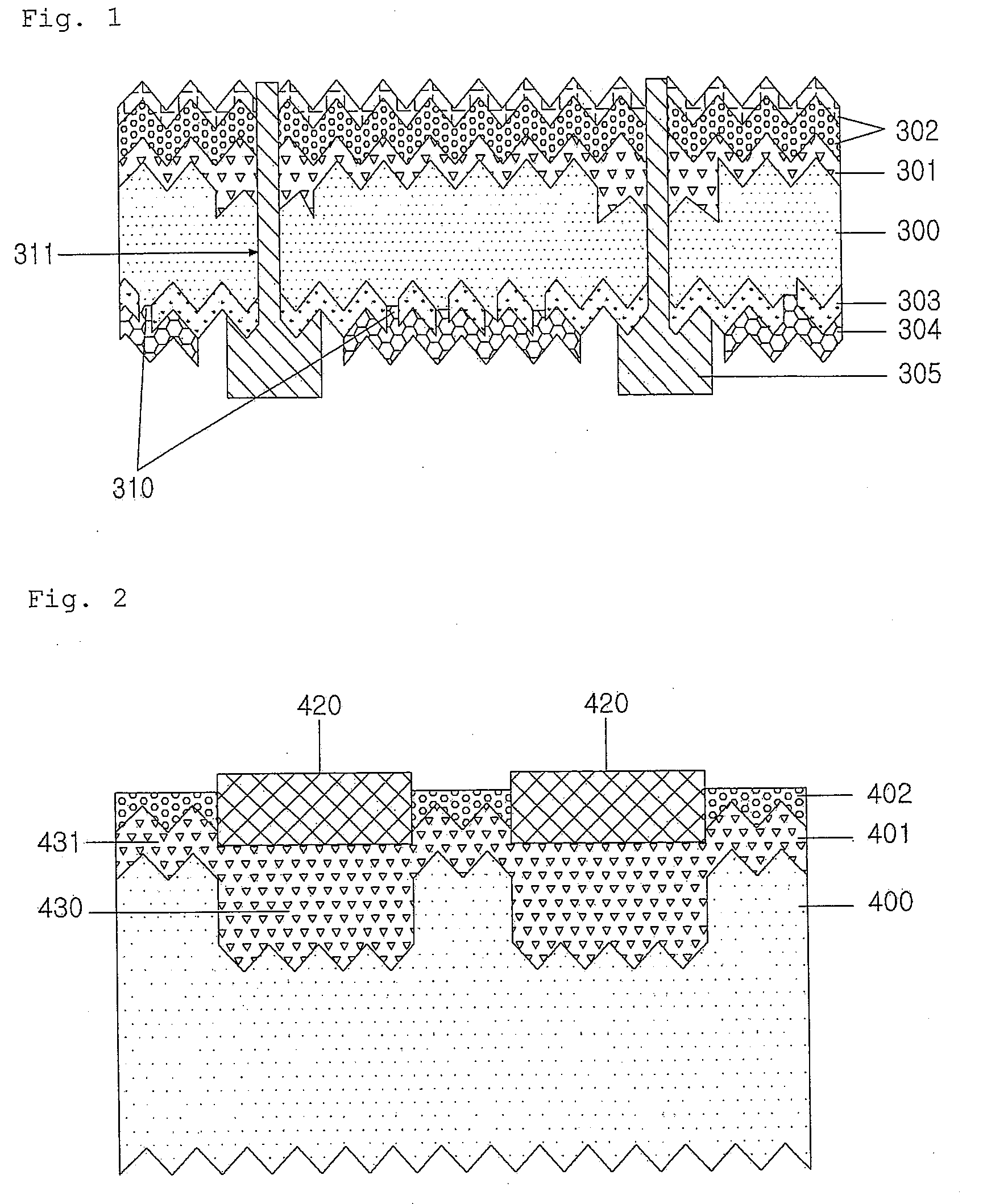

Photovoltaic device and manufacturing method thereof

InactiveUS6878921B2Simple interfaceJunction characteristics can be upgradedFinal product manufactureMaterial analysis by optical meansHydrogenThin layer

A photovoltaic device having a crystalline semiconductor and an amorphous semiconductor thin film so that junction characteristics can be upgraded. The photovoltaic device includes an i-type amorphous silicon thin film and a p-type amorphous silicon thin layer laminated in this order on a front surface of an n-type single crystalline silicon substrate, and an i-type amorphous silicon layer and an n-type amorphous silicon layer laminated in this order on a rear surface of the single crystalline silicon substrate, wherein an i-type amorphous silicon film is formed after the front surface of the single crystalline silicon substrate is exposed to a plasma discharge using mixed gas of hydrogen gas and a gas containing boron so that atoms of boron may be interposed on an interface between the single crystalline silicon substrate and the i-type amorphous silicon layer.

Owner:SANYO ELECTRIC CO LTD

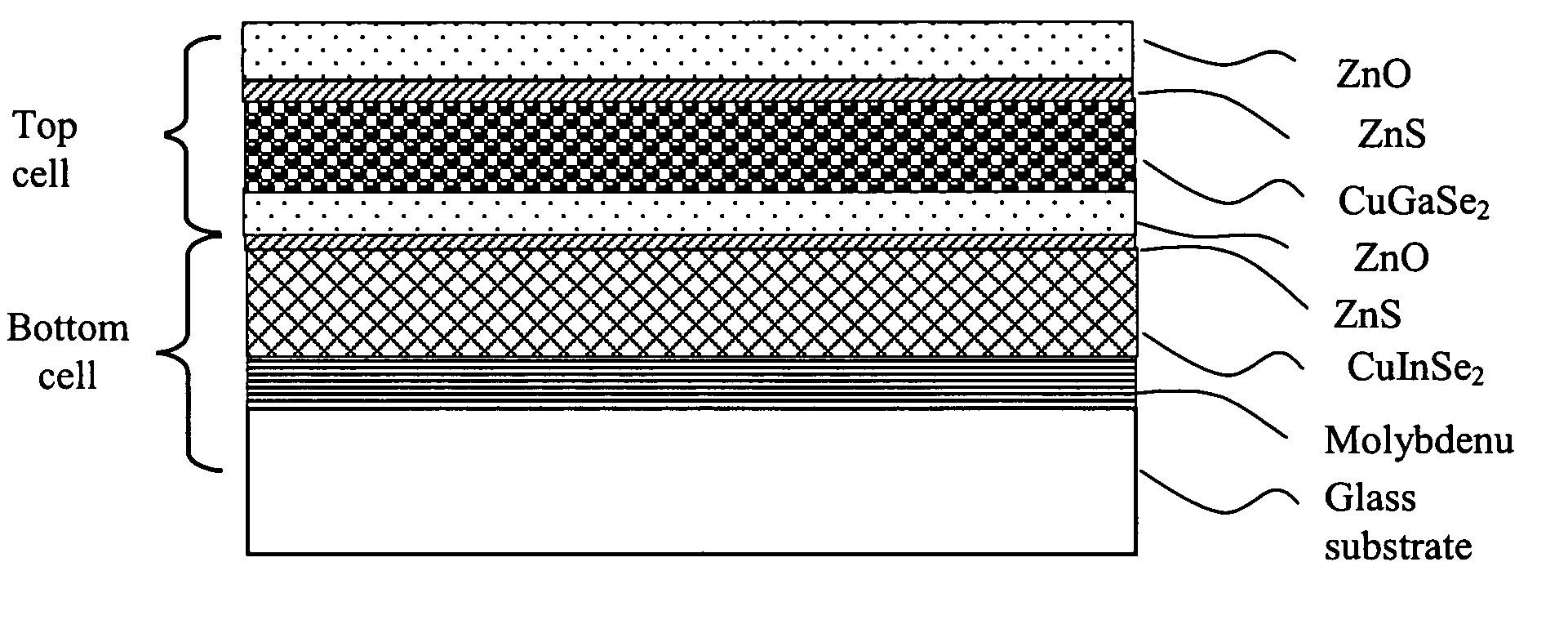

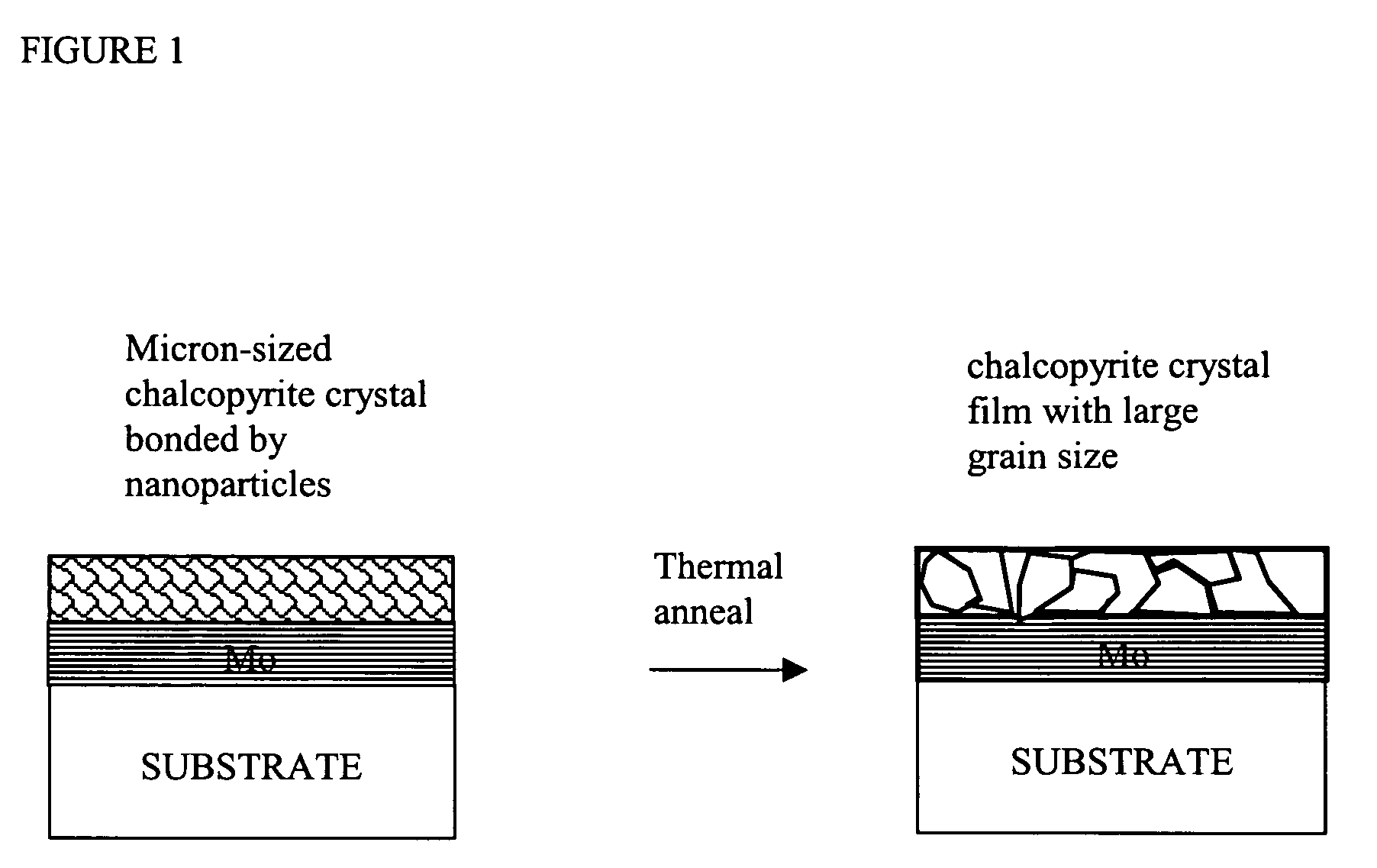

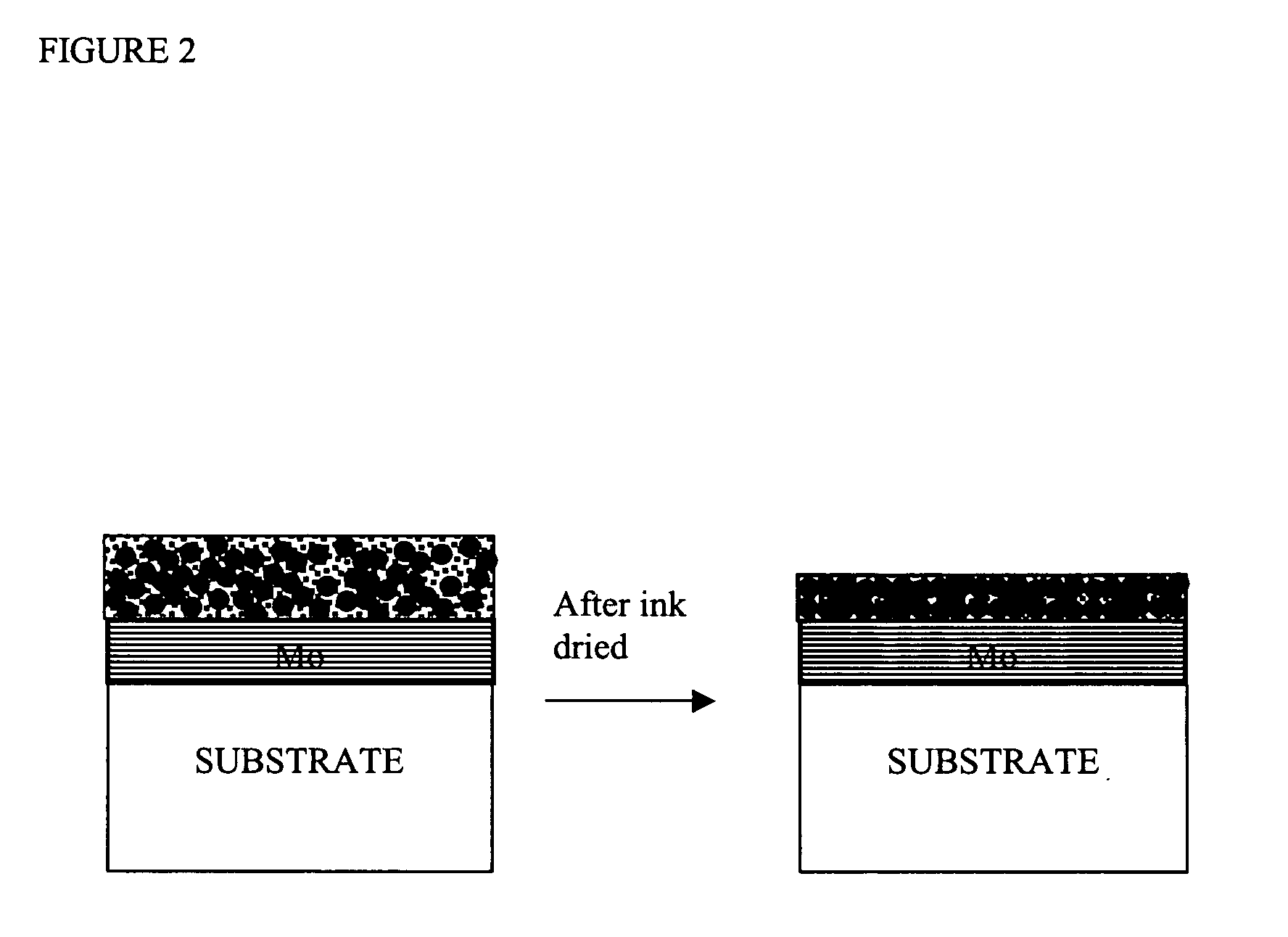

Manufacture of thin solar cells based on ink printing technology

ActiveUS20110065228A1Increase the open circuit voltageLoss can be compensatedFinal product manufactureSemiconductor/solid-state device manufacturingBrickTandem solar cell

Semiconductor ink is disclosed for use in printing thin film solar cell absorber layer. The semiconductor ink is particularly useful in fabricating multi junction tandem solar cell wherein a high bandgap absorber layer as the top cell and a lower band gap absorber layer as the bottom cell. The ink contains ingredients of IB-IIIA-VIA compound with micron-sized semiconductor as the main building “bricks” and nano-sized semiconductor as the binder to fulfill the formation of smooth semiconductive film with micron-sized crystal grain size. Thus formed ink can be used in direct printing for the fabrication of low cost high performance solar cells.

Owner:GUANMAT OPTOELECTRONIC MATERIALS (JIANGXI) INC

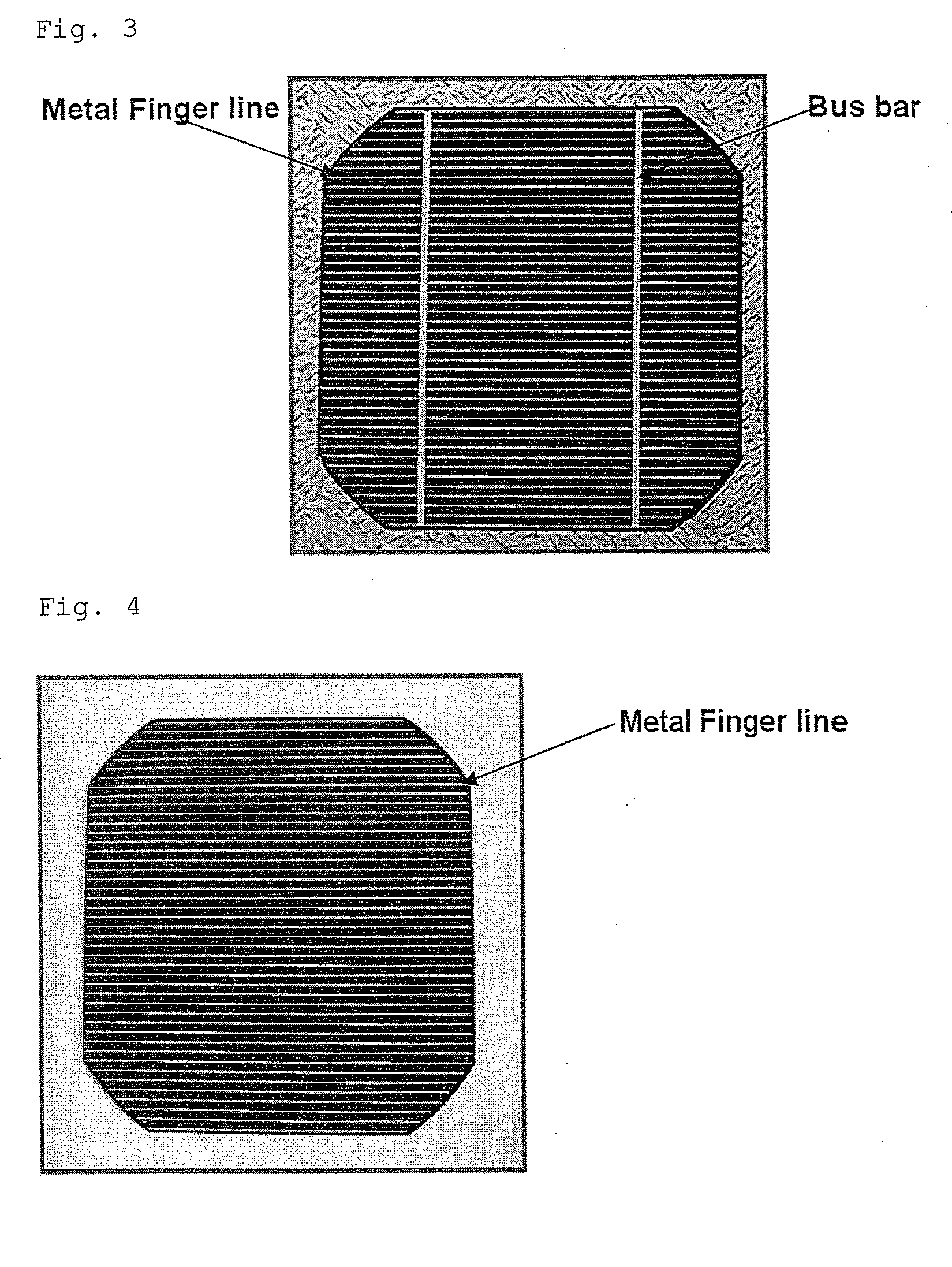

Solar cell and solar cell module group

InactiveCN104810412AImprove collection efficiencyReduce the chance of compoundingPhotovoltaic energy generationSemiconductor devicesCharge carrierPower flow

The invention discloses a solar cell and a solar cell module group. The solar cell comprises a substrate, a positive electrode, and a back electrode. The substrate comprises a light-receiving surface where the positive electrode is arranged, a back surface where the back electrode is arranged, and an emitter electrode layer which is located on the light-receiving surface and is provided with a heavily doped region and a light doped region. The positive electrode comprises a first convergence electrode, a second convergence electrode, and a plurality of finger-shaped electrodes. The heavily doped region is provided with a first heavily doped part and a second heavily doped part, which are located between the first convergence electrode and the second convergence electrode. The solar cell can improve the collection efficiency of charge carriers, and reduces the recombination probability of charge carriers, thereby improving the collection efficiency of current, and improving the photoelectric conversion efficiency and open-circuit voltage of the solar cell.

Owner:MOTECH INDUSTRIES

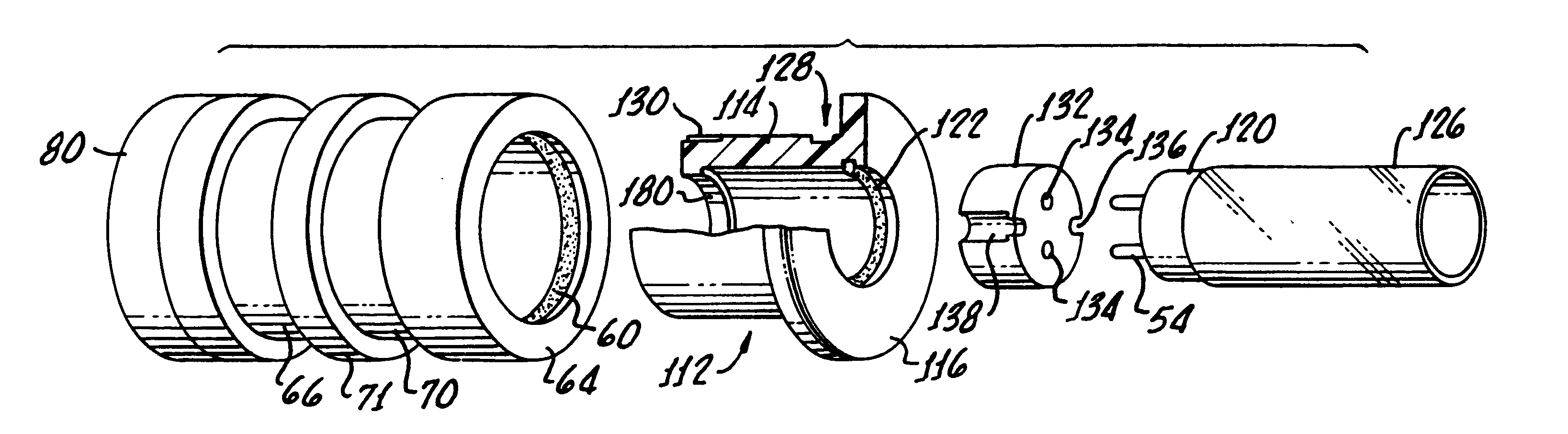

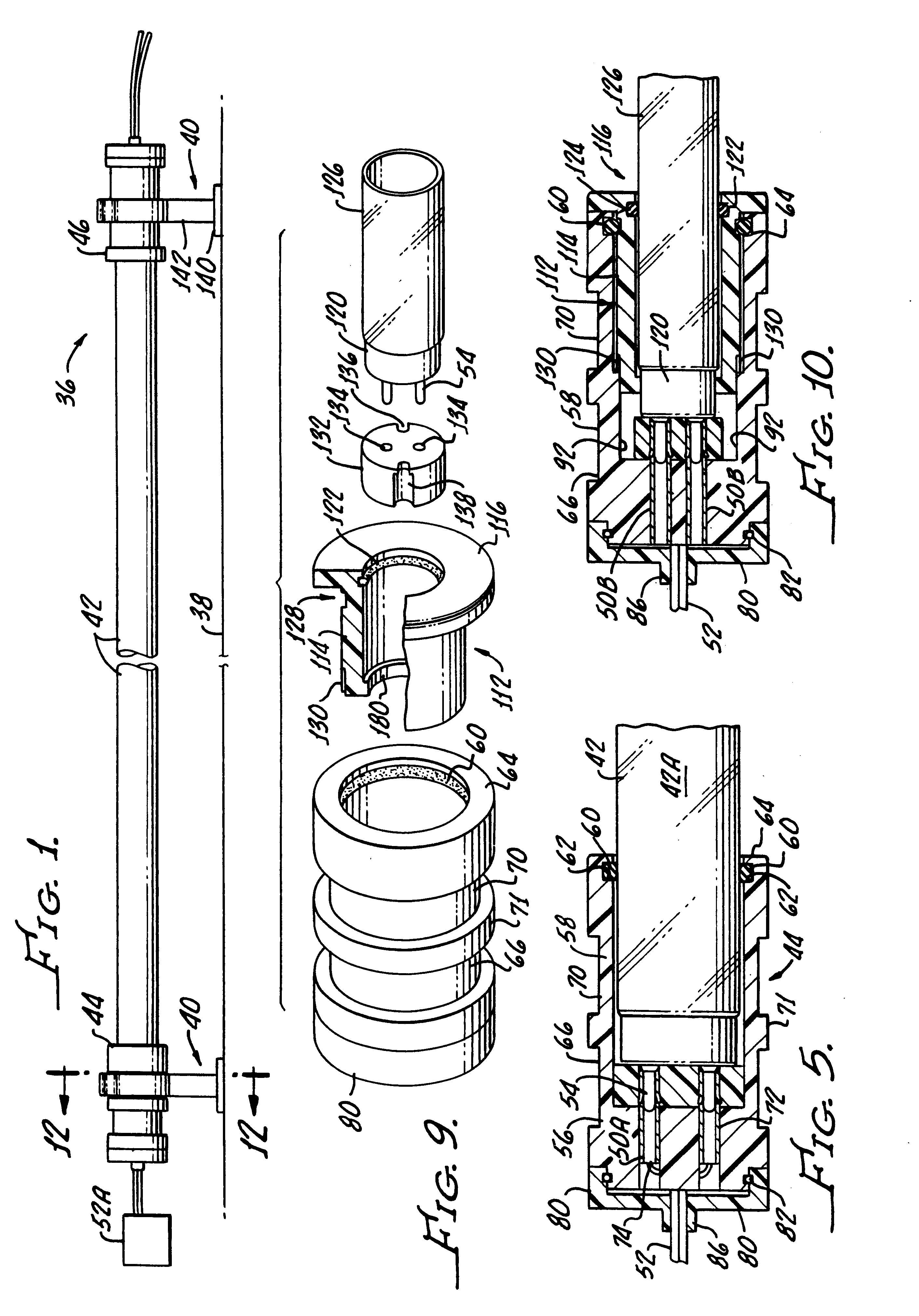

Lighting system method and apparatus socket assembly lamp insulator assembly and components thereof

InactiveUS6632100B1High open circuit voltageGreat flexibilityCoupling device connectionsMechanical apparatusLighting systemEnvironmental effect

A socket is described for a lighting assembly having a socket body and an electrical connector with a seal in the socket to seal around a light source. The socket is preferably configured to be independent of the mounting arrangement for the lighting assembly. An insulator is also disclosed for a lamp such as a fluorescent lamp having a body which covers the contact on the lamp so as to form a recessed lamp conductor. The combination of a socket and lamp insulator is also disclosed for providing a socket and insulator assembly for reducing the possibility of injury or damage due to high open circuit voltage, environmental effects and the like. Additionally, a lighting assembly is disclosed incorporating the insulator, socket and mounting arrangements.< / PTEXT>

Owner:ANTHONY INC

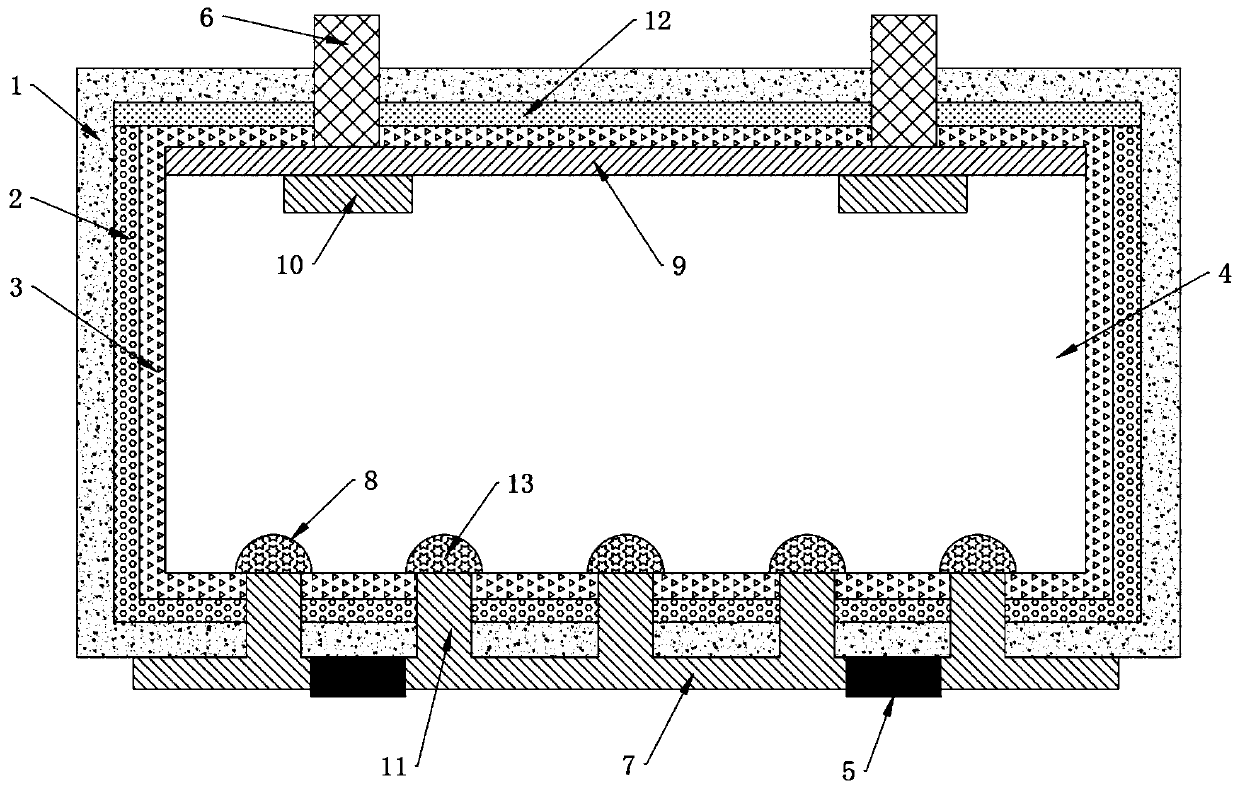

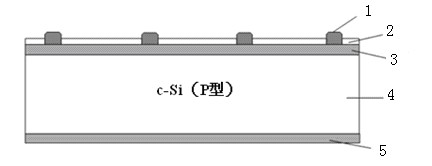

Solar cell with composite dielectric passivation layer structure and preparation process thereof

PendingCN110459615AIncrease short circuit currentIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationDielectricRefractive index

The invention discloses a solar cell with a composite dielectric passivation layer structure and a preparation process thereof. A silicon oxide film, an alumina film and a silicon nitride or silicon oxynitride film are deposited in turn on the front, back and sides of a p-type silicon substrate to form a composite dielectric film on the whole surface, and windows are opened locally to lead electrodes out. Through aluminum oxide, silicon dioxide, silicon oxynitride, silicon nitride with different refractive indexes and a back surface passivation layer with a laminated structure of the materials, the back surface recombination rate is greatly reduced, the back reflectivity is improved, the CTM of a module is reduced, and the light attenuation and heat-assisted light attenuation and the anti-PID performance of the cell are improved. The structure can be made on a boron / gallium-doped p-type monocrystalline silicon, p-type polycrystalline silicon or p-type monocrystalline-silicon-like substrate, and a passivation method based on the composite dielectric film passivation structure can be used to manufacture PERC cells, double-sided PERC+ cells and imbricate PERC cells. Based on the preparation process steps and sequence, the corresponding preparation mode and the process parameter range of the laminated structure, the making of the cell can be well completed.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID +2

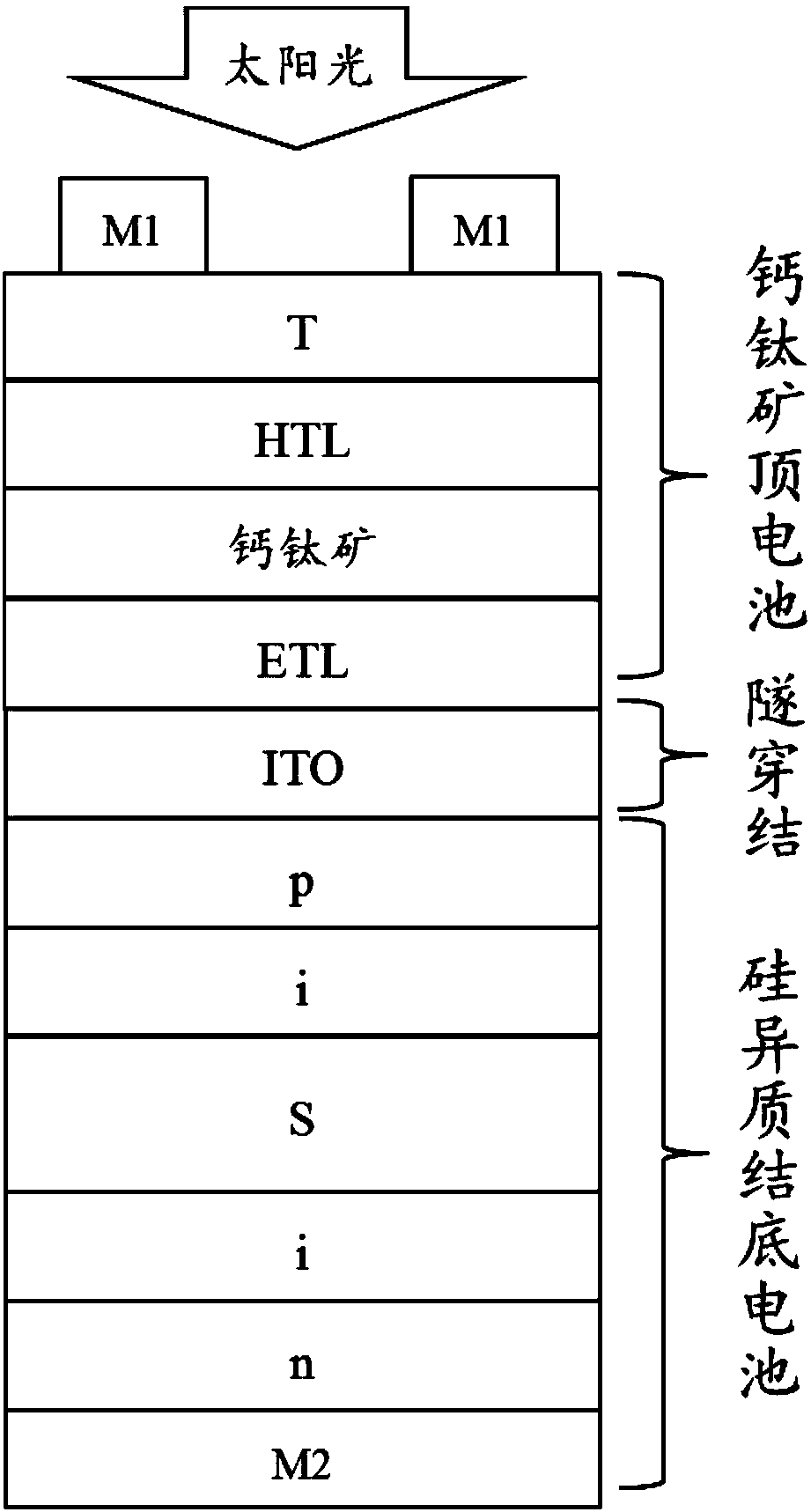

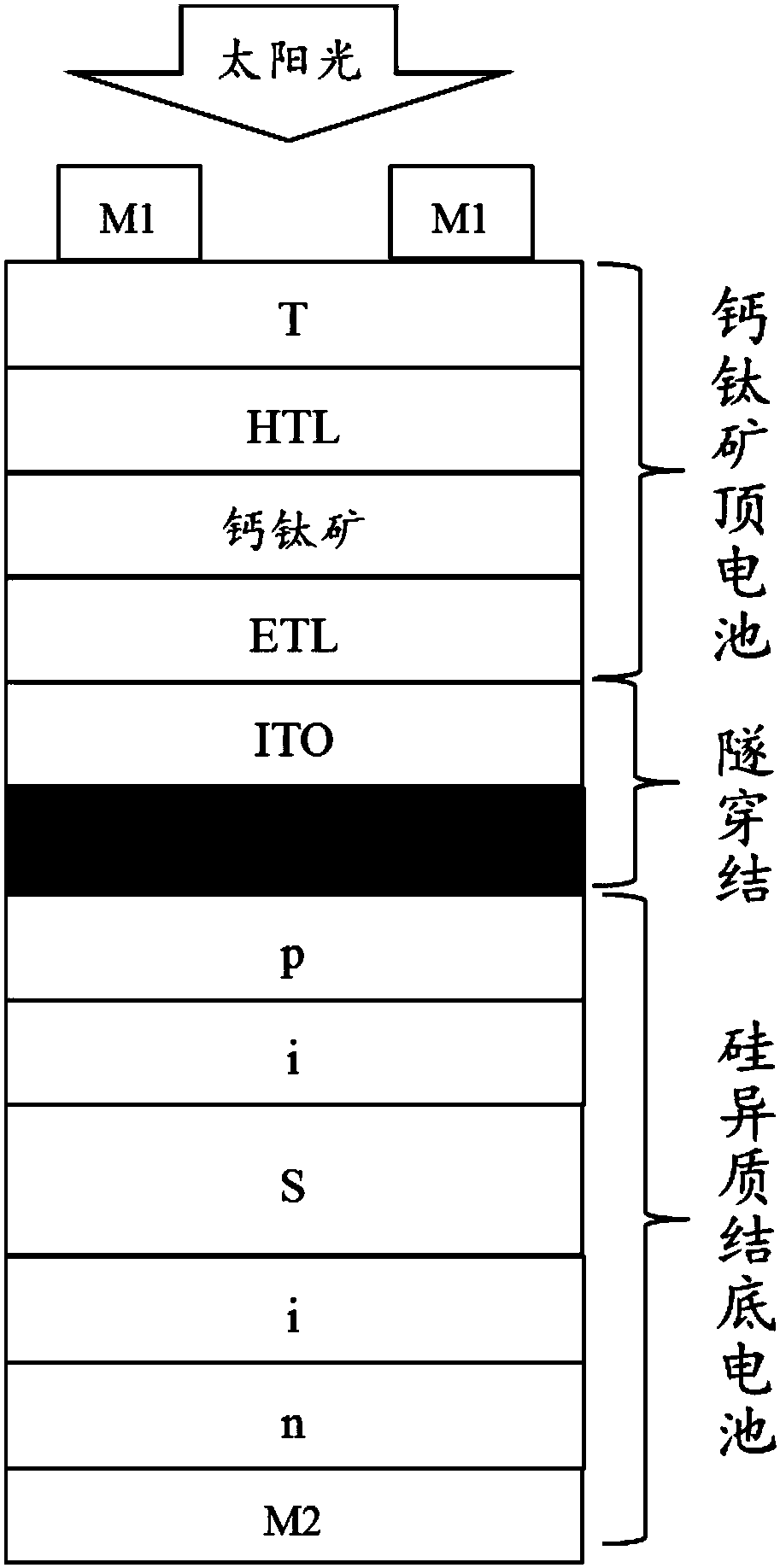

Structure design of tunnel junction in Perovskite/silicon heterojunction lamination solar battery

InactiveCN107564989AFacilitate hole extractionSmall pressure drop lossFinal product manufactureSolid-state devicesHeterojunctionValence band

The invention provides a structure design of tunnel junction in Perovskite / silicon heterojunction lamination solar battery, which relates to the field of solar batteries. A tunneling composite layer TRL with narrow band gap and high doping concentration is added at the junction of the top and bottom part of a lamination battery, and the quite small energy level difference between the conduction band and the valence band can effectively strengthen the carrier recombination at the tunneling junction. The gradient band order at the bottom battery p layer and the tunneling junction can effectivelyenhance the cavity draw-off of the bottom battery and the tunneling junction, and thereby a large amount of charge accumulation among the tunneling junction interfaces can be prevented. After the adding of the TRL having high doping concentration, the defect density of states at the tunneling junction is increased. The electronic cavity assists tunneling through defects, and the probability of recombination and tunneling can be increased. With the adoption of the heterojunction, the spectrum response of the bottom battery can be effectively enhanced, and the opening and pressing loss can be reduced. The preparation method is simple and easy to carry out.

Owner:NANKAI UNIV +1

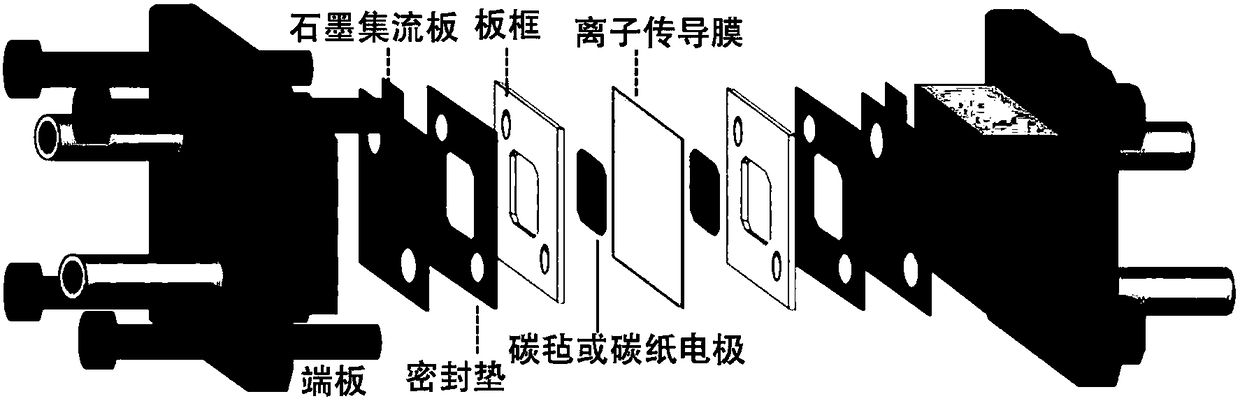

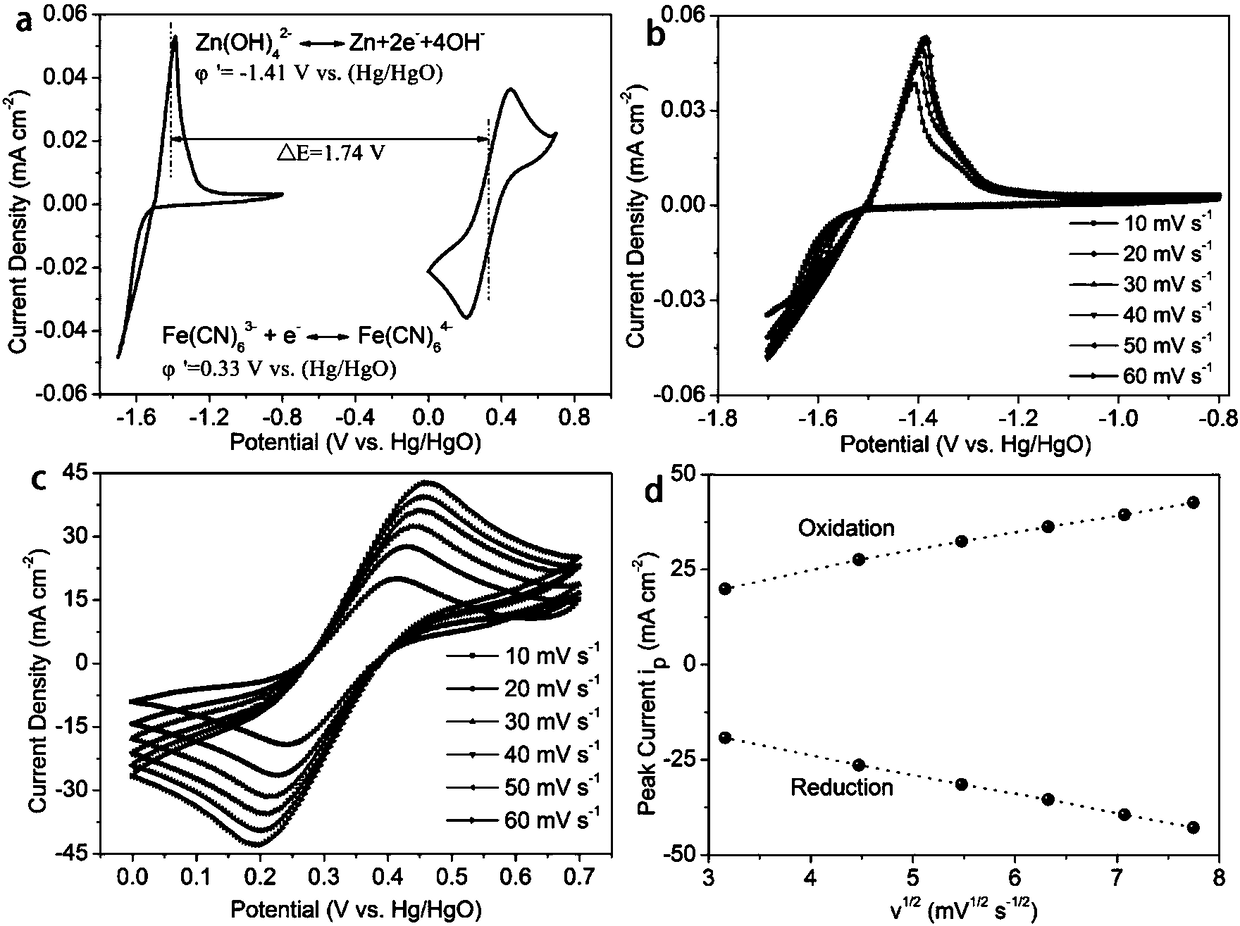

Alkaline zinc-iron flow battery

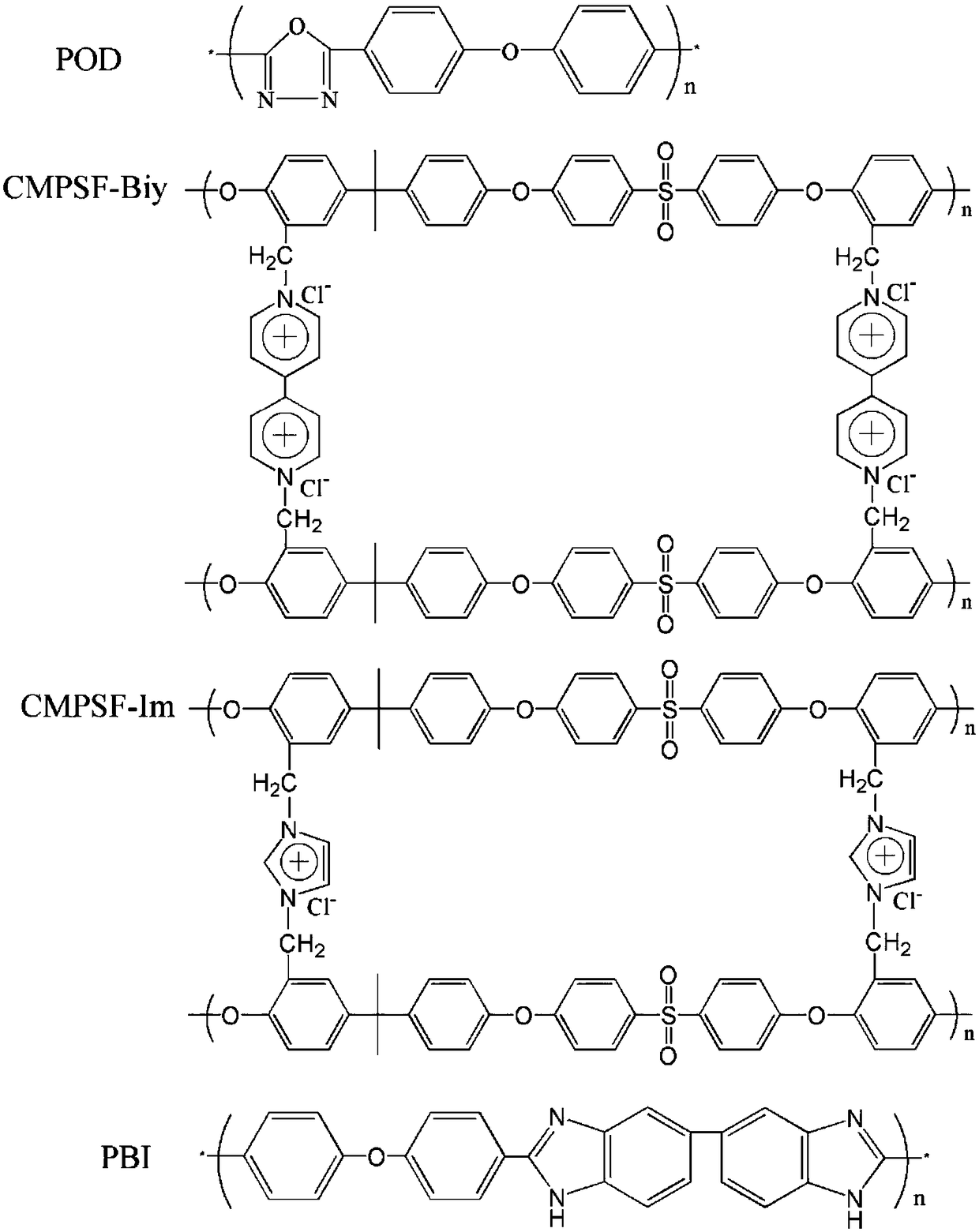

InactiveCN108461784ARich reservesLow costCell electrodesRegenerative fuel cellsHigh energyCarbon felt

The invention relates to an alkaline zinc-iron flow battery, wherein an ion conduction membrane is prepared from an aromatic polymer containing nitrogen heterocycle, electrodes are carbon felt or carbon paper, a positive electrode electrolytic solution is the mixed aqueous solution of ferrocyanide and strong alkali, a negative electrode electrolytic solution is the mixed aqueous solution of a zincsalt or / and a zinc oxide and strong alkali, the concentrations of the strong alkalis in the positive electrode electrolytic solution and the negative electrode electrolytic solution are 0.001-10 mol / L, and the concentrations of the active substances in the positive electrode electrolytic solution and the negative electrode electrolytic solution are 0.001-3 mol / L. According to the present invention, a class of the alkaline zinc-iron flow batteries with characteristics of high energy density, high power density and long service life are provided, wherein the performance of the batteries is comparable to or superior to the current mature all-vanadium flow batteries, and the batteries have good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

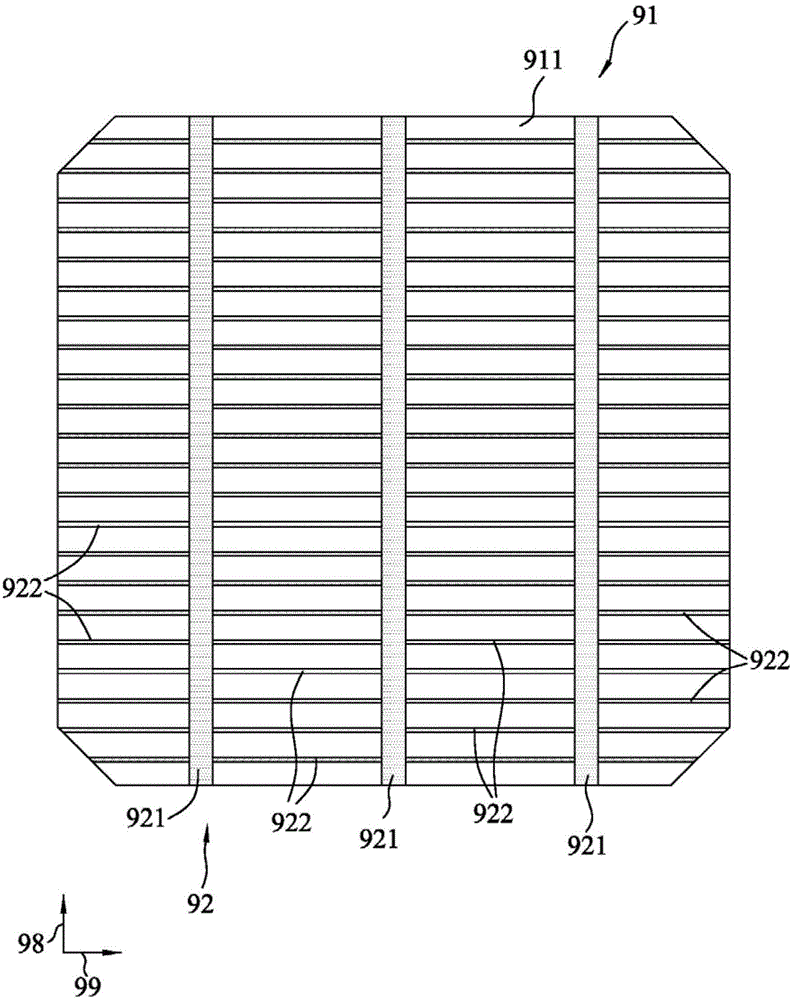

Low-cost efficient solar cell electrode grid line structure

The invention discloses a low-cost efficient solar cell electrode grid line structure which comprises two parts of main grid lines and thin grid lines, wherein the main grid lines are symmetrically distributed by taking a silicon wafer center as a center, the thin grid lines are equidistantly distributed in the way of being vertical to the main grid lines in parallel, the main grid lines adopt a sectional type design, and all the subsections are connected by thin lines. The electrode grid line structure adopts a design that the grid lines are thinned, the shading areas of the grid lines are reduced, the number of the grid lines is increased so that the lateral transmission loss of a carrier is lowered and the collection efficiency of the carrier is increased; moreover, the main grid lines are divided into sections, thinned and hollowed out additionally, so the silver usage is reduced, the manufacturing cost of a solar cell is reduced, meanwhile, the contact area compound is lowered, accordingly, the open-circuit voltage of the solar cell is increased, and the cost is greatly lowered; and compared with the widespread products of the industry, in the design scheme which is obtained by optimizing the scheme, the shading area of the grid lines on the front side of the solar cell is reduced by about 1%, the conversion efficiency is improved by 0.2-0.3%, and the silver paste consumption is reduced by about 35%.

Owner:JA SOLAR TECH YANGZHOU

Method for preparing colorful film for protecting solar cell thin grid line metal electrode by adopting mask

InactiveCN101834230ANot easily oxidizedGuaranteed electrical conductivityFinal product manufactureSemiconductor devicesButt jointMetal electrodes

The invention relates to a method for preparing a colorful film for protecting a solar cell thin grid line metal electrode by adopting a mask. In the method, after a solar cell is prepared, a mask is utilized to cover a main grid line metal electrode on the front surface of the solar cell, a film is coated on the area which is not covered by the mask for the second time, and a dielectric layer for protecting the thin grid line metal electrode is prepared to form a structure comprising the dielectric layer, the thin grid line metal electrode and a passivation layer. The method can protect the thin grid line metal electrode against easy oxidation, and the main grid line metal electrode can be normally connected by welding rods. The passivation effect of the front surface can be enhanced through optimizing the passivation layer; the reflectivity of the front surface of the solar cell can be reduced and color regulation can be realized through regulating the dielectric layer; and characters, figures, graphics and the like can be displayed on the front surface of the solar cell through changing a mask pattern. In addition, the secondary film coating method is convenient to be in butt joint with the traditional crystalline silicon solar cell preparation process and is easy for industrialization.

Owner:SUN YAT SEN UNIV

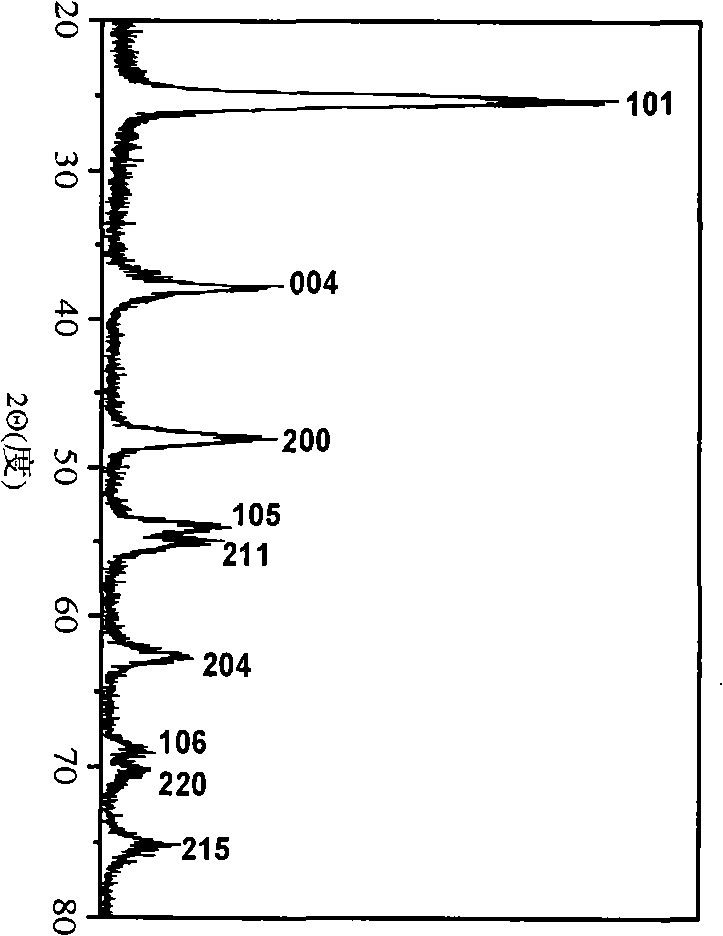

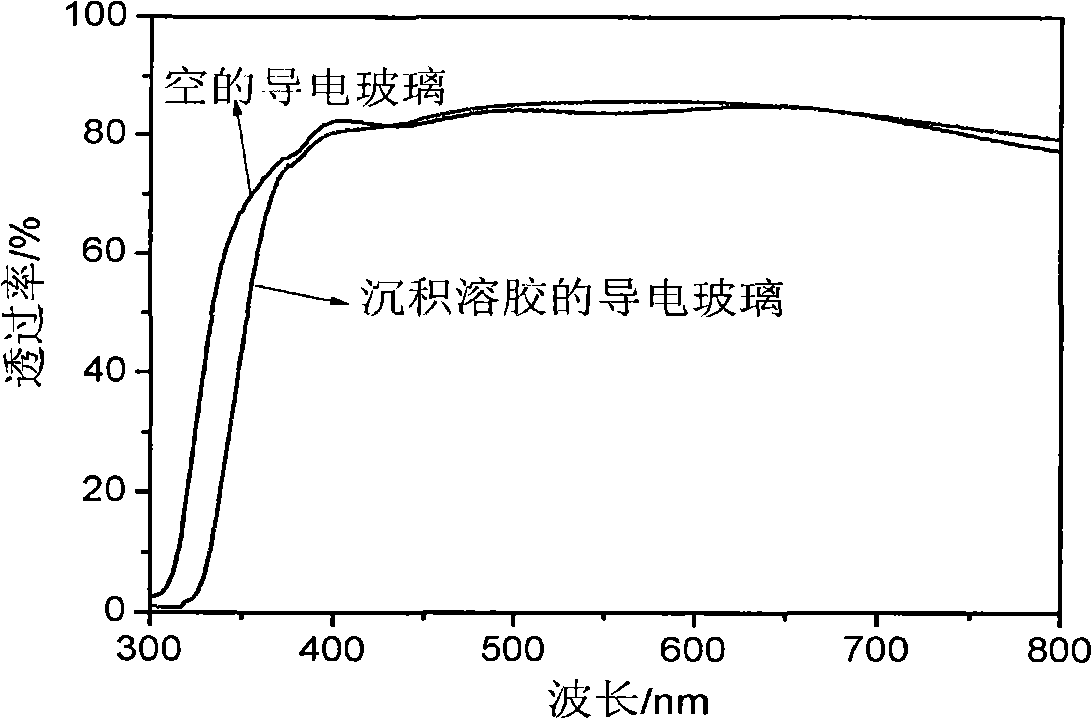

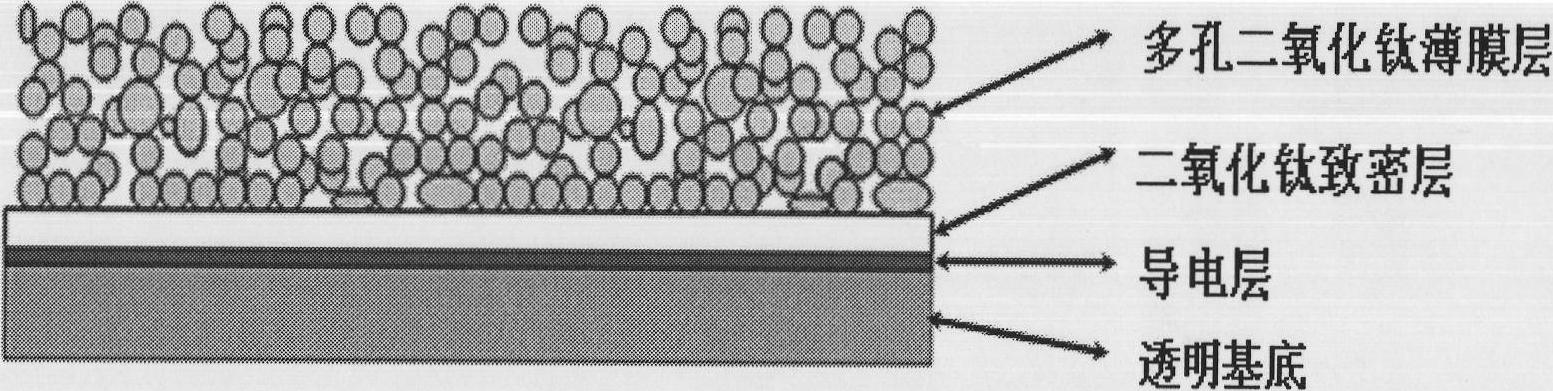

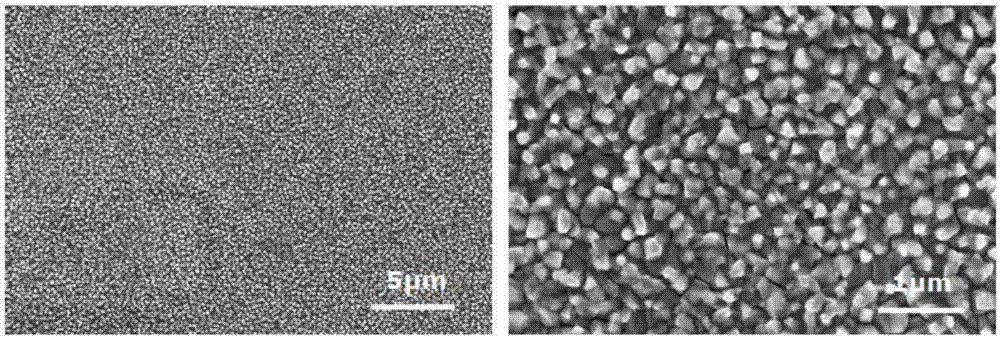

Preparation method of photo anode of dye-sensitized solar cell with optical gradient

InactiveCN101794670AReduce chance of recombinationUniform particle size distributionLight-sensitive devicesSolid-state devicesSpray coatingHYDROSOL

The invention relates to a preparation method of photo anode of dye-sensitized solar cell with optical gradient, comprising the following steps: (1), adding sodium hydroxide or ammonia water into the inorganic titanium slat used as the precursor to generate the precipitation, washing the precipitation with water to acquire solid in the gel manner, peptizing the same to prepare the pale yellow transparent solution, diluting the prepared solution, and performing hydro-thermal process on the same so as to prepare the transparent TiO2 solution of anatase phase; (2), depositing a TiO2 compact layer on a conductive substrate by spin-coating, dipping / coating or casting method; (3), depositing a layer of porous TiO2 film on the TiO2 compact layer by screen printing, blade coating method or spray coating method; and (4), calcining the film with two structure so as to form the photo anode with optical gradient. In the invention, the colloidal sol for preparing the transparent compact layer does not contain any organic matter and other impurities; the high temperature sintering is not required; the blocking layer formed between the conductive layer and the porous film blocks the corrosion of electrolyte on the substrate; and the preparation method has excellent application foreground.

Owner:DONGHUA UNIV

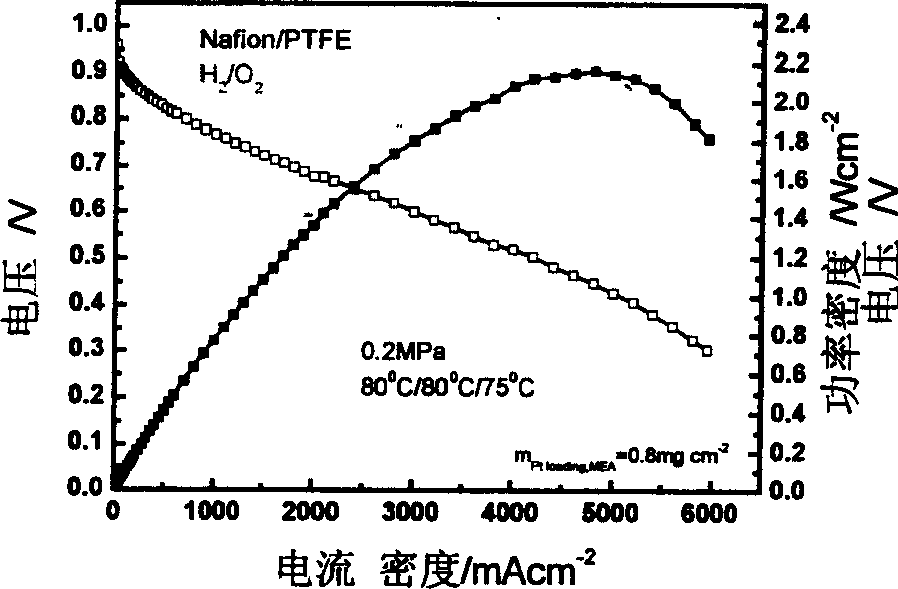

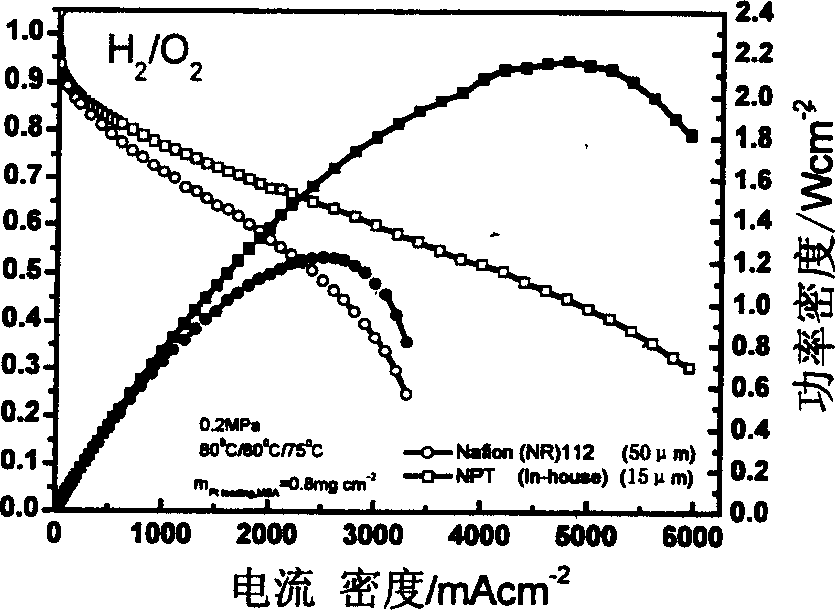

Composite proton exchange membrane synthesizing method for fuel cell

ActiveCN1845363AThe synthesis method is simpleSimple methodCell electrodesElectrolysisSynthesis methods

The related synthesis method for composite proton exchange membrane on fuel cell comprises: taking surface modification to the porous teflon membrane to reduce water contact angle and enhance wettability, and dipping into mid / low-boiling point solvent for standby; sealing and heating the solid macromolecular electrolyte with high-boiling point solvent, and adding mid / low boiling point solvent to prepare solution; casting on the film, and heating to volatilize the solvent for crystallizing heat treatment. This invention has well physical and chemical performance.

Owner:SUNRISE POWER CO LTD

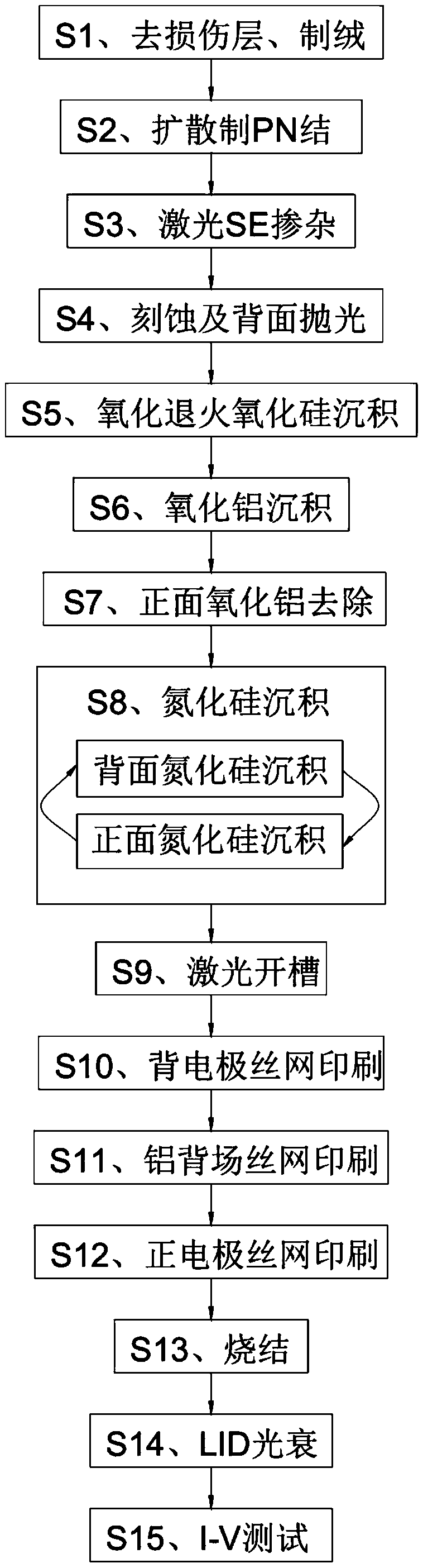

Novel crystalline silicon solar cell and manufacturing method thereof

InactiveCN102064216AImprove surface passivation effectReduce surface recombination rateFinal product manufacturePhotovoltaic energy generationHeterojunctionMaterials science

The invention discloses a novel crystalline silicon solar cell. The novel crystalline silicon solar cell comprises a crystalline silicon matrix, wherein the front surface of the crystalline silicon matrix has an emitter structure, and the back surface of the crystalline silicon matrix has a heterojunction structure; the heterojunction structure comprises an intrinsically hydrogenated amorphous silicon film, a hydrogenated amorphous silicon film, a transparent conductive oxide film and a metal conductive electrode in turn; the intrinsically hydrogenated amorphous silicon film covers the entire back surface of the crystalline silicon matrix; the hydrogenated amorphous silicon film is heavily doped by using a dopant which has the same conduction type as that of the matrix; and the metal conductive electrode passes through the transparent conductive oxide film and is in ohmic contact with a heavily doped layer. The invention also discloses a manufacturing method of the crystalline silicon solar cell. The crystalline silicon solar cell with the structure can reduce composite loss on the surface; meanwhile, the back surface of the solar cell forms a better light trap structure to improve open-circuit voltage of the solar cell, so that conversion efficiency of the solar cell is improved.

Owner:JA SOLAR TECH YANGZHOU

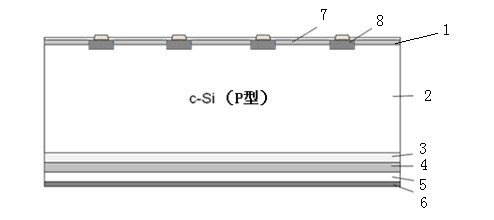

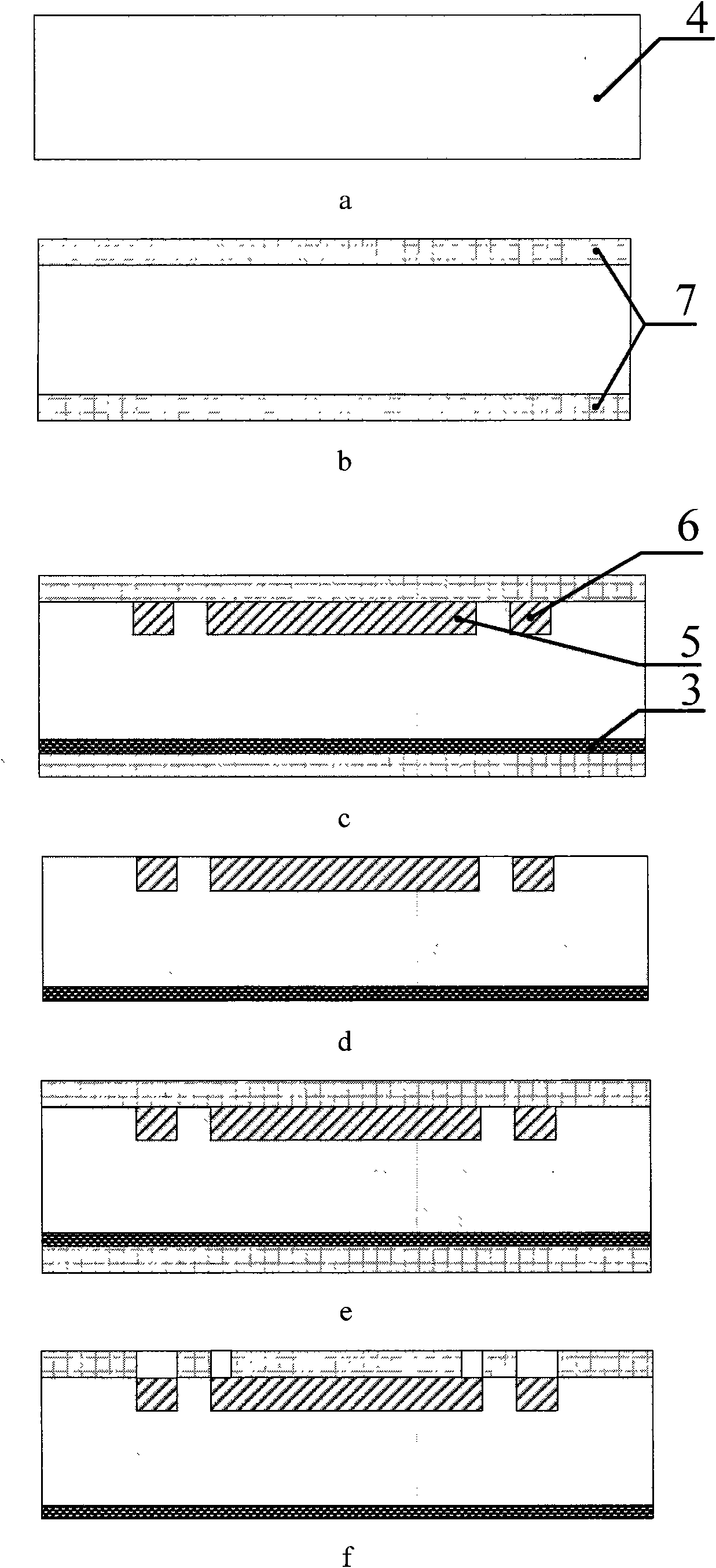

Micro nuclear battery with protection ring structure and manufacturing method thereof

InactiveCN101599308ASmall temperature changeImprove energy conversion efficiencyRadiation electrical energyElectrical batteryEngineering

The invention discloses a PN junction or PIN junction type micro nuclear battery and a manufacturing method thereof, belonging to the fields of semiconductor, nuclear physics and micro energy source. The battery is provided with a protection ring 6 in the periphery ring-shaped region of a p+ type semiconductor layer 5 on the basis of traditional PN junction or PIN junction type micro nuclear battery; meanwhile a protection ring contact electrode 8 is arranged above the protection ring 6 for leading an electrical signal out; in addition, the manufacturing method of the nuclear battery is also disclosed. In the micro nuclear battery disclosed by the invention, the added protection ring inhibits surface leakage and influence of interface state current on radiation induced current, indirectly increases open circuit voltage, and also improves sensibility of elements on low-energy radioactive source, thus improving energy conversion efficiency of elements.

Owner:江苏福克斯电气集团有限公司 +1

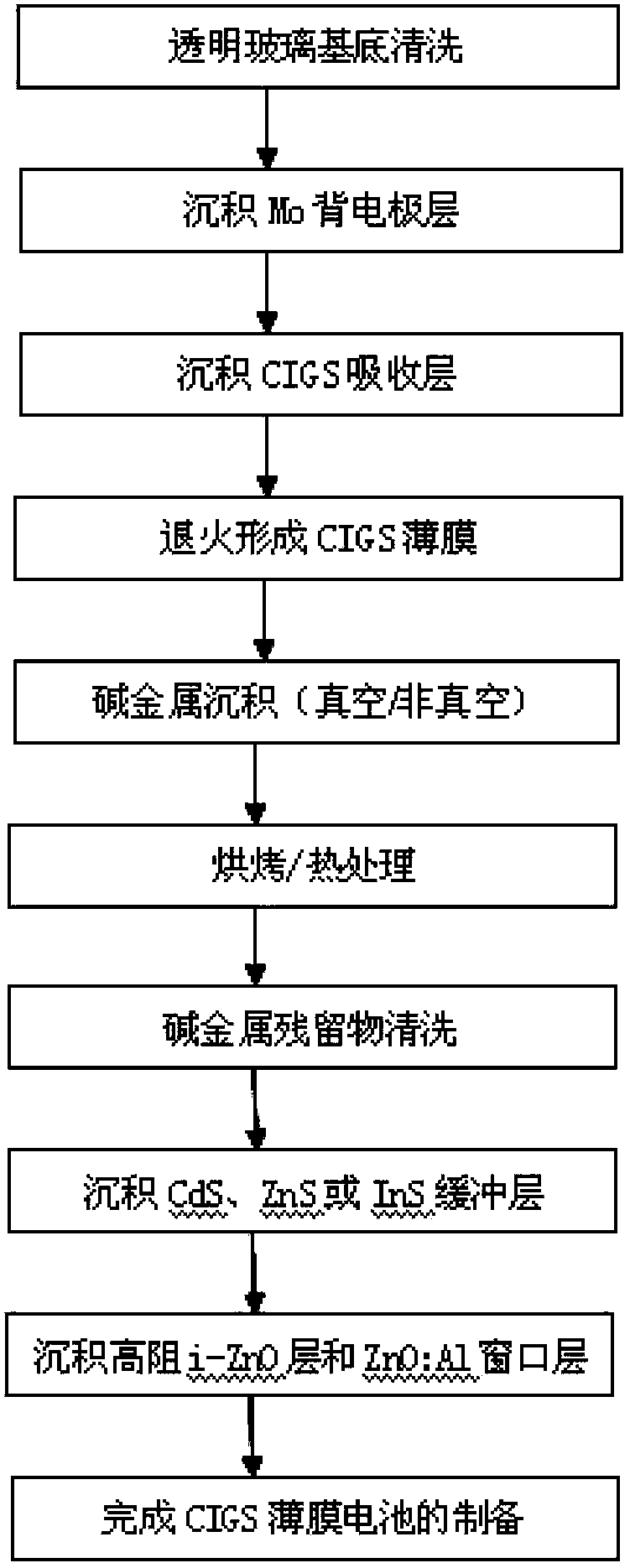

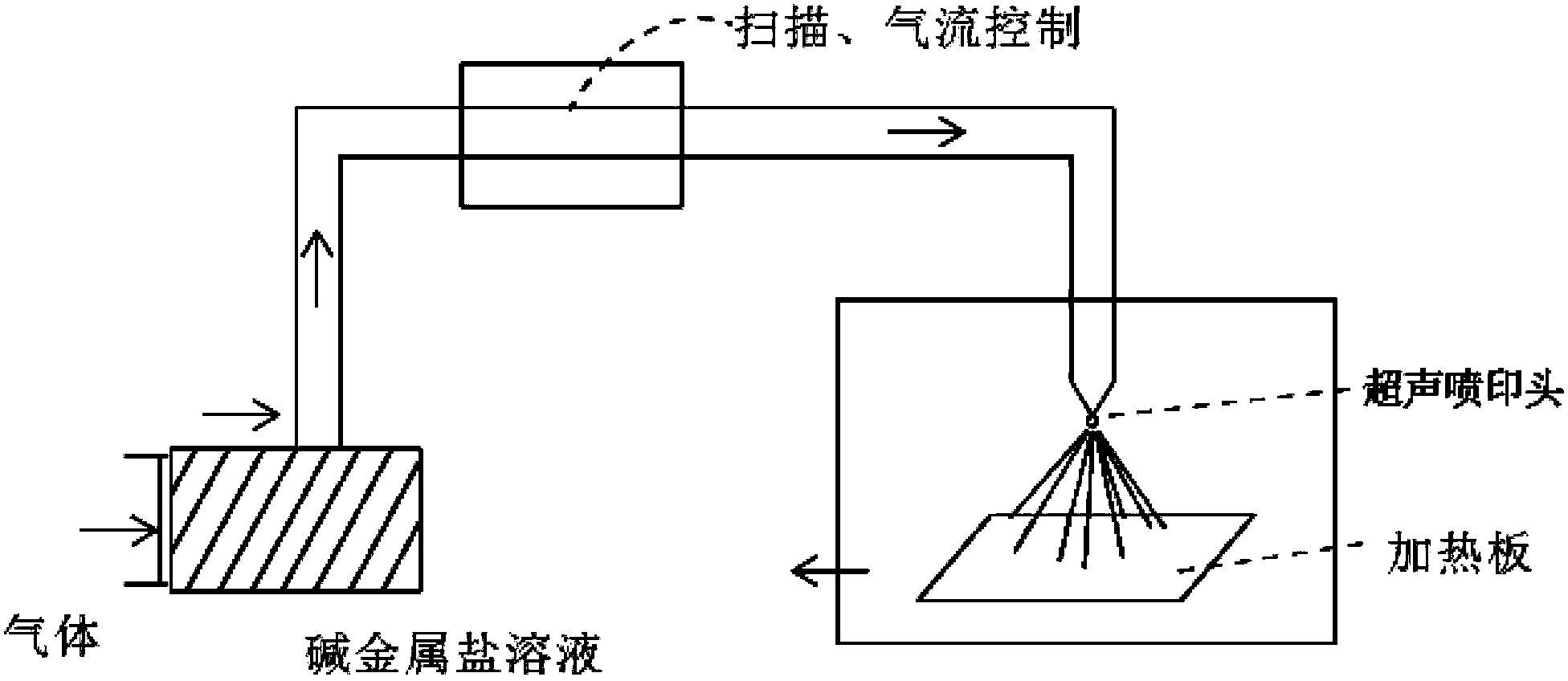

Alkali metal doping method in large-scale production of CIGS (copper, indium, gallium, selenium) thin-film solar cell

ActiveCN103474505AThe design idea is clearEasy to operateFinal product manufactureSemiconductor devicesHigh resistanceIndium

Provided is an alkali metal doping method in the large-scale production of CIGS (copper, indium, gallium, selenium) thin-film solar cells. The method comprises a step of depositing an Mo metal back electrode layer on a glass substrate, a stainless indium substrate or a flexible substrate; a step of preparing a CIGS optical absorption layer; performing alkali metal element doping and deposition on the CIGS optical absorption layer; a step of performing thermal treatment on the alkali metal thin film formed after the deposition so as to make the alkali metal permeate into a CIGS crystal boundary and to improve characteristics of the crystal boundary; a step of cleaning alkali metal residues; a step of depositing a CdS, ZnS or InS buffer layer on the CIGS thin film after the cleaning of the alkali metal residues; and a step of depositing a high-resistance i-ZnO layer and a high-resistance ZnO:Al window layer, and thus a CIGS solar cell is formed. According to the alkali metal doping method, after annealing, the permeation of the alkali metal does not affect the generation of the CIGS crystal lattices; after the permeation of the alkali metal into the CIGS optical absorption layer, filling factors are substantially improved and the cell photoelectric conversion efficiency is improved when the open circuit voltage is improved.

Owner:ZHEJIANG SHANGYUE OPTOELECTRONICS TECH

Conjugated Polymers and Their Use in Optoelectronic Devices

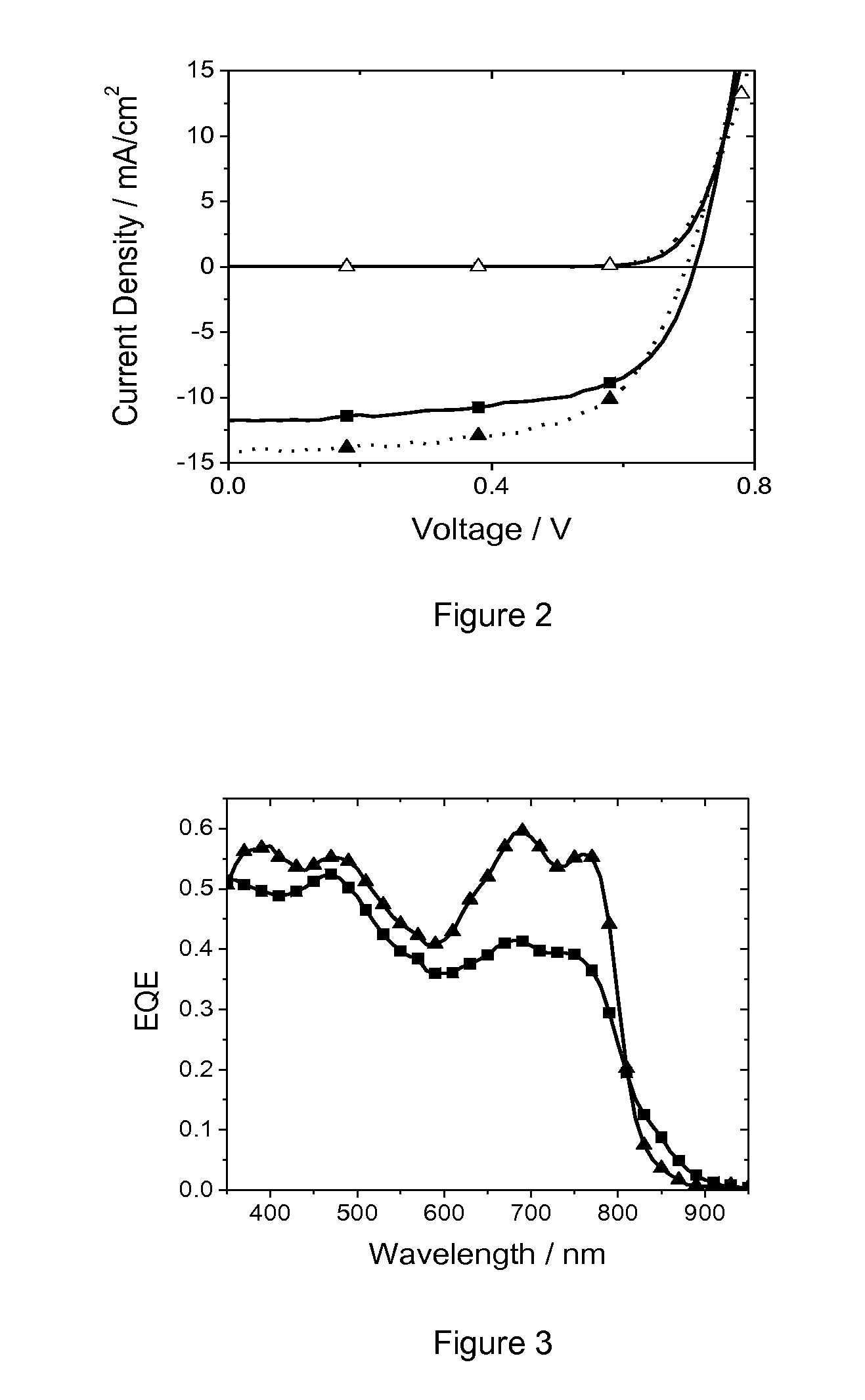

ActiveUS20120186652A1Enhanced light absorptionGood charge transport characteristicNanoinformaticsSolid-state devicesSolubilityPhotodetector

Disclosed are certain polymeric compounds and their use as organic semiconductors in organic and hybrid optical, optoelectronic, and / or electronic devices such as photovoltaic cells, light emitting diodes, light emitting transistors, field effect transistors, and photodetectors. The disclosed compounds can provide improved device performance, for example, as measured by power conversion efficiency, fill factor, open circuit voltage, field-effect mobility, on / off current ratios, and / or air stability when used in photovoltaic cells or transistors. The disclosed compounds can have good solubility in common solvents enabling device fabrication via solution processes.

Owner:RAYNERGY TEK INC

Solar energy cell with double-layer perovskite film structure and manufacturing method thereof

ActiveCN106910828AIncrease UV-Vis absorptionHigh crystallinitySolid-state devicesSemiconductor/solid-state device manufacturingSilver electrodeEngineering

The invention discloses a manufacturing method for the solar energy cell with double-layer perovskite film structure, and the method comprises the following steps: 1) selecting a conductive substrate; etching patterns on the conductive substrate and obtaining the etched conductive substrate; 2) preparing an electron transport layer or a hole transport layer; (3) preparing a film with a double-layer perovskite structure; 4) preparing a hole transport layer or an electron transport layer; and 5) hotly plating a gold or silver electrode on the hole transport layer or the electron transport layer to obtain an n-I-P-type or p-I-N-type solar cell with the double-layer perovskite thin film structure. The invention further discloses a solar energy cell manufactured and obtained from the above method. The manufacturing method is environmentally friendly, can change the morphology, the crystallinity and the interface of the perovskite film and increases the photoelectric performance of a device.

Owner:SOUTH CHINA NORMAL UNIVERSITY

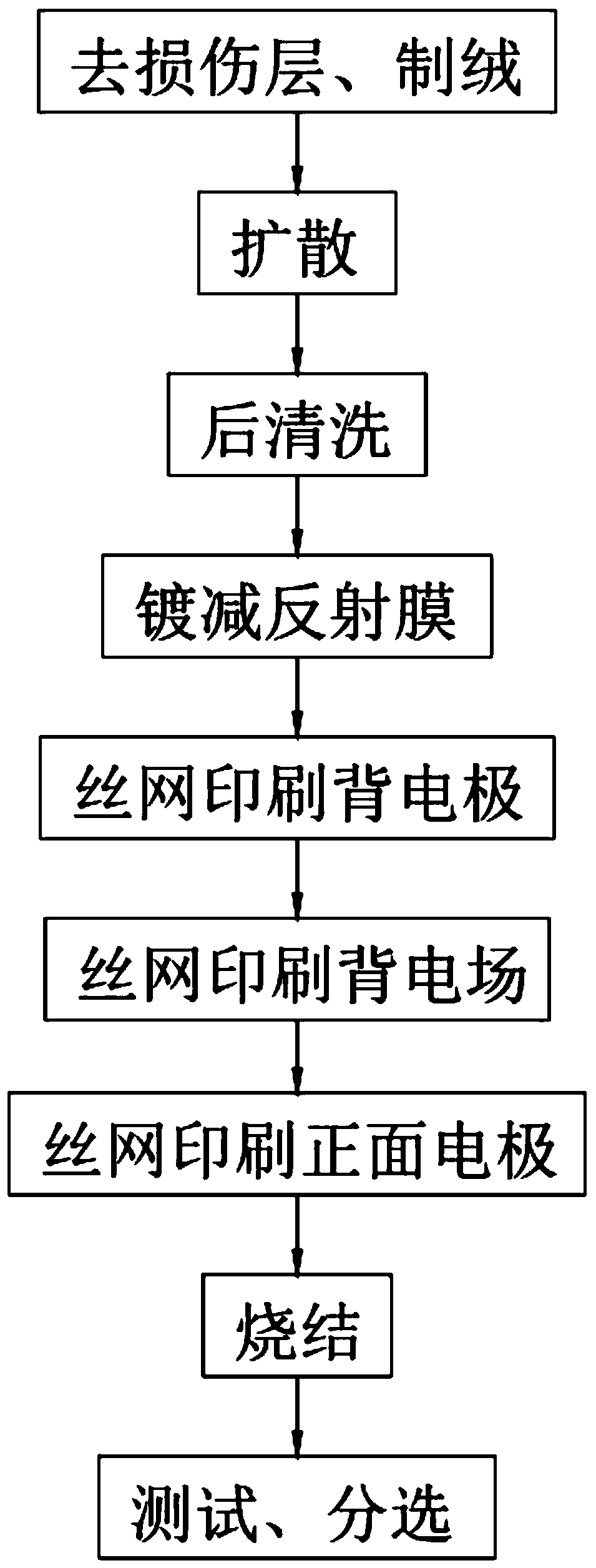

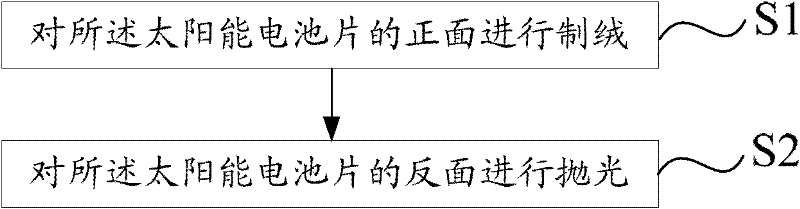

Texturing method for solar cell

InactiveCN102185011AImprove utilization efficiencyReduce recombination rateFinal product manufactureSemiconductor devicesWave responseHigh reflectivity

The embodiment of the invention discloses a texturing method for a solar cell. The method comprises the following steps of: texturing the front surface of the solar cell; and polishing the back surface of the solar cell. By the provided texturing method, a low-reflectivity textured surface structure is formed on the front surface of the solar cell, and a high-reflectivity polished surface structure is formed on the back surface of the solar cell; and by the high-reflectivity polished surface structure, the long wave response is increased, and a recombination rate of a back metal electrode and a silicon wafer is reduced; and the open-circuit voltage, the short-circuit current and filling factors are improved, so the utilization efficiency of the solar cell can be improved. Furthermore, the texturing method is lower in cost, and is simple, so the texturing method can be widely applied to commercial production.

Owner:JETION SOLAR HLDG

Method for manufacturing silicon solar cell

InactiveCN101783374ALow sheet resistanceLower ohmic contactFinal product manufactureSemiconductor devicesMetallic electrodeOhmic contact

The invention discloses a method for manufacturing a silicon solar cell. In the process of manufacturing a PN junction on a silicon wafer, a selective diffusion technology method is adopted, i,e. laser is utilized to heat a position, on which a positive electrode intends to be manufactured, on the surface of the silicon wafer; and under the action of heating, phosphorus in a phosphorus source uniformly adhered on the surface diffuses towards the inner of the silicon wafer, thus a heavy doping zone with smaller sheet resistance is formed at the position on which the positive electrode intends to be manufactured to effectively reduce the sheet resistance of the silicon solar cell, thereby not only being beneficial for increasing the open-circuit voltage of the silicon solar cell; the increase of the open-circuit voltage effectively improves the conversion efficiency of the silicon solar cell, reduces ohmic contact of a metal electrode and the silicon solar cell, thereby reducing the series resistance of the silicon solar cell, and being capable of meeting the purpose of industrialized production better.

Owner:SUN EARTH SOLAR POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com