Preparation method of photo anode of dye-sensitized solar cell with optical gradient

A technology for solar cells and dye sensitization, applied in the field of photoanode manufacturing of dye-sensitized solar cells, can solve problems such as corrosion of conductive glass, and achieve the effects of reducing compounding, preventing corrosion and improving photocurrent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

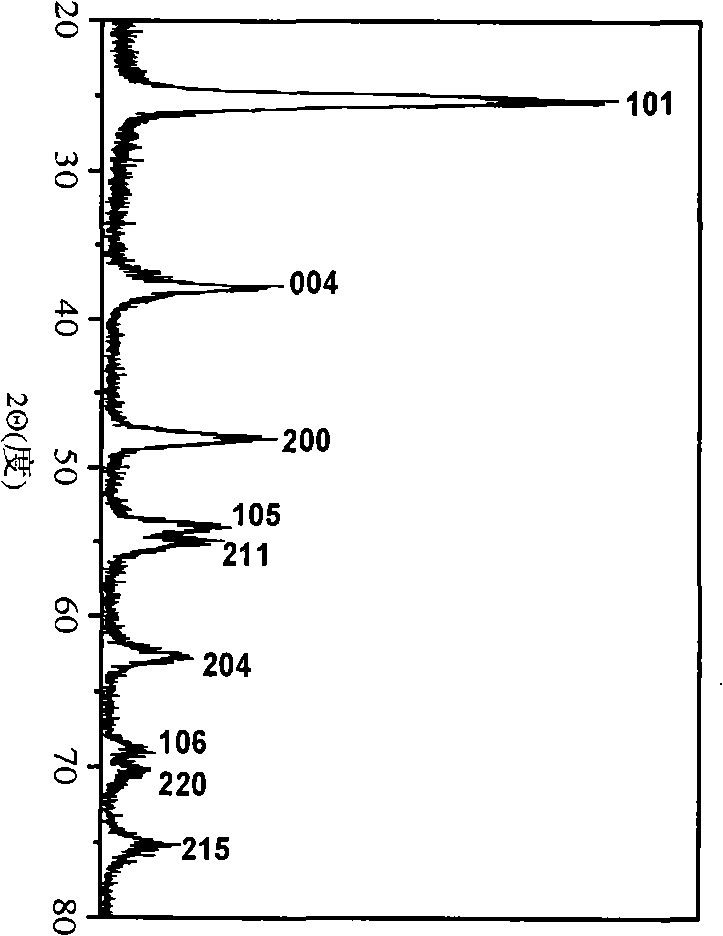

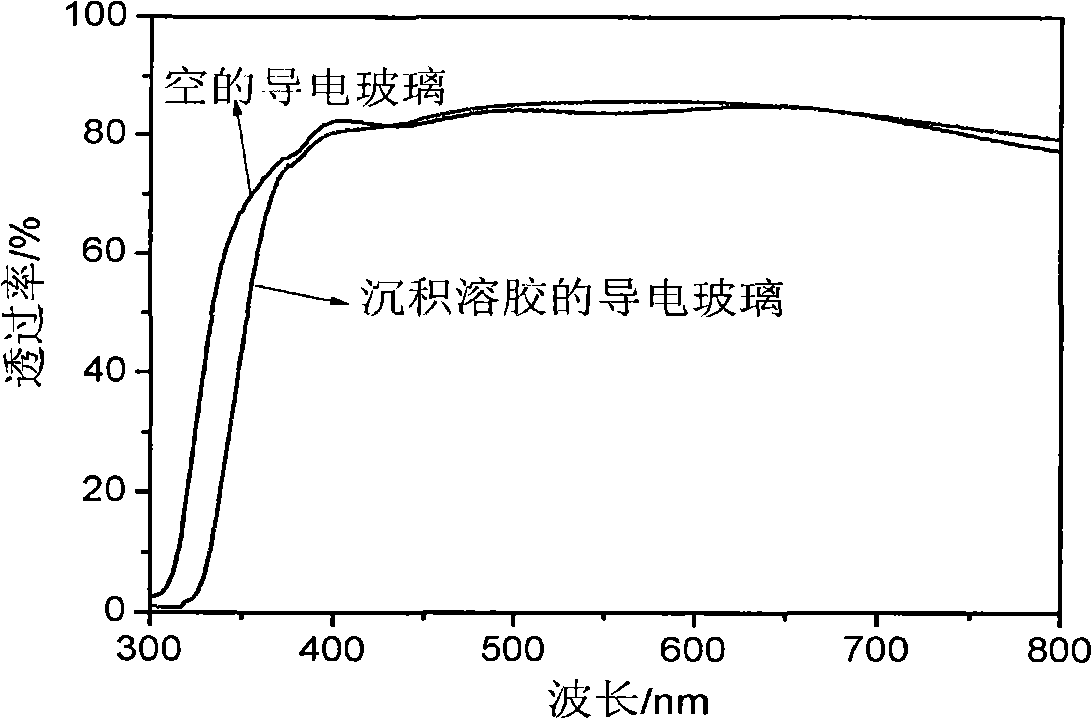

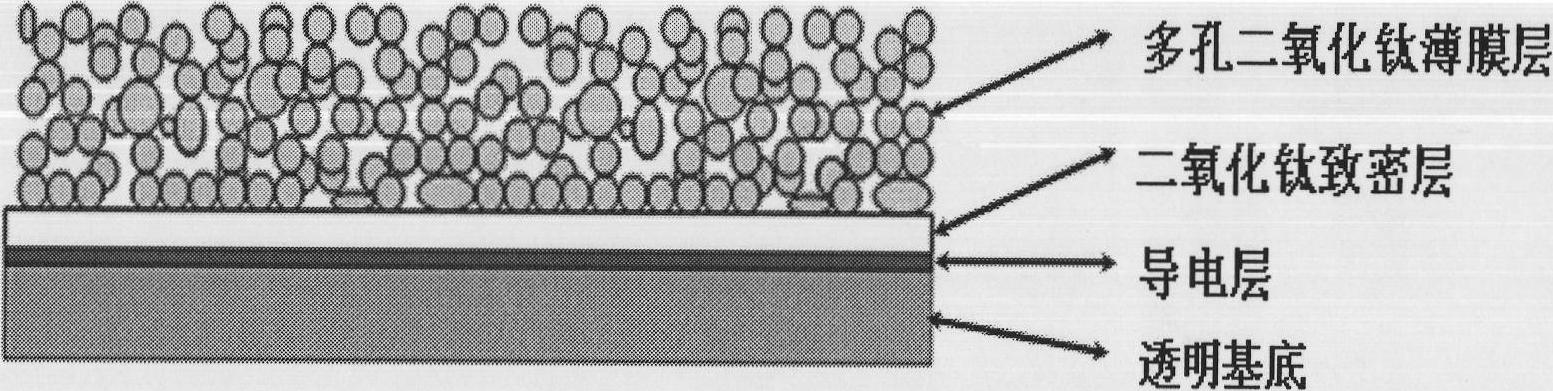

[0031] After the 1M titanium sulfate solution was heated to 60°C, 4M sodium hydroxide solution was added dropwise, neutralized until the pH value was approximately equal to 7, and a white precipitate was obtained, which was washed repeatedly with distilled water to obtain a gel-like solid. Take 80 grams of wet precipitate (containing about 12 grams of titanium dioxide) and disperse it in 100 milliliters of 30% hydrogen peroxide, and degumming at 60° C. for 2 hours to obtain a light yellow transparent solution. Take 10 ml of the transparent solution, dilute it to 40 ml, add it to a hydrothermal kettle, and take it out after 120°C hydrothermal treatment for 12 hours to form a transparent sol. Get the powder that 20 milliliters of sol vacuum drying obtains and carry out XRD analysis, X-ray diffraction (XRD) result shows that titanium dioxide wherein is anatase phase, as figure 1 As shown, it can be seen as a pure anatase phase with a grain size of 7-8 nm. Prepare 50 ml of titan...

Embodiment 2

[0033] After heating the 1M titanium sulfate solution to 60°C, add 4M ammonia solution dropwise to the 1M titanium sulfate solution, and neutralize until the pH value is approximately equal to 7 to obtain a white precipitate, which is washed repeatedly with distilled water to obtain a gel-like solid. Take the wet precipitate 80 grams (converted into titanium dioxide is 12 grams) is dispersed in 300 milliliters of 30% hydrogen peroxide, degummed at 60 ℃ for 1 hour, obtains light yellow transparent solution, gets this transparent solution 20 milliliters, dilutes to 40 milliliters, adds to Hydrothermal kettle, 180 degrees hydrothermal treatment for 12 hours, take out to form a transparent sol. Prepare 50 milliliters of titanium dioxide sol with a concentration of 1 wt%, place it in a 100 milliliter glass beaker, and set aside. After cleaning the FTO conductive glass, soak it in the titanium dioxide sol for 30 minutes, then take it out and dry it at room temperature for 30 minutes...

Embodiment 3

[0035] After heating the 0.85M titanium sulfate solution to 70°C, add 4M sodium hydroxide solution dropwise to the 0.85M titanium sulfate solution, neutralize until the pH value is approximately equal to 7, and obtain a white precipitate, which is washed repeatedly with distilled water to obtain a gel-like solid , get 80 grams of wet precipitation (converted into titanium dioxide to be 12 grams) and disperse it in 200 milliliters of 30% hydrogen peroxide, obtain light yellow transparent solution, get this transparent solution 30 milliliters, dilute to 70 milliliters, join in hydrothermal kettle, After 24 hours of hydrothermal treatment at 150 degrees, it was taken out to form a transparent sol. Prepare 50 ml of titanium dioxide sol with a concentration of 2wt%, place it in a 100 ml glass beaker, and set aside. After cleaning the ITO conductive glass, soak it in the titanium dioxide sol for 50 minutes, then take it out and dry it in an oven for 30 minutes at 80°C. After impreg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com