Photocatalytic membrane, preparation method thereof and degradation application of photocatalytic membrane on disinfection by-product precursor

A technology of disinfection by-products and photocatalytic film, applied in the field of photocatalytic degradation, can solve the problems of low utilization rate of sunlight, low reuse rate, easy loss of catalyst, etc. The effect of facilitating large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

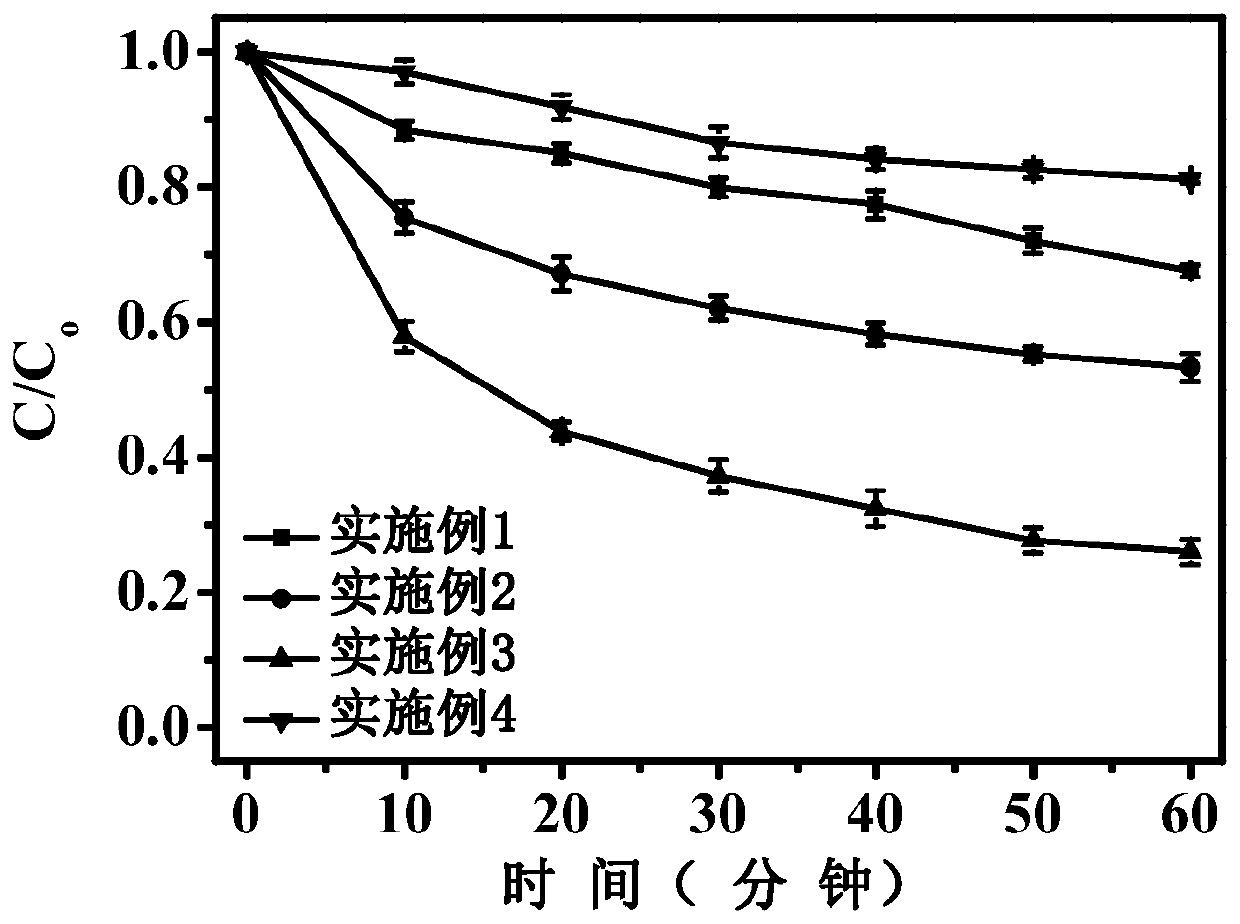

Embodiment 1

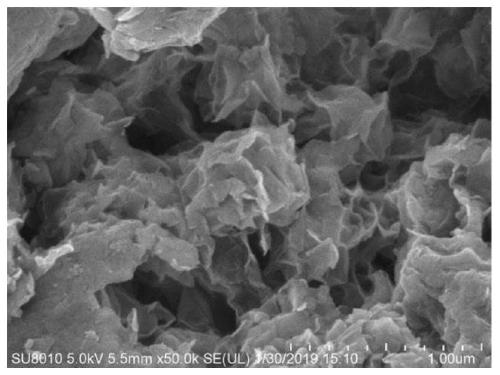

[0064] (1) Configure 18ml of 10% ethanol aqueous solution, take 2ml of GO concentrated solution and place it in the ethanol solution, and ultrasonically disperse it for 3 hours. At this time, the concentration of GO ethanol solution is 1mg / ml. After centrifuging at a high speed for 15 minutes, take the upper suspension of the centrifuge tube for later use.

[0065] (2) Weigh 0.242g of sodium molybdate and 0.381g of thiourea and dissolve in 12.1ml of the above GO suspension, stir evenly, and disperse by ultrasonic.

[0066] (3) The mixed solution was transferred to a 50ml hydrothermal reaction kettle, heated to 210° C. in a muffle furnace, and the reaction was continued for 24 hours.

[0067] (4) The obtained product is centrifuged and washed 3 times at high speed with deionized water and ethanol to remove excess impurities or organic matter on the surface.

[0068] (5) Dry the product in an oven at 70°C for 12 hours, then grind it in an agate mortar for several times, and fil...

Embodiment 2

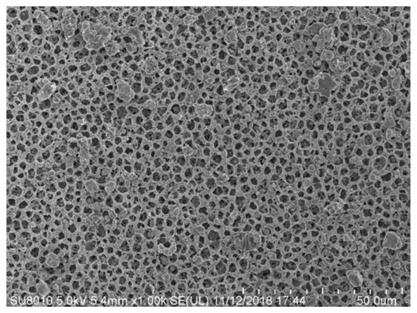

[0072] (1) Configure 18ml of 10% ethanol aqueous solution, take 2ml of GO concentrated solution and place it in the ethanol solution, and ultrasonically disperse it for 3 hours. At this time, the concentration of GO ethanol solution is 1mg / ml. After centrifuging at a high speed for 15 minutes, take the upper suspension of the centrifuge tube for later use.

[0073] (2) Weigh 0.242g of sodium molybdate and 0.381g of thiourea and dissolve in 24.2ml of the above GO suspension, stir evenly, and ultrasonically disperse.

[0074](3) The mixed solution was transferred to a 50ml hydrothermal reaction kettle, heated to 210° C. in a muffle furnace, and the reaction was continued for 24 hours.

[0075] (4) The obtained product is centrifuged and washed 3 times at high speed with deionized water and ethanol to remove excess impurities or organic matter on the surface.

[0076] (5) Dry the product in an oven at 70°C for 12 hours, then grind it in an agate mortar for several times, and fil...

Embodiment 3

[0080] The difference from Example 2 is only that the volume of the GO suspension in step (2) is 48.4ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com