Patents

Literature

600results about "Paper forming aids addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

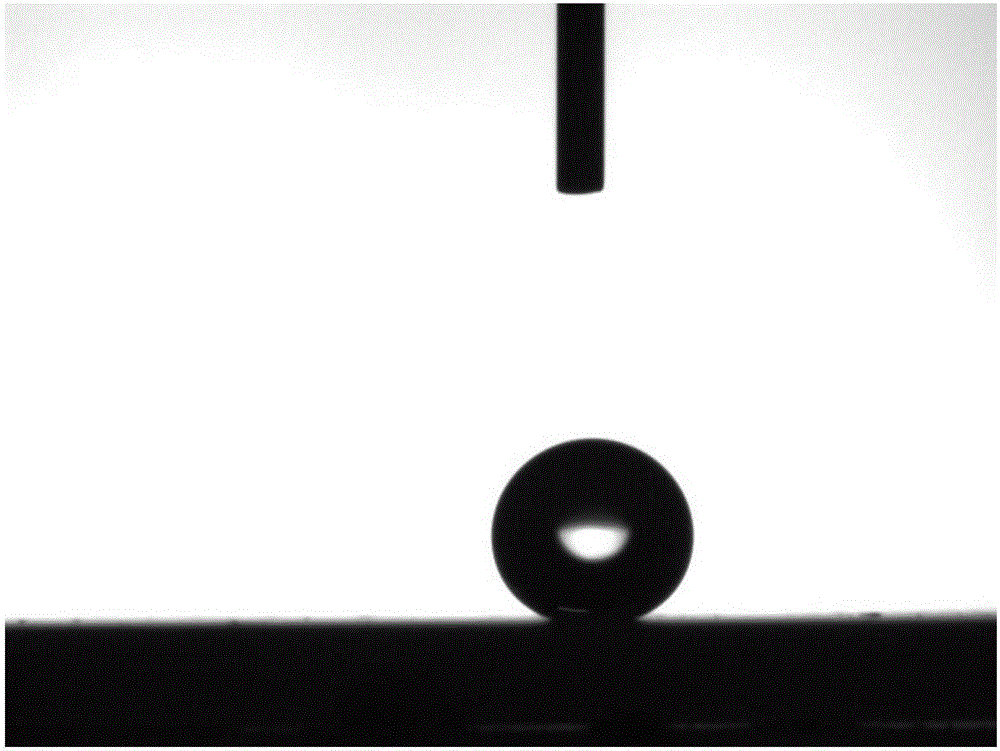

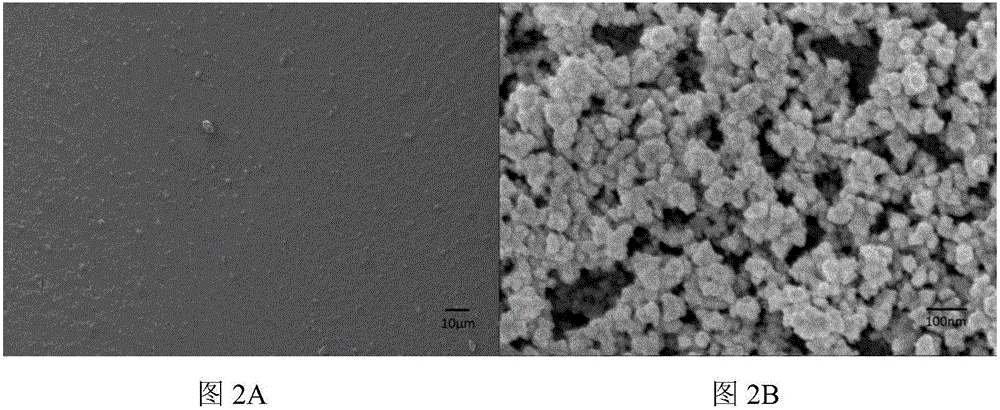

Super-hydrophobic nanometer transparent coating and preparation method thereof

ActiveCN104987520AExcellent superhydrophobic propertiesHigh transparencyCoatings with pigmentsFibre treatmentOrganic solventUltrasonic dispersion

The invention provides a super-hydrophobic nanometer transparent coating and a preparation method thereof and belongs to the technical field of super-hydrophobic paint. The method includes the steps that firstly, a first category of inorganic nanometer particles are added into an organic solution, and ultrasonic dispersion is performed; secondly, dispersing agents and a second category of inorganic nanometer particles are added, and ultrasonic dispersion is performed so that a dispersion solution can be obtained; crosslinking agents and additives are added in the dispersion solution, ultrasonic dispersion is performed, finally, low-surface energy polymers are added, mixtures are evenly mixed, and transparent and clear super-hydrophobic paint is obtained; the surface of a solid base materials is coated with the transparent and clear super-hydrophobic paint, and the super-hydrophobic nanometer transparent coating is obtained through low-temperature thermal drying and curing. The super-hydrophobic performance of the super-hydrophobic nanometer transparent coating prepared through the method is excellent, the contact angle can be 160 degrees, the rolling angle is 1-7 degrees, the super-hydrophobic nanometer transparent coating can be sprayed to the surfaces of most of common materials, the morphology of the surfaces of the materials are not changed, and the application prospects and the application potency are very wide.

Owner:BEIHANG UNIV

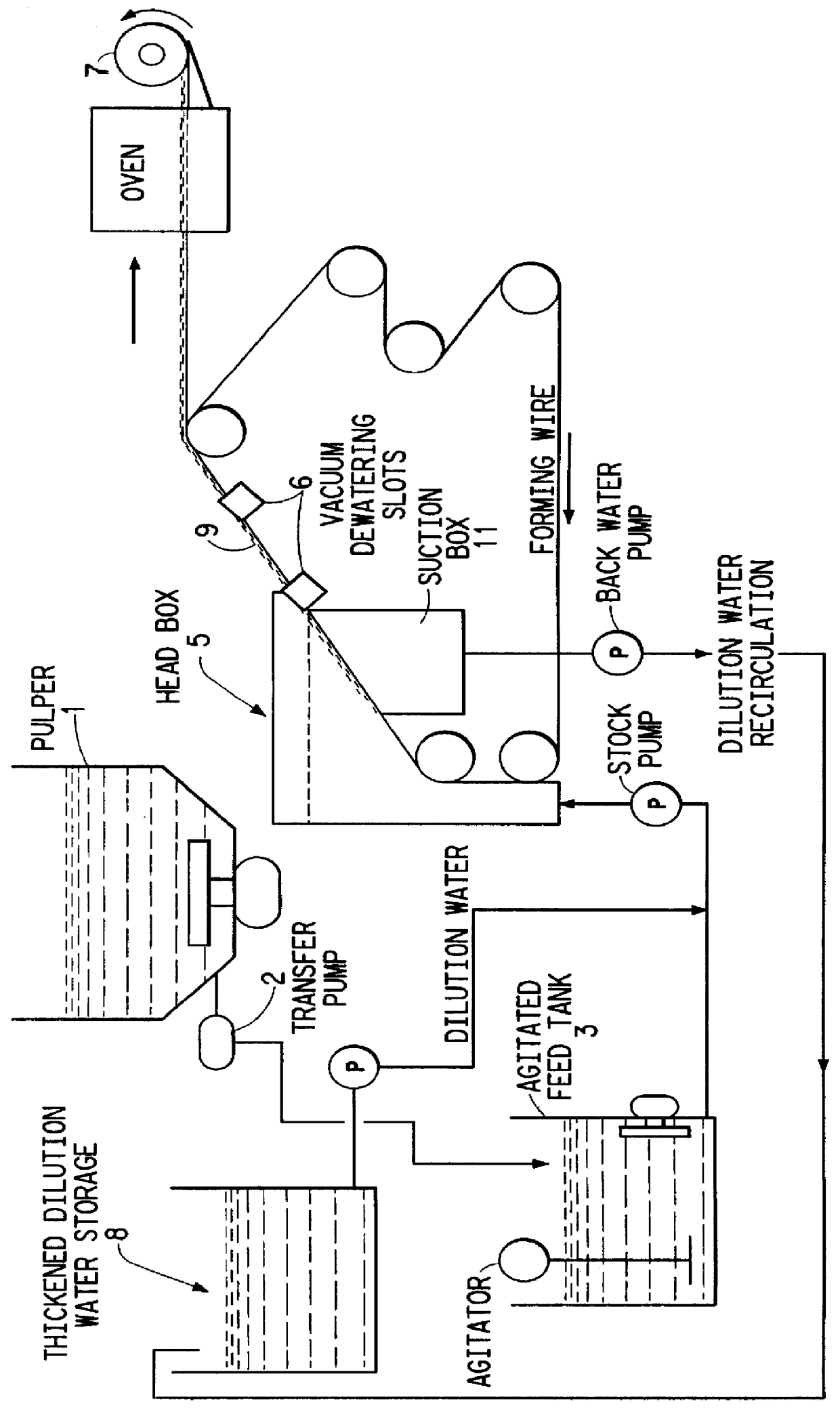

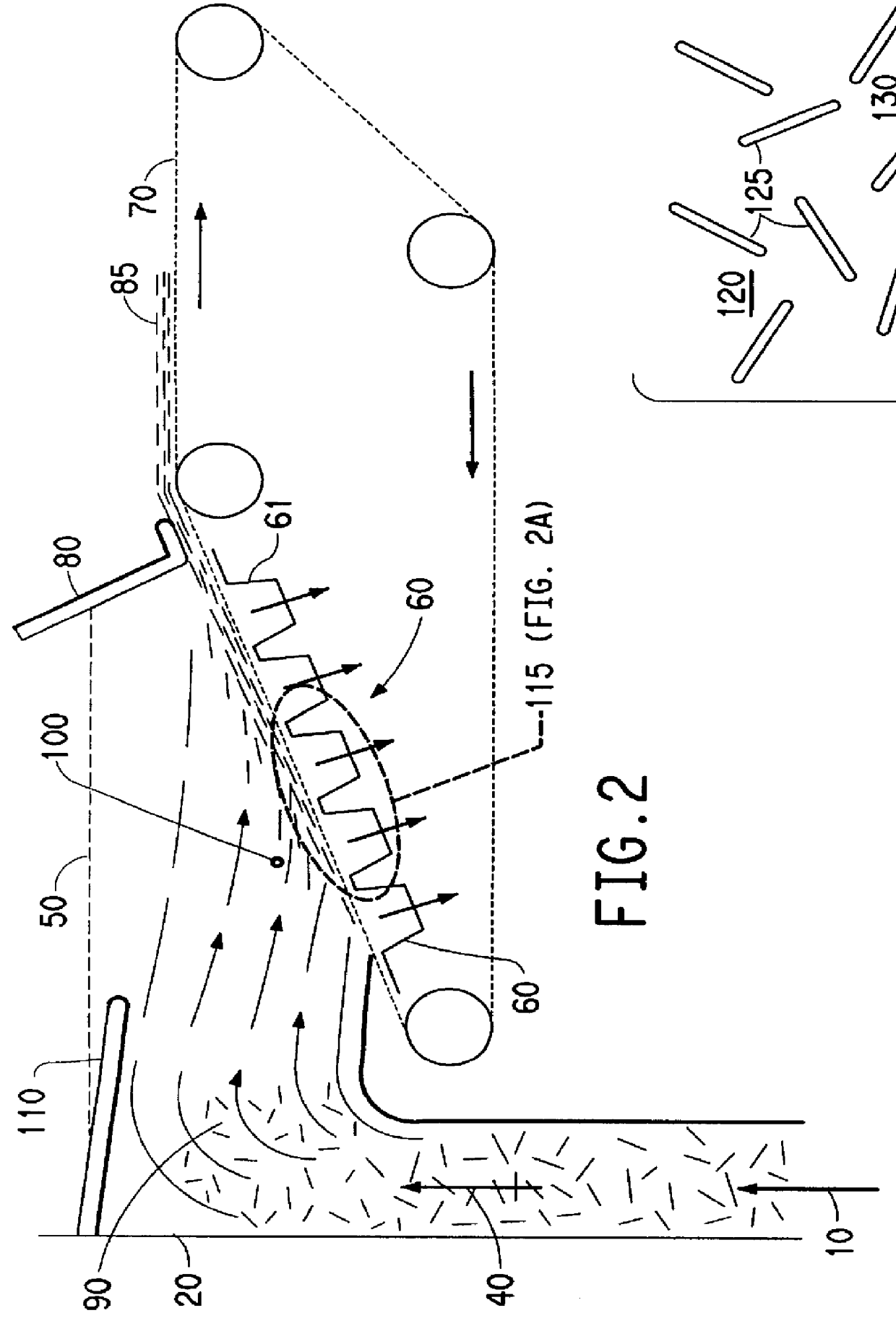

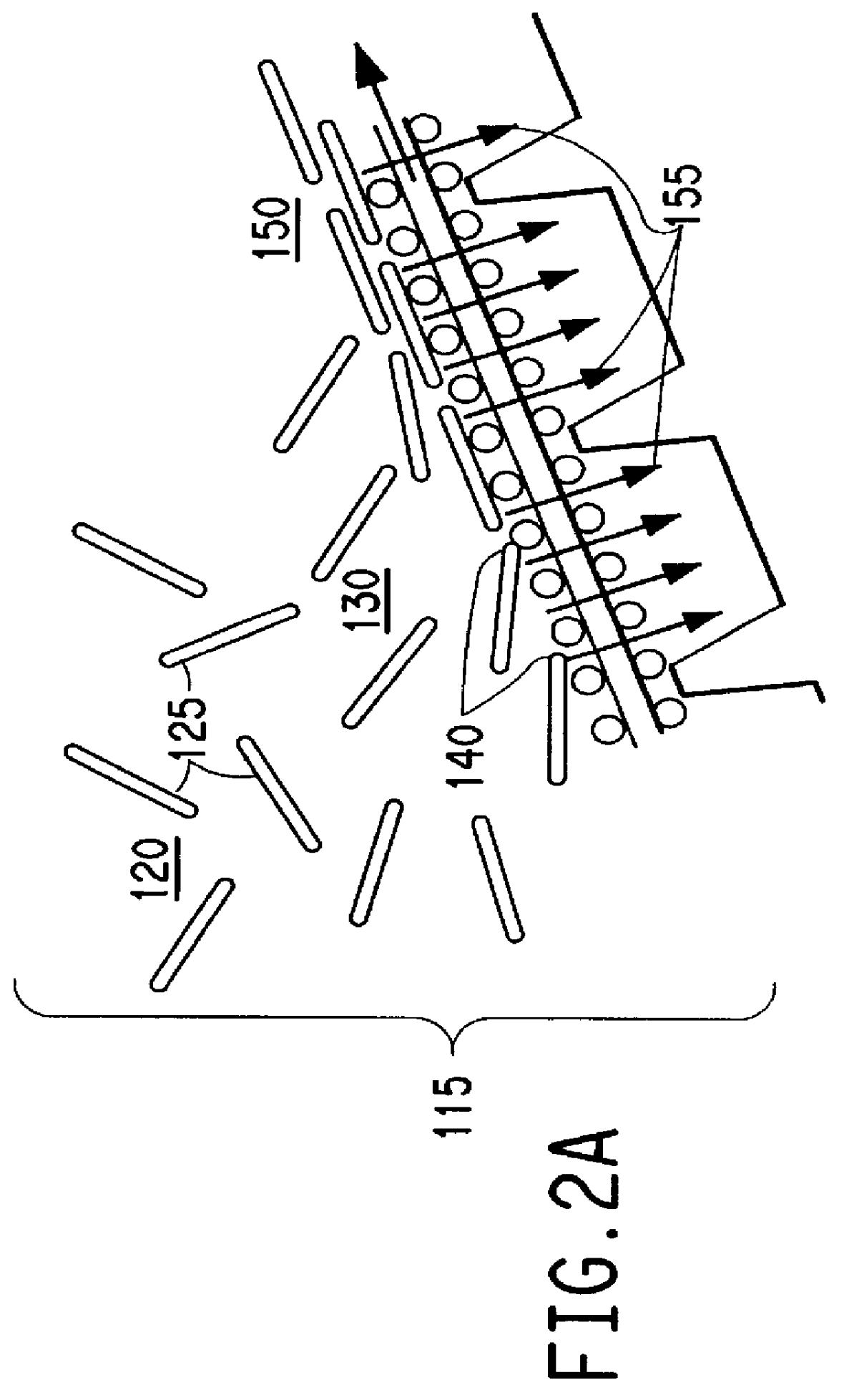

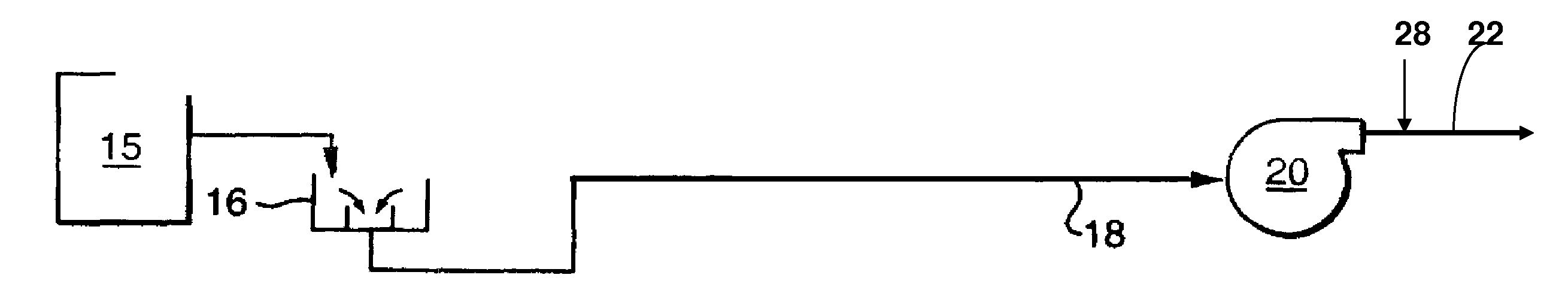

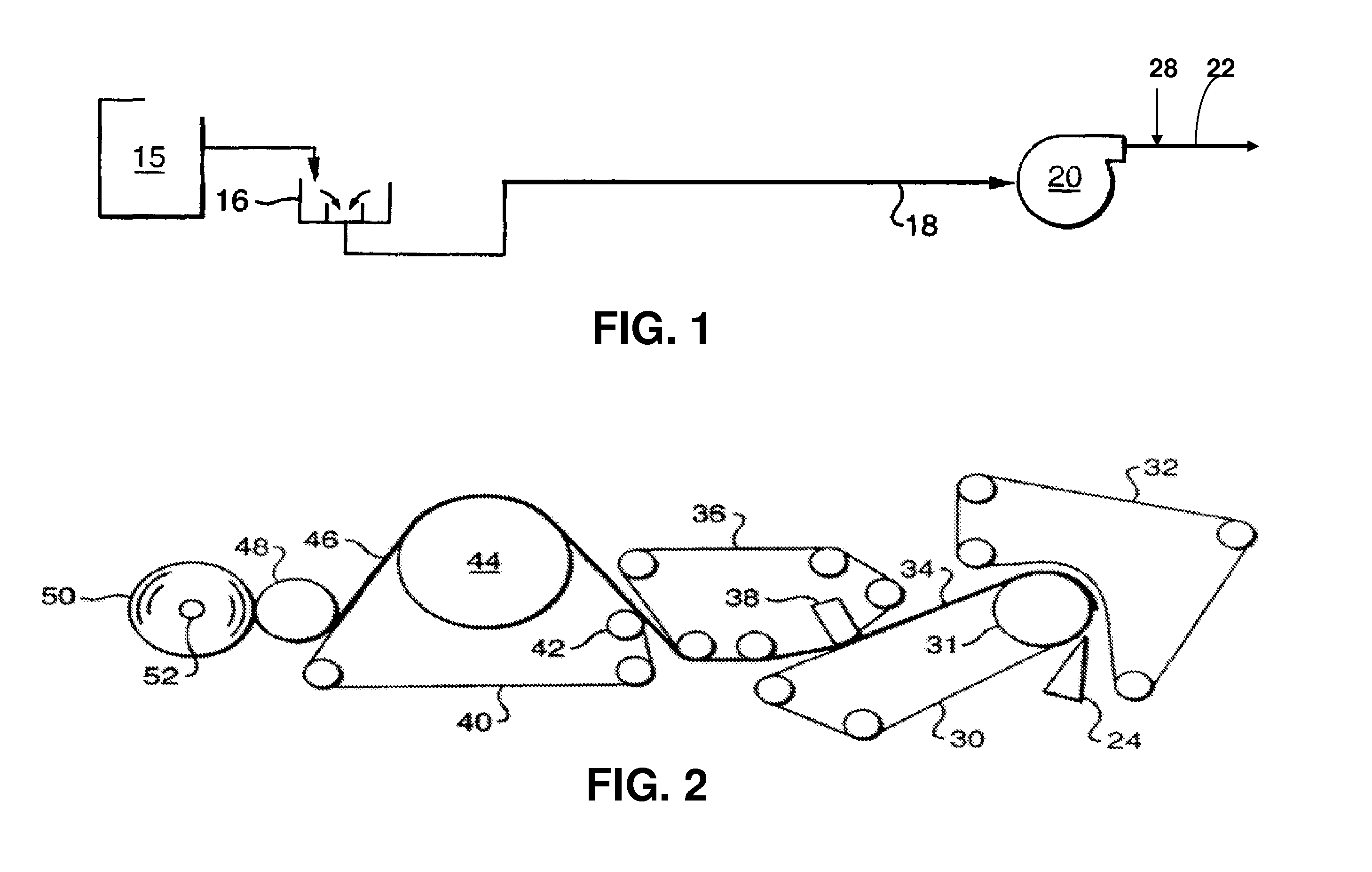

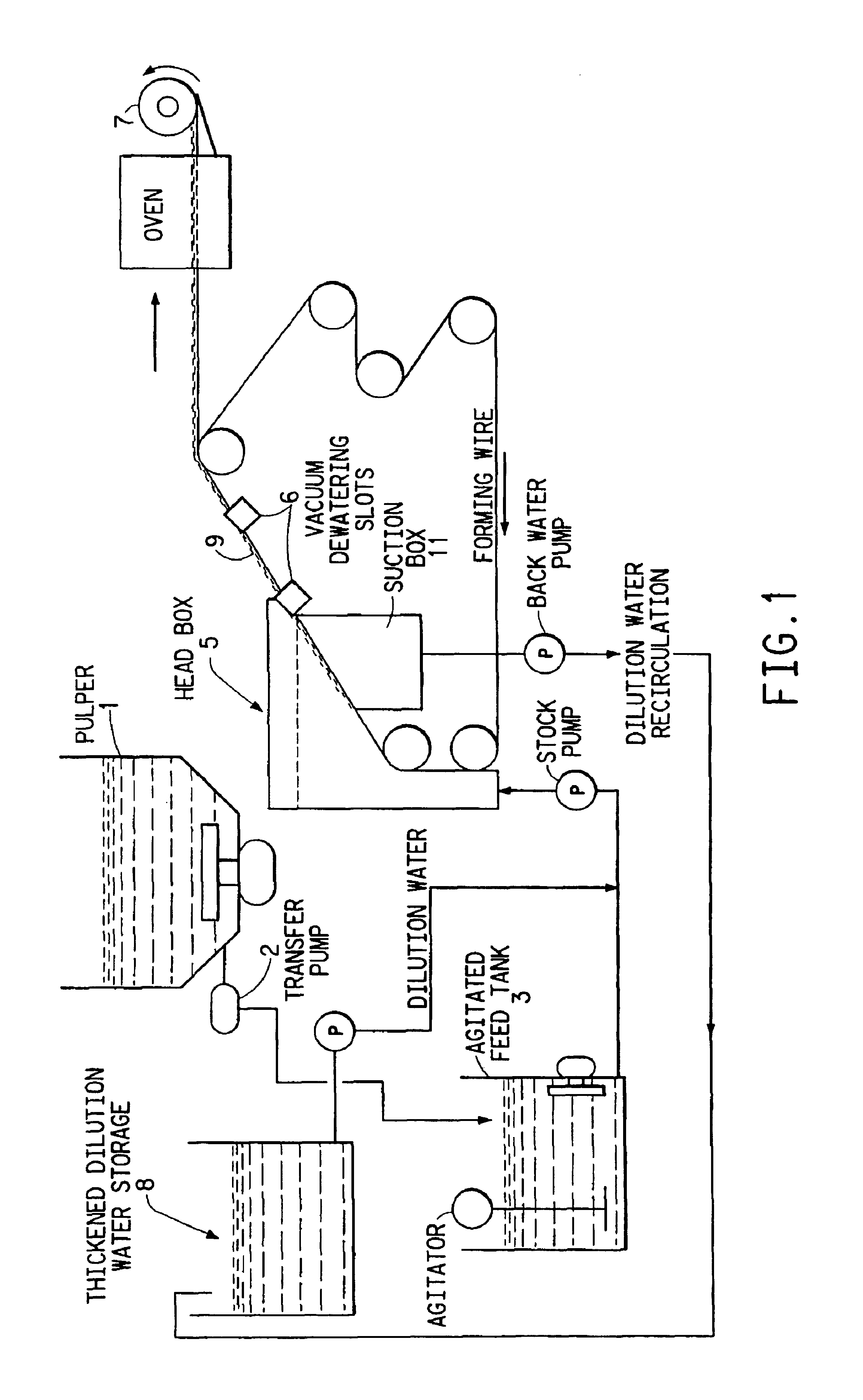

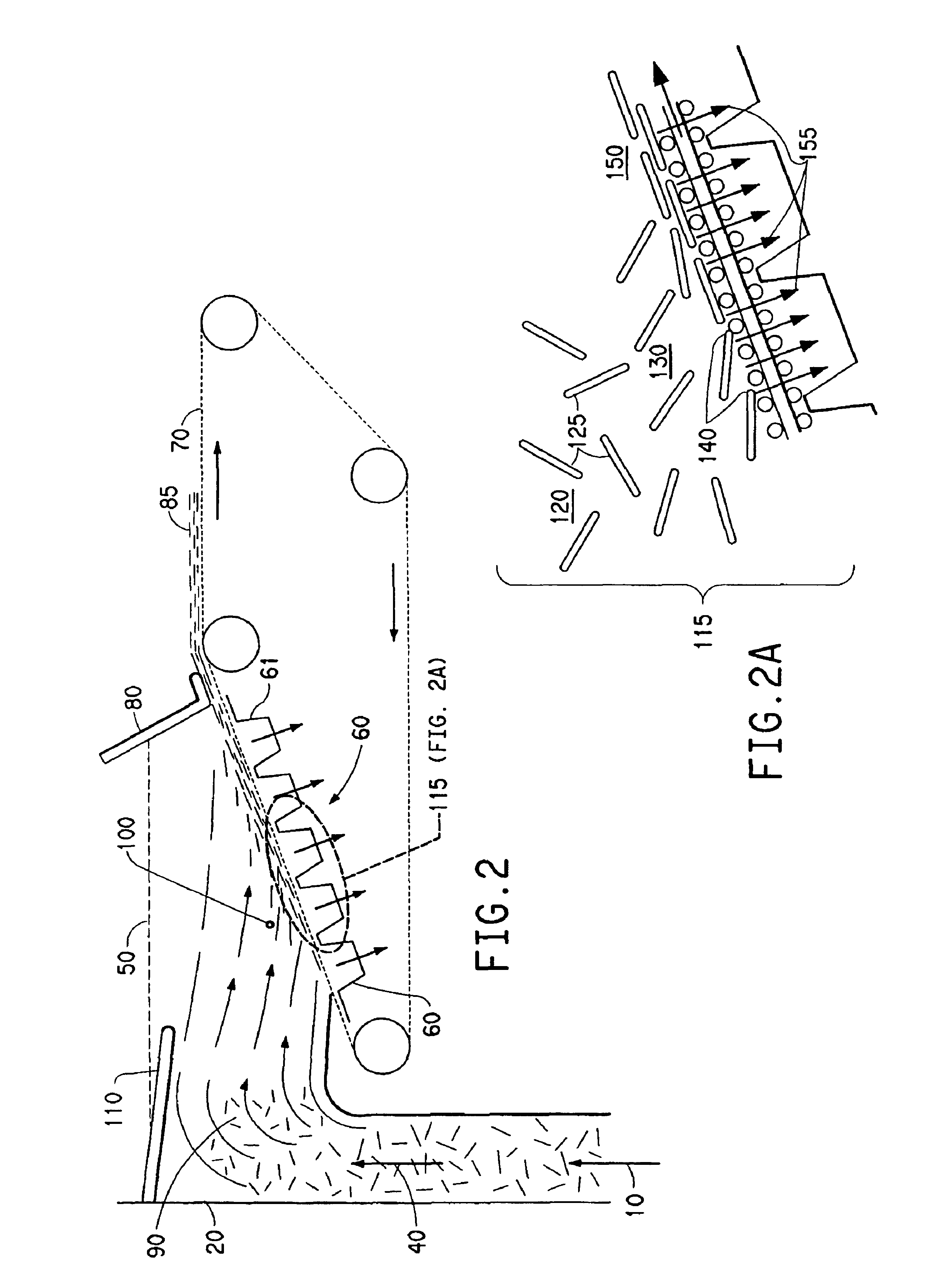

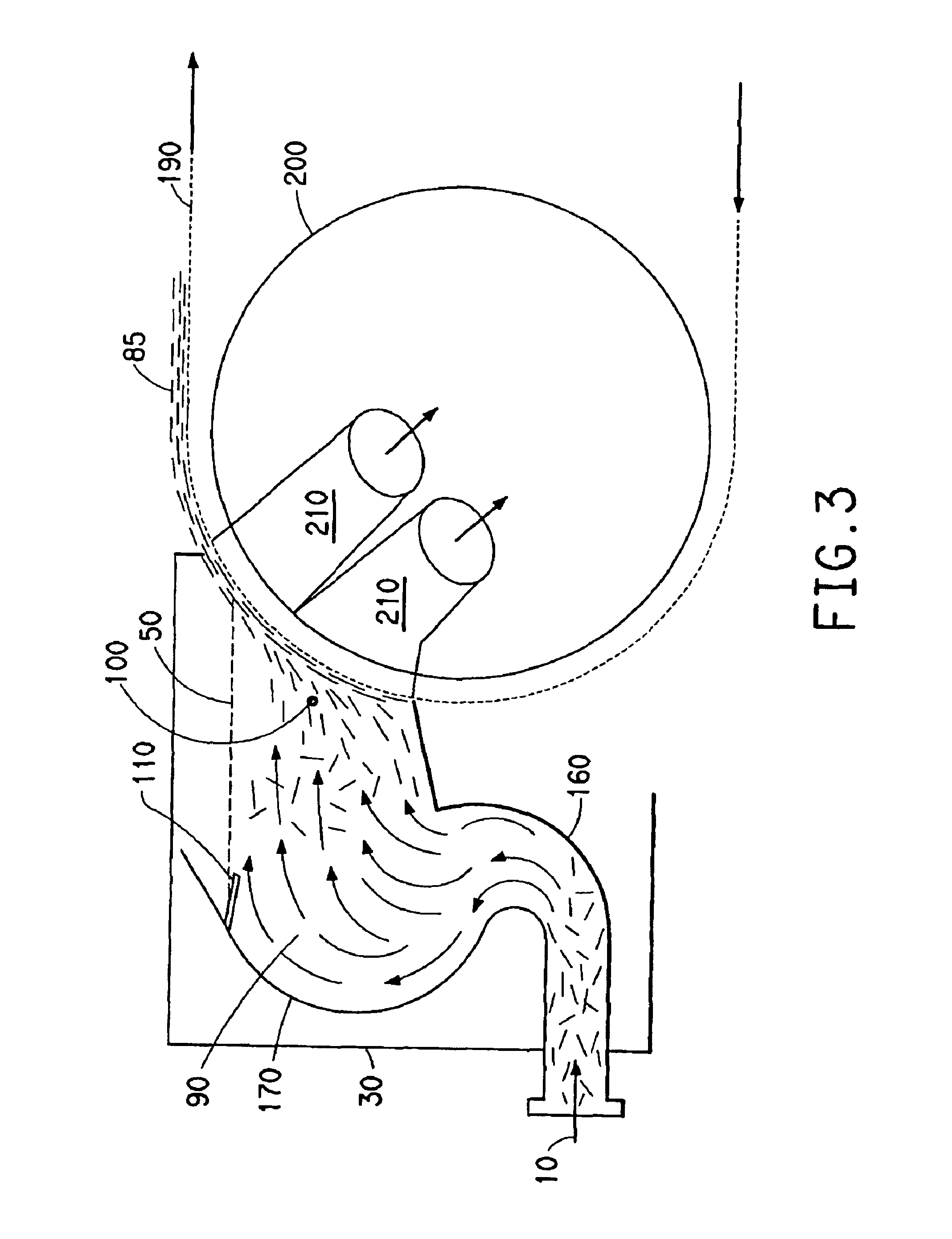

Wetlay process for manufacture of highly-oriented fibrous mats

A mat containing highly machine direction oriented (90% or greater), discontinuous reinforcement fibers, is produced on inclined wire or rotary paper making machinery. Fibers are first uniformly dispersed in an aqueous medium containing thickeners and wetting agents. In one embodiment, antifoaming agents are also added to prevent floating fibers which entangle and reduce orientation. Thermoplastic fibers or particles may also be included. Stock is brought into an open headbox in a flow pattern which allows the fibers to decelerate before approaching the porous suction belt (wire). As the fibers approach the suction belt, the fibers begin to turn and align in the streamline so as to present one end toward the suction wire. The leading ends of the fibers are gripped by the moving belt which drags the fibers out of the dispersion stock in a straight line. The porous mat produced may be dried and bonded through hot air, heat and / or pressure, or chemical binders. Stacks of such mats may be compressed partially to produce porous structures, or fully to produce

Owner:VIRGINIA TECH FOUND

Process for the production of paper

InactiveUS6113741AGood effectImprove retentionNatural cellulose pulp/paperSpecial paperWater flowCellulose fiber

The invention relates to a process for the production of paper on a paper machine containing a dilution headbox in which a main aqueous flow containing cellulosic fibres and filler is mixed in said headbox with a diluting aqueous flow to form a resulting aqueous flow which is ejected onto a wire and dewatered to form a web of paper, wherein one or more components providing improved retention are introduced into the main aqueous flow and an additive resulting in slower dewatering and / or being selected from non-ionic and anionic organic polymers is introduced into the diluting aqueous flow.

Owner:EKA CHEM AC LTD

Paper making method tobacco sheet producing process using double-grid method

ActiveCN101011183AObvious style traitsShorten the timeTobacco preparationPaper forming aids additionFiberSlag

The invention relates to a method for producing the tobacco sheet via dual-mesh paper making method, which comprises that preparing the tobacco slag, tobacco powder and ash via grinding machine to the tobacco powder at 80-100 deals and the ultra-fine tobacco powder at 120-800 deals; immerging the tobacco stem in water for 1-2 hours, separating the solid and liquid, concentrating the extractive solution into 15-25 degree / Be', adding the ultra-fine tobacco powder at 5-30% of the weight of concentrated solution, to obtain the coat liquid of sheet; the solid extracted from the tobacco stem is decomposed to prepare pulp, to be mixed with external pulped fiber, to be divided into two parts to be shaped via the meshes; spraying the tobacco powder at 80-100 deals on the base sheet of one paper machine, and covering this base sheet via another wet base sheet produced by another paper machine, to obtain the composite wet base sheet; compressing, dewatering, drying to obtain the base sheet; immerging and coating the base sheet in the coat liquid, drying, breaking to obtain the final product. The invention can improve the smell of sheet tobacco.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Composite conductive paper of carbon fiber

InactiveCN101003956AHigh porosityImprove conductivityPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperFiberCarbon fibers

The present invention discloses a composite conductive carbon fiber paper. Its preparation process includes the following steps: using acrylonitrile carbon fiber and other carbon material as raw material, adopting polyphenylamine, conventional polyvinyl alcohol and water-soluble phenolic resin and mixing them, and using their mixture as adhesive, the polyphenylamine is conductive high-molecular polymer; mixing sodium alginate and conventional dispersing agent; adopting wet-process paper-making technique to make paper; vacuum drying the obtained carbon paper, then using Teflon emulsion whose concentration is 5%-20% to make treatment; finally, introducing nitrogen gas and making carbonization, carbonization temperature is higher than 1000 deg.C, so as to obtain the invented composite conductive carbon fiber paper. Said composite conductive carbon fiber paper mainly is used in fuel cell field.

Owner:DONGHUA UNIV

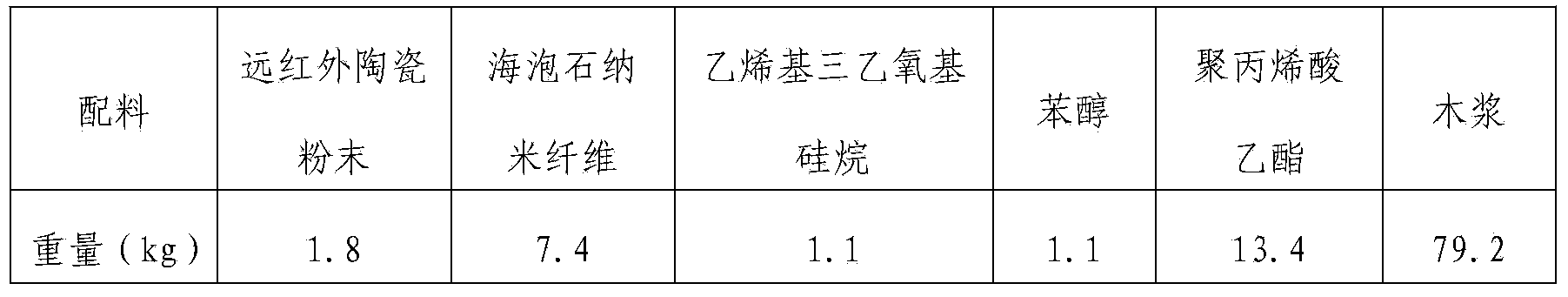

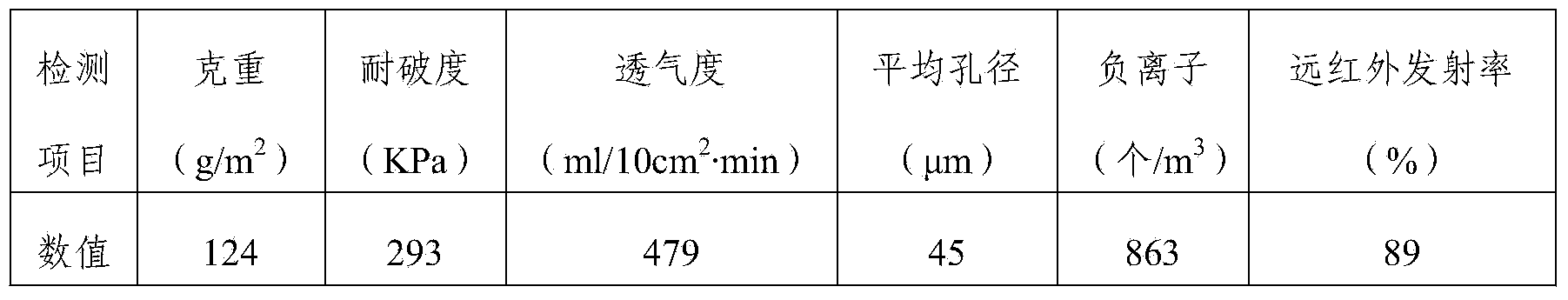

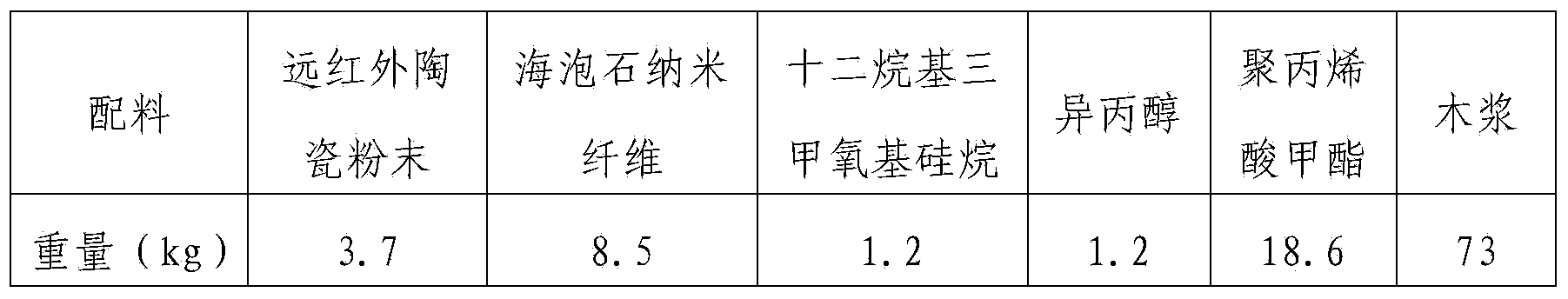

Filter paper for environmental-friendly automobile filter and preparation method of filter paper

InactiveCN103774503ASimple processHigh filtration precisionInorganic fibres/flakesWater-repelling agents additionExhaust gas emissionsEmission standard

The invention relates to filter paper for an environmental-friendly automobile filter. The filter paper for the environmental-friendly automobile filter is prepared from the following components in parts by weight: 1-5 parts of far infrared ceramic powder, 2-20 parts of sepiolite nanofibers, 0.8-1.6 parts of a silane coupling agent, 0.8-1.6 parts of a diluent, 9-20 parts of a sizing agent and 60-96 parts of wood pulp. Air, fuel oil and engine oil filters made of the filter paper are obvious in comprehensive effect; pollutants generated by exhaust gas emission of an automobile are reduced by 16-47%; the dynamic performance is improved by 6-12%; fuel oil can be saved by 2-5%; the emission standard reaches the European IV standard.

Owner:北京联飞翔科技股份有限公司

Tissue Products Containing Microalgae Materials

Dry products, and particularly dry tissue substrates, including a blend of conventional papermaking fibers and microalgae are disclosed herein. Use of a cationic retention aid in the dry tissue substrates helps to provide a tissue sheet retaining the microalgae without being detrimental to tissue properties such as caliper, bulk, air permeability, slough and absorbent capacity. Additionally, use of a flocculating agent may agglomerate the microalgae and make it easier to retain the microalgae within the tissue sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

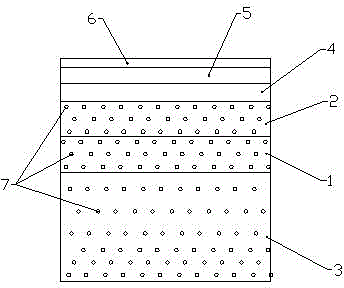

Coated craft paper and production method thereof

ActiveCN102912691AIncrease varietyImprove qualityCoatings with pigmentsSpecial paperAfter treatmentPulp and paper industry

The invention discloses coated craft paper and a production method thereof. The coated craft paper comprises a core paper layer; the upper side of the core paper layer is a surface paper layer, and the lower side is a bottom paper layer; a coating layer is arranged on the upper surface of the surface paper layer; the bottom paper layer and the core paper layer are prepared by the steps of: dosing the waste paper, preparing waste paper pulp to obtain non-deinked waste paper pulp, and manufacturing paper through a paper layer to obtain a wet bottom paper layer and a wet core paper layer; the surface paper layer is prepared by the steps of: manufacturing paper through a paper layer by taking the UKP pulp, the non-deinked waste paper pulp or the mixture of the UKP pulp and the non-deinked waste paper pulp as the pulp to obtain a wet surface paper layer; and the wet bottom paper layer, the wet core paper layer and the wet surface paper layer are subjected to the steps of compounding with the coated body paper, preliminary drying, sizing, later drying, paper surface calendering, paper surface coating and after-treatment to obtain the coated craft paper. The available waste paper types are increased, and the fiber source is wider; and meanwhile, the quality of the waste paper pulp is effectively stabilized so as to guarantee the quality stability of the coated body paper and the white-surface craft paper and avoid easy layering, splitting and scaling.

Owner:山东晨鸣纸业集团股份有限公司 +1

Method for producing paper towel

InactiveCN102912676AReduce intensityHigh strengthWater-repelling agents additionReinforcing agents additionFiberPaper towel

The invention relates to a manufacturing method of a crepe paper product. A method for producing a paper towel comprises the following steps of: selecting 70-80 % of bleached softwood pulp and 20-30 % of straw pulp as raw materials; pulping the pulp by using a pulper, after beating the pulp by using a disc mill and adding auxiliary materials of an expanding agent, a softening agent and a wet strength agent to the pulp, molding, dehydrating and squeezing the pulp by using a Harper fourdrinier system; creping a wet paper sheet in a creping cylinder when the dryness of the wet paper sheet is 30-45 %, wherein an angle between a creping knife and the tangential line of a cylinder surface is 20-30 degrees, the cutting edge angle of a scraping knife sticking to the cylinder surface is 60-85 degrees, and the speed ratio of the creping cylinder and a heating cylinder is 1.15-1.18:1; and then drying the wet paper sheet by using the heating cylinder; and winding, rewinding and slicing the paper sheet so as to obtain a finished product. The method for producing the paper towel, provided by the invention, has the advantages as follows: through fiber variety and proportion selection and through the adoption of a wet creping process, the paper towel are produced; and the produced the paper towel has the advantages of tensile strength and proper air permeability; and the strength, wet strength, hydrophobicity, air permeability, flexibility and the like of the paper towel all reach higher standards; therefore, high quality and low cost are achieved.

Owner:QUANZHOU HUAXIANG PAPER IND

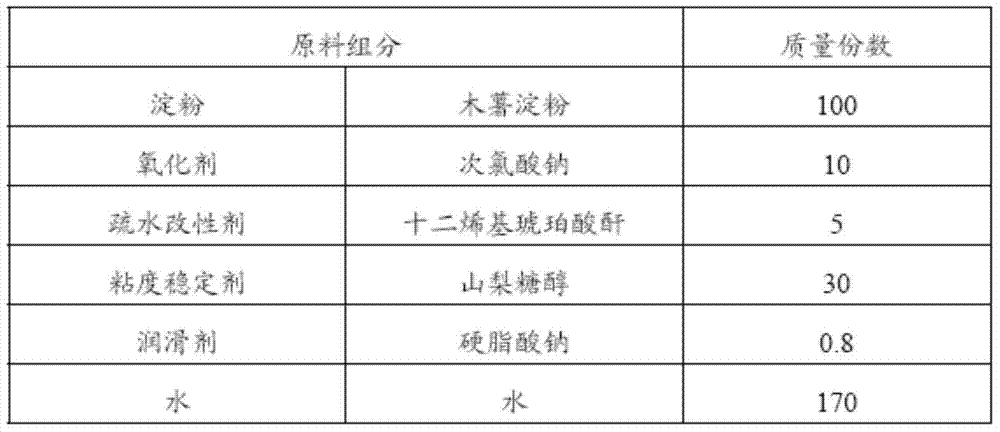

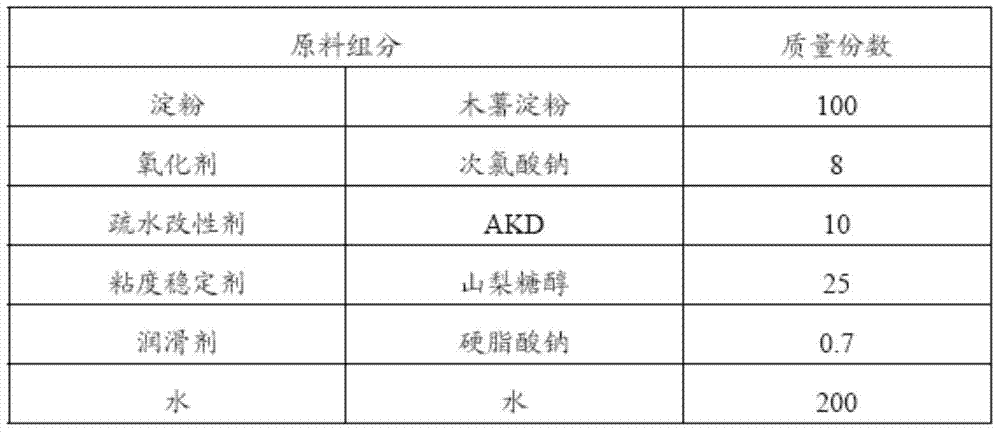

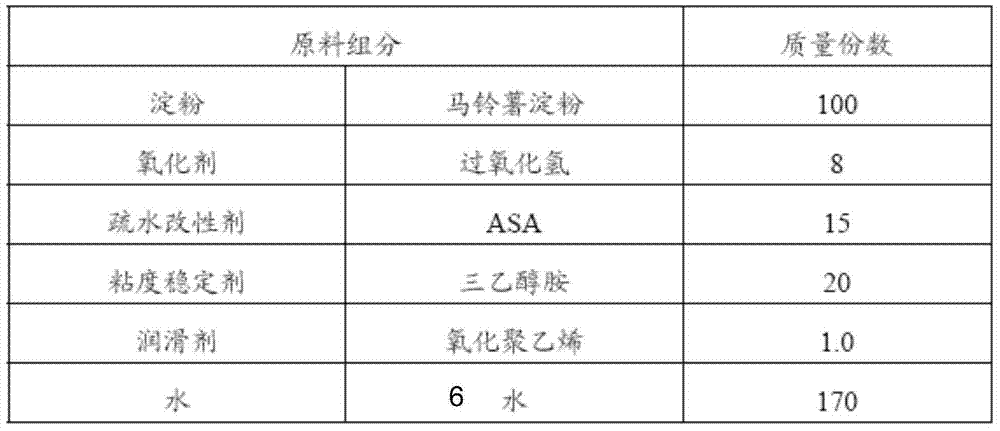

Latex for papermaking, preparation method and coating containing latex for papermaking

ActiveCN103757980AImprove performanceImprove water resistancePaper forming aids additionEpoxyPapermaking

The invention provides latex for papermaking. The latex contains starch, oxidants, hydrophobic modifying agents and water, wherein the dosage of the oxidants is 7-10% of the mass of starch; the dosage of the hydrophobic modifying agents is 5-20% of the mass of the starch; the hydrophobic modifying agents are selected from at least one of dodecenyl succinic anhydride, maleic anhydride, epoxy chloropropane, an alkyl ketene dimmer, alkenyl succinic anhydride, a styrene-acrylate copolymer, a silane coupling agent and a titanate coupling agent. The invention also provides a preparation method of the latex for papermaking and a coating containing the latex for papermaking. The problems that the wet strength of finished paper is poor and dusting happens easily because the paper is coated with the starch-based latex for papermaking in existing processes are solved.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Coating and coating used coated paper

ActiveCN103590282AHigh glossReduce the risk of bad printsDefoamers additionCoatings with pigmentsStrong acidsPaper sheet

The invention provides a coating used in the papermaking field. The coating contains nanometer microcrystalline cellulose, a pigment, a latex, an assistant and water, and the nanometer microcrystalline cellulose is highly-crystallized cellulose having a length of 100-500nm and a width of 3-100nm obtained by hydrolyzing a cellulose raw material in a strong acid; and the bone dry mass parts of the nanometer microcrystalline cellulose, the pigment, the latex, the assistant and water in the coating are 0.02-10, 75-95, 5-15 and 0.35-10 respectively. The invention also provides a coated paper made by using the coating. The coating is coated on the surface of paper to effectively improve the glossiness, the post-print glossiness and the roughness of the coated paper in order to improve the paper quality.

Owner:GOLD EAST PAPER JIANGSU

Manufacturing method of high-bulk coating printing paper

ActiveCN102877365AReduce smoothnessDegree of reductionDefoamers additionCoatings with pigmentsColor printingPulp and paper industry

The invention discloses a manufacturing method of high-bulk coating printing paper. In the method, high proportion chemical pulp is adopted for coating body paper, light calcium carbonate is used as filler, and high bulk is achieved. A door roller coating machine is used for coating the body paper, and the coating paint adopts plastic paint with a given proportion and a hollow structure, so that the bulk of the coat and the formed paper brightness can be effectively improved. Meanwhile, a soft calender is used for pre-calendering and polishing the coated body paper, so that the fineness of the paper surface is greatly improved while the thickness of the original paper is maintained. The bulk of the high-bulk coating printing paper manufactured through the method is 1.3 to 1.5 cm<3> / g and is far better than that of the ordinary copper paper and light coating paper; and meanwhile, the surface of the paper is smooth and fine, so that printed patterns are full and rich in color, image dots are clear and strong in three-dimensional impression, and the paper is applicable to top-grade color printing.

Owner:MCC PAPER YINHE

Composite non-woven fabric and production method thereof

ActiveCN104264366ASolve hydrophobicSolve the breathability problemSynthetic cellulose/non-cellulose material pulp/paperNon-woven fabricsTextile fiberNonwoven fabric

The invention relates to the field of non-woven fabric, in particular to a composite non-woven fabric and a production method thereof. The composite non-woven fabric comprises, by weight, 15-48 parts of diatomite, 20-85 parts of fiber superpolymers and 0.5-3 parts of textile assistant. According to the composite non-woven fabric, inorganic powder of the diatomite is added into textile-fiber non-woven fabric to produce the non-woven fabric with a diatomite function, namely diatomite cloth, so that a part of textile fibers are replaced to reduce cost, and the objectives of saving oil resources and energy and reducing carbon dioxide emission are achieved; hydroxide radicals of the fibers are increased, so that the problems that a non-woven fabric body is hydrophobic and airtight and does not have a heat insulation function are solved.

Owner:白山星泰硅藻土新材料有限公司

Processing method of resin-impregnated film adhesive with low formaldehyde release

InactiveCN104611985AReduce the chance of outward releaseFree aldehyde reductionPaper coatingPaper/cardboardResin coatingPolyresin

The invention relates to a processing method of a resin-impregnated film adhesive with low formaldehyde release. The method comprises the following steps: additionally arranging roll coating equipment in an impregnating process, hermetically coating a layer of amine-aldehyde resin by utilizing the roll coating equipment after primary impregnation of urea-formaldehyde resin, going in and out of a first section of baking oven, performing secondary amine aldehyde resin coating up and down, going in a second section of baking oven, drying and cooling, and cutting the finished resin-impregnated film adhesive. The processing method has the benefits that (1) a formaldehyde accelerant is adopted in the resin glue production process, so that relative free aldehyde in a glue solution is reduced; (2) as the roll coating equipment is additionally arranged, and the amine-aldehyde resin is hermetically coated immediately after primary impregnation and then goes in the first section of baking oven to be dried, the amine-aldehyde resin forms a good sealing layer, and the outward release probability of formaldehyde is reduced; the formaldehyde release amount of the prepared finished resin-impregnated film adhesive is reduced from original less than or equal to 1.5 mg / l to below 1.0 mg / l.

Owner:ZHEJIANG DILONG NEW MATERIAL

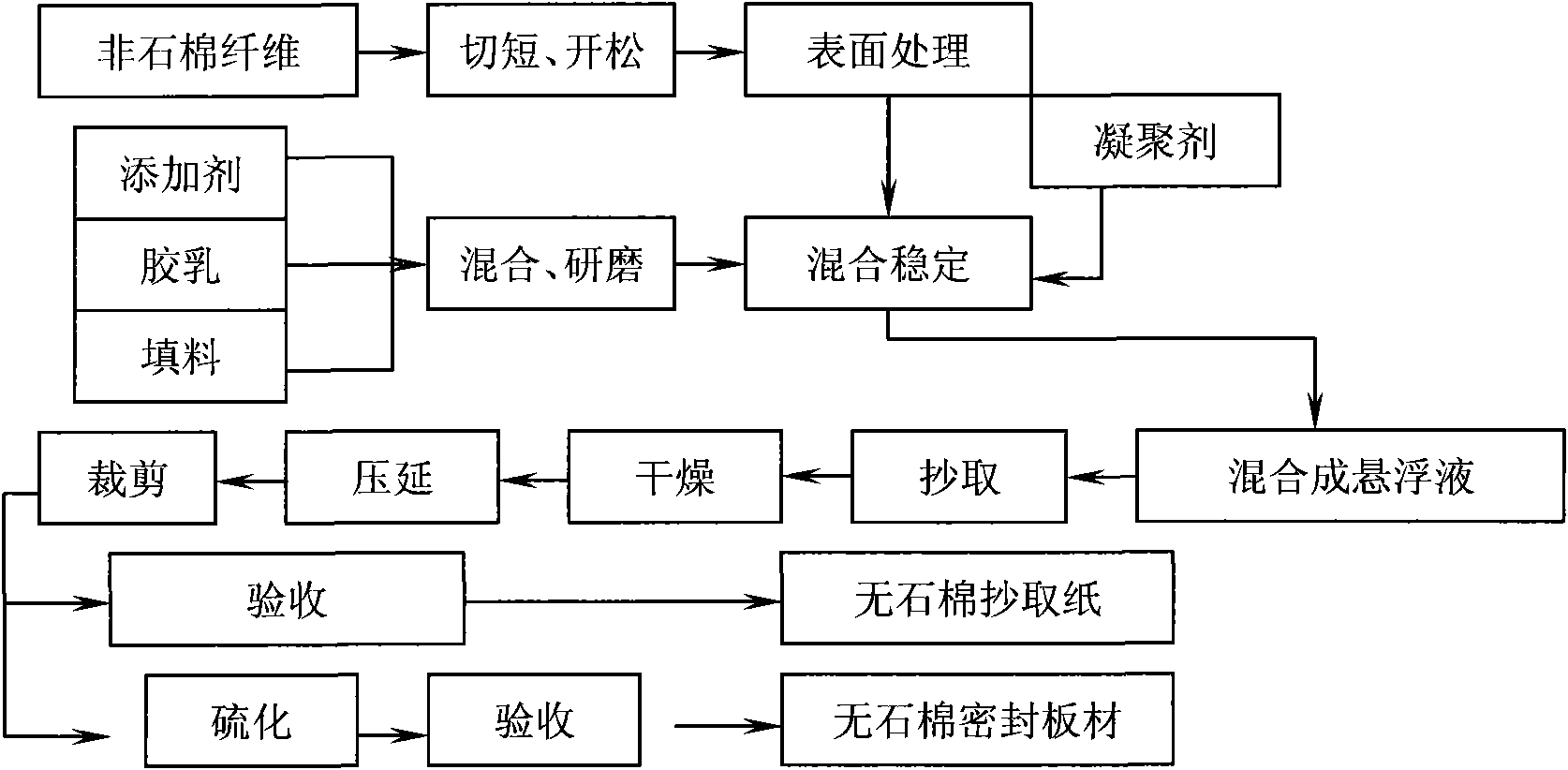

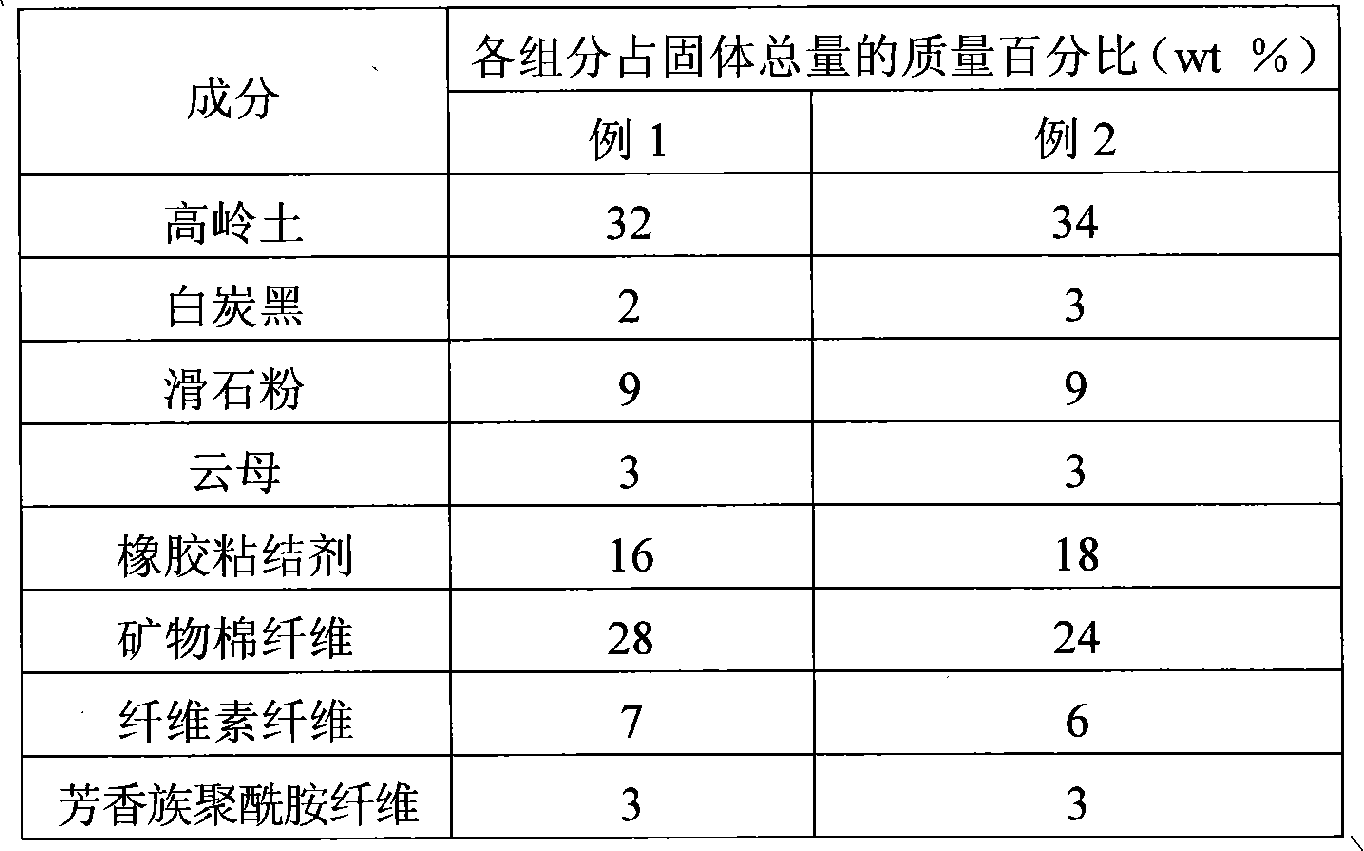

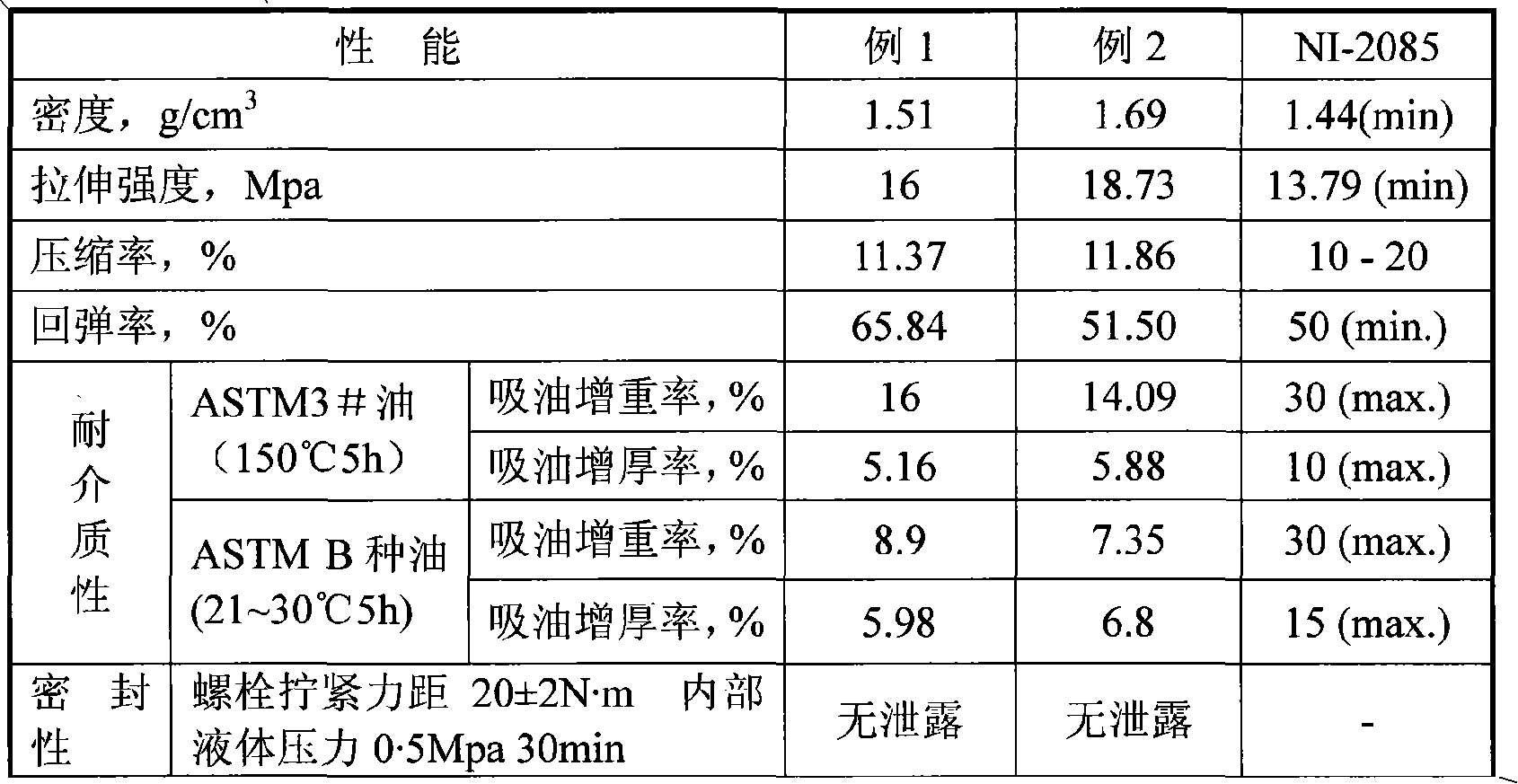

Method for preparing copy sheet used for sealing gasket

InactiveCN101575829AReasonable choiceNo pollution in the processFibreboardInorganic fibres/flakesAsbestos sheetVulcanization

The invention relates to a method for manufacturing a sealing gasket, in particular to a method for preparing a copy sheet used for a sealing gasket which does not contain asbestos fiber, belonging to the field of sealing materials. The copy sheet contains the main components of mineral cotton fiber, cellulose fiber, aromatic polyamide fiber, rubber cement and kaoline; the components are mixed to a dispersed system containing water, then a paper-making technique is adopted to dehydrate gradually and form a layer, and a finished product of the copy sheet is manufactured by compression, drying and vulcanization. The sealing gasket manufactured by the sheet has tensile strength, compression resilience performance, medium resistance and sealing performance and the like equivalent to that of the copying asbestos sealing gasket and can completely replace asbestos sheets for manufacturing the sealing materials of the gasket and the like.

Owner:KUNMING UNIV OF SCI & TECH +1

Producing method of wallpaper

InactiveCN104404832AElasticGood three-dimensionalCoatings with pigmentsCovering/liningsScreen printingSurface layer

The invention relates to a producing method of wallpaper. The producing method includes following steps: (1) unreeling non-woven paper on a printing machine and feeding the non-woven paper into a coating machine; (2) coating a surface of the non-woven paper with a PVC layer through a first PVC foaming slurry material by the coating machine, and performing plastification, foaming and cooling to obtain a foamed semi-product; (3) unreeling the foamed semi-product and feeding the foamed semi-product into a circular screen printing apparatus, printing color and stereo simulative patterns on a surface layer of the foamed semi-product through a second PVC foaming slurry material by the circular screen printing apparatus, drying the foamed semi-product in hot air and cooling the foamed semi-product to obtain a printed semi-product; (4) feeding the printed semi-product into a drying oven for performing temperature-increasing foaming; and (5) feeding a wallpaper semi-product into a cooling roller for cooling the wallpaper semi-product to room temperature with circulating water to obtain the wallpaper. Compared with a method in the prior art, the method is simple in production processes. The two different PVC foaming slurry materials are employed for coating, printing and relatively matched foaming. The wallpaper has a stereoscopic and simulative decorative effect.

Owner:桂林威迈壁纸有限公司

Method for producing degradable material with manioc waste and wine stillage

InactiveCN101302734AWith foldableCompressive and folding resistantNatural cellulose pulp/paperReinforcing agents additionCartonPaperboard

The invention discloses a method for producing a novel degradable material by manioc dreg and pot ale and comprises the following steps: the manioc dreg or the pot ale is purified, ground, cleaned, drained and mixed with dry paper pulp according to the weight proportion of a to b; wherein, the a lies between 2 and 5, and the b lies between 5 and 8; a papermaking addition agent is added, and the mixture is molded and parched, thus obtaining the degradable material product. Paper pulps of vegetable fiber such as waste newspapers, carton paper, paperboards and other paper pulps of vegetable fiber materials can be taken as the dry paper pulp. The method for producing the novel degradable material by the manioc dreg and the pot ale adequately utilizes wastes of manioc resources such as the manioc dreg, the pot ale to produce the novel industrial degradable material with good quality and low cost, replaces degradable materials of cellular plastics, and not only solves the difficult processing problem of wastes and changes wastes into valuable, but also effectively generates the actions of controlling and eliminating the white pollution; furthermore, the method for producing the novel degradable material by the manioc waste and the pot ale has uncomplicated technique, short production period, low cost, low energy consumption, simple and convenient operation, high product stability and good economic, social and environment-protective benefits.

Owner:广西农垦明阳生化有限公司

Coated paper coating containing nano particle modified adhesive and preparation method thereof

ActiveCN104594121AGood optical performanceImprove surface printabilityDefoamers additionCoatings with pigmentsAdhesivePigment particle

The invention relates to a coated paper coating containing a nano particle modified adhesive and a preparation method thereof. The coating dislcosed by the invention is composed of Kaolin, heavy calcium carbonate, modified styrene acrylic emulsion, sodium carboxymethyl cellulose, sodium hexametaphosphate, a water repellent agent, a lubricant, an anti-foaming agent, ammonium hydroxide and water. The preparation method comprises the following steps: firstly, adding the dispersing agent into water and stirring evenly, adding pigment particles, stirring for 30min at speed of 2000r / min, after slowing down the stirring speed to 1000r / min, adding the adhesive nano calcium carbonate modified styrene-butyl acrylate emulsion, water repellent agent, lubricant and anti-foaming agent, continuing to perform shearing dispersion at the speed of 1000r / min for 10min, regulating pH to 8.0, and finally, filtering a coarse material through a 200-mesh screen to get the coated paper coating. The coating obtained by the preparation method has the characteristics of high solid content, low viscosity, good water retention capacity and low production cost.

Owner:ZHEJIANG SCI-TECH UNIV

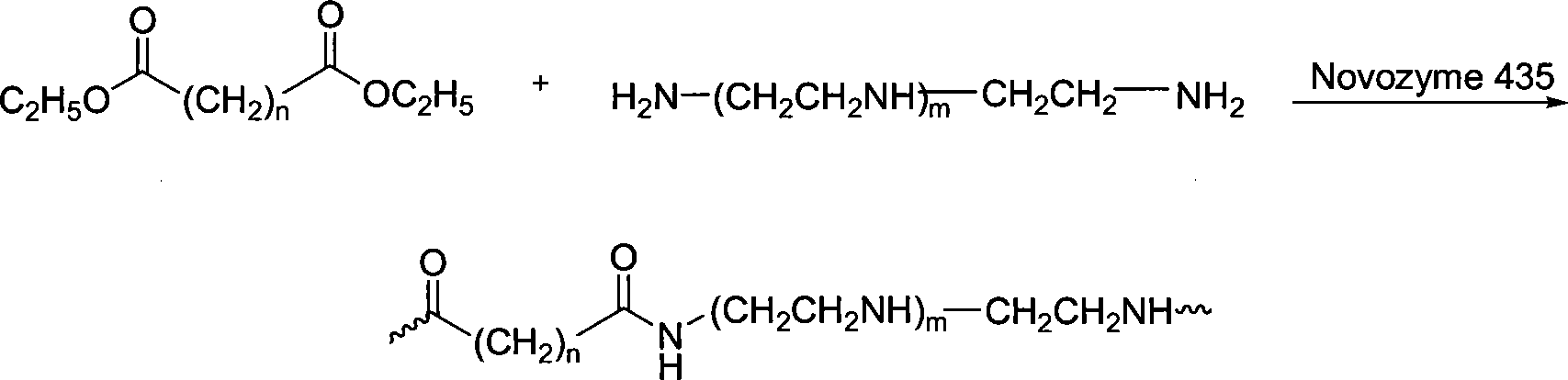

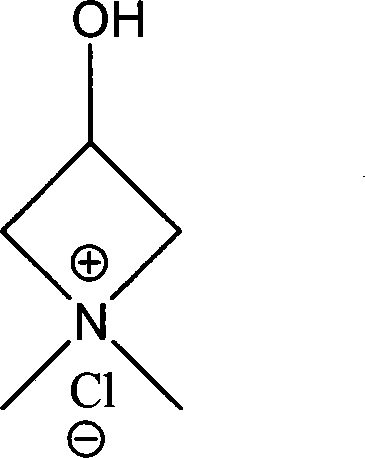

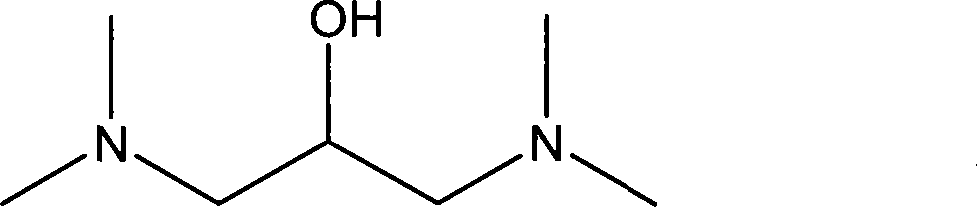

Polyamide-epichlorohydrin resin cylinder adhesive

InactiveCN101235610ARaw materials are easy to getOptimize process flowPaper forming aids additionAdhesivePolyamide

The invention relates to polyamide-epichlorohydrin resin sticking cylinder agent, which is used for a crinkling technique in producing tissue paper. The method of the invention comprises: taking polyamine and secondary lipid as raw materials, taking water, carbinol and ethanol as dissolvant (or not adding the dissolvent), adding little amount of activator for catalyze reaction to generate polyamide prepolymer, then, reacting with the epichlorohydrin under certain acidity-alkalinity and under the condition that stabilizing agent is existed and the temperature is 60-80DEG C, generating polyamide-epichlorohydrin resin, adjusting the pH value, cooling and discharging materials, and obtaining the polyamide-epichlorohydrin resin sticking cylinder agent. The sticking cylinder agent product of the invention has stable performance and can improve the crinkling unevenness in the crinkling technique and paper cutting phenomenon in the crinkling process when in use.

Owner:EAST CHINA UNIV OF SCI & TECH

Wallpaper base paper capable of adsorbing formaldehyde and production method thereof

ActiveCN104746382AImprove breathabilityHas the function of absorbing formaldehydeDefoamers additionCoatings with pigmentsFiberAdsorption effect

The invention discloses wallpaper base paper capable of adsorbing formaldehyde which is made by using a special process, and wall paper prepared by the wallpaper base paper has a function of adsorbing indoor free formaldehyde. Functional fibers are added into pulp of wallpaper base paper capable of adsorbing formaldehyde, so that the air permeability and the adsorption capability of the paper are improved; formaldehyde adsorbent and calcined diatomaceous earth are added into a coating solution so that an adsorption effect is improved. The base paper provided by the invention can further comprise a thin additional coating having a formaldehyde adsorption function with strong directivity; the wallpaper base paper adhered with the coating is suitable for being used in places in which a large amount of formaldehyde needs to be removed. The invention aims to protect the wallpaper base paper capable of adsorbing formaldehyde, and the wallpaper base paper capable of adsorbing formaldehyde is prepared from the following raw materials in percentage by weight: 30-80 percent of wood pulp, 15-60 percent of a functional fiber, and 5-10 percent of an auxiliary.

Owner:SHANDONG LUNAN NEW MATERIALS

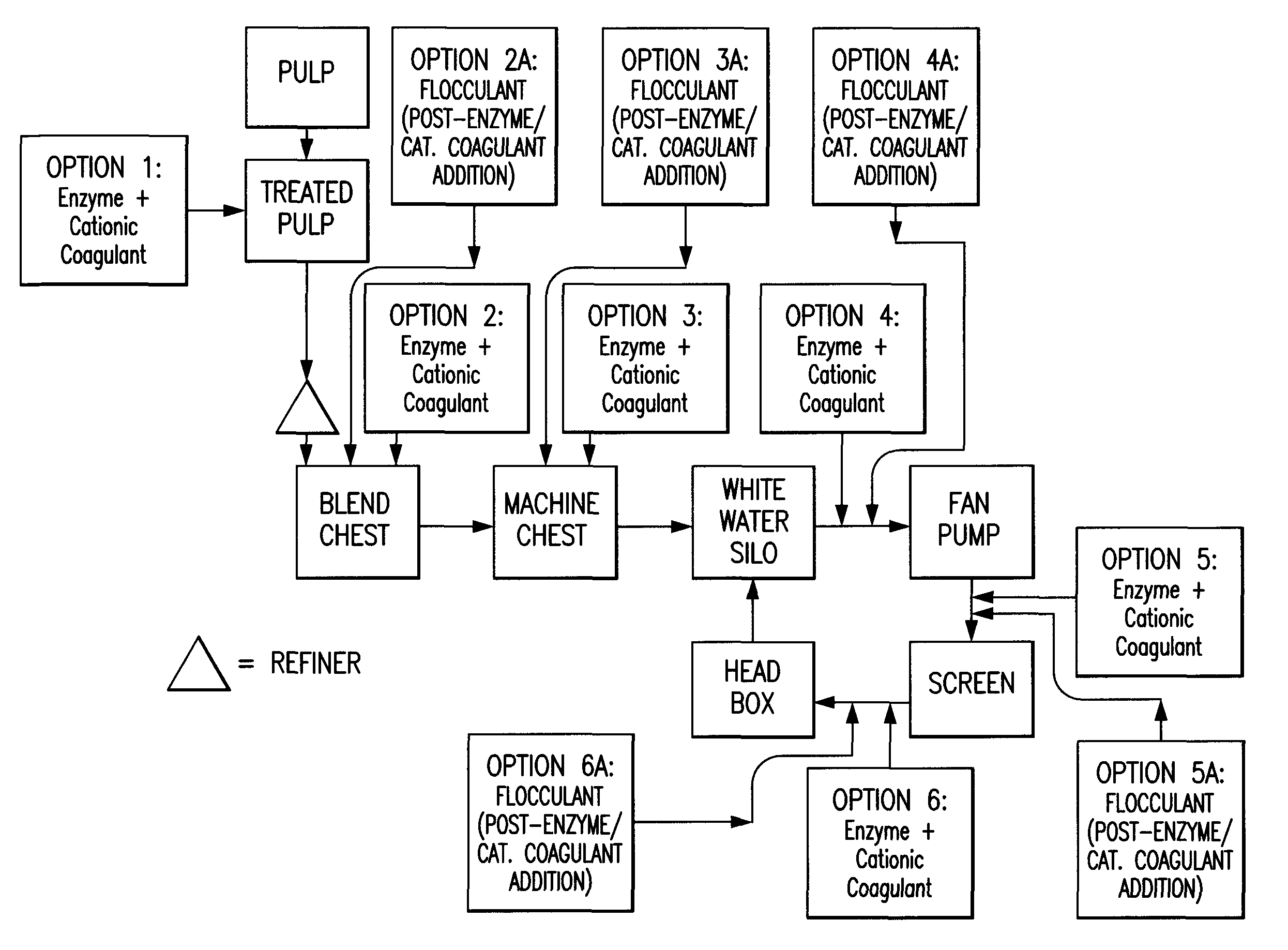

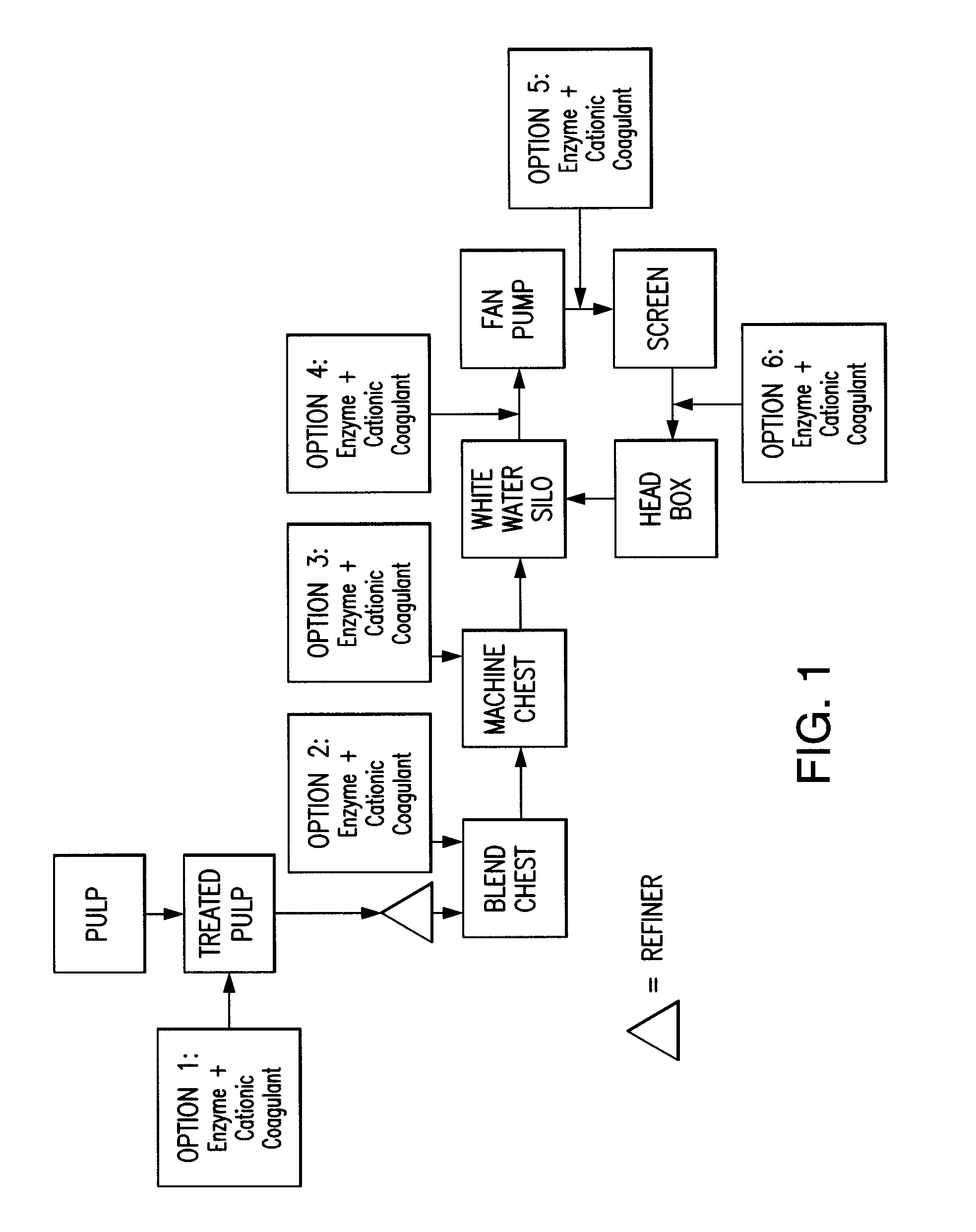

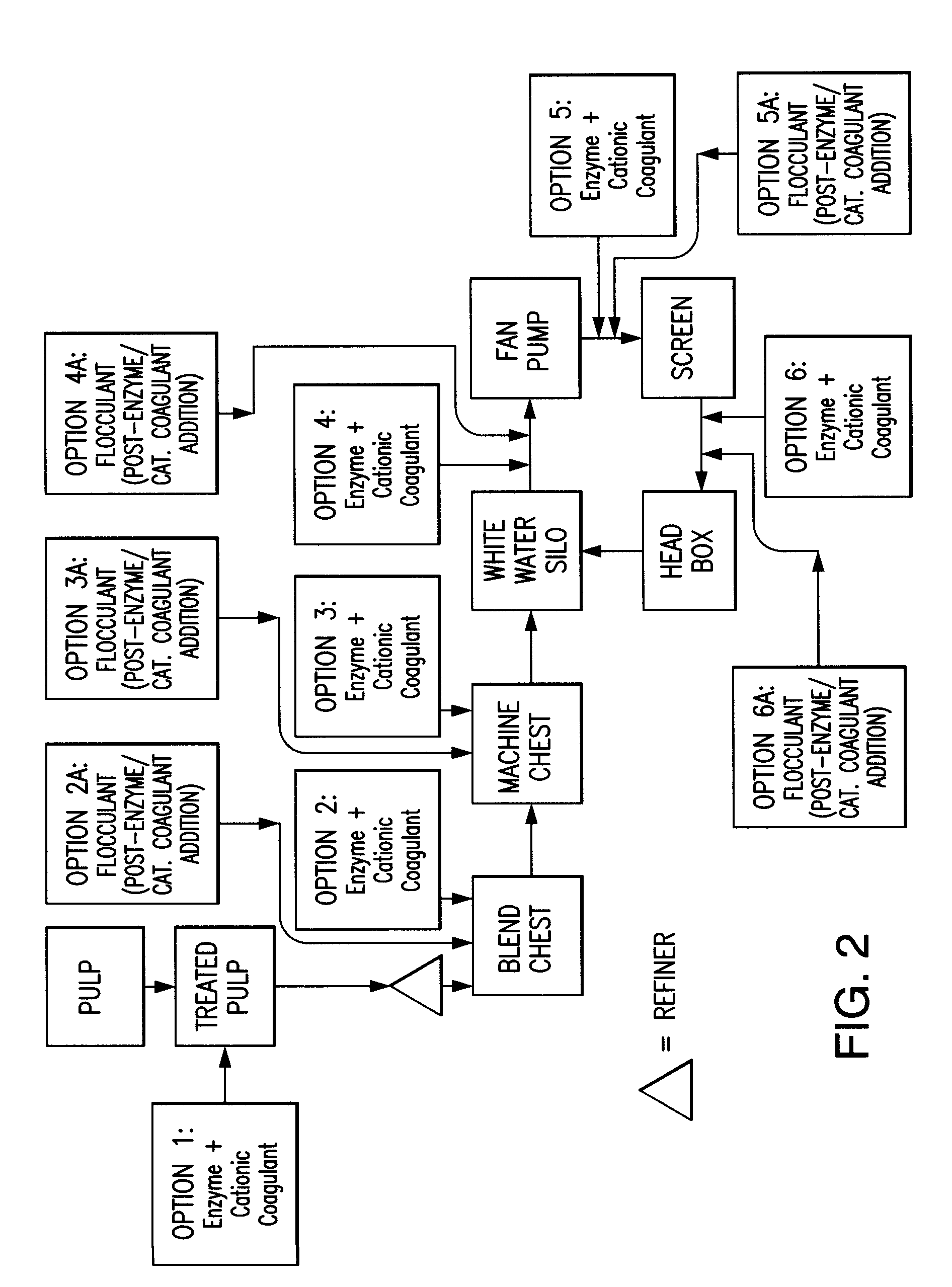

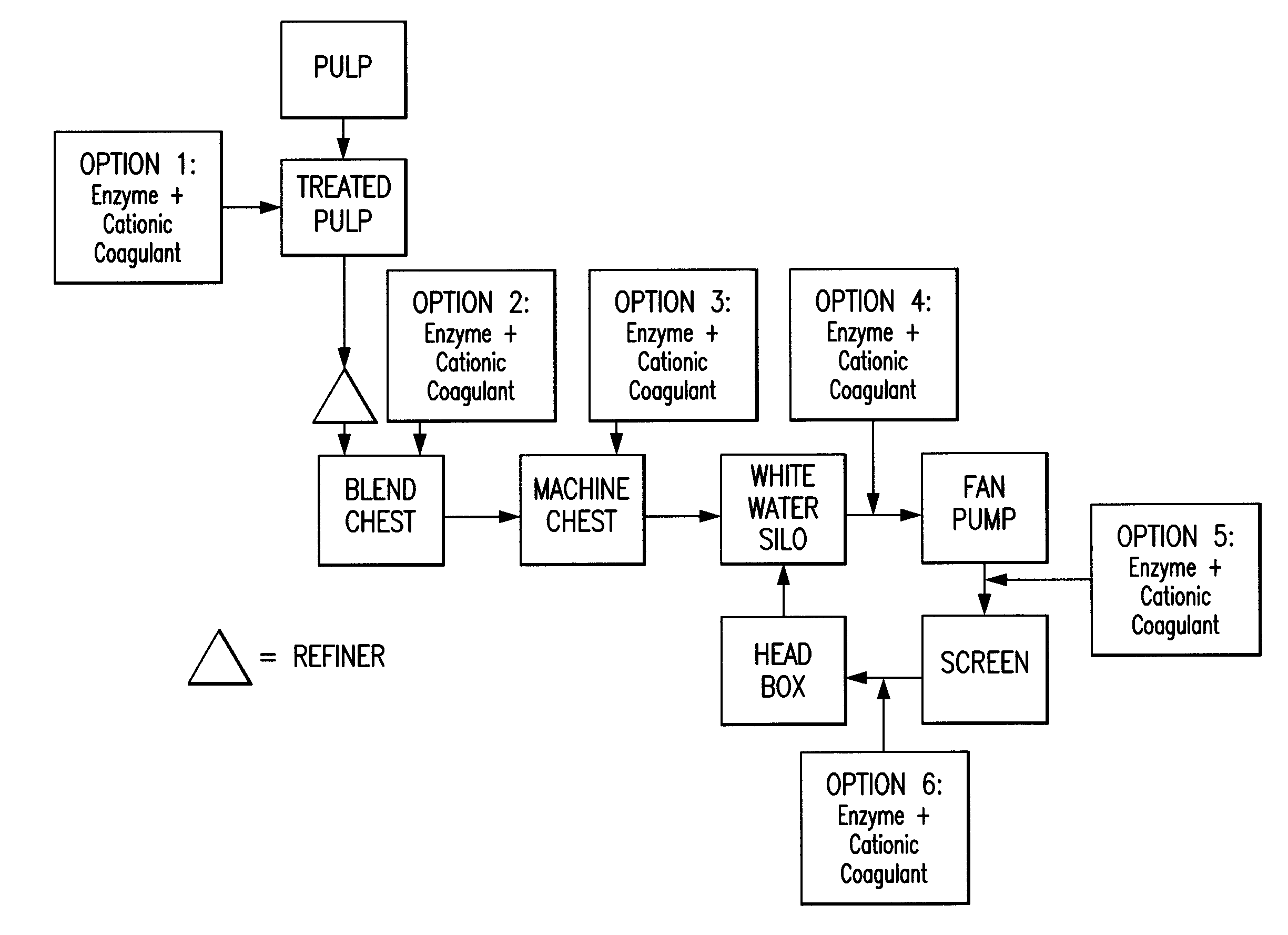

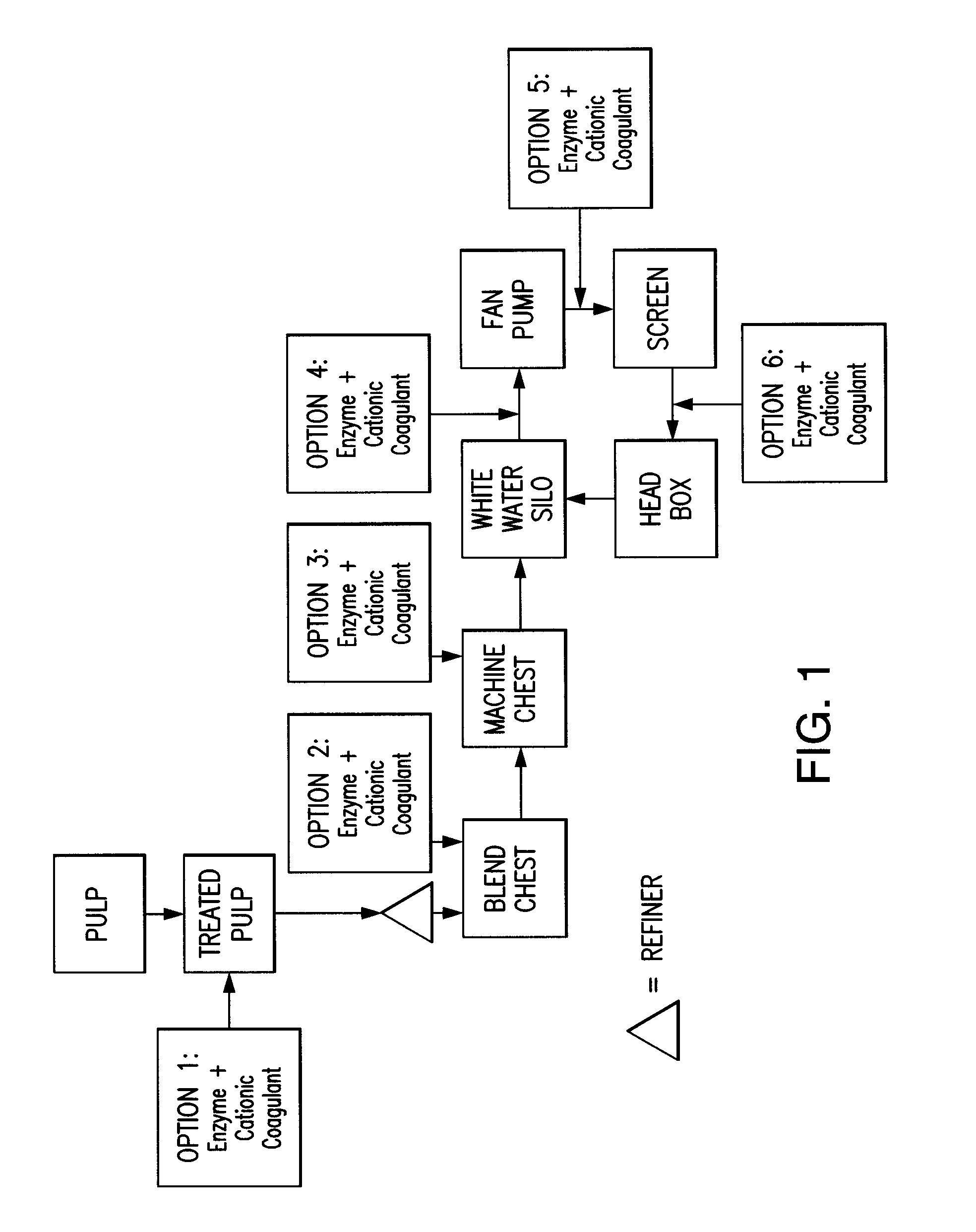

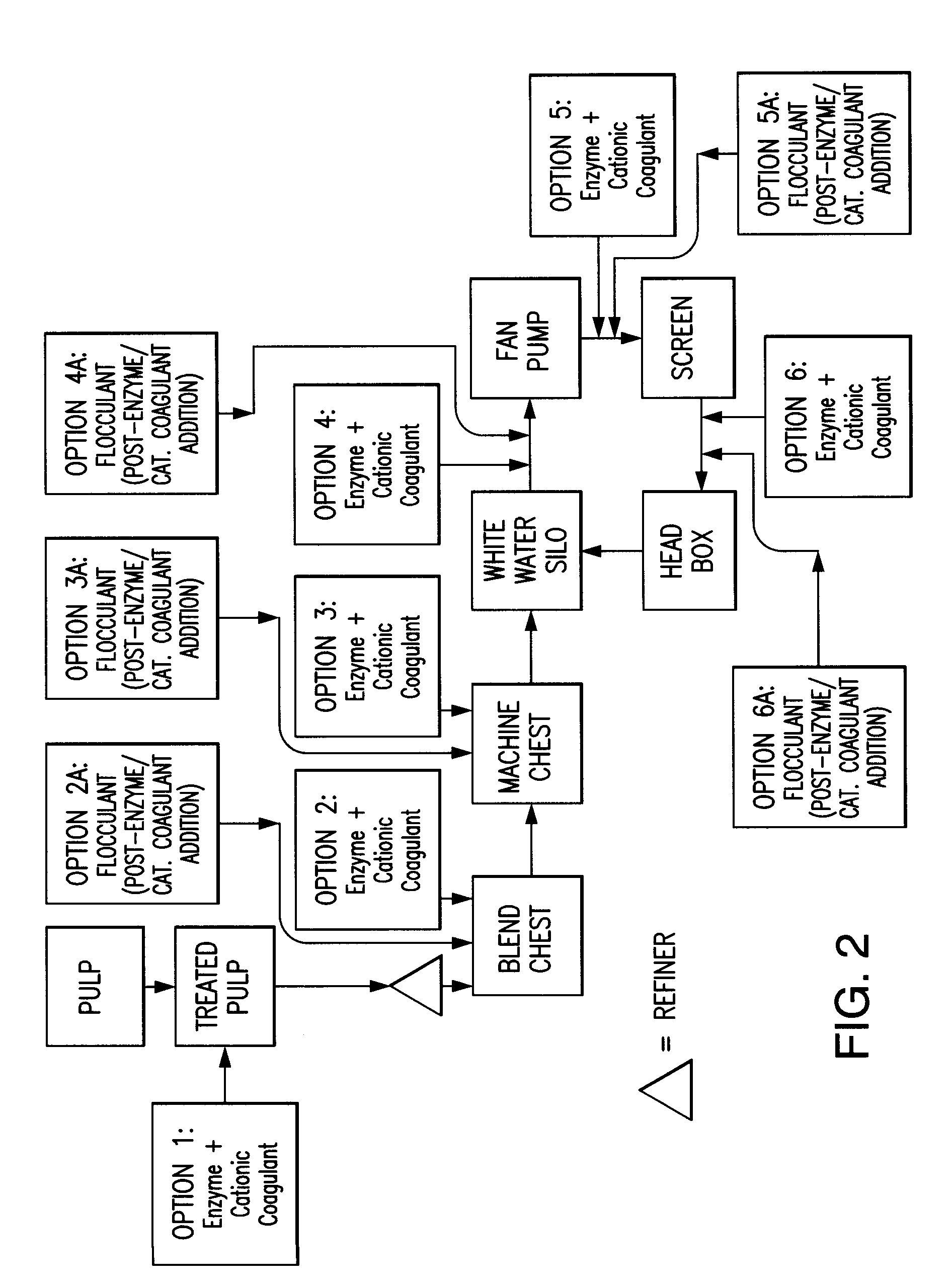

Paper making processes and system using enzyme and cationic coagulant combination

ActiveUS8454798B2Improved cellulosic pulp drainage and retentionHigh retention rateNatural cellulose pulp/paperSpecial paperPaperboardPulp and paper industry

A method is described for making paper or paper board by applying a composition containing enzyme and cationic coagulant to papermaking pulp prior to paper forming to preferably improve drainage, retention, or both. Sheets of pulp from which paper or paperboard products are made with the method can exhibit excellent drainage, excellent retention of pulp fines, or both. The method also can be applied to other pulp treatments, such as waste water treatments. A system for making such treatments of paper furnish is also provided.

Owner:BUCKMAN LAB INT INC

Highly-oriented fibrous mats

A mat containing highly machine direction oriented (90% or greater), discontinuous reinforcement fibers, is produced on inclined wire or rotary paper making machinery. Fibers are first uniformly dispersed in an aqueous medium containing thickeners and wetting agents. In one embodiment, antifoaming agents are also added to prevent floating fibers which entangle and reduce orientation. Thermoplastic fibers or particles may also be included. Stock is brought into an open headbox in a flow pattern which allows the fibers to decelerate before approaching the porous suction belt (wire). As the fibers approach the suction belt, the fibers begin to turn and align in the streamline so as to present one end toward the suction wire. The leading ends of the fibers are gripped by the moving belt which drags the fibers out of the dispersion stock in a straight line. The porous mat produced may be dried and bonded through hot air, heat and / or pressure, or chemical binders. Stacks of such mats may be compressed partially to produce porous structures, or fully to produce impervious, rigid structural panels or shapes.

Owner:VIRGINIA TECH FOUND

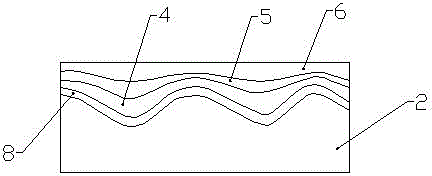

Wallpaper and preparation method thereof

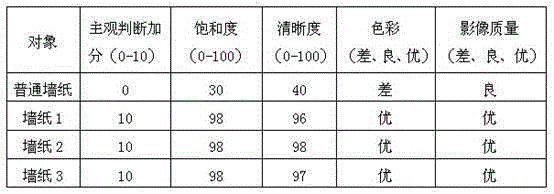

ActiveCN105178110AIncrease reflectionImproved viewing angle balanceDefoamers additionCovering/liningsFiberCyclohexanone

The present invention discloses a wallpaper and a preparation method thereof, wherein the wallpaper comprises 40-80 parts of paper pulp, 10-15 parts of tree bark powder, 1-2 parts of borosilicate, 0.4-0.8 part of nanometer powder, 2-4 parts of calcium hypochlorite, 4-7 parts of polycarbonate, 3-6 parts of polyethylene terephthalic acid ester, 3-5 parts of 2,6-dibenzylidene cyclohexanone, 2-4 parts of carbon fibers, 3-6 parts of diethyl phthalate, 2-5 parts of glass fiber filament, 1-3 parts of carboxymethyl cellulose, 2-4 parts of polyacrylic acid fibers, 0.4-1 part of an anti-forming agent, 8-10 parts of a film forming agent, and 1-3 parts of a dispersant. The wallpaper has characteristics of high reflective property, visual angle balance improving and gain increasing so as to provide high projection effect, good image saturation degree and high definition, and further has characteristics of green environmental protection, wear resistance and good stability.

Owner:香山红叶集团有限公司

Waterproof coating of carton

ActiveCN102704330AGood chemical stabilityImprove insulation performanceCoatingsPaper forming aids additionParaffin waxEmulsion

The invention relates to a waterproof coating, in particular to a waterproof coating of a carton, which comprises the following components in weight part: 30-120 parts of paraffin micro-emulsion, 50-90 parts of simethicone, and 4-8 parts of emulsifier. The waterproof coating is prepared according to a method as follows: (1) heating the paraffin micro-emulsion to 50-180 degree C; (2) adding simethicone and stirring for 0.5-3 hours; and (3) adding the emulsifier, stirring at a high speed for 10-40 minutes, and cooling to the room temperature. The waterproof coating of the carton, disclosed by the invention, has no pollution on the human body and the environment, can be combined with the base material firmly, and has excellent waterproof property.

Owner:ANHUI JINDUN PAINT

Paper Making Processes and System Using Enzyme and Cationic Coagulant Combination

ActiveUS20110253333A1Improved cellulosic pulp drainageImprove retentionNatural cellulose pulp/paperSpecial paperWastewaterPaperboard

A method is described for making paper or paper board by applying a composition containing enzyme and cationic coagulant to papermaking pulp prior to paper forming to preferably improve drainage, retention, or both. Sheets of pulp from which paper or paperboard products are made with the method can exhibit excellent drainage, excellent retention of pulp fines, or both. The method also can be applied to other pulp treatments, such as waste water treatments. A system for making such treatments of paper furnish is also provided.

Owner:BUCKMAN LAB INT INC

Application of waterborne back-coating emulsion (humectant) in packaging industry

InactiveCN104594124AChange flatnessControl balanceDefoamers additionPaper coatingEmulsionAcrylic resin

The invention provides an application of a waterborne back-coating emulsion (humectant), and in particular discloses an application of the waterborne back-coating emulsion (humectant) in the packaging industry. The waterborne back-coating emulsion (humectant) is coated on the back surface of a piece of paper before an article is packaged by the paper, namely the waterborne back-coating emulsion (humectant) is pre-coated on the back surface of the paper by virtue of a coating machine before the article is packaged by the paper, wherein the waterborne back-coating emulsion (humectant) accounts for 0.8-2.4% of the weight of the paper, is obtained by the steps of adding an appropriate amount of an auxiliary agent into an acrylic resin solution, mixing, stirring for dispersion and filtering, is simple and convenient to prepare and is obvious in effect. By applying the waterborne back-coating emulsion (humectant) to the packaging industry, particularly, the aluminized paper processing industry, the flatness of the paper cannot be reduced due to changes of air humidity in the long-term storage process of the paper, so that the paper is ensured to be beautiful, the operation is relatively simple and smooth in the use processes including printing and the like, and special requirements on equipment are avoided.

Owner:江苏琛亚印材科技有限公司

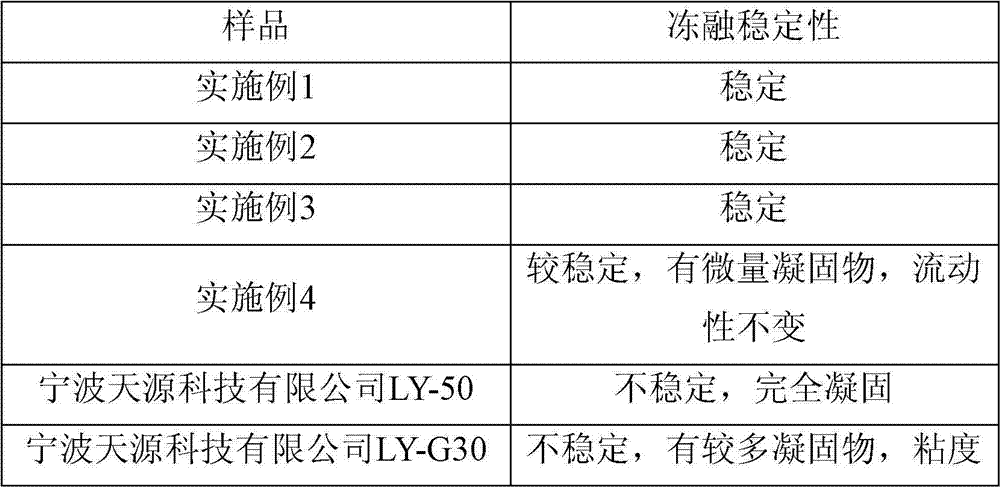

Calcium stearate dispersing liquid for papermaking and preparation method thereof

InactiveCN102828440AGood storage stabilityImprove mechanical stabilityDefoamers additionPaper coatingFreeze thawingPolyvinyl alcohol

The invention discloses a calcium stearate dispersing liquid for papermaking and a preparation method thereof. The liquid comprises, by weight percent, 30 to 60 % of water, 30 to 60 % of stearic acid, 5 to 15 % of calcium hydrate, 0.8 to 3.2 % of a dispersant, 1 to 2.5 % of an emulsifier A, 1 to 4 % of an emulsifier B, 0.3 to 0.6 % of an emulsification auxiliary agent, 0.1 to 0.8 % of an stabilizing agent, 0.4 to 3 % of a catalyst, 0.3 to 0.5 % of an antifoaming agent, and 1 to 2.8 % of a modified polyvinyl alcohol aqueous solution. The invention further discloses a preparation method of the calcium stearate dispersing liquid for papermaking. The calcium stearate dispersing liquid for papermaking and the preparation method thereof are simple to operate and suitable for industrial production, and the prepared calcium stearate dispersing liquid for papermaking is good in stability, and has greatly improved freeze-thaw stability especially.

Owner:ZHEJIANG HEXIN TECH

Decorative plate finishing paper and production method thereof

The invention aims to replace wood veneer and technical wood by using a piece of novel decorative plate finishing paper for artificial plate veneering. A piece of base paper which is 150-350g / m<2> is adopted, the upper layer of the base paper is printed with simulated natural and precious trees which are infrequent day by day, other artistic patterns can be also innovated and printed, and a vivid effect can be achieved after lamination. Due to adoption of chemical fiber in the decorative plate finishing base paper, the paper strength can be improved, and the paper is soft and tough. The decorative plate finishing paper is mainly applicable to veneering of artificial plates such as fiber boards and chipboards, and can replace veneering materials such as wood veneer and technical wood, and the finishing paper can have flame retardancy after being coated with a flame retardant adhesive.

Owner:SHANDONG LUNAN NEW MATERIALS

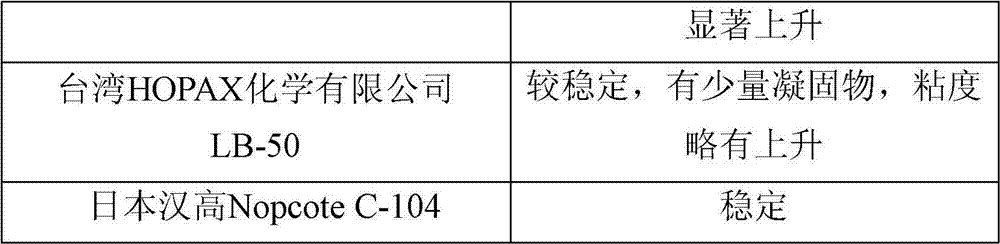

Method for preparing polyimide fiber paper

ActiveCN102926270AHigh strengthInnovativePaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperFiber bundleUltimate tensile strength

The invention discloses a method for preparing polyimide fiber paper, and the method comprises the following steps: firstly, carrying out dispersing treatment on a polyamide acid fiber bundle by using a standard fiber disperser, adding a fiber dispersant and a fiber binder, and then manufacturing a certain amount of polyamide acid fiber body paper in a standard paper sheet former; carrying out spraying or impregnating treatment on the polyamide acid fiber body paper by using a 1-10wt% of polyimide resin liquid, so that the polyimide resin liquid is uniformly distributed on the surface of the body paper, and drying the body paper; prepressing the body paper; and treating the body paper for 15-60 minutes at a temperature of 300-420 DEG C, and cooling the obtained product so as to obtain polyimide fiber paper. The method for preparing the polyimide fiber paper disclosed by the invention can be used for facilitating the reduction of consumption for beating and the improvement of paper evenness; and through the heat treatment on paper, a crosslinking reaction is generated among fibers, so that the binding force among fibers is increased, the strength properties of the paper are improved, and the application requirements of the paper in special fields are met.

Owner:SHAANXI UNIV OF SCI & TECH

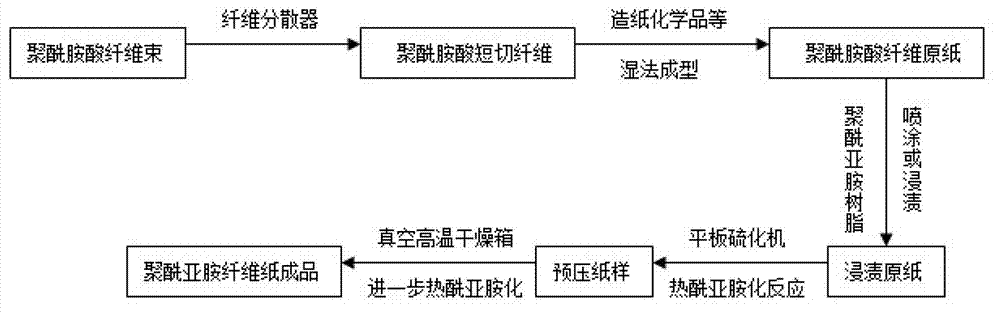

Paper making method for straw fiber pulping by 'enzymatic conversion and puffing'

InactiveCN1924187AReduce consumptionSimplify the pulping processPretreatment with alkaline reacting compoundsPaper/cardboardFiberWater discharge

This invention relates to one enzyme and puffing weed fiber pastry paper processing method, which combines biological science, life science and mechanic process to realize paper process without dirty water discharge. The method is characterized by the following: through grinding for clutter and mixture removing and cutting into short weed fiber materials into press machine; adding H2O2 solution and fiber enzyme B and induce agent C for pressing then for enzyme transmission and sending into puffing machine to get rough pastry.

Owner:汤兴然

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com