Method for preparing polyimide fiber paper

A technology of polyimide fiber and polyimide resin is applied in the field of preparation of polyimide fiber paper, which can solve the problem of high investment in equipment and products, increased bonding force between fibers, poor paper strength performance and electrical performance and other issues to achieve the effect of promoting upgrading, upgrading, and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

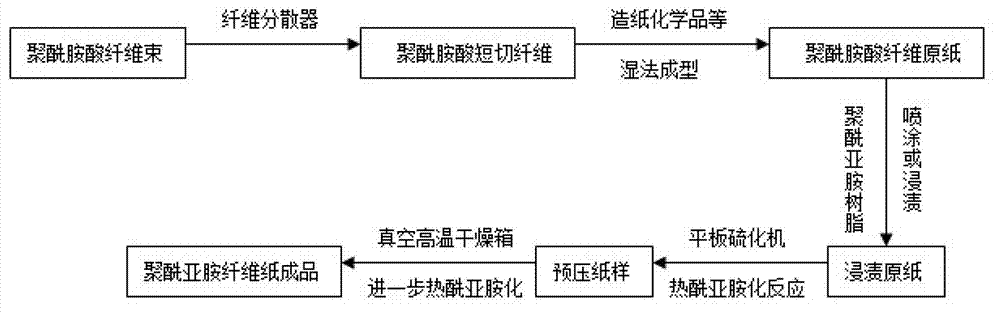

[0021] The preparation method of polyimide fiber paper of the present invention, as figure 1 As shown, the specific steps are as follows:

[0022] Step 1: Use a standard fiber disperser to disperse the polyamic acid fiber bundles, add polyethylene oxide (PEO) equivalent to 0.02% to 0.2% of the mass of the polyamic acid fiber as a fiber dispersant, equivalent to the mass of the polyamic acid fiber 2% to 15% of aramid para-position pulp is used as a fiber binder, and a certain amount of polyamic acid fiber base paper is made in a standard paper former;

[0023] Step 2: Spray or impregnate the polyamic acid fiber base paper with a polyimide resin solution with a concentration of 1-10%, so that the polyimide resin solution is evenly distributed on the base paper surface, and place it at a temperature of 60 Dry in a blast drying oven at ~100°C for 30-120 minutes to completely evaporate the solvent in the paper;

[0024] Step 3: Prepress the impregnated and dried polyimide fiber p...

Embodiment 1

[0027] Disperse the polyamic acid fiber bundles with a standard fiber disperser, add 0.1% polyethylene oxide (PEO) as a fiber dispersant, 8% aramid para-position pulp as a fiber binder, and form it on a standard paper sheet A certain amount of polyamic acid fiber base paper is made in the machine; the polyamic acid fiber base paper is sprayed or dipped with a polyimide resin solution with a concentration of 4%, so that the polyimide resin solution is evenly distributed on the base paper surface, Place it in a blast drying oven at 80°C for 90 minutes to dry the solvent in the paper; vulcanize the impregnated and dried polyimide fiber paper on a flat plate with a temperature of 220°C and a pressure of 10MPa Machine pre-compression 4min;. After the paper sample was pre-pressed, it was placed in a vacuum high-temperature drying oven, and treated at a temperature of 350°C for 30 minutes. After the above treatment, the paper sample was taken out and cooled to obtain a polyimide fibe...

Embodiment 2

[0029] Disperse the polyamic acid fiber bundles with a standard fiber disperser, add 0.02% polyethylene oxide (PEO) as a fiber dispersant, 2% aramid para-position pulp as a fiber binder, and form it on a standard paper sheet A certain amount of polyamic acid fiber base paper is made in the machine; the polyamic acid fiber base paper is sprayed or dipped with a polyimide resin solution with a concentration of 1%, so that the polyimide resin solution is evenly distributed on the base paper surface, Dry it in a blast drying oven at 60°C for 30 minutes to completely volatilize the solvent in the paper; vulcanize the impregnated and dried polyimide fiber paper on a flat plate with a temperature of 150°C and a pressure of 3MPa Machine pre-press 10min;. After the paper sample was pre-pressed, it was placed in a vacuum high-temperature drying oven, and treated at a temperature of 300 ° C for 15 minutes. After the above treatment, the paper sample was taken out and cooled to obtain a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com