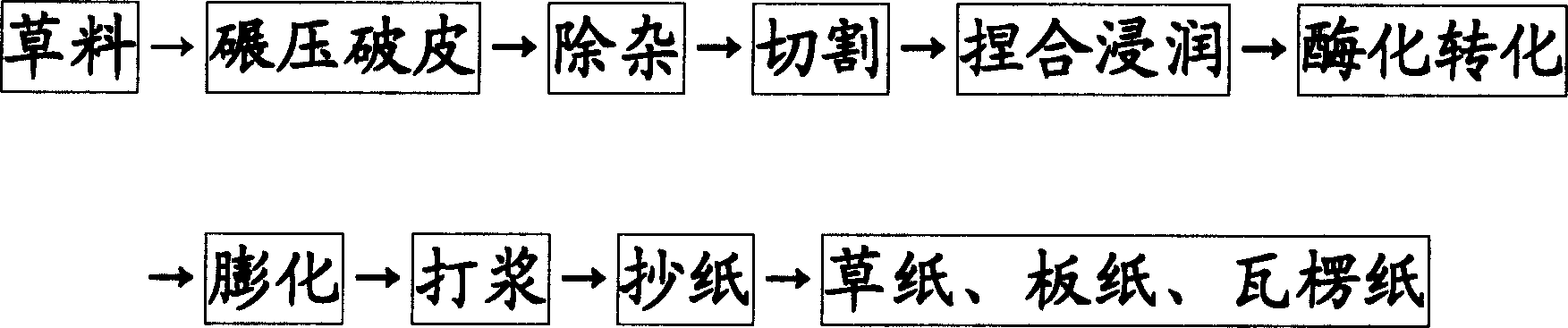

Paper making method for straw fiber pulping by 'enzymatic conversion and puffing'

A technology of pulping, papermaking and grass, which is applied in the field of grass fiber pulping and papermaking, can solve the problems of short soaking time of raw materials, incomplete pollution of straw pulp, difficulty in meeting the requirements of large-scale production, etc., and achieve the reduction of production equipment and auxiliary Equipment, saving social and environmental treatment costs, saving water for pulping and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The forage is wheat straw. Spread the wheat straw in the yard. The thickness of the wheat straw is roughly uniform. After rolling, turning, and rolling again with a tractor, use a flat vibrating screen to remove dust and other sundries, and then use a grass cutter to cut the wheat straw into 2- The 3 cm long short joints were sampled to test the content of moisture, cellulose, hemicellulose and lignin in wheat straw. And weigh 100 kilograms of forage, put it into a kneader with a volume of 1000 liters, start the kneader, spray H2O2 aqueous solution A first, or an aqueous solution of organic solvents such as oxalic acid, acetone or methanol, stir evenly, and then disperse the cellulose After the enzyme B is stirred evenly, disperse and sprinkle in the inducing melt-promoting agent C until the forage is co-kneaded and infiltrated in the kneader for 30-40 minutes, wherein the weight ratio of the absolute dry weight of the forage to the H2O2 aqueous solution is 100:19±1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com