Patents

Literature

976results about How to "Fully broken" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

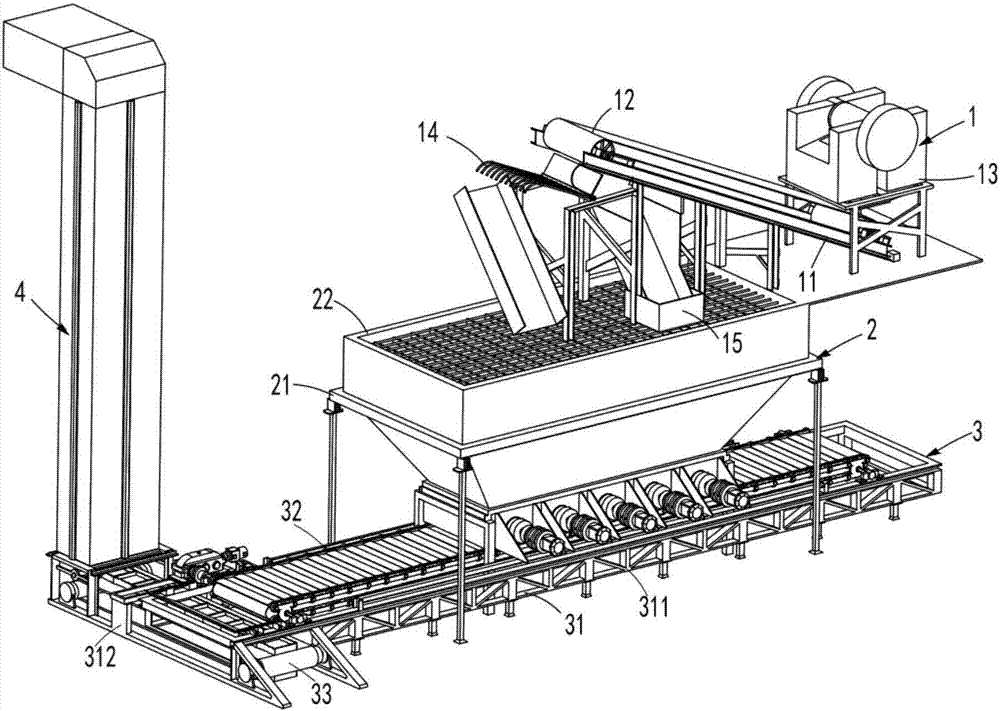

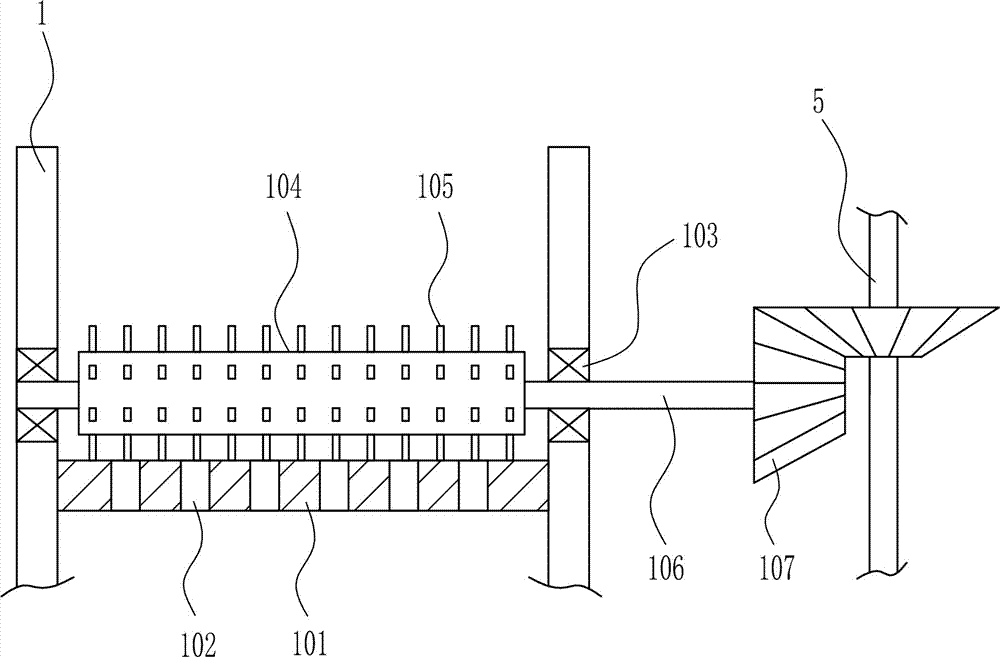

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

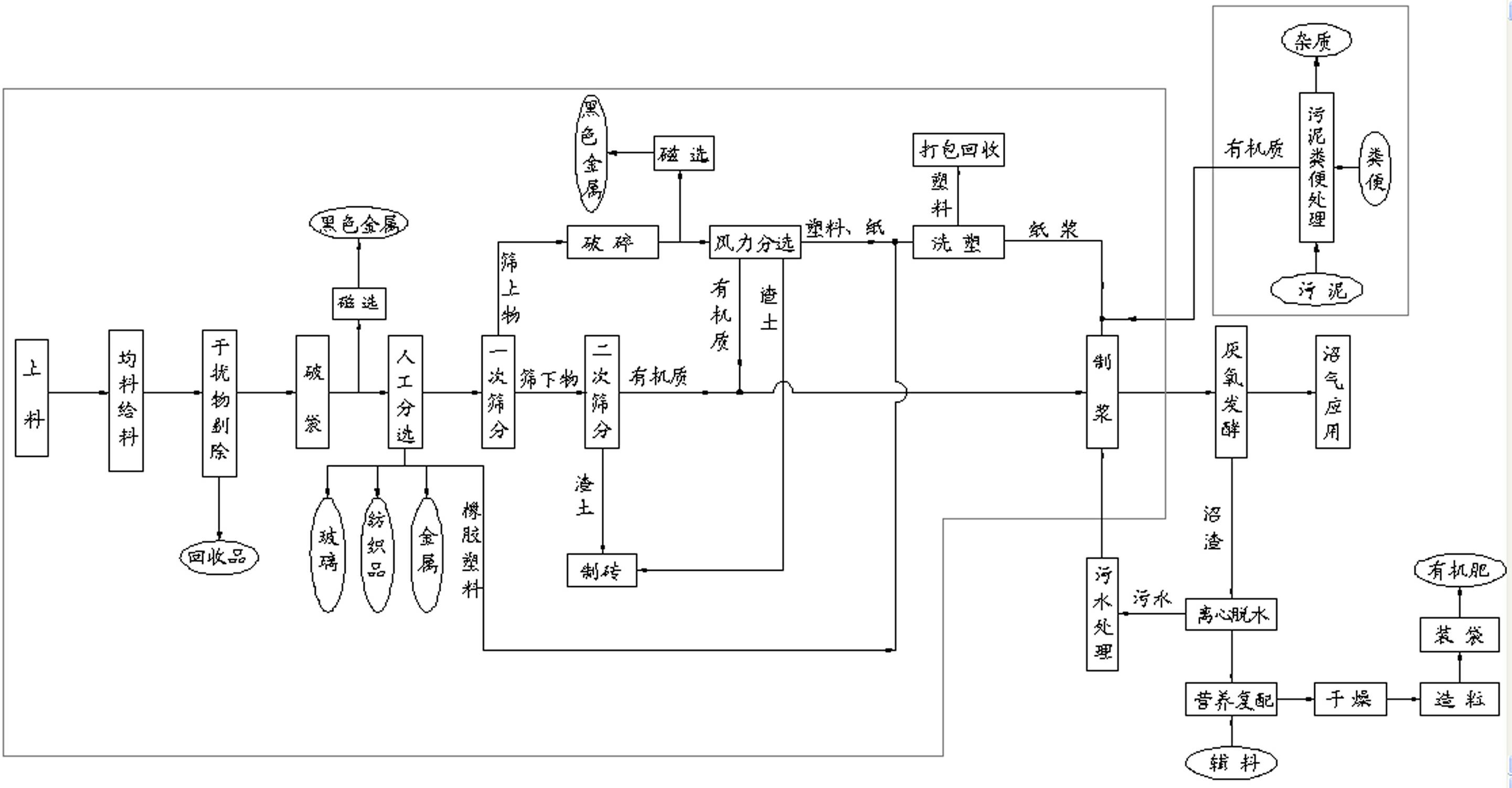

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

Manufacturing method of large-calibre seamless titanium alloy barrel body

InactiveCN101733641AWide range of sizesEasy to prepareOther manufacturing equipments/toolsTitanium alloyMachining

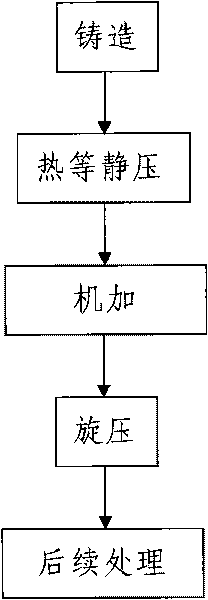

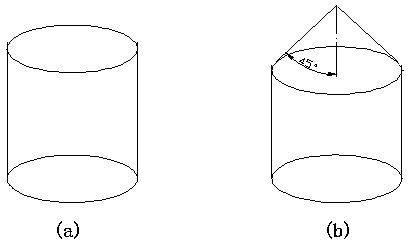

The invention discloses a manufacturing method of a large-calibre seamless titanium alloy barrel body, which comprises the steps of: 1, casting: casting titanium alloy raw materials into a large-calibre titanium alloy barrel blank by using a vacuum smelting furnace and through a vacuum smelting method; 2, hot isostatic pressing: performing the hot isostatic pressing for the large-bore titanium alloy barrel blank in an inert protective atmosphere by using a hot isostatic pressing device; 3, mechanical machining: processing a chamfer angle for spinning at the head of the large-bore titanium alloy barrel blank after the hot isostatic pressing by using mechanical processing equipment to obtain a spinning barrel blank; 4, spinning: thermally spinning the mechanically processed spinning barrel blank with the total deformation rate not less than 60% for many times by using spinning equipment to obtain a large-bore seamless titanium alloy thin-wall barrel body; and 5, subsequent treatment. The production process has short process flow, high yield, low cost, high utilization rate of materials and easy realization, and the defects of the large-bore seamless titanium alloy barrel body, such as complex process, high cost, low yield and the like of the traditional production process can be effectively solved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

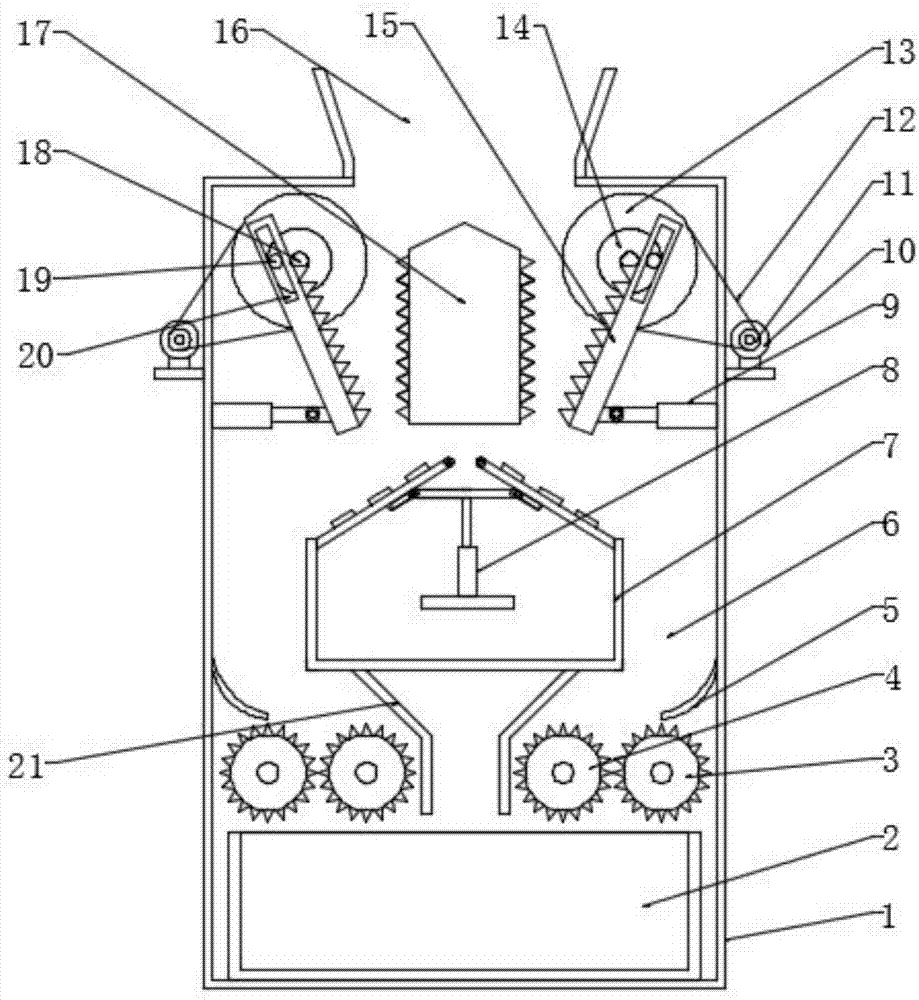

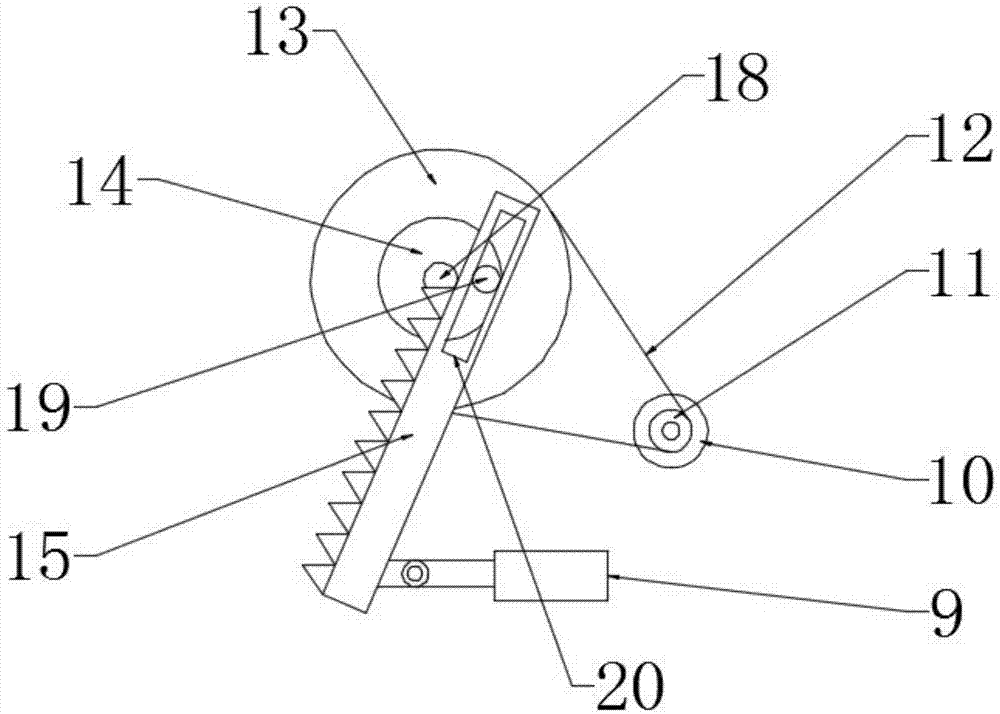

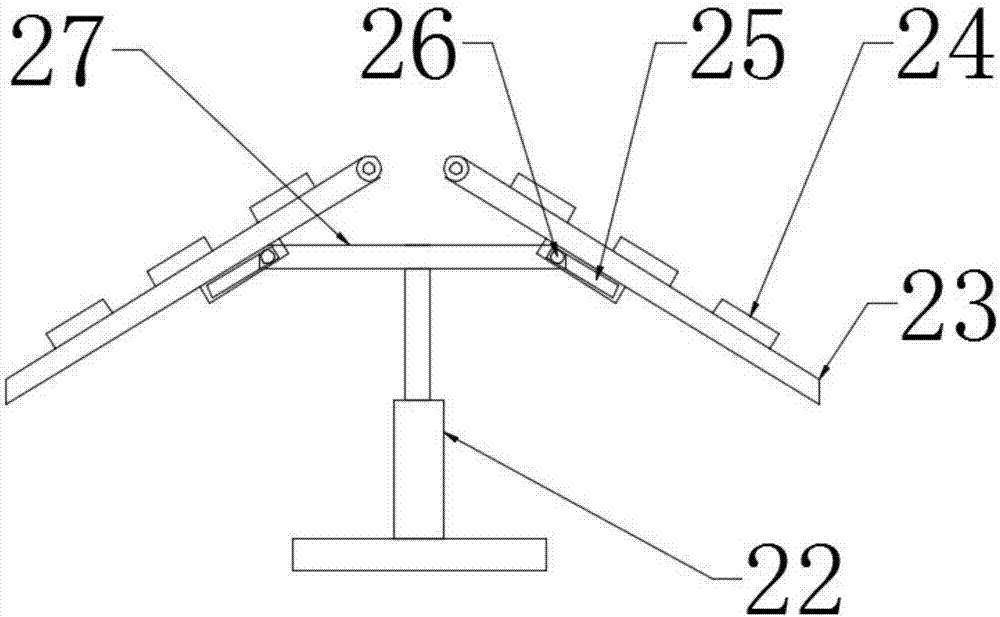

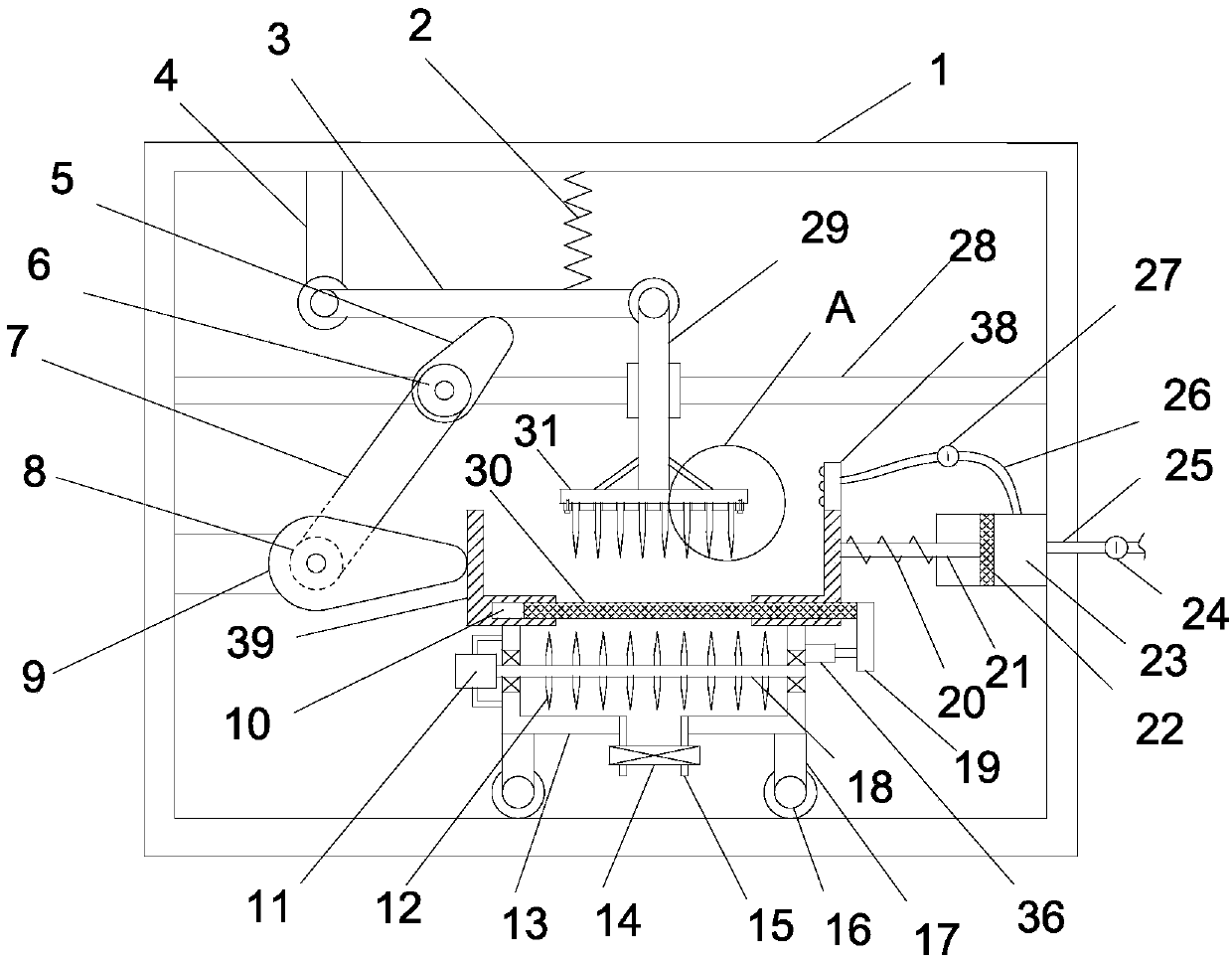

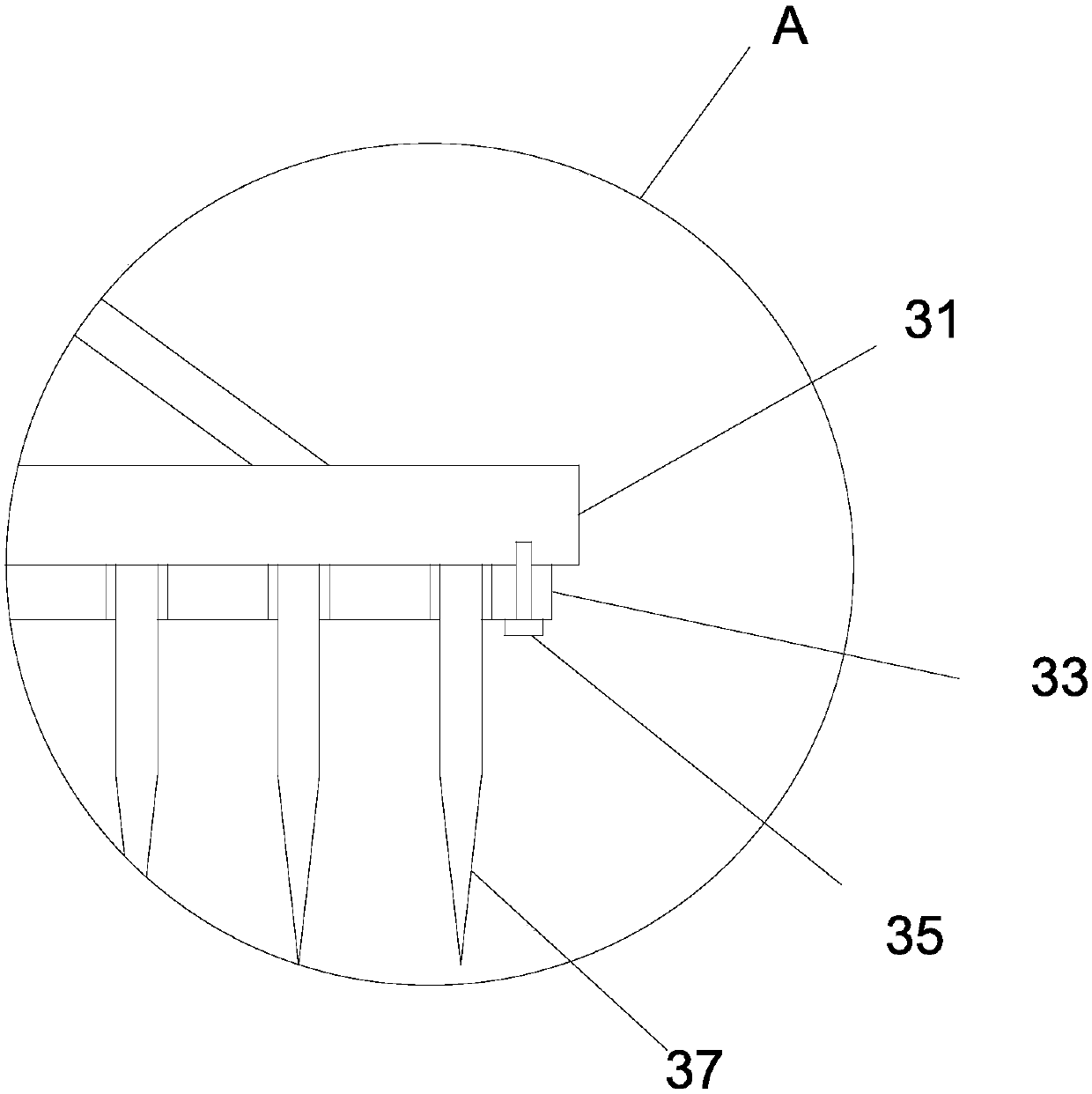

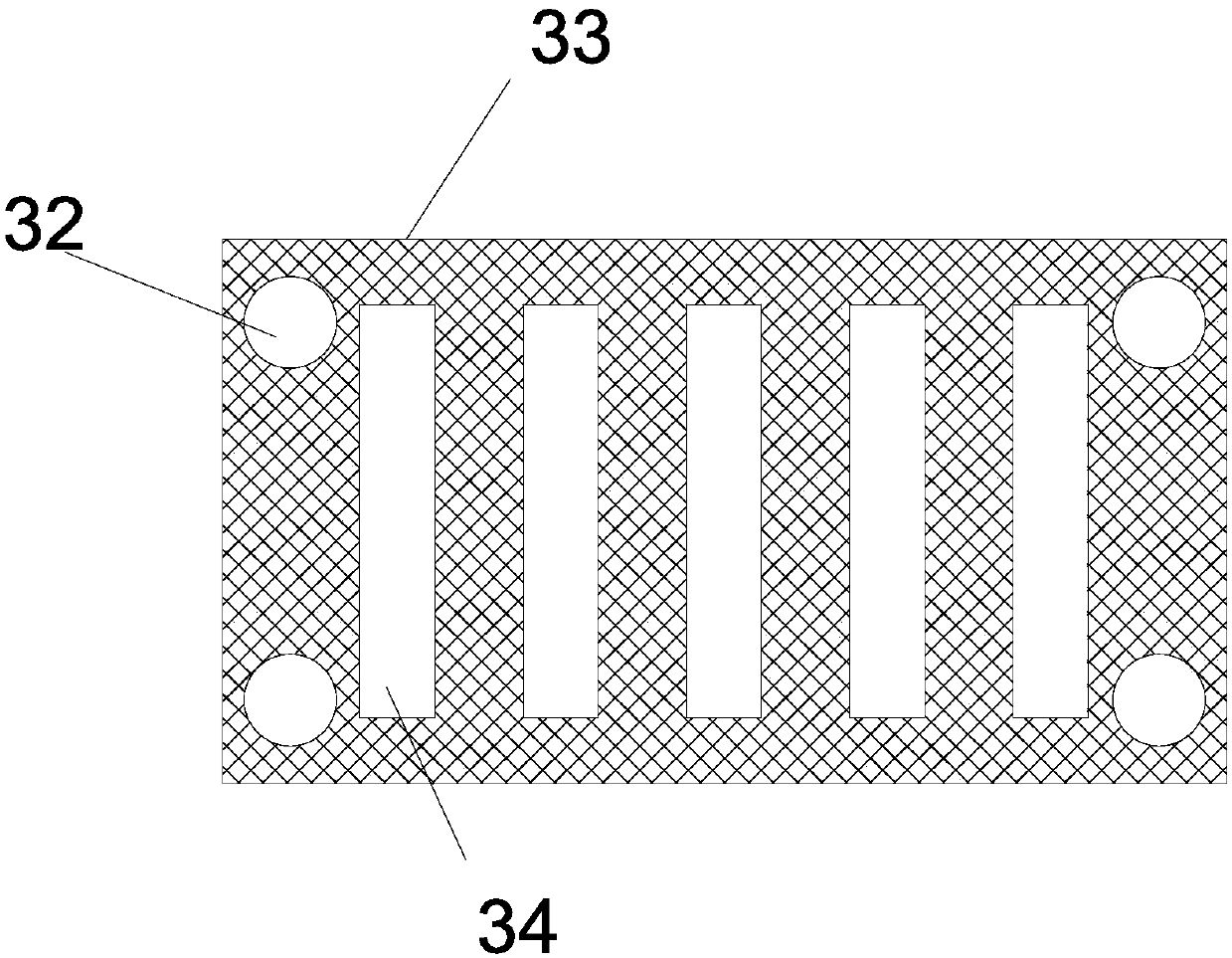

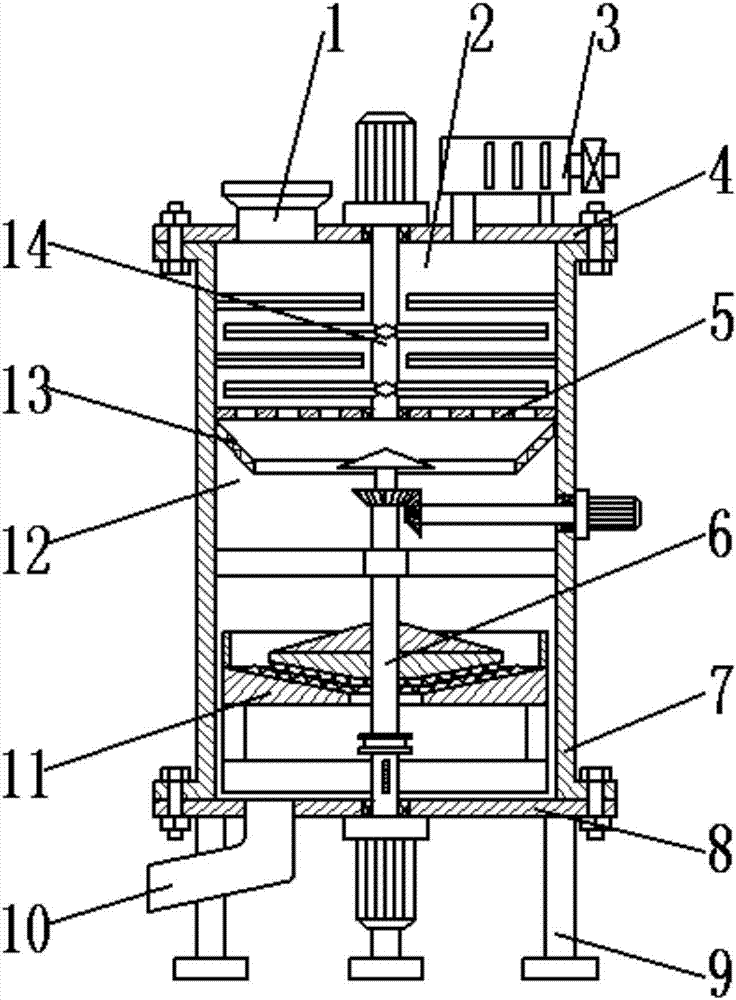

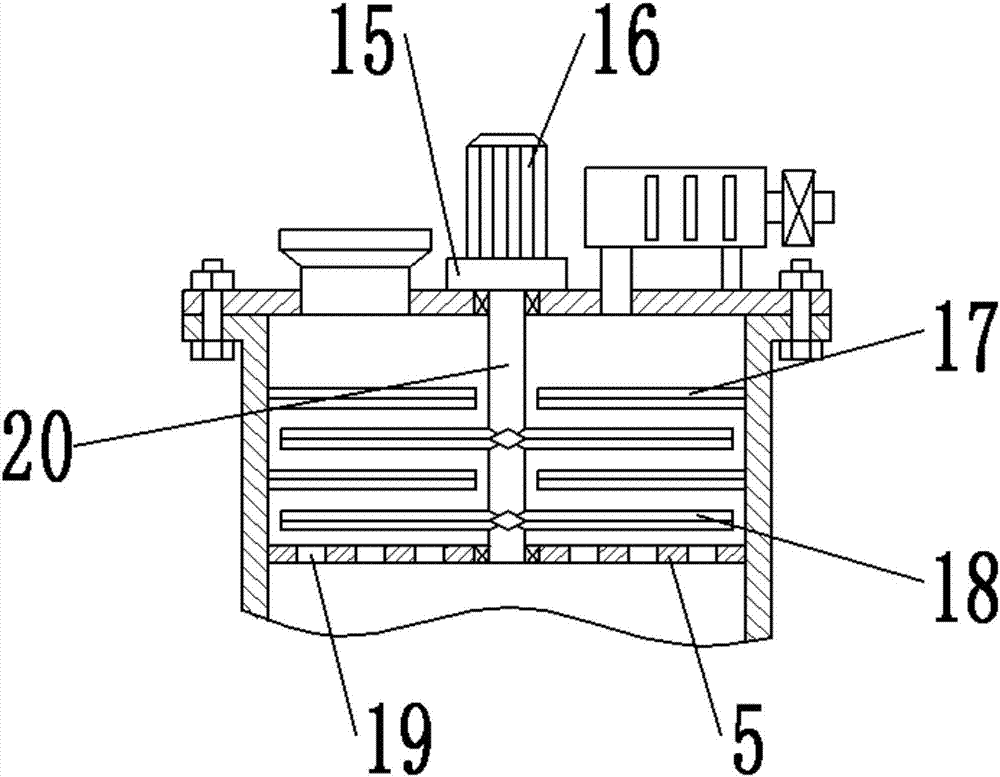

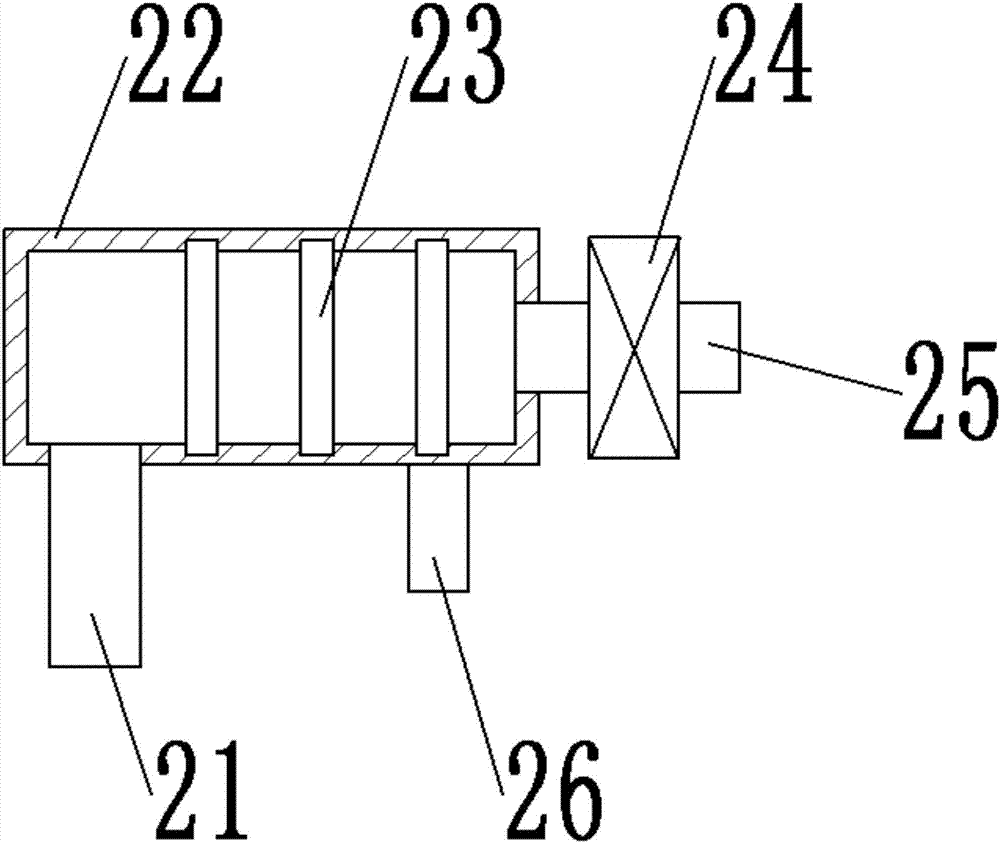

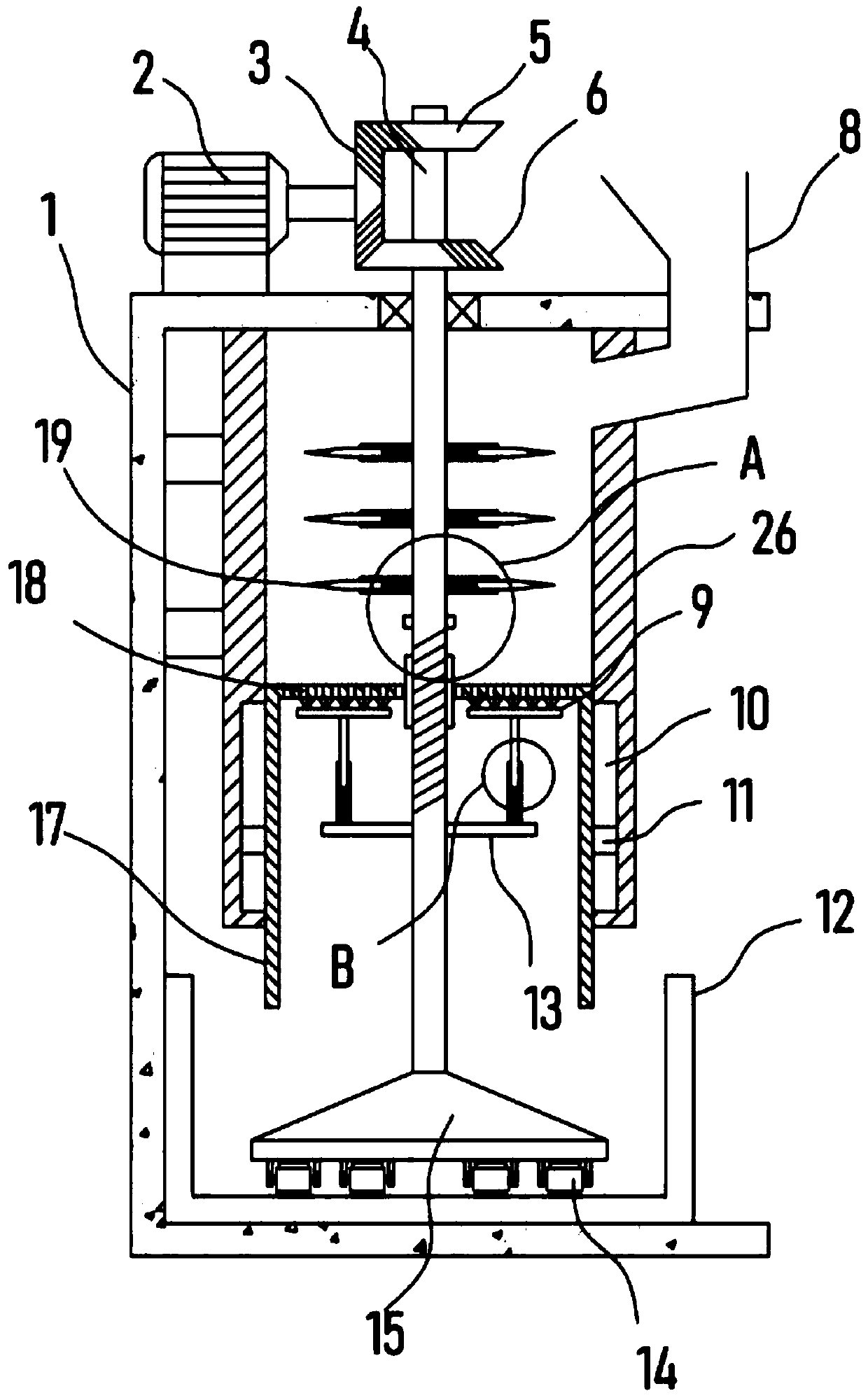

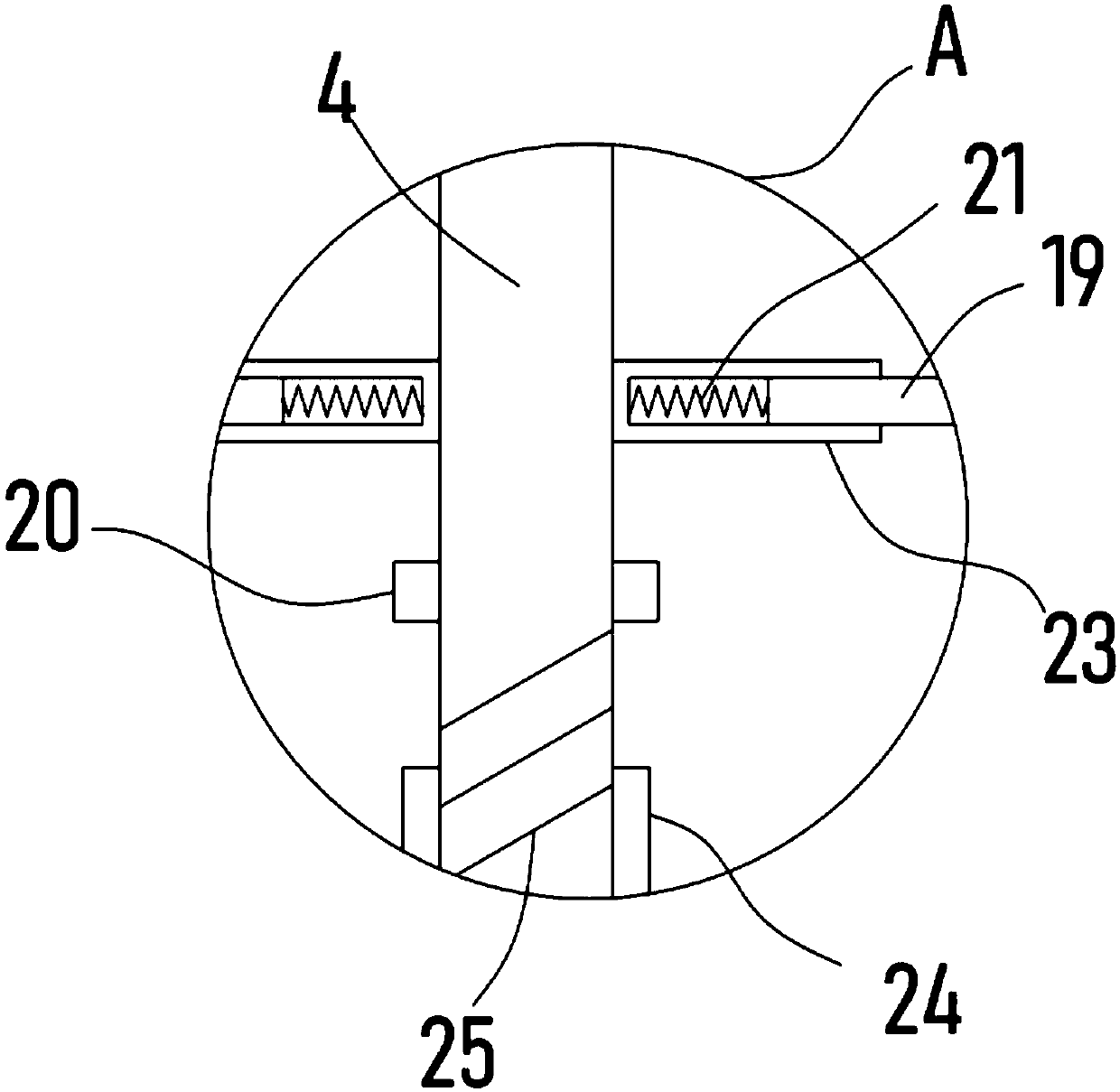

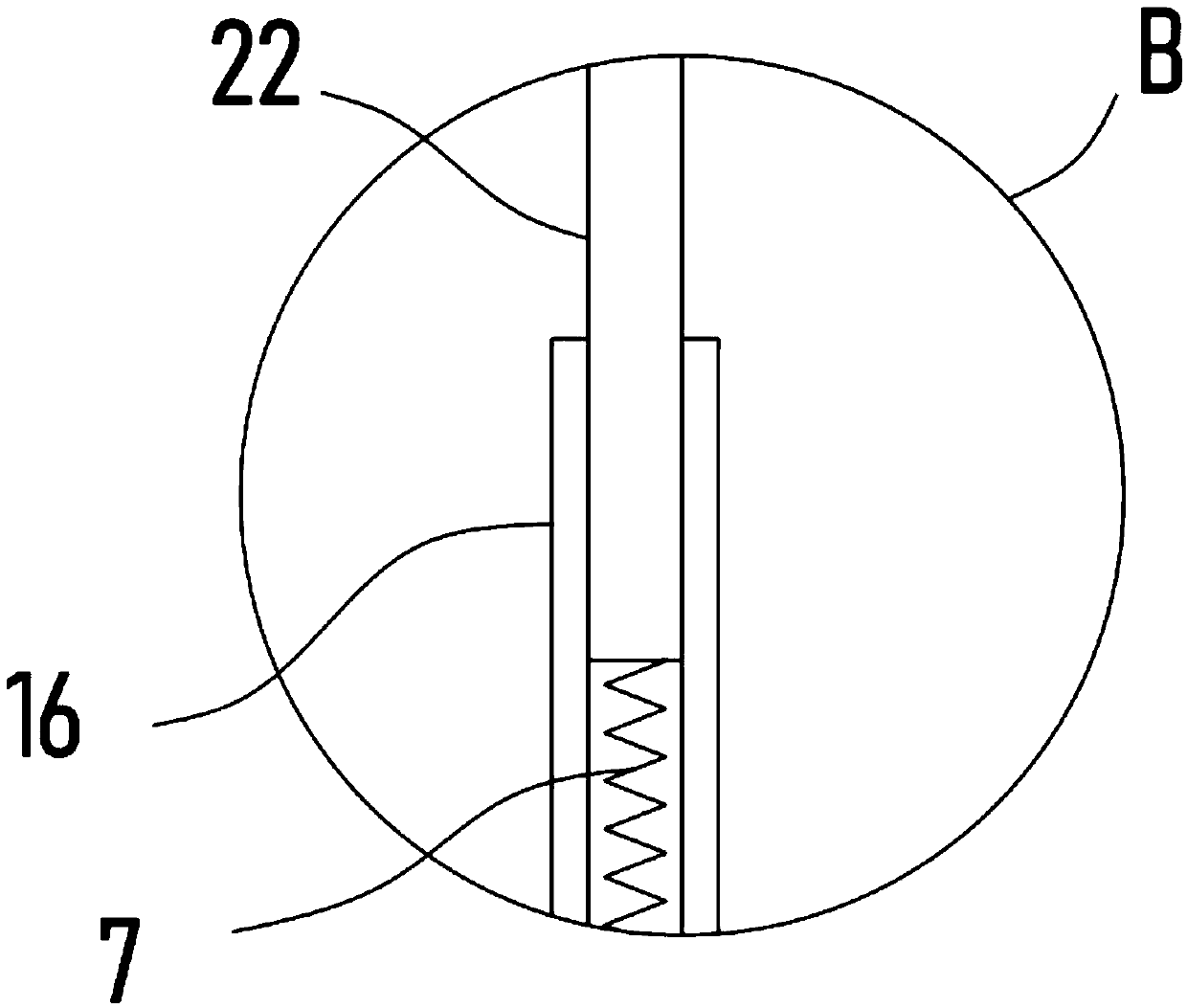

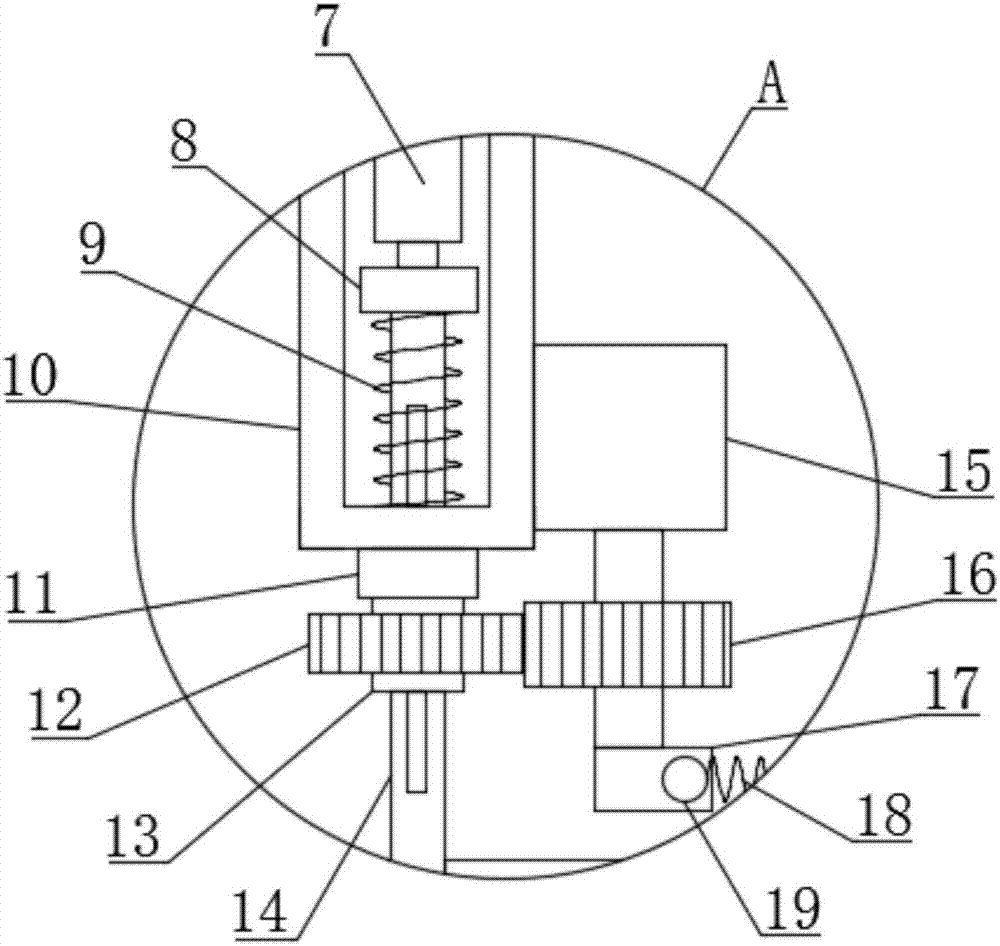

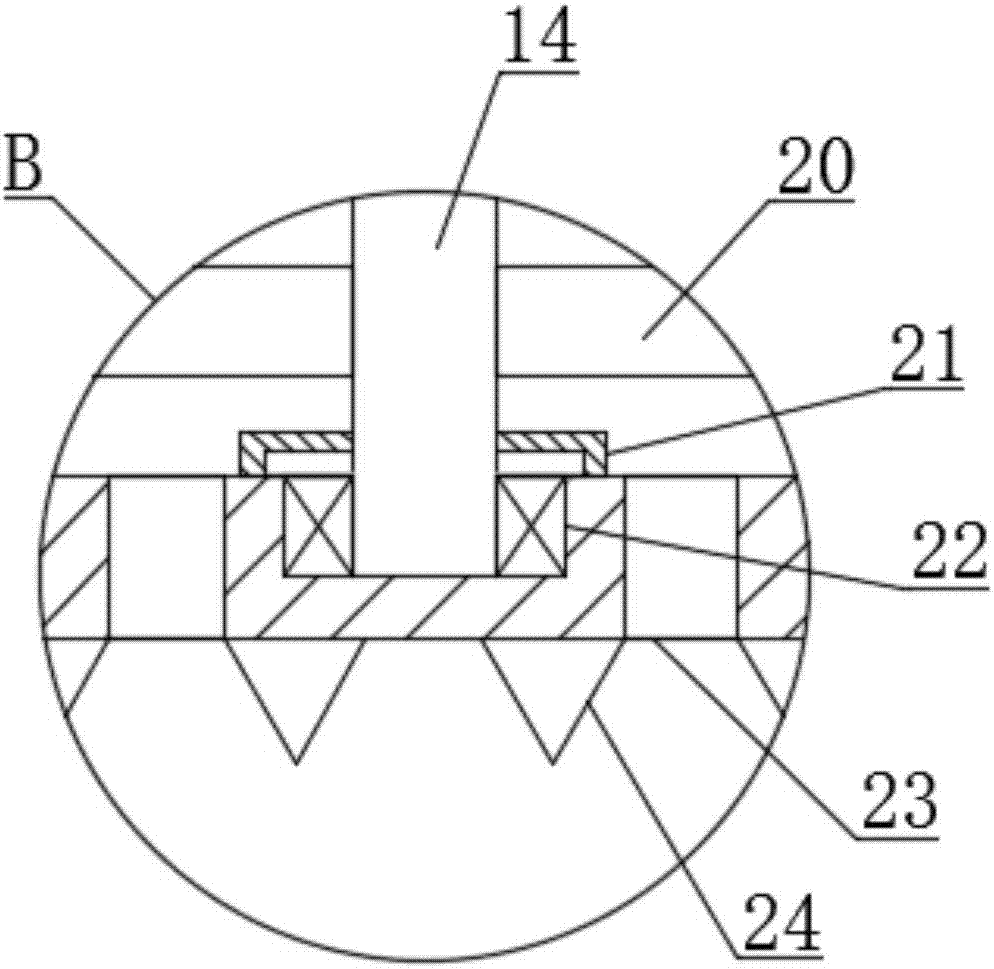

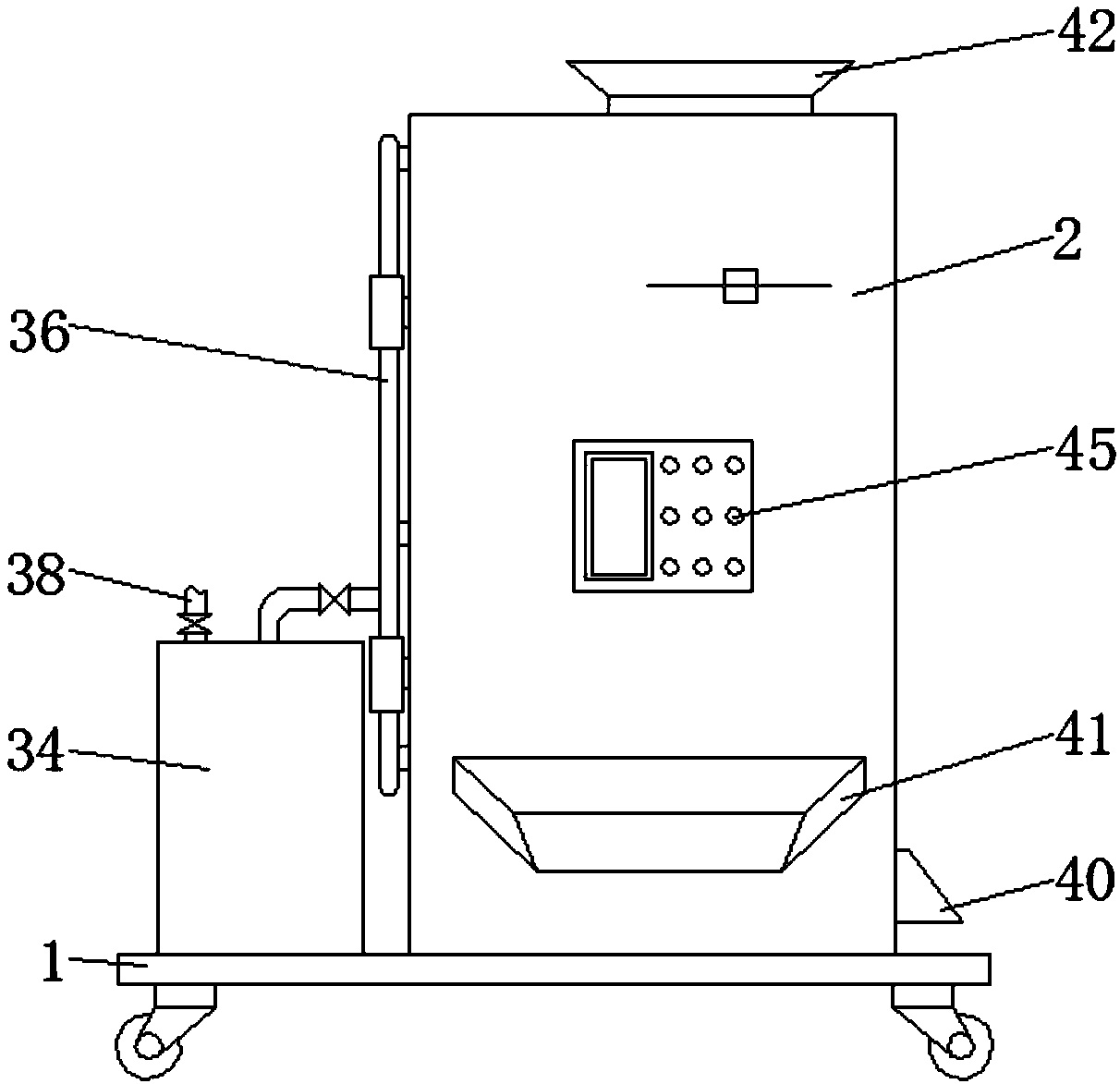

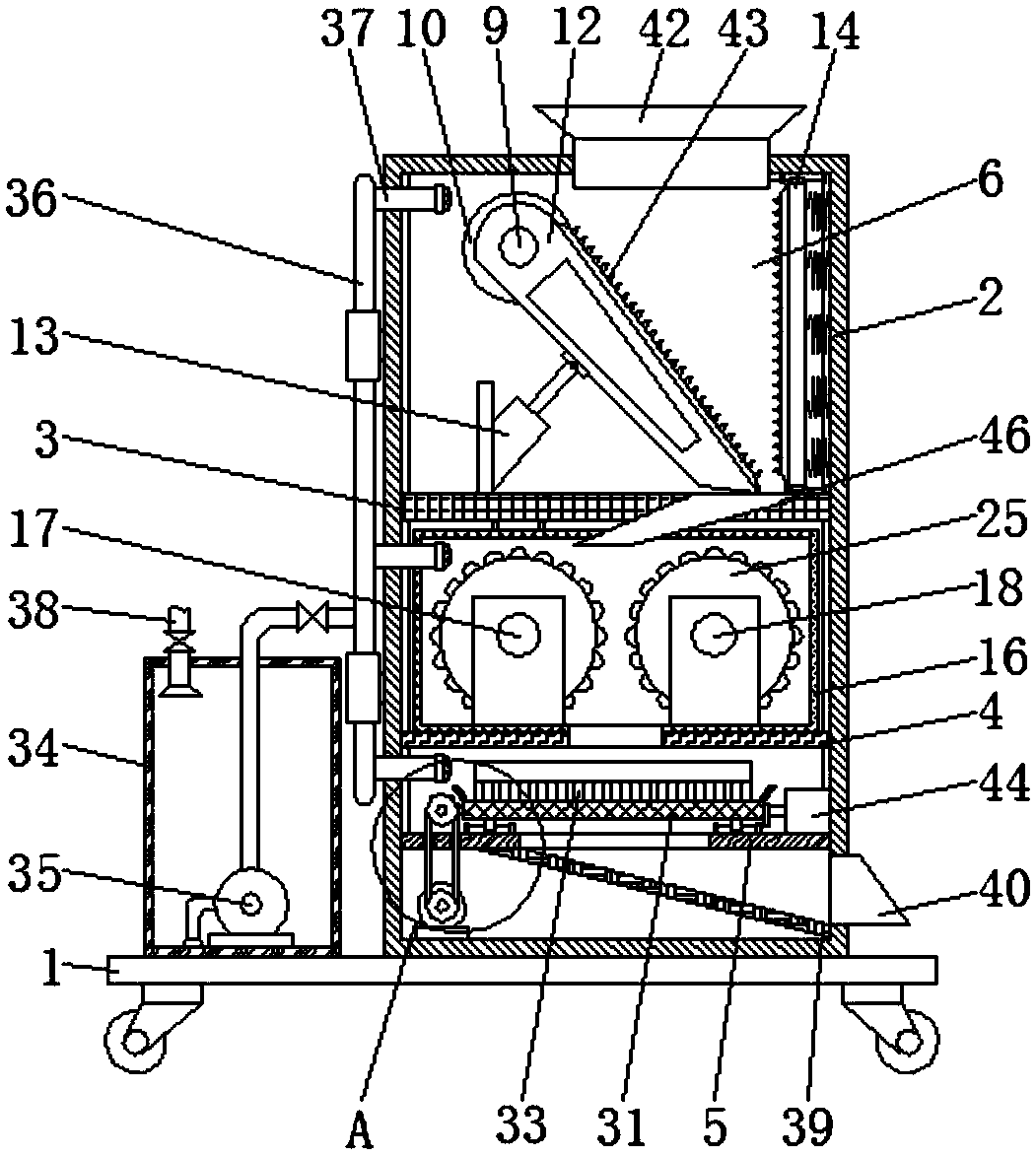

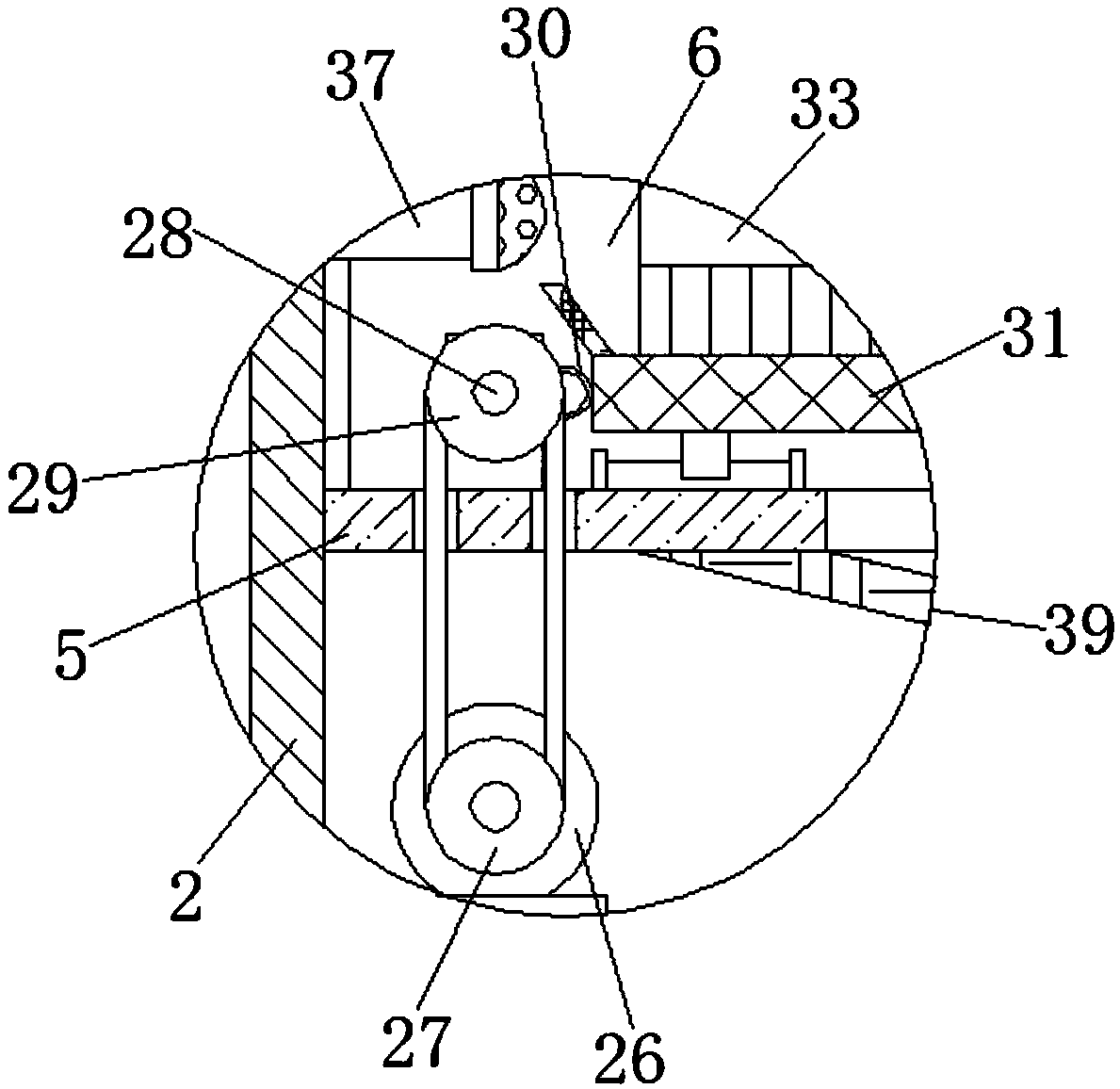

Efficient crushing device for construction waste recovery

InactiveCN107350004AAdjustable sizeGood for subsequent crushingMagnetic separationGrain treatmentsHydraulic cylinderIron removal

The invention discloses an efficient crushing device for construction waste recovery. The efficient crushing device comprises a box body, and a preliminary breaking mechanism is fixedly arranged at the upper part of the inner chamber of the box body. The preliminary breaking mechanism comprises a fixed breaking plate, a movable breaking plate, a disc, a hydraulic cylinder and a motor. An iron removal mechanism is arranged under the preliminary breaking mechanism, and a first crushing roller and a second crushing roller are arranged under the iron removal mechanism. In the falling process of massive construction wastes, the preliminary breaking mechanism breaks the massive construction wastes step by step, so that metal in the wastes is exposed. Moreover, follow-up crushing is facilitated, and the crushing efficiency is improved. The size of broken particles of construction wastes can be adjusted, and the breaking degree can be adjusted. The construction wastes are subjected to second level of crushing through the first crushing roller and the second crushing roller, and the construction wastes are crushed more thoroughly. The crushing effect is good, and the crushing efficiency is high. The metal, such as steel bars in the construction wastes can be removed through the iron removal mechanism and are collected. The efficient crushing device has the advantages of simple structure and convenience in operation.

Owner:广西综改咨询服务有限公司

Super plastic forming method for plate type heat converter special titanium plate

InactiveCN101121178AHigh yield strengthEasy to processRoll mill control devicesFurnace typesPlate heat exchangerTitanium

The present invention relates to a superplastic forming method for the titanium plate specially used for the plate type heat exchanger, which belongs to the field of mechanical processing technology. The present invention comprises the following steps that spongy titanium is chosen to be the melted raw material; the spongy titanium is placed in a vacuum plasma smelting furnace to be directly cast into plate base; the plate base forms a plate of a thickness of 2.0 to 2.4 mm after the process of heating, hot rolling, acid and alkali washing; second heating, hot rolling and acid and alkali washing and annealing; the plate of a thickness of 2.0 to 2.4 mm after the annealing in the vacuum smelting furnace forms a titanium plate of a thickness of 0.5 to 0.6 mm after the process of cold rolling, cleaning, second annealing and cold rolling, acid and alkali washing and third annealing. The present invention adopts the process that the spongy titanium which contains oxygen, iron and nitrogen of comparatively high content is directly processed into the titanium plate base in the plasma smelting furnace and directly rolled into the plate without forging and pressing.

Owner:上海桦厦实业有限公司

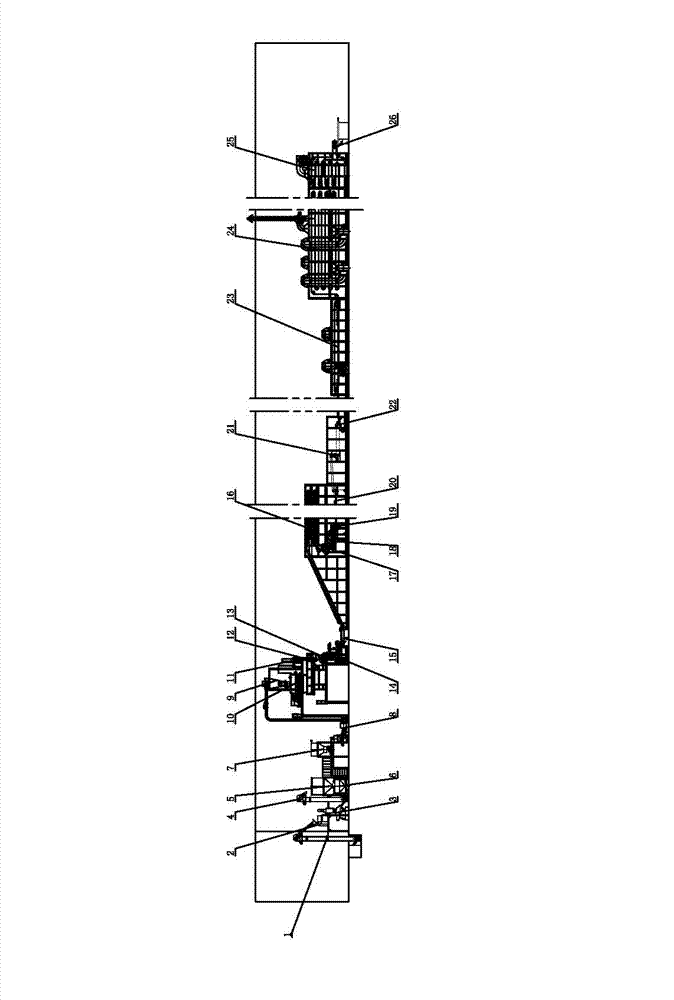

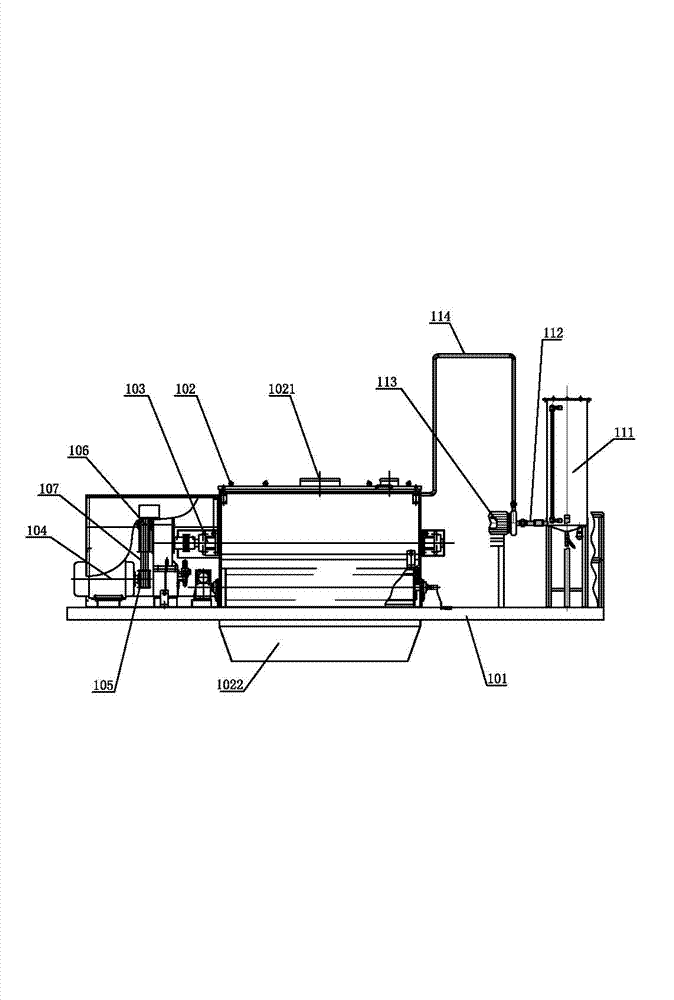

Rice noodle production line and rice noodle production process

The invention discloses a rice noodle production line and a rice noodle production process. The rice noodle production line comprises a first rice elevator, a rice polisher, a specific gravity sand remover, a second rice elevator, a rice storage tank, a jet rice washer, a water-rice separator, a rice grinder, a dry powder pneumatic conveyor, a powder mixer, a quantitative water adding barrel, a dough aging conveyor, a dough feeder, a continuous dough cooking device, a swing dough separator, a dough body aging machine, a dough body crumbler, an automatic curing machine, a noodle extruder, a noodle aging machine, a quantitative cutter, a folding forming machine, a predrying shaping machine, a drying machine, an air cooler and a packaging conveyor. The rice noodle production process comprises making rice into dough, curing, conveying, crumbling, feeding, curing, separating the dough by swinging, aging dough bodies, crumbling the dough bodies, automatically curing, extruding noodles, aging the noodles, quantitatively cutting, forming by folding, predrying, shaping, drying, air cooling and packaging. The rice noodle production line and the rice noodle production process are simple and low in cost. The rice noodles produced is fine in quality and taste and high in puffing degree.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

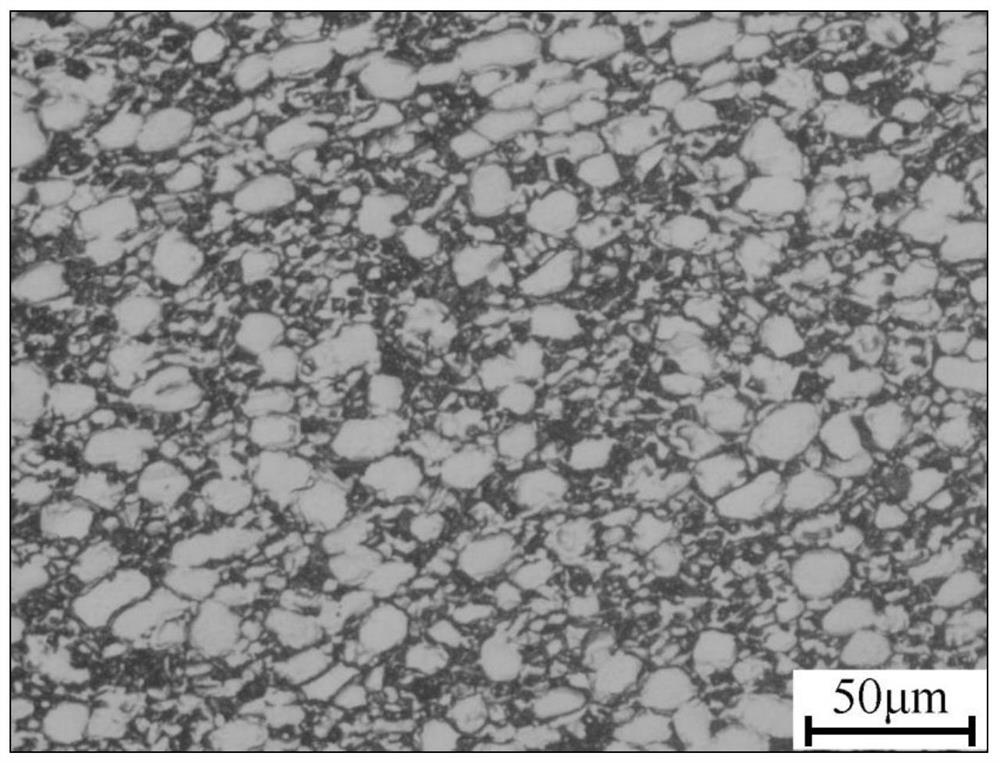

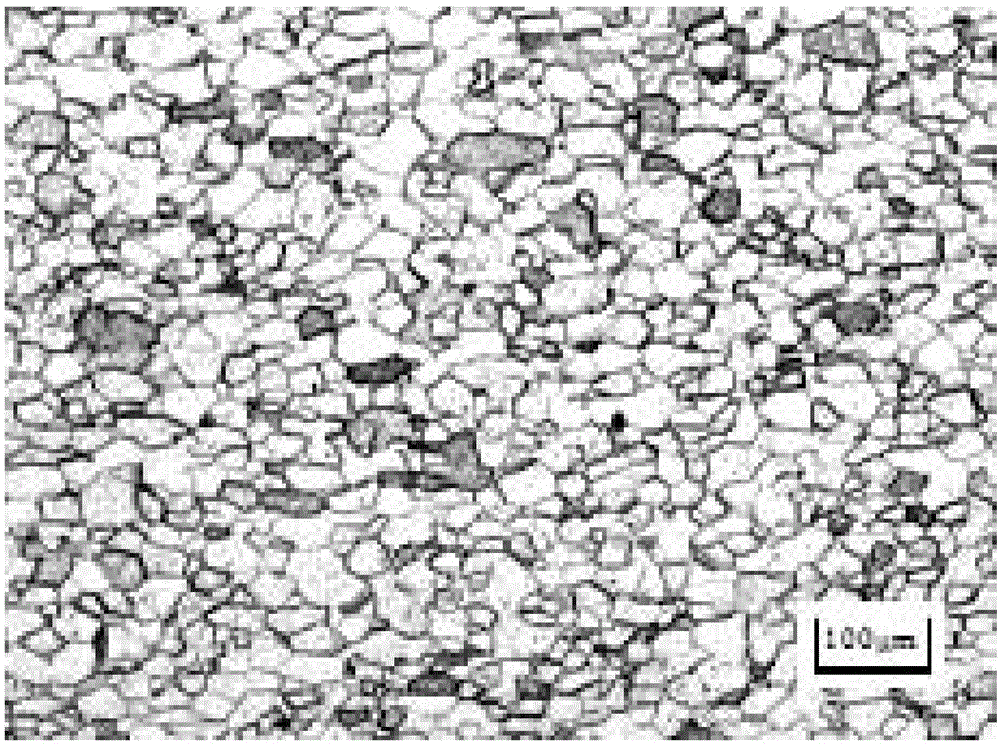

Cast ingot cogging forging technology for improving structure uniformity of forging stocks of titanium alloy

The invention discloses a cast ingot cogging forging technology for improving the structure uniformity of large-thickness forging stocks of titanium alloy. Cogging forging is carried out on the titanium alloy two heating times under the condition of the heating temperature of 1150 DEG C and 1100 DEG C; the titanium alloy is forged at a heating time under the condition of the heating temperature being 20-45 DEG C below the temperature of a beta phase transformation point; the titanium alloy is forged at a heating time under the condition of the heating temperature being 30-80 DEG C above the temperature of the beta phase transformation point; the titanium alloy is forged 2-5 heating times under the condition of the heating temperature being 20-45 DEG C below the temperature of the beta phase transformation point, and then the large-size titanium alloy forging stocks with the even structure are obtained. The cast ingot cogging forging technology is suitable for large cast ingot cogging and forging stock forging of titanium alloy of an alpha type or an alpha-beta type or an approximate-beta type, and requirements for manufacturing of large-size titanium alloy casting pieces or parts which are needed for manufacturing planes and have high requirements for structure temperature uniformity can be met.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

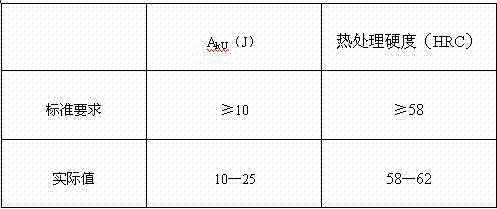

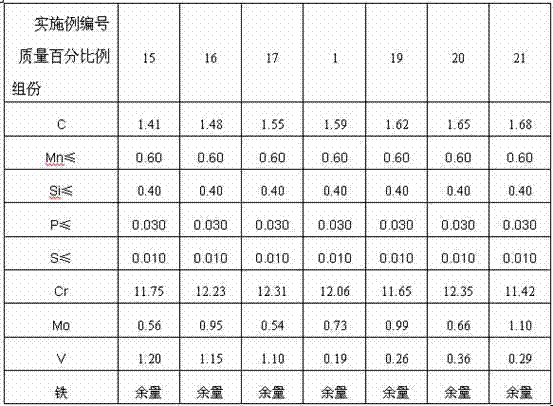

Method for manufacturing large cake forgings of high-carbon and high-chromium cold working die steel

The invention discloses a method for manufacturing large cake forgings of high-carbon and high-chromium cold working die steel. The method is characterized by comprising the following steps of: obtaining Cr12MoV or Cr12Mo1V1 steel by adopting primary smelting with an electric furnace, ladle refining and vacuum degassing process smelting; pouring the tapped steel to form a 6 to 9t octangular ingot; conveying the octangular ingot to a press at the temperature of more than or equal to 300 DEG C, forging the octangular ingot to a blank with the diameter of 300 to 700 millimeters, removing surface defects by annealing, polishing or turning and local grinding, performing cold saw cutting on the end face and blanking to form a cake blank; and heating the cake blank to the temperature of between 1,150 and 1,190 DEG C, upsetting and forging the cake blank by using the press, annealing and turning, and thus obtaining the large cake forgings of the high-carbon and high-chromium cold working die steel. By adopting the method, the yield is improved to 40 to 60 percent; and the manufactured large cake forgings of the high-carbon and high-chromium cold working die steel can comprehensively meet the requirements of hardness, impact toughness and the like and ultrasonic flaw detection quality.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

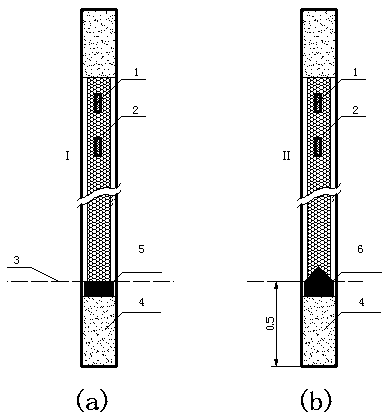

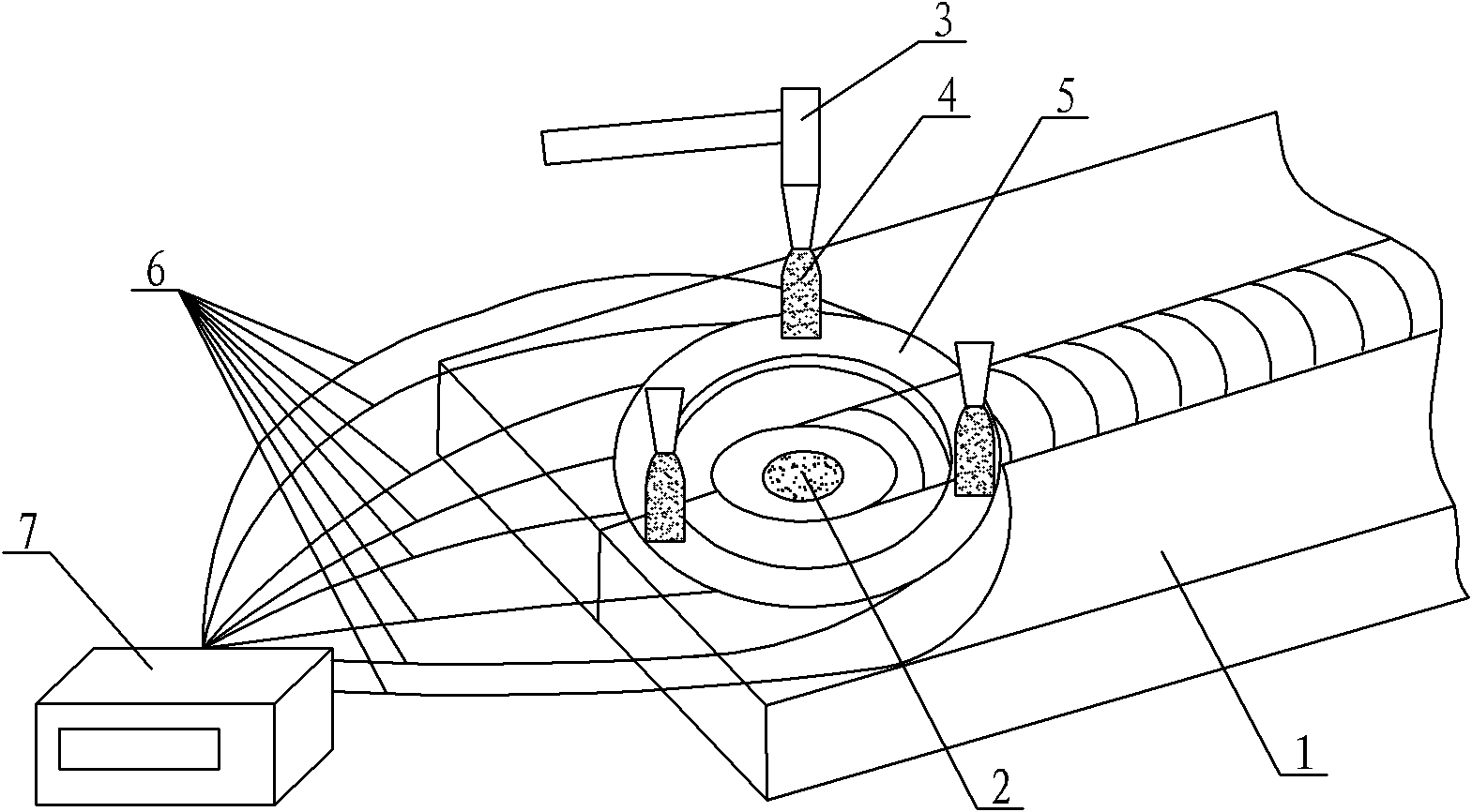

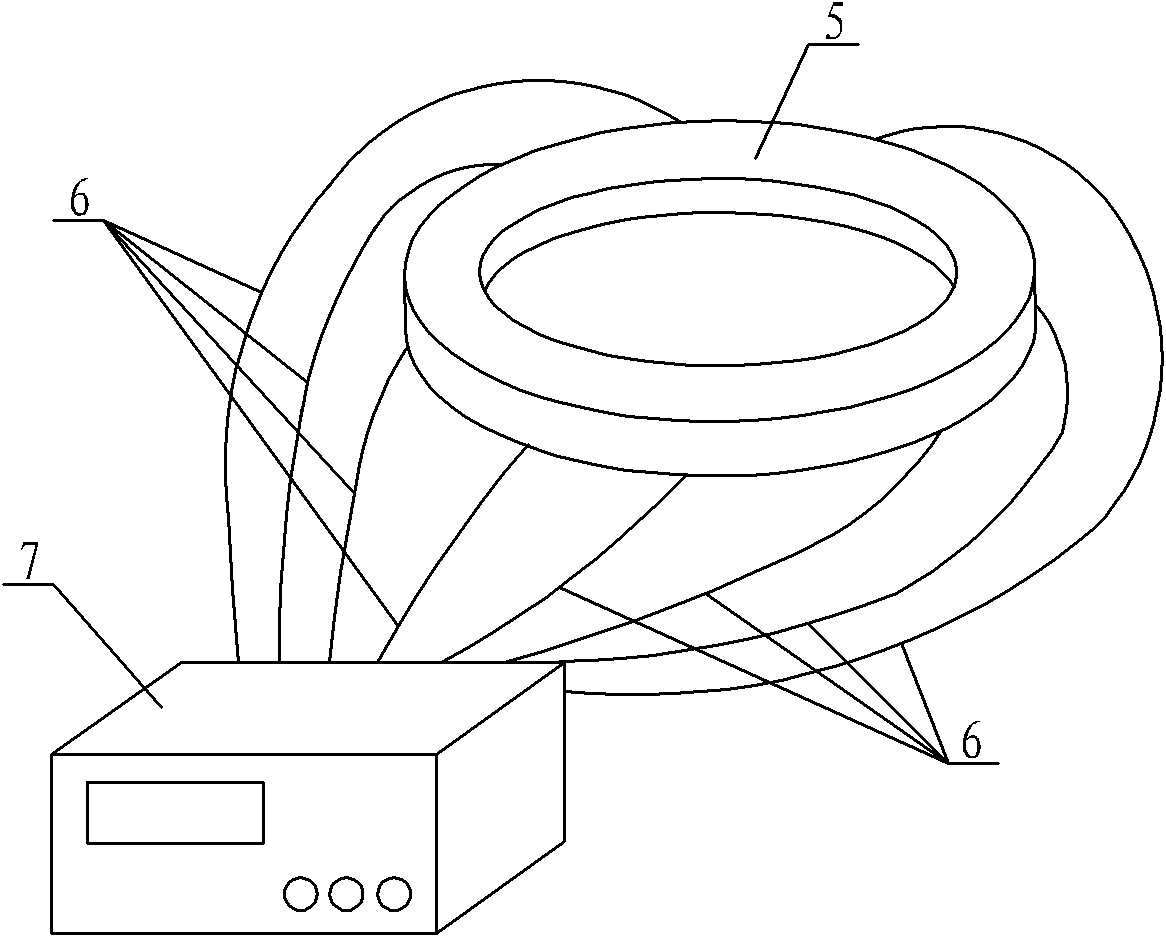

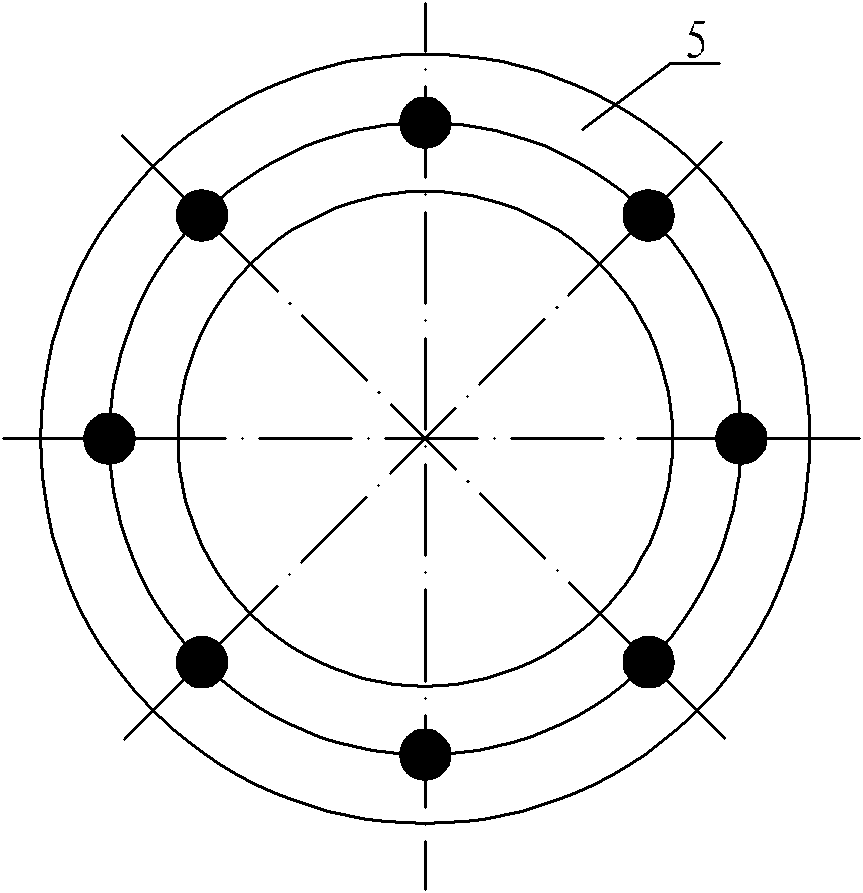

Axial embedded blast hole of reinforced concrete beam and blasting demolition method

The invention provides an axial embedded blast hole of a reinforced concrete beam and a blasting demolition method. The blast hole is formed in the mode that a pipe is embedded in the beam in the axial direction, continuous or discontinuous charging is adopted in the blast hole, a detonating fuse is arranged in the blast hole in an overall-length mode, a stirrup is cut off, and other technical means are taken. In this way, drilling operation is avoided, the number of blast holes and the number of detonators are reduced, consumption of explosive and the detonators is reduced, the smashing effect on reinforced concrete is improved, and the damage of explosion to the environment is reduced. The axial embedded blast hole of the reinforced concrete beam and the blasting demolition method can bring remarkable economic and social benefits.

Owner:HUBEI UNIV OF TECH +1

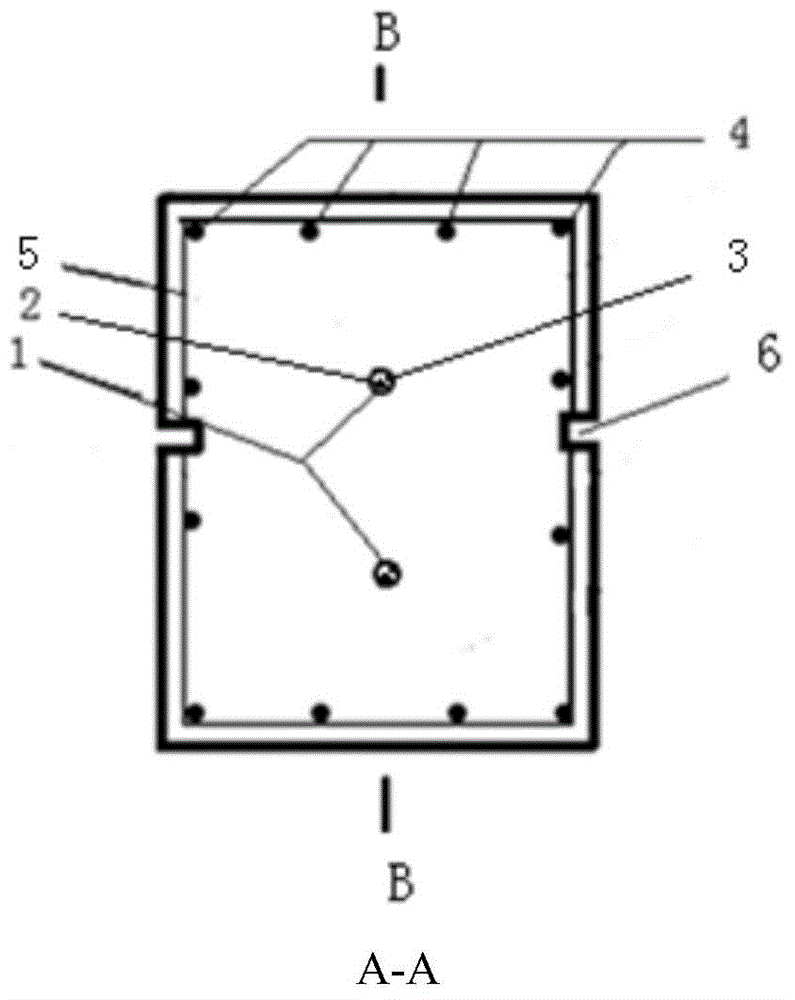

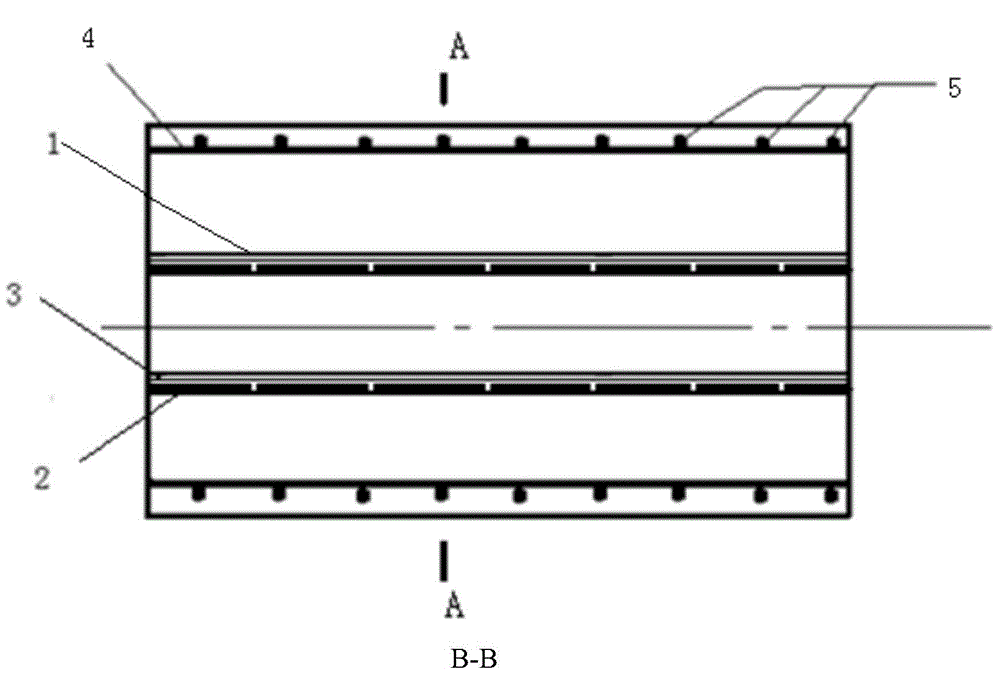

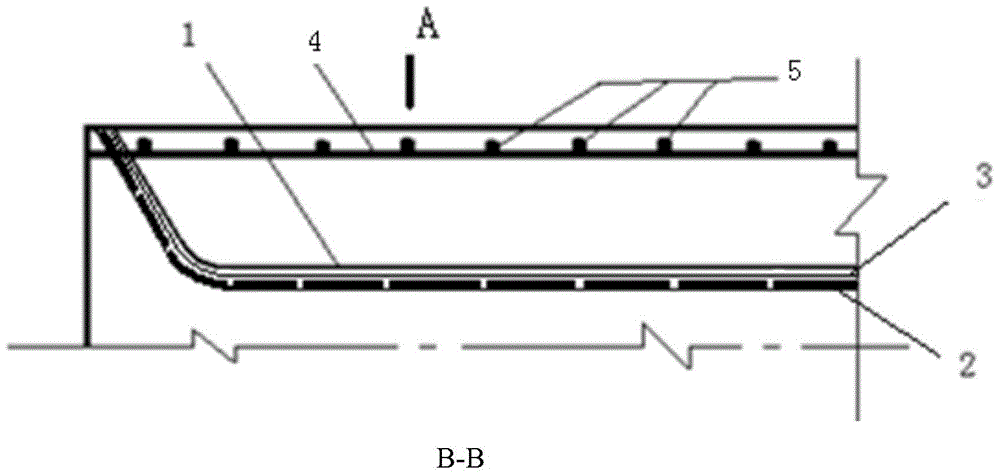

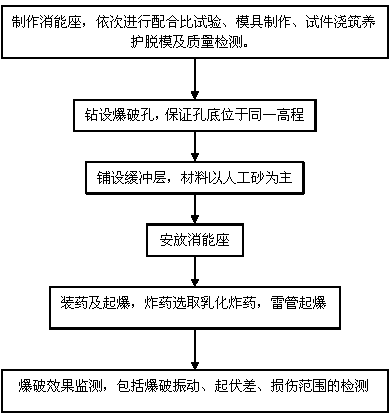

Method for blasting and excavating dam foundation and rock foundation

The invention discloses a method for blasting and excavating a dam foundation and a rock foundation. The method comprises the steps of step 1, drilling blast holes, and paving buffer layers at the bottom parts of the blast holes; step 2, vertically installing energy dissipation seats on the buffer layers, and filling explosive, wherein the energy dissipation seats are prepared by adopting concrete, the concrete is formed by cement, water, iron sand, superplasticizer and gel, the water-cement ratio is 0.24-0.28, the mass ratio of the iron sand and the cement is (1.6-3.0):1, and the mass of the superplasticizer is 1.0%-2.0% of that of the cement; step 3, blasting through a detonator. The method disclosed by the invention has the advantages that the operation is quick and convenient, the construction cost is low, the blast shock waves are reflected for multiple times through the energy dissipation seats, the energy of the blast shock waves is induced to gather in the horizontal direction, the full crushing of rock bodies between adjacent blast holes can be realized, the blasting efficiency can be further increased, meanwhile, the damage to the bottom parts of the blast holes can be further reduced, and the flatness of an excavation surface is increased.

Owner:WUHAN UNIV

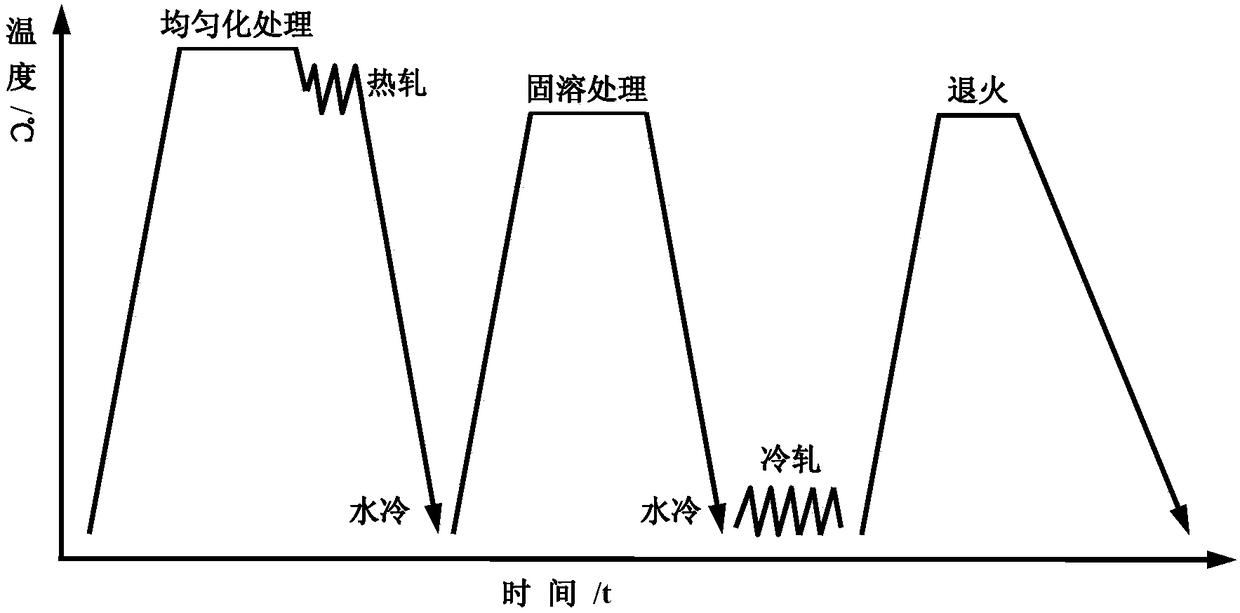

High-strength high-ductility low-density steel plate of 1200 MPa grade and manufacturing method thereof

The invention relates to a high-strength high-ductility low-density steel plate of the 1200 MPa grade and a manufacturing method thereof. The high-strength high-ductility low-density steel plate is prepared from the following components according to mass percent: 0.7 to 1% of C, 13 to 20% of Mn, 8 to 11% of Al, 1 to 4% of Ni, less than 0.1% of Si, less than 0.01% of S, less than 0.01% of P, 0 to 0.1% of Ti, 0 to 0.1% of Nb and 0 to 0.15% of V; the tensile strength is 1200 to 1300 MPa, the elongation is 30 to 40%, and the density is 6.5 to 7 g / cm<3>. The manufacturing method comprises the following steps of (1) smelting molten steel according to the components, and pouring; (2) heating to 1100 to 1200 DEG C, performing hot rolling after heat preservation, and performing water cooling to theroom temperature after hot rolling is finished; (3) heating to 900 to 1100 DEG C, and performing water cooling after heat preservation; (4) performing cold rolling after pickling; and (5) heating to800 to 1000 DEG C, and performing air cooling after heat preservation. The low-density steel plate has high strength and high ductility.

Owner:NORTHEASTERN UNIV

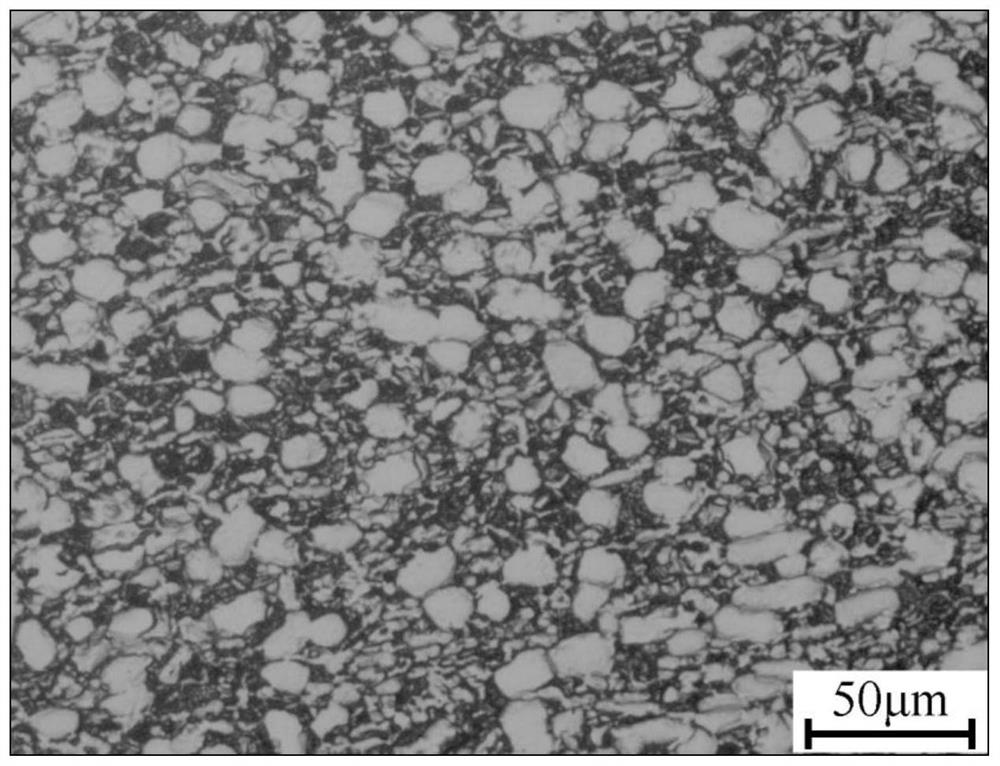

Processing method of fine-grain superplastic TA15 titanium alloy medium-thickness plate

The invention discloses a processing method of a fine-grain superplastic TA15 titanium alloy medium-thickness plate. The processing method comprises the following steps that 1, vacuum consumable arc melting is carried out to obtain a TA15 titanium alloy cast ingot; 2, after heat preservation, a primary forging stock is obtained through upsetting, drawing, cogging and forging; 3, after heat preservation, a second-stage forging stock is obtained through beta-phase region upsetting and drawing forging; 4, upsetting and drawing forging in an alpha + beta two-phase region is carried out to obtain afourth-stage forging stock; 5, a forge piece is obtained through upsetting, drawing and finish forging; 6, after heat preservation, a first-fire rolled plate blank is obtained through first-fire rolling; 7, after heat preservation, a second-fire rolled plate blank is obtained through second-fire rolling; and 8, the TA15 titanium alloy medium-thickness plate is obtained through annealing treatment. According to the processing method of the fine-grain superplastic TA15 titanium alloy medium-thickness plate, the corresponding deformation temperature is selected and combined with multi-heating-number large-deformation upsetting and drawing forging, so that the TA15 titanium alloy cast ingot with a coarse structure is crushed under the large deformation, driving force is provided for recrystallization, the grain refinement and homogenization degree is improved, and the fine-grain superplasticity TA15 titanium alloy medium-thickness plate is obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

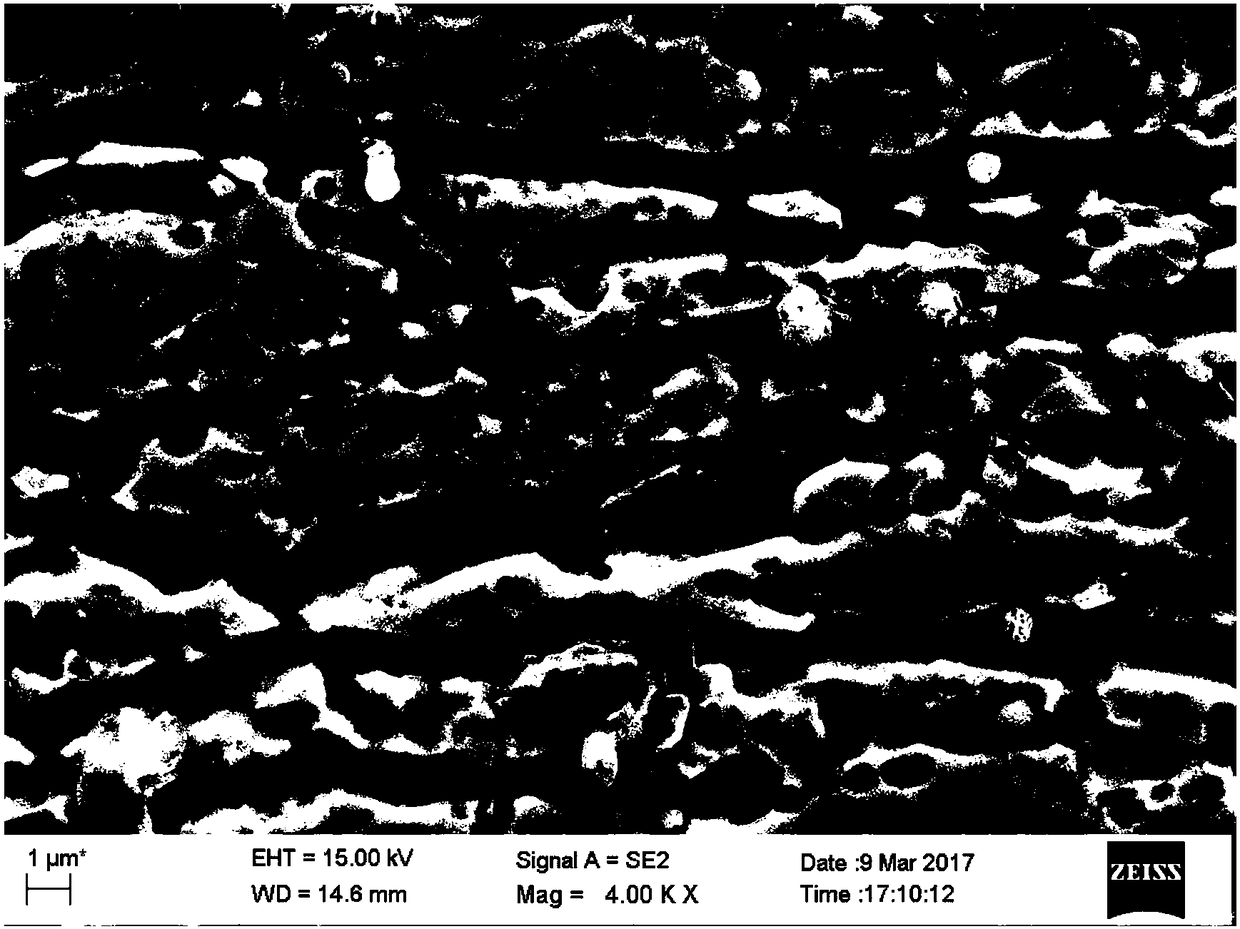

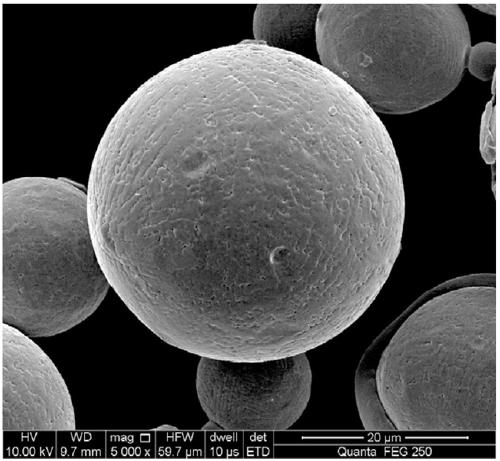

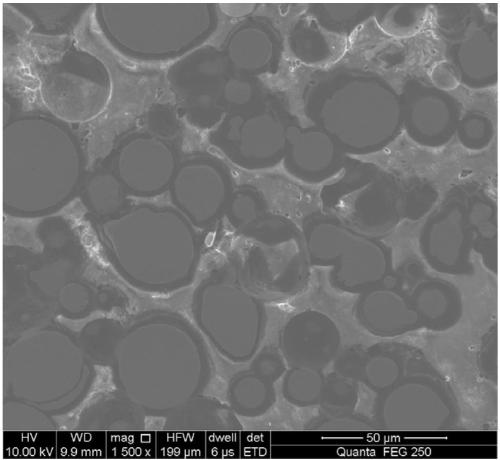

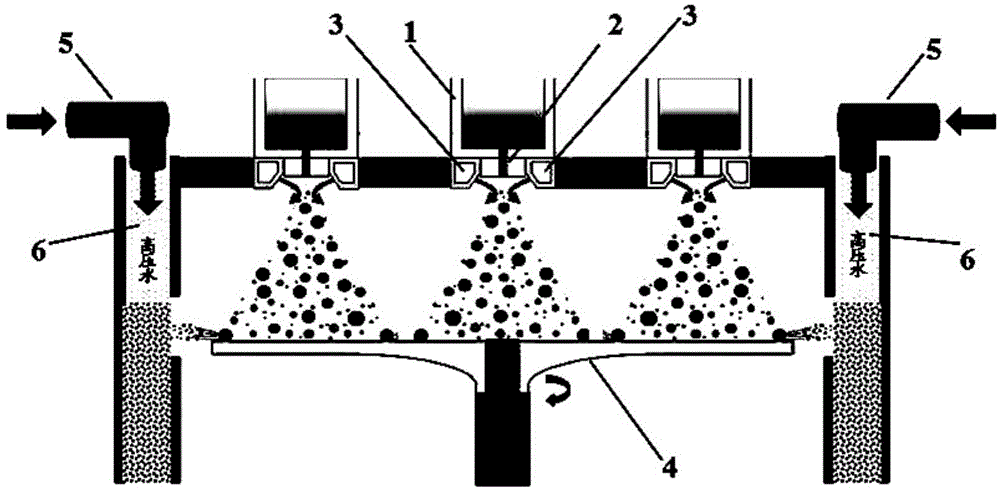

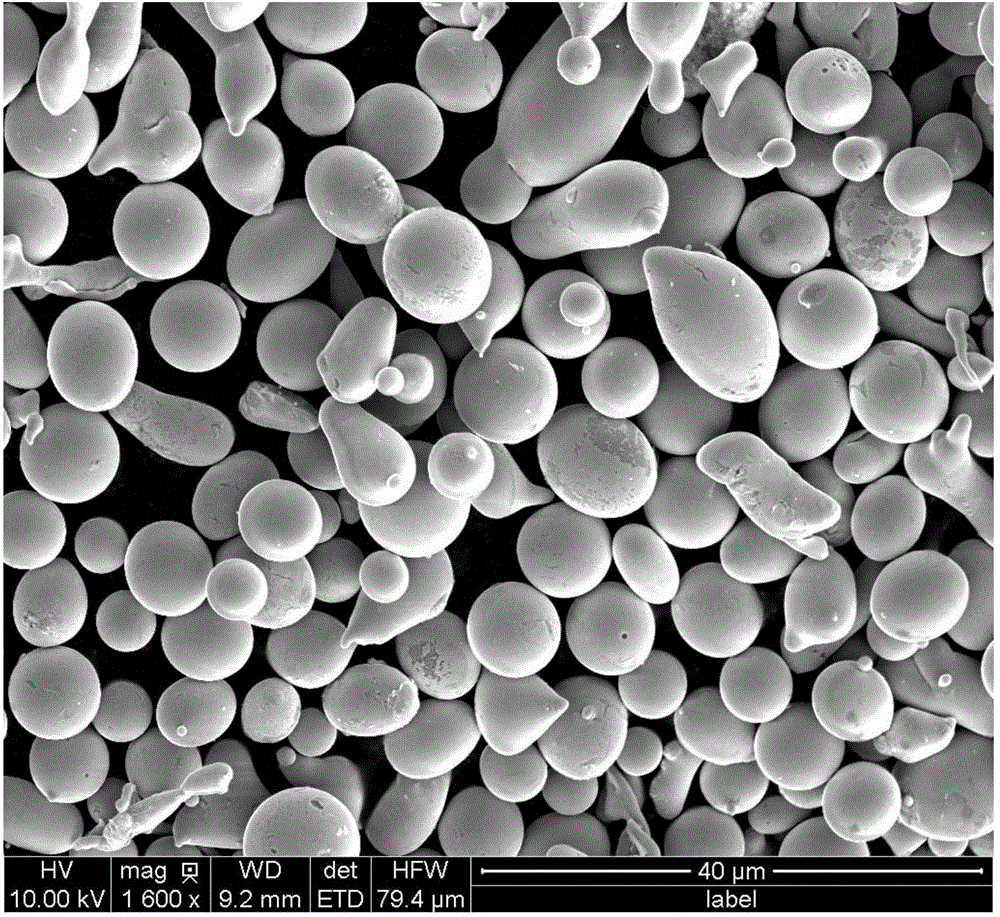

Preparation method for nickel-base superalloy powder for laser forming

ActiveCN108941588AHigh sphericityHigh yieldAdditive manufacturing apparatusTransportation and packagingOxygen contentHot Temperature

The invention discloses a preparation method for nickel-base superalloy powder for laser forming, and belongs to the field of superalloy and powder metallurgy. According to the preparation method, vacuum induction melting and argon atomization powder making technologies are adopted, and the nickel-base superalloy powder suitable for laser forming is prepared. The nickel-base superalloy powder prepared through the method is high in small grain size powder, high in degree of sphericity, low in oxygen content, good in flowing performance, free of hollow defects, less in satellite powder and capable of meeting the technical requirement for laser forming.

Owner:CENT SOUTH UNIV

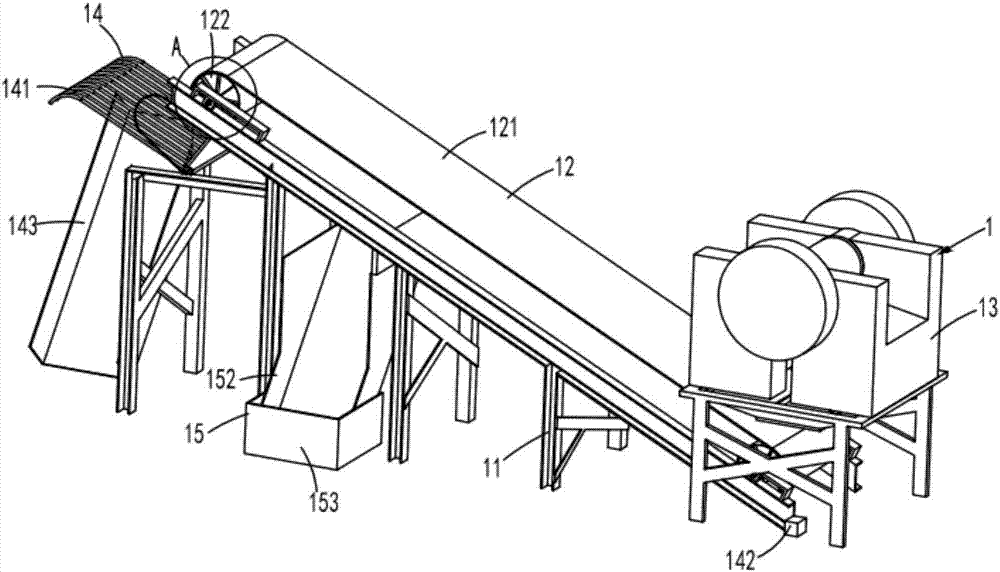

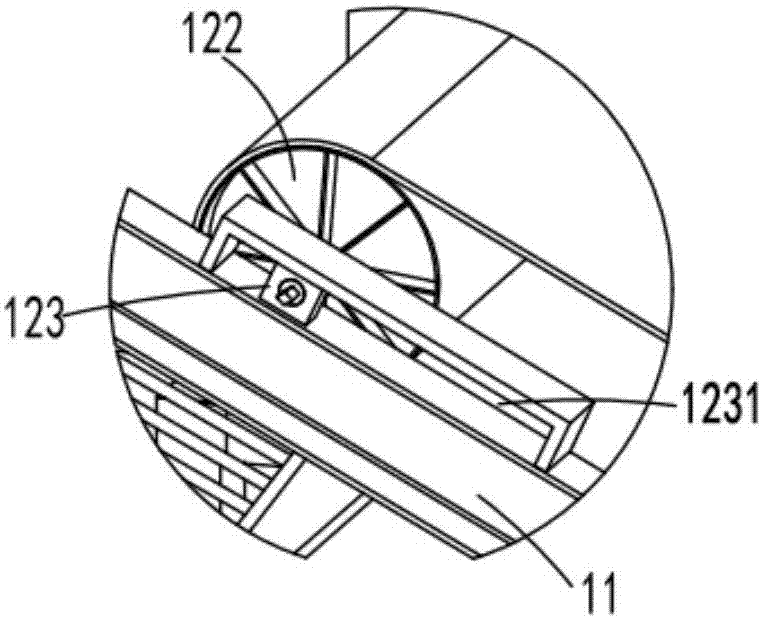

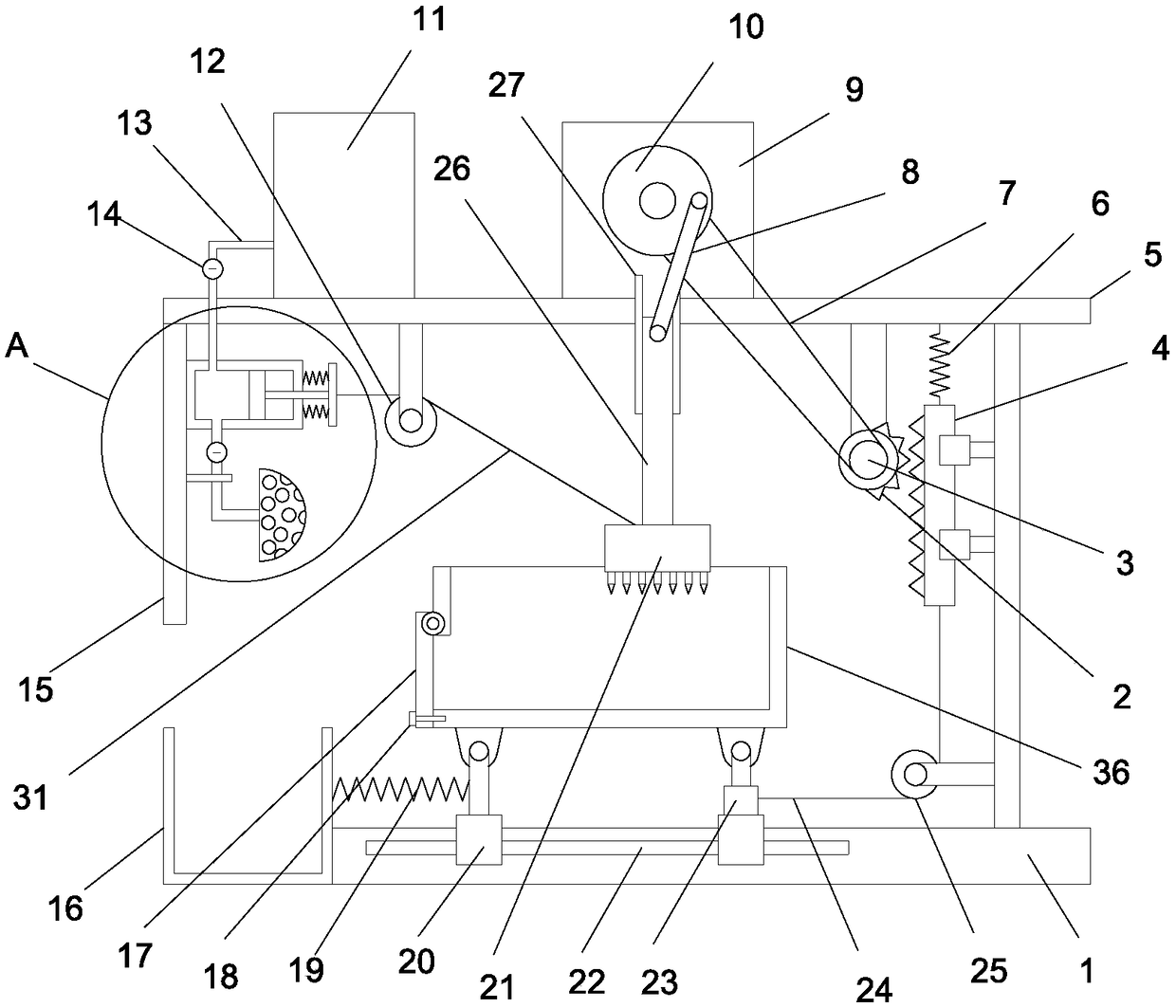

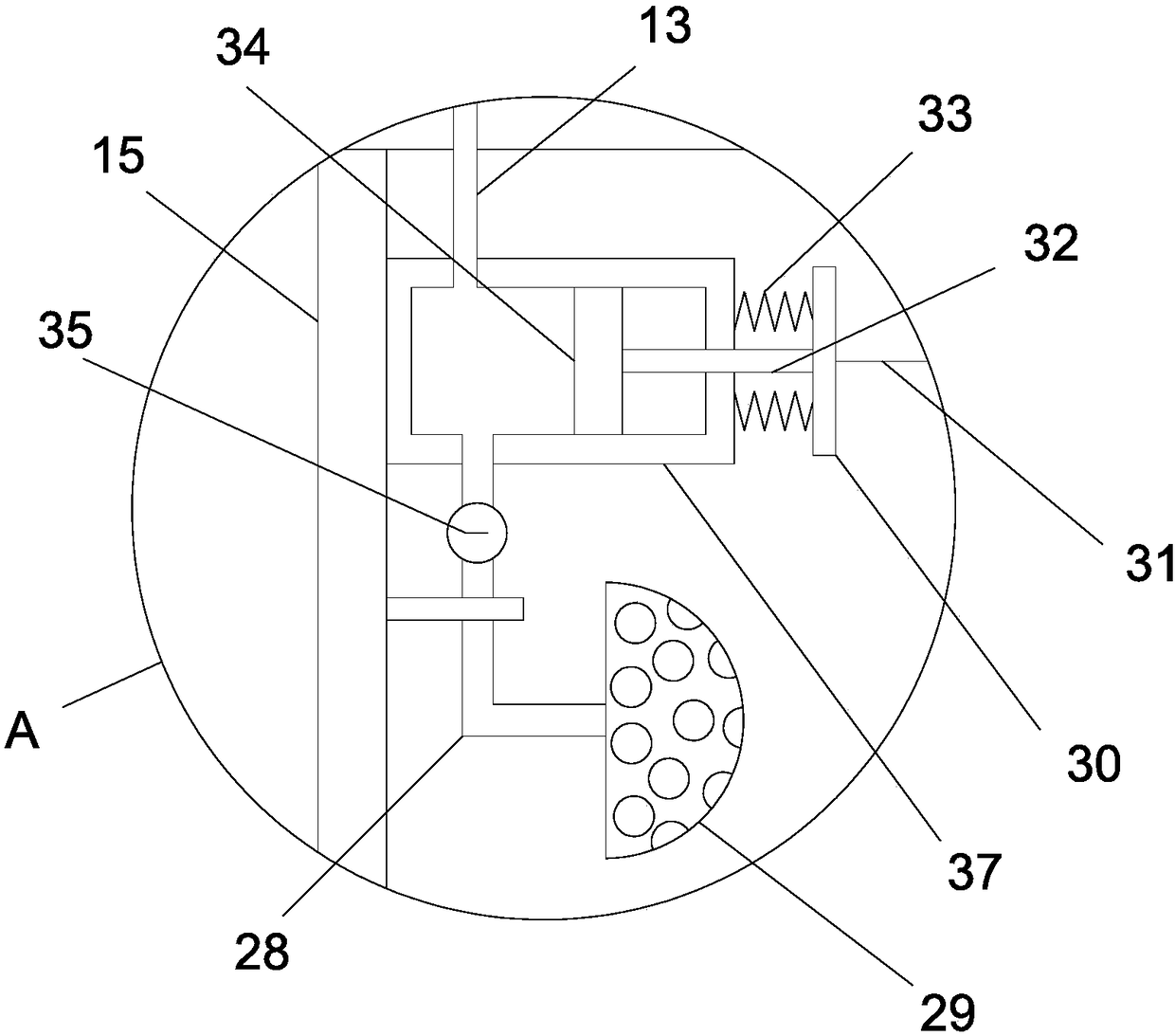

Heavy metal pollution soil treatment system and process

InactiveCN107309256ASimple structureClean thoroughlyContaminated soil reclamationMagnetic separationSoil treatmentPollution soil

The invention discloses and provides a heavy metal polluted soil treatment system and process, aiming to solve the screening problem of magnetic heavy metal pollutants in polluted soil, which includes a first crushing and screening mechanism, a second crushing and screening mechanism, and a transfer and conveying mechanism And the lifting mechanism, through the oblique lifting and throwing of the heavy metal contaminated soil after the initial crushing to the screening rake with magnetic adsorption, the secondary crushing of the heavy metal contaminated soil is carried out by the screening rake, and the heavy metal contaminated soil is sucked out by magnetic adsorption The magnetic heavy metals contained in it improve the quality and efficiency of heavy metal pollutants in the subsequent treatment process.

Owner:浙江明境环保科技集团有限公司

Dust falling type medical waste crushing treatment device

InactiveCN108405045AFully brokenSpread evenlyUsing liquid separation agentMedical waste disposalDisinfectantReciprocating motion

The invention discloses a dust falling type medical waste crushing treatment device. The dust falling type medical waste crushing treatment device comprises a bottom plate. A supporting column is vertically and fixedly arranged on the bottom plate. An impact pressing block located in a crushing tank is fixedly arranged at the lower end of an impact rod. An incomplete gear is rotatably arranged onthe lower bottom surface of an upper top plate. A straight rack in engaged connection with the incomplete gear is vertically and slidably arranged on the right side of the incomplete gear. According to the dust falling type medical waste crushing treatment device, the impact pressing block is driven by up-down reciprocating motion of the impact rod to conduct repeated impact crushing on medical waste in the crushing tank. The crushing tank is pulled to do left-right reciprocating motion through a first pull rope under the elastic action force of a limiting spring II to enable the medical wastein the crushing tank to be jittered and uniformly spread, and the impact pressing block is promoted to conduct sufficient impact crushing on the medical waste. During the period, a piston head does back and forth reciprocating sliding in a water collection sleeve to make a spray head spray disinfectant rightwards intermittently to achieve the disinfection effect and dust falling effect on the medical waste. The dust falling type medical waste crushing treatment device is friendlier to environment.

Owner:丁小标

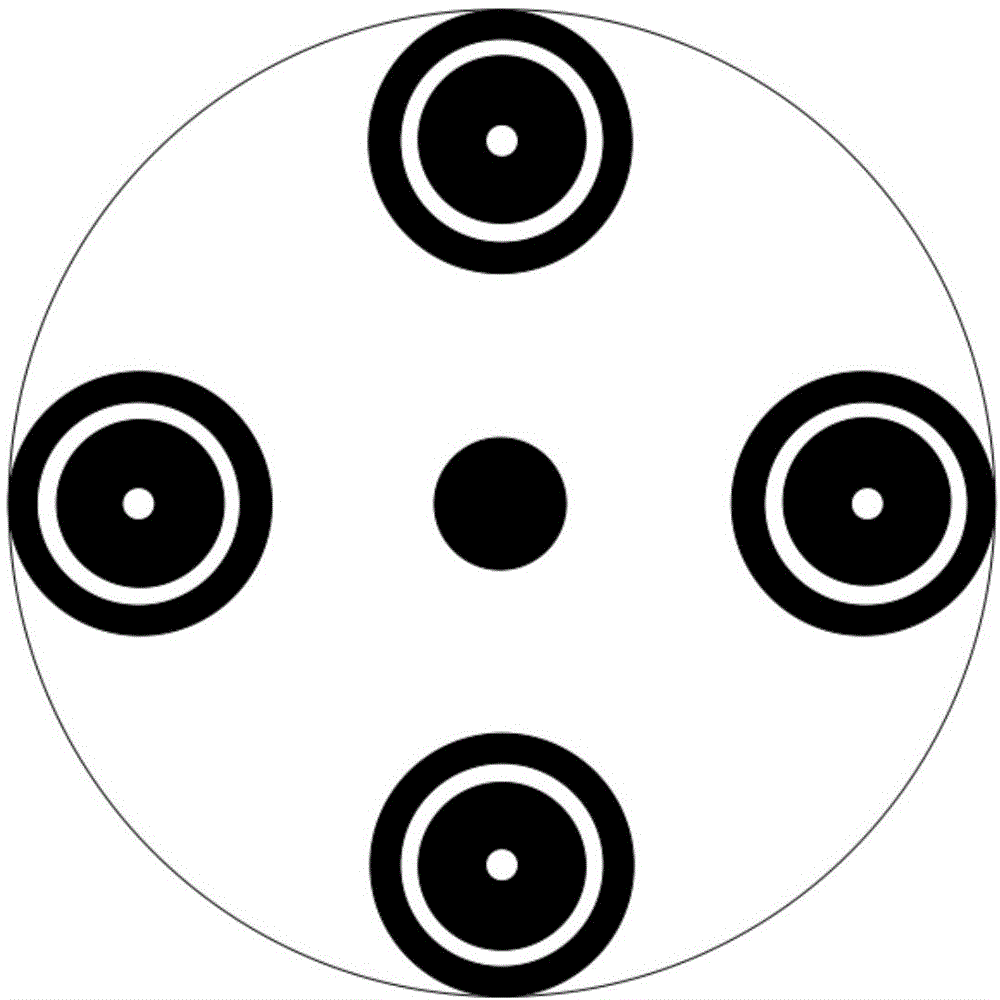

Preparation method for fine metal powder and equipment achieving method

The invention provides a preparation method for fine metal powder and equipment achieving the method. On the one hand, metal materials are fused and atomized into liquid drops to be sprayed to a high-speed rotation disc and smashed into small liquid drops, and the center spraying axis of the liquid drops is perpendicular to the rotation disc face; on the other hand, the liquid drops sprayed to the high-speed rotation disc are cooled after being smashed, and the metal powder is obtained. Compared with the prior art, the metal powder prepared through the method is fine in grain size, good in degree of sphericity and narrow in grain size distribution range and has good application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

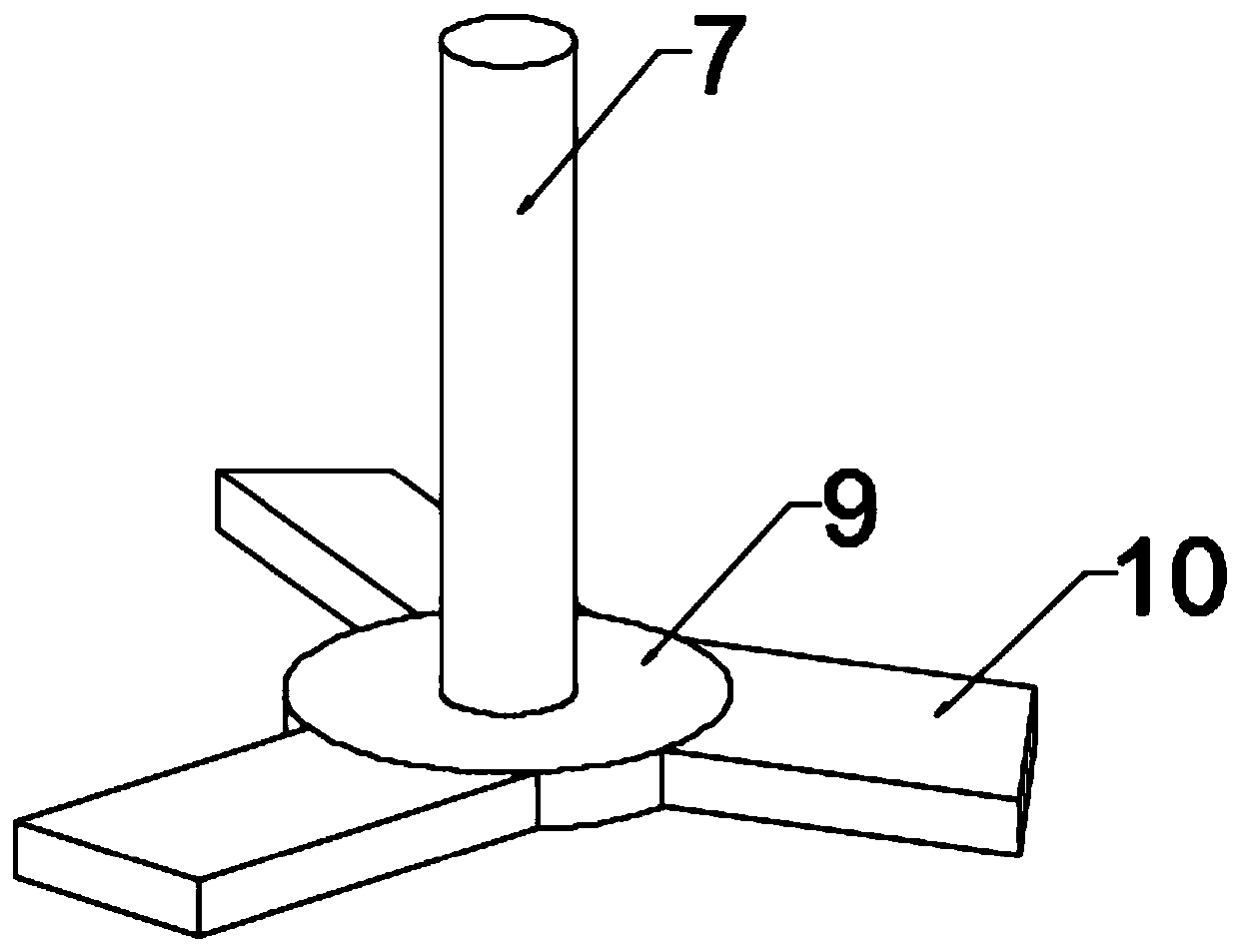

Electric arc preheating repair welding method for stir friction plug

InactiveCN101966621AFull plastic flowSufficient plastic flow, the stirring needle is not easy to breakNon-electric welding apparatusFriction weldingPore diameter

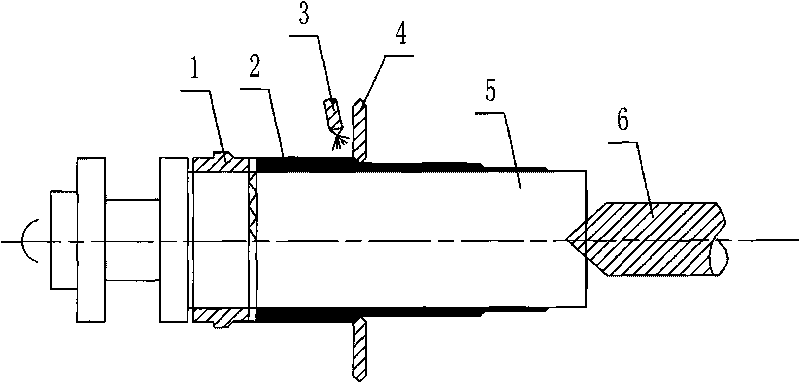

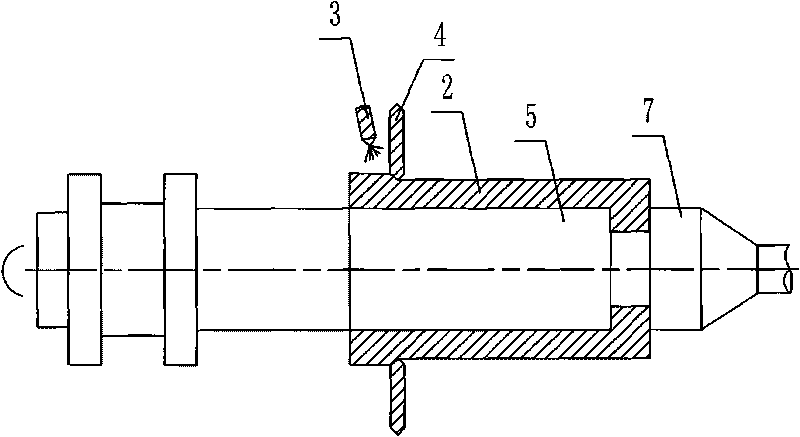

The invention discloses an electric arc preheating repair welding method for a stir friction plug, relates to a repair welding method for the stir friction plug and aims to solve the problem of poor continuous flowability of a material because a stirring needle is broken before complete plastic deformation and flow under the action of strong resisting force of a material at a repair welding position of the stir friction plug. The method comprises the following steps of: 1, performing electric arc preheating on a key hole left by friction stir welding or secondary friction stir welding repairing, namely, putting a circular ring at a key hole position until the center of the circular ring is coincided with that of the key hole, performing electric arc heating on the circular ring by using a tungsten electrode argon arc welding machine at the temperature of between 180 and 200 DEG C and transferring heat to a region needing repair welding after the circular ring is heated so as to preheat the key hole in the region needing repair welding, wherein the central pore diameter of the circular ring is greater than that of the key hole; and 2, performing repair welding on the key hole, namely, during repair welding, moving a welding tool towards a welding direction by 1 to 5 millimeters and allowing the stirring needle to undergo plastic deformation and flow so as to fill the key hole. The method is used for performing repair welding on the weld defects of the stir friction welding and the key hole.

Owner:HARBIN INST OF TECH

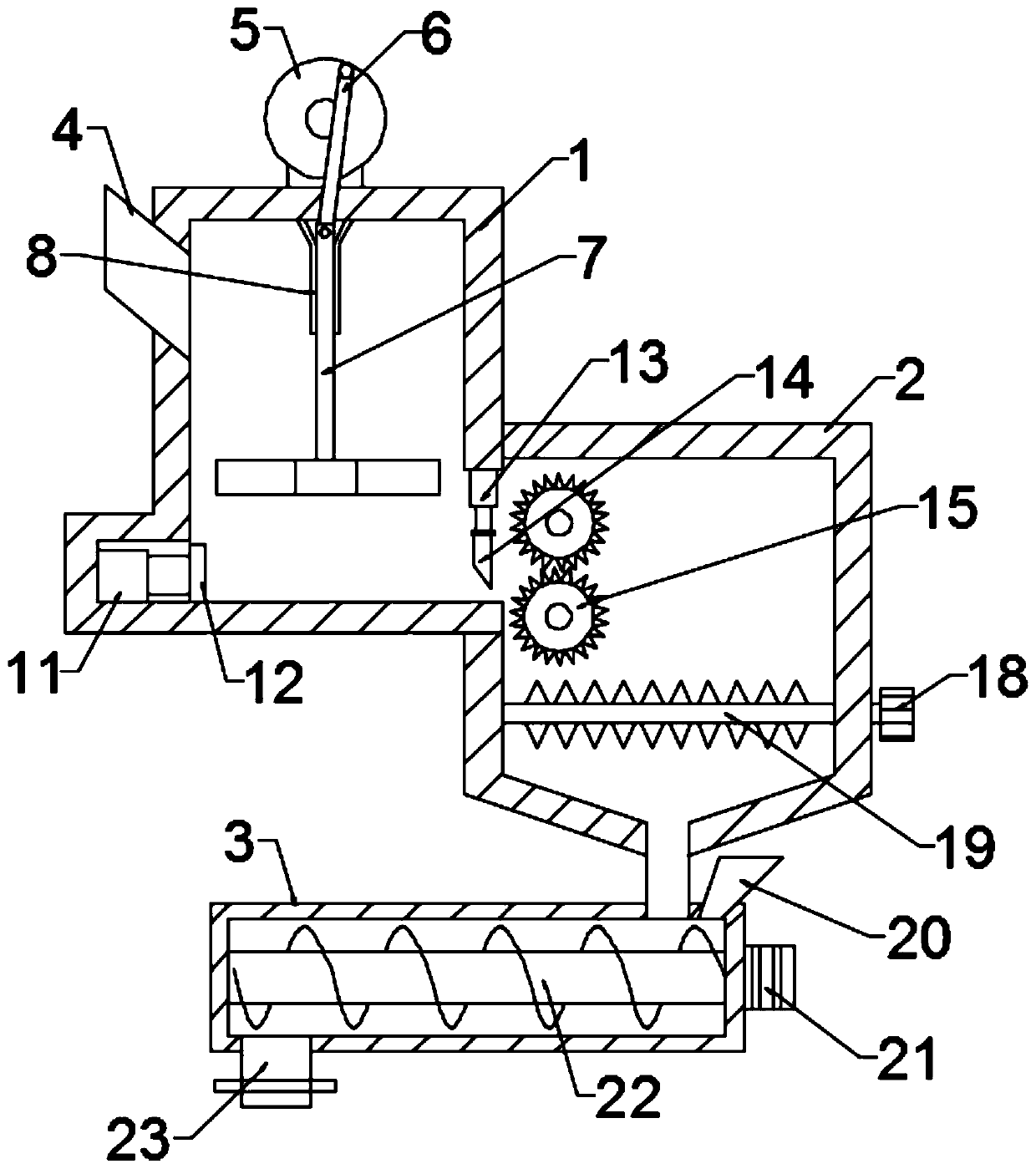

Waste recovery device for nonwoven fabric processing

ActiveCN110438791AFully brokenFilament forming substance formingSevering textilesScrapWaste recovery

The invention relates to the technical field of nonwoven fabrics and particularly discloses a waste recovery device for nonwoven fabric processing. The waste recovery device comprises a pressing chamber, a crushing chamber and a screw extruding chamber in sequential connection. The pressing chamber is used for compacting nonwoven fabric waste; the crushing chamber is used for crushing the nonwovenfabric waste; the screw extruding chamber is used for heating and melting the nonwoven fabric waste. The side wall of the top end of the pressing chamber is provided with a feeding port, a repeated pressing mechanism is arranged in the pressing chamber, a pushing-out mechanism is arranged at the bottom end of the pressing chamber, a two-stage crushing mechanism is arranged in the crushing chamber, and a shearing extrusion mechanism is arranged in the screw extruding chamber. The waste recovery device has advantages that leftover materials cut in a nonwoven fabric processing process can be comprehensively recovered, various mechanical functions are integrated, the problem of proneness to entangling of cutting parts in nonwoven fabric cutting in the prior art is solved, and potential safetyhazards are avoided.

Owner:蔡启义

Process for preparing yeast culture by taking hulled spirit distilled grains as raw material

ActiveCN103549116AReduce crude fiber contentHigh nutritional valueFood processingAnimal feeding stuffYeastNutritive values

The invention discloses a process for preparing a yeast culture by taking hulled spirit distilled grains as a raw material. The process comprises the following steps: hulling the spirit distilled grains; preparing materials; activating a strain; inoculating and mixing; controlling temperature to ferment; performing enzymolysis and wall breaking, and the like. The hulls are separated by using a mechanical method, so that the coarse fiber content of the yeast culture product is reduced, and the nutritive value and the application range of the product are improved. The hulls which are separated from the spirit distilled grains can be used as a boiler fuel after being mixed with coal to provide a heat source for drying the product, so that the drying cost is reduced, comprehensive utilization is realized, and no pollution is caused. The coarse fiber content of the product is over 50 percent less than the coarse fiber contents of the conventional spirit distilled grains and similar products, the situation that the conventional spirit distilled grain product is only suitable for ruminating animals is solved, the application range of the product is expanded, and the development of the market is facilitated.

Owner:江苏益元泰生物技术有限公司

Tantalum target and manufacturing method thereof

ActiveCN104451567AFully brokenUniform deformationVacuum evaporation coatingSputtering coatingIngotThermal treatment

The invention provides a tantalum target and a manufacturing method thereof; the manufacturing method comprises the steps: firstly, performing a first forging to a tantalum ingot and obtaining a primary forged blank; performing a second forging and a first thermal treatment to the primary forged blank obtained in the previous step and obtaining a secondary forged blank; performing a third forging and a second thermal treatment to the secondary forged blank obtained in the previous step and obtaining a tertiary forged blank; performing a fourth forging and a third thermal treatment to the tertiary forged blank obtained in the previous step and obtaining a quartus forged blank; and finally, rolling and performing a fourth thermal treatment to the quartus forged blank obtained in the previous step and obtaining the tantalum target; the first forging is a rotary forging; the temperature of the first forging is 800-1400 degrees centigrade. The prepared tantalum target is uniform in texture distribution, small in grain size and capable of satisfying usage requirements in high-level semiconductor film-coating industries.

Owner:NINGXIA ORIENT TANTALUM IND

Straw crushing device for livestock breeding

InactiveCN107624387AFully crushed and refinedGuaranteed normal cuttingShaking/oscillating/vibrating mixersUsing liquid separation agentSlagScrew thread

The invention discloses a straw crushing device for livestock breeding. The straw crushing device includes an operating room, a horizontal rod is fixedly arranged inside the operating room in a horizontal mode, a sliding rod is arranged penetratingly on the horizontal rod in a vertical sliding mode, the upper end of the sliding rod is connected with the end, away from a hanging rod, of a rotatingplate in a hinged mode, a number of cutting blades are arranged at equal spacing on the bottom of a connecting plate, locking screws are arranged on screw holes in a penetrating mode, and the lockingscrews are connected with the connecting plate in threaded fit; a number of crushing blades are arranged on the surface of a rotating shaft uniformly, and a water inlet pipe connected with an externalwater source is arranged on a water drawing sleeve. The straw crushing device for livestock breeding is ingenious in structure and convenient to operate, and a first crushing effect is achieved through straws receiving the cutting handling of the cutting blade and then receiving the rotary cutting and crushing of the crushing blades, the situation that longer straws clamp crushing blades is avoided, meanwhile the straws receive full crushing refinement, the straws sandwiched between the cutting blades or stuck on the cutting blades can be removed through the removal of a slag filter plate, and the normal cutting of the straws by the cutting blades is ensured.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

Lump lime smashing equipment for building construction

InactiveCN107199092AEfficient crushingFully brokenDispersed particle filtrationCocoaArchitectural engineeringComminution

The invention provides lump lime smashing equipment for building construction. The lump lime smashing equipment comprises a tank body; the tank body is arranged to be a hollow cylinder with two ends communicated, an upper cover is arranged at an opening in the top of the tank body, and a bottom cover is arranged at an opening in the bottom of the tank body; a feeding pipe is fixedly welded to the left side of the surface of the upper cover, and a dust absorption device is arranged on the right side of the surface of the upper cover; the interior of the tank body is divided by a separating plate into a breaking cavity and a smashing cavity; a material guide disc is fixedly welded to the lower surface of the separating plate; a breaking device is arranged in the breaking cavity; and an upper smashing device and a lower smashing device are arranged in the smashing cavity. According to the lump lime smashing equipment, blocky limb is shorn and smashed through the smashing device; the upper smashing device and the lower smashing device are arranged, relative rotation of a lower smashing disc and an upper smashing disc is used, an upper smashing block and a lower smashing block are used for grinding and smashing the smashed lime, the lime is firstly broken and secondly smashed, sufficient smashing of the lime is facilitated, and the smashing quality and the smashing uniformity are improved.

Owner:合肥多智科技开发有限公司

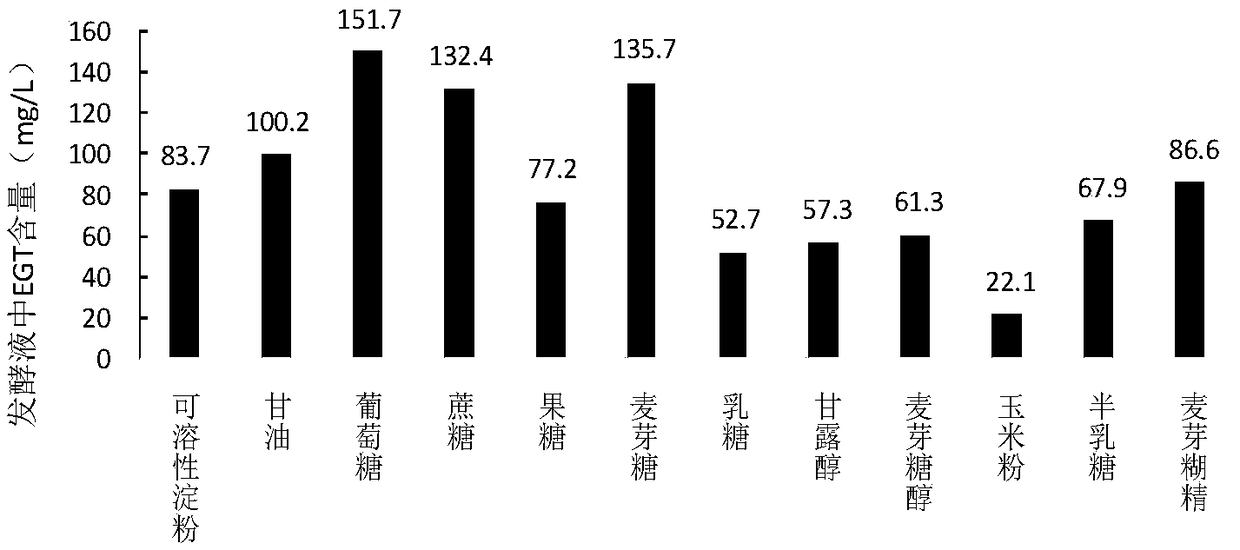

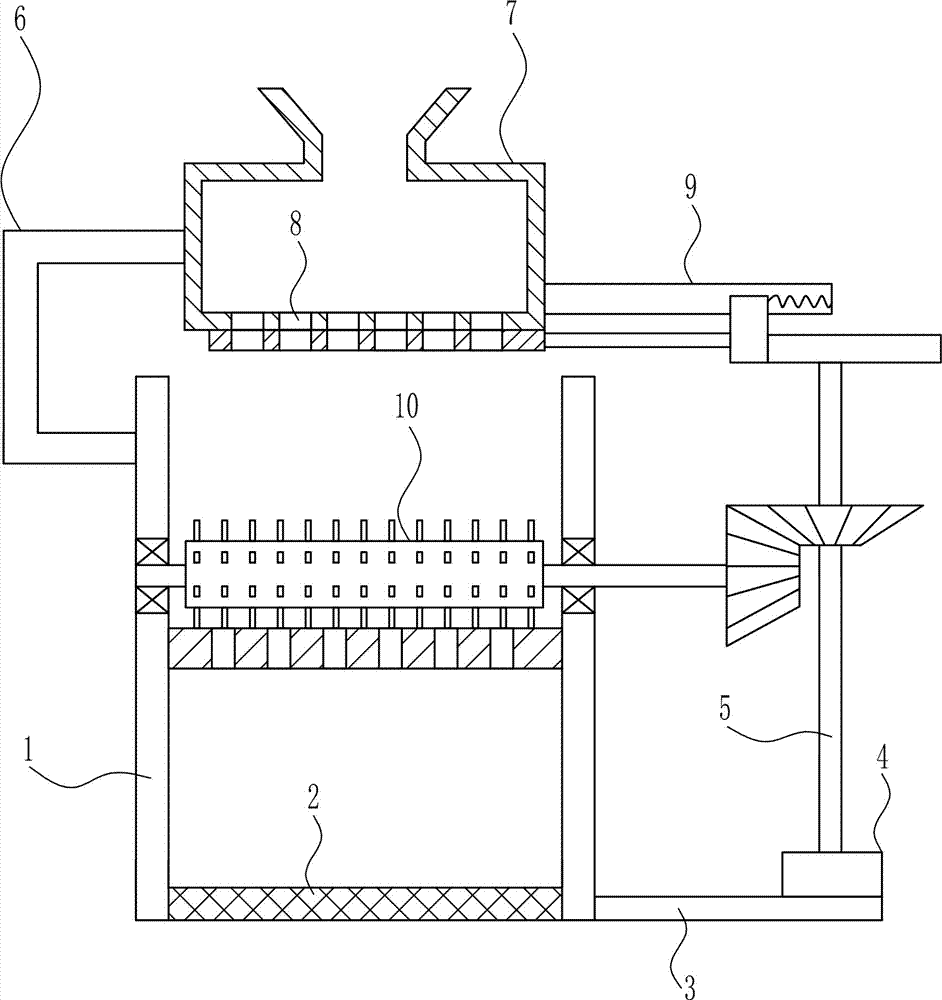

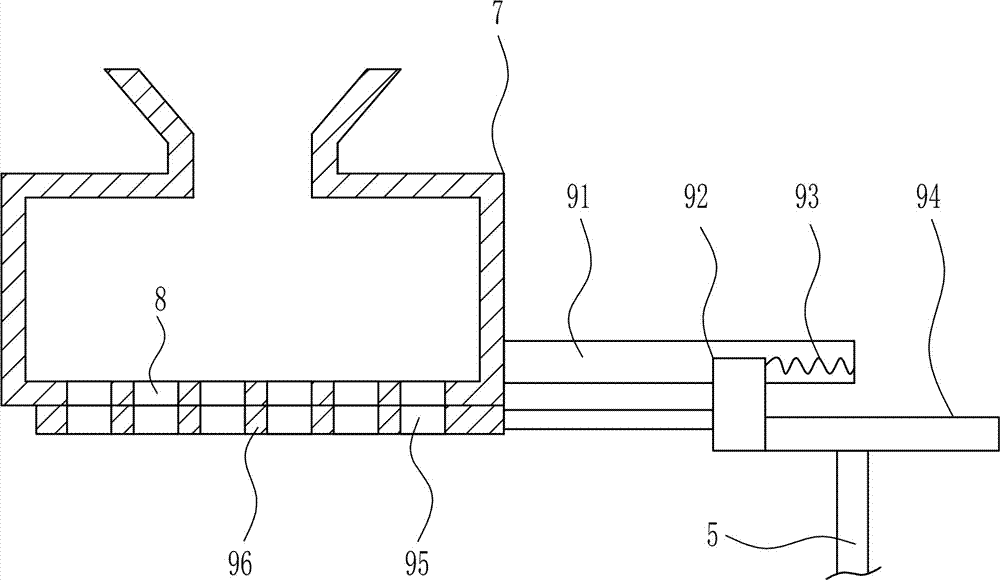

Biosynthesis preparation method for ergothioneine, and fermentation culture medium

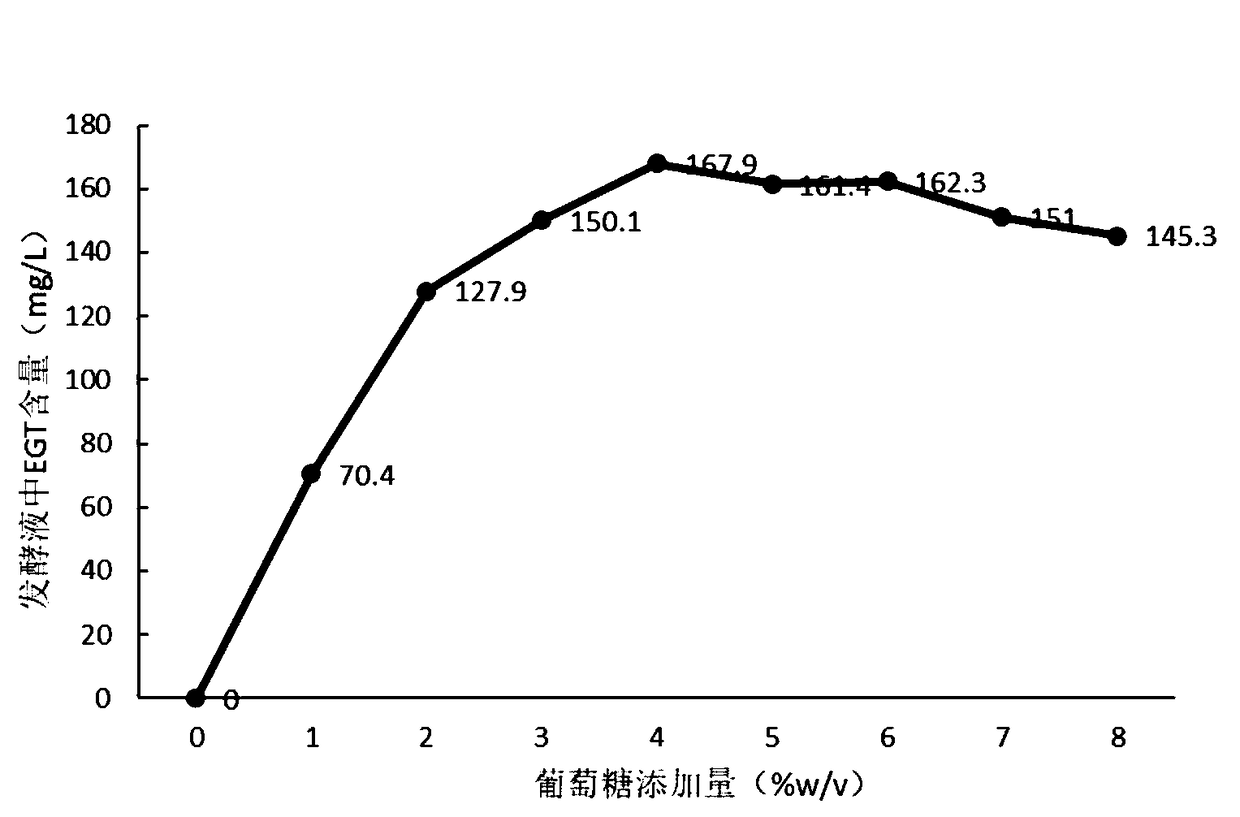

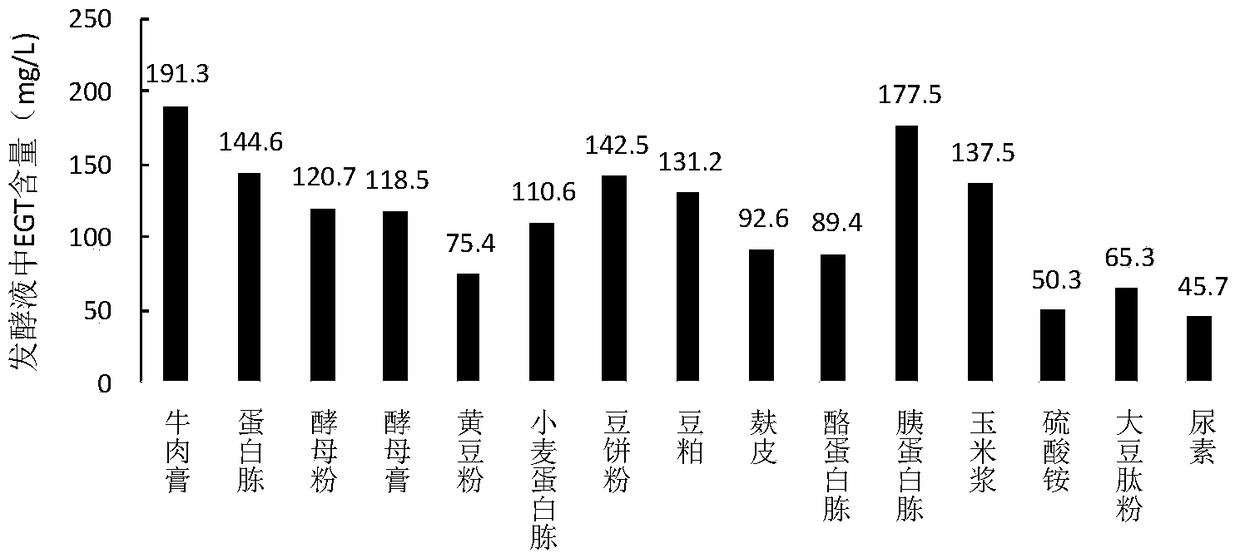

ActiveCN109439701AIncrease productionEasy to judgeMicroorganism based processesFermentationHydrogenMycelium

The invention relates to a biosynthesis preparation method for ergothioneine, and a fermentation culture medium. The method comprises the following steps of S1: inoculating Hericium erinaceus myceliumslant cultures to a liquid seed culture medium to be cultured to obtain seed liquid; S2: inoculating the obtained seed liquid to the fermentation culture medium to be fermented, adding precusor substances for culturing, and fermenting to a fermentation destination through pH (Potential of Hydrogen) judging a fermentation liquor; S3: after fermentation finishes, adding enzyme, carrying out enzymolysis to the destination, raising the temperature to kill enzyme, and lixiviating the ergothioneine in the cell of the mycelium to the fermentation liquor out of the cell. By use of the method disclosed by the invention, the yield of the ergothioneine can be improved, the fermentation destination can be quickly and simply judged, fermentation byproducts are reduced, the enzyme is used for breakingmycelium cells, and ergothioneine is safe to be lixiviated.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

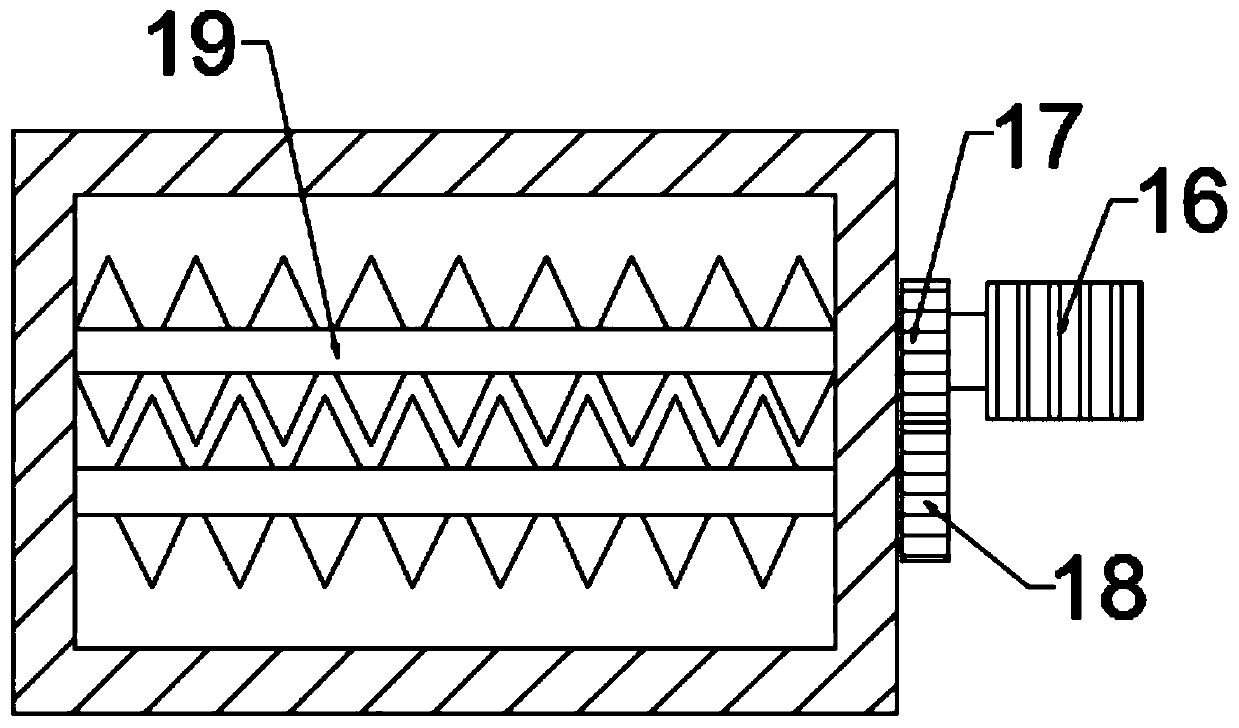

Graphite powder multi-stage grinding equipment for novel power battery production

InactiveCN107350057AFully brokenHighly corrosiveLighting applicationsMechanical apparatusPower batteryElectrical battery

The invention relates to a grinding device, in particular to a graphite powder multistage grinding device for new energy battery production. The technical problem to be solved by the present invention is to provide a graphite powder multistage grinding equipment for new energy battery production that can fully crush graphite and automatically add graphite for grinding. In order to solve the above technical problems, the present invention provides such a graphite powder multi-stage grinding equipment for new energy battery production, including a box, a filter screen, a mounting plate, a motor, a first rotating rod, a connecting rod, a storage box, etc.; The bottom wall of the box is connected with a filter screen, the lower side of the right wall of the box is connected with a mounting plate, the motor is installed on the right side of the top of the mounting plate, the output shaft of the motor is connected with the first rotating rod, and the upper side of the left wall of the box is connected with a connecting rod . The present invention designs a graphite powder multi-stage grinding equipment for new energy battery production. The first rotating rod drives the moving plate to move left and right so that the graphite is intermittently dropped from the storage box into the box.

Owner:叶世平

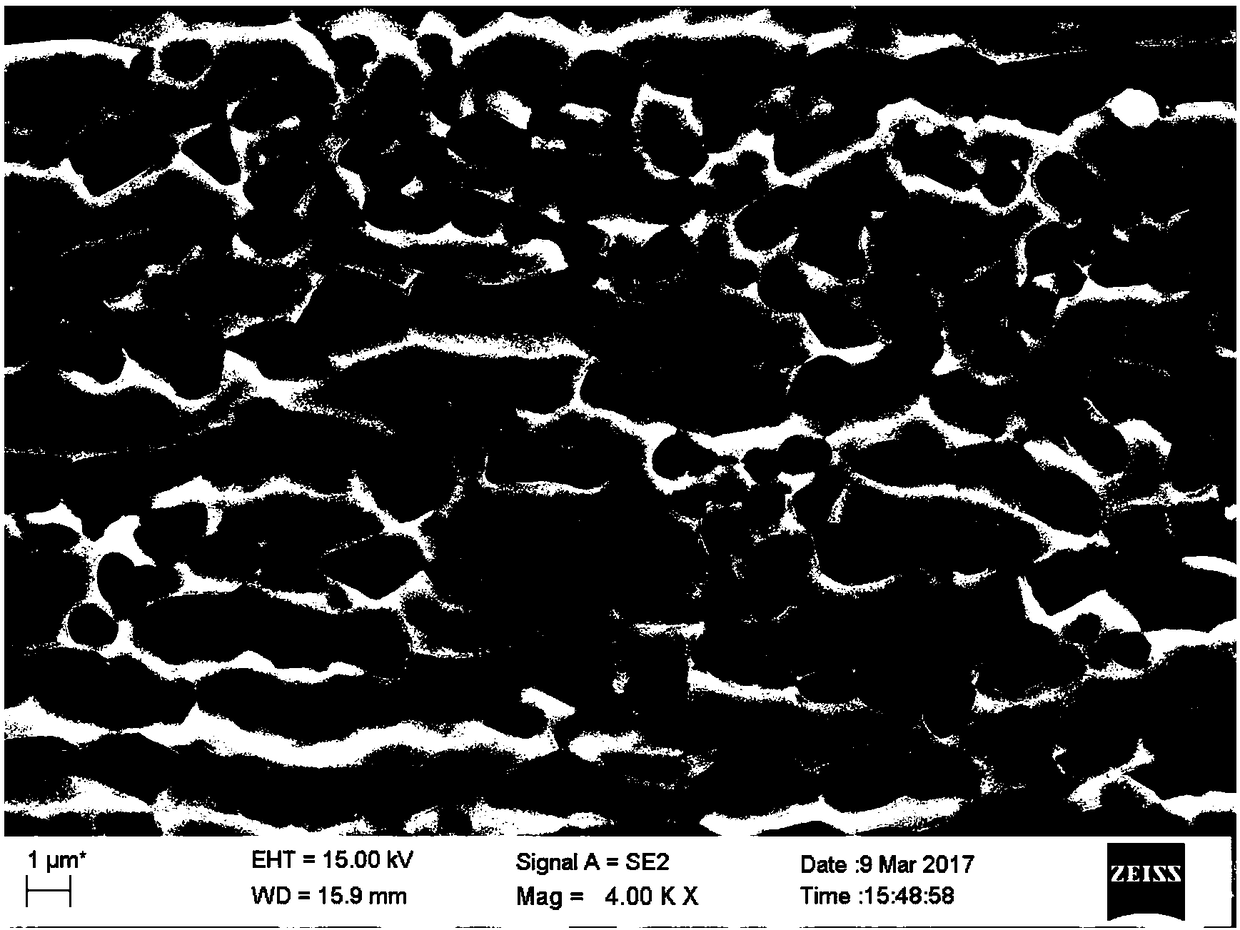

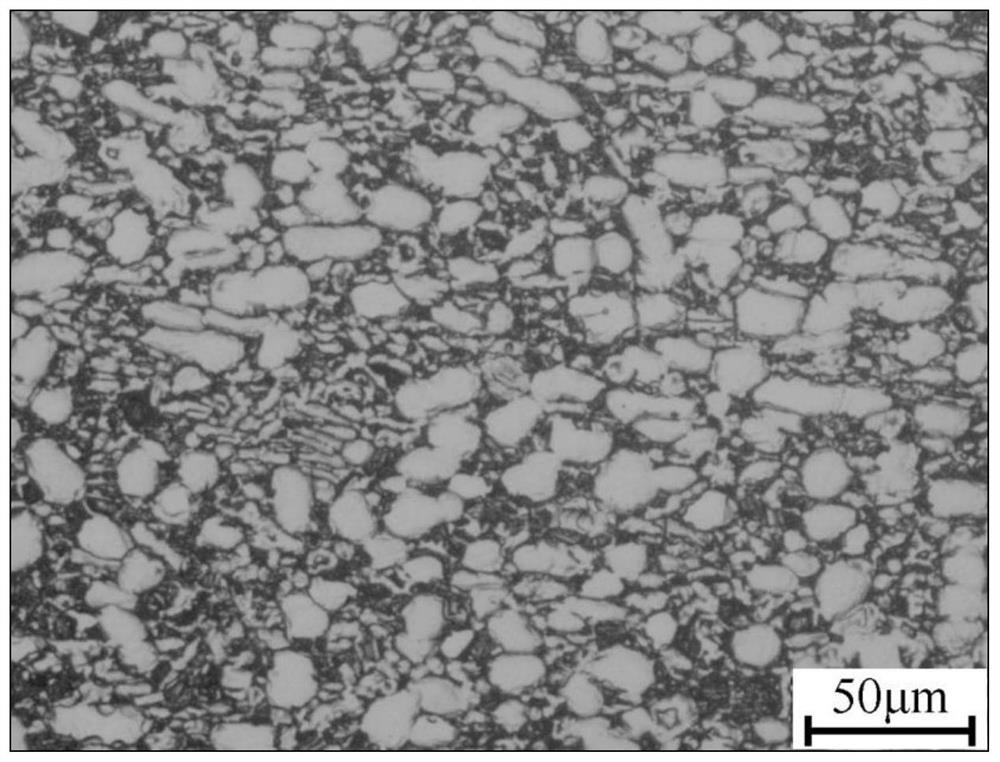

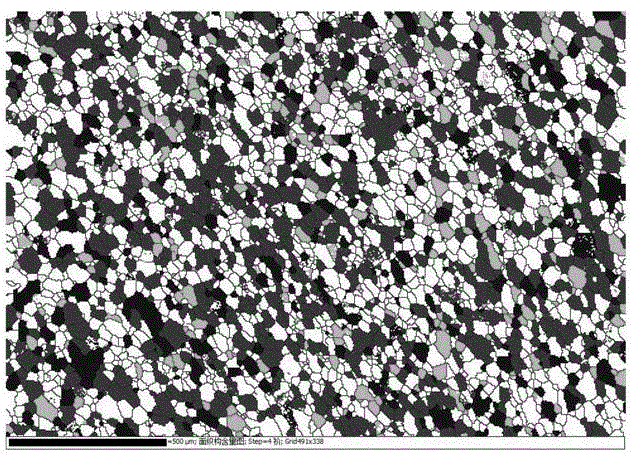

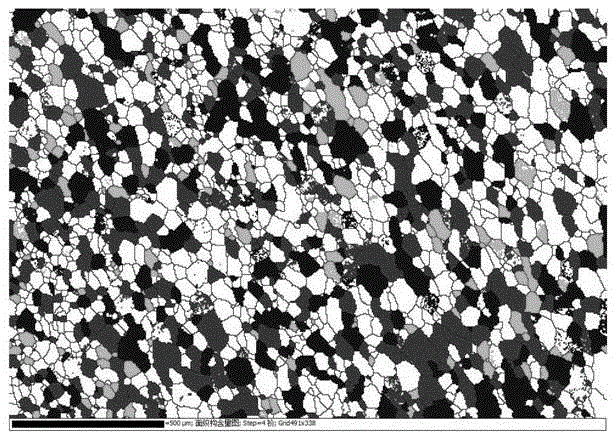

Preparation method of 650 DEG C high-temperature titanium alloy sheet for superplastic forming

ActiveCN109750185AFully brokenWeaken phase transition textureMetal rolling arrangementsBeta phaseWork in process

The invention provides a preparation method of a 650 DEG C high-temperature titanium alloy sheet for superplastic forming. The preparation method adopts hot rolling machining to obtain 650 DEG C titanium alloy sheets with excellent superplastic properties. The preparation method comprises the steps that (1) after a 650 DEG C titanium alloy casting ingot is heated, cogging and forging are carried out, and a sheet blank for titanium alloy rolling is obtained; (2) after the obtained sheet blank is coated with a coating and is heated, cogging and rolling are carried out on a rolling machine; (3) after the sheet blank is heated, second rolling is carried out; (4) after the sheet blank is subjected to heat treatment above the beta phase transformation point, rapid water quenching cooling is carried out; (5) after the sheet blank is heated, third hot rolling is carried out; (6) after the sheet blank is heated, fourth reversing hot rolling is carried out; (7) the obtained blank is assembled and welded, and a coated overlapping rolling package is obtained; (8) after the overlapping rolling package is heated, hot rolling is carried out, and a semi-finished sheet is obtained; and (9) after the semi-finished sheet is subjected to creep deformation and forming correction, annealing and acid and alkali washing, a finished 650 DEG C titanium alloy sheet with thickness of 0.8-2.0 mm is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing immune polysaccharide and yeast extract by utilizing beer yeast dregs for feeding

InactiveCN1806653AImprove decomposition abilityWill not affect the function of fermentationFood processingAnimal feeding stuffOrganismBiology

The invention provides a method of making mangel immune polysaccharides and yeasts extract, belonging to the technique field of preparing biological products, such as polysaccharides, by yeasts. Said method includes the following steps: brewers' yeast residue bitter-removing, foreign substance-removing, brewers' yeast autolysis, brewers' yeast complex enzymolysis and deactivation, segregation of polysaccharides and protein hydrolysate liquid, blink spray drying of mangel immune polysaccharides and yeasts extract, etc; it is characterized on: high yield, good quality, low cost, and could achieve the aim of preparing mangel immune polysaccharides and yeasts extract at the same time from identical yeast material, enhance the availability ratio of yeasts, avoid pollution to the environment in traditional method as a result of simply preparing one certain product and discharging other assistant liquid.

Owner:HANGZHOU ZHONGDE AQUATIC FEED

Grain crushing and grinding integrated device for agricultural production

InactiveCN109622142AImprove crushing efficiencyFully brokenSievingScreeningAgricultural engineeringElectric machinery

The invention discloses a grain crushing and grinding integrated device for agricultural production, and relates to the technical field of agricultural machinery. The grain crushing and grinding integrated device for the agricultural production comprises a supporting frame, a driving motor is fixed to the supporting frame, and a crushing cylinder with a feeding pipe is vertically fixed into the supporting frame. The crushing cylinder slidably sleeves an inverted lifting cylinder, an external thread connected with a crushing shaft in a threaded mode is arranged on the surface of the crushing shaft in an attacking mode, and a collection slot fixed on the supporting frame is formed directly below the lifting cylinder. According to the grain crushing and grinding integrated device for the agricultural production, a rotating crushing effect of grain particles in the crushing cylinder is realized by rotating a cutting blade, the grain particles can be shifted up and down on the lifting cylinder, and the cutting blade can fully crush the grain particles; and meanwhile, screening holes in the lifting cylinder play a role in screening the crushed grain particles, grain in the crushing cylinder is enabled to be reduced, the crushing efficiency of the cutting blade is improved, meanwhile, an arranged grinding roller can grind the grain particles in the collecting tank, and the crushing degree is greatly improved.

Owner:刘学

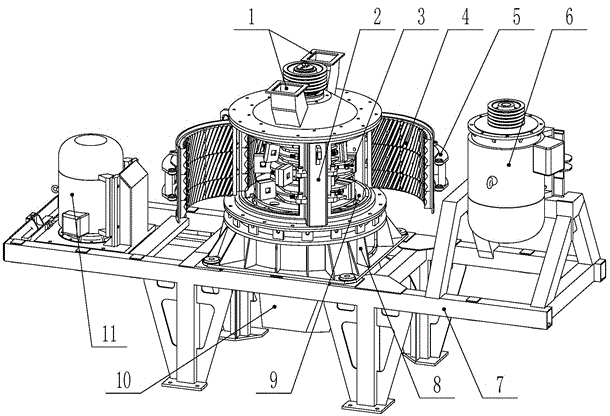

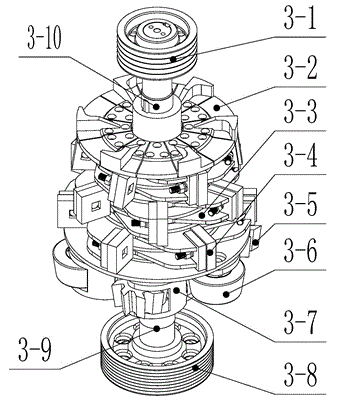

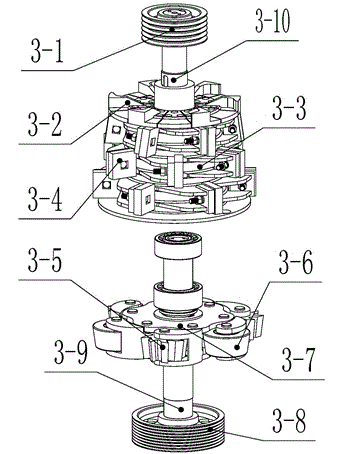

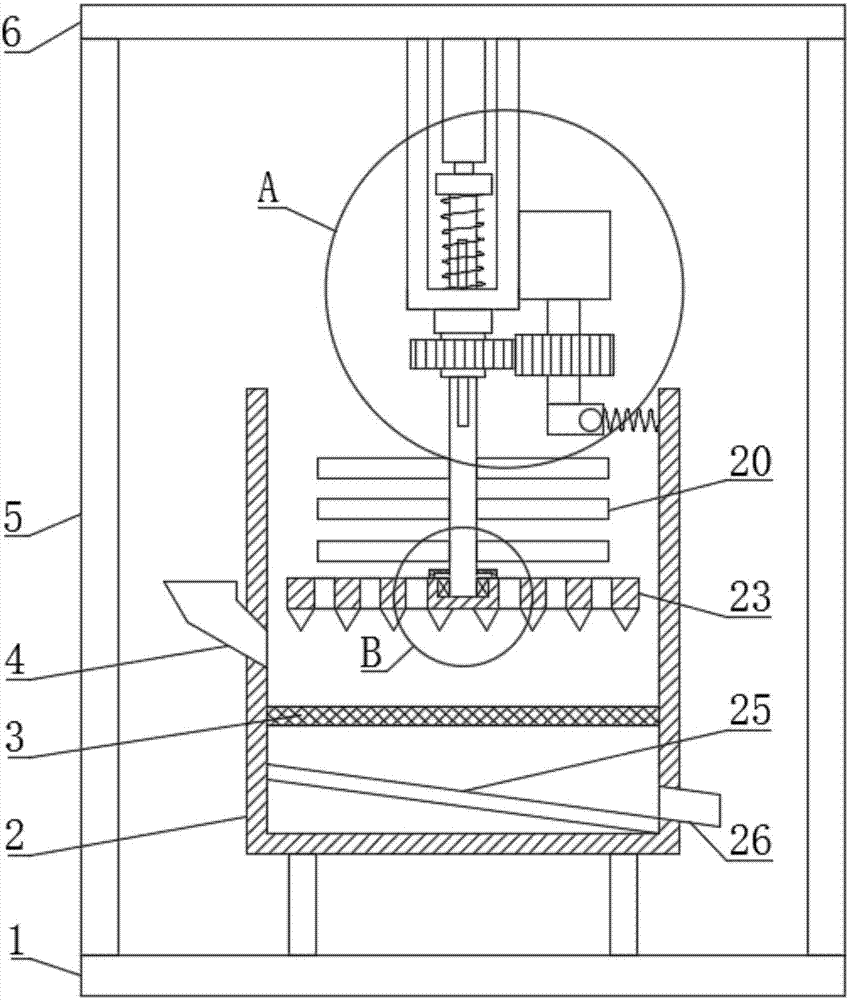

Vertical combined crushing and grinding machine

The invention provides a vertical combined crushing and grinding machine. The vertical combined crushing and grinding machine comprises an integral support, a grinding cavity seat, a cylinder body, a vertical rotor body, a spiral impact plate, a discharge hopper, charge hoppers, a turnover door, a grinding cavity wall lining plate, an electromotor, a crushing mechanism and a grinding mechanism. The vertical combined crushing and grinding machine enables the material crushing and grinding processes to be realized by one machine, is compact in structure and small in occupied area, saves the process, and improves the efficiency. Materials are impacted and crushed at high speed by a hammer head on a tower-shaped hammer seat in a spiral through crushing cavity, are thrown to the turnover door, are rebounded to the hammer head on the tower-shaped hammer seat, and are crushed repeatedly in the way, so as to guarantee relatively sufficient crushing. A centrifugal rotation roller acts on a grinding cavity wall lining plate, the materials are ground and crushed to 1mm below, and the qualified materials discharged from the discharge hopper finally are uniform in granularity and high in crushing ratio. In addition, the crushing and grinding cavity of the through combined crushing and grinding machine of the design is difficult to block, is smooth in material discharge and is long in service life, and the industrial cost is reduced.

Owner:四川皇龙智能破碎技术股份有限公司

Method for processing cold-making green tea

InactiveCN102726553AAvoid high temperaturePreserve the flavorPre-extraction tea treatmentFlavorChemistry

The invention discloses a method for processing cold-making green tea, comprising the following steps of: deactivating enzymes of fresh tea leaves by a vacuum microwave method, carrying out vitrification, followed by ultramicro crushing, carrying out vacuum freeze drying, crushing caking tea, packing by the use of a tea filter bag, and carrying out vacuum packing by the use of a plastic-aluminum bag for external packing, so as to prepare the cold-making green tea product. The vacuum microwave method for deactivating enzymes has advantages of rapid speed for killing enzyme and low action temperature; ultramicro crushing after vitrification realizes full crushing of tea under the low-temperature condition; and vacuum packing avoids oxidation, moisture absorption and browning of the product during the storage process. The cold-making green tea has advantages of good color, excellent flavor and rapid cold-making speed.

Owner:FUJIAN AGRI & FORESTRY UNIV

Construction waste dual-crushing and screening device

PendingCN107469940AFully brokenPromote fragmentationGrain treatmentsConstruction waste recoveryHydraulic cylinderGear wheel

The invention discloses a construction waste dual-crushing and screening device which comprises a base, wherein a crushing box is fixedly arranged on the base through a bracket; a sieve plate is fixedly arranged in the crushing box; support plates are arranged on left and right sides of the top of the base; a top plate is arranged at the tops of the support plates; a U-shaped plate is fixedly arranged at the bottom of the top plate; a hydraulic cylinder is further arranged at the bottom of the top plate; the bottom end of the piston rod of the hydraulic cylinder is rotatably connected with a first mounted bearing; a spline shaft is fixedly connected with the bottom of the first mounted bearing; a compression spring is connected onto the spline shaft in a sleeving manner; a second mounted bearing is further arranged at the bottom of the U-shaped plate; a rotary sleeve is rotatably connected below the second mounted bearing; a first gear is mounted on the rotary sleeve; smashing blades are further mounted on the spline shaft; and the bottom end of the spline shaft is rotatably connected with a crushing plate through a bearing. According to the construction waste dual-crushing and screening device, construction waste is first extruded and crushed by the crushing plate, and then, the crushed construction waste penetrates through through holes in the crushing plate to be crushed by the smashing blades rotating at a high speed, so that the construction waste is more sufficiently crushed.

Owner:ZHENGZHOU UNIV

Building cement waste breaking and cleaning device

InactiveCN107930834AEasy to break and clean upAchieve double crushingSievingScreeningArchitectural engineeringEngineering

The invention discloses a building cement waste breaking and cleaning device, and relates to the technical field of building facilities. The device comprises a bottom plate, a breaking box is fixedlyconnected to the top of the bottom plate, a partition plate, a mounting plate and a supporting plate are fixedly connected between the two sides of the inner wall of the breaking box from top to bottom in sequence, a separation plate is arranged between the top of the partition plate and the inner wall of the breaking box, a separation plate is arranged between the bottom of the partition plate and the top of the mounting plate, and a separation plate is arranged between the bottom of the mounting plate and the top of the supporting plate. According to the building cement waste breaking and cleaning device, the breaking effect is greatly enhanced, the breaking efficiency is well improved, building cement can be sufficiently broken, one breaking device can automatically carry out two-time breaking, people do not need to waste a large amount of time for building cement block breaking, work burdens of the people are reduced, and the building cement blocks can be rapidly and efficiently broken.

Owner:HUANGHE S & T COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com