Grain crushing and grinding integrated device for agricultural production

A technology for crushing and grinding grains, applied in grain processing, solid separation, sieving, etc., can solve problems such as insufficient crushing, achieve the effect of improving crushing efficiency and degree of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

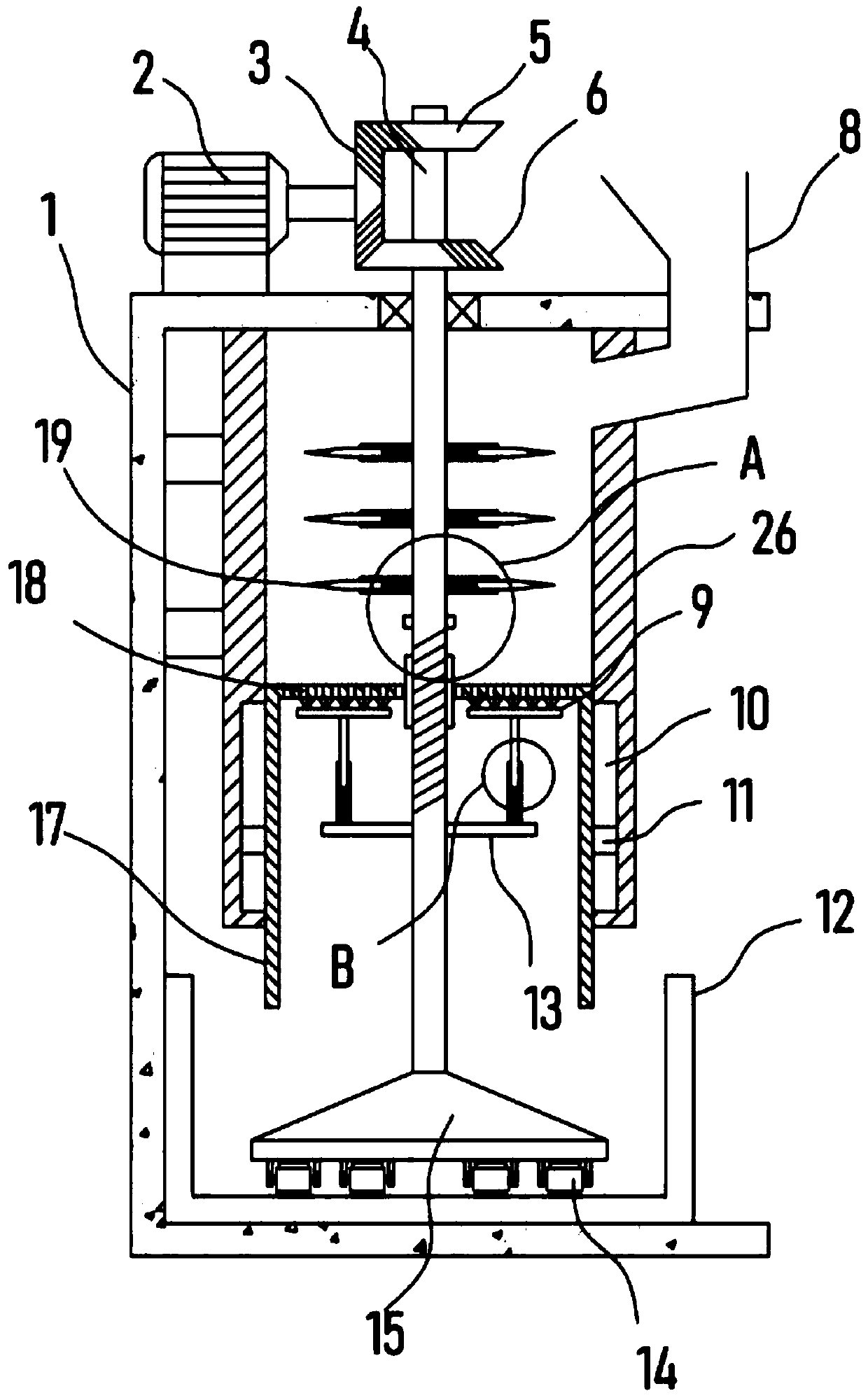

[0022] see Figure 1-3 , a grain crushing and grinding integrated device for agricultural production, comprising a support frame 1, a drive motor 2 is fixed on the support frame 1, a crushing cylinder 26 with a feed pipe 8 is vertically fixed in the support frame 1, and the feed pipe 8 passes through the support frame 1. 8. Grain grains to be crushed can be added into the crushing cylinder 26.

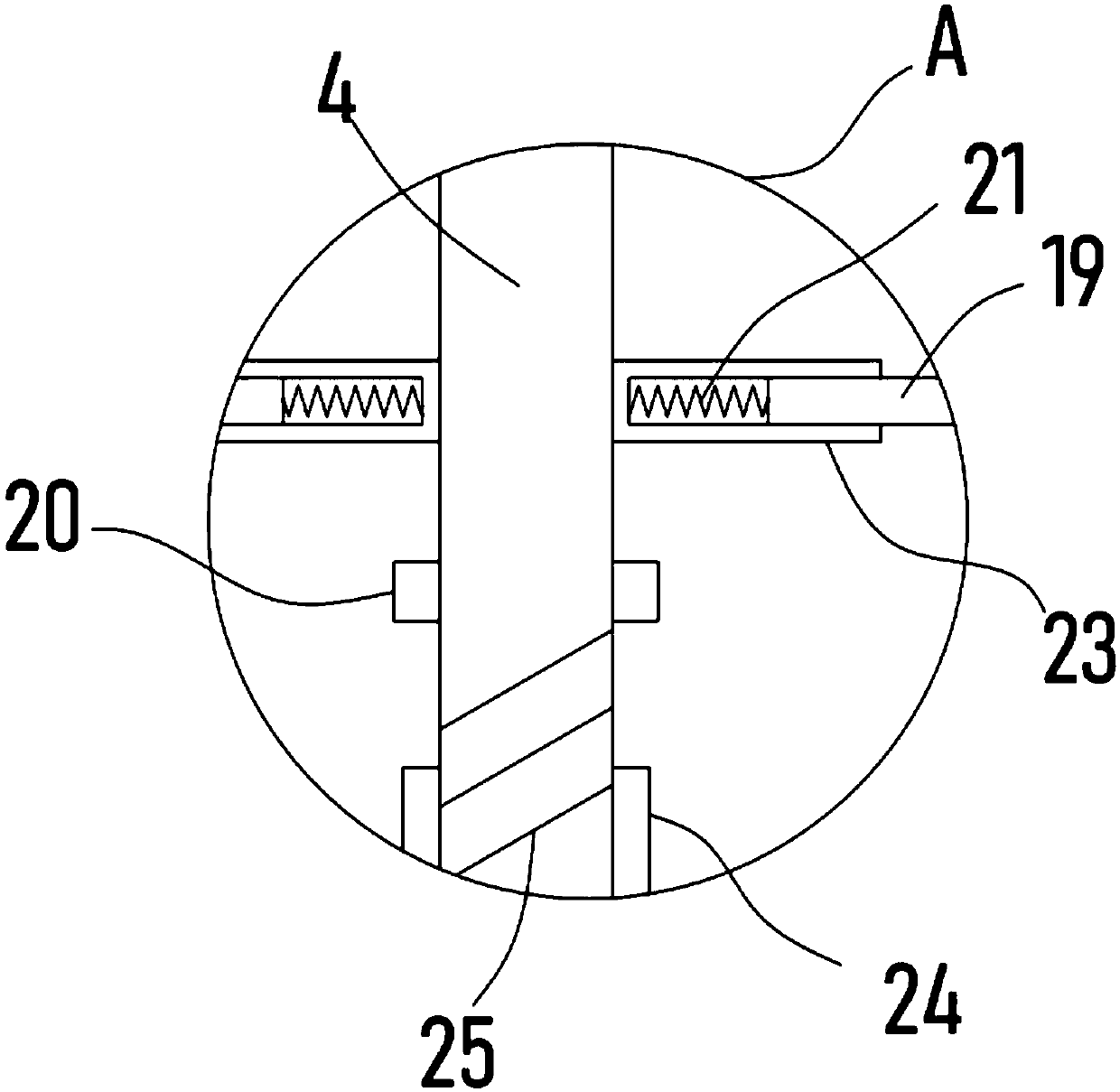

[0023] A crushing shaft 4 is arranged vertically in a rotating manner in the crushing cylinder 26, and several equally spaced cutting blades 19 are evenly arranged on the surface of the crushing shaft 4. The sliding sleeve in the crushing cylinder 26 is provided with an inverted lifting cylinder 17, and the lifting cylinder 17 Several sieve holes 18 are evenly opened on the upper surface, and a threaded sleeve 24 is vertically penetrated and fixed on the lifting cylinder 17. The thread 25 is provided with a collection tank 12 fixed on the support frame 1 just below the lifting tube 17...

Embodiment 2

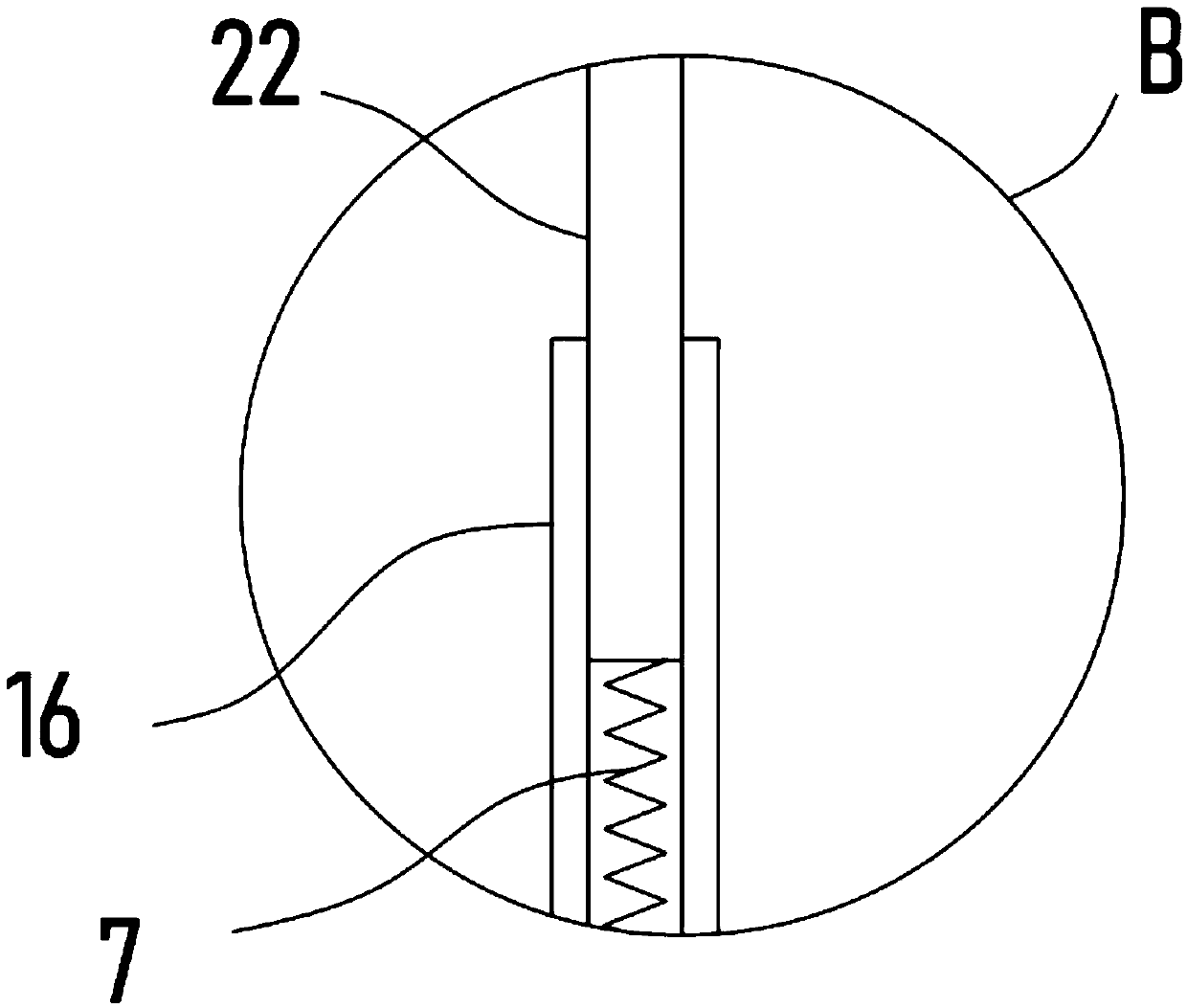

[0030] On the basis of Embodiment 1, in addition, an extension plate 13 is fixedly installed on the side wall of the crushing shaft 4, a sleeve 16 is vertically fixed on the extension plate 13, a support slide shaft 22 is slidably installed on the sleeve 16, and the support slide shaft 22 The upper end is horizontally fixed with a brush plate 9 abutting against the inner top of the lifting tube 17 . Vertically installed in the sleeve 16 is a longitudinal limit spring 7 whose two ends are respectively fixed in the sleeve 16 and the lower end of the supporting slide shaft 22 .

[0031] The extension plate 13 rotates with the rotation of the crushing shaft 4, and then the sleeve 16 drives the support slide shaft 22 to rotate. At this time, the brush plate 9 at the upper end of the support slide shaft 22 rotates and screens the screen hole 18 at the top of the lifting cylinder 17. Cleaning up promotes that the smaller grain crumbs can fall in the collecting tank 12 in time, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com