Patents

Literature

157 results about "Grain crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The purpose of grain crushing is to crack open the outer husk of the grain, exposing the rich center. Well-milled grain will leave the husk in tact, like the opening of a clam.

Method for controlling solidification structure of large-size TC4-DT titanium alloy ingot

The invention discloses a method for controlling a solidification structure of a large-size TC4-DT titanium alloy ingot. The method particularly comprises the steps that batching is conducted on sponge titanium and intermediate alloy according to the proportion required by the GB / T3620.1, the materials are pressed into an electrode block after being mixed, the electrode block is subjected to vacuum plasma welding and then subjected to vacuum arc furnace smelting, the arc stabilizing current and the arc stabilizing period are strictly controlled when third-time smelting is conducted in the smelting process, and lastly the finished ingot product is obtained after surface machining is conducted. According to the method, VAR three-time smelting is conducted, the solidification structure of the TC4-DT titanium alloy ingot is uniformized by adopting an appropriate arc stabilizing parameter technology when third-time smelting is conducted, and therefore the problem that grain crushing is difficult in the forging process due to the fact that the solidification structure of an existing large-size (ranging from phi 720 mm to phi 1,000 mm) TC4-DT titanium alloy ingot is thick and big is solved.

Owner:西部超导材料科技股份有限公司

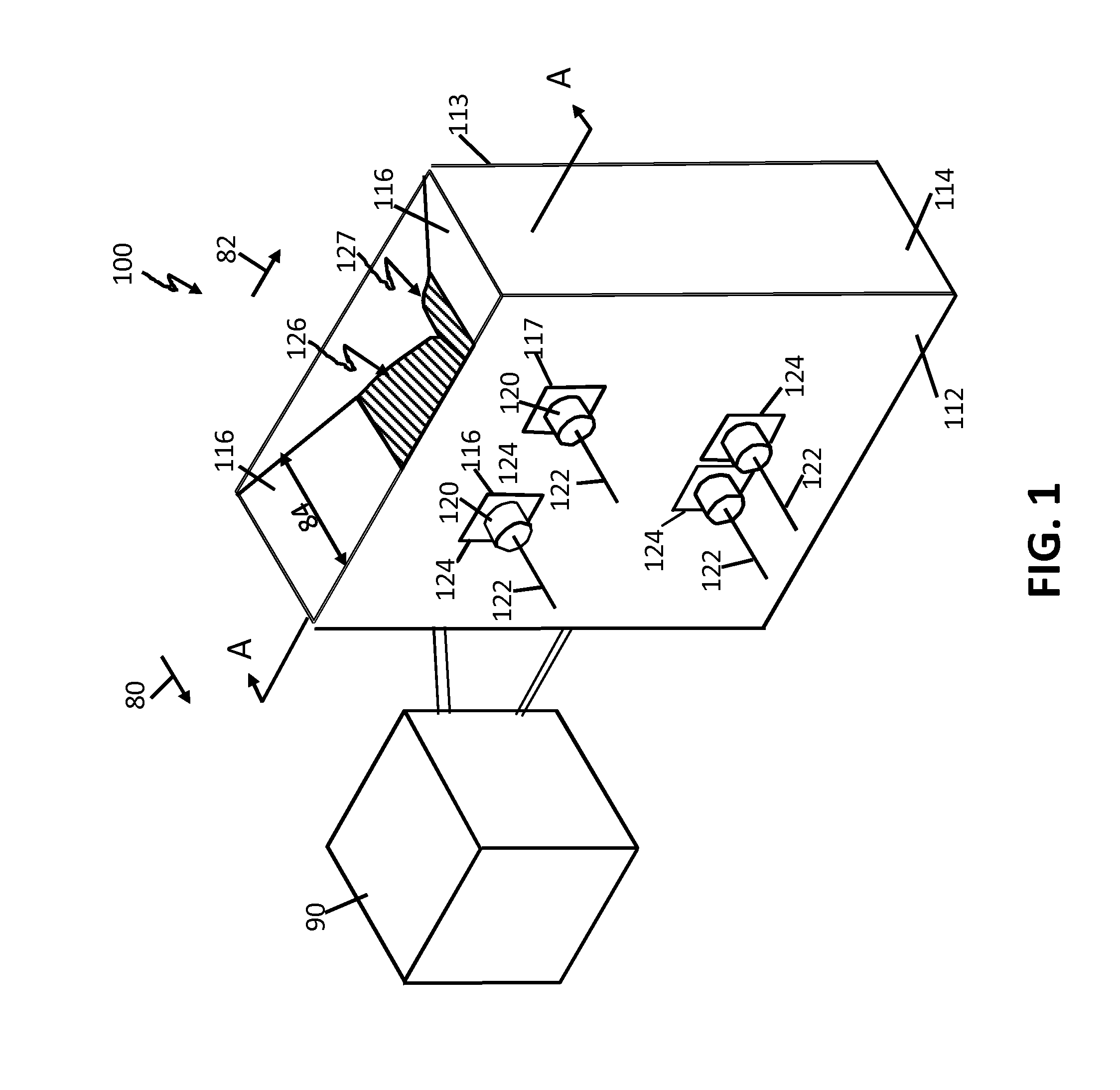

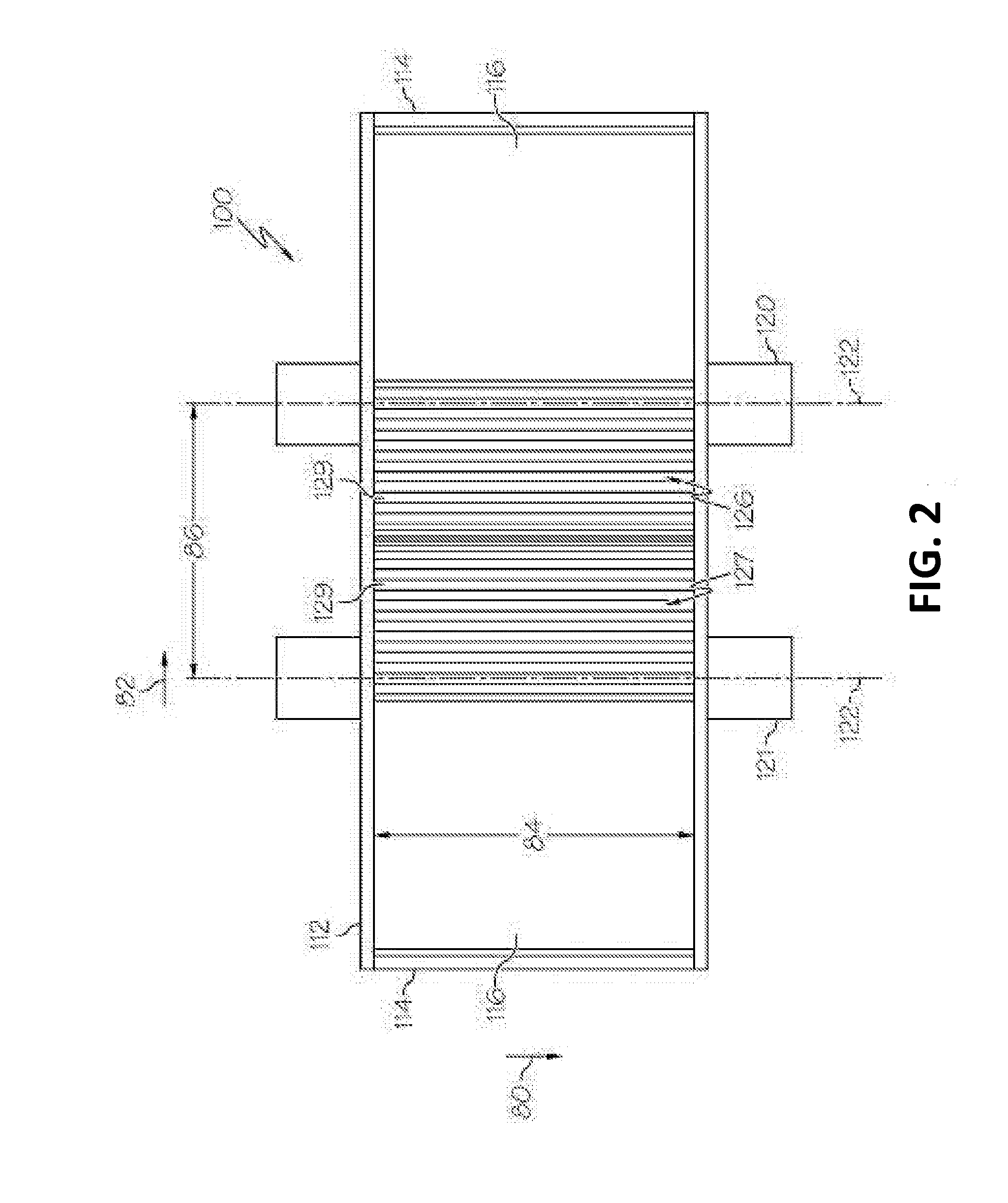

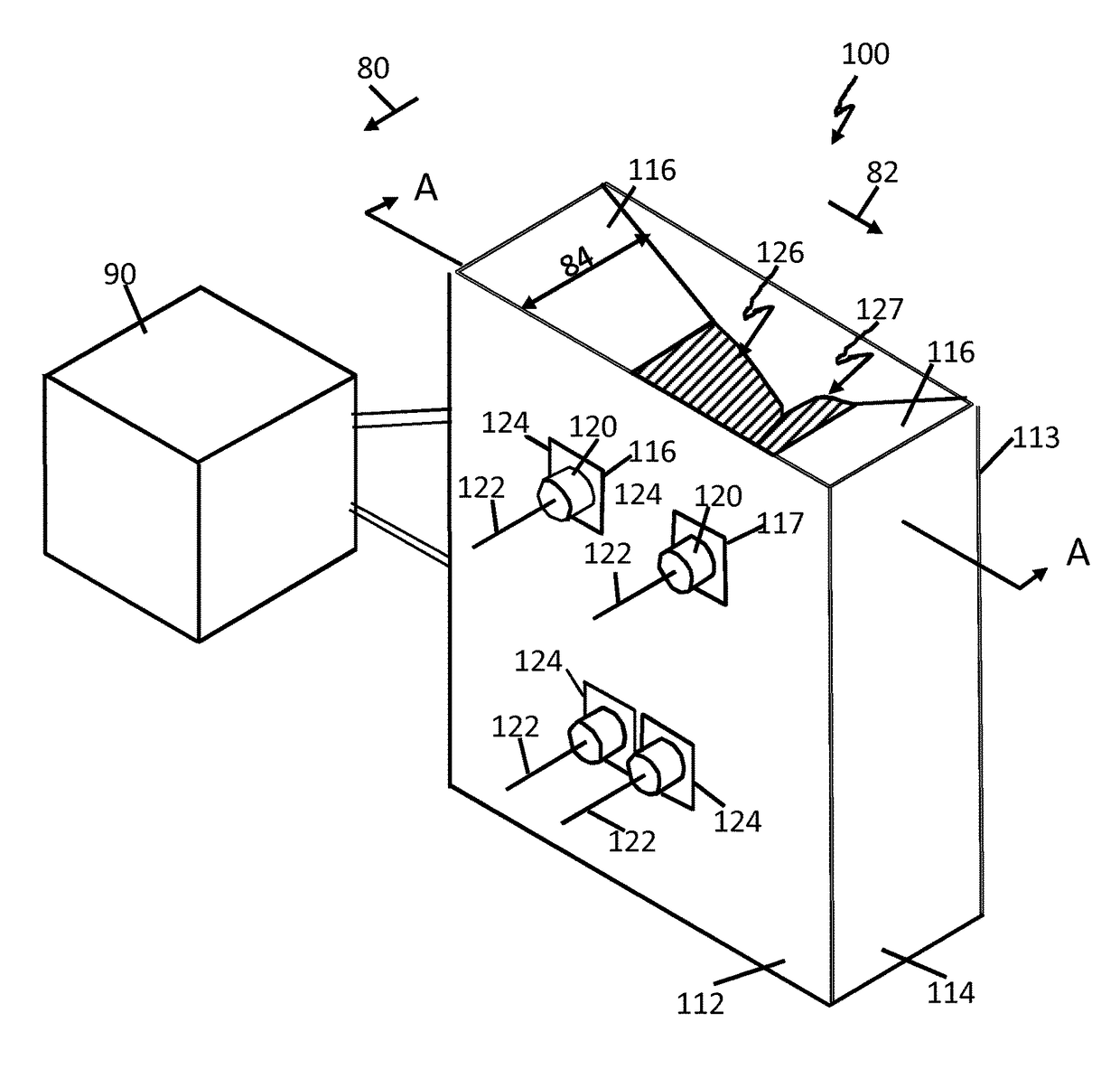

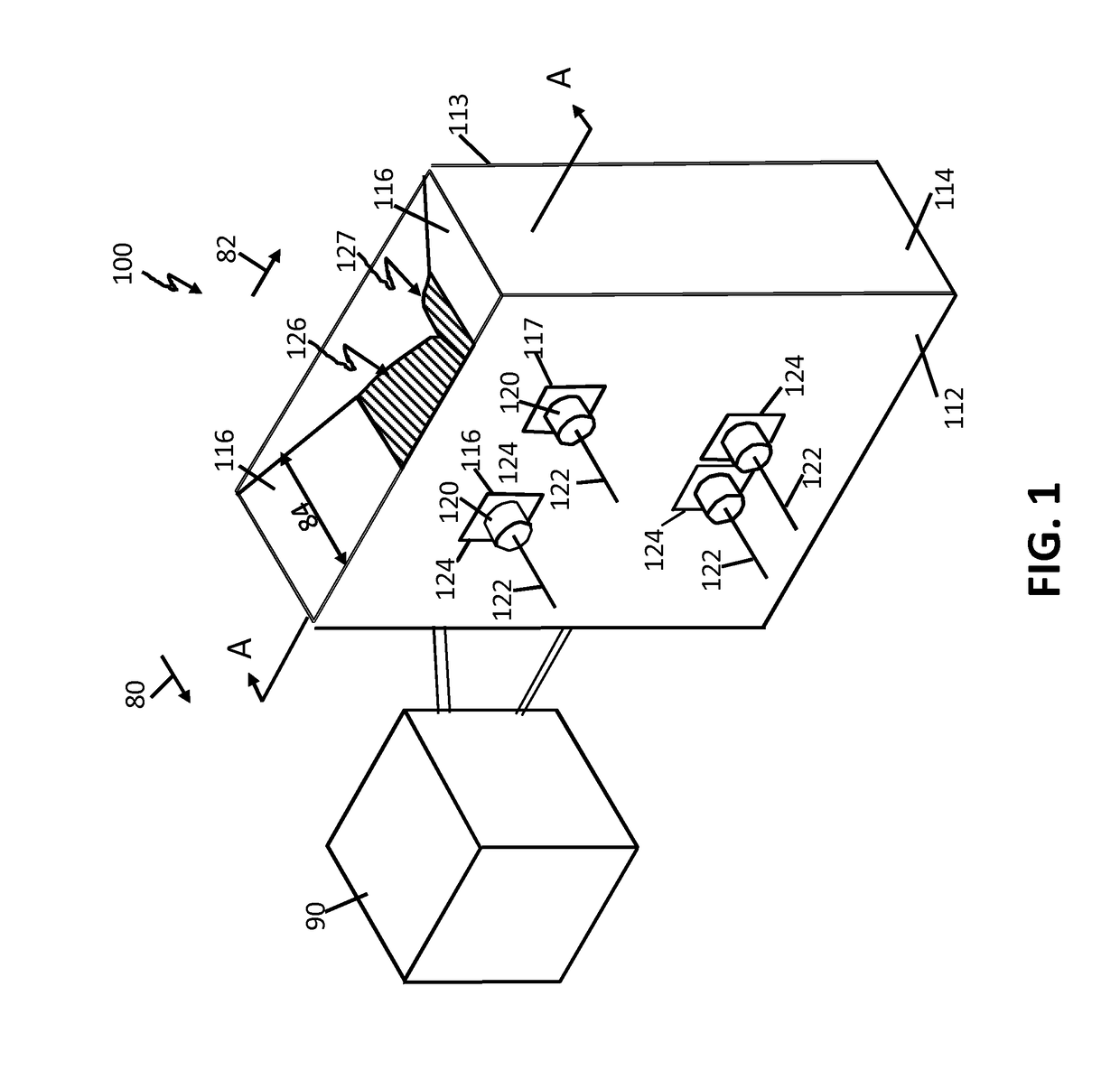

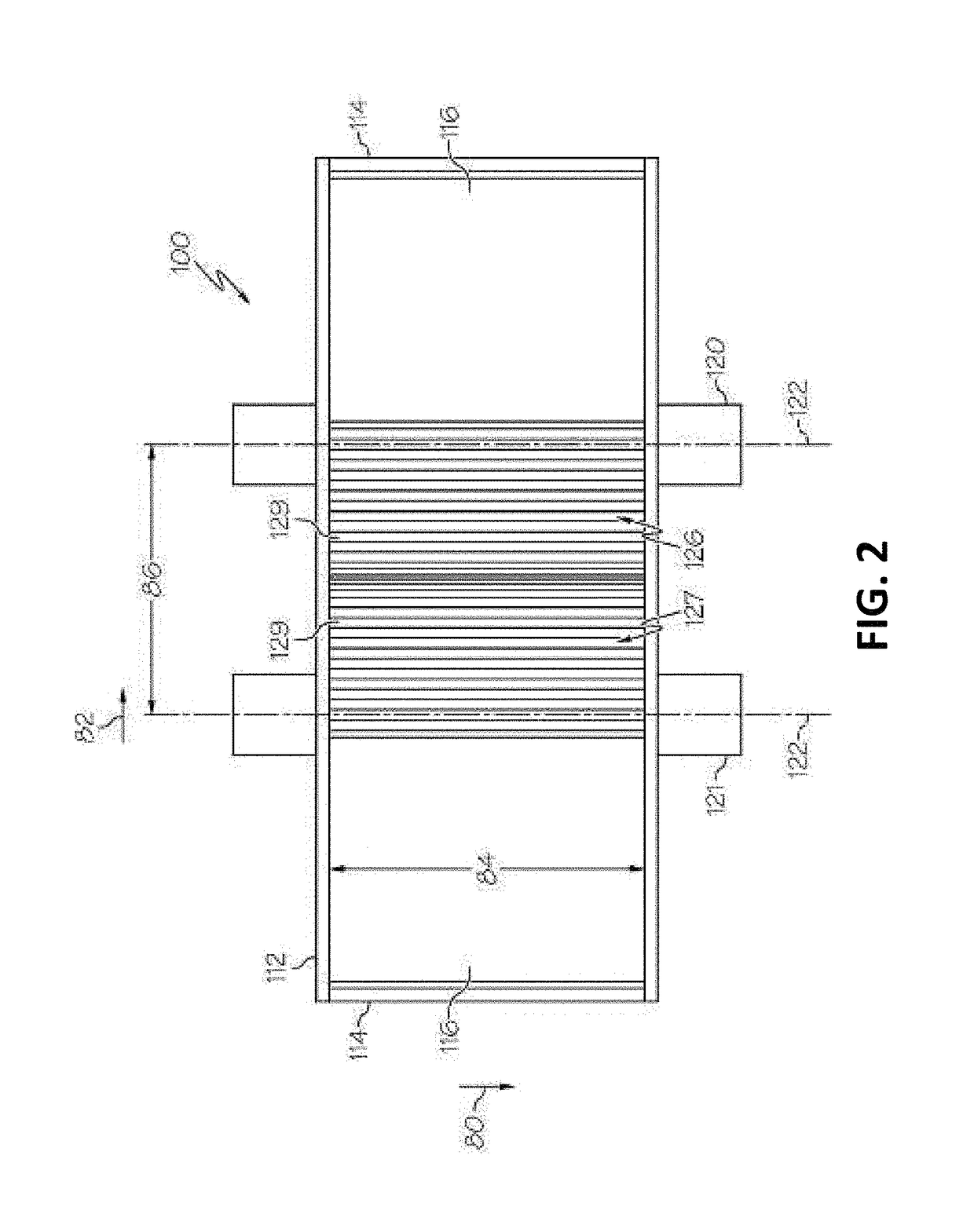

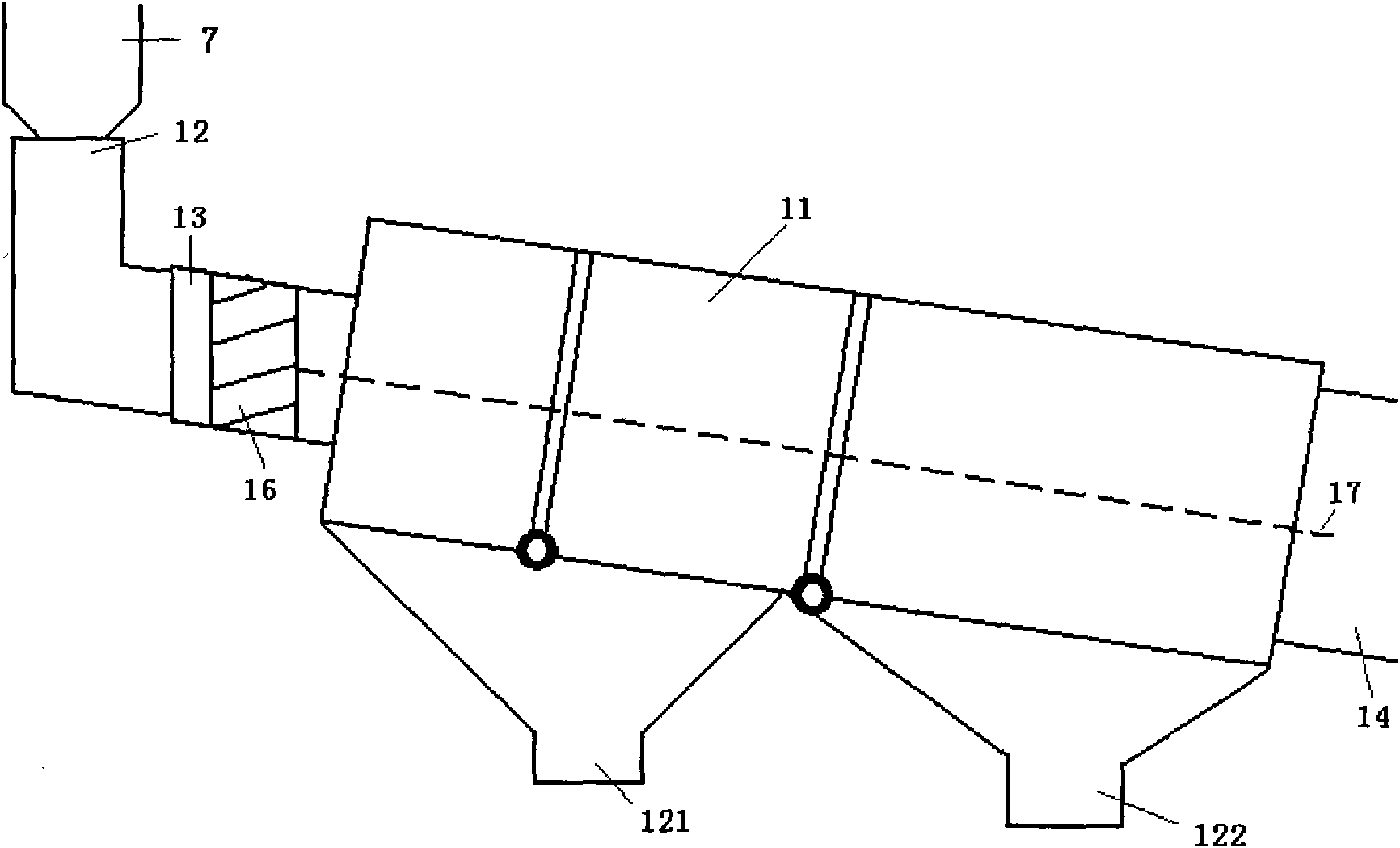

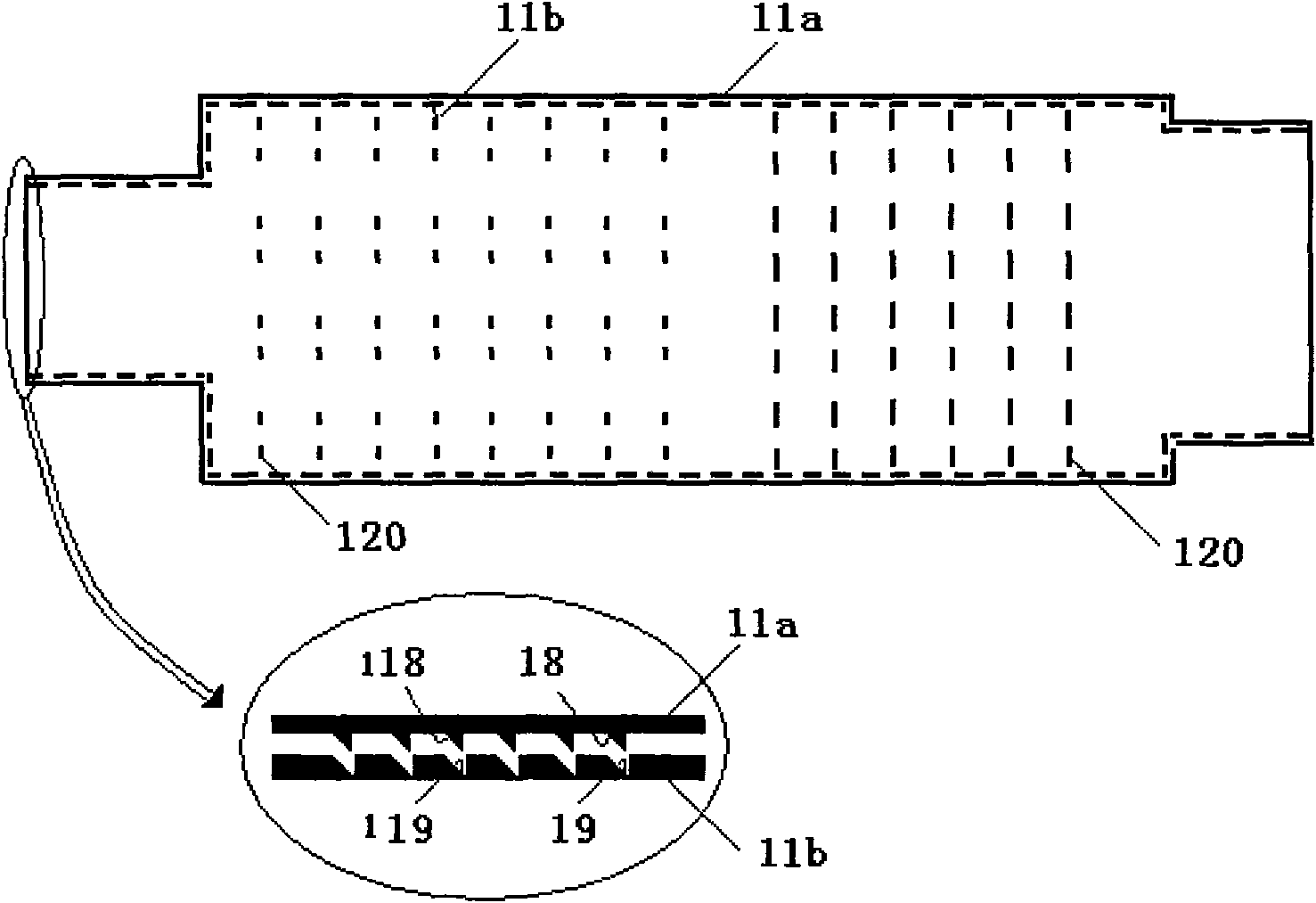

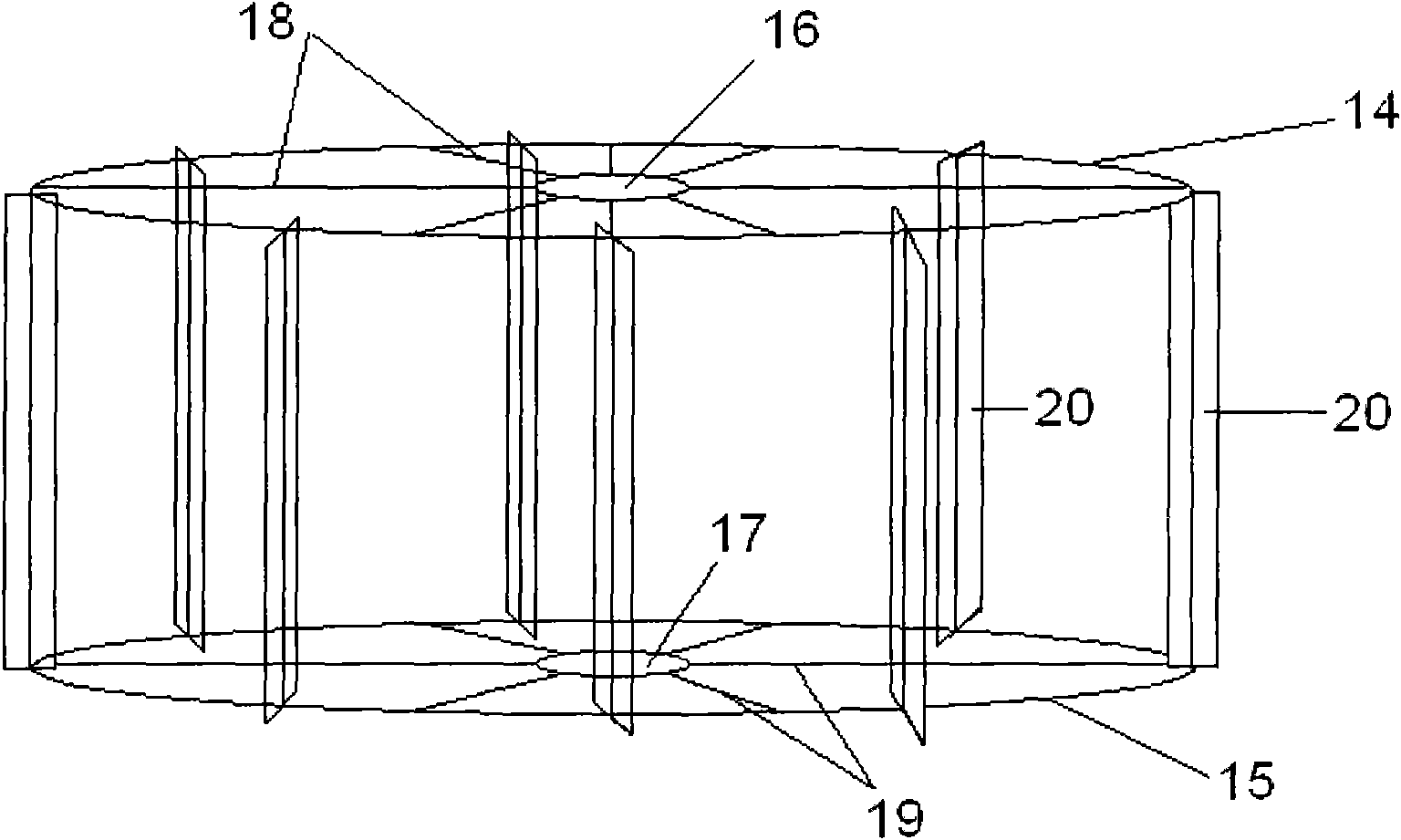

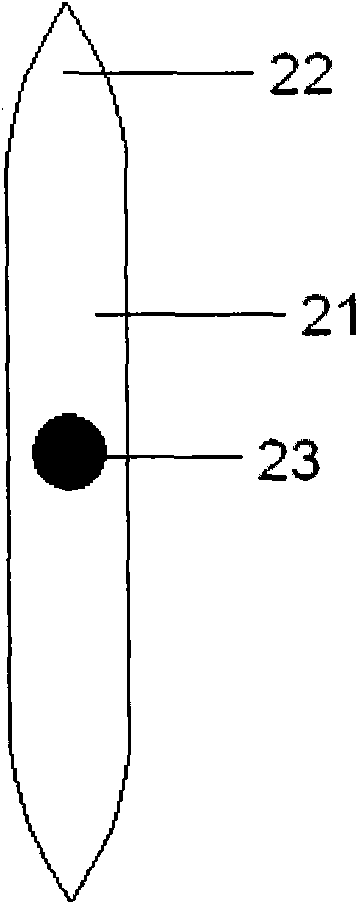

Grain Crushing Apparatuses and Processes

ActiveUS20150028139A1Little and no wasteGreat feed conversionCocoaGrain treatmentsEngineeringGrain crushing

Disclosed are grain crushing apparatuses and processes for processing grain. In one embodiment, a grain crushing apparatus includes a first and second sidewall spaced apart from one another a throat dimension in a first direction, and a first and second support shaft positioned transverse to the first and sidewall. The grain crushing apparatus also includes a first and second grain crushing roller. The grain crushing rollers are intermeshed with one another and maintained at positions spaced apart from one another such that they overlap by a distance less than the tooth height. The process is a method for the grown and harvested grain to be shelled, cleaned, stored and then incrementally or iteratively crushed by the shown apparatus or an equal type such that the crushed grain of various sizes may be separated by a sieve and remain as crushed grain with the germ protected uncut, unruptured and intact.

Owner:US SEC THE ARMY THE

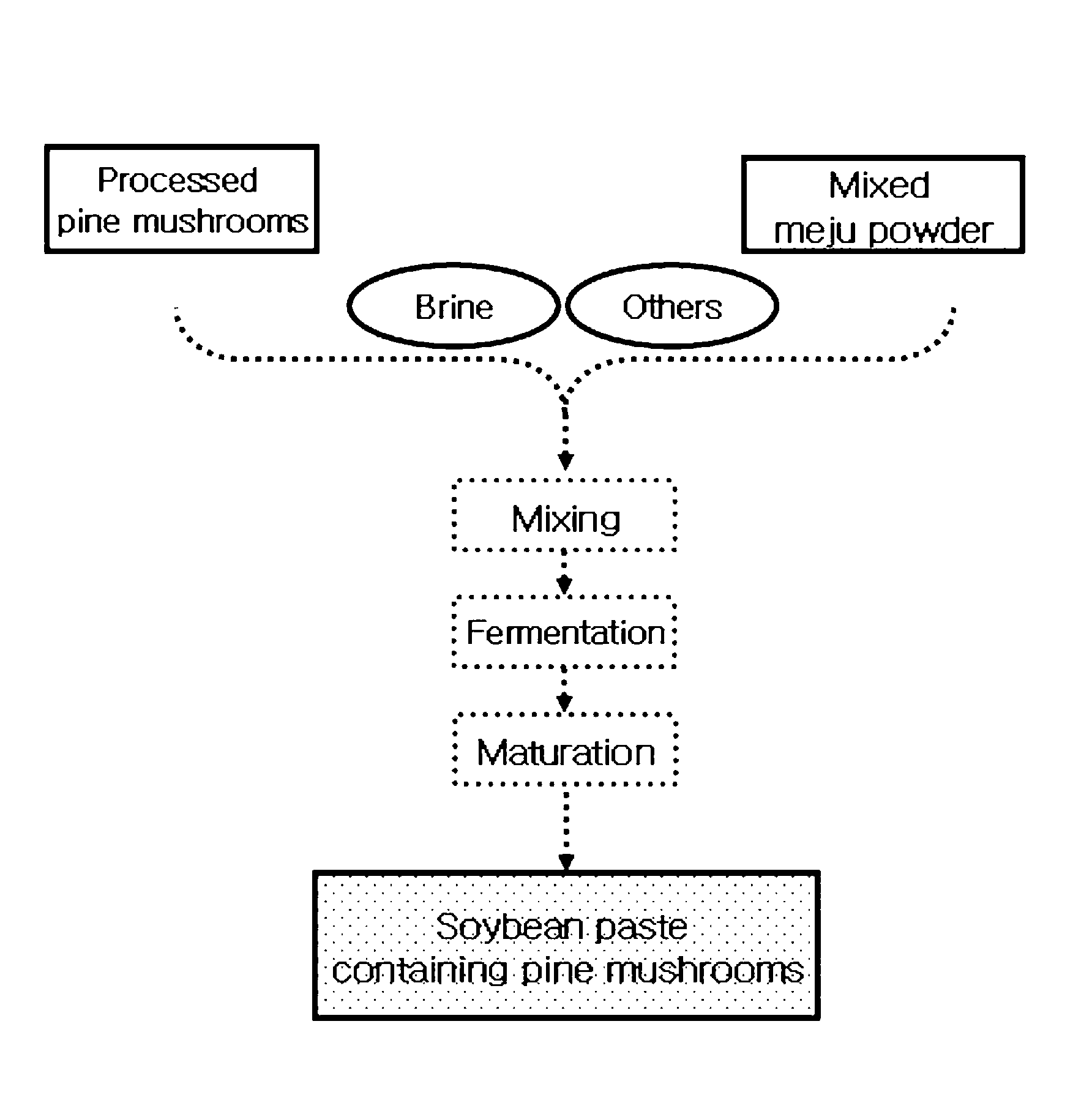

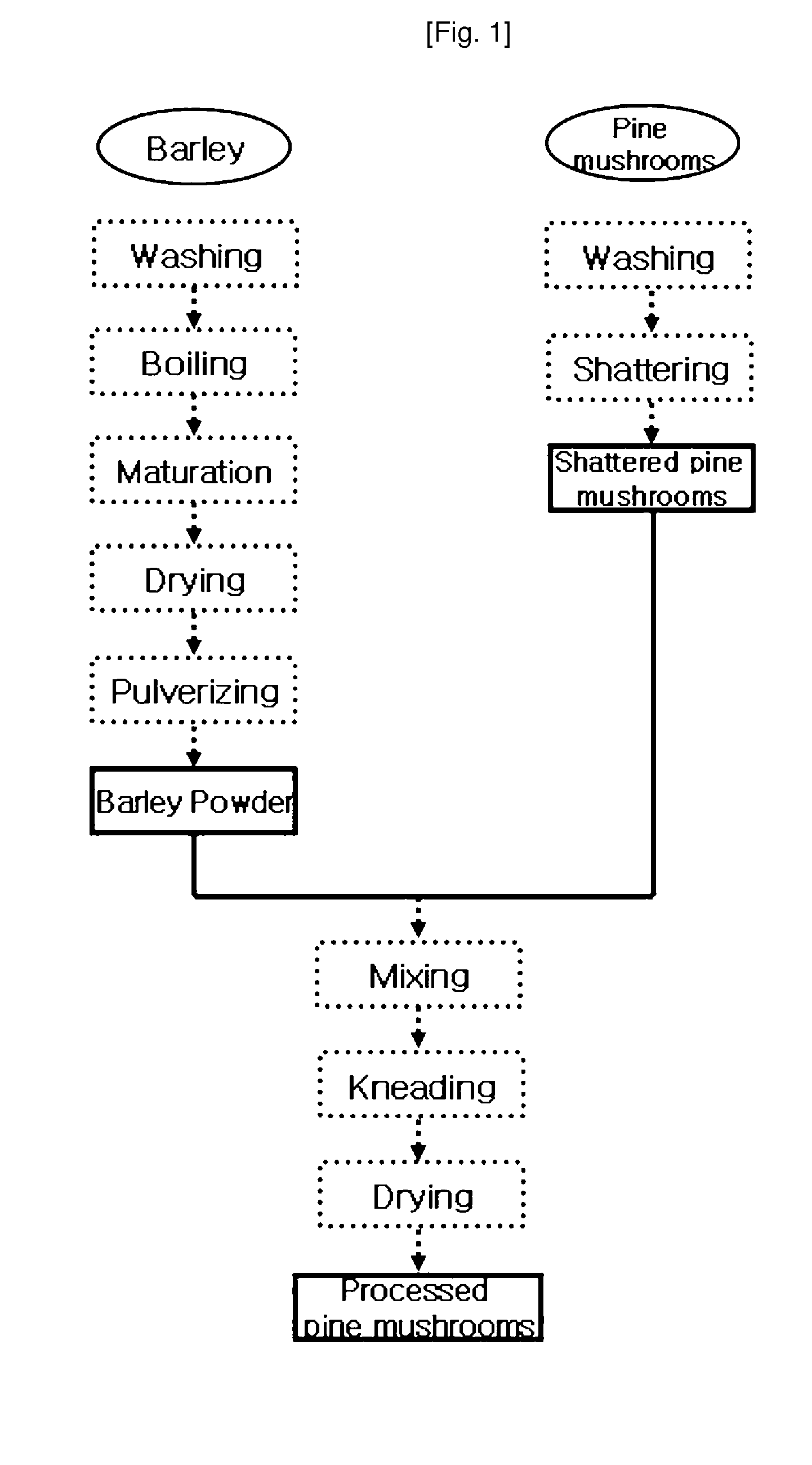

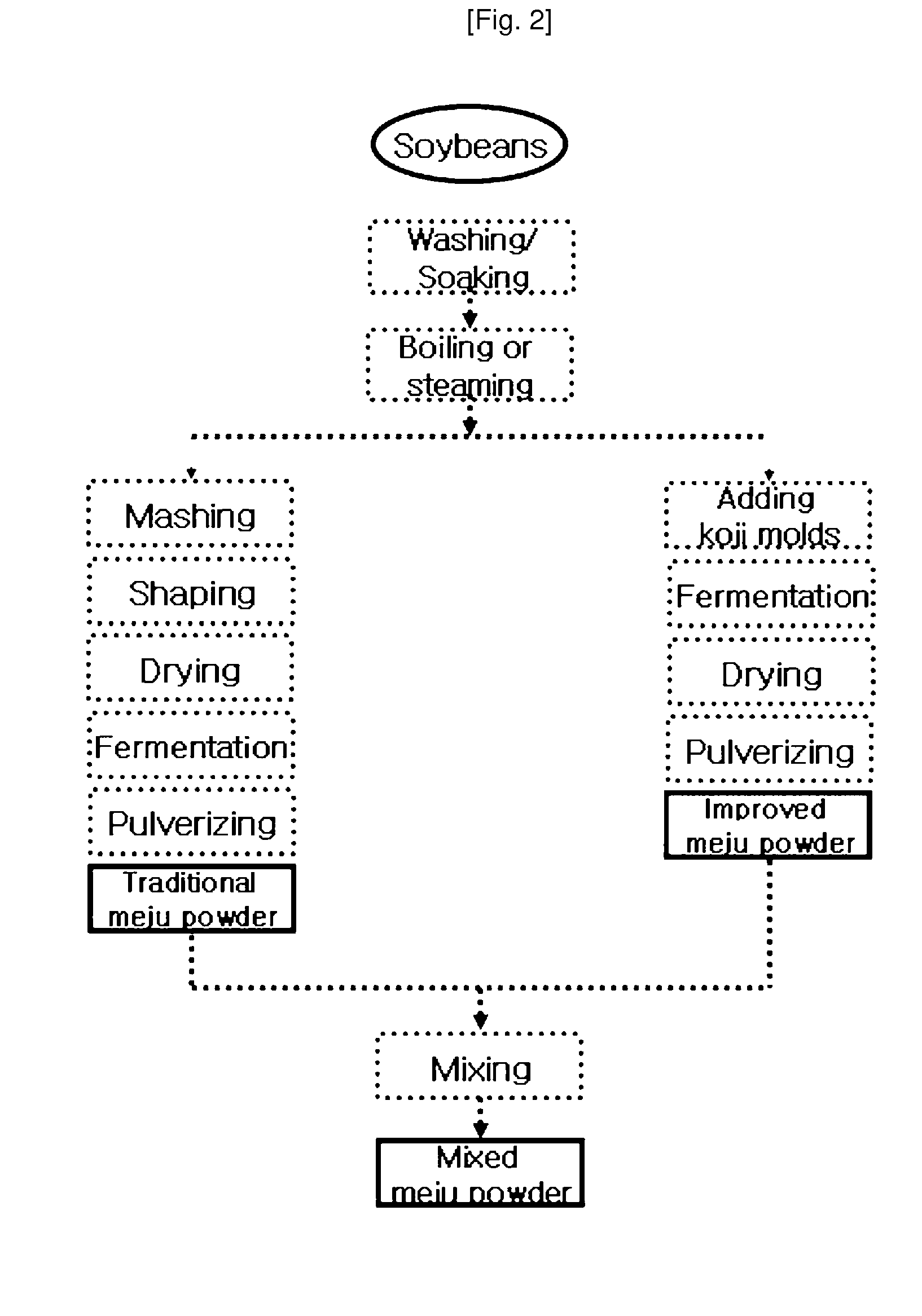

Method for Producing Soybean Paste Containing Pine Mushroom

InactiveUS20090053363A1Improve flavor qualityImprove taste qualityFood preparationFood flavorMushroom

The present invention relates to a method for producing a soybean paste containing pine mushrooms, which comprises processing pine mushrooms, mixing the processed pine mushrooms with fermented soybeans (meju), fermenting and maturating the meju mixed with the processed pine mushrooms, wherein the step of processing pine mushrooms comprises shattering raw pine mushrooms which are neither heated nor dried; boiling grains in water, maturating the boiled grains, drying the mature grains and pulverizing the dried grains to grain powder; and mixing the shattered pine mushrooms with the resulting grain powder, kneading the resulting mixture and drying the resulting dough. According to the present invention, we can produce a soybean paste containing pine mushrooms, which can maximize the unique tastes, flavors and nutritive elements of pine mushrooms and minimize the loss of nutritive elements in soybeans.

Owner:AN YEONG HWAN

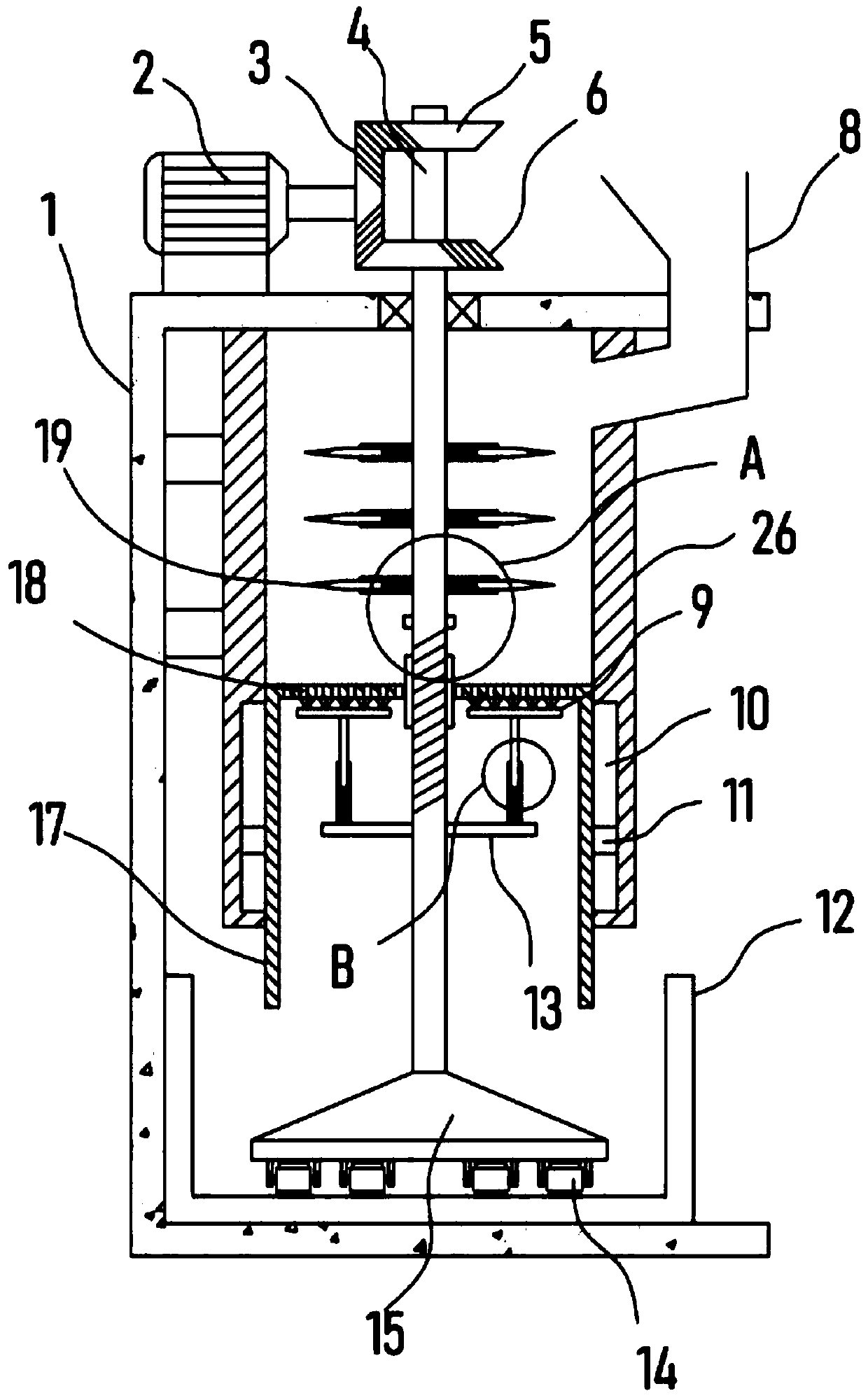

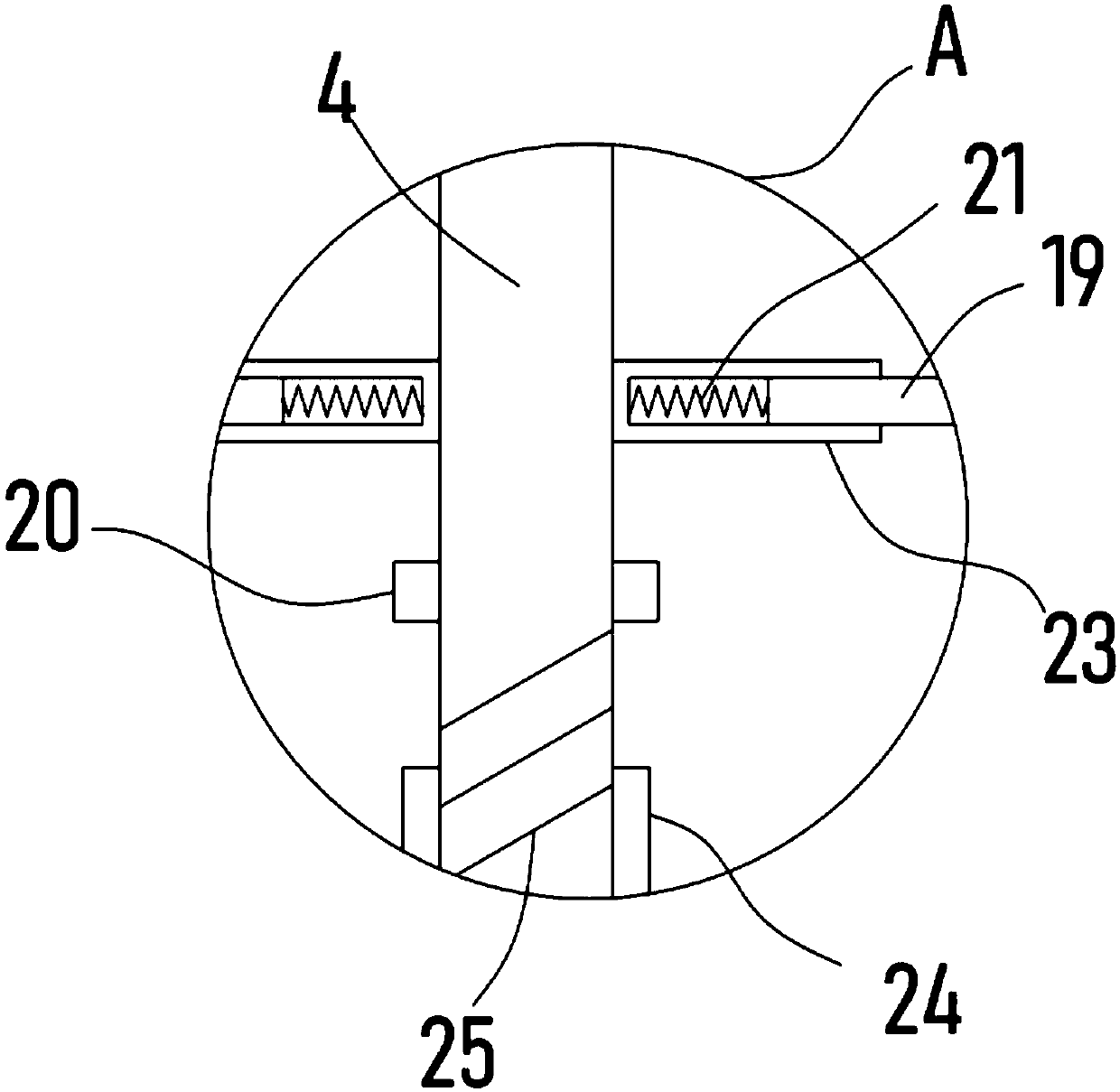

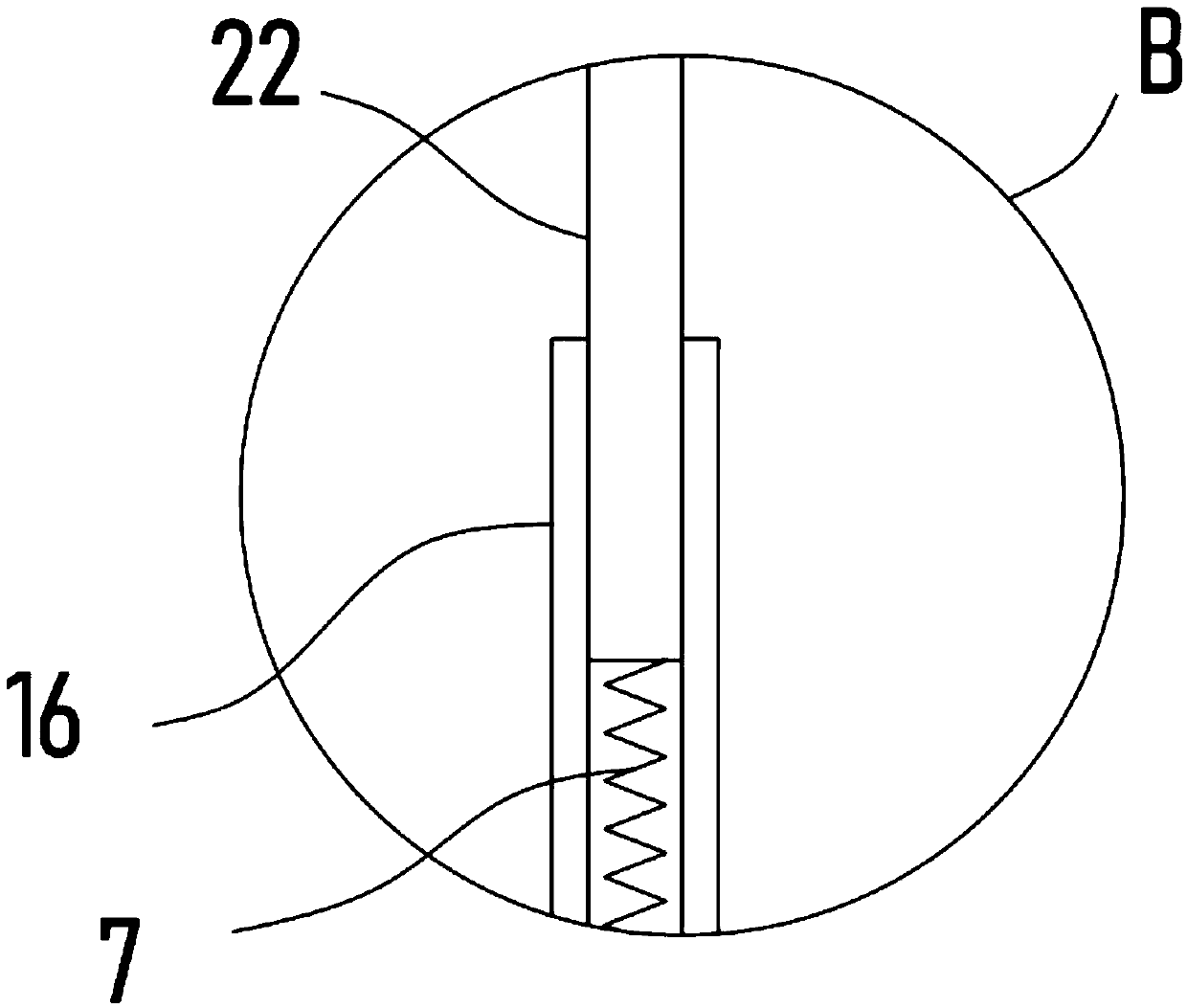

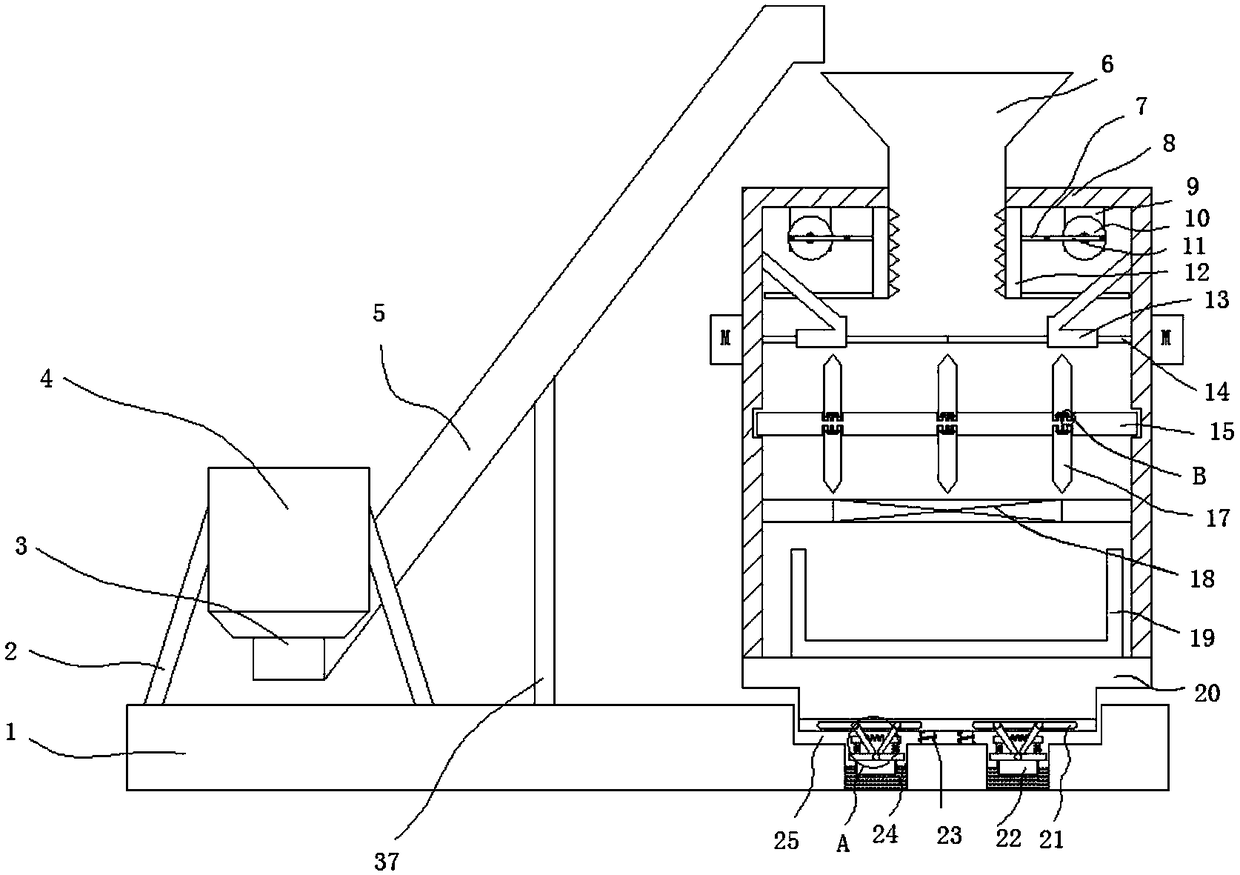

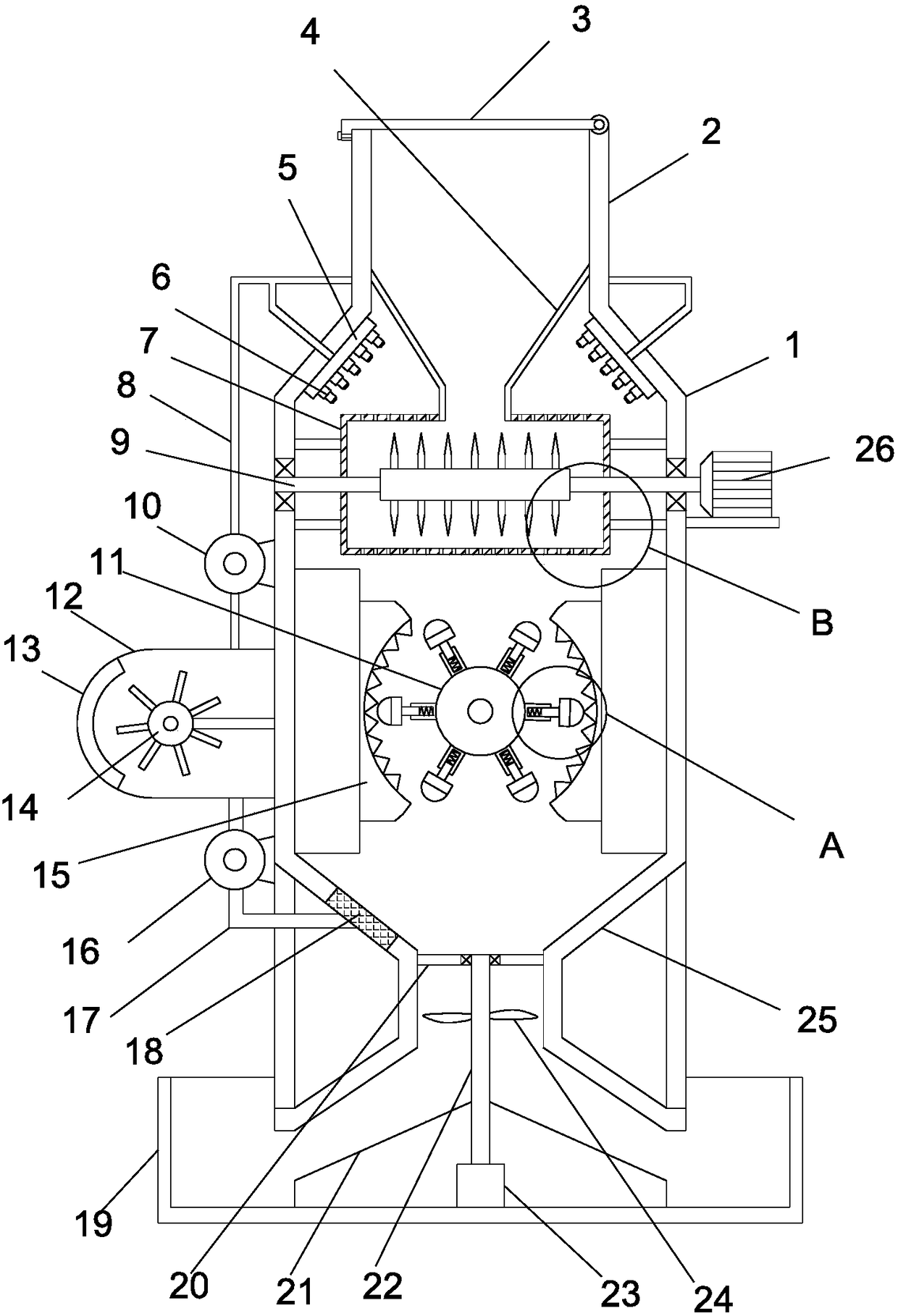

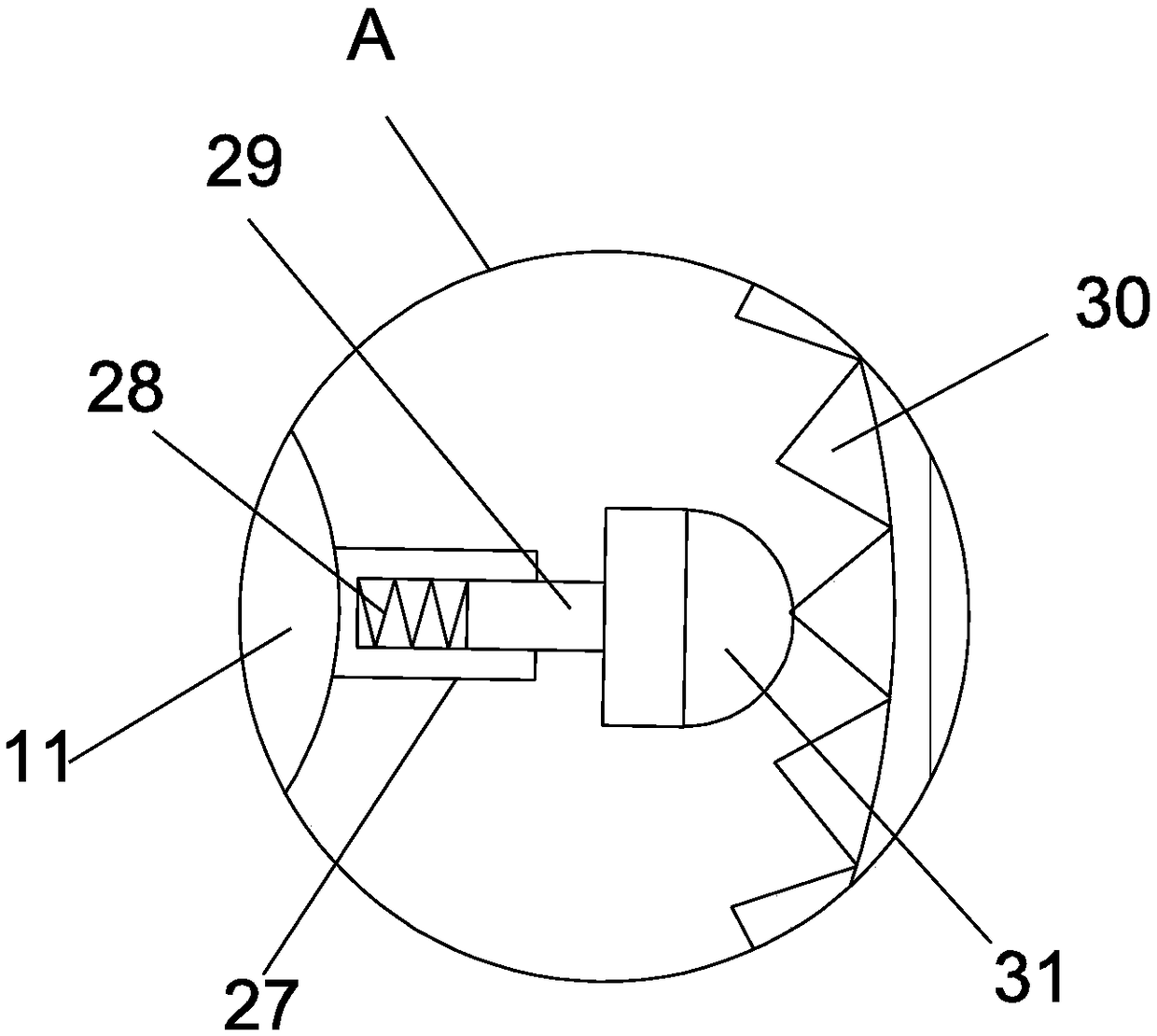

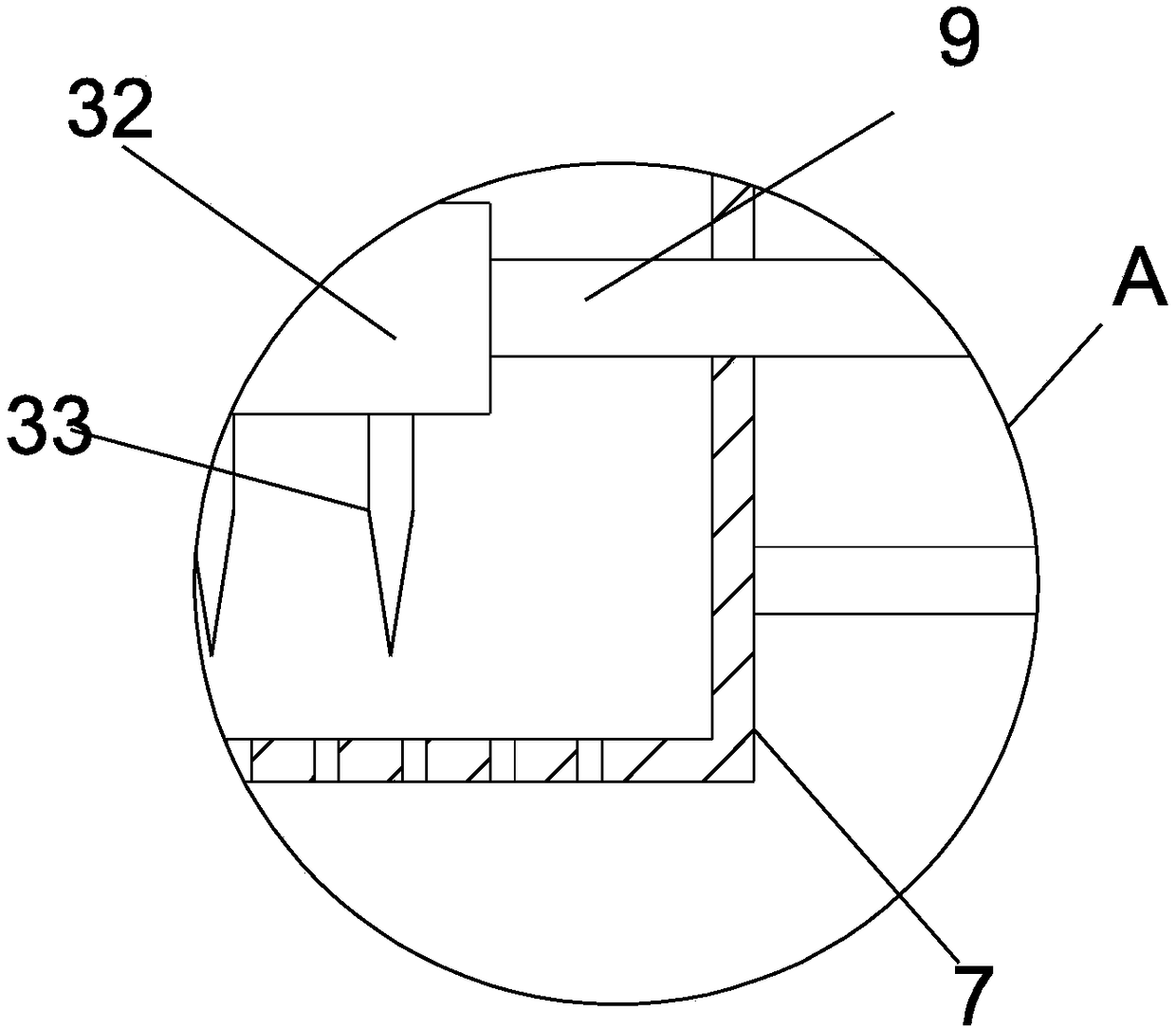

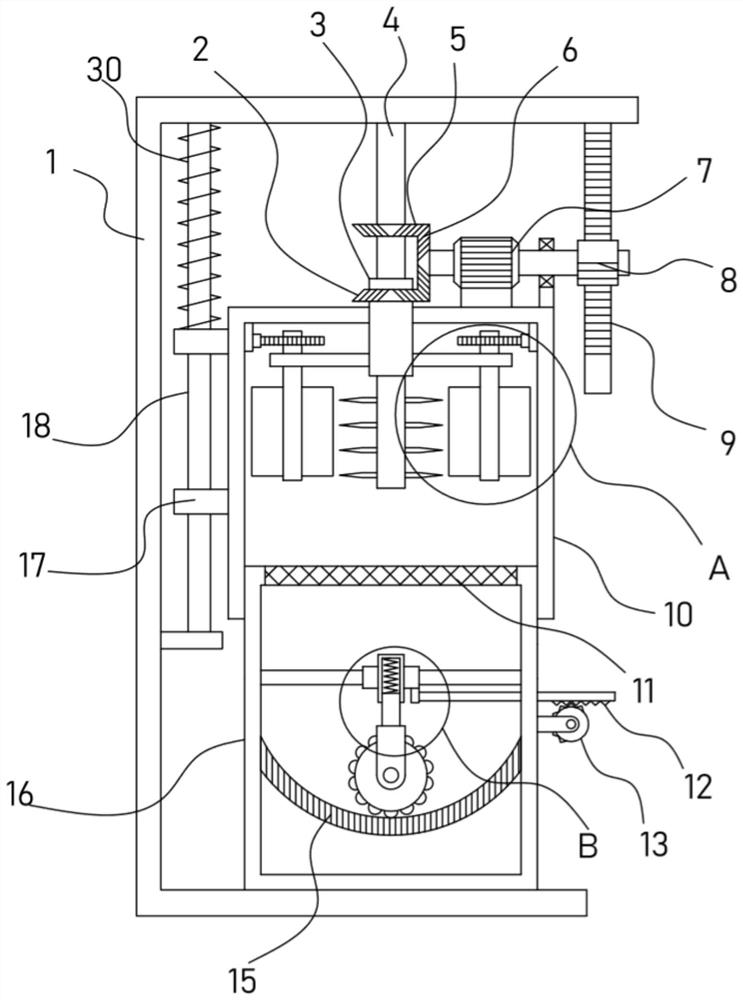

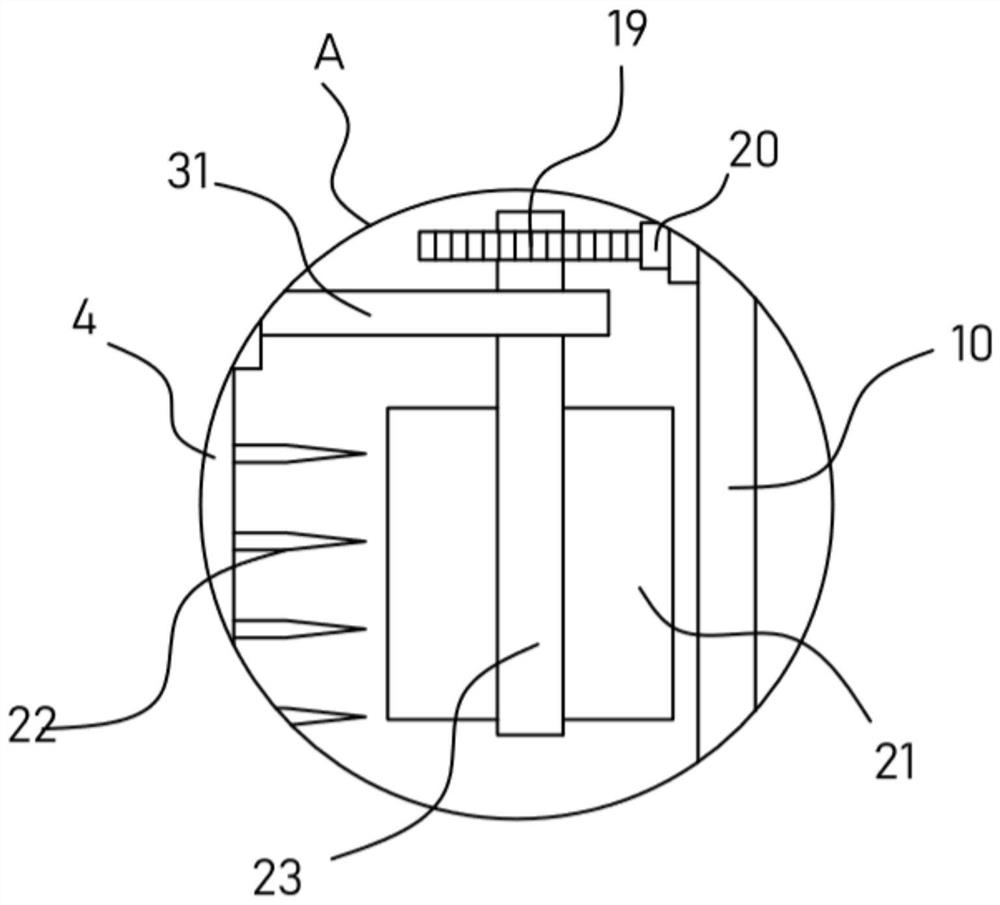

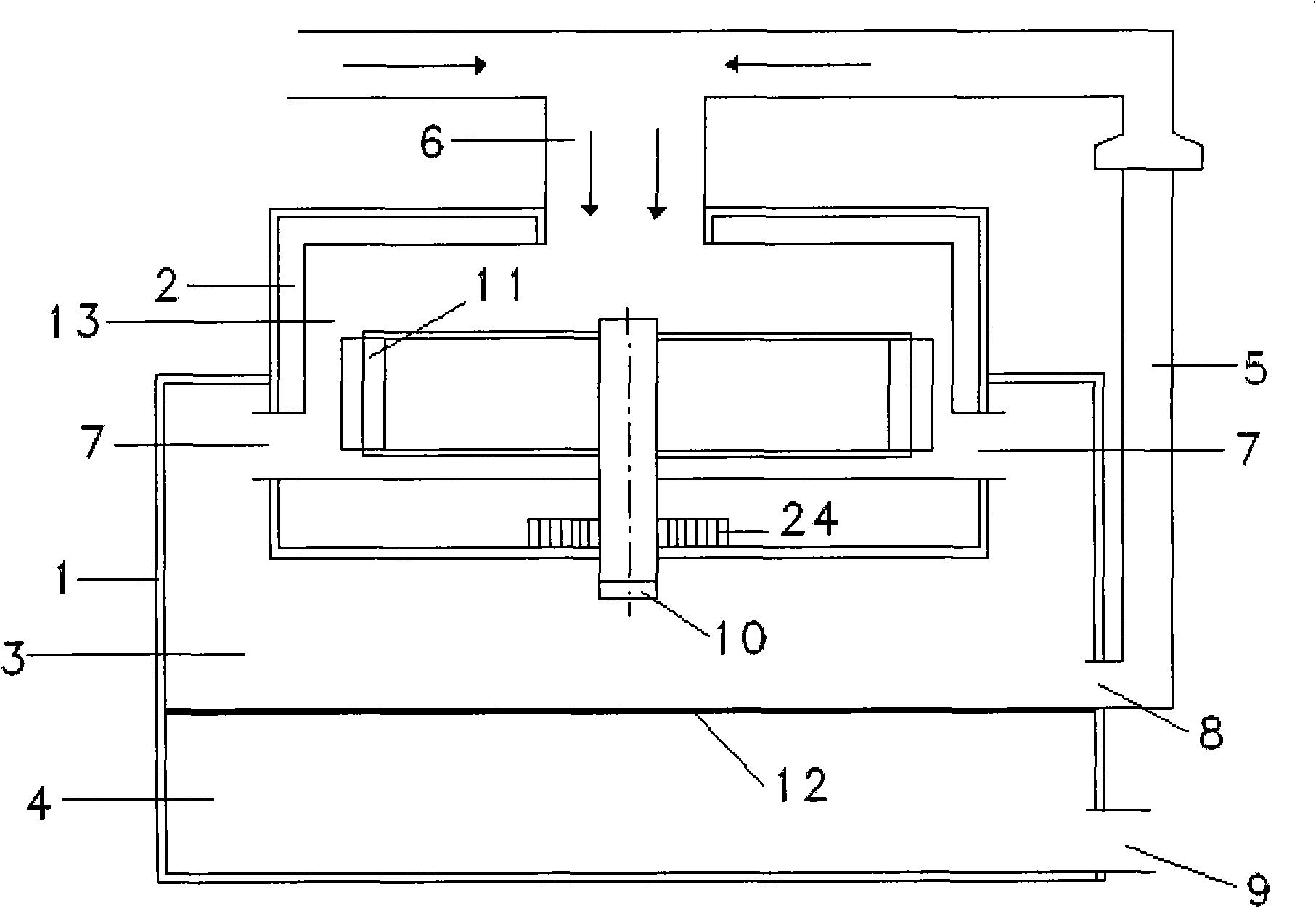

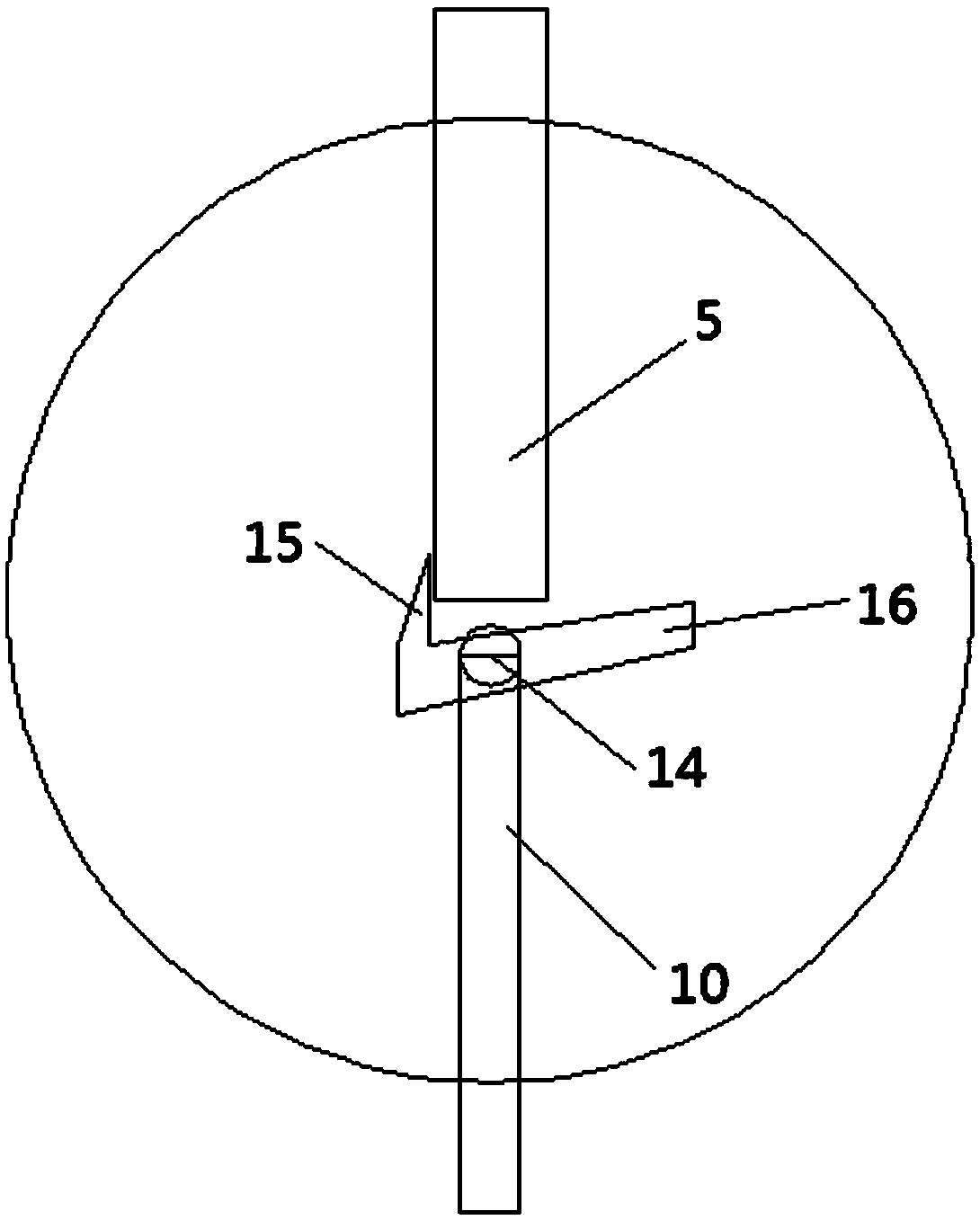

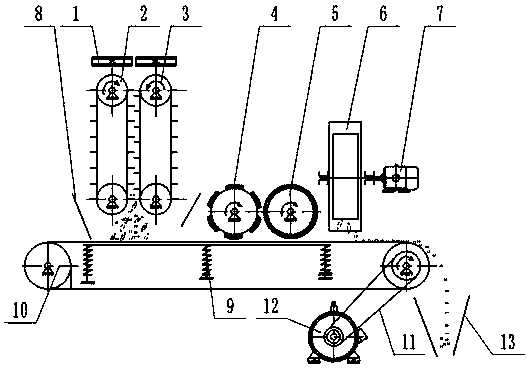

Grain crushing and grinding integrated device for agricultural production

InactiveCN109622142AImprove crushing efficiencyFully brokenSievingScreeningAgricultural engineeringElectric machinery

The invention discloses a grain crushing and grinding integrated device for agricultural production, and relates to the technical field of agricultural machinery. The grain crushing and grinding integrated device for the agricultural production comprises a supporting frame, a driving motor is fixed to the supporting frame, and a crushing cylinder with a feeding pipe is vertically fixed into the supporting frame. The crushing cylinder slidably sleeves an inverted lifting cylinder, an external thread connected with a crushing shaft in a threaded mode is arranged on the surface of the crushing shaft in an attacking mode, and a collection slot fixed on the supporting frame is formed directly below the lifting cylinder. According to the grain crushing and grinding integrated device for the agricultural production, a rotating crushing effect of grain particles in the crushing cylinder is realized by rotating a cutting blade, the grain particles can be shifted up and down on the lifting cylinder, and the cutting blade can fully crush the grain particles; and meanwhile, screening holes in the lifting cylinder play a role in screening the crushed grain particles, grain in the crushing cylinder is enabled to be reduced, the crushing efficiency of the cutting blade is improved, meanwhile, an arranged grinding roller can grind the grain particles in the collecting tank, and the crushing degree is greatly improved.

Owner:刘学

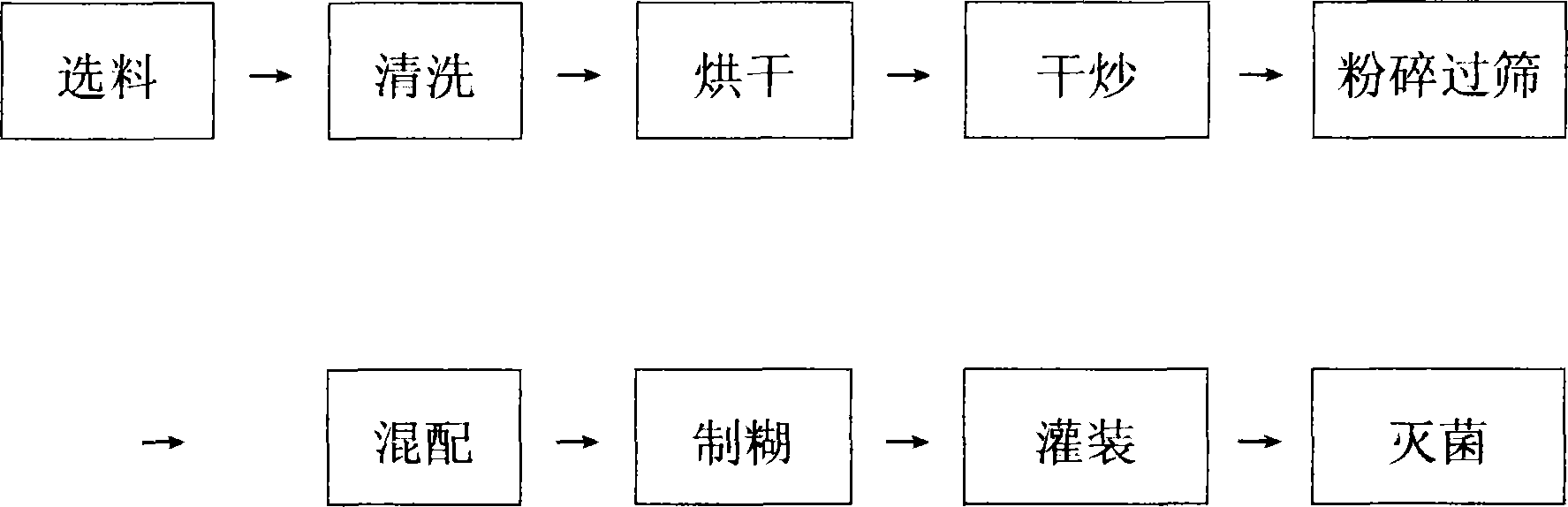

Energetic nourishing brei

InactiveCN101156687AEasy to drinkRich varietyMilk preparationFood preparationThermal energyFruit juice

The invention relates to high-energy nutritional conjee which is made through processing by taking cereal as the main material, and grain legume, milk, fruit juice, nut, sesame and meat as the auxiliary material. The invention is characterized in that the weight ratio of the main components is as follows: 60 to 90 parts of cereal, 10 to 40 parts of auxiliary material, and 150 to 300 parts of water, the production process comprises the following steps: material selecting, washing, drying, stir-frying, smashing and sieving, mixing, paste preparing, filling and sterilization. Stir-frying: the grain legume, the nut and the sesame of the cereal, and the auxiliary material are fried till being slight yellow and giving out the scent; smashing: the cereal is smashed and sieved by 100 to 150 mesh screen, the grain legume, the nut and the sesame are smashed and sieved by 10 to 20 mesh screen, and the meat is made into smashed meat and meat floss; paste preparing: the cereal powder is adopted according to the ratio, and is diluted into paste with cold water, and is then put into a prepared pot filled with boiling water, and stirred while being heated, and the auxiliary material is added after the paste is made, and stirred till being uniform. The conjee has high thermal energy, and one box of nutritional conjee has 500 to 800 kcal, either cold or hot is available, the drinking is convenient, the conjee is in a large variety, and thereby being beneficial to all ages. The invention is an ideal food for workers, students, elders and patients.

Owner:王庆书

Grain pulverizing device for agricultural processing

InactiveCN108970681AHigh crushing and grinding efficiencyGrain treatmentsAgricultural engineeringReducer

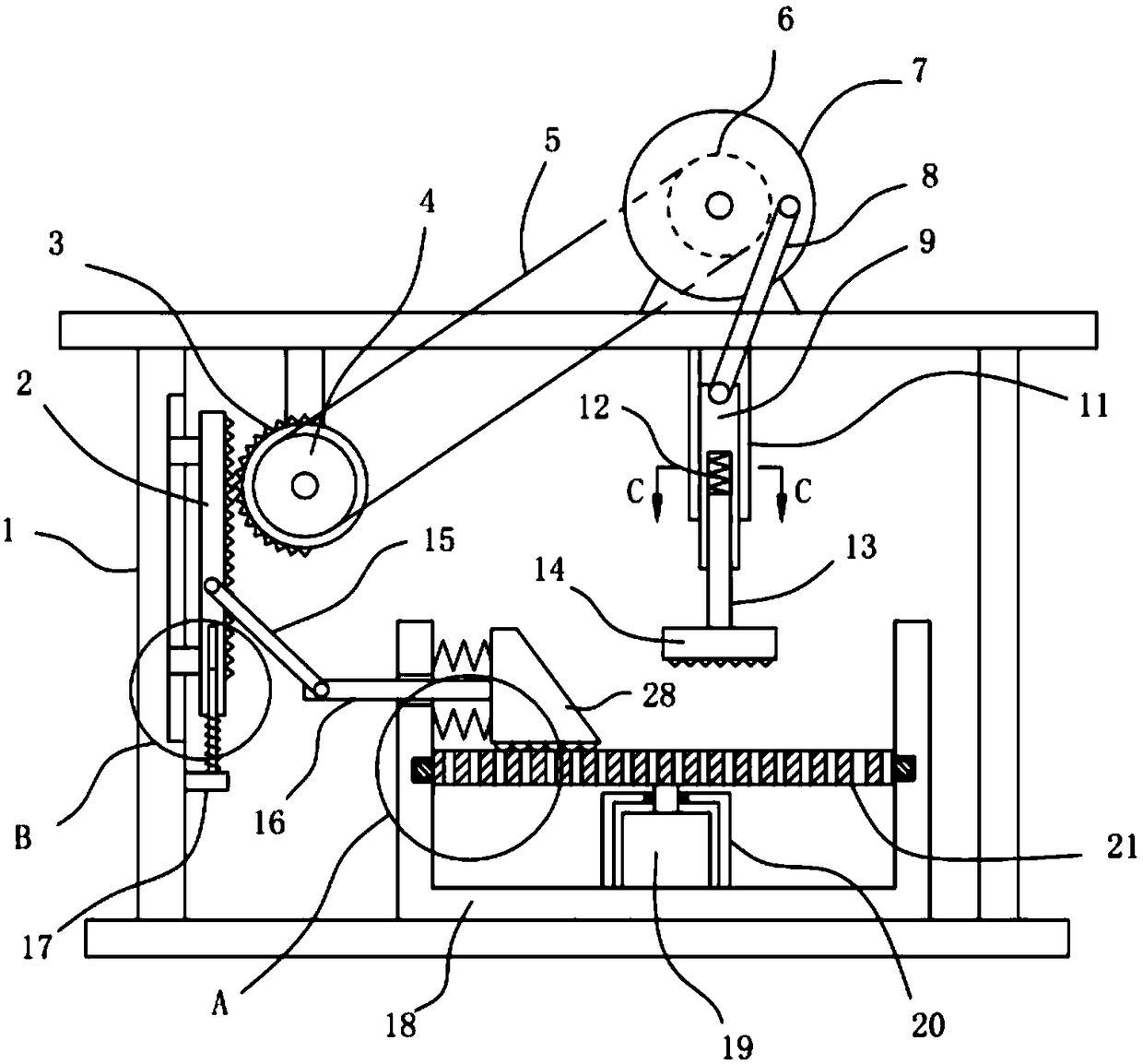

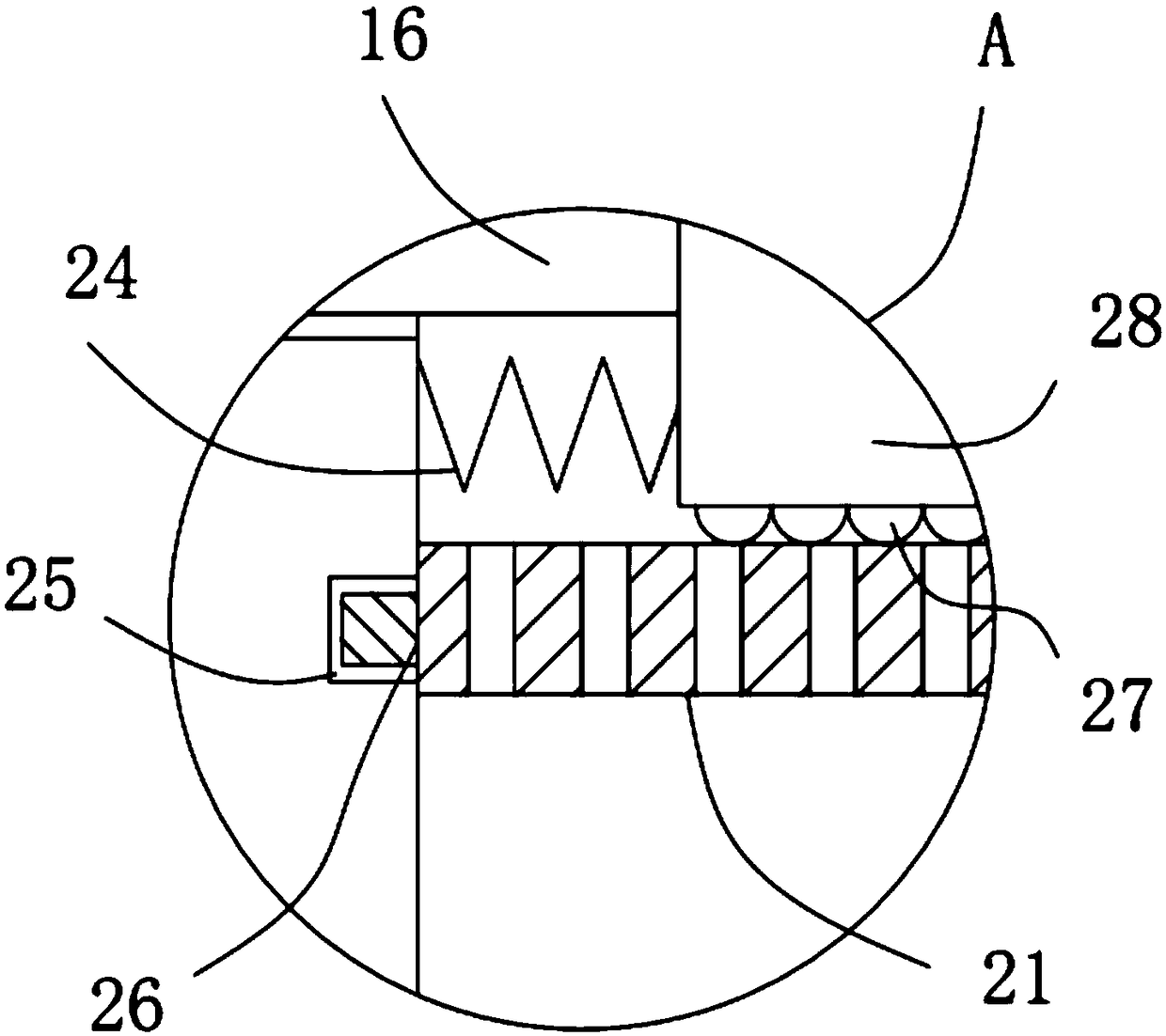

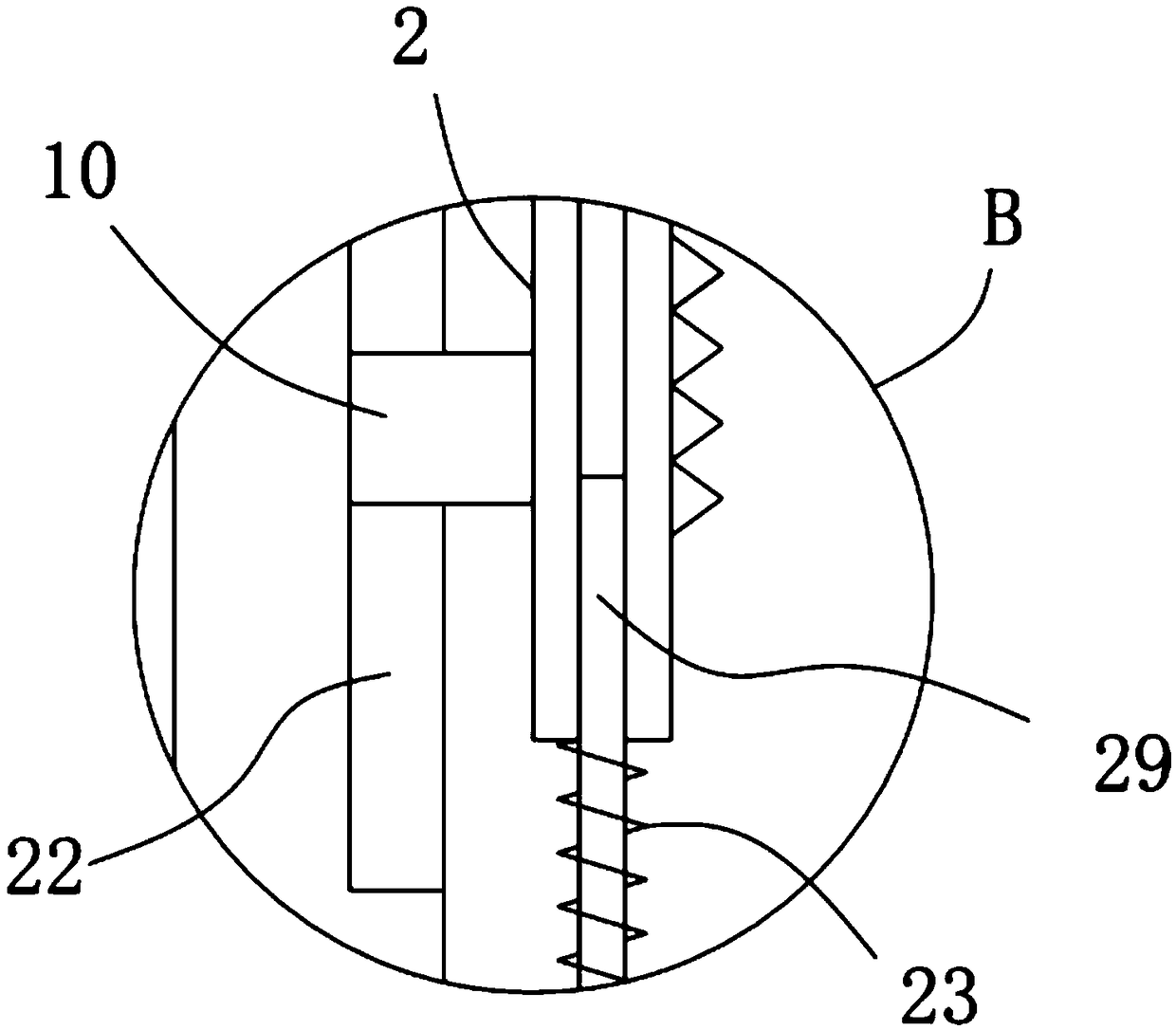

The invention discloses a grain pulverizing device for agricultural processing, which relates to the technical field of agricultural machineries, and comprises a support frame, a wheel is rotationallyarranged on the top of the support frame, an active pulley is coaxially fixed on the back of the wheel, a crushing groove is fixedly installed in the support frame, a reducer motor is arranged in a motor cover, a sliding rod is arranged in a sleeve in a vertical sliding type, a damping spring, the lower end of which is fixed to the upper end of a sliding shaft, is fixed in the sliding rod, a drive rod is hinged between the sliding rod and the wheel, the upper end of the drive rod is eccentrically hinged at the front surface of the wheel, the sliding shaft is arranged in the sliding rod in a vertical sliding type, and a crushing plate in the crushing groove is fixedly installed at the lower end of the sliding shaft; and the invention impact crushes grains through the up and down reciprocating movement of a crushing plate, and repeatedly grinds the grains through horizontal reciprocating movement of a grinding wedge, and at the same time, a sieve plate is driven by a reducer motor to rotate, in order to allow the grains to be fully pulverized and ground. The grain pulverizing device for agricultural processing disclosed by the invention has a very high grain crushing and grinding efficiency.

Owner:徐得强

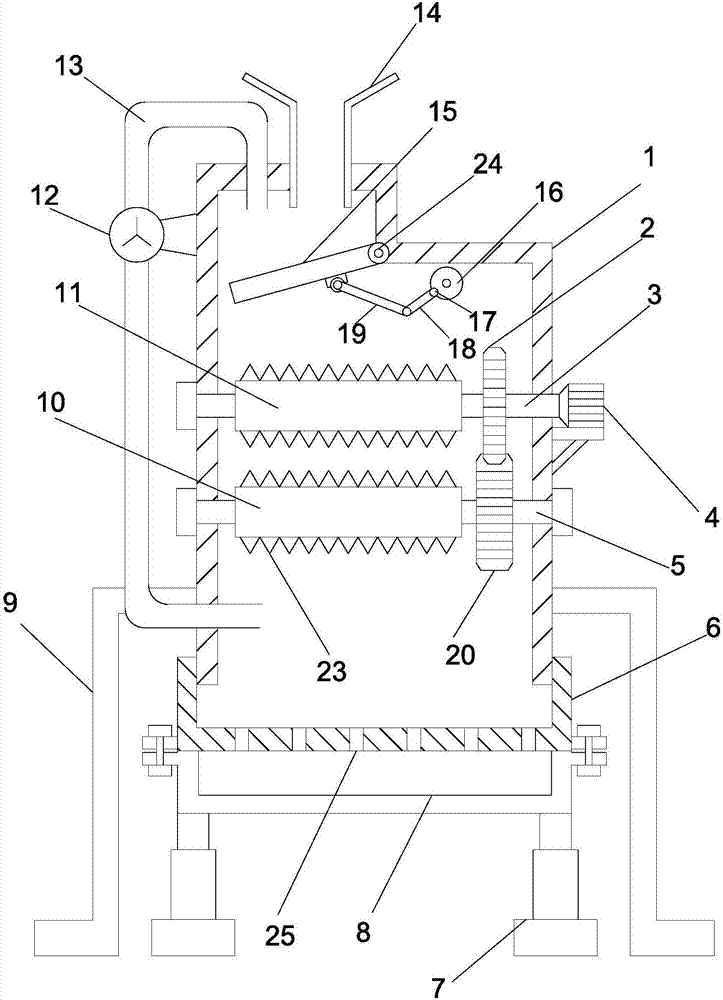

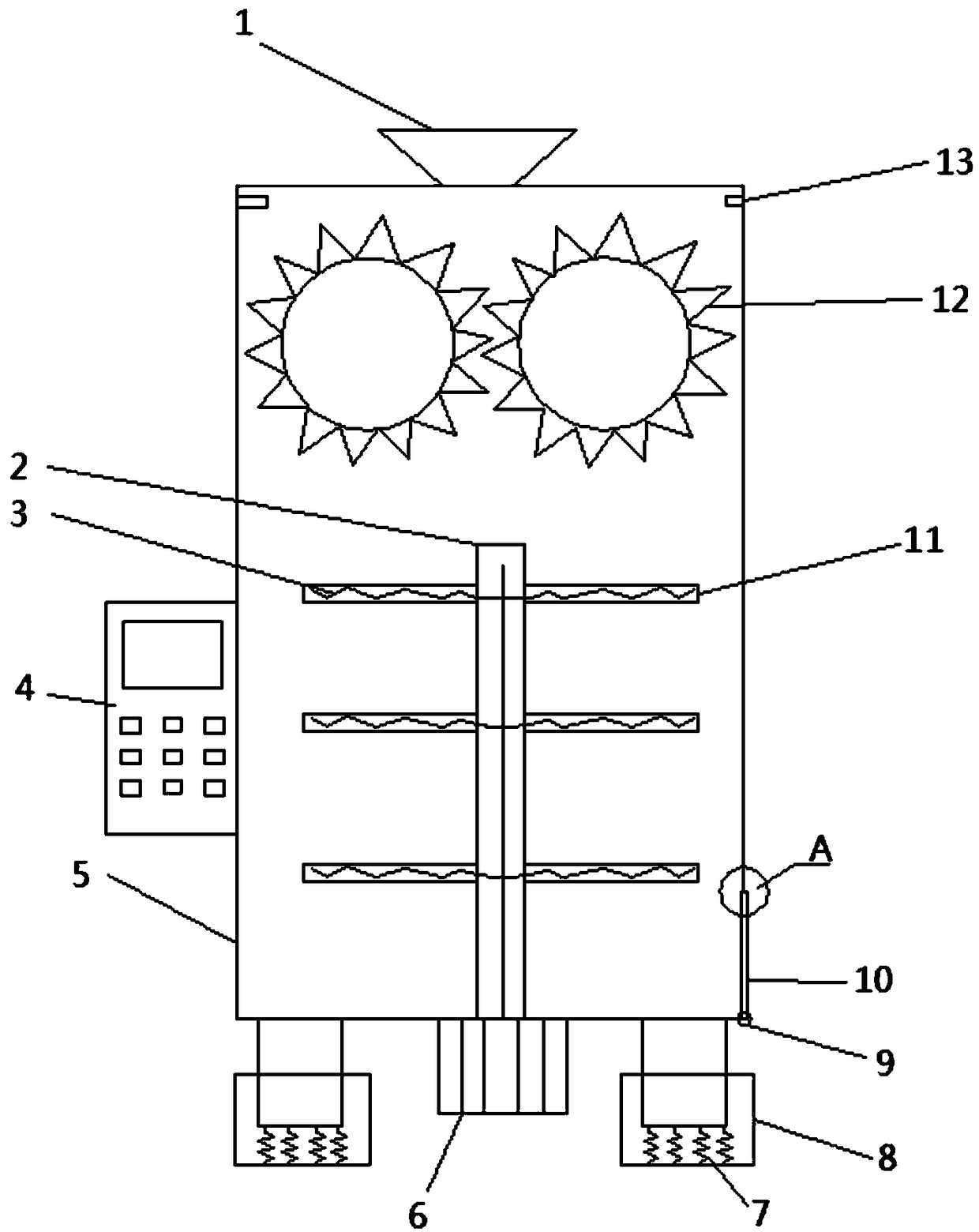

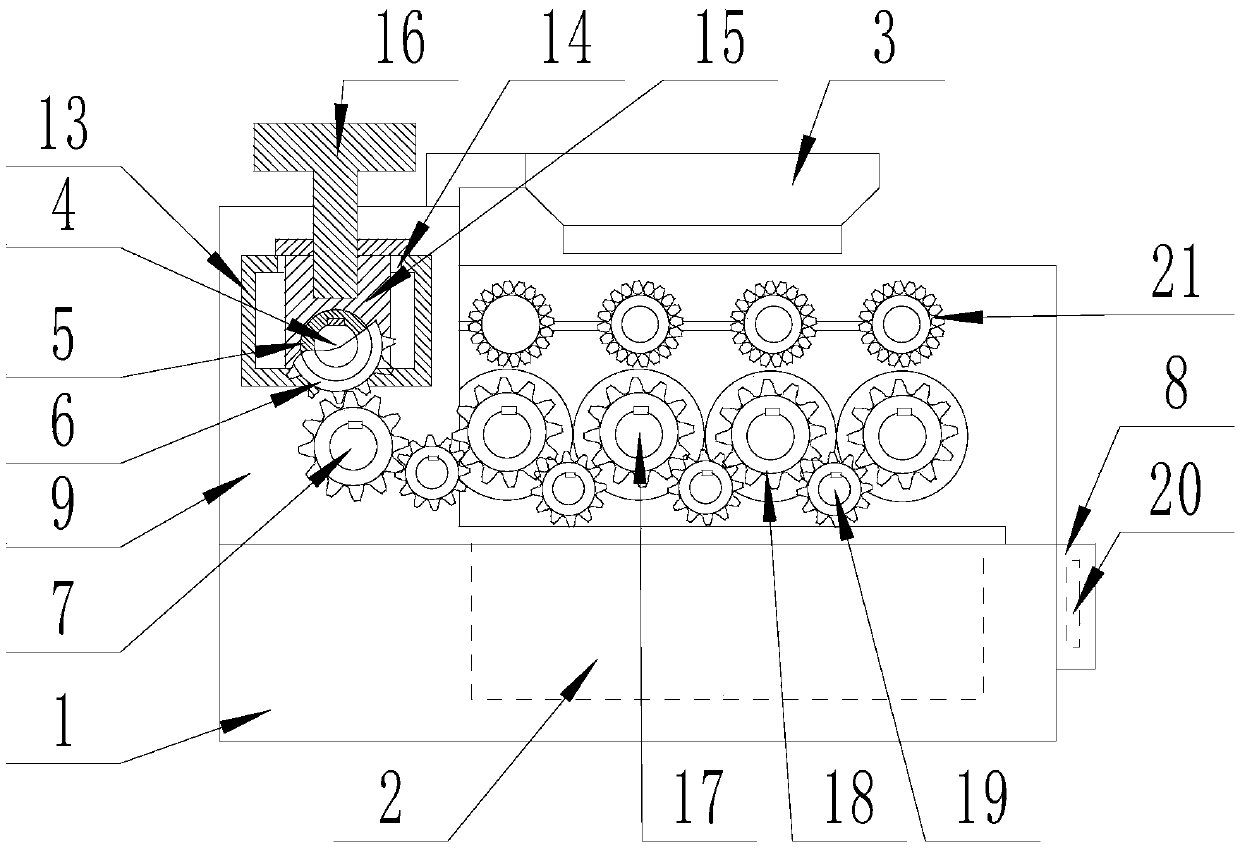

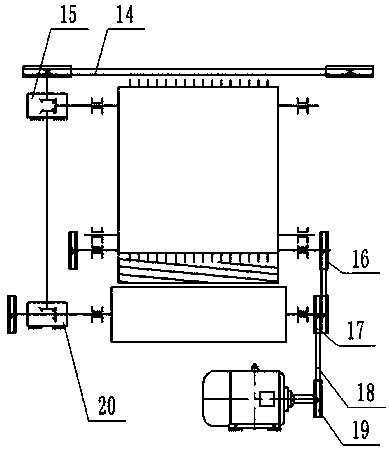

Smashing device for grain processing

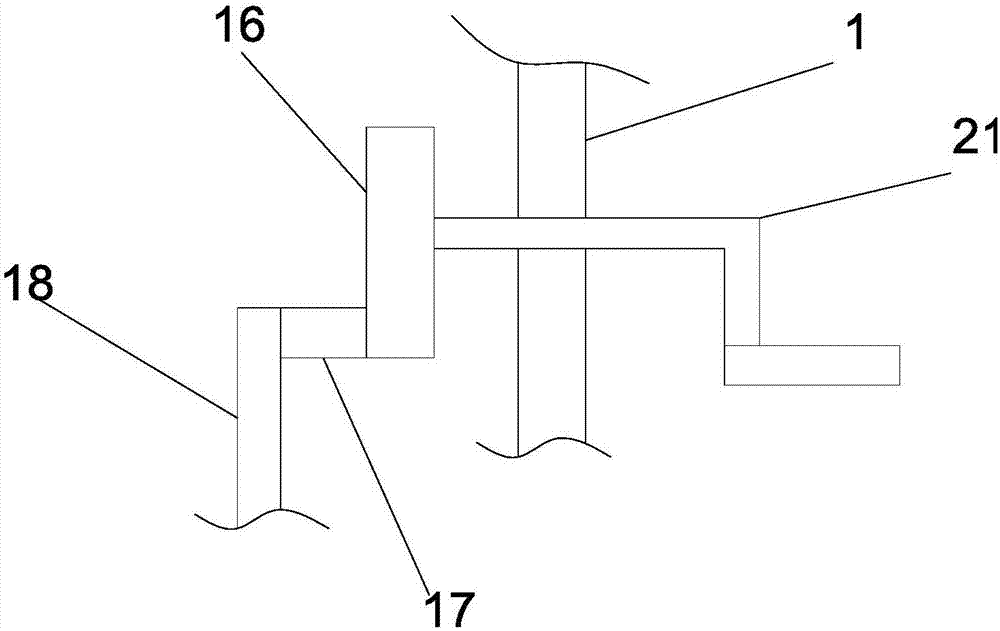

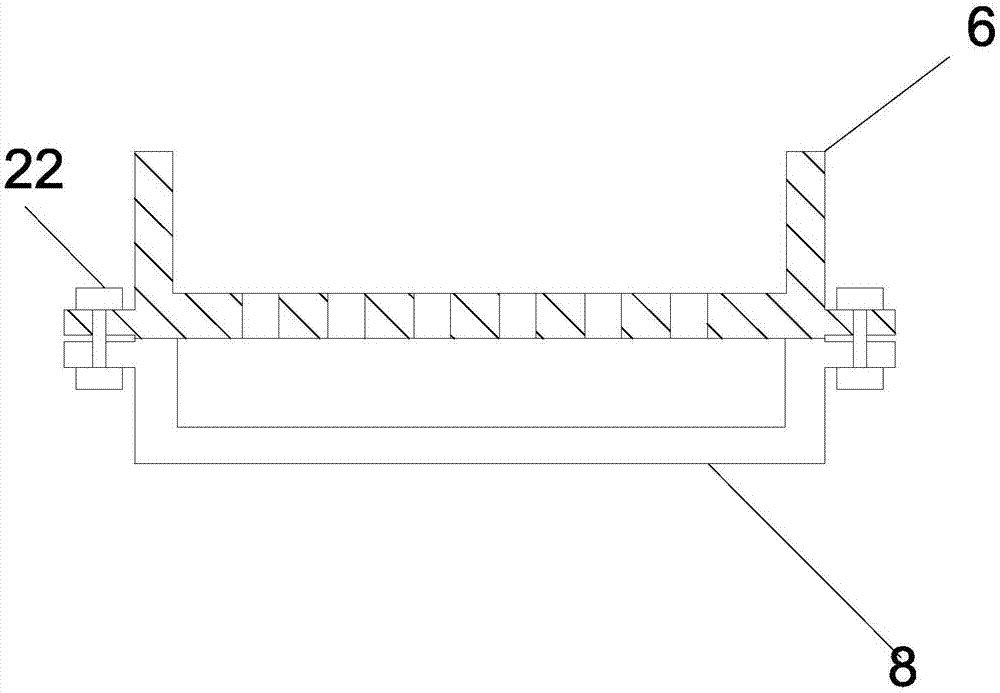

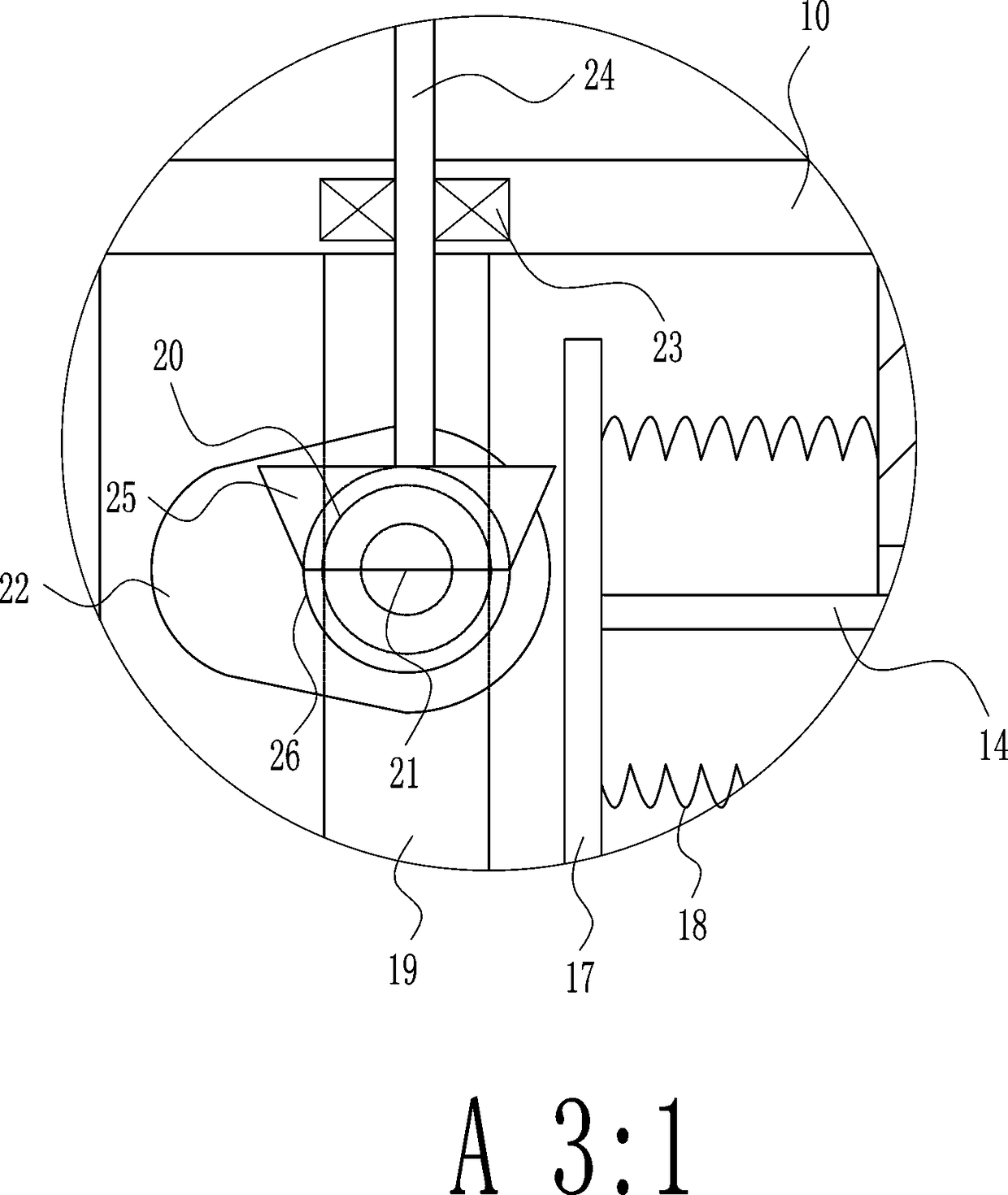

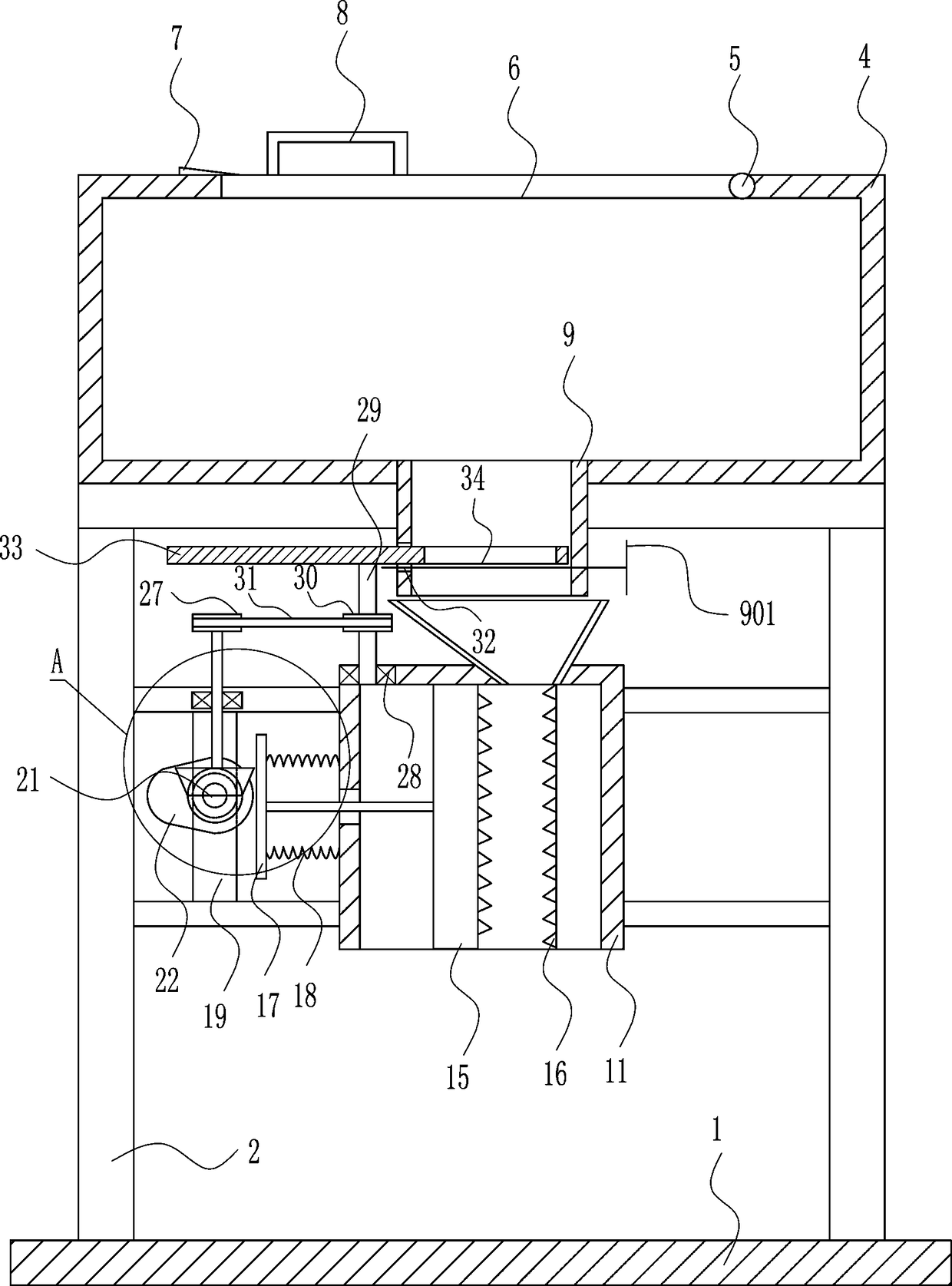

InactiveCN106938215ASmash fullyAvoid affecting the crushing effectGrain treatmentsDrive shaftGear wheel

The invention discloses a smashing device for grain processing. The smashing device for grain processing comprises a box body; a feed port and a delivery pipe are arranged at the top of the box body, and a draught fan is installed on the delivery pipe; a drive motor is arranged on the right side of the box body, and a driving shaft is fixedly installed on the drive motor; a drive gear and a first smashing roller are fixedly installed on the driving shaft; a driven shaft is arranged on the box body, a driven gear is fixedly installed on the driven shaft, and blades are respectively arranged on the outer surfaces of a first smashing roller and a second smashing roller; a movable baffle plate is arranged in the box body, a second connection rod is arranged at the lower part of the movable baffle plate, and a first connection rod is hinged to the right end of the second connection rod; a connecting shaft is arranged at the right end of the first connection rod in a rotational manner and is provided with a turntable; a first collecting tank is arranged at the bottom of the box body in a sleeving manner, a sieve pore is formed in the first collecting tank, and a second collecting tank is arranged at the lower part of the first collecting tank. The smashing device for grain processing disclosed by the invention can more fully and completely smash the grains, and simultaneously can avoid dust pollution caused by a large number of dust overflowing from the feed port in the smashing process.

Owner:惠安县丽佳智能设备有限公司

Process for brewing white liquor of Maotai flavor

InactiveCN102304447ARemove Lao ChenRemoval of pesticide residuesAlcoholic beverage preparationPesticide residueDissolution

The invention discloses a process for brewing white liquor of Maotai flavor, which mainly comprises the following steps in turn: preparing grains, carrying out primary feeding, wetting grains, adding yeasts, piling, blending, carrying out secondary feeding, fermenting, collecting liquor and the like, wherein a broomcorn raw material used in primary feeding and secondary feeding are not crushed. In the invention, instead of the conventional grain crushing process, a non-crushed whole grain soaking process is adopted; and the breakthrough in the conventional technical means removes old grains, pesticide residue and odor from the grain raw material and can effectively control the starch dissolution rate and improve quality of the liquor.

Owner:CHONGQING TONGGU WINE

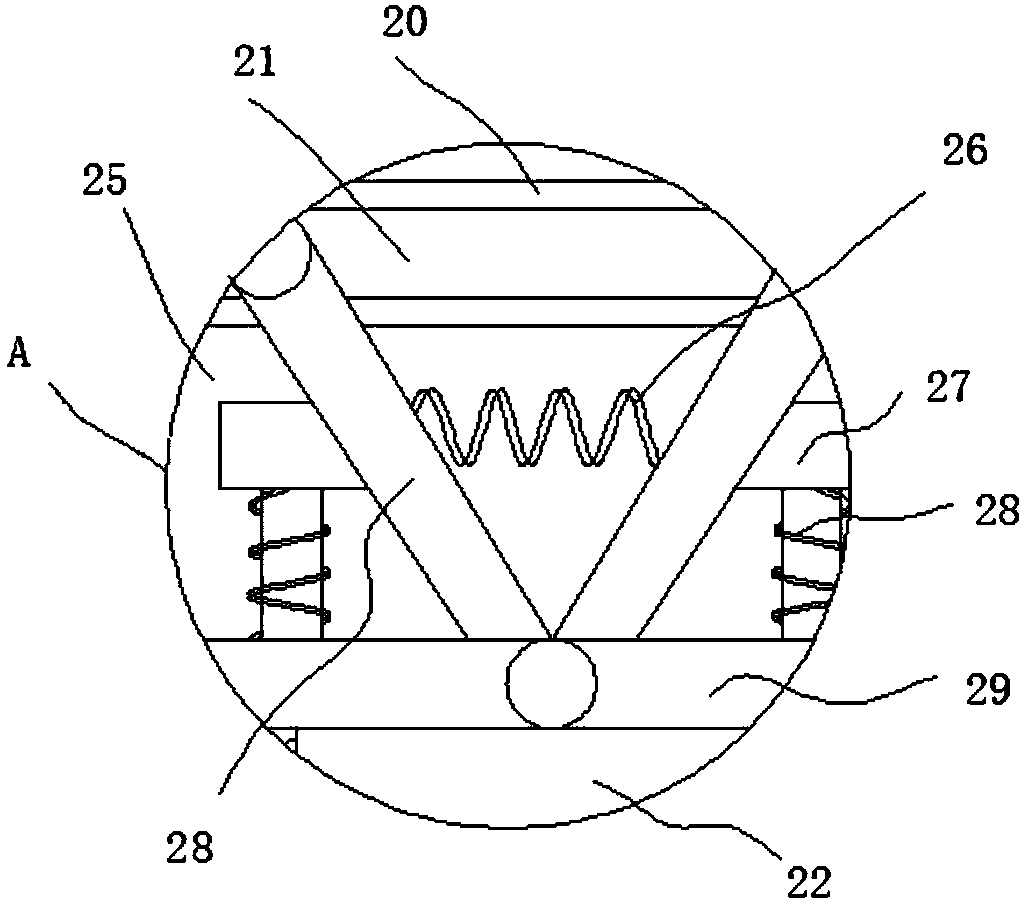

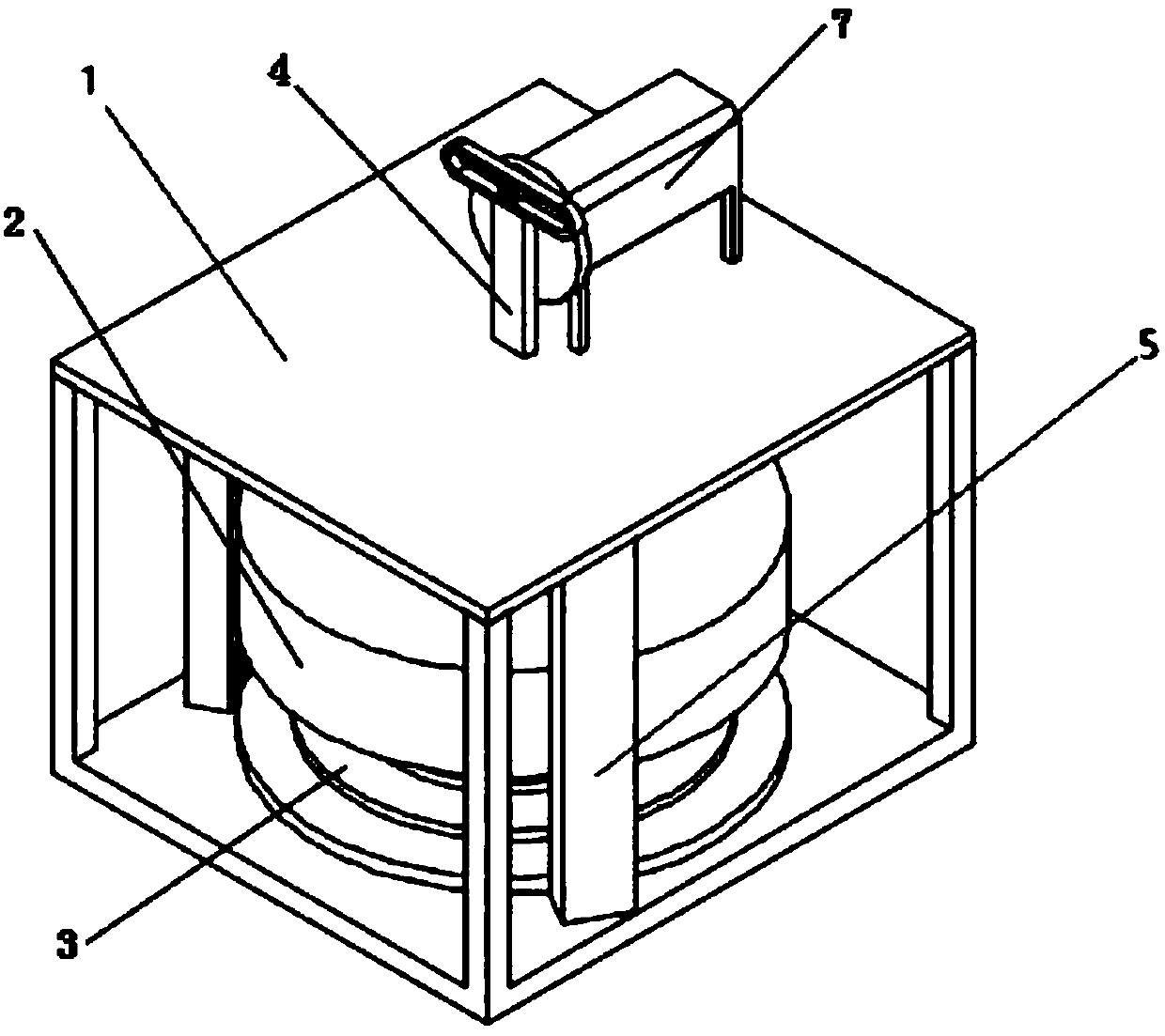

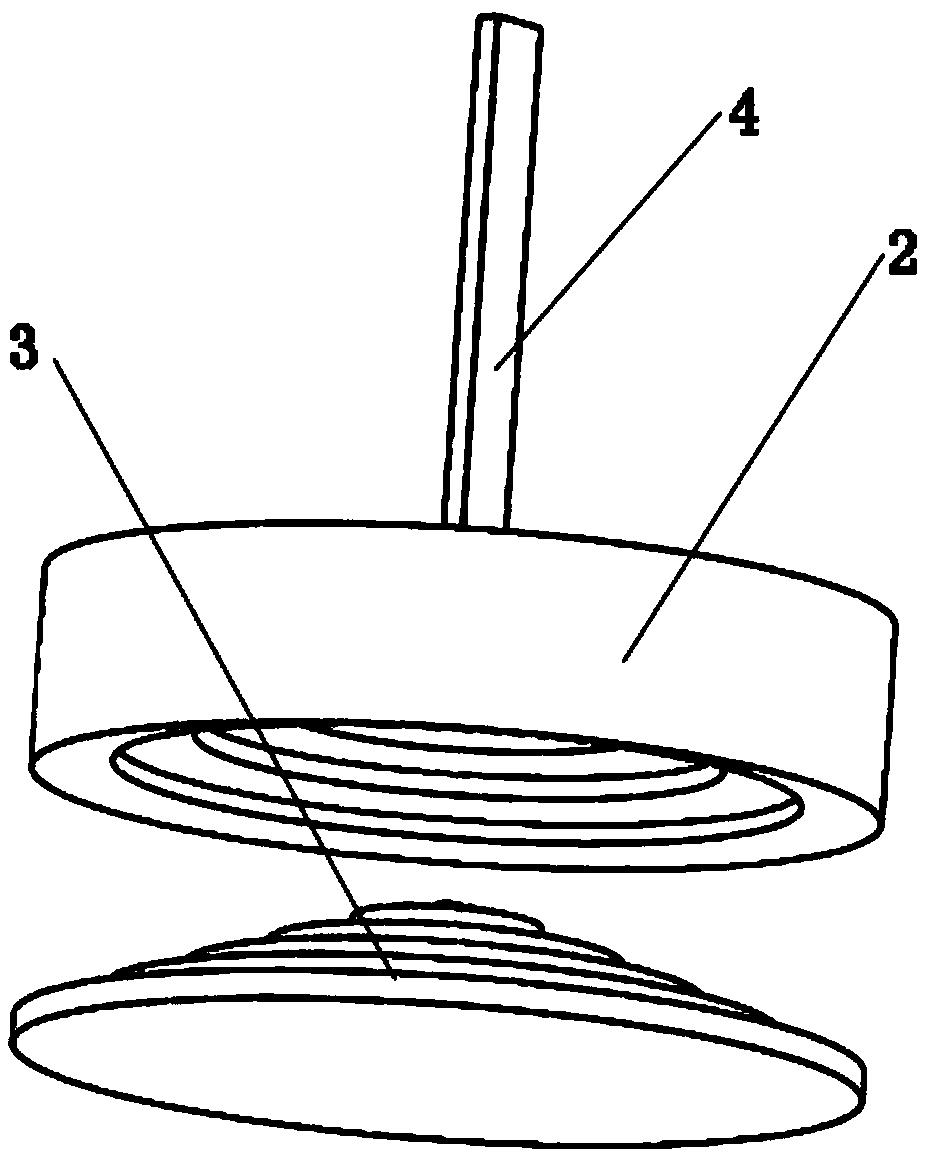

Animal husbandry grain granule crushing device

ActiveCN108499680ARealize the effect of indirect cuttingEasy to collectFeeding-stuffGrain treatmentsEngineeringAnimal husbandry

The invention relates to a crushing device, and especially relates to an animal husbandry grain granule crushing device. The technical problem to be solved in the invention is to provide the animal husbandry grain crushing device capable of automatically and uniformly crushing. The animal husbandry grain granule crushing device provided to solve the technical problem comprises a mounting plate, supporting frames, a fixed plate, a storage box, a hinge, a cover plate, a stopper block, a handle, a discharging tube, a valve, a fixed rod, a crushing box and a feeding hopper; and the supporting frames are arranged at the left side and the right side of the top of the mounting plate in a front and back symmetric manner, the fixed plate is arranged at the tops of the left and right supporting frames, the storage box is arranged at the top of the fixed plate, the hinge is arranged at the right side of the top of the storage box, and the cover plate is arranged on the hinge. The device can achieve automatic and uniform crushing effect, so grain granules are automatically and uniformly broken, and people's efficiency is effectively accelerated.

Owner:安徽中意之旅信息科技有限公司

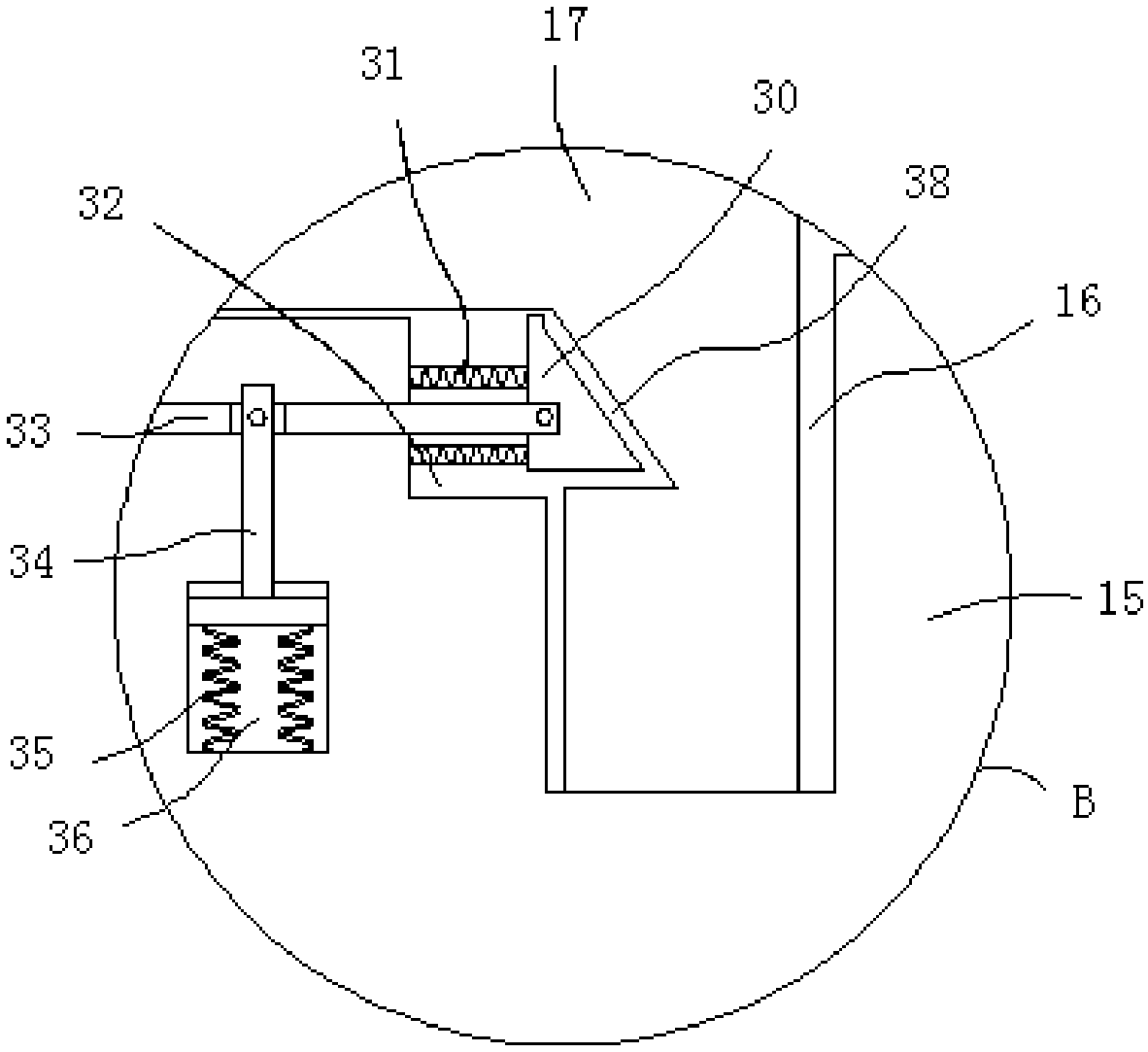

Agricultural grain crushing device

InactiveCN108246468AEasy to replaceSimple structureNon-rotating vibration suppressionGrain treatmentsEngineeringCereal grain

The invention discloses an agricultural grain crushing device. The device comprises a base, a damping device is arranged on the base, the base is provided with a shell through the damping device, a conveying device is arranged on one side of the shell, a feeding device is arranged at one end of the shell, an extrusion device is arranged on the inner side wall of the shell, first baffle plates aresymmetrically connected to the inner side walls of the two sides of the shell, and an electric telescopic rod is inserted into the first baffle plates; and one end of the electric telescopic rod penetrates through the side wall of the shell and is connected with a first driving motor, and the side wall of the shell is rotationally connected with a rotating shaft. According to the device, the structure is simple, and the operation is easy; through the interaction of structures such as the damping device, the buffering effect is achieved when the device operates, vibration is reduced, so that parts are protected; cutters can be replaced conveniently through clamping devices, so that the working efficiency is improved; and through the interaction of structures such as the extrusion device andthe cutters, the crushing effect can be better.

Owner:GUIZHOU RUIHANG INTELLIGENT TECH CO LTD

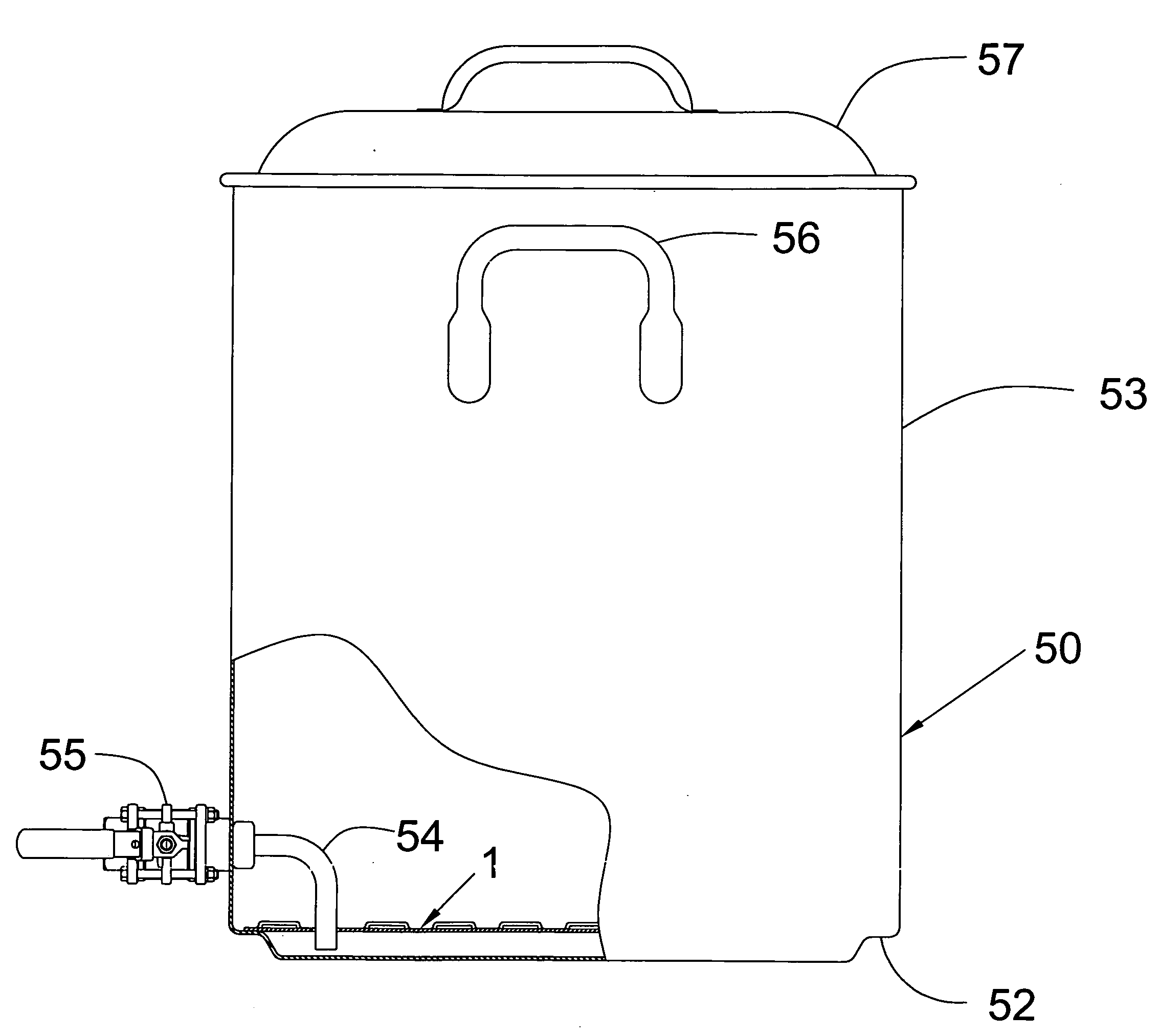

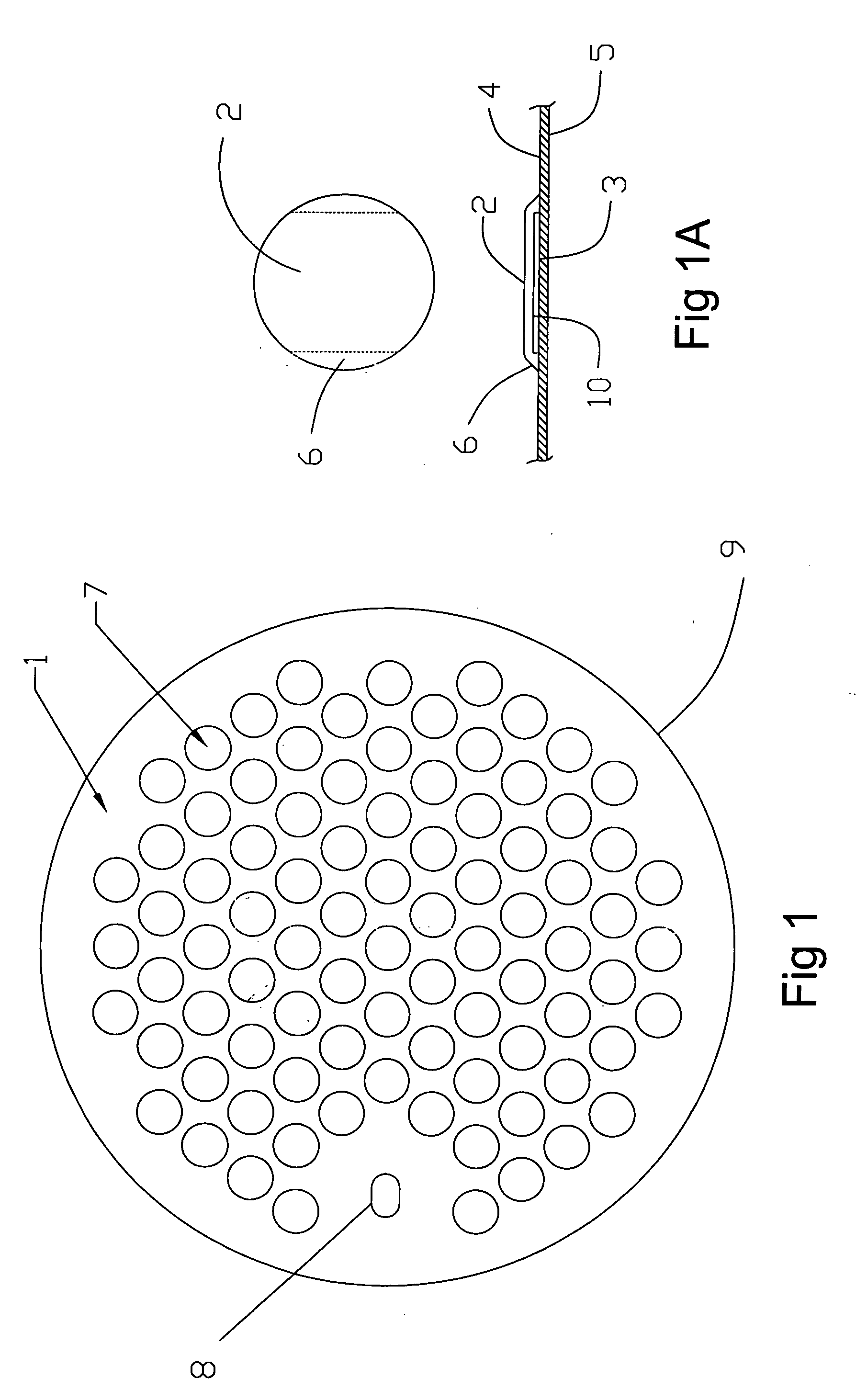

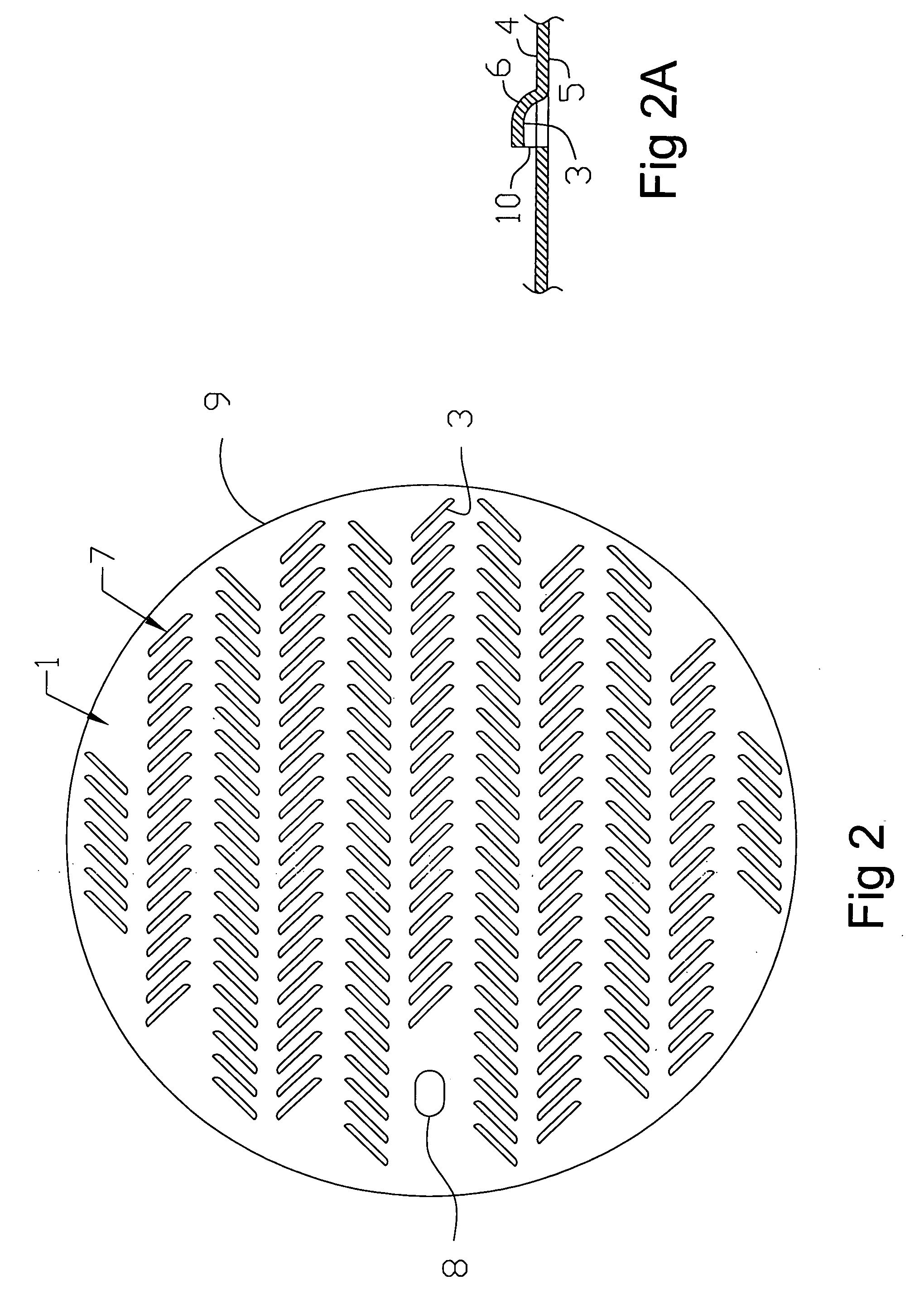

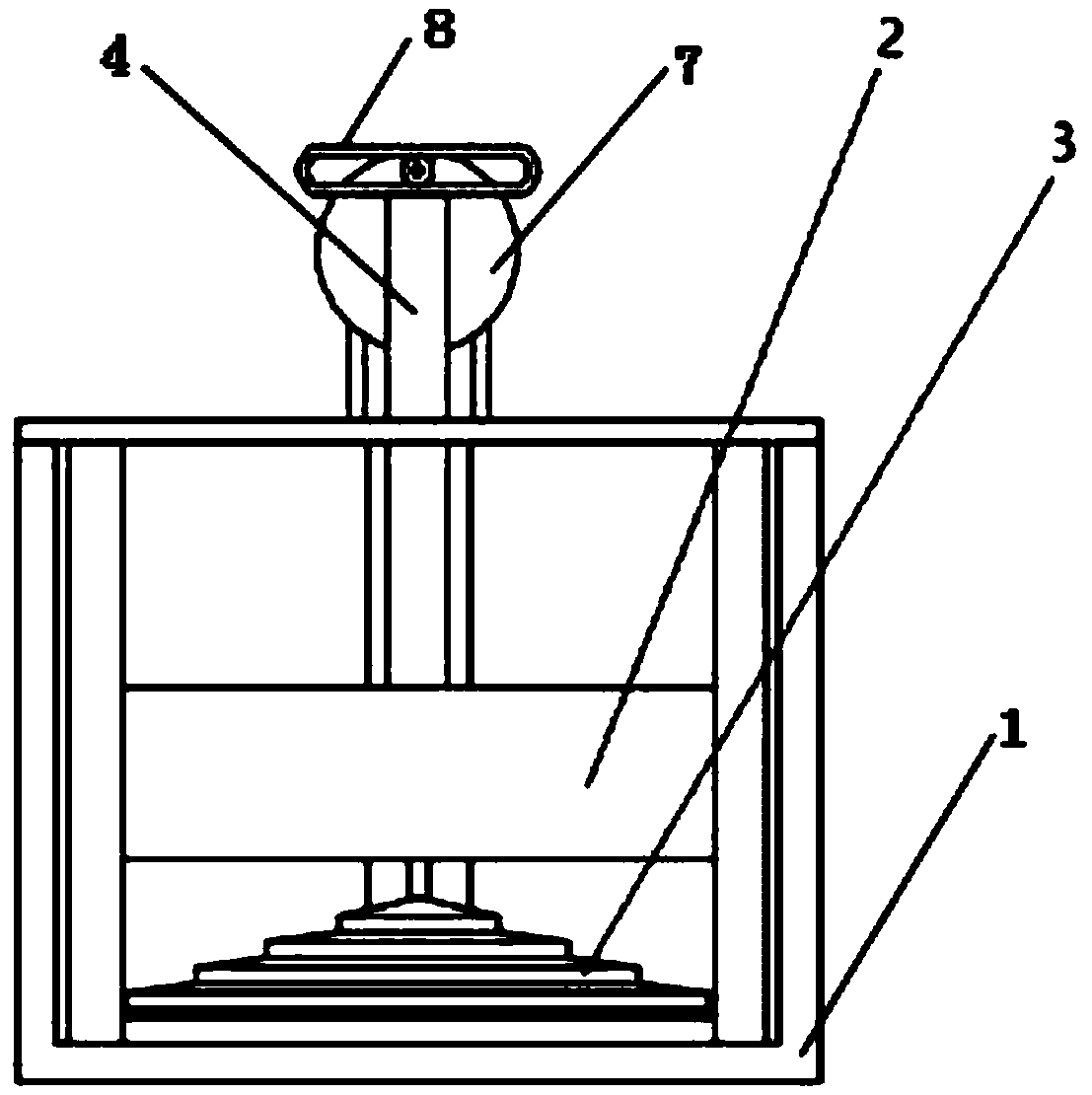

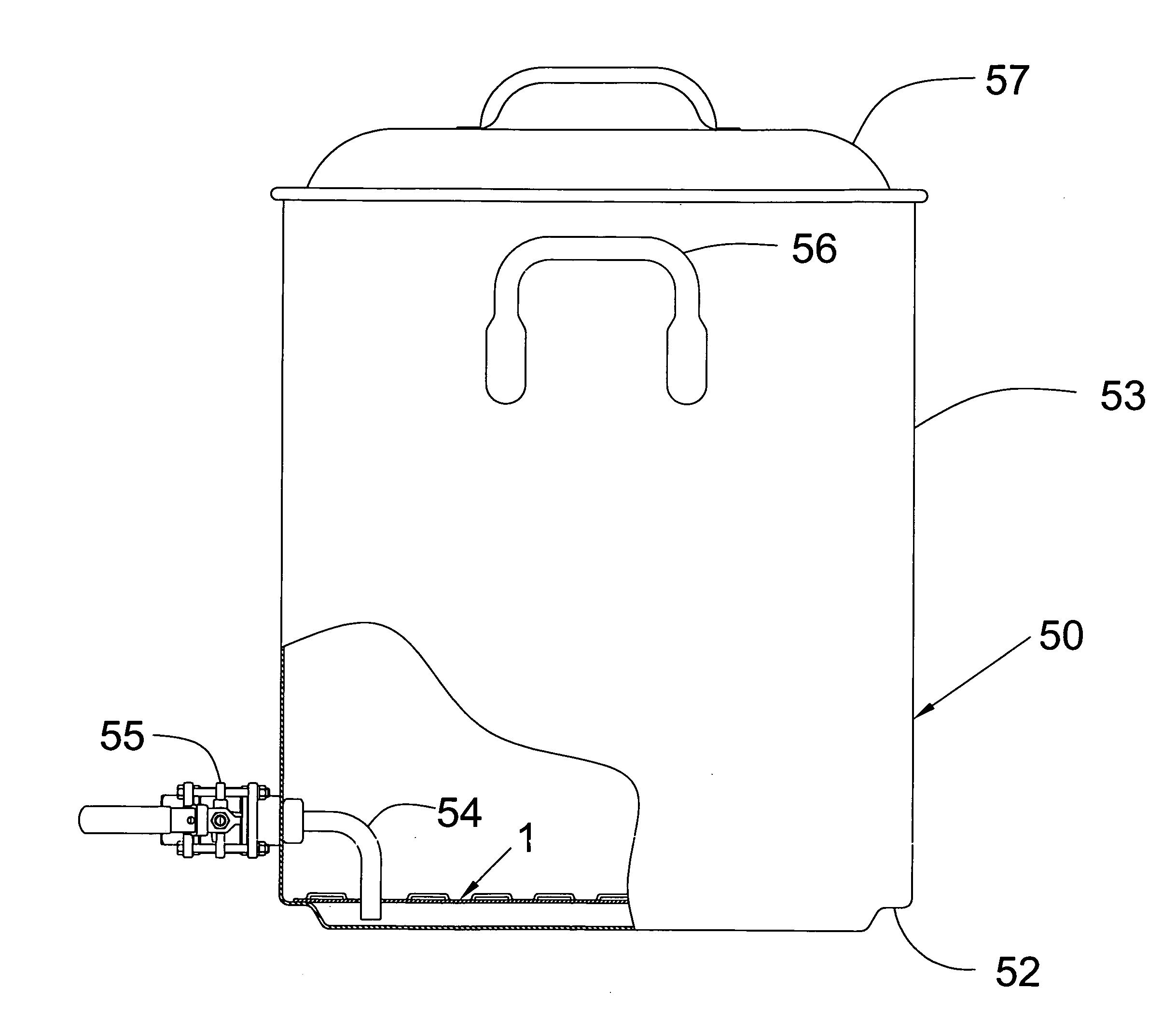

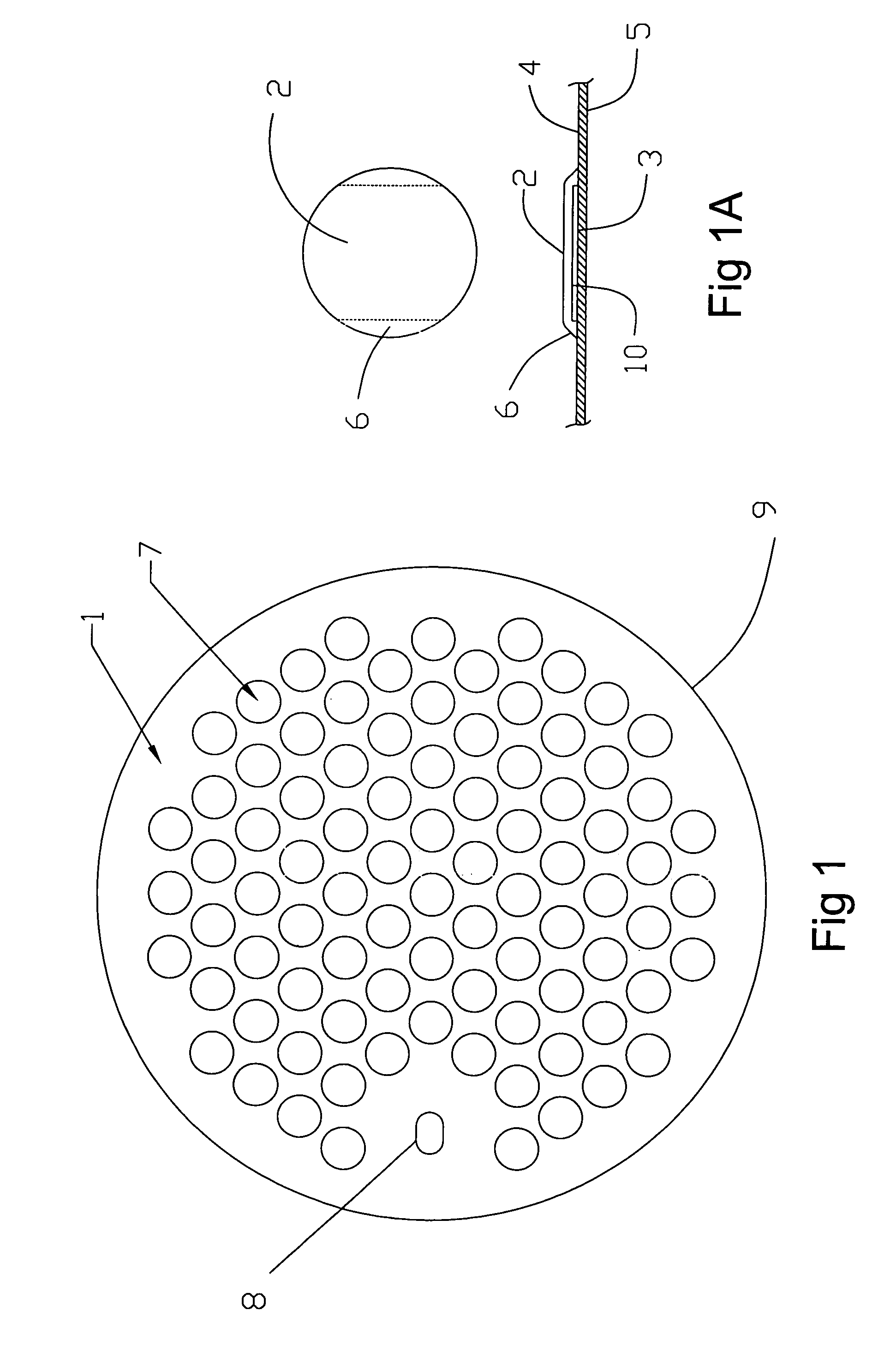

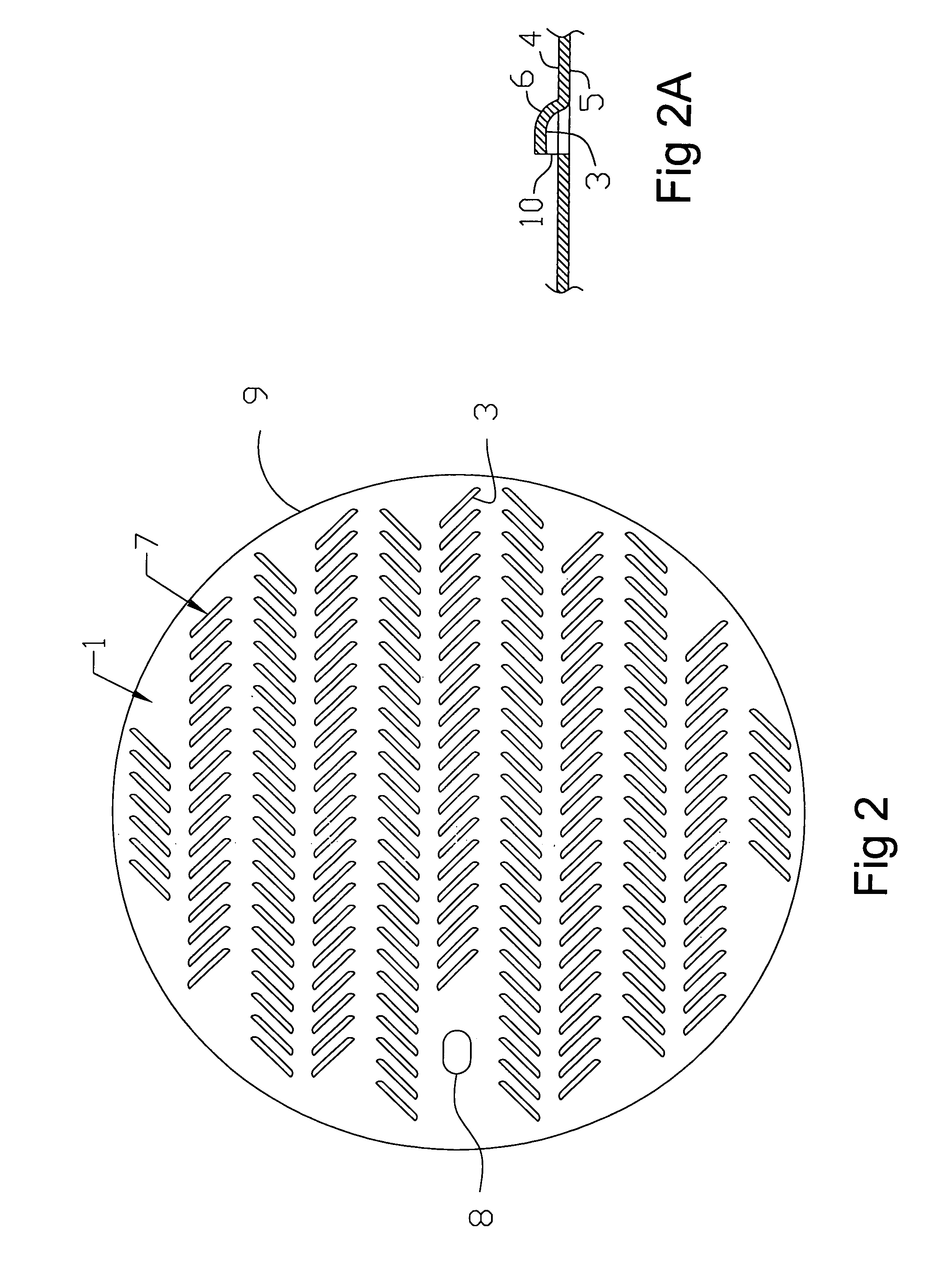

Lauter tun false bottom

A system for filtering spent grains from unfermented beer is disclosed. The system has a pot assembly having a stock pot wall, lid, drain tube and outlet valve. A louvered false bottom is positioned in the pot assembly and forms an opening between the false bottom and the stock pot wall. The louvered false bottom has a plurality of raised louvers spaced over the false bottom. Each of the louvers has a top surface, a bottom surface, a leg and a slot. The slot can be made larger or smaller according to the grain crush size.

Owner:BLICHMANN JOHN RICHARD

Sintered abrasive grain crushing device and method

PendingCN109663628APrevent splashGuaranteed cutting edge qualityGrain treatmentsReciprocating motionStile

The invention relates to a sintered abrasive grain crushing device and method. The device comprises a rack, a hammer head, a hammer seat, a connecting rod, a scotch yoke and a motor. The hammer head and the hammer seat are each of a step structure with four or more stages, the step faces are inclined faces inclined downwards, and the hammer seat is overall of a circular table structure. When the hammer head and the hammer seat are buckled, the buckling gap of the two stages of steps on the bottommost layer is zero, and the buckling gaps of other steps are sequentially increased from bottom totop. The hammer seat is fixed to the bottom of the rack. The top of the hammer head is fixedly connected with the connecting rod. The top of the connecting rod is fixedly connected with the scotch yoke, an output shaft of the motor is arranged in the scotch yoke, and the scotch yoke is driven by the motor to drive the connecting rod to do vertical reciprocating motion. The device has the advantages that the multi-step hammer head and hammer seat structure is adopted, the crushing efficiency is effectively improved, and splashing of abrasive grain scraps is avoided; and by means of the design of sliding pins and sliding grooves, it is effectively guaranteed that the hammer head only does straight-up and straight-down reciprocating crushing motion, and then the cutting edge quality of an abrasive grain surface grinding phase is guaranteed.

Owner:UNIV OF SCI & TECH LIAONING

Energy-saving type grain crushing air dryer

InactiveCN108452927APromote fragmentationSpeed up sievingDrying gas arrangementsGrain treatmentsDrive shaftEngineering

The invention discloses an energy-saving type grain crushing air dryer which comprises a body, wherein a material feeding pipe is vertically and fixedly mounted on the body; a movable cover plate is arranged on the material feeding pipe in a rotatable manner; a second motor is fixedly mounted on the right side wall of the body; an output shaft of the second motor is coaxially and fixedly equippedwith a driving shaft; a conical channel is formed inside the body; a horizontal rod is arranged in the conical channel; a rotating shaft is arranged on the horizontal rod in a rotatable manner. According to the energy-saving type grain crushing air dryer disclosed by the invention, a crushing roller drives a crushing blade to crush grains in a crushing meshed barrel in a rotatable manner, so thatcrushing of the grains is promoted, in addition, a rotary dispersion effect on the grains is achieved, screening of grain particles by the crushing meshed barrel is promoted, and drying of the grainsby hot air is accelerated; a grinding convex block and crushing teeth squeeze and grind the grains in a rotatable manner, so that the crushing and refining degree is greatly increased; the hot air canbe recycled inside the body, so as to realize cyclic and repeated use of heat energy; therefore, energy is greatly saved, and the grain drying efficiency is improved.

Owner:李凯

Grain crushing apparatuses and processes

Owner:US SEC THE ARMY THE

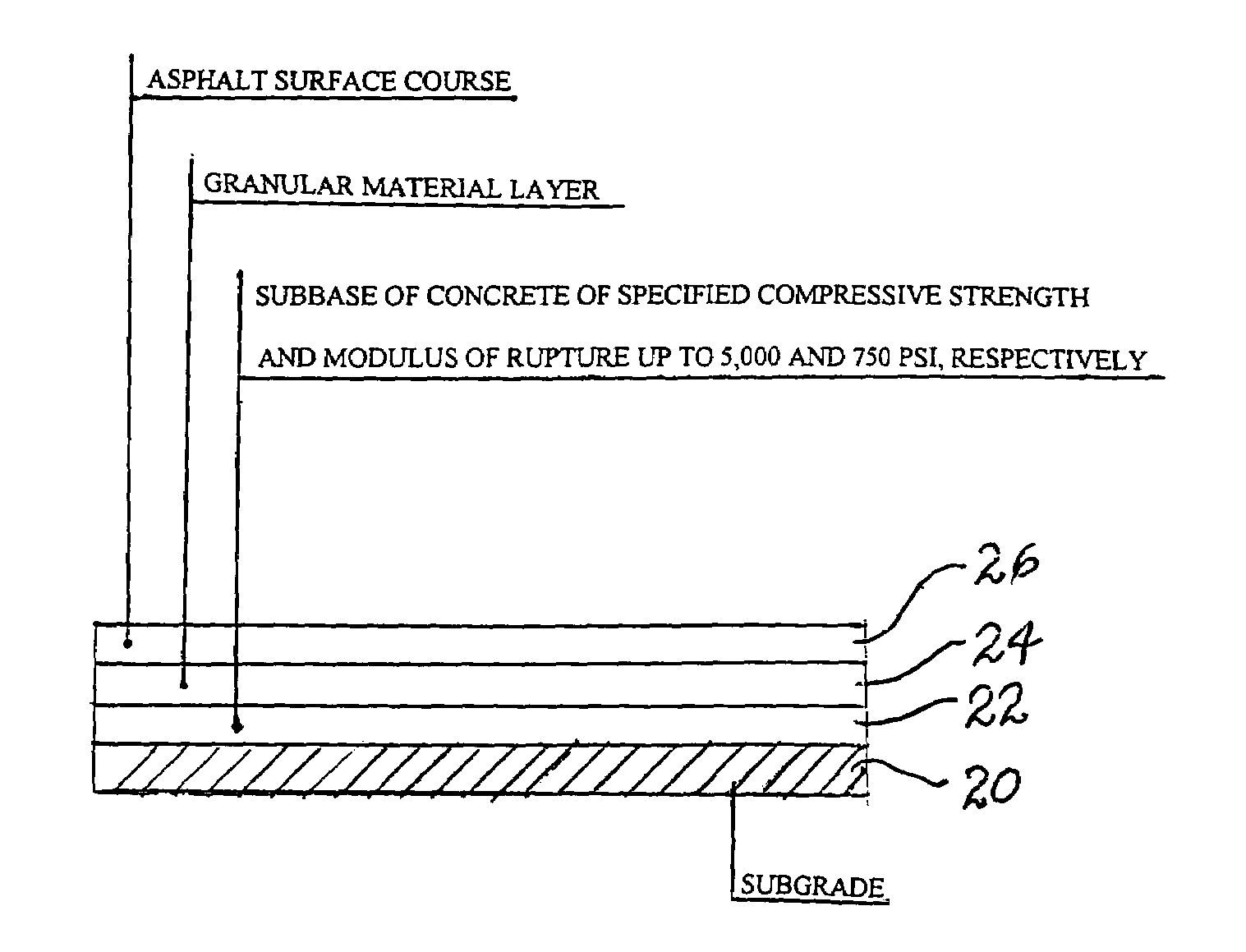

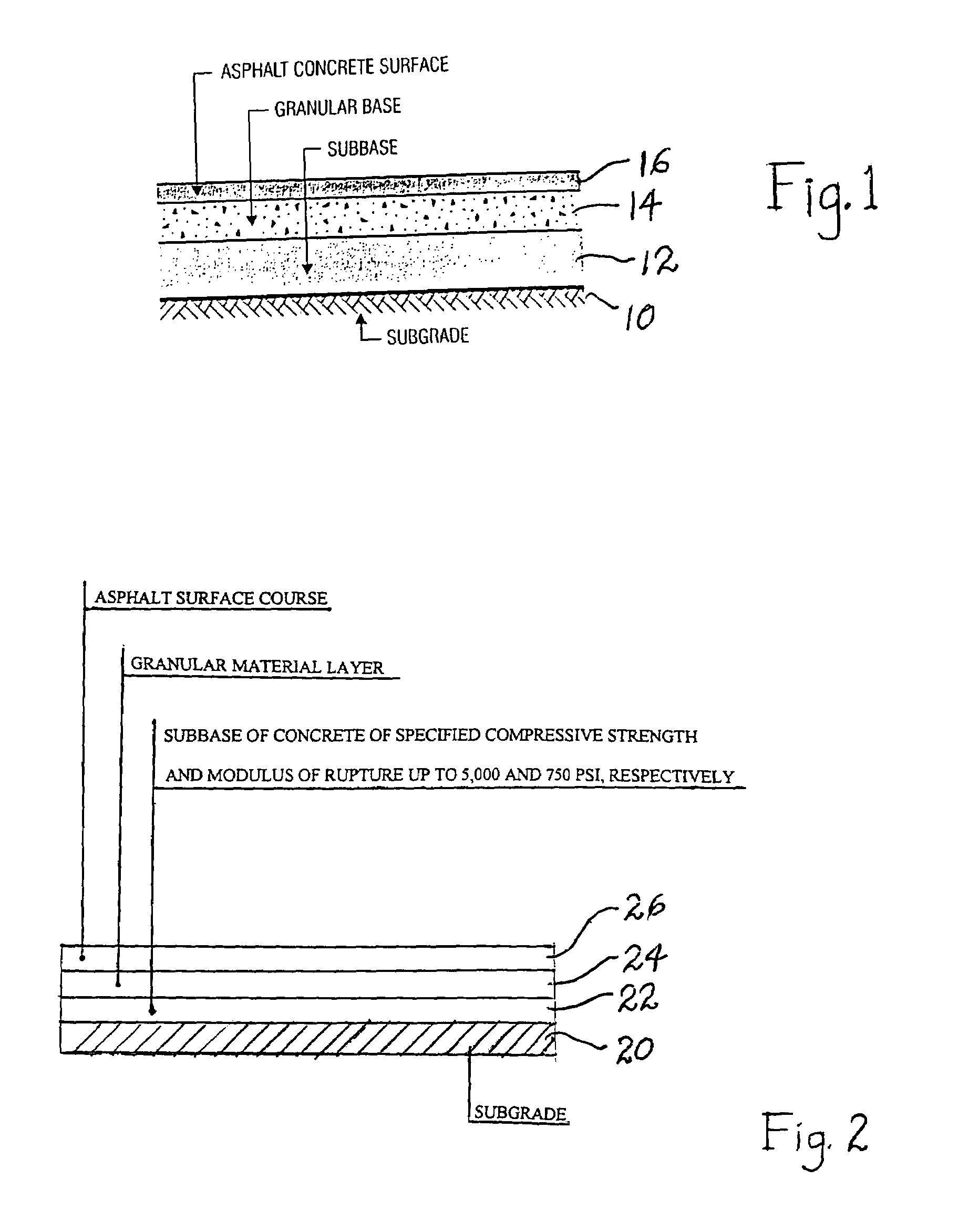

Asphalt concrete pavement with concrete subbase with the enriched quarry limestone waste as a coarse aggregate

Owner:SAPOZHNIKOV NAUM

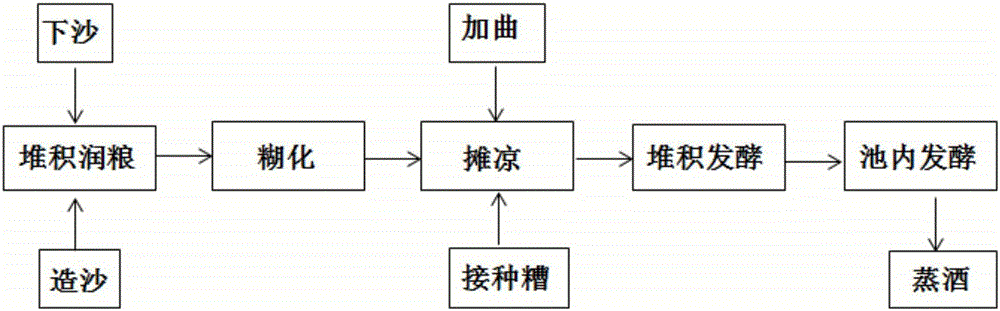

Soy sauce flavor type Baijiu brewing process in cold and dry environments

PendingCN106118949ASolve the problem of heating upSolve the problem of incomplete fermentationAlcoholic beverage preparationDry seasonDistillation

The invention discloses a soy sauce flavor type Baijiu brewing process in cold and dry environments, wherein the brewing process includes the procedures of grain moistening, gelatinization, spreading cooling, stacking fermentation, tank internal fermentation, and wine steaming; the whole brewing process can be summarized up to two times of grain feeding (grain adding and grain crushing), eight times of fermentation, seven times of wine flowing, and three-high process (high temperature starter making, high temperature stacking fermentation, and high temperature wine distillation). A base wine obtained by the brewing process has pure wine body, has prominent soy sauce flavor, and is mellow and long in aftertaste; compared with the prior art, the problems that stacked fermented grains in cold and dry seasons have the temperature difficultly rising and are incomplete to ferment are solved.

Owner:ANHUI GUJING DISTILLERY

Lauter tun false bottom

ActiveUS8146484B2Bioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringLouver

Owner:BLICHMANN JOHN RICHARD

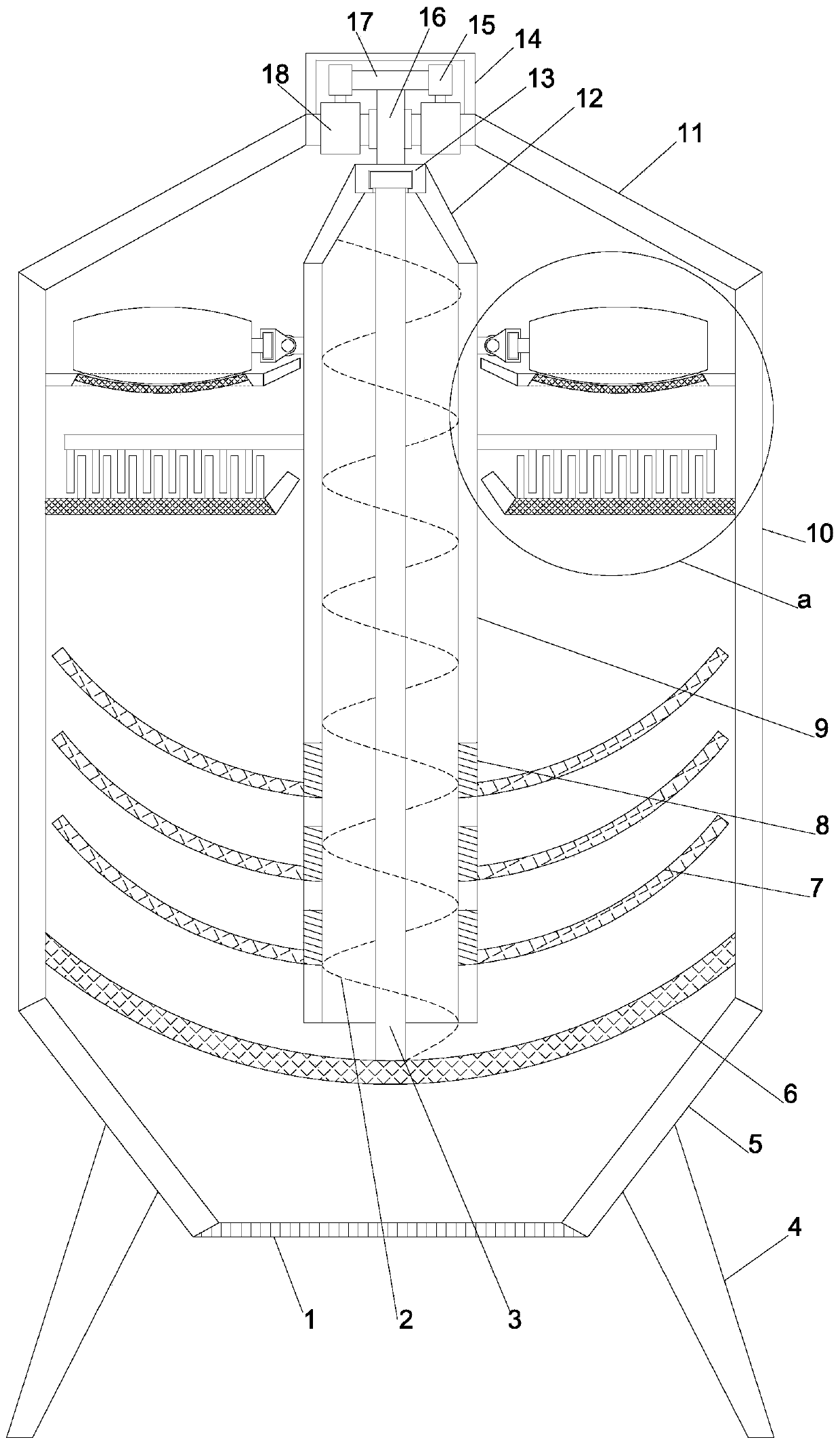

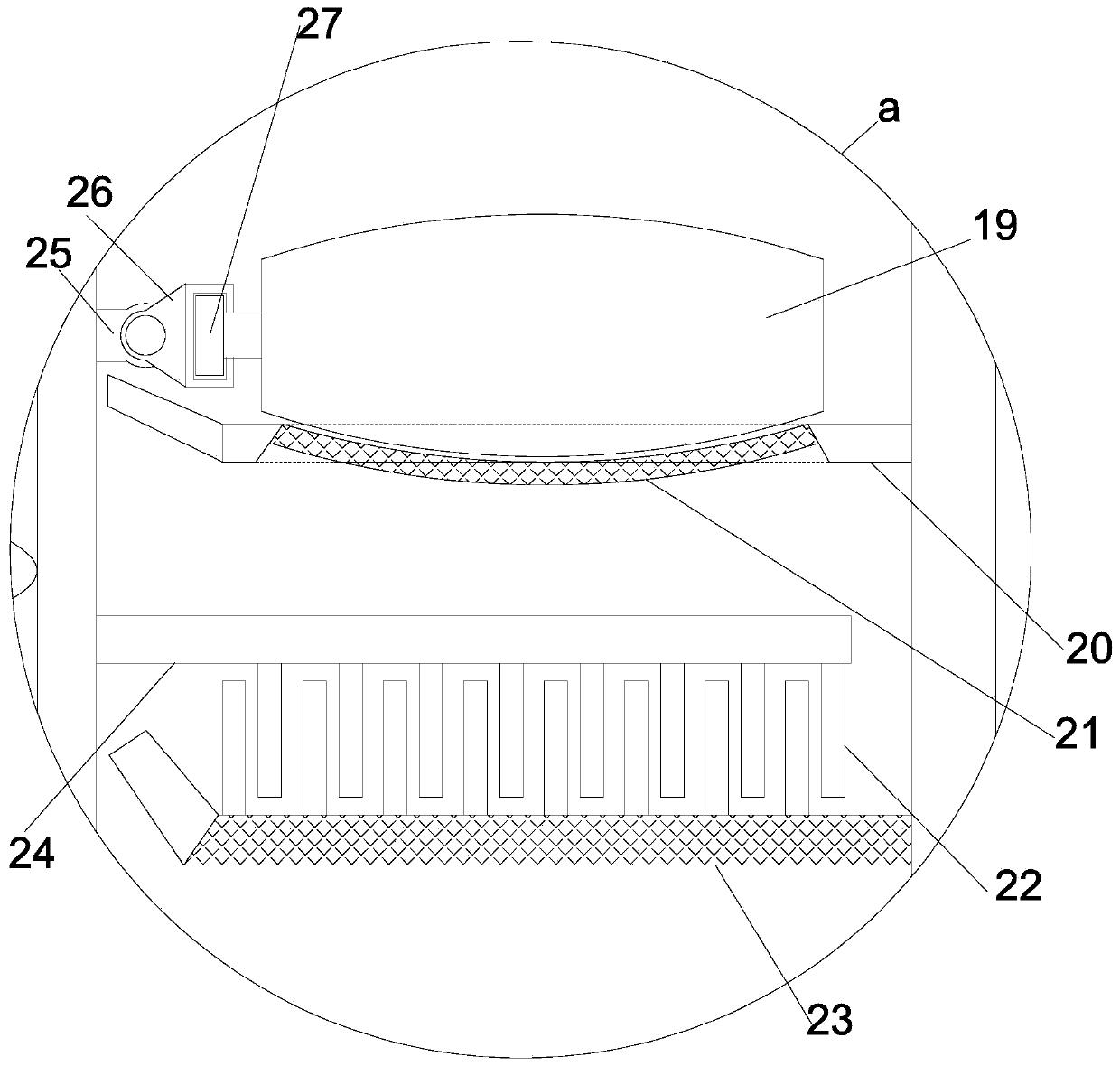

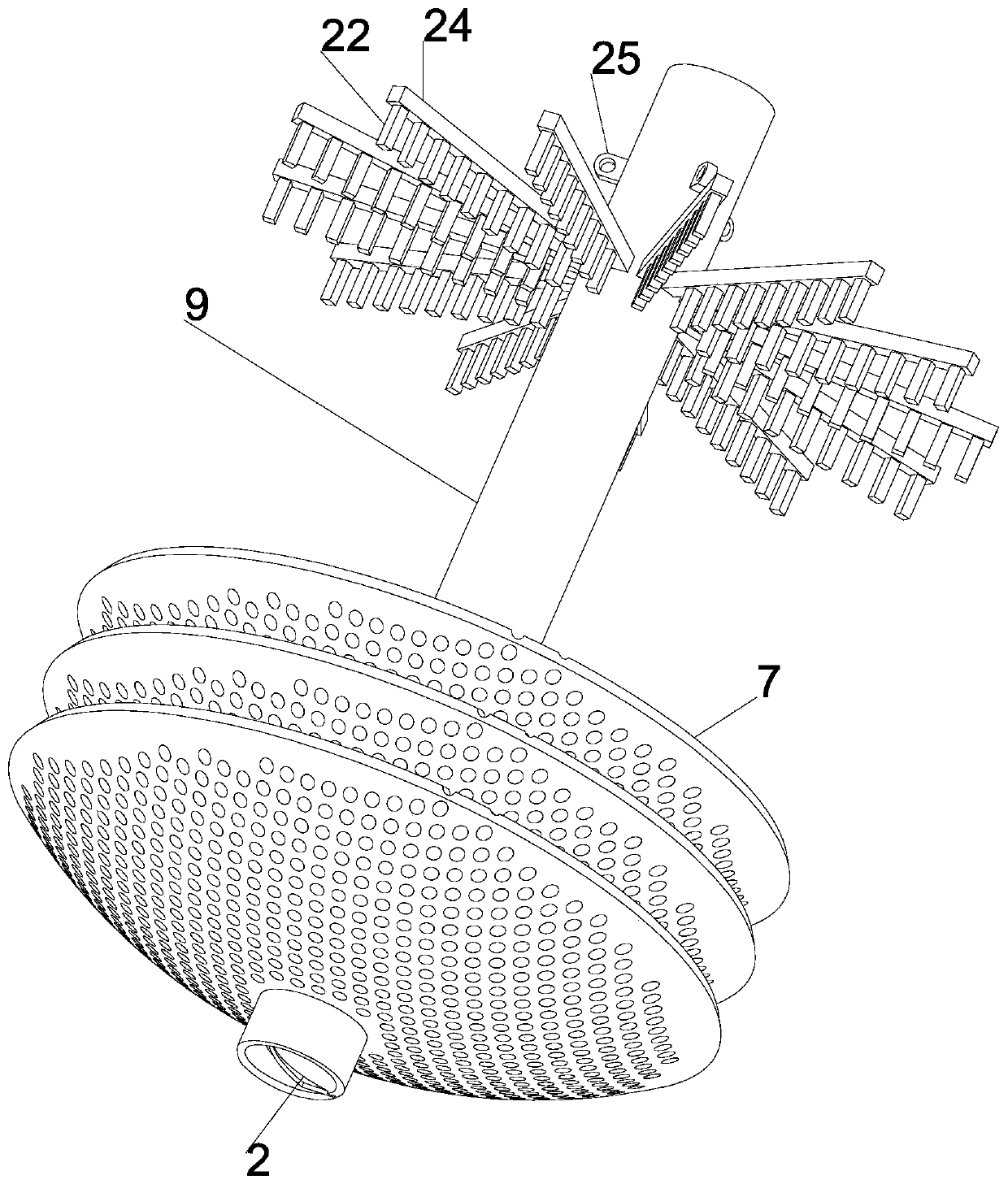

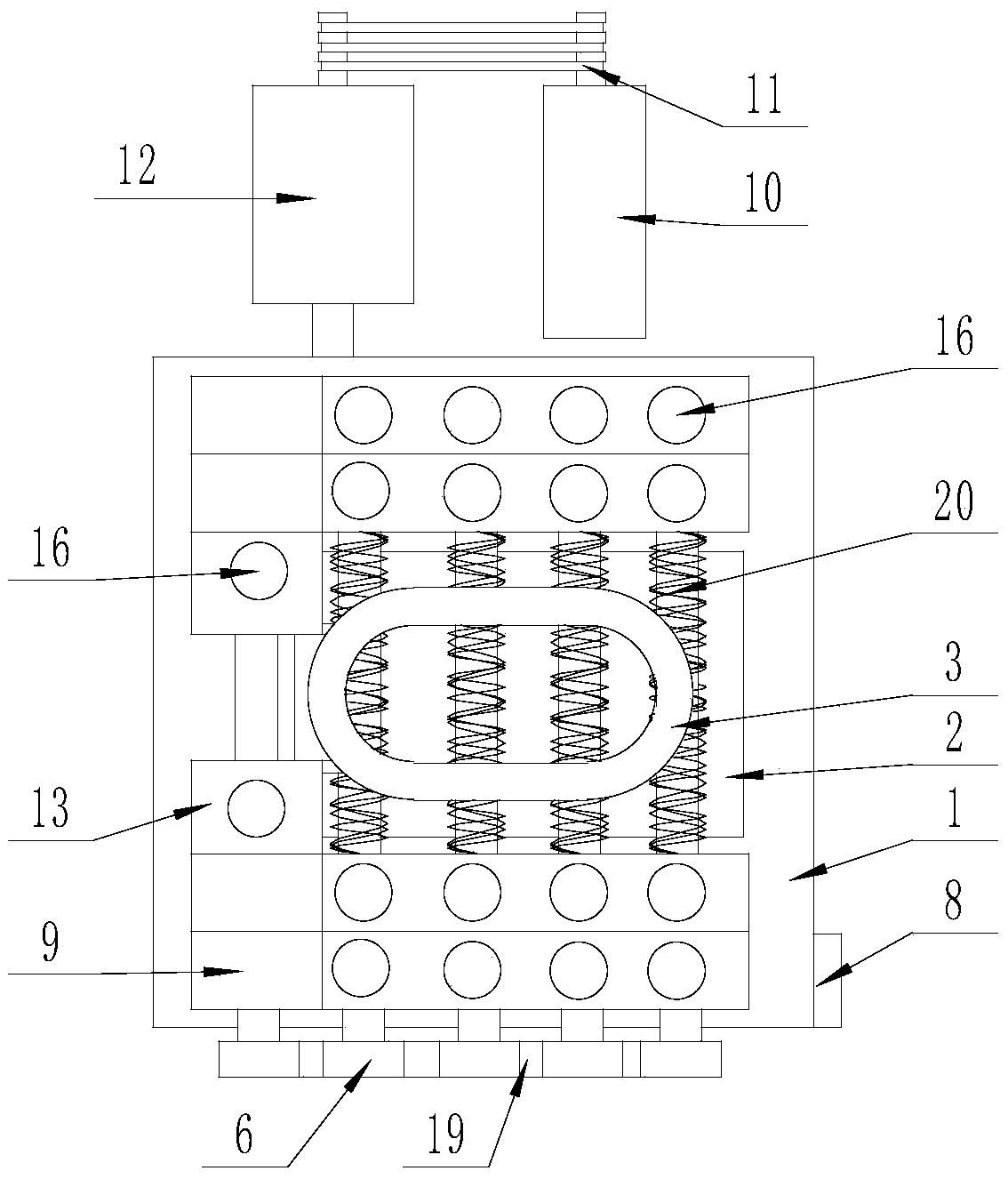

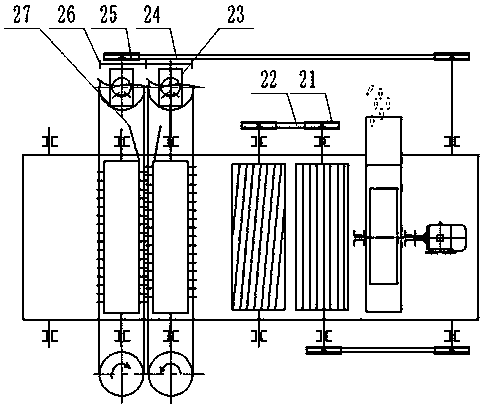

Grain crushing and grinding device for food processing

InactiveCN112108227AFully brokenFully detailedGrain treatmentsReciprocating motionAgricultural engineering

The invention discloses a grain crushing and grinding device for food processing, and relates to the technical field of food processing. The grain crushing and grinding device comprises a fixing frame, an arc-shaped mesh plate is arranged in a grinding box, a dispersing mechanism is in transmission connection with a crushing mechanism, and a lifting mechanism for driving a crushing box to vertically lift is in transmission connection with a double-shaft motor; a translation mechanism is arranged on the fixing frame, and a grinding mechanism abutting against the arc-shaped mesh plate is installed on the translation mechanism. According to the grain crushing and grinding device for the food processing, grains inside the crushing box are rotationally crushed and refined through the arranged crushing mechanism, the arranged lifting mechanism can drive the crushing box to vertically lift, namely the crushing mechanism can vertically lift to be continuously adjusted, and the effect of fullycrushing the grains in different position areas in the crushing box is achieved; and the arranged dispersing mechanism can achieve the dispersing effect of the grains, the crushing sufficient degree is higher, the arranged grinding mechanism can be driven by the translation mechanism to do transverse reciprocating motion and repeatedly grind the grains, and sufficient refining of the grains is effectively guaranteed.

Owner:盐池县荣桂昌食品科技有限公司

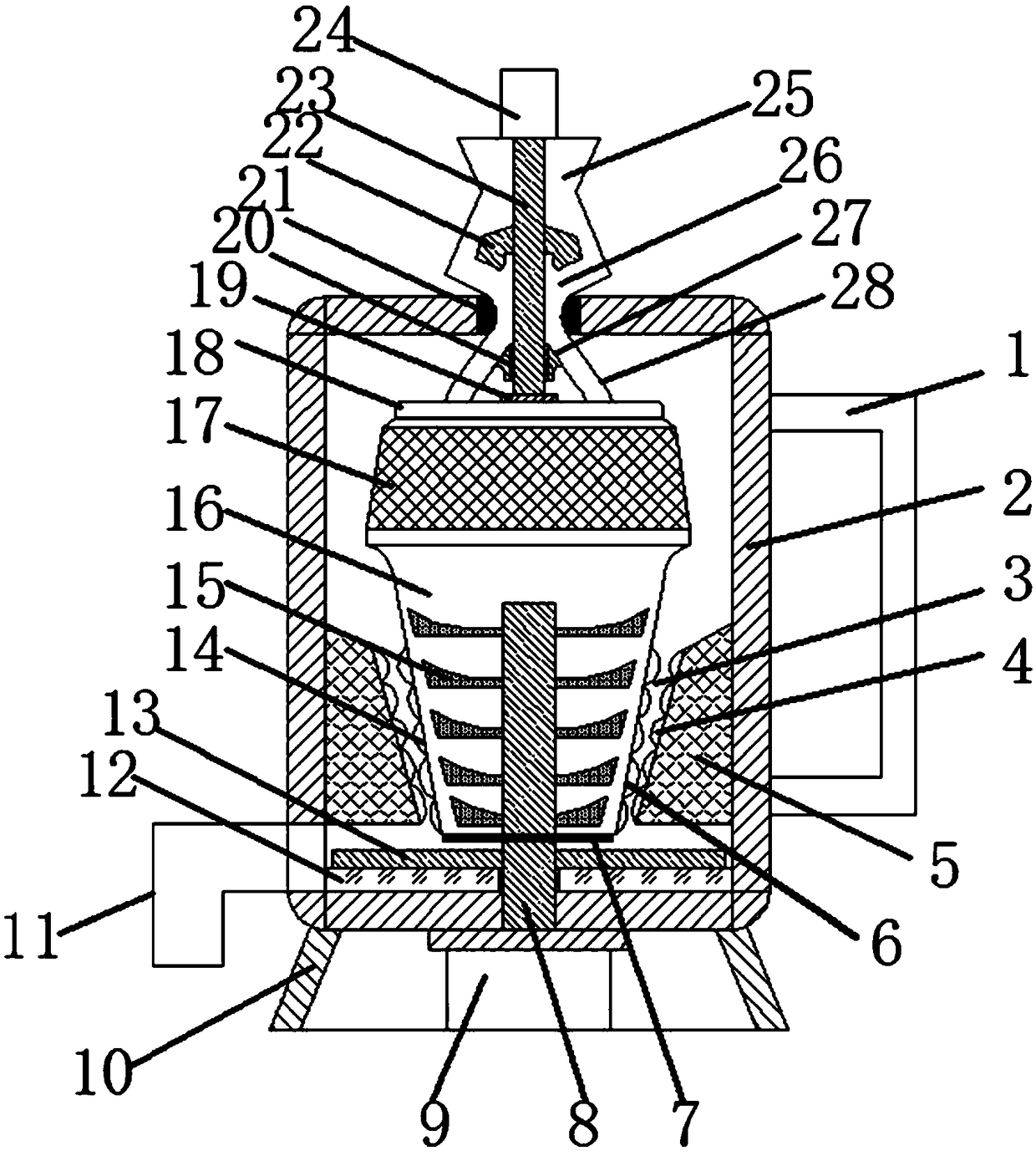

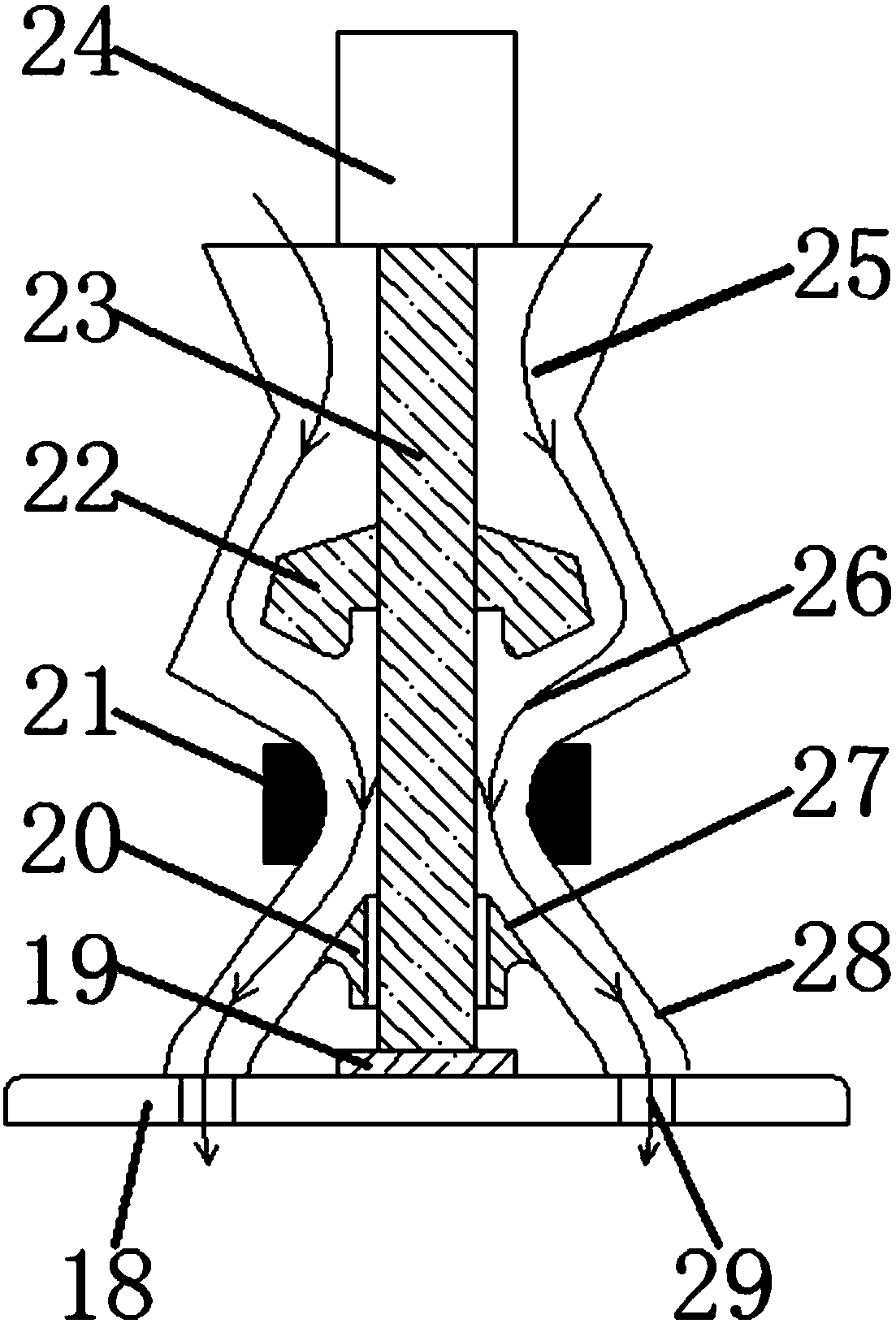

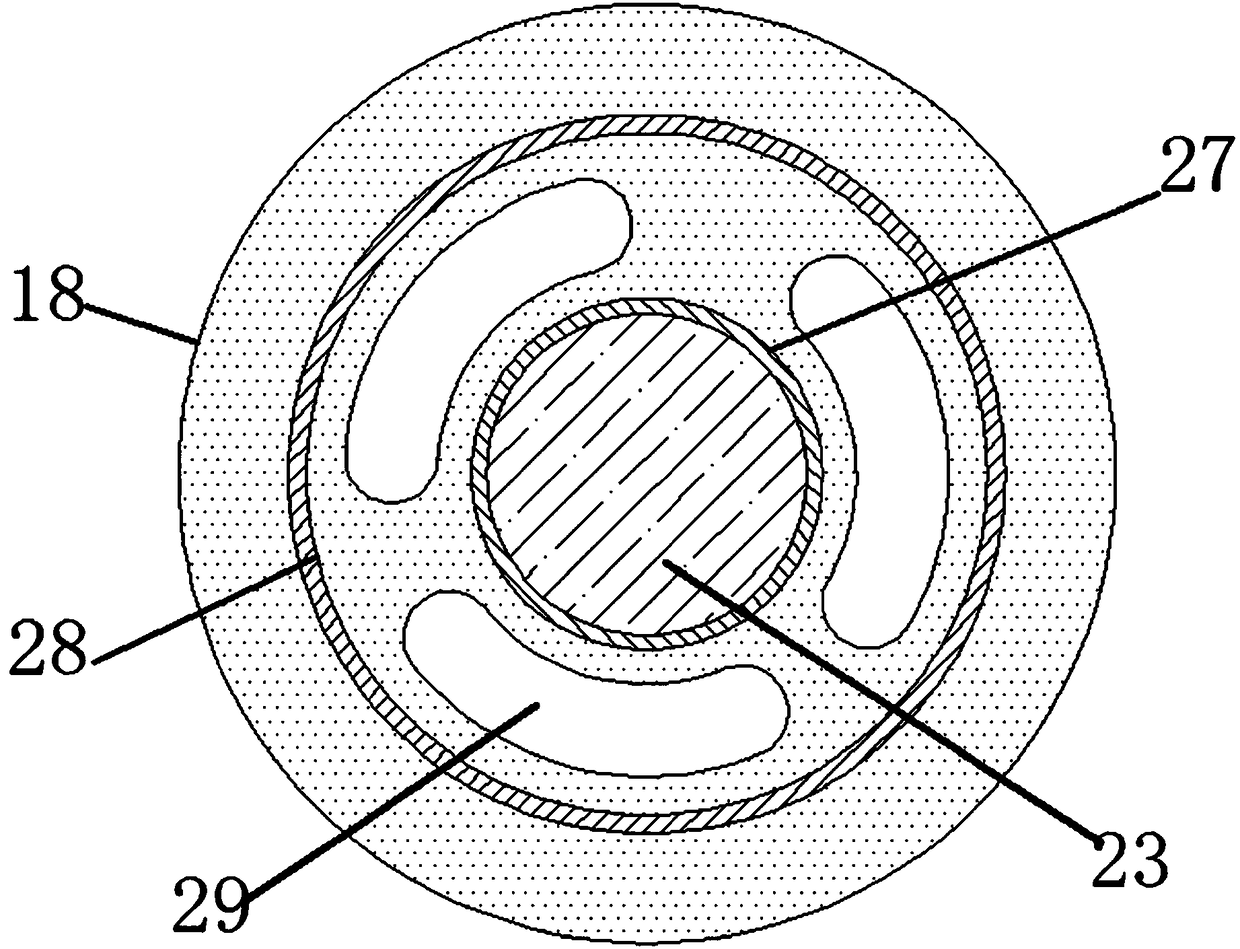

Circulation lifting and screening type multistage grain crushing device

ActiveCN110420715AReduce selection requirementsImprove processing qualityGrain treatmentsEngineeringGrain crushing

The invention relates to the field of agricultural production, and particularly relates to a circulation lifting and screening type multistage grain crushing device. The device comprises a vertically-arranged supporting mounting cylinder, the lower end of the supporting installation cylinder is provided with a conical surface guide cylinder, a discharging hole is formed in the lower end of the conical surface guide cylinder, a plurality of supporting mounting columns are arranged at equal angles on the outer side of the conical surface guide cylinder, a driving installation cover is verticallyarranged right above the supporting installation cylinder, and the outer ends of the feeding mounting columns are connected with the upper end of the supporting mounting cylinder. Through the multi-motor planetary gear driving structure, the transmission efficiency of the device is high, the requirement for motor selection is reduced, two-stage crushing is realized through the synchronous drivingstructure, so that the transmission efficiency of the device is high, the crushing quality is good, the crushing quality of the device is further improved through the structural design of circulatingscreening and lifting, and the processing quality of cereals is remarkably improved.

Owner:安徽省东全米业股份有限公司

Household grain crushing, centrifugal screening and grinding device

InactiveCN108435386AGuarantee sufficiencyAvoid cloggingGrain treatmentsIntegrated operationsEngineering

The invention discloses a household grain crushing, centrifugal screening and grinding device. The household grain crushing, centrifugal screening and grinding device comprises a grain crushing and grinding housing, a grinding wedge, a cleaning brush, a centrifugal barrel and crushing blades, wherein an external guiding cone is fixed in the middle of the top end of the grain crushing and grindinghousing; a centrifugal motor is fixed in the middle of the top end of the external guiding cone; a centrifugal rotating shaft is connected to the bottom of the centrifugal motor; a fixed block is connected to the bottom end of the centrifugal rotating shaft and welded on a feeding plate; the centrifugal barrel is connected to the bottom of the feeding plate; a plurality of internal grinding teethare formed on the outer side wall of the centrifugal barrel; the grinding wedge is fixed on the inner wall of the grain crushing and grinding housing on the outer side of the centrifugal barrel; and aplurality of external grinding teeth are formed on the grinding wedge. The household grain crushing, centrifugal screening and grinding device facilitates discharging of entered grains to prevent a feeding channel from blockage, guarantees sufficient grain crushing and uniform crushed grain sizes, achieves centrifugal screening and separation while crushing, and realizes integrated operation of grain adding, crushing, centrifugal screening, grinding, sweeping and discharging.

Owner:韩志杰

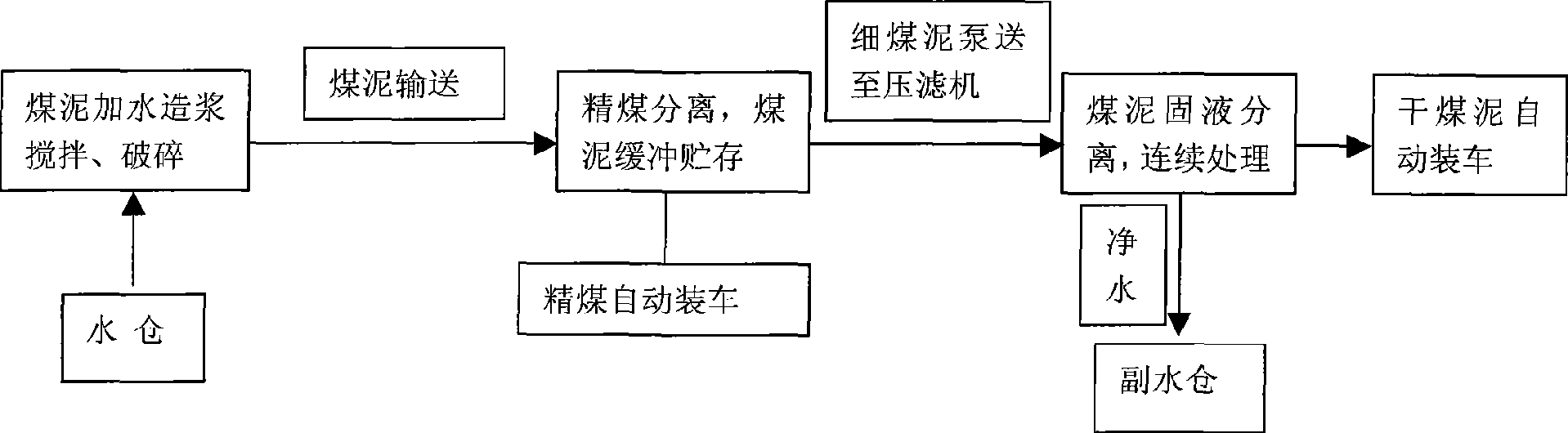

Coal slurry excavating and processing method for coal mine water warehouse

InactiveCN101503965AEasy to transportEasy to storeBuilding braking devicesPeat miningFilter pressCoal slurry

The invention relates to a method for dredging and treating coal slurry in various water sumps of coal mine, in particular to a method for dredging and treating coal slurry in a water sump of a coal mine. The method is not only applicable to the water sump of the coal mine, but also used for dredging and treatment of silt in various laneway water sumps. The method for dredging and treating the coal slurry in the water sump of the coal mine comprises the steps of diluting the coal slurry, stirring and slurry making, large-grain crushing, coal slurry conveying, cleaned coal extraction, coal slurry filter pressing (solid separation) and the like. The method can be used for automatically dredging and treating the coal slurry in various water sumps and extract the cleaned coal from the coal slurry so that the solid coal slurry is convenient to transport and store and the coal slurry is changed into valuable, and simultaneously the method improves the production efficiency.

Owner:XUZHOU TIANKE MACHINERY MFG

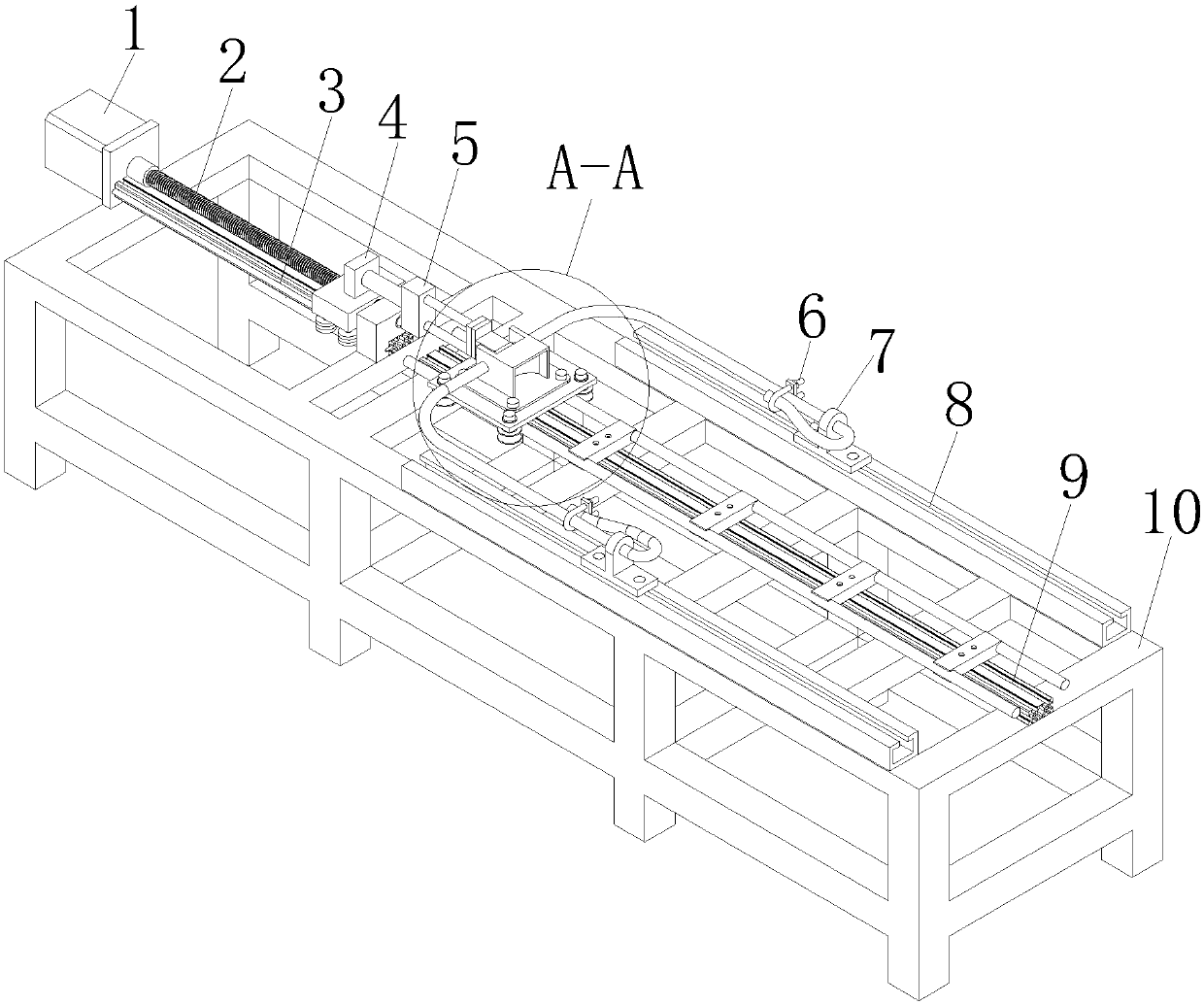

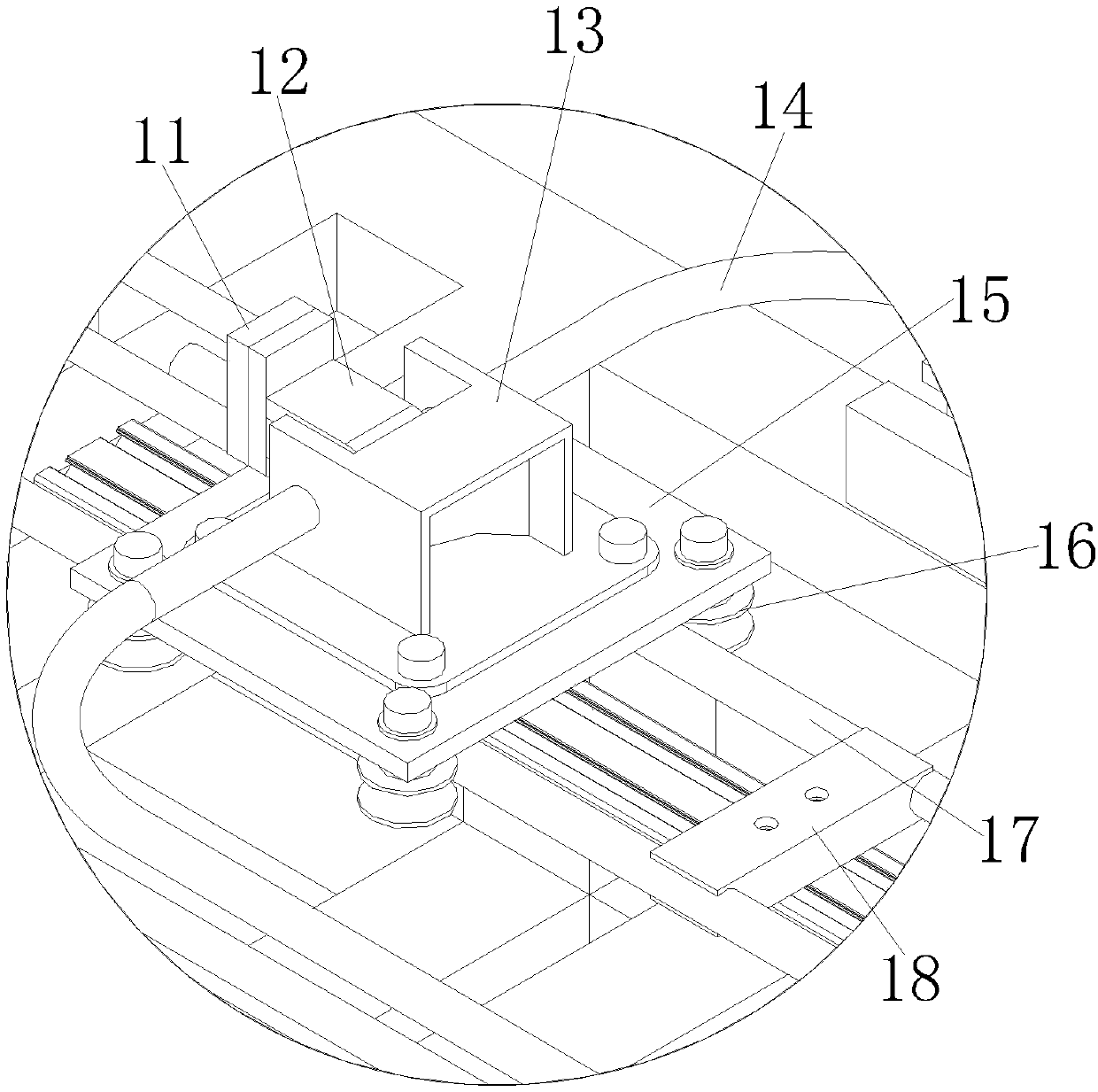

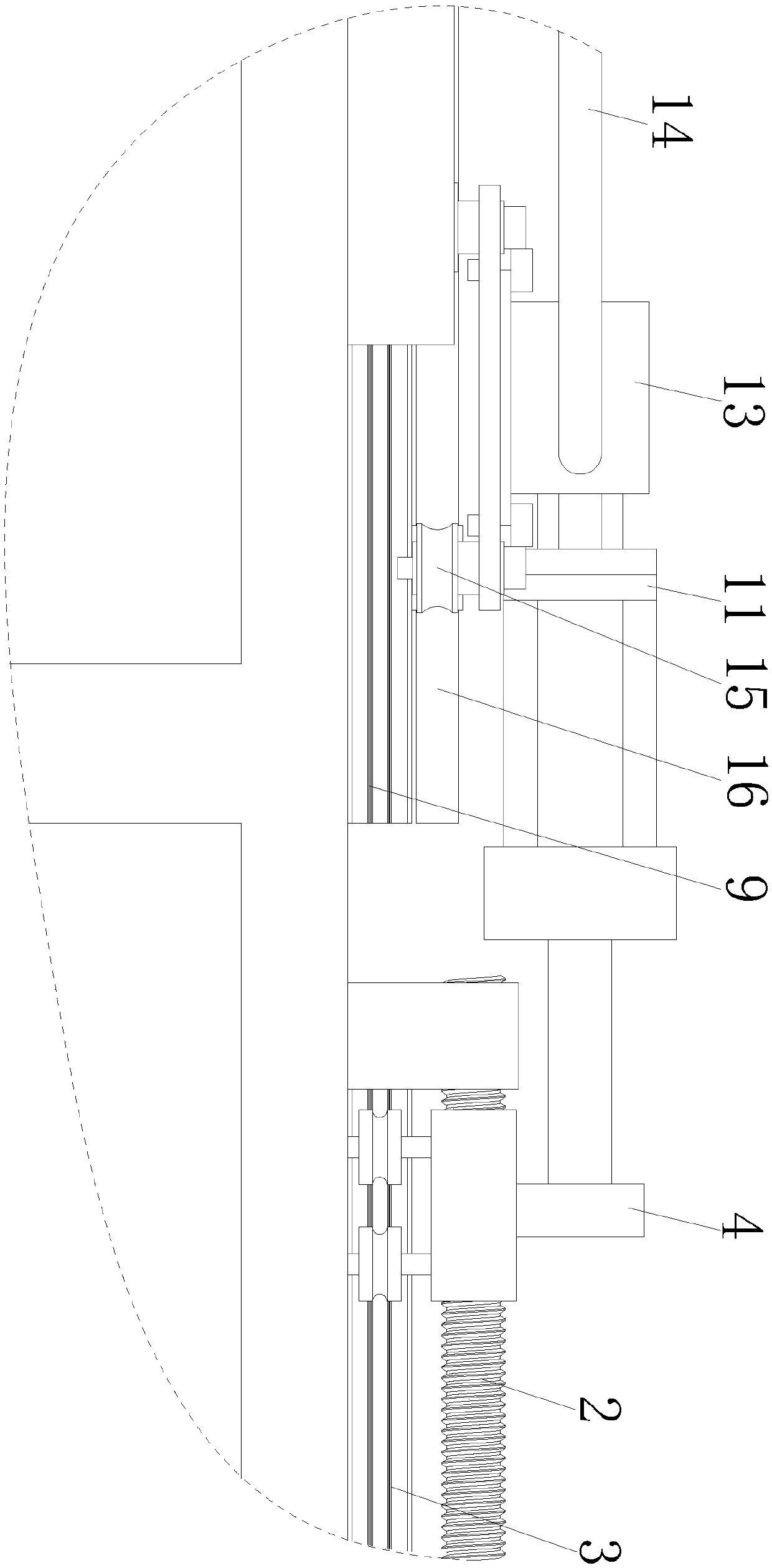

Grain impact crushing tester

PendingCN107621423AImpact crushingReduce distractionsStrength propertiesEngineeringMechanical engineering

The invention discloses a grain impact crushing tester which comprises a base, wherein a servo motor is arranged on the base; a screw rod is connected with the servo motor; a slide rail is arranged onone side of the screw rod; a tension device is connected with one end of the screw rod, away from the servo motor; a force measuring sensor is arranged on one side of the tension device; an electromagnet is arranged on one side of the force measuring sensor. The grain impact crushing tester disclosed by the invention is capable of driving the screw rod to rotate by the servo motor, so as to pulla pushing block connected with an elastic rope to move; when an elastic force detected by the force measuring sensor reaches a calibrated force, a signal is sent for automatically cutting off the electromagnet, so that grain impact crushing is realized; an impact crushing platform is capable of accurately controlling an impact crushing force, and meanwhile, the pushing block is capable of pushingthe grains for impact crushing without interference at the disconnecting moment through the connection of the electromagnet, so that uncertain factor interference is reduced; and the crushing effect can be judged by observing the grain crushing result.

Owner:FUJIAN UNIV OF TECH

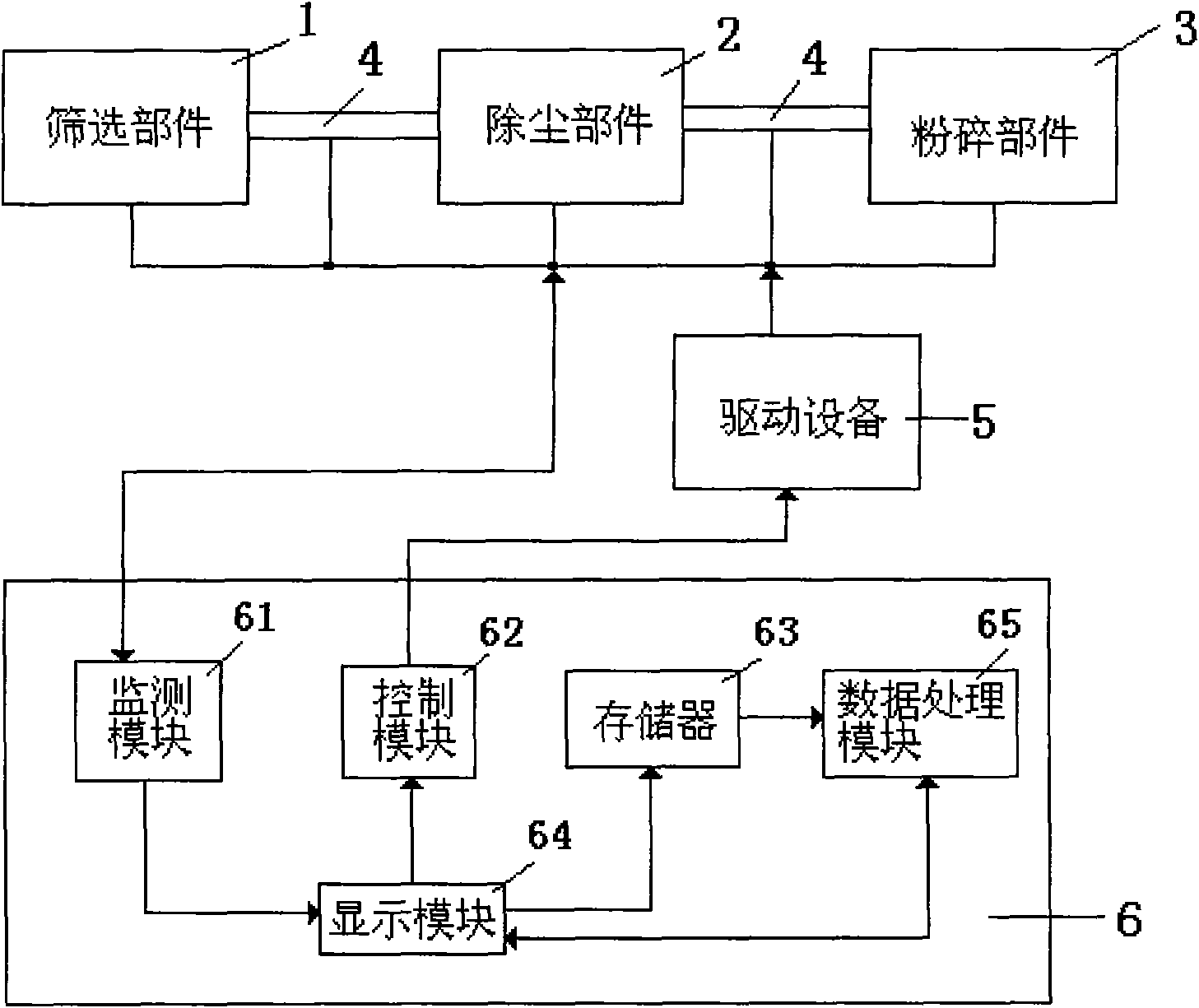

Intelligent control method for complete grain crushing system

InactiveCN101923324AImprove work efficiencyReal-time monitoring of operationComputer controlSimulator controlData informationComputer module

The invention relates to an intelligent control method for a complete grain crushing system, which comprises the following steps that: an administrator inputs related data information to a memory and a data processing module through a display module respectively; the administrator inputs running parameters of each device through the display module, and stores the running parameters to the memory; the display module drives each device to run through a control module and a drive device; a monitoring module monitors the running condition of each device, feeds the running information of each device back to the display module in real time and stores the running information to the memory; and the administrator adjusts the running parameters of each device in real time. The intelligent control method for the complete grain crushing system can monitor each device in real time by combining the computer technology, handle problems in time and greatly improve the work efficiency of the system.

Owner:SHANGHAI YI CHEN INFORMATION TECH DEV

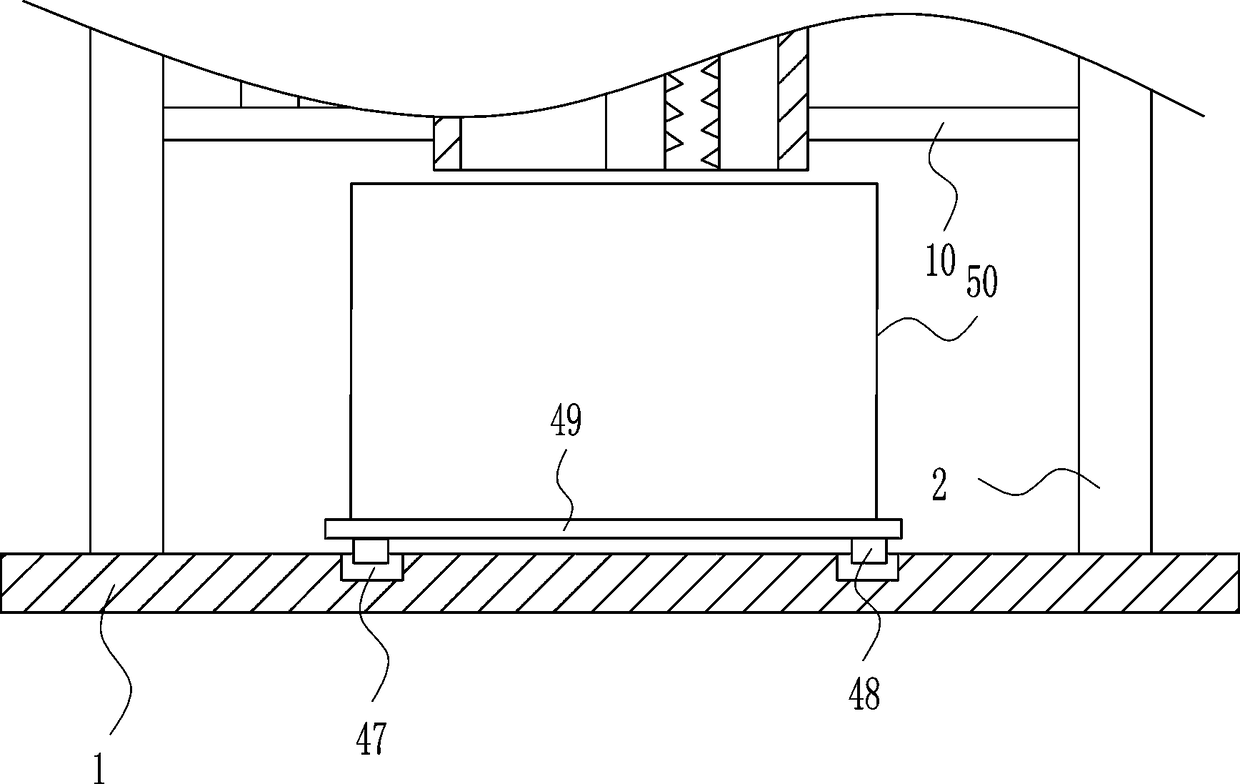

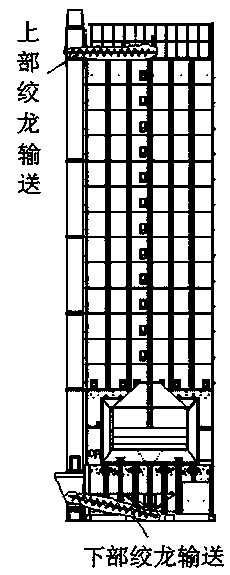

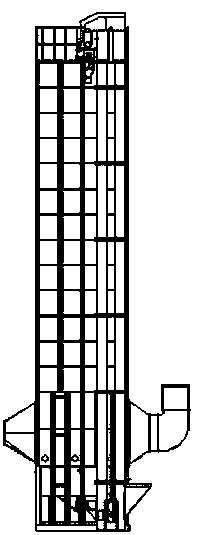

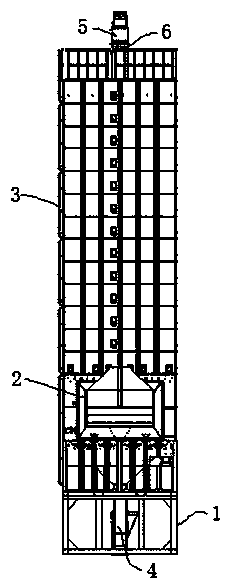

Vertical dryer free of packing auger

InactiveCN110631335AThere is no failure problemReduce breakage rateDrying gas arrangementsSeed preservation by dryingGrain storageEngineering

The invention relates to the technical field of food processing equipment, in particular to a vertical dryer free of a packing auger. The vertical dryer free of the packing auger is used for solving the technical problems that in the prior art, when the packing auger is utilized for conveying grain, during repeated circulating processing, grain crushing, packing auger abrasion and low grain processing efficiency are likely to be caused. The vertical dryer free of the packing auger comprises an elevator, a drying bin and a grain storage bin. The drying bin is located below the grain storage bin, and a drying mechanism is arranged in the drying bin. Grain stored in the grain storage bin is evenly dried by the drying mechanism and then directly guided into the elevator through an obliquely arranged down pipe, the grain is conveyed to the top of the drier from the elevator from bottom to top, then the grain is conveyed into the grain storage bin through an up-flow pipe to be stored, and the circulating processing action of whole grain production is completed. The vertical dryer free of the packing auger is ingenious in design and layout and easy to operate, the grain crushing rate is greatly reduced, cost is slow, and the drying effect is remarkable; and the grain production efficiency and quality are effectively improved, and the vertical dryer free of the packing auger is worthyof popularization.

Owner:ANHUI ZHENGYANG MACHINERY TECH

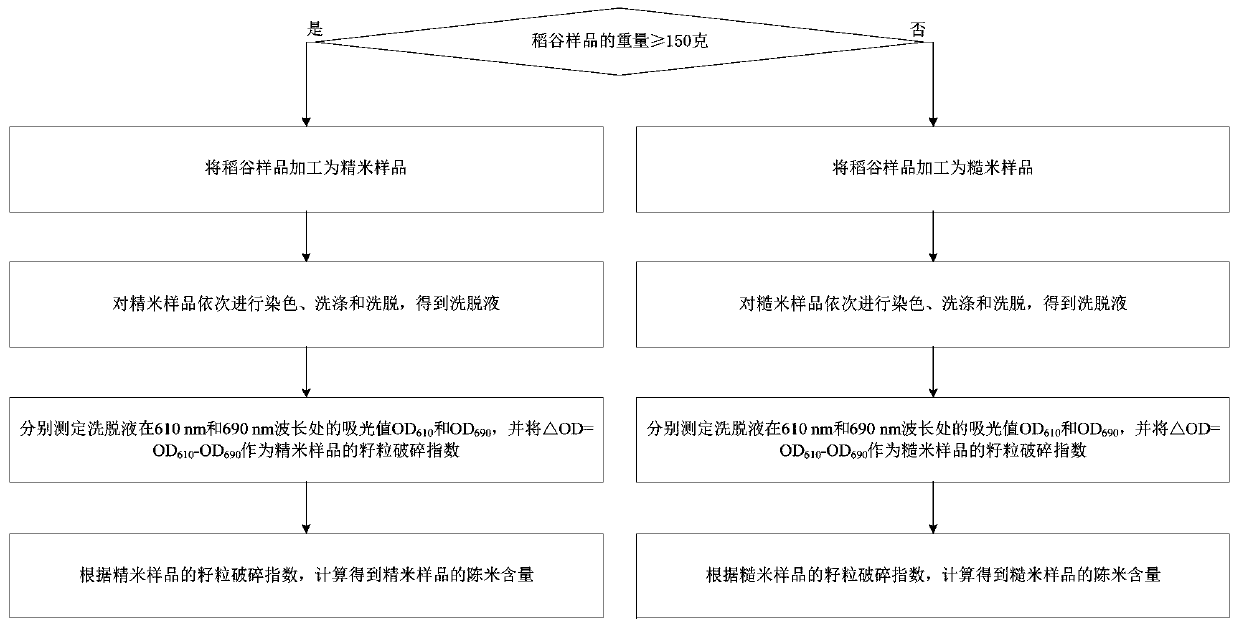

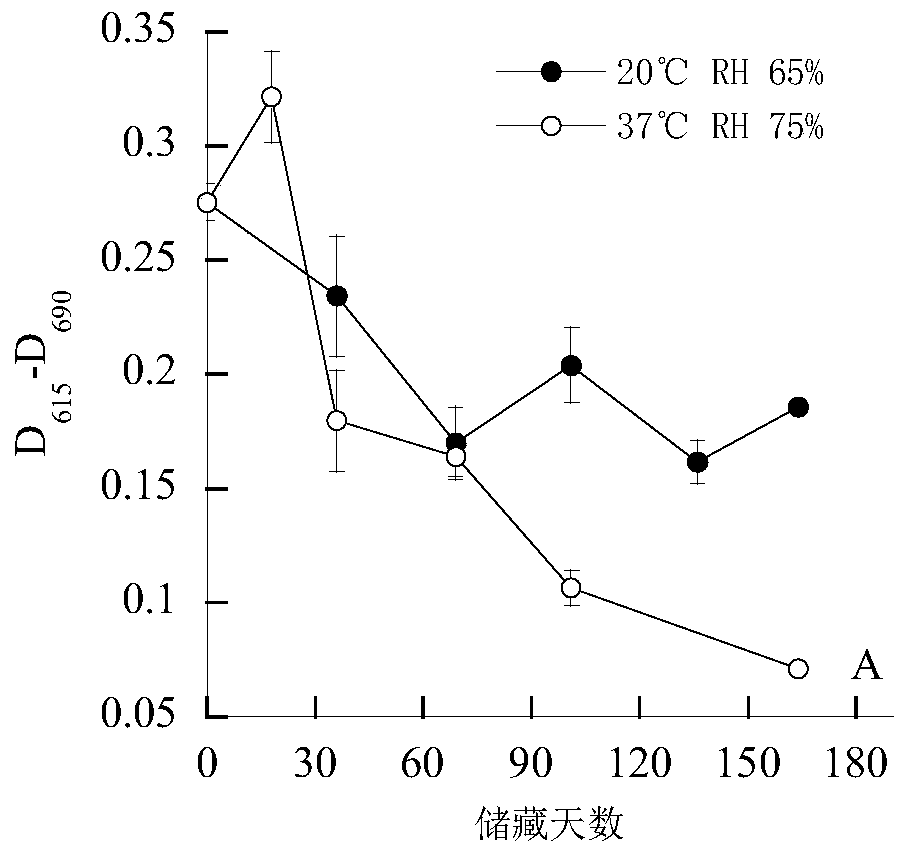

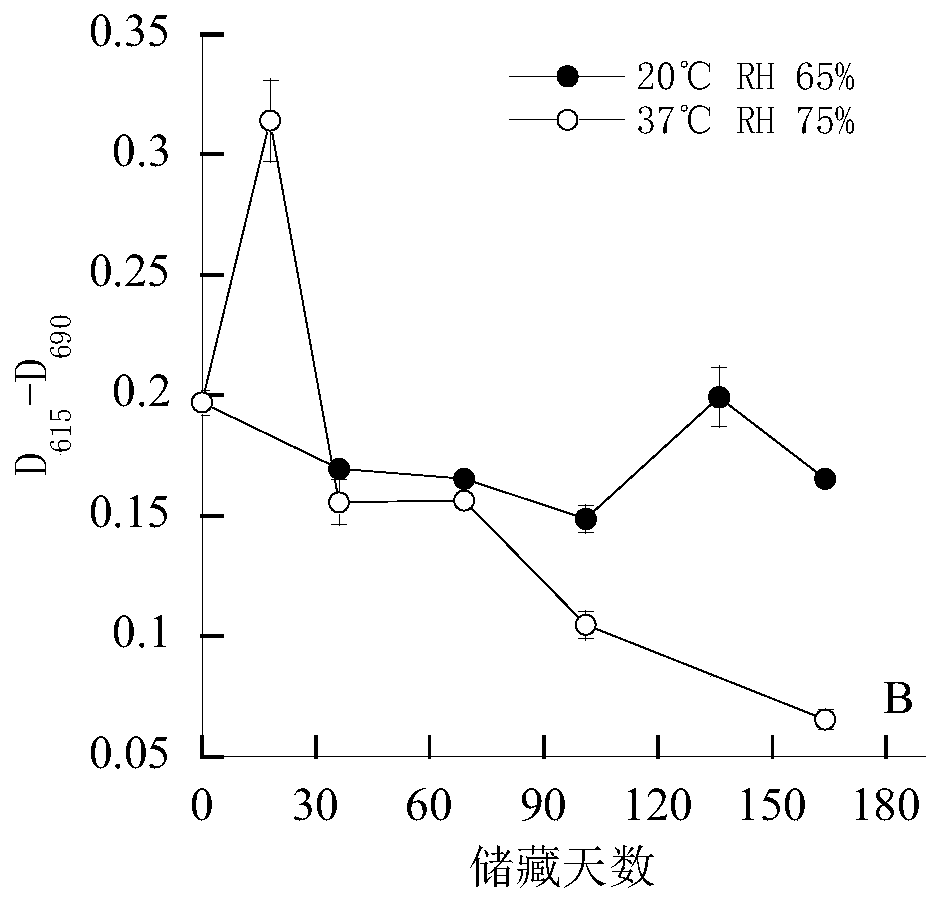

Method for detecting freshness of unhusked rice

ActiveCN109991115AAccurate detection of freshnessThe test result is accurateColor/spectral properties measurementsMaterial weighingLength waveRice grain

The invention discloses a method for detecting freshness of unhusked rice. According to the specific implementation mode, the method for detecting the freshness of the unhusked rice comprises the steps that dyeing, washing and eluting are carried out in sequence on polished rice samples or brown rice samples processed by the paddy to obtain an eluent; light absorption values OD610 and OD690 of theeluent at wavelength positions of 610 nm and 690 nm are separately measured, and deltaOD=OD610-OD690 is used as a grain crushed index of the polished rice samples or the brown rice samples; and the aging rice content of the polished rice samples or the brown rice samples is obtained according to the grain crushed index of the polished rice samples or the brown rice samples. The implementation mode can accurately detect the freshness of the unhusked rice and rice.

Owner:ACAD OF NAT FOOD & STRATEGIC RESERVES ADMINISTRATION +1

Grain crushing and screening device

InactiveCN101837310AIncreased chance of collisionImprove crushing effectSievingScreeningEngineeringGrain crushing

The invention relates to a grain crushing and screening device which comprises a machine frame, wherein the interior of the machine frame is provided with a crushing cavity, a screening cavity, a collecting cavity and a recovering delivery pipe; the crushing cavity, the screening cavity and the collecting cavity are sequentially arranged from top to bottom; and the recovering delivery pipe is respectively connected with the screening cavity and the crushing cavity. The grain crushing and screening device integrates the crushing and screening, greatly saves the occupation space and has simple structure. The grain crushing and screening device is provided with the recovering delivery pipe, can send back grain particles with particles being not in line with the size requirement again, and realizes the multi-stage crushing, good crushing effect and high working efficiency.

Owner:SHANGHAI YI CHEN INFORMATION TECH DEV

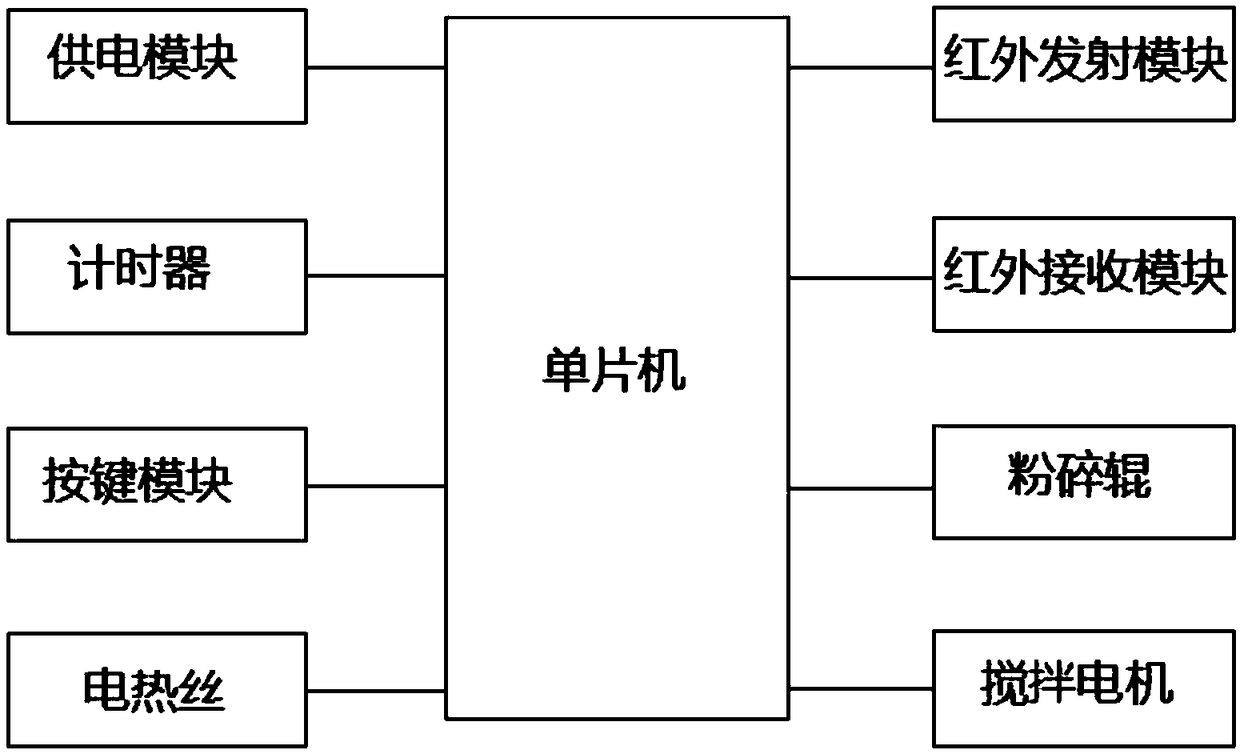

Grain crushing and drying all-in-one machine

InactiveCN109357500AKeep dryEnergy savingDrying solid materialsDrying machines with non-progressive movementsEngineeringEnergy conservation

The invention discloses a grain crushing and drying all-in-one machine. The grain crushing and drying all-in-one machine comprises a box body, a plurality of bases are arranged at the bottom of the box body, a feeding hole used for feeding is formed in the top of the box body, a stirring motor is arranged at the bottom of the box body, a motor shaft of the stirring motor is connected with a stirring shaft, the stirring shaft is located in the box body, two crushing rollers are further arranged inside the box body, the crushing rollers are located above the stirring shaft, an infrared correlation module is arranged above the crushing roller, and an electric heating tube is arranged in the stirring shaft. According to the grain crushing and drying all-in-one machine, traditional drying equipment and crushing equipment are integrated into a whole, the grain can be crushed and dried at the same time, the grain can be continuously heated and stirred in the drying process, so that the effectof drying is improved, meanwhile, the grain crushing and drying all-in-one machine has the advantages of energy conservation and shock absorption.

Owner:巩同庆

Grain grinding device

InactiveCN105498899AStable UniformityEasy to clean and maintainGrain treatmentsGrain storageEngineering

The invention discloses a grain grinding device. The grain grinding device comprises a workbench and a groove formed in the workbench, wherein a grain storage hopper is arranged above the groove; wheel carrier groups are arranged at the left and right sides of the workbench respectively; grinding units are arranged on the two wheel carrier groups and are connected with the groove in the workbench in a lapping manner; driving units driving the grinding units to move are arranged at the front and rear sides of the workbench; the grinding units are jointly formed by driving grinding mechanisms and driven grinding mechanisms, which are arranged on the wheel carrier groups; a controller is arranged on the workbench and is electrically connected with the driving units. The grain grinding device has the beneficial effects of simple structure and strong practicability.

Owner:王晓晓

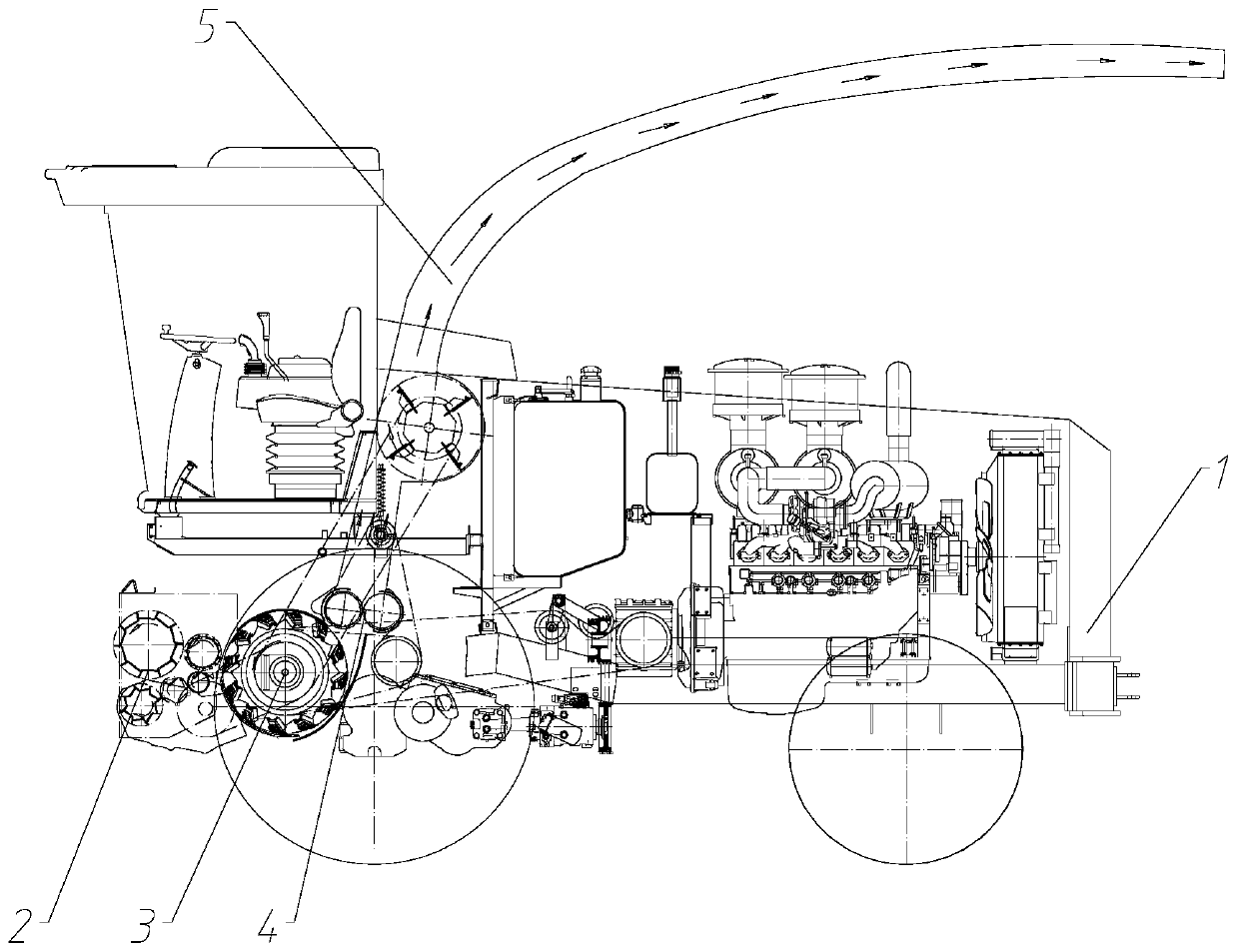

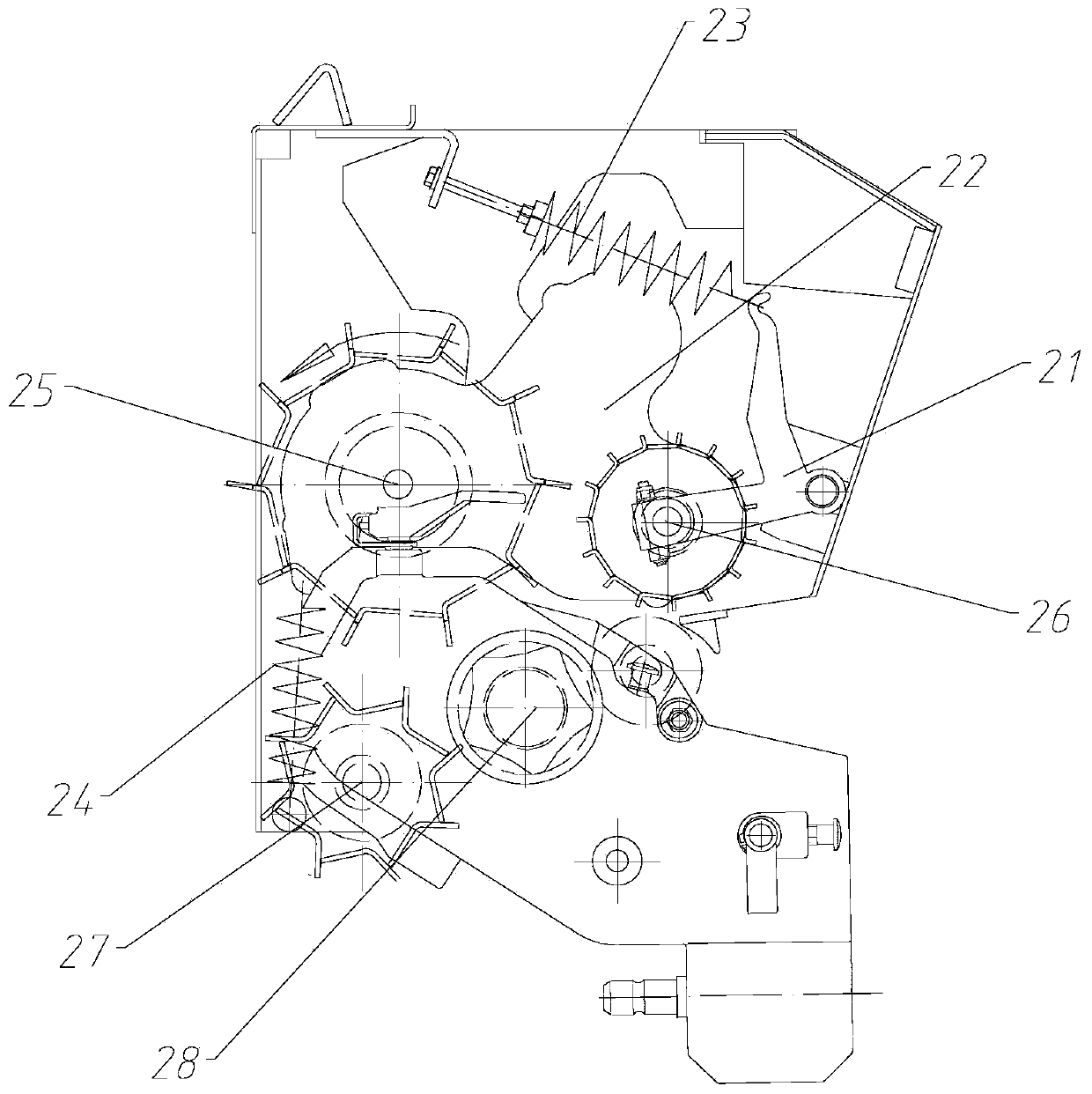

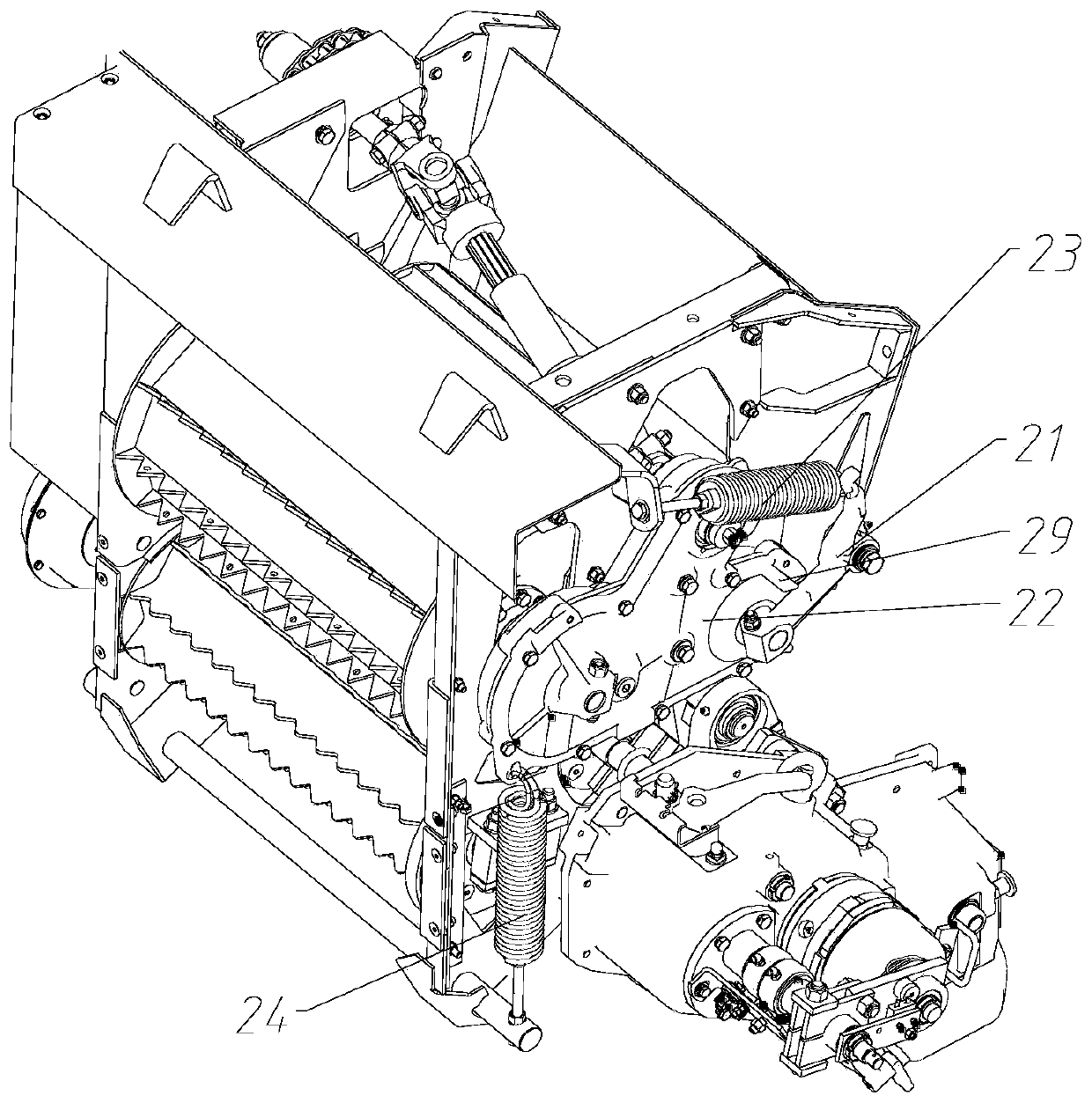

Flexible-stripping and pressure-friction type soybean breeding thresher

The invention relates to a flexible-stripping and pressure-friction type soybean breeding thresher and belongs to agricultural machinery. The thresher is mainly composed of a clamping conveying device, a stripping device, a pressure-friction threshing roller, a rethreshing roller, a transverse conveying device, a flexible spring support, a dust-collecting and impurity-removing fan, a material collecting port, a flow seed tank, a gearbox and a conventional transmission component and the like. The thresher performs segmented compound type separation and threshing operation on soybean plants to avoid the crushing of stalks of the soybean plants, and thus the problems of grain crushing, entrainment loss rise and varietal complexity and the like caused by complex structure of a cleaning deviceresulting from the similarity of the characteristics of soybean materials are solved. The thresher can complete operations of threshing, rethreshing, separation and cleaning and the like of soybean plants in one time. The whole thresher has no blind corner, the threshing of many varieties does not need cleaning, flexible part pressure-friction type bionic threshing is adopted in the whole production process, and the damage to seeds caused by hard blows does not occur. The thresher can meet the requirements of scientific research for precision and efficiency of the soybean breeding threshing process.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Novel green fodder harvester

PendingCN111201904AThe gap is convenient and more accurateIncrease the gapCrop conditionersMowersAgricultural scienceAgricultural engineering

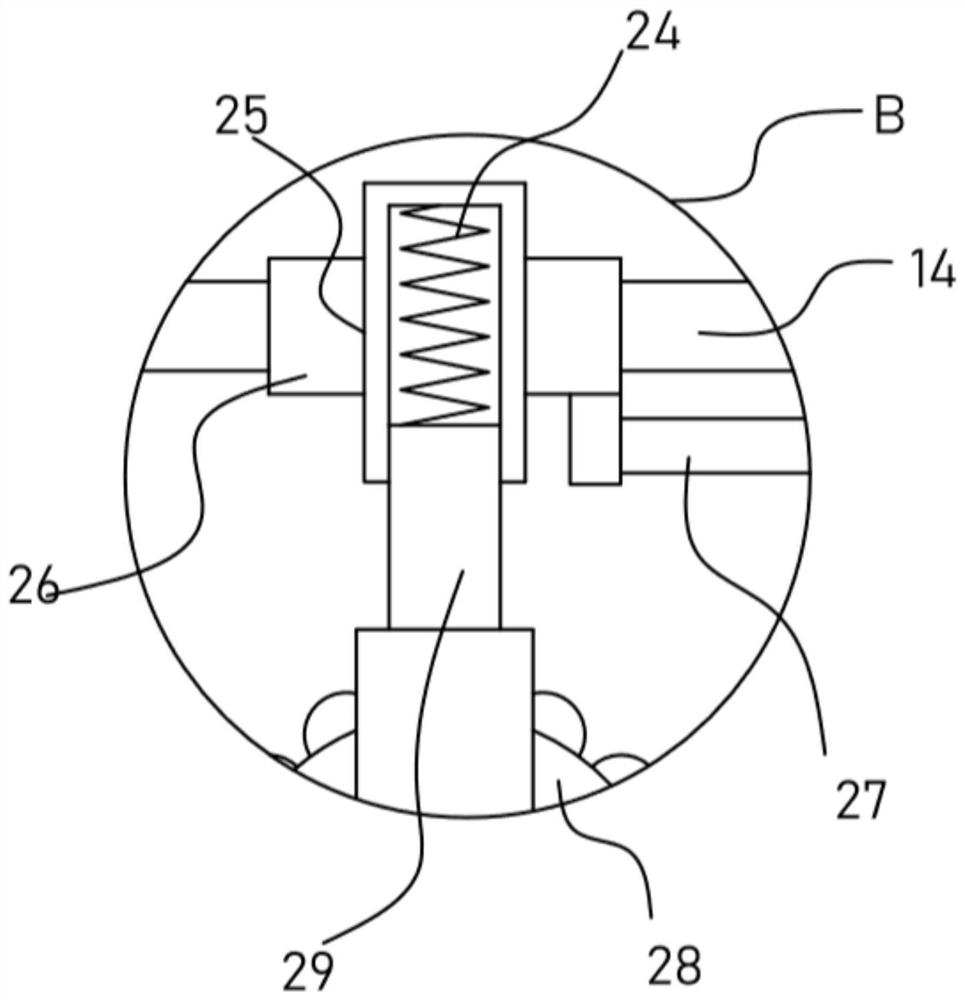

The invention belongs to the technical field of agricultural machinery, and provides a novel green fodder harvester. The novel green fodder harvester comprises a harvester body, a feeding device, a chopping device, a grain crushing device and a throwing device, wherein the grain crushing device comprises a fixing roller, a rotating frame, a floating roller, a regulating wedge block, a gap regulating screw rod and an elastic device; the fixing roller is rotationally arranged on the harvester body; the rotating frame is rotationally arranged on the harvester body; the floating roller is rotationally arranged on the rotating frame, and a gap between the fixing roller and the floating roller form a material passage; the regulating wedge block is glidingly arranged on the harvester body, and the inclined surface of the regulating wedge block is in contact with the side wall of the rotating frame; the gap regulating screw rod is arranged on the machine body, and the end part of the regulating screw rod is connected with the regulating wedge block; and the elastic device is used for providing elastic force for enabling the rotating frame to approach to the fixing roller. By the technicalscheme, the problems of regulation inconvenience and inaccuracy during crushing rate regulation of the green fodder harvester in the prior art are solved.

Owner:SHIJIAZHUANG MEIDI MACHINERY CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com