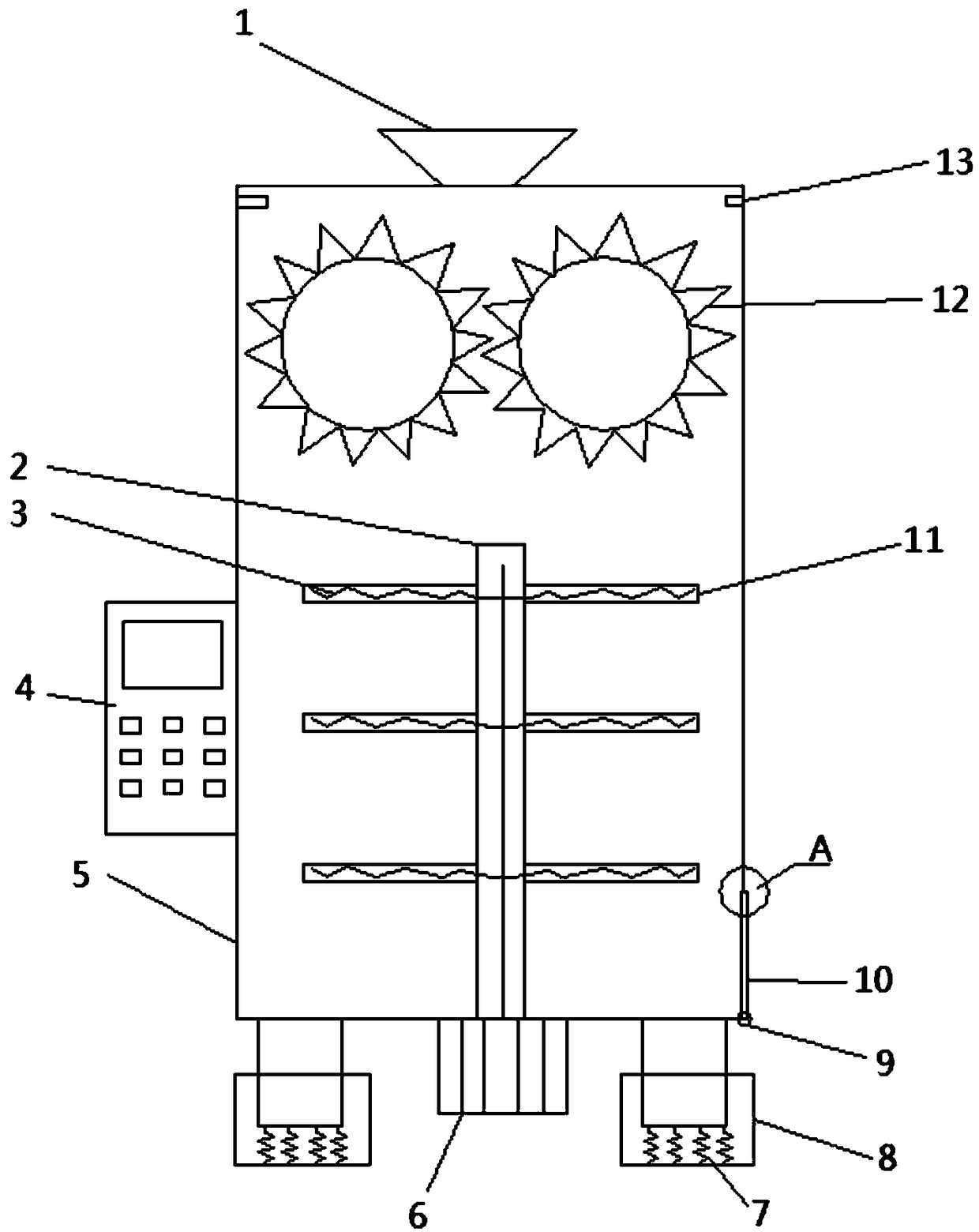

Grain crushing and drying all-in-one machine

An all-in-one machine and drying technology, which is applied in the direction of drying solid materials, non-progressive dryers, dryers, etc., can solve the problems of excessive heat or electric energy, consumption, environmental pollution, etc., and achieve the effect of increasing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

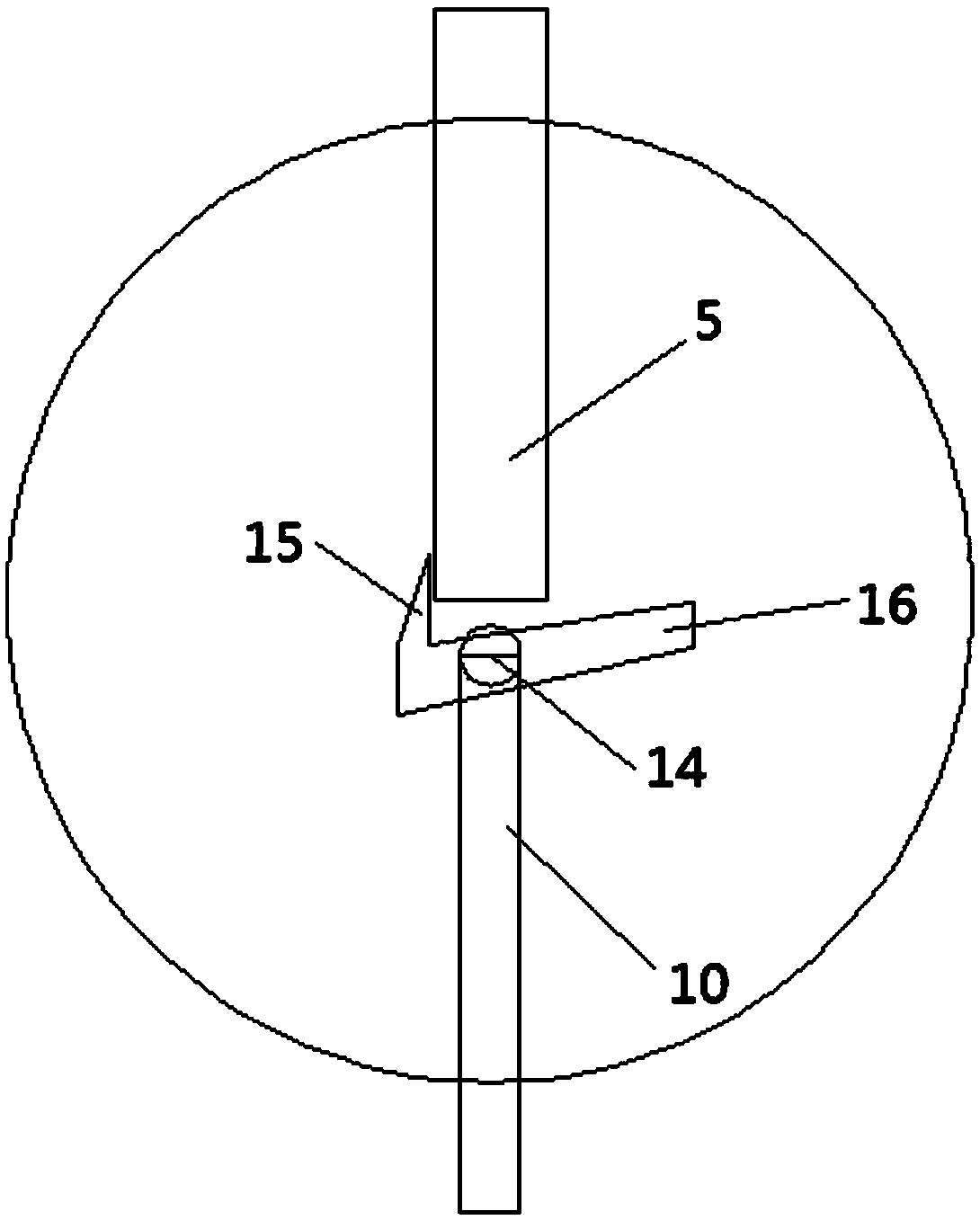

Examples

Embodiment 2

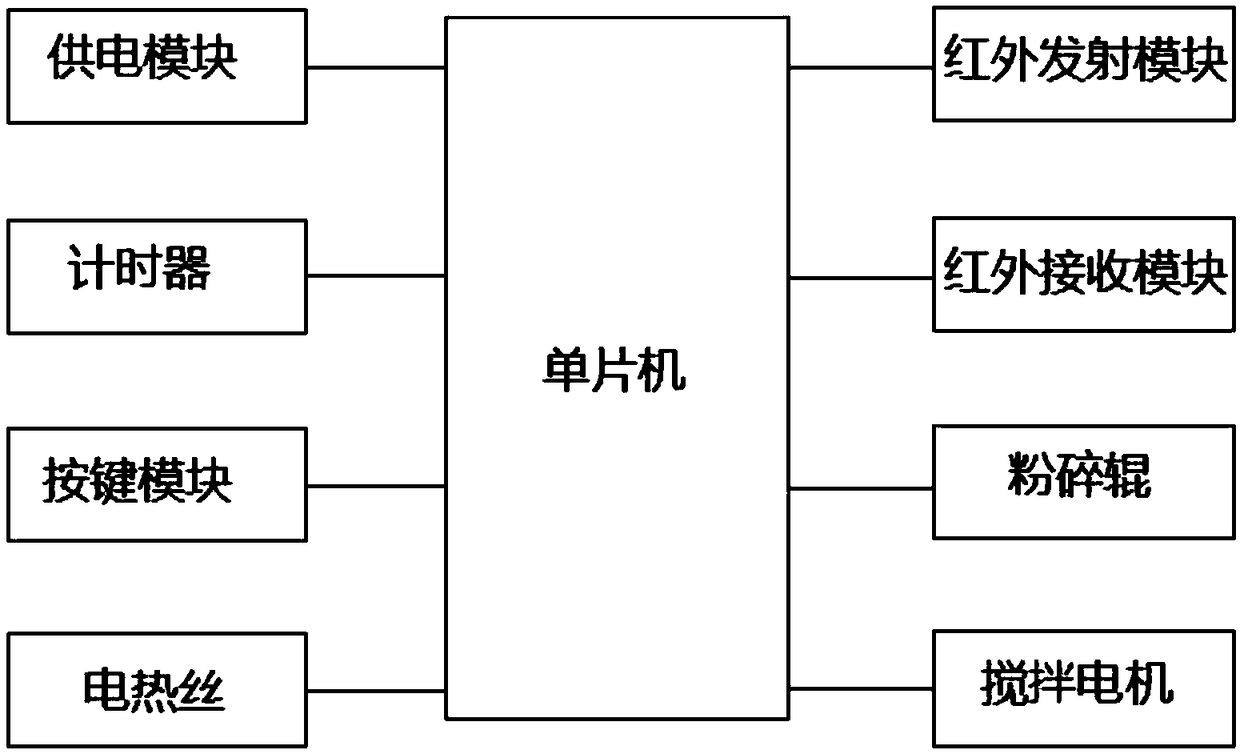

[0022] Embodiment 2: On the basis of Embodiment 1, a controller 4 is installed on the outer wall of the box body 5 of this design. Controller 4 comprises single-chip microcomputer, button module, timer and power supply module, as image 3 As shown, the single chip microcomputer is respectively connected to the timer, power supply module, key module, heating wire, infrared emission module, infrared reception module, crushing roller and stirring motor through the I / O interface. SCM can choose AT89 series, STC89 series, etc. Users can manually control the working time of the crushing roller, stirring motor and heating wire through the button module, and the detection module composed of infrared emission module and infrared receiving module can automatically control the movement of the crushing roller. The principle is as follows: the infrared emitting module and the infrared receiving module form the infrared optical path. When grain enters the feeding port, the infrared optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com