Patents

Literature

7302results about "Drying goods handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

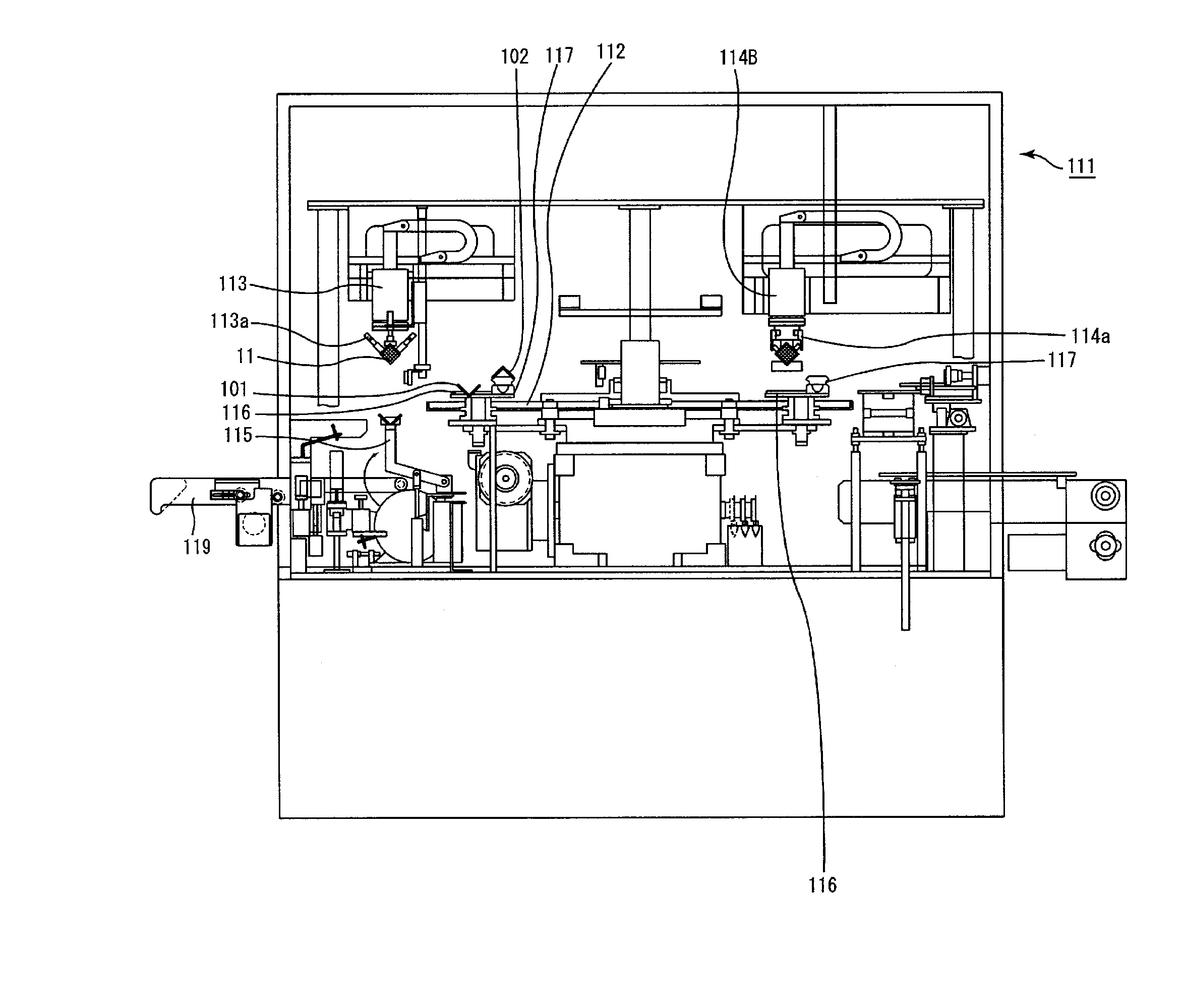

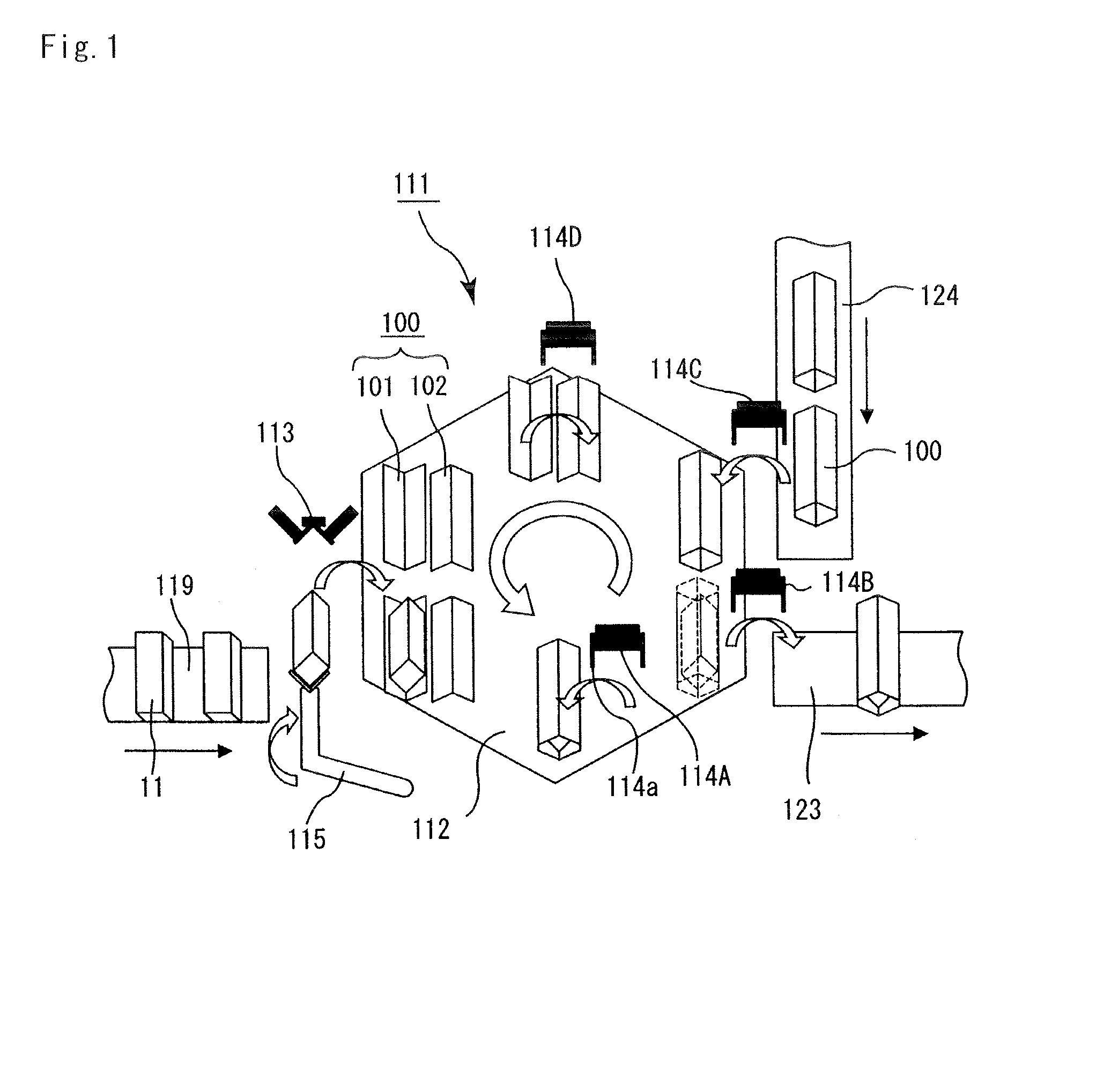

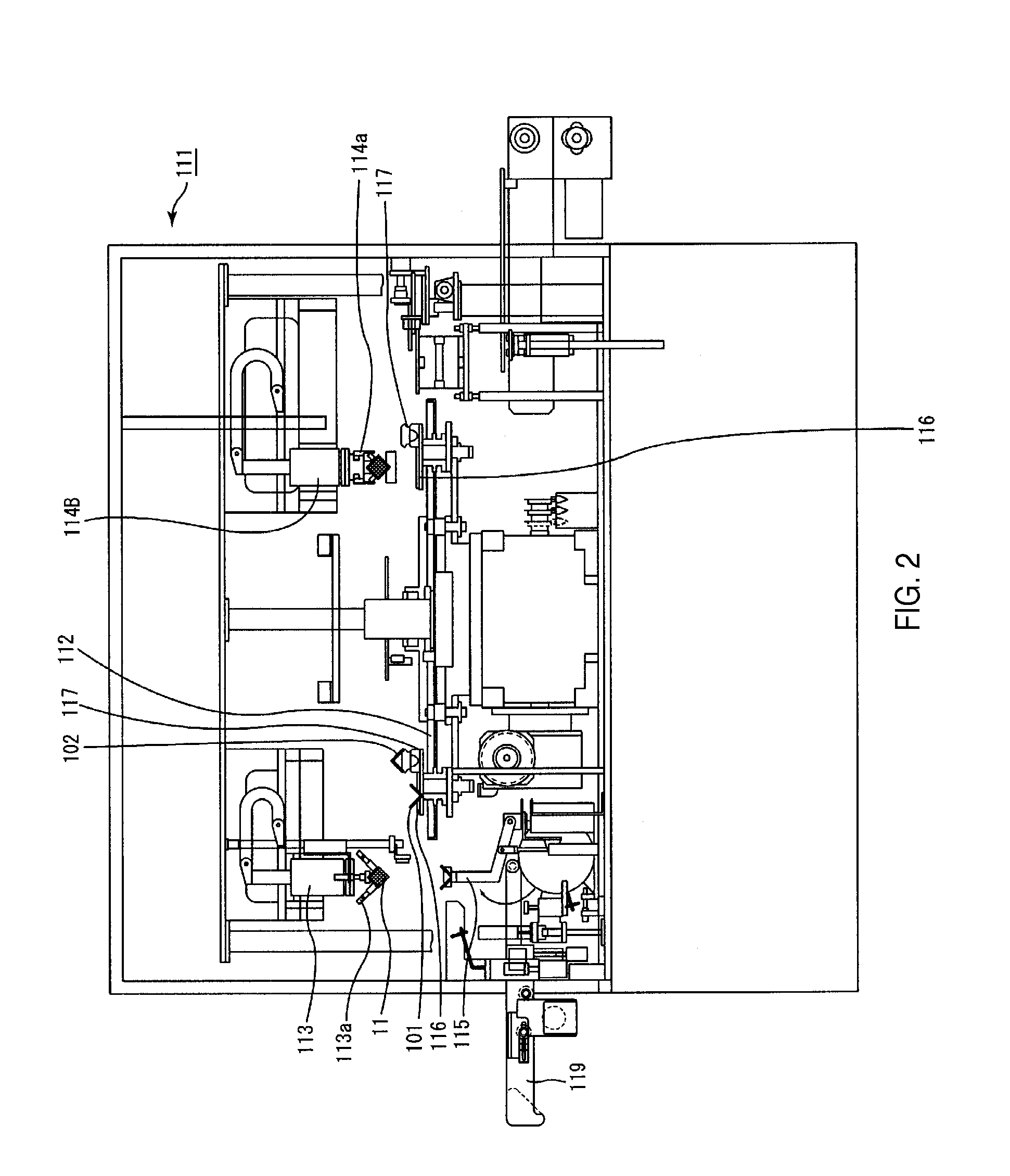

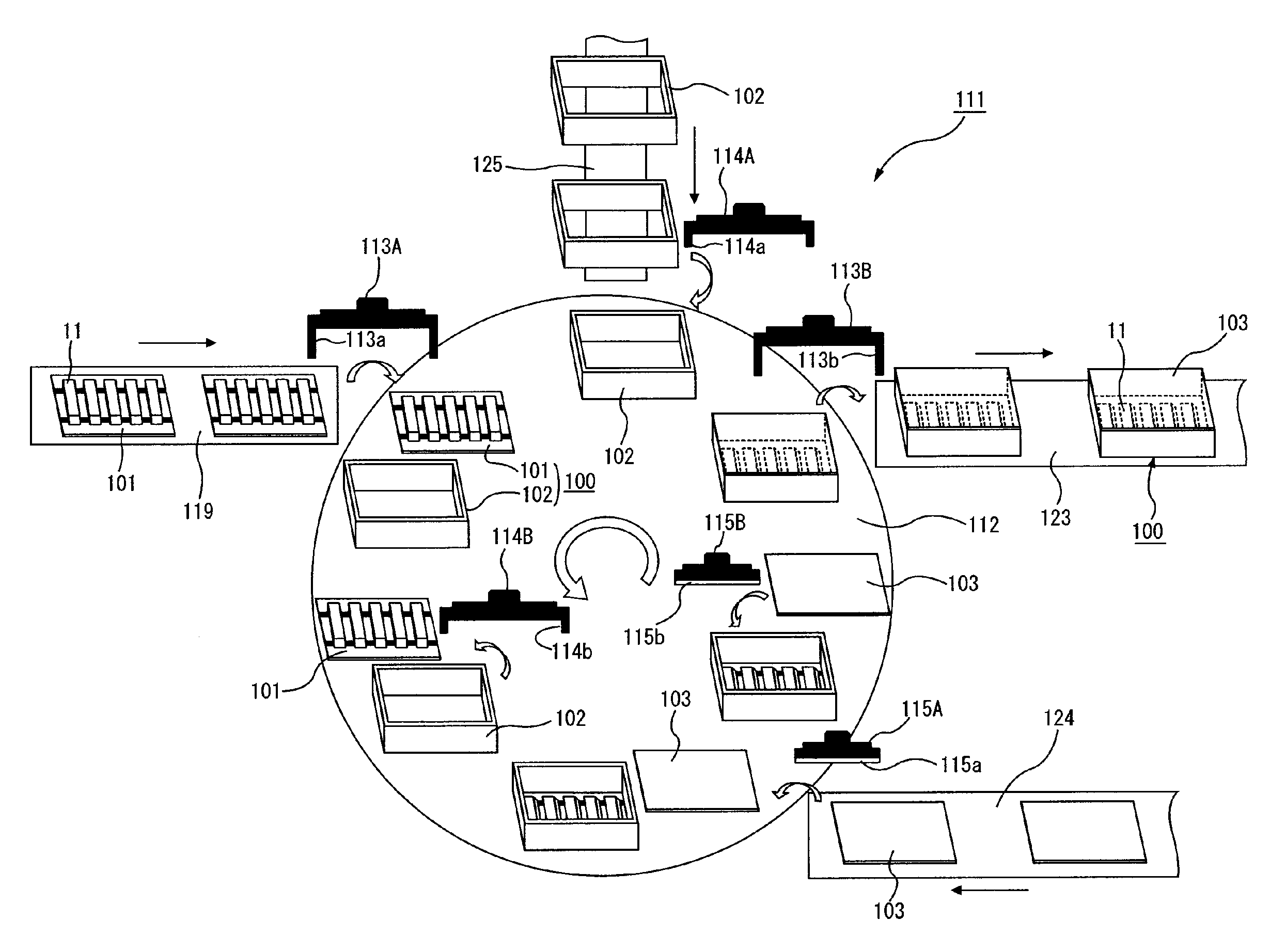

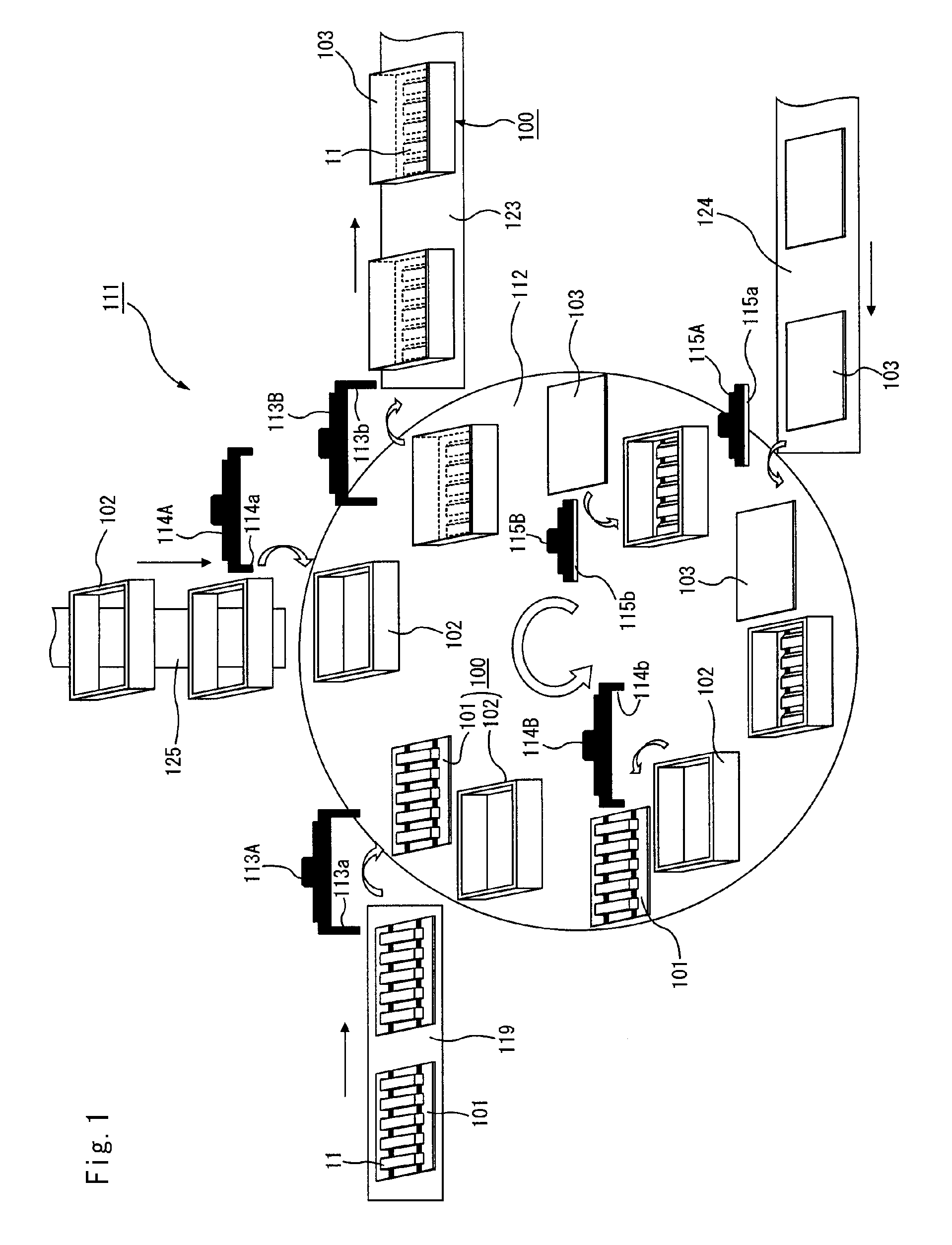

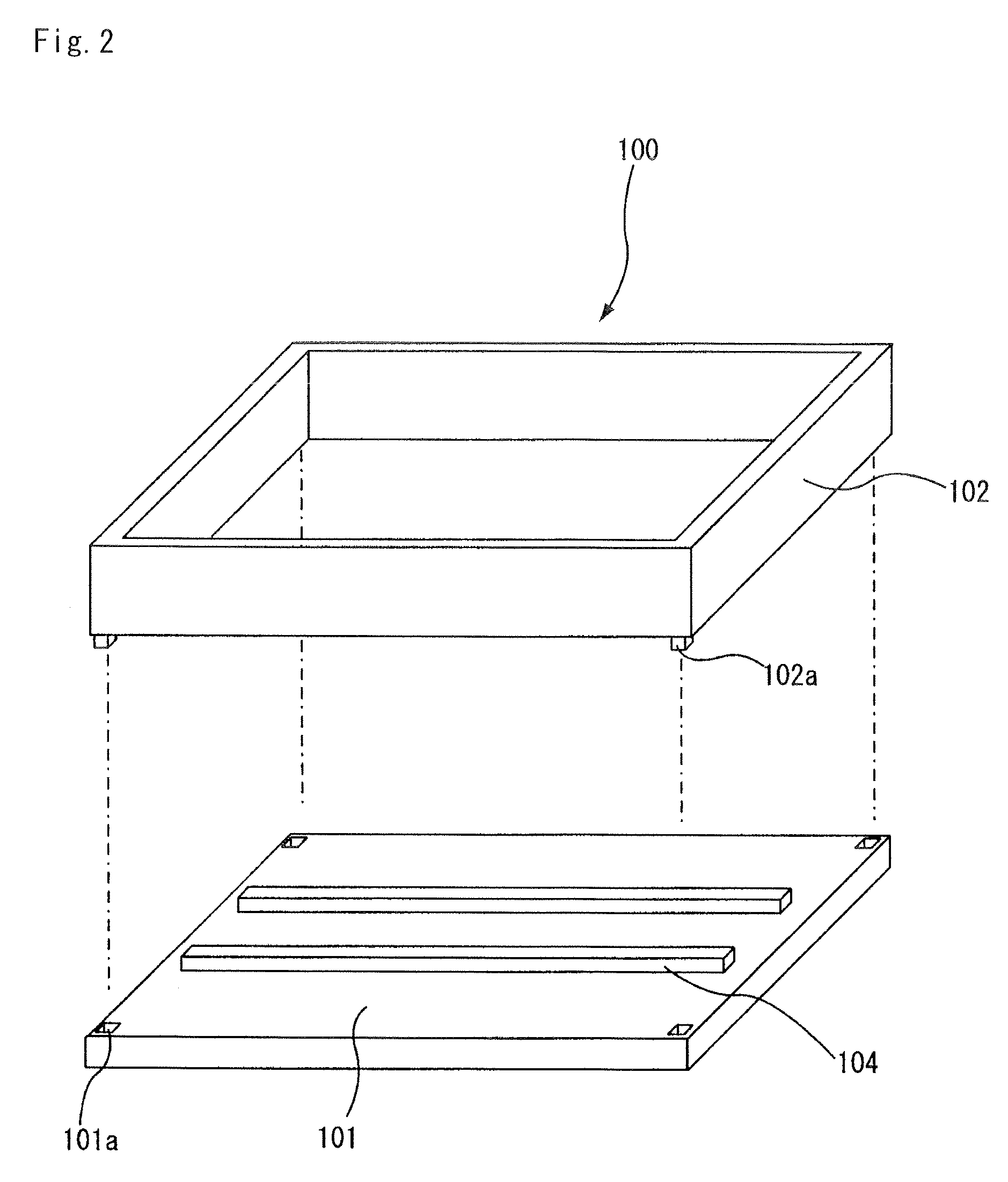

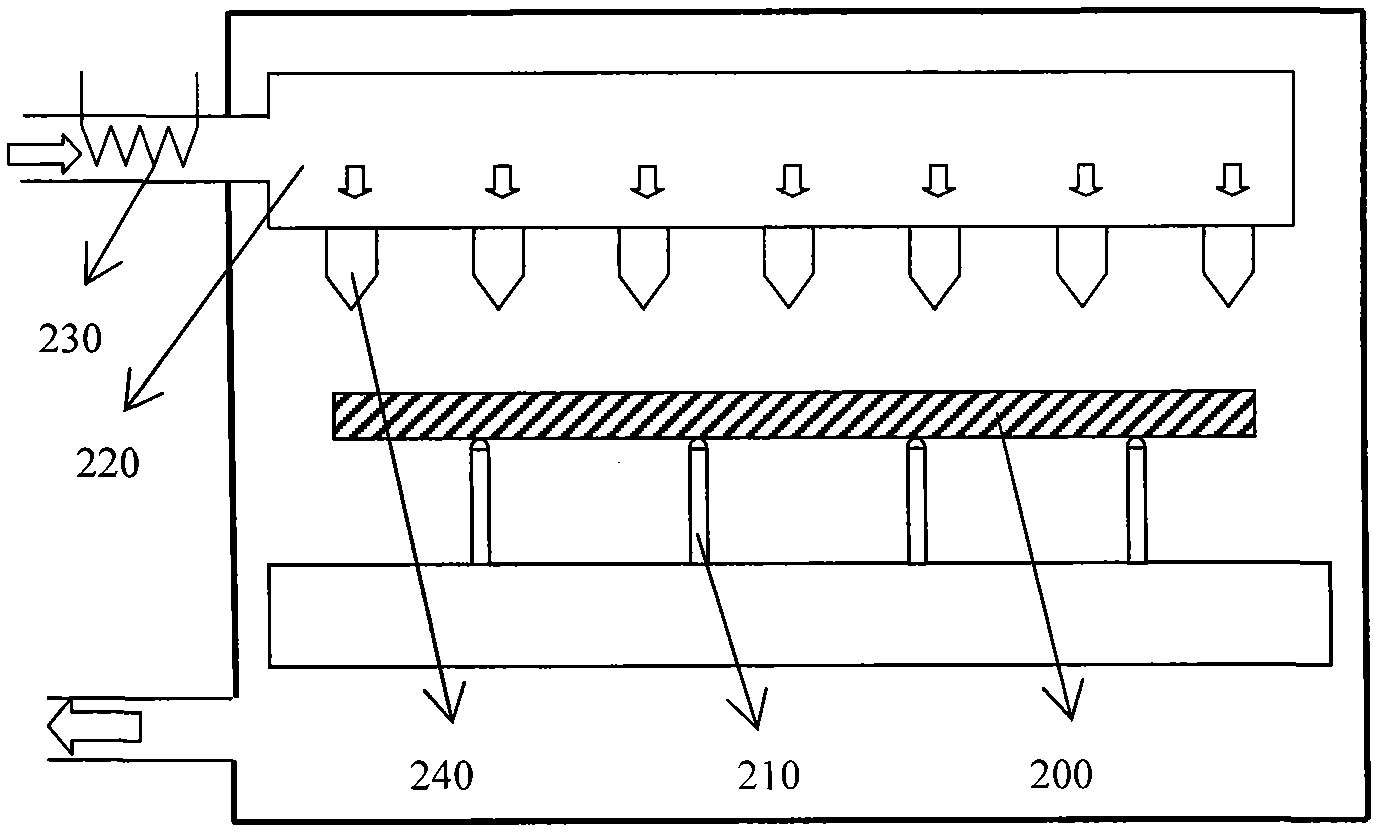

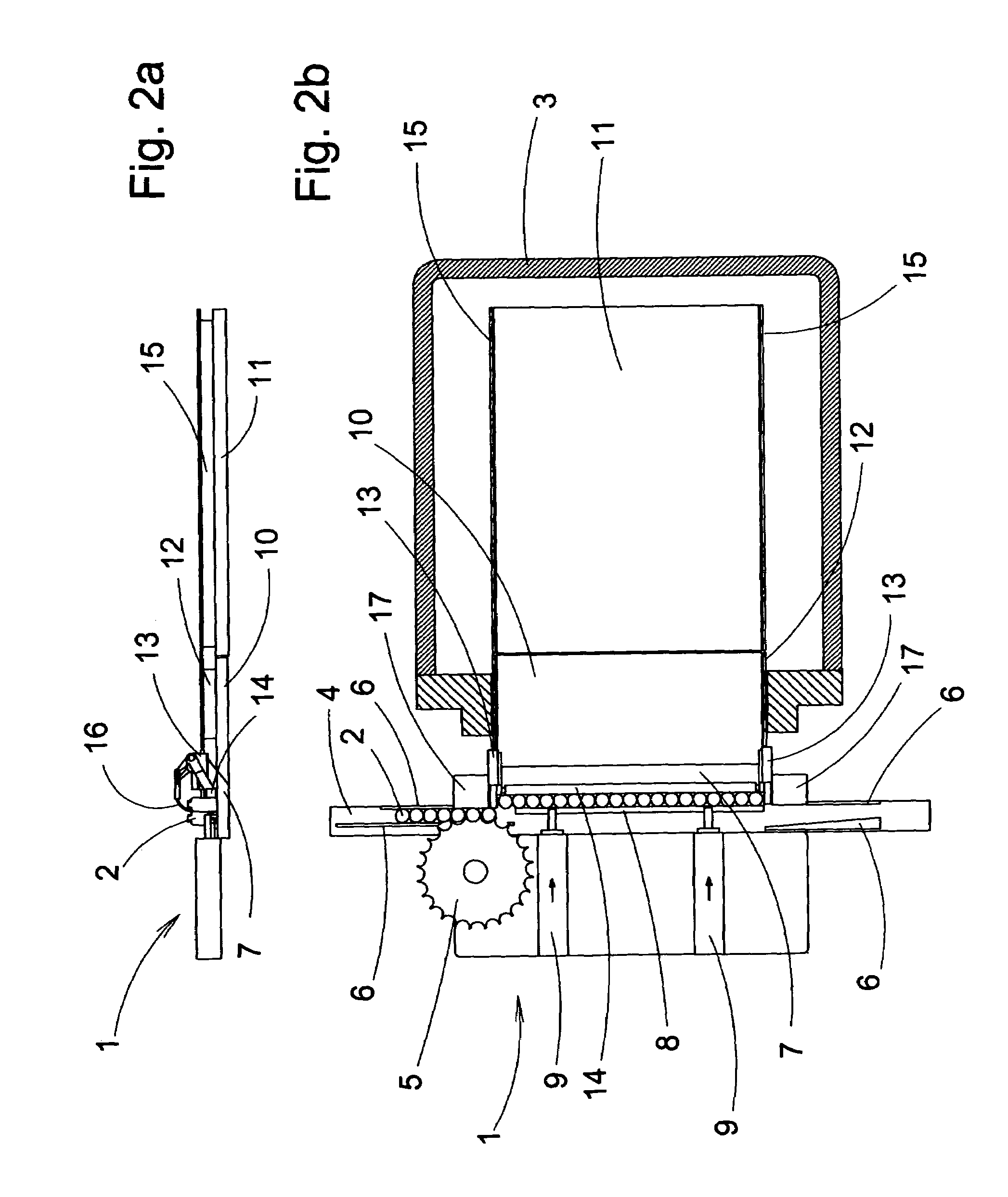

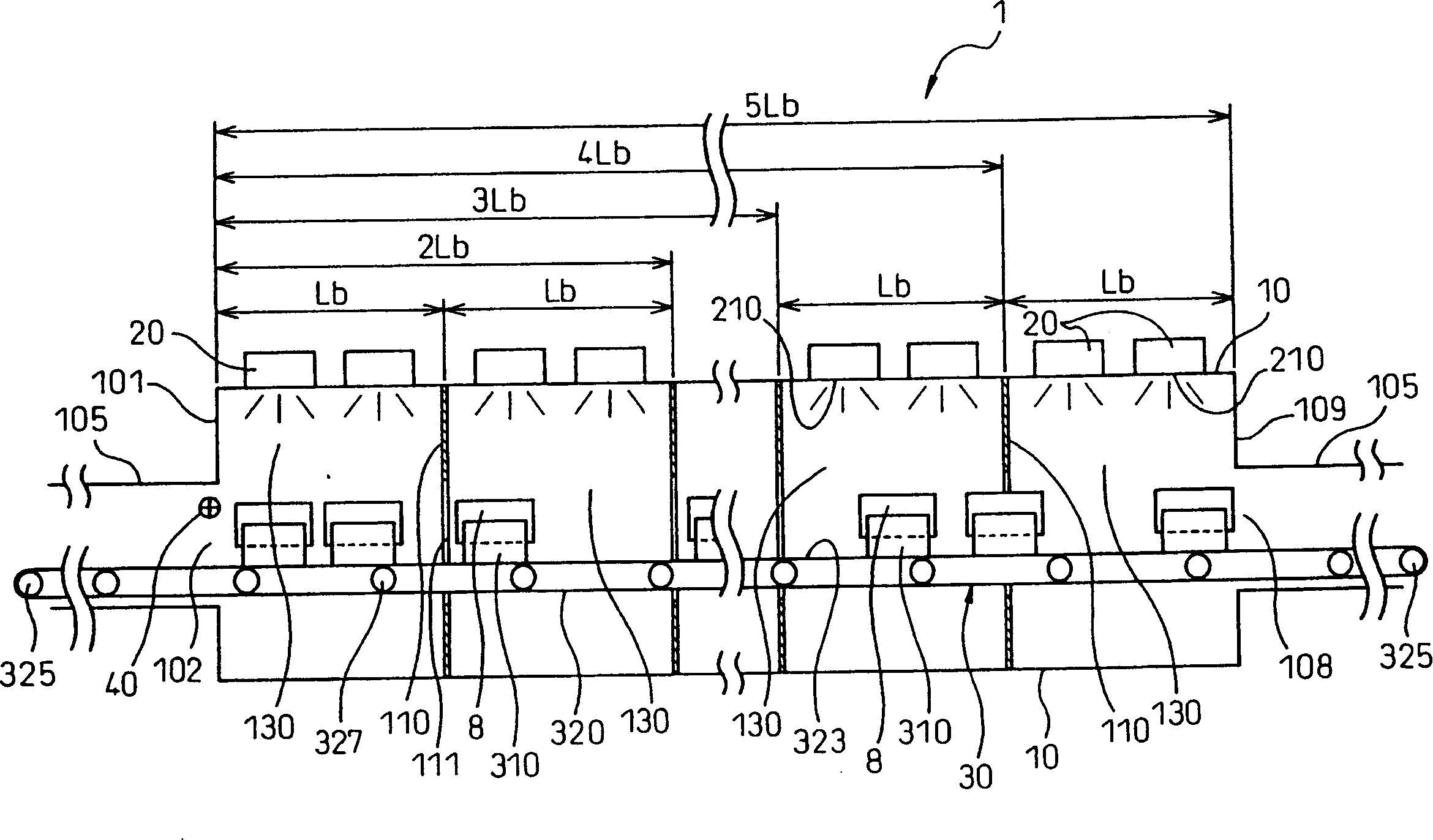

Drying jig assembling apparatus, drying jig disassembling apparatus, drying jig circulating apparatus, drying method of ceramic molded body, and method for manufacturing honeycomb structure

InactiveUS20080106008A1Drying using combination processesAuxillary shaping apparatusHoneycomb structureClosed state

A drying jig circulating apparatus includes a drying jig assembling apparatus for assembling a drying jig on a movable table, a drying apparatus for drying a ceramic molded body held by the drying jig, and a drying jig disassembling apparatus for disassembling the drying jig on a movable table, and a drying jig circulating conveyor for transporting the drying jig from the disassembling apparatus to the assembling apparatus. The drying jig is configured by two or more separate jigs with a fixing member that integrates the separate jigs, or formed by one openable jig with a fixing member for maintaining a closed state. The drying jig assembling apparatus further includes a molded body mounting mechanism, a ceramic molded body holding mechanism, and a jig delivering mechanism. The drying jig disassembling apparatus further includes a jig receiving mechanism, a jig releasing mechanism, and a molded body taking-out mechanism.

Owner:IBIDEN CO LTD

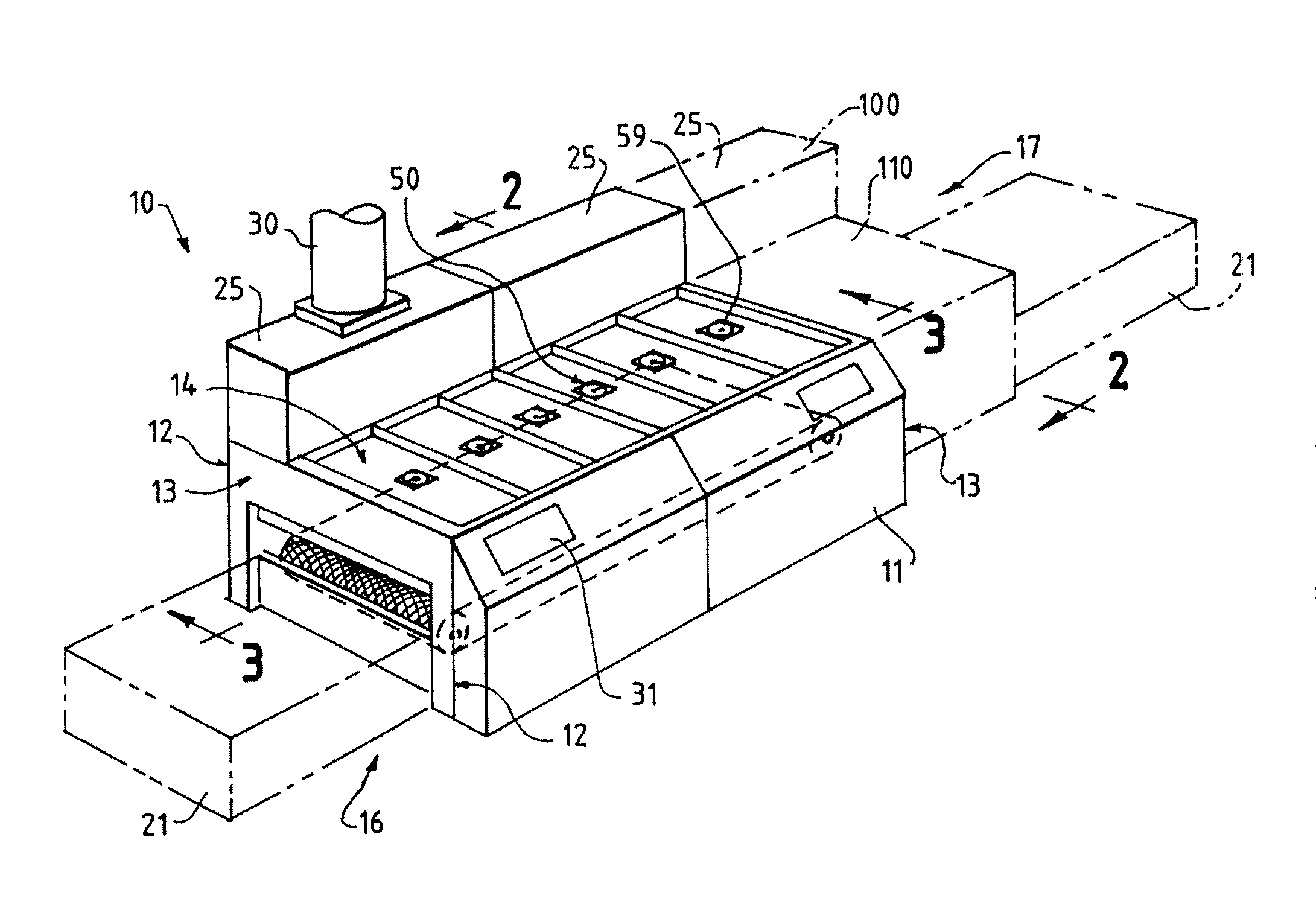

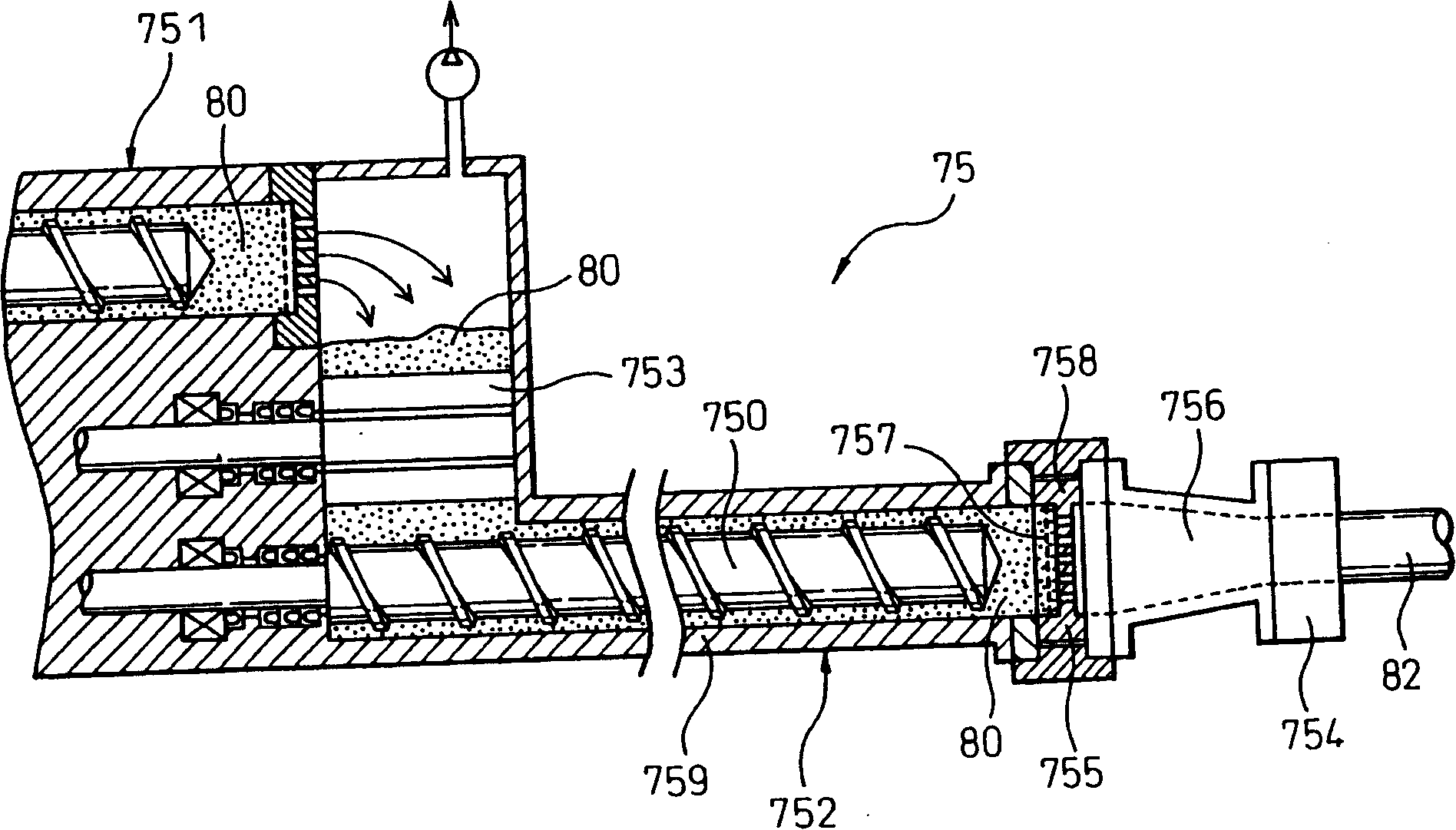

System and method for biomass fractioning

ActiveUS20100180805A1Easy inputIncrease productionDrying solid materials with heatBiofuelsSyngasThin sheet

A biomass fractionator and method are described for inputting ground biomass and outputting several vapor streams of bio-intermediate compounds along with syngas and biochar. In one embodiment, a method for biomass fractioning, comprises dispensing biomass into thin sheets of ground biomass; subjecting the thin sheets to ramps of temperature; and selectively collecting various groups of compounds as they are released from the thin sheets.

Owner:COOL PLANET ENERGY SYST

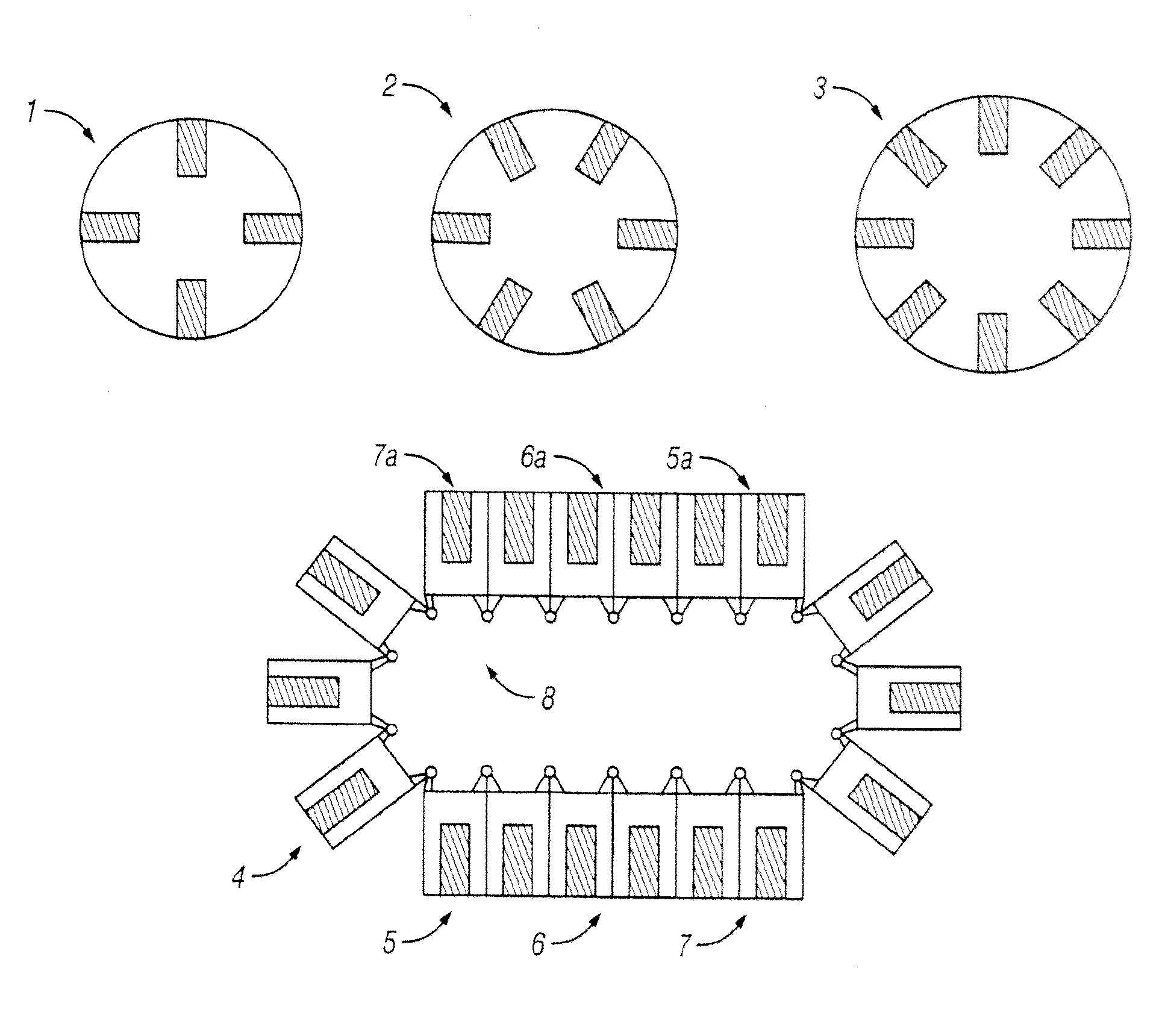

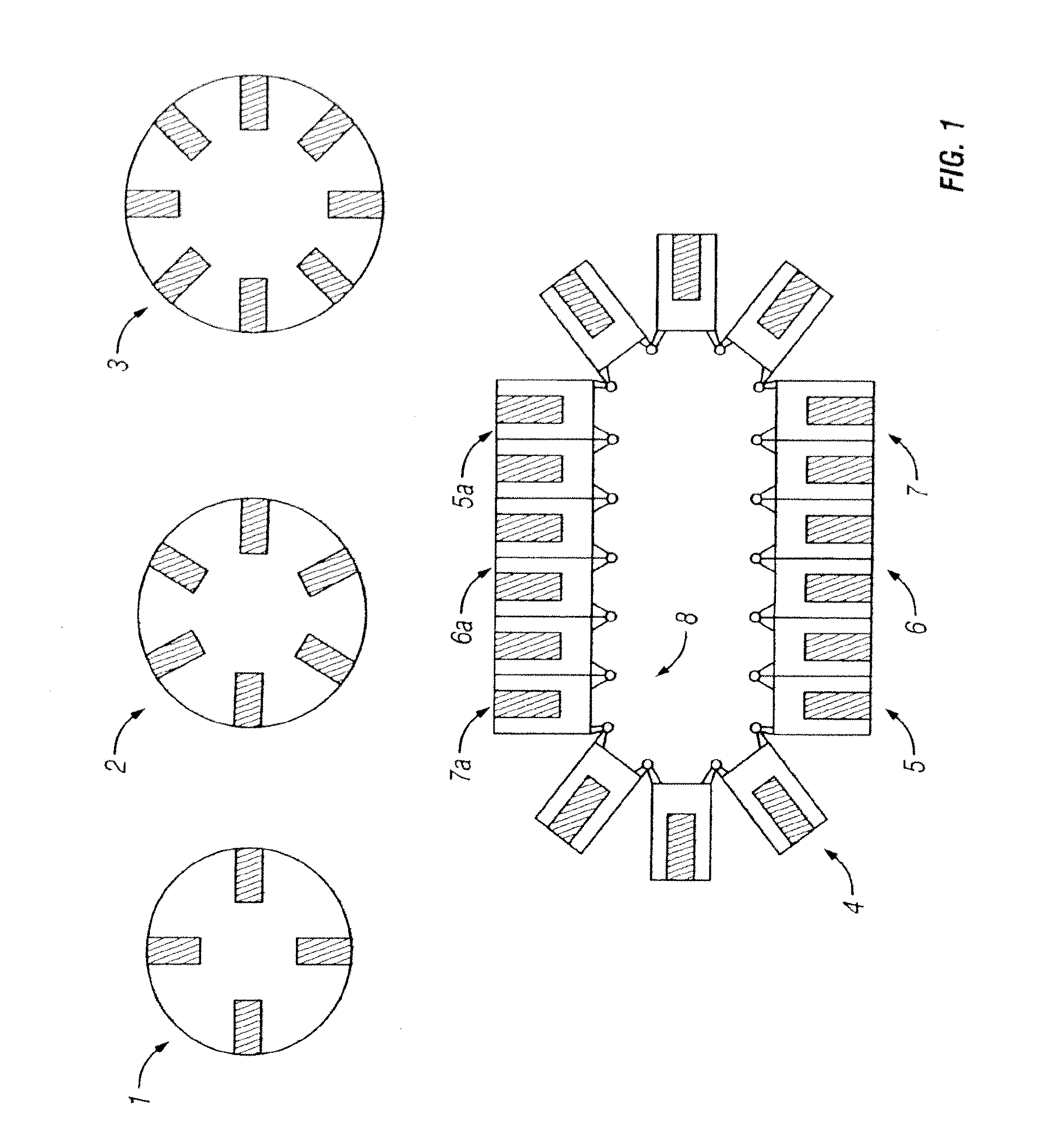

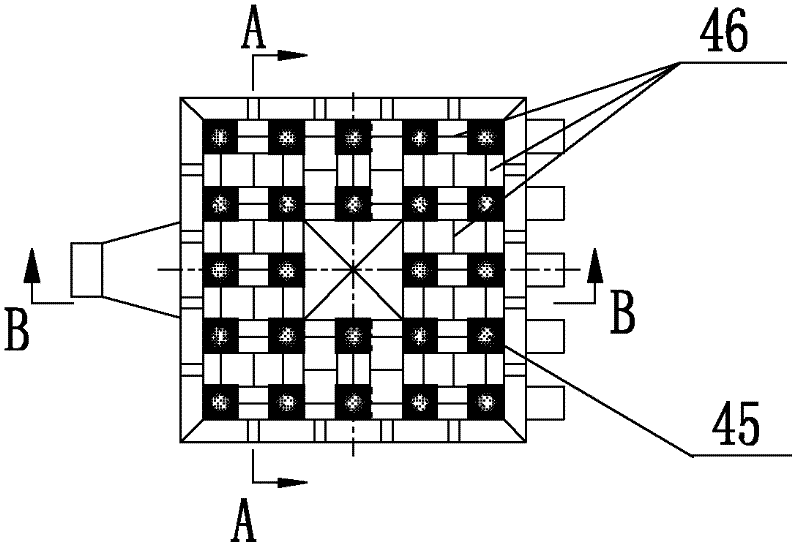

Firing jig assembling apparatus, firing jig disassembling apparatus, circulating apparatus, method for firing ceramic molded body, and method for manufacturing honeycomb structure

A circulating apparatus includes a firing jig assembling apparatus, a firing furnace, a firing jig disassembling apparatus, and a transporting conveyor. The firing jig assembling apparatus includes a lid member attaching mechanism that attaches the lid member to a predetermined position of the firing jig placed on the table or the conveyor; and a jig delivering mechanism that delivers the firing jig which has the ceramic molded body being mounted thereon and the lid member being attached thereto, to the firing furnace. The firing jig disassembling apparatus further includes a jig receiving mechanism that receives the firing jig which has the fired ceramic molded body being mounted thereon and the lid member being attached thereto, from the firing furnace; and a lid member detaching mechanism that detaches the lid member from the firing jig placed on the table or the conveyor with the lid member being attached thereto.

Owner:IBIDEN CO LTD

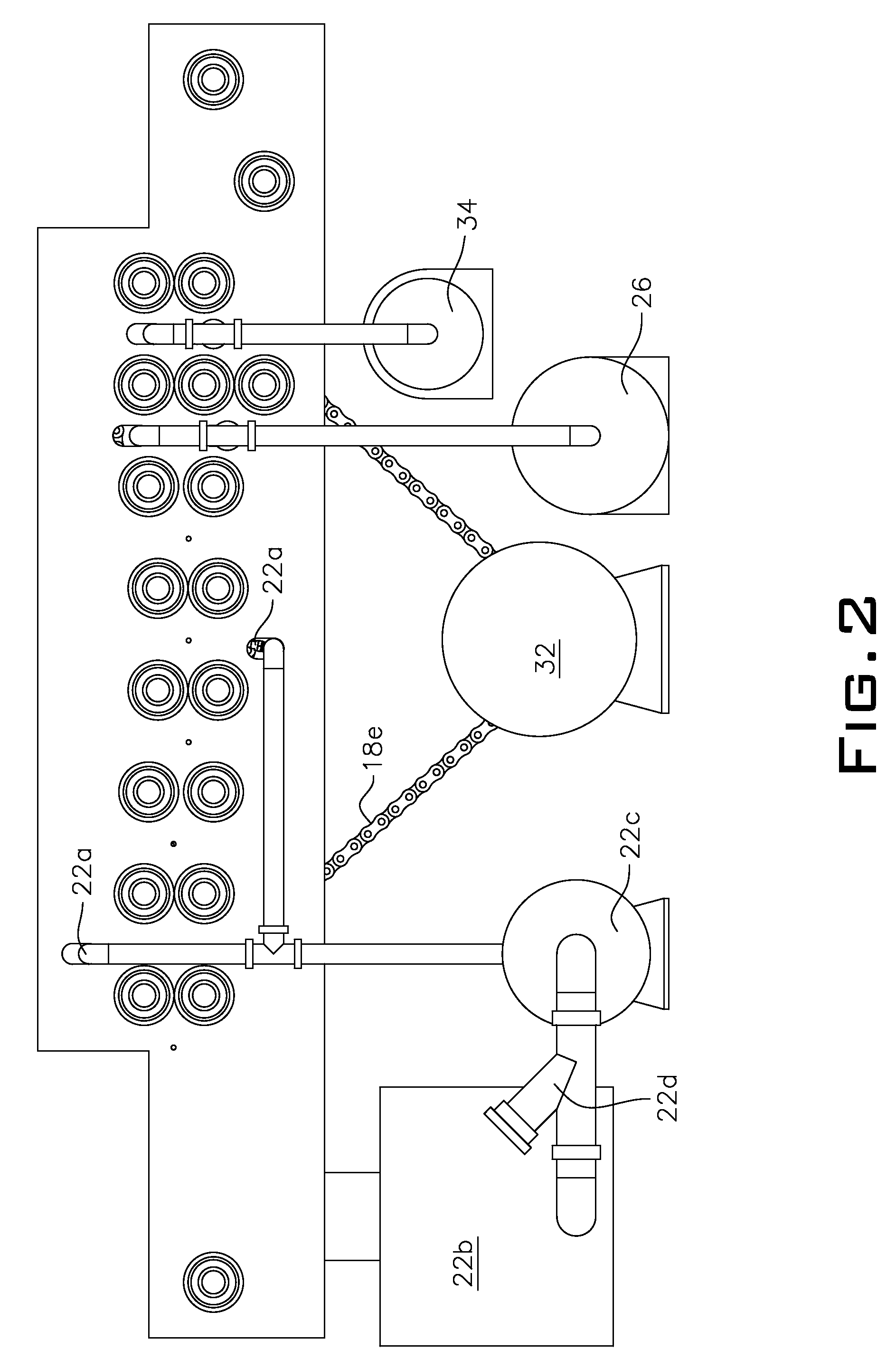

System and method for biomass fractioning

ActiveUS20110177466A1Easy inputIncrease productionDrying solid materials with heatOther heat production devicesSyngasThin sheet

A biomass fractionator and method are described for inputting ground biomass and outputting several vapor streams of bio-intermediate compounds along with syngas and biochar. In one embodiment, a method for biomass fractioning, comprises dispensing biomass into thin sheets of ground biomass; subjecting the thin sheets to ramps of temperature; and selectively collecting various groups of compounds as they are released from the thin sheets.

Owner:COOL PLANET ENERGY SYST

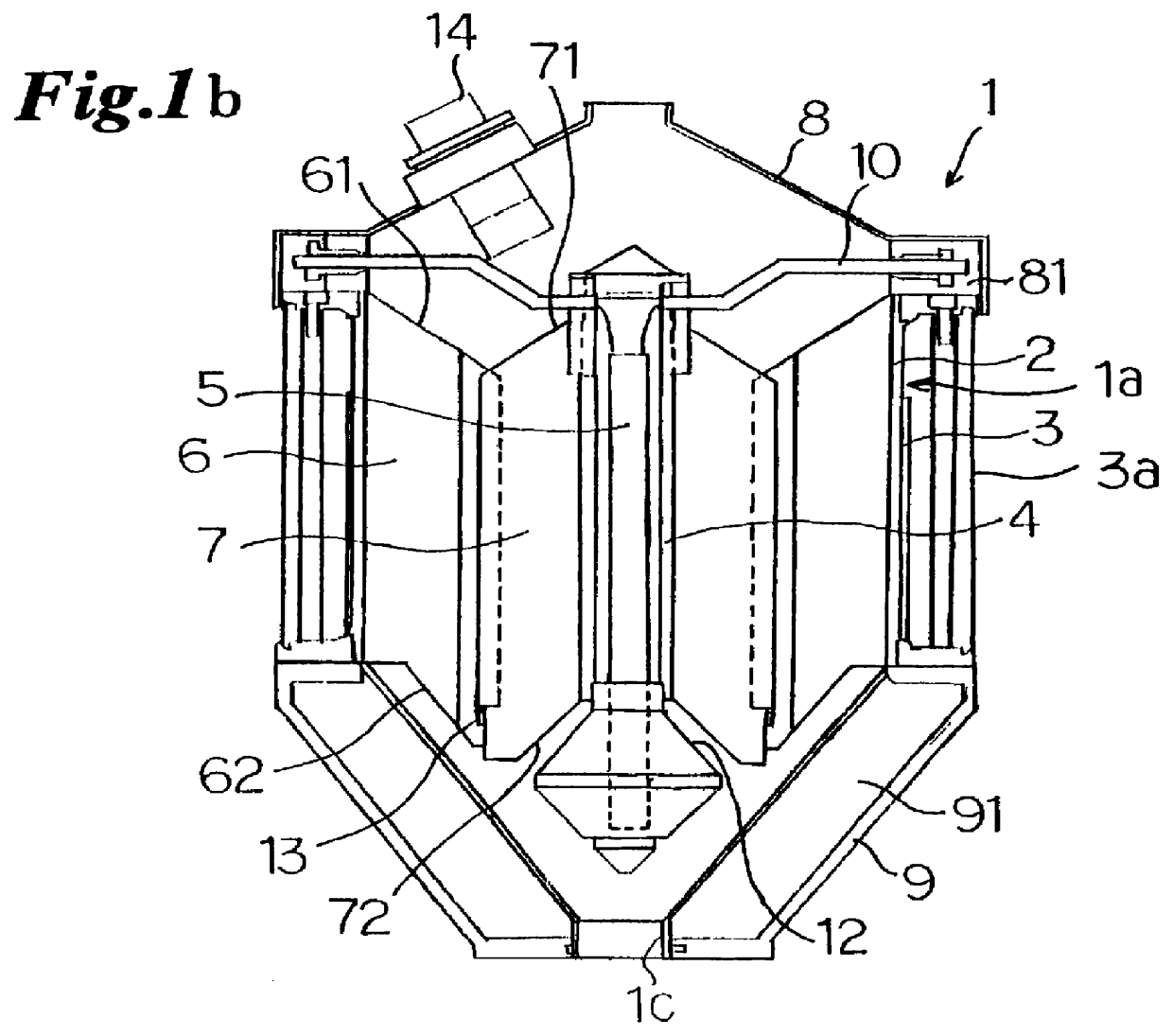

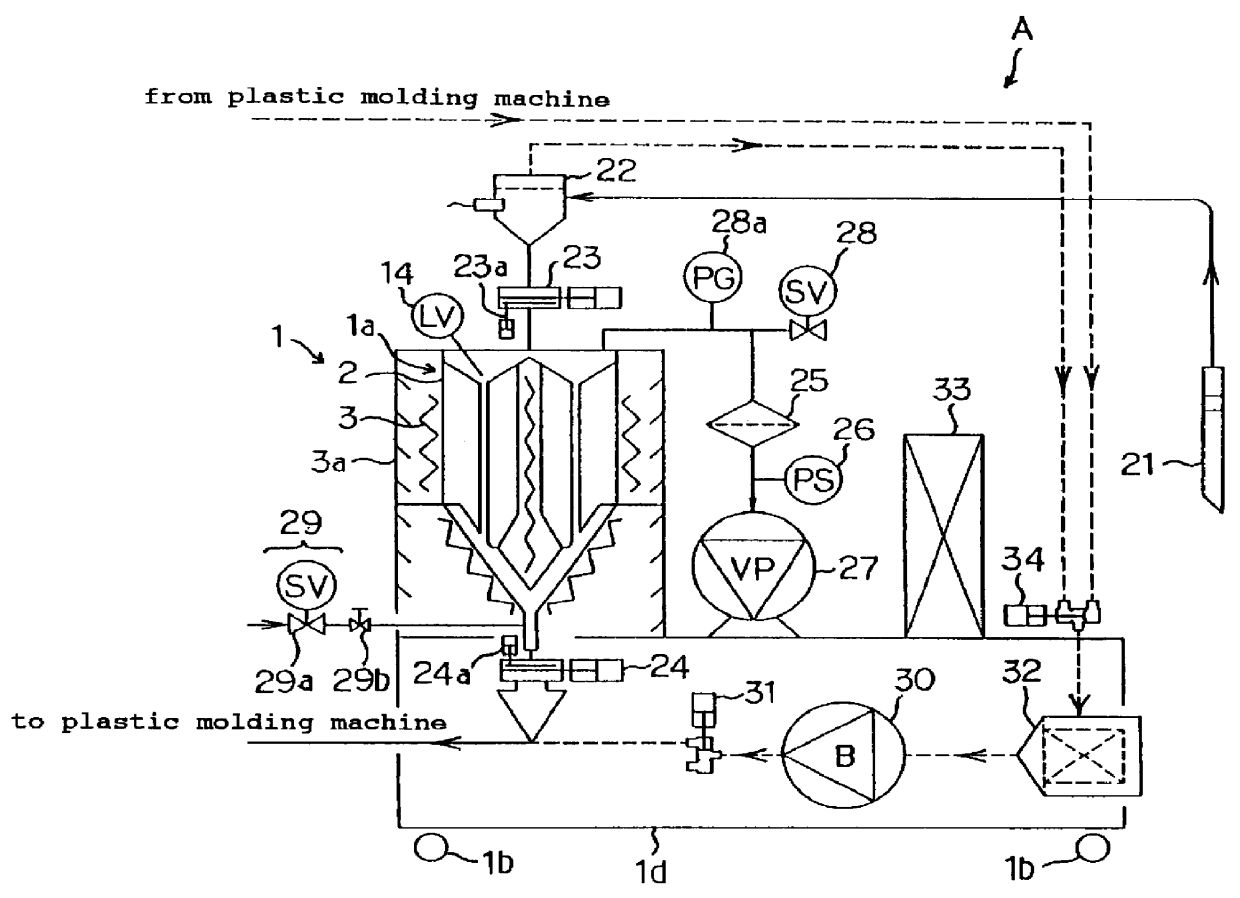

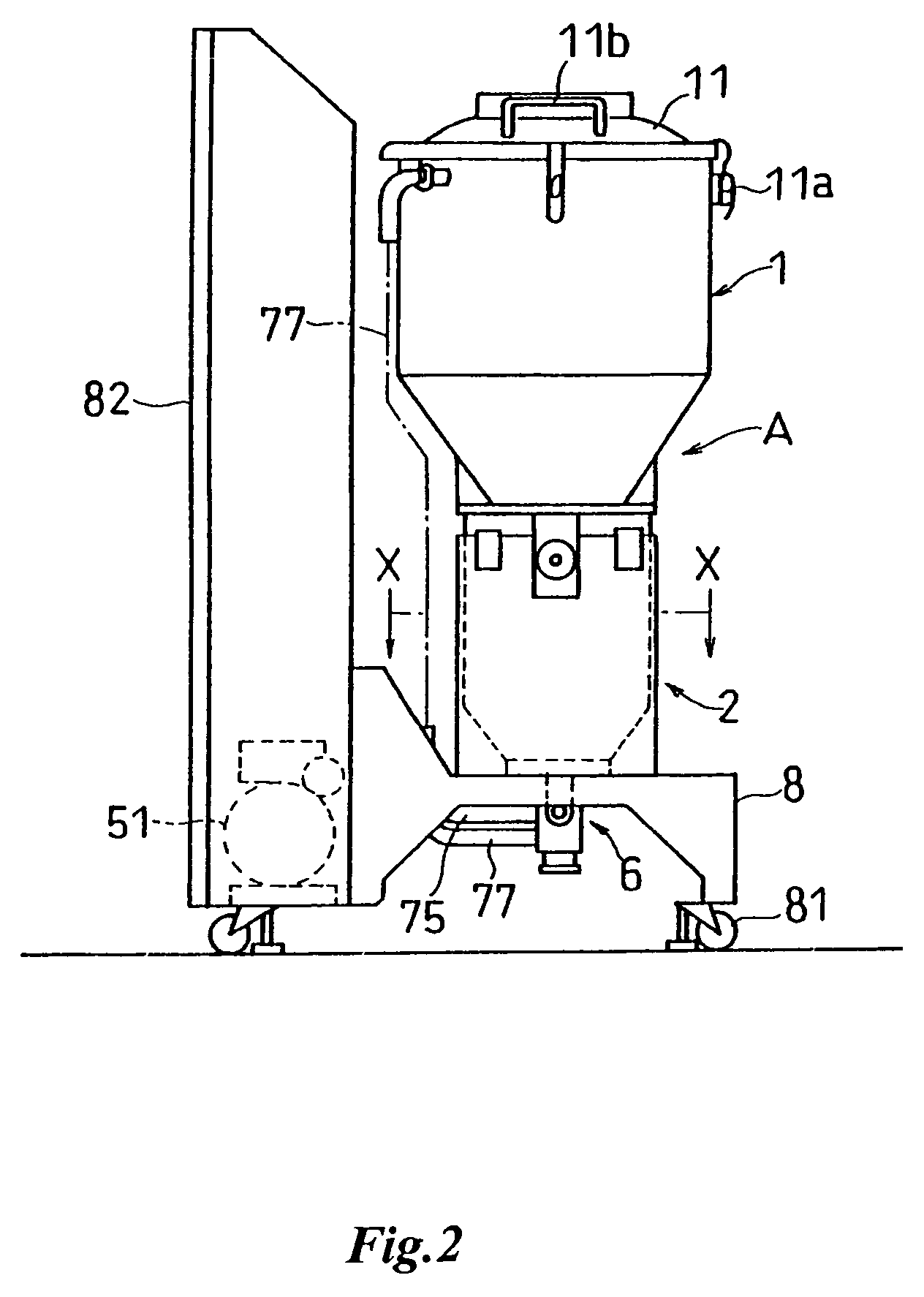

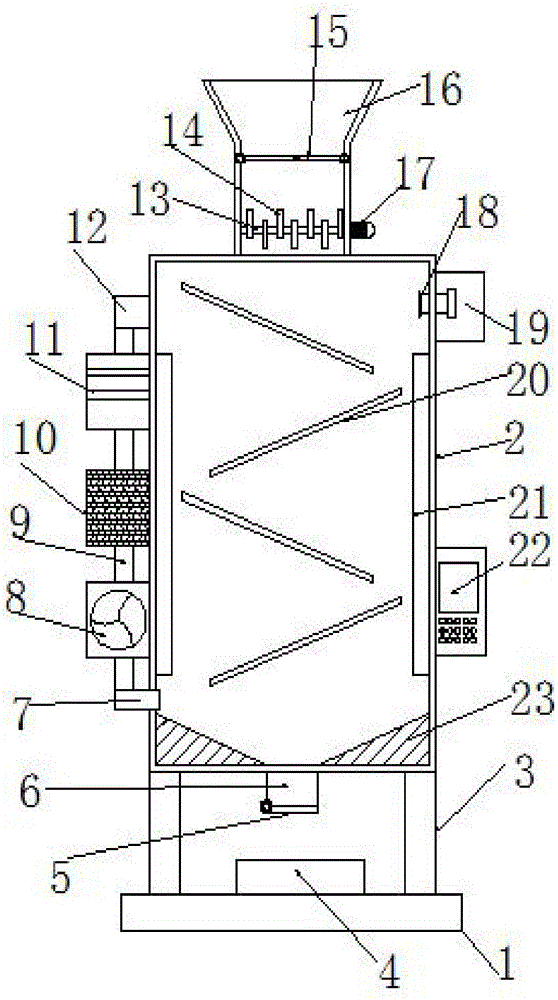

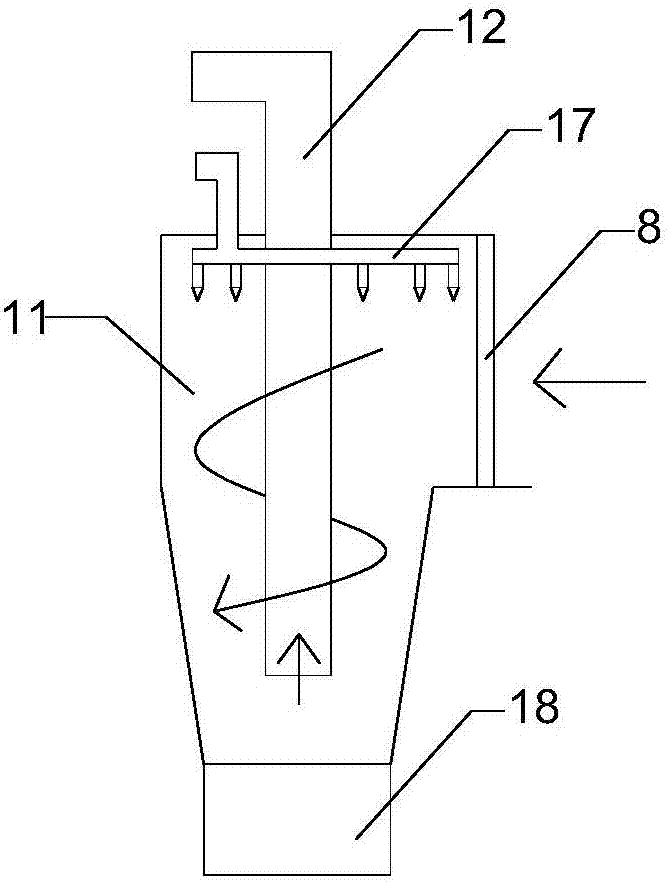

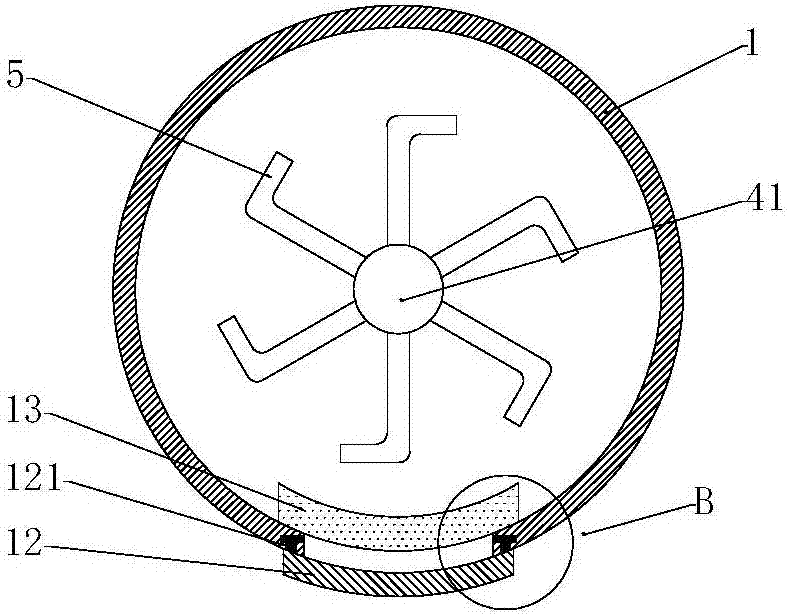

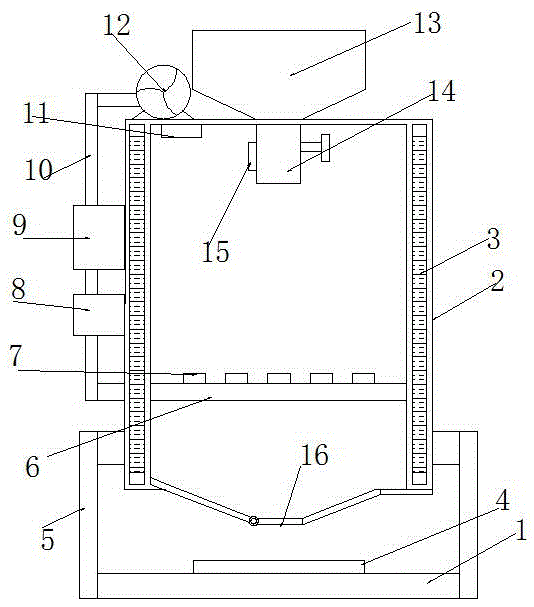

Vacuum-type automatic dehumidifying and drying apparatus for powdered or granular material

InactiveUS6163976AEfficient conductionImprove heating efficiencyDrying solid materials with heatDrying solid materials without heatEngineeringMechanical engineering

A vacuum-type automatic dehumidifying and drying apparatus for powdered or granular material such as a pelletized or powdered resin or the like, provided with a drying hopper connected to an evacuating means having at its bottom a material discharge valve, and provided with a material collector communicating with the drying hopper via a material feeding valve above the drying hopper for collecting the powdered material therein. The apparatus comprises a double constructed drying hopper having a cylindrical main body made of a high heat conductivity material provided on its inner peripheral surface with plural fins, which define compartment walls, projecting inwardly and provided on its outer peripheral surface with a heating means surrounding the cylindrical main body. The main body is outwardly enclosed with a heat insulation wall, and comprises an outer air inlet for introducing outer air thereinto, a material sensor for detecting amount of the material stored in the hopper, and an evacuating means connected to the main body.

Owner:MATSUI MFG

Glassware cleaning and drying equipment for medical experiments

InactiveUS20200108426A1Continuous cleaningIncrease flexibilityHollow article cleaningDrying gas arrangementsGlass vesselElectric machinery

The invention discloses a glassware cleaning and drying equipment for medical experiments, which includes a device cabinet, wherein a cleaning space is provided in the device cabinet, a brushing space communicating with the cleaning space is provided on a bottom wall of the cleaning space, and a water pump is fixedly installed in the left inner wall of the brushing space. The nozzle is fixedly installed on the output pipe. The brushing motor is started. The brushing motor drives the gear shaft to rotate. The brush cylinder and the washing brush that the gear shaft rotates rotate. The medical glassware is cleaned and disinfected. The effect of individual treatment is better and the disinfection is more thorough. The chuck can be changed according to the size of the clamped utensils. There is no need to change the mold for clamping the utensils.

Owner:WU MEIJUN

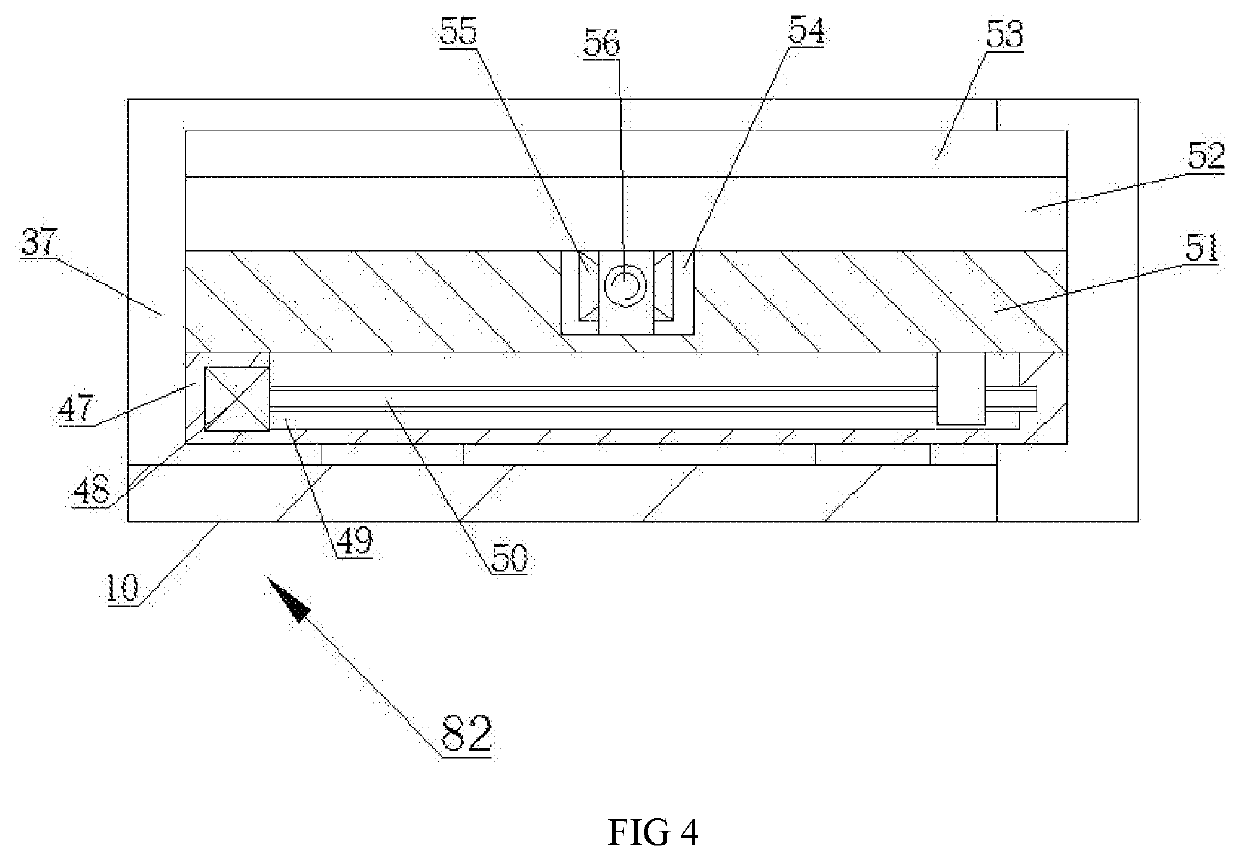

Drying-storing apparatus for powdered or granular material and feeding system for powdered or granular material

InactiveUS7703217B2Improve efficiencySimple materialDrying using combination processesDrying solid materials with heatProcess engineeringMaterial storage

A drying and storing apparatus for powdered or granular material and a feeding system for powdered or granular material. The apparatus comprises a heating and drying chamber having a discharge port at its lower end and a thermal conductive heating means therein and a hopper chamber connected to the upper end of the heating and drying chamber, in which the heating and drying chamber and the hopper chamber constitute a integrally combined material storage processing tank for powdered or granular material.

Owner:MATSUI MFG

Dried product discharge system

InactiveUS6890129B2Simple structureLow costBulk conveyorsDrying solid materialsPneumatic circuitEngineering

A system for discharging dried product, particularly for drying filters, drying units and the like, comprising, on a container for treating and containing a dried product, a discharge hole that is controlled by a discharge valve, interposed on a pneumatic circuit suitable to produce a circulation of fluid in output from the discharge hole. An agitator is also provided which acts on the dried product to facilitate its outward conveyance.

Owner:3V COGEIM

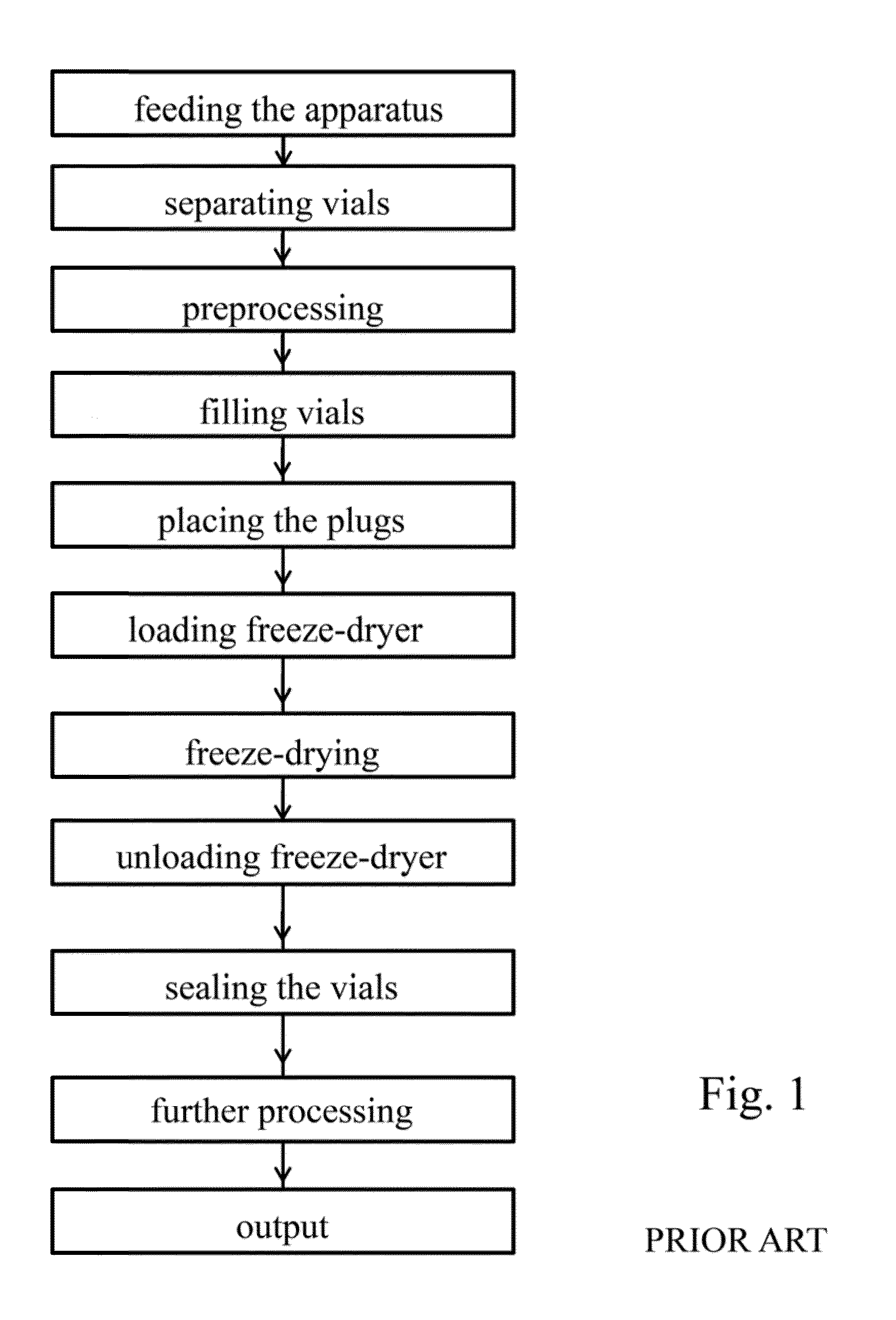

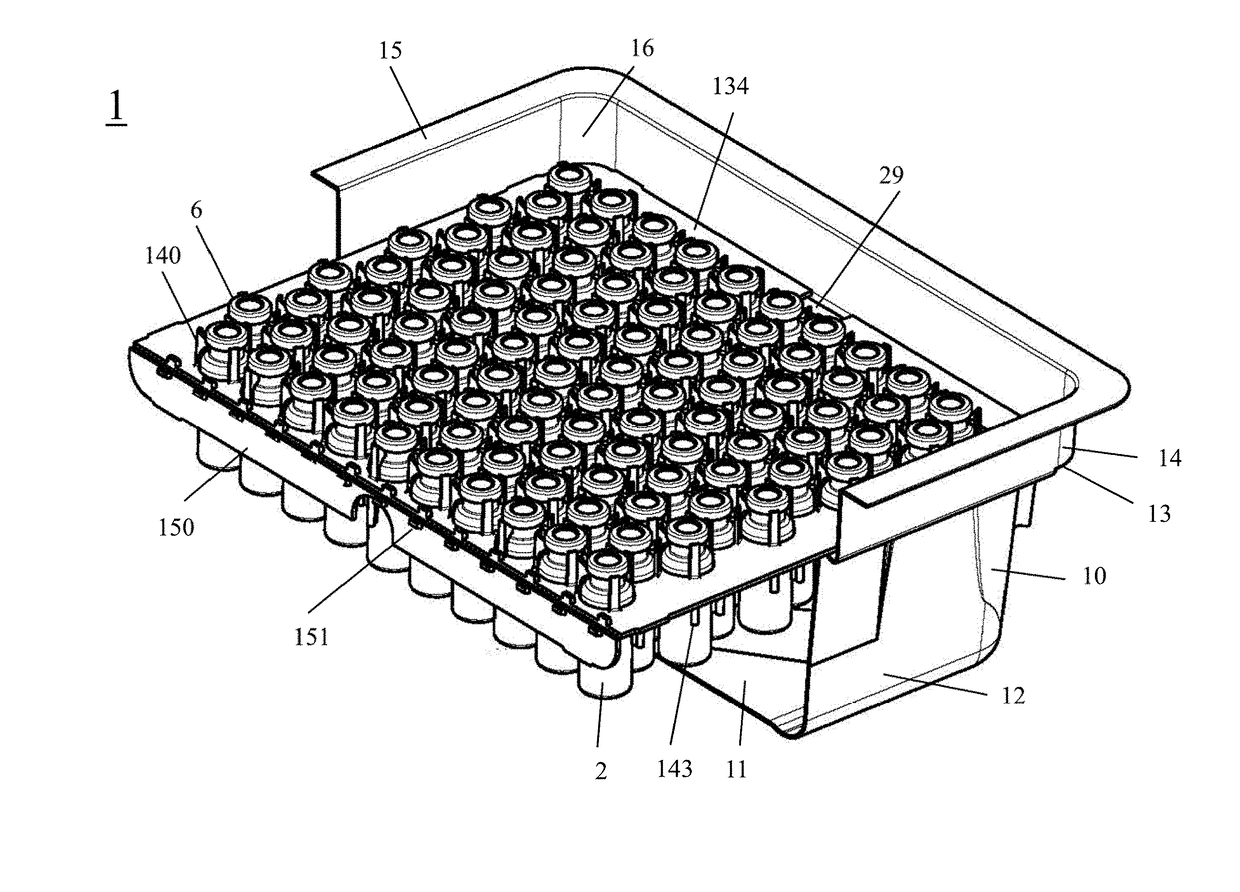

Process and apparatus for treating containers for storing substances for medical, pharmaceutical or cosmetic applications

ActiveUS20150089830A1Improve cooling effectLow costDrying solid materials without heatContainer/bottle contructionFreeze-dryingEngineering

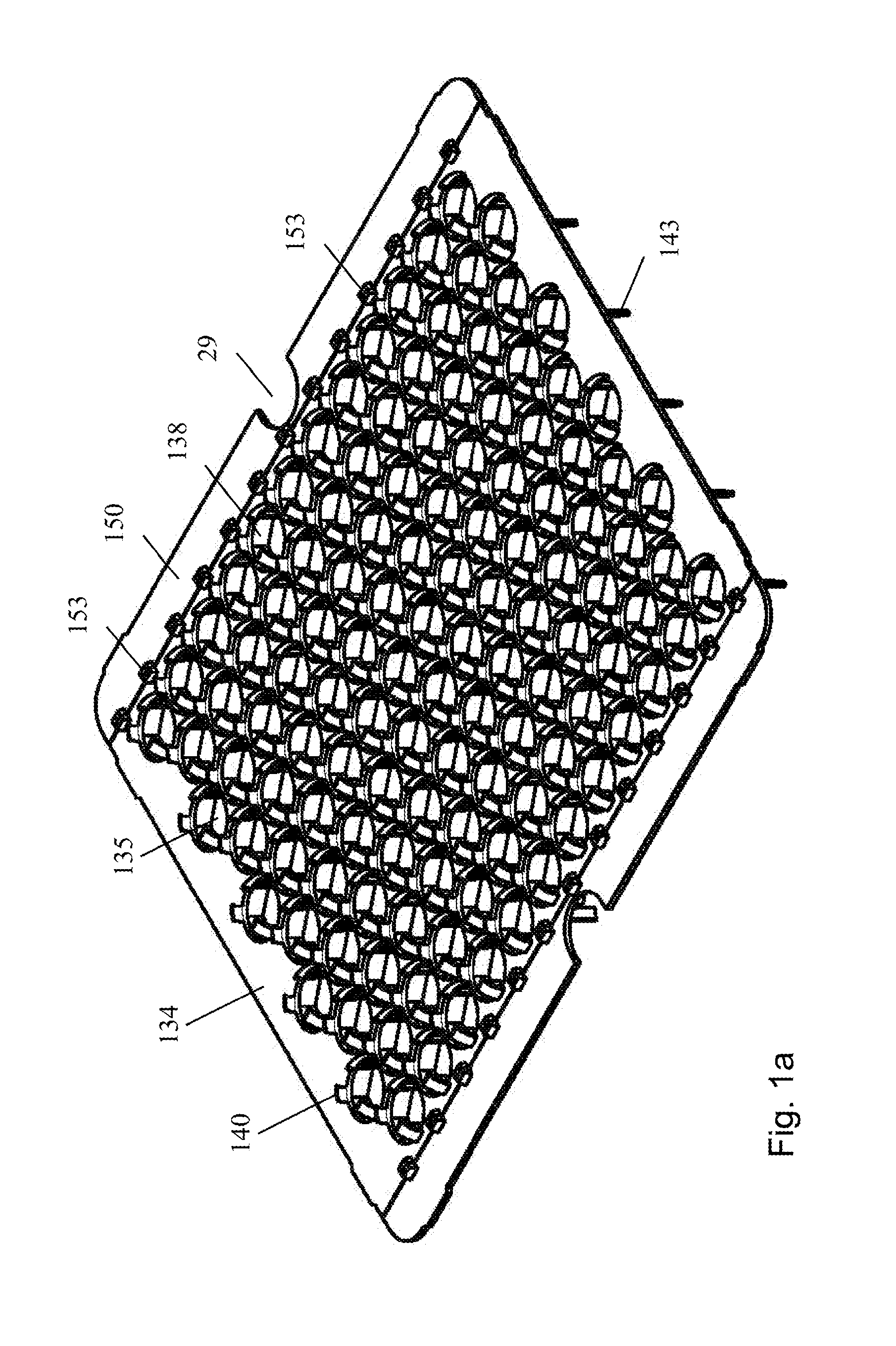

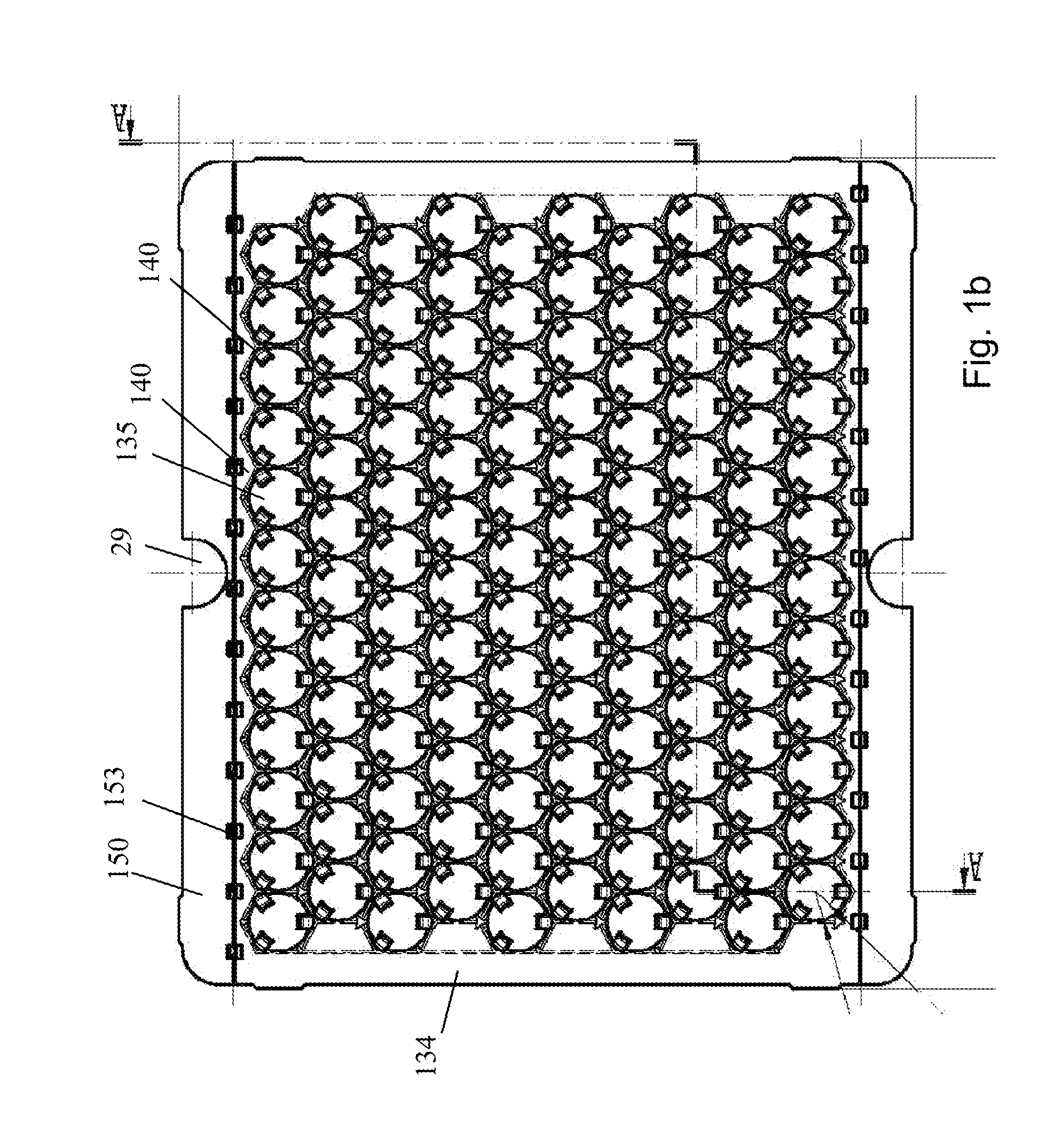

In a process and apparatus for treating or processing containers (2) that are used for storing substances for medical, pharmaceutical or cosmetic applications or contain the same, cylindrical containers open at least at one end are automatically led past or pass through processing stations for treatment or processing by means of a conveying device, while said containers are jointly held by a carrier (25; 134) in a regular two-dimensional arrangement. The carrier comprises a plurality of openings or receptacles (32; 39; 87; 120), which determine the regular arrangement.According to the invention, the treatment or processing of the containers is performed on or in at least one of the processing stations while the containers are supported by the carrier. This opens up new possibilities for treating or processing the containers, for example when crimping metal lids or during freeze-drying.

Owner:SCHOTT PHARMA AG & CO KGAA

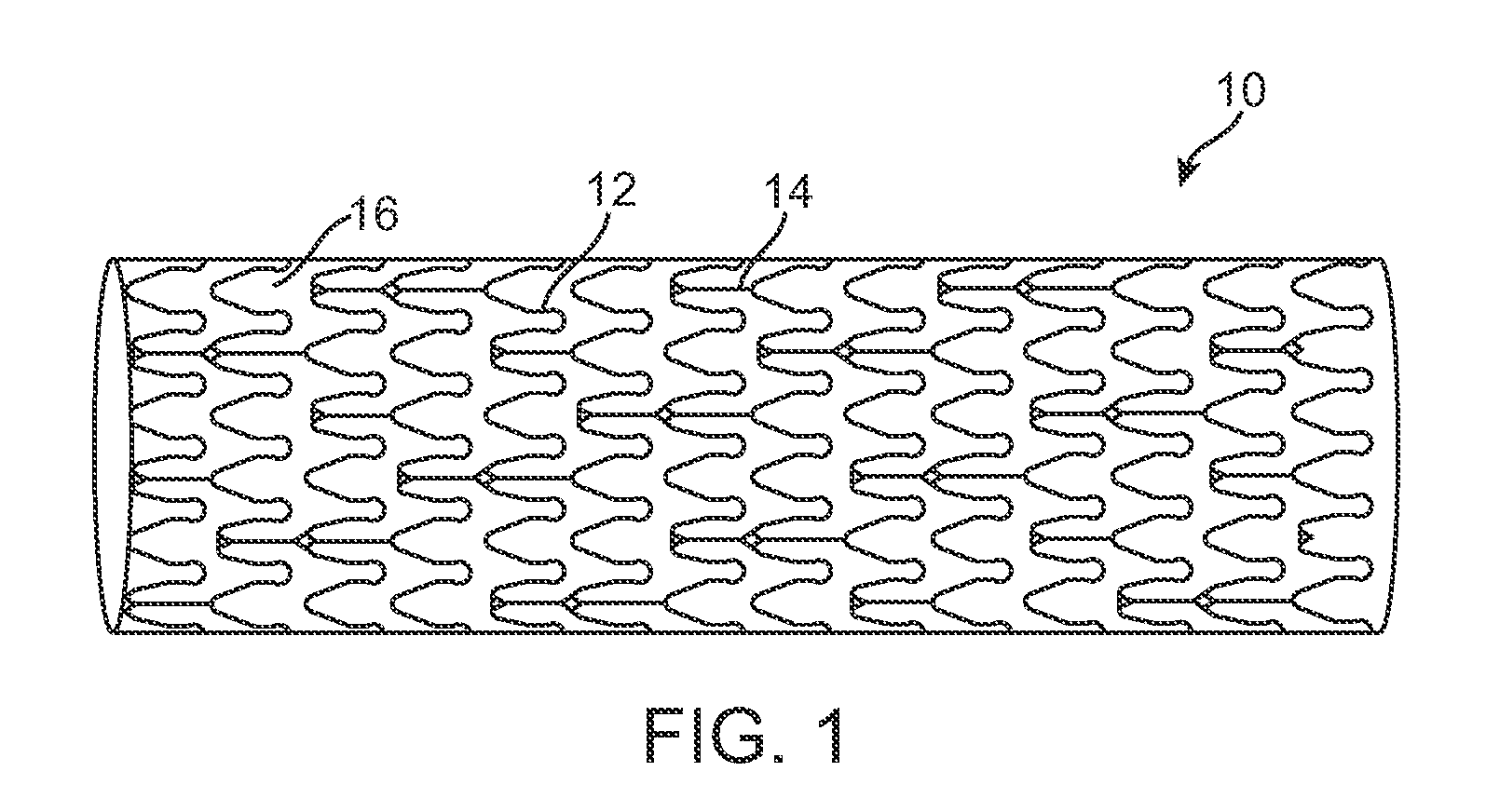

Methods and devices for drying coated stents

Various embodiments of methods and devices for drying coated stents in an oven are described herein.

Owner:ATS AUTOMATION TOOLING SYSTEMS +1

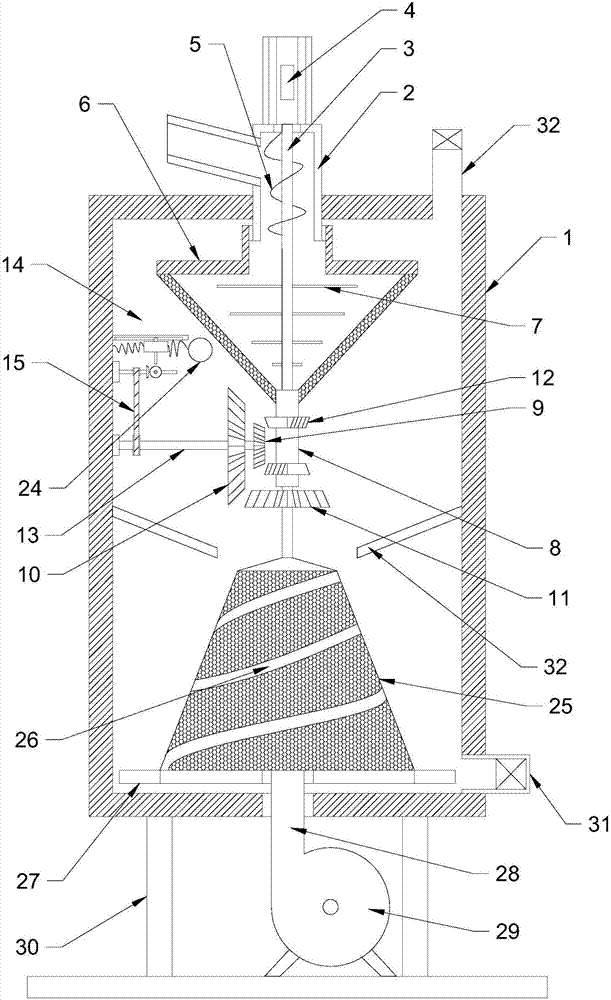

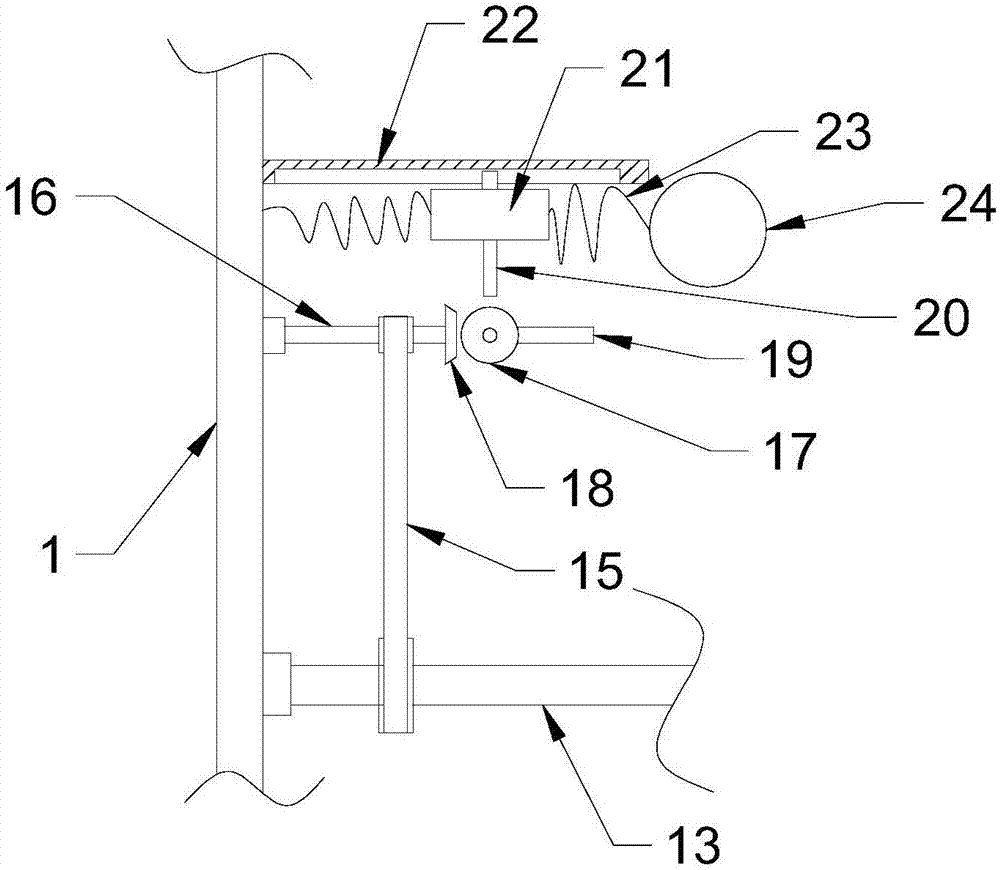

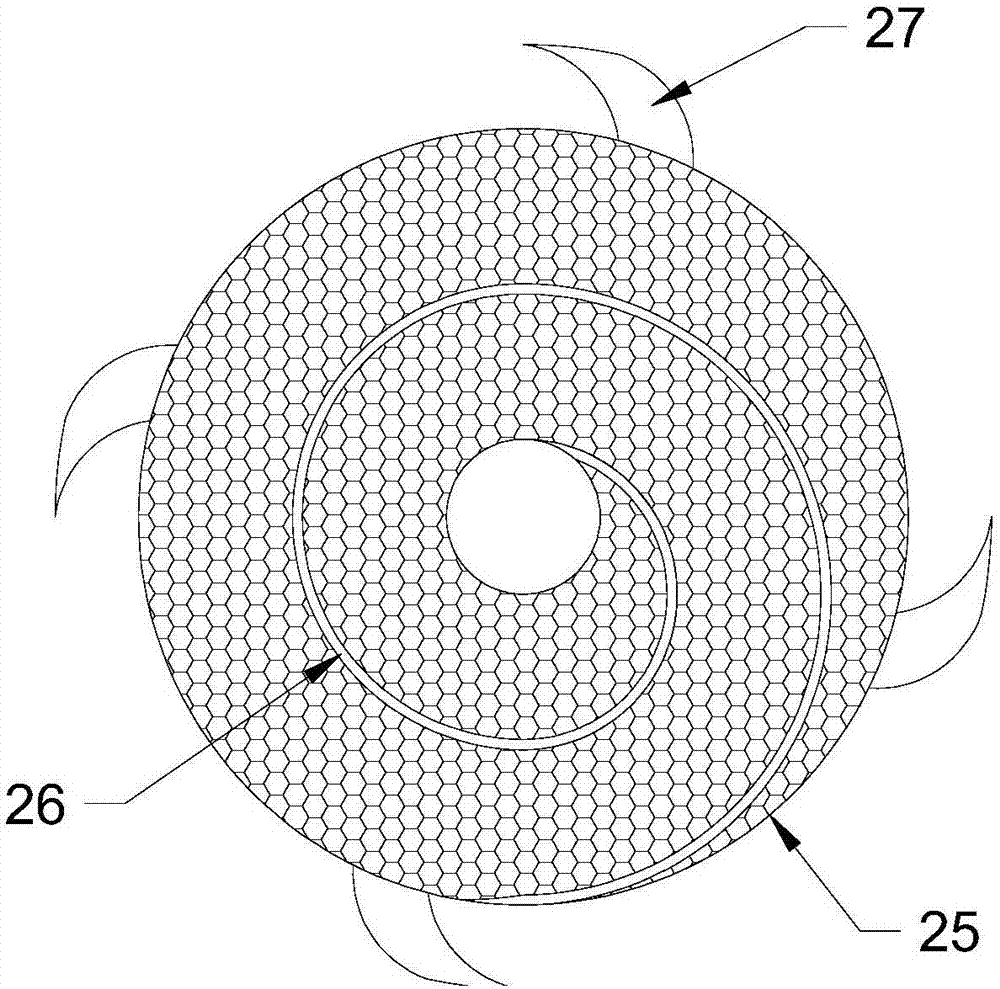

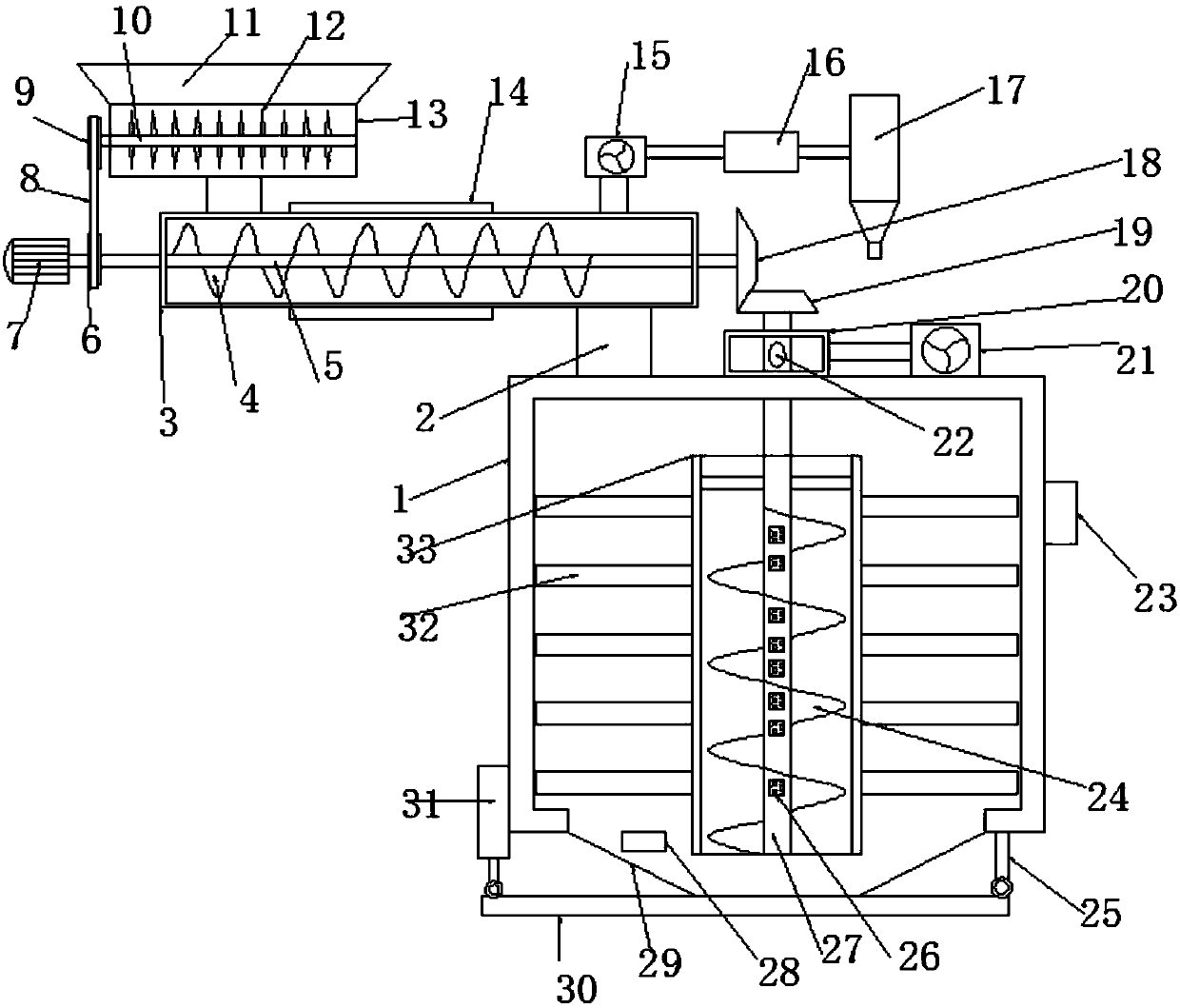

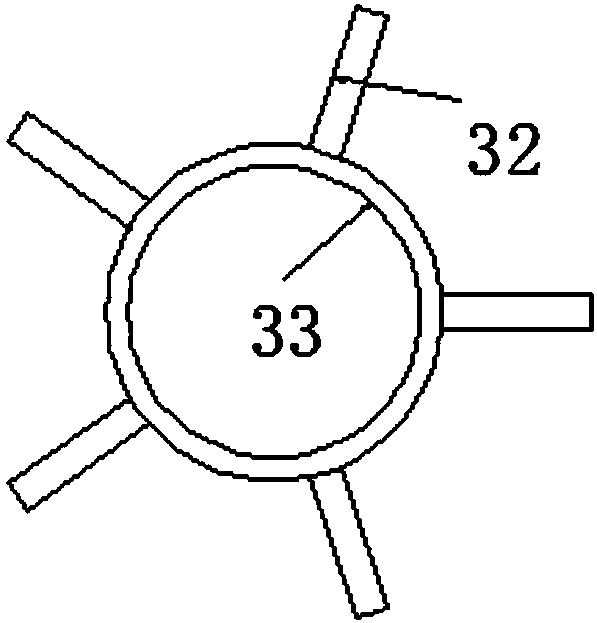

Rotary feed crushing and drying device

ActiveCN107952540ACrushed fullyFull and efficient screeningSievingFeeding-stuffDischarge efficiencyEngineering

The invention discloses a rotary feed crushing and drying device including a machine body; a crushing screen cylinder is arranged in the machine body, a knocking device is arranged on the left side ofthe crushing screen cylinder, and a drying conical cylinder is arranged below the crushing screen cylinder. According to the rotary feed crushing and drying device, a crushing knife and a crushing screen cylinder with a periodic square rotation are used to fully smash and screen feed, thereby improving the efficiency of smashing and screening. The knocking device linkaged with a rotary shaft canknock the outer wall of the crushing screen cylinder, and the clogging of screen holes and the feed residues can be avoided. The drying conical cylinder with a cone structure and an annular stock guide are used to enable the feed to roll down uniformly on the surface of a drying screen cylinder, the feed is evenly dried, a spiral raised line is provided to increase the falling time of the feed, and the drying effect is ensured. According to an arc-shaped feed discharging scraper and a feed discharging pipe which is in tangential communication with the machine body, the feed discharging efficiency is increased, so that the feed discharging is more thorough.

Owner:南宁扬翔农牧有限公司

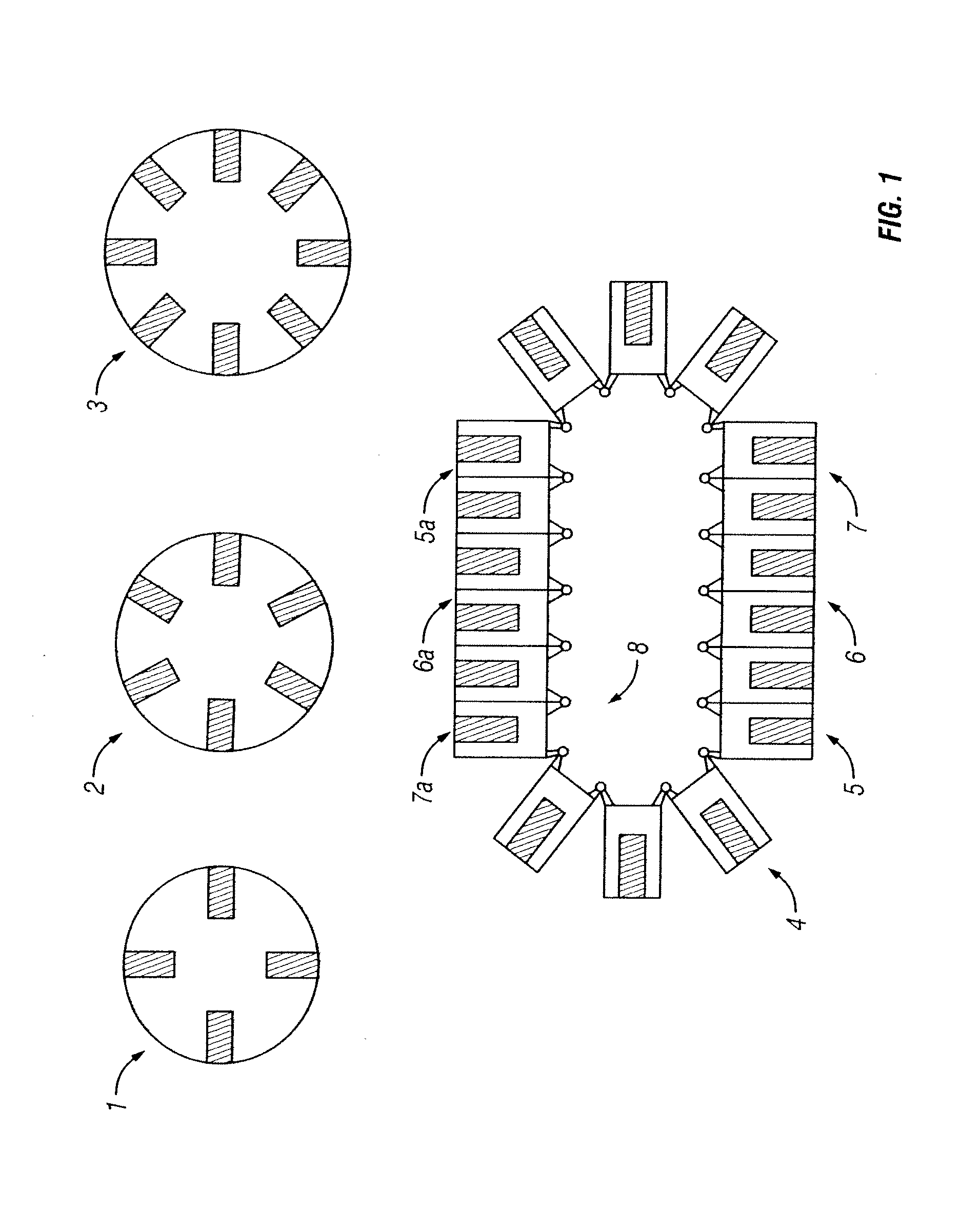

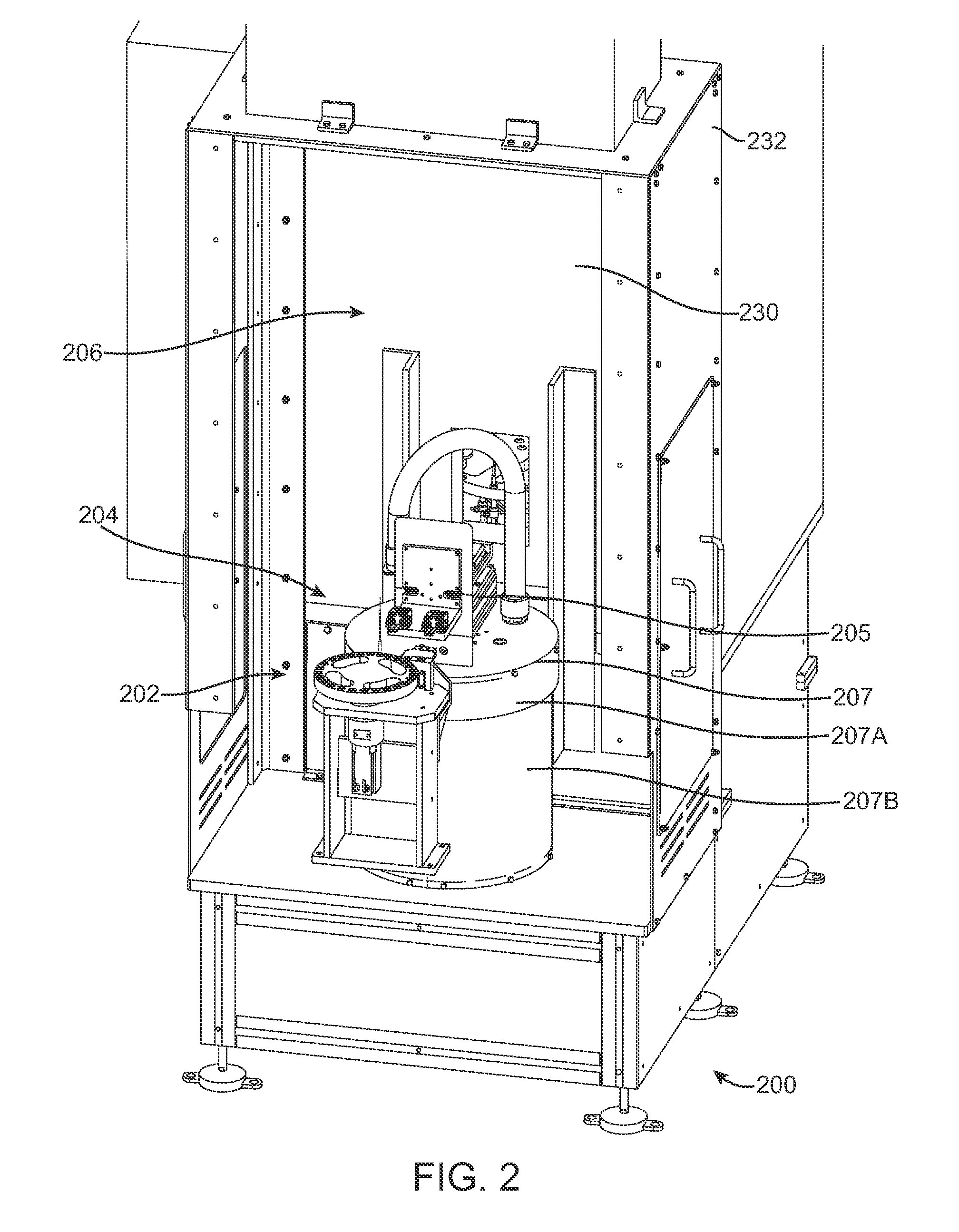

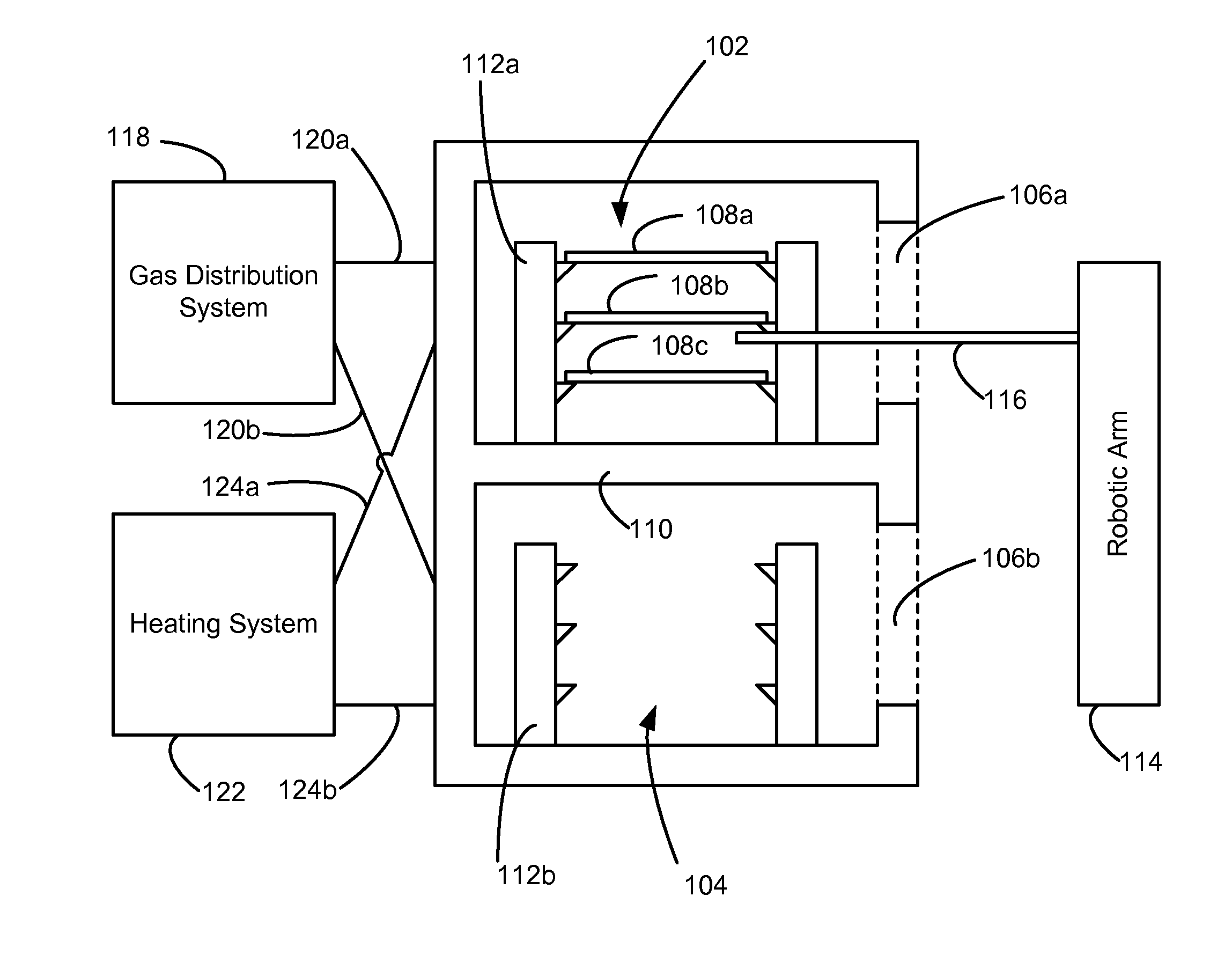

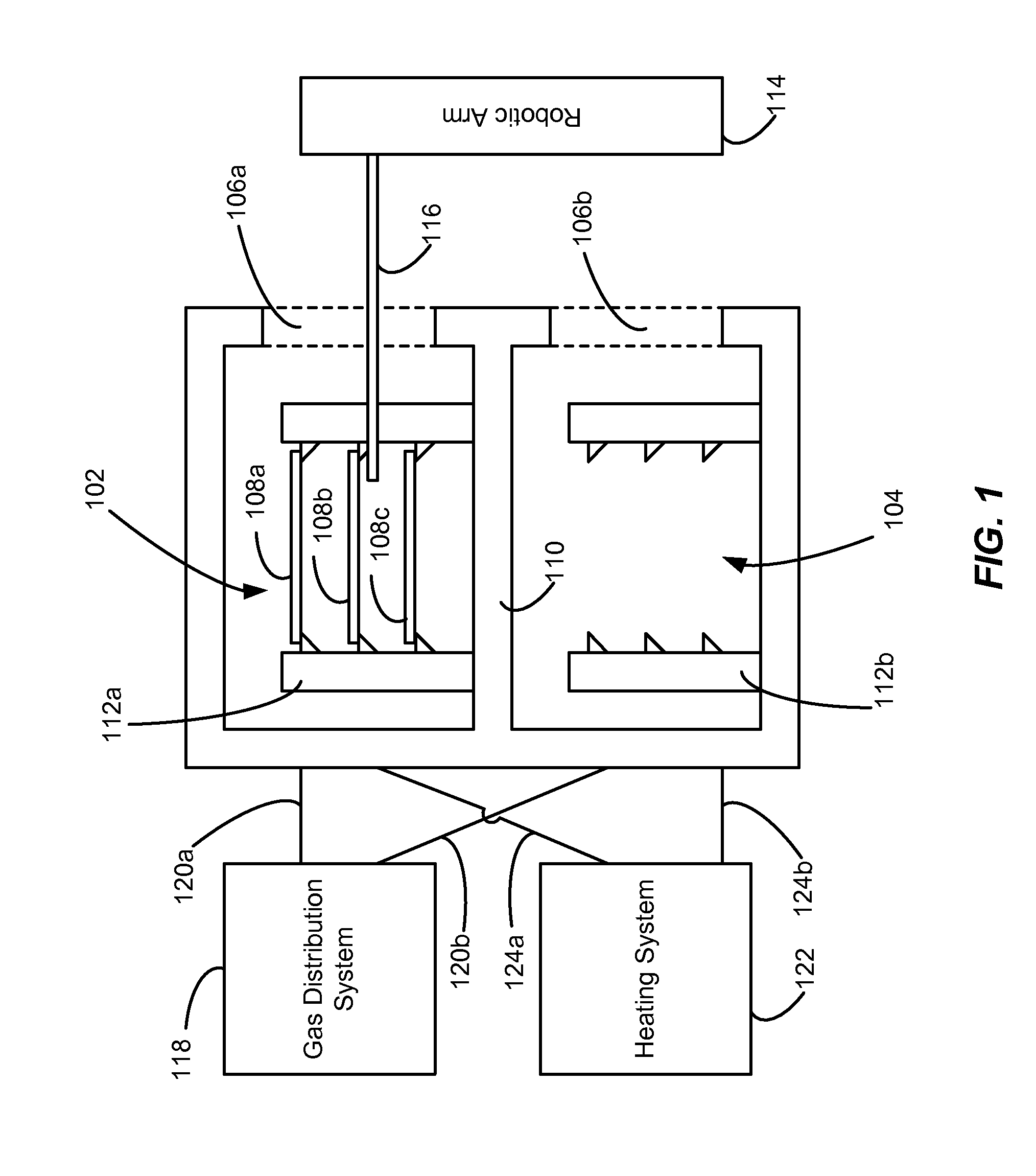

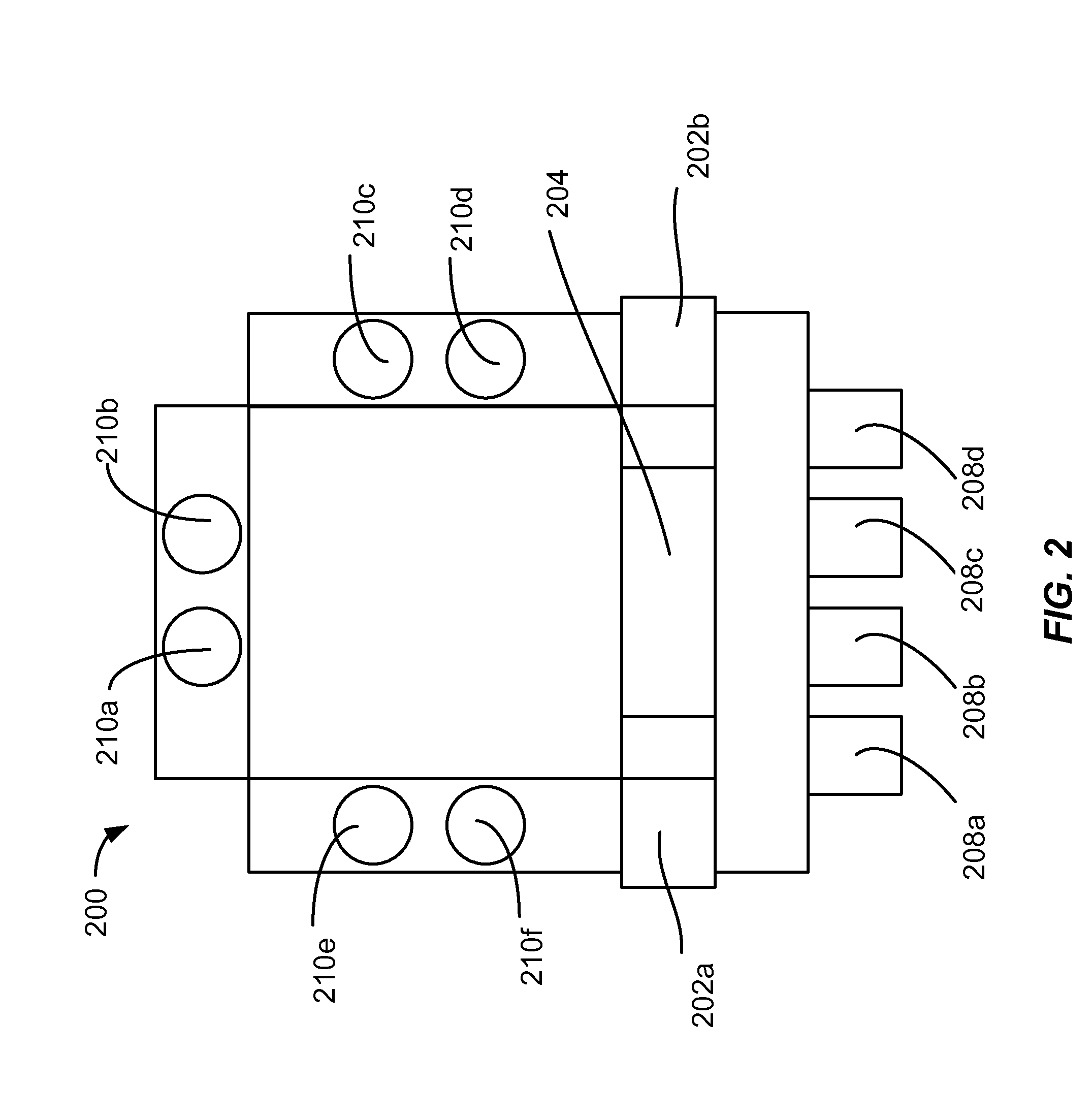

Module for ozone cure and post-cure moisture treatment

ActiveUS20120079982A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingWater vaporEngineering

A substrate processing system that has a plurality of deposition chambers, and one or more robotic arms for moving a substrate between one or more of a deposition chamber, load lock holding area, and a curing and treatment module. The substrate curing and treatment module is attached to the load-lock substrate holding area, and may include: The curing chamber for curing a dielectric layer in an atmosphere comprising ozone, and a treatment chamber for treating the cured dielectric layer in an atmosphere comprising water vapor. The chambers may be vertically aligned, have one or more access doors, and may include a heating system to adjust the curing and / or heating chambers between two or more temperatures respectively.

Owner:APPLIED MATERIALS INC

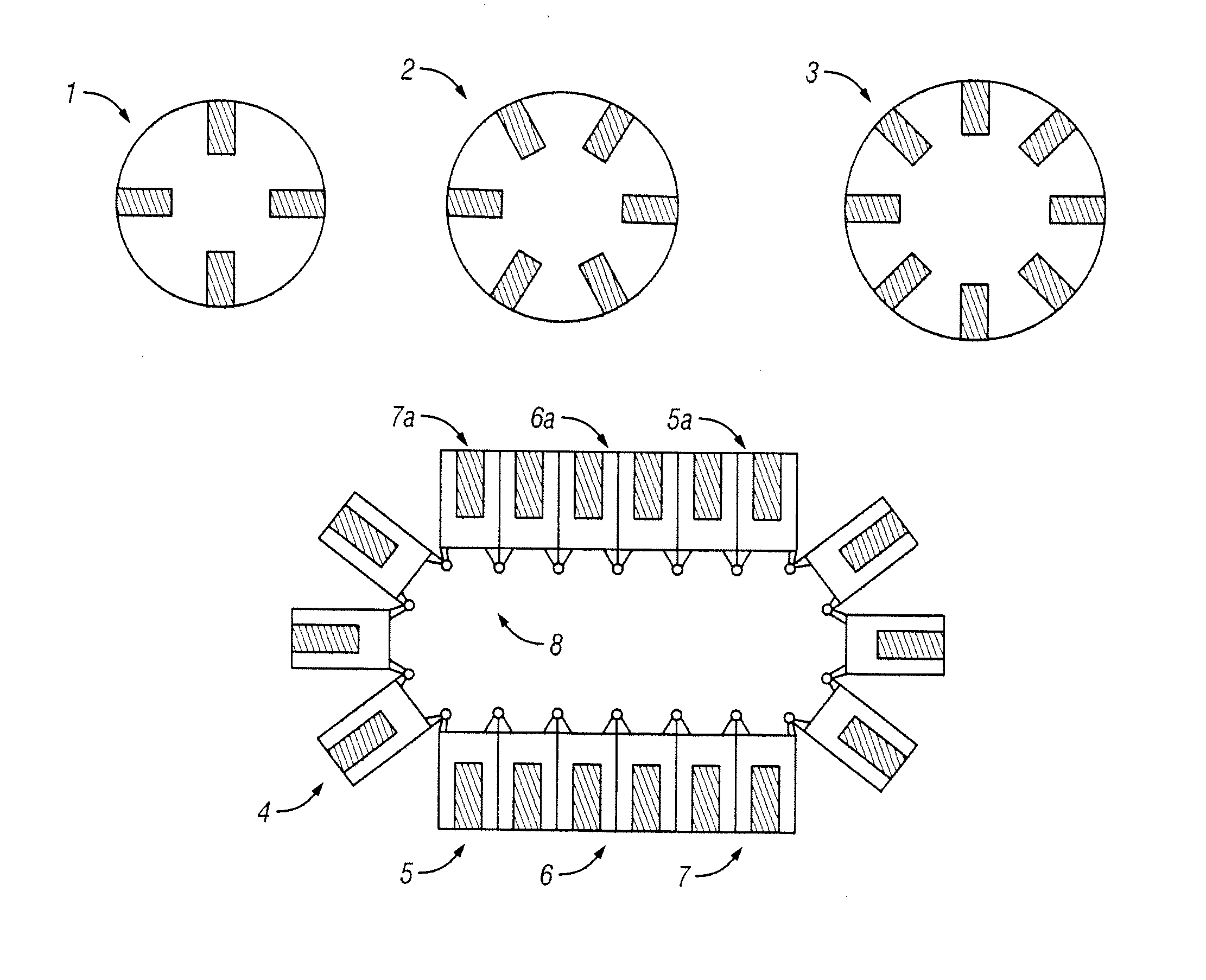

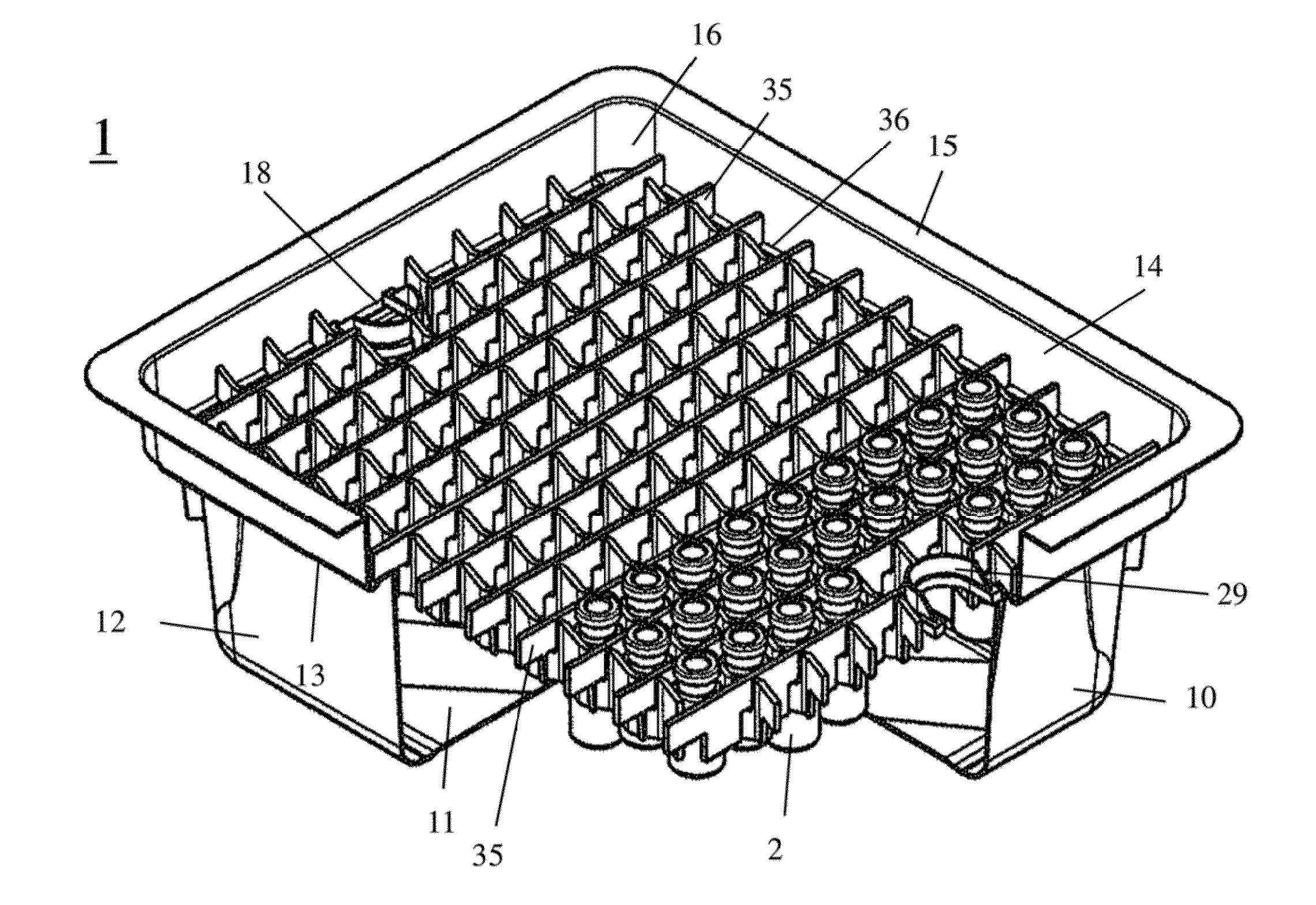

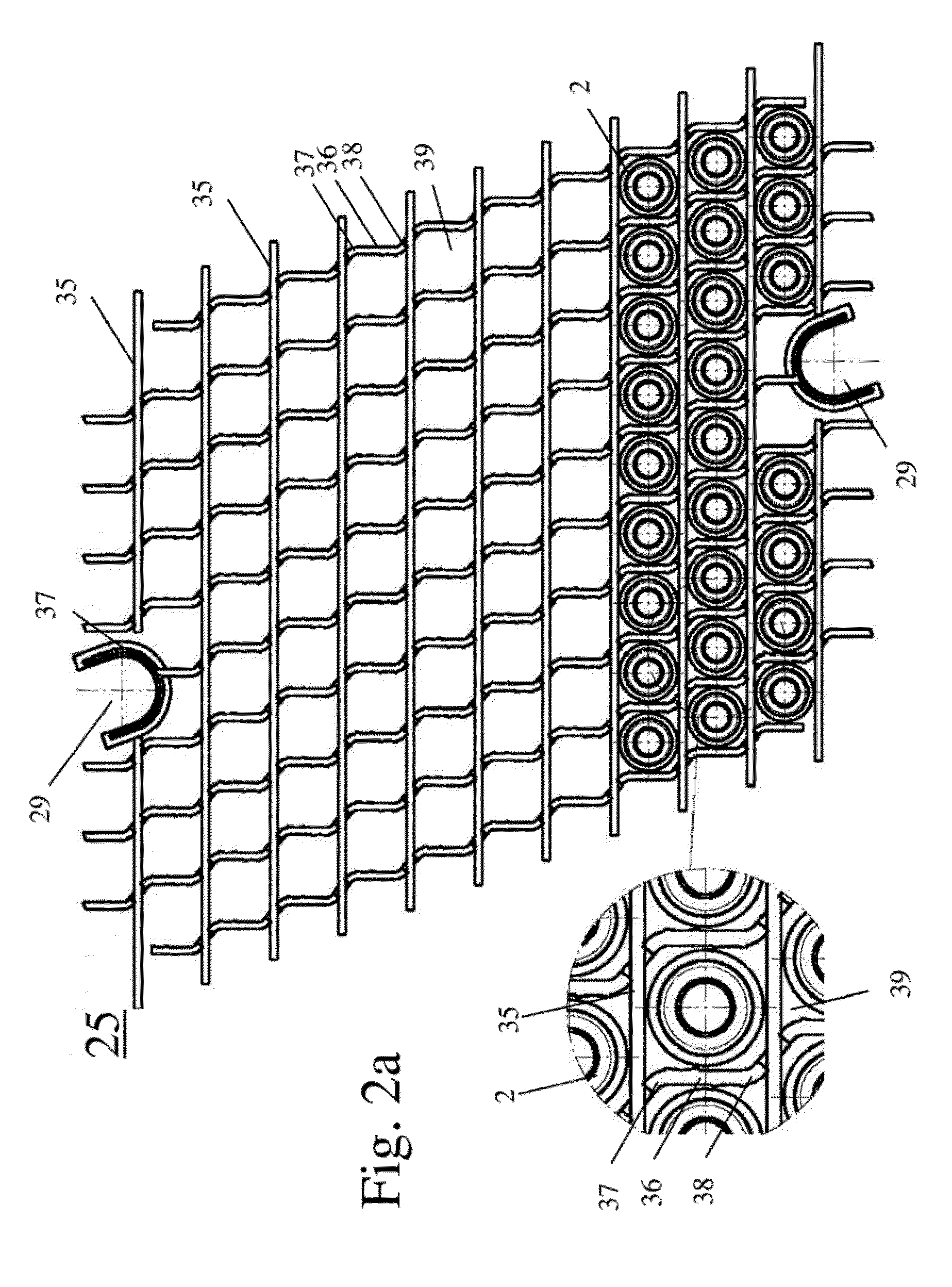

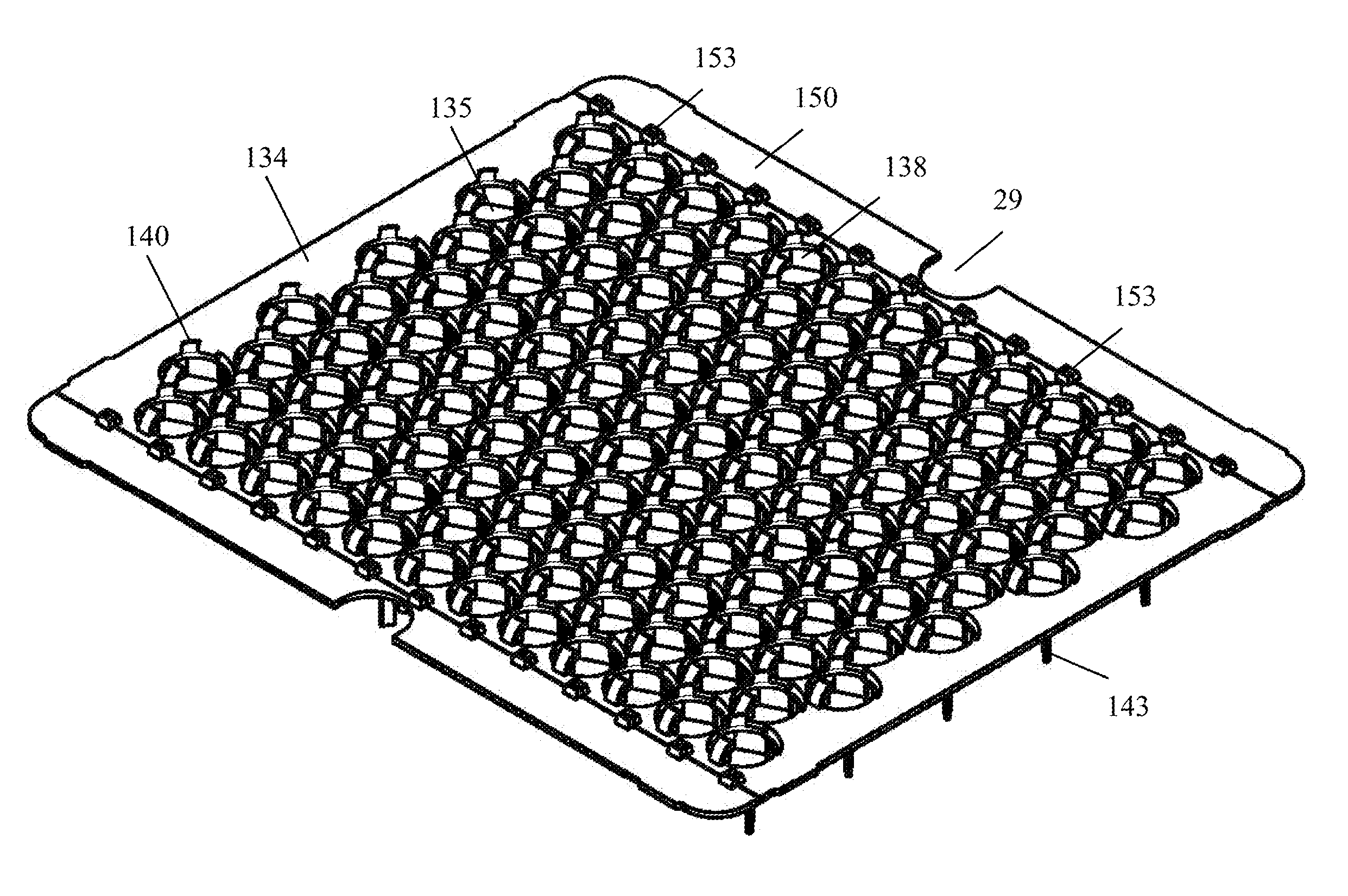

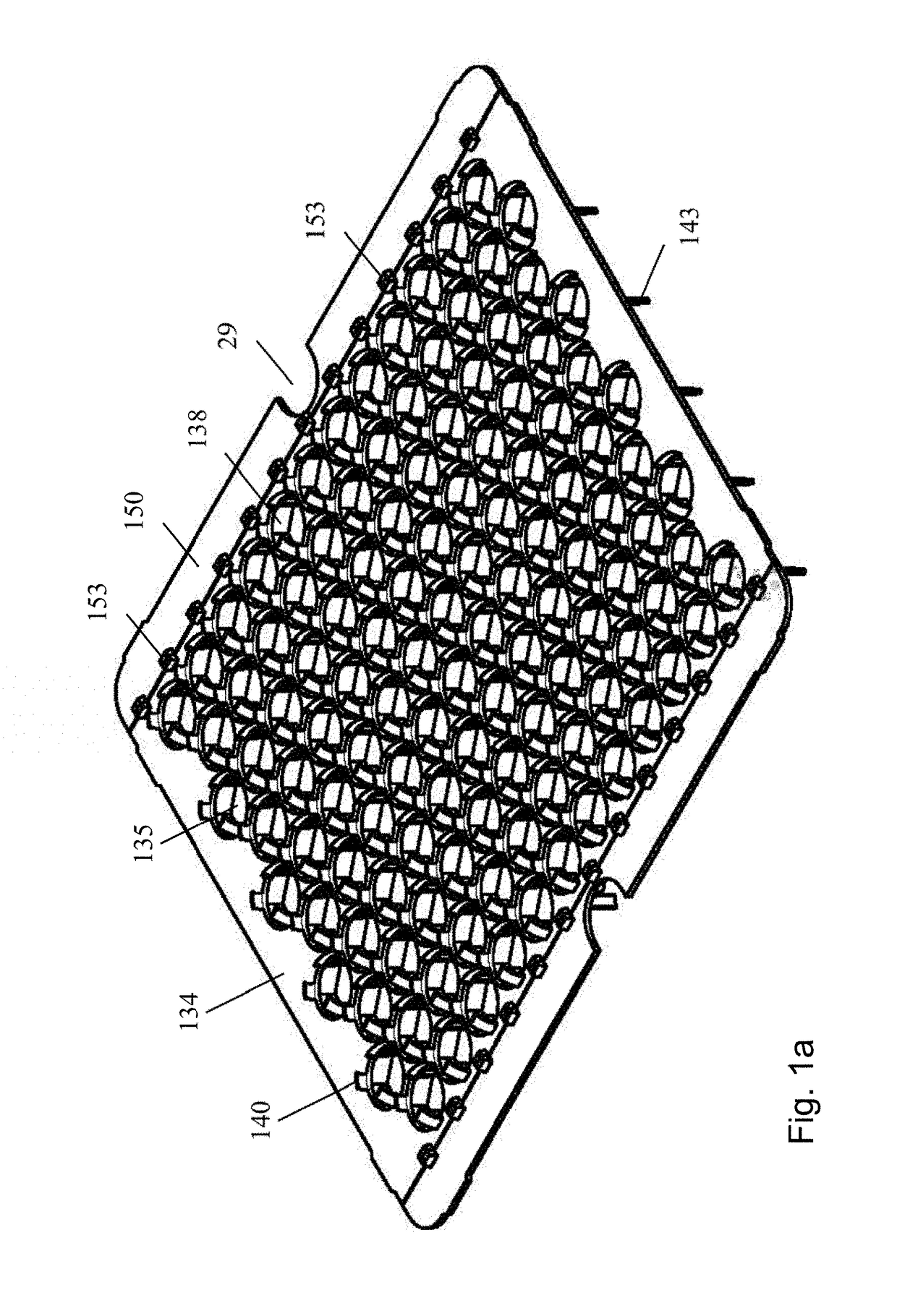

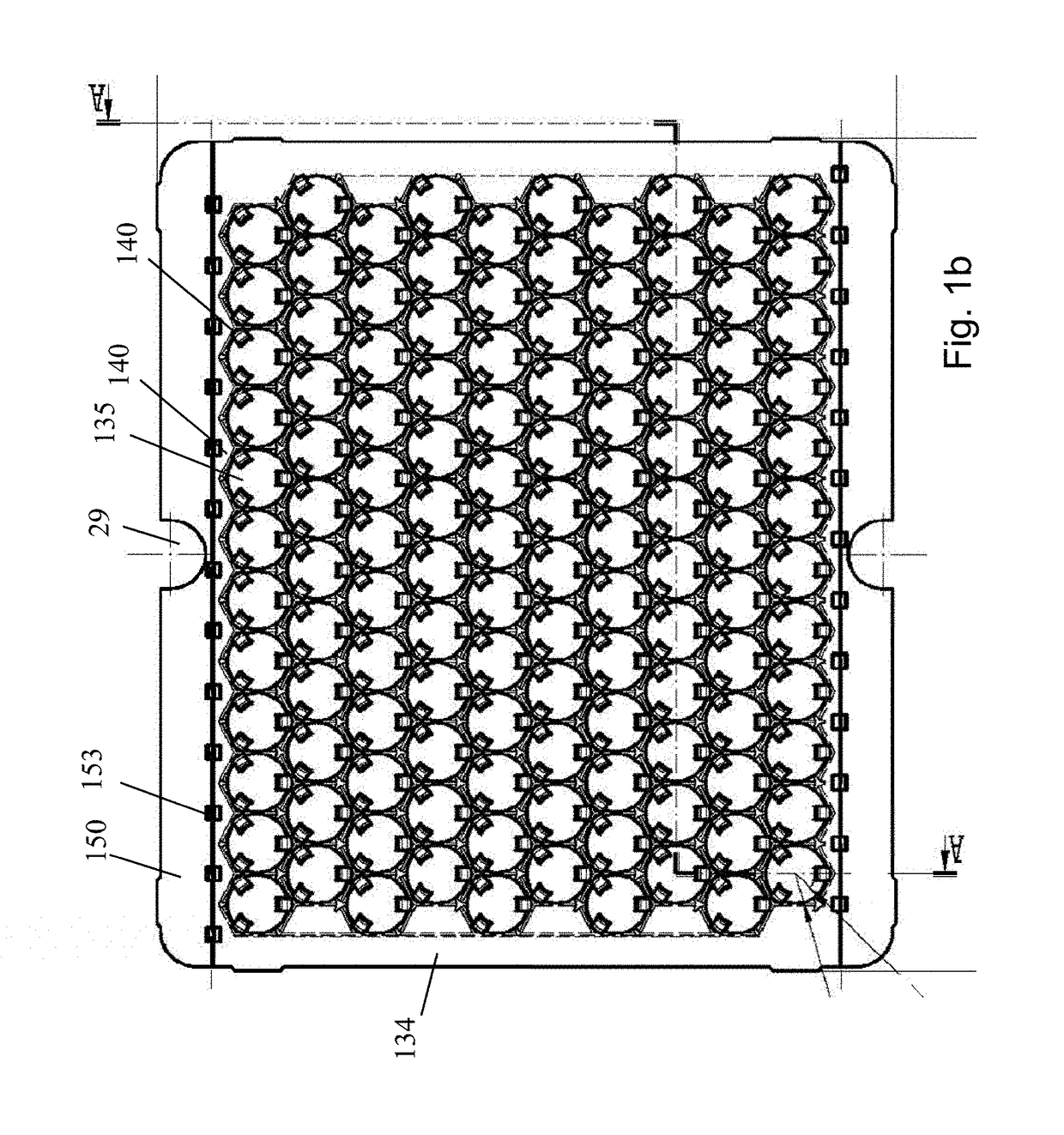

Holding structure for concurrently holding a plurality of containers for substances for medical, pharmaceutical or cosmetic applications as well as transport or packaging container comprising the same

ActiveUS20150166212A1Simple structureThe method is simple and reliableDrying solid materials without heatPharmaceutical containersPharmaceutical drugSurgery

A holding structure for concurrently holding a plurality of containers for substances for cosmetic, medical or pharmaceutical applications, in particular of vials, is provided. The holder includes a carrier having a plurality of apertures or receptacles into which the containers can be inserted and holding means for holding the containers in the apertures or receptacles. The holding means has at least two holding tabs, which are provided at the edge of a respective aperture or receptacle and protrude from an upper side of the carrier for holding the respective container. The holding tabs are resiliently pivoted or folded back as the containers are inserted into the apertures or receptacles and so that the holding tabs are matched to the containers such that these are held by the holding tabs with a radial clearance and low tension.

Owner:SCHOTT PHARMA AG & CO KGAA

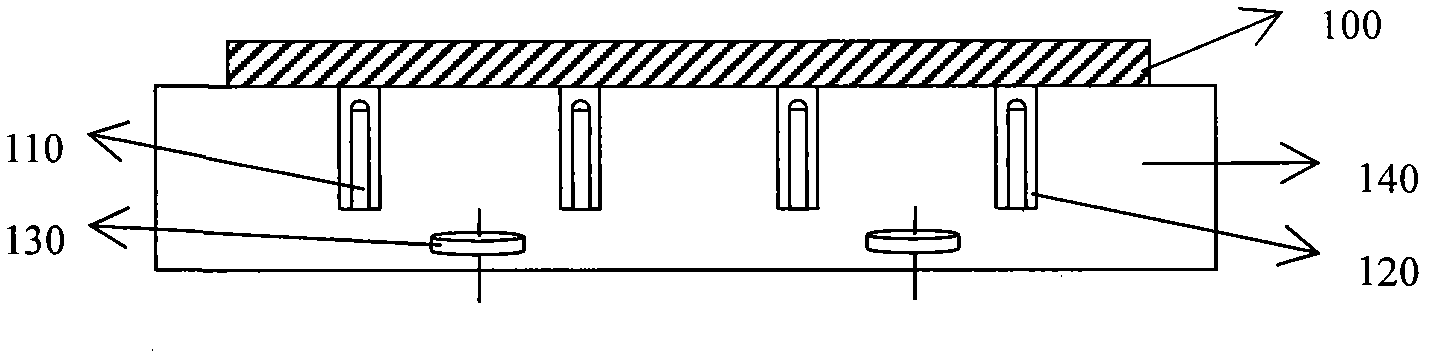

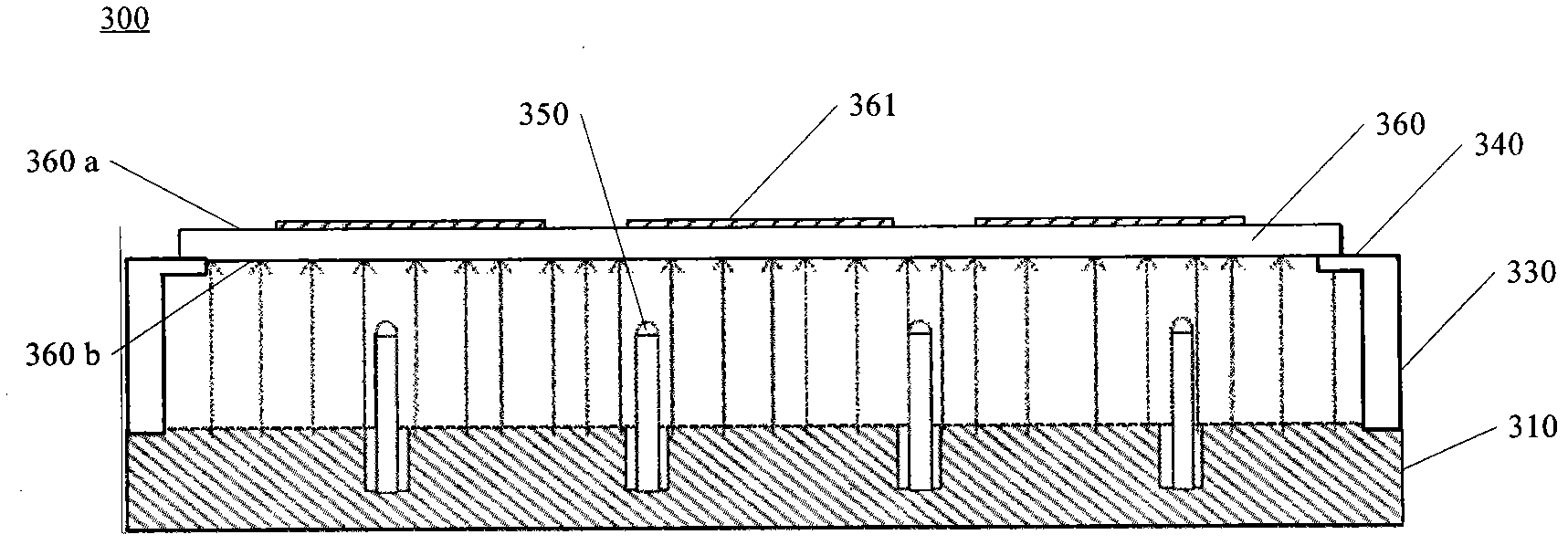

Alignment film drying device and method

InactiveCN102085511AEvenly heatedQuality improvementDrying solid materials with heatPretreated surfacesFilm materialLiquid crystal

The invention provides an alignment film drying device and method which are used for drying an alignment film material which is formed on a first surface of a substrate and diluted by a solvent. The device comprises a heating table, a peripheral support mechanism, multiple support pins and a lifting mechanism, wherein the heating table is used for heating a second surface of the substrate, and multiple air holes are uniformly distributed on the heating table; the peripheral support mechanism is arranged around the heating table and used for supporting the edge of the second surface of the substrate; the multiple support pins are uniformly distributed in the upper surface of the heating table; and the lifting mechanism controls the periphery support mechanism and the support pins to perform lifting. According to the invention, the phenomenon of drying non-uniformity in the drying process of the alignment film can be eliminated, the quality of the alignment film is optimized, the display characteristics of a liquid crystal panel are enhanced, and the quality and acceptability of the liquid crystal panel are improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Internal circulation type traditional Chinese medicine drying equipment

InactiveCN107940974AReduce volumeFully dryDrying machine combinationsDrying gas arrangementsSpiral bladeBiochemical engineering

The invention discloses internal circulation type traditional Chinese medicine drying equipment. The equipment comprises a processing box, a connecting channel and a feeding cylinder; the connecting channel is formed in the left upper end of the processing box, and the upper end of the connecting channel is connected with and fixed to the feeding cylinder, a pushing shaft is arranged in the feeding cylinder in a penetrating mode, and a spiral blade is arranged on the pushing shaft; a heating block sleeves the outer side of the feeding cylinder and is used for heating materials in the feeding cylinder, the two ends of the pushing shaft penetrate through the feeding cylinder, the left end of the pushing shaft is fixedly connected with the output end of a driving motor, and a driving gear isarranged at the right end of the pushing shaft; and a driving belt wheel is arranged on the part, close to the driving motor, of the pushing shaft, a feeding pipe is arranged on the upper left side ofthe feeding cylinder, and a crushing box is arranged at the upper end of the feeding pipe. According to the equipment, the structure is simple and reasonable; the materials are crushed in advance sothat the size of the materials can be reduced, and later drying can be facilitated; and meanwhile, circulation drying of the materials in the processing box can be realized through the equipment so that the materials can be fully dried, and the equipment is high in practicability.

Owner:马良彬

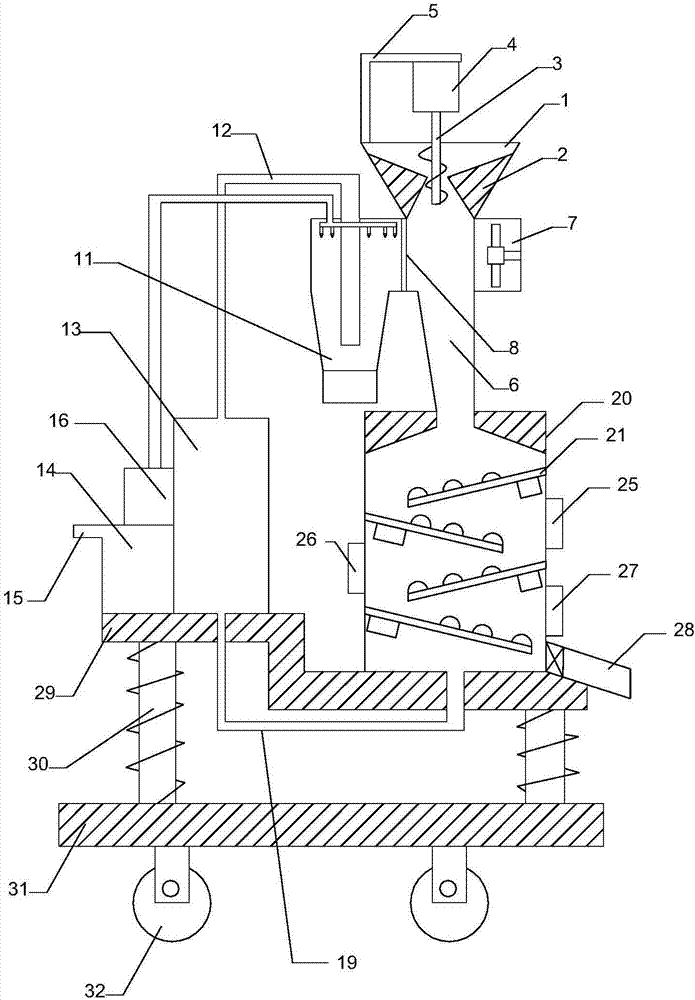

Environment-friendly anti-blocking tea leaf drying machine

InactiveCN106017040AAchieve recyclingRealize wastePre-extraction tea treatmentTea dryingDrive shaftAgricultural engineering

The invention discloses an environment-friendly anti-blocking tea dryer, which comprises a base and a drying box, a drying box is arranged above the base, a leg is arranged between the lower end of the drying box and the base, and a There is a discharge pipe, the upper end of the base below the discharge pipe is provided with a feeding conveyor belt, the upper end of the drying box is provided with a feeding hopper, and a feeding channel is provided between the feeding hopper and the drying box, and the right side is placed horizontally in the feeding channel. There are several eccentric wheels on the drive shaft. The right end of the drive shaft passes through the right side of the feeding channel and connects with the output end of the driving motor. There are several guide ramps in the drying box below the feeding channel. The left side of the drying box is provided with an air outlet and an air inlet respectively from top to bottom, and the air inlet and the air outlet are connected through a circulation conduit. The structure of the invention is simple and reasonable, and the heat in the waste gas is recovered and utilized. The device reduces the pollution to the environment, saves energy and protects the environment, and has strong practicability.

Owner:SUQIAN HUAIHAI TECH SERVICES

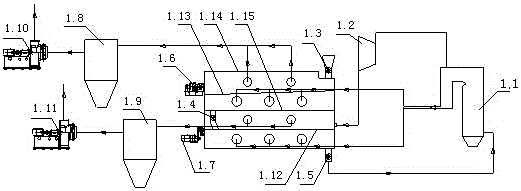

Brown coal drying method and device utilizing waste heat of smoke and steam of power plant

ActiveCN106382790AImprove economyImprove operational efficiencyDrying solid materials with heatDrying gas arrangementsBrown coalProcess engineering

The invention discloses a brown coal drying method and device utilizing waste heat of smoke and steam of a power plant. The drying method comprises two-time drying treatment, wherein the two-time drying treatment comprises the steps that firstly, the high-temperature smoke directly discharged by a power plant coal fired boiler is utilized for conducting first-time drying treatment on damp materials, the high-temperature smoke directly makes uniform contact with the damp materials, and intermediate materials are obtained; and secondly, the high-temperature smoke and the high-temperature steam directly discharged by the power plant coal fired boiler are utilized for conducting second-time drying treatment on the intermediate materials at the same time, the high-temperature smoke directly makes uniform contact with the intermediate materials, meanwhile, the intermediate materials make uniform contact with a heat exchange pipe inflated with the steam for heat exchange, dried materials are obtained, and second-time drying treatment is achieved. The brown coal drying method and device have the beneficial effects that the power plant waste heat serves as a heat source for brown coal drying, the running economical efficiency of a power plant generator set is improved, a system for drying the brown coal and a brown coal power generation system are integrated, efficient utilization of power plant energy and optimization of a technology system are achieved, and the brown coal drying method and device belong to the poly-generation technology of the power plant.

Owner:邹平双飞成套设备有限公司

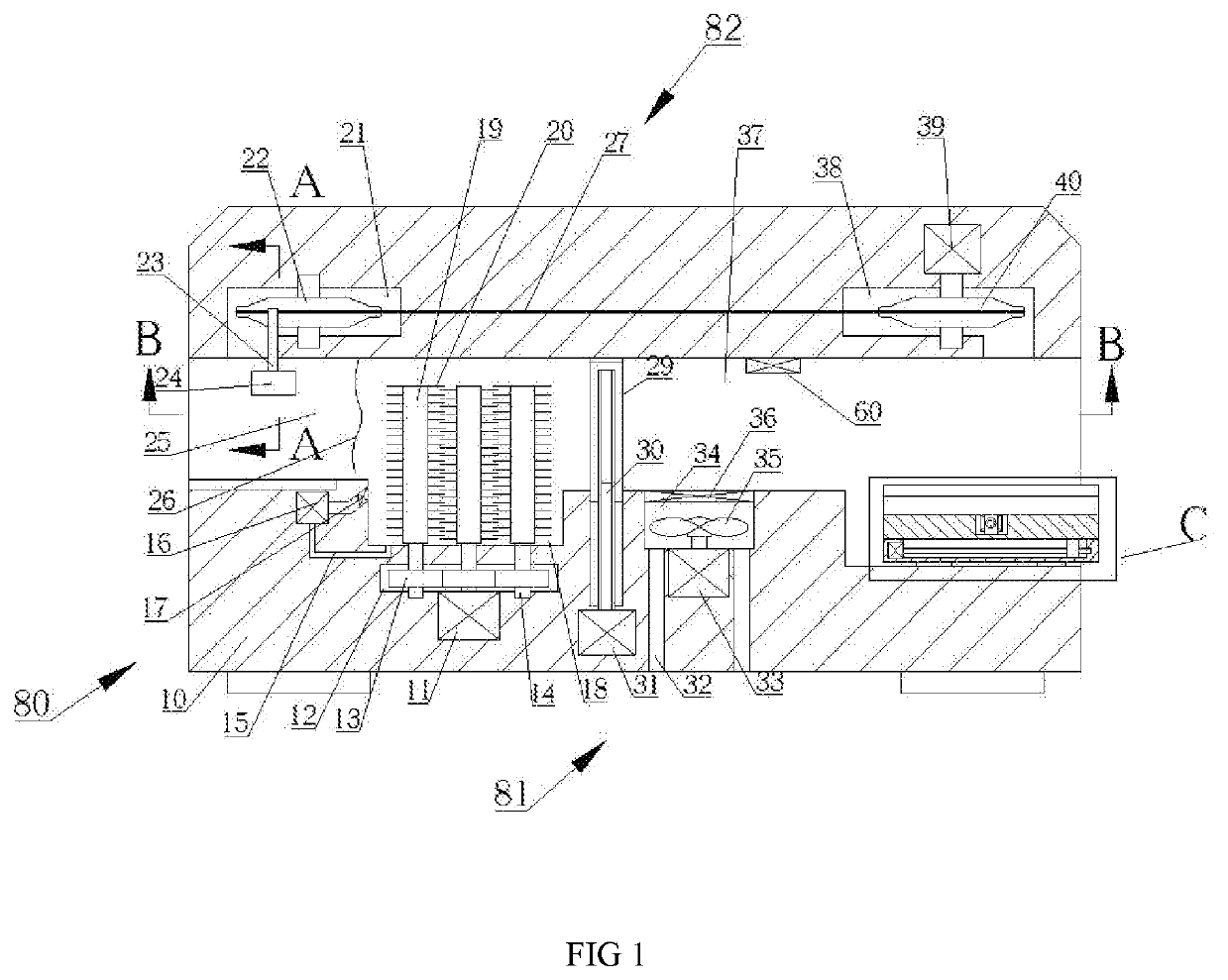

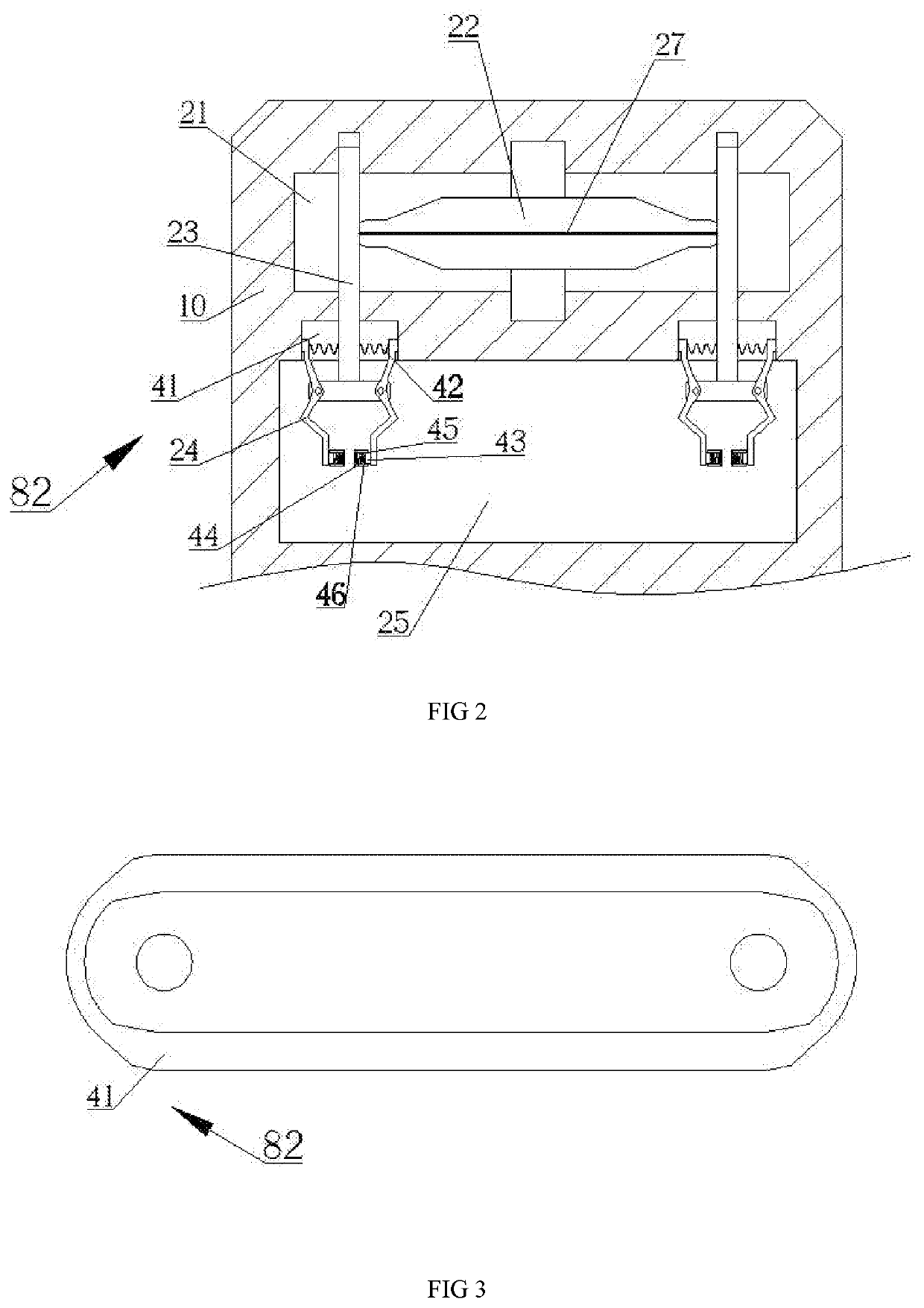

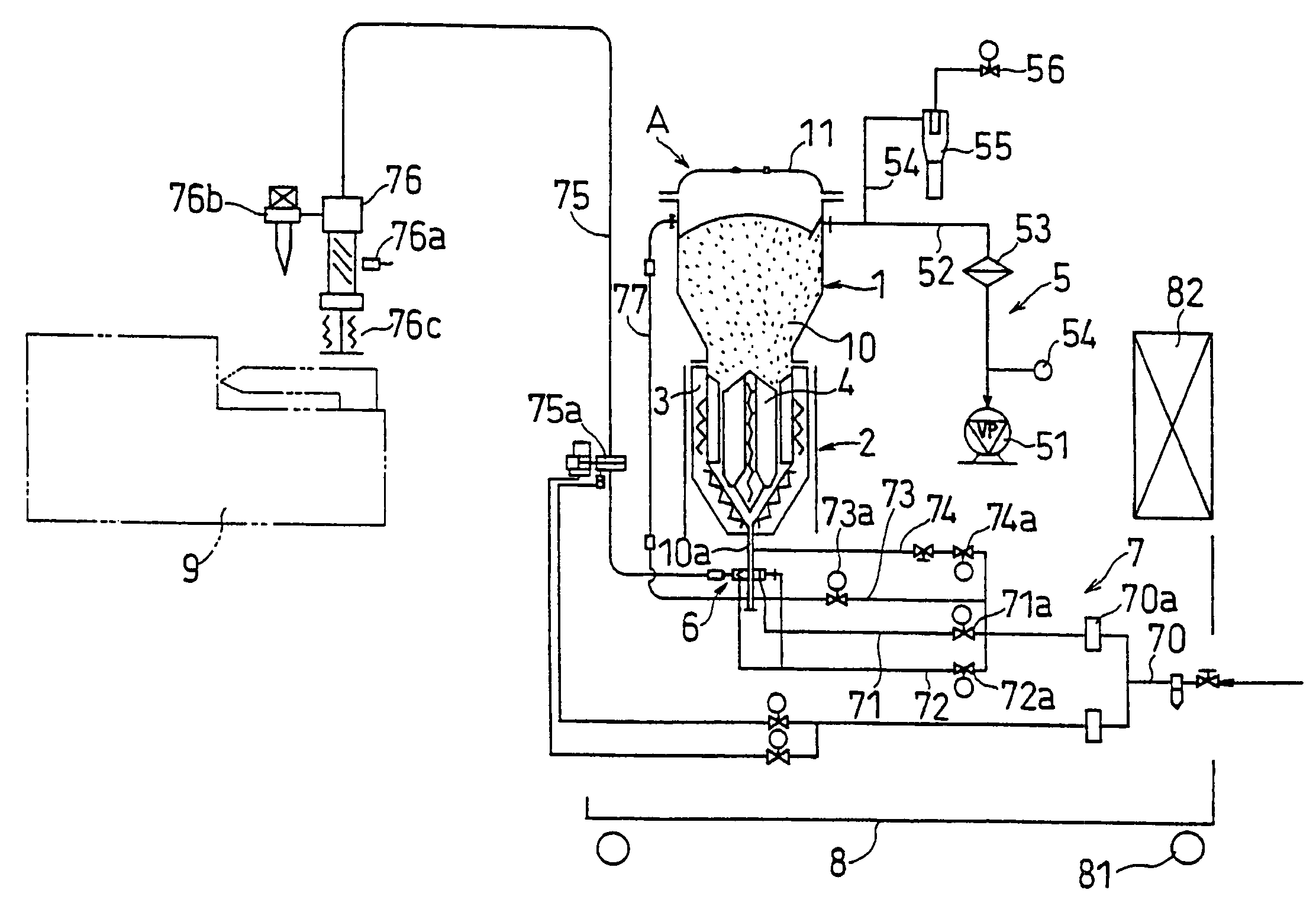

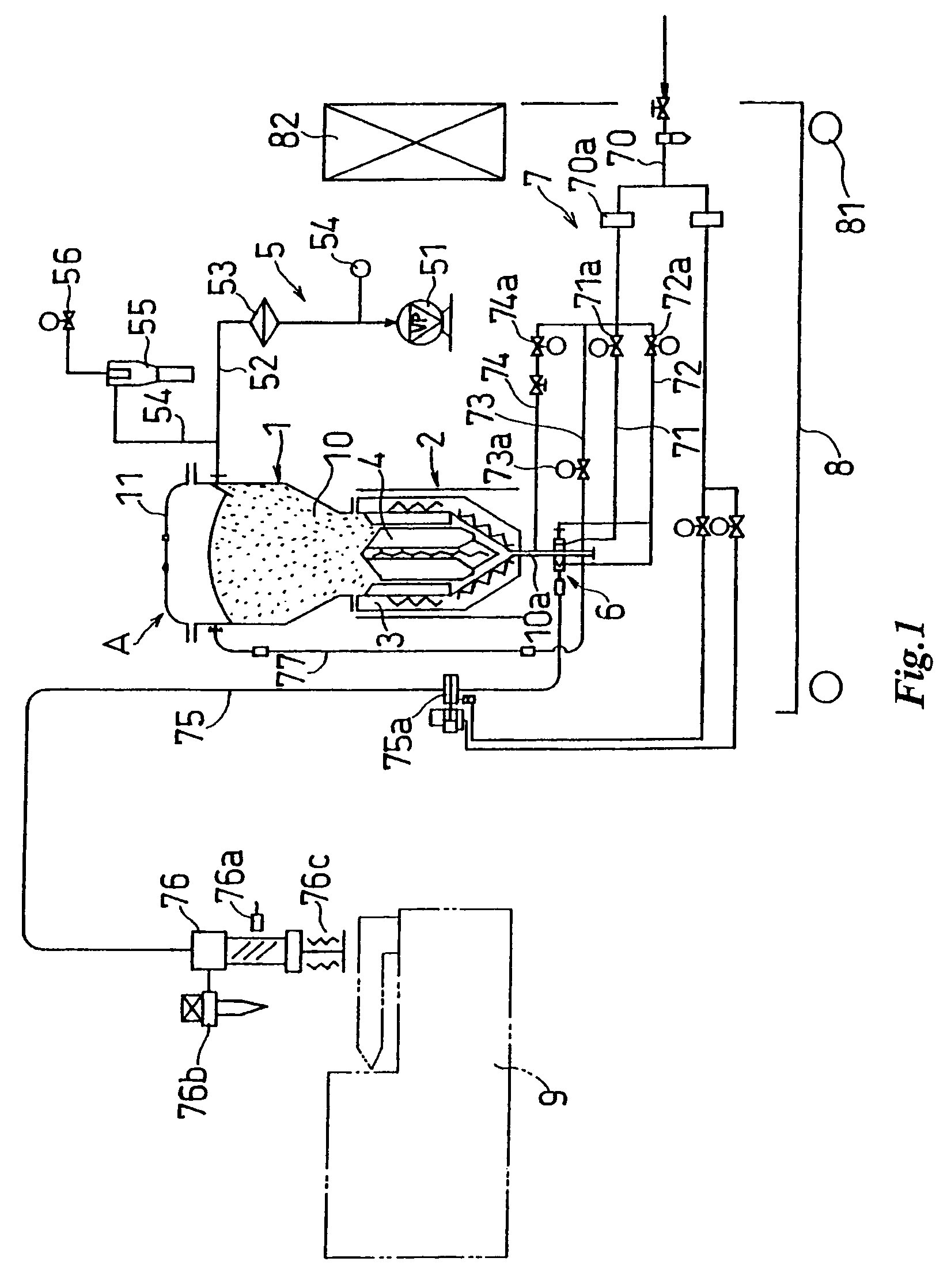

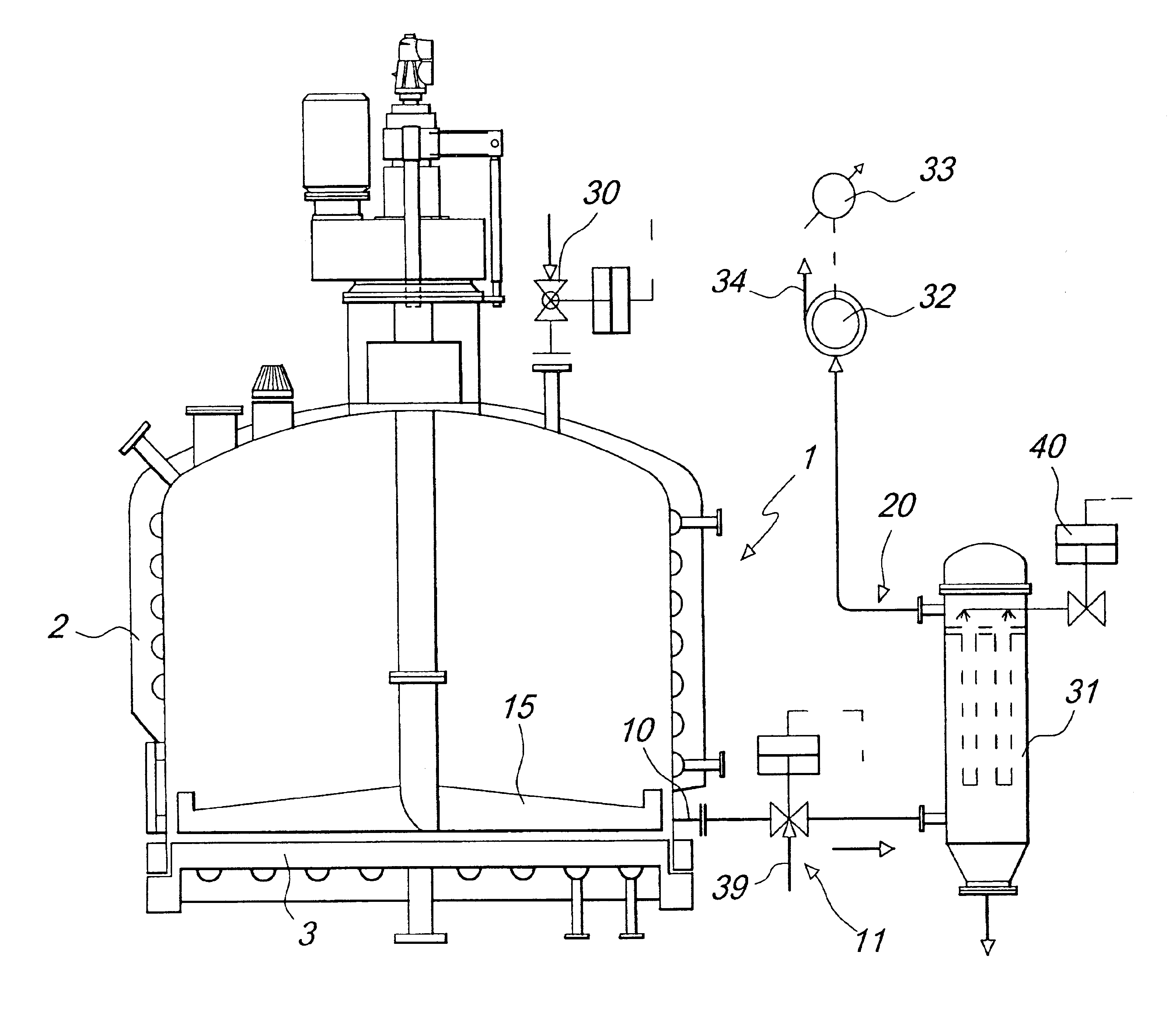

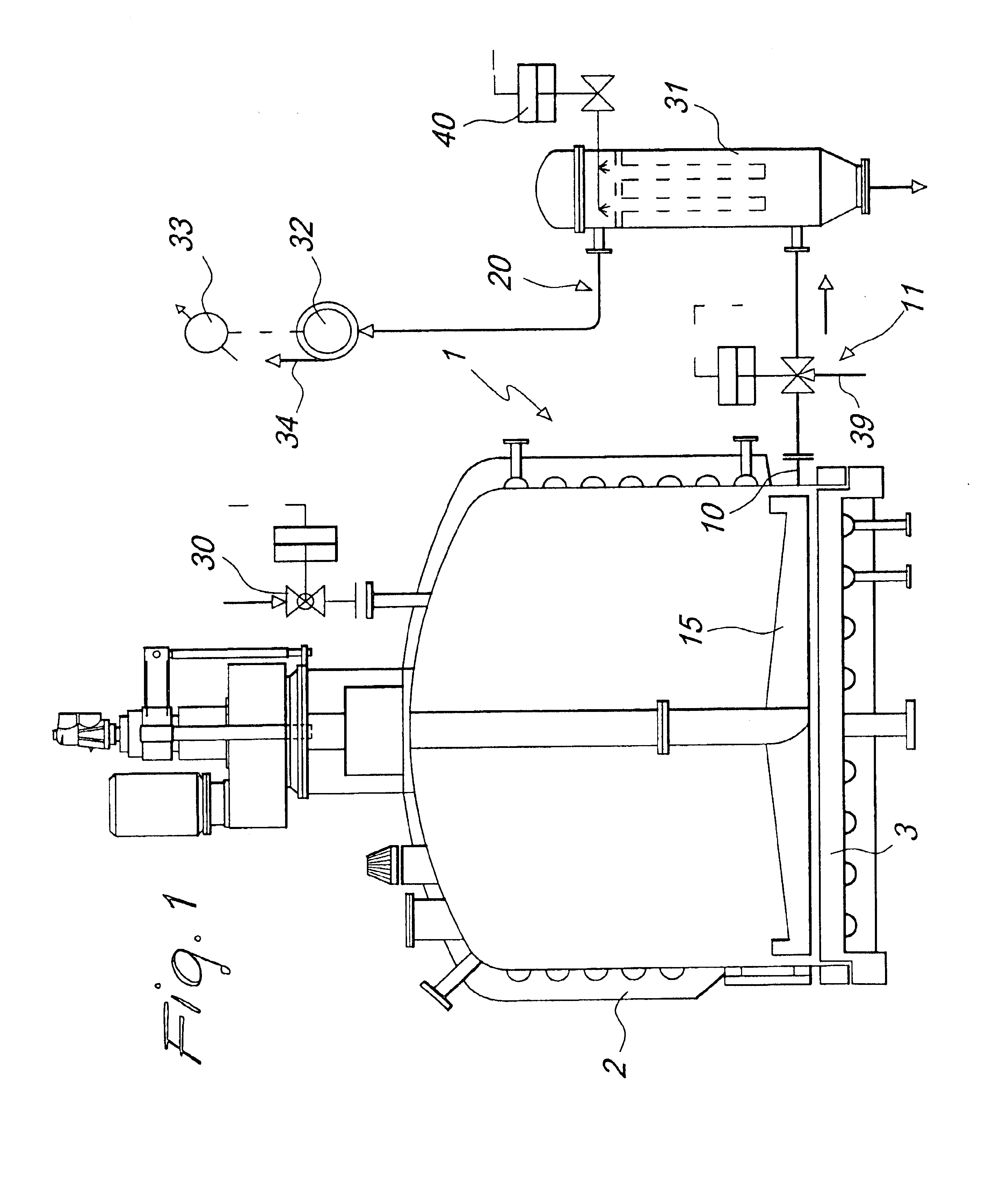

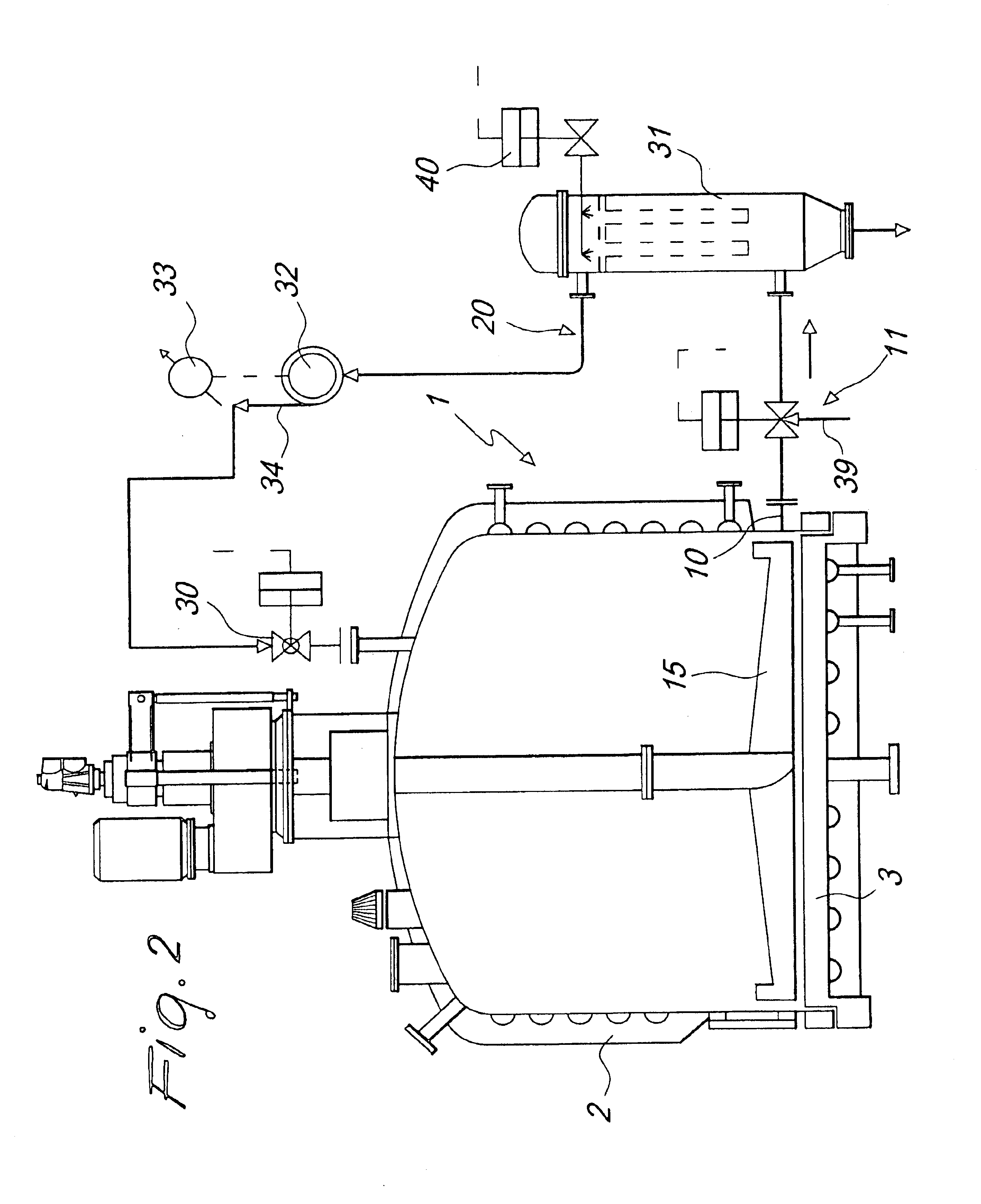

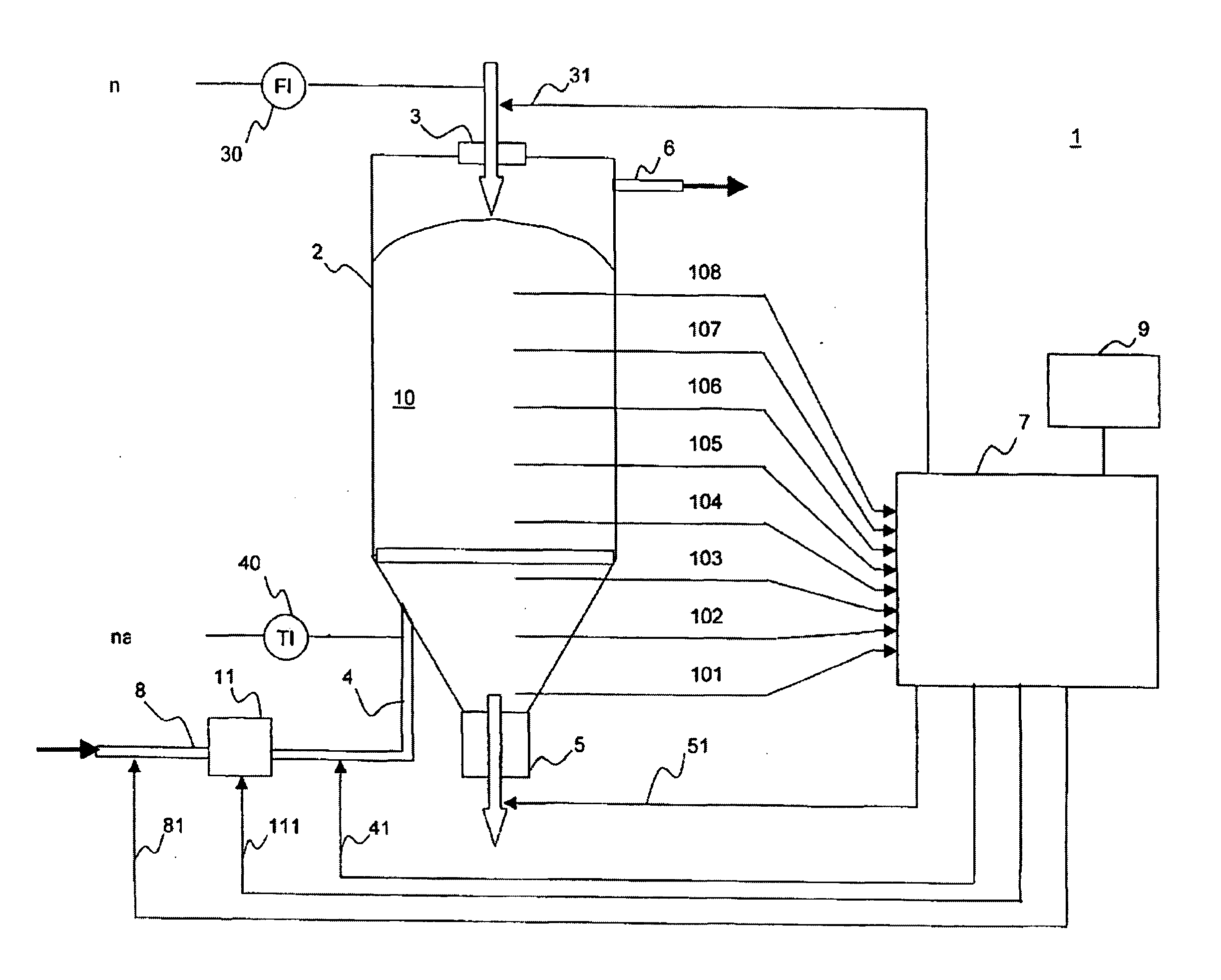

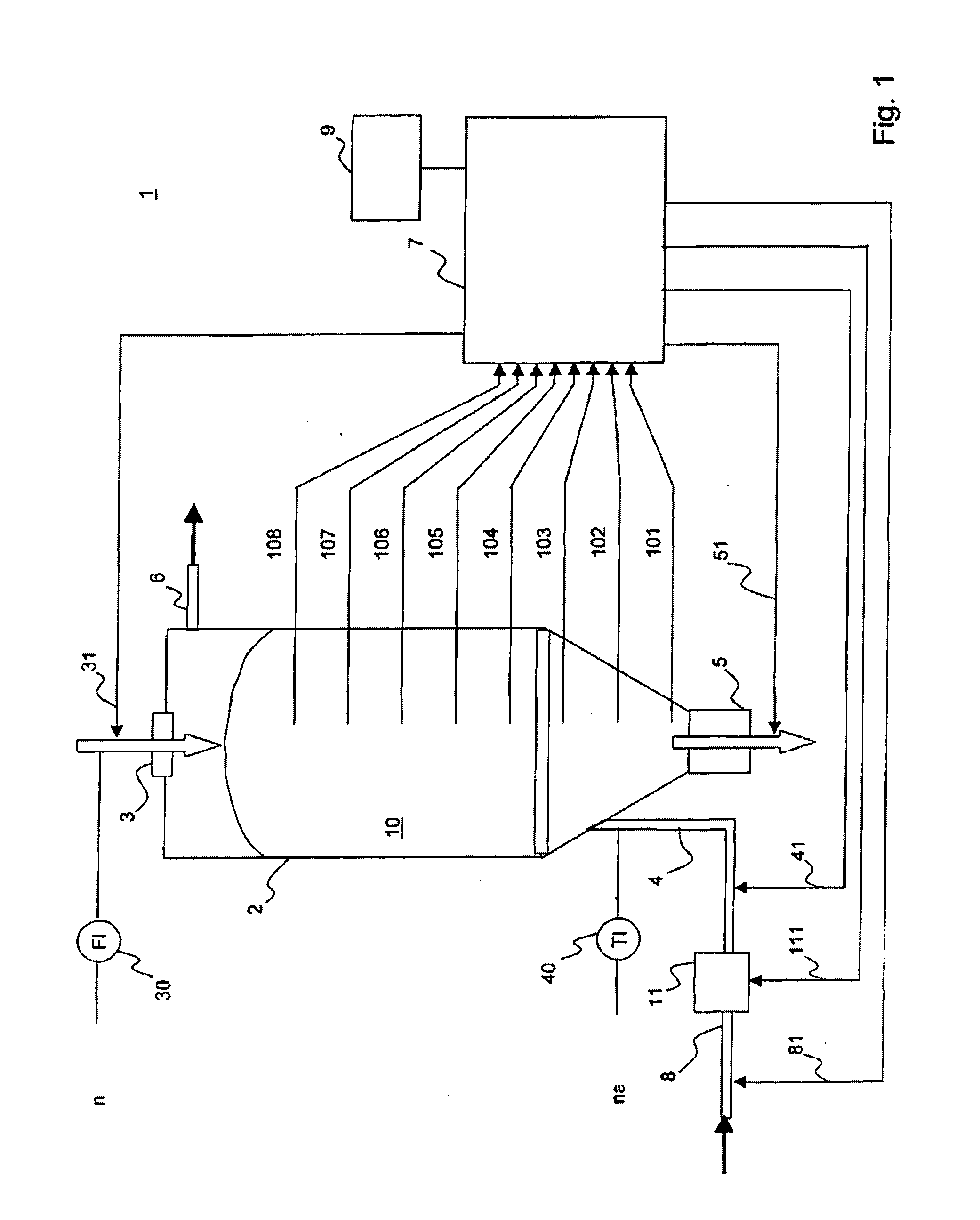

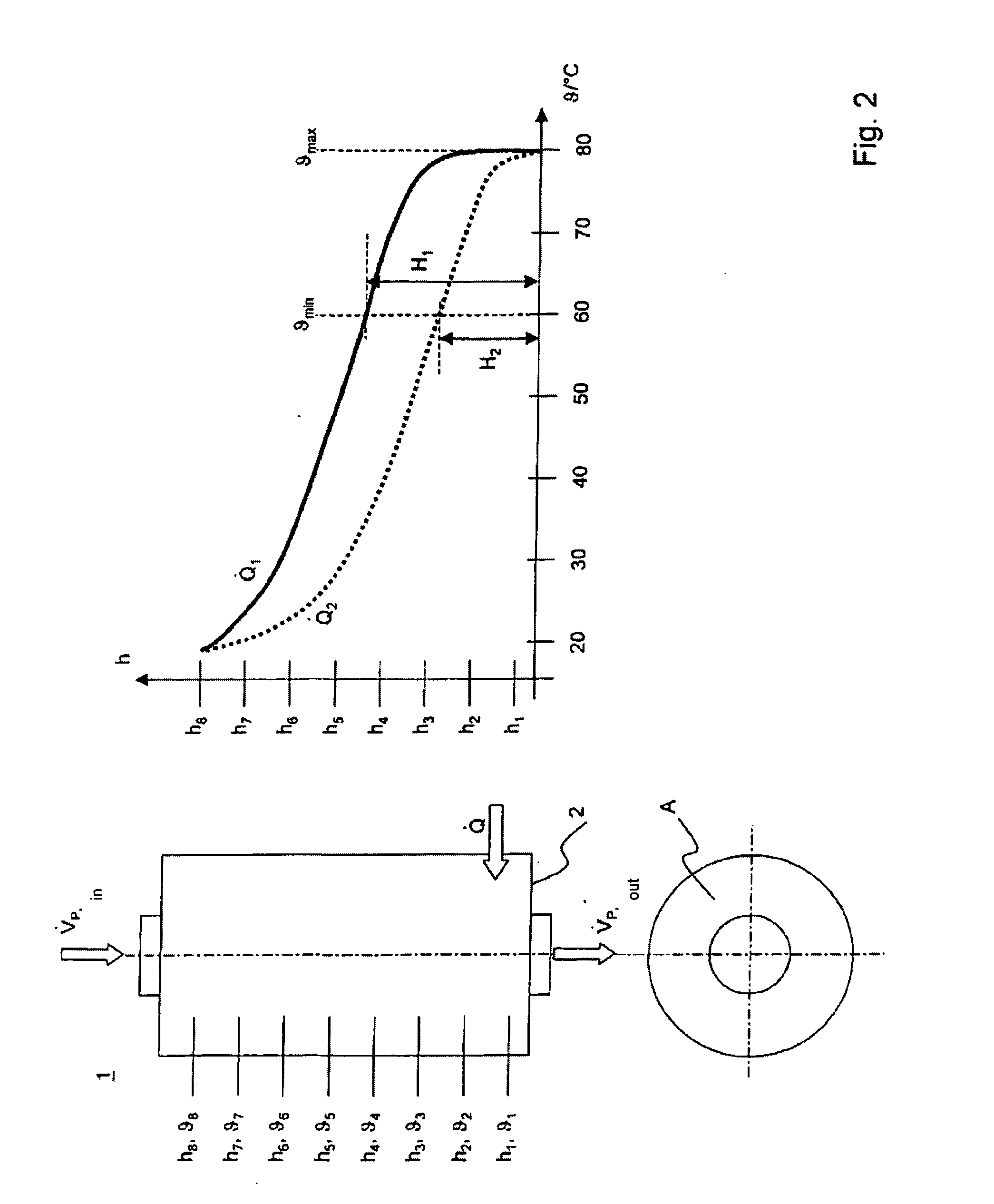

Automatic control of the drying of particulate material

InactiveUS20060168843A1Reduce trafficAvoid large quantitiesDrying solid materials with heatDrying gas arrangementsAutomatic controlProcess engineering

A method and apparatus for drying particulate material in which the drying and discharge of the particulate material may be superimposed in such a way as to permit continuous drying of particulate material even when the supply is not continuous. The quantity of heat supplied to the particulate material is controlled as a function of signals (i; hi) from temperature sensors mounted in the particulate material, which signals represent temperatures detected locally, and also as a function of a preselectable residence time (Tv) of the particulate material at a temperature within a preselectable target temperature range (min, max) and a preselectable throughput of dried particulate material such that the particulate material discharged has a temperature within the target temperature range (min, max) at least during the residence time (Tv).

Owner:PROTEC POLYMER PROCESSING

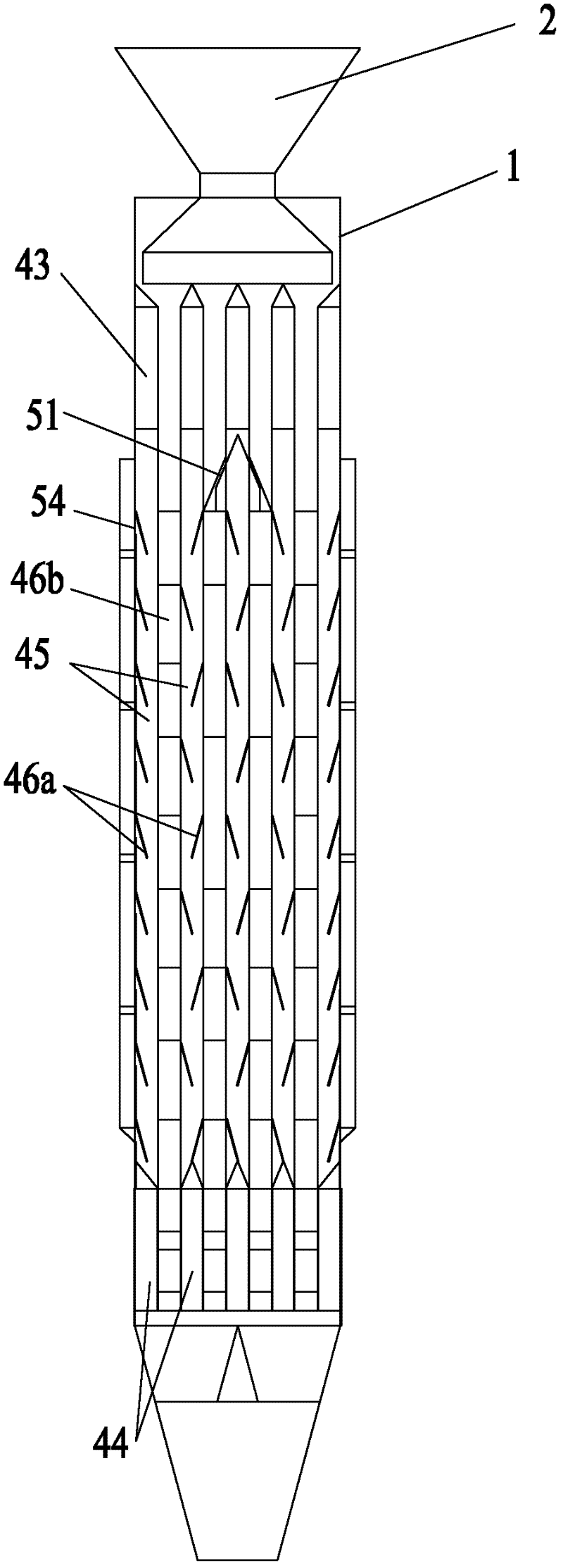

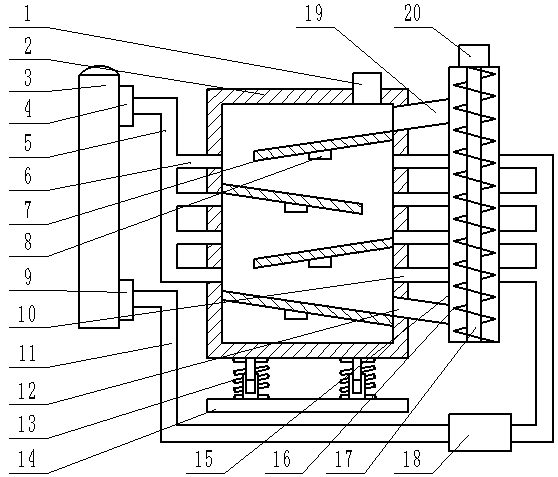

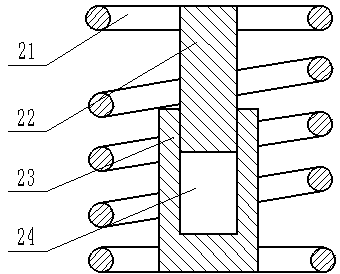

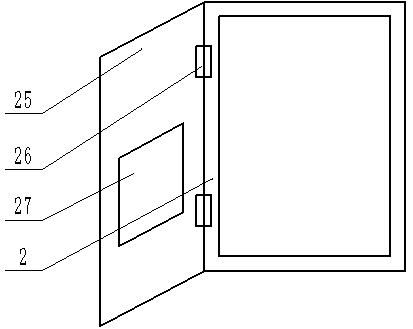

High-quality coal product production equipment and production system

InactiveCN102260559AHigh calorific valueContinuous operationDrying solid materials with heatEnergy inputProduct gasProcess engineering

The invention discloses a high-quality coal product production plant which comprises a shell and a heat conduction mechanism arranged in the shell, wherein the heat conduction mechanism is provided with a heat conduction medium inlet near the discharge end, and provided with a heat conduction medium outlet near the feed end; the heat conduction mechanism comprises a plurality of sets of heat conduction units which are distributed at intervals; each heat conduction unit comprises a plurality of heat conduction tubes which are communicated with the heat conduction medium inlet and the heat conduction medium outlet; a plurality of fins, which slope downwards, are longitudinally arranged between adjacent heat conduction tubes; and the lower end of each fin arranged between the heat conduction tubes beside the exhaust passage slopes away from the exhaust passage, so as to shield the exhaust port arranged in the wall surface of the exhaust passage. Since the fins, which are arranged in the blanking space between the heat condition tubes, can turn over the material and discharge gas, the gas can be discharged in time, and heat can be transferred quickly, thereby obtaining the high-quality coal product. The invention also discloses a high-quality coal product production system.

Owner:QIANQIU ENERGY SHANGHAI

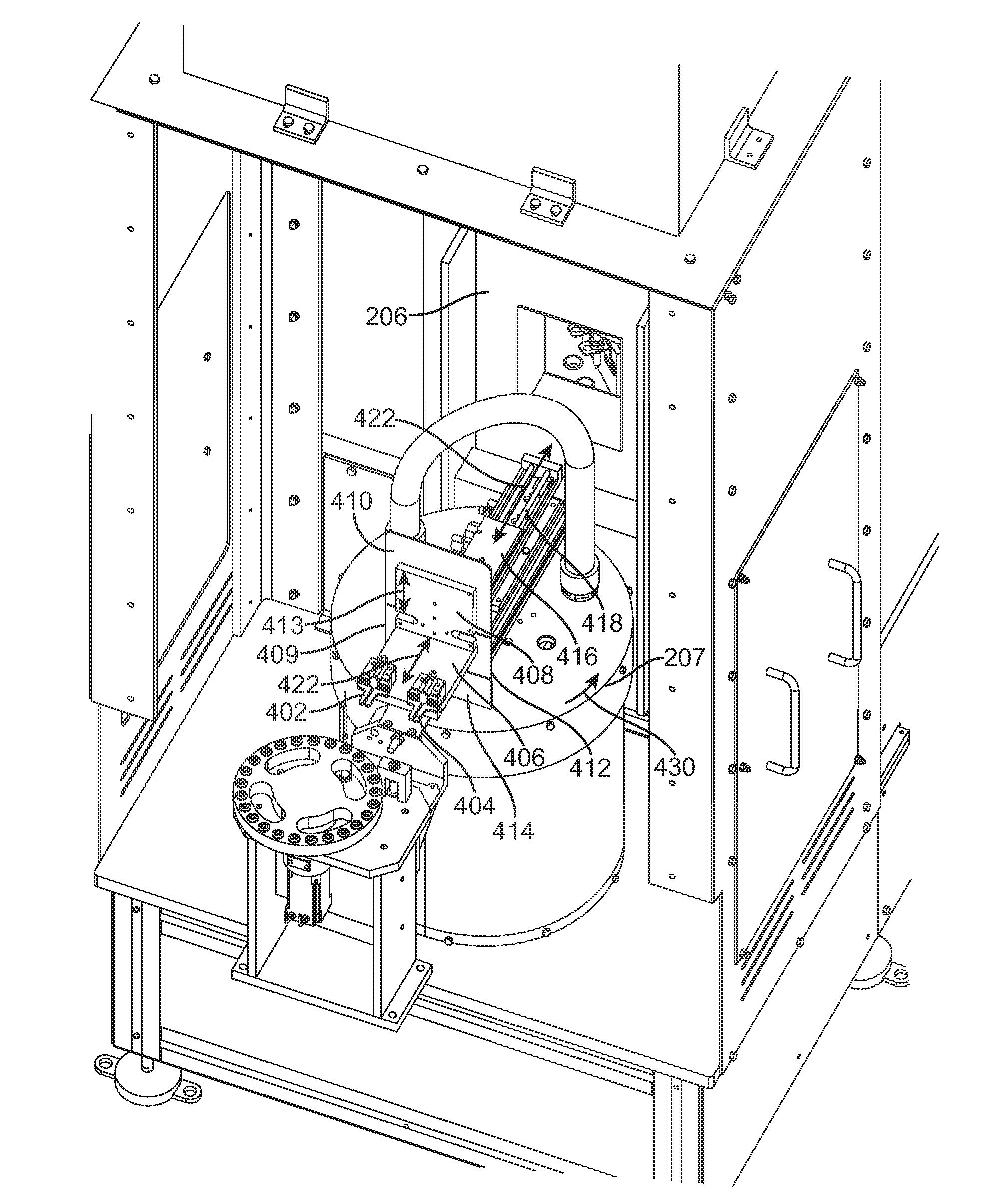

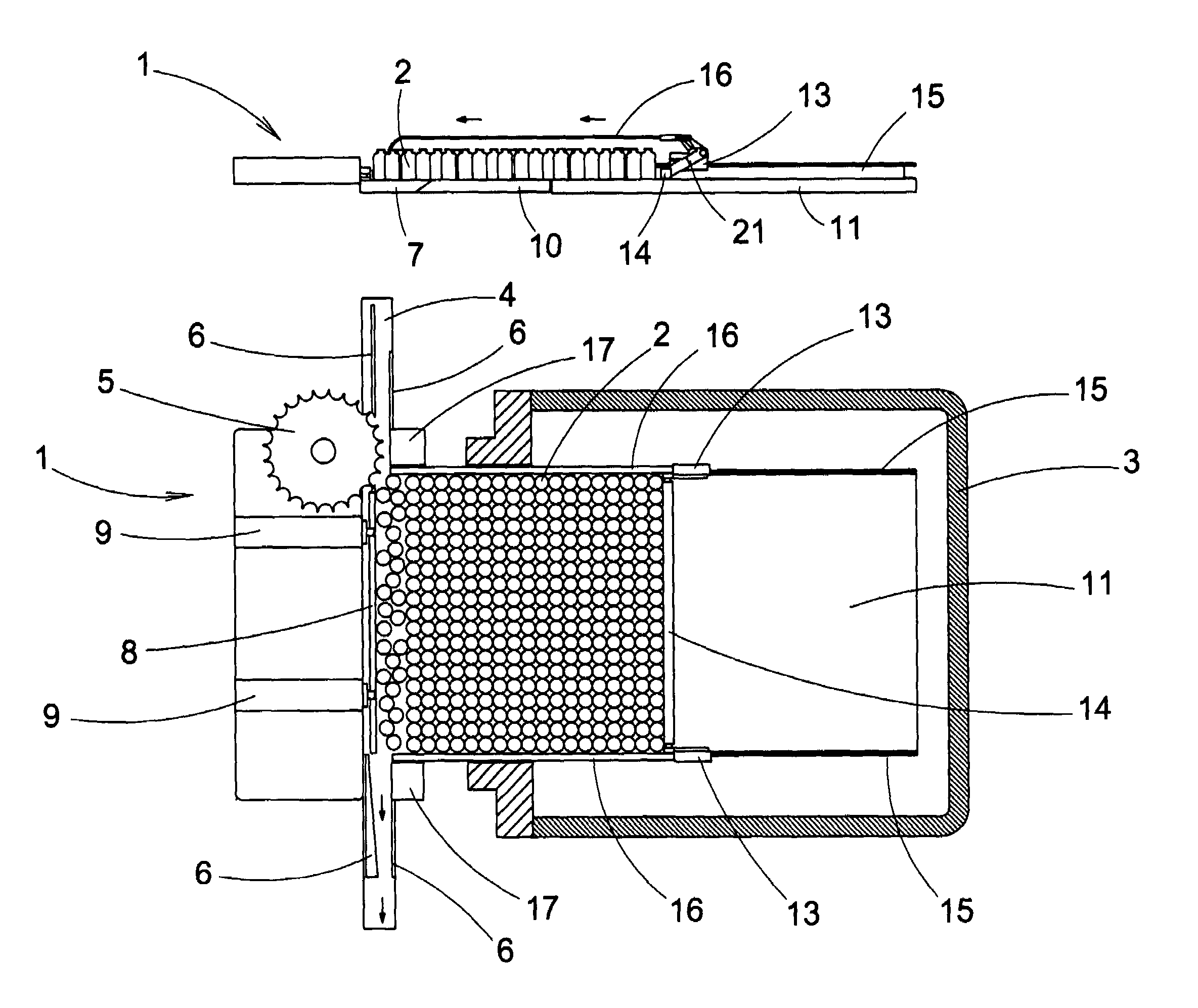

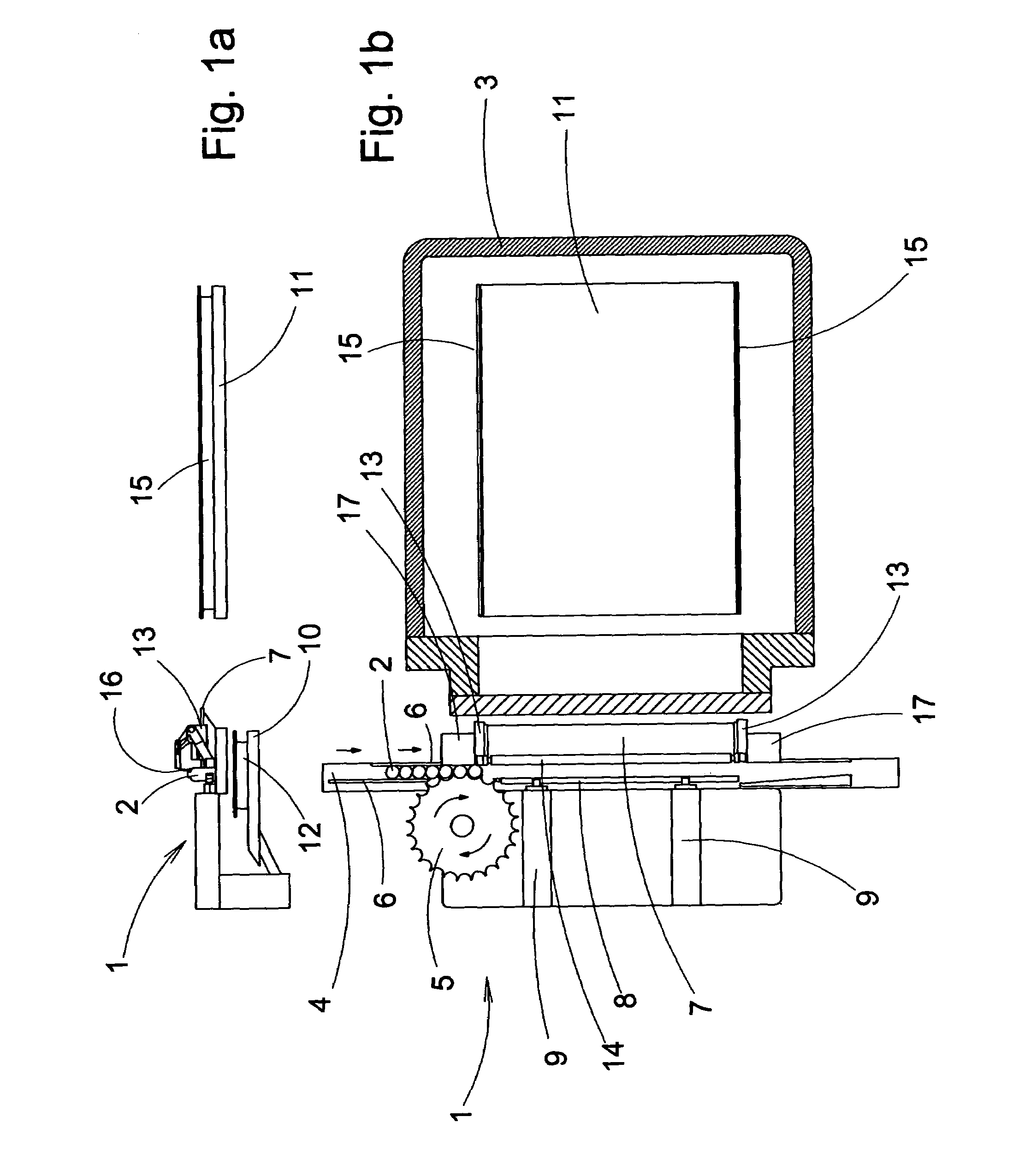

Device for loading and unloading containers

ActiveUS7343696B2Easy alignmentEasy to implementDrying solid materials without heatDrying machines with progressive movementsMechanical engineering

Owner:IMA TELSTAR

Hot air circulation grain drying device

InactiveCN107156291AImprove qualityReduce churnDrying gas arrangementsSeed preservation by dryingEngineeringHeat losses

The invention discloses a hot gas circulation grain drying equipment, which comprises a dehumidifier and a drying box; a dust removal channel is arranged above the drying box, and a winnowing device is arranged on the right side of the dust removal channel; the dust removal channel is connected with a cyclone dust collector A drying box is connected under the dust removal channel; a drying plate is arranged in the drying box; a first hot air blower, a second hot air blower and a third hot air blower are arranged between the drying plates. The present invention realizes the full utilization of the hot air and separate drying of the grains with different drying degrees by providing a circulating hot air drying device and hot air blowers with different powers, reducing heat loss and saving energy; the present invention is provided with staggered distribution The drying plate improves the drying efficiency and the drying effect; the invention is equipped with a high-school dust removal device to remove dust and shriveled grains in the grain, improves the quality of the grain, and saves storage space.

Owner:惠安益源信息技术咨询有限公司

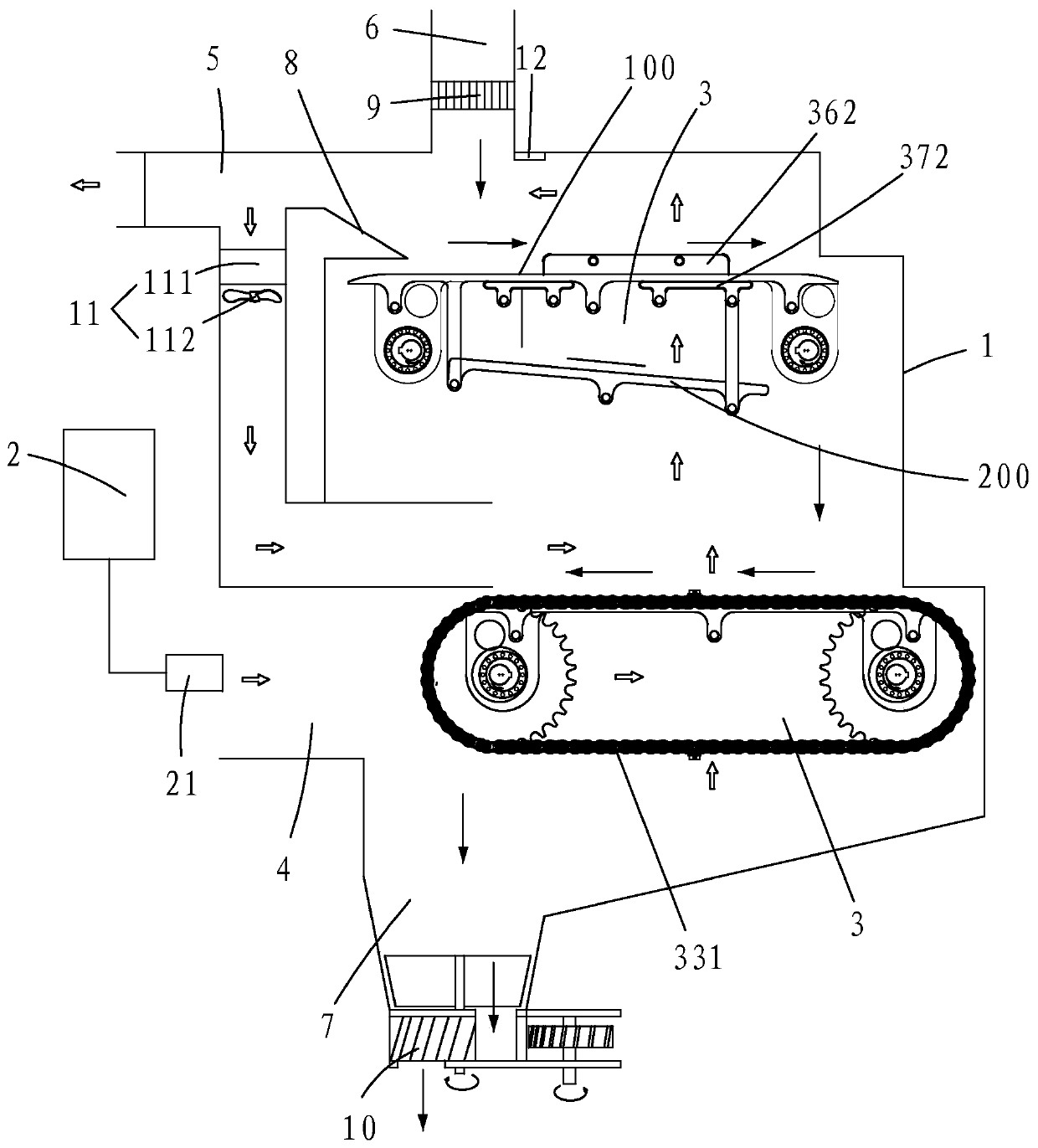

Cereal circular drying equipment

InactiveCN107687757AAvoid accumulationImprove drying qualityDrying gas arrangementsSeed preservation by dryingEngineeringHot blast

The invention discloses cereal circular drying equipment. The cereal circular drying equipment comprises a box body, a hot-blast stove and a lifting drum. A plurality of guide plates are arranged in the box body; the box body communicates to the lifting drum through a discharge pipe and a feeding pipe; a bottom plate is arranged below the box body; a plurality of damping devices are arranged between the bottom plate and the bottom surface of the box body; a plurality of air inlet branch pipes are uniformly arranged on the outer side wall of the left end of the box body; the air inlet branch pipes are connected to the air outlet of the hot blast stove through a main air inlet pipe; a plurality of air outlet branch pipes are uniformly arranged on the outer side wall of the right side of thebox body and are connected to the air inlet of the hot blast stove through a main air outlet pipe; the main air outlet pipe is connected to a dedusting and dehumidifying device; and the dedusting anddehumidifying device comprises a barrel. The cereal circular drying equipment disclosed by the invention is simple in structure and reasonable in design, can utilize human energy to the maximum extentby means of circulating air, and is very high in drying efficiency on cereals, and furthermore, the drying quality of cereals is very good and the dehydrating rate is very high.

Owner:俞纪洪

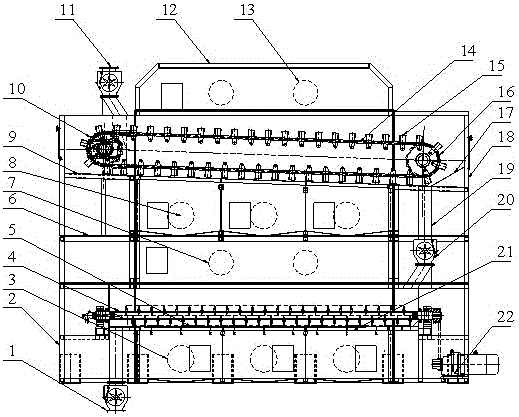

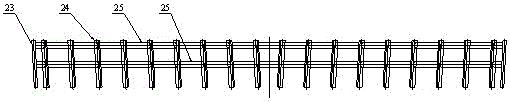

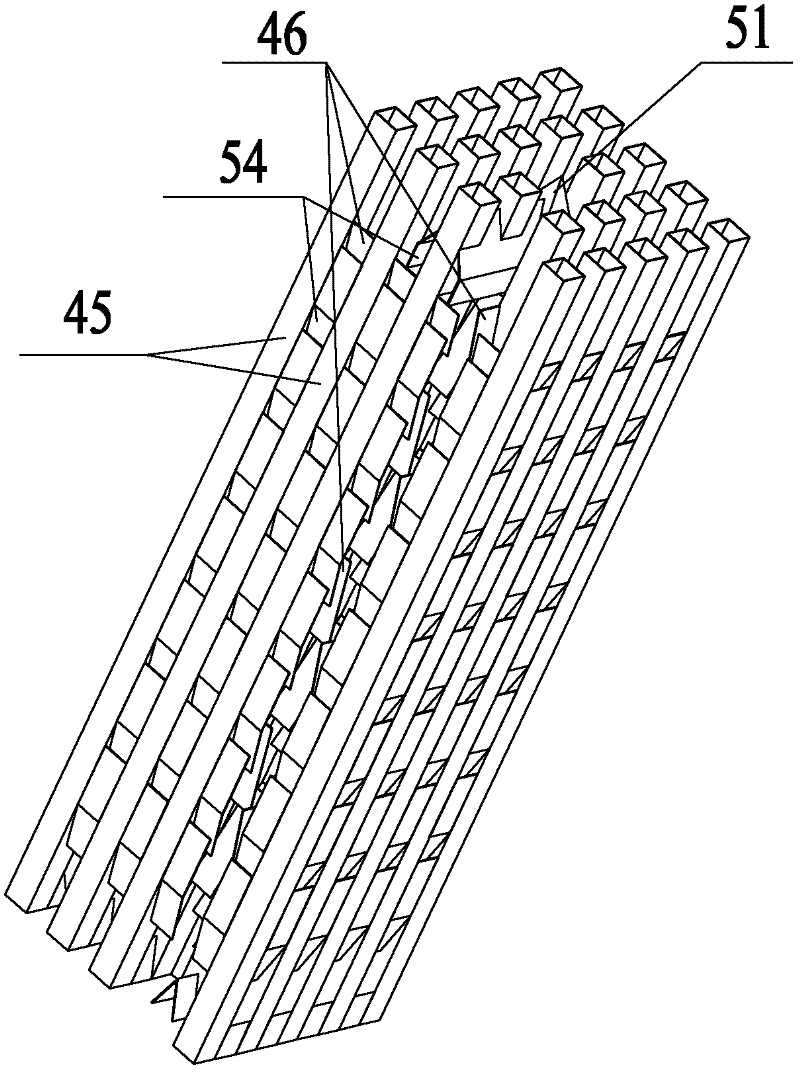

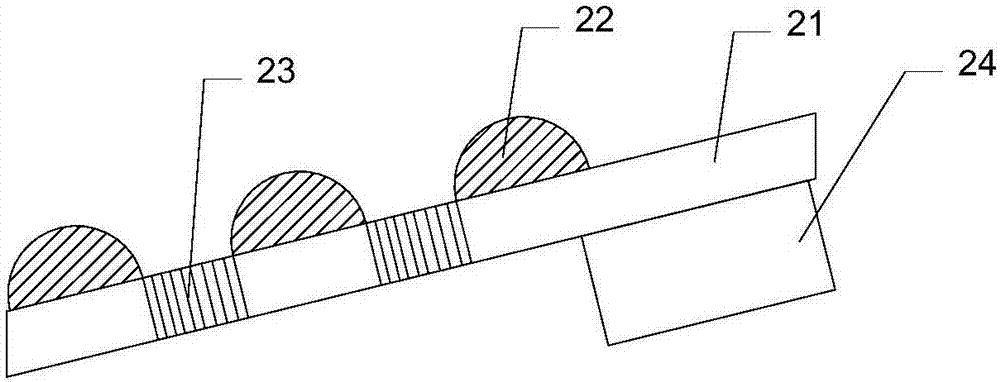

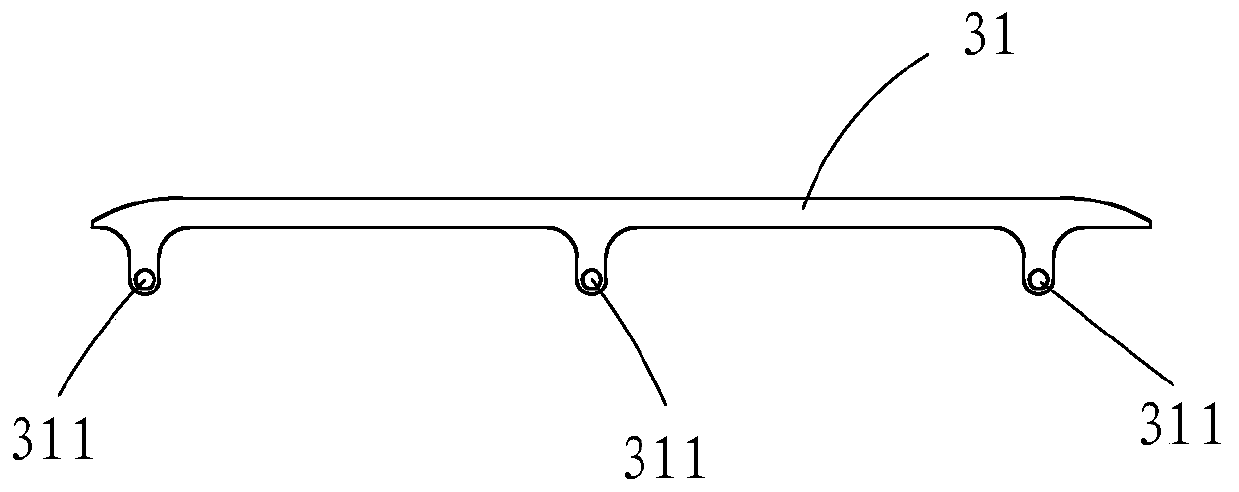

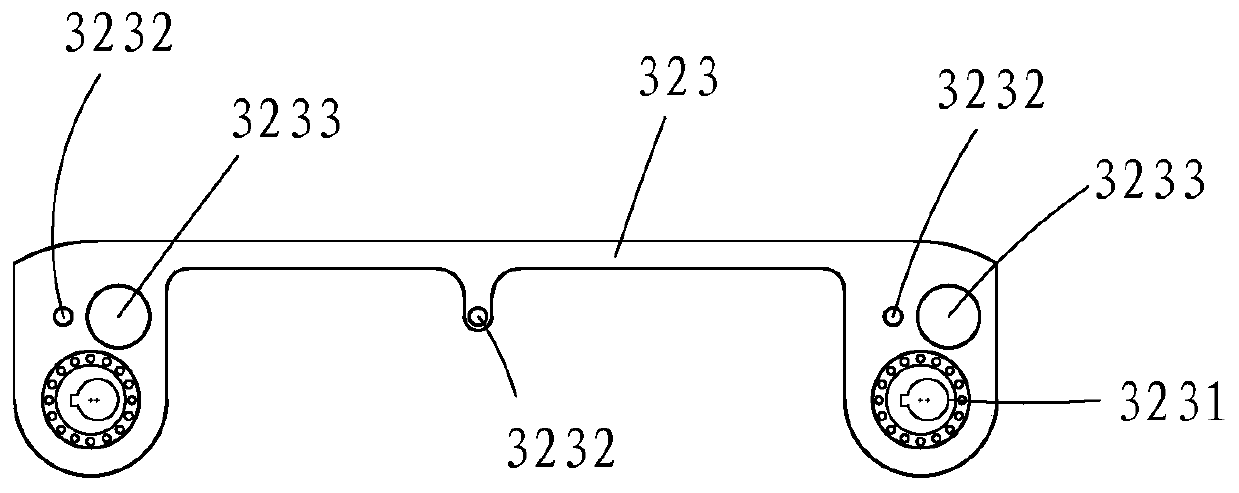

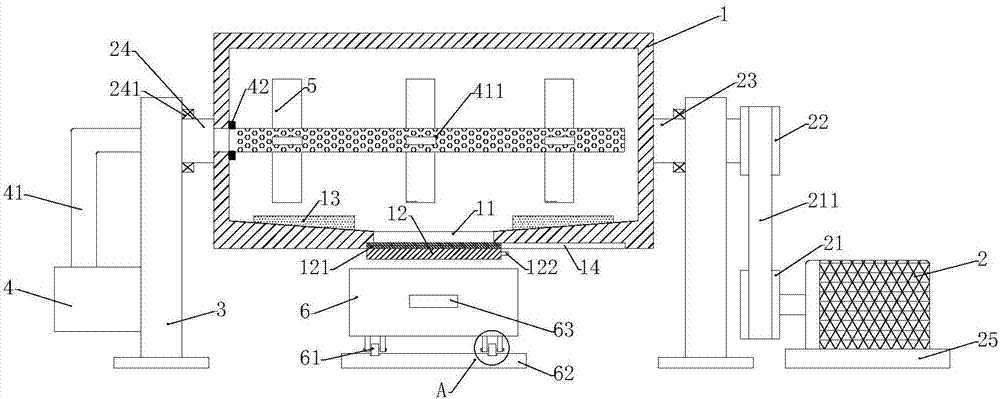

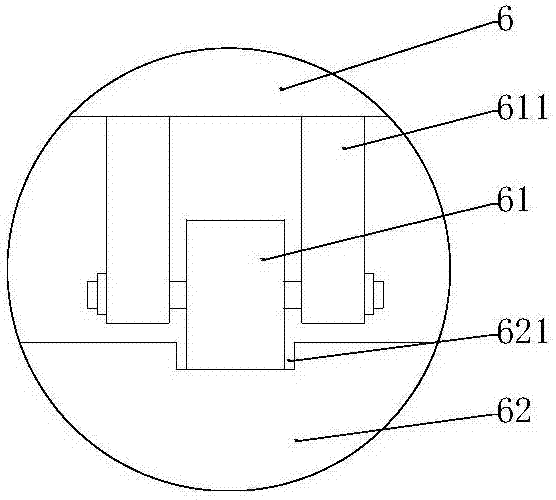

Peristaltic propulsion type drying equipment

PendingCN110487026AEasy to dryEfficient dryingSludge treatment by de-watering/drying/thickeningDrying gas arrangementsProcess engineeringHeat supply

The invention discloses peristaltic propulsion type drying equipment. The peristaltic propulsion type drying equipment comprises a heat supply module, a drying chamber and a material conveying devicearranged in the drying chamber, wherein the drying chamber is provided with a heat source inlet, a heat source outlet, a material inlet and a material outlet; a heat source of the heat supply module is arranged at the position of the heat source inlet and used for providing a heat source for the drying chamber; the material conveying device is used for providing a platform for horizontally pavingmaterials and pushing materials, and comprises two or more groups of grid strips which are laminated at intervals to form a laminated propelling type material conveying platform; a gap is formed between every two adjacent grid strips; and when the materials are conveyed forwards, the ventilation gaps are kept smooth, and the advancing materials are repeatedly overturned. According to the peristaltic propulsion type drying equipment, in the material conveying process, the interactive grid strips generate the transparent gaps, so that the mobility of air is improved, and the materials are advantageously dried.

Owner:AMCON FUJIAN ENVIRONMENT PROTECTION EQUIP CO LTD

Efficient grain drying device capable of achieving feeding easily

InactiveCN106979674AFully contactedGuaranteed drying effectDrying gas arrangementsSeed preservation by dryingAgricultural engineeringStacker

The invention discloses a high-efficiency and easy-to-cut grain drying device, which includes a drying cylinder, a motor, symmetrically arranged support columns, a hot air blower and a material receiving frame; the drying cylinder is arranged between two support columns; The center position of the bottom of the drying cylinder is provided with a discharge opening, and a cover plate is arranged on the discharge opening, and the bottom of the drying cylinder is located on both sides of the discharge opening, and counterweights are fixed symmetrically; the hot air blower is installed on the left side On the supporting column, the hot air blower is connected to the hot air pipe, and the hot air pipe runs through the connecting shaft from the axis of the connecting shaft and goes deep into the right side of the drying cylinder. The hot air pipe is densely provided with air outlets; the hot air pipe is deeply dried A plurality of turning plates are fixed on the periphery of the tube body of the cylinder; a material receiving frame is arranged at the position directly facing the discharge opening under the drying cylinder. The grain drying device of the present invention has good drying effect and is convenient for unloading.

Owner:合肥智慧殿机械设计有限公司

Process and apparatus for the treatment or processing of containers for substances for medical, pharmaceutical or cosmetic applications

ActiveUS20170183113A1Simple and reliable processThe method is simple and reliableClosures with freeze-dryingDrying solid materials without heatEngineeringMedical treatment

Disclosed is a process for the treatment or processing of containers that serve for storing, or contain, substances for medical, pharmaceutical or cosmetic applications, wherein the containers are conveyed automatically, by a conveyor, past at least one processing station or pass it for the treatment or processing. In the process, a plurality of containers is conveyed by the conveyor while being held by a carrier in a regular arrangement. The containers held on the carrier are raised to a raised position for the treatment or processing at or in the respective processing station and are lowered after the treatment or processing, to be held again on the carrier in the regular arrangement. The carrier is configured such that the containers can be held on the carrier during the entire process. A negative pressure acts on the bottoms of the containers in order to lower them.

Owner:SCHOTT PHARMA AG & CO KGAA

Tea leaf drying device

InactiveCN105605889AAvoid damageImprove filtering effectDrying solid materials with heatDrying solid materials without heatPulp and paper industryHeat losses

The invention discloses a tea leaf drying device. The tea leaf drying device comprises a base and a drying box. The drying box is arranged above the base, supporting legs are arranged between the drying box and the base, an electromagnetic heating coil is embedded in the wall of the drying box, a feeding hopper is arranged at the upper end of the drying box, a discharging pipe is arranged at the lower end, located in the drying box, of the feeding hopper, an air jet pipe is arranged in the drying box, an air jet port is formed in the upper side of the wall of the air jet pipe, an exhaust port is formed in the upper left end of the drying box, the air outlet end of the exhaust port is connected with a circulating fan, an air outlet of the circulating fan is connected with the air inlet end of the air jet pipe through an air guide pipe, the air guide pipe penetrates through a filtering box and a dehumidifying box in sequence from top to bottom, a discharging door is further arranged at the bottom of the drying box, and a conveying belt is further arranged on a base at the lower end of the drying box. The tea leaf drying device is simple and reasonable in structure, high in heating efficiency and good in drying effect; heat loss is avoided while dryness of air in the drying box is maintained, and thus the effect of saving energy is achieved.

Owner:廖志标

Dryer Conveyor Speed Control Apparatus and Method

InactiveUS20140047731A1Drying solid materials without heatDrying gas arrangementsSpeed control systemControl system

In one embodiment, a conveyor speed control system for a dryer is provided. The system includes a dryer having a housing with an entrance and an exit, and a conveyor within the housing, the conveyor capable of moving at a desired speed. A sensor senses the temperature of the interior of the dryer housing. A controller is provided. The controller receives a signal from the temperature sensor. The controller also controls the speed of the conveyor, and limits the speed of the conveyor to a desired speed until a desired dryer housing temperature is attained.

Owner:M&R PRINTING EQUIP

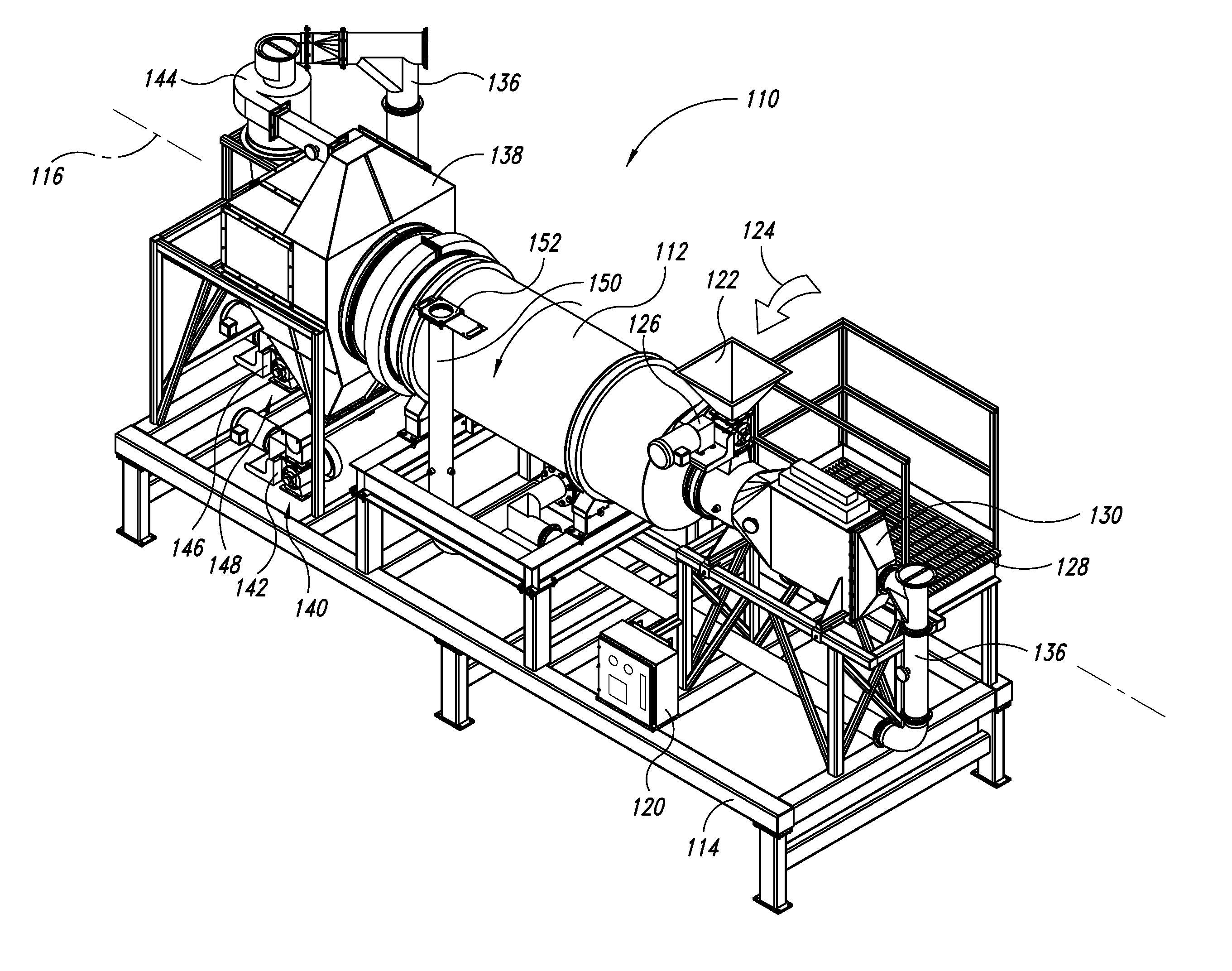

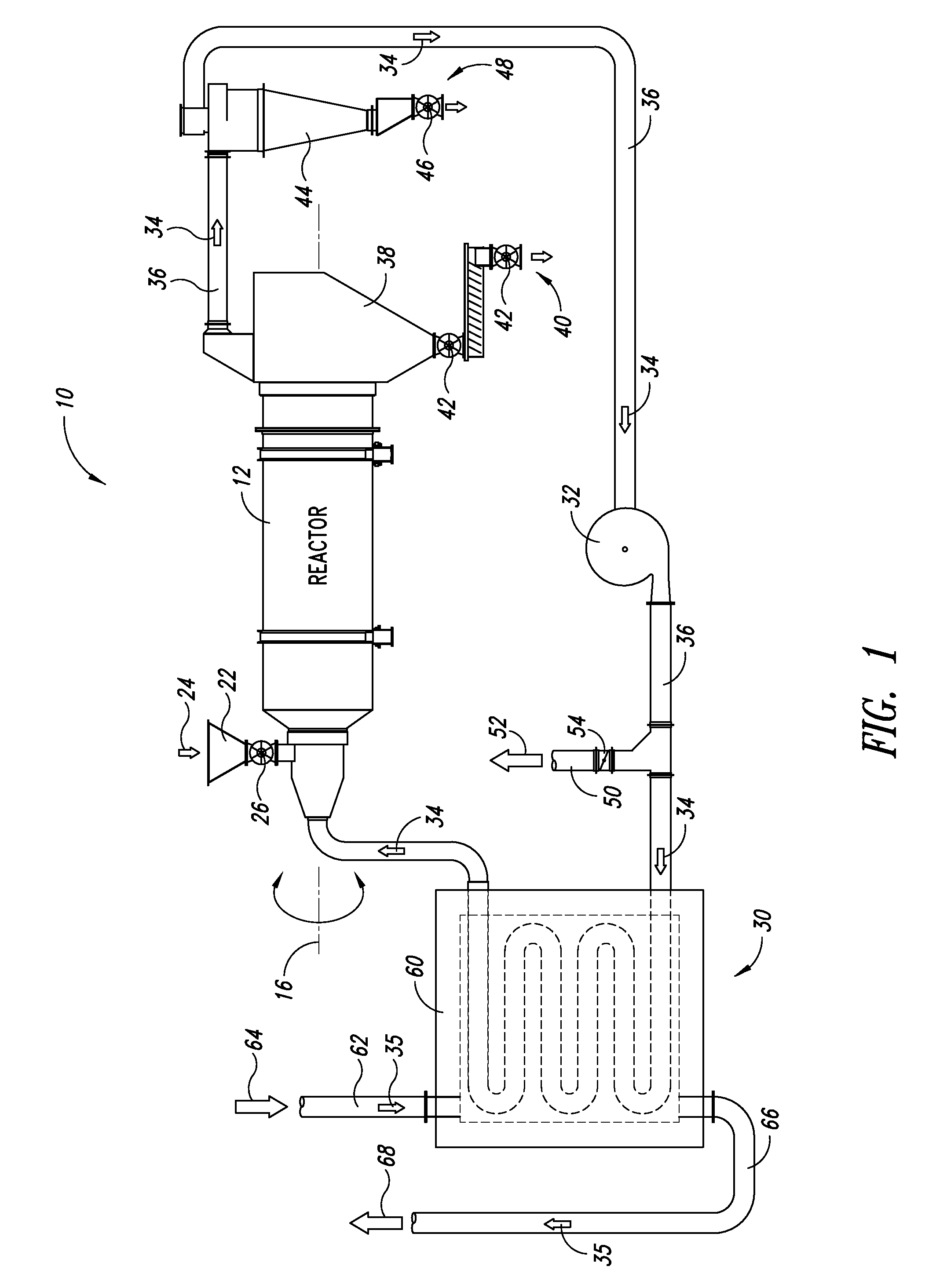

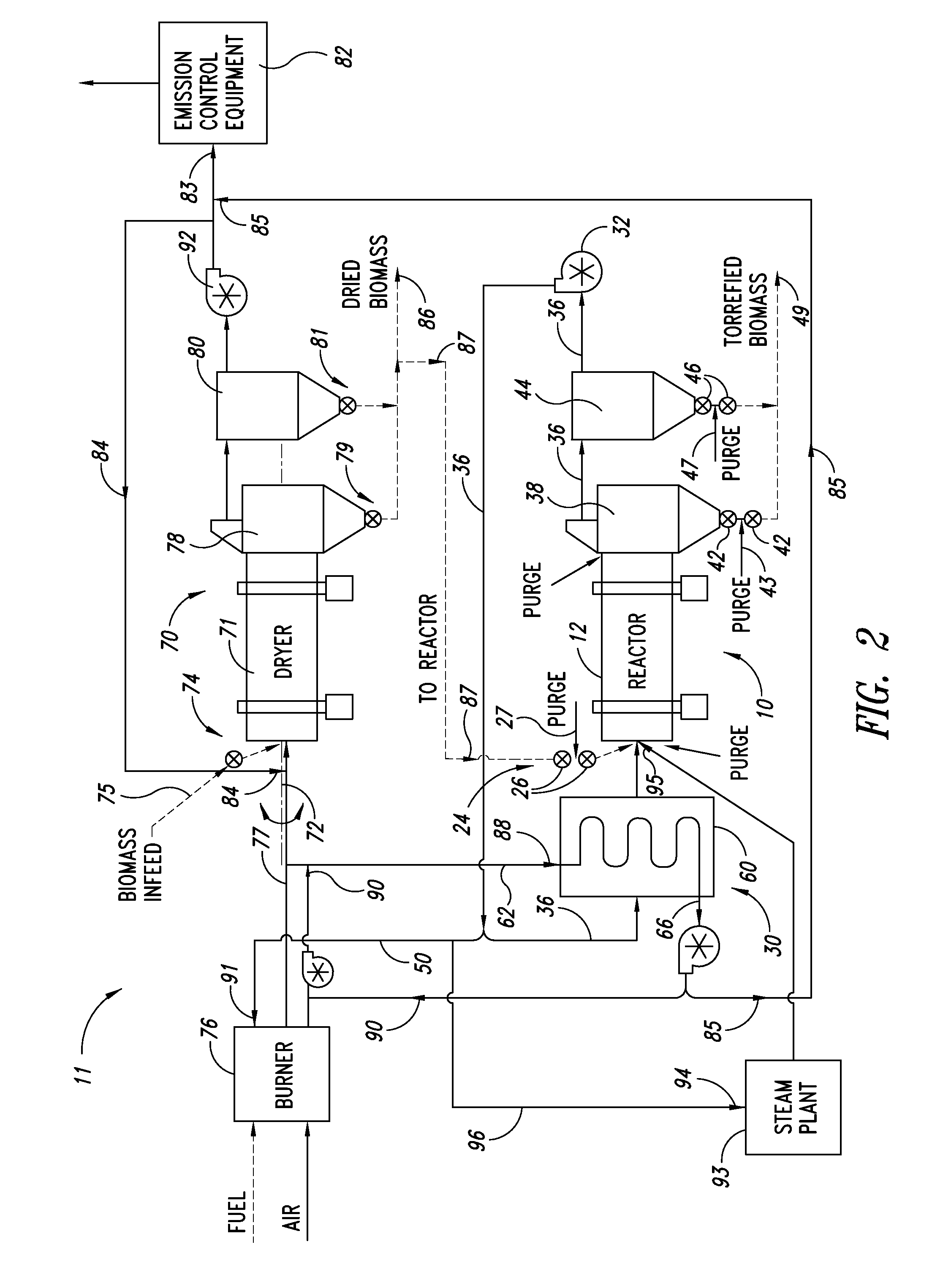

Biomass torrefaction system and method

ActiveUS8246788B2Improve scalabilityEasy to controlCombustible gas coke oven heatingDrying solid materials with heatProcess engineeringTorrefaction

A biomass torrefaction system is provided which enables a continuous torrefaction process that involves the introduction of biomass particles into a rotating reactor drum having a low oxygen environment. The particles are conveyed through the drum by a heated gas stream and simultaneously torrefied thereby. Gas exiting the drum is recirculated back to a heat source for reheating the gas prior to reentering the drum. A method of biomass torrefaction is also provided.

Owner:TEAL SALES

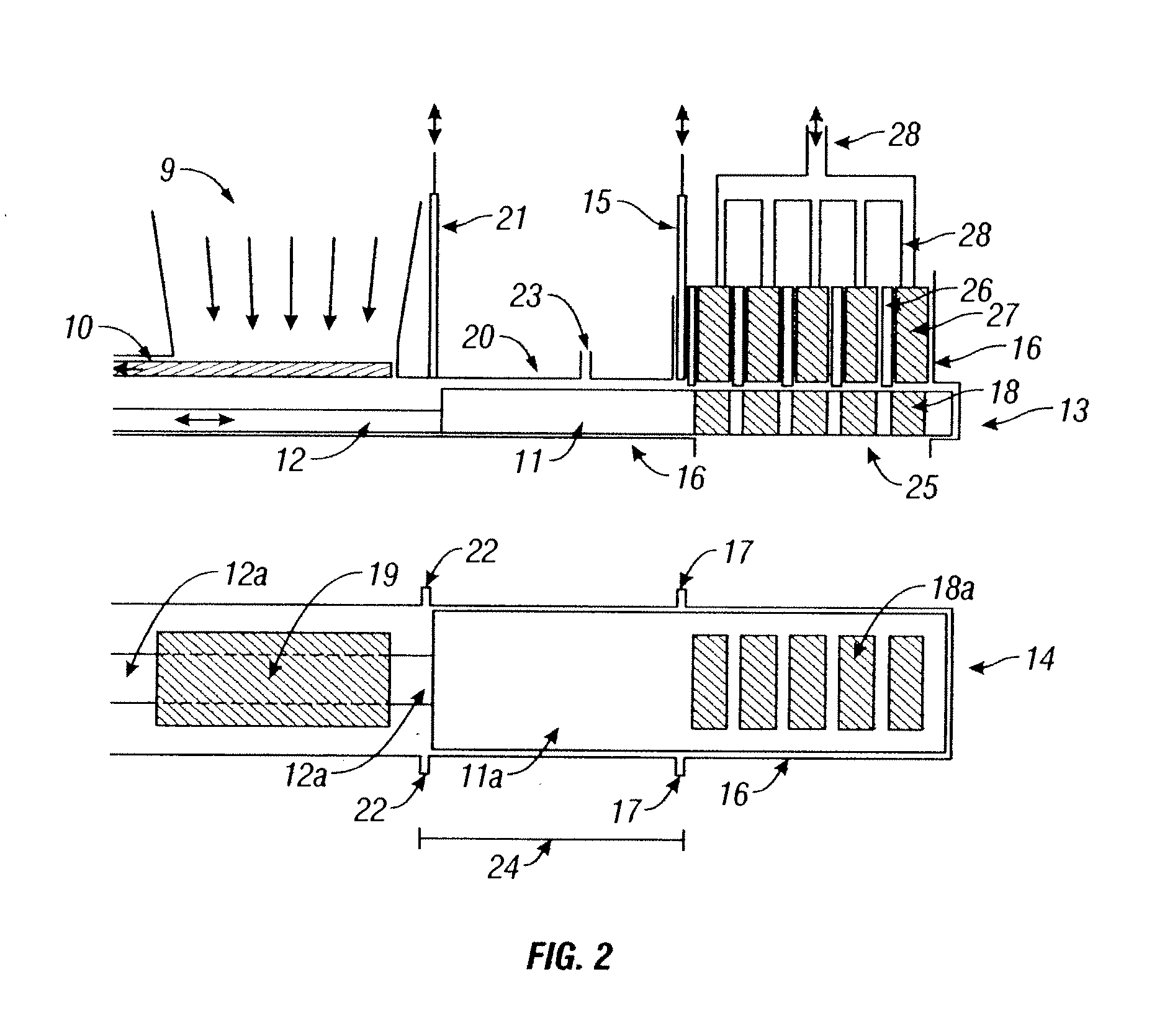

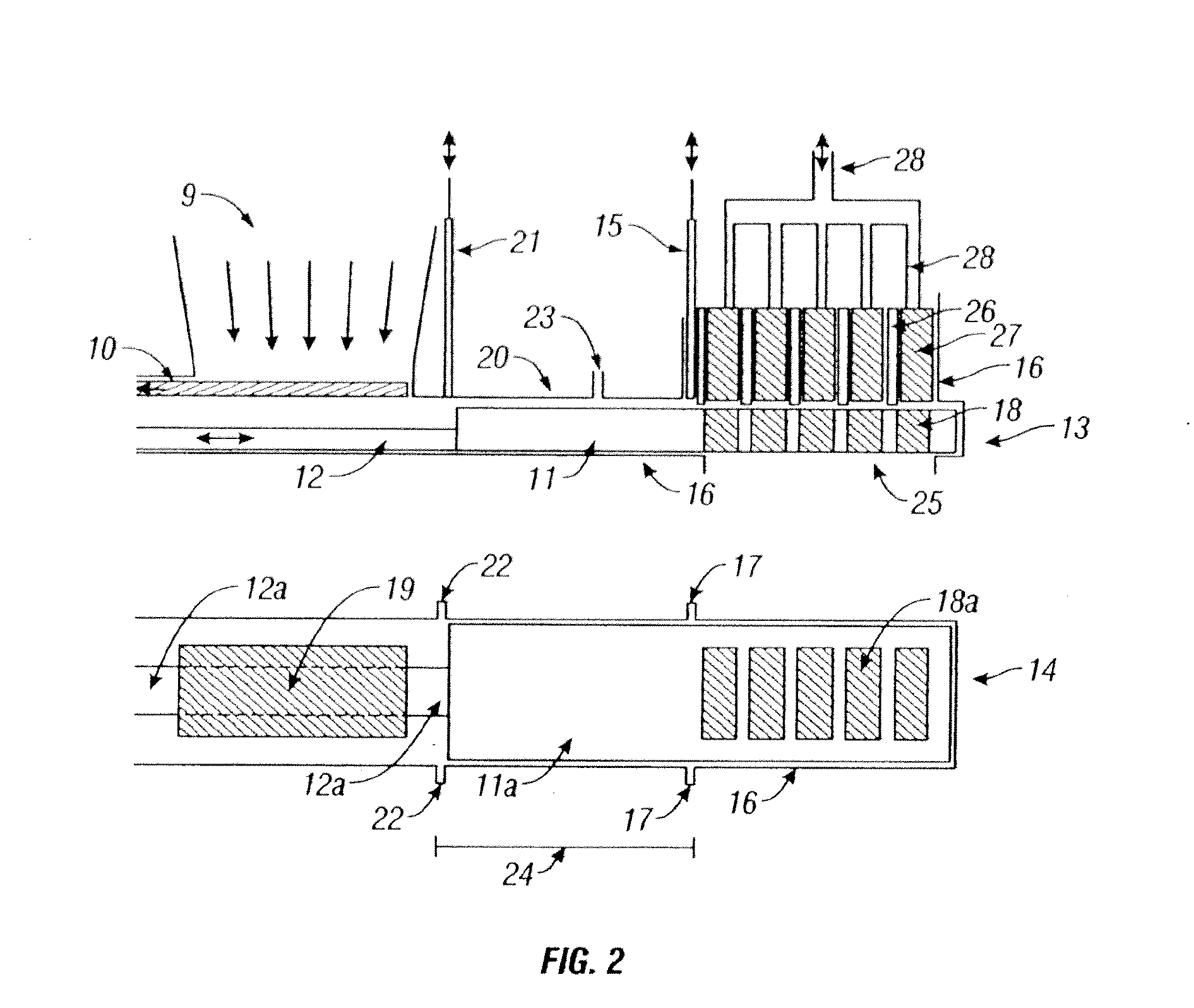

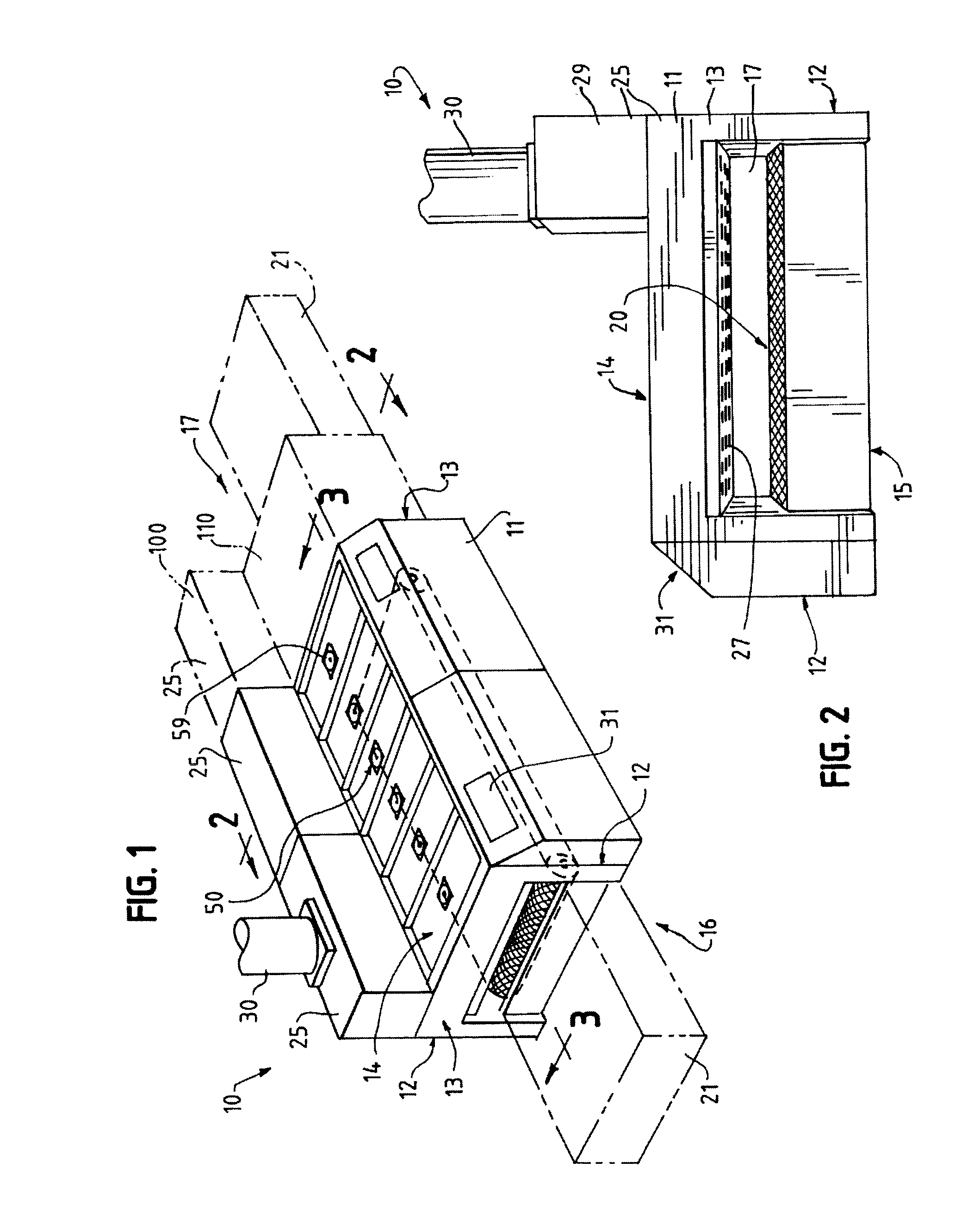

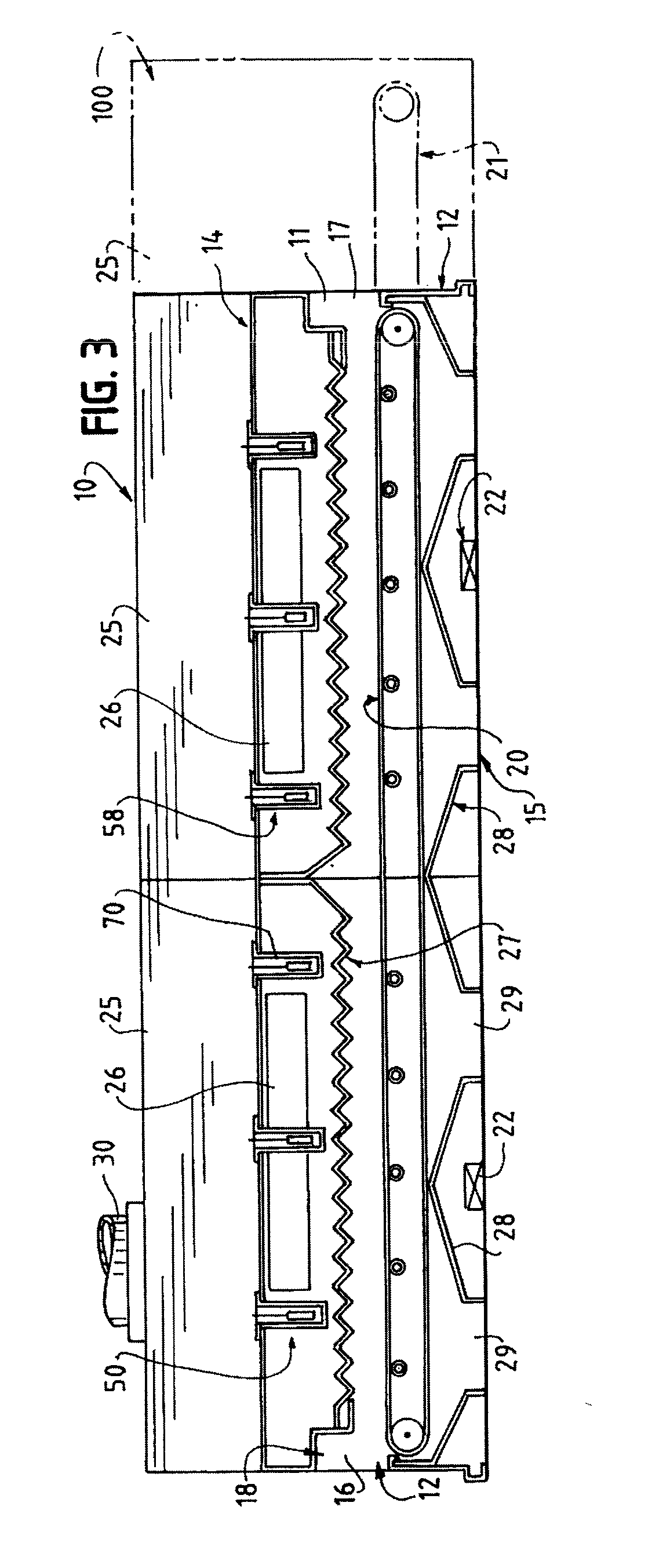

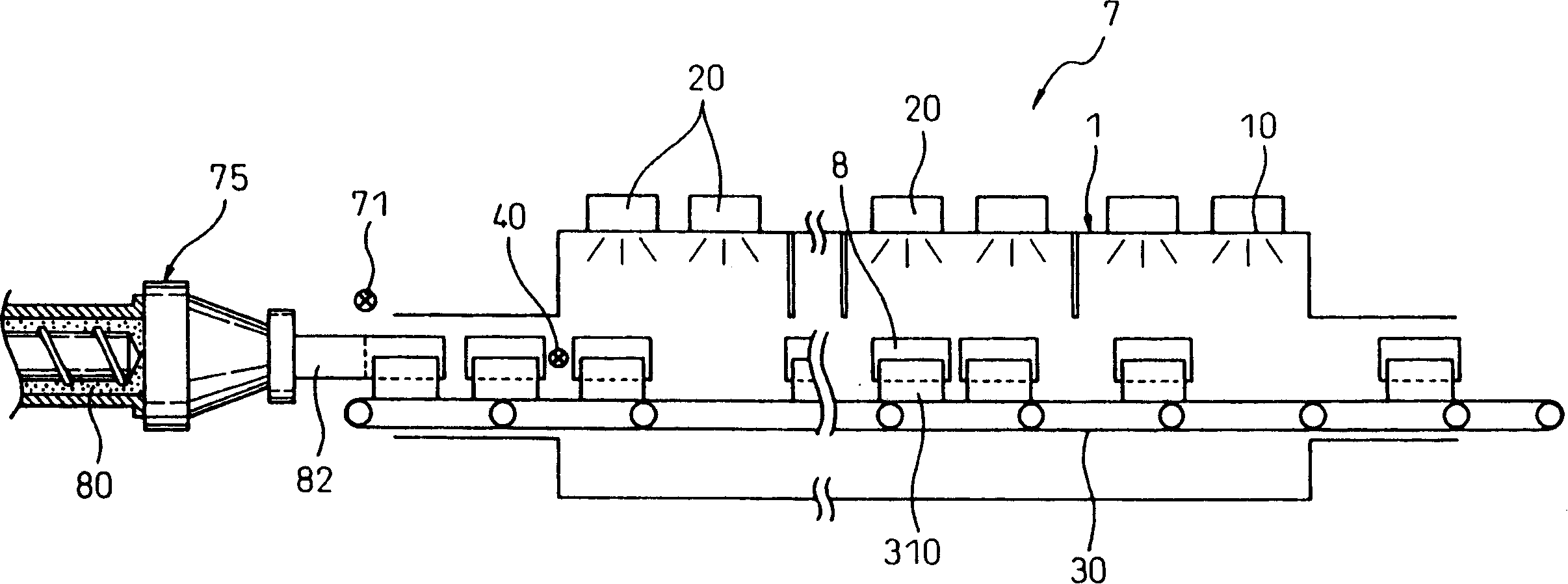

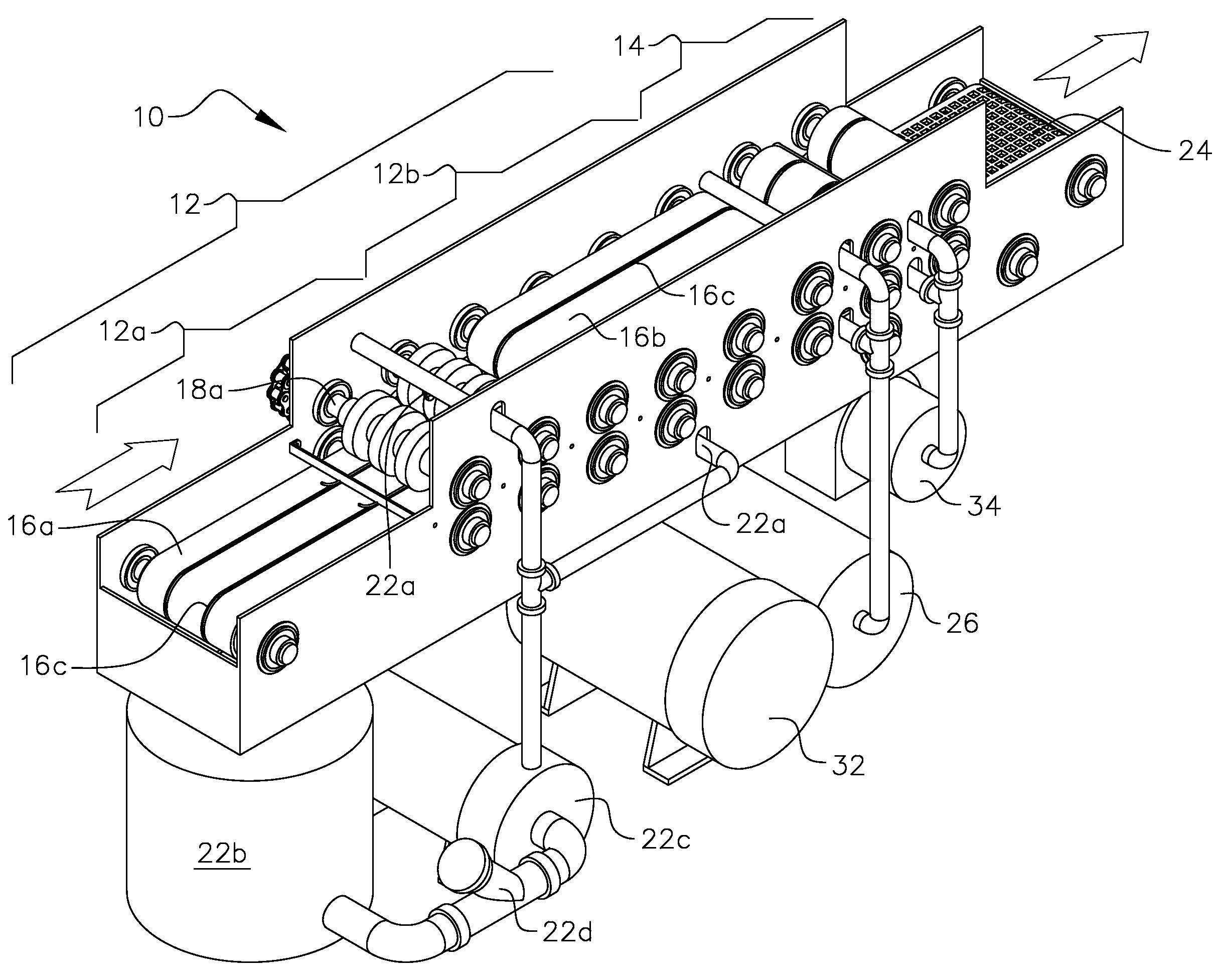

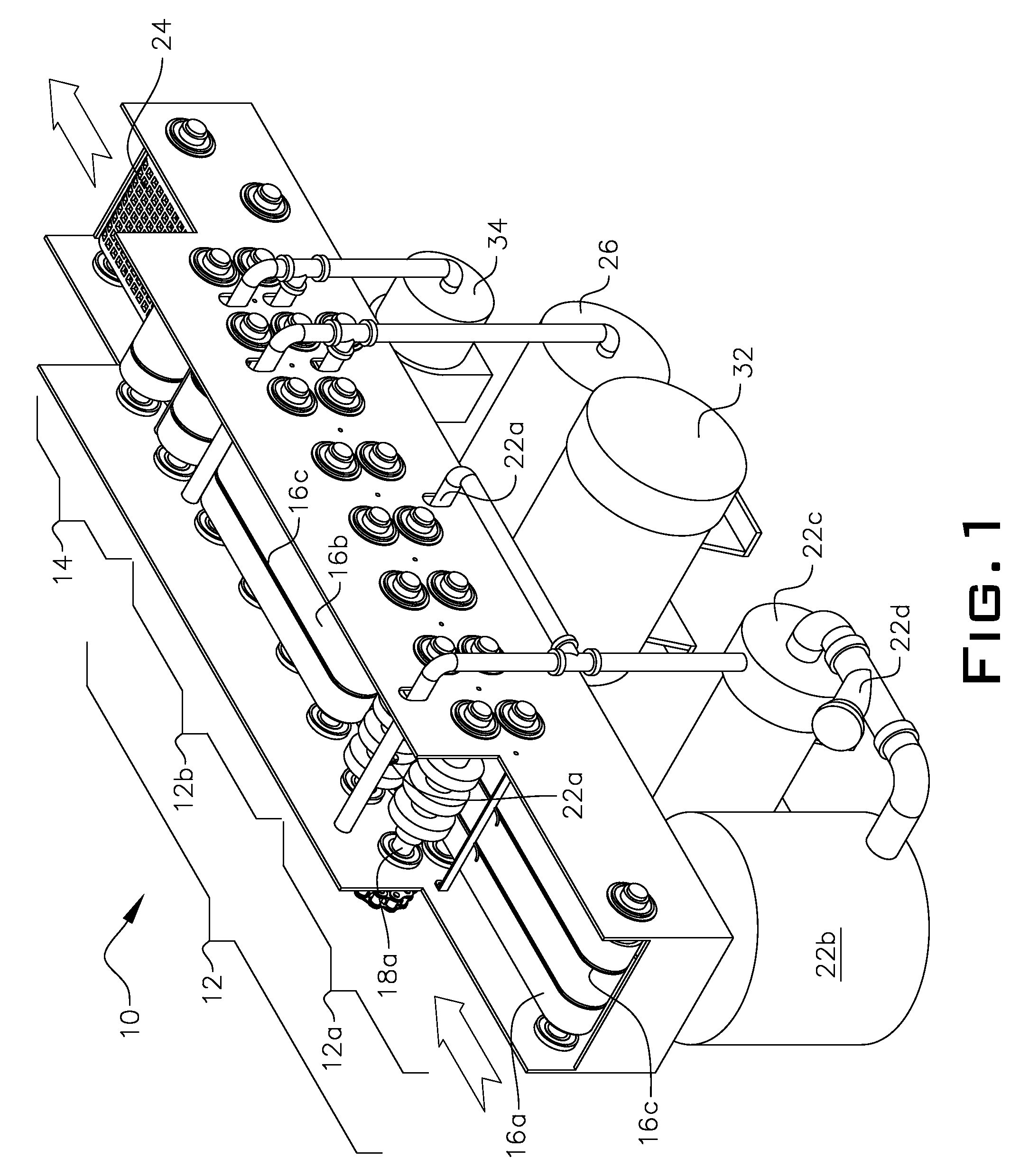

Method and device for drying ceramic products

An apparatus and a method, for drying ceramic molded articles, are disclosed. A drying apparatus (1) comprises a drying chamber (10) for accommodating ceramic molded articles (8), a plurality of microwave generators (20) for supplying microwave energy into the drying chamber, and a conveyor (30) for charging the ceramic molded articles (8) continuously into the drying chamber (10), conveying the ceramic molded articles through the drying chamber, and delivering the ceramic molded articles from the drying chamber. The drying chamber (10) has arranged therein a plurality of the microwave generators (20) and at least a sensor (40) for detecting the distribution of the ceramic molded articles (8) in the drying chamber (10). Each microwave generator (20) is adapted to change the output thereof in accordance with the distribution of the ceramic molded articles (8) detected by the sensor (40).

Owner:DENSO CORP +1

Paper currency cleansing/reconditioning/sanitizing system and method

InactiveUS20090301679A1% coverageProlong solution useCellulosic pulp after-treatmentMechanical cleaningForeign matterHigh pressure

A paper currency method and system, which is comprised of multi-stages of sections or areas for cleaning and / or sanitizing / and or drying with input and output to receive and dispense. A roller and conveyor, opposed to each other with pressure fluid or air jets, remove dirt, oils, and other foreign matter from the currency. When desired by the end user, the currency passes through a sanitation section using a sanitation solution to effectively kill viral and fungal organisms. After the cleaning processes is complete, the currency passes through a drying portion using squeezing rollers, high-pressure air and heat to remove moisture and to complete the reconditioning process.

Owner:THERMAL STERILIZATION SPECIALTIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com