High-quality coal product production equipment and production system

一种生产装置、优质煤的技术,应用在蒸汽机装置、炉、照明和加热设备等方向,能够解决不能褐煤提质处理、单位能量运输成本高、水分高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

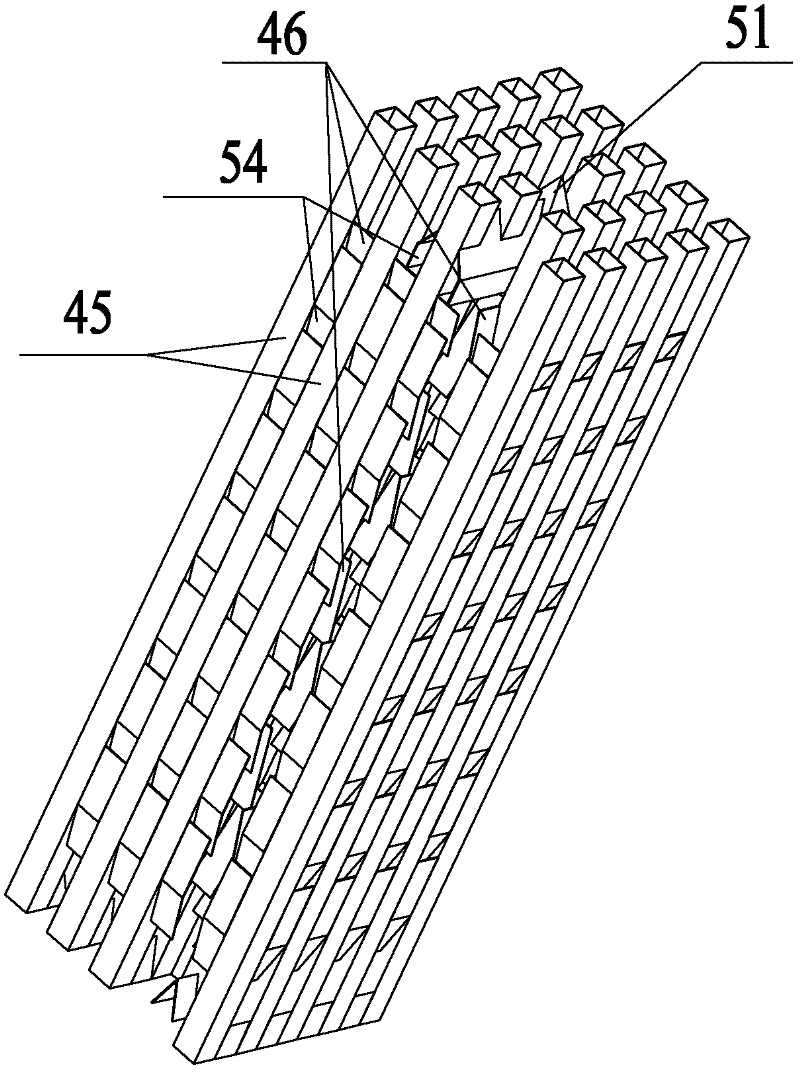

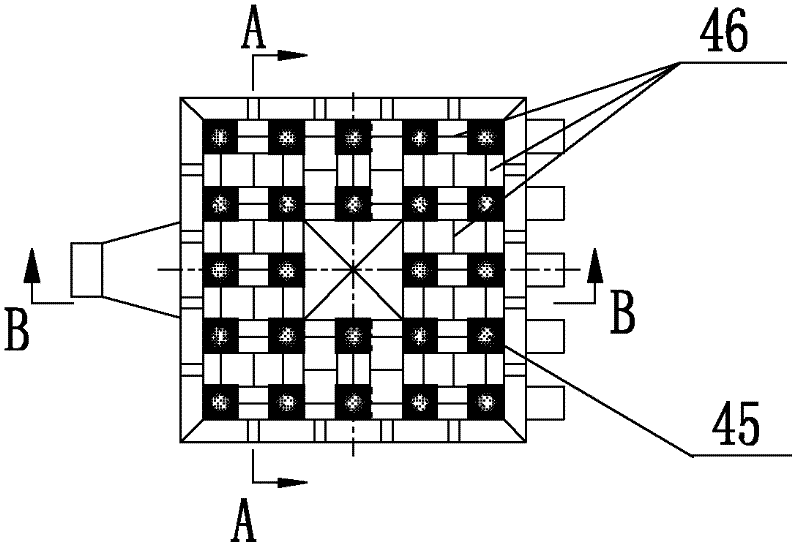

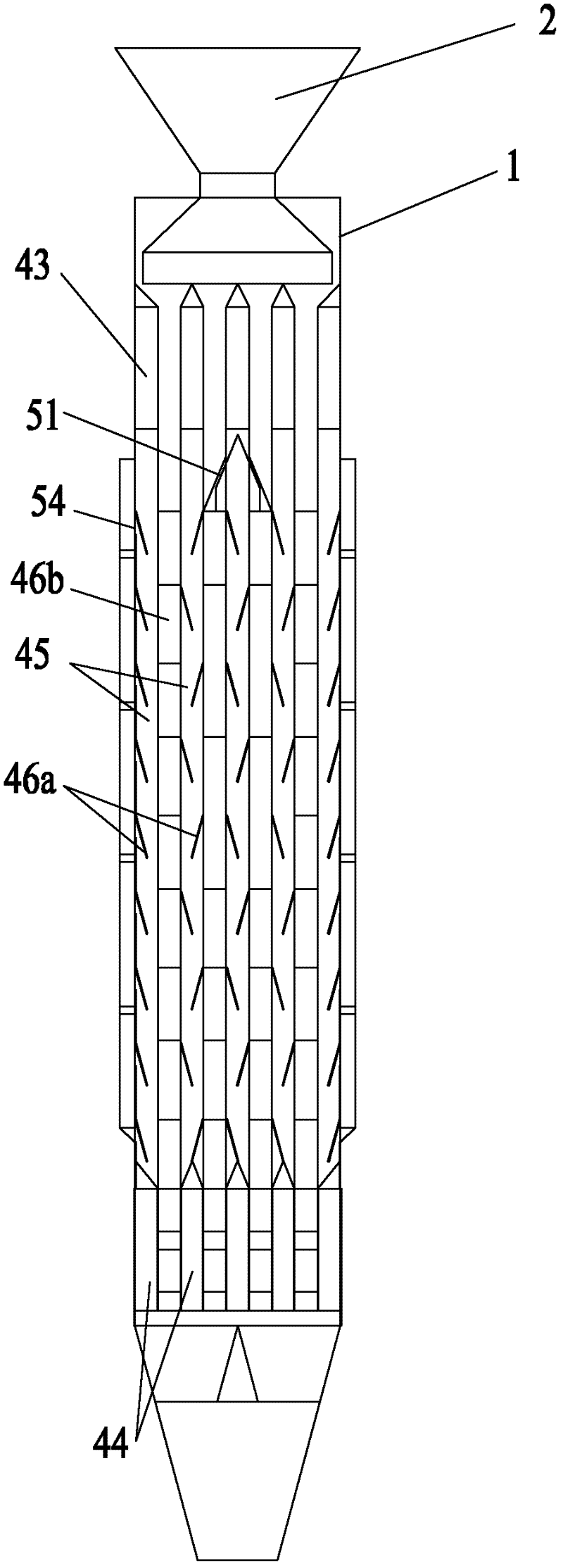

[0176] see Figure 12 to Figure 18 ,in Figure 12 for Figure 13 The G-G cross-sectional schematic diagram, Figure 13 for Figure 12 Schematic diagram of the F-F section. The difference between the present invention and Embodiment 1 is that the number of heat conduction units in this embodiment is 8, except for the two heat conduction units located in the middle, each of the other heat conduction units contains 8 heat conduction pipes. In this embodiment, The first-level fins arranged between the heat-conducting tubes adjacent to the exhaust passage are consistent with the arrangement of Embodiment 1, and among the multiple first-level fins arranged longitudinally between the remaining heat-conducting tubes and adjacent heat-conducting tubes, It includes two sets of first-level fins, one of which is set on one side of the space between the two heat pipes, the lower ends of the first-level fins in this set deviate to the direction close to the center line of the shell, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com