Patents

Literature

93results about How to "High volatile content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

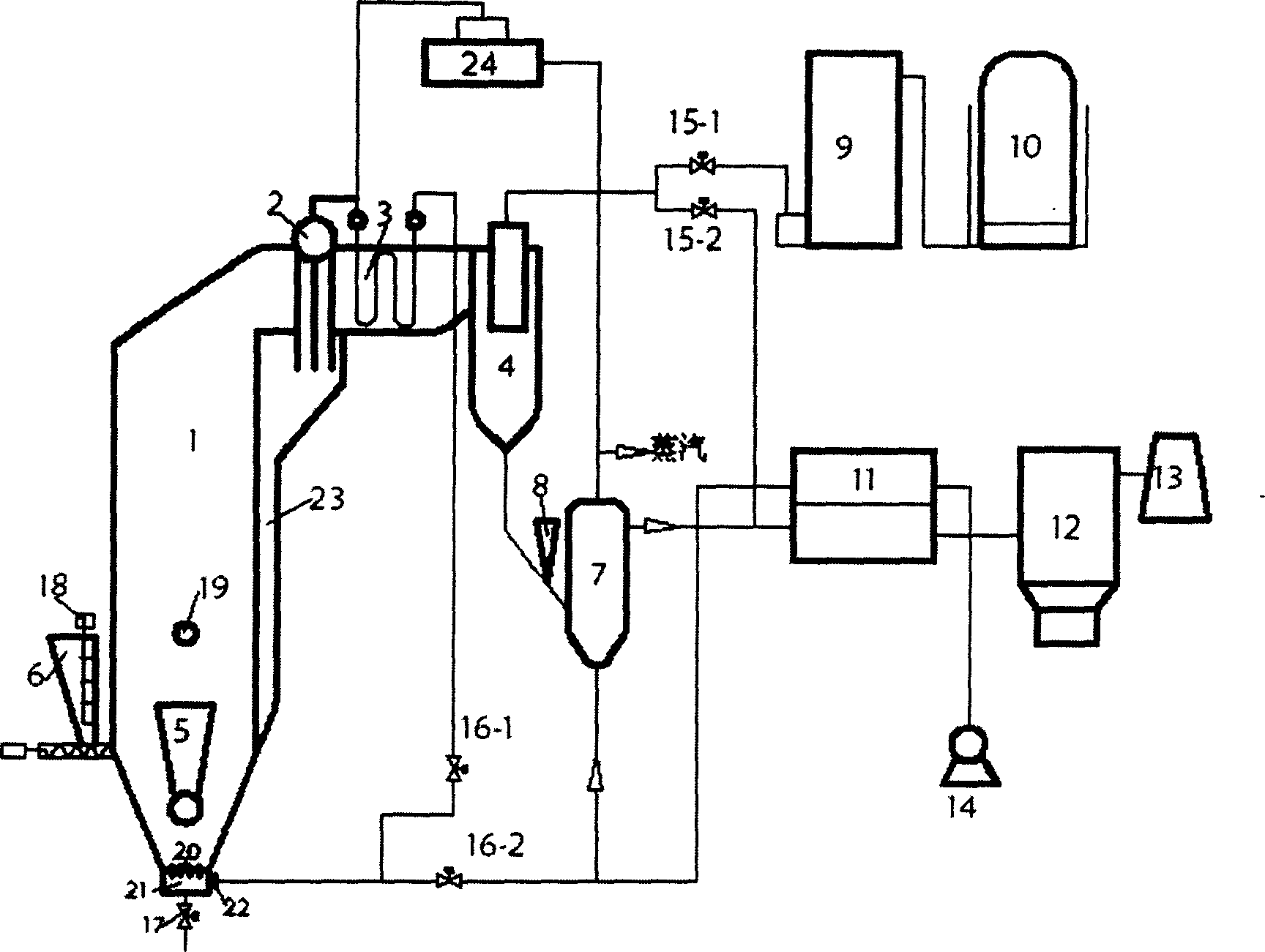

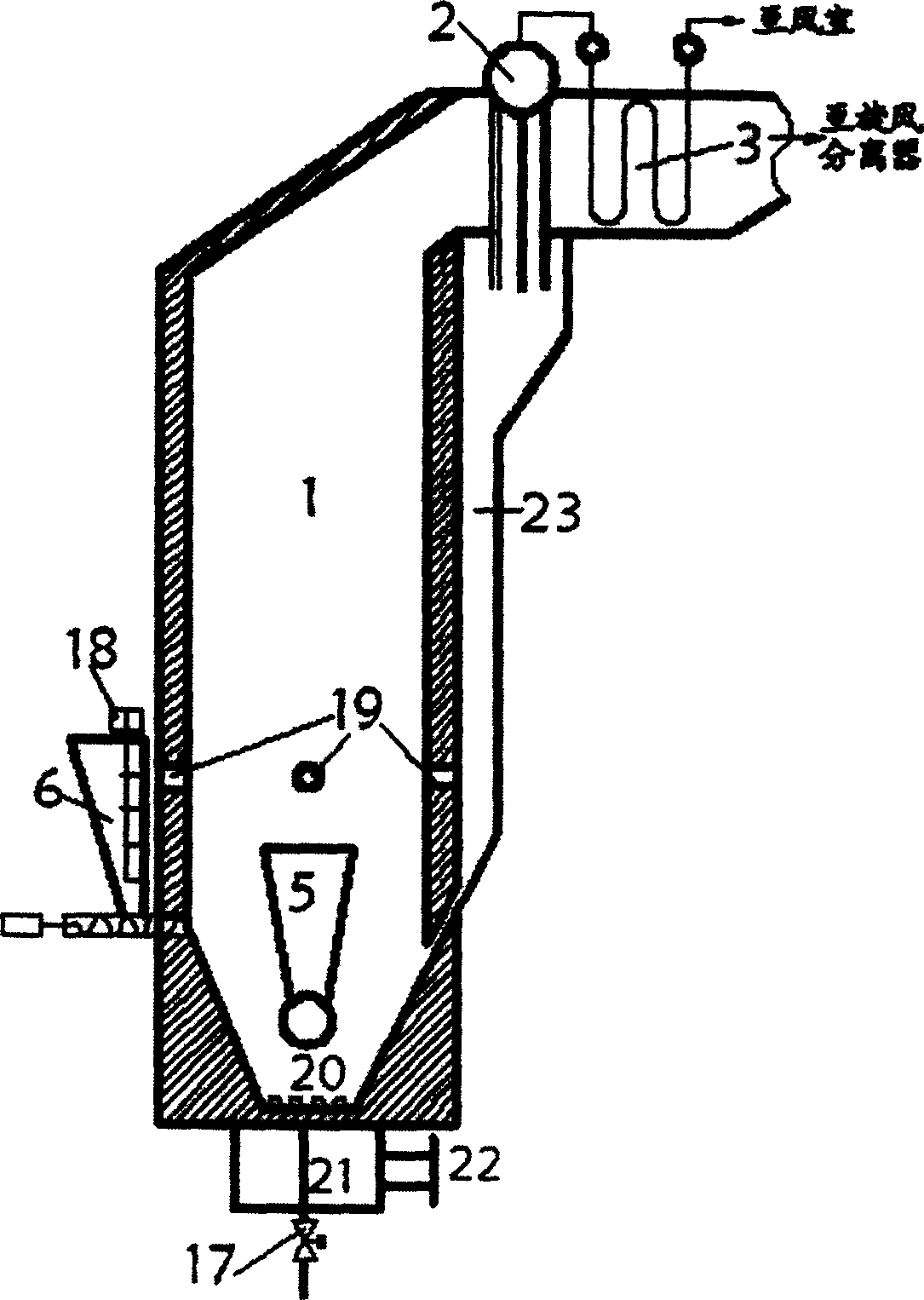

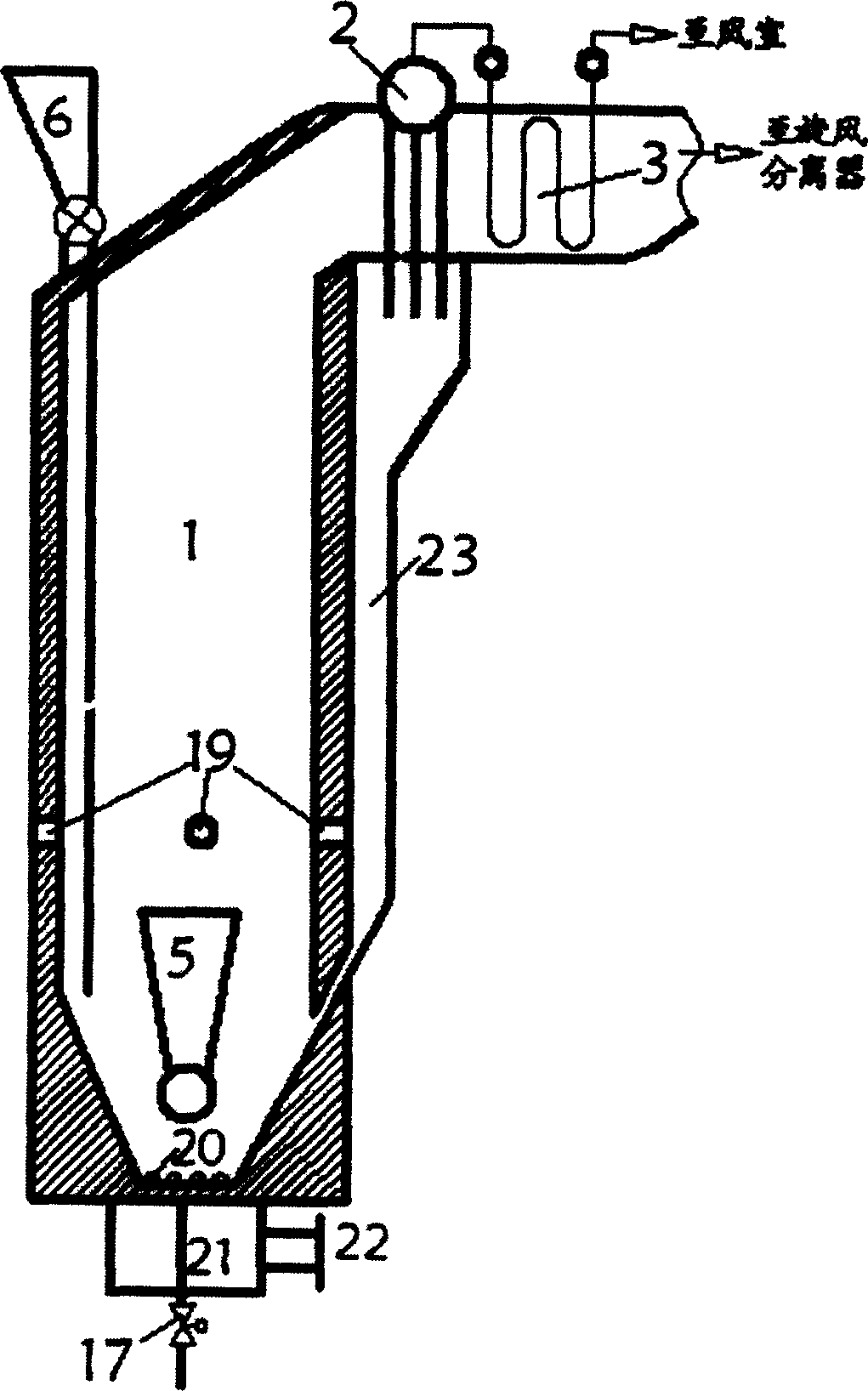

Gasification method and device for biomass and coal mixed fluidized-bed

ActiveCN1557919AEasy to makeRich sourcesGranular/pulverulent flues gasificationWater vaporProduced water

The present invention relates to energy source apparatus, and is one kind of simple biomass-coal mixture gasifying method and apparatus capable of producing high heat value gas and no tar. Inside fluidized bed gasifying furnace, biomass and coal as gasified material is burnt and gasified intermittently. In the burning stage, coal and blast are supplied to the furnace, so that coal is burnt in fluidizing state to produce heat; in the gasifying stage, vapor and biomass are supplied to the furnace, so that the high temperature carbon material layer produces water gas reaction in fluidizing state and biomass is dry distilled and pyrolyzed at high temperature to produce high heat value gas, which is cooled and made to enter the gas purifying system. By combining of biomass and coal with different advantages, the present invention produces high heat value fuel gas without tar.

Owner:JIANGSU UNIV

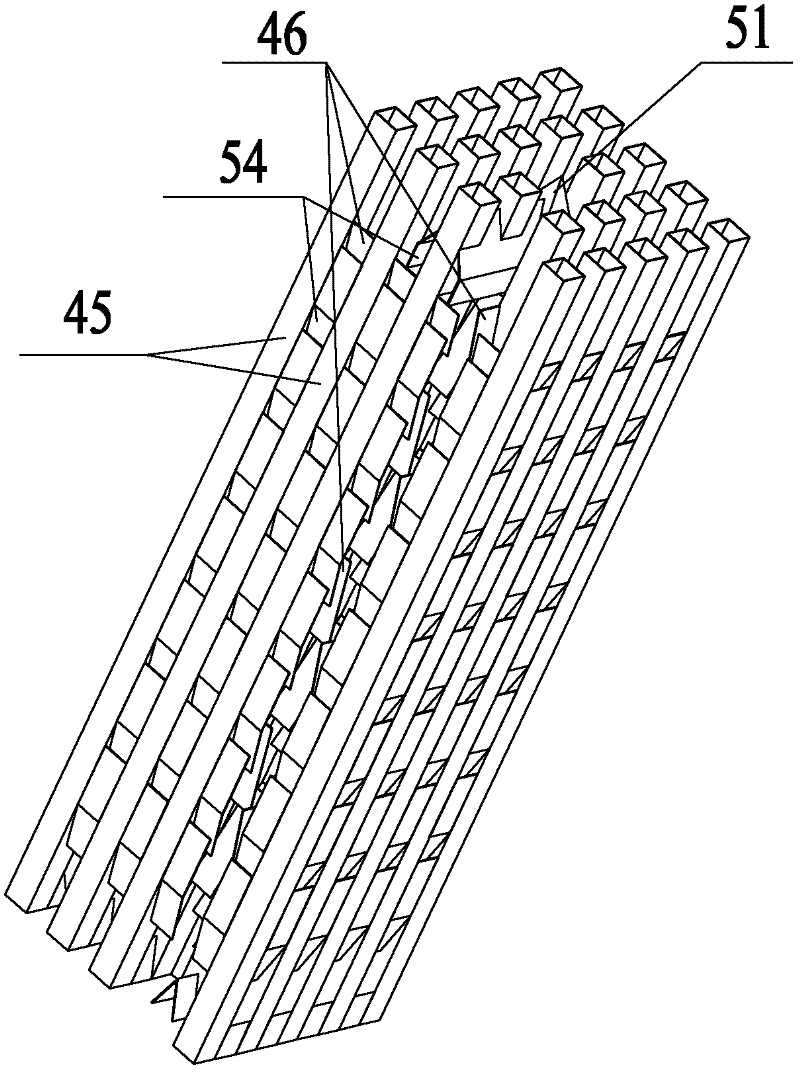

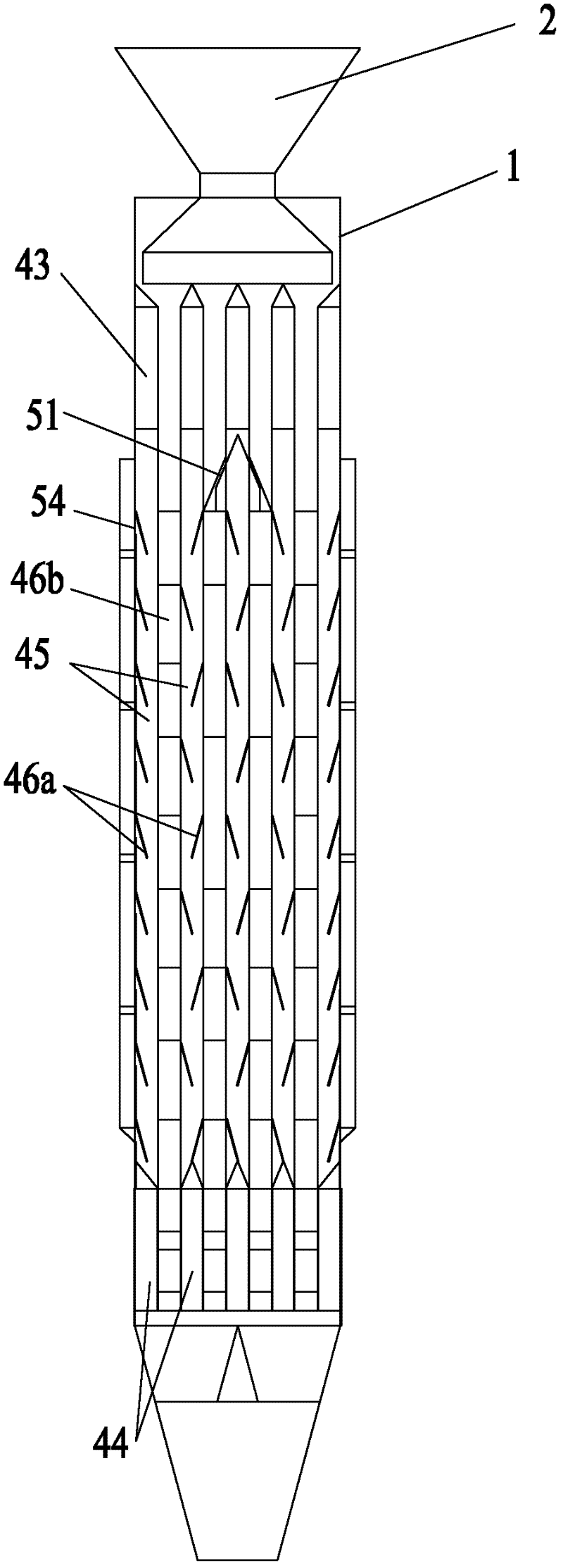

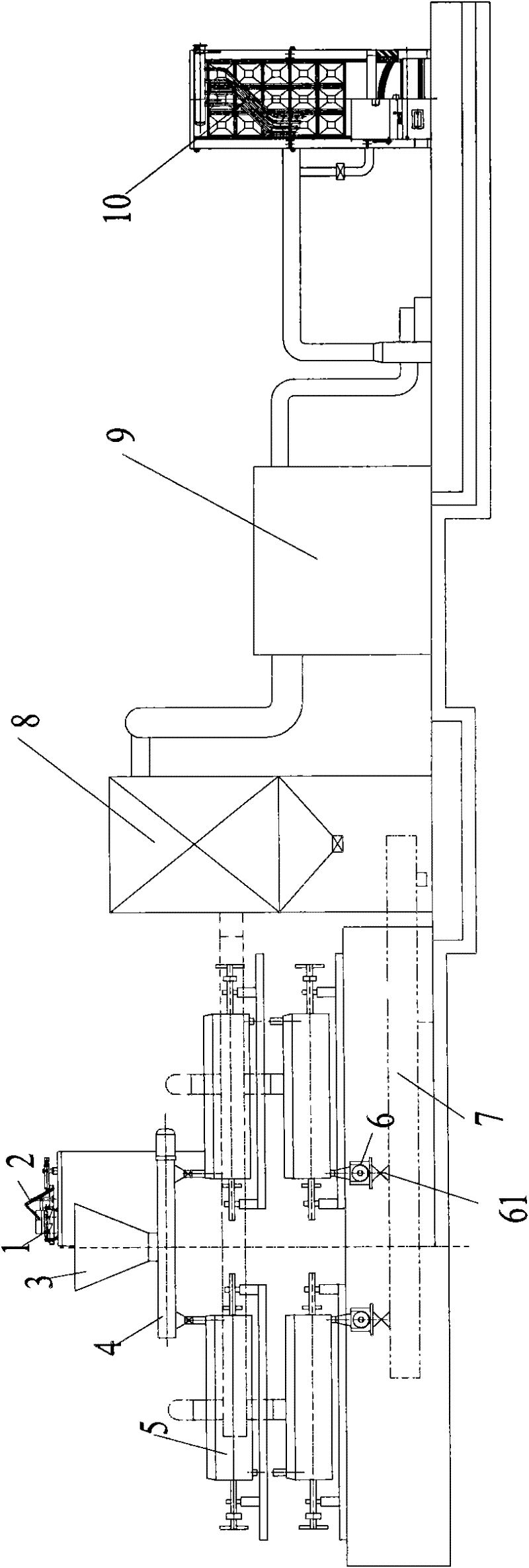

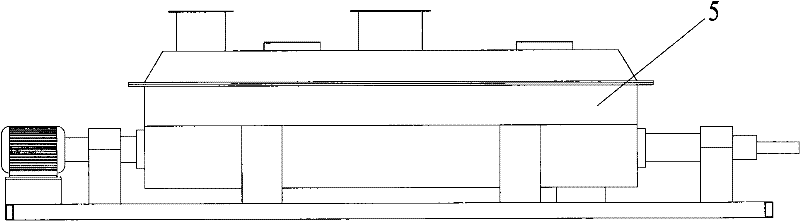

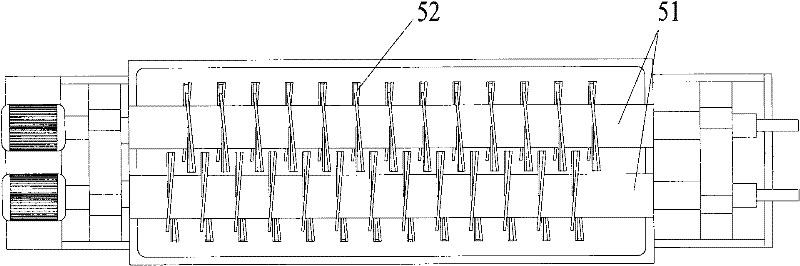

High-quality coal product production equipment and production system

InactiveCN102260559AHigh calorific valueContinuous operationDrying solid materials with heatEnergy inputProduct gasProcess engineering

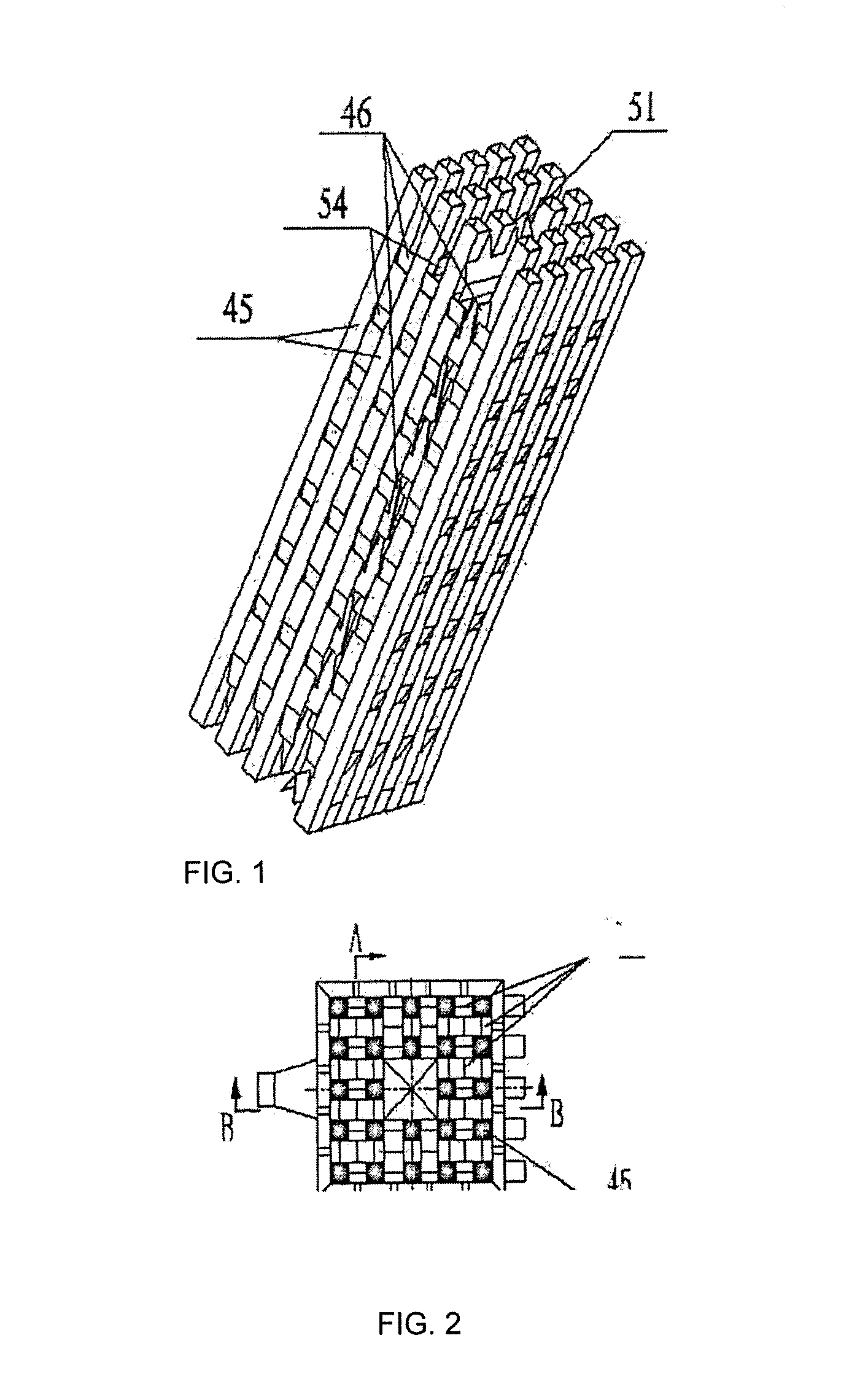

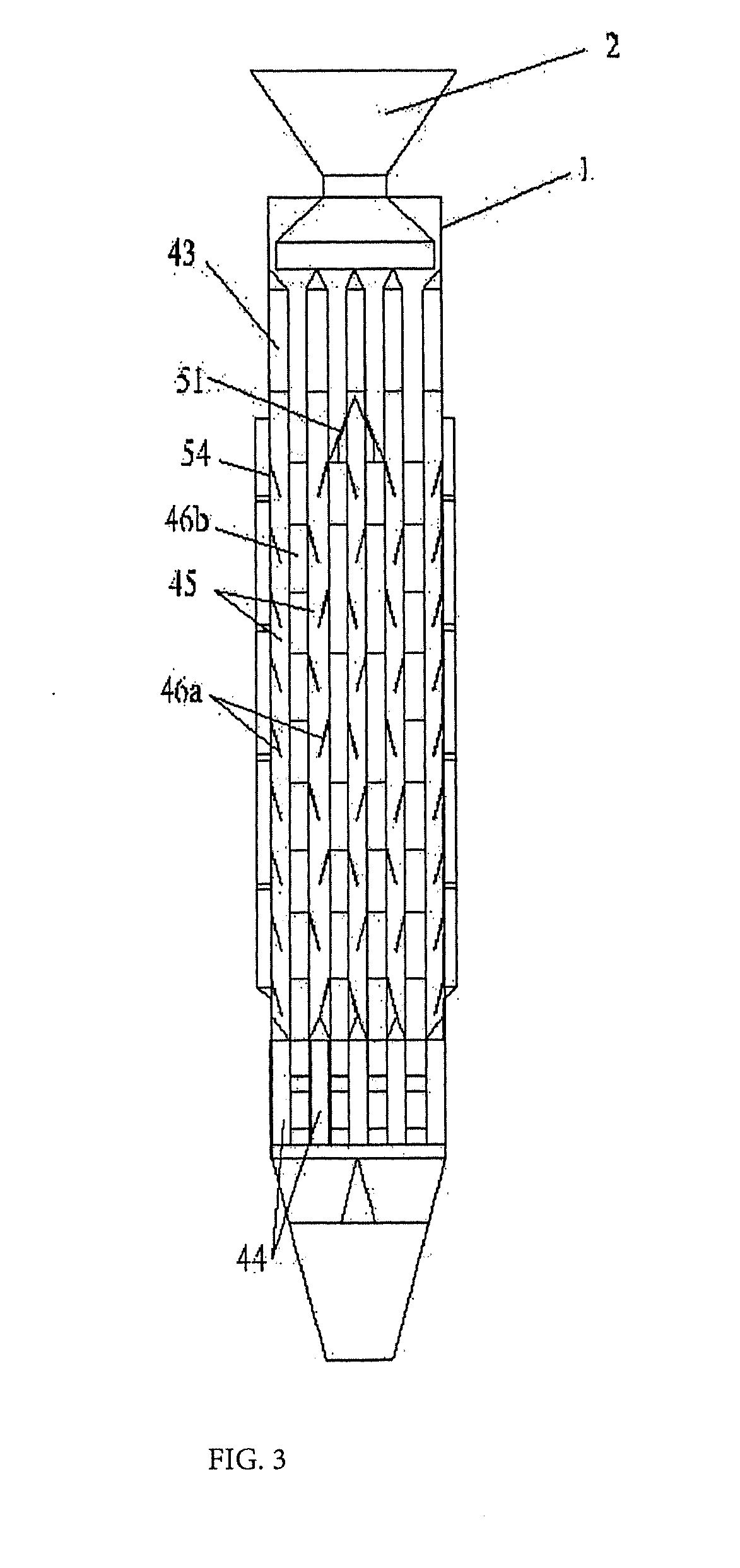

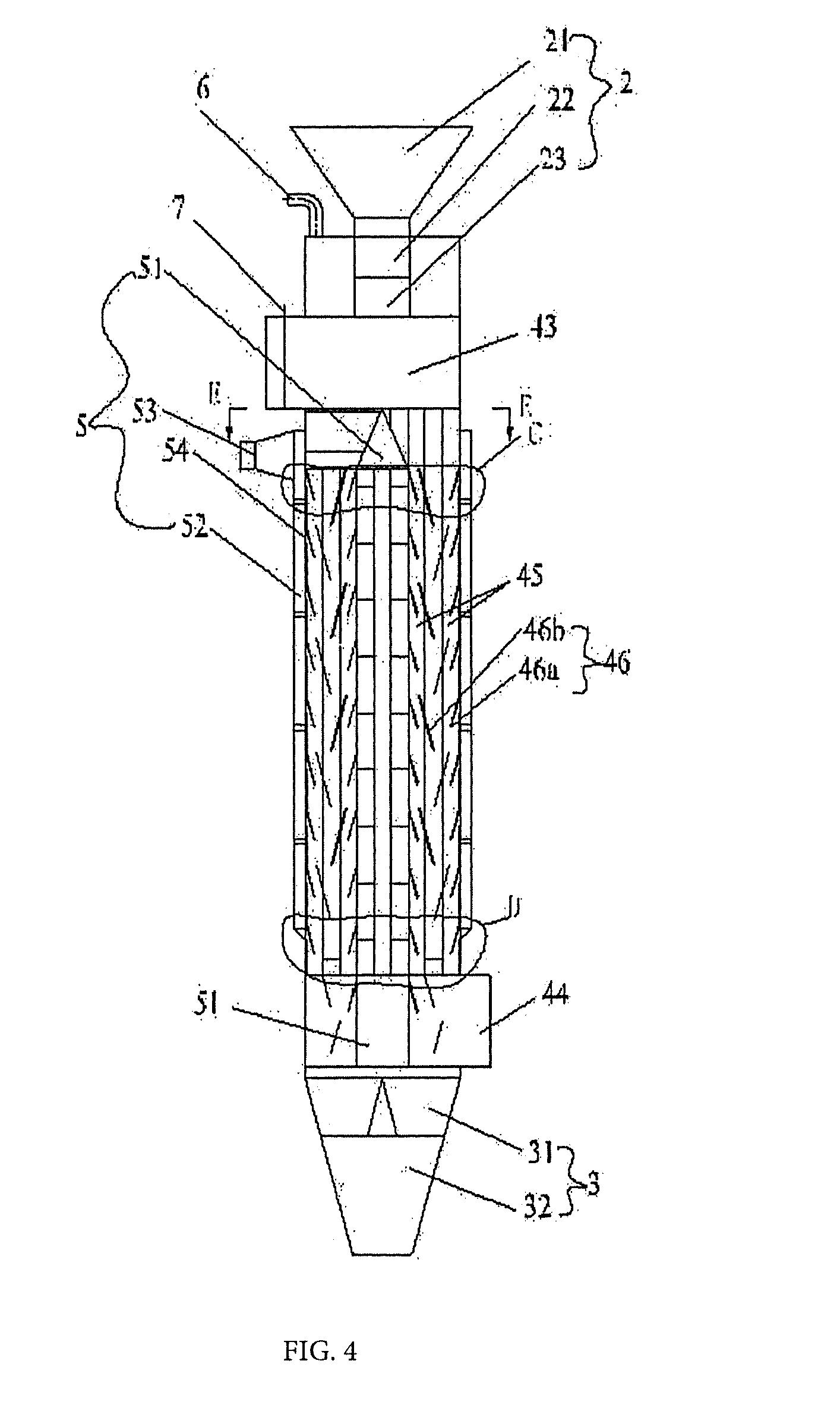

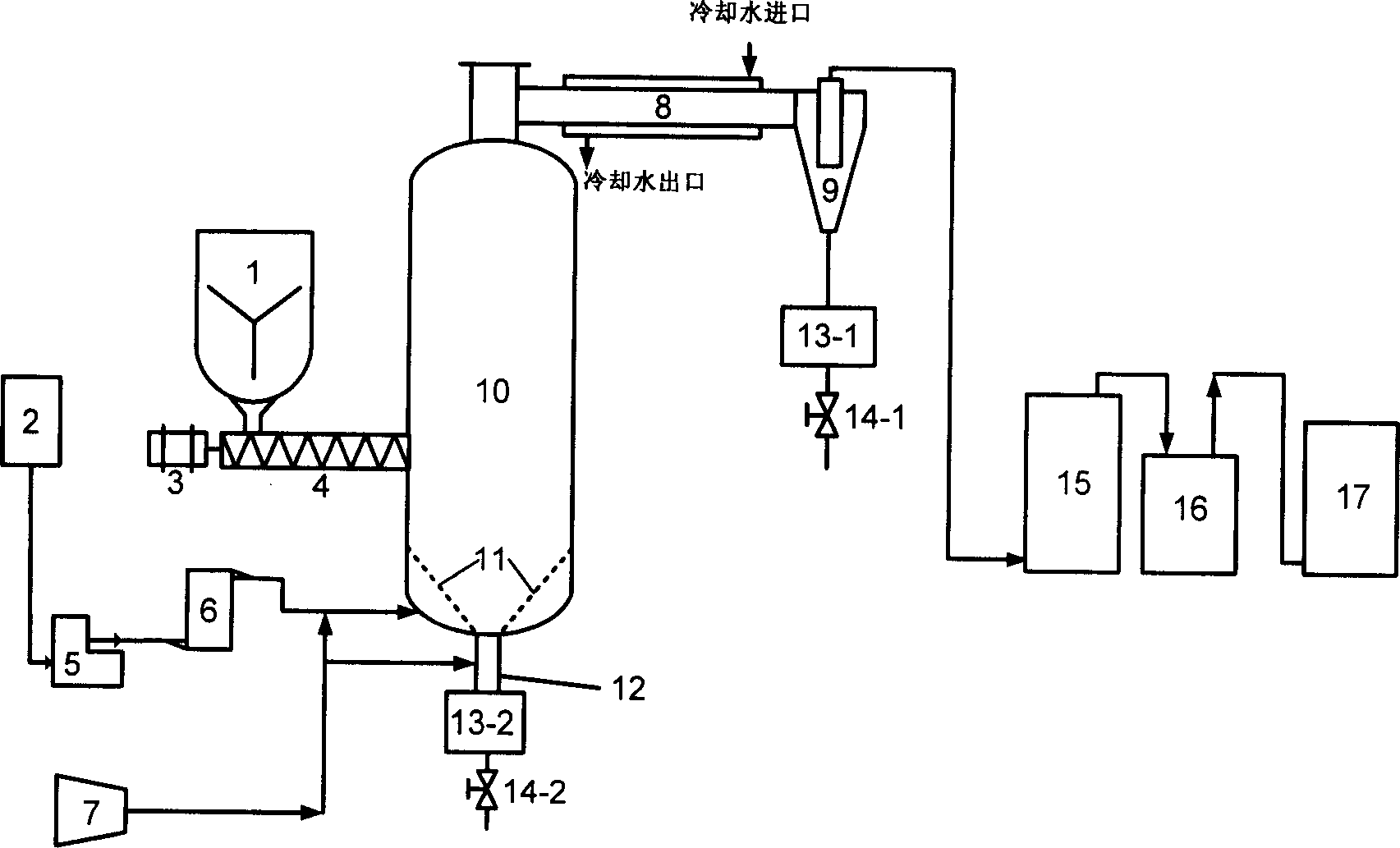

The invention discloses a high-quality coal product production plant which comprises a shell and a heat conduction mechanism arranged in the shell, wherein the heat conduction mechanism is provided with a heat conduction medium inlet near the discharge end, and provided with a heat conduction medium outlet near the feed end; the heat conduction mechanism comprises a plurality of sets of heat conduction units which are distributed at intervals; each heat conduction unit comprises a plurality of heat conduction tubes which are communicated with the heat conduction medium inlet and the heat conduction medium outlet; a plurality of fins, which slope downwards, are longitudinally arranged between adjacent heat conduction tubes; and the lower end of each fin arranged between the heat conduction tubes beside the exhaust passage slopes away from the exhaust passage, so as to shield the exhaust port arranged in the wall surface of the exhaust passage. Since the fins, which are arranged in the blanking space between the heat condition tubes, can turn over the material and discharge gas, the gas can be discharged in time, and heat can be transferred quickly, thereby obtaining the high-quality coal product. The invention also discloses a high-quality coal product production system.

Owner:QIANQIU ENERGY SHANGHAI

Boiler coal combustion-improving desulfurizing agent composition and preparation method thereof

ActiveCN103194294AGood synergyHigh selectivitySolid fuelsFuel additivesActivated attapulgiteSodium acetate

The invention provides a boiler coal combustion-improving desulfurizing agent composition. The composition comprises the following components in parts by weight: 3-9 parts of sodium carbonate, 1-2 parts of sodium acetate, 3-9 parts of calcium carbonate, 4-9 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 3-10 parts of ferric oxide, 8-22 parts of potassium permanganate, 8-22 parts of potassium chlorate, 15-40 parts of activated attapulgite clay, 7-13 parts of manganese oxide, 4-8 parts of copper oxide, 4-8 parts of alumina, 3-8 parts of copper carbonate, 3-10 parts of zinc oxide, 3-10 parts of zinc nitrate, 4-11 parts of sodium dichromate, 0.5-1.5 parts of barium molybdate, 0.5-1.5 parts of vanadium pentoxide, 0.2-0.5 part of cerium oxide and 1-3 parts of dispersing agent JFC. The composition is an additive suitable for coal-fired boilers in the petroleum, chemical, power, thermoelectricity and metallurgy industries, can absorb and solidify sulfur dioxide generated in the combustion process, adsorbs dust and other harmful substances in quantity and simultaneously removes smoke dust scales and jelly adhering to the inner walls of combustors, thus inhibiting the concentration of flue gas emission.

Owner:GANSU HEIMA PETROCHEM ENG

Biomass moulded coal and preparation method thereof

InactiveCN101985575ALow calorific valueLow volatileBiofuelsSolid fuelsFixation agentSodium hydroxide

The invention provides a method for preparing biomass moulded coal by using biomass and inferior smokeless pulverized coal as raw materials. The biomass moulded coal is prepared by uniformly mixing the biomass, the inferior smokeless pulverized coal and additives (a sulfur fixation agent, a biomass binder, an oxidant and a waterproofing agent), and performing low-pressure compression moulding by a wet method, wherein the sulfur fixation agent is calcined lime CaO; the biomass binder is light yellow dope prepared by treating bagasse by using 1 to 2 percent sodium hydroxide solution; the oxidant is potassium permanganate; and the waterproofing agent is tar or a binder. The biomass moulded coal comprises following raw materials in part by mass: 40 to 65 parts of inferior smokeless pulverized coal, 25 to 55 parts of biomass and 5 to 10 parts of additive. The biomass moulded coal has the advantages of low cost, low ignition point, high burn-off rate and integrative desulfurization and water proofing performance, and has great significance of energy conservation and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

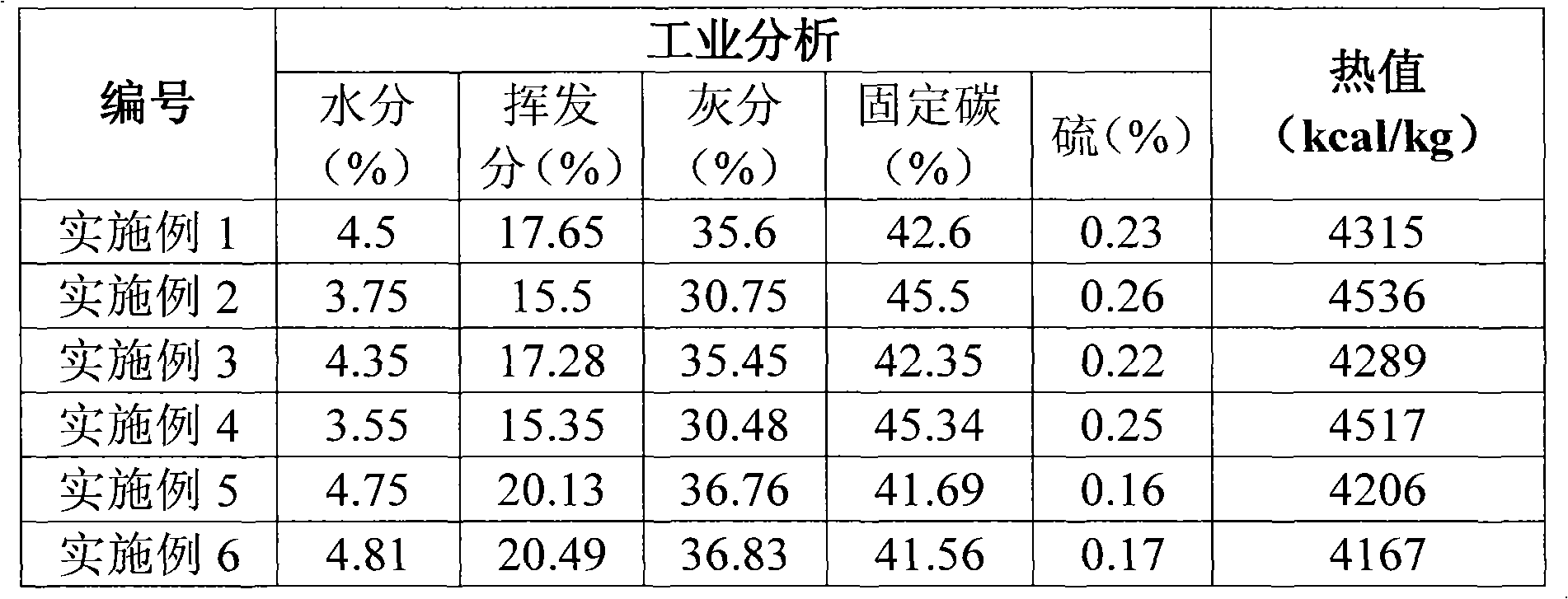

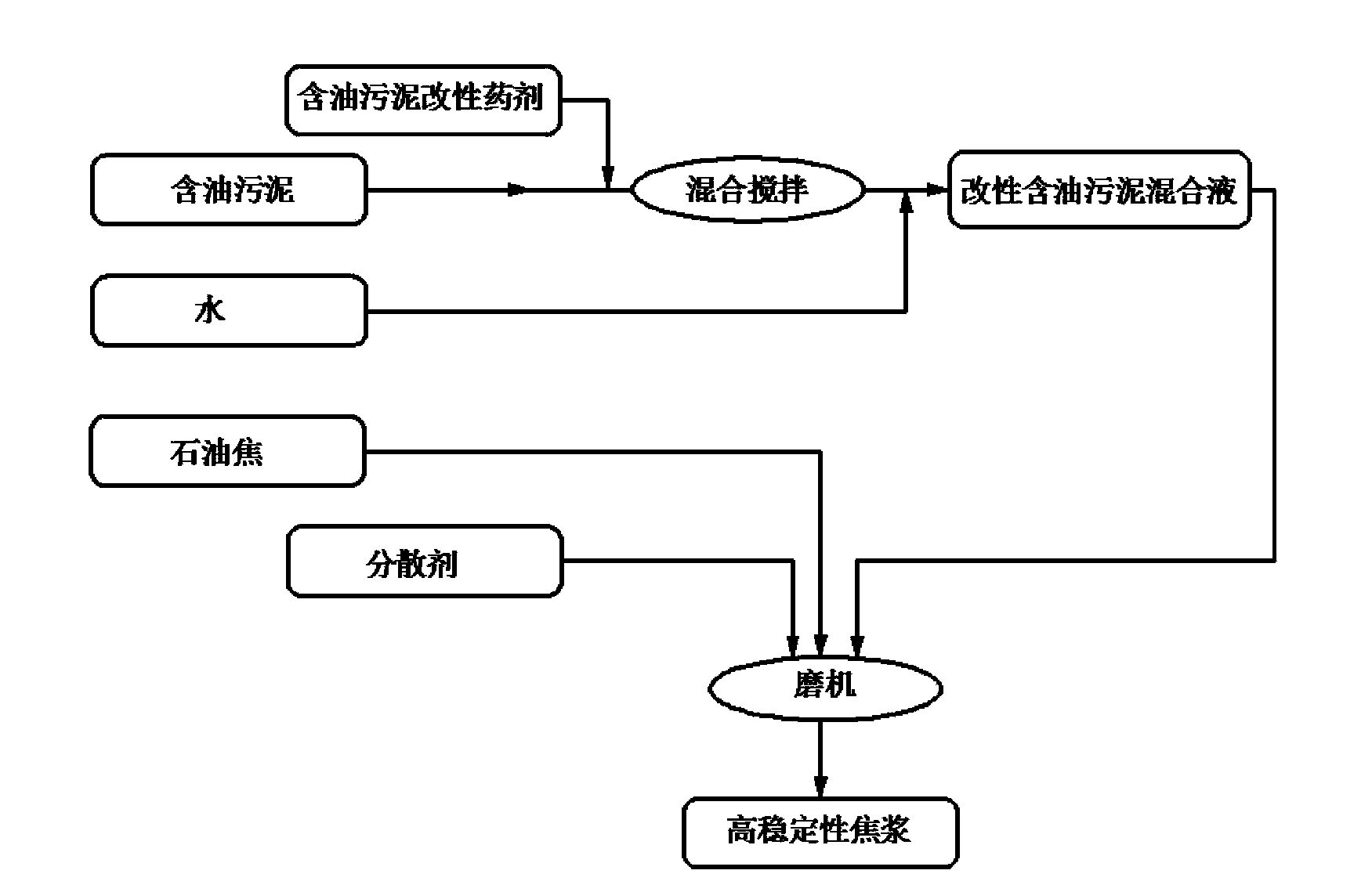

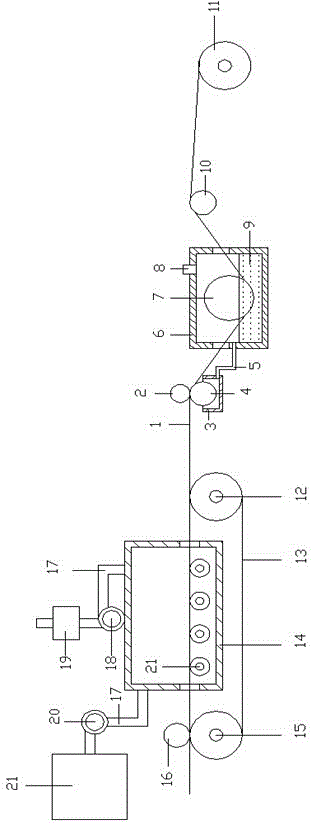

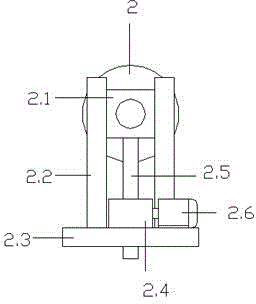

Oily sludge coke water slurry and preparation method thereof

The invention relates to oily sludge coke water slurry and a preparation method thereof. The oily sludge coke water slurry comprises the following components: by mass percent, 50%-75% of petroleum coke, 0.1%-15% of oily sludge, 0.001%-1% of a dispersant, 0%-1% of an oily sludge modifying agent and the balance of water; wherein the dispersant is a mixture of one or a plurality of substances comprising surfactants of naphthalene sulfonates, polycarboxylates, humic acids or lignosulfonates, the oily sludge modifying agent is inorganic salts of divalent or trivalent iron, aluminum or calcium metal ions, and the oily sludge is an oil and water mixture produced in mining, transportation and processing processes of crude oil; and the oily sludge coke water slurry prepared by the preparation method has the advantages of high calorific value and good liquidity and stability, is easy to store, transport and atomize, can be used as combustion or gasification raw materials and has large-scale application prospects.

Owner:PETROCHINA CO LTD +1

Low-cost high-activity catalytic type desulphurization active coke and preparation method thereof

ActiveCN104028218AImprove desulfurization effectReduce usageOther chemical processesDispersed particle separationPyrolusiteWater vapor

The invention provides a low-cost high-activity catalytic type desulphurization active coke. The low-cost high-activity catalytic type desulphurization active coke is a material which is activated, extruded and formed by mainly components comprising carbonization soft coal and pyrolusite; the percentage of weight of manganese is not less than 1.6%; the saturated sulphur capacity of the desulphurization active coke is 140-181mg / g; the specific surface area is 319-363m<2> / g; the iodine value is 344-393mg / g. The preparation method of the low-cost high-activity catalytic type desulphurization active coke comprises the following steps: firstly carbonizing smoke, crushing the pyrolusite and the soft coal carbonization material into powder, adding the soft pyrolusite powder into the soft coal carbonization material powder and uniformly mixing, then adding water to mix till the material is free of powder aggregate, adding coal tar, fully kneading and then extruding, forming and drying, causing the dried material to be subjected to activation reaction under the conditions with N2 protection and water vapor, finally cooling the material along with a furnace to room temperature under the N2 protection to obtain the low-cost high-activity catalytic type desulphurization active coke. By virtue of the low-cost high-activity catalytic type desulphurization active coke, the problems of low desulfuration capacity, regeneration frequency, large use amount and high operation cost of the currently-used desulfuration active coke can be solved.

Owner:SICHUAN UNIV

Preprocessing method of raw materials for ferrosilicon smelting

InactiveCN101280356AReduce the degree of deteriorationGood volatileSocial benefitsPretreatment method

The invention relates to the smelting technology, in particular to silicon iron smelting raw material and a preprocessing method. The preprocessing method comprises the following steps: firstly, silicon contained raw material is mixed with the carbonaceous reducing agent according to a certain ratio; secondly, a 40 to 80 mm oval or oblate pellet is pressed into form through a mechanical way; thirdly, after drying, the percentage of moisture is controlled for less than two percent, and then the raw material can be used as silicon iron smelting raw material. The silicon iron smelting raw material and the preprocessing method have the advantages that the raw material resource is rich, the price is inexpensive, and the energy saving effect is obvious, simultaneously, because a great amount of , the silicon fine powder and siliceous colliery waste are adopted by the technology, the social benefit and the environmental benefit are quite good.

Owner:樊玉山

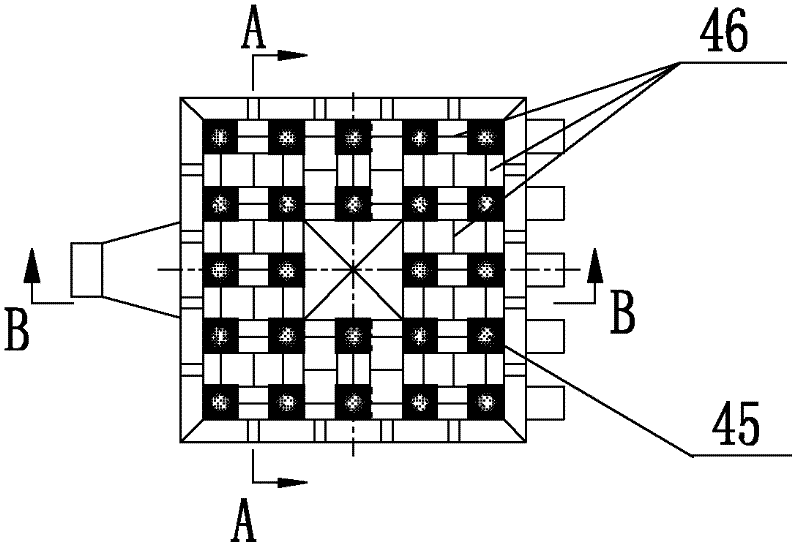

Apparatus and system for manufacturing quality coal products

InactiveUS20140352168A1Low costReduce wasteDrying solid materials with heatDrying gas arrangementsHeat conductingProcess engineering

The present application discloses an apparatus for manufacturing high-quality coal products. In certain embodiments, the apparatus comprises a housing and a heat conducting mechanism disposed within the housing. The heat conducting mechanism is provided with a heat conducting medium inlet proximate a material outlet end and a thermal conduction medium outlet proximate a material inlet end. The heat conducting mechanism comprises multiple groups of heat conducting units and the heating conducting unit comprises a plurality of heat conducting tubes. The heat conducting tubes are in communication with the heat conducting medium inlet and outlet. A plurality of fins inclining downward relative to the vertical direction are arranged along the longitudinal direction between adjacent heat conducting tubes. The present application also discloses a system for manufacturing high-quality coal products, comprising a material feed apparatus, a high-quality coal product production apparatus, a heat-conducting medium supply apparatus, and a recycling processing apparatus.

Owner:BAIRONG LI

Method for preparing fuel gas by fluidized bed co-gasification of biomass and coal

ActiveCN1865408AHigh volatile contentHigh carbon reactivityGranular/pulverulent flues gasificationWater vaporFluidized bed

The invention discloses a fuel gas preparing method of gasified biology material and coal fluid bed, which comprises the following steps: grinding biology material into grain dimension less than 5 mm; blending the 5 mm grain with 2 mm grain; heating the gasification stove to 700-800 deg.c; putting biology material and coal in the gasification stove; injecting air and steam; keeping the temperature in the stove at 900-1100 deg.c to generate fuel gas without tar. The invention simplifies the technology, which is easy to realize large-scale manufacturing.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

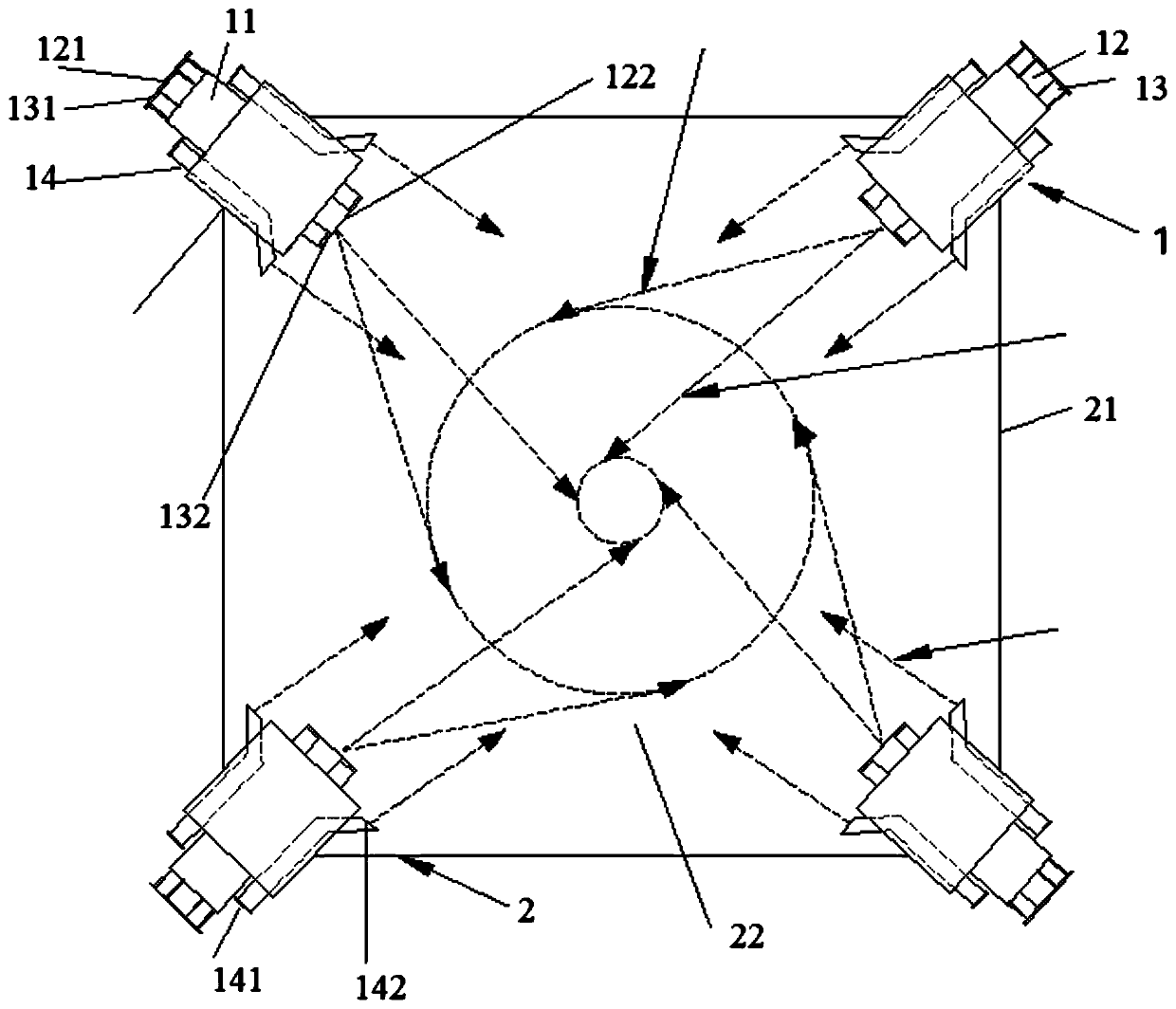

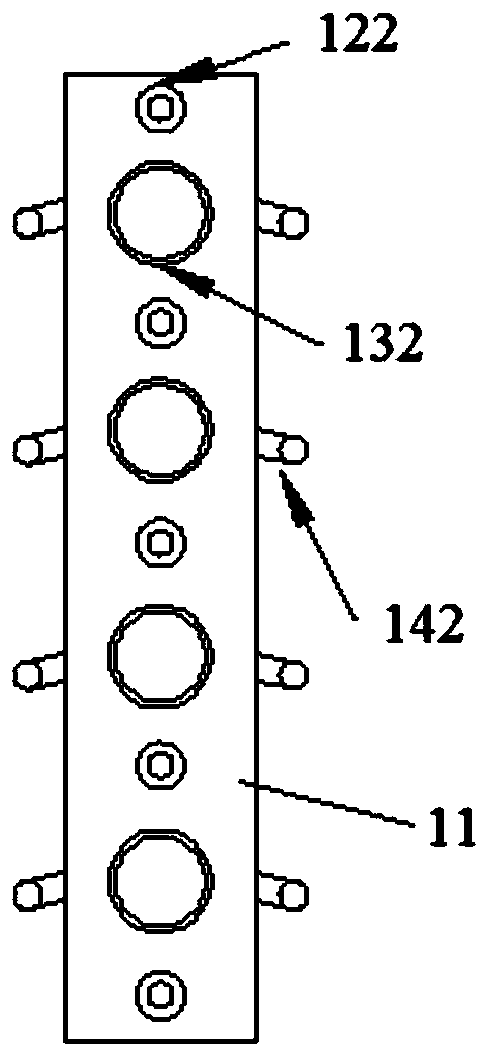

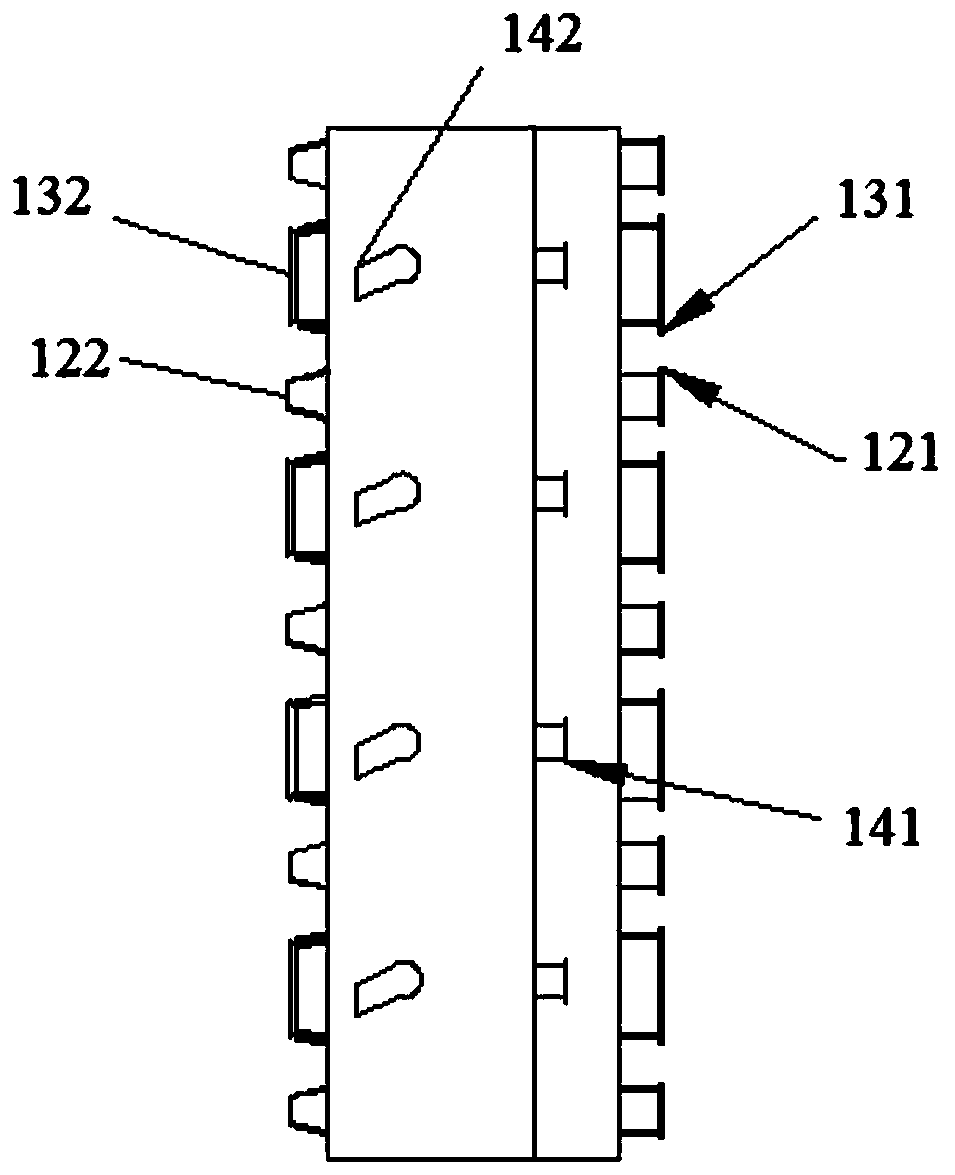

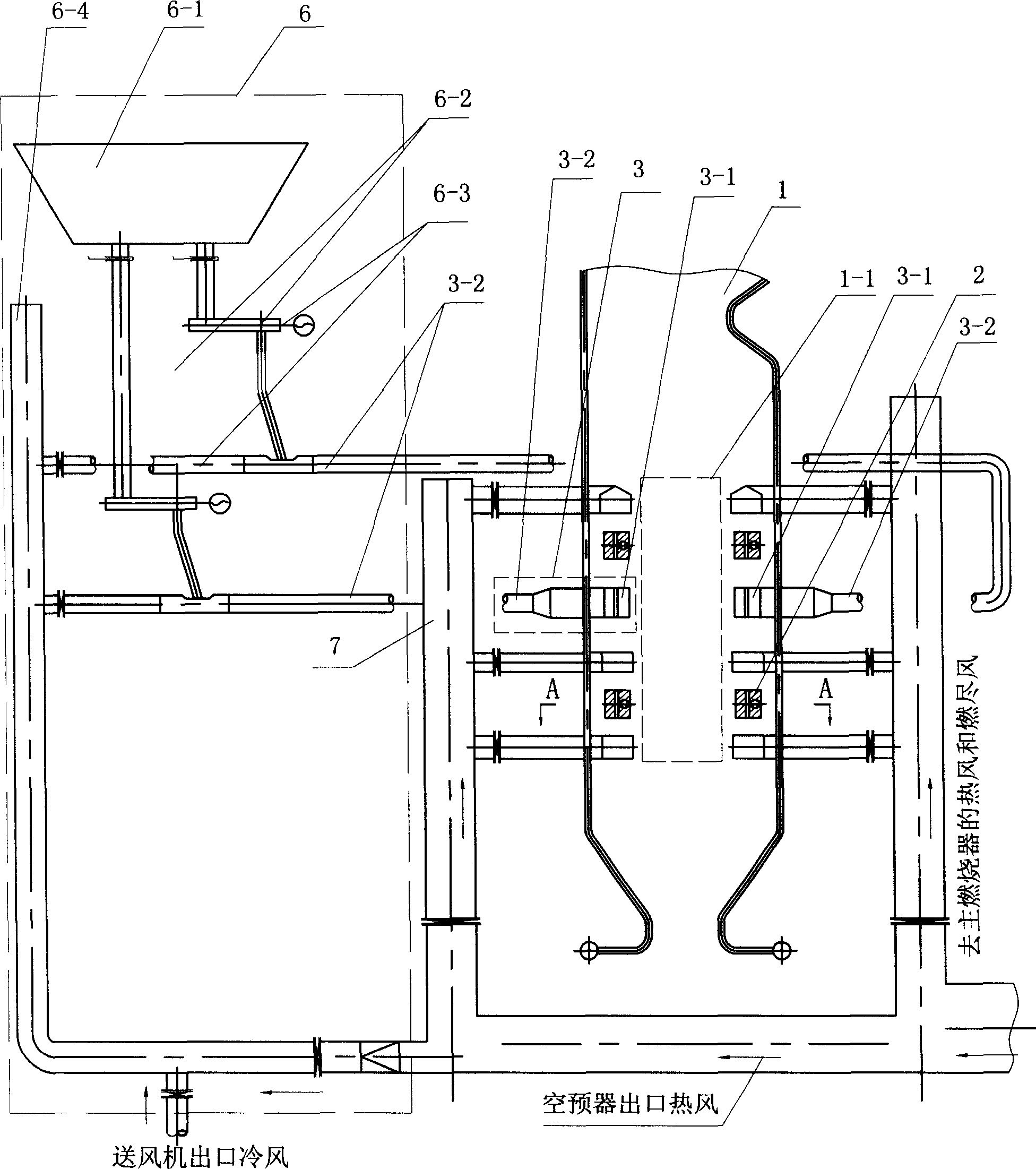

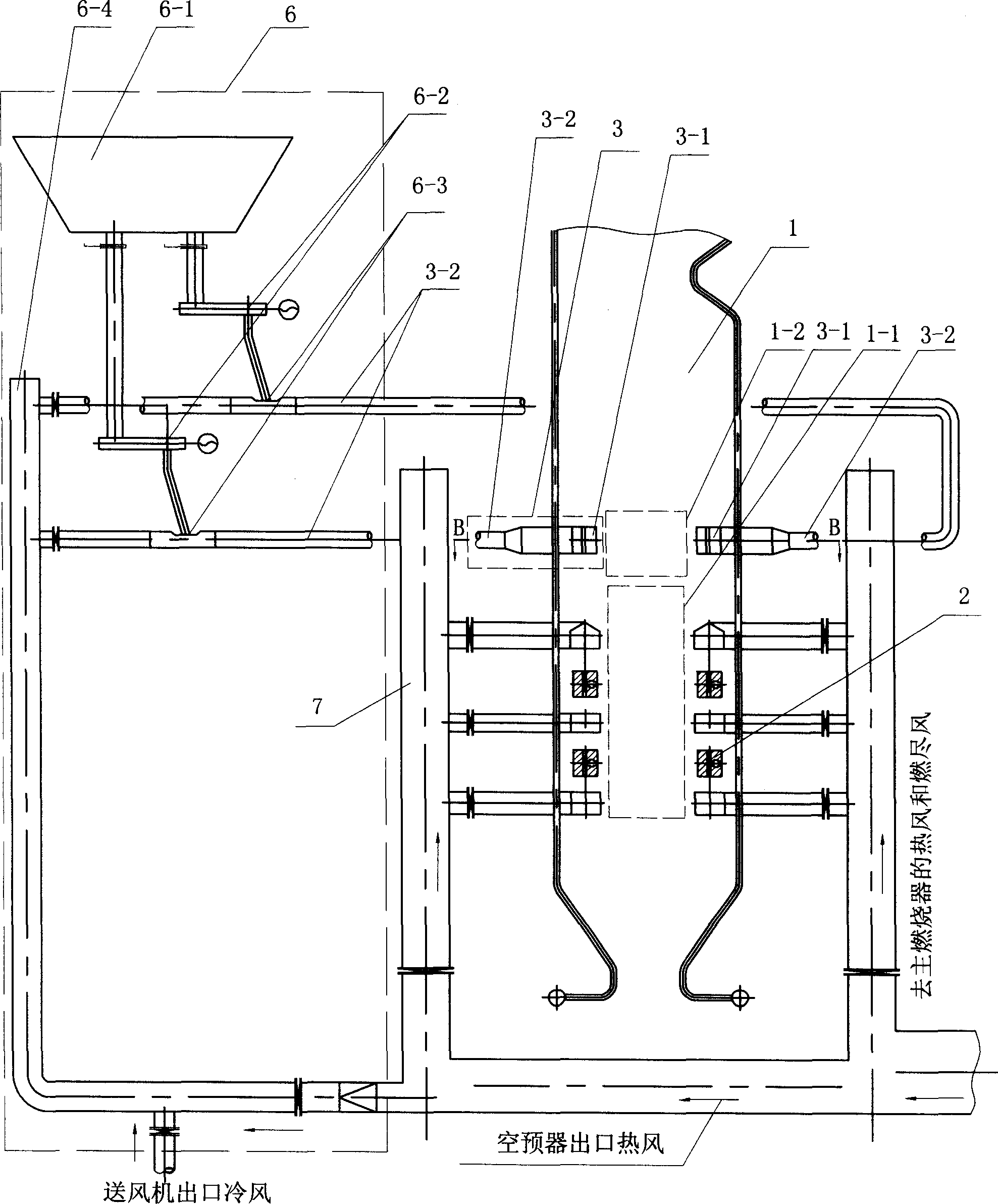

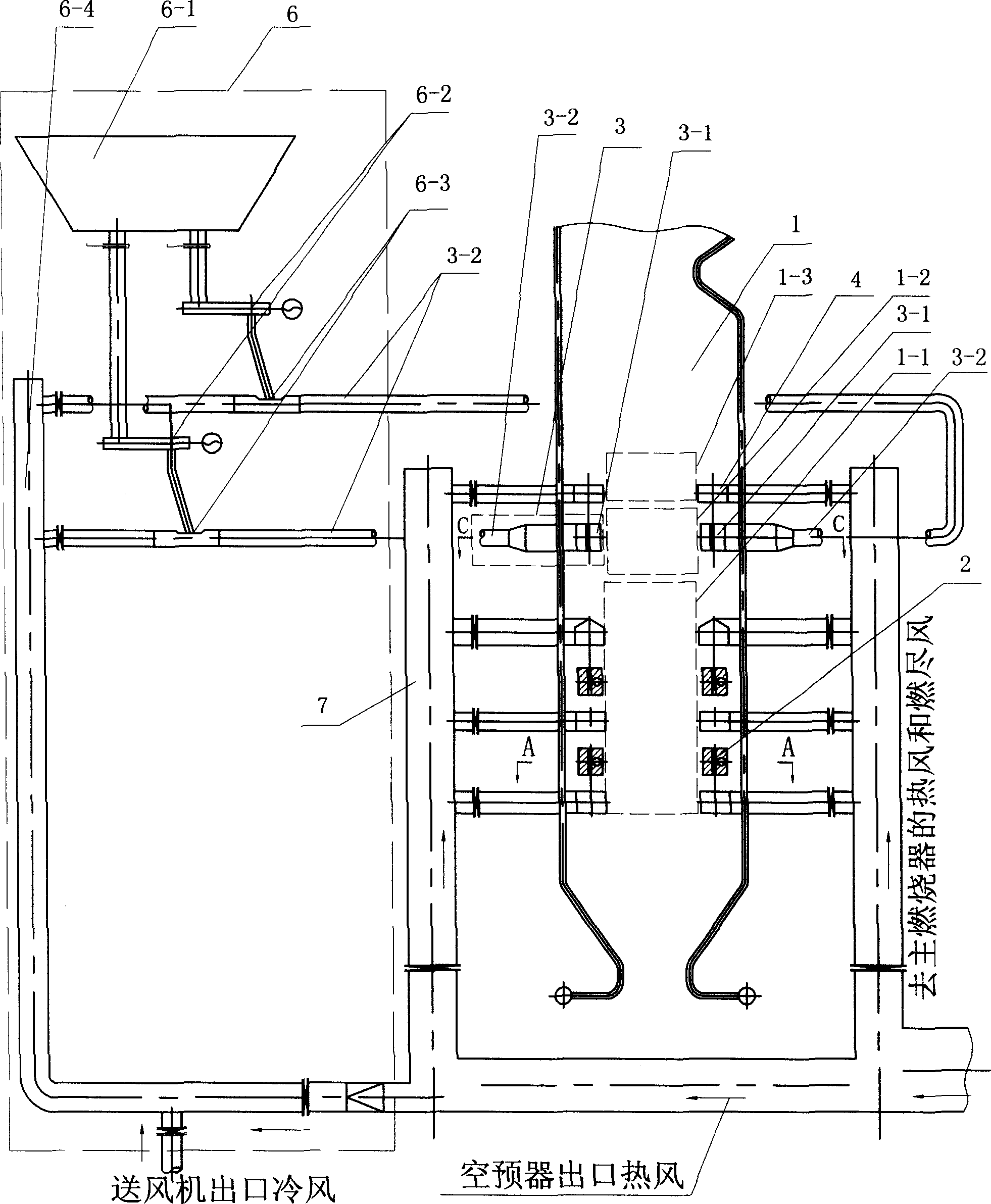

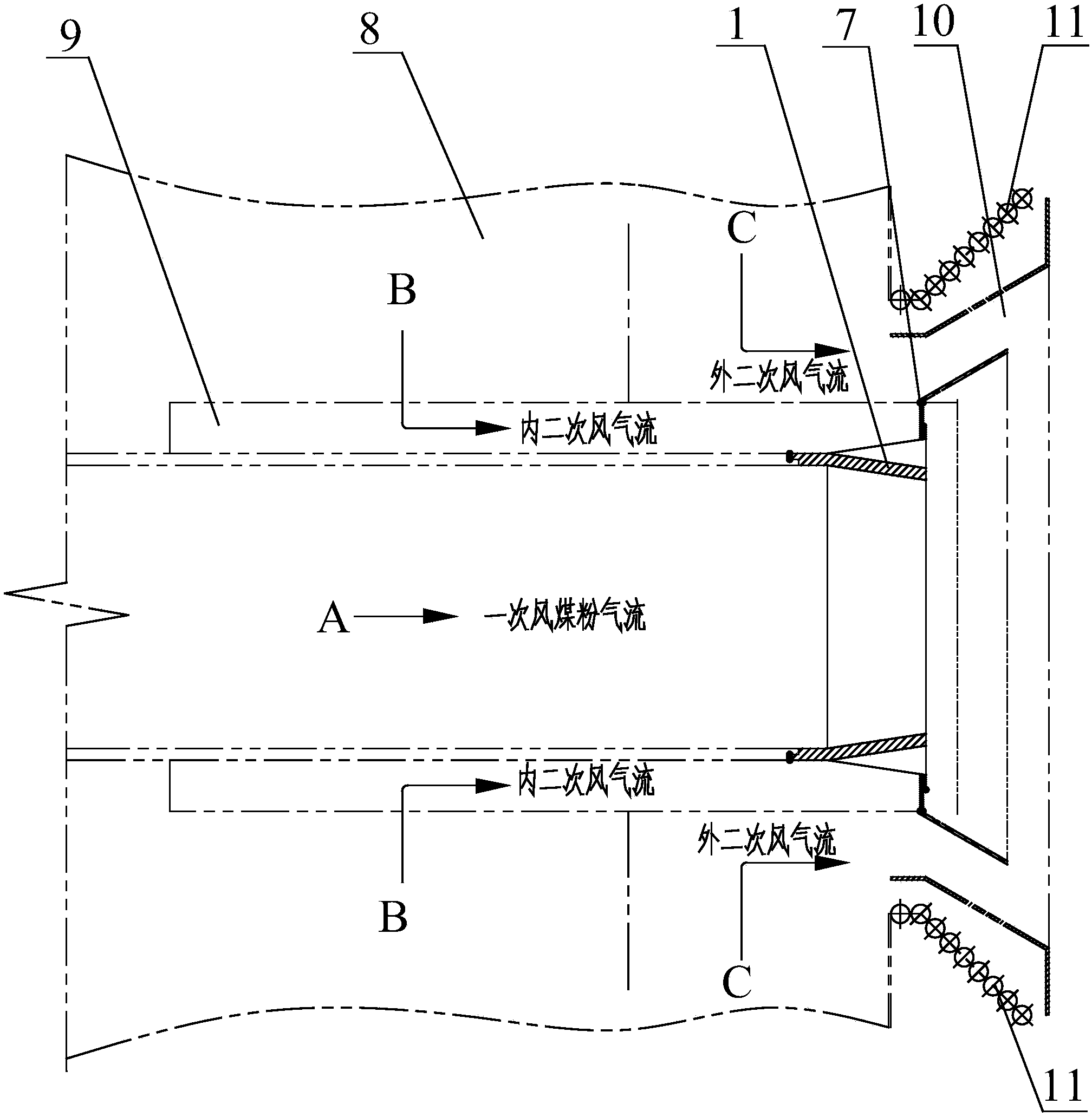

Low-load stable-combustion boiler combustor and combustion method and application thereof

ActiveCN109812803AGood heatCoal type adaptability and load regulation are goodCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSlagAutomotive engineering

The invention discloses a low-load stable-combustion boiler combustor which comprises combustor bodies and a hearth. The combustor body comprises a shell, a secondary air pipe arranged in the center of the shell, a primary air pipe surrounding the two sides of the secondary air pipe, a biomass fuel pipe tightly attached to the inner wall of the shell, and the combustor bodies are arranged on the four corners of the hearth. The invention further discloses a combustion method of the low-load stable-combustion boiler combustor. During full-load combustion of the hearth, a biomass fuel inlet is closed, only pulverized coal combustion is adopted for hearth combustion, biomass combustion is not adopted, and hearth slag is relieved. During low-load operation, pulverized coal entering the hearth is reduced, the temperature of the hearth is reduced, flame combustion is unstable, in order to ensure stable combustion, the biomass fuel inlet is opened for feeding biomass fuel, and it is ensured that flame combustion is stable by means of the characteristics that biomass is high in volatile component, easy to ignite and good in heating value.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

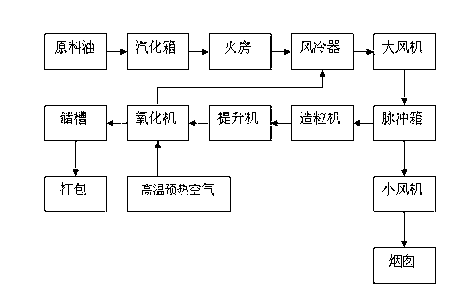

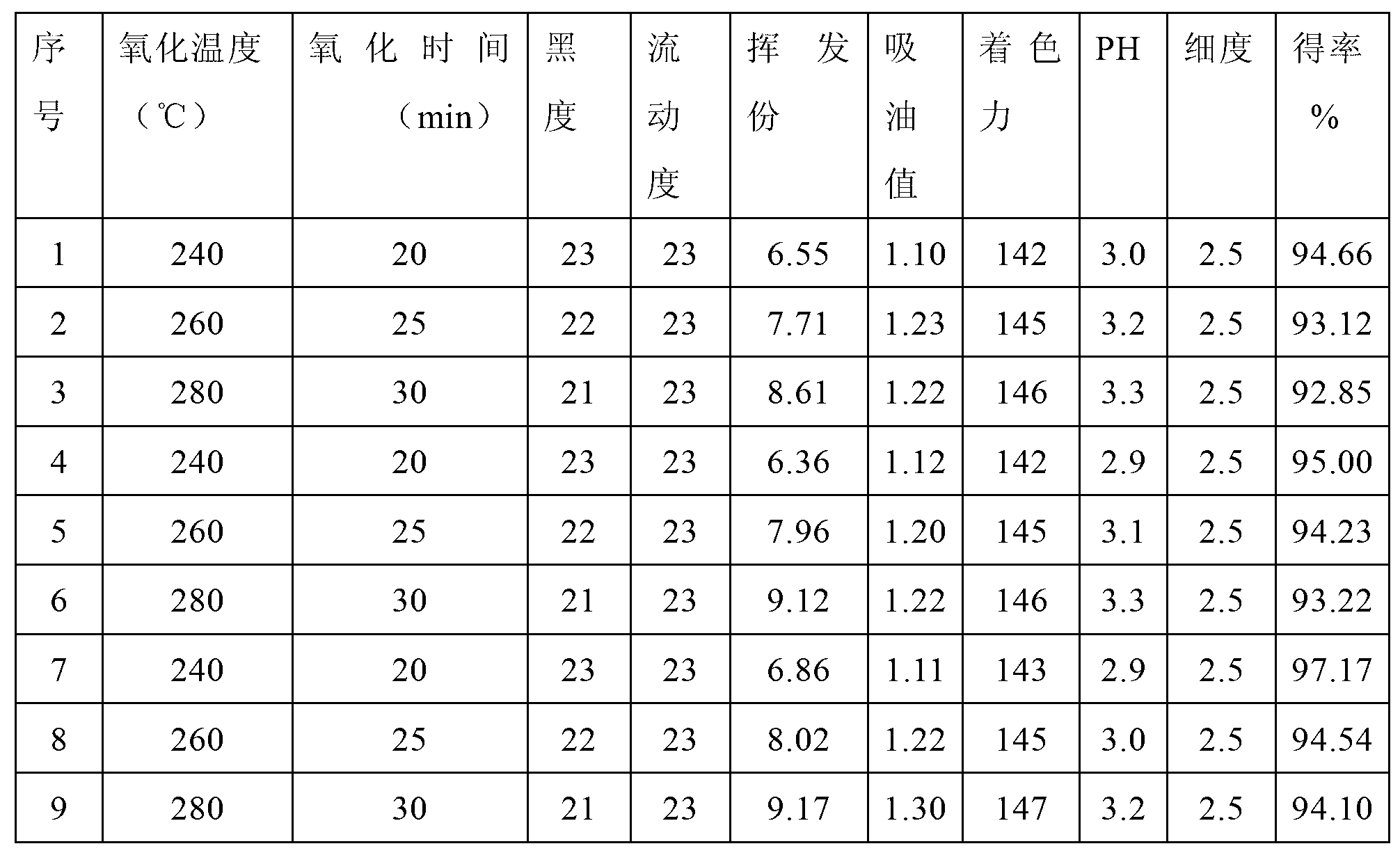

Improved method for producing pigment carbon black

The invention relates to an improved method for producing pigment carbon black. The method comprises the following steps: heating and dehydrating raw oil, conveying the heated raw oil to a vaporizing tank through a pipeline, heating the vaporizing tank so as to vaporize the raw oil, enabling preheated combustible gas to pass through a liquid level of the raw oil in the vaporizing tank so as to mix the oil vapor with the combustible gas, conveying the mixed gas to a carbon black reactor for incomplete combustion and cracking through an oil gas header pipe to produce carbon black, cooling the carbon black and then conveying the cooled carbon black into a pelletizer for pelletizing, performing magnetic separation on the pelletized carbon black, then conveying into an oxidizing machine for performing thermal oxidation treatment, conveying the thermal oxidation-treated carbon black into a cooling tank for cooling to normal temperature, and then conveying to a carbon black storage tank for packaging and storing. The water-soluble pigment carbon black produced by adopting the method is high in volatile matters and dispersity as well as color intensity and low in pH value. The application performances of the pigment carbon black on oil ink, leather, coating, paint and the like can be greatly improved.

Owner:上海焦化化工发展商社

Lignitic coal modifying processing system and technology

InactiveCN102175074AIncrease oil temperatureIncrease valueSolid fuelsDrying solid materialsCombustionHeat conducting

The invention discloses a lignitic coal modifying processing system which comprises a raw material delivery device, a drying device and a heat conducting oil furnace, wherein the drying device is respectively connected with the raw material delivery device and the heat conducting oil furnace; the raw material delivery device delivers the lignitic coal raw material to the drying device; the heat conducting oil furnace delivers the heat conducting oil to the drying device; and the lignitic coal is modified by the drying devices through the heat conduction of the heat conducting oil under the environment of isolating external materials. According to the lignitic coal modifying processing system provided by the invention, because the lignitic coal is subjected to heat conduction by utilizing the high-temperature heat conducting oil, simultaneously the lignitic coal is dried by isolating the influence of the external materials, not only can the heat value of the lignitic coal be improved, but also the volatile can be improved, and the moisture of the lignitic coal is reduced, thus the lignitic coal is dried fully, the moisture of the obtained lignitic coal product is obviously reduced, the heating productivity is improved greatly, the self-combustion of the coal can be prevented and the coal is convenient to transport and store, the system is good for the use of power generation, gas making, chemical engineering, and the like.

Owner:QIANQIU ENERGY SHANGHAI

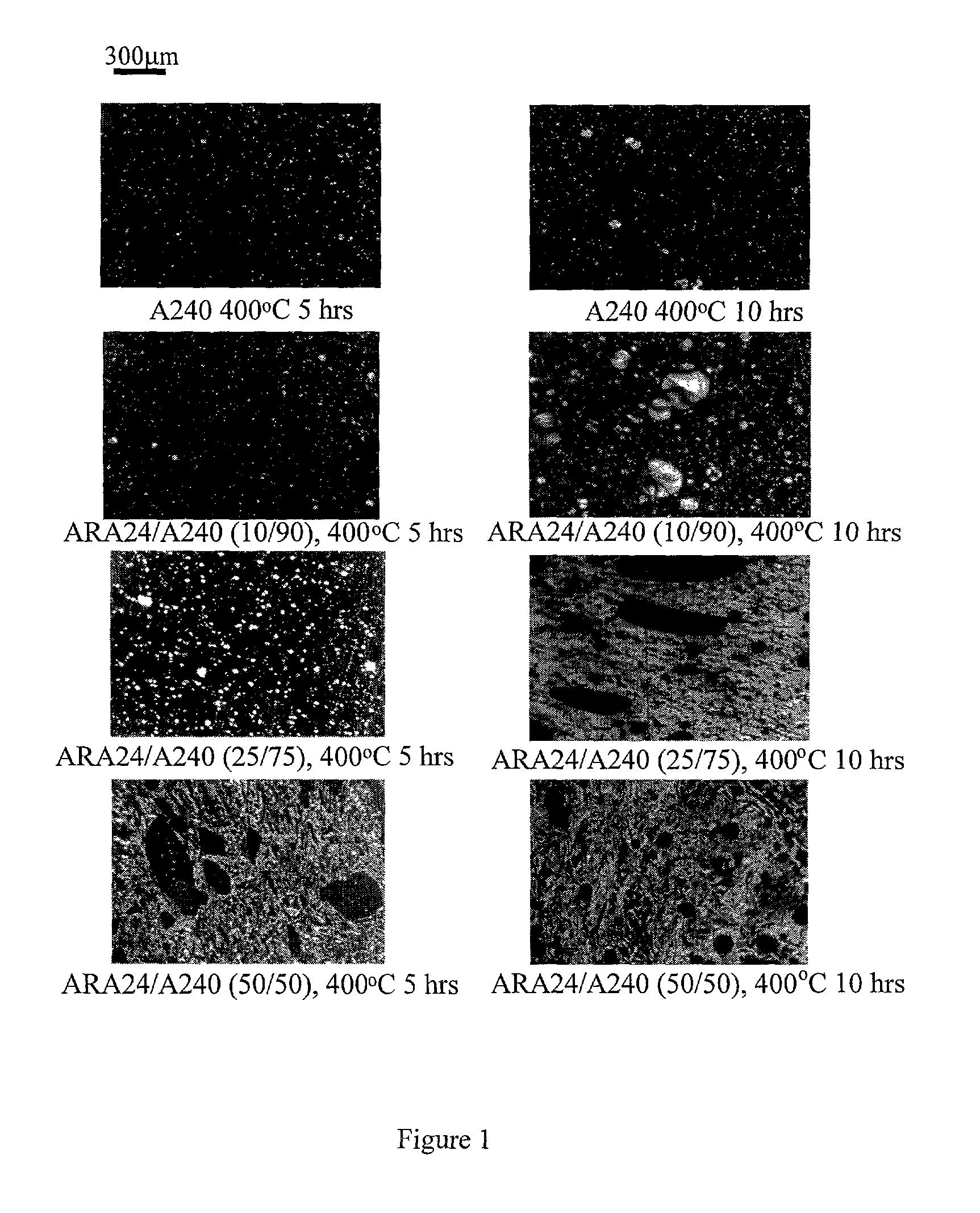

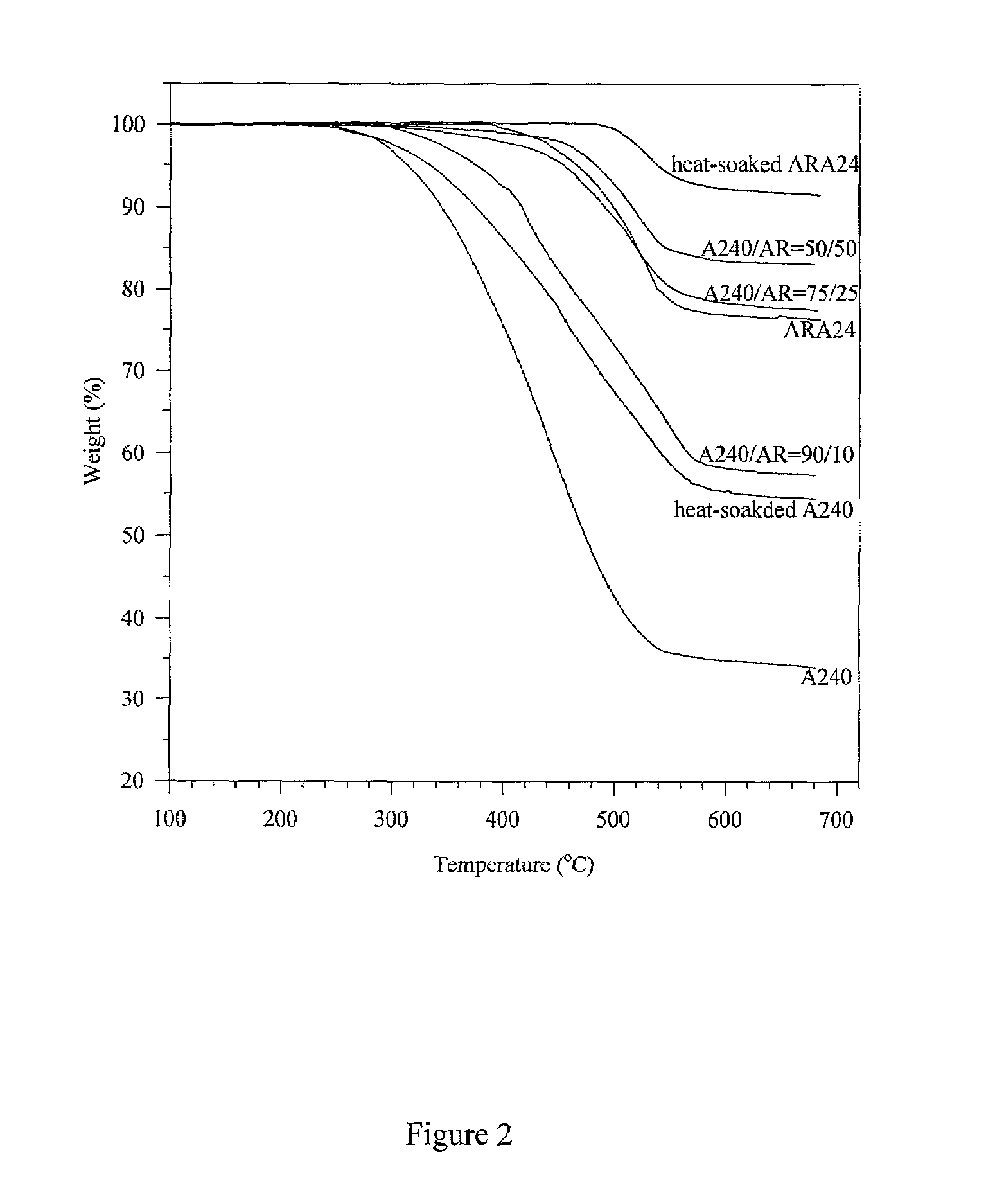

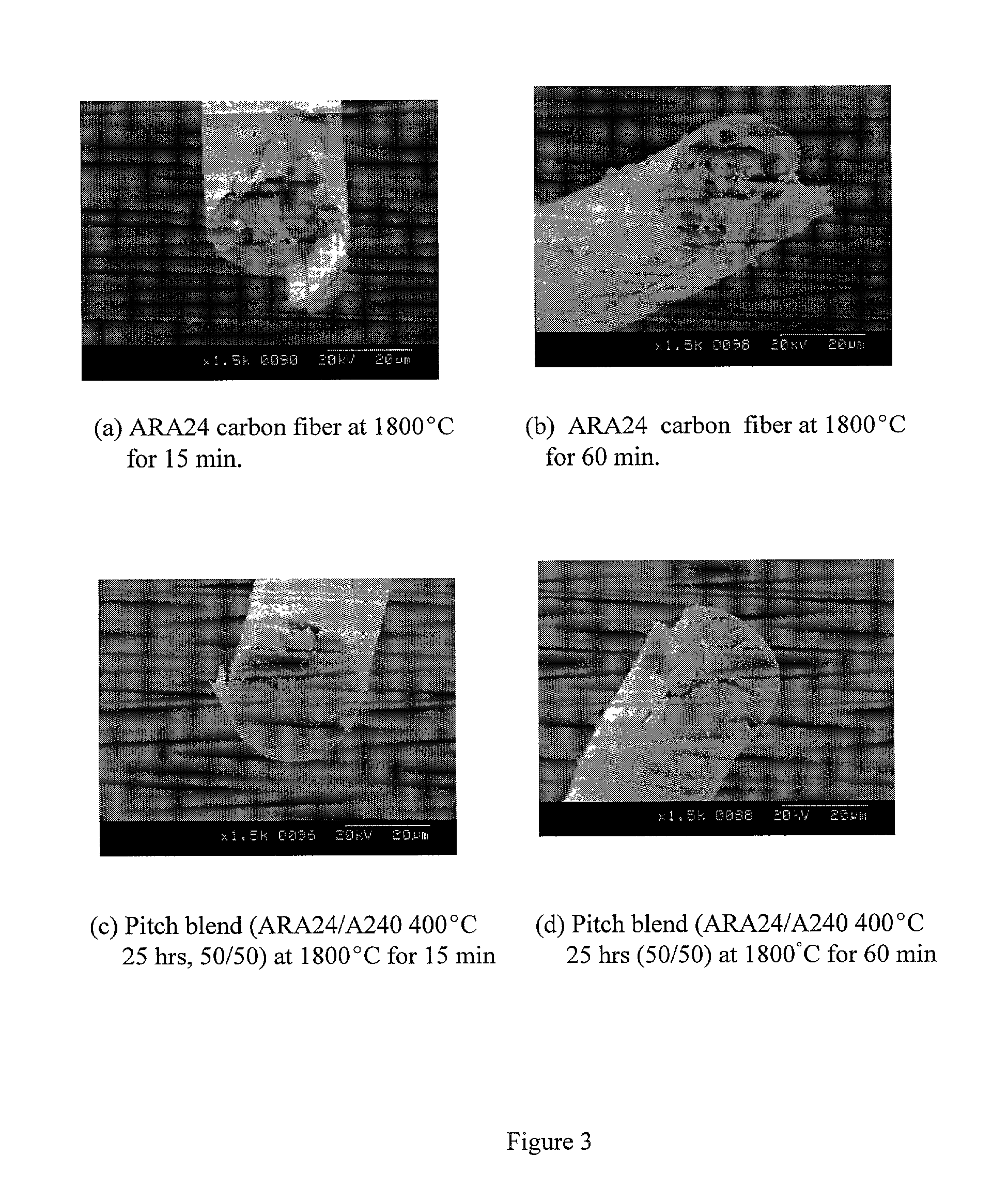

Carbonized pitch moldings prepared from synthetic mesophase pitch and heat-soaked isotropic pitch

InactiveUS7018526B1Little or noHigh volatile contentWorking-up pitch/asphalt/bitumen by chemical meansFibre chemical featuresFiberIsotropic pitch

The present invention provides carbonized pitch articles and methods for producing the same. Synthetic mesophase pitch is mixed with partially anisotropic pitch, which may be selected from heat-soaked isotropic pitch and heat-soaked mixtures of isotropic pitch and mesophase pitch. In producing carbon moldings, the mesophase pitch is first stabilized to make it at least partially infusible, prior to mixing. In producing carbon fibers, the mesophase pitch will not typically be stabilized before mixing, rather, the resultant pitch fiber, produced from the mixture, will be stabilized by oxidation and air. The resultant fibers and moldings are carbonized according to conventional methods.

Owner:THE UNIVERSITY OF AKRON

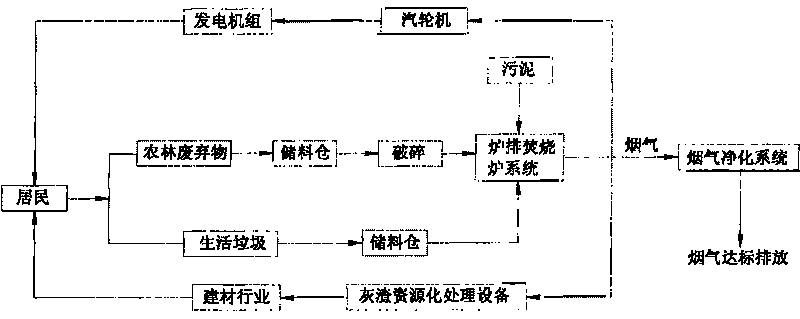

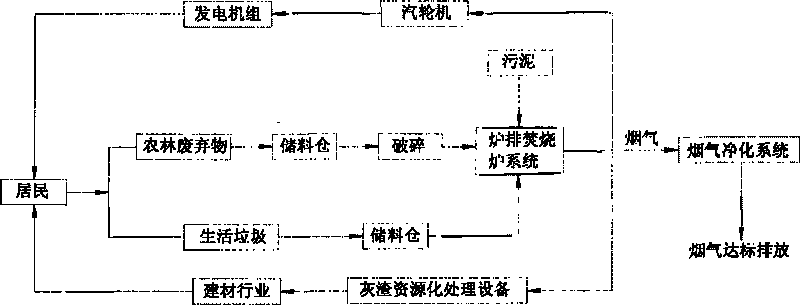

Method for mixed burning of agriculture and forestry waste, sludge and household garbage by using grate furnace

The invention relates to the technical field of energy environmental engineering and provides a method for mixed burning of agriculture and forestry waste, sludge and household garbage by using a grate furnace. The method comprises burning the agriculture and forestry waste, sludge and household garbage in a grate garbage burning furnace, igniting by using agriculture and forestry waste, and adding household garbage and sludge in the furnace to realize mixed burning when the temperature of the furnace rises to 850 DEG C, wherein the mass percent of the agriculture and forestry in the mixed fuel is within 40 percent, the mass percent of sludge in the mixed fuel is within 30 percent, the burning temperature of the grate burning furnace is controlled at 850 to 1000 DEG C, and the smoke gas generated by burning stayed in the furnace is controlled above two seconds. The invention is low in the cost, improves the burning efficiency of the garbage burning furnace, solves the problem of pollution caused by the sludge, ensures that the agriculture and forestry waste can be recycled, reduces discharge of pollutants, particularly heavy metal and dioxin and reduces the consumption of fossil energy.

Owner:SOUTHEAST UNIV

Biomass and powder coal mixed combustion and biomass recombusting and denitrating combustion apparatus

InactiveCN1673619AEmission reductionHigh volatile contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorRoom temperature

The present invention is one burning apparatus for the composite burning of biomass and coal powder and re-burning and denitrifying of biomass. The burning apparatus includes hearth, main coal powder burning area inside the hearth, main nozzles and biomass nozzles installed on the four corner of the hearth. The present invention has the following advantages: lower NOx exhaust rate, burning out of biomass fuel, large scale utilization of biomass, reduced room temperature CO2, and lowered SOx exhaust and simple apparatus structure.

Owner:HARBIN INST OF TECH

Chromium-based boiler slag-removing ash-removal coal-saving composition and preparation method thereof

ActiveCN104910996AHigh active specific surface areaHigh hydrogen contentSolid fuelsFuel additivesPetroleumElectric power

The present invention relates to an additive product suitable for coal-fired boilers of electric power, thermal power, petroleum, chemical and metallurgical industries, and particularly relates to a chromium-based boiler slag-removing ash-removal coal-saving composition, and the chromium-based boiler slag-removing ash-removal coal-saving composition consists of the following components in parts by weight: 50 to 65 parts of chromium oxide, 8 to 15 parts of copper oxide, 5 to 9 parts of cerium oxide, 5 to 9 parts of barium molybdate, 7 to 14 parts of cobaltous oxide, 12 to 17 parts of potassium permanganate, 10 to 16 parts of manganese carbonate, 12 to 17 parts of barium carbonate, 8 to 15 parts of titanium dioxide, zinc oxide, 15 to 20 parts of zinc oxide, 6 to 10 parts of potassium chlorate, 6 to 10 parts of potassium perchlorate, 20 to 28 parts of sodium carbonate, 25 to 35 parts of active attapulgite carclazyte and 0.1 to 0.3 part of alkyl glycerol ether sulfonate. The chromium-based boiler slag-removing ash-removal coal-saving composition is an environmentally-friendly product which is efficient in combustion helping, and high in coal saving ratio, can reduce pollution, improve combustion efficiency, and extend the boiler service life, and is convenient to use and stable in performance, and when in use, only the chromium-based boiler slag-removing ash-removal coal-saving composition is added into a fuel to participate in the combustion without equipment transformation.

Owner:GANSU HEIMA PETROCHEM ENG

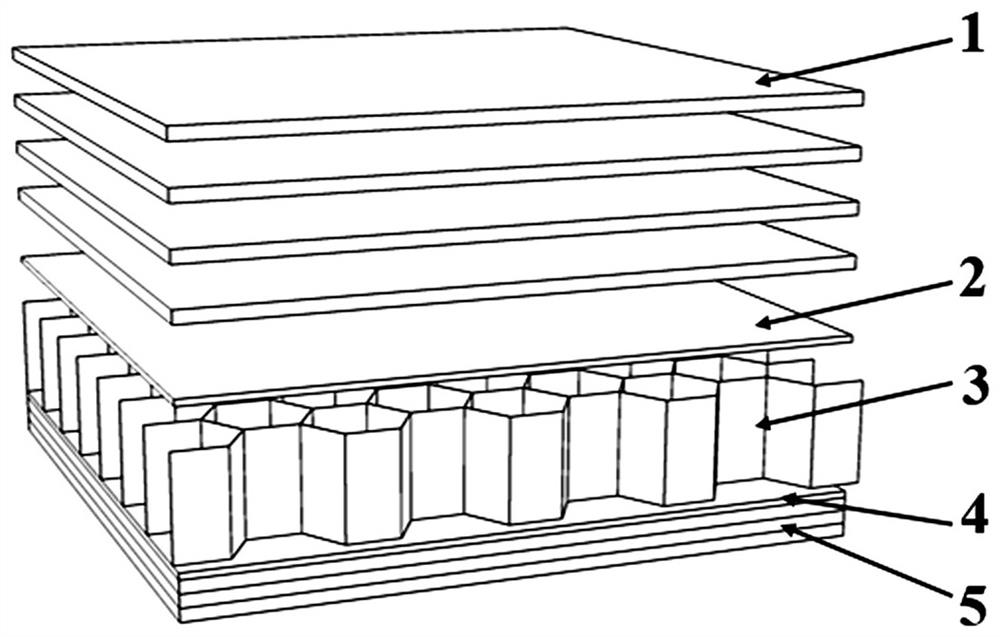

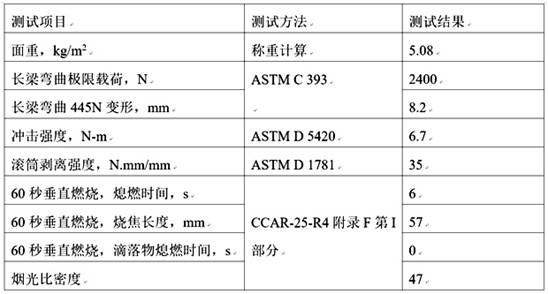

Impact-resistant flame-retardant floor and preparation method thereof

ActiveCN113650375AImprove flame retardant performanceImprove toughnessGlass/slag layered productsFirming agentAirplane

The invention provides an impact-resistant flame-retardant floor and a preparation method thereof. The floor comprises an upper panel made of a phenolic resin composite material, an upper bonding layer, a honeycomb core, a lower bonding layer and a lower panel made of the phenolic resin composite material, wherein the above members are sequentially overlapped; and the upper panel and / or the lower panel are / is prepared from phenolic resin prepreg, and preparation raw materials of the upper panel and / or the lower panel comprise phenolic resin and a reinforcing material. The preparation raw materials of the phenolic resin comprise the following components: 0-100 parts of thermoplastic phenolic resin, 0-100 parts of thermosetting phenolic resin, 1-15 parts of a flame retardant, 5-100 parts of a toughening agent, 0.05-1 part of a coupling agent and 0-20 parts of a curing agent, wherein the weight parts of the thermoplastic phenolic resin and the thermosetting phenolic resin are not 0 at the same time. According to the impact-resistant flame-retardant floor, through honeycomb sandwich structure configuration design, forming process design, and toughening and flame-retardant modification on the hot-melt phenolic prepreg, the obtained floor has the characteristics of high impact resistance, flame retardance and low smoke density, and the performance requirements of being used as a passenger and cargo compartment floor material of an airplane are met.

Owner:北京玻钢院复合材料有限公司

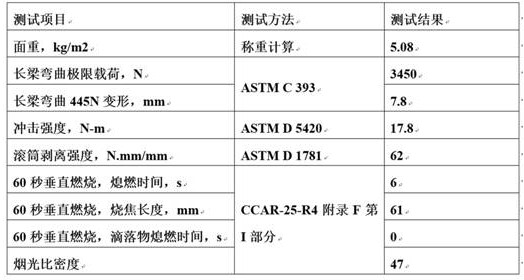

Preparation method of Ageratina-adenophora-base high-specific-area activated carbon

The invention relates to a preparation method of Ageratina-adenophora-base high-specific-area activated carbon, belonging to the field of environmental protection. The method comprises the following steps: uniformly mixing KOH and an Ageratina adenophora carbonization material in a solid-phase state, filling into a ceramic crucible, and putting into a microwave high-temperature reactor; introducing nitrogen to evacuate air in the furnace, heating under microwaves to the last fewer minutes, quickly blowing CO2 into a guide tube communicated with the bottom of the ceramic crucible, and meanwhile, starting an ultrasonic generator; after finishing heating, washing the activated material with water, and recovering the residual KOH activator; and sequentially carrying out acid washing, water washing and drying to obtain the high-specific-area activated carbon. By using the Ageratina adenophora as the raw material, the method uses the CO2 bottom blowing mode to enhance the activation effect of the carbonization material, thereby lowering the production cost of the activated carbon, relieving the environmental pollution, changing harmful substances and waste into valuable substances and implementing comprehensive utilization of natural resources. The high-specific-area activated carbon can be effectively used in the fields of adsorptive collection of gasoline and other organic substances in automobile exhaust emissions and fuel system volatile substances, solvent recovery and the like.

Owner:KUNMING UNIV OF SCI & TECH

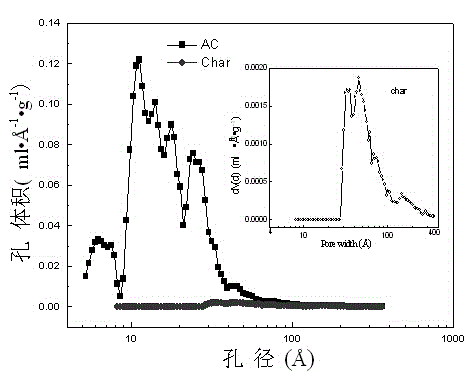

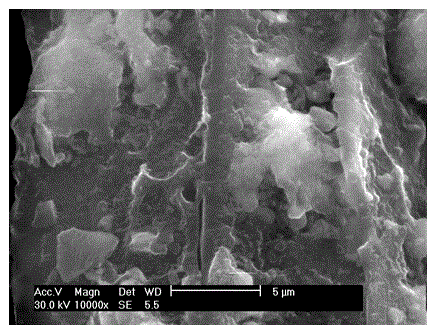

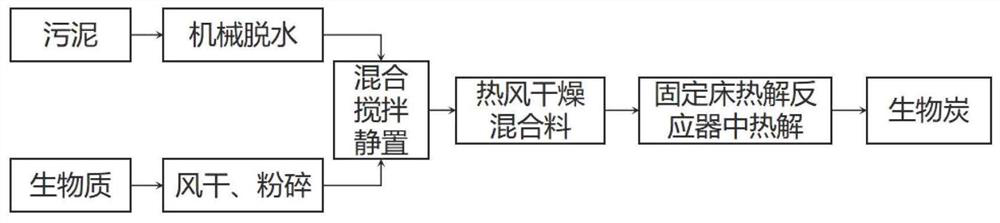

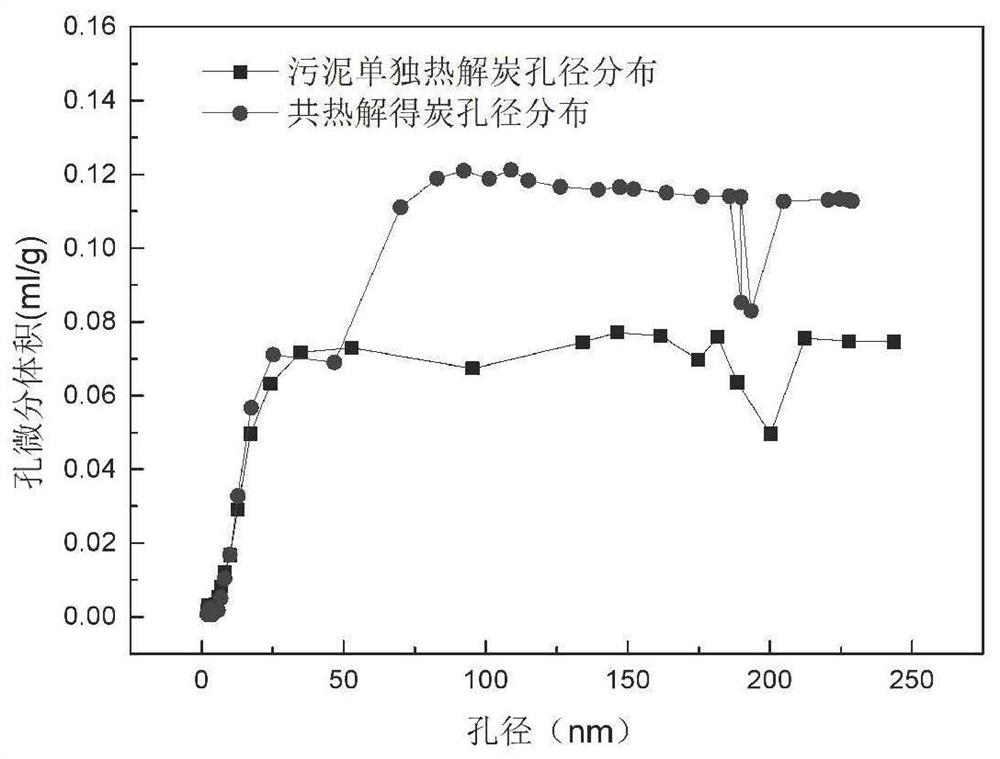

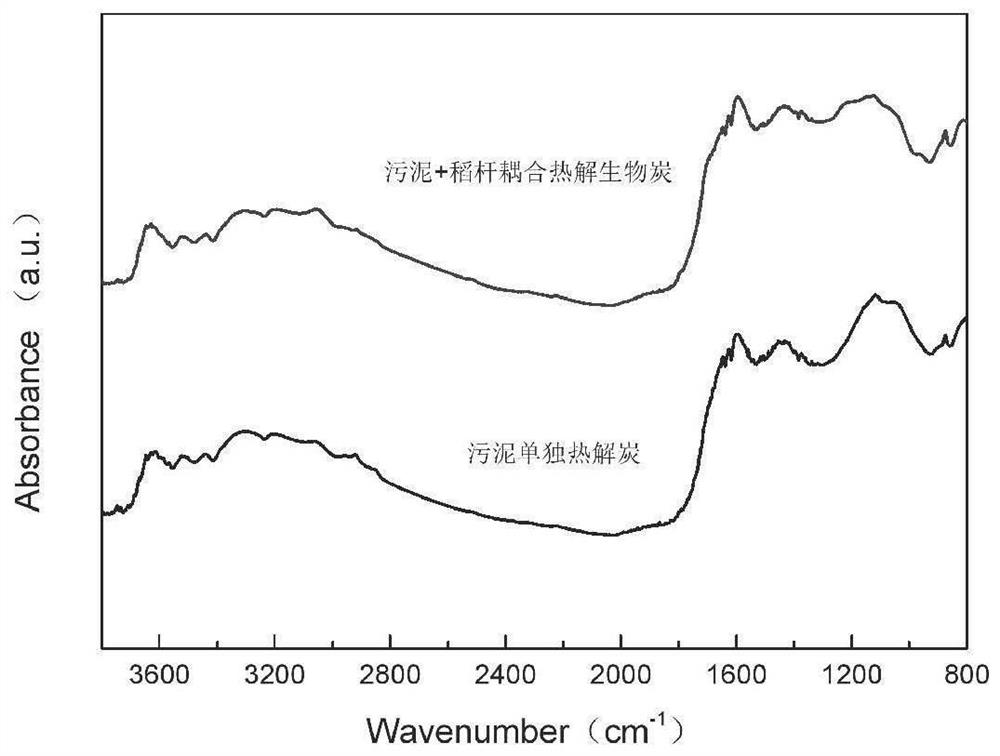

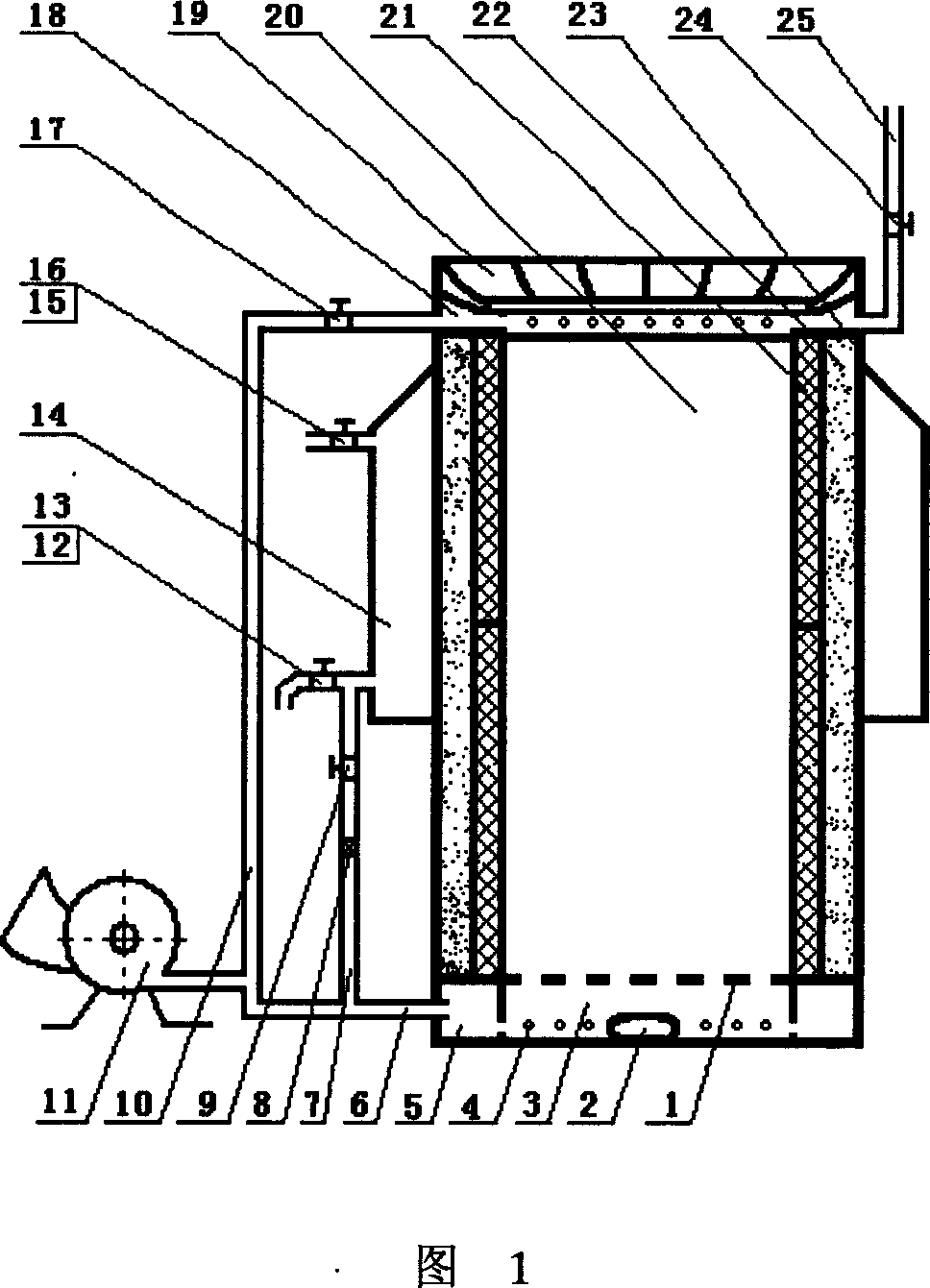

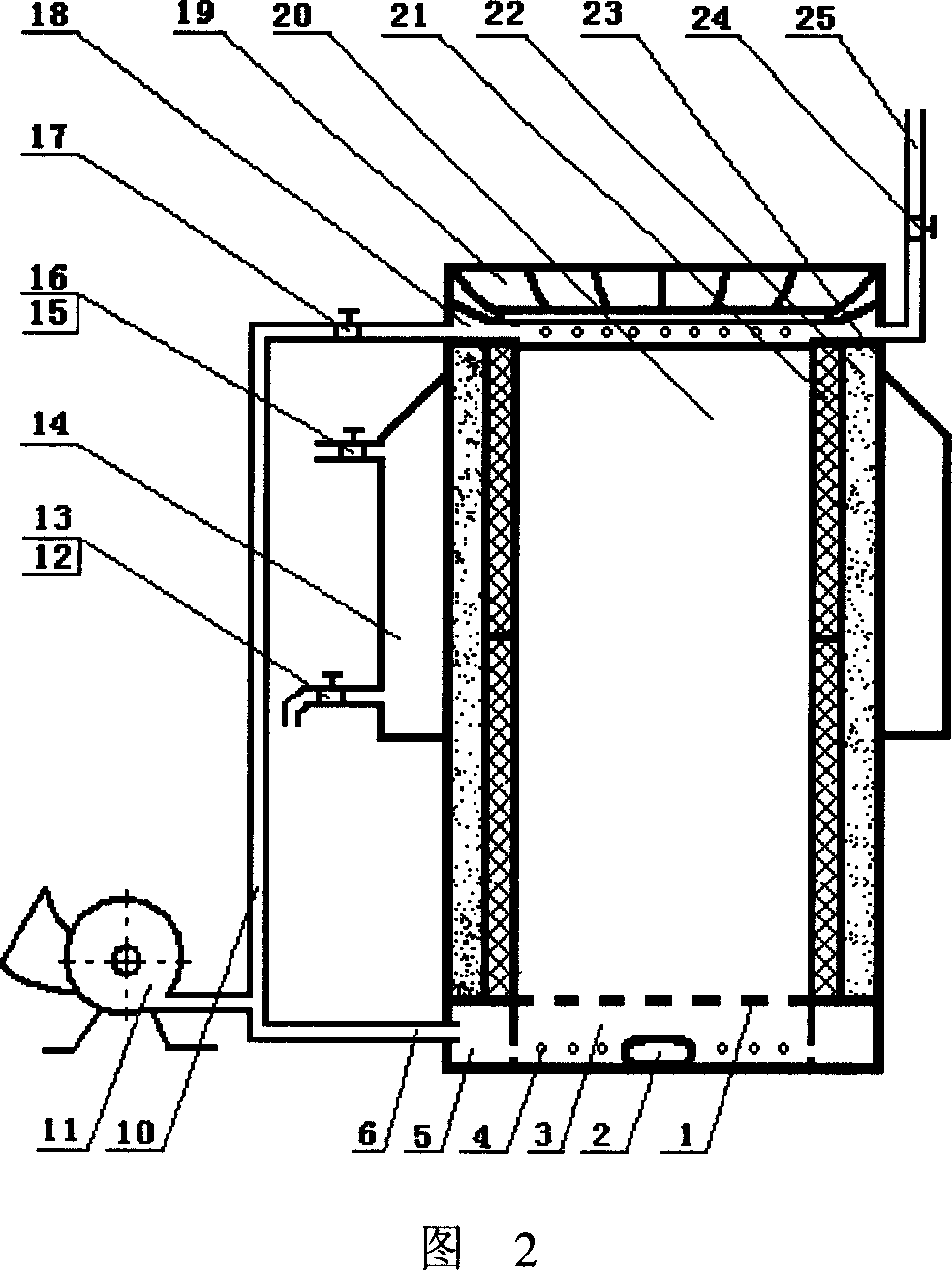

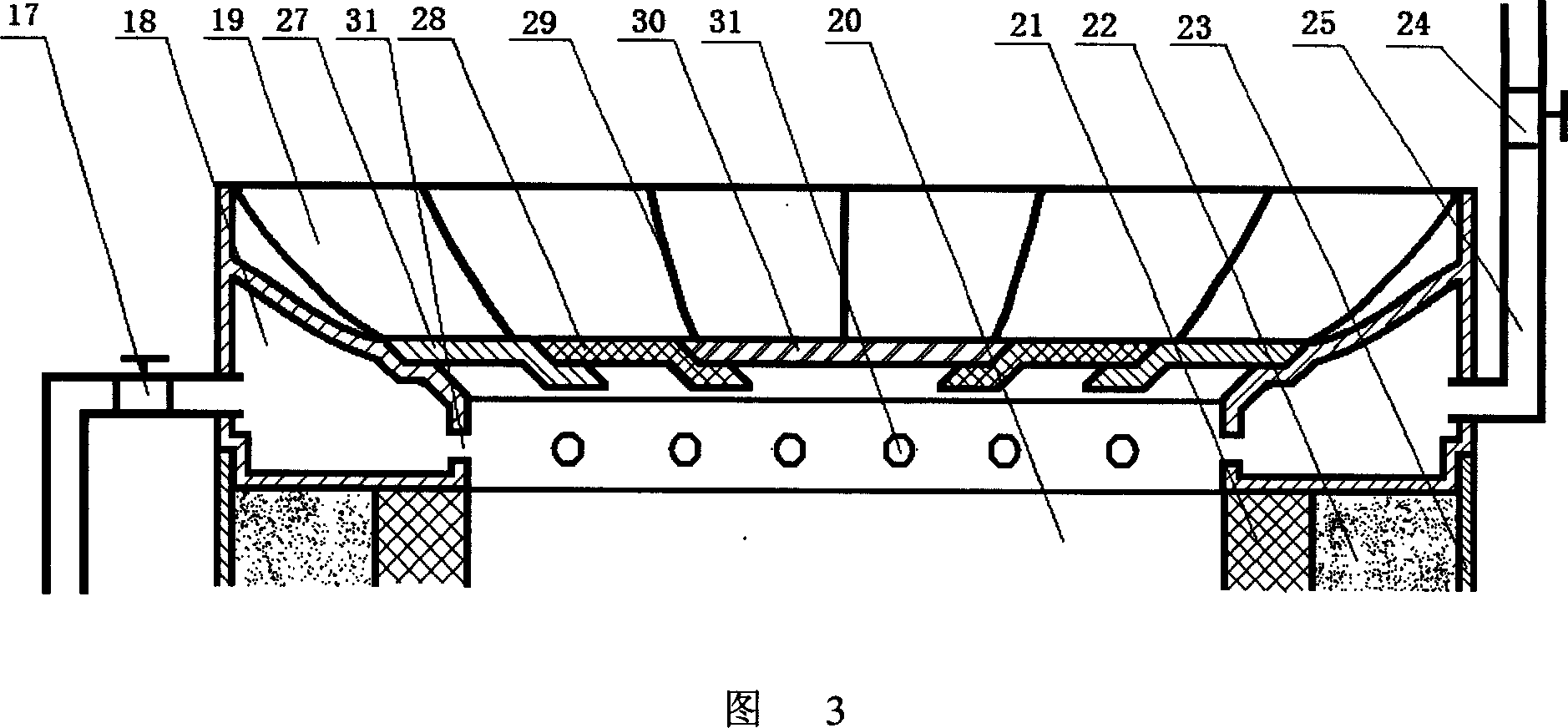

Method for preparing biochar and solidifying heavy metals through coupling sludge with biomass pyrolysis

ActiveCN112919754AHigh volatile contentIncrease oil production rateOther chemical processesWater contaminantsSludgeBiochar

The invention discloses a method for preparing biochar and solidifying heavy metals by coupling sludge with biomass pyrolysis, which comprises the following steps: 1) pretreating biomass, and mechanically dehydrating sludge; 2) fully and uniformly mixing the treated biomass and sludge, adding into a stirrer, stirring and standing to obtain a mixture; step 3) adding the mixture into a drying furnace for dewatering and drying to obtain a dried sludge-biomass mixture; and 4) adding the sludge-biomass mixture into a pyrolyzing furnace, pyrolyzing in an anaerobic or anoxic environment, and cooling solid residues after the pyrolysis is completed to obtain the biochar. According to the method for preparing the biochar and solidifying the heavy metal through sludge coupling biomass pyrolysis, the biochar can be prepared through sludge pyrolysis efficiently, meanwhile, the heavy metal in the biochar is solidified, and heavy metal pollution is greatly reduced.

Owner:SOUTHEAST UNIV

Biological-material-tall stove

InactiveCN1936429AEasy centralized processingEasy to addDomestic stoves or rangesEnergy inputHearthBiological materials

This invention relates to a biological material ball stove including a fan, a secondary wind pipe, a valve, a flowmeter, a supply pipe, a gasification agent pipe, a loop air pre-heating chamber, a loop air conduction chamber, a stove head, a stove body, a heat preservation layer, an inner container and biological material balls, in which, the upper part of outside of the stove is a water tank made of stainless steel, the fan is connected with the loop air pre-heating chamber at the bottom of the hearth via a gasification agent pipe, the heat preservation layer, the inner container and the hearth are orderly placed in the body, a grate is under the hearth and the stove head is above it, the loop air conduction chamber is at the bottom of the head, the secondary wind pipe and the chimney are at the outside wall of the conduction chamber with a stage along the internal wall for placing a stove cover.

Owner:刘春生

Biomass pellet fuel and preparation method thereof

The invention discloses a biomass pellet fuel and a preparation method thereof. The biomass pellet fuel is prepared from the following raw materials: straw, peanut shells, cotton stalks, yellow tobacco stalks, cashew nut shells, Chinese hawthorn seeds, a lubricant and an additive. The preparation method for the biomass pellet fuel comprises the following steps: 1, pulverizing and screening the rawmaterials; 2, uniformly mixing all the raw materials under stirring; 3, performing extrusion granulation; and 4, performing drying so as to obtain the biomass pellet fuel. According to the invention,the raw materials of the invention are easily available and have low cost; the waste is turned into the valuable; and the fuel has the advantages of long burning time, large calorific value, high density, low sulfur content, low water content and low ash content. The fuel is a high-calorific-value, clean, pollution-free and environmentally-friendly product which is sufficient in combustion, low in ash accumulation and free of slagging, has good performance and can be promoted and applied.

Owner:临沂环创环保科技有限公司

Biomass compound coal for tobacco flue-curing and preparation method thereof

InactiveCN101899344AHigh volatile contentReduce carbon contentSolid fuelsWaste based fuelAdhesiveAnthracite

The invention discloses biomass compound coal for tobacco flue-curing, which is especially suitable for combustion requirements of bulk curing barn curing equipment. The invention also discloses a preparation method thereof. The invention adopts the following technical scheme to realize the aims: the biomass compound coal for tobacco flue-curing is prepared by the following components by weight percent: 57-95% of coal slime, 0-19% of soft coal with high heat productivity, 0-19% of anthracite, 2-3% of smashed plant straw and 2-2.5% of adhesive, wherein the compound coal also comprises a sulphur fixing agent; and the preparation method has the steps of weighting and mixing the components, and evenly pressing to obtain the product. Based on the scheme, the biomass compound coal for tobacco flue-curing can be obtained, which is especially suitable for combustion requirements of bulk curing barn curing equipment.

Owner:YUNNAN TOBACCO CORP QUJING BRANCH

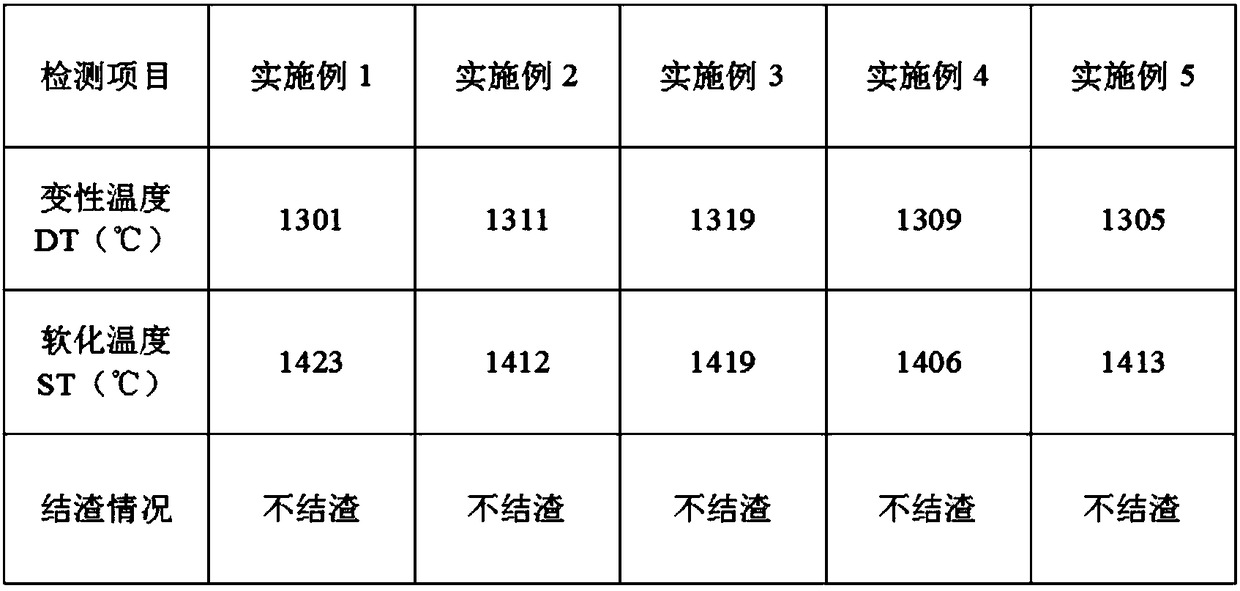

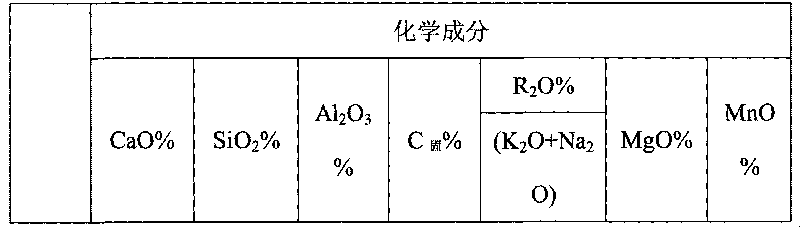

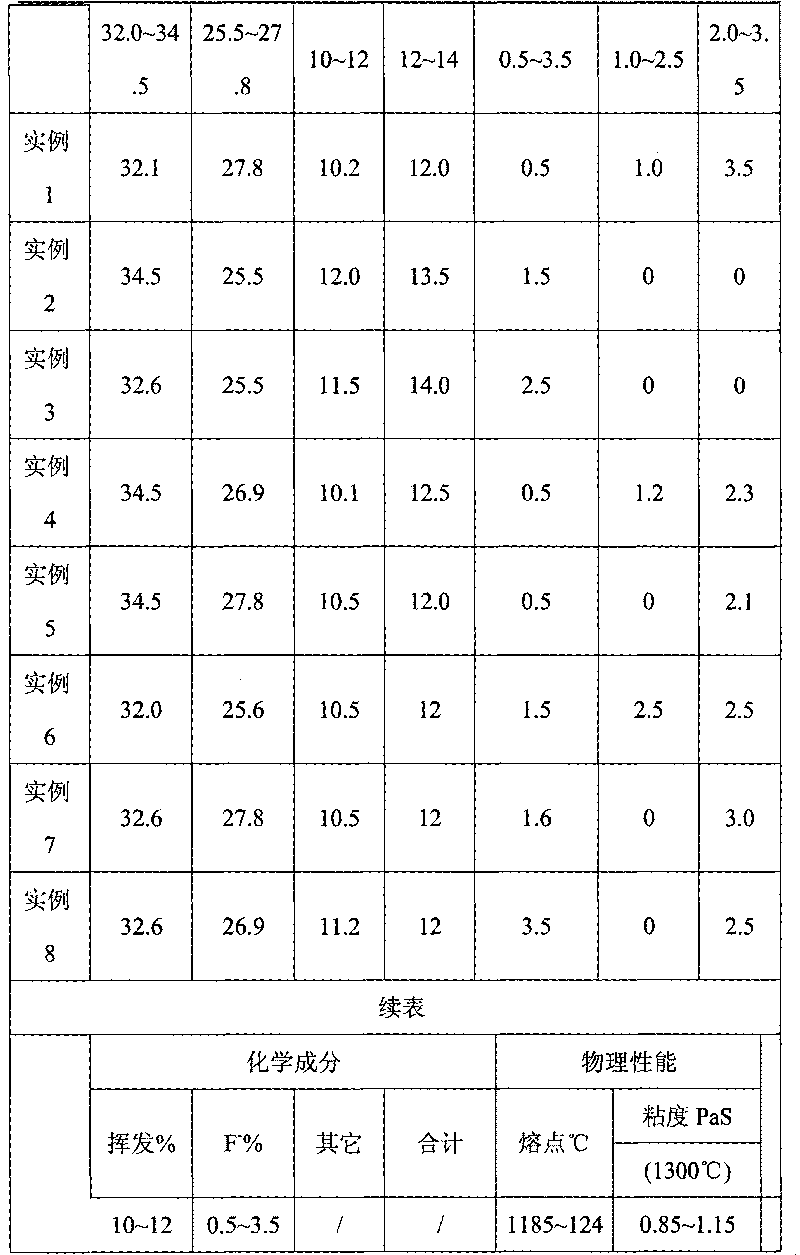

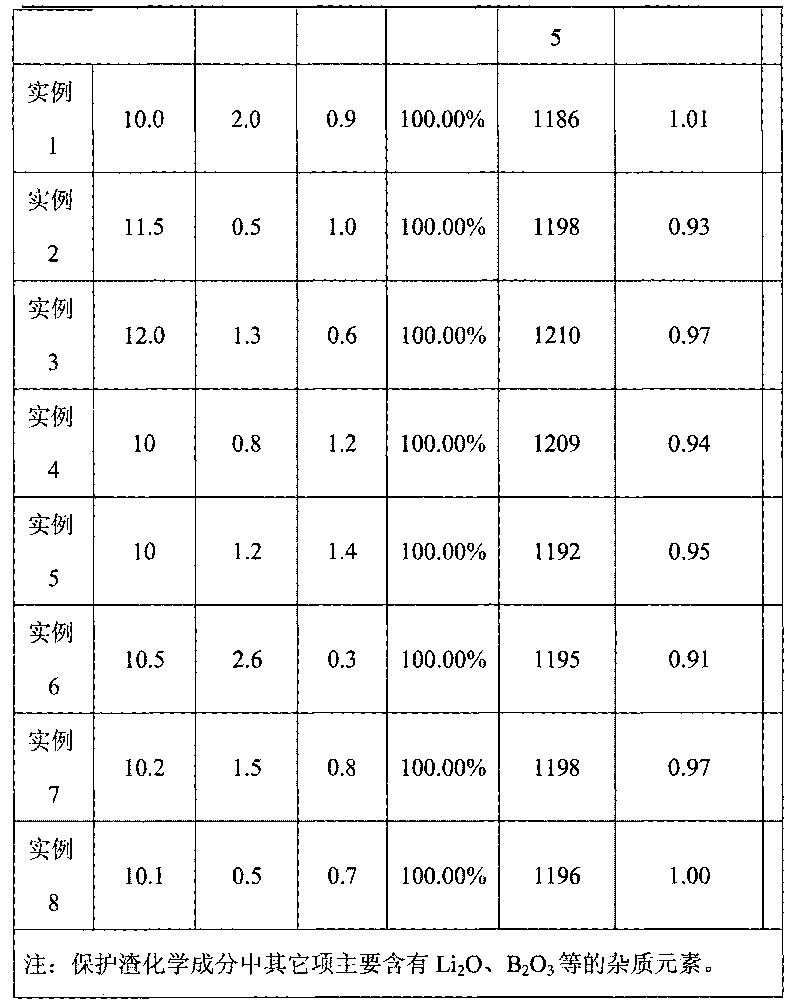

Covering slag for beam blank continuous casting crystallizer

ActiveCN101758175AImprove stabilityCoordinating comprehensive performanceSlagContinuous casting mold

The invention provides covering slag for a beam blank continuous casting crystallizer, comprising the following components in weight percent (%): 32.0%-34.5% of CaO, 25.5%-27.8% of SiO2, 10%-12% of Al2O3, 0.5%-3.5% of F, 12%-14% of solid C, 0.5%-3.5% of R2O and 10%-12% of volatiles. The production practice indicates that the surface cracks of a beam blank are greatly reduced and the rejection rate of the beam blank with cracks is obviously decreased to below 3.0 kg / ton from 16.5 kg / ton; and in the process of continuous casting, the phenomenon of bong rarely happens, and the bonding breakout is decreased to 0.02% from 0.13%.

Owner:MAANSHAN IRON & STEEL CO LTD

Synthesis-gas carbon-based catalyst preparation method by reforming methane and carbon dioxide

ActiveCN104984769ALarge specific surface areaHigh catalytic activityCarbon compoundsHydrogen productionAtmosphereMethane

The invention relates to a synthesis-gas carbon-based catalyst preparation method by reforming methane and carbon dioxide. The method comprises the following steps that 1 coal with the grain size ranging from 60-80 meshes is liquefied directly, the residue is mixed with a composite modifying agent according to a mass ratio of 1:1-3, and the mixture is grinded uniformly; the composite modifying agent comprises, by weight, 90-98% of alkali and 2-20% of nitrate; 2 the obtained mixture grinded uniformly is heated in inert atmosphere to conduct carbonizing treatment; 3 the mixture in which carbonizing treatment is conducted is cooled and washed to be neutral; 4 the mixture washed to be neutral is dried, and the carbon-based catalyst is obtained. According to the synthesis-gas carbon-based catalyst preparation method by reforming the methane and the carbon dioxide, the residue CLR of shenhua coal being liquefied directly is used as raw material, the carbon-based catalyst is obtained through the carbonizing treatment on the residue, the main by-product produced in the direct coal liquefaction process is utilized effectively, the preparation method is simple, and the prepared catalyst is large in specific surface area; the catalyst has a good catalytic activity on the reforming reaction of the methane and the carbon dioxide.

Owner:陕西荷螓能源科技有限公司

Resin coating and curing device for production of glass fiber board

InactiveCN104441701AThe operation process is simple and convenientImprove work efficiencyEngineeringFiberboard

The invention discloses a resin coating and curing device for production of a glass fiber board. The resin coating and curing device comprises a glass fiber cloth roll material conveying roller, a coating box and a curing furnace, wherein the glass fiber cloth roll material conveying roller is arranged at an input end; a guide roller is arranged on the left side of the roll material conveying roller; the coating box is arranged on the left side of the guide roller; a feeding hole is formed in the top of the coating box; a coating roller is arranged in the coating box; a regulating roller is arranged on the left side of the coating box; a receiving box is arranged at the lower end of the regulating roller; the bottom of the receiving box is communicated with the sidewall of the coating box by a pipeline; the curing furnace is arranged on the left side of the regulating roller; a plurality of supporting rollers are arranged in the curing furnace and are connected with a conveying belt in a driving manner; the conveying belt is driven by conveying rollers arranged at the two ends of the curing furnace; the upper end of the curing furnace is connected with a heating air blowing device; the side end of the curing furnace is connected with an air absorbing purifying device. The resin coating and curing device disclosed by the invention is reasonable in structural design and can be used for conveniently and rapidly controlling the thickness of the glass fiber board and also ensuring that the content of volatile matter in the curing furnace is not too high.

Owner:SUQIAN TIANCAI GLASS FIBER

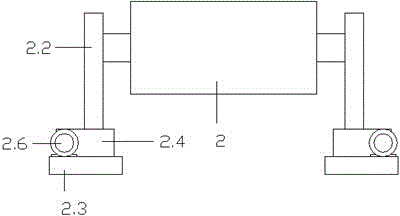

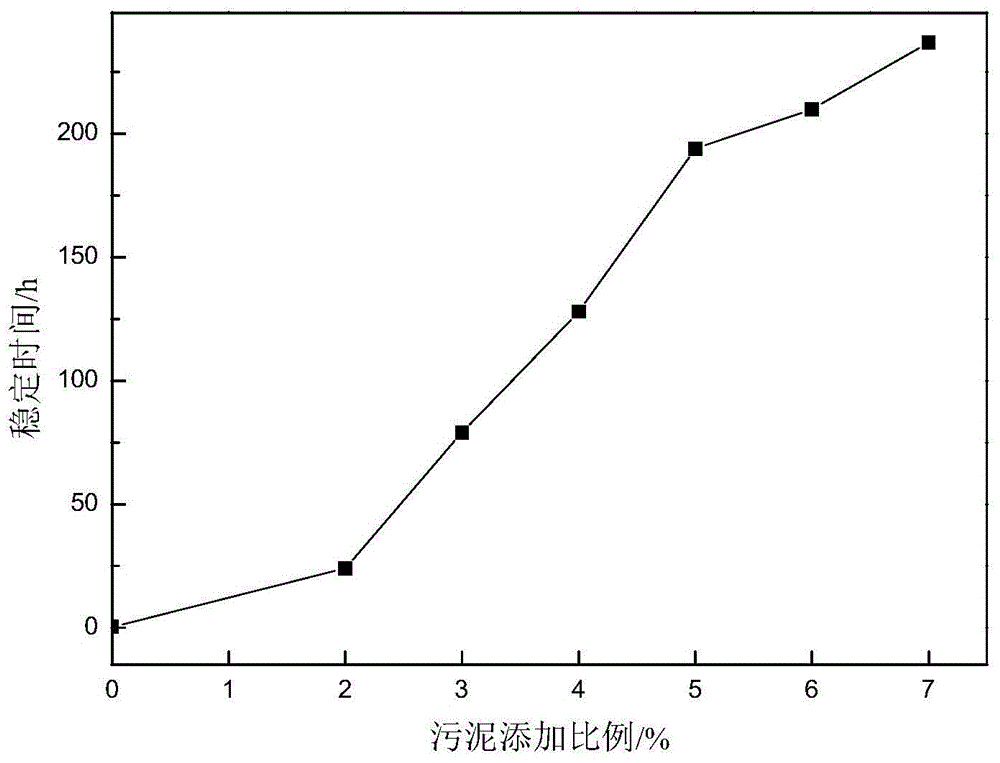

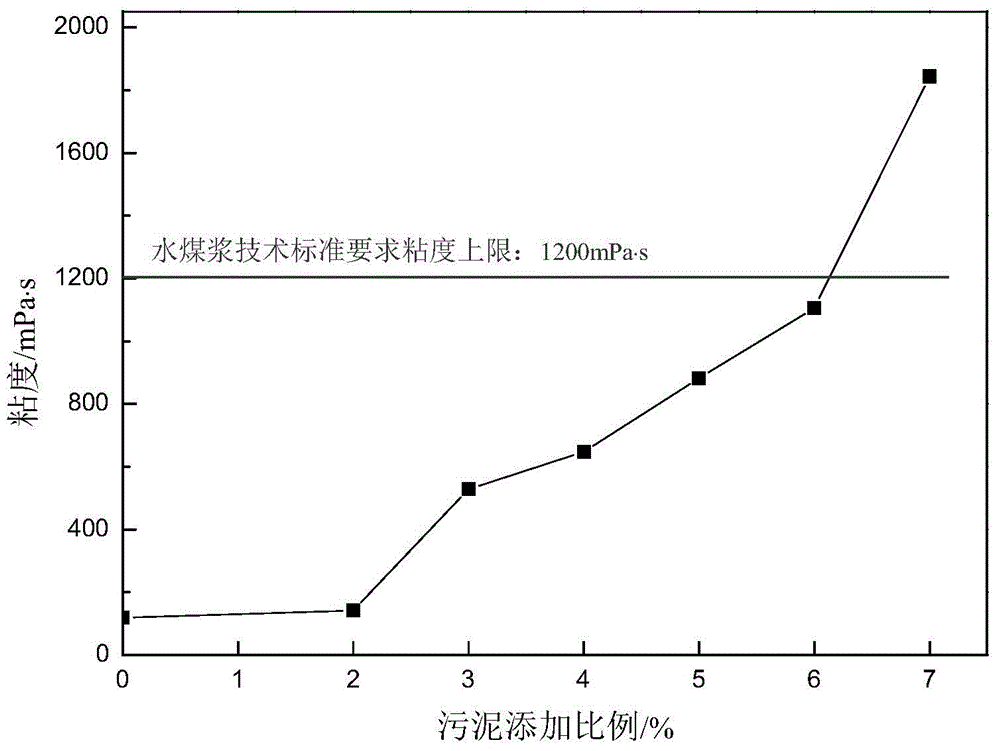

Method for improving stability of water-coke slurry

The invention relates to a method for improving stability of water-coke slurry. The water-coke slurry is prepared from the raw materials, including petroleum coke, activated sludge, water and a dispersing agent. The method comprises the steps of (1) sieving petroleum coke through a sieve, and remaining petroleum coke of which the particle size is less than 0.8mm; (2) dissolving the dispersing agent into water, and uniformly agitating for later use; (3) integrally uniformly mixing the dispersing agent solution obtained in step (2) and activated sludge, pouring into a ball mill tank together with the petroleum coke processed in step (1), wherein the quantity ratio of large balls to small balls in the ball mill tank is 30: 150; a ball mill rotates at the speed of 230 to 380r / min; the ball milling costs 30 to 50 minutes; (4) filtering the slurry obtained by ball milling through a sieve with 40 meshes so as to remove impurities and large particles and obtain water-coke slurry. According to the method, the activated sludge is doped into the water-coke slurry to greatly improve the stability of the water-coke slurry, so that the problem of poor stability of the water-coke slurry can be completely solved; meanwhile, a new treatment way is provided to the activated sludge of a melting plant, and the sludge treatment cost of the melting plant can be reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

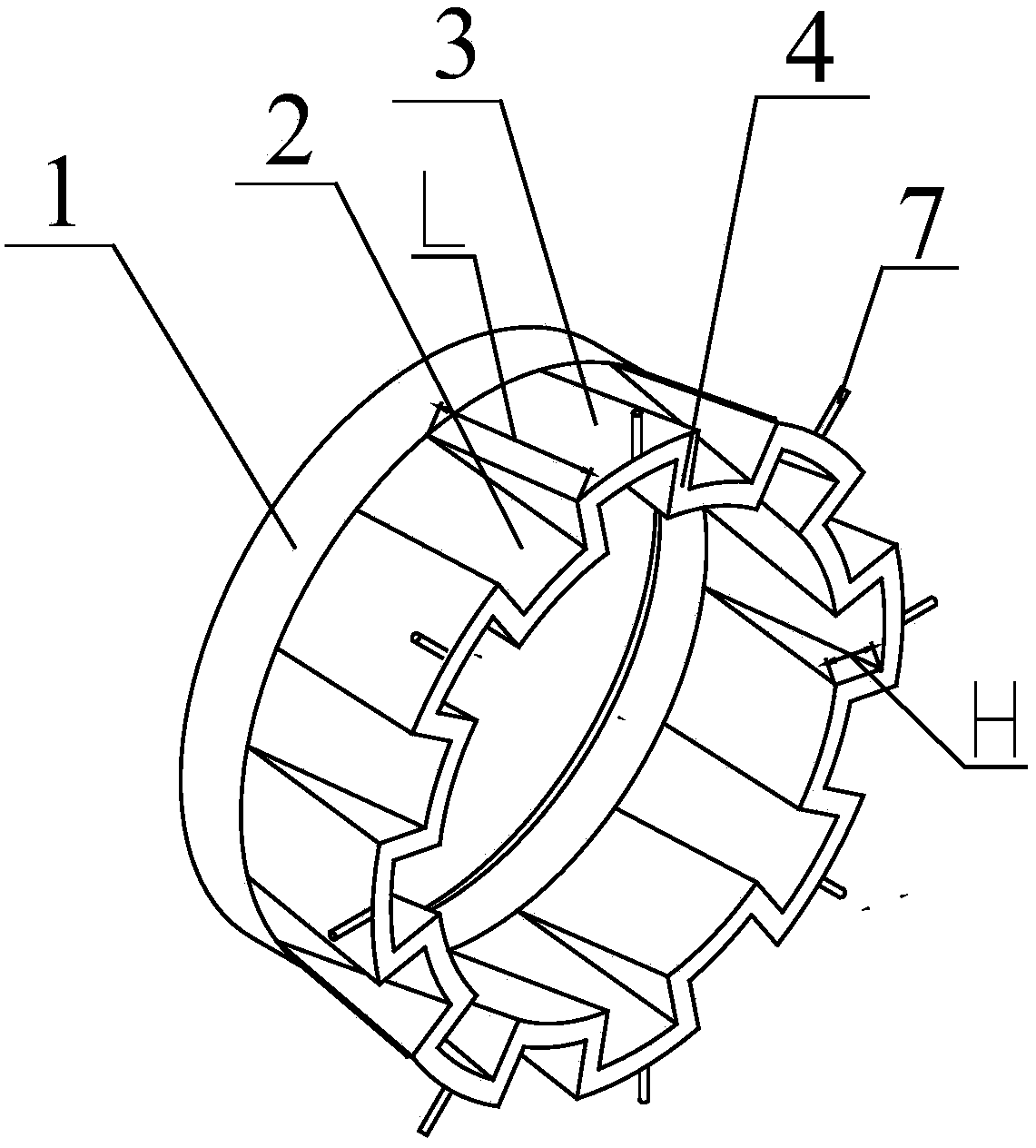

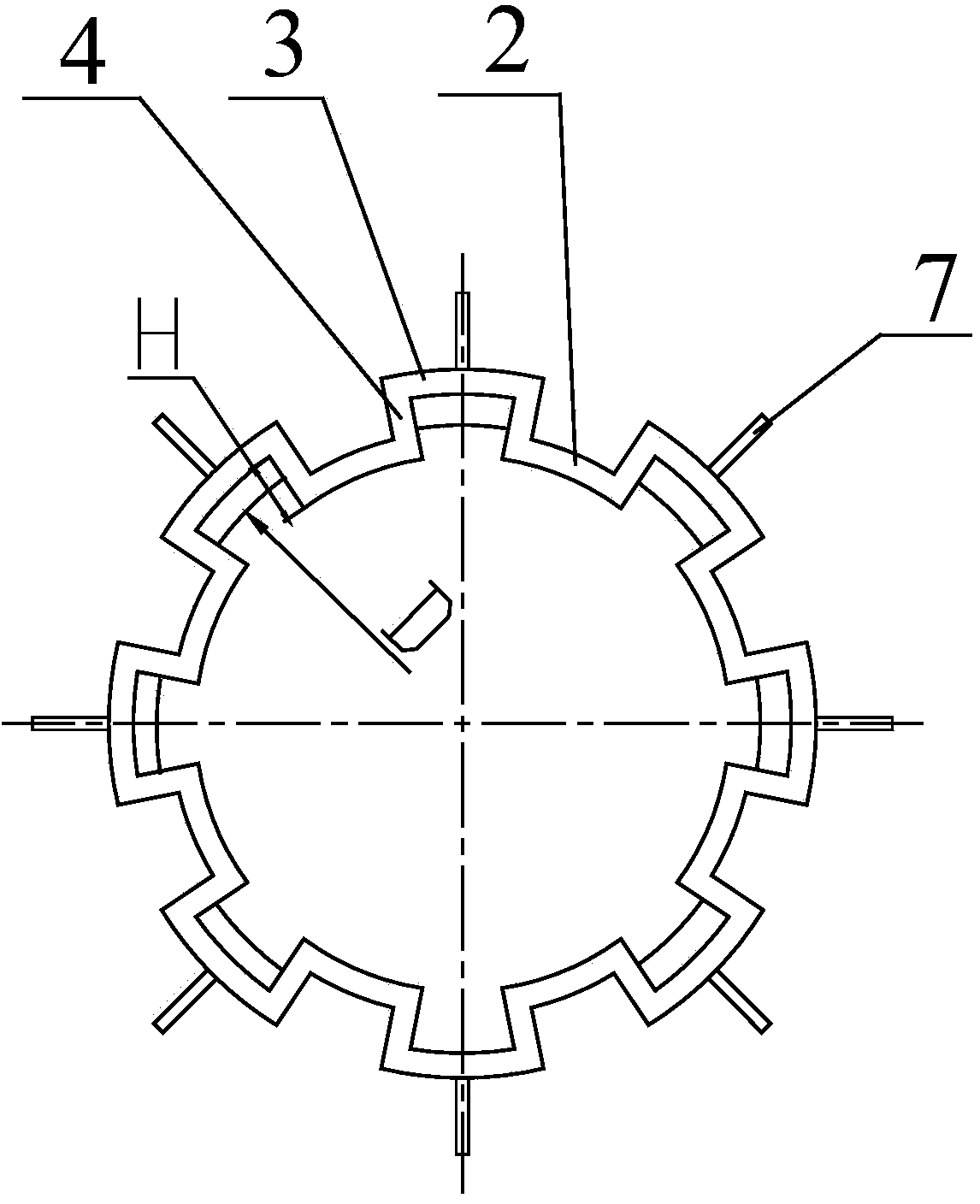

Internal contraction and external expansion type nozzle for swirl pulverized coal burner

ActiveCN103411214AReduce the impact of a direct collisionGuaranteed strong ignition and stable combustion performancePulverulent fuel combustion burnersCoal particleCoal fired

The invention discloses an internal contraction and external expansion type nozzle for a swirl pulverized coal burner. The opening section of a nozzle body is in a two-sided battlement guide structure and comprises internal contraction type flow deflectors and external expansion type flow deflectors which are arranged circumferentially in a staggered mode, radiuses of sections of the internal contraction type flow deflectors from the root to the end decrease gradually with the diameter D of the inner cavity of the opening section of the nozzle body serving as the reference, radiuses of sections of the external expansion type flow deflectors from the root to the end increase gradually with the diameter D of the inner cavity of the opening section of the nozzle body serving as the reference, and adjacent internal contraction type flow deflectors and external expansion type flow deflectors are connected through radial transition plates. The internal contraction and external expansion type nozzle has a good guide effect on pulverized coal airflow, direct impact of pulverized coal particles on the nozzle is reduced, the pulverized coal airflow is mixed with external hot smoke intensely for heat exchange when sprayed from the nozzle, strong ignition and stable combustion performances of the pulverized coal are guaranteed, the pulverized coal airflow resistance can be effectively reduced, abrasion to the nozzle is small, and the service life of the nozzle is long. The internal contraction and external expansion type nozzle is particularly suitable for coal-fired boilers of swirl pulverized coal burners with front and back walls in cross arrangement.

Owner:中节环立为(武汉)能源技术有限公司

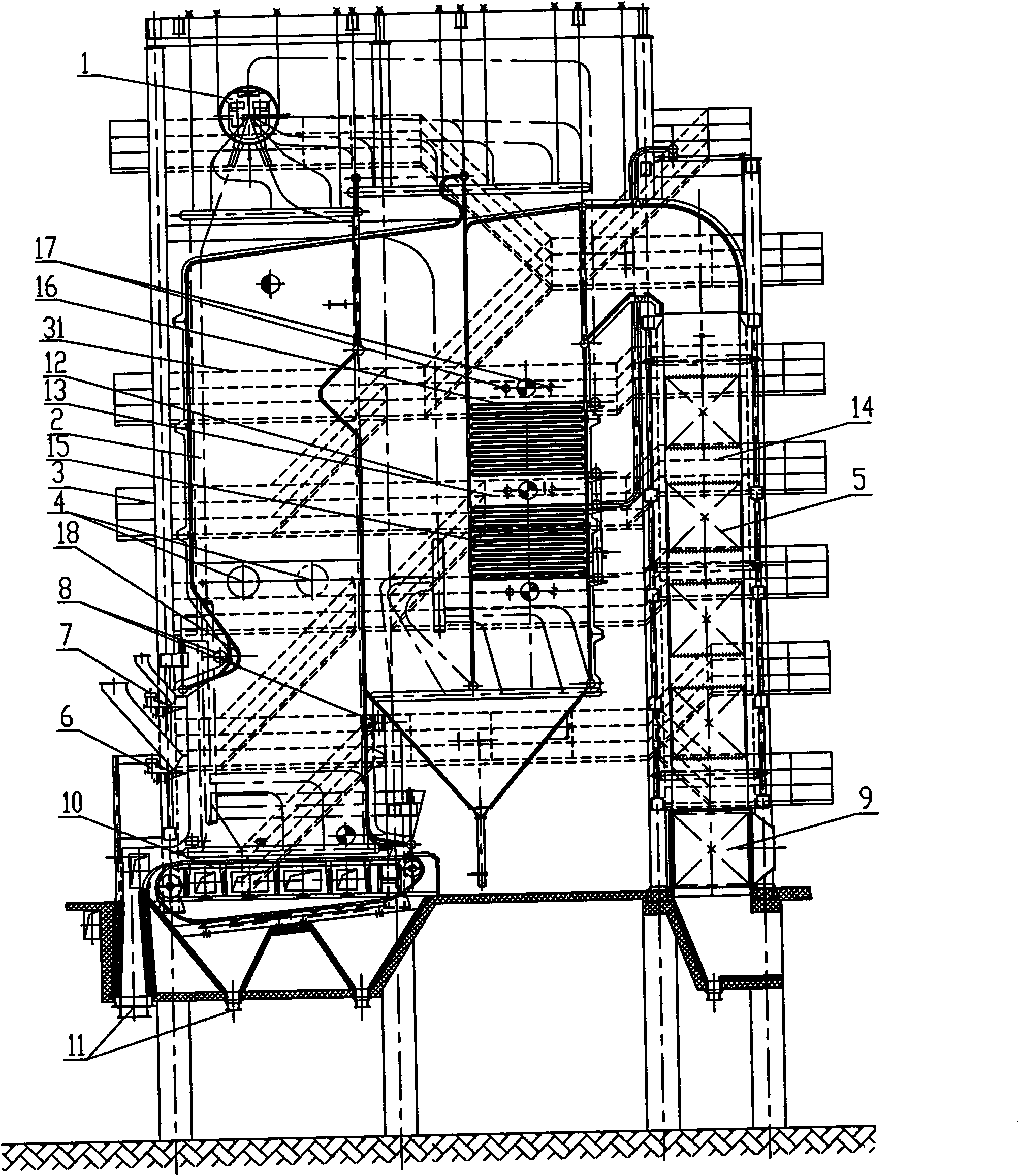

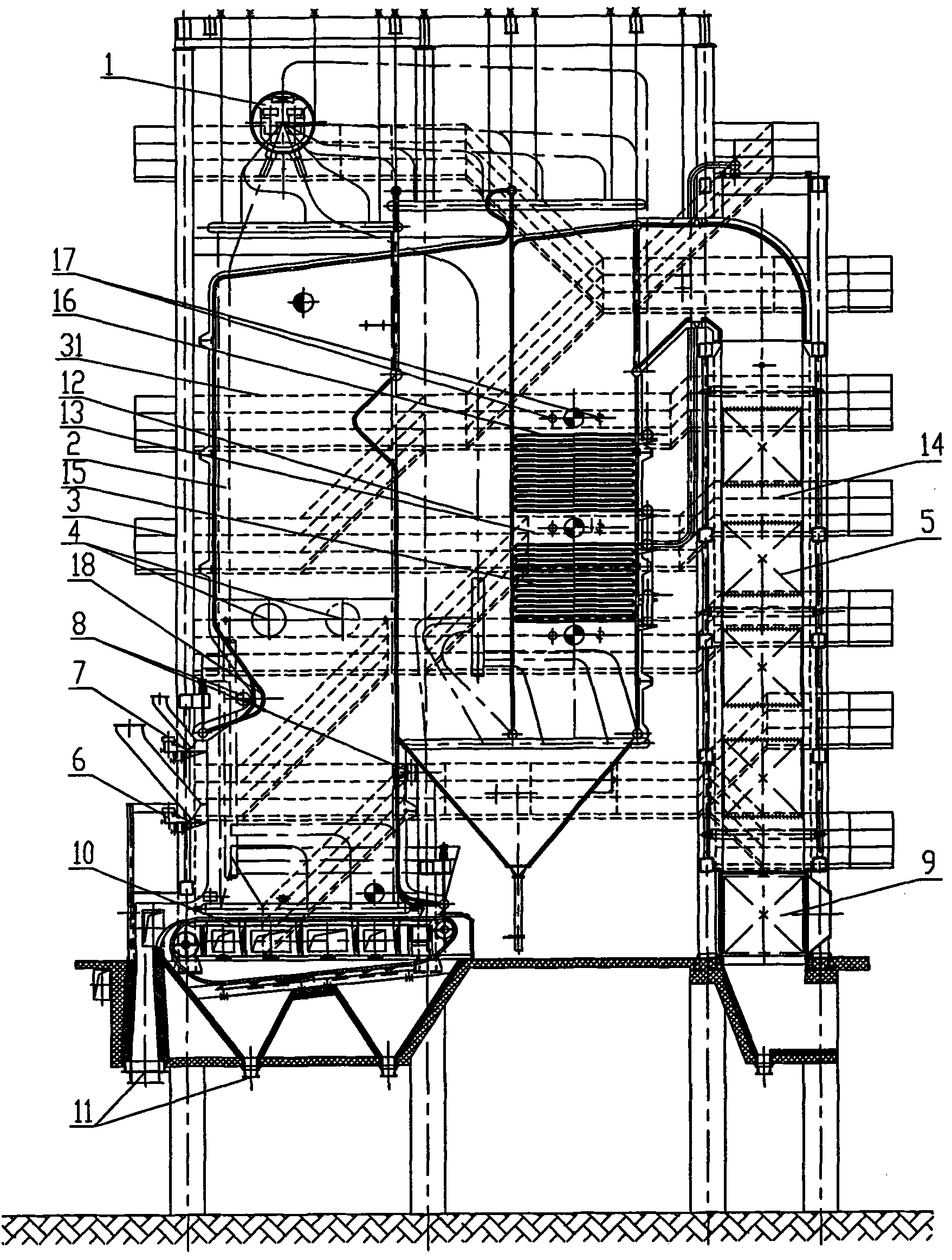

Boiler for derived fuel RDF, waste plastics RPF and waste wood of combustion of refuses

ActiveCN101852422AAvoid cokingHigh volatile contentCasings/liningsSteam boilersRefuse-derived fuelSocial benefits

The invention discloses a boiler for derived fuel RDF, waste plastics RPF and waste wood of combustion of refuses, mainly comprising a hearth, a burnout chamber, a superheater chamber and a rear flue duct, wherein the burnout chamber, the superheater chamber and the rear flue duct are successively connected behind the hearth; a drum is arranged above the hearth, and a reverse chain fire grate is arranged on the lower part of the hearth; slag trapping and ash discharging equipment is arranged below the reverse chain fire grate; the front wall of the lower part of the hearth is provided with a waste wood spray seeding device and a refuse derived fuel RDF and waste plastics RPF spray seeding device which are communicated with the inner part of the hearth, and the waste wood spray seeding device is arranged below the refuse derived fuel RDF and waste plastics RPF spray seeding device. In the invention, the steam produced by using refuse derived fuel RDF, the waste plastics RPF and the waste wood to be combusted in a boiler is used for generating electricity and supplying steam. The invneiton has the social benefit of saving energy and reducing environmental pollution and has favourable economic benefit.

Owner:ZHEJIANG WEIMING ENVIRONMENT PROTECTION

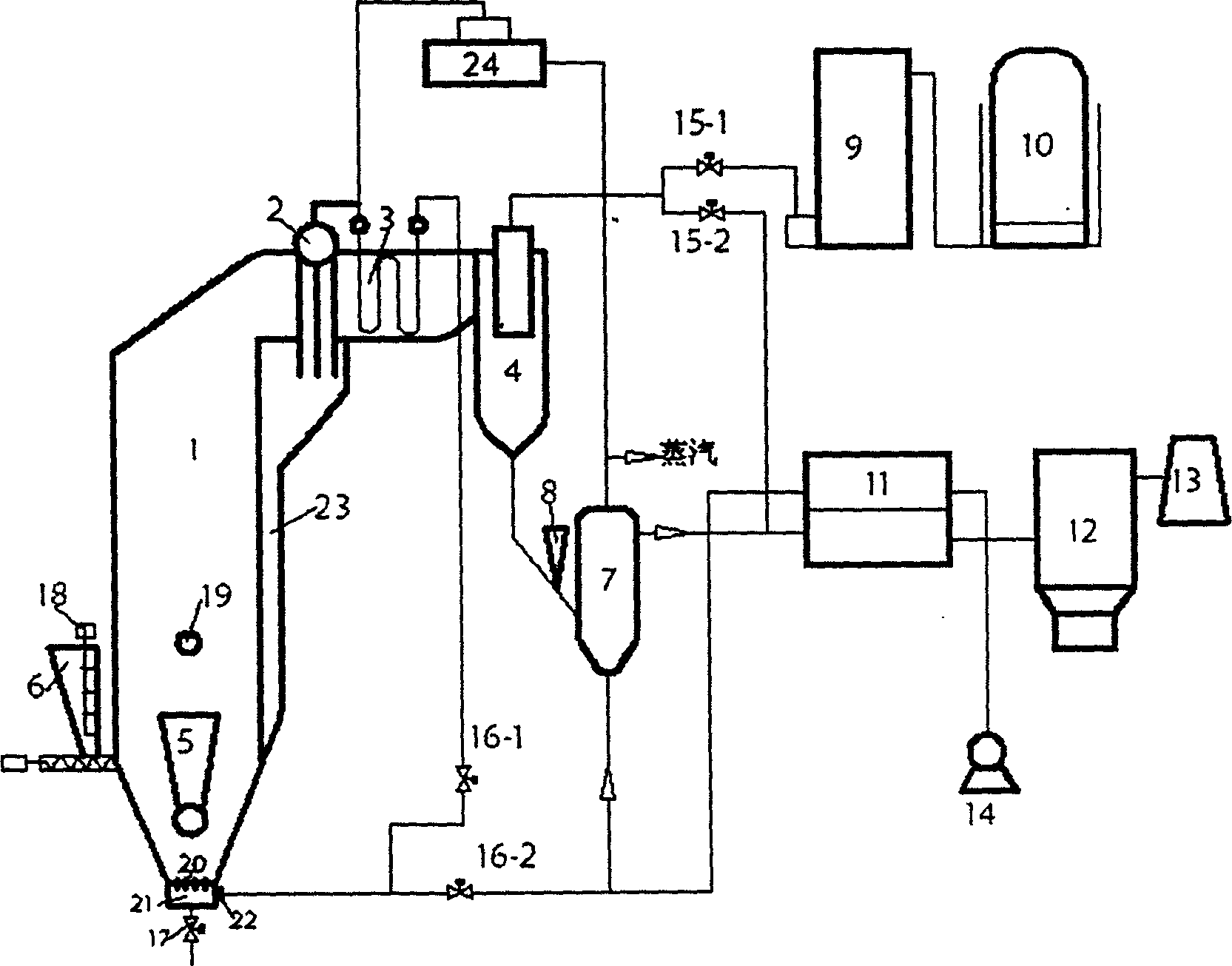

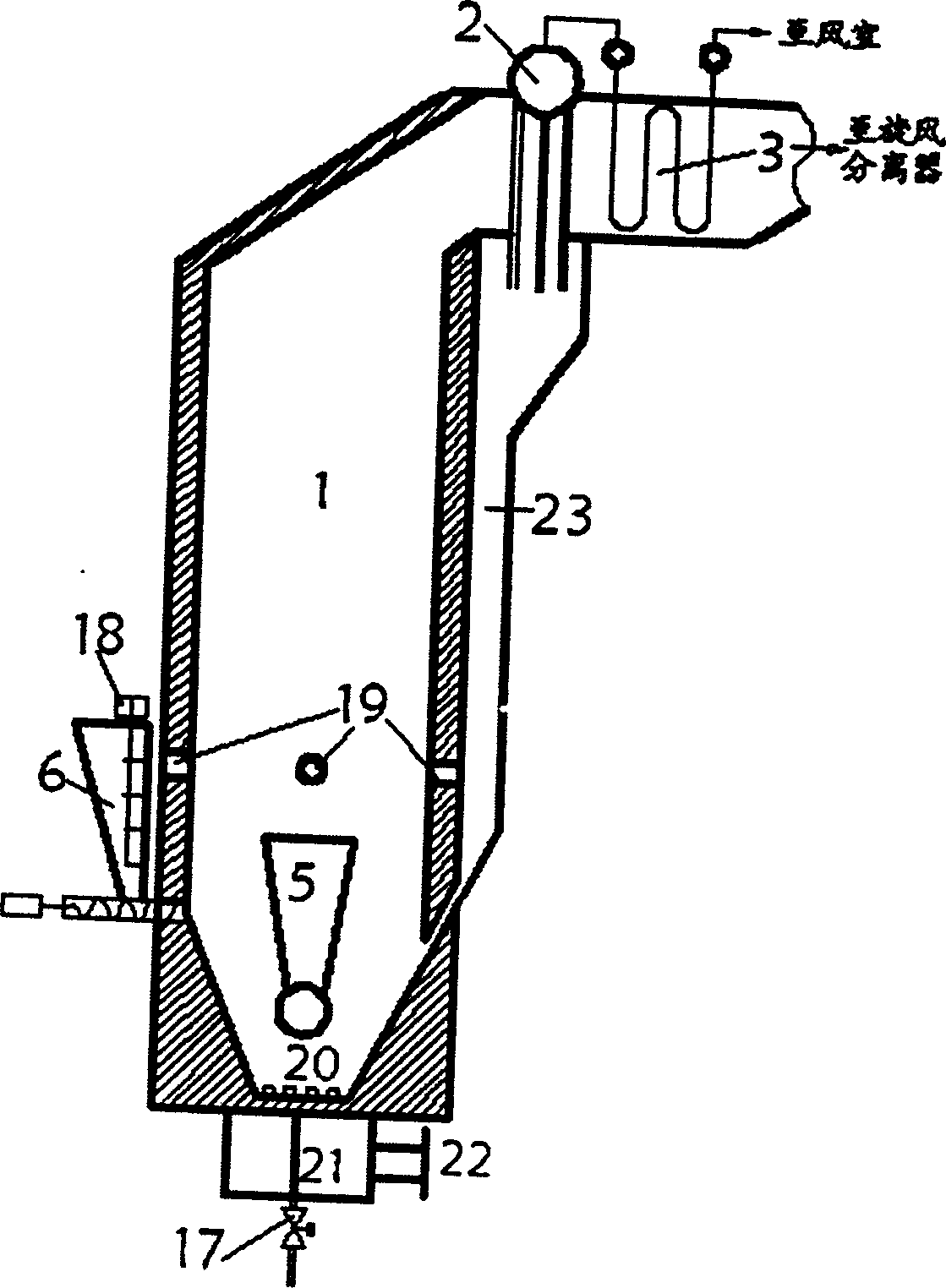

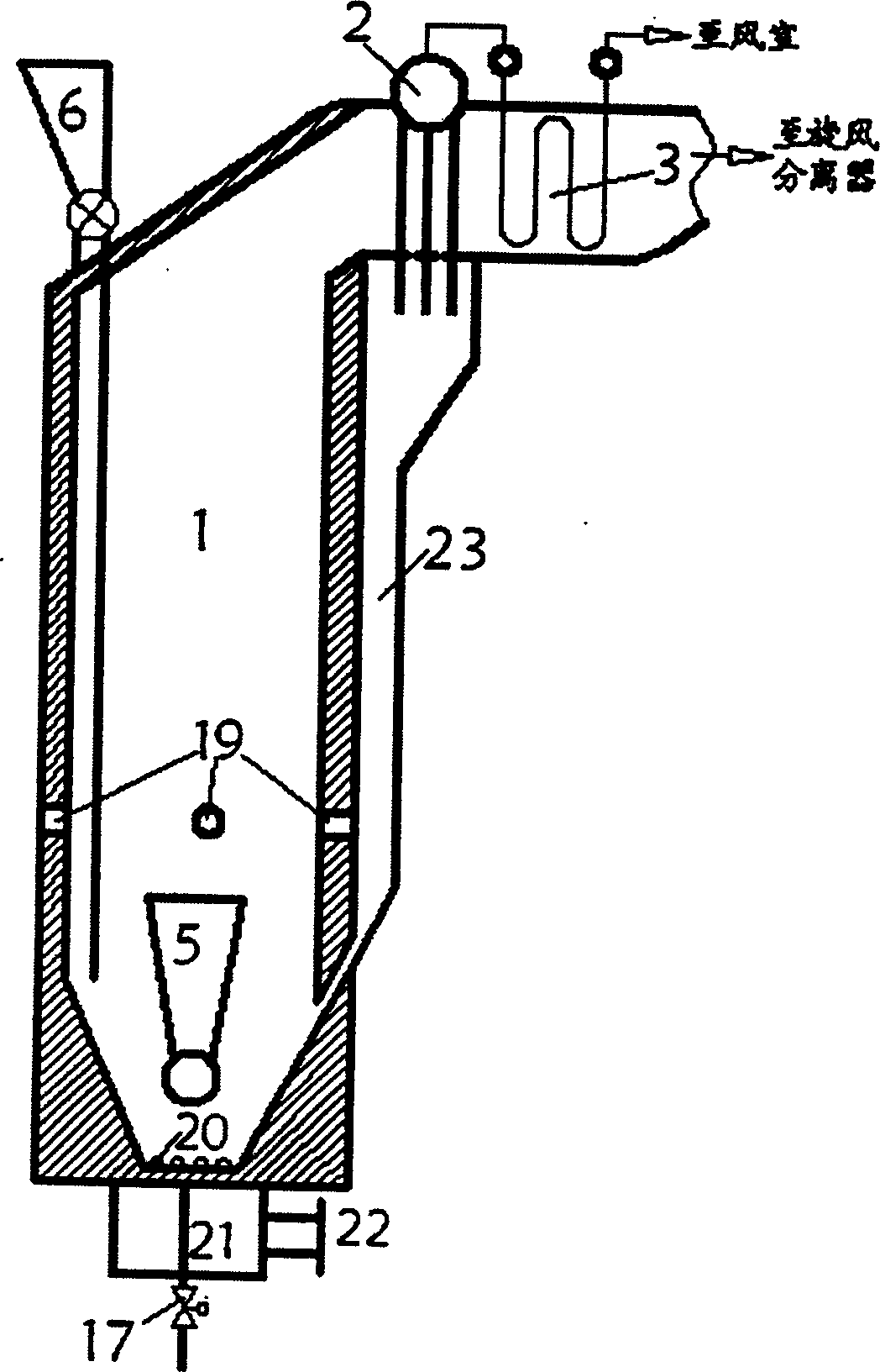

Biomass and coal mixed fluidized-bed gasification method and device

ActiveCN1230498CHigh volatile contentLess fixed carbonCombined combustion mitigationGranular/pulverulent flues gasificationWater vaporProduced water

The present invention relates to energy source apparatus, and is one kind of simple biomass-coal mixture gasifying method and apparatus capable of producing high heat value gas and no tar. Inside fluidized bed gasifying furnace, biomass and coal as gasified material is burnt and gasified intermittently. In the burning stage, coal and blast are supplied to the furnace, so that coal is burnt in fluidizing state to produce heat; in the gasifying stage, vapor and biomass are supplied to the furnace, so that the high temperature carbon material layer produces water gas reaction in fluidizing state and biomass is dry distilled and pyrolyzed at high temperature to produce high heat value gas, which is cooled and made to enter the gas purifying system. By combining of biomass and coal with different advantages, the present invention produces high heat value fuel gas without tar.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com