Biomass and powder coal mixed combustion and biomass recombusting and denitrating combustion apparatus

A combustion device and biomass technology, applied to the combustion of block fuel and liquid fuel, the combustion of block fuel and gaseous fuel, the combustion of block fuel and powder fuel, etc., which can solve the problem of ineffective utilization of biomass Material energy, large NOx emissions, reduction of NOx emissions, biomass reburning and denitrification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

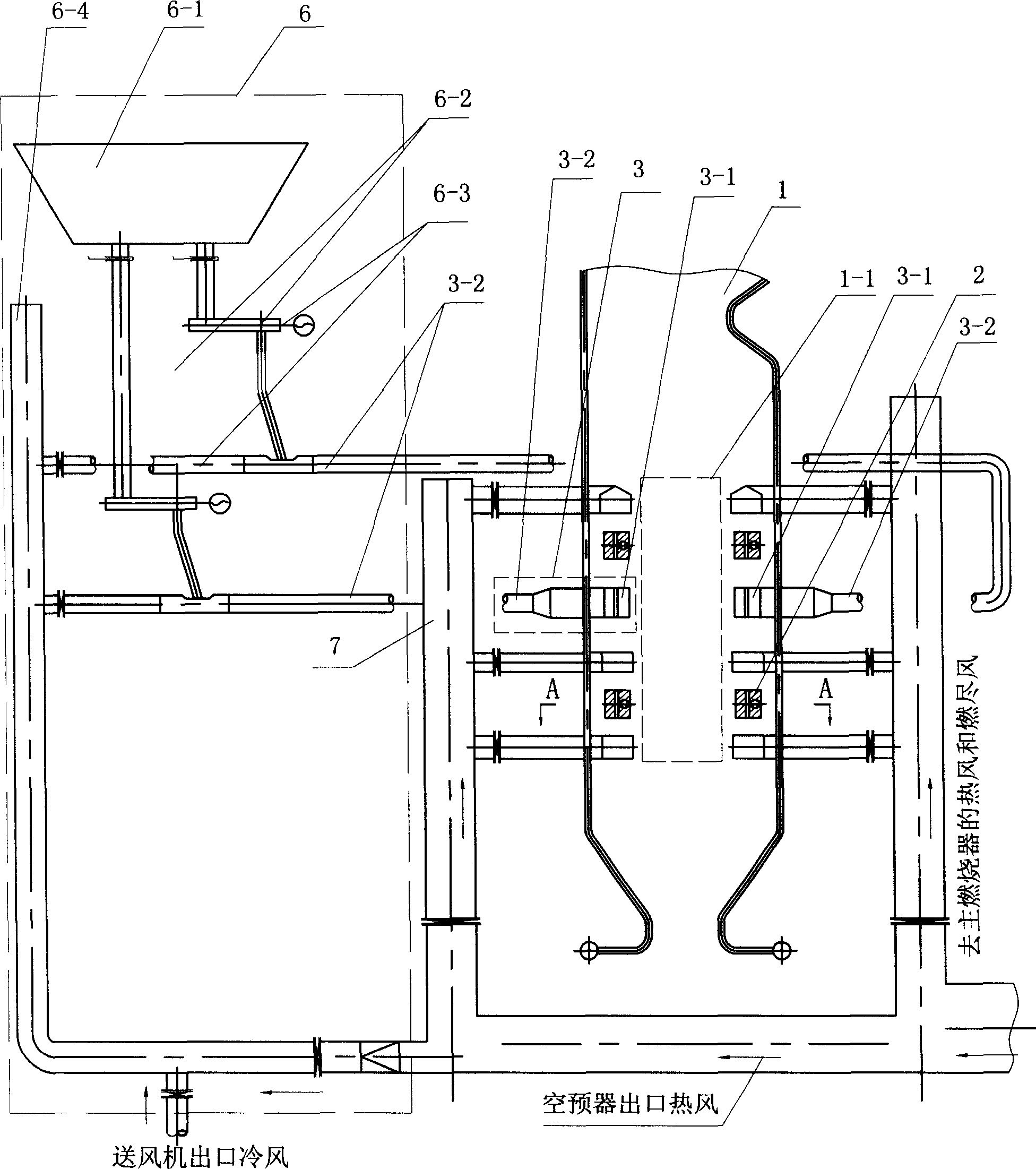

[0006] Specific implementation mode one: refer to figure 1 , Figure 4 , the present embodiment includes a furnace 1, a pulverized coal main combustion zone 1-1 is arranged in the furnace 1, and a burner thick-thin spout 2 is installed on the four corners of the furnace furnace of the pulverized coal main combustion zone 1-1, and the furnace 1 A biomass burner spout 3-1 is also installed on the side wall or four corners. The biomass burner nozzle 3-1 in this embodiment is installed on the furnace side wall of the pulverized coal main combustion zone 1-1. The biomass burner nozzle 3 - 1 and the biomass delivery connecting pipe 3 - 2 connected thereto together form the biomass burner 3 . The biomass burner 3 is connected to the pneumatic conveying system 6 of the biomass fuel, and the pneumatic conveying system 6 of the biomass fuel includes a biomass fuel hopper 6-1, a biomass fuel feeder 6-2, and a mixer 6-3 And pneumatic conveying pipeline 6-4, described biomass fuel hoppe...

specific Embodiment approach 2

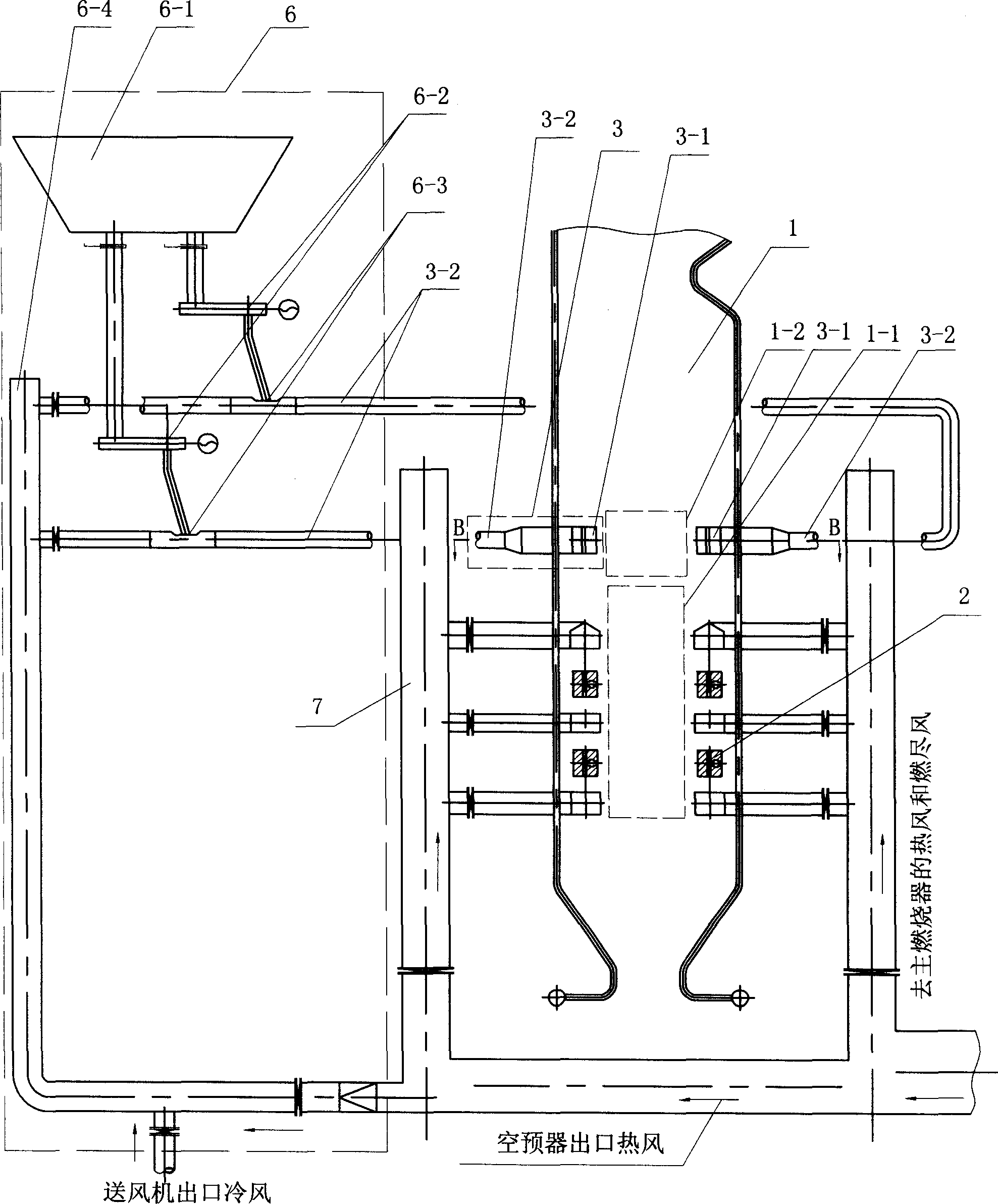

[0008] Specific implementation mode two: refer to figure 2 , in this embodiment, the upper part of the biomass combustion zone 1-1 is a reduction zone 1-2. The difference between this embodiment and the first embodiment is that the biomass burner nozzle 3-1 is installed in the reduction zone 1-2 on the furnace side wall, refer to Figure 5 , At this time, the reduction zone 1-2 is a biomass combustion zone.

[0009] When the primary air pulverized coal airflow is sent into the furnace 1, it is divided into a dense coal pulverized airflow and a light coal pulverized airflow respectively by the thick and thin burner nozzles in the horizontal direction. The ignition heat of the airflow increases the speed of flame propagation, which can ensure the stable combustion of pulverized coal in the main combustion zone 1-1, and the combustion of pulverized coal in the airflow of concentrated pulverized coal and airflow of light coal pulverized is deviated from the stoichiometric ratio,...

specific Embodiment approach 3

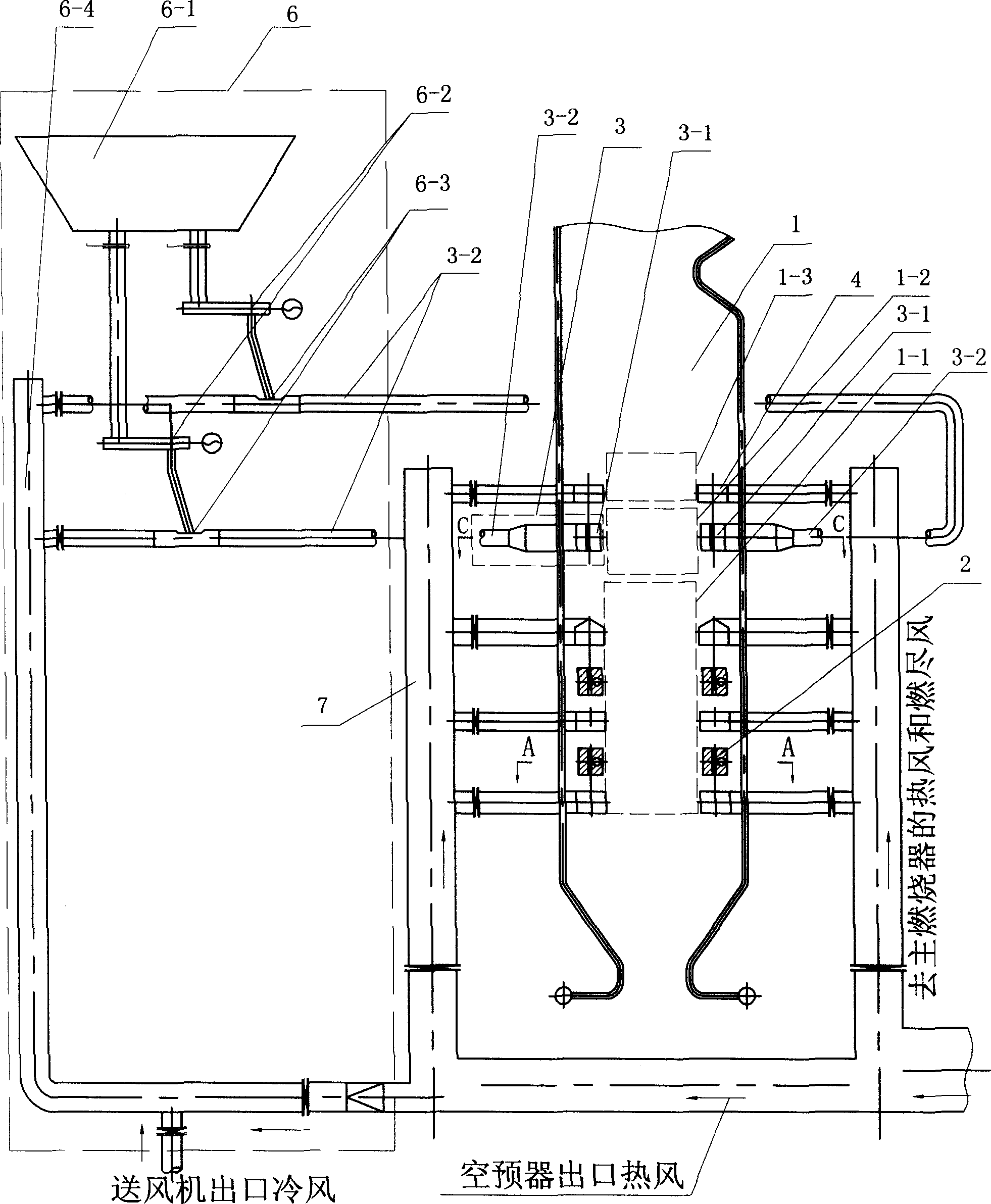

[0010] Specific implementation mode three: refer to image 3 , the upper part of the reduction zone 1-2 is the burnout zone 1-3. The difference between this embodiment and the second embodiment is that the burnout air nozzle is installed on the furnace side wall or four corners of the burnout zone 1-3 4. The overburning air nozzle 4 is in communication with the air supply duct 7; refer to Figure 6 , The biomass burner spout 3-1 is installed on the four corners of the hearth of the reduction zone 1-2.

[0011] The overfire air nozzle 4 is mainly used to provide oxygen for the burnout of biomass fuel and pulverized coal. The burn-out air is sent into the burn-out area 1-3 in the upper part of the furnace. Since some air is sprayed into this area from the nozzle 4, it can promote the further combustion of biomass fuel and coal powder particles, and at the same time reduce the air volume in the lower furnace, so that The pulverized coal and biomass in the lower furnace are burn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com