Patents

Literature

114results about How to "Not easy to catch fire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

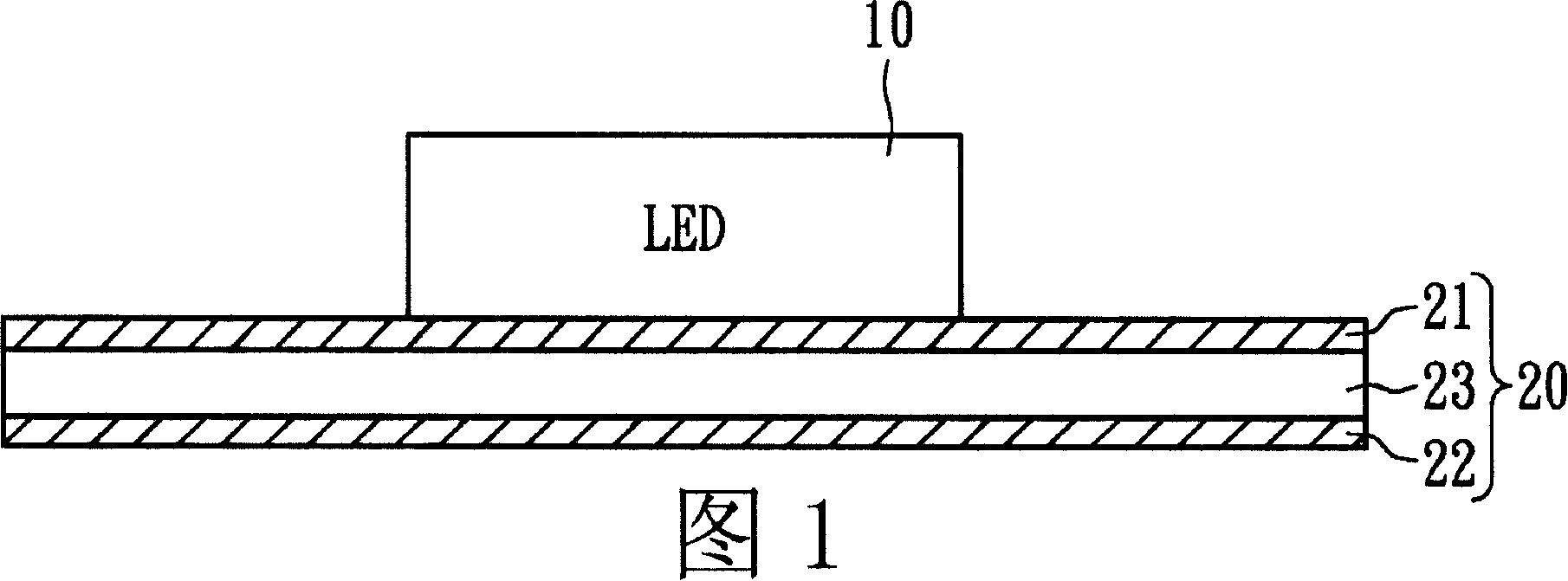

Heat radiation substrate of electronic element

InactiveCN101140915AHigh melting pointNot easy to catch fireSemiconductor/solid-state device detailsSolid-state devicesDielectricHeat conducting

A thermolytic underlay of the electronic component comprises a first metal layer, a second metal layer and a heat-conducting macromolecule dielectric insulated material layer. The said first metal layer surface bears the said electronic component like the LED component. The heat-conducting macromolecule dielectric insulated material layer is lapped between the first and second metal layer to form physical contact, wherein the interface includes at least one slightly rugged face with the roughness concentration larger than 7.0 Rz. The said slightly rugged face includes a plurality of grain diameters of the strumae mainly distributed between 0.1 and 100 micron. The coefficient of heat conductivity of the said heat-conducting macromolecule dielectric insulated material layer is larger than 1W / m is multiplied by K with thickness less than 0.5mm and contains fluorinated high molecular polymer (1) with the melting point higher than 150 degrees centigrade and the volume percent between 40% and 70%, and the heat-conducting stuffing (2) interspersed among the said fluorinated high molecular polymer with the volume percent between 40% and 70%.

Owner:POLYTRONICS TECH

Automobile antifreeze

ActiveCN101698793AHigh flash pointNot easy to catch fireHeat-exchange elementsAutomotive engineeringAntifreeze

The invention relates to an automobile antifreeze which comprises the following components by weight percent: 90-96% of alcohols, 1%-5% of water, 0%-0.5% of pigments and 3%-7% of additives. Compared with the prior art, the automobile antifreeze has strong corrosion resistance and can effectively prevent the scale formation, and the automobile antifreeze further has excellent protection performance for any material of a cooling part of an engine and excellent performances of anti-freezing in winter, anti-boiling in summer, anti-scale and anti-corrosion all over the year and the like and can effectively protect a water cooling system of an automobile, prolong the service life of the water cooling system of the automobile, reduce the cost, simultaneously have the environmental protection advantage and achieve the requirements of British standard BS6580:1992.

Owner:SHANGHAI DELIAN CHEM

Detergent for print ink cleaner and its preparing process

InactiveCN1363635ANo swellingNo pollution in the processChemical paints/ink removersOrganic acidPrinting ink

A detergent for print ink is a mixture of solutions A and B. Said solution A is prepared from emtrol and ester. Said solution B is composed of organic acid and water. Its advantages include high detergency to ink roller and rubber, not combustible and no environment pollution.

Owner:TAIYUAN UNIV OF TECH

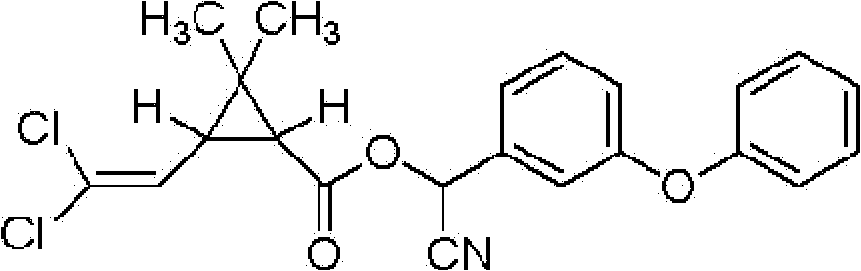

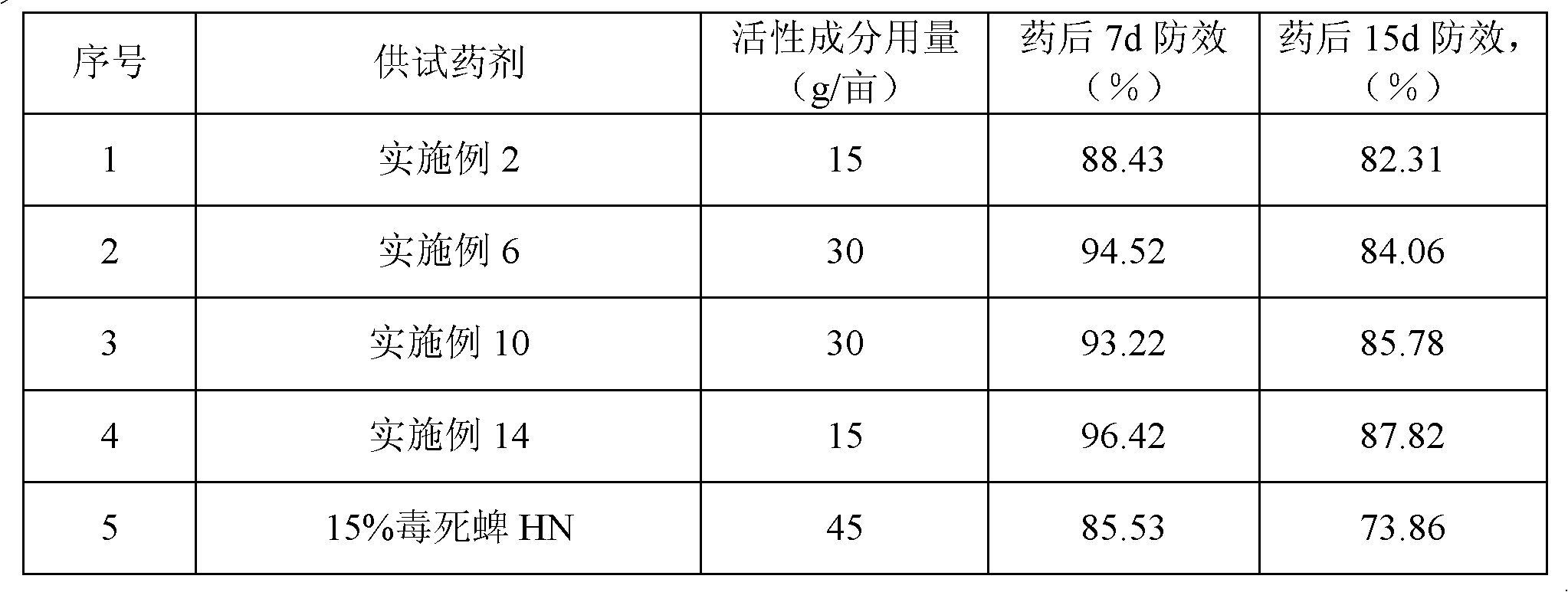

Hot fogging concentrate containing cypermethrin

InactiveCN102630698AReduce total usageImprove the effect of prevention and controlBiocideAnimal repellantsCypermethrinChlorpyrifos

The invention discloses a hot fogging concentrate containing cypermethrin, which is prepared by using cypermethrin or the mixture of cypermethrin and an active component II as the effective constituent, and adding accessory ingredient and solvent, wherein the active component II is any one of chlorpyrifos, dimethoate and nitenpyram. By using the cypermethrin as the effective constituent, the hot fogging concentrate comprises the following components by weight percent: 1.6-30% of cypermethrin, 1-20% of accessory ingredient and the balance of solvent. By using any one of the cypermethrin and the active component II as the effective constituent, the hot fogging concentrate comprises the following components by weight percent: 0.1-20% of cypermethrin, 0.1-40% of active component II, 1-20% of accessory ingredient and the balance of solvent. The hot fogging concentrate disclosed by the invention is applicable to a hot fogging machine for preventing insect pests on sugarcane, corn, tobacco, fruit trees and forests. The hot fogging concentrate has the advantages of high working efficiency, strong knock-down activity, synergetic effect, good preventing effect, simpleness in operation, water and labor saving, safety, environmental friendliness, and the like.

Owner:GAUNGXI TIANYUAN BIOCHEM

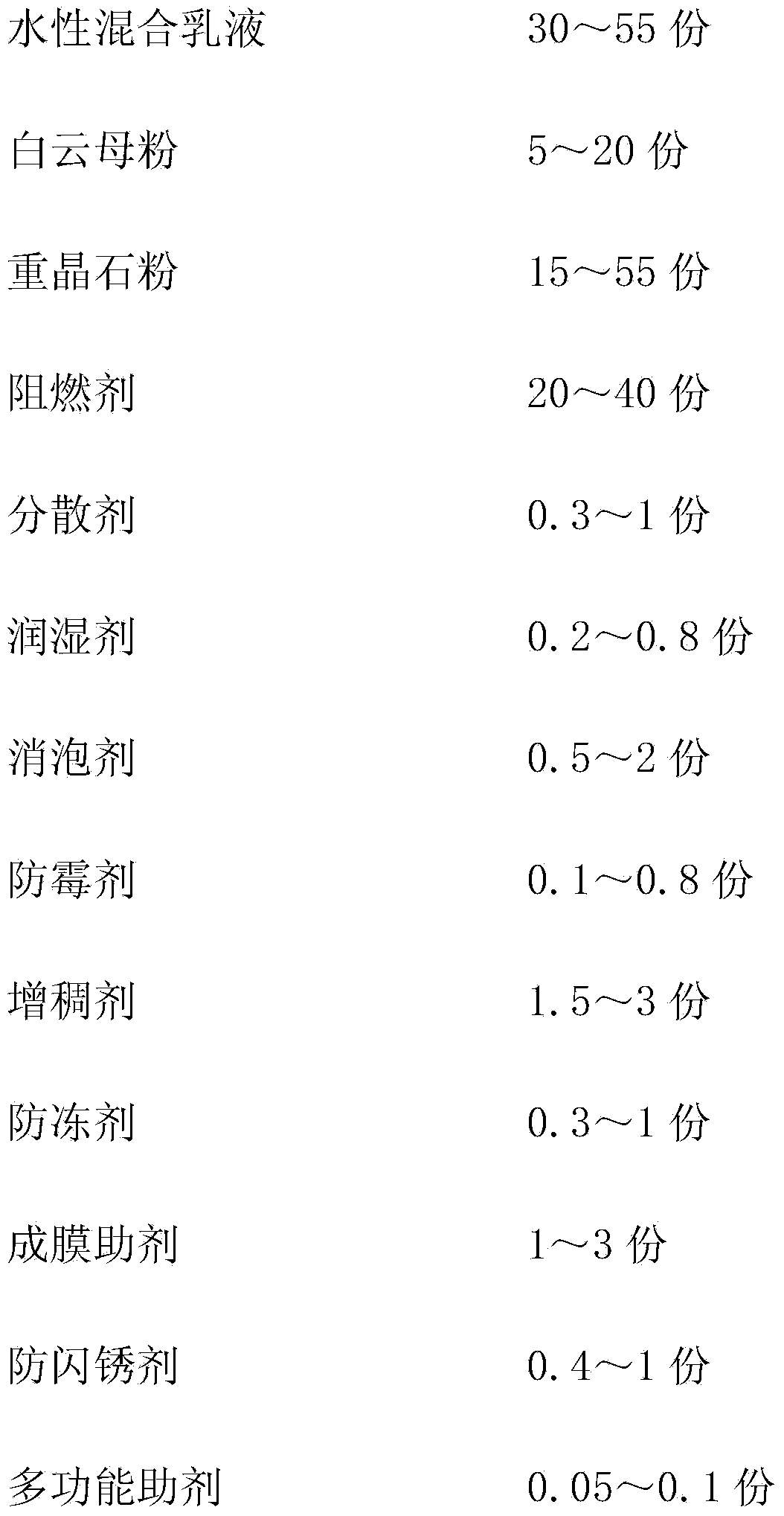

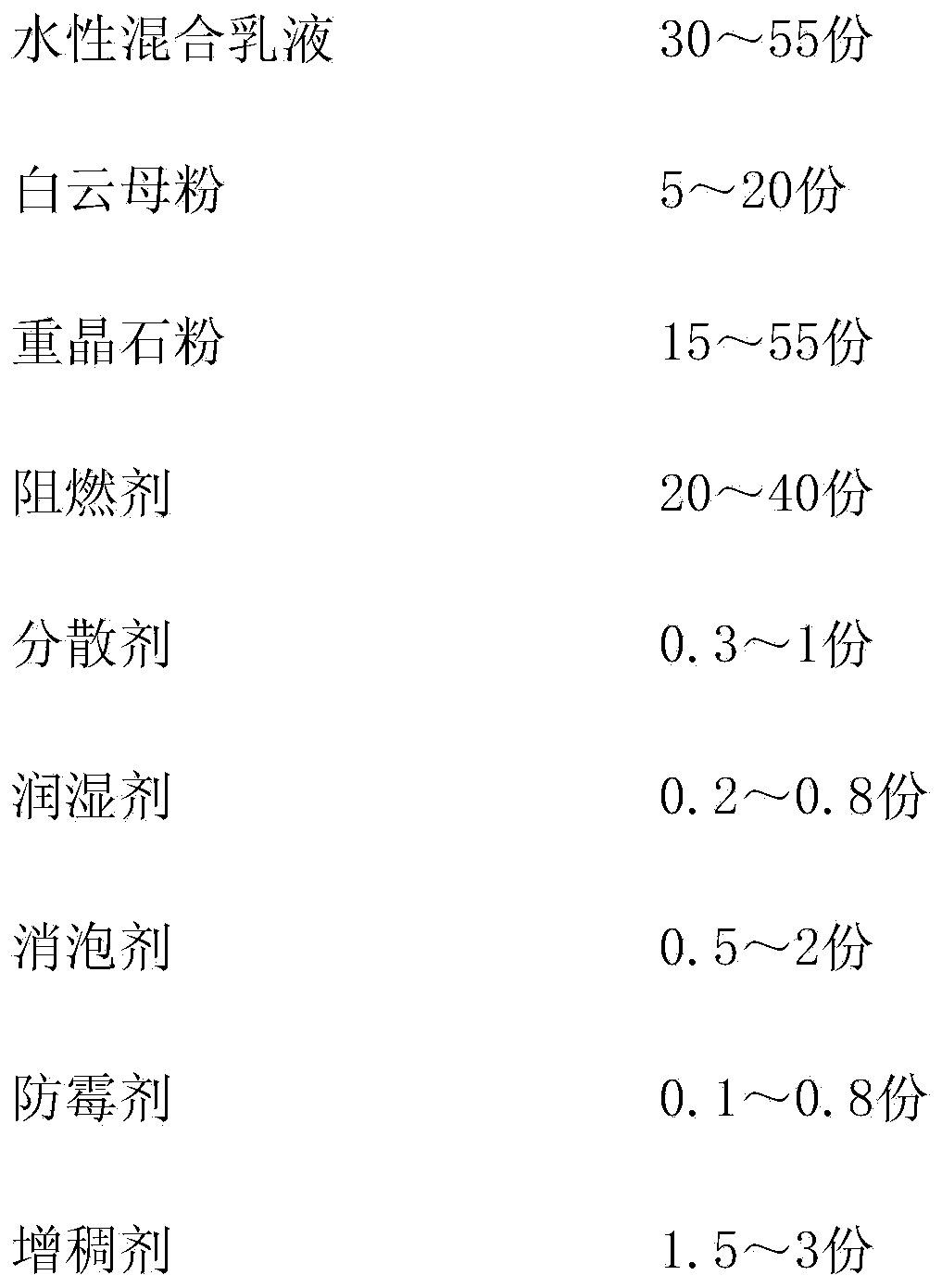

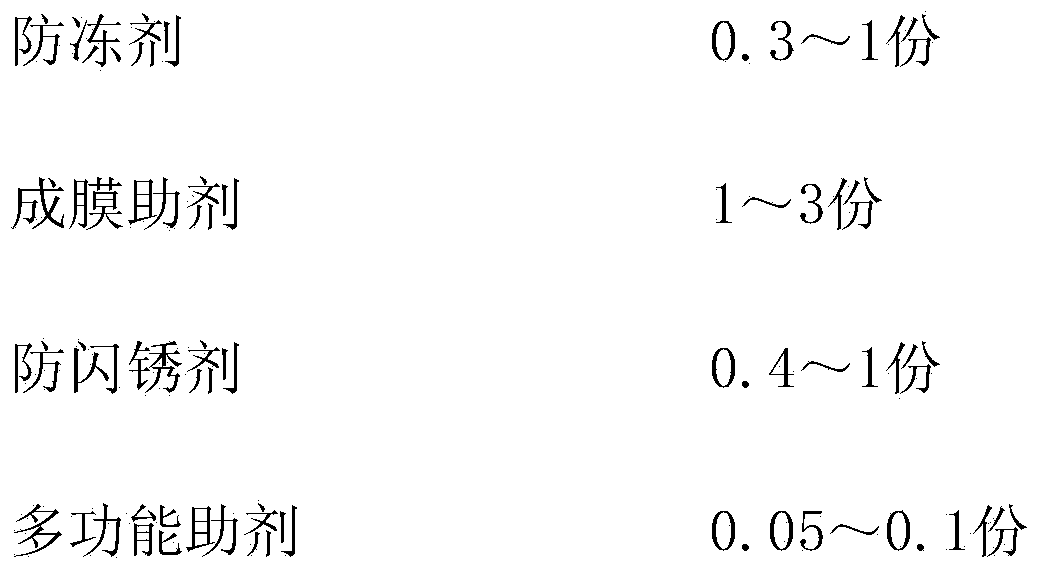

Water-borne sound-insulating damping coating for ship and preparation method thereof

InactiveCN104004418AImproved damping propertiesGood flame retardant performanceAnti-corrosive paintsSteel platesEmulsion

The invention provides a water-borne sound-insulating damping coating for a ship. According to the water-borne sound-insulating damping coating for the ship, water-borne mixed emulsion is used as film forming matter, inorganic filter is used as main filler, and coating aids are added. The water-borne sound-insulating damping coating for the ship mainly comprises, by weight, 30 parts to 55 parts of water-borne styrene-acrylic emulsion which is of an interpenetrated network structure, 30 parts to 60 parts of the inorganic filler and 20 parts to 40 parts of fire retardants. The water-borne sound-insulating damping coating for the ship is prepared by preparing the water-borne mixed emulsion, adding the filler and the aids, and conducting paint mixing, white mica powder is used as functional damping filler, and blanc fixe is used as functional sound-insulating filler. The water-borne sound-insulating damping coating for the ship has the advantages that the recombination loss factor is high, and the sound insulation coefficient is high; the performance of being rapidly dried at normal temperature can be achieved; the adhesive force to a steel plate is high; the fire retardant property is high, and the shipment use requirement is met; the steel plate is free of rust; the workability is high; no hazardous substances exist, and environmental friendliness is achieved.

Owner:太仓市兰燕新材料有限公司

Paraffin remover and preparation method thereof

InactiveCN104371685AImprove the difficulty that cannot be usedImprove solubilityDrilling compositionPotassium hydroxideSurface-active agents

The invention provides a paraffin remover and a preparation method thereof. The paraffin remover comprises the following components (in percentage by weight): 15%-25% of alcohol ether, 7%-12% of fatty alcohol-polyoxyethylene ether, 0.15%-0.25% of alkali, 13%-15% of antifreezing fluids, 5%-10% of ethylene glycol and 30%-40% of emulsifying agents, wherein the emulsifying agent is a mixture of oleic acid, linoleic acid, composite vinegar of resin and triethanolamine, the antifreezing fluids comprise propylene glycol butyl ether acetate and ethylene glycol butyl ether acetate, and the alkali is any one of sodium hydroxide or potassium hydroxide. The preparation method of the paraffin remover comprises the following steps: adding the alkali to the fatty alcohol-polyoxyethylene ether to generate a surface active agent; adding the surface active agent to alcohol ether, and stirring under the condition of normal temperature and pressure; and then sequentially adding the antifreezing fluids, the ethylene glycol and the emulsifying agents so as to obtain the paraffin remover. The paraffin remover provided by the invention has the advantages of safety in use, low possibility in ignition and low solidifying point and meets the requirement for usage under the condition of extreme cold.

Owner:TIANJIN DAGANG OILFIELD BINGANG GRP BOHONG PETROLEUM CHEM

Environmental protective diesel oil, and preparation method

This invention relates to environmentally friendly diesel oil, which is composed of: diesel oil 13-20 parts, water 15-30 parts, plant oil 20-25 parts, methanol 8-11 parts, kerosene 10-30 parts, and composite additive 5-8 parts. The composite additive is composed of: triton X-100 2.0-2.65 parts, ethanolamine 1.5-3 parts, NaOH 14-16 parts, 99.5% ammonia solution 50-55 parts, n-butylamine 5.0-6..0 parts, isopropane 18-21 parts, water 2.0-2.3 parts, and cetane 0.2-1.0 parts. The environmentally friendly diesel oil is prepared in a raw material tank, an aid tank, a product tank, a sealing device, a high-energy static magnetic device and pipelines. This invention solves the problems of low stability, easy separation of oil and water, large amount of emulsifier, high price and difficult transportation faced by present W / O emulsified diesel oil, and has such advantages as abundant raw materials and wide applications.

Owner:陈志红

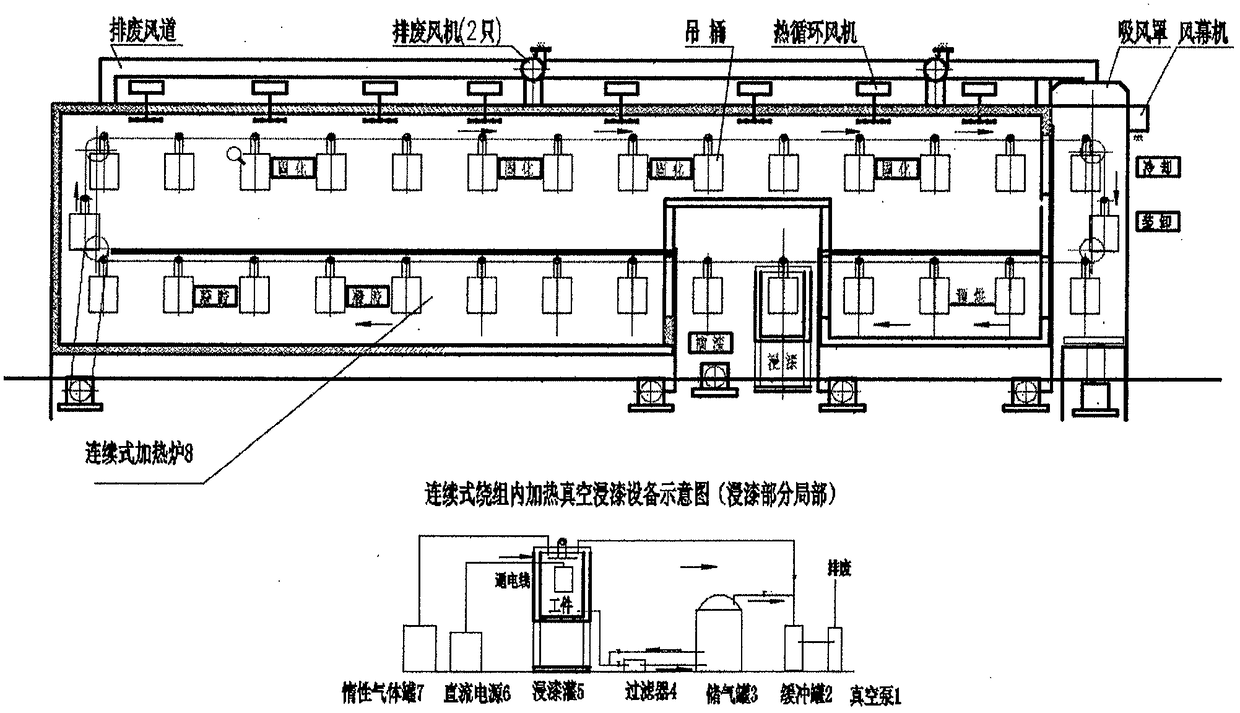

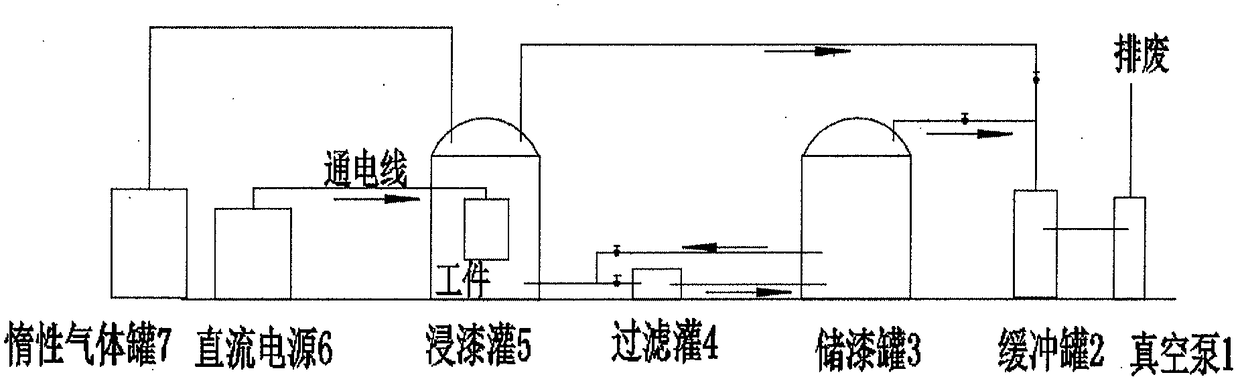

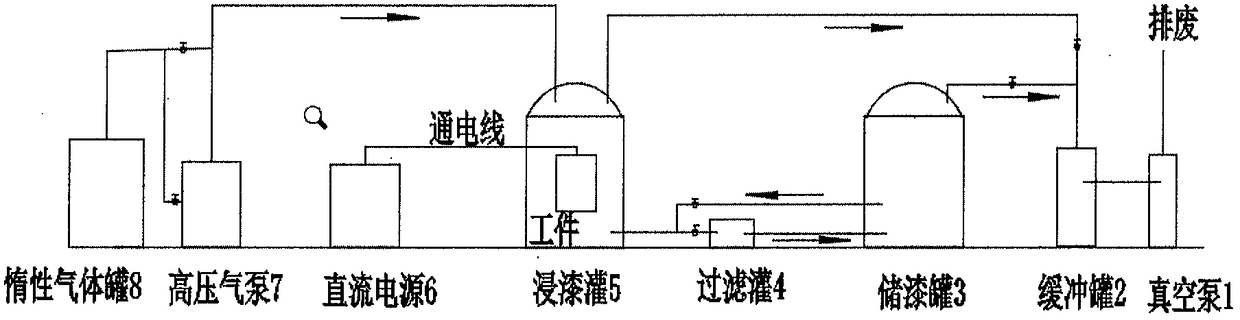

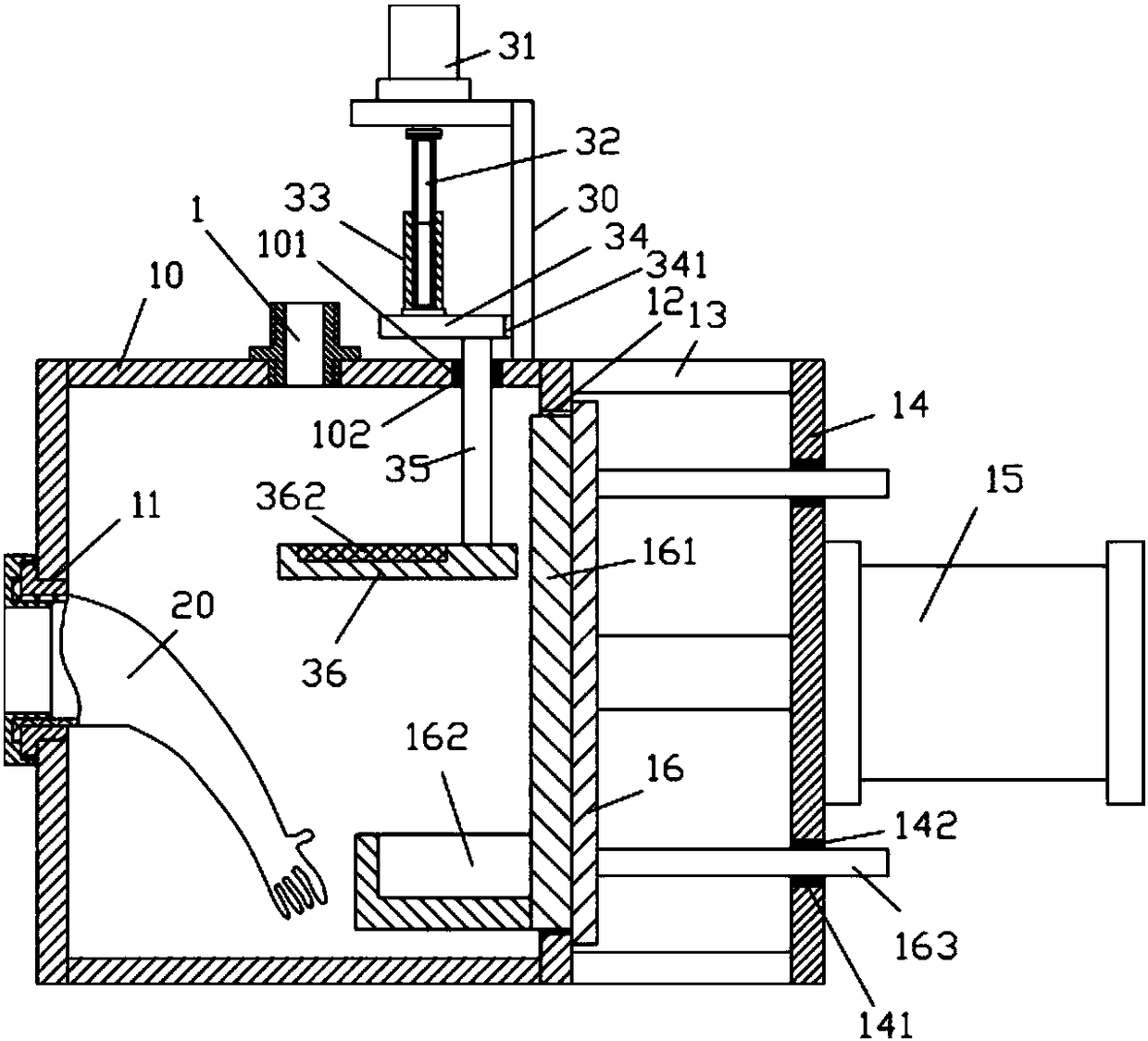

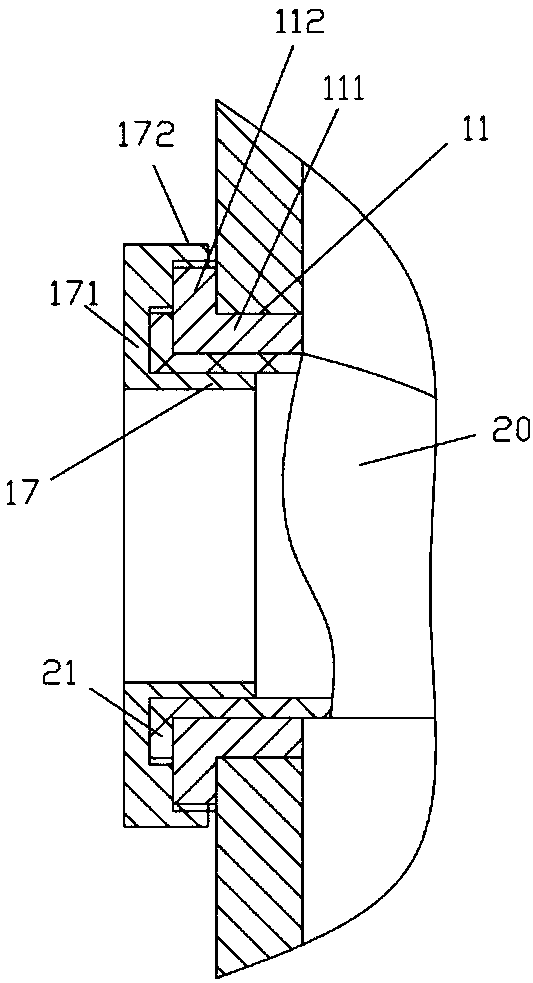

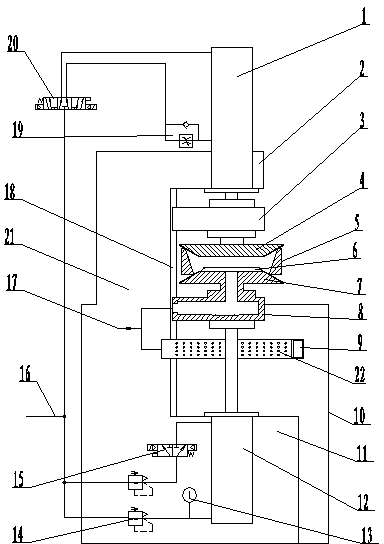

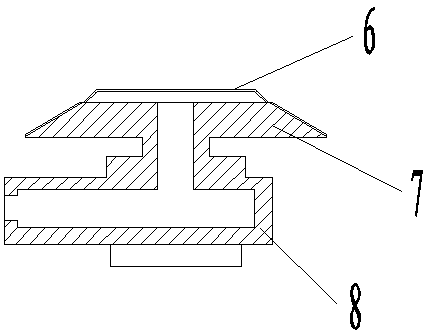

Internal-winding-heating vacuum and vacuum pressure paint immersion equipment

PendingCN108282061AReduce churnImprove permeabilityManufacturing dynamo-electric machinesCoils manufactureTransformerHigh energy

The invention discloses internal-winding-heating vacuum and vacuum pressure paint immersion equipment applicable to winding paint immersion insulation treatment of electrical equipment of various lowvoltage motors, high voltage motors, new energy vehicle motors, transformers, mutual inductors and the like with an aim to solve problems that current domestic winding insulation treatment equipment adopts oven or oven tunnel heating resulting in poor permeability of winding, less paint for insulation treatment, high energy consumption and the like while common internal heating paint immersion equipment widely adopted abroad is low in production efficiency, poor in security and the like. The vacuum and vacuum pressure paint immersion equipment is characterized in that an internal winding heating technology is adopted during paint immersion, special direct-current power supply is used, the winding is charged with large direct current, winding temperature is raised, and insulation paint is cured; compared with the equipment using the oven or oven tunnel heating method, the vacuum and vacuum pressure paint immersion equipment has the advantages that paint adherence is highly increased, loss of the insulation paint is remarkably reduced, the permeability is improved, and energy consumption is reduced; compared with the common internal winding heating method, the internal-winding-heating vacuum and vacuum pressure paint immersion equipment is high in permeability and production and safe and reliable.

Owner:赵文英 +1

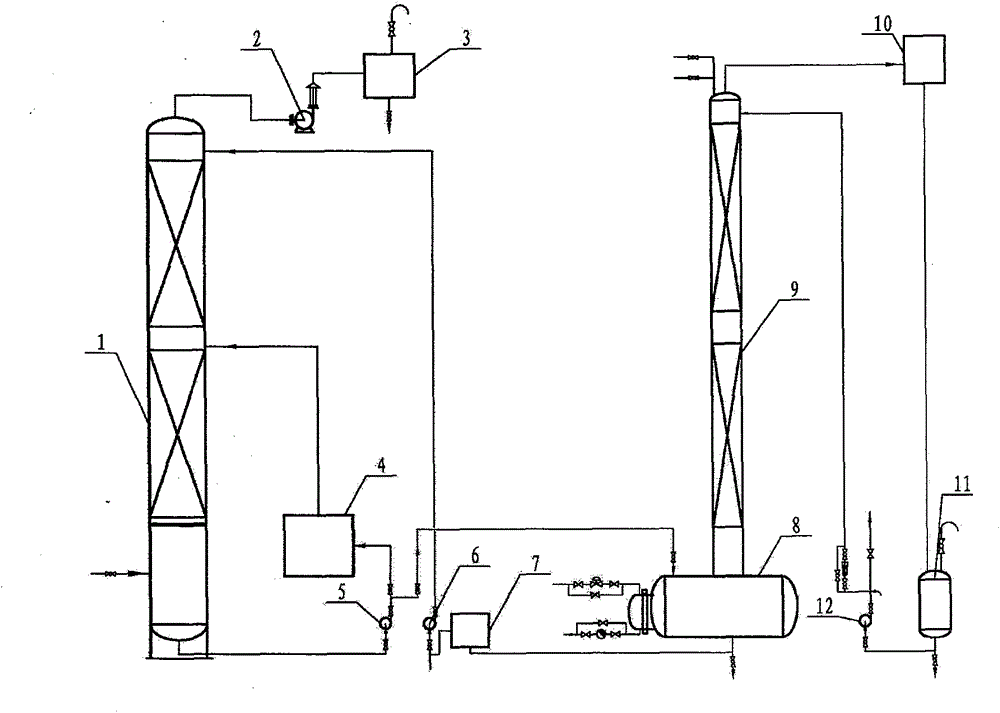

Organic exhaust-gas processing method

InactiveCN105327591ANot easy to catch fireFully automatic control is easy to operateDispersed particle separationHigh concentrationPhenol

The invention relates to an organic volatile gas recovery technology and an apparatus thereof. The recovery technology comprises the following operation flow: 1) introducing volatile gas into an absorbing tower for being absorbed; 2) performing cyclic absorption on an absorption solution; 3) desorbing the absorption solution; 4) cooling the desorbed gas; 5) performing recycle recovery utilization on the absorption solution; and 6) finally, processing gas in an adsorption tank and then discharging the gas. The processing method is suitable for gas with high concentration, large flow and large concentration fluctuation such as mercaptan, thioether, organic acidity, phenol, methylphenol, amine, acetaldehyde, alcohol, hydrocarbons and acetone, or occasion of polymerizable organic compounds.

Owner:北京日新达能技术有限公司

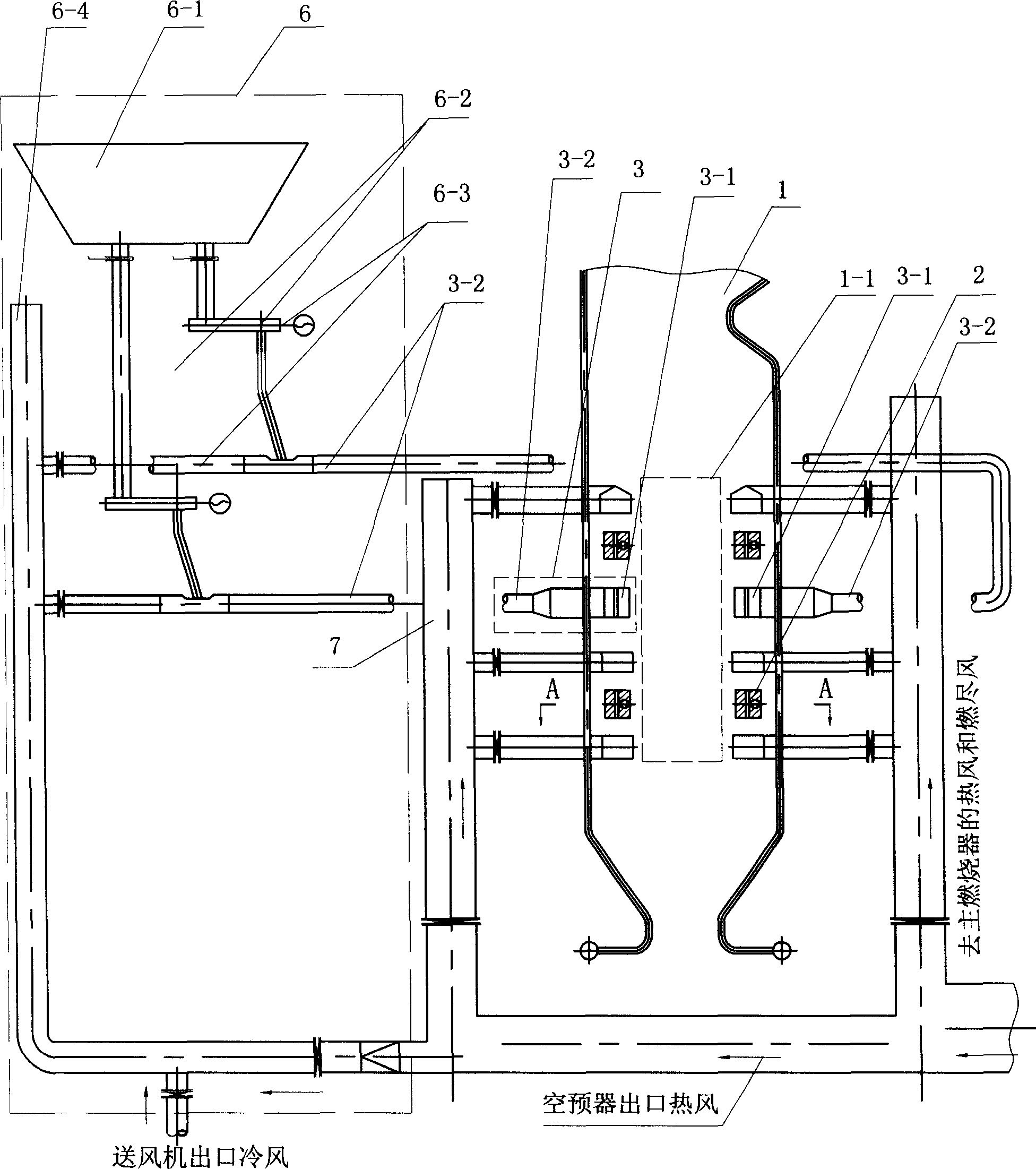

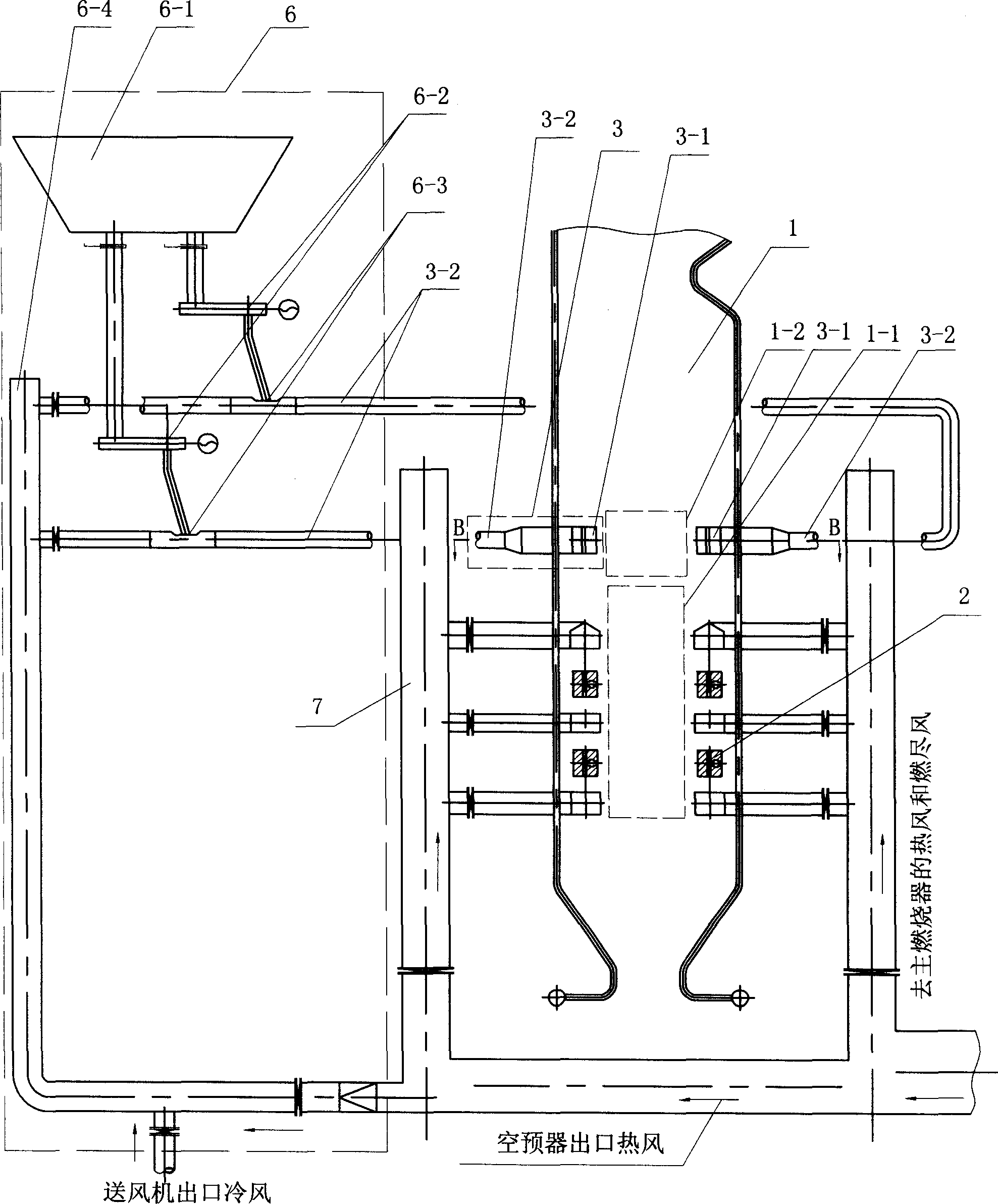

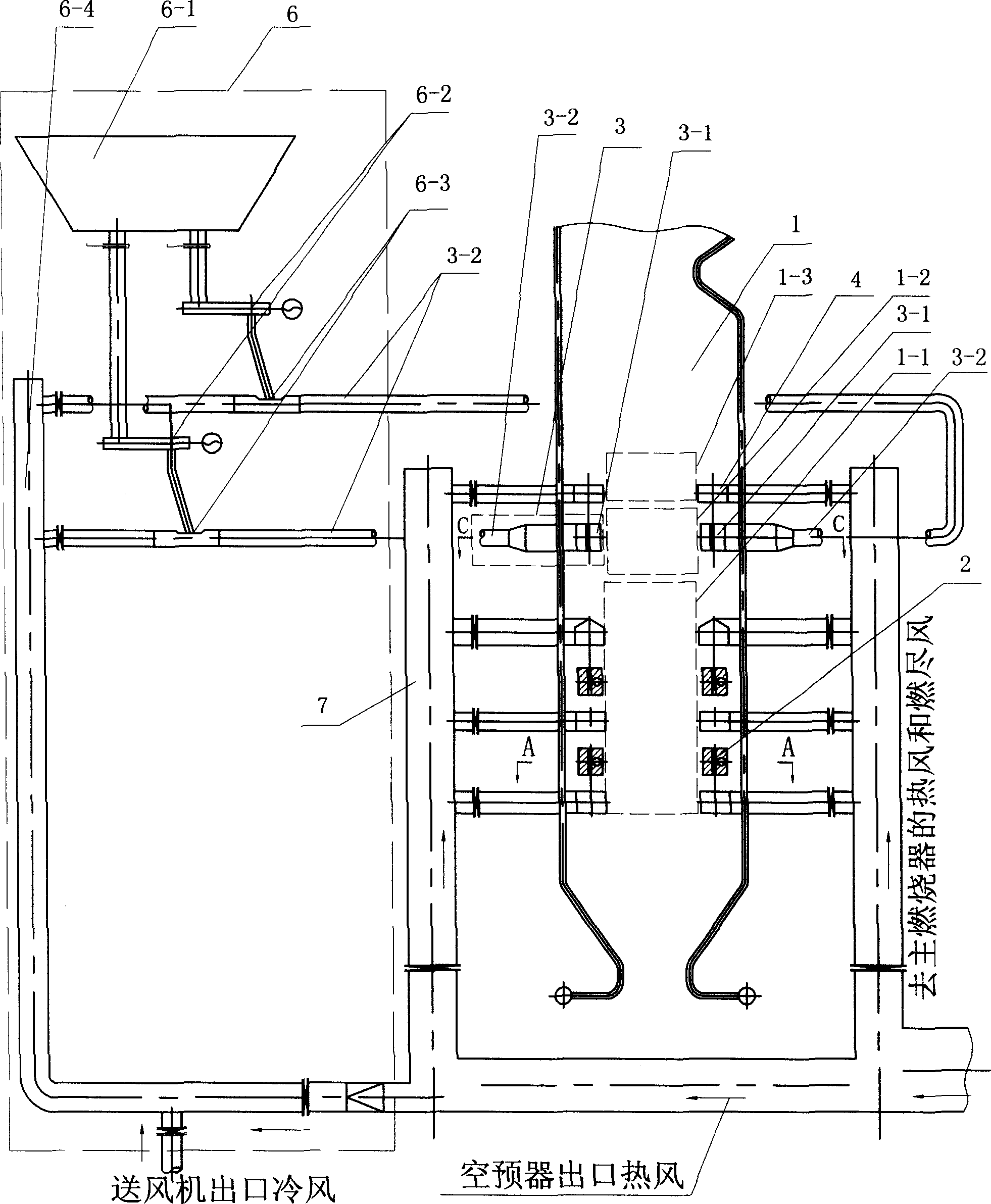

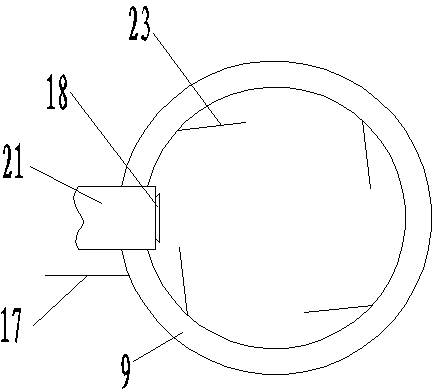

Biomass and powder coal mixed combustion and biomass recombusting and denitrating combustion apparatus

InactiveCN1673619AEmission reductionHigh volatile contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorRoom temperature

The present invention is one burning apparatus for the composite burning of biomass and coal powder and re-burning and denitrifying of biomass. The burning apparatus includes hearth, main coal powder burning area inside the hearth, main nozzles and biomass nozzles installed on the four corner of the hearth. The present invention has the following advantages: lower NOx exhaust rate, burning out of biomass fuel, large scale utilization of biomass, reduced room temperature CO2, and lowered SOx exhaust and simple apparatus structure.

Owner:HARBIN INST OF TECH

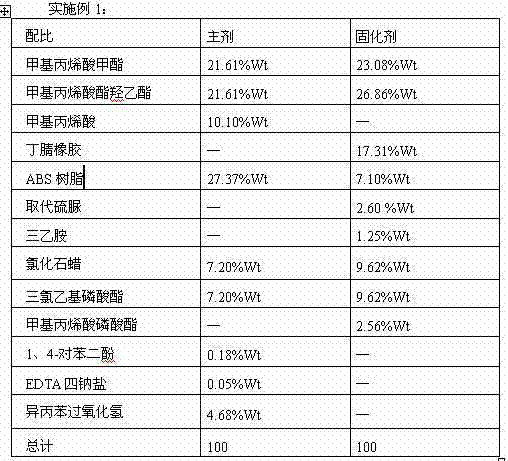

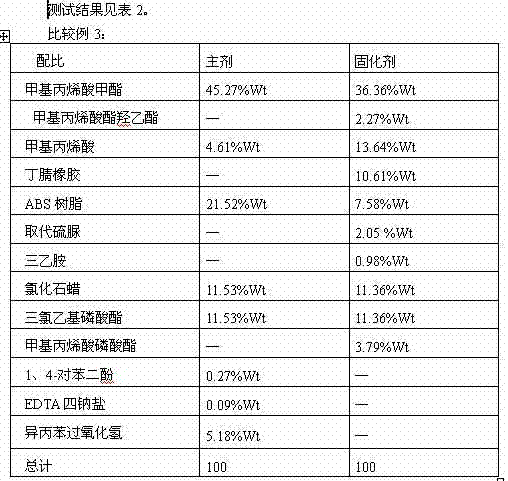

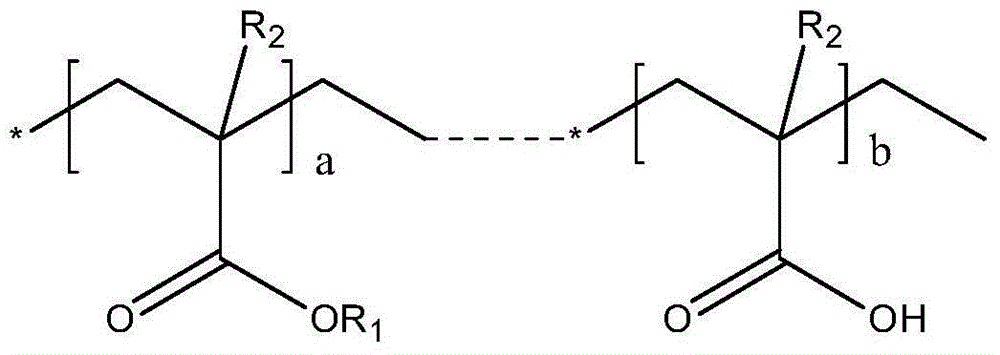

Acrylate adhesive for spot welding process

ActiveCN102533131AImprove flame retardancyNot easy to catch fireOrganic non-macromolecular adhesiveFire retardantAdhesive

The invention relates to an acrylate adhesive for a spot welding process and belongs to the technical field of a double-component acrylate structural adhesive, and is mainly used for solving the problems that the existing acrylate adhesive is extremely easy to ignite and burn when in spot welding. The acrylate adhesive is characterized by mainly comprising a main agent component and a solidifyingagent component, wherein (1) the main agent component comprises the following raw materials by weight percent: 42%-85% of acrylate monomer containing at least one vinyl group, 0%-12% of methacrylic acid, 0%-30% of elastomer, 0.01%-1% of stabilizing agent, 0%-30% of toughening resin, 0%-20% of fire retardant and 0.5%-8% of peroxide; (2) the solidifying agent component comprises the following raw materials by weight percent: 40%-90% of acrylate monomer containing at least one vinyl group, 0%-23% of elastomer, 0%-20% of methacrylic acid, 1%-10% of accelerating agent, 0%-30% of toughening resin and 0%-20% of fire retardant; and (3) at least one component in the main agent and the solidifying agent contains 10%-30% of elastomer. The acrylate adhesive disclosed by the invention has the characteristic that the adhesive can be used for the spot welding process and can be widely applied to the fields of machinery manufacturing and maintenance.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

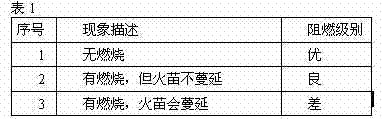

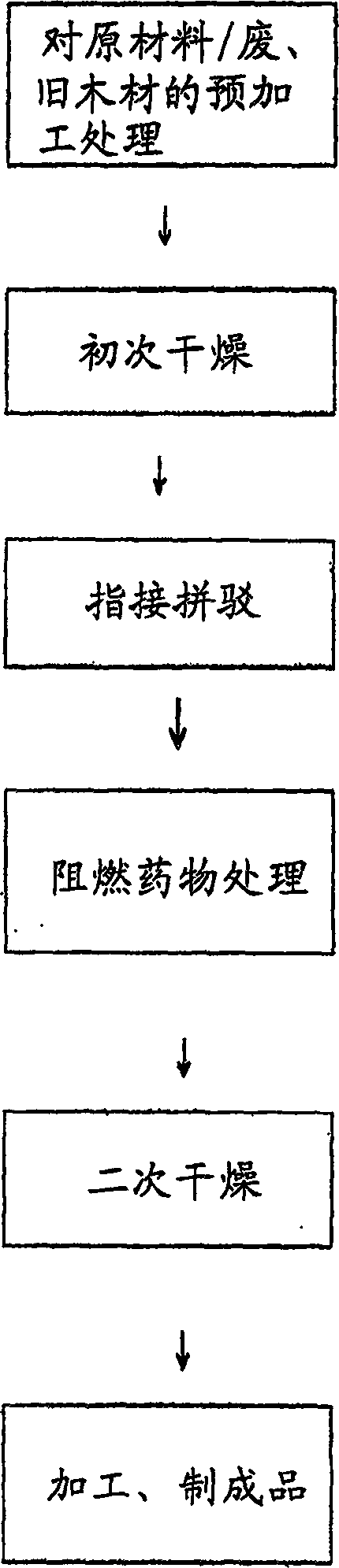

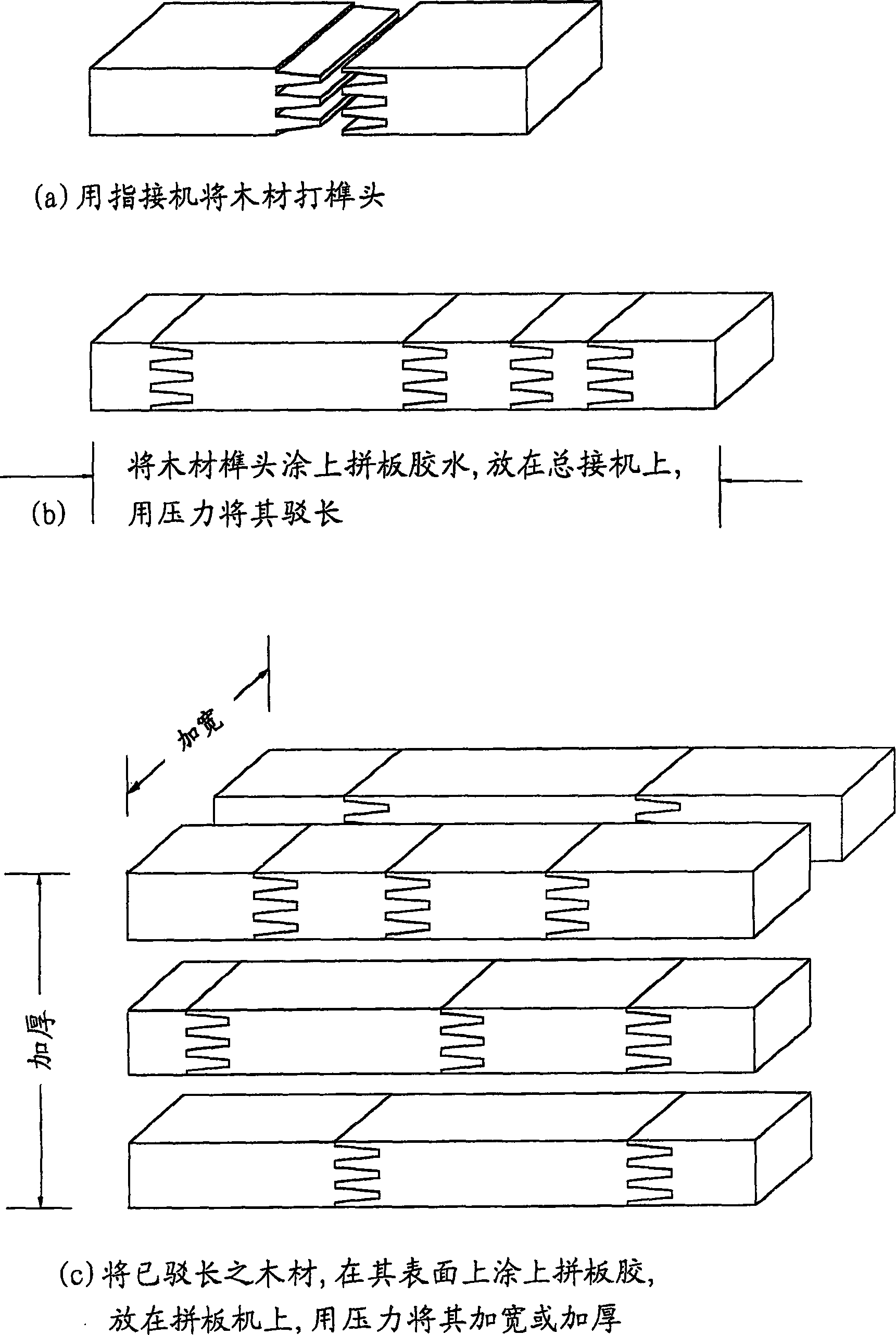

Method for fireproofing and fire retardant timber reconstituted circularly

InactiveCN1872509AImprove fire and flame retardant performanceIncrease profitLayered productsWood dampingFireproofingPulp and paper industry

Owner:谭仲渘

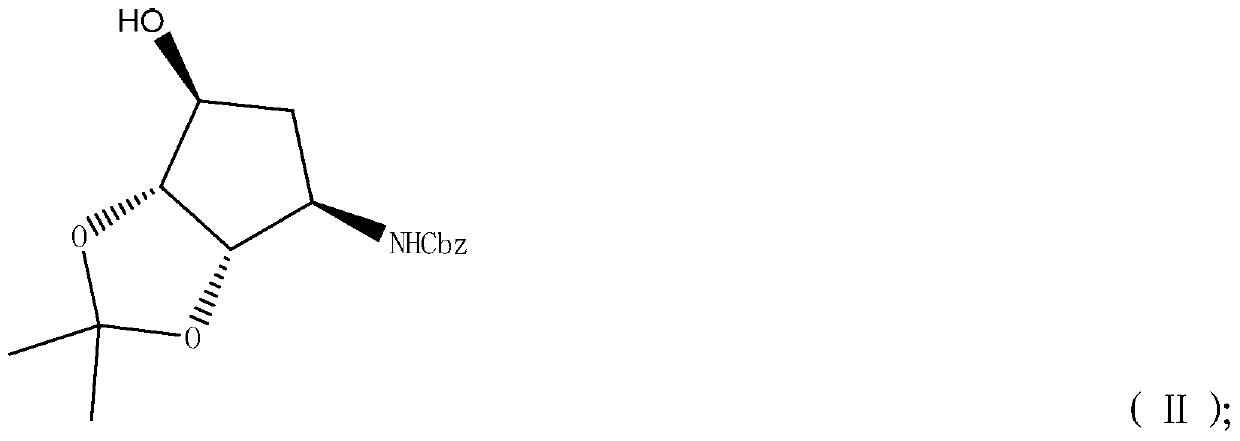

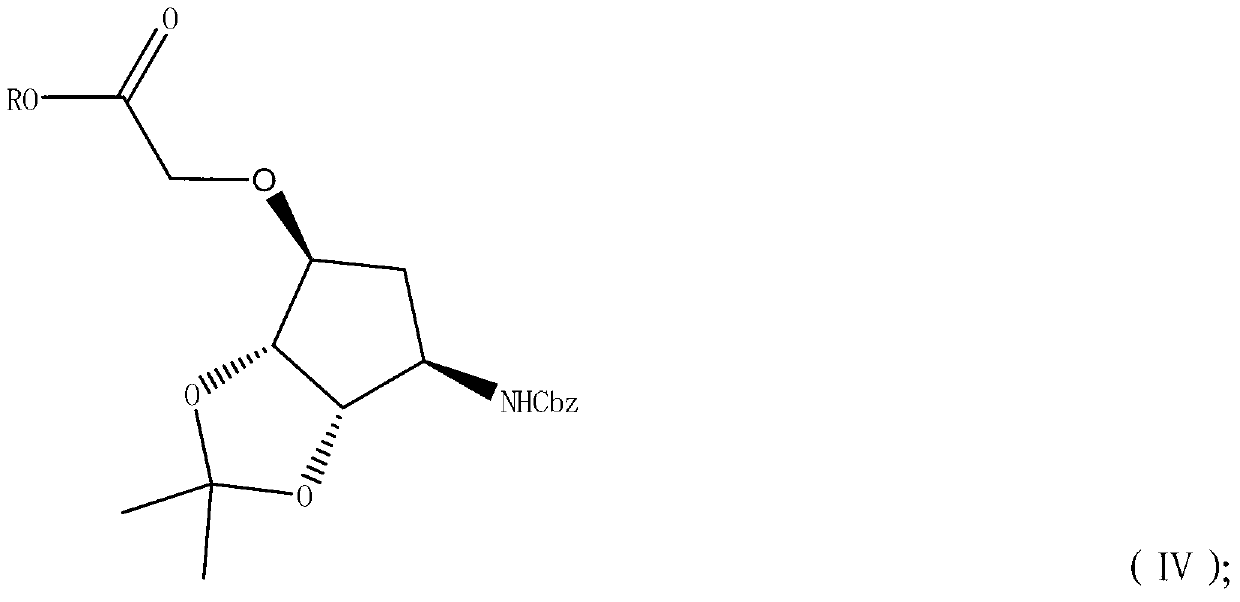

Preparation method of ticagrelor midbody

ActiveCN103275056AStable in natureEasy to addOrganic chemistryBulk chemical productionAlcoholTicagrelor

The invention discloses a of a ticagrelor midbody. The preparation method comprises the following steps of: by taking chiral cyclopentanol protected by N-Cbz under an alkaline condition as a starting material, converting the starting material to a compound IV by utilizing an etherification reaction, then reducing under a system of a reducing agent and alcohol to obtain a compound V, and at last, removing protecting groups to obtain a icagrelor midbody I. The whole reaction process is short in time; the purity of the product is high; the yield is high; and each midbody is easily purified. The needed materials are cheap and easily-available, so that the preparation preparation saves time and production cost, is favorable for large-scale industry production and has important significance.

Owner:ZHEJIANG APELOA JIAYUAN PHARMA +1

A flame retardant wire coat and a preparing method thereof

InactiveCN106916375ASimple methodImprove flame retardant performancePlastic/resin/waxes insulatorsAntioxidantPlasticizer

A flame retardant wire coat and a preparing method thereof are disclosed. The method includes mixing polypropylene, polyvinyl chloride, asbestos, butadiene-acrylonitrile rubber, a stabilizer, a plasticizer and an antioxidant, then melting the mixture to obtain a melt liquid M, and molding the melt liquid M through an extruding machine group to obtain the wire coat. Problems that flame retardance of insulating coats of common wires is poor, and once short circuits or other situations occur, the insulating coats are liable to be on fire are overcome by the wire coat and the method.

Owner:HEFEI PULFI WIRE TECH CO LTD

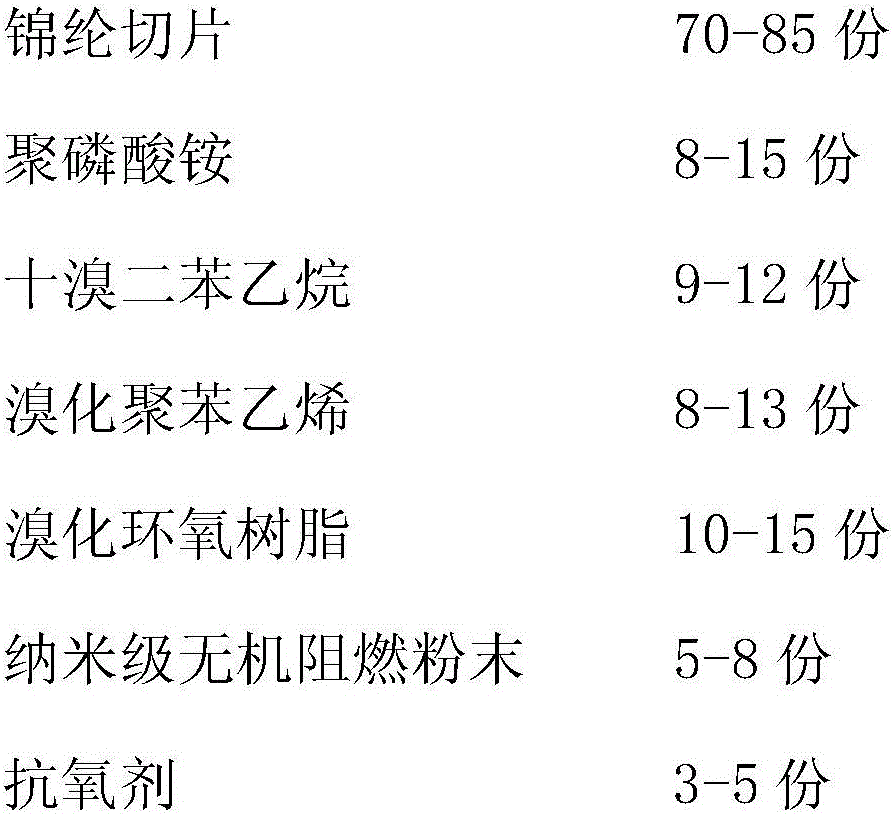

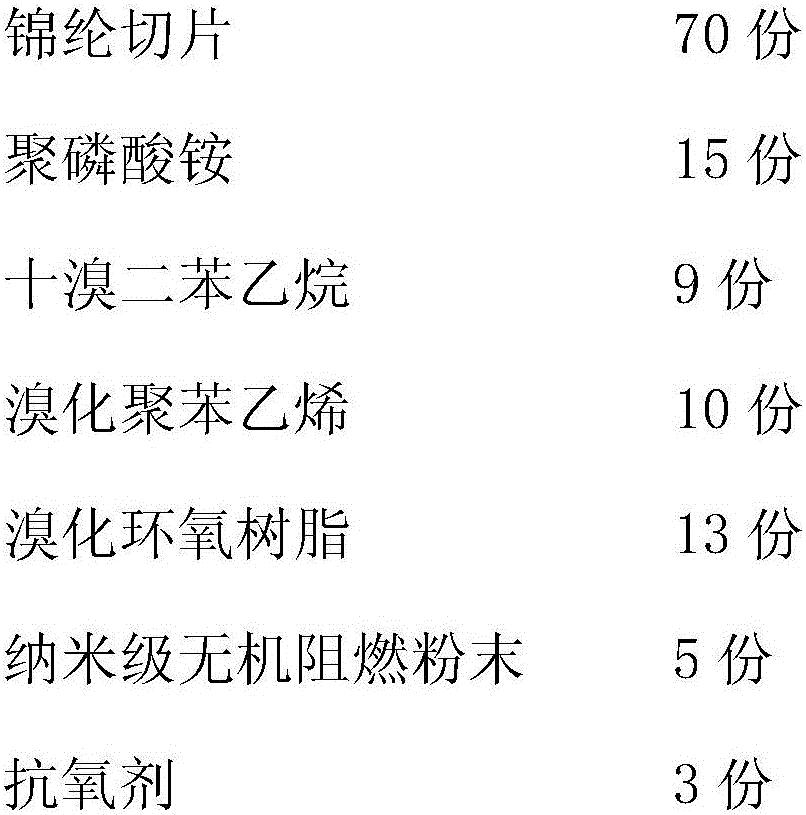

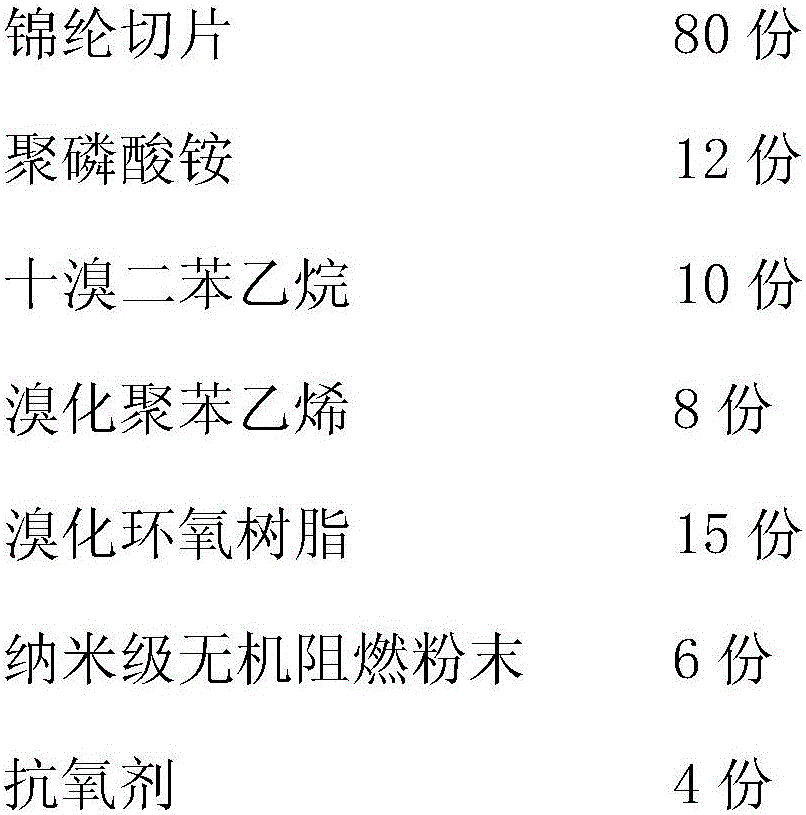

Anti-flaming modified polyamide fiber

PendingCN106521685AImprove flame retardant performanceNot easy to catch fireFlame-proof filament manufactureMonocomponent polyamides artificial filamentAmmonium polyphosphateFlame resistance

The invention discloses anti-flaming modified polyamide fiber. The anti-flaming modified polyamide fiber is prepared from the following components in parts by mass: 70 to 85 parts of polyamide chips, 8 to 15 parts of ammonium polyphosphate, 9 to 12 parts of decabromodiphenyl ethane, 8 to 13 parts of brominated polystyrene, 10 to 15 parts of brominated epoxy resin, 5 to 8 parts of nanoscale inorganic anti-flaming powder and 3 to 5 parts of antioxidant. According to the anti-flaming modified polyamide fiber disclosed by the invention, by adding the components having an anti-flaming function in polyamide, the anti-flaming modified polyamide fiber has very good flame resistance, an article prepared from the anti-flaming modified polyamide fiber is not easy to catch fire, the fire is not easy to quickly spread and amplify after the article catches the fire, a large amount of poisonous and harmful gas is not easy to generate during a combustion process, and pollution to external environment is smaller.

Owner:ZHEJIANG YINAN FIBER TECH

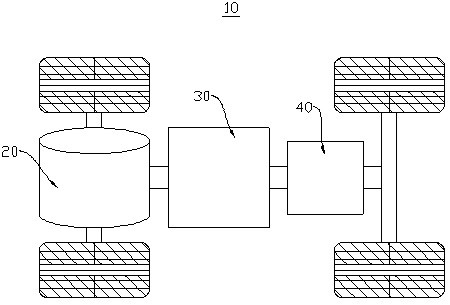

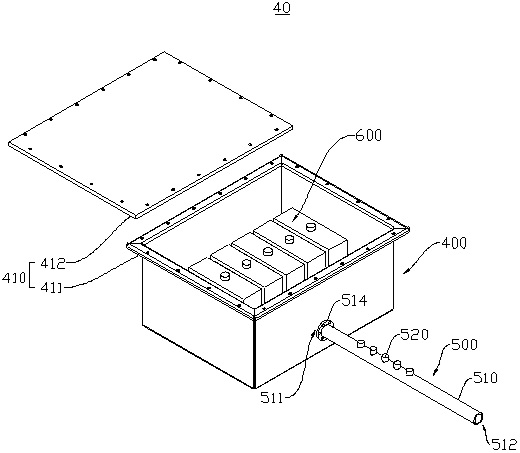

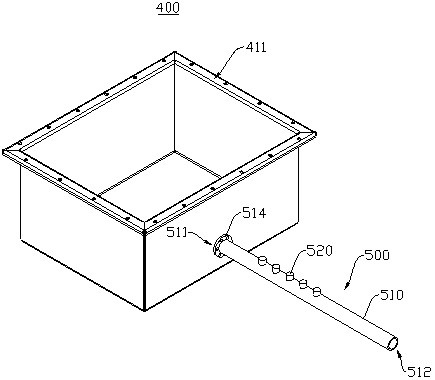

Fire-fighting device, box body assembly, battery, electric device and method for preparing battery

ActiveCN112103445AReduce the temperatureReduce concentrationFinal product manufactureNon-aqueous electrolyte cellsElectrical batteryCombustible gas

The invention provides a fire-fighting device, a box body assembly, a battery, an electric device and a method for preparing the battery, and relates to the technical field of battery safety. The fireprotection device comprises a pipeline, a gas release mechanism and a blocking structure, wherein the pipeline is provided with a gas inlet end and a gas exhaust end, and the gas inlet end is used for being connected with a box body of the battery, so the combustible gas generated during thermal runaway of the battery can enter the pipeline from the box body through the gas inlet end and is exhausted out of the pipeline through the gas exhaust end; the gas release mechanism is used for being connected with a pipeline, and the gas release mechanism is configured to release fire-fighting gas into the pipeline when the battery is in thermal runaway; the pipeline is internally provided with a blocking structure, and the blocking structure is used for blocking combustible gas and fire-fightinggas and changing the flowing direction, so the combustible gas and the fire-fighting gas can be mixed before being discharged out of the pipeline. The fire protection device provided by the inventioncan reduce the risk of generating open fire during thermal runaway of the battery, and can inhibit spreading of the thermal runaway of the battery.

Owner:JIANGSU CONTEMPORARY AMPEREX TECHNOLOGY LIMITED

Cleaning aerosol composition for household air conditioner and preparation method thereof

ActiveCN104893838AReduce usageEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSoftened waterSolvent

The invention discloses a cleaning aerosol composition for a household air conditioner and a preparation method thereof. The cleaning aerosol composition for the household air conditioner contains the main ingredients in percentage by weight: 30-70% of softened water, 0.01-0.5% of surfactant, 0.01-15% of acrylic (acrylate) copolymer, 0.05-0.5% of composite corrosion inhibitor, 0.01-0.5% of bactericide, 5-50% of solvent and the balance of LPG (Liquefied Petroleum Gas). The cleaning aerosol composition for the air conditioner, disclosed by the invention, contains the acrylic (acrylate) copolymer and the composite corrosion inhibitor, so that the cleaning performance, stability and corrosion resistance of products are remarkably improved, and the cleaning aerosol composition has good application prospects.

Owner:广州超威生物科技有限公司

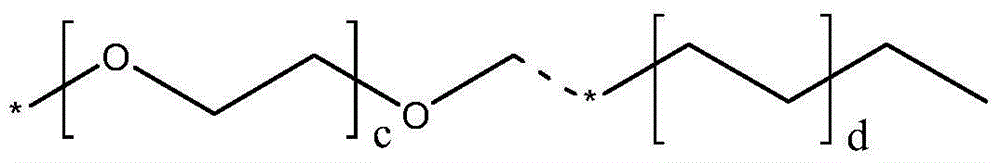

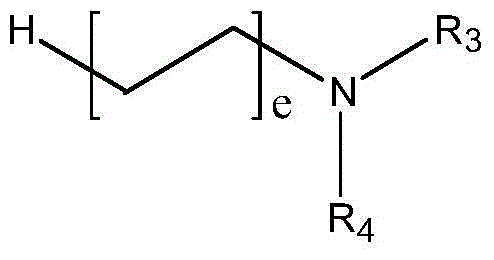

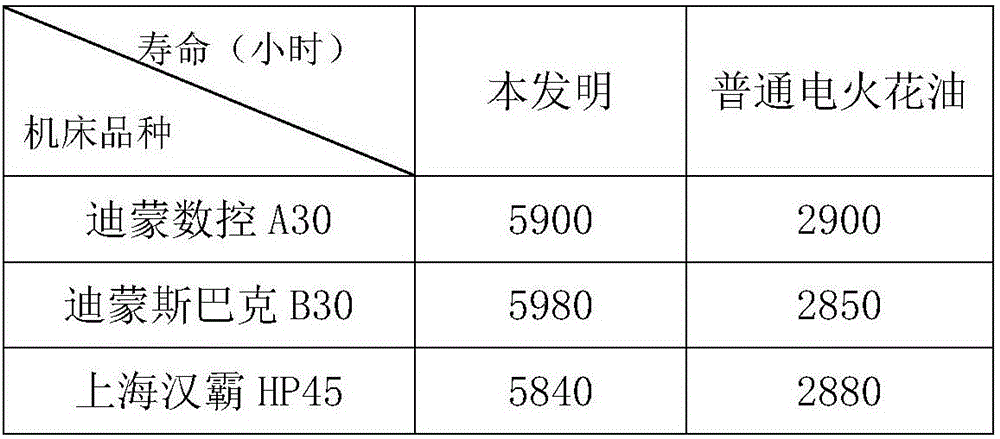

EDM oil for mirror EDM and preparation method therefor

The invention discloses an electric discharge machining (EDM) oil for mirror EDM. The oil comprises the following raw materials in parts by weight: 6 to 10 parts of solvent oil D110 (Nanjing Beautychem Co.Ltd), 0.7 to 1 parts of poly epoxy succinic acid, 2 to 3 parts of dodecyl phenyl succinic acid, 0.1 to 0.14 parts of triallyl isocyanurate, 0.02 to 0.04 parts of 1,2,3 - benzotriazole, 0.1 to 0.2 parts of polyimide, 1 to 2 parts of polyacrylamide, 75 to 85 parts of n-alkanes solvent oil, 0.6 to 1 parts of isopropyl oleate, 1.5 to 2 parts of corrosion inhibitor, 0.05 to 0.06 parts of zinc acetylacetonate, 0.01 to 0.02 parts of polyglycerol fatty acid ester, 2 to 4 parts of N - vinyl pyrrolidone, 0.3 to 0.4 parts of ethyl orthosilicate and 0.1 to 0.2 parts of simethicone. The finished product produced by the invention is high in chemical stability, relatively long in service life, good in environmental protection and outstanding in comprehensive performance.

Owner:浙江模德科技有限公司

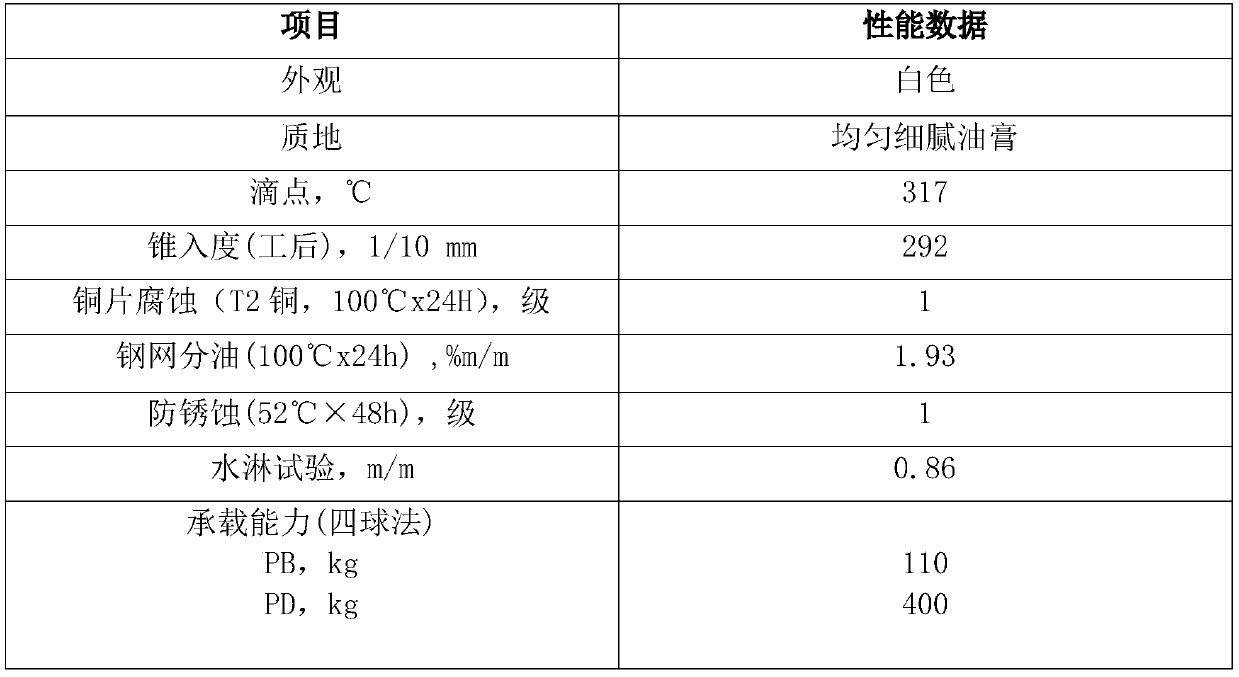

Synthetic low-carbon ultrahigh temperature grease and preparation method

ActiveCN109943402AImprove performanceGood value for moneyLubricant compositionAntioxidantPrice ratio

A synthetic low-carbon ultrahigh temperature grease and a preparation method comprise trimellitate, polyisobutylene, polyurea, and functional additives; wherein polyurea includes MDI, tallow amine andcyclohexylamine; the functional additives include a high temperature antioxidant, an anti-copper corrosion additive, an anti-rust and anti-corrosion agent for ferrous metals, a flame retardant lubricant, a flame retardant anti-smoke agent, and an ultrahigh temperature solid lubricant. First, synthetic polyurea grease is prepared in a grease-making kettle; then, the temperature of materials in thekettle is raised to 120-130 DEG C until the water in the kettle is completely drained; the temperature of the materials in the kettle is raised to 170+ / -3 DEG C, and the materials are kept at this temperature for about 10 minutes. A cooling system is started; when the temperature of the materials in the kettle drops to 150 DEG C, the functional additives are added in sequence and metering, and the synthetic low-carbon ultrahigh temperature grease is obtained. The synthetic low-carbon ultrahigh temperature grease has the advantages of comprehensive and excellent performance, strong bearing capacity, good properties of anti-wear and anti-friction, good adhesion, strong resistance to high temperature and ultrahigh temperature, low tendency of carbon deposition, long service life and high performance-price ratio.

Owner:SHANDONG KEYSTONE LUBRICANT TECH

Production and reproduction method of seamless active carbon articles and products produced thereby

InactiveCN1541940AImprove adsorption capacityWide variety of sourcesOther chemical processesCarbon compoundsRoom temperatureEngineering

The present invention is the production, regeneration process and product of seamless active carbon product. The production process of the active carbon product includes setting timber or bamboo material inside one sealed container with exhaust port, raising temperature in certain rate gradually up to 600 deg.c, maintaining for certain time, lowering temperature in the same rate to room temperature to obtain the seamless active carbon product. The regeneration process is basically the same as the production process but has highest temperature of 400 deg.c and vacuum degree of 0.7-0.9 Pa maintained inside the container. The product may be further produced into artistic work through further processing, coloring and other steps and may be used in adsorbing harmful gas in air.

Owner:李韬

Jet nozzle of mild combustion chamber of gas turbine

ActiveCN107990353AGuaranteed combustion efficiencyAvoid shockContinuous combustion chamberRefluxUltrasound attenuation

A jet nozzle of a mild combustion chamber of a gas turbine comprises a fuel inside nozzle, a fuel outside spray hole, multiple rotational flow groove channels, an outside pipeline and an inside pipeline. The mixing uniformity of fuel and air at a jet nozzle outlet is improved, the outside fuel-air equivalence ratio is relatively low, flame root lifting is facilitated, too-early ignition does not occur easily, jets of the jet nozzle belong to weak rotational flows, the overall pressure loss is relatively low, the axial speed is not prone to attenuation, and increase of the smoke reflux ratio ofthe combustion chamber is facilitated.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

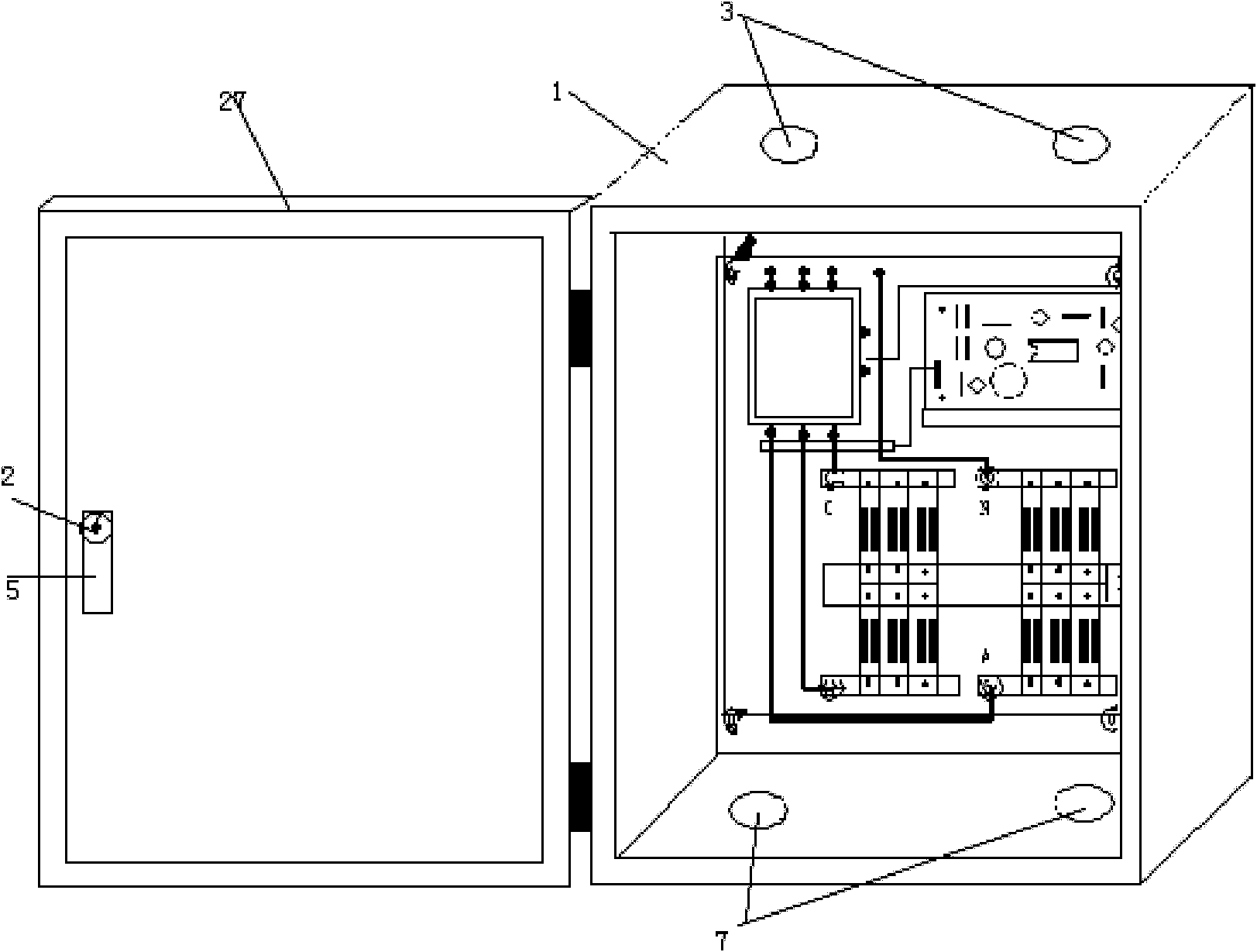

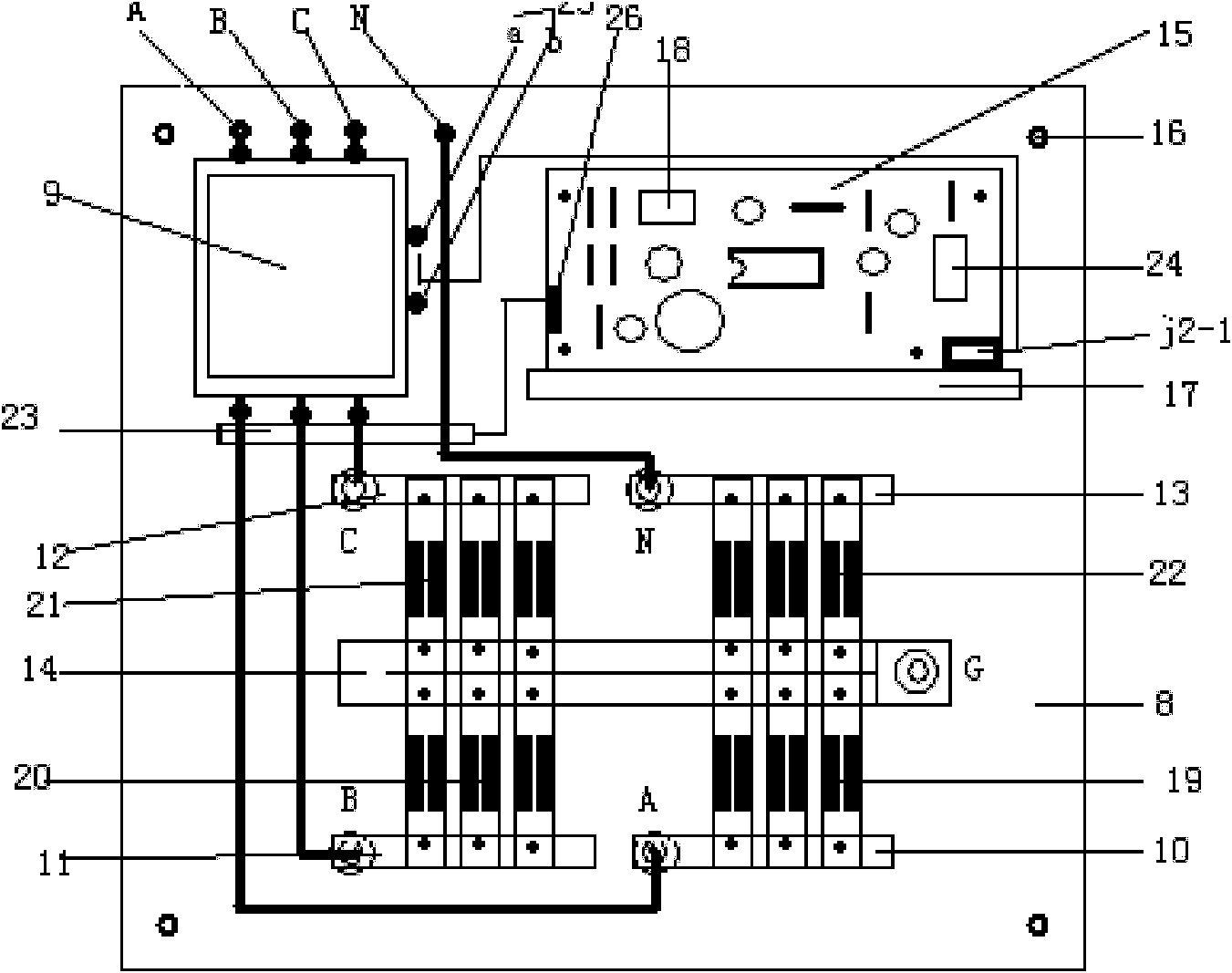

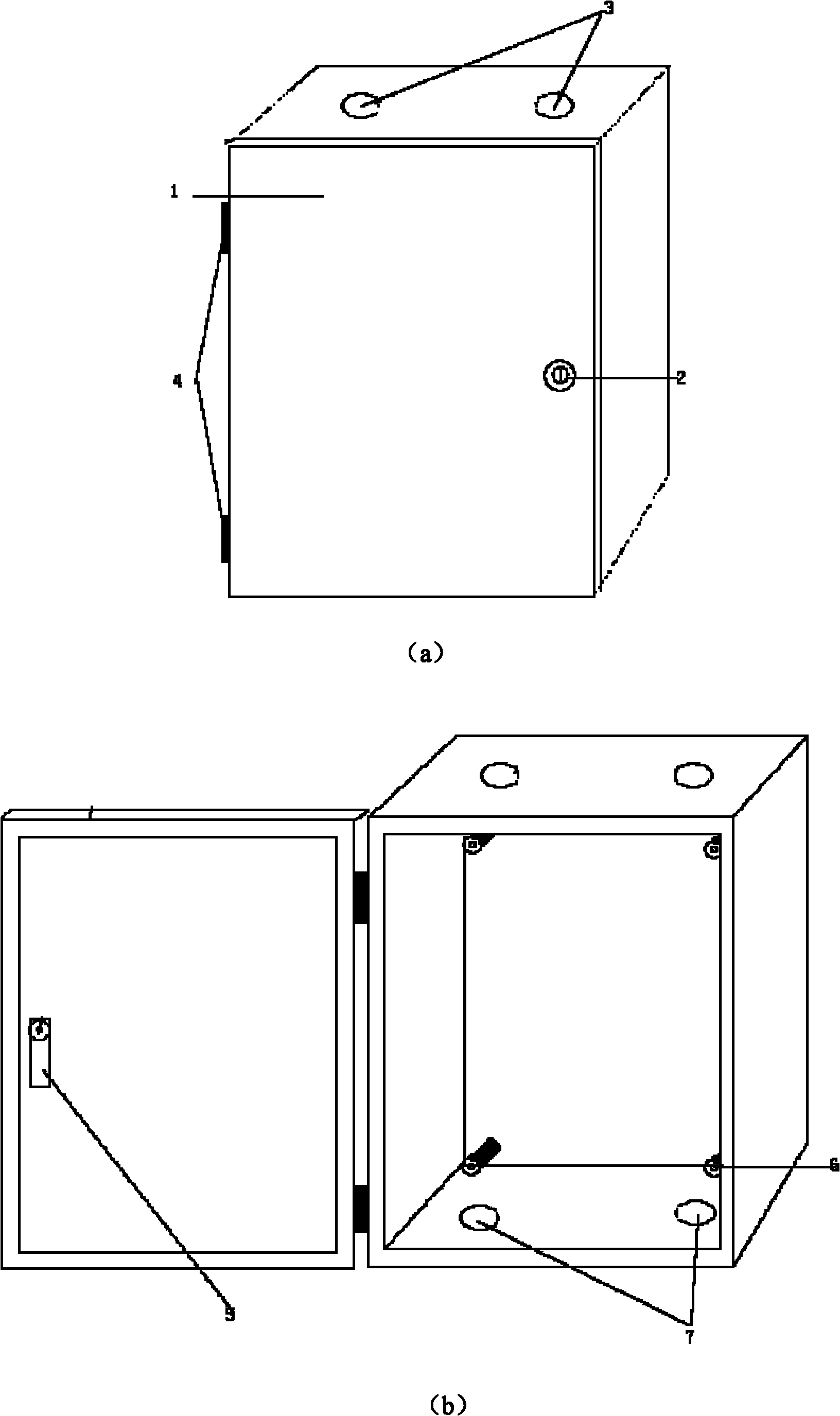

Overvoltage, overcurrent, leakage and lightning protection multifunctional solar electric supply protection controller

InactiveCN102064521ASimple structureNot easy to catch fireEmergency protective arrangements for limiting excess voltage/currentArrangements responsive to excess voltageOvervoltageTransformer

The invention discloses an overvoltage, overcurrent, leakage and lightning protection multifunctional solar electric supply protection controller. At thunder and lightning, high voltage of more than kilovolts and current of scores of kilo-amperes flow through three phase lines and a zero line of an AC contactor simultaneously and pass through a voltage transformer to be connected with four copper plates of a connecting terminal. A piezoresistor is arranged as an over-voltage suppression circuit connected with the copper plates to discharge to the ground. When the discharge voltage and current exceed the predetermined values, a current induction relay actuates and the voltage transformer is connected with a detection control circuit to drive j1, j2 and the AC contactor to complete the connection and the disconnected of the electric supply respectively. When people contacts with the leakage circuit or electric equipment, the leakage current reaches at a regulated current value so that the electric supply is cut off to protect the people. The overvoltage, overcurrent, leakage and lightning protection multifunctional solar electric supply protection controller has a simple structure, and can be connected in series in any 380V or 220V AC circuits, is not easy to fire and high in safety. Few resistance elements are adopted in the control circuit and each branch circuit so that the cost is saved.

Owner:储应坤

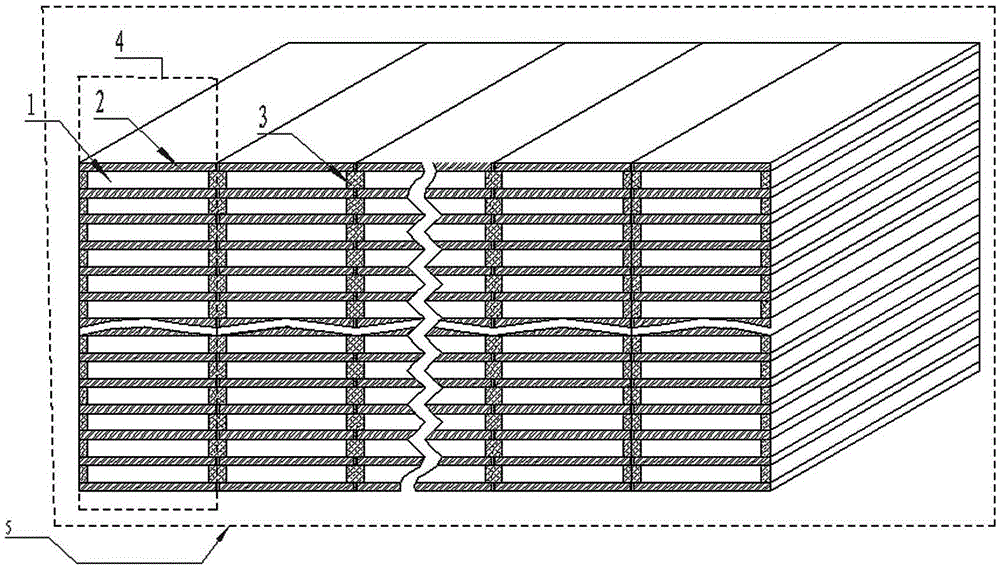

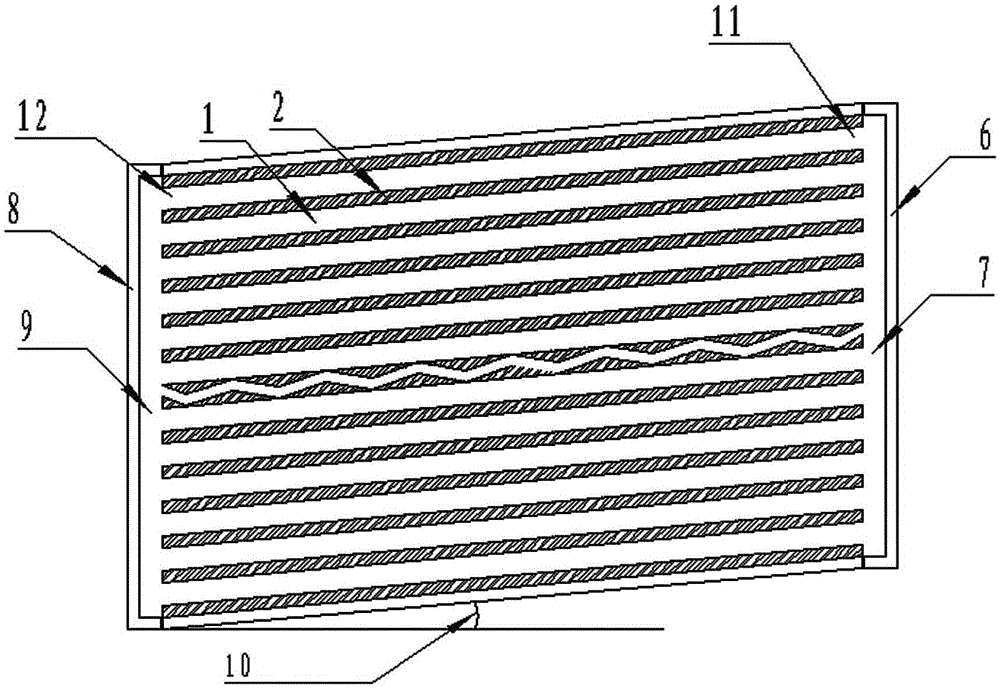

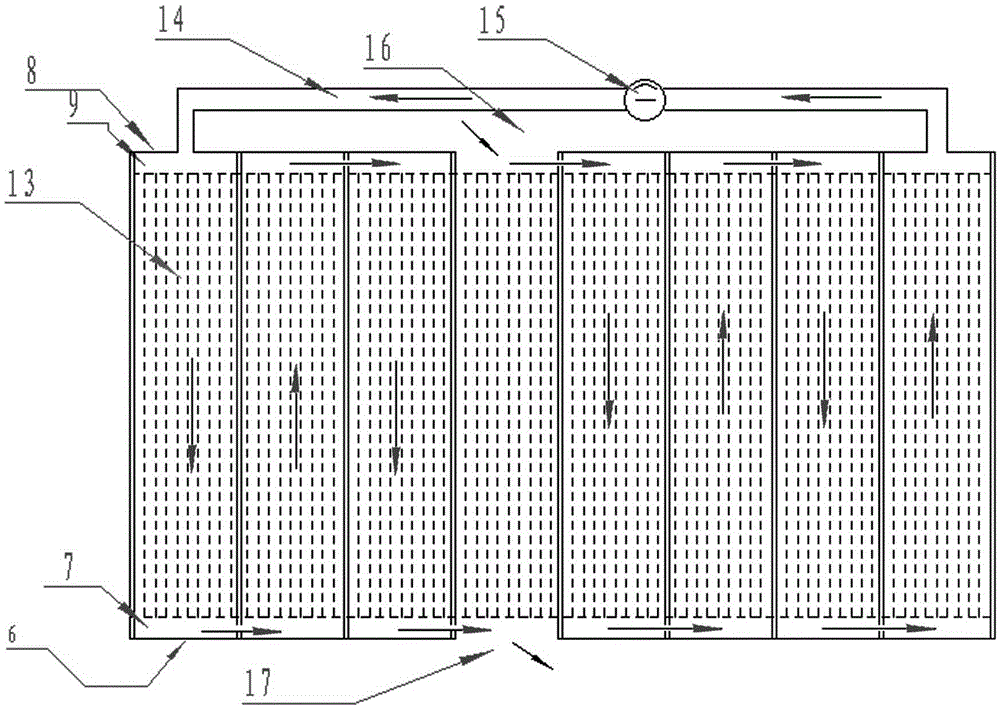

Multi-layer and multi-stage pipe tunnel slide type veneer drying device

InactiveCN105352277ALabor savingSave deliveryDrying gas arrangementsDrying chambers/containersHeating oilInsulation layer

The invention discloses a multi-layer and multi-stage pipe tunnel slide type veneer drying device. The multi-layer and multi-stage pipe tunnel slide type veneer drying device comprises a drying box, a conduction oil boiler, a conduction oil circulating pipeline and a circulating pump, wherein the conduction oil circulating pipeline is connected with the drying box and the conduction oil boiler, and the circulating pump is arranged on the conduction oil circulating pipeline. A drying frame is arranged in the drying box, and a heat insulation layer is arranged on the periphery of the drying box. Being different from the prior art, the drying frame is formed by heating plates and bearing and supporting partition plates, wherein the heating plates are arranged in parallel in the quasi-horizontal direction, heating oil pipelines are buried in the heating plates, and the bearing and supporting partition plates are arranged in parallel in the vertical direction; a plurality of layers and a plurality of columns of flat rectangular pipe-tunnel-shaped spaces of the same specification are formed in the drying frame at equal intervals and in parallel and serve as pipe tunnel type drying chambers, and material enters or exits from the drying chambers in a sliding mode. The multi-layer and multi-stage pipe tunnel slide type veneer drying device has the advantages that the manpower and the electric energy are saved, the heat energy is reasonably recycled, the heat dissipation rate is low, it is difficult to catch fire but easy to extinguish fire, the structure is simple, the manufacturing cost is low, the investment is small, and use and popularization are convenient.

Owner:黄达宏

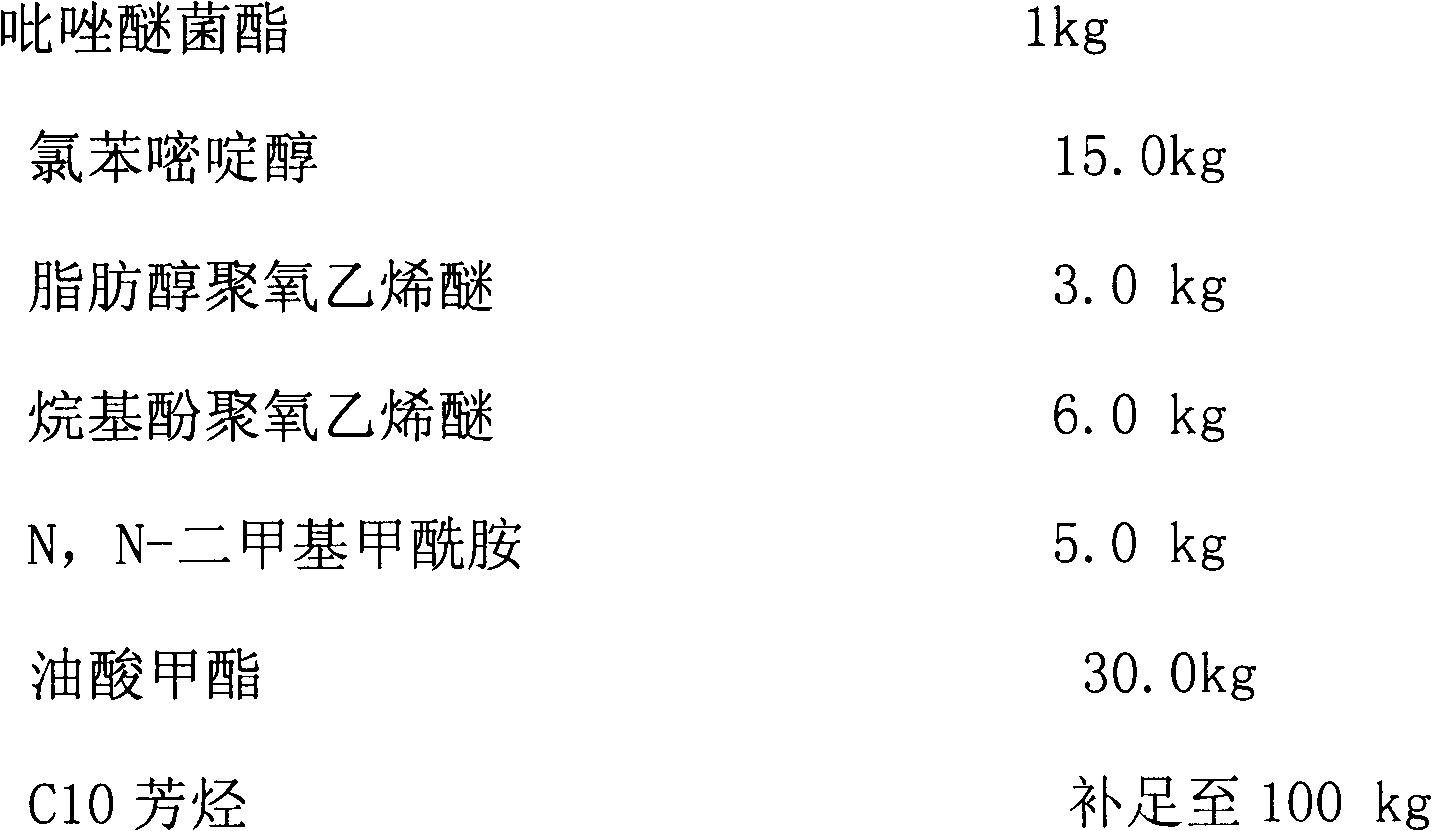

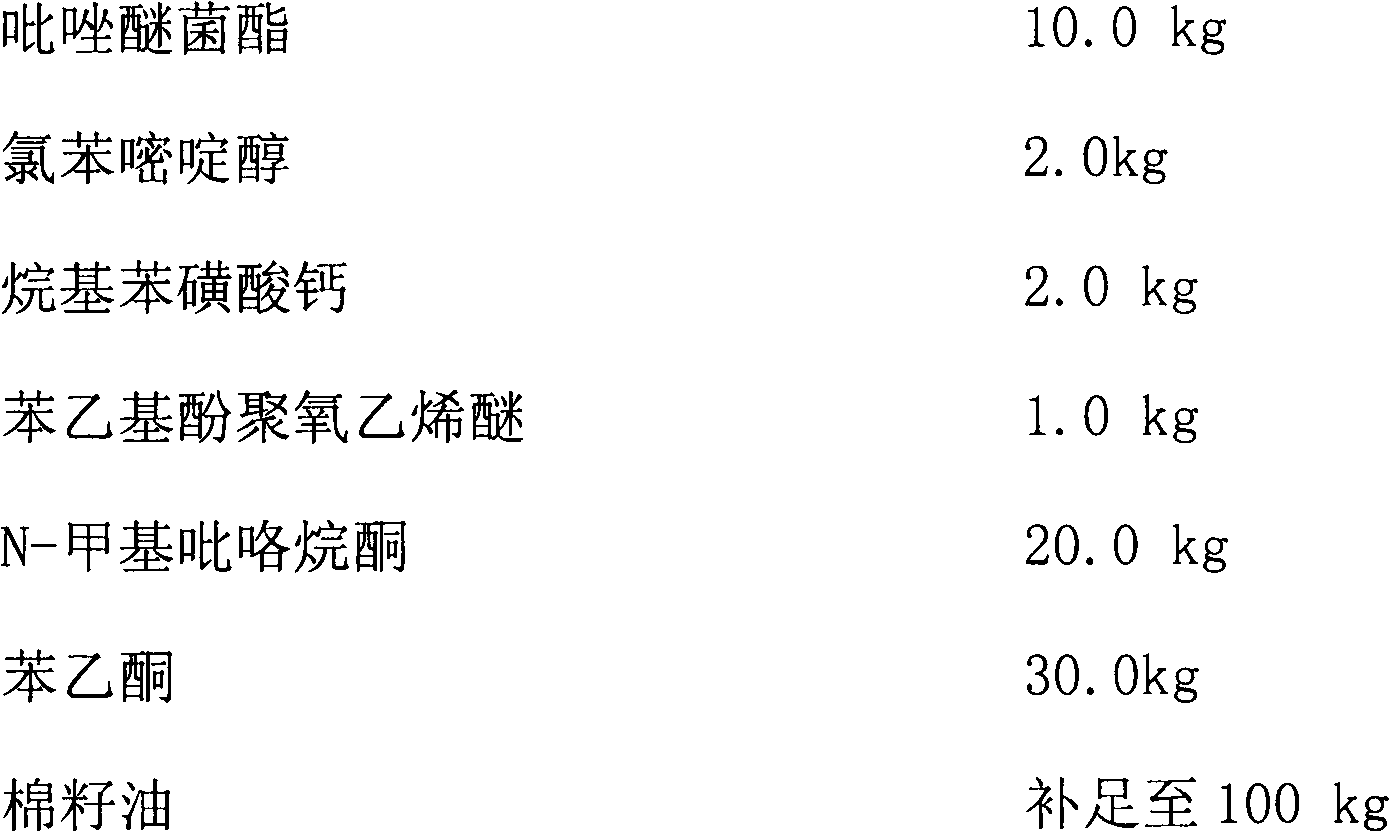

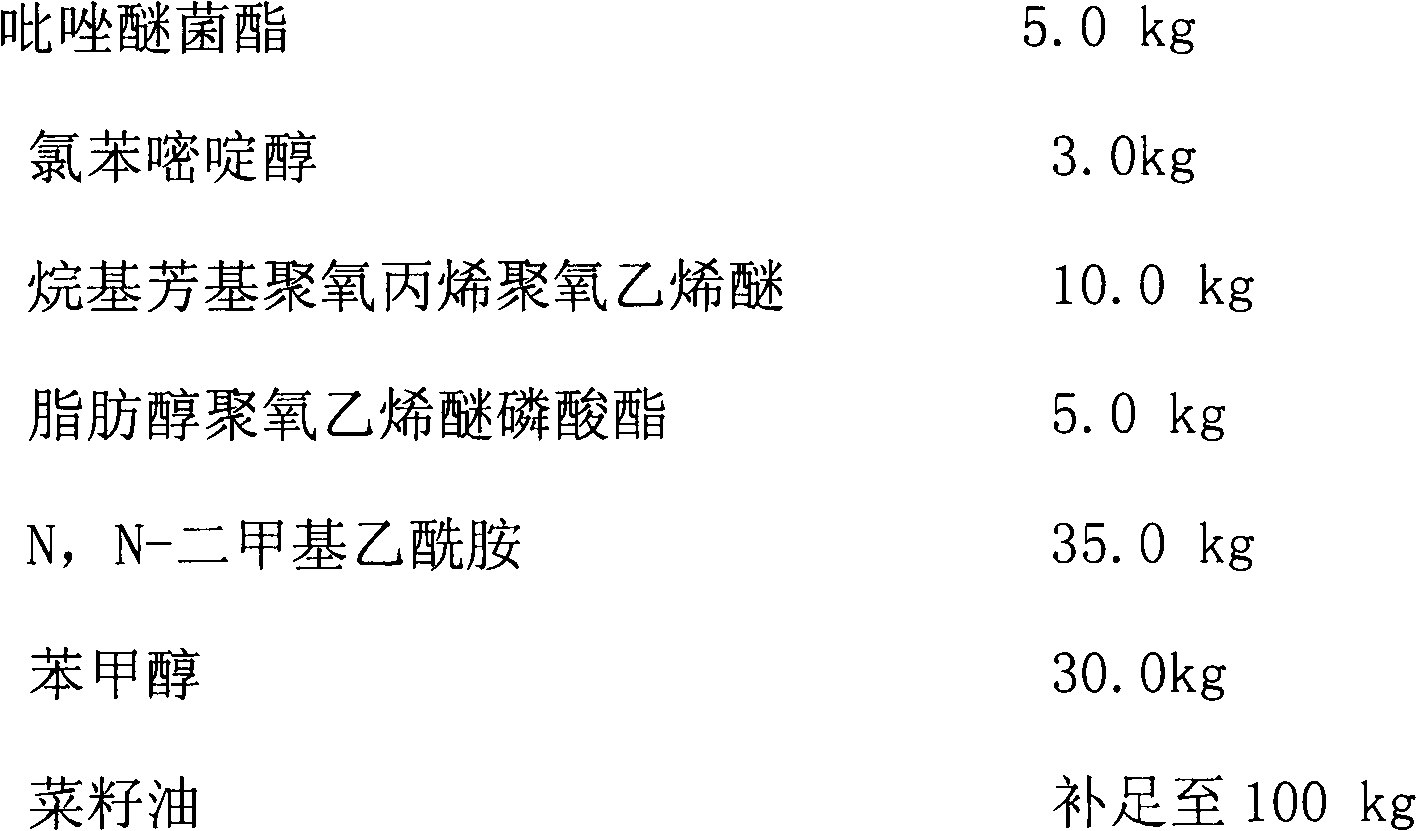

Hot fogging concentrate containing pyraclostrobin and sterol synthesis inhibitor

The invention discloses a hot fogging concentrate containing pyraclostrobin and a sterol synthesis inhibitor. The hot fogging concentrate comprises an active ingredient, an aid, a solvent and a cosolvent, wherein the active ingredient is formed by compounding pyraclostrobin and the sterol synthesis inhibitor; the content of pyraclostrobin is 1-10%; the content of the sterol synthesis inhibitor is 2-20%; and the contents of other ingredients including the aid and the solvent complement the percent to 100%. The hot fogging concentrate is suitable for hot fogging machines to spray fog and is used for controlling powdery mildew and anthracnose of such crops as fruit trees and woods. The hot fogging concentrate has the advantages of high work efficiency, synergy, good control effect, simpleness in operation, water and labor saving, safety, environmental friendliness and the like.

Owner:YULIN NORMAL UNIVERSITY

Third-dimensional ecologic wallpaper and exterior wall tile

The invention relates to a third-dimensional ecologic wallpaper and an exterior wall tile. The formula of the third-dimensional ecologic wallpaper and the exterior wall tile comprises, by mass, 20-99% of rubber, 1-50% of a flame retardation material, 1-75% of stone sand or powder, 1-10% of a pigment, 0.5-30% of a curing agent, 1-50% of an assistant, and 1-75% of fiber or rice straw analog filler; or comprises, by mass, 1-99% of flexible resin, 1-99% of rigid resin, 1-50% of the flame retardation material, 0.5-60% of the curing agent, 1-50% of the assistant, 1-10% of the pigment, 1-75% of stone sand or powder analog, and 1-75% of the fiber or rice straw analog filler. The wallpaper and the exterior wall tile have the advantages of temperature toleration, good flame retardation performance, certain artistic appreciating values, extremely less pollution discharge and electricity consumption due to no traditional printing or gas combustion technologies in the production process, recycling, safety, low carbon and environmental protection.

Owner:惠州市创鑫隆实业有限公司

Cloth for anti-bacterial sofa cover and preparation method thereof

InactiveCN108277567AHas antibacterial propertiesProtect healthBiochemical fibre treatmentFibre typesPolyesterEmulsion

The invention discloses cloth for an anti-bacterial sofa cover and a preparation method thereof. The cloth for the anti-bacterial sofa cover is prepared from, by weight, acrylic acid elastic emulsion,a softener, linen fibers, polyacrylonitrile fibers, chitin fibers, flame-retardant polyester fibers, an anti-bacterial solution, a macromolecular resin matrix, inorganic powder and distilled water; the preparation method of the cloth for the anti-bacterial sofa cover includes the following steps that 1, the raw materials are weighed and taken; 2, acrylic acid elastic emulsion, the softener, the macromolecular resin matrix and the inorganic powder are dissolved in the distilled water and then mixed through a stirrer; 3, the materials which are well mixed are poured into a spinning machine; 4,the materials in the spinning machine is extruded out to form mixed fibers, and the mixed fibers are made into fabric; 5, the fabric is placed in the anti-bacterial solution to be soaked, and after being taken out, the fabric is dried and spun into the gray cloth. The prepared cloth for the anti-bacterial sofa cover has an anti-bacterial effect and can kill various bacteria and viruses staining the sofa cover during usage, and therefore, users' health is ensured.

Owner:HAINING MEILI KNITTING CO LTD

Closed spraying box with lifting tool plate inside

The invention discloses a closed spraying box with a lifting tool plate inside. The closed spraying box comprises a transparent box body, a through hole is formed in the middle of a left side plate ofthe transparent box body, the end of a rubber glove is inserted into the through hole and fixed in the transparent box body, and the rubber glove stretches into the transparent box body. An upper lifting supporting frame is fixed to the top face of a top pate of the transparent box body, a telescopic motor is fixed to the top face of a top plate of the upper lifting supporting frame, an output shaft of the telescopic motor penetrates through the top plate of the upper lifting supporting fame and is connected with a vertical screw rod through a coupler, the vertical screw rod is in threaded connection with a telescopic swivel nut, a lifting plate is fixed to the bottom end of the telescopic swivel nut, a telescopic plate is fixed to the bottom face of the lifting plate, and the telescopicrod is inserted into a main through hole in the top plate of the transparent box body. A component to be machined can be placed into a placing groove and located in the transparent box body to be machined, since a lifting placing plate is arranged inside, the component to be machined can be placed in a classified mode, gas is not likely to scatter out, and a fire is not likely to be caused.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Composite wax clearing agent

InactiveCN107384353AImprove solubilityDissolve fastDrilling compositionIsobutanolAdditive ingredient

The invention relates to a composite wax clearing agent, and belongs to the field of oil field chemical application. The composite wax clearing agent is prepared from the following raw materials in parts by weight: 40 to 50 parts of microemulsion, 30 to 40 parts of mixed slurry and 2 to 4 parts of thickening agents, wherein the microemulsion is prepared from the following ingredients in parts by weight: 20 to 30 parts of surfactants, 5 to 10 parts of cosurfactants, 10 to 20 parts of plant oil, 2 to 5 parts of emulsifiers, 0.2 to 0.4 part of metal chelators and 100 to 120 parts of water. According to a preparation method of the mixed slurry, through being metered in parts by weight, 3 to 5 parts of nanometer titanium dioxide, 4 to 6 parts of quartzite, 15 to 20 parts of kieselguhr, 3 to 5 parts of vermiculite, 1 to 3 parts of alpha-sodium allylsulfonate, 2 to 5 parts of nonylphenol polyoxyethylene ether and 70 to 90 parts of isobutanol are respectively selected. The materials are mixed and are discharged after the ball milling; mixed slurry is obtained. The prepared composite wax clearing agent has the advantages that the wax cleaning speed is high; the safety performance is relatively high; harm cannot be easily caused on the human body.

Owner:常州市雄泰纺织品有限公司

Hardening and tempering method in pump body manufacturing

InactiveCN101892362AIncreased impact valueImprove hardenabilityQuenching agentsPotassium nitrateManufacturing technology

The invention discloses a hardening and tempering method in pump body manufacturing, and belongs to the technical field of pump body machining and manufacturing. The method comprises the processes of normalizing, hardening, primary high-temperature tempering, secondary high-temperature tempering and medium-temperature tempering, namely two-time high-temperature tempering and once medium-temperature tempering are performed after hardening. Simultaneously, sodium nitrate, sodium nitrate and potassium nitrate serve as a medium, namely a mixed solution consisting of 25 weight percent of the sodium nitrate, 20 weight percent of the sodium nitrite, 20 weight percent of the potassium nitrate and 35 weight percent of water, so as to improve the hardenability of a product, and simultaneously reduce a surface pulling stress to be crucially effective in stopping hardening cracks. The method of the invention effectively improves an impact value of a pump body at the temperature of -40 DEG C and the mechanical property of the pump body, has high safety in a hardening and tempering processes, improves working environment and reduces the labor intensity of production staff.

Owner:JINXI IND GRP

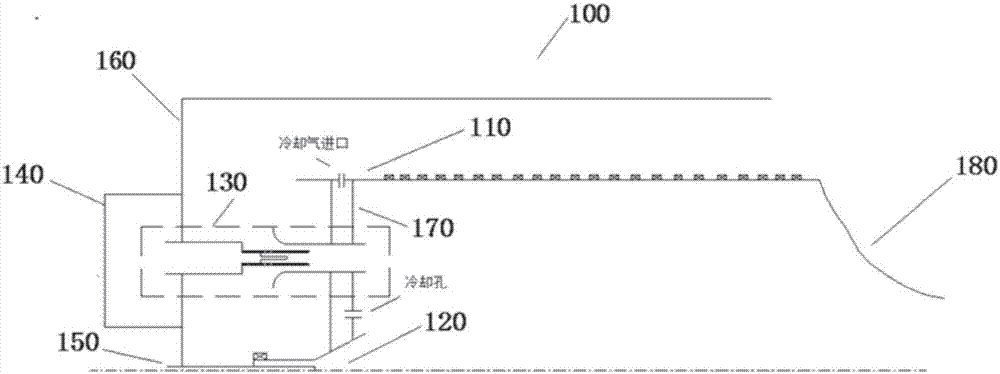

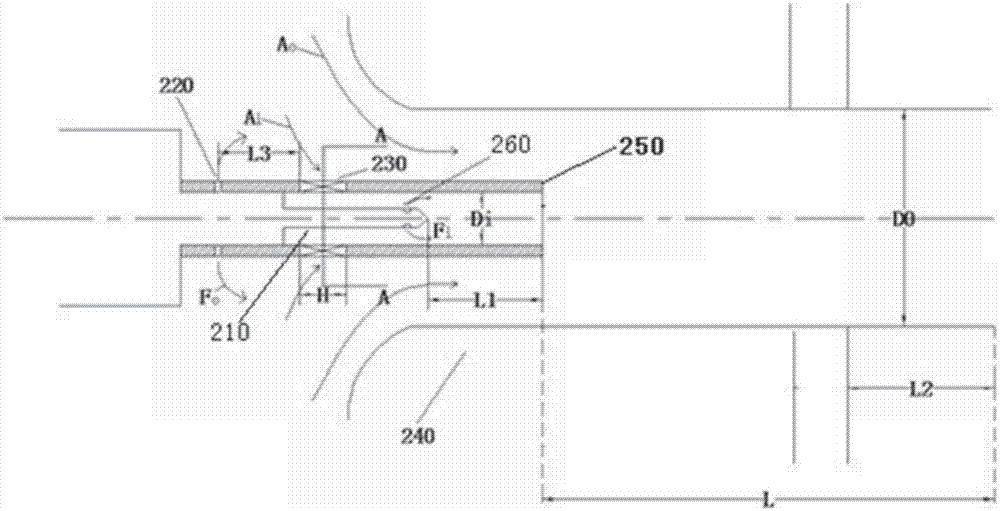

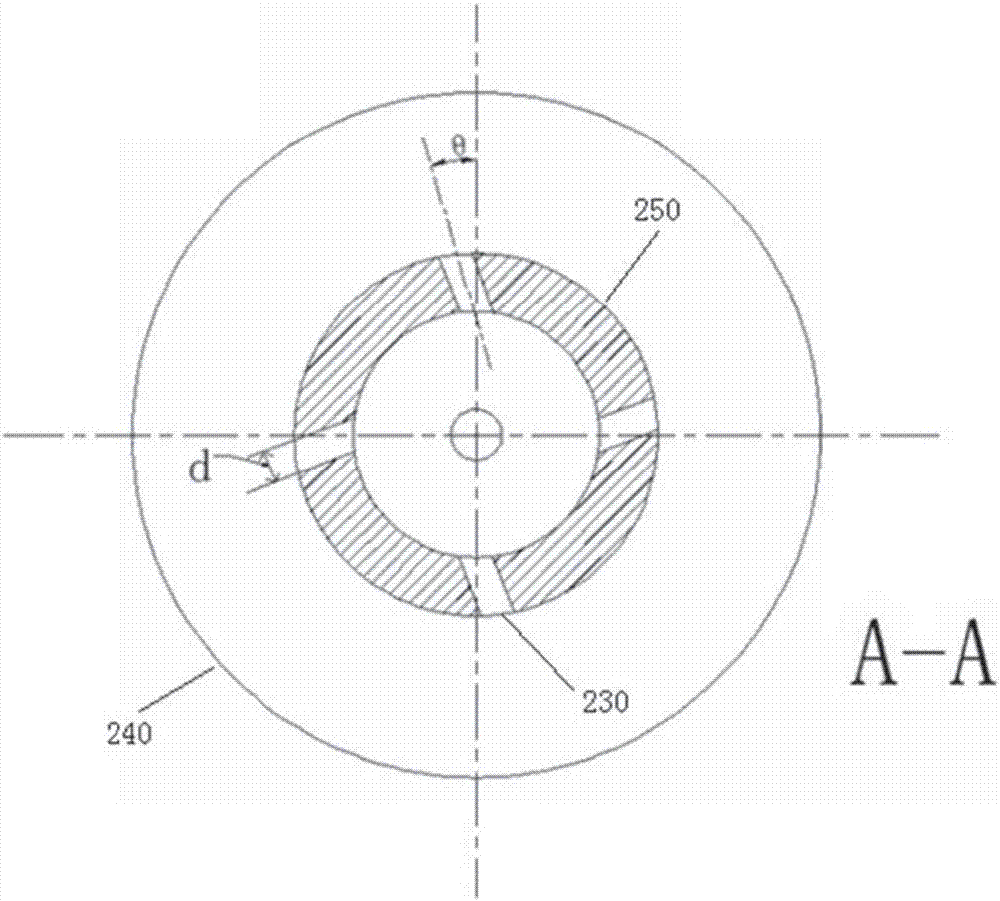

Die press quenching device for fully quenching steel ferrules

ActiveCN103451406AIncrease manufacturing costReduce manufacturing costsFurnace typesHeat treatment process controlHigh pressureQuenching

The invention relates to a heat treatment quenching device, in particular to a die press quenching device for fully quenching steel ferrules. The die press quenching device comprises a base, a stand column at one side of the base and a cross beam at the upper end of the stand column, wherein an upper sliding block and a lower sliding block are respectively arranged on a guiding rail of the stand column, and piston rods of an upper die cylinder and a lower die cylinder are respectively connected with the upper sliding block and the lower sliding block. The die press quenching device is characterized in that a high-pressure pipeline is connected with the upper die cylinder and the lower die cylinder respectively, a one-way speed regulating valve and a reversing valve I, which are used for controlling the speed and the direction of the upper die cylinder, are respectively arranged on a high pressure pipeline connected with the upper die cylinder, a pressure regulating valve and a reversing valve II, which are used for controlling the pressure and the direction of the lower die cylinder, are respectively arranged on a high pressure pipeline connected with the lower die cylinder, and cooling oil for quenching is connected with an oil outlet and an oil spraying ring on the lower die. According to the device, the press quenching force and the press quenching speed can be precisely regulated, the quenching time is short, the deformation of quenched workpieces is small, the quenching quality is effectively ensured, and existing quenching and controlling technologies are greatly improved.

Owner:NINGXIA MACHINERY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com