Heat radiation substrate of electronic element

A technology of electronic components and substrates, which is applied in the field of heat dissipation substrates for heat dissipation of electronic components, and can solve problems such as insufficient heat dissipation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

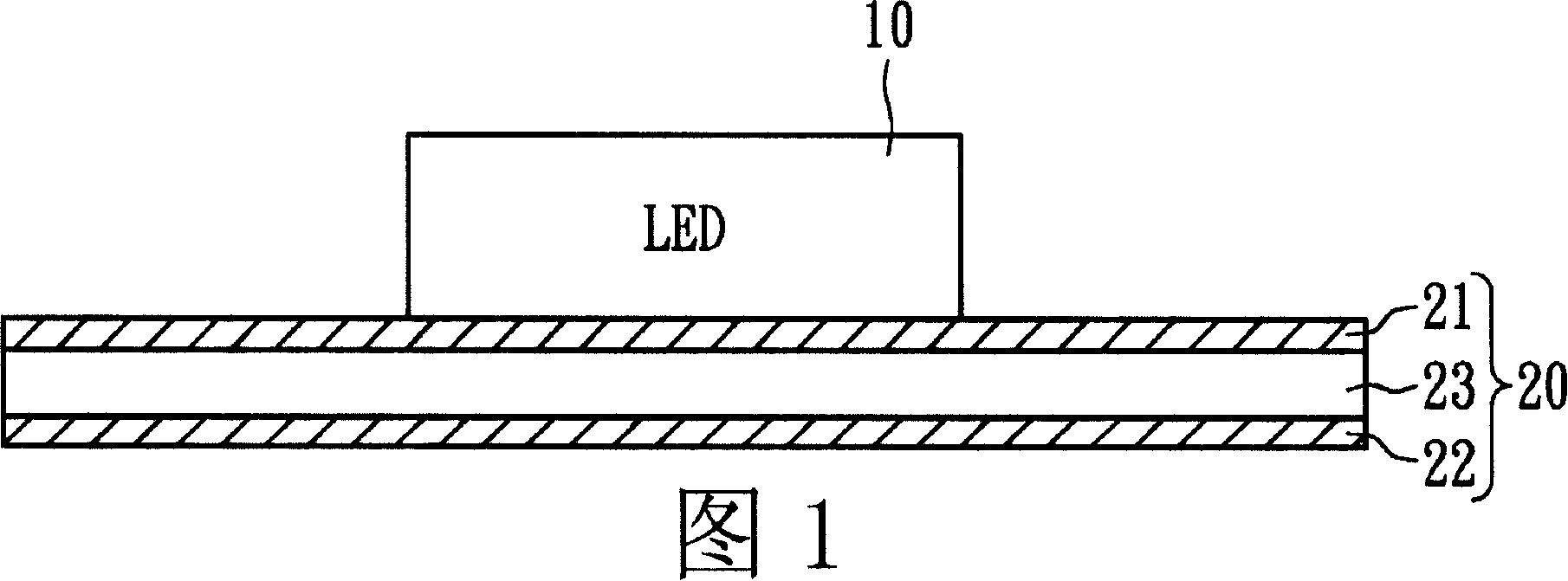

[0012] Referring to FIG. 1 , an LED element 10 is carried on a heat dissipation substrate 20 . The heat dissipation substrate 20 includes a first metal layer 21 , a second metal layer 22 and a thermally conductive polymer dielectric insulating material layer 23 stacked between the first metal layer 21 and the second metal layer 22 . The LED element 10 is disposed on the surface of the first metal layer 21, and the interface between the first and second metal layers 21 and 22 forms a physical contact with the thermally conductive polymer dielectric insulating material layer 23, and wherein At least one interface is a micro-rough surface, and the micro-rough surface includes a plurality of tumor-like protrusions, and the particle diameters of the nodule-like protrusions are mainly distributed between 0.1 and 100 microns, thereby increasing the tensile strength between them.

[0013] The manufacturing method of the above-mentioned heat dissipation substrate 20 is exemplified as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com