Anti-flaming modified polyamide fiber

A nylon fiber and modification technology, which is applied in the fields of nylon fiber and chemical industry, can solve problems such as easy to cause fire, and achieve the effects of not easy to catch fire, less pollution, and good flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

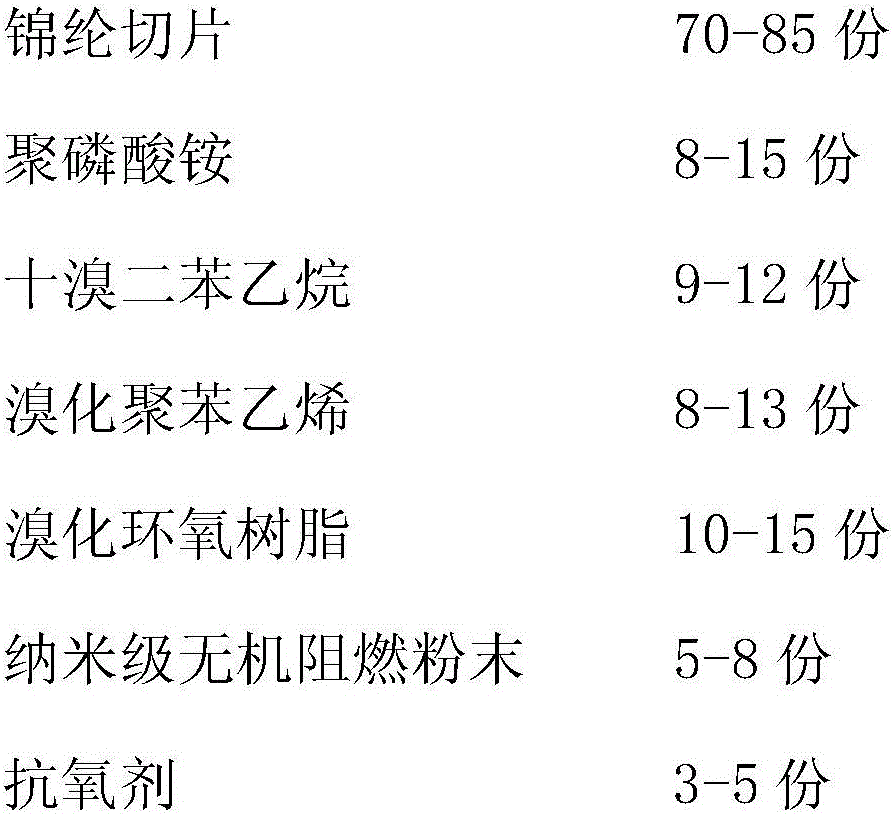

[0023] A flame-retardant modified nylon fiber of the present invention comprises the following components and the mass parts of each component are:

[0024]

specific Embodiment 2

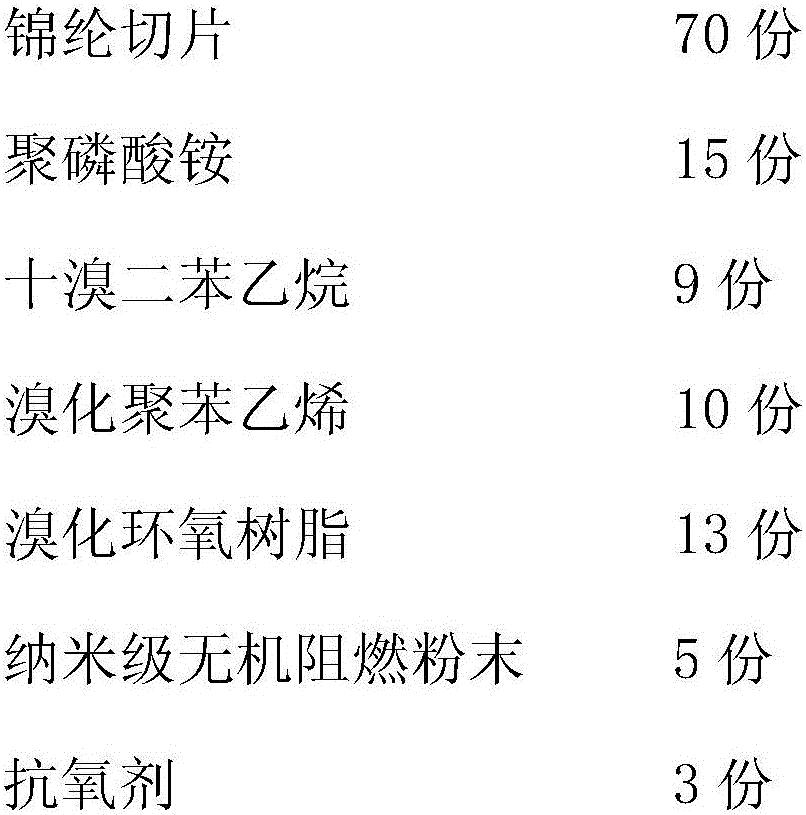

[0026] A flame-retardant modified nylon fiber of the present invention comprises the following components and the mass parts of each component are:

[0027]

[0028]

specific Embodiment 3

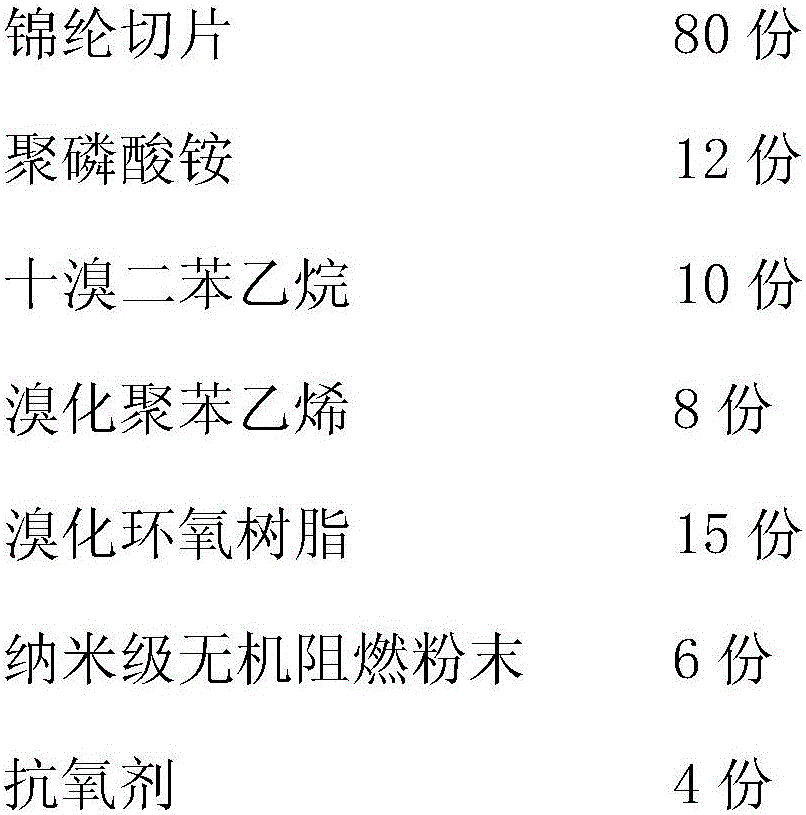

[0030] A flame-retardant modified nylon fiber of the present invention comprises the following components and the mass parts of each component are:

[0031]

[0032] In the above three specific examples, the ammonium polyphosphate is type II ammonium polyphosphate with a degree of polymerization greater than 1000, and the nanoscale inorganic flame-retardant powder is calcium carbonate, barium sulfate, glass microspheres, kaolin, wollastonite, mica, hydroxide One or a mixture of aluminum, magnesium hydroxide, diatomaceous earth or silicon dioxide, the antioxidant is one or a mixture of antioxidant 1098, antioxidant 1076 or antioxidant SEED .

[0033] Working process of the present invention:

[0034] During the working process of the flame-retardant modified nylon fiber of the present invention, various components with flame-retardant functions are added to the nylon, so that the nylon fiber has good flame-retardant performance, and the articles made of the nylon fiber are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com