High-performance halogen-free flame retardant ABS modified resin and preparation method thereof

A modified resin, high-performance technology, applied in the field of high-performance halogen-free flame-retardant ABS modified resin and its preparation, can solve the problems of poor physical properties of flame-retardant ABS, rubber phase graft shell damage, high molding processing temperature, etc. , to achieve the effect of overcoming poor flame retardant performance, increasing the degree of peeling, and improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

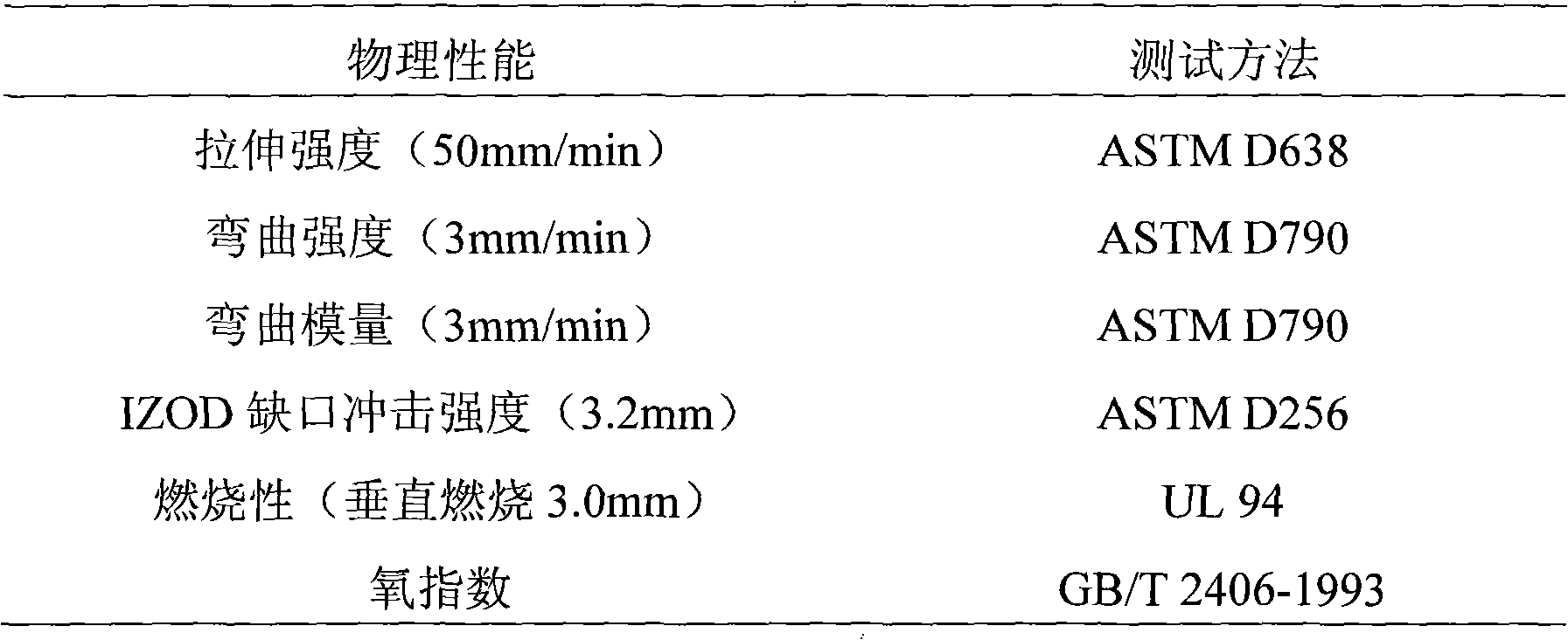

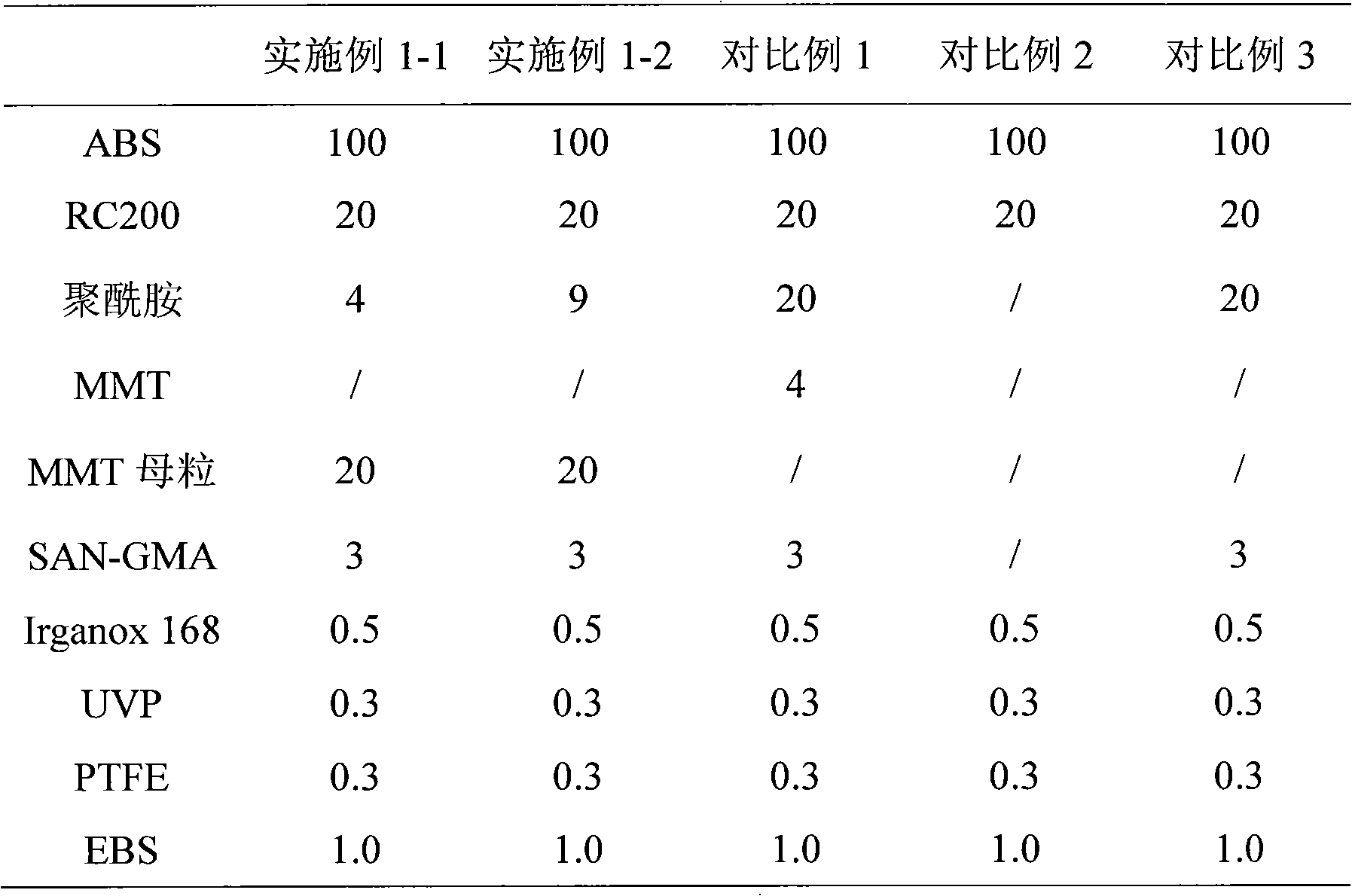

[0067] Embodiment 1 comprises embodiment 1-1 and 1-2, and its formula is as shown in table 2; The formula of comparative example 1,2,3 is also as shown in table 2;

[0068] In Table 2:

[0069] ABS resin is PA757, Taiwan CHIMEI company;

[0070] Phosphate ester flame retardant is RC200, Rich Chemical;

[0071] The polyamide is CM1017, Toray Corporation of Japan;

[0072] Nano MMT, Nanolin DK1, Zhejiang Fenghong Clay Chemicals;

[0073] MMT masterbatch, with CM1017 as the carrier, 20% masterbatch;

[0074] The compatibilizer is SAN-GMA, Shanghai Rizhisheng New Technology Development Co., Ltd.;

[0075] The antioxidant is Irganox, 168Ciba;

[0076] The light stabilizer is UVP, Ciba;

[0077] The anti-dripping agent is PTFE, Guangzhou Entropy Energy Polymer Co., Ltd.;

[0078] The processing aid is EBS (ethylene bis stearic acid amide), commercially available.

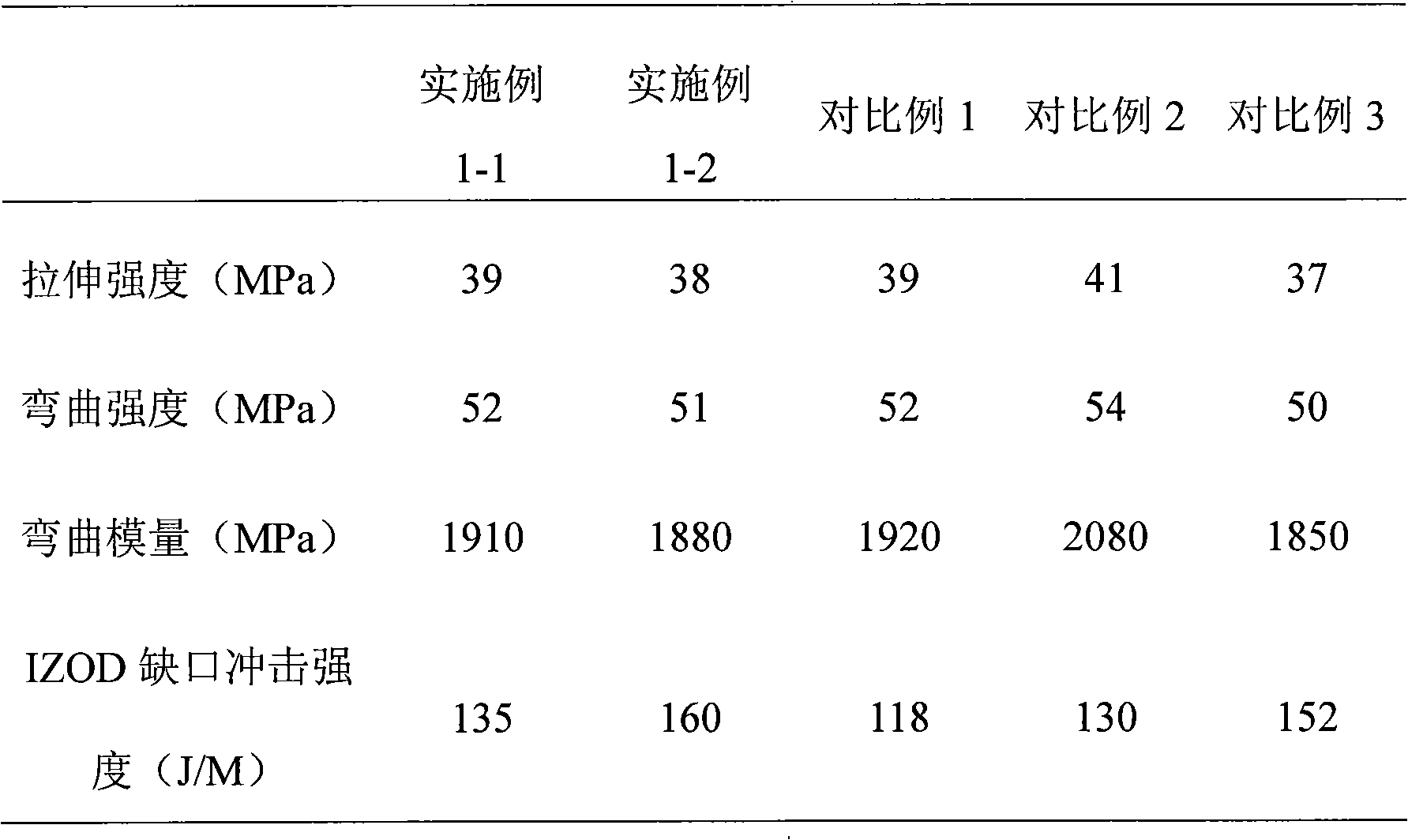

[0079] The performance tests of Examples 1-1, 1-2 and Comparative Examples 1, 2, 3 are shown in Table 3.

[00...

Embodiment 2

[0086] Embodiment 2 comprises embodiment 2-1, 2-2 and 2-3, and its formula is as shown in table 4; The formula of comparative example 4 is also as shown in table 3;

[0087] In Table 3:

[0088] Tougheners include: EMA toughener, French Akema company;

[0089] ABS high rubber powder, Korea Kumho Petrochemical;

[0090] SBS, Yueyang Petrochemical;

[0091] All the other raw and auxiliary materials are the same as in Example 1.

[0092] The performance tests of Examples 2-1, 2-2, 2-3 and Comparative Example 4 are shown in Table 5.

[0093] The formula table of table 4 embodiment 2-1, 2-2, 2-3 and comparative example 4

[0094]

Example 2-1

Example 2-1

Example 2-2

Comparative example 4

ABS

100

100

100

100

RC200

20

20

20

25

4

4

4

/

MMT masterbatch

20

20

20

/

EMA

8

/

/

/

ABS high rubber powder

/

...

Embodiment 3

[0098] Embodiment 3 comprises embodiment 3-1, 3-2 and 3-3, and its formula is as shown in table 6; The formula of comparative example 5 is also as shown in table 6;

[0099] In Table 6:

[0100] Polyamide 1 (PA-1), the content of terminal amino groups is 56×10 -6 mol / g;

[0101] Polyamide 2 (PA-2), the content of terminal amino groups is 42×10 -6 mol / g;

[0102] Polyamide 3 (PA-3), the content of terminal amino groups is 28×10 -6 mol / g;

[0103] The MMT masterbatch takes the corresponding polyamide as the carrier, and the rest of the raw and auxiliary materials are the same as in Example 1.

[0104] The performance tests of Examples 3-1, 3-2, 3-3 and Comparative Example 5 are shown in Table 7.

[0105] The formula table of table 6 embodiment 3-1, 3-2, 3-3 and comparative example 5

[0106]

Example 3-1

Example 3-2

Example 3-3

Comparative example 5

ABS

100

100

100

100

RC200

20

20

20

20

P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com